Patents

Literature

112results about How to "Improve Motion Control Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

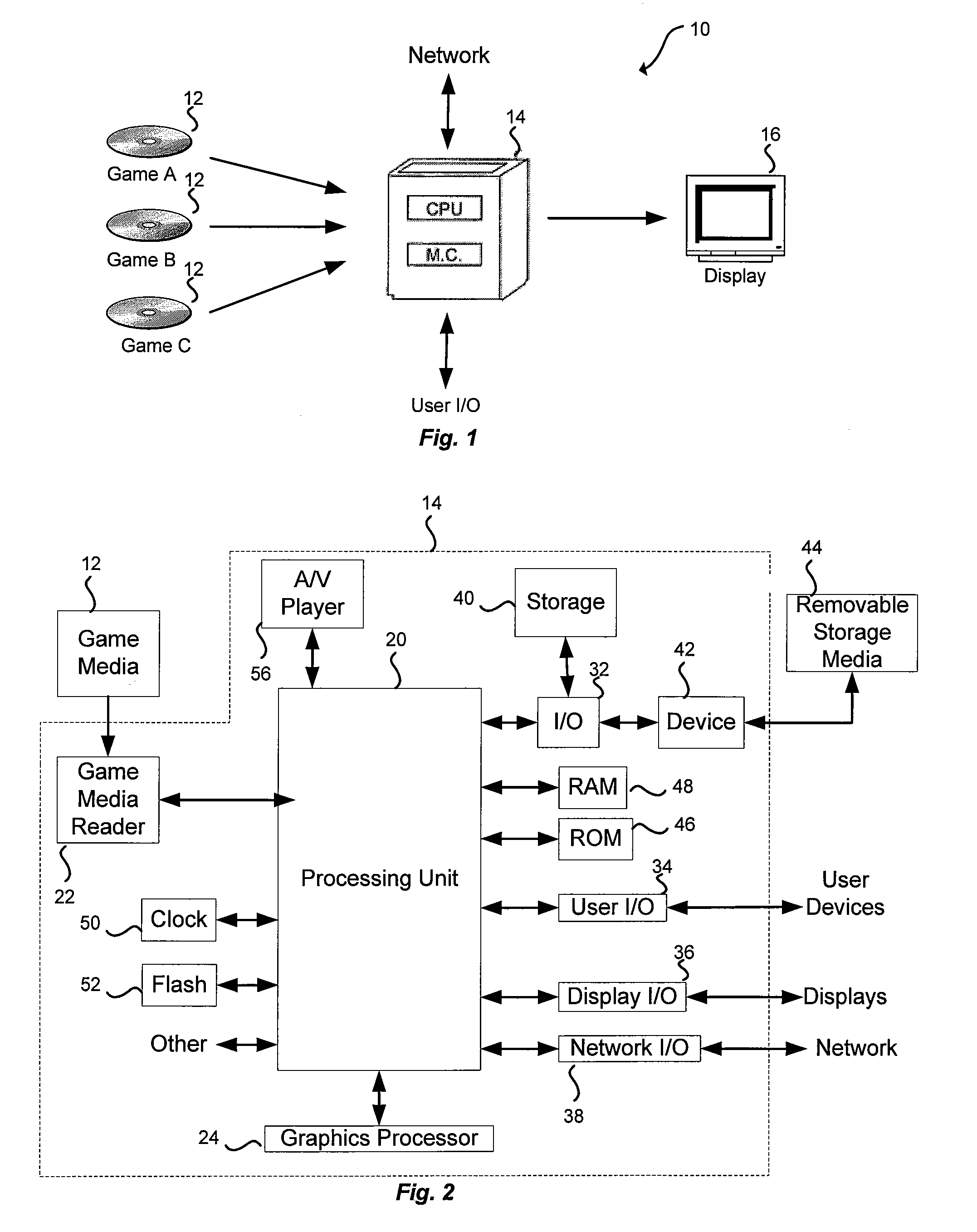

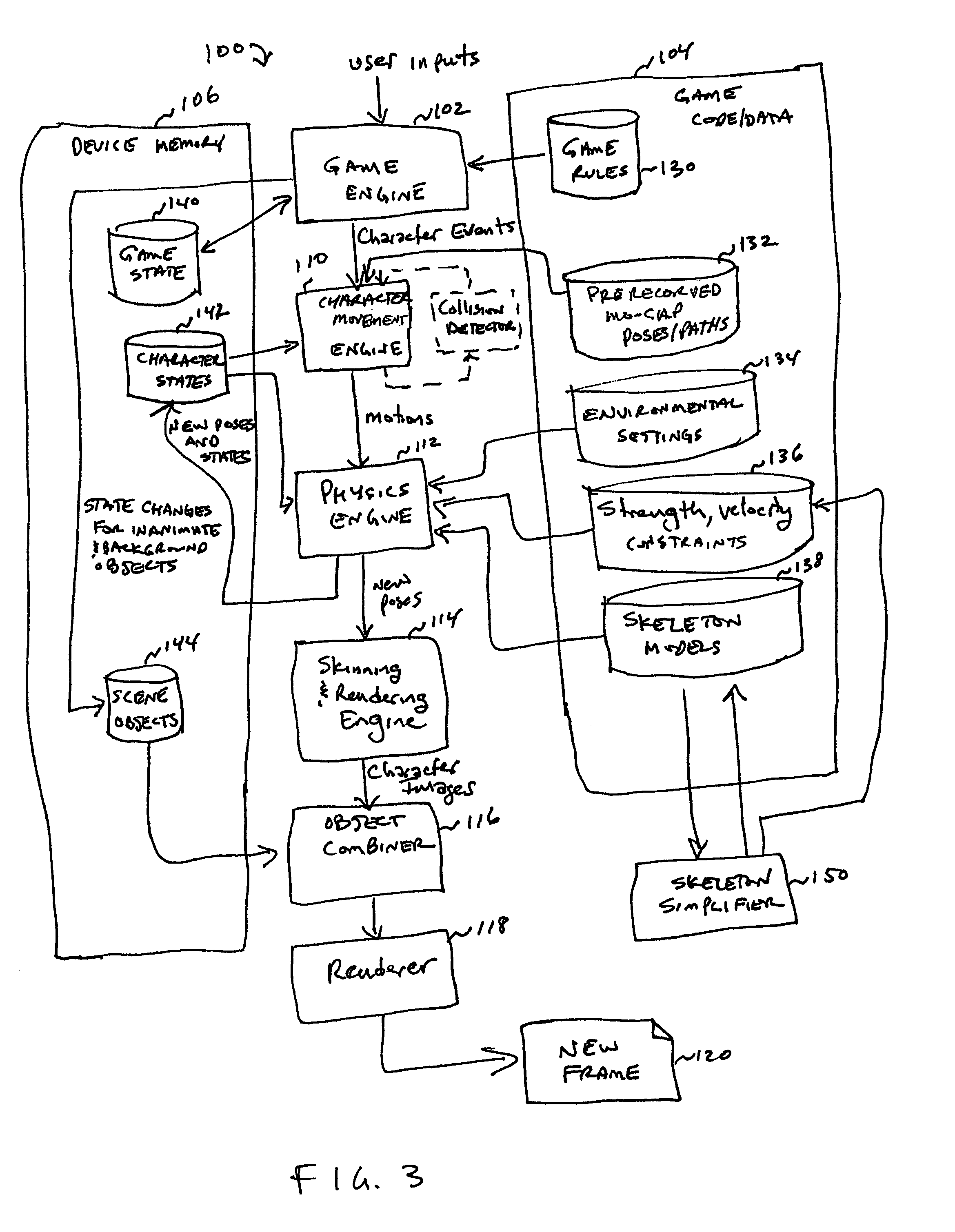

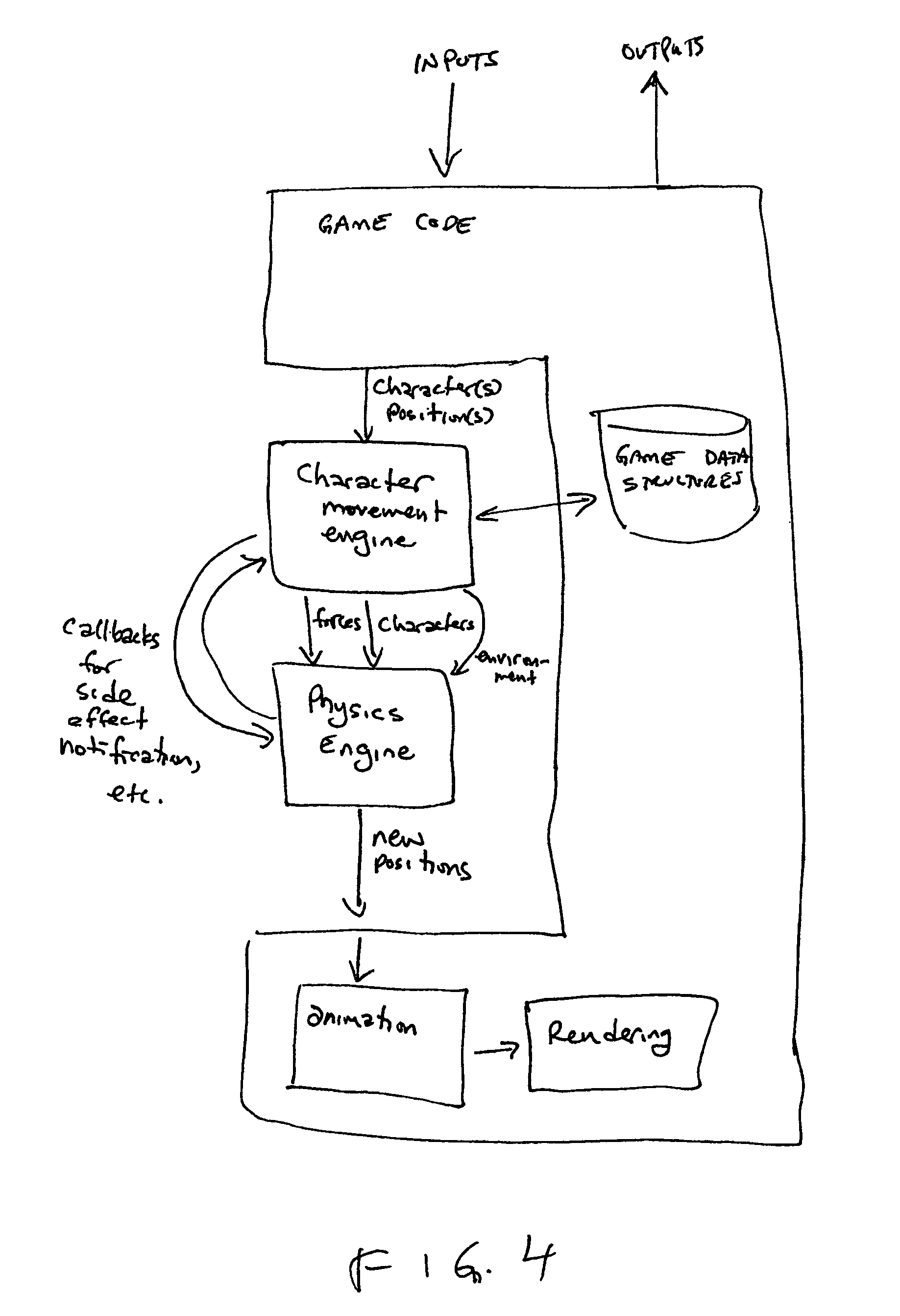

Computer animation of simulated characters using combinations of motion-capture data and external force modelling or other physics models

ActiveUS7403202B1Processing speedEasy to handleImage analysisVisual presentationComputer animationGraphics

Embodiments of the present invention provide methods and apparatus wherein physics models are integrated with motion capture animation to allow for variability in animations, dynamic response, such as animating events different from those for which motion capture data was obtained, including changes in character purpose and collisions. The physical model may include sets of internal forces and / or external forces. To facilitate the integration of mo-cap animation data with physics models, mo-cap animation data is played back using forces on physical models rather than directly setting joint angles or positions in a graphical skeleton, which allows the animation to be dynamically altered in real-time in a physically realistic manner by external forces and impulses.

Owner:ELECTRONICS ARTS INC

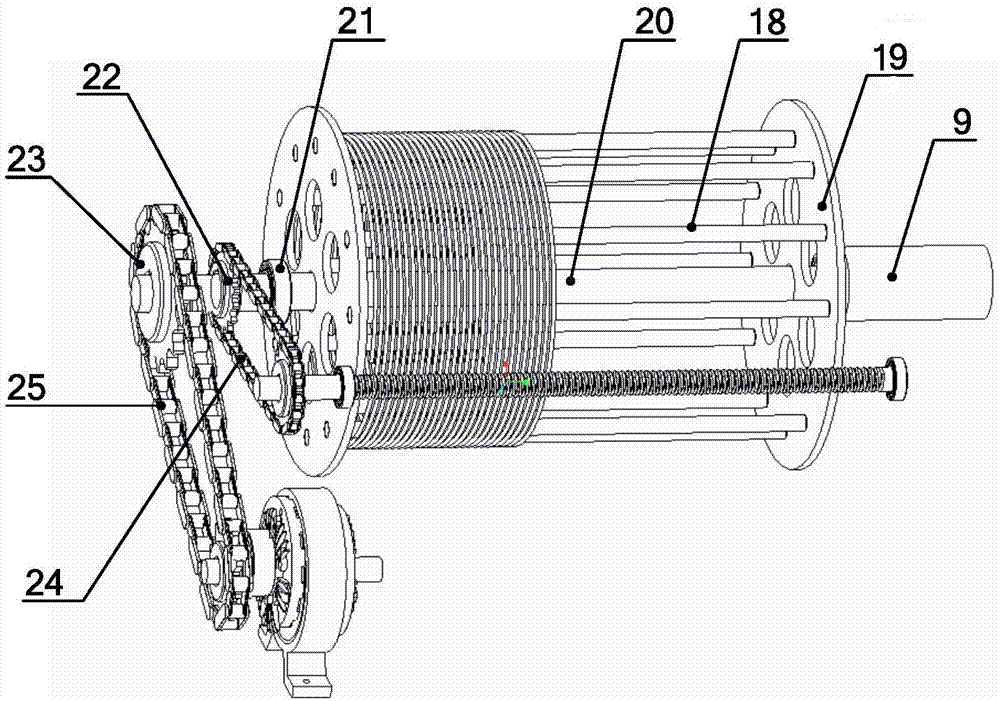

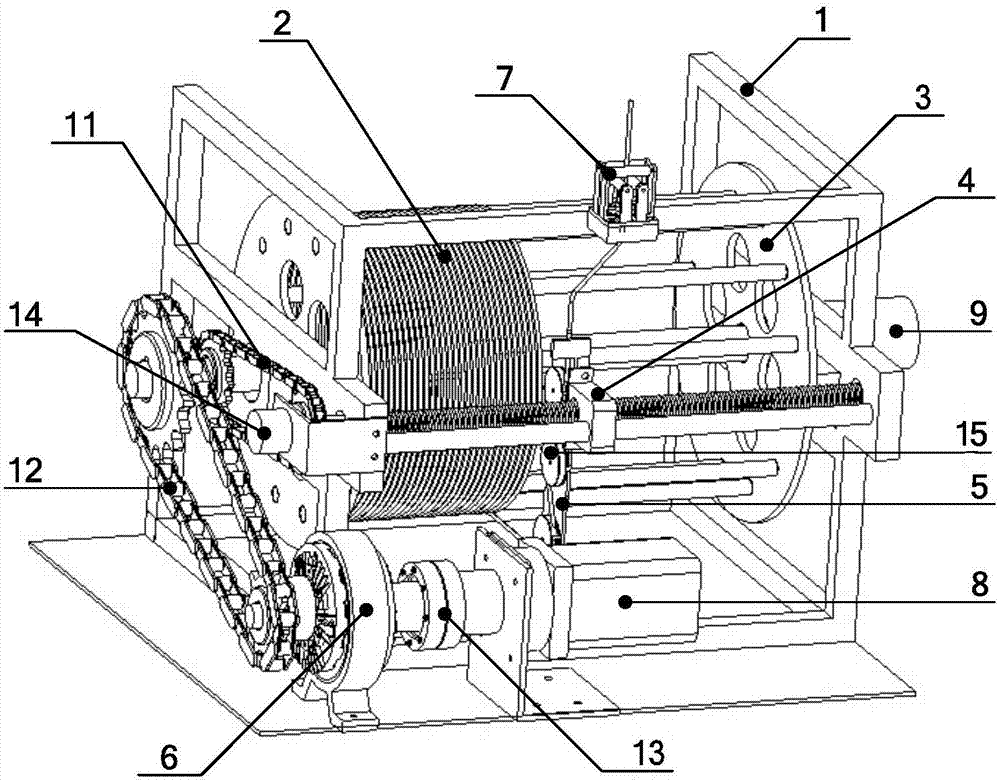

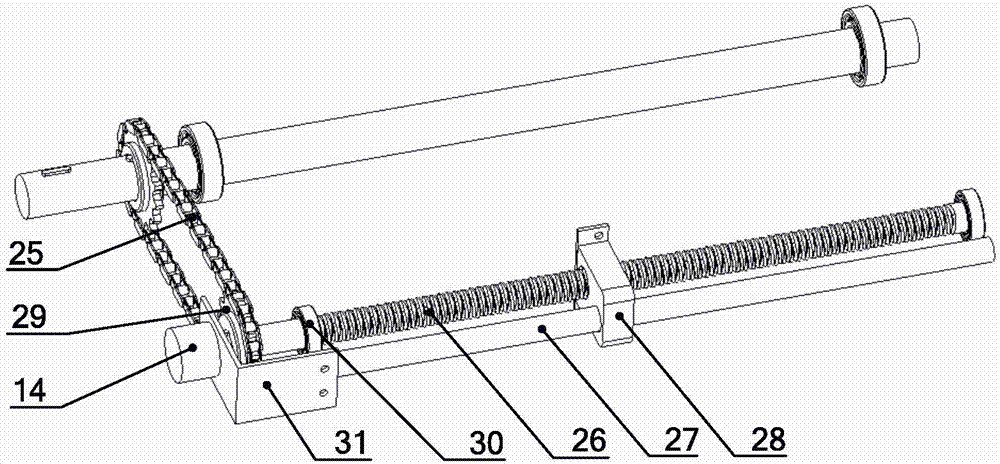

Cable tension self-adjustment winch and control method thereof

ActiveCN106946097AImprove Motion Control AccuracyOvercoming Low Intensity ProblemsFilament handlingMaximum torqueAutomatic control

The invention discloses a cable tension self-adjustment winch and a control method thereof, and belongs to the field of automatic control. The cable tension self-adjustment winch comprises a winding drum and a driving device driving the winding drum to rotate; the driving device is electrically connected with a control device; a winding displacement device parallel to the axial direction of the winding drum is arranged on the outer side of the winding drum; the winding drum is linked with the winding displacement device; a tension detection device is arranged on the winding displacement device, is located between the winding displacement device and the winding drum, and is electrically connected with the control device; and a tension protection device is connected with between the driving device and the winding drum, limits maximum torque output by the driving device and is connected with the control device. Through the measurement on winding and unwinding stressed states and winding and unwinding movement states of a cable and a clutch state of the tension protection device, self-adaption control is carried out on a rotating speed and torque of the winding drum, so that winding and unwinding movement of the cable is coordinated with active movement of a high-speed mobile object, and cable breakage is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

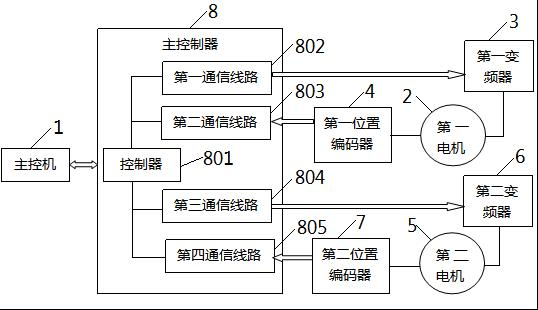

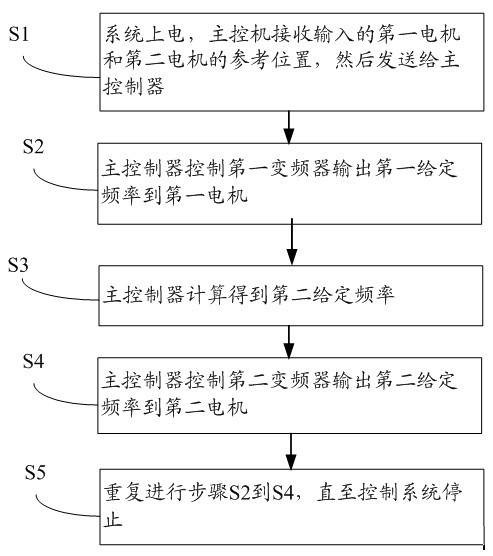

Dual-motor synchronous control system and implementation method

InactiveCN102355176AImprove Motion Control AccuracyIncrease flexibilityMultiple dynamo-electric motors speed regulationFrequency changerControl system

The invention discloses a dual-motor synchronous control system, which comprises a master unit, a first frequency converter, a first position coder, a second frequency converter, a second position coder and a master controller, wherein the master unit is used for inputting a user instruction; the first frequency converter and the first position coder are connected with a first motor; the second frequency converter and the second position coder are connected with a second motor; the master controller is connected with the master unit, and comprises a controller and four communication lines connected with the controller; the controller is a control algorithm software program run on the master controller; and the four communication lines comprise a first communication line connected with the first frequency converter, a second communication line connected with the first position coder, a third communication line connected with the second frequency converter and a fourth communication line connected with the second position coder. By an implementation method for the dual-motor synchronous control system provided by the invention, the first and second motors meet position synchronization running requirements; high motion control accuracy and the relatively higher flexibility of the system are achieved; and simultaneously, the system and the method have the advantages of operating simplicity, low cost and the like, and are easy to popularize.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

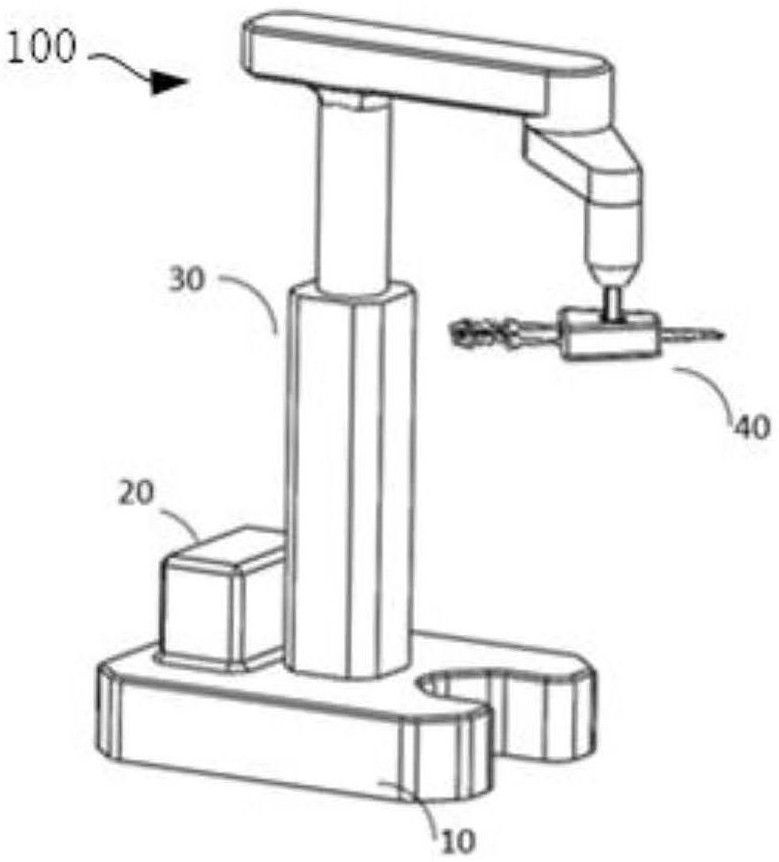

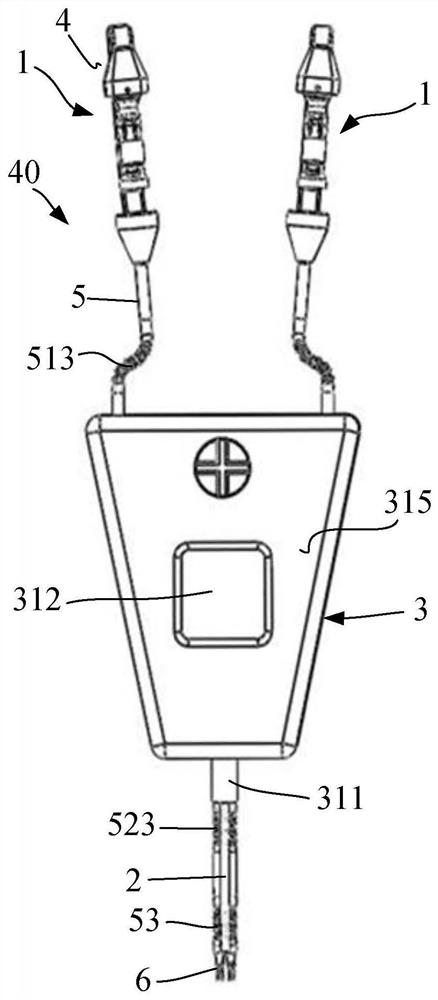

Surgical robot adjustment system

ActiveCN105232155AImprove Motion Control AccuracyImprove the success rate of surgerySurgical robotsSurgical robotEngineering

The invention provides a surgical robot adjustment system. Each mechanical arm is provided with an optical target lens, positions and Euler angles of the optical target lenses are measured by an optical tracking instrument, a calculation module calculates according to measured values to obtain a posture mapping relation of the optical target lenses, and a posture mapping relation of surgical instrument arms is obtained by calculation according to the posture mapping relation of the optical target lenses and a posture mapping relation between the surgical instrument arm of each mechanical arm and the optical target lens on the corresponding mechanical arm. A surgical robot controls postures of corresponding surgical instrument arms according to the posture mapping relation of surgical instrument arms, and accordingly movement control precision of the surgical robot is improved.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

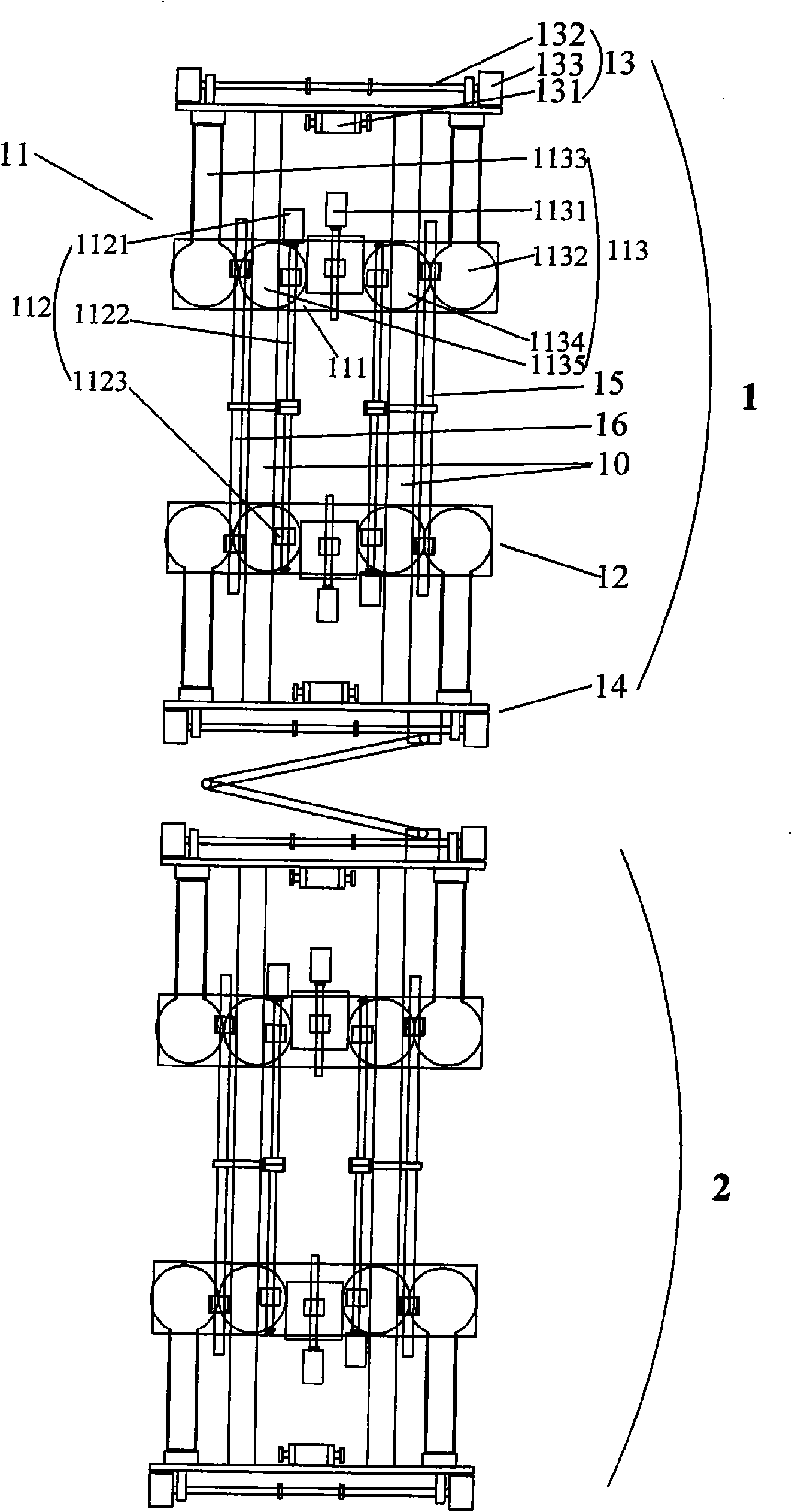

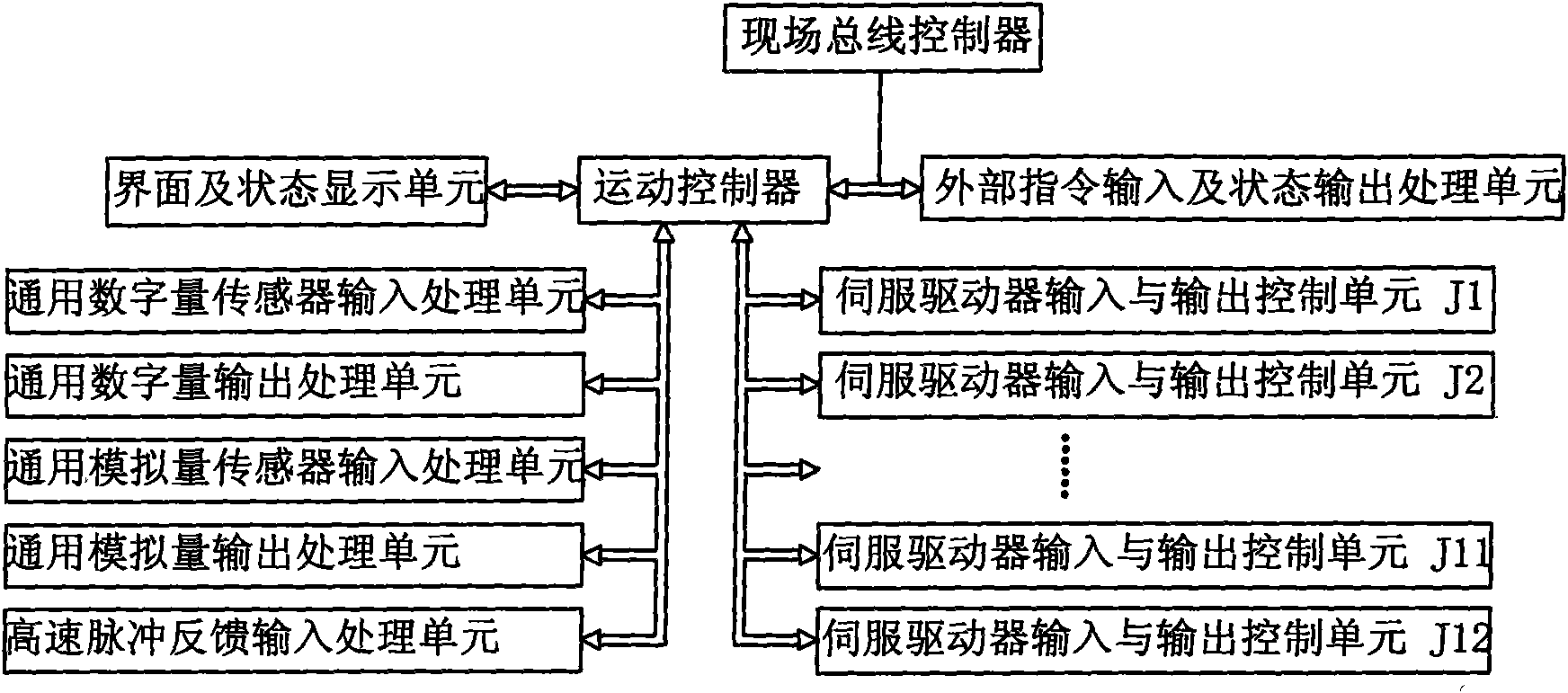

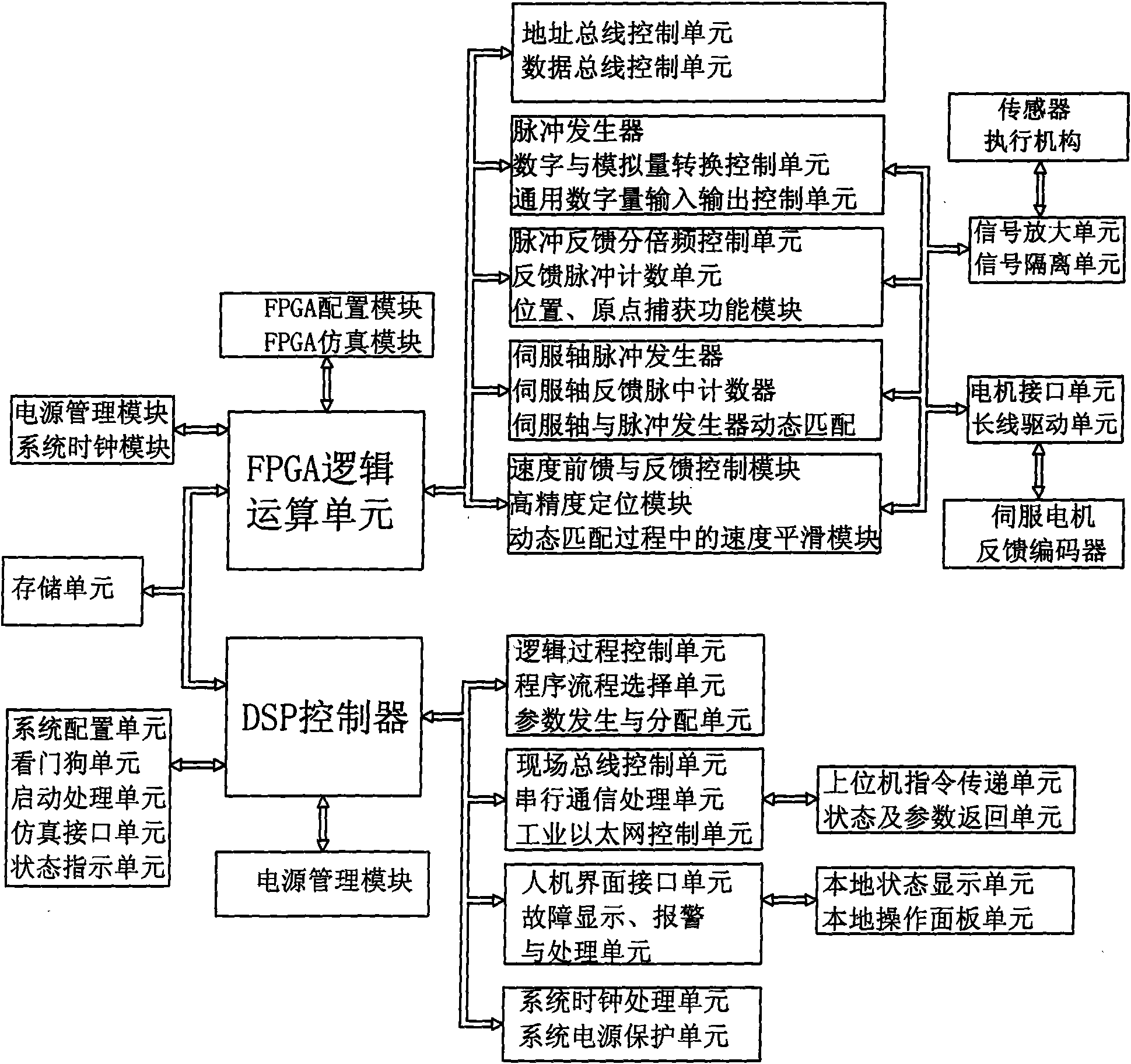

Intelligent vehicle carrier and control system and control method thereof

InactiveCN101655708AMotion control precision and high response speedClear system architectureTotal factory controlProgramme total factory controlPower componentMovement control

The invention relates to an intelligent vehicle carrier and a control system and a control method thereof. The intelligent vehicle carrier comprises a travel driving motor, a knockout plate driving motor and a holding arm driving motor, which are all servo motors. The control system comprises a motion controller as the core cell and a plurality of peripheral modules which are connected with the motion controller so that the motion controller can carry out data exchange with the outside. The motion controller comprises a DSP module which is mainly in charge of logical flows and a logical operation module which carries out concrete logic implementation and logical output. The DSP module is connected with the logical operation module. Relative to the prior art, the invention has the followingbeneficial effects: as the servo motors are adopted as power components, the overall height of the intelligent vehicle carrier can be lower, and the motion control precision and response speed are higher; the control system has clear architecture and higher reliability, stability and working efficiency.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

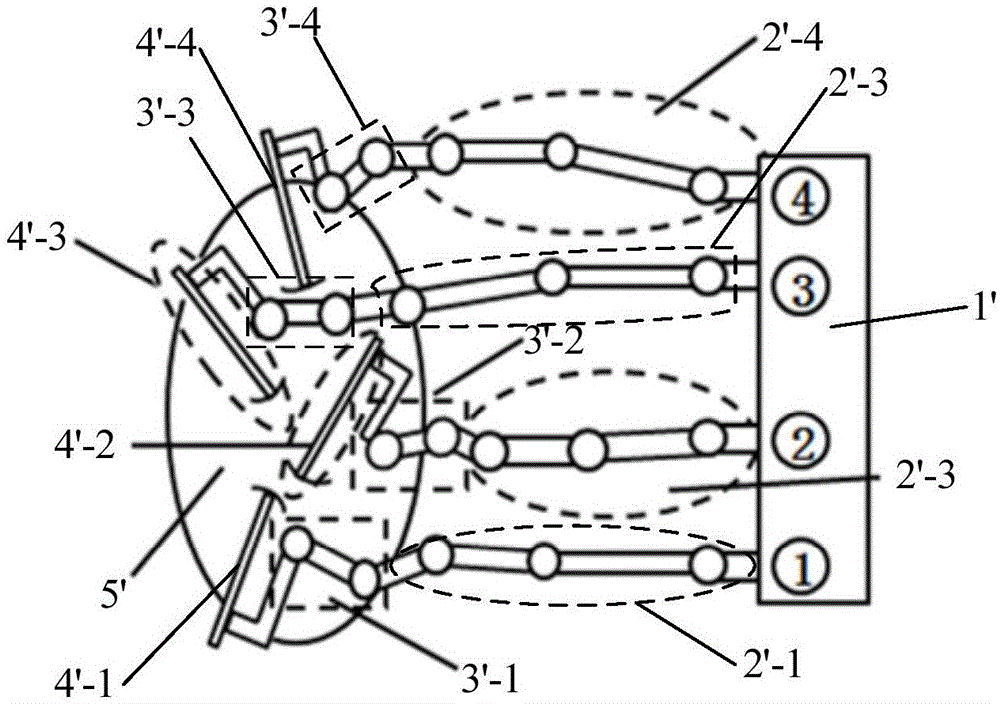

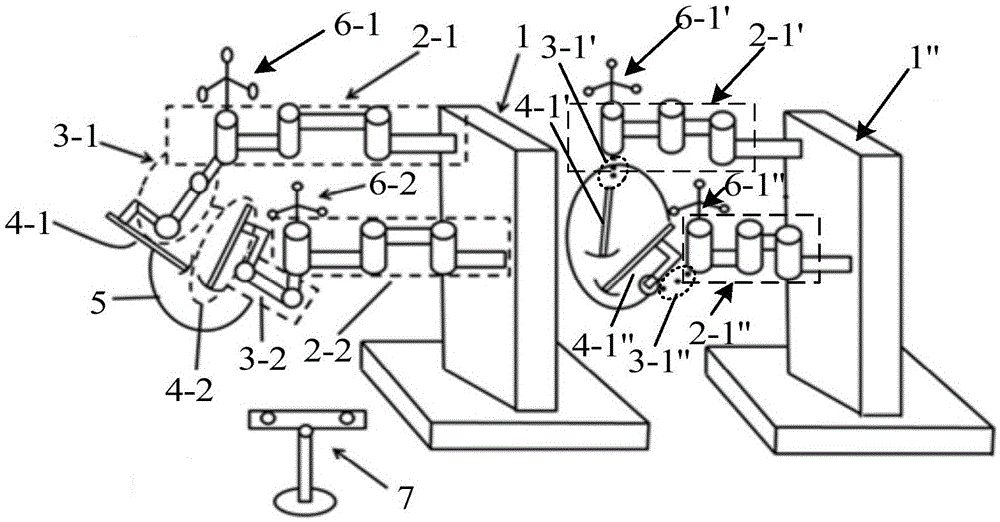

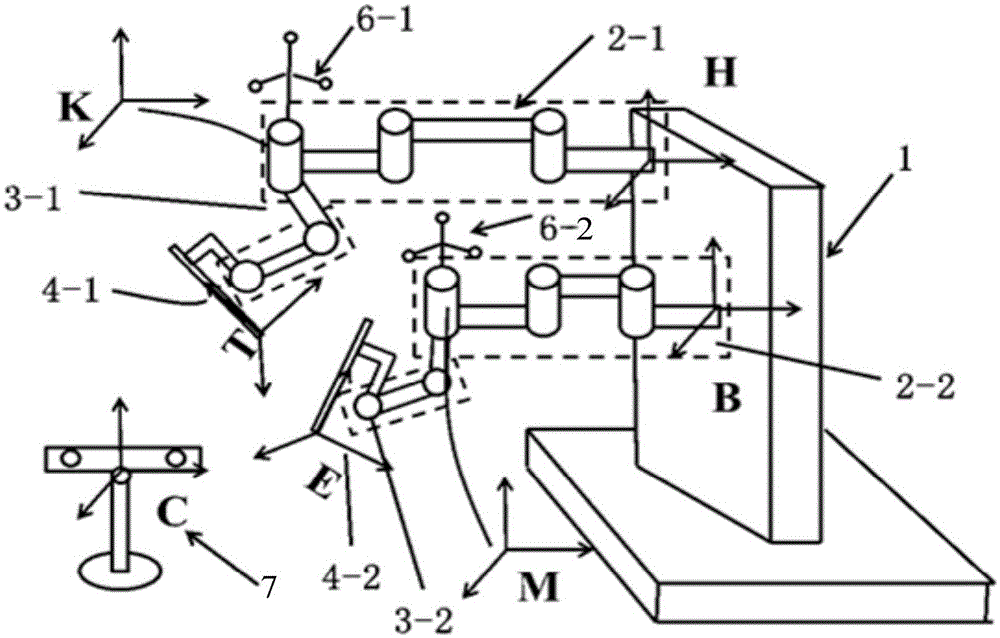

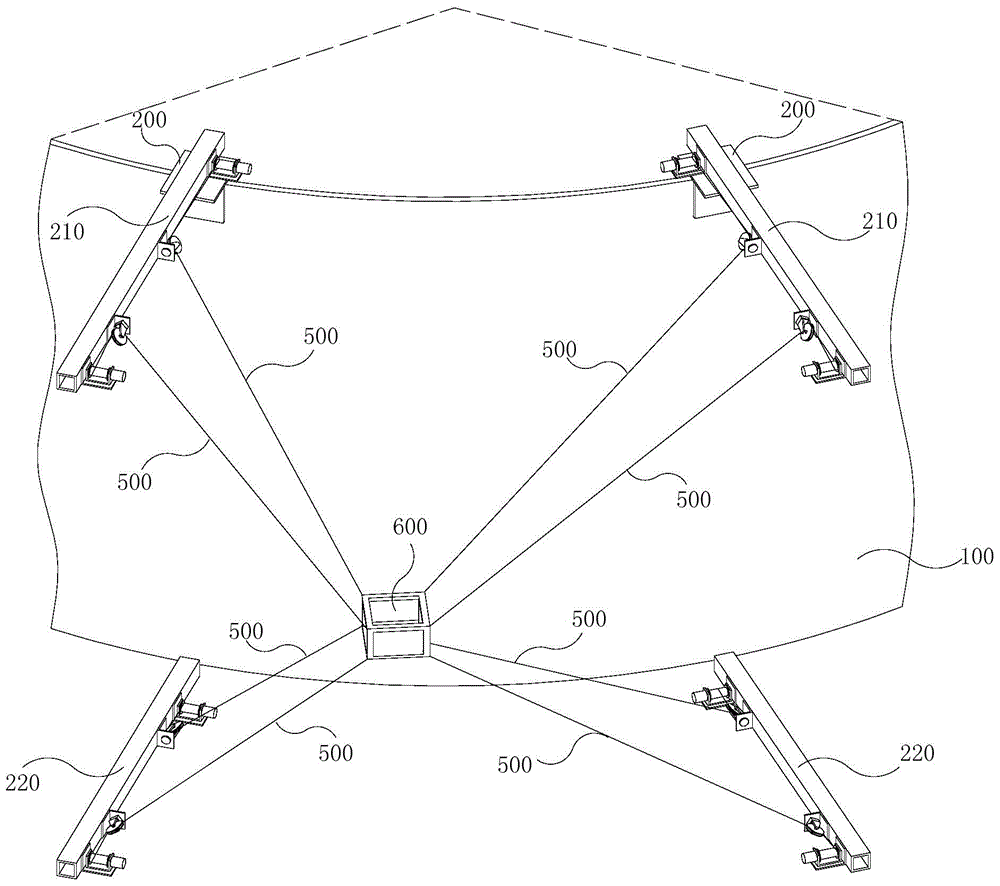

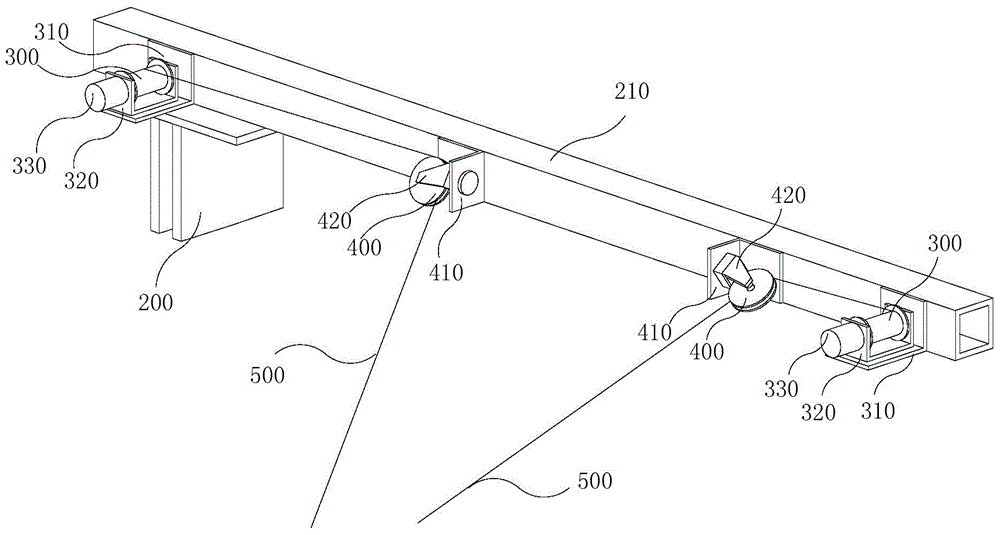

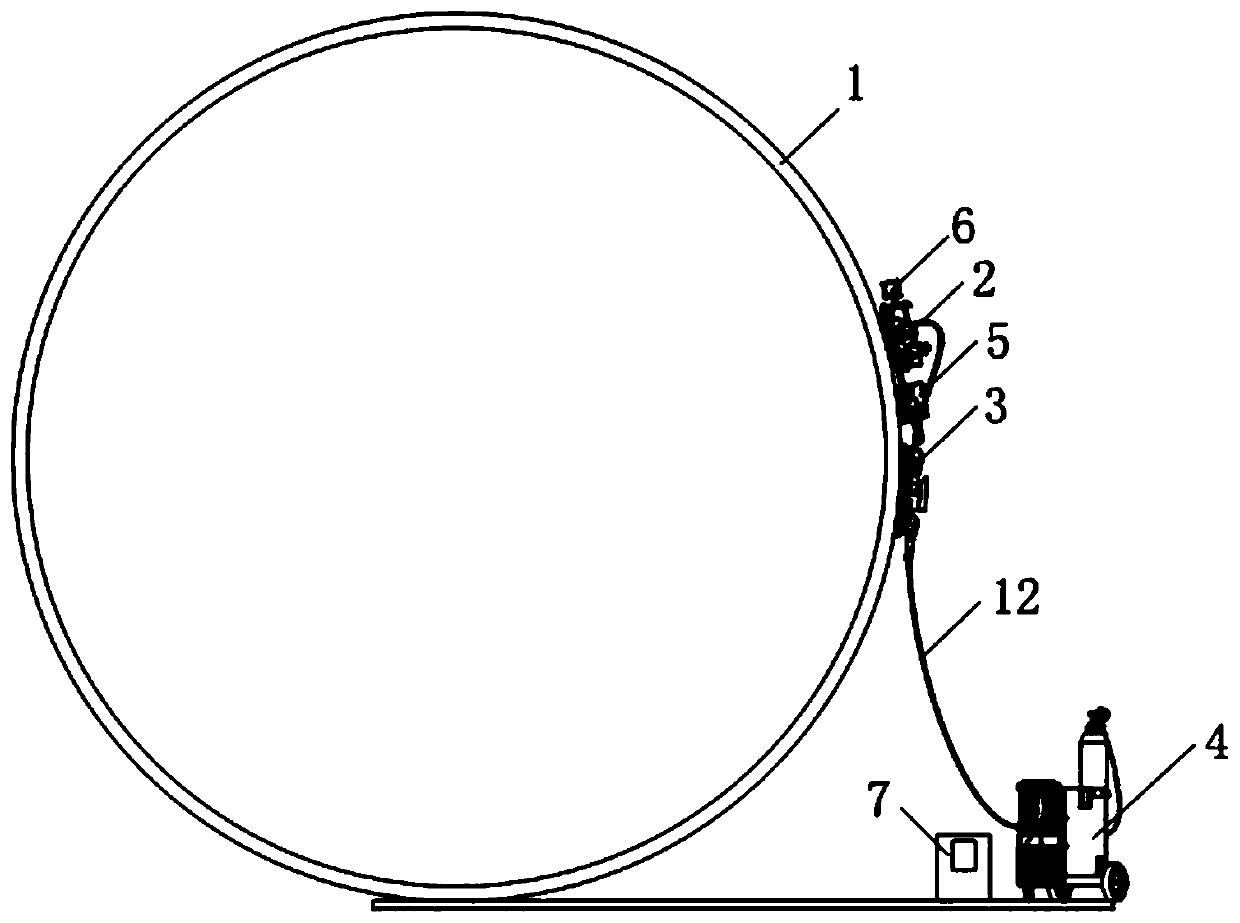

Rope parallel robot for overhauling large vertical storage tank

ActiveCN104440877AImprove Motion Control AccuracyLow costProgramme-controlled manipulatorControl systemModularity

A rope parallel robot for overhauling a large vertical storage tank comprises ropes, rope driving units, rope guide devices, a work platform, supporting rods, fixing pieces, a control system and other parts, the number of the ropes is eight, the number of the rope driving units and the number of the rope guide devices are eight correspondingly, and the rope driving units and the rope guide devices are installed on the outer side of the vertical storage tank and make the work platform to move along the outer side sector cylindrical face of the vertical storage tank with a certain load. The rope parallel robot is demounted and built on the outer side of the vertical storage tank multiple times so that the overhauling work of all the outer surfaces can be achieved; furthermore, a position sensor or a force sensor can be installed in a matched mode to improve the safety performance of the system. The standardized and modularized technology can be used, the varieties of parts in the system can be reduced, the universality among parts is high, and the rope parallel robot can adapt to the overhauling work of vertical storage tanks ranging from 10 m to 80 m.

Owner:TSINGHUA UNIV

Bionic-tentacle-based robot autonomous navigation method

ActiveCN105509729AGuaranteed real-timeSmall amount of calculationNavigational calculation instrumentsPosition/course control in two dimensionsBionicsSimulation

A bionic-tentacle-based robot autonomous navigation method is disclosed, according to the autonomous navigation method, a ''bionic tentacle'' model is disclosed from the point of view of bionics for understanding of sensor information, the autonomous navigation method comprises four walking behavior manners and six behavior trigger conditions, the walking behavior manners comprise aligned steering, straight advancing, avoiding and turning and arc circumvent, the behavior trigger conditions comprise alignment condition, yawing condition, meeting condition, avoiding condition, breaking-away condition and end condition, a bionic tentacle is used for perception of unknown environment around for real-time stimulation and triggering of a corresponding walking behavior, the whole process is designed based on bionics, the bionic-tentacle-based robot autonomous navigation method is suitable for a determined-target-point autonomous navigation task for a robot in unknown environment, can ignore obstacle edge shape restrictions, and is well adaptable to complex obstacle situations.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

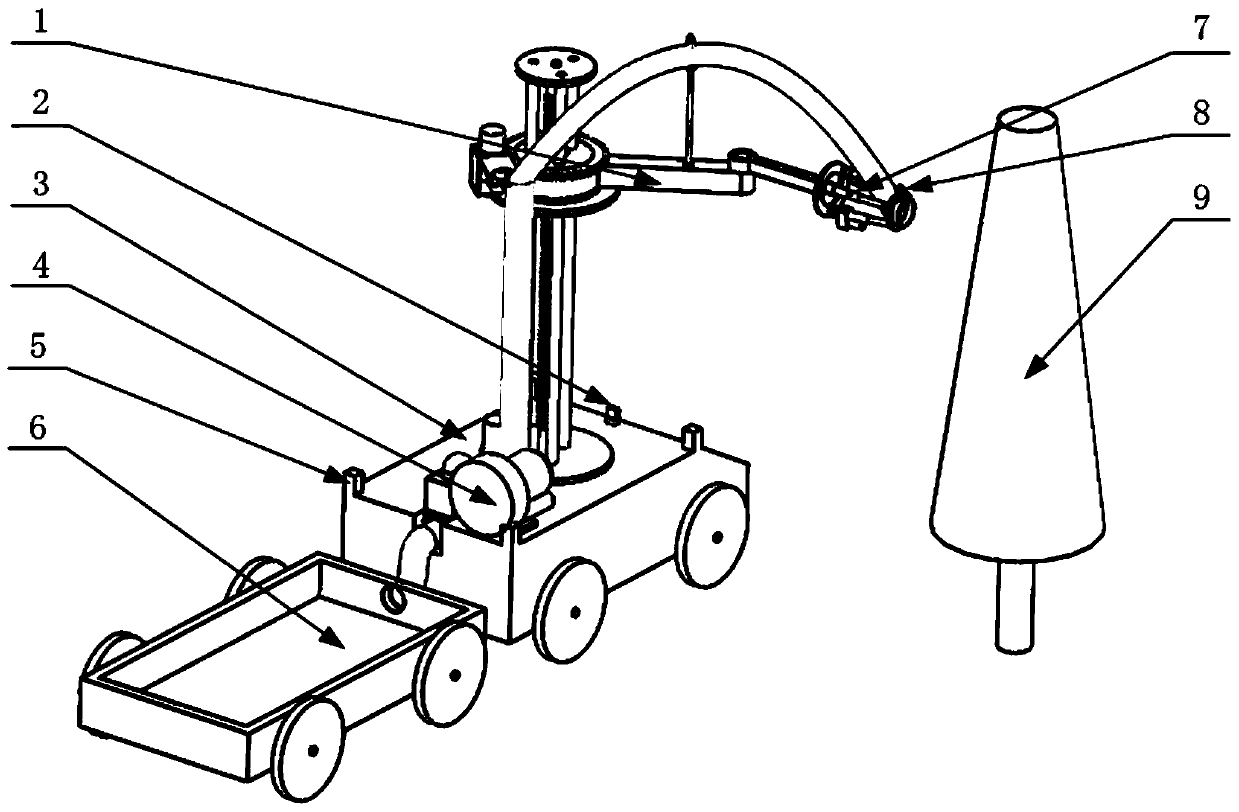

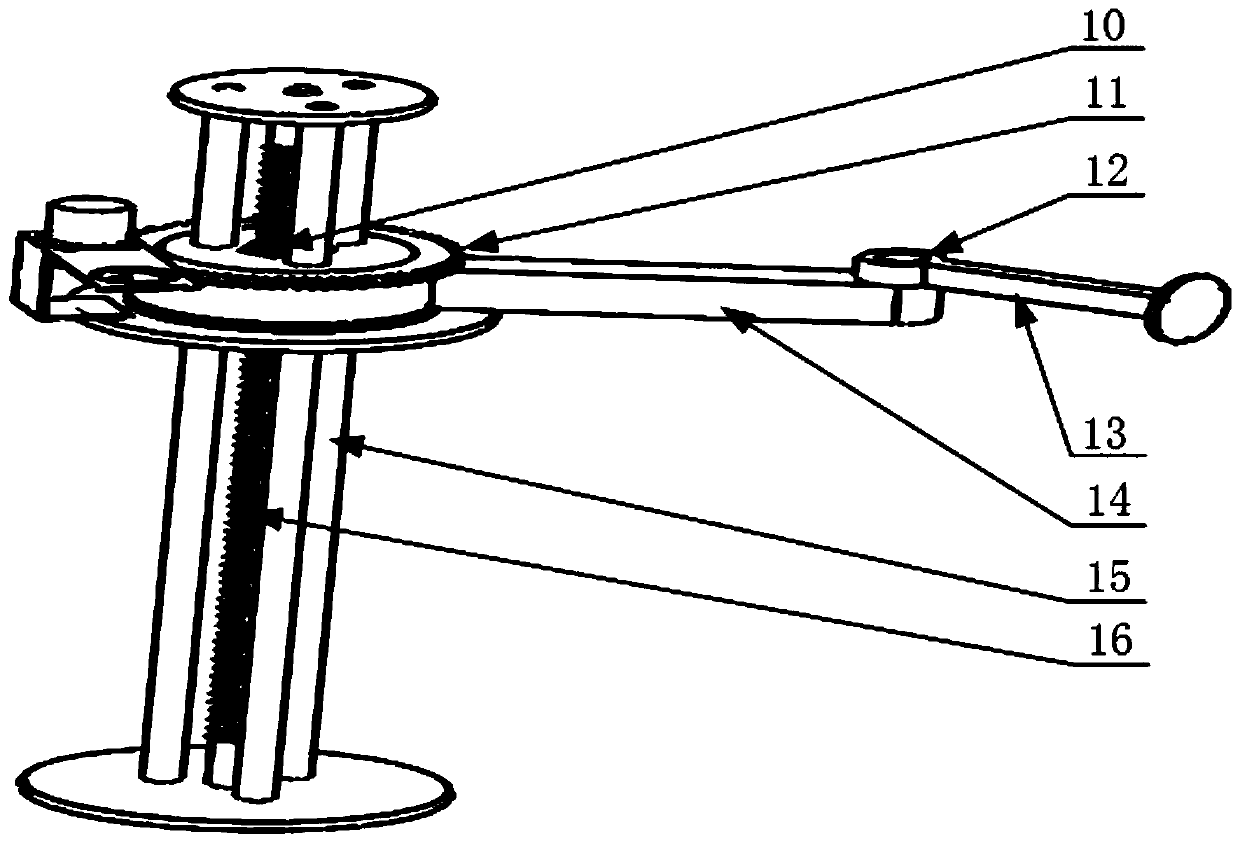

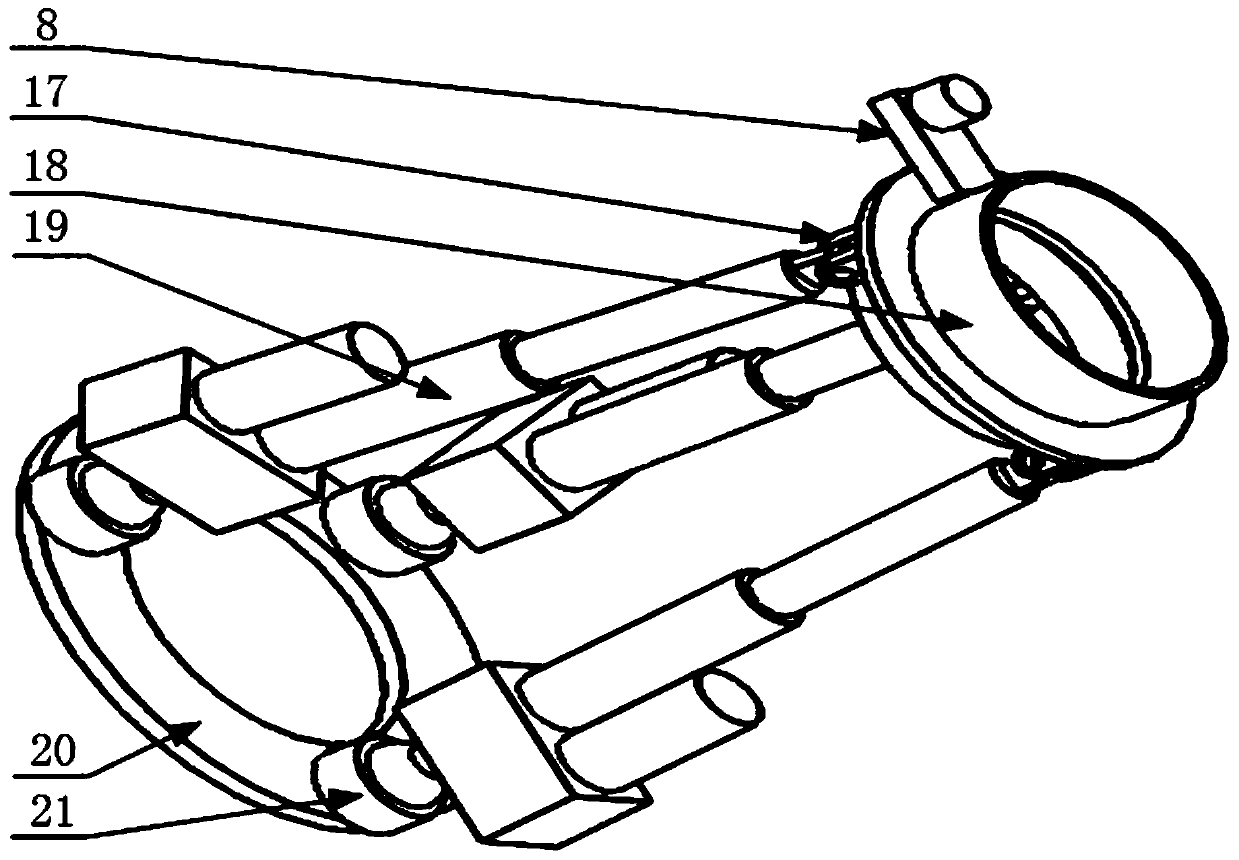

Fruit and vegetable picking robot and control method thereof

ActiveCN109773788ASimple structureLow costProgramme-controlled manipulatorPicking devicesCamera imageControl system

The invention discloses a fruit and vegetable picking robot and a control method thereof. The fruit and vegetable picking robot includes a mobile platform, a picking mechanical arm, a picking hand, acontrol system and a trailer. The mobile platform is connected with the trailer. The picking mechanical arm is installed on the mobile platform, and the picking hand is installed at the tail end of the mechanical arm. An eye-in-hand camera for obtaining pose information of a target object is mounted at the edge of the picking hand, the picking hand is provided with a vacuum picking device for picking fruits and vegetables, and the vacuum picking device conveys the fruits and vegetables to the trailer through vacuum tubes. A parallel adjusting mechanism is driven by six servo electric cylindersto realize the six-degree-of-freedom pose adjustment of the camera. The control system is used for processing the generation and transmission of camera image information and pose adjustment commands.The fruit and vegetable picking robot has the advantages of low cost, high precision, wide application range and the like, and is conveniently used in the picking process of various agricultural fruits and vegetables.

Owner:XI AN JIAOTONG UNIV

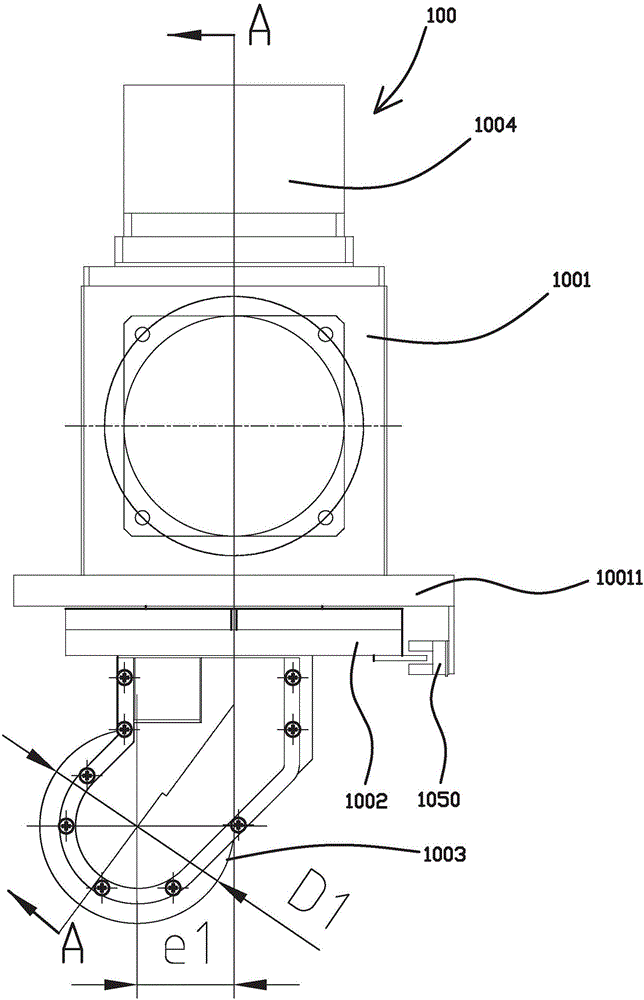

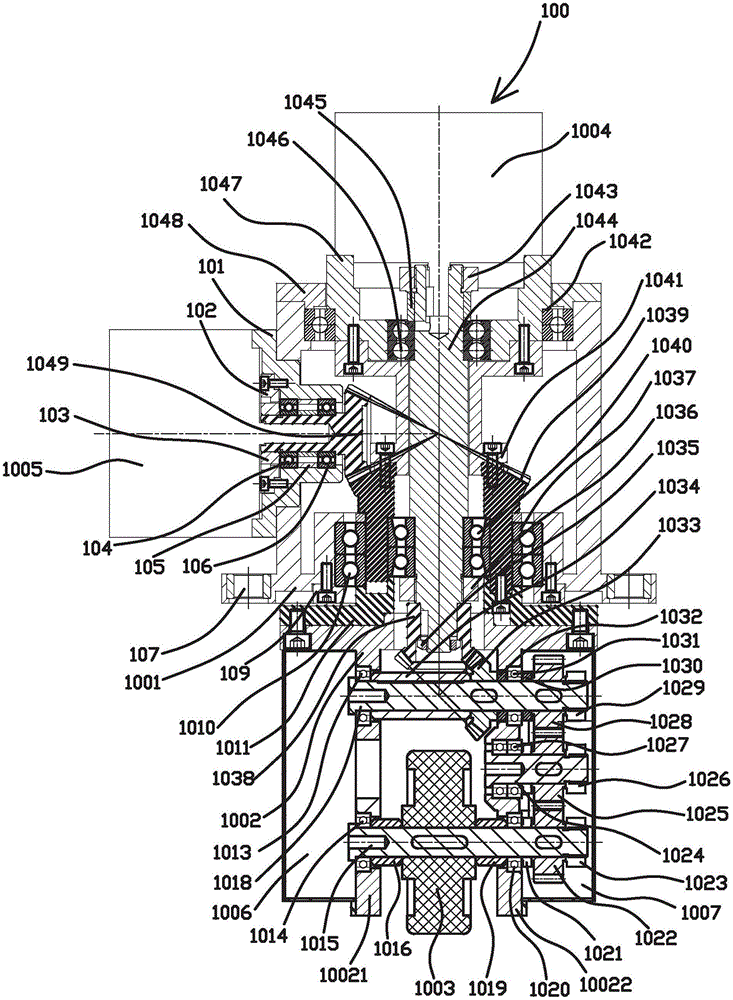

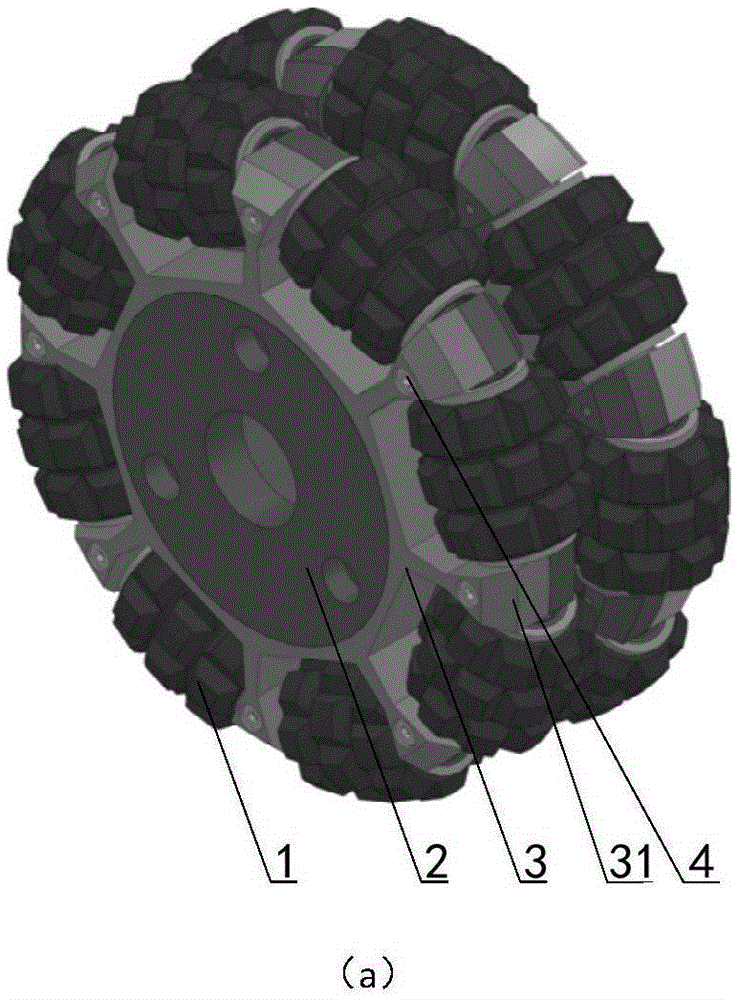

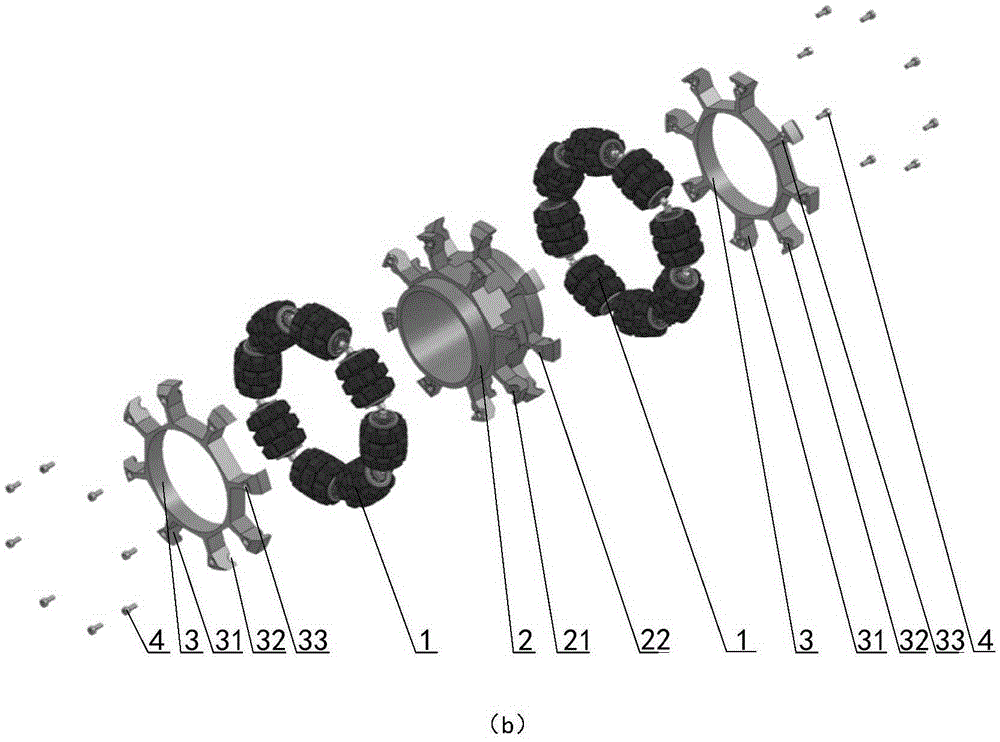

Omnidirectional moving platform and dynamic universal wheel thereof

ActiveCN105882784ANo sideslipSimple structureMotor depositionWheelsDegrees of freedomMovement control

The invention discloses an omnidirectional moving platform and a dynamic universal wheel thereof. The dynamic universal wheel comprises an upper frame, a lower frame, a roller, a first motor and a second motor, the lower frame is rotatably connected to the upper frame, the roller is rotatably mounted to the lower frame, the first motor is mounted on the upper frame and used for driving the lower frame to rotate, the second motor is connected with the roller to drive the same to roll, and rotating of the lower frame and rolling of the roller are controlled independently through the first motor and the second motor respectively. When the omnidirectional moving platform runs, degrees of freedom of steering and driving motion are not coupled, so that no extra rolling motion of the roller is output during steering motion; a special mechanism does not need to be added for decoupling, so that the omnidirectional moving platform is simple in structure, free of lateral sliding during running, smooth in steering motion and high in motion control accuracy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

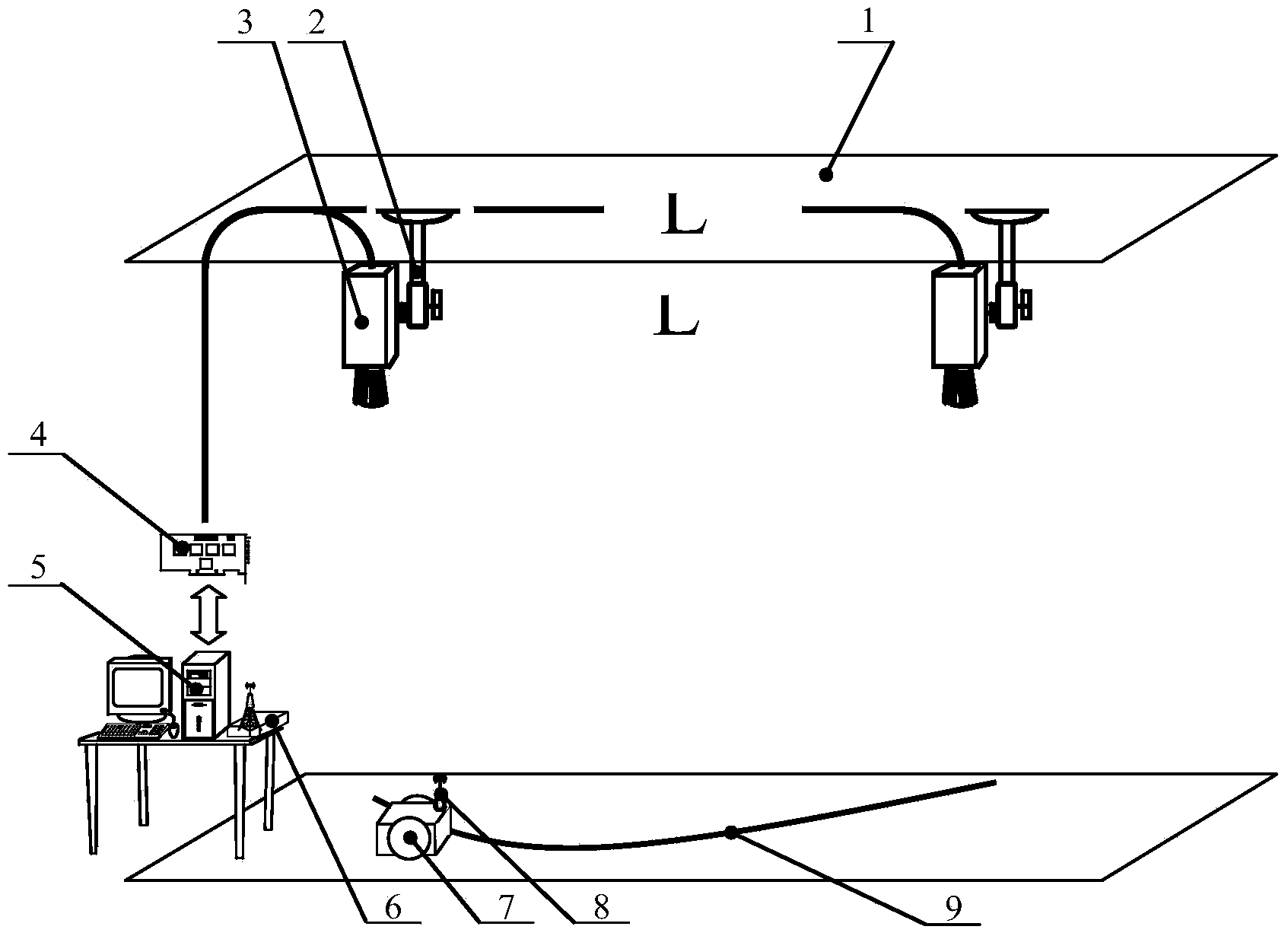

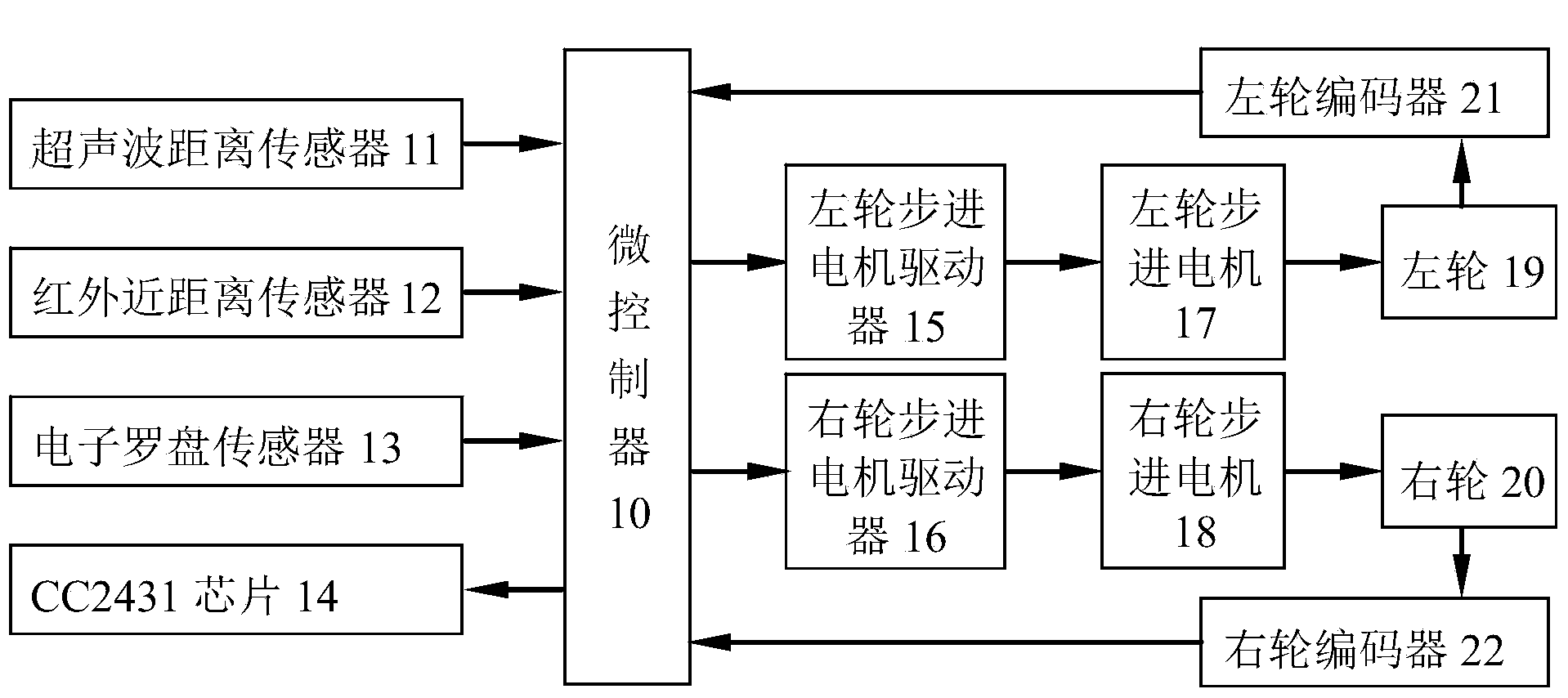

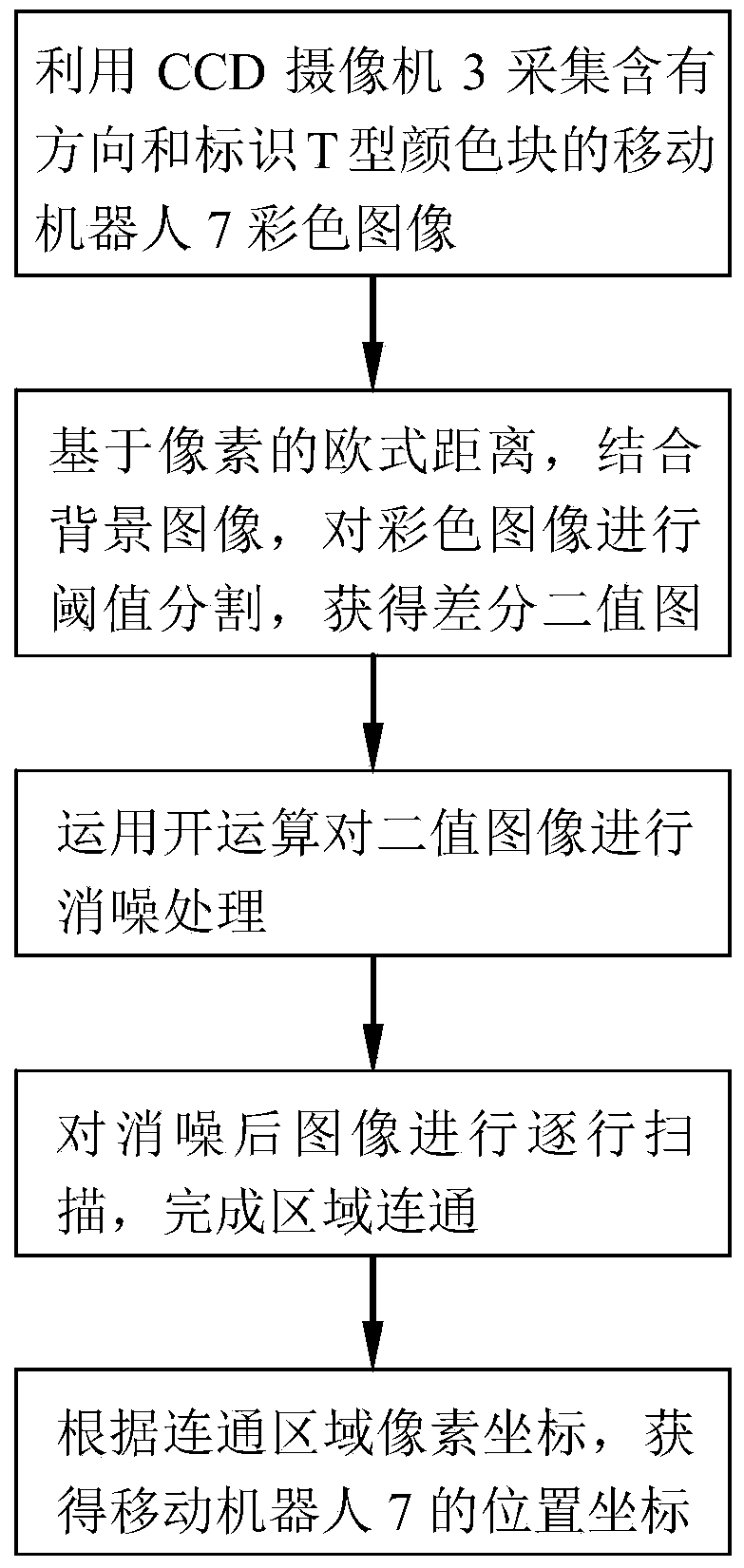

Motion control system and method of mobile robot in intelligent space

InactiveCN103454919AImprove Motion Control AccuracySmall amount of calculationAdaptive controlPosition/course control in two dimensionsMobile robot controlControl system

The invention discloses a motion control system and method of a mobile robot in an intelligent space. The motion control system is composed of the intelligent space and the mobile robot. The intelligent space comprises a monitoring host, a distributed visual system and a wireless sensor network system based on Zigbee. The motion control method of the mobile robot in the intelligent space comprises the steps that pose information of the mobile robot is obtained at first; then control deviation e of the mobile robot is obtained; mobile robot multi-objective self-regulation PID motion control based on an RBF identification network is conducted at last. Compared with an existing mobile robot control system based on a vehicle-mounted video, the motion control system and method of the mobile robot in the intelligent space have the advantages of being small in calculated amount, good in instantaneity, and more accurate in motion control.

Owner:JIANGSU UNIV OF SCI & TECH

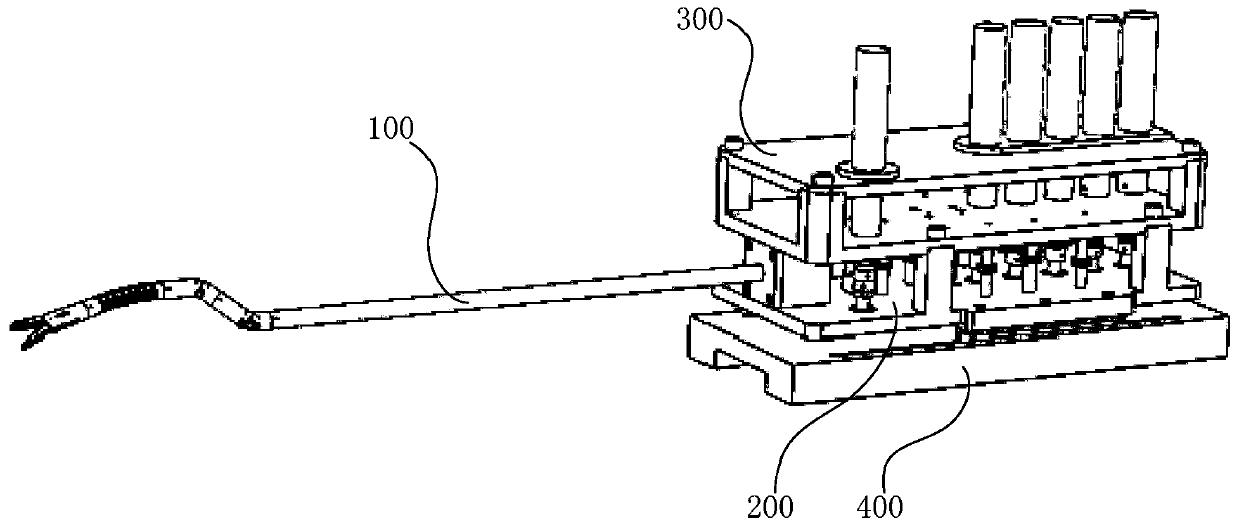

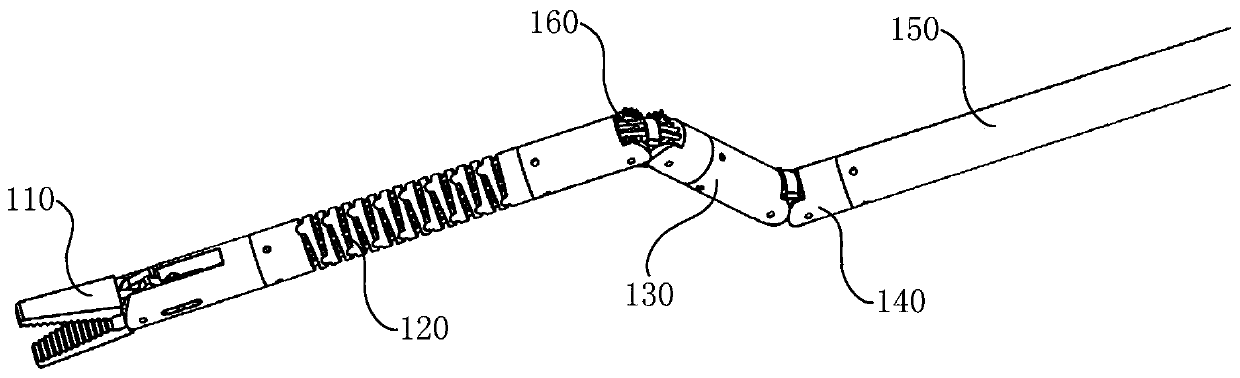

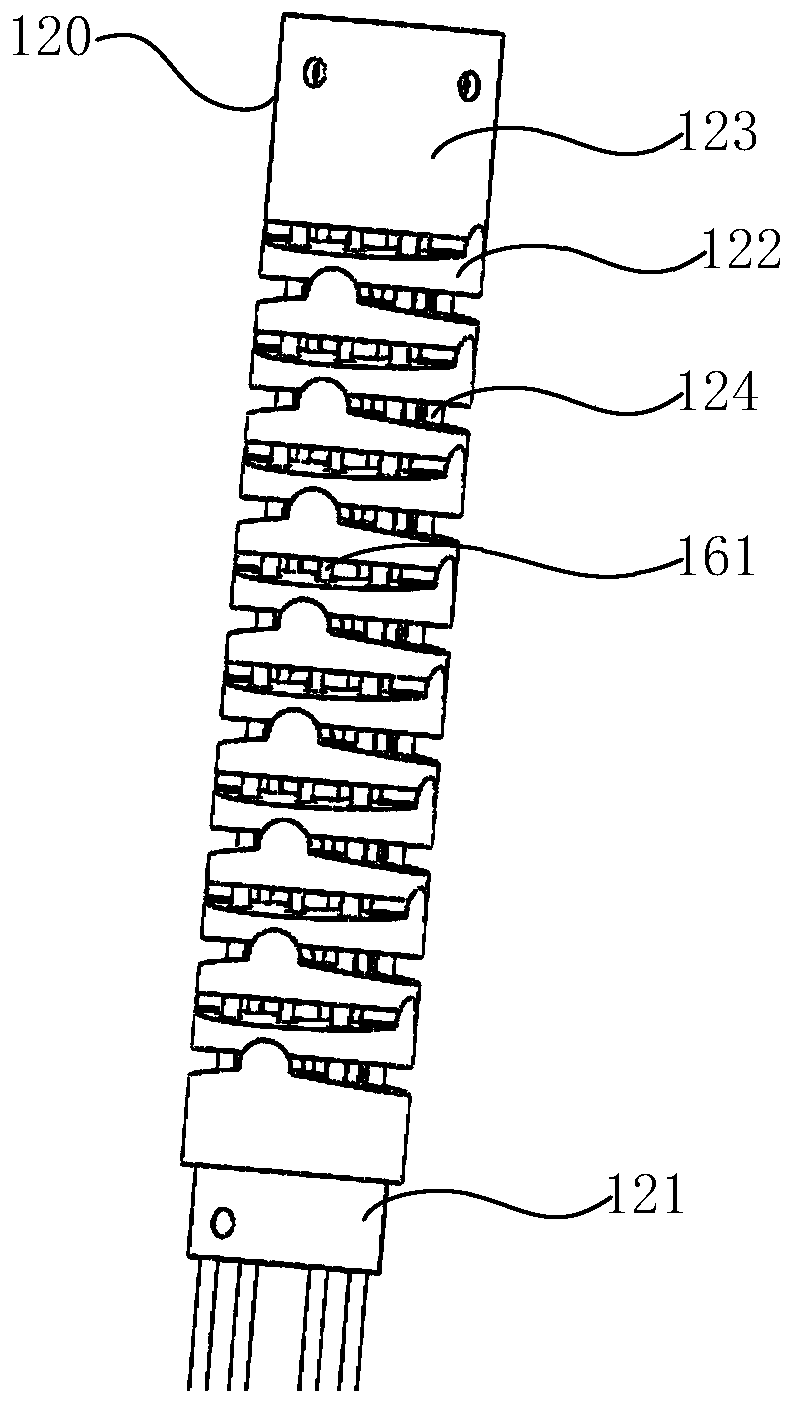

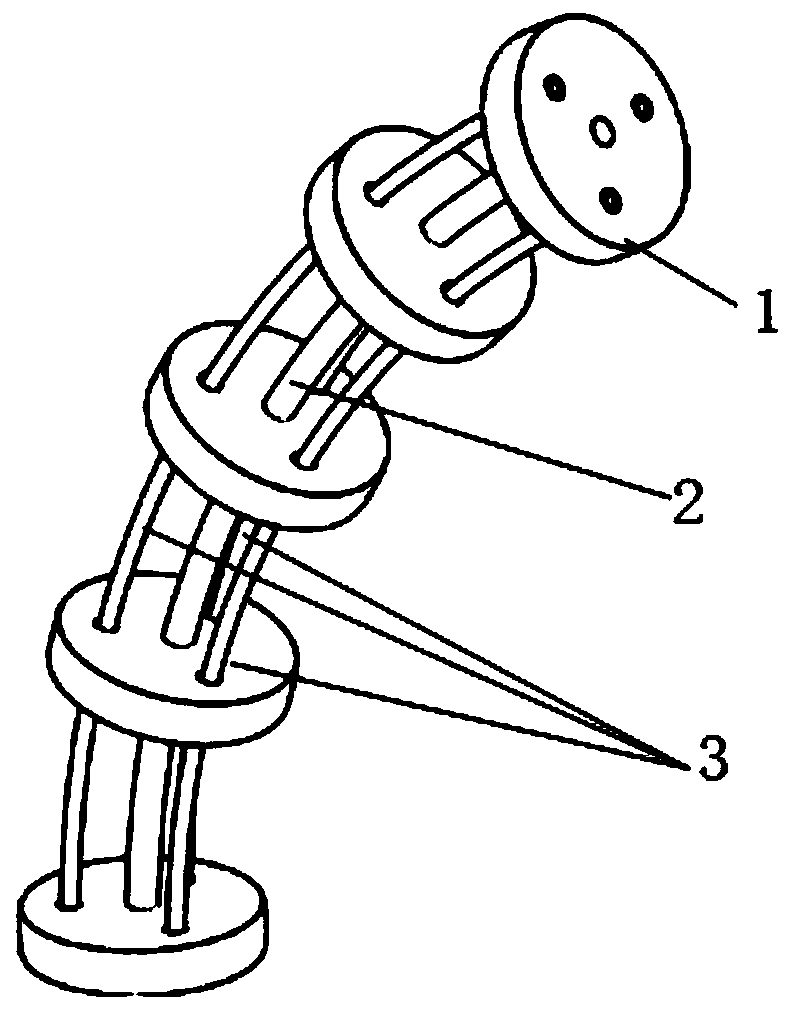

Snake-shaped surgical robot applied to minimally invasive surgery

ActiveCN111437036AEasy to operateGood resistance to deformationSurgical robotsPhysical medicine and rehabilitationMinimally invasive procedures

The invention provides a snake-shaped surgical robot applied to minimally invasive surgery. The snake-shaped surgical robot comprises a sliding table module, a pulley module connected to the sliding table module in a sliding manner, a driving module arranged on the pulley module and a mechanical arm connected with the pulley module, wherein the driving module provides power for the mechanical armthrough the pulley module; the mechanical arm comprises an operation actuator, a first joint which is connected with the operation actuator and can do bending motion, and a second joint which is connected with the first joint and can do swinging motion, wherein the first joint is of a continuum structure, and the second joint is of a gear meshing structure. The mechanical arm is formed by matchingthe continuum structure and the gear meshing structure; the rigidity of the mechanical arm is effectively improved in the premise that the flexible movement and the deformation capability of the tailend of the mechanical arm can be ensured; and moreover, the coupling effect of the mechanical arm of an existing surgical robot can be achieved or improved, and the motion control precision of the mechanical arm is improved. Compared with the existing surgical robot, the snake-shaped surgical robot is high in operability.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

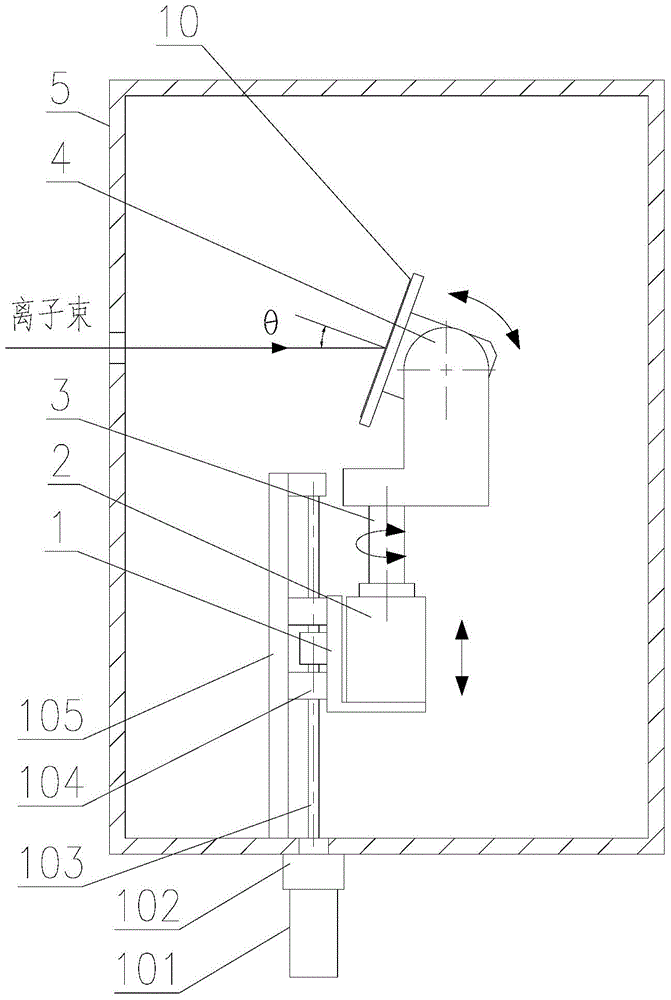

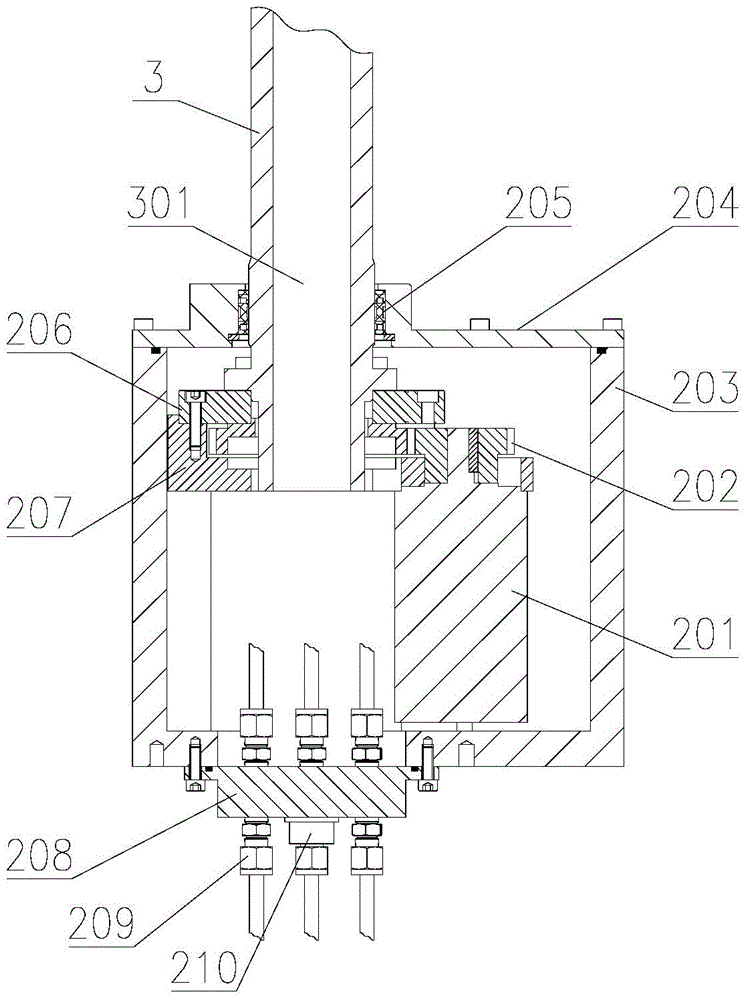

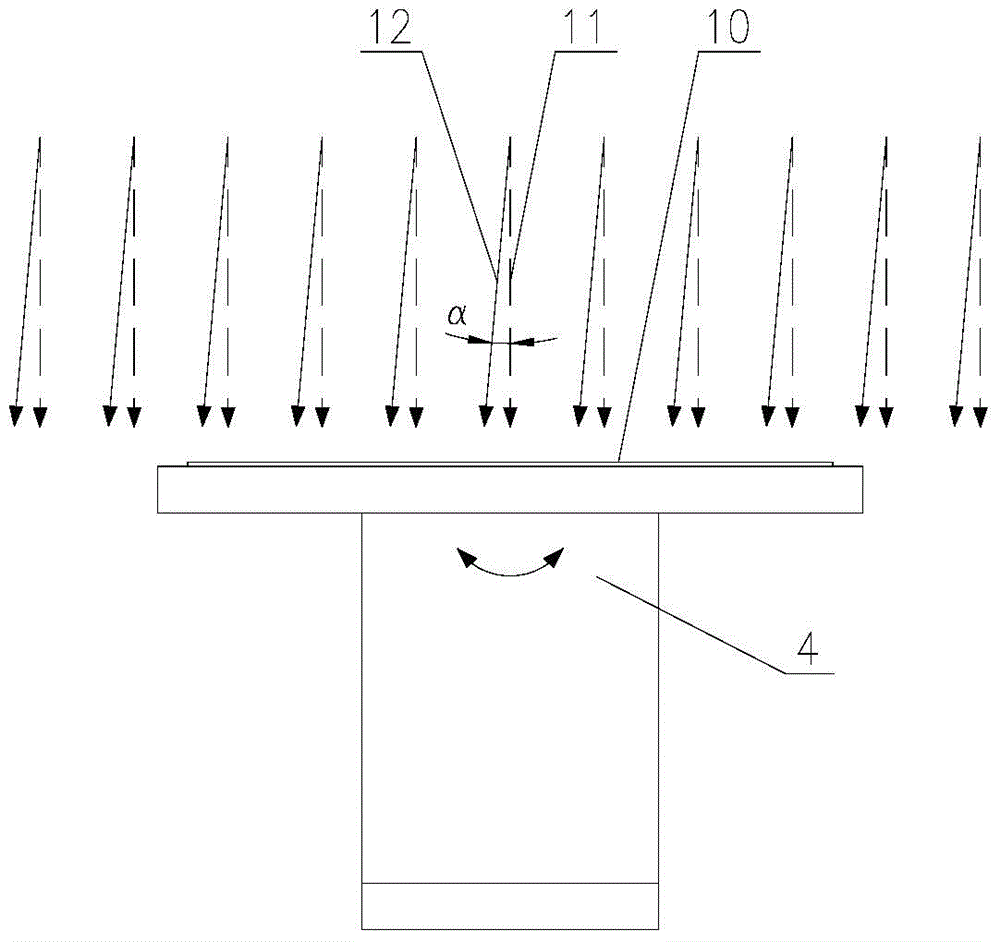

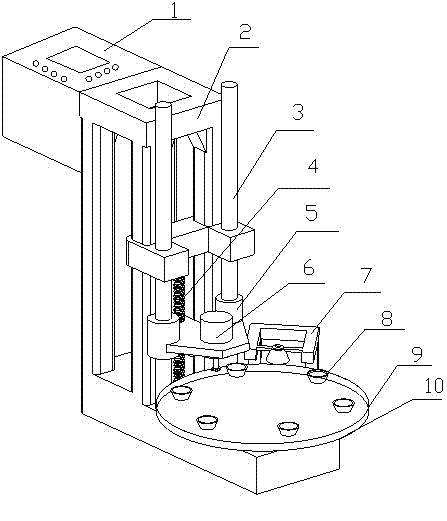

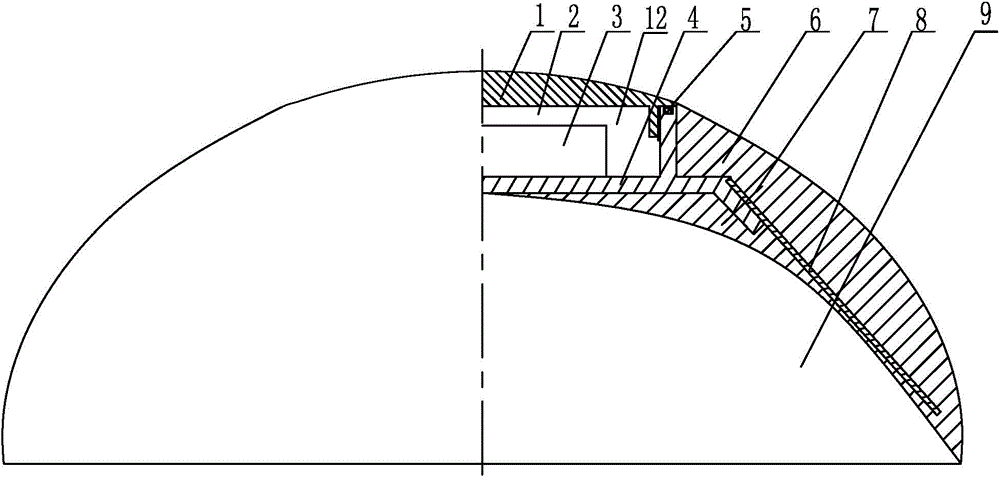

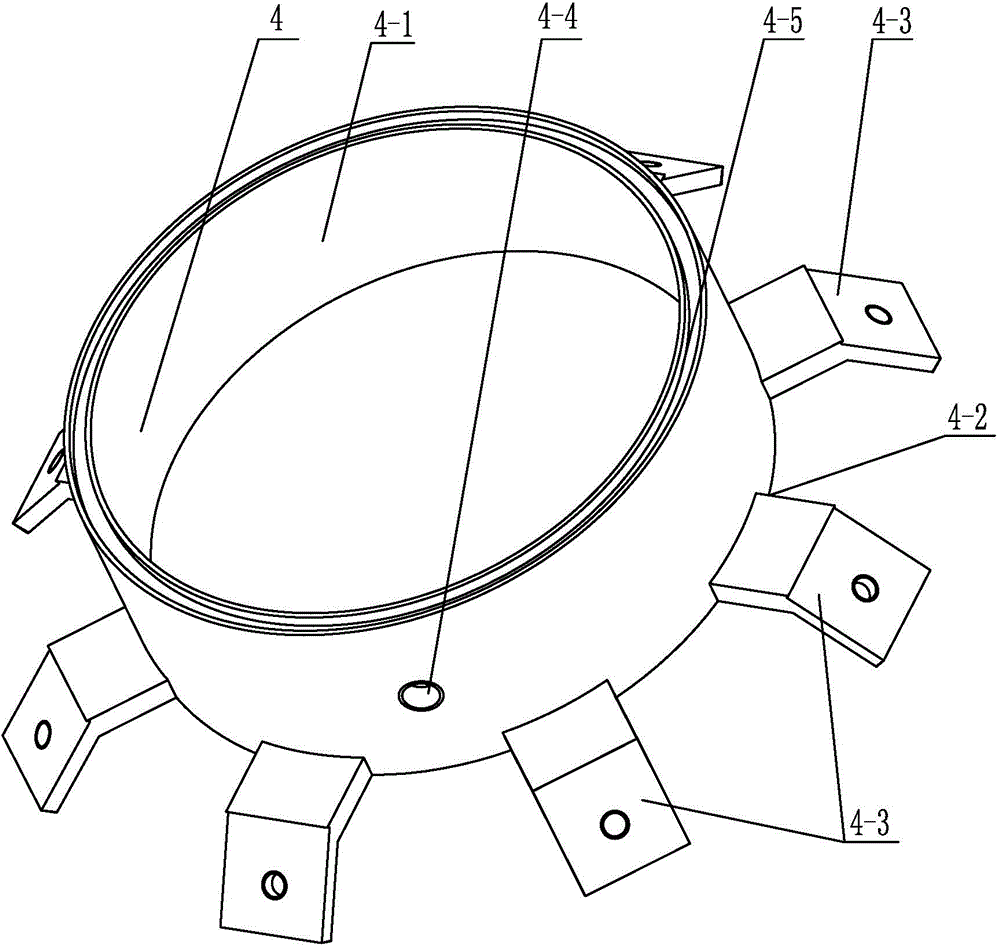

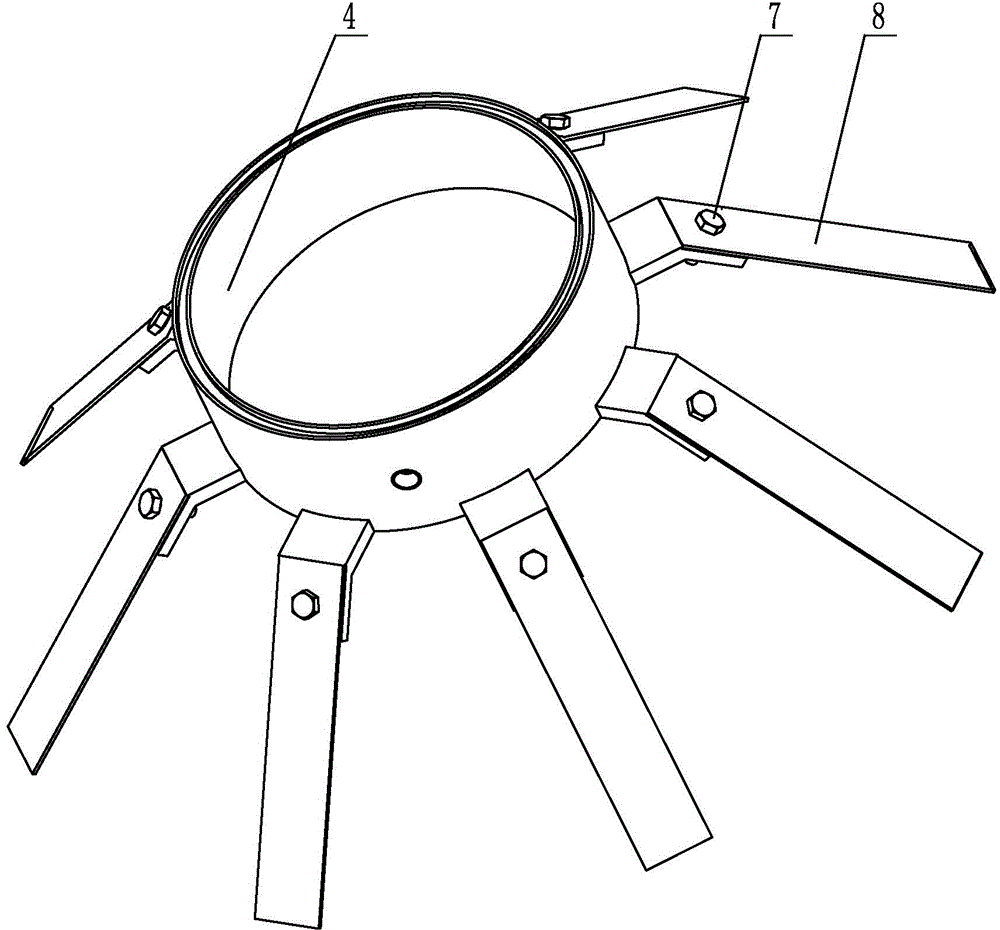

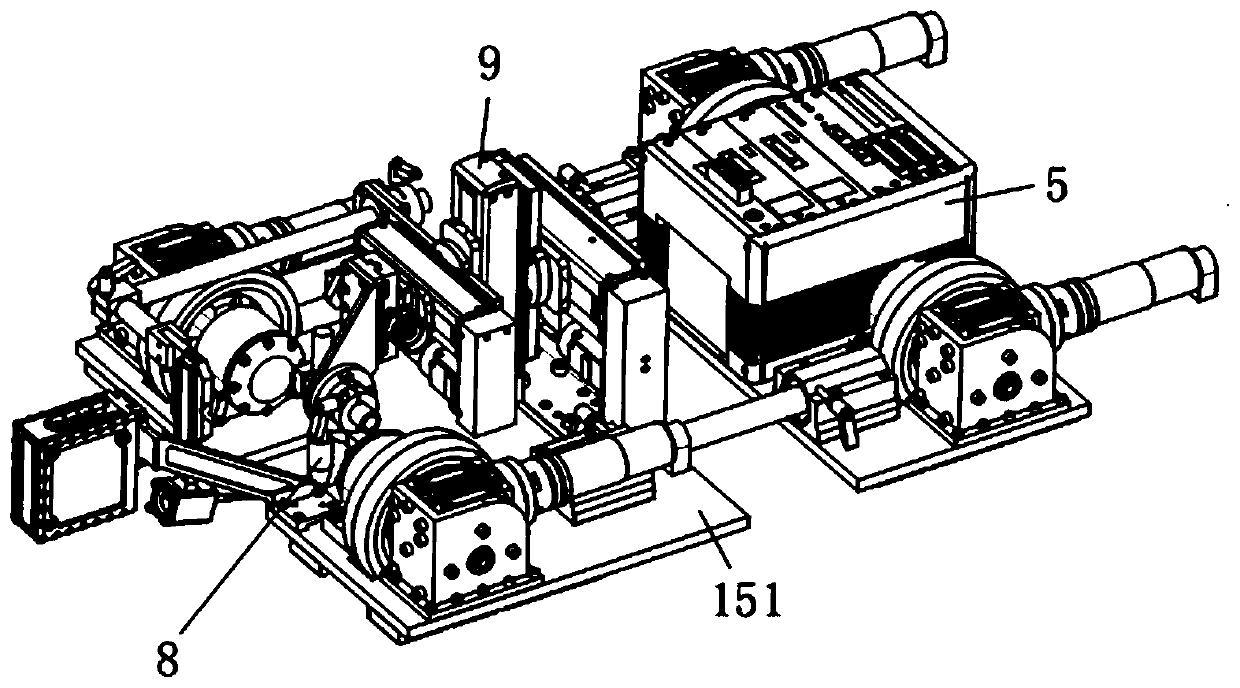

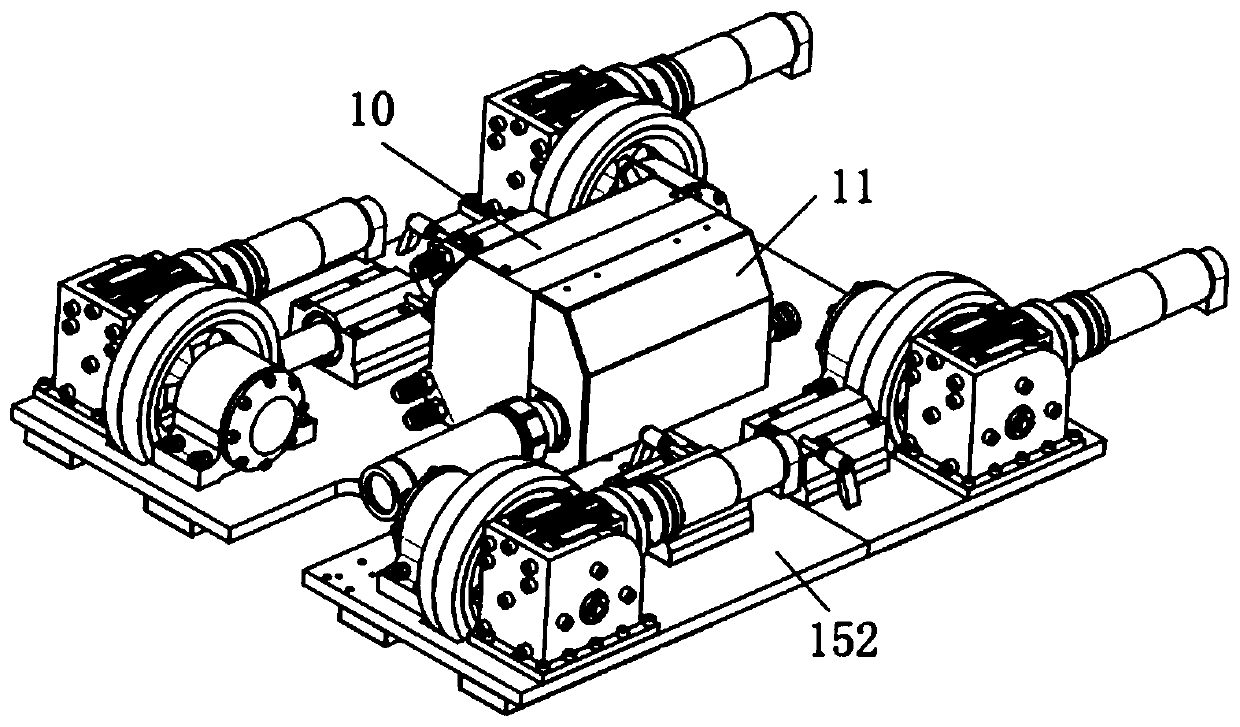

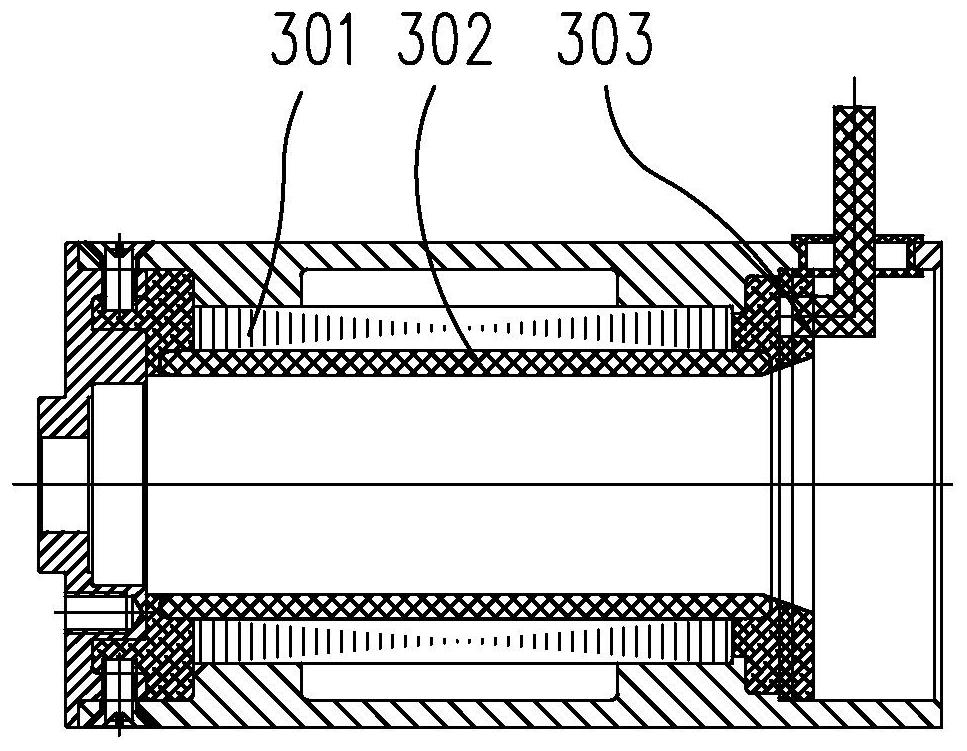

Ion implanter scanning device and scanning method

InactiveCN104409307AStable rotary sealReliable rotary sealElectric discharge tubesAngular degreesEngineering

The invention discloses an ion implanter scanning device and a scanning method. The scanning device comprises a fixed base, a vertical scanning mechanism which is installed on the fixed base and capable of moving up and down along the fixed base vertically, a horizontal rotation mechanism which is installed on the vertical scanning mechanism and can horizontally rotate and a scanning shaft which is installed on the horizontal rotation mechanism; the top end of the scanning shaft is provided with a target platform which can rotate along with the scanning shaft and used for clamping a wafer; an angle adjusting mechanism which adjusts the chip gradient is installed on the target platform to rectify an iron implantation angle. The scanning method comprises arranging an implantation angle theta firstly and calculating the scanning stroke s and the scanning times n; enabling the target platform 4 to rotate by an angle alpha to perform angularity correction, enabling the target platform 4 to incline to the implantation angle theta and finally aching scanning. The scanning device and method can achieve target platform vertical direction scanning movement, meanwhile can enable the target platform to rotate surrounding the scanning shaft through the horizontal rotation mechanism to perform angle correction and can achieve more accurate implantation angle control.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

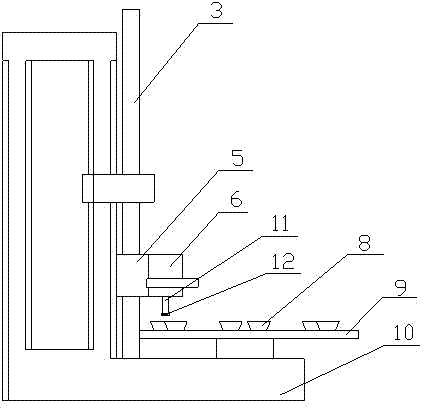

Automatic garlic root cutting machine based on image processing technique

InactiveCN103027368AAchieve consistencyAchieve precisionFood treatmentHuman interactionAutomatic control

The invention relates to an automatic garlic root cutting machine based on an image processing technique. The automatic garlic root cutting machine comprises a base, a machine frame, a control box I, a material conveying mechanism, a cutting mechanism and an image collecting mechanism, wherein the control box I, the material conveying mechanism and the cutting mechanism are arranged on the machine frame, the control box is respectively connected with the material conveying mechanism and the cutting mechanism, the material conveying mechanism comprises a driving motor I and a material disc, the driving motor I and the material disc are fixedly arranged on the base, the cutting structure comprises a driving motor II, slide rails, a ball screw and a cutting knife, the cutting knife is arranged on the cutting seat, the cutting seat is also provided with a cutting motor and a site detection device, the cutting seat is fixedly connected with the ball screw, the cutting knife is slidingly connected with the slide rails, the image collecting mechanism is connected with the control box, the image collecting mechanism comprises a bracket and a lens, the lens is arranged on the bracket, and the lens is arranged directly above the circle of material cups. The automatic garlic root cutting machine has the advantages that the garlic root cutting quality is improved, and the loss is reduced; and the functions of real-time communication, human-human interaction and multiple protections are realized, and the automatic control of the garlic root cutting is realized.

Owner:QINGDAO AGRI UNIV

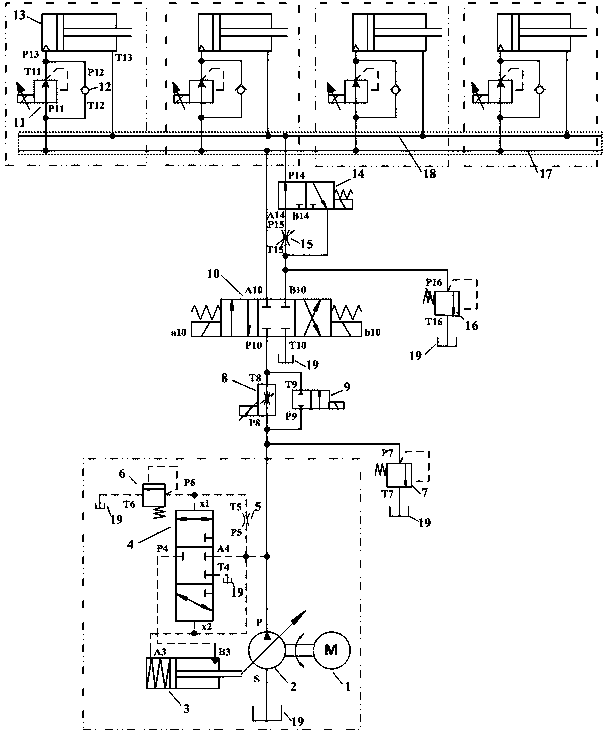

Pressure-flow whole-process-adaptive TBM (tunnel boring machine) propelling hydraulic system

InactiveCN103727099AIncrease flexibilityReduce control difficultyServomotor componentsFluid-pressure actuator componentsEngineeringTunnel boring machine

The invention discloses a pressure-flow whole-process-adaptive TBM (tunnel boring machine) propelling hydraulic system which comprises a motor, a variable pump, a variable cylinder, a three-position three-way reversing valve, a throttling port, an overflow valve, a safety valve, a proportional speed adjusting valve, a two-position two-way reversing valve, a three-position four-way proportional reversing valve, four proportional pressure reducing valves, four one-way valves, four hydraulic cylinders, a two-position three-way reversing valve, a variable throttling port, a proportional overflow valve, an oil incoming pipe, an oil returning pipe and an oil tank. The proportional speed adjusting valve is adopted to primarily adjust flow of the system, each propelling hydraulic cylinder is controlled by adopting an independent proportional pressure reducing valve, so that realtime coordinate control can be realized in the whole process of quick propelling, normal propelling and quick backing of a TBM. The pressure-flow whole-process-adaptive TBM propelling hydraulic system can adapt to tunneling conditions of complex geographic environments and is suitable for propelling motion control of propelling, supporting and step-changing whole-process hard rock tunneling equipment under various geographic conditions.

Owner:ZHEJIANG UNIV

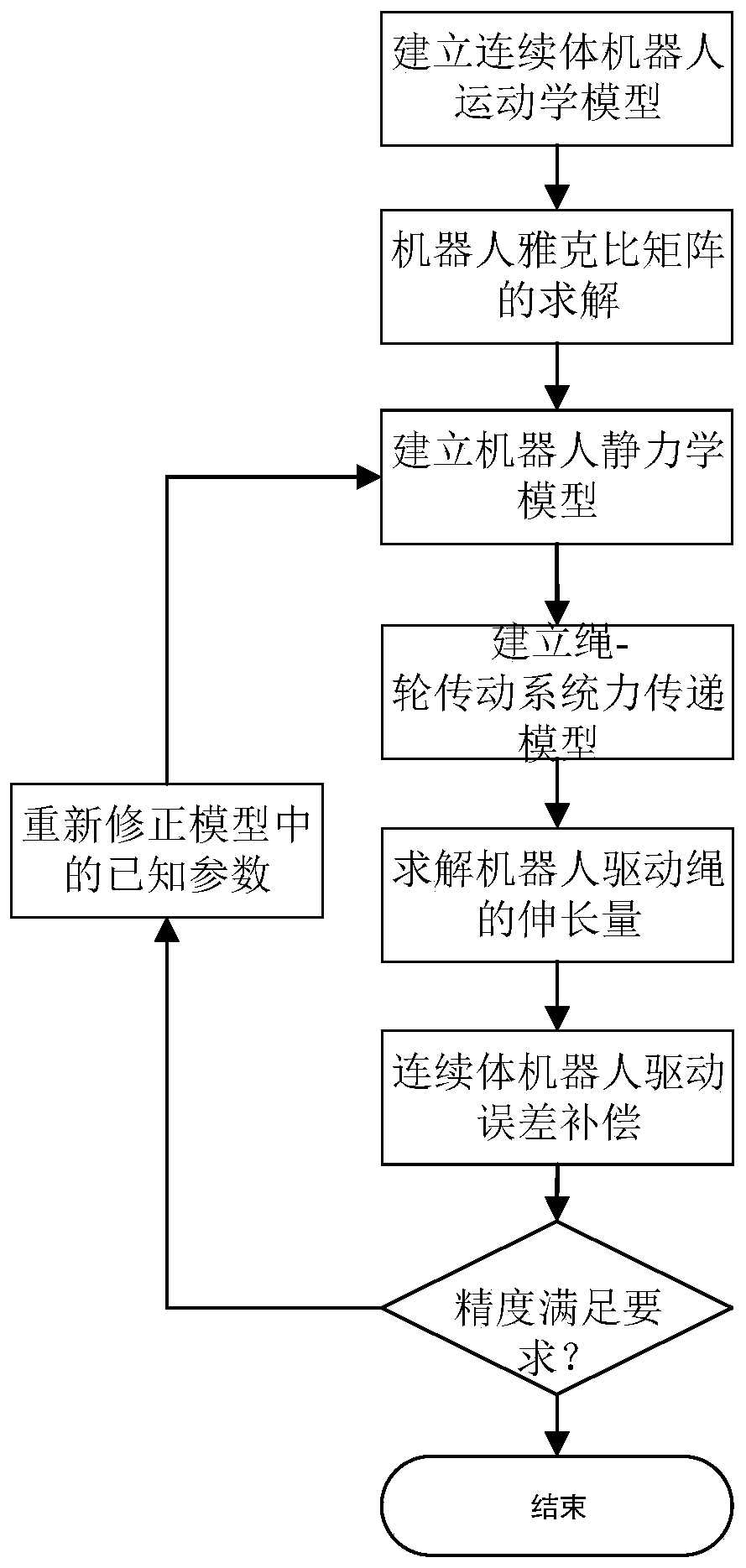

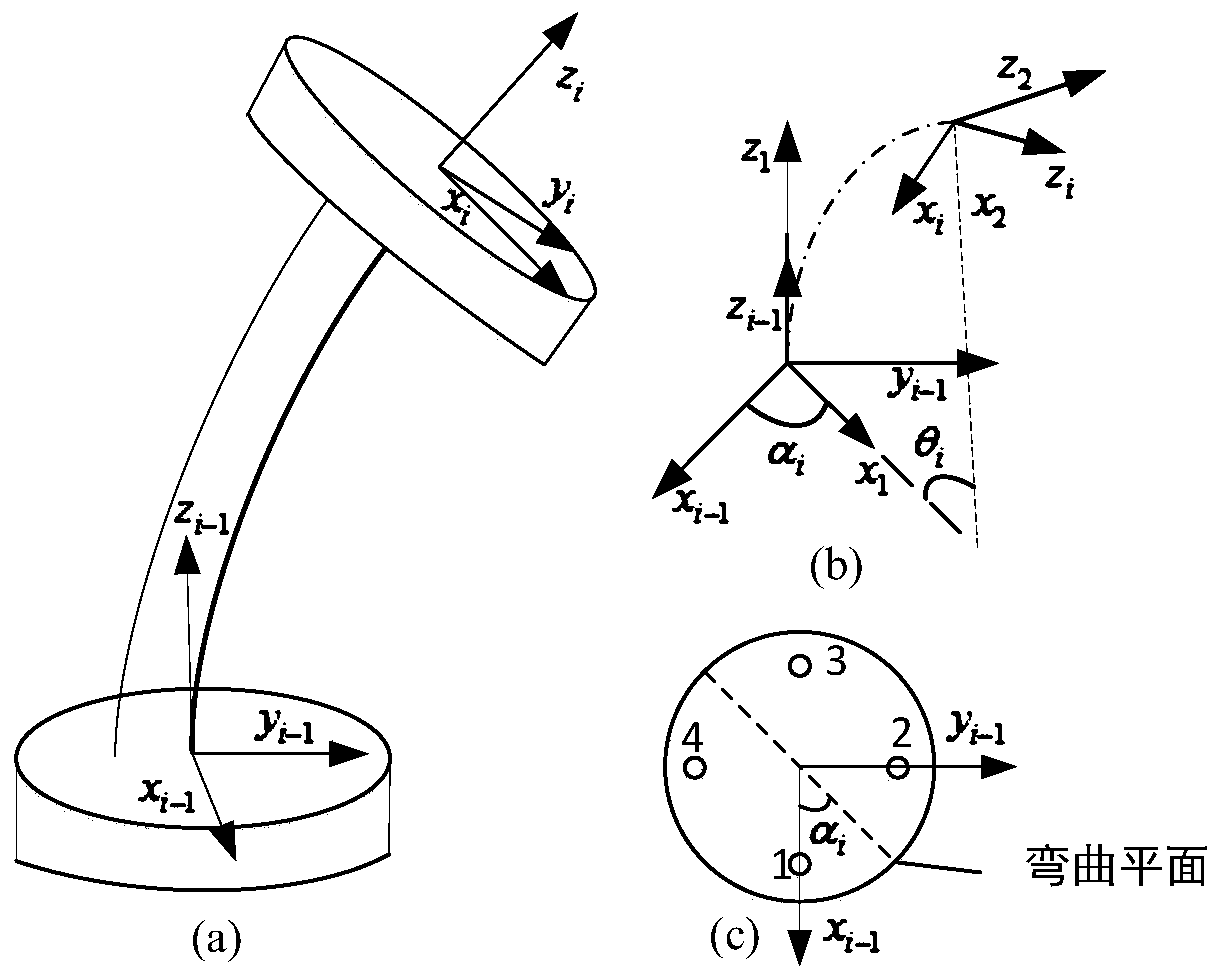

Driving compensation method for rope-driving continuum robot

ActiveCN110193827AImprove Motion Control AccuracyHigh control precisionProgramme-controlled manipulatorSimulationVirtual work

The invention discloses a driving compensation method for a rope-driving continuum robot. The method specifically comprises the following steps of establishing a kinematic model of the continuum robot by combining a segmented constant curvature arc hypothesis and a geometric analysis method; solving Jacobian matrix of the robot based on differential transformation principle; establishing a statics model of the robot based on virtual work principle; building a force transmission model of a rope-wheel drive system based on Coulomb friction; solving the elongation of a robot driving rope based on Hooke's law; and feeding back the driving rope length compensation amount to a control unit to realize error compensation of the transmission system of the continuum robot and improve the motion control precision of the robot. The method of has the characteristics of simplicity, high efficiency, low cost, good universality and the like, avoids using expensive measuring sensors, and realizes thepurpose of improving the motion control precision of the robot by establishing a driving error compensation model of the continuum robot system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

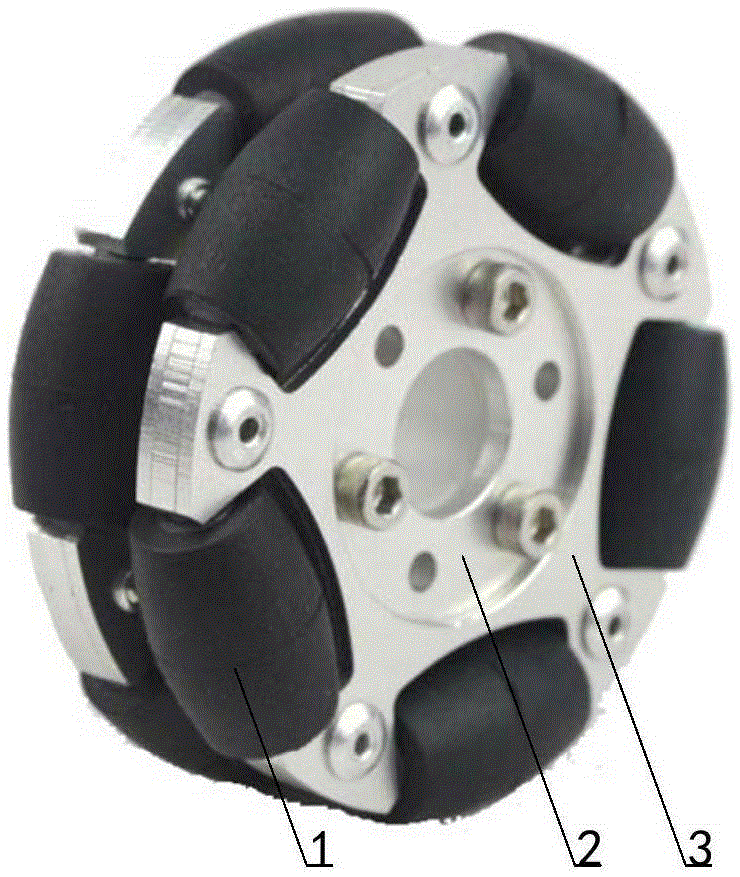

Omnidirectional wheel

The invention provides an omnidirectional wheel which comprises a plurality of driven wheels, a wheel hub and two end covers, wherein each driven wheel comprises a support shaft, a support sleeve, a rubber sleeve, two linings and two bearings; the support shaft sequentially passes through one lining, one bearing, the support sleeve, the other bearing and the other lining; the two bearings are clamped at two ends of the support sleeve, so that the support sleeve can not generate displacement in radial and axial directions relative to the support shaft; the outer ring of each bearing can rotate relative to the support shaft, and the inner ring of each bearing is relatively fixed with the support shaft; and one side of each lining is clamped in the wheel hub, and the other side of each lining clamps the inner ring of each bearing. The omnidirectional wheel provided by the invention overcomes the defects that the existing omnidirectional wheel is poor in motion control precision and the driven wheels stall and are not convenient to disassemble and assemble.

Owner:NAT UNIV OF DEFENSE TECH

Jellyfish imitating underwater propelling device driven by embedded flexible joints

InactiveCN104443331AEvenly distributedIncrease in sizePropulsive elements of non-rotary typeMovement controlEngineering

Owner:HARBIN INST OF TECH

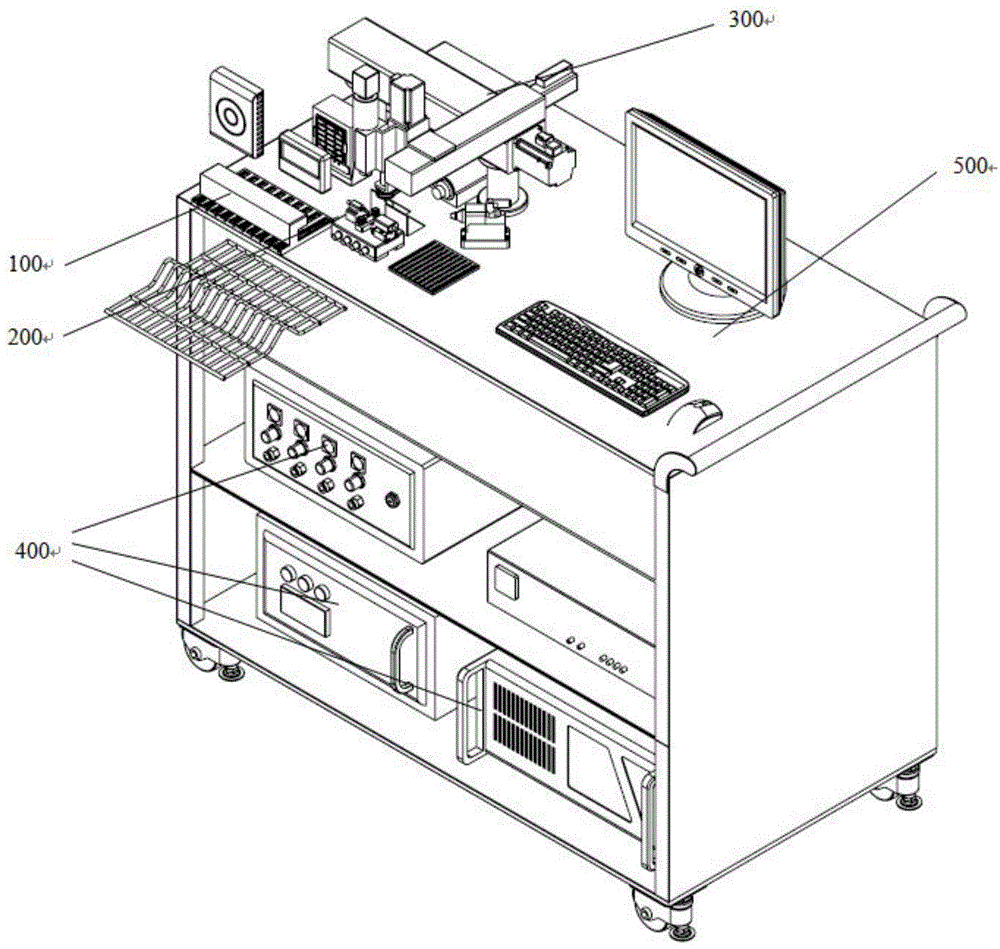

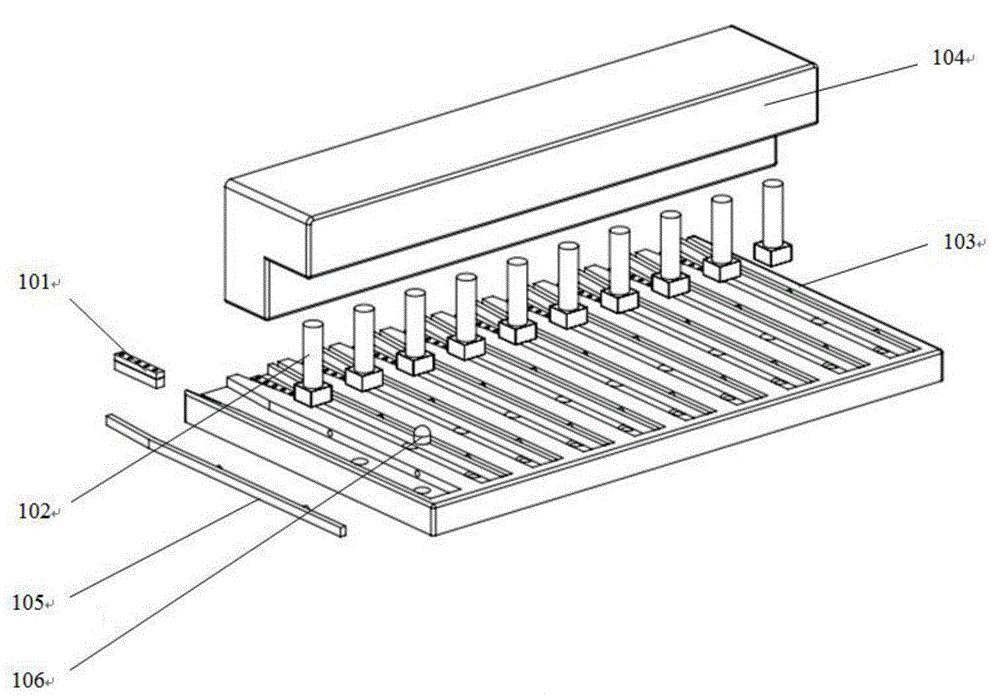

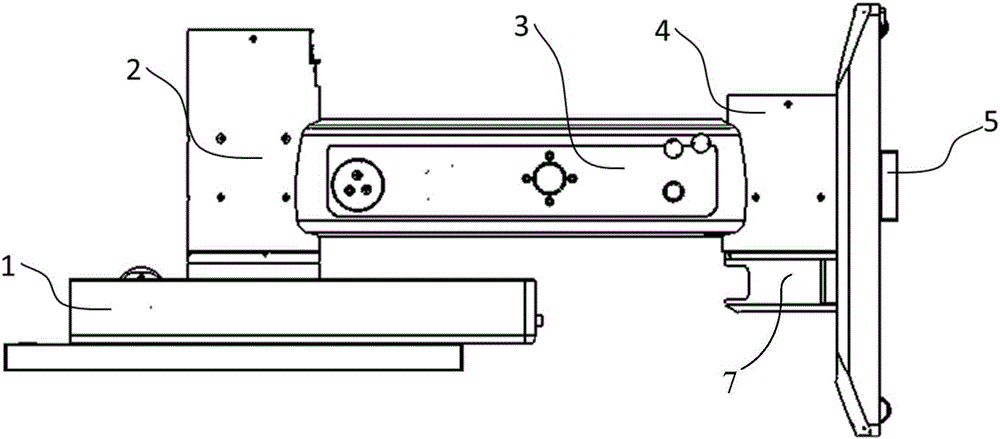

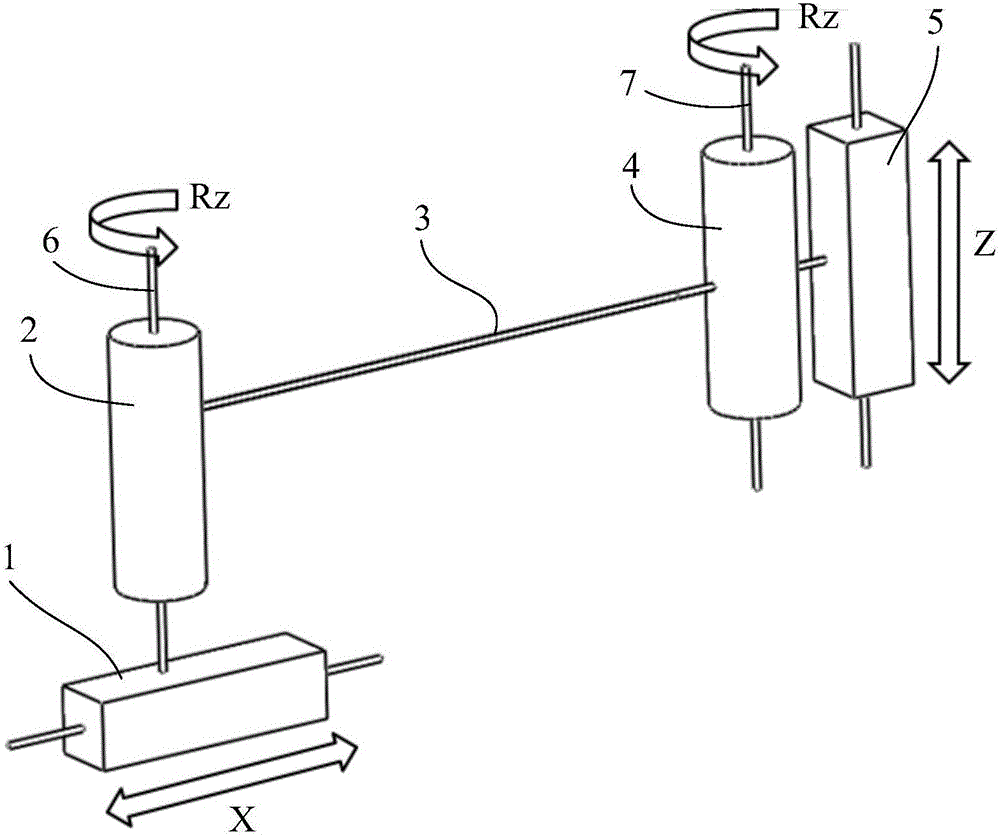

High-efficiency automatic sampling inspection equipment for SMD material tray

ActiveCN104837328AQuick automatic spot checkCompact structureElectrical componentsIndividual semiconductor device testingEngineering

The invention discloses high-efficiency automatic sampling inspection equipment for SMD material tray, which is characterized in that the sampling inspection equipment comprises a material belt positioning unit, a detecting unit, a pickup unit and a component box; wherein the material belt positioning unit is used for fixing and positioning the material belts with different widths; the components on the material belt are picked through the pickup unit; furthermore the components are transferred to the detecting unit in high precision for realizing quick inspection for component parameters; and afterwards, successively placing the components after inspection into the component box. The high-efficiency automatic sampling inspection equipment can realize quick automatic sampling inspection on rolled SMD material trays, and has advantages of high-efficiency inspection, simple structure, convenient use, etc.

Owner:HUAZHONG UNIV OF SCI & TECH

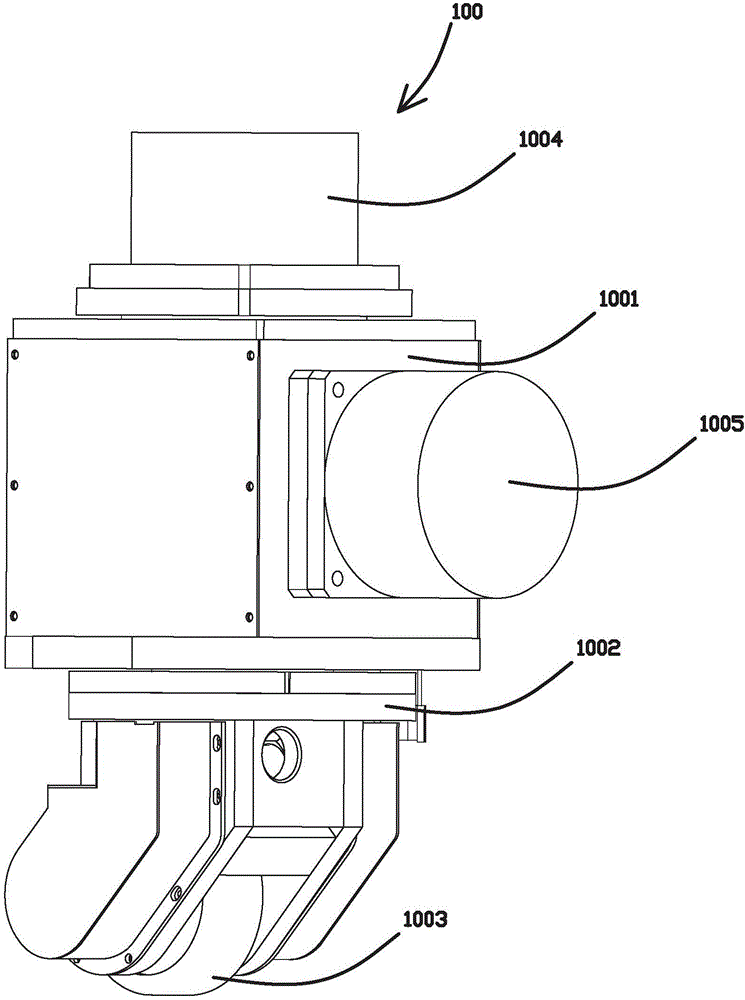

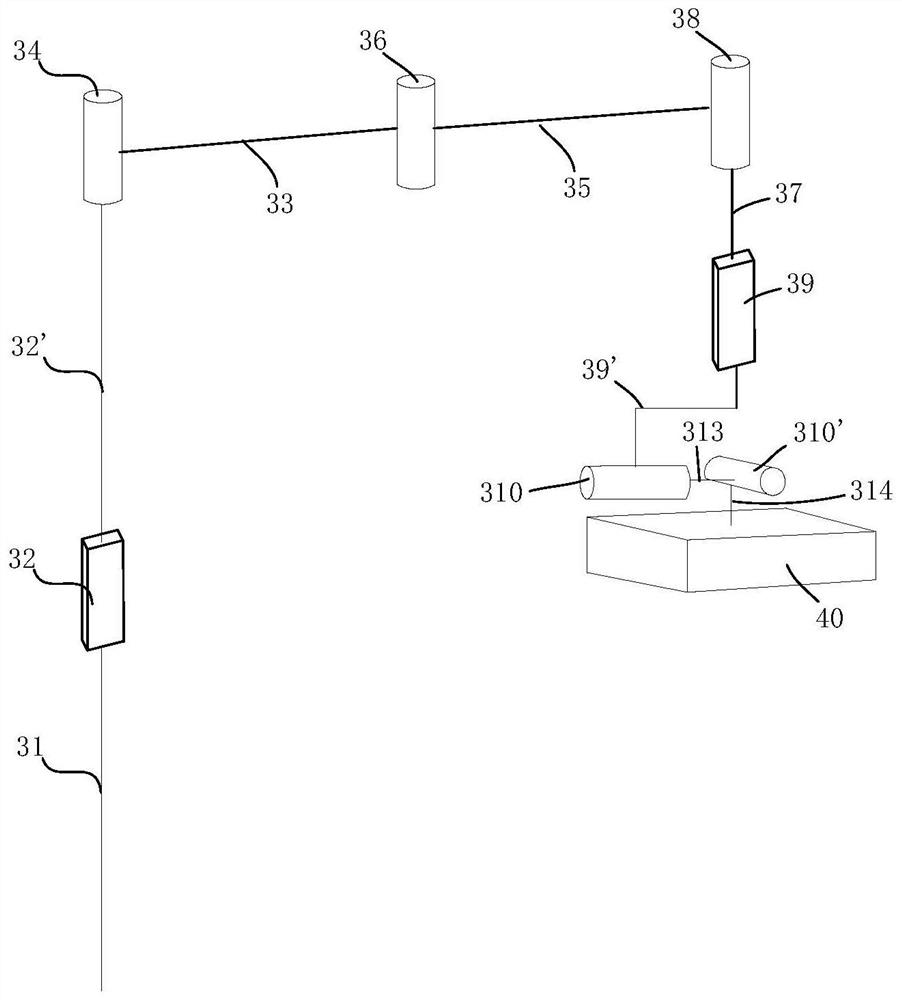

Operation robot and mechanical arm thereof

ActiveCN106175934ASmall form factorLight in massProgramme-controlled manipulatorDiagnosticsStructure relationEngineering

The invention provides an operation robot and a mechanical arm thereof. The mechanical arm comprises a horizontal moving joint, a first rotating joint, a connecting arm and a vertical moving joint. The first rotating joint comprises a first rotating shaft and a first outer cylinder arranged on the first rotating shaft in a sleeving mode, and the first outer cylinder can rotate around the first rotating shaft. The connecting arm is connected with the first outer cylinder and the vertical moving joint. The vertical moving joint comprises a connector and is used for driving an external component connected with the connector to move in the vertical direction. The horizontal moving joint is connected with the first rotating shaft and used for driving the first rotating joint to move in the horizontal direction. According to the operation robot and the mechanical arm thereof, the horizontal movement of the mechanical arm can be achieved through the horizontal moving joint, and the vertical movement of the mechanical arm can be achieved through the vertical moving joint; as the number of the joints is small, the structure relation is simplified, the appearance size of the mechanical arm is reduced, and the overall mass of the mechanical arm is reduced; besides, the precision of movement control is high, additional movement displacement can be avoided, and operation is easier and more convenient.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

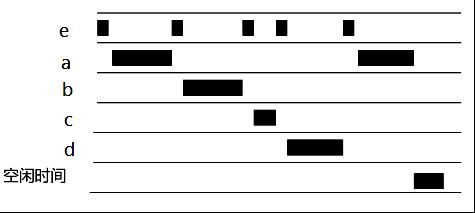

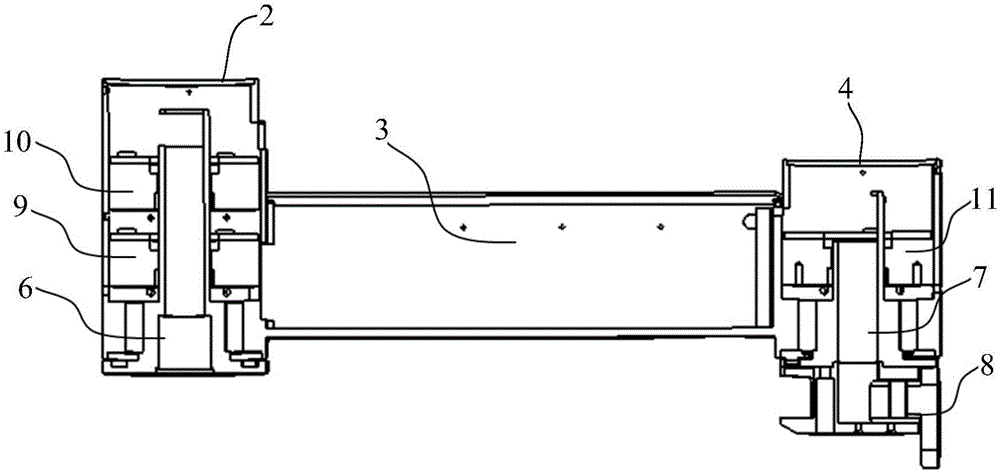

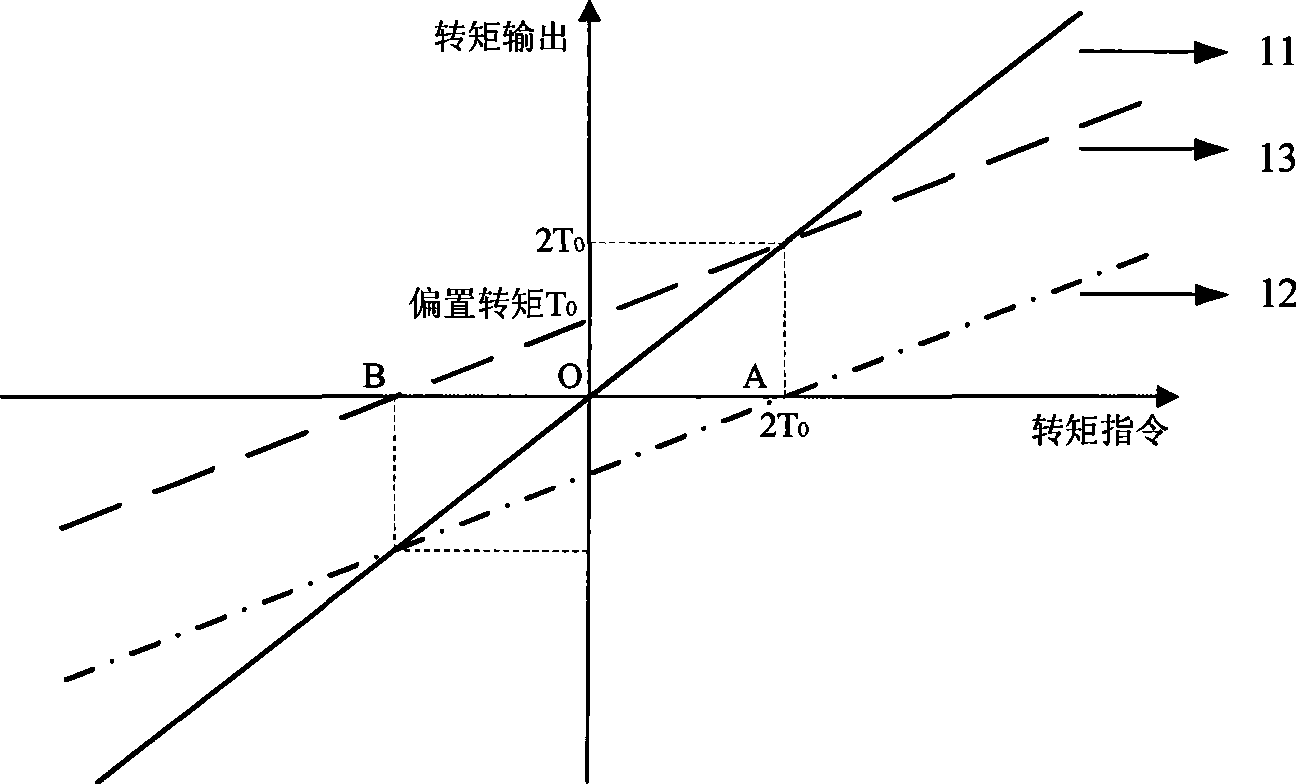

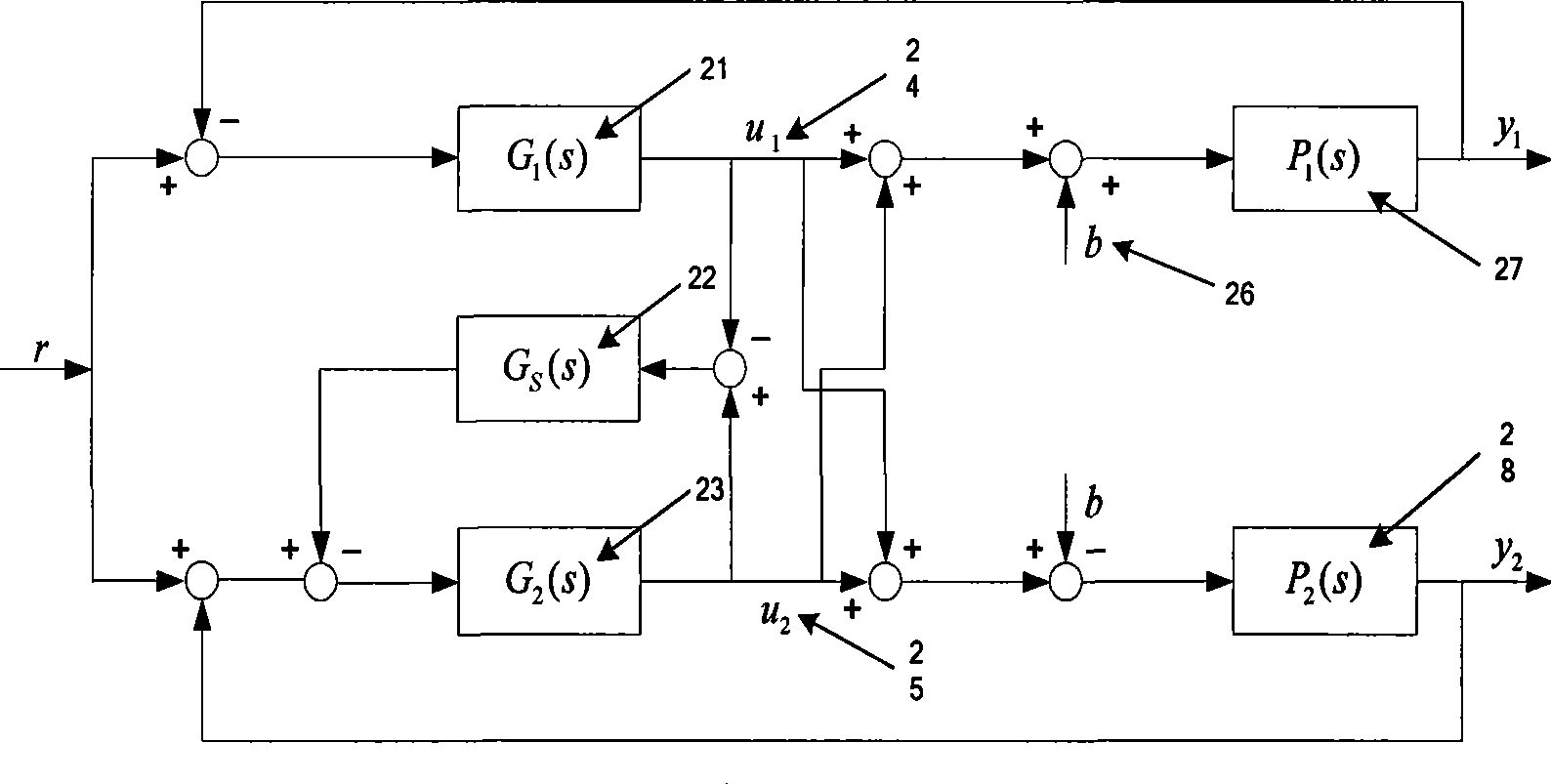

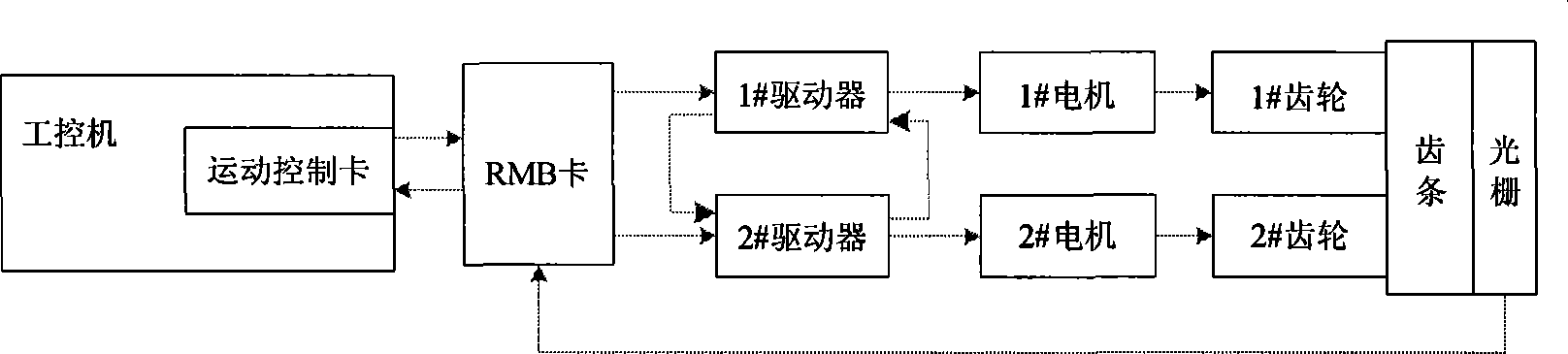

Control method for enhancing kinematic accuracy by double-motor drive based on real-time control network

InactiveCN101364105AImprove Motion Control AccuracyHigh precisionControllers with particular characteristicsTotal factory controlMotor driveGrating

The invention discloses a double-motor drive control method on a real-time control network basis for improving the kinematic accuracy. The method comprises the following steps: 1) establishing the communication between a motion control card and a D / A converter based on a SynqNet real-time control network; 2) operating the motion control card to allow the D / A converter to output the same motion commands to two motor drivers; 3) operating the two motors respectively to drive two gears on the same rack, wherein the driving power is shared by the two motors; 4) operating the two motor drivers to control the two motors respectively and output the same adjustable bias torques in the opposite direction; 5) allowing the two motors to make the strictly synchronous movement by intersecting and accumulating the outputs from a synchronous compensator and the two motors; and 6) arranging a linear grating on the rack, wherein the position measurement information of the linear grating is input to the motion control card to achieve the effect of closed-loop control. The double-motor drive control method on a real-time control network basis greatly increases the accuracy of the rack-gear transmission system, ensures the adjustable bias torque, meets different requirements for load and speed and has good real-time property, controllability and reliability.

Owner:ZHEJIANG UNIV +1

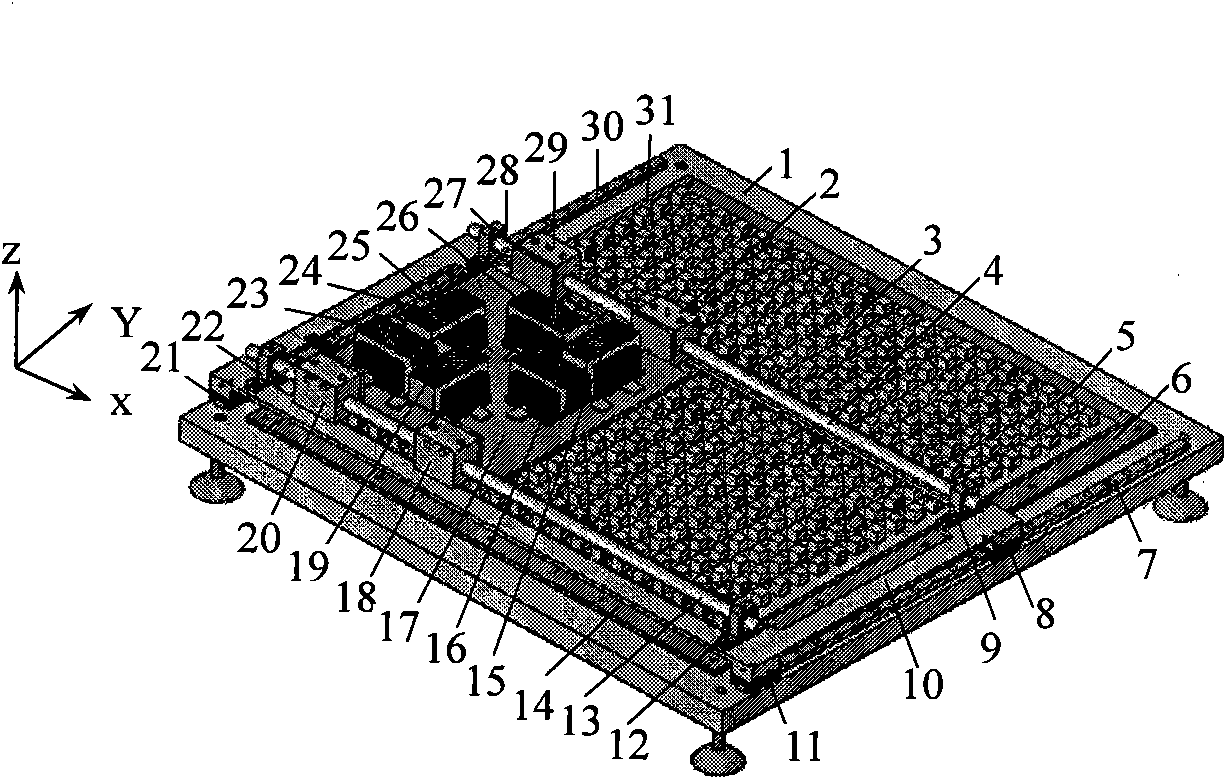

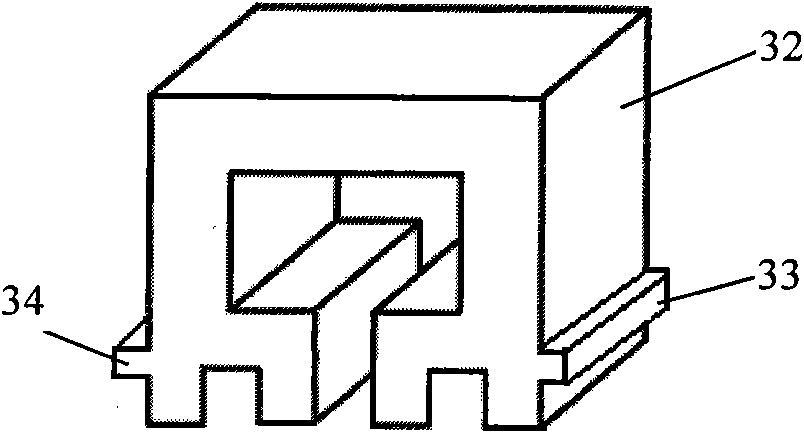

Direct-drive switched reluctance planar motor

InactiveCN101888163AReduce distortionGuaranteed clearancePropulsion systemsElectric machineClassical mechanics

The invention discloses a direct-drive switched reluctance planar motor, which belongs to the field of electromechanical research. The motor is characterized in that a right lug boss 33 and a left lug boss 34 are arranged on the two sides of a rotor core 32 and matched with a rotor buckle to fix an XA-phase rotor 24, an XB-phase rotor 19, an XC-phase rotor 15, a YA-phase rotor 23, a YB-phase rotor 16 and a YC-phase rotor 26 on a rotor rack 17; the height of the rotor buckle is 0.3 to 0.5mm less than those of the right lug boss 33 and the left lug boss 34; a first right connecting plate 36, a second right connecting plate 37, a first left connecting plate 38 and a second left connecting plate 39 are arranged on the two sides of a rotor rack plate 35; on one hand, the first right connecting plate 36, the second right connecting plate 37, the first left connecting plate 38 and the second left connecting plate 39 are fixedly connected with the rotor rack plate 35; on the other hand, the connecting plates are also fixedly connected with a first straight bearing 29, a second straight bearing 2, a third straight bearing 18 and a fourth straight bearing 20; and thus the rotor rack 17 can flexibly move along a first guide shaft 4 in x direction and a second guide shaft 13 in the x direction.

Owner:TAIYUAN UNIV OF TECH

Master-slave wall-climbing welding robot system suitable for large steel structural part

ActiveCN110814472ARealize all-position automatic weldingImprove working environmentElectrode holder supportersWelding accessoriesRobotic systemsRobot position

The invention relates to a master-slave wall-climbing welding robot system suitable for a large steel structural part. A master wall-climbing welding robot carries a welding gun and tracks a welding seam to move; a slave wall-climbing relay wire feeding robot loads welding related equipment, such as a wire feeder and a wire reel, bears cable drag force and follows the master wall-climbing weldingrobot to move to cooperate to complete field installing and welding operation; the overall weight of the master wall-climbing welding robot is relatively low and moves flexibly, which is beneficial toquick adjustment of robot positions and welding gun postures; the slave wall-climbing relay wire feeding robot is high in load capacity and relatively low in control precision requirement, and can feed a wire for the master wall-climbing welding robot in short distance for welding; the wire is output stably; the welding quality is easy to ensure; both the master wall-climbing welding robot and the slave wall-climbing relay wire feeding robot adopt a permanent magnet gap adsorption and wheel type motion mechanism; an adsorption mechanism is separated from a motion mechanism; the flexibility ofrobot motion is further improved; and the motion control precision of the robot is improved.

Owner:TSINGHUA UNIV +1

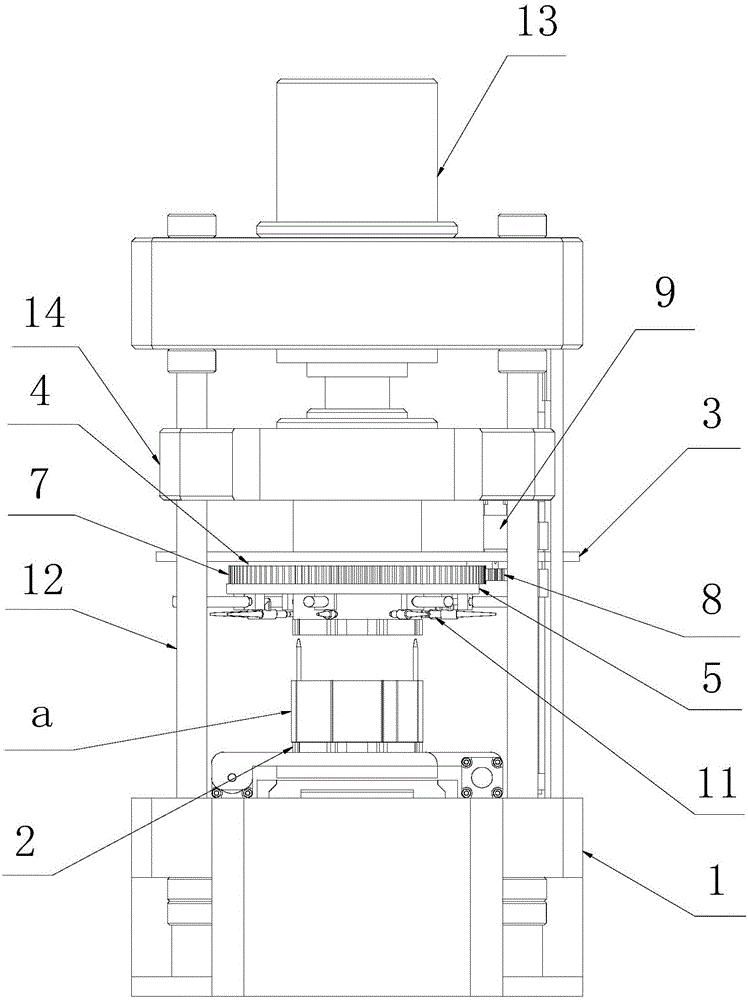

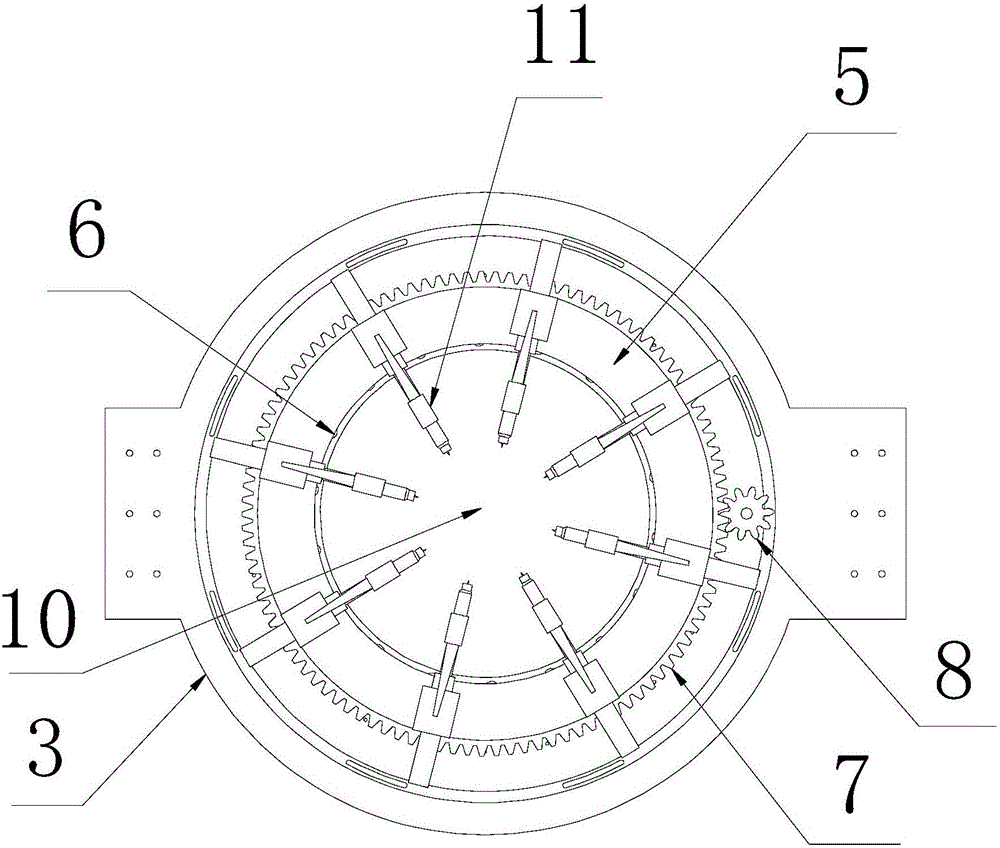

Rotation type welding device for silicon steel sheet

ActiveCN106238988AHigh degree of automationImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive motorSilicon

The invention discloses a rotation type welding device for a silicon steel sheet. The rotation type welding device comprises a welding working table provided with a silicon steel sheet positioning tool, and is characterized in that the welding working table is provided with a lifting mechanism and a rotation type welding gun mechanism driven by the lifting mechanism to lift; the rotation type welding gun mechanism comprises a lifting plate, an annular core shaft fixed to the lifting plate in the longitudinal direction and a welding gun positioning ring installed on the annular core shaft through a bearing in a sleeving manner; the rotation type welding device further comprises a driving motor which is arranged on the lifting plate, is connected with the welding gun positioning ring through a transmission mechanism, and drives the welding gun positioning ring to rotate; and an opening for the silicon steel sheet to penetrate is formed in the position, on the inner side of the annular core shaft, of the lifting plate, and at least one welding gun is fixed to the welding gun positioning ring along the periphery. By means of the device, manual work can be replaced for conducting inclined welding operation on the silicon steel sheet, the automatic degree is high, and the operation efficiency and the product quality can be greatly improved.

Owner:KUNSHAN LIMAHE AUTOMATION SCI & TECH

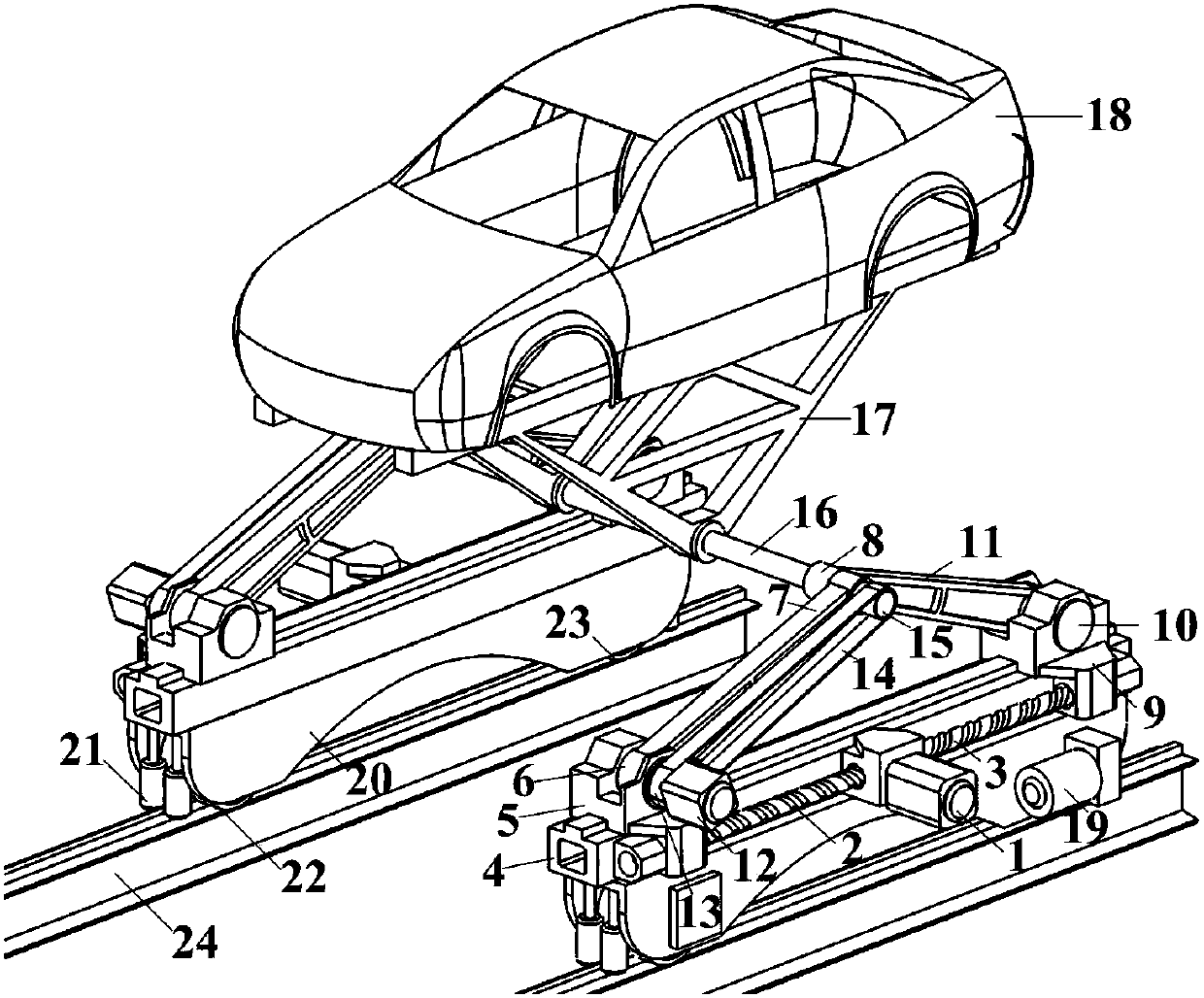

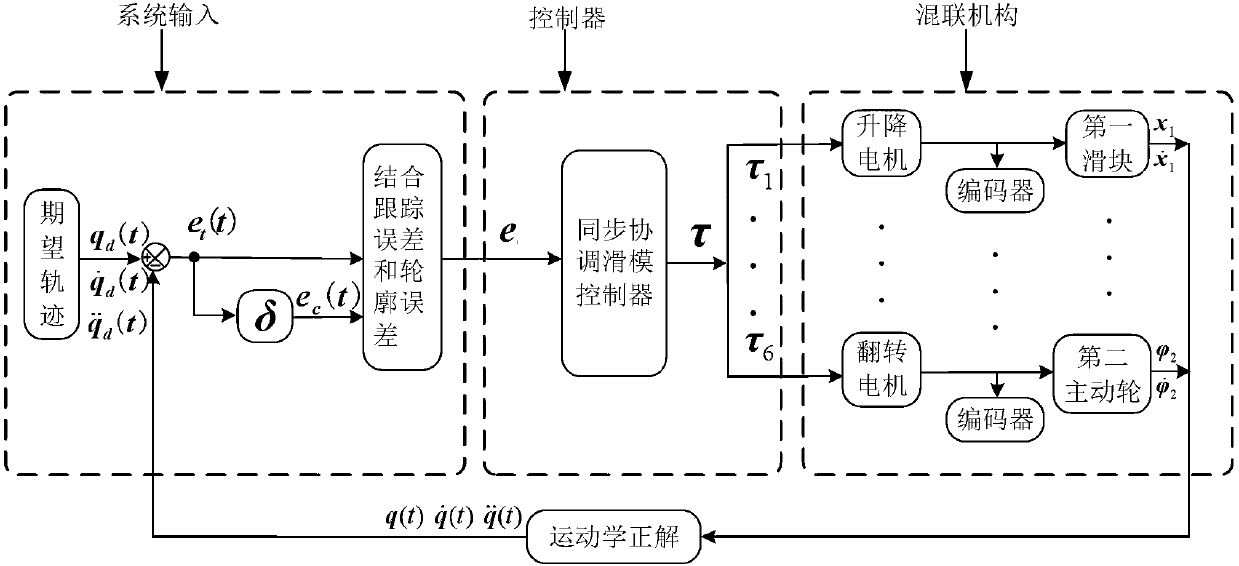

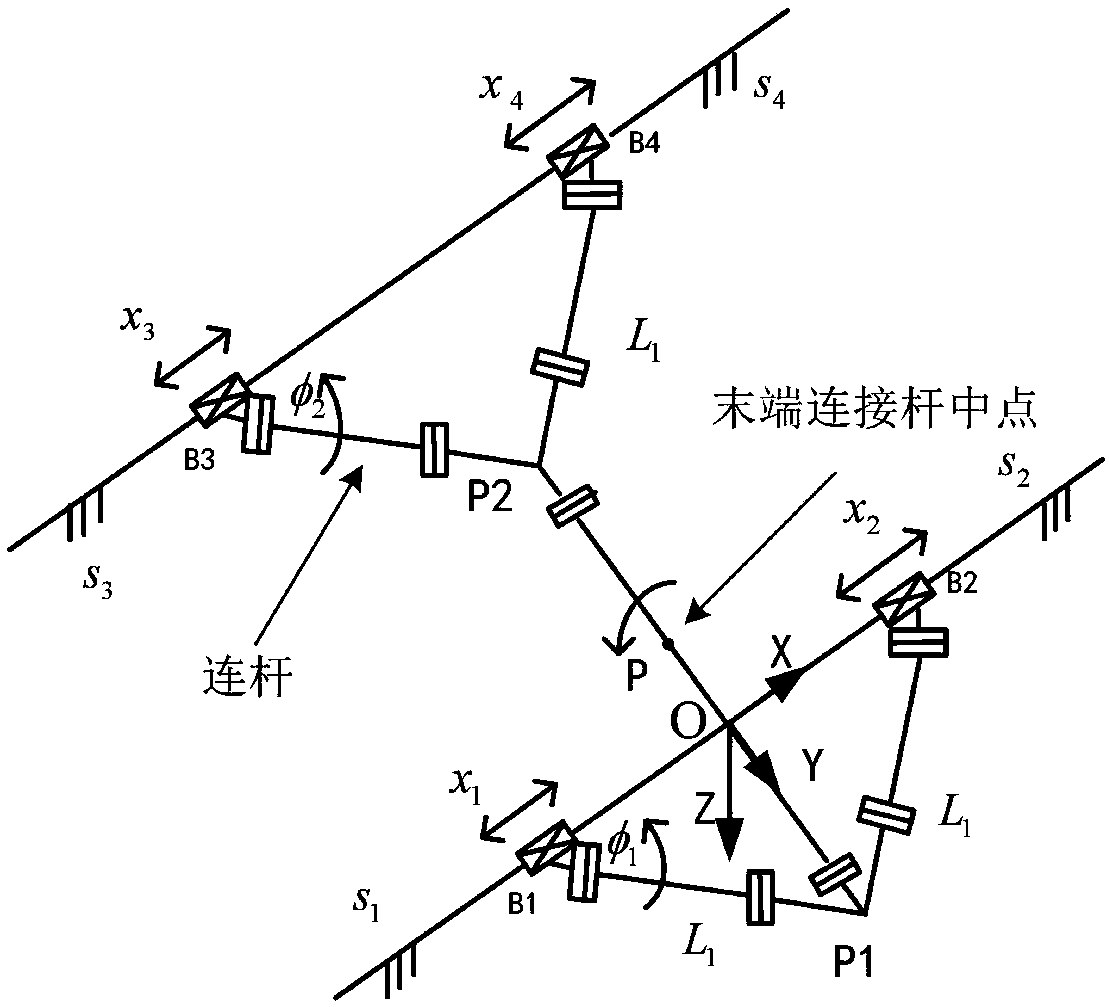

Synchronous coordinated sliding-mode control method for series-parallel automobile electrophoretic coating conveying mechanism based on comprehensive error

InactiveCN107505844ARealize motion controlImprove Motion Control AccuracyAdaptive controlEngineeringCoating

The invention discloses a synchronous coordinated sliding-mode control method for a series-parallel automobile electrophoretic coating conveying mechanism based on a comprehensive error. The synchronous coordinated sliding-mode control method comprises the steps of firstly, building a kinetic model of the mechanism by adopting a Lagrangian method, and performing motion trajectory planning on the mechanism; providing a comprehensive error combining a tail end tracking error and a contour error of the mechanism in allusion to structural characteristics and movement characteristics of the mechanism in order to improve the trajectory tracking accuracy of the tail end of the mechanism loaded with an automobile body-in-white for coating and conveying in the operating process of the conveying mechanism, and designing a synchronous coordinated sliding-mode controller based on the comprehensive error; and finally, and realizing comprehensive error based synchronous coordinated sliding-mode control for the conveying mechanism through software programming. The synchronous coordinated sliding-mode control method realizes control based on the comprehensive error, can effectively improve the motion control precision of the tail end of the conveying mechanism and realizes high-precision automobile electrophoretic coating conveying.

Owner:JIANGSU UNIV

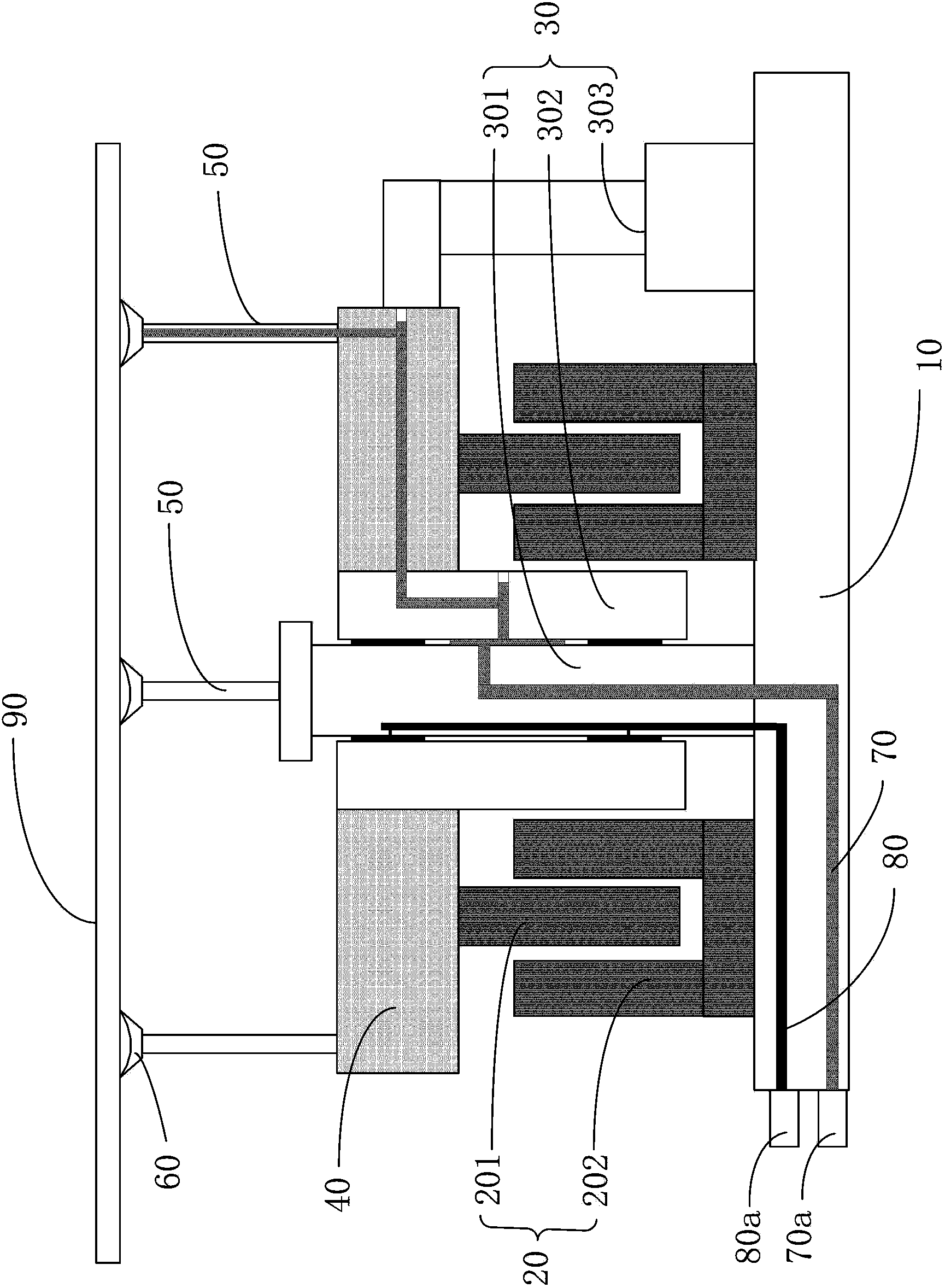

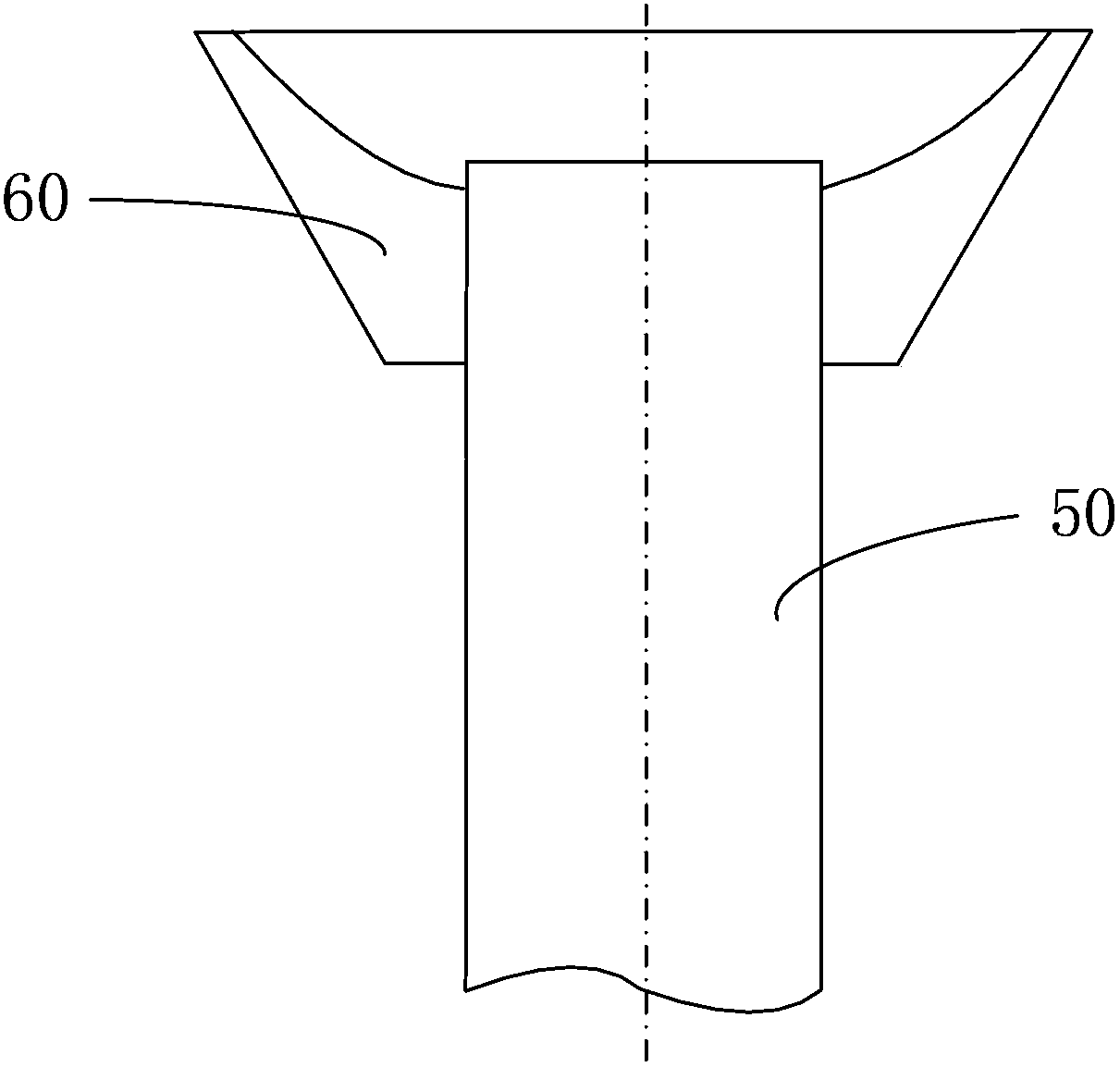

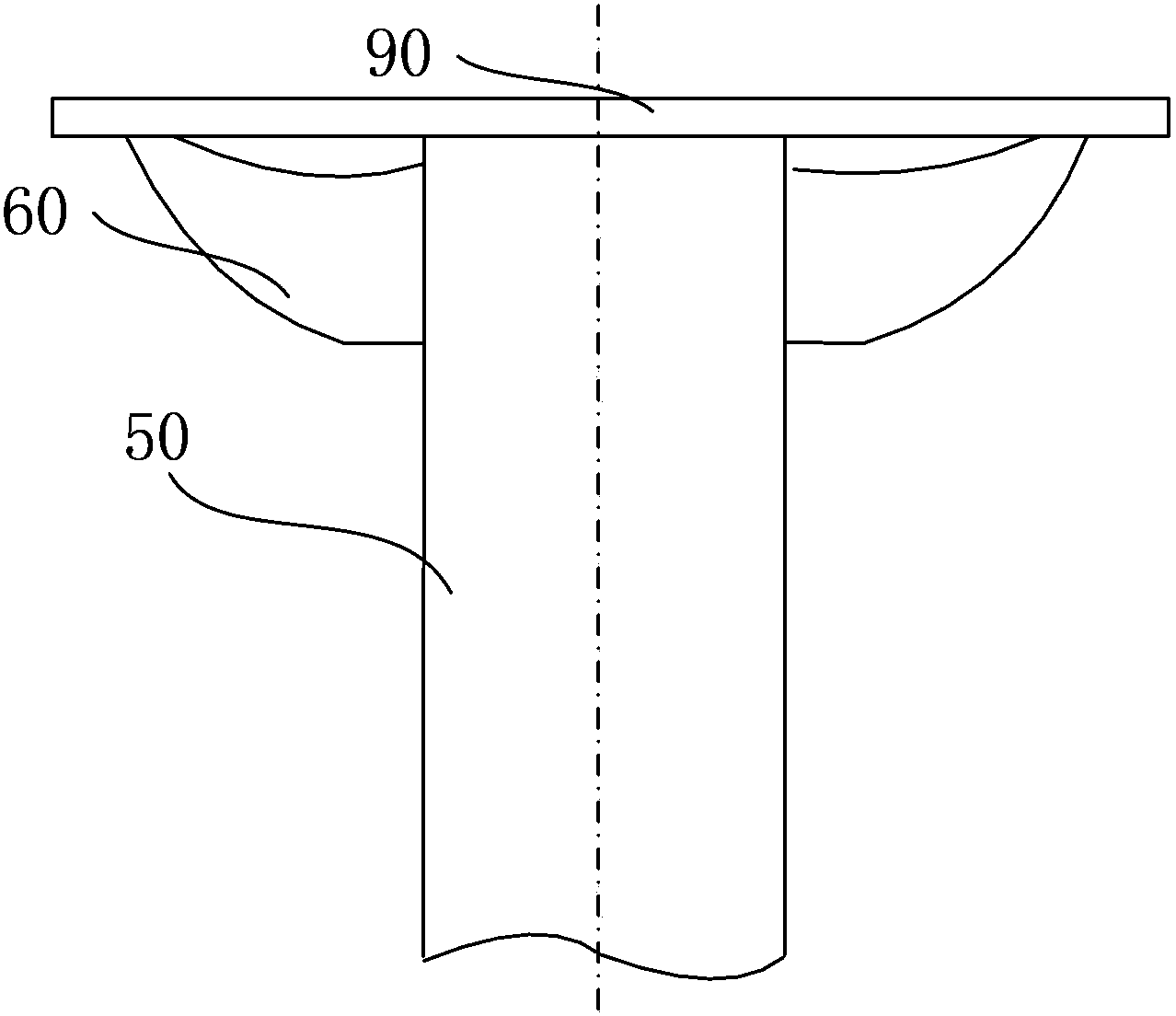

Silicon slice ejection mechanism

ActiveCN103901735ARigid softFit tightlyPhotomechanical exposure apparatusMicrolithography exposure apparatusMetallic materialsEngineering

The invention discloses a silicon slice ejection mechanism, comprising a base, a drive mechanism, a guide mechanism, a connection plate and an ejection pin, wherein the drive mechanism is fixed on the base; the ejection pin and the guide mechanism are fixed on the connection plate; the silicon slice ejection mechanism also comprises a flexible suction plate; the flexible suction plate is arranged at the top of the ejection pin and connected with the ejection pin; and the connection height of the inner side of the flexible suction plate is smaller than the height of the top surface of the ejection pin. The flexible suction plate is additionally arranged at the top of the ejection pin; compared with a nonmetallic material in the prior art, the flexible suction plate is softer and can be in tight fit with a warping sheet and an ultra-thin sheet to achieve a vacuum and leak-proof effect, and thus the effective adsorption of the silicon slice is ensured.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

Surgical instrument platform

ActiveCN111888012AImprove accuracyImprove Motion Control AccuracySurgical instrument supportSurgical manipulatorsSurgical ManipulationEngineering

The present invention relates to a surgical instrument platform including a base, an adjusting assembly and an instrument assembly. The adjusting assembly is disposed on the base and is composed of amechanical arm; and the instrument assembly includes a surgical instrument and an instrument platform, the surgical instrument is detachably disposed on the instrument platform, the instrument platform is connected with the end of the mechanical arm, the surgical instrument includes an operation end, a connecting assembly and an end executor connected in sequence as well as a sensing component, adriving component, a transmission component and a control component, wherein the connecting assembly includes a first connecting structure and a second connecting structure, the near end of the firstconnecting structure is connected with the operation end, the far end of the first connecting structure is connected with the instrument platform, the far end of the second connecting structure is connected with the end executor, and the near end of the second connecting structure is connected with the instrument platform. The sensing component detects the movement of the first connecting structure, and the control component controls the driving component to drive the second connecting structure to move by virtue of the transmission component according to the movement of the first connecting structure. The surgical instrument platform has the advantages of higher precision and reliability as well as labor saving and convenience in surgery operation.

Owner:SHANGHAI MICROPORT MEDBOT (GRP) CO LTD

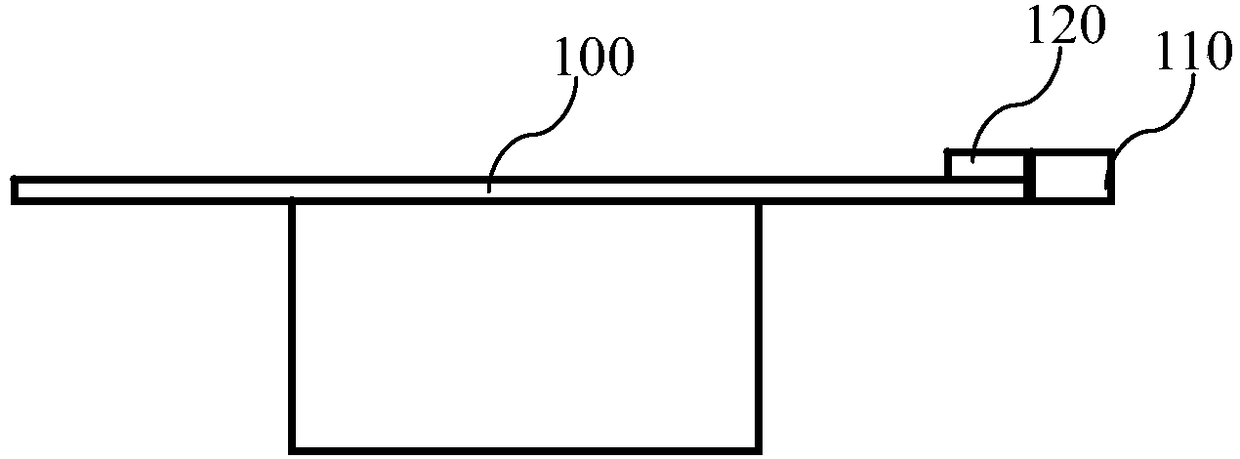

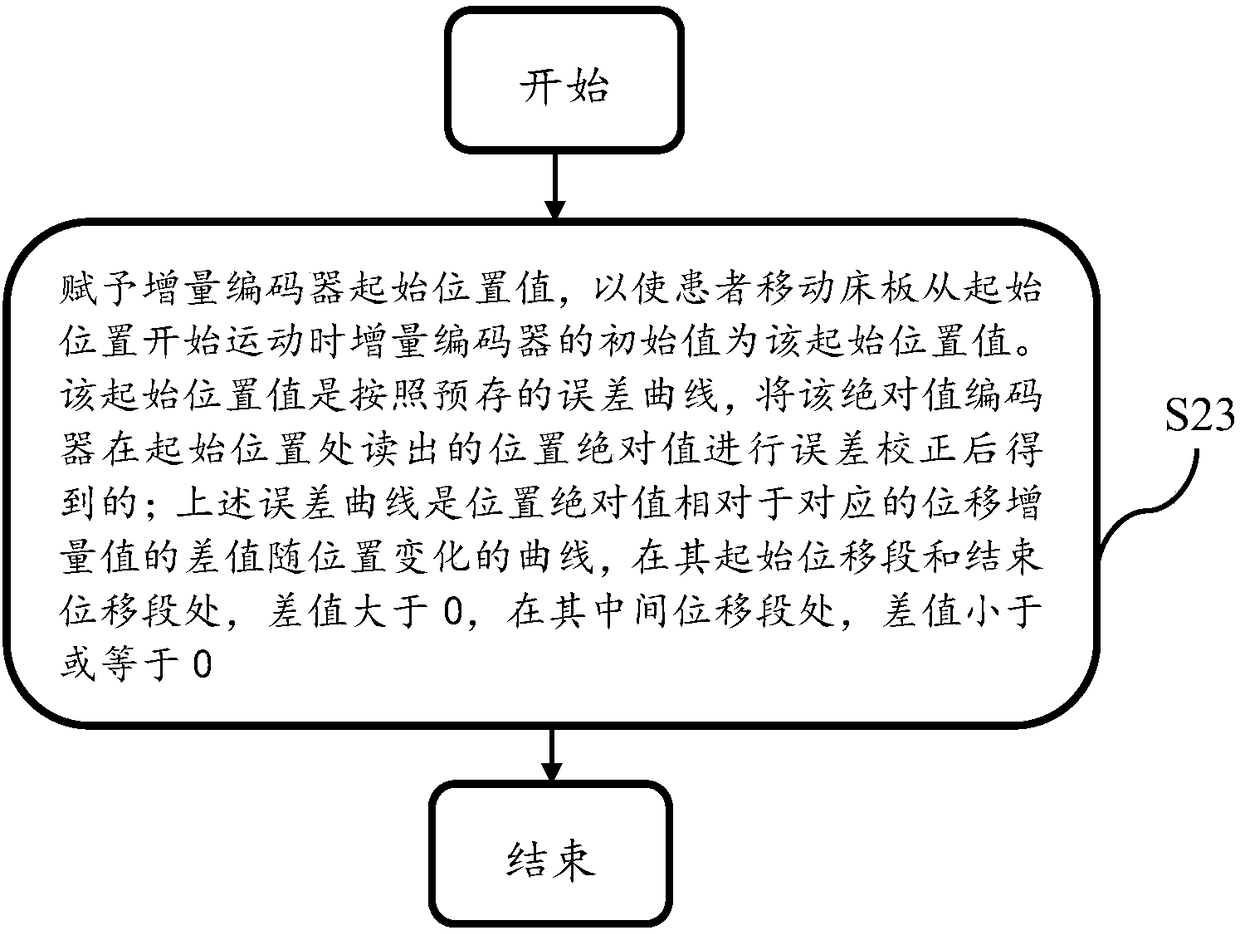

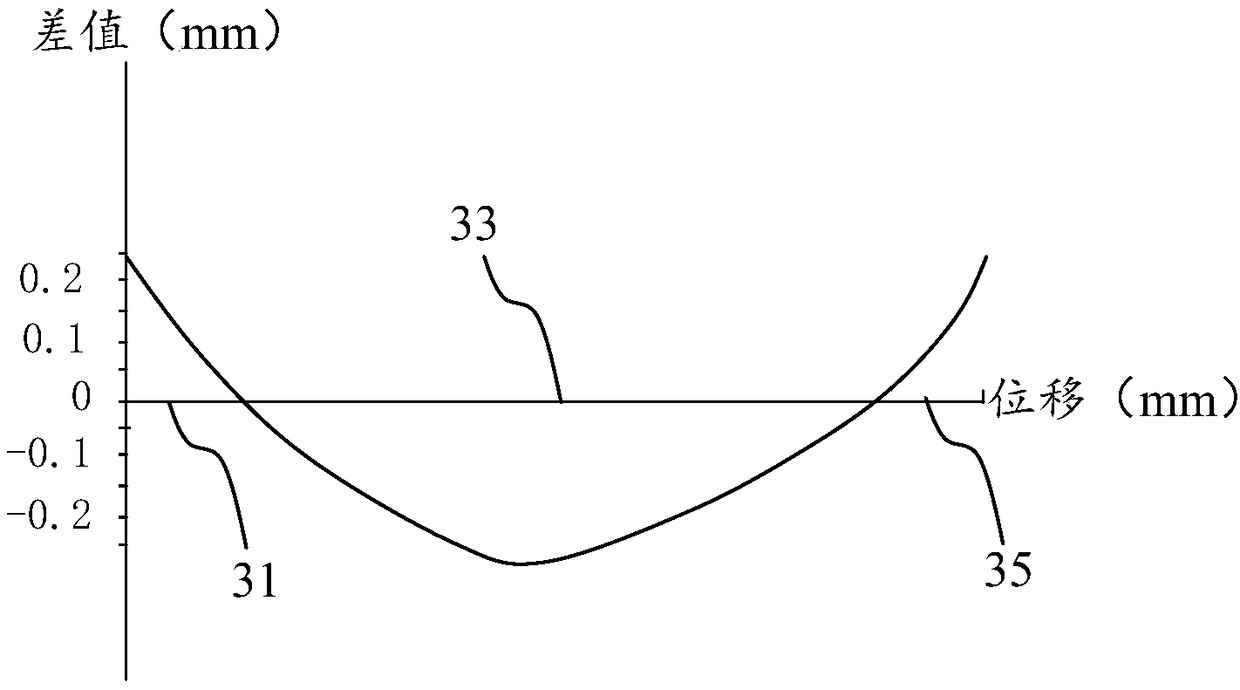

Motion control device and method for patient moving bed board and computer program

PendingCN109381216AImprove Motion Control AccuracyRadiation diagnostic device controlPatient positioning for diagnosticsSmallerThanBed boards

The invention provides a motion control device and method for a patient moving bed board and a computer program. The method comprises the step that an incremental encoder is endowed with an initial position value so that when the patient moving bed board starts to move from the initial position, the initial value of the incremental encoder is the initial position value, wherein the initial position value is obtained after error correction of a position absolute value read by an absolute value encoder at the initial position according to a pre-stored error curve; the error curve is a curve, changing with positions, of the position absolute value relative to a corresponding displacement increment value, the curve comprises a starting displacement section, an intermediate displacement sectionand an end displacement section which are continuous in sequence, the difference is larger than 0 at the starting displacement section and the end displacement section, and the difference is smallerthan or equal to 0 at the intermediate displacement section.

Owner:GENERAL ELECTRIC CO

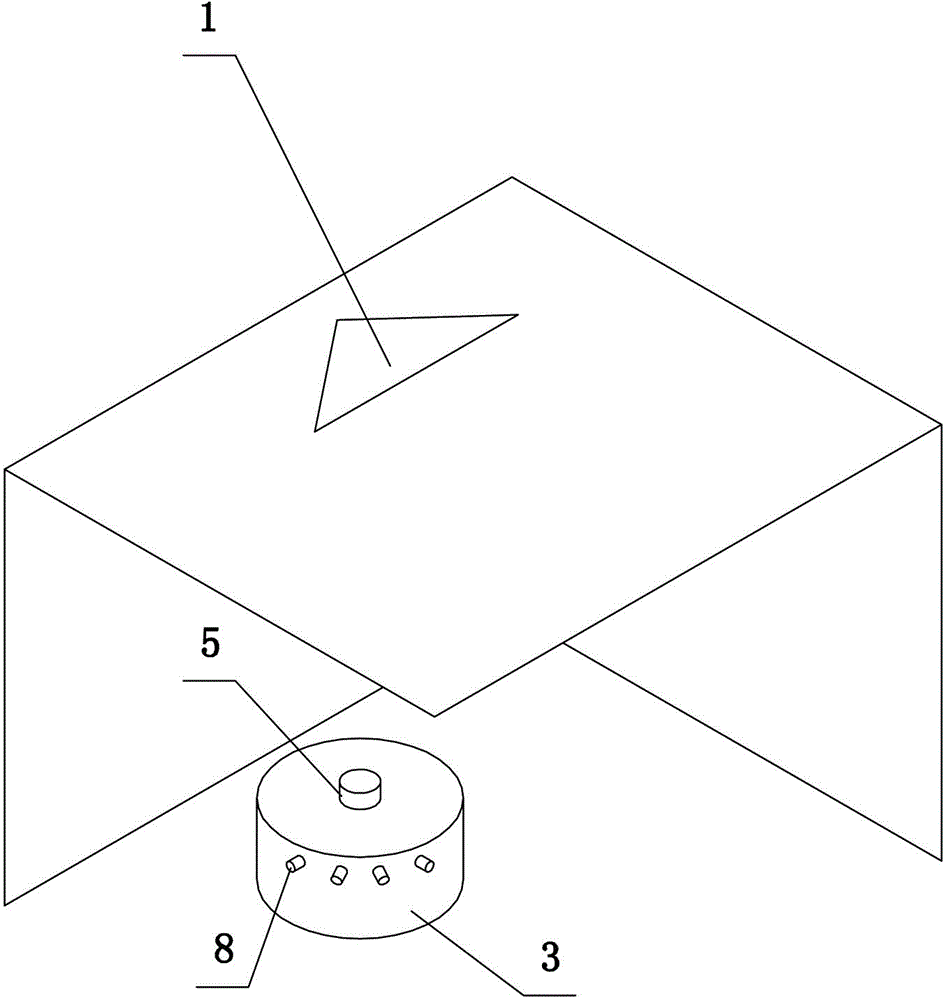

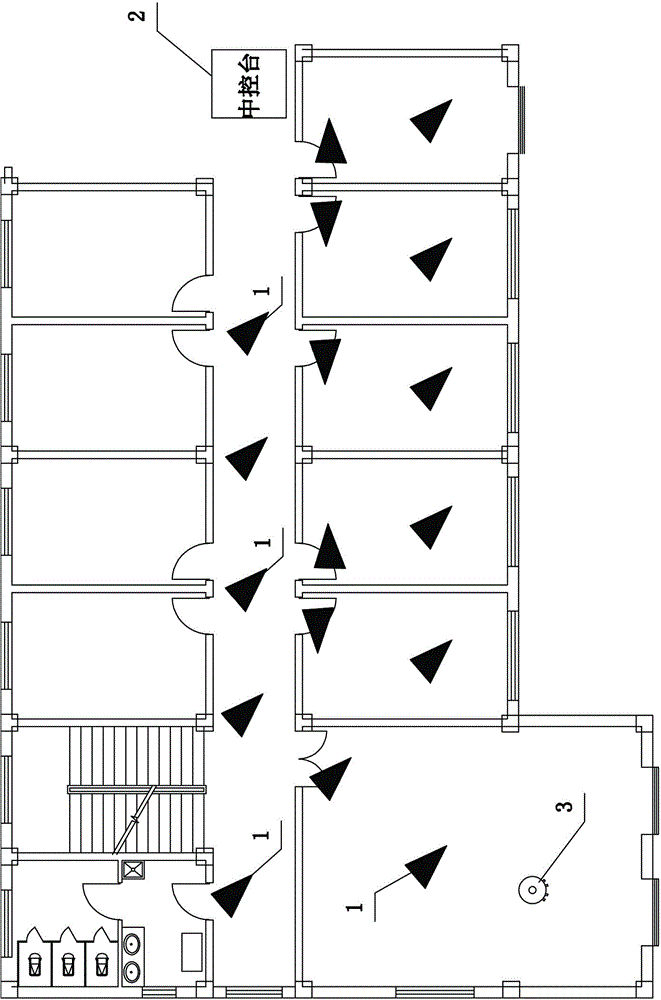

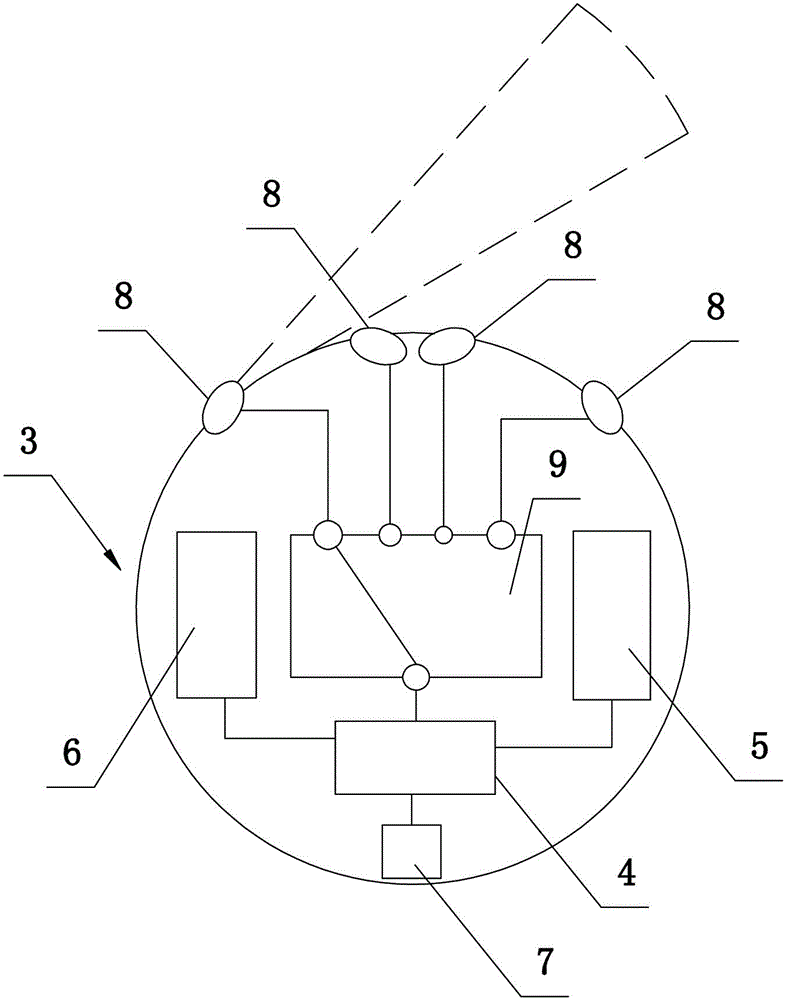

Walking control system and method for robot

ActiveCN104950892AReduce manufacturing costReduce intelligence requirementsPosition/course control in two dimensionsControl systemEngineering

A walking control system for a robot comprises a plurality of infrared light sources arranged in ceilings of each room or corridor, a wheeled robot and a console, wherein the wheeled robot can be used for moving from a first position to multiple different second positions, the infrared light sources are arranged in walking paths from the first position to the second positions, the wheeled robot comprises a control unit, a recognition unit and a moving unit, one moving path is formed from the first position to each second position, and the console forms multiple different infrared light source light-emitting combinations through controlling on or off of the infrared light sources. Each infrared light source light-emitting combination corresponds to one moving path, so that selection of the walking paths of the robot is completely realized through the console, the intelligence requirement for the wheeled robot is greatly reduced, the manufacturing cost of the robot is saved, and basic requirements for control accuracy and running efficiency can be met.

Owner:厦门狄耐克物联智慧科技有限公司

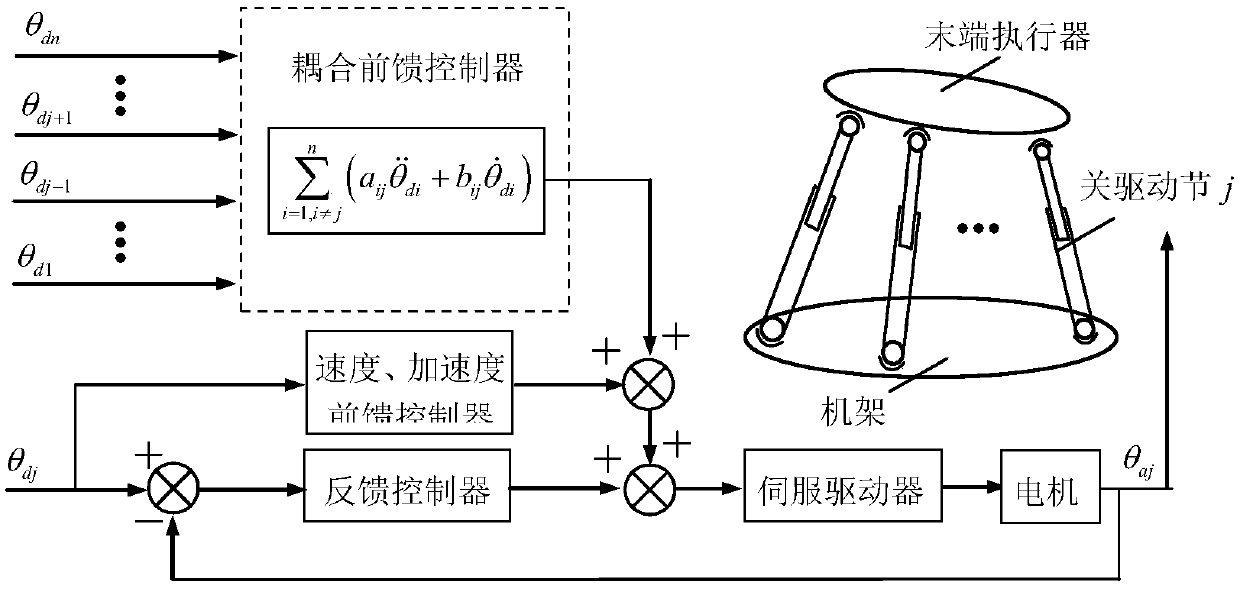

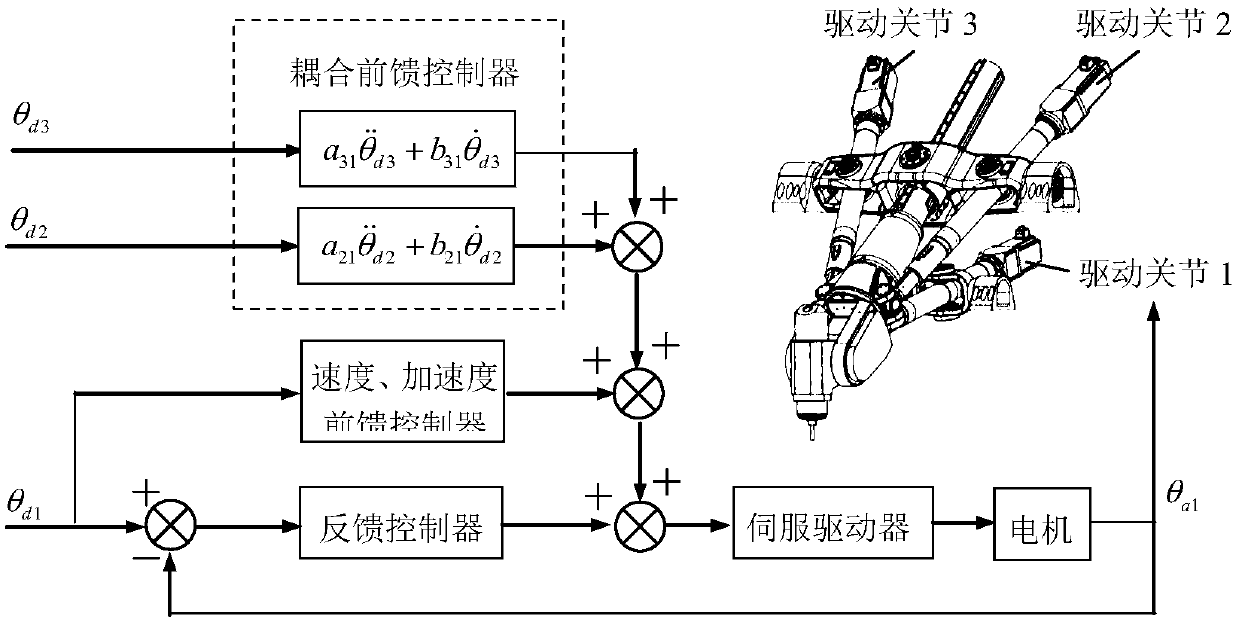

Coupling forward feedback control method aiming at robot

ActiveCN108724195AReal-time compensation for coupled disturbancesImprove Motion Control AccuracyProgramme-controlled manipulatorProportion integration differentiationCoupling

The invention discloses a coupling forward feedback control method aiming at a robot. The coupling forward feedback control method comprises the following steps: step 1, connecting each joint servo driver of the robot with a PID (Proportion Integration Differentiation) feedback controller and a speed and acceleration forward feedback controller; step 2, taking expected rotation angles of other joint motors except a controlled joint motor as first-order and second-order differentials; multiplying the first-order differential by a corresponding speed forward feedback gain and multiplying the second-order differential by a corresponding acceleration forward feedback gain; summarizing to obtain a coupling forward feedback control instruction; step 3, adding a feedback control instruction and aforward feedback control instruction obtained by step 1, and the coupling forward feedback control instruction obtained by step 2, and outputting to a servo driver of the controlled joint motor. By adopting the method disclosed by the invention, coupling disturbance between joints can be compensated in real time, without the need of complicated dynamic calculation, so that the movement control precision of the robot in high-speed and high-acceleration application scenarios is improved.

Owner:TIANJIN UNIV

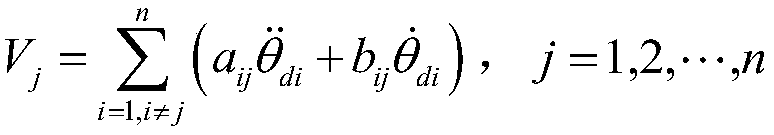

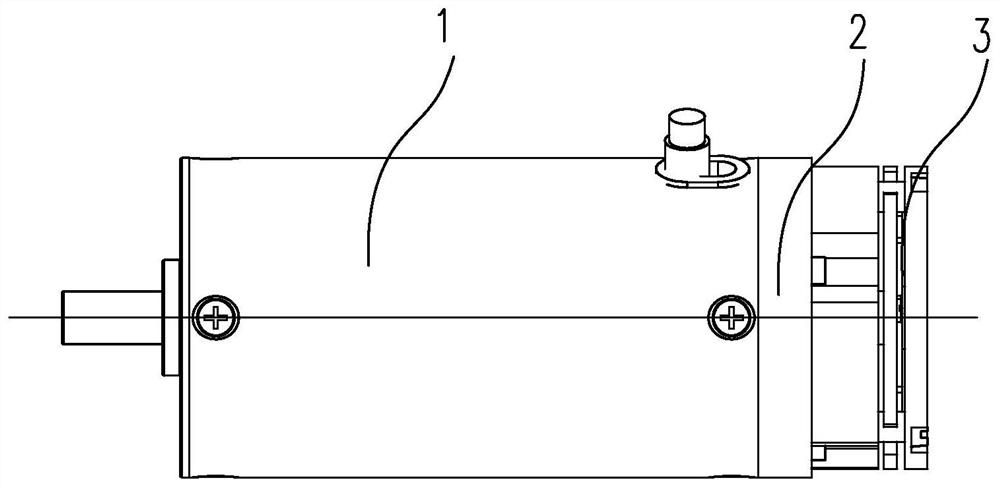

Coreless brushless direct current motor with locking device

PendingCN111711303ABrake meetRealize component integrationManufacturing stator/rotor bodiesEmbedding prefabricated windingsDC - Direct currentElectric machine

The invention discloses a coreless brushless direct current motor with a locking device. The motor comprises a motor main body and a locking device. An output end is arranged at the front part of themotor main body. A locking device is arranged at the rear part of the motor main body. The motor main body realizes output of torque, rotating speed and power function indexes. The motor main body iscomposed of a front end cover, a stator armature, a casing, a rotor and a rear end cover. The front end cover is arranged at the front end of the casing, the rear end cover is arranged at the rear endof the casing, the rotor is installed in the middle of the casing, and the stator armature is arranged outside the rotor in a matching manner. By optimizing the sizes of parts of the motor, the rotorposition sensor and the locking device and through the multifunctional design of the parts, the size of the motor is fully utilized, the axial and radial sizes of the motor are reduced, and product miniaturization and high power density are achieved.

Owner:杭州精导智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com