Rope parallel robot for overhauling large vertical storage tank

A technology of vertical storage tanks and robots, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as high manufacturing costs, toxicity, and impact on storage tank safety, and achieve the effect of reducing use and maintenance costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

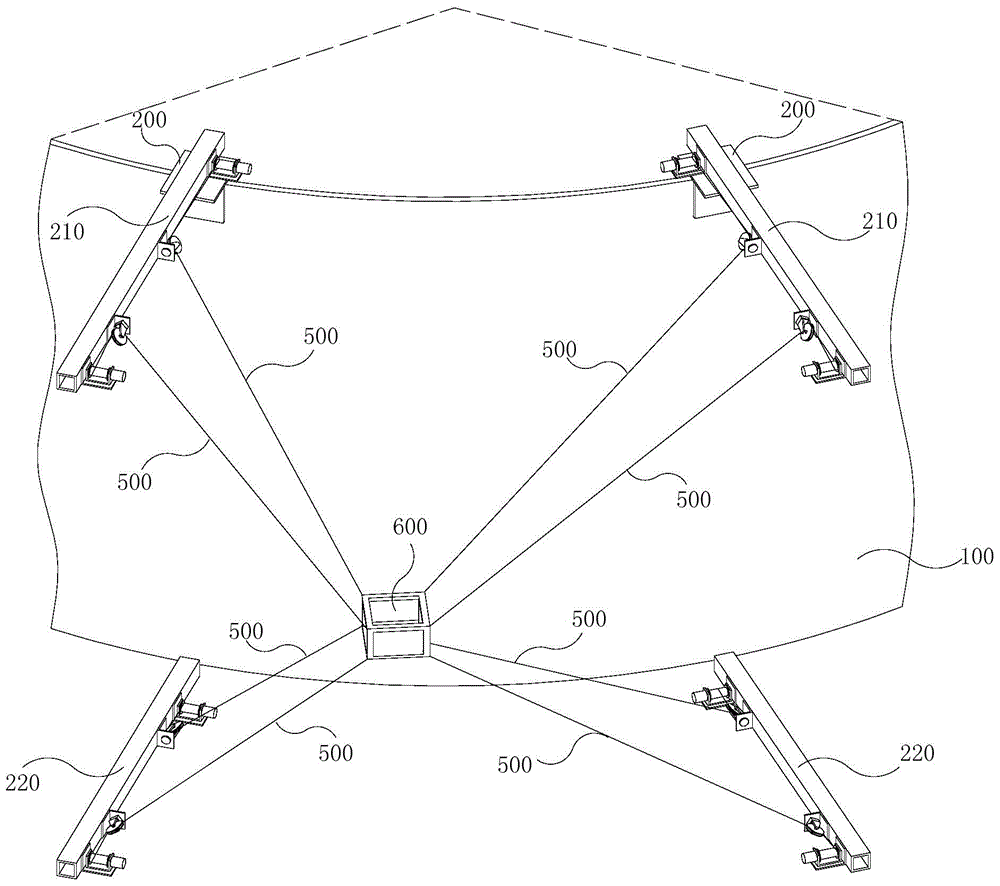

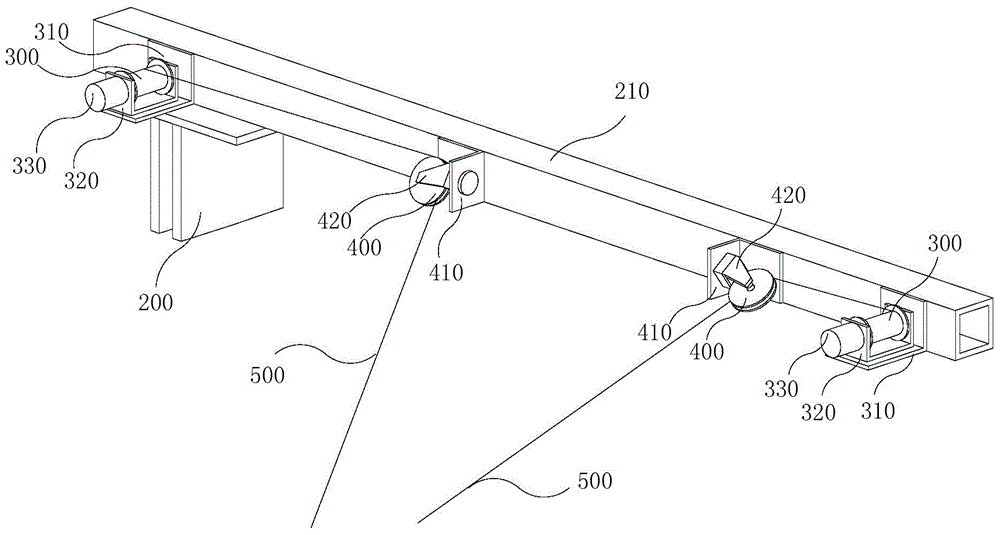

[0036] The invention relates to a cable-parallel robot for maintenance of large vertical storage tanks such as figure 1As shown, a large vertical storage tank with a diameter of 20 m is used as a typical example to illustrate the specific implementation of the present invention: the cable parallel robot consists of a rope 500, a rope drive unit, a rope guide, a working platform 600, and a support rod 210 (220), fixing parts 200, control system and other components, wherein there are eight ropes 500, eight sets of rope drive units, eight sets of rope guides, one end of the rope 500 is connected to the working platform 600, and the other end Pass through the rope guide device and connect to the drum 300 of the rope drive unit. The eight cable exit points formed by eight groups of rope guide devices adopt an arrangement of four above and four below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com