Patents

Literature

135results about How to "Precise motion control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

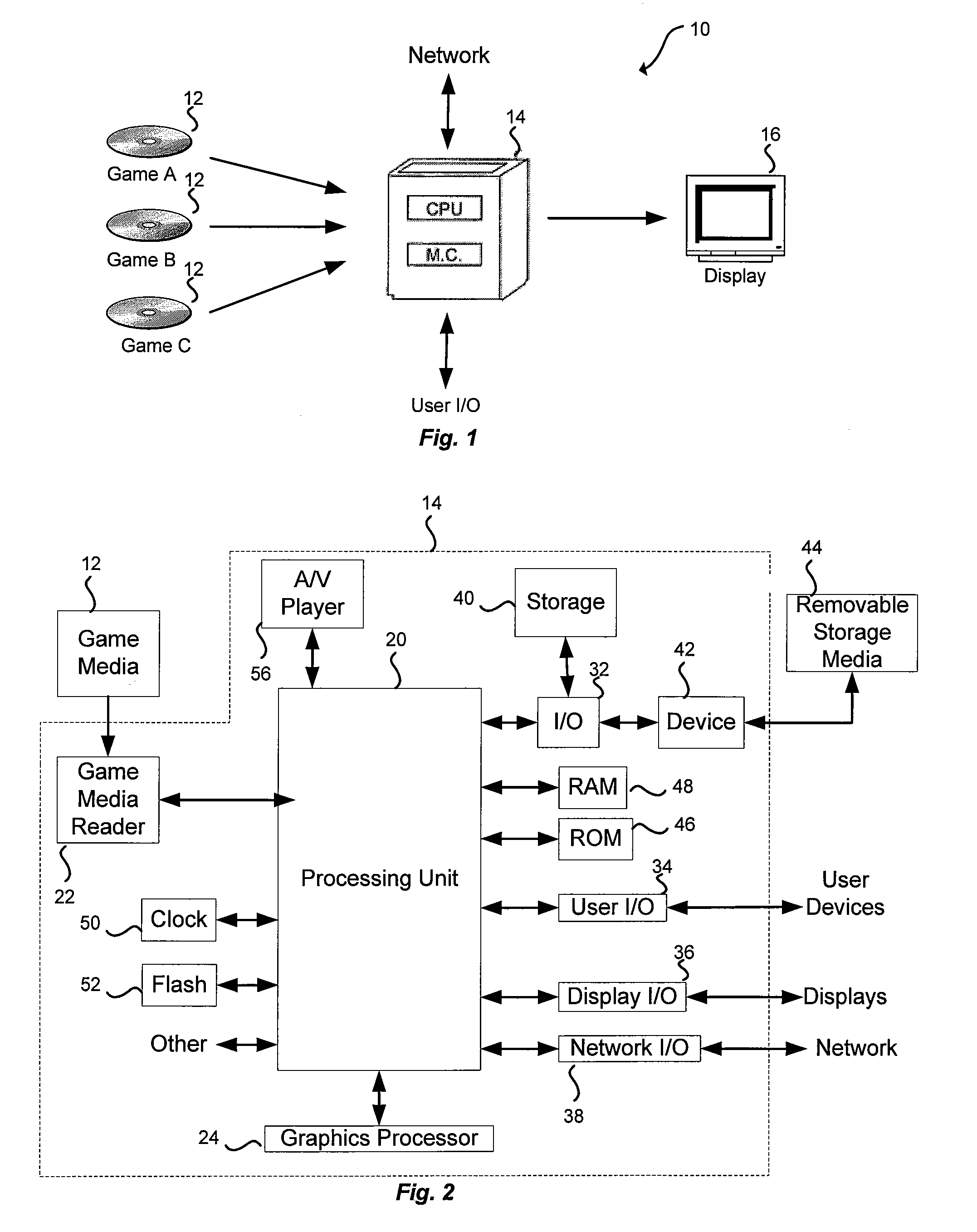

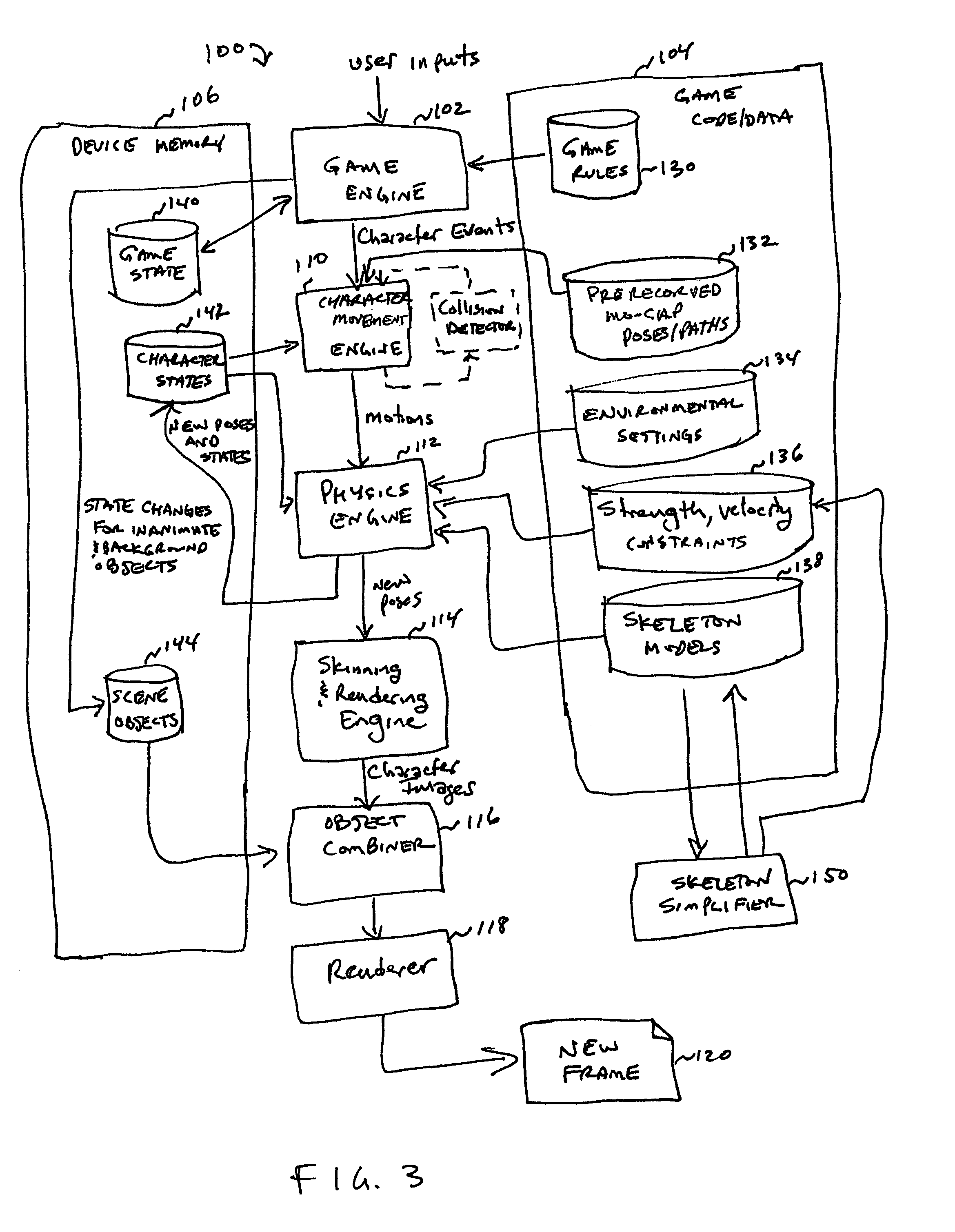

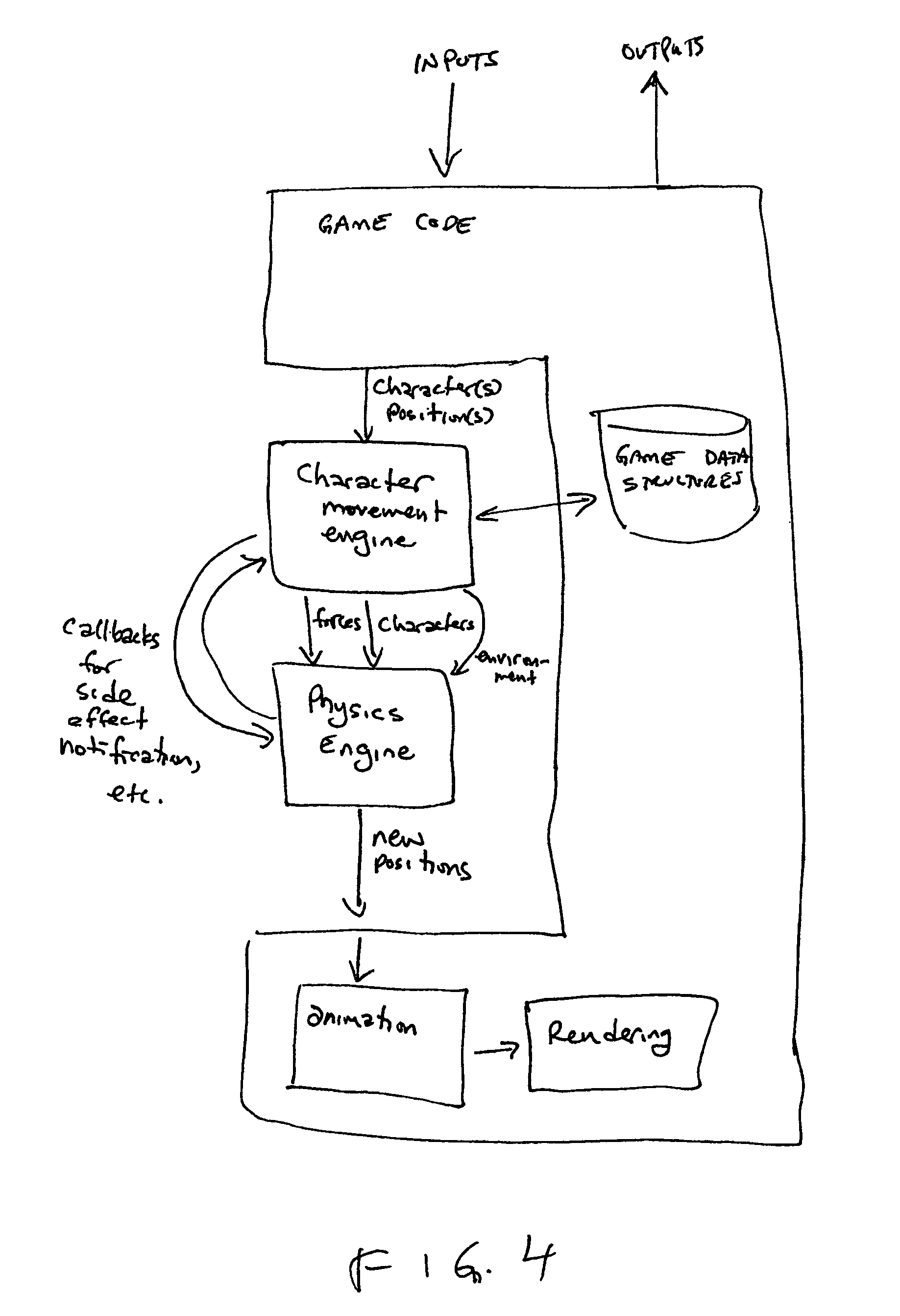

Computer animation of simulated characters using combinations of motion-capture data and external force modelling or other physics models

ActiveUS7403202B1Processing speedEasy to handleImage analysisVisual presentationComputer animationGraphics

Embodiments of the present invention provide methods and apparatus wherein physics models are integrated with motion capture animation to allow for variability in animations, dynamic response, such as animating events different from those for which motion capture data was obtained, including changes in character purpose and collisions. The physical model may include sets of internal forces and / or external forces. To facilitate the integration of mo-cap animation data with physics models, mo-cap animation data is played back using forces on physical models rather than directly setting joint angles or positions in a graphical skeleton, which allows the animation to be dynamically altered in real-time in a physically realistic manner by external forces and impulses.

Owner:ELECTRONICS ARTS INC

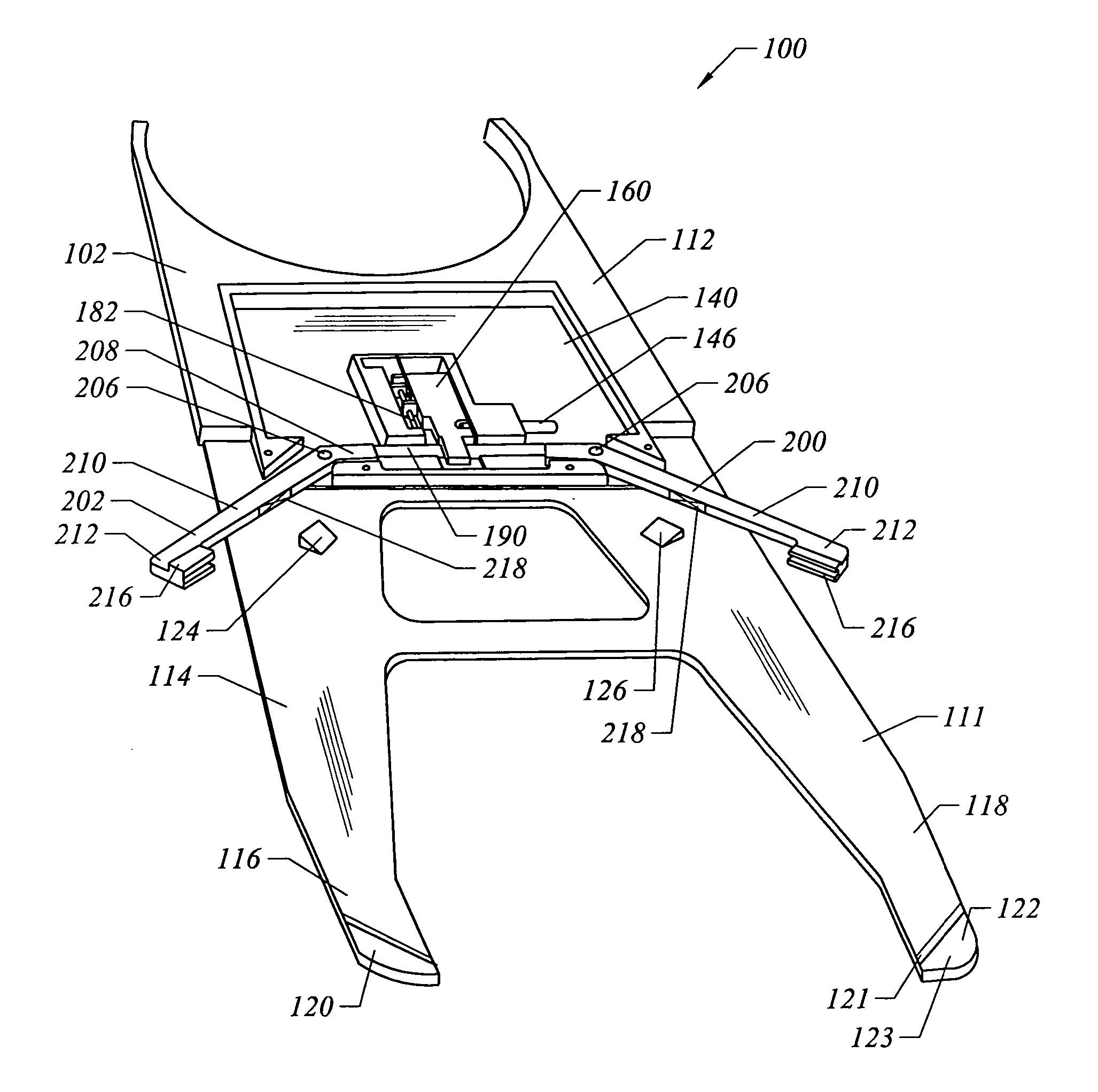

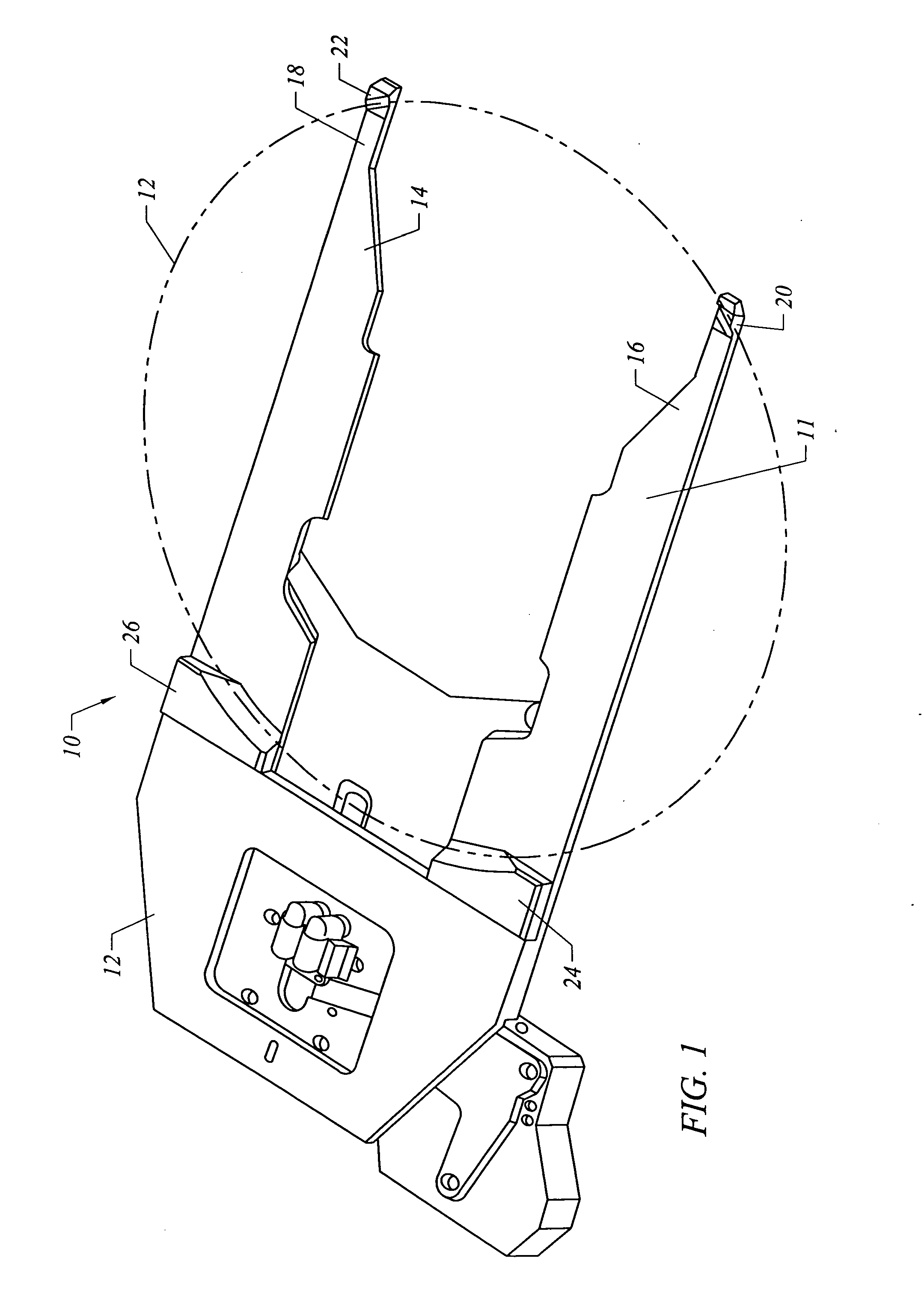

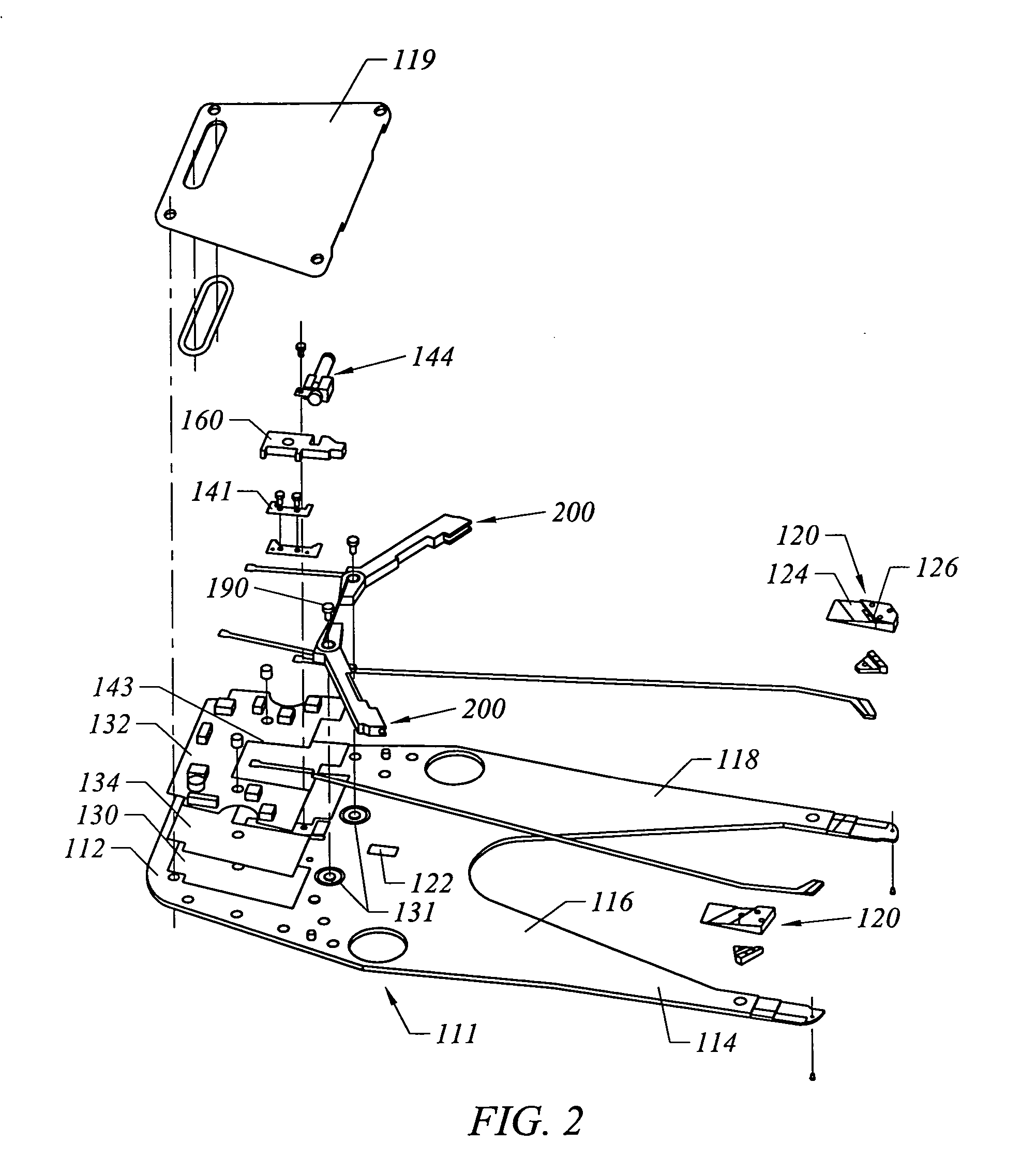

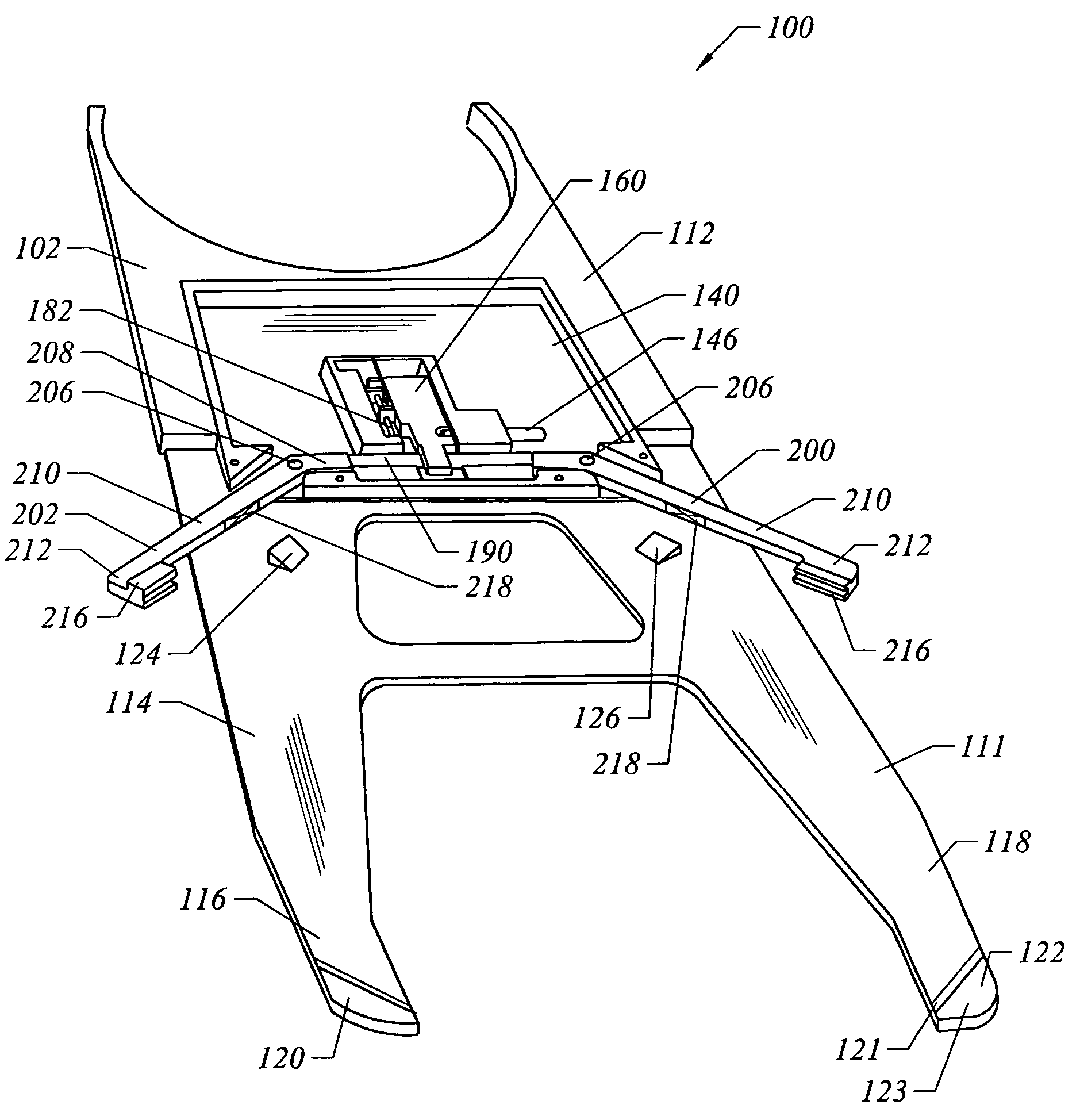

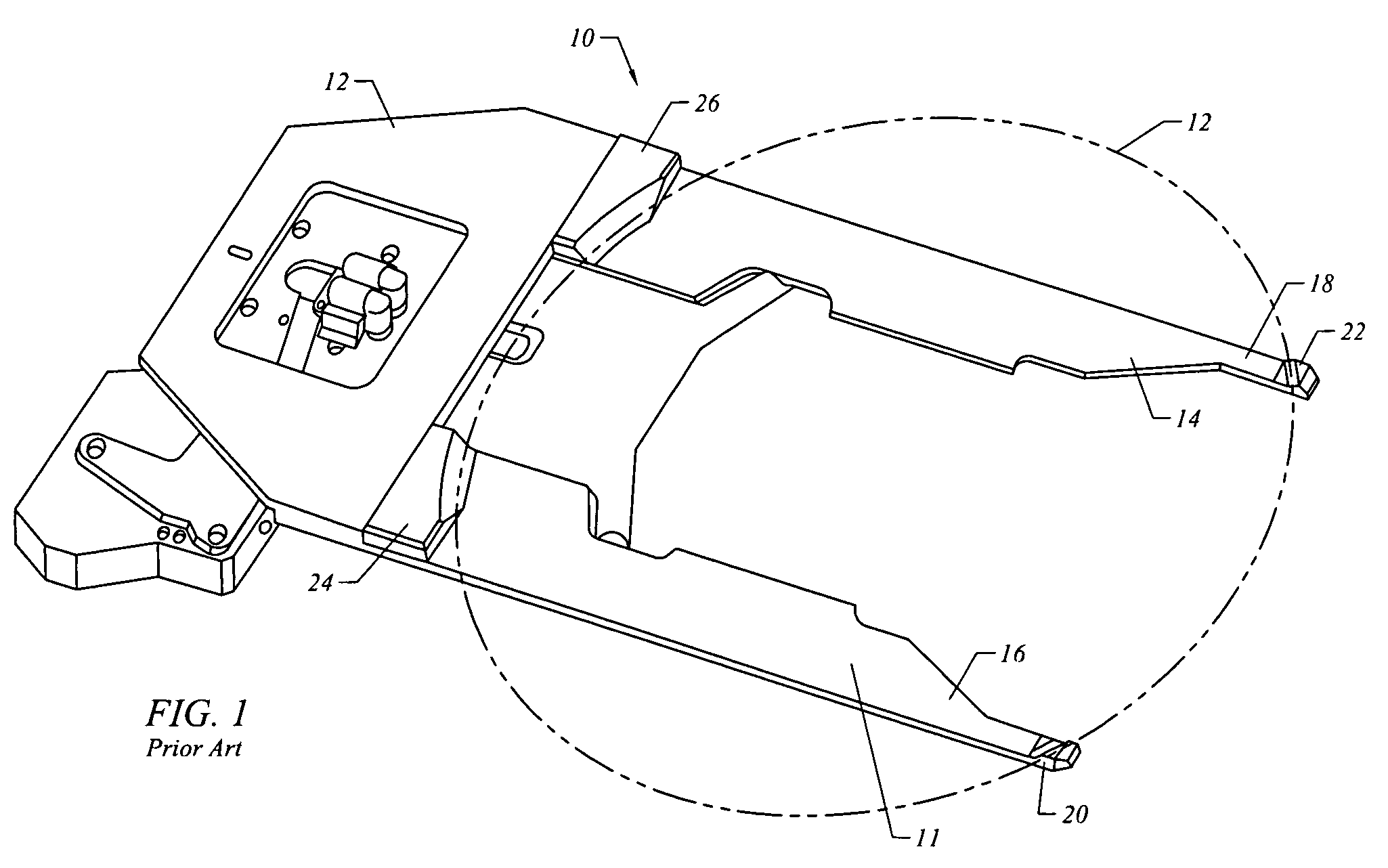

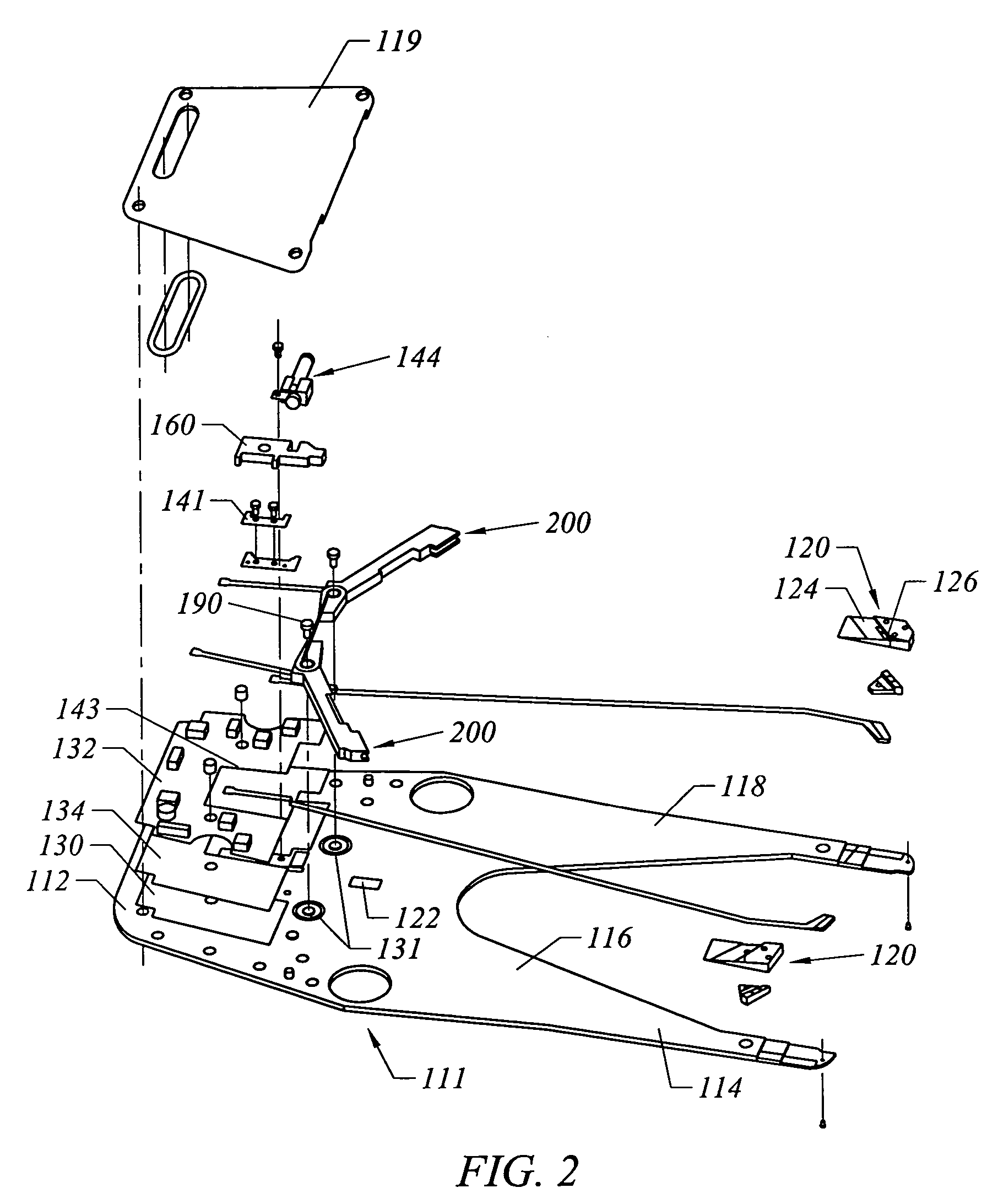

Active edge gripping end effector

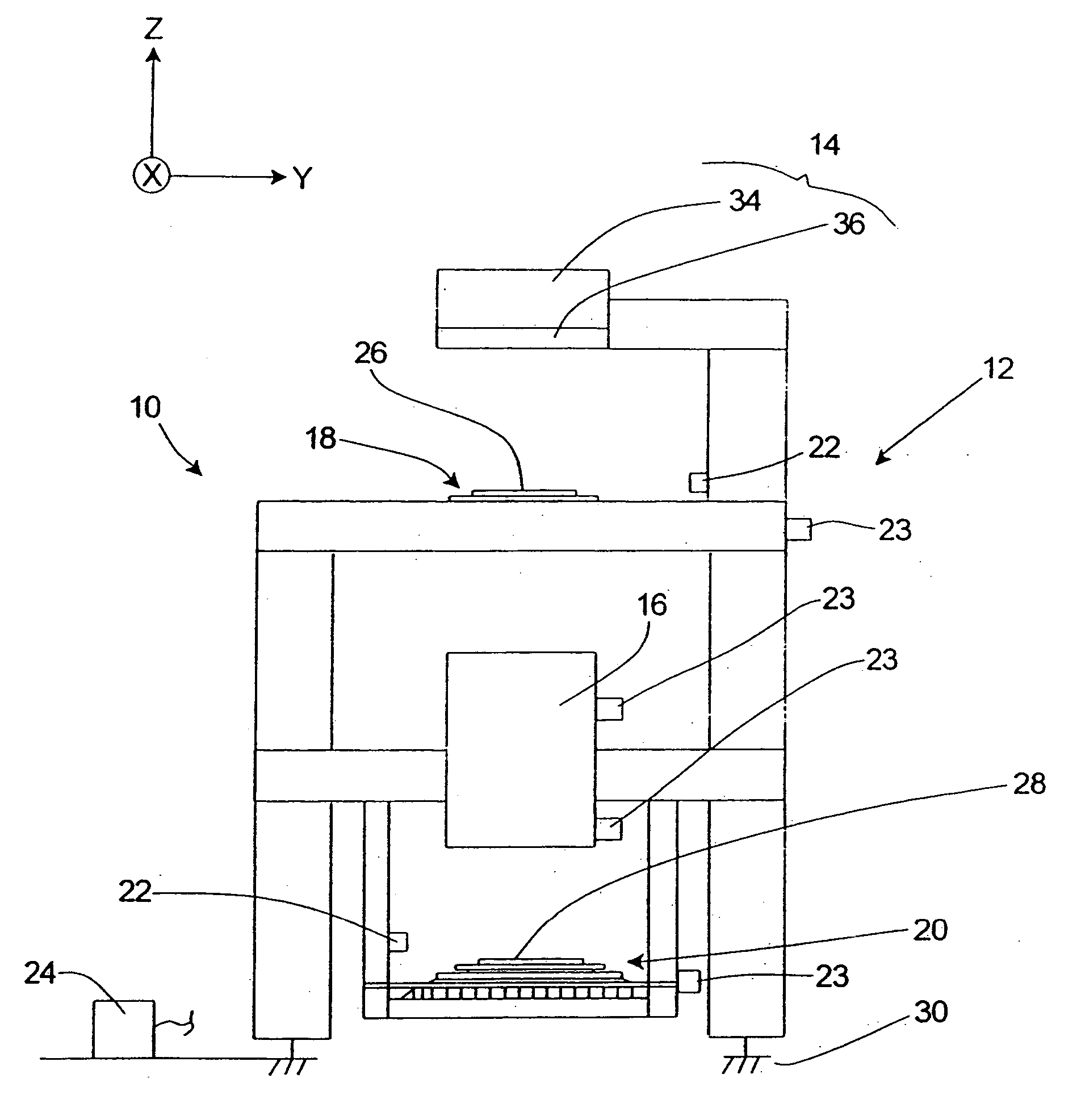

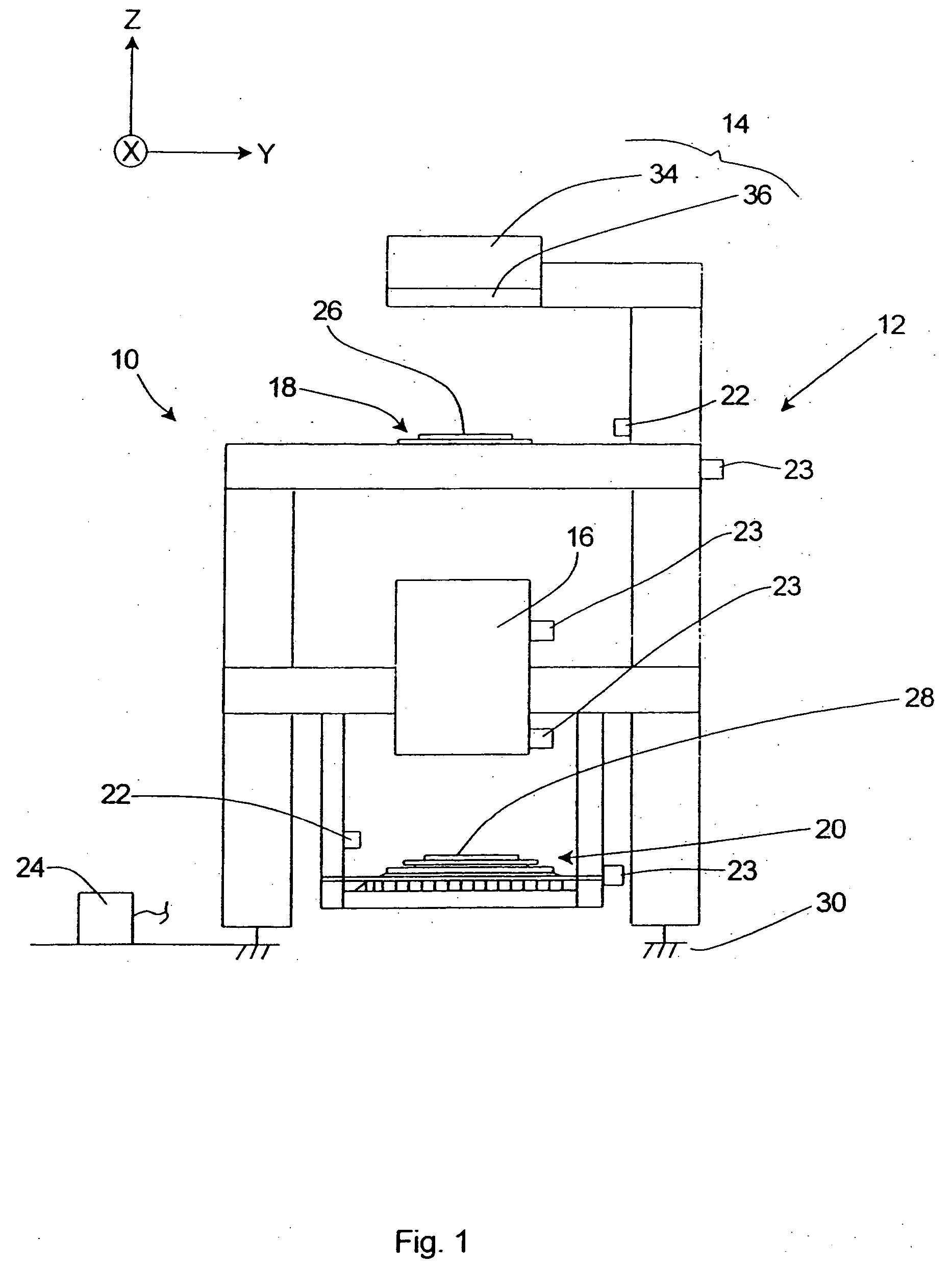

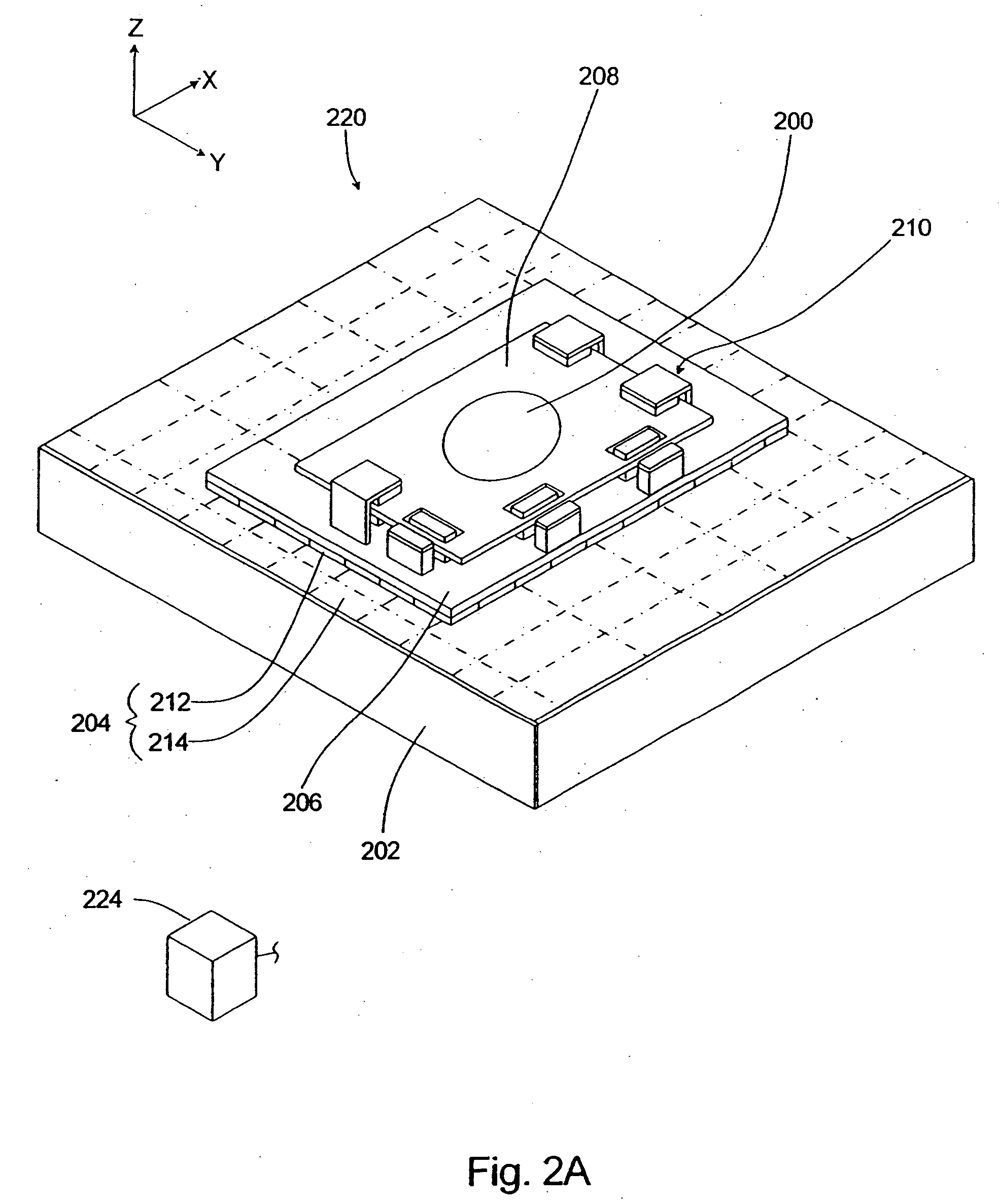

ActiveUS20050017529A1Minimize impactReduces large impact forceGripping headsSemiconductor/solid-state device manufacturingActive edgeEngineering

The present invention generally relates to an end effector that utilizes a gripping mechanism to grip a peripheral edge of the wafer and secure the wafer to the end effector. In one embodiment, the gripping mechanism includes a pair of gripper arms that pivot between a wafer-loading position and a wafer-engaging position. In another embodiment, an active plunger moves linearly between the wafer-loading and wafer-engaging positions. Both the gripper arms and the plunger device are driven by a motor assembly. A force feedback system monitors the force the gripping mechanism exerts on the wafer and, based on the amount of force, controls the operation of the motor assembly to dynamically adjust the position of the gripping mechanism.

Owner:BOOKS AUTOMATION US LLC

Active edge gripping and effector

InactiveUS7300082B2Good centering effectMinimize slidingGripping headsSemiconductor/solid-state device manufacturingActive edgeSystem monitor

Owner:BOOKS AUTOMATION US LLC

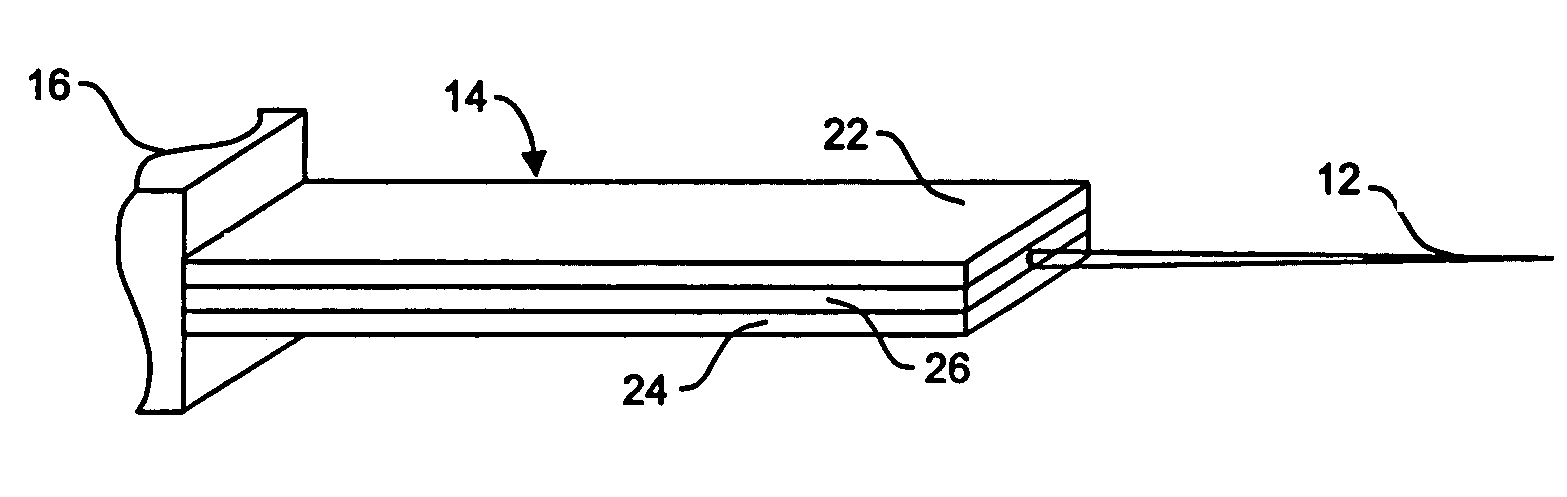

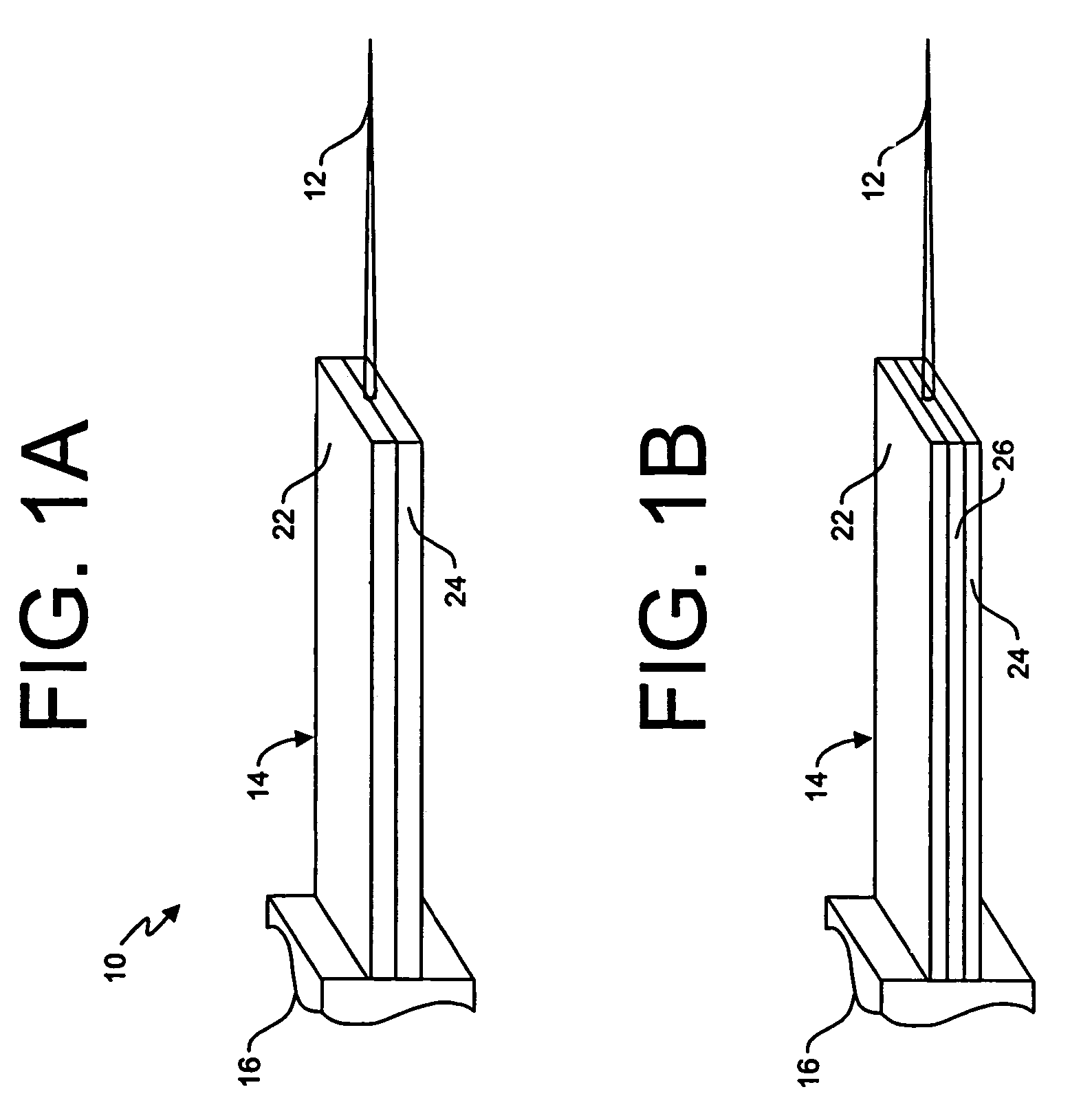

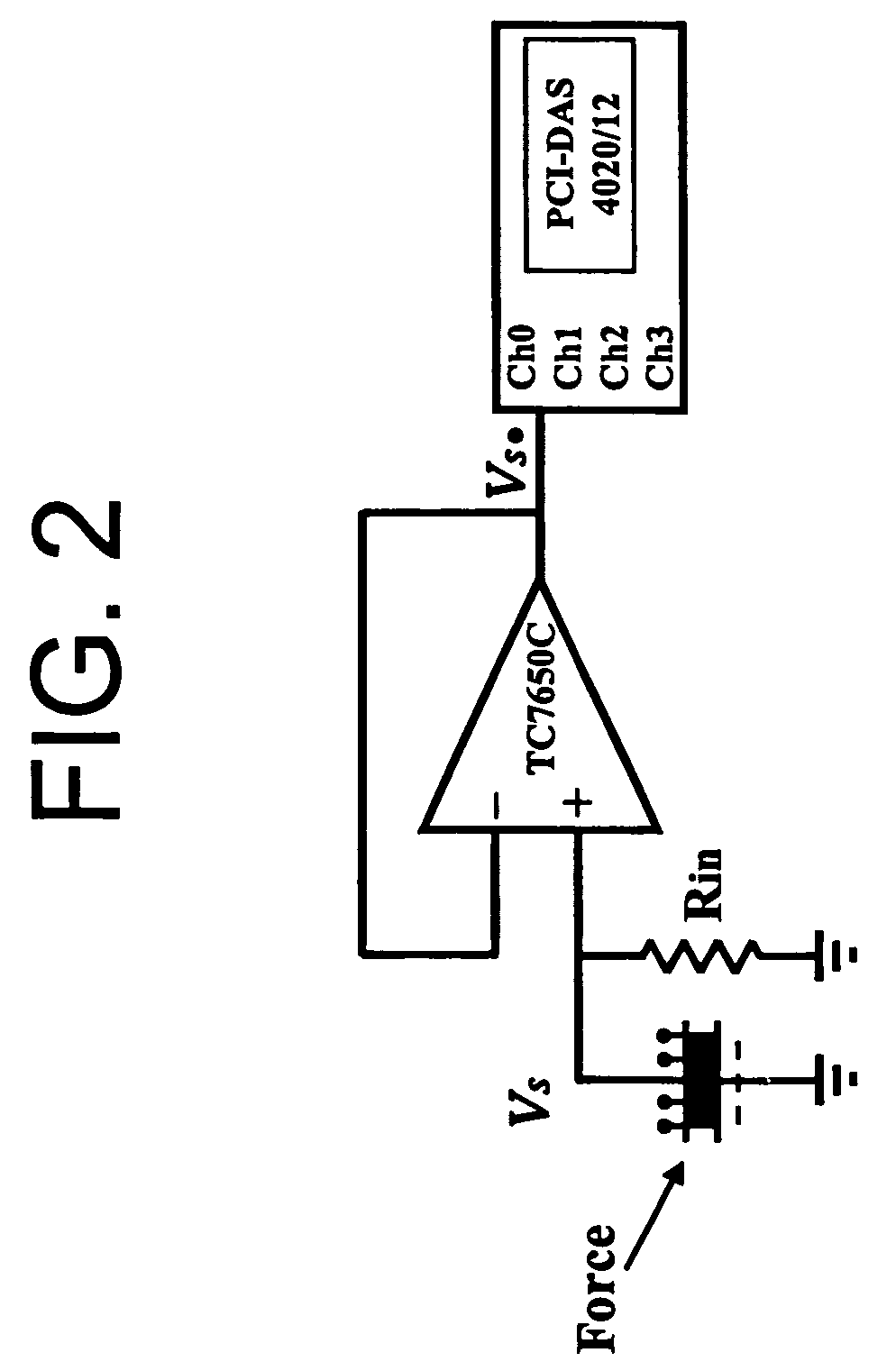

Active sensor for micro force measurement

InactiveUS7367242B2Quick balancePrecise motion controlVibration measurement in solidsForce measurement by measuring frquency variationsElectricityEngineering

An active micro-force sensor is provided for use on a micromanipulation device. The active micro-force sensor includes a cantilever structure having an actuator layer of piezoelectric material and a sensing layer of piezoelectric material bonded together. When an external force is exerted on the sensor, the sensor deforms and an applied force signal is recorded by the sensing layer. The applied force signal is then fed back to the actuating layer of the sensor via a servoed transfer function or servo controller, so that a counteracting deformation can be generated by the bending moment from the servoed actuating layer to quickly balance the deformation caused by the external micro-force. Once balanced, the sensor beam comes back to straight status and the tip will remain in its equilibrium position, thus the sensor stiffness seems to be virtually improved so that the accurate motion control of the sensor tip can be reached, especially, at the same time, the micro-force can also be obtained by solving the counteracting balance voltage applied to the actuating layer.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Linear motor force ripple identification and compensation with iterative learning control

InactiveUS20060170382A1Increase heightIncrease speedProgramme controlMotor control for low load efficiencyEngineeringPeak value

Embodiments of the present invention are directed to compensating for force ripple of an apparatus driven by a force produced by a linear motor. In one embodiment, a method of compensating for force ripple comprises generating force commands for a trajectory starting at a plurality of starting positions of the apparatus driven by the linear motor to produce different trajectory motions based on the same trajectory at the plurality of starting positions, the force commands each including peaks of large acceleration / deceleration and valleys of low force levels; calculating an average of the force commands during large acceleration / deceleration generated based on trajectory motions for the plurality of starting positions; calculating a variation ratio of the force command for each trajectory motion to the calculated average of the force commands; and compensating for force ripple in the apparatus based on the calculated variation ratio to control the force applied by the linear motor to the apparatus.

Owner:NIKON CORP

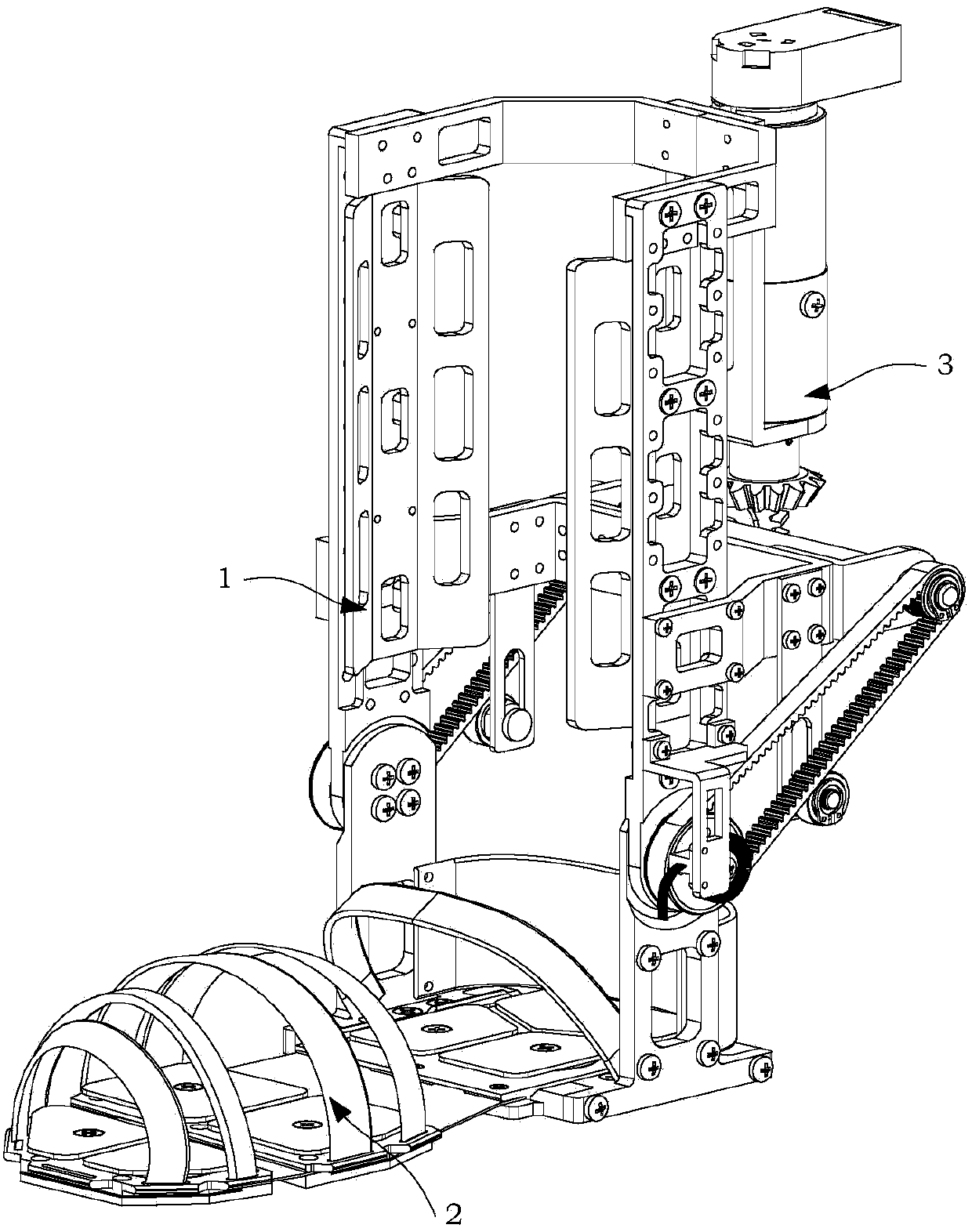

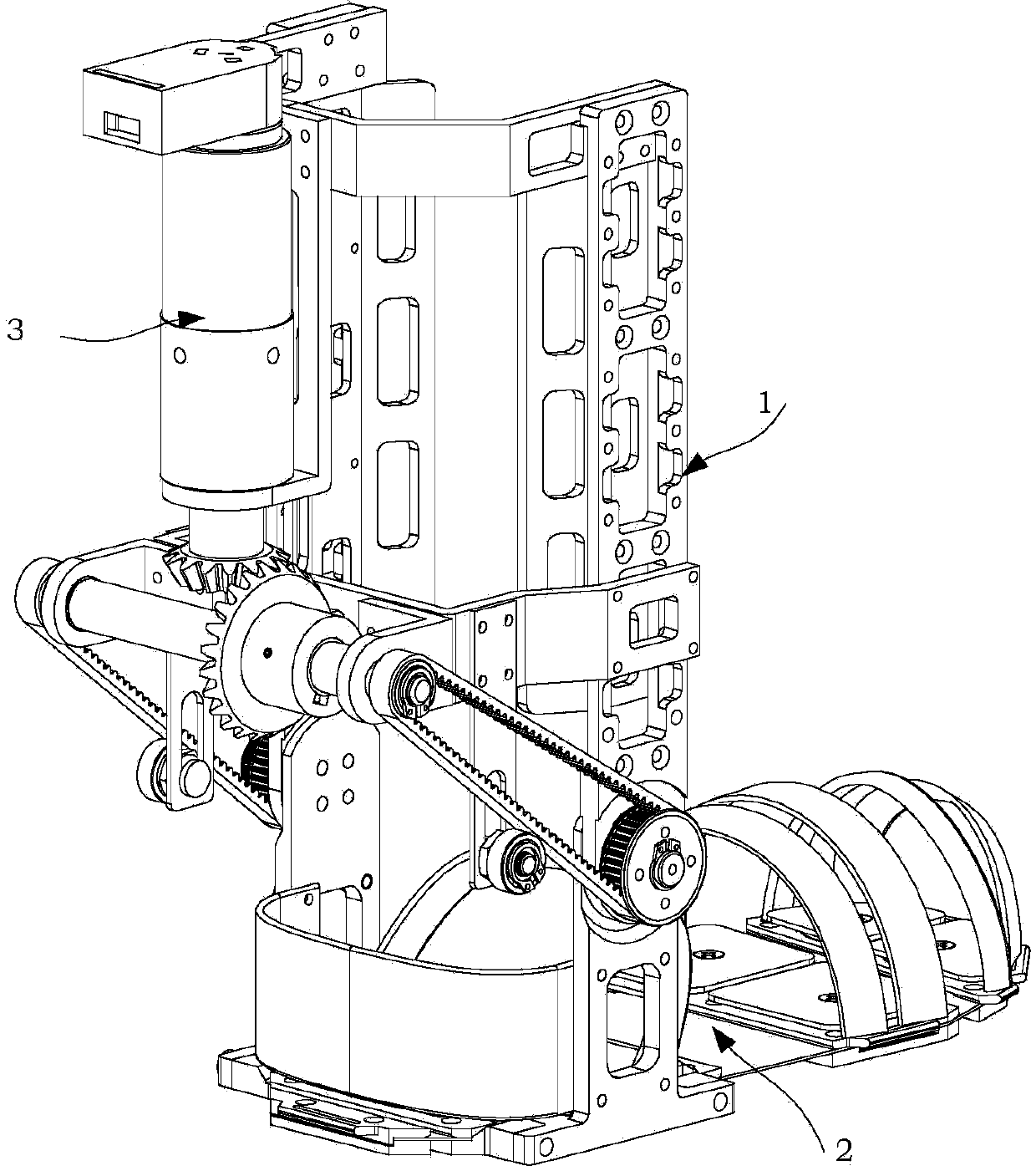

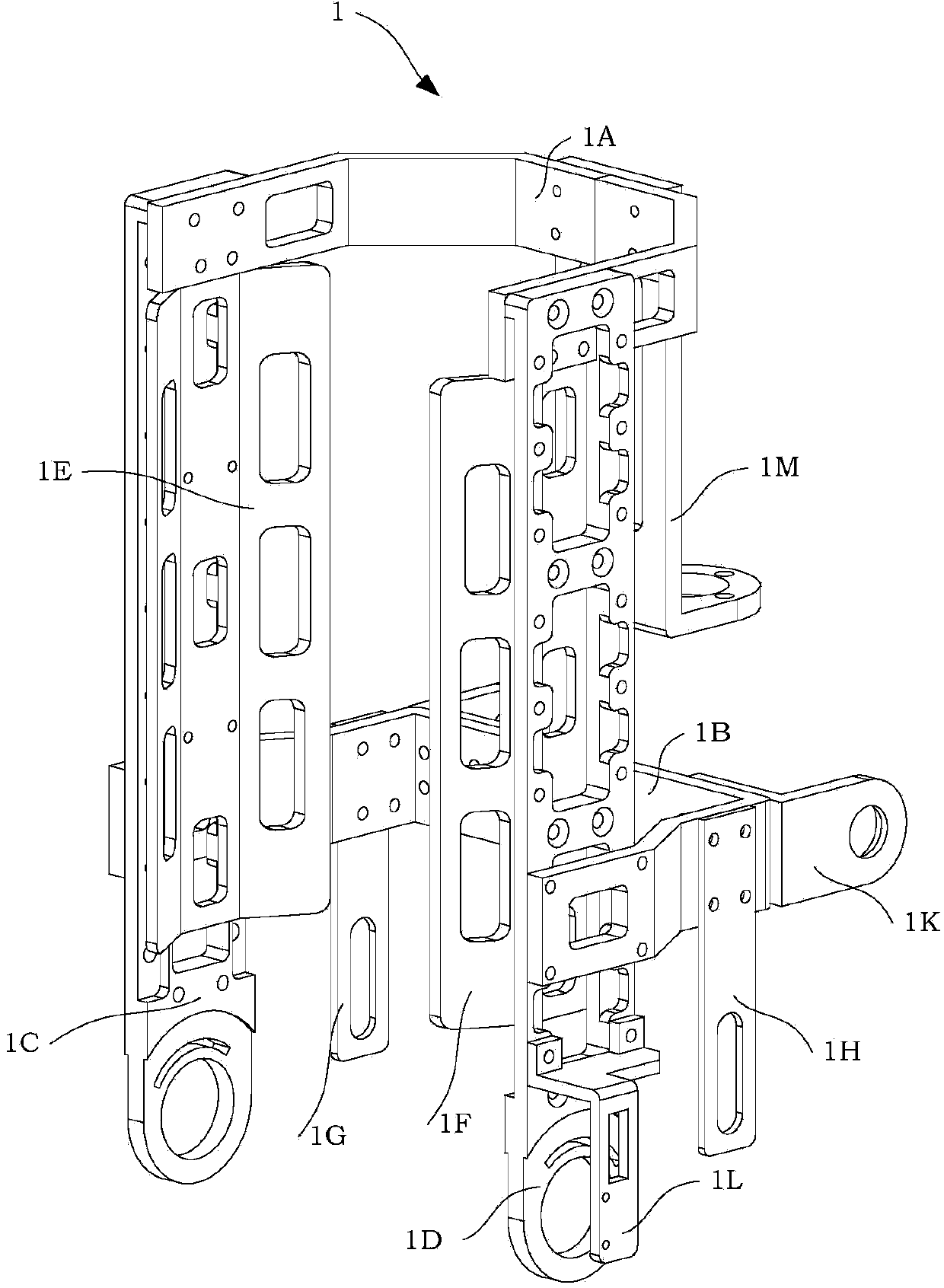

Active driving ankle foot orthosis with plantar pressure detection function

The invention discloses an active driving ankle foot orthosis with a plantar pressure detection function. The active driving ankle foot orthosis comprises a shank fixing component, a foot sensing component and an active driving component. The active driving component drives a driving bevel gear through a direct current motor; the driving bevel gear is meshed with a driven bevel gear; the driven bevel gear is mounted on a transmission shaft; a synchronous pulley, a synchronous belt and a tensioning screw are respectively formed at two ends of the transmission shaft. Seven film pressure sensors and an accelerometer are arranged in the foot sensing component. The active driving ankle foot orthosis has the advantages that on one hand, an intelligent pressure sensing foot is designed according to body bionics, a sensing heel and a sole are mutually connected through a spring steel sheet, the segmented structure of a human foot is simulated, and toes and the sole can be freely bent during walking, and on the other hand, active driving free degree is designed on the sagittal plane of an ankle joint, foot drop of a patient is prevented, meanwhile, power for the patient to go ahead is effectively provided through the driving of the direct current motor, and the walking load of the patient is reduced.

Owner:BEIHANG UNIV

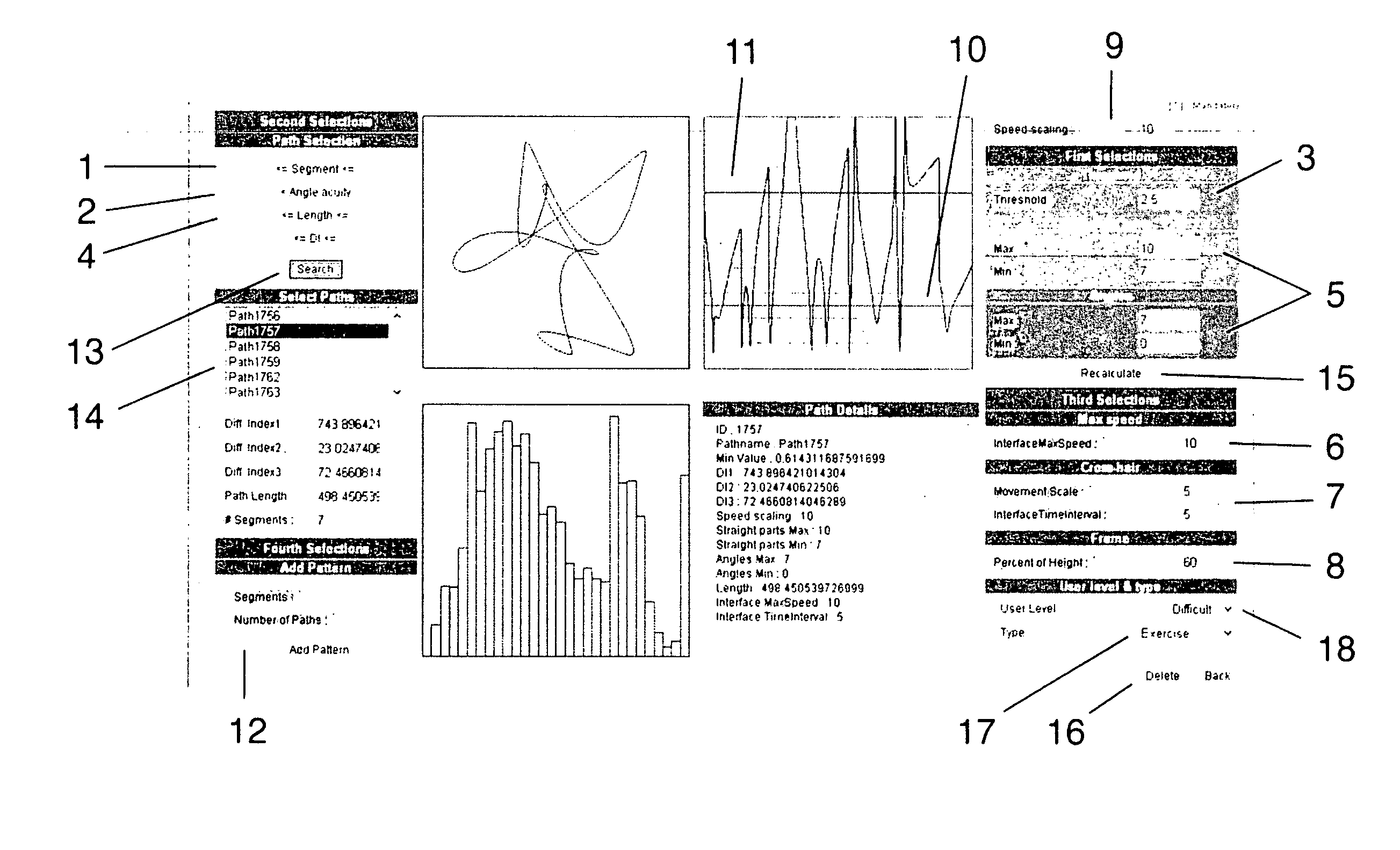

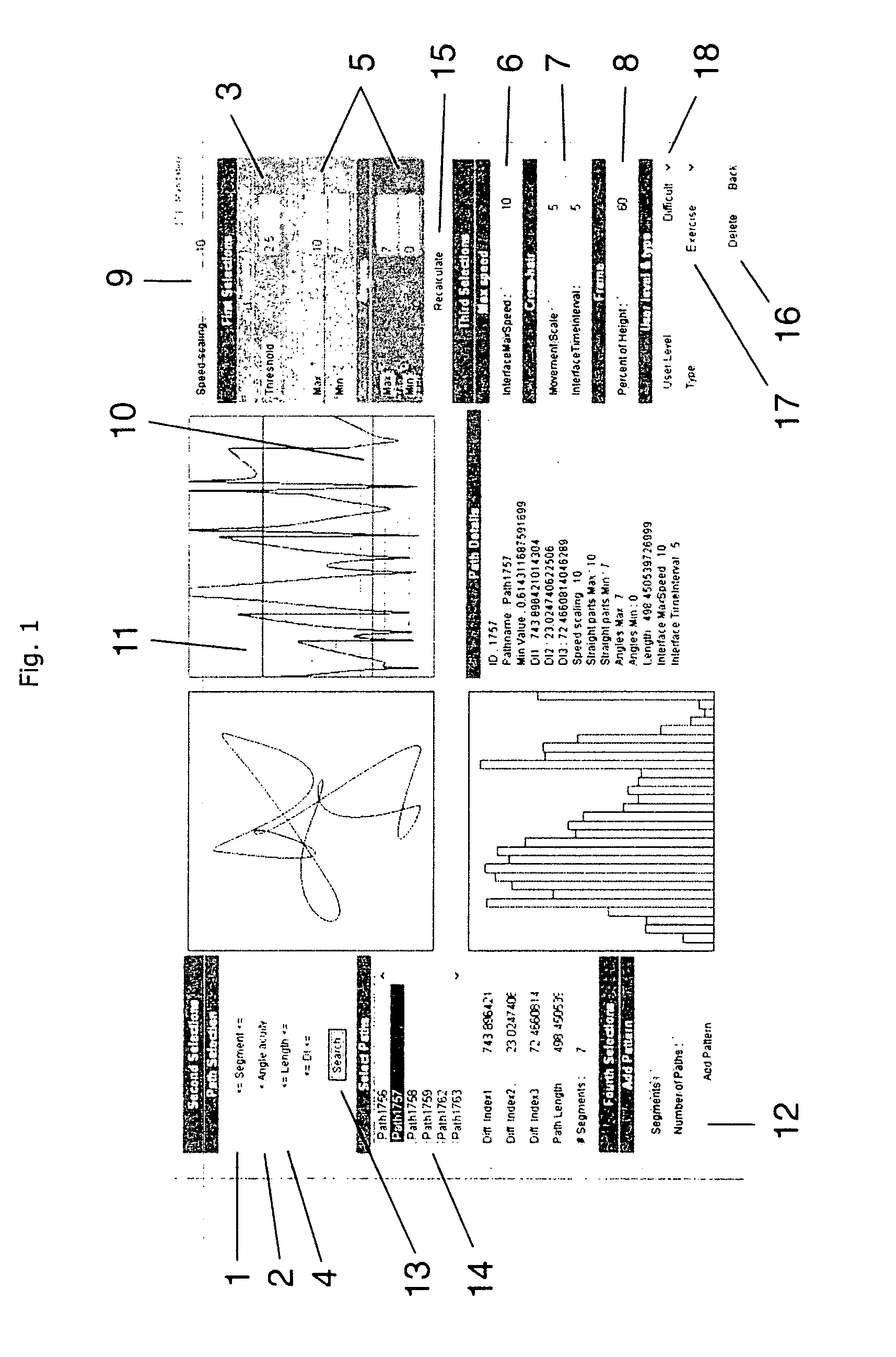

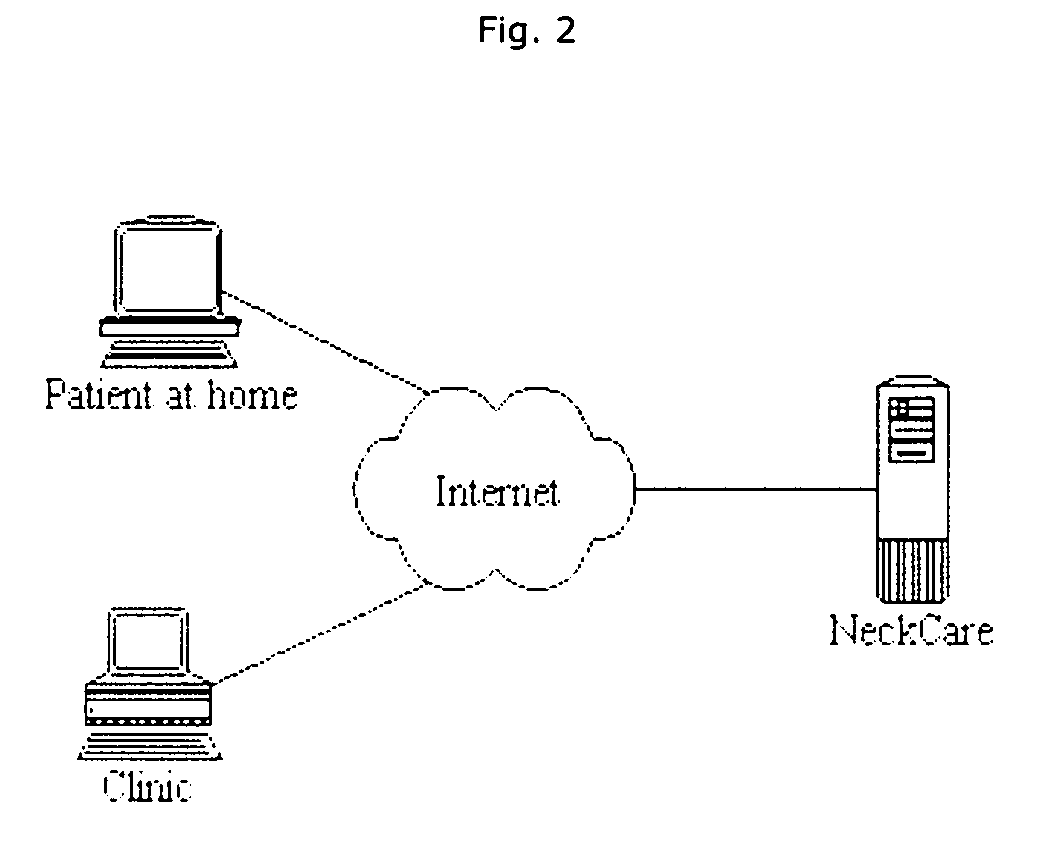

Method for accurate assessment and graded training of sensorimotor functions

ActiveUS20120133655A1Precise motion controlReliable and validDigital computer detailsAcceleration measurementBody regionMovement control

The invention relates, to the field of motion tracking and sensorimotor assessment and training, by providing a method, system and software for tracking of a target by moving the head and neck or other body part in two or three-dimensional space. In particular the invention teaches a method to create incremental difficult classes of unpredictable movement patterns according to specific criteria. The created movement patterns can be used to accurately grade the deficits of movement control and other sensorimotor deficits of the head / neck and consequently a treatment can be prescribed which starts at each patient's impairment level by using the same method. The invention provides also a reliable and valid method to detect fraudulent neck compensation claims from genuine deficits by said assessment of sensorimotor function.

Owner:NECKCARE HLDG EHF

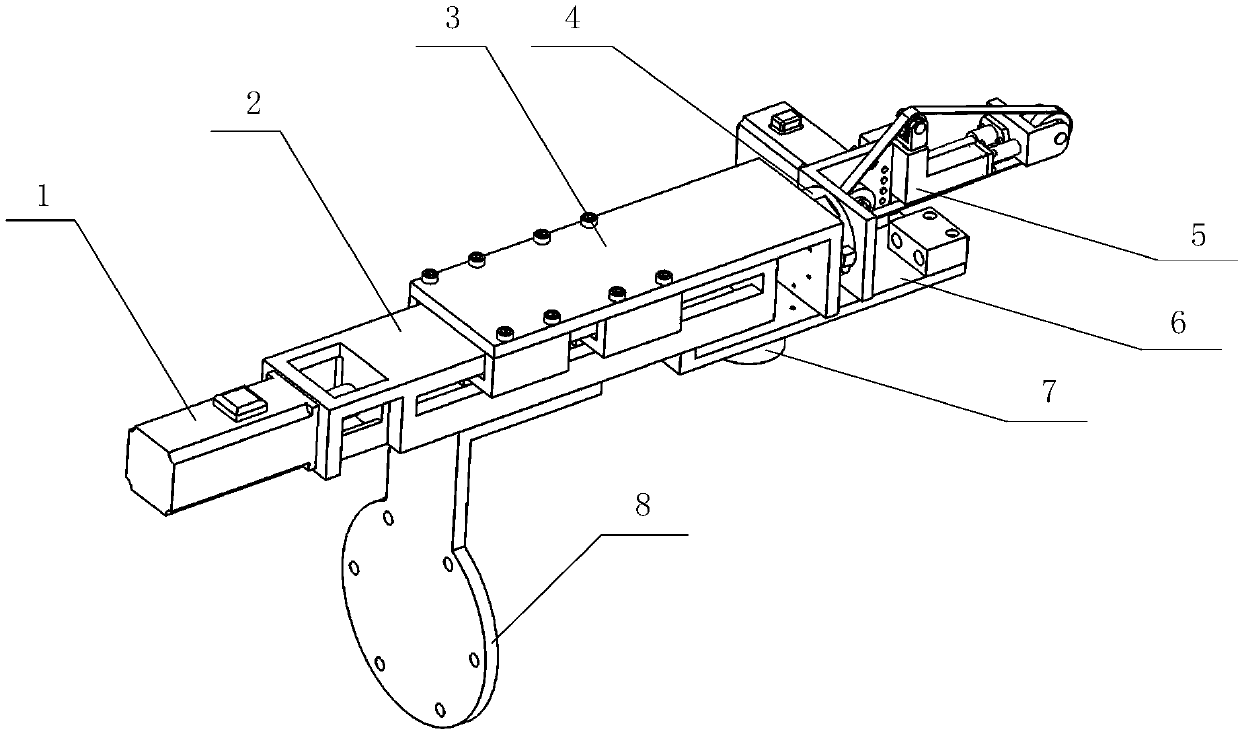

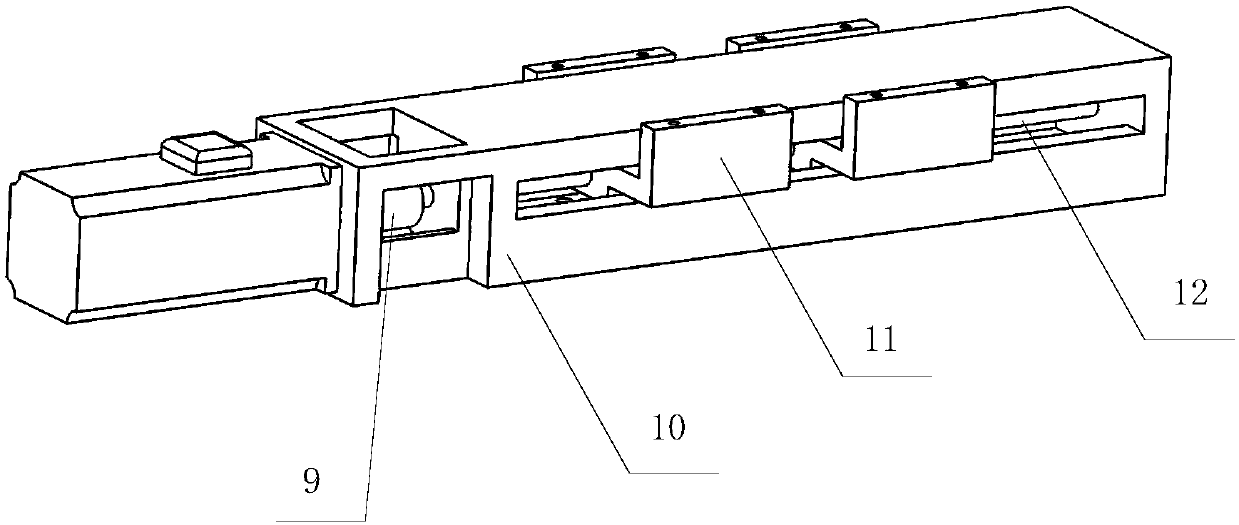

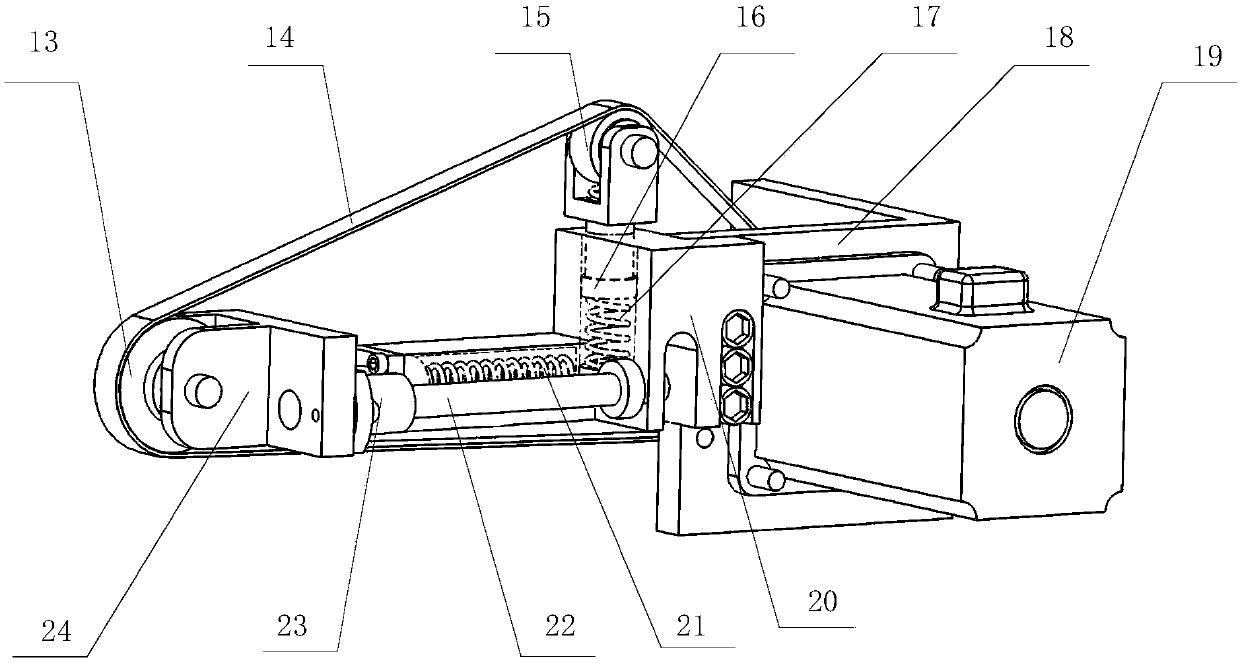

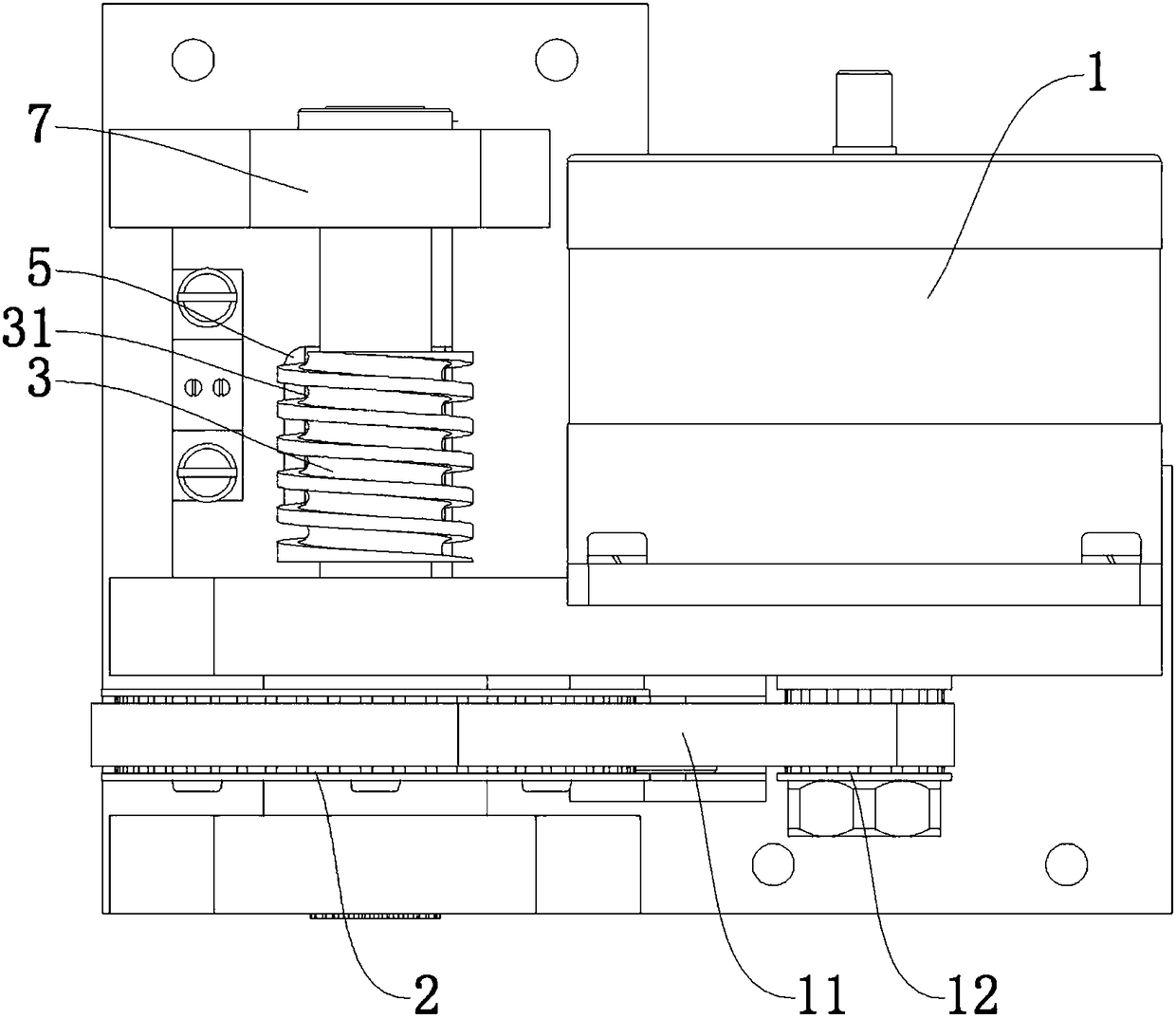

Integrated active-passive compliant one-dimensional variable force grinding and polishing device and control method

ActiveCN108044463ARealize variable force flexible contactAvoid shockBelt grinding machinesAutomatic grinding controlLinear motionManufacturing technology

The invention belongs to the technical field of intelligent processing and manufacturing, and particularly discloses an integrated active-passive compliant one-dimensional variable force grinding andpolishing device and a control method. The integrated active-passive compliant one-dimensional variable force grinding and polishing device comprises a linear module servo motion platform, a mountingflange, a limiting plate, a position and orientation sensor, a speed-adjustable compliant grinding and polishing mechanism and a controller, and the linear module servo motion platform is used for driving the grinding and polishing mechanism to perform linear motion; the mounting flange and the limiting plate are mounted on a base of the linear module servo motion platform, and the position and orientation sensor and the speed-adjustable compliant grinding and polishing mechanism are installed on the limiting plate; and the position and orientation sensor is used for measuring position and orientation of the one-dimensional variable force grinding and polishing device and sending the position and orientation to the controller, a force sensor is arranged between the compliant grinding and polishing mechanism and sliding blocks, the force sensor is used for collecting a contact force signal and send to the controller which can calculate speed control quantity, and the speed-adjustable compliant grinding and polishing mechanism is driven to move by rotation of a servo motor according to the speed control quantity. According to the integrated active-passive compliant one-dimensional variable force grinding and polishing device and the control method, the contact status of a abrasive belt and a workpiece can be adjusted in real time, and a stable and compliant grinding and polishingprocess is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

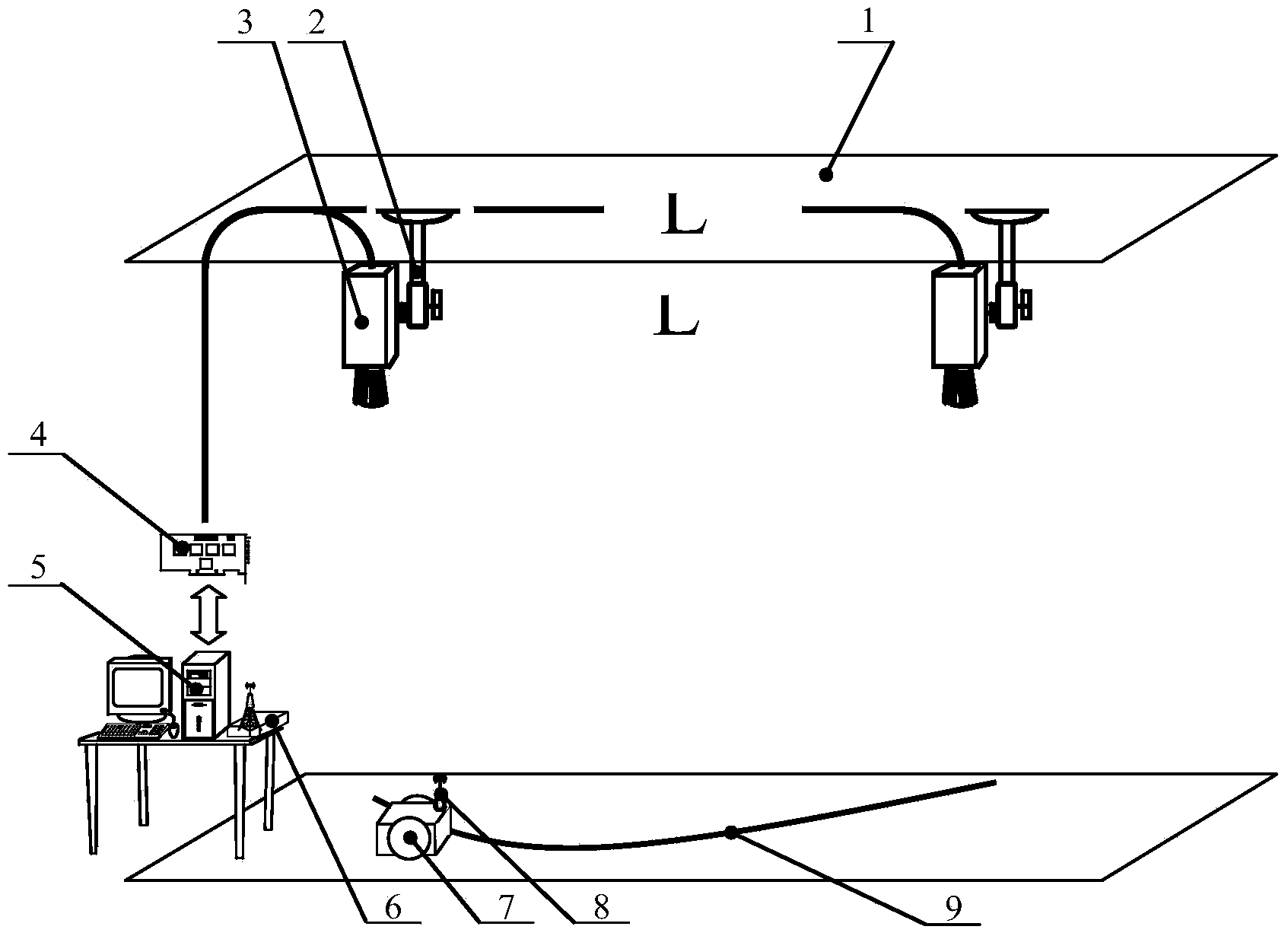

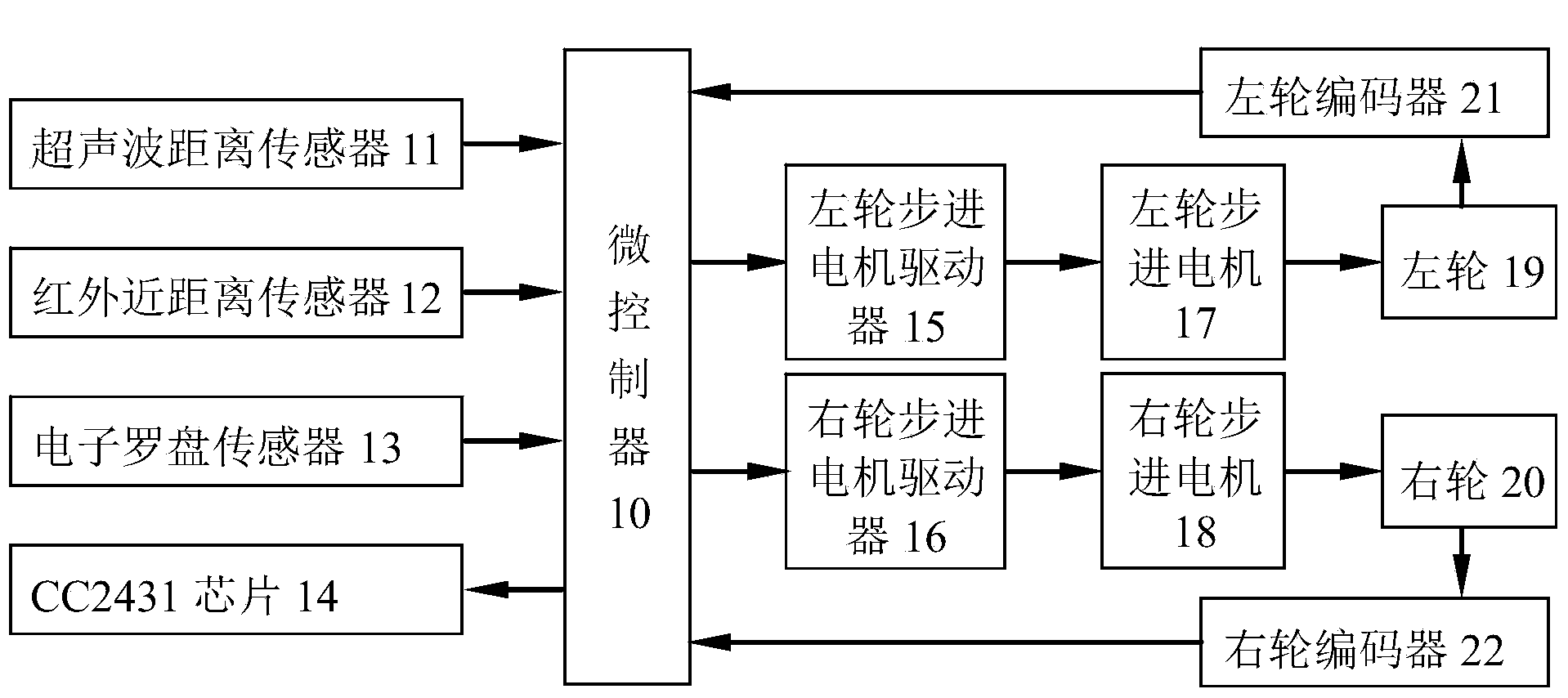

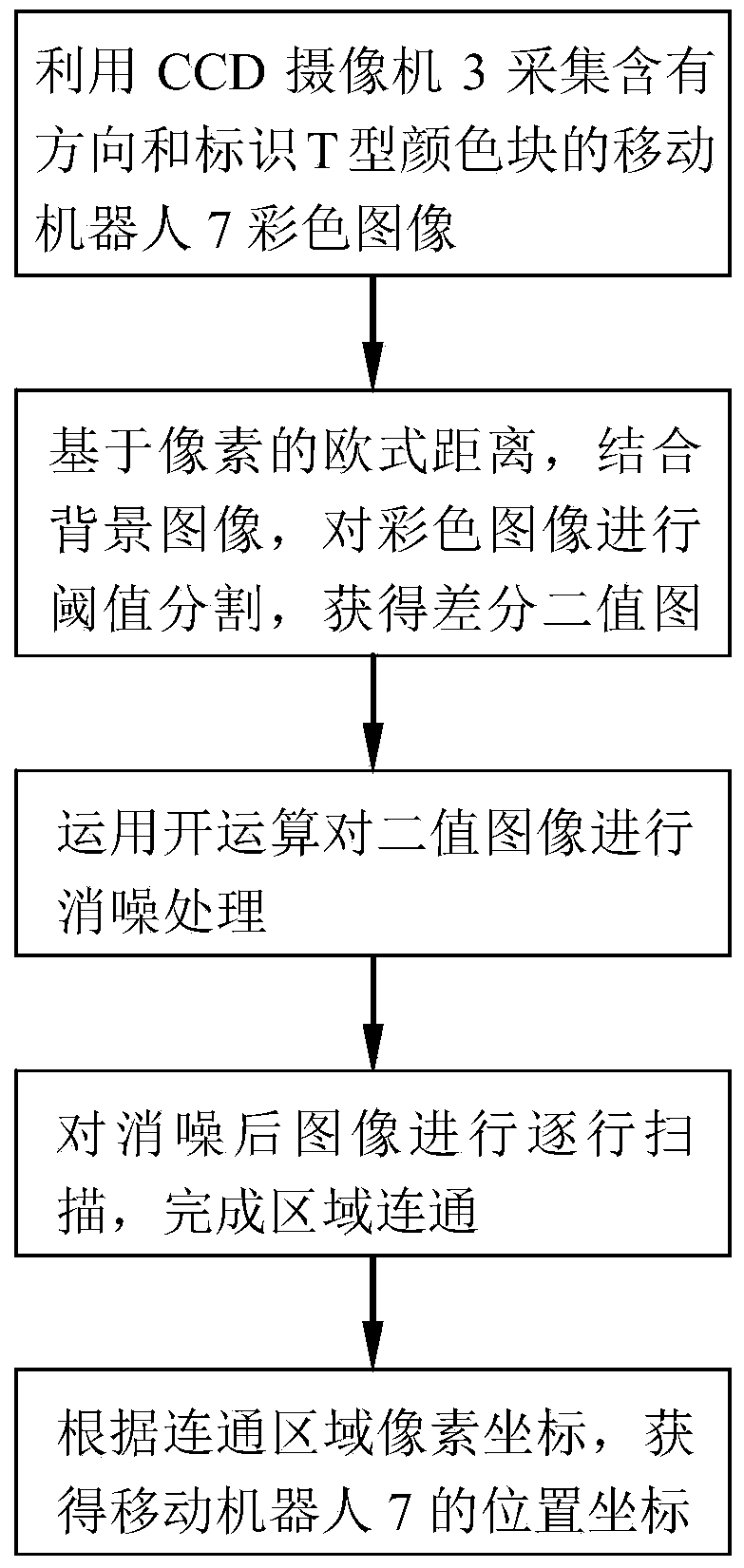

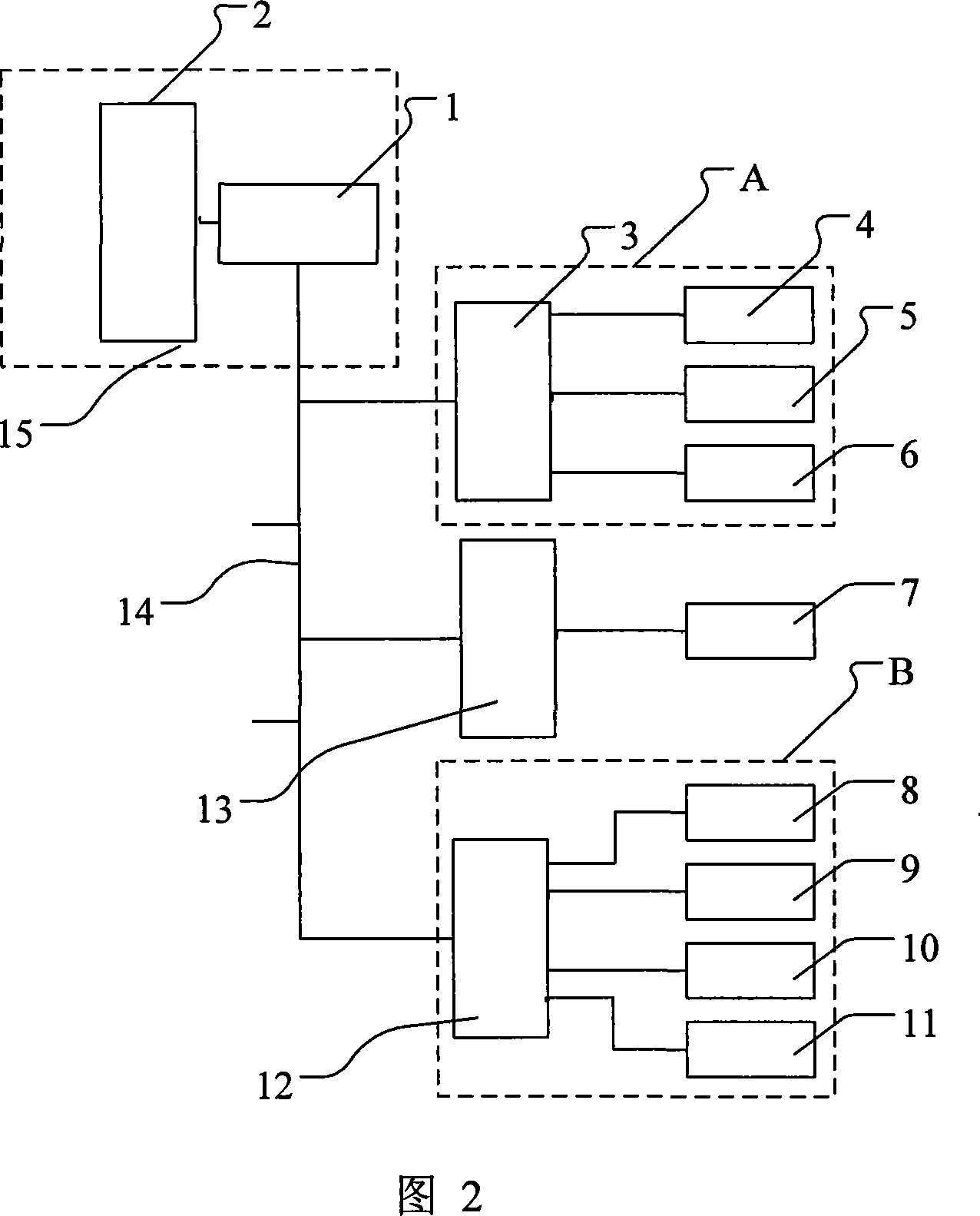

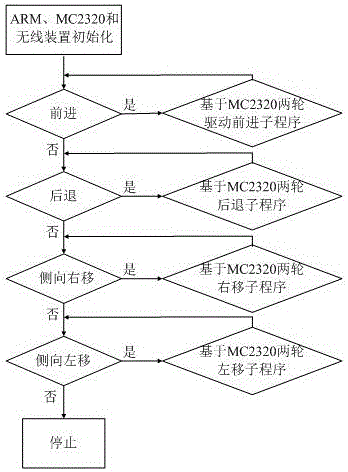

Motion control system and method of mobile robot in intelligent space

InactiveCN103454919AImprove Motion Control AccuracySmall amount of calculationAdaptive controlPosition/course control in two dimensionsMobile robot controlControl system

The invention discloses a motion control system and method of a mobile robot in an intelligent space. The motion control system is composed of the intelligent space and the mobile robot. The intelligent space comprises a monitoring host, a distributed visual system and a wireless sensor network system based on Zigbee. The motion control method of the mobile robot in the intelligent space comprises the steps that pose information of the mobile robot is obtained at first; then control deviation e of the mobile robot is obtained; mobile robot multi-objective self-regulation PID motion control based on an RBF identification network is conducted at last. Compared with an existing mobile robot control system based on a vehicle-mounted video, the motion control system and method of the mobile robot in the intelligent space have the advantages of being small in calculated amount, good in instantaneity, and more accurate in motion control.

Owner:JIANGSU UNIV OF SCI & TECH

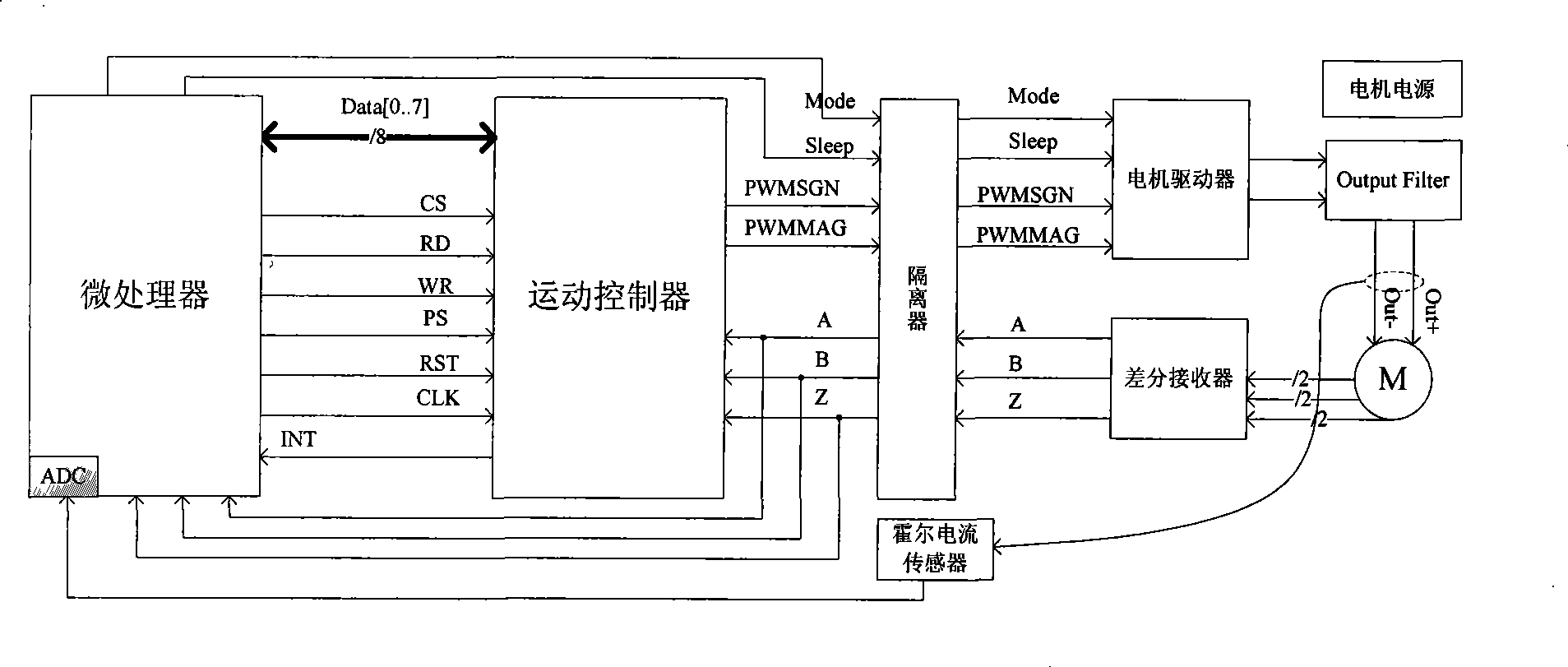

Four-dimensional ultrasound probe motor control system

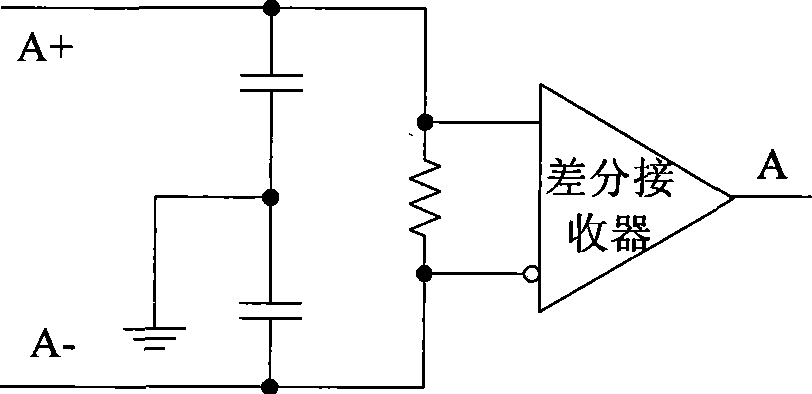

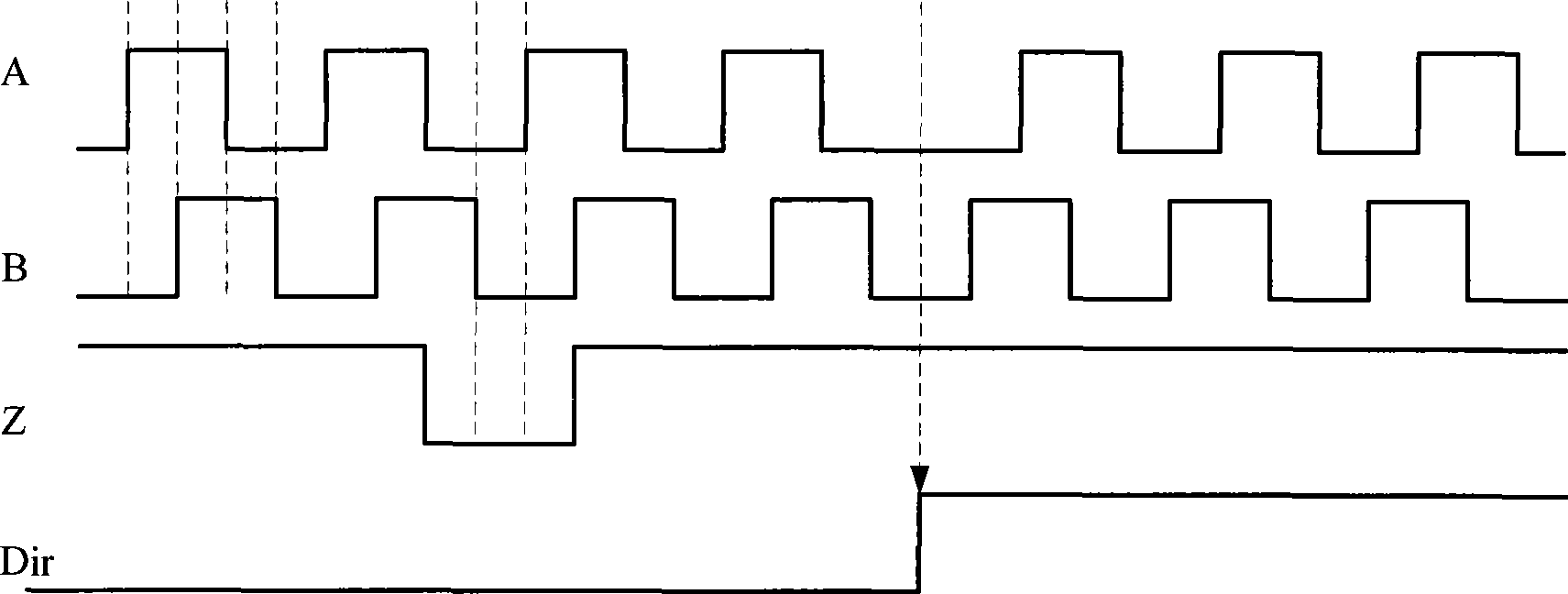

InactiveCN101480347AReduce chance of vibrationRealize closed-loop controlTomographyFour dimensional ultrasoundControl signal

The invention discloses a four-dimensional ultrasonic probe motor control system which comprises a microprocessor, a motion controller, a motor driver and a coder, wherein the microprocessor and the motion controller are sequentially connected with the motor driver, the motor driver is connected with a servo motor, the coder is connected with a rotating shaft of the servo motor, the output end of the coder is respectively connected with the microprocessor and the motion controller, the microprocessor is used for sending commands for controlling the motion of the servo motor to the motion controller, the coder is used for respectively outputting at least one path of detection signals to the microprocessor and the motion controller, the motion controller is used for outputting control signals for controlling the motion of the motor to the motor driver according to the commands and the detection signals, and the motor driver is used for driving the servo motor according to the control signals.

Owner:SHENZHEN LANDWIND IND

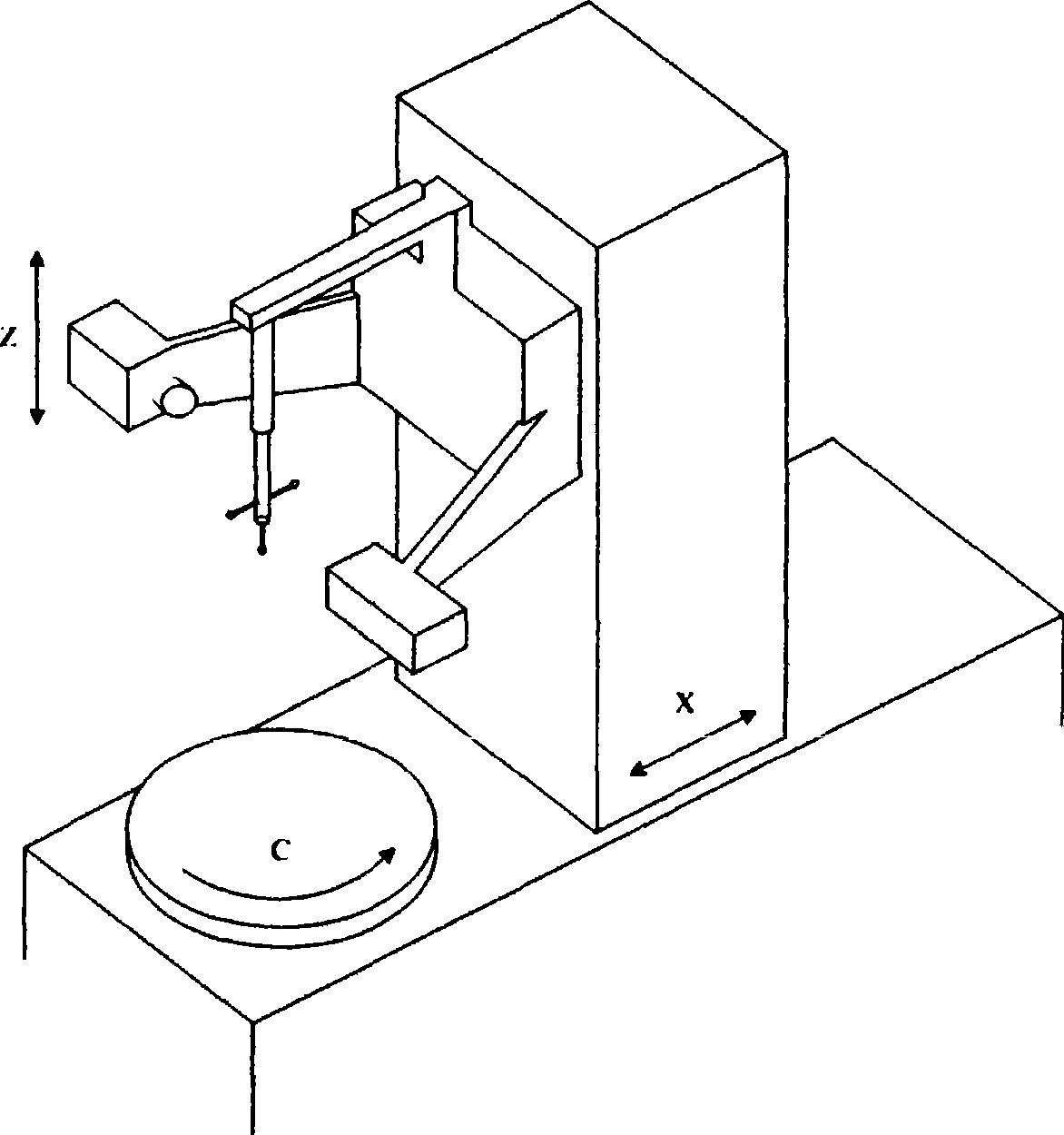

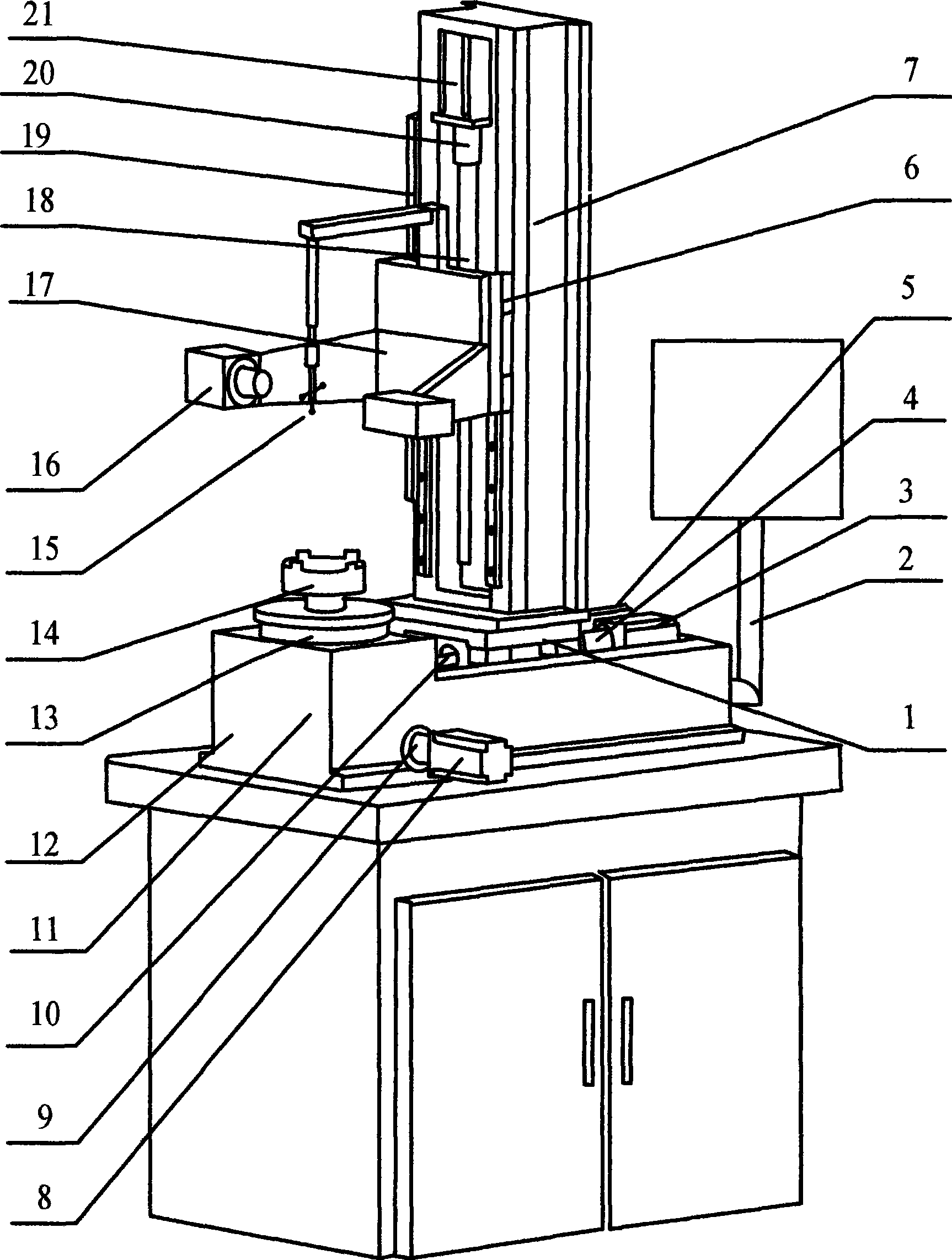

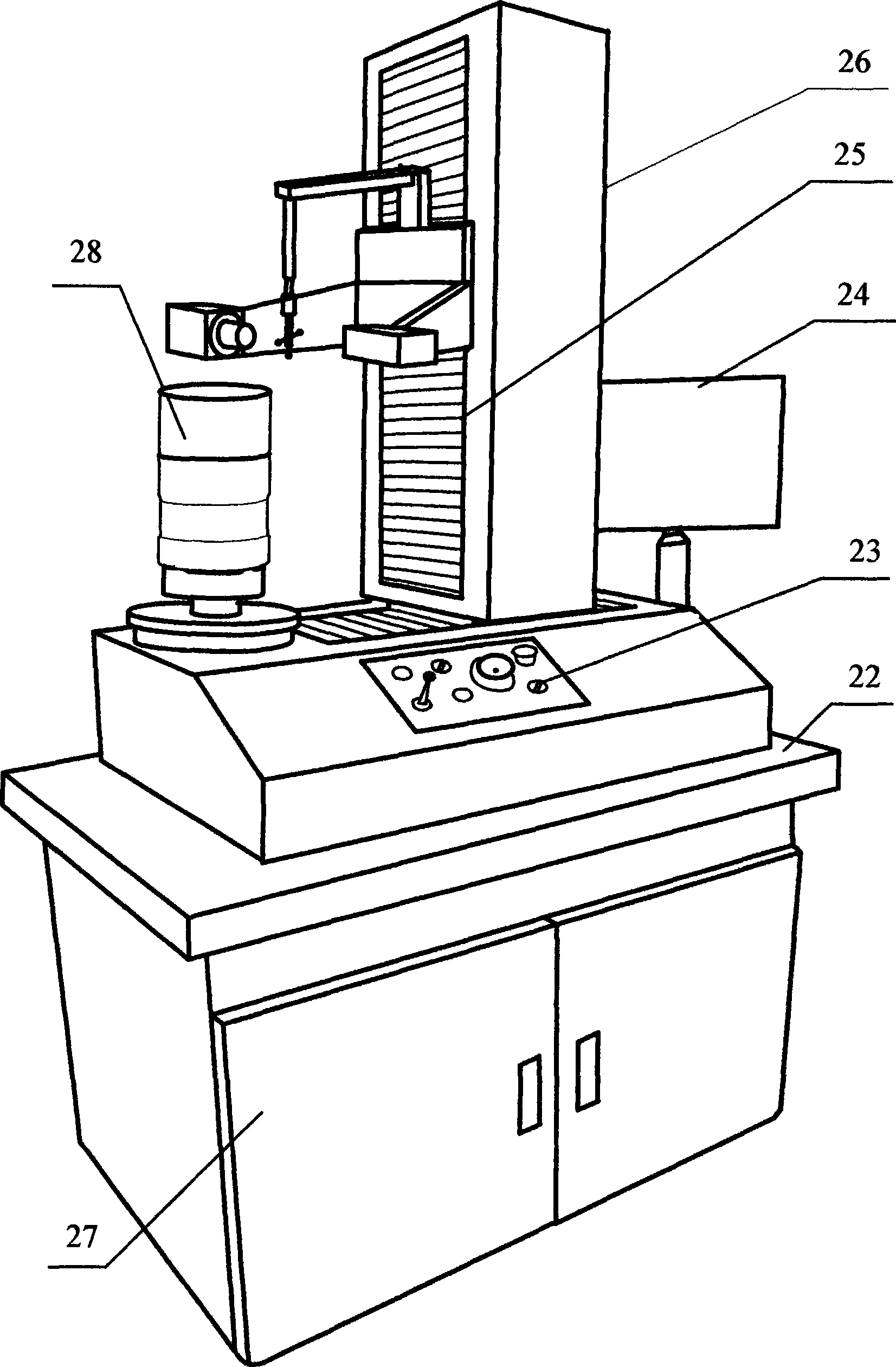

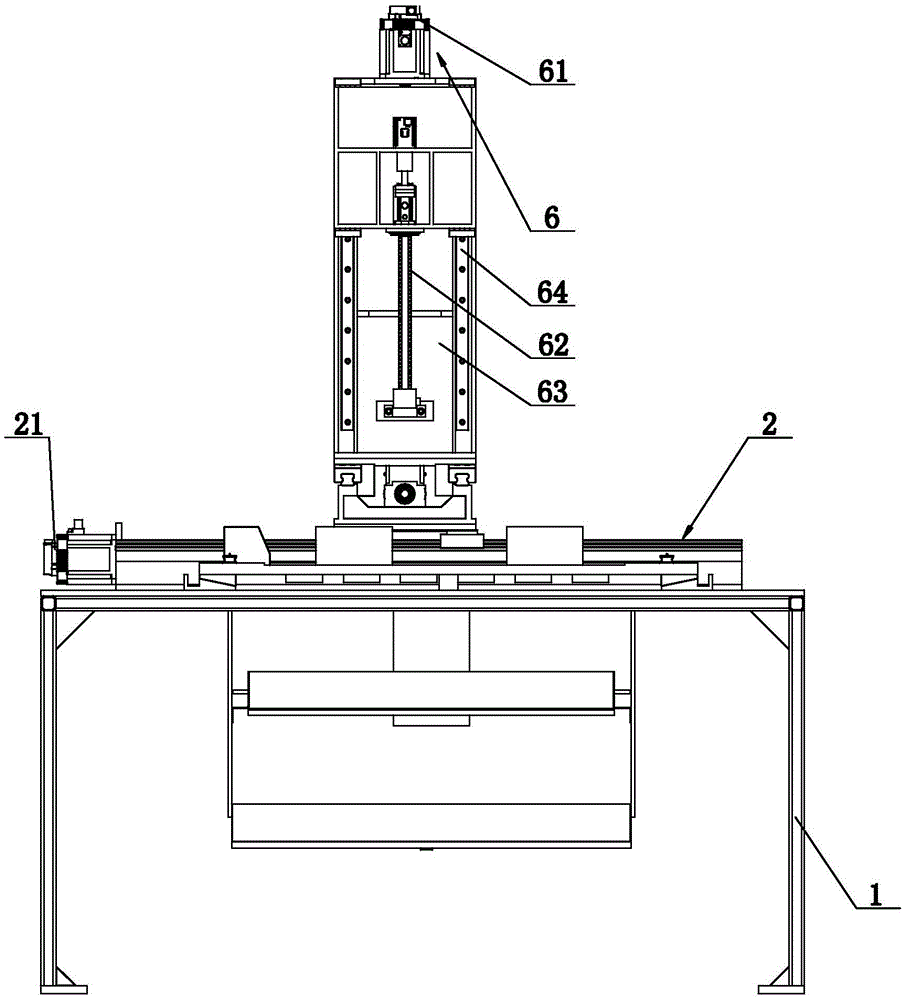

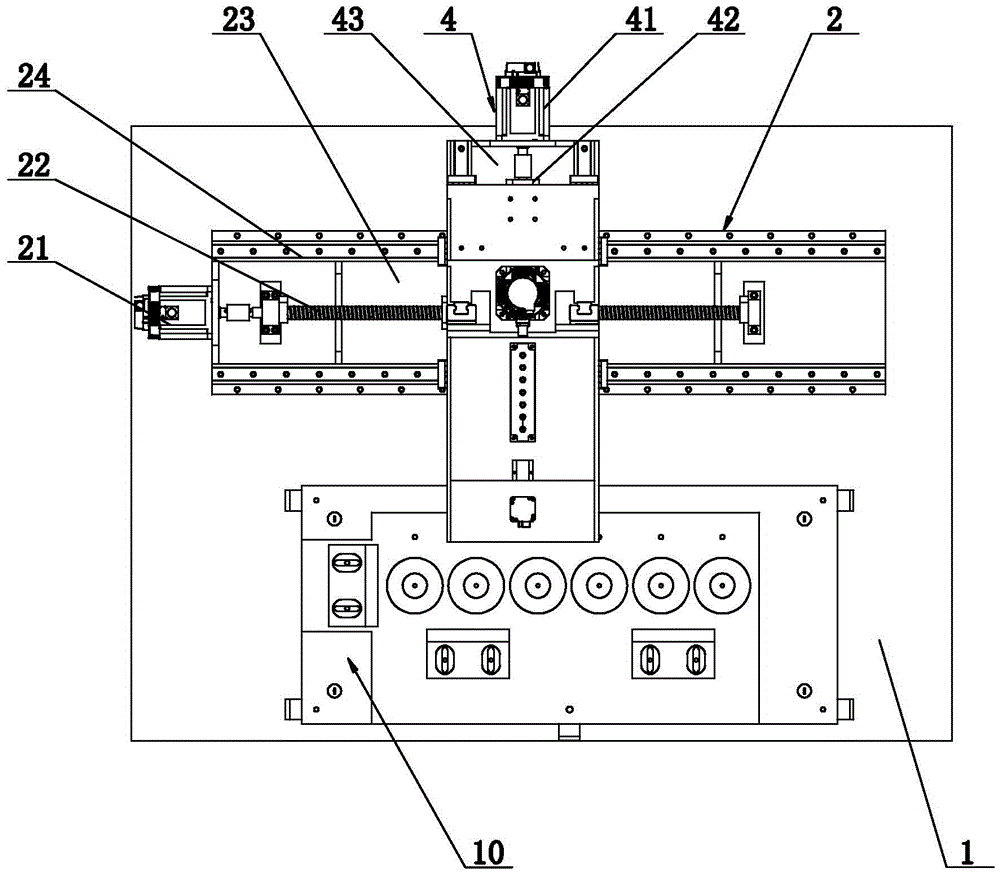

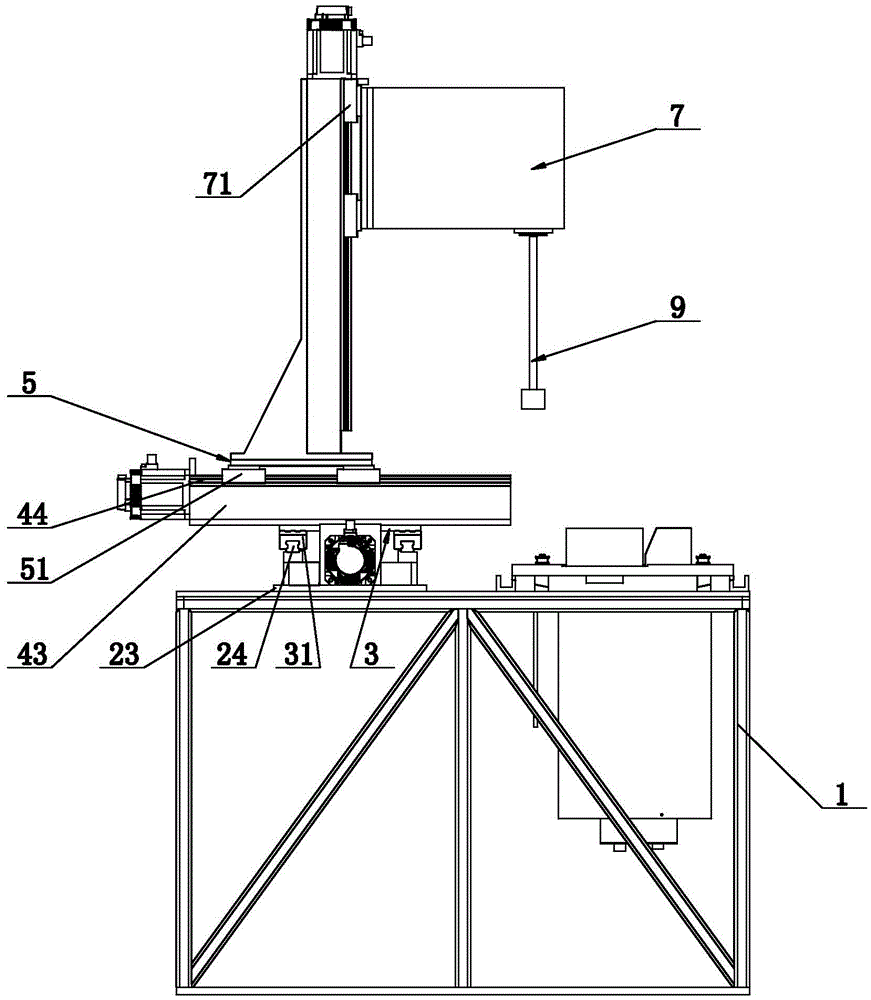

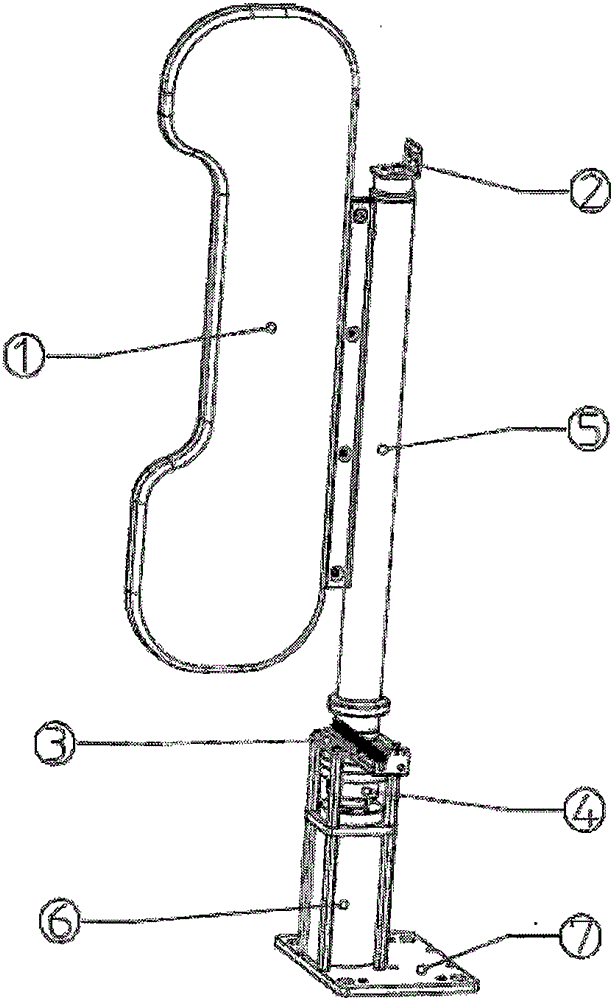

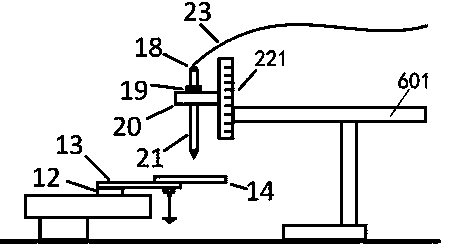

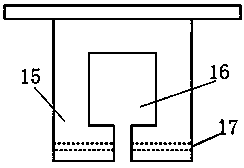

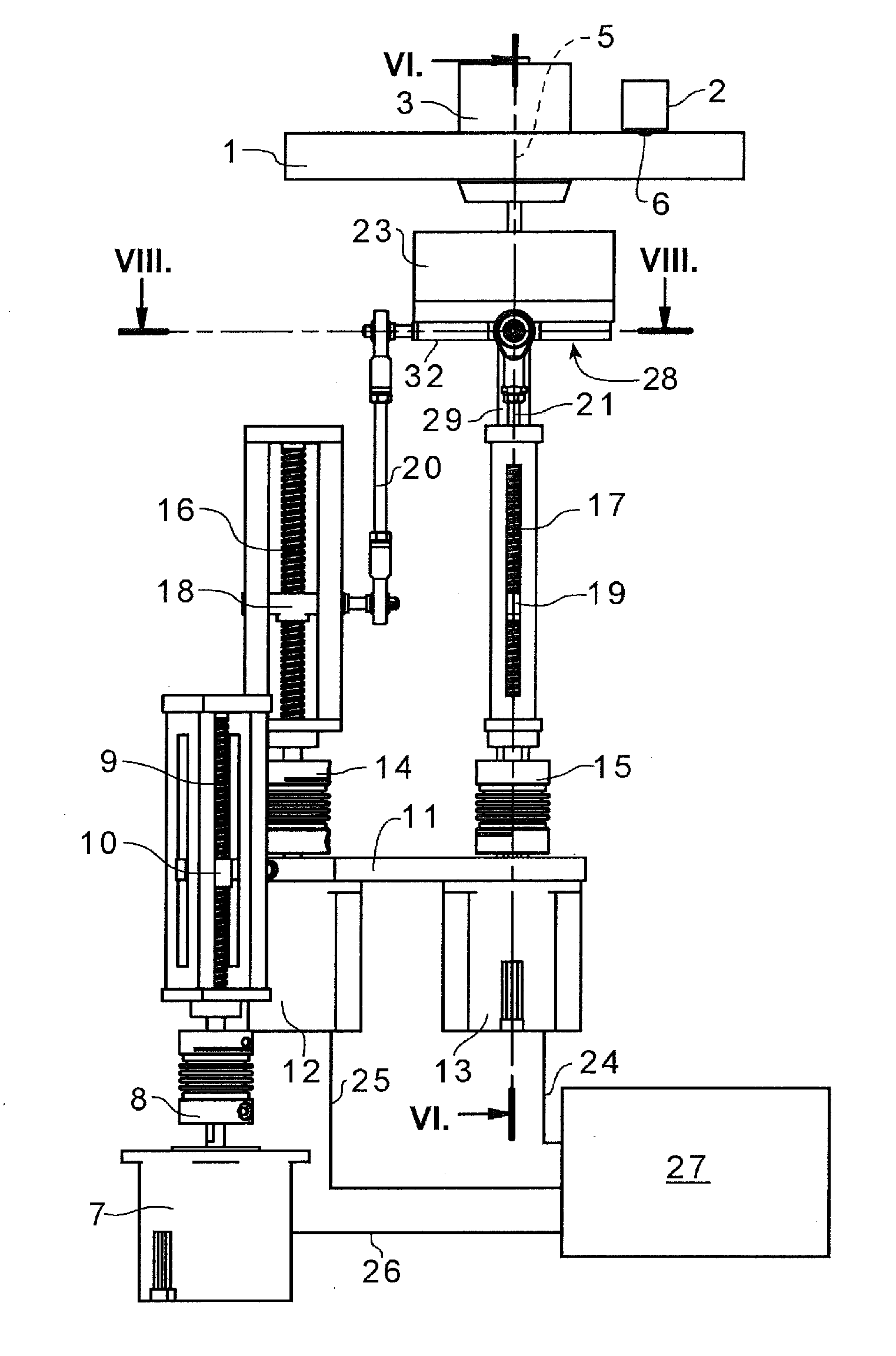

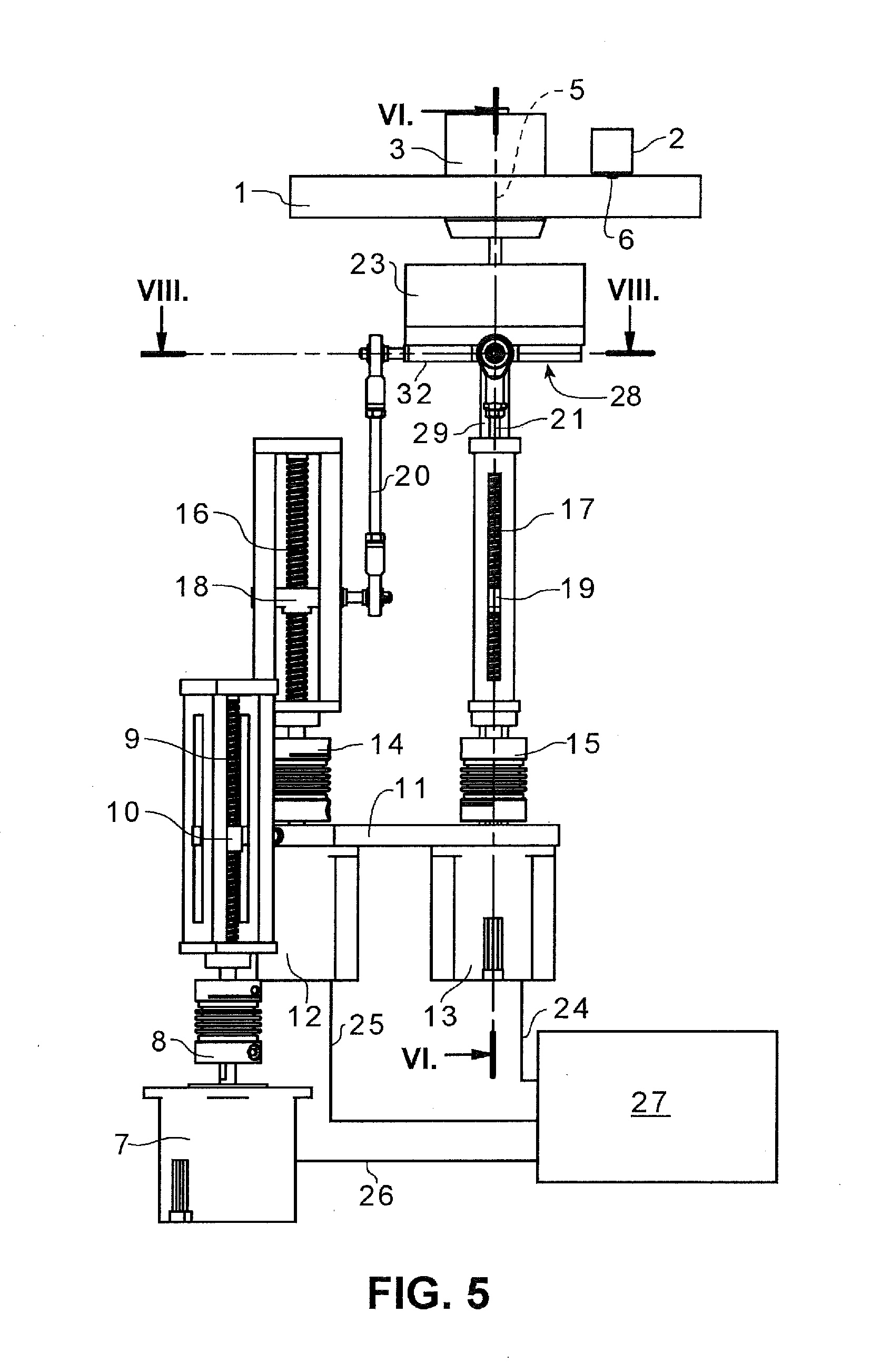

Cylinder liner intelligent detection device

InactiveCN101387495AImprove information processing abilityHigh degree of opennessUsing optical meansRotary stageDisplay device

The invention belongs to the technical field of instruments and meters, and particularly relates to a precise intelligent detecting device for a cylinder sleeve. The intelligent detecting device for the cylinder sleeve mainly comprises a base 12 in the X axis direction, a main shaft revolving stage 13 revolving in the C axis direction, an upright post 7 in the Z axis direction, an electric control cabinet 27, a marble platform 22, a measuring rack 17, a shell 26, a dust shield 25, an operation panel 23, a display 24 and a display supporting stem 2. The checking device has the characteristics of high precision, high efficiency and automatic detection, and is suitable for various cylinder sleeve products.

Owner:TIANJIN UNIV

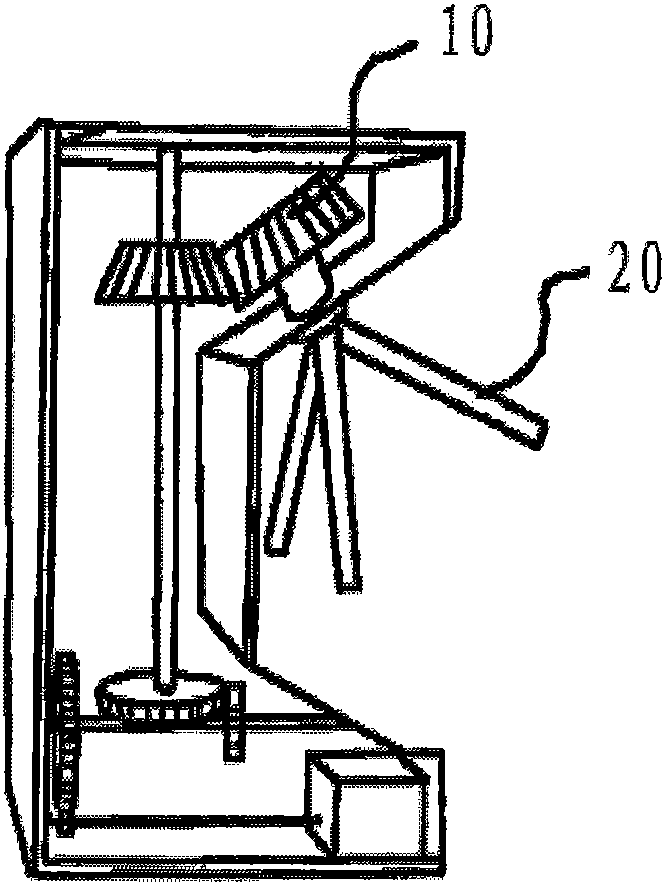

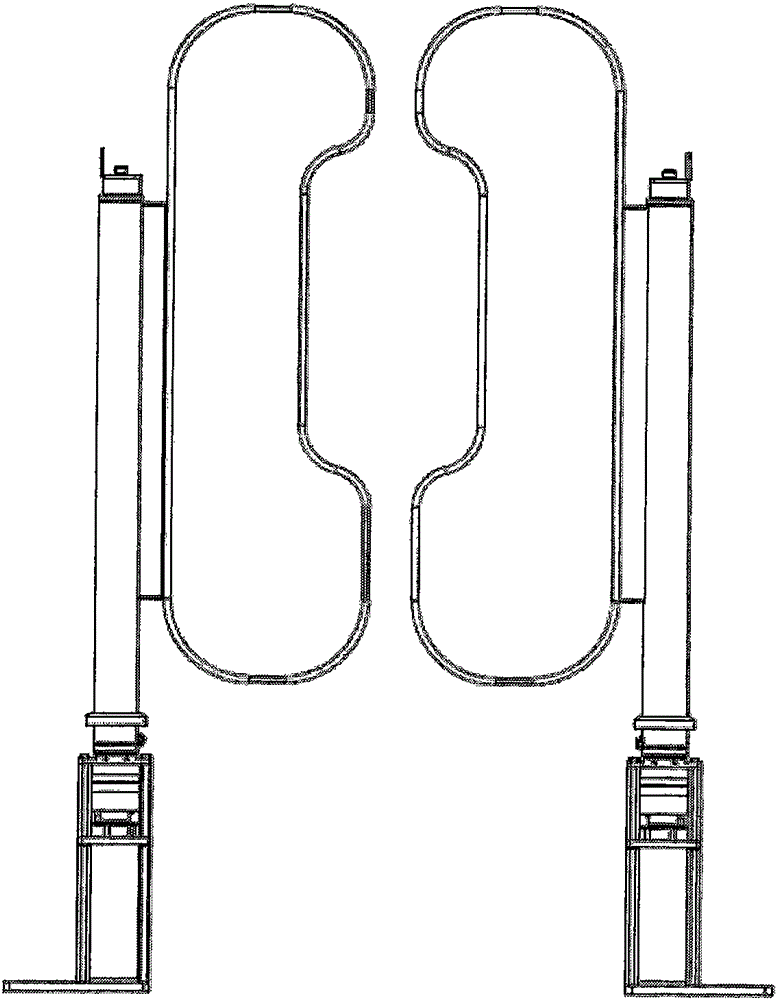

Automatic brush electroplating equipment

The invention discloses automatic brush electroplating equipment belonging to the technical field of engine reproduction equipment. The automatic brush electroplating equipment comprises a rack, wherein the rack is slidably provided with a first slide box driven by a first power device along the X direction; the first slide box is slidably provided with a second slide box driven by a second power device along the Y direction; the second slide box is slidably provided with a third slide box driven by a third power device along the Z direction; the third slide box is rotationally provided with a plating pen driven by a fourth power device and arranged along the Z direction; the side, located on the first slide box, on the rack is fixedly provided with a clamp for clamping a workpiece; and the rack is also provided with a plating solution supply and recovery system. By using the automatic brush electroplating equipment provided by the invention, automatic operation is realized, the motion control is precise, the uniformity of a plating layer is ensured, the labor efficiency is increased, and the repaired workpiece is small in size difference; and the automatic brush electroplating equipment is suitable for mass remanufacture.

Owner:WEICHAI POWER CO LTD

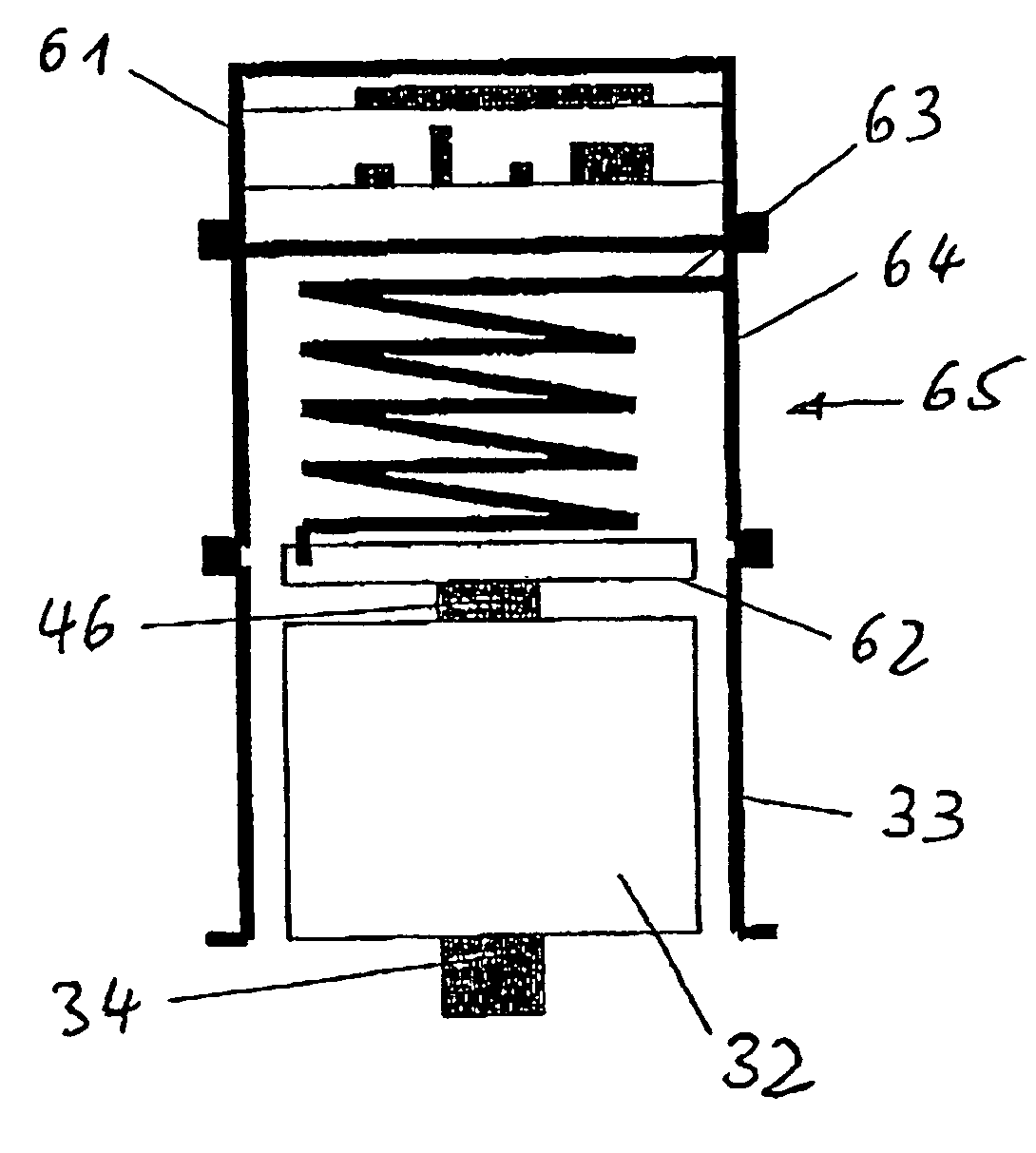

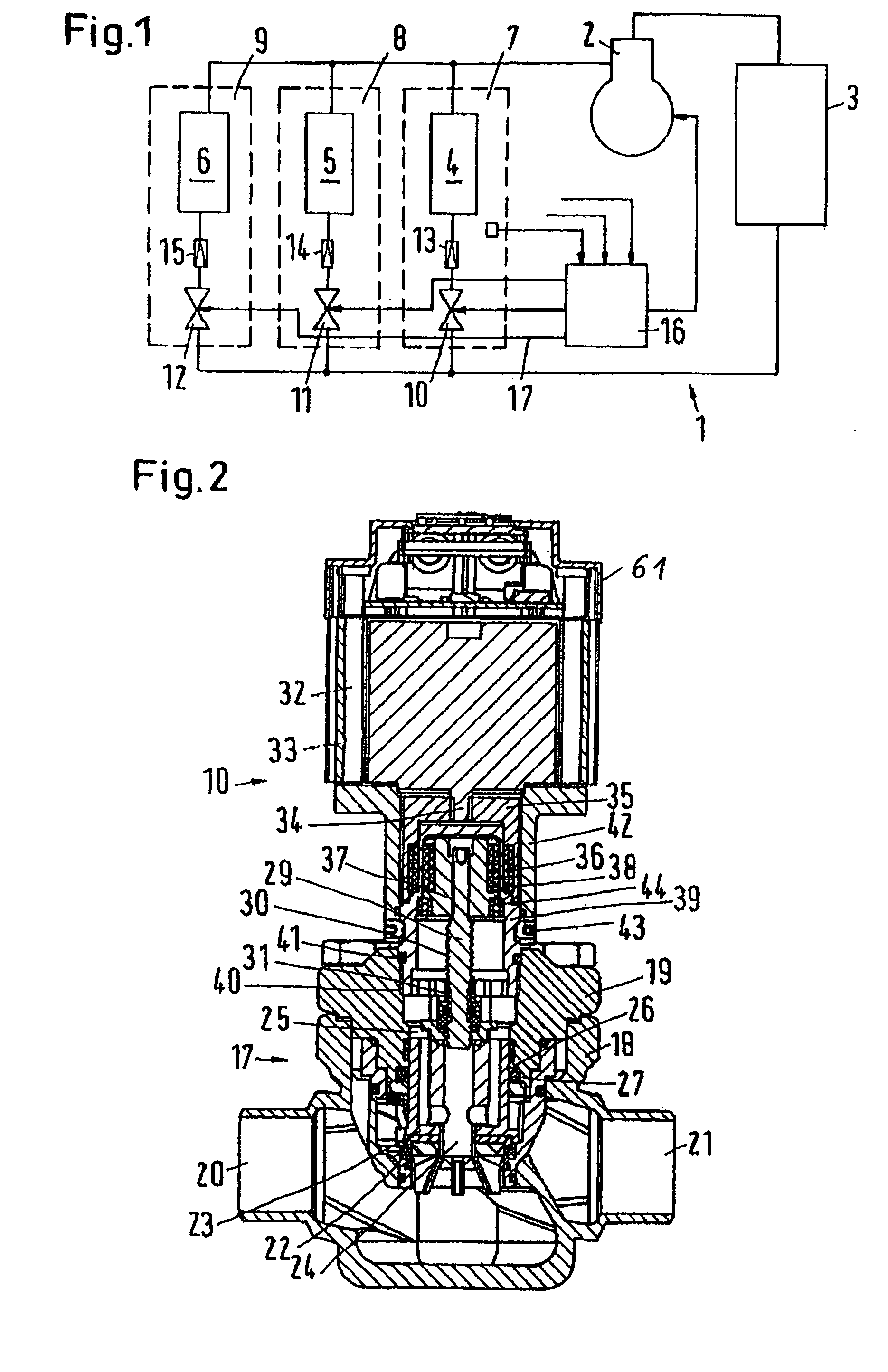

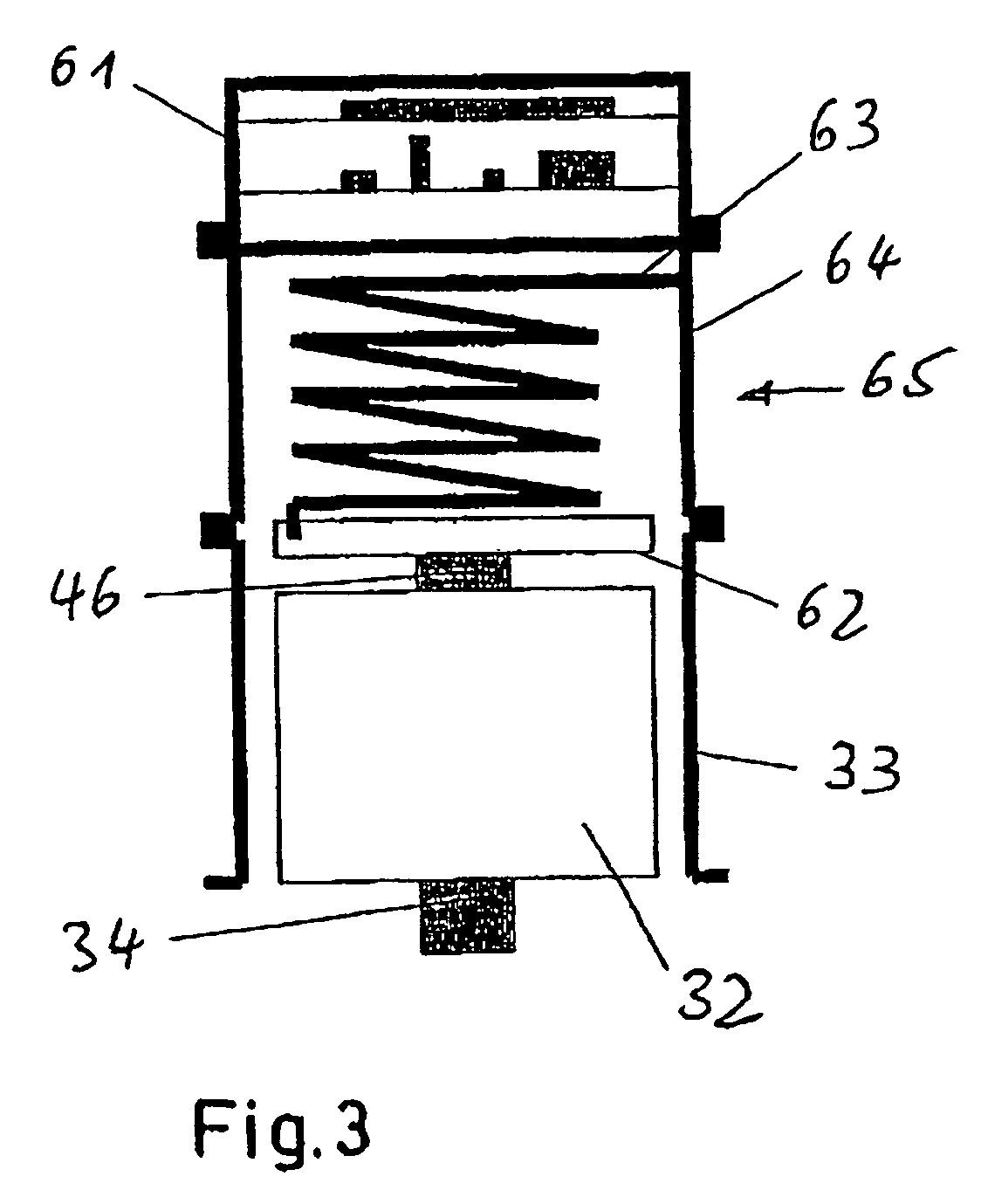

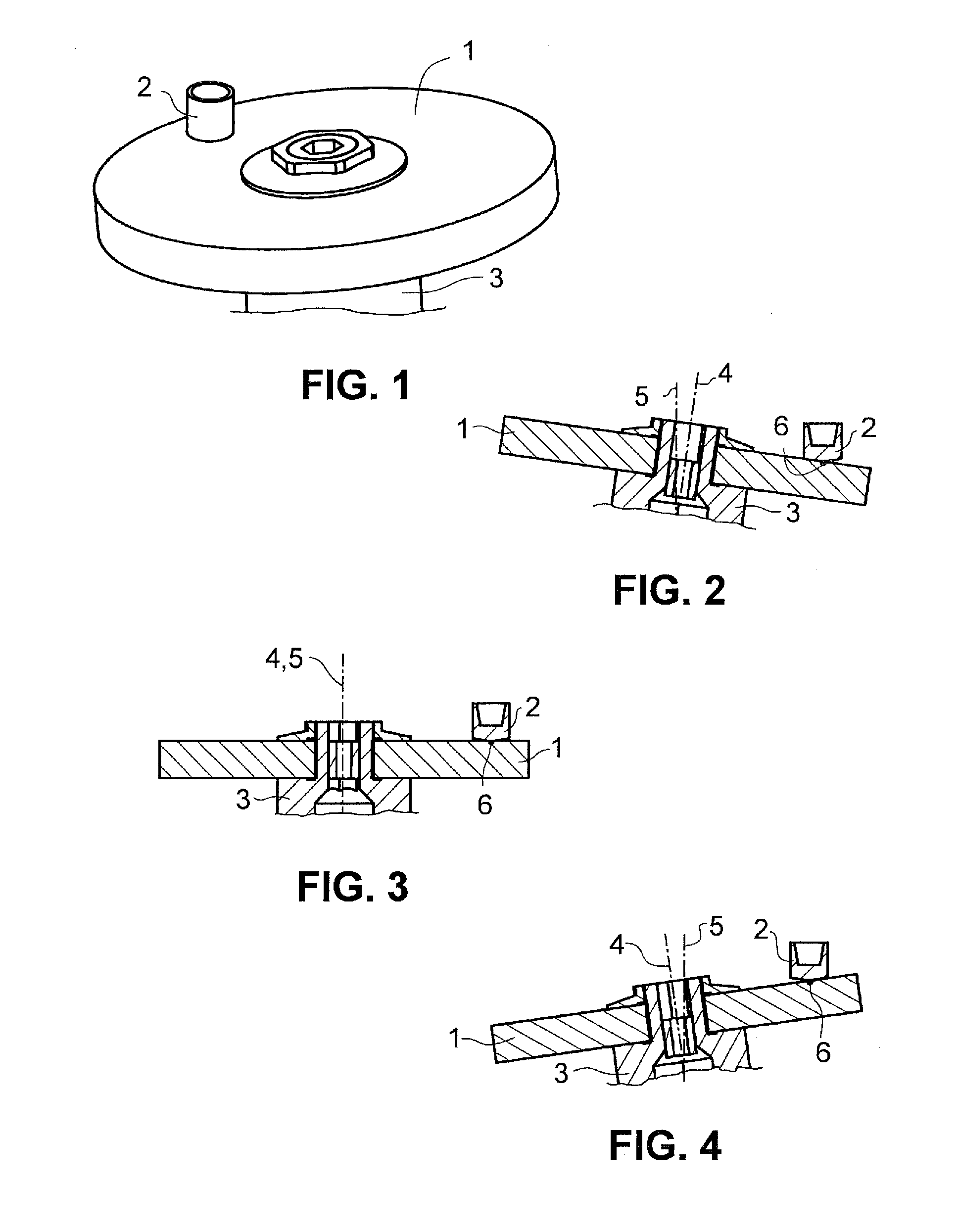

Fail safe valve

ActiveUS6997430B2Ensure tightnessSmall and inexpensive controlOperating means/releasing devices for valvesPressure relieving devices on sealing facesLine tubingCoupling

The invention concerns a fail-safe valve having a valve element, and a control motor being connected with the valve element via a driveline. It is endeavored to ensure the tightness of the refrigeration system in a simple manner. For this purpose, it is ensured that the valve element is located inside and the control motor outside a closed valve housing, that the drive line has a magnetic coupling, which acts through the housing, and that the valve element is pressure-released. In addition, a resetting device is provided that causes the valve element to be returned to a predetermined position upon the undesired cessation of control motor operation.

Owner:DANFOSS AS

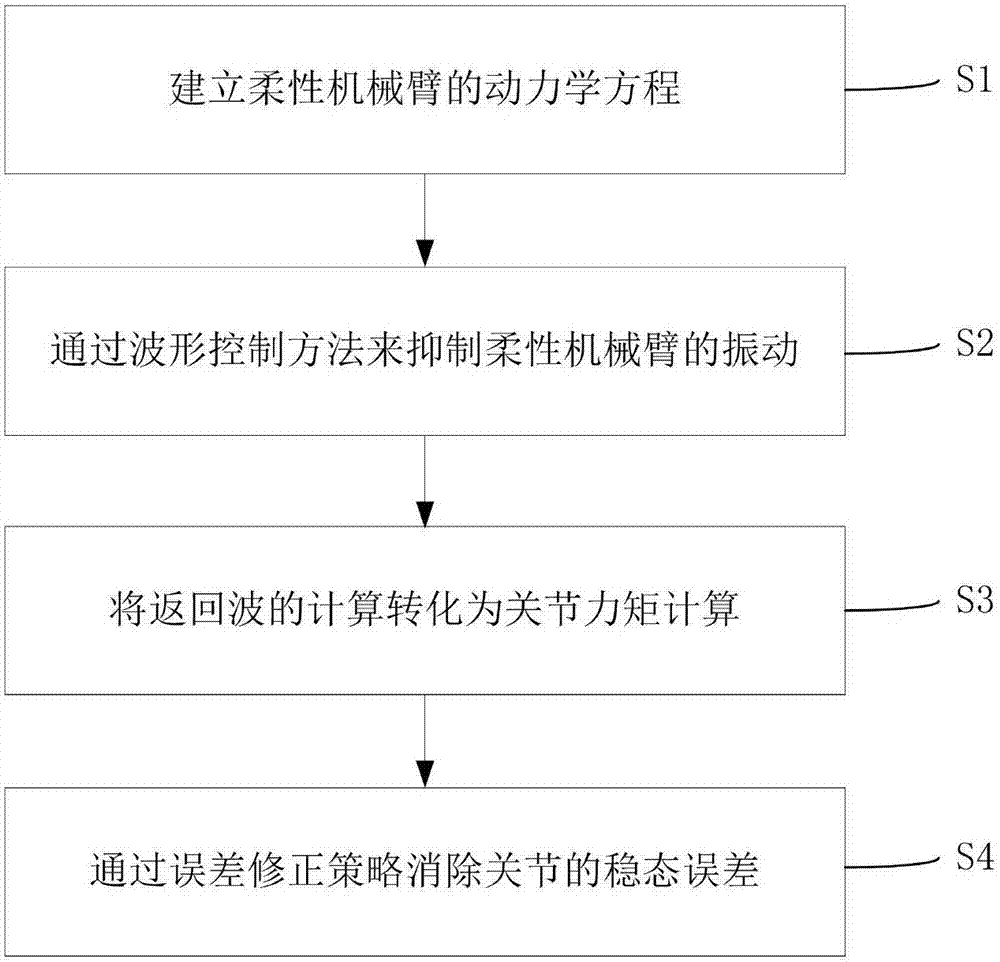

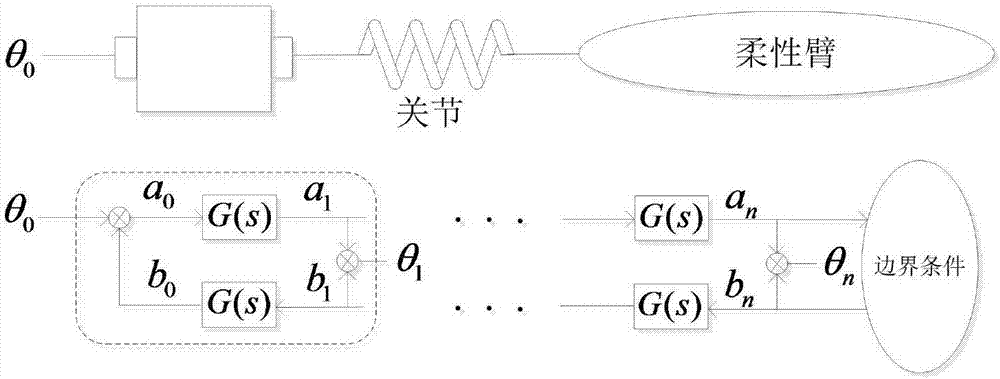

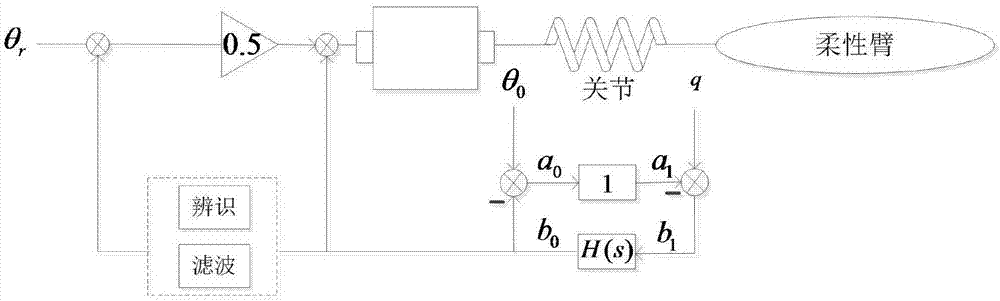

Residual oscillation suppression method for flexible manipulator

ActiveCN106914895ATo achieve the purpose of vibration suppressionNo added complexityProgramme-controlled manipulatorJointsPhysical modelManipulator

The invention discloses a residual oscillation suppression method for a flexible manipulator. The residual oscillation suppression method comprises the following steps: S1, building a kinetic equation of the flexible manipulator; and S2, suppressing oscillation of the flexible manipulator through a waveform control method. The residual oscillation suppression method for the flexible manipulator can realize oscillation suppression of the flexible manipulator without an accurate physical model.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

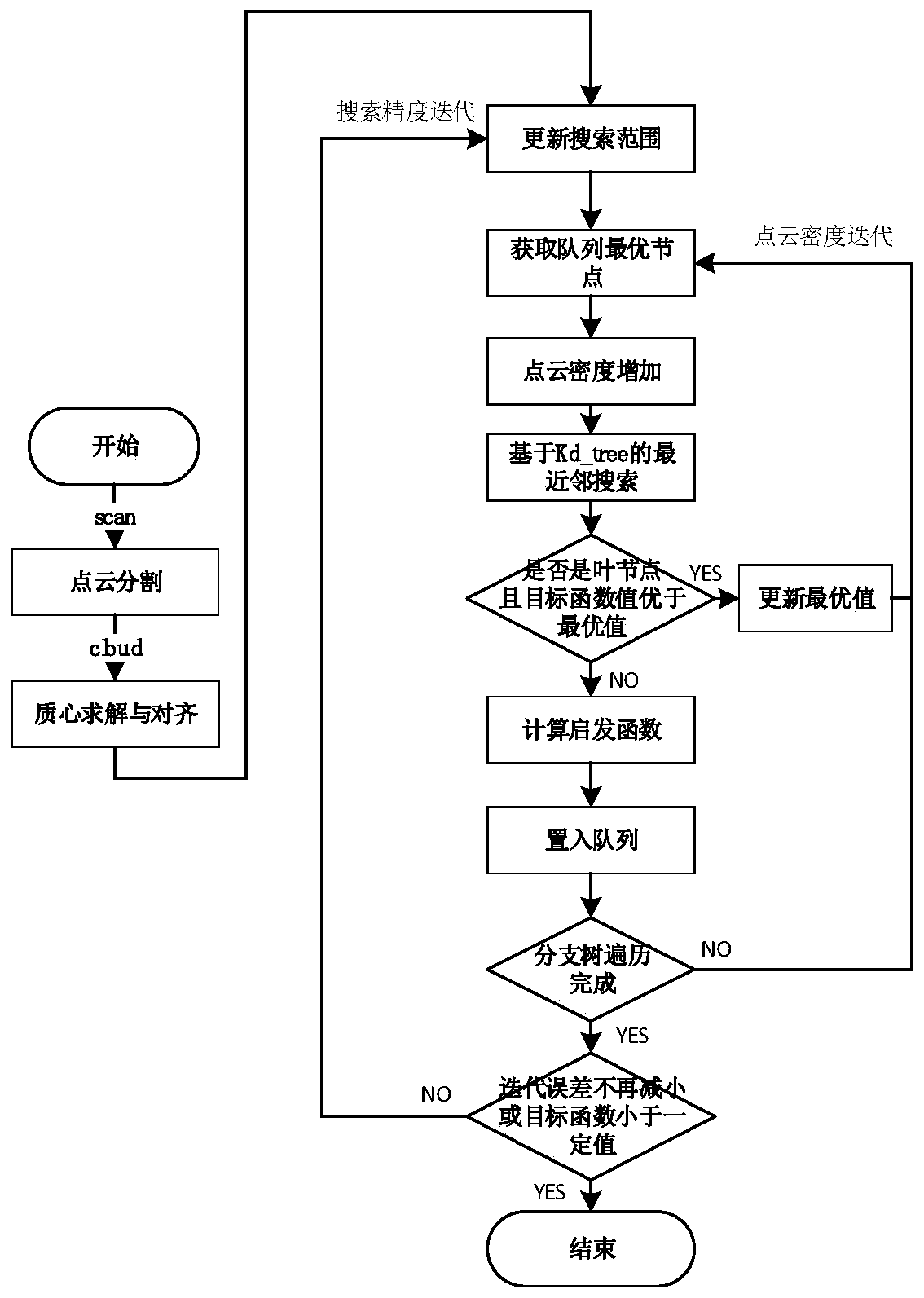

Laser navigation AGV high-precision positioning and target alignment control method

ActiveCN111352420ASolve the problem of high precision positioningSmooth motion controlPosition/course control in two dimensionsVehiclesEngineeringMotion controller

The invention discloses a laser navigation AGV high-precision positioning and target alignment control method, and relates to the technical field of mobile robot navigation. Point cloud segmentation and extraction is performed on the target environment features based on the laser point cloud to realize the capability of the AGV to acquire the target feature point cloud in real time; based on a nearest neighbor method, the problems of finding corresponding points in point cloud matching and establishing a target function are solved; a multi-resolution search matching method based on gradient point cloud density is designed, and branch and bound optimization search is carried out. High-precision and low-delay matching of the AGV for the target feature point cloud is realized, and the problemof high-precision positioning of the laser navigation AGV at a specific task point is solved; based on an AGV smooth motion controller, the capability of AGV smooth and accurate motion control to reach a target point is realized. The problems of laser navigation AGV high-precision positioning, pose alignment, charging butt joint and other target alignment control are solved, and the defects thatthe positioning precision of the SLAM technology is insufficient, and a traditional alignment control method is too high in cost are overcome.

Owner:XIAMEN UNIV +1

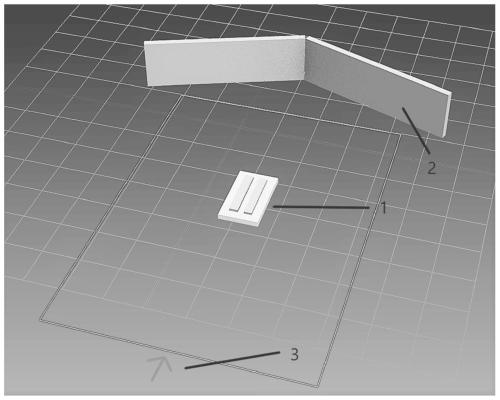

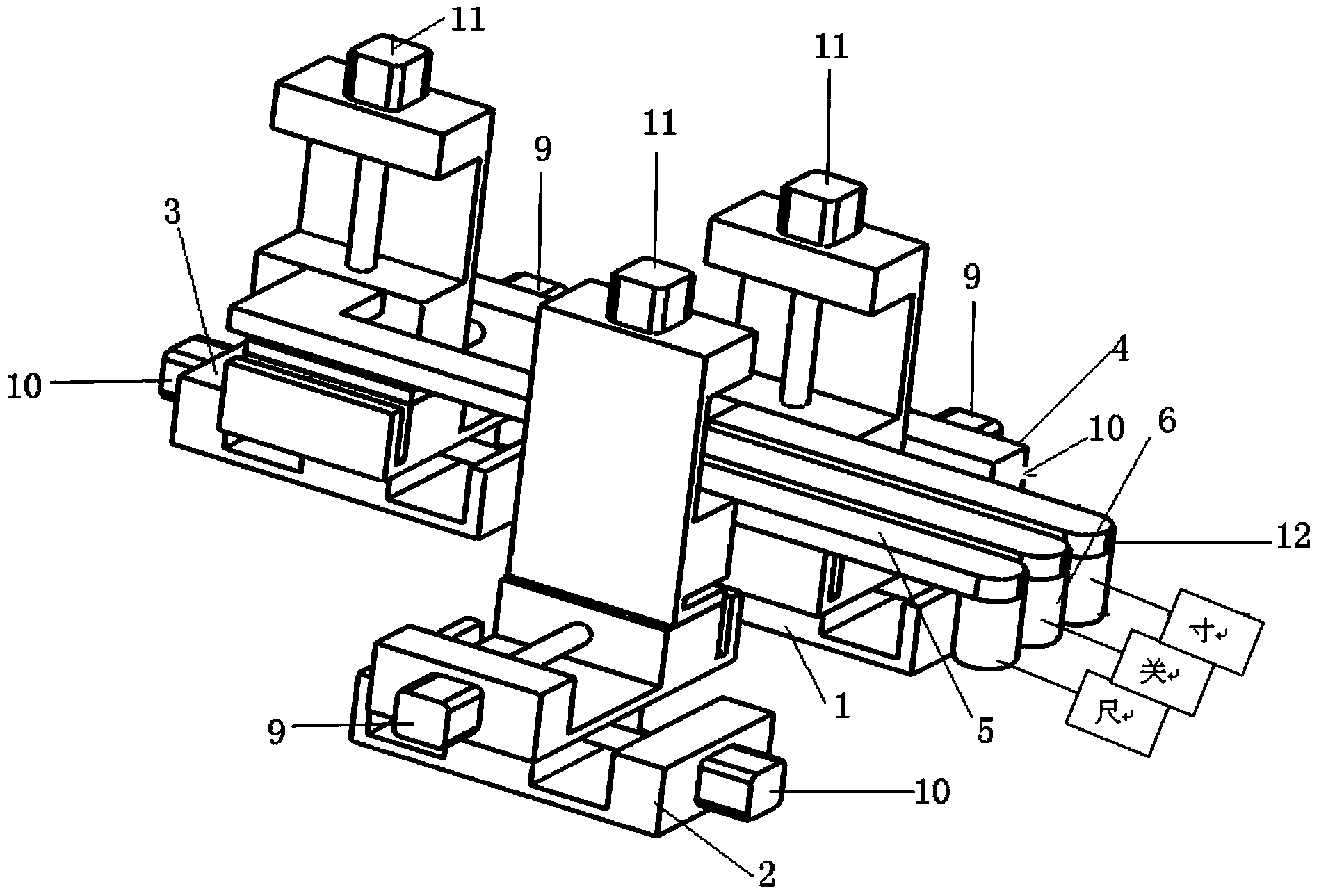

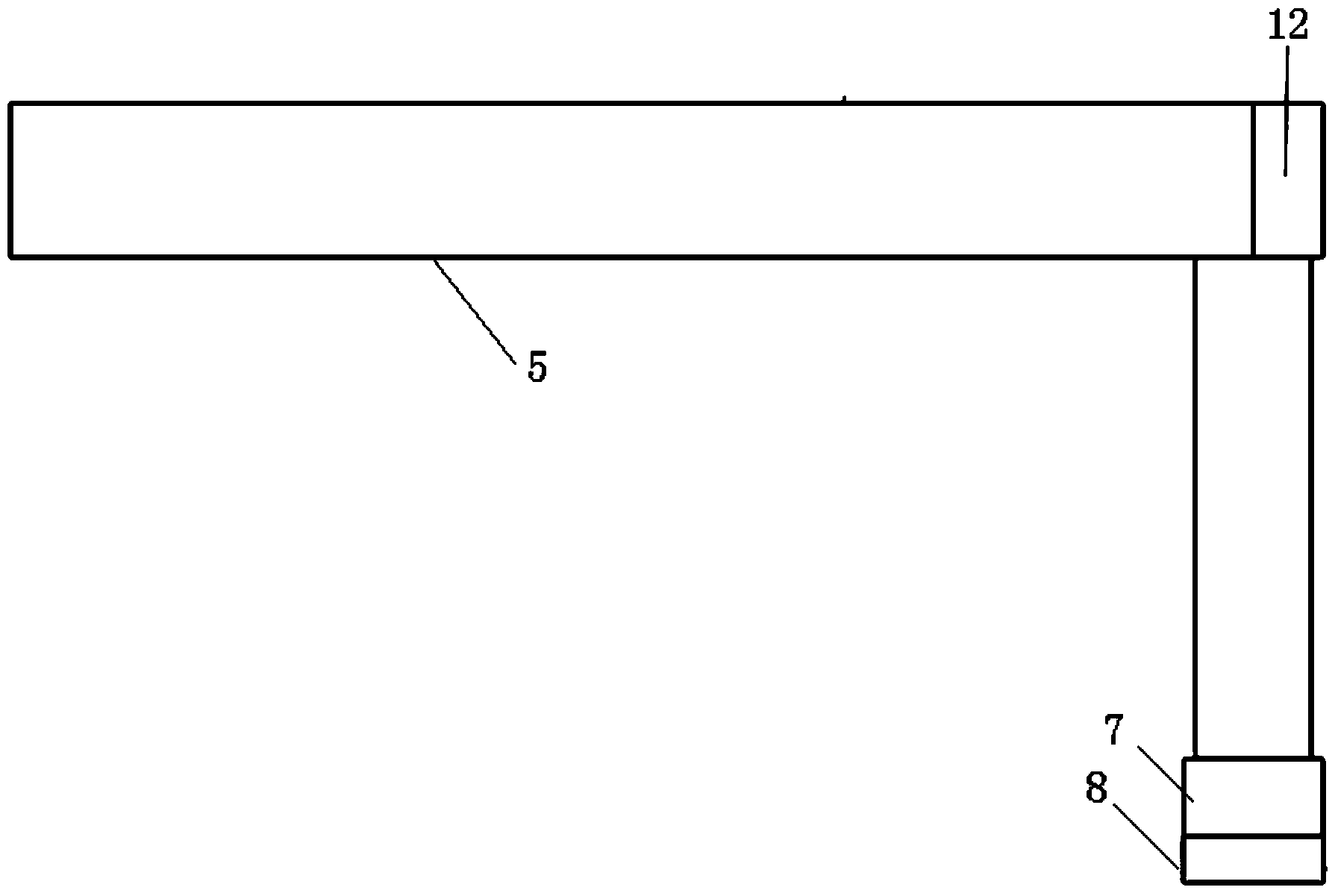

Three-probe mechanical device applicable to traditional Chinese medicine pulse detection

The invention discloses a three-probe mechanical device which is applicable to traditional Chinese medicine pulse detection. The three-probe mechanical device comprises a soleplate and three worktables, wherein the three worktables are arranged on the soleplate; each worktable is connected with a connecting rod through a connecting-rod bracket, and the other end of each connecting rod is sequentially connected with a probe and a pressure sensor; each worktable is used for controlling the connecting rod which is connected with the worktable to move in X-axis, Y-axis and Z-axis directions; each connecting rod is vertically connected with the corresponding connecting-rod bracket; the three connecting rods are distributed in one plane. The three probes in the three-probe mechanical device synchronously move and can be used for simultaneously acquiring pulse-condition signals at three places at the wrist where the pulse is usually taken on the human Cunkou pulse, so that the effect of high operating speed is achieved.

Owner:北京清科建投资管理有限公司

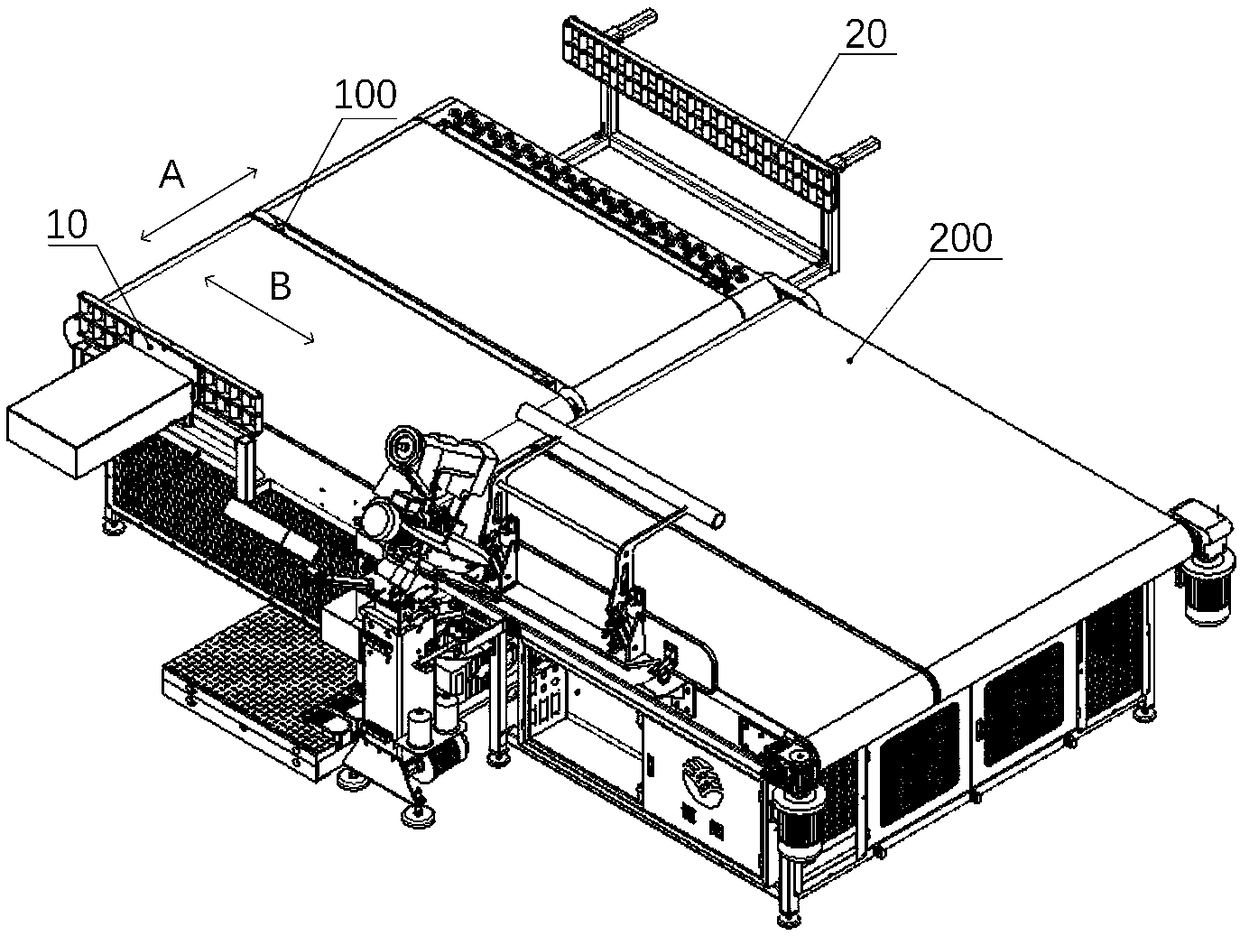

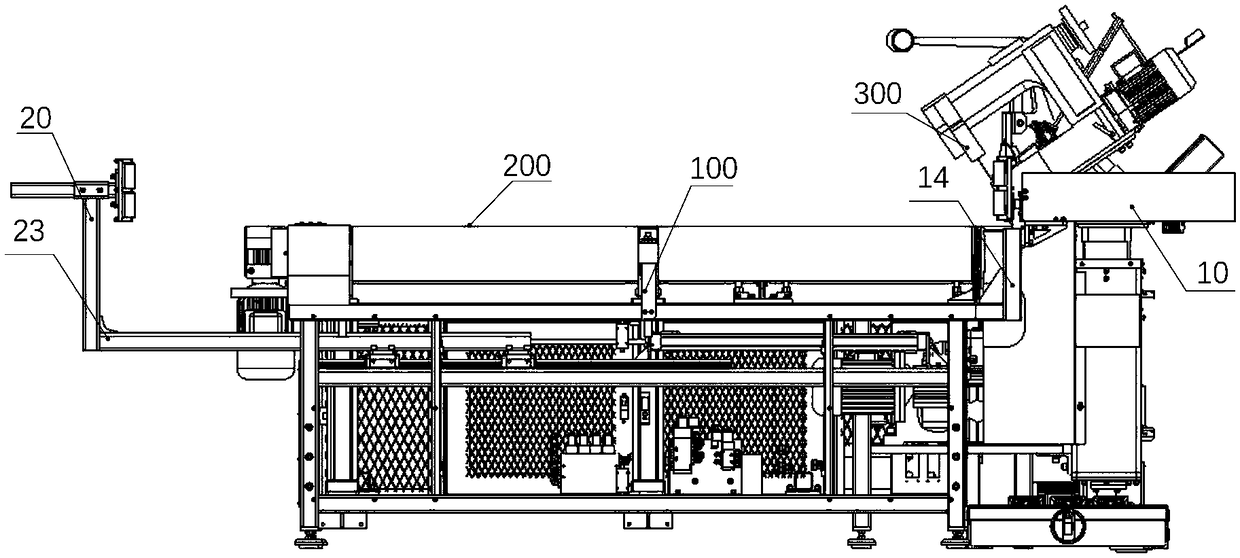

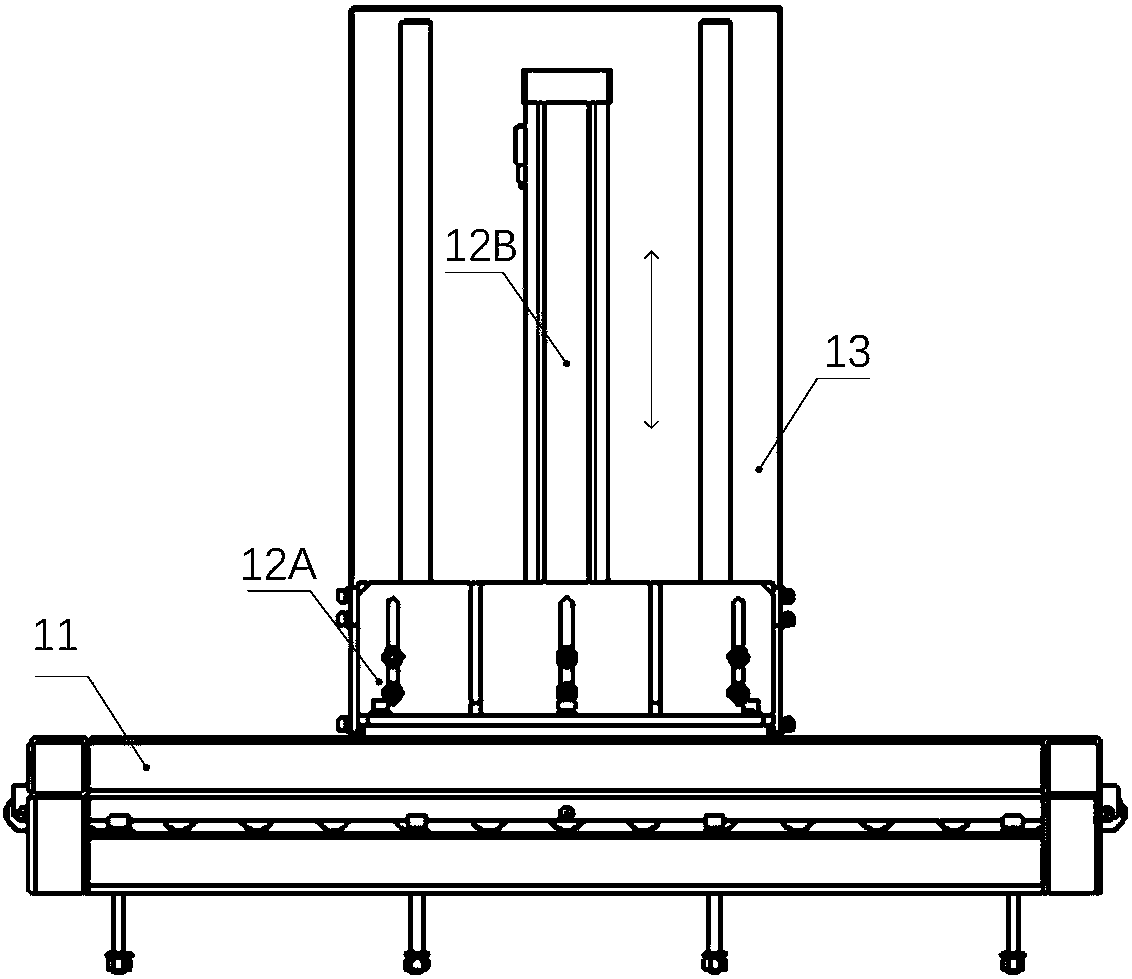

Mattress edge matching machine and control method thereof

ActiveCN108570770AIncrease productivitySave operating timeProgramme-controlled sewing machinesMattress sewingEngineeringMechanical engineering

The invention relates to a mattress edge matching machine and a control method thereof. The mattress edge matching machine comprises a mattress conveying plane and a first centering part, wherein themattress conveying plane extends in a horizontal direction; the first centering part is arranged on a first side of the mattress conveying plane; the first centering part is suitable for pushing a mattress which is placed on a conveying plane surface to move into an edge matching start position inwards along a straight line in a direction of a relatively long side of the mattress. By adopting themattress edge matching machine provided by the invention, an automatic level is increased, operation of manual mattress centering can be avoided, and the operation time can be shortened. Therefore, equipment output can be increased, and the production efficiency of mattresses can be improved.

Owner:FOSHAN YUANTIAN MATTRESS MACHINERY

Gate channel pat door device and control method

ActiveCN105155964APrecise motion controlSensitive feedbackPower-operated mechanismLeaf bladeEngineering

The invention provides a gate channel pat door device and a control method, and belongs to the field of security and protection, entrance guard and stadium entering and exiting control of rail transit, ticket selling and checking services, buildings and specific places. The gate channel pat door device comprises a pat door. The pat door comprises a leaf blade, a leaf blade supporting column, a spring and a base. The leaf blade is fixed to the leaf blade supporting column through a fixing piece. A connecting mechanism is arranged below the leaf blade supporting column. The lower end of the connecting mechanism is fixed to the base. One end of the spring is fixed to the upper end face of the connecting mechanism, and the other end of the spring is fixed to the column face of the leaf blade supporting column.

Owner:艾弗世(苏州)专用设备股份有限公司

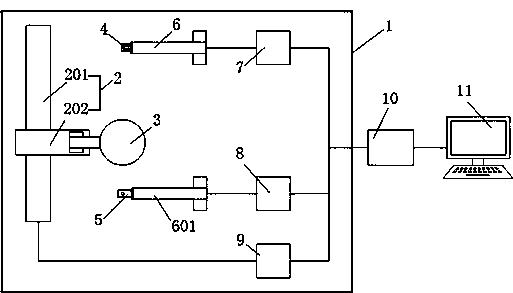

Automatic dielectric material surface charge measuring device on basis of two-axis slide table

PendingCN108152354AReal-time processingEasy to operateMaterial analysis by electric/magnetic meansDielectricMeasurement device

The invention discloses an automatic dielectric material surface charge measuring device on the basis of a two-axis slide table, and belongs to the field of solid dielectric material surface charge measurement. The automatic dielectric material surface charge measuring device comprises the two-axis movement slide table, an electrometer probe support, a high-voltage electrode support and an upper PC (personal computer). A dielectric test specimen support is connected with the two-axis movement slide table and can be driven by the two-axis movement slide table to move in a plane; the electrometer probe support and the high-voltage electrode support are arranged in an upper space of the movement plane of the dielectric test specimen support; the upper PC is in communication connection with the two-axis movement slide table, the electrometer probe support and the high-voltage electrode support, and surface charge detection can be carried out on test specimens on the dielectric test specimen support by the two-axis movement slide table, the electrometer probe support and the high-voltage electrode support under the control of the upper PC. Compared with the prior art, the automatic dielectric material surface charge measuring device has the advantages that the automatic dielectric material surface charge measuring device is easy to operate and accurate in movement control; acquireddata can be processed in real time, and surface charge distribution conditions of materials can be visually displayed by the aid of software.

Owner:SICHUAN UNIV

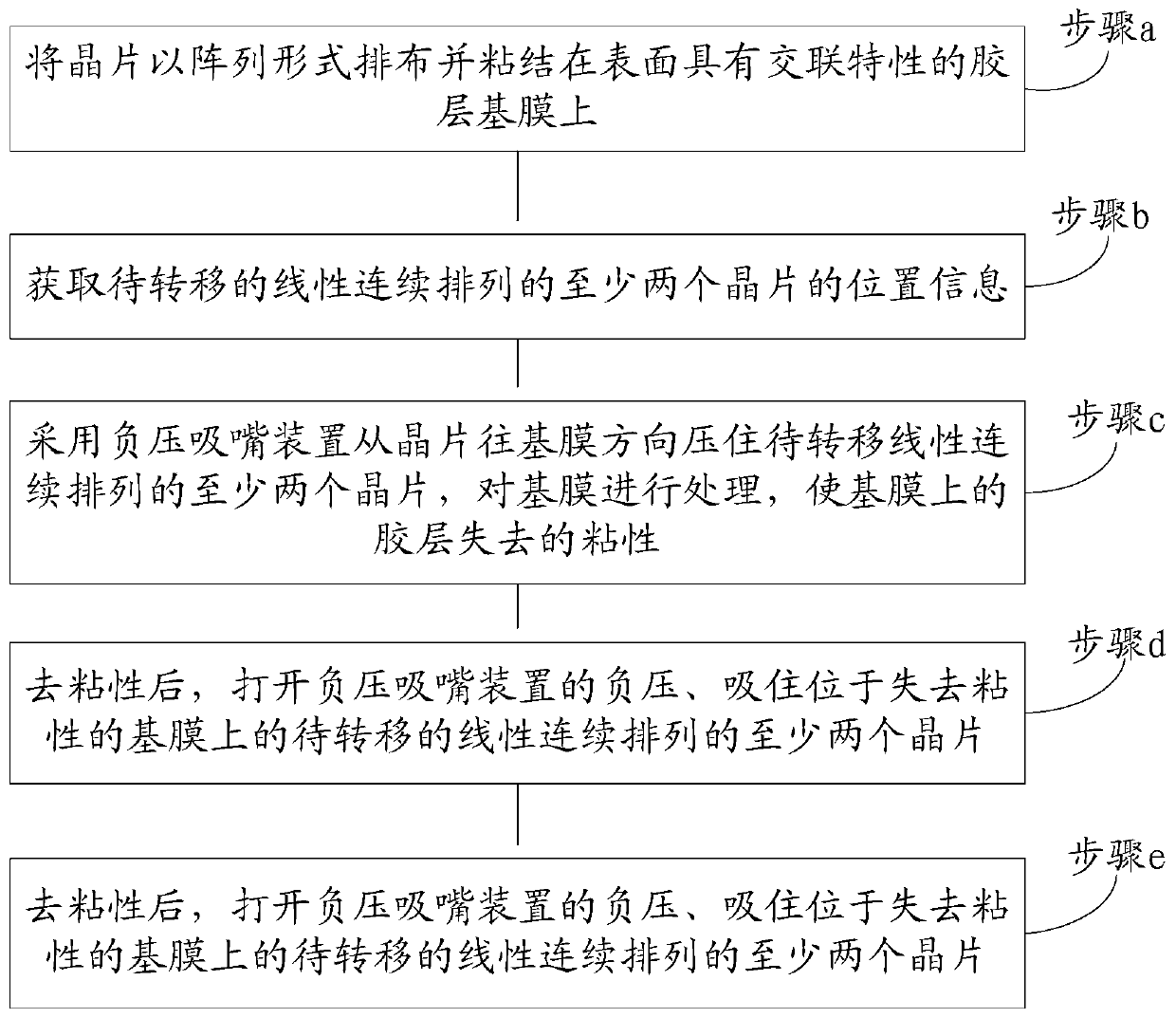

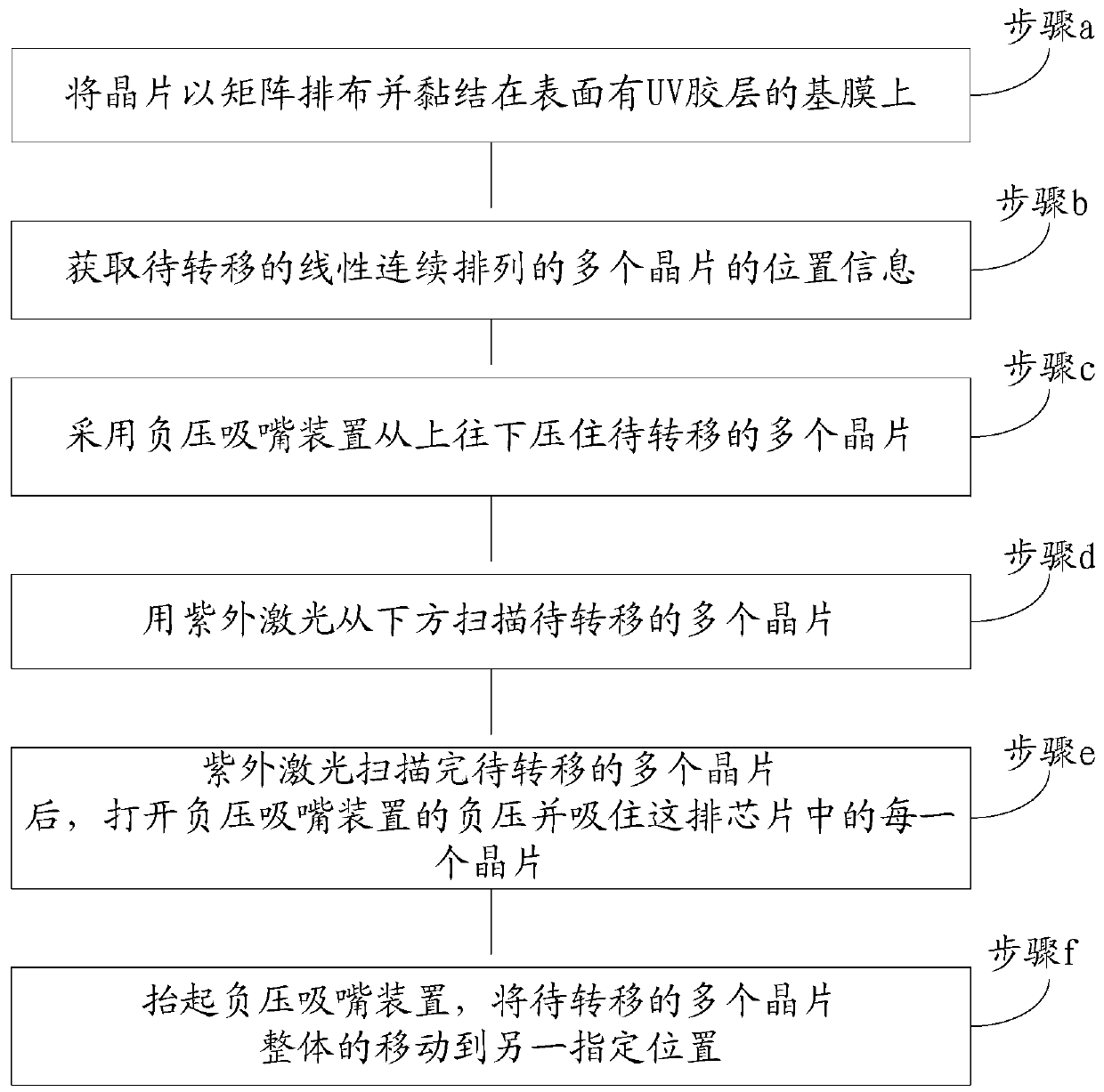

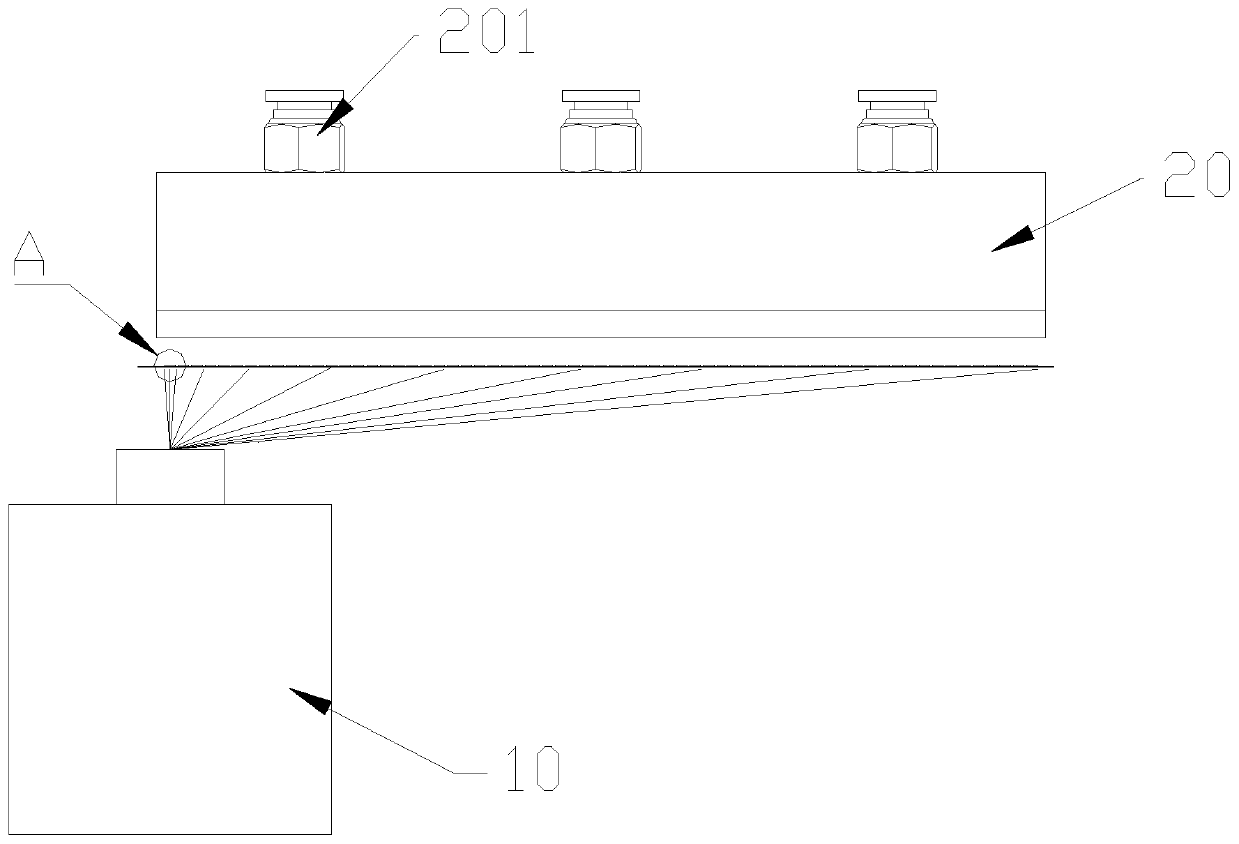

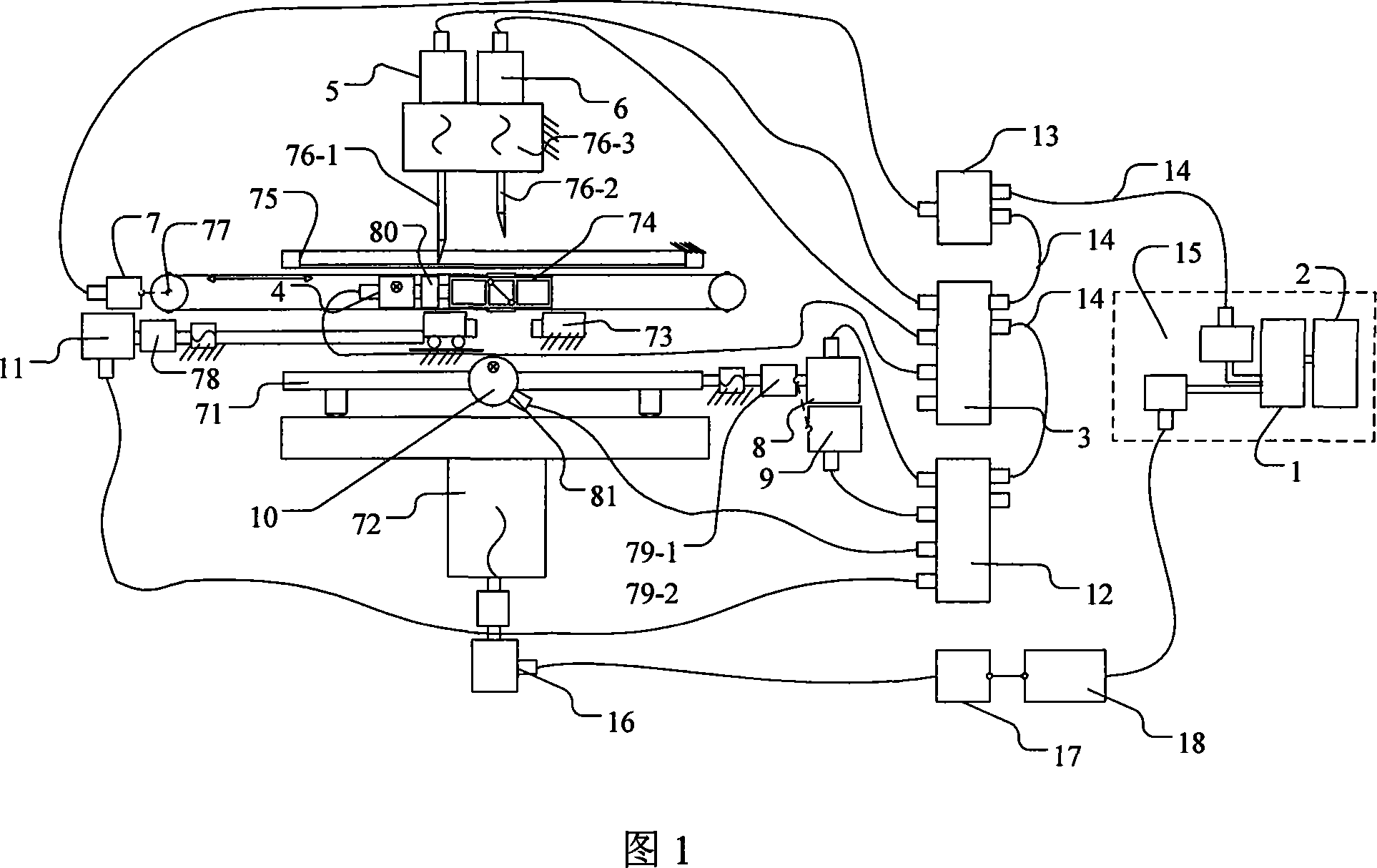

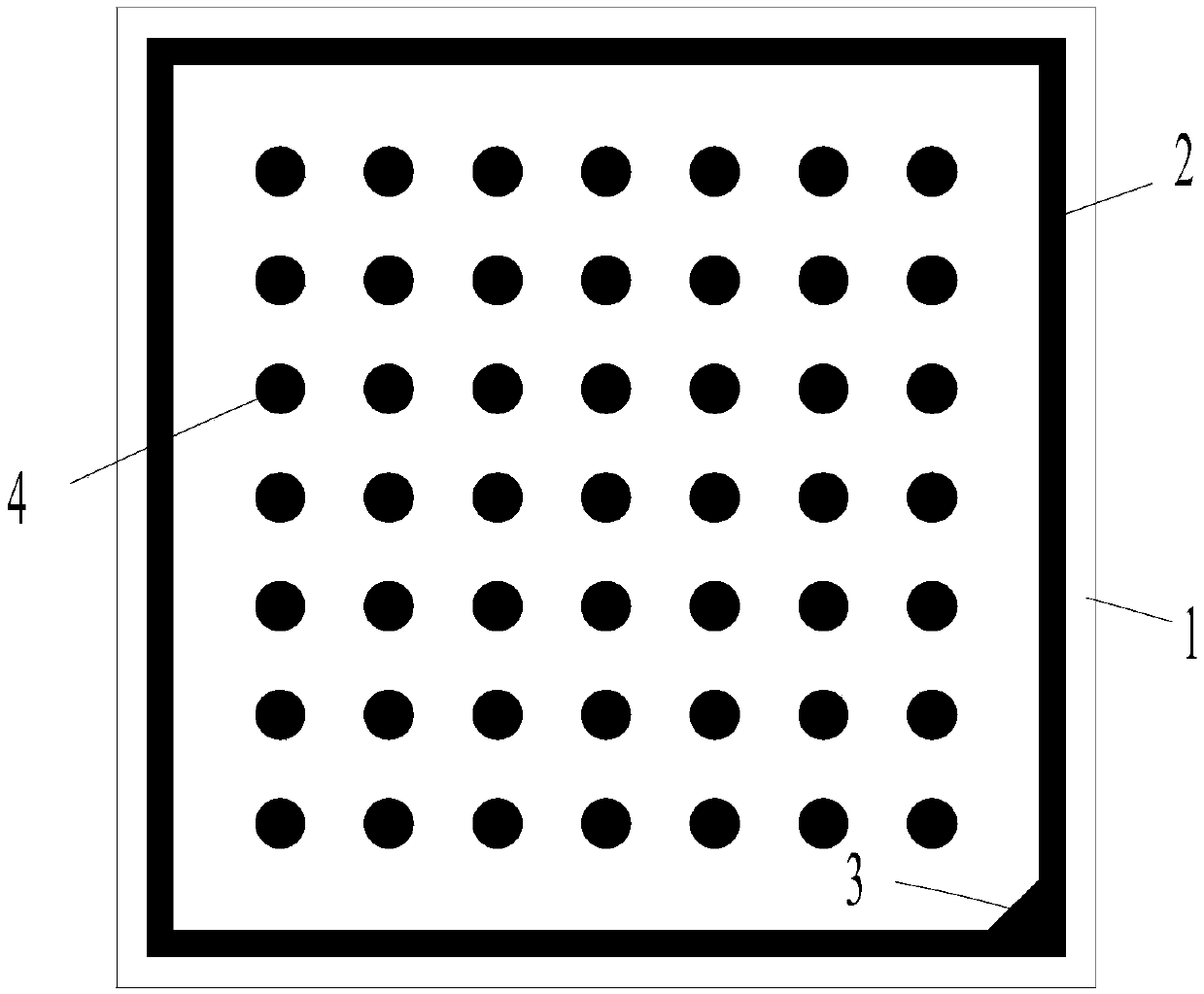

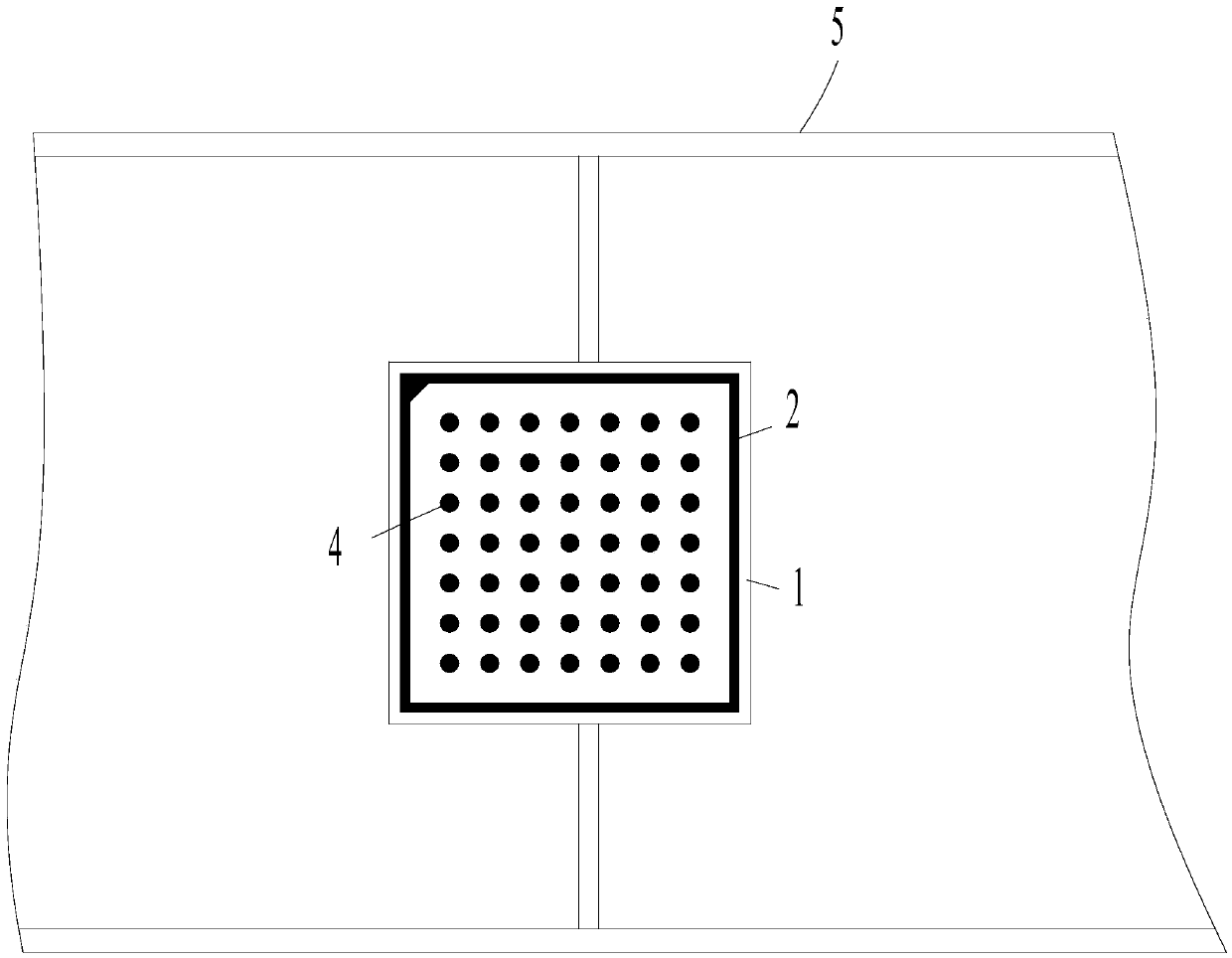

Wafer bonding process for transferring multiple wafers at one time

InactiveCN109950183AShorten the timePrecise motion controlSemiconductor/solid-state device manufacturingSemiconductor devicesCross-linkEngineering

The invention discloses a wafer bonding process for transferring multiple wafers at one time. The process comprises a step of arranging the wafers in an array form and bonding the wafers on an adhesive layer base film with a cross-linking property on the surface, a step of obtaining the position information of at least two wafers which are to be transferred and are in a linear continuous arrangement, a step of pressing the at least two wafers which are to be transferred and are in a linear continuous arrangement by using a vacuum suction nozzle device in a direction from the wafers to the basefilm such that an adhesive layer on the base film loses viscosity, a step of starting the negative pressure of the vacuum suction nozzle device and sucking the at least two wafers which are to be transferred and are in a linear continuous arrangement on the base film which loses viscosity after the adhesive layer on the base film loses viscosity, and a step of lifting the vacuum suction nozzle device and integrally moving the at least two wafers which are to be transferred and are in a linear continuous arrangement to a substrate which is provided with a pad coated with a viscous material. According to the invention, a row of wafers can be transferred at a time, the transfer efficiency is doubled, and the time required for transferring chips is reduced.

Owner:SHENZHEN FONTAI IND TECH CO LTD

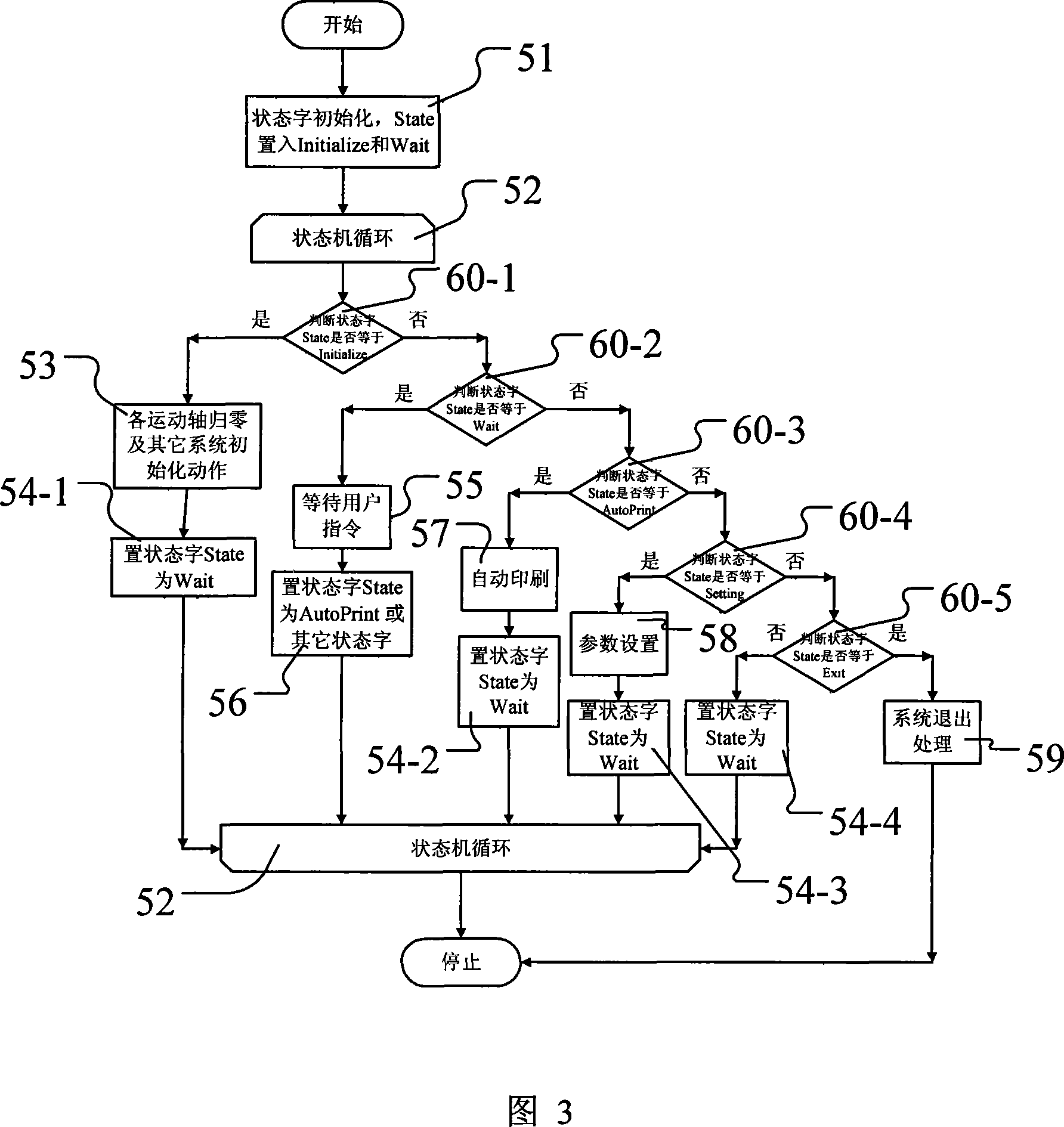

Serial multi-axis stepper control method and system for tin paste printing machine

The invention discloses a serial multi-shaft step control method and system used in solder paste printing machine. The invention cooperative controls plural key moving shafts for solder paste printing by plural working conditions of the solder paste printing machine such as initialization, waiting, automatic print, quit, configuration and so on. A DC 4-axis step servo driver in the system drives X-axis stepper motor and scraper Z1-axis stepper motor and scraper Z2-axis stepper motor of camera; a DC 4-axis step servo driver drives platform Y1-axis stepper motor, platform Y2-axis stepper motor, platform X-axis stepper motor and wide rail axis stepper motor; An AC single axis step servo driver drives camera Y-axis stepper motor. The invention can effectively improve cooperative control capacity and alignment accuracy for PCB solder paste printing machine, has less wiring, and high resistance to electromagnetic interference, compact structure and abounding control functions, and is applicable for various PCB solder paste printing machine.

Owner:SOUTH CHINA UNIV OF TECH

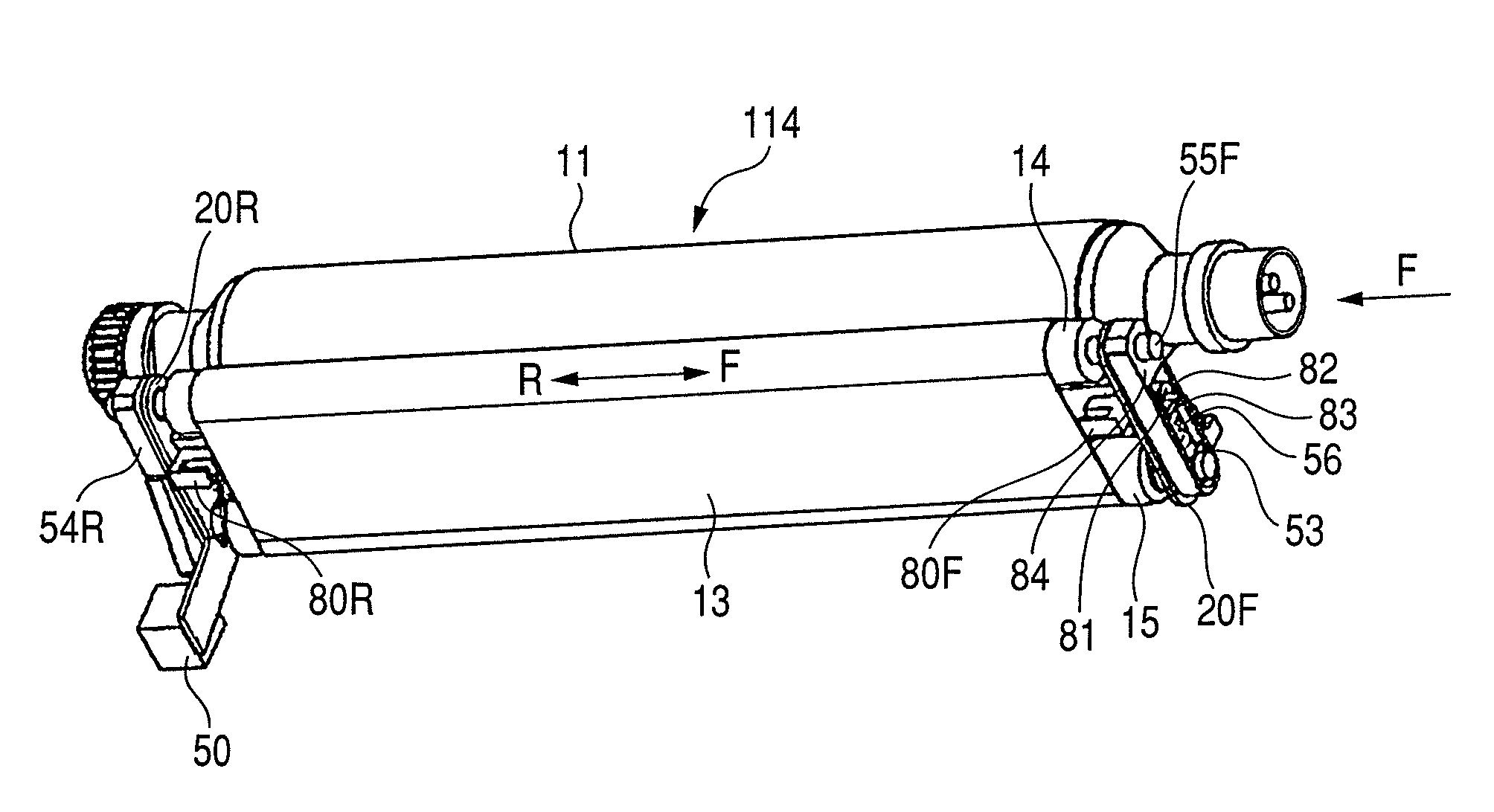

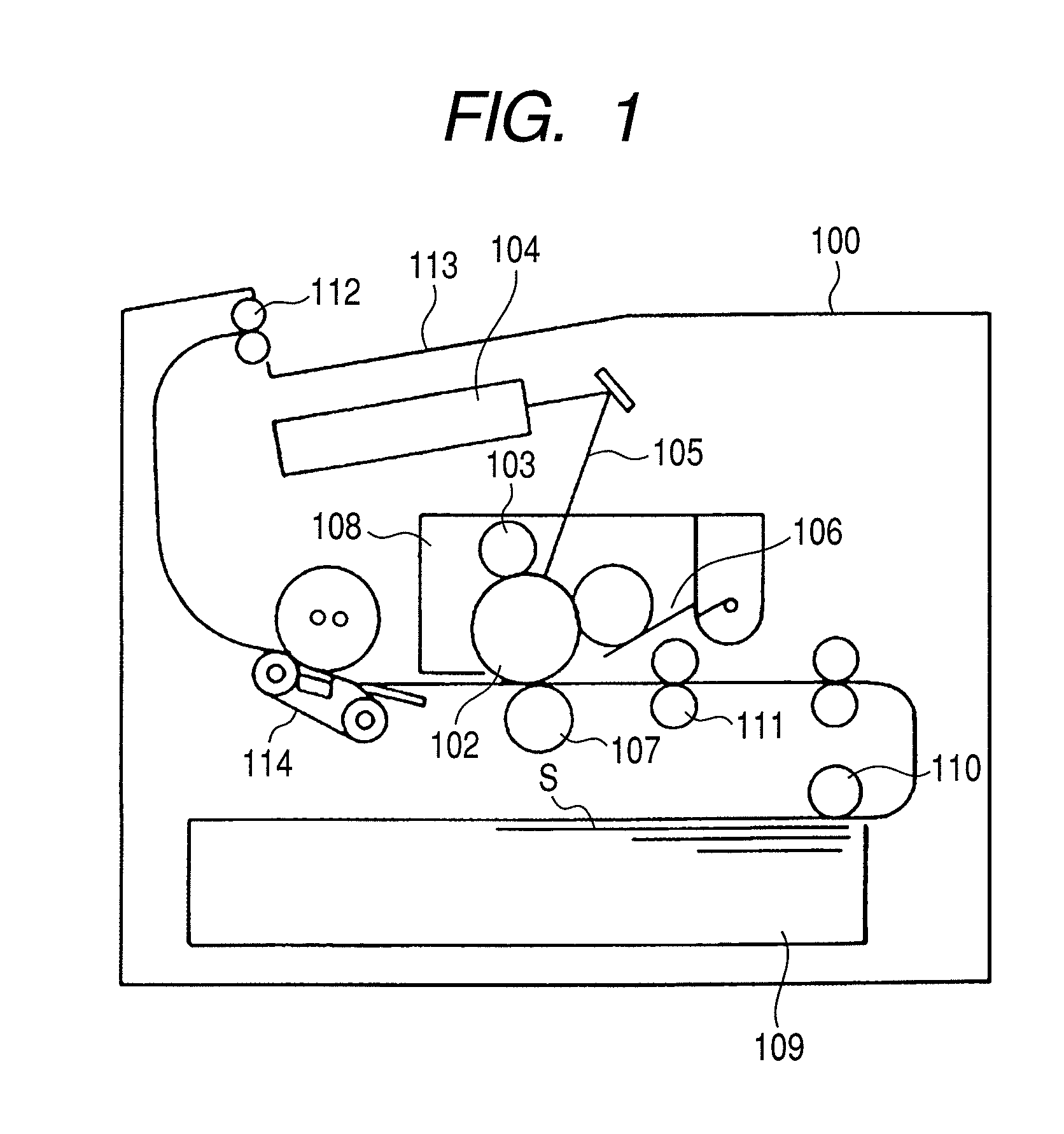

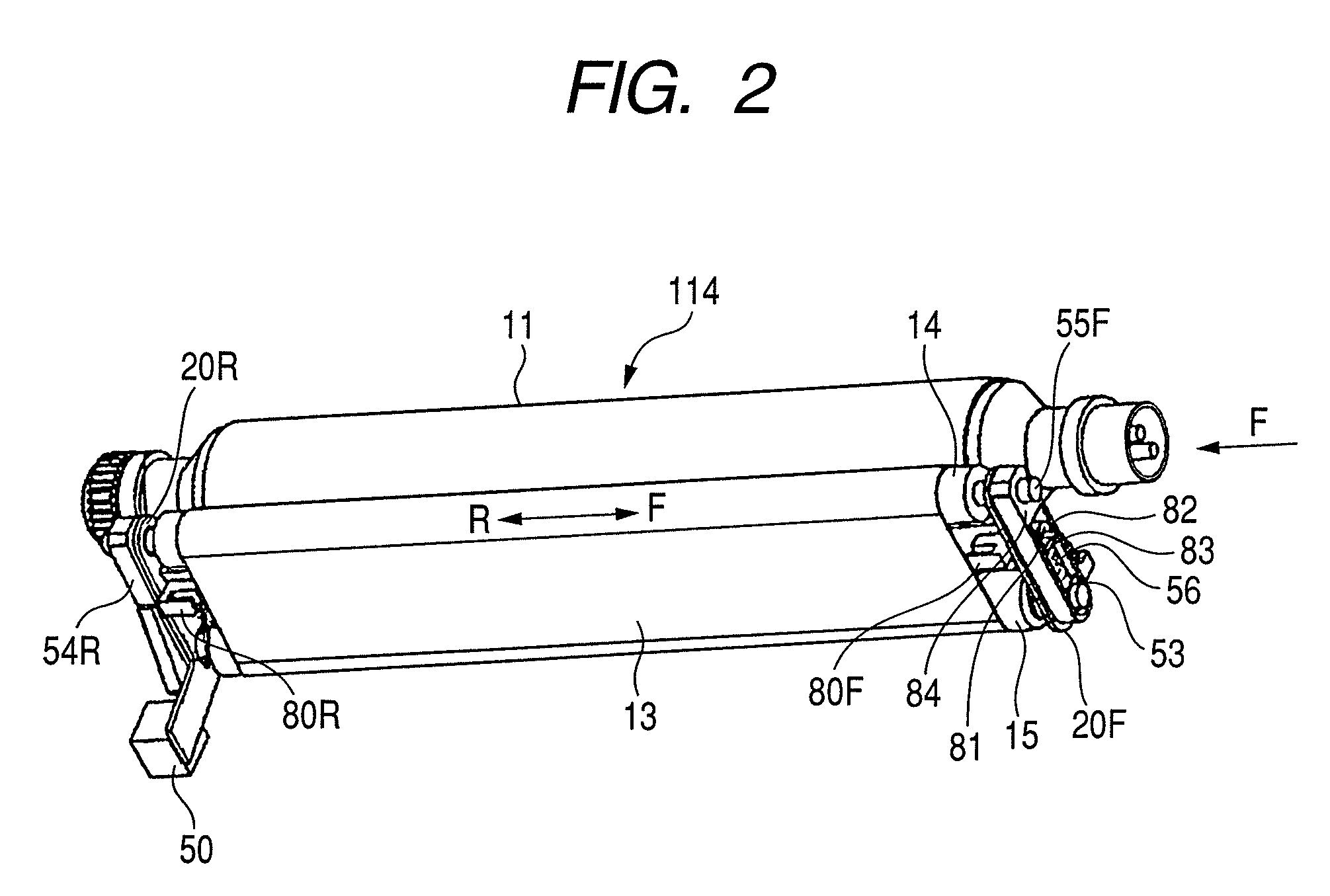

Conveyor-belt apparatus and image heating apparatus changing the belt tension in accordance with the moving state of the belt

InactiveUS8095058B2Preventing enlargement of the apparatusPrecise motion controlConveyorsElectrographic process apparatusConveyor beltEngineering

Owner:CANON KK

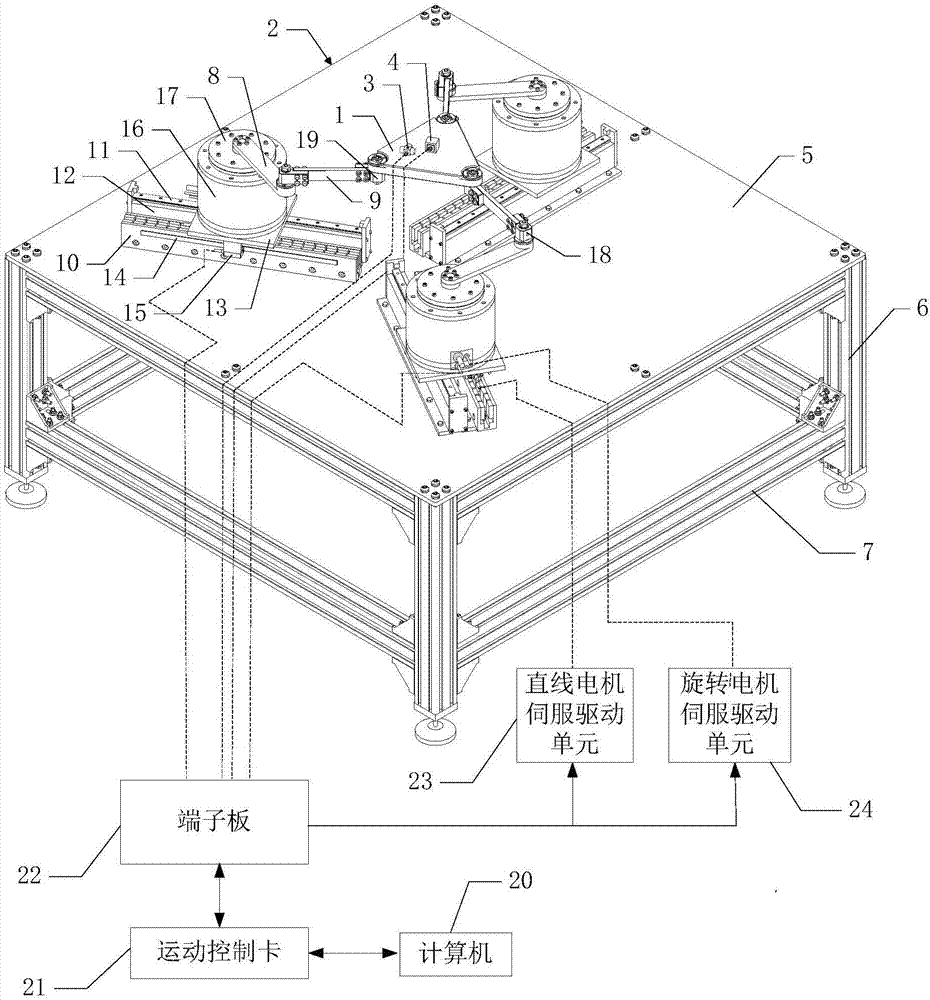

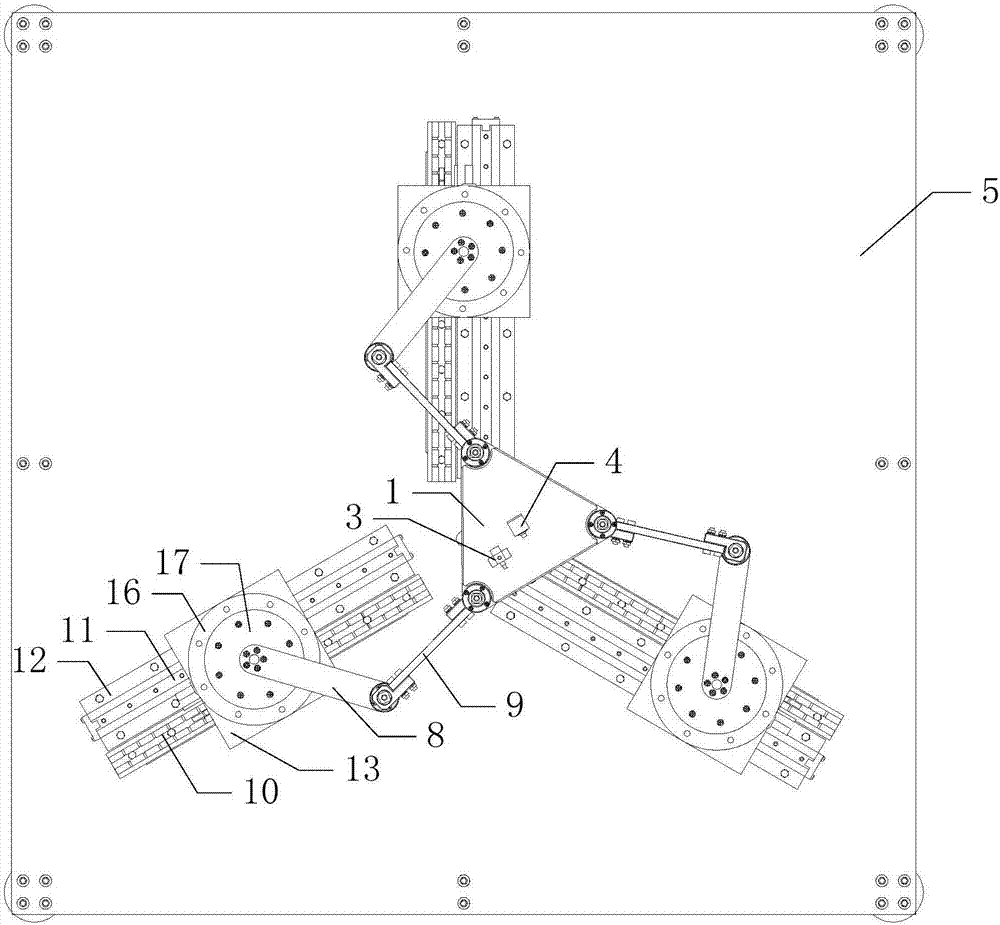

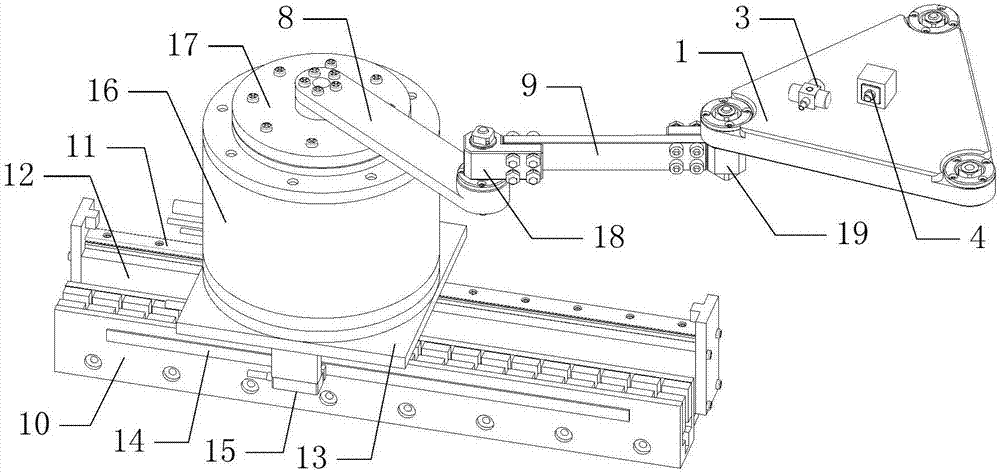

Direct-driven redundant planar parallel mechanism control device and redundant planar parallel mechanism control method

PendingCN107139193AEasy to controlReduce noiseProgramme-controlled manipulatorControl engineeringElectric machinery

The invention discloses a direct-driven redundant planar parallel mechanism control device and a redundant planar parallel mechanism control method. The device comprises a parallel mechanism body and a control unit. The parallel mechanism body comprises a movable platform and three parallel branches. The movable platform is in a shape of equilateral triangle and provided with an angular acceleration sensor and an acceleration sensor. Each parallel branch comprises a linear motor module with a displacement sensor, a rotary motor module with an encoder, a rigid active bar and a rigid passive bar. The control unit is connected with the angular acceleration sensor, the acceleration sensor, the linear motor module and the rotary motor module. Through hybrid driving of linear motors and rotary motors, the working space of the parallel mechanism is enlarged, and movement parameters of the movable platform are measured by means of the multiple sensors to serve as feedback signals, the movement control accuracy of the parallel mechanism reaches the high level.

Owner:SOUTH CHINA UNIV OF TECH

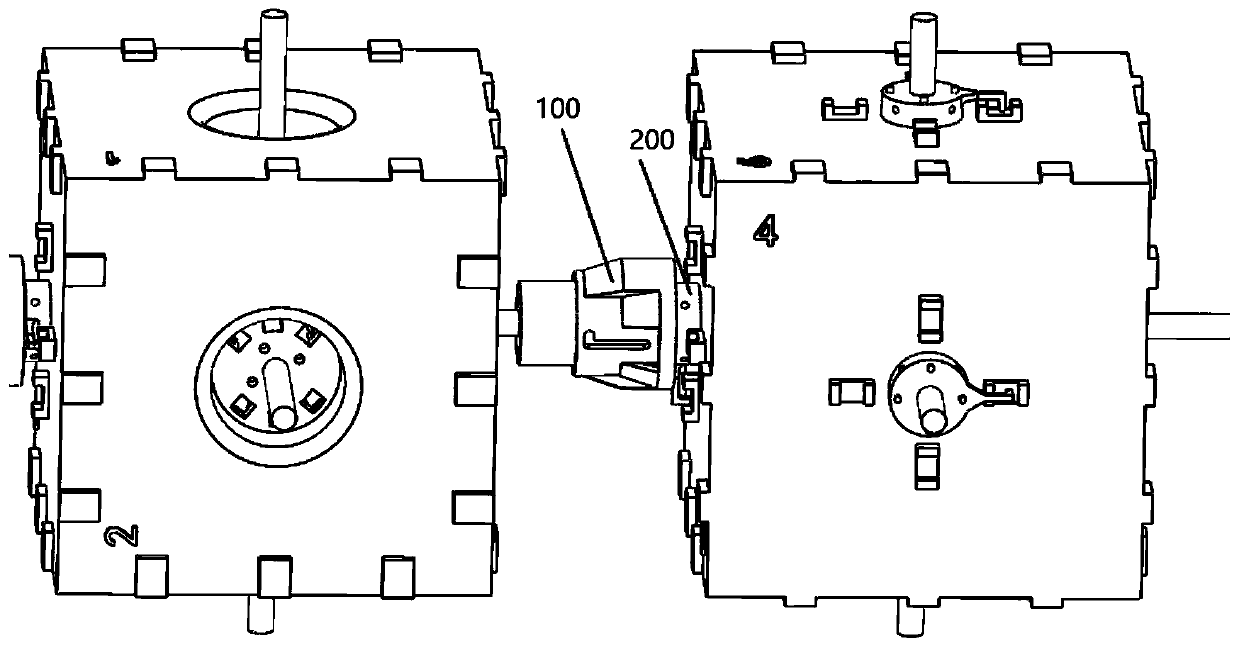

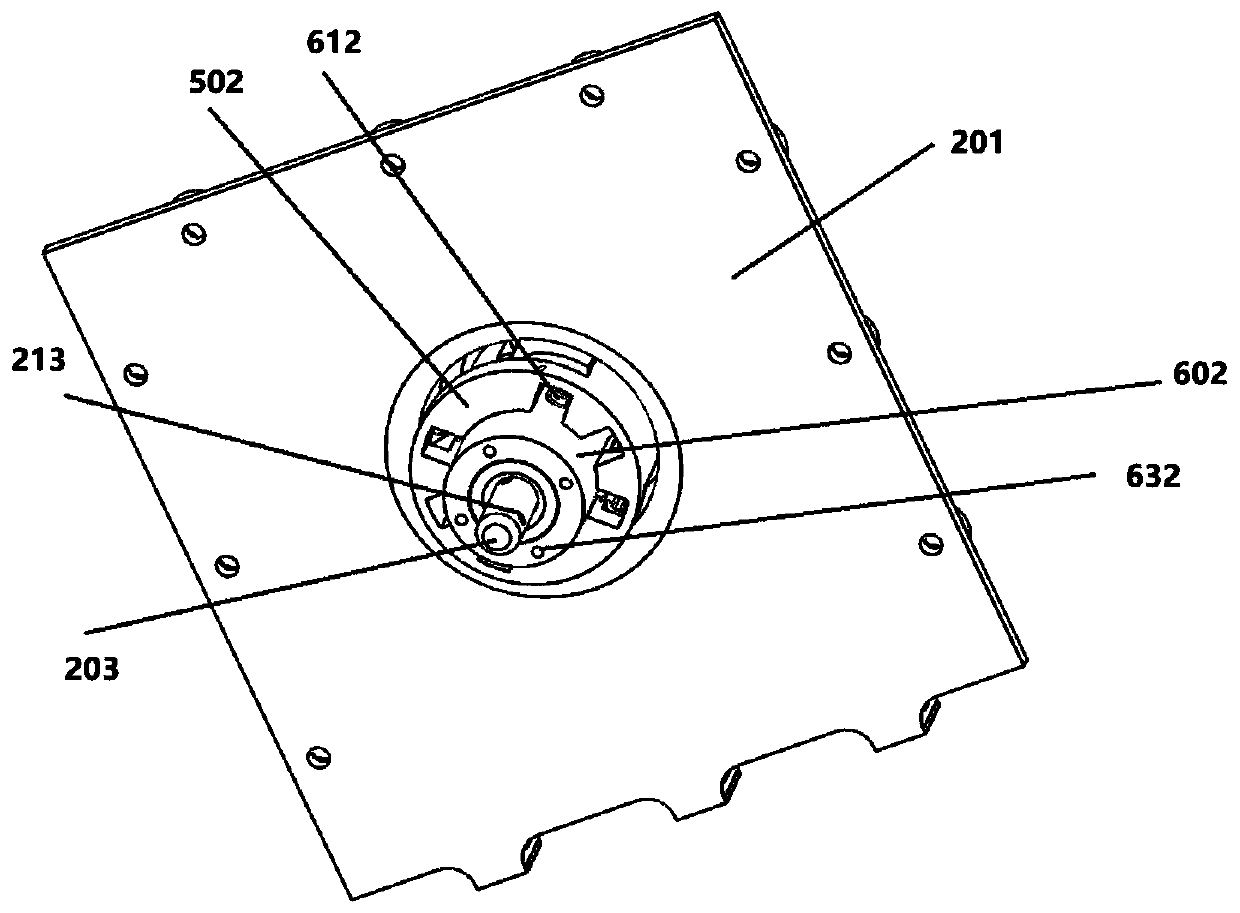

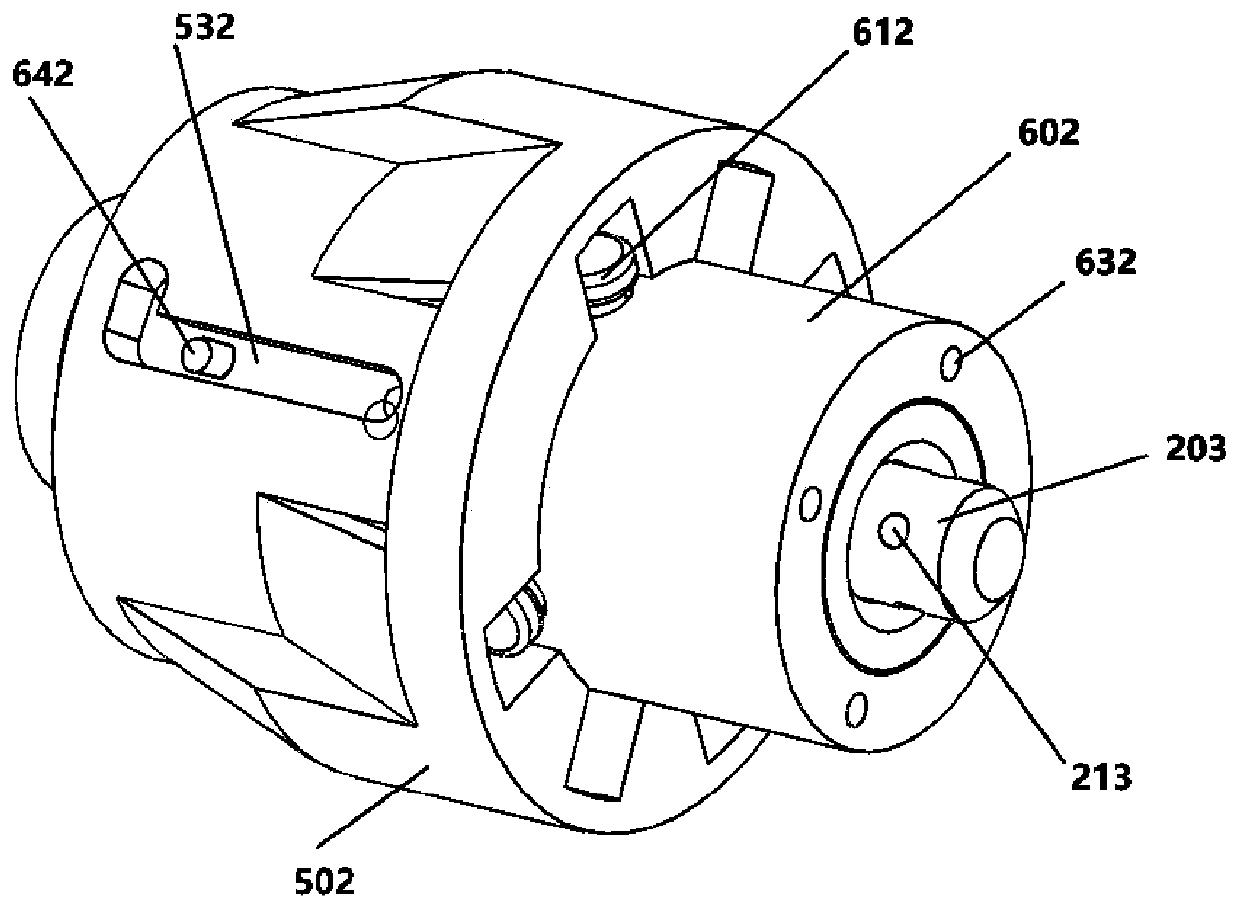

Butt joint mechanism of reconfigurable robot

The invention discloses a butt joint mechanism of a reconfigurable robot. The butt joint mechanism comprises a driving surface module and / or a driven surface module, wherein the driving surface modulecomprises a driving butt joint mechanism and a guide rod, the driving butt joint mechanism can horizontally move along the axis direction of the guide rod, the driven surface module comprises a driven butt joint mechanism, and the driving butt joint mechanism of a reconfigurable robot module is used for horizontally moving along the guide rod to be in butt joint with and fixed to the driven buttjoint mechanism of the other reconfigurable robot module, so that the driving surface module can be in butt joint with the driven surface module so as to complete butt joint of the two reconfigurablerobot modules. Butt joint mechanism of the reconfigurable robot has the characteristics of being capable of adopting a pure mechanical structure, reliable in connection, convenient to assemble and disassemble, flexible in movement, convenient to maintain, low in cost and the like, and the butt joint mechanism can be widely applied to but not limited to butt joint and separation of modular robots and other devices.

Owner:SHANGHAI JIAO TONG UNIV

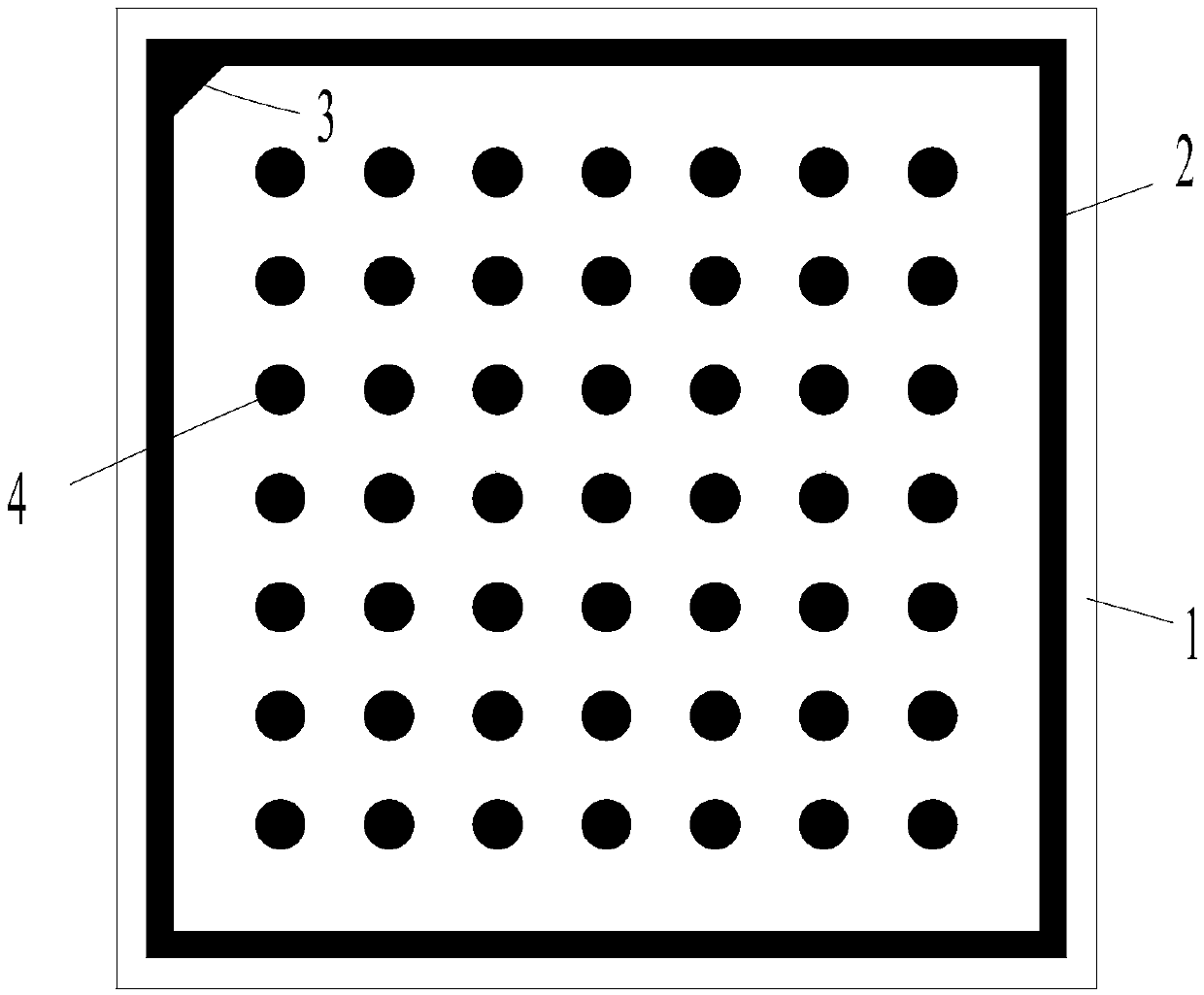

Badminton robot camera calibration method

ActiveCN105513074APrecise motion controlImage enhancementImage analysisBlack pointDirection information

The present invention discloses a badminton robot camera calibration method which comprises a step of using a calibration plate to calibrate the internal and external parameters of cameras, wherein due to the structure of the equal distance and size of the black points of the calibration plate, the two-dimensional position and the orientation information of the calibration plate can be easily identified in an image, a step of establishing the correspondence between the cameras and a real world through a corresponding relation according to physical distance between the black points on the calibration plate, and establishing the equation of the internal parameter, and a step of using left and right cameras to carry out calibration to obtain the internal parameters of the cameras, wherein since the left and right cameras are corresponding to the same calibration plate in left and right images, thus the corresponding relation which is an external parameter matrix between the left and right cameras can be established on the above basis.

Owner:四川新尚人工智能科技有限公司

Device and method for grinding workpieces using a control unit

ActiveUS20150239092A1Easy to calculatePrecise motion controlEdge grinding machinesGrinding wheel securing apparatusEngineeringActuator

A system for grinding solid workpieces includes a grinding wheel, a bearing for rotatable mounting of the grinding wheel about an axis of rotation, and a grinding wheel drive for rotating the grinding wheel. The system allows the production of freely-definable surfaces on the face of the rigid workpiece that comes into contact with the grinding wheel. The bearing is fastened to a pivotable and displaceable bearing carrier. The bearing plane is pivotable in any desired direction with respect to an initial plane and is displaceable in a direction perpendicular to the initial plane. Actuators are coupled to the bearing carrier to pivot and displace the bearing carrier. A digital control unit controls and synchronizes the actuators such that the surface of the grinding wheel creates a freely-definable face about a positionally fixed reference point which is at a radial distance from the center point of the grinding wheel.

Owner:MATUSCHEK MESSTECHN

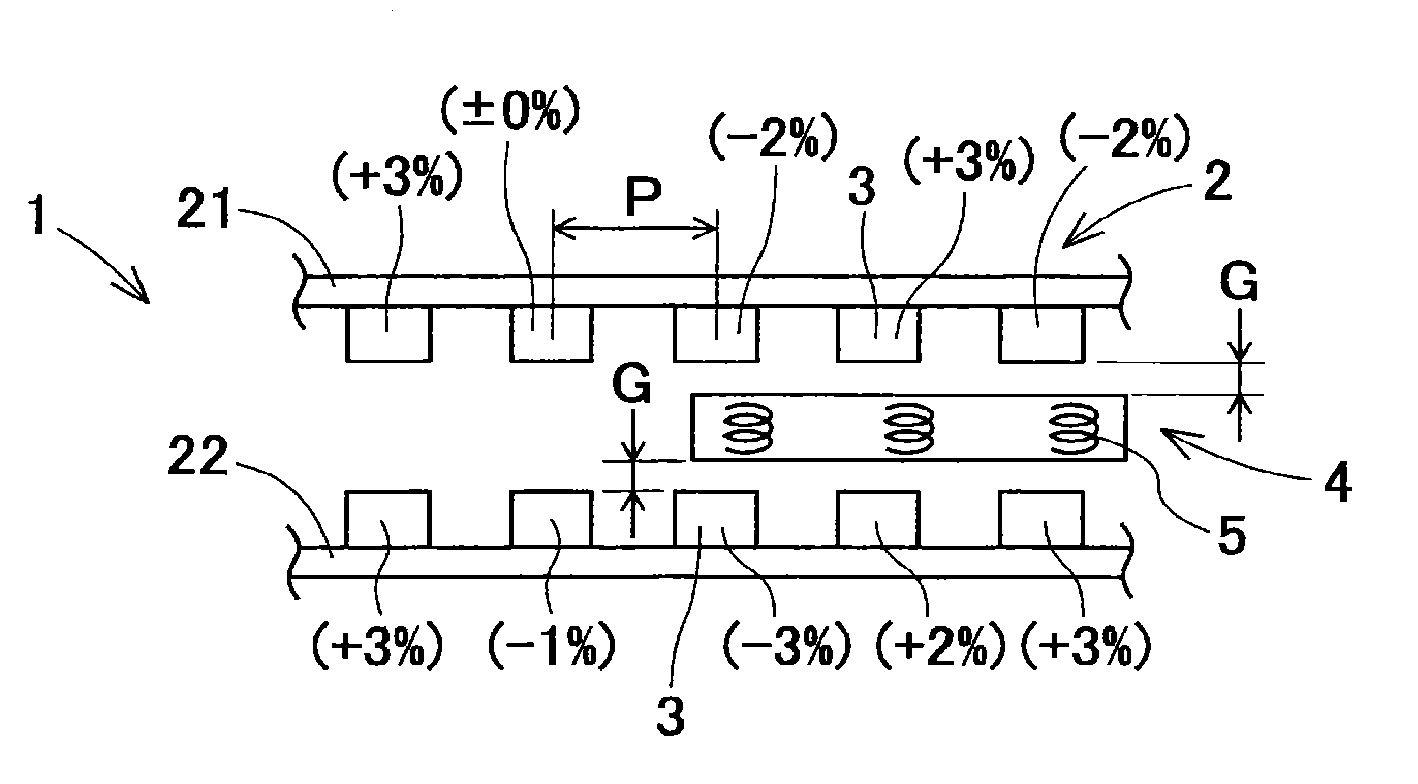

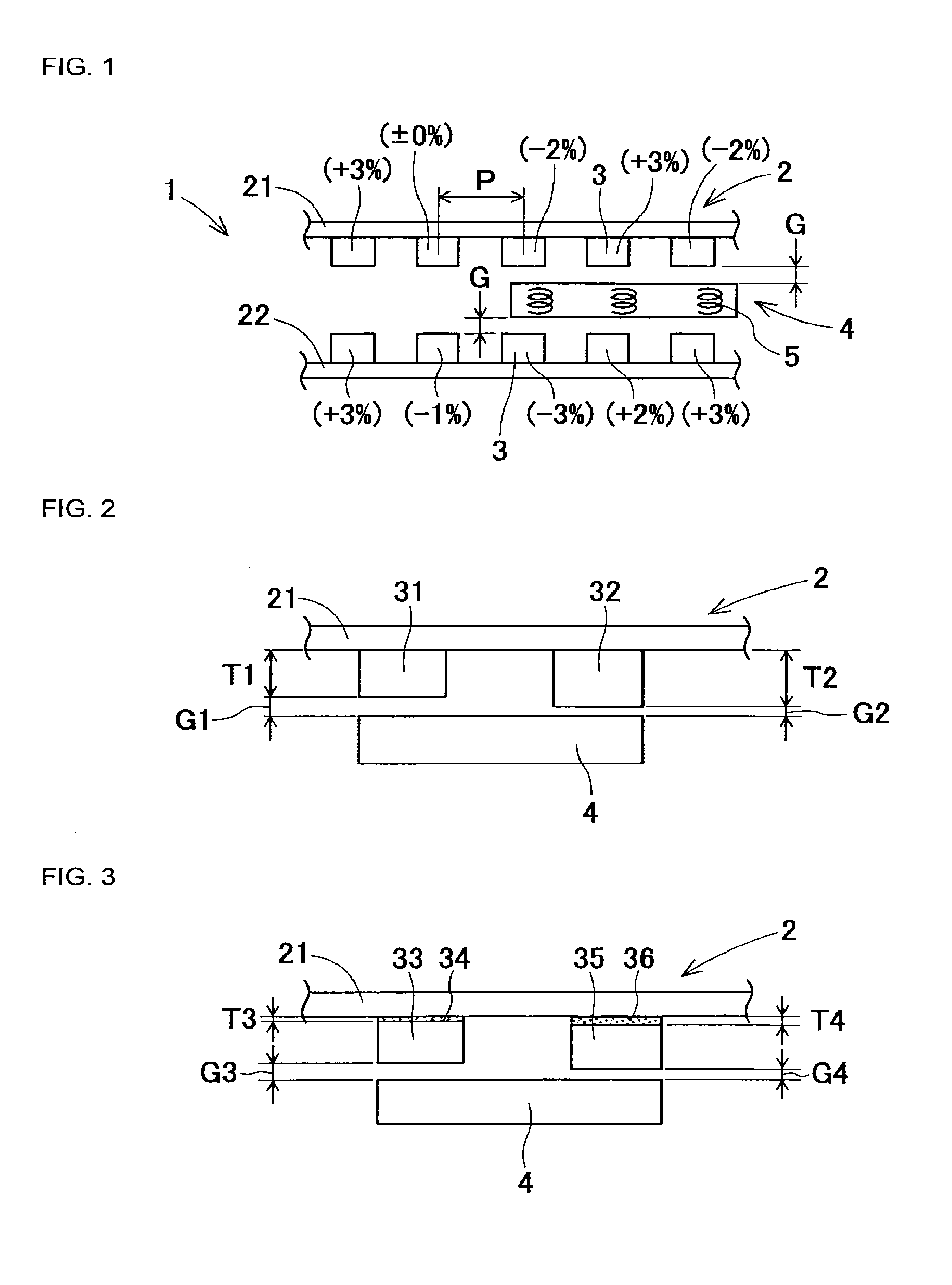

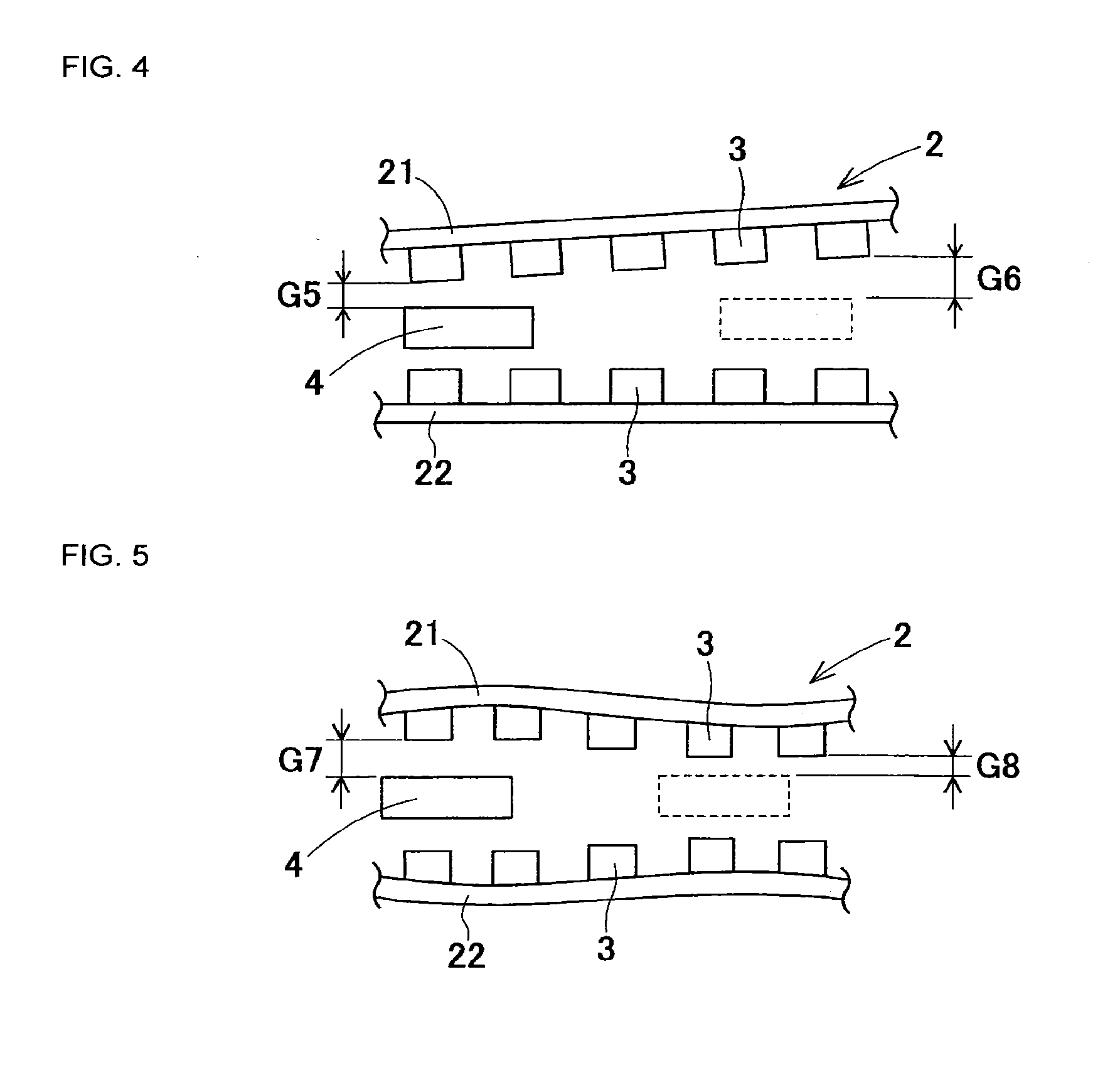

Thrust constant derivation method and movement control method of linear motor, and thrust constant derivation device and movement control device of linear motor

ActiveUS20160315574A1Possible to carry outIncrease derivation precisionAC motor controlElectric motor controlElectric machineMovement control

A method of deriving a thrust constant representing an occurrence rate of a thrust in relation to a current in a linear motor which includes a magnet extending in a movement direction, and a moving body which includes a coil mounted to a track member in a movable manner, the linear motor generating a thrust in the movement direction between the magnet and the coil by causing the current to flow in the coil, in which an average thrust constant which is an average thrust constant in a long movement zone on the track member is derived based on actual measurement, local thrust constants which are local thrust constants of a plurality of locations on the track member are derived based on each actual measurement, and the thrust constants are derived based on the average thrust constant and the local thrust constant of each location.

Owner:FUJI MASCH MFG CO LTD

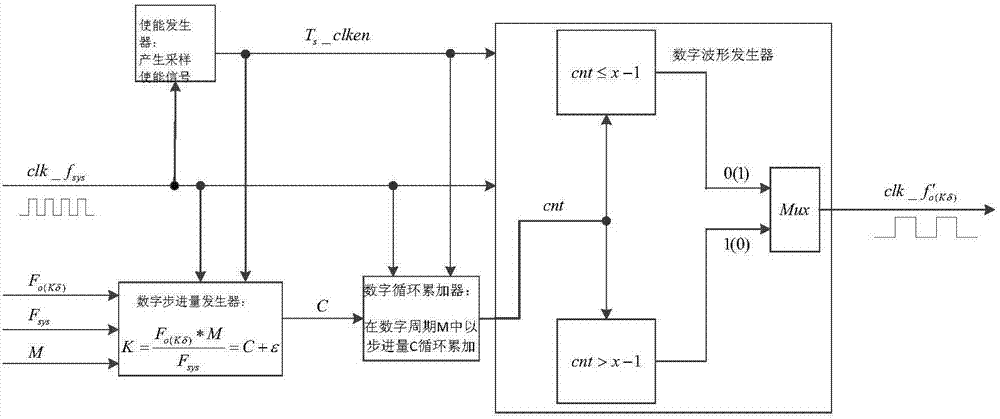

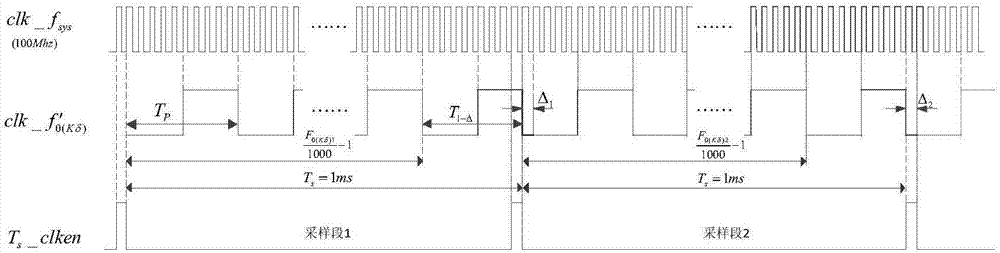

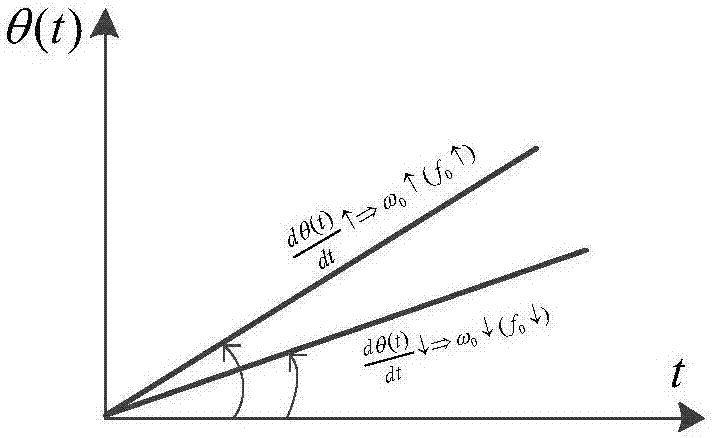

Pulse generation method based on digital frequency synthesis technology

InactiveCN107153352AAccurate number of pulsesUniform and stable pulseAdaptive controlPhase noiseComputer science

The invention discloses a pulse generation method based on the digital frequency synthesis technology. The method comprises steps that under a system clock, through an enablement generator, a sampling enablement signal is generated, under the system clock and a sampling enablement clock, firstly, through a digital stepping amount generator, digital stepping amount is acquired through calculation; secondly, through a cycle accumulator, in a digital period scope, cycle accumulation is carried out at the digital stepping amount; and lastly, through a waveform generator, according to a set threshold and a present calculation value of the cycle accumulator, comparison is carried out, and target pulses are generated. The method is advantaged in that the accurate, uniform and stable pulses are generated, and phase noise and switch noise are low.

Owner:SOUTH CHINA UNIV OF TECH

Rope driving device for improving control accuracy

ActiveCN108724160AHigh control precisionEasy to controlProgramme-controlled manipulatorEngineeringConductor Coil

The invention discloses a rope driving device for improving the control accuracy. The rope driving device comprises a transmission wheel driven to rotate by a motor, a reel rotating along with the transmission wheel, and a rope wound on the reel; the reel can move relative to the transmission axle in the rotating process, and a spiral clamping groove used for clamping the winding of the rope is formed in the surface of the reel; and the axial movement rate of the reel is the same as that of the rope in the clamping groove, through the synchronous movement of the separation point of the reel and the rope, the swing of the rope relative to the reel is eliminated, and the output of the rope can be accurately controlled accordingly. The rope driving device has the key advantages that the rotating angle of the reel is linearly related to the input and output amount of the rope, the rope driving device is easy to control, compact in structure and easy to maintain, and the control accuracy ofthe rope is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

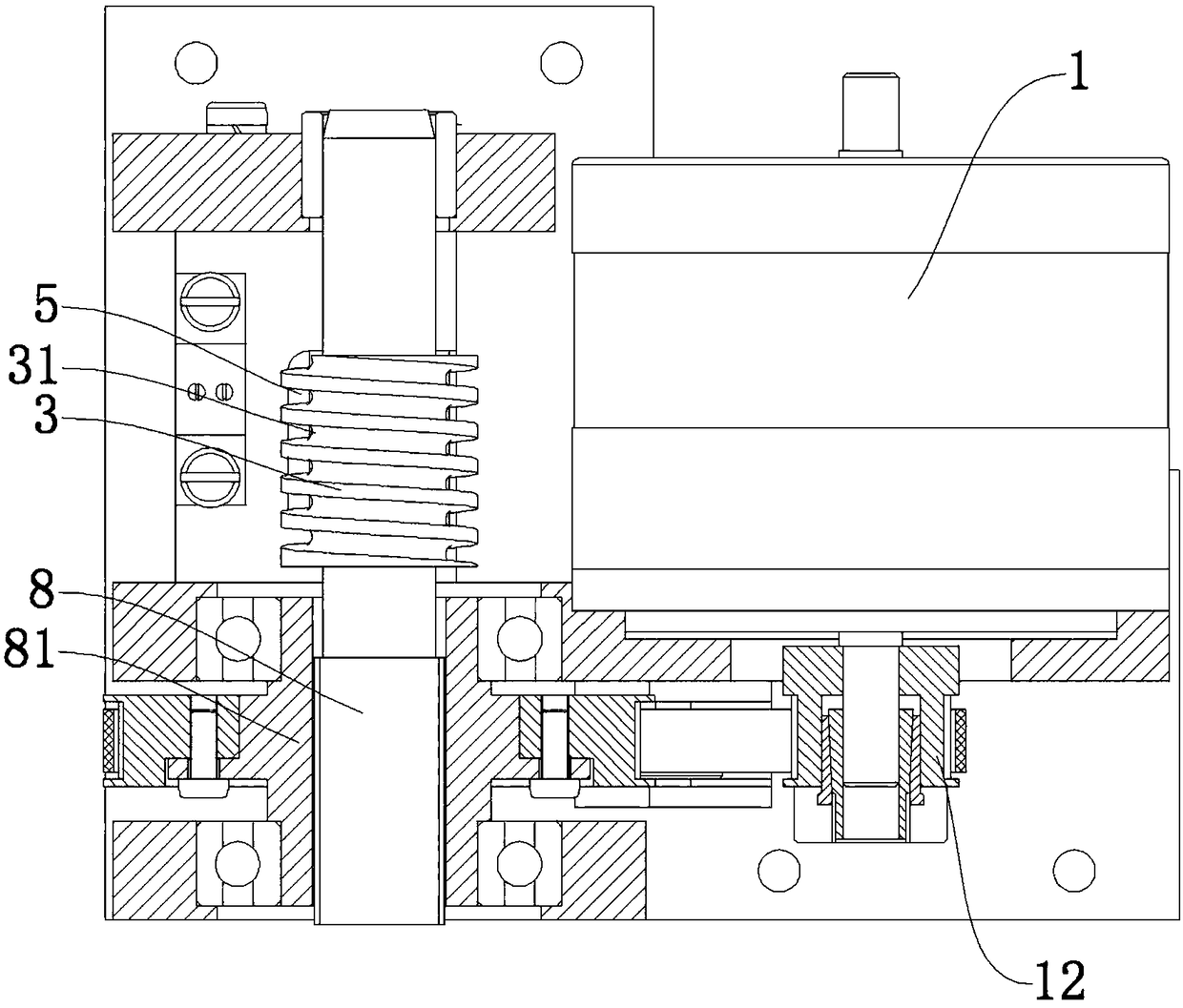

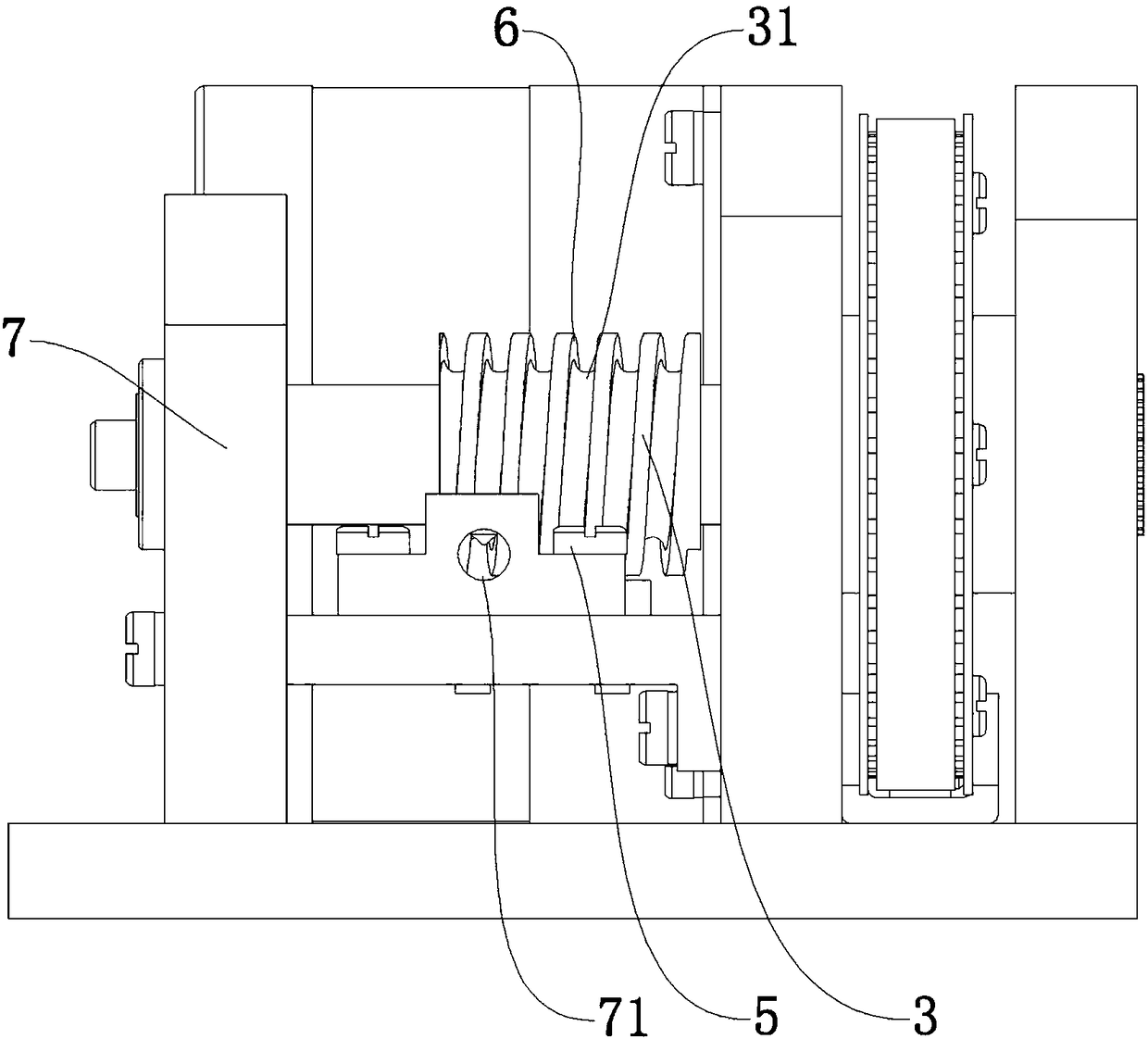

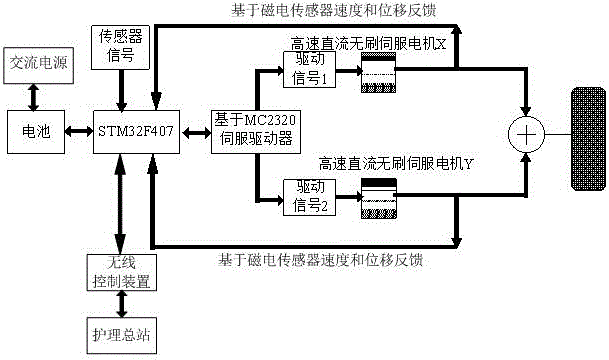

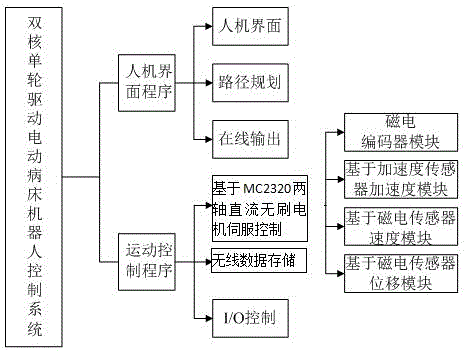

Wireless double-core double-wheel drive robot electric sickbed control system

InactiveCN105997392AGuaranteed stabilityEnsure safetyNursing bedsManipulatorEngineeringOpto electronic

The invention discloses a wireless double-core double-wheel drive robot electric sickbed control system. The system comprises a control device, a motion control system, a direct-current brushless servo motor X and a direct-current brushless servo motor Y. The motion control system comprises an ARM chip controller, an image acquisition module, a wireless local area network module and a motion control chip. The ARM chip controller and the motion control chip are in communication with the control device and are in communication with each other, and the direct-current brushless servo motor X and the direct-current brushless servo motor Y are in communication with the ARM chip controller. An electric sickbed is provided with a navigation photoelectric sensor, a start button SS, a lateral steering button SK, a retreat button SB and an acceleration sensor. The wireless double-core double-wheel drive robot electric sickbed control system is high in computation speed, convenient to operate, safe, stable, precise in motion control and capable of achieving long-distance control of the robot electric sickbed.

Owner:JIANGSU ROBOBOR ROBOT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com