Serial multi-axis stepper control method and system for tin paste printing machine

A solder paste printing machine and stepping control technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve the problem of high cost, and achieve the effect of strong control function, multi-axis coordinated control, and strong anti-electromagnetic interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

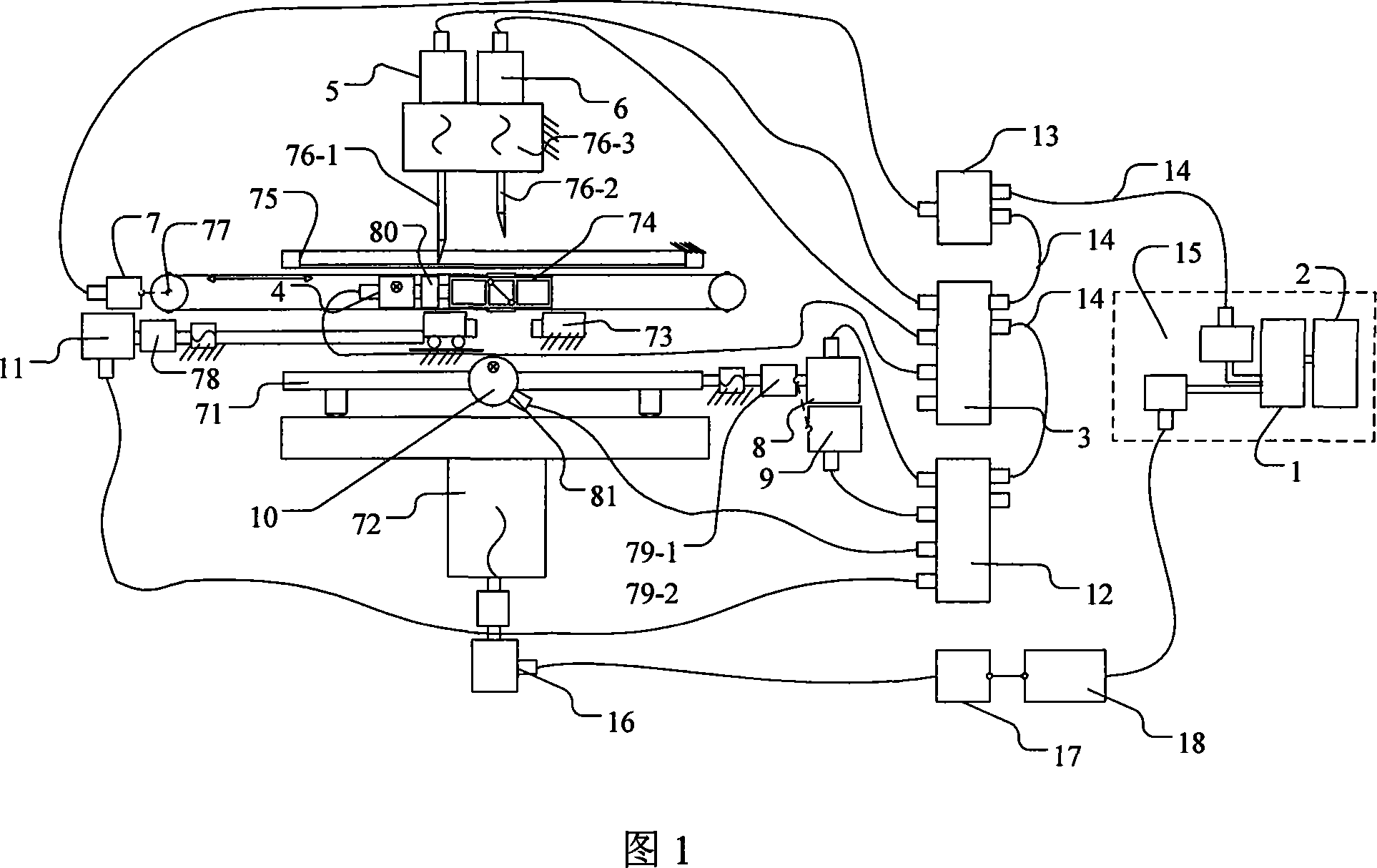

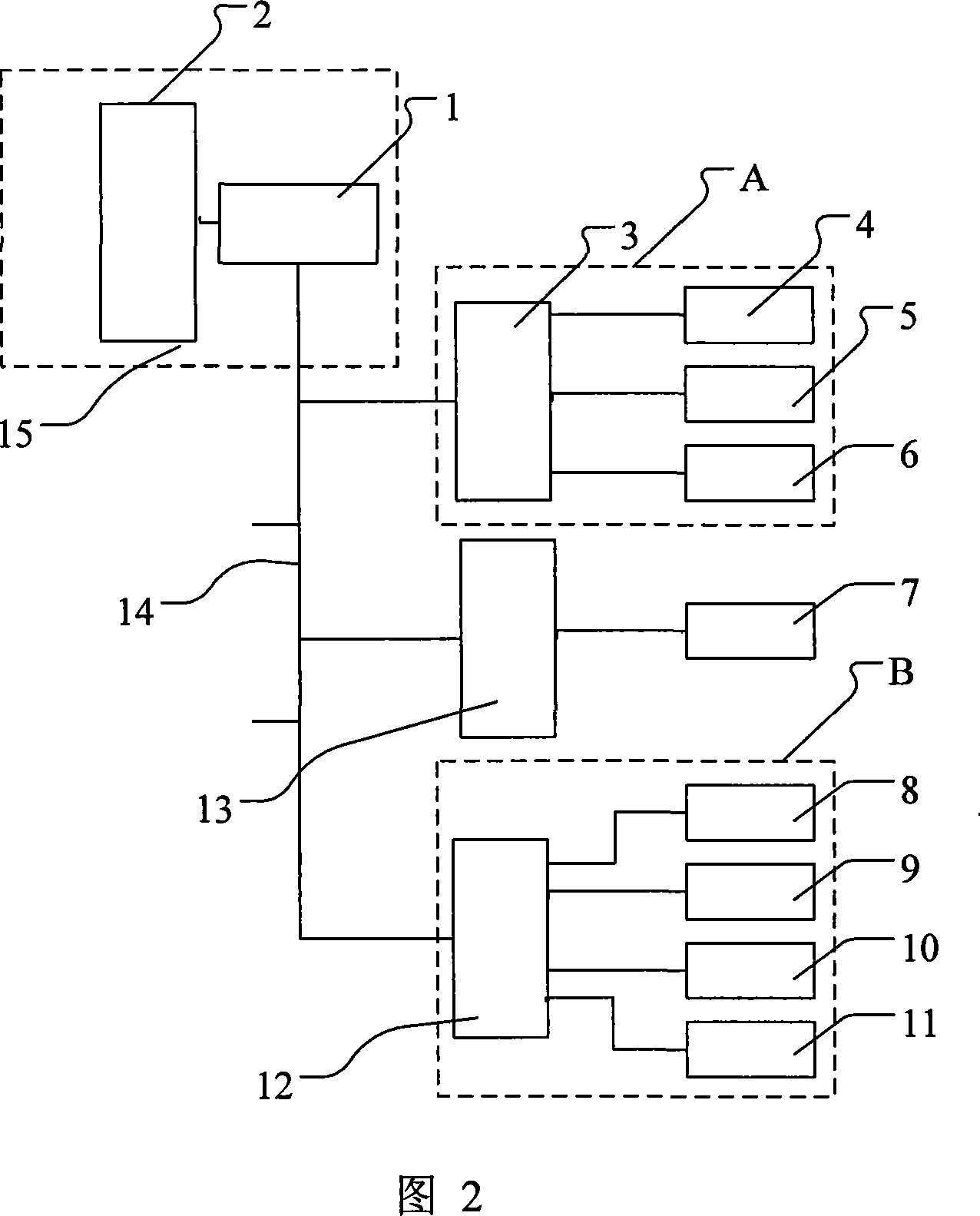

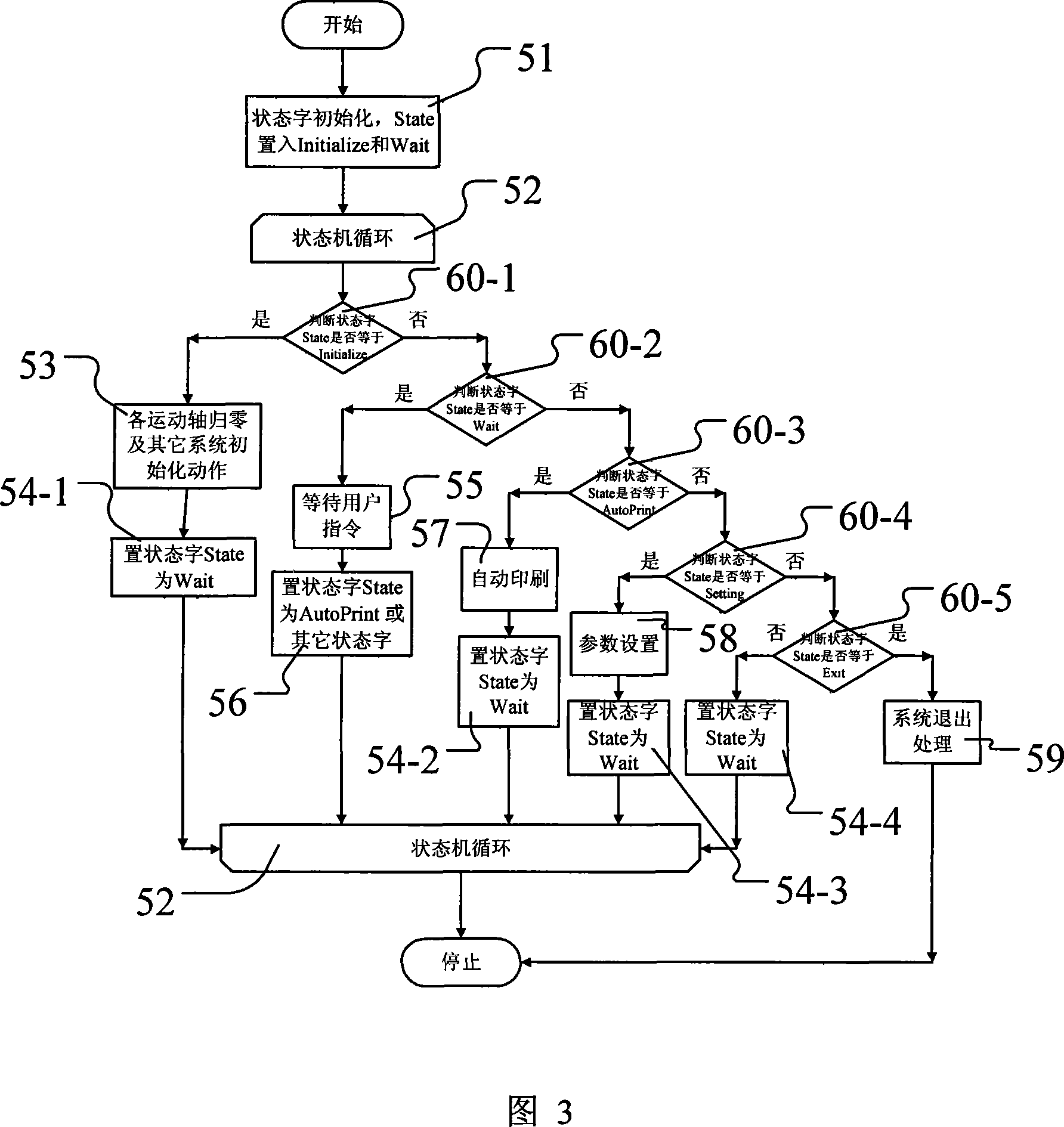

[0029] As shown in Figure 1, a typical PCB screen solder paste printing machine mainly includes a steel mesh 75, a platform 71, a platform lifting device 72, a PCB board conveying device 73, a camera device 74, a front scraper 76-1, and a rear scraper 76 -2. Scraper transmission device 76-3, platform X-axis transmission device 81, platform Y1-axis transmission device 79-1, platform Y2-axis transmission device 79-2, PCB rail width transmission device 78, camera X-axis transmission device 80, camera Y-axis transmission device 77 and the multi-axis control system of the present invention. The scraper Z1 stepper motor 5 and the scraper Z2 stepper motor 6 of the multi-axis control system of the solder paste printing machine of the present invention are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com