Hybrid ceramic matrix composite turbine blades for improved processibility and performance

a composite turbine blade and hybrid technology, applied in the direction of wind turbines with perpendicular air flow, machines/engines, climate sustainability, etc., can solve the problems of insufficient high compressive strength, inability to achieve high compressive strength, and inability to use the concept of polymeric matrix composites (pmcs) in the past, so as to improve the crack arresting ability and resist crack formation. , the effect of improving the toughness of back fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

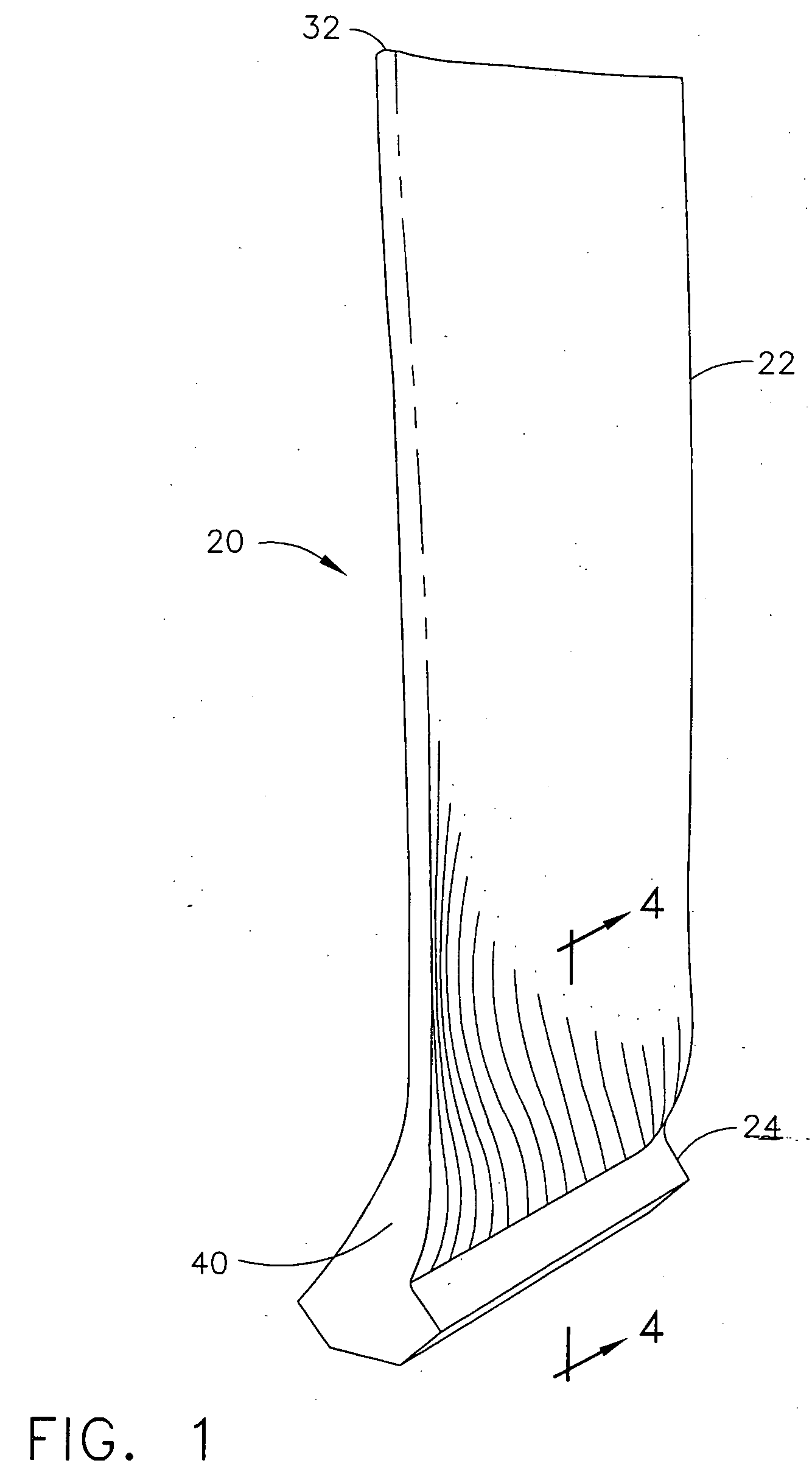

[0027]FIG. 1 depicts an exemplary aircraft engine LPT blade 20. In this illustration a turbine blade 20 comprises a ceramic matrix composite material. The turbine blade 20 includes an airfoil 22 against which the flow of hot exhaust gas is directed. The turbine blade 20 is mounted to a turbine disk (not shown) by a dovetail 24 that extends downwardly from the airfoil 22 and engages a slot of similar geometry on the turbine disk. The LPT blade of the present invnetion does not have an integral platform. A separate platform is provided to minimize the exposure of the dovetail to hot gases of combustion. The airfoil may be described as having a root end 40 and an oppositely disposed tip end 32.

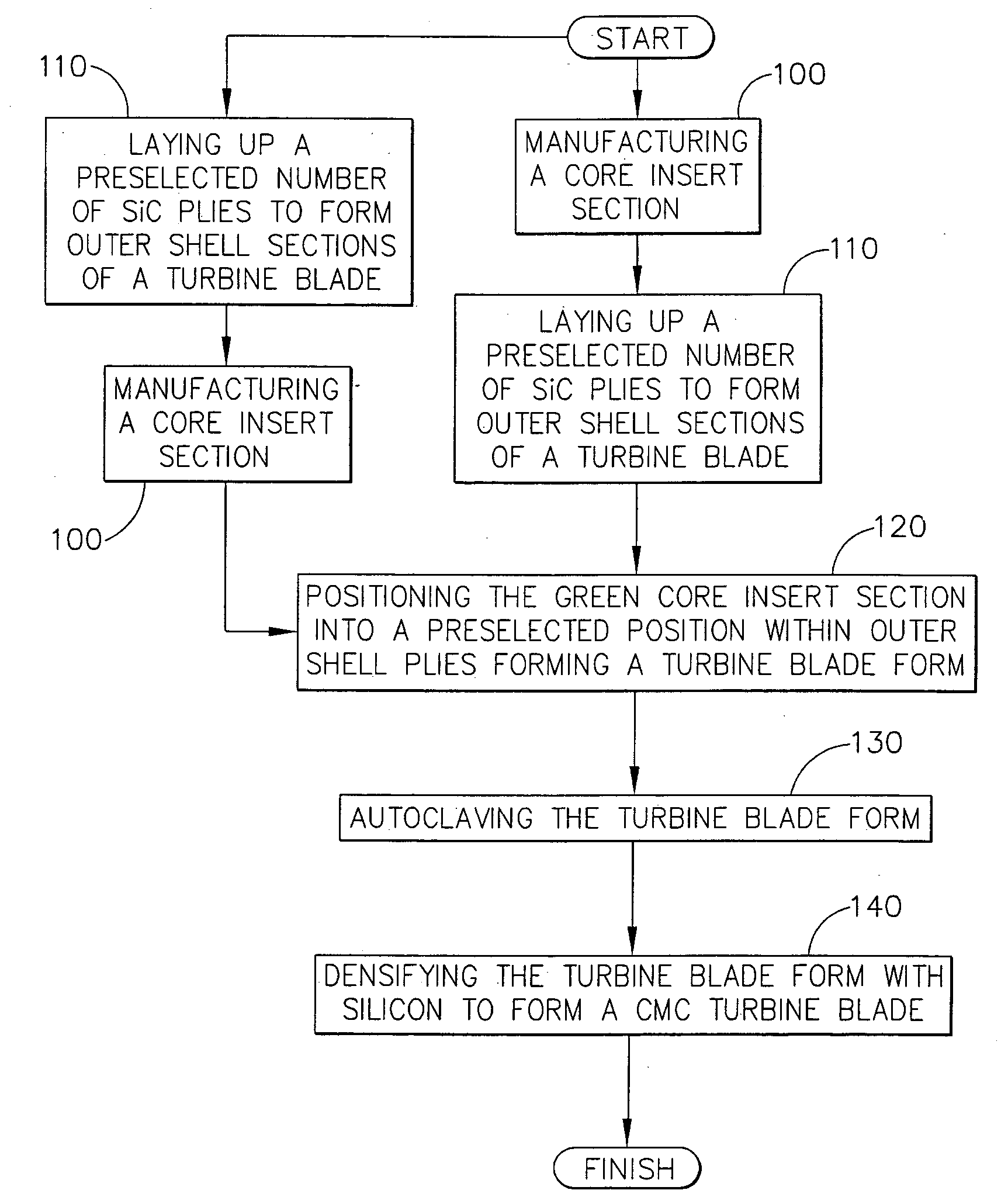

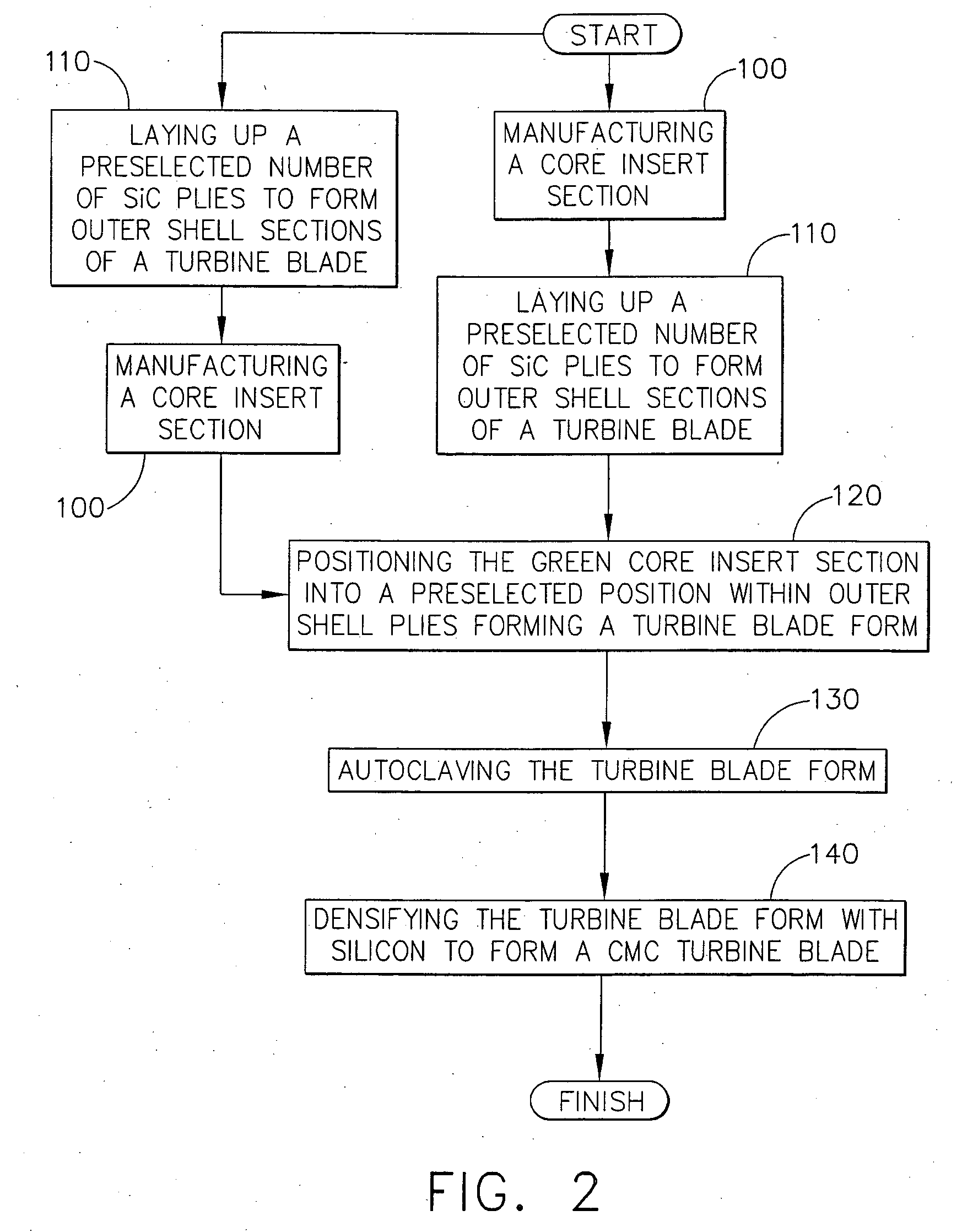

[0028]FIG. 2 is a flow chart illustrating a method of manufacture of a CMC turbine blade of the present invention using a method of silicon carbide-silicon carbide CMC manufacture known as a “prepreg” melt infiltration process (prepreg MI). Initially, outer shell SiC preforms are manufactured us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume percent | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com