Modularized bionic wall climbing robot

A wall-climbing robot and modular technology, applied in the field of robotics, can solve problems such as difficult steering, weak ability to overcome obstacles and wall transitions, poor maneuverability, etc., and achieve simple manufacturing and maintenance, low cost, and simple construction and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

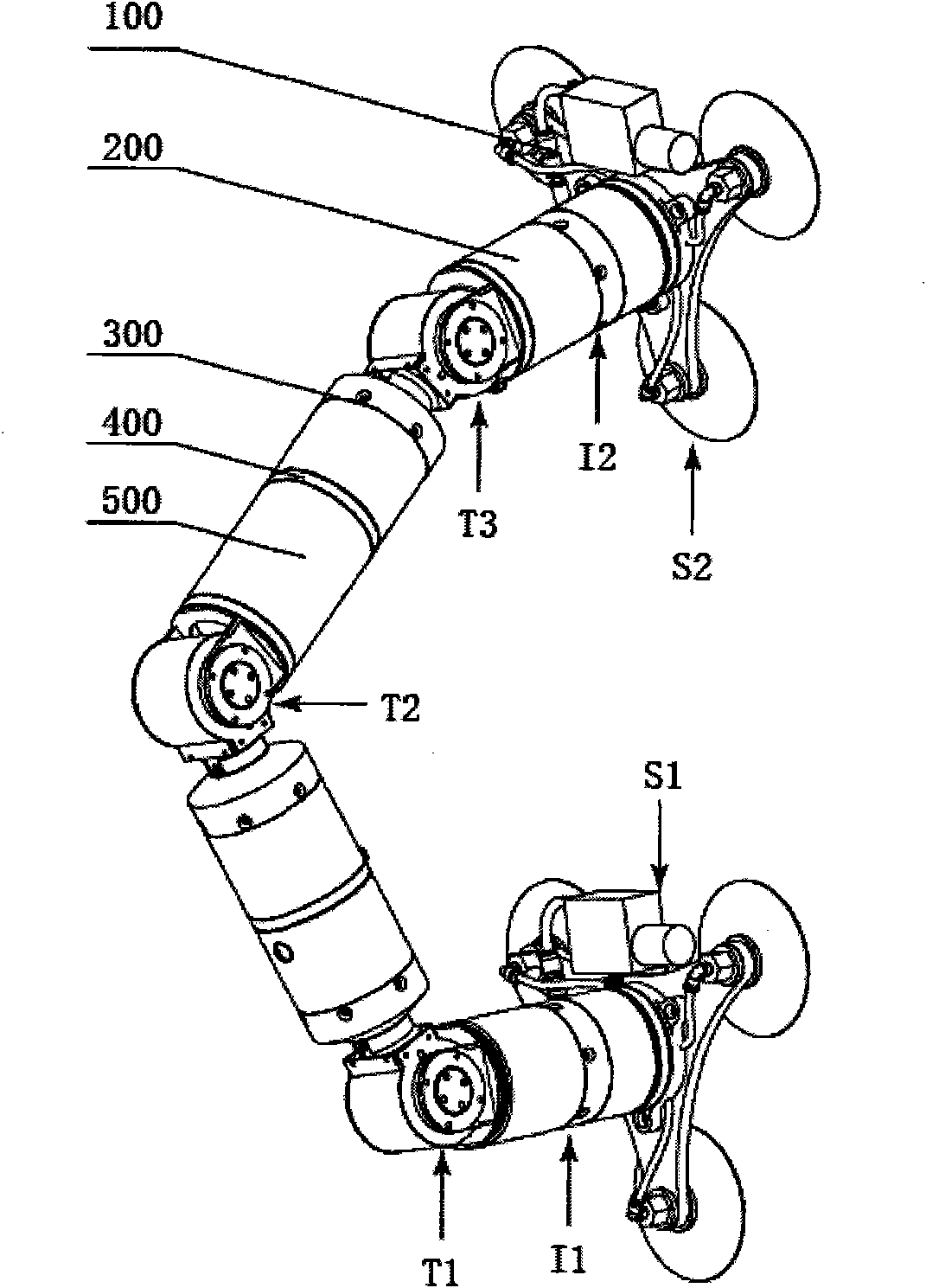

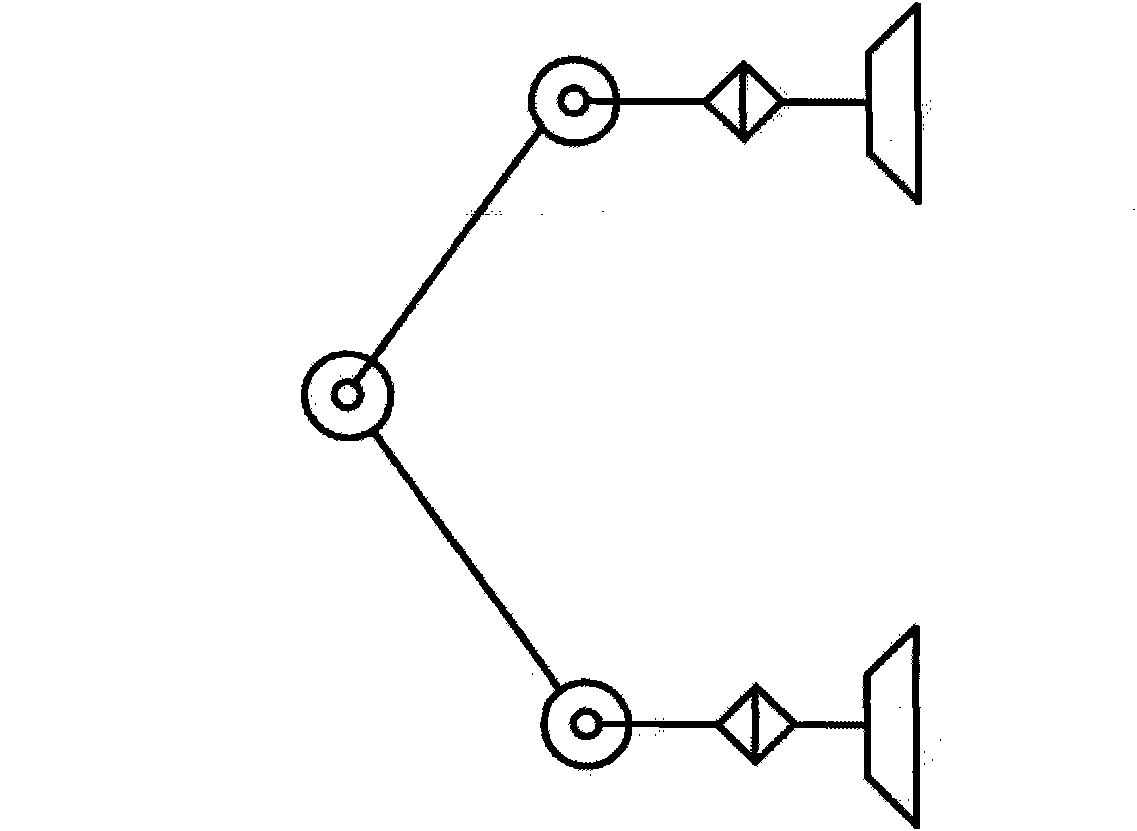

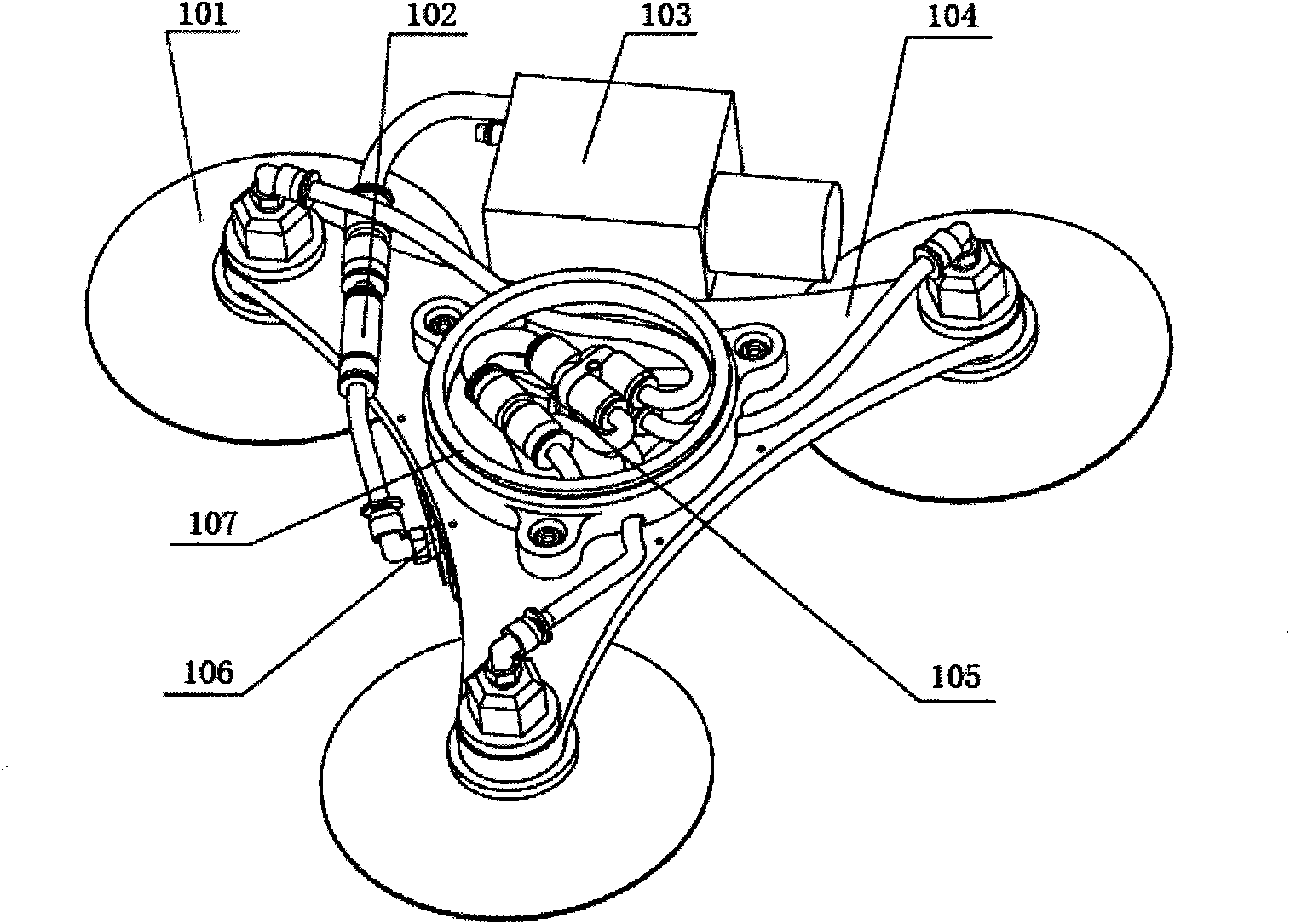

[0031] Such as figure 1 , 2 As shown, the body of the modular bionic wall-climbing robot has five degrees of freedom and is composed of five single-degree-of-freedom joint modules, with vacuum adsorption modules 100 connected at both ends, and there are seven modules in total. Each module is connected in series in sequence, the sequence is: first vacuum adsorption module S1-first I-shaped joint module I1-first T-shaped joint module T1-second T-shaped joint module T2-third T-shaped joint module T3- The second type I joint module I2-the second vacuum adsorption module S2. A joint sleeve 500 is inserted between the second and third T-shaped modules, so that the structures at the ends of the robot are symmetrical with respect to the joint rotation axis of the second T-shaped module T2. The joint rotation axes of the three T-shaped joint modules 300 are parallel to each other, and are naturally perpendicular to the joint axes of the I-shaped joint modules 200 at both ends. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com