Patents

Literature

593 results about "Material density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material density, more often referred to simply as density, is a quantitative expression of the amount of mass contained per unit volume . The standard unit is the kilogram per meter cubed (kg/m 3 or kg · m -3 ). Density is sometimes expressed in grams per centimeter cubed (g/cm 3 or gm · cm-3).

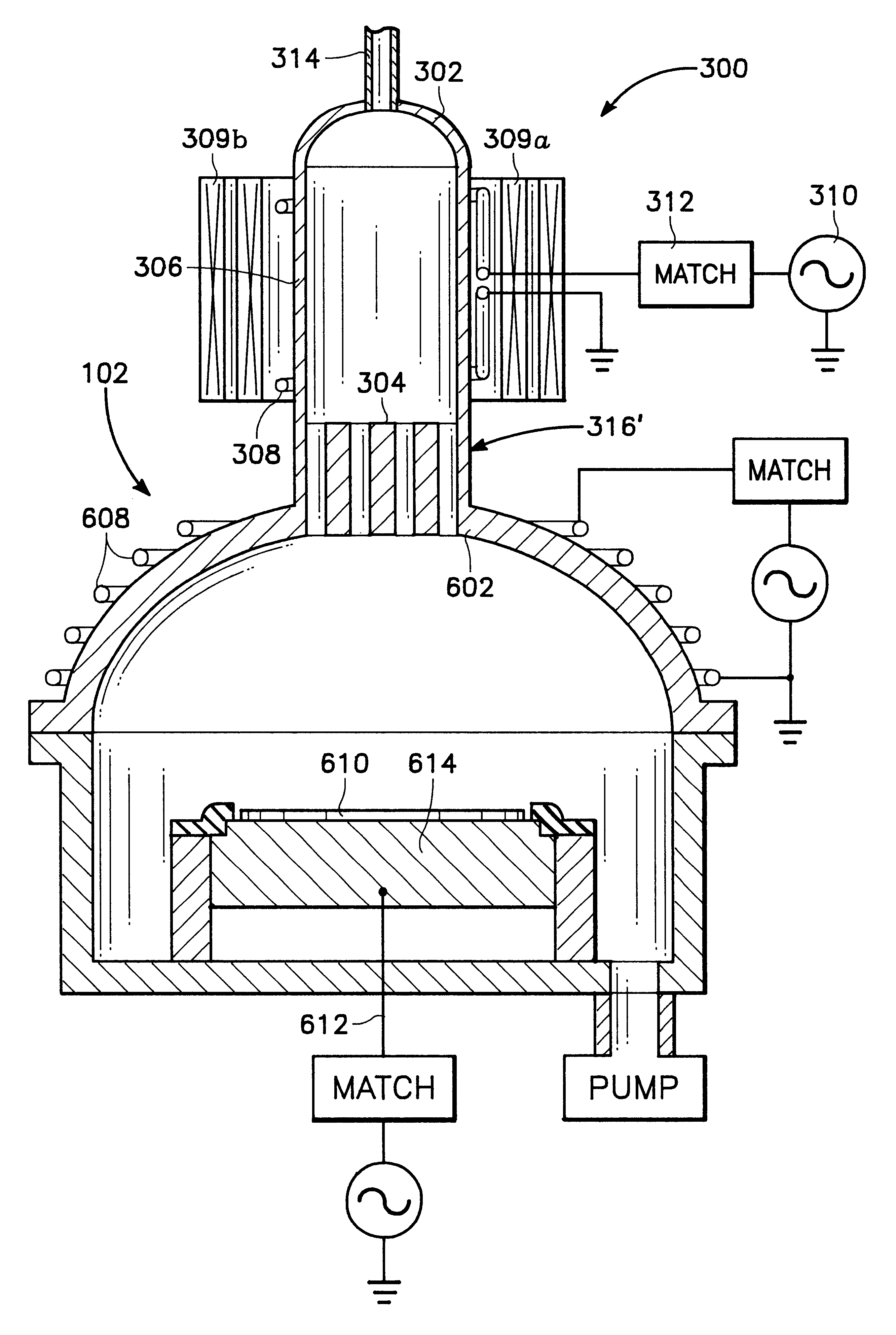

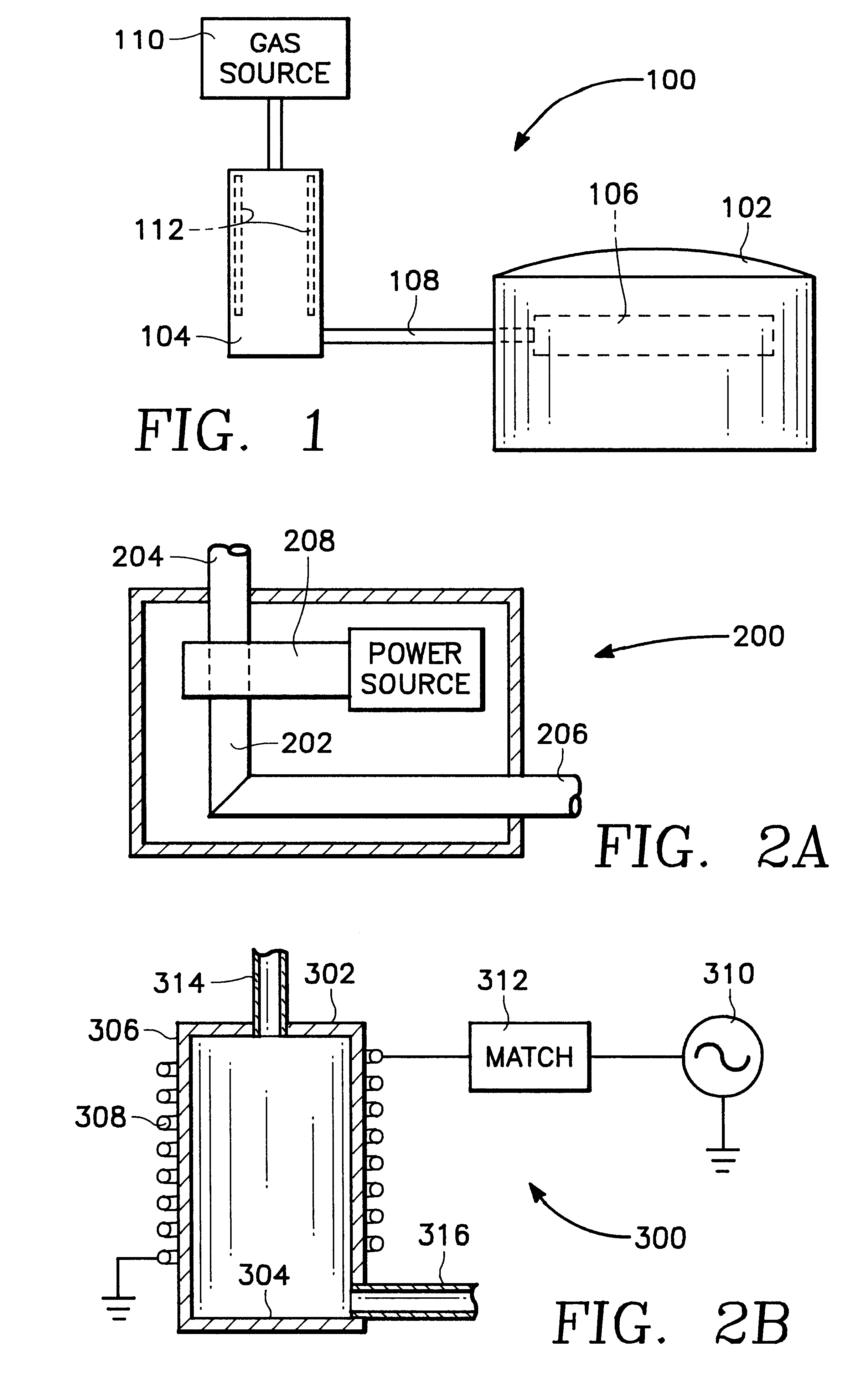

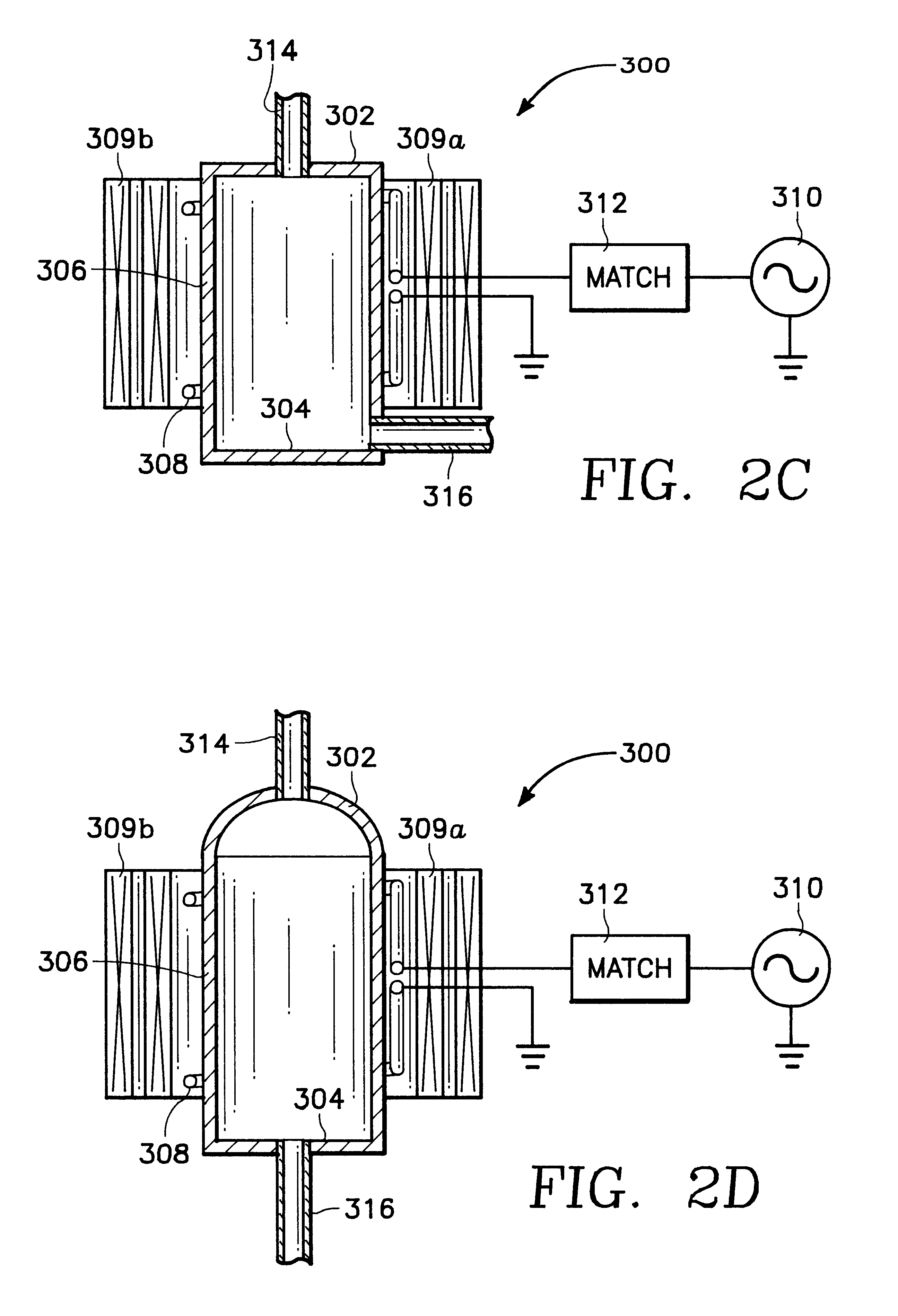

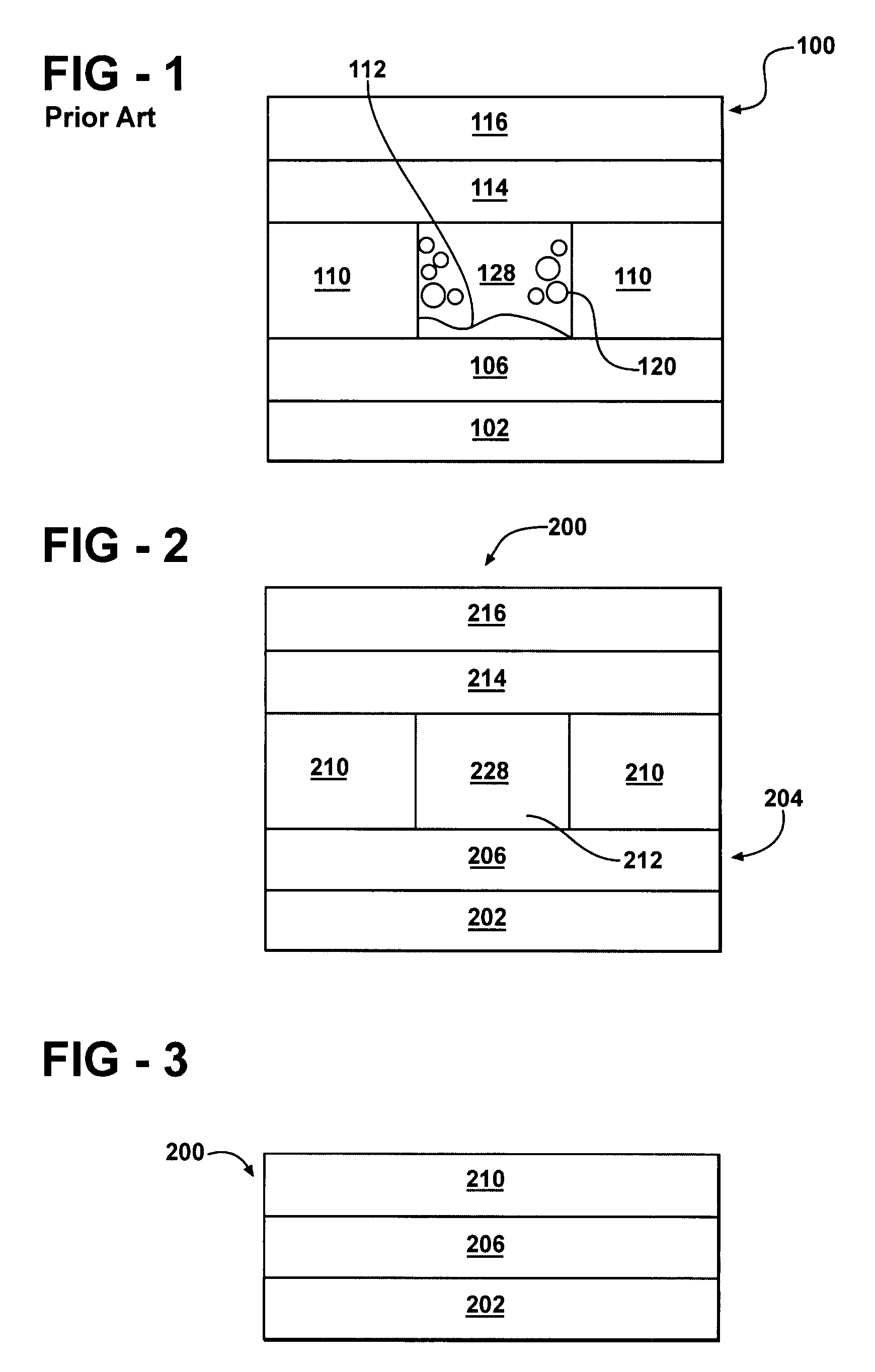

Plasma assisted processing chamber with separate control of species density

InactiveUS6352049B1Electric discharge tubesSemiconductor/solid-state device manufacturingMaterial densityPlasma glucose

The present invention provides an apparatus and method, for plasma assisted processing of a workpiece, which provides for separate control of species density within a processing plasma. The present invention has a processing chamber and at least one collateral chamber. The collateral chamber is capable of generating a collateral plasma and delivering it to the processing chamber. To control the densities of the particle species within the processing chamber the present invention may have: a filter interposed between the collateral chamber and the processing chamber, primary chamber source power, several collateral chambers providing separate inputs to the processing chamber, or combinations thereof. Collateral plasma may be: filtered, combined with primary chamber generated plasma, combined with another collateral plasma, or combinations thereof to separately control the densities of the species comprising the processing plasma.

Owner:APPLIED MATERIALS INC

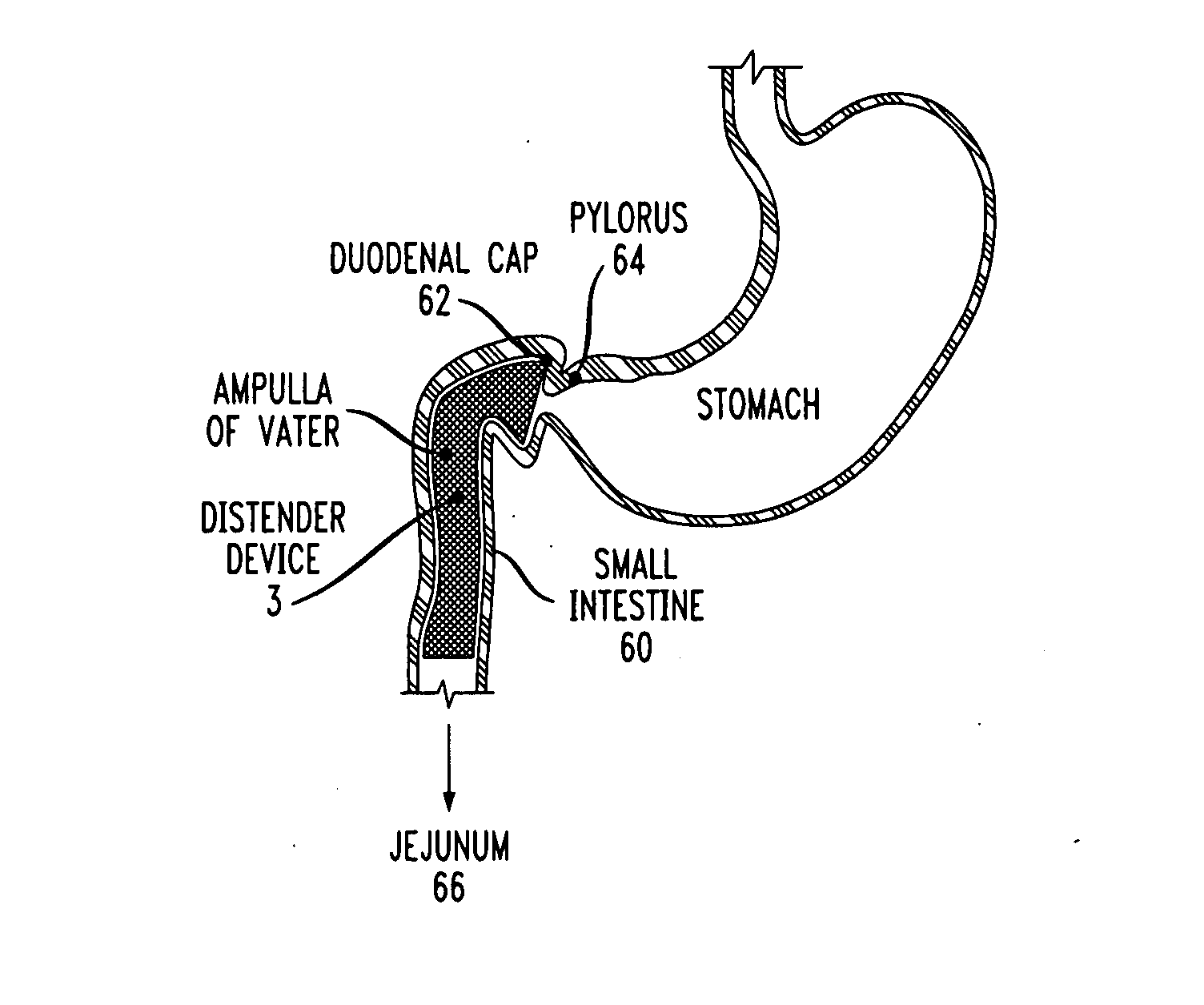

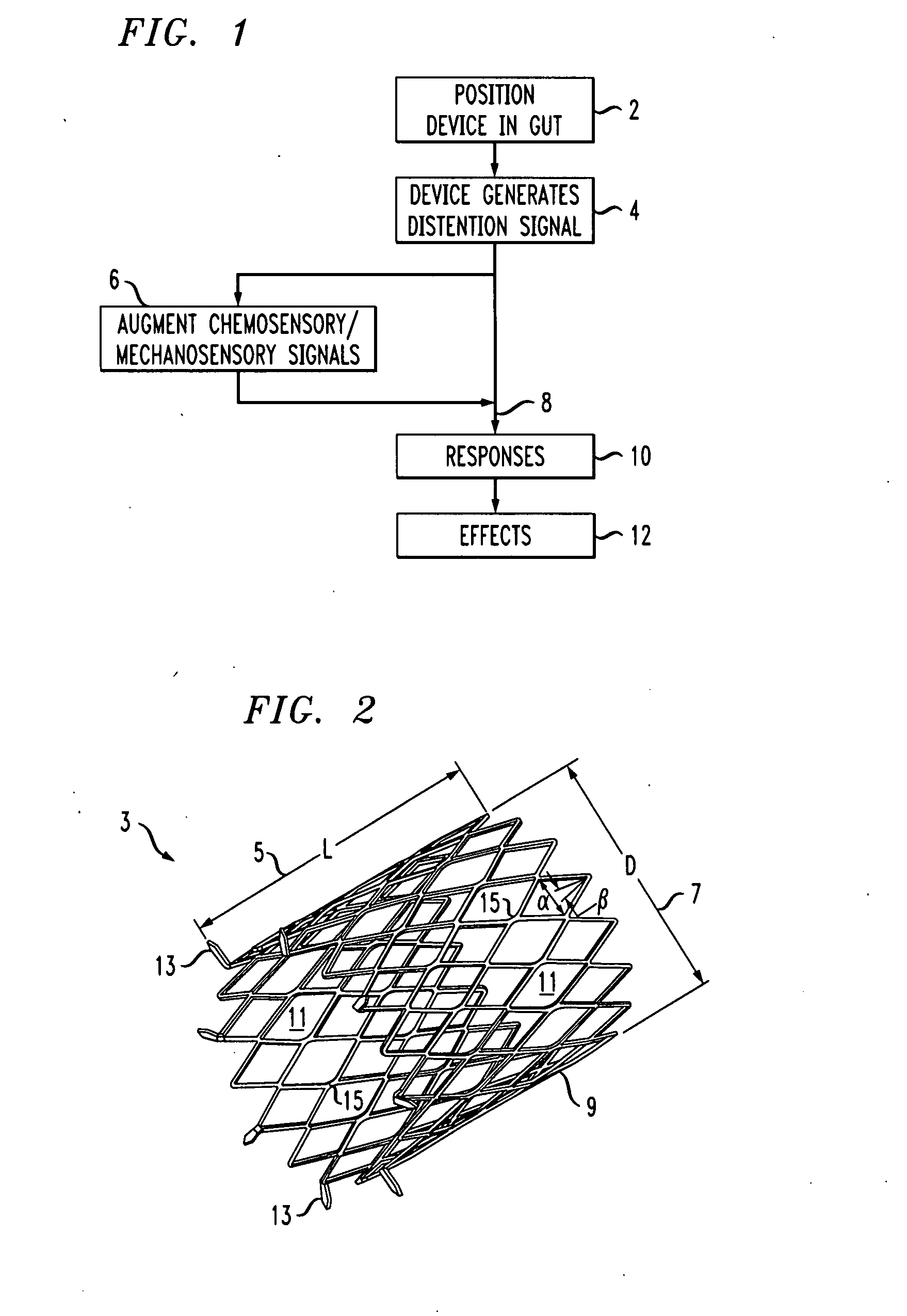

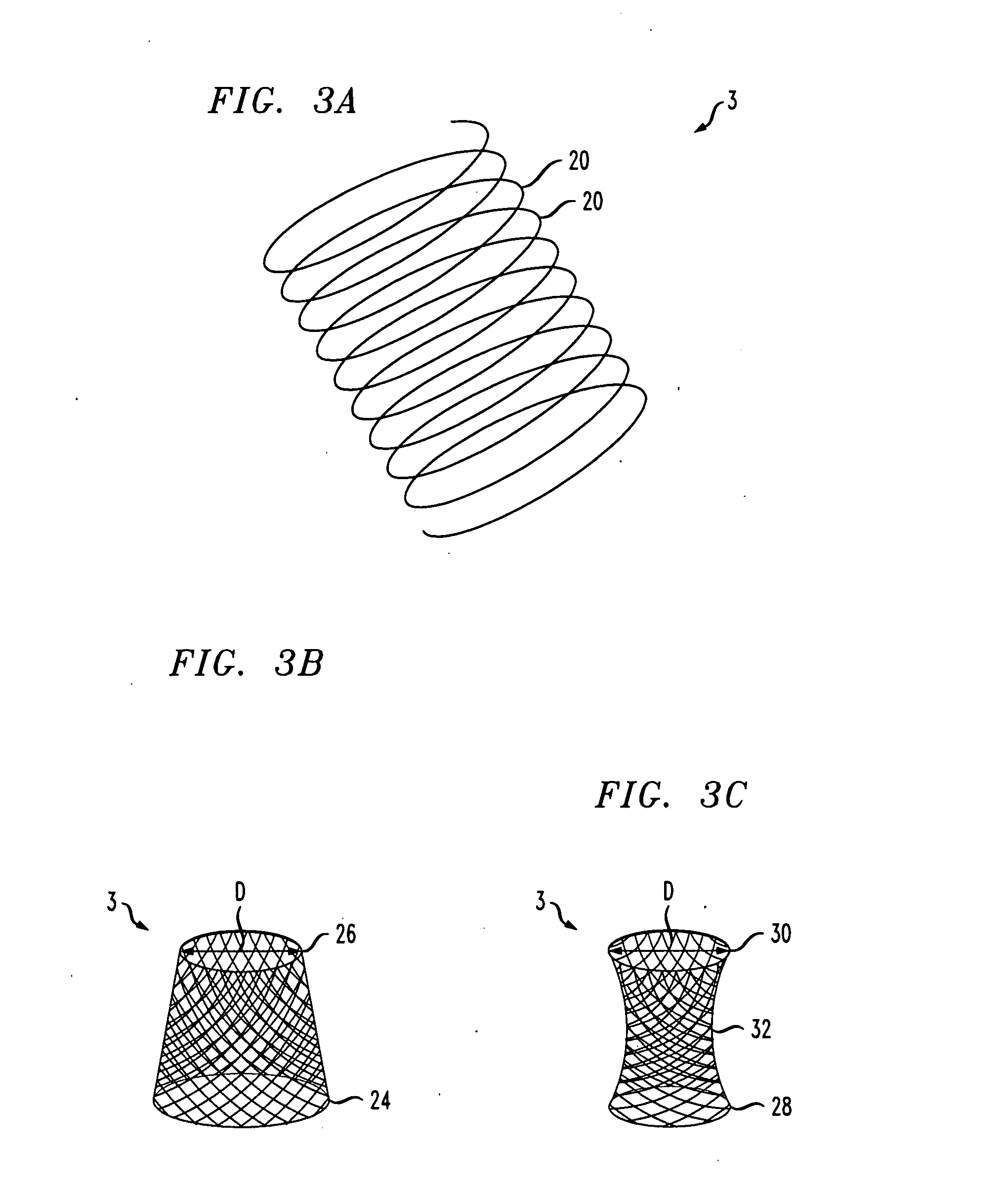

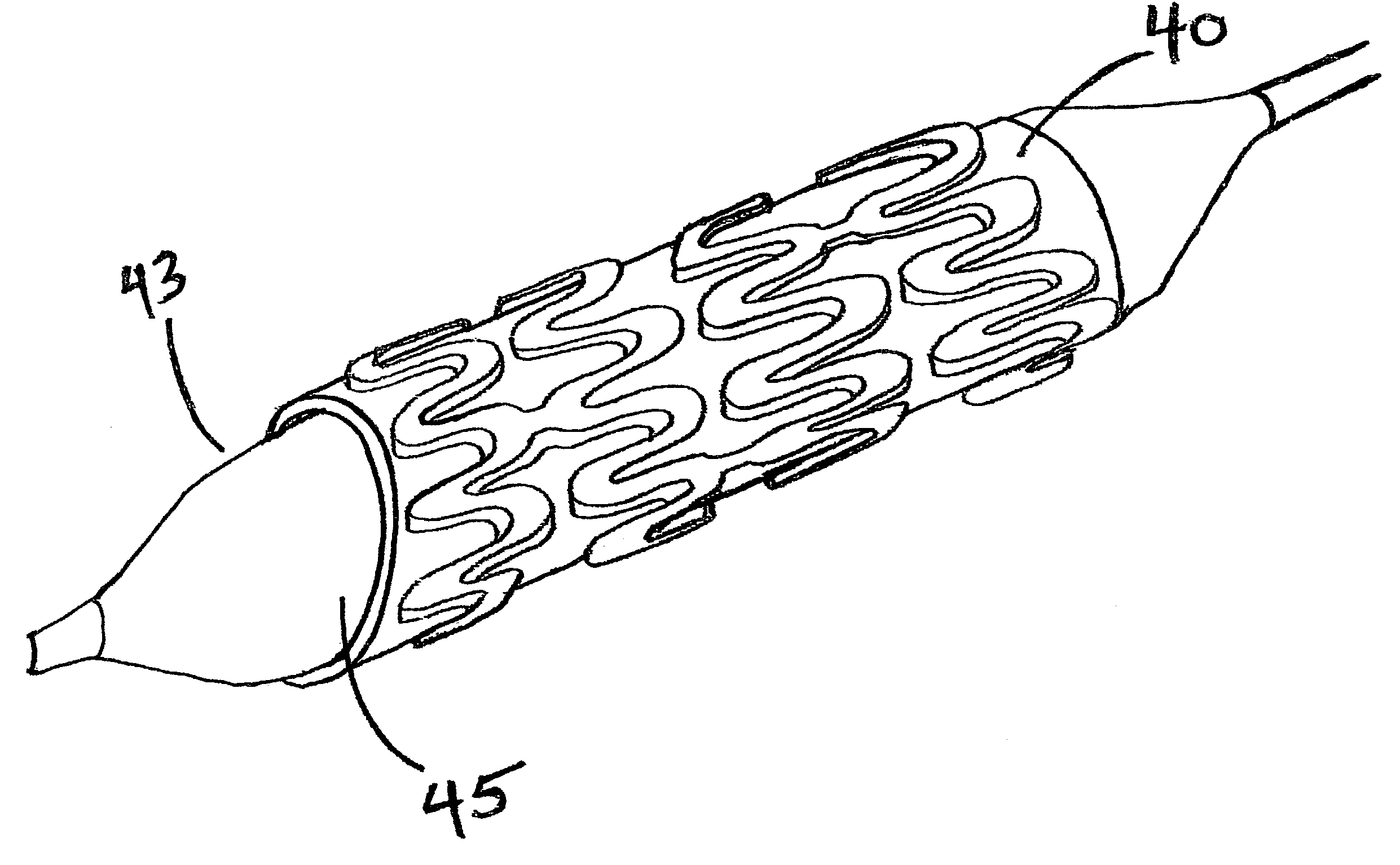

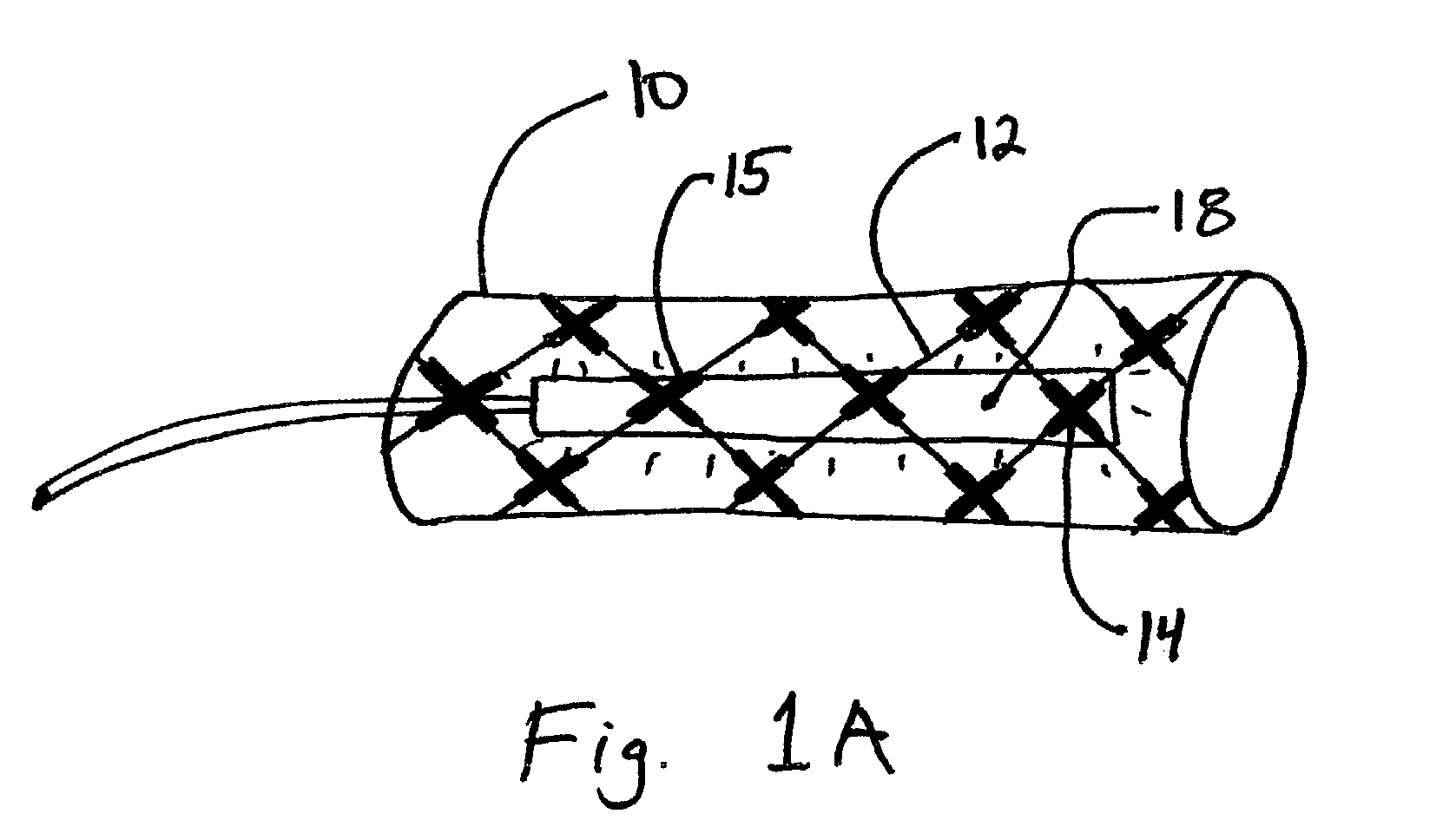

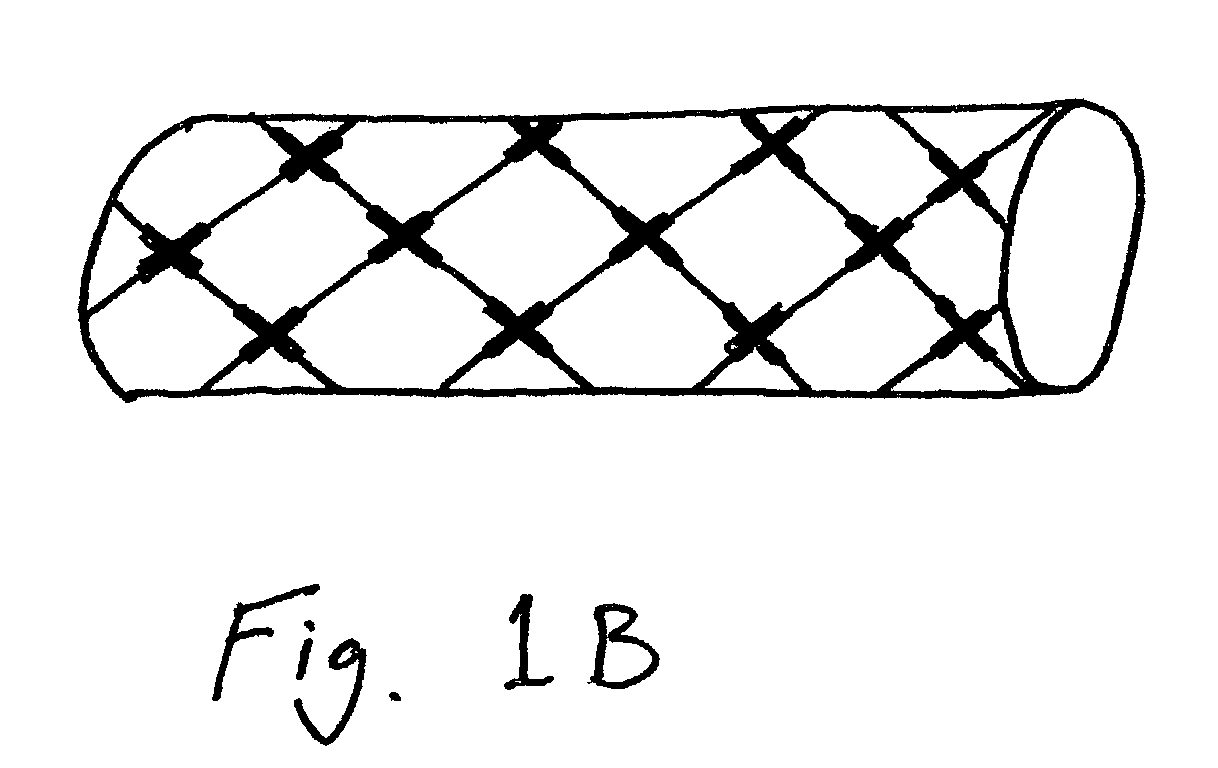

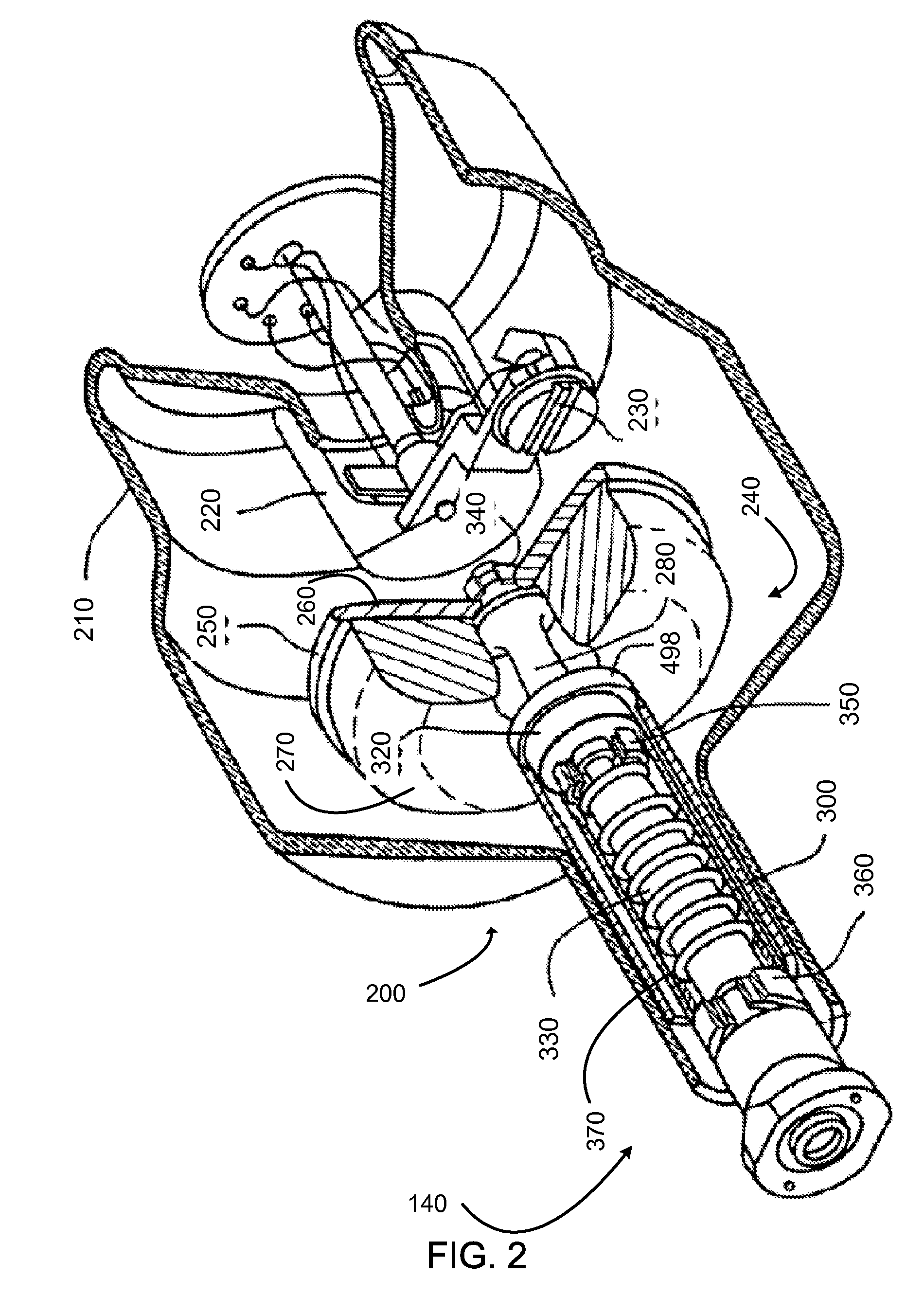

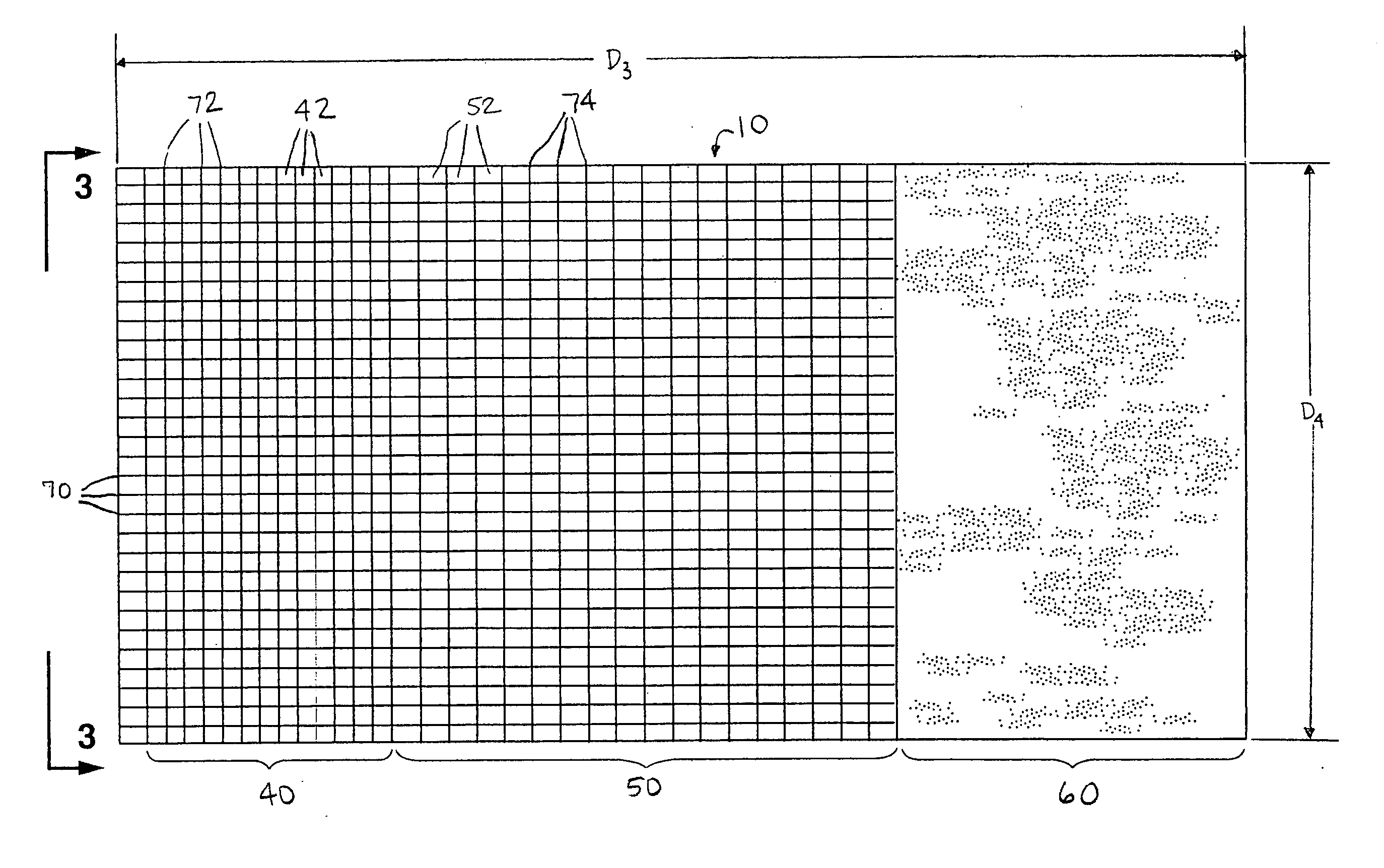

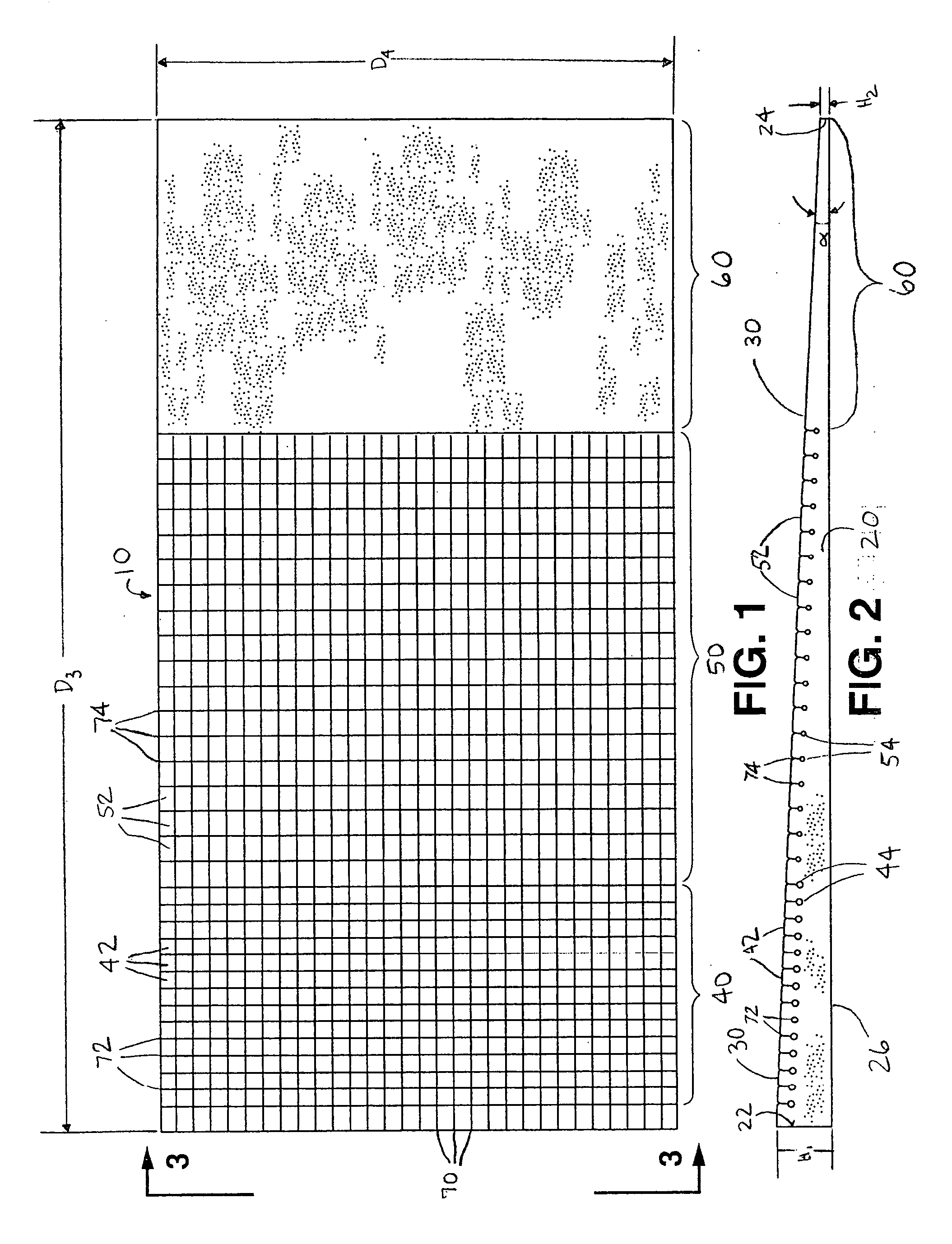

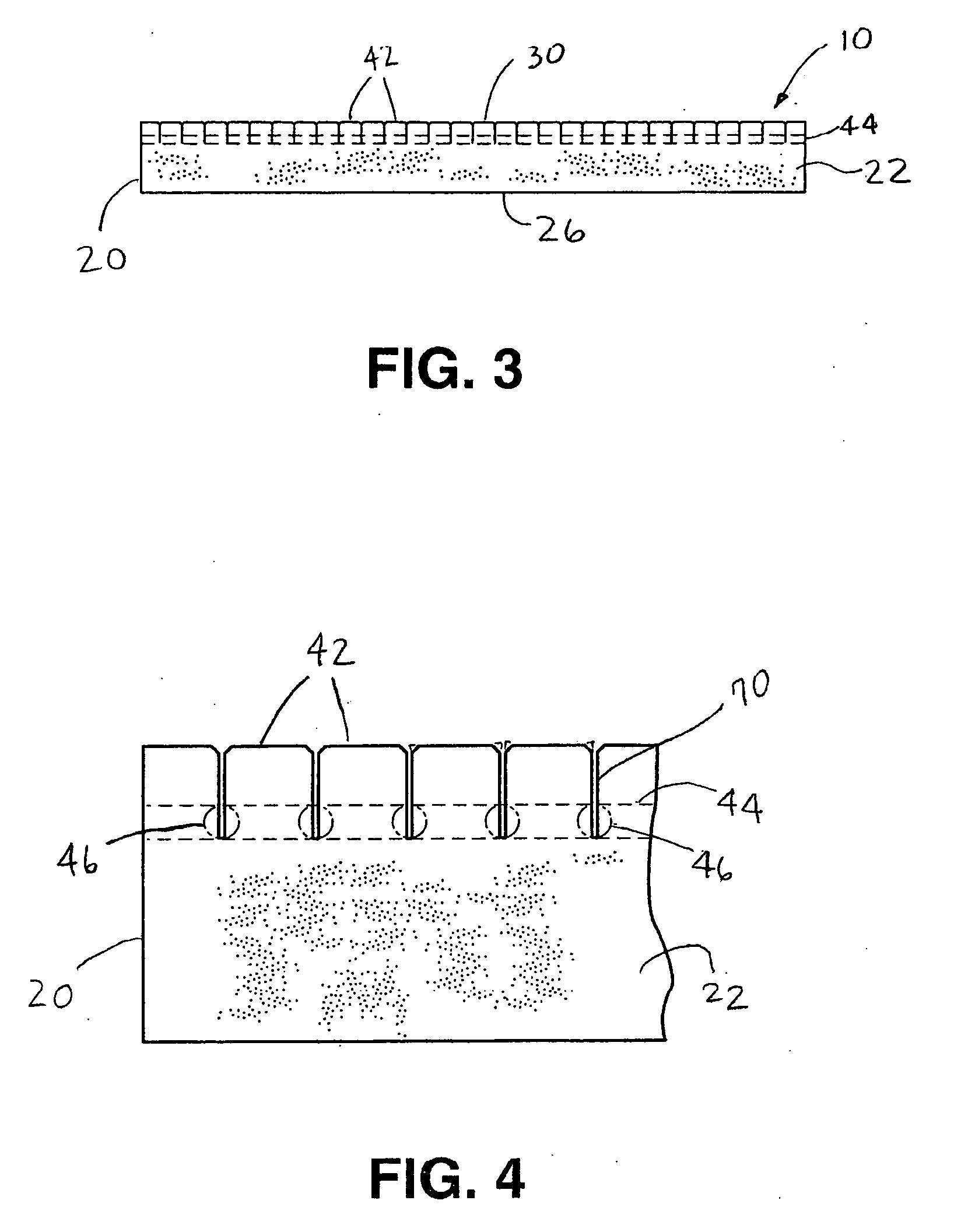

Distender device and method for treatment of obesity and metabolic and other diseases

A gastrointestinal implant device is positioned in a patient's small intestine or rectum and produces an outward force that itself produces a distension signal which is a therapeutically useful neural or humoral signal that evokes satiogenic or weight loss effects by itself. The device may advantageously be placed in the duodenum adjacent the pylorus or in the jejunum, ileum or rectum. The distension signals may amplify chemosensory or mechanosensory signals such as enteroendocrine secretions within the patient. The device may be a mesh and include a low material density that allows for unrestricted chyme absorption within the small intestine and unrestricted chyme flow through the gastrointestinal system. A method includes inserting the device into the patient then either retrieving the device after treatment is complete or allowing a device formed of a biodegradable material to degrade in time after treatment is complete.

Owner:ADVANCED NEUROMODULATION SYST INC

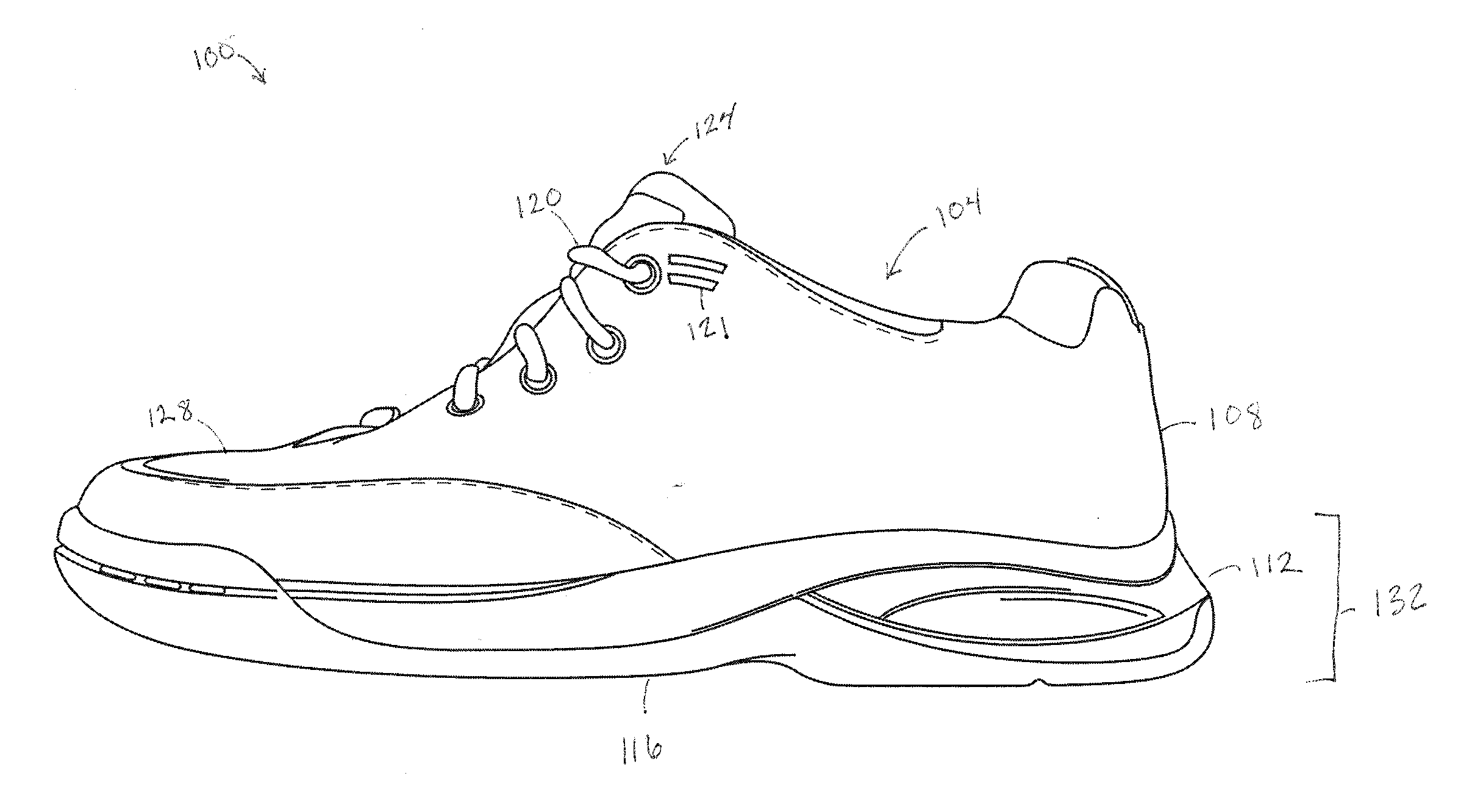

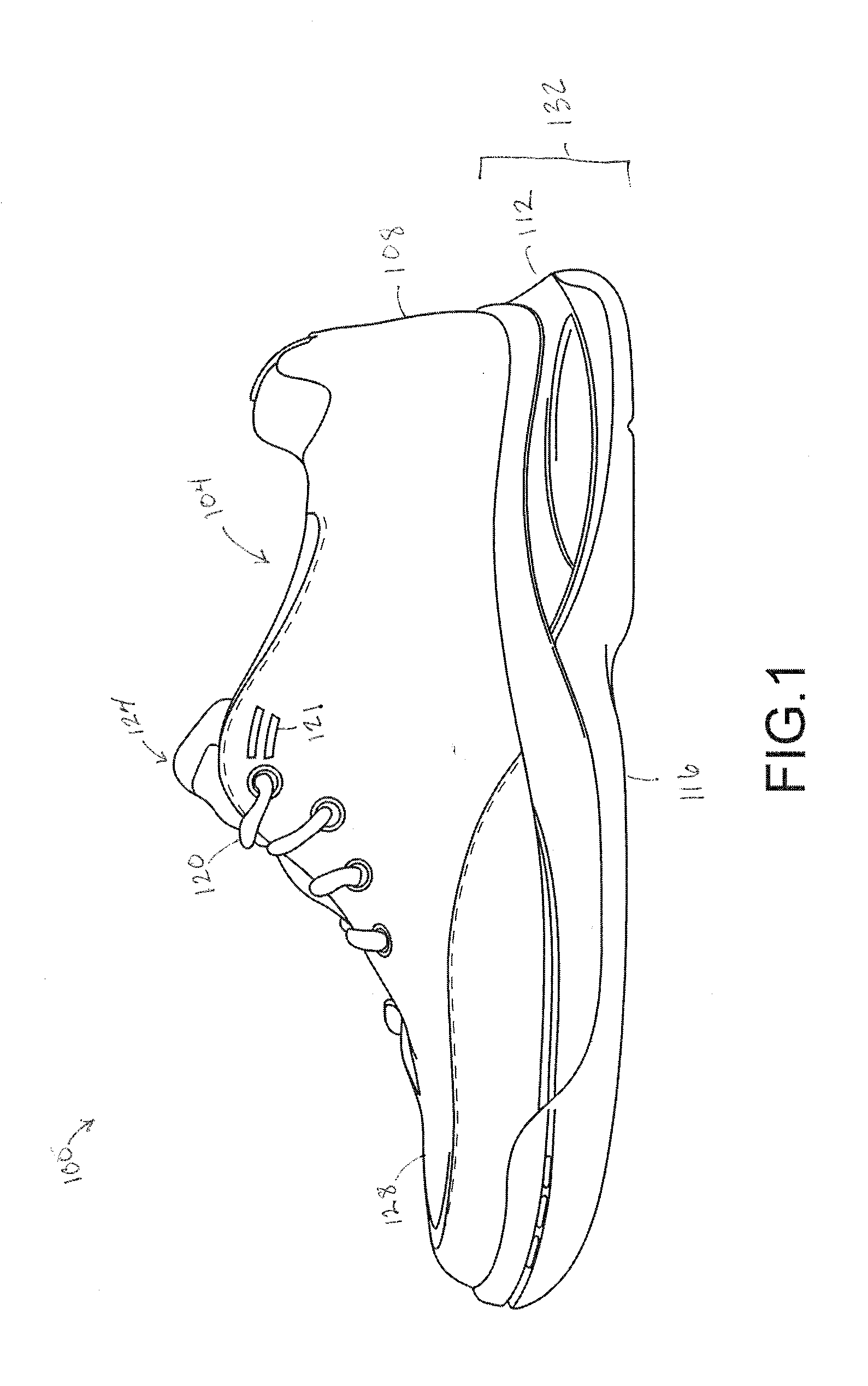

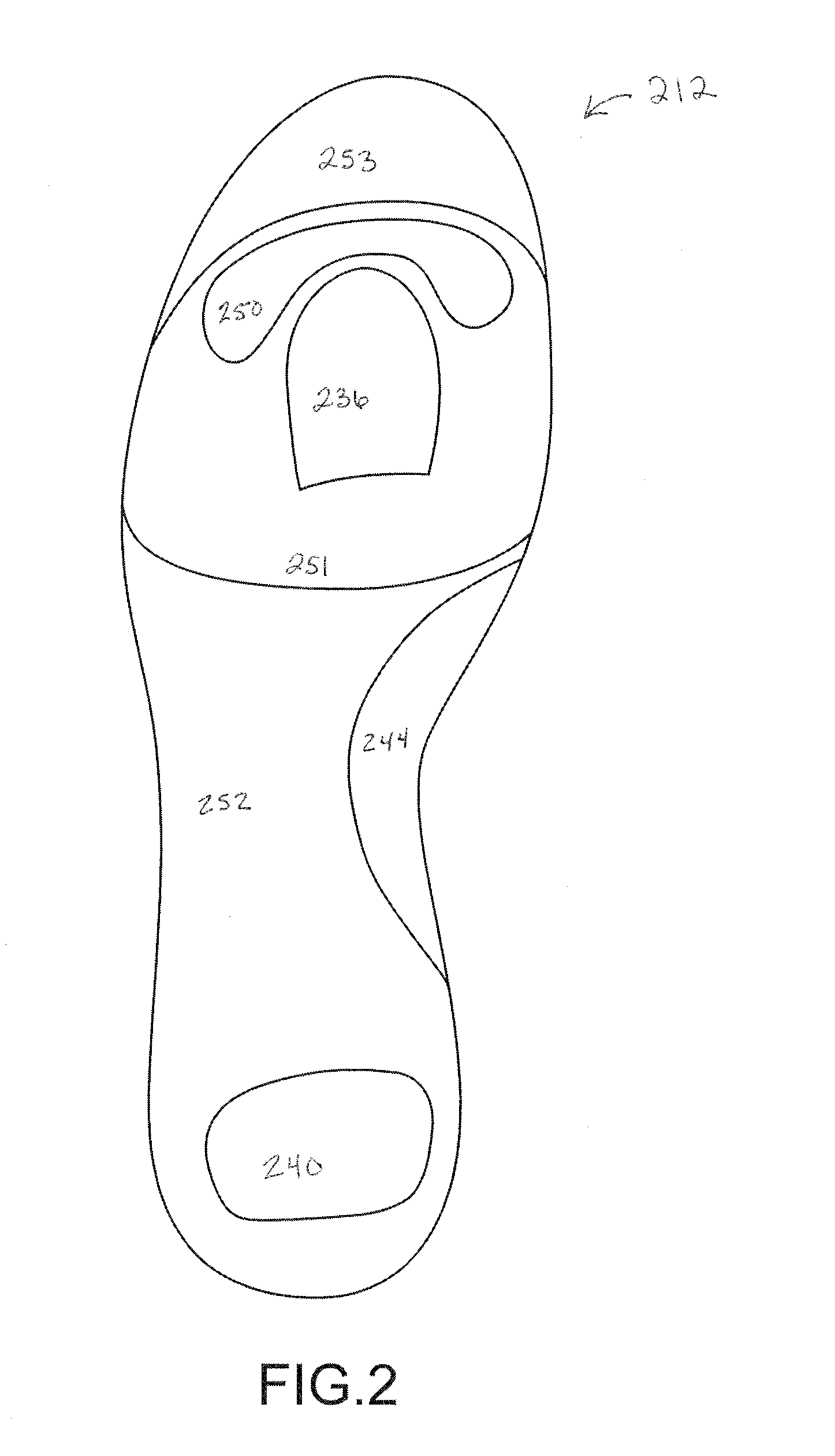

Dual rigidity shoe sole

InactiveUS20120000095A1Efficient transfer of energyReduce energy lossSolesUpperEngineeringMaterial density

Owner:DASHAMERICA

Photocurable endoprosthesis system

Novel endoprostheses comprising one or more photocurable materials are disclosed. Said endoprostheses may comprise regions wherein said photocurable materials are selectively disposed about said endoprosthesis and are cured according to desired parameters to achieve varying desired properties. Said properties may include but are not limited to cross-linking density, material density, modulus of elasticity, rate of erosion, extensibility, compressibility, mechanical strength, tensile strength, crystallinity, diffusion coefficient, and permeability.

Owner:SYNECOR LLC

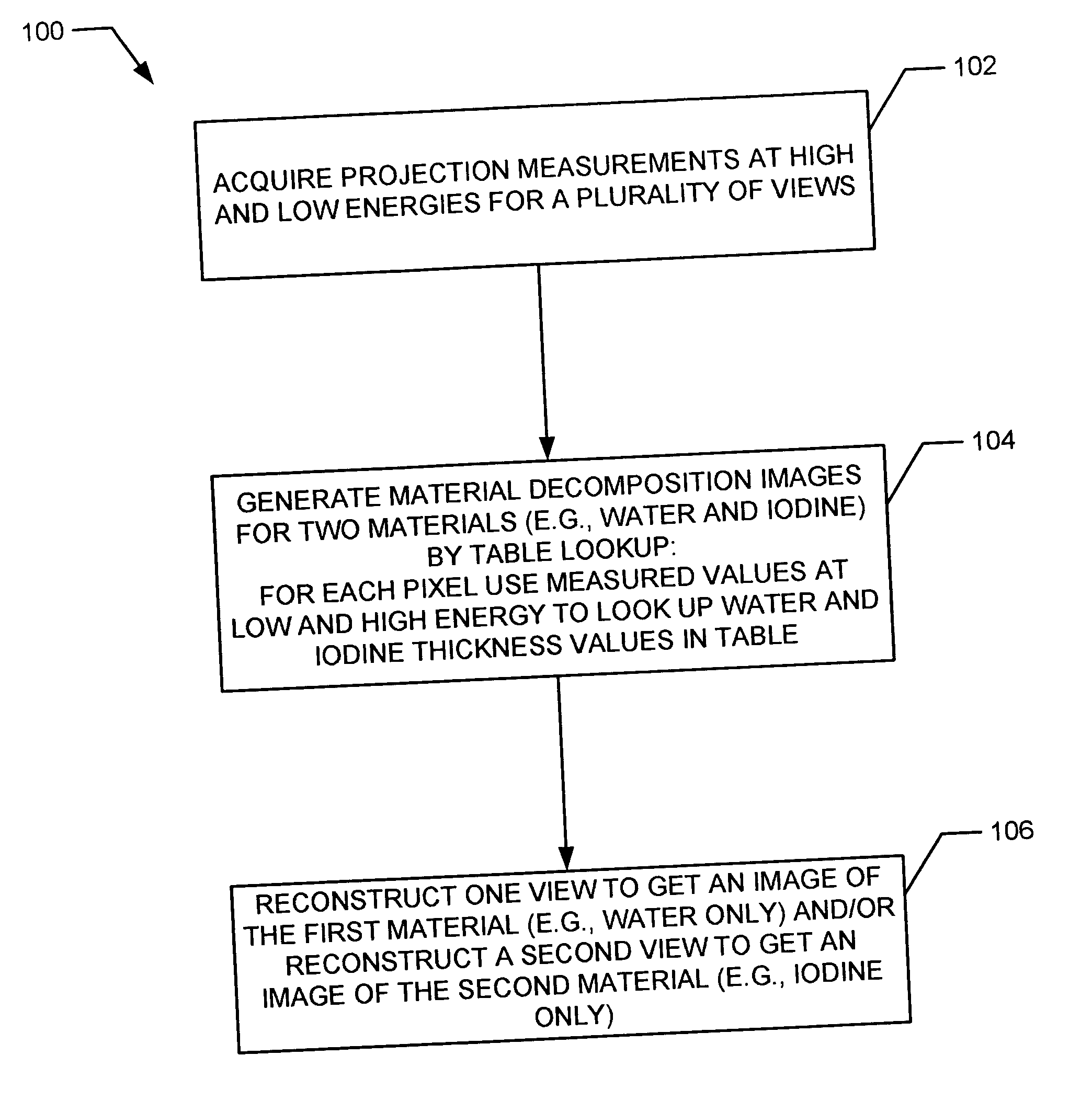

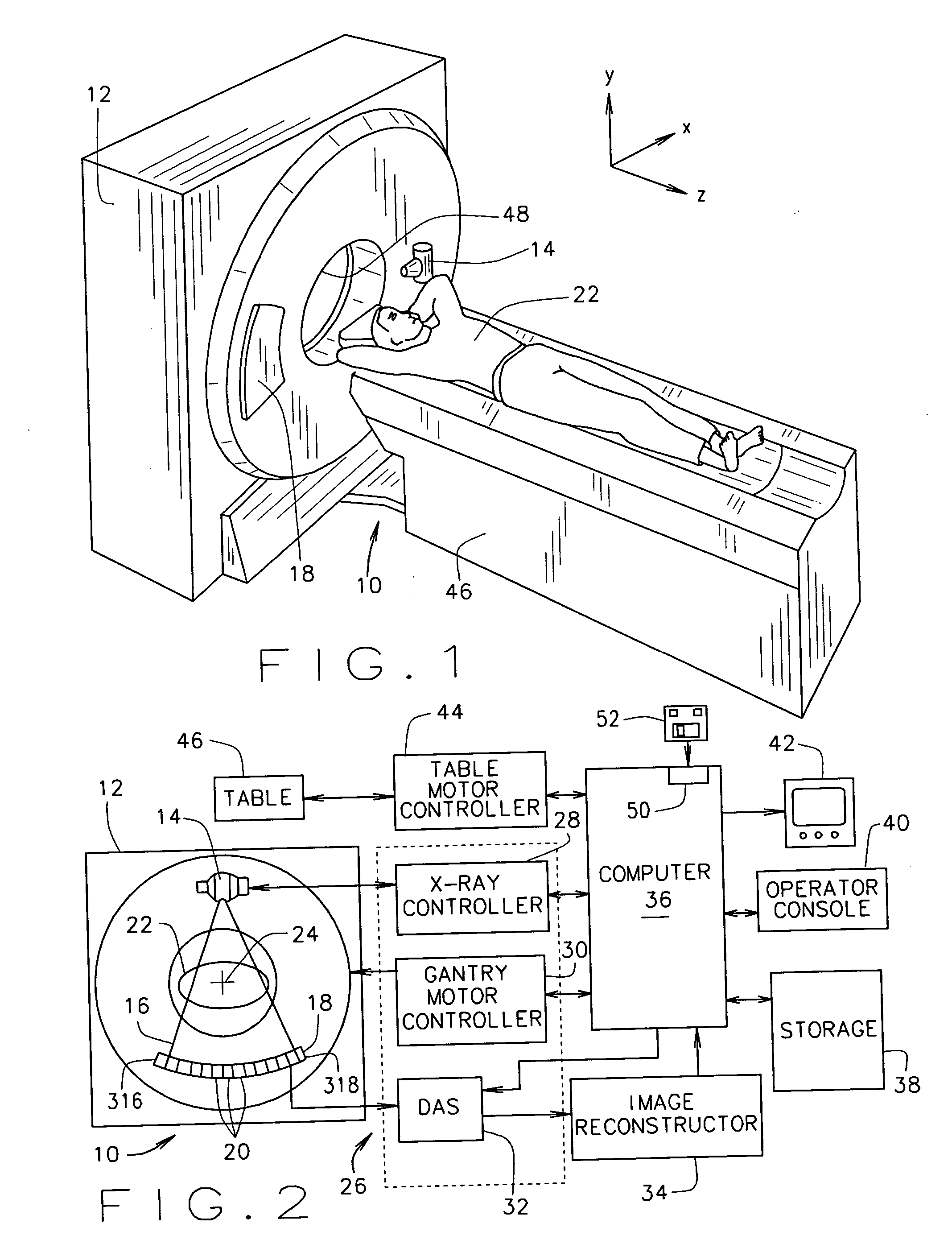

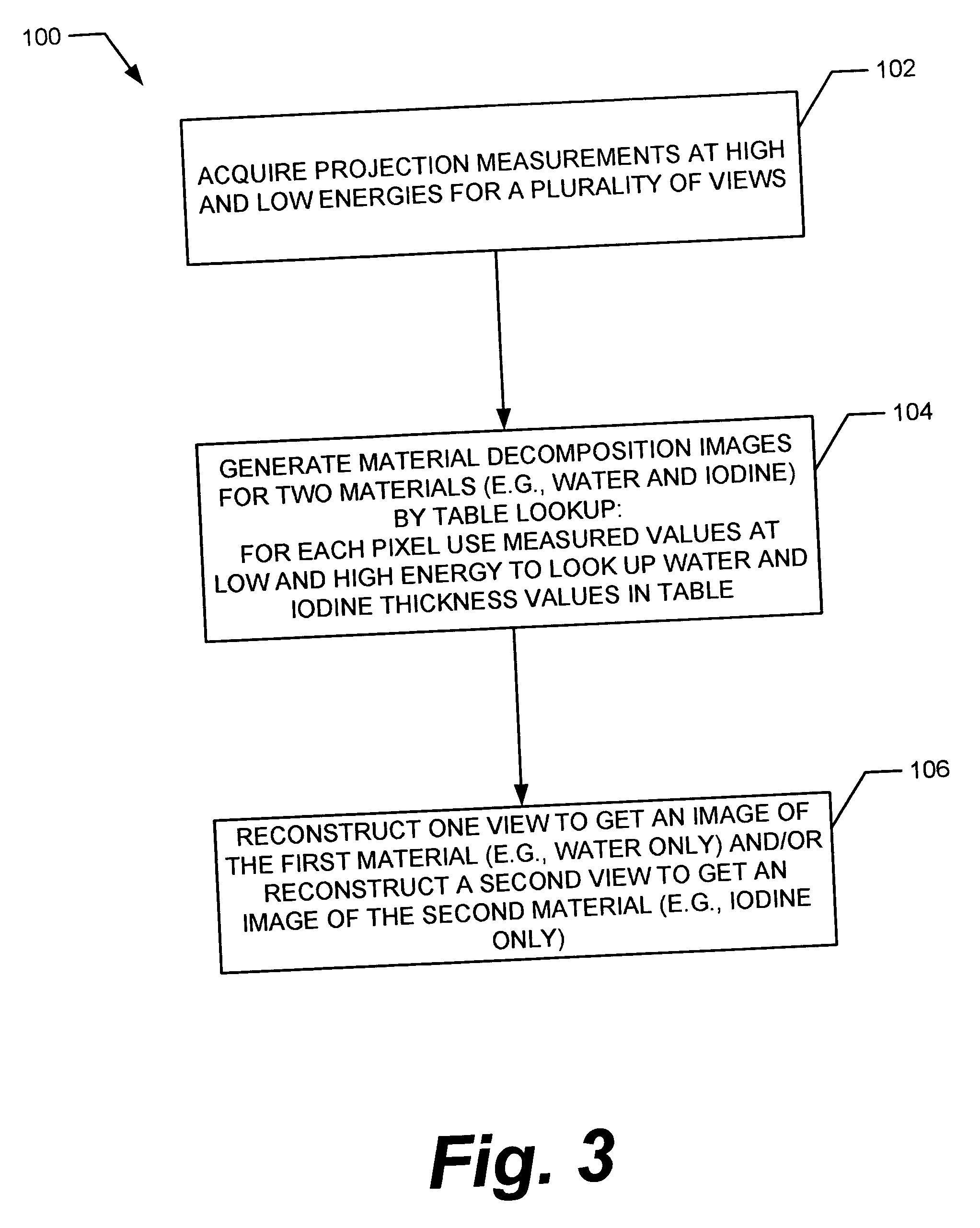

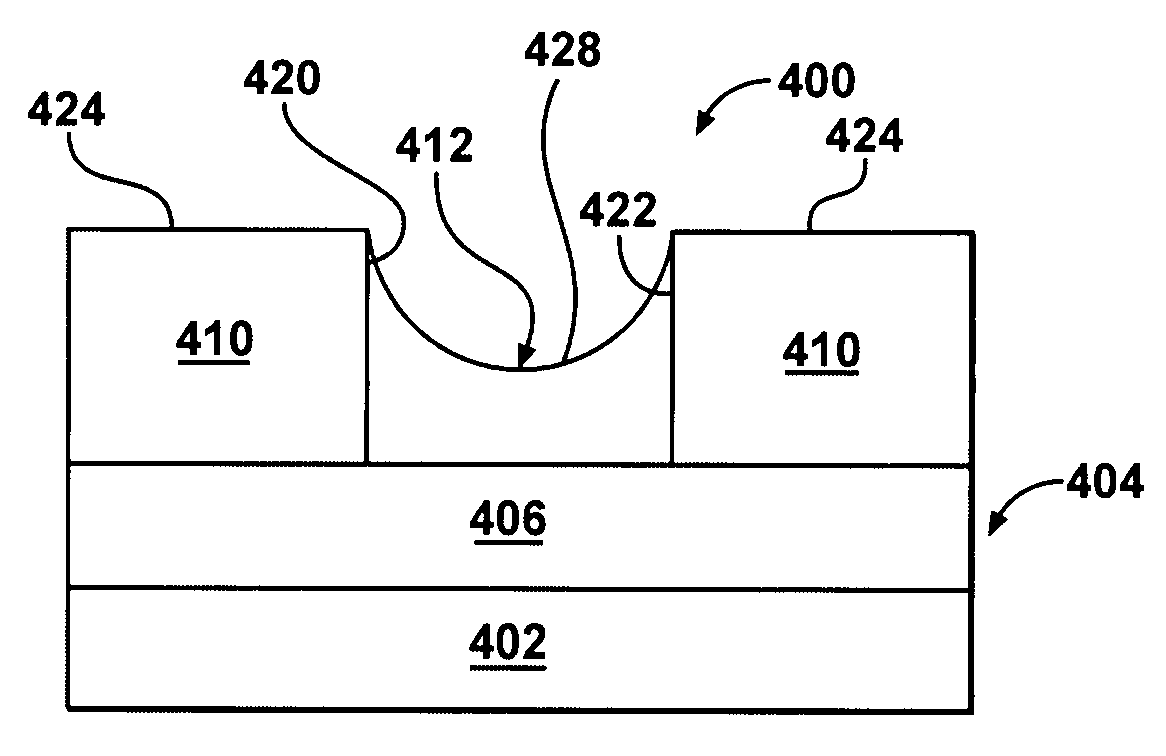

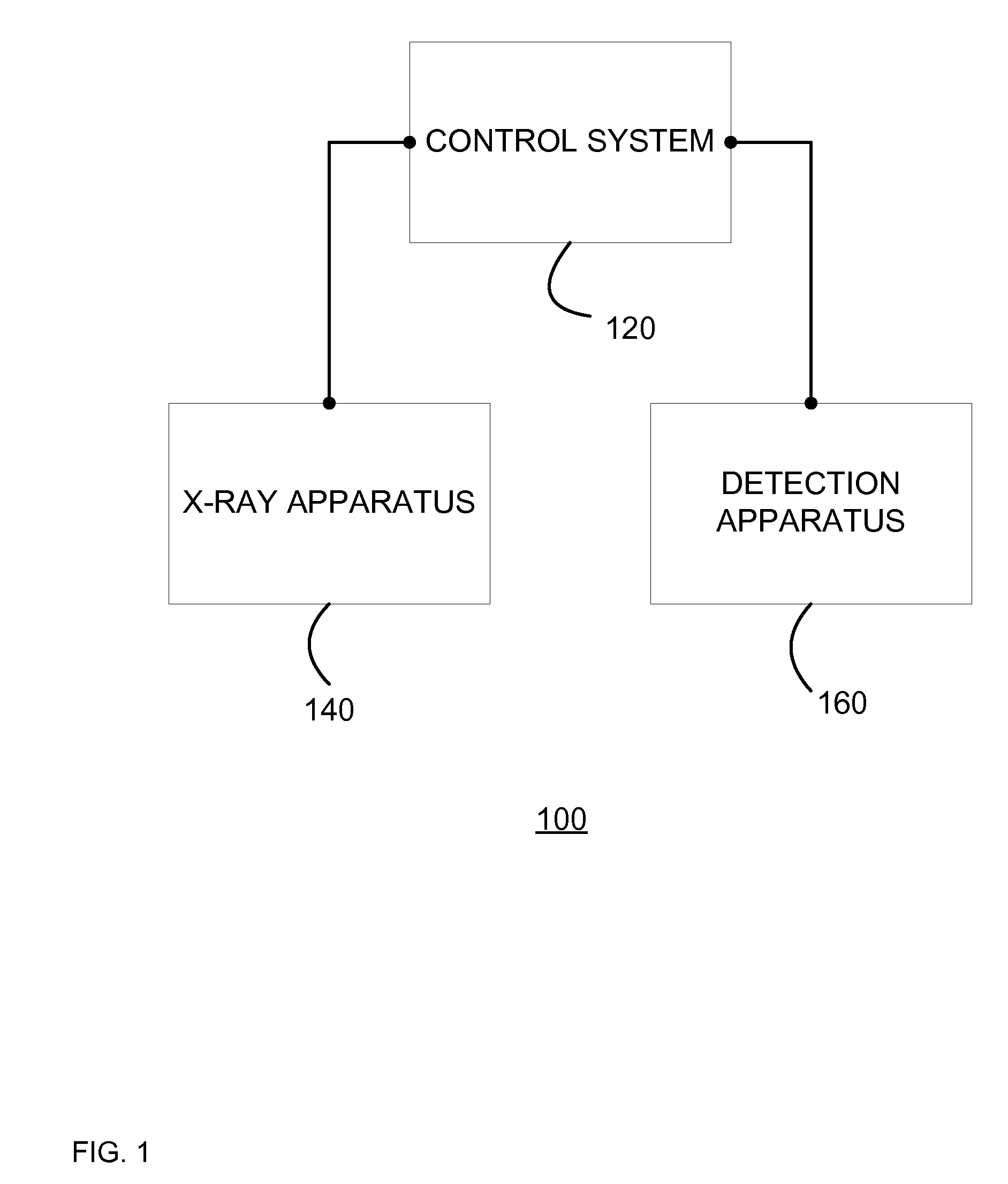

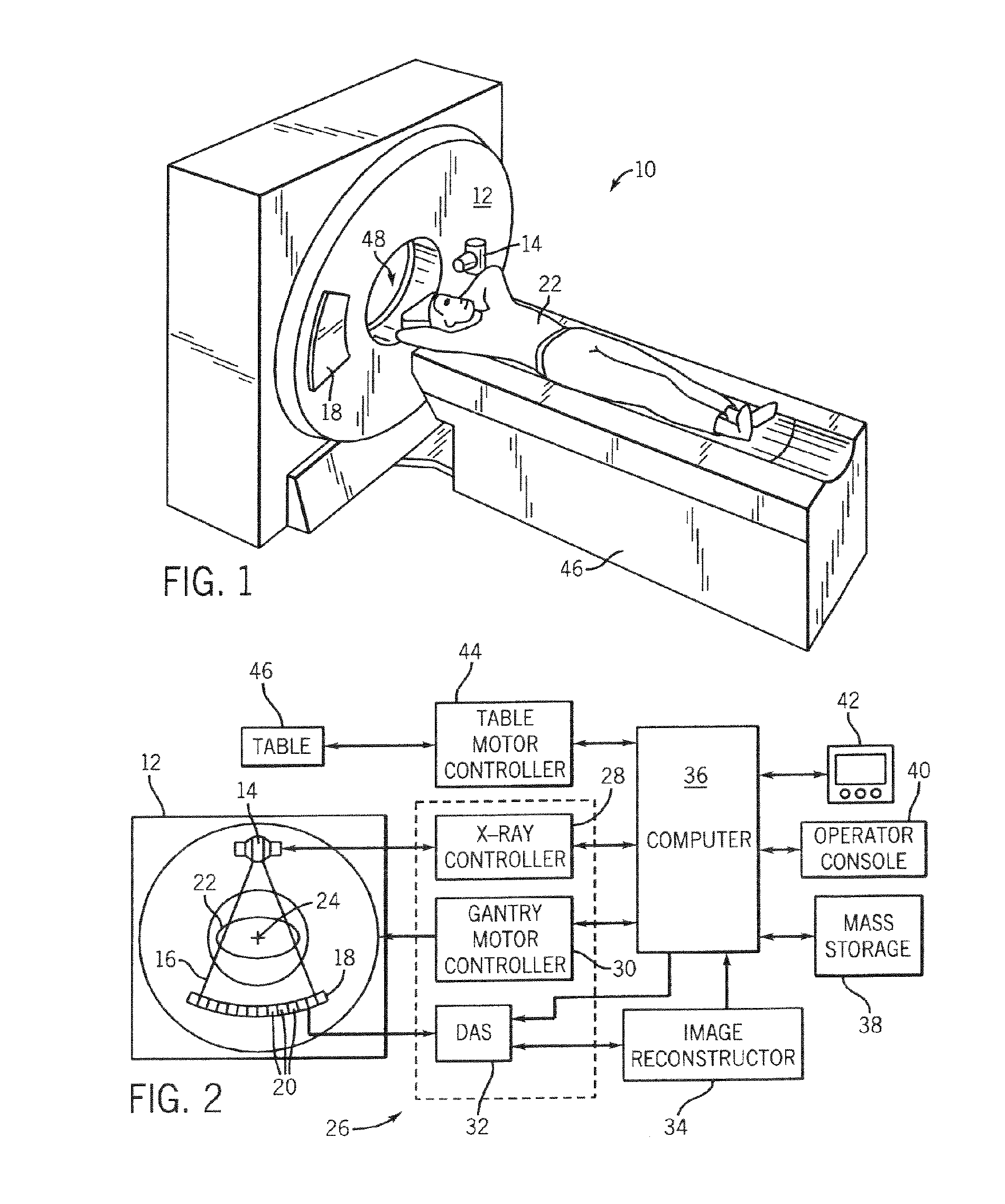

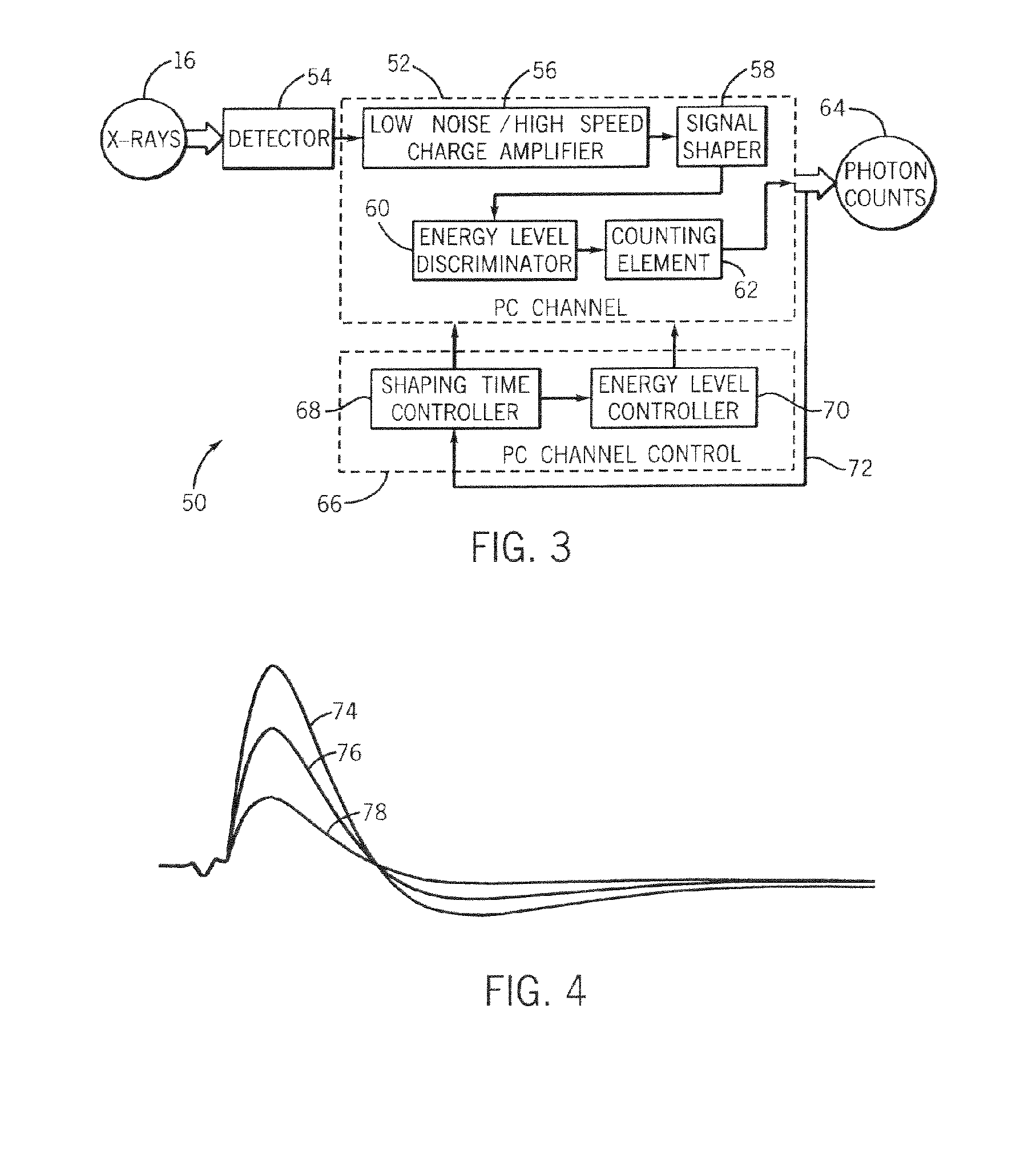

Methods and apparatus for identification and imaging of specific materials

InactiveUS20050084069A1Easy to quantifyImprove visibilityRadiation/particle handlingComputerised tomographsHigh energyData acquisition

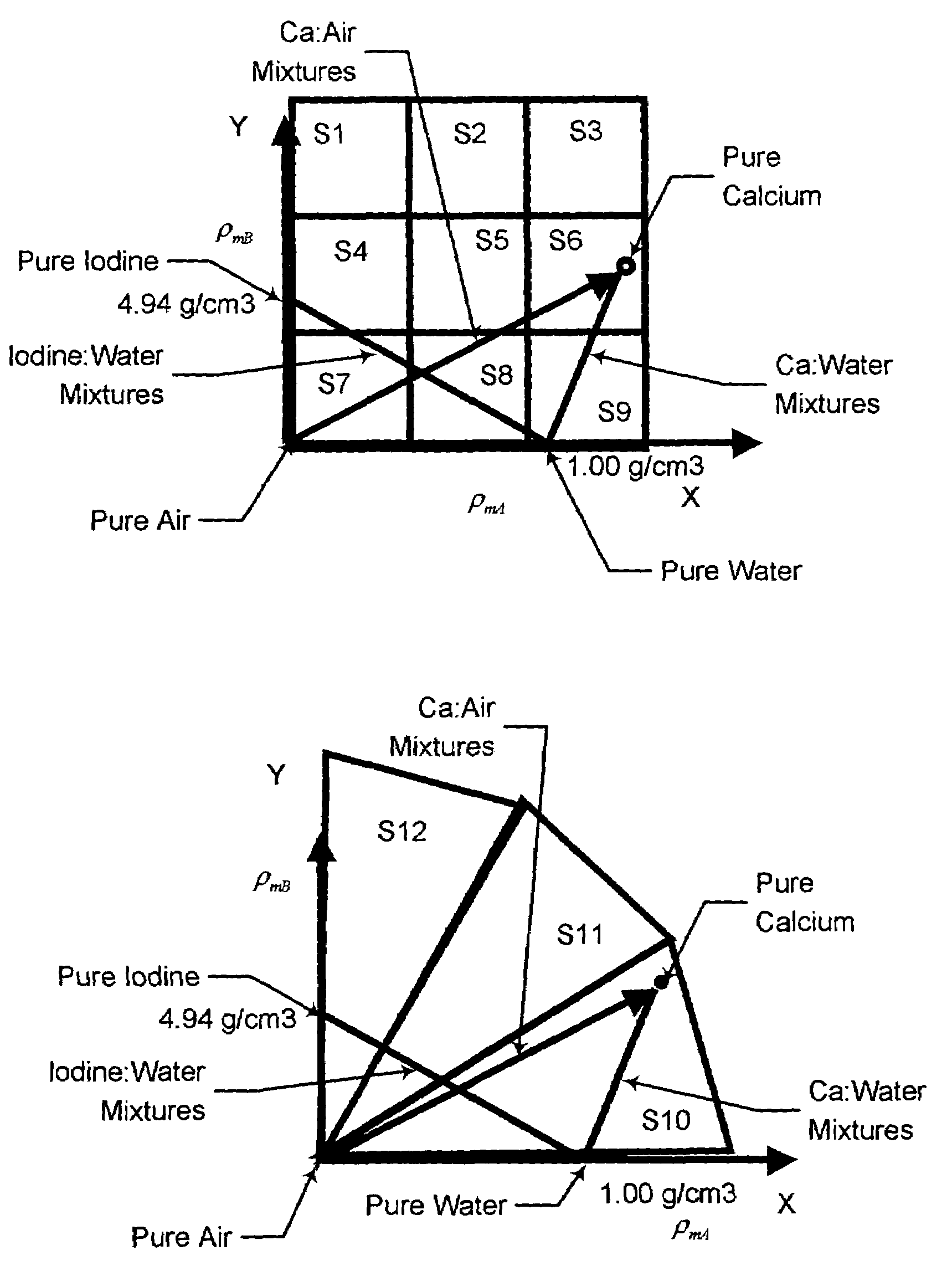

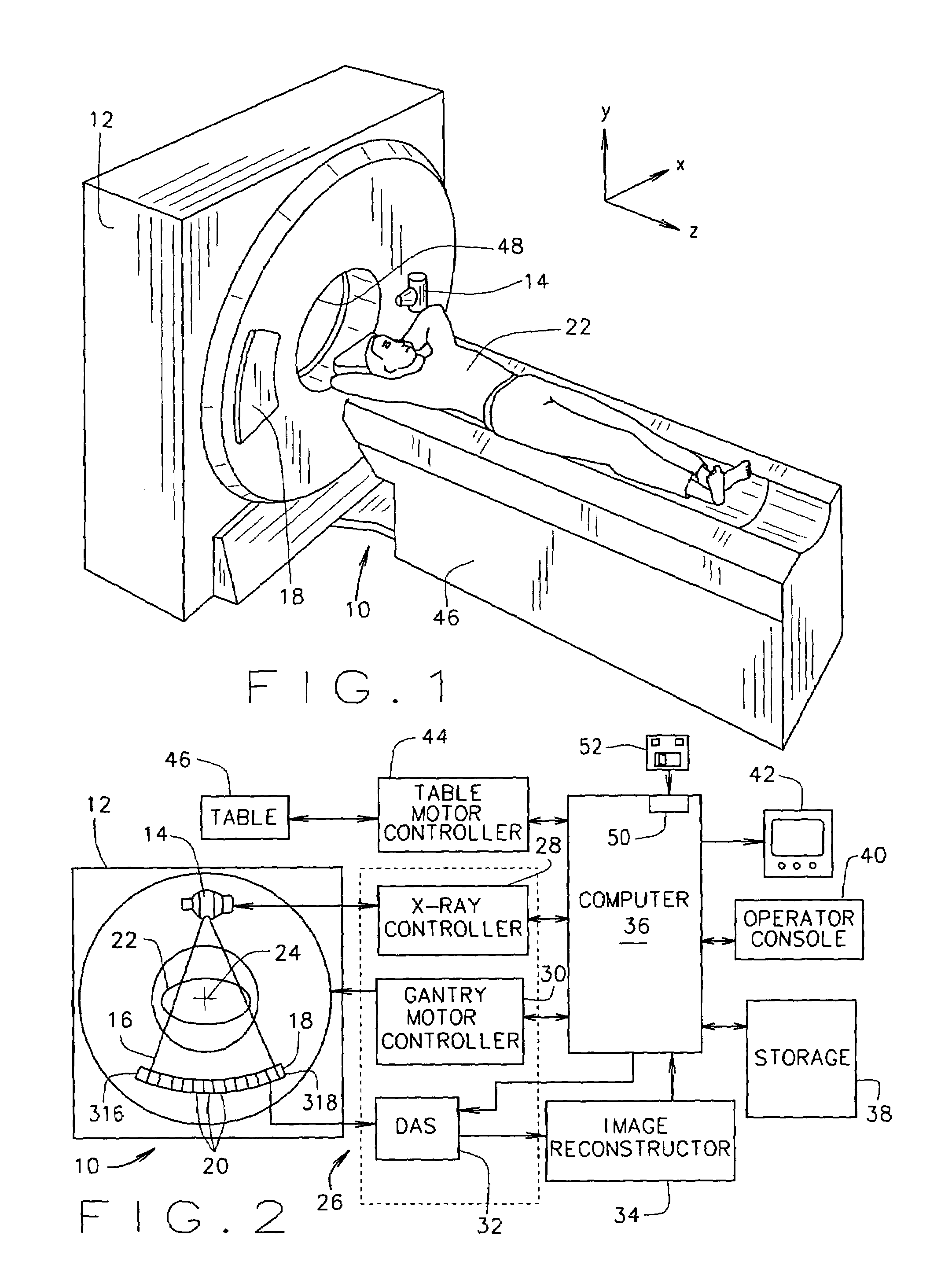

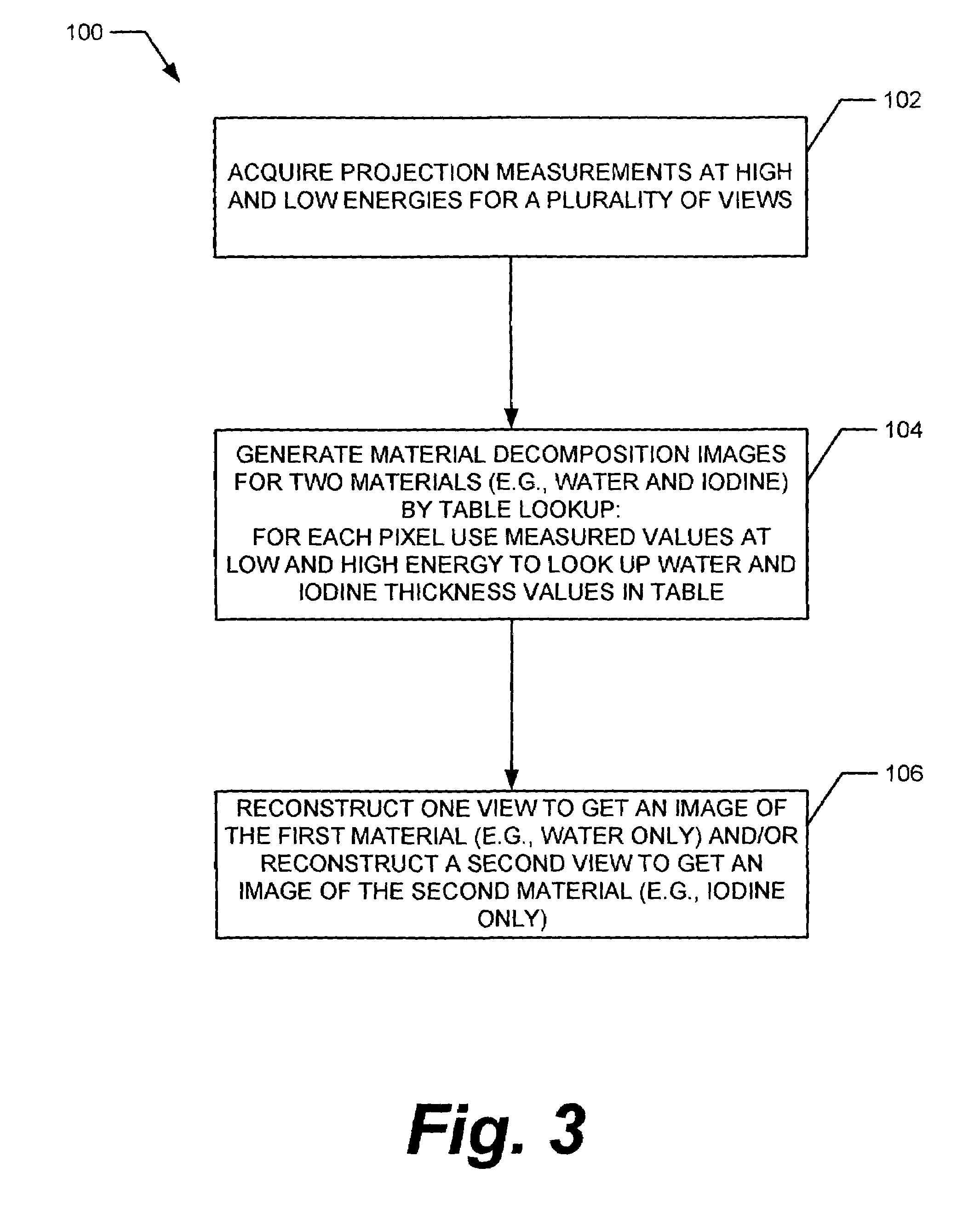

A method for analyzing materials in an object includes acquiring x-ray projection data of the object at high energy and at low energy for a plurality of views. The acquired x-ray projection data is utilized in a material decomposition to determine material densities at each pixel for two selected basis materials. A composition of an object at each pixel is determined utilizing a determined mapping of material density regions for the two selected basis materials. An image indicative of the composition of the object is displayed utilizing the determined composition.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Liquid phase deposition of contacts in programmable resistance and switching devices

ActiveUS7566643B2High densityHigh resistivitySemiconductor/solid-state device manufacturingComposite electrodeConductive materials

Owner:OVONYX MEMORY TECH LLC

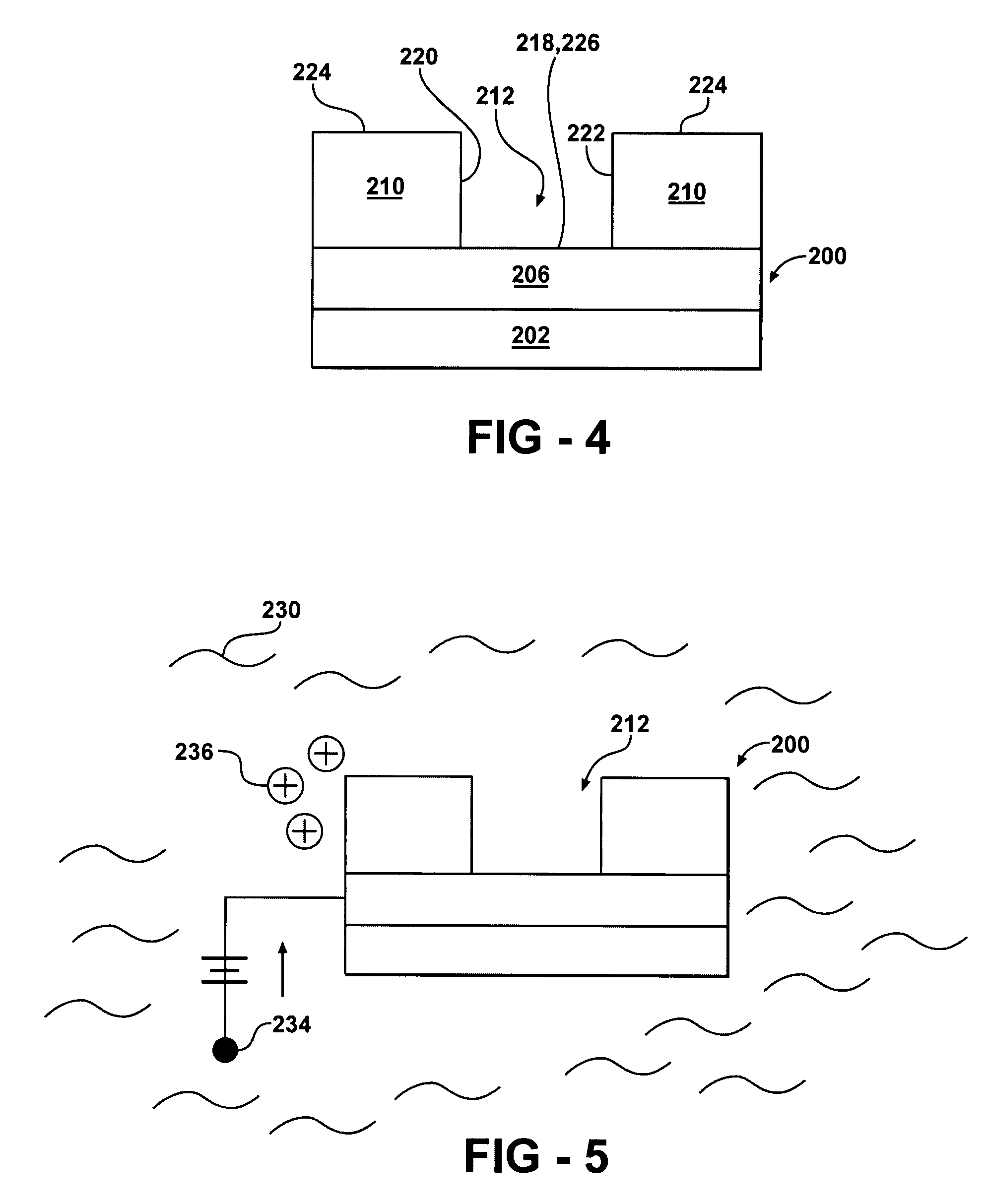

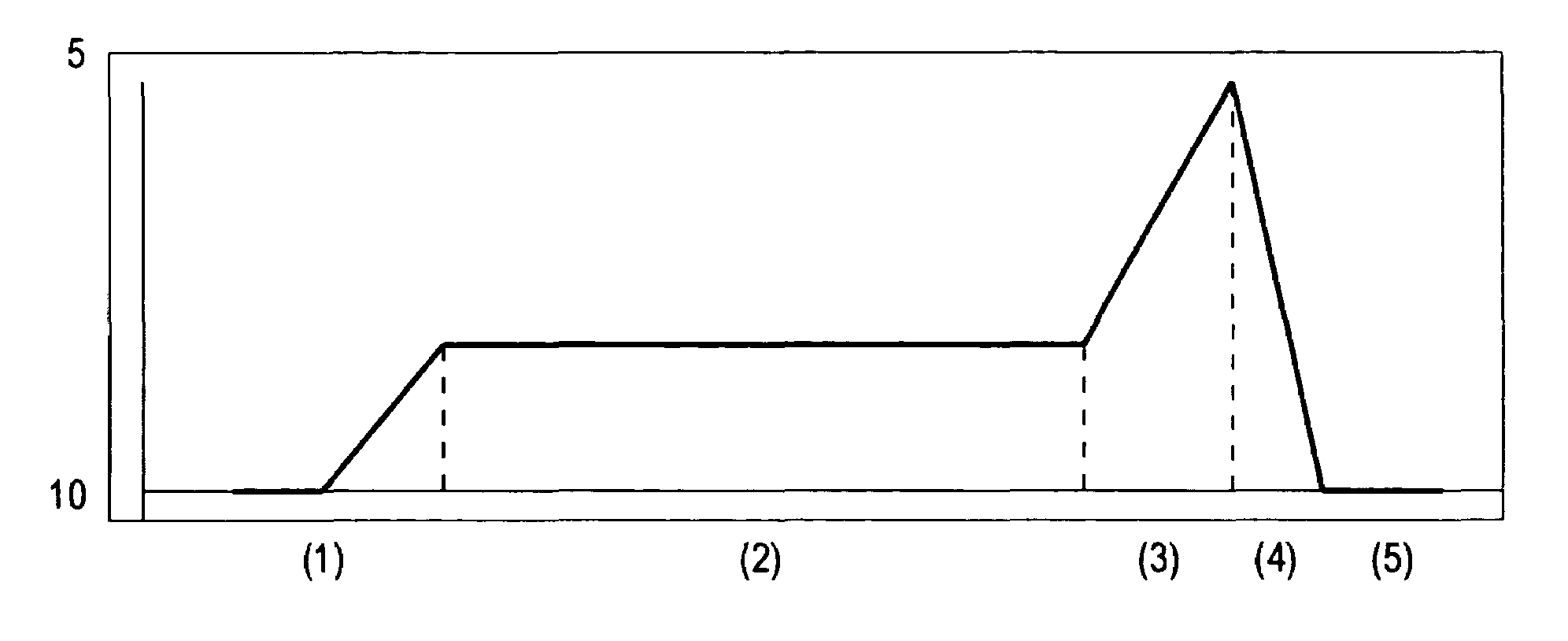

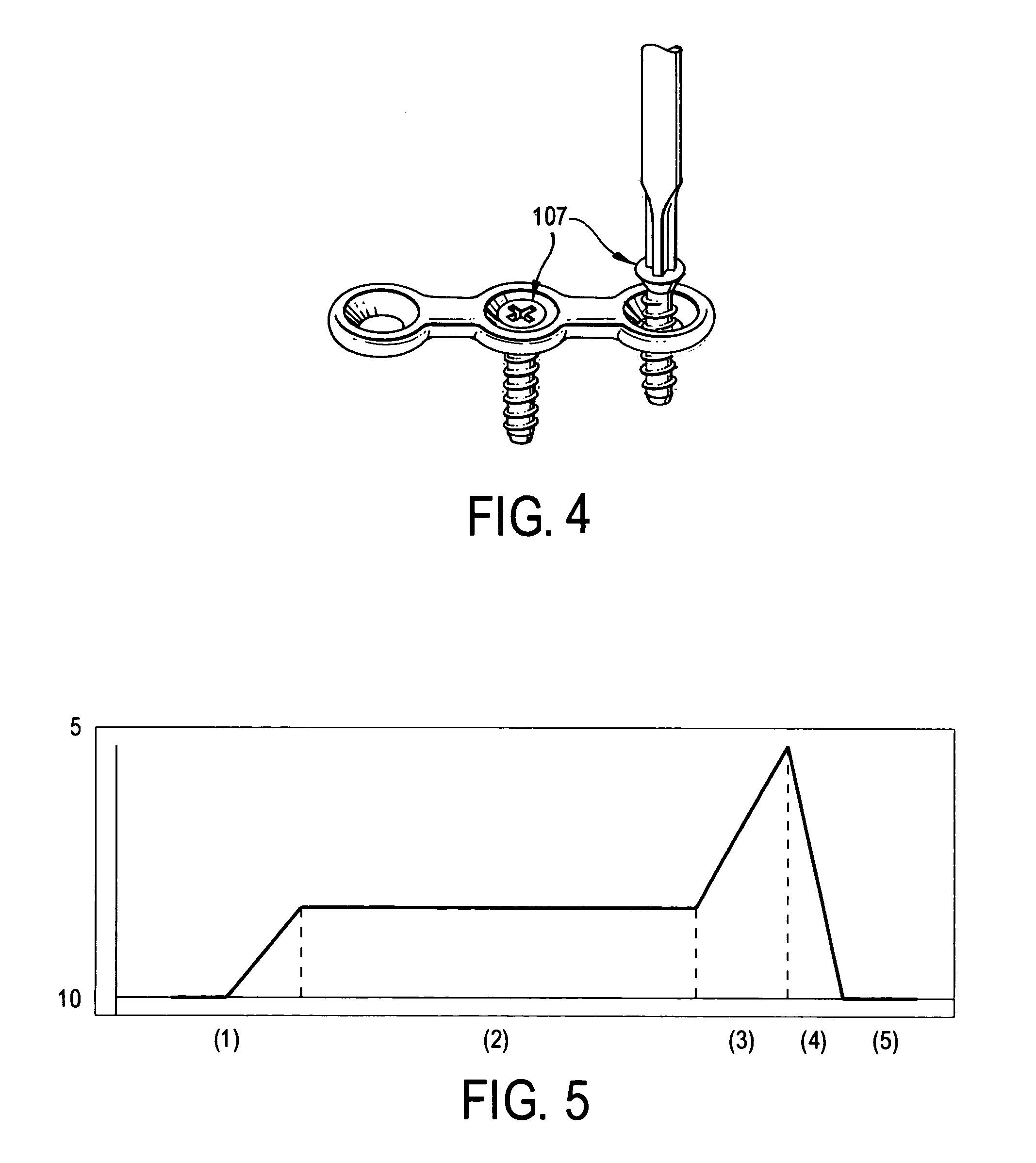

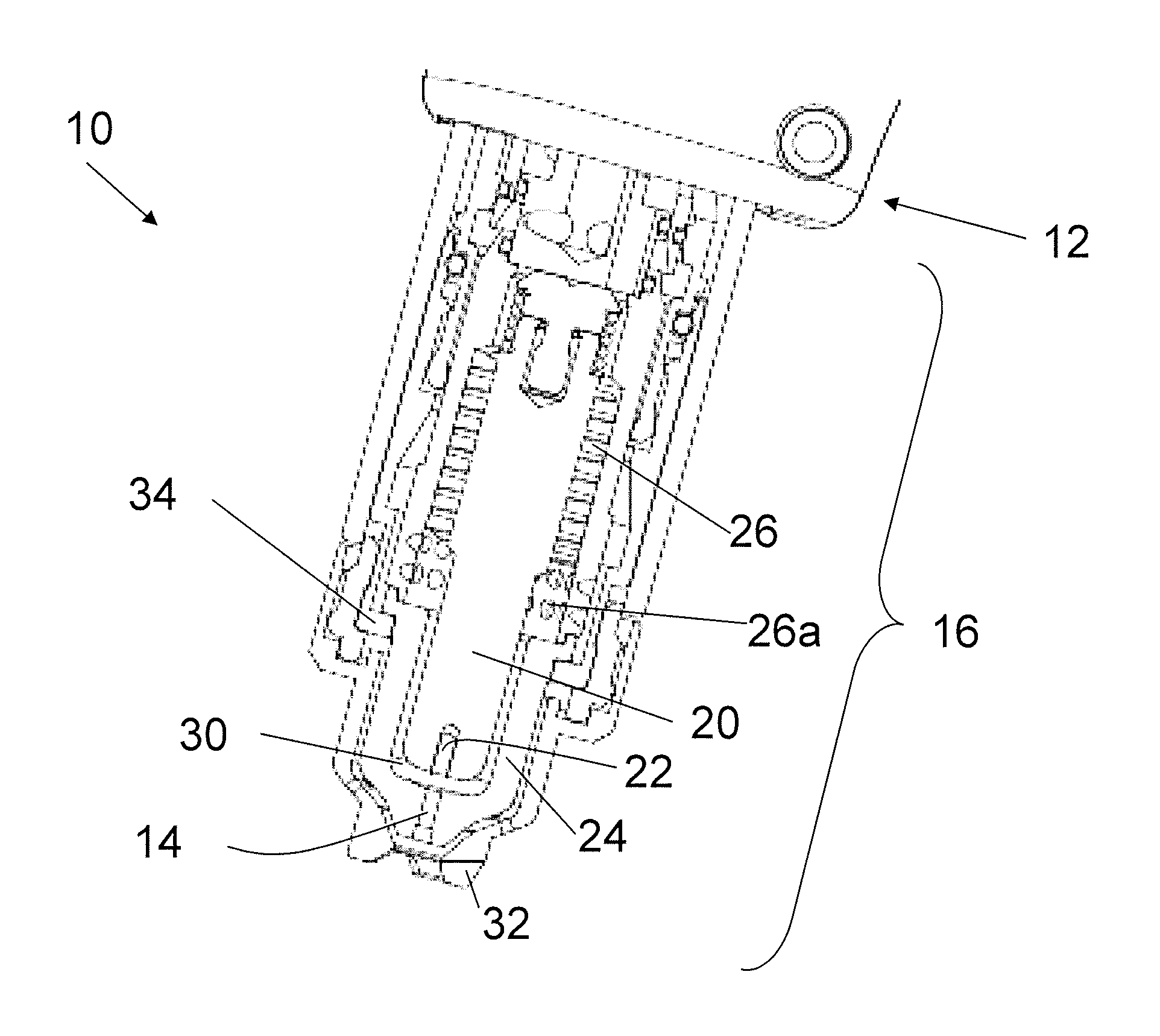

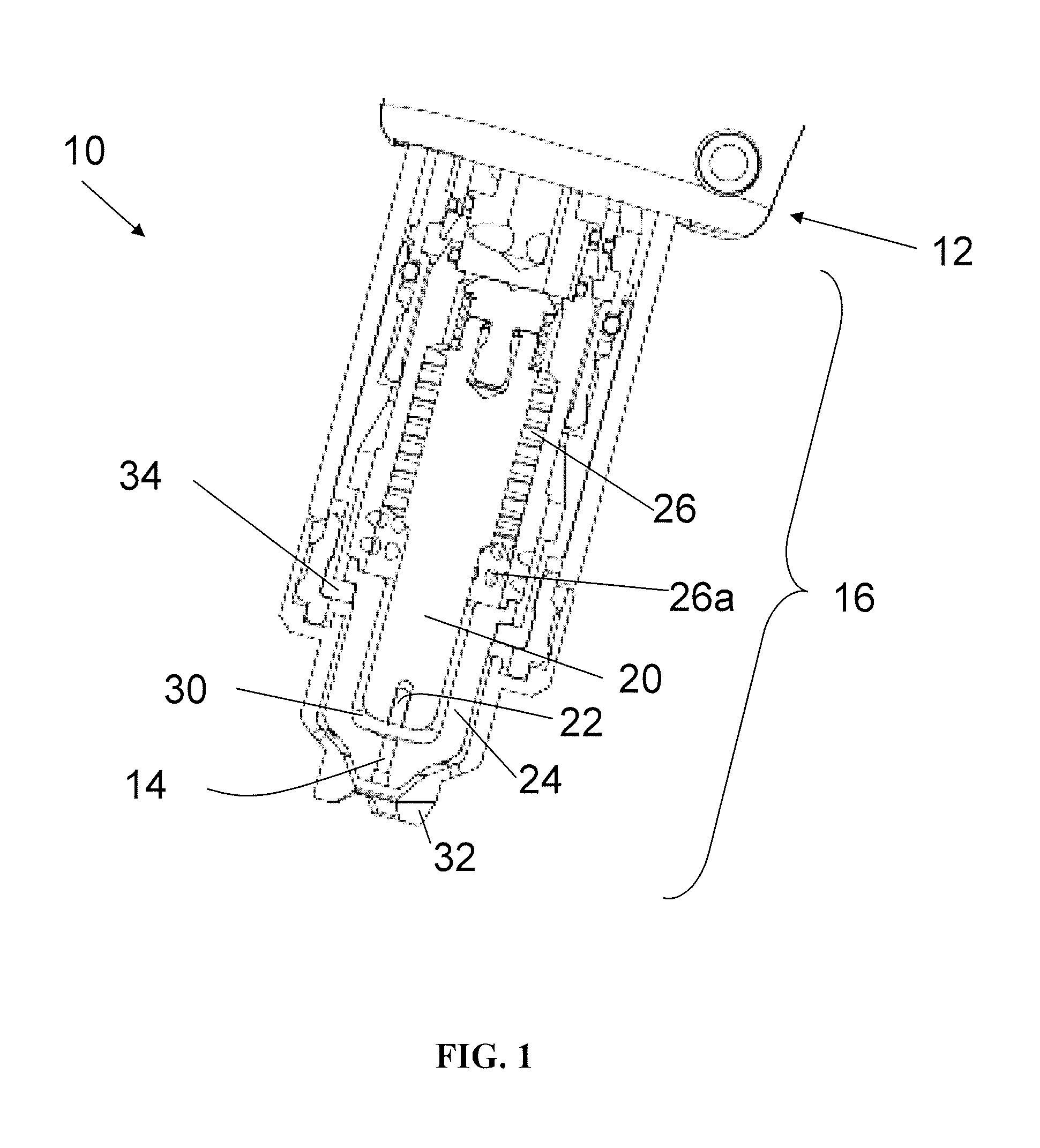

Method of monitoring and controlling the seating of screws to the optimum point of grip independent of screw size and material density

ActiveUS7091683B1Smoothes torque riseFalling smoothlyDC motor speed/torque controlDiagnosticsControl systemAnalog signal

A method of controlling a motor (106) used to drive a screwdriver bit (105) such that screws (107) are seated to the optimum point of grip between the screw (107) and the work piece material. An electronic control circuit controls the speed and output torque of the motor (106). The control system utilizes pulse width modulation (PWM) to control motor (106) speed and torque. The PWM signal controls the duty cycle of the transistors that supply current to the motor (106). The amount of current flowing through the motor (106) coils is proportional to the amount of torque the motor (106) is producing. Motor (106) current is measured as voltage produced across a precision resistor that is in series with the motor (106) coils. As the current in the motor (106) increases, the voltage across the resistor increases (V=IR). To accurately measure the torque, as measured by the voltage across the precision resistor, a capacitor with a resistor and / or a diode is used to average the analog signal that is measured by the microprocessor. The microprocessor further filters the analog signal using an averaging formula to produce a stable value corresponding to motor (106) torque / current. When a decrease in current, corresponding to a drop in torque, is detected at the optimum point of grip, the controller (100) stops the motor (106).

Owner:INTELLIGENT AUTOMATION DESIGN

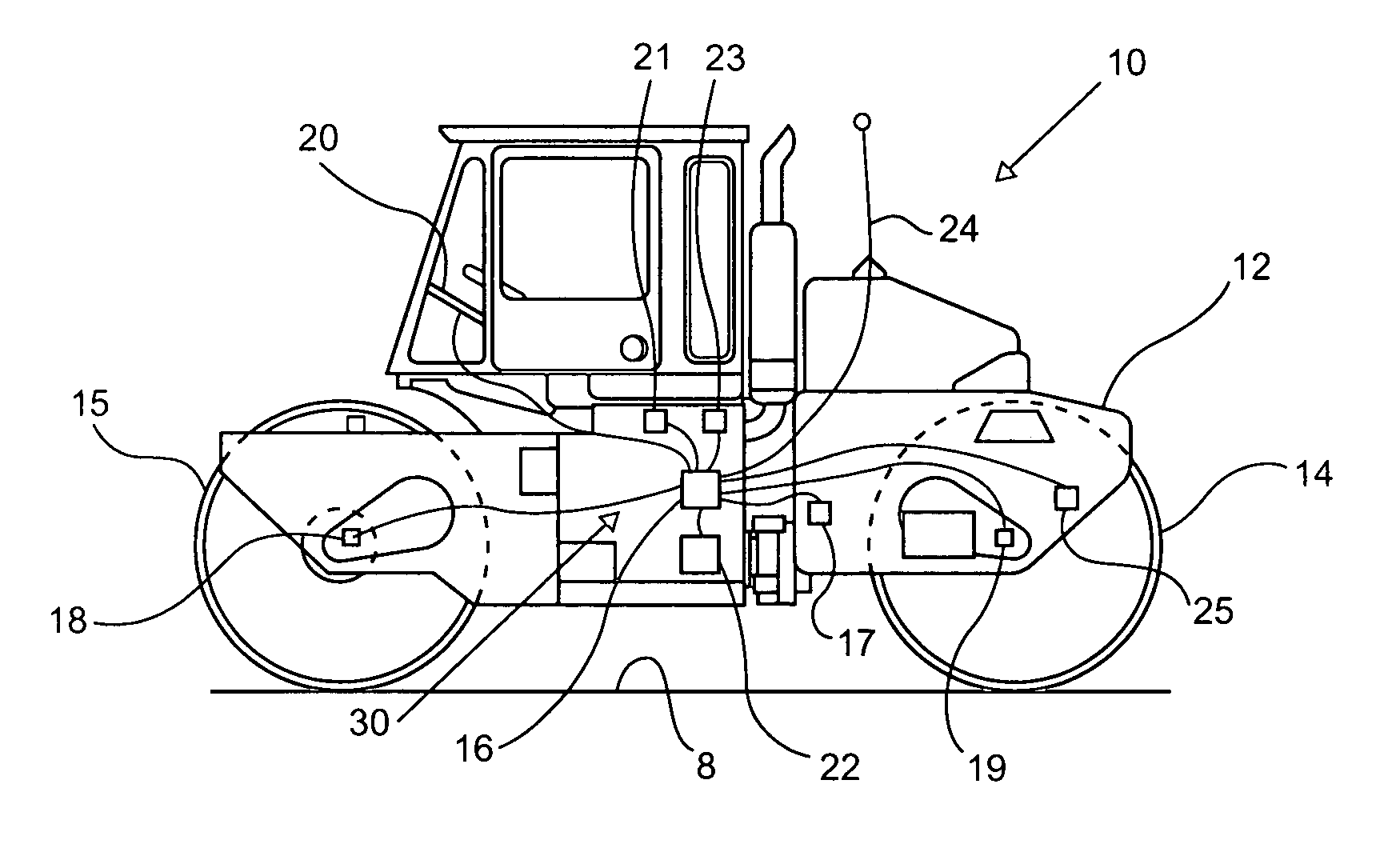

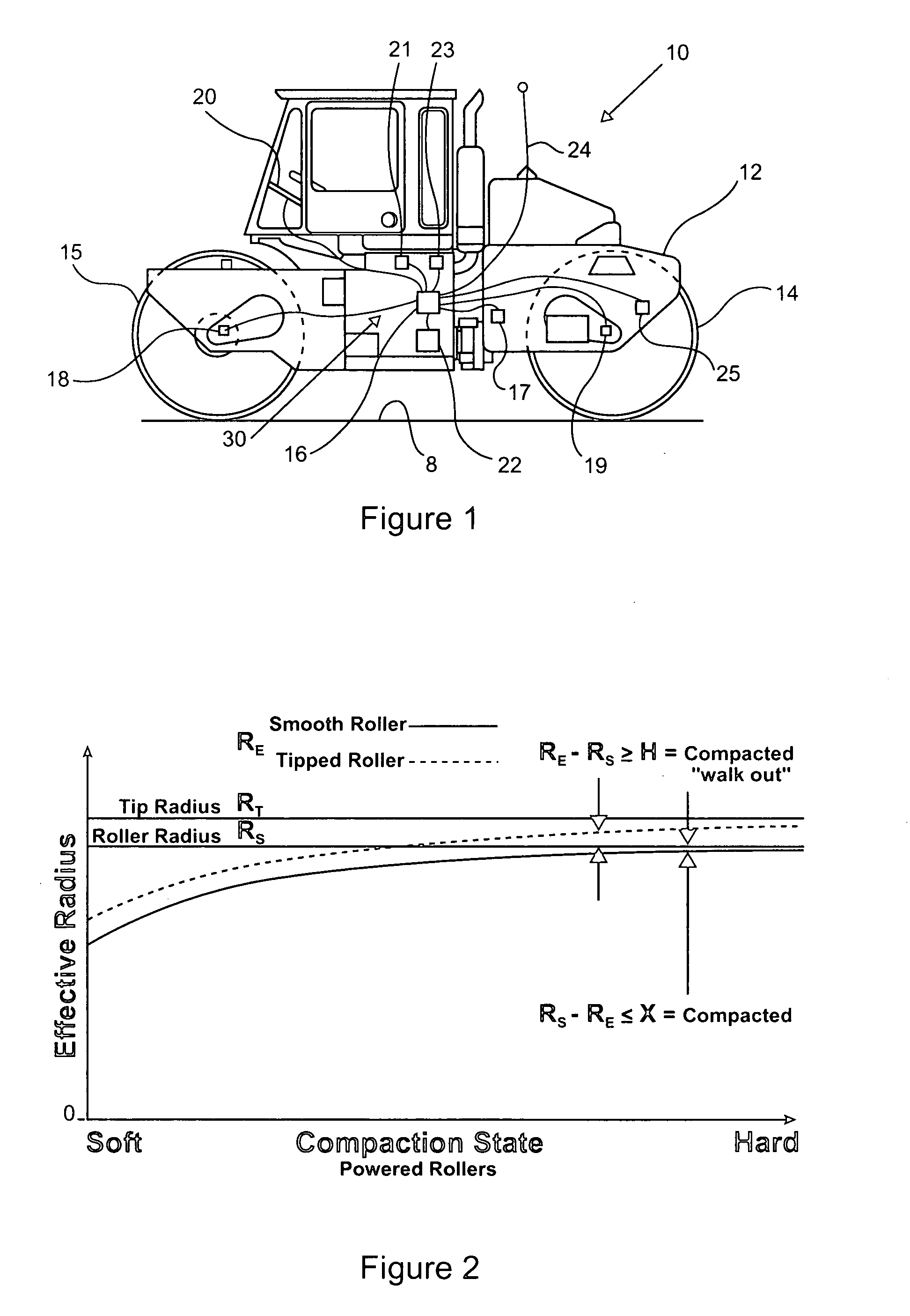

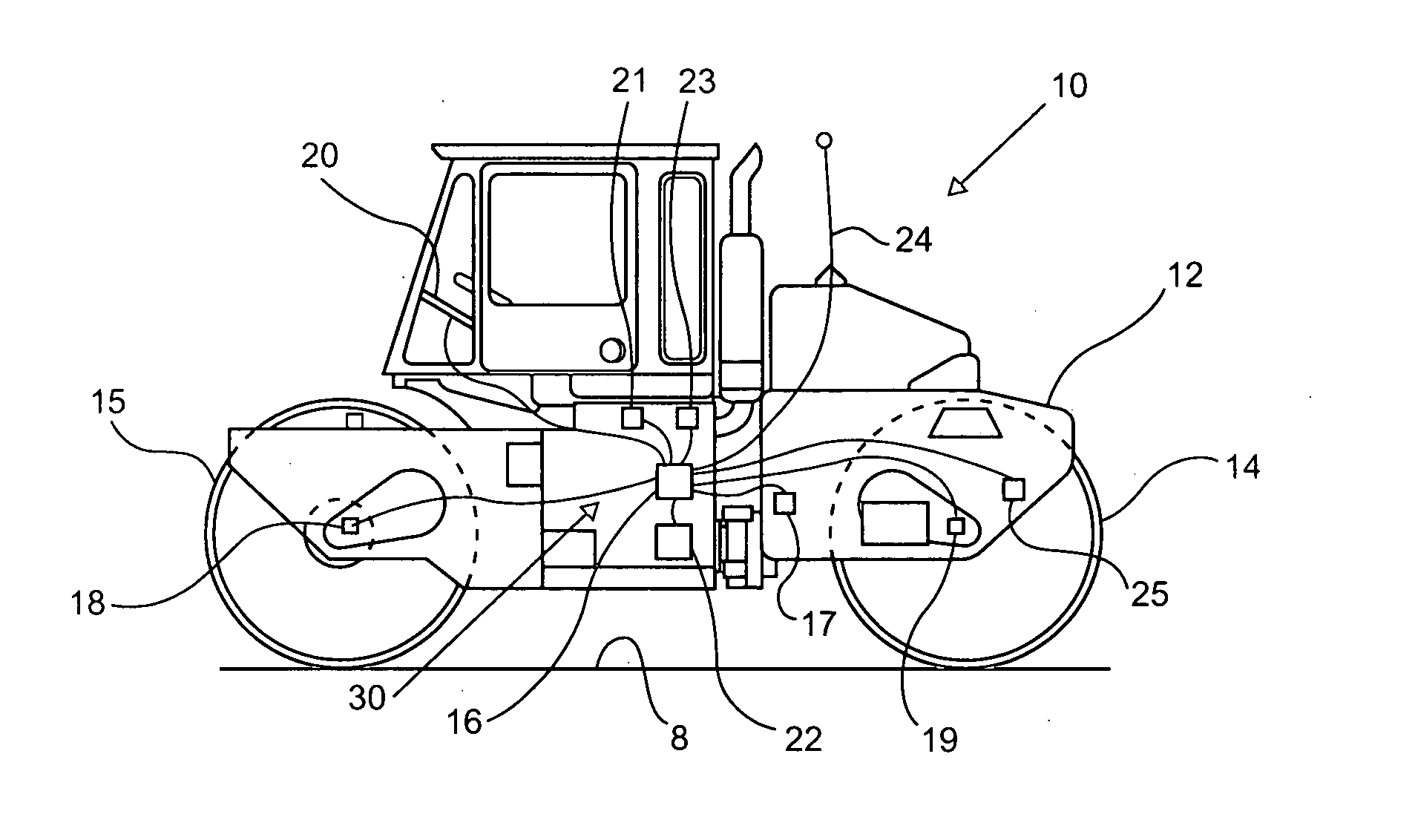

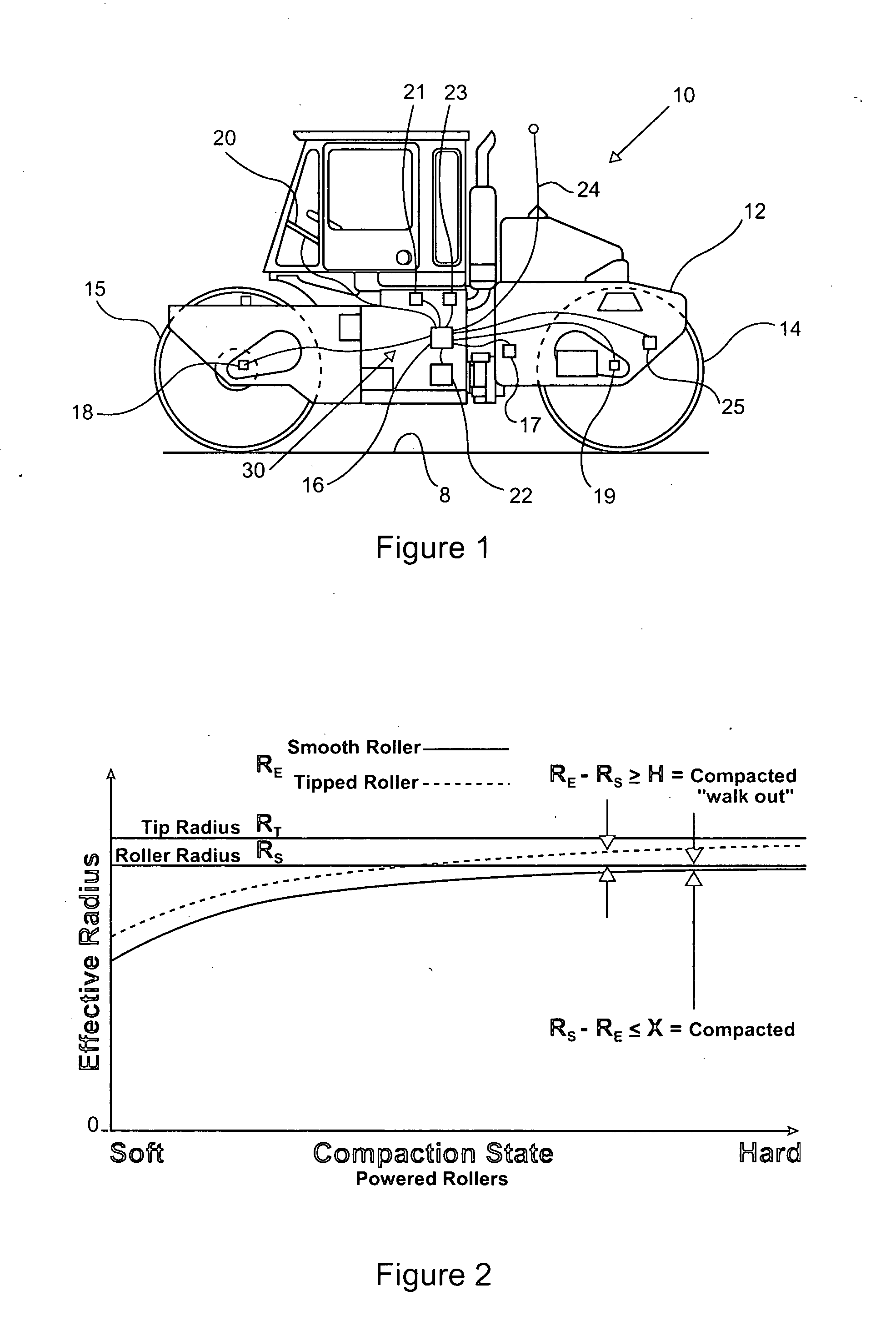

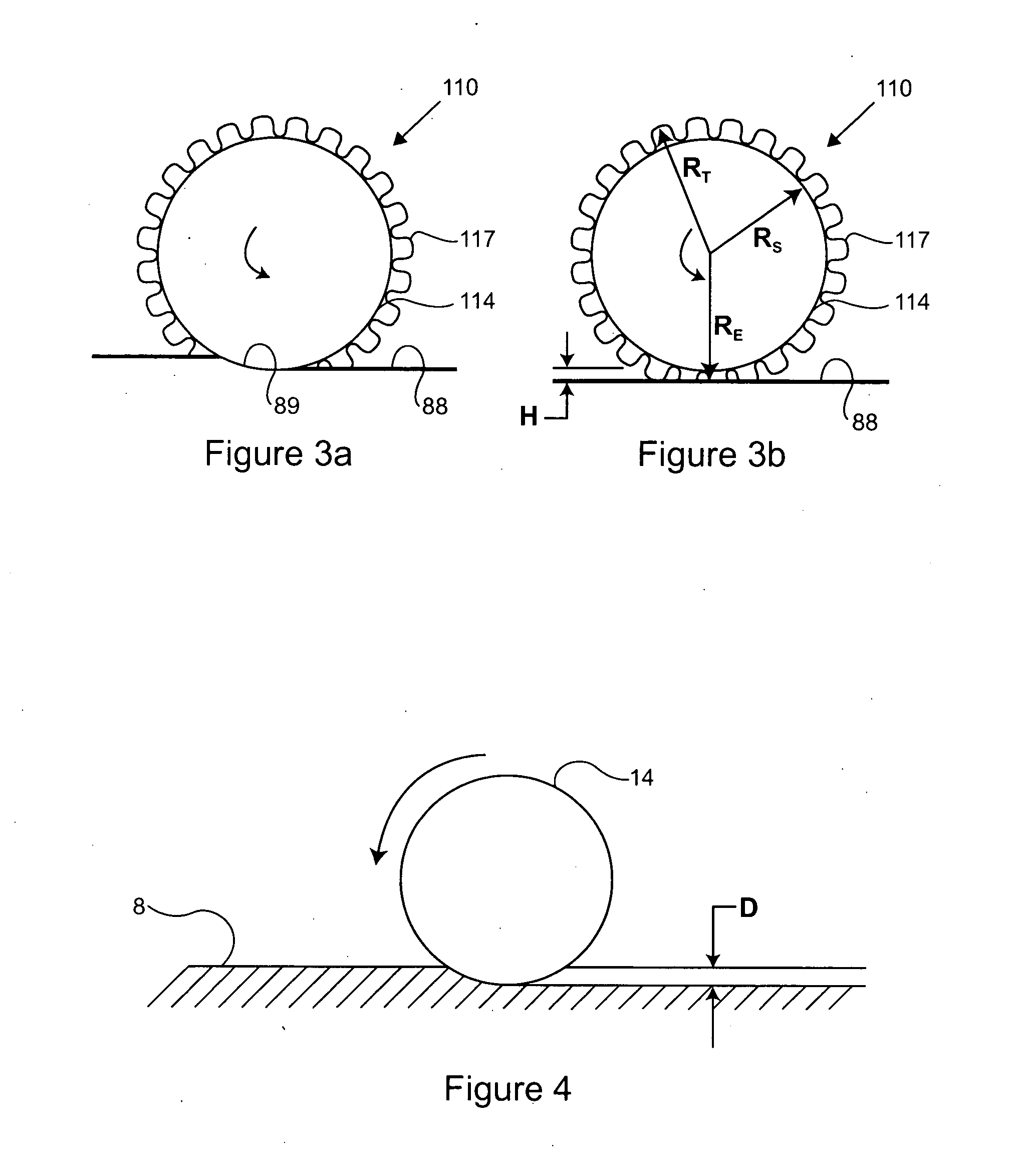

Compaction quality assurance based upon quantifying compactor interaction with base material

InactiveUS6973821B2Material strength using tensile/compressive forcesMeasurement/indication equipmentsEnergy transferDowntime

In most construction processes, some quality assurance compaction test must be performed on a base material before further construction can take place on or relative to the compacted base material. In order to avoid costly downtime associated with waiting for a quality assurance test to be performed, the present invention contemplates generating compaction quality assurance data using on-board generated compaction quality control data. The quality control compaction data is based upon quantifying a sinkage deformation interaction between the compactor and the base material. The interaction might include monitoring an effective roller radius of the compactor, or an amount of energy transferred or consumed when the compactor moves over the base material, or even measuring a rut depth caused by the compactor. The compaction quality assurance data can be indicative of a proof rolling test result, a walk out test result, a penetrometer test result, a base material density test result, or possibly even a compactor sinkage into the base material.

Owner:CATERPILLAR INC

Methods and apparatus for identification and imaging of specific materials

InactiveUS6987833B2Easy to quantifyImprove visibilityRadiation/particle handlingComputerised tomographsHigh energyX-ray

A method for analyzing materials in an object includes acquiring x-ray projection data of the object at high energy and at low energy for a plurality of views. The acquired x-ray projection data is utilized in a material decomposition to determine material densities at each pixel for two selected basis materials. A composition of an object at each pixel is determined utilizing a determined mapping of material density regions for the two selected basis materials. An image indicative of the composition of the object is displayed utilizing the determined composition.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Fluid property regulator

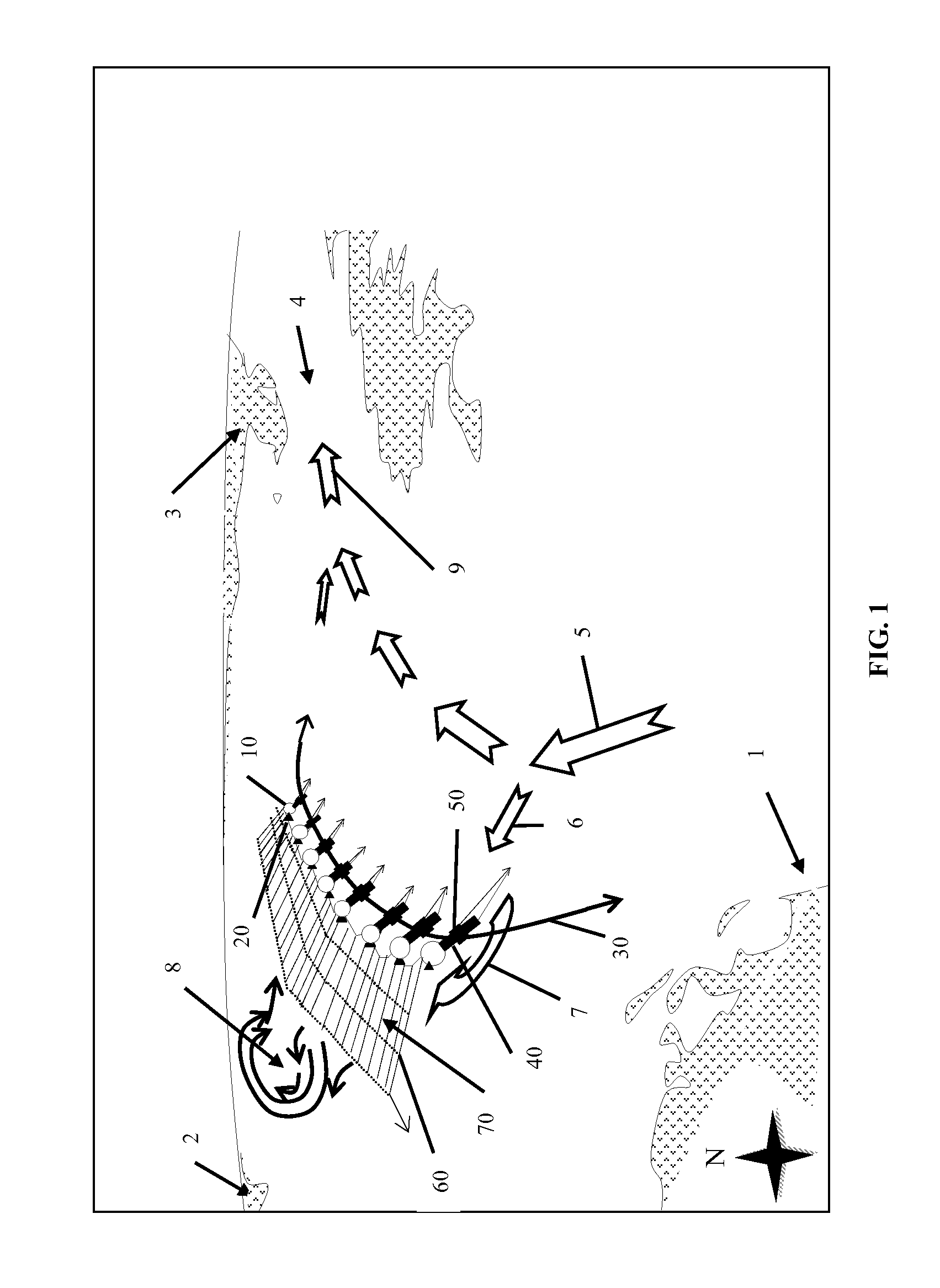

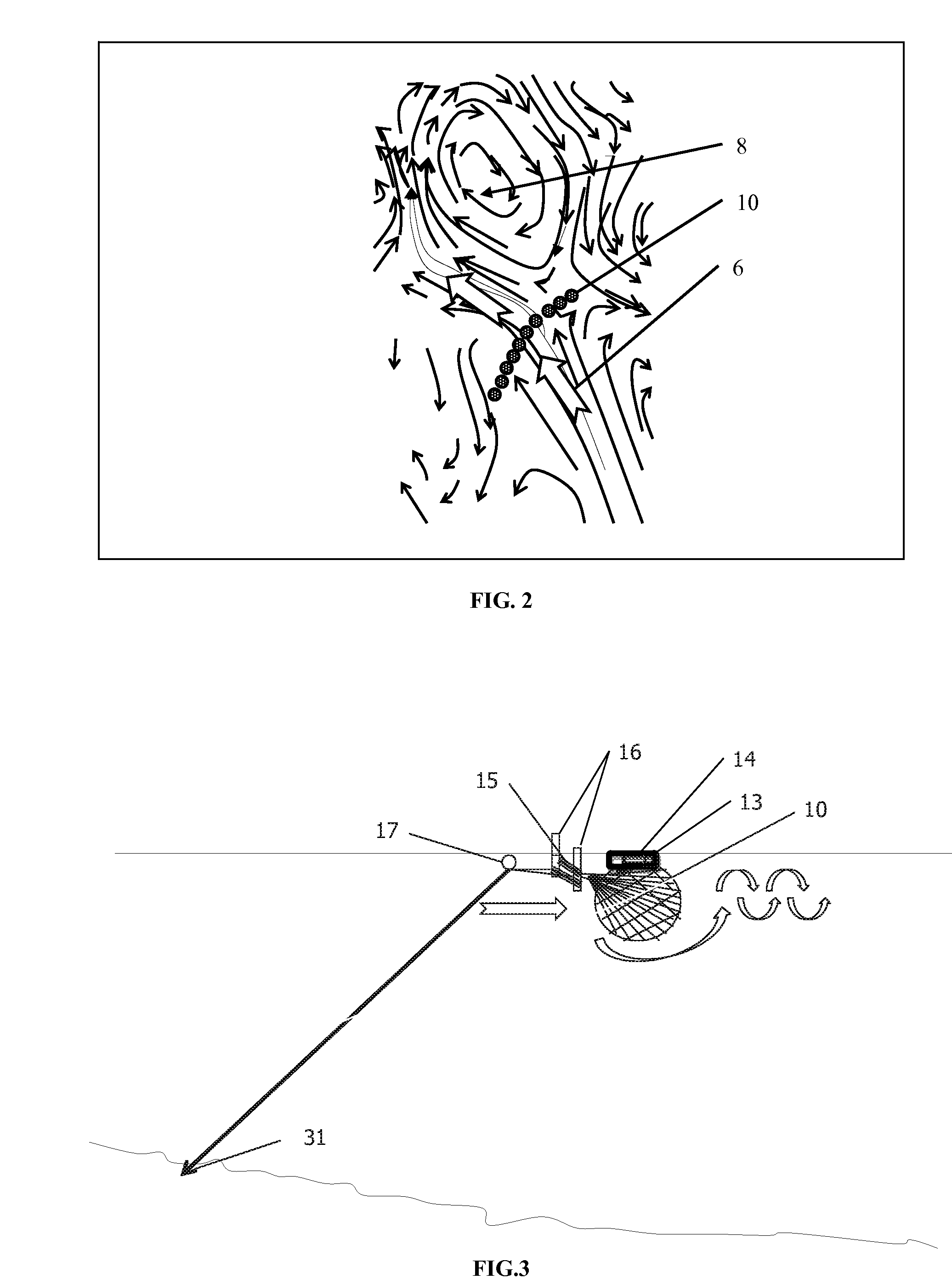

InactiveUS20080277492A1Low average atmospheric temperatureReduce greenhouse gasFog dispersionMachines/enginesAtmospheric airVolumetric Mass Density

A self-sufficient material property profile regulation method and system, for adjusting fluid property profiles such as in an ocean of multiple property layers, is described. Using this Fluid Property Regulator, the property profiles of a non-enclosed material, including property profiles related to material density, chemical characteristics and space-time position, are affected due to motion of the material relative to a body in the flow stream. The state of other matter with which the initial material then makes direct or indirect contact is also affected. For example, in the case of a liquid such as an ocean current, the temperature, salinity, nutrient content and other properties may be destratified (i.e. layers being combined) as the system lifts large quantities of deep water and combines this material with surface water in the downstream far-field region of the system. The resulting regulation of such ocean water property profiles may then also indirectly affect the properties of the atmosphere above the ocean so that the system can be said to affect planetary properties both oceanic and atmospheric. Rather than merely discharging a pumped material, such as cold water that might quickly re-submerge, the system regulates lasting property profiles. The new Fluid Property Regulator system described in this invention regulates material properties to produce desired outcomes such as increased food and energy production as well as to prevent undesirable outcomes such as hurricanes, elevated planetary temperatures, decreased planetary ice sheet size, raised sea level and glacial freshwater incursions that can halt important major currents.

Owner:CANNON DAVID J

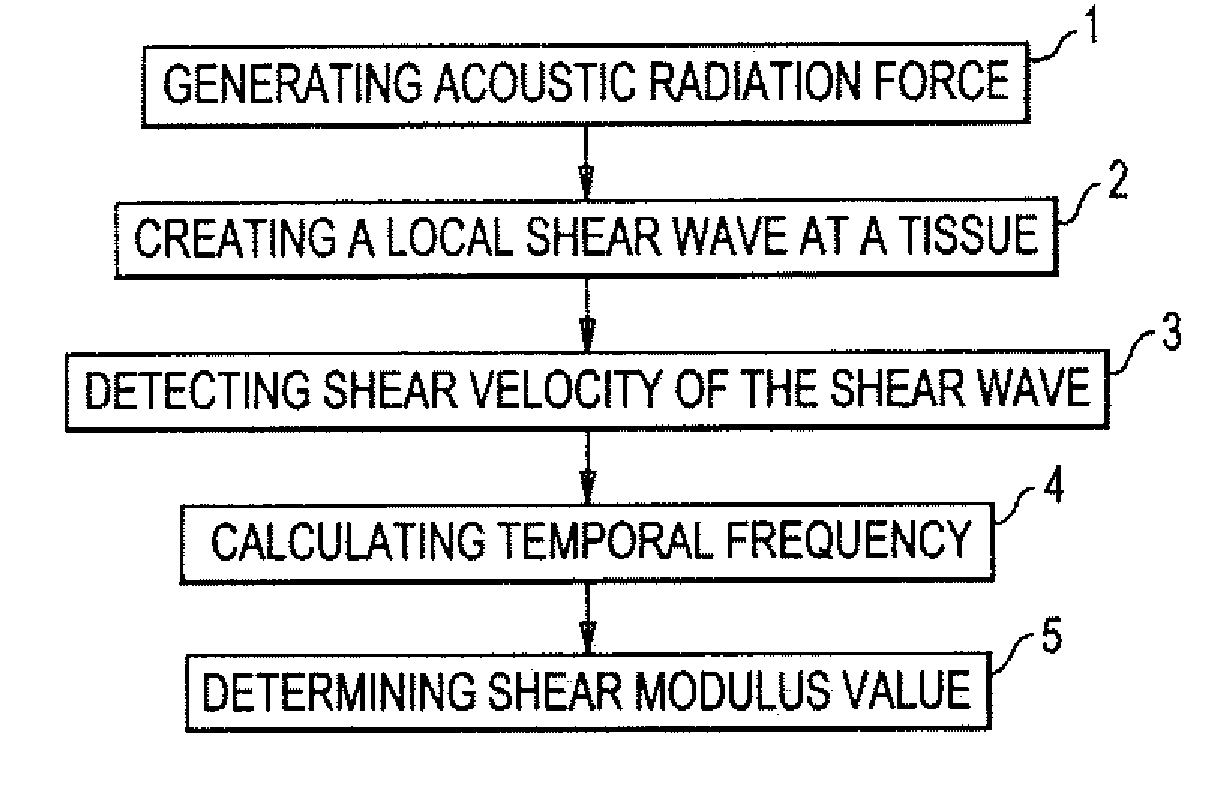

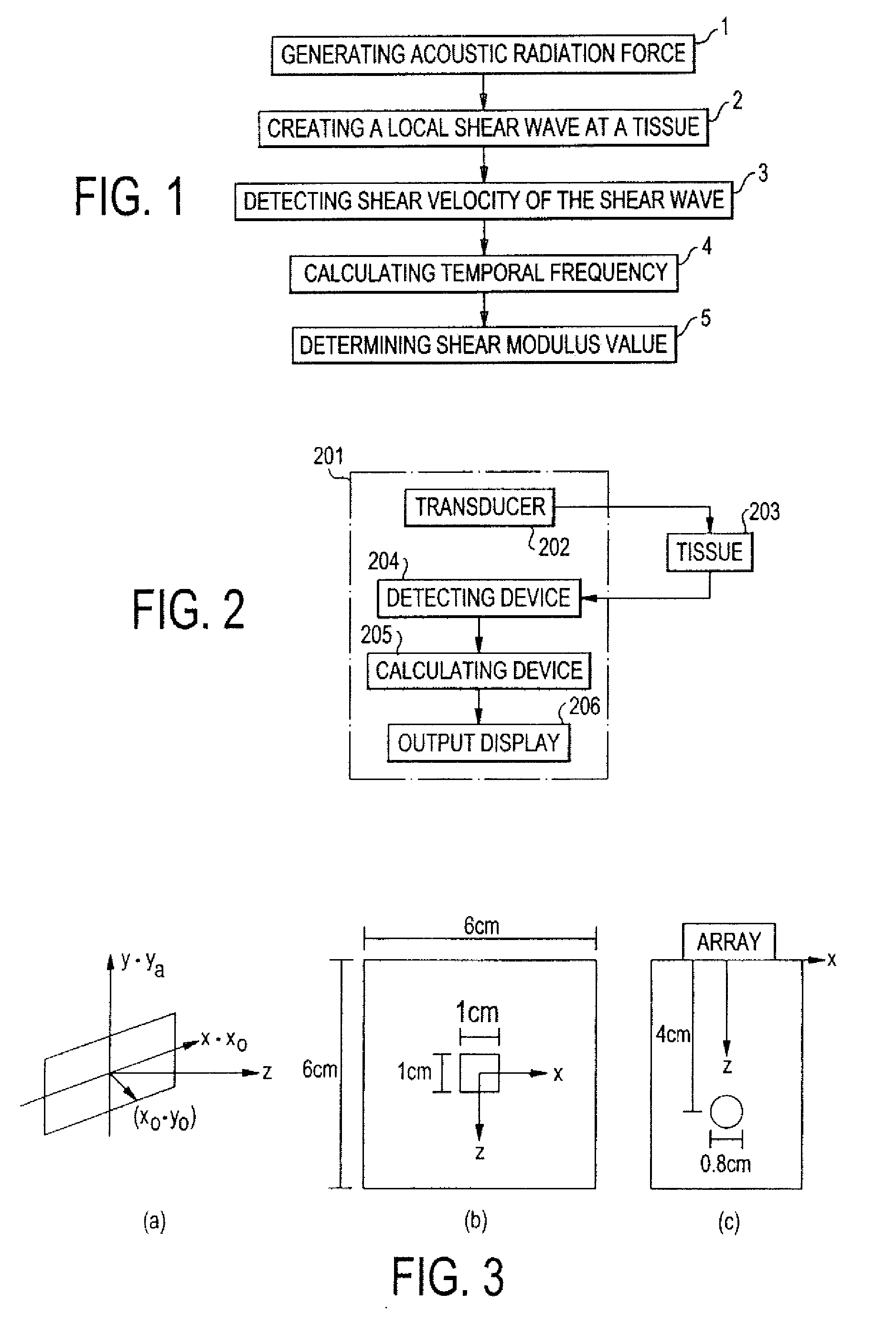

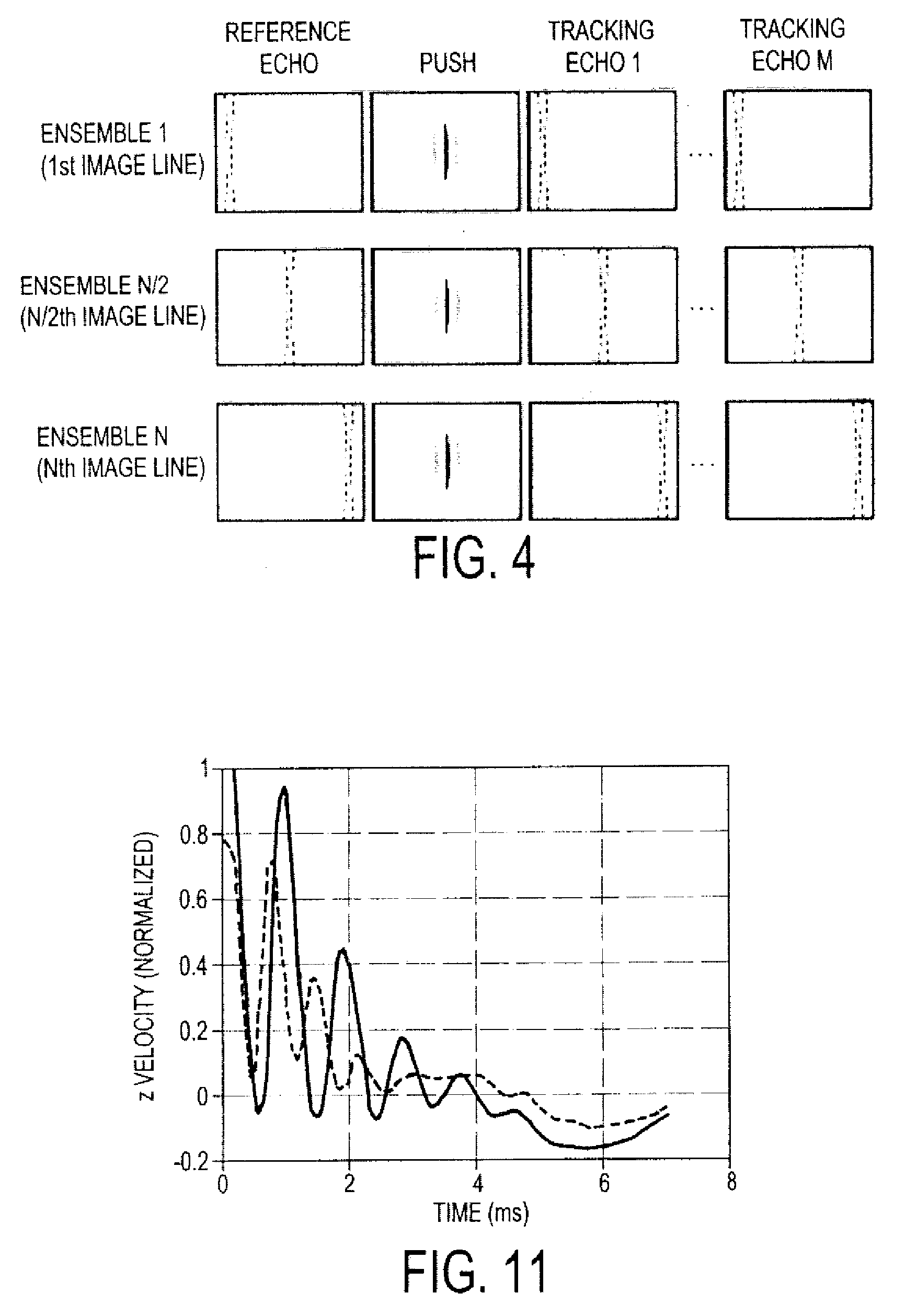

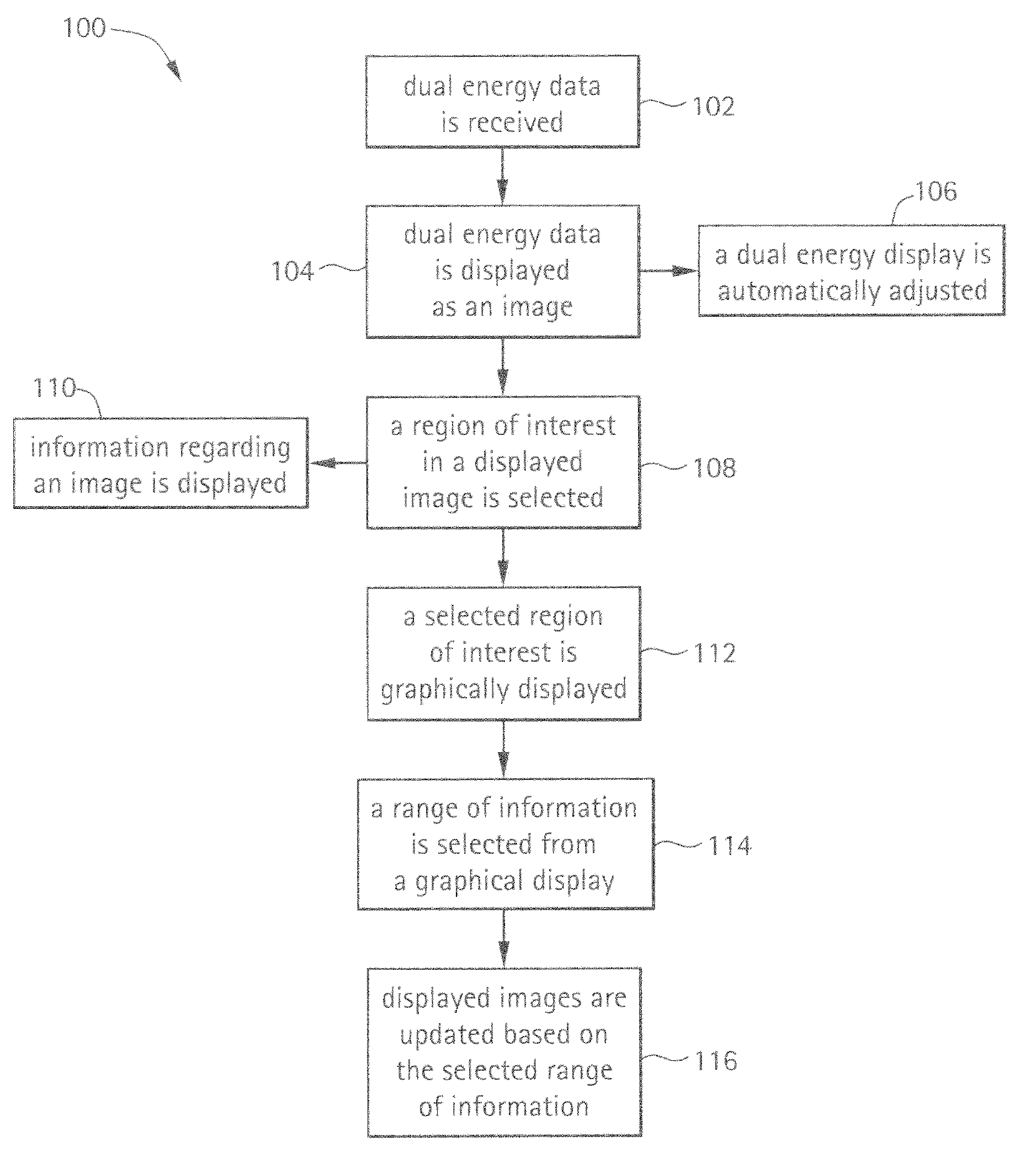

Shear modulus estimation by application of spatially modulated impulse acoustic radiation force approximation

ActiveUS20090056453A1Quantitative measurement of the shear modulus of the tissueVibration measurement in solidsVibration measurement in fluidShear modulusSonification

A method for determining a shear modulus of an elastic material with a known density value is provided. In this method, a spatially modulated acoustic radiation force is used to initially generate a disturbance of known spatial frequency or wavelength. The propagation of this initial displacement as a shear wave is measured using ultrasound tracking methods. A temporal frequency is determined based on the shear wave. The shear modulus of the elastic material at the point of excitation may be calculated using the values of the spatial wavelength, material density, and temporal frequency.

Owner:UNIVERSITY OF ROCHESTER

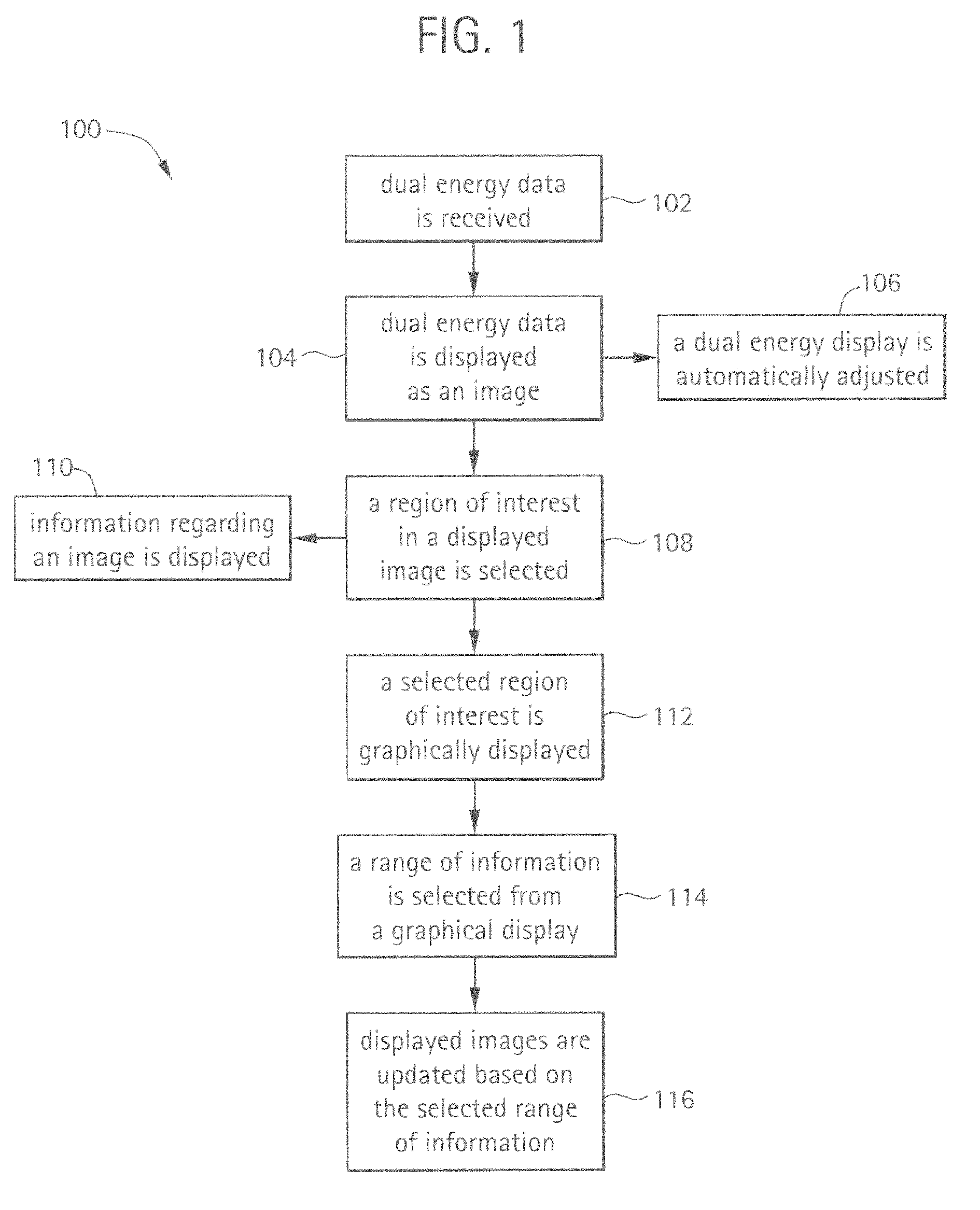

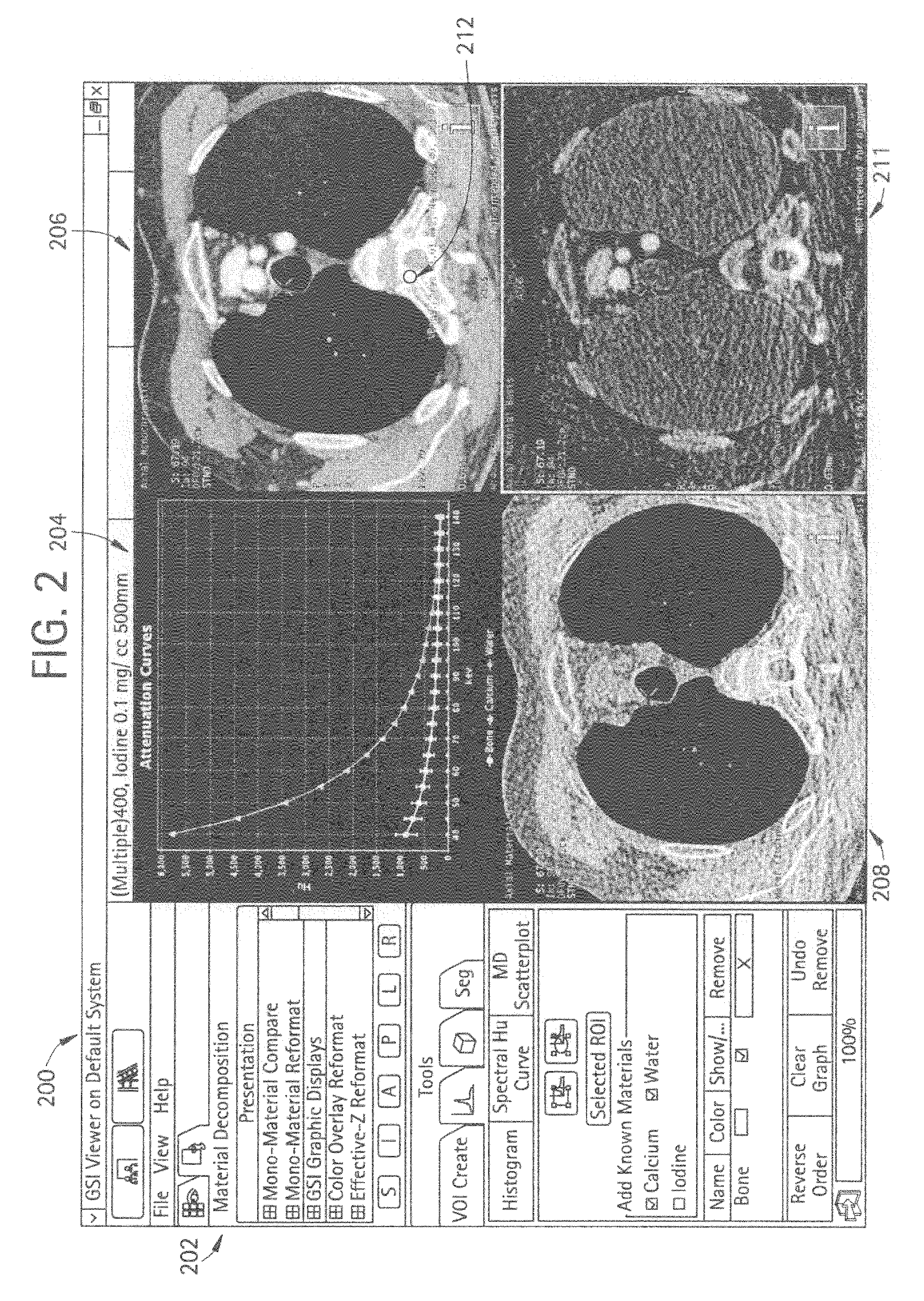

Systems and Methods for Displaying Multi-Energy Data

ActiveUS20100131885A1Input/output for user-computer interactionLocal control/monitoringUltrasound attenuationGraphics

Systems, methods and computer instructions for displaying multi-energy data are provided. Certain methods include: receiving multi-energy data from an operably connected data source; displaying the multi-energy data as an image via a graphical user interface; selecting a region of interest in the displayed image; and displaying information regarding the region of interest via the graphical user interface. Certain methods include: (1) displaying a graph that includes an attenuation line depicting radiodensity versus energy level; (2) displaying a material density graph of a region of interest and / or of results of segmenting a region of interest; and / or (3) displaying information in a window configured to be movable about an interface. Certain methods include: receiving multi-energy data from an operably connected data source; and displaying the multi-energy data as a fused image via a graphical user interface.

Owner:GENERAL ELECTRIC CO

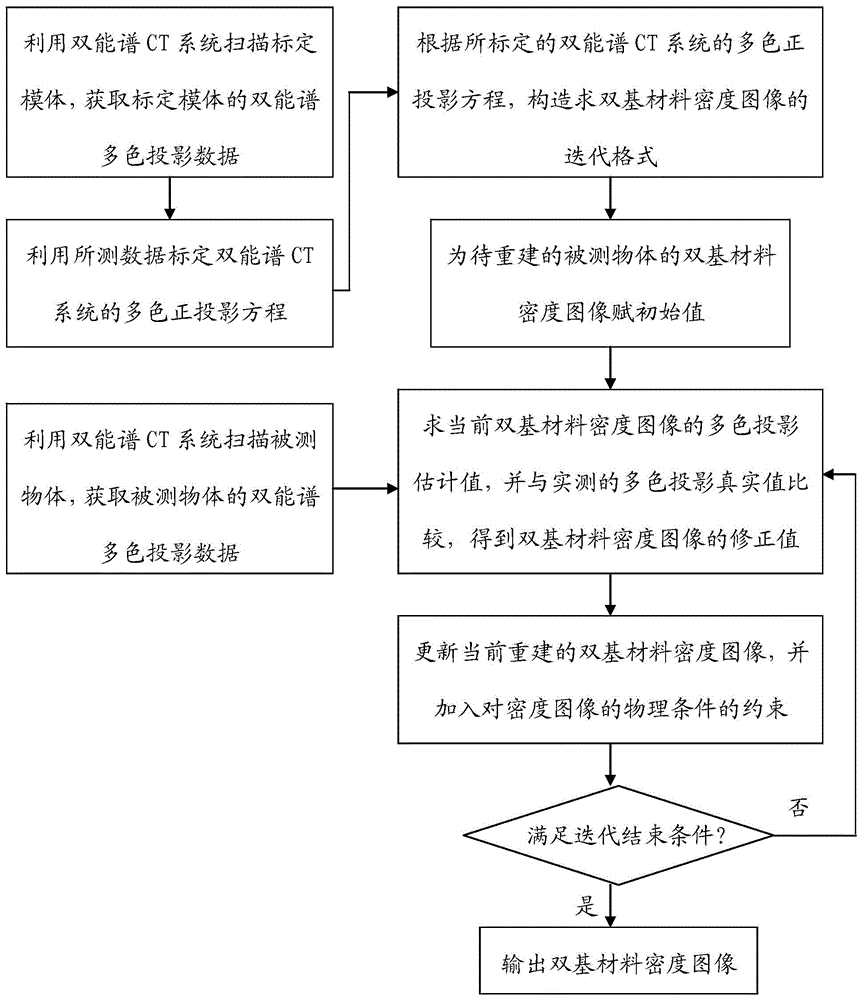

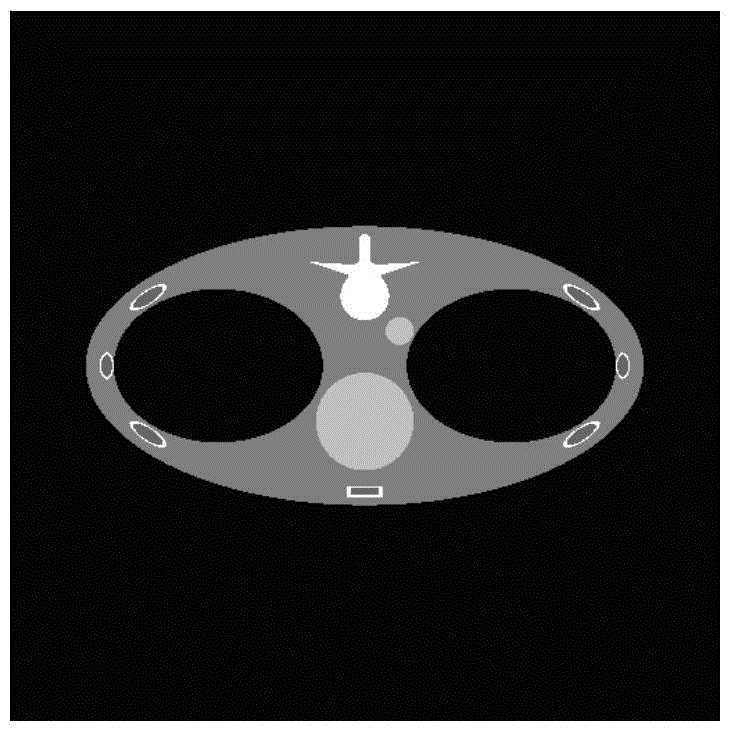

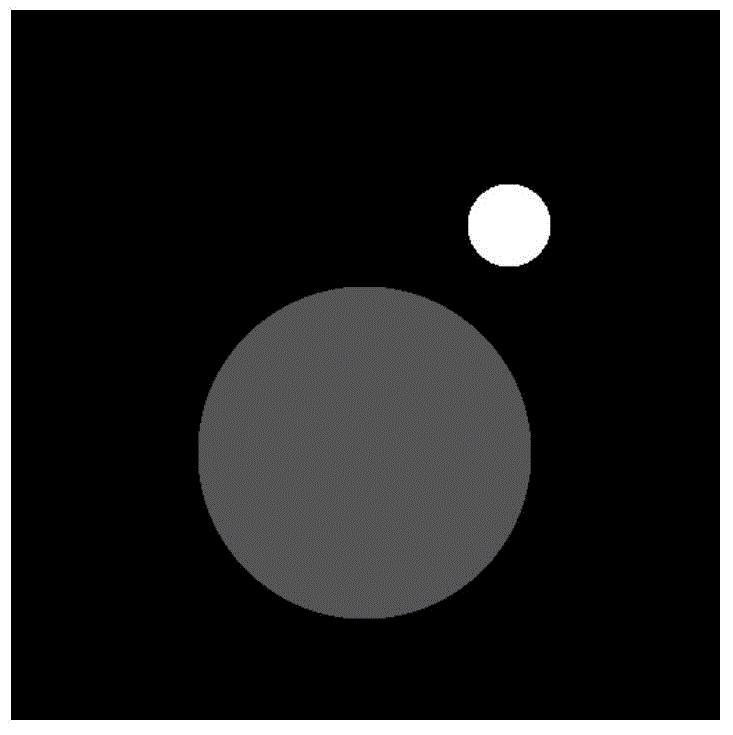

Method for iterating and reconstructing double-energy-spectrum CT image

InactiveCN103559729ALow energy spectrumImprove applicabilityImage enhancement2D-image generationAttenuation coefficientHigh energy

The invention discloses a method for iterating and reconstructing a double-energy-spectrum CT image. The method is used for reconstructing a base material density image of a measured object and comprises the following steps of (1) selecting a calibration model body containing tow types of different base materials according to the size of a material of the measured object; measuring the model body through a double-energy-spectrum CT system, and calibrating a double-energy-spectrum multi-color orthographic projection equation presenting a curvilinear relationship between a multi-color projection value and base material thickness combination; (2) collecting double-energy-spectrum multi-color projection data of the measured object by utilizing the double-energy-spectrum CT system; (3) constructing a iterative scheme according to the calibrated multi-color orthographic projection equation, and iterating and reconstructing the double-base-material density image of the measured object through comparison with the practically measured multi-color projection data and addition of a physical constraint condition. Compared with the existing method, the method for iterating and reconstructing the double-energy-spectrum CT image has the advantages that the high energy spectrum and the low energy spectrum of the double-energy-spectrum CT system and an attenuation coefficient of the base materials do not need to be detected in advance, and meanwhile the method is applied to the situation that the high energy spectrum and the low energy spectrum are matched with each other or not in geometry.

Owner:CAPITAL NORMAL UNIVERSITY +1

High-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and preparation method thereof

The invention relates to a high-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and a preparation method thereof. The method comprises the following steps: by using a two-dimensional fabric laying or three-dimensional four-direction knitted continuous silicon nitride fiber preform as a reinforcing body, carrying out interface coating preparation on the reinforcing body fiber surface with a polyboron azane precursor by half-vitrification; compounding the precursor mainly composed of polyboron azane with an impregnation liquid to prepare a base; and carrying out vacuum pressure impregnation, desolventization, pressure crosslinking curing and cracking densification to obtain the final silicon nitride fiber-reinforced composite material. The preparation method greatly enhances the impregnation efficiency, enhances the material density by 18-40%, and finally obtains the novel wave-transparent material system with excellent high temperature resistance. The strength retention rate of the material at 1200 DEG C and 1500 DEG C is 70-94%. Compared with the silicon nitride ceramic material, the novel wave-transparent material has obviously higher breaking strain.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Wave-absorbing foam concrete and preparation method for

InactiveCN102674881ASimple preparation processRaw materials are easy to getCeramicwareFoam concreteFiber

The invention relates to a preparation method for wave-absorbing foam concrete. The preparation method comprises the following step of mixing cement, a physical foaming agent, a wave absorbing agent, a polycarboxylic-acid high-efficiency water reducing agent and water. The preparation method is characterized in that the wave absorbing agent is metal powder, ferrite, fiber, carbon black, crystal whisker or carbon nano tube, wherein the wave absorbing agent and water are mixed according to the mass ratio of 1-40:60-100. The wave-absorbing foam concrete is prepared by premixing the wave absorbing agent by an internal mixing method, mixing uniformly, adding foam and stirring, casting and molding and curing. The wave-absorbing foam concrete has the characteristics of simple molding process, low material density and good wave-absorbing performance.

Owner:DALIAN UNIV OF TECH

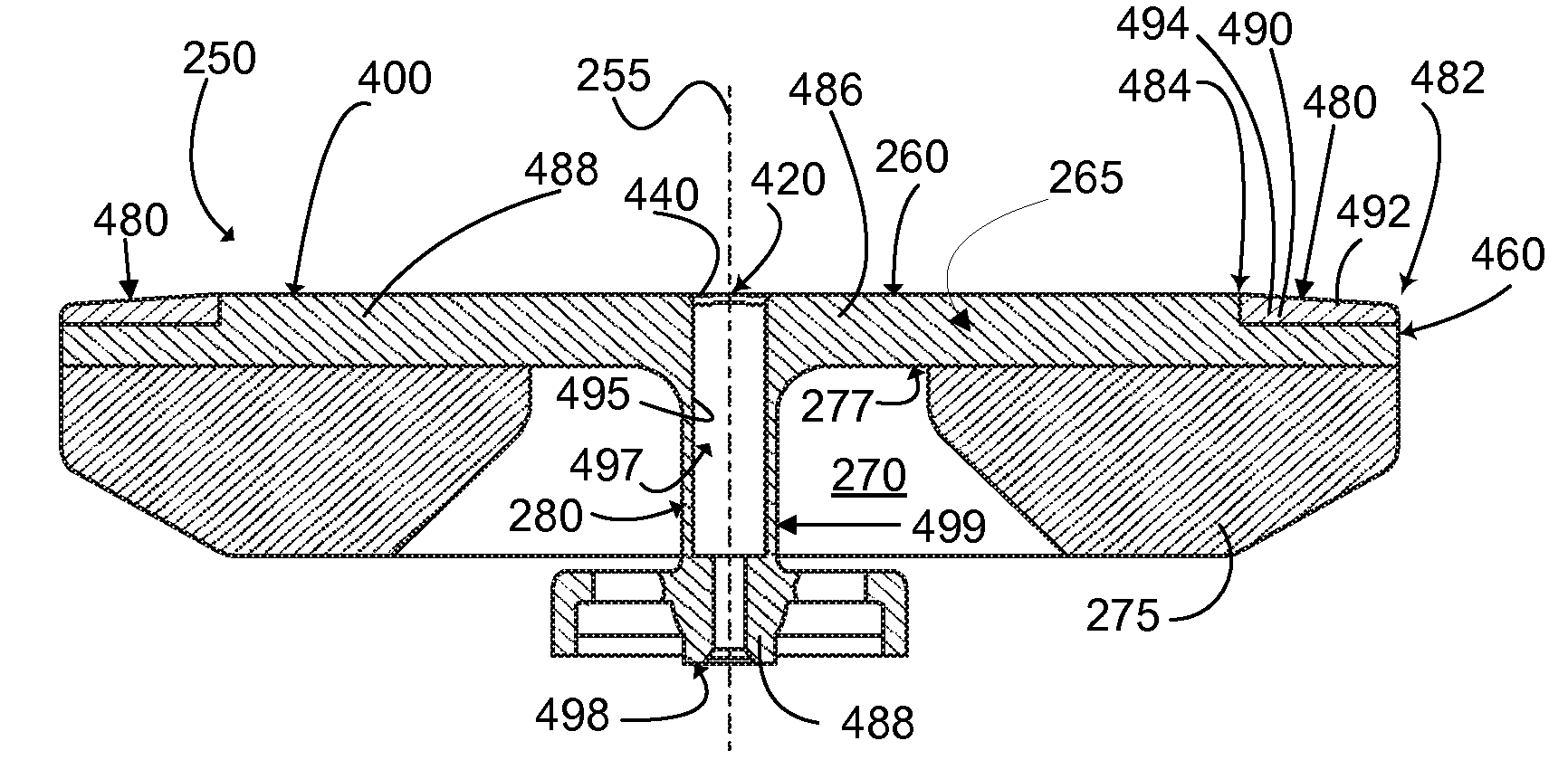

X-ray system, X-ray apparatus, X-ray target, and methods for manufacturing same

In some embodiments, an X-ray target includes a target cap formed of a substrate material and a focal track layer of emitting material, and at least one of the substrate material and the emitting material has a density greater than about 95.0% of theoretical density. In some embodiments, a method of manufacturing an X-ray target includes forming an intermediate target cap form of substrate material and a focal track layer of emitting material, and compacting the intermediate target cap form by application of gas pressure at elevated temperature to form a final target cap form, and at least the substrate material is dense substrate material having a final density greater than an intermediate density or the emitting material is dense emitting material having a final emitting material density greater than an intermediate emitting material density.

Owner:GENERAL ELECTRIC CO

Composite Consumables for a Plasma Arc Torch

ActiveUS20140021175A1Reduce cost timeReduce machining timeLine/current collector detailsArc welding apparatusSpray nozzleEngineering

An electrode is provided for use in a plasma arc torch. The electrode includes a body having a forward portion, a middle portion and an aft portion. The forward portion includes an electrode tip comprising a conductive first material, wherein the electrode tip includes: 1) a pilot contact region for initiating a pilot arc across the nozzle and 2) an emitter. The middle portion comprises a second material and defines a proximal end for mating with the forward portion and a distal end for mating with the aft portion. The material density of the second material is at least half of the material density of the first material. The electrode also includes an electrically conductive path extending from the forward portion to the aft portion of the body.

Owner:HYPERTHERM INC

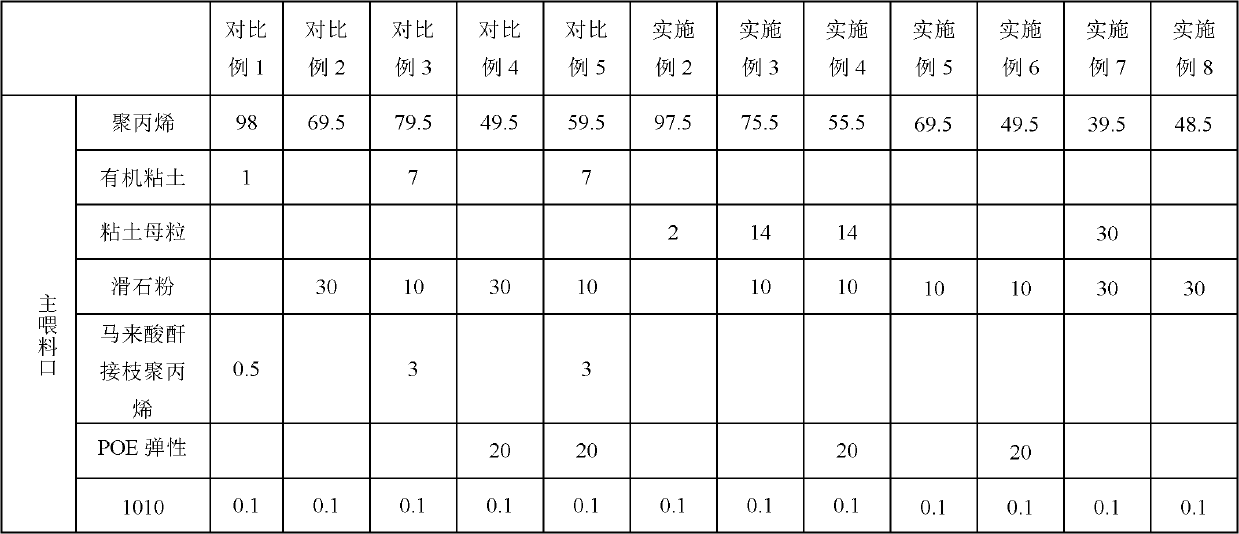

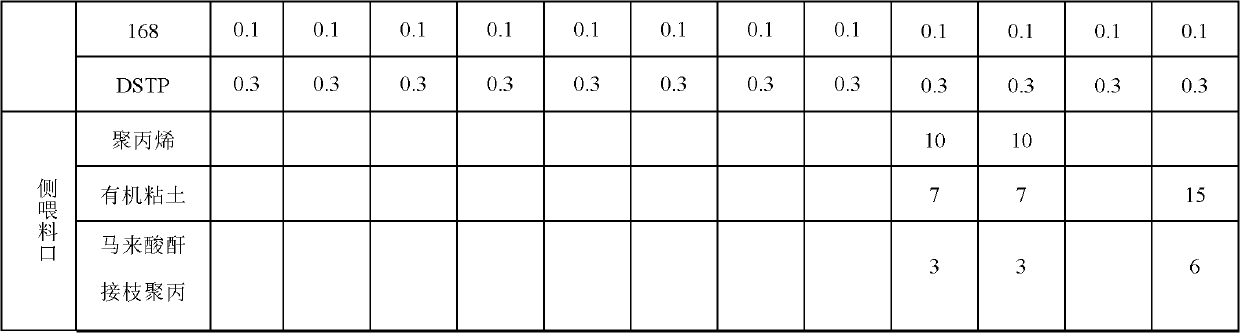

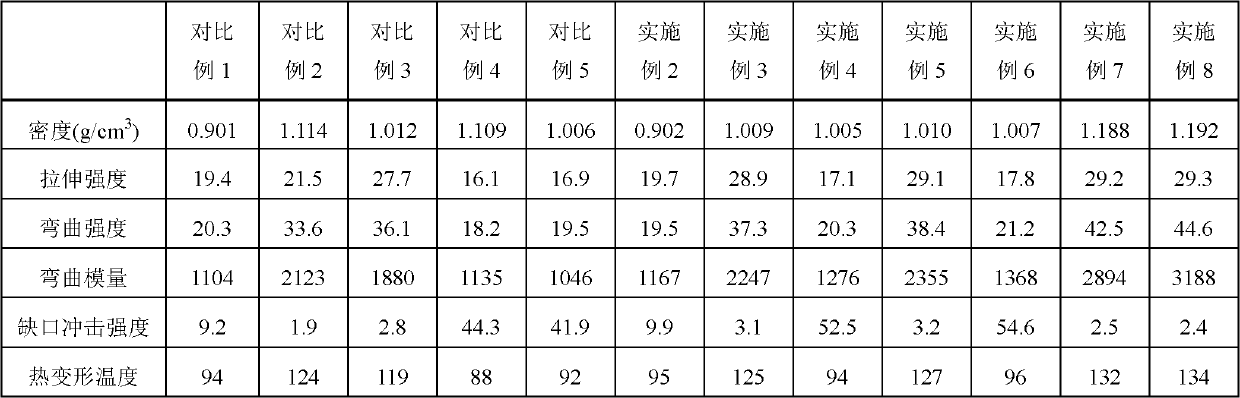

High-performance polypropylene nano composite material and preparation method thereof

The invention discloses a high-performance polypropylene nano composite material and a preparation method thereof, and belongs to the field of polymer modification and processing. The high-performance polypropylene nano composite material comprises the components in percent by weight: 39 to 98% of polypropylene, 1 to 15% organic clay, 0 to 30% of inorganic filling material, 0.1 to 6% of compatilizer, 0 to 20% of flexibilizer, 0.2 to 2% of stabilizer, and 0 to 4% of other additive. Through the cooperative modification of nanoscale organic clay and micron-sized talcum powder to polypropylene, a nano composite material with higher rigidity, higher tenacity and other performance is obtained at a lower material density.

Owner:SHANGHAI PRET COMPOSITES

Method for preparing high-performance iron nickel magnetically soft alloy by using powder metallurgy process

The invention discloses a method for preparing high-performance iron nickel magnetically soft alloy by using a powder metallurgy process, which belongs to the technical field of powder metallurgy. The method comprises the following steps of: 1, uniformly mixing various powder such as iron powder, nickel powder, molybdenum powder, silicon powder, copper powder, cobalt powder, chrome powder, niobium powder, tungsten powder, aluminum powder and titanium powder according to a certain ratio, wherein the nickel content ranges from 30 to 78 percent; or the alloy powder prepared according to a certain alloy component ratio is directly used as a raw material; 2, forming the powder which is obtained by step 1 into a blank with a certain shape by using a powder metallurgy forming method; 3, sintering the formed blank, which is obtained by the step 2, under the pressure of between 0 and 1,000 MPa and at the temperature of between 600 and 1,500 DEG C for 10 to 4,000 minutes; and 4, processing the sintered body obtained by the step 3 under the pressure of between 0 and 4,000 MPa and at the temperature of between 600 and 1,600 DEG C for 0 and 4,000 minutes. The method has the characteristic that: by improving the sintering and thermal treatment systems, the material density is improved, the micro texture and structure of the material are improved, the impurity content is reduced, and the magnetically soft alloy product with the maximal magnetic conductivity of no less than 40 mH / m and with the coercive force of no more than 20 A / m can be prepared.

Owner:UNIV OF SCI & TECH BEIJING

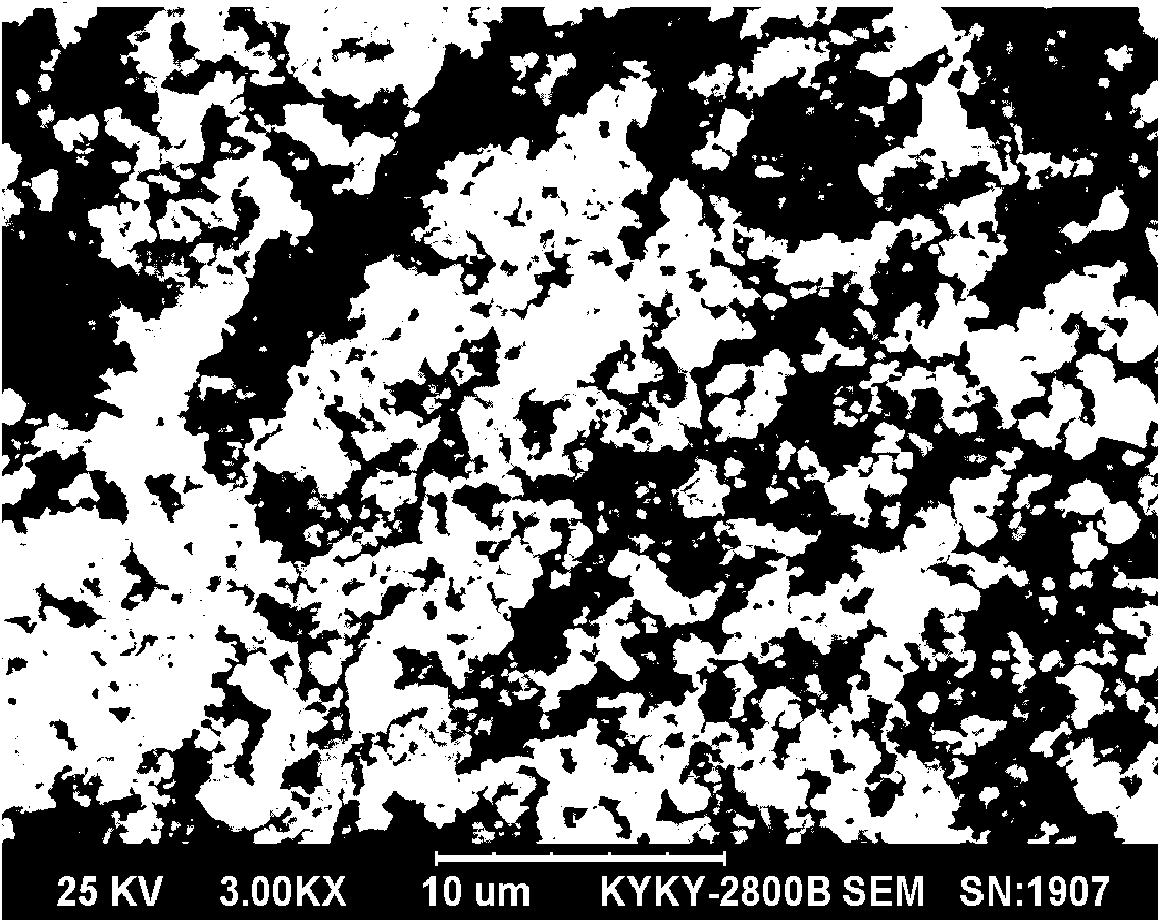

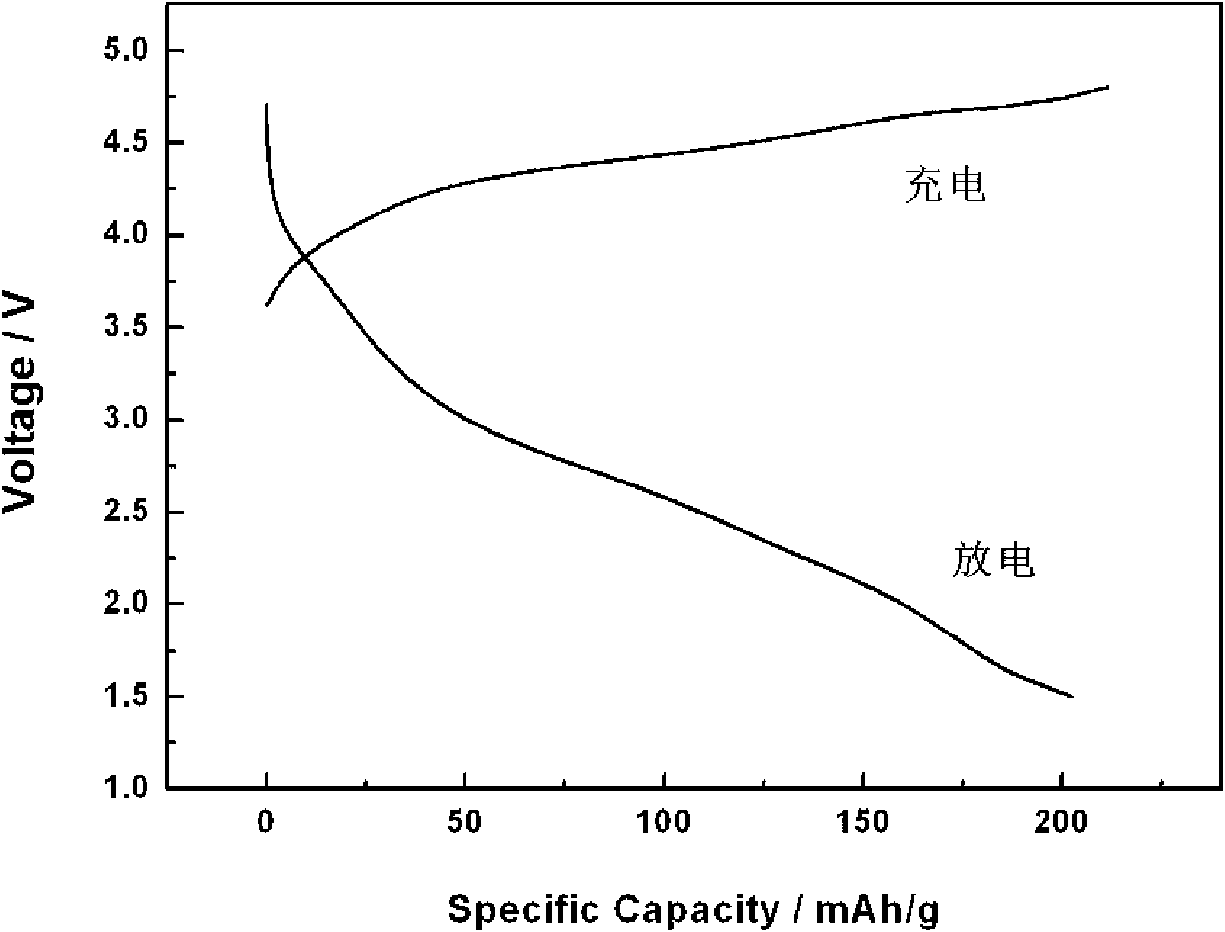

Silicate anodal material for lithium ion battery and preparation method thereof

ActiveCN101635345AImprove conductivityThe surface of the material is evenly distributedElectrode manufacturing processesActive material electrodesState of artMagnification

The invention discloses a silicate anodal material for lithium ion batteries and a preparation method thereof to solve the technical problem of the enhancement of the material density of the silicate anodal material. The general formula of the anodal material is Li2MSiO4 / D, wherein the Li2MSiO4 is the active substance of the silicate anodal material, D is a modifying agent doped and covered on the surface of the Li2MSiO4. The preparation method comprises the following steps: preparing a modifying agent source solution; putting the Li2MSiO4 into the solution to obtain a mixture; and carrying out spraying, drying, hot processing and fusion processing on the mixture. Compared with the prior art, the invention utilizes a liquid-phase method to cover, modify and fuse the silicate anodal material so as to ensure that the silicate anodal material has the characteristics of high stacking density, high compacted density, high volume specific capacity, favorable processing performance of batteries and low cost. Batteries produced by the silicate anodal material have higher safety performance, magnification performance and cyclic performance.

Owner:BTR NEW MATERIAL GRP CO LTD

Inclined mattress pad

InactiveUS20060179580A1Precise positioningReduce morbidityStuffed mattressesSpring mattressesEngineeringLoad deflection

A full length mattress pad is provides improved patient support for all parts of the user's body through provision of a support surface supplement for use with existing support surfaces, such as for use on top of a conventional mattress or hospital bed. The pad has a body of resilient material having a relatively flat, planar lower surface for being received on top of the existing support surface, and has a length at least generally the same as that of the mattress, or at least long enough to support the full length of a user. An inclined upper surface is defined by the body of resilient material, and has a plurality of different longitudinal sections. The plurality of different longitudinal sections collectively define a predetermined angle of inclination for the inclined upper surface which is relatively constant along the entire length of the body of resilient material relative to its planar lower surface. At least one of the plurality of different longitudinal sections has a relatively flat surface inclined at the predetermined angle of inclination, while at least one other of the plurality of different longitudinal sections has a surface formed with respective or different projections therein, so that improved patient support is provided through a combination of the inclined upper surface and the plurality of different longitudinal sections. Preferably, the predetermined angle of inclination is no more than about 10°. Characteristics of the plurality of longitudinal sections are selected based upon one or more of the type of resilient material used, the thickness of such material, the change in thickness of such material due to the predetermined angle of inclination, the material density, and the indention load deflection characteristics of such material, with such selection and combination of characteristics determined so as to optimize the inclined pad for support for the user's body which is engineered on the basis of the intended end use of said mattress pad. The longitudinal sections are also formed by one or both of longitudinal and lateral cuts within a selected portion of the inclined upper surface, also preselected to address the relieving of support pressure points to decrease the chance of decubitus ulcers in users of the mattress pad. At least one of the depths, widths, and lengths of such cuts, forming cross-sectional shapes of the different or respective projections, are preselected on the basis of the intended end use of said mattress pad. A plurality of channels may be formed between adjacent of the respective projections, for dissipating heat and moisture from a user who is supported on the inclined upper surface, to increase the health and comfort of such user.

Owner:SPAN-AMERICA MEDICAL SYSTEMS

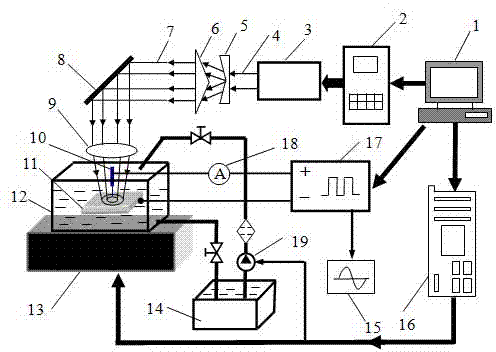

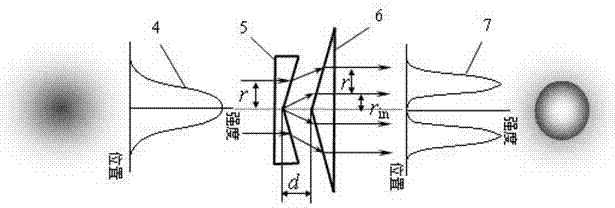

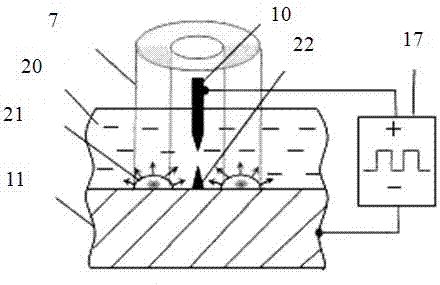

Electrochemical composite decomposition manufacturing method and device of laser light tube electrode

ActiveCN103572341ADoes not affect transmissionEfficient compositeCellsOptical elementsSolid lightDecomposition

The invention relates to an electrochemical composite decomposition manufacturing method and an electrochemical composite decomposition manufacturing device of a laser light tube electrode. Solid pulse laser is changed into an annular hollow laser beam with central light strength as zero by a light beam modulating system; compression shock is generated for electrochemical deposition in a non-solid light tube electrode by utilizing annular laser to irradiate expansion of plasma; decomposition stress is removed, a cathode reaction gas is exhausted, and material density is improved; moreover, the deposition reaction is only generated on the light beam with central laser energy as zero, so that the electrochemical composite deposition processing, repairing and surface performance strengthening which are high in quality and good in locality are realized. The electrochemical composite decomposition manufacturing method and the electrochemical composite decomposition manufacturing device disclosed by the invention are suitable for processing, repairing and surface performance strengthening of micro high-performance metal components, and belong to the field of micro quick forming and processing.

Owner:JIANGSU UNIV

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

High-fill high-resilience soft expanded polyethylene material and preparation method thereof

The invention discloses a high-fill high-resilience soft expanded polyethylene material which comprises the following raw materials in parts by weight: 15-20 parts of polyethylene, 5-20 parts of an elastomer, 60-80 parts of modified calcium carbonate, 1-10 parts of a chemical foaming agent, 0.5-1.5 parts of a cross-linking agent and 1-5 parts of a physical foaming agent. The invention further discloses a preparation method of the high-fill high-resilience soft expanded polyethylene material. The preparation method has the benefits as follows: the high-fill high-resilience soft expanded polyethylene material with the calcium carbonate filling amount reaching up to 55%-75% can be prepared, the rigidity, the hardness and the compression strength of the material are improved on the basis of keeping the elasticity of the expanded material, and the material density is reduced; the production process is simple, the cost can be greatly reduced, and economy and practicability are achieved.

Owner:GUANGZHOU MBS COMPANY

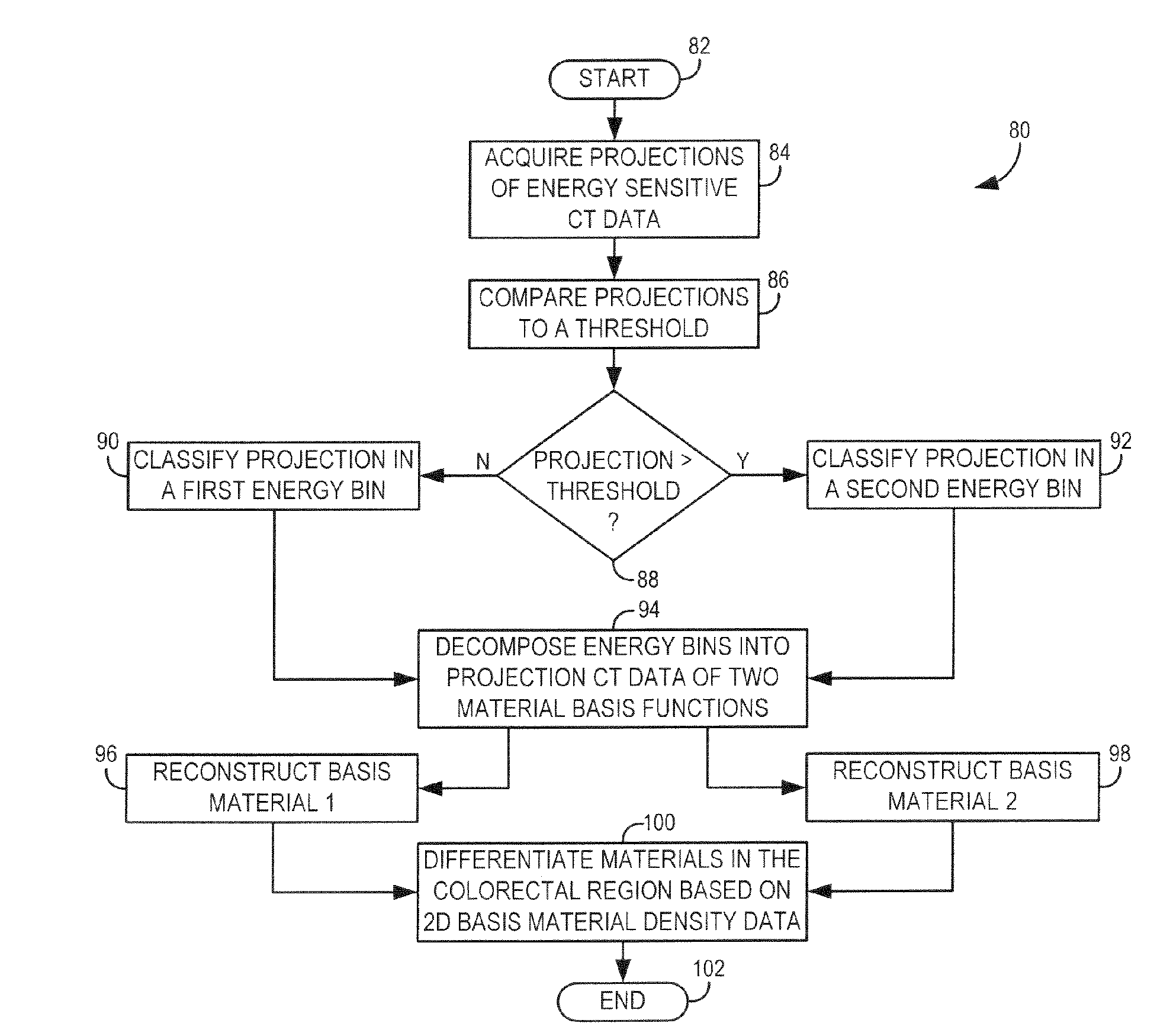

CT colonography system

ActiveUS7209536B2Material analysis using wave/particle radiationRadiation/particle handlingNuclear medicineMaterial density

A method and system of CT colonography is presented that includes the acquisition of energy sensitive or energy-discriminating CT data from a colorectal region of a subject. CT data is acquired and decomposed into basis material density maps and used to differentiate and enhance contrast between tissues in the colorectal region. The invention is particularly applicable with the detection of colon polyps without cathartic preparation or insufflation of the colorectal region. The invention is further directed to the automatic detection of colon polyps.

Owner:GENERAL ELECTRIC CO

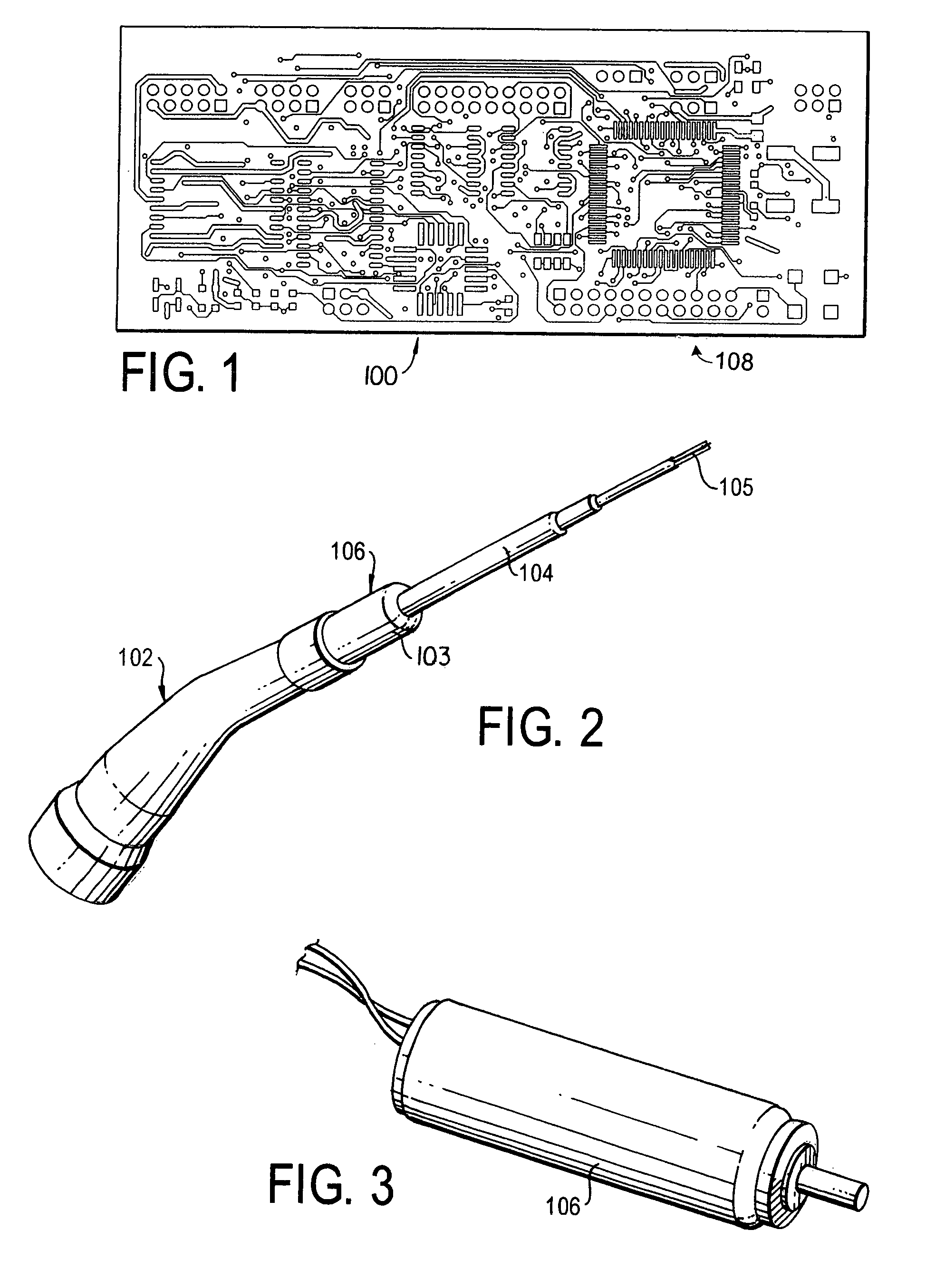

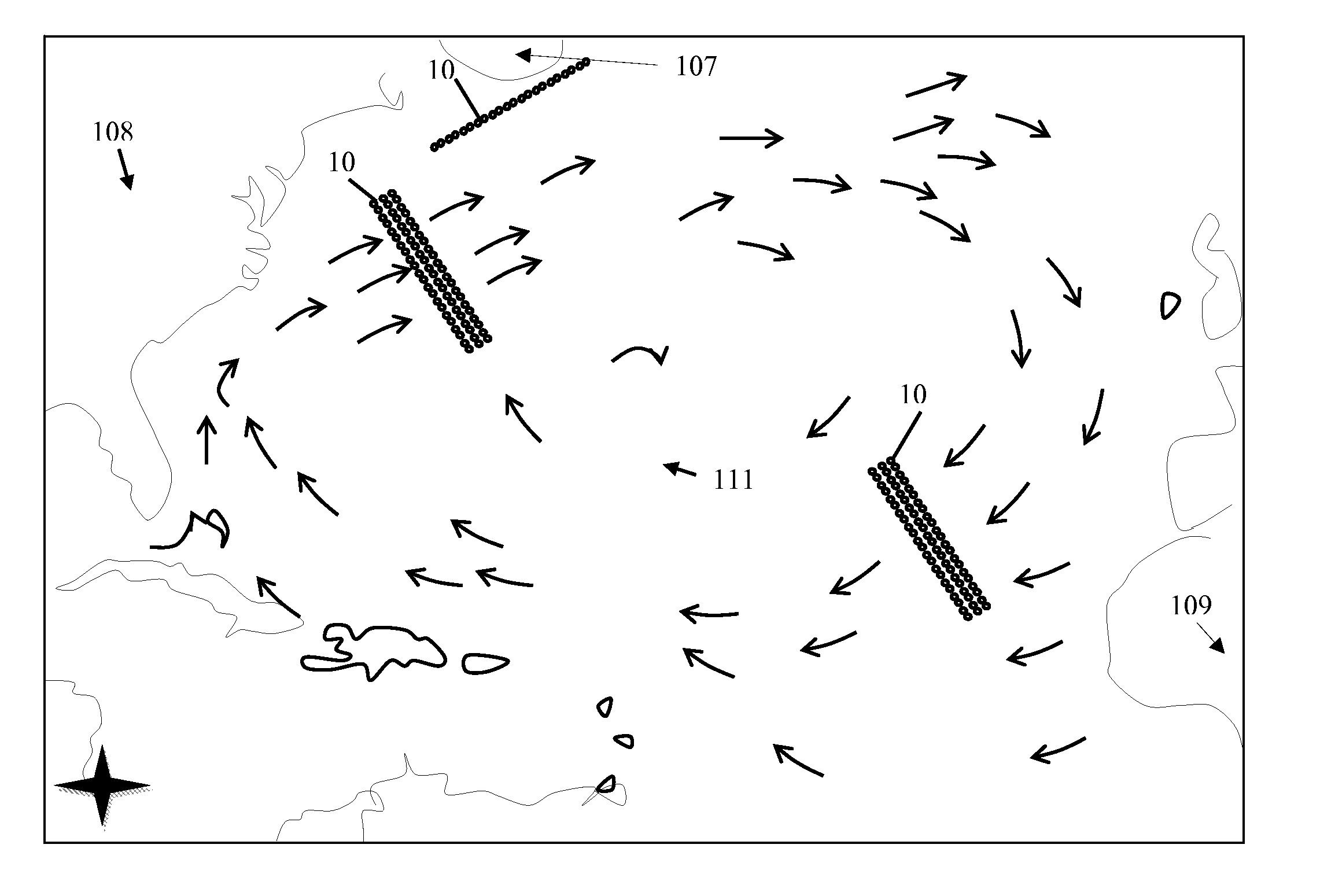

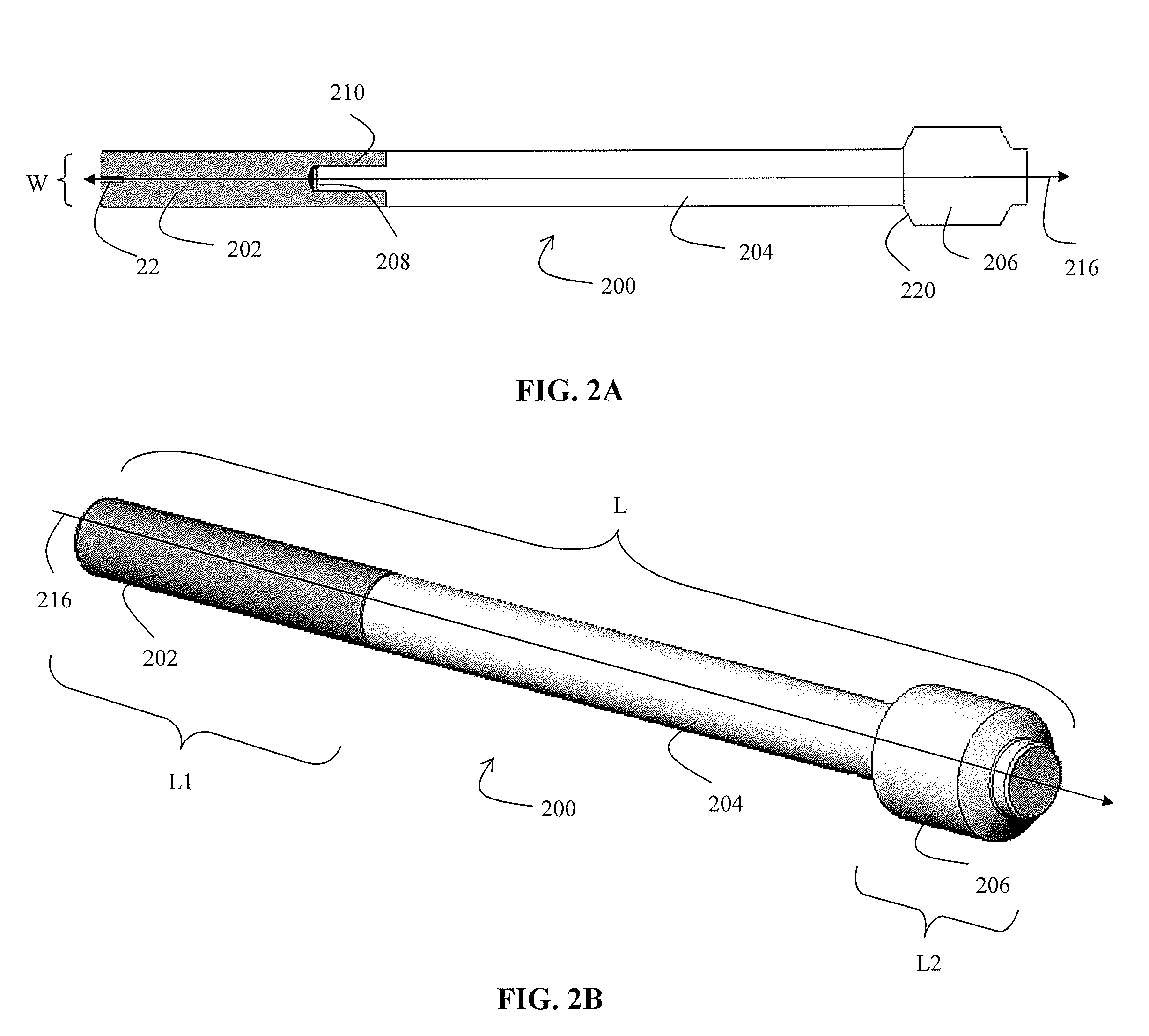

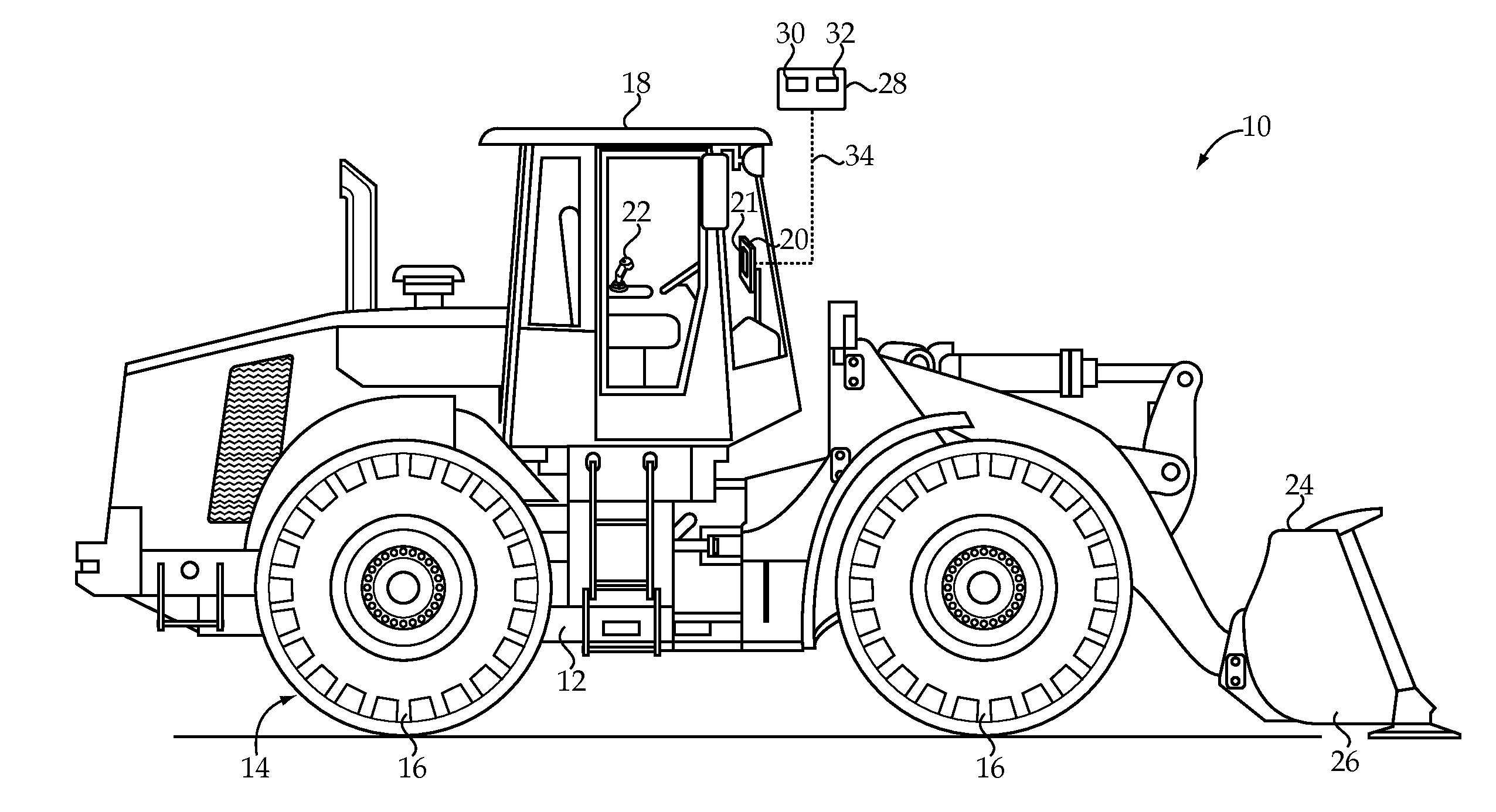

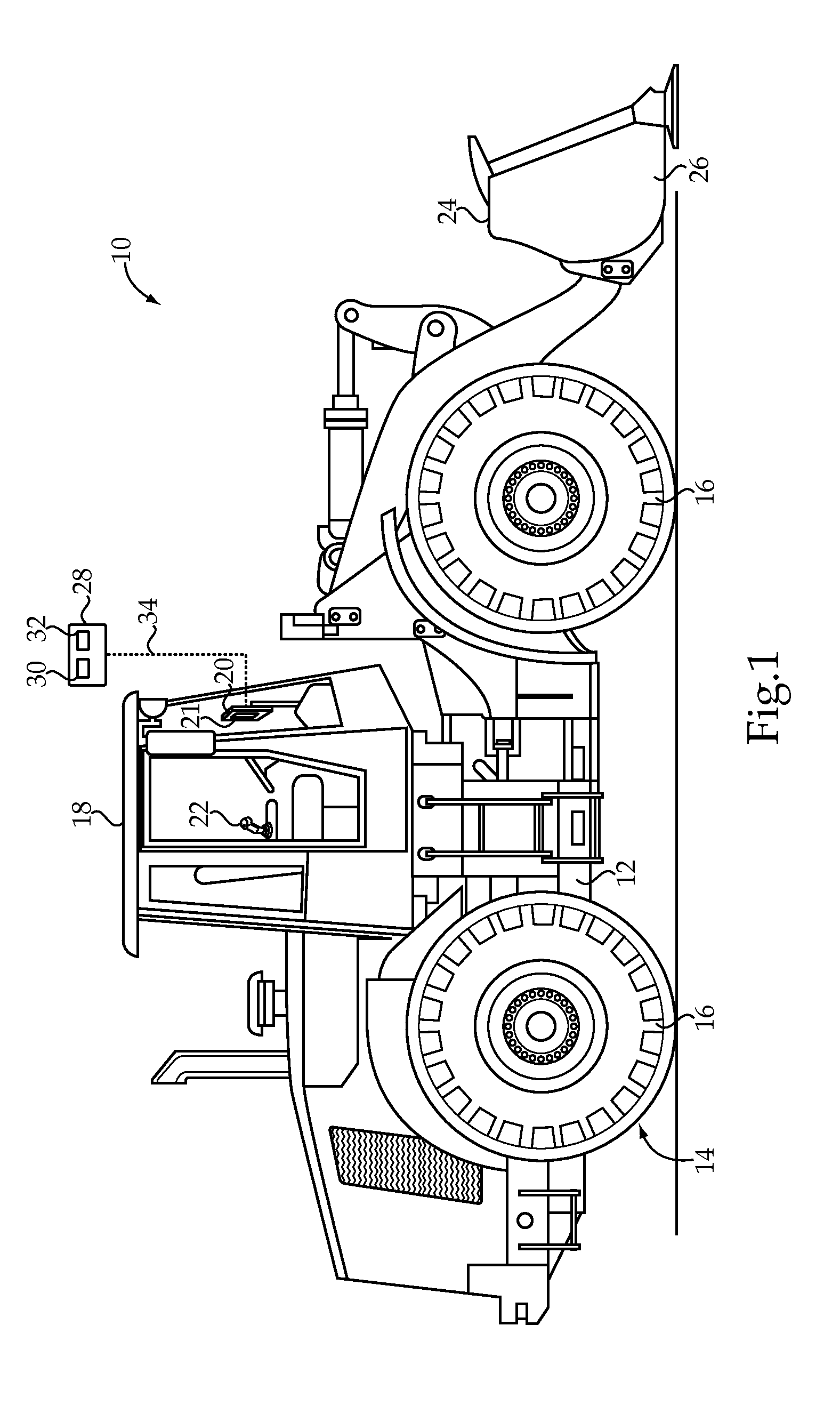

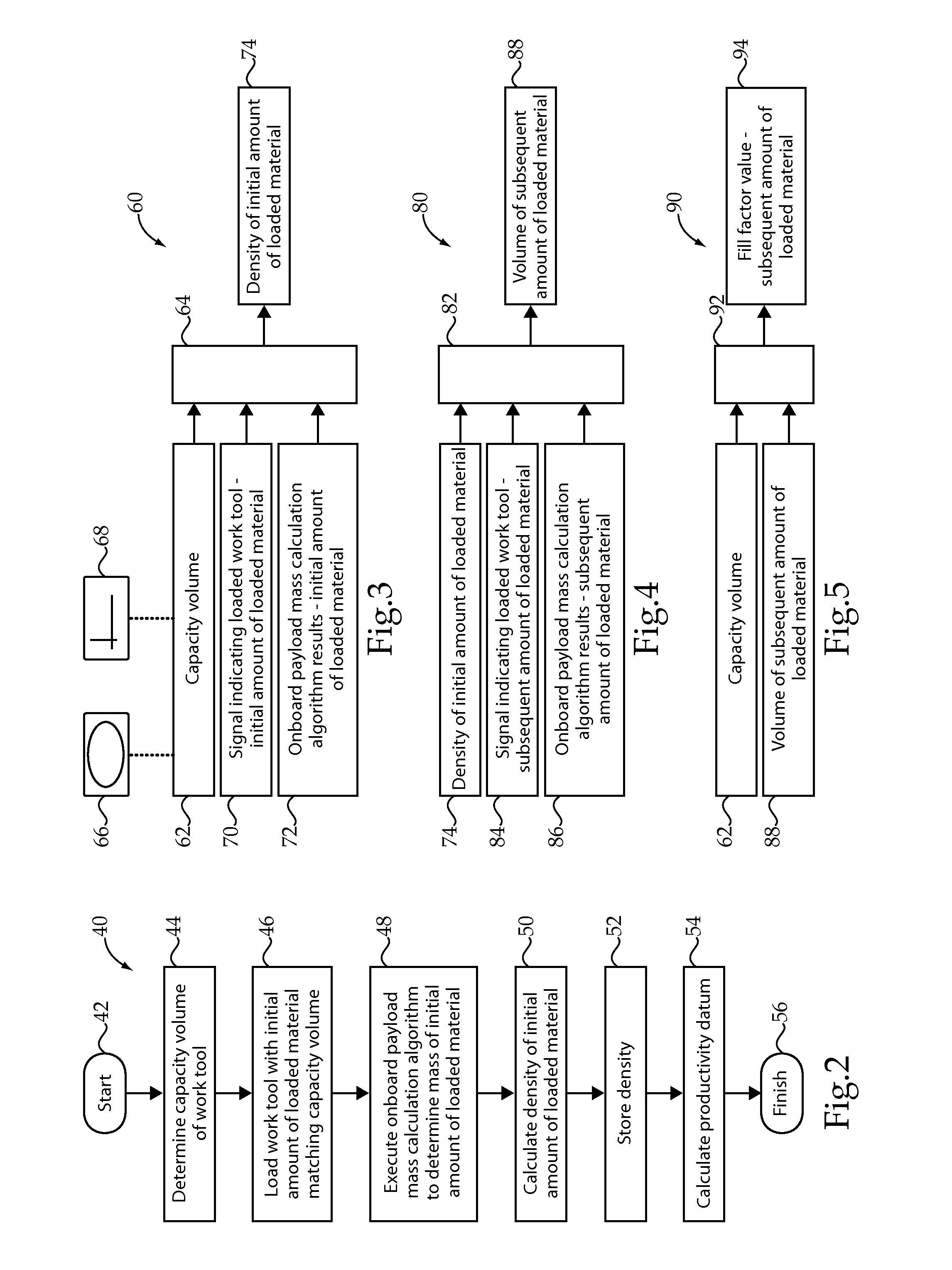

Payload material density calculation and machine using same

ActiveUS8838331B2Vehicle testingRegistering/indicating working of vehiclesProduction rateElectronic controller

A method of determining payload material density includes a step of determining a capacity volume of a work tool of a machine using an electronic controller of the machine. The work tool is loaded with an initial amount of loaded material matching the capacity volume, and an onboard payload mass calculation algorithm is executed using the electronic controller to determine a mass of the initial amount of loaded material. A density of the initial amount of loaded material is calculated responsive to the mass of the initial amount of loaded material and the capacity volume using the electronic controller. The density of the initial amount of loaded material is stored using the electronic controller, and a productivity datum is calculated responsive to the density of the initial amount of loaded material and a subsequent amount of loaded material.

Owner:CATERPILLAR INC

Compaction quality assurance based upon quantifying compactor interaction with base material

InactiveUS20050183512A1Material strength using tensile/compressive forcesMeasurement/indication equipmentsEnergy transferQuality assurance

In most construction processes, some quality assurance compaction test must be performed on a base material before further construction can take place on or relative to the compacted base material. In order to avoid costly downtime associated with waiting for a quality assurance test to be performed, the present invention contemplates generating compaction quality assurance data using on-board generated compaction quality control data. The quality control compaction data is based upon quantifying a sinkage deformation interaction between the compactor and the base material. The interaction might include monitoring an effective roller radius of the compactor, or an amount of energy transferred or consumed when the compactor moves over the base material, or even measuring a rut depth caused by the compactor. The compaction quality assurance data can be indicative of a proof rolling test result, a walk out test result, a penetrometer test result, a base material density test result, or possibly even a compactor sinkage into the base material.

Owner:CATERPILLAR INC

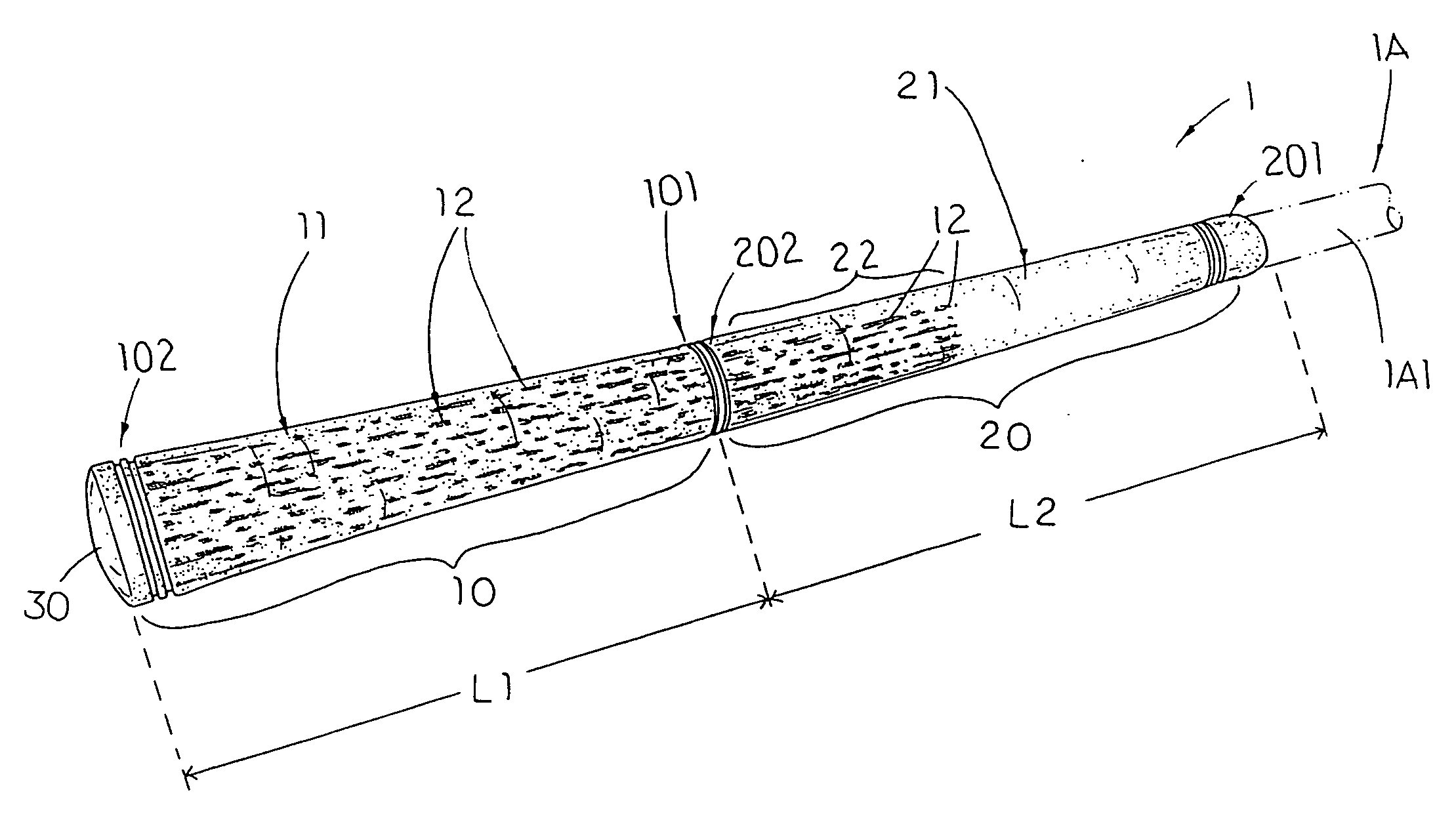

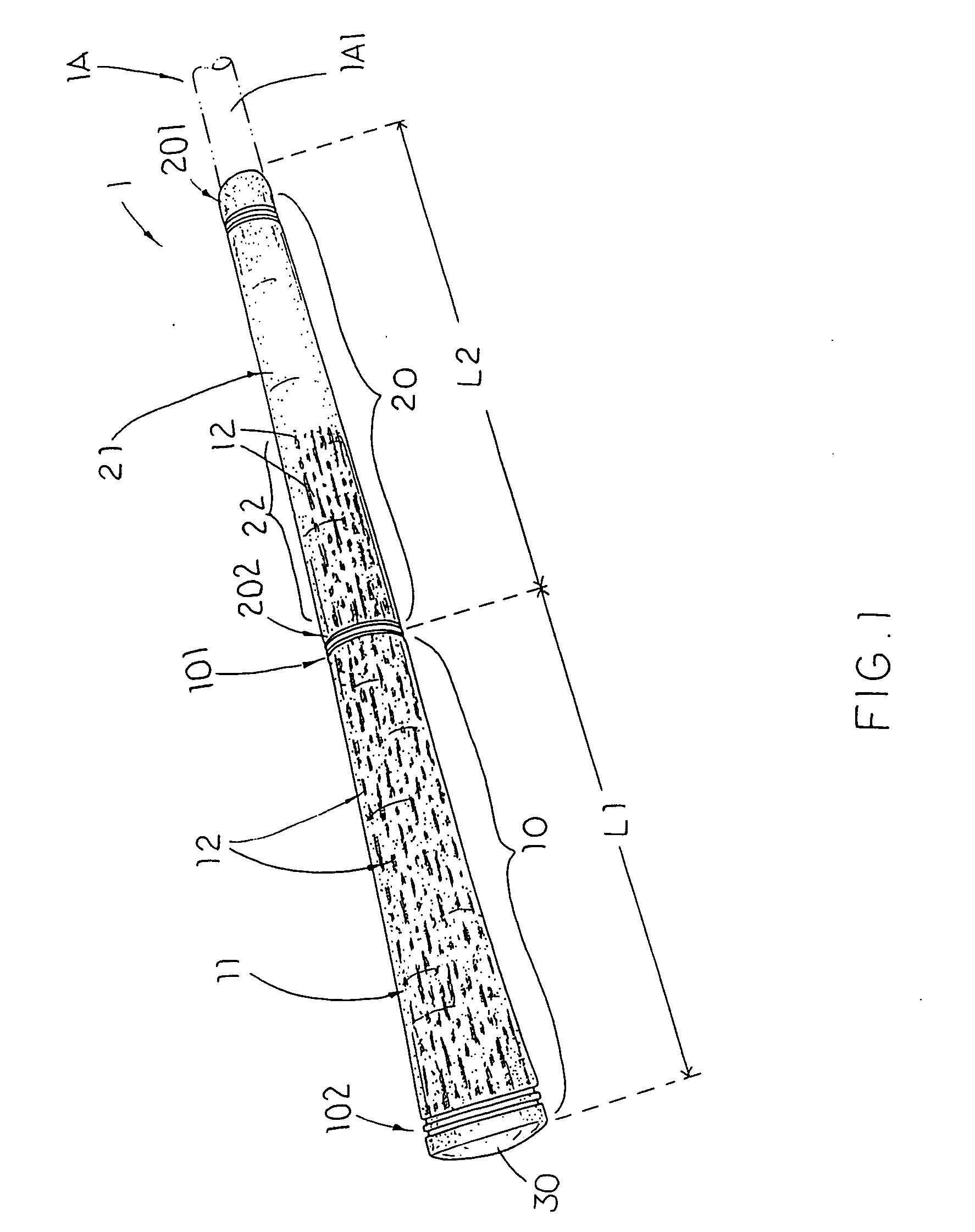

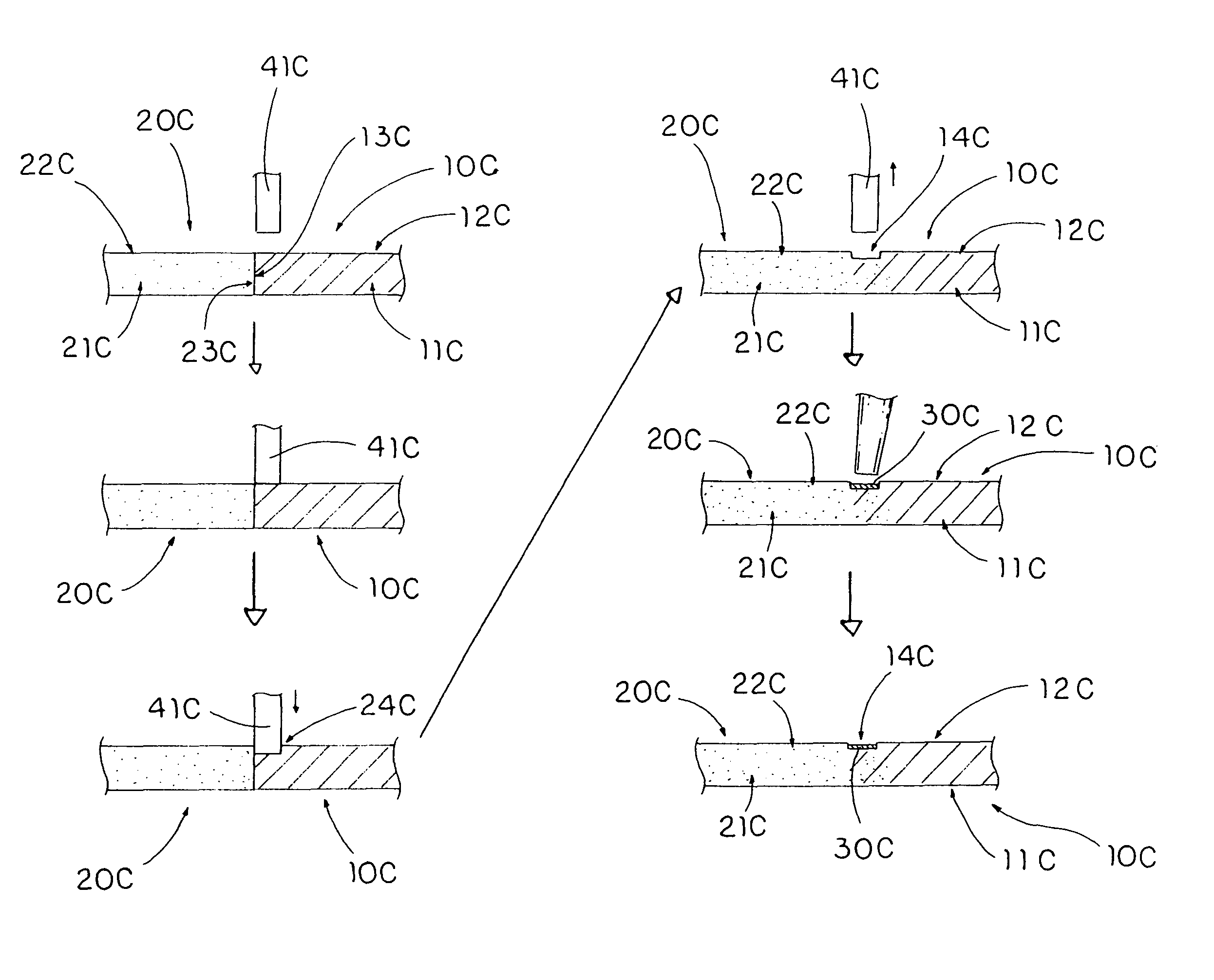

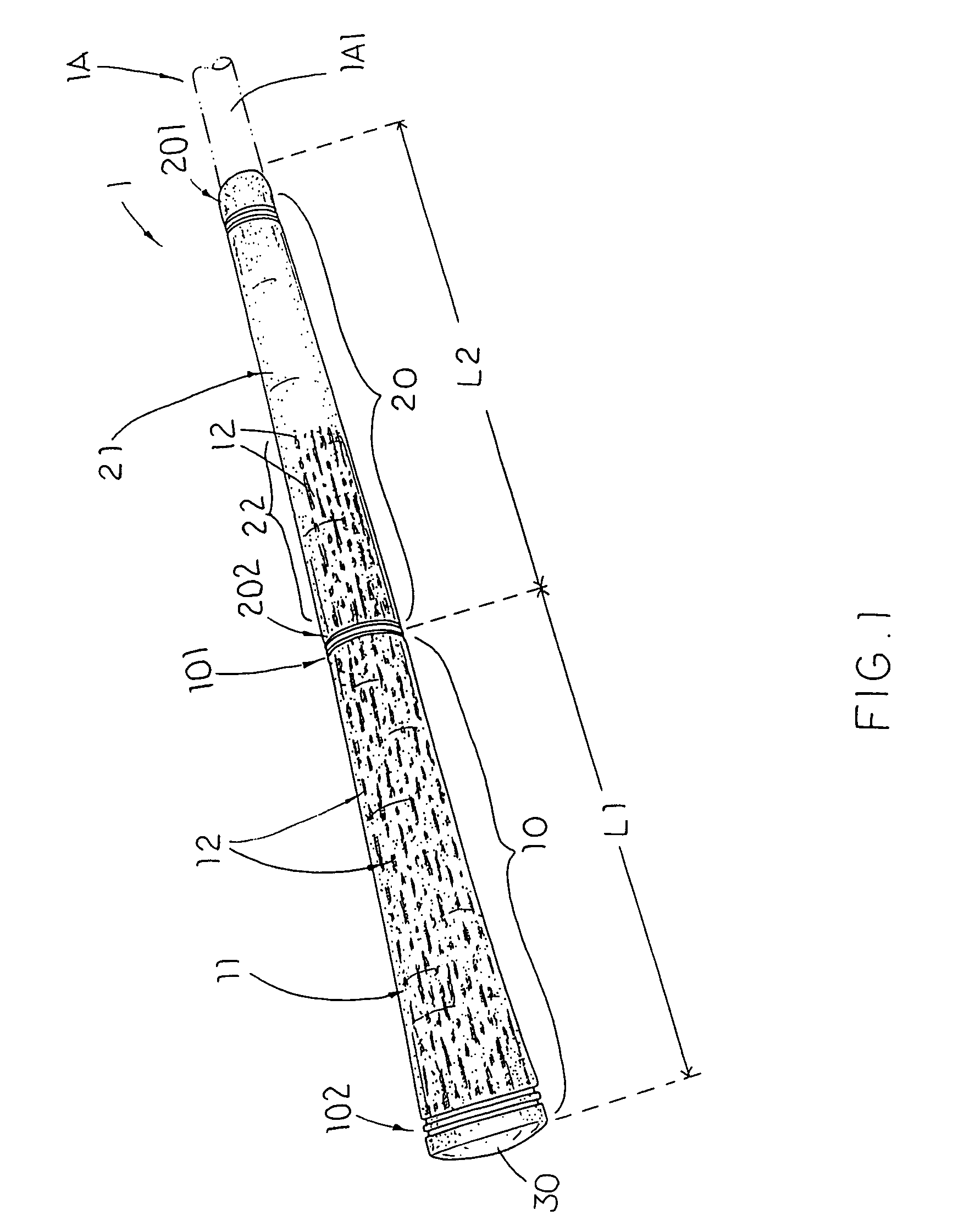

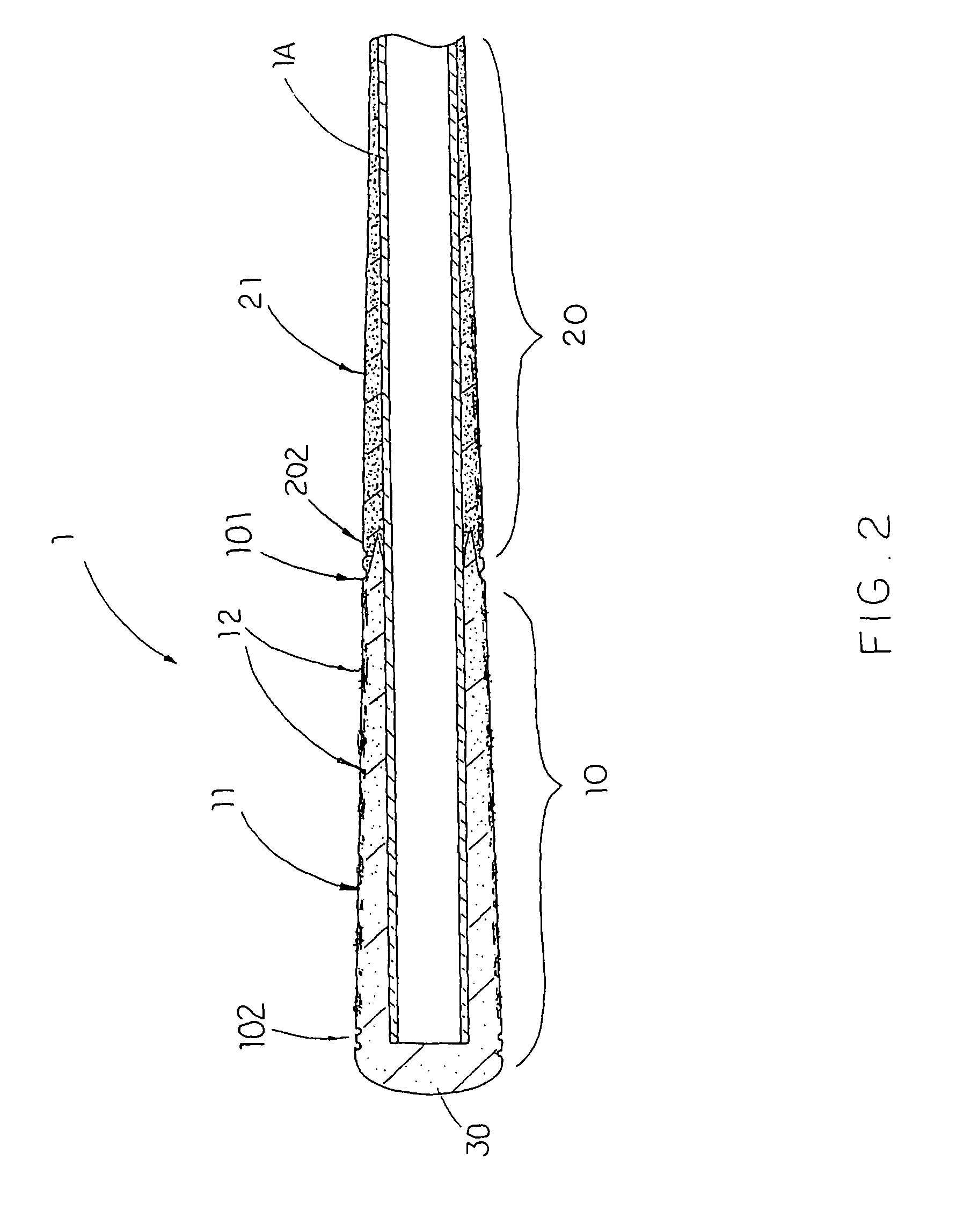

Golf club grip and manufacturing method thereof

InactiveUS20080125238A1Better holding the golf clubEasy to controlWood working apparatusCeramic shaping apparatusDark colorEngineering

A golf club grip includes a first grip member and a second grip member. The first grip member has a dark color and a first material density. The second grip member which has a light color and a second material density which is greater than the first material density, wherein the first grip member is integrated with the second grip member in an edge-to-edge manner to form an elongated tubular structure. When the first grip member and the second grip member is heated to integrate with each other, particles of the second grip member crosses over the first grip member to form a predetermined amount of light color at the first grip member, while the light color formed at the first grip member is adapted to be overlaid by the dark color so as to render the light color and the dark color sharply distinguishable on the gold club grip.

Owner:CHEN YUNG HSIANG

Golf club grip and manufacturing method thereof

InactiveUS7749094B2Better holding the golf clubEasy to controlWood working apparatusCeramic shaping apparatusDark colorGolf Ball

A golf club grip includes a first grip member and a second grip member. The first grip member has a dark color and a first material density. The second grip member which has a light color and a second material density which is greater than the first material density, wherein the first grip member is integrated with the second grip member in an edge-to-edge manner to form an elongated tubular structure. When the first grip member and the second grip member is heated to integrate with each other, particles of the second grip member crosses over the first grip member to form a predetermined amount of light color at the first grip member, while the light color formed at the first grip member is adapted to be overlaid by the dark color so as to render the light color and the dark color sharply distinguishable on the gold club grip.

Owner:CHEN YUNG HSIANG

Presintering process for reducing inequality in density of sintered material

The present invention discloses a presinter technology for reducing the ununiformity of sintering material density, including: (a) providing a mixture, which comprises (i) a first sintered material with impurity, which generates higher vapor tension than the pure material due the impurity during the sintering process; and (ii) a second material, which has better affinity to the impurity than the first sintering material; (b) heating the mixture with adequate time at certain temperature, to make the second material weaken partly the trend that the first sintering material increases the vapor tension during the sintering process. Other implementing solutions are also disclosed in the present invention.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com