Patents

Literature

217 results about "Micro texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

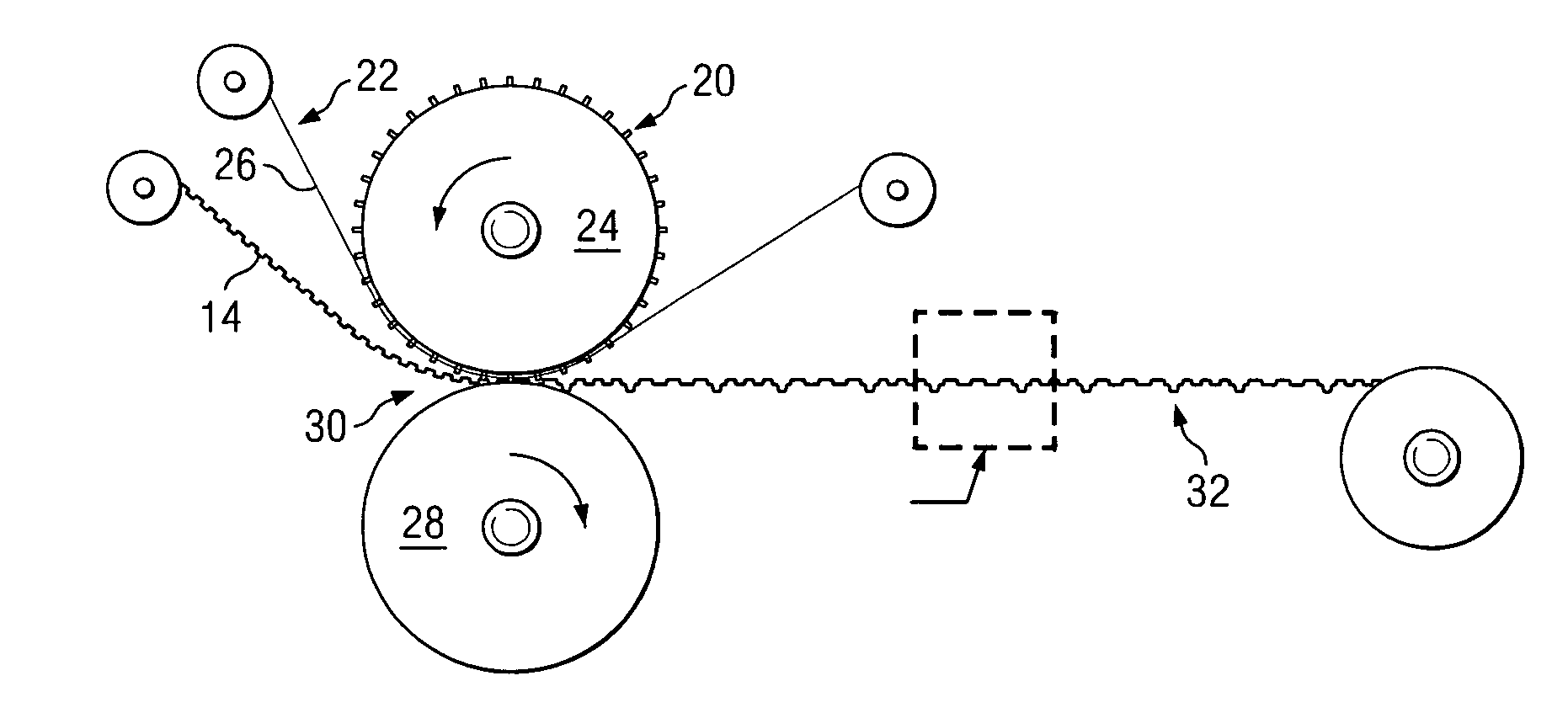

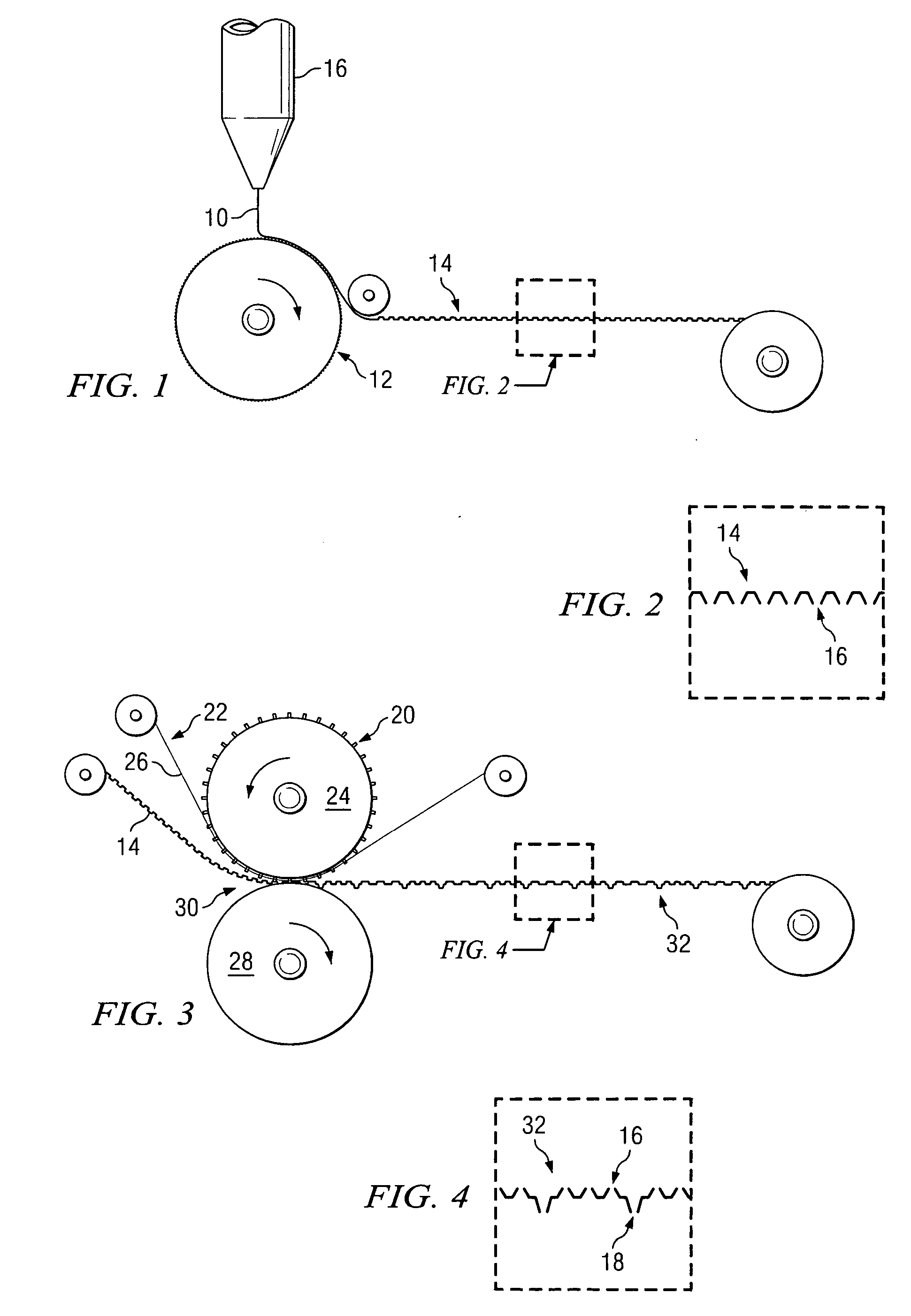

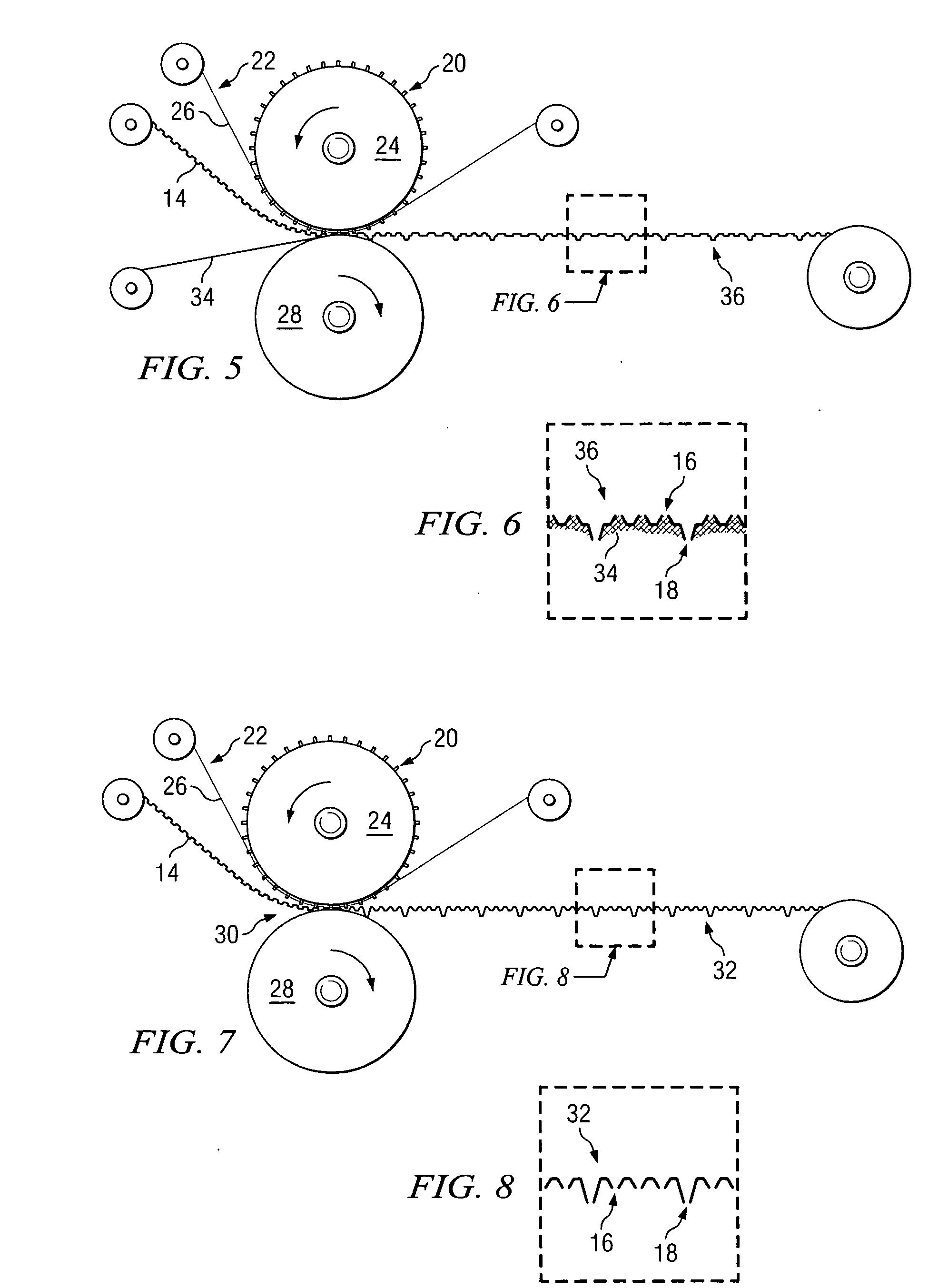

Apertured material for use in absorbent articles and method of making the same

Owner:TREDEGAR FILM PROD CORP

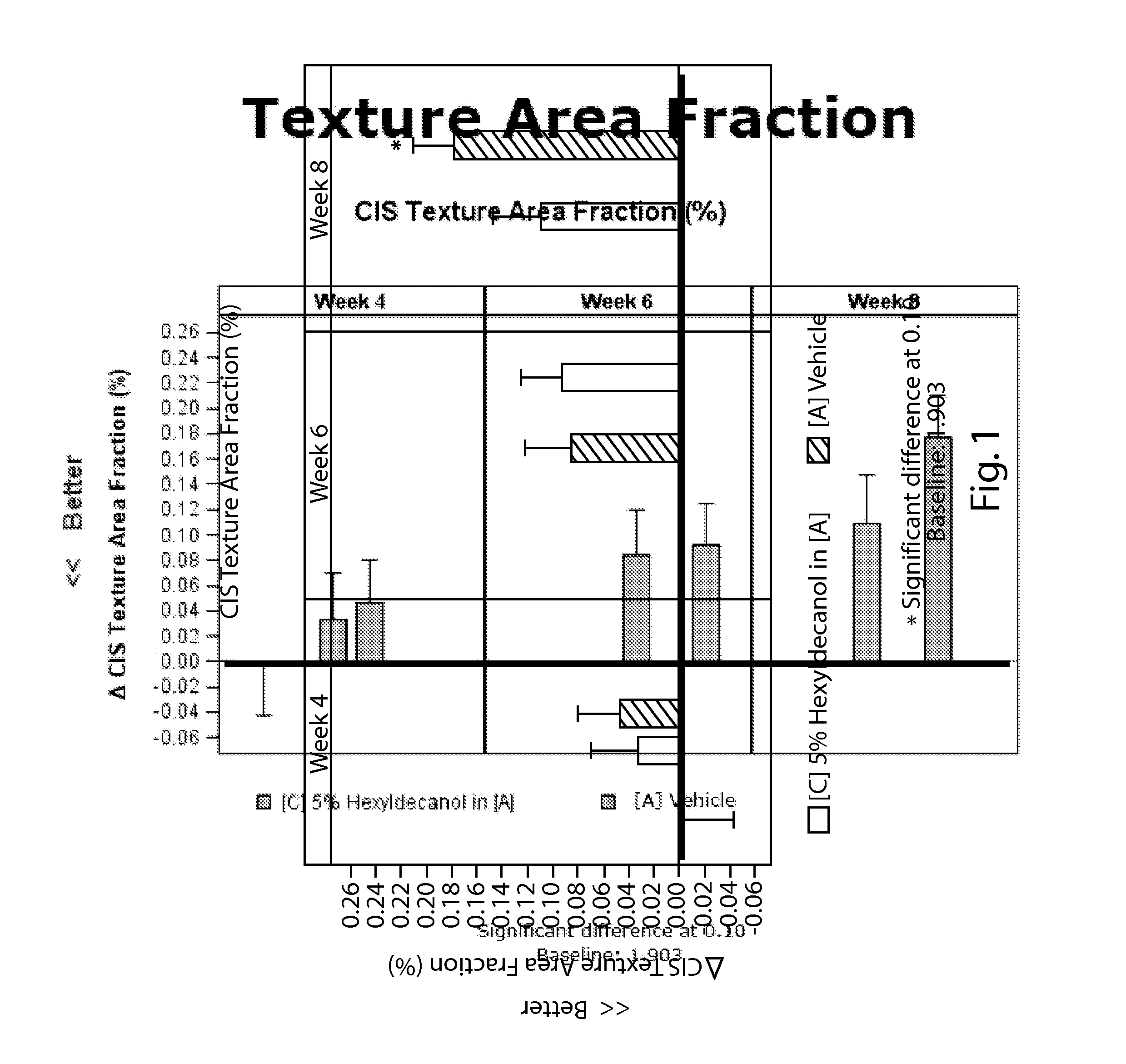

Compositions and Methods for Improving the Appearance of Facial Texture

InactiveUS20120156146A1Good lookingAppearance of texture is enhancedBiocideCosmetic preparationsFacial skinMicro texture

A method of improving the appearance of facial texture may comprise the step of applying a composition comprising an effective amount of a material that regulates hyaluronic acid synthesis to an area of textured facial skin, wherein the composition is applied for a period of time sufficient for the material to improve the appearance of the facial texture. In some embodiments, the material that regulates hyaluronic acid synthesis is hexyldecanol. The method may also include the step of identifying facial texture on a facial skin surface. In particular embodiments, the facial skin texture is selected from the group consisting of macro-texture, micro-texture, and combinations thereof.

Owner:THE PROCTER & GAMBLE COMPANY

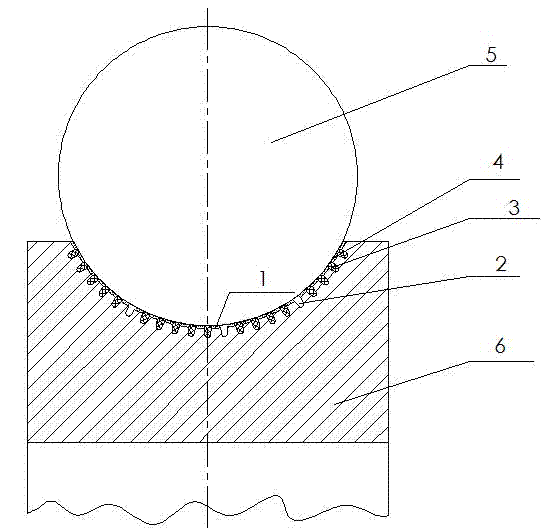

Method for self-lubricating treatment of laser micro-texture of bearing

InactiveCN102226459AImprove complex working conditionsGuaranteed carrying capacityBearing componentsLaser beam welding apparatusGraphiteOptoelectronics

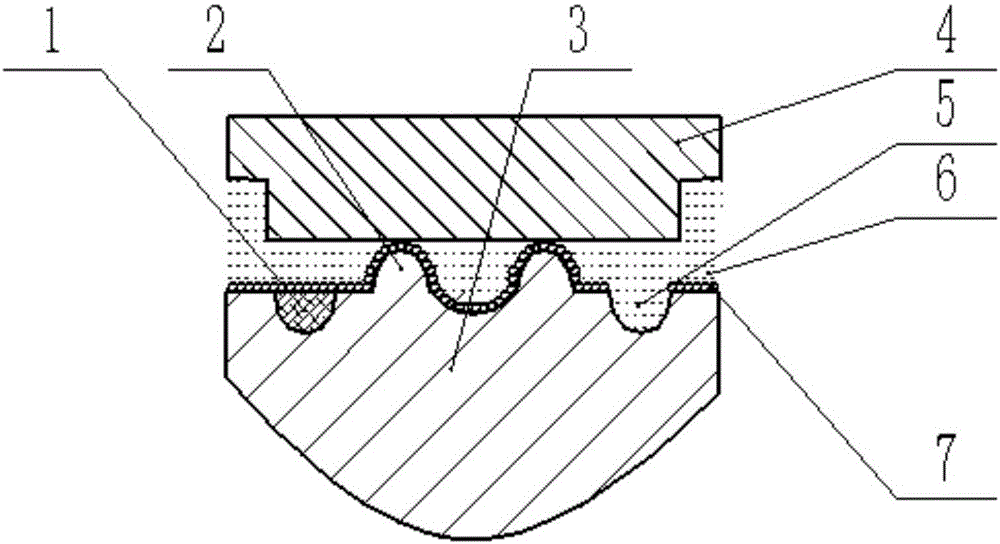

The invention discloses a method for self-lubricating treatment of laser micro-texture of bearings. The invention comprises the following steps: firstly performing laser micro-processing technology of micro recessed cavities or micro grooves on a bearing surface, and then performing molding and bonding technology by a self-lubricating composite material on the bearing surface; the self-lubricating composite material comprises the following components by mass: 10-15% of polyimide (PI); 8-13% of graphite powder; 40-50% of polytetrafluoroethylene; 25-29% of MoS2; 0-5% of additives. By the self-lubricating treatment of laser micro-texture of a bearing, the invention guarantees the bearing capacity and the fitting accuracy of the bearing, realizes an optimized distribution of the lubricant on the bearing working surface, and improves comprehensive performance of antifriction and wear resistance of the bearing under complicated working conditions.

Owner:JIANGSU UNIV

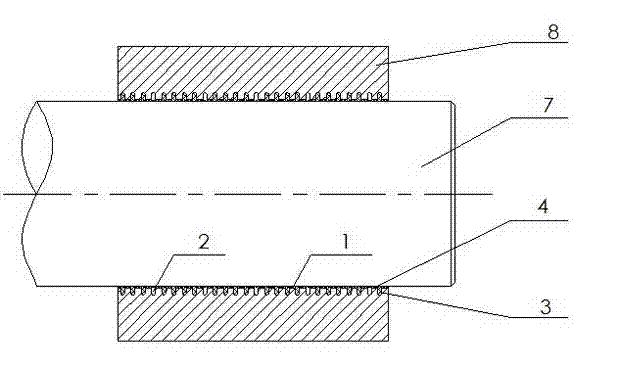

Guiding sliding friction pair of multi-element composite texture, processing method and application of guiding sliding friction pair

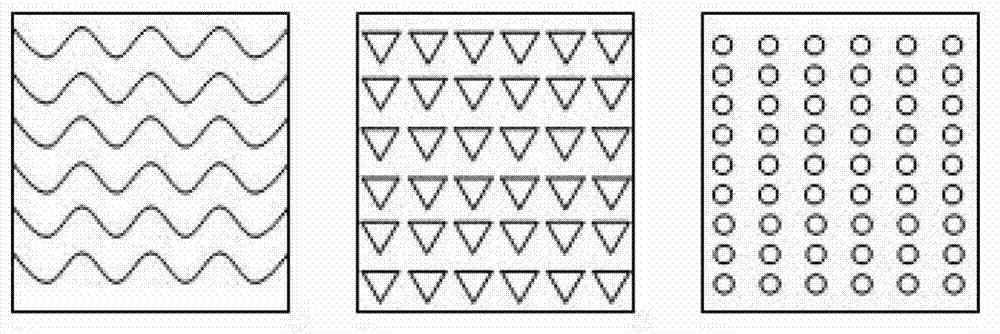

ActiveCN106090001AReduce friction and wearInhibit crawling phenomenonLinear bearingsShaftsLow speedMicro texture

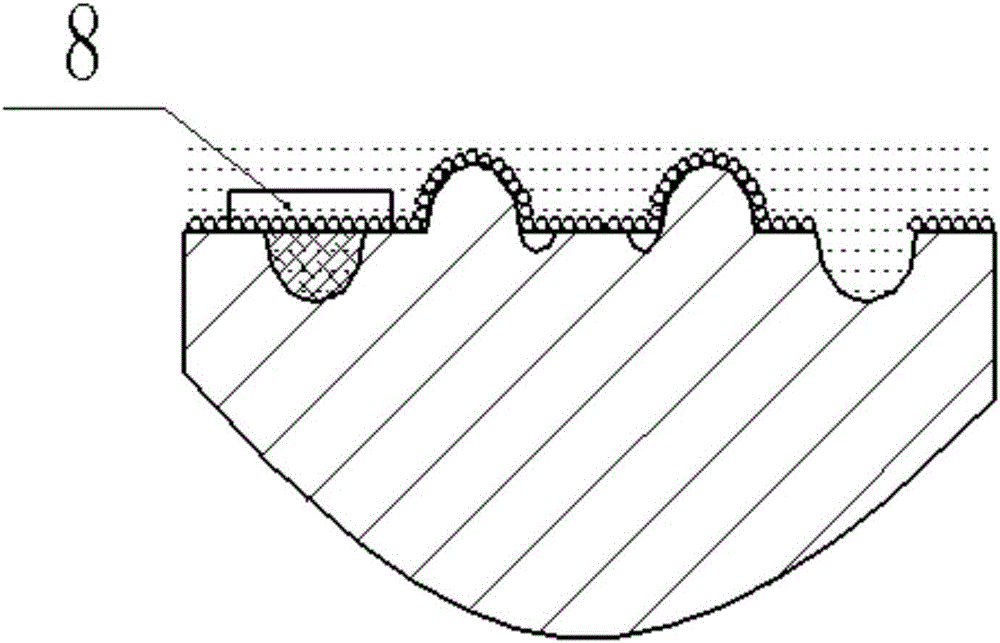

The invention provides a guiding sliding friction pair of a multi-element composite texture, a processing method and application of the guiding sliding friction pair. Composite micro-texture morphology with orderly and uniformly distributed miniature pits and miniature protrusions is processed on a working plane of the friction pair through a laser device, and the miniature pits are filled with composite nanometer solid lubricants through a filling-pressing process. The laser micro-texture method is adopted to carry out non-contact processing and nanometer composite material filling and coating on a working plane of a guide rail, the creeping phenomenon of the machine tool guide rail can be effectively suppressed, the guide rail can be effectively lubricated under complex working conditions of a low speed, heavy load and the like, and the effects of reducing friction and resisting bonding are achieved.

Owner:JIANGSU UNIV

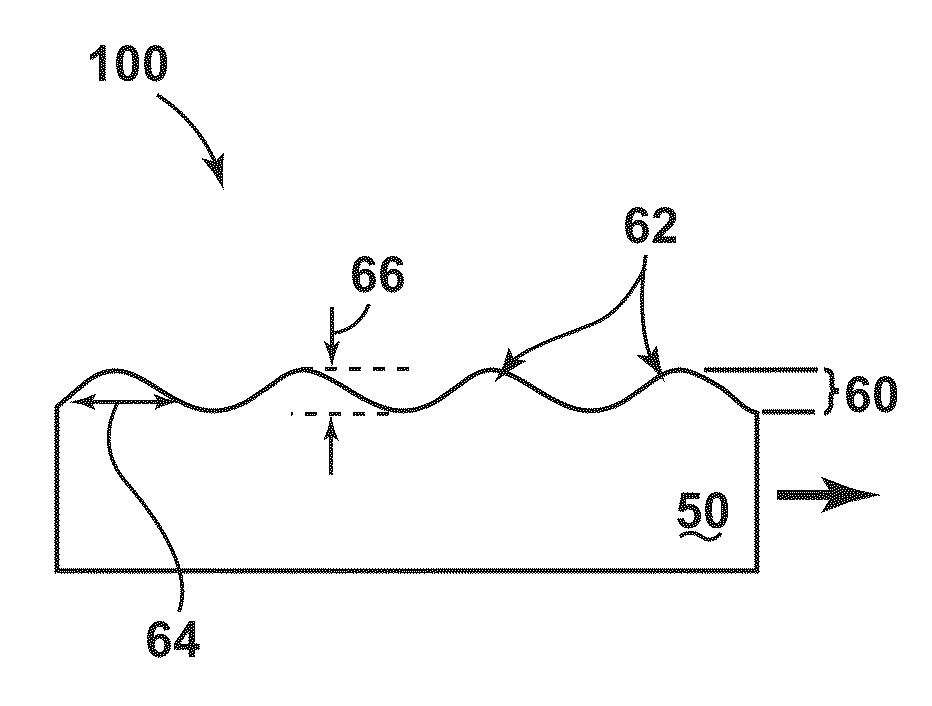

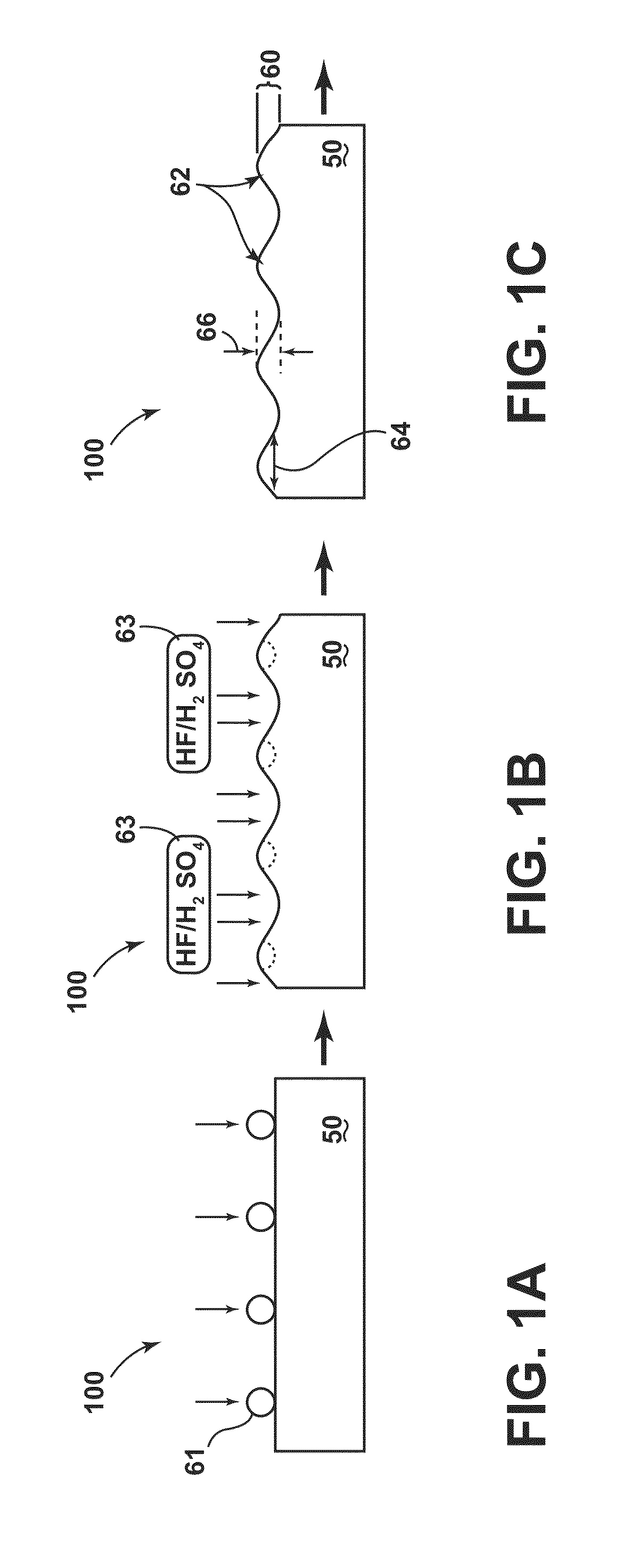

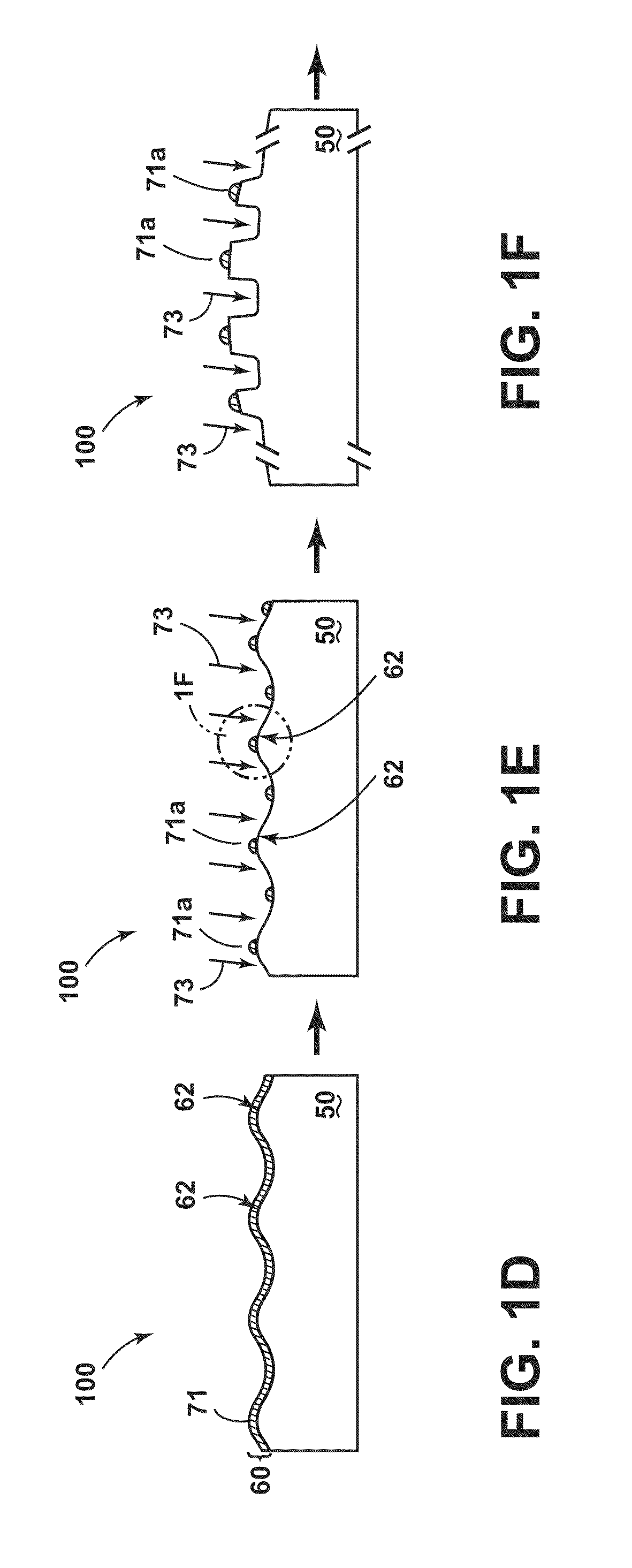

Articles with monolithic, structured surfaces and methods for making and using same

A textured article that includes a transparent substrate having at least one primary surface and a glass, glass-ceramic or ceramic composition; a micro-textured surface on the primary surface of the substrate, the micro-textured surface comprising a plurality of hillocks; and a nano-structured surface on the micro-textured surface, the nano-structured surface comprising a plurality of nano-sized protrusions or a multilayer coating comprising a plurality of layers having a nano-scale thickness. Further, the hillocks have an average height of about 10 to about 1000 nm and an average longest lateral cross-sectional dimension of about 1 to about 100 μm, and the nano-sized protrusions have an average height of about 10 to about 500 nm and an average longest lateral cross-sectional dimension of about 10 to about 500 nm. The substrate may be chemically strengthened with a compressive stress greater than about 500 MPa and a compressive depth-of-layer greater than about 15 μm.

Owner:ICREA +2

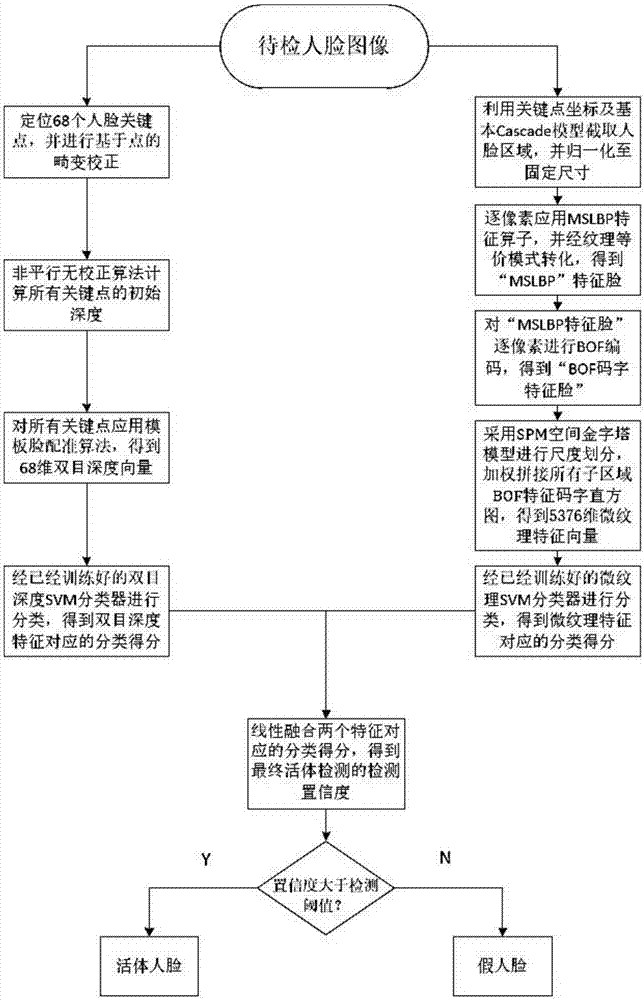

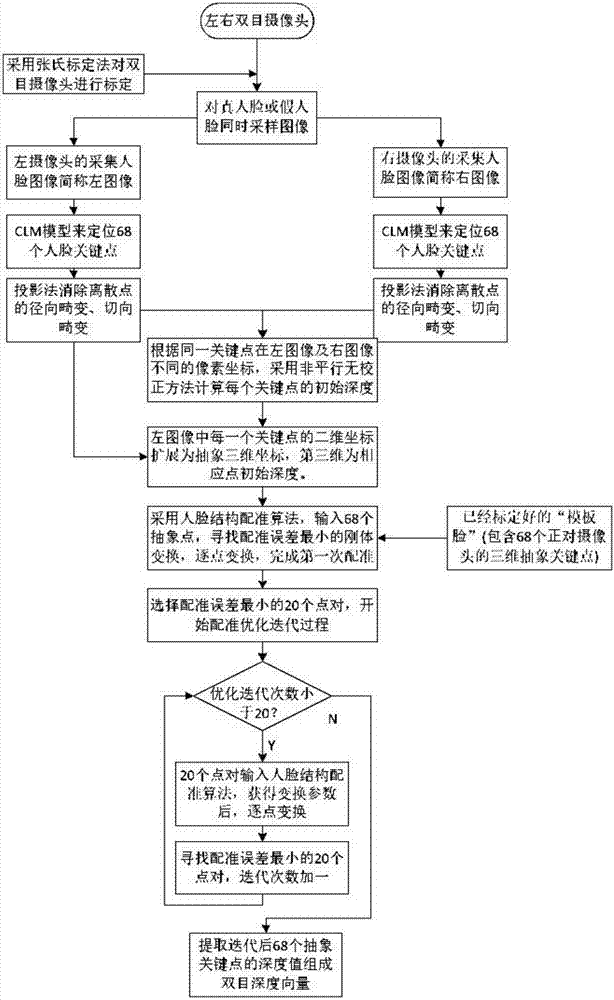

Binocular vision depth feature and apparent feature-combined face living body detection method

The present invention provides a binocular vision depth feature and apparent feature-combined face living body detection method. The method includes the following steps that: step 1, a binocular vision system is established; step 2, a face is detected through the binocular vision system, so that a plurality of key points can be obtained; step 3, a binocular vision depth feature and a classification score corresponding to the binocular vision depth feature are obtained; step 4, a complete face area is intercepted from a left image, the complete face area is normalized to a fixed size, and a local binary pattern (LBP) feature is extracted so as to be adopted as an apparent feature descriptor; step 5, a face living body detection score corresponding to a micro-texture feature is obtained; and step 6, the classification score corresponding to the binocular vision depth feature obtained in the step 3 and the face living body detection score corresponding to the micro-texture feature obtained in the step 5 are fused in a decision-making layer, so that whether an image to be detected is a live body can be judged. The binocular vision depth feature and apparent feature-combined face living body detection method of the invention has the advantages of simple algorithm, high operation speed, high precision and the like. With the method adopted, a new and reliable method can be provided for living body face detection.

Owner:SHANGHAI JIAO TONG UNIV

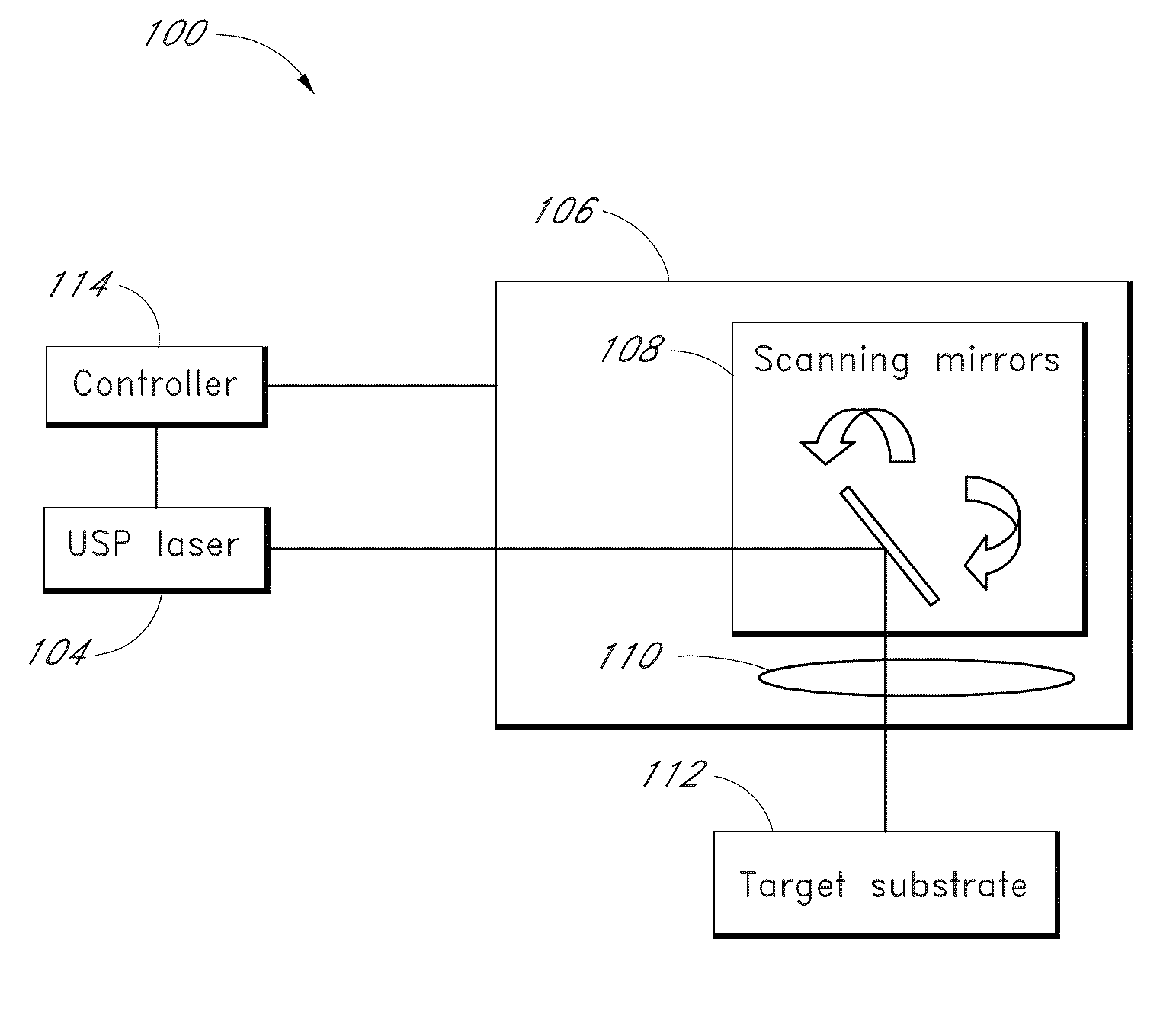

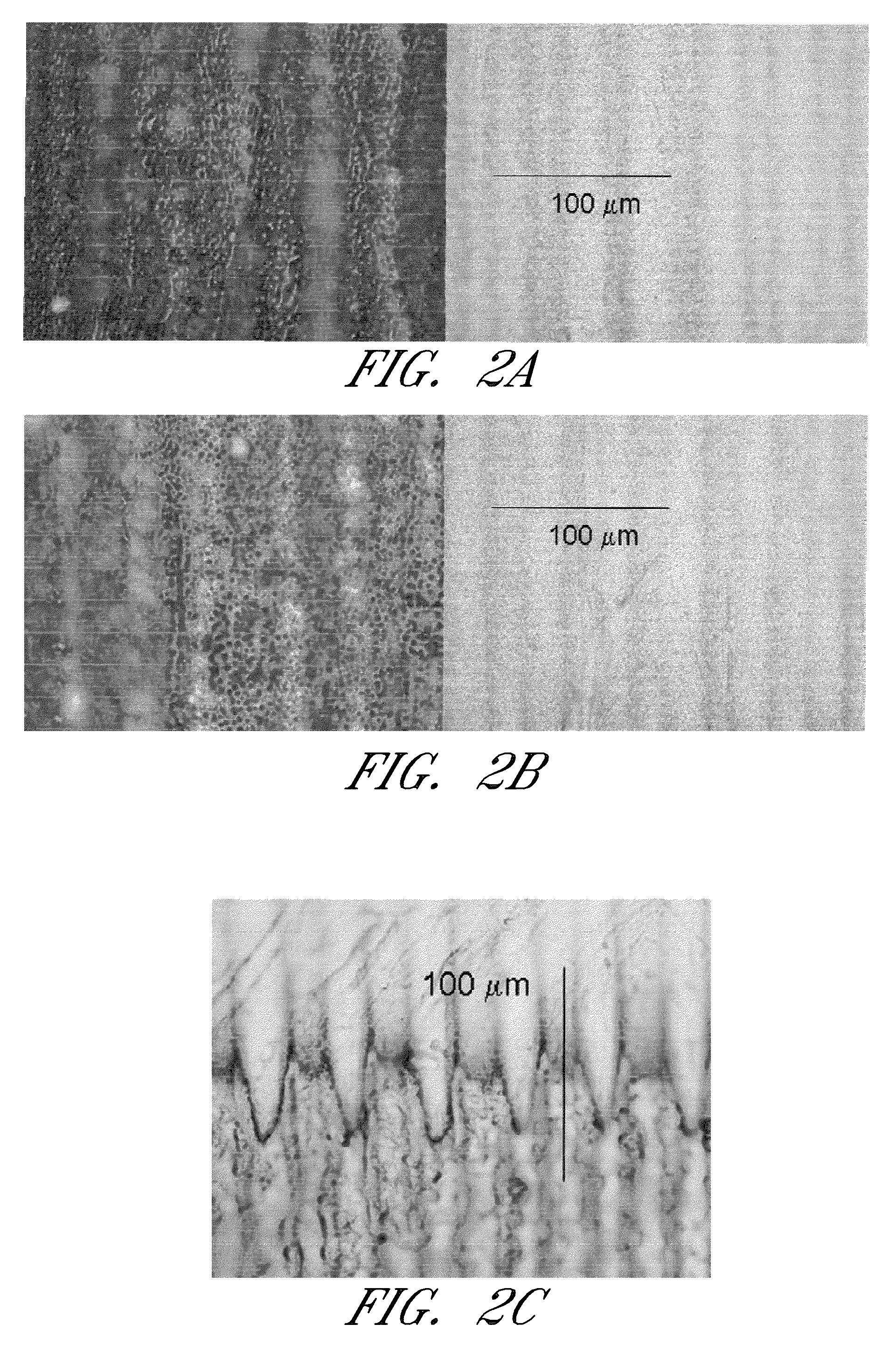

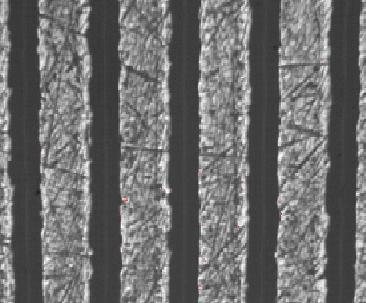

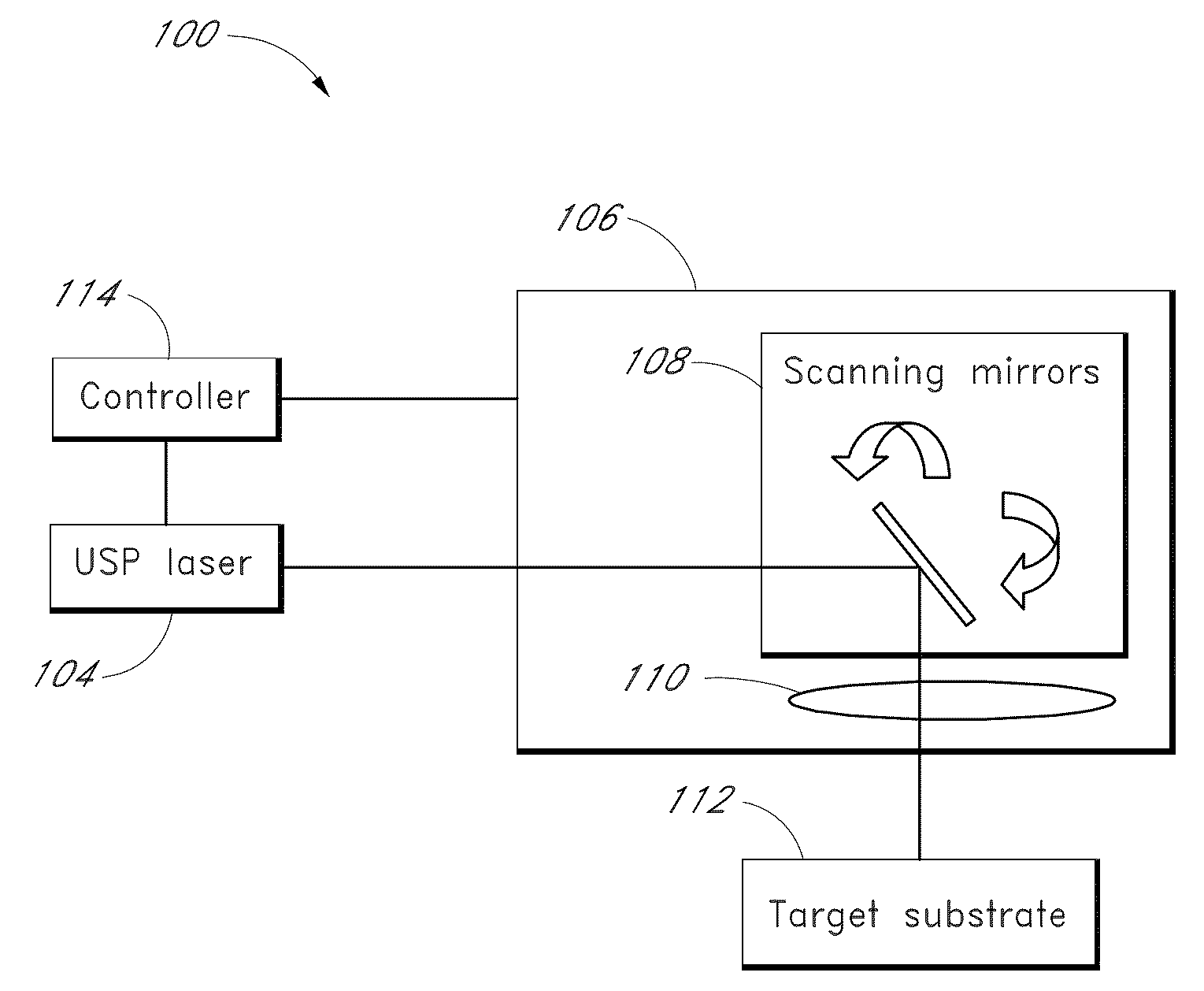

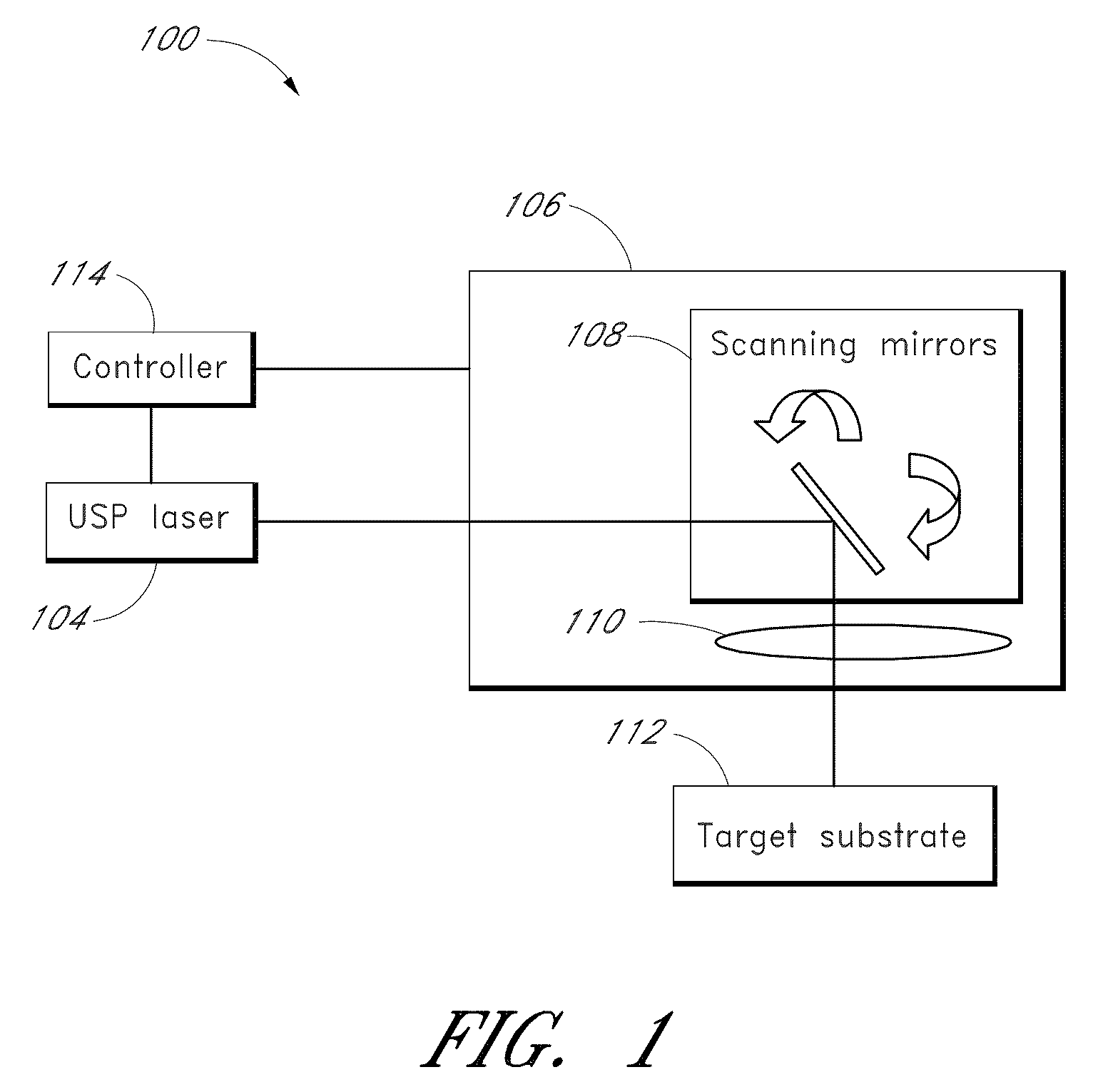

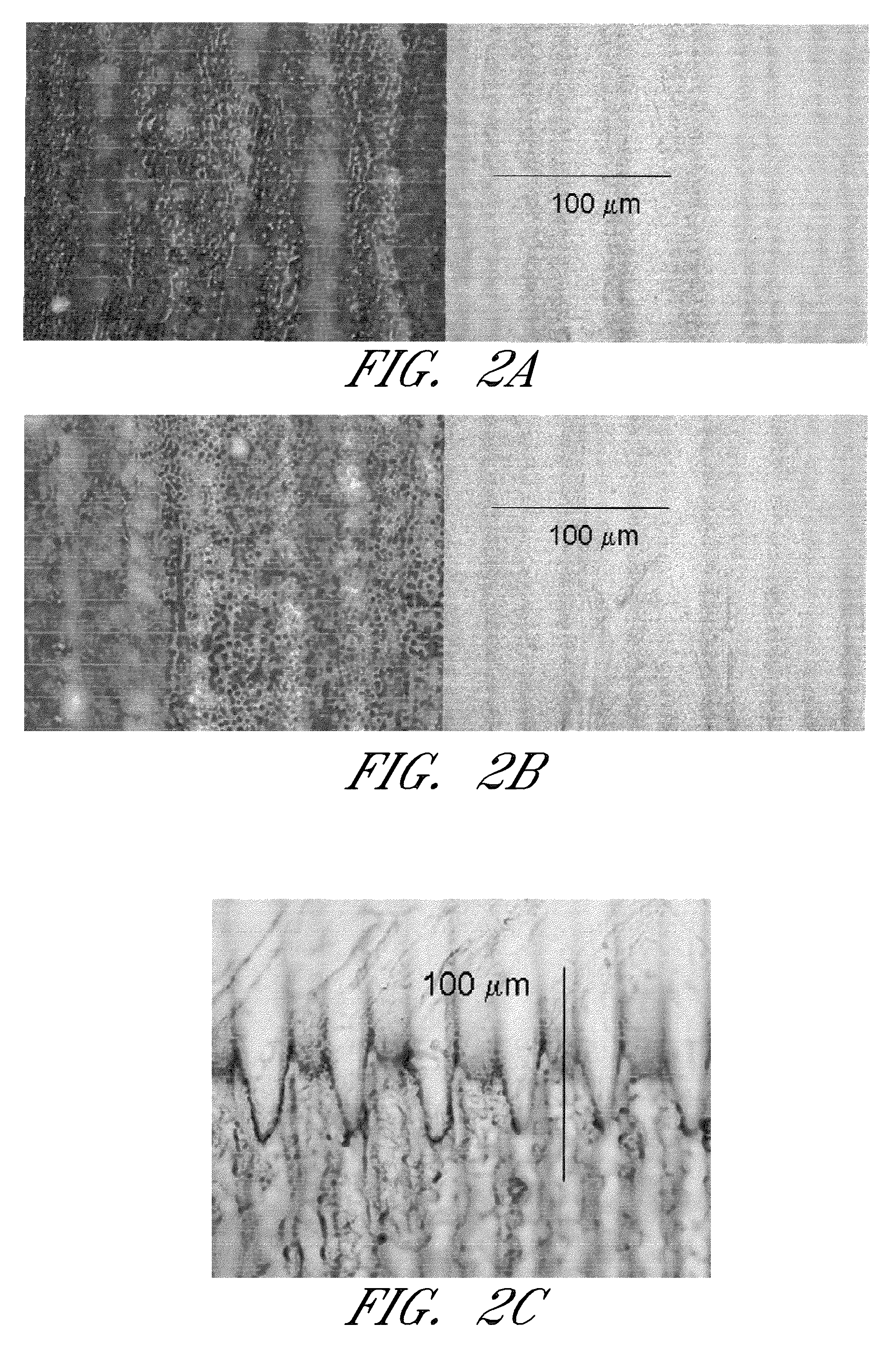

Ultrashort laser micro-texture printing

InactiveUS8405885B2Smooth changeEasy to produceDigitally marking record carriersDigital computer detailsMicro structureUltrashort laser

Systems and methods for providing laser texturing of solid substrates are disclosed. The texturing may be used to provide grayscale images obtainable from substrates, which may include steel, aluminum, glass, and silicon. In some embodiments, images may be obtainable from the substrate by modifying the reflective, diffractive, and / or absorptive features of the substrate or the substrate surface by forming random, periodic, and / or semi-periodic micro-structure features on the substrate (or substrate surface) by an ultrafast laser pulse train. The ultrafast pulse train may be modulated in order to vary, for example, optical exposure time, pulse train intensity, laser polarization, laser wavelength, or a combination of the aforementioned. The ultrafast pulse train and the substrate may be scanned with respect to each other to provide different optical energies to different regions of the substrate (or substrate surface). In some embodiments, the image is provided by making one or more passes of the ultrafast laser pulse train relative to the substrate.

Owner:IMRA AMERICA

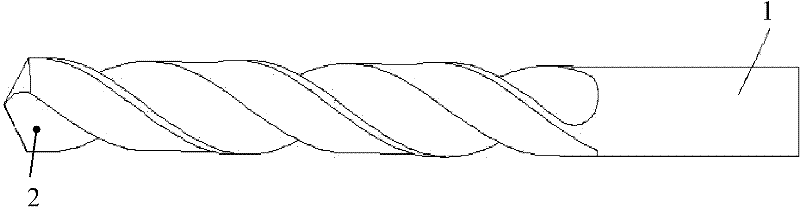

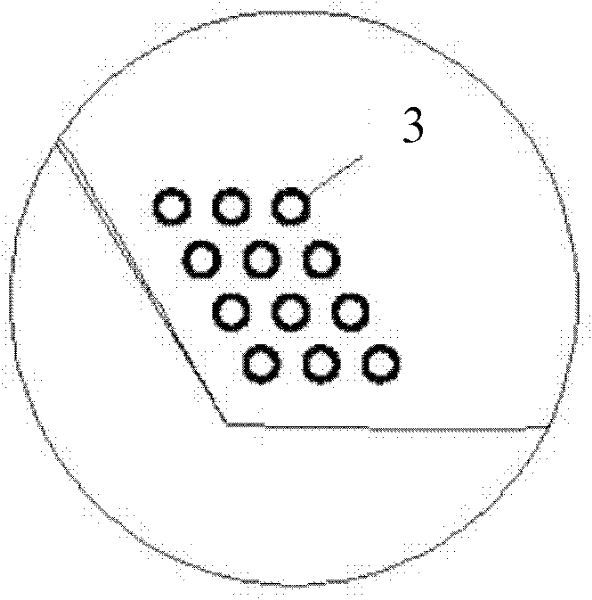

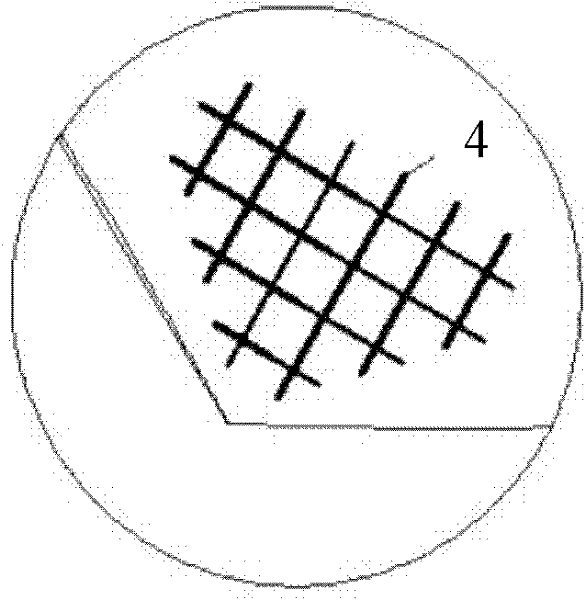

Micro-texture self-lubricating drilling bit and manufacturing method thereof

InactiveCN102189287AExtend your lifeAvoid pollutionTransportation and packagingTrepanning drillsManufacturing technologyEngineering

The invention belongs to the technical field of mechanical cutting tool manufacturing, and in particular relates to a micro-texture self-lubricating drilling bit and a manufacturing method thereof. A knife-chipping contact area of the rack face of the micro-texture self-lubricating drilling bit is provided with a plurality of micro-textures which are filled with a solid lubricant; during dry drilling, under the action of high temperature, the solid lubricant in the micro-textures is rapidly softened and is applied to the rack face of the drilling bit; a continuous solid lubricating layer is formed on the knife-chipping contact area of the rack face of the drilling bit, thereby being capable of preventing bonding, decreasing friction, reducing abrasion and prolonging the service life of the drilling bit. The micro-texture self-lubricating drilling bit can be widely applied to the drilling and machining of dry-type drilling and difficulty-machined materials, can overcome the environmental pollution caused by cutting fluid, realizes clean production and reduces the cost.

Owner:SHANDONG UNIV

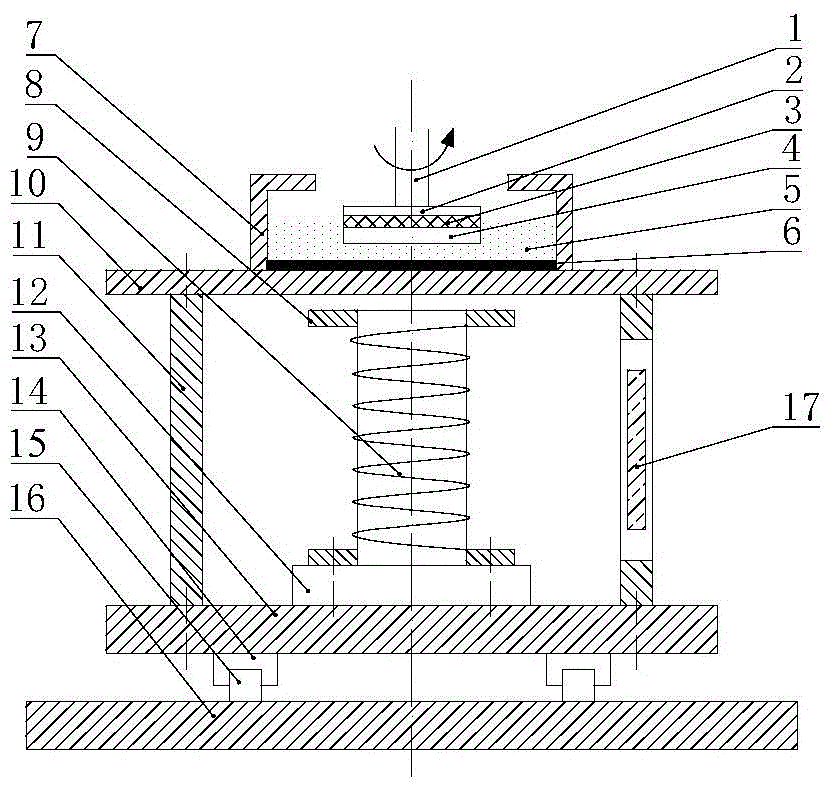

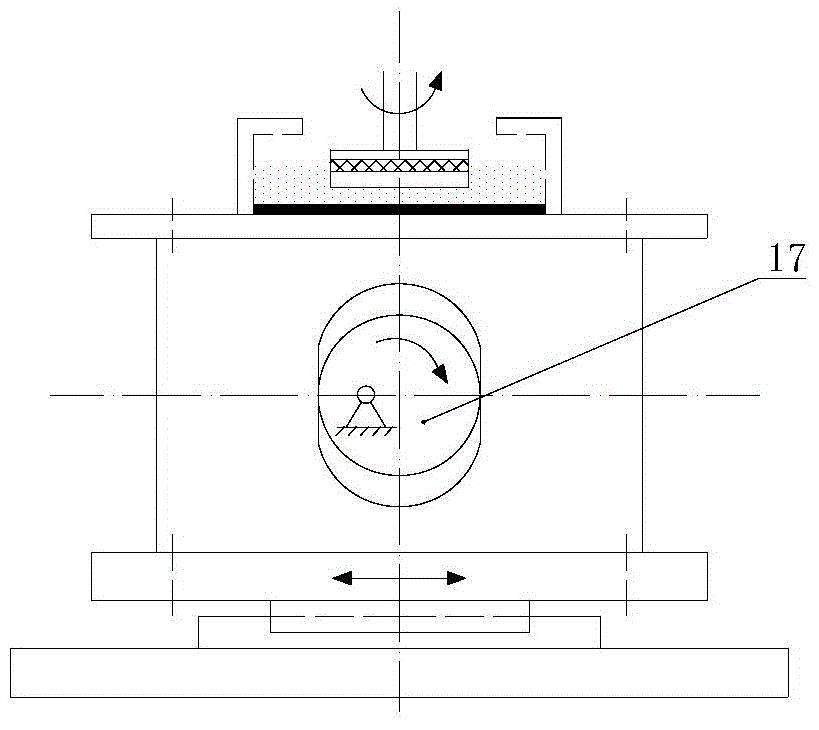

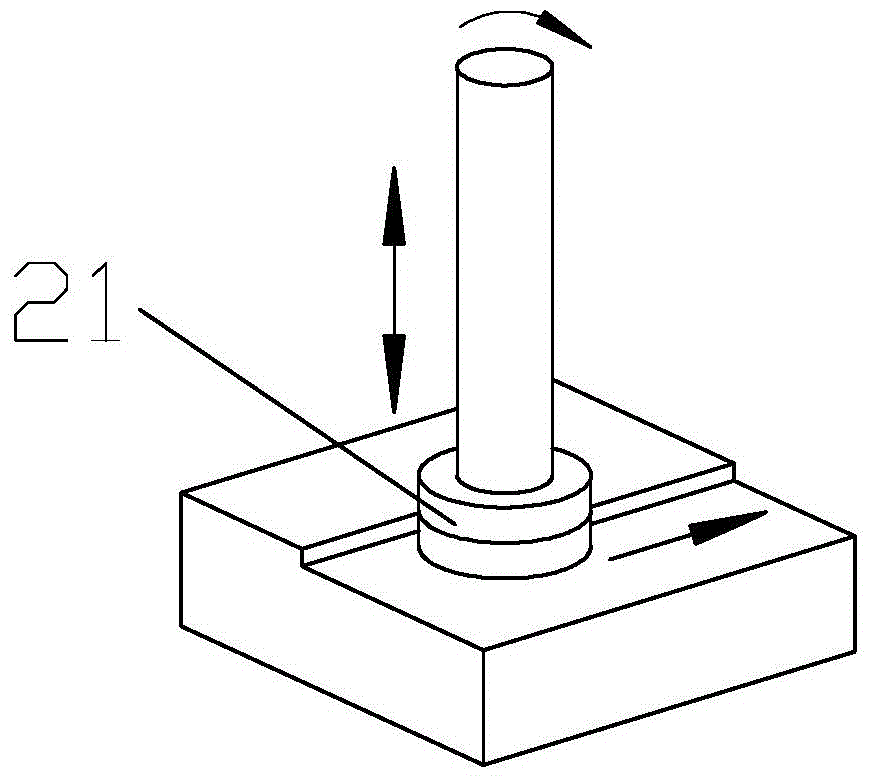

Magnetorheological polishing device and method

ActiveCN104308671ANo need to increase sizeIncrease cycle exchangeReciprocating motionMagnetorheological fluid

The invention discloses a magnetorheological polishing device. A polishing head consists of a workpiece shaft, a nonmagnetic fixture fixed at the lower end of the workpiece shaft and a soft magnetic plate arranged between the nonmagnetic fixture and the workpiece shaft; a fluid carrying groove containing magnetorheogical fluid is positioned below the polishing head; the bottom of the fluid carrying groove is provided with a polishing pad; an electromagnet is positioned below the fluid carrying groove and is kept 12-18mm away from a workpiece; the electromagnet and the fluid carrying groove are driven by a reciprocating transmission mechanism and linearly reciprocate parallel to the polished surface of the workpiece. The device is used for magnetorheological polishing, the flux density of the electromagnet is 0.1-0.4T, the reciprocating travel is slightly greater or equal to the workpiece polishing length, and the reciprocating speed is 0.5-5mm / s. A surface material of the workpiece is removed under the compound motion of translational motion of a magnetic field and rotation of the workpiece. The device has the advantages of good homogenization of the magnetic field, smooth exchange of the magnetorheogical fluid in a polishing area, easy discharge of processing scraps, good homogenization of micro textures of the polished surface of the workpiece and the like, and is particularly suitable for grinding and polishing large-plane surfaces of narrow and long workpieces.

Owner:NORTHEASTERN UNIV

Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

InactiveCN102628544AImprove adaptabilityImprove lubrication and anti-wear performancePortable liftingBase-materialsLaser processingHexagonal boron nitride

The invention discloses a micro-embedded self-lubricating texture on the surfaces of a gear and a cam and a preparation method thereof. The preparation method comprises the following steps of: performing micro texture processing on the surfaces of the gear and the cam by an Nd: YAG laser processing technology; and embedding a solid lubricant into the micro texture on the surfaces of the gear and the cam by a molding bonding technology of a self-lubricating composite material. The self-lubricating composite material comprises the following formula components in percentage by mass: 15 to 85 percent of polyimide (PI), 0 to 85 percent of polytetrafluoroethylene (PTFE), 10 to 40 percent of MoS2, 0 to 15 percent of WS2, 0 to 16 percent of graphite fluoride, 5 to 15 percent of graphite, 0 to 12 percent of PbO, 0 to 6 percent of antimony trioxide, 0 to 10 percent of CaF2 or BaF2, 0 to 15 percent of hexagonal boron nitride, 0 to 15 percent of nano lubricant and 0 to 5 percent of additive. According to the micro-embedded self-lubricating texture, the self-lubricating texture is subjected to micro embedding on the surfaces of the gear and the cam to ensure that the solid lubricant on the friction surface is stably supplied and uniformly coated, so that the lubrication and anti-wear properties of friction pairs such as the gear and the cam under complicated and harsh operating conditions are improved.

Owner:JIANGSU UNIV

Method for preparing high-performance iron nickel magnetically soft alloy by using powder metallurgy process

The invention discloses a method for preparing high-performance iron nickel magnetically soft alloy by using a powder metallurgy process, which belongs to the technical field of powder metallurgy. The method comprises the following steps of: 1, uniformly mixing various powder such as iron powder, nickel powder, molybdenum powder, silicon powder, copper powder, cobalt powder, chrome powder, niobium powder, tungsten powder, aluminum powder and titanium powder according to a certain ratio, wherein the nickel content ranges from 30 to 78 percent; or the alloy powder prepared according to a certain alloy component ratio is directly used as a raw material; 2, forming the powder which is obtained by step 1 into a blank with a certain shape by using a powder metallurgy forming method; 3, sintering the formed blank, which is obtained by the step 2, under the pressure of between 0 and 1,000 MPa and at the temperature of between 600 and 1,500 DEG C for 10 to 4,000 minutes; and 4, processing the sintered body obtained by the step 3 under the pressure of between 0 and 4,000 MPa and at the temperature of between 600 and 1,600 DEG C for 0 and 4,000 minutes. The method has the characteristic that: by improving the sintering and thermal treatment systems, the material density is improved, the micro texture and structure of the material are improved, the impurity content is reduced, and the magnetically soft alloy product with the maximal magnetic conductivity of no less than 40 mH / m and with the coercive force of no more than 20 A / m can be prepared.

Owner:UNIV OF SCI & TECH BEIJING

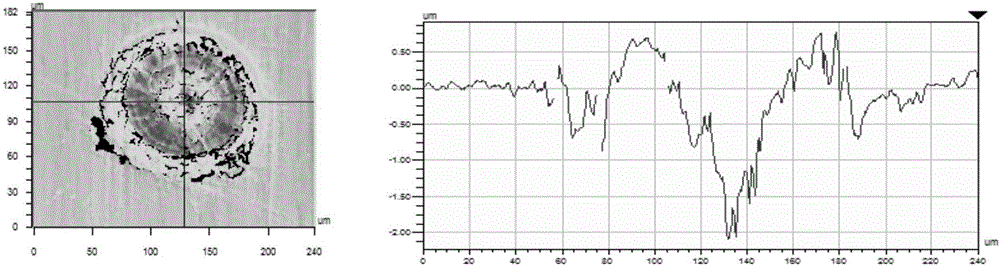

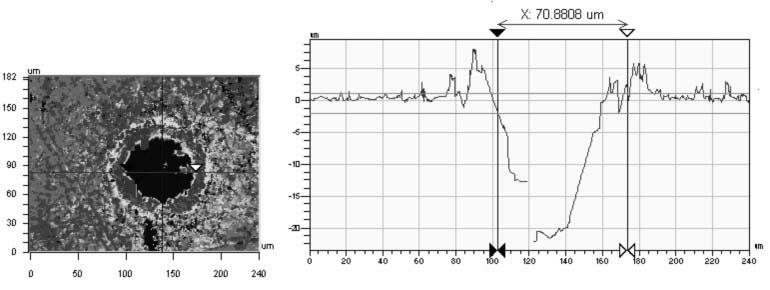

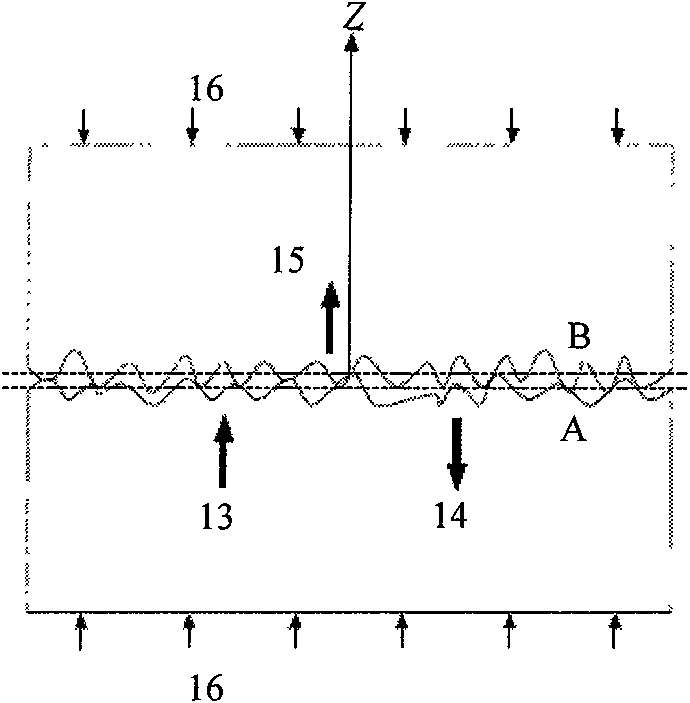

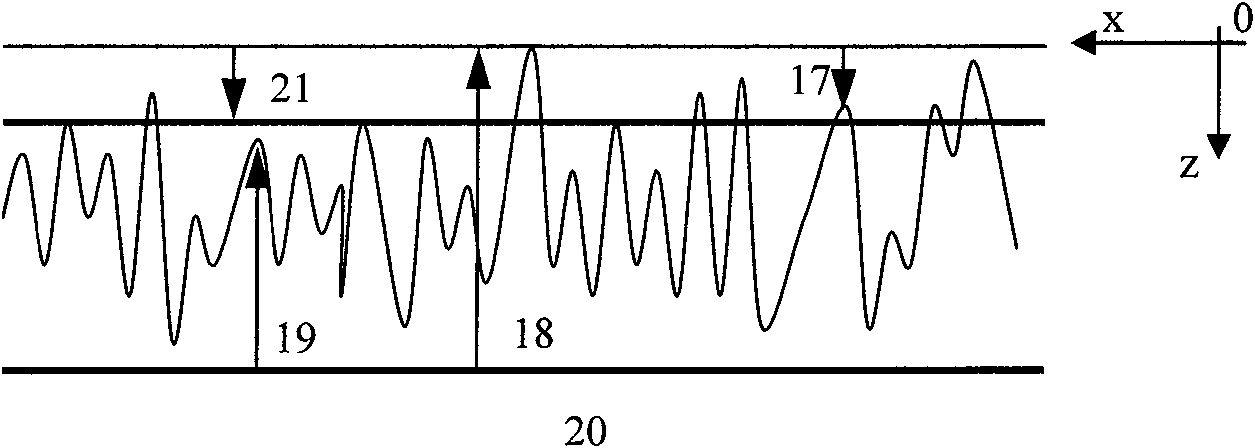

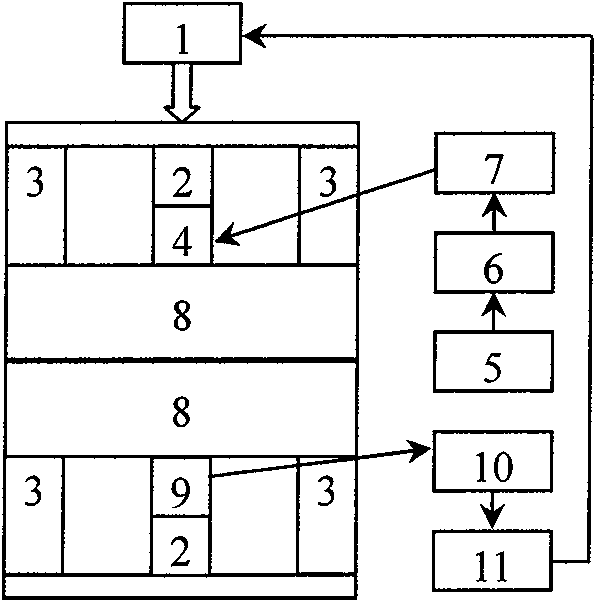

Imperfect interface contact state nonlinear ultrasonic evaluation method based on micro texture

ActiveCN101666780ARealize contact status evaluationHigh sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationNonlinear ultrasound

The invention relates to an interface contact state nonlinear ultrasonic testing method which belongs to the nondestructive testing filed. The method comprises the following steps: determining the frequency and the periodicity of detection signals according to the size and the material performance of a test piece forming a contact interface; by applying different pressures to a rough interface, changing the contact state, and carrying out ultrasonic transmission detection test on the rough interface; by carrying out nonlinear least-squares approximation processing on testing data of the test,determining micro characteristic composite parameters of the interface, computing a first-order rigidity coefficient and a second-order rigidity coefficient which are used for expressing the characteristics of the rough interface, and realizing ultrasonic expression of the contact characteristics of different rough interfaces. In the invention, the nonlinear ultrasonic coefficients are adopted toexpress the contact characteristics of the interface, the nonlinear ultrasonic detection has higher sensitivity comparing with the linear ultrasonic; by combining the micro texture and the rigidity relation of the interface, the method enables the macroscopic property of the interaction of the ultrasonic and the contact interface to be associated with the microcosmic property of the contact surface, thereby evaluating contact states of different microcosmic interfaces.

Owner:BEIJING UNIV OF TECH

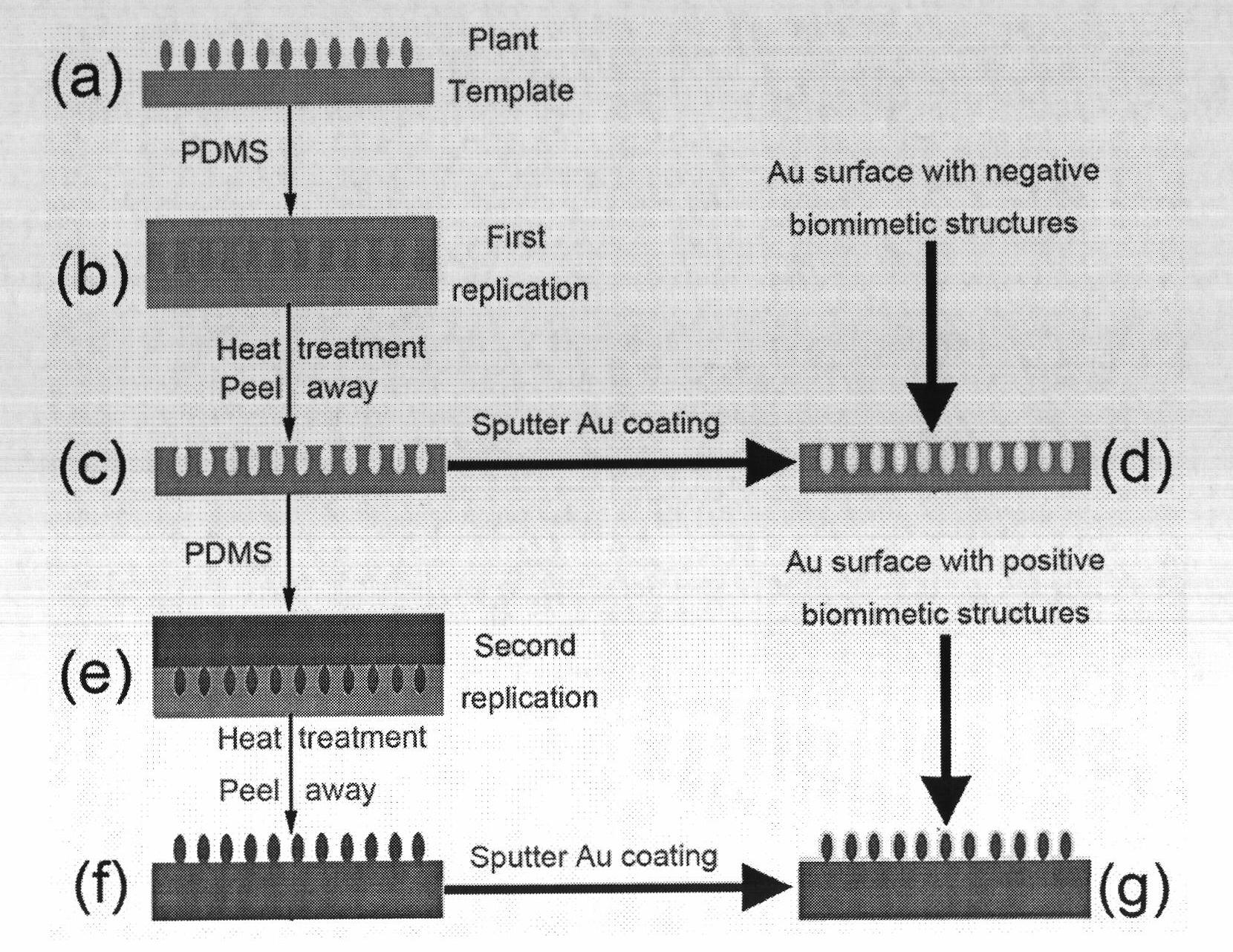

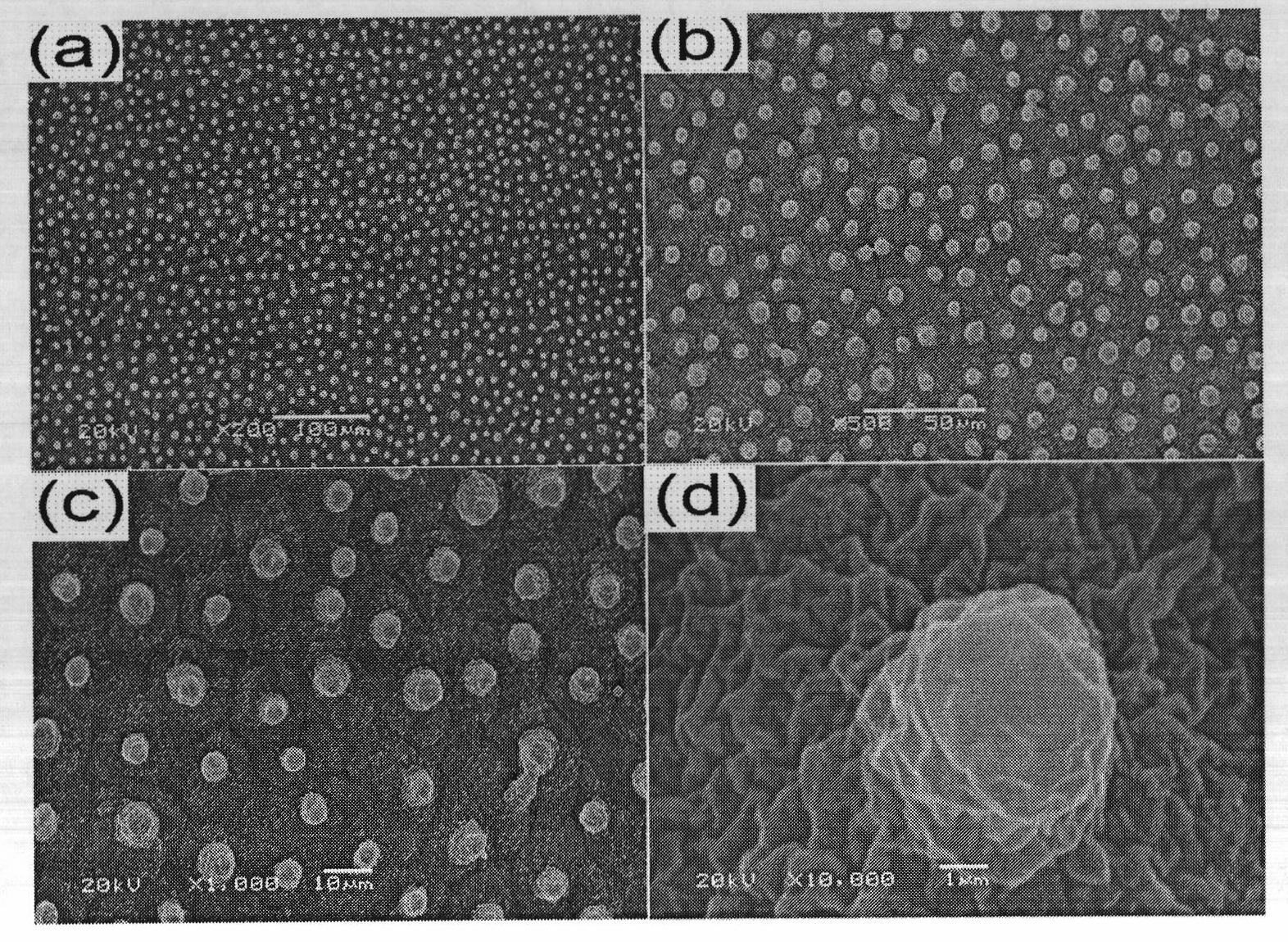

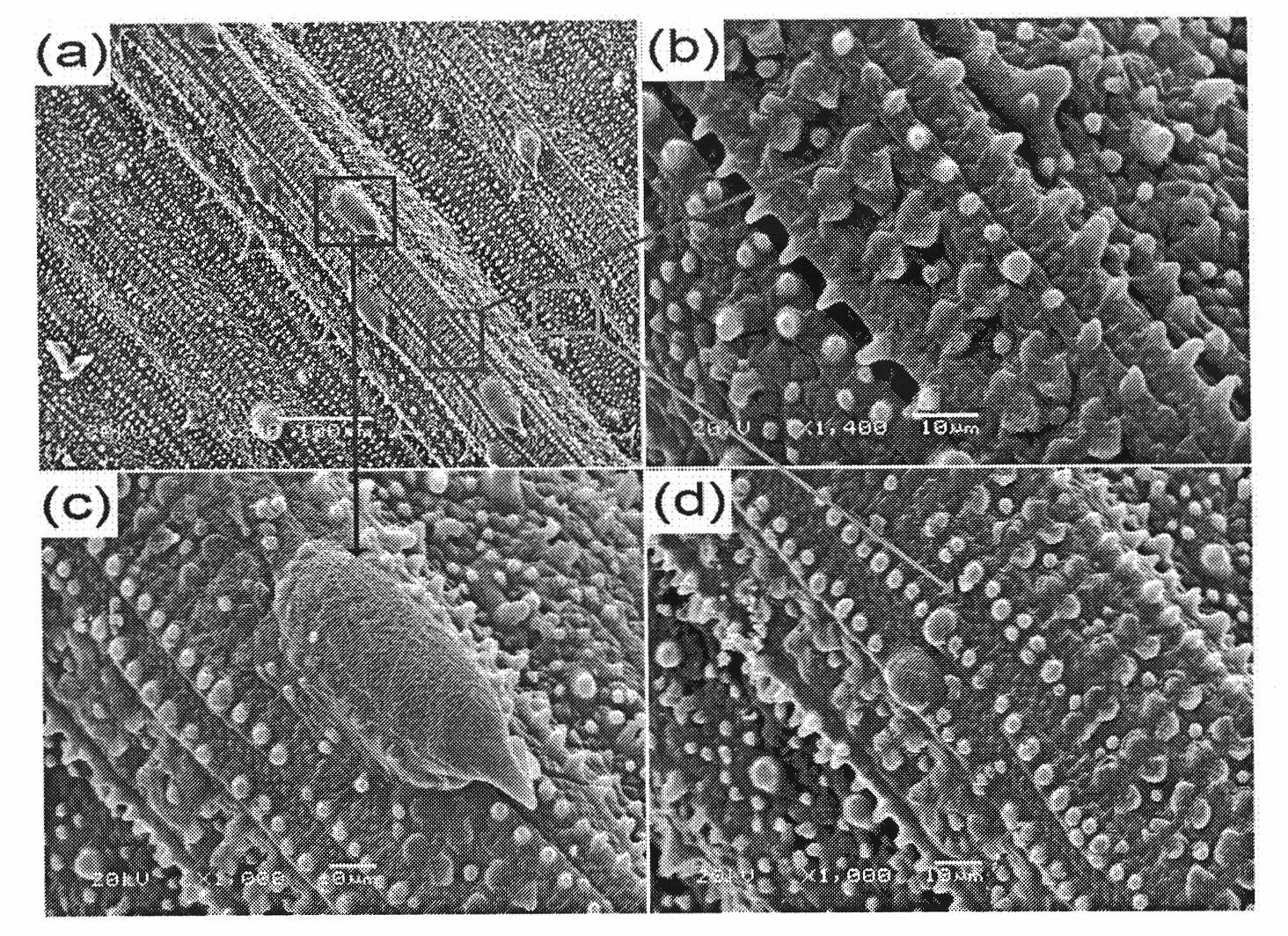

Preparation method of bionic controllable adhesive hydrophobic gold surface

ActiveCN101942638AControlled AdhesionSimple preparation processVacuum evaporation coatingSputtering coatingAdhesivePipette

The invention relates to a preparation method of a bionic controllable-adhesiveness hydrophobic gold surface. The method comprises the following steps: using a biological material in the natural world as a template, and preparing the controllable-adhesiveness hydrophobic gold surface with the same surface micro texture of the biological prototype by using the soft seal technology and surface chemical modification method. The surface micro texture is a typical micro / nano dualistic structure. The micro / nano dualistic structure gold surface with front and back patterns of lotus leaves and rice leaves is obtained. The gold surfaces with different bionic micro / nano textures have different adhesiveness for water drops, and can be used for design of engineering, biorobots and the like. The gold surface with front pattern micro texture has rolling property and hydrophobicity, and the gold surface with back pattern has adhesiveness and hydrophobicity; and the gold surface can be used as a manipulator to realize nondestructive transportation of micro drops, liquid-carried materials, biological micro solution pipettes and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

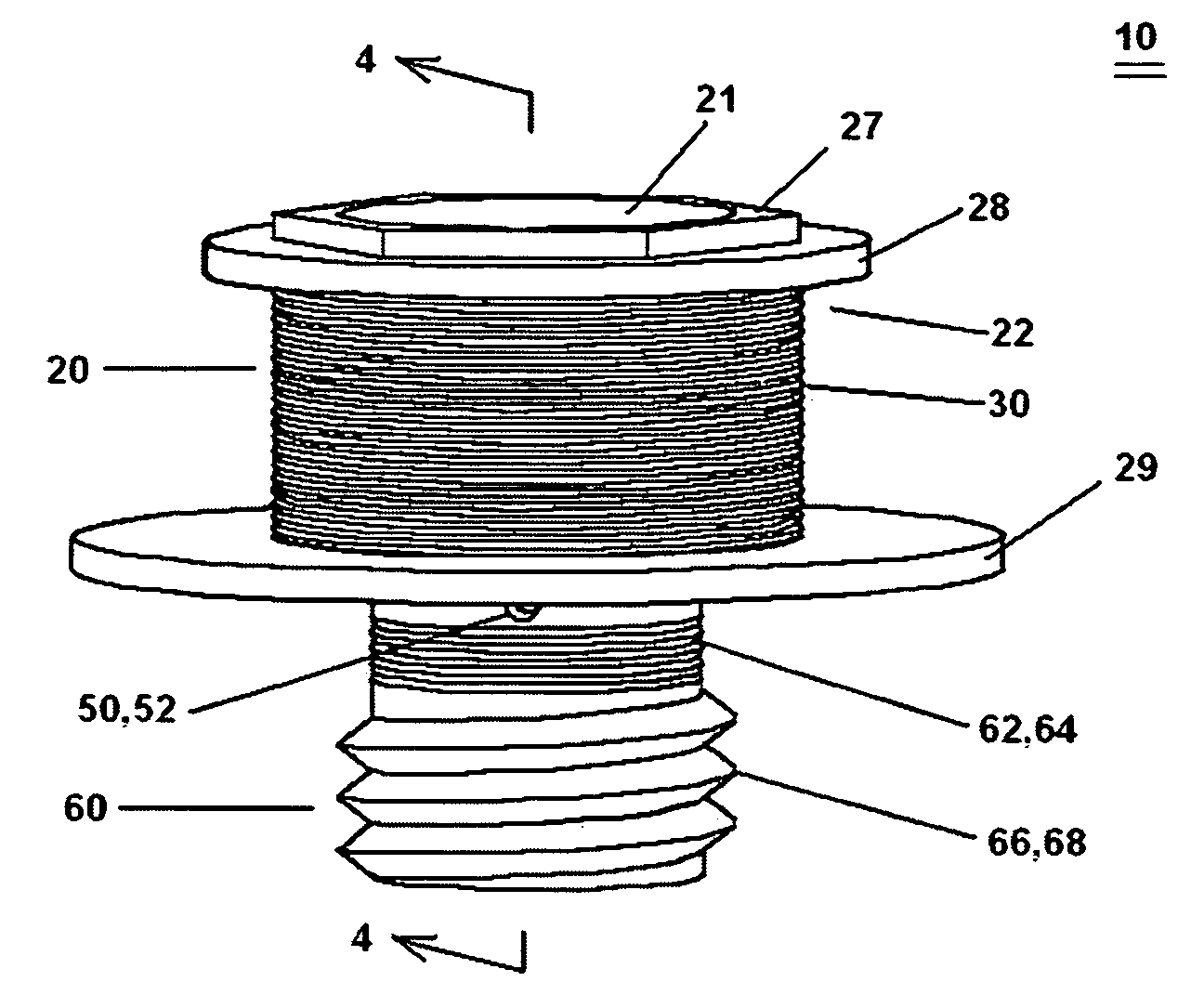

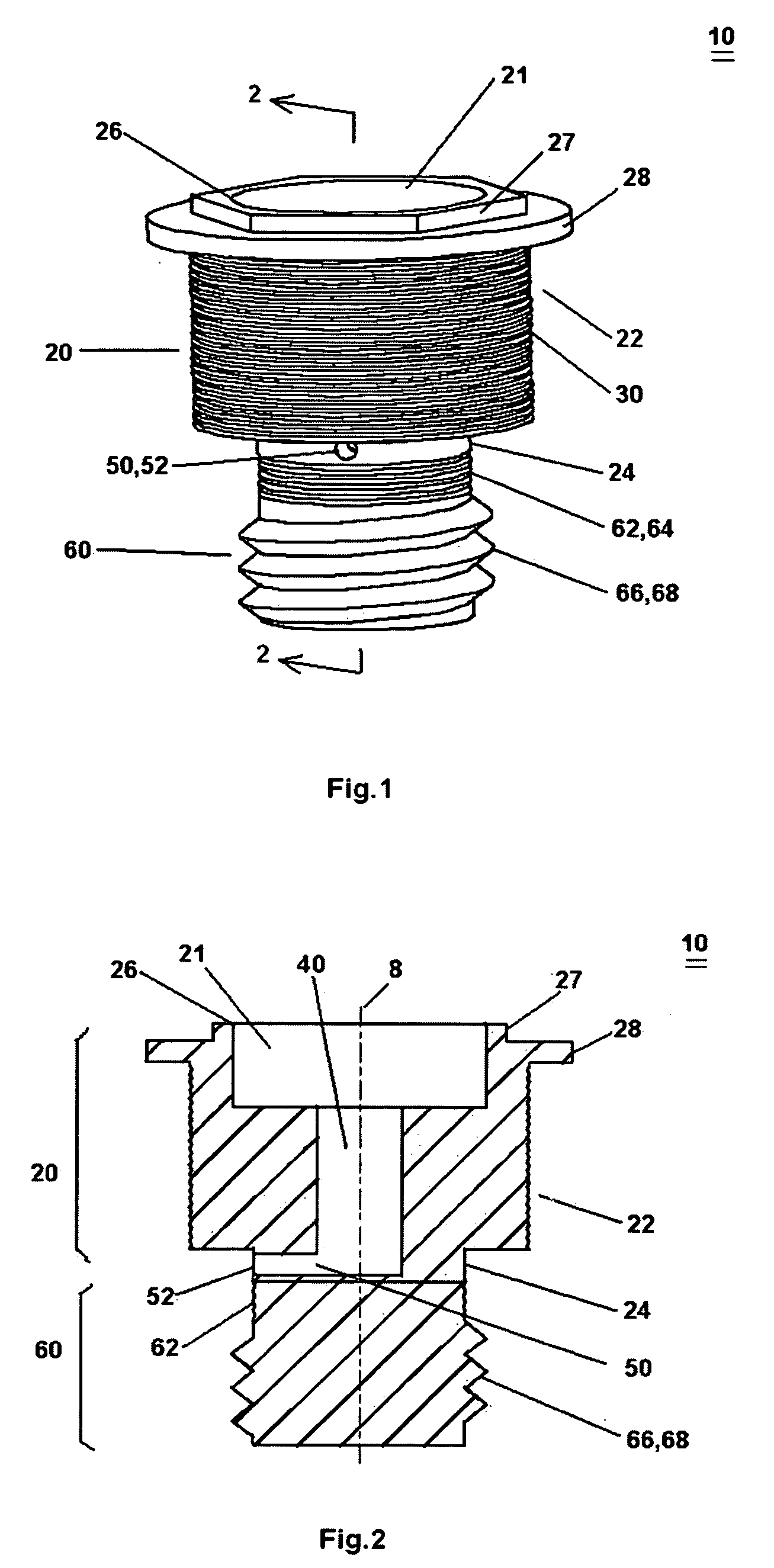

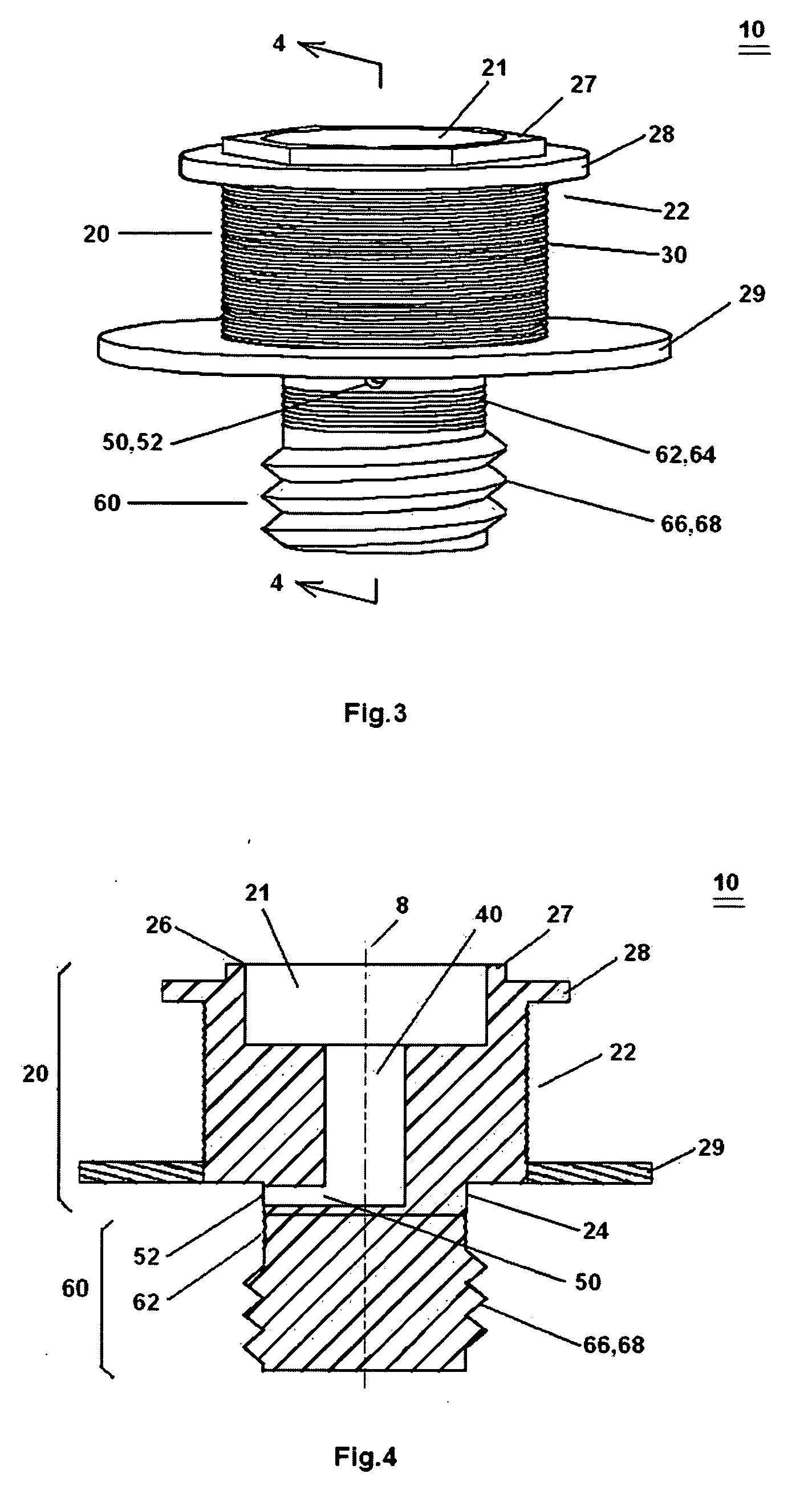

Transcutaneous port having micro-textured surfaces for tissue and bone integration

A transcutaneous port includes a subcutaneous port section and a bone fixation section. The subcutaneous port section has upper portion which has an axial channel and a first micro-textured external surface, and a lower portion which has therein a transverse channel connecting to the axial channel. The bone fixation section has a transosseous collar portion which has a second micro-textured external surface, and a threaded shaft portion. The first and second micro-textured external surfaces include a multiplicity of alternating microgrooves and ridges for tissue and bone integration. The transcutaneous port is surgically implanted into a site of a patient and a conductive wire is introduced from the axial channel to the transverse channel, and placed in the subcutaneous soft tissue and in contact with a neural signal source for transmitting neural signals to a prosthetic motor device.

Owner:EVOLLUTION IP HLDG

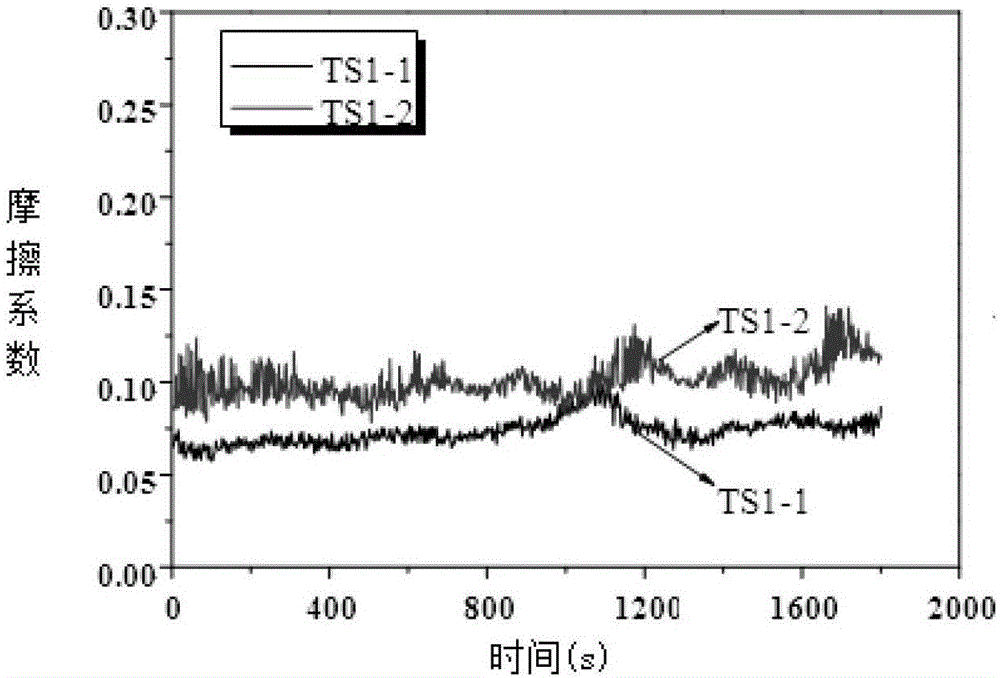

Solid lubrication treatment method for friction pair laser micro-texture surface

InactiveCN105782243AImprove carrying capacityOptimize the spraying processShaftsBearing componentsPre treatmentHigh pressure

The invention provides a solid lubrication treatment method for a friction pair laser micro-texture surface. The method comprises the steps that a micro-pit shape is machined on the surface of a friction pair through the laser surface texturing technology; all components in a self-lubrication composite are evenly mixed and dried to be used later; the surface micro-pit in a pre-treated die is filled with the self-lubrication composite through a die hot-press curing filling method; pressure maintaining hot-press curing filling is conducted through a hot press; then, the filled friction pair is heated for 20 min at the temperature of 250 DEG C and then protected by 99.9% of N2 to be heated for 30 min at the temperature ranging from 370 DEG C to 385 DEG C, insulating sintering is conducted for 0.5 h-1.0 h, and sintering forming is conducted after cooling; and solid lubrication can be finished after surface posttreatment. According to the method, the high-temperature sliding friction performance of the self-lubrication surface of a micro-texture can be improved, a good lubricating effect can be achieved under the conditions such as the high temperature and the high pressure, the bearing capability of a nanometer composite solid lubricating agent is effectively improved, and the nanometer composite solid lubricating agent can be applied under some complex and strict work conditions.

Owner:JIANGSU UNIV

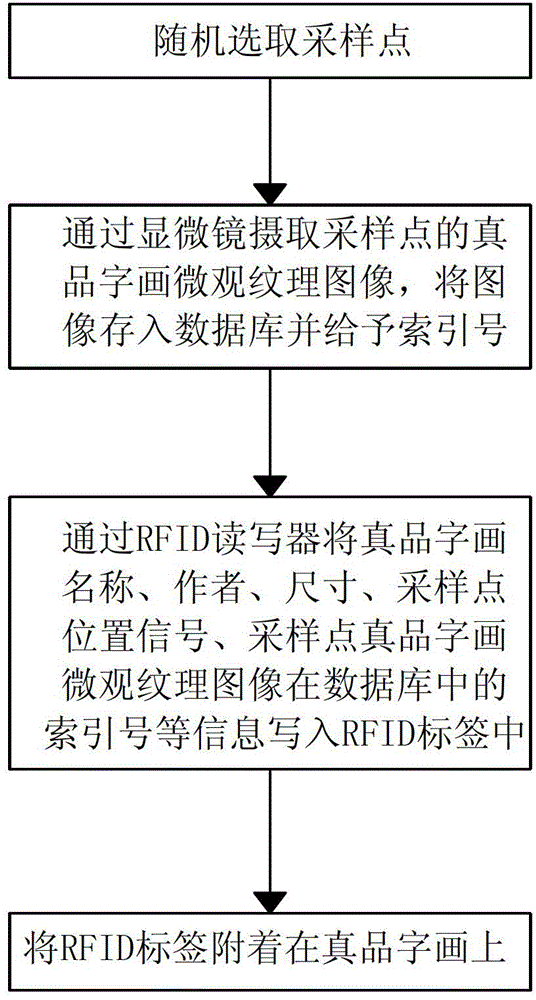

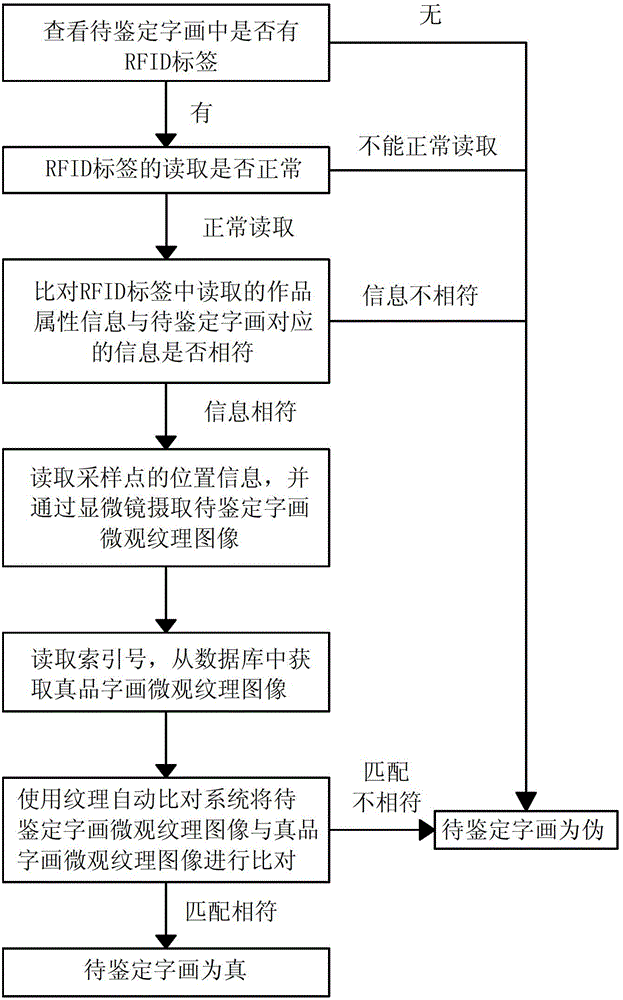

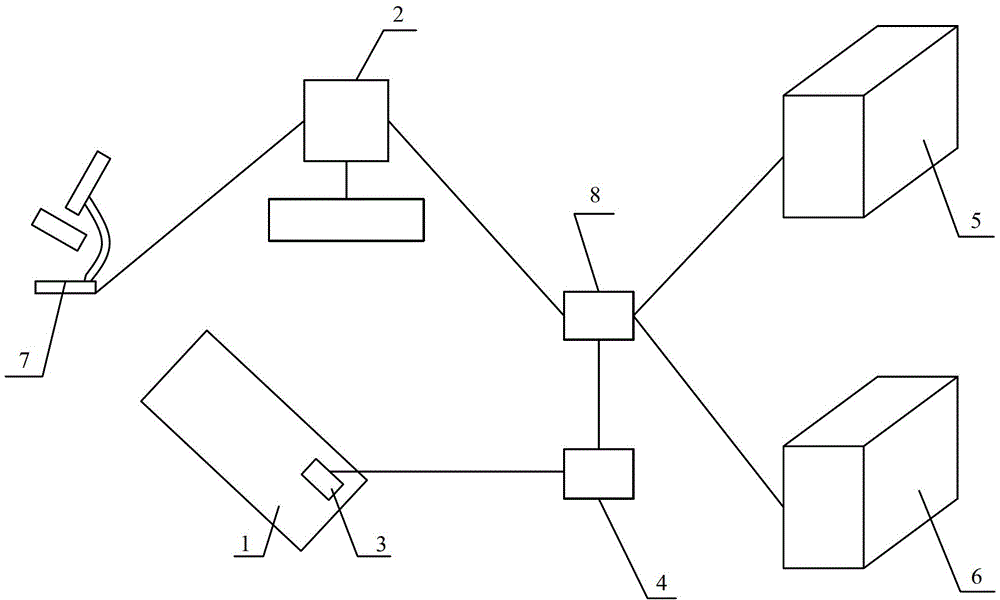

Anti-fake method and system based on calligraphy and painting micro-texture

InactiveCN103065109AImprove identification efficiencySimplify the authentication processSensing record carriersRecord carriers used with machinesPattern recognitionComputer graphics (images)

The invention provides an anti-fake method and a system based on calligraphy and painting micro-texture which includes the following steps: A. selecting sampling points on genuine calligraphies and paintings, obtaining genuine calligraphy and painting micro-texture images of the sampling points through image capture devices, and saving the calligraphy and painting micro-texture images in a database; B. saving work property information and position information of the genuine calligraphies and paintings in the database; C. querying corresponding records in the database according to the work property information of calligraphies and paintings under identification, and reading the position information on the sampling points and the genuine calligraphy and painting micro-texture images of the corresponding records; D. obtaining under-identification-calligraphy-and-painting micro-texture images of the calligraphies and paintings under identification on the sampling points through the image capture devices; and E. comparing the under-identification calligraphy and painting micro-texture images with the genuine calligraphy and painting micro-texture images, if the images match with each others, the calligraphies and paintings under identification are genuine, otherwise, the calligraphies and paintings under identification are fake. According to the anti-fake method and the system based on calligraphy and painting micro-texture, the authenticity of the calligraphies and paintings under identification is determined by whether the micro-texture images of the sampling points match with the genuine calligraphy and painting micro-texture images or not, so that the anti-fake level is greatly improved.

Owner:SHANGHAI NEWWORLD SOUVENIR CO LTD +1

Ultrashort laser micro-texture printing

InactiveUS20090268265A1Smooth changeEasy to produceDigitally marking record carriersDigital computer detailsMicro structureUltrashort laser

Systems and methods for providing laser texturing of solid substrates are disclosed. The texturing may be used to provide grayscale images obtainable from substrates, which may include steel, aluminum, glass, and silicon. In some embodiments, images may be obtainable from the substrate by modifying the reflective, diffractive, and / or absorptive features of the substrate or the substrate surface by forming random, periodic, and / or semi-periodic micro-structure features on the substrate (or substrate surface) by an ultrafast laser pulse train. The ultrafast pulse train may be modulated in order to vary, for example, optical exposure time, pulse train intensity, laser polarization, laser wavelength, or a combination of the aforementioned. The ultrafast pulse train and the substrate may be scanned with respect to each other to provide different optical energies to different regions of the substrate (or substrate surface). In some embodiments, the image is provided by making one or more passes of the ultrafast laser pulse train relative to the substrate.

Owner:IMRA AMERICA

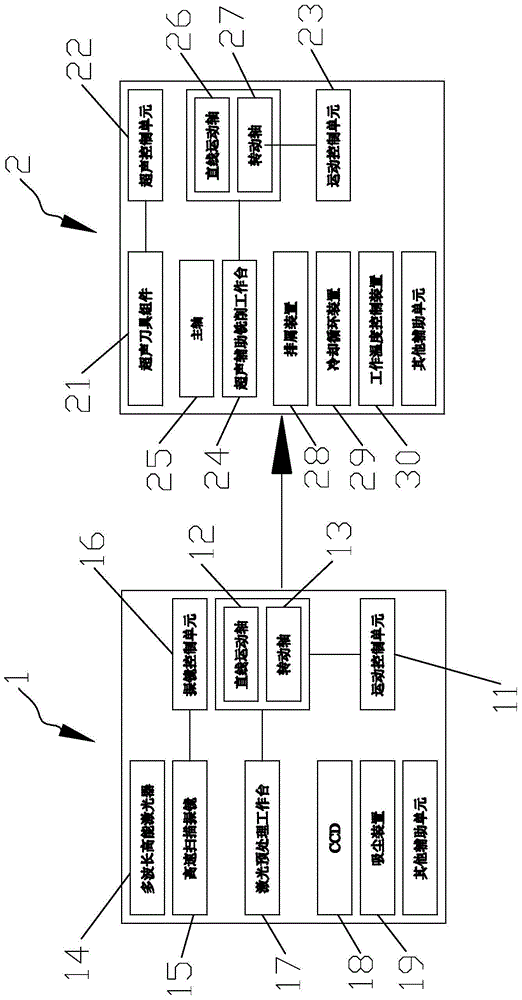

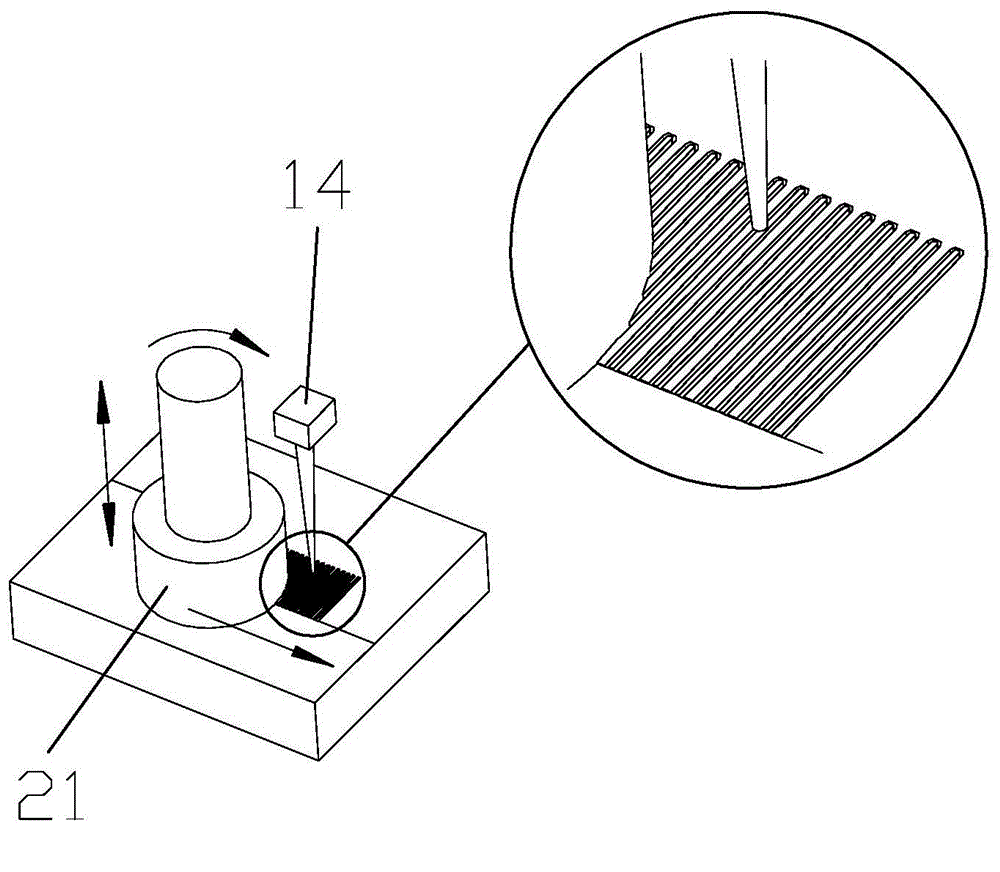

Auxiliary ultrasound milling technological method for laser micro-texture prefabricating and machining system

ActiveCN106271493AImprove machinabilityReduce processing difficultyOther manufacturing equipments/toolsUltrasonic vibrationMachining system

The invention provides an auxiliary ultrasound milling technological method for laser micro-texture prefabricating. The technological method comprises a laser pretreatment step and an ultrasound auxiliary milling step. The laser pretreatment step comprises the sub-steps that a position parameter of a to-be-machined material is adjusted, so that the position parameter of the to-be-machined material is in accordance with a first predetermined position parameter; and a laser beam is generated, and the spatial posture, corresponding to the to-be-machined material, of the laser beam is adjusted. The ultrasound auxiliary milling step comprises the sub-steps that the position parameter of the to-be-machined materials subjected to laser pretreatment is adjusted, so that the position parameter of the to-be-machined material is in accordance with a second predetermined position parameter; ultrasound vibration of an ultrasound cutter assembly is controlled; the ultrasound cutter assembly is rotated, and the rotation freedom degree, corresponding to the to-be-machined material subjected to laser pretreatment, of the ultrasound cutter assembly is adjusted; and the position relation between the ultrasound cutter assembly and the to-be-machined material subjected to laser pretreatment in the X direction, the Y direction and the Z direction is changed. The invention further relates to an auxiliary ultrasound milling machining system for laser micro-texture prefabricating.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

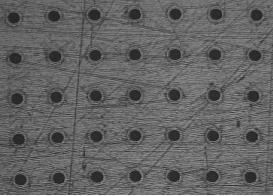

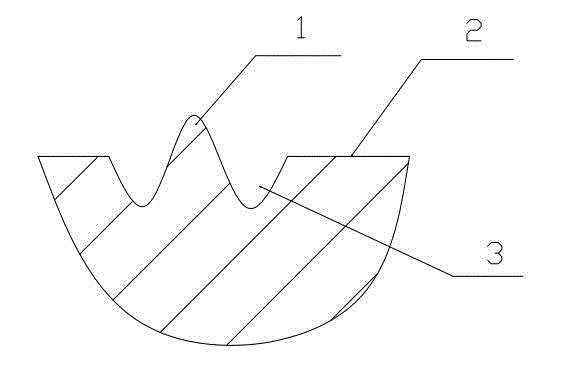

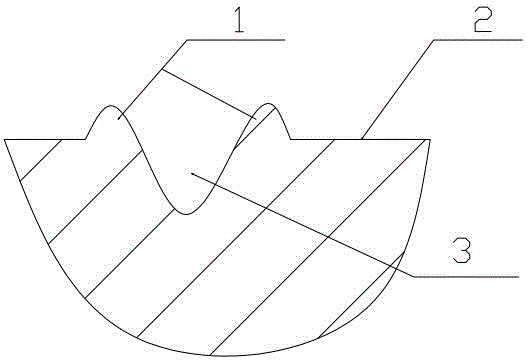

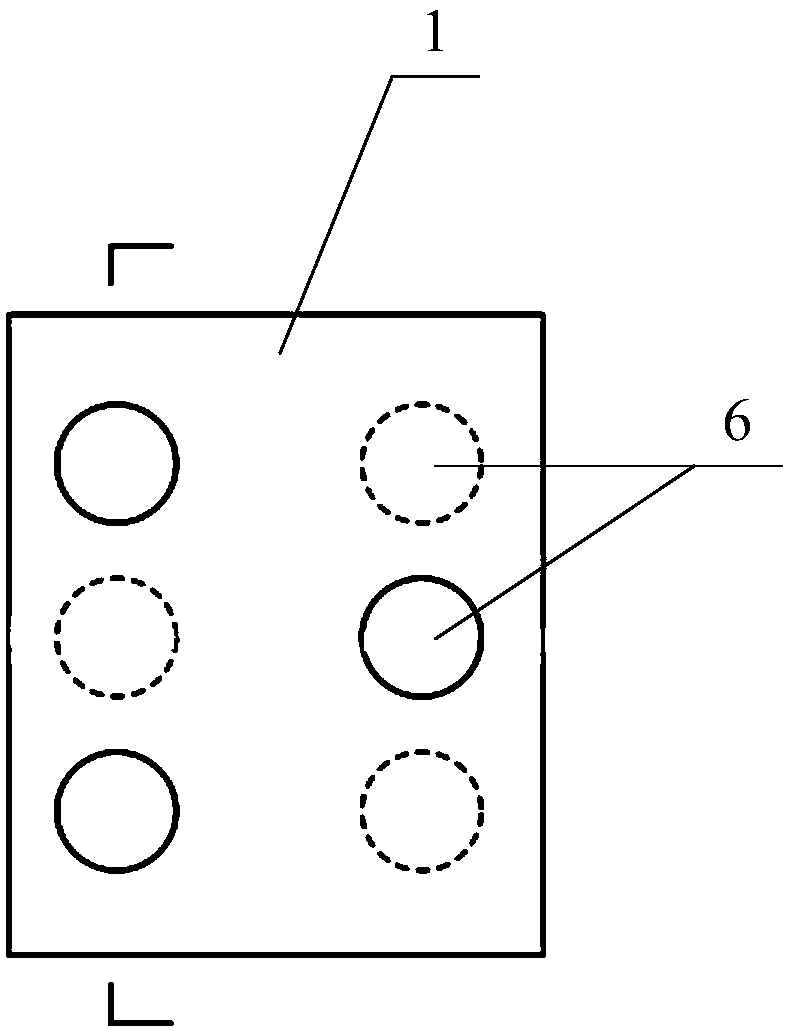

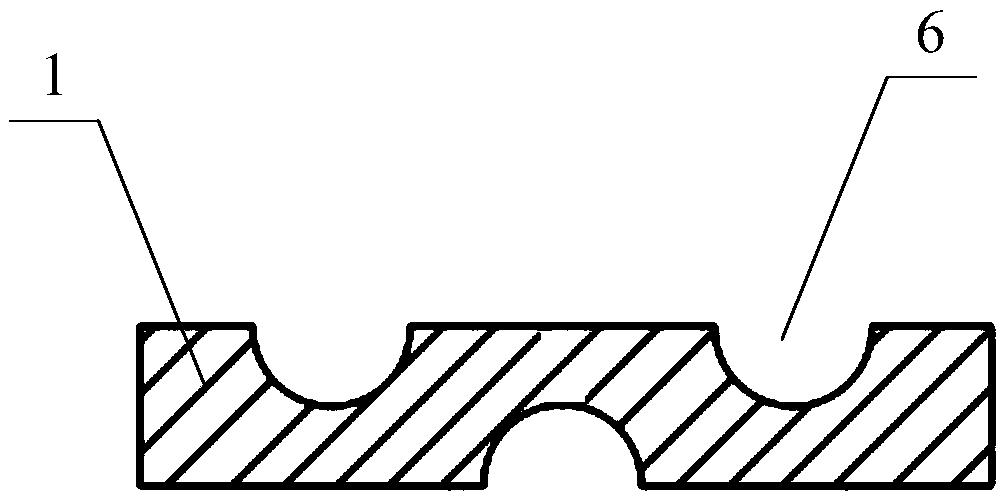

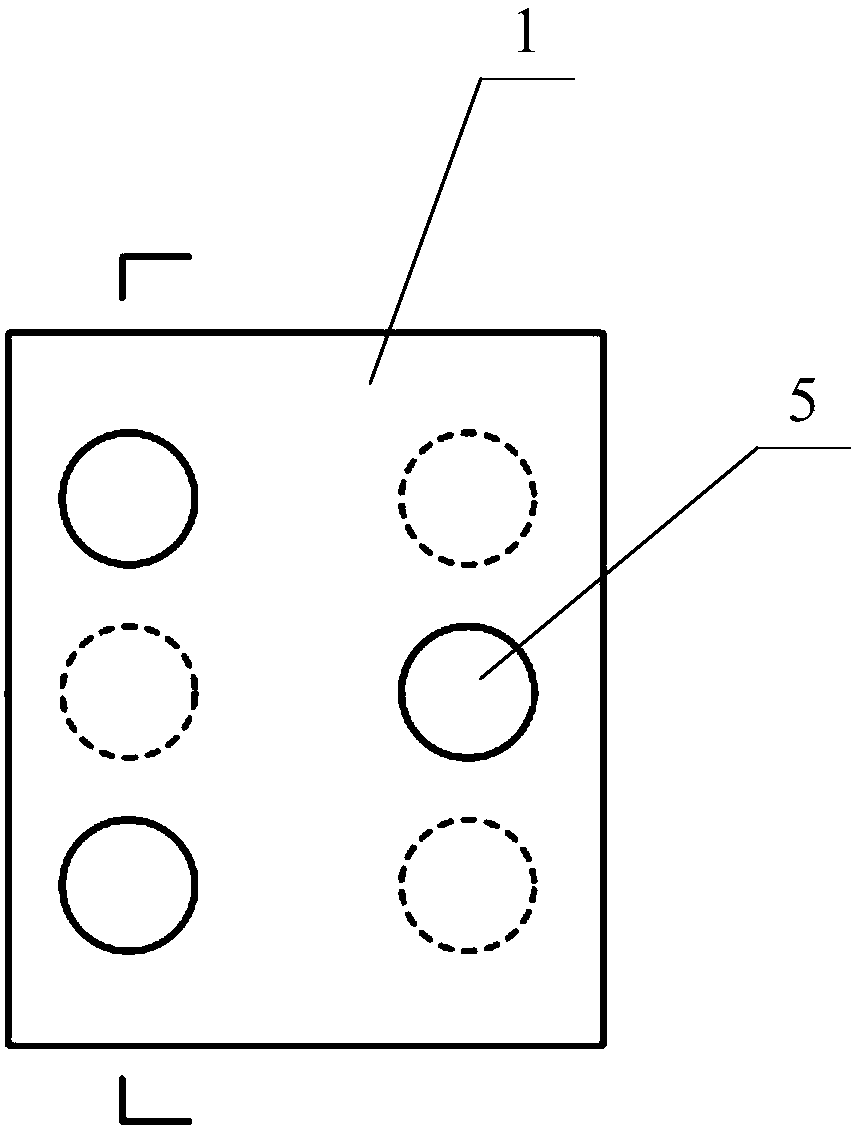

Composite micro-texturing guide rail

InactiveCN104551701AAvoid crawlingImprove wear resistanceLarge fixed membersStatic frictionEngineering

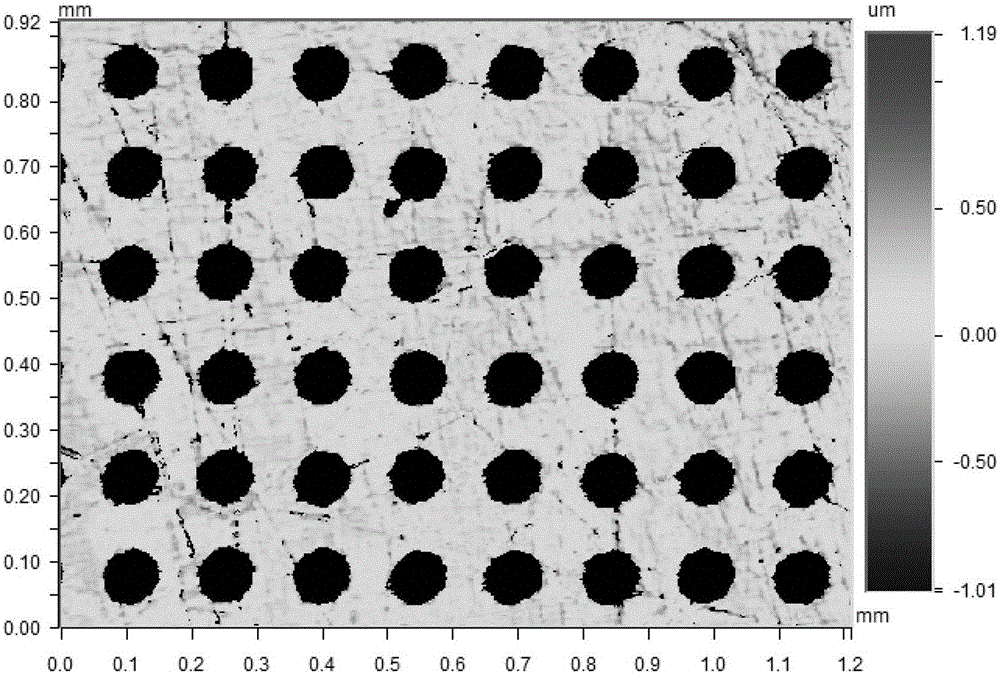

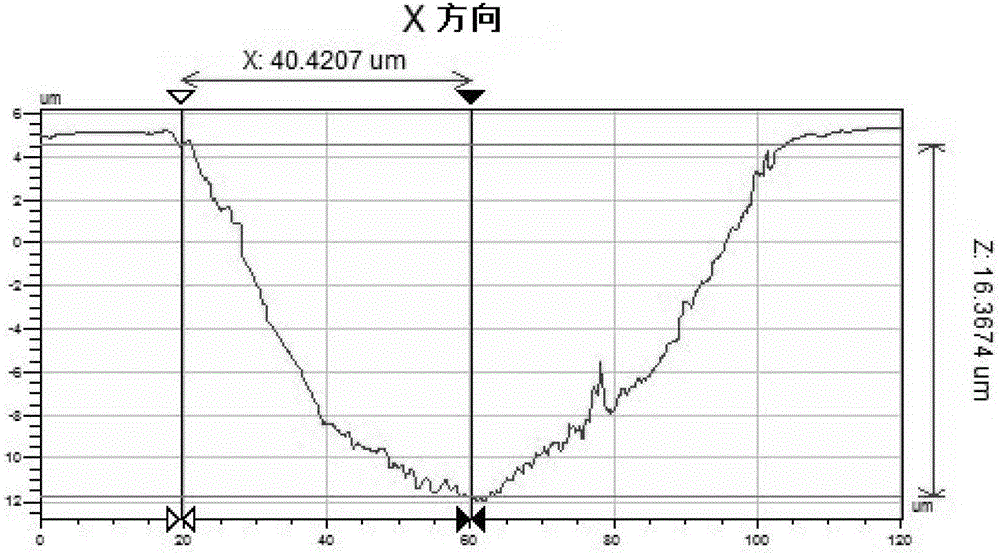

The invention discloses a method for designing a composite micro-texturing guide rail. In the invention, orderly distributed composite micro textures are initiatively processed on a working surface of the guide rail by laser, and the geometrical parameters of the composite micro textures that diameters d of recesses are equal to 100 microns to 500 microns, depths h of the recesses are equal to 1 micron to 50 microns, diameters D of raised shoulders are equal to 50 microns to 450 microns, heights H of the raised shoulders are equal to 1 micron to 70 microns, and diameters of micro bump texture flat tops are equal to 5 micron to 550 microns, area ratio is 15%-65% and interval S is equal to 200 microns to1500 microns. According to the invention, dynamic friction and static friction on surface of the guide rail can be balanced, creeping phenomenon can be inhibited effectively, service life is prolonged obviously, and stability and machining quality are improved.

Owner:JIANGSU UNIV

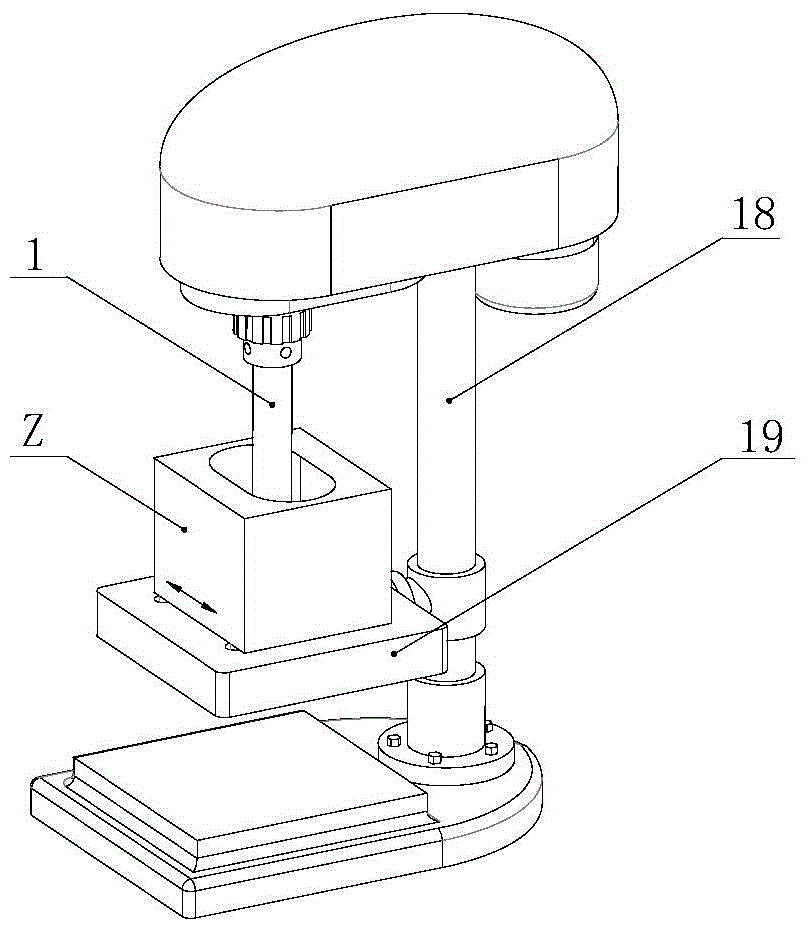

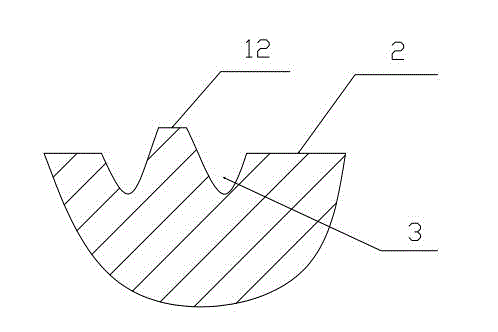

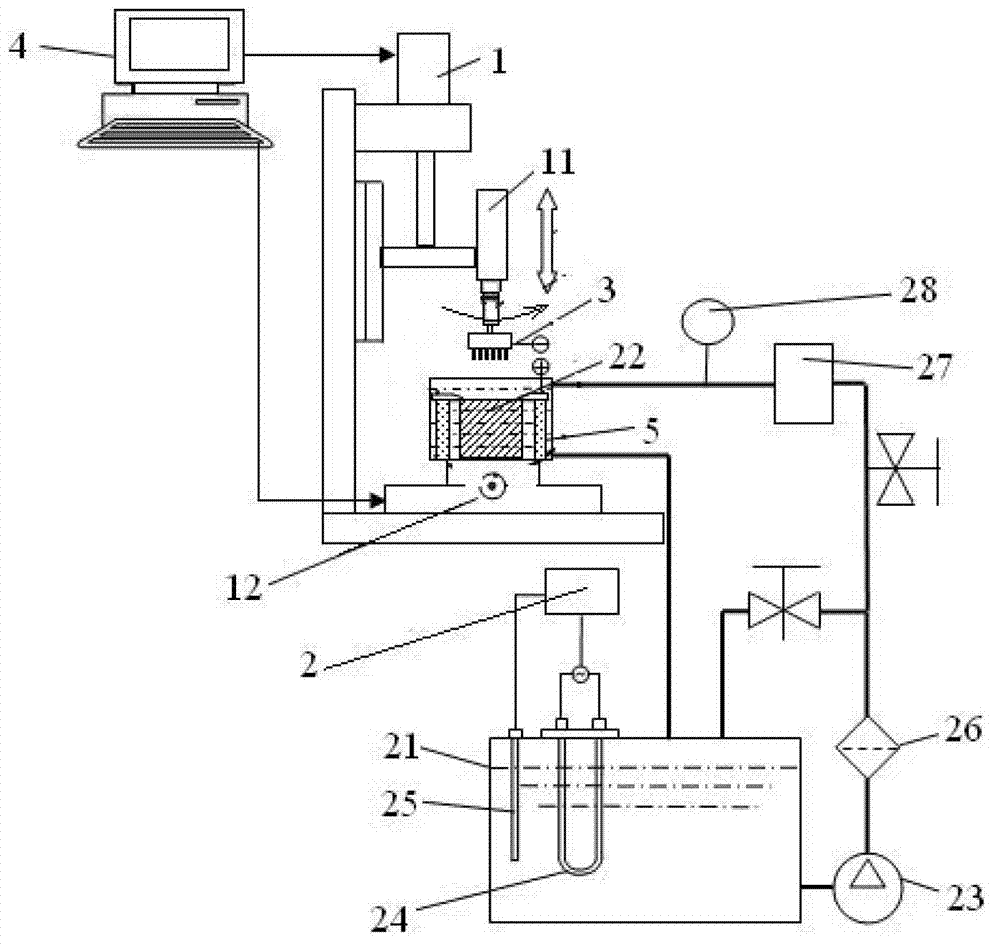

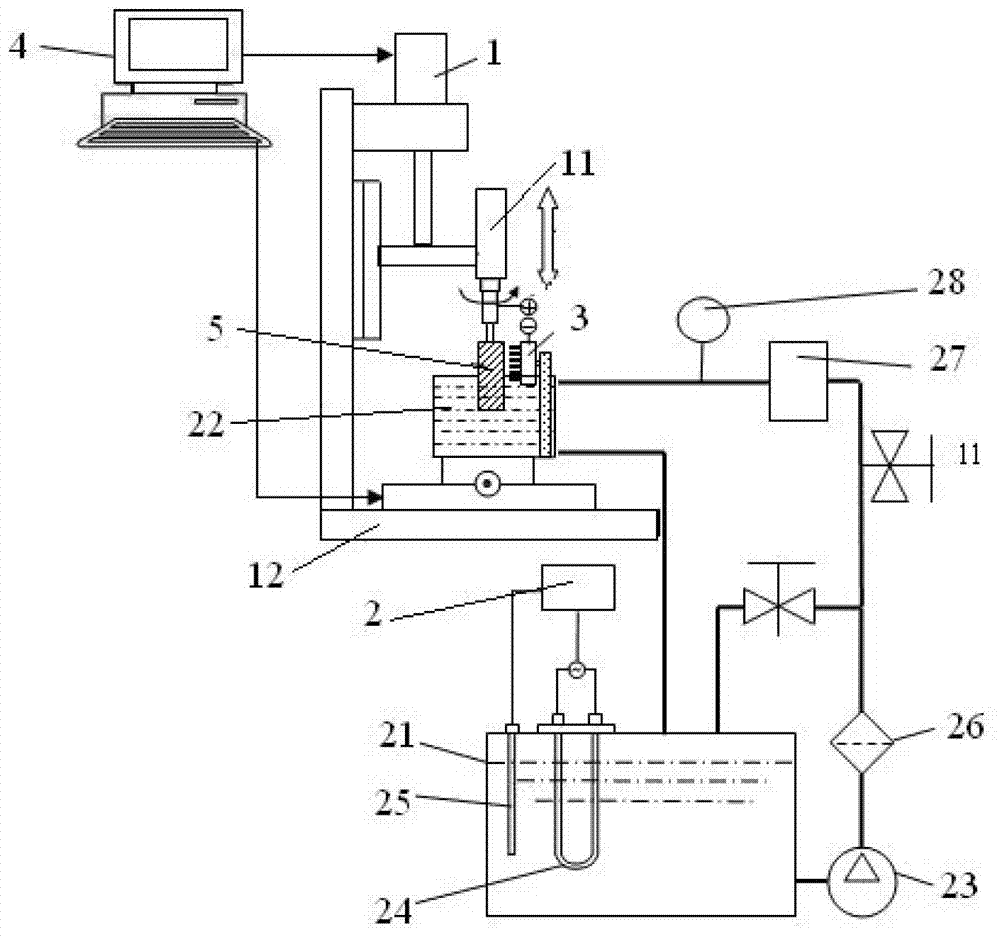

Metal surface micro texture group electrode direct writing micro electrolysis processing method and dedicated device

InactiveCN103111696AAvoid deformationReduce processing stepsMachining working media supply/regenerationElectrolysisDirect writing

Provided is a metal surface micro texture array electrode direct writing micro electrolysis processing method and a dedicated device. The processing method includes a first step of processing metal surface micro texture of workpieces to be processed by adopting line-shaped array electrodes, and a second step of enabling the array electrodes to conduct relative movement with the workpieces to be processed under the control of a machine tool numerical control system and processing the micro texture out of the surfaces of the workpieces to be processed under the conditions of flow of electrolyte and power-on of a processing power supply. The dedicated device comprises a machine tool, an electrolyte circulating device, a line-shaped array electrodes, a computer and a power supply provided with an anode and a cathode, the electrolyte circulating device and the line-shaped array electrodes are respectively in electric connection with the computer and meanwhile controlled by the machine numerical control system matched with the computer. The metal surface micro texture group electrode direct writing micro electrolysis processing method and the dedicated device has the advantages of being capable of processing complicated texture structure with the electrodes in simple shapes, free from need to manufacture a mask plate, short in processing cycle, high-efficiency, capable of avoiding deformation of the surfaces of the workpieces and 'secondary processing' and good in quality.

Owner:ZHEJIANG UNIV OF TECH

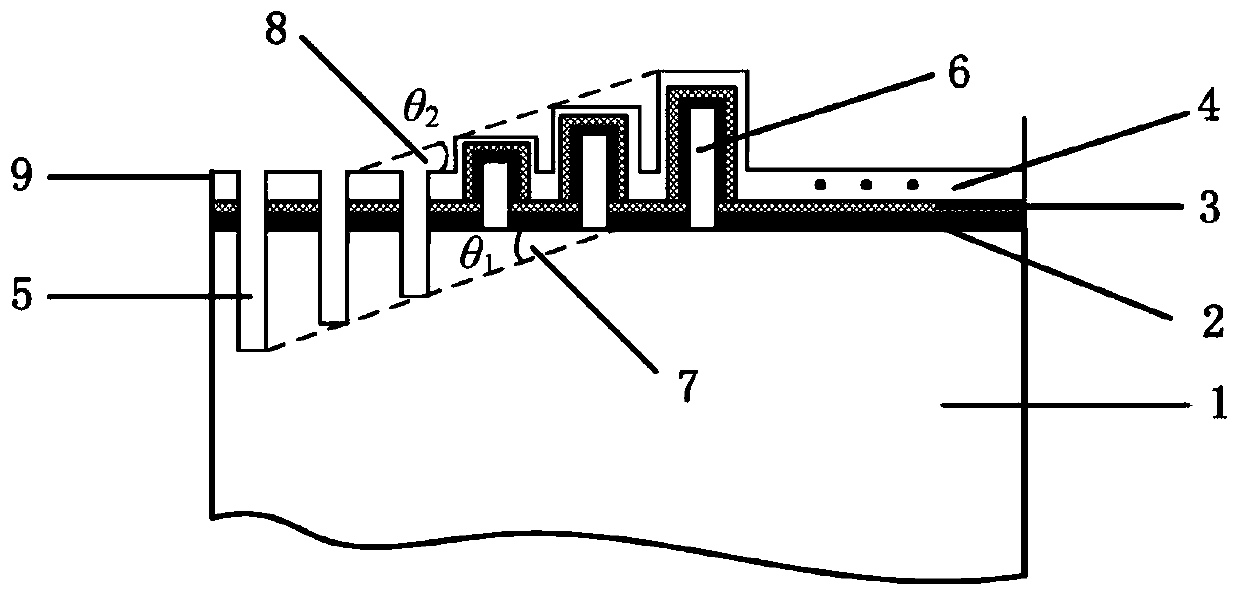

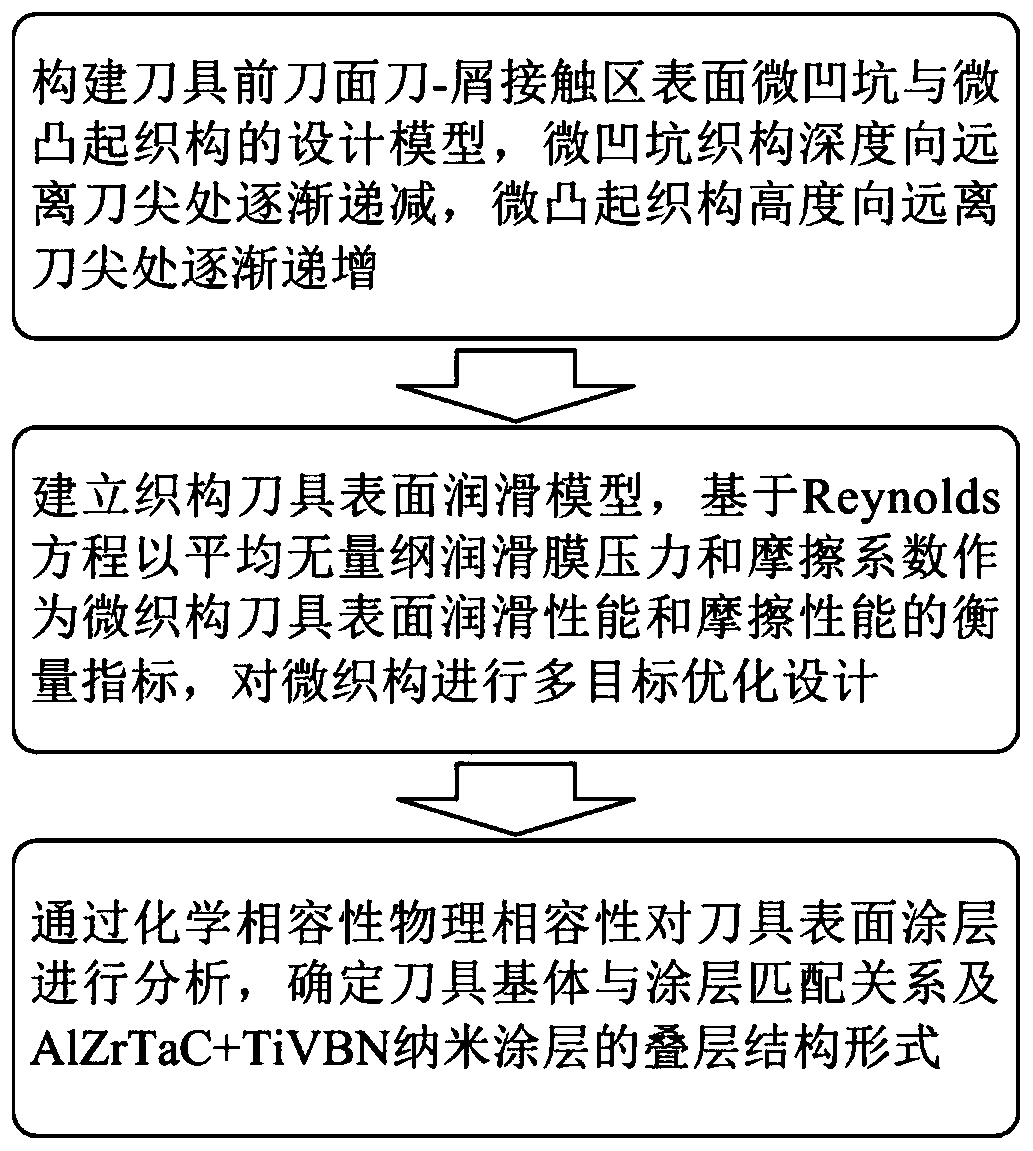

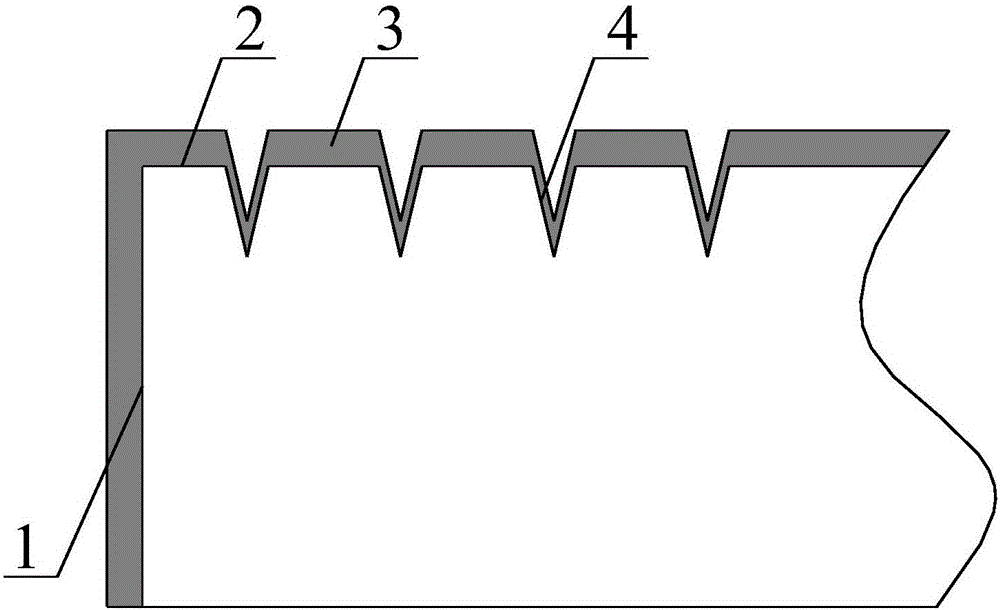

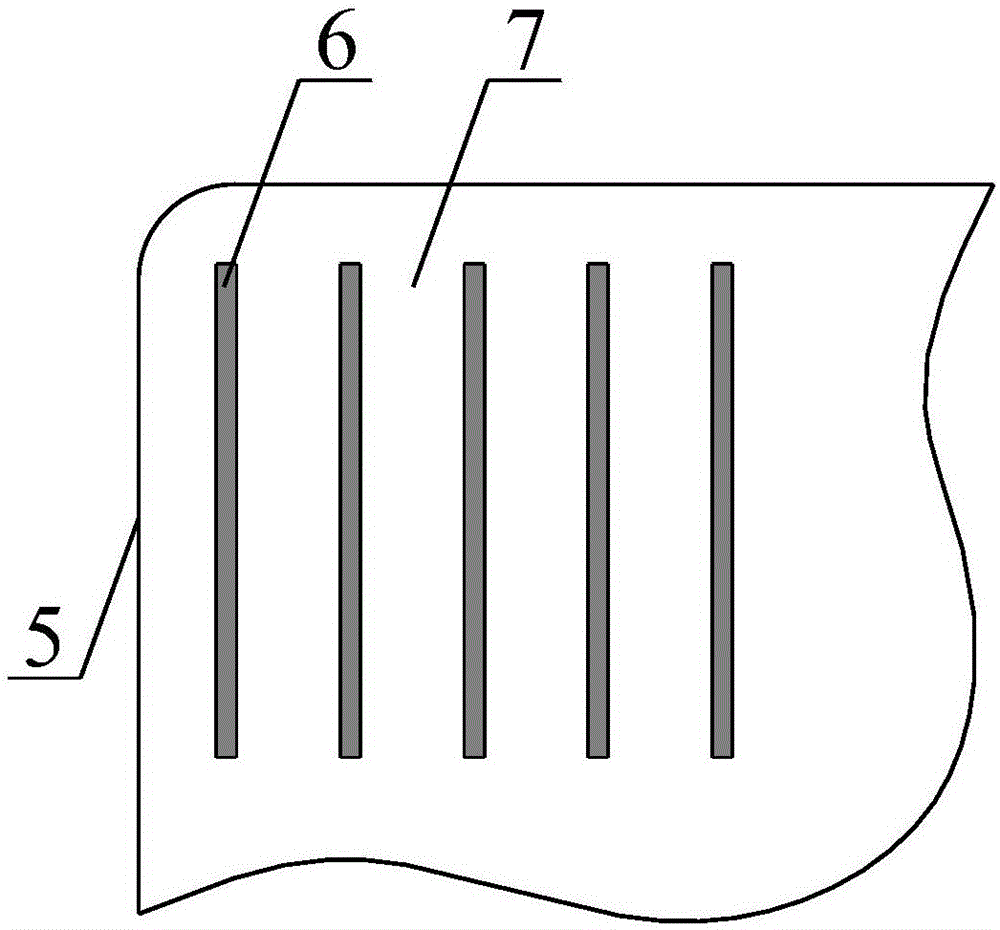

Bionic texture and coating layer cooperated anti-friction cutter and design method thereof

The invention discloses a bionic texture and coating layer cooperated anti-friction cutter and a design method thereof. The cutter adopts a basal body material of high-speed steel, hard alloys or ceramic; a bionic micro pit and micro projection composite texture is arranged in a cutter-chip contact area on the front cutter surface of the basal body material of the cutter; AlZrTaC+TiVBN alternate-distributed nanometer laminate coating layers are arranged on the surfaces of the texture and a basal body; the alternate laminate coating layers at least comprise single layers of 10 AlZrTaC layers and 10 TiVBN layers; and the thickness of the single layers of AlZrTaC and TiVBN is not bigger than100 nm. The design method of the cutter comprises the following steps: a design model of a micro texture on the surface of the cutter-chip contact area on the front cutter surface of the cutter is built; the oil film pressure and the friction coefficients of the cutter-chip contact interface are analyzed based on a Reynolds equation to optimize the geometric size of the micro texture and the depth or height gradual change dip angles theta 1 and theta 2; and through physical compatibility and chemical compatibility analysis, a laminate structural form of AlZrTaC+TiVBN coating layers is built. The cutter synthesizes the characteristics of the micro texture and the nanometer laminate coating layers, can reduce the friction and the wear of the cutter in the lubricating liquid cutting process, and can be widely applied to the cutting in the cutting liquid mode.

Owner:SOUTHEAST UNIV

Micro-texture ZrVSiN self-adaptive coated cutting tool and preparation process thereof

ActiveCN106498393AHigh hardnessImprove wear resistanceSuperimposed coating processManufacturing technologyAlloy

The invention belongs to the technical field of mechanical cutting tool manufacture, and in particular, relates to a micro-texture ZrVSiN self-adaptive coated cutting tool and a preparation process thereof. A basal body material of the cutting tool is ceramics or a hard alloy, and a micro-texture is processed on a basal body of a front tool face of the cutting tool; coating layers on the surface of the cutting tool is provided with a ZrVSiN self-adaptive coating layer and a Zr transition layer from top to bottom. The application of the ZrVSiN self-adaptive coating layer can make a layer of VO2, V2O3, V2O5 and other vanadium oxide products having a lubrication effect formed on the surface of the cutting tool through a reaction of V in a cutting process with oxygen in air, and a glaze layer with V2O5 glass phase is produced in quantity along with rising of the temperature, so that the friction of a tool-chip contact area is reduced; V2O5 is a liquid phase when the temperature is 500 DEG C or more, the micro-texture can store the V2O5 liquid-phase lubricant, and loss of the vanadium oxide products having the lubrication effect is prevented. The cutting tool can be widely applied in dry cutting and cutting processing of hard-to-process materials.

Owner:湖南富石数控刀具有限公司

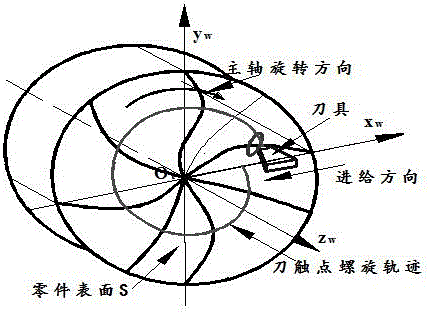

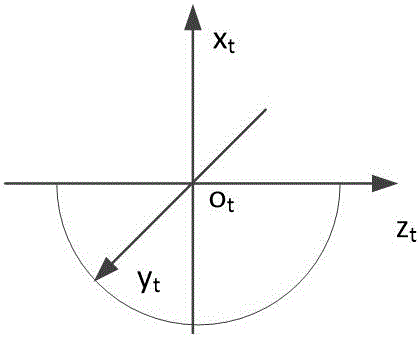

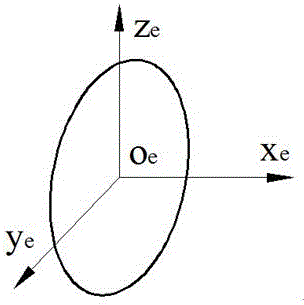

Three-dimensional ellipse vibration auxiliary cutting micro-texture morphology modeling method

The present invention discloses a three-dimensional ellipse vibration auxiliary cutting micro-texture morphology modeling method. A workpiece coordinate system, a cutter coordinate system and a local coordinate system of three-dimensional ellipse vibration auxiliary cutting are established. In the cutter coordinate system and the local coordinate system of three-dimensional ellipse vibration auxiliary cutting, a cutter point arc curvilinear equation and a three-dimensional ellipse vibration expression are established according to the processing parameters and the ellipse vibration parameters. In the workpiece coordinate system, workpiece parameters and machine tool parameters are set. In the process of processing surfaces S of parts, the cutter location point Pt locus of the surface S of a general turning part is calculated, on the basis of obtaining the cutter location point Pt locus of the general turning part, the three-dimensional ellipse vibration on the cutter location point Pt is applied, the cutter location point P2t2 of the three-dimensional ellipse vibration applied on the cutter location point is calculated, the cutter is interacted with the surface S of the parts along the cutter location point P2t2 locus, and a micro-texture morphology is generated on the surface S of the parts. The problem of generation of the surface morphology of the three-dimensional ellipse vibration auxiliary cutting microgroove can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

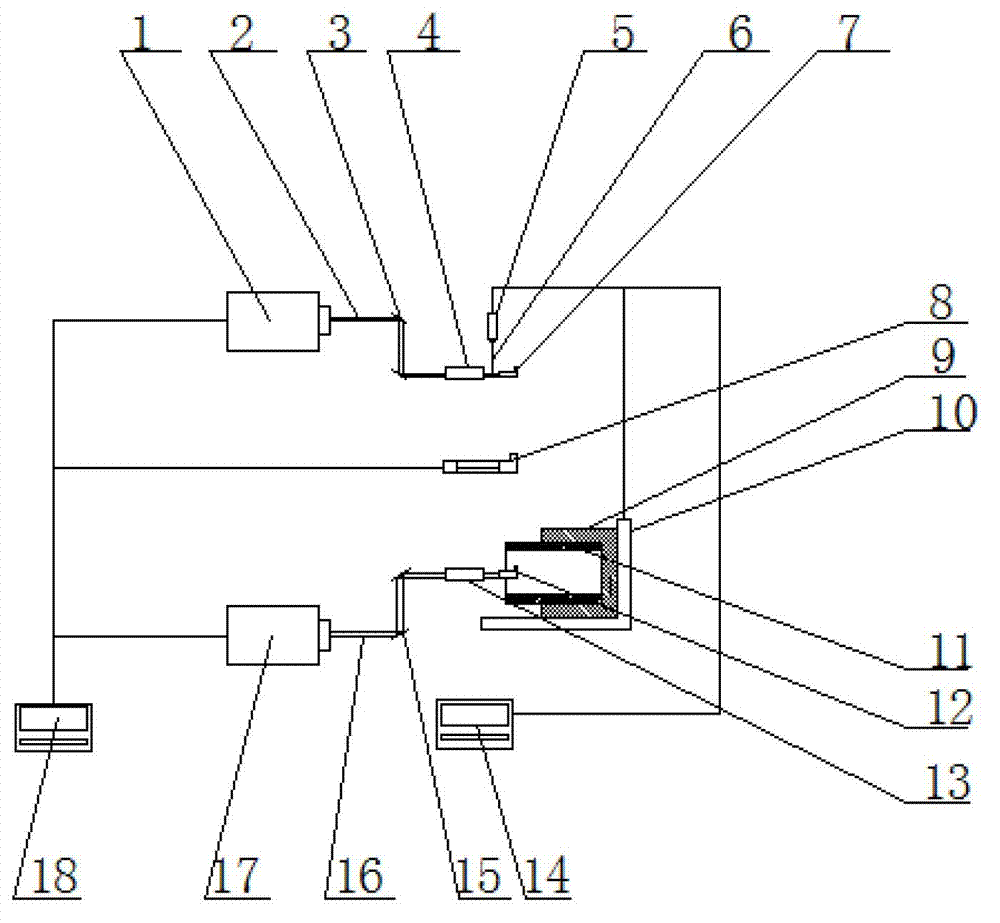

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

Micro-textured negative plate for preliminary lithium supplementing and preparation method thereof

ActiveCN108847474AAlleviate volume expansionDisperse expansion stressElectrode carriers/collectorsElectrode collector coatingConvex structureLithium

The invention discloses a micro-textured negative plate for preliminary lithium supplementing and a preparation method thereof. The micro-textured negative plate for preliminary lithium supplementingcomprises a negative current collector, micro-textures, preliminary lithium supplementing layers covering the surfaces of pits of the corresponding micro-textures, and active material dressing layerscovering the negative current collector and filling the pits, wherein the micro-textures are arranged on single or double side surfaces of the negative current collector and are of a concave-convex structure. The preliminary lithium supplementing layers are arranged between the negative current collector and the active material dressing layers and are only located on the surfaces of the pits of the micro-textures, so that the cohesive force between active materials and the current collector is not affected, the expansion stress of the active materials can be dispersed, the irreversible capacity is effectively compensated and the first efficiency is improved. Therefore, according to the micro-textured negative plate for preliminary lithium supplementing disclosed by the invention, effectivelithium supplementing can be achieved, volume expansion of the negative plate is relieved, the stability of a negative electrode system is ensured and the problem in the field at the present stage issolved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

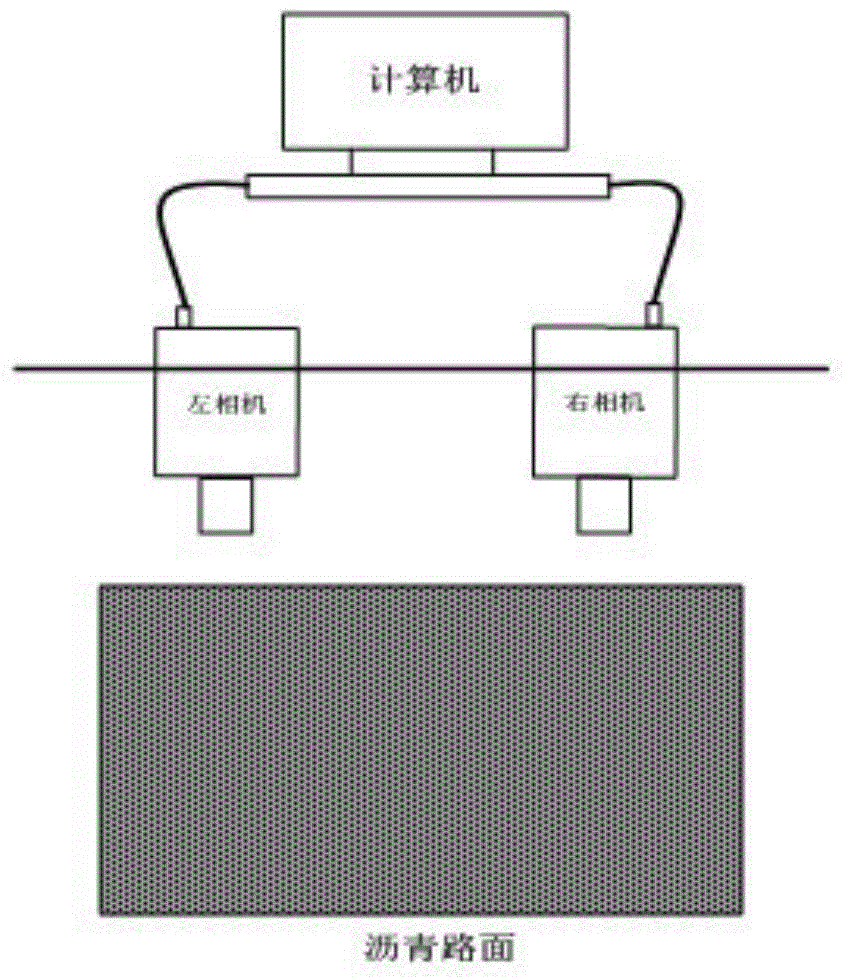

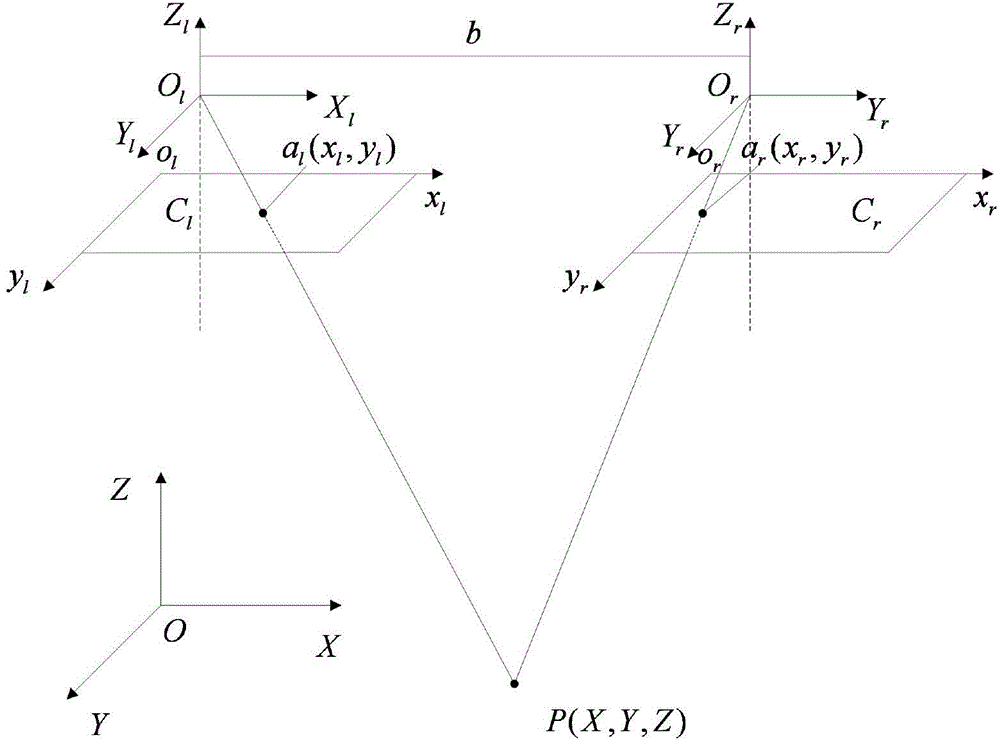

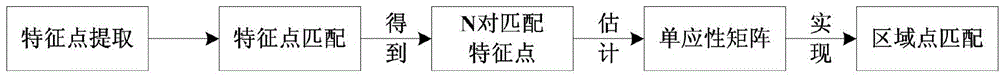

SIFT-based (scale-invariant feature transform) binocular vision three-dimensional image reconstruction method of asphalt pavement micro-texture

InactiveCN104361627AFast and accurate extraction and reconstruction3D-image rendering3D modellingStereo matchingScale-invariant feature transform

The invention discloses an SIFT-based (scale-invariant feature transform) binocular vision three-dimensional image reconstruction method of asphalt pavement micro-texture. A computer in a binocular vision system controls a left camera and a right camera to simultaneously acquire an image pair containing asphalt pavement information; feature point matching is performed through a binocular vision stereo matching algorithm based on an SIFT algorithm, further allowing regional point stereo matching; three-dimensional coordinates of the f asphalt pavement micro-texture are acquired through a binocular vision three-dimensional image reconstruction model of the asphalt pavement micro-texture, a surface point three-dimensional coordinate set is formed, and three-dimensional image reconstruction of the asphalt pavement micro-texture is achieved. The real three-dimensional image reconstruction model of the asphalt pavement micro-texture is provided for mechanical and hydro-mechanical finite element analysis of asphalt pavements, and basis is laid for following searches.

Owner:WUHAN UNIV OF SCI & TECH

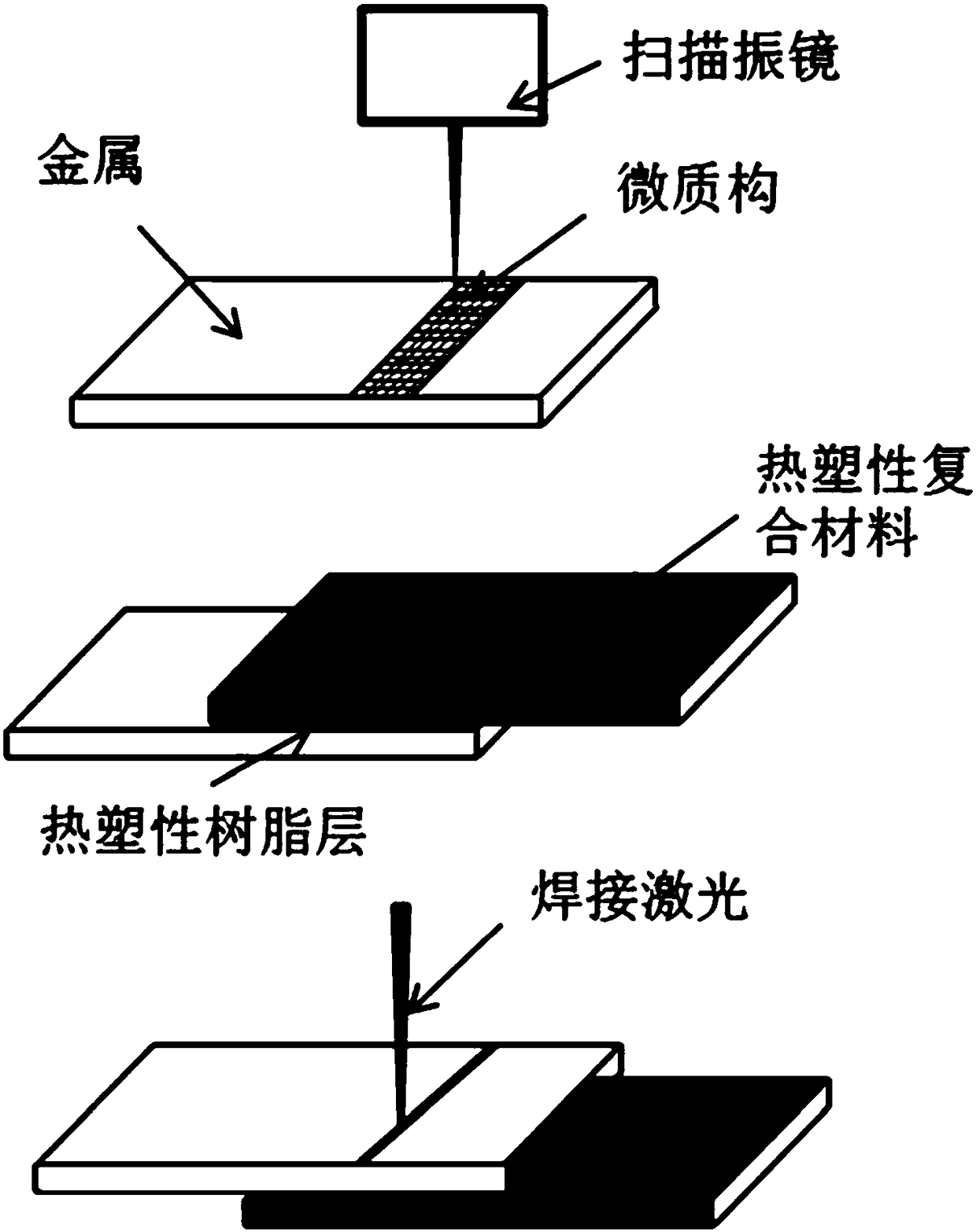

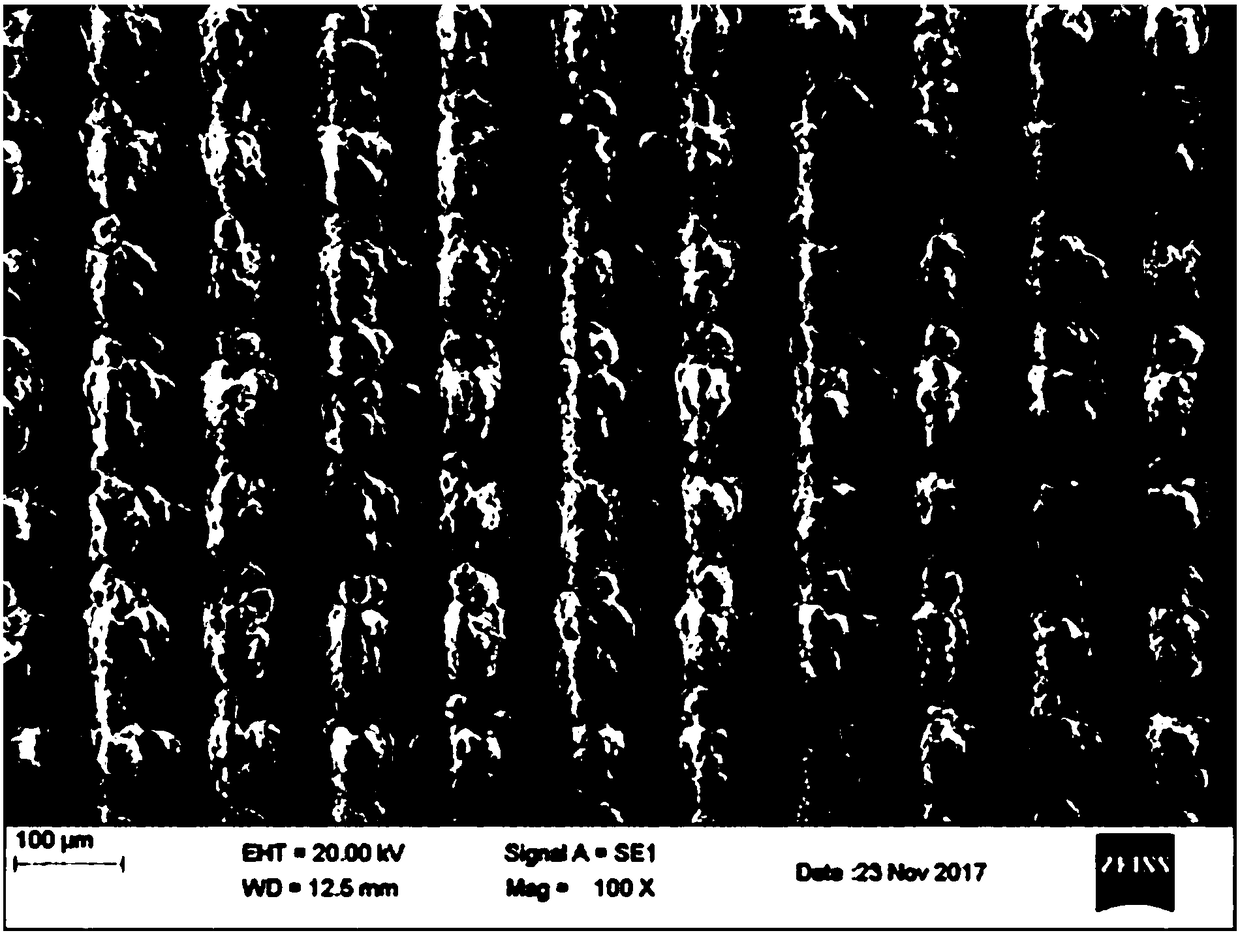

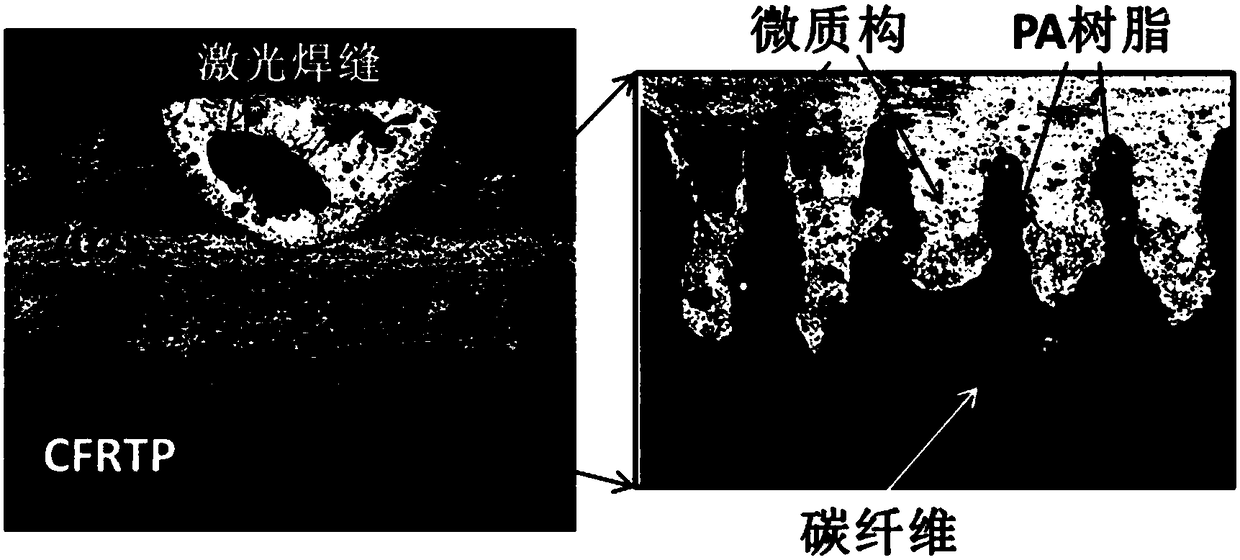

Method for improving connection strength of thermoplastic composite and metal

The invention belongs to the technical field of welding and discloses a method for improving connection strength of a thermoplastic composite and metal. The method comprises the following steps that S1, a micro texture is prepared in a to-be-connected area of the surface of the metal through a short-pulse laser; S2, a layer of thermoplastic resin material is laid on the surface of the micro texture; and S3, heat conduction connection is conducted on the thermoplastic composite and the metal through a laser. According to the method, on the one hand, the micro texture is prepared in the to-be-connected area of the surface of the metal, the contact area of the thermoplastic composite and the metal is increased, and an occlusion structure is formed; on the other hand, the layer of thermoplastic resin material is added between the thermoplastic composite and the metal, the thermoplastic resin material is in a molten state during laser welding, thus the thermoplastic resin material and the metal are fully connected, and finally the connection strength of the thermoplastic composite and the metal is improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

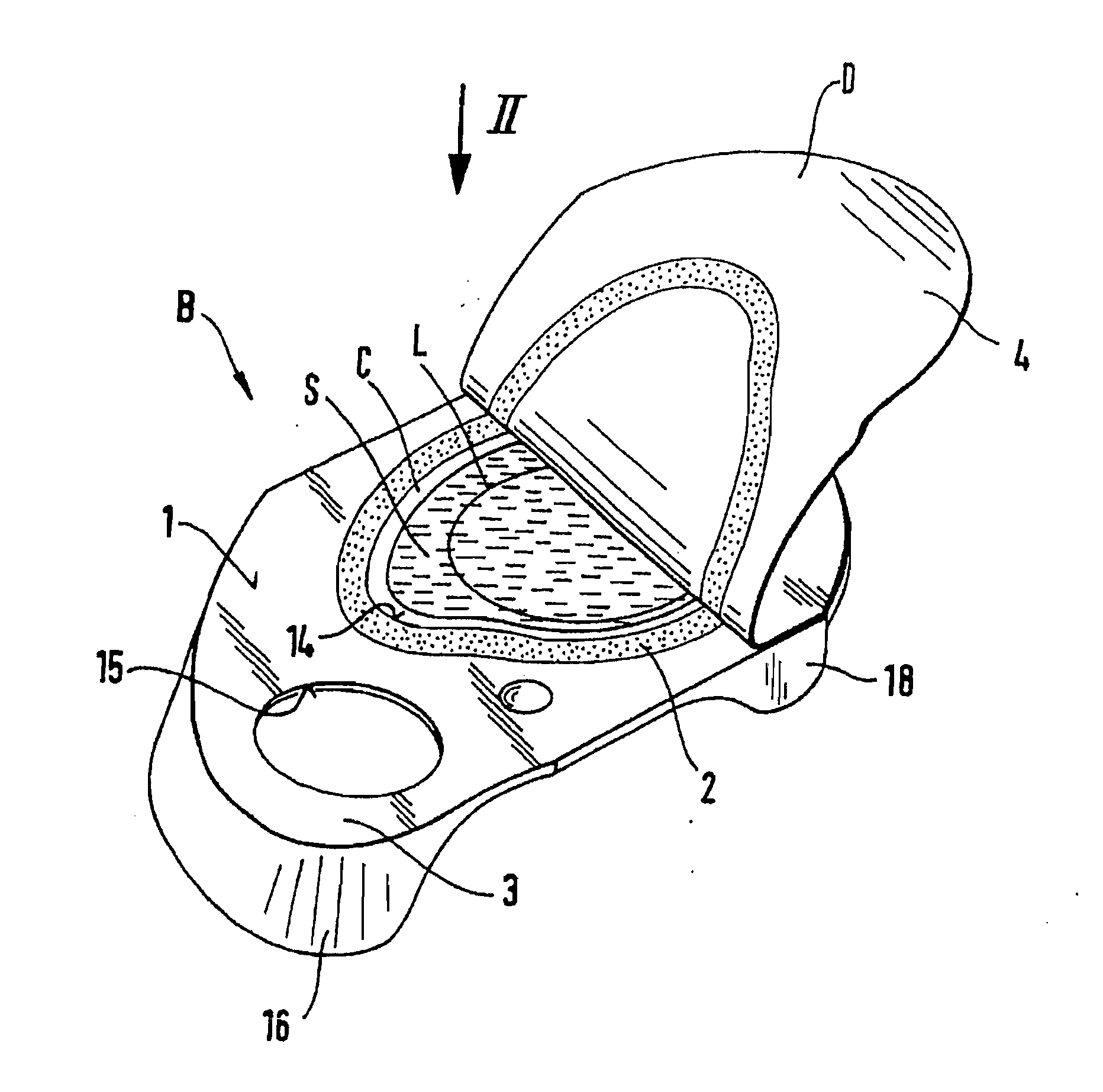

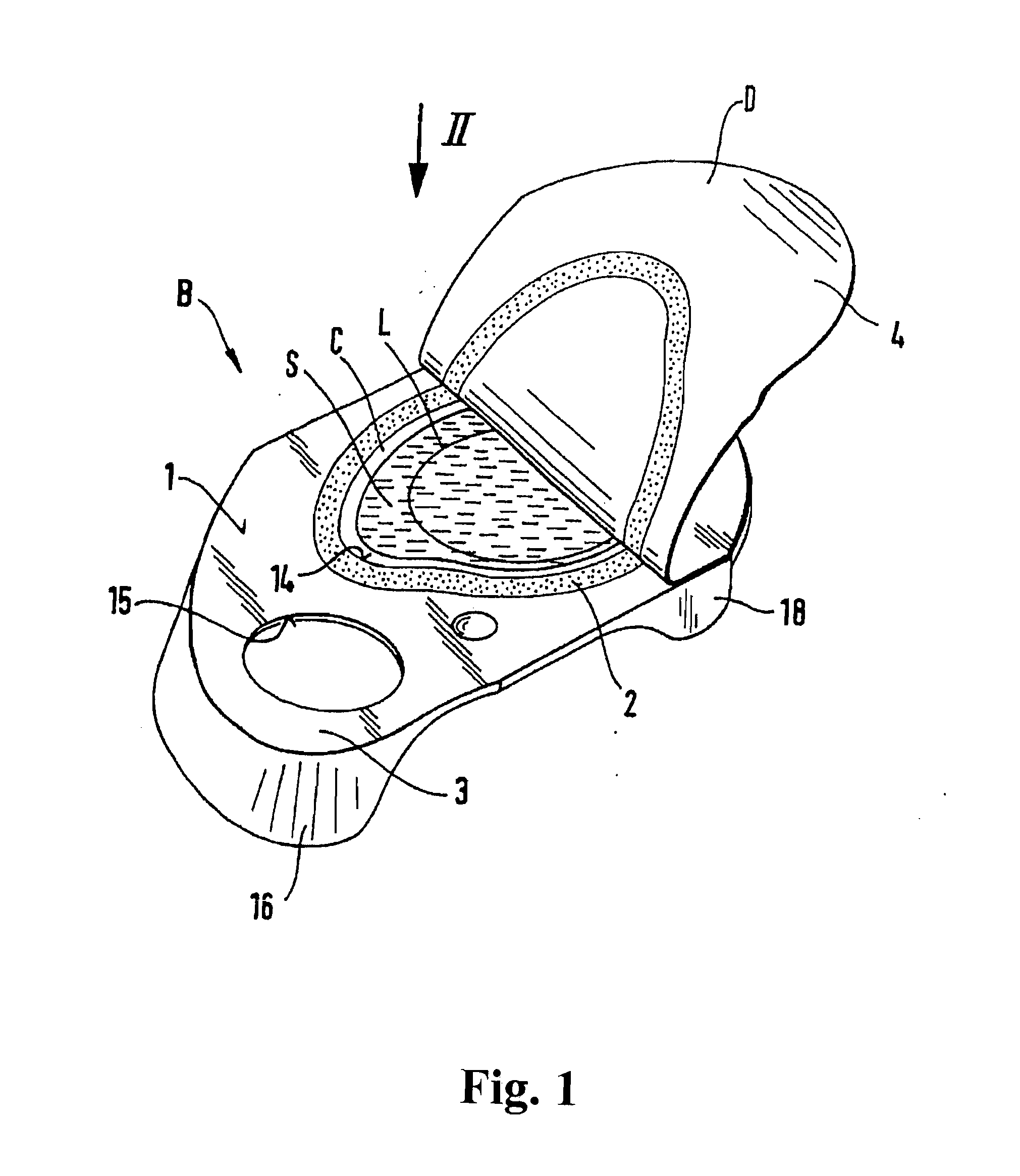

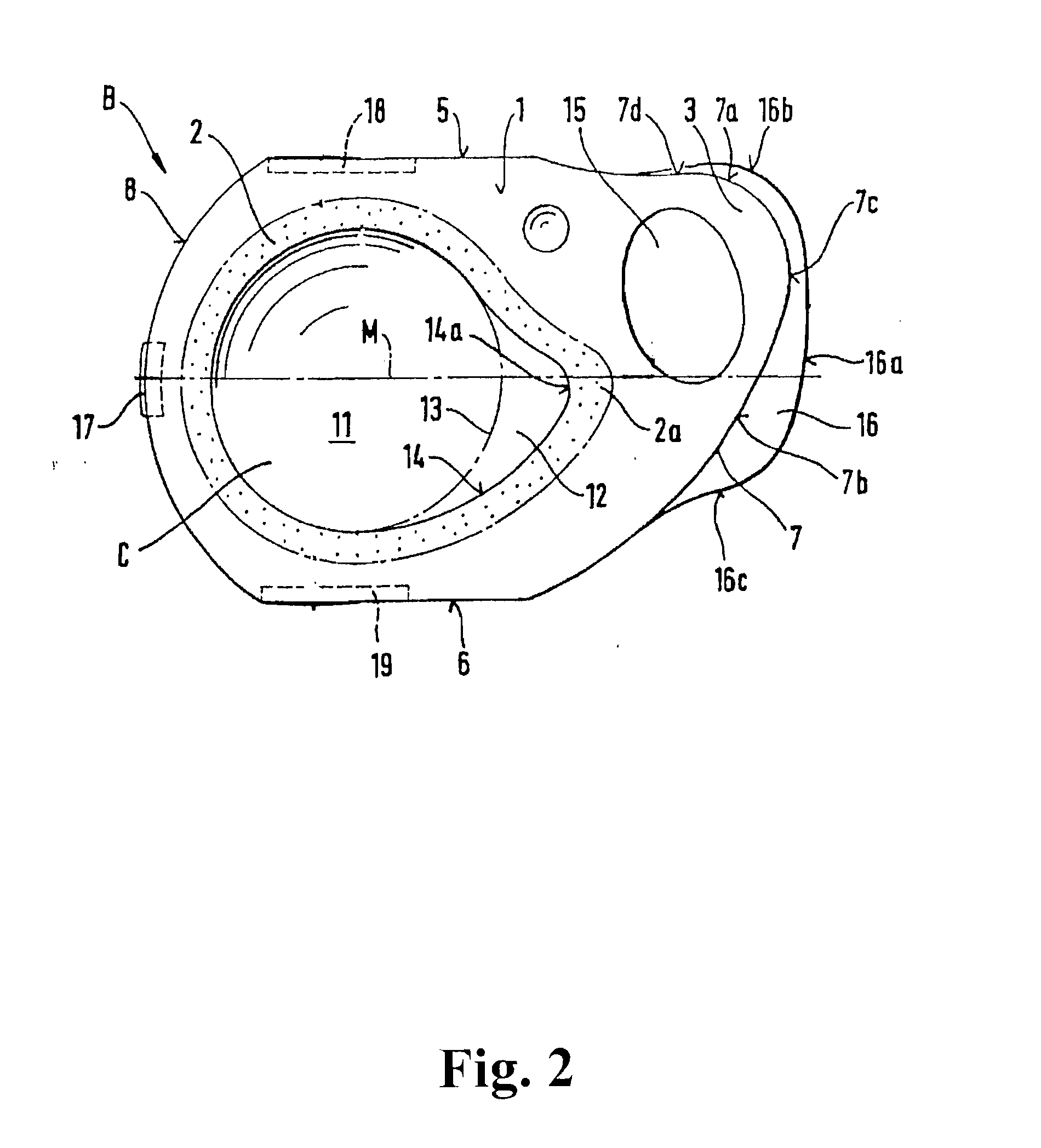

Contact Lens Package

A plastic container for storing a hydrogel contact lens in a liquid, the container comprising: a cavity and a substantially flat flange that extends in a plane around the opening periphery of the cavity, and the flange having a sealing area round the circumference of the cavity. Furthermore, the sealing area has a micro-texture pattern. When sealing the container with a flexible cover sheet which is a laminate material having a metal foil layer and at least one polymer layer to form a storage package of the soft contact lens, the micro-texture pattern of the sealing area engages a laminate foil cover and displaces water beads present between the laminate foil cover and the plastic container in the sealing area around the cavity to form a heat seal.

Owner:ALCON INC

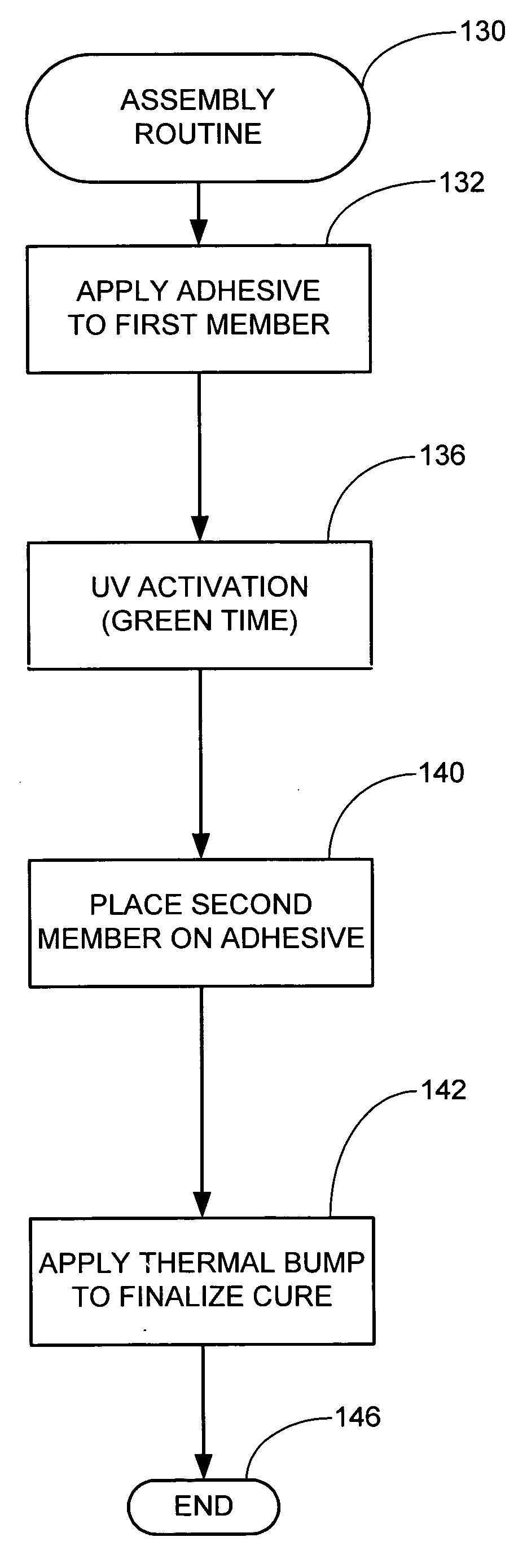

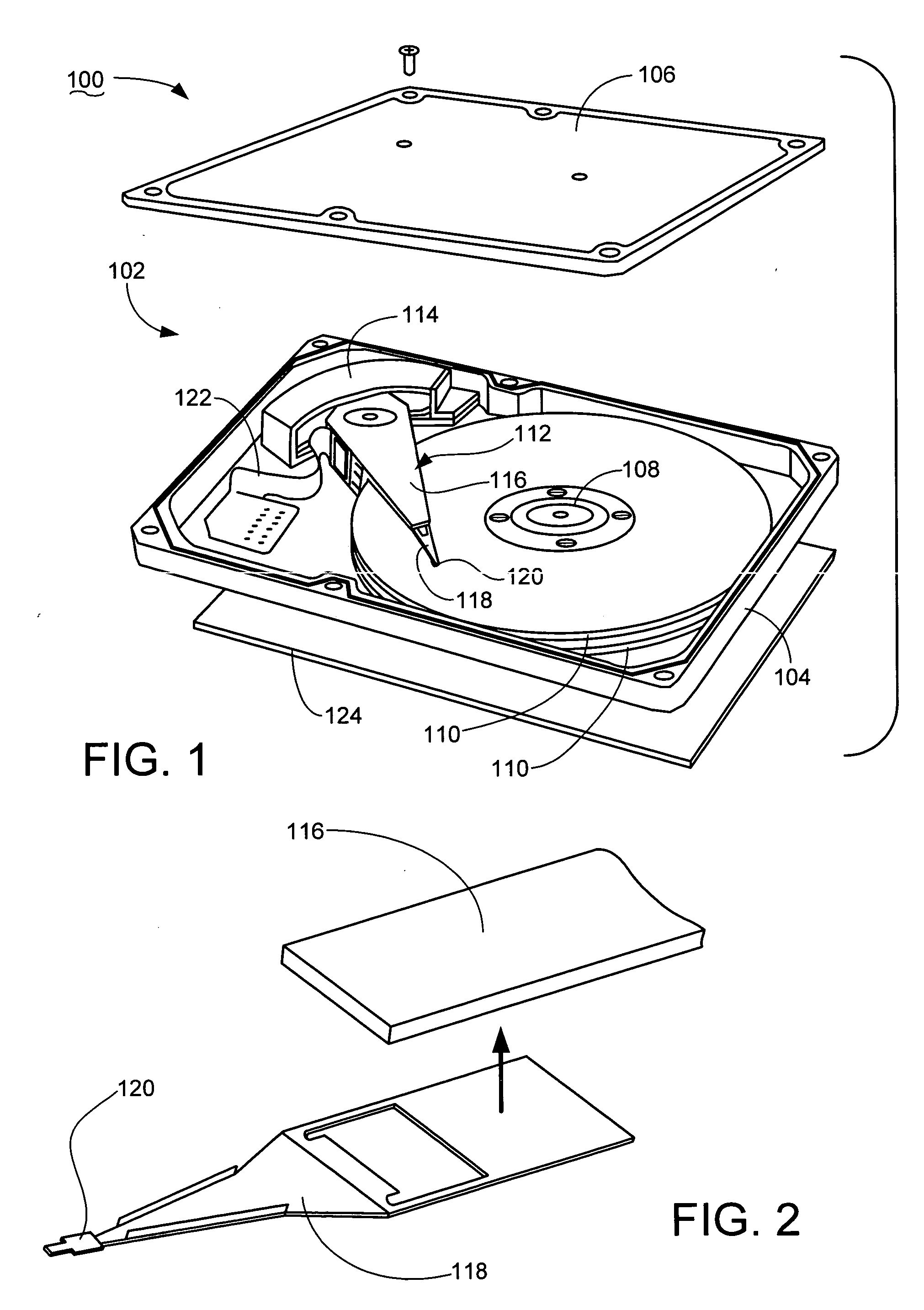

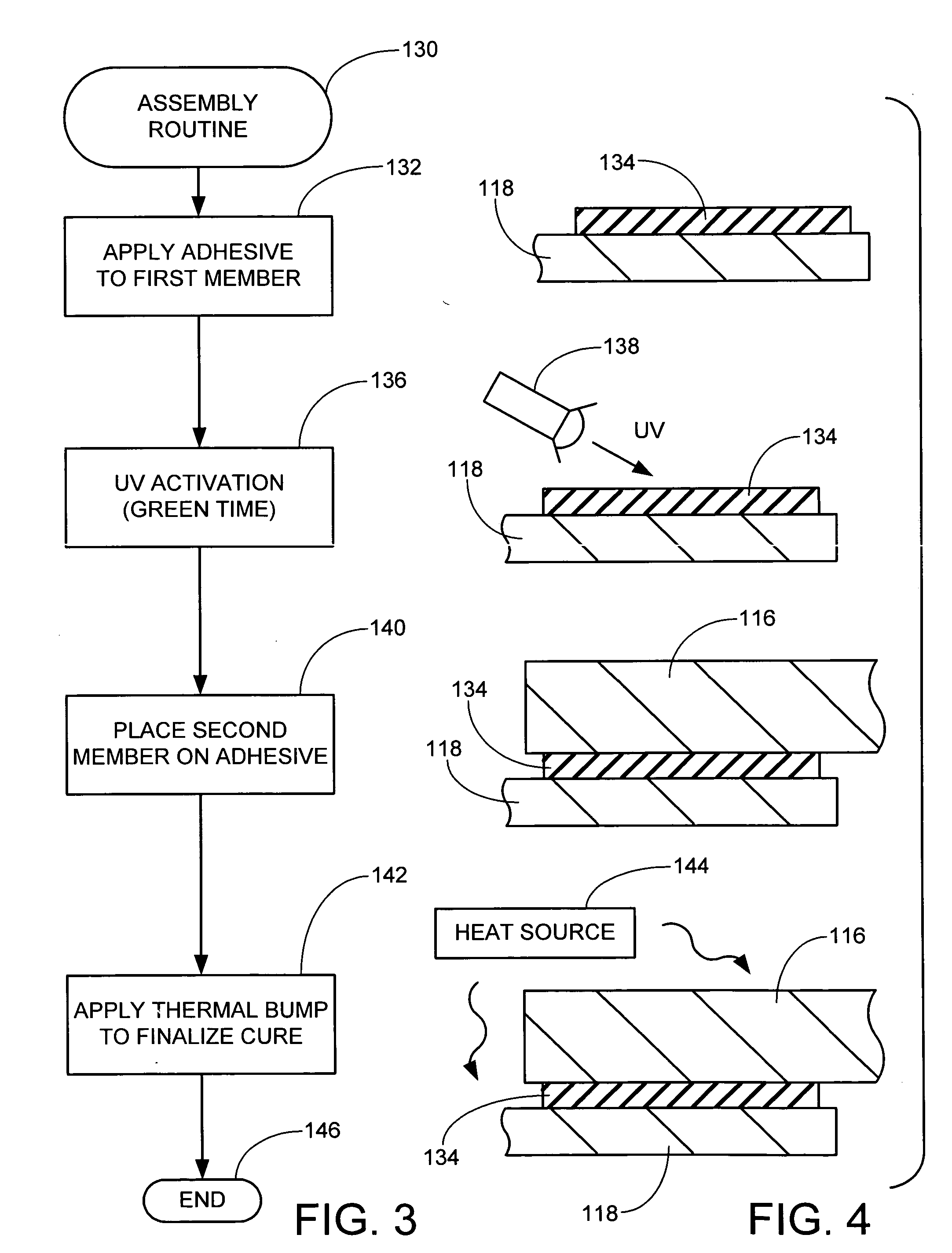

Adhesive attachment of a first member to a second member

InactiveUS20060292377A1Control adhesive thicknessUnity of structure can be improvedCarrier constructional parts dispositionLamination ancillary operationsVitrificationAdhesive

Apparatus and method for adhesively attaching a first member to a second member, such as components of a data storage device. Preferably, an adhesive is applied to the first member and exposed to ultraviolet light. The second member is placed onto the adhesive, and heat is applied to finalize curing. The adhesive is subsequently cooled to a temperature below a glass transition temperature (Tg) of the adhesive to detach the first and second members. Respective mating surfaces of the first and second members are preferably provided with different adhesive coupling characteristics, such as by provision of a surface adhesive promotor or a micro-texturized pattern to only one member. In this way, upon detachment of the first and second members, substantially all of the adhesive is removed from the other member. A filler material further establishes adhesive thickness and enhances structural unity of the adhesive during detachment of the respective members.

Owner:SEAGATE TECH LLC

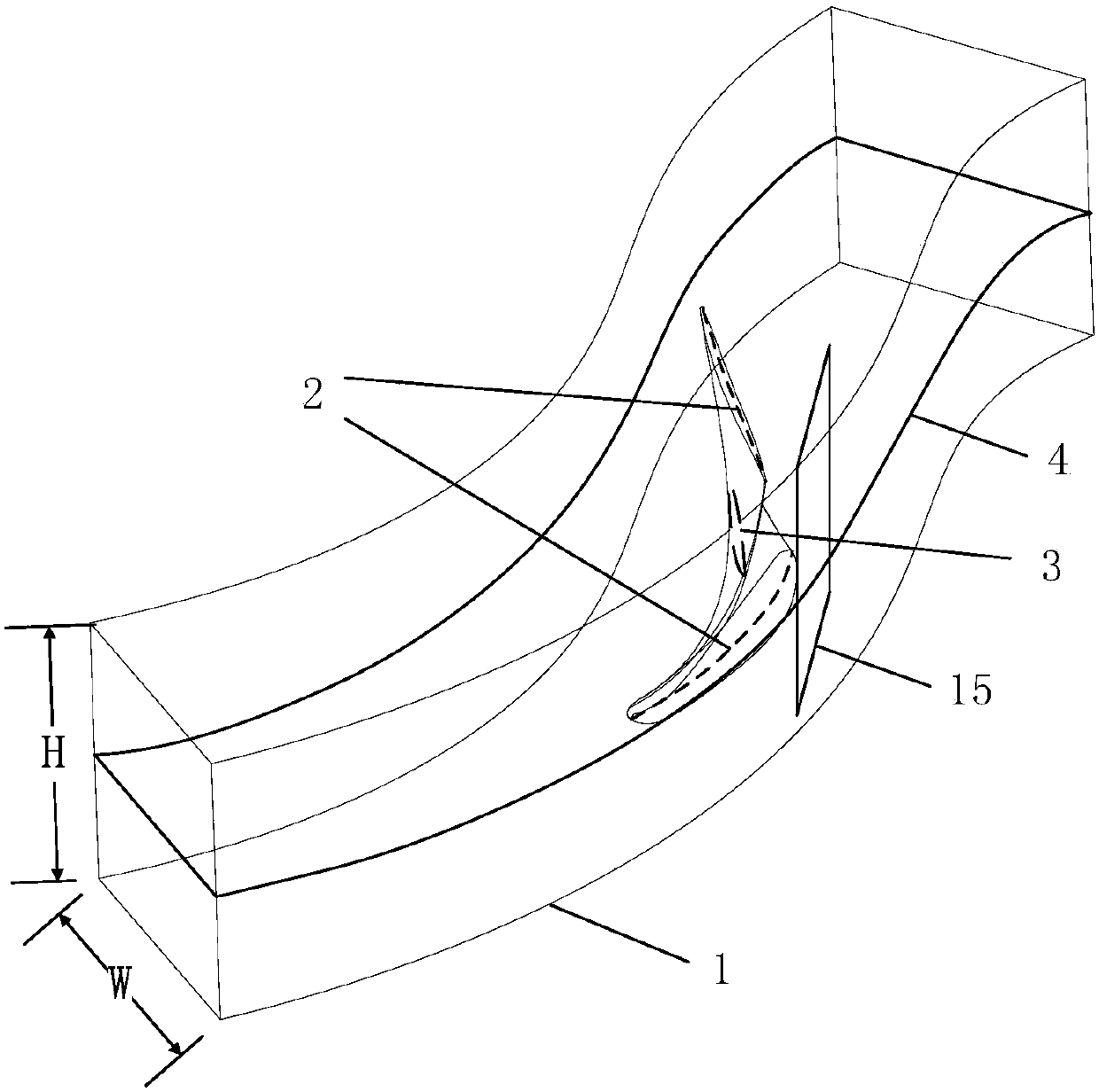

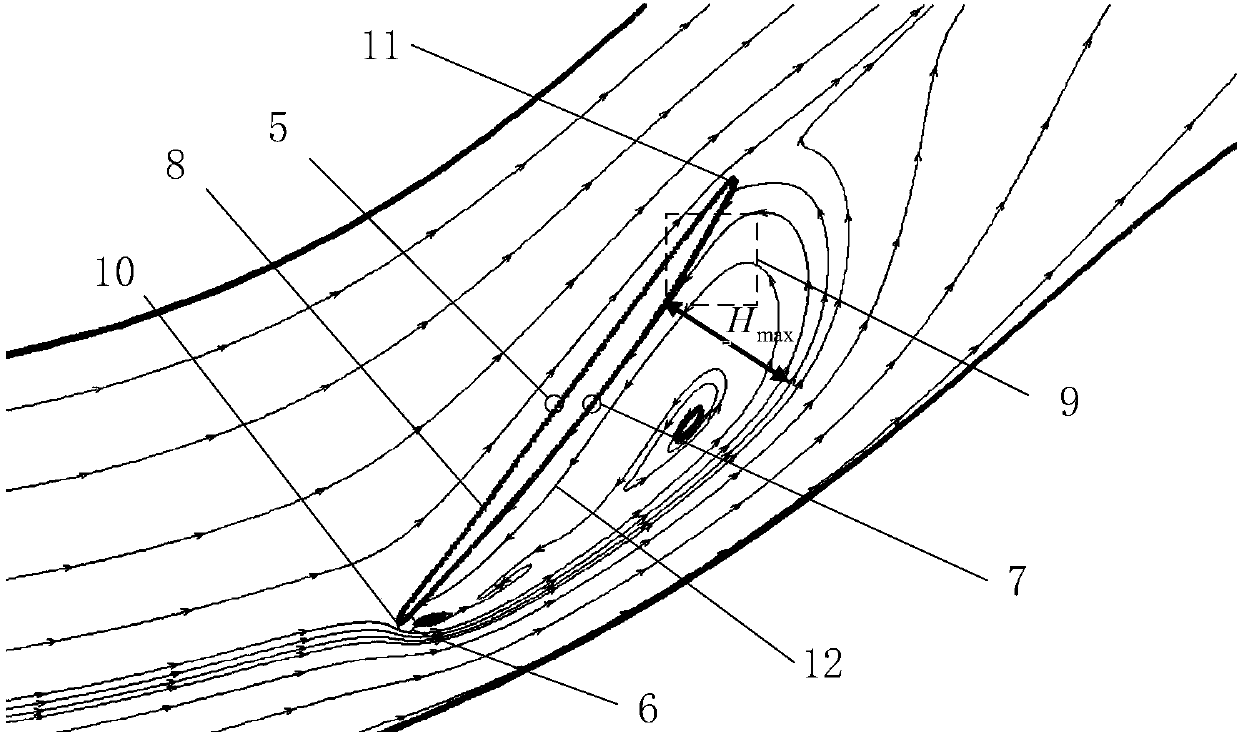

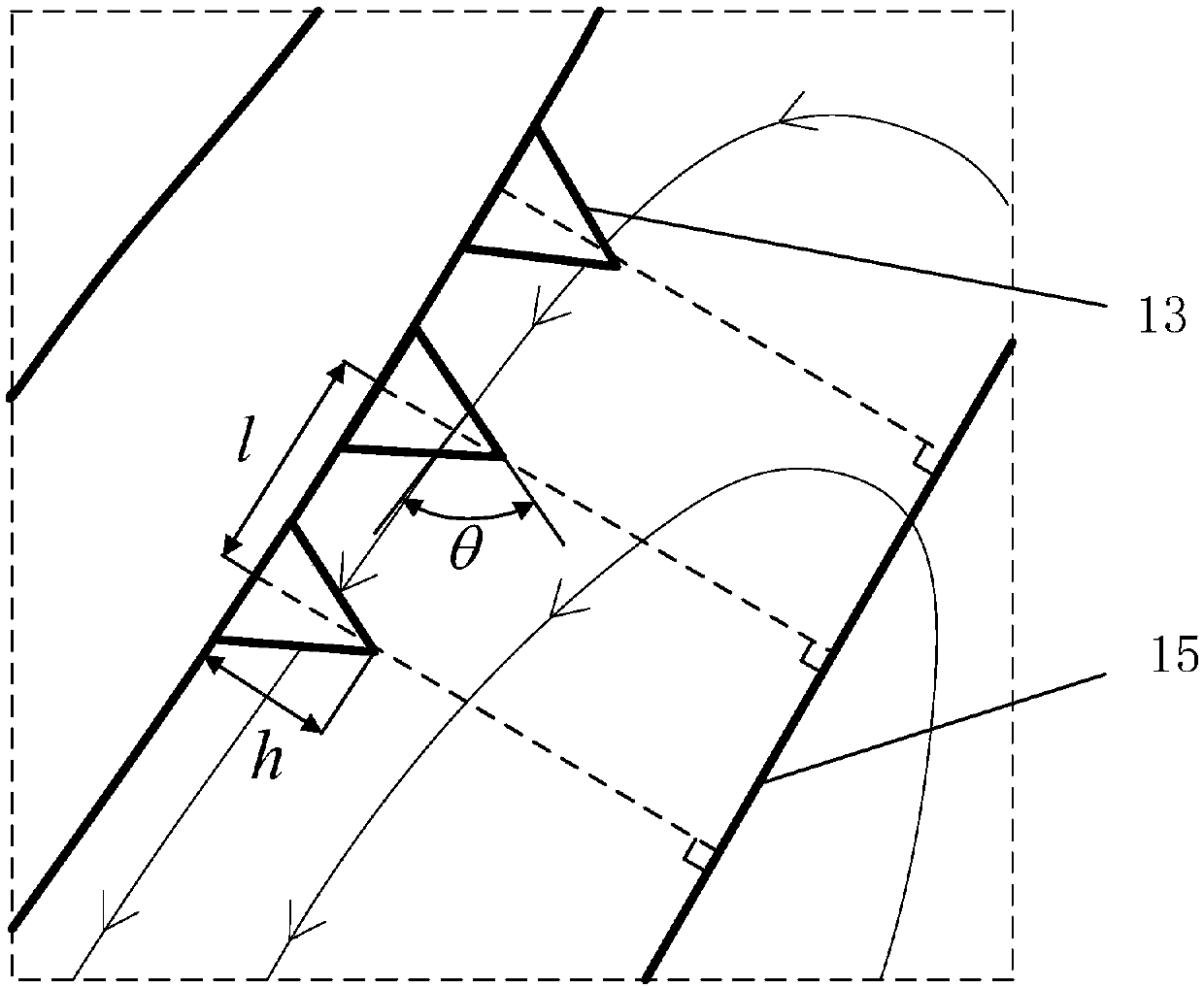

Design method of impeller blade drag reduction micro-texture

ActiveCN107742011ALow air resistanceReduce consumptionGeometric CADSustainable transportationImpellerEngineering

The invention discloses a design method of a blade surface drag reduction micro-texture, and belongs to the field of blade drag reduction. According to an impeller blade model, a flow field domain isestablished; numerical simulation is carried out on the flow field domain, a streamline graph of the middle section of a blade in the height direction is obtained, and accordingly a blade pressure surface, a boundary layer separation area and a suction surface backflow area serve as a micro-texture placement area; the micro-texture placement area is closely attached to a blade wing-shaped arrangement micro-texture section, and the micro-texture placement area sweeps on the surface of the blade in the height direction of the blade to form ribs or grooves; finite element simulation is conductedon the blade model with the rib or groove micro-texture to optimize the placement position and the section shape of the micro-texture, the placement position and the section shape of the micro-texturewith the best drag reduction are obtained, and accordingly the blade surface drag reduction micro-texture is constructed. The drag reduction of the optimized blade surface drag reduction micro-texture reaches 5-10%, the energy consumption is reduced, fuel resources are saved, and the design method of the drag reduction micro-texture can be applied and popularized in other fields.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com