Metal surface micro texture group electrode direct writing micro electrolysis processing method and dedicated device

A metal surface and processing method technology, applied in the field of metal surface micro-texture group electrode direct writing micro-electrochemical machining, can solve the problems of complex process method, long processing cycle, tool wear, etc., to avoid tool wear, shorten processing cycle, The effect of good workpiece processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 The direct-writing micro-electrolytic machining method of metal surface micro-texture group electrodes includes the following steps:

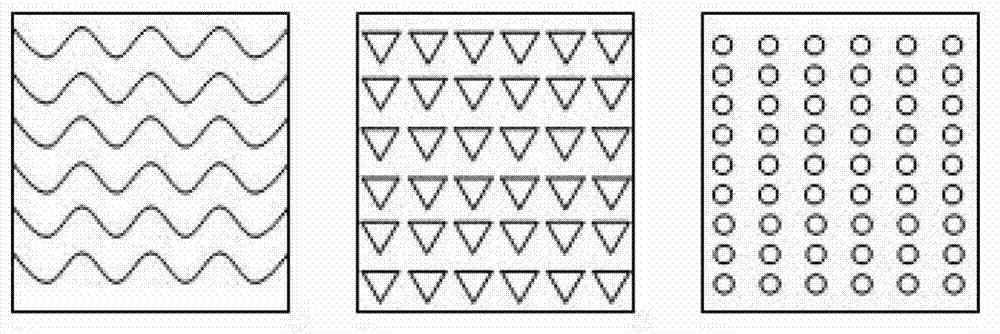

[0024] 1) Using row-shaped group electrodes to process the micro-texture of the metal surface of the workpiece to be processed;

[0025] 2) Under the control of the numerical control system of the machine tool, the row-shaped group electrodes move relative to the workpiece to be processed. When the electrolyte is circulated and the processing power is turned on, the micro-texture is processed on the surface of the workpiece to be processed.

Embodiment 2

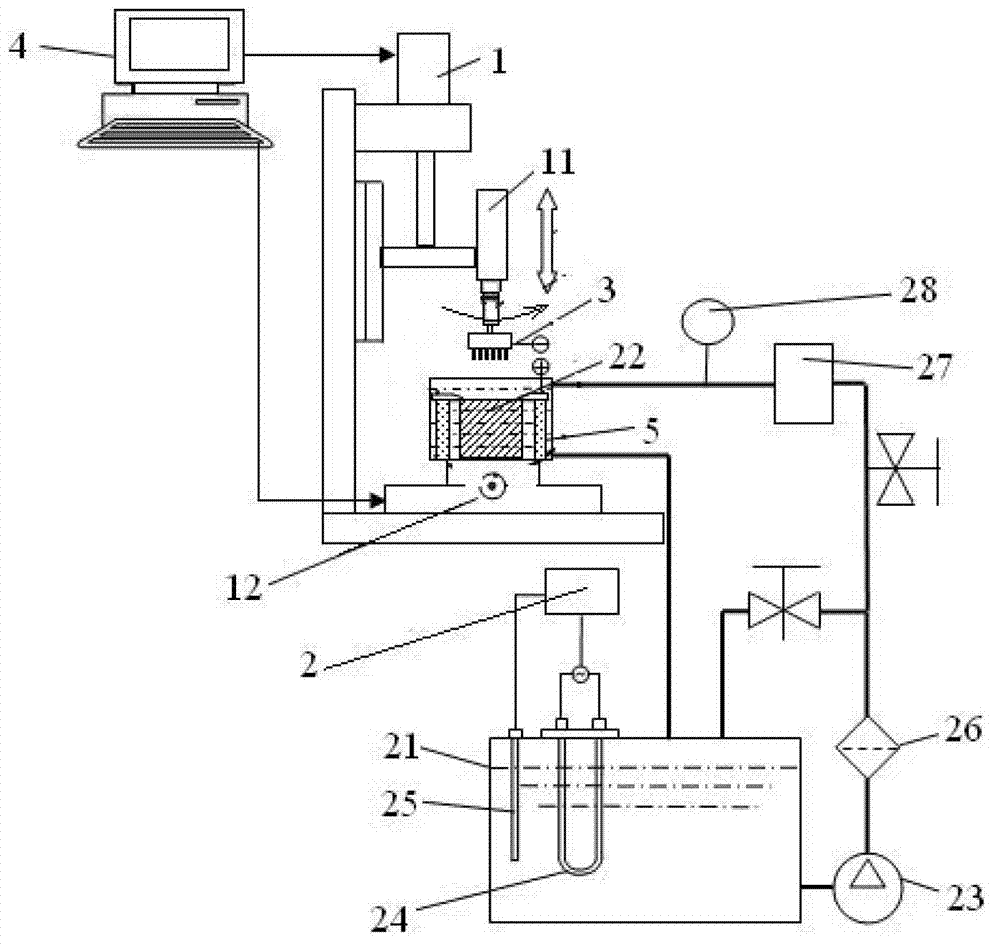

[0026] Embodiment 2 According to the special equipment of the processing method of embodiment 1, comprise machine tool 1, electrolyte circulation device 2, row shape group electrode 3, computer 4 and be equipped with the power supply of positive pole and negative pole, described machine tool 1, described Electrolyte circulation device 2 and described row-like group electrode 3 are all electrically connected with described computer 4, and are simultaneously controlled by the machine tool numerical control system configured in described computer 4; Described row-like group electrode 3 is according to The shape of the workpiece 5 to be processed is selectively installed on the main shaft 11 of the machine tool 1 or the electrolyte circulation device 2, and the row-shaped group electrodes 3 are electrically connected to the negative pole of the power supply, and the workpiece 5 to be processed Correspondingly installed on the electrolyte circulation device 2 or the main shaft 11 of...

Embodiment 3

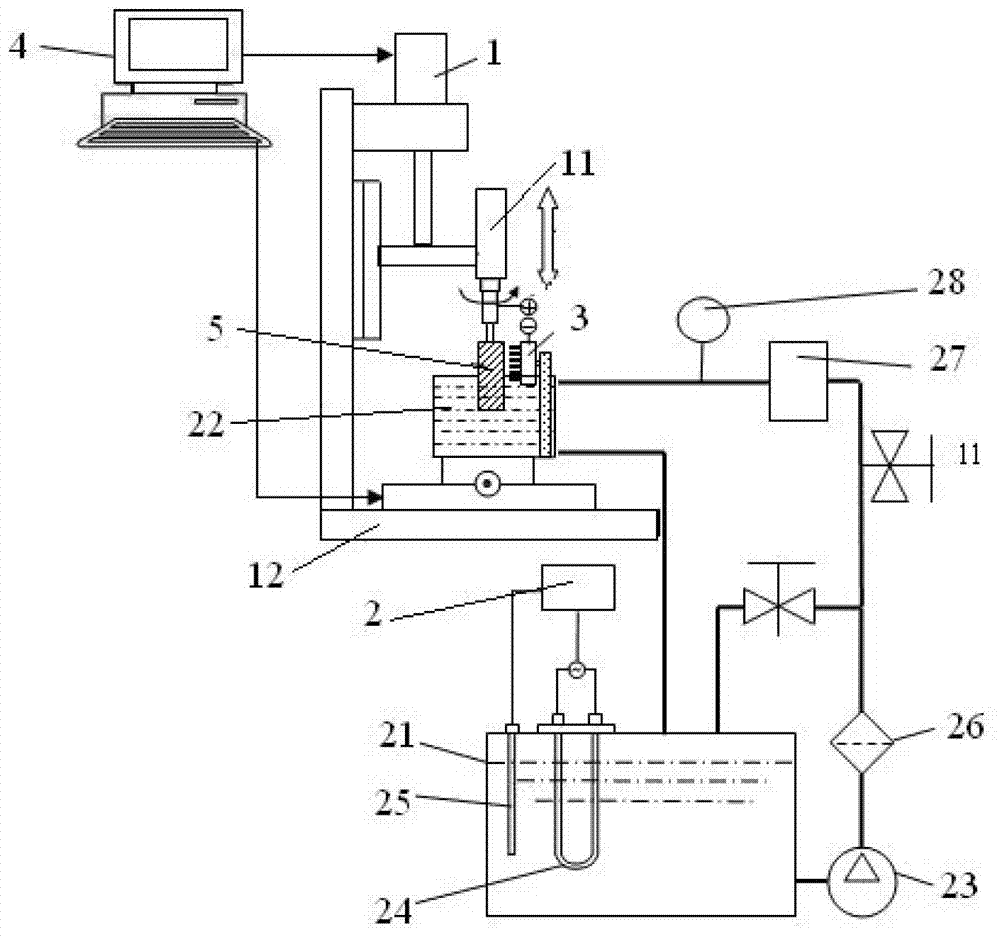

[0033] Embodiment 3 The difference between this embodiment and Embodiment 2 is that the workpiece 5 to be processed is a cylindrical structure, the row-shaped group electrodes 3 are installed in the electrolytic cell 22, and the workpiece 5 to be processed is installed on the spindle of the machine tool 1 11, the rest of the structure and implementation are the same as in Example 1.

[0034] The workpiece 5 to be processed is a cylindrical structure. At this time, the row-shaped group electrodes 3 are installed in the electrolytic cell 22, the workpiece 5 to be processed is installed on the main shaft 11 of the machine tool 1, and then the computer 4 is turned on, and the computer 4 is correspondingly turned on. CNC machine control system, after setting the corresponding parameters, connect the row group electrode 3 with the negative pole of the power supply, connect the workpiece 5 to be processed with the positive pole of the power supply, and start processing, and control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com