Patents

Literature

279 results about "Texture processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of cutter surface antisticking antifriction micro mosaic composite texture

InactiveCN103111819AIncreased durabilityImprove cutting efficiencyManufacturing technologyBuilt up edge

The invention discloses a preparation method of a cutter surface antisticking antifriction micro mosaic composite texture and belongs to the technical field of mechanical cutting tool manufacture. The preparation method comprises the steps of carrying out texturing overlaid and microcavity / groove composite texture processing on the working surface of a cutter by using laser, and filling solid lubricant into the microcavity / groove texture of the cutter surface in a pressed and embedded mode. The preparation method of the cutter surface antisticking antifriction micro mosaic composite texture overcomes monotony of the existing cutter texture method, improves aintisticking performance of the front cutter surface of the cutter, preventing generation of a built-up edge, performs the function of storing and conveying of the texturing overlaid and microcavity / groove composite texture on cutting fluid, performs cooling and lubrication action on the cutter and achieves the purposes of improving durability and cutting efficiency of the cutter and ensuring machining quality of a workpiece surface.

Owner:JIANGSU UNIV

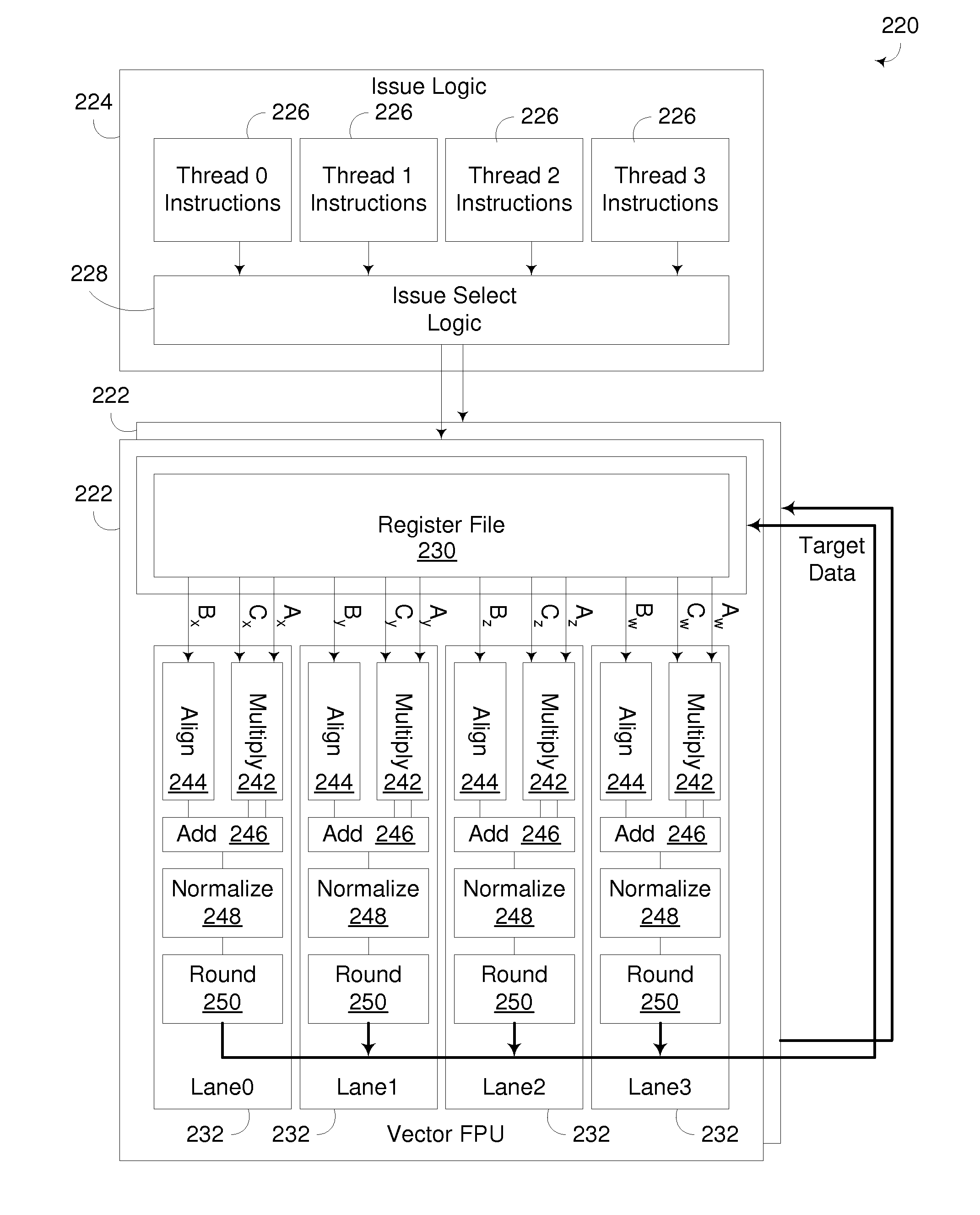

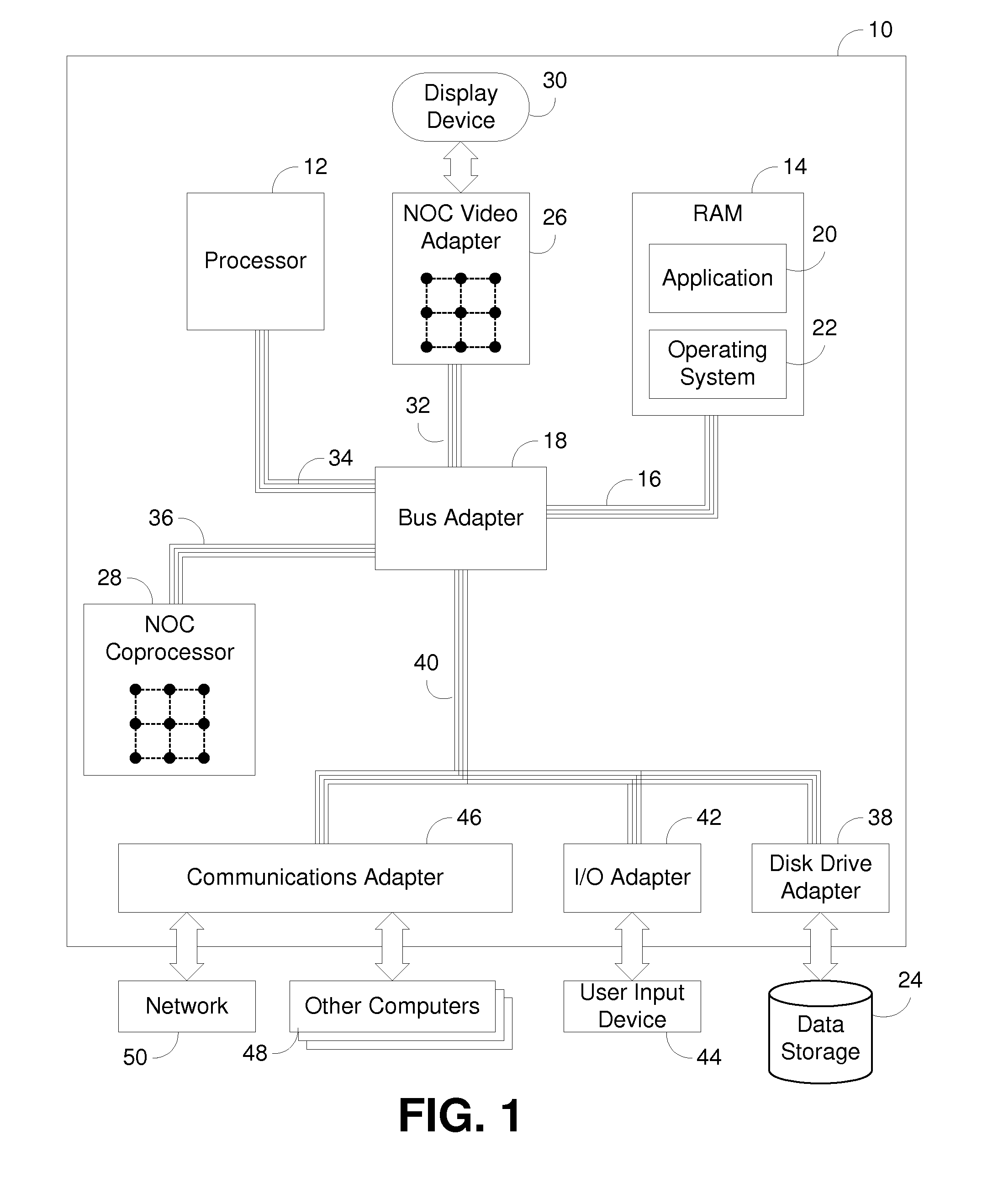

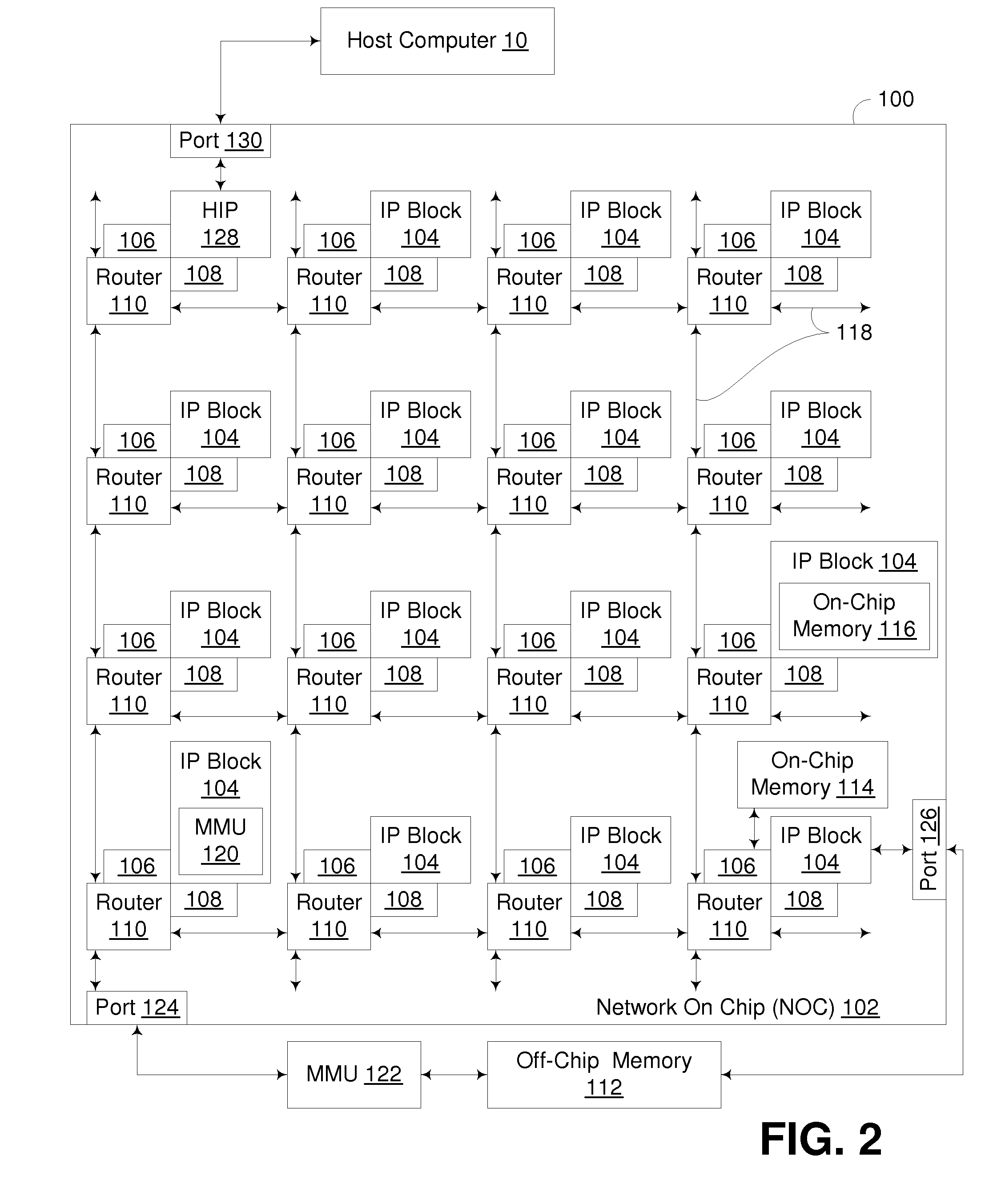

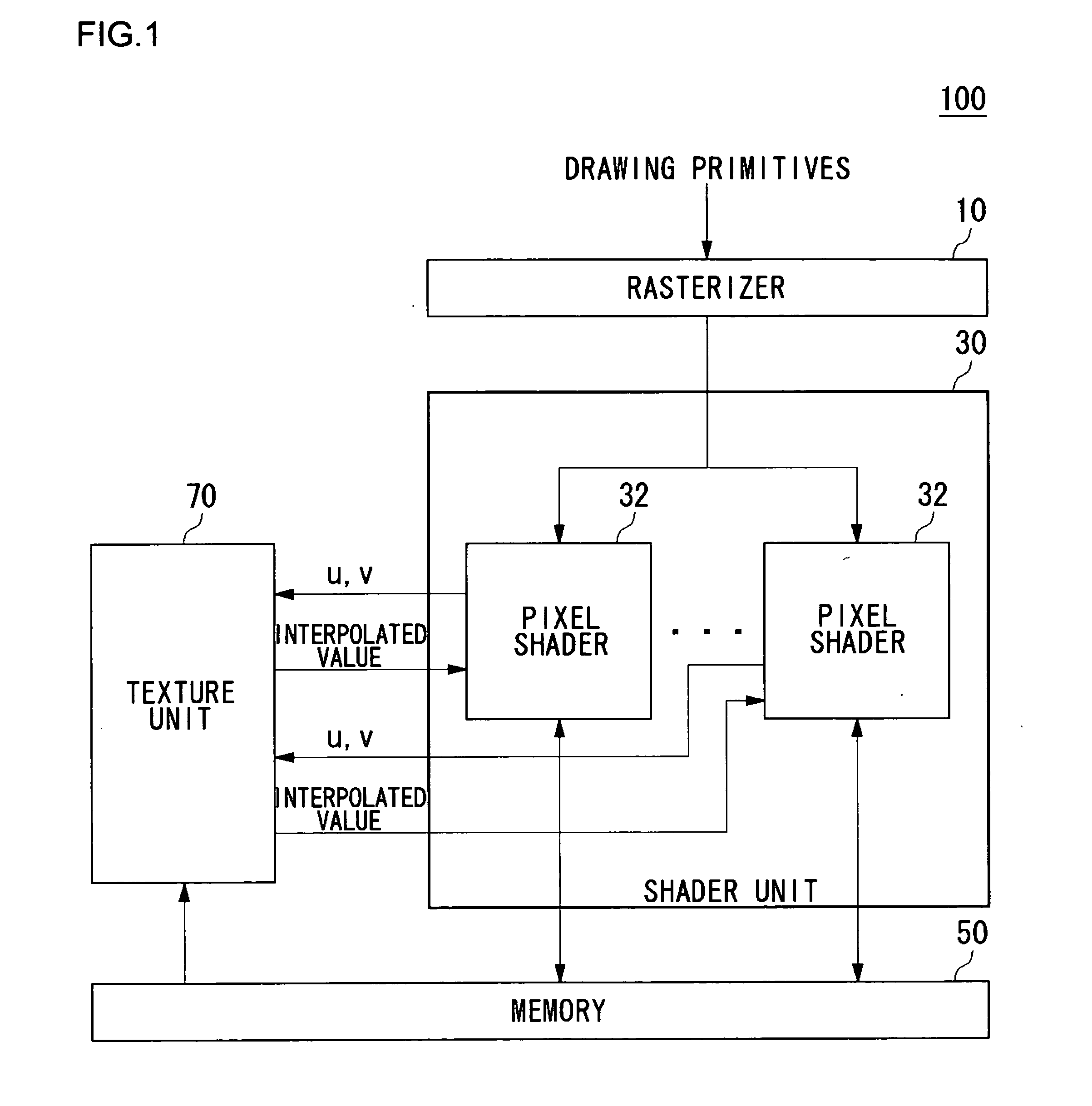

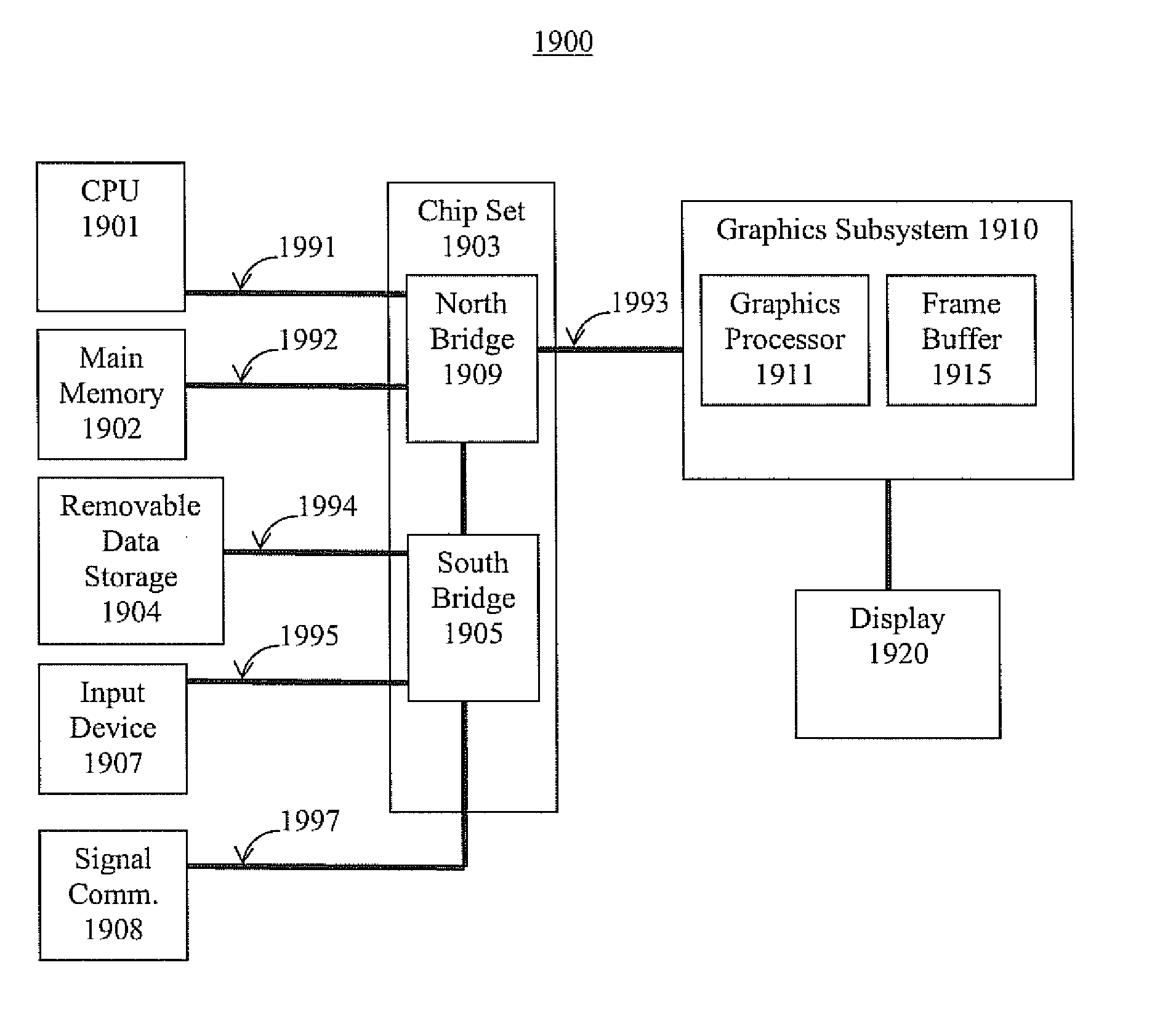

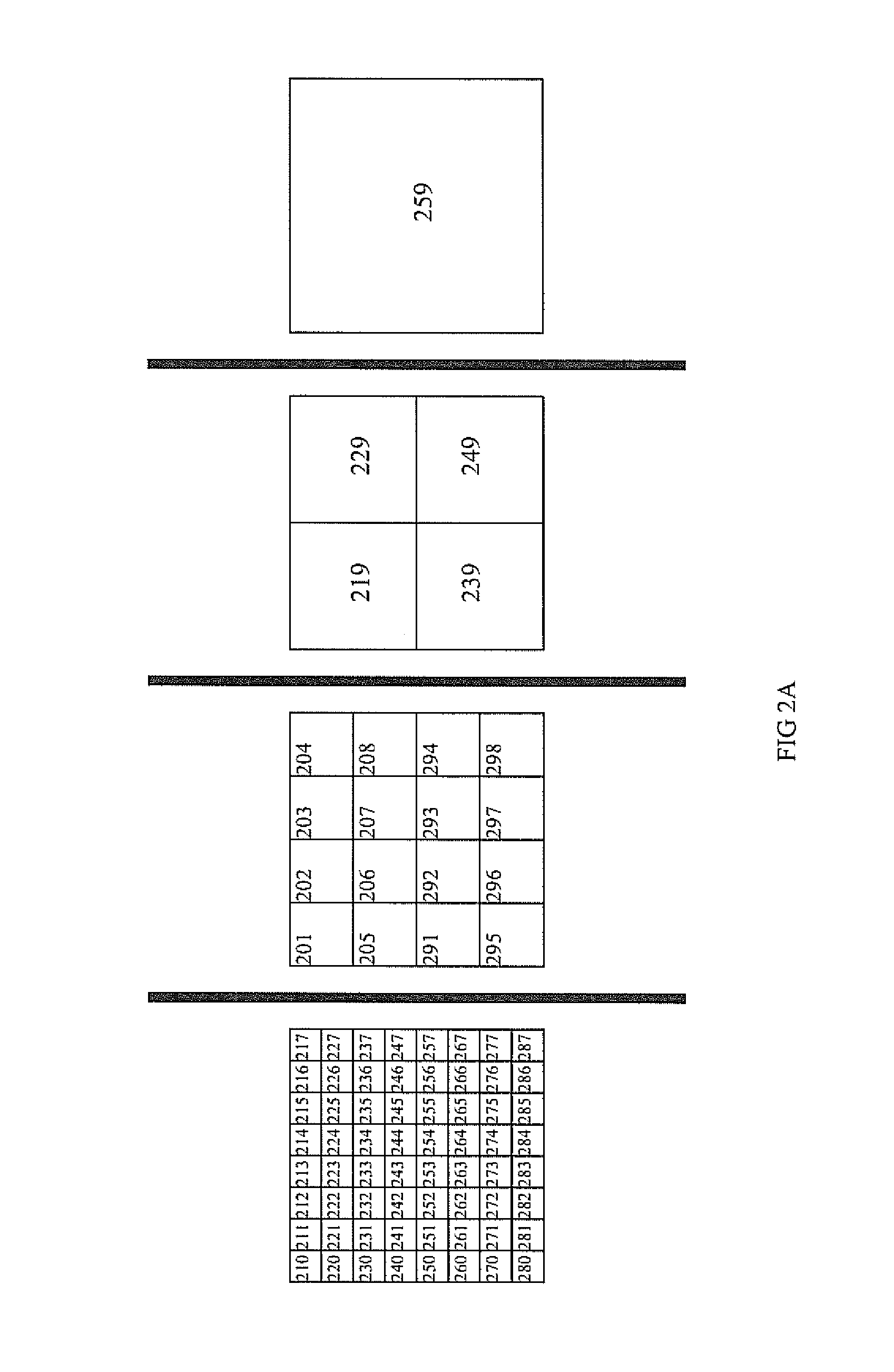

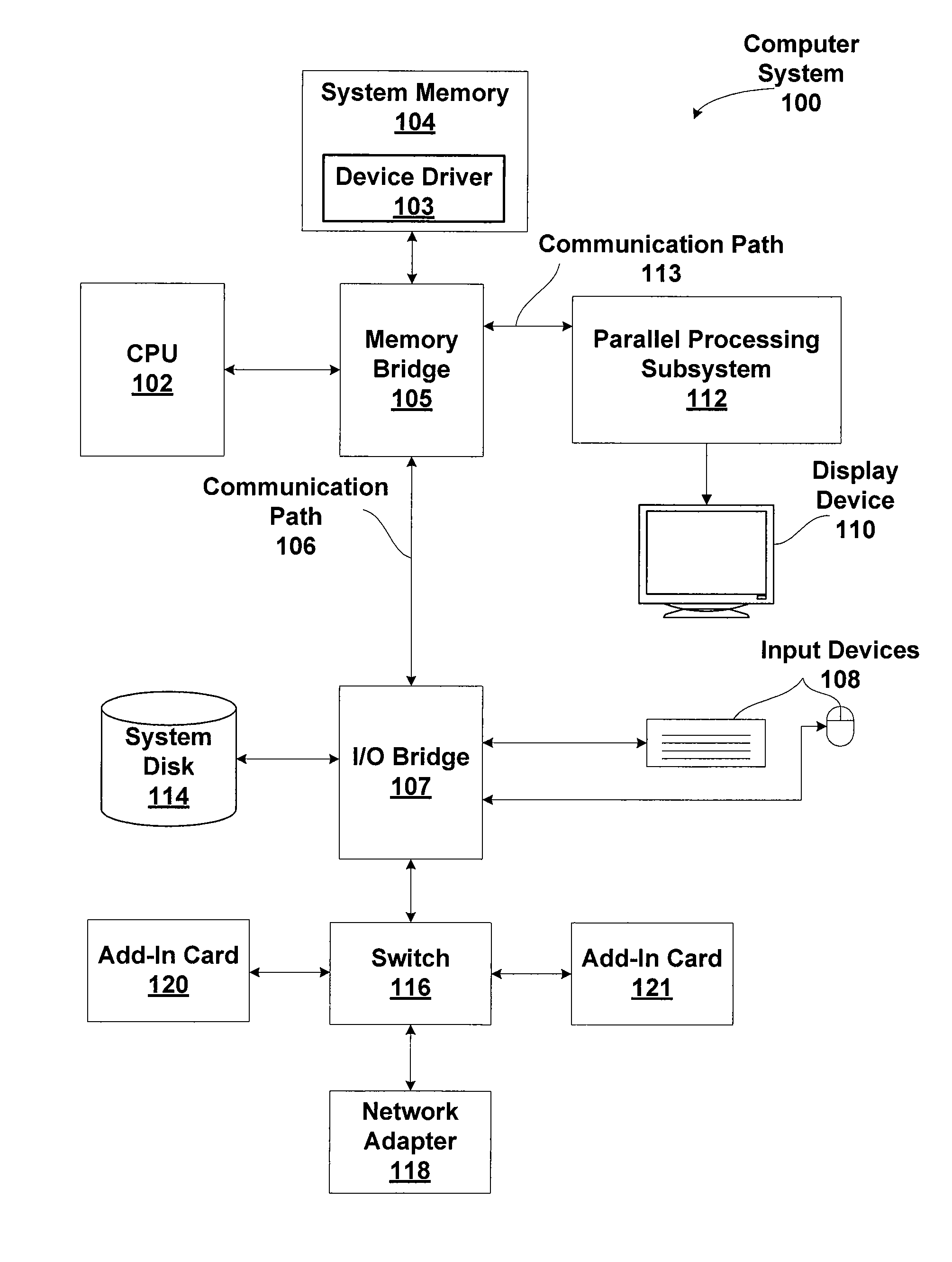

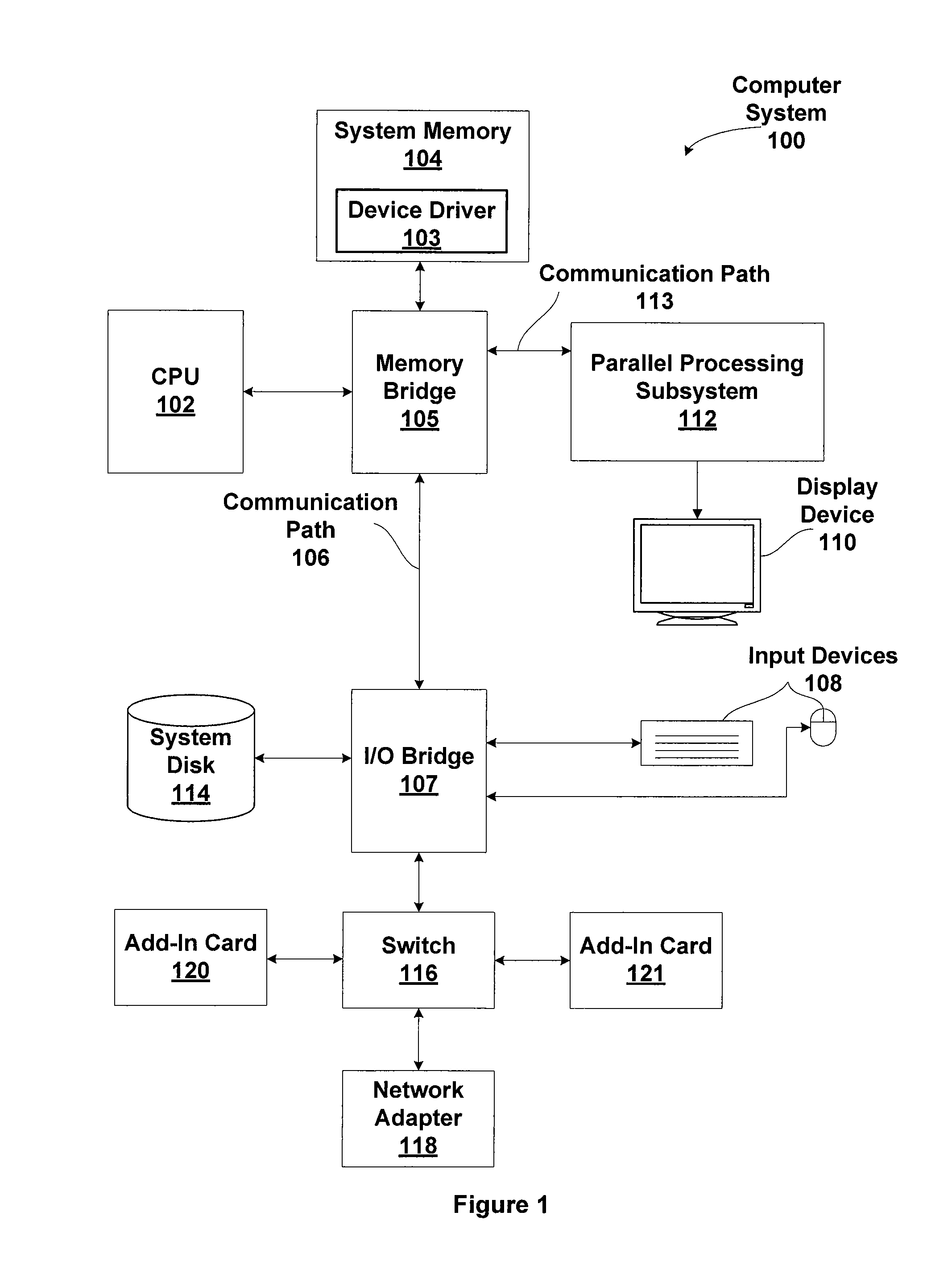

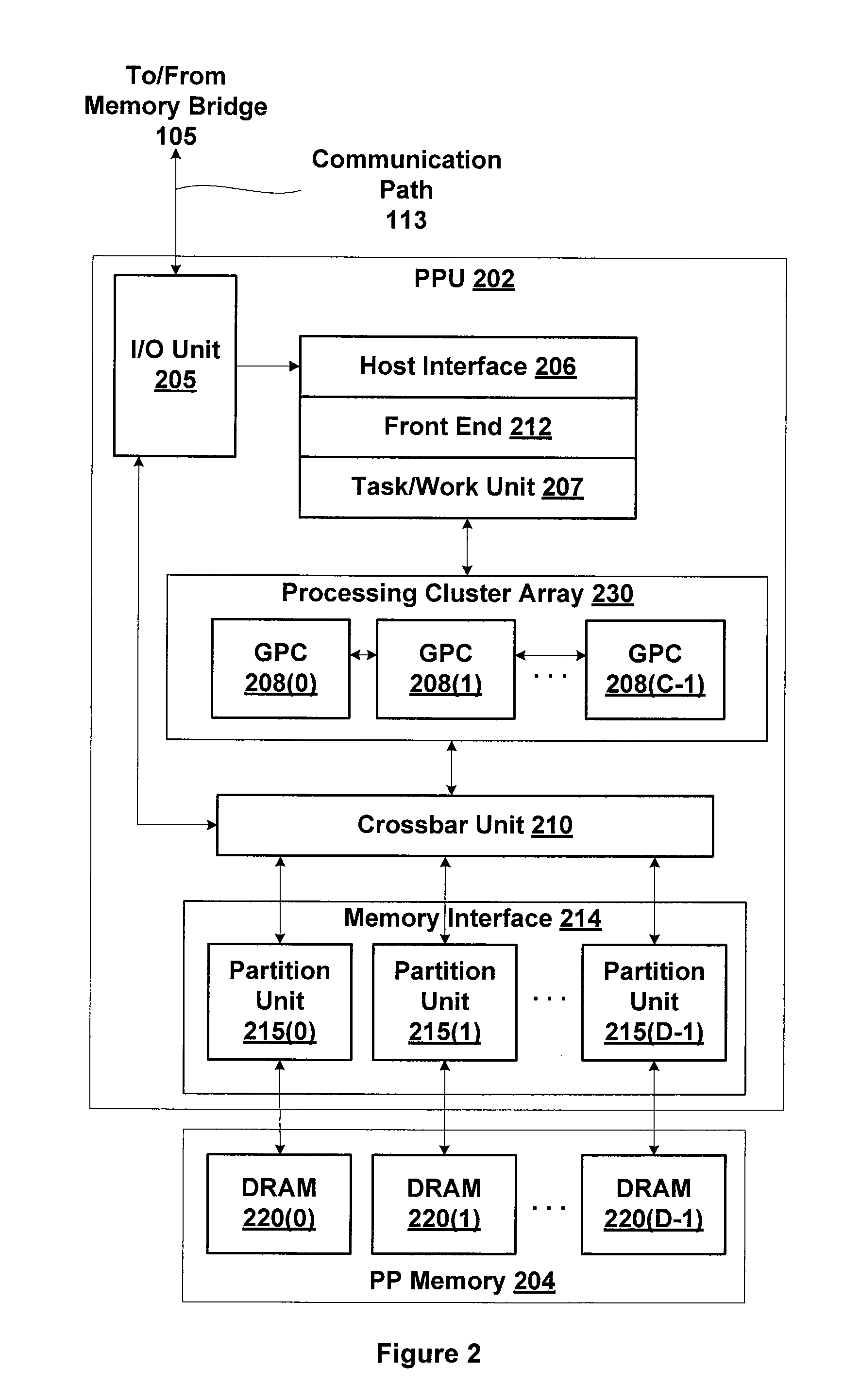

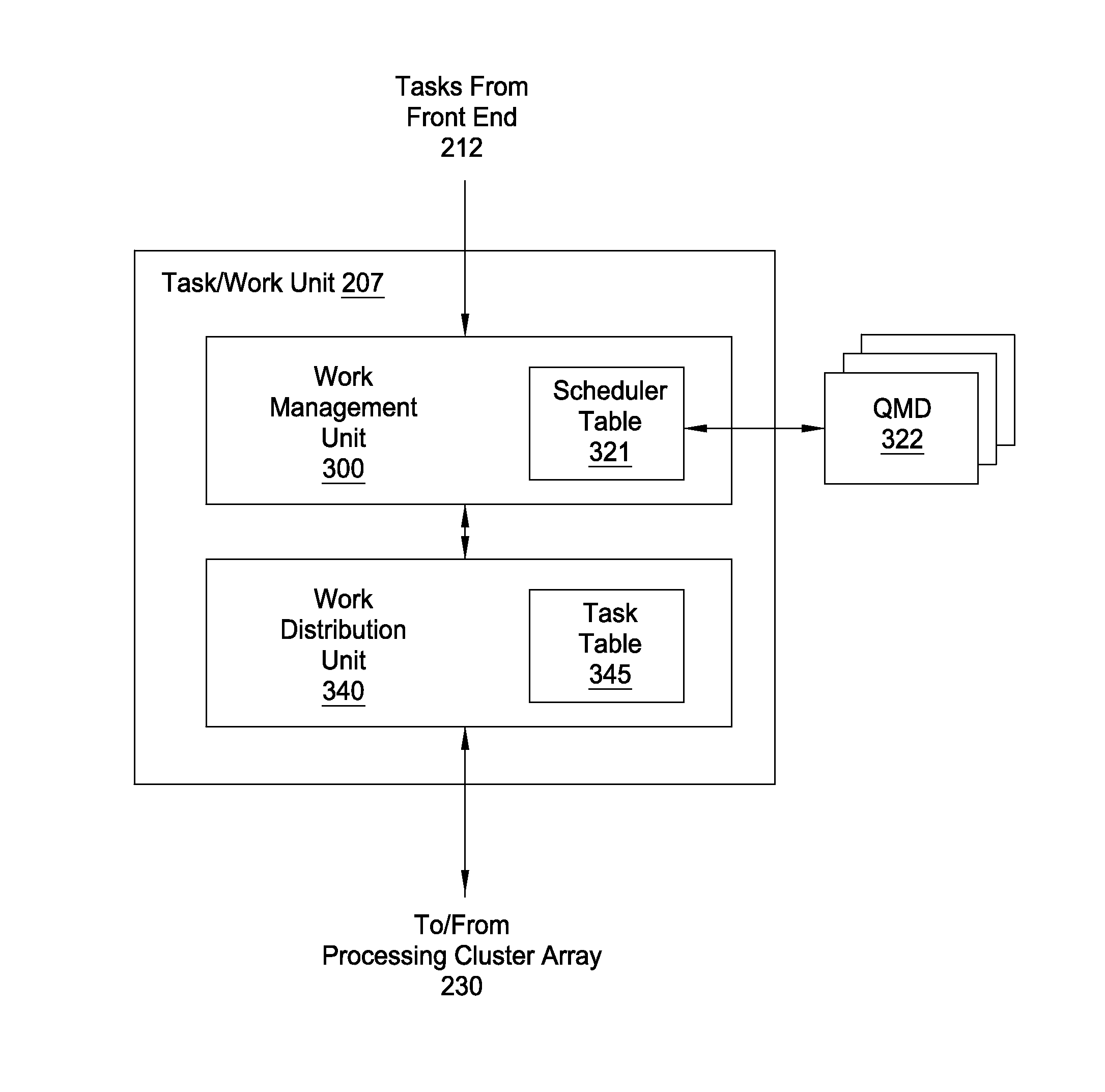

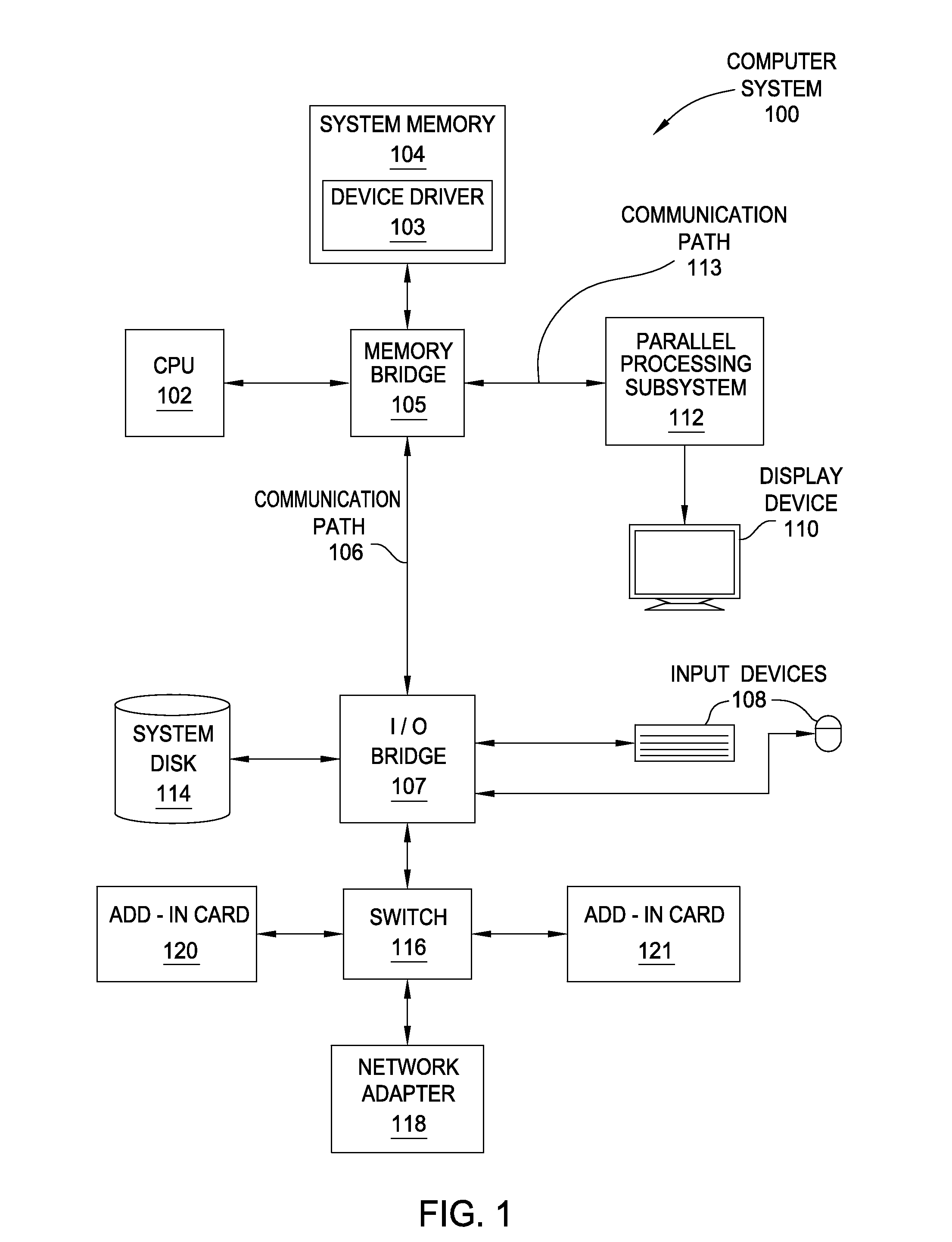

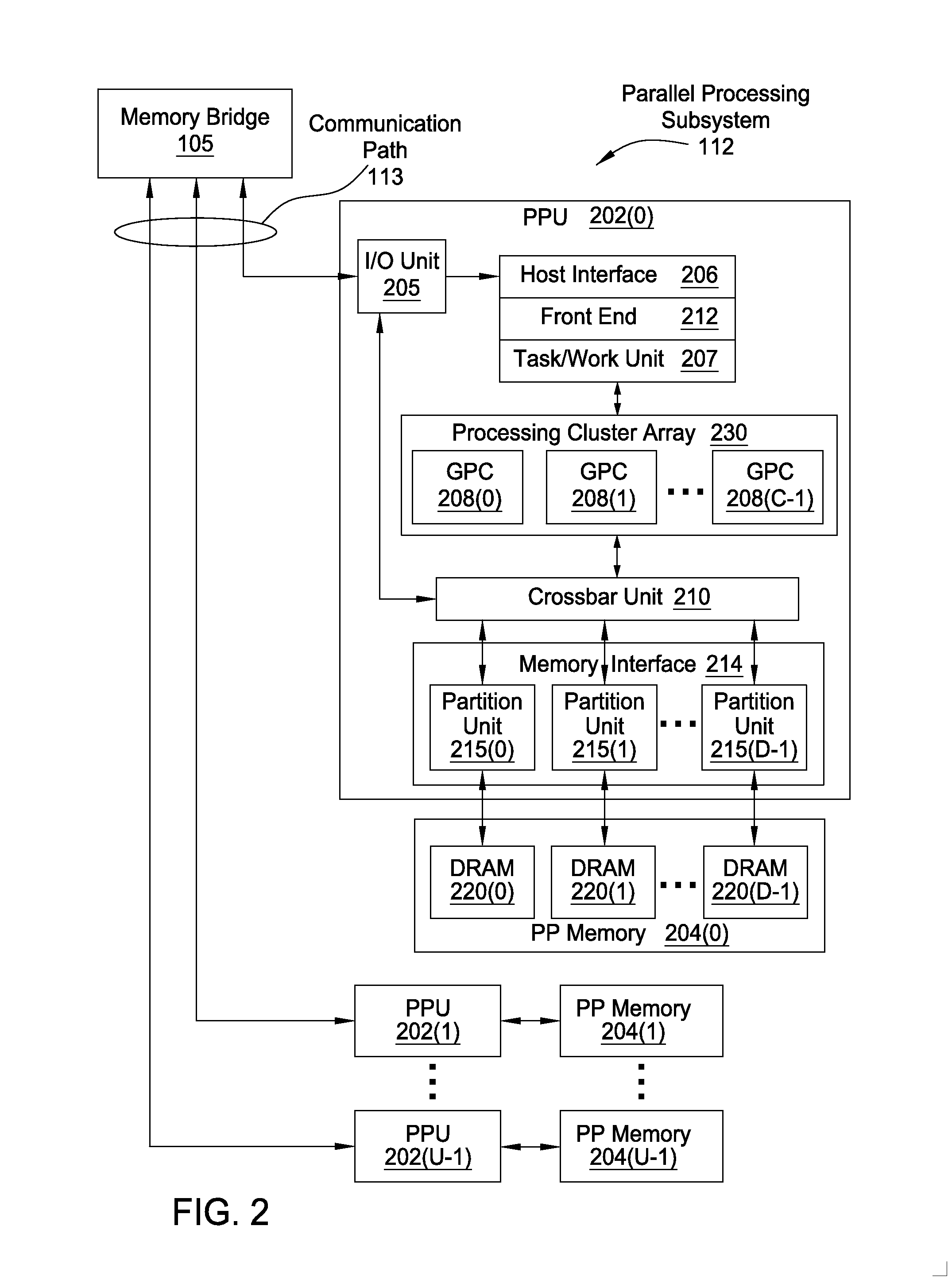

Efficient Texture Processing of Pixel Groups with SIMD Execution Unit

ActiveUS20090187734A1Increase profitMaximize utilizationCathode-ray tube indicatorsProcessor architectures/configurationExecution unitTexture processing

A circuit arrangement and method perform concurrent texture processing of groups of pixels with a single instruction multiple data (SIMD) execution unit to improve the utilization of the SIMD execution unit when performing scalar operations associated with a texture processing algorithm. In addition, when utilized in connection with a multi-threaded SIMD execution unit, groups of pixels may be concurrently processed in different threads executed by the SIMD execution unit to further maximize the utilization of the SIMD execution unit by reducing the adverse effects of dependencies in scalar and / or vector operations incorporated into a texture processing algorithm.

Owner:RAKUTEN GRP INC

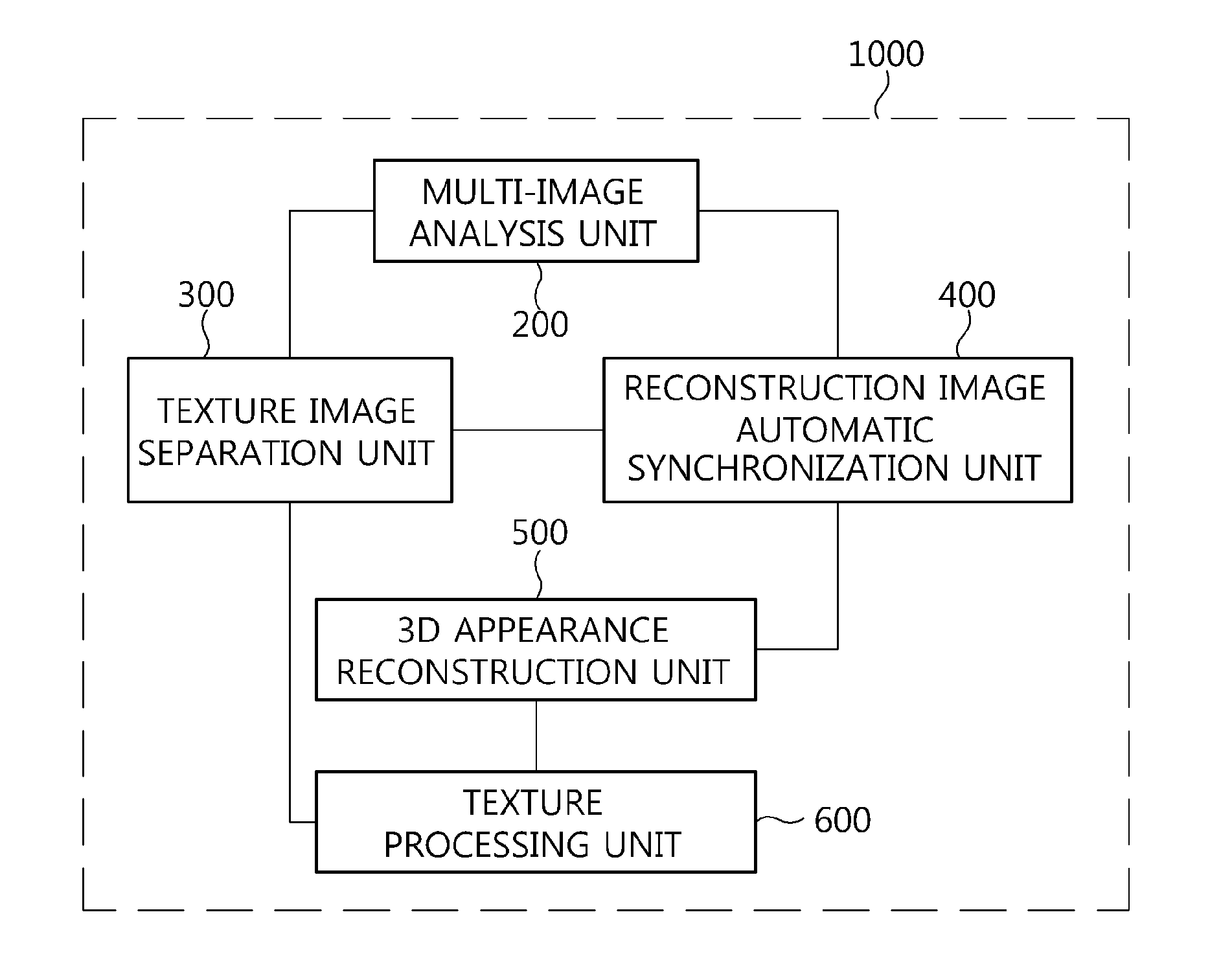

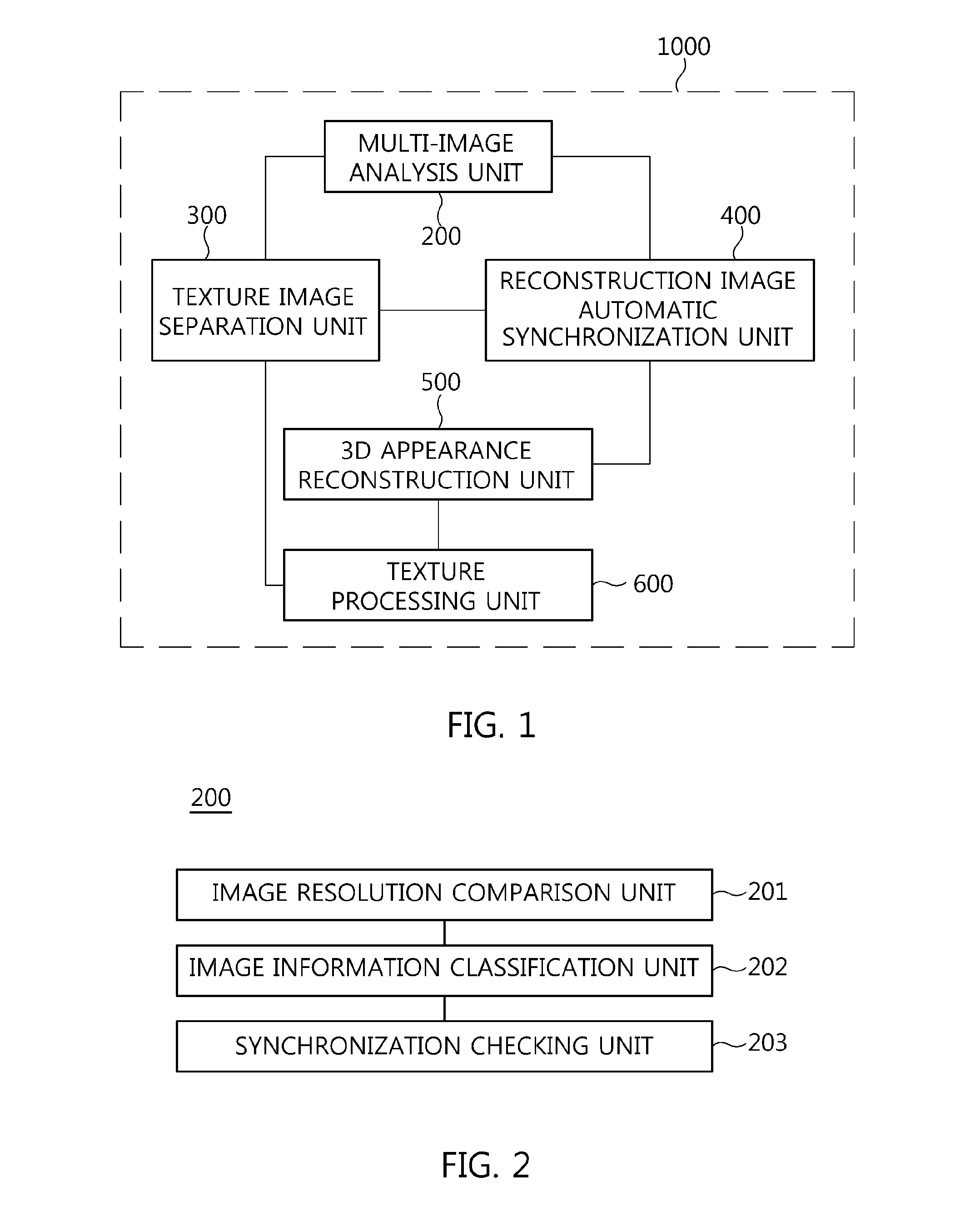

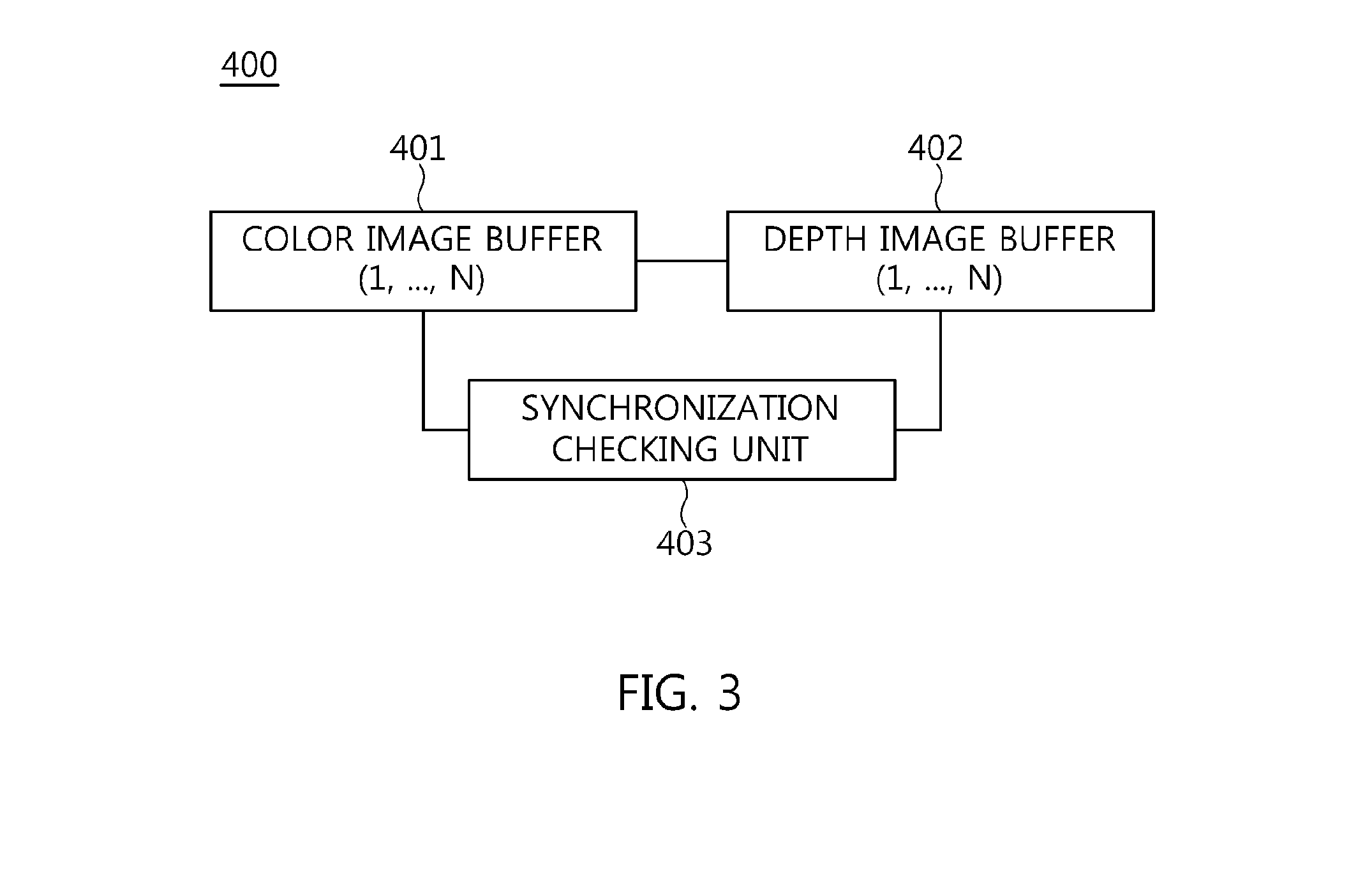

Apparatus and method for reconstructing three dimensional faces based on multiple cameras

InactiveUS20130301906A1Improve convenienceEasy to useImage enhancementDetails involving processing stepsMulti-imageImage resolution

Disclosed herein are an apparatus and method for reconstructing a three-dimensional (3D) face based on multiple cameras. The apparatus includes a multi-image analysis unit, a texture image separation unit, a reconstruction image automatic synchronization unit, a 3D appearance reconstruction unit, and a texture processing unit. The multi-image analysis unit determines the resolution information of images received from a plurality of cameras, and determines whether the images have been synchronized with each other. The texture image separation unit separates a texture processing image by comparing the resolutions of the received images. The reconstruction image automatic synchronization unit synchronizes images that are determined to be asynchronous images by the multi-image analysis unit. The 3D appearance reconstruction unit computes the 3D coordinate values of the synchronized images, and reconstructs a 3D appearance image. The texture processing unit reconstructs a 3D image by mapping the texture processing image to the 3D appearance image.

Owner:ELECTRONICS & TELECOMM RES INST

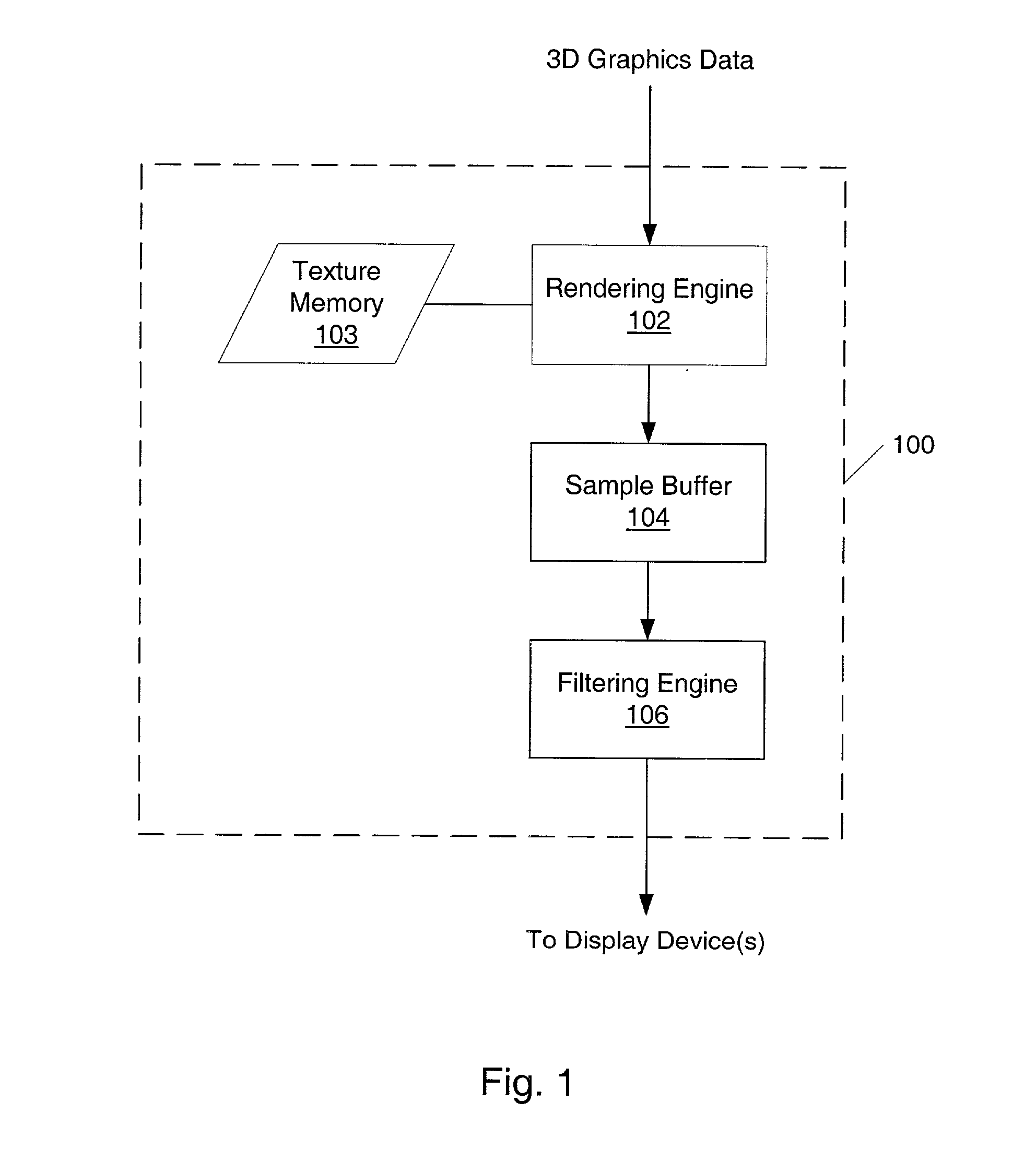

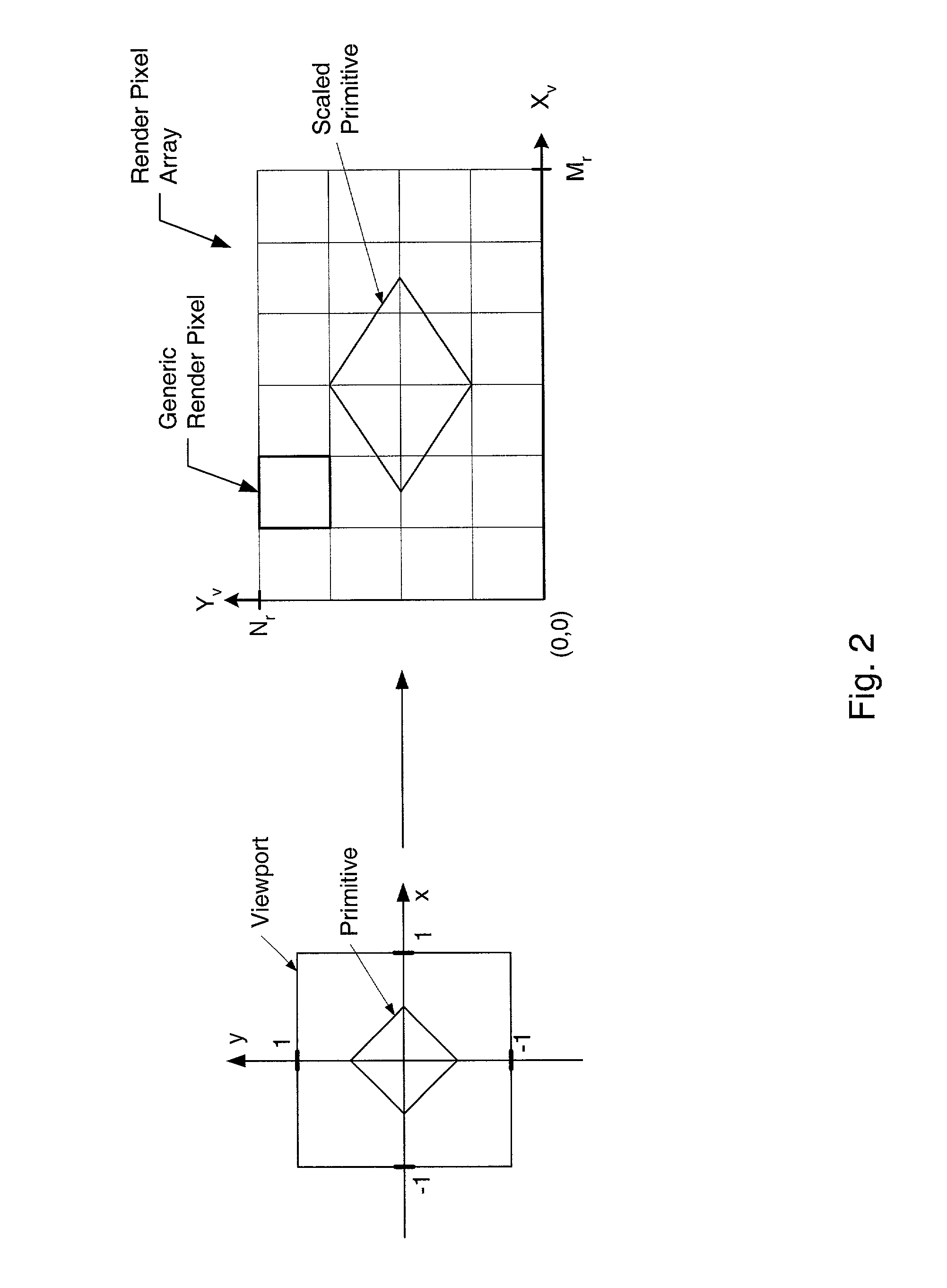

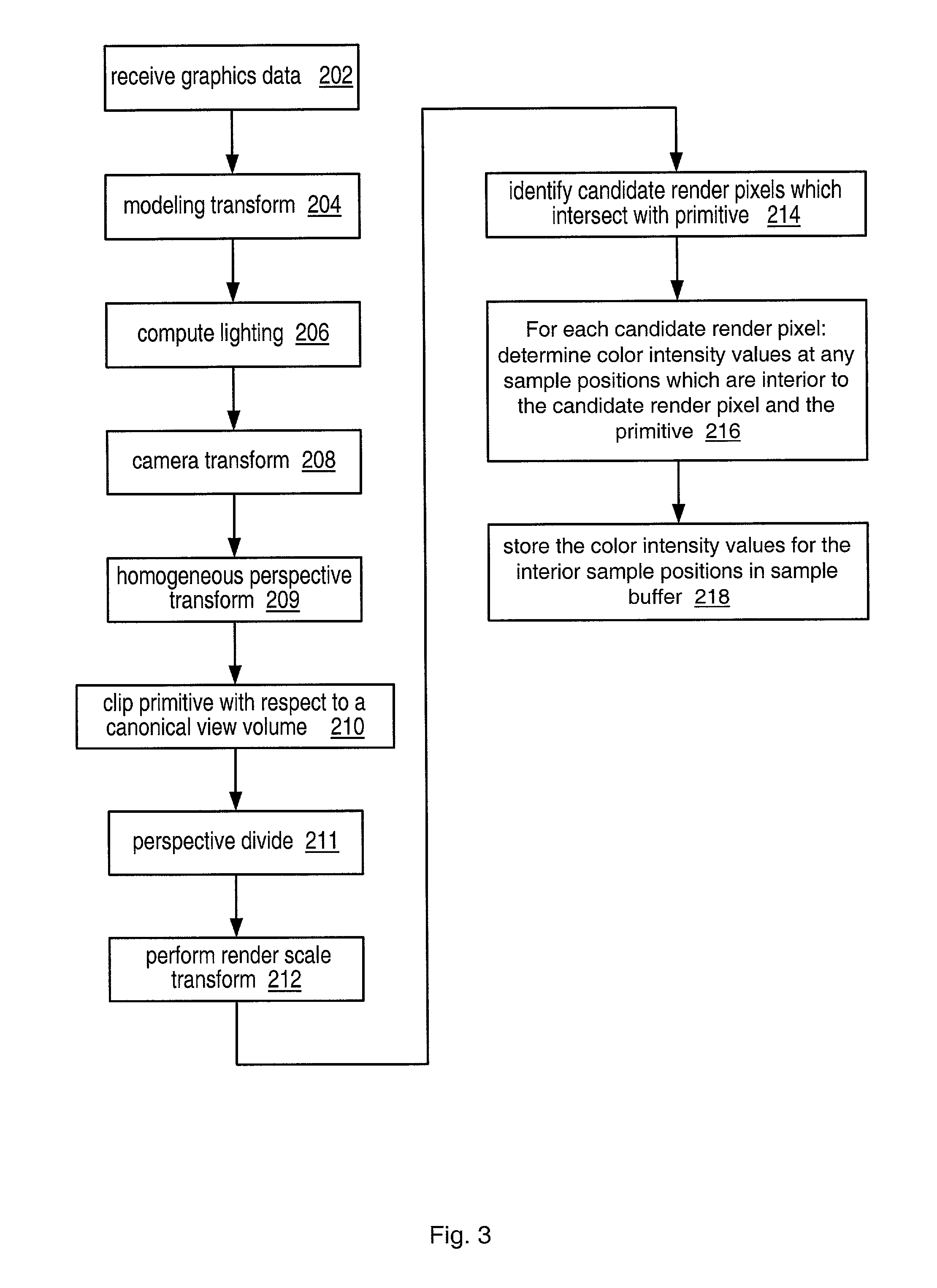

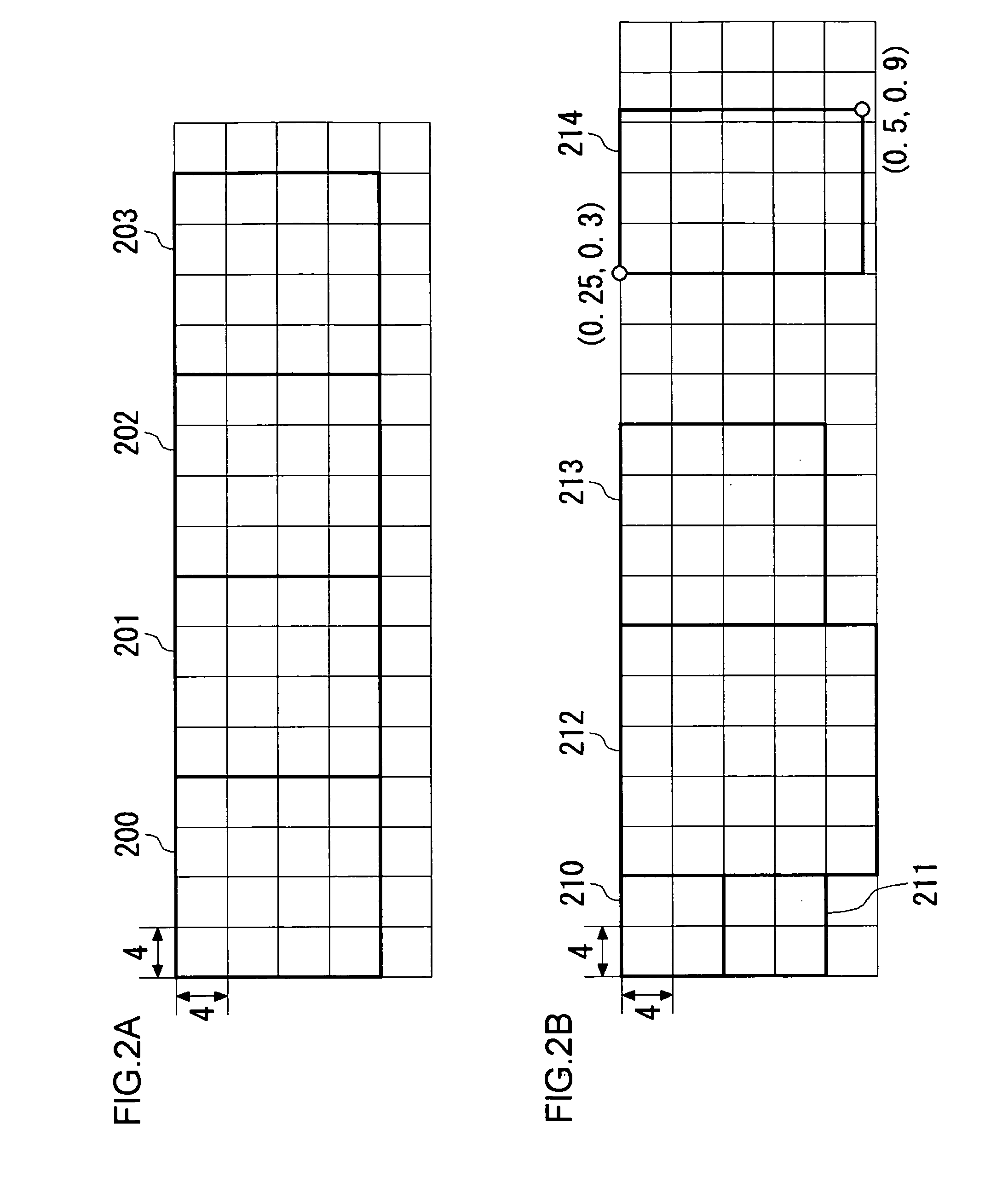

Static and dynamic video resizing

InactiveUS20010048435A1Drawing from basic elementsGeometric image transformationGraphicsGraphic system

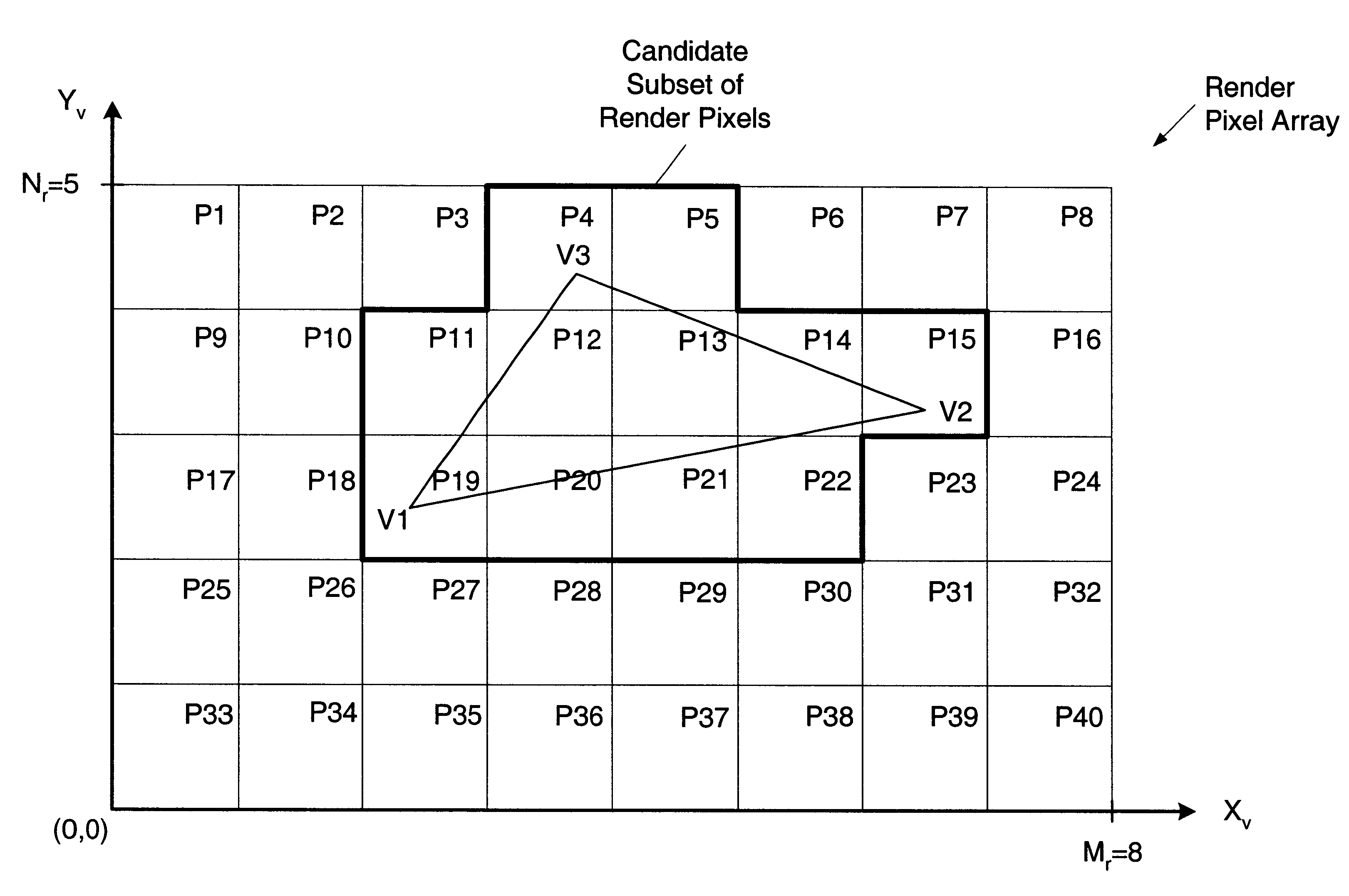

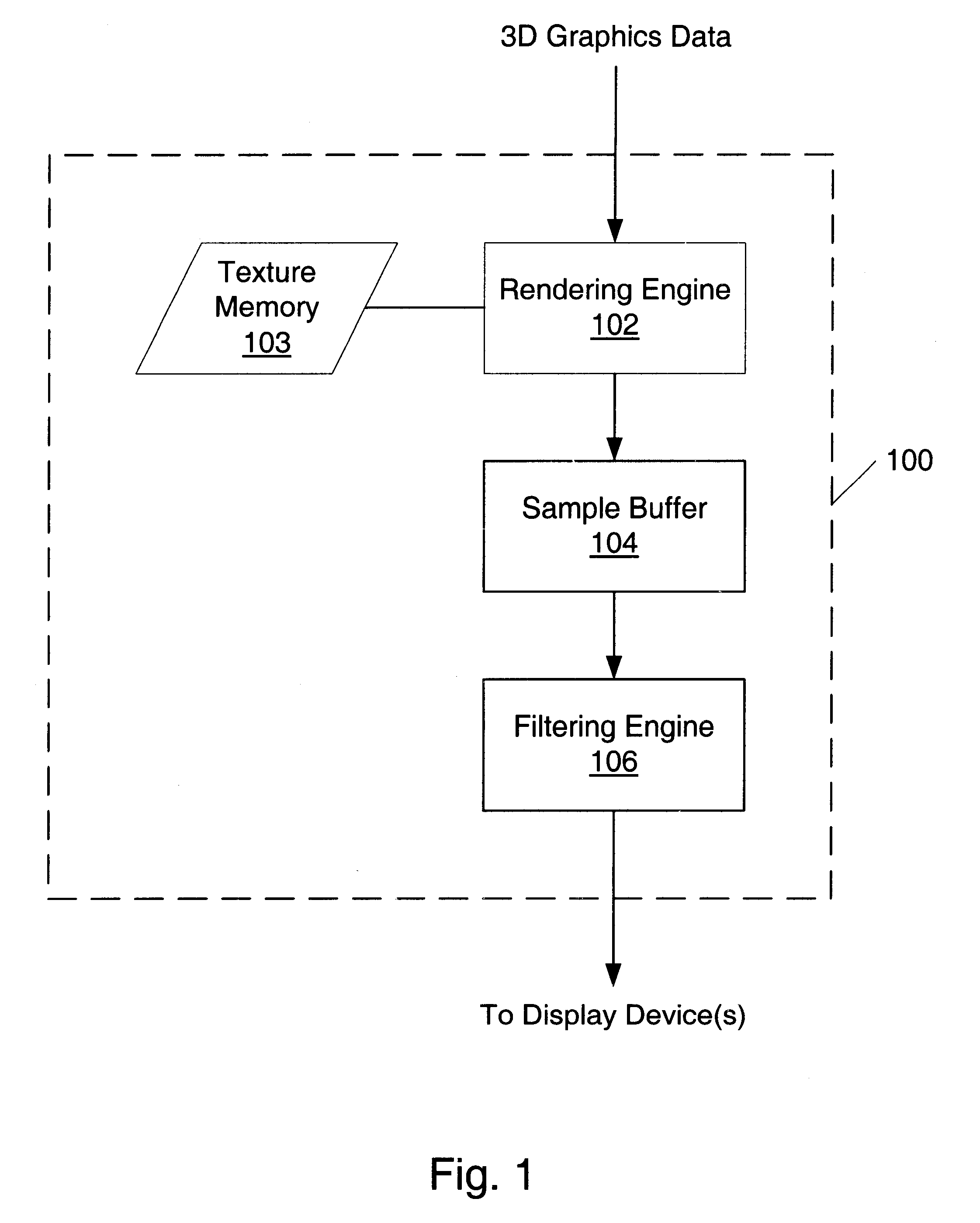

A graphics system comprises a texture memory, a rendering engine, a sample buffer and a filtering engine. The rendering engine renders received primitives based on a render pixel array whose vertical and horizontal resolutions are dynamically programmable. The rendering engine determines render pixels that geometrically intersect a primitive. For each intersecting render pixel, a texture access may be required (if texture processing is turned on) to determine texture values. The texture values may be used to compute sample values at sample positions interior to the sample render pixel and the primitive. A controlling agent may decrease the vertical and horizontal resolutions of the render pixel array to control frame render time. The filtering engine may programmably generate virtual pixel centers covering the render pixel array. Any change in the render pixel resolutions may require an accommodating change in the virtual pixel array parameters.

Owner:ORACLE INT CORP

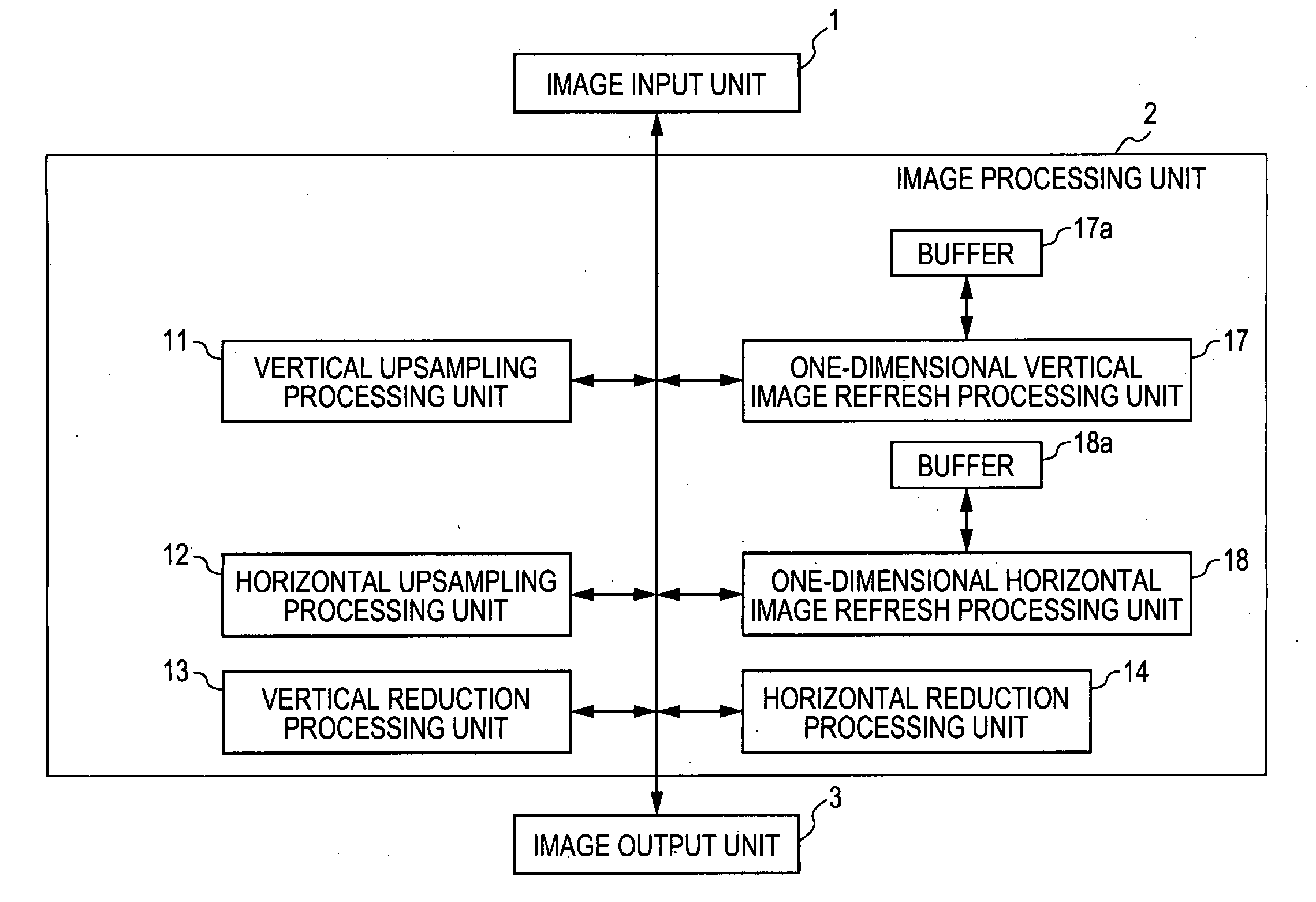

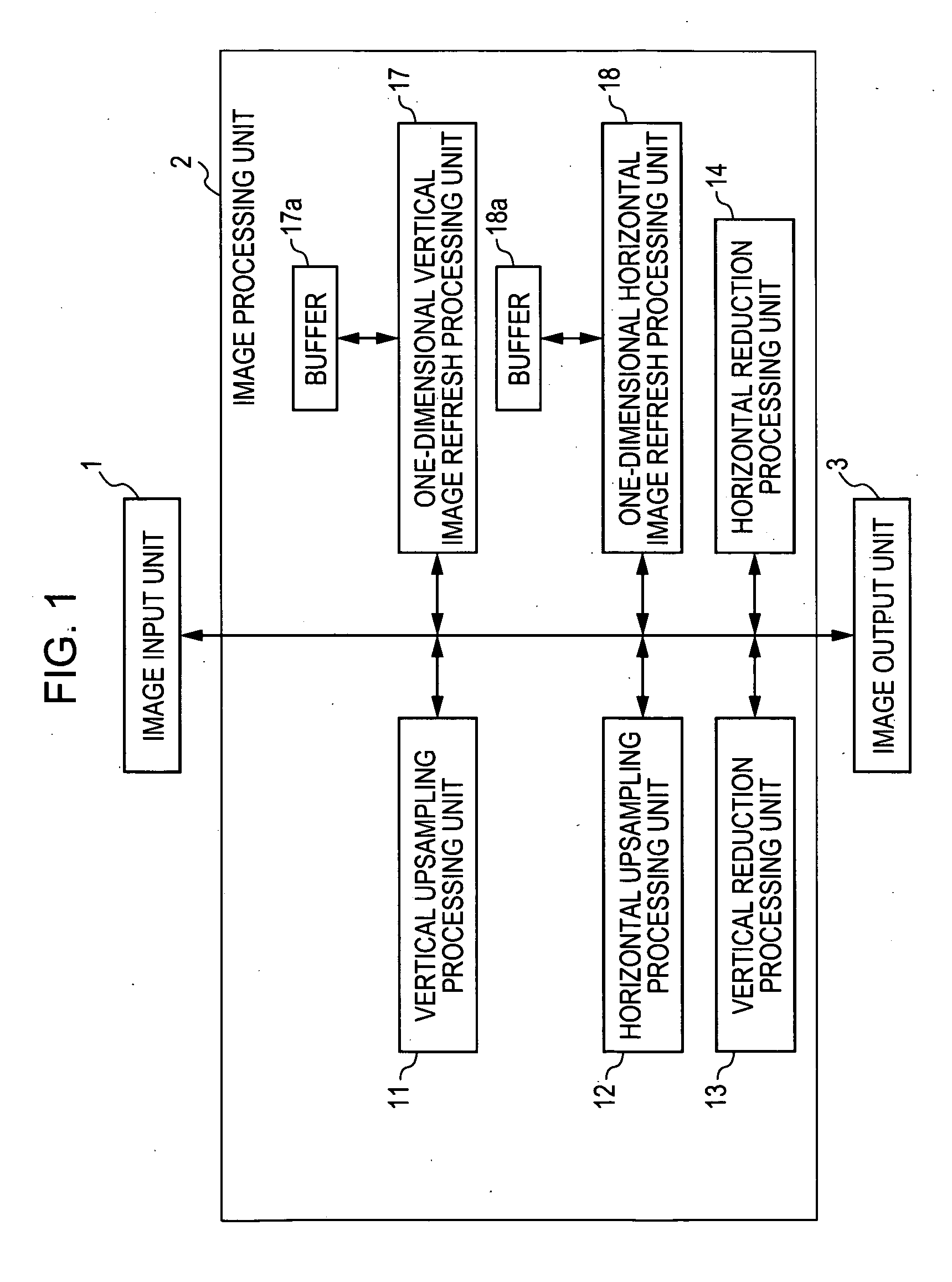

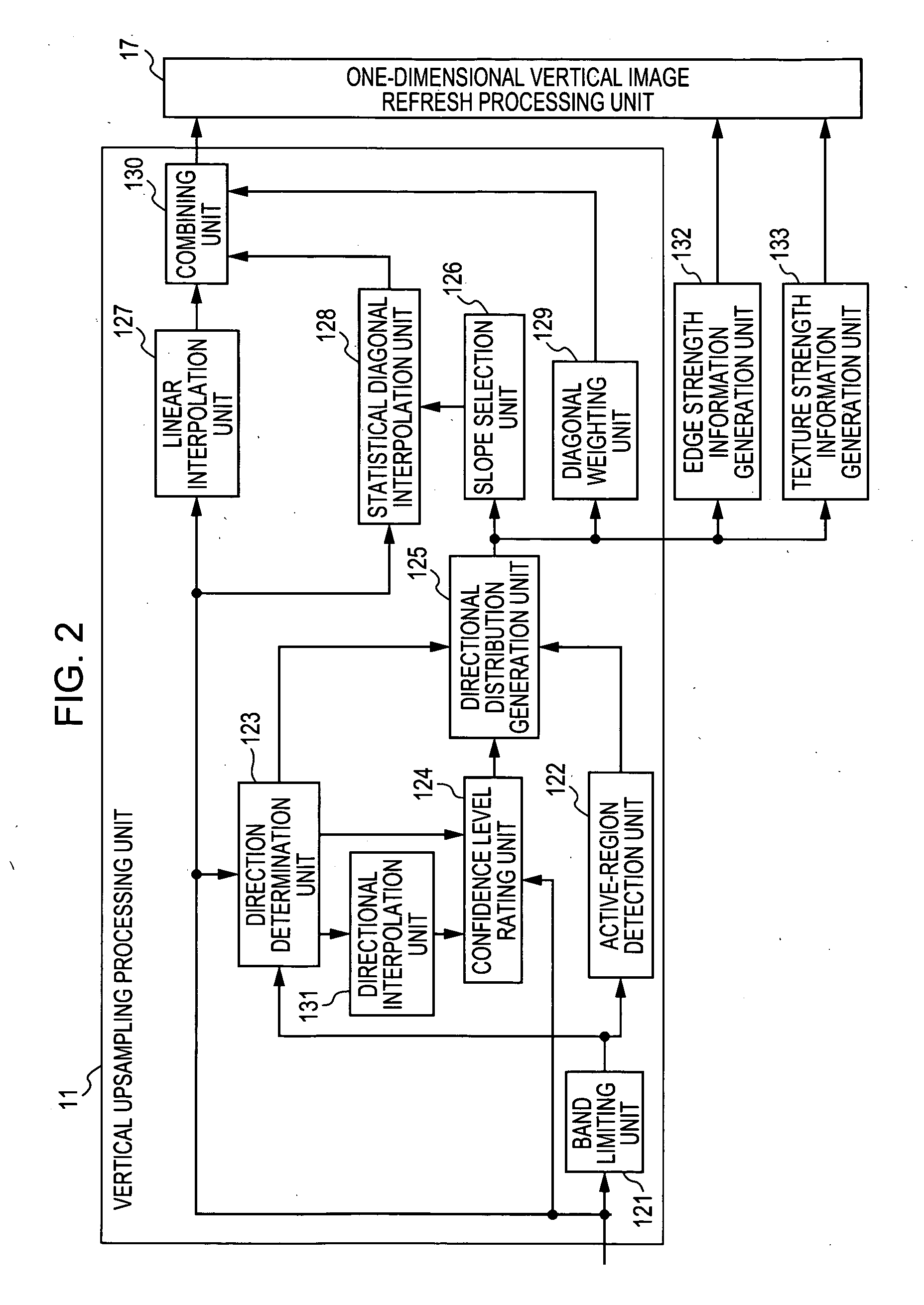

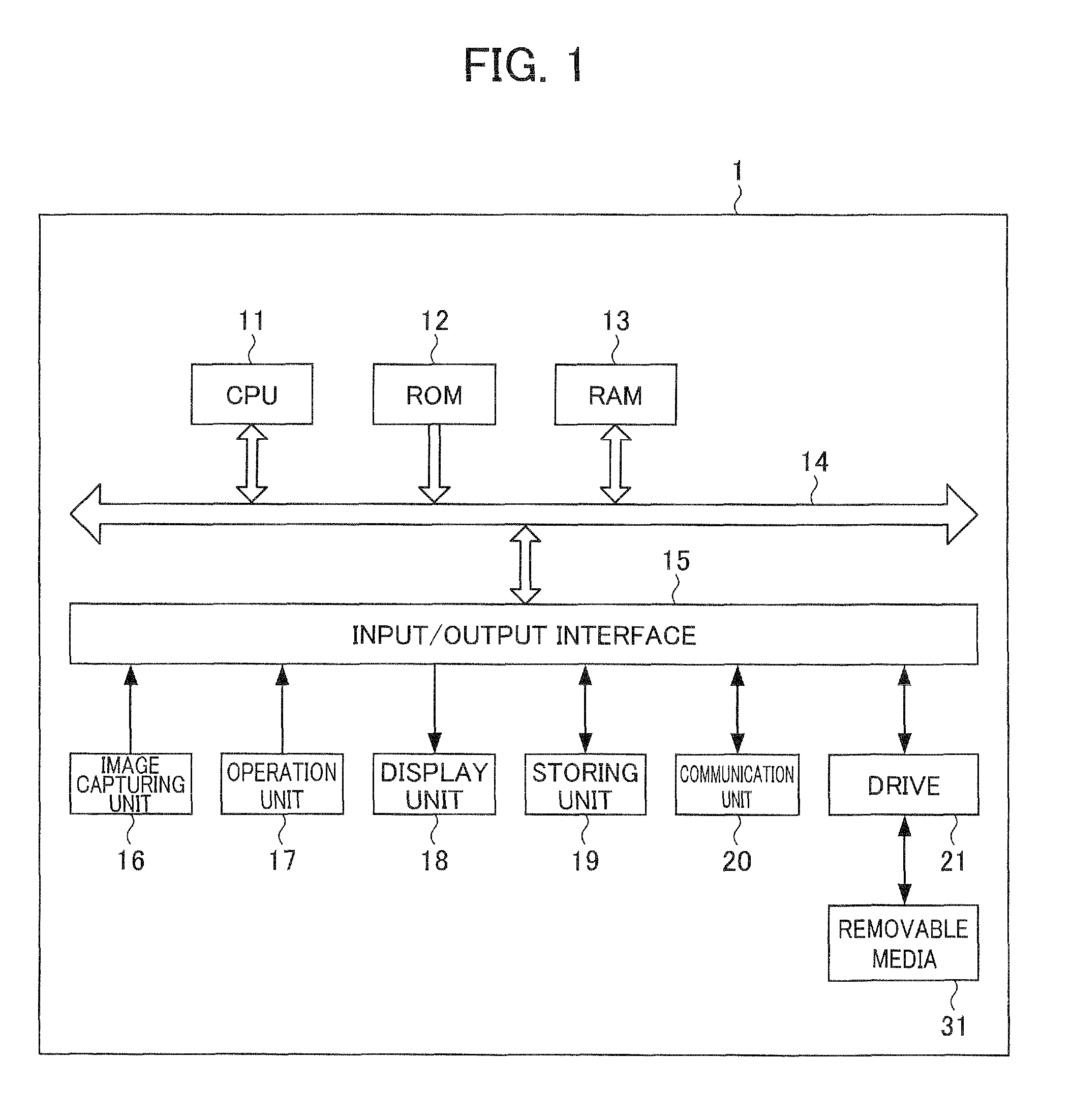

Information processing apparatus, information processing method, recording medium, and program

InactiveUS20060115184A1Accurate collectionPrecise processImage enhancementImage analysisPattern recognitionInformation processing

In an image processing apparatus for converting resolution of an image, a weight for a statistical diagonal interpolation pixel is set based on a slope having the statistically highest confidence level, the statistical diagonal interpolation pixel is combined with a different pixel interpolated by a different interpolation so as to generate a combined interpolated pixel based on the set weight, information is generated for quantitatively evaluating the strength of an edge and the strength of texture, a texture mixed pixel is generated by combining the combined interpolated pixel with a texture pixel generated by performing texture filtering on the pixel 6f interest based on the texture strength information, and an edge mixed pixel is generated as a pixel at the position of interest by combining an edge pixel generated by performing filtering on the pixel of interest with the generated texture mixed pixel based on the edge strength information.

Owner:SONY CORP

Method for preparing multi-channel 3D nano texture mold

A method for preparing a multi-channel 3D nano texture mold comprises the steps of: coating photoresist on a PET photoetching material, and then entering a stainless steel dust-free furnace for dryingfor standby; arranging a mask pattern plate on the raw rubber surface of the PET photoetching material, vacuuming for photoetching, taking out the mask pattern plate after the photoetching is completed, putting the prepared developer into a cleaning box, putting the photoetching-finished PET photoetching material into the cleaning box for cleaning, displaying the pattern on the PET photoetching material, dehydrating and spinning to obtain a first texture layer; then, performing second texture layer photoetching process which is similar to the first layer, realizing second texture processing superposition to obtain the multi-channel 3D nano-texture mold. The method has the advantages of simple manufacturing process, low cost, reusability, multi-texture superposition, better texture rendering effect and improved working efficiency.

Owner:唐鸿微迅新材料科技有限公司

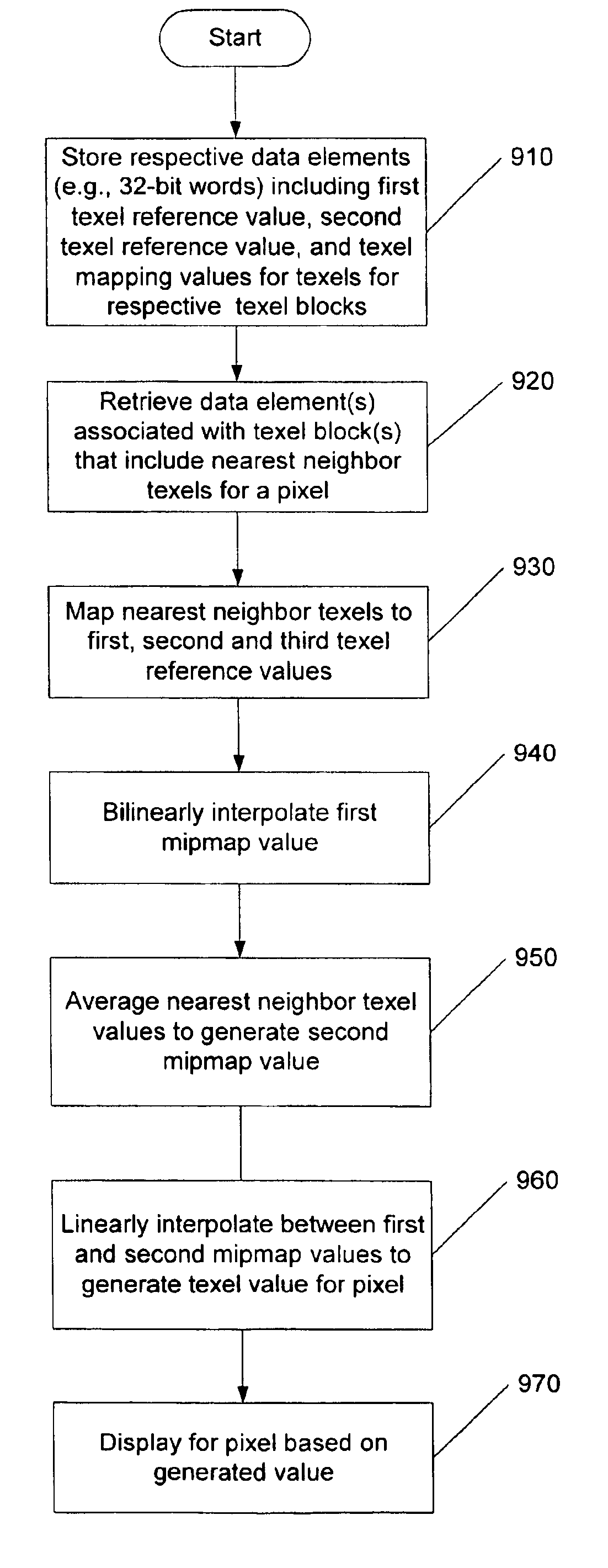

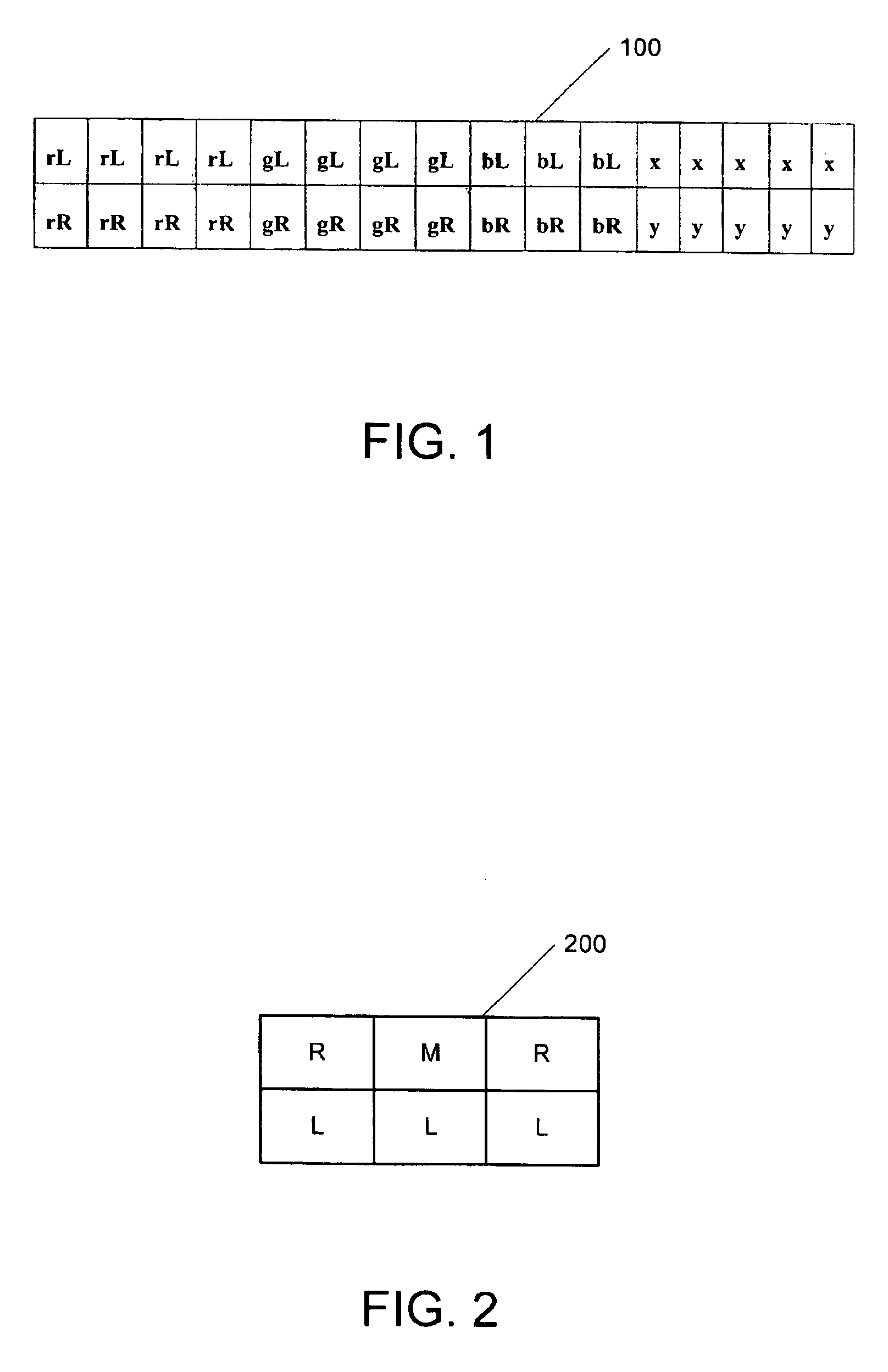

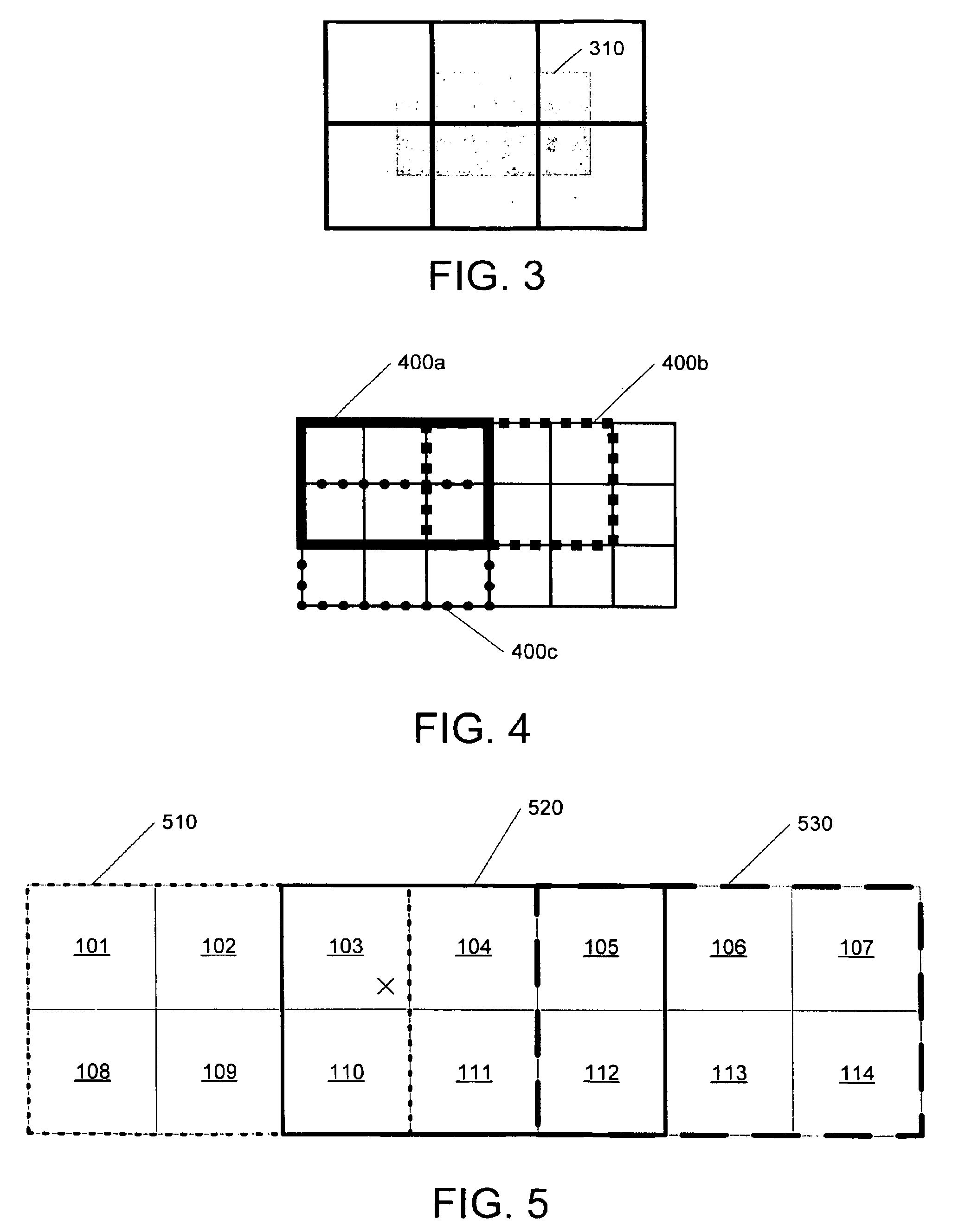

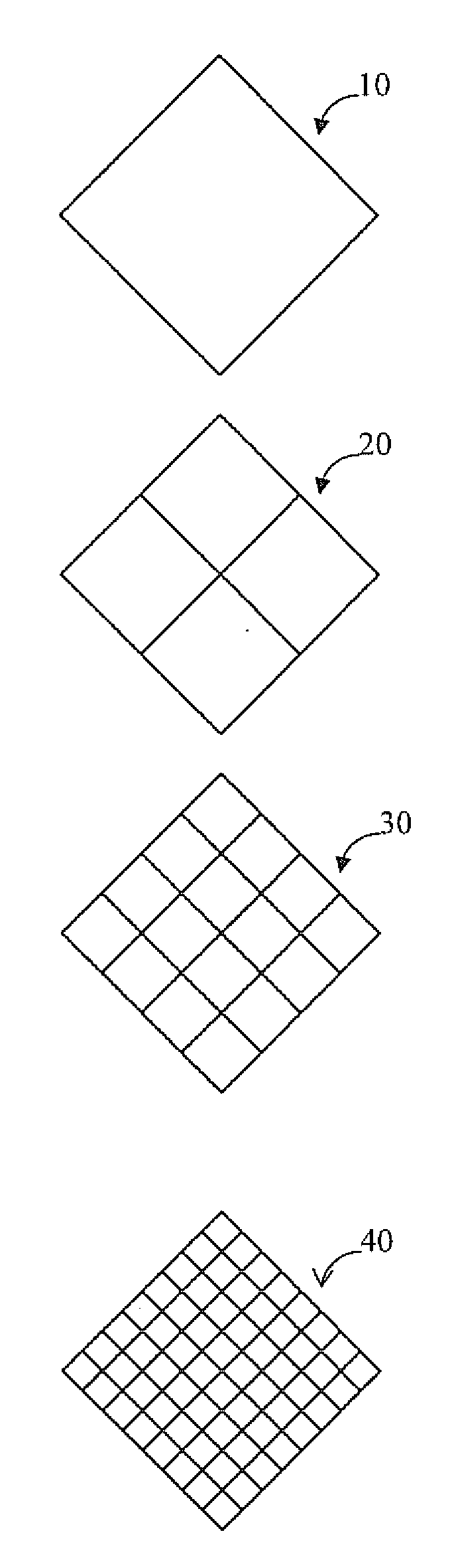

Graphics texture processing methods, apparatus and computer program products using texture compression, block overlapping and/or texture filtering

A pixel is textured by storing a first texel reference value, a second texel reference value, and texel mapping values where each texel mapping value represents a k-tuple of (ternary) references to the first texel reference value, the second texel reference value and a third texel reference value to thereby represent a block of texels. A pixel value for the pixel is generated from the stored texel values and the pixel is displayed responsive to the generated pixel value. In some embodiments, respective pluralities of texel reference values and texel mapping values that map thereto are stored for respective ones of a plurality of overlapping blocks of texels. In further embodiments, a first mipmap value for a pixel is bilinearly interpolated from the retrieved texel values for the set of nearest neighbor texels. A second mipmap value for the pixel is generated by averaging the retrieved texel values for the set of nearest neighbor texels. A pixel value for the pixel is generated by interpolating between the first and second mipmap values. The present invention may be embodied as methods, apparatus and computer program products.

Owner:TELEFON AB LM ERICSSON (PUBL)

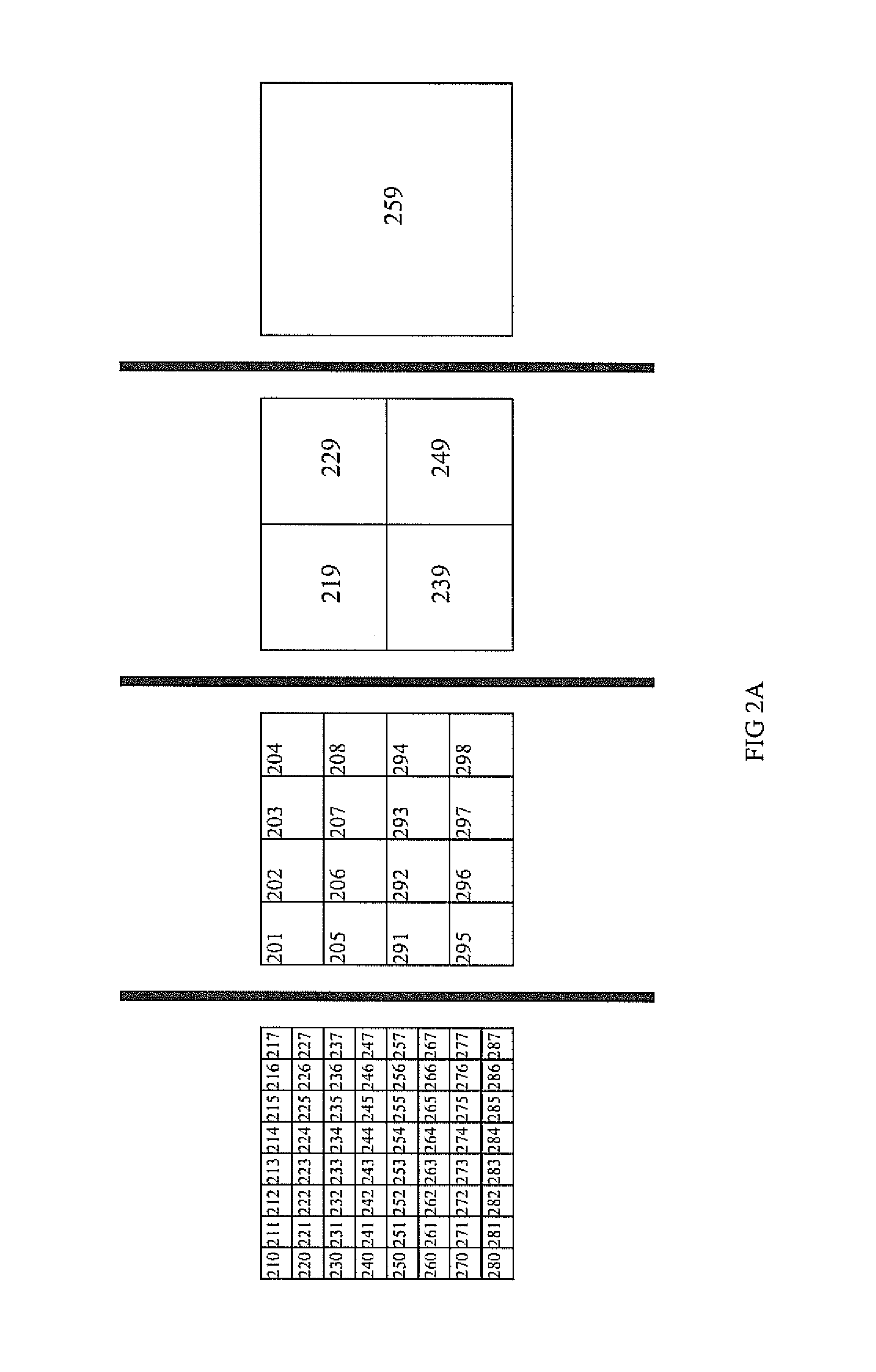

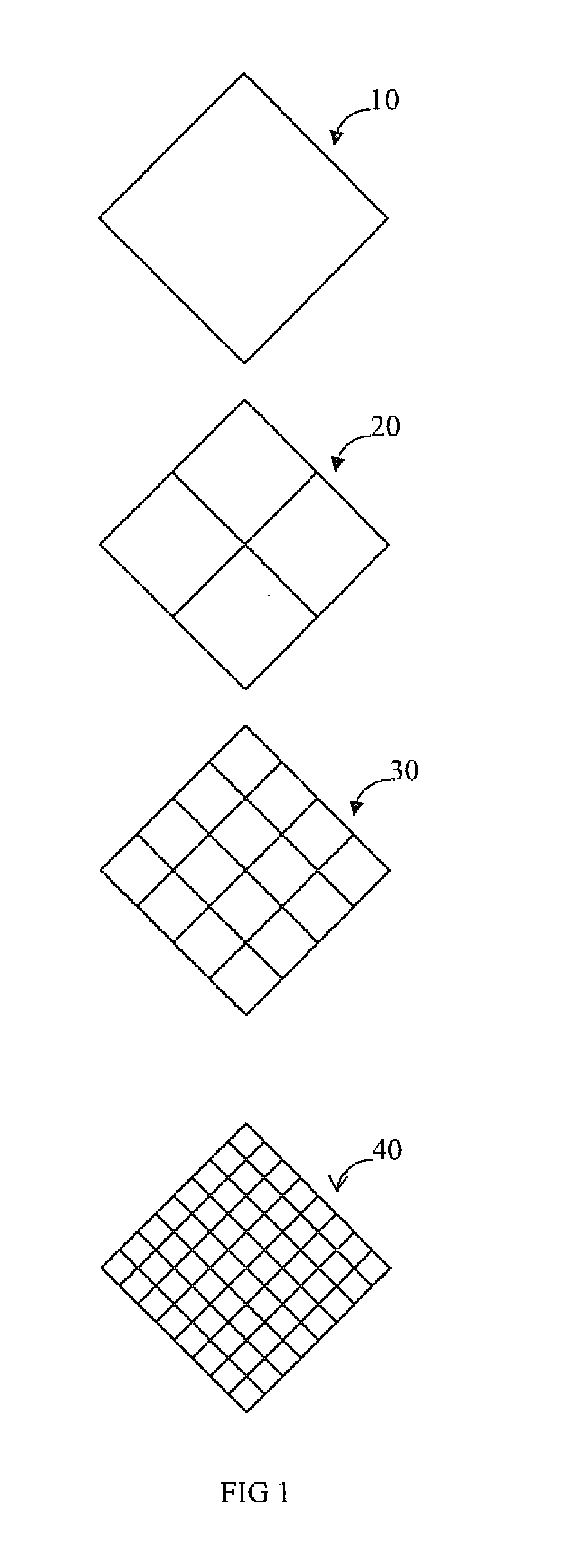

Sparse texture systems and methods

ActiveUS20110157206A1Image enhancementGeometric image transformationPattern recognitionTexture processing

Systems and methods for texture processing are presented. In one embodiment a texture method includes creating a sparse texture residency translation map; performing a probe process utilizing the sparse texture residency translation map information to return a finest LOD that contains the texels for a texture lookup operation; and performing the texture lookup operation utilizing the finest LOD. In one exemplary implementation, the finest LOD is utilized as a minimum LOD clamp during the texture lookup operation. A finest LOD number indicates a minimum resident LOD and a sparse texture residency translation map includes one finest LOD number per tile of a sparse texture. The sparse texture residency translation can indicate a minimum resident LOD.

Owner:NVIDIA CORP

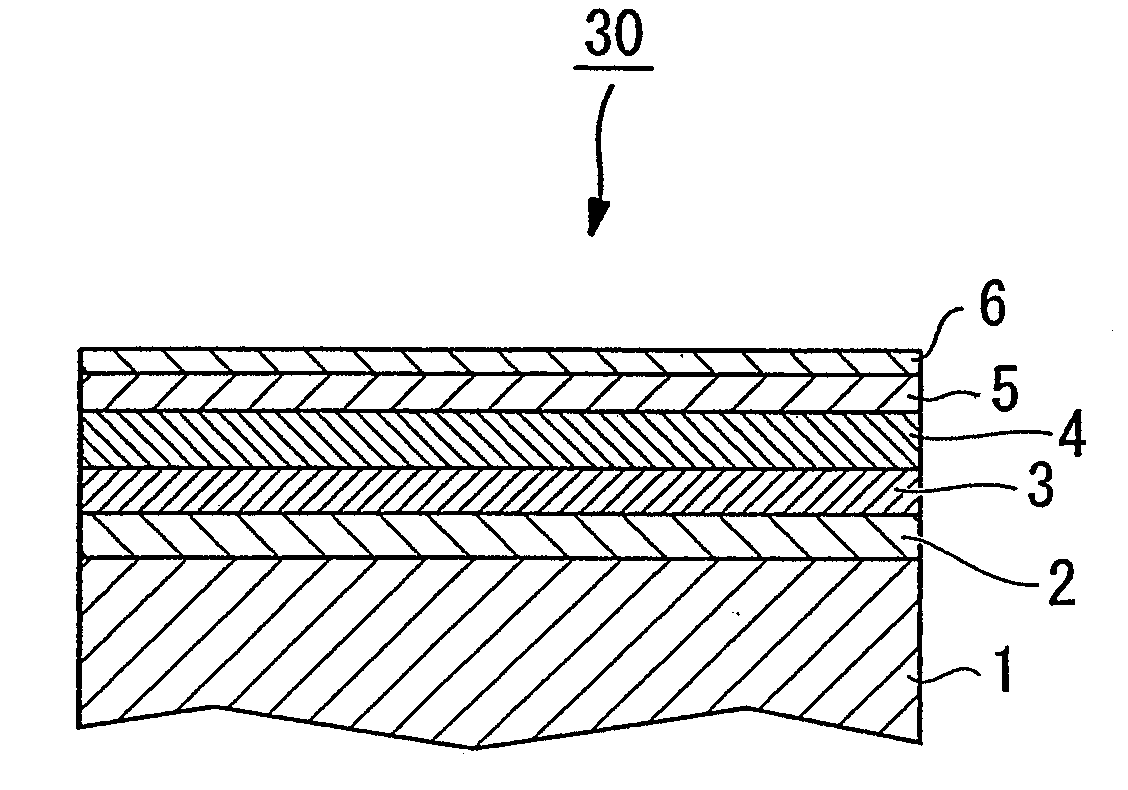

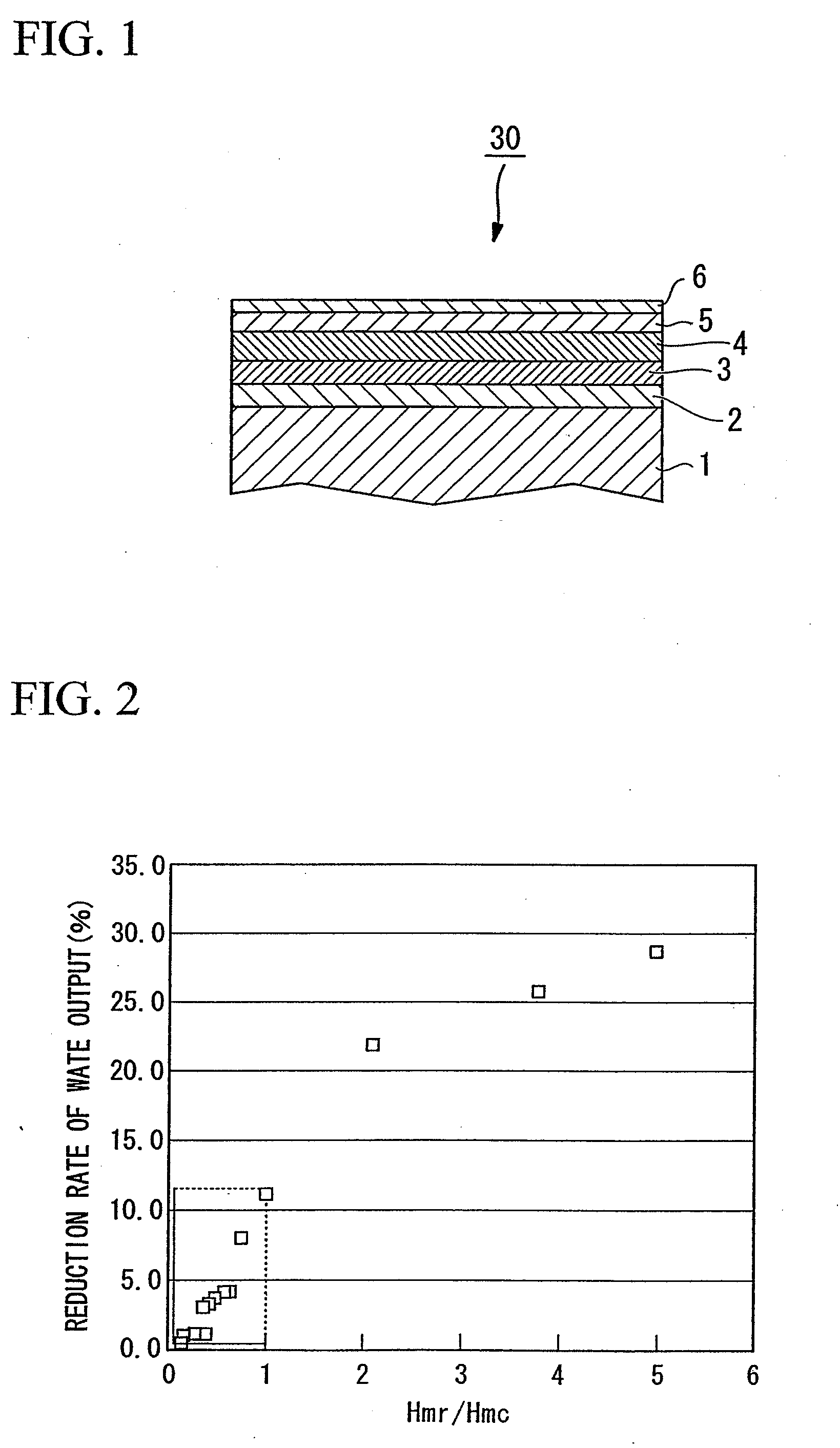

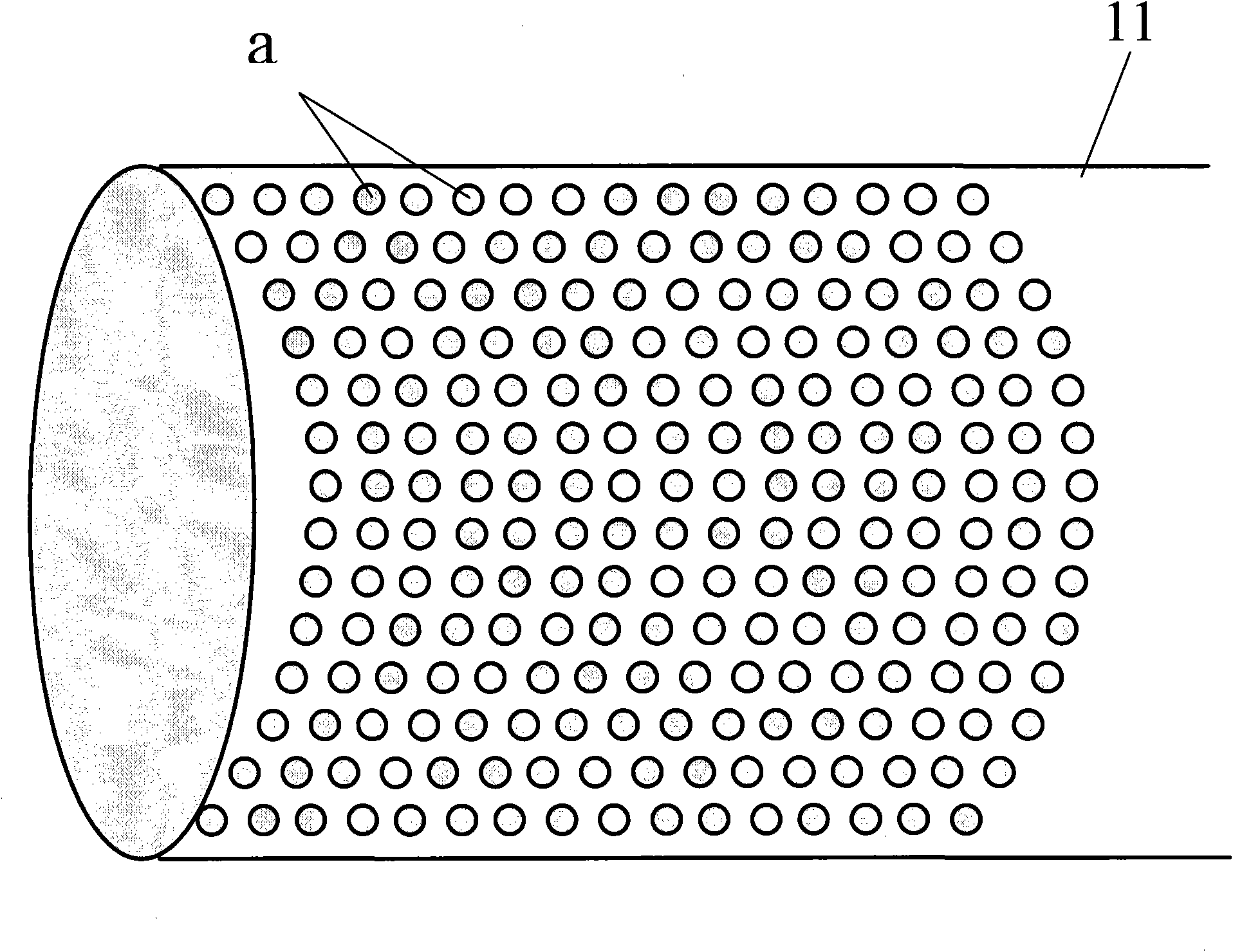

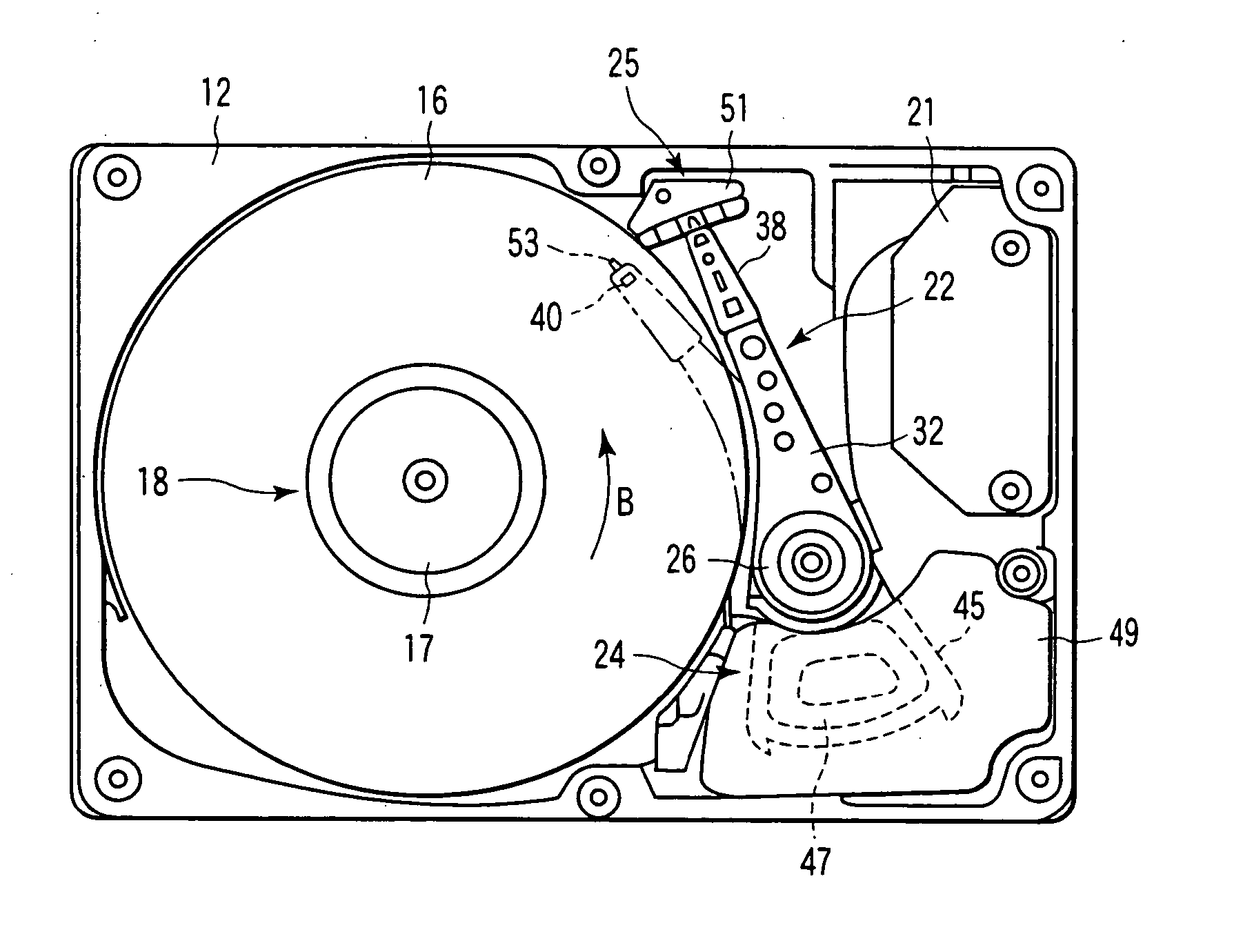

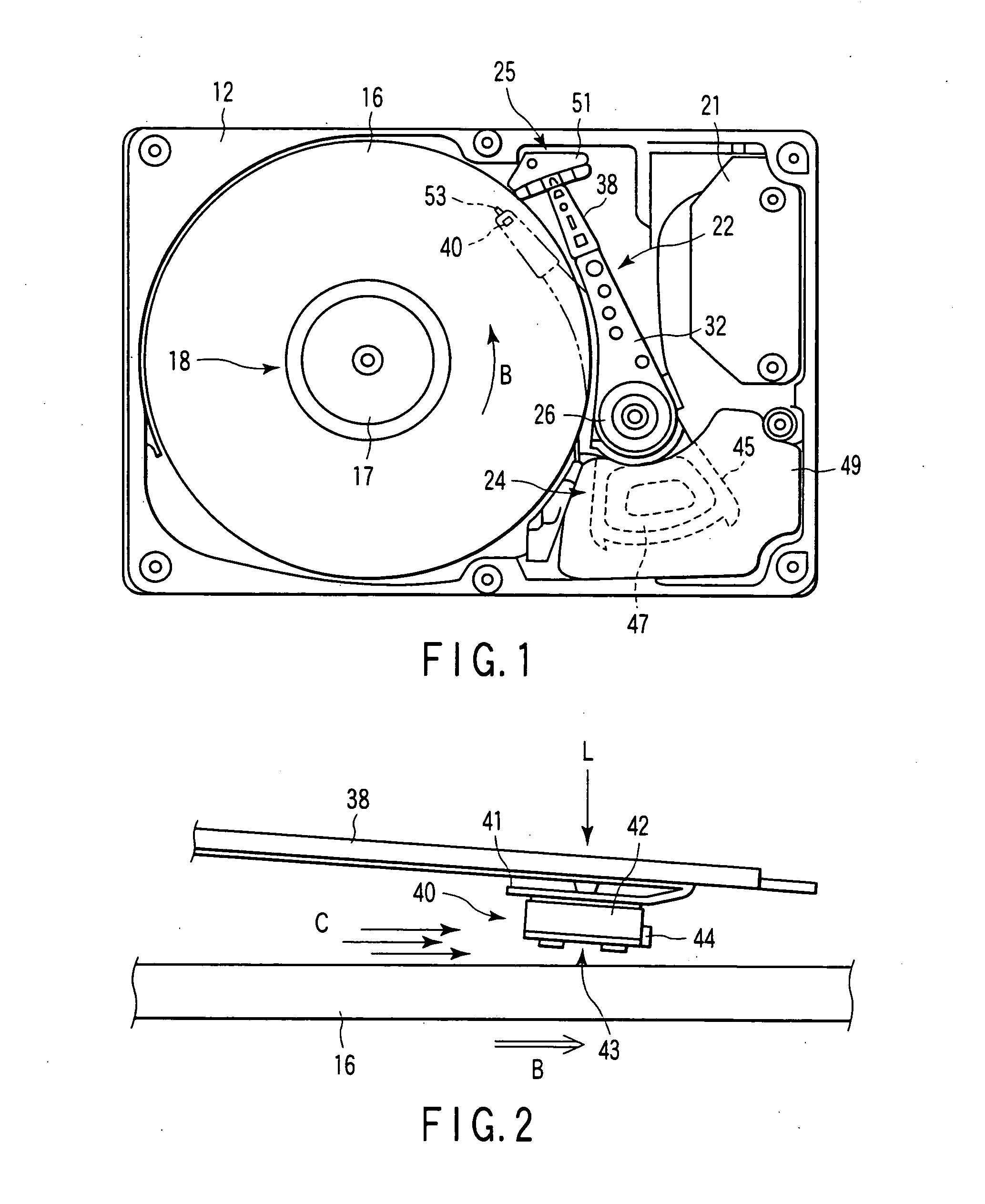

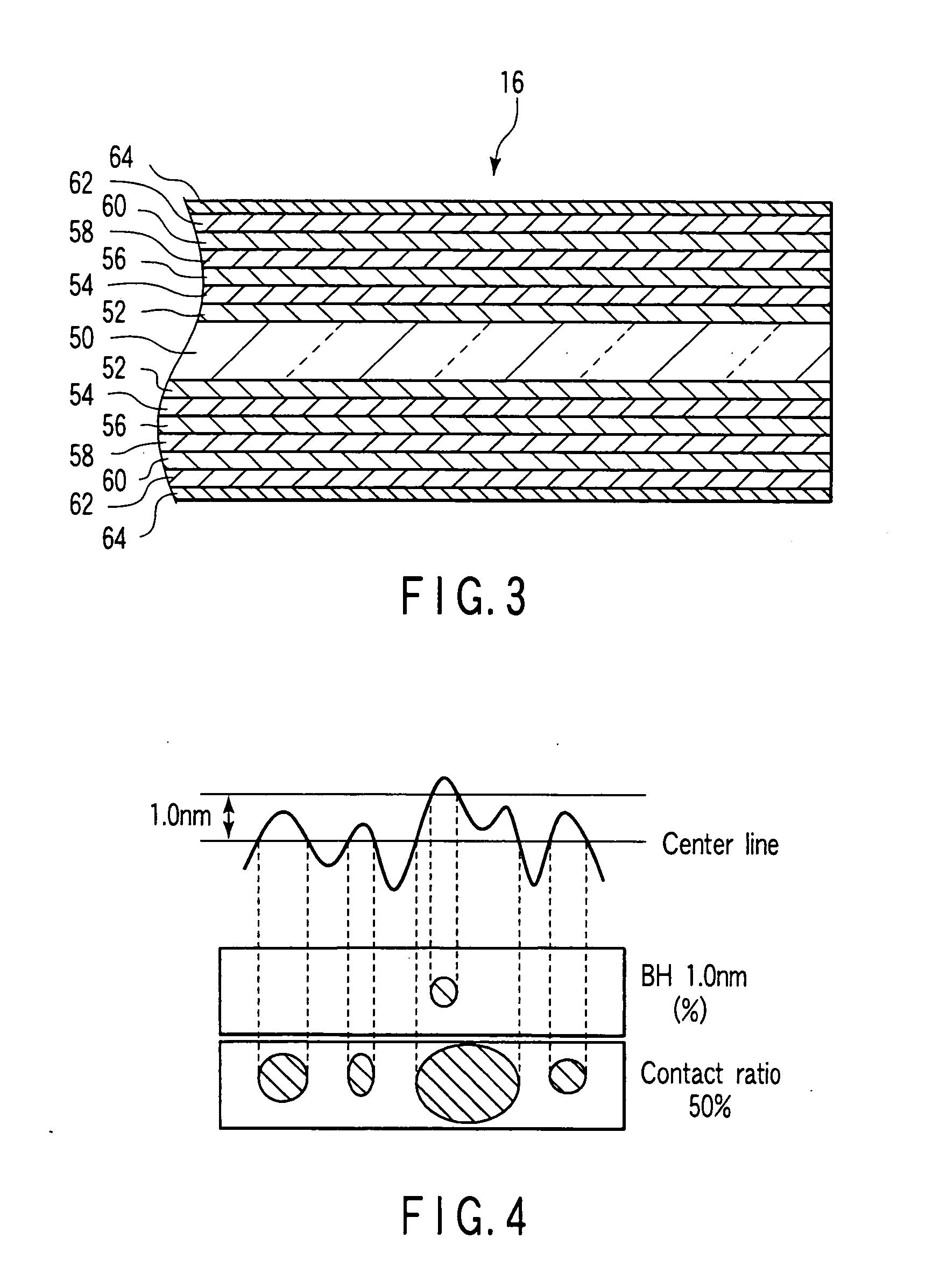

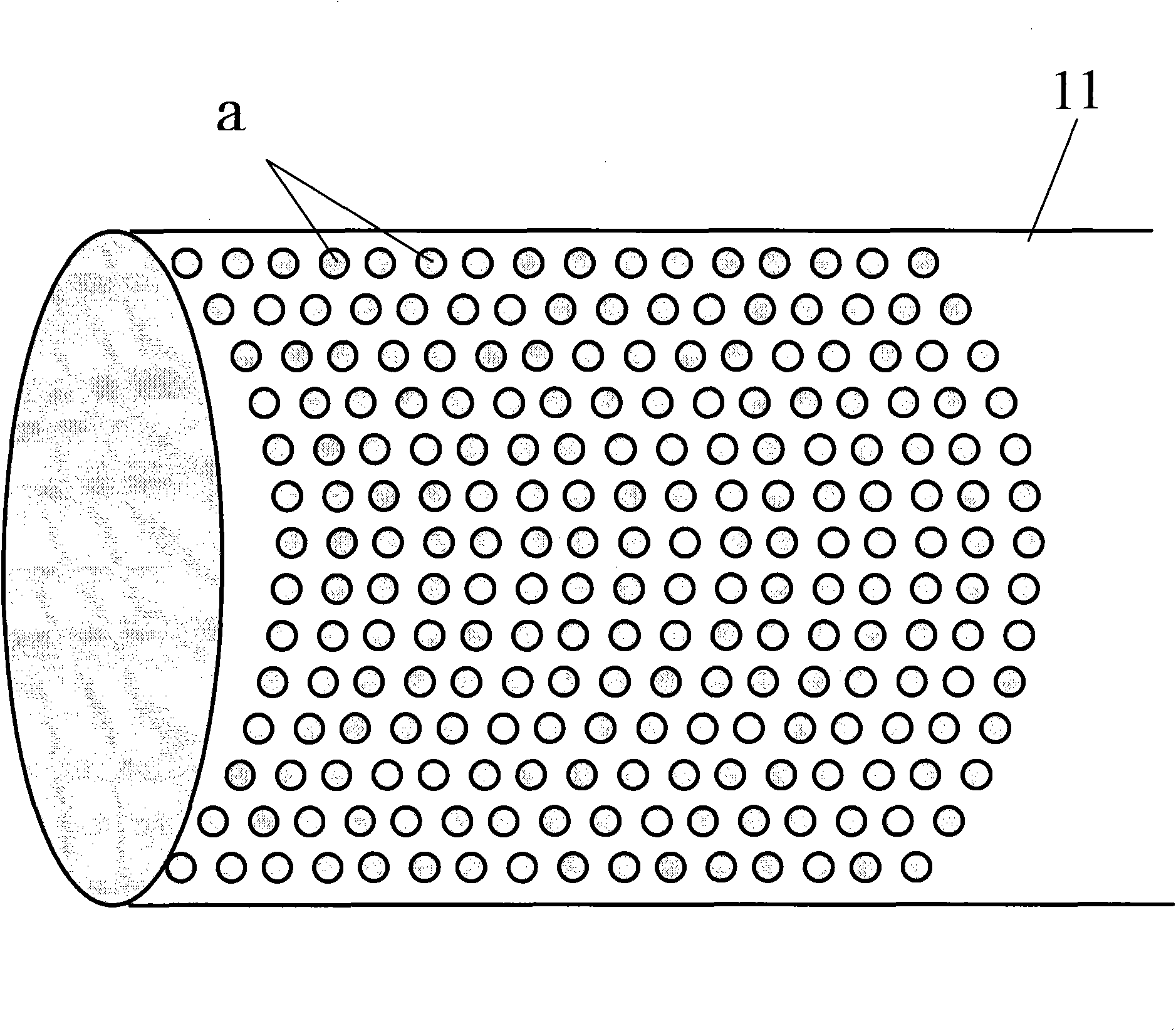

Magnetic recording medium, production process thereof, and magnetic recording and reproducing apparatus

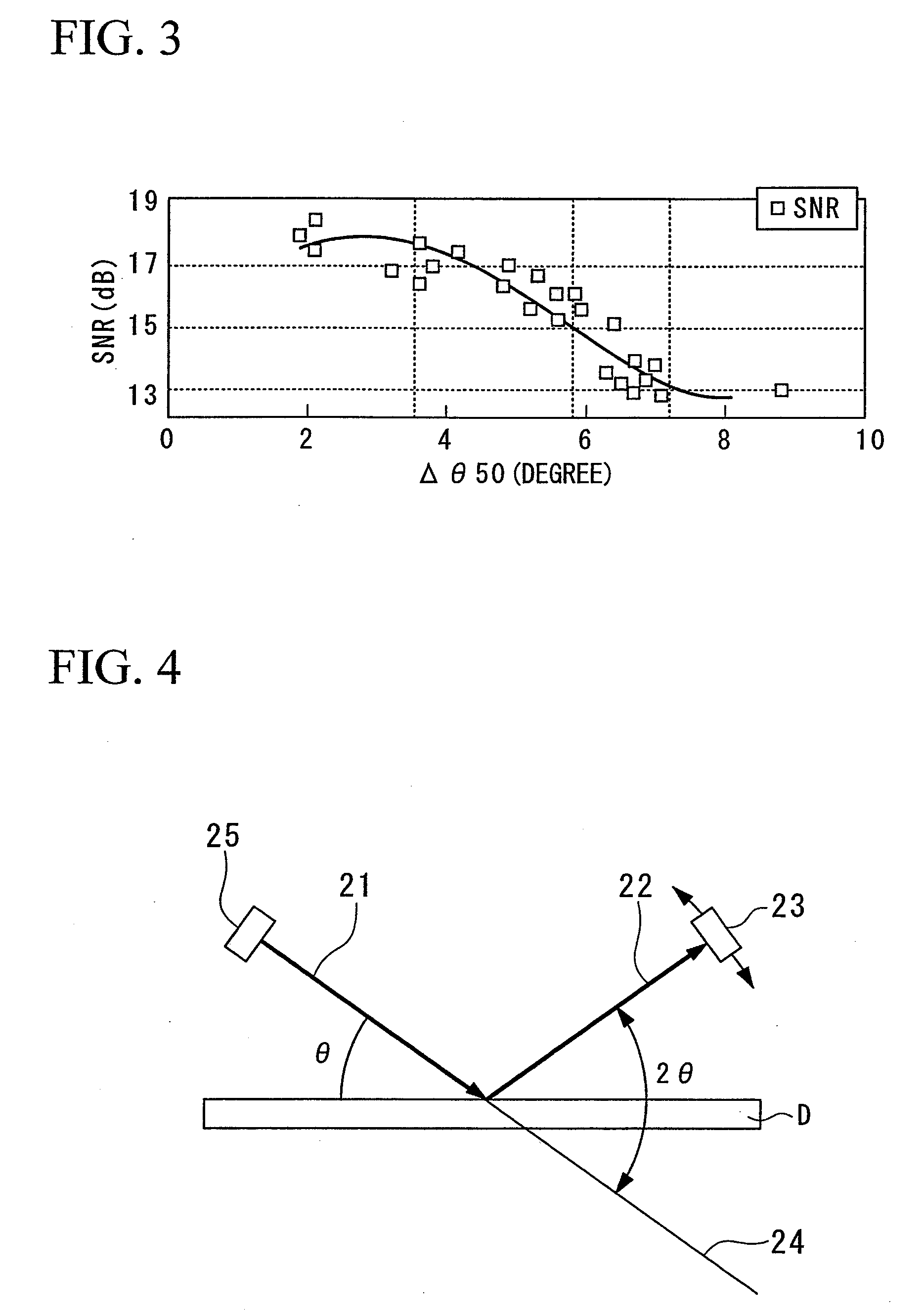

InactiveUS20090142625A1Improve signal-to-noise ratioImprove recording densityDifferent record carrier formsMagnetic materials for record carriersColloidal silicaRocking curve

The present invention provides a magnetic recording medium which enables improvement of the layer quality of magnetic layer grown on the surface of a soft magnetic underlayer by conducting excellent control of crystal orientation by imparting an optimal half-width of the Rocking curve (Δθ50), as well as obtainment of SNR that suppresses generation of TA and enables realization of high-density recording. The magnetic recording medium includes a soft magnetic underlayer, an orientation control layer, a perpendicular magnetic recording layer, and a protective layer, which are disposed on top of a non-magnetic substrate; wherein the magnetic anisotropy ratio (Hmr / Hmc) of the soft magnetic underlayer is 1 or less, and Δθ50 is 1 to 6 degrees. The soft magnetic underlayer is formed on the primary surface of the non-magnetic substrate where the primary surface has been polished one substrate at a time by a sheet-type texture processing device using polishing tape and a slurry containing colloidal silica abrasive grain.

Owner:SHOWA DENKO KK

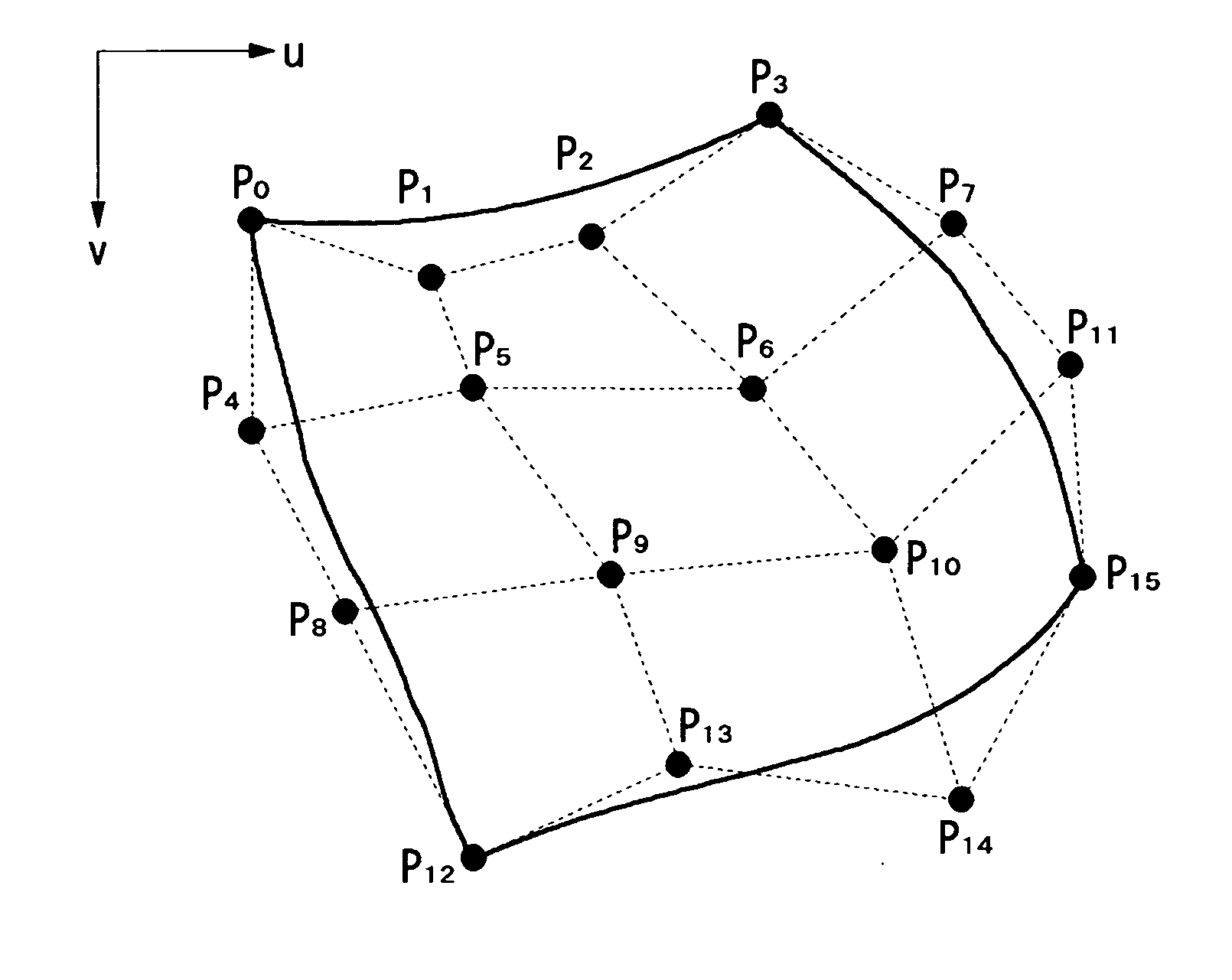

Drawing processing apparatus, texture processing apparatus, and tessellation method

InactiveUS20060197760A1Large memory capacityPerforming processing efficientlyAnalogue computers for chemical processesCathode-ray tube indicatorsLoad instructionComputer graphics (images)

Owner:SONY COMPUTER ENTERTAINMENT INC

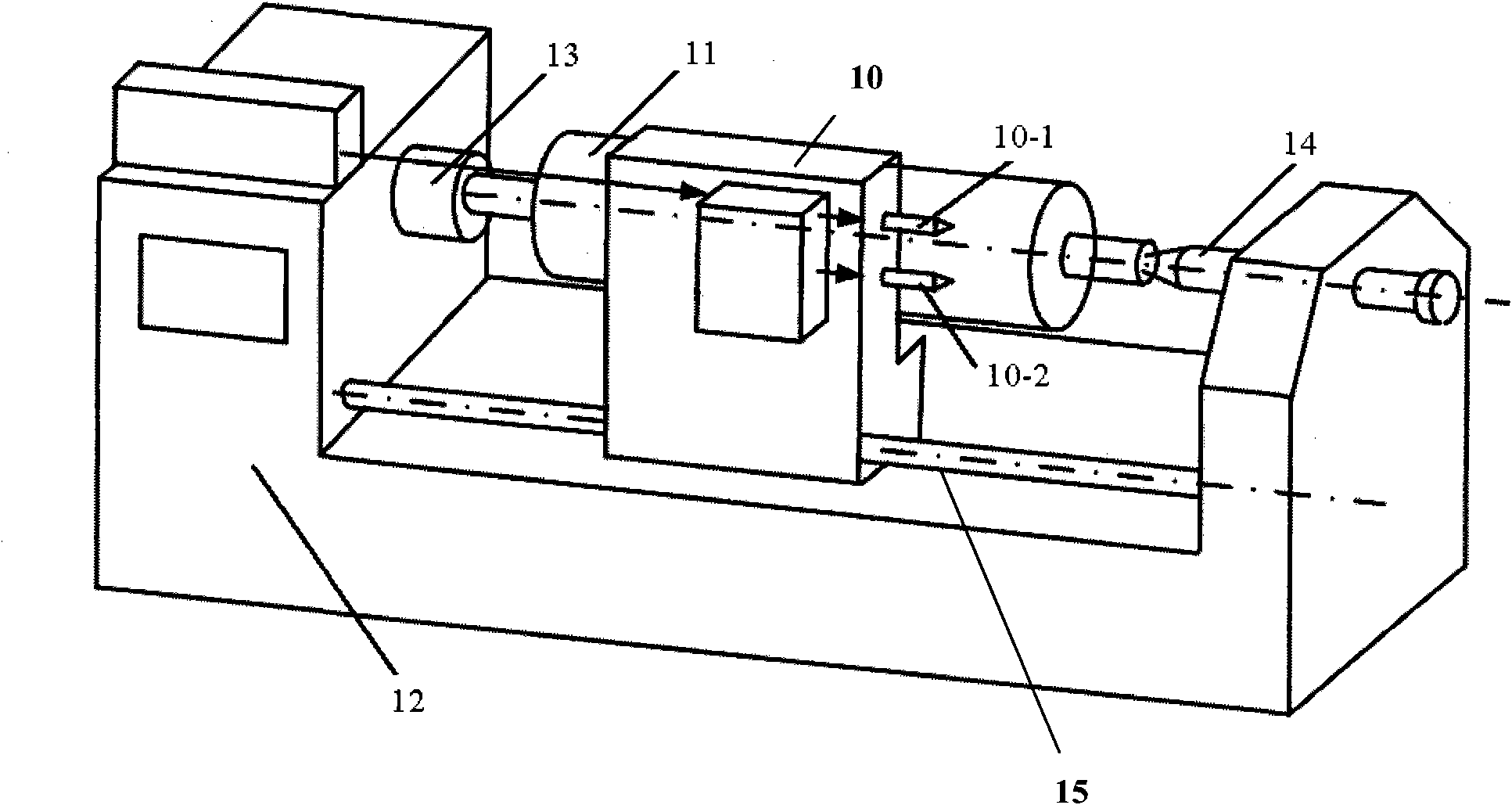

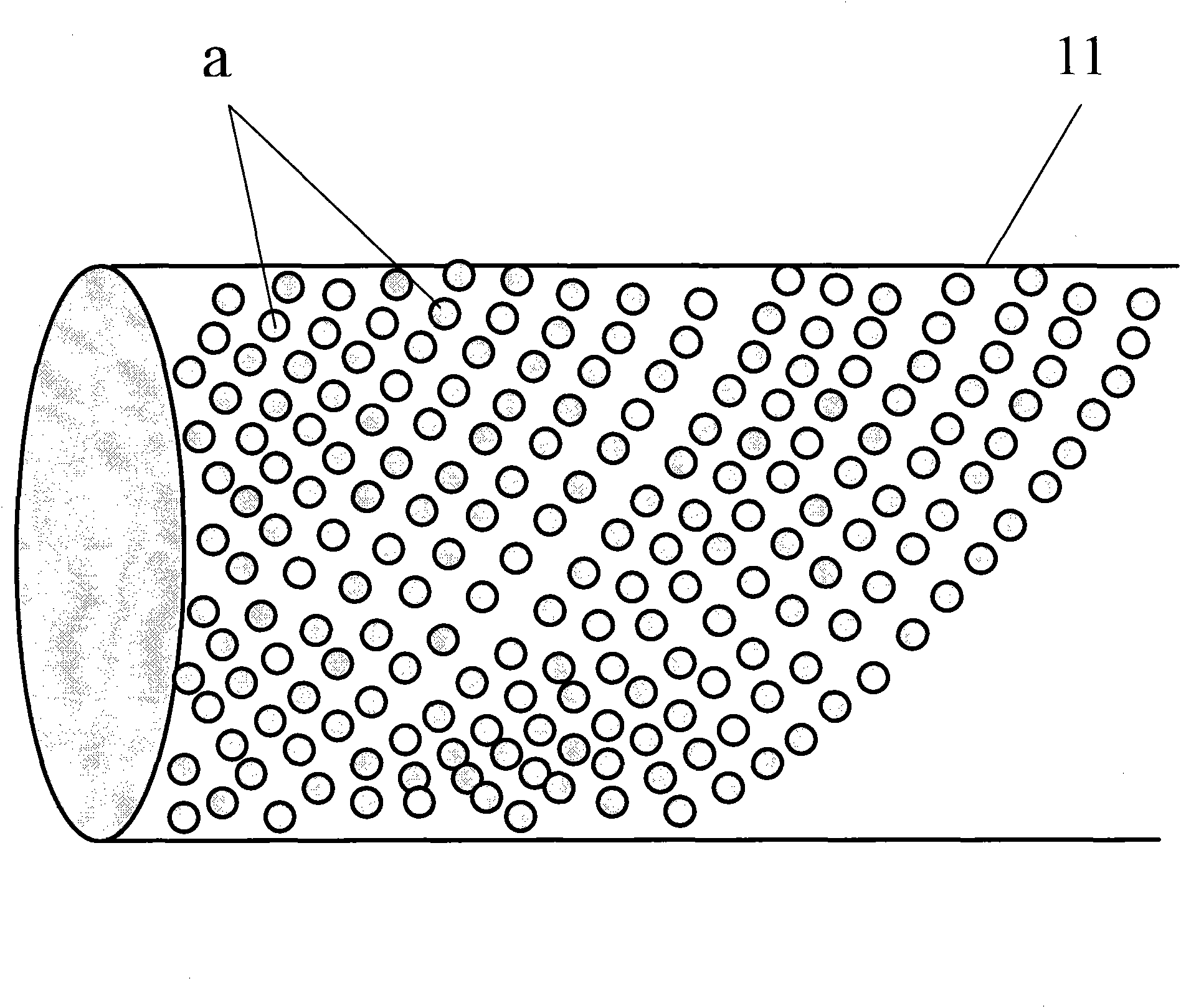

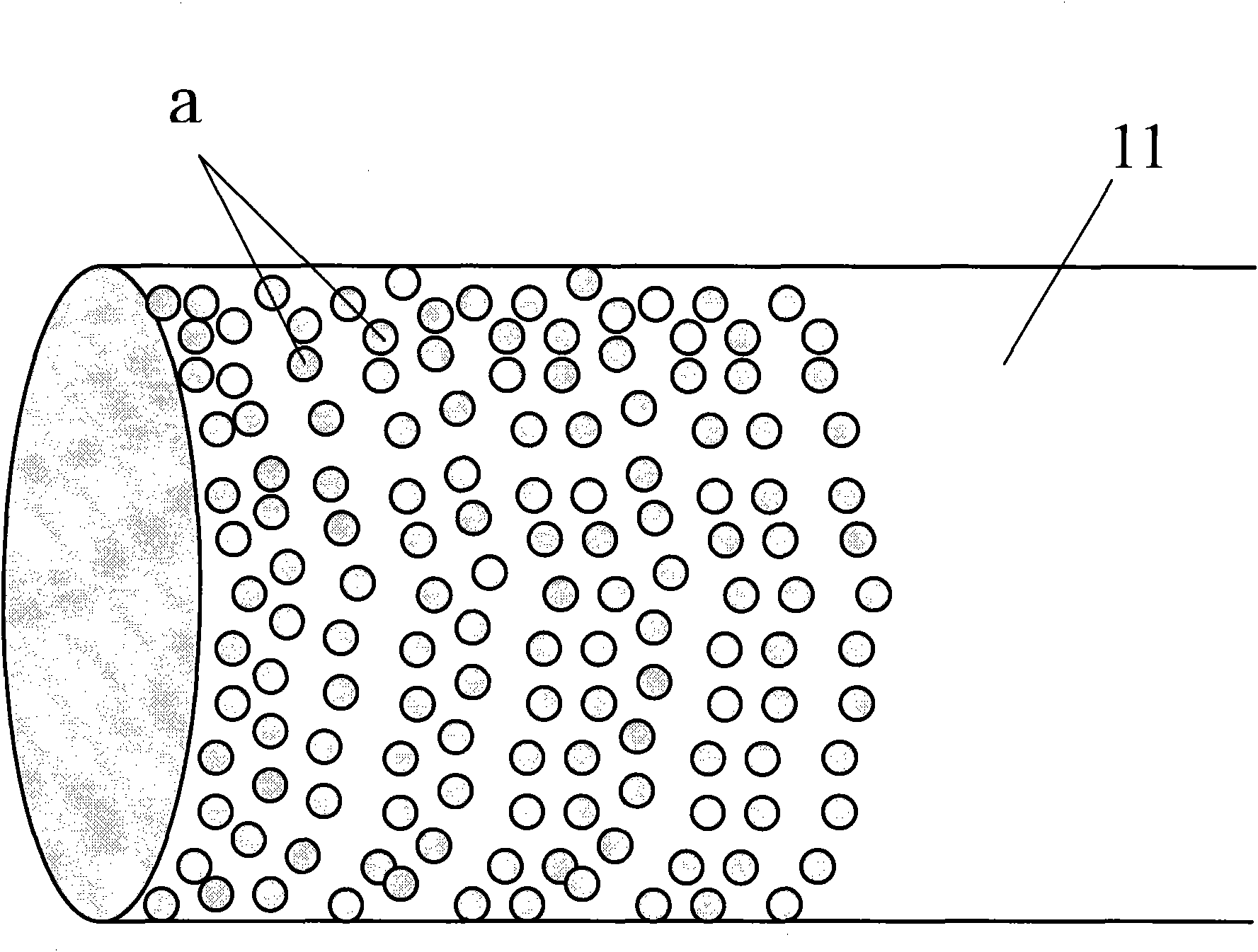

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

Surface texturing processing method of monocrystalline silicon solar cell

InactiveCN104630900AHigh speedImprove uniformityAfter-treatment detailsFinal product manufactureSodium hydroxideIon

The invention discloses a surface texturing processing method of a monocrystalline silicon solar cell. The processing method comprises the following steps: cleaning oil stains and finger prints on a surface of a monocrystalline silicon wafer by ultrasonic; surface texturing, which comprises putting the ultrasonic cleaned monocrystalline silicon wafer into a texturing tank which contains a sodium hydroxide solution having a mass volume percentage of 2%, performing surface corrosion texturing processing; and adding TS4 as a texturing catalyst into the sodium hydroxide solution to increase a silicon surface corrosion speed and uniformity of surface corrosion; removing an oxide from the surface of the monocrystalline silicon wafer, and cleaning the monocrystalline silicon wafer by using a hydrofluoric acid solution (a concentration of 49%) with a volume percentage of 16%; removing metal ions, and cleaning the monocrystalline silicon wafer by using a hydrochloric acid solution (a concentration of 37%) with a volume percentage of 28%; and drying the final monocrystalline silicon wafer with a pyramid-shaped surface. According to the invention, a surface texturing speed of the monocrystalline silicon wafer is increased; uniformity of surface texturing of the monocrystalline silicon wafer is improved; and then monocrystalline silicon solar cell prepared by the method is higher in photoelectric conversion efficiency of the solar cell and good in stability. The surface texturing processing method is a better choice for application of photovoltaic power generation.

Owner:江苏天宇光伏科技有限公司

Sparse texture systems and methods

ActiveUS20110157207A1Cathode-ray tube indicators3D-image renderingPattern recognitionTexture processing

Systems and methods for texture processing are presented. In one embodiment a texture method includes creating a sparse texture residency translation map; performing a probe process utilizing the sparse texture residency translation map information to return a finest LOD that contains the texels for a texture lookup operation; and performing the texture lookup operation utilizing the finest LOD. In one exemplary implementation, the finest LOD is utilized as a minimum LOD clamp during the texture lookup operation. A finest LOD number indicates a minimum resident LOD and a sparse texture residency translation map includes one finest LOD number per tile of a sparse texture. The sparse texture residency translation can indicate a minimum resident LOD.

Owner:NVIDIA CORP

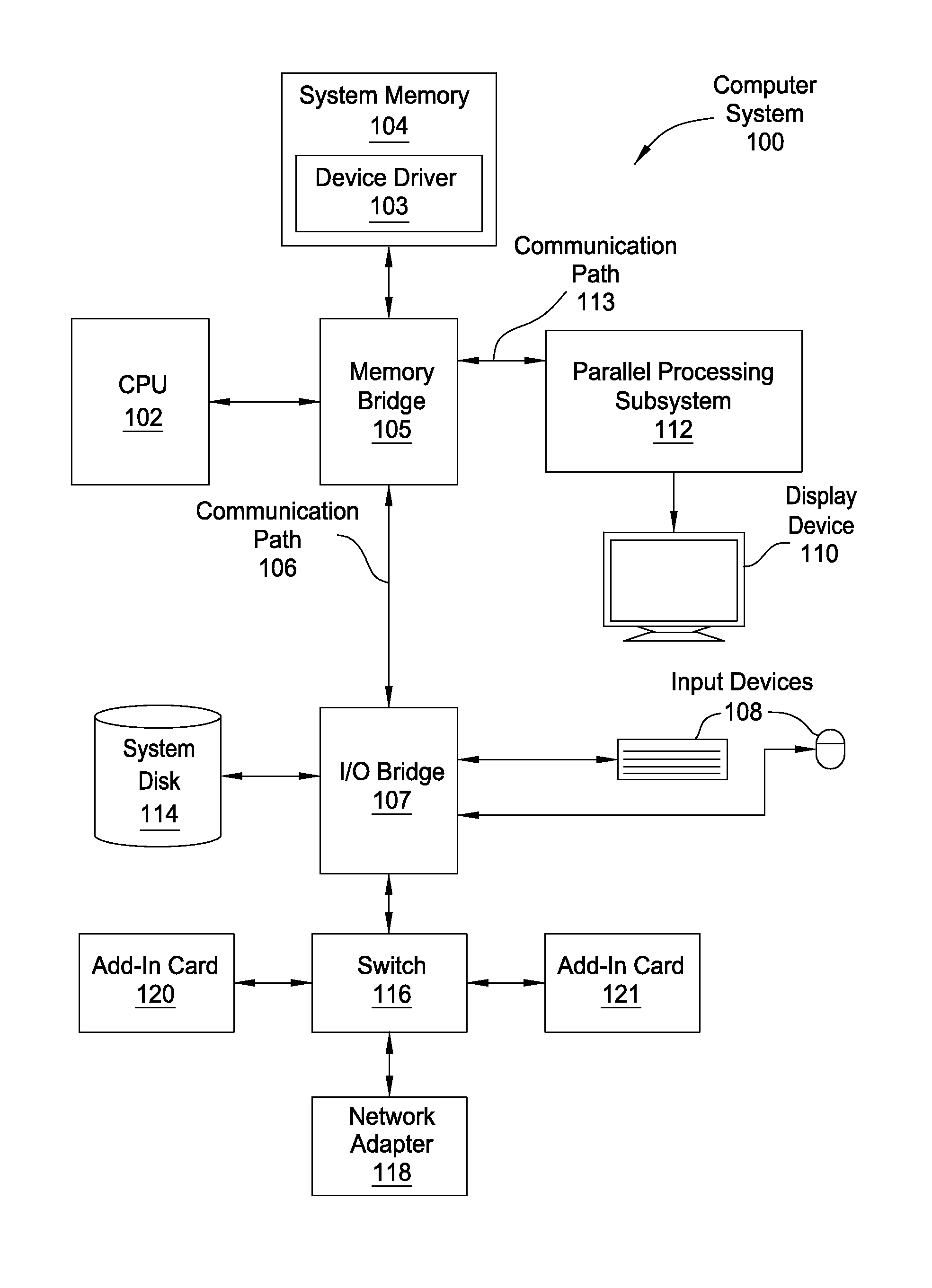

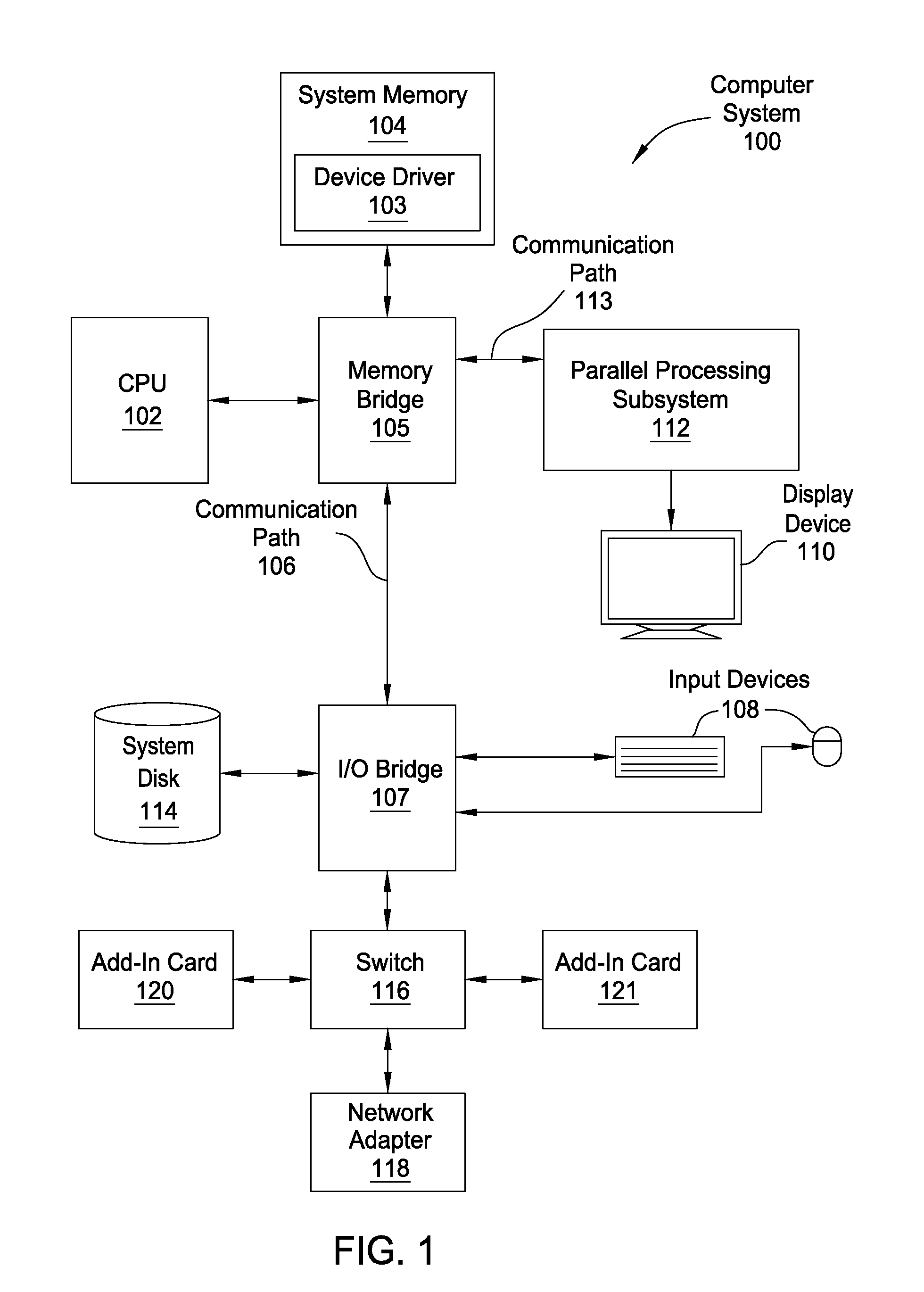

Approach to caching decoded texture data with variable dimensions

ActiveUS20150097851A1Improve throughputEfficient packagingTexturing/coloringImage memory managementParallel computingTexture processing

A texture processing pipeline is configured to store decoded texture data within a cache unit in order to expedite the processing of texture requests. When a texture request is processed, the texture processing pipeline queries the cache unit to determine whether the requested data is resident in the cache. If the data is not resident in the cache unit, a cache miss occurs. The texture processing pipeline then reads encoded texture data from global memory, decodes that data, and writes different portions of the decoded memory into the cache unit at specific locations according to a caching map. If the data is, in fact, resident in the cache unit, a cache hit occurs, and the texture processing pipeline then reads decoded portions of the requested texture data from the cache unit and combines those portions according to the caching map.

Owner:NVIDIA CORP

Static and dynamic video resizing

Owner:ORACLE INT CORP

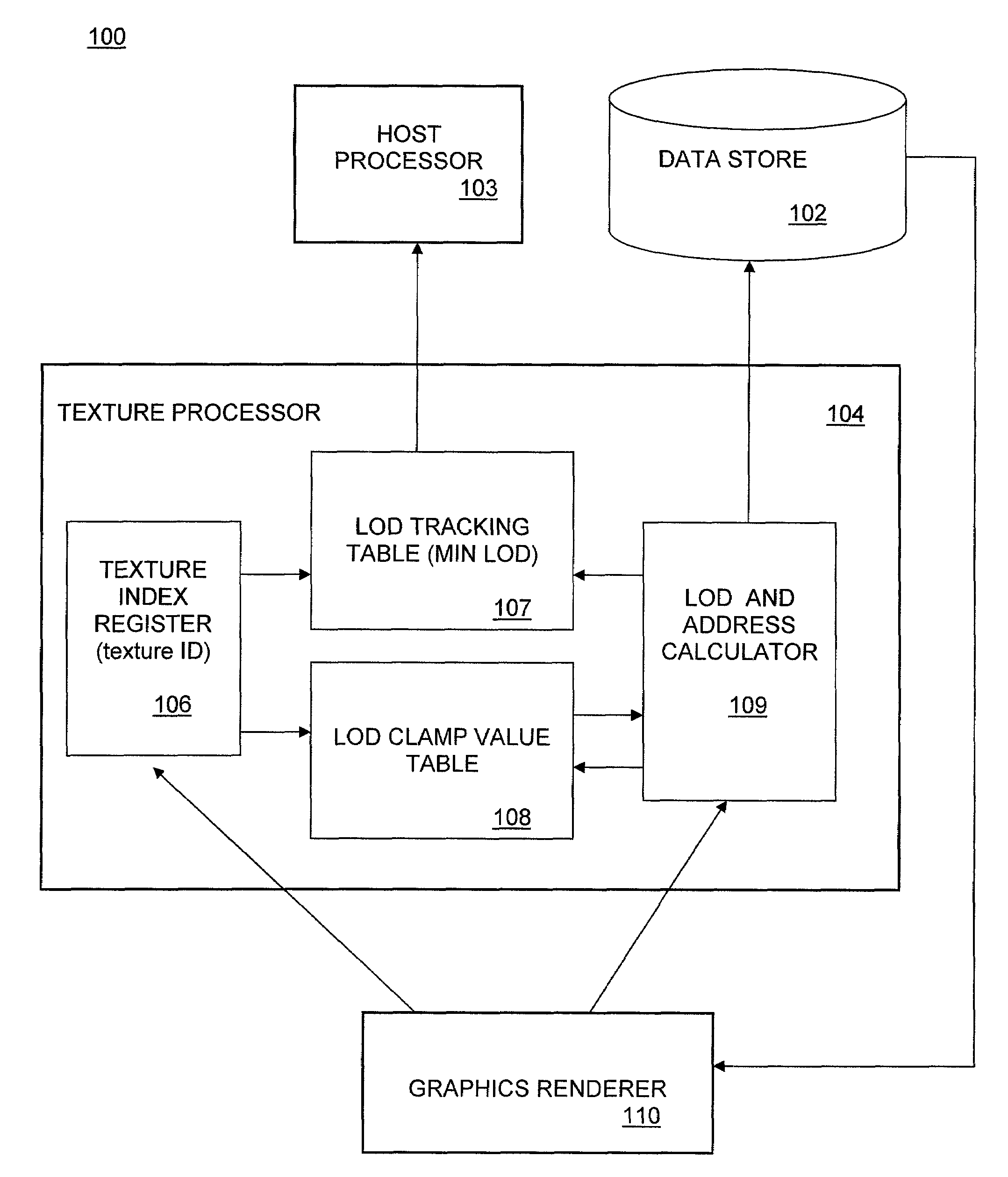

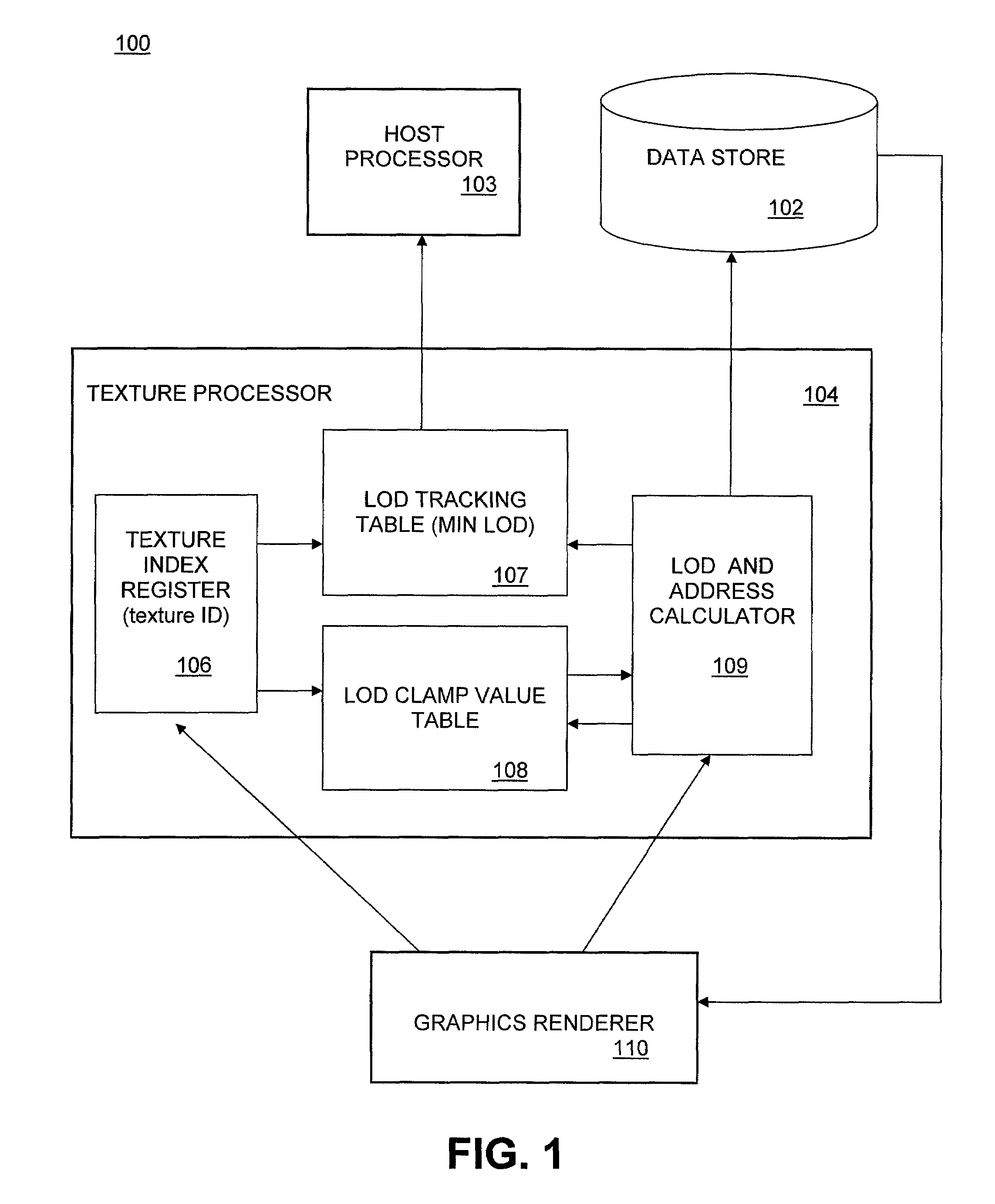

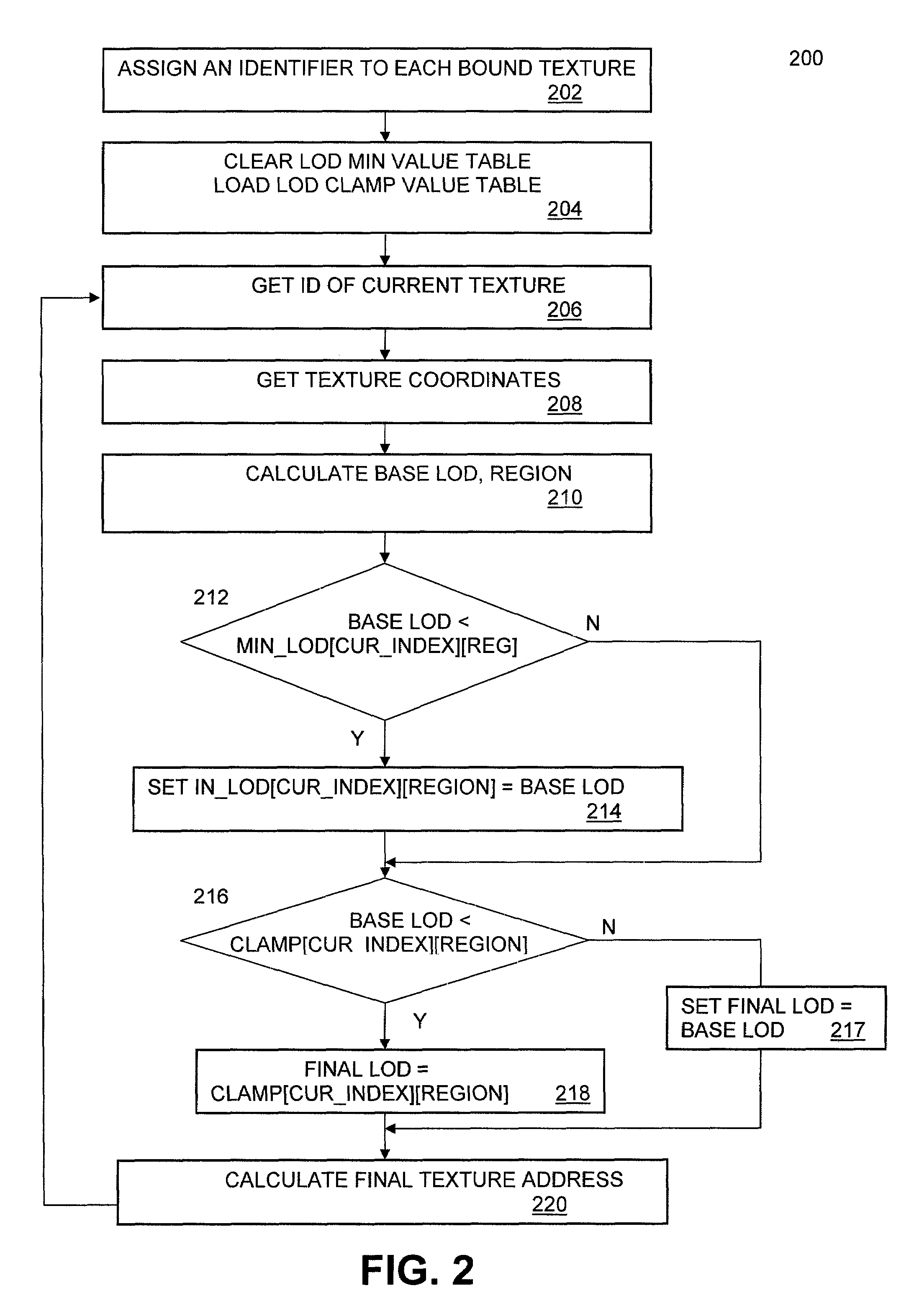

Texture Level Tracking, Feedback, and Clamping System for Graphics Processors

Embodiments include a texture mapping processor incorporating a dynamic level of detail map for use in a graphics processing system. Level of detail values are defined, with 0 being the finest and corresponding to the largest mipmap level. Each bound texture in a graphics object is assigned an identifier. This identifier is used as an index into a minimum-LOD value tracking table that is updated whenever a texel is fetched. A texture processing module controls when the tracking table is initialized and read back, and which identifiers are tracked. The minimum-LOD values in the tracking table are accompanied by a coarse region access mask to associate a minimum LOD value with a specific region of the image or object. A clamping table contains LOD clamp values for each region and a region code that specifies the coarseness of the LOD associated with each region of the texture.

Owner:ADVANCED MICRO DEVICES INC

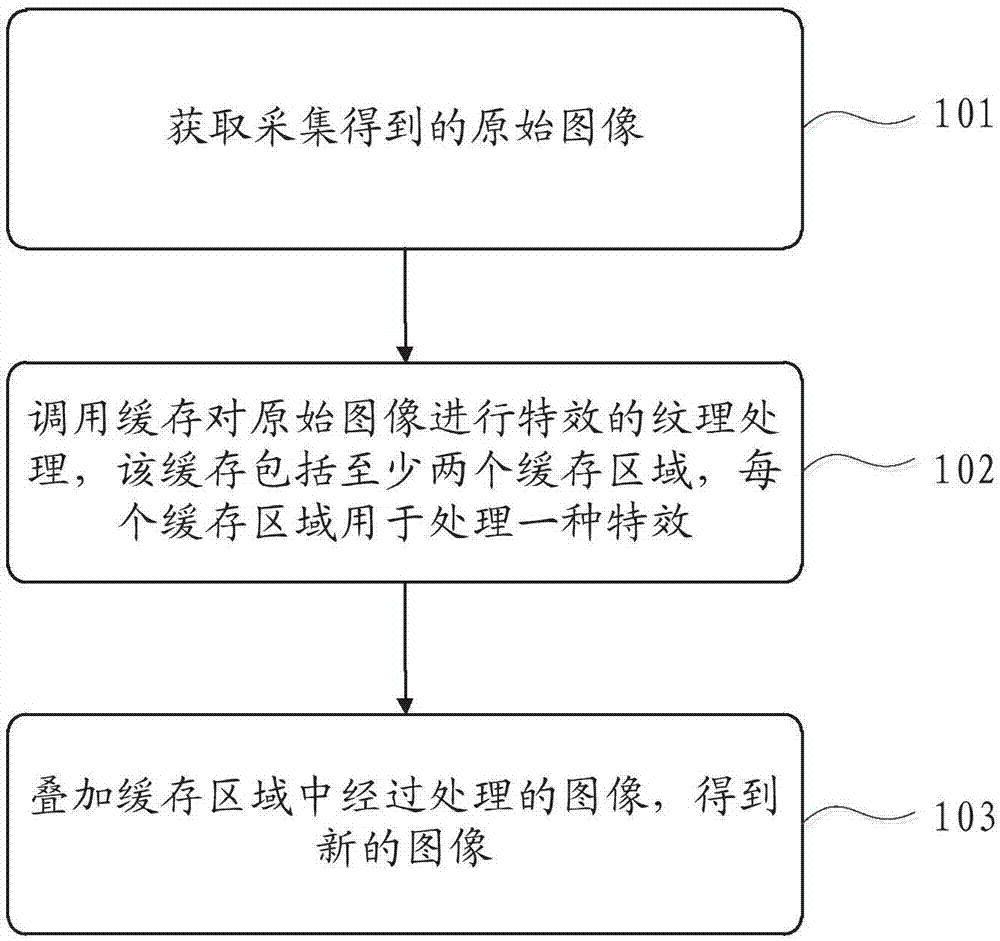

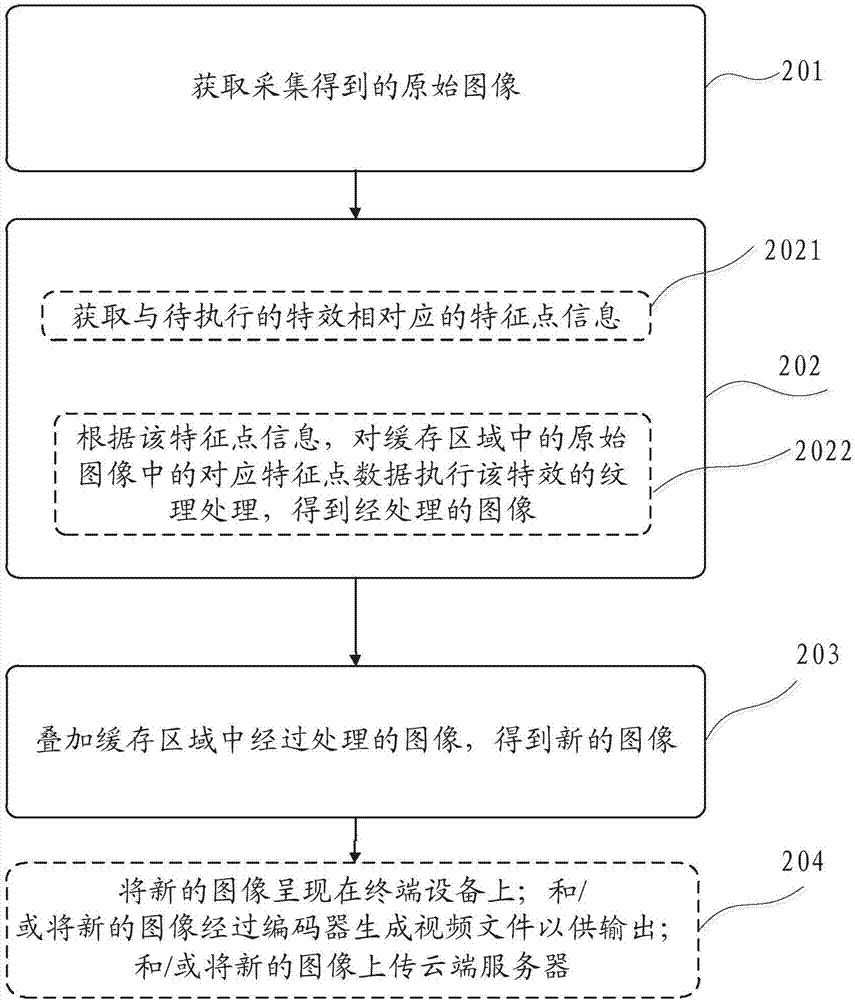

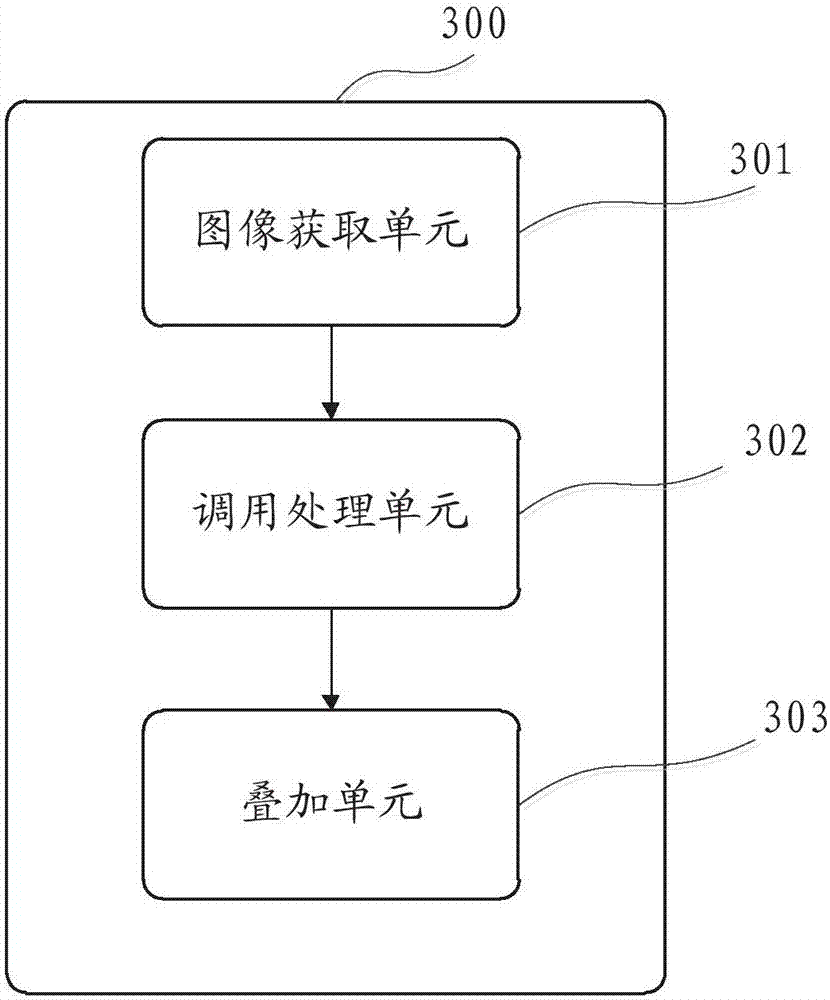

Image processing method and device, terminal device and storage medium thereof

InactiveCN108012091AInterestingImprove processing efficiencyTelevision system detailsColor television detailsImaging processingComputer graphics (images)

The invention discloses an image processing method and device, a terminal device and a storage medium thereof. The method comprises the following steps: acquiring a collected original image; calling acache to perform special-effect texture processing on the original image, wherein the cache comprises at least two cache areas, and each cache area is used for processing a special effect; and overlapping the image processed in the cache areas to obtain a new image. According to the technical solution of the embodiment of the invention, texture superposition processing of at least two special effects is performed on the image by calling a cache comprising at least two cache areas, so that the photographing interestingness of a user is enriched; the data processing efficiency can be further improved through texture processing.

Owner:BEIJING QIHOO TECH CO LTD

Production process for microstructural texture colour crystal glass

InactiveCN105563959AReflect the metal textureReflect personalizationLamination ancillary operationsSynthetic resin layered productsWeather resistanceReflective layer

The invention relates to a production process for microstructural texture colour crystal glass. According to the production process, the microstructural texture colour crystal glass is produced by five processes of pretreatment processing treatment, microstructural layer texture treatment, reflecting layer treatment, window ink layer treatment and protective ink layer treatment. The production process for the microstructural texture colour crystal glass has the advantages that the microstructural texture colour crystal glass produced by adopting the production process can reproduce tiny patterns, even nano-scale line texture patterns; texture and individuation can be embodied, and the weather resistance is extremely high; in addition, the input-output ratio is high, and the product quality is more stable through low-temperature ink protection as well as inorganic high-temperature ink and glass sintering, and the production cost of the process is low.

Owner:JIANGSU FANHUA GLASS CO LTD

Load/store operations in texture hardware

ActiveUS20150084975A1Small surface areaReduce power consumptionMemory architecture accessing/allocationImage memory managementParallel computingTexture memory

Approaches are disclosed for performing memory access operations in a texture processing pipeline having a first portion configured to process texture memory access operations and a second portion configured to process non-texture memory access operations. A texture unit receives a memory access request. The texture unit determines whether the memory access request includes a texture memory access operation. If the memory access request includes a texture memory access operation, then the texture unit processes the memory access request via at least the first portion of the texture processing pipeline, otherwise, the texture unit processes the memory access request via at least the second portion of the texture processing pipeline. One advantage of the disclosed approach is that the same processing and cache memory may be used for both texture operations and load / store operations to various other address spaces, leading to reduced surface area and power consumption.

Owner:NVIDIA CORP

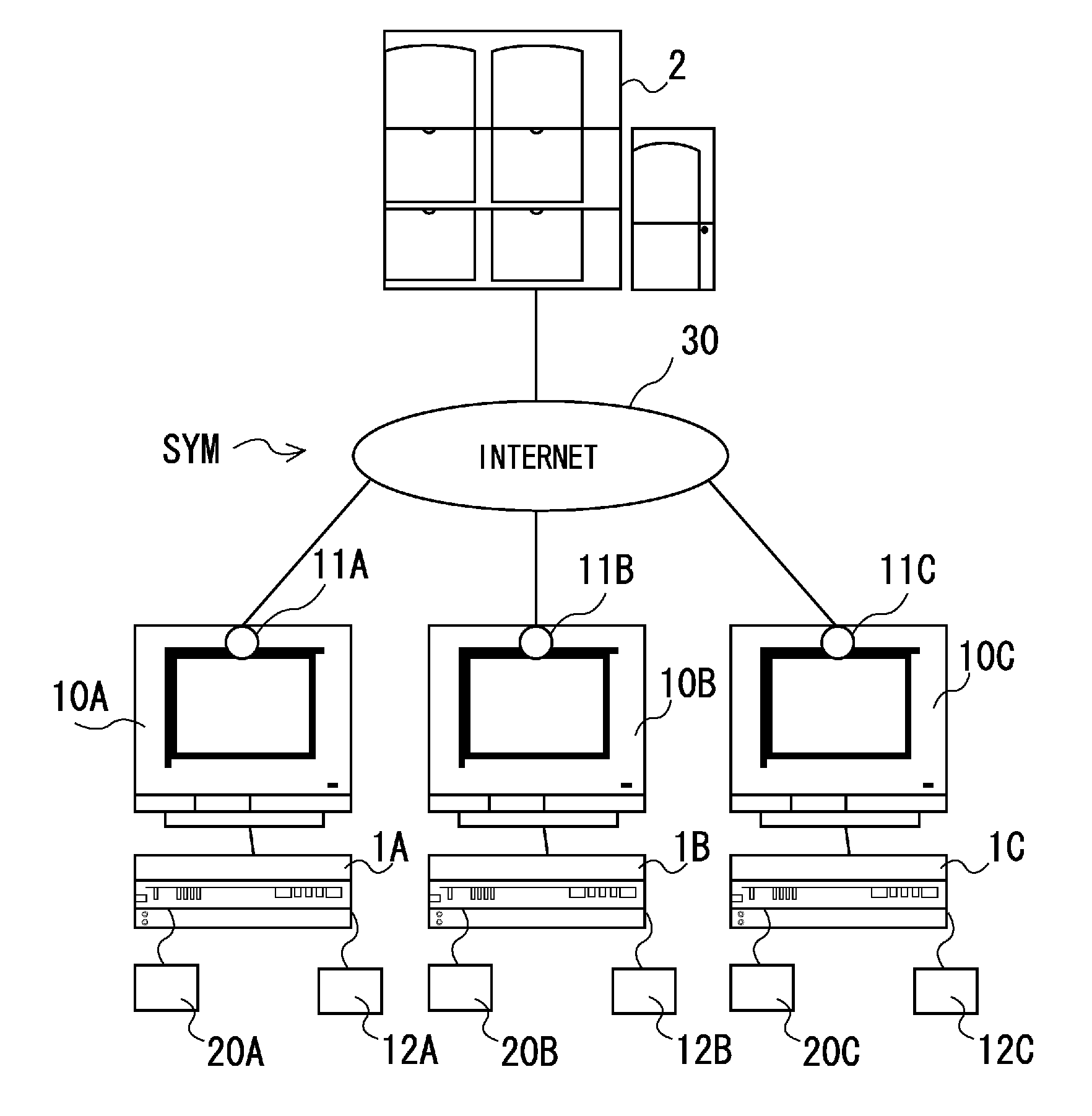

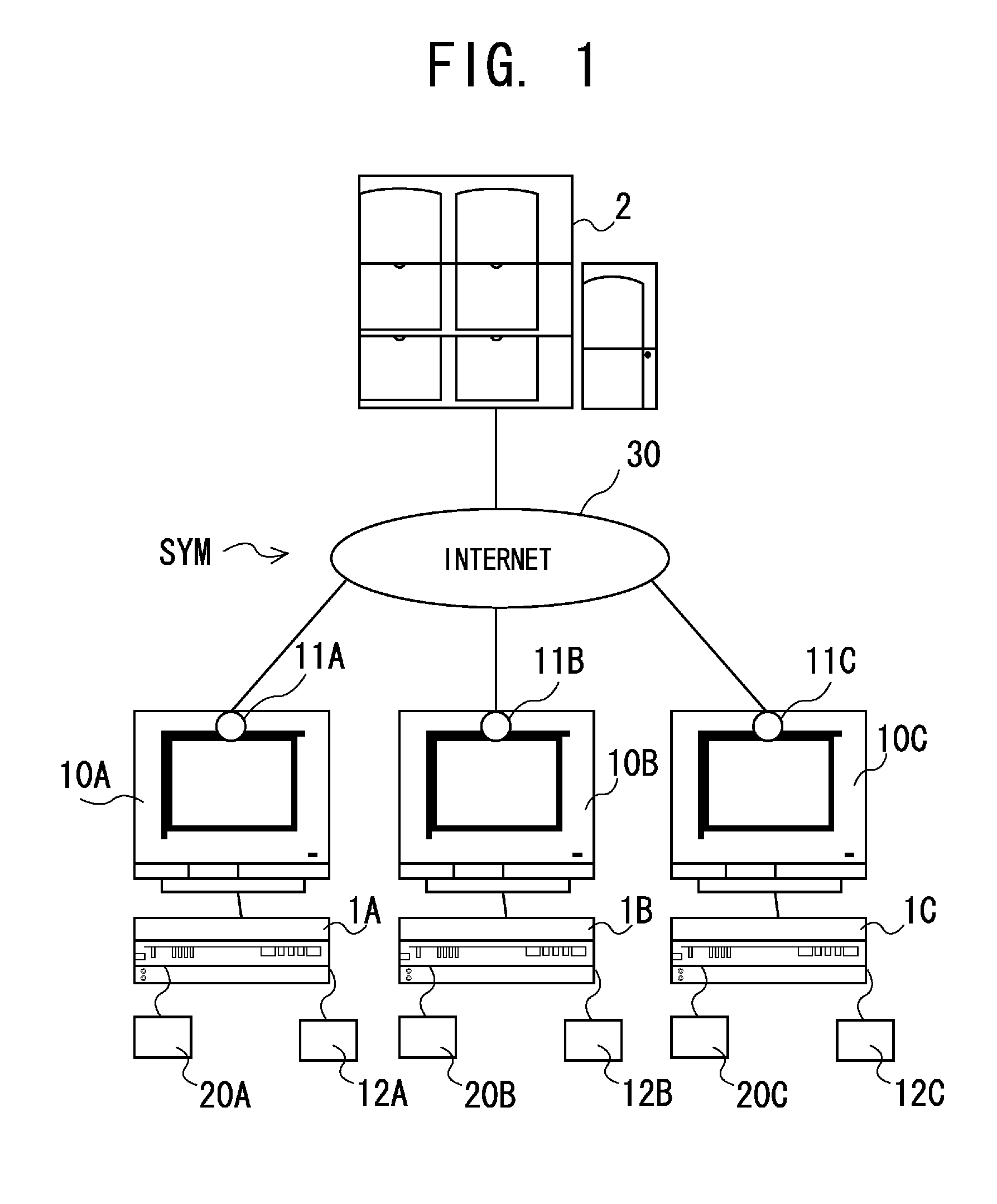

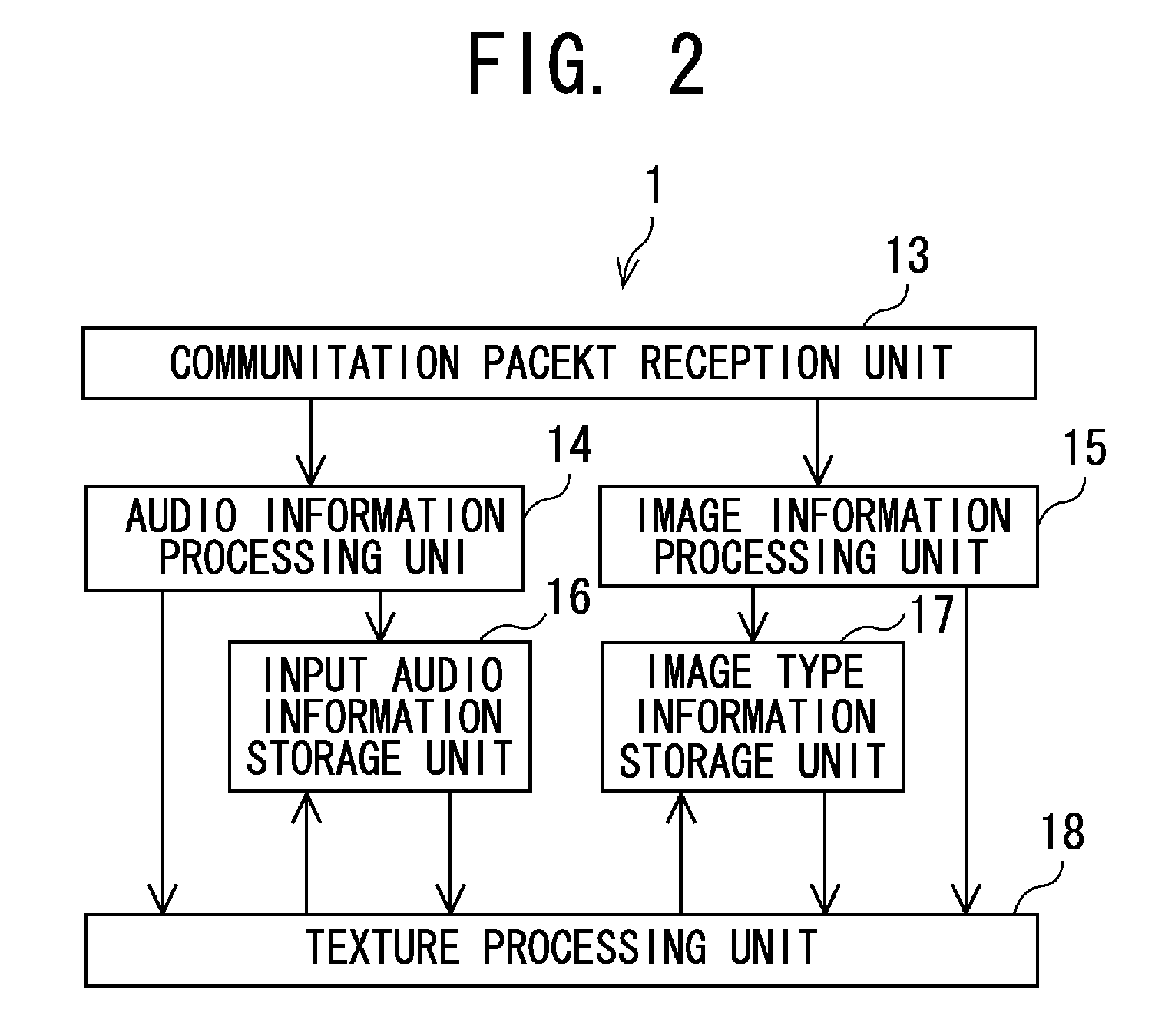

Communication System, Communication Apparatus, Communication Program, And Computer-Readable Storage Medium Stored With The Communication Program

ActiveUS20090024703A1Multiple digital computer combinationsTelevision systemsComputer hardwareCommunications system

The client apparatus 1 is connected to a network and includes a communication packet reception unit 13 and a texture processing unit 18. The communication packet reception unit 13 receives image data, audio data, and image type information designating type of the image data, which are transmitted from another client apparatus connected to the network. The texture processing unit 18 renders an image for the received image data. Moreover, the texture processing unit 18 subjects the image for the image data to a predetermined processing when the image type information received by the communication packet reception unit 13 is information of a predetermined image.

Owner:SONY COMPUTER ENTERTAINMENT INC

Sparse texture systems and methods

ActiveUS20110157205A1Cathode-ray tube indicators3D-image renderingPattern recognitionTexture processing

Systems and methods for texture processing are presented. In one embodiment a texture method includes creating a sparse texture residency translation map; performing a probe process utilizing the sparse texture residency translation map information to return a finest LOD that contains the texels for a texture lookup operation; and performing the texture lookup operation utilizing the finest LOD. In one exemplary implementation, the finest LOD is utilized as a minimum LOD clamp during the texture lookup operation. A finest LOD number indicates a minimum resident LOD and a sparse texture residency translation map includes one finest LOD number per tile of a sparse texture. The sparse texture residency translation can indicate a minimum resident LOD.

Owner:NVIDIA CORP

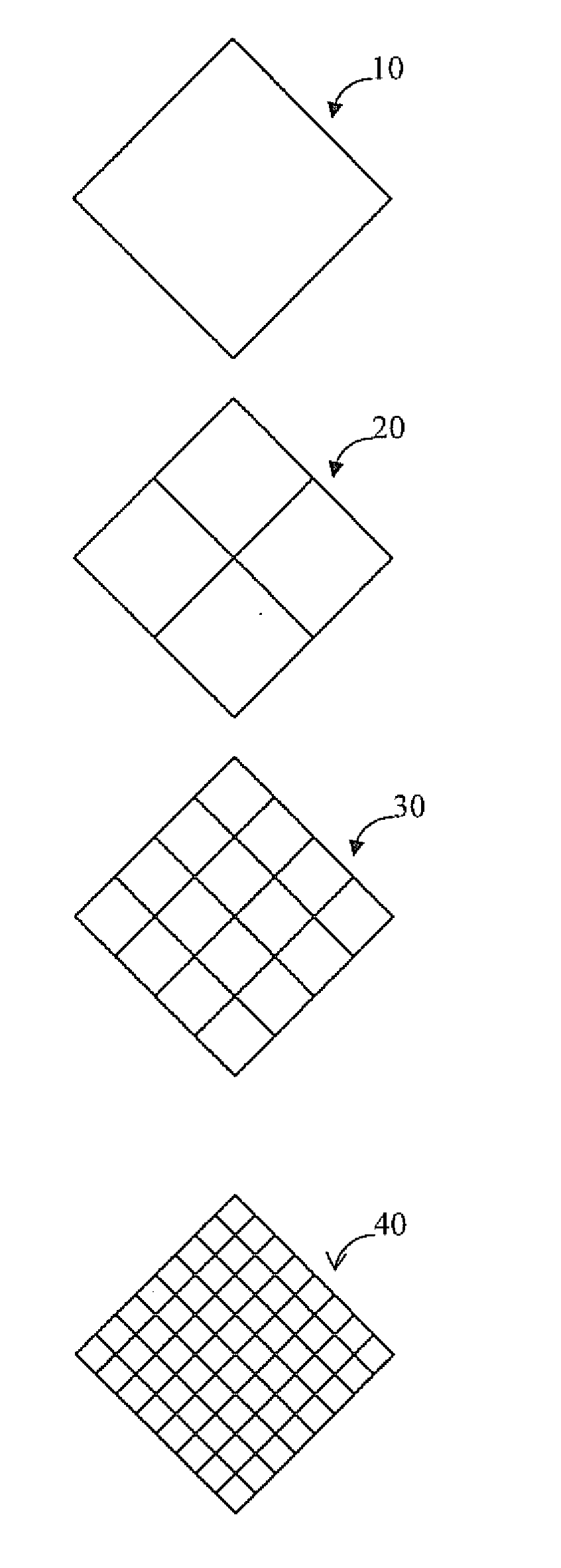

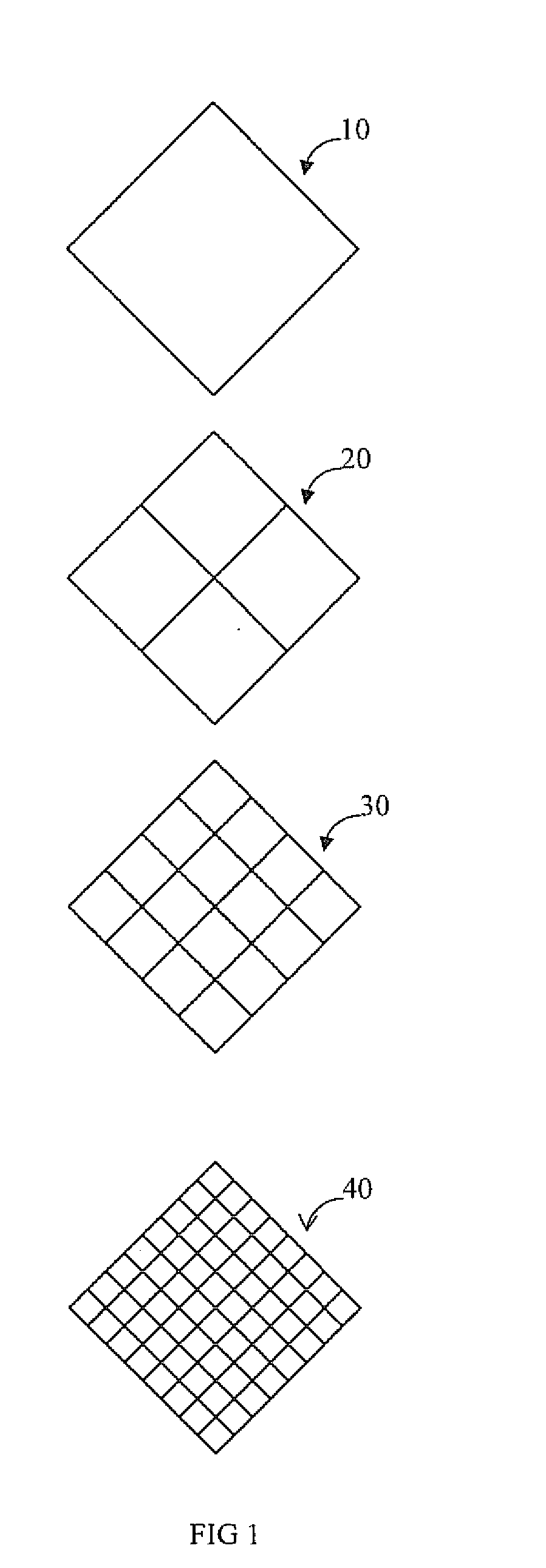

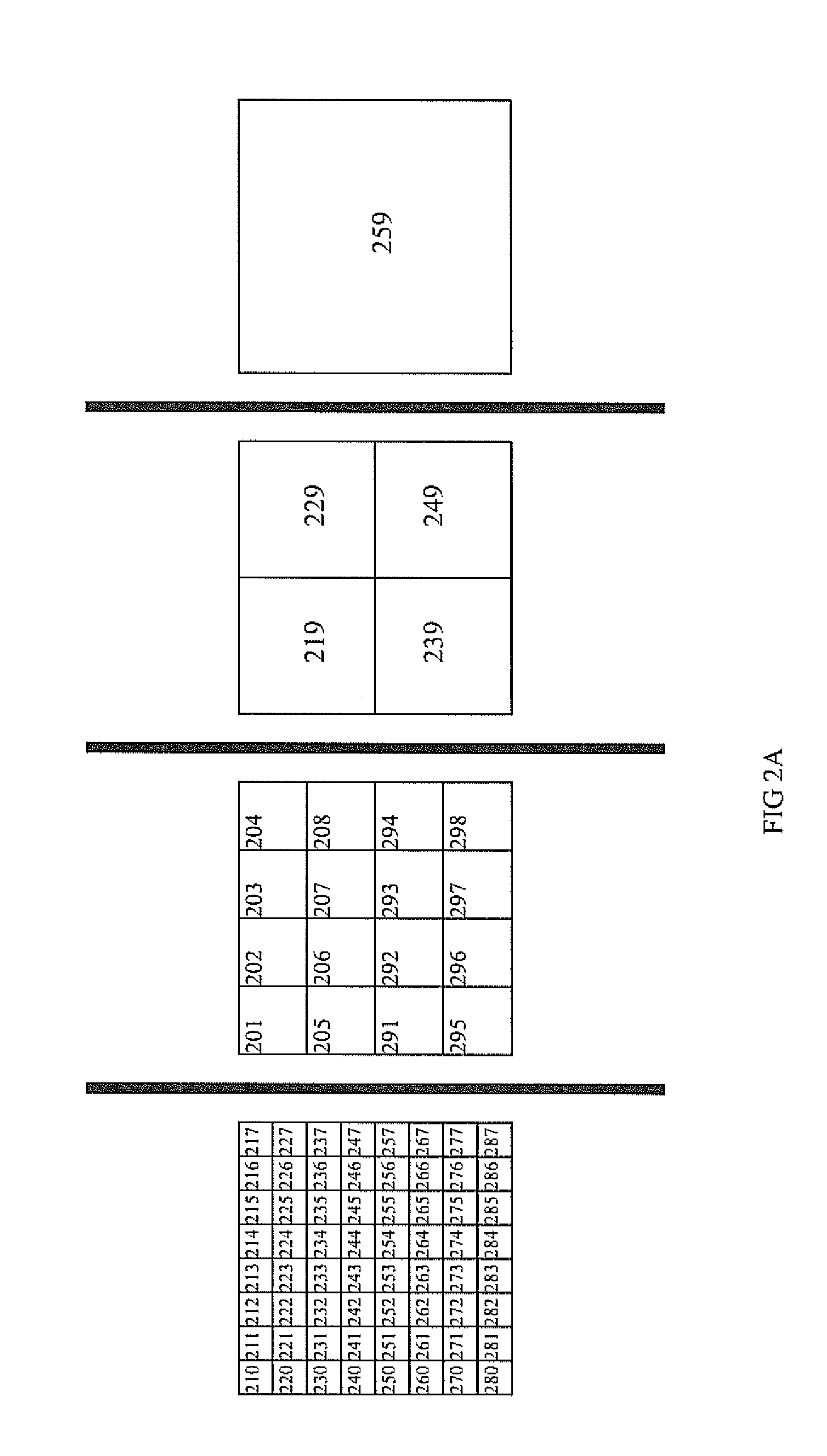

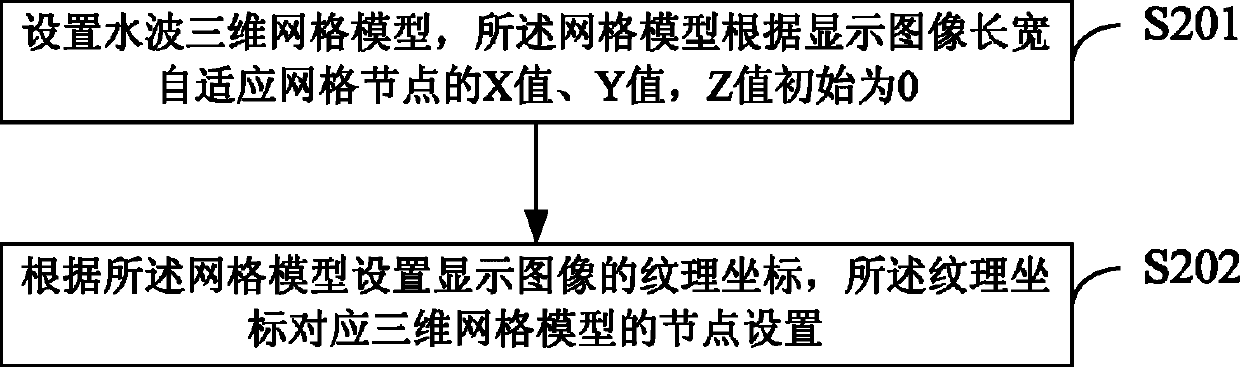

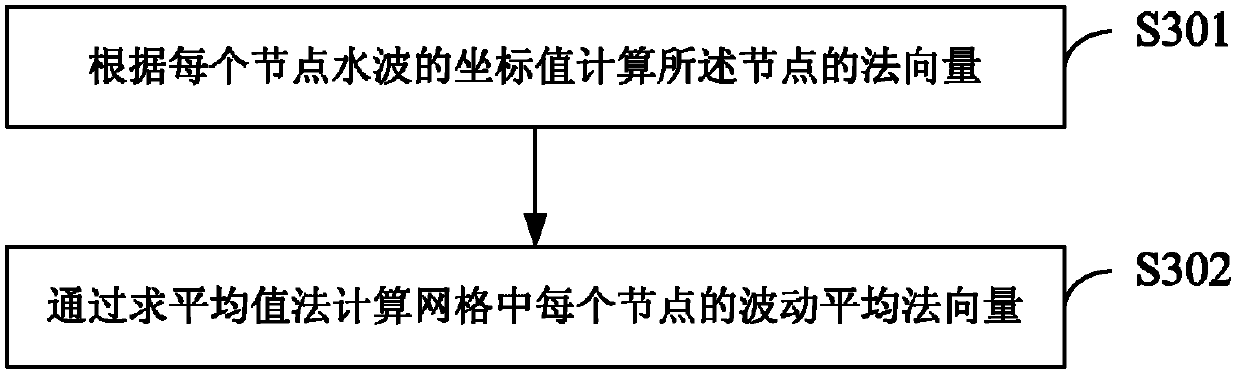

Real-time water wave texture processing method based on 2D (Two-dimensional) grid

ActiveCN102592297AReduce demandFilling planer surface with attributesImaging processingWave equation

The invention is applicable to the field of image processing, and provides a real-time water wave texture processing method based on a 2D (Two-dimensional) grid. The method comprises the following steps: setting the grid for simulating water wave texture according to the length-width ratio of a display image and setting a texture coordinate for each node in the grid; simulating the transfer of a water wave into a sine wave and calculating the height valve when the water wave reaches each node of the grid according to a wave equation; calculating the increment of the texture coordinate of each node according to the height valve of each node and fluctuation average method vectors; and rendering the fluctuation of the generated water wave on a real time according to the increment of the texture coordinate and the fluctuation average method vectors. According to the embodiment of the invention, the texture coordinate is set for each node of the grid, the increment of the texture coordinate is calculated according to the height value of each node, and a water wave image is further simulated, so that the water wave image can be simulated only through calculating a wave equation without a derivation algorithm, an integral algorithm and other complicated algorithms, and the demands on display equipment hardware is reduced.

Owner:TCL CORPORATION

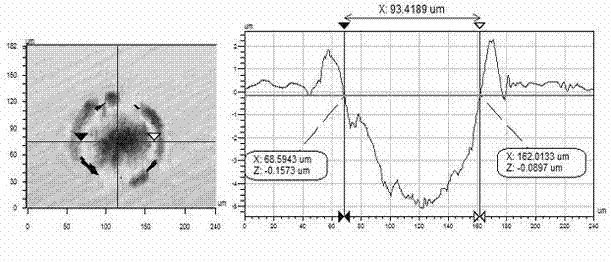

Magnetic disk and magnetic disk apparatus equipped with magnetic disk

InactiveUS20050052987A1Improve recording densityImprove reliabilityMagnetic materials for record carriersBase layers for recording layersMagnetic anisotropySurface roughness

A texture processing for imparting a magnetic orientation in the circumferential direction is applied to a substrate so as to impart a magnetic anisotropy to the magnetic disk in the circumferential direction. An underlying film, a magnetic recording film, a protective film, and a lubricating film are laminated one upon the other on the surface of the substrate. The surface of the magnetic disk has a value of the contact ratio [BH 1.0 nm] falling within a range of 7% to 15% in a region having a height not smaller than 1.0 nm, based on the height at which the contact ratio in the bearing curve of a surface roughness is 50%.

Owner:KK TOSHIBA +1

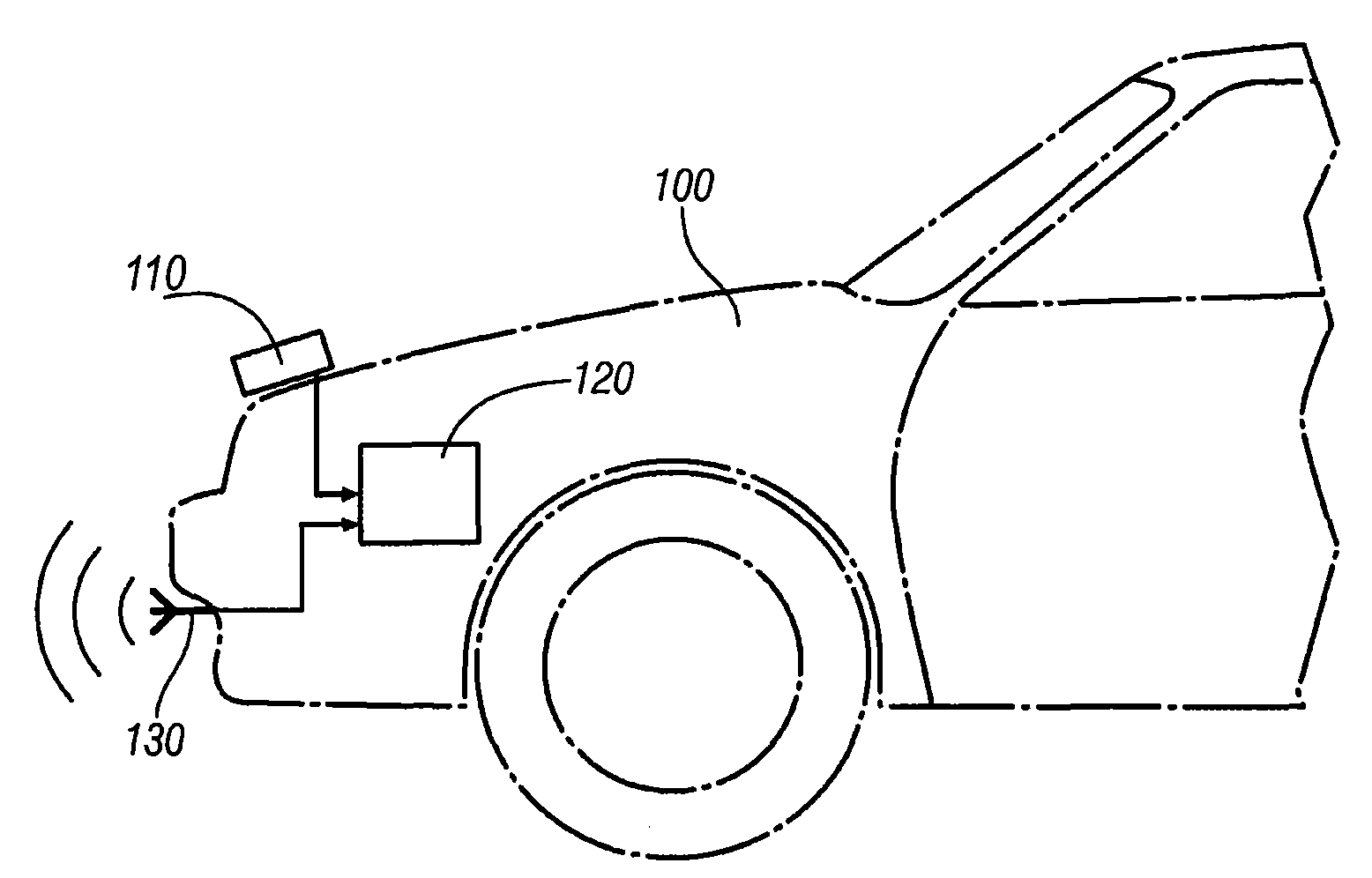

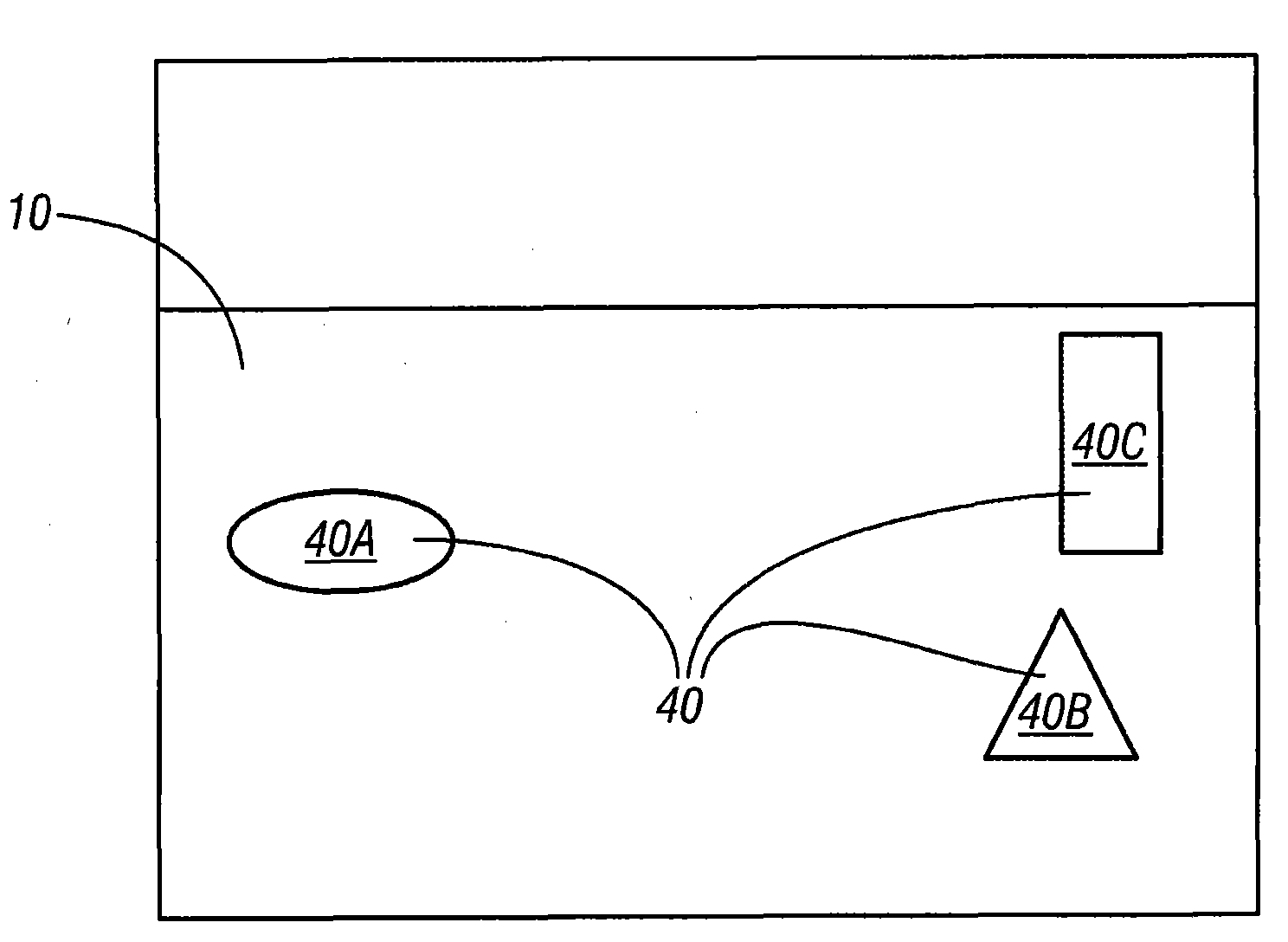

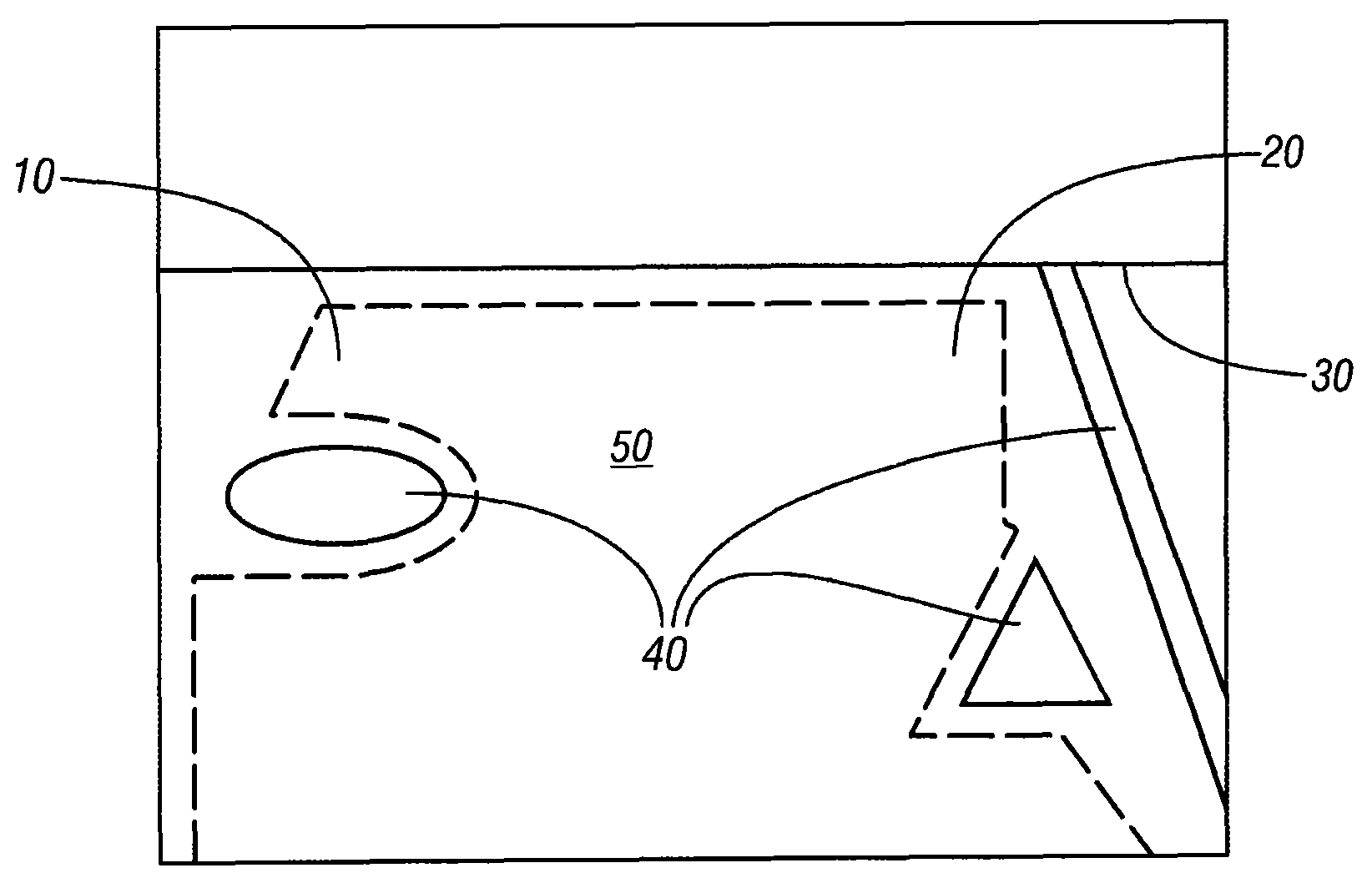

No-texture clear path detection based on pixel

ActiveCN101900567AImage enhancementInstruments for road network navigationRoad surfaceTexture processing

The invention relates to a no-texture clear path detection based on pixel. A method for detecting a clear path of travel for a vehicle by analysing a plurality of imaged generated by a camera on the vehicle, comprises: monitoring the images, wherein each image comprises pixels; analysing the images using the no-texture processing project, comprising: filtering the image to separate the image partcapable of showing the clear surface capable of estimating the latent road surface with other image part capable of not showing the latent road surface. The clear path is determined based on the clear surface and the clear path is used for operating the vehicle.

Owner:GM GLOBAL TECH OPERATIONS LLC

Image processing apparatus, image processing system, and image processing method

InactiveUS20050179695A1Efficiently perform image processingEasy to handleCathode-ray tube indicatorsImage data processing detailsImaging processingProcessing element

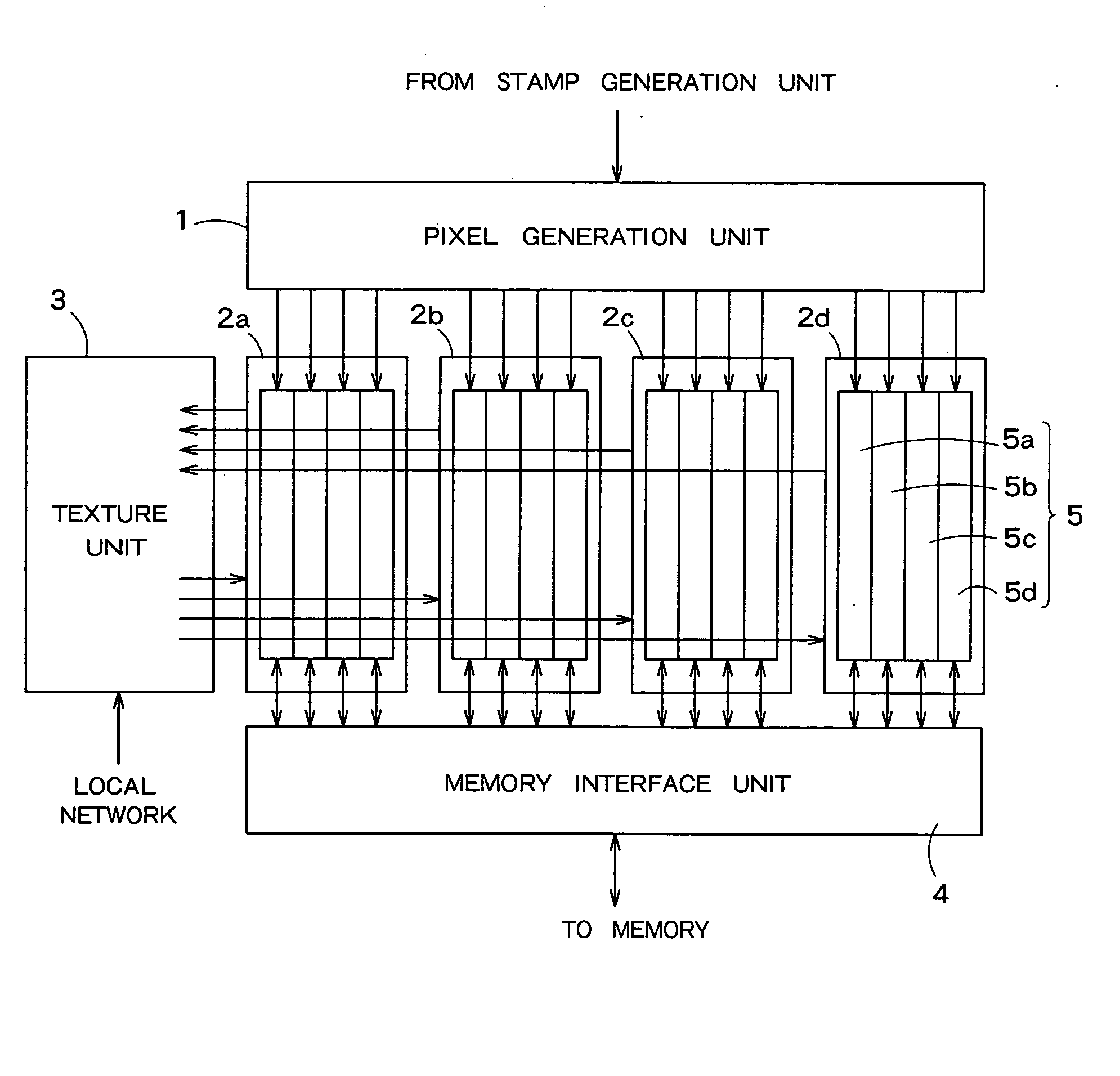

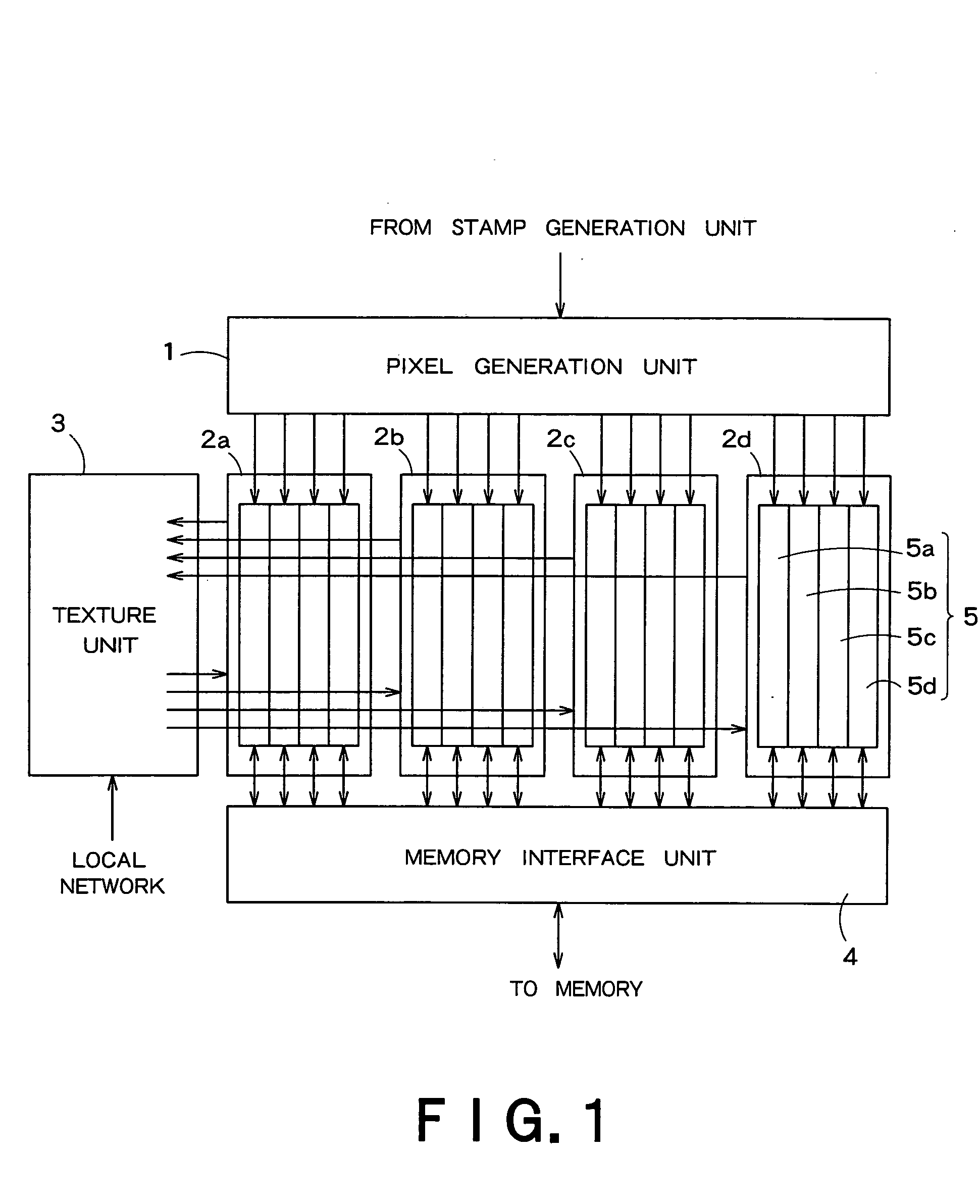

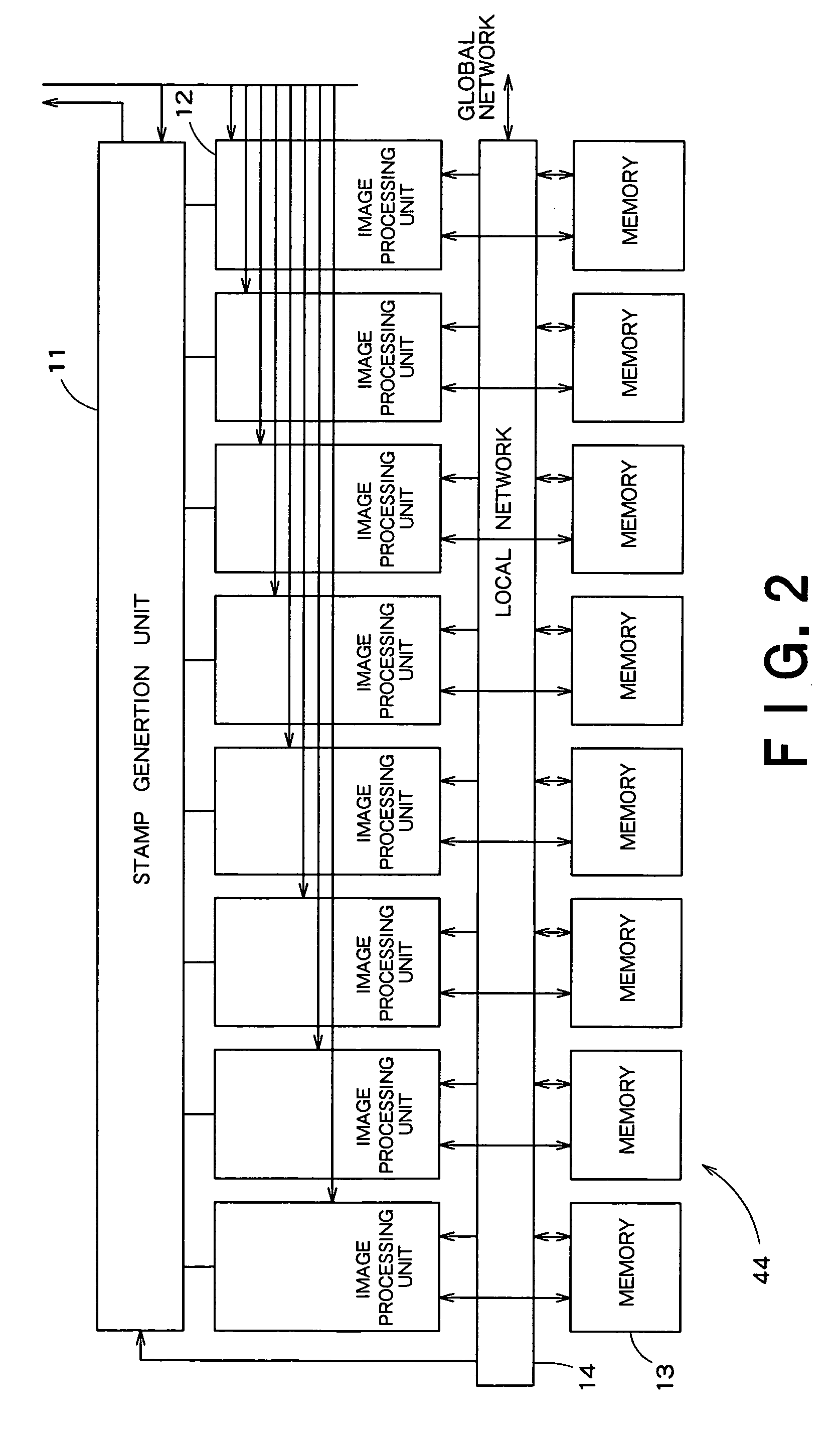

An image processing apparatus, comprising: a pixel generation unit configured to generate parameters of pixels in stamps based on values of typical pixels in the stamps having a plurality of pixels and derivatives of the parameters characterizing the image; a plurality of calculation processing units, each performing image processing of the stamps different from each other based on the parameters of the pixels generated by said pixel generation unit; and a texture processing unit configured to perform processing related to texture data in accordance with instructions from said plurality of calculation processing units, wherein each of said plurality of calculation processing units has a plurality of calculators which perform image processing of adjacent pixels in the corresponding stamp in parallel; and said pixel generation unit supplies the parameters of the adjacent pixels in the stamp which have no dependence to each other, to said plurality of calculation processing units, respectively.

Owner:KK TOSHIBA

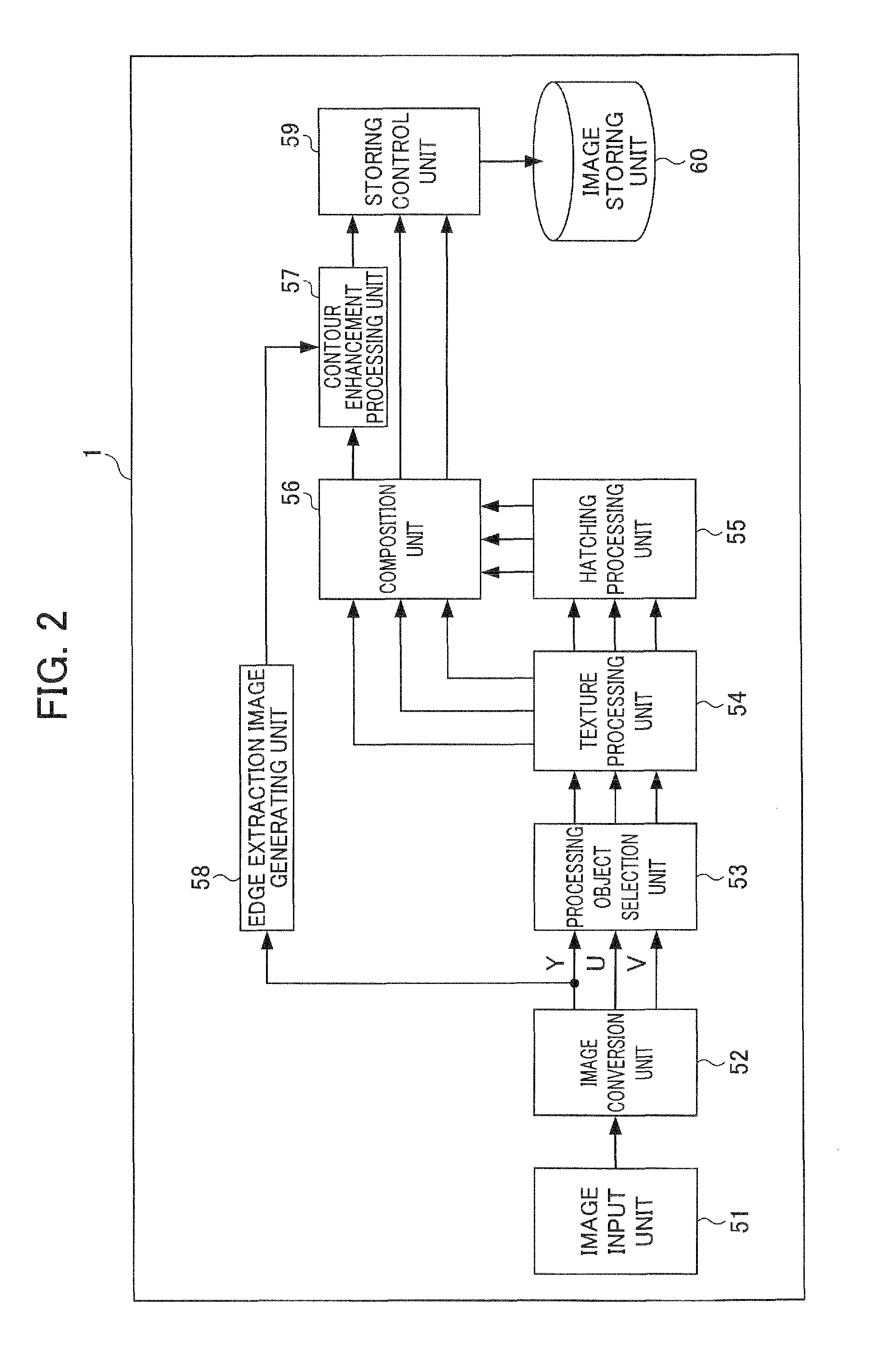

Image processing apparatus and storage medium having stored therein an image processing program

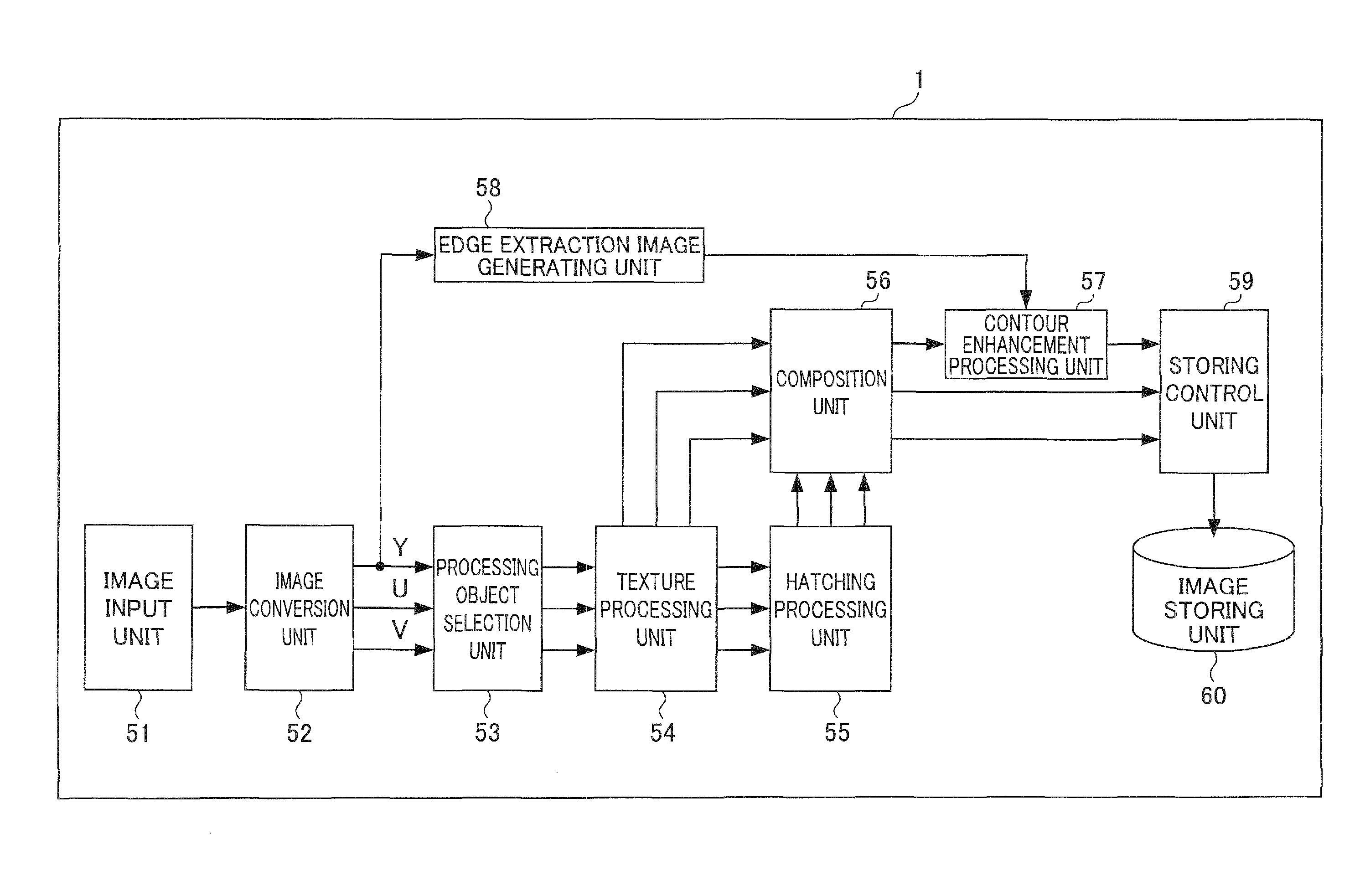

ActiveUS8289342B2High artistic qualityQuality improvementTelevision system detailsImage enhancementPattern recognitionImaging processing

A texture processing unit 54 carries out texture processing on data of a plurality of pixels selected by a processing object selection unit 53 using the same brush stroke pattern and respective colors of the pixels. A hatching processing unit 55 carries out hatching processing of adding diagonal expression substantially perpendicular to the orientation of the stroke pattern on data of an area of low luminance (i.e., dark) pixels from among the image data including YUV components using the respective colors of the pixels. The composition unit 56 carries out composition processing of compositing the image data outputted from the hatching processing unit 55 with the image data outputted from the texture processing unit 54.

Owner:CASIO COMPUTER CO LTD

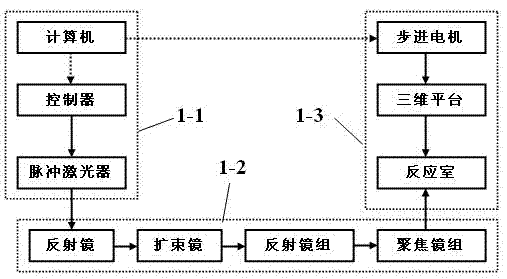

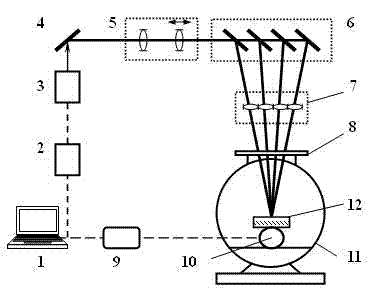

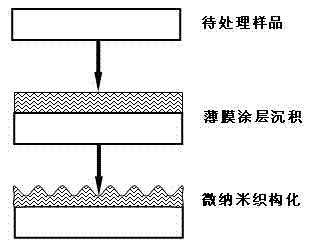

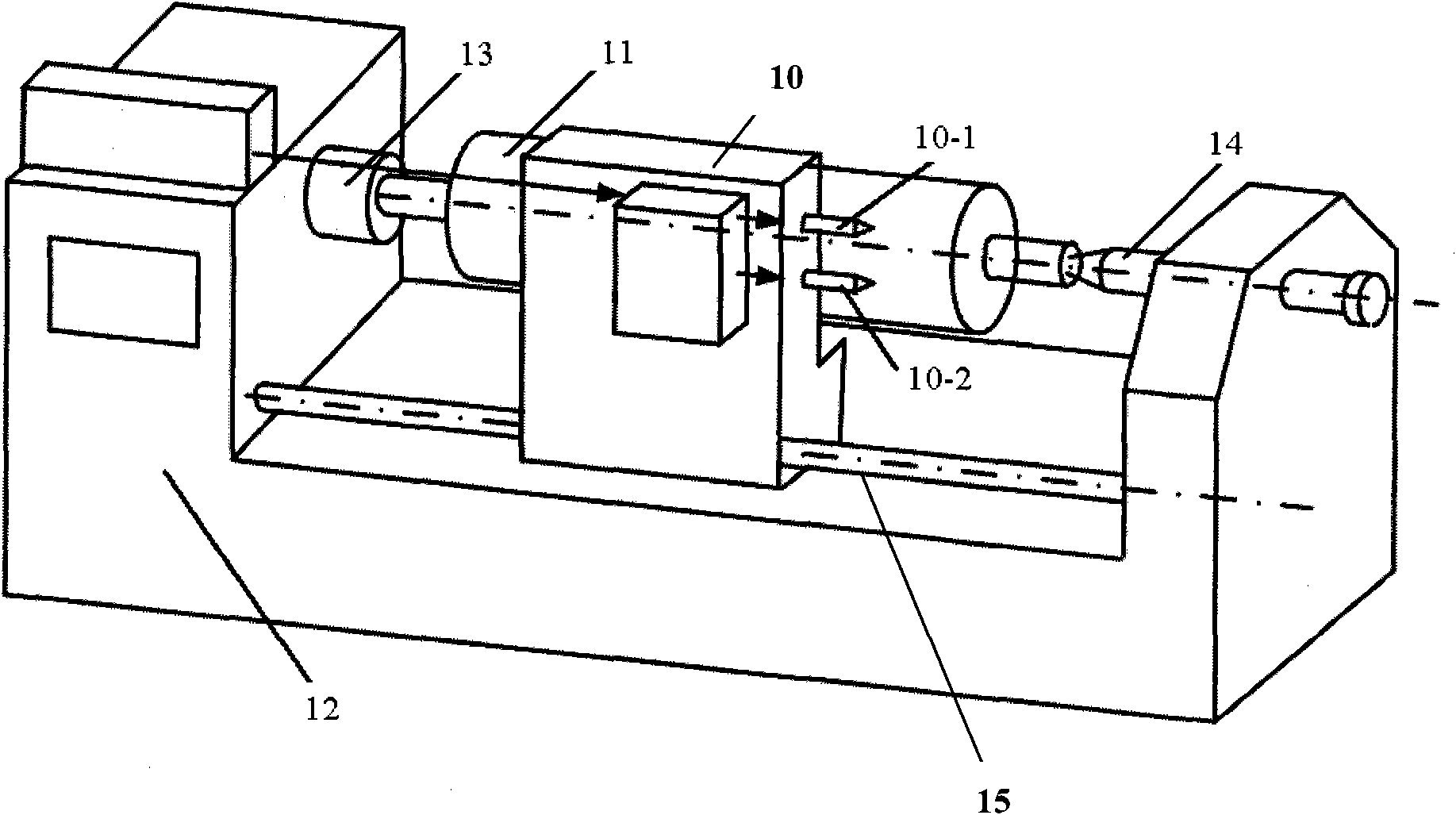

Method and device for preparing film coating micronano texture

InactiveCN102418082AImprove anti-friction and anti-wear propertiesControllable texture sizeDecorative surface effectsNanotechnologySurface engineeringChemical reaction

The invention relates to a method and a device for preparing a film coating micronano texture and belongs to a film coating of surface engineering. The preparation method comprises the steps of preparing at early stage, depositing the film coating, preparing the micronano texture and performing aftertreatment. The special device is a multi-beam pulse laser micronano texture processing system device. The multi-beam pulse laser micronano texture processing system device comprises a pulse laser module, an optical path transmission module and a precise scanning module which are connected with one another sequentially. The invention has the advantages that: the method and the device are convenient in processing and high in efficiency; preparation for the film coating deposition micronano texture on the surface of a material is realized by one laser source; the process is simple, and easy to control; the prepared samples are not subjected to a complex posttreatment process; the application range is wide; ultraviolet pulse laser has the characteristics of large photon energy and short wavelength and can perform precise micronano texture treatment on any materials; chemical reaction of various gases can be induced; and film coating deposition can be performed efficiently.

Owner:CHINA UNIV OF MINING & TECH

Laser texturing processing method on surface of roller

InactiveCN101642849AImprove rolling qualityImprove wear resistanceLaser beam welding apparatusSheet steelSlag

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized by leading focal light spots to randomly swing with low amplitude from left and right at a preset spiral line so as to produce the irregularly distributedtexturing spots on the surface of the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbed by texturing concave holes crisscross distributed on the peripheral directionof the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

Technique for performing memory access operations via texture hardware

ActiveUS20140173258A1Efficient use ofMemory architecture accessing/allocationDigital computer detailsLine tubingData access

A texture processing pipeline can be configured to service memory access requests that represent texture data access operations or generic data access operations. When the texture processing pipeline receives a memory access request that represents a texture data access operation, the texture processing pipeline may retrieve texture data based on texture coordinates. When the memory access request represents a generic data access operation, the texture pipeline extracts a virtual address from the memory access request and then retrieves data based on the virtual address. The texture processing pipeline is also configured to cache generic data retrieved on behalf of a group of threads and to then invalidate that generic data when the group of threads exits.

Owner:NVIDIA CORP

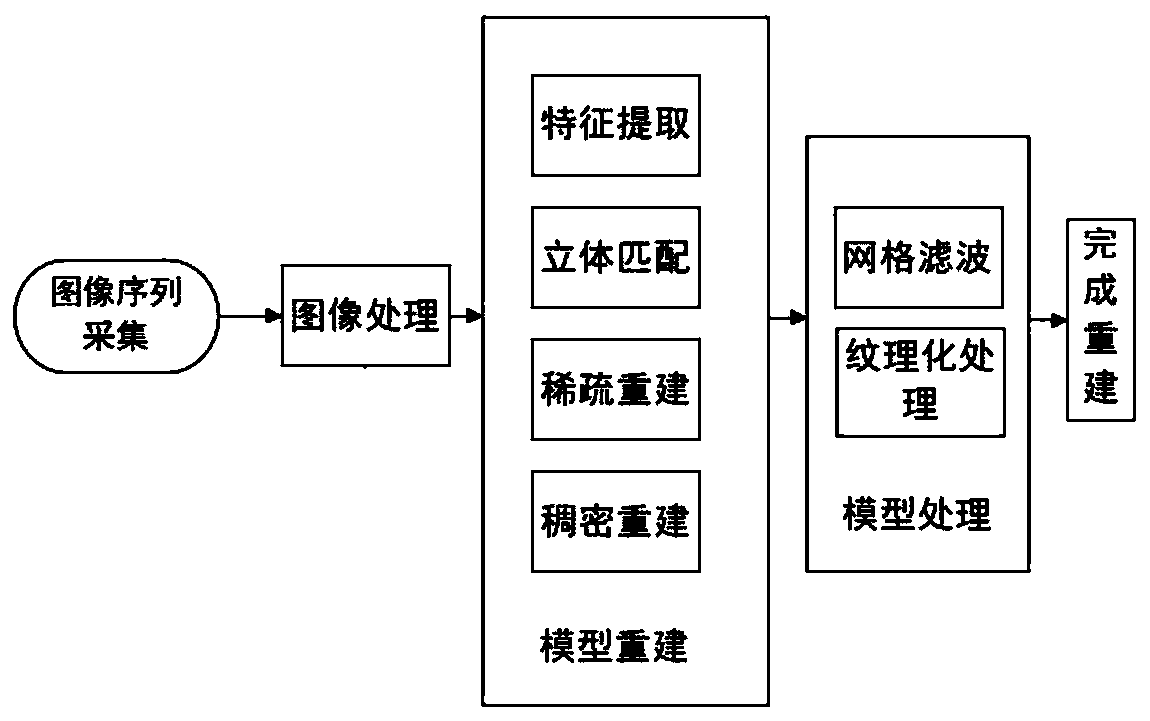

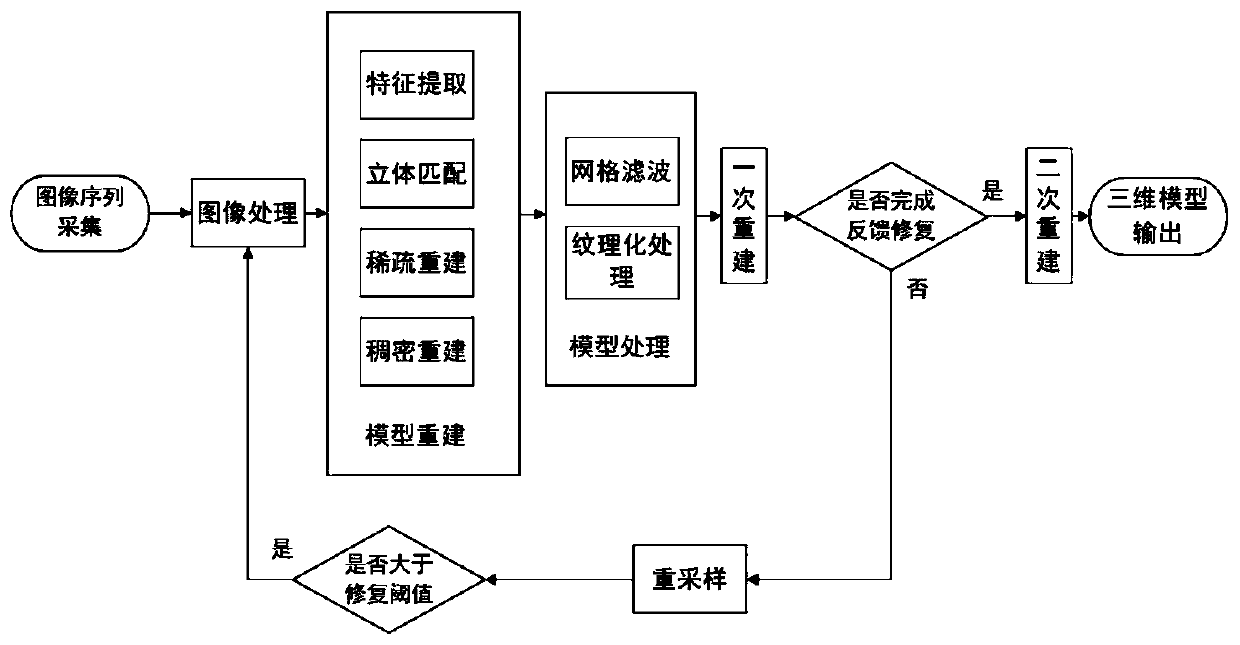

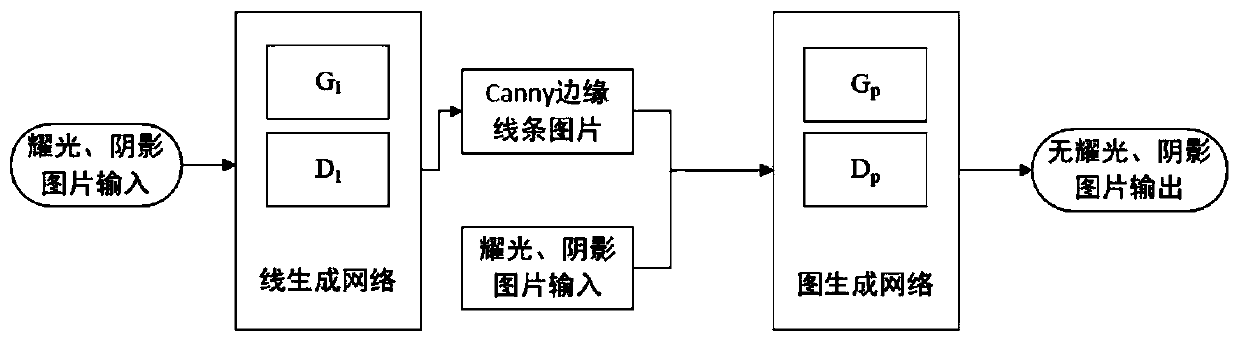

Method and device for establishing three-dimensional reconstruction model of space moving target

ActiveCN111063021AReduce distortionGood precisionImage enhancementImage analysisPoint cloudComputer graphics (images)

The invention discloses a method and a device for establishing a three-dimensional reconstruction model of a space moving target. The method comprises the following steps: acquiring a space monocularimage sequence of space debris or a failure satellite; adopting the trained generative adversarial network to train a spatial monocular image sequence so as to eliminate flare and shadow of each spatial monocular image in the spatial monocular image sequence, and generating a first image sequence; extracting a feature value matching relationship between each image in the first image sequence and other images through a scale invariant feature transformation method; establishing a three-dimensional model sparse point cloud of the space debris or the failure satellite according to the characteristic value matching relationship; generating a three-dimensional model grid model according to the three-dimensional model sparse point cloud, and sequentially performing grid filtering and texturing processing on the three-dimensional model grid model to obtain a three-dimensional reconstruction model of space debris or a failure satellite; according to the invention, the problem of distortion ofthe three-dimensional reconstruction model when the three-dimensional reconstruction model of the spatial moving target is reconstructed according to the spatial monocular image sequence can be solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com