Patents

Literature

57 results about "Built up edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In single point cutting of metals, a built up edge (BUE) is an accumulation of material against the rake face, that seizes to the tool tip, separating it from the chip.

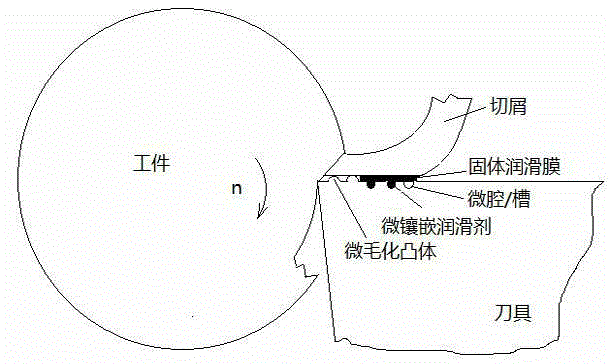

Preparation method of cutter surface antisticking antifriction micro mosaic composite texture

InactiveCN103111819AIncreased durabilityImprove cutting efficiencyManufacturing technologyBuilt up edge

The invention discloses a preparation method of a cutter surface antisticking antifriction micro mosaic composite texture and belongs to the technical field of mechanical cutting tool manufacture. The preparation method comprises the steps of carrying out texturing overlaid and microcavity / groove composite texture processing on the working surface of a cutter by using laser, and filling solid lubricant into the microcavity / groove texture of the cutter surface in a pressed and embedded mode. The preparation method of the cutter surface antisticking antifriction micro mosaic composite texture overcomes monotony of the existing cutter texture method, improves aintisticking performance of the front cutter surface of the cutter, preventing generation of a built-up edge, performs the function of storing and conveying of the texturing overlaid and microcavity / groove composite texture on cutting fluid, performs cooling and lubrication action on the cutter and achieves the purposes of improving durability and cutting efficiency of the cutter and ensuring machining quality of a workpiece surface.

Owner:JIANGSU UNIV

Laser compound strengthening technology

InactiveCN103060528AIncrease the residual compressive stressEase of productionFurnace typesMetallic material coating processesShock waveHeat transmission

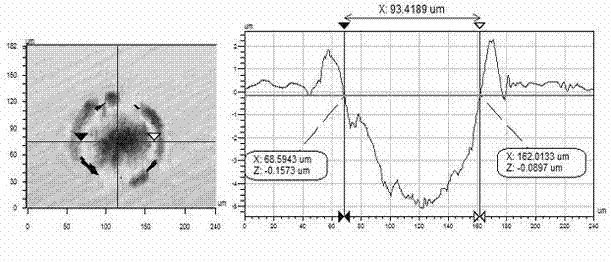

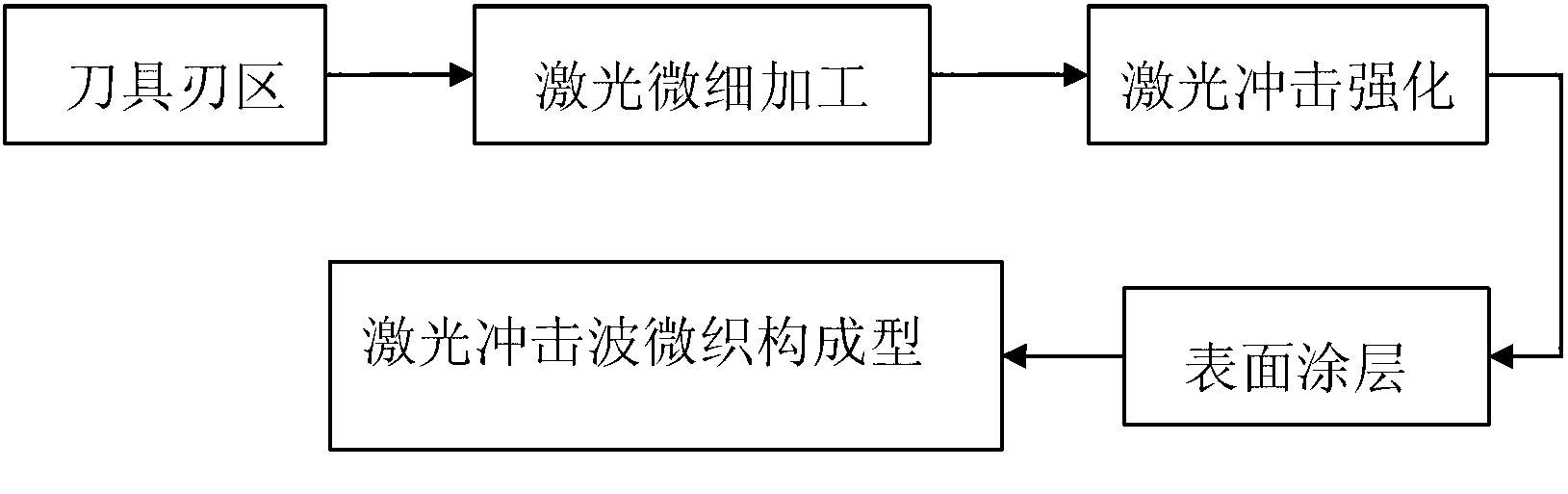

The invention provides a laser compound strengthening technology, which comprises the following steps of (1) carrying out femtosecond laser micro machining on a blade area of a hard alloy cutter, so as to obtain pits arranged in certain sequence; (2) carrying out laser shock peening in the blade area of the hard alloy cutter; (3) coating on the surface of the cutter after laser shock peening; and (4) carrying out laser shock wave microtexture forming process on the blade area of the coated hard alloy cutter, so as to obtain a laser compound strengthening model. The laser compound strengthening technology comprises four steps, namely, laser micro machining, laser chock peening, surface coating, and the laser shock wave microtexture. According to the laser compound strengthening technology, residual compressive stress, infiltration characteristic, heat transmission, cooling and lubricating conditions of the blade area can be obviously improved, built-up edges and burrs are reduced, and nickel base material is prevented from being attached to the surface of the cutter, so that the service life of the cutter is prolonged, and the stability of the manufacture quality is improved.

Owner:WENZHOU UNIVERSITY +2

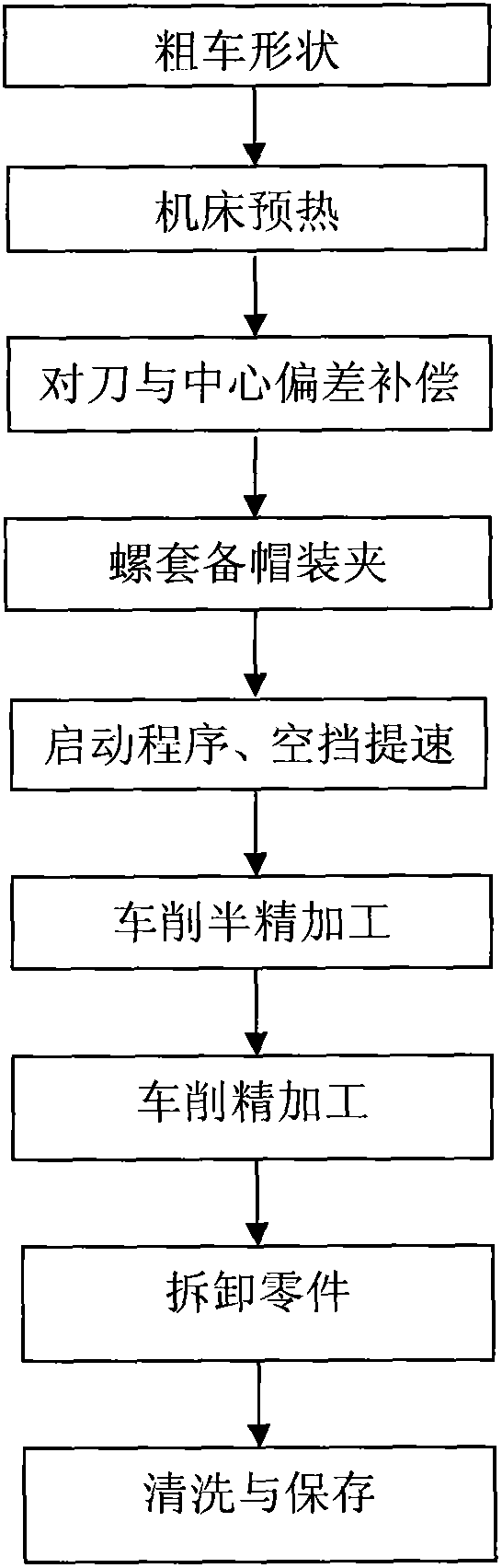

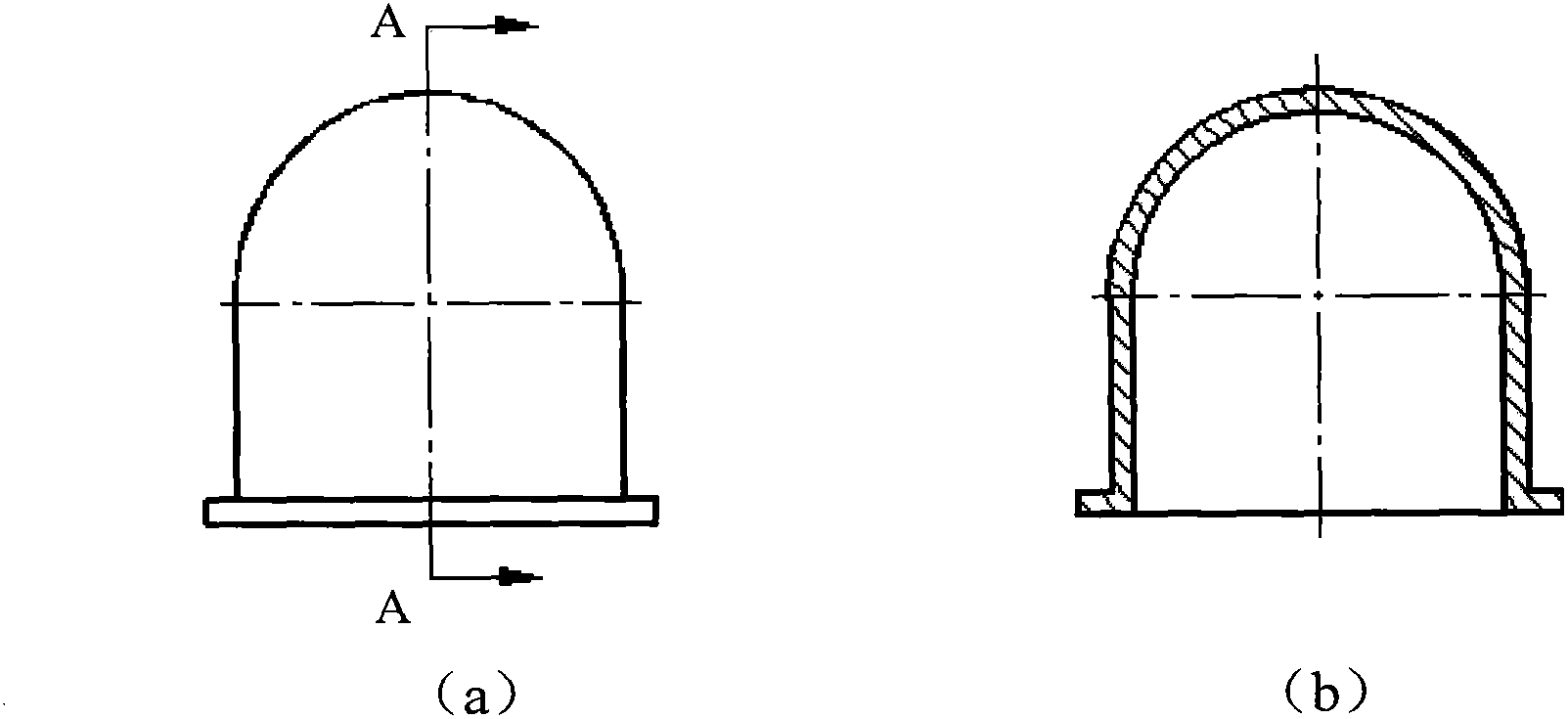

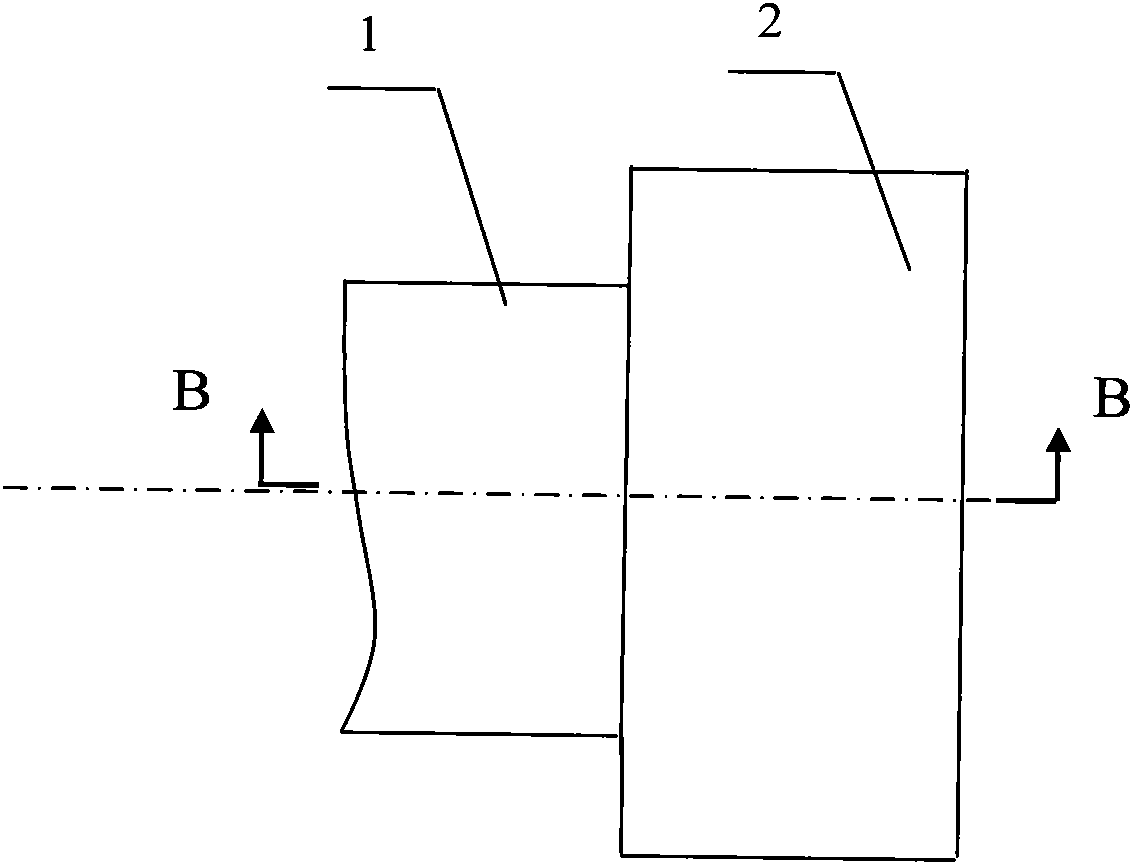

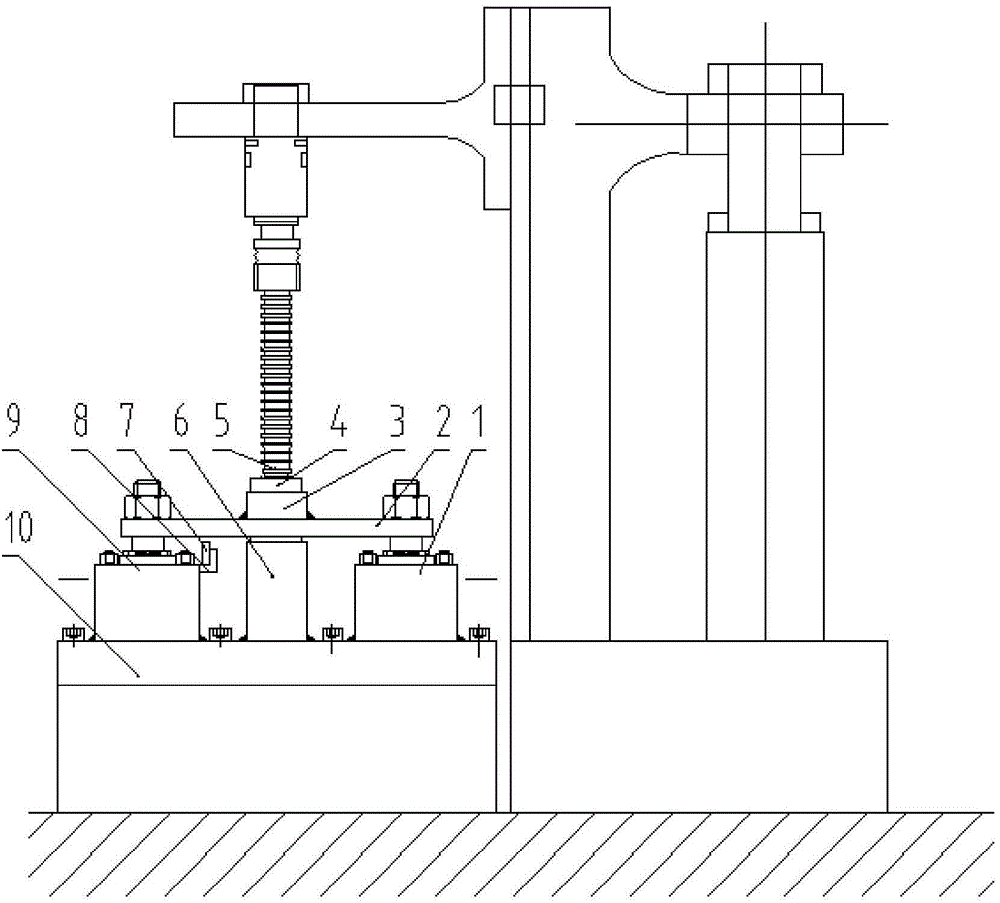

Precision finishing method of inner spherical surface of high-purity aluminum thin-wall part

The invention belongs to the processing technology of a precise component made from special material, and relates to a processing method of a high-purity aluminum precise element. In the invention, the high-purity aluminum thin-wall part is clamped on a spindle of a numerical control machine through a screw sleeve cap and quakeproof improvement so as to achieve the purposes of accurately positioning based on an end surface and simultaneously improving the radial force; reasonable tool structure parameters for cutting the high-purity aluminum material are obtained by early research so as to improve the previous tool; then a reasonable tool setting method is adopted so that the central point of the tool is precisely meshed with the center of a workpiece; and numerically-controlled turning processing is performed. Compared with the previous processing methods, the processing method of the high-purity aluminum precise part provided by the invention can be used for changing the condition that the high quality of surface of a part cannot be obtained before, and overcoming the problems of deformation, vibration, wave, built-up edge and the like in the processing, so that the inner spherical surface of the part reaches the level of a mirror bright surface and the requirements on light reflection are met; and moreover, the processing quality is stable, and the efficiency is high.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

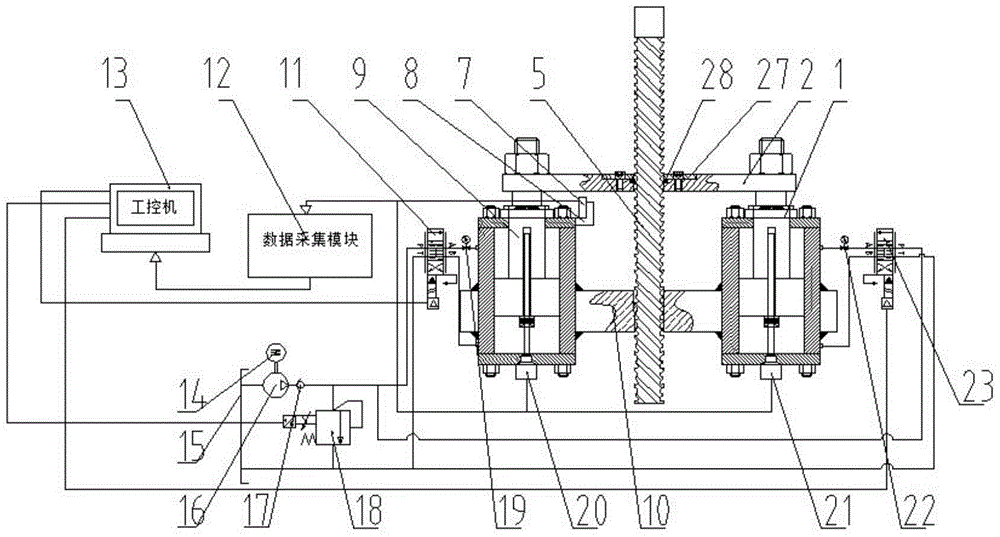

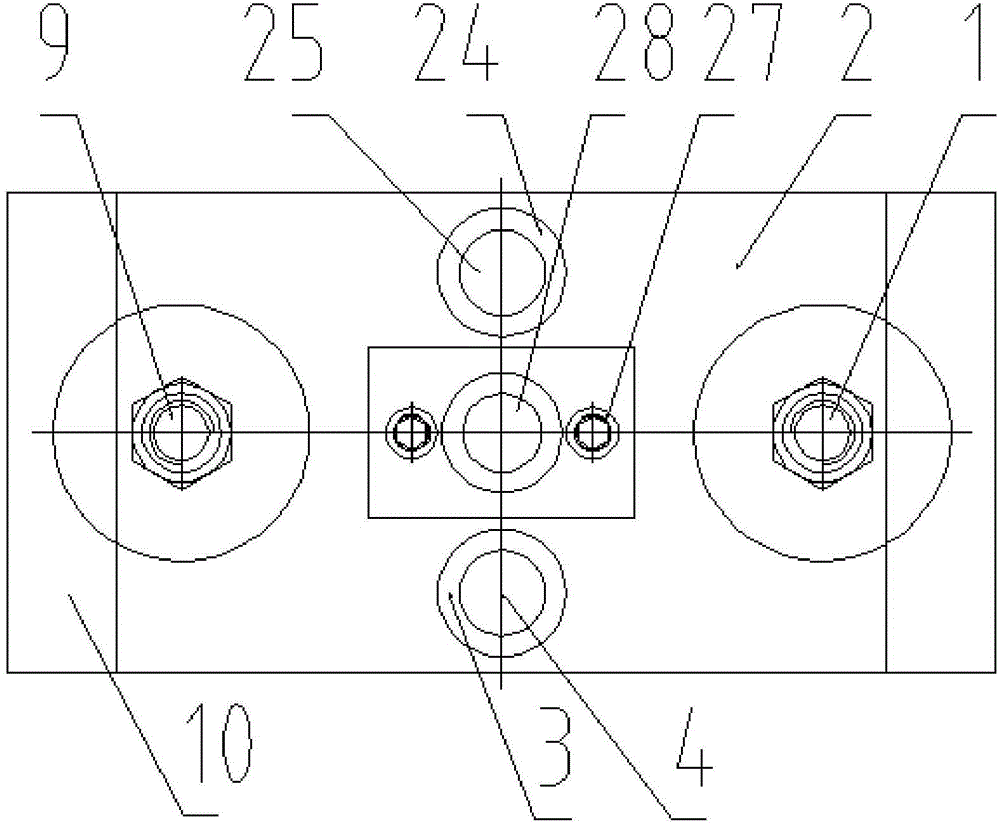

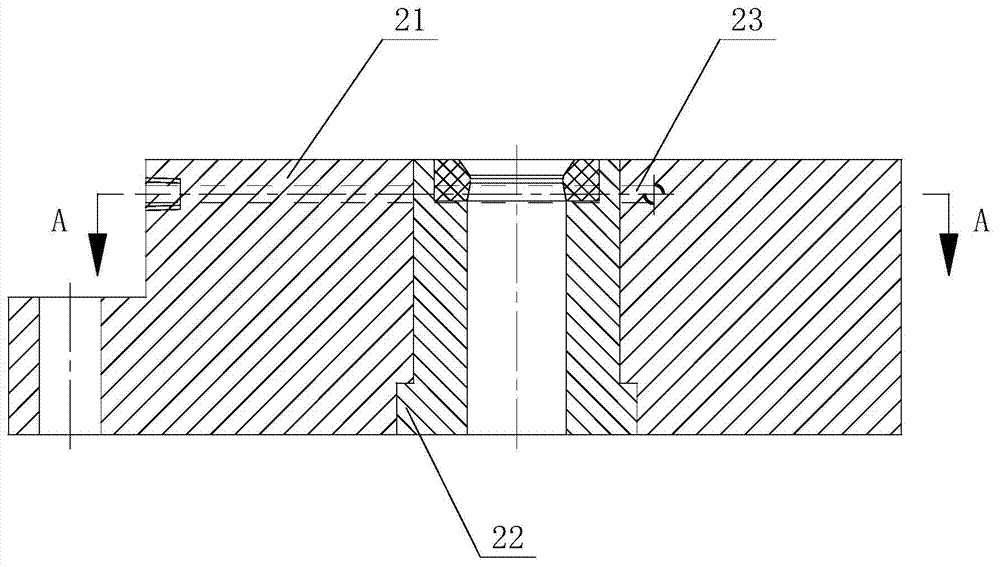

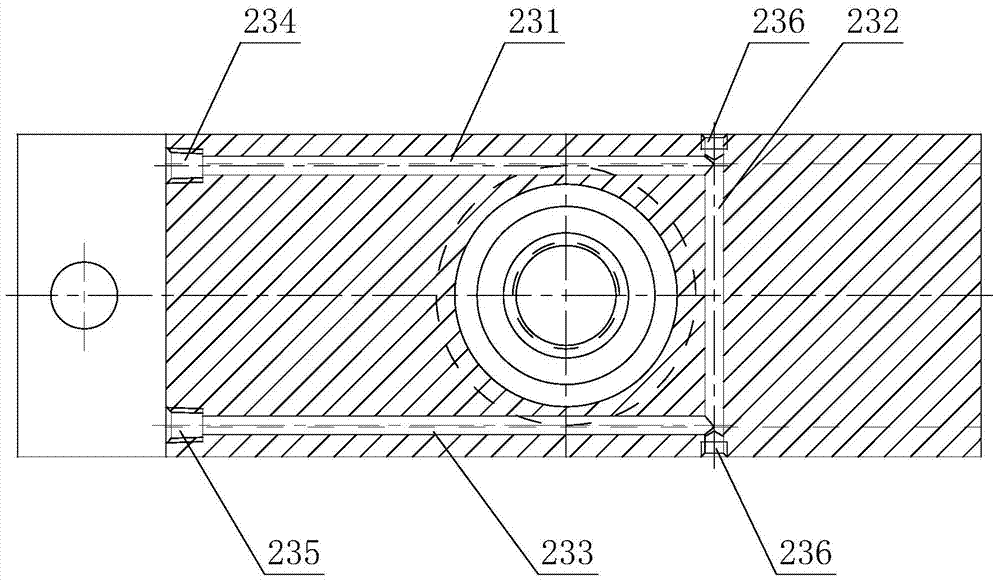

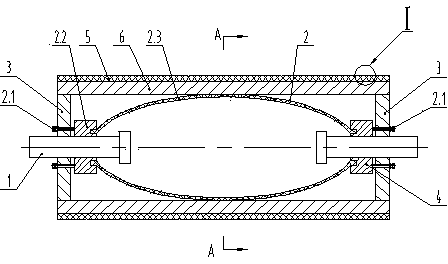

Double-cylinder electro-hydraulic servo synchronous excitation cutting device and method

InactiveCN104525462AImprove processing qualityExtend your lifeServomotorsMechanical vibrations separationHydraulic pumpBuilt up edge

The invention discloses a double-cylinder electro-hydraulic servo synchronous excitation cutting device and a double-cylinder electro-hydraulic servo synchronous excitation cutting method. The device includes a first vibration hydraulic cylinder, a workbench, a first guide pillar guide sleeve, a first guide pillar, a first guide pillar fixing sleeve, an eddy current sensor, a sensor support, a second vibration hydraulic cylinder, a pedestal, a first servo valve, a data acquisition module, an industrial personal computer, an electromotor, an oil source, a hydraulic pump, a check valve, an overflow valve, a first pressure flow sensor, a first piston displacement sensor, a second piston displacement sensor, a second pressure flow sensor, a second servo valve, a second guide pillar guide sleeve, a second guide pillar, a second guide pillar fixing sleeve and a fixture. According to the double-cylinder electro-hydraulic servo synchronous excitation cutting device, high-frequency and periodical contact and separation phenomena of a tool and a workpiece occur during a cut machining process, and through the separation property of the tool and the workpiece, the effects on improving the machining quality of the workpiece, prolonging the service life of the tool, improving the surface smoothness of the cutting surface and reducing the built-up edge are achieved.

Owner:HANGZHOU DIANZI UNIV

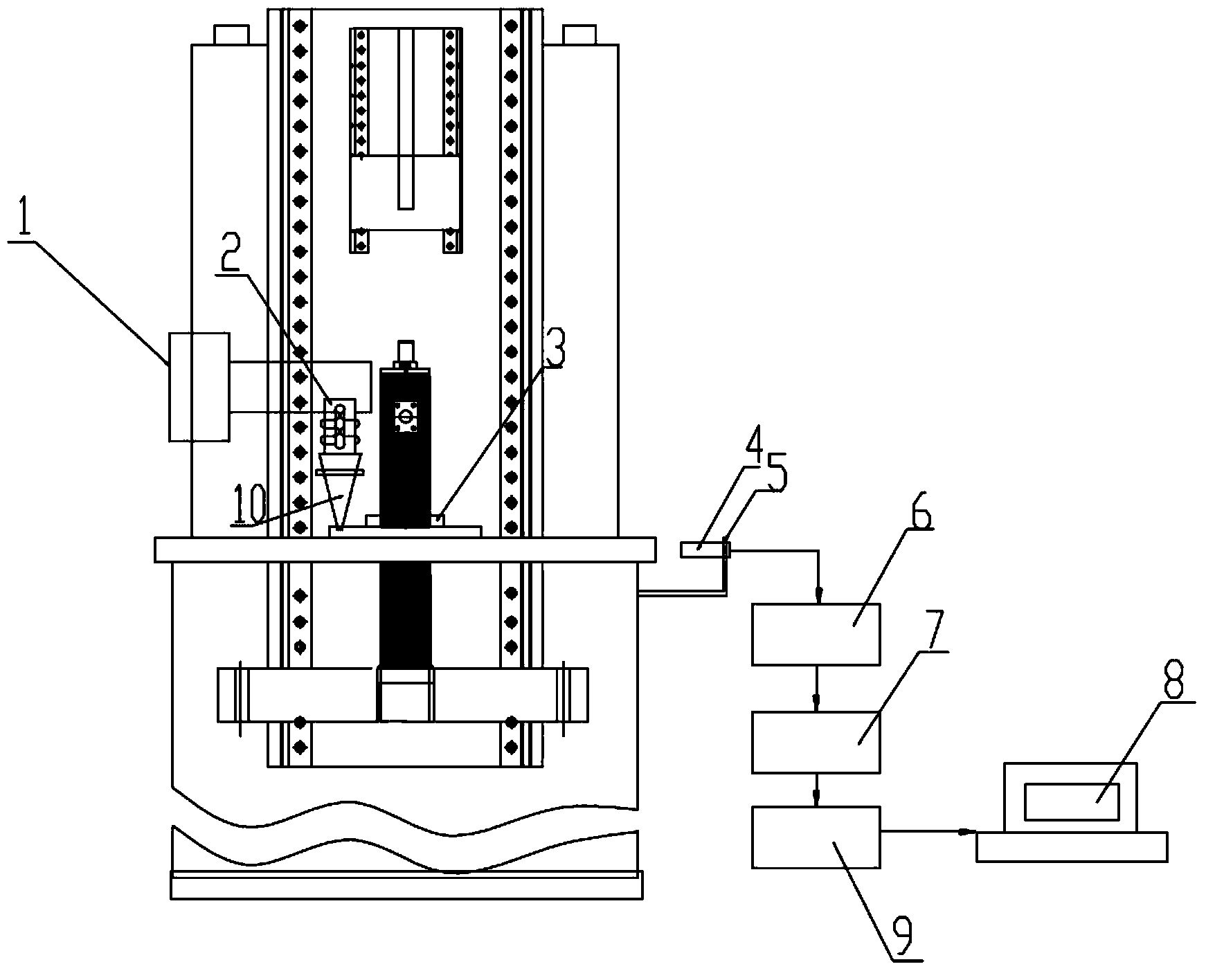

Device for broaching workpiece with help of additional ultrasonic vibration

InactiveCN103962629AImprove processing qualityImprove the finishBroaching machinesBuilt up edgeData acquisition

The invention discloses a device for broaching a workpiece with the help of additional ultrasonic vibration. In the prior art, an existing device is complex in structure and not high in accuracy. The device comprises an ultrasonic generator, an ultrasonic energy exchanger, a working table, an eddy current sensor, a sensor support, an ultrasonic amplitude-change pole, a front amplifier, a conversion plate, a data acquisition card and an industrial personal computer. During broaching, a tool and the workpiece make contact with each other and are separated from each other periodically at a high frequency; it is quite different from that the tool and the workpiece make contact with each other all the time during normal broaching. During ultrasonic vibration broaching, the effects of improving workpiece machining quality, prolonging the service life of a broach, improving broaching surface smoothness and reducing built-up edges on the broach can be achieved according to the characteristic that the tool and the workpiece can be separated from each other.

Owner:HANGZHOU DIANZI UNIV

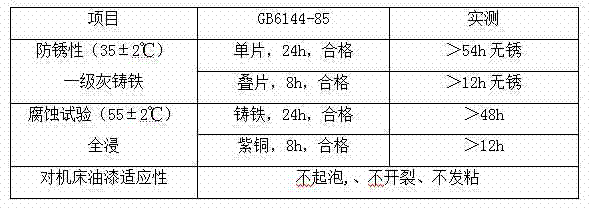

High-property microemulsion cutting liquid

InactiveCN104531308AStrong anti-friction and extreme pressure performanceInhibitionLubricant compositionFriction reductionPolymer science

The invention discloses a high-property microemulsion cutting liquid which is characterized by being prepared from the following raw materials in percentage by weight: 10-30% of mineral oil, 3-15% of a lubrication extreme pressure agent, 5-10% of an anti-rusting agent, 5-12% of a surfactant, 0.2-3% of a corrosion inhibitor, 0.2-2% of an antibacterial anti-mould agent and the balance of water. The high-property microemulsion cutting liquid disclosed by the invention is free of phosphorus, sulfur and chlorine type extreme pressure additives, the microemulsion cutting liquid prepared according to the formula is very high in friction reduction extreme pressure resistance and good in cleaning effect; the generation of scale-fins and built-up edges can be effectively inhibited, adhesion or abrasion of cutting tools is prevented, the surface machining precision is improved, the service life of the cutting tools is prolonged, the cooling property of the machining process can be met, and due to unique formula design, the microemulsion cutting liquid is very high in biological stability, long in use period and free of irritation or pollution.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

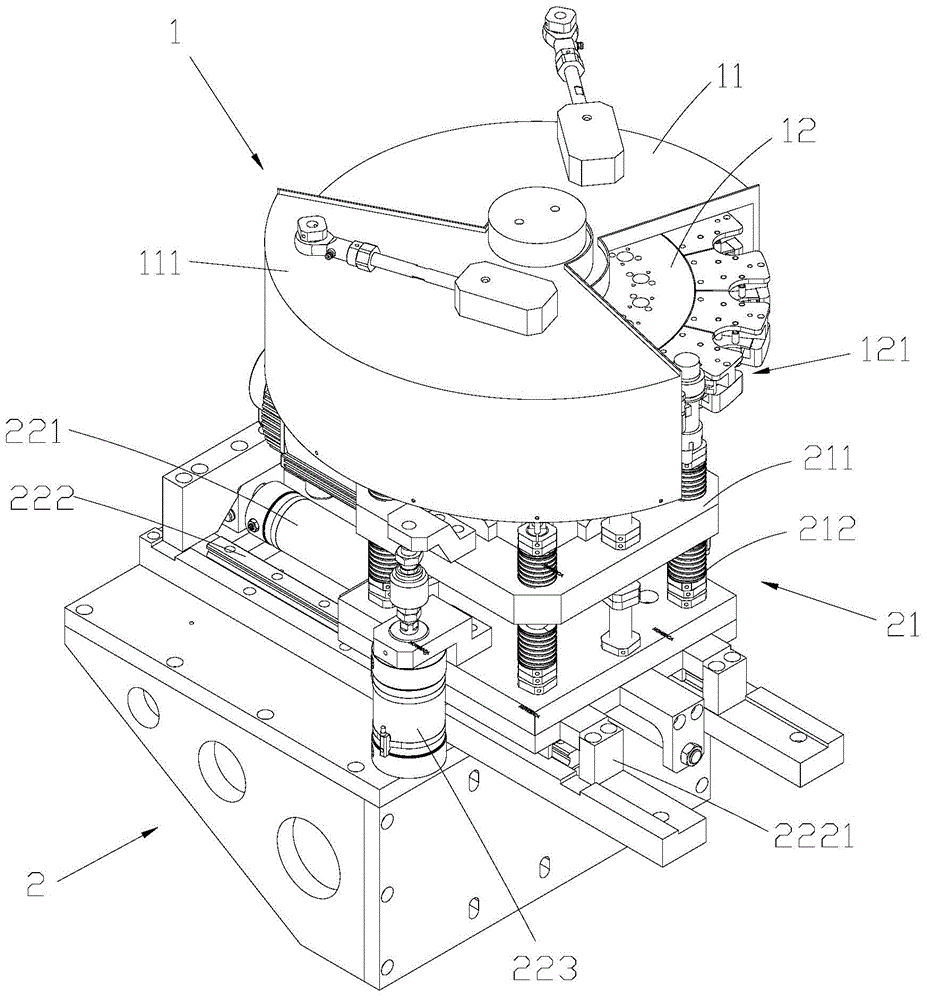

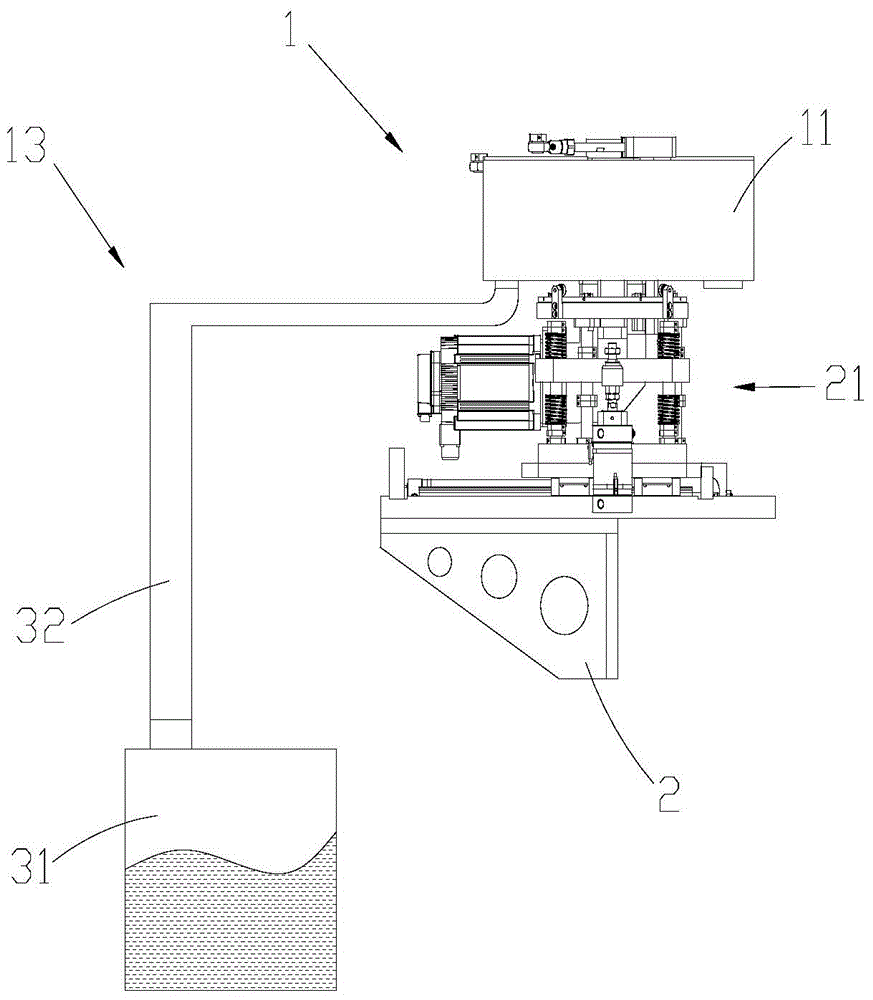

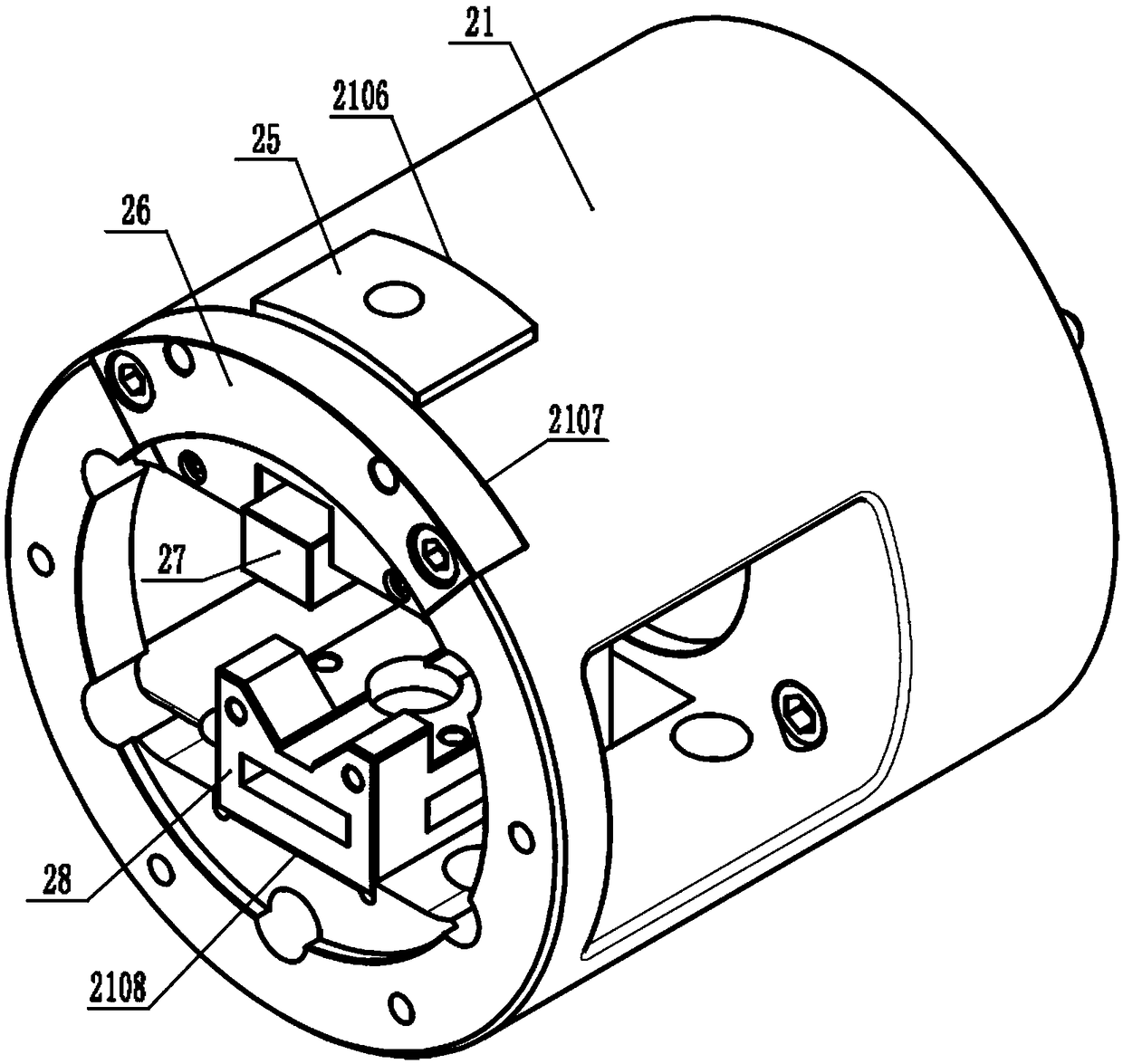

Self cleaning magazine tool and machine tool

ActiveCN105312945AEliminate accumulated tumorsImprove machining accuracyPositioning apparatusMaintainance and safety accessoriesBuilt up edgeEngineering

The invention relates to the technical field of non-ferrous metal mirror surface processing, and discloses a self cleaning magazine tool and a machine tool, wherein the self cleaning magazine tool is arranged on the machine tool, is used for storing a cutter and cleaning built-up edges on the cuter and comprises a cutterhead; a plurality of cuter positions capable of fixing the cutter are arranged on the cutterhead; the self cleaning magazine tool also comprises a cleaning cabin, an ultrasonic wave generator and a circulation structure; the ultrasonic wave generator is arranged on the cleaning cabin; the circulation structure can provide cleaning liquid for the cleaning cabin; the cutterhead is positioned in an inner cavity of the cleaning cabin; the cleaning cabin is provided with a notch exposing the cutter positions; the notch part is provided with an opening / closing structure capable of being opened and closed. The self cleaning magazine tool has the advantages that after the cutter is stored into the self cleaning magazine tool, the cleaning is performed through the ultrasonic wave generator and the cleaning liquid; cut chips on the cutter are prevented from being accumulated to form the built-up edges; the long-service-life and efficient high-precision processing of the cutter can be maintained.

Owner:SHENZHEN SEEKOO TECH

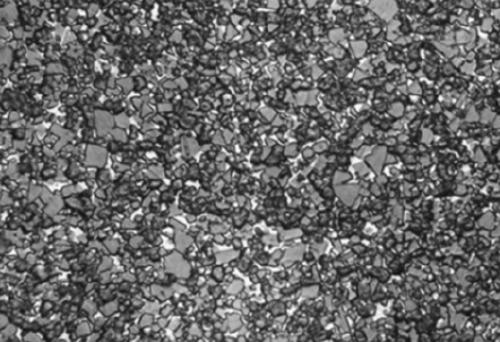

TiC-1 hard alloy and preparation method thereof

The invention discloses a TiC-1 hard alloy and a preparation method thereof, which relate to the technical field of manufacturing of alloys and are used for solving the problems of easiness in producing built-up edges and crescent depression wear existing in the conventional WC-Co alloy. The TiC-1 hard alloy comprises the following components in percentage by weight: 6.8-7.2 percent of Ni, 2.8-3.2 percent of Mo and the balance of TiC.

Owner:成都科力铁硬质合金有限公司

Cold-rolled silicon steel normal-temperature zero-release oil removal agent and preparation method thereof

The invention discloses a cold-rolled silicon steel normal-temperature zero-release oil removal agent. The oil removal agent is prepared from 100-150 parts by weight of organic bionic acid, 80-120 parts by weight of a biological ferment, 10-30 parts by weight of a bio-enzyme, 5-10 parts by weight of a surfactant and 5-10 parts by weight of a sterilization algicide. The oil removal agent does not contain phosphorus, sodium and other metal ions, does not contain persistent organic pollutants, can undergo a decomposition reaction with acid, base, oil and ferric oxide, brightens the cleaned product and produces the final decomposition products such as water and carbon dioxide. The oil removal agent does not contain any metal ions. The cleaned metal ions and calcium and magnesium ions are complexed and do not produce precipitates so that the silicon steel cleaning spray water and a cleaning agent diluent can be recycled until thorough natural consumption. The oil removal agent has a strong ion complexing capacity, hardly produces precipitates, has a strong effect of cleaning water scales and blue-green algae of a cleaning tank and does not produce built-up edges on a cleaning roller, a driving roller and a magnesium oxide coated roller.

Owner:ZHEJIANG HUAYING STEEL TECH CO LTD

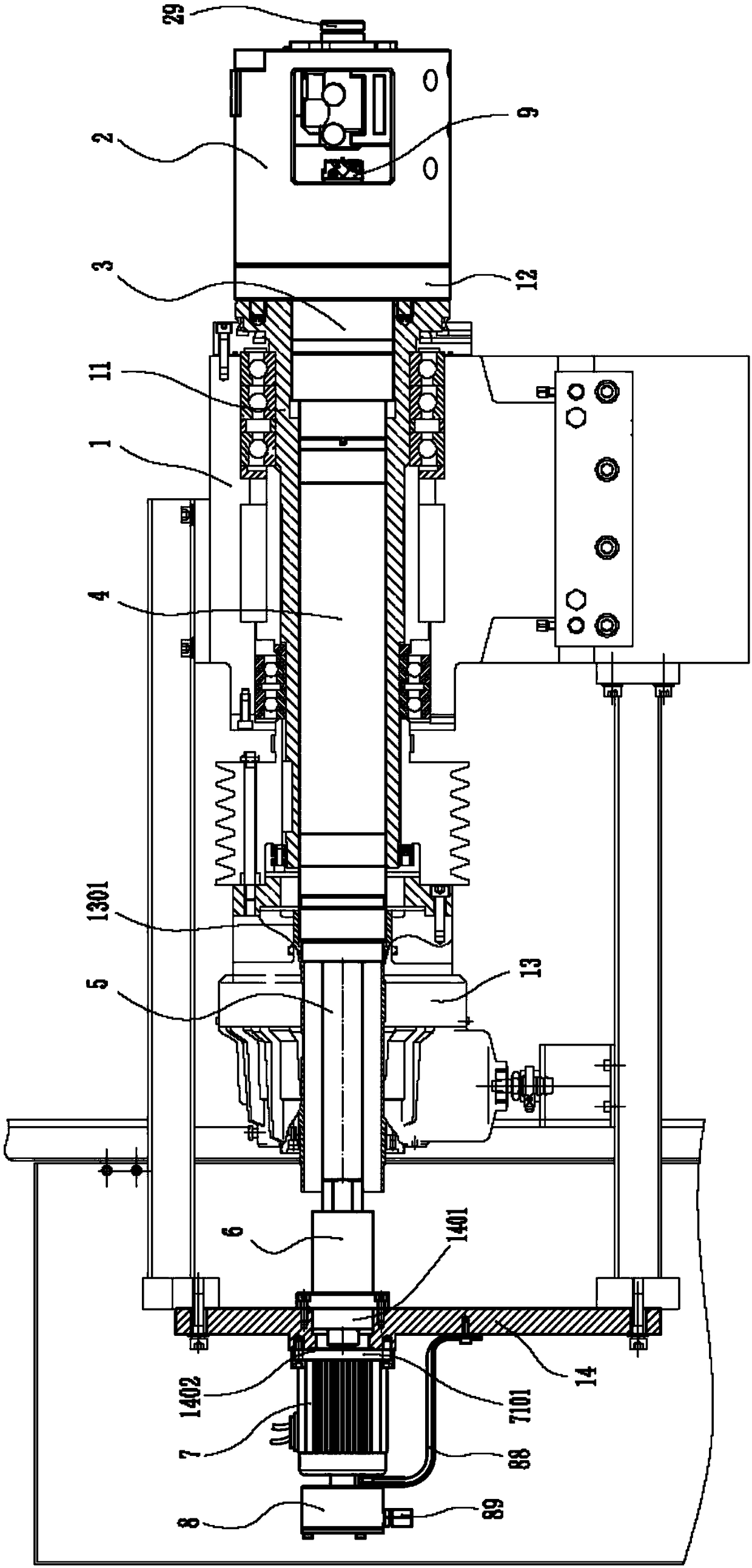

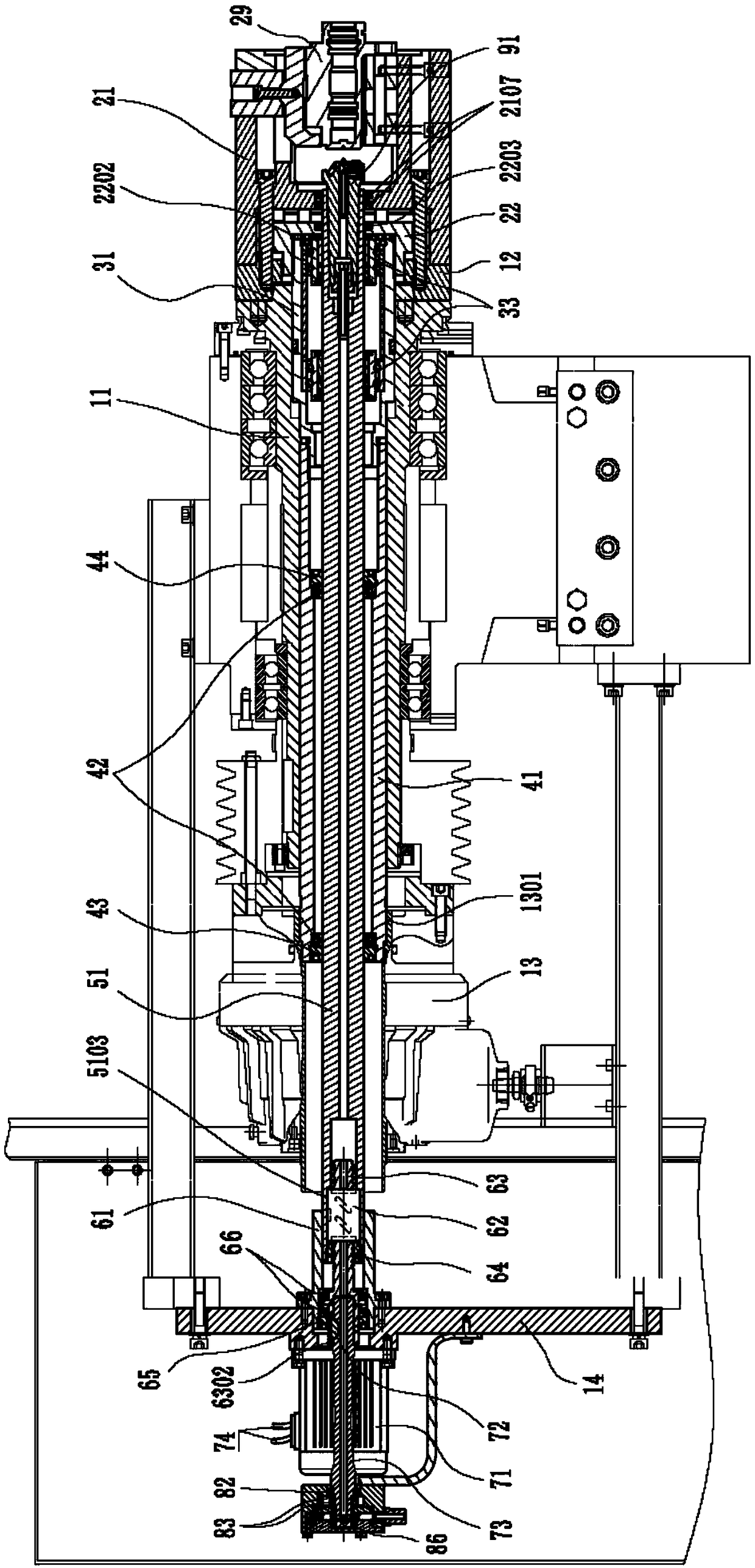

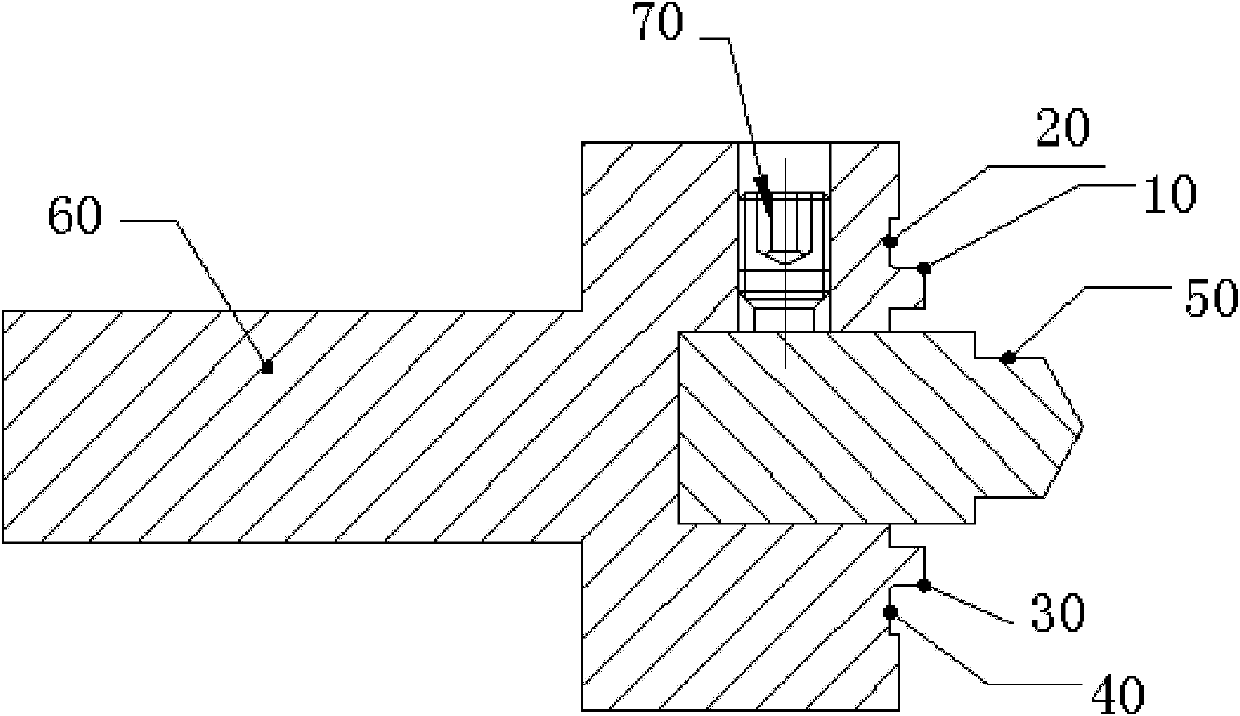

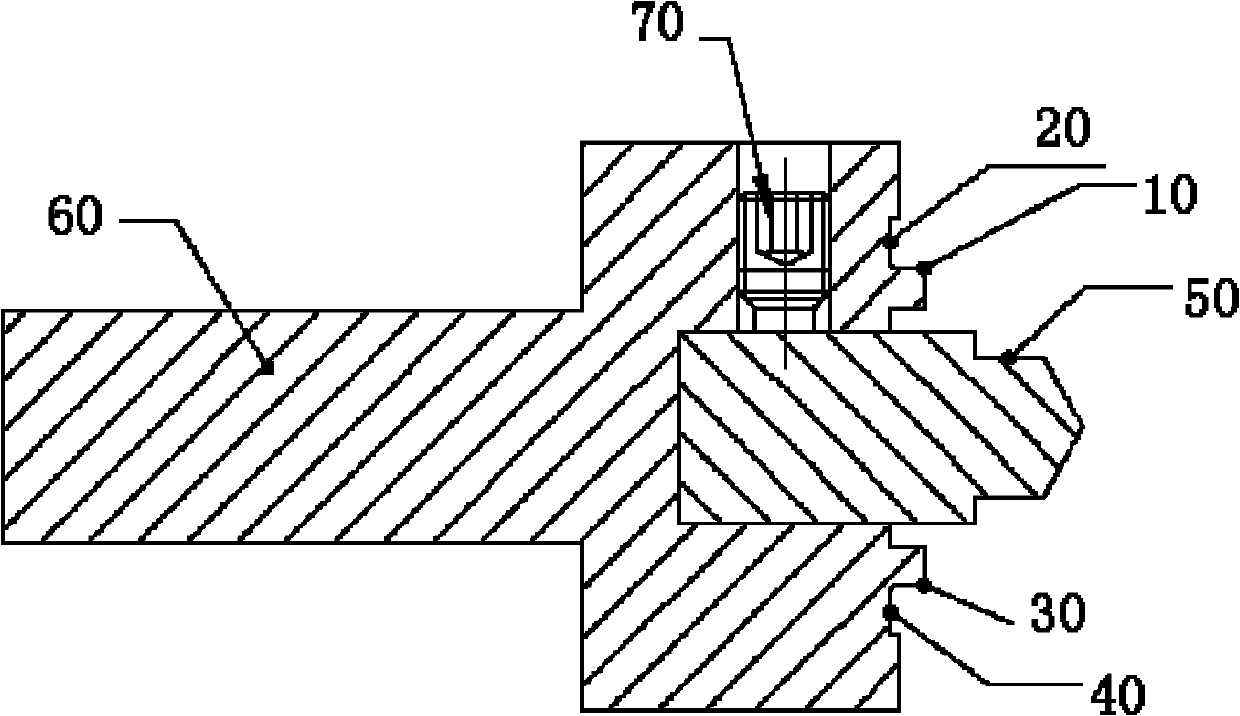

Numerically controlled lathe spindle drilling device

ActiveCN108941627AReduce labor intensitySimple processTransportation and packagingWork clamping meansFriction reductionBall bearing

The invention relates to a numerically controlled lathe spindle drilling device, and belongs to drilling devices. The numerically controlled lathe spindle drilling device comprises a numerically controlled lathe, a clamp, a supporting sleeve, a pull pipe, a mandrel, a ball screw pair, an improved servo motor, a liquid flow device and a drilling taper shank combined cutter. According to the numerically controlled lathe spindle drilling device, a deep groove oilless combined ball bearing is arranged, so that the assembling precision and strength of the mandrel are improved, moreover, the mandrelis not limited by high-speed rotation of a machine tool spindle in a bearing hole, the axial reciprocating motion is free, the friction is reduced, the cutting stability of the cutter is improved, acutting fluid of the drilling device enters a cutting area through a liquid conveying hole inside the drilling device, so that the cutter and a workpiece are cooled, the cutting deformation is reduced, a built-up edge is prevented from being generated, the service life of the cutter is prolonged, and the product quality is improved; the drilling device has the advantages that the workpiece is clamped once, the two ends of the workpiece can be machined at the same time, multiple passes of working procedures are completed, the process can be optimized, the process flow can be shortened, the production efficiency can be improved, and the labor intensity of workers can be reduced.

Owner:长春科技学院

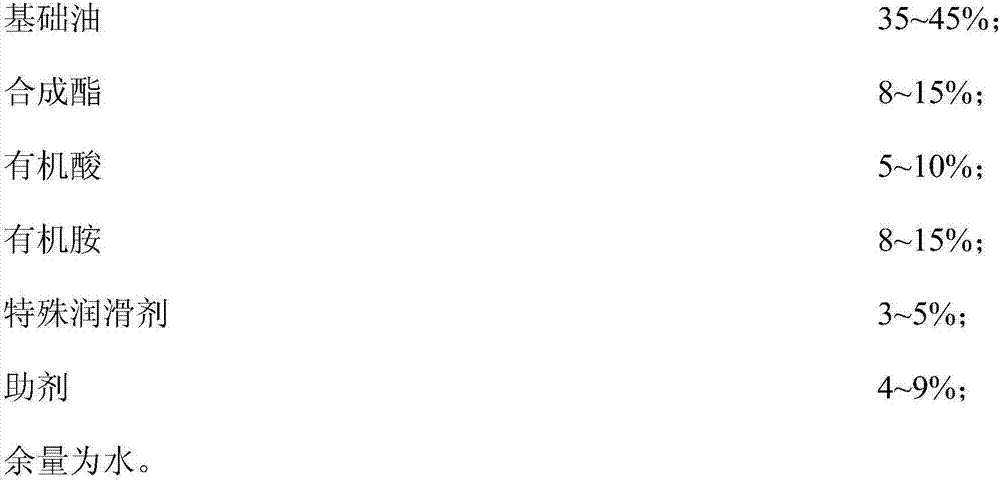

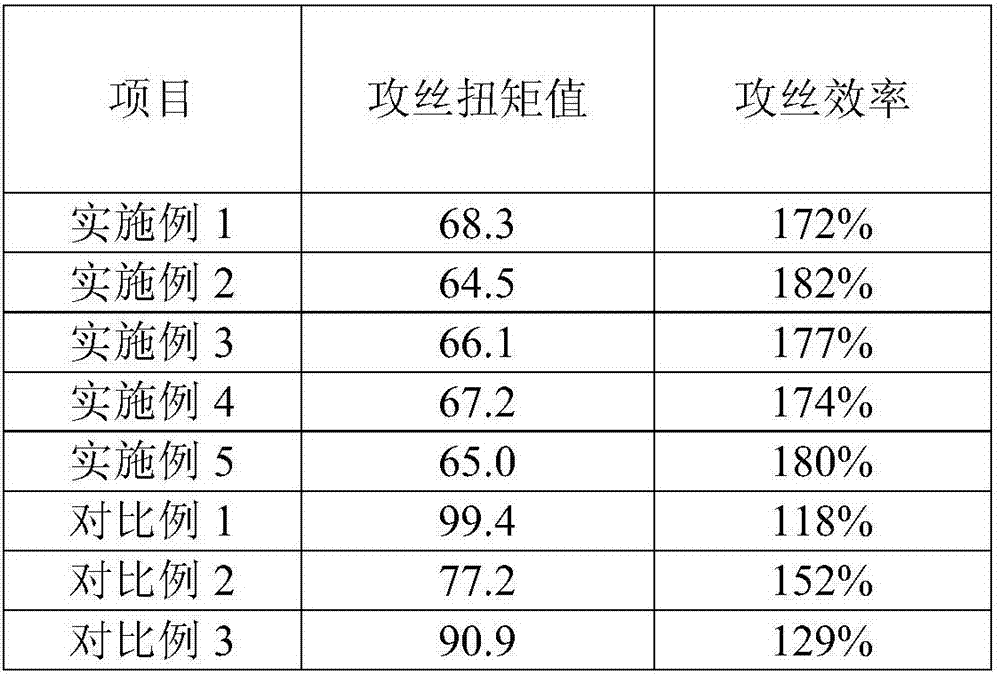

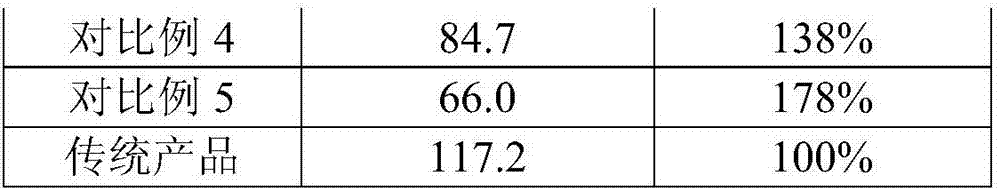

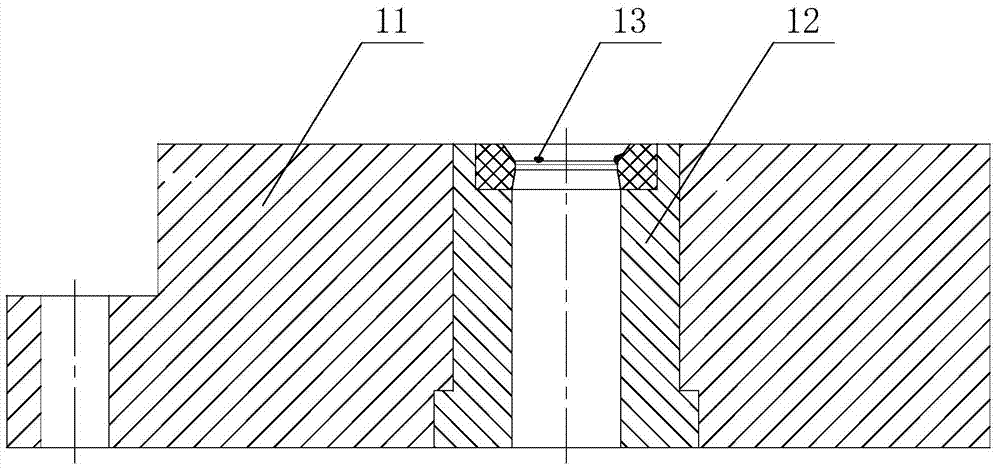

Metalworking fluid, and preparation method and application thereof

ActiveCN107164062AImprove the lubrication effectAvoid it happening againLubricant compositionOrganic acidWorking fluid

The invention provides a metalworking fluid. The metalworking fluid comprises base oil, synthetic ester, an organic acid, an organic amine, a special lubricant, an assistant and water. The working fluid has the advantages of excellent lubricating properties at a low concentration, satisfactory protection of new working surfaces and cutter surfaces, prevention of the generation of built-up edges and abrasion, excellent antibacterial property and high biological stability at a low concentration, improvement of lubrication without chlorine, phosphorus, sulfur and other common extreme pressure lubricants, and small harms to the environment and the operating personnel.

Owner:QUAKER CHEM CHINA

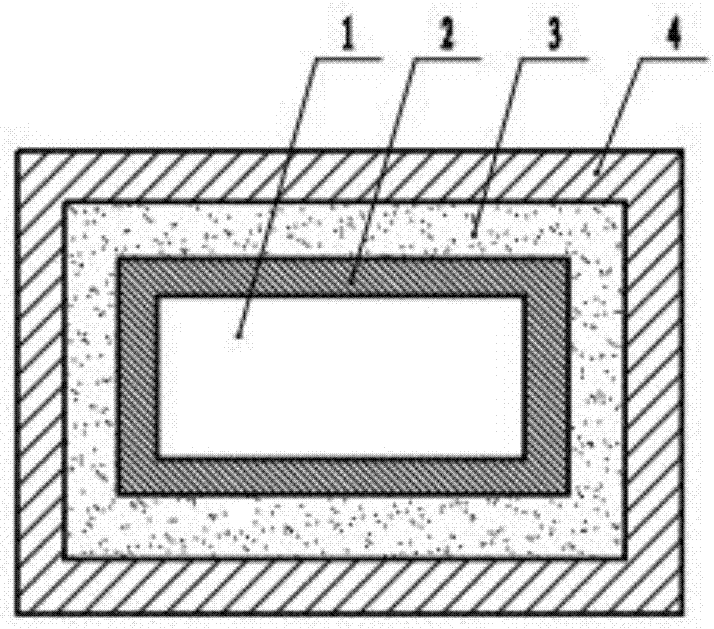

Drawing die

The invention discloses a drawing die. The drawing die comprises a concave die socket and a concave die arranged in the concave die socket, wherein a cooling channel is formed in the concave die socket. According to the drawing die, the cooling channel is additionally formed in the concave die socket so that the concave die socket can be subjected to forced cooling; besides, a water cooling machine is arranged to lower the temperature of cooling water, so that the cooling effect is further enhanced; by the adoption of the concave die socket of the structure, the temperature of the concave die socket only ranges from 20 DEG C to 25 DEG C when the air temperature is 35 DEG C, so that the temperature of the concave die is reduced substantially, the deposition phenomenon of built-up edges is greatly reduced, the frequency of machine halts for die repairing is lowered, the continuous operation time is prolonged, the production efficiency is improved, and output is increased.

Owner:无锡金杨丸伊电子有限公司

Water-based cutting fluid stable in quality and uniform to disperse and preparation method of water-based cutting fluid

The invention discloses a water-based cutting fluid stable in quality and uniform to disperse. The water-based cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of sodium molybdate, 2-3 parts of triethanolamine, 1.5-2.5 parts of carboxylic acid, 3.5-5 parts of polysorbate-80, 2-4 parts of castor oil, 4-5 parts of sodium ricinoleate, 2-3 parts of tartaric acid, 6-8 parts of nanosilicon dioxide, 2-3 parts of octadecylamine N-oleoyl sarcosinate, 5-7 parts of an auxiliary and 200 parts of deionized water. According to the water-based cutting fluid, a grinding material nanosilicon dioxide and a surfactant are mixed, so that not only is the wear resistance enhanced, but also the grinding material is uniform to disperse, thereby promoting the quality of the cutting fluid. Matched with the auxiliary, the wear resistance, dispersibility, lubricity and film-forming property of the cutting fluid are enhanced. The cutting fluid disclosed by the invention has excellent lubricating and wear resisting performance, cleaning cooling performance and anti-rust corrosion resisting performance, can avoid generation of built-up edges and effectively protects cutters and improves the processing quality. The cutting fluid is simple to operate and low in cost.

Owner:XUZHOU SANHE AUTOMATIC CONTROL EQUIP

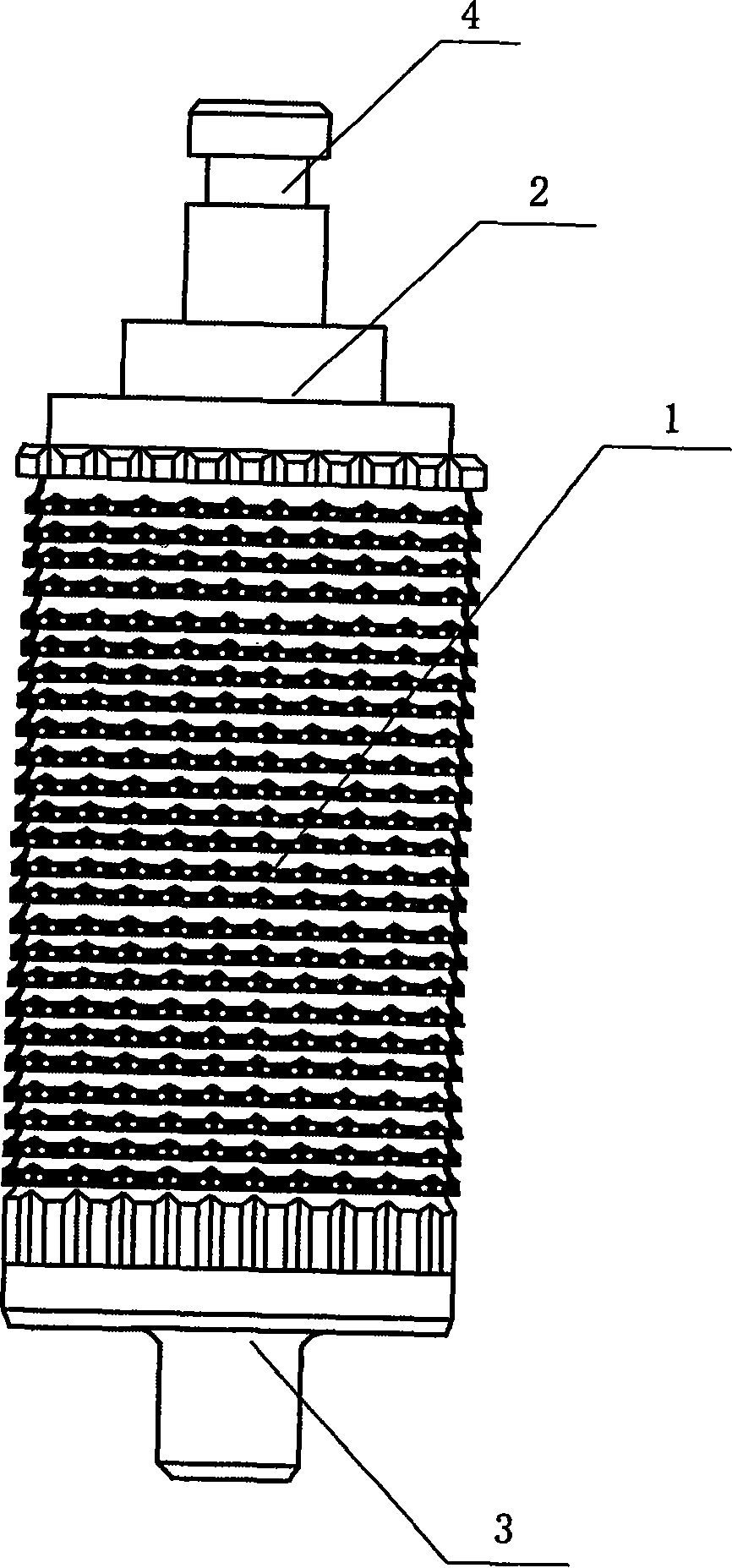

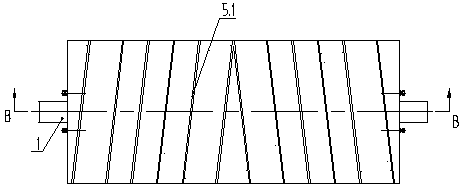

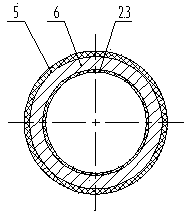

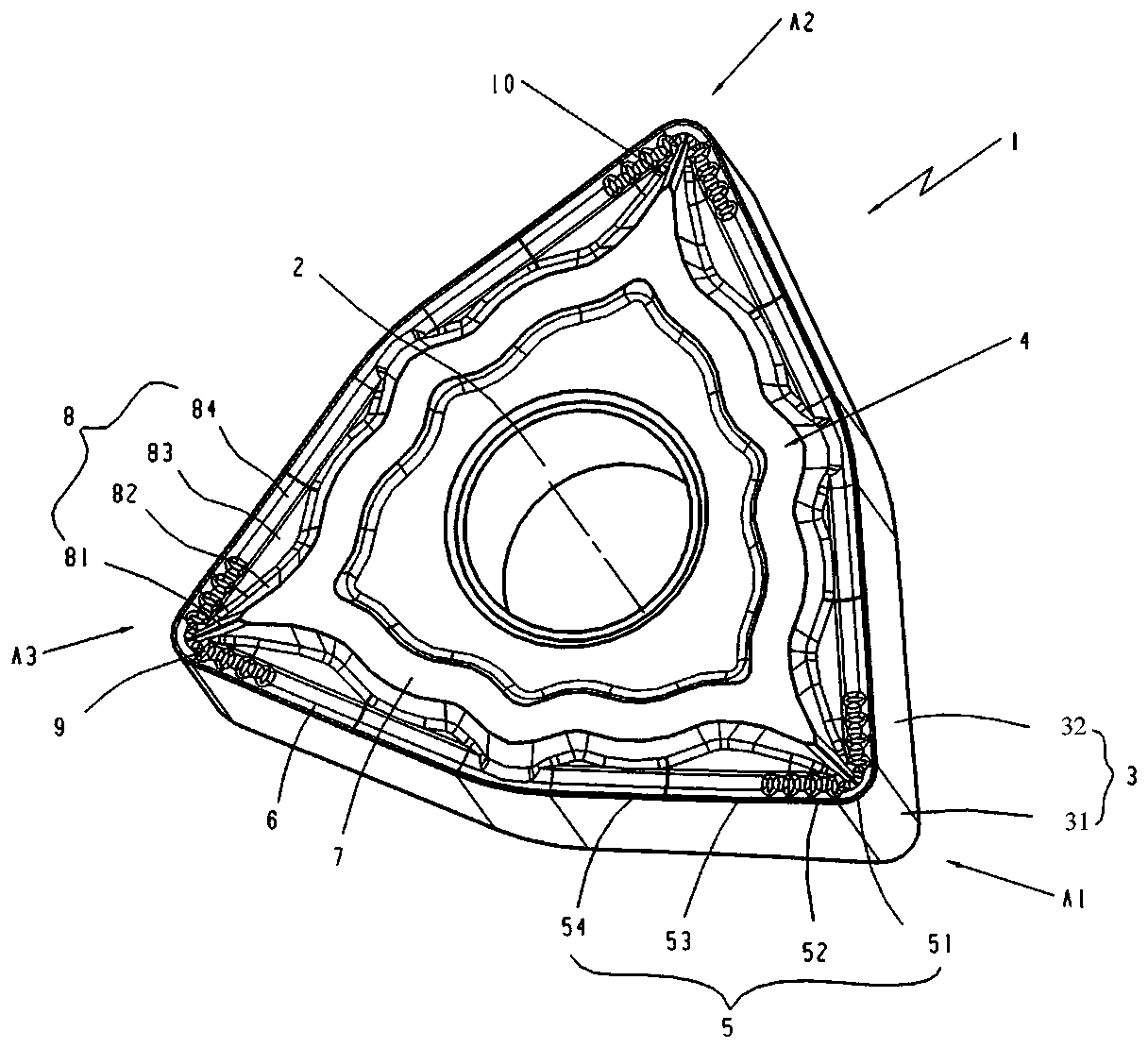

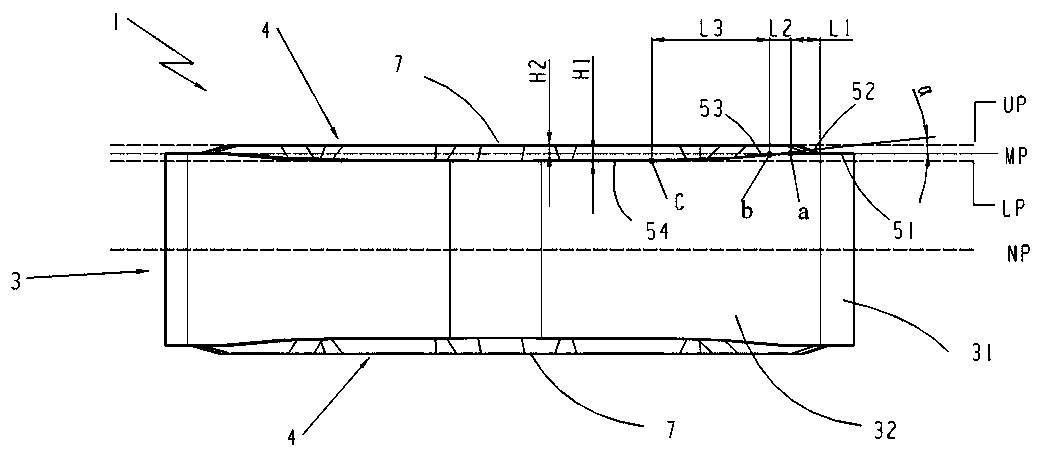

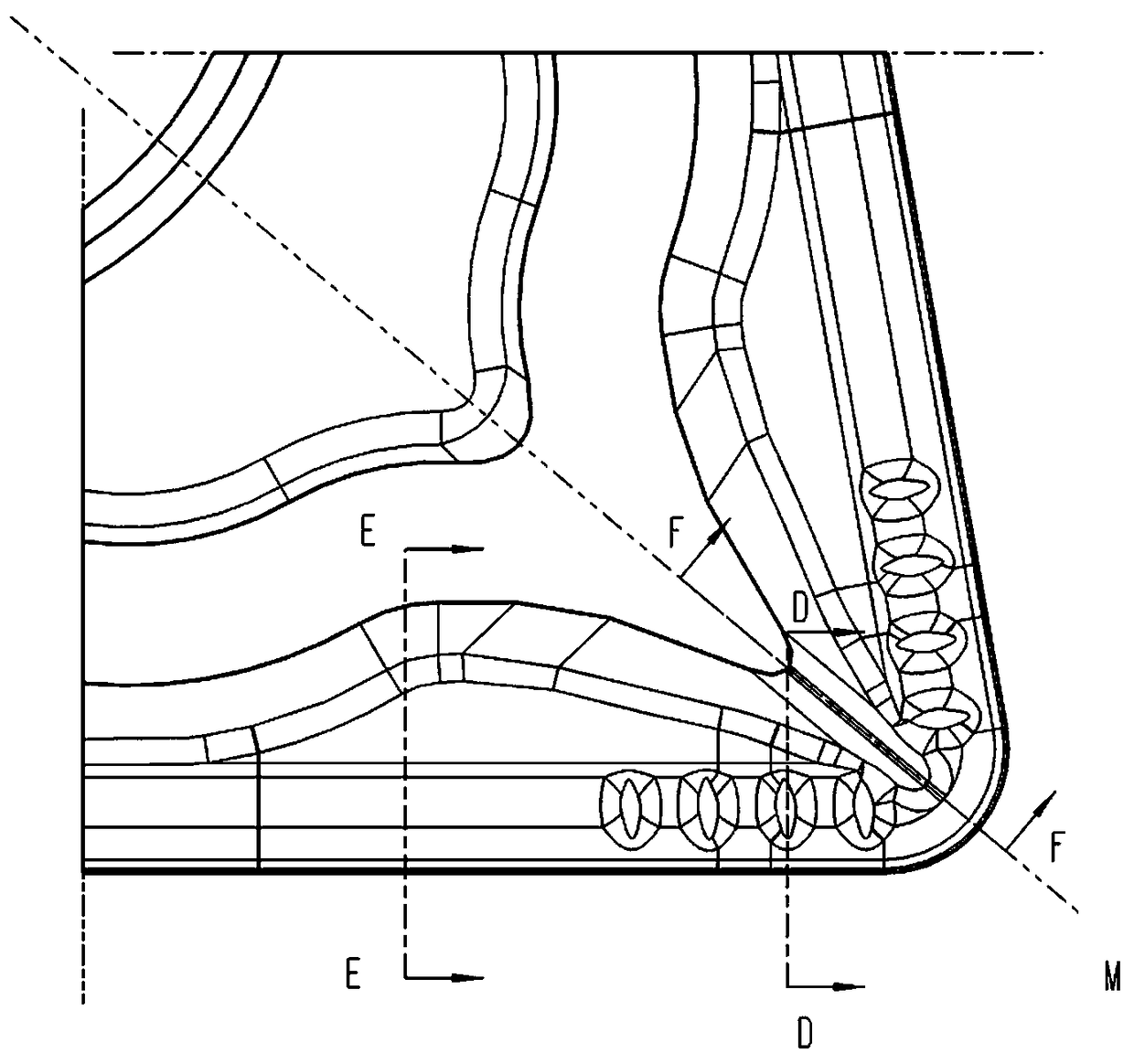

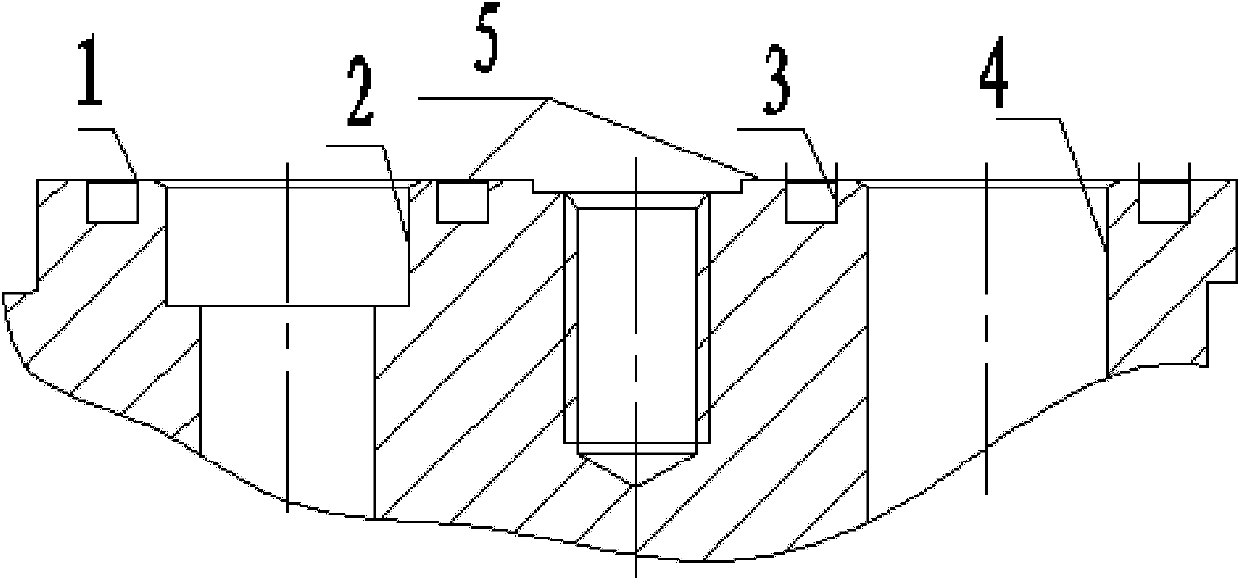

Knife tool for processing gear ring

InactiveCN101249576ANot easy to scratchNot easy to produceGear teeth manufacturing toolsGear teethMilling cutterBuilt up edge

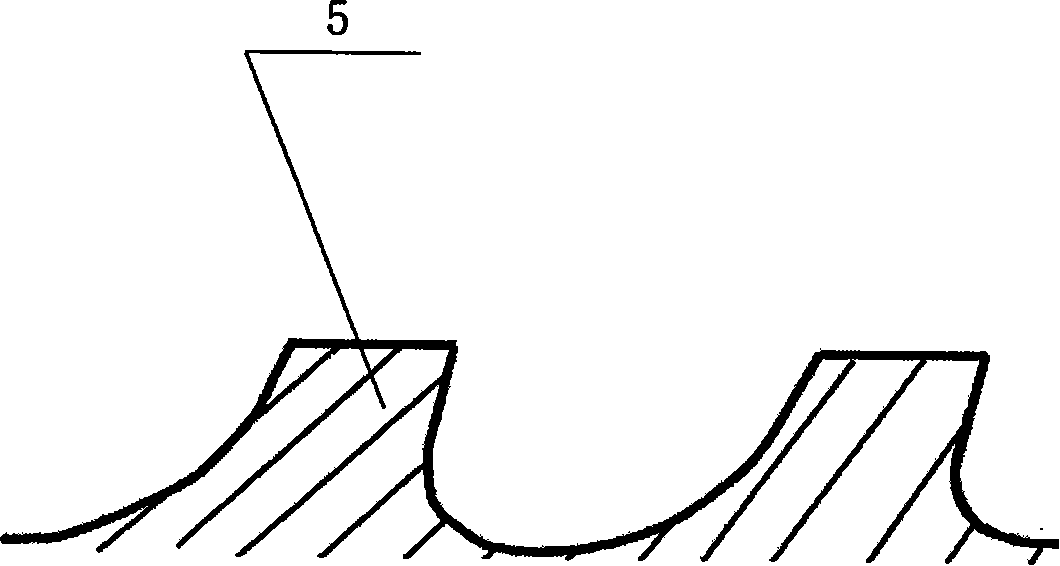

The invention provides a cutting tool for processing ring gear, which comprises a columnar cutting section (1) with a front handle (2) at one end and a rear handle (3) at the other end, wherein the cutting section (1) is integrated with the front handle (2) and the rear handle (3); a clamping handle (4) is arranged on the end head of the front handle (2); and a multi-ring cutting blade (5) is distributed on the surface of the cutting section (1). The cutting blade of the cutting tool is a spiral double-angle milling cutter, so that the cutting blade has an inclination angle to achieve thin cutting and prevent scratching workpiece surface, thus reducing deformation resistance, reducing cutting heat, preventing the formation of built-up edge, prolonging the service life of the cutting tool, improving the processing accuracy, achieving good processing effect, and preventing deformation of the processed product. Additionally, the cutting tool can simplify the processing procedure and reduce the production cost. The cutting section is a split hierarchical structure, which can satisfy different processing requirements to achieve wide application range.

Owner:泰州市海博汽车科技有限公司

Cutting tool

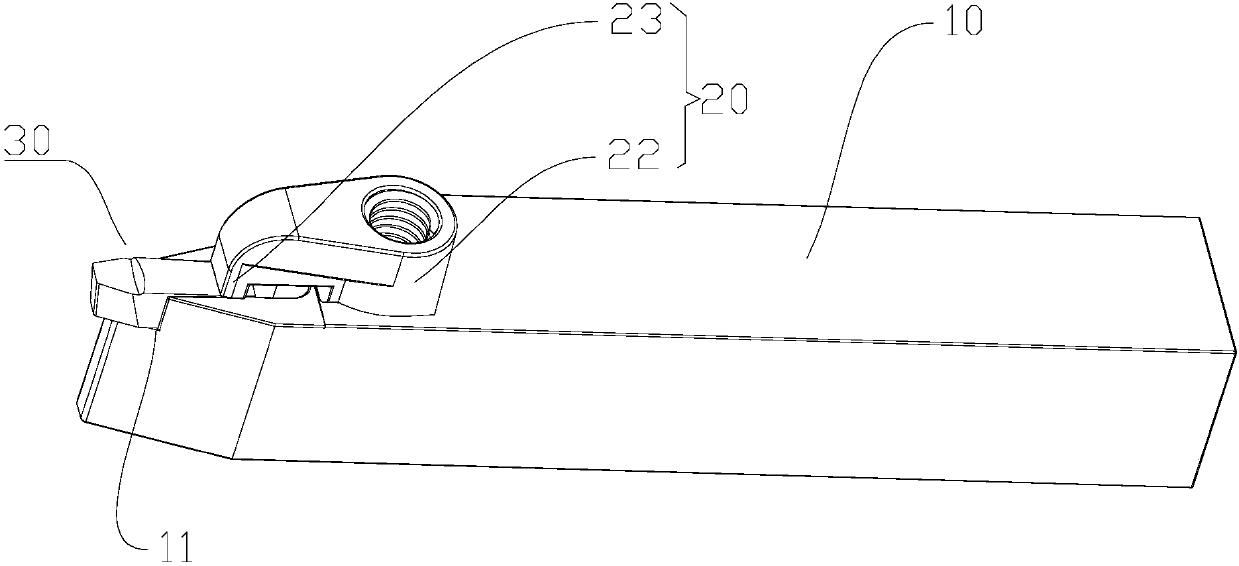

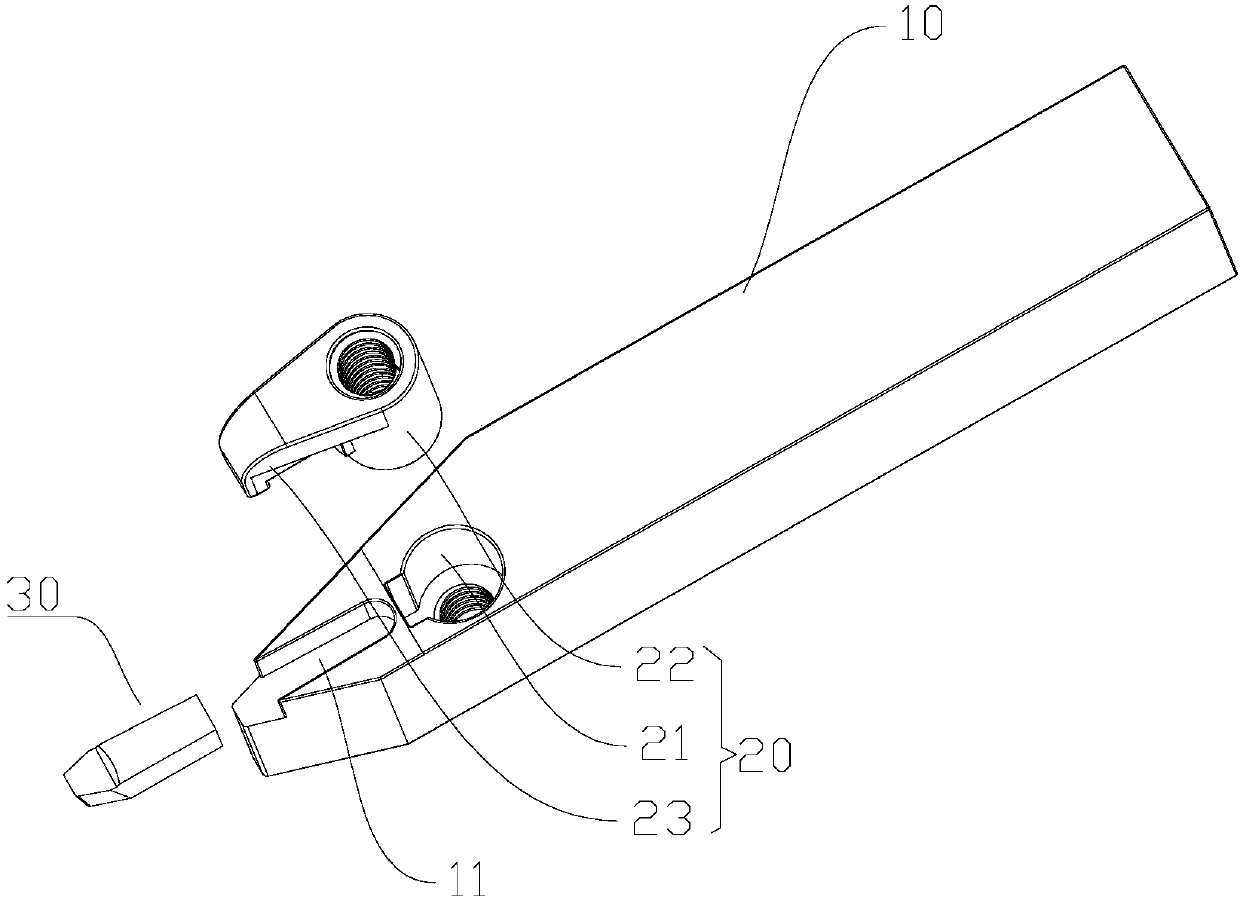

PendingCN108031876ANot prone to vibrations and lateral deflectionImprove experienceTurning toolsBuilt up edgeEngineering

The invention discloses a cutting tool, and relates to the field of machinery manufacturing metal cutting machining. The cutting tool comprises a tool holder. Cutting faces with three cutting edges are formed at an end of the tool holder by means of grinding, and a chip removal groove is further formed in a joint of the cutting faces and the tool holder. The cutting tool has the advantages that the cutting faces with the three cutting edges are formed in the end of the tool holder by means of grinding, the three cutting edges can simultaneously vertically and horizontally transversely move when belt pulleys are about to be lathed by users, accordingly, the belt pulleys can be lathed, and the cutting tool is high in efficiency; the chip removal groove is formed in the cutting tool, and accordingly chips can be smoothly removed; accumulated chips are difficult to stick to the cutting tool, built-up edges can be prevented, heat can be quickly dissipated, abrasion and tipping can be prevented, and accordingly the service life of the cutting tool can be prolonged.

Owner:张伟东

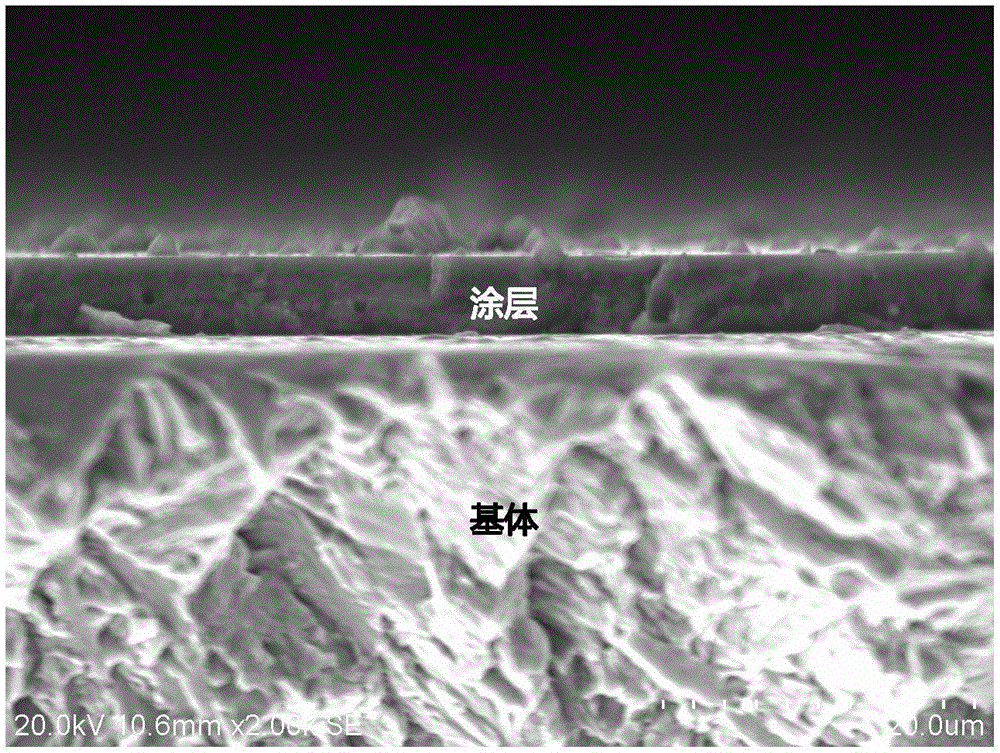

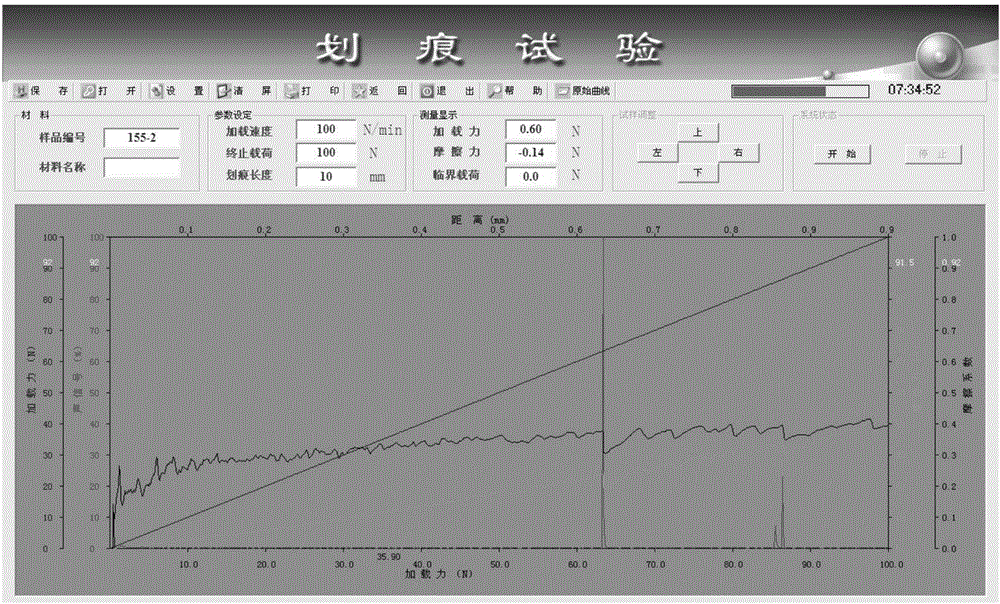

Ti-Ag-N nano-composite coating and preparation method thereof

InactiveCN106756821AImprove bindingRefine the grain sizeVacuum evaporation coatingSputtering coatingMetallic materialsBuilt up edge

The invention belongs to the technical field of ultra-hard nano-composite coatings deposited on surfaces of metal materials, and particularly relates to a Ti-Ag-N nano-composite coating and a preparation method thereof. By adoption of the Ti-Ag-N nano-composite coating and the preparation method thereof, the technical problems that a large amount of heat is generated due to a high friction coefficient of a nc-TiN / a-Si3N4 nano-composite coating, and built-up edges are still generated on the front tool face of a coated cutting tool are solved. According to the distance away from a matrix, the nano-composite coating sequentially comprises a transition layer, an intermediate layer and a Ti-Ag-N layer from inside to outside, wherein the transition layer is formed by a Ti film on the surface of the matrix, and the intermediate layer is formed by a TiN film. According to the preparation method, the arc ion plating technique is used for completing preparation of the Ti-Ag-N nano-composite coating. The nano-composite coating prepared through the method has high hardness and also has the advantages that the tenacity is high, the film-matrix bonding force is high, and the friction coefficient is small.

Owner:南京煜弧真空镀膜科技有限公司

Stable-quality cutting fluid with bactericidal effect and preparation method thereof

InactiveCN104120011AImprove the bactericidal effectEffective protectionLubricant compositionDispersityPhenethyl alcohol

The invention discloses a stable-quality cutting fluid with bactericidal effect. The invention is characterized in that the cutting fluid is prepared from the following raw materials in parts by weight: 1-2 parts of lime sulfur, 5-7 parts of lime powder, 2-3 parts of nano diamond powder, 2-4 parts of epoxy soybean oil, 1-2 parts of sodium gluconate, 0.8-1.4 parts of chitosan, 3-4.5 parts of phenethyl alcohol oleate, 1-1.5 parts of sodium diacetate, 3-4 parts of sodium dodecyl benzene sulfonate, 5-7 parts of assistant and 200 parts of deionized water. The nano diamond powder and surfactant are mixed by grinding to enhance the dispersion effect, so that the quality is stable and uniform; by adding the lime sulfur, the cutting fluid has favorable bactericidal effect; and the assistant enhances the wear resistance, dispersity, lubricating property and film formation property of the cutting fluid. The cutting fluid has excellent lubricating property, cleaning property and rust resistance, can prevent the built-up edge from generation, effectively protects the cutter, and enhances the processing quality.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Special dressing liquid for ELID (Electrolytic In-process Dressing) composite material and preparation method of special dressing liquid

ActiveCN110029006AImprove grinding performanceReduce grinding lossLubricant compositionSodium phosphatesPolyethylene glycol

The invention discloses a special dressing liquid for an ELID (Electrolytic In-process Dressing) composite material and a preparation method of the special dressing liquid and belongs to the field ofprecise-ultraprecise on-line electrolysis trimming and dressing. The special dressing liquid comprises the following constitution components: engine oil, soybean oil, thiopropyl triethoxy silane, dodecyl succinate diethanolamide, dimethicone, molybdenum disulfide, dialkyl phosphorodithioic zinc, nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, silicone emulsion, a morpholinederivative, boric acid, methyl benzotriazole, naphthenate, tri-m-tolyl phosphate, sulfide fatty acid ester, diethanol amine, triethanolamine, lauric acid, polyethylene glycol, sodium phosphate and deionized water. The dressing liquid has functions of electrolysis removal and trimming grinding in addition to properties of common dressing liquids, excellent cutting performance of grinding granulesin grinding wheels can be constantly maintained, and the problems that a composite material is low in removal rate, built-up edges are generated and processing surface quality and precision are low inthe machining process can be solved.

Owner:BEIJING UNIV OF TECH

Strengthened-type sink roller capable of preventing build-up edge

InactiveCN104388871AImprove flexural strengthReduce distortionHot-dipping/immersion processesWear resistantBuilt up edge

Owner:TAIZHOU SANJIANG SPECIAL STEEL MFG

2Cr13 stainless steel turning process

InactiveCN104741623AReduce the number of tool changesIncrease productivitySurface roughnessSize change

The invention discloses a 2Cr13 stainless steel turning process; and in the turning of a 2Cr13 stainless steel part, such several aspects as heat treatment of materials, selection of cutter materials, cutter cutting angles and cutting liquid are properly treated. The 2Cr13 stainless steel turning process overcomes such defects as easy cutter sticking, generation of built-up edges, workpiece size change, influence on the surface roughness, difficult winding and breaking of chips and easy damage of machined workpiece surfaces.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

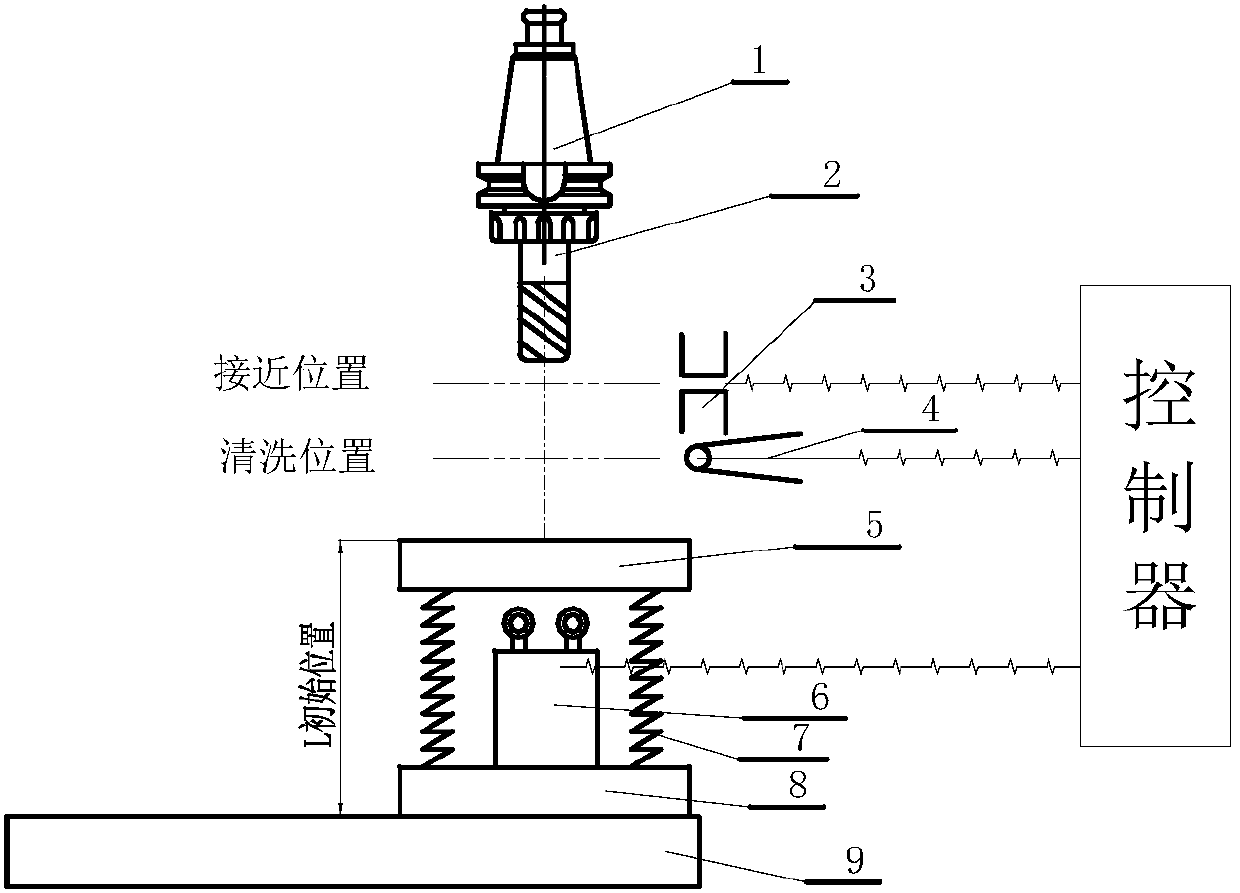

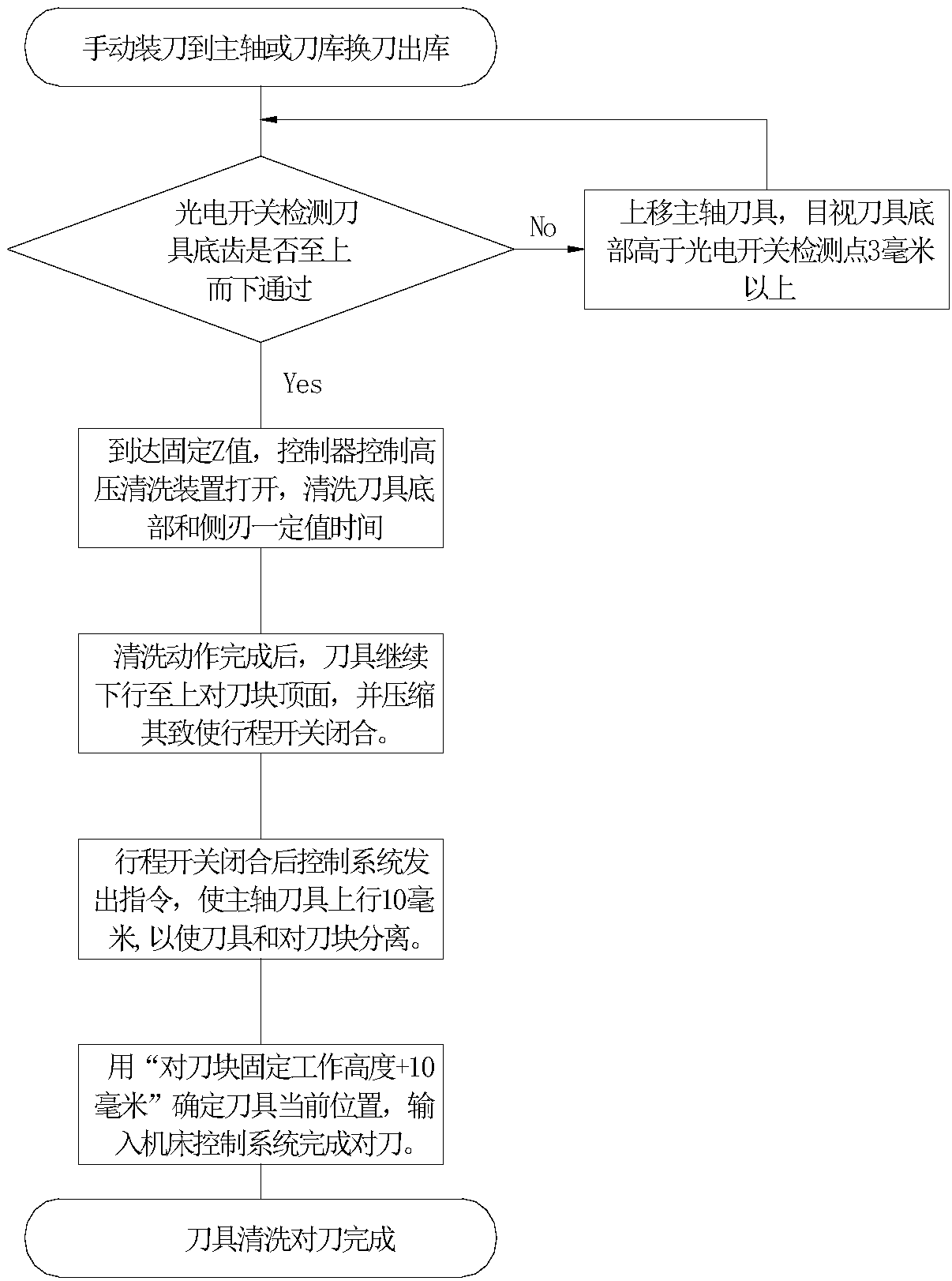

Method for automatically cleaning tools and measuring lengths of tools on line

The invention discloses a method for automatically cleaning tools and measuring lengths of the tools on line, and belongs to the technical field of machine tool clamps. A device is additionally arranged on a numerical-control machine tool, so that in a using process, the numerical-control machine tool can be matched with existing tools of a tool magazine to be equipped with all tools to start processing a part after programming is completed once workpieces are clamped; and a tool setting long instruction is added during primary processing. All the tools are cleaned under high pressure to ensure the effect that scrap iron bonding is avoided, so that built-up edge production probability is also reduced. Tool data measurement is accurate, and interferences of artificial factors are avoided. The method is suitable for high-quality efficient production.

Owner:SHAANXI AVIATION ELECTRICAL

Coating blade for steel component processing and preparing method thereof

ActiveCN109128136AImprove wear resistanceReduce decompositionTransportation and packagingMetal-working apparatusBuilt up edgeAlloy

The invention relates to the field of cutting tools and particularly relates to a coating blade for steel component processing and a preparing method thereof. The coating blade for steel component processing comprises a cemented carbide base and a coating, wherein the thickness of a cubic-carbide-free layer on the cemented carbide base is 5-10mum. The preparing method of the coating blade for steel component processing comprises the following steps: after uniformly mixing Co, TaNb8, (W, Ti)CN, WC and a forming agent, pouring the mixture into a drum type ball mill to carry out ball milling; then, pressing and sintering the ball-milled mixture to make a blade with the cemented carbide base; and coating the blade with the cemented carbide base with the coating, and carrying out sand blastingtreatment to obtain the coating blade for steel component processing. The making technology of the coating blade for steel component processing, which is provided by the invention, is simple, the wearresistance of the blade is improved, crater wear can be effectively inhibited, and the production of built-up edges is reduced.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

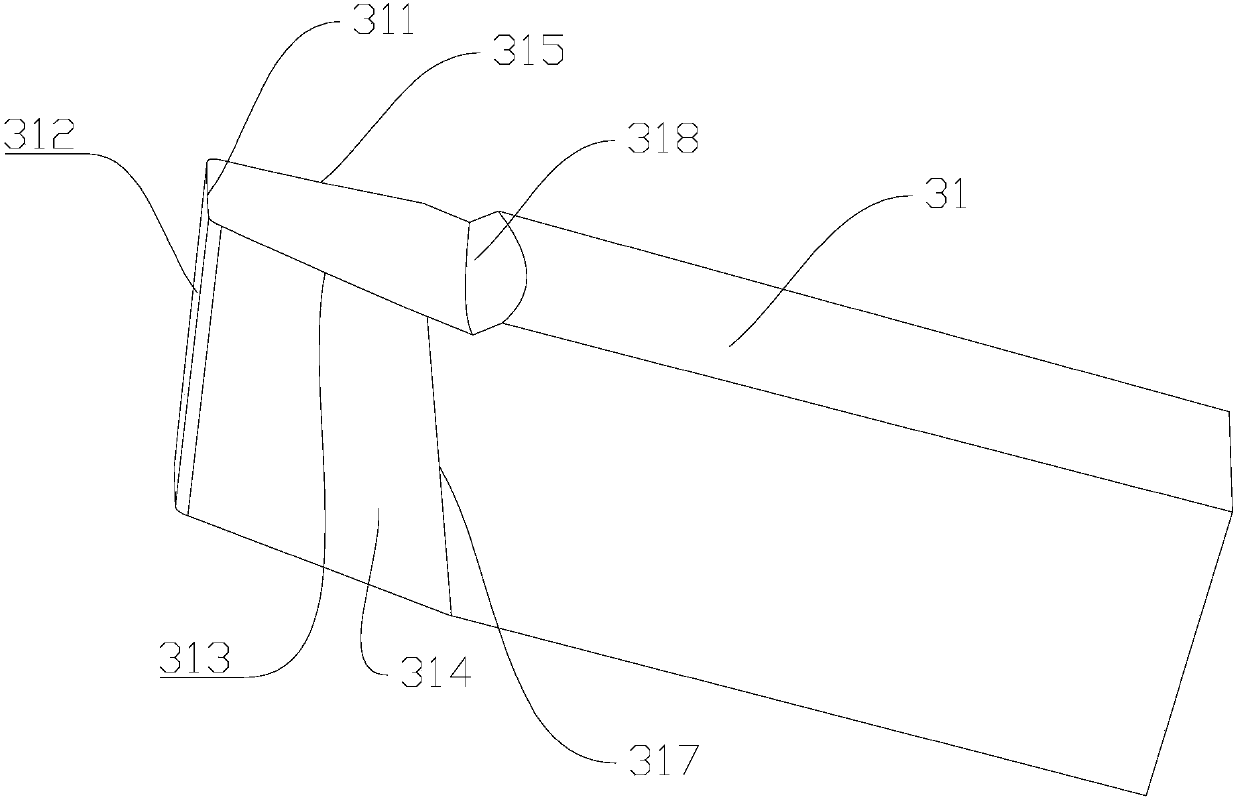

Double-face groove profile cutting blade

The invention relates to the technical field of metal cutting, and discloses a double-face groove profile cutting blade. A blade body is of a geometric structure, wherein the geometric structure is provided with a polygon and is symmetric up and down. A positioning hole is formed in the geometric center. The blade body is composed of an upper end face, a lower end face, a plurality of side surfaces and an arc side face located between every two adjacent side surfaces, and the upper end face and the lower end face are provided with supporting surfaces between the edges of scrap cutting tables and the positioning hole. The top corner of the blade is provided with no fewer than one cutting unit part, and each cutting unit part is composed of a cutting edge, the corresponding scrap cutting table and a scrap cutting guiding protruding part, wherein the scrap cutting table is composed of a front blade face and a plurality of cutting guiding faces, the scrap cutting guiding protruding part isarranged at the top corner of the cutting unit part, and the cutting edge is composed of an arc cutting edge body, a main cutting edge body, a transition cutting edge body and an auxiliary cutting edge body. Through the blade, the sharpness and stability of the cutting edges are improved, scrap cutting and discharging are smooth, blade abrasion is reduced, and the phenomenon of built-up edges iseffectively restrained.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

Processing method for automobile compressor rear cover

InactiveCN102029410AEasy to operateImprove efficiencyTurning toolsTurning machinesBuilt up edgeEngineering

The invention relates to a processing method for an automobile compressor rear cover, comprising the following steps of: designing a cutter; arranging a first cutter point, a second cutter point, a third cutter point, a fourth cutter point and a fifth cutter point which correspond to the slot bottom of the rear cover on the cutter; during processing, naturally forming a built-up edge at the right-angle part of the cutter to generate a chamfer of R0.3-R0.5 at the corresponding part of the rear cover; and when the built-up edge reaches a certain size, naturally dropping the built-up edge due to a cutting force, and then forming a new built-up edge. The invention has the advantages that the exhaust port of the processed rear cover is molded in one step so that the processing operation is convenient and the efficiency is high; moreover, the product quality is stable.

Owner:SHANGHAI GUANGYU AUTOMOBILE AIR CONDITIONING COMPRESSOR

Metal cutting fluid with sterilizing and deodorizing functions and preparation method of metal cutting fluid

ActiveCN104120016AEffective protectionPrevent spoilageLubricant compositionHexagonal boron nitrideBuilt up edge

The invention discloses a metal cutting fluid with sterilizing and deodorizing functions. The metal cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 3-4 parts of chlorinated paraffin, 4-6 parts of 2-ethylhexyl epoxystearate, 3-5 parts of glycerin, 4-6 parts of petroleum barium sulfonate, 2-3 parts of petroleum sodium sulfonate, 5-6 parts of hexagonal boron nitride, 2-3 parts of polytetrafluoroethylene, 2-3 parts of boric acid, 1-2 parts of thiophosphate, 5-7 parts of auxiliary and 200 parts of deionized water. The metal cutting fluid is excellent in lubricating property, wear resistance, cleaning and cooling performances as well as rust prevention and corrosion resistance and capable of avoiding generating built-up edges and effectively protecting a cutter; due to the addition of the auxiliary, the metal cutting fluid has favorable wear resistance, dispersibility, lubricating property and film forming property; due to the addition of thiophosphate, the metal cutting fluid has a favorable antibacterial effect and is prevented from going bad and becoming smelly; the metal cutting fluid is suitable for processing and cutting various metals, simple in operation and low in cost.

Owner:菏泽市汇信知识产权运营有限公司

Preparation method of cutter surface antisticking antifriction micro mosaic composite texture

InactiveCN103111819BIncreased durabilityImprove cutting efficiencyManufacturing technologyBuilt up edge

Owner:JIANGSU UNIV

ZrNbCN gradient composite coated tool and preparation technology thereof

InactiveCN107400863AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingSputteringBuilt up edge

The invention belongs to the field of machine manufacturing tools and particularly relates to a ZrNbCN gradient composite coated tool and a preparation technology thereof. The coated tool comprises a tool base, a Ti transition layer, a ZrNbC transition layer and a ZrNbCN gradient composite coating with gradually changed N content sequentially from inside to outside and is prepared with an unbalanced magnetron sputtering and arc plating composite coating method. According to the ultrahard ZrNbCN compound coating, Zr and Nb are added to the coating and the N content of structural constitution of the coating is changed gradually, so that the combination usability of the tool can be improved. The coated tool has quite high hardness, strength, compression resistance, impact toughness, wear resistance and corrosion resistance. Friction and adhesion between the tool and a workpiece in a cutting process can be reduced, built-up edges are not produced easily, good surface roughness is obtained, the cutting force and the cutting temperature can be reduced by 35% or more, the oxidation resistance of the coated tool is improved by 60% or higher, the service life of the tool is prolonged by 50% or more and the durability of the tool is improved by 50% or higher.

Owner:JINING UNIV

High-precision processing method for graphite cutter

InactiveCN108642562AHigh hardnessWear-resistantPolycrystalline material growthVacuum evaporation coatingBuilt up edgeAlloy substrate

The invention discloses a high-precision processing method for a graphite cutter. The high-precision processing method comprises the following steps: A, preparation of an alloy substrate which is a tungsten steel substrate; B, purification of the alloy substrate; and C, deposition of a monocrystal diamond coating on the surface of the substrate. The high-precision processing method provided by theinvention has the following beneficial effects: tungsten steel has a series of excellent properties like high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, and specifically, high hardness and wear resistance of the tungsten steel can increase the service life of a cutter; the connecting bond between carbon atoms in diamond is an sp<3> hybrid covalent bond, so strong binding force, stability and directionality are obtained; monocrystal diamond is insusceptible to sticking the cutter and generating built-up edges during cutting, so the qualityof the processing surface is good, and surface roughness is low during processing of non-ferrous metals; and compared with an ordinary diamond coating, the cutter prepared by using the method provided by the invention has a service life increased by 10 to 15 times, has higher processing precision, wear resistance and durability, and is an edge tool for processing of a silicon-aluminum material.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

A kind of cold-rolled silicon steel room temperature zero-emission degreasing agent and preparation method thereof

The invention discloses a cold-rolled silicon steel normal-temperature zero-release oil removal agent. The oil removal agent is prepared from 100-150 parts by weight of organic bionic acid, 80-120 parts by weight of a biological ferment, 10-30 parts by weight of a bio-enzyme, 5-10 parts by weight of a surfactant and 5-10 parts by weight of a sterilization algicide. The oil removal agent does not contain phosphorus, sodium and other metal ions, does not contain persistent organic pollutants, can undergo a decomposition reaction with acid, base, oil and ferric oxide, brightens the cleaned product and produces the final decomposition products such as water and carbon dioxide. The oil removal agent does not contain any metal ions. The cleaned metal ions and calcium and magnesium ions are complexed and do not produce precipitates so that the silicon steel cleaning spray water and a cleaning agent diluent can be recycled until thorough natural consumption. The oil removal agent has a strong ion complexing capacity, hardly produces precipitates, has a strong effect of cleaning water scales and blue-green algae of a cleaning tank and does not produce built-up edges on a cleaning roller, a driving roller and a magnesium oxide coated roller.

Owner:ZHEJIANG HUAYING STEEL TECH CO LTD

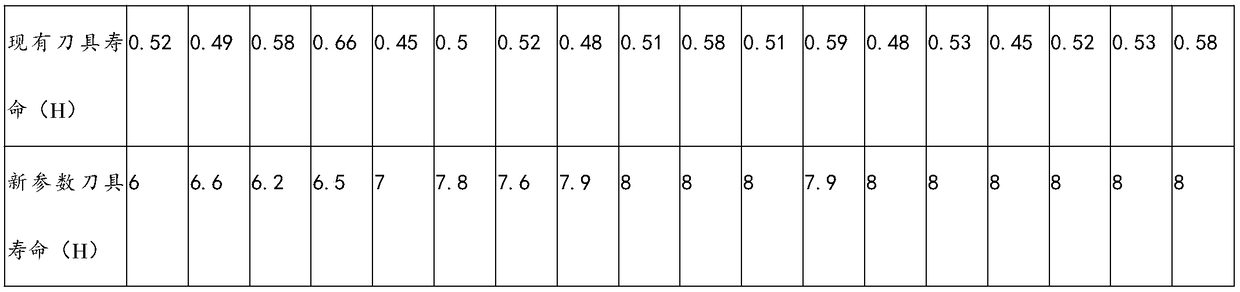

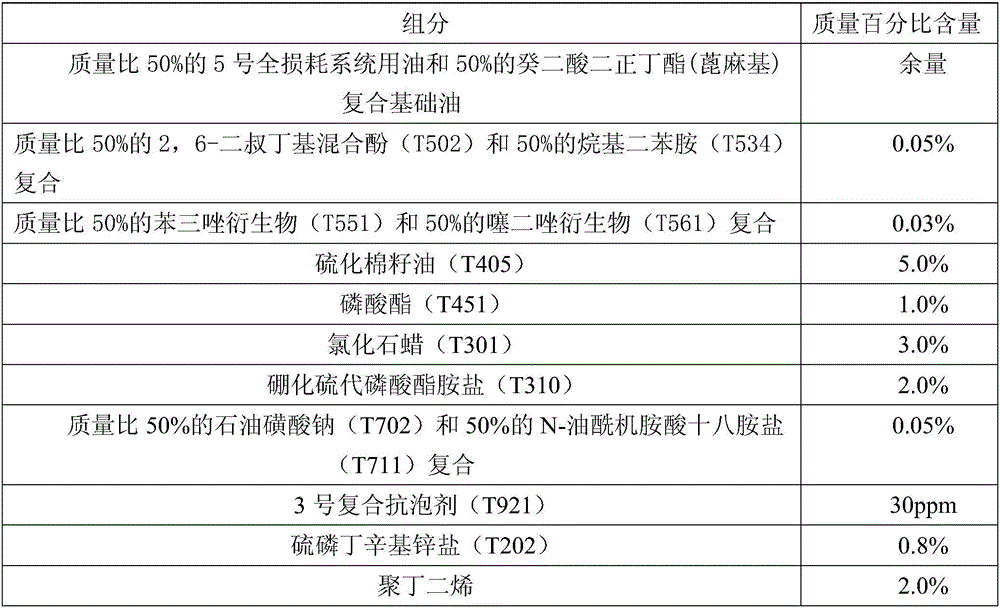

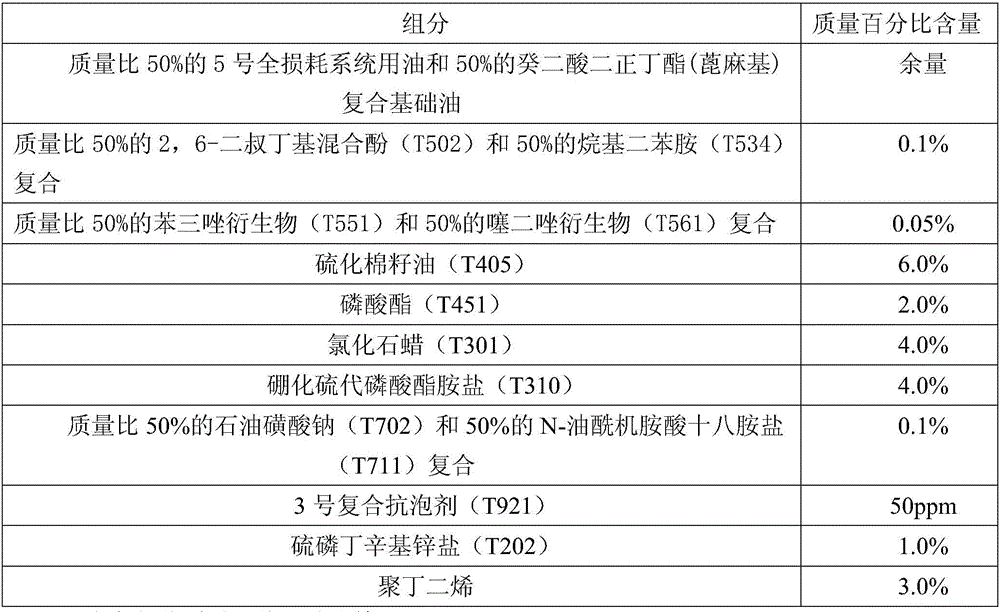

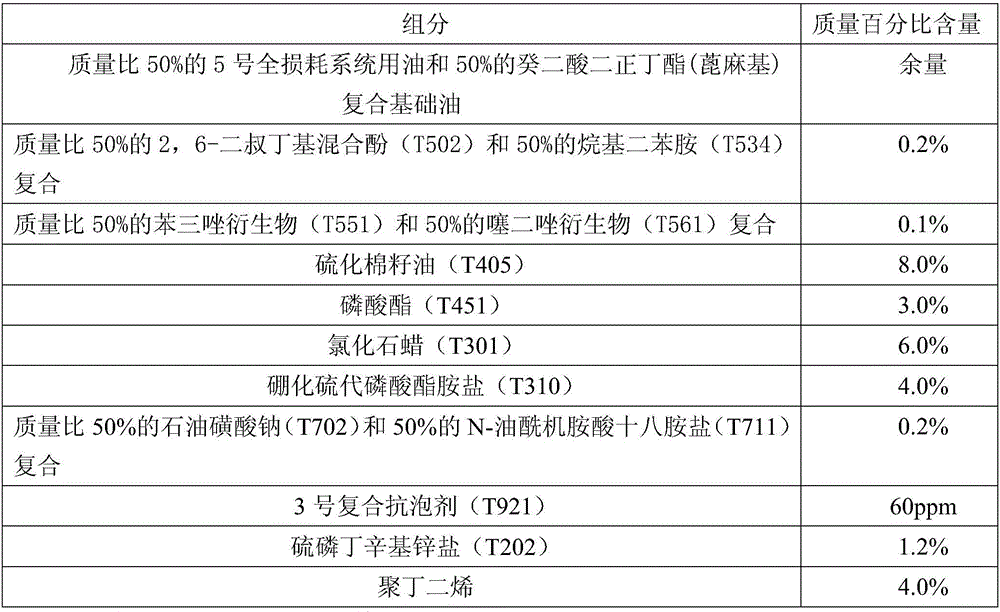

Environment-friendly composition of cutting fluid for drilling machining of common carbon structural steel

InactiveCN106433927ASuppress generationImprove cooling effectLubricant compositionDibutyl sebacateAntioxidant

The invention discloses an environment-friendly composition of cutting fluid for drilling machining of common carbon structural steel. The environment-friendly composition adopts composite base oil of 50% of number 5 total loss system oil and 50% of dibutyl sebacate (castor based) as base oil, together with a plurality of composite additives, including an antioxidant, a metal deactivator, an oiliness agent, a friction improver, an extreme pressure agent, an antiwear agent, an antirust agent, an anti-foaming agent, an oxidation and corrosion inhibitor, an antifogging agent and the like. The environment-friendly composition has a good cooling effect to remove heat generated by high temperature deformation and friction and inhibit generation of built-up edges, good diameter lubricity to reduce frictional wear between a blade and a bearing and ensure a good lubrication state of a cutter at high temperature in a cutting area, and good permeability and chip removal capability to timely permeate the cutting fluid to the blade and keep smooth discharge of cuttings.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com