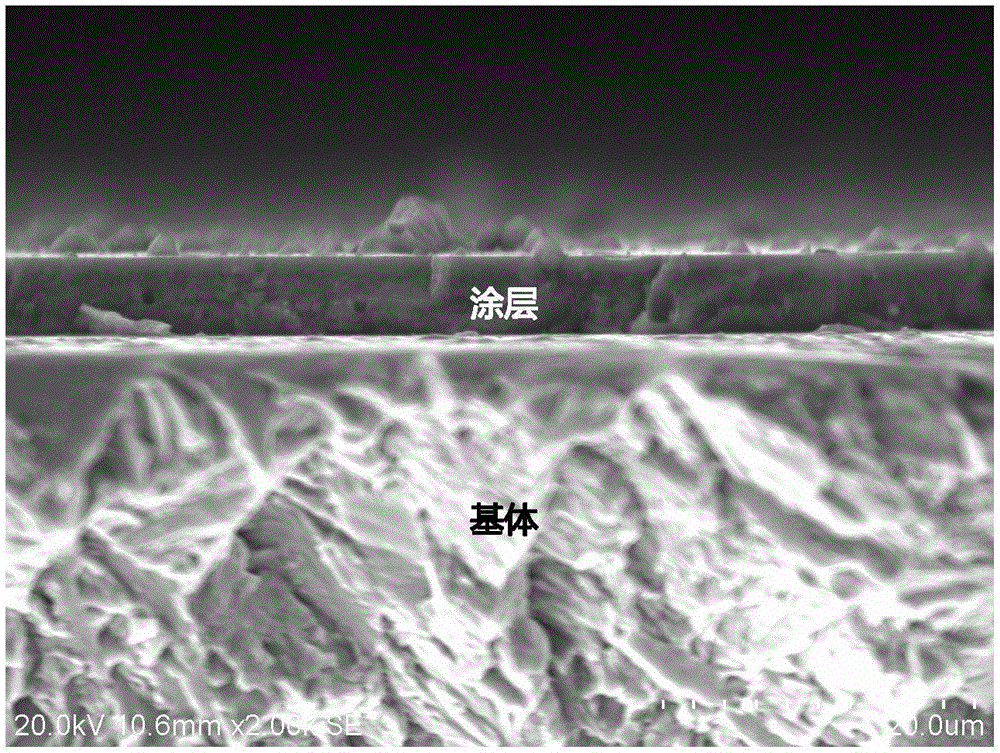

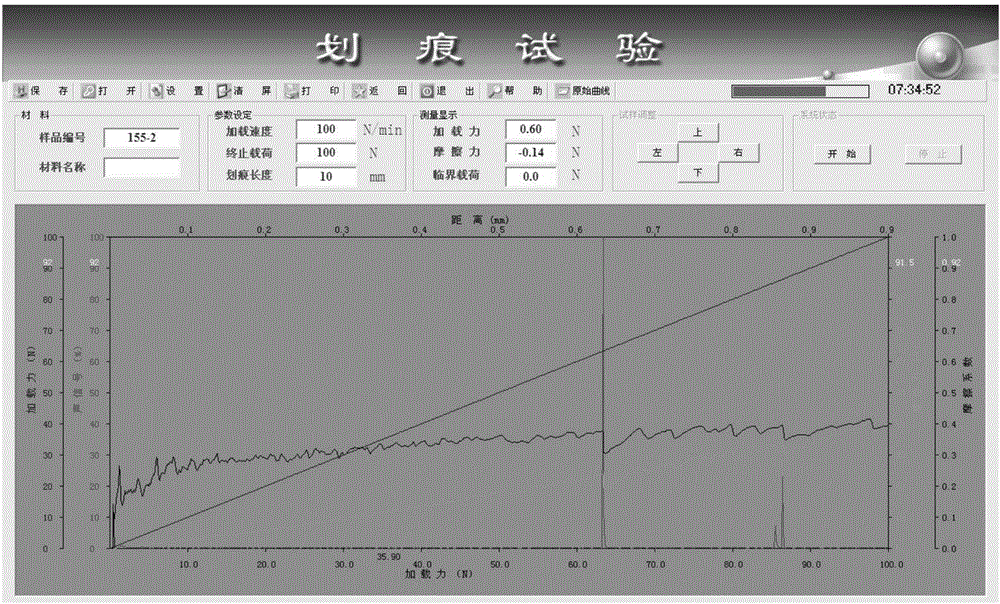

Ti-Ag-N nano-composite coating and preparation method thereof

A nanocomposite coating, ti-ag-n technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve high brittleness and friction coefficient, large internal stress of coating, adhesion and wear coating layer and other problems, to improve the hardness and fracture toughness, reduce the internal stress of the coating, and reduce the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Plating transition layer: the substrate is made of high-speed steel (grade W18Cr4V), the size of the sample is 25mm×10mm×2mm, and the size of the coating surface is 25mm×10mm. The surface before coating is ground, polished, ultrasonically cleaned and dried, and then placed on the sample stage of the vacuum chamber until the vacuum degree in the vacuum chamber reaches 6×10 -3 At Pa, heat the vacuum chamber to 400°C, feed argon gas into the vacuum chamber, set the gas flow rate to 100 sccm, control the air pressure at 2.0 Pa, apply pulse negative bias voltage -800V to the substrate, and perform glow cleaning on the sample for 20 minutes; then , adjust the argon gas flow rate, adjust the vacuum chamber pressure to 0.2Pa, and turn on the titanium target arc source at the same time, the arc current is stable at 70A, bombard the sample with Ti ions for 5min; adjust the pulse negative bias to -300V, and deposit Ti film for 3min ; Then, using a pure titanium target, stop argon ...

Embodiment 2

[0030] The base material is cemented carbide (grade YG6), the size of the sample is 20mm×20mm×4mm, and the size of the coated surface is 20mm×20mm. The surface before coating is ground, polished, ultrasonically cleaned and dried, and then placed on the sample stage of the vacuum chamber until the vacuum degree in the vacuum chamber reaches 4×10 -3 At Pa, turn on the gas mass flow controller, pass argon to 1.0Pa, apply a pulsed negative bias to -600V on the substrate, and perform glow cleaning on the sample for 15 minutes; then, adjust the flow of argon to adjust the pressure of the vacuum chamber to 0.6 Pa, turn on the titanium target arc source at the same time, the arc current is stable at 80A, and bombard the sample with Ti ions for 5 minutes; adjust the pulse negative bias to -300V, and deposit the Ti metal layer for 3 minutes; then, use a pure titanium target and stop the argon gas flow Nitrogen, adjust the air pressure to 1.0Pa; adjust the substrate pulse negative bias t...

Embodiment 3

[0033] The substrate is made of high-speed steel (grade W6Mo5Cr4V2), the size of the sample is 20mm×10mm×2mm, and the size of the coated surface is 20mm×10mm. The surface before coating is ground, polished, ultrasonically cleaned and dried, and then placed on the sample stage of the vacuum chamber until the vacuum degree in the vacuum chamber reaches 4×10 -3At Pa, pass argon gas to 2.0Pa, apply pulse negative bias to -700V on the substrate, and perform glow cleaning on the sample for 30 minutes; then, adjust the Ar gas flow rate to adjust the vacuum chamber pressure to 0.3Pa, and turn on the titanium target arc source at the same time , the arc current was stabilized at 80A, and the sample was bombarded with Ti ions for 8 minutes; the pure titanium target was used, the argon gas was stopped and nitrogen gas was introduced, and the air pressure was adjusted to 1.0Pa; the substrate pulse negative bias was adjusted to -300V, and the target current was adjusted to 90A. TiN film fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com