Patents

Literature

149results about How to "Lubricate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

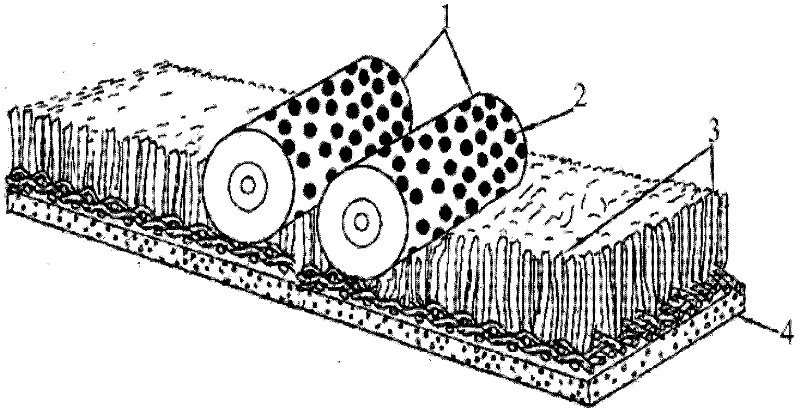

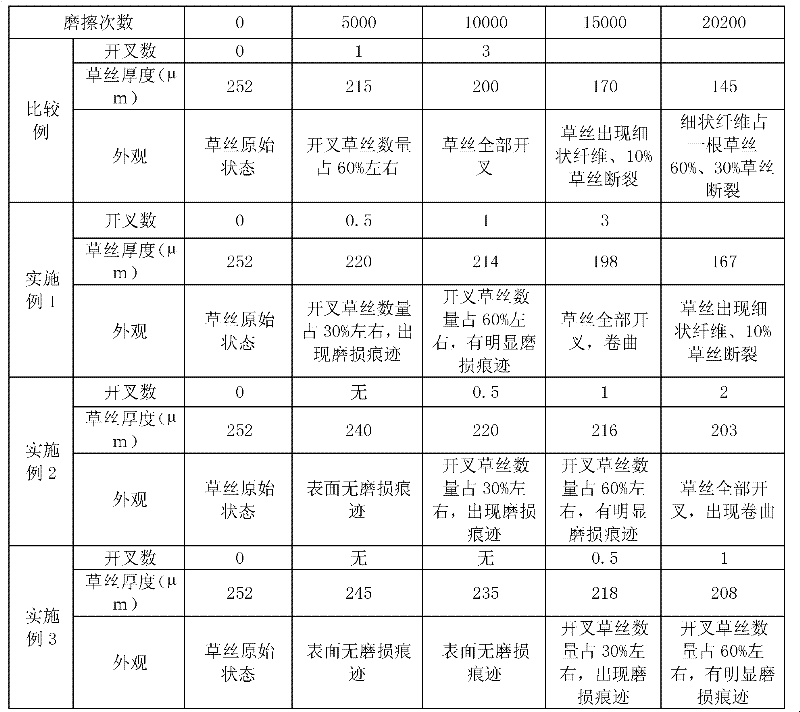

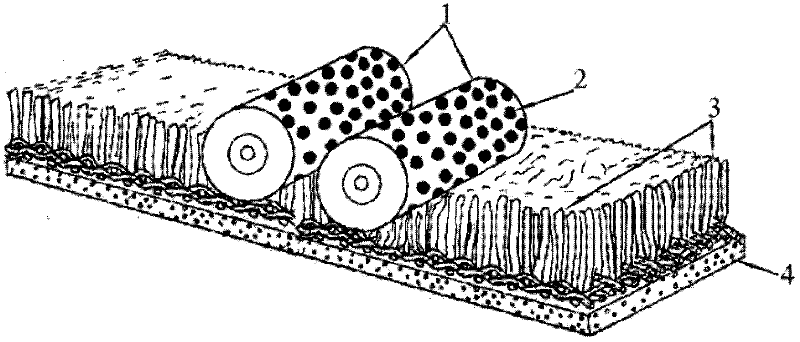

Wear-resistant artificial turf fiber

ActiveCN102493011AReduce wear rateImprove wear resistanceArtificial filament heat treatmentGround pavingsMasterbatchFiber

The invention relates to a wear-resistant artificial turf fiber made of the following raw materials by weight: 60 to 95 parts of matrix resin, 1 to 10 parts of wear-resistant masterbatch, 1 to 10 parts of color masterbatch, and 2 to 5 parts of age resister; and the wear-resistant masterbatch contains silicone powder. The wear-resistant artificial turf fiber has a greatly improved wear resisting property, thereby being suitable for places such as schools and the like where the wear-resistant artificial turf fiber is required to be used frequently for a long time. The wear-resistant artificial turf fiber has the advantages that the preparation method is simple; and the cost is low.

Owner:TAISHAN SPORTS IND GRP +1

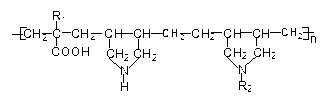

Amphiprotic amphiphilic leather retanning fatting agent and preparation method thereof

ActiveCN103131804APromote absorptionLubricateTanning treatmentLeather impregnationFiberPolymer science

The invention discloses amphiprotic amphiphilic leather retanning fatting agent and a preparation method of the amphiprotic amphiphilic leather retanning fatting agent. The constituent of the amphiprotic amphiphilic leather retanning fatting agent is (methyl) crylic acid-N-alkyl diene propyl amine-diallylamine terpolymer. According to the preparation method of the amphiprotic amphiphilic leather retanning fatting agent, N-alkyl diene propyl amine is firstly prepared, then the N-alkyl diene propyl amine, diallylamine, and (methyl) crylic acid are adopted for a free radical copolymerization reaction under the acidic condition to obtain an aqueous dispersoid containing the (methyl) crylic acid-N-alkyl diene propyl amine-diallylamine terpolymer, the solid content of a product is adjusted to 15-20% with water, and the amphiprotic amphiphilic leather retanning fatting agent is obtained. The molecular structure of the amphiprotic amphiphilic leather retanning fatting agent contains carboxyl of negative ions and tertiary amino of positive ions, and the polymer can display different electrical properties under different conditions of potential of hydrogen (PH), meanwhile the polymer contains alkyl of a long chain, and functions of lubrication fibers can be achieved. The polymer has the function of retanning, fatting and dyeing assistance at the same time, physical and mechanical properties of processed crust leather, such as tensile strength, fullness, softness and elasticity, are all improved, the surface of the processed crust leather is strong in lubrication feel and comfortable in hand feel, and the leather has a good waterproof performance.

Owner:四川德赛尔新材料科技有限公司

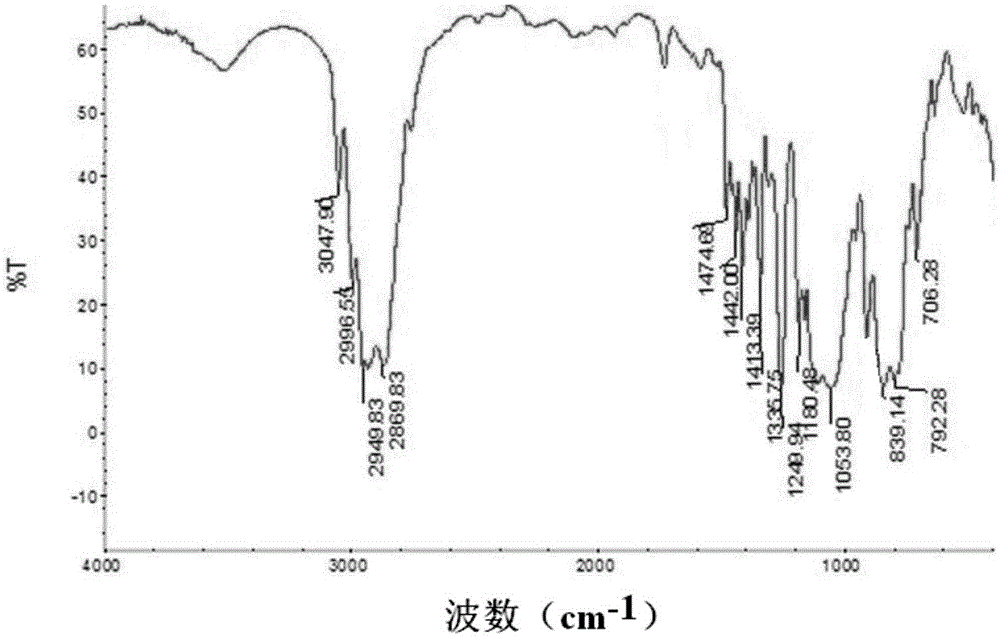

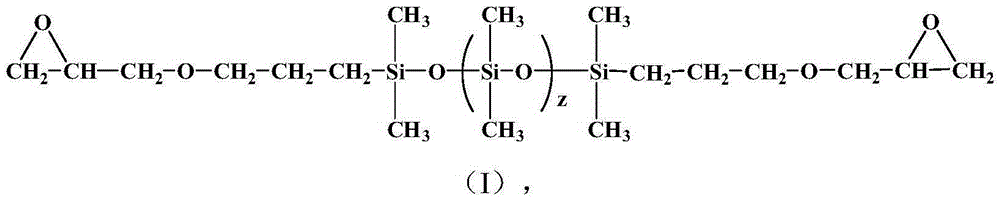

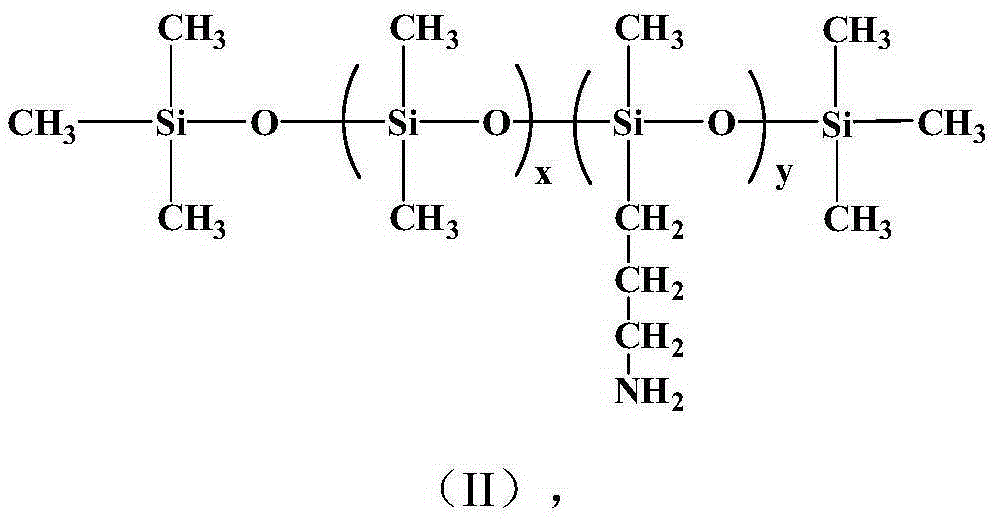

Compound for improving heat resistance of amino-modified silicone oil carbon fiber oil formulation and preparation and application thereof

ActiveCN105297427ASolve gelationSolve the problem of sticky rollerSilicon organic compoundsCarbon fibresFiberSide chain

The invention relates to a compound for improving the heat resistance of an amino-modified silicone oil carbon fiber oil formulation and preparation and application thereof. The compound has the structure shown in a formula (I). The compound is added into the oil formulation to be used by compounding with side chain aminopropyl-modified silicone oil with the kinematic viscosity of 80 cp-300 cp and the amino value of 0.15 mmol / g-0.20 mmol / g, the heat resistance of the oil formulation is greatly improved, and the problems of glue solidifying and roll sticking of the modified silicon oil formulation and modified silicon oil formulation embrittling and fracturing which occur in pre-oxidizing at 350 DEG C are solved.

Owner:新元化学(山东)股份有限公司

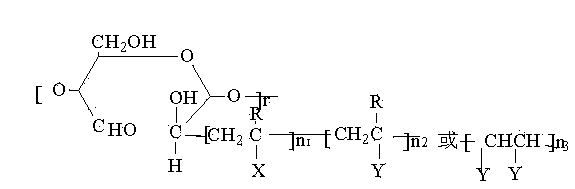

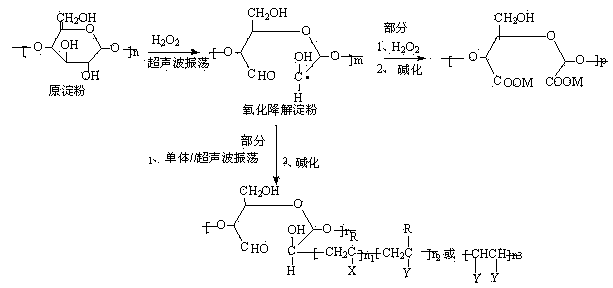

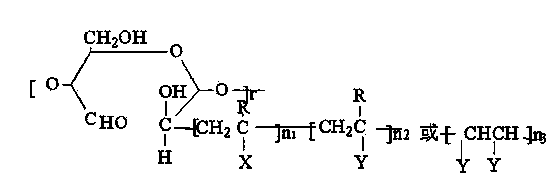

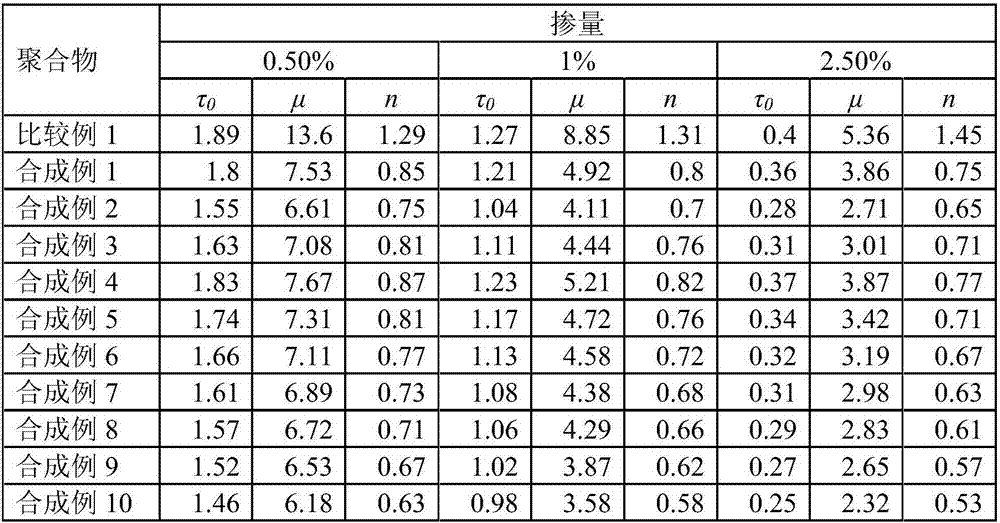

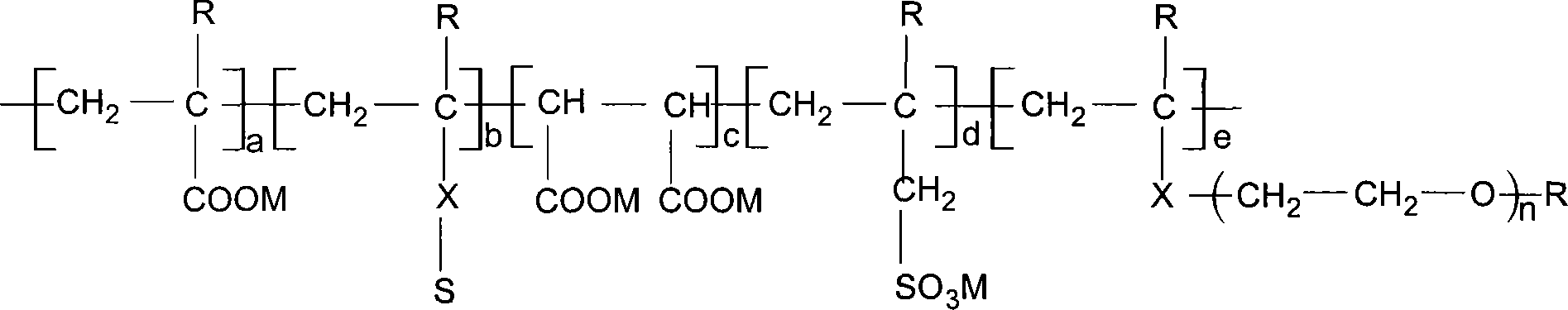

Oxydative degradation starch grafted polycarboxylate superplasticizer and preparation method thereof

InactiveCN103864338AImprove oxidative degradation efficiencyImprove the efficiency of graft polymerization reactionPolymer scienceSuperplasticizer

The invention belongs to the technical field of cement concrete admixtures, and in particular relates to an oxydative degradation starch grafted polycarboxylate superplasticizer and a preparation method thereof. The invention provides a resource of raw materials for preparing the novel efficient polycarboxylate superplasticizer, namely, natural and degradable starch is introduced to take the place of most part of petrochemical materials, the raw materials are wide and sustainable in resource, and not only is the cost lowered, but also the environment is protected.

Owner:UNIV OF JINAN

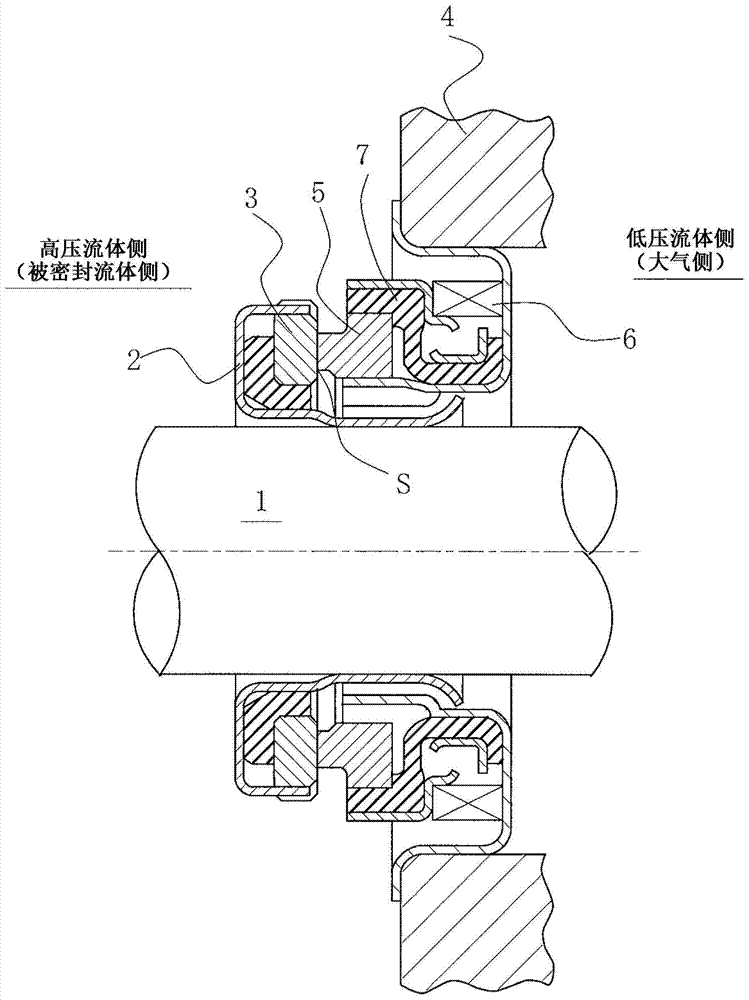

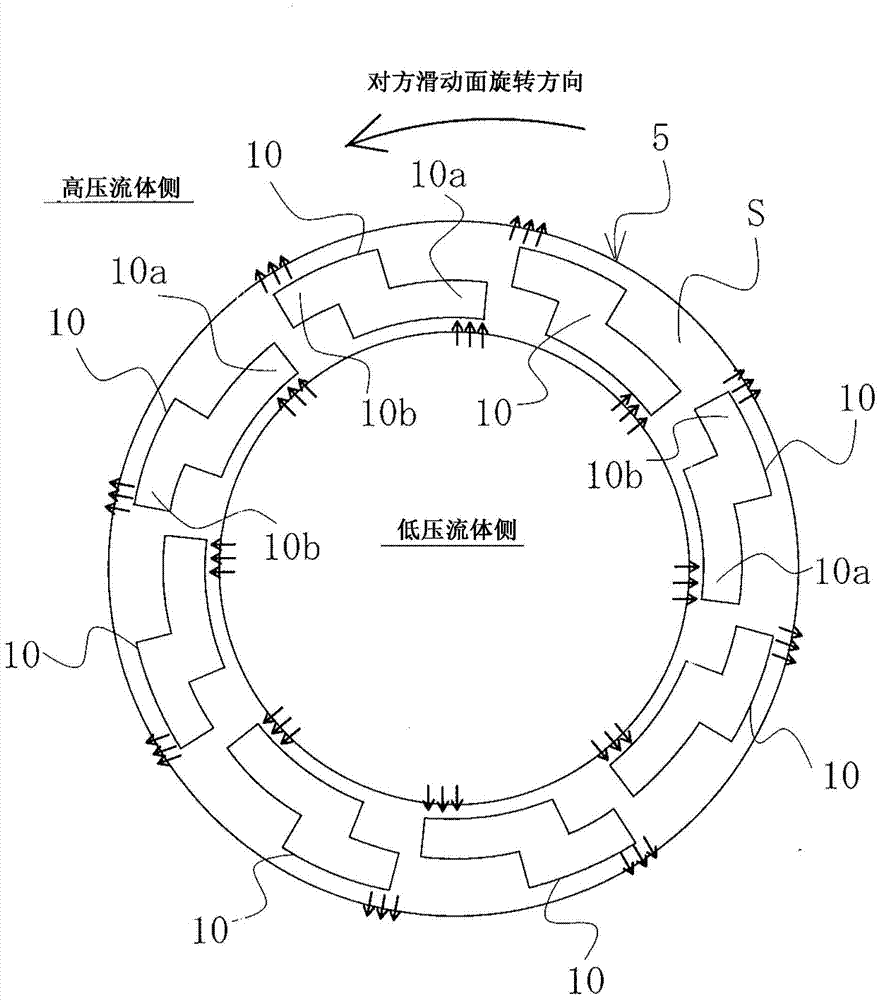

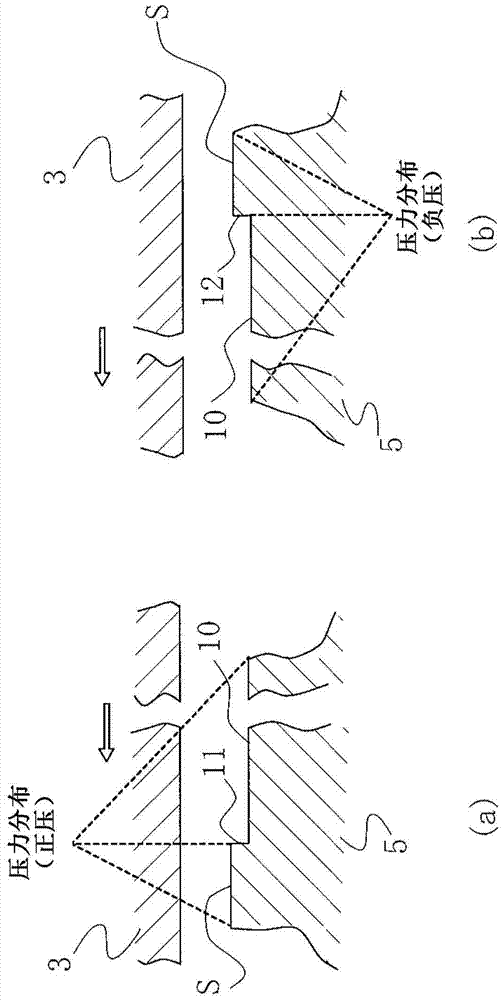

Sliding part

Provided is a sliding part providing functionality for both leak prevention and lubrication with no relation to the magnitude of the pressure difference between the inner and outer circumference of a sliding face by drawing in a fluid with a cavitation region on the upstream side of a depressed portion, such as a dimple formed on the sliding face, and generating positive pressure between the sliding faces on the downstream side of the dimple. A sliding part is characterized in that: dimples are provided on the sliding face on one of a pair of sliding parts that slide relative to each other; a cavitation forming region on the upstream side of each dimple is disposed near a low pressure fluid side and a positive pressure generating region on the downstream side is disposed near a high pressure fluid side; and the fluid drawn in with the cavitation forming region of the dimple is returned to the high pressure fluid side from the positive pressure generating region by passing through the inside of the dimple.

Owner:EAGLE INDS

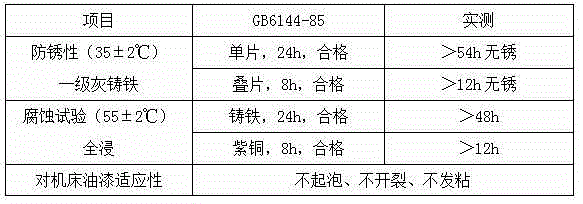

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

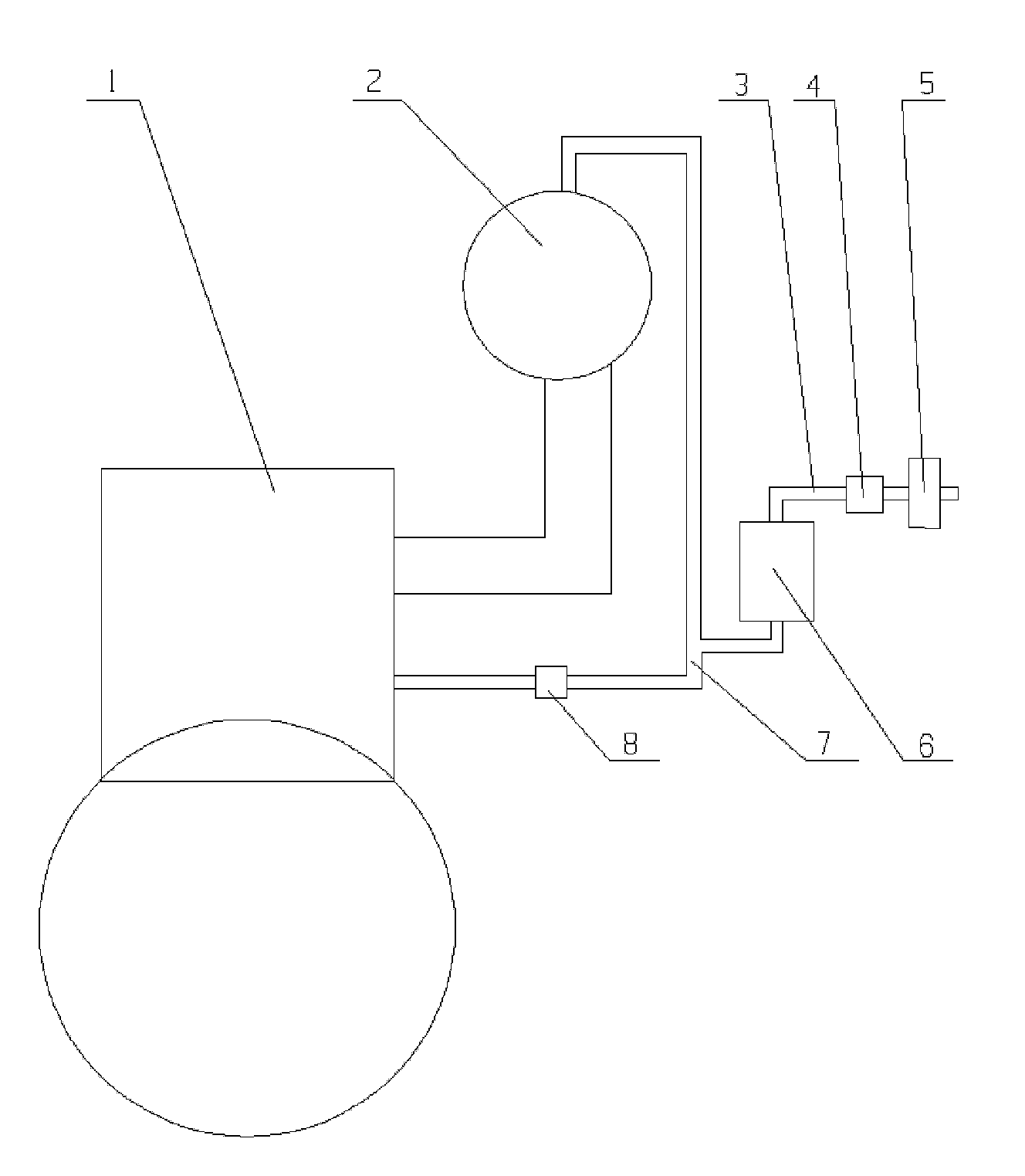

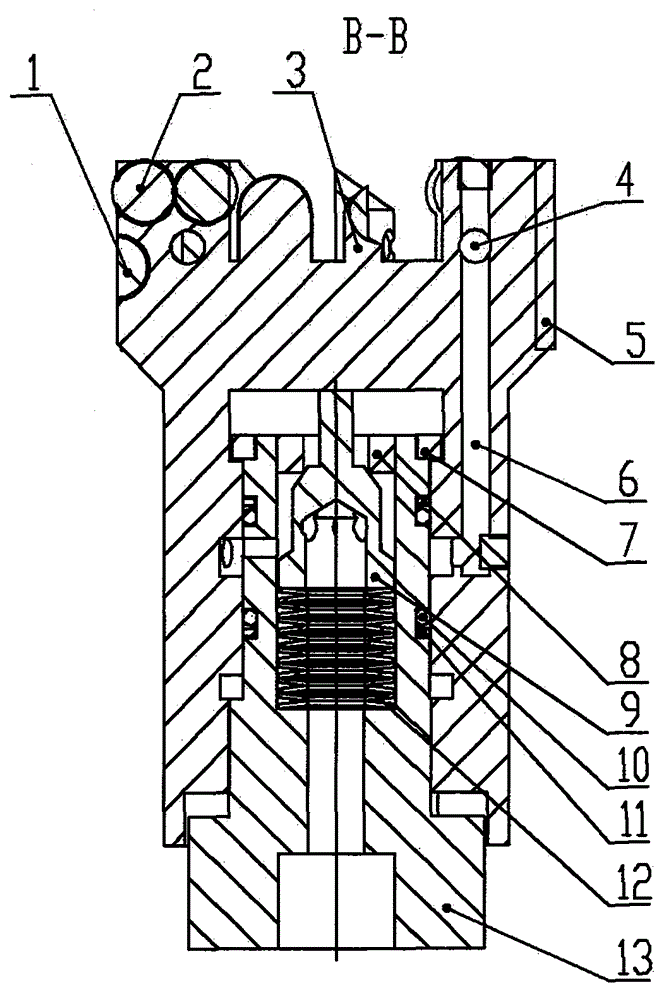

Fuel cut-off protection device for turbocharger

ActiveCN103184928AMeet frequent start and stopMeet the working conditions of unplanned downtimeMachines/enginesEngine componentsTurbochargerPetroleum engineering

The invention discloses a fuel cut-off protection device for a turbocharger. The fuel cut-off protection device comprises a three-way oil tube, wherein the first branch of the three-way oil tube is connected with the turbocharger; the second branch of the three-way oil tube is connected with a lubricating oil circuit of an engine; the third branch of the three-way oil tube is connected with the fuel cut-off protection device of the turbocharger; a one-way valve which is conducted from the engine to the three-way oil tube along a single direction is arranged in the first branch; and the fuel cut-off protection device is used for storing lubricating oil during normal running of the engine, and inputting the stored lubricating oil into the turbocharger when the engine stops running. The fuel cut-off protection device for the turbocharger can be used for storing lubricating oil during running of the engine, and can be used for inputting the stored lubricating oil into the turbocharger when the engine stops running to cool and lubricate, so that energy can be saved; and the fuel cut-off protection device for the turbocharger is suitable for the situations of frequent start and stop and halt and unexpected halt of the engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

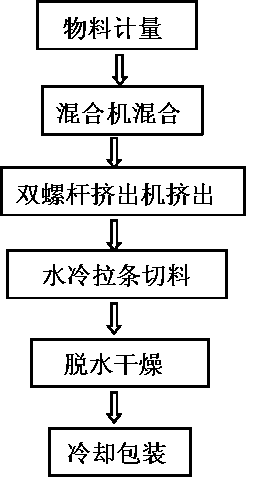

Foaming silicone master batch as well as preparation method and application thereof

The invention relates to the field of high-molecular materials. The usage amount of silicone powder as an additive is generally lower than 5 parts by weight; in order to solve the problem that the silicone powder is unequally dispersed after being directly added and blended with a granular material base body, the invention provides a foaming silicone master batch. The foaming silicone master batch is prepared by blending the following components in parts by weight: 100 parts of thermoplastic high-molecular resin, 70-150 parts of the silicone powder, 0.5-1 part of foaming agents and 2-8 parts of an antioxidant. The foaming silicone master batch has the advantages of light weight and low density, and is easy to blend and disperse together with the granular thermoplastic high-molecular resin.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

Phosphate leather fat liquoring agent and preparation method thereof

The invention provides a phosphate leather fat liquoring agent and a preparation method thereof. A phosphorylated polyether modified aminosilicone leather fat liquoring agent is prepared by modifying aminosilicone with allyl polyether and P2O5 serving as raw materials. An active group phosphate radical in a molecular structure can react with an amino group in a leather fiber structure, and can be tightly combined with chromium in chrome tanned leather in the form of a coordination bond, so that a phosphorylation product can be stored in leather fiber for a long time, and leather is endowed with certain flame retardance and antistatic property. A certain quantity of hydrophilic oxyethyl groups are introduced onto the molecular structure, so that the properties of water solubility, acid resistance, electrolyte resistance and the like of aminosilicone are improved effectively, and the self-emulsifying property of aminosilicone is enhanced. Aminosilicone is a leather fat liquoring agent per se, and can be used for endowing leather with higher flexibility and fullness and enhancing the physical and mechanical properties such as tear resistance, thickening rate and the like of the leather; and the leather fat liquoring agent with the structure has higher development and application values.

Owner:SHAANXI UNIV OF SCI & TECH

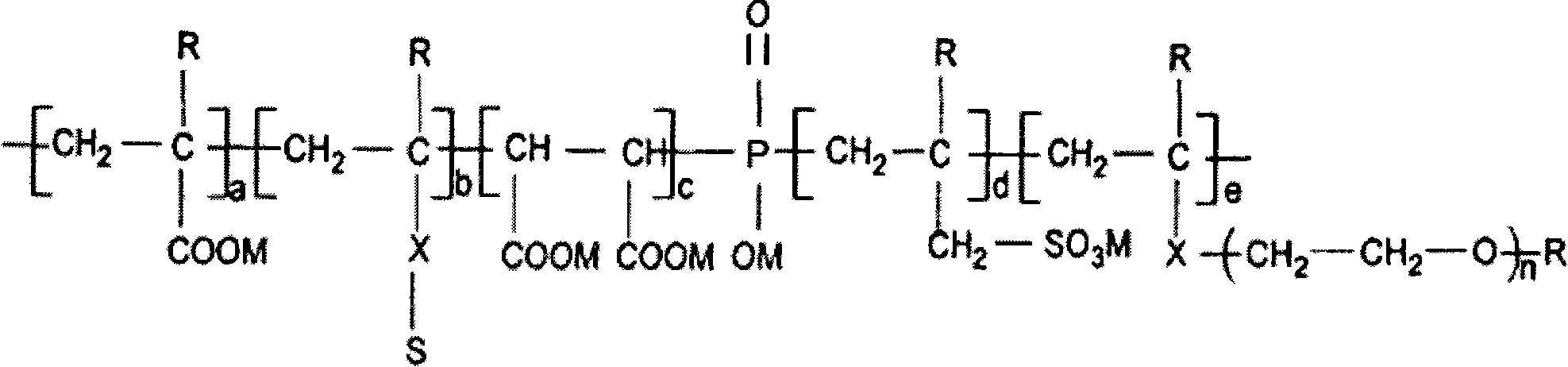

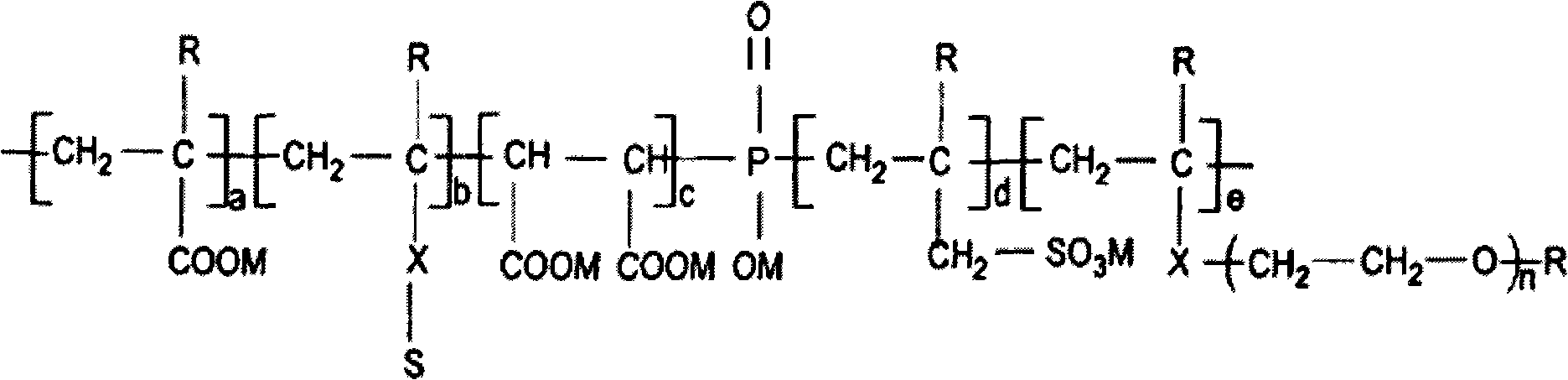

Water-soluble polymer and application thereof

ActiveCN107964070AAchieving viscosity-reducing propertiesHas viscosity reducing propertiesWater dispersibleWater soluble

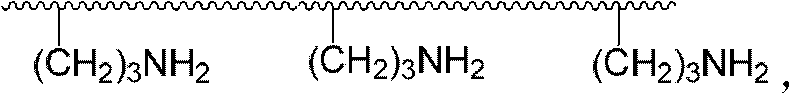

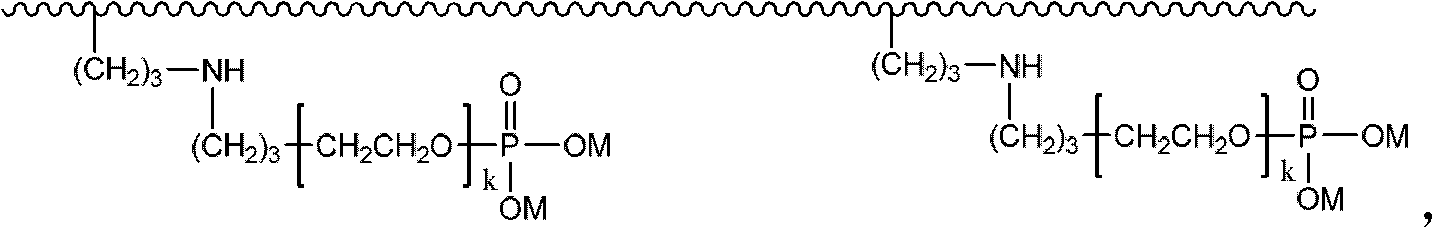

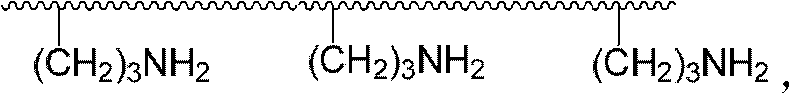

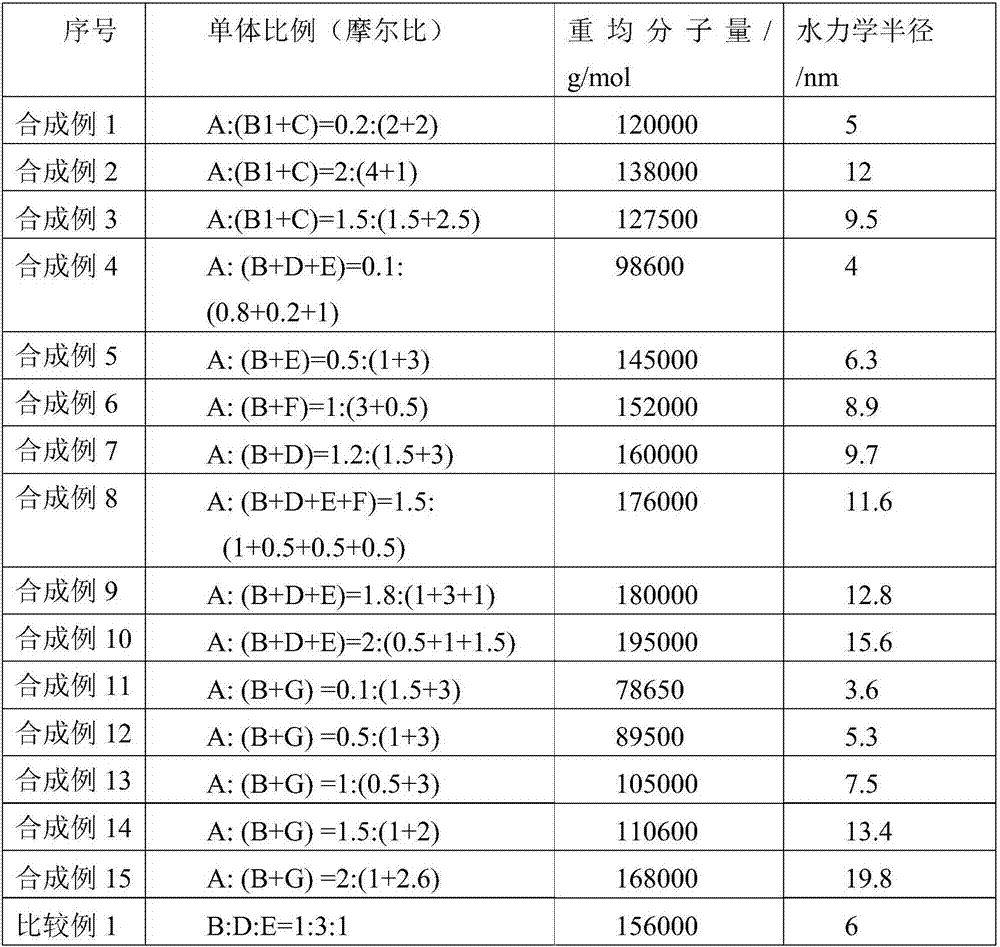

The invention provides a water-soluble polymer. The water-soluble polymer is obtained by polymerization of a hydrophobic monomer A, a macromonomer B1 and an alkenyl-containing quaternary ammonium saltmonomer C; or the hydrophobic monomer A and at least one of the macromonomer B, an acrylic monomer D, a sulfonic monomer E and a phosphonic monomer F; or the hydrophobic monomer A, the macromonomer B1 and an electroneutral monomer G. The invention also provides application of the water dispersible polymer in concrete or cement. When used as a pumping agent, the water dispersible polymer providedby the invention has viscosity reduction properties, at the same time can endow concrete with good fluidity, and segregation and bleeding resistance, and ensures considerable transmission stability.

Owner:TSINGHUA UNIV

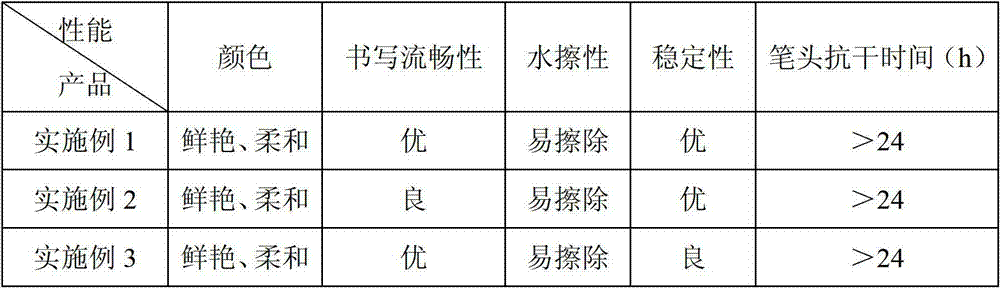

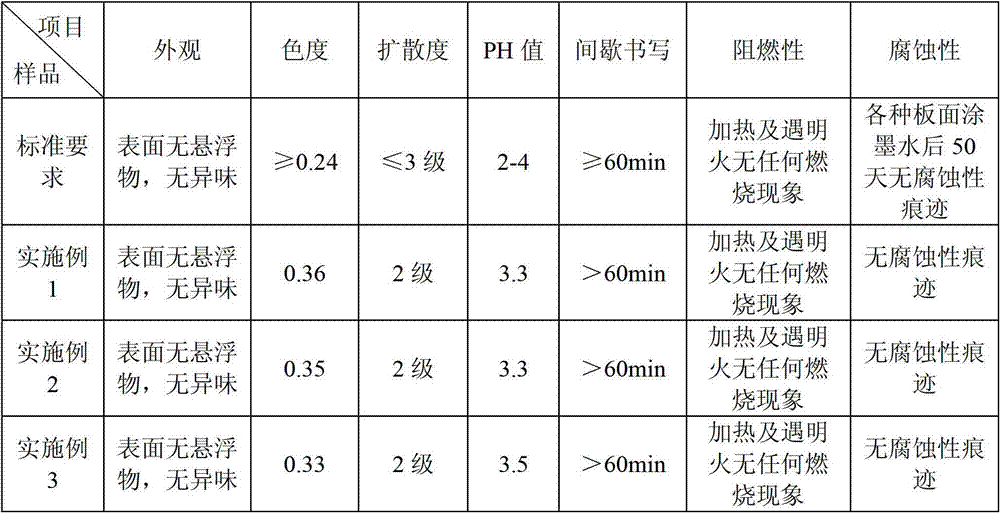

Environmental-friendly writing ink for white board pen

The invention discloses an environmental-friendly writing ink for a white board pen. The writing ink is made from the following materials in part by weight: 4-8 parts of plant pigments, 6-10 parts of emulsifying agents, 2-5 parts of castor oil, 3-7 parts of palygouskite, 15-25 parts of ethanol and 30-80 parts of deionized water. The ink has the advantages of environment protection, safety, stable long-placed performance, bright and soft color and smoothness in writing, can be quickly erased by water and is particularly applicable to the teaching white board pen.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP

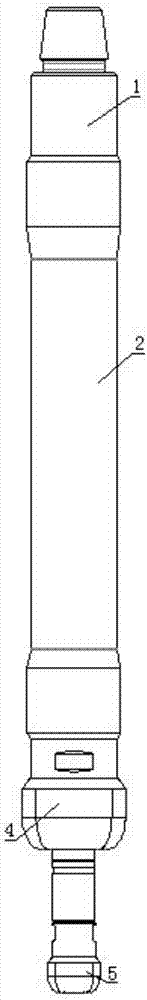

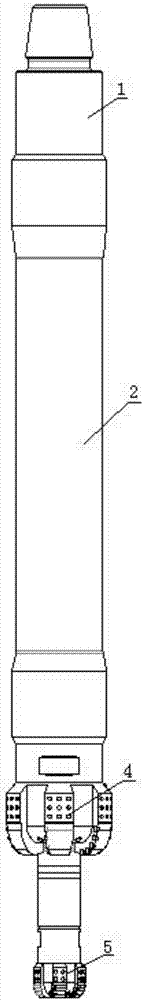

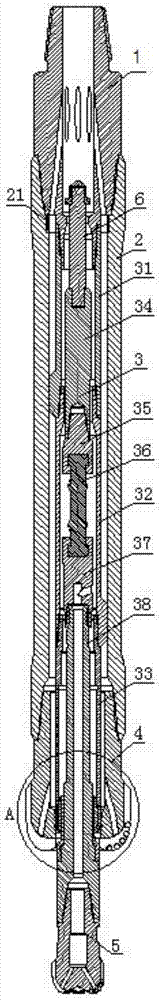

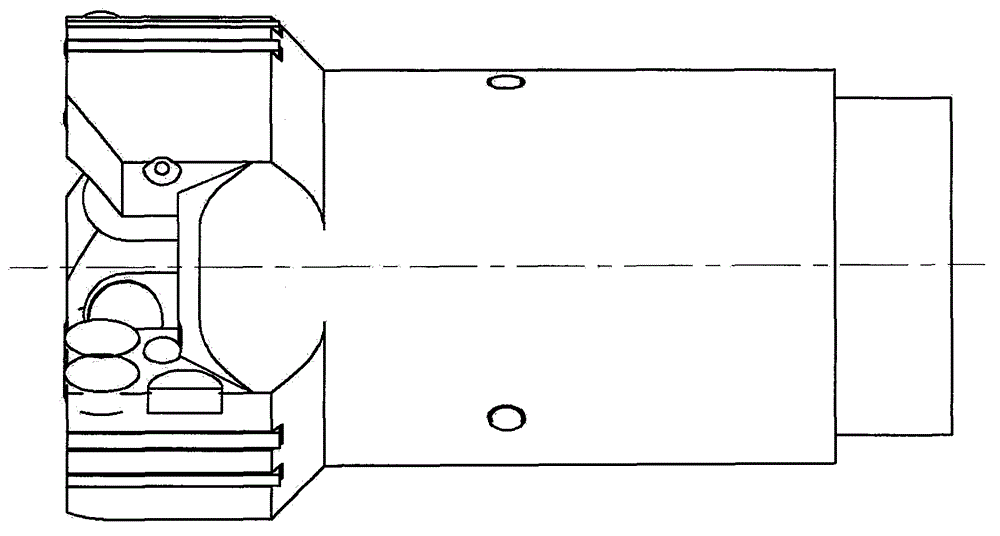

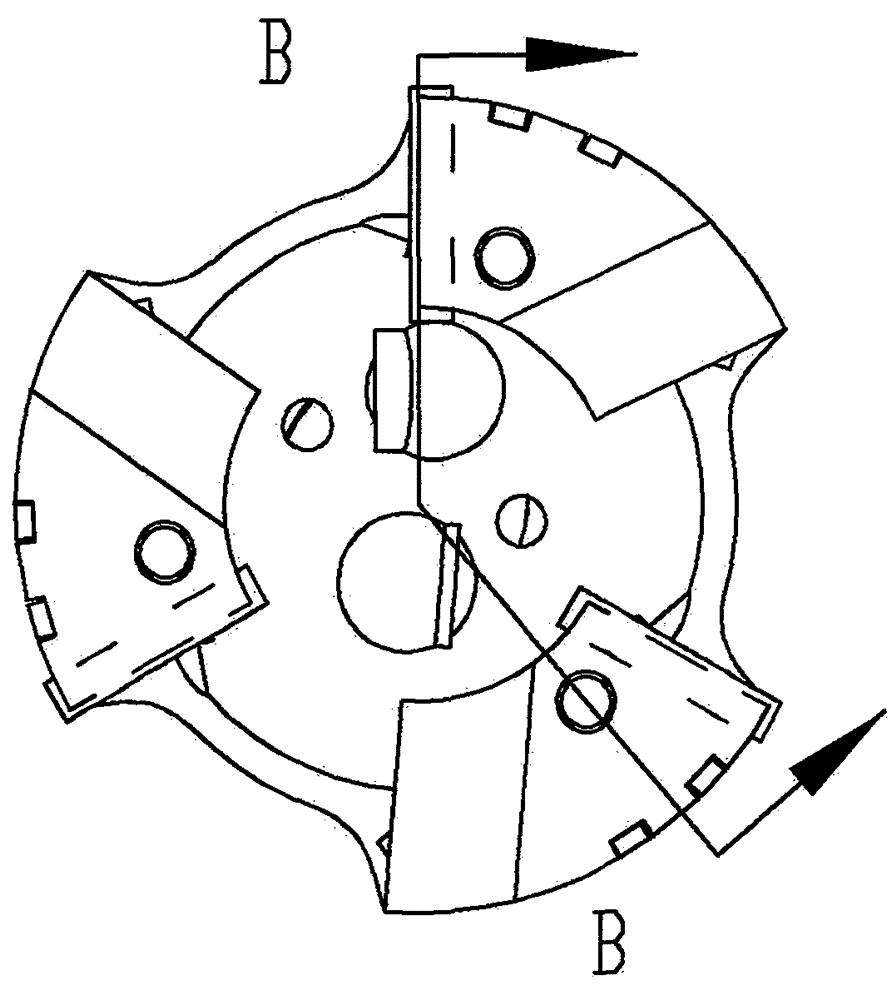

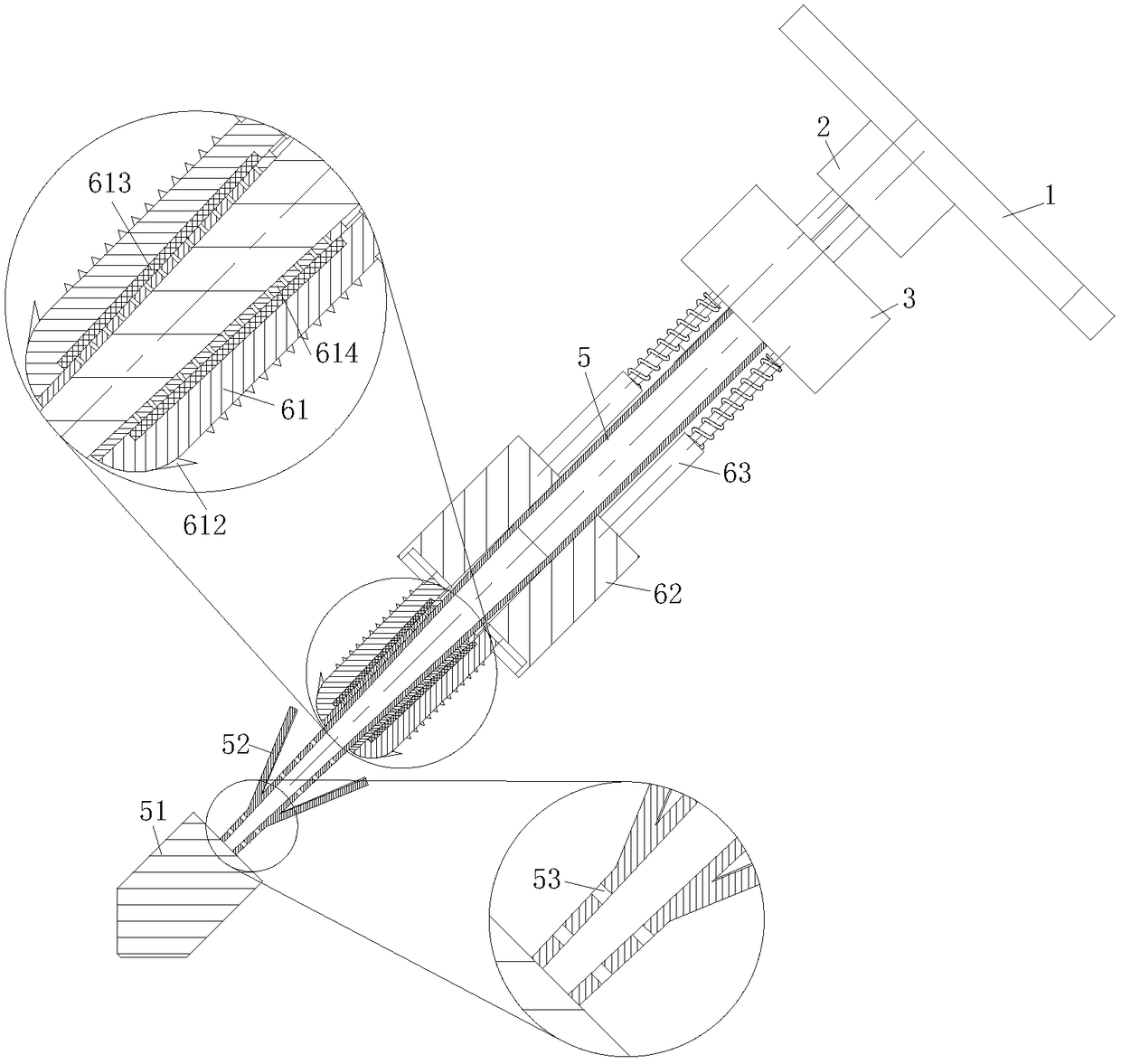

Drilling speed increasing device with composite drill bit

The invention relates to the field of petroleum and natural gas drilling equipment, in particular to a drilling speed increasing device with a composite drill bit. According to the technical scheme, the drilling speed increasing device with the composite drill bit comprises a multifunctional connector, the multifunctional connector is connected with a shell and a screw driving assembly, and the screw driving assembly is sleeved with the shell; the end, away from the multifunctional connector, of the shell is connected with a reaming drill bit body, and the end, away from the multifunctional connector, of the screw driving assembly is connected with a pilot drill bit body; water holes are formed in the reaming drill bit body and the pilot bit body; and the reaming drill bit body is a diamond drill bit or a roller bit, and the pilot bit body is a diamond drill bit or a roller bit. According to the drilling speed increasing device, the pilot bit body can achieve two-stage speed increasing, accordingly the overall drilling speed is increased, and the problems that a pilot bit of an existing two-stage drilling device is low in rotation speed and not obvious in drilling speed increasing are solved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

Multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit

InactiveCN104481411AImprove applicabilityImprove drilling efficiencyDrill bitsHigh pressure waterAlloy

The invention relates to a multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit, which is applicable to lubricating and cooling the drill bit and automatically drilling holes in a drilling process of a complex geological structure and has high drilling efficiency, long life and high applicability. The multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit comprises a special alloy crown part, and a diamond composite sheet is additionally arranged, so the wear degree of steel can be effectively relieved, the consistency in aperture is guaranteed, and the phenomenon of shrinkage is avoided. The high-pressure water jet of the drill bit is very beneficial for assisting in the drilling efficiency; the drilling diameter of the water jet is larger than the drilling diameter of the conventional mechanical rotary cut drilling, and the aperture of a soft coal seam at a local area can be increased by 20-30 times. The drill bit can be used for performing other drilling construction processes in combination with product characteristics when water circulates through a region drilled to meet the requirement of the process in a cut joint outside a fracturing breakage region, a hole collapse region, a hole blockage region, a gas accumulation region and a region with coal blast and spray holes, and the construction is integrally performed to save time and labor.

Owner:XUZHOU BOAN TECH DEV

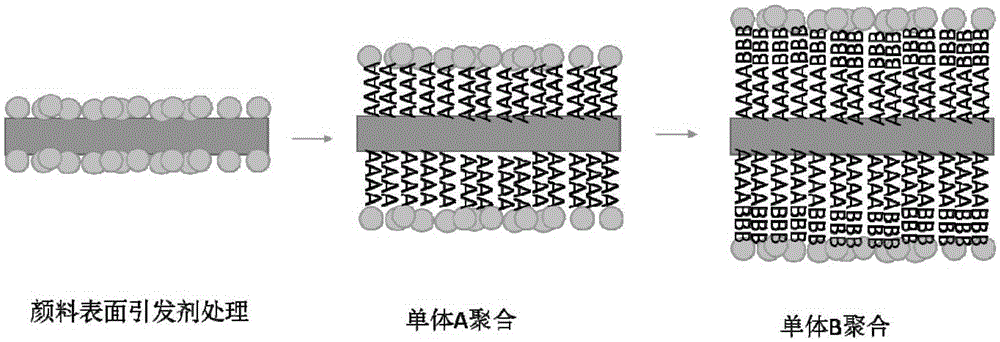

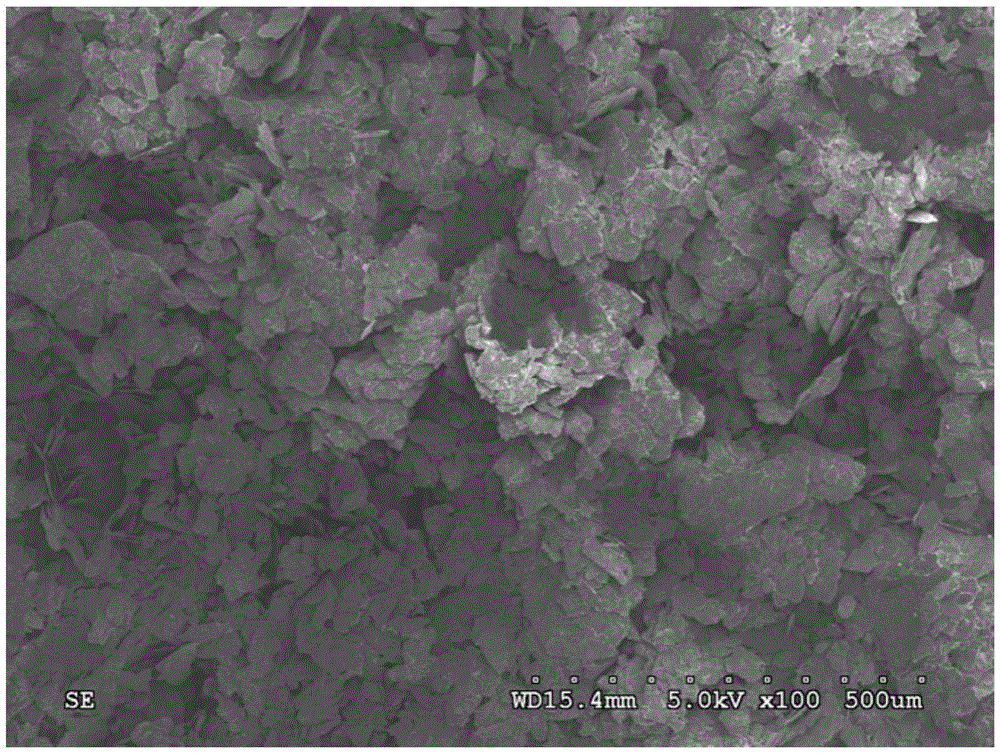

Preparation method for resin with free-spraying special texture effect

The invention belongs to the field of resin preparation technologies, and particularly relates to a preparation method for resin with the free-spraying special texture effect. According to the preparation method, an ATRP initiator is bonded on the surface of a metal pigment, monomers are precisely polymerized on the surface of the pigment one by one through controllable polymerization to form a uniform macromolecular coating, and therefore the problem that multiple flaky particles of a special-effect pigment are bonded in a crosslinking mode through traditional free radical polymerization and disorder polymerization is fundamentally solved. In addition, due to the fact that in the ATRP controllable polymerization process, the initiator is always located at the front end of a macromolecular chain and the activity of the initiator is continuously kept, the macromolecular coating can be regulated through design and selection of the monomers to enable the macromolecular coating to have the good compatibility with a resin substrate, and the dispersibility of the special-effect pigment in the resin substrate is effectively improved. The special-effect pigment coated in this way can be matched with multiple kinds of engineering plastic resin such as ABS, PC, PBT, PMMA and nylon to prepare the corresponding high-quality resin with the free-spraying special texture effect.

Owner:CHANGZHOU XUANMING NEW MATERIAL TECH CO LTD

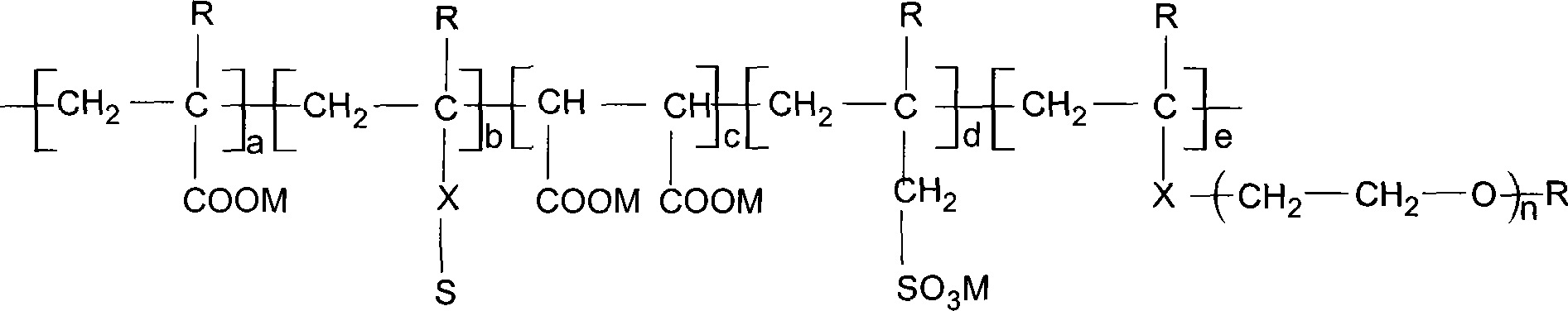

Oligose graft modification polycarboxylic acids high efficiency water reducing agent and preparation method thereof

The invention relates to a polycarboxylic acid high-efficiency water reducer and a preparation method thereof. The preparation method of oligosaccharide graft modified polycarboxylic acid high-efficiency water reducer is characterized in that it comprises the following steps: 1) functional side chain grafting: oligosaccharide and methoxypolyethylene glycol (or polyethylene glycol Diol) and unsaturated carboxylic acid (or unsaturated acid anhydride) carry out esterification reaction to obtain esterification product; 2) free radical copolymerization: the esterification product, unsaturated carboxylic acid (or unsaturated acid anhydride), sulfonic acid group Free radical copolymerization of monomers in aqueous solution according to a certain ratio to obtain copolymerized products; after the reaction is completed, add alkali solution to adjust the pH to 7-8 to obtain the product. The product of the invention has excellent and stable performance, simple synthesis process, easy control of reaction conditions, wide source of raw materials, can reduce production cost, and has certain green and environmental protection functions.

Owner:WUHAN UNIV OF TECH

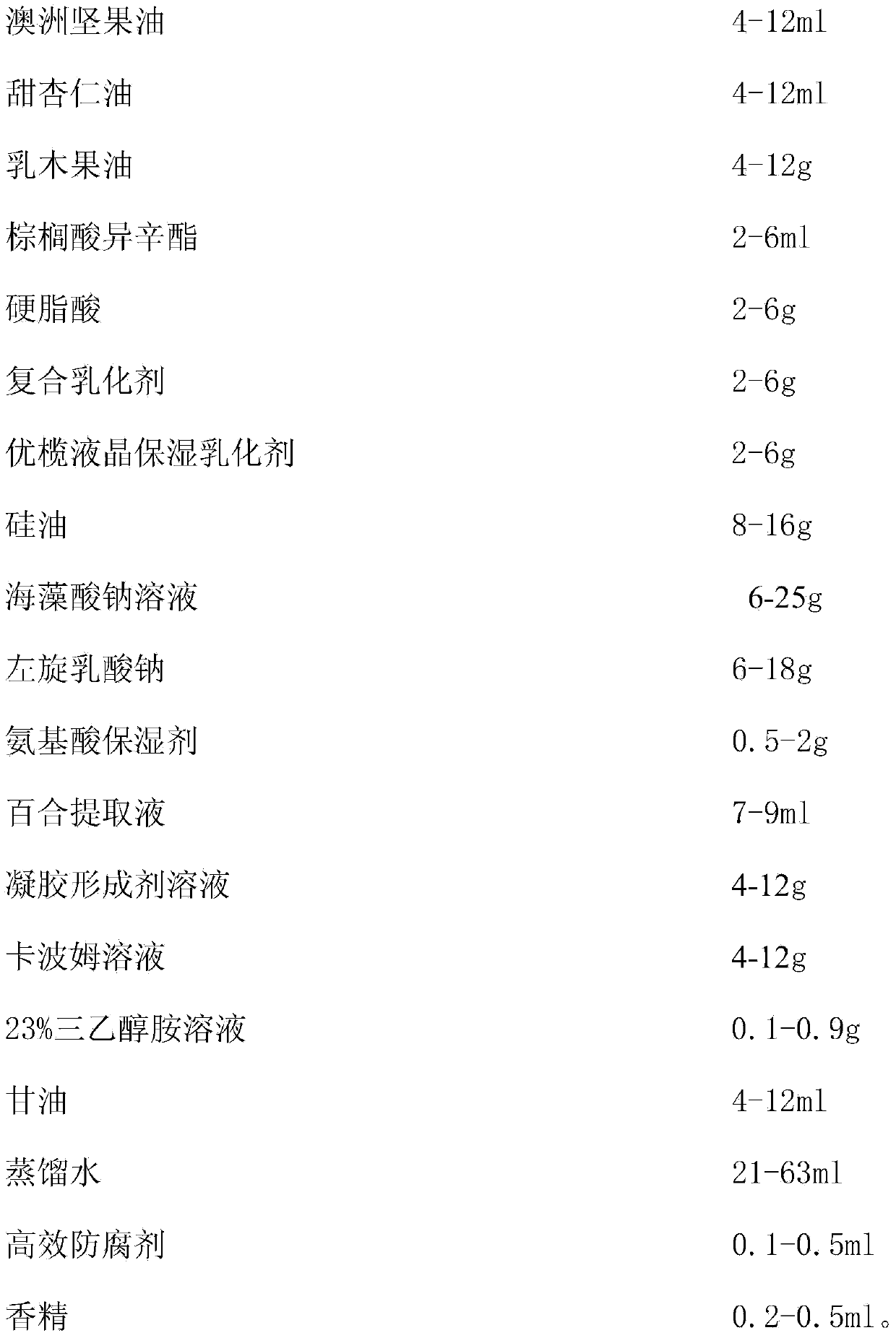

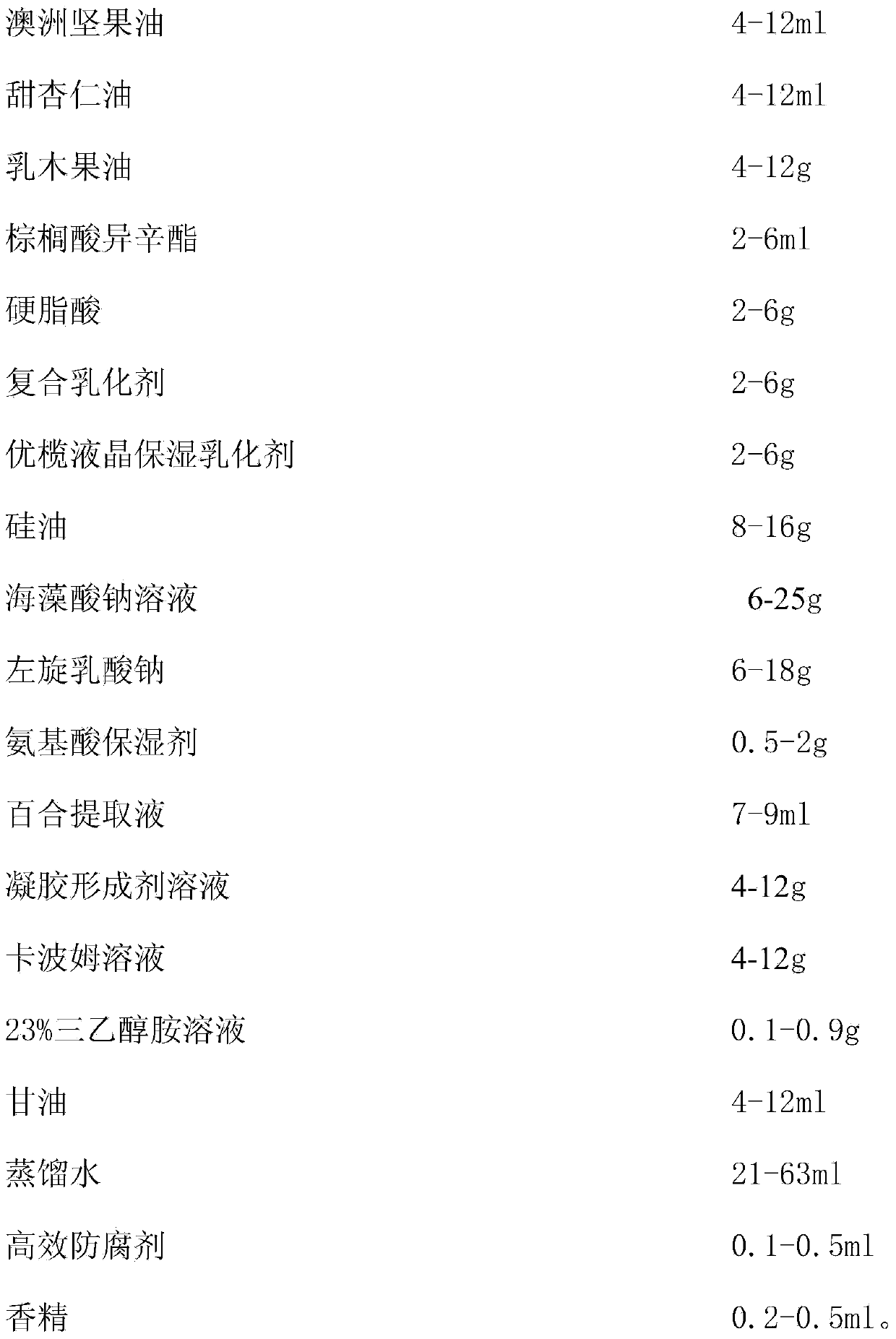

Shining, moisturizing and skin-finishing cream and preparation method thereof

ActiveCN103989601ANot easily oxidizedImprove permeabilityCosmetic preparationsToilet preparationsSodium lactateAdditive ingredient

The invention relates to shining, moisturizing and skin-finishing cream and a preparation method thereof. The cream comprises the following matters: macadimia nut oil, sweet almond oil, shea butter, isooctyl palmitate, stearic acid, a compound emulsifier, a superior olive liquid crystal moisturizing emulsifier, silicone oil, a sodium alginate solution, left-handed sodium lactate, an amino acid moisturizer, a lily extracting solution, a gel formation agent solution, a Carbomer solution, a 23% triethanolamine solution, glycerol, distilled water, an efficient preservative and essence. Compared with the prior art, a lot of natural plant components are added into the cream prepared by the invention, so that the cream is suitable for various skins. On the one hand, facial cells are accelerated to regenerate by lily essence, left-handed sodium lactate and the like to realize the shining effect. On the other hand, natural plant oils such as macadimia nut oil and sweet almond oil are used, so that the facial skin has the moisturizing and skin-finishing effect, metabolism is accelerated, moisture of skin is prevented from losing, and the facial skin is ruddy and glossy.

Owner:江西登云健康美业互联有限公司

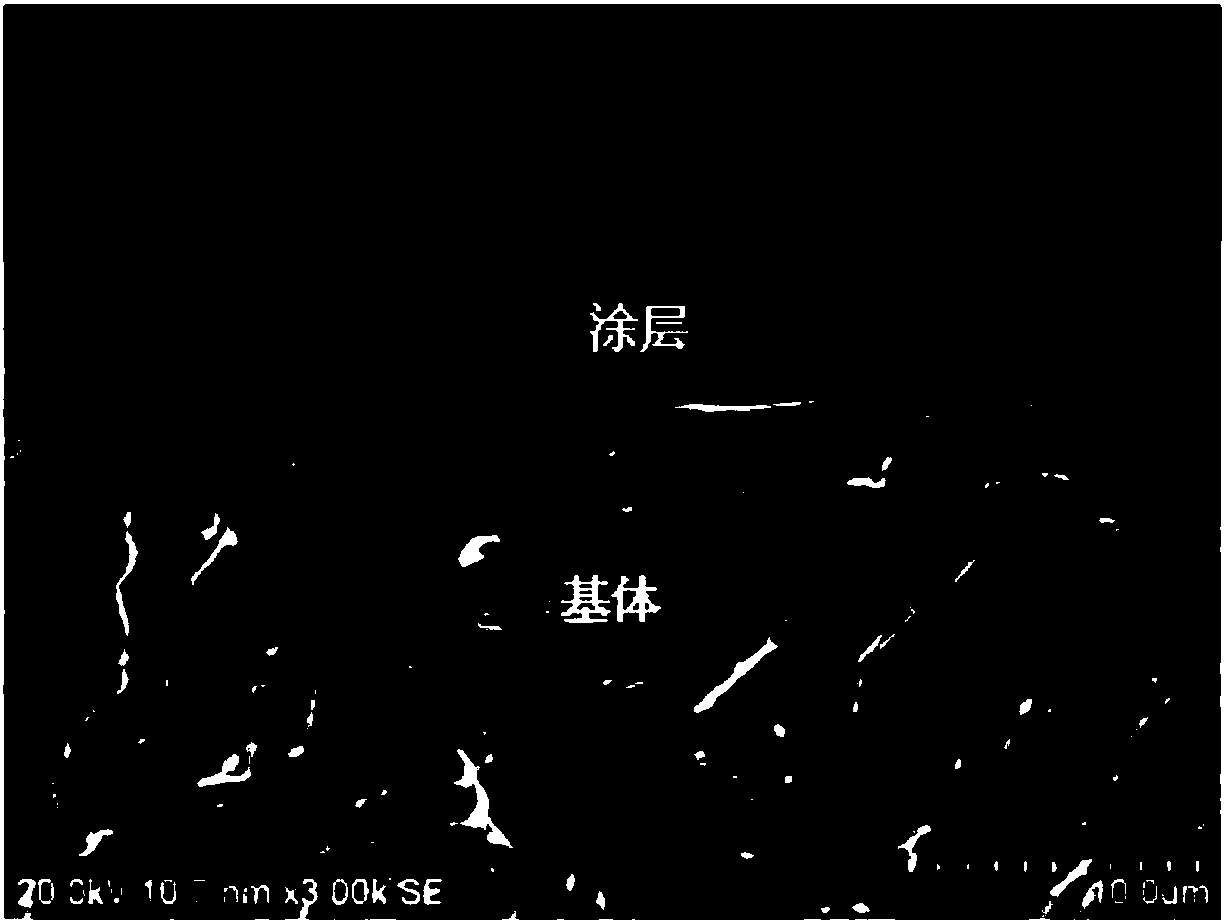

Ti-Cu-N nanometer composite anti-microbial coating and preparation method thereof

InactiveCN108070829ARefine the grain sizeReduce internal stressVacuum evaporation coatingSputtering coatingMicrometerHardness

The invention belongs to the technical field of metal material surface deposition nanometer composite anti-microbial coatings and particularly relates to a titanium nitride copper (called Ti-Cu-N in the following) nanometer composite anti-microbial coating and a preparation method thereof. A transition layer formed by a Ti film, a middle layer formed by a TiN film and a Ti-Cu-N layer are sequentially arranged on the surface of a base body, and the thickness of the Ti-Cu-N nanometer composite anti-microbial coating ranges from 1 micrometer to 10 micrometers. According to the coating, the magnetic field enhancement arc ion plating technology is adopted for completion, and the nanometer composite anti-microbial coating prepared through the method has good anti-microbial performance and also has the beneficial effects of being high in hardness, good in coating toughness, resistant to abrasion and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

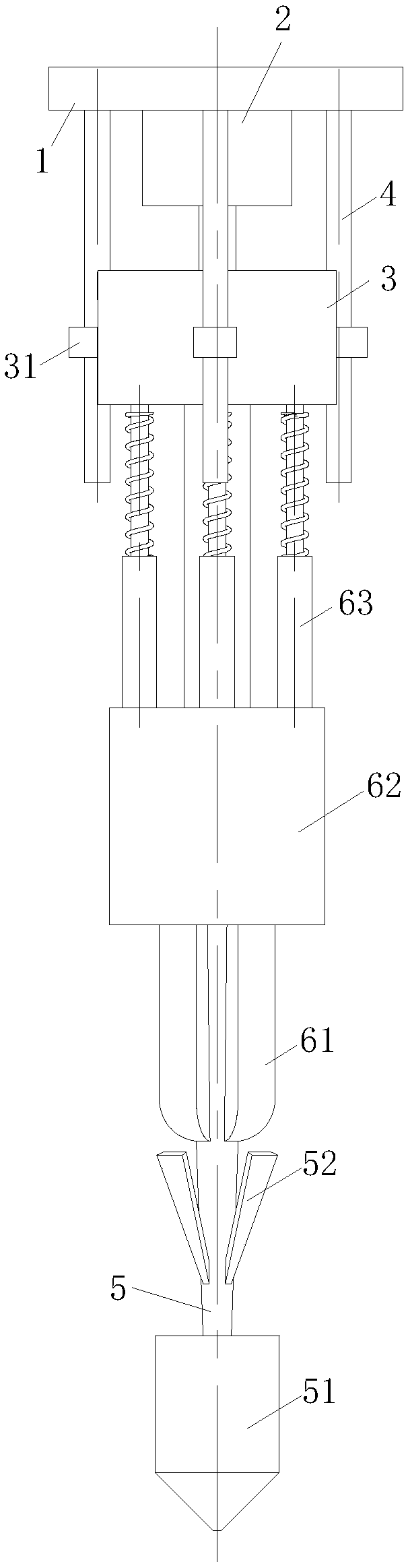

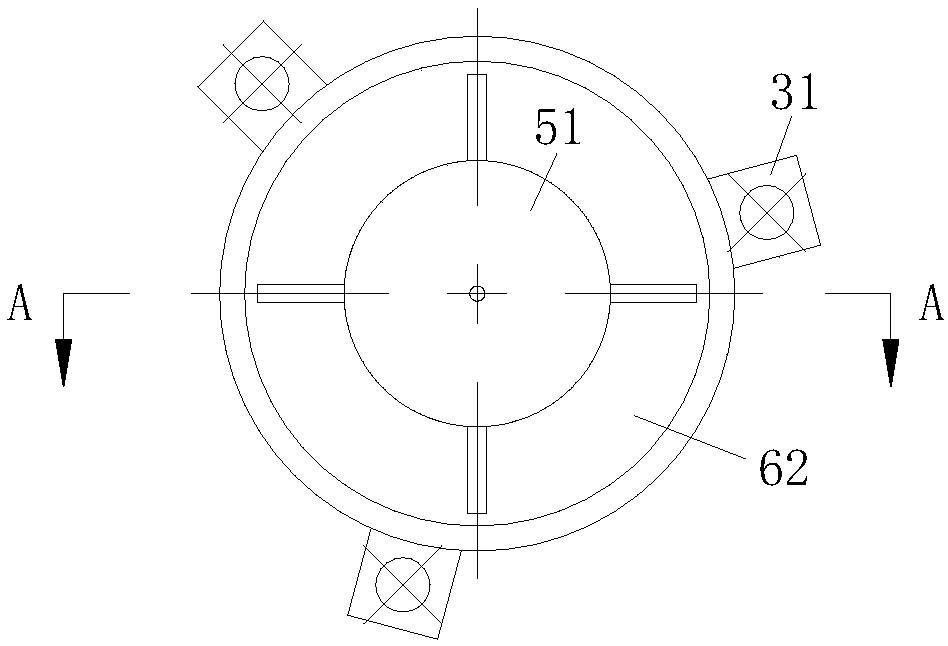

Rock drilling and braking integrated machine

ActiveCN108222931AAchieve brokenAvoid repositioningConstructionsSlitting machinesEngineeringDrill bit

The invention belongs to the field of drilling and splitting devices, and particularly discloses a rock drilling and braking integrated machine. The rock drilling and braking integrated machine comprises a fixed plate, an oil cylinder, a motor, a guide pillar, a pushing ram and a crushing module. The oil cylinder is fixed on the fixed plate, the end head of the oil cylinder is fixedly connected with the motor, a group of sliding blocks are fixedly arranged on the periphery of the motor, and the sliding blocks are connected to the guide pillar in a sleeving mode. The guide pillar is arranged onthe fixed plate, the oil cylinder can push the motor to move up and down along the guide pillar, and a rotating shaft of the motor is fixedly connected with the pushing ram, and the periphery of thepushing ram is connected with the crushing module in a fit mode. The crushing module comprises a wedge block, an installation disk and an expansion link, and the end head of the pushing ram is fixedlyconnected with a drill. When the rock drilling and braking integrated machine is drilled to the design depth, under the action of the pushing ram, the crushing module expands the hole to the surrounding area to achieve rock breaking. The rock drilling and braking integrated machine integrates drilling and splitting to avoid secondary positioning of a crushing rod, so that the drilling and splitting work is carried out in a coherent mode, the working process is simplified, and the working efficiency is improved.

Owner:淮北通鸣矿业有限公司

Preparation method for high-compactness niobium oxide rotary target material

InactiveCN103668068ALow resistivityImprove conductivityVacuum evaporation coatingSputtering coatingCeramic moldingOmega

The invention relates to a preparation method for a high-compactness niobium oxide rotary target material, relates to a preparation method for a ceramic molding product by using niobium oxide as base material, and aims to solve the technical problem that the rotary target material produced through the conventional spraying technology is low in density. The preparation method comprises the following steps: I, pre-treating niobium oxide powder; II, using a hot-pressing sintering process and a high-temperature demoulding process to prepare the crude product of a rotary target; III, performing finish machining on the crude product of the rotary target. The preparation method has the advantages that the cost is low, the cycle is short, energy consumption is low, and the production efficiency is high. The rotary target material prepared through the preparation method is no less than 4.59 / cm<3> in density, less than 9*10-3 omega.cm in electrical resistivity, good in conductivity, and high in yield. The prepared rotary target material is applied to the fields of solar cells, liquid crystal displays, ion displays, mobile phone touch screens, optical glass and gas sensors.

Owner:河北东同光电科技有限公司

Method for rapidly synthesizing polycarboxylic acid water reducers through microwaves and supersonic waves

InactiveCN102826783AWide variety of sourcesReduce manufacturing costOrganic synthesisPolyethylene glycol

A method for promoting the synthesis of polycarboxylic acid system cement water reducers through using microwaves and supersonic waves utilizes the microwaves to improve the temperature of reactants to make the interface temperature rapidly reach above 80DEG C. The reactants rapidly complete a reaction through stirring and vibrating reaction mediums by supersonic waves. The time for completing the reaction of the reactants is reduced to 10-30min under the radiation of the microwaves and the supersonic waves from original 5-10h. The method belongs to the organic synthesis field. In the invention, the relation between performance requirements of the cement water reducer and the monomer molecule structure activity is analyzed, and the monomer molecule structure selection and the monomer ration are optimized, so monosaccharide oligosaccharides comprising glucose and maltose, polyethylene glycol, hydroquinone, sodium methylbenzenesulfonate, methylpropylbenzene, sodium sulfonate, ammonium persulfate and sodium hypophosphite are selected. A microwave and supersonic wave technology is introduced on the basis of the adoption of the ammonium persulfate and the sodium hypophosphite as the initiators to rapidly synthesize polycarboxylic acid system water reducer products through utilizing the microwaves and the supersonic waves. The method provided by the invention has the advantages of substantial time shortening, energy consumption reduction, pollution reduction, and improvement of the paste fluidities of the products, is a new method having the characteristics of safety, high efficiency and energy saving, environmental protection and simple operation, and accords with the trend of times.

Owner:谢艾民

Method and device for reducing metal dust in electric wire and cable drawing process

The invention relates to a method and a device for reducing metal dust in the electric wire and cable drawing process. A heating tube is mounted in front of a wire inlet of drawing equipment, two ends of the heating tube are sealed with sealing pads made of high-temperature-resistant materials, in-out ports matched with the diameter of a metal pole required to be drawn in size are reserved in the sealing pads at two ends, and the metal pole required to be drawn directly enters a first die of the drawing equipment after heated in the heating tube. The temperature in the heating tube is set to range from 300 DEG C to 350 DEG C if the metal pole is made of copper and set to range from 300 DEG C to 320 DEG C if the metal pole is made of an aluminum and aluminum alloy. With the adoption of the method and device, production of the metal dust is avoided essentially, the safety performance is improved, harm of the metal dust to the body health of a worker and serious accidents are avoided, the work efficiency is improved, the production cost is saved, the product quality is guaranteed, and the method and the device have great usage value.

Owner:SINOSTAR CABLE CO LTD

Passive wireless centralized reading meter

The invention belongs to the technical field of water meter processing and discloses a passive wireless centralized reading meter. The water meter comprises a shell, wherein the shell is prepared from the following raw materials: talcum powder, titanium carbide, molybdenum disulfide, glass fibers, graphite fibers, kaolin, attapulgite, boric acid, hydroxyethyl cellulose, polydimethylsiloxane, chitosan, polycarbonate, phenolic resin, aluminum nitride, silicon carbide, aluminum oxide, copper powder and iron powder. The passive wireless centralized reading meter disclosed by the invention is wide in application range and good in stability and has good application prospects.

Owner:HAIMEN CANGYUN MACHINERY CO LTD

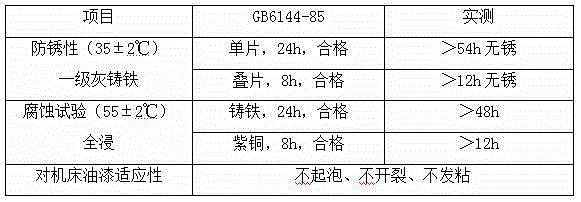

Anti-corrosive cutting fluid

InactiveCN104611119AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene glycolPhytosterol

The invention discloses anti-corrosive cutting fluid. The anti-corrosive cutting fluid comprises the following materials in parts by weight: 0.1-0.2 part of phosphotungstic acid, 0.7-1 part of tetramethylammonium nitrate, 1-2 parts of naphthenic soap, 2-3 parts of toluene diisocynate, 1-2 parts of sodium benzoate, 0.6-1 part of methyl isobutyl ketone, 0.1-0.2 part of zinc cyanurate, 3-5 parts of barium petroleum sulfonate, 0.6-1 part of 8-hydroxyquinoline, 0.8-2 parts of calcium lactate, 0.7-2 parts of isopropyl palmitate, 0.5-1 part of phytosterol, 0.8-1 part of methyl tin mercaptide, 70-80 parts of deionized water, 2-3 parts of polyaniline and 6-7 parts of rare-soil function additives. The anti-corrosive cutting fluid disclosed by the invention has the advantages that in the added rare-soil function additives, alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified, so that the stable anti-rusting effect can be achieved; due to the added nano silicon dioxide, certain lubricity can be achieved, the cutting force, the friction and the power consumption can be reduced; lanthanum sulfate not only has certain anti-corrosive property, but also can improve the anti-corrosive and slow-release effects; and the additives have good oleophilic and hydrophilic properties and high emulsifying and dispersing performances, and the anti-corrosive property, the lubricity, the anti-rusting property and the stability of finished cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

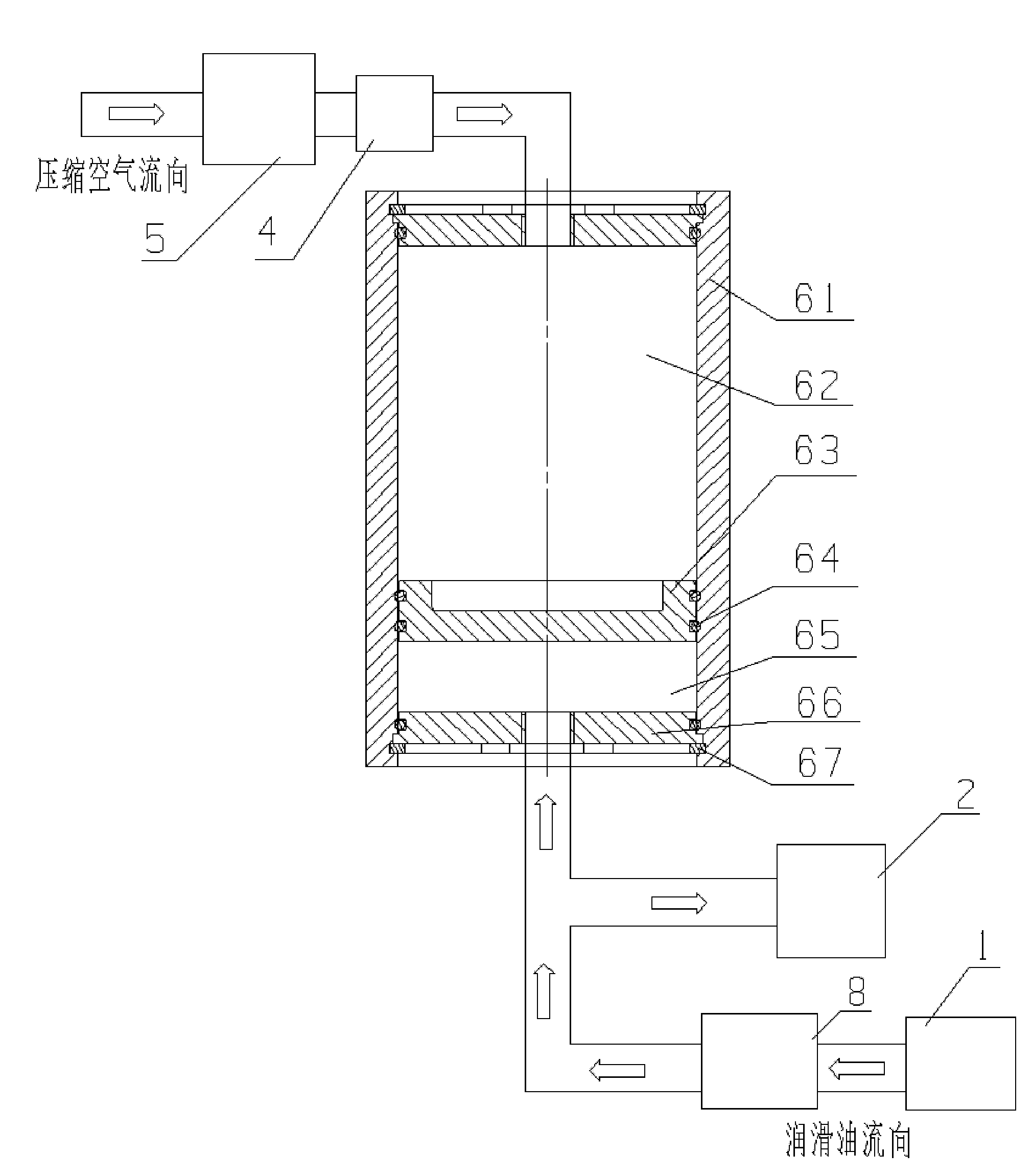

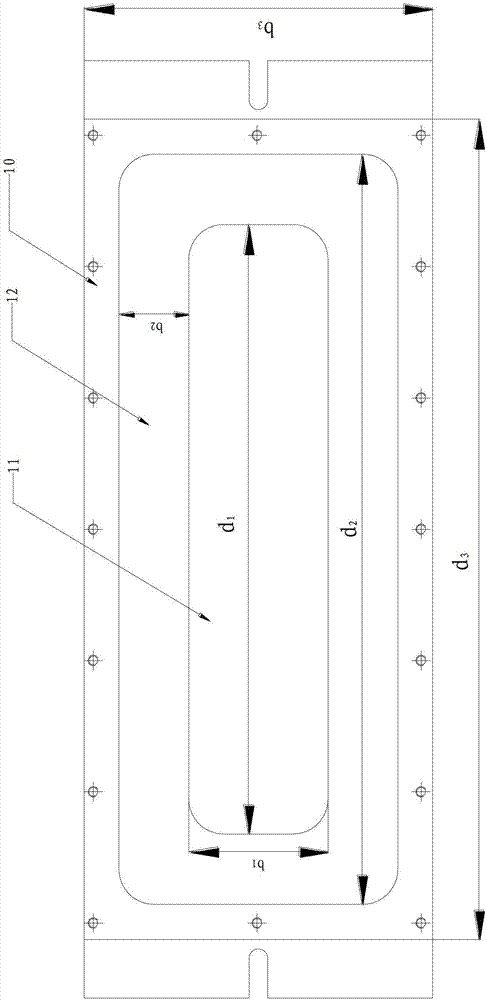

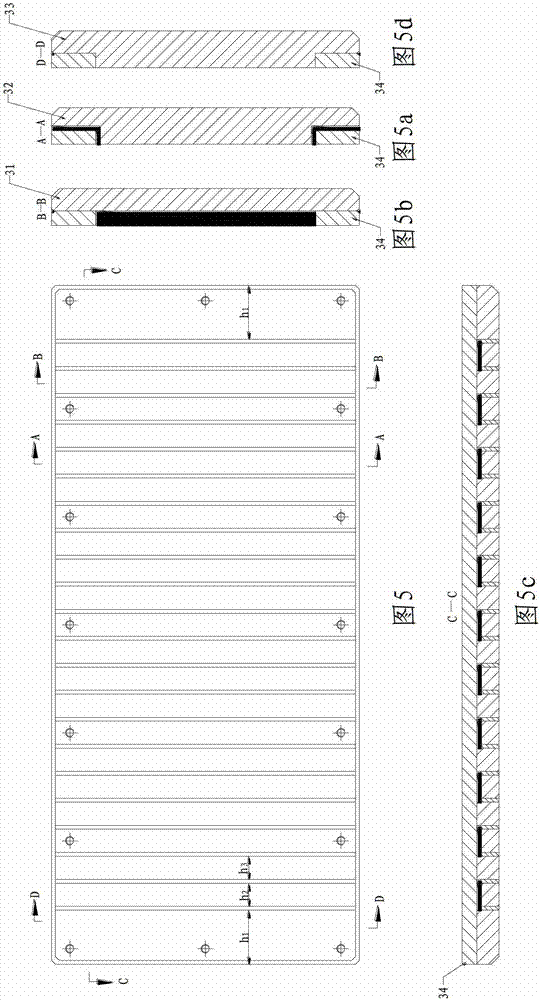

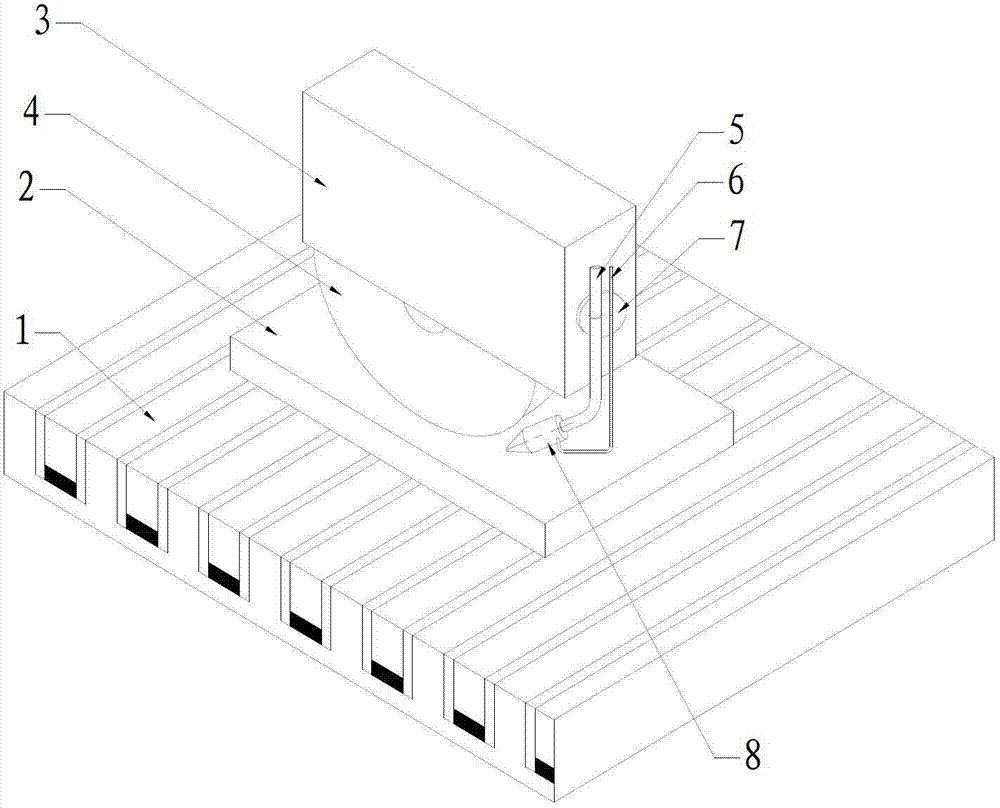

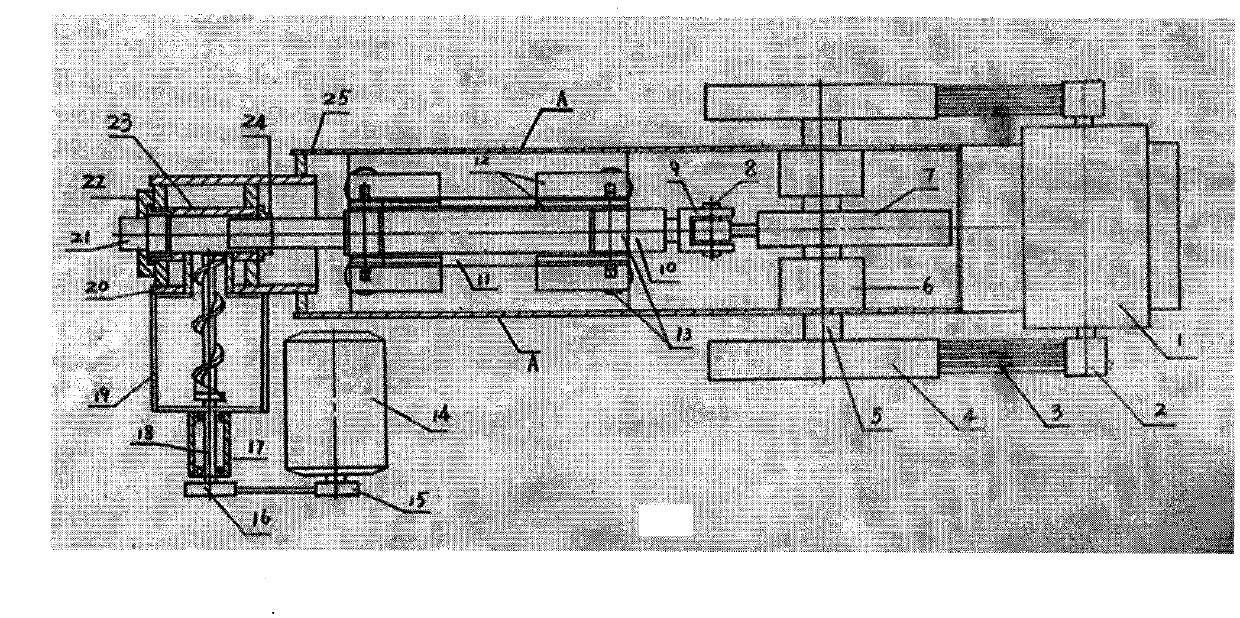

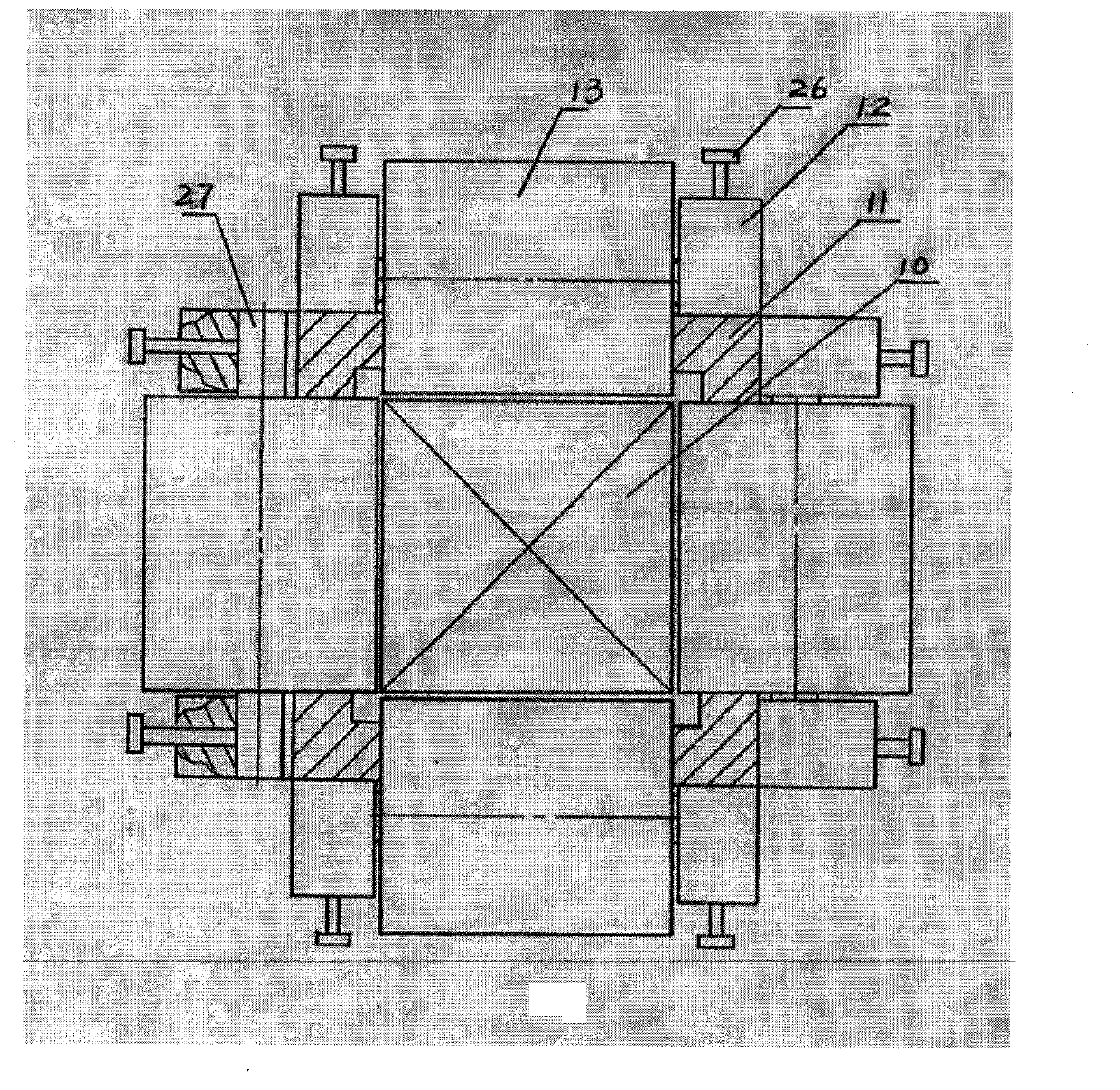

Magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming process and device

ActiveCN103192323AImprove adsorption capacityImprove cooling effectGrinding/polishing safety devicesMagnetic tension forceMagnetite Nanoparticles

The invention relates to a magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming process and a magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming device. The magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming device includes a magnetic force working table onto which a work piece is attached; a grinding wheel is arranged on the processing position of the work piece, a nozzle is arranged on the position of the grinding wheel cover, and the position of the grinding wheel cover is matched with the work piece; the nozzle is connected with a magnetic nanofluid liquid supply device through a magnetic nanofluid delivery pipe, and connected with an air compressor through an air compressor delivery pipe; the magnetic nanofluid and compressed air formed into a three-phase flow spray after being mixed and accelerated in the nozzle, wherein the three-phase flow spray is a mixed spray of the compressed air, the magnetic nanoparticles and grinding-fluid-based oil particles; and the three-phase flow spray enters the grinding area between the work piece and the grinding wheel, the magnetic force working table is in magnetic coupling with the three-phase flow spray, and an oil film is formed on the surface of the work piece. The magnetic nanoparticle jet flow and magnetic force working table coupling oil film forming device delivers the magnetic nanoparticle fluid to the nozzle and forms a lubricating oil film on the surface of the work piece of the magnetic worktable, so that the maximum cooling and lubricating of a grinding processing area is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

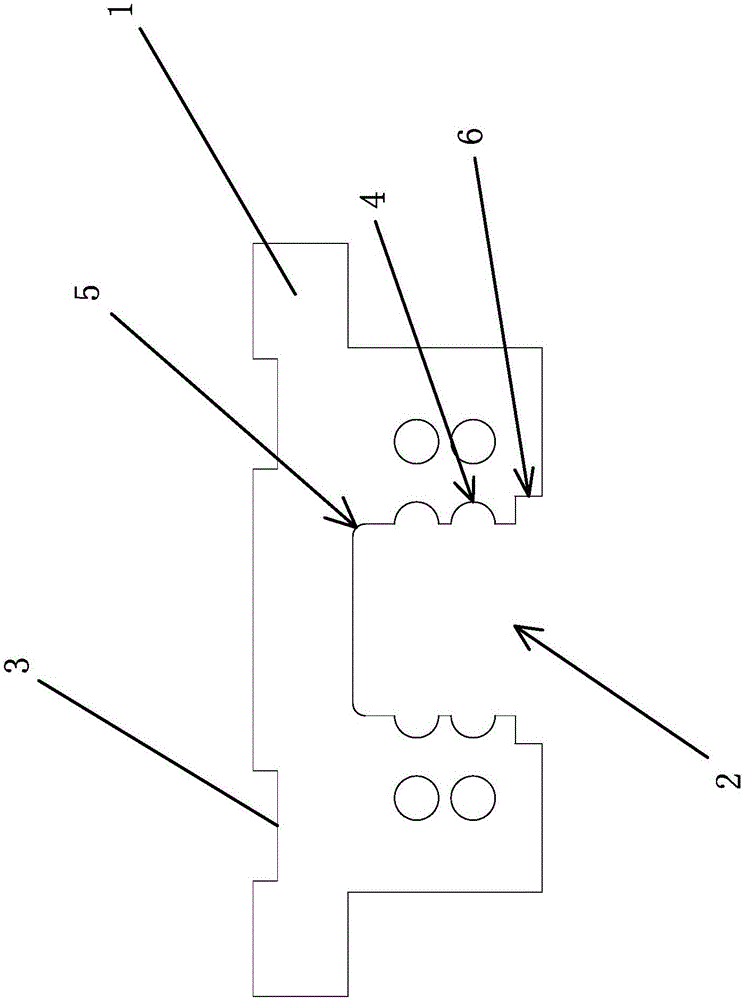

Linear guide rail pair and machining technology thereof

The invention provides a linear guide rail pair and a machining technology thereof, and belongs to the technical field of linear guide rail pairs. The linear guide rail pair comprises a sliding block body. The linear guide rail pair is characterized in that the body is in a U shape; a guide rail groove is formed in the bottom of the body, an installing groove is formed in the upper end face of the body, and two arc load grooves for supporting balls are formed in the inner walls of the two sides of the guide rail groove respectively; the two corners of the bottom of the guide rail groove are circular chamfers; and steps are arranged at the opening ends of the guide rail groove. The machining technology of the linear guide rail pair comprises the following steps of raw material preparing, head cutting, head rolling, head grinding, polishing, parkerising, saponifying and drawing. According to the linear guide rail pair, a unique double-arc structure is adopted in the load grooves, and when the impact load and the heavy load are borne, the bearing contact area is enlarged, and the rigidity of the system is improved. According to the machining technology of the linear guide rail pair, one-time joint forming is achieved during drawing, a plurality of later machining procedures are omitted, and cost, labor and the production time are saved.

Owner:浙江建鑫型钢科技股份有限公司

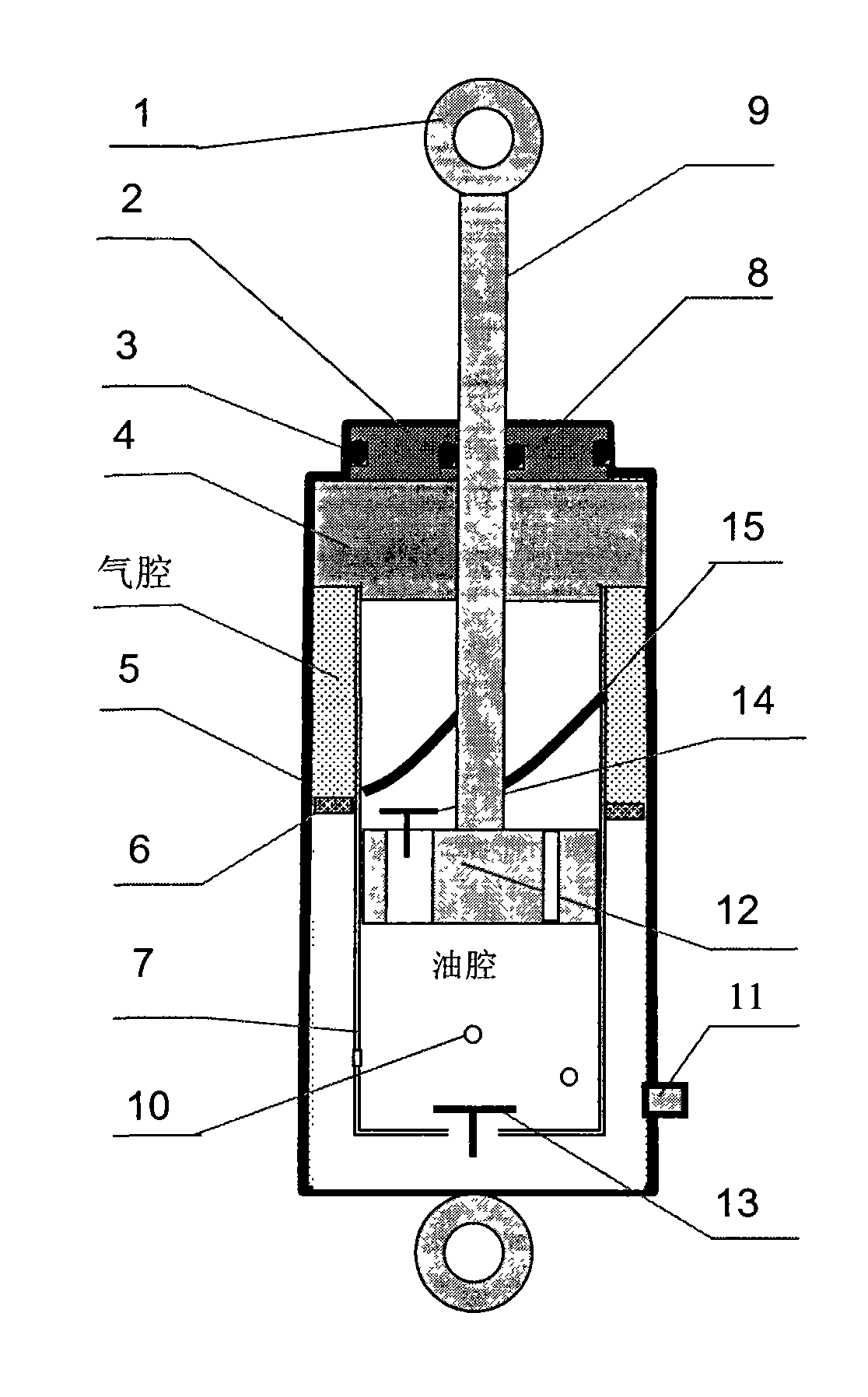

Load bearing type damping changing impact damper

InactiveCN101178107AImprove carrying capacityGood nonlinear characteristicsSpringsGas and liquid based dampersGas springEngineering

The invention relates to a bearing-typed variable damper used for an automobile suspension, comprising a dual-cylinder oil cylinder with an internal cavity and an external cavity with an upper port consisting of an internal cylinder and an external cylinder sealed by a guider and a sealing seat, a piston arranged in the internal cavity of the oil cylinder and a piston rod connected with the piston, a check valve in the bottom part of the internal cylinder communicated with the internal cavity and the external cavity of the dual-cylinder oil cylinder, a piston check valve arranged on the piston and communicated with an upper cavity and a lower cavity, and a charging connector arranged at the lower part of the external cylinder. The invention is characterized in that the piston check valve is a normal check valve without throttle holes; the side wall at the lower part of the internal cylinder is provided with a compressed damping hole communicated with the internal cavity and the external cavity; a static seal is arranged between the sealing seat and the external cylinder; a high pressure sealing ring is arranged between the sealing seat and the piston rod. The structure of the invention is designed between the normal dual-cylinder damper and an oil-gas spring. Owning to the adopted high pressure sealing structure, the invention has the advantages of bearing static loads, and leading the normal automobile suspension to increase the bearing capability and to have the ideal nonlinear characteristic.

Owner:郭孔辉

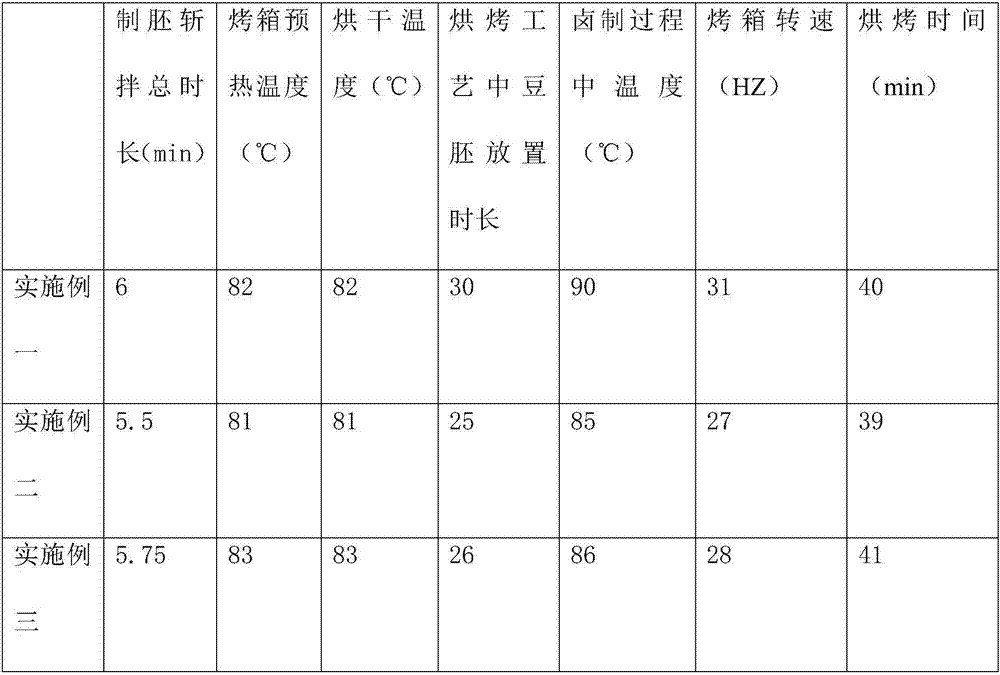

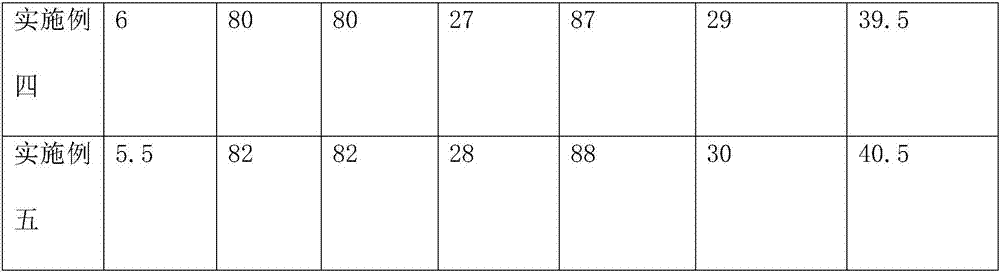

Processing technology of walnut dried tofu

The invention discloses a processing technology of walnut dried tofu. The processing technology comprises blank making, refrigeration, blank cutting, marinating, baking and mixing. The processing technology disclosed by the invention solves the problems of bad mouthfeel and single taste of existing dried tofu.

Owner:贵州健素食品科技有限公司

Cutting fluid for machine tool

InactiveCN104611110AGood hydrophilic and lipophilic propertiesGood emulsifying and dispersing propertiesLubricant compositionPolyethylene glycolDiphenylamine

The invention discloses cutting fluid for a machine tool. The cutting fluid comprises the following materials in parts by weight: 0.5-1 part of alkylated diphenylamine, 2-3 parts of tetrabutyl titanate, 0.6-1 parts of potassium fluotitanate, 3-5 parts of allyl polyethylene glycol, 0.8-1 part of barium stearate, 1-2 parts of methyl pentachlorostearate, 0.3-1 part of 2-bromo-4-methylphenol, 1-2 parts of dioctyl azelate, 1-3 parts of sodium hydrogen sulfite, 0.4-1 part of molybdenum disulfide, 2-3 parts of potassium citrate, 70-80 parts of deionized water, 6-7 parts of rare-soil functional additive and 6-8 parts of boric acid. The cutting fluid disclosed by the invention has the advantages that in the added rare-soil function additives, alkenyl succinate, wool fat and polyethylene glycol 4000 are blended and modified, so that the stable anti-rusting effect can be achieved; due to the added nano silicon dioxide, certain lubricity can be achieved, and the cutting force, the friction and the power consumption can be reduced; lanthanum sulfate not only has certain anti-corrosive property, but also can improve the anti-corrosive and slow-release effects; and the additives have good oleophilic and hydrophilic properties and high emulsifying and dispersing performances, and the anti-corrosive property, the lubricity, the anti-rusting property and the stability of finished cutting fluid can be effectively improved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Stamping type granulator

Provided is a stamping type granulator. Two ends outside a spindle (5) are sleeved by bearing seats (6), an eccentric wheel (7) is installed in the middle of the spindle (5), a connection rod shaft (8) is connected with a connection rod seat (9) and the eccentric wheel (7), one end of a stamping rod (10) is connected with the connection rod seat (9), the other end of the stamping rod (10) is located on one side in a stamping chamber (23), and the other side in the stamping chamber (23) is provided with a stamping die (21). The stamping die (21) is installed on a stamping seat (20). One end of an auger shaft (18) is fixed on an auger seat (17), the other end of the auger shaft (18) passes through a feeding hopper (19) to enter the stamping chamber (23), and a small belt pulley (16) is installed on the auger shaft (18). Two pulley groups are welded on two ends of a square frame (11), a middle section of the stamping rod (10) is a cuboid. Pulleys (13) at two ends of the square frame (11) clamp the stamping rod (10). The stamping type granulator greatly prolongs the service life of accessories and improves the efficiency.

Owner:汤晓春

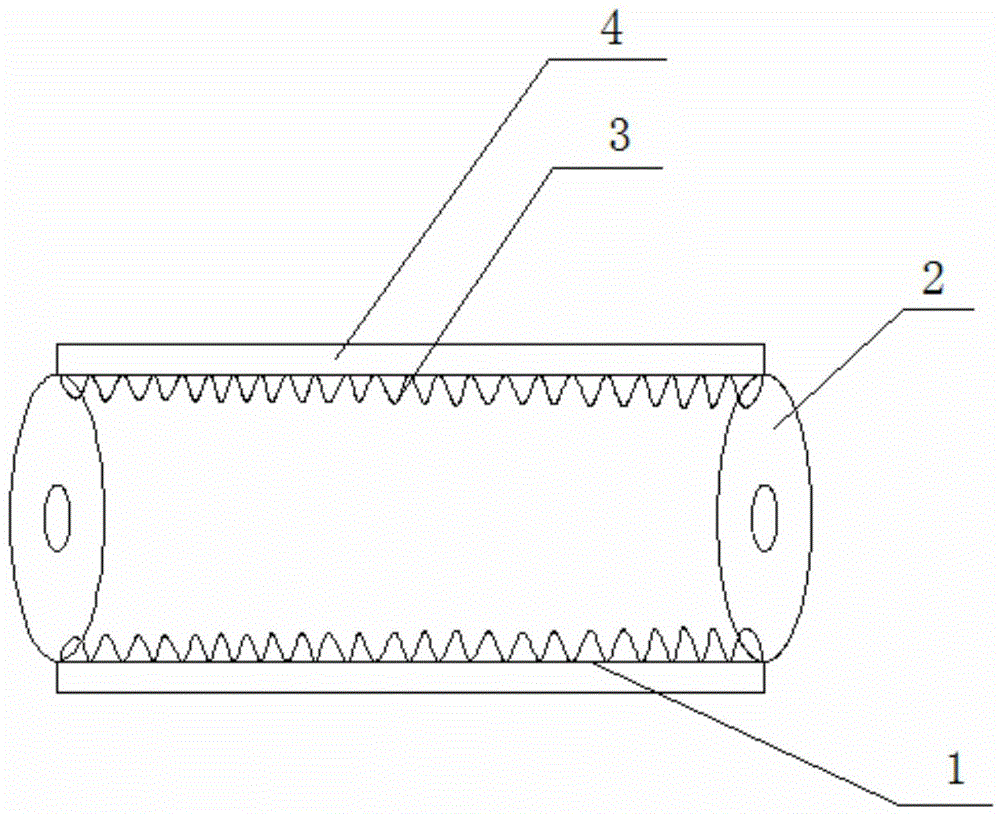

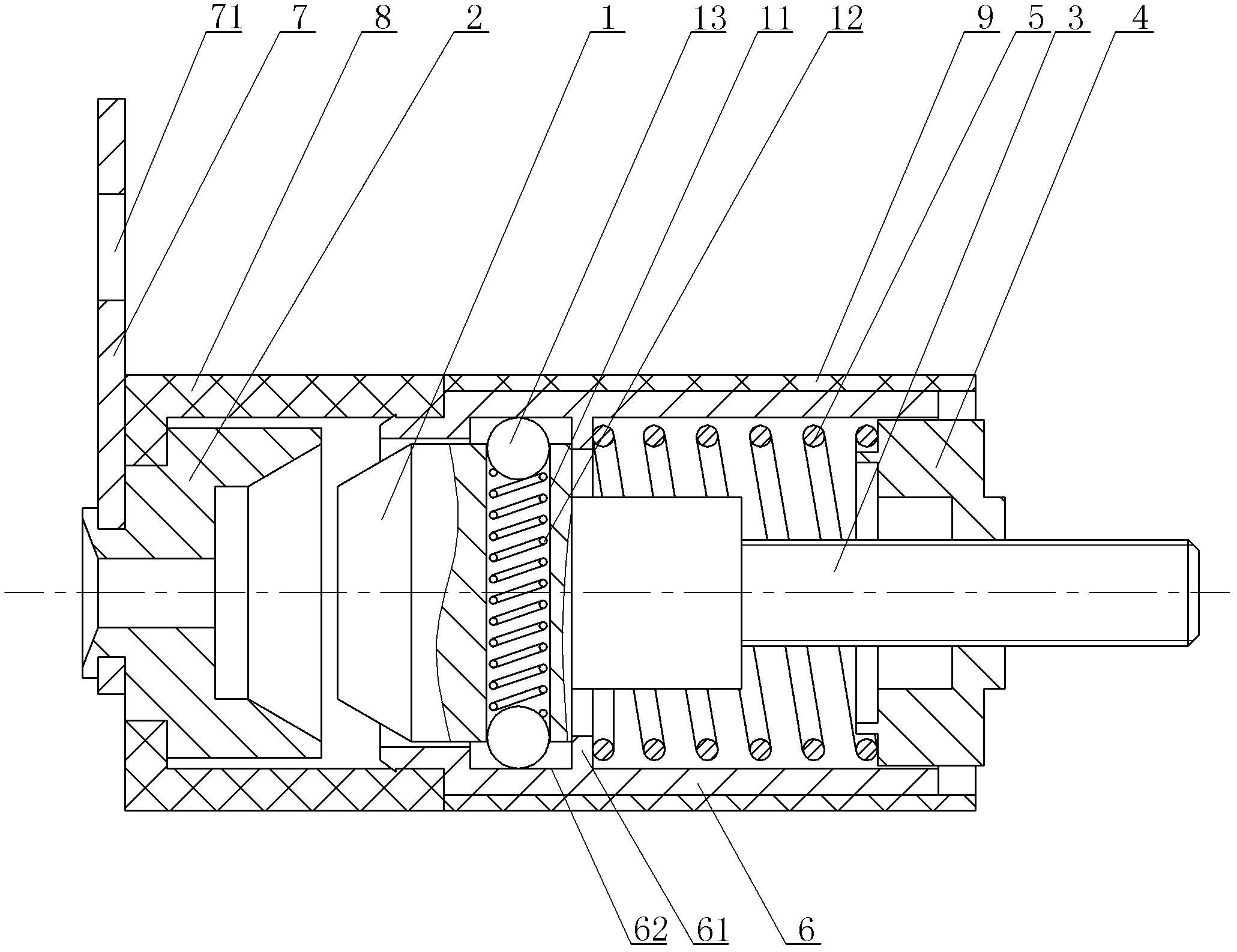

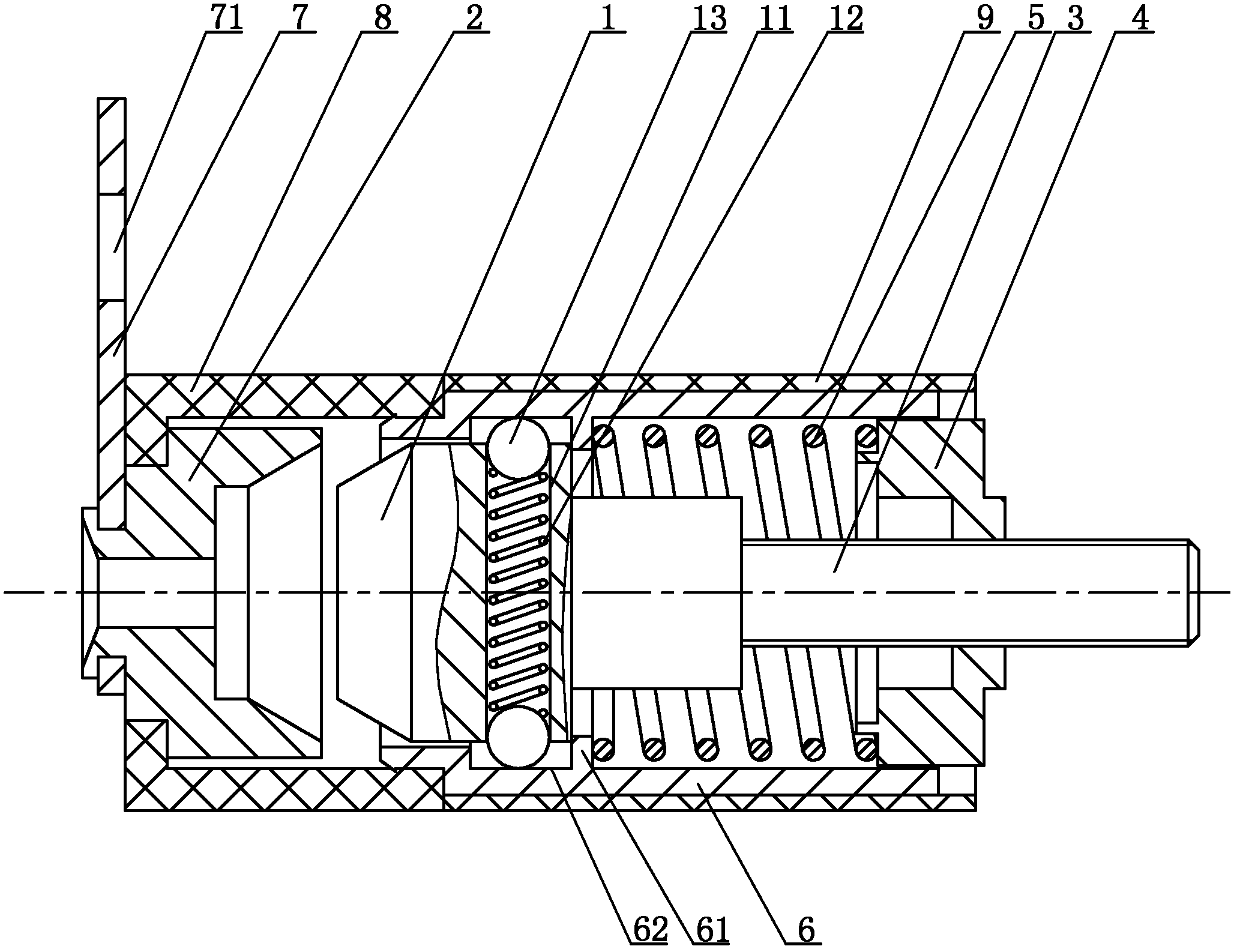

Shorting switch for starter of brushless hydraulically-damped motor

A shorting switch for a starter of a brushless hydraulically-damped motor mainly solves the problem of a conventional vacuum switch that arcs are generated between a movable contact and a fixed contact during starting of a motor. The shorting switch is characterized in that a movable contact (1), a conductive push rod (3), a centrifugal block (4) and a pressing spring (5) are arranged in a guide sleeve (6), wherein a spacing ring (61) and a annular groove (62) are arranged on the inner wall of the guide sleeve (6); a radial through hole (11) is formed on the movable contact (1); a spring (12) and two steel balls (13) are arranged in the through hole (11); the conductive push rod (3) penetrates the spacing ring (61); and the pressing spring (5) is placed between the centrifugal block (4) and the spacing ring (61). By adopting the shorting switch, the movable contact and the fixed contact are instantly connected during start of the motor, arcs can not be generated in insulating liquid, the hazard caused by the arcs is radically eradicated, and the insulating liquid satisfies the functions of lubrication, heat dissipation, insulation, arc extinguishing and the like on the movable contact, the fixed contact, the conductive push rod and the centrifugal block.

Owner:WENZHOU SHUGUANG STARTING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com