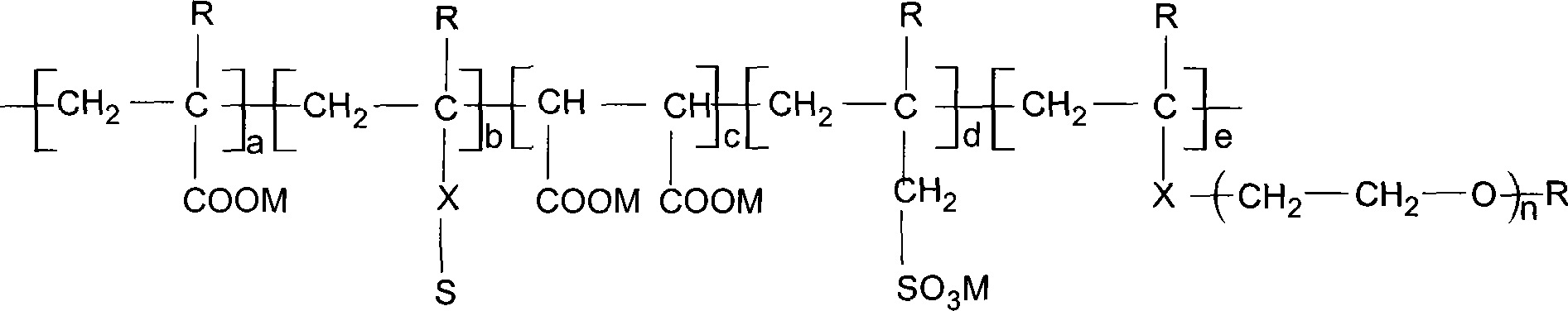

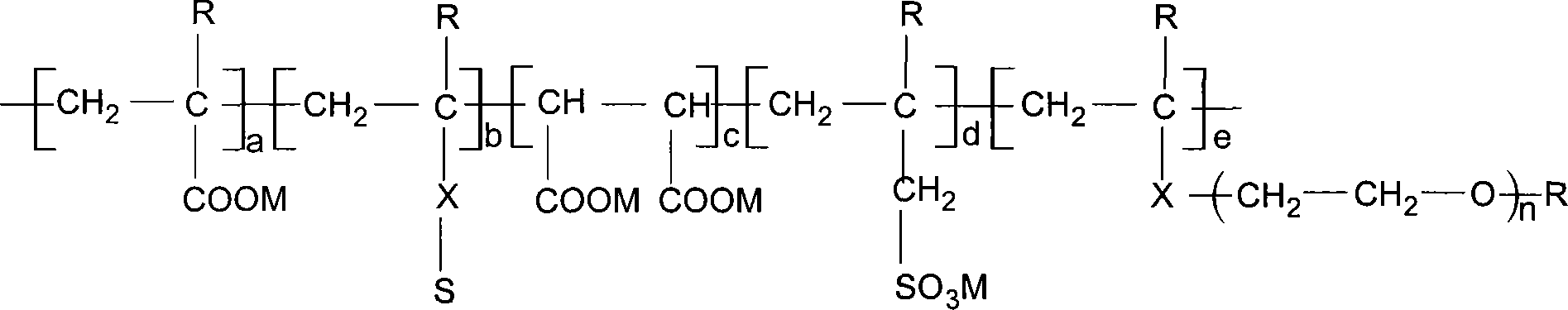

Oligose graft modification polycarboxylic acids high efficiency water reducing agent and preparation method thereof

A high-efficiency water reducer and graft modification technology, applied in the field of concrete admixtures, can solve the problems of variety and performance limitations, and achieve the effects of easy control of reaction conditions, wide source of raw materials, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Be the polyethylene glycol 100.0g that molecular weight is 1000, sucrose 8.55g, catalyst p-toluenesulfonic acid 1.62g (1.5% of raw material gross mass), polymerization inhibitor hydroquinone 0.11g (0.1% of raw material gross mass) add Stir the four-neck flask to heat up. When the temperature rises to 90-100°C, add 13.53g of acrylic acid dropwise from a drop funnel. After reacting for 9±0.5h, take a sample to measure the esterification rate, stop the reaction, and obtain the esterified product.

[0042] Add 35.55g of sodium methacrylate, 9.50g of chain transfer agent isopropanol and 167.33g of distilled water into the reactor, heat to 60-90°C, and dropwise add the esterification product, 29.70g of acrylic acid, and 5.62g of persulfuric acid The initiator aqueous solution obtained by dissolving ammonium in 20g of water was added dropwise in 60-120min, and after reacting for 5±0.5h, it was cooled, and the pH value was adjusted to 7-8 with a mass concentration of 40% NaOH so...

Embodiment 2

[0044] Be the polyethylene glycol 100.0g that molecular weight is 1000, sucrose 4.28g, catalyst p-toluenesulfonic acid 1.56g (1.5% of raw material gross mass), polymerization inhibitor hydroquinone 0.10g (0.1% of raw material gross mass) add Stir and heat the four-neck flask to heat up. When the temperature rises to 90-100°C, add 12.16g of acrylic acid dropwise from a drop funnel. After reacting for 9±0.5h, take a sample to measure the esterification rate, stop the reaction, and obtain the esterified product.

[0045] Add 37.33g of sodium methpropylene sulfonate, 6.0g of chain transfer agent isopropanol and 354.02g of distilled water into the reactor, heat to 60-90°C, add dropwise the esterification product, 33.24g of acrylic acid, and 5.61g of persulfuric acid The initiator aqueous solution obtained by dissolving ammonium in 20g of water was added dropwise in 60-120min, and after reacting for 5±0.5h, it was cooled, and the pH value was adjusted to 7-8 with a mass concentration...

Embodiment 3

[0047] The polyethylene glycol 80.0g that molecular weight is 800, sucrose 8.55g, catalyst p-toluenesulfonic acid 1.33g (1.5% of raw material gross mass), polymerization inhibitor hydroquinone 0.09g (0.1% of raw material gross mass) add Stir the four-neck flask to heat up. When the temperature rises to 90-100°C, add 13.5g of acrylic acid dropwise from a drop funnel. After reacting for 9±0.5h, take a sample to measure the esterification rate, stop the reaction, and obtain the esterified product.

[0048] Add 40.59g of sodium methpropylene sulfonate, 9.50g of chain transfer agent isopropanol and 158.49g of distilled water into the reactor, heat to 60-90°C, add dropwise the esterification product, 35.85g of acrylic acid, and 5.35g of persulfuric acid The initiator aqueous solution obtained by dissolving ammonium in 20g of water was added dropwise in 60-120min, and after reacting for 5±0.5h, it was cooled, and the pH value was adjusted to 7-8 with a mass concentration of 40% NaOH s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com