Patents

Literature

81results about How to "Avoid repositioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

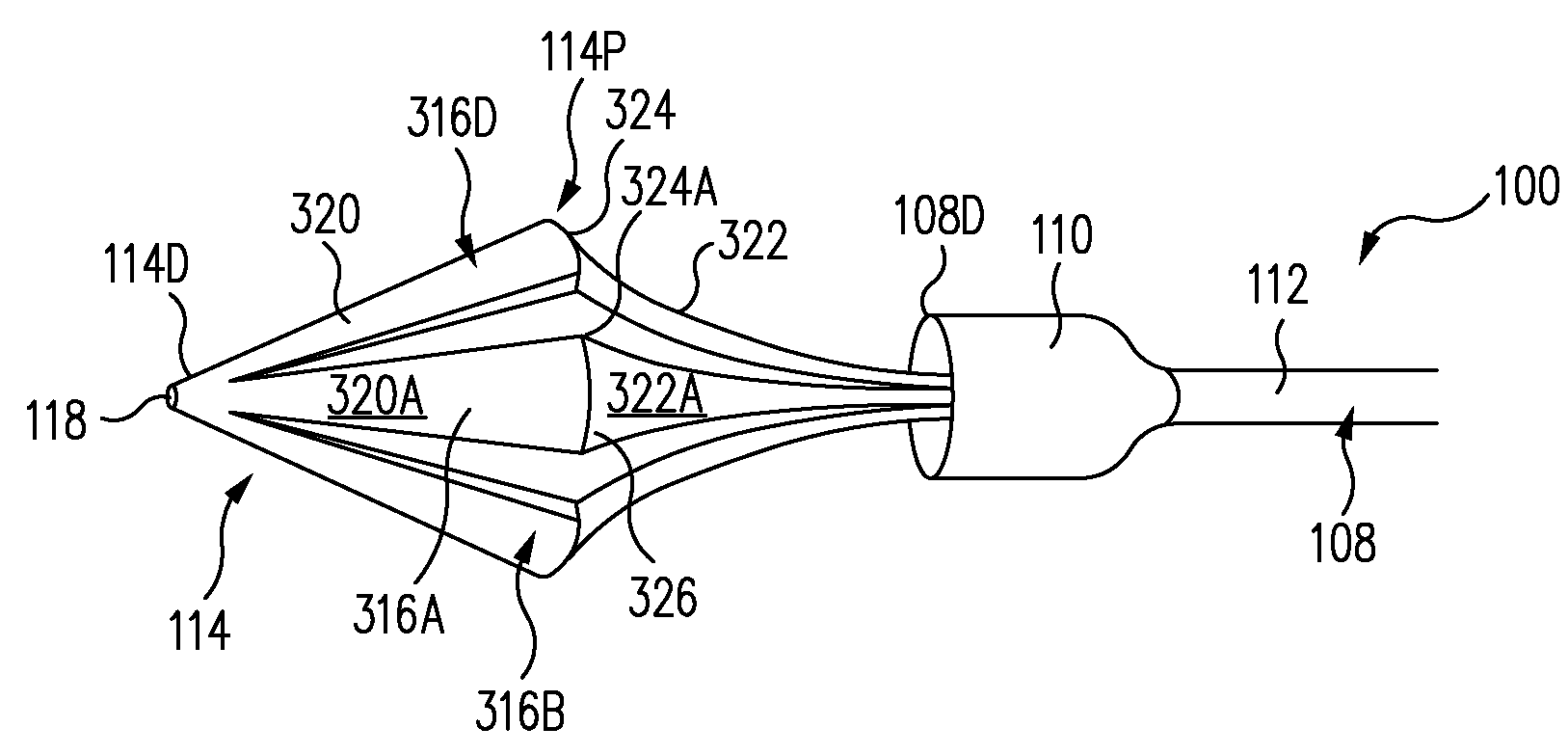

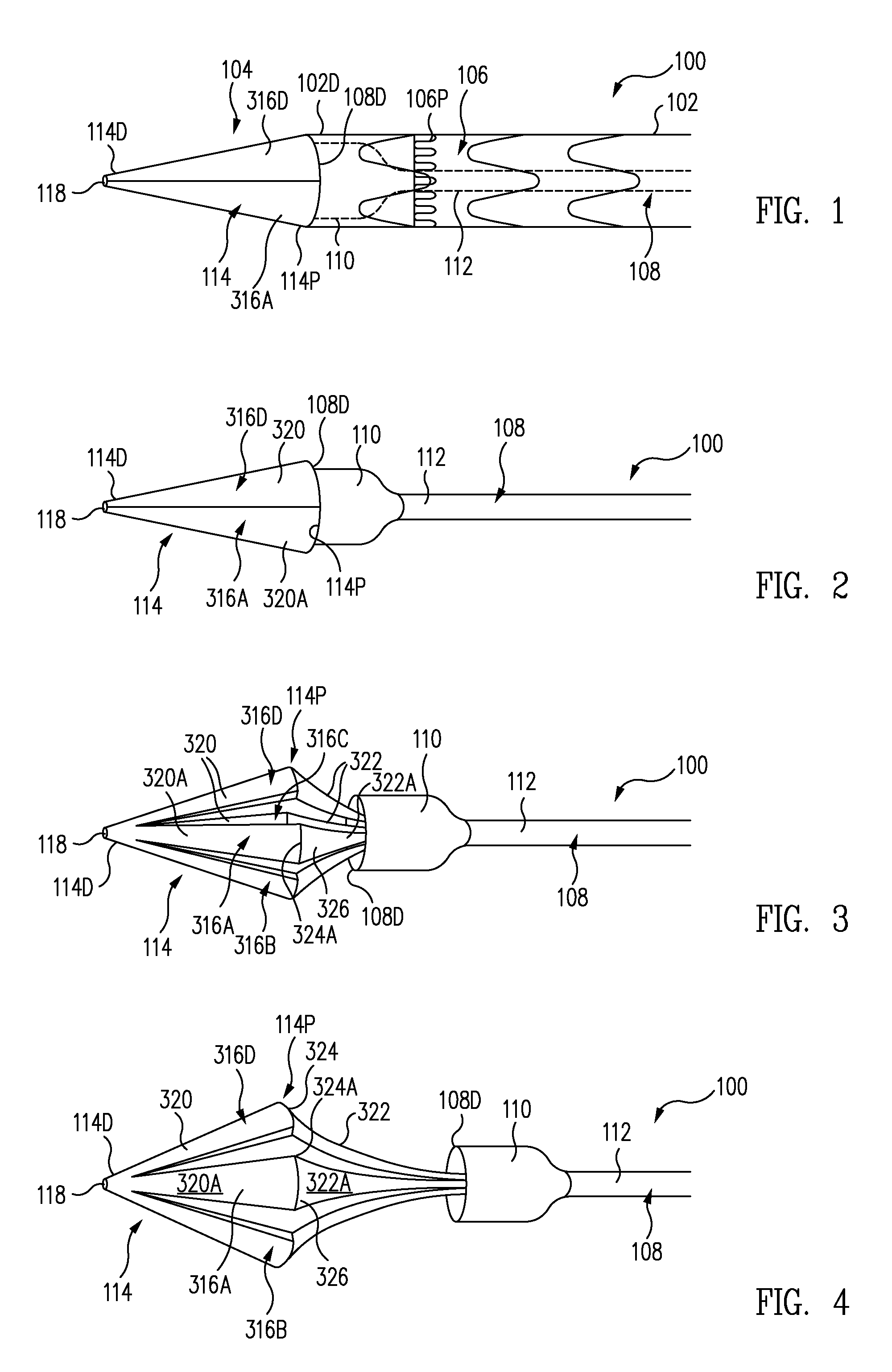

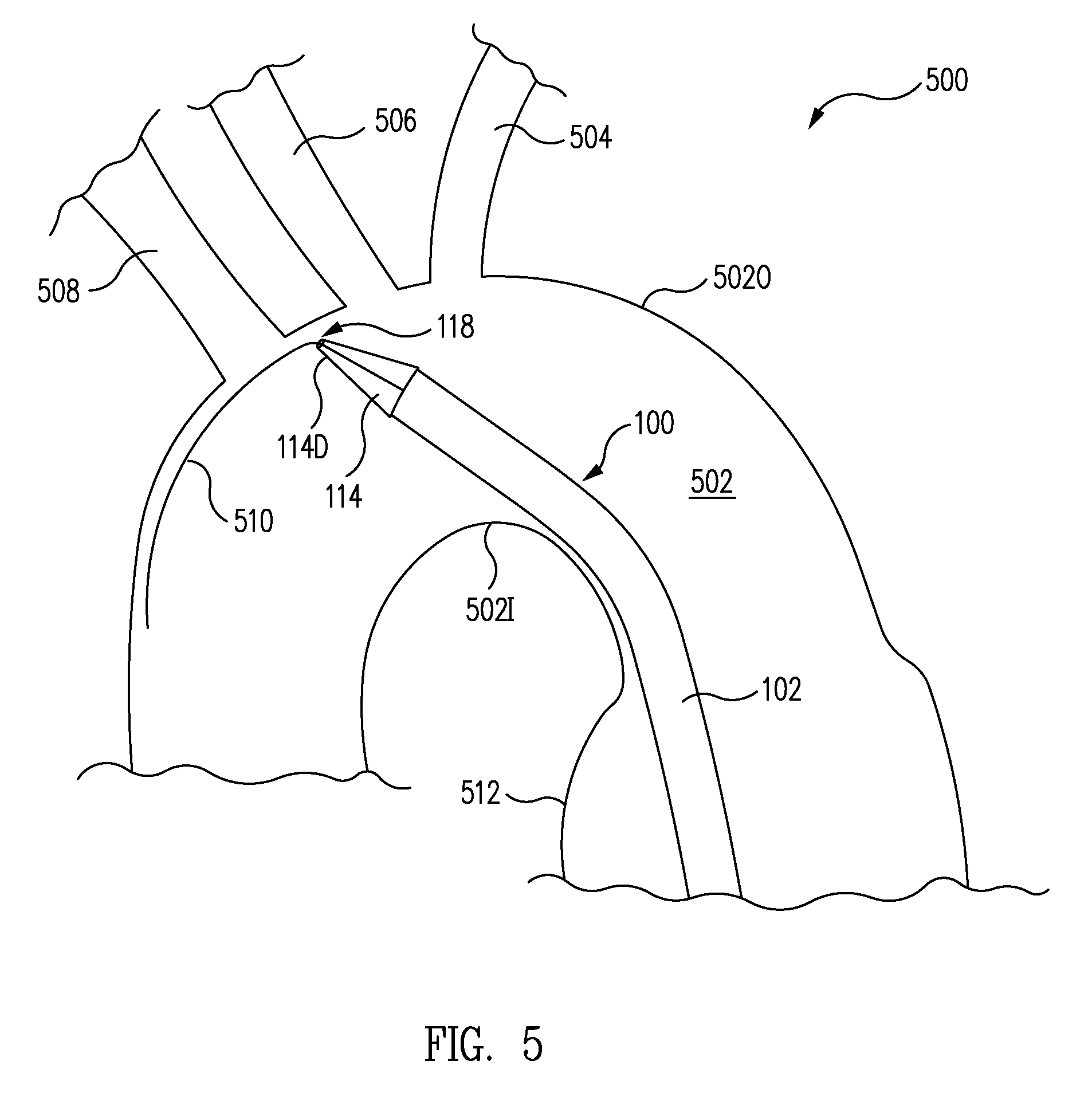

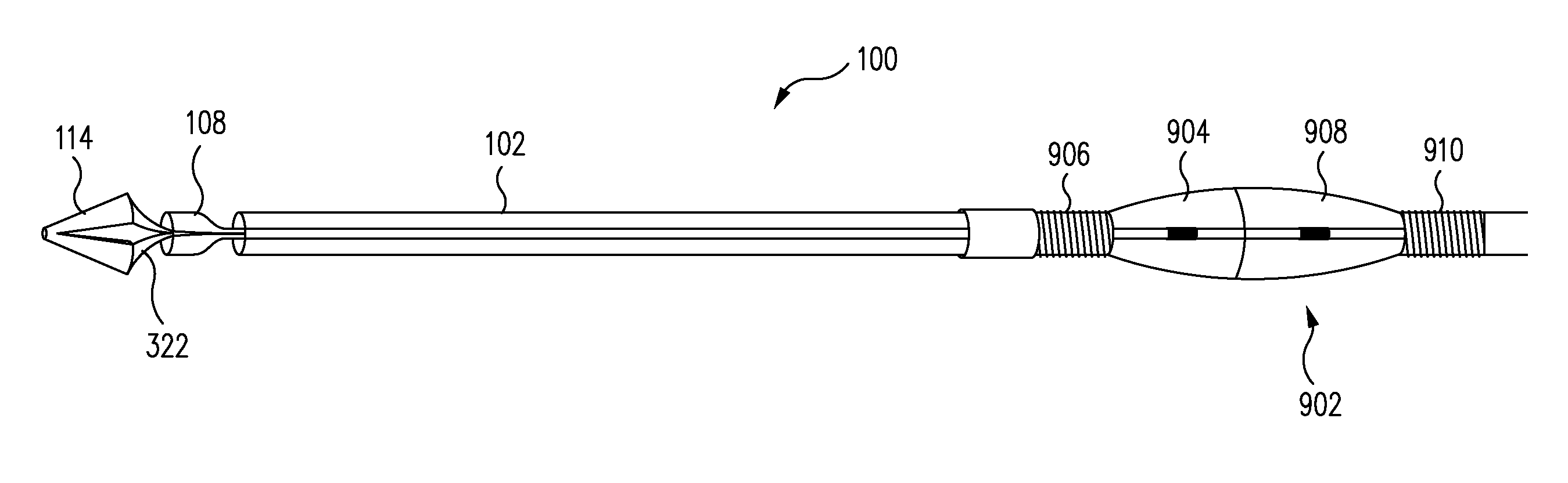

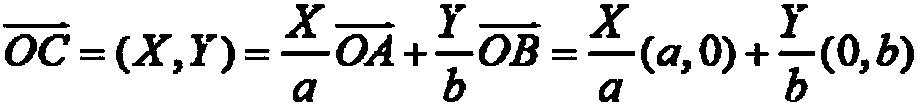

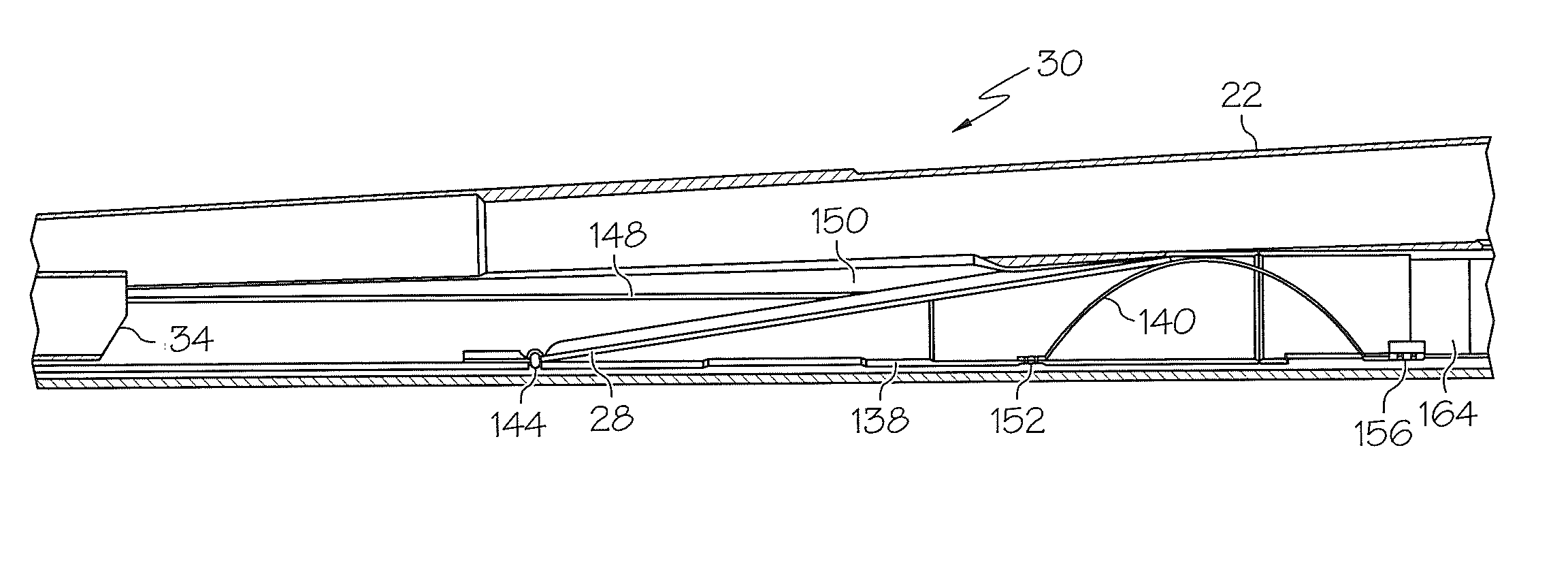

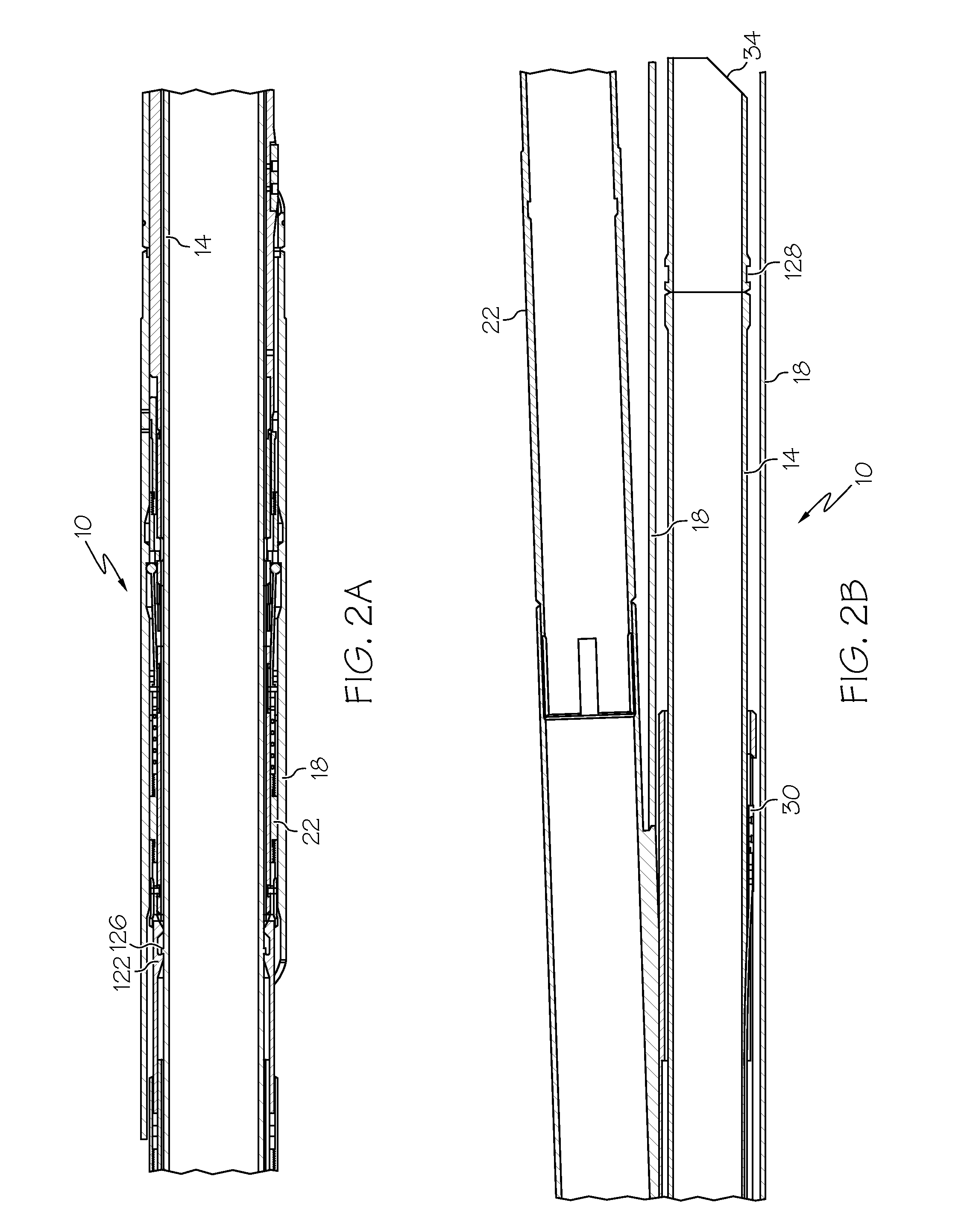

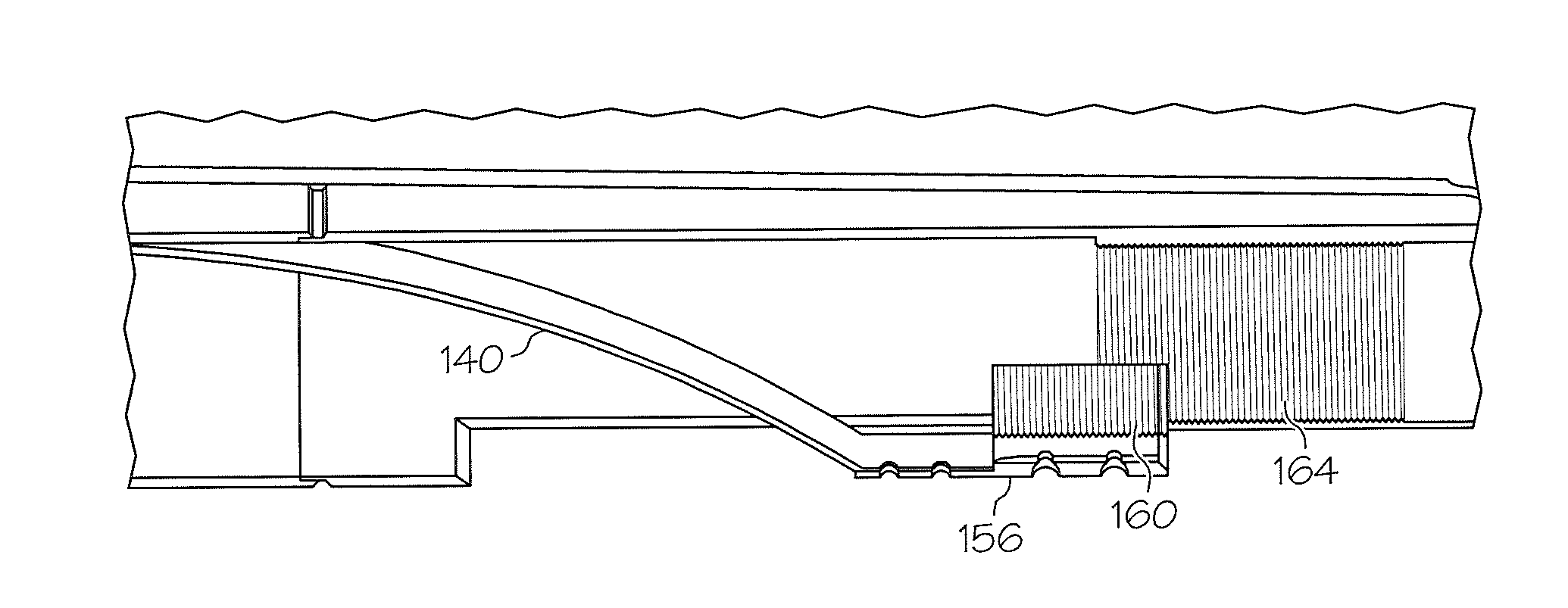

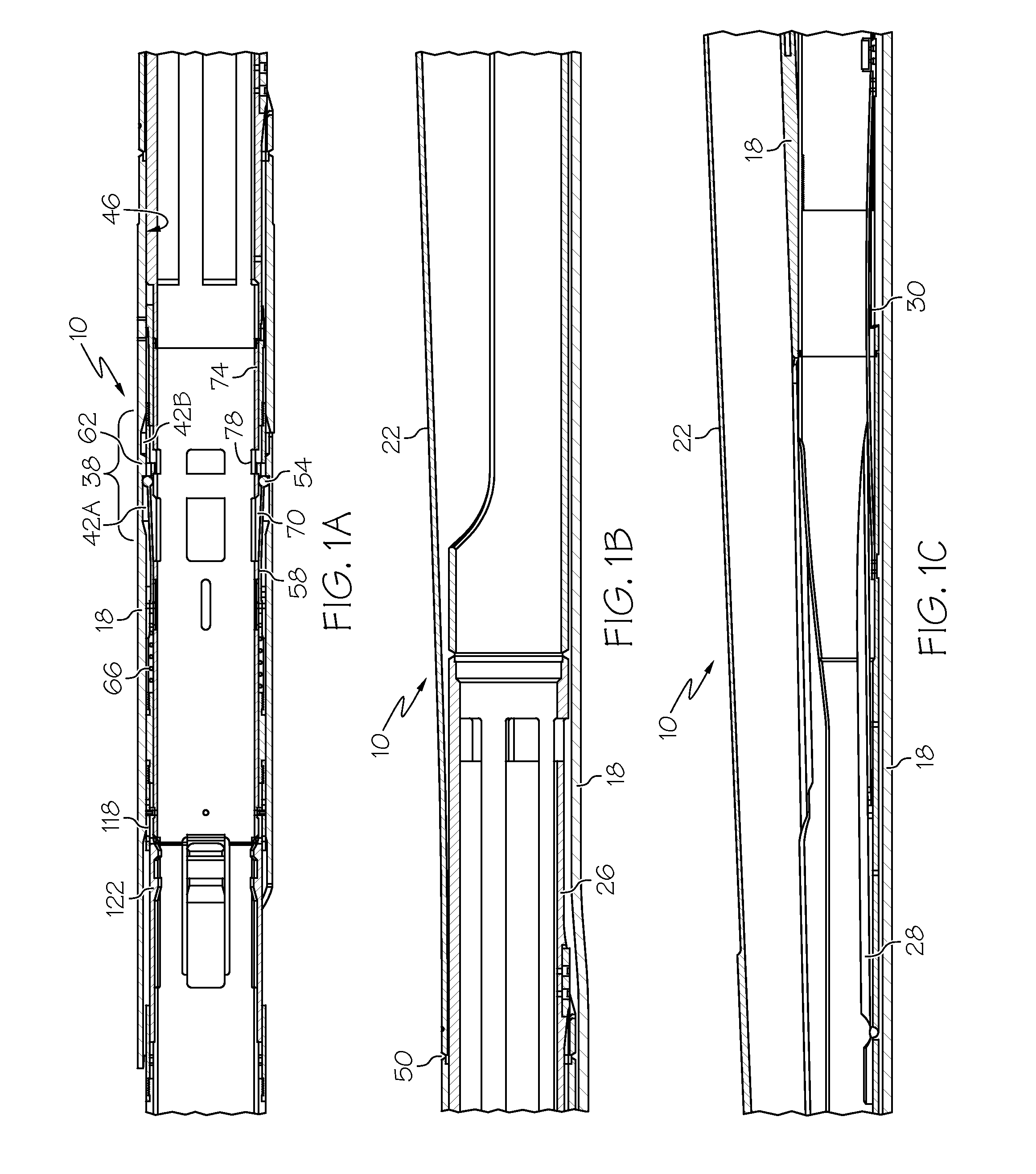

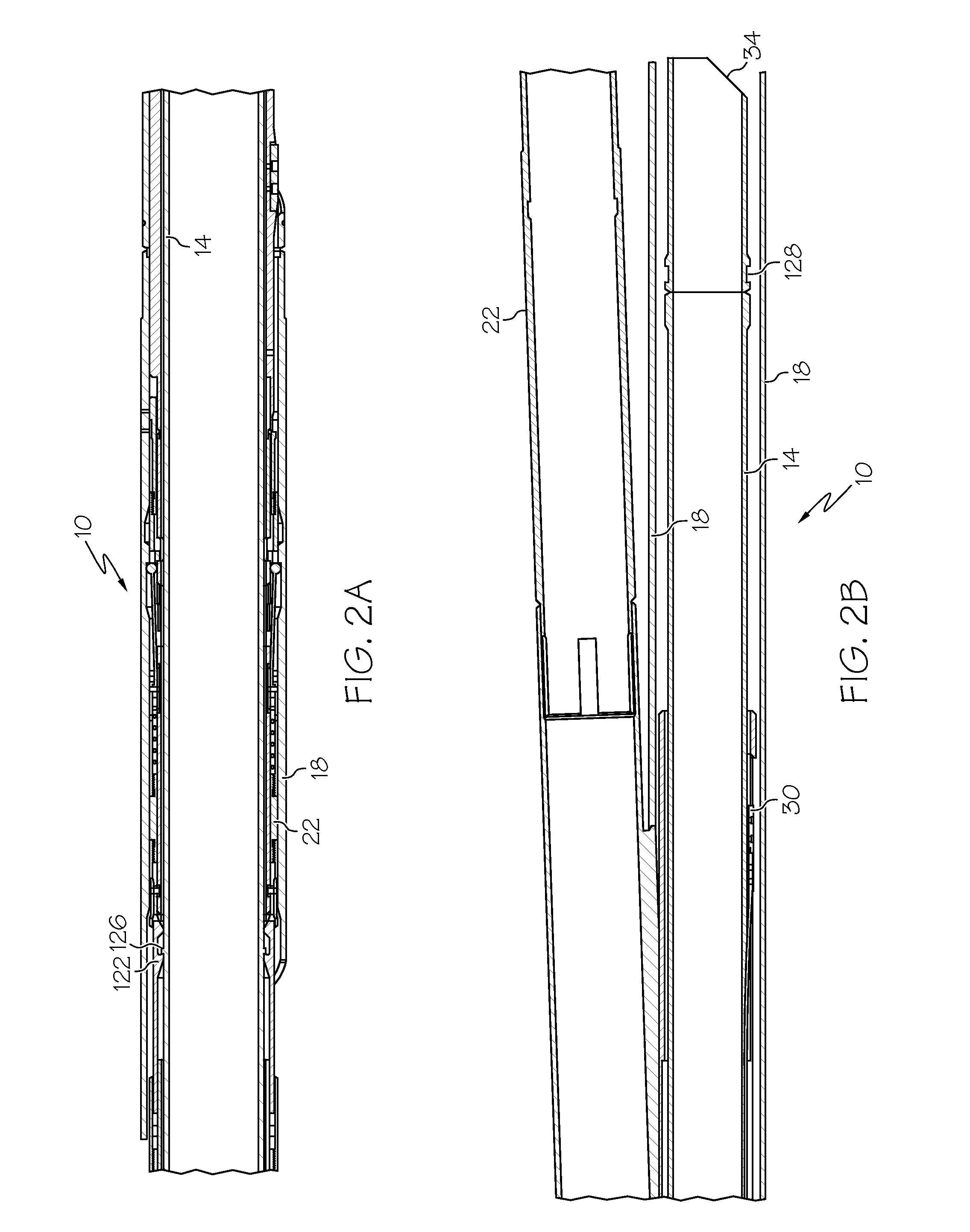

Expandable Tip Delivery System and Method

ActiveUS20080255652A1Avoid the needAvoid repositioningGuide needlesStentsStent graftingDelivery system

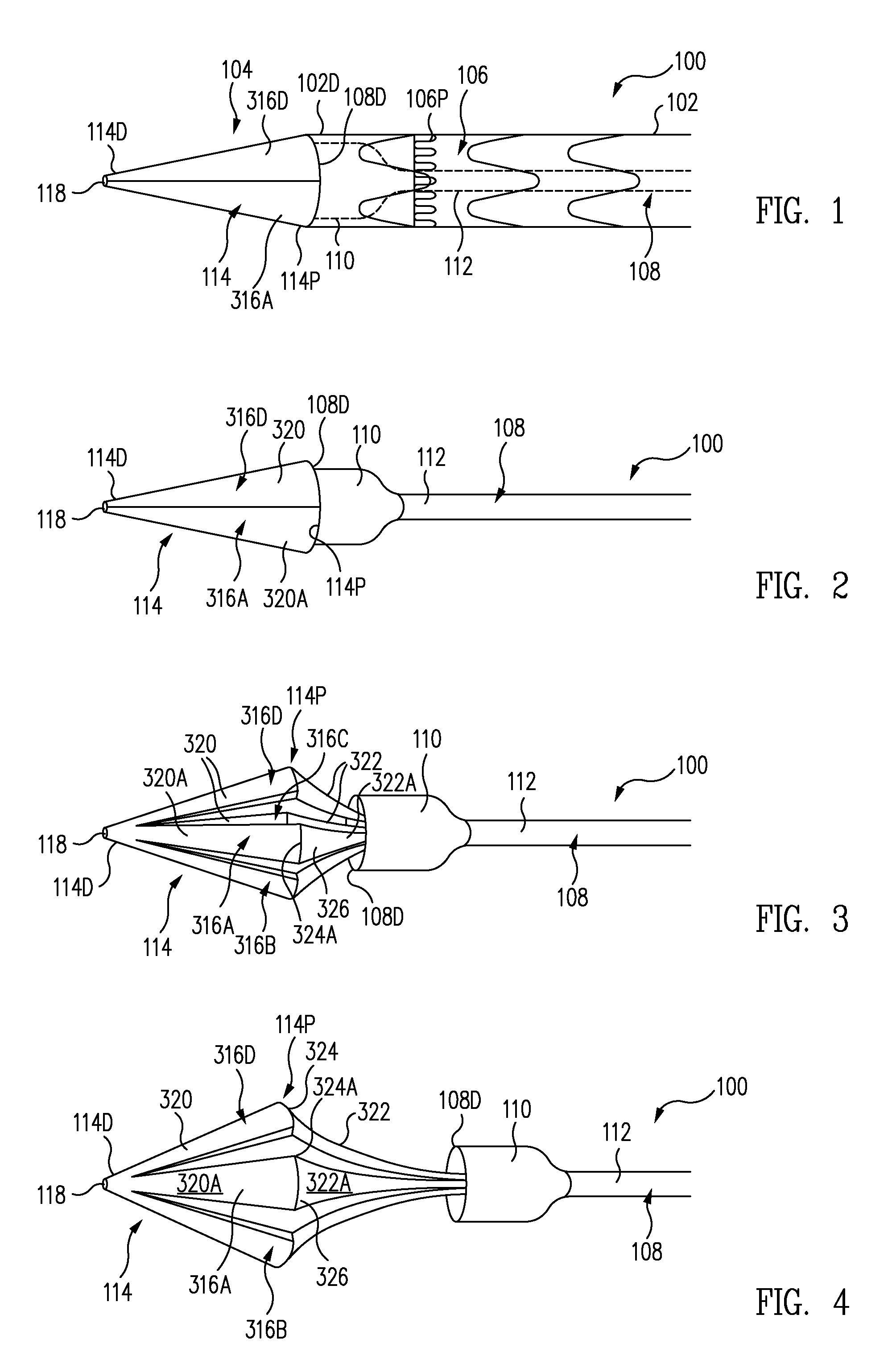

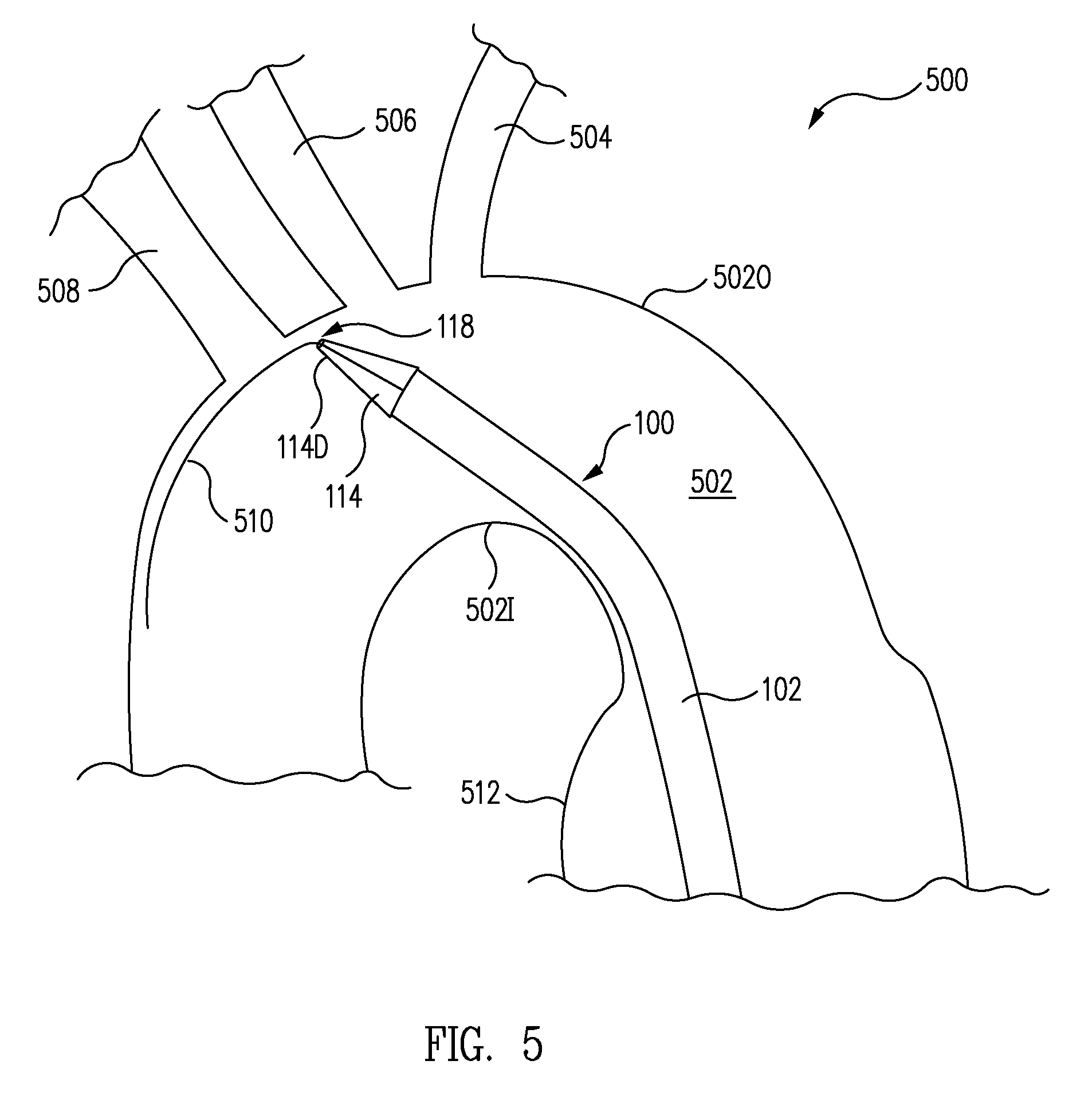

A method of deploying a stent-graft in a curved vessel includes deploying an expandable tip to center a proximal end of the catheter containing a stent-graft in the curved vessel. A sheath is retracted to expose the stent-graft and the stent-graft self-expands into the curved vessel. By centering the catheter containing the stent-graft prior to deployment with the expandable tip, the accuracy of stent graft placement within the curved vessel is improved.

Owner:MEDTRONIC VASCULAR INC

Expandable tip delivery system and method

A method of deploying a stent-graft in a curved vessel includes deploying an expandable tip to center a proximal end of the catheter containing a stent-graft in the curved vessel. A sheath is retracted to expose the stent-graft and the stent-graft self-expands into the curved vessel. By centering the catheter containing the stent-graft prior to deployment with the expandable tip, the accuracy of stent graft placement within the curved vessel is improved.

Owner:MEDTRONIC VASCULAR INC

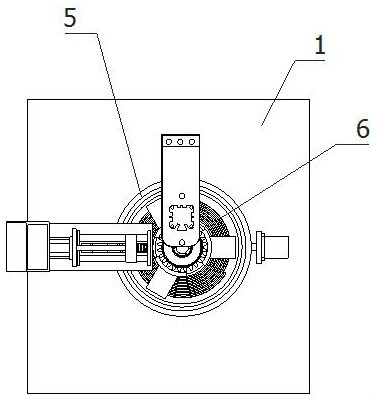

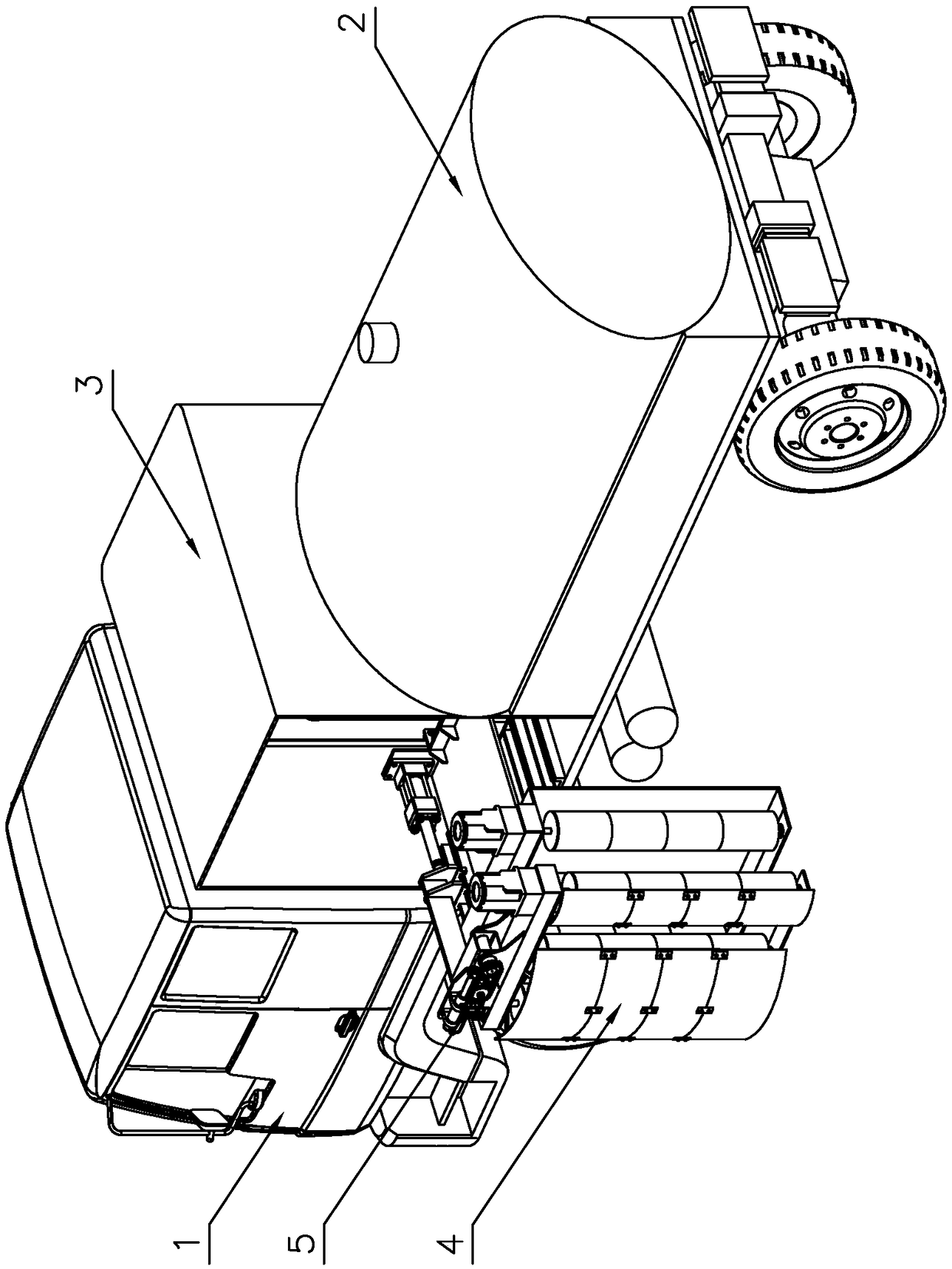

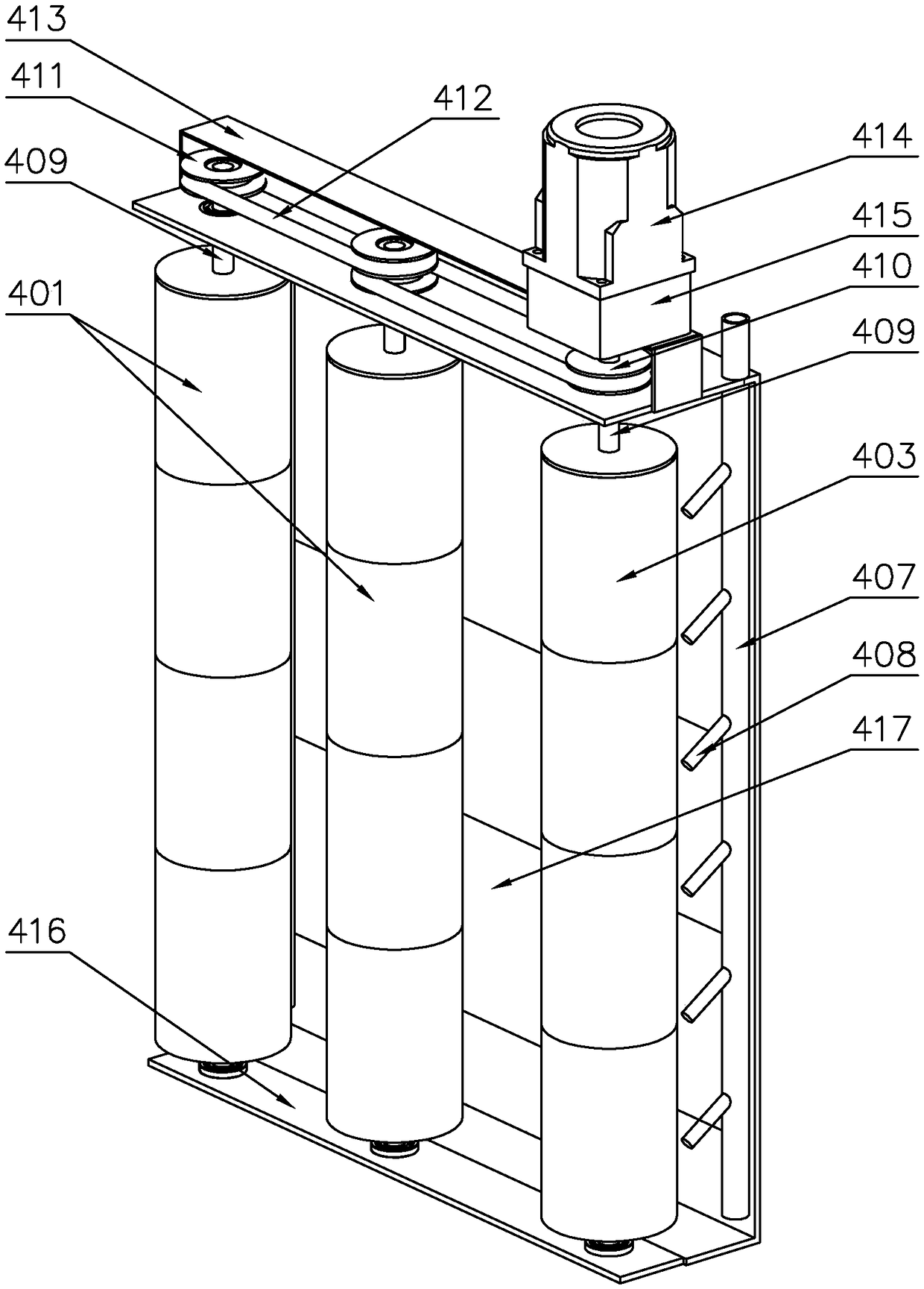

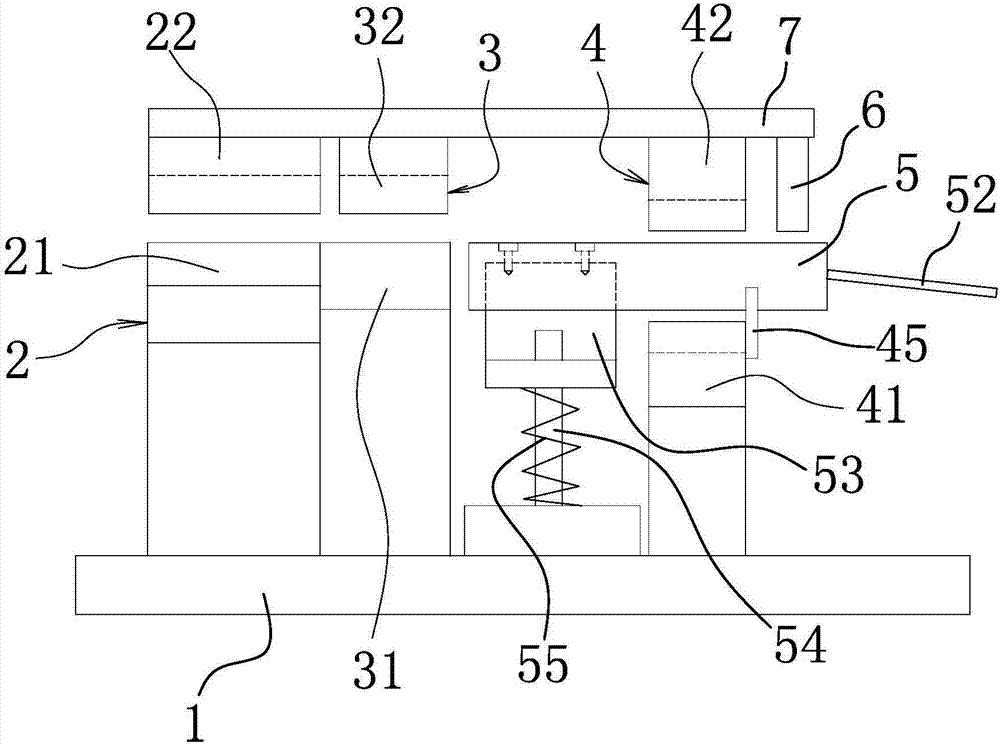

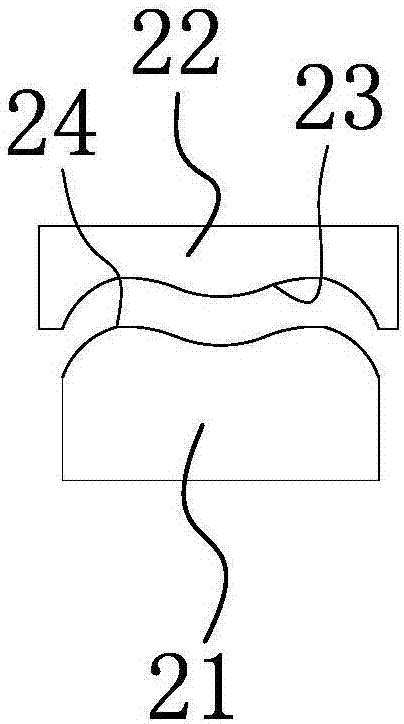

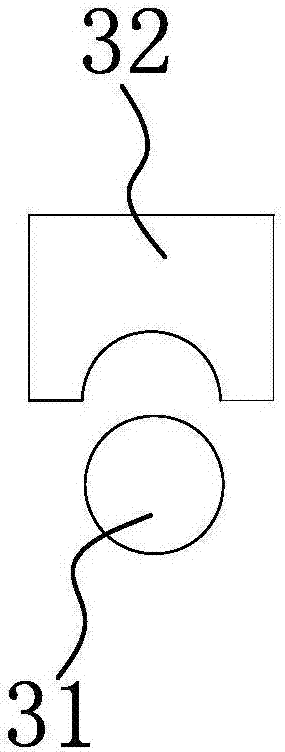

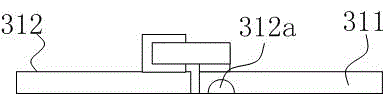

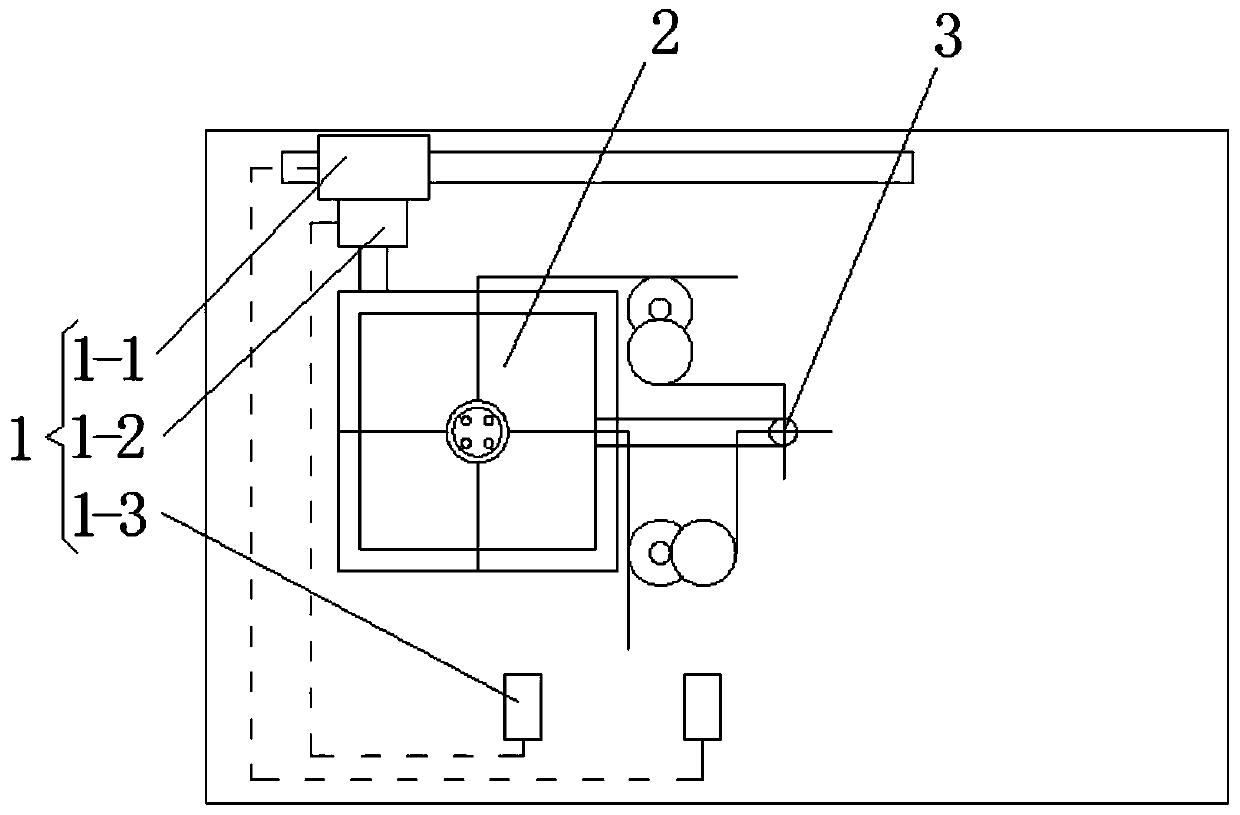

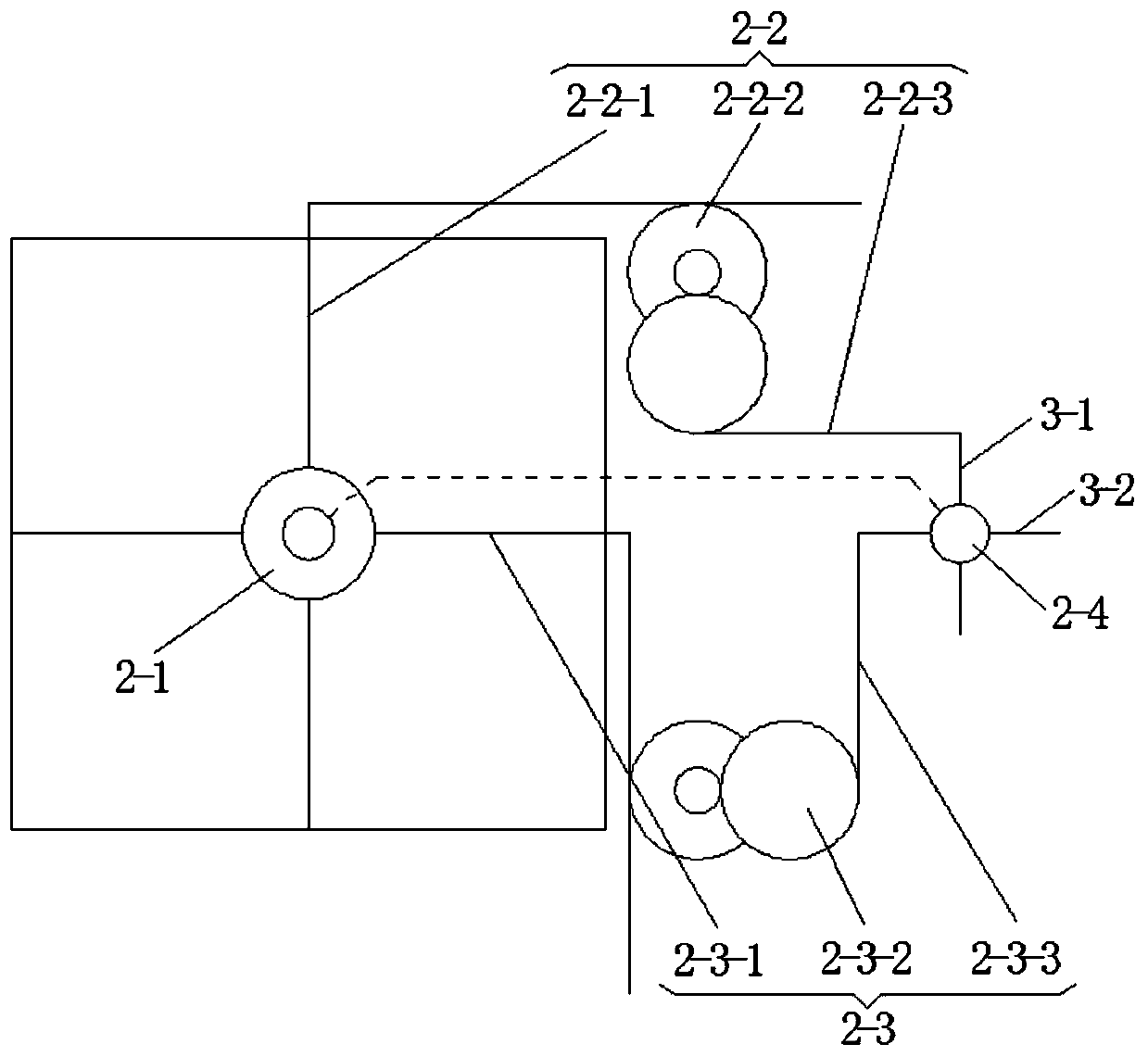

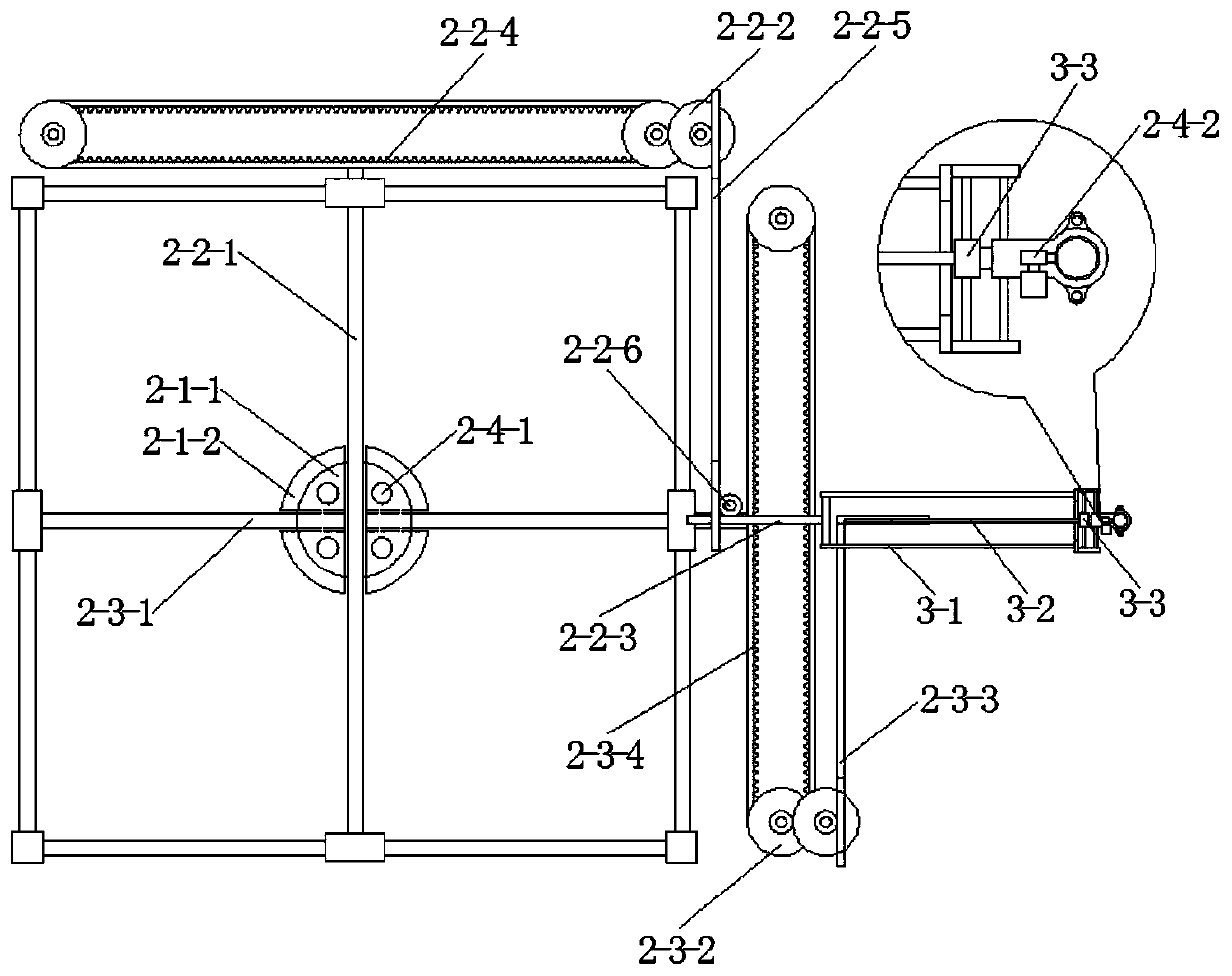

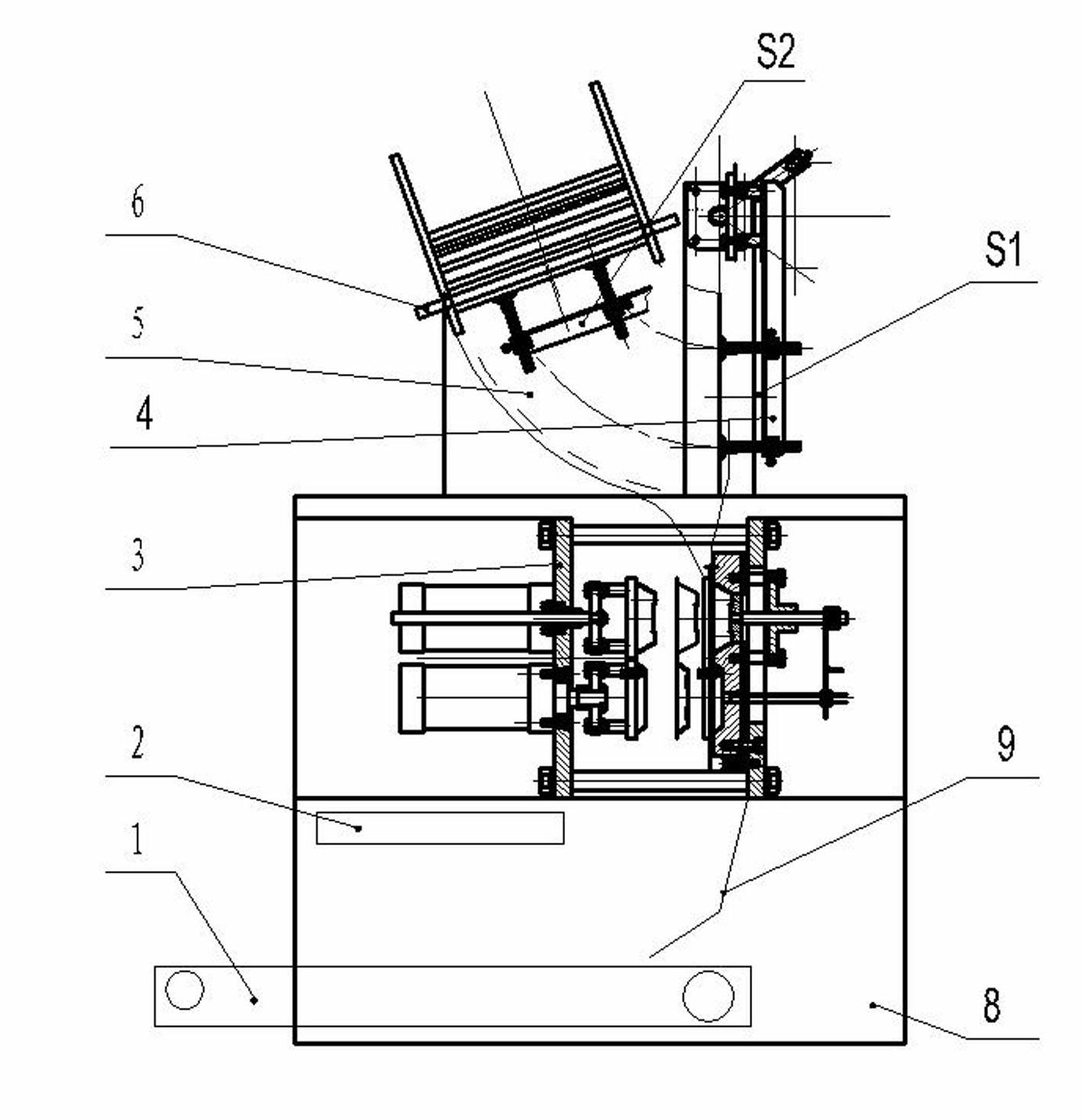

Multi-angle synchronous efficient grinding equipment for automobile brake disc

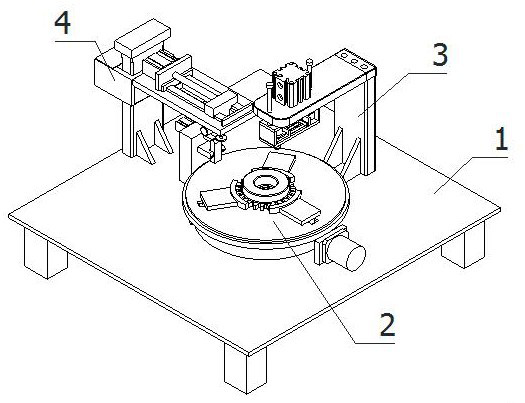

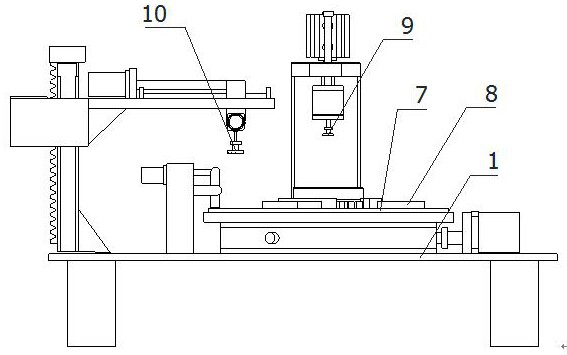

ActiveCN112025432AEffective positioningSynchronous and efficient grinding equipment can be positioned accurately and efficientlyRevolution surface grinding machinesGrinding drivesEngineeringSurface grinding

The invention relates to the technical field of automobile brake disc grinding machining, in particular to multi-angle synchronous efficient grinding equipment for an automobile brake disc. The equipment further comprises a machining platform, a clamping rotating assembly, a top surface grinding assembly and a side wall chamfering and grinding assembly, wherein the clamping rotating assembly comprises a mounting disc, a transmission disc, a positioning disc, a clamping jaw and a pressing mechanism; the top surface grinding assembly comprises a first lifting mechanism, a first horizontal displacement mechanism and a top end horizontal grinding mechanism, and the top end horizontal grinding mechanism comprises a horizontal grinding disc capable of grinding the top surface of the automobile brake disc; and the side wall chamfering and grinding assembly comprises a second lifting mechanism, a second horizontal displacement mechanism, an angle adjusting mechanism and a side wall chamferingand grinding mechanism, and the side wall chamfering and grinding mechanism comprises a side wall grinding disc. The equipment shown can precisely and efficiently position and clamp the automobile brake disc, and the surface, the side wall and the edge of the brake disc are synchronously and accurately ground, such that the working efficiency is greatly improved, and repositioning is avoided.

Owner:浙江杭万汽车零部件实业有限公司

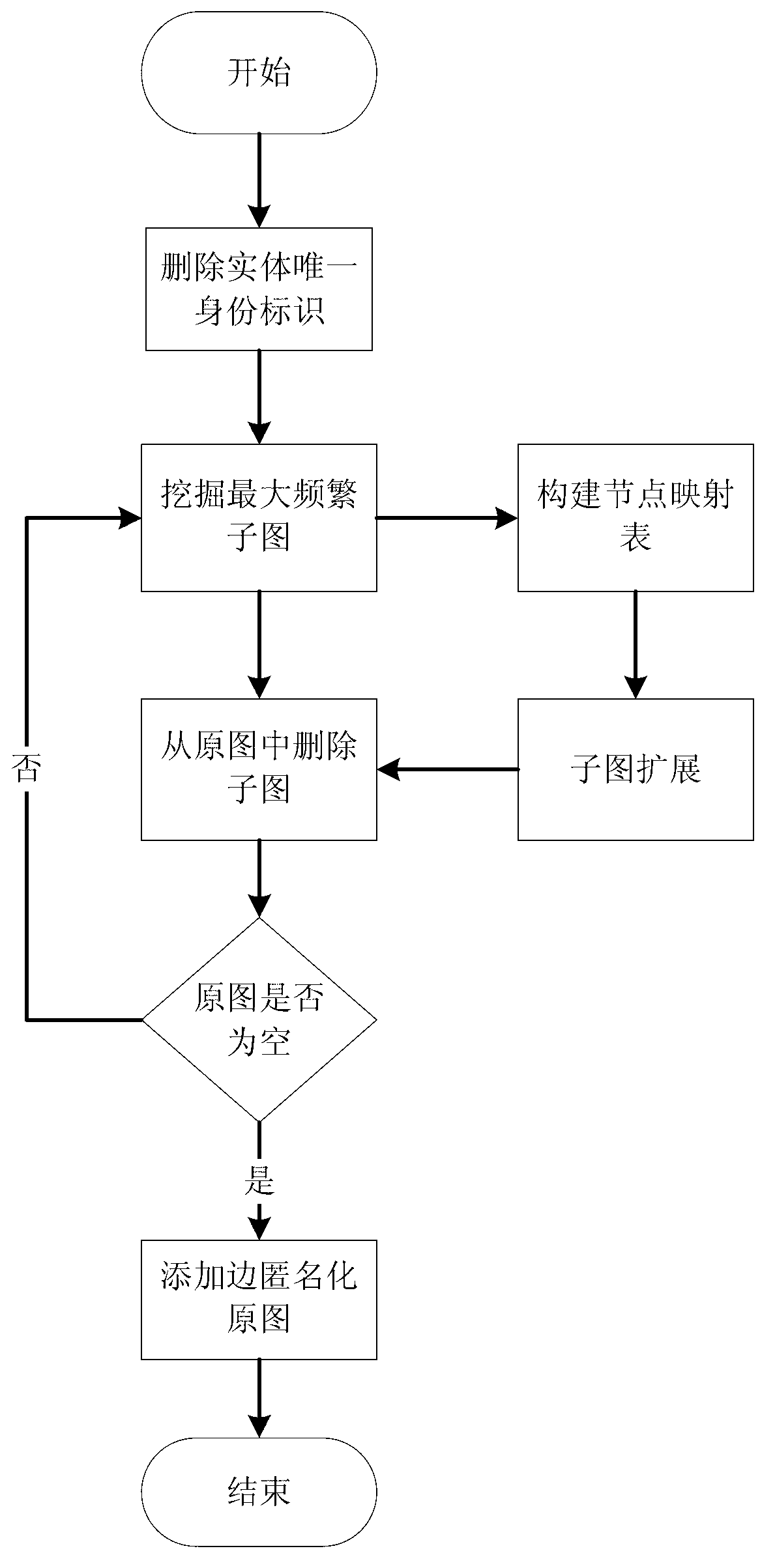

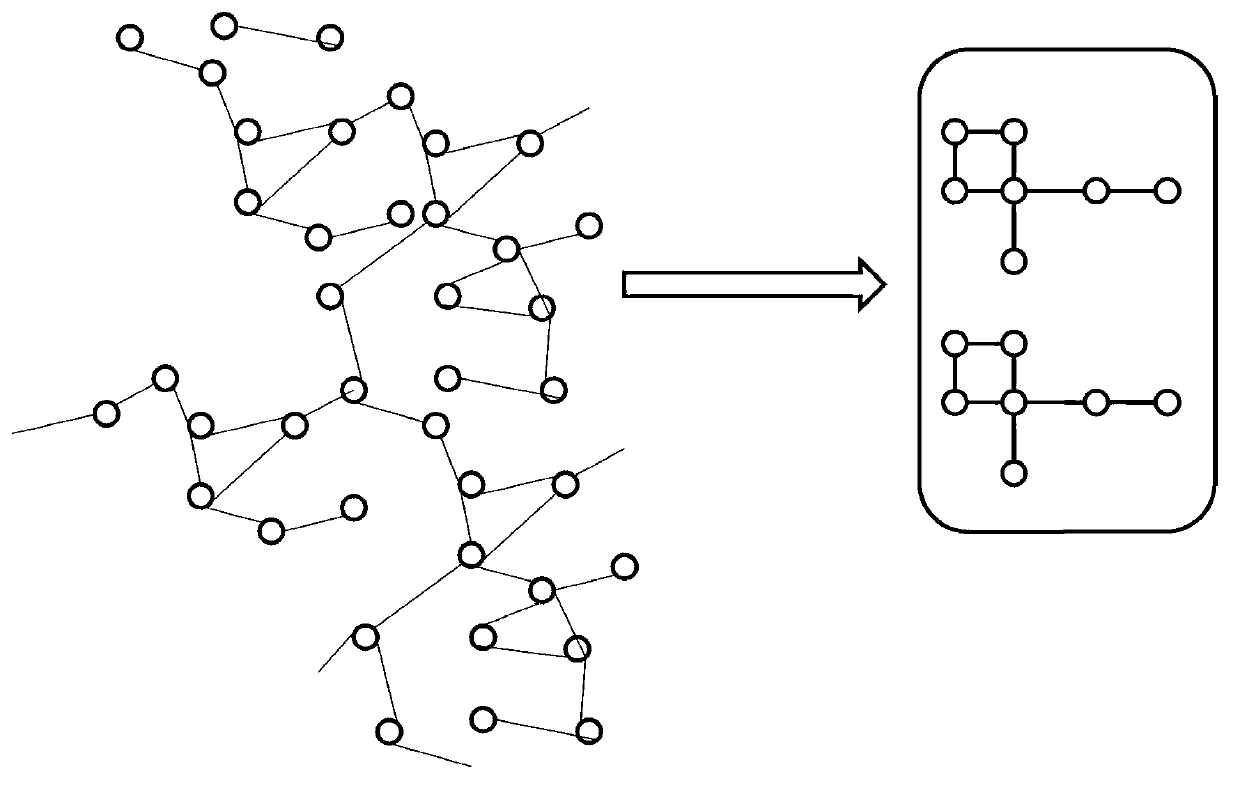

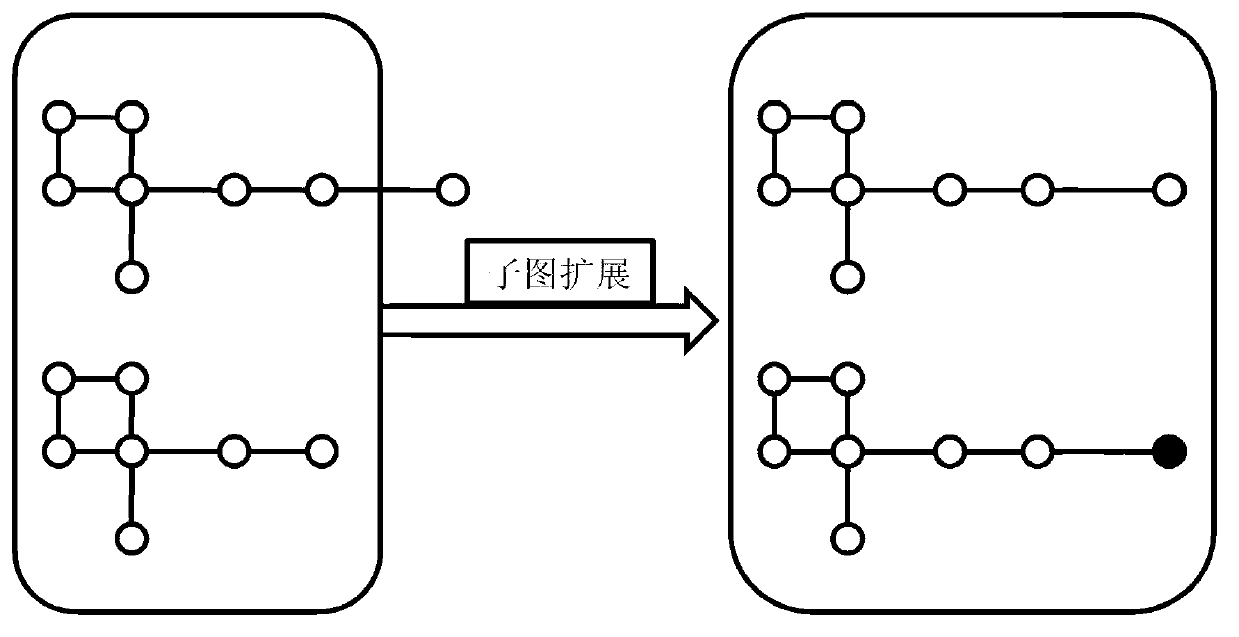

Privacy protecting method for social network based on undirected graph modification

ActiveCN103218397AAvoid repositioningProtect personal privacyDigital data protectionSpecial data processing applicationsNODALUndirected graph

The invention discloses a privacy protecting method for a social network based on undirected graph modification. The method comprises the following steps: (1) establishing an undirected graph of the social network; (2) digging the maximum frequent subgraph; (3) establishing a node mapping relation; (4) iteratively expanding the subgraph and improving the mapping table; and (6) forming an anonymity isomorphic graph by adding mapping lines and virtual nodes to the undirected graph. According to the method, the virtual nodes are added, so that each node has other nodes symmetrical thereto, so that re-positioning of user identity is avoided, and personal privacy safety of the user is effectively protected. In addition, the local structure of the social network is finely modified, social network graph data can be externally and safely issued, so that the method is suitable for researching characteristic analysis and statistics of the local structure of the social network, and promotes data digging technology in research and application in the field of social network.

Owner:ZHEJIANG UNIV

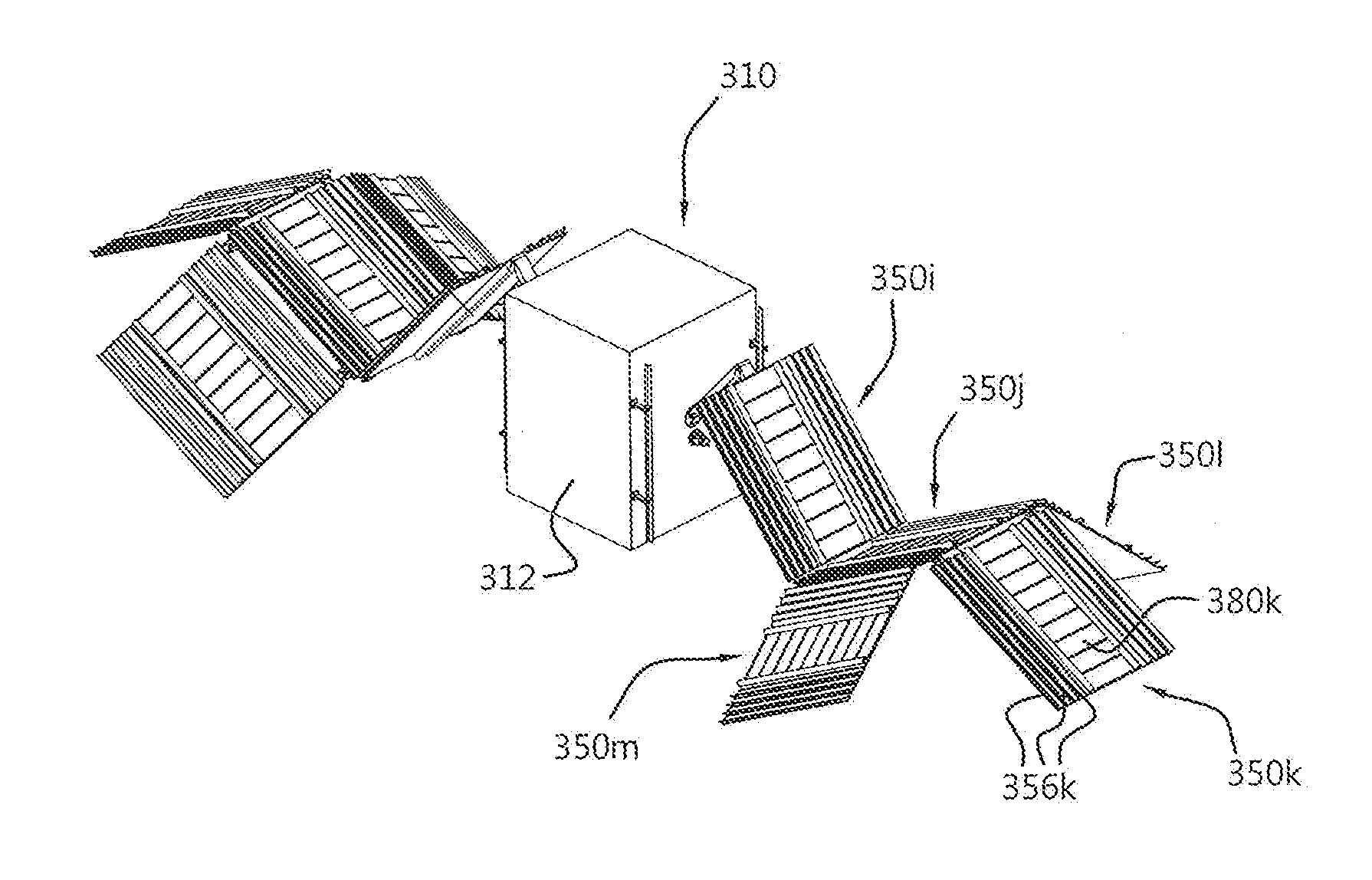

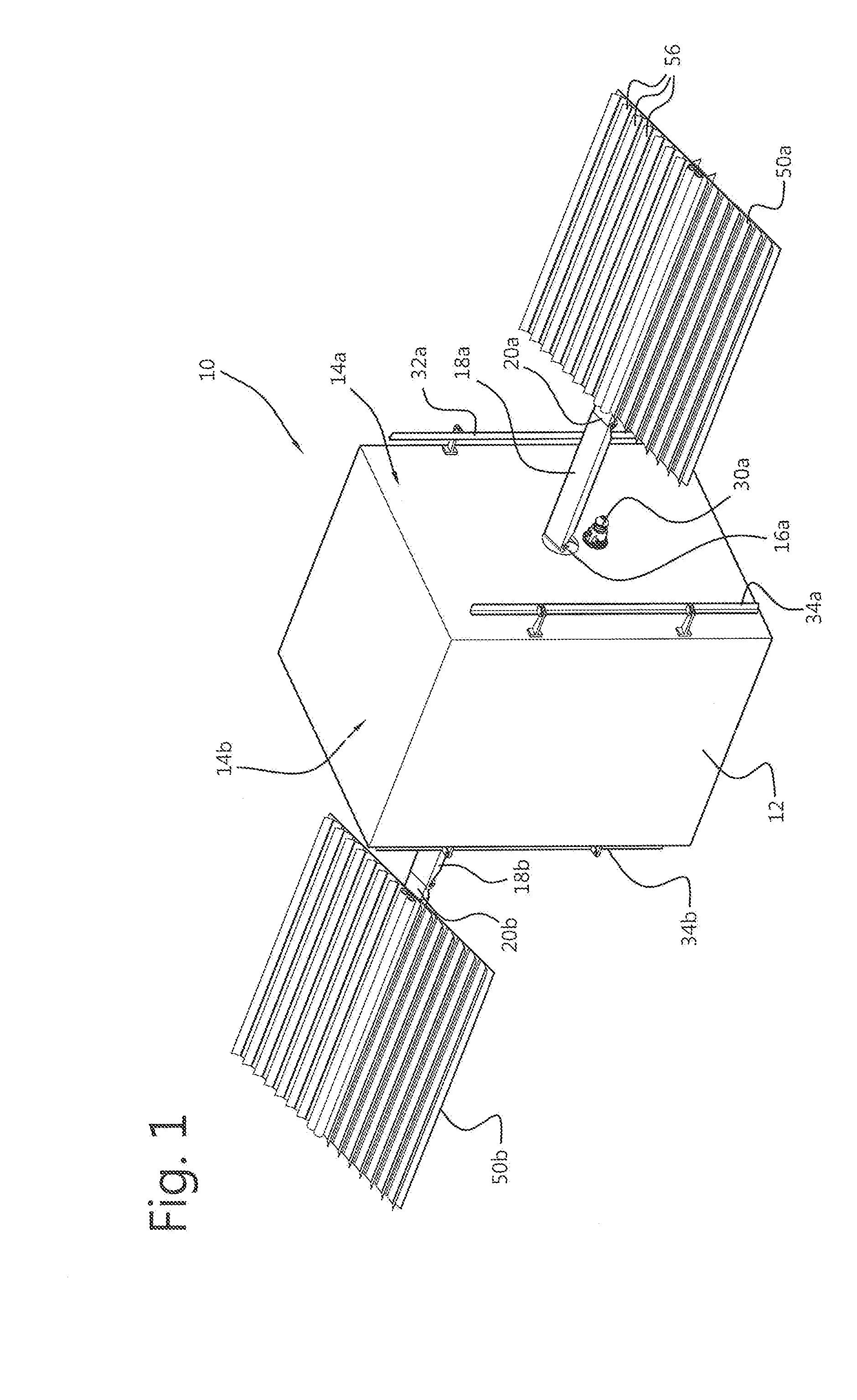

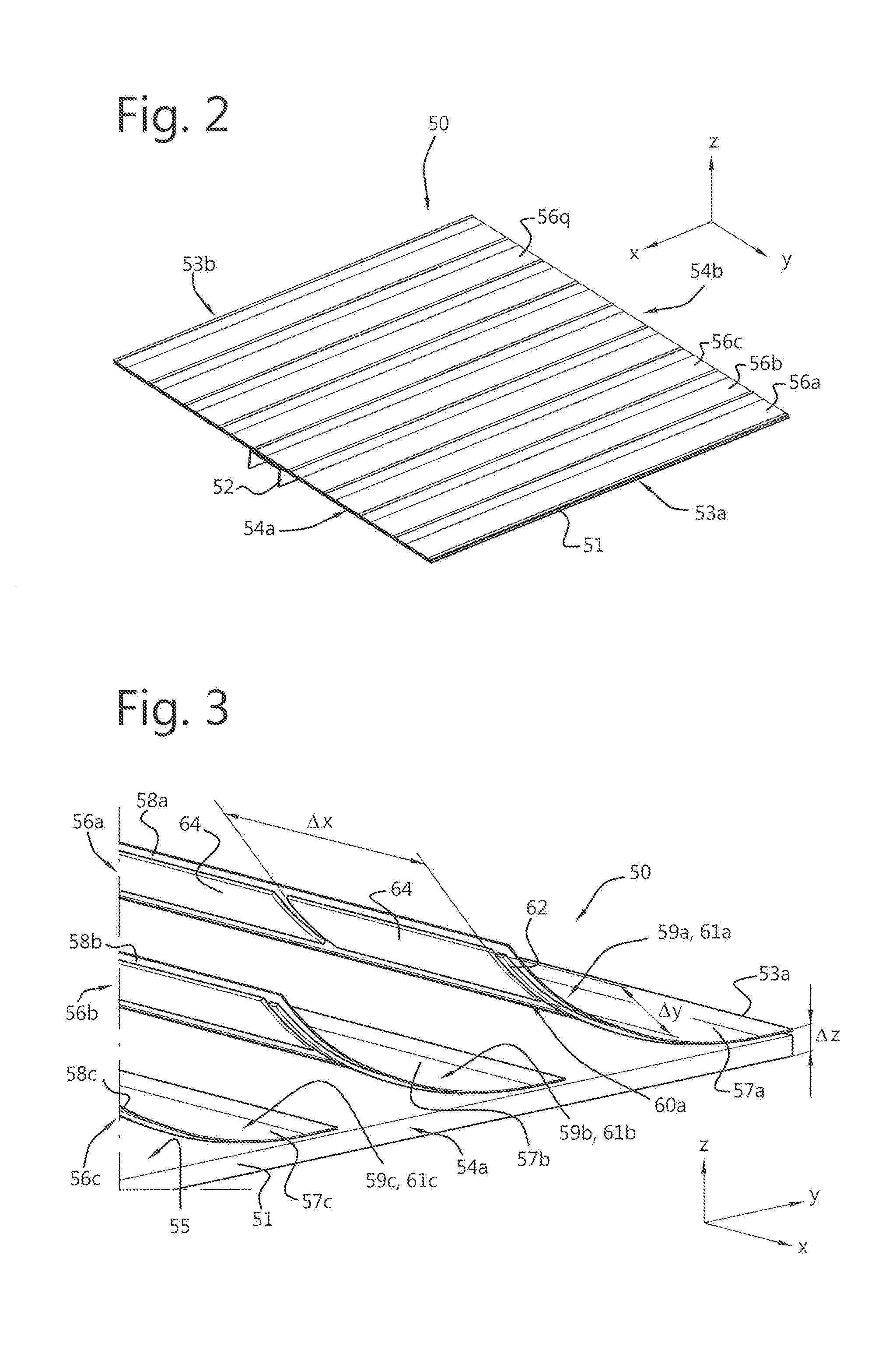

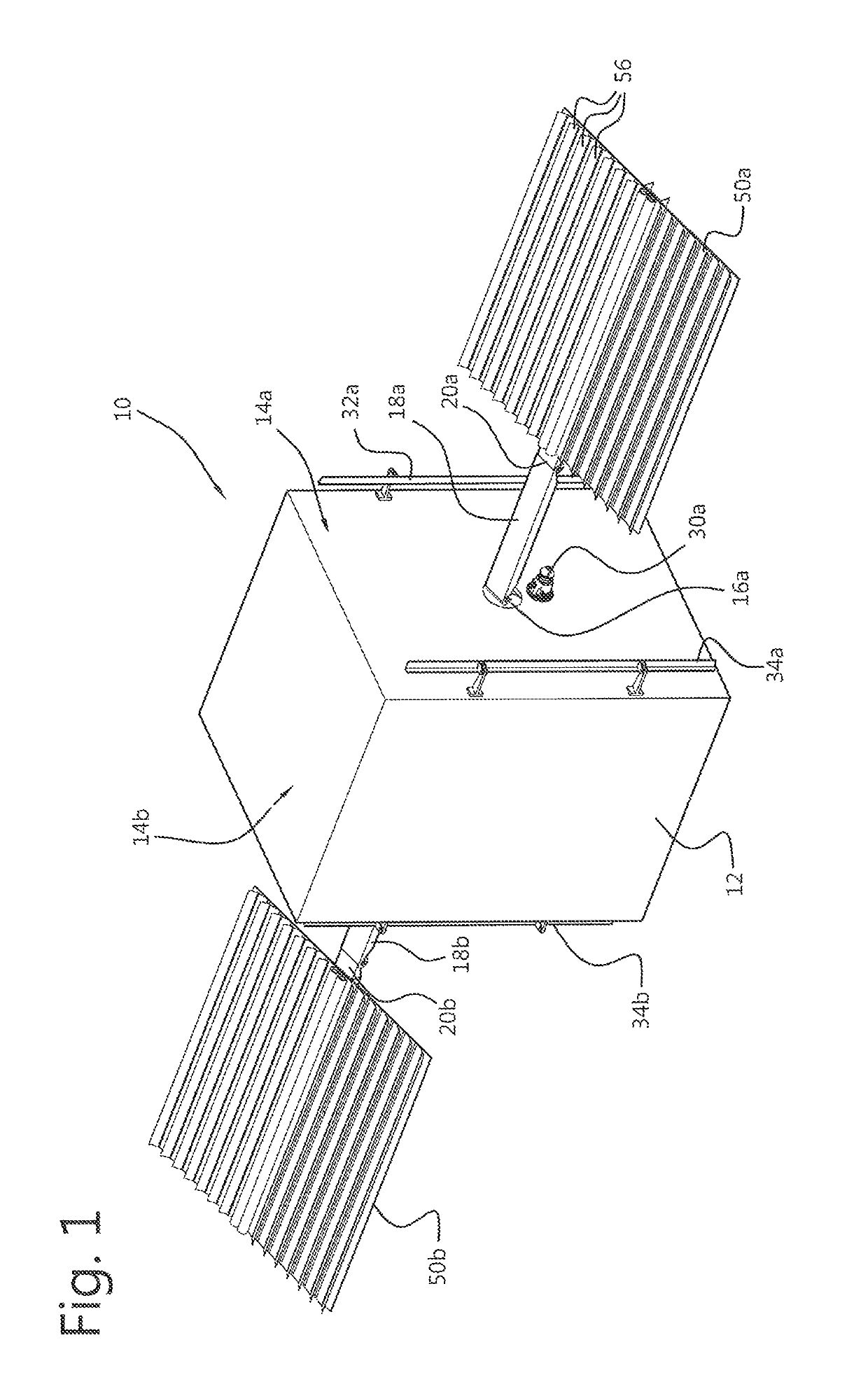

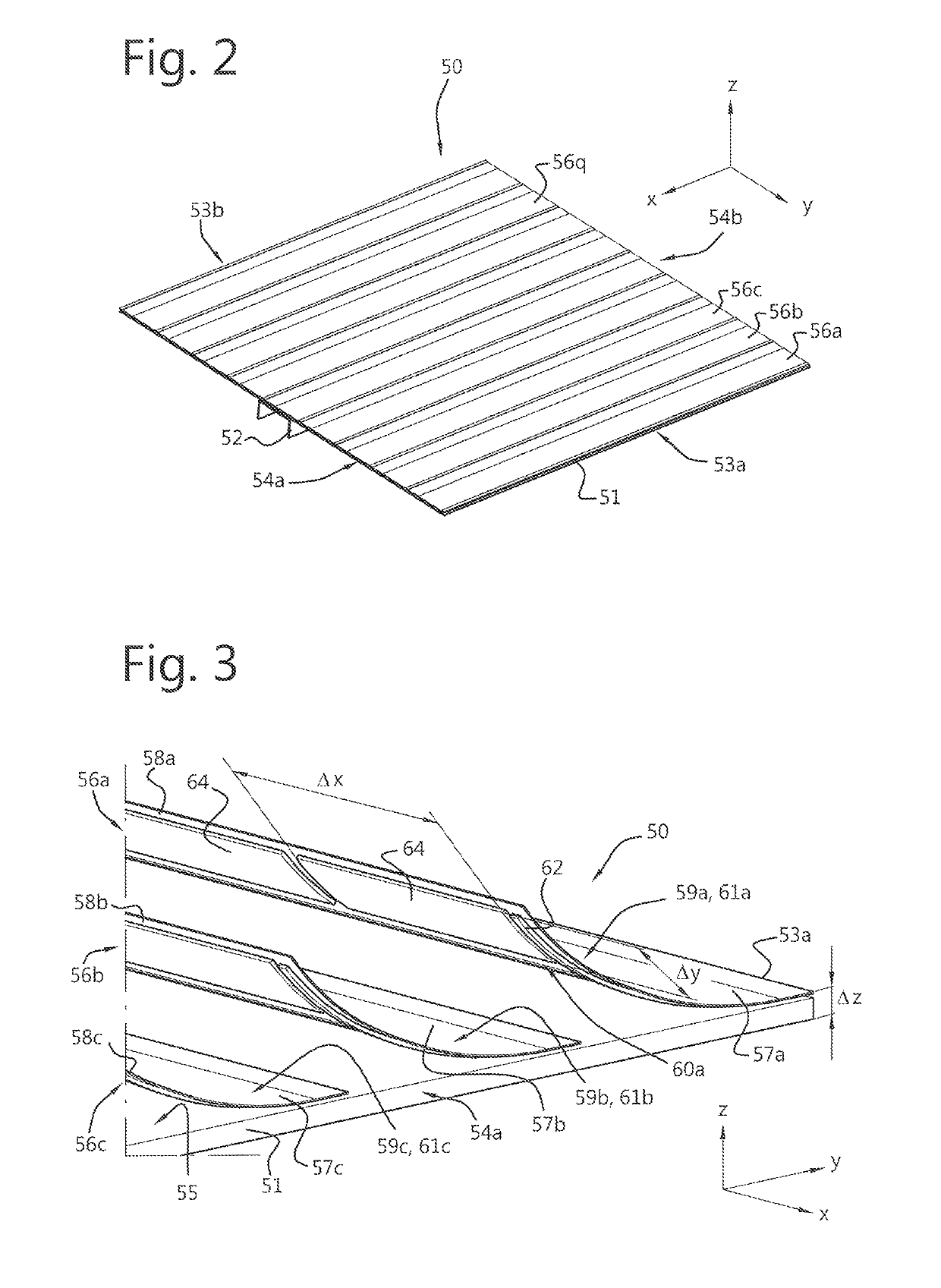

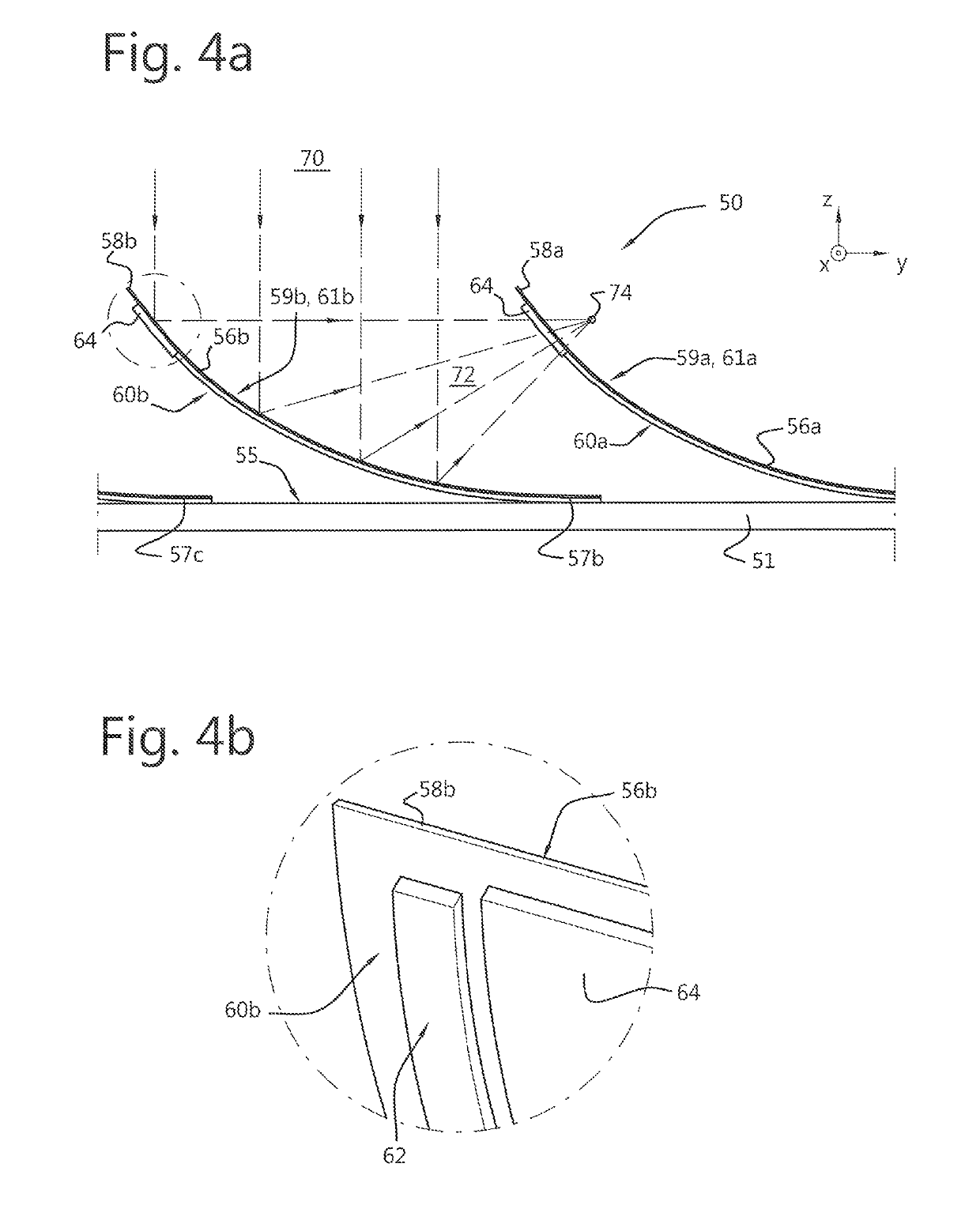

Solar Panel with Flexible Optical Elements

ActiveUS20170063296A1Raise the resonance frequencyIncrease stiffnessPhotovoltaic supportsSolar heating energyEngineeringSolar concentrator

A solar array (50) for a spacecraft (10), comprising a solar concentrator that is provided with photovoltaic cells and reflective areas configured for reflecting solar radiation towards the photovoltaic cells, wherein the reflective areas and the photovoltaic cells are provided on opposite surfaces of concentrator reflector sheet members (56) that are repositionable from a retracted state wherein the concentrator reflector sheet members are in a substantially flat arrangement, to a extended state wherein the concentrator reflector sheet members are raised to allow the reflective areas to reflect solar radiation towards the exposed photovoltaic cells.Alternatively or in addition, the solar array may comprise a support panel, which may be at least partially flexible for retaining the support panel in a bent panel shape when the solar array is in the stowed state fixed at a position near a body of the spacecraft.

Owner:AIRBUS DEFENCE & SPACE NETHERLANDS

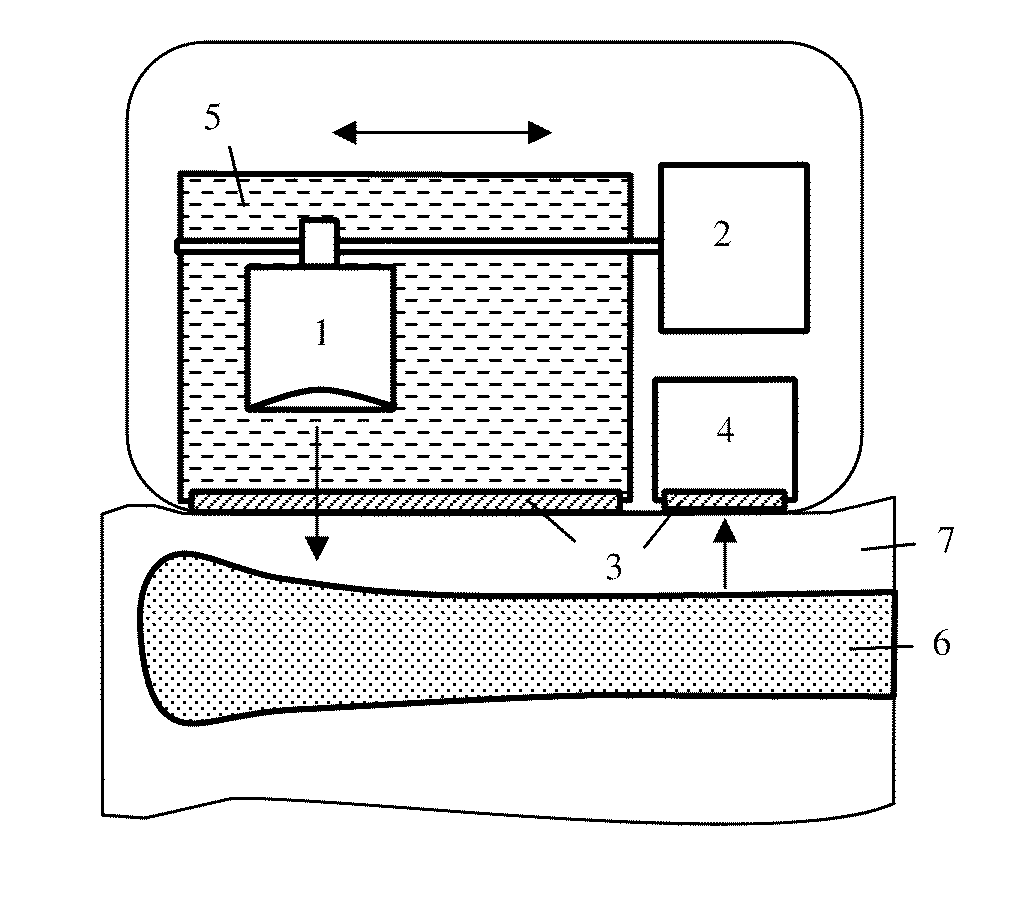

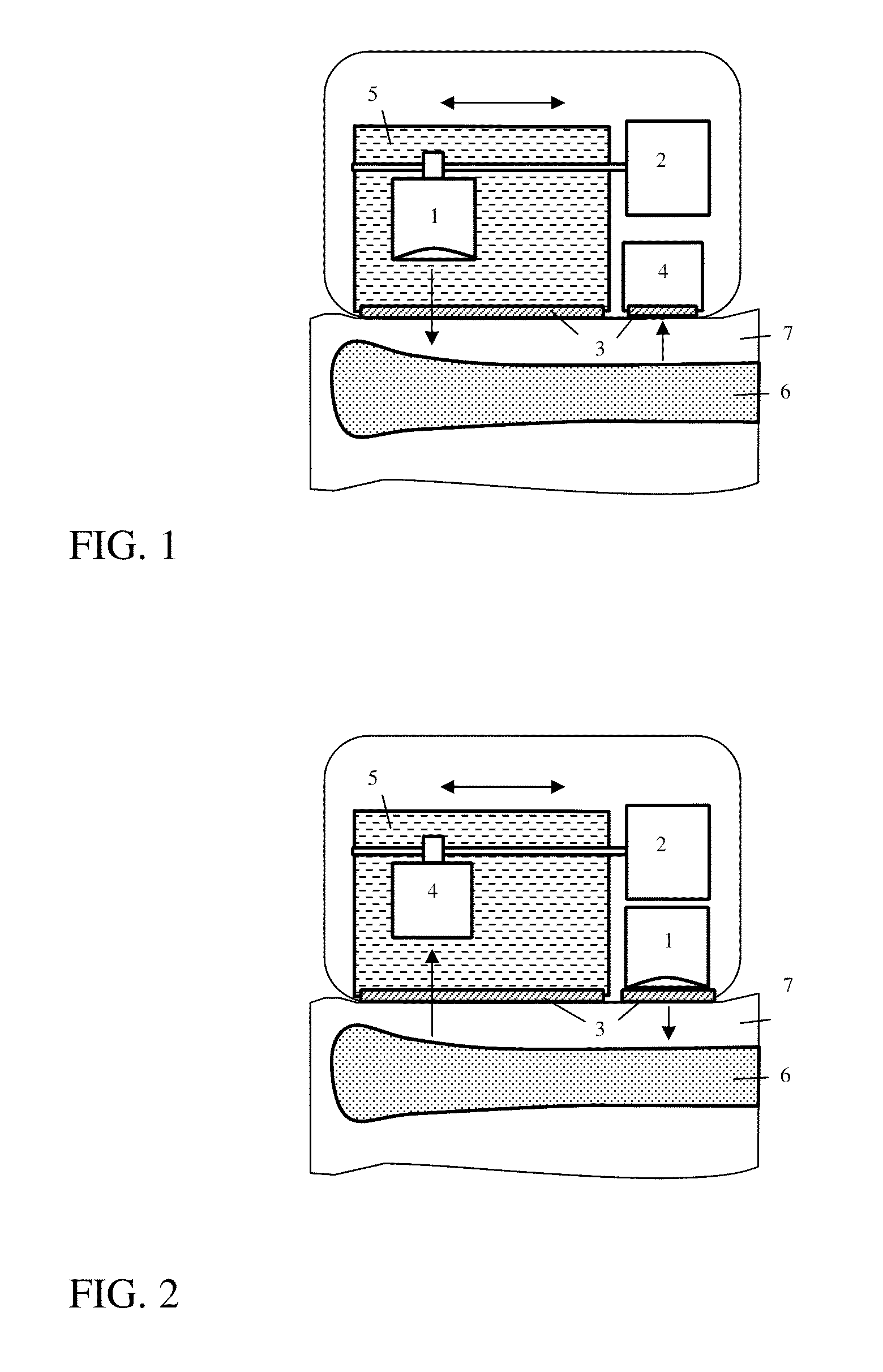

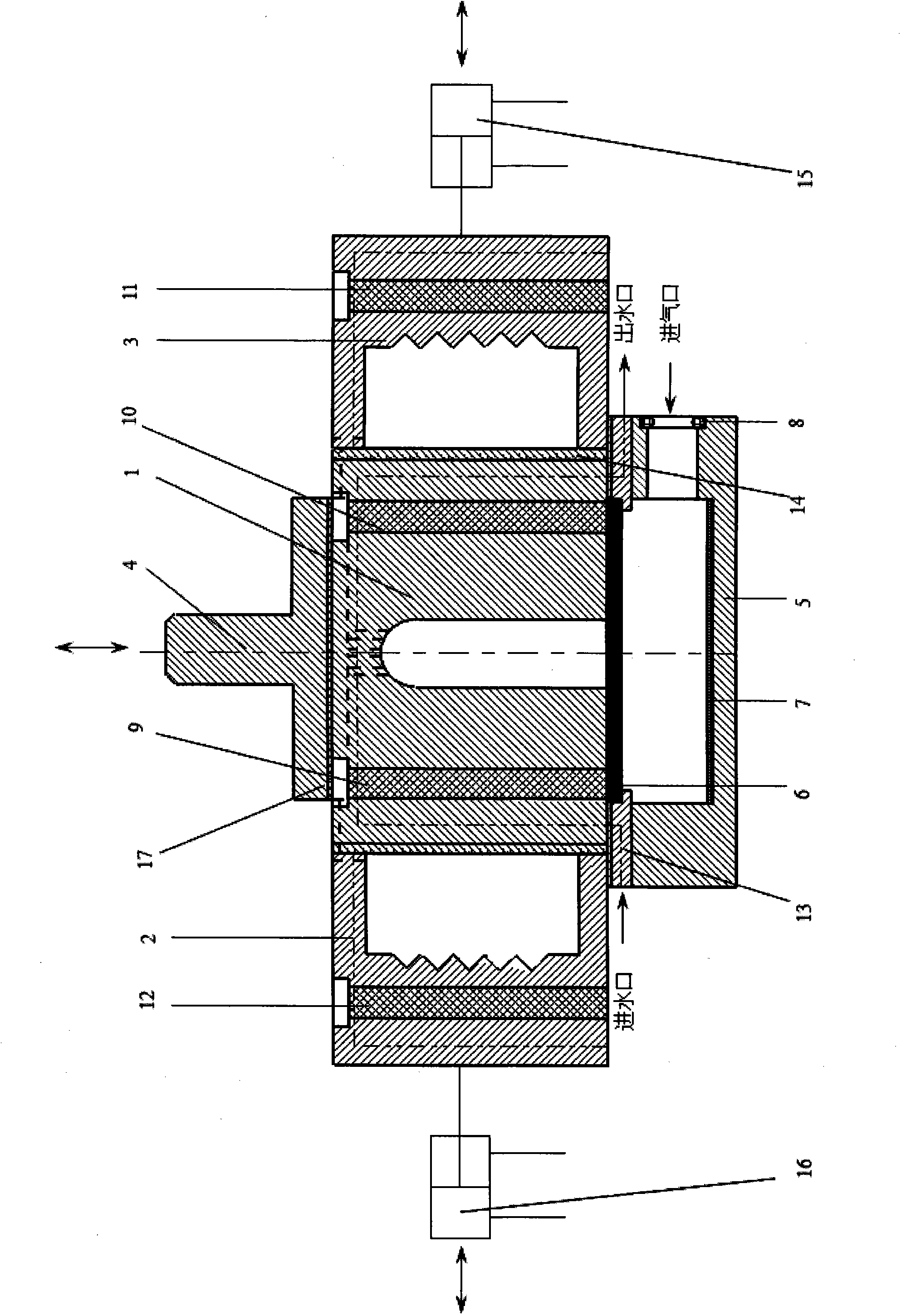

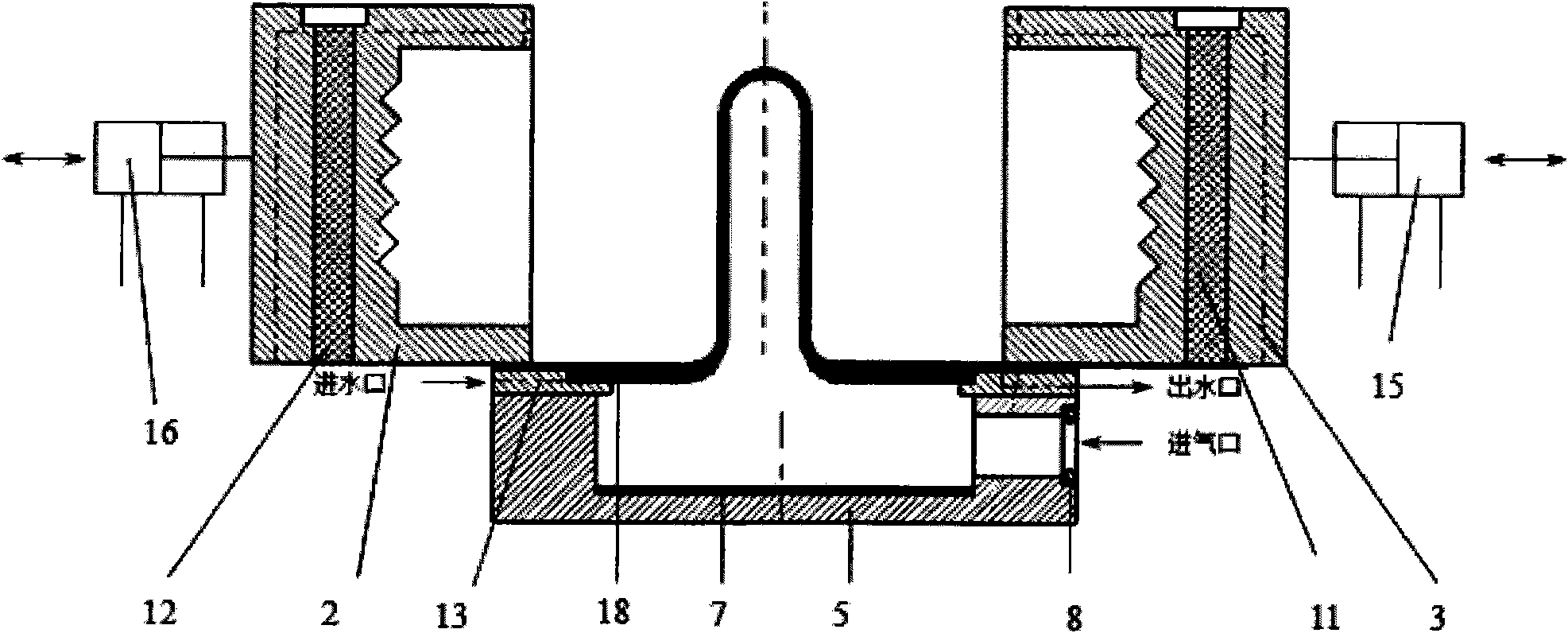

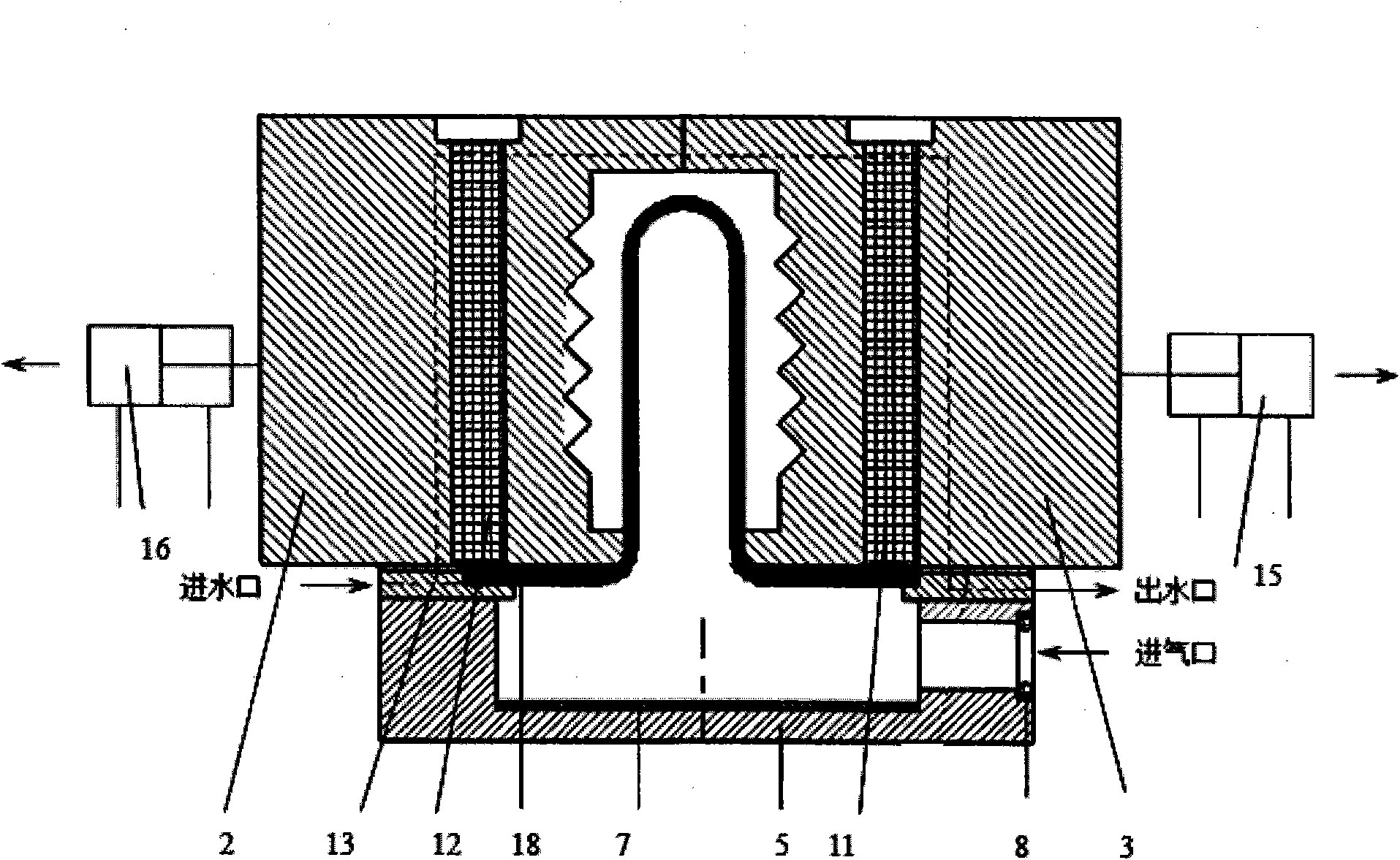

Ultrasonometer for bone assessment in infants

InactiveUS20110092818A1Short timeMinimal compressionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic sensorAcoustic radiation force

An ultrasonometer for bone assessment in infants includes a focusing acoustic wave transducer, an acoustic wave detector, and an elongated chamber filled with an acoustically-coupling fluid. The chamber is equipped with an acoustically-transparent flexible membrane facing the extremity of the infant. Supporting means such as a gliding rod is adapted to retain at least one of the transducer or the detector inside the chamber facing the subject. Supporting means is further adapted to move the transducer or detector along the chamber to perform the bone scanning without repositioning of the probe. A focused ultrasound transducer is adapted to remotely generate an acoustic wave in the bone by acoustic radiation force.

Owner:ARTANN LAB

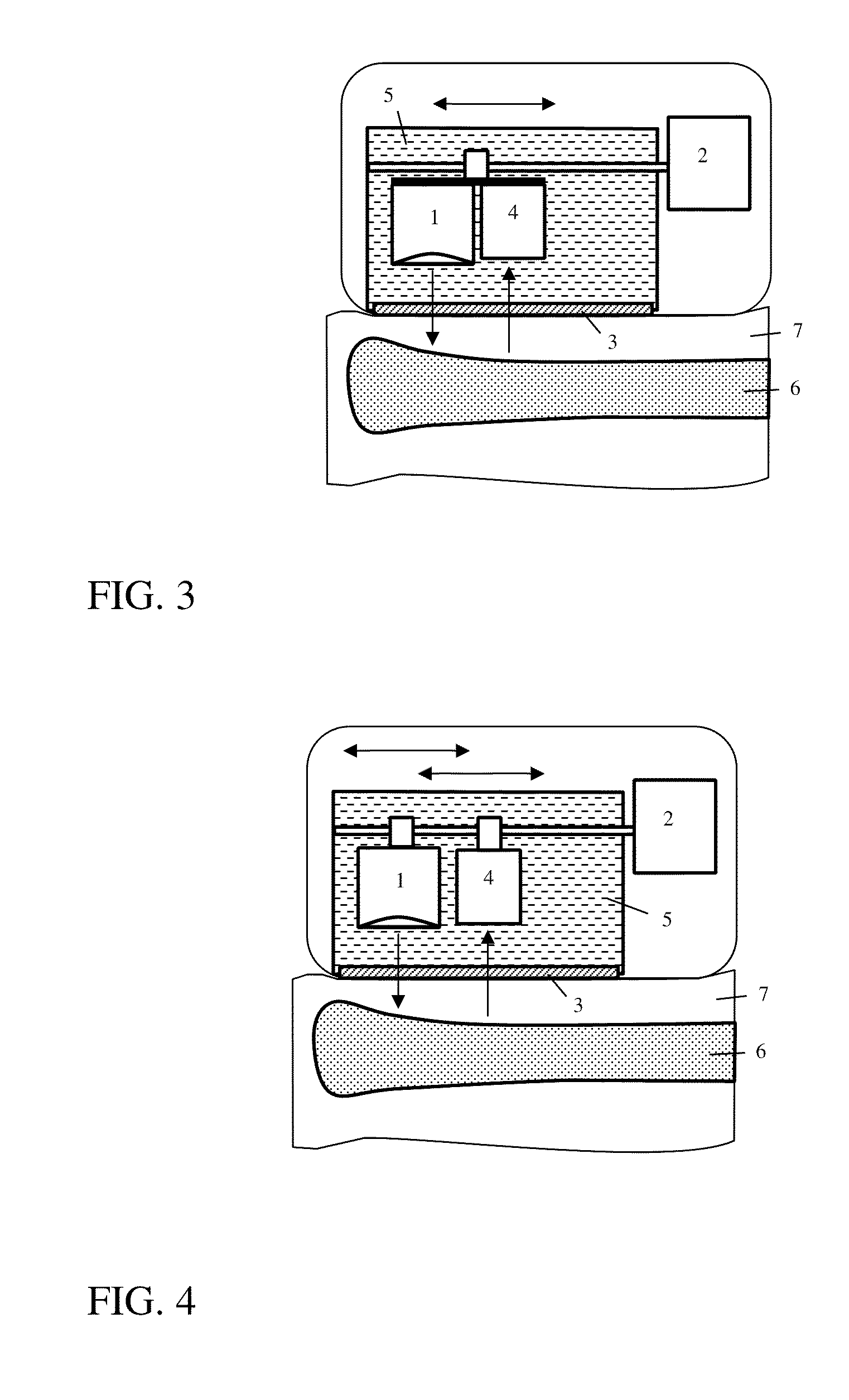

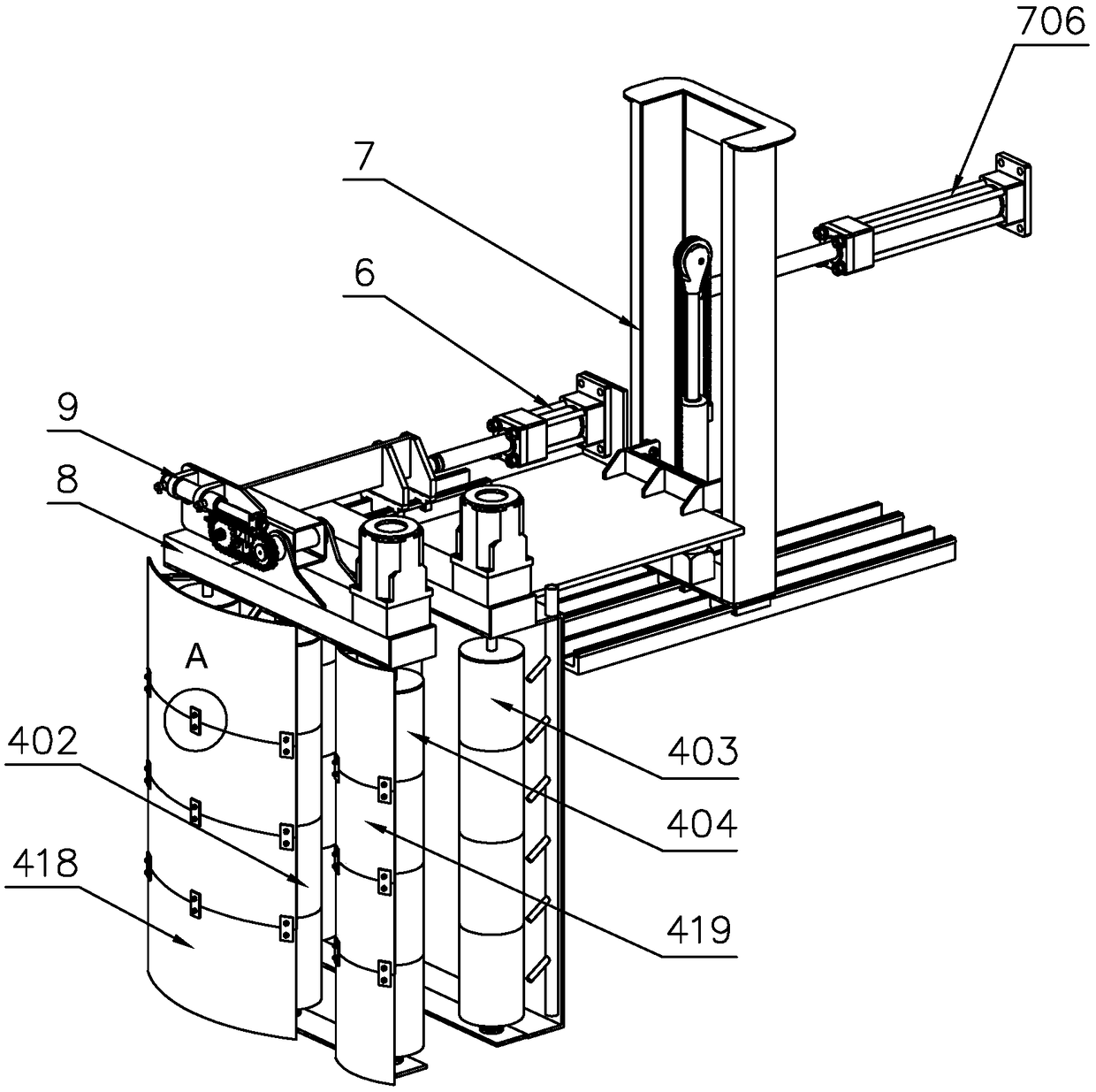

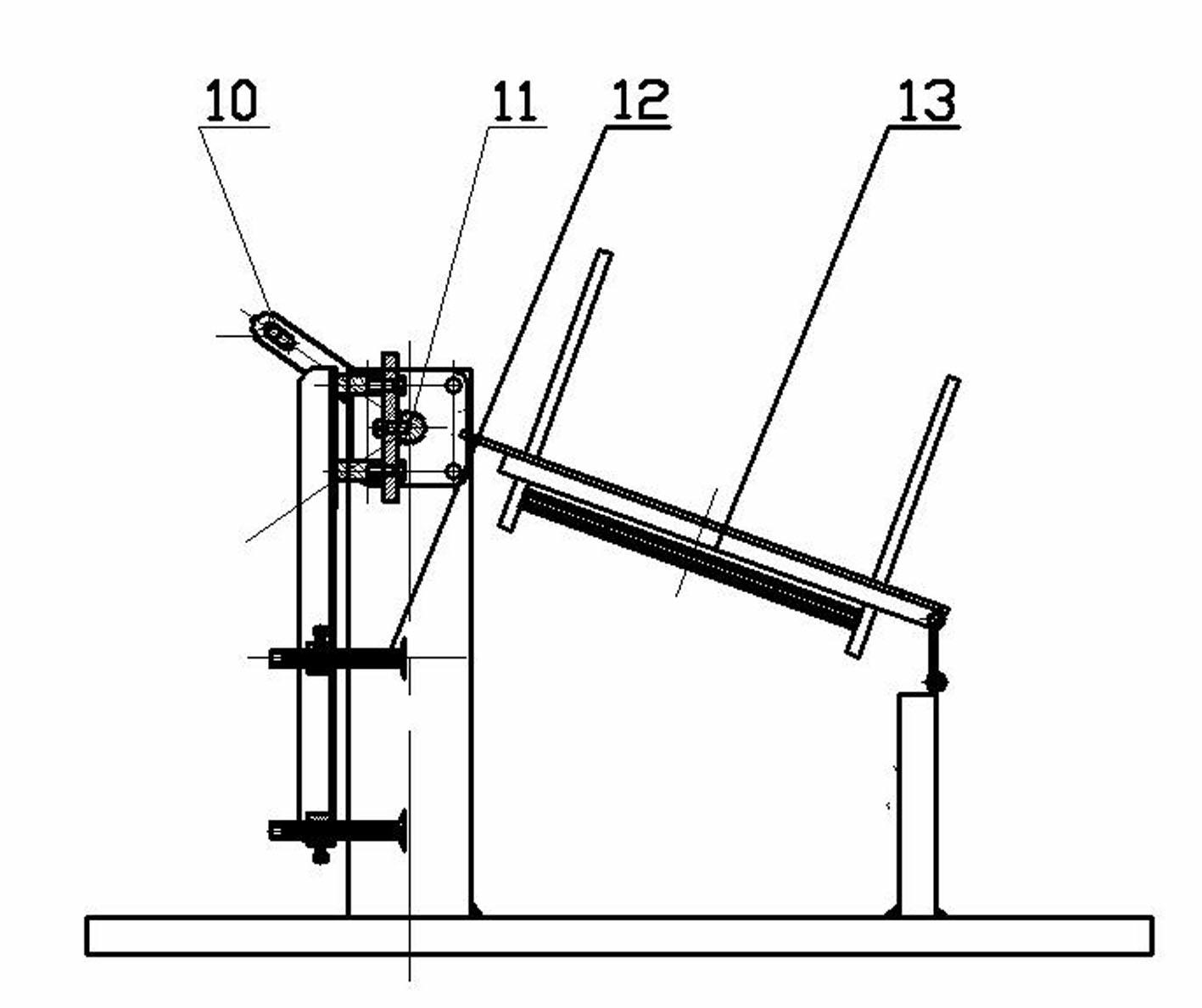

Vehicle-mounted road fence cleaning device for municipal use

InactiveCN109183689AAvoid repositioningImprove scrubbing efficiencyRoad cleaningWater storage tankSprocket

The invention discloses a vehicle-mounted road fence cleaning device for municipal use. A water storage tank is arranged on a sprinkler vehicle body and a storage tank is arranged on one side of the water storage tank. A lifting device is arranged in the contain box, and the lifting device comprises a lifting frame, a lifting cylinder, a sprocket wheel III, a chain and a sliding block; a cleaningdevice is arranged on one side of the lifting device, and the cleaning device comprises a fixed brush roller, an adjusting brush roller, a transmission box and a transmission device, wherein the transmission box is provided with a transmission device; a high-pressure water pipe is arranged on one side of the fixed brush roller; the other side of the guard rail is provided with an adjusting brush roller symmetrical to the fixed brush roller, and the structure and size of the adjusting brush roller are consistent with those of the fixed brush roller. The upper part of the transmission box of theadjusting brush roller is provided with an obstacle overtaking device. When the invention meets obstacles such as traffic indication signs, the adjusting brush roller is folded up by using a flippingdevice and a retracting device, and the adjusting brush roller is reset by using the flipping device and the retracting device after the flipping device and the retracting device pass over the obstacles, thereby avoiding the repositioning of the cleaning device and improving the scrubbing efficiency.

Owner:房思群

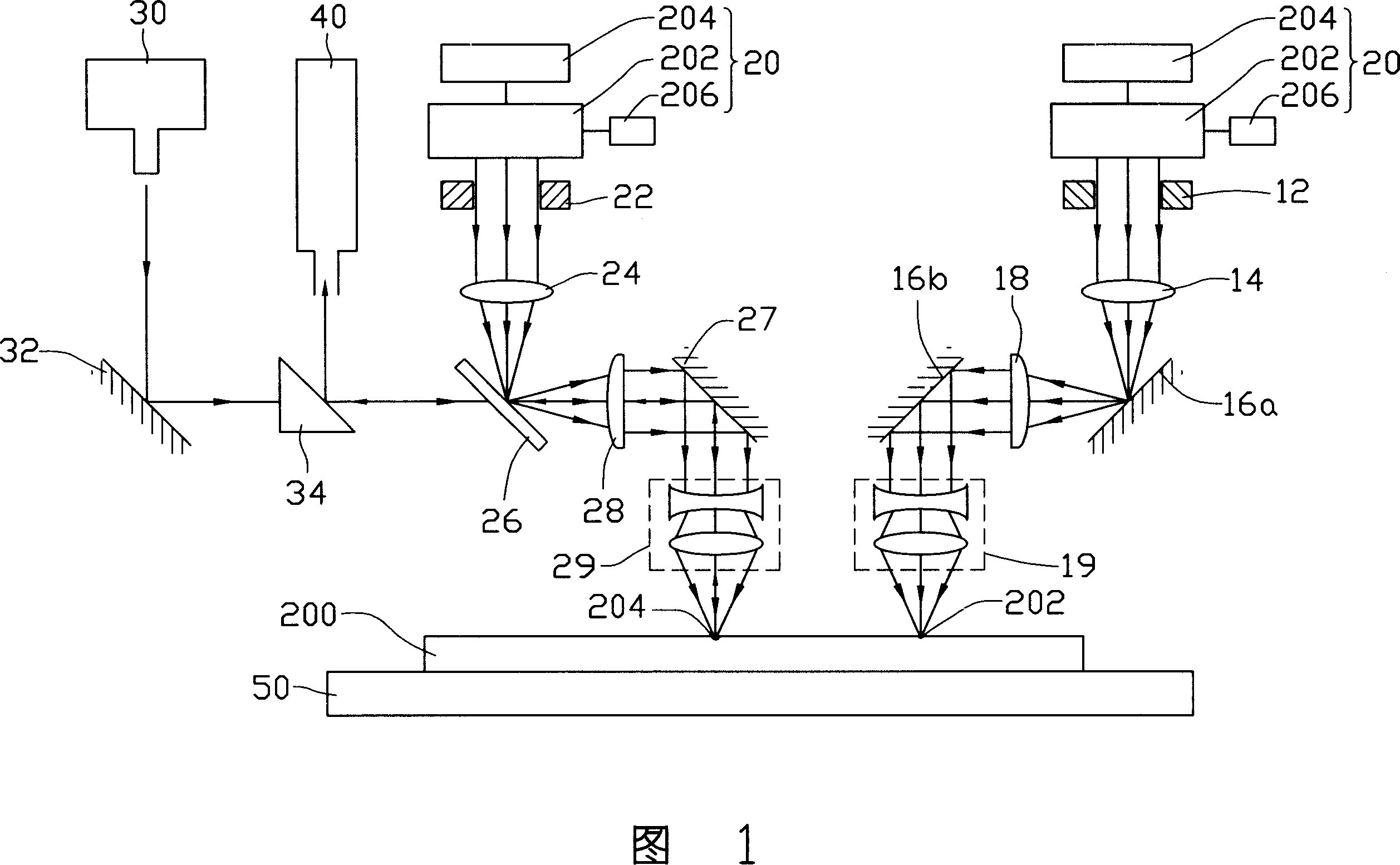

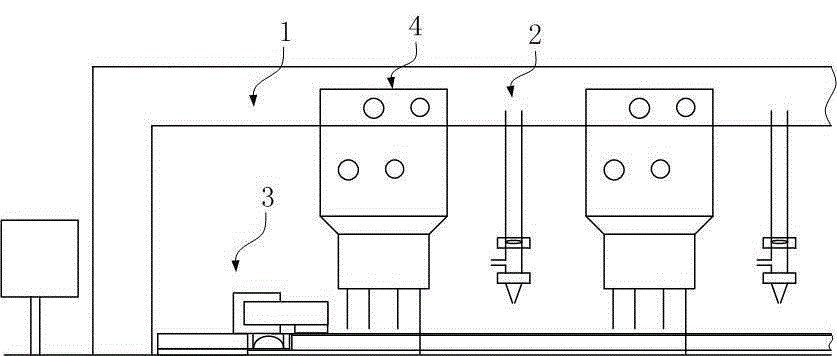

Laser processing system

InactiveCN1978120AImprove machining accuracyRealize monitoringActive medium materialLaser beam welding apparatusLaser processingLength wave

The present invention relates to a laser processing system. It includes a first laser device for outputting a first wavelength laser beam, the wavelength of said first wavelength laser beam is lambda 1; a first optical component for collecting first wavelength laser beam onto first object processing position of workpiece to be processed; a second laser device for outputting a second wavelength laser beam, the wavelength of said second wavelength laser beam is lambda 2, said lambda 2 is not equal to lambda 1; a second optical component for collecting said second wavelength laser beam onto second object processing position of workpiece to be processed, said second object processing position is different from first object processing position in absorption wavelength; a third laser device for outputting a monitoring laser beam onto the object processing position with shorter absorption wavelength in first object processing position and second object processing position, the wavelength of said monitoring laser beam is positioned in visible light range; and an optical detection device for receiving monitoring laser beam reflected from said object processing position so as to produce a detection signal.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

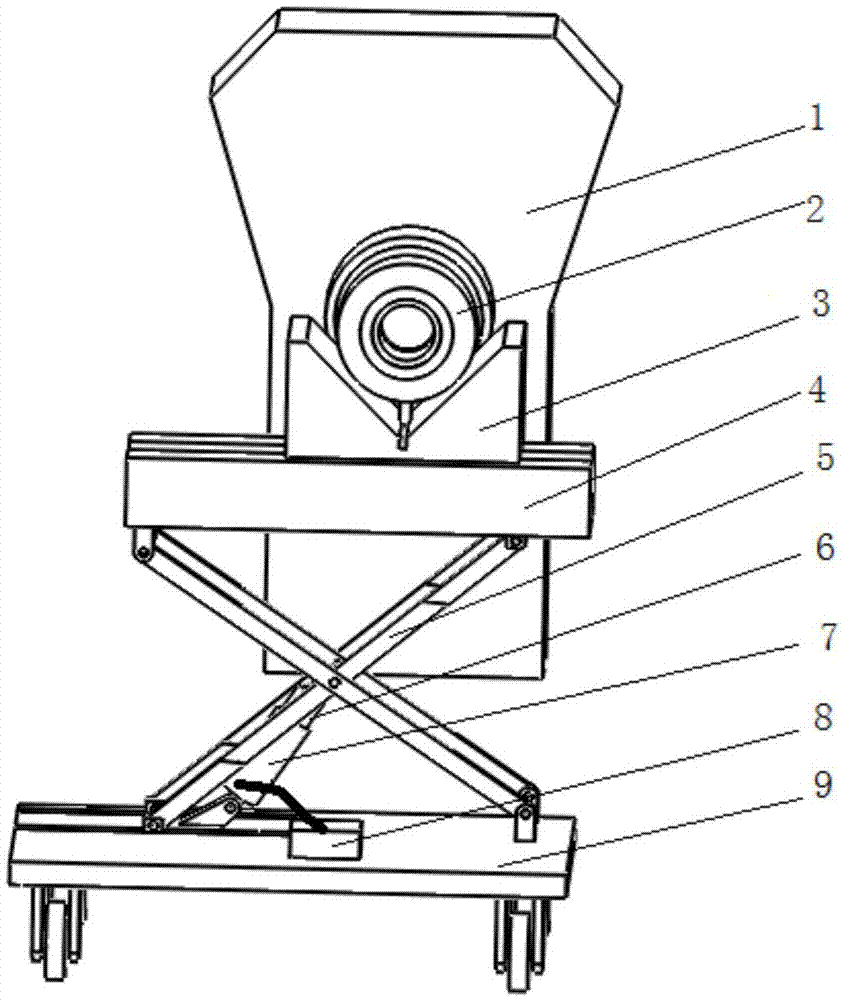

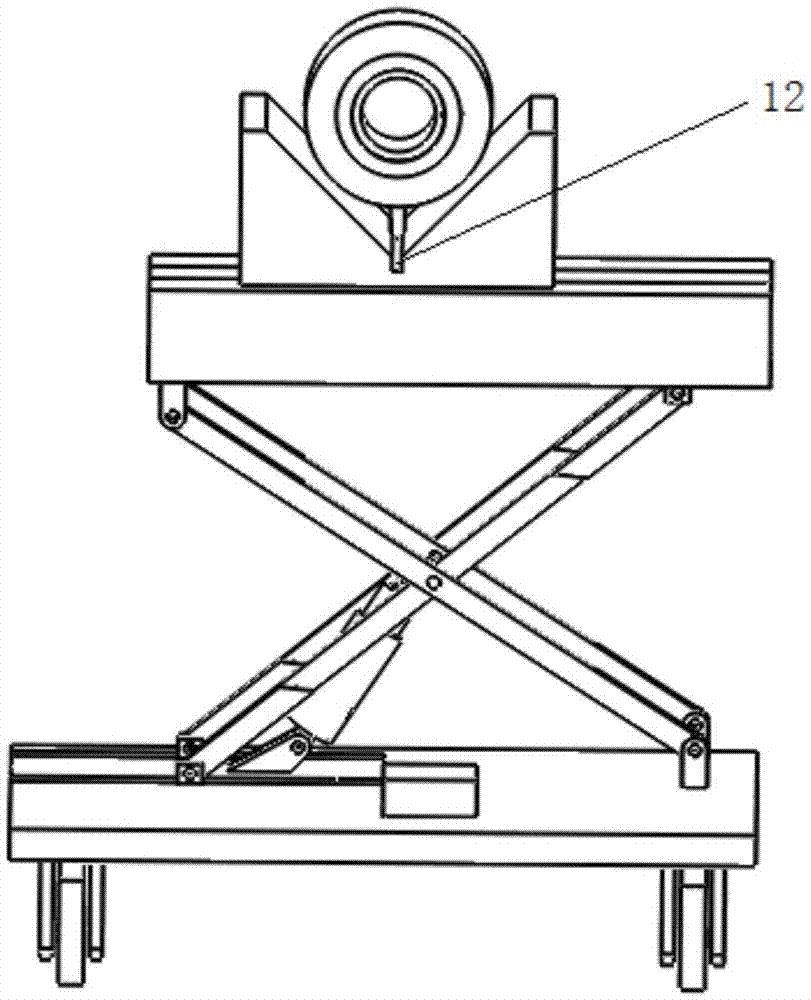

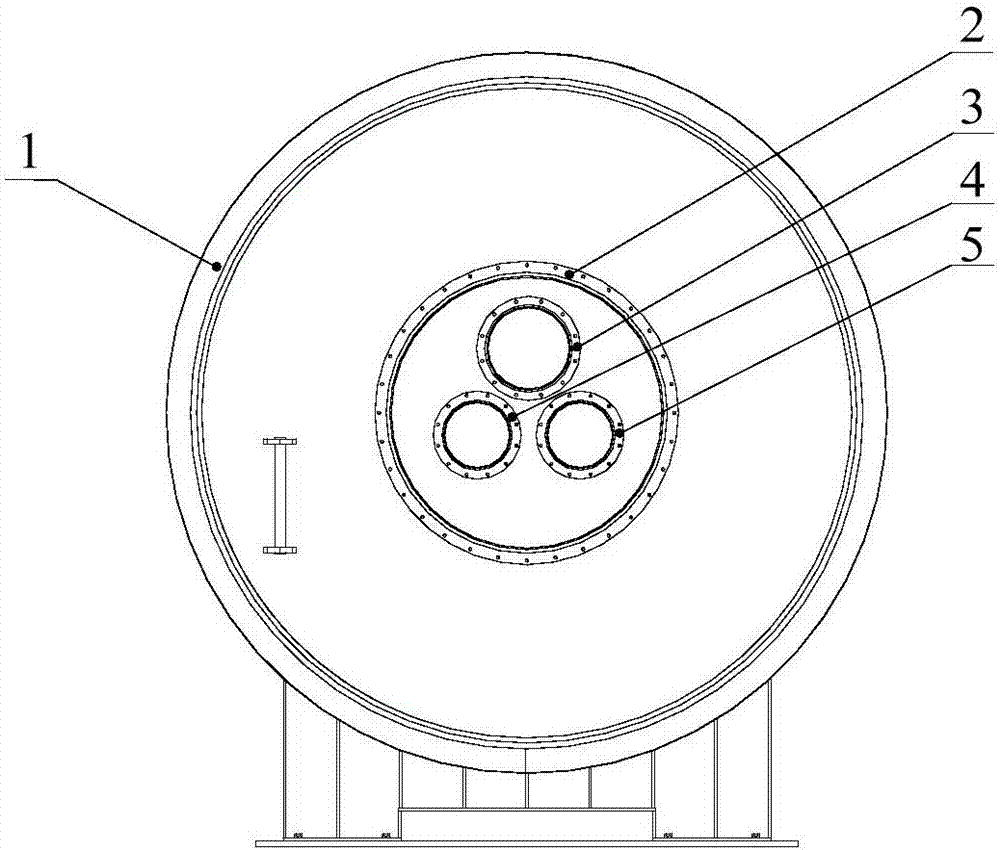

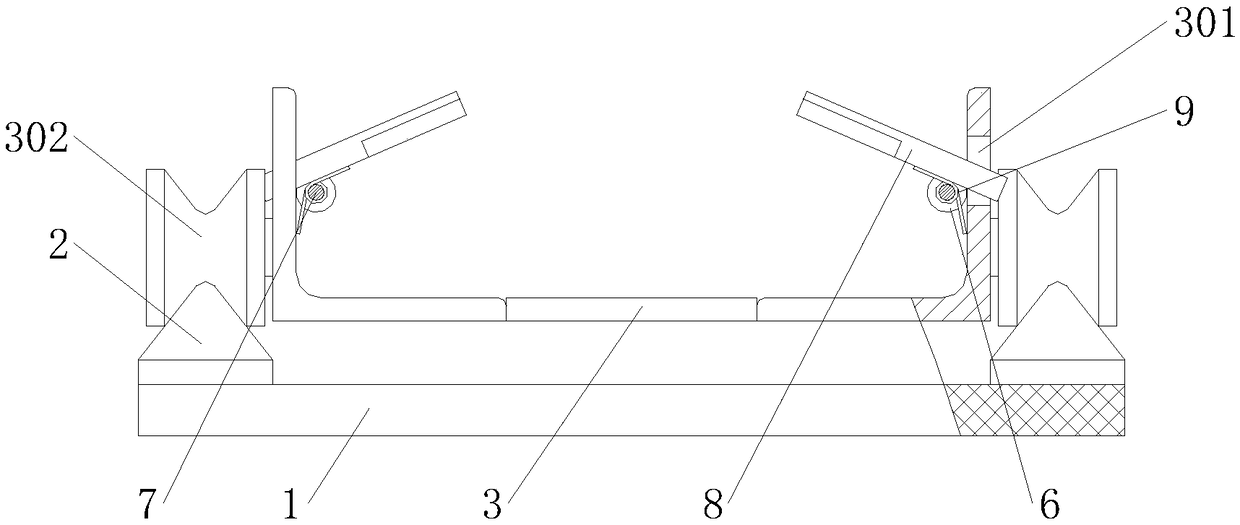

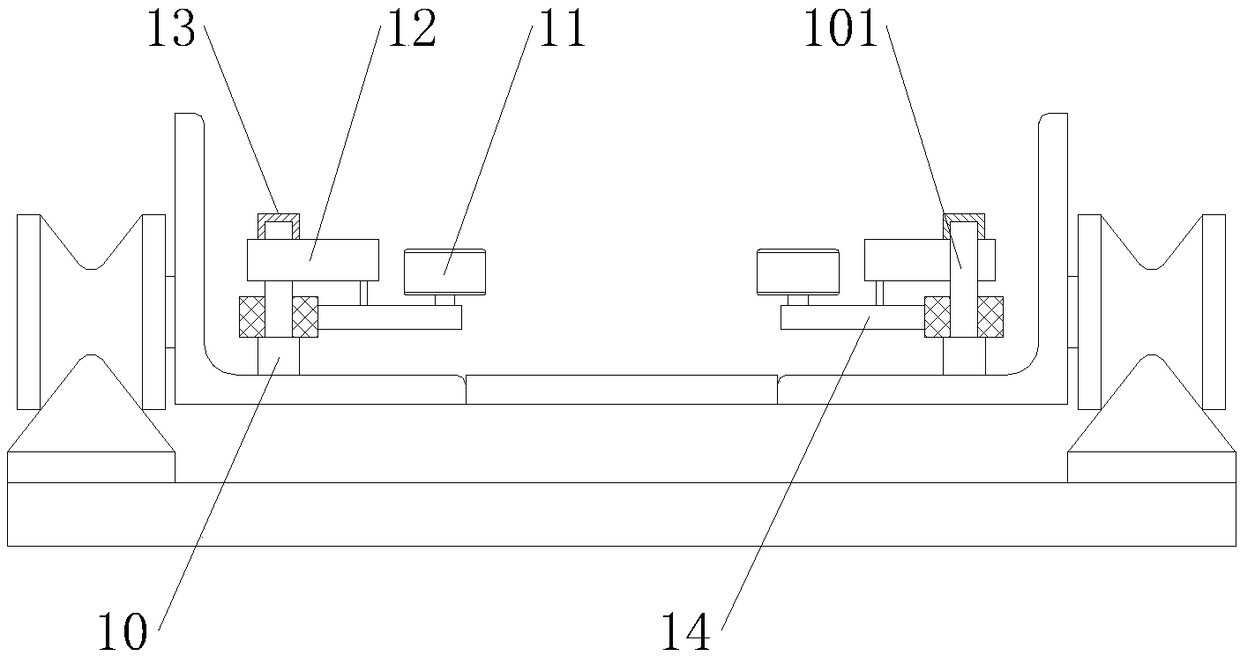

Support platform for installing and disassembling diesel engine crankshaft vibration reducer

ActiveCN105436869AAutomatic centeringAchieve phase lockCrankshaftsMetal working apparatusEngineeringMechanical engineering

The invention discloses a support platform for installing and disassembling a diesel engine crankshaft vibration reducer. The support platform comprises an axial V-shaped groove for supporting the vibration reducer, a horizontal movable table, and a hydraulic lifting device positioned below the horizontal movable table; a first slide block extends below the axial V-shaped groove; and a first chute matched with the first slide block for use is formed in the horizontal movable table. The support platform for installing and disassembling the diesel engine crankshaft vibration reducer has such advantages as simple structure, convenience for operation, high installation efficiency and good safety, supports and fixes the vibration reducer, enhances the balance of the vibration reducer in the installation process, and prevents the lifting of the vibration reducer; and the transverse motion of the axial V-shaped groove and a lifting mechanism can realize automatic centering of an inner hole of the vibration reducer and the axis of a crankshaft in all directions so as to quickly finish the coaxiality matching of the inner hole of the vibration reducer and the crankshaft.

Owner:JIANGSU UNIV OF SCI & TECH

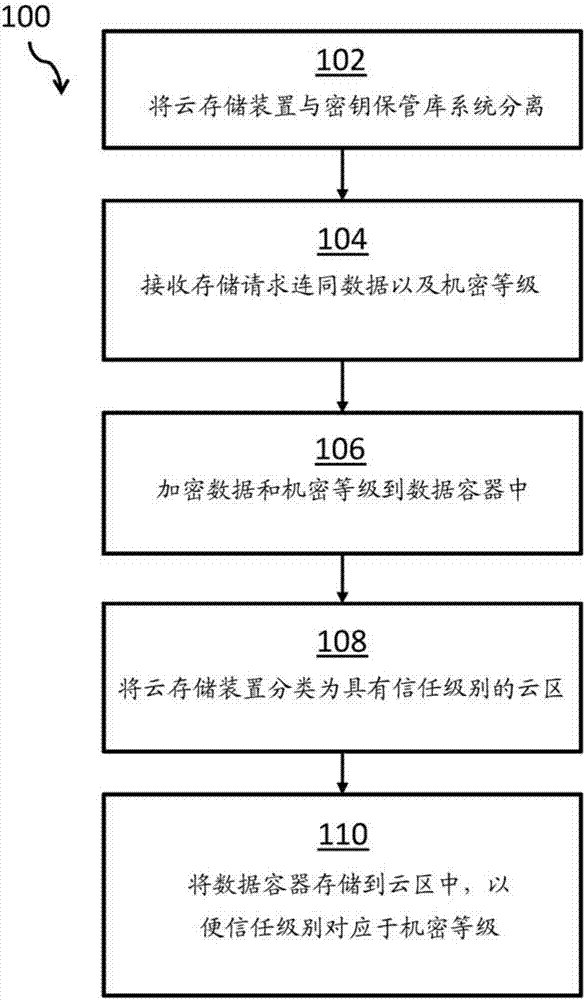

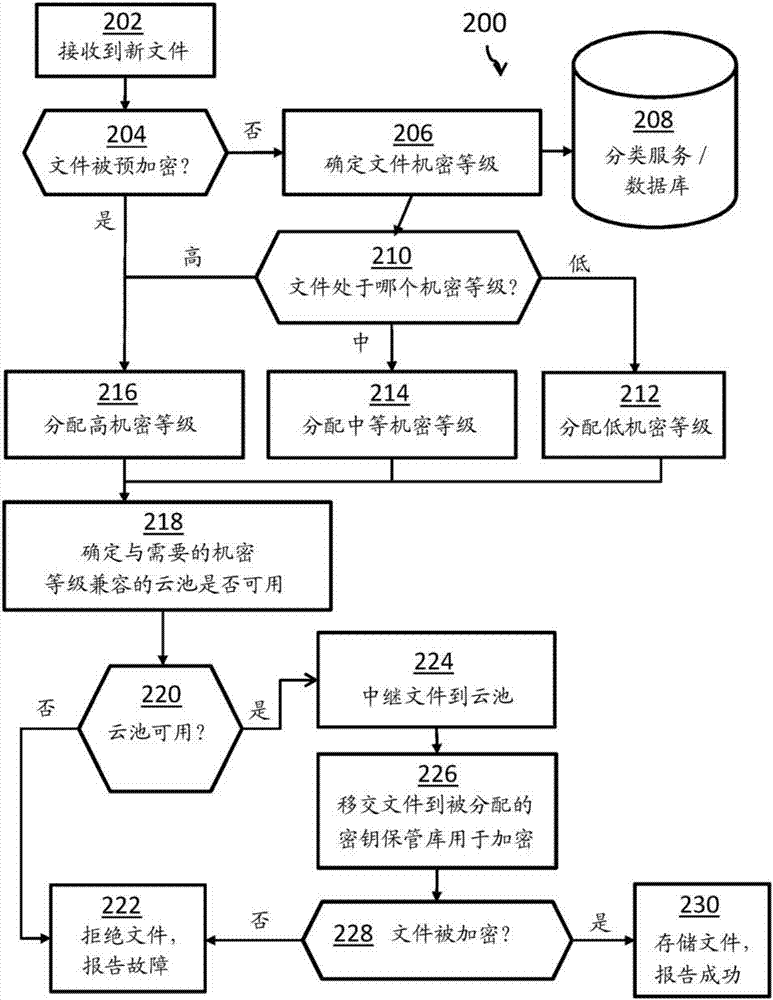

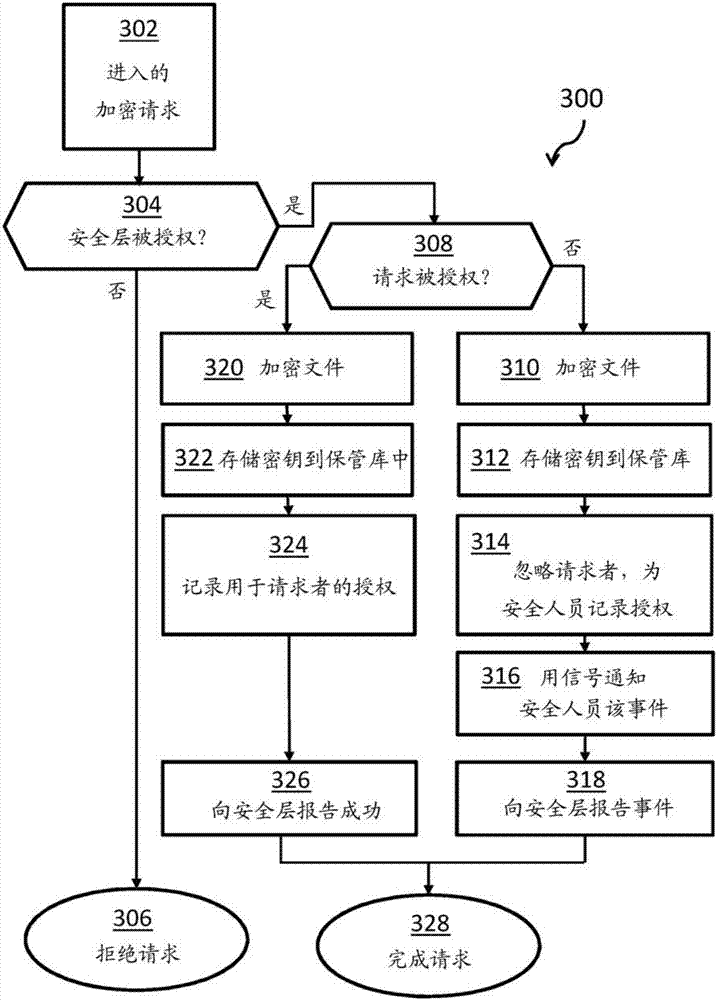

Automated management of confidential data in cloud environments

ActiveCN107003815AAvoid repositioningEnsure mutual trustInput/output to record carriersComputer security arrangementsConfidentialityTrust level

A method for storing data in a Cloud environment may be provided. The Cloud environment comprises a security layer. The method comprises physically separating the Cloud storage from a key vault system, and receiving a storage request together with a confidentiality rating, wherein the storage request together with data and the confidentiality rating is received via the Cloud storage access interface by the security layer. The method further comprises encrypting the data to be stored and the confidentiality rating on request of the security layer by the key vault system into a data container, categorizing the Cloud storage into Cloud zones, wherein each Cloud zone is assigned a trust level; and storing the data container in one of the Cloud zones of the Cloud storage such that the trust level of the one of the Cloud zones corresponds to the confidentiality rating.

Owner:IBM CORP

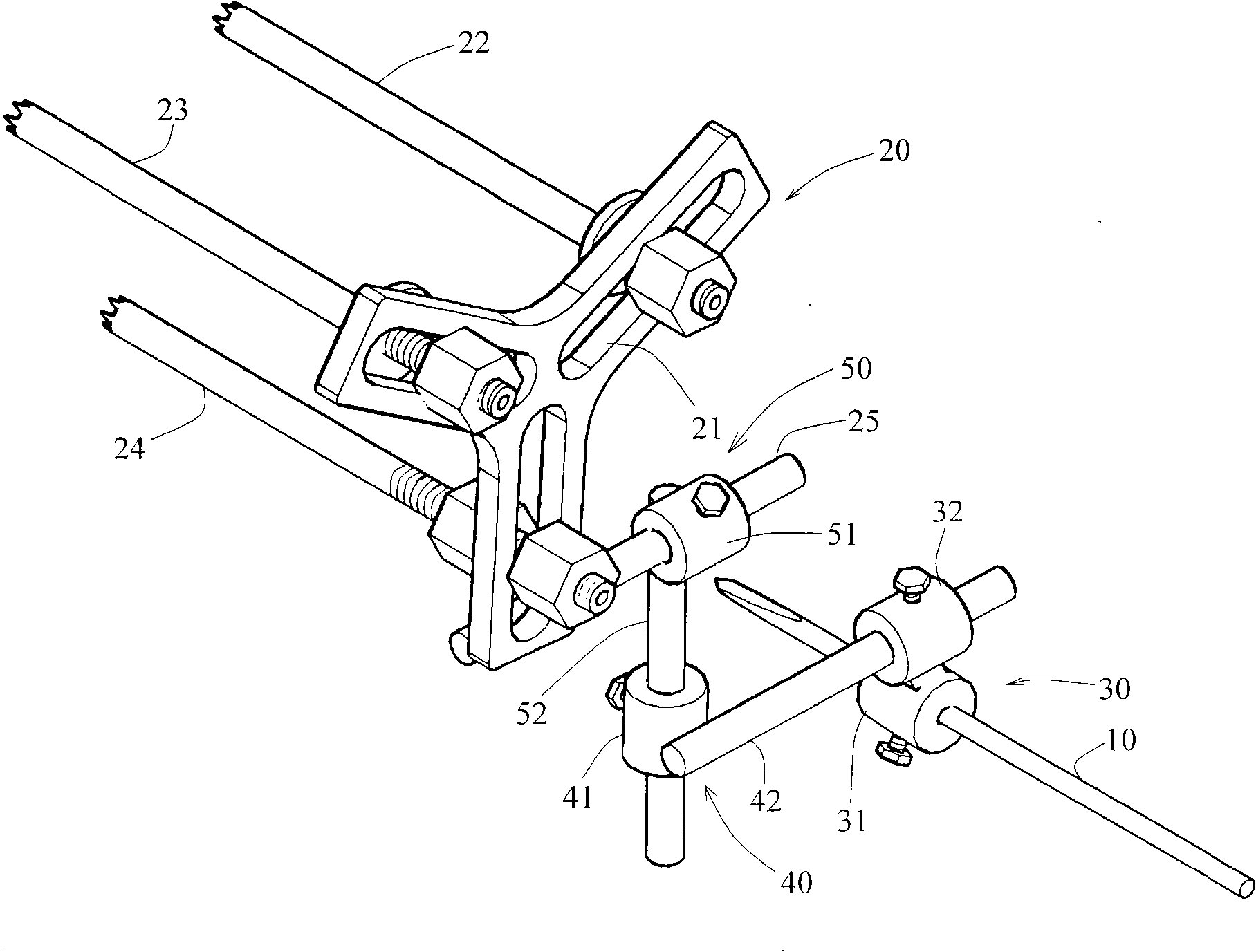

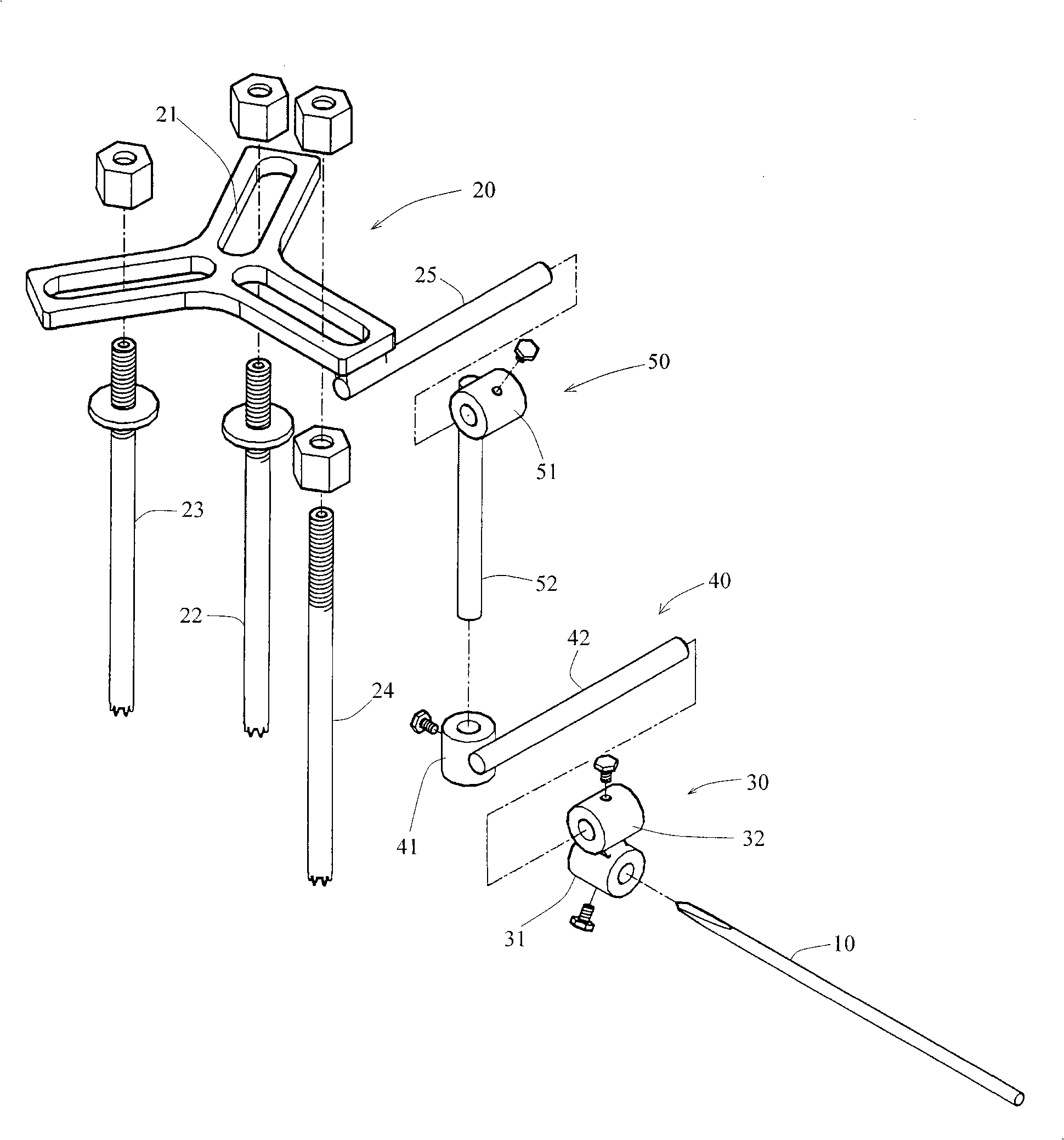

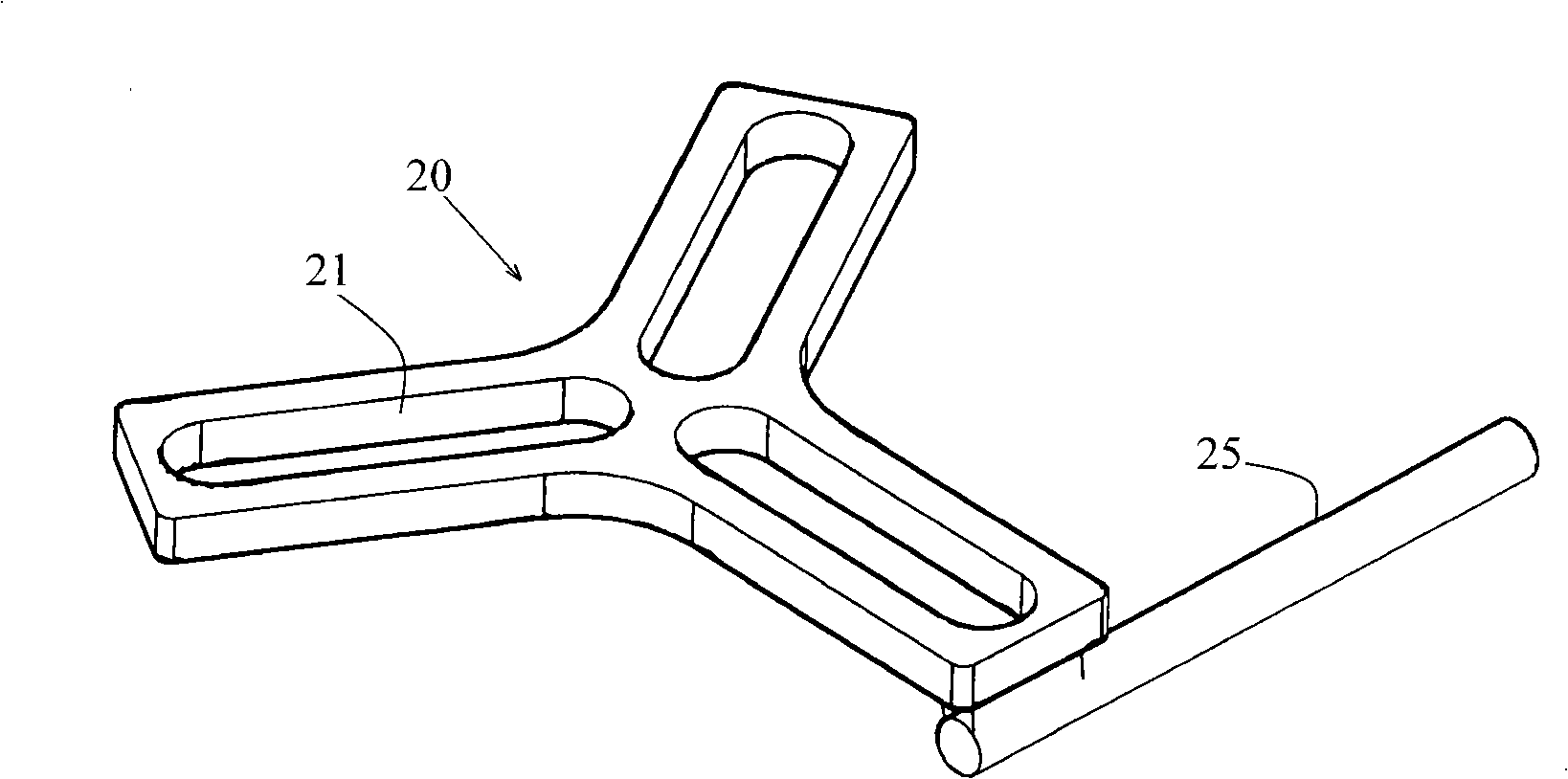

Hollow screw internal fixation guide pin locater of femoral neck fracture

InactiveCN101336840AConvenient and fast precise positioningAvoid repositioningSurgeryFemurEngineering

The invention provides a hollow screw internal fixation guide pin positioner for femoral neck fracture, comprising a fixing lever for supporting and positioning the positioner on a femur; a three-point positioning rack including a rack body, three positioning levers and a connection lever; a first pivoting section pivoted on the fixing lever; a second pivoting section pivoted on the first pivoting section; a third pivoting section pivoted on the second pivoting section and pivoted on the connection lever of the fixing rack. According to the technical scheme above, the fracture positioner can adjust positioning position and angle direction, can overcome defects of being difficult to fix and unable to be observed under flouroscopy of the conventional fixing device, also can conveniently and quickly position femoral neck fracture accurately, and once successful positioning can be obtained. By driving the screw guide pin into the femoral neck through a center hole of the positioning lever, repeated positioning is avoided, shortened surgery time, reduced partial hemorrhage, reduced sclerotin quality reduction, and increased fixing strength for the femoral neck are obtained.

Owner:夏胜利

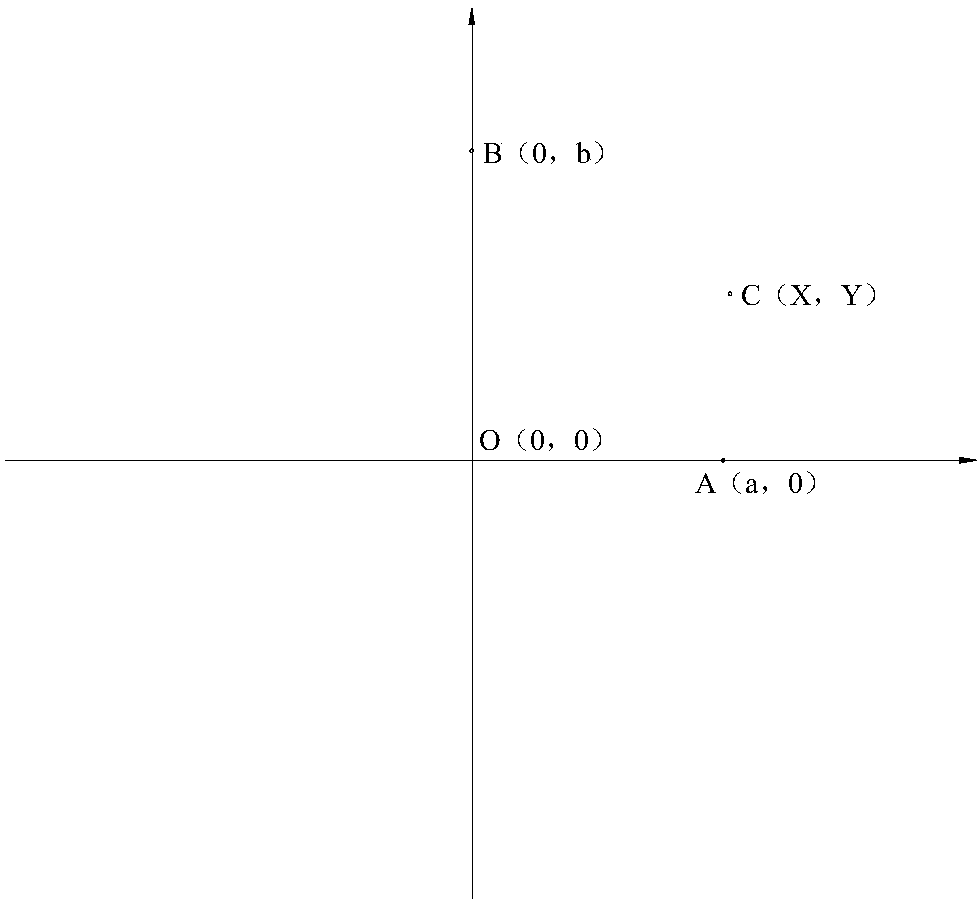

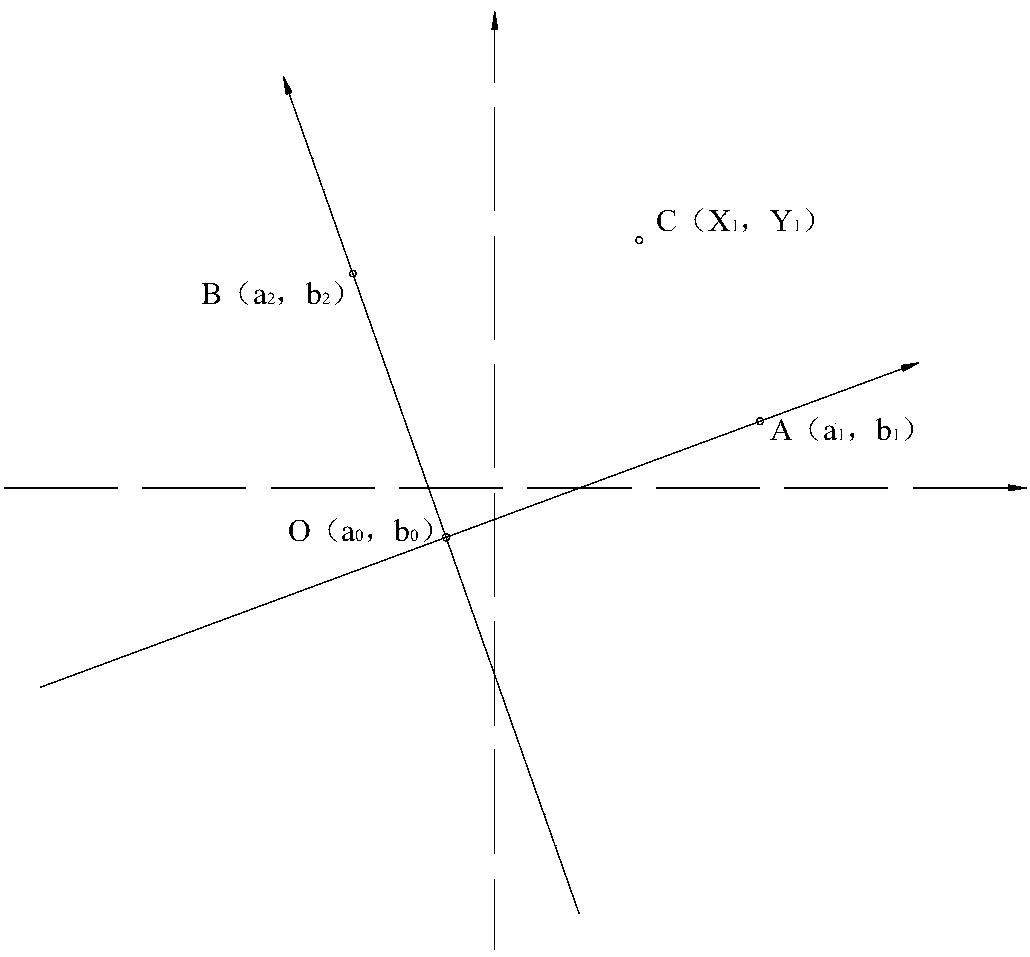

Method for converting coordinates of A-S universal sample table into coordinates of AFM sample table

ActiveCN108548943AAvoid repositioningRealize joint useScanning probe microscopyComputational physicsComputer science

The invention provides a method for converting the coordinates of an A-S universal sample table into the coordinates of an AFM sample table. The method comprises the following steps: (1) placing an A-S universal sample table provided with a sample in an SEM to observe the A-S universal sample table, and finding out a target area; (2) recording the target coordinates of the area; (3) transferring the A-S universal sample table to the AFM sample table, and obtaining the new coordinates of the target coordinates in the AFM sample table. According to the method provided by the invention, the method for converting the coordinates of the A-S universal sample table into the coordinates of the AFM sample table is provided. The method solves the problem that the coordinates of a target point need to be repositioned after the A-S universal sample table is transferred to the AFM sample table in the prior art. As a result, the combination of the SEM and the AFM is achieved. The working efficiencyof the AFM is greatly improved, and the cognition of researchers to nanometer materials is greatly enriched.

Owner:SOUTH CHINA UNIV OF TECH

Diverting tool

Owner:BAKER HUGHES HLDG LLC

Diverting tool

Owner:BAKER HUGHES INC

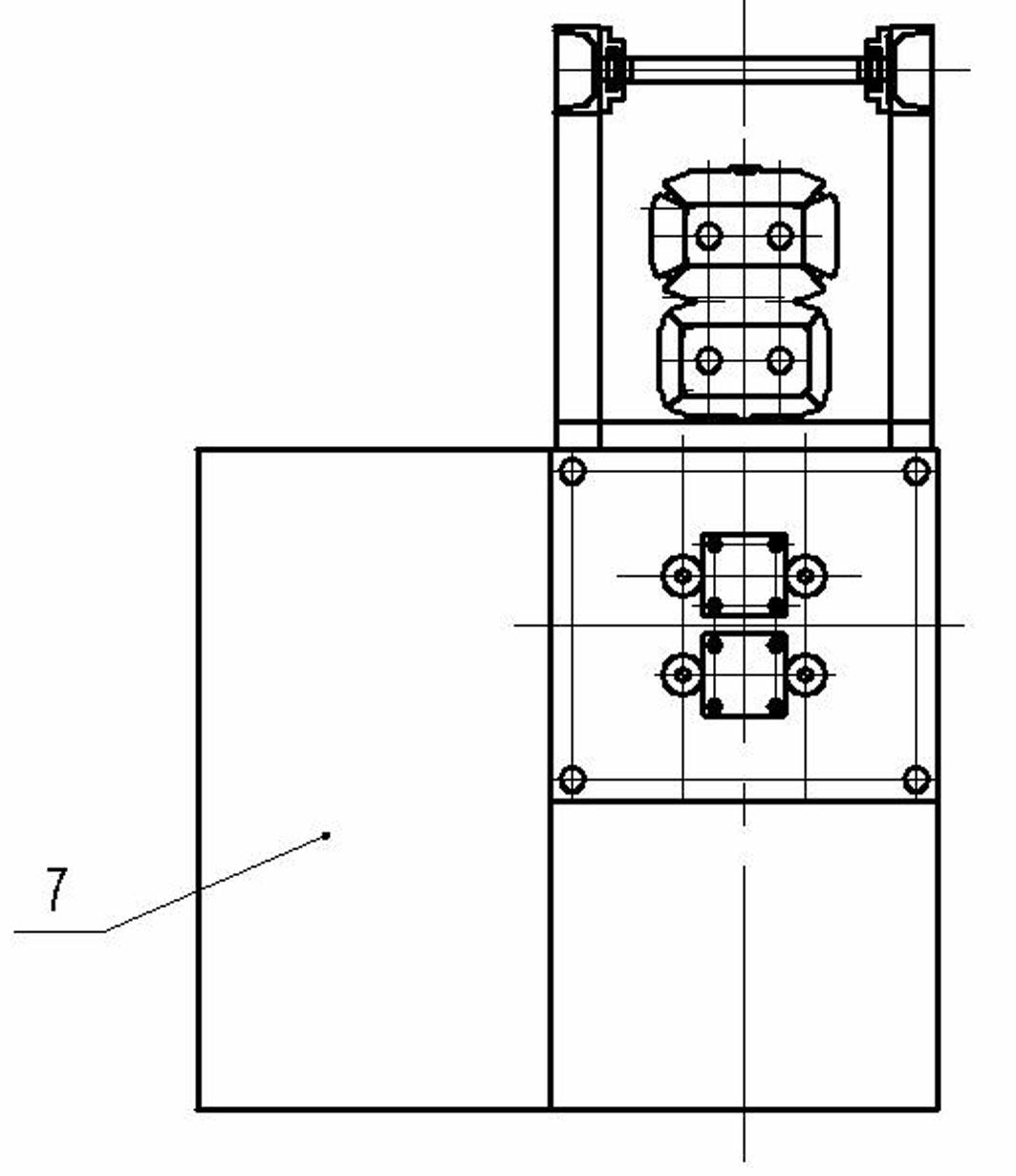

Three-station edge rolling mold for aluminum-based cam shaft sleeve

The invention belongs to the technical field of machinery, and particularly relates to a three-station edge rolling mold for an aluminum-based cam shaft sleeve. The problems that in the prior arm, the design is unreasonable are solved. The three-station edge rolling mold for the aluminum-based cam shaft sleeve comprises a bottom plate, and a primary pre-bending module, a secondary pre-bending module and an edge rolling module are sequentially arranged on the bottom plate. The mold further comprises a cantilever type hasp compression rod which is arranged between the secondary pre-bending module and the edge rolling module and can rise and fall in the vertical direction, wherein the cantilever type hasp compression rod is horizontally arranged, the suspension end of the cantilever type hasp compression rod extends into the edge rolling module, the end portion of the suspension end of the cantilever type hasp compression rod extends to the outer side of the front end of the edge rolling module, and the cantilever type hasp compression rod is connected with a compression rod lifting driving structure which can drive the cantilever type hasp compression rod to rise and fall in the vertical direction to flatten hasps of a shaft sleeve. The three-station edge rolling mold for the aluminum-based cam shaft sleeve has the advantage of being capable of improving the machining quality and production efficiency.

Owner:嘉兴亿腾自动化科技有限公司

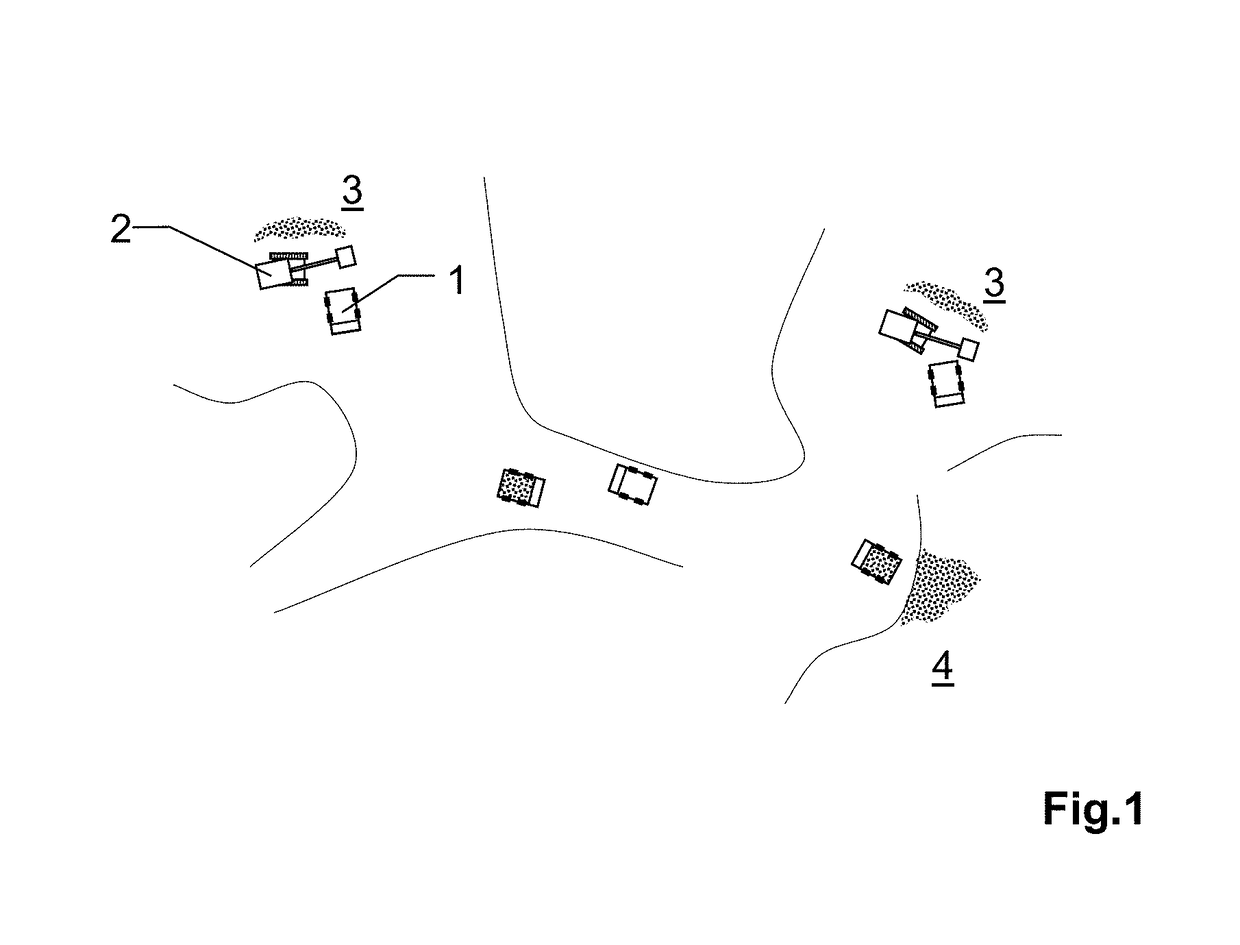

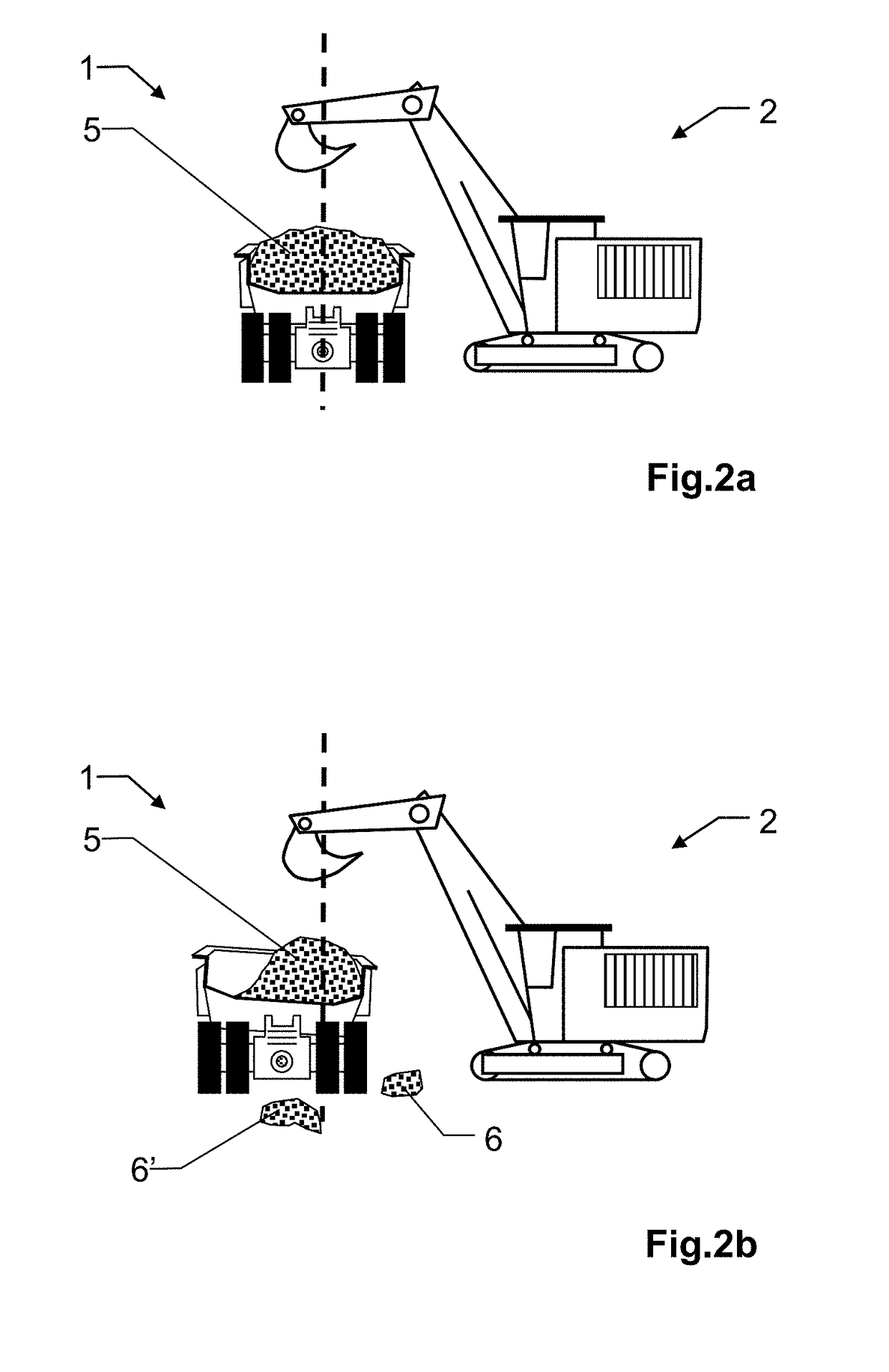

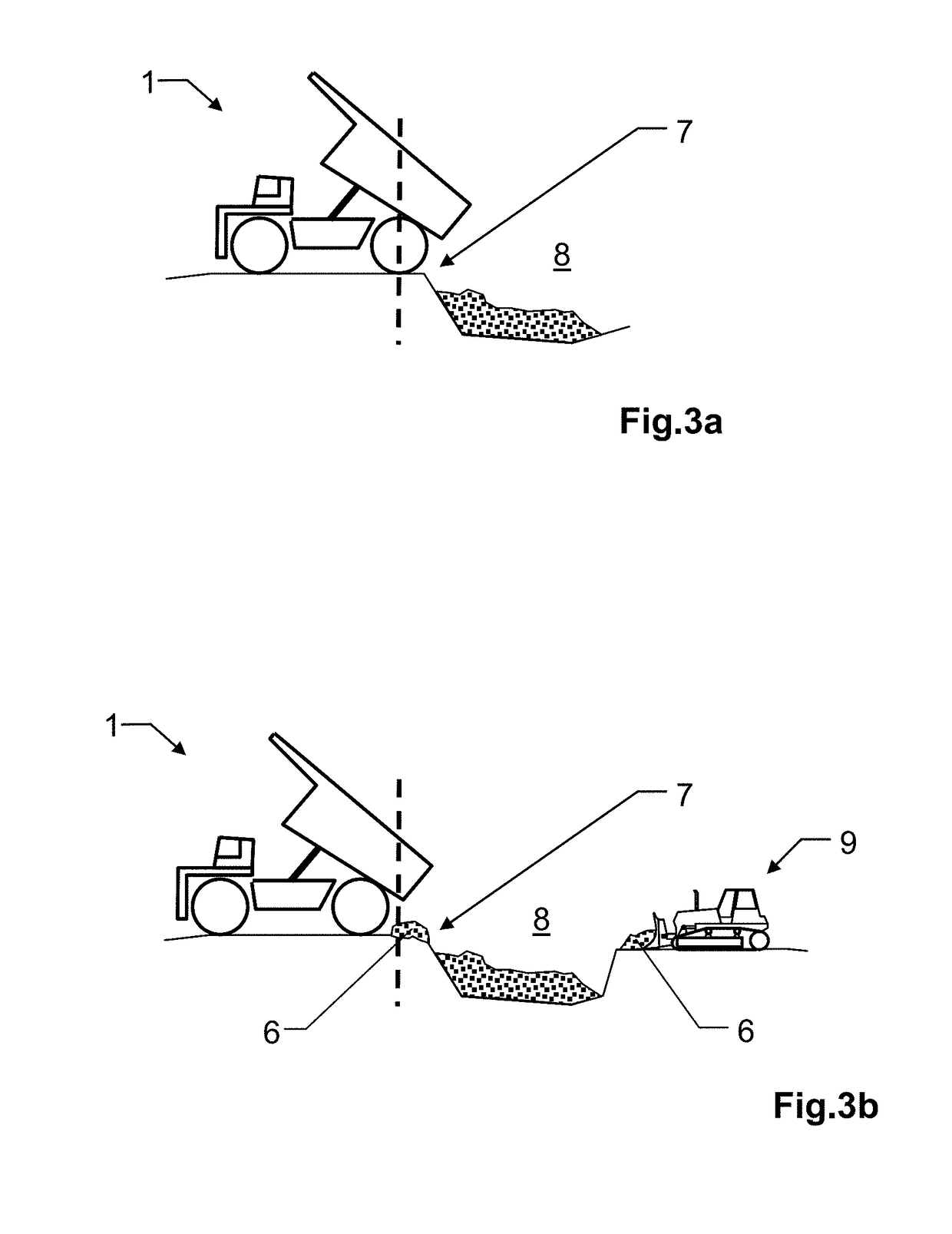

Driving assistance system for reversing a mining haulage vehicle

ActiveUS20180354557A1Minimize equipment down timeMinimize maintenance outlayRegistering/indicating working of vehiclesSteering partsTruckAuxiliary system

A driving assistance system for reversing a mining haulage vehicle, particularly for reversing a haul truck into a defined target position in a loading or dumping area, wherein the driving assistance system is configured that the target position is determined based on a logged loading tool position of the earthmoving machine, wherein steering instructions are provided to a light indicator when the transmission of the haulage vehicle is shifted to reverse.

Owner:SAFEMINE +1

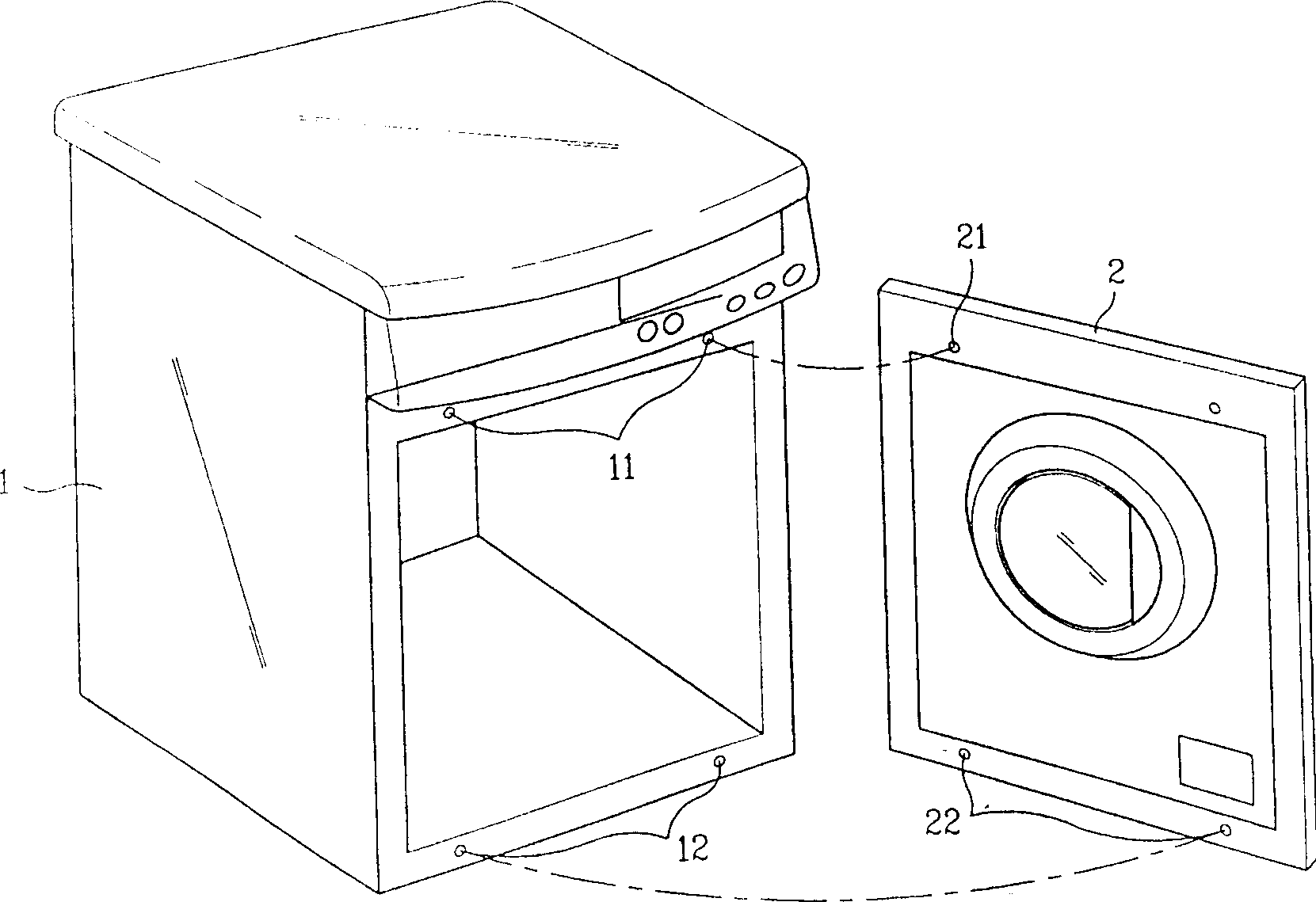

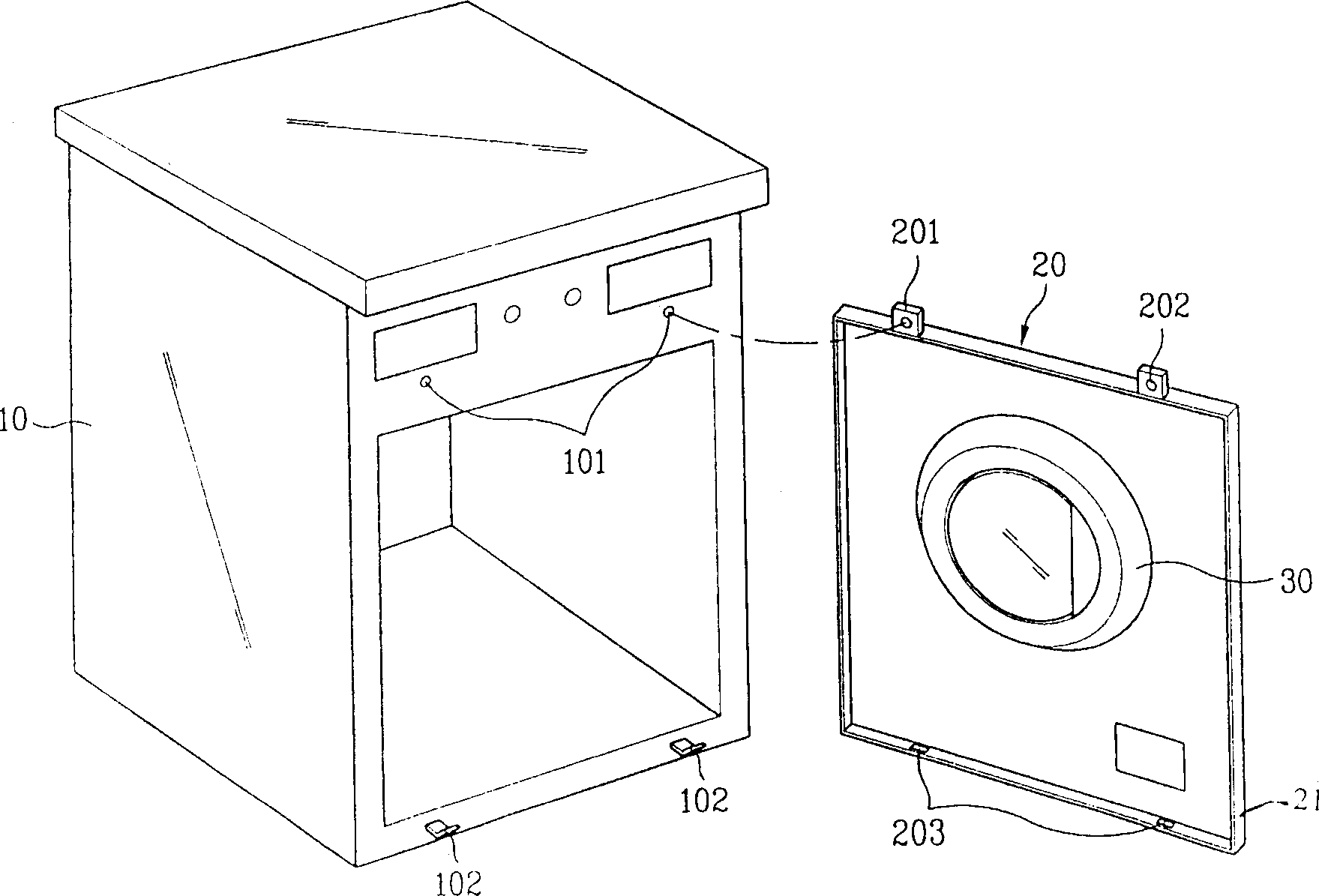

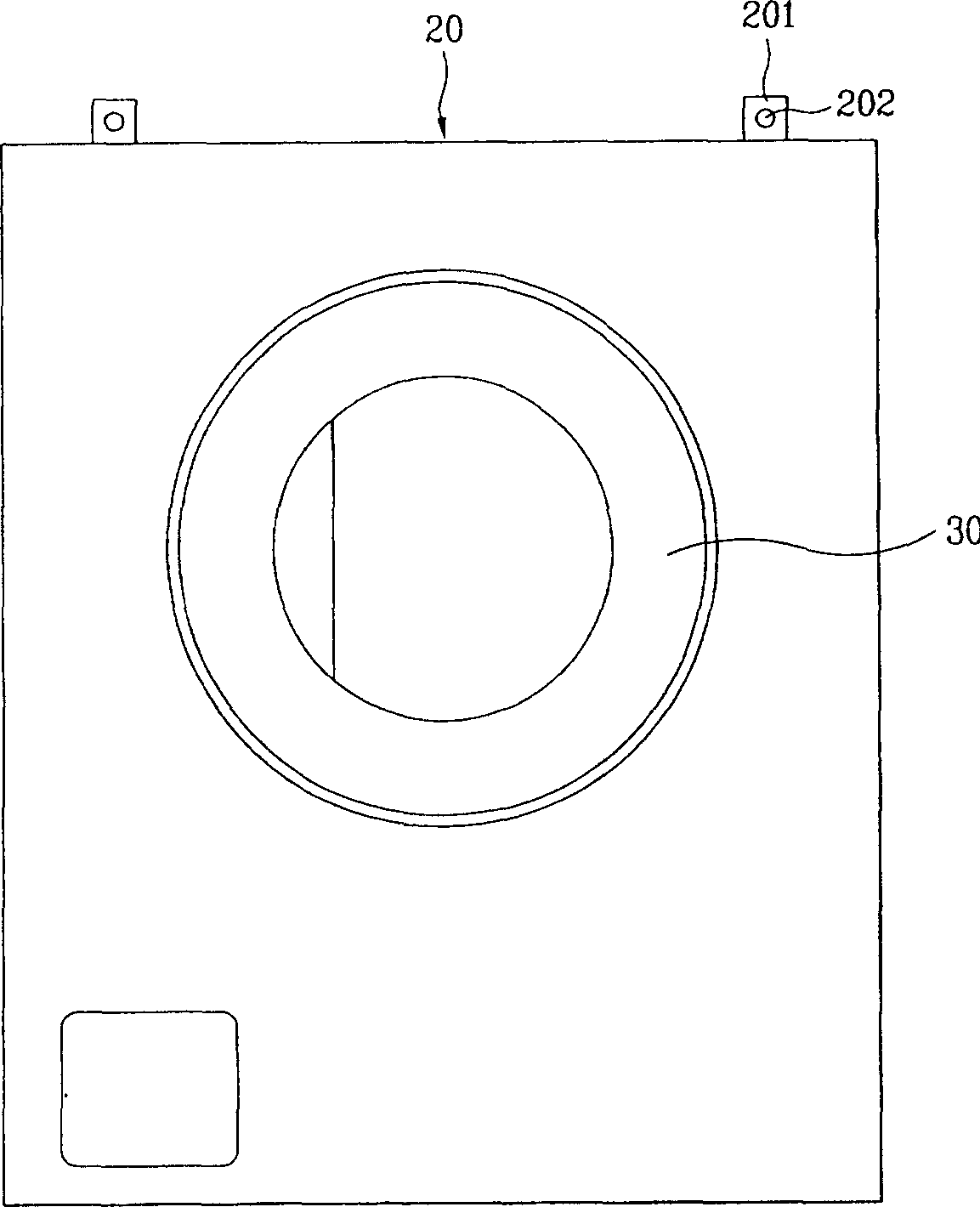

Machine box outer case connection structure of rolling drum washing machine

InactiveCN1683669AEasy connectionAvoid repositioningOther washing machinesTextiles and paperEngineeringMechanical engineering

The installation structure of machine box of rolling drum washing machine includes one box with opened front side and one casing fixed to front of the box to constitute the door of the washing machine. There are two or more corresponding connecting holes in each of the box and the casing, and connecting part. The installation structure features that there are at least one fixed board in the lower front part of the box and corresponding fixing slot in the lower part of the casing. The present invention makes it easy to install the casing in front of the box.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

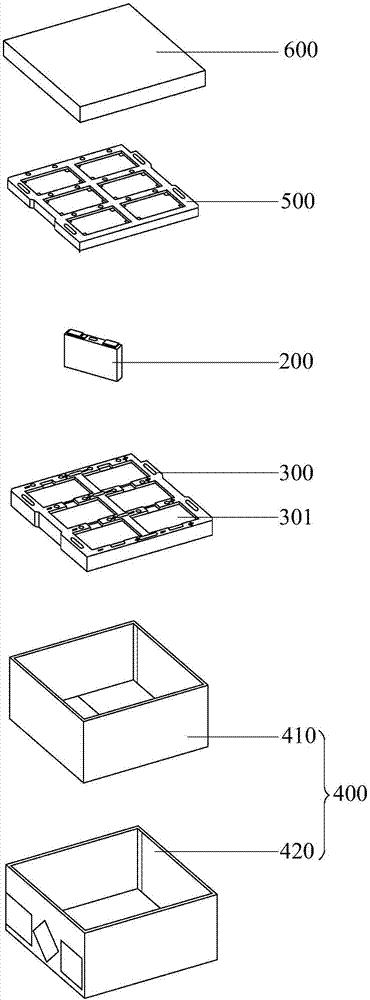

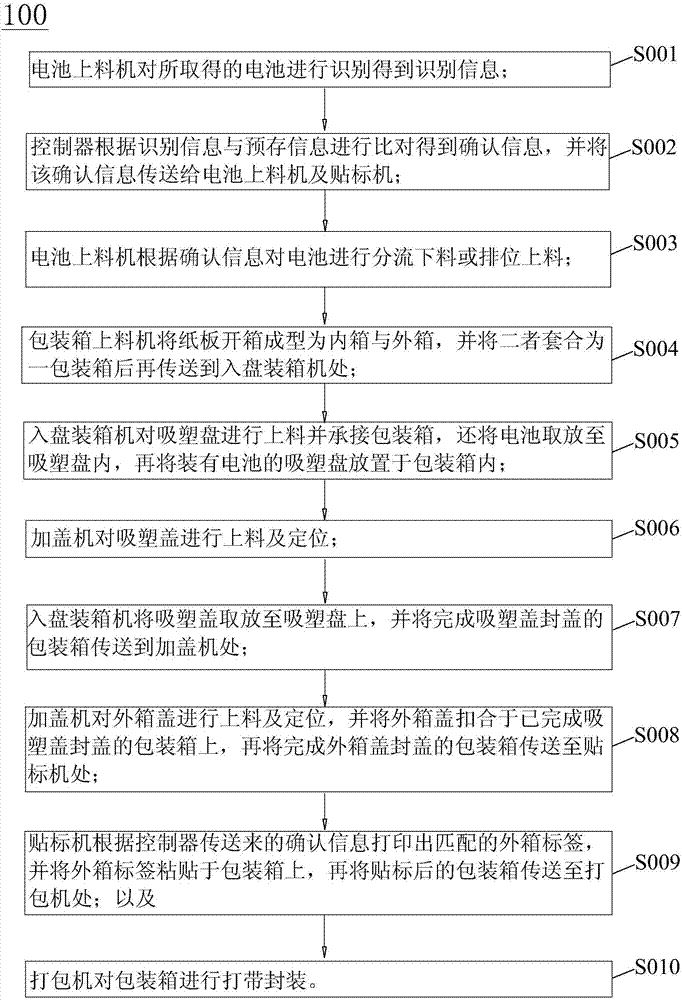

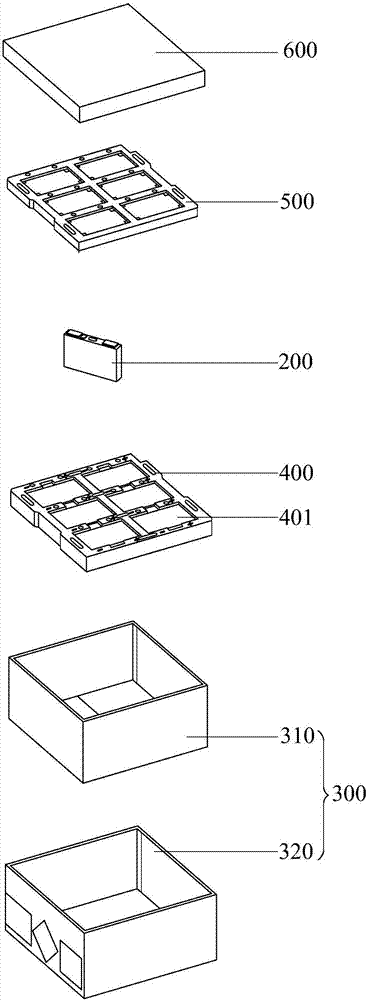

Battery packaging method

ActiveCN106976580AAchieve high integrationEliminate packaging errorsIndividual articlesPackaging machinesCardboardElectrical battery

The invention discloses a battery packaging method. The method comprises the steps that identification information is obtained by identifying batteries on a battery feeder; confirmation information is transmitted to the battery feeder and a labeling machine by a controller according to the identification information; distribution offline or arrangement feeding is conducted on the batteries by the battery feeder; paperboards are unpacked by a packaging box feeder to form an inner box body and an outer box body, and the inner box body and the outer box body are nested into the packing box; the batteries are taken and put into a plastic tray by a tray feeding boxing machine, and the plastic tray is arranged in the packing box; a plastic cover is fed and positioned by a cover adding machine; the plastic cover is taken and put on the plastic disc by the tray feeding boxing machine, and then the packing box covered with the plastic cover is conveyed to the cover adding machine; an outer box cover is fed and positioned by the cover adding machine, the outer box cover is bucked to the packaging box sealed with the plastic cover, and then the packaging box sealed with the outer box cover is conveyed to the labeling machine; and labeling is conducted by the labeling machine, and packaging is conducted by the packaging machine. The battery packaging method is high in degree of automation, high in efficiency and capable of lowering the cost effectively.

Owner:DONGGUAN WORLD PRECISION MACHINERY

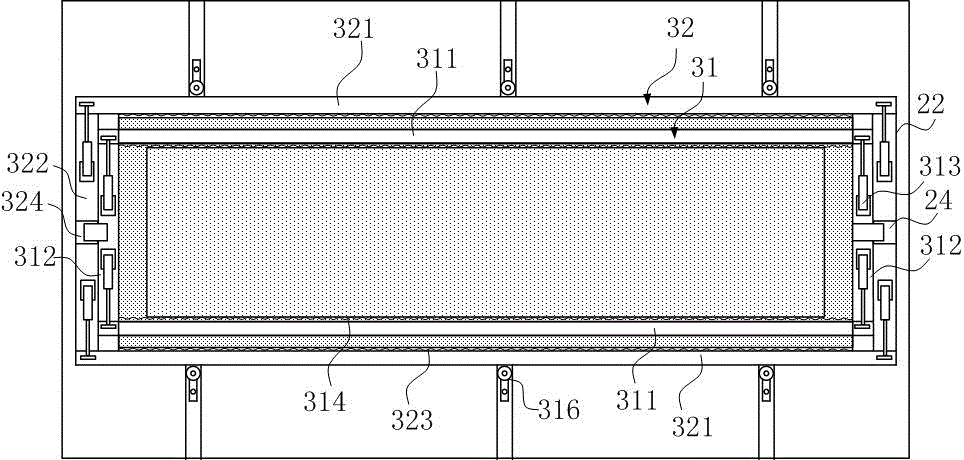

Stereoscopic laser embroidery machine

ActiveCN105256476APrevent cutting defectsAffect cutting defectsAutomatic machinesAuxillary devicesAC - Alternating currentLocking mechanism

The invention discloses a stereoscopic laser embroidery machine. The stereoscopic laser embroidery machine comprises a working table, a plurality of laser cutting heads and embroidery machine heads. The plurality of laser cutting heads and embroidery machine heads are evenly spaced on the crossbeam of the working table. The stereoscopic laser embroidery machine also comprises a double-layer cloth locking mechanism arranged on the working table surface under the laser cutting heads in a sliding manner. A laser cutting head light source is generated from a CO2 laser driven by a high-voltage stable circuit. The double-layer cloth locking mechanism comprises an inner frame and an outer frame. Cloth is arranged through slide fasteners and is tensioned through a tensioning cylinder. Through the high-voltage stable circuit, the laser cutting heads output laser stably, the situation is prevented that the laser output power is affected by alternating current network power supply fluctuation and the double-layer cloth generates unnecessary cutting defects, the double-layer cloth locking mechanism facilitates replacing of upper and lower layer cloth, repositioning of the upper and lower layer cloth in layered processing is avoided, the complex programs for replacing of the lower cloth are reduced effectively, the production benefits can be raised by more than 50%, and embroidery product is raised furthest.

Owner:广东中康织绣科技有限公司

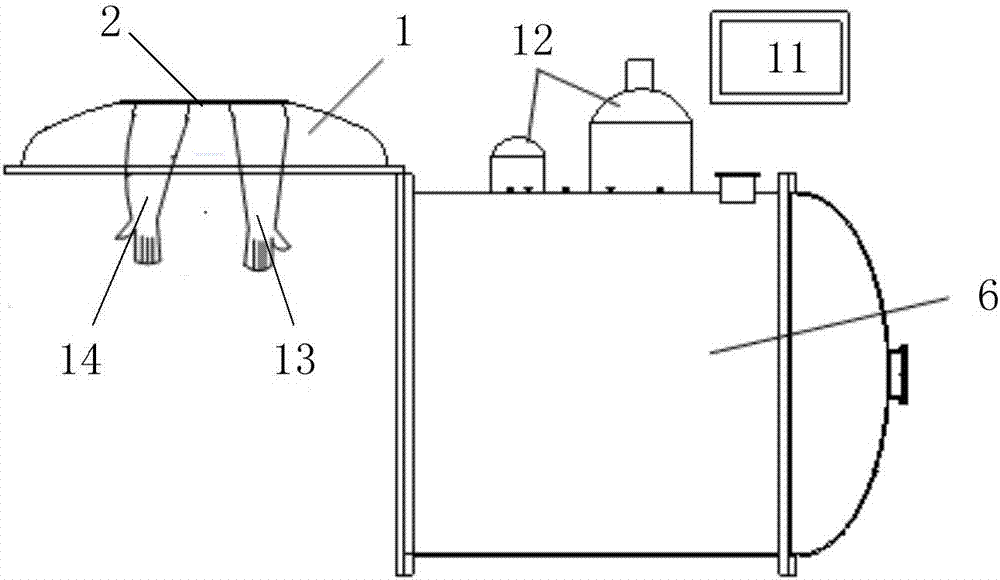

Outboard on-orbit operated ground test method of spacecrafts

InactiveCN107097982AChange positionAvoid repositioningCosmonautic condition simulationsTest articleAtmospheric pressure

The invention provides an outboard on-orbit operated ground test method of spacecrafts. The ground test method comprises the following steps of installing a test article to a servo mechanism, installing gloves of an outboard space suit, and closing the door of a vacuum tank; adjusting the test article to fit the operating position of the gloves of the outboard space suit, regulating the air pressure in the vacuum tank to a preset pressure value, and completing an outboard test operation by a user wearing the gloves of the outboard space suit; returning to the original state after the test operation. The ground test method achieves verification of the outboard on-orbit operated ground test of spacecrafts, and solves the problem that outboard on-orbit operated tests need verifying during long-term on-orbit flights of the spacecrafts.

Owner:BEIJING SPACE TECH RES & TEST CENT

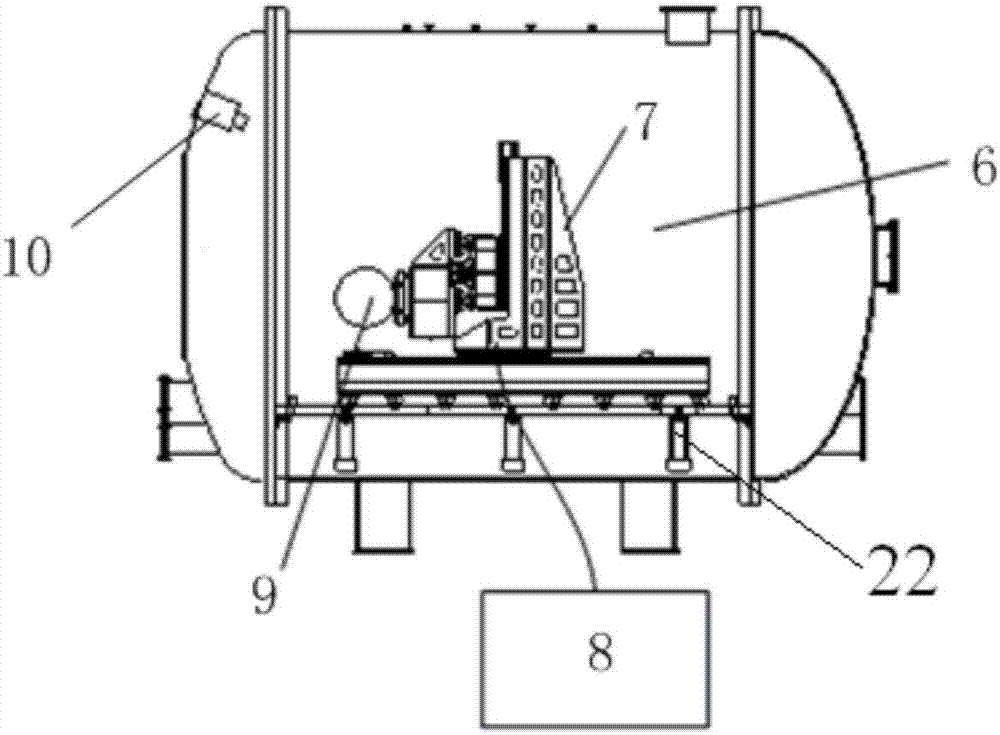

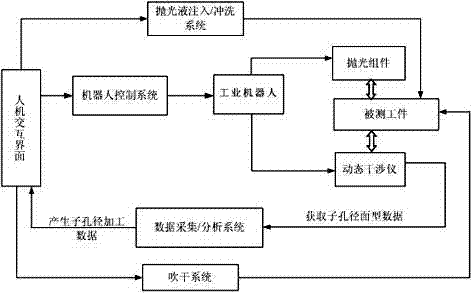

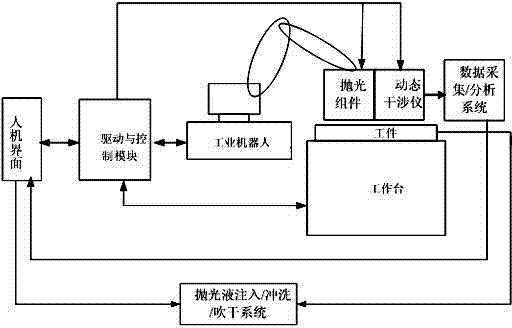

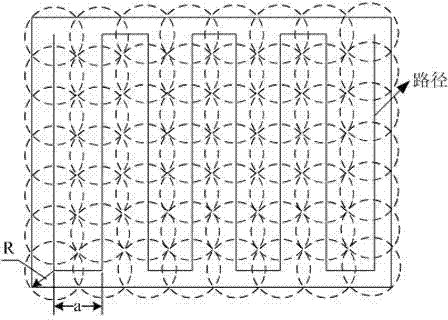

Real-time grinding and polishing method based on dynamic interferometer

InactiveCN103862373AAvoid measurement errorsReal-time measurementGrinding feed controlManufacturing technologyOptical measurements

The invention belongs to the technical field of modern optical measurement and manufacture and particularly relates to a real-time grinding and polishing method based on a dynamic interferometer. The real-time grinding and polishing method comprises the specific steps: (1) according to the placement position coordinate of a workpiece, the equation of a curved surface to be measured and the sizes of corresponding hole diameters measured by the dynamic interferometer at different measuring distances, software is utilized for analyzing the number, the sizes, the positions and the moving paths needing to be measured by the dynamic interferometer; (2) measurement and processing of sub hole diameters are carried out on the curved surface to be measured by a polishing component or the interferometer according to the set measuring path, the measured surface shape data are used for determining the residence time in the measured sub hole diameters and the setting of the moving trail of a grinding head in real time; (3) after washing and blow-drying the surface shape in the range of the measured hole diameters, the workpiece is polished / ground by an industrial robot. The real-time grinding and polishing method has the advantages that the cost of a used system is low, the universality and the practicability are good, dynamic online measurement and processing of multiple surface shapes can be realized and the polishing accuracy and the conformity of the polished surface shapes are high.

Owner:FUDAN UNIV

Two-step blow forming method and device for amorphous alloy special-shaped tube

The invention discloses a two-step blow forming method and a two-step blow molding device for an amorphous alloy special-shaped tube, and belongs to the field of the plastic forming of amorphous alloys. The method comprises the following steps of: heating a preformed variable-thickness amorphous alloy plate blank to a supercooling liquid phase area, introducing preheating pressure gas, and performing blow forming until the plate blank is adhered to a die to complete the performing of an amorphous alloy tube blank; and cooling the tube blank quickly, heating to the supercooling liquid phase area to perform secondary blow forming, and after cooling, opening the die to complete the forming of the amorphous alloy special-shaped tube. In the method, the forming capacity of amorphous alloy parts with complex shapes is improved by the two-step preblow forming of the variable-thickness amorphous alloy plate blank and the amorphous alloy tube blank, and the method and the device also can be used for the blow forming of containers and shell and cover parts which are made of amorphous alloy.

Owner:JIANGSU UNIV

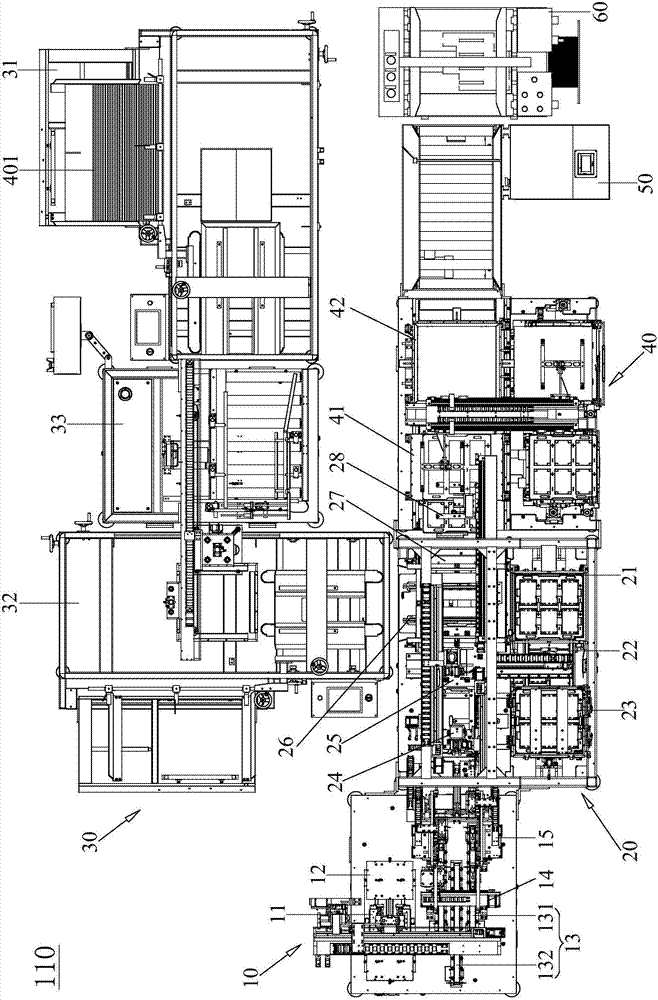

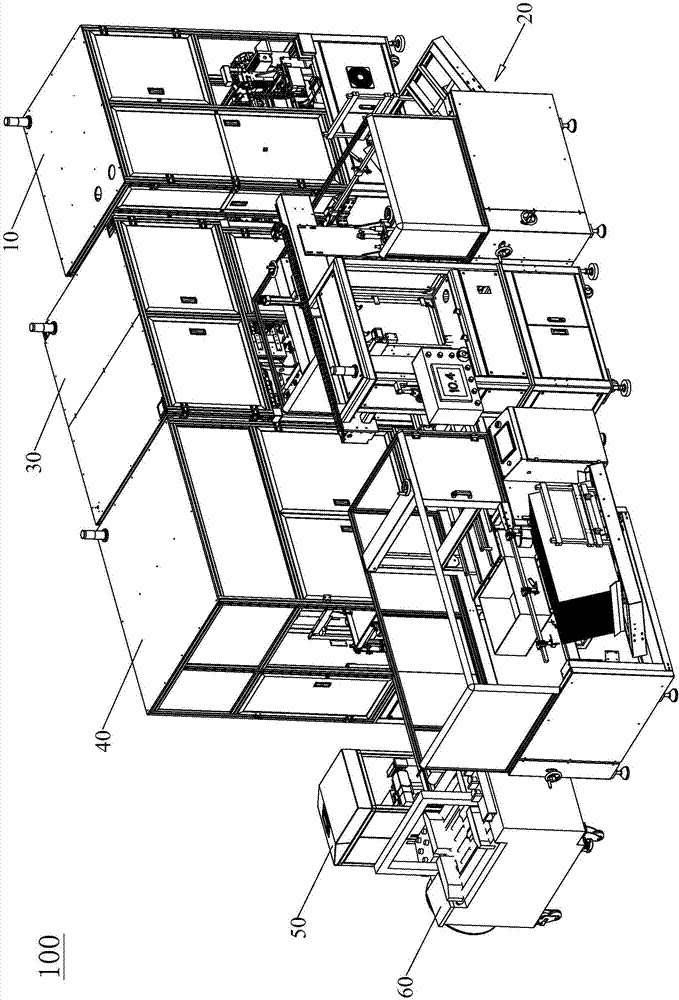

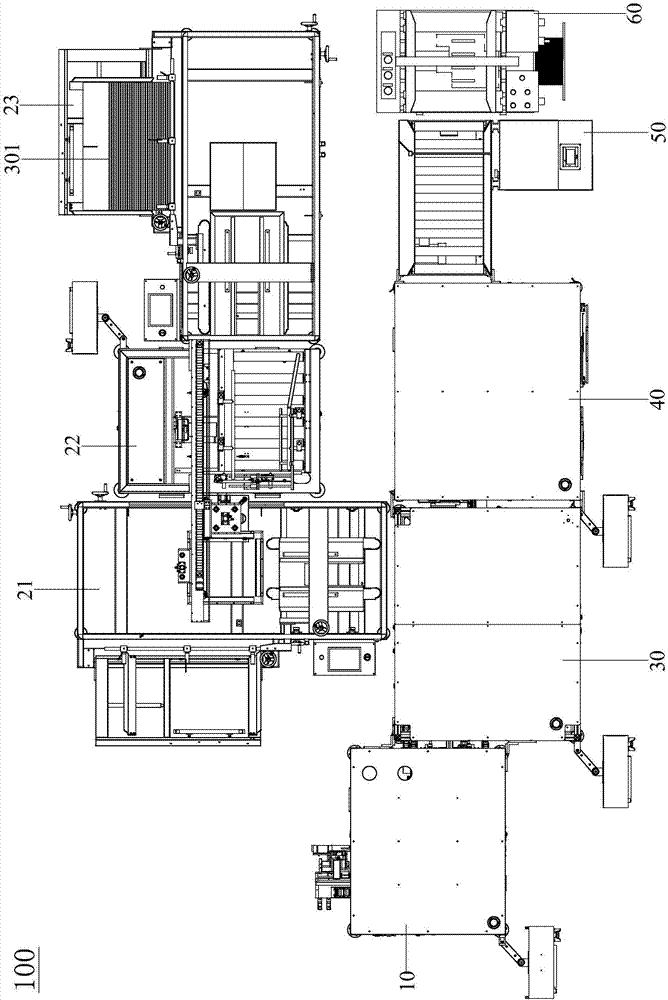

Battery packing line

ActiveCN107098021AHigh precisionAchieve high integrationIndividual articlesPackaging machinesElectricityControl system

The invention discloses a battery packing line, which comprises a battery feeding machine, a packing box feeding machine, an entering and box filling machine, a capping machine, a labelling machine, a packing machine and a control system. The battery feeding machine is used for scanning, ranking and feeding obtained batteries; the packing box feeding machine is used for opening and forming an inner box and an outer box, and casing the inner box and the outer box to form a packing box; the entering and box filling machine is used for carrying feeding of the packing box and a blister plate, putting batteries into the blister plate, placing the blister plate in the packing box, and buckling a blister cover on the blister plate; the capping machine is used for feeding the blister cover and an outer box cover, and buckling the outer box cover on the packing box; the labelling machine is used for printing a label and pasting the label on the packing box; the packing machine is used for taping and packaging the packing box; and the control system is electrically connected with the equipment so as to control the coordinated actions among the equipment. The battery packing line provided by the invention realizes automated assembly line production of battery packing, and is high in automation degree, high in efficiency and high in packing accuracy.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Solar panel with flexible optical elements

ActiveUS10340843B2Reduce in quantityReduce the overall heightPhotovoltaic supportsSolar heating energyEngineeringReflective layer

A solar array (50) for a spacecraft (10), comprising a solar concentrator that is provided with photovoltaic cells and reflective areas configured for reflecting solar radiation towards the photovoltaic cells, wherein the reflective areas and the photovoltaic cells are provided on opposite surfaces of concentrator reflector sheet members (56) that are repositionable from a retracted state wherein the concentrator reflector sheet members are in a substantially flat arrangement, to a extended state wherein the concentrator reflector sheet members are raised to allow the reflective areas to reflect solar radiation towards the exposed photovoltaic cells.Alternatively or in addition, the solar array may comprise a support panel, which may be at least partially flexible for retaining the support panel in a bent panel shape when the solar array is in the stowed state fixed at a position near a body of the spacecraft.

Owner:AIRBUS DEFENCE & SPACE NETHERLANDS

Auxiliary writing method convenient to control

The invention belongs to the technical field of writing equipment, in particular to an auxiliary writing method convenient to control. The auxiliary writing method comprises the steps of locating a writing head, and adjusting the writing position; when the writing head is located, firstly, locating the writing head with a first character lattice on the first line, and then, rotating test paper tolocate a tail character lattice on the first line with the writing head, so that locating of all character lattices is completed; and when the writing position is adjusted, conducting stepping movement of character lattice distances in the horizontal direction, and conducting stepping movement of line distances in the vertical direction, so that automatic locating of the writing position is achieved in the writing process. By means of the auxiliary writing method, auxiliary Chinese writing can be achieved in the test process conveniently.

Owner:那亮

Bamboo chip clamping device for drilling

InactiveCN108556094AImprove positioning efficiencyGood clamping stabilityDrilling machinesCane mechanical workingTorsion springEngineering

The invention discloses a bamboo chip clamping device for drilling. The bamboo chip clamping device for drilling comprises a cushion plate; a support base capable of sliding is arranged on the cushionplate by a mountain-shaped rail; multiple first clamping modules and second clamping modules are distributed on the support base at intervals; the first clamping modules comprise sleeves fixed on thetwo sides of the support base; clamping plates are connected into the sleeves by rotating shafts; torsion springs, cooperating with the clamping plates, are arranged at the middle parts of the rotating shafts; limiting holes are formed in the support base on the outer sides of the clamping plates; one ends of the clamping plates extend to the outer side of the support base by the limiting holes,and inclined grooves are formed in the other ends of the clamping plates; the second clamping modules comprise rotating arms; the inner sides of the rotating arms are connected with the support base by stand columns; collision blocks capable of rotating are connected to the outer sides of the rotating arms; flat wire springs are arranged on the outer sides of the stand columns above the rotating arms; and the two ends of the flat wire springs are connected with the stand columns and the rotating arms. The bamboo chip clamping device for drilling has the characteristics of high positioning andmounting efficiency and high clamping stability.

Owner:安吉席丫丫竹木有限公司

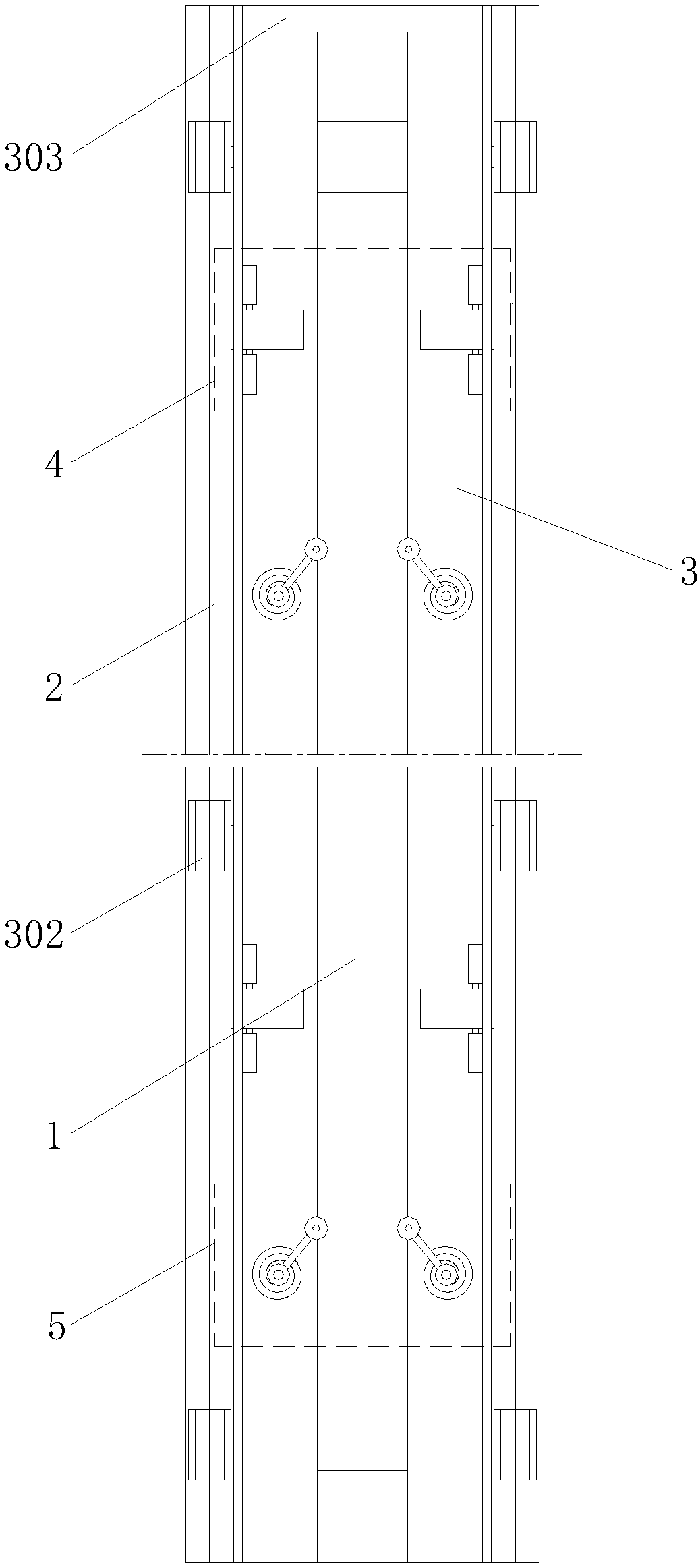

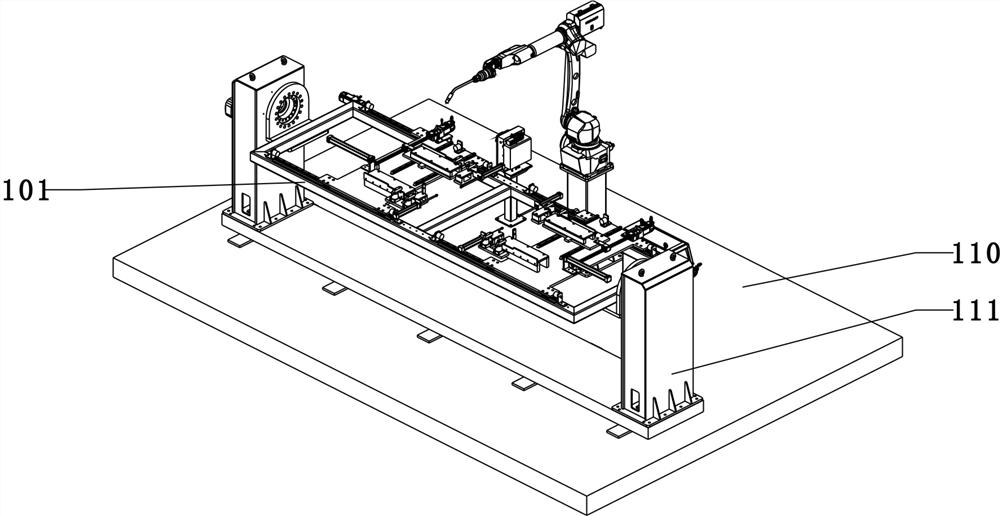

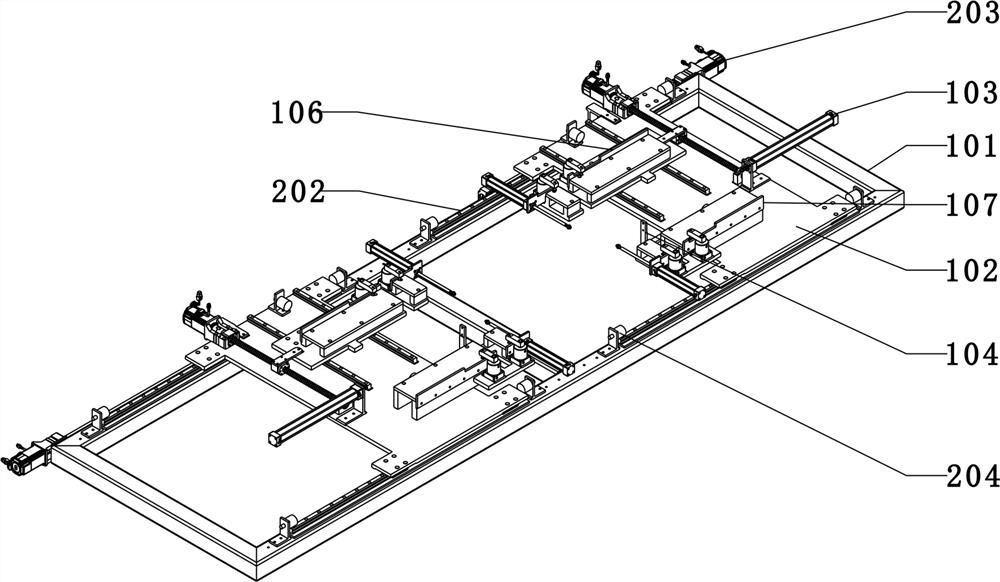

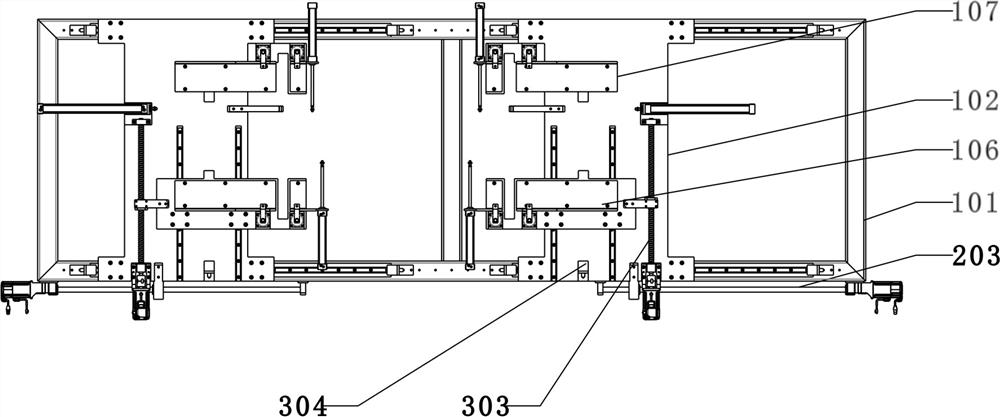

Rib plate positioning and clamping tool for robot welding and positioning method

ActiveCN113634974AClamp firmlyEasy to knowWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention relates to the technical field of machining of large rib plates of crane main beams, in particular to a rib plate positioning and clamping tool for robot welding and a positioning method. The rib plate positioning and clamping tool comprises a bottom plate, a position changing machine installed on the bottom plate, a frame installed at the output end of the position changing machine, a displacement platform and a splicing assembly formed by correspondingly splicing a first workpiece, a second workpiece, a third workpiece and a fourth workpiece, wherein the third workpiece and the fourth workpiece are arranged between the first workpiece and the second workpiece at intervals. According to the rib plate positioning and clamping tool for robot welding and the positioning method, after a workpiece needing to be positioned and clamped is placed on the tool, splicing and clamping can be automatically achieved, the workpiece is pressed to be prevented from falling off from the tool, after clamping, a welding robot can conveniently weld a splicing assembly, the welding efficiency is improved, and meanwhile, the splicing assembly can be driven to rotate, and therefore the welding robot can weld the two faces of the rib plate conveniently.

Owner:HENAN WEIHUA HEAVY MACHINE +1

Forming machine for boxes with covers and special mold

InactiveCN102555297AMeet the inherent characteristics of poor ductilityOvercoming the inherent characteristics of poor ductilityEnvelopes/bags making machineryForming processes

The invention discloses a forming machine for boxes with covers and a special mold. The scheme that a box body and a cover body are formed sequentially is adopted. Particular technique includes final form arrangement with a concave mold matching with a box, a convex mold is divided into two separate bodies, one separate body is a box body convex mold, the other separate body is a cover body concave mold, the two separate bodies are respectively provided with driving portions, and accordingly the technical scheme of sequential stamping can be met. Correspondingly, a prepressing component is assembled on one separate body, namely the prepressing component is arranged on the separate body which is not in stamping at first, accordingly, after the separate body which is in stamping at first is positioned in place, a workpiece of a corresponding portion is jacked into the corresponding concave mold by the other separate body, detention of the corresponding workpiece is reduced in the process, normal mobility can be realized, mobility required to be realized is greatly reduced when the workpiece of the corresponding separate body is stamped and formed, and the problem of drawing breakage due to high mobility required in a forming process is solved.

Owner:济南绿宝纸制品有限公司

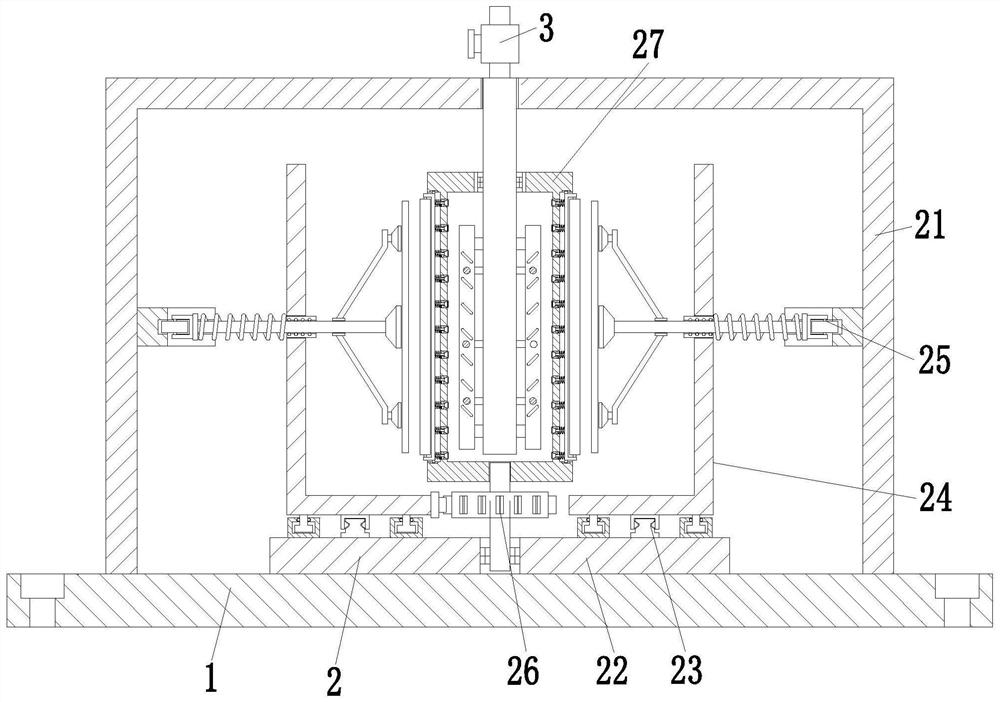

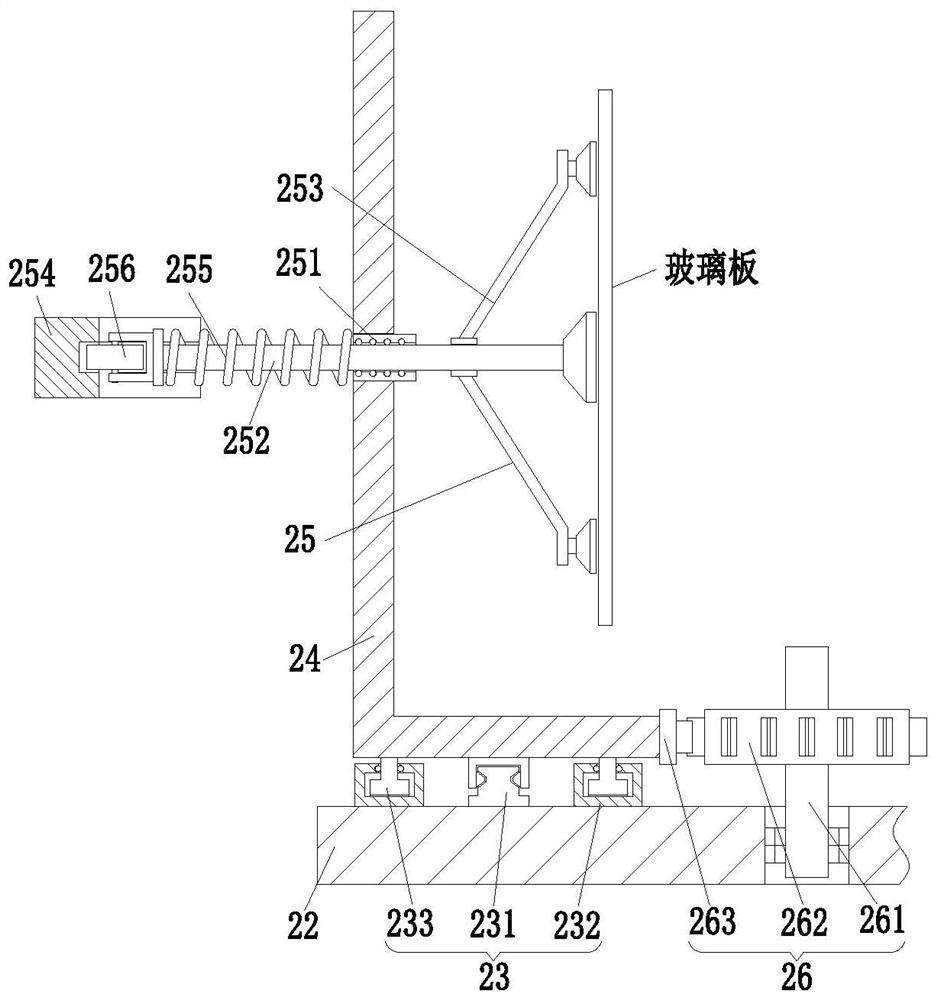

Explosion-proof tempered glass production and processing machine

InactiveCN111890752AGlue effectiveGood for subsequent bondingTransportation and packagingRotary stirring mixersToughened glassGlass sheet

The invention relates to an explosion-proof tempered glass production and processing machine which comprises a bottom plate, a laminating device and a feeding pipe, mounting holes are uniformly formedin the bottom plate, the laminating device is mounted in the middle of the upper end of the bottom plate, the feeding pipe is mounted at the upper end of the laminating device, and the feeding pipe is connected with an external glue pump. According to the invention, when the surface of a glass plate is glued by the existing equipment, the problems that gluing effect is poor, the glue solution cannot be effectively and uniformly coated on the surface of the glass plate, subsequent bonding of the glass plate is not facilitated, and gaps are easily formed between bonded glass plates are solved,when existing equipment is used for bonding the surfaces of the glued glass plates, the glass plates cannot be directly bonded and pressed, generally, the glass plates need to be subjected to secondary positioning, deviation of the bonded glass is easily caused, and the follow-up using effect of the glass is affected.

Owner:袁利华

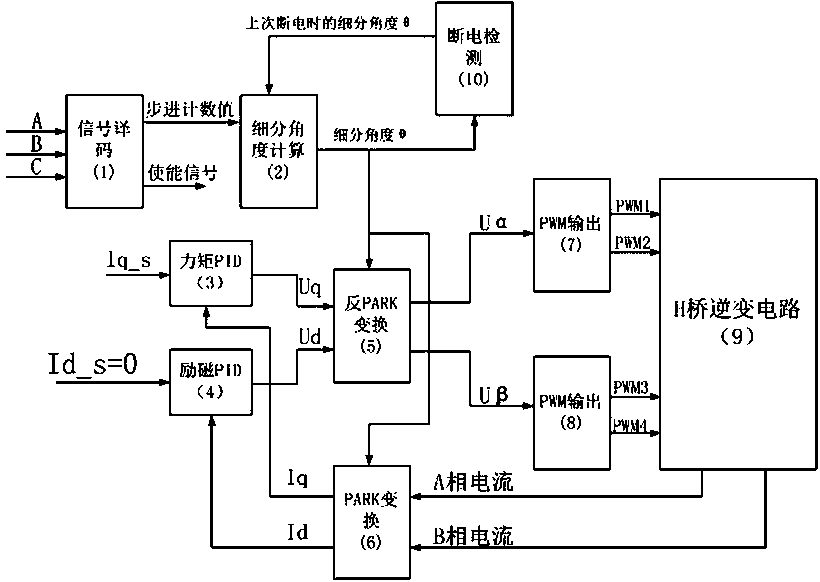

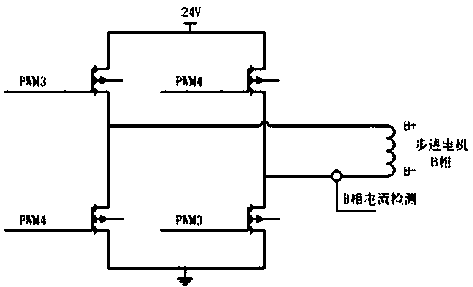

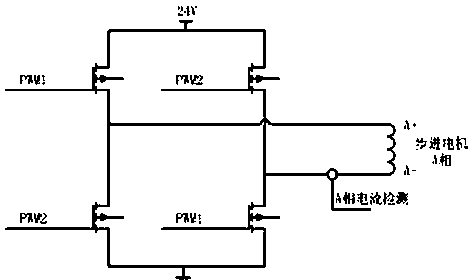

Special hybrid stepping motor driver for linear cutting machine tool

PendingCN108544044AAvoid repositioningSame angleDynamo-electric converter controlElectric circuitsControl powerControl system

The invention provides a special hybrid stepping motor driver for a linear cutting machine tool, and relates to a driver. The special hybrid stepping motor comprises a signal decoding module, a subdivision angle calculation module, a torque PID controller, an excitation PID controller, an inverse PARK conversion module, a PARK conversion module, a PWM output module, an H-bridge inverter circuit and a power-off detection module; and after the power is cut off, the power-off detection module automatically saves the current subdivision angle theta, and after the next incoming call, and the subdivision angle theta before the previous outage is sent to the subdivision angle calculation module, and the subdivision angle calculation module calculates a current subdivision angle theta according to the last subdivision angle theta and the stepping count value sent by the signal decoding module. On the basis of not changing an existing linear cutting control system, the enabling and forward andreverse rotation control of the stepping motor is realized by decoding five-phase ten-beat or three-phase six-beat signals, and meanwhile, by saving and controlling power-off of the subdivision angle, the angle of a motor shaft when the motor shaft is not deviated from the halt during power-on is achieved.

Owner:宁波科路机械设备有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com