Laser processing system

A laser processing and laser beam technology, applied in lasers, laser welding equipment, laser parts and other directions, can solve the problems of low processing accuracy, waste of time, and high equipment investment costs, to increase processing accuracy, avoid repositioning, improve The effect of processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

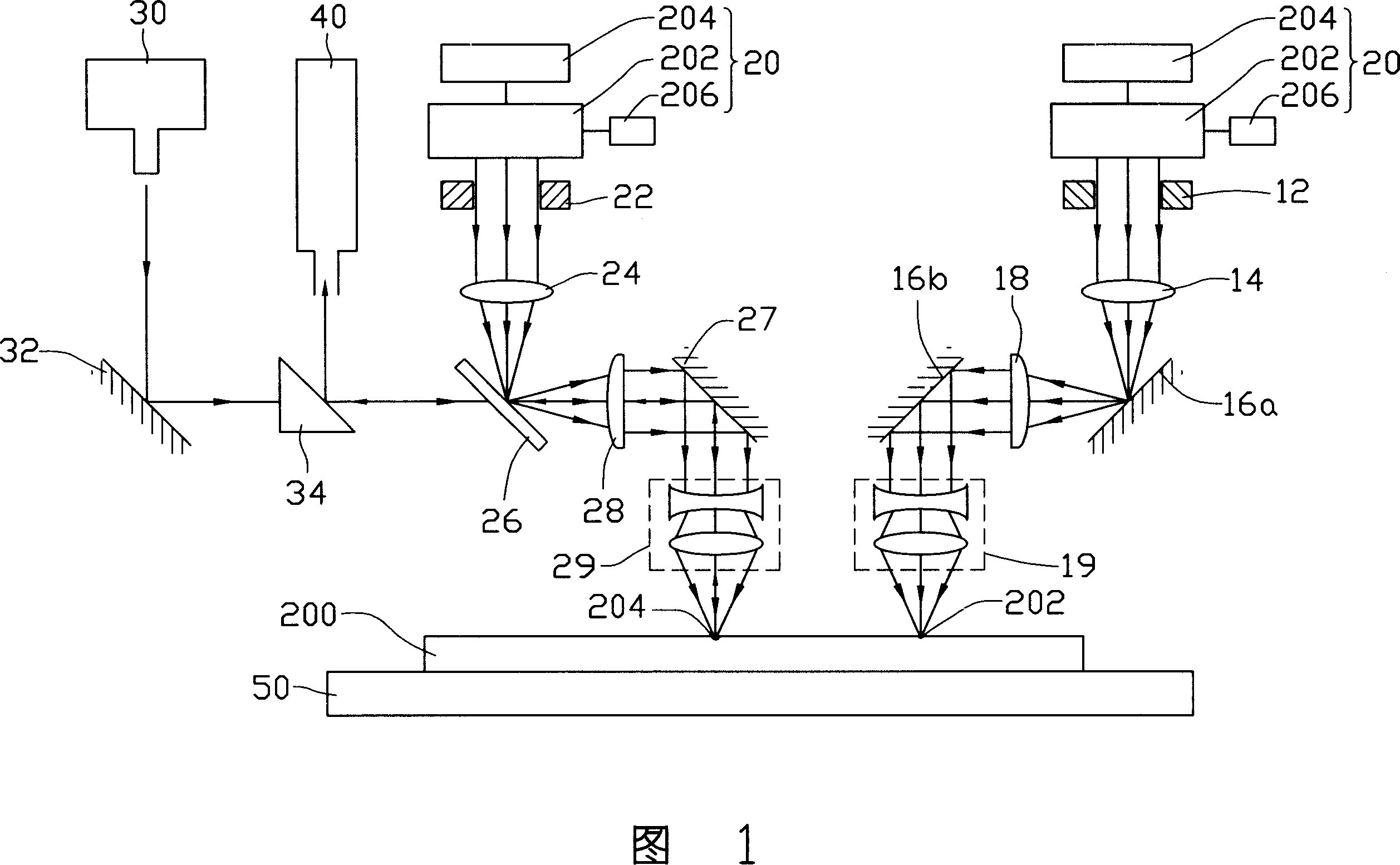

[0011] Referring to FIG. 1, an embodiment of the present invention provides a laser processing system 100, which includes: a first laser device 10, a first optical component, a second laser device 20, a second optical component, a third laser device 30, and a light detection device 40.

[0012] The first laser device 10 is used to output a first wavelength laser beam for processing the workpiece 200 to be processed, and the wavelength λ of the first wavelength laser beam 1 Longer, usually in the wavelength range of 2.4-15 microns, more suitable for laser processing of materials such as glass and ceramics with longer absorption wavelengths. The first laser device 10 includes a first laser 102 , a controller 104 and a cooler 106 . The first laser 102 is used to produce a laser beam with a first wavelength for processing a workpiece 200 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com