Battery packaging method

A packaging method and battery technology, applied in the field of packaging, can solve the problems of increased processing procedures and manufacturing costs, insufficient support, and inability to protect batteries, etc., to achieve good load bearing, eliminate packaging errors, and reduce processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

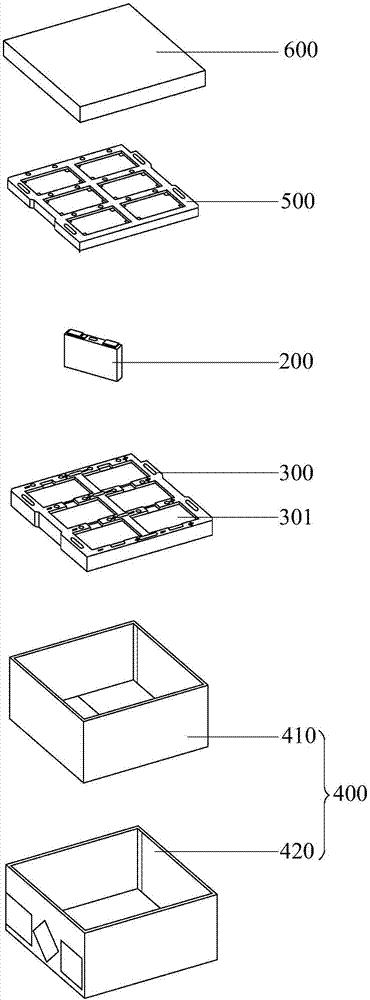

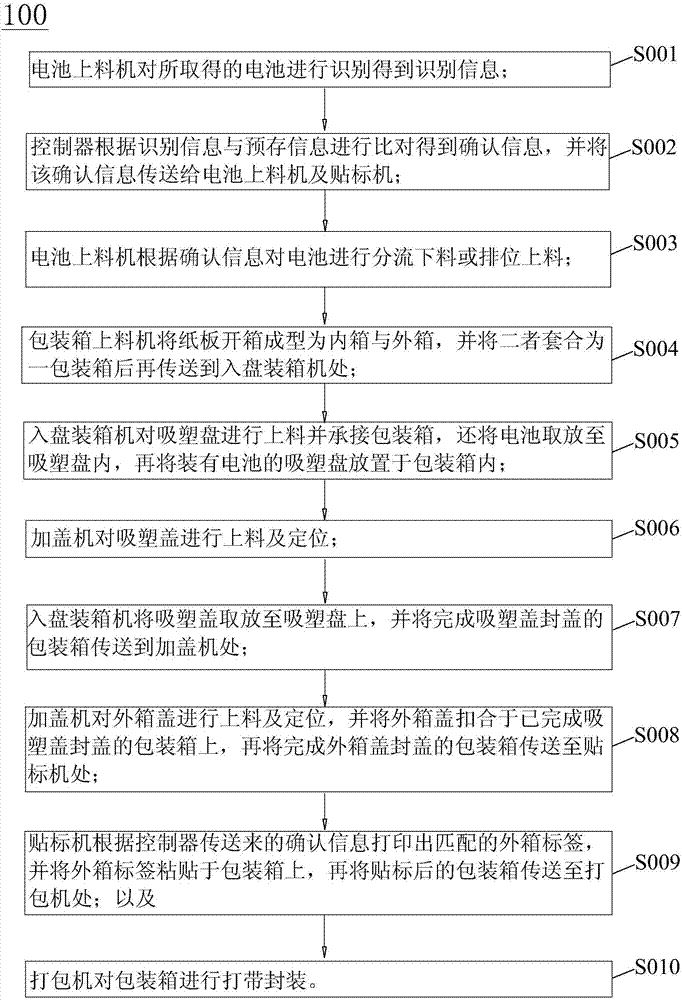

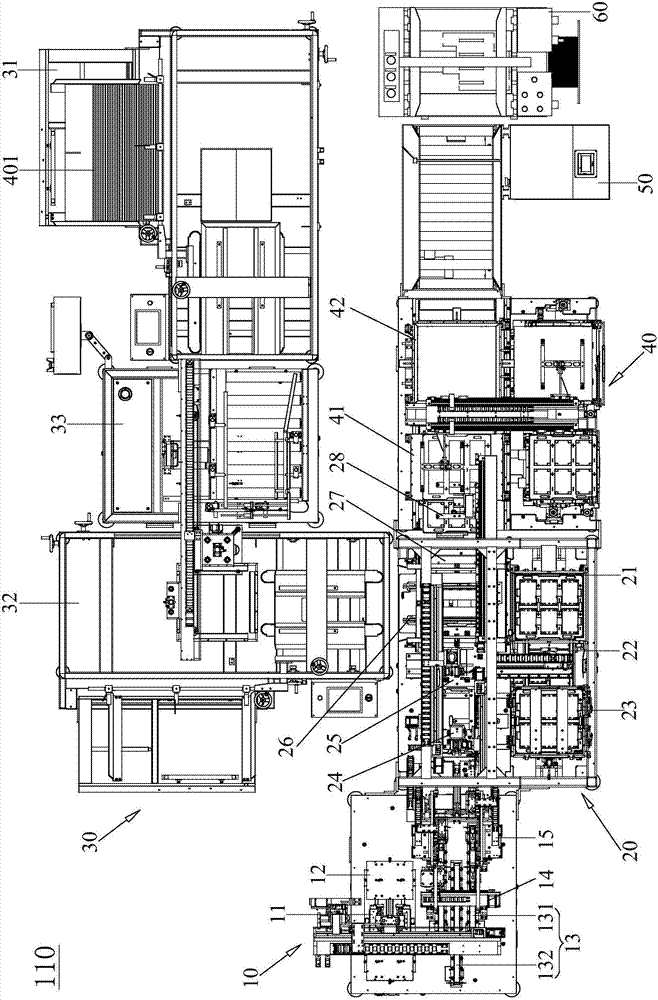

[0030] see Figure 1 to Figure 3 , the present invention discloses a battery packaging method 100, which is used to put the battery 200 into the blister tray 300 and then put it into the packing box 400 which is composed of the inner box 410 and the outer box 420, and then successively pass the battery 200 The plastic cover 500 and the outer box cover 600 carry out the sealing of the blister tray and the outer box. The battery packaging method 100 disclosed in the present invention can specifically be realized through a packaging line 110, and the battery packaging method 100 includes the following steps:

[0031] S001 The battery feeder 10 identifies the obtained battery 200 to obtain identification information;

[0032] Specifically, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com