Patents

Literature

65results about How to "Advanced principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

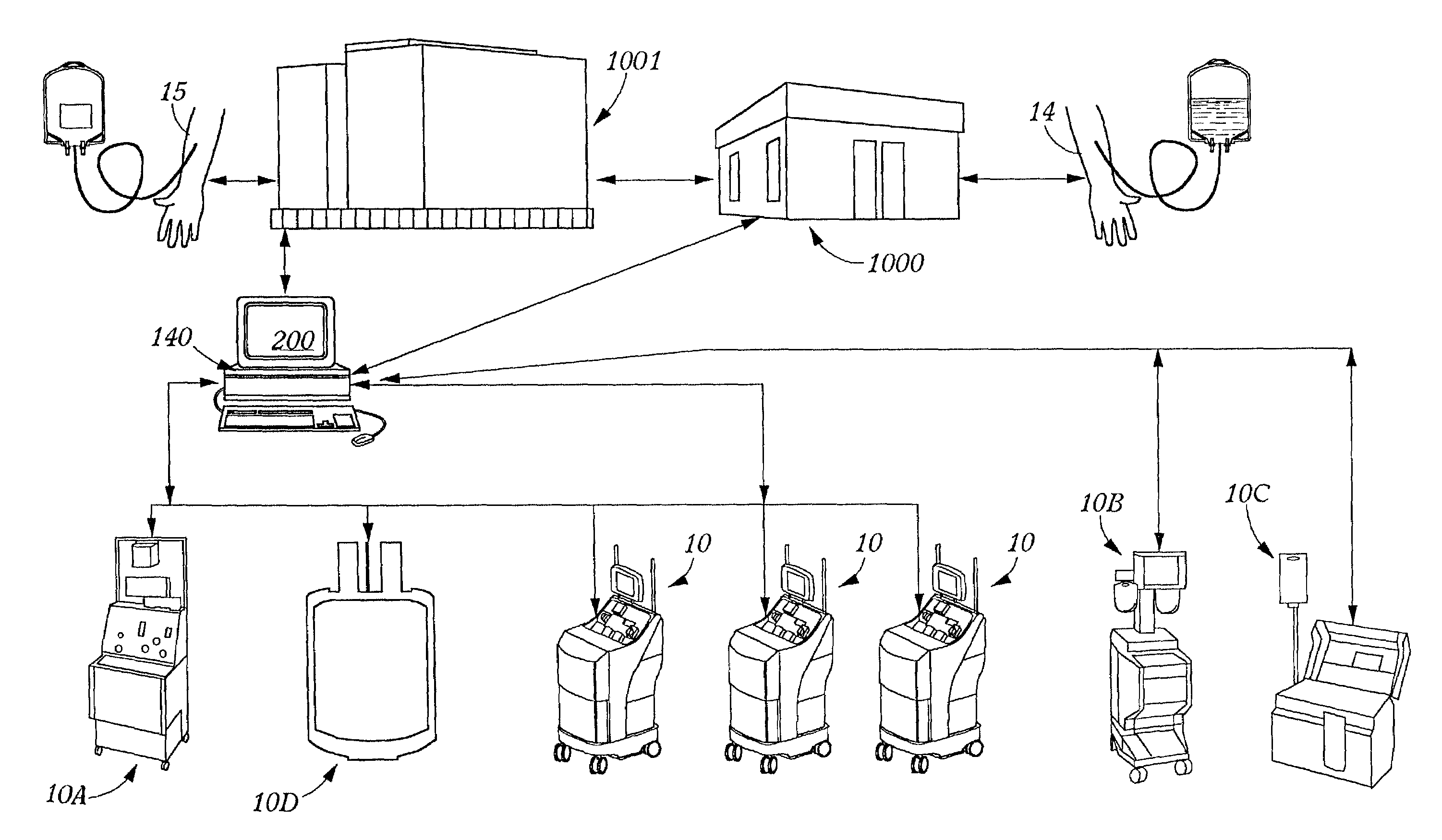

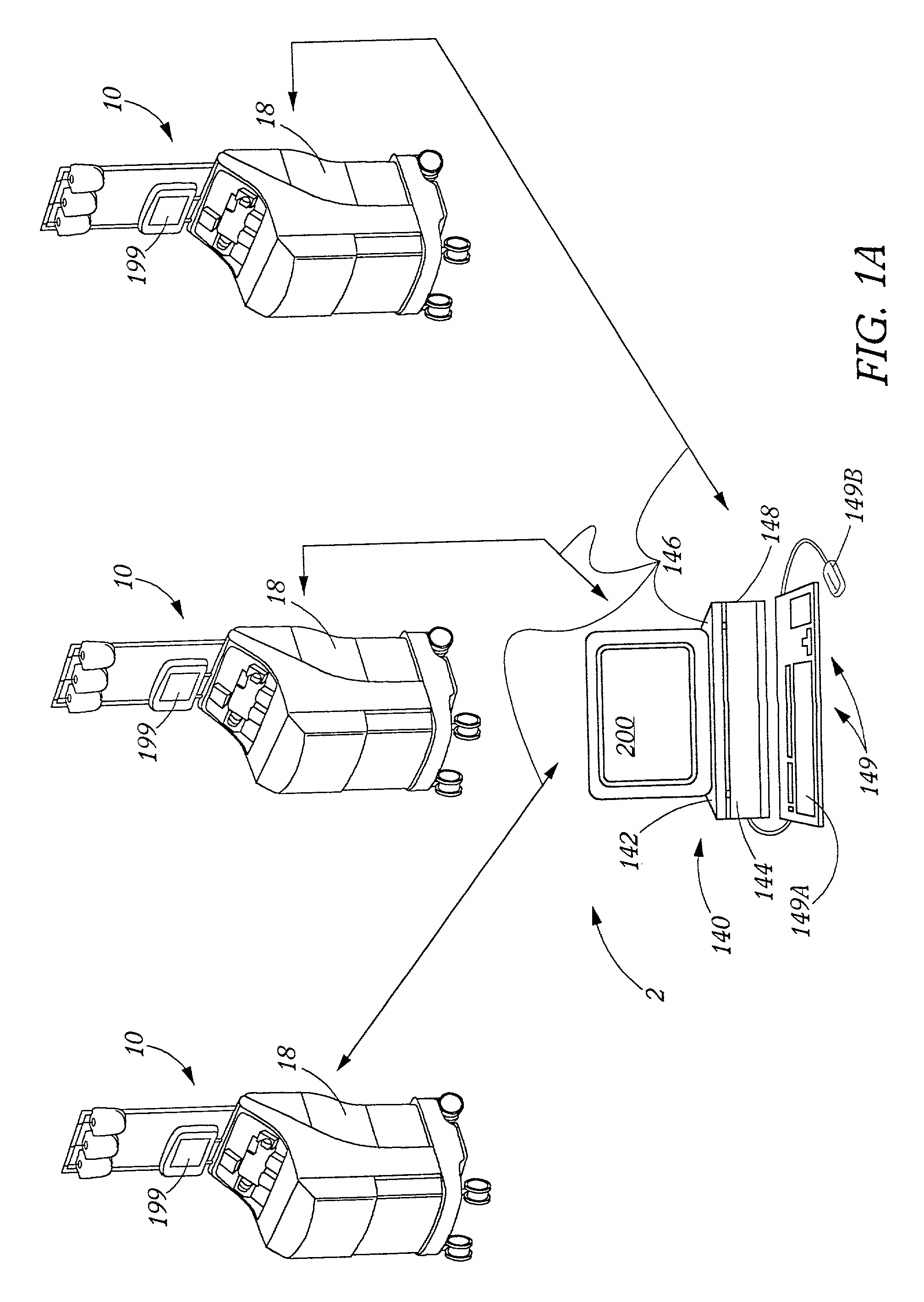

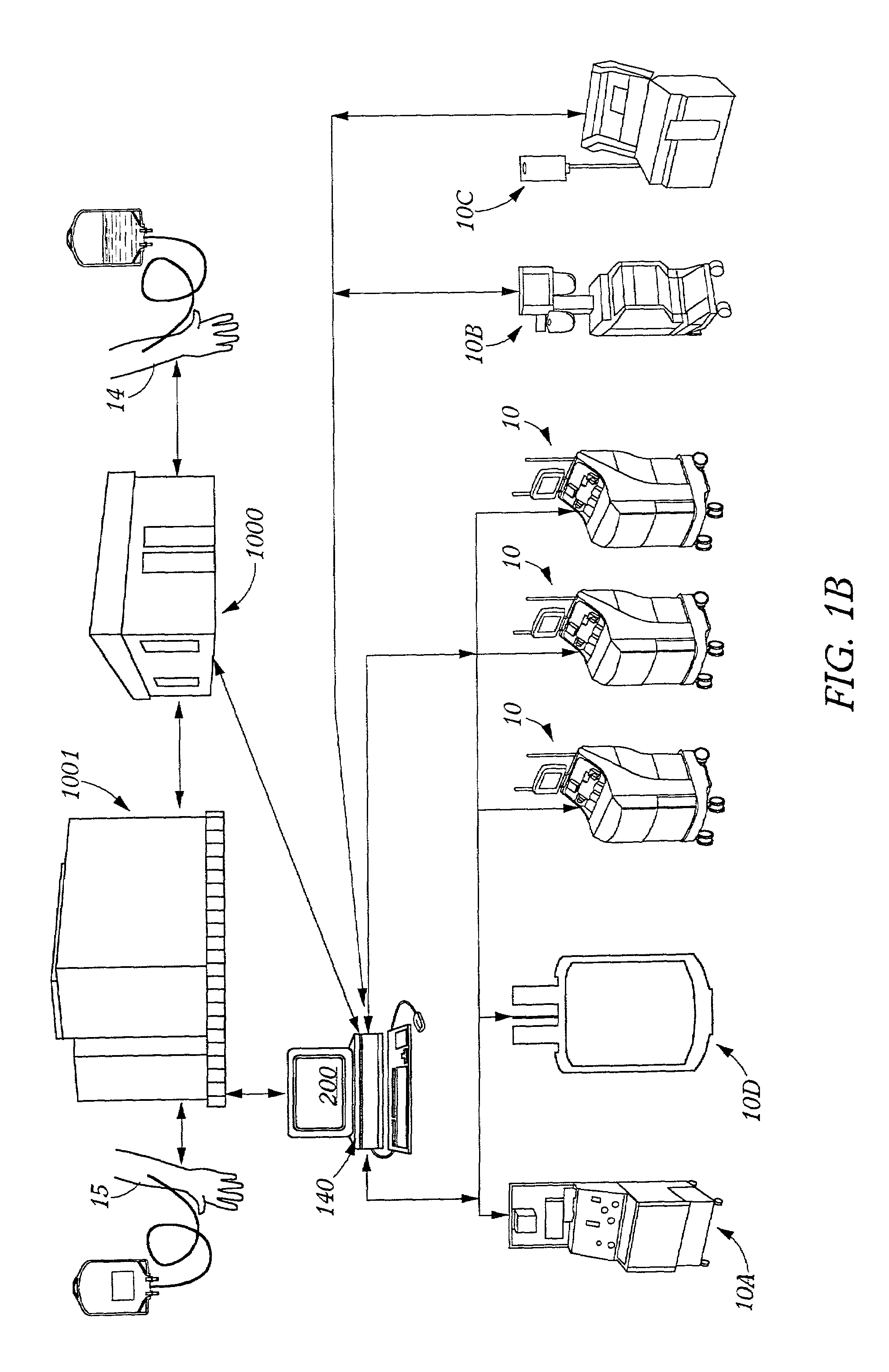

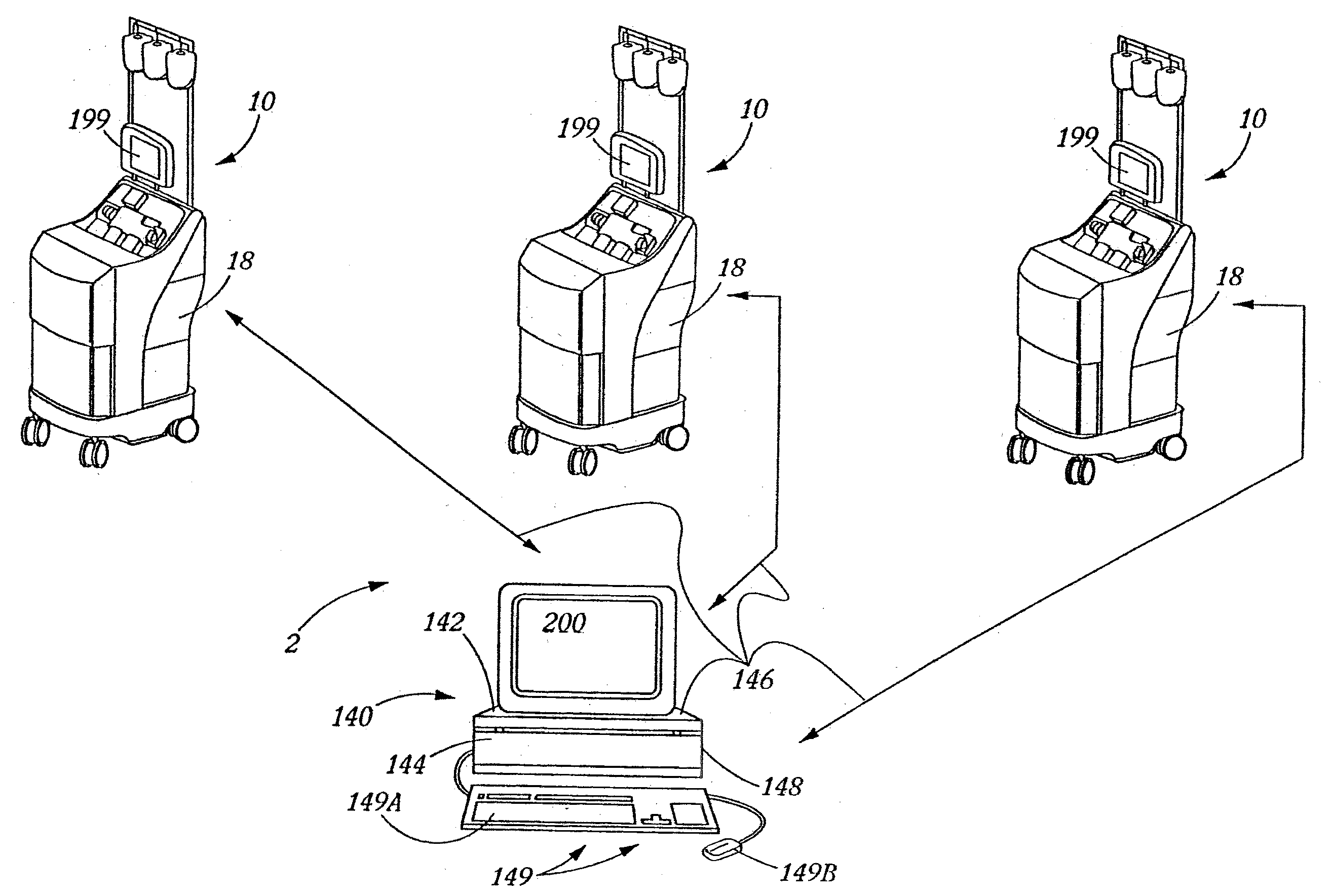

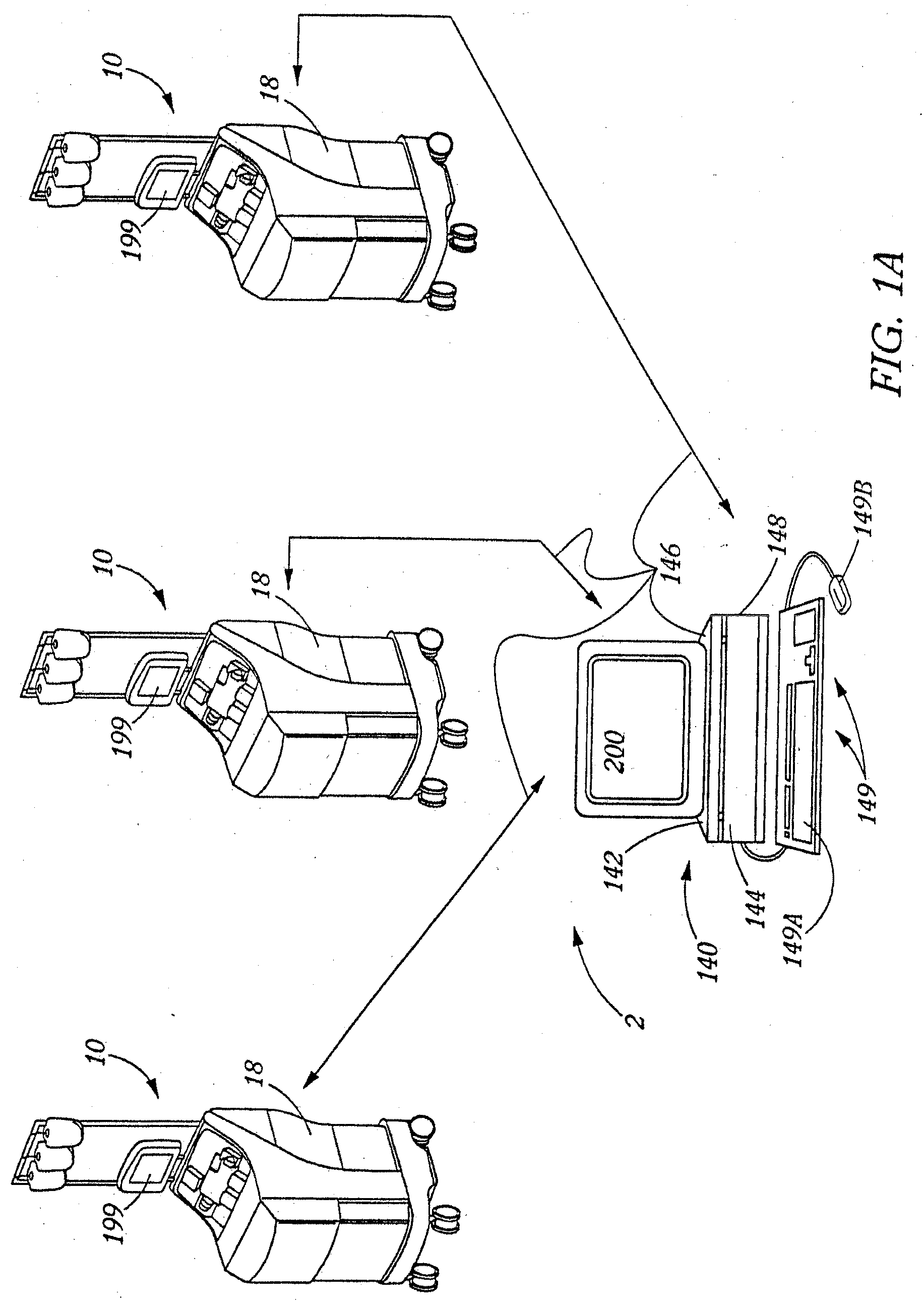

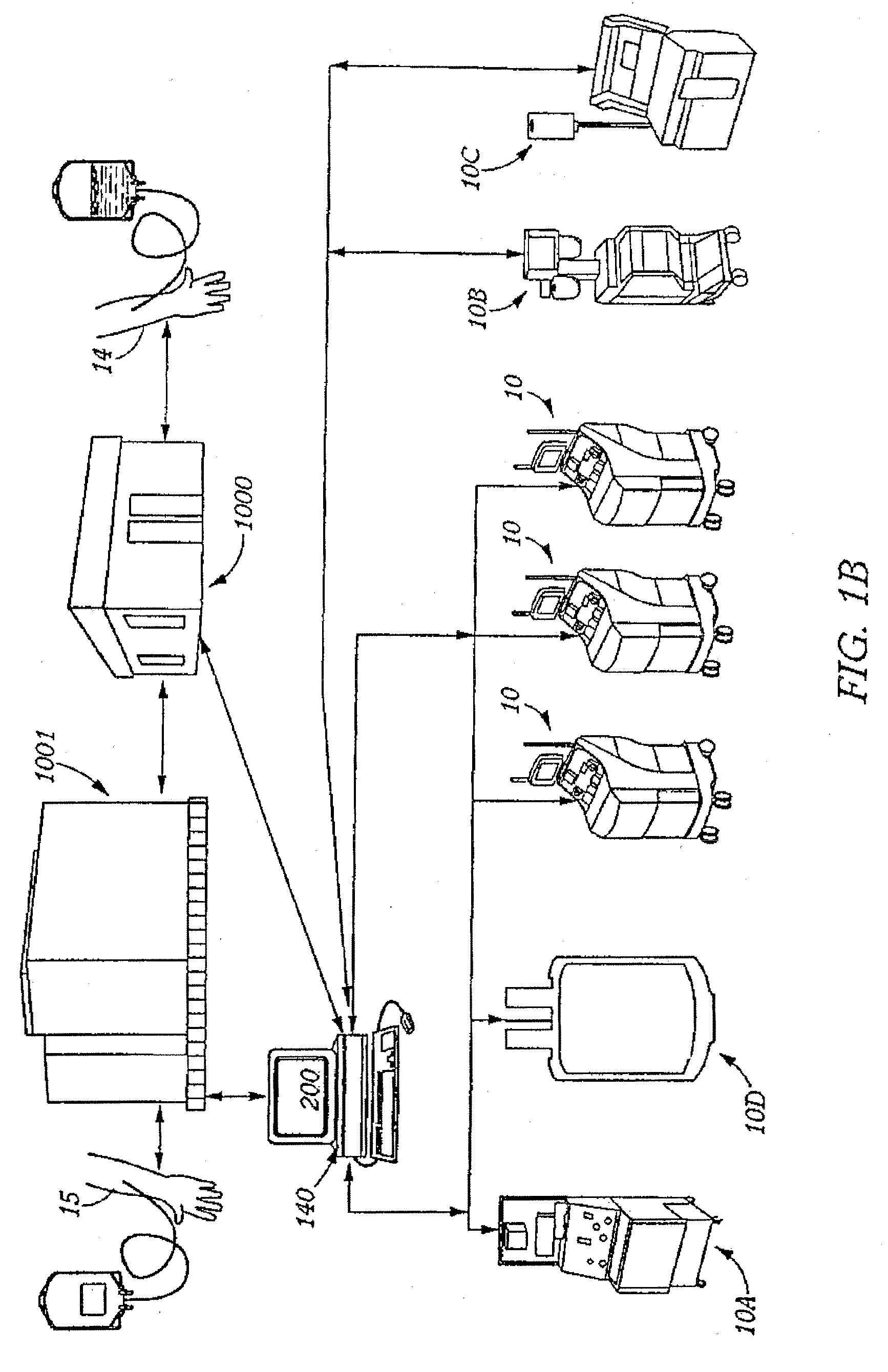

Extracorporeal blood processing information management system

ActiveUS7072769B2Simplified storage and controlEase and optimize and operationMechanical/radiation/invasive therapiesOther blood circulation devicesBlood componentCollection system

A blood component collection system with manipulation and optimization capabilities. In one embodiment, process parameters are derived from an input / configured predetermined blood component yield and which is based upon the maximization of at least one process parameter. Thereafter, the blood component collection procedure is performed with these derived process control parameters. In another embodiment, process parameters are derived from an input total procedure time from a maximized value for at least one of the other process control parameters so as to maximize blood component yield in this fixed time. Thereafter, the blood component collection procedure is performed with these derived parameters.

Owner:TERUMO BCT

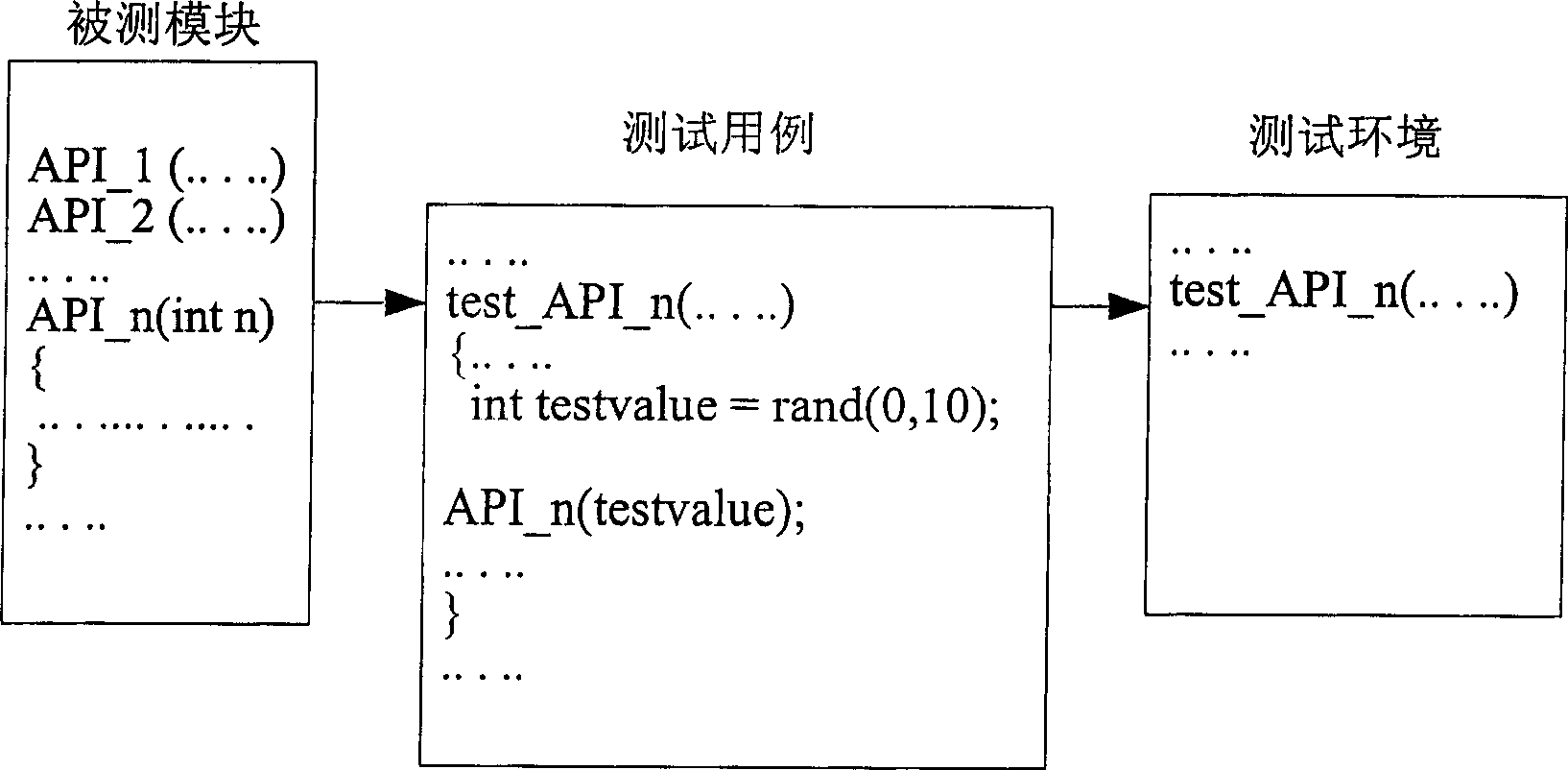

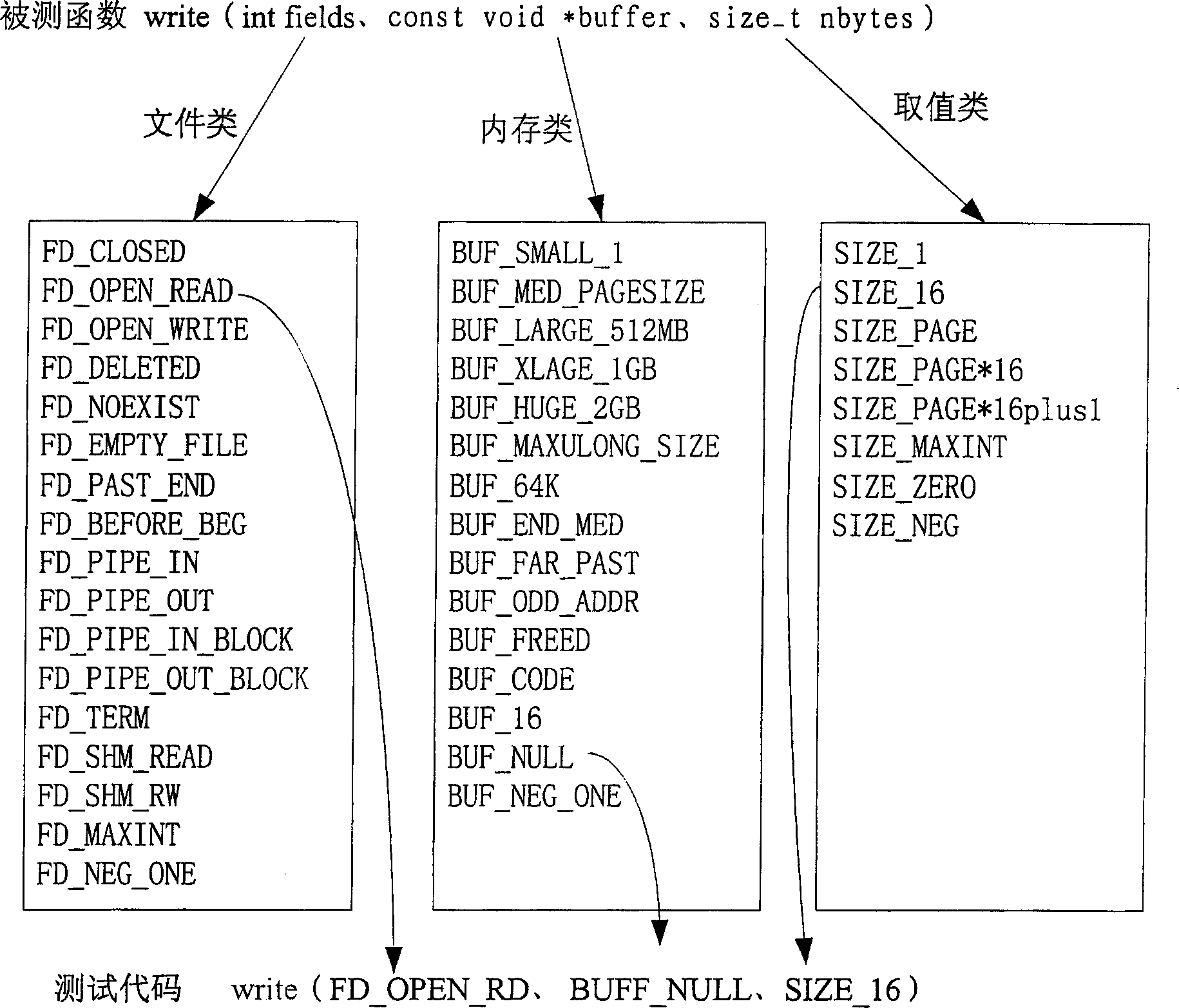

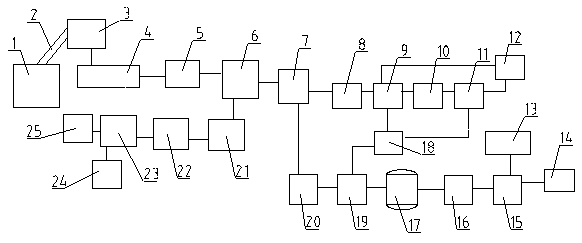

Method and device for testing software product robustness

InactiveCN1776643ASimple and clear requirementsHigh degree of autonomySoftware testing/debuggingComputer hardwareTest fixture

The method includes steps: parsing object to be tested, picking up tested information from the object tested; displaying the picked test information, receiving test information input from user; generating test case based on the picked test information and the inputted test information; combining the test case and object to be tested creates testing target codes; running the testing target codes implements test for robustness of software product. The invention also related to device for testing robustness of software product. The invention can realizes automatic generation and automatic extraction for test information of tested object.

Owner:HUAWEI TECH CO LTD

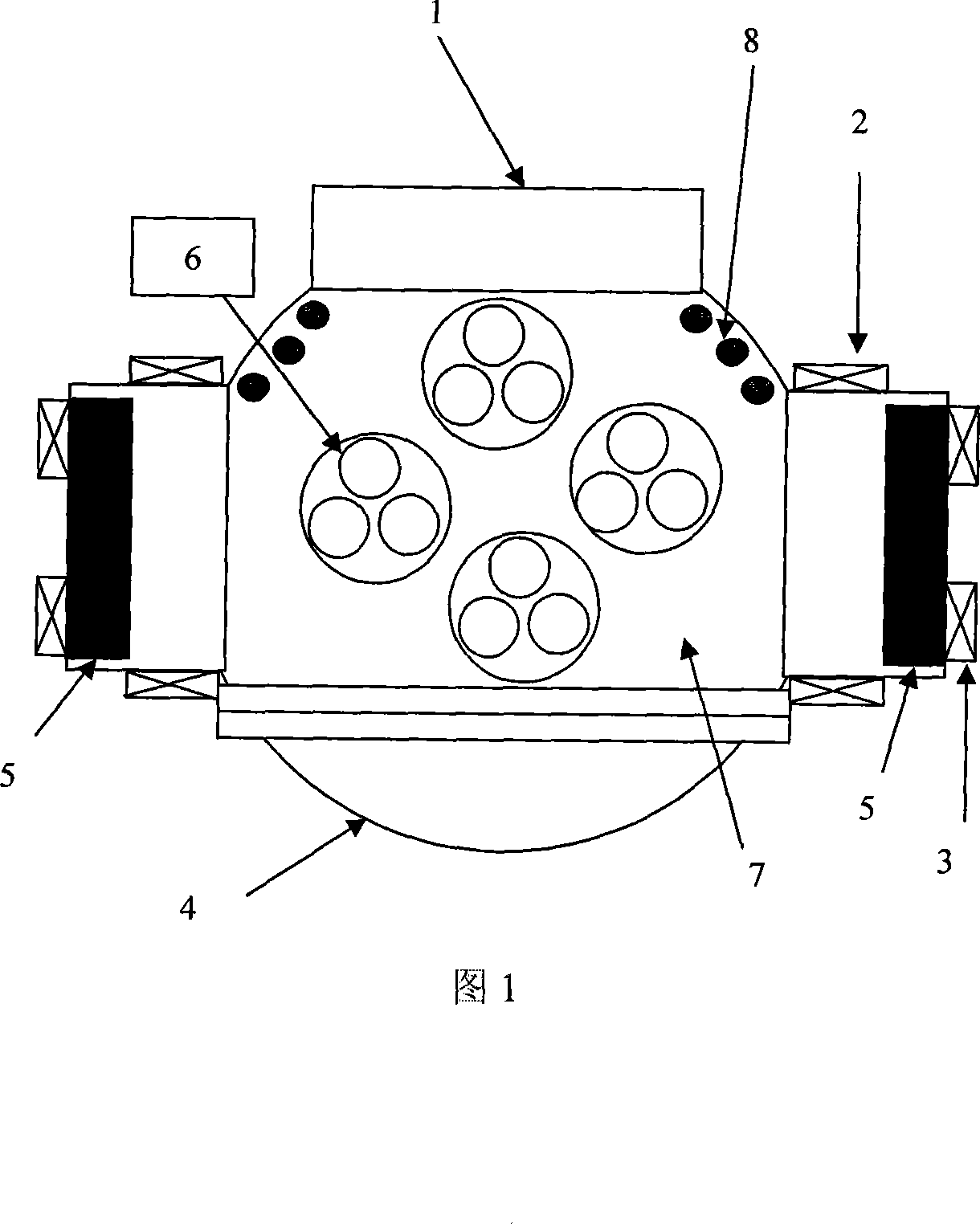

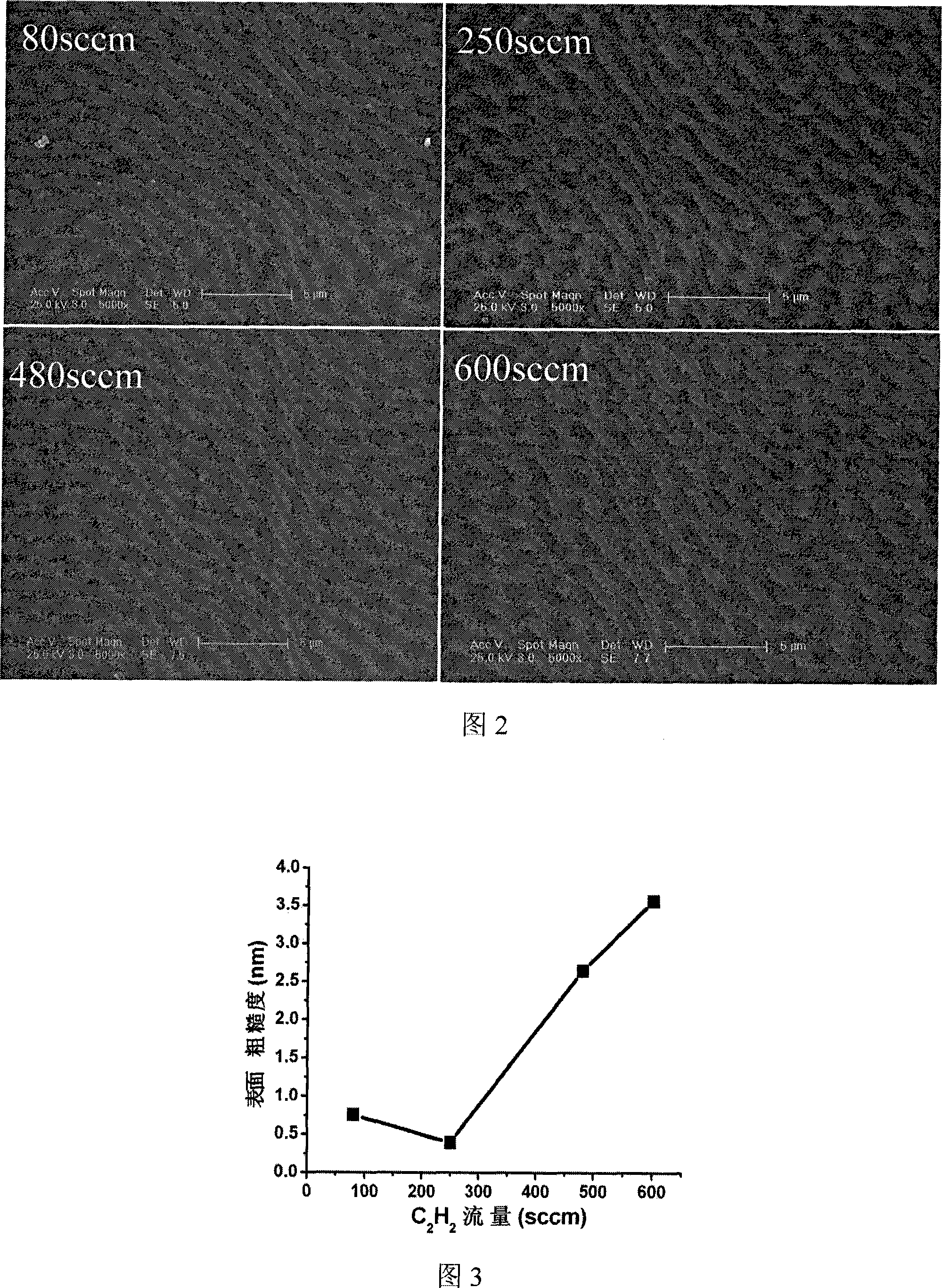

Method for preparing nano composite diamond coating

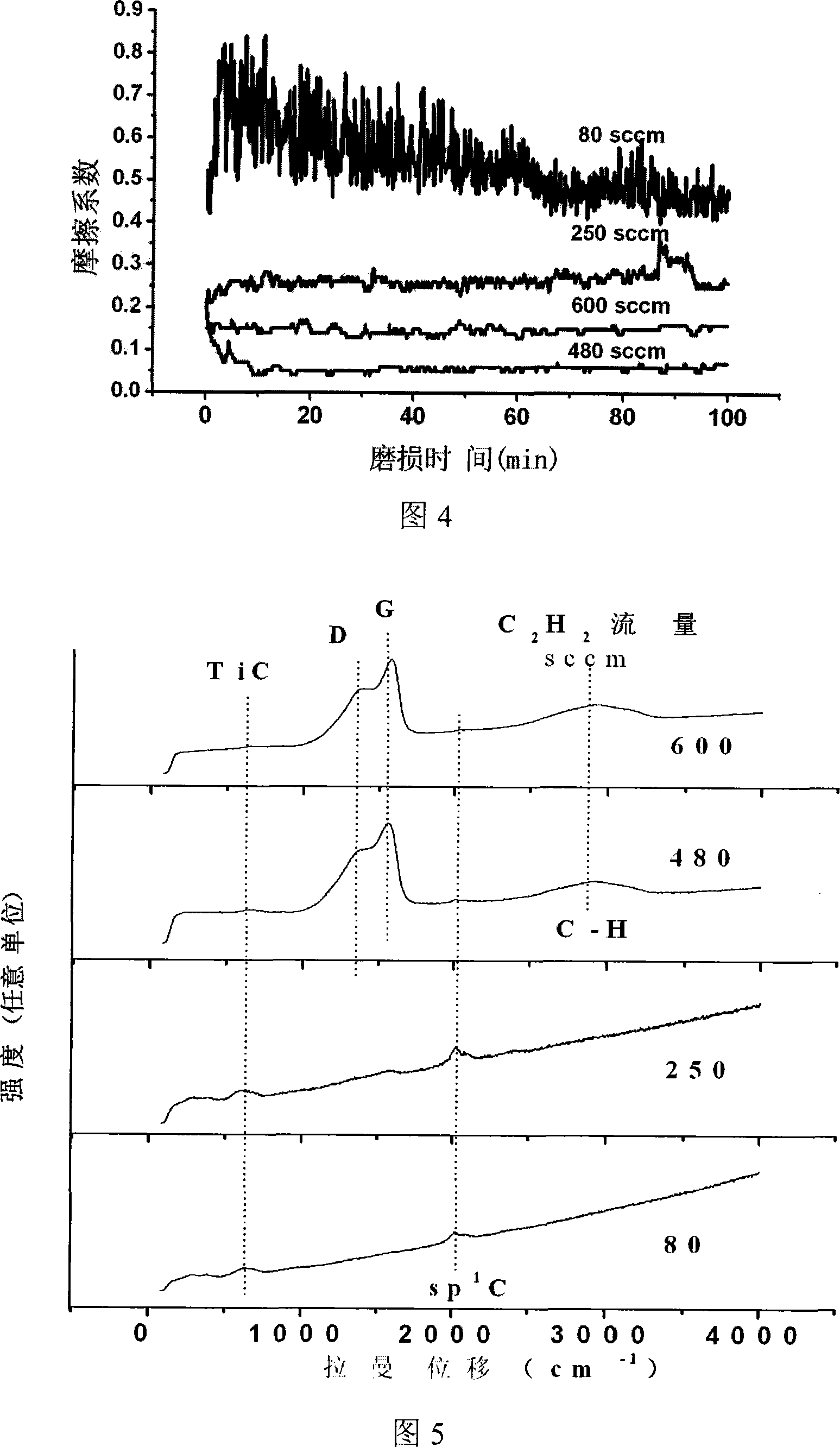

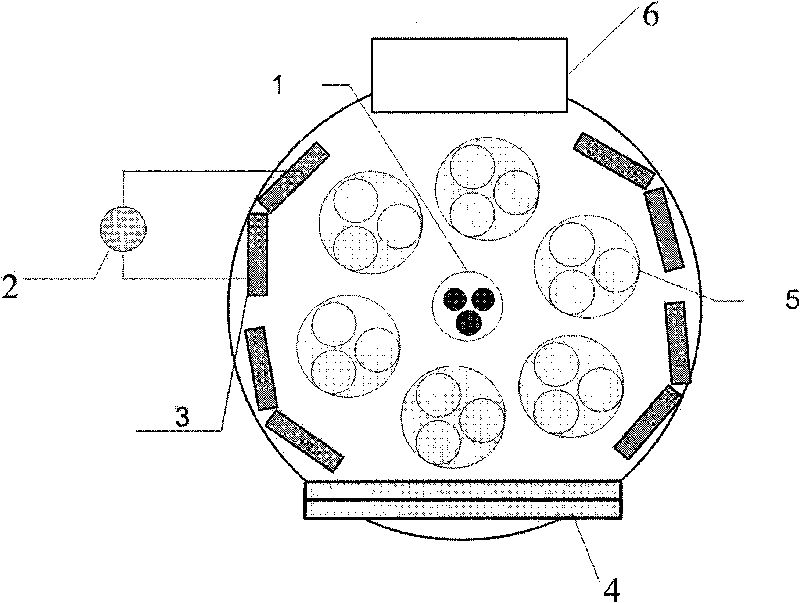

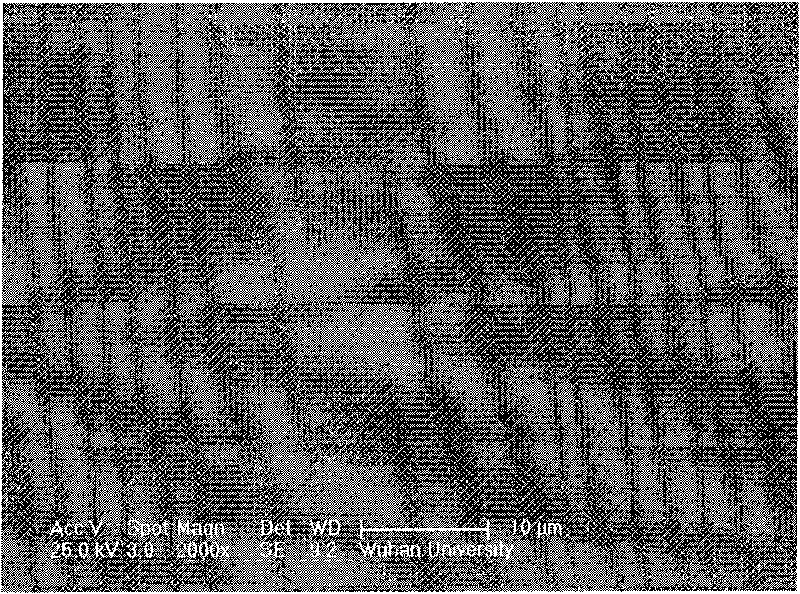

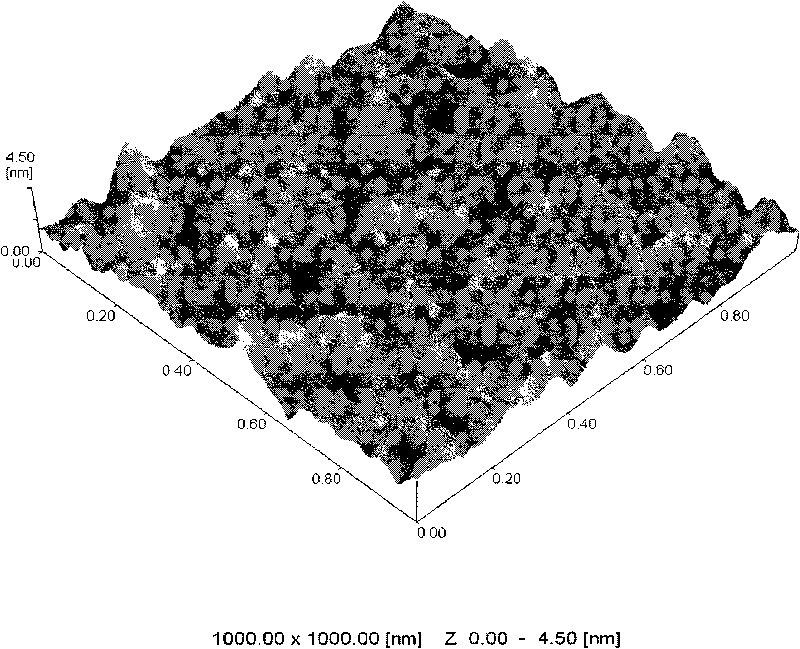

InactiveCN101113516AIncrease growth rateEliminate pollutionChemical vapor deposition coatingCarbon ionAlloy

The invention discloses a preparation method of a nano complex diamond-like coating layer. The method utilizes the cathode arc discharge controlled by a magnetic field, and excessive ethyne gas is introduced to the front of a metal target, and a metal carbide layer is formed on the target surface, metal carbide can be steamed from the target surface while the arc moves; furthermore, under the function of an auxiliary magnetic field, the front of the arc target utilizes the arc discharge to generate strong plasma ionized ethyne gas, and generate high ionized carbon ions; under the function of bias, the metal carbide steamed from the target surface and carbon ions generated by ethyne form a carbide doped nano complex diamond-like coating layer. The diamond-like coating layer prepared by the invention has the advantages of high coating hardness, strong adhesive force, high coating growing speed and production efficiency, low production cost and simple equipment structure, etc.; the invention can be applied to preparing the diamond-like coating layer of different thickness on all kinds of workpieces such as hard alloy, high speed steel, stainless steel, carbon steel, die steel, etc. according to different using requirements.

Owner:WUHAN UNIV

Method for preparing compound diamond-like carbon coating by using medium-frequency magnetic-control glow discharge method

InactiveCN101701332AHigh hardnessImprove the lubrication effectVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention relates to a method for preparing a nano compound diamond-like carbon coating, which is realized in a way that: glow discharge is produced by using a medium-frequency magnetic-control sputtering target; argon and excessive hydrocarbon gases are introduced, so that the metal on the target surface reacts with the hydrocarbon gases to produce metallic carbides; when the argon ions bombard the target surface, the target surface sputters the metallic carbides; strong plasma produced by the glow discharge of the target surface ionize the hydrocarbon gases, so that the hydrocarbon gases produce highly-ionized carbon ions; and the carbides sputtered from the target surface and the highly-ionized carbon ions produced from the hydrocarbon gases form a high-hardness carbide-doped nano compound diamond-like carbon coating on a workpiece surface. The coating prepared by the invention has the characteristics of high hardness, strong adhesive force, high growth speed, high production efficiency, low depositing temperature, low production cost, simple equipment structure and the like; and diamond-like carbon coatings with different thicknesses can be prepared on hard alloy, high-speed steel and various other workpieces.

Owner:WUHAN UNIV

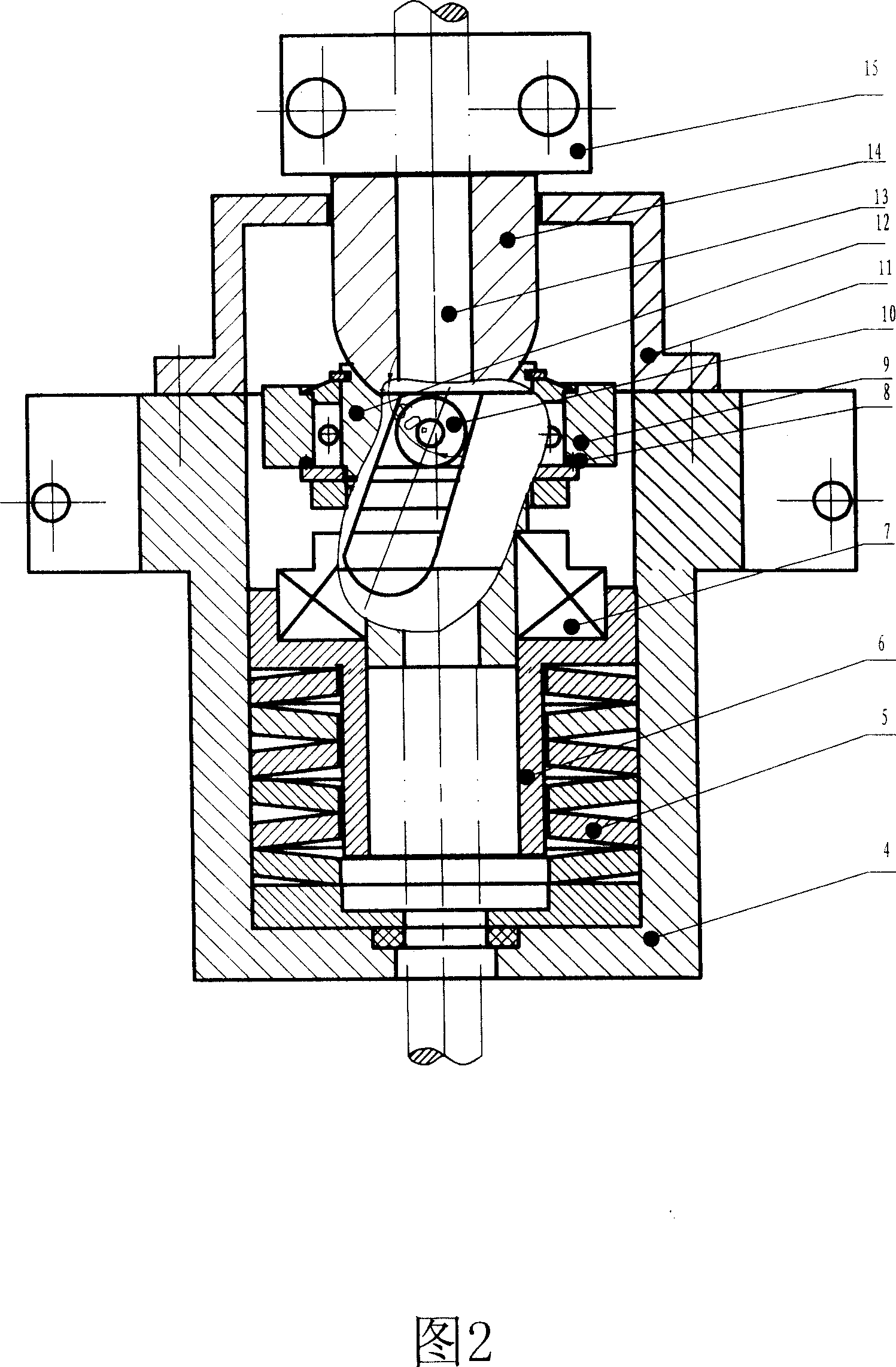

Sucker rod rope suspension apparatus

InactiveCN100999985AChange positional relationshipOvercome the defect of eccentric wearDrilling rodsFluid removalEngineeringClockwise

The sucker rod rotating rope hanger consists of a casing, a butterfly spring, a bearing, a bearer, a sucker rod seat, a ratchet wheel, a driving member, and other parts. Its operation principle is that during the sucker rod moves upwards, the increased sucker rod weight and the compressed spring make the driving member rotates clockwise while moving downwards; during the sucker rod moves downwards, the decreased sucker rod weight and the extending spring and the single direction rotating ratchet wheel make the driving member rotates counterclockwise idly; so that each motion period of the sucker rod makes the sucker rod under the action of the rope hanger rotate by some angle.

Owner:HENAN XINYU PETROLEUM MACHINERY MFG

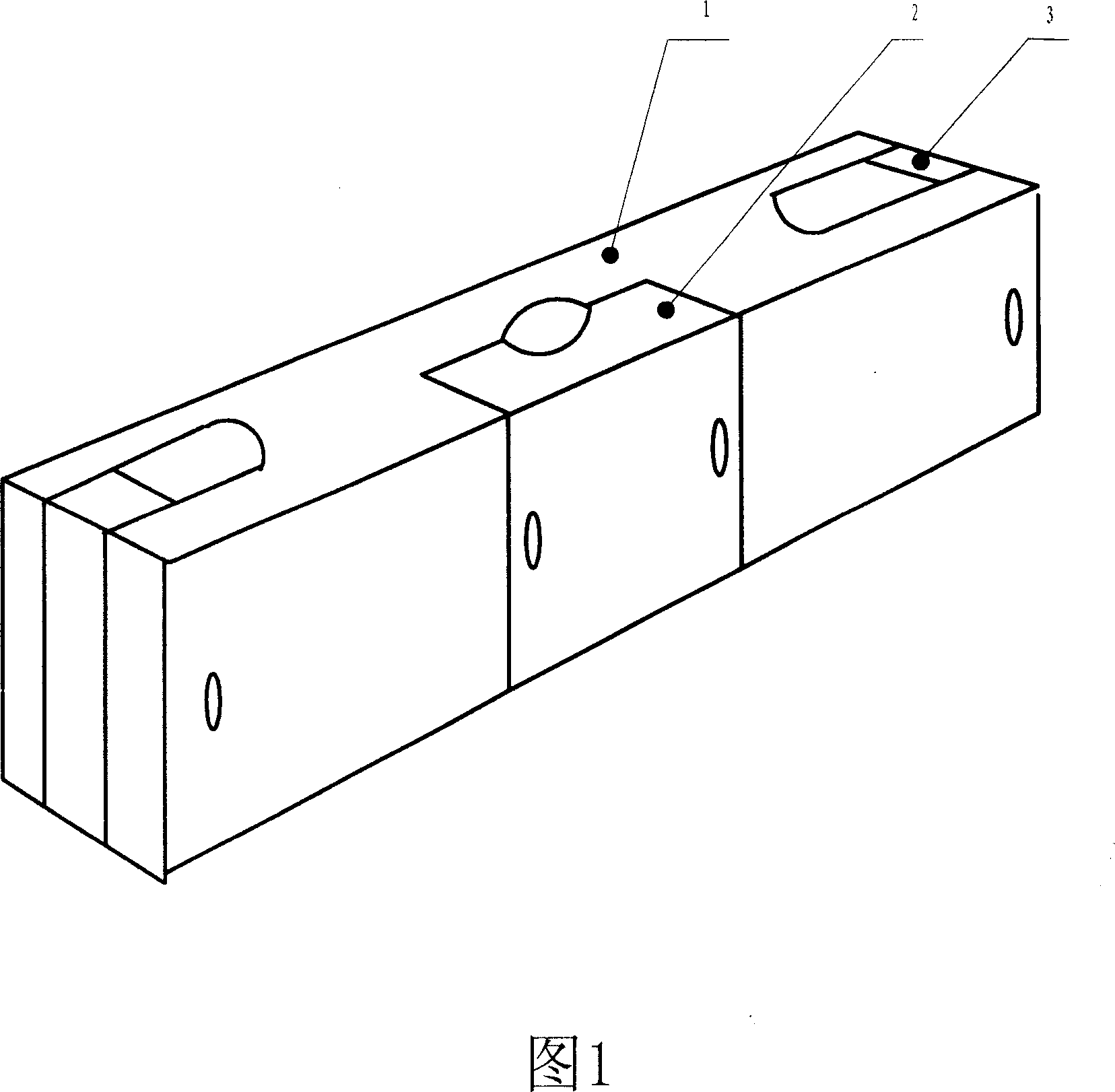

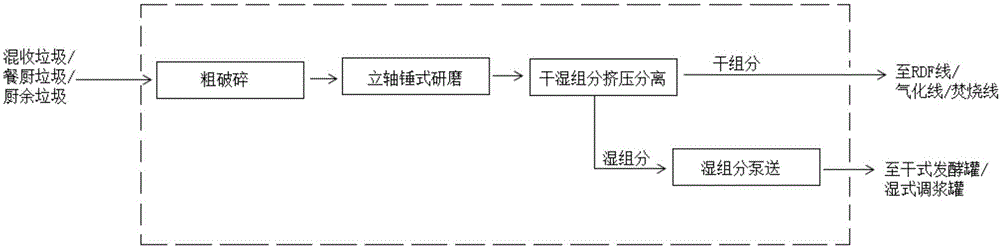

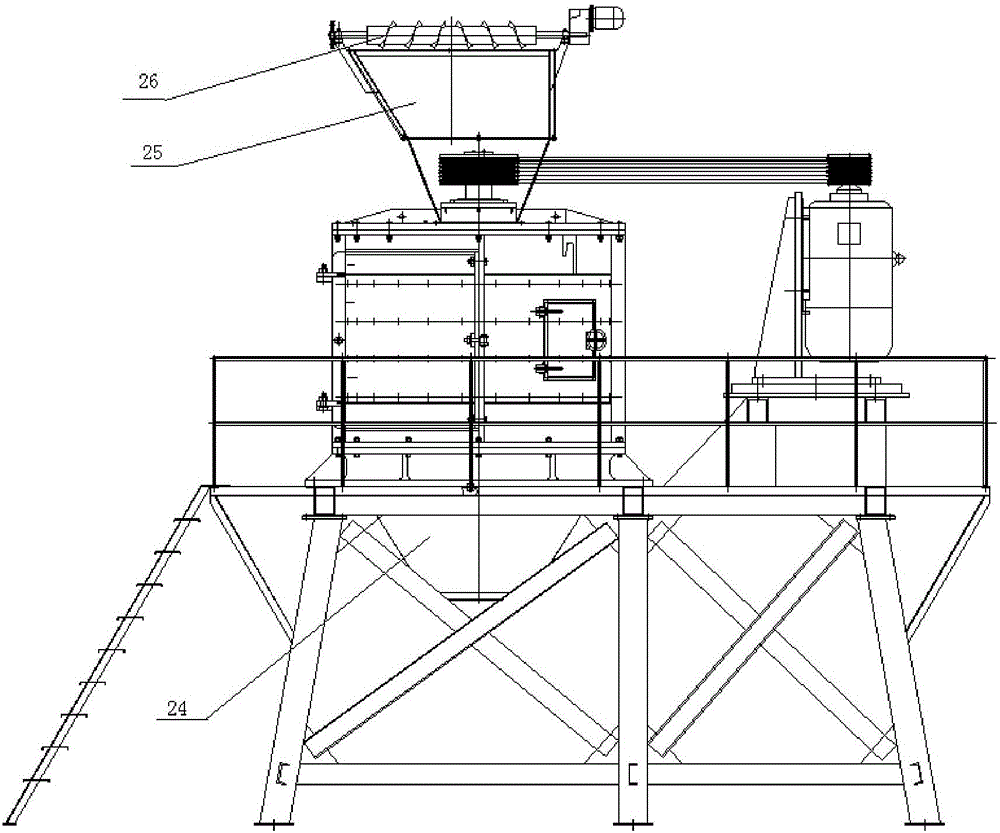

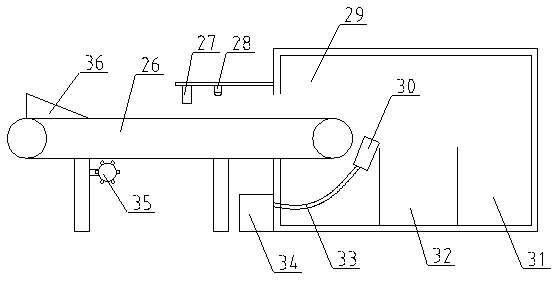

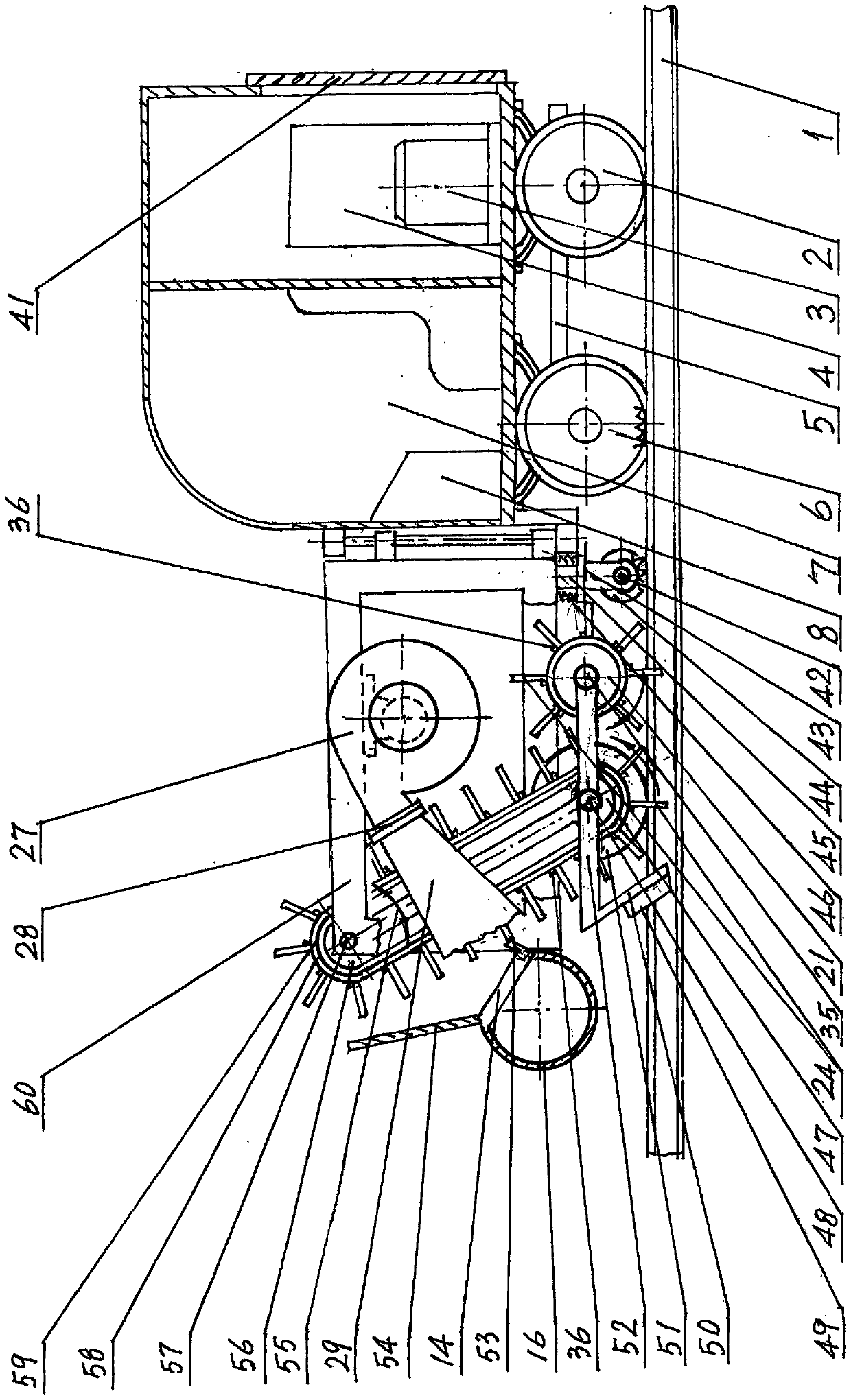

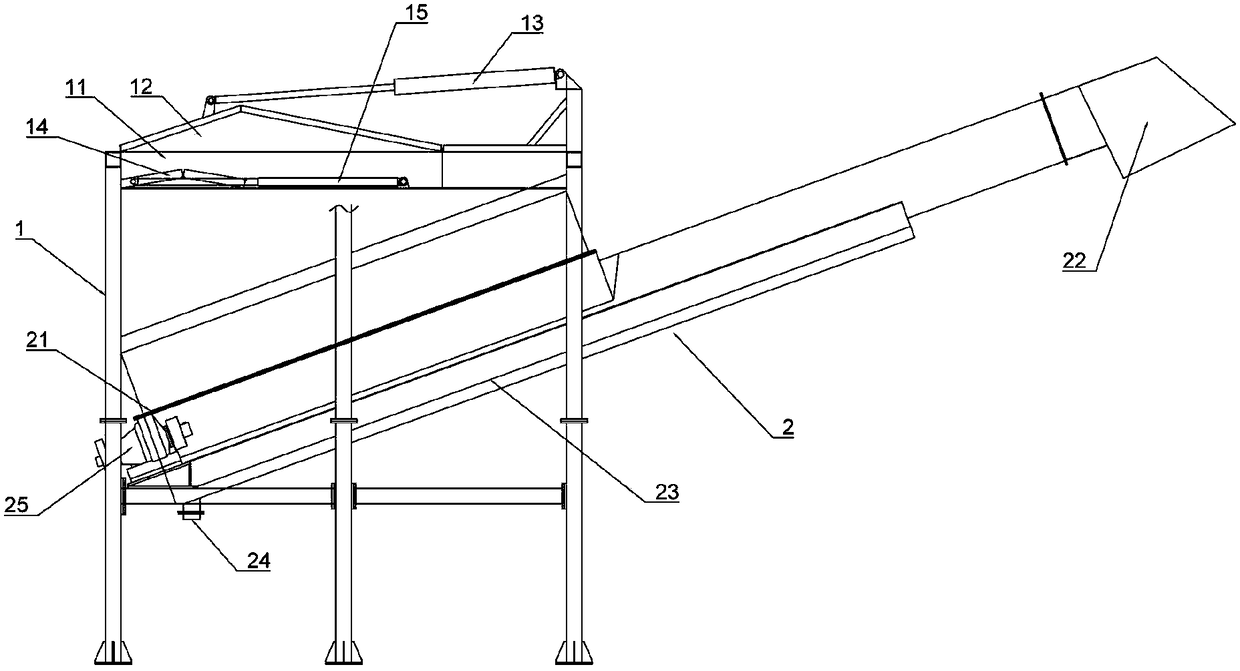

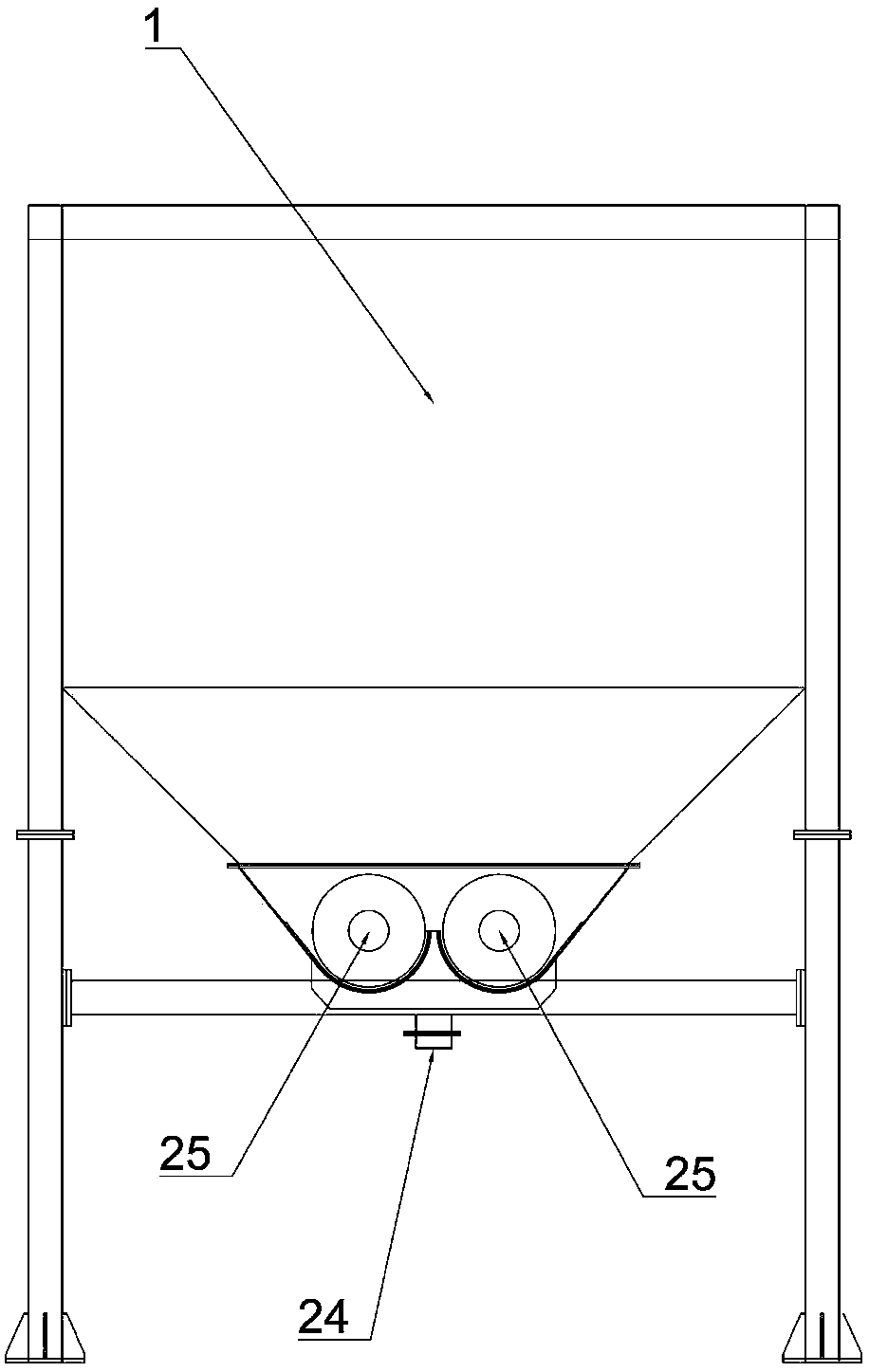

Mechanical pretreatment system and process for municipal domestic waste comprehensive treatment

ActiveCN106734083AEnable co-processingAdvanced principleSolid waste disposalGrain treatmentsAdditive ingredientOrganic matter

The invention discloses a mechanical pretreatment system for municipal domestic waste comprehensive treatment (marsh production). The system comprises a coarse crushing unit, a vertical shaft hammer type grinding unit and a dry-wet component extrusion and separation unit which are arranged in sequence. The units are sequentially connected through a conveying machine. The invention further discloses a mechanical pretreatment process for municipal domestic waste comprehensive treatment adopting the mechanical pretreatment system. The process comprises the process steps of coarse crushing, vertical shaft hammer type grinding and dry-wet component extrusion and separation. The technical defects that organic matter separation efficiency is low and the impurity content is high according to existing domestic waste comprehensive treatment mechanical pretreatment are overcome, the waste receiving adaptability is high, the equipment integration degree is high, continuous stable operation is achieved, various kinds of domestic waste with complex ingredients are used as raw materials, dry and wet components are produced to meet different follow-up technological requirements, coordinated treatment of various kinds of municipal domestic waste is achieved, and the system and the process are suitable for being applied and popularized.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD +1

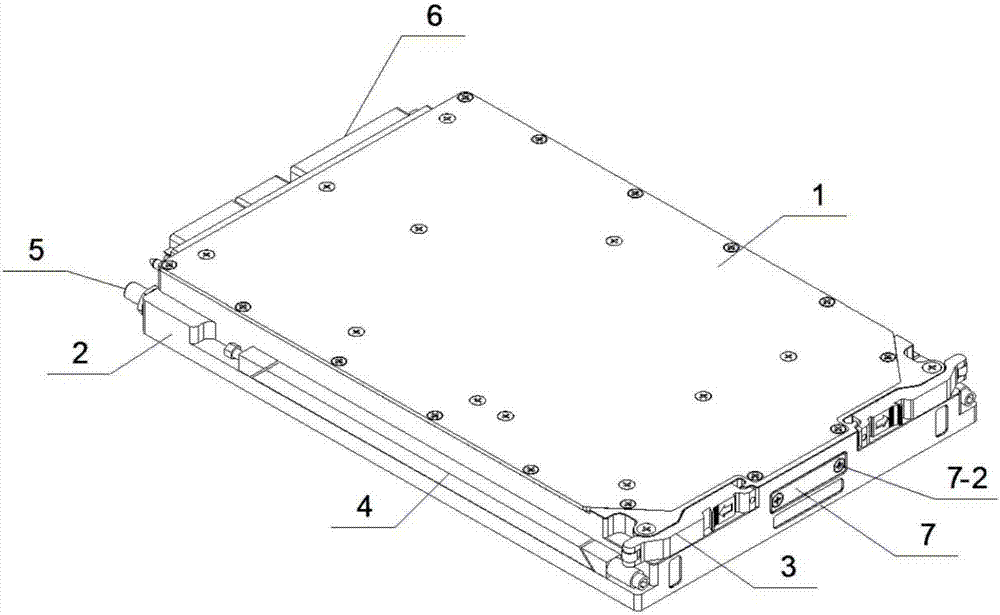

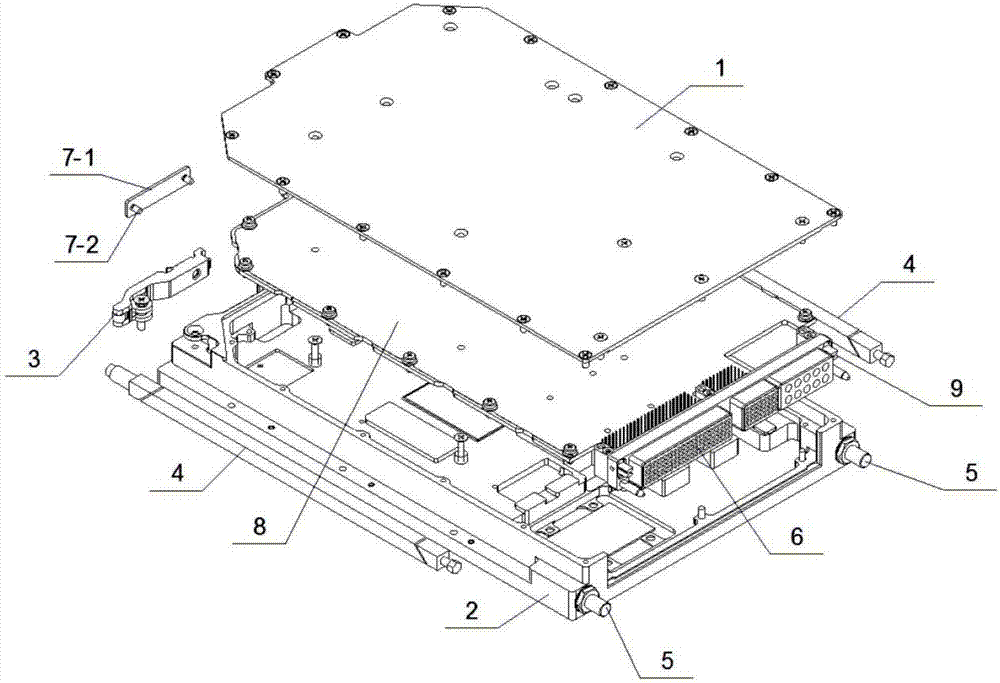

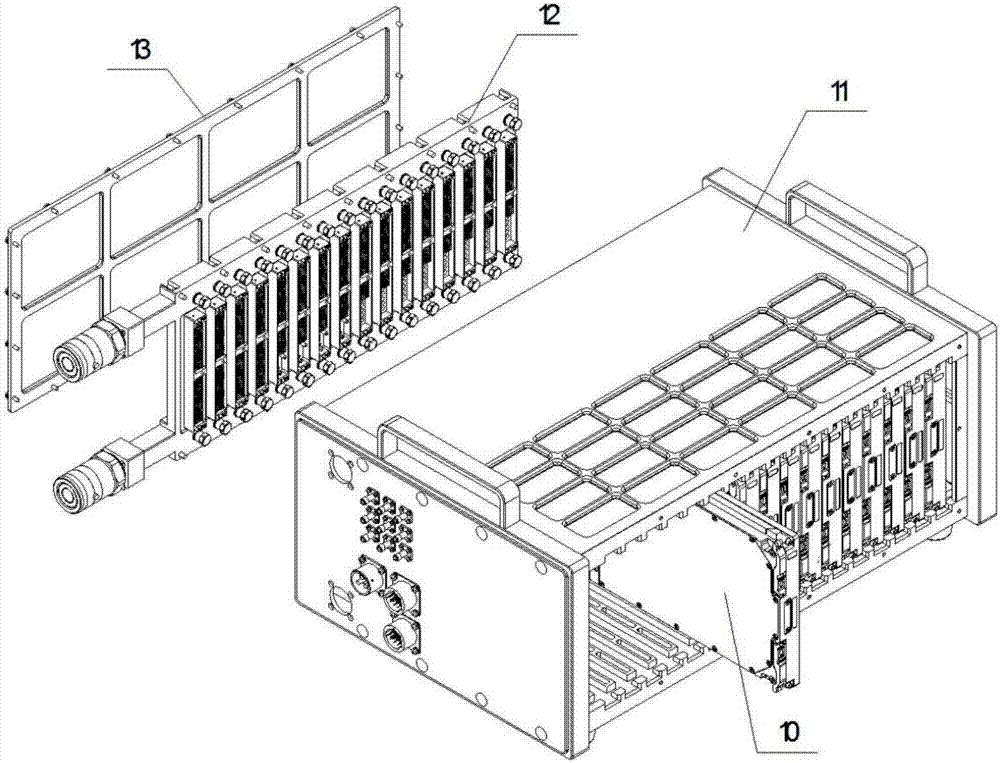

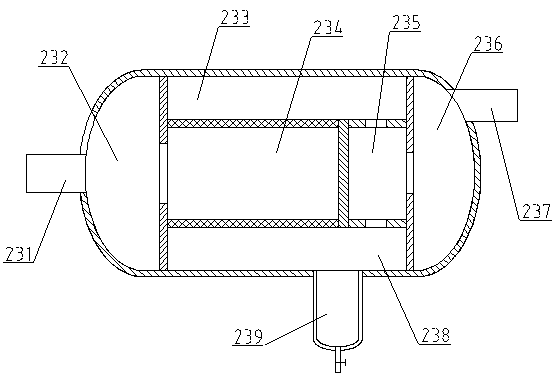

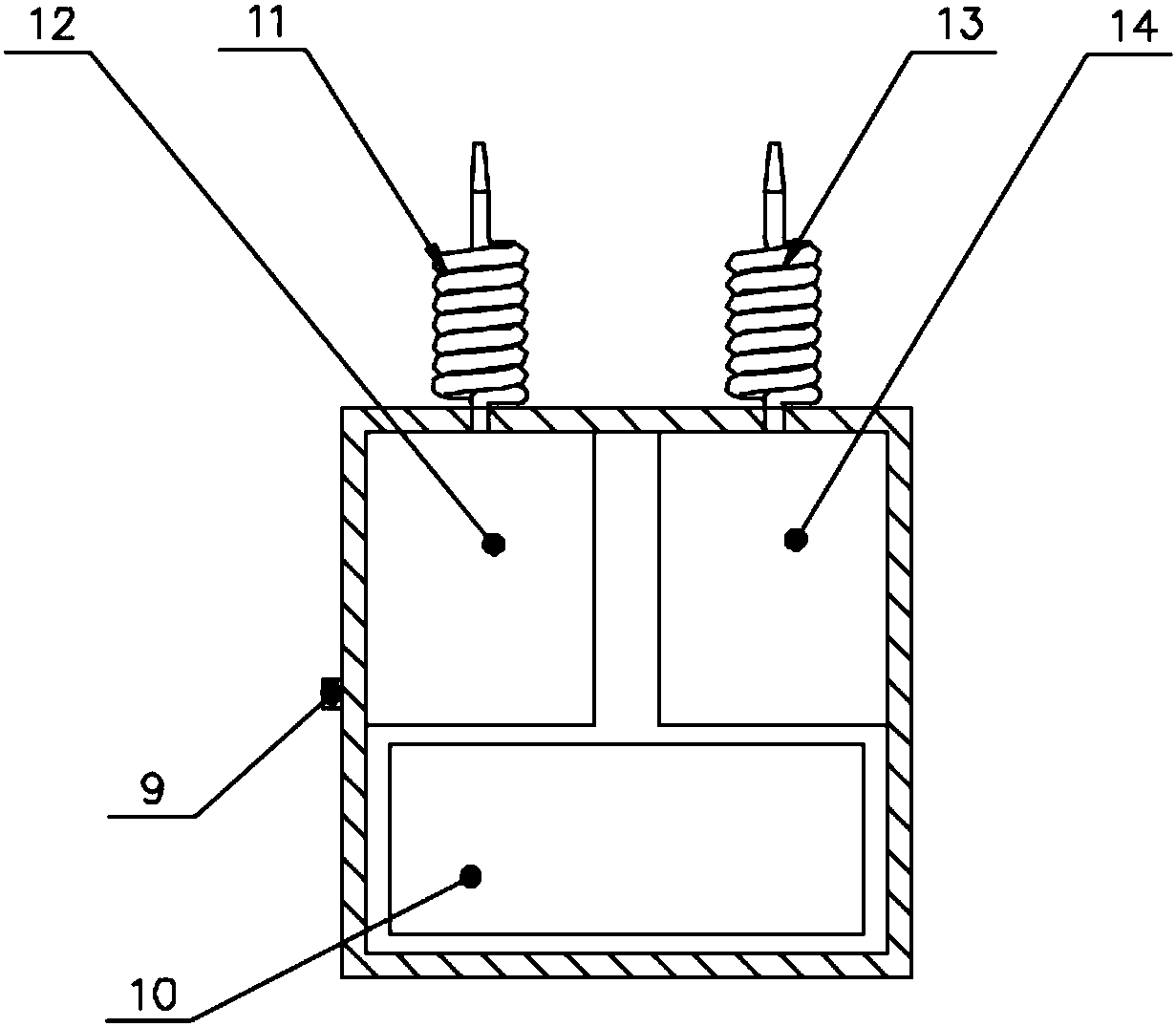

Blind plug type liquid cooling module

InactiveCN107172863AEasy to debug and maintainQuick changeCooling/ventilation/heating modificationsCooling channelMechanical engineering

A blind plug type liquid cooling module comprises a liquid cooling cavity which is composed of a cavity, a built-in flow channel, and fluid. A puller is arranged in the front of the liquid cooling cavity. A floating blind plug connector is arranged in the rear of the liquid cooling cavity. A plurality of printed boards or devices are arranged in the middle. Locking strips are arranged at both sides. A cover plate is arranged at least above. The cover plate, the liquid cooling cavity and the floating blind plug connector constitute an isolated chamber which provides electromagnetic shielding and salt fog isolation for the printed boards or the devices. A blind plug liquid cooling joint is arranged in the rear of the liquid cooling cavity. A cooling channel is formed between the blind plug liquid cooling joint and the built-in flow channel of the liquid cooling cavity. Cooling liquid circulates in the cooling channel to cool the printed boards or the devices.

Owner:叶发亮

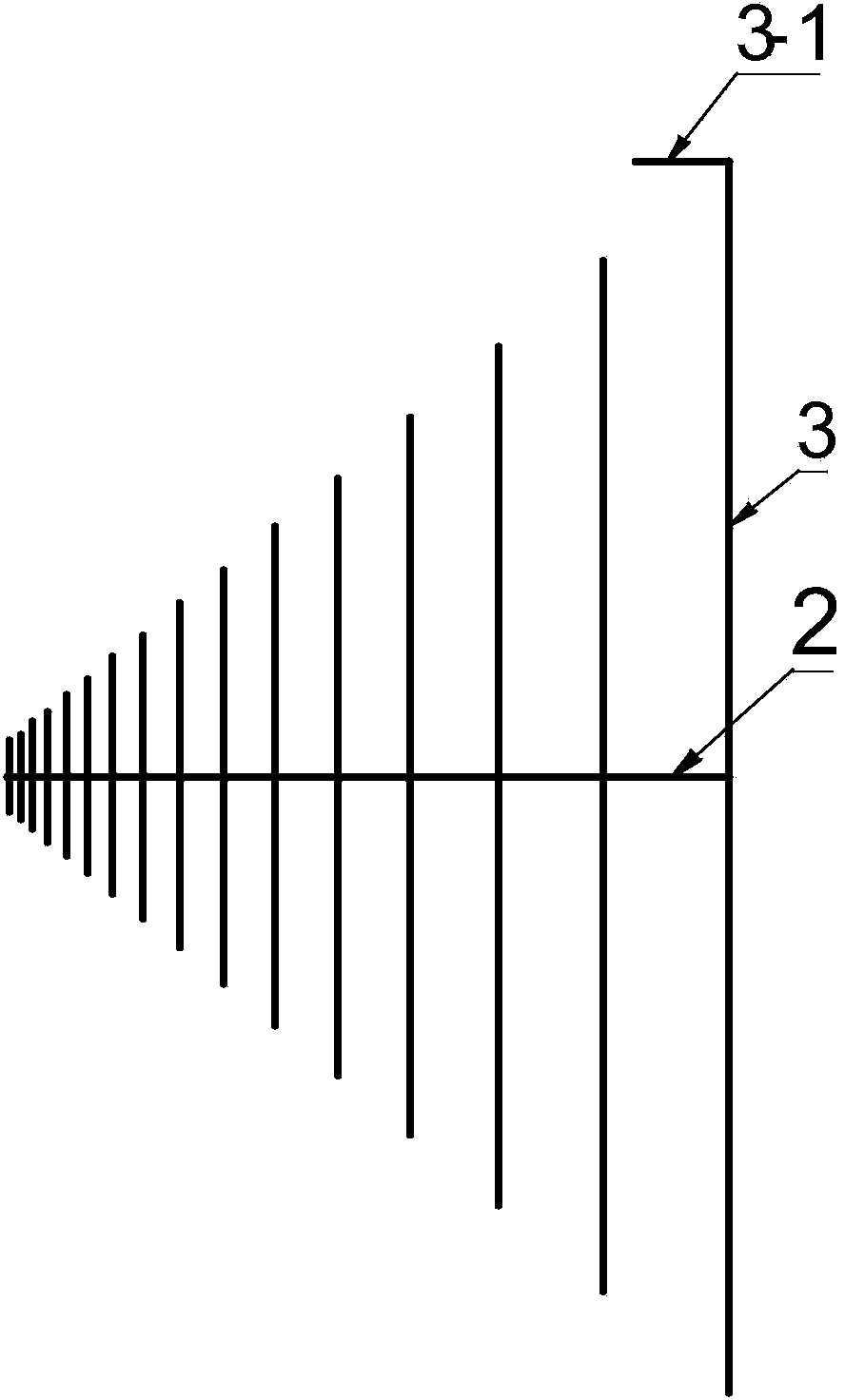

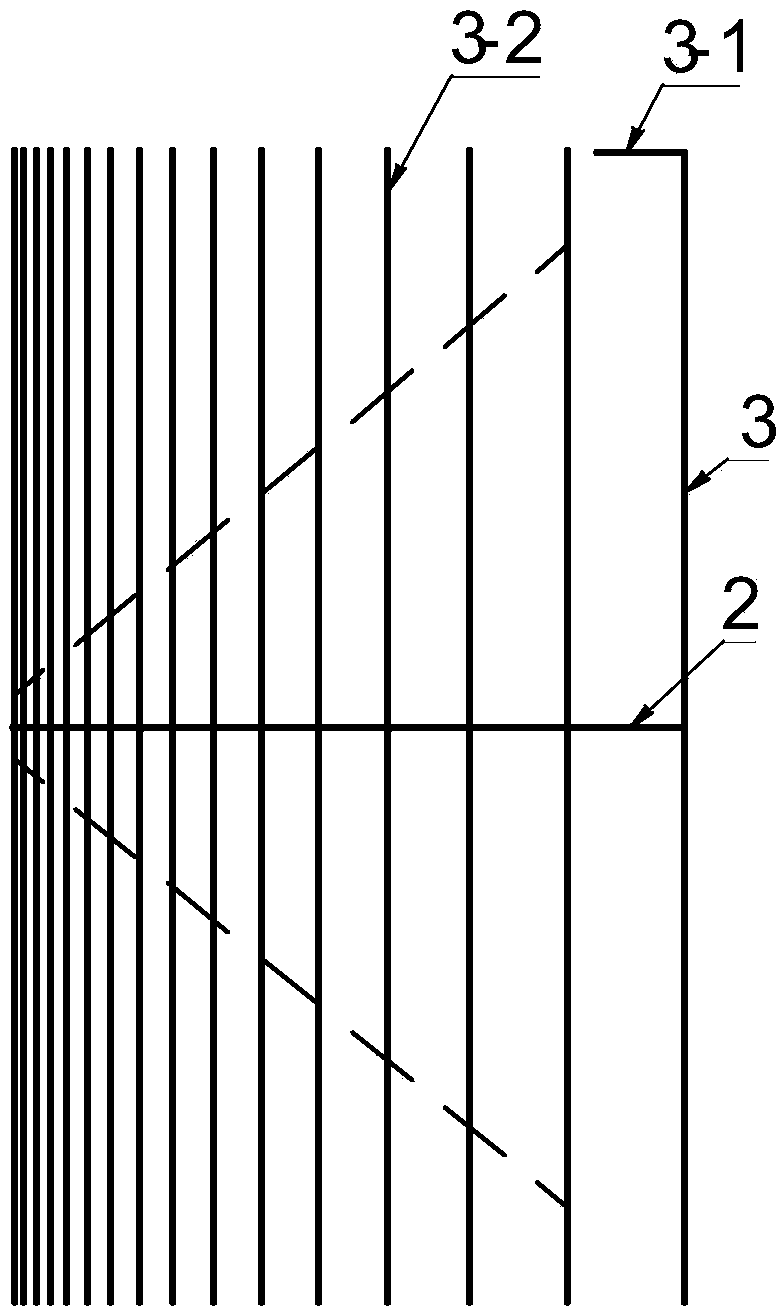

Full-automatic log periodic antenna

ActiveCN104332711AAdvanced principleReliable structureLogperiodic antennasAntenna supports/mountingsEngineeringResponse ability

The invention discloses a full-automatic log periodic antenna. The full-automatic log periodic antenna is capable of meeting high mobility requirement, fixing requirement or the like application requirements. The full-automatic log periodic antenna takes full advantages of the lifting function of an antenna mast, a soft line oscillator and an automatic line winder for winding and storing the soft line oscillator to full automatically mount, wind and store antenna. The full-automatic log periodic antenna realizes to full automatically switch the antenna working states without manual operation; the full-automatic log periodic antenna is easy to highly and organically integrate with a carrying platform, the platform shape is rarely influenced, and the cross-country mobility of a carrying tool is not influenced; the full-automatic log periodic antenna can adapt to the application requirements of different special fields and greatly improve the quick response ability of the system.

Owner:36TH RES INST OF CETC

Eductional geomagnetic field measurement experimental apparatus

InactiveCN1888936AAdvanced principleLow priceElectric/magnetic detectionAcoustic wave reradiationData displayEngineering

The magnetic field test experiment equipment for teaching field belongs to test technology field. It relates to test system, pedestal, bracket, the first pin, rotating cylinder, the first handle, rotary table, the second handle, bushing, motherboard, copper pole, the second pin, dial and hand. The test system is made up by sensor, exterior circuit and data display part. The two parts fix on the motherboard respectively by two copper poles, the four copper poles connects with rotary table, the second handle connects with it which connects with the second pin by bushing. The second pin tightly assorts to rotating cylinder, the latter connects to bracket through the first pin which tightly assorts to bracket. The hand and the first handle fix on the rotating cylinder, the dial stick to the left to bracket that sets on the pedestal vertically. Its magnetoresistance sensor is small and low cost with high sensitivity, resist-electromagnetism yawp, resist-disturb capability, and dependability and is suitable to the teaching experiment in high school and academy.

Owner:SHANGHAI JIAO TONG UNIV

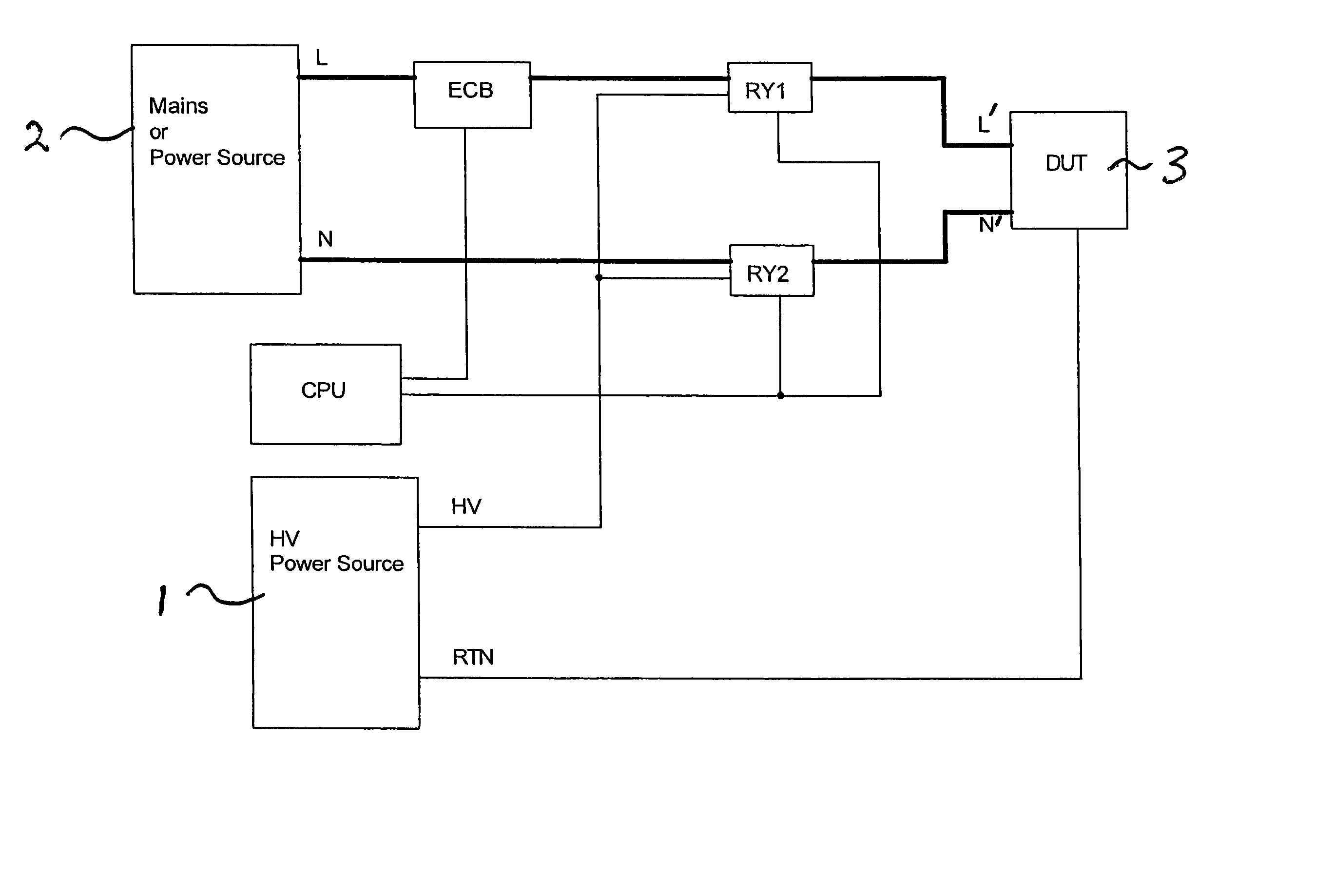

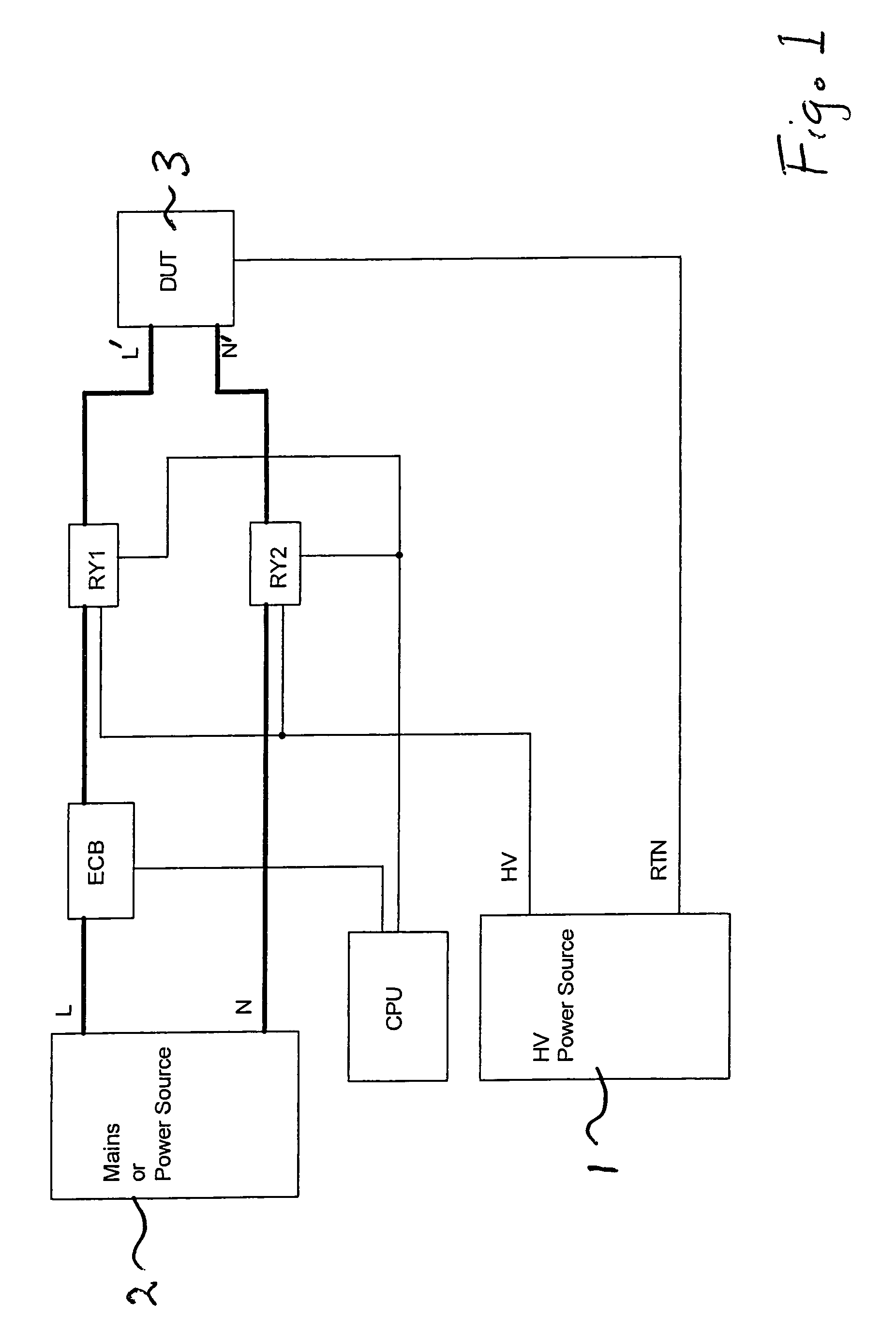

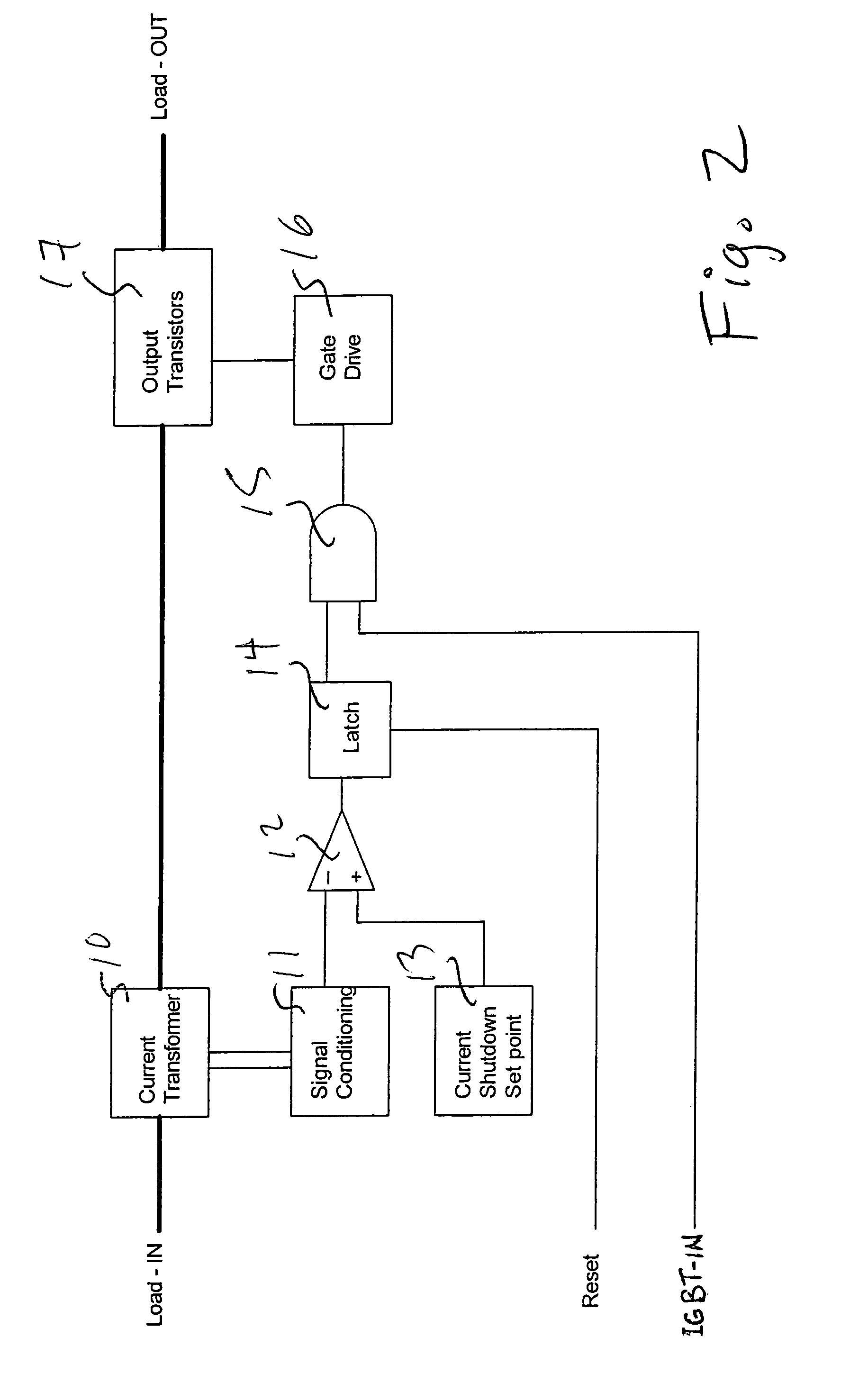

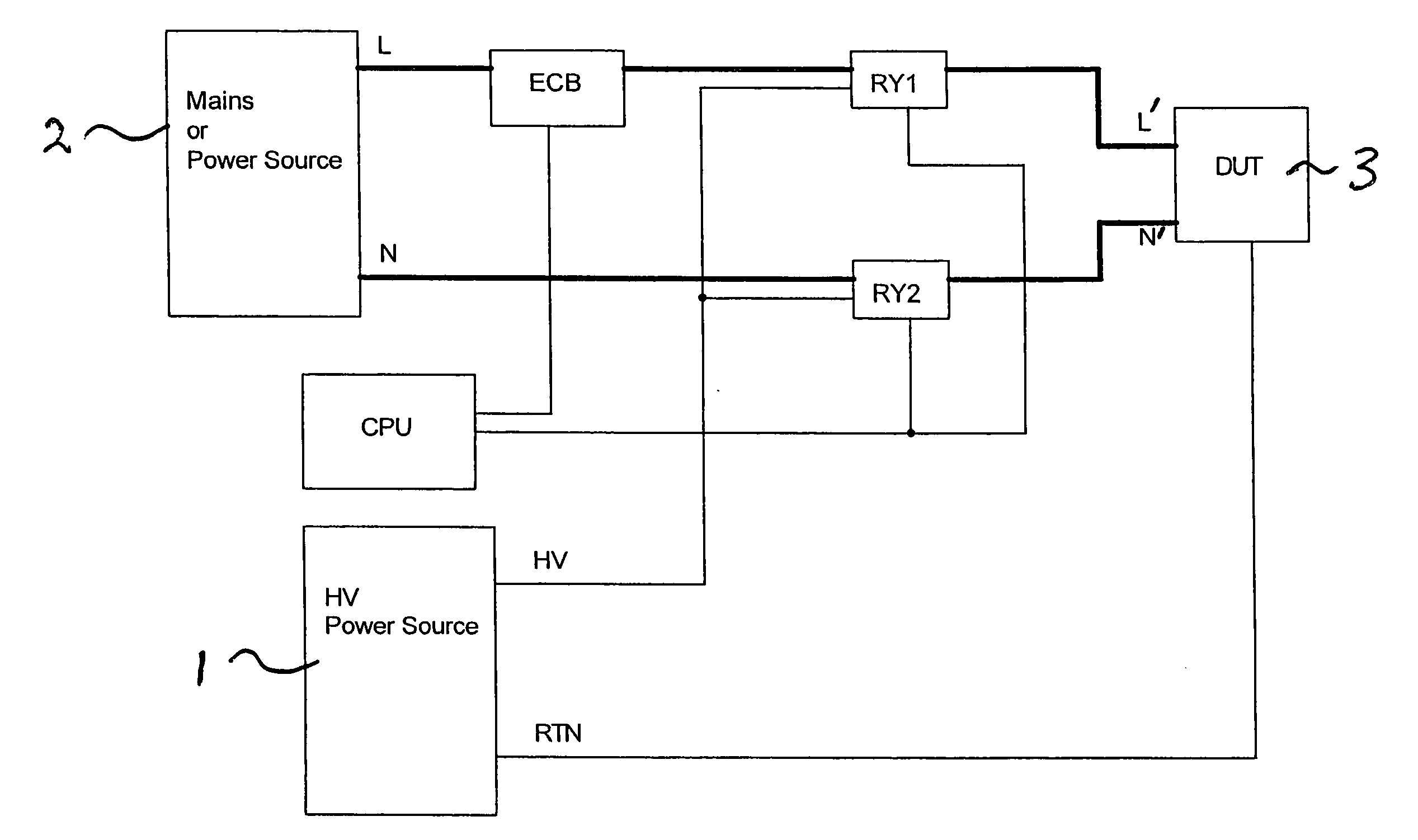

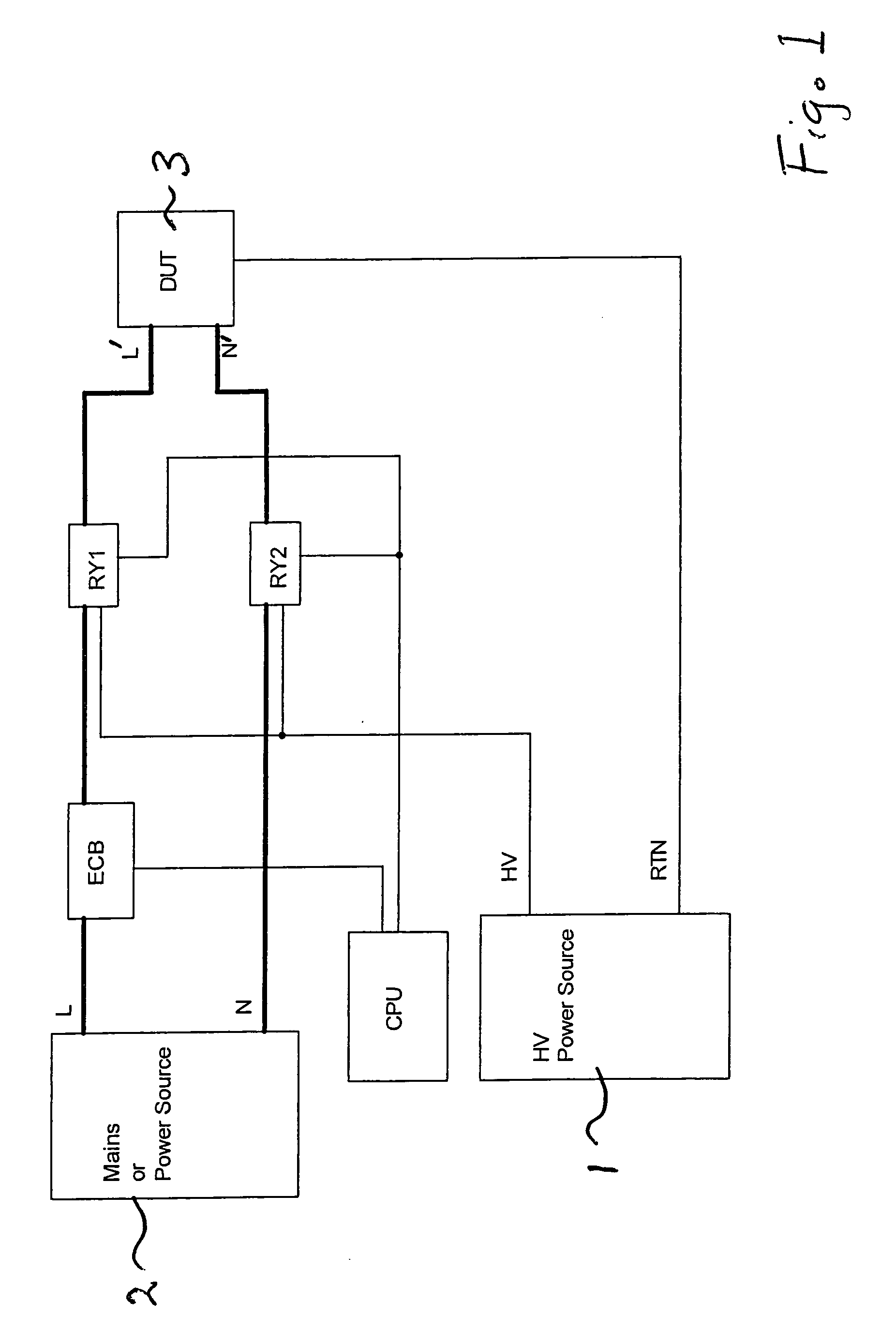

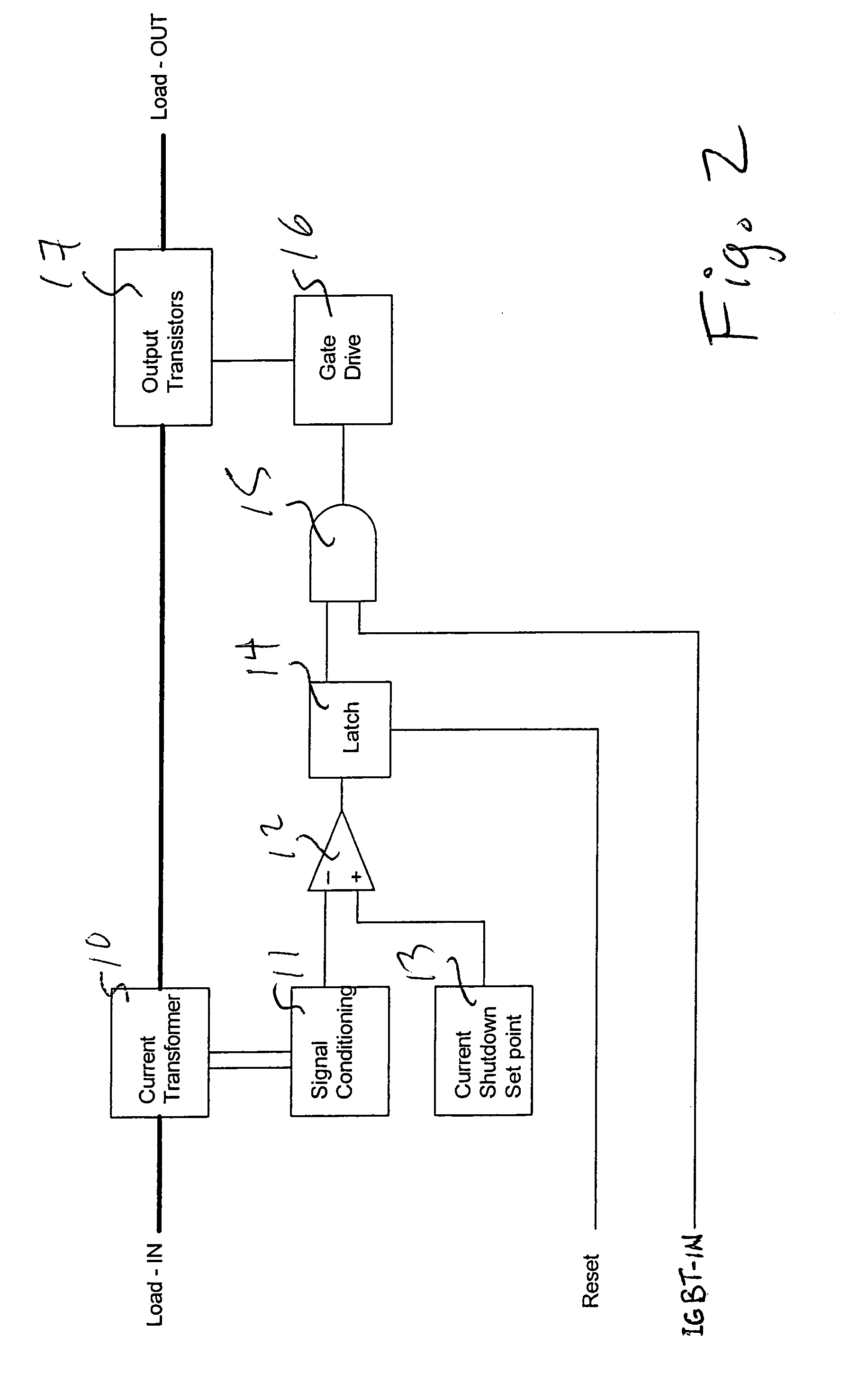

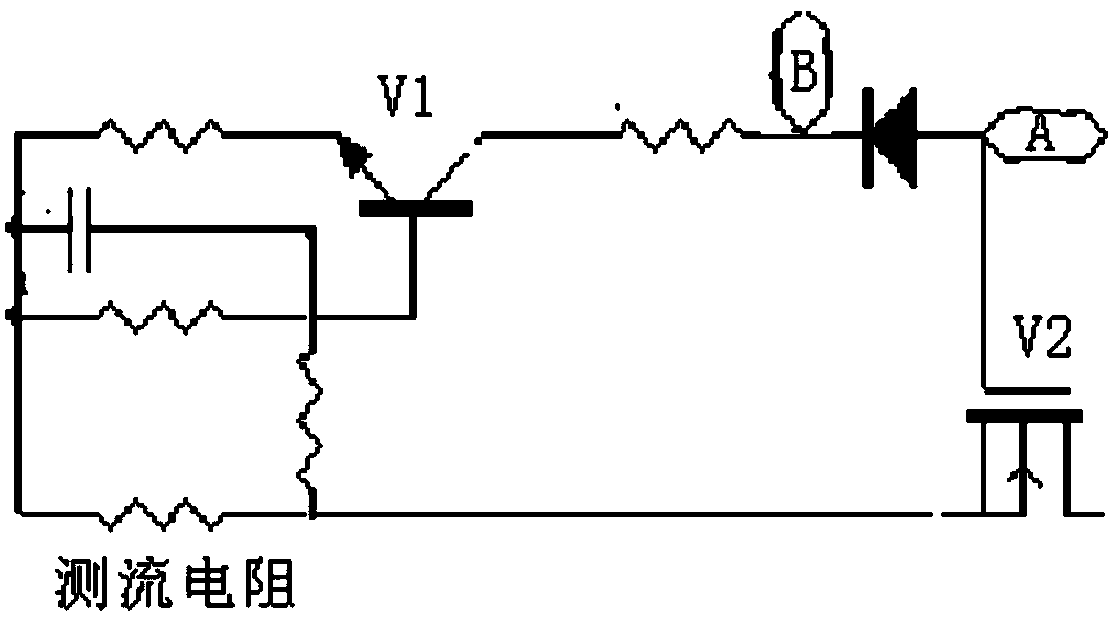

Safety tester having a high-voltage switching relay protected by an in-line electronic circuit breaker

InactiveUS7330342B2Low costSmall sizeElectrical testingArrangements responsive to excess currentConsistency testEngineering

A multiple function safety compliance test instrument includes a high voltage output switching relay protected by a solid state in-line circuit breaker.

Owner:ASSOCD RES

Safety tester having a high-voltage switching relay protected by an in-line electronic circuit breaker

InactiveUS20060227479A1Low costSmall sizeElectrical testingArrangements responsive to excess currentSolid-stateElectronic circuit

A multiple function safety compliance test instrument includes a high voltage output switching relay protected by a solid state in-line circuit breaker.

Owner:ASSOCD RES

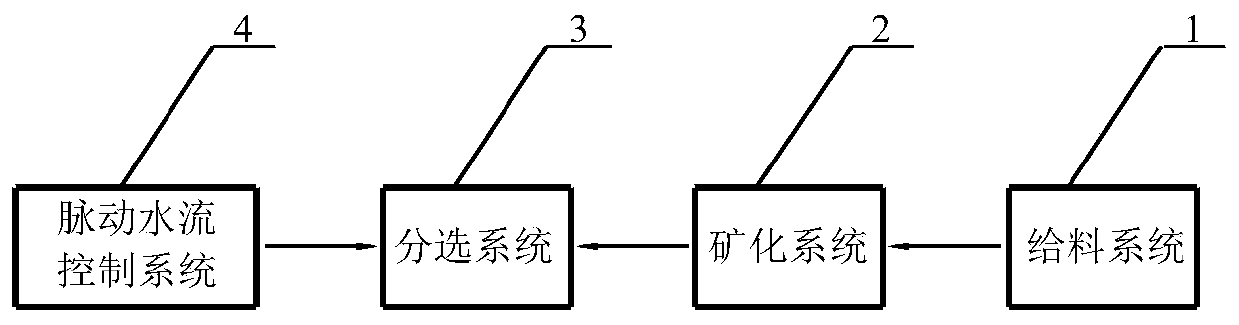

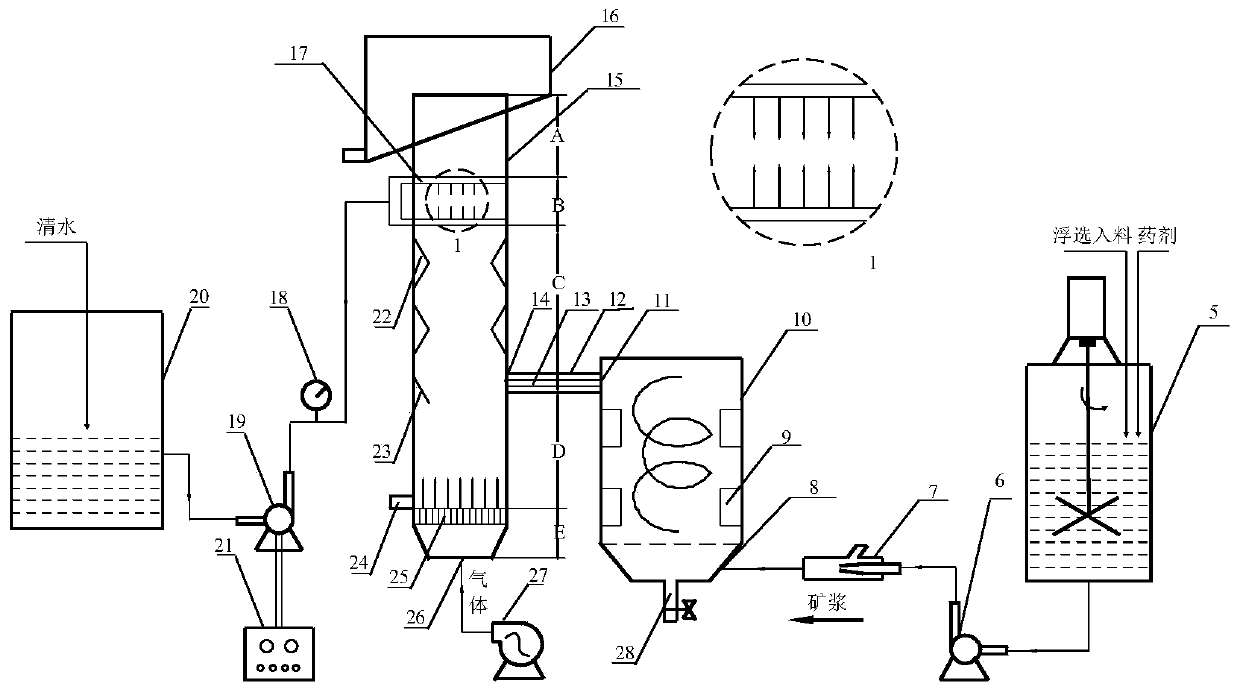

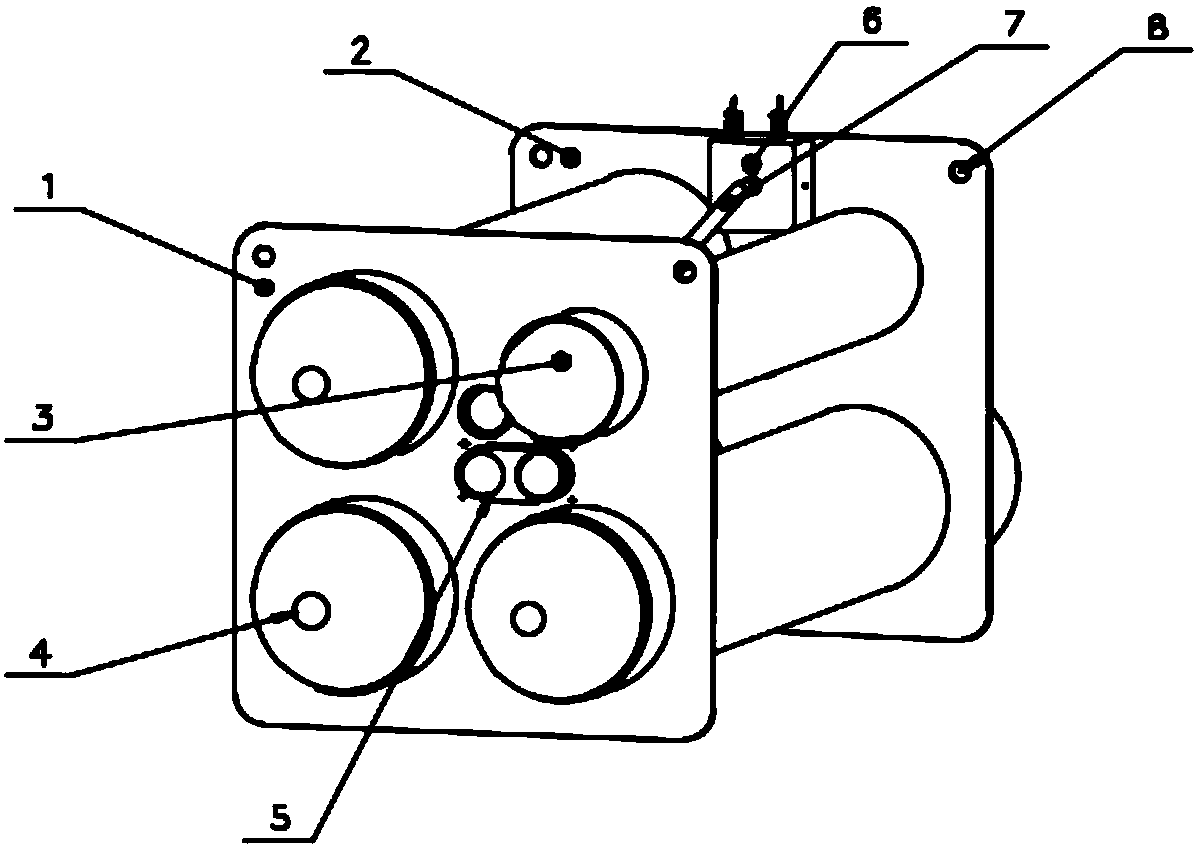

High ash fine grain coal slurry separation equipment and method

ActiveCN109759242AImprove recycling effectIncrease the probability of collisionSeparation devicesFlotationControl systemWater flow

The invention provides a high ash fine grain coal slurry separation equipment and method which areapplicable to the field of coal washing. The separation equipment comprises four parts, specifically afeeding system, a mineralization system, a separation system and a pulse water flow control system. The equipment is characterized in that a coal slurry mineralization area is separated from a separation area, and the ore separation system is internally provided with a damping block and a pulse water flow device. Flotation materials are fed into the feeding system, the size mixing operation is completed, coal slurry subjected to size mixing enters the mineralization system to be subjected to turbulent collision, mineralized bubbles are formed, the mineralized bubbles enter the separation system after passing through a disorder eliminating pipe, meanwhile the pulse water flow control system supplies the separation system with pulse water flows with certain frequency and waveform, the finecoal ash content is lowered, and the coal slurry separation selectivity is improved. Recycling of low ash coarse particles is effectively improved, high ash thin slurry carried by water flow and the thin slurry covering the surface of the particles are beneficially reduced by means of the damping block and the pulse water flow effect, and the separation selectivity is improved. The equipment has high coal slurry adaptability on different coal qualities, the separation effect is good, the separation efficiency is high, the production operation cost is low, and the economical benefit is outstanding.

Owner:CHINA UNIV OF MINING & TECH +1

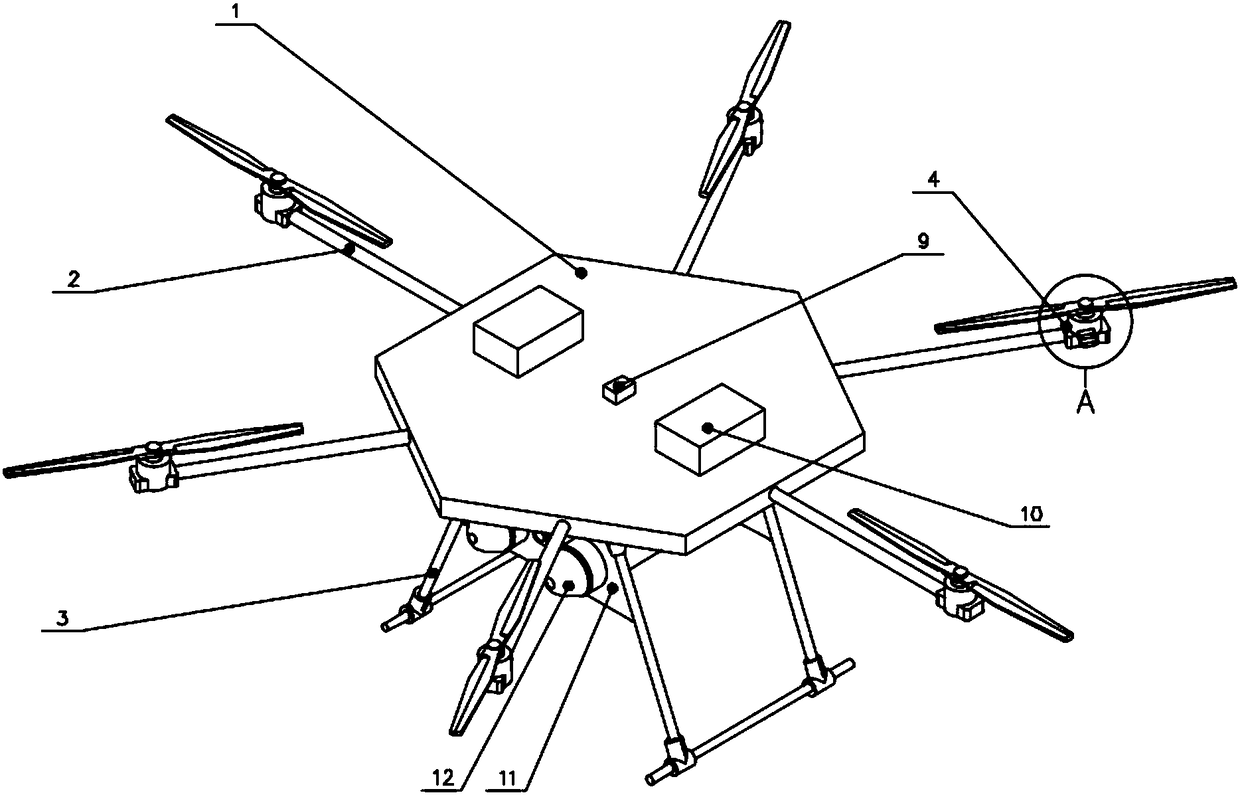

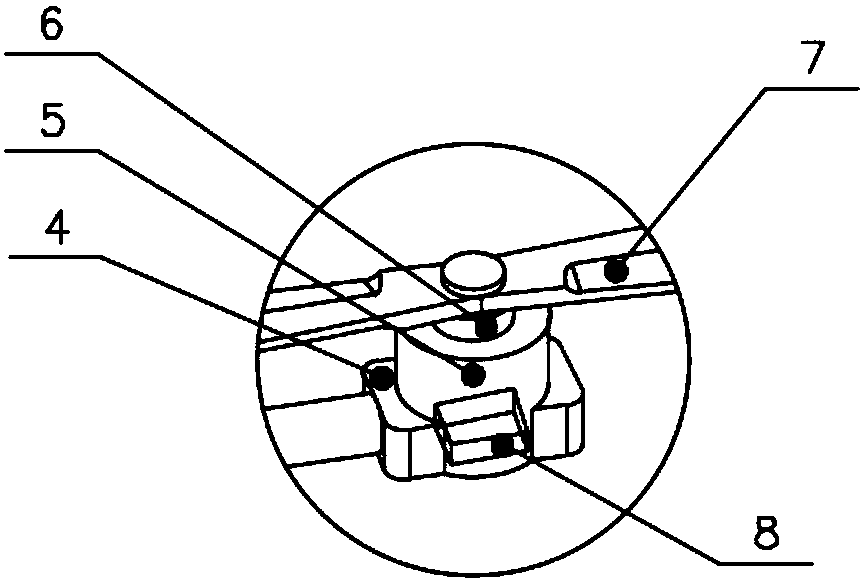

Multi-rotor fire extinguishing unmanned aerial vehicle (UAV) system

PendingCN108438221ASolve the puzzle of saving livesSolve the speed problemAircraft componentsFire rescuePropellerUncrewed vehicle

The invention relates to a multi-rotor fire extinguishing unmanned aerial vehicle (UAV) system, comprising a chassis, engine arms, an undercarriage, motor bases, motors, quick release propeller seats,propellers, a flight control system, a battery pack and a fire extinguishing pod, wherein the engine arms are installed at the periphery of the undercarriage by means of engine arm folding connectionpieces; the undercarriage is installed under a main body of the chassis by means of a connection piece; the motor bases are respectively installed at terminals of the engine arms; the motors are installed on the motor bases; an electronic speed controller is also installed on each motor base; the quick release propeller seats are respectively installed on the motors; the propellers are installedon the quick release propeller seats; the flight control system is installed at the central position of the top of the chassis; the battery pack is installed on the top of the chassis; the fire extinguishing pod is installed under the chassis and is internally filled with fire extinguishing bullets. The multi-rotor fire extinguishing UAV system has the advantages of being simple in structure, easyto manufacture, practical and efficient.

Owner:南京壹诺为航空科技有限公司

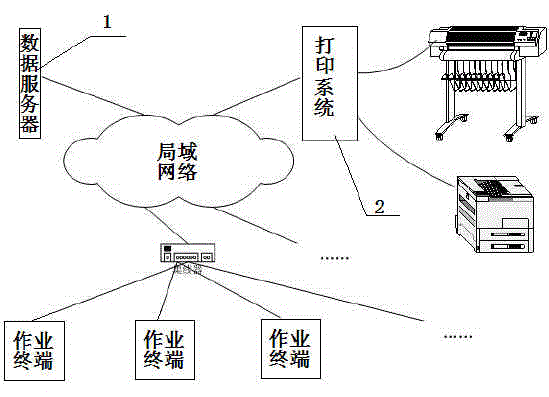

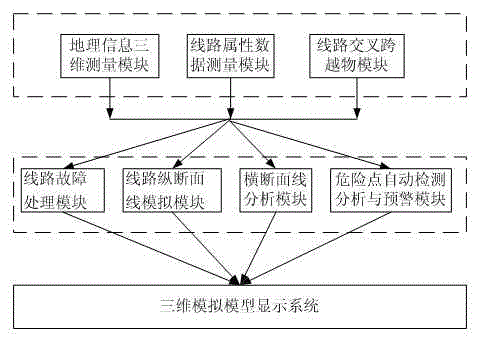

Three-dimensional visualized intelligent monitoring system for extra-high voltage transmission line

ActiveCN102946069AThree-dimensional visualization intelligent monitoring realizationRealize section analysisApparatus for overhead lines/cablesThree dimensional simulationData simulation

The invention discloses a three-dimensional visualized intelligent monitoring system for an extra-high voltage transmission line. The three-dimensional visualized intelligent monitoring system comprises an extra-high voltage transmission line data collecting system, a three-dimensional simulation model, a line data analog system and a three-dimensional simulation model display system, wherein the extra-high voltage transmission line data collecting system is used for obtaining basic geographic data along the line of an extra-high voltage direct-current transmission line and line attribute data, the three-dimensional simulation model is used for building real scenes of the extra-high voltage transmission line, and the line data analog system forms extra-high voltage transmission line monitoring signals. A three-dimensional laser radar measuring technology and a three-dimensional reverse modeling technology are adopted, a three-dimensional visualized intelligent monitoring platform is established, and three-dimensional monitoring of a direct-current extra-high voltage transmission line corridor is achieved. Automatic detection analysis and early warning of dangerous points are achieved. Cross section analysis of the line, ground feature and earth surfaces is achieved, a powerful analysis tool can be provided for overhauling, rebuilding and expanding and the like of the extra-high voltage transmission line, massive devices and channel resources are saved, share of information resources is achieved, and application of information resources is facilitated.

Owner:MAINTENANCE BRANCH OF STATE GRID CHONGQING ELECTRIC POWER +1

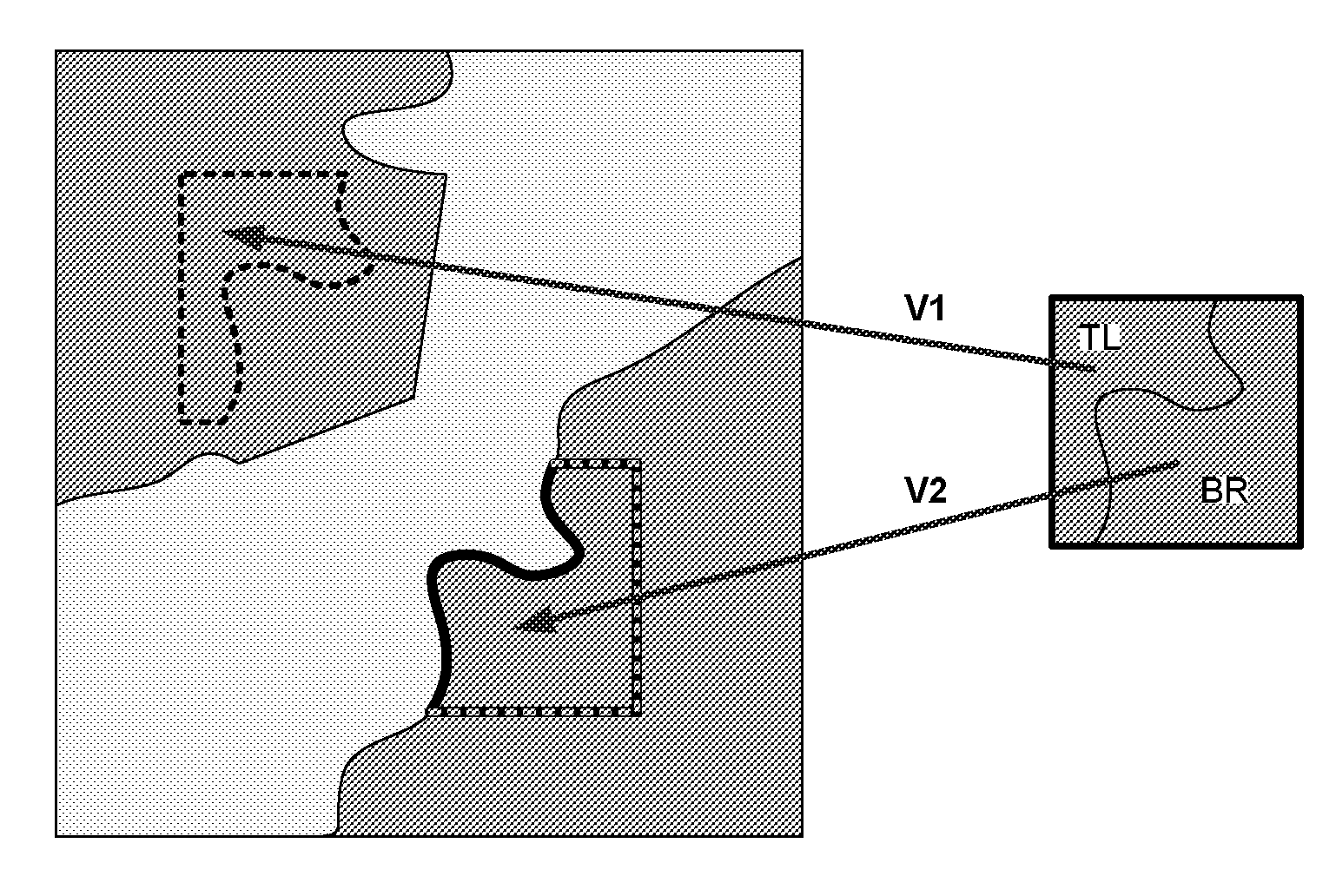

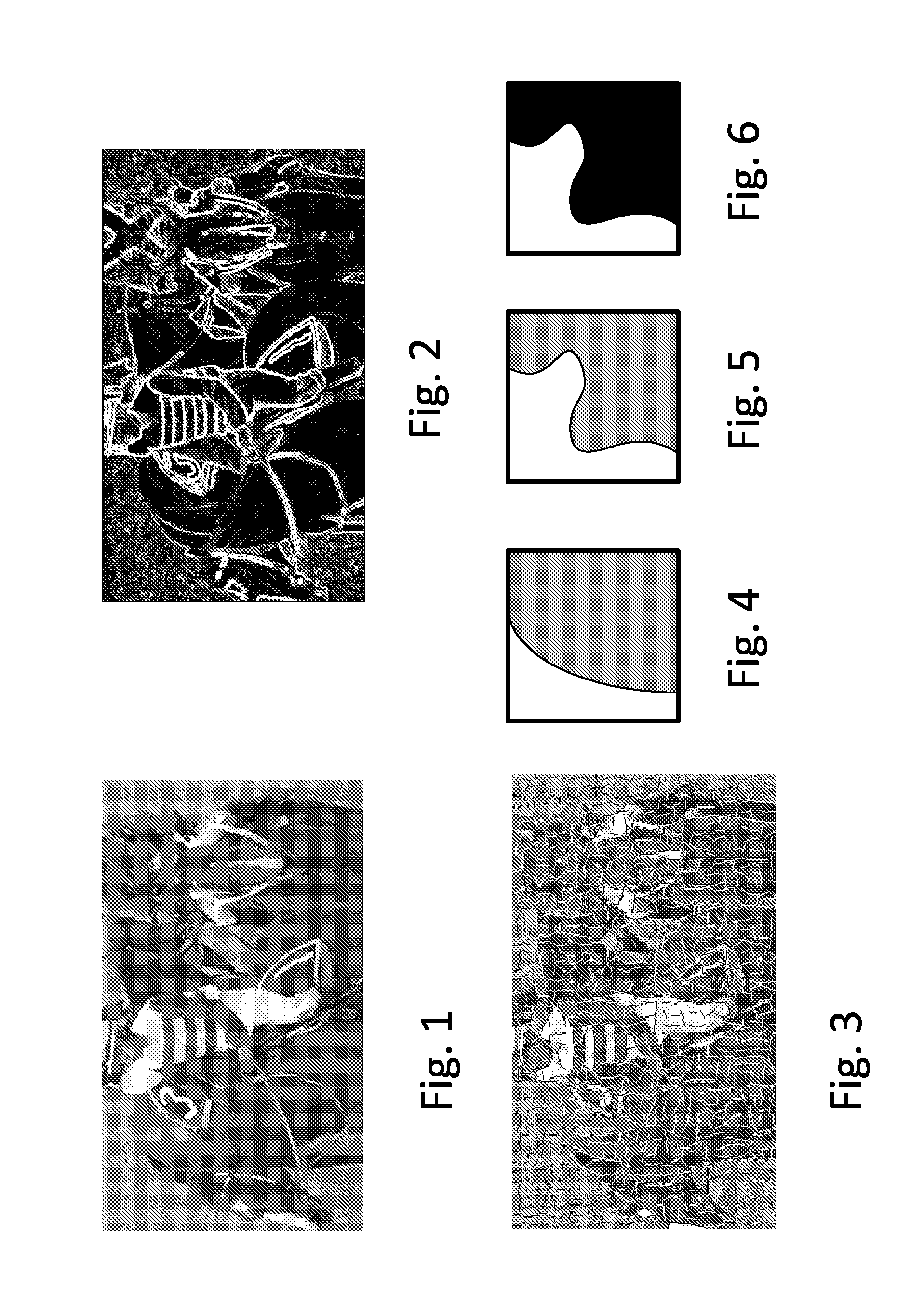

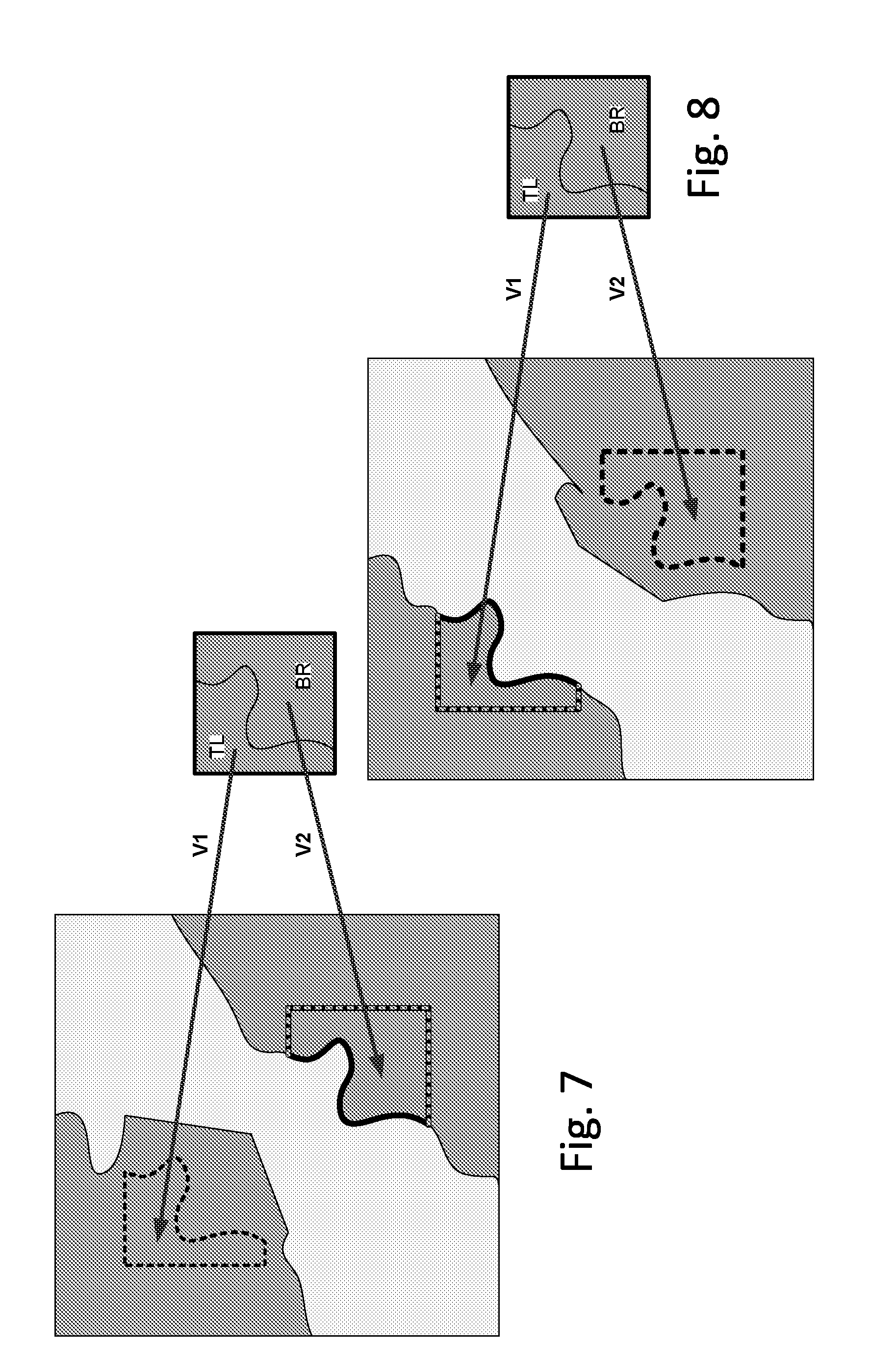

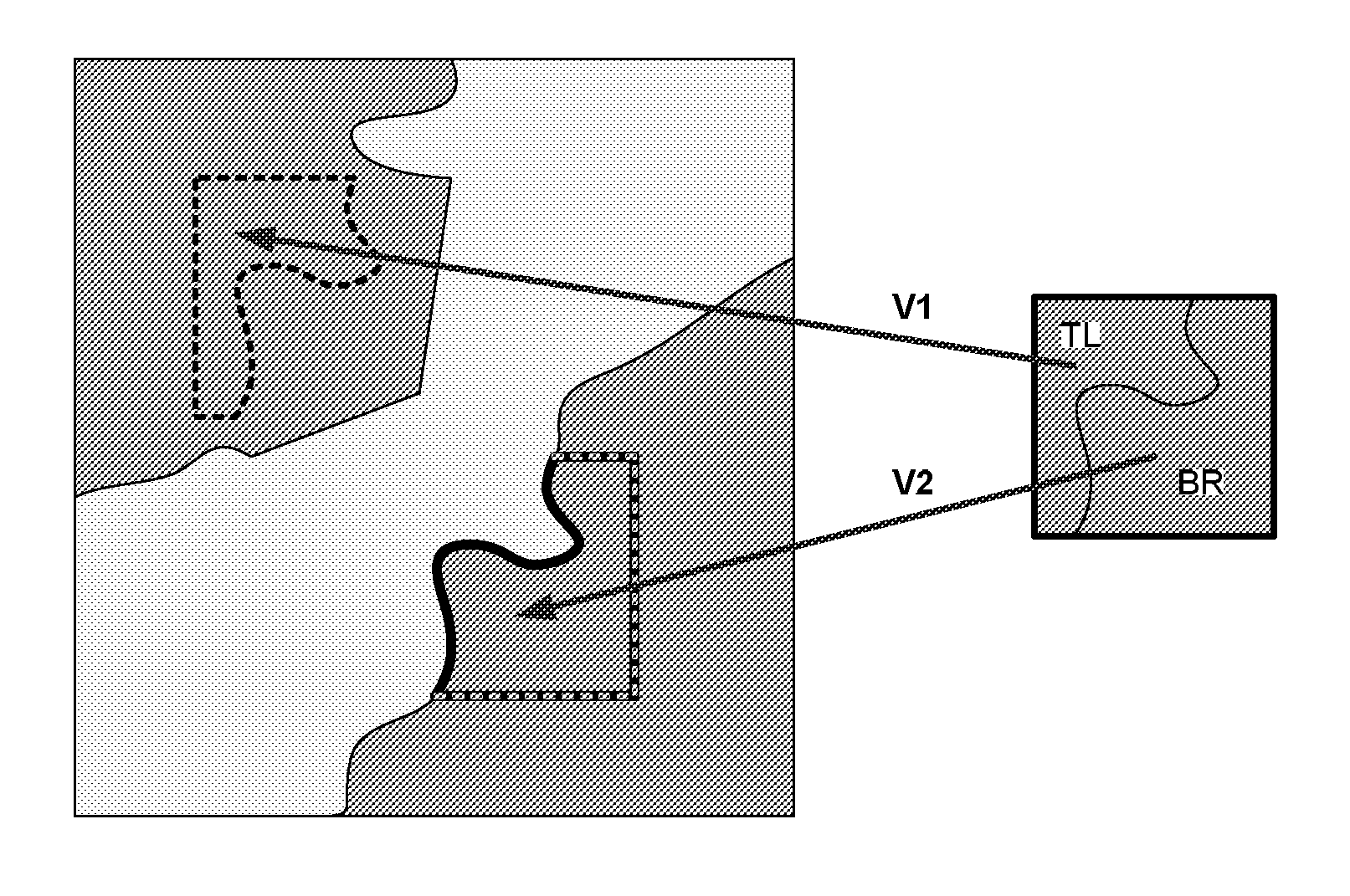

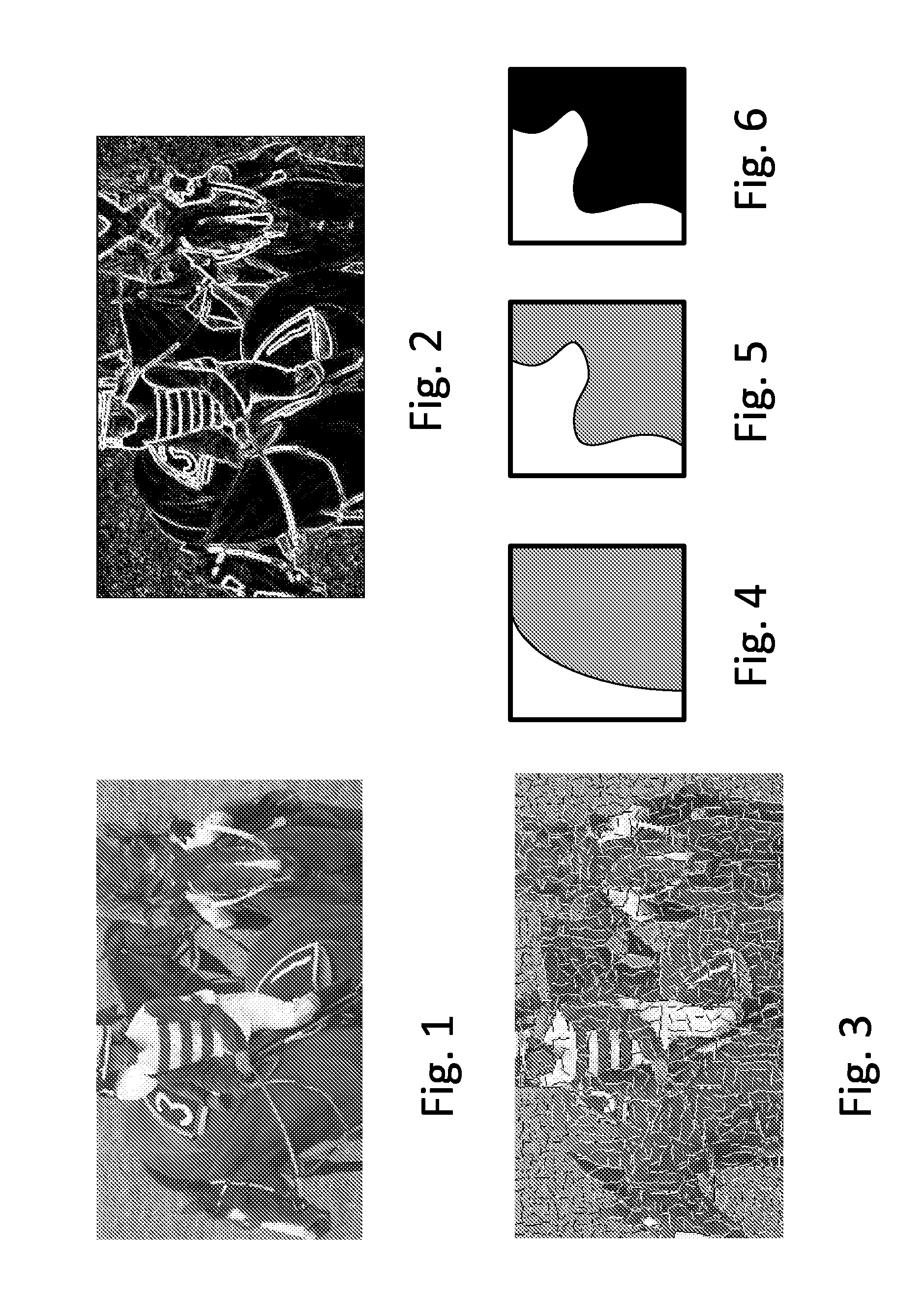

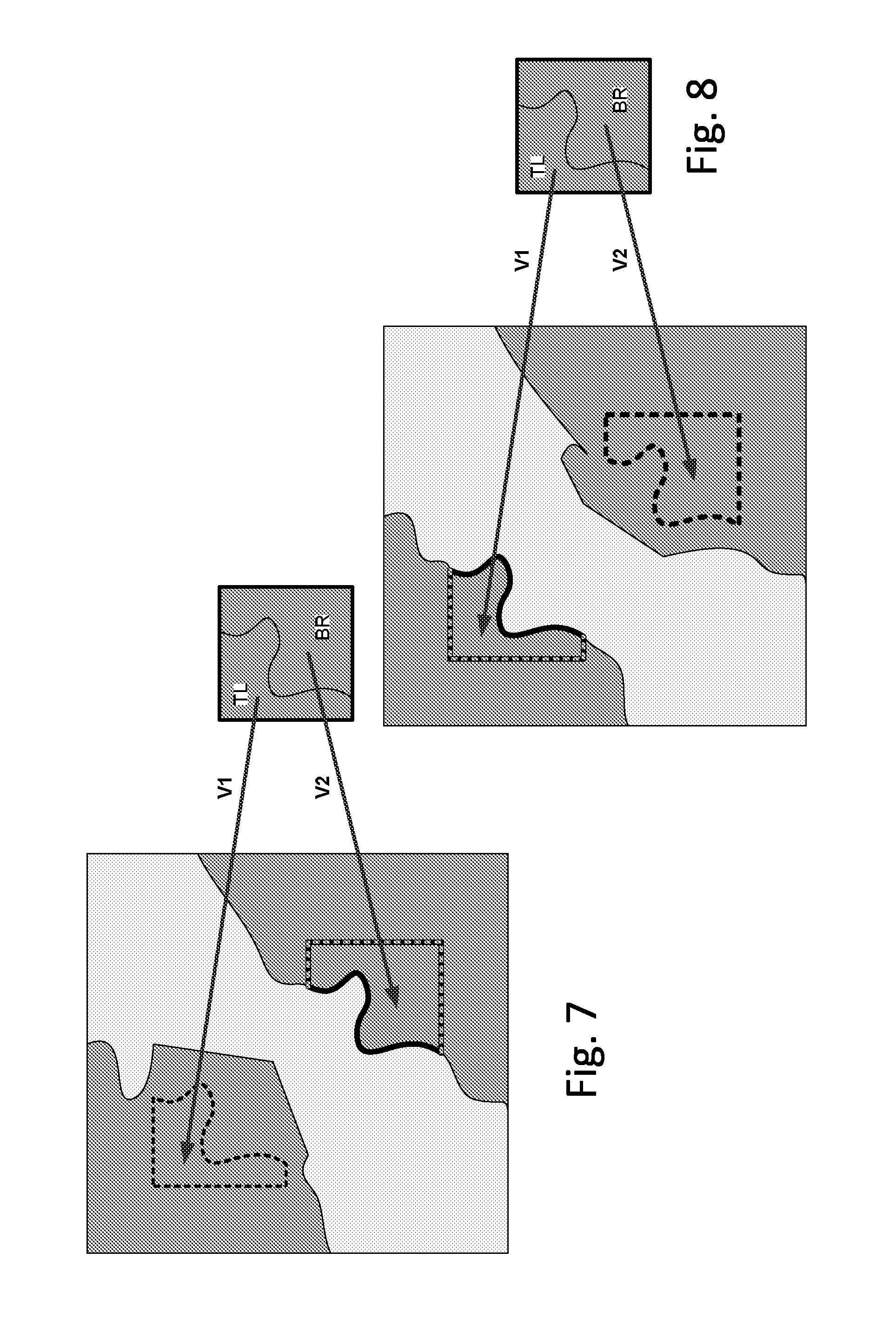

Method for reconstructing a current block of an image and corresponding encoding method, corresponding devices as well as storage medium carrying an images encoded in a bit stream

ActiveUS20130208982A1Reduce coding costsAdvanced principleImage codingCharacter and pattern recognitionMotion vectorReference block

Owner:INTERDIGITAL MADISON PATENT HLDG

Testing method for dynamic modulus of bituminous mixture

InactiveCN105203414AFix location issuesAdvanced principleMaterial strength using repeated/pulsating forcesRoad surfaceEngineering

The invention discloses an indoor testing method for dynamic modulus of a bituminous mixture. The method comprises the following steps that 1, a track forming instrument is used for manufacturing a track plate, and trapezoidal test pieces of the fixed size are cut out from the track plate; 2, the lower bottoms of the trapezoidal test pieces are fixed to a base, the upper bottoms are fixed to a protecting crown, and the test pieces are placed at the testing temperature for heat preserving for at least 4 hours; 3, two testing pieces fixed well in one group are taken and installed onto loading equipment, the base is fixed, the protecting crown is connected with a horizontal loading rod, and the loading rod exerts continuous sine horizontal loads at different frequency and strain levels on the tops of the test pieces; 4, in the loading process, corresponding stress and strain parameters are collected, and the dynamic modulus is calculated. The trapezoidal test pieces are used, the single-point loads are exerted on the ends of the test pieces, bending, pulling and shearing comprehensive stress is generated in the test pieces, real stress situation of a pavement structure can be effectively simulated, the principles are advanced, and the testing method is easy to operate and convenient to popularize.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Extracorporeal blood processing information management system

InactiveUS20060052949A1Simplified donor data storageEasy to controlMechanical/radiation/invasive therapiesOther blood circulation devicesBlood componentCollection system

A blood component collection system with manipulation and optimization capabilities. Process parameters are derived from an input / configured predetermined blood component yield and which is based upon the maximization of at least one process parameter. Thereafter, the blood component collection procedure is performed with these derived process control parameters. Also, process parameters are derived from an input total procedure time from a maximized value for at least one of the other process control parameters so as to maximize blood component yield in this fixed time. Thereafter, the blood component collection procedure is performed with these derived parameters.

Owner:GAMBRO

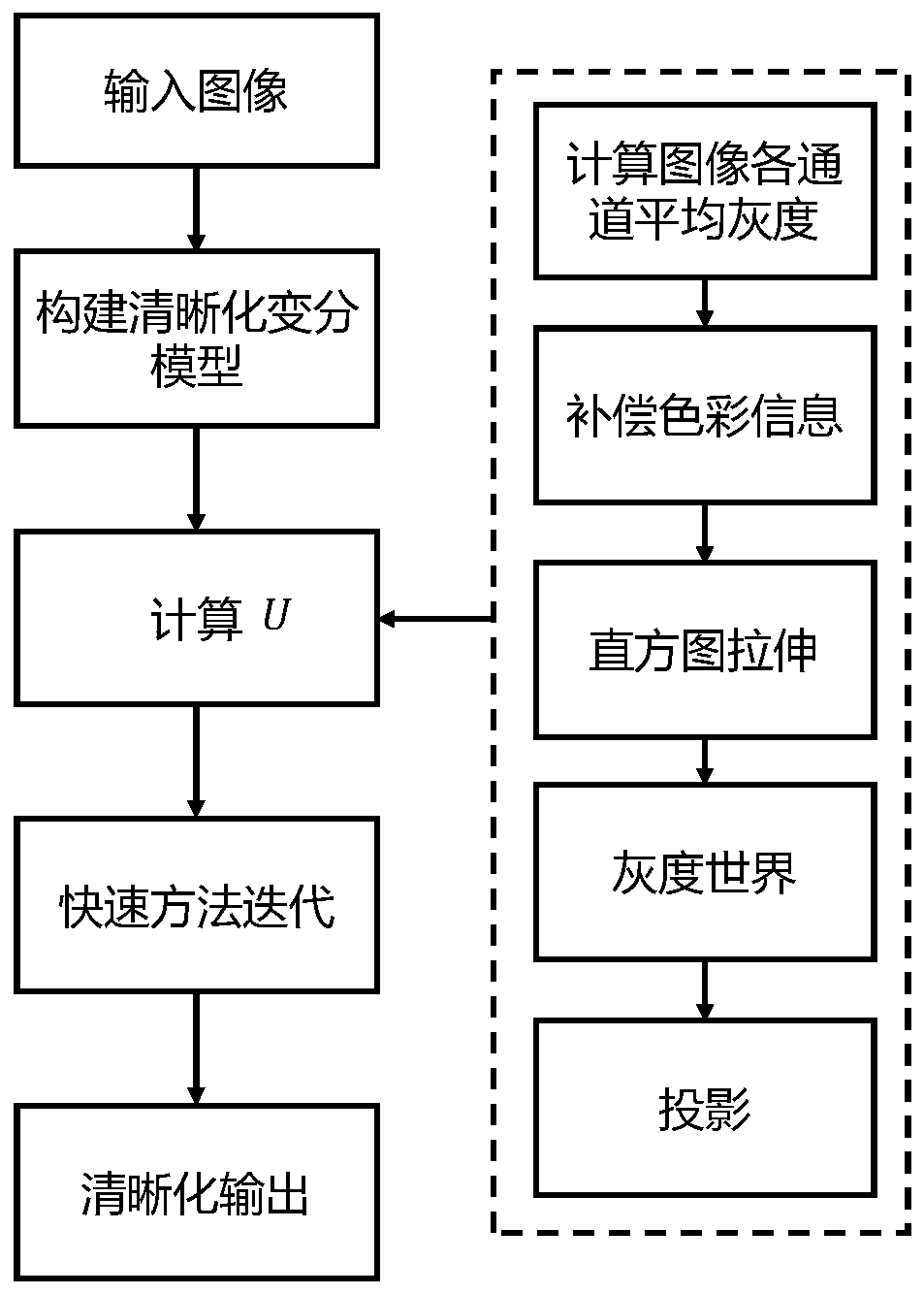

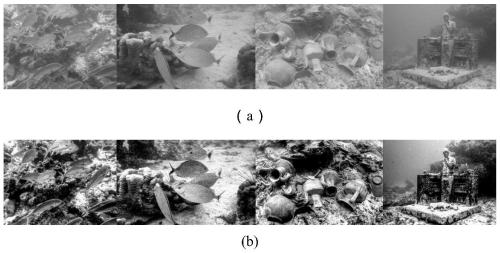

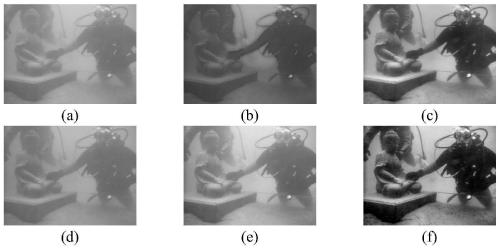

Underwater image sharpening enhancement method

ActiveCN111462022AEffective correctionImprove clarityImage enhancementImage analysisColor correctionRadiology

The invention belongs to the technical field of digital image processing, and relates to an underwater image sharpening enhancement method. A color correction strategy and a contrast enhancement strategy are combined to execute a sharpening process of an underwater image, the color correction strategy is used for eliminating attenuation difference caused by propagation attributes of light in a medium or artificial illumination and improving the color cast problem, and the contrast enhancement strategy is used for improving the contrast so as to eliminate the atomized appearance of the image and expose more scene details. The method is simple, the principle is scientific and reliable, the detectable image structure characteristics can be effectively increased, the underwater image definition is enhanced, the variational framework has good coupling, and the method can be combined with other technologies or used as a preprocessing step to be widely applied to the field of computer vision.

Owner:QINGDAO UNIV

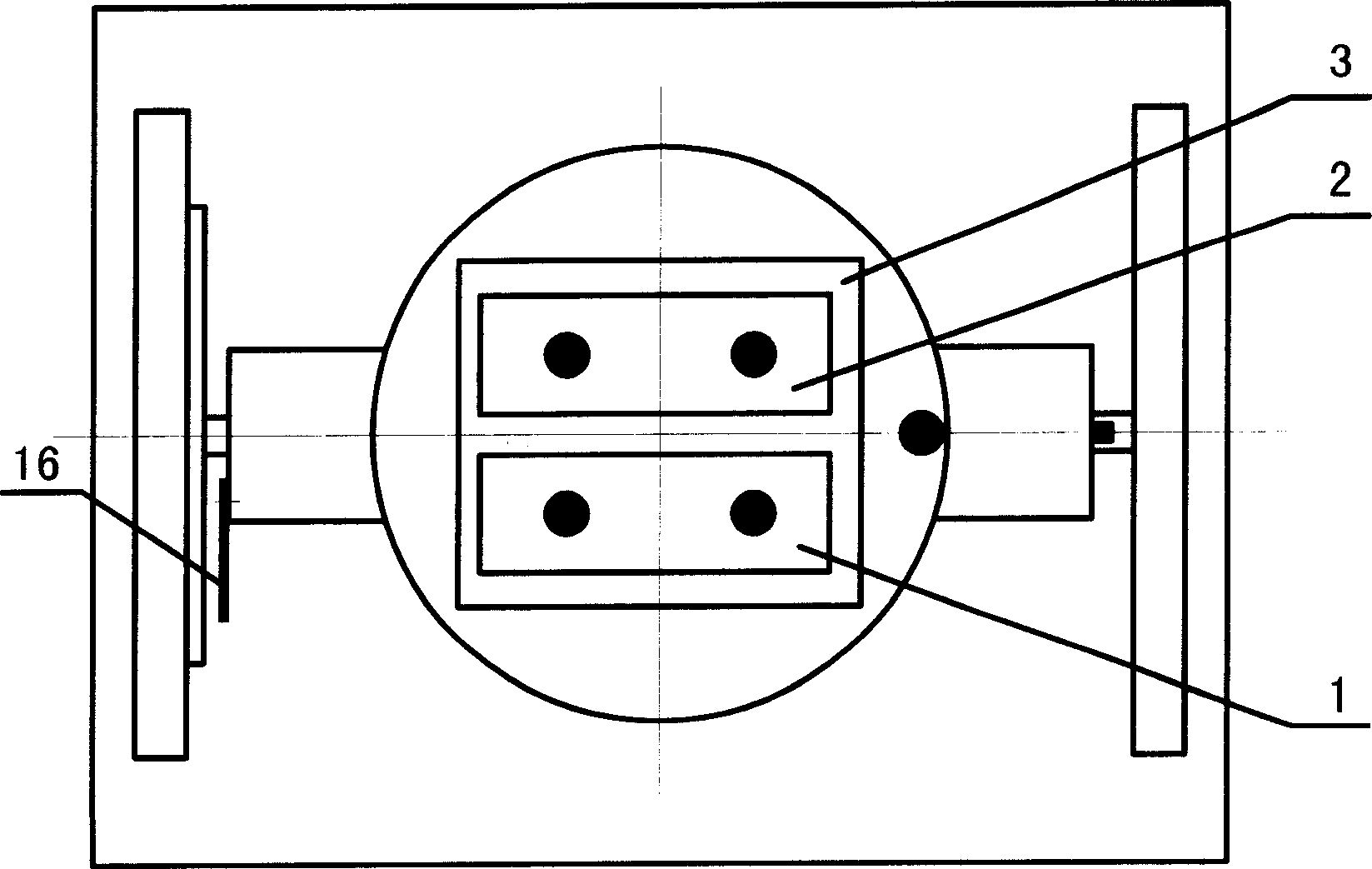

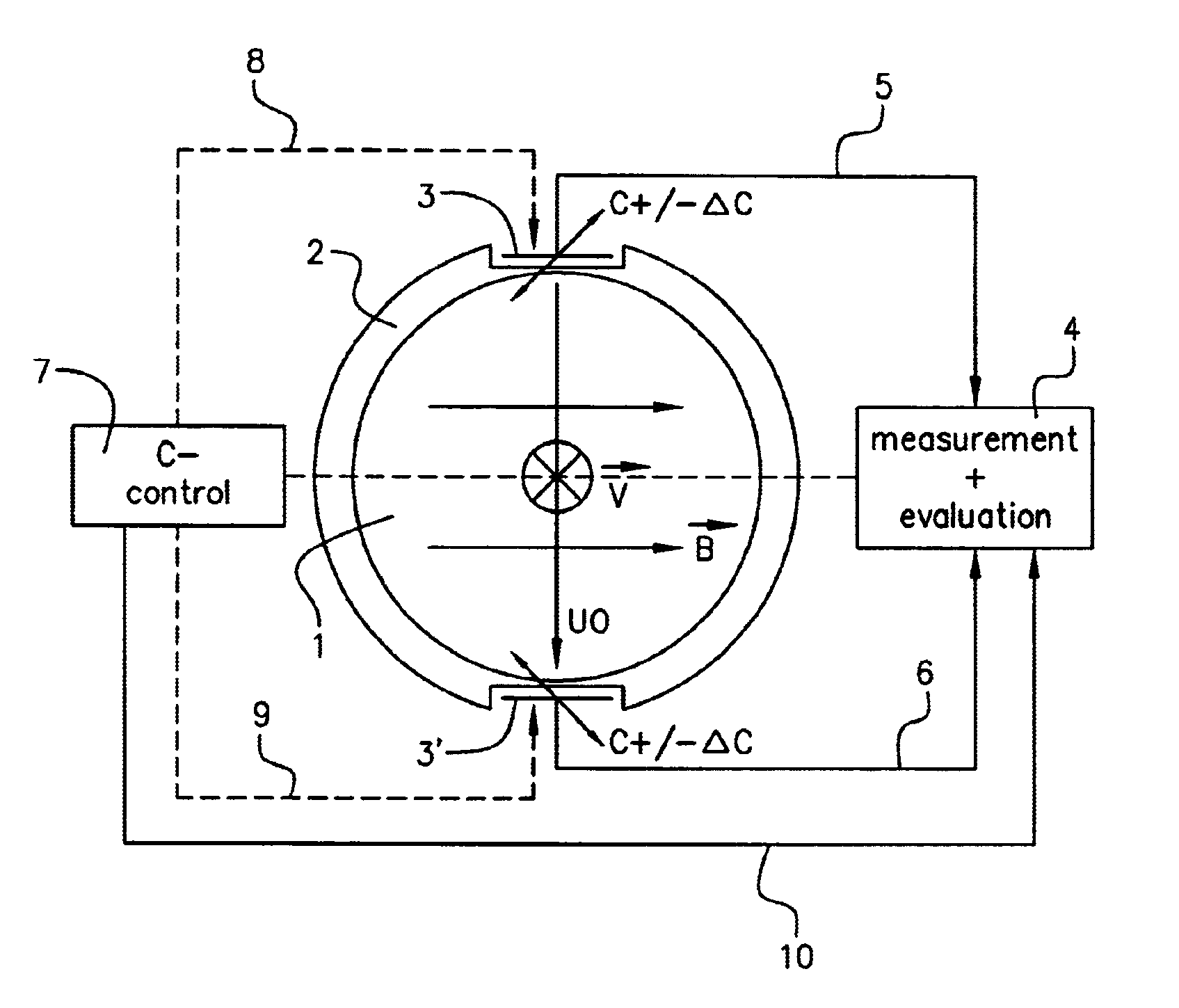

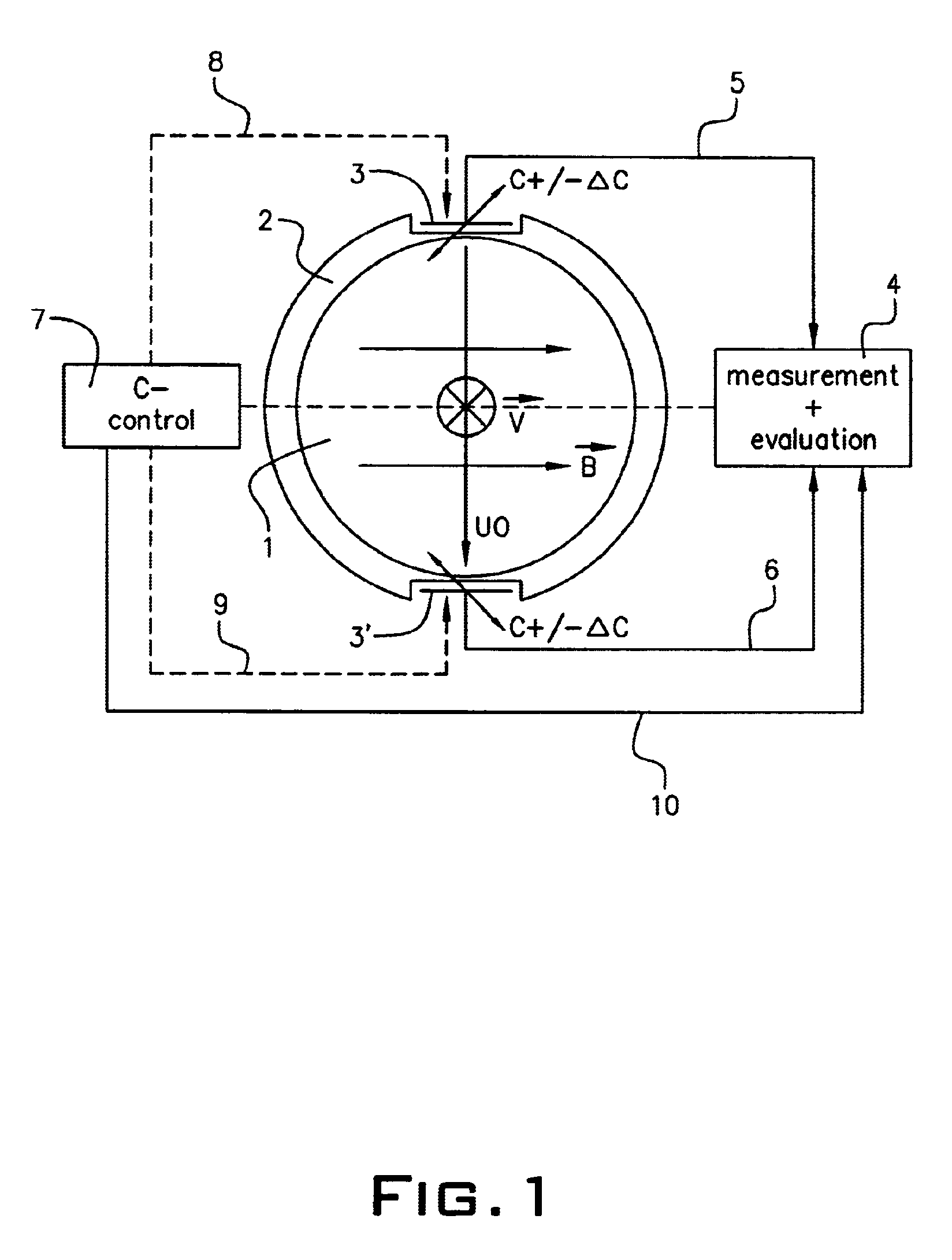

Method for measuring a medium that flows through a measuring tube

InactiveUS7028558B2Maximum sensitivityExcellent operationVolume/mass flow by electromagnetic flowmetersPhysicsCapacitance

A method for measuring a flow rate of a medium through a measuring tube which is penetrated by a constant magnetic field orthogonal to a flow direction and in which an electrical voltage building up in the medium is sensed by electrodes, insulted with respect to the medium and located on an outer wall of the measuring tube in a plane orthogonal to the flow direction of the medium, in which the capacitance of at least one capacitive unit is formed by the electrodes, and a measuring tube interior area and a charge change brought about by a change to the at least one capacitive is determined, and from this a voltage is established which is determinative of the flow rate of the medium through the measuring tube.

Owner:ZYLUM BETEILIGUNGSGMBH & PATENTE II

Garbage refinement pretreatment system and method for garbage incineration power plant

InactiveCN109489043AHigh fuel valueRealize sortingMagnetic separationIncinerator apparatusPower stationMagnetic separator

The invention discloses a garbage refinement pretreatment system and a method for a garbage incineration power plant, comprising a garbage storage pool and a sorting system, wherein the sorting systemcomprises a bag breaking machine, an intelligent sorting platform, a crusher and an extruder; a slurry outlet of the extruder is sequentially connected with a slurry pool and an oil-water separator;a solid outlet of the extruder is connected with a bouncing sieving machine; an oversize product outlet of the bouncing sieving machine is sequentially connected with a first magnetic separator, a first sorting machine, a disc sieving machine and a second sorting machine; the combustible material outlet of the second sorting machine is connected with a combustible storage bin; a screen underflow outlet of the bouncing sieving machine is sequentially connected with a second magnetic separator and a star disc sieving machine, and the combustible material outlet of the star disc sieving machine is connected with the combustible material storage bin. The pretreatment technology adopted by this system has advanced principle, good sorting effect; the sorting combustible material has high heat value and high single-line treatment capacity; therefore the pretreatment technology is a more optimized, more suitable, more economical and more reliable garbage refinement pretreatment technology.

Owner:QUJING YUNDIAN TOUXIN ENERGY POWER GENERATION

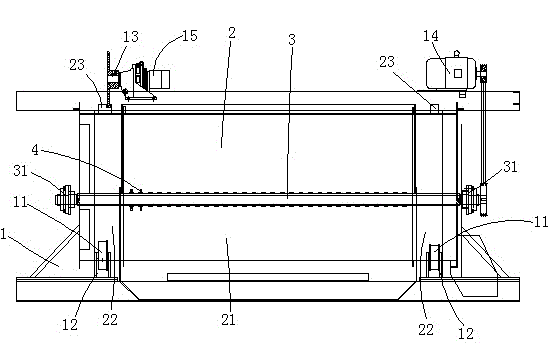

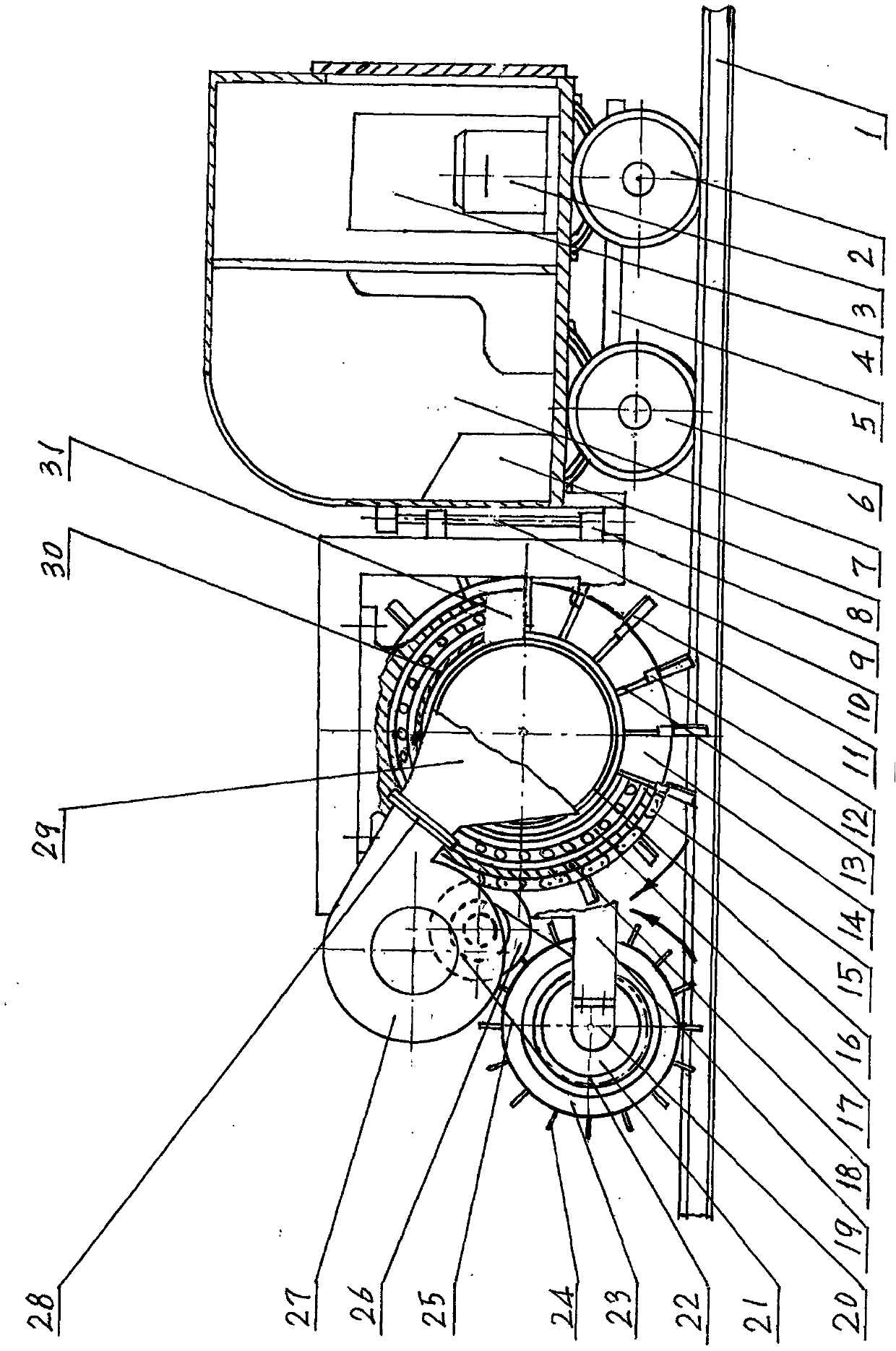

Garbage screening machine with flail knife crushing function

ActiveCN103551368AImprove crushing effectStrong crushingSievingSolid waste disposalRotational axisKinematics

The invention discloses a garbage screening machine with a flail knife crushing function. The garbage screening machine comprises a rack body, a rotary roller screen and a crushing rotary shaft, wherein supporting wheels are arranged on a bottom side plate of the rack body; the rotary roller screen is placed above the supporting wheels; a working cavity is formed in the middle of the rotary roller screen; the crushing rotary shaft penetrates into the working cavity of the rotary roller screen; the rotation direction of the crushing rotary shaft is opposite to that of the rotary roller screen; a flail knife assembly is arranged on the crushing rotary shaft; crushing blades are arranged on the flail knife assembly; two ends of the crushing rotary shaft are respectively provided with a rotary shaft seat; the rotary shaft seats are assembled on the rack body. The garbage screening machine adopts a dual-action mode of opposite shaft screen rotation, is high in material crushing capacity and good in crushing effect, adopts a flail knife crushing mode and adopts a principle of inertial kinematics in physics; the rotary roller screen is independently adopted, and screen holes in the rotary roller screen can be prevented from being blocked; by arranging a water spraying pipe, double effects of cleaning the wall surface of the rotary roller screen and cleaning materials are achieved; the viscosity of the materials is reduced, and the materials are convenient to crush.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

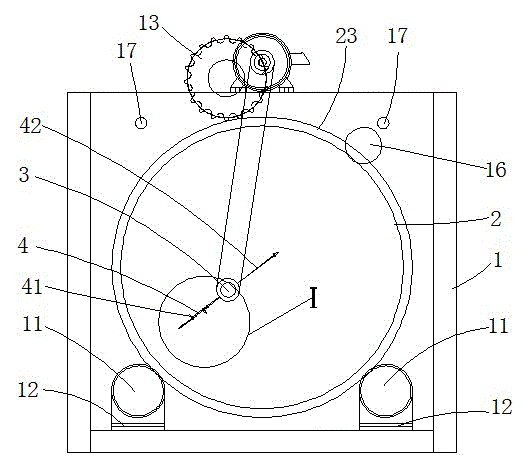

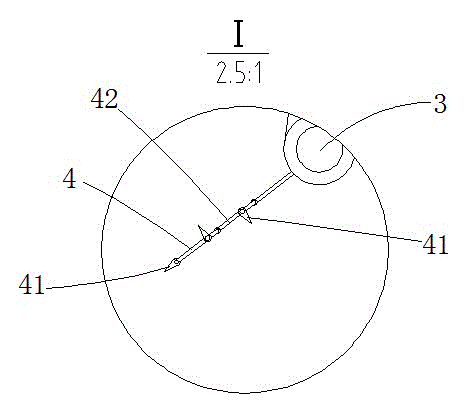

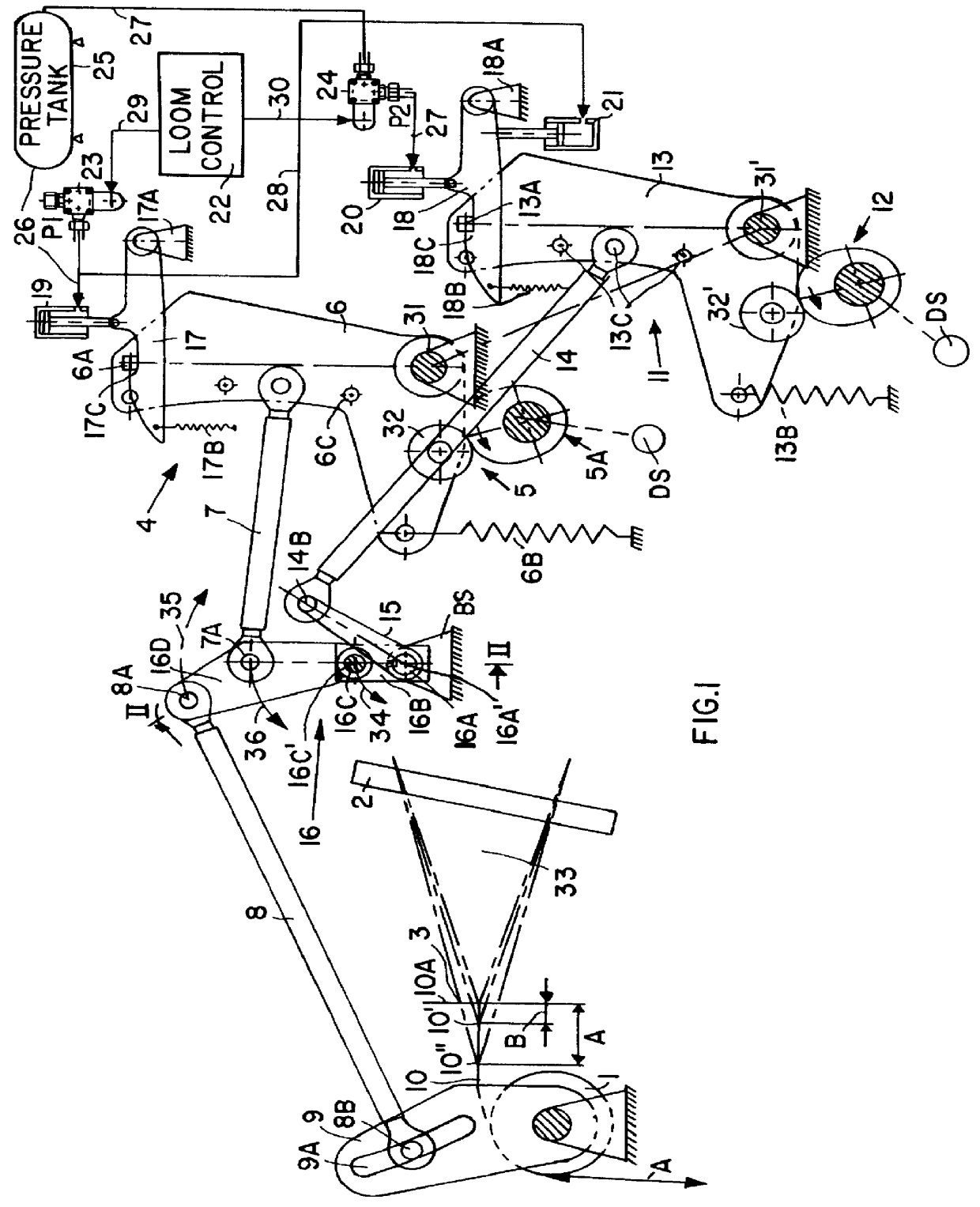

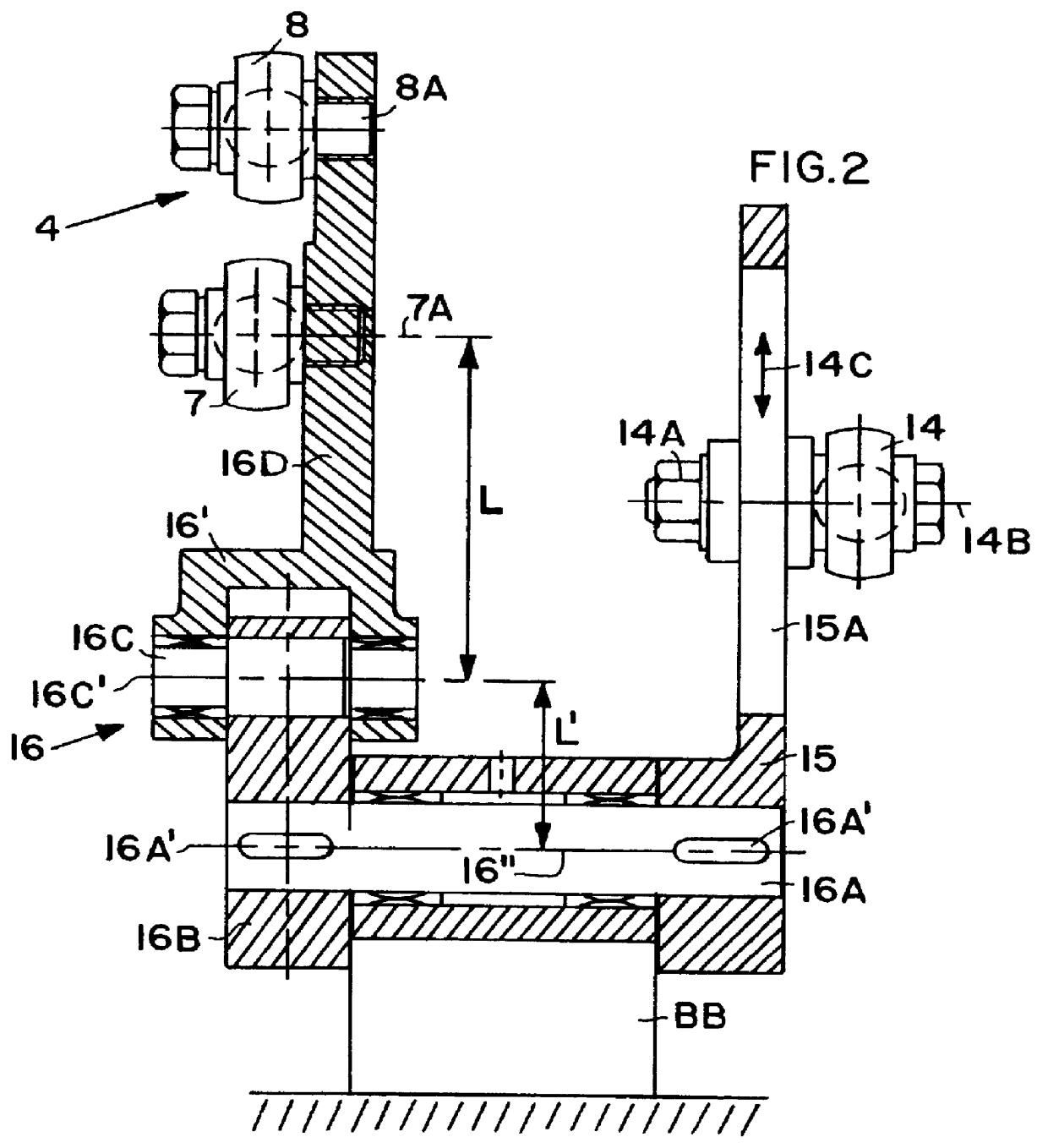

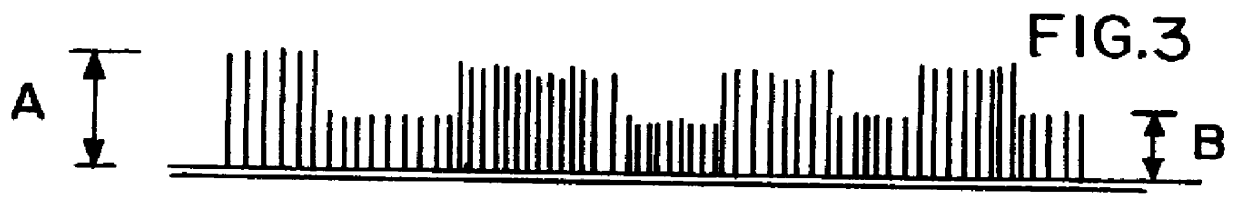

Method and loom for weaving first and/or second pile lengths while weaving terry fabric

Two different pile heights (a, b) can be selectively formed during the weaving of terry fabric on a loom by shifting the fabric with its actual beat-up line (10a) back and forth relative to a base beat-up line (3). First and second fabric shifting oscillating motions are performed by first and second power or motion transmission couplings (4, 11) driven through eccentric drives (5, 12) from a main loom drive shaft (DS) and controlled through valves by a central loom control (22) in such a way that a second oscillation with a different amplitude is superimposed on a first oscillation between beat-up groups of weft beat-up motions including partial weft beat-ups and a full weft beat-up motion of a reed (2) in the loom. Different oscillation amplitudes cause a beat-up line shift of different length (a or b) whereby different pile heights are formed.

Owner:LINDAUER DORNIER GMBH

Airborne firefighting fire-extinguishment pod for unmanned aerial vehicle

PendingCN108128456AImprove versatilityAccurate calculationAircraft componentsFire rescueUncrewed vehicleTest measurement

The invention relates to an airborne firefighting fire-extinguishment pod for an unmanned aerial vehicle. The airborne firefighting fire-extinguishment pod for the unmanned aerial vehicle comprises afront connection plate, a rear connection plate, launch canisters, a dual-optical sighting device and a control box. The front connection plate and the rear connection plate are oppositely arranged, provided with first mounting holes and connected to an unmanned aerial vehicle platform through the first mounting holes. The launch canisters are mounted between the front connection plate and the rear connection plate. The dual-optical sighting device is mounted on the front connection plate, and the control box is mounted on the rear connection plate and electrically connected with the dual-optical sighting device through a connection cable. The dual-optical sighting device in the airborne firefighting fire-extinguishment pod for the unmanned aerial vehicle can indicate a target fire sourceaccurately and prompts a ground operator to launch a fire-extinguishment bomb at the right time according to a post-back video image, and the pod can receive a ground launch control instruction to launch the fire-extinguishment bomb reliably; and through test measurement, the impact point is deviated from the center of the fire source by 0.5 m or below.

Owner:江苏天域航空科技集团股份有限公司

Railway ice and snow removing car and method

PendingCN110130265AAdvantages of deicing and snow removal vehiclesMerit methodRailway cleaningEngineeringIce accretion

The invention discloses a railway ice and snow removing method. The railway ice and snow removing method comprises the steps: a railcar provided with wheels matched with a rail and used for providingdriving force is placed on a railway; a frame body is mounted at the front end of the railcar, and thus the frame body can travel along the rail under the effect of the driving force of the railcar; when the frame body travels along the rail, accumulated snow and accumulated ice on the railway are shoveled away through a snow shoveling device mounted on the frame body; the accumulated snow and theaccumulated ice which are shoveled away by the snow shoveling device are collected through a flow guiding pipe mounted on the frame body; and through a snow spraying device mounted on the frame body,the accumulated snow and the accumulated ice which enter the flow guiding pipe are conveyed out from the air outlet end of the flow guiding pipe. According to the railway ice and snow removing method, the wild snow and the solid snow on the railway can be removed, the accumulated ice on the rail can also be removed, the ice and snow removing efficiency is high, and fast traffic is facilitated. Inaddition, the invention further provides the railway ice and snow removing car.

Owner:极地雪龙环境技术有限公司

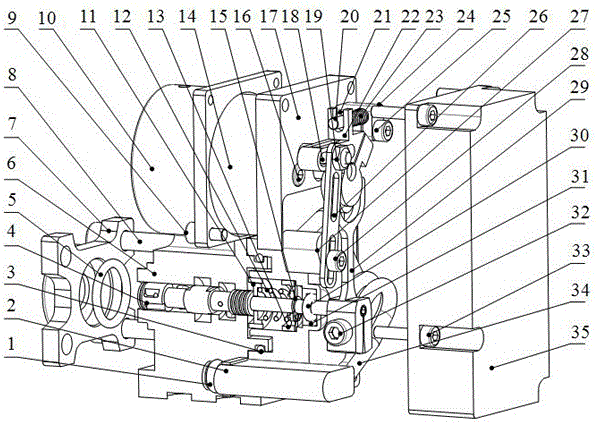

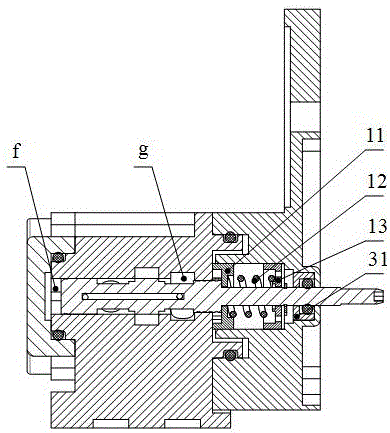

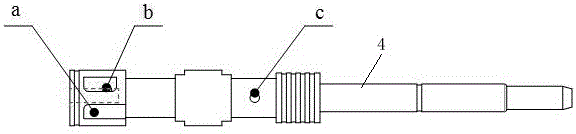

Bourdon tube force feedback type 2D electrical-hydraulic pressure servo valve

ActiveCN106438551AImprove anti-pollution performanceCompact structureOperating means/releasing devices for valvesServomotor componentsElectricityClosed loop feedback

The invention relates to a bourdon tube force feedback type 2D electrical-hydraulic pressure servo valve. The bourdon tube force feedback type 2D electrical-hydraulic pressure servo valve is characterized by comprising a valve body module, an electrical-mechanical converter module, a transmission mechanism module and a bourdon tube feedback module; the bourdon tube feedback module is matched with the valve body module and the electrical-mechanical converter module; the electrical-mechanical converter module is matched with the valve body module through the transmission mechanism module; and the bourdon tube feedback module monitors the displacement of a valve core in the valve body module and an electrical signal of a rotary electromagnet of the electrical-mechanical converter module in real time, and closed loop feedback is formed. The deflection angle of the rotary electromagnet is controlled through the magnitude of input currents, thus the deflection angle of the valve core is changed, the axial movement distance is achieved through the 2D valve core, so that the opening size of a control valve is controlled, and control over outlet pressure is achieved. Structurally, an original two-level or multilevel structural form is simplified greatly, and the requirements for industrial simplicity and compactness are met.

Owner:ZHEJIANG UNIV OF TECH

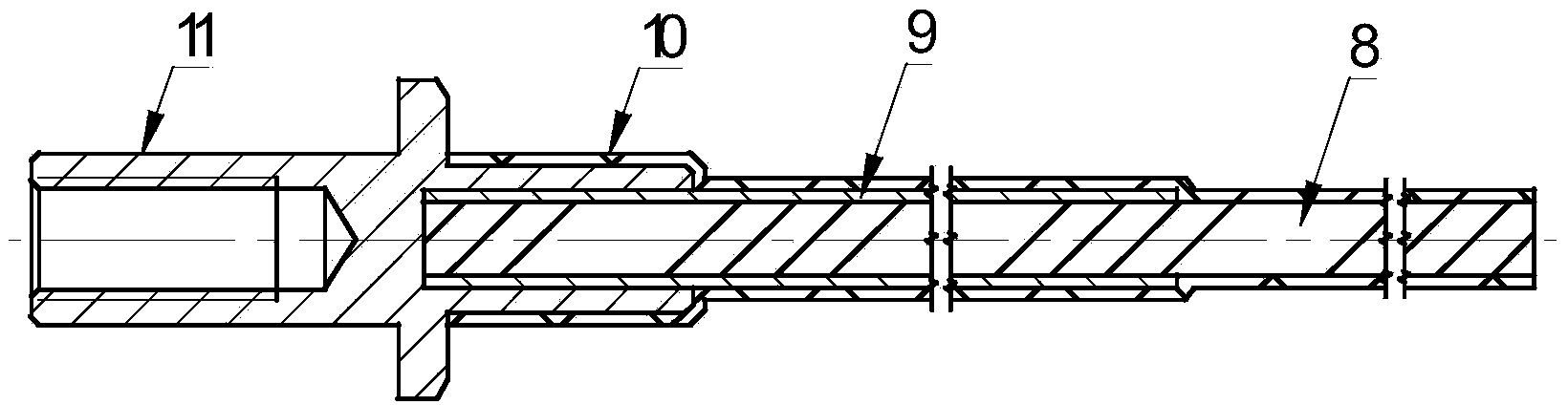

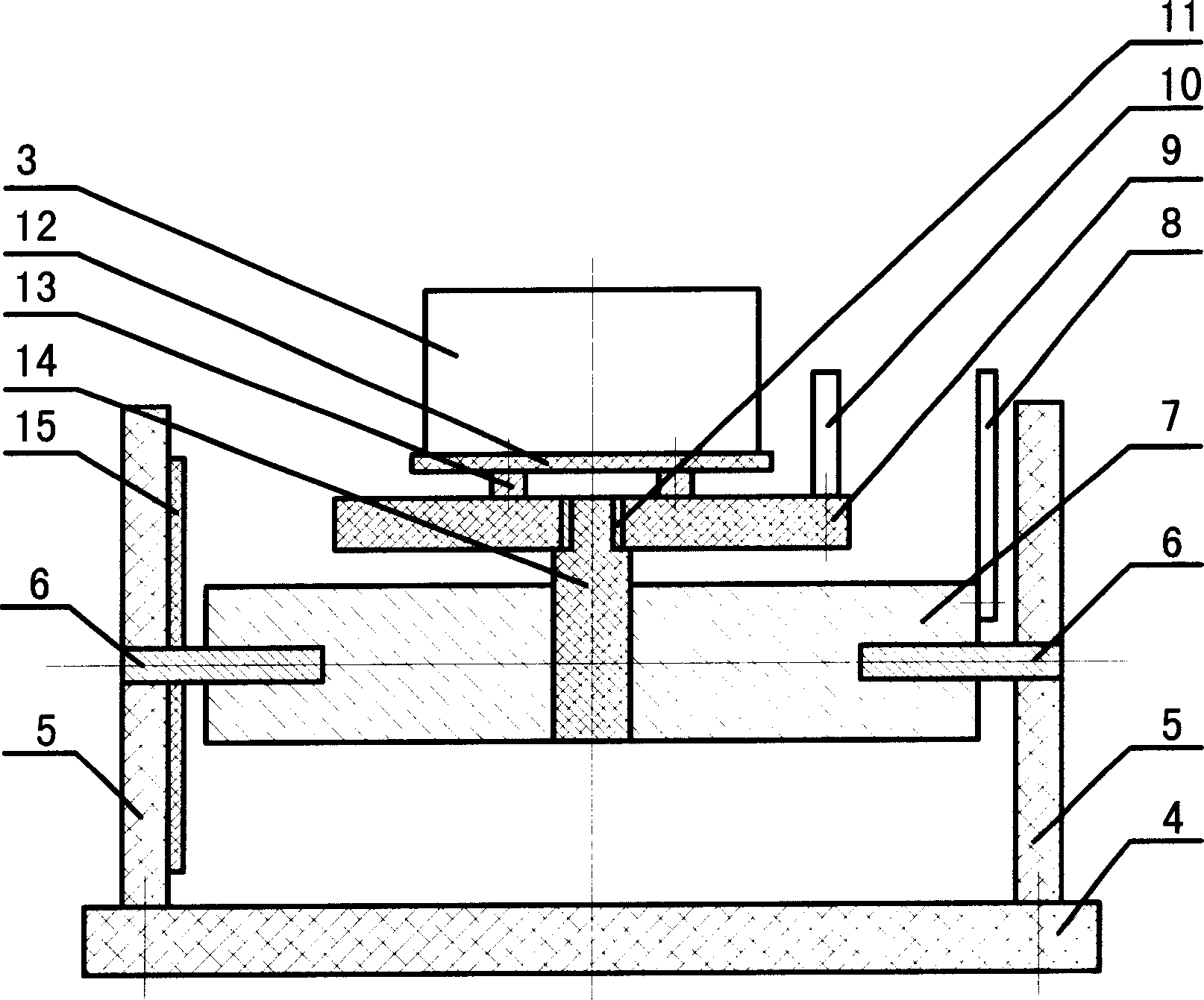

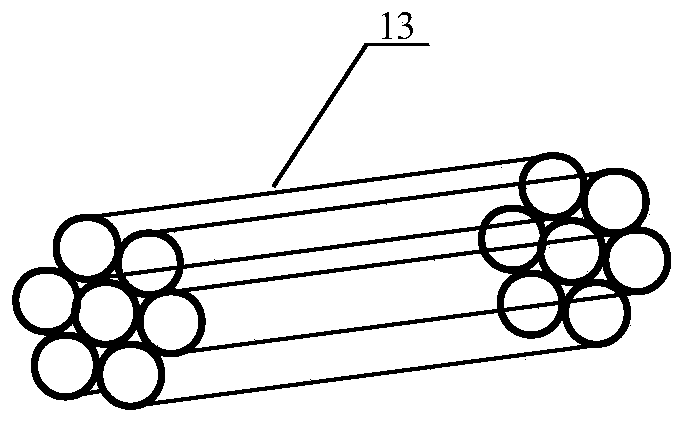

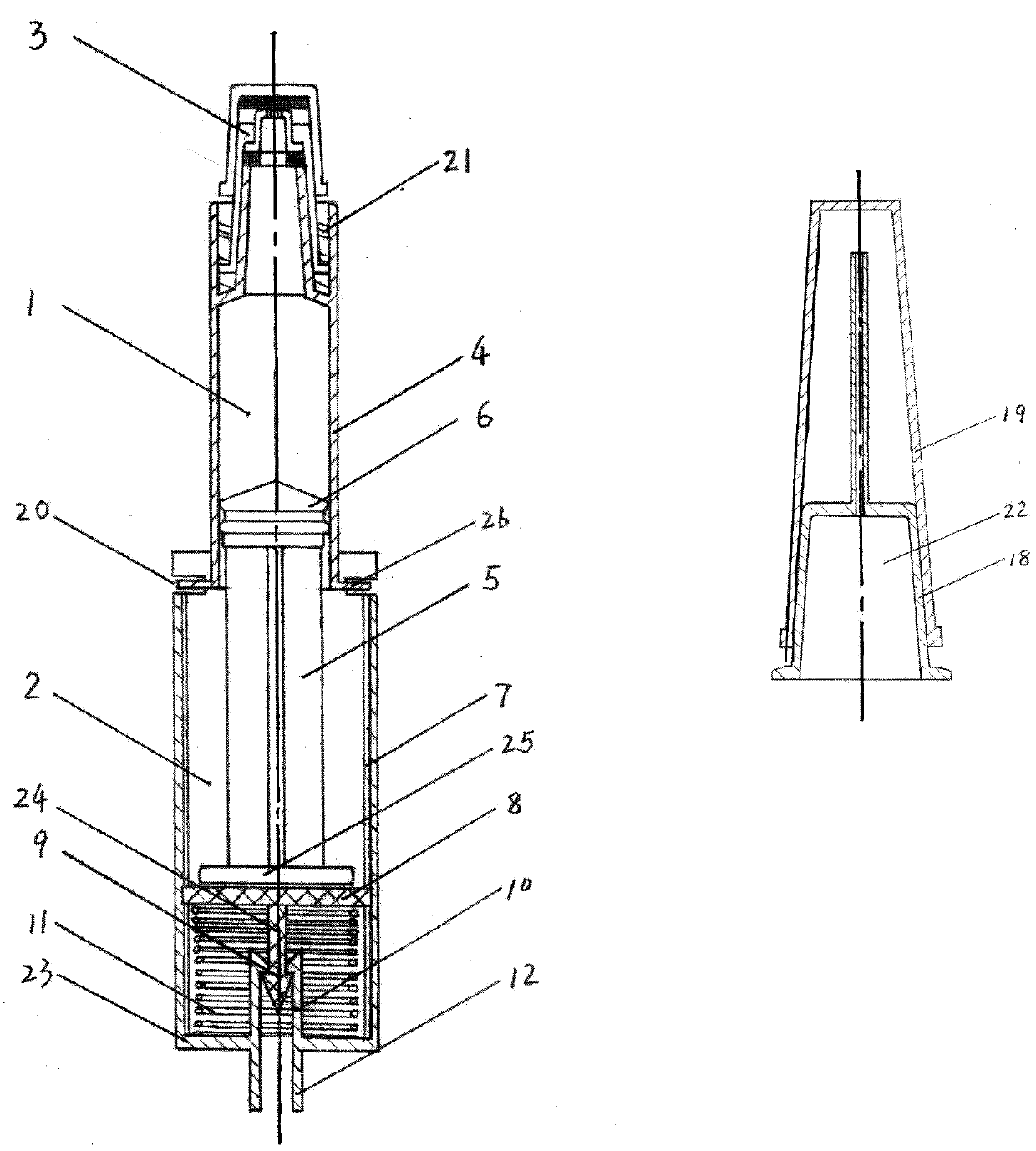

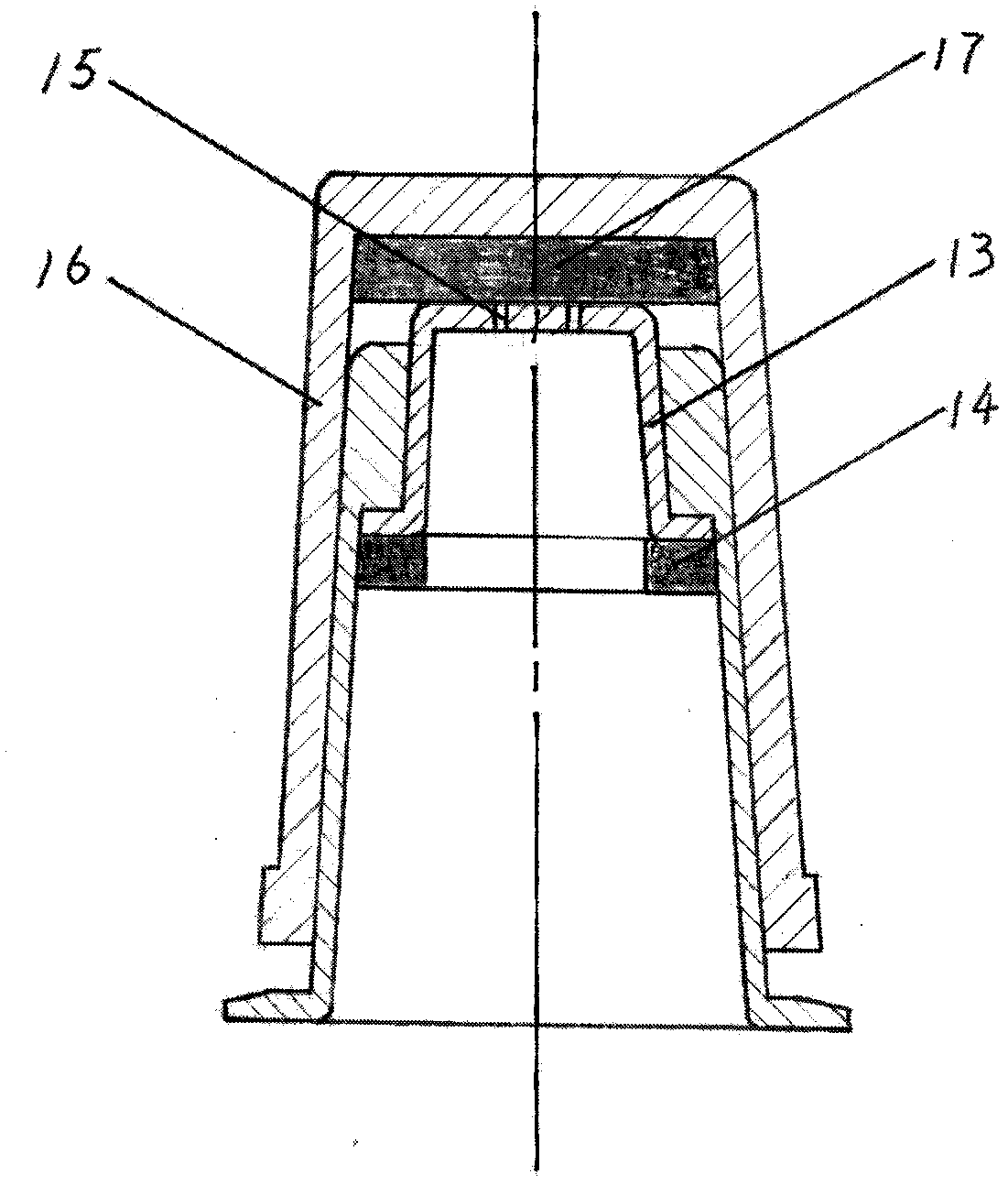

Simple needleless injector

ActiveCN108042886AReliable principleAdvanced principleJet injection syringesIntravenous devicesNeedle Free InjectionMedical equipment

The invention discloses a simple needleless injector and belongs to the field of medical equipment. The simple needleless injector includes an injector part (1) and a pressure providing part (2); theinjector part (1) is composed of a jacket (4), a core rod (5), a rubber plug (6), an injection head (3) and a liquid pumping head (22); the pressure providing part (2) is composed of a shell (23), a pressure shaft (24) and a spring (11). The needleless injector is characterized in that an omega-shaped stainless steel piece (13) of the injection head (3) is provided with one to ten micropores (15)with the diameter of 1-10 mu; the liquid pumping head (22) refers to a plastic injection needle; a spring (11) of the pressure providing part (2) refers to a pressure spring with the pressure more than 1kg; when the needleless injector is in use, the liquid pumping head (22) is used for pumping medicinal liquid, the injection head (3) is replaced, the injector part (1) is connected with the pressure providing part (2), the injection head (3) is aligned to the injector part, the spring (11) is triggered, the medicinal liquid is injected into muscle at high pressure, and injection is completed.The simple needleless injector is applied to intramuscular injection and can be applied to insulin and vaccine injection.

Owner:四川护理职业学院

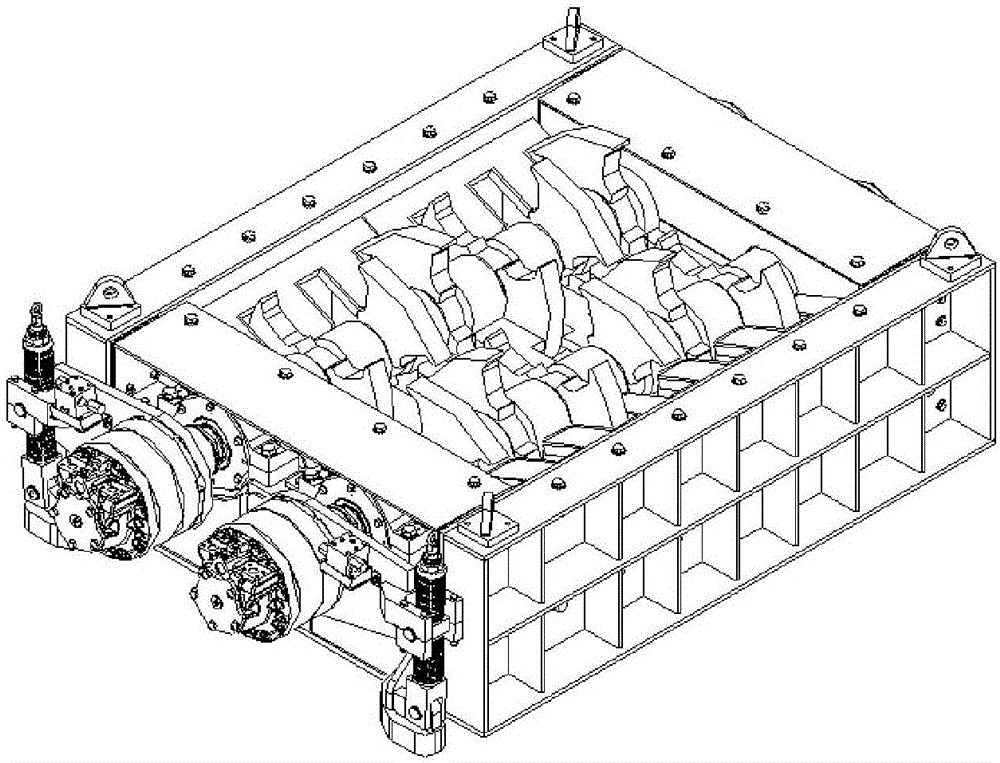

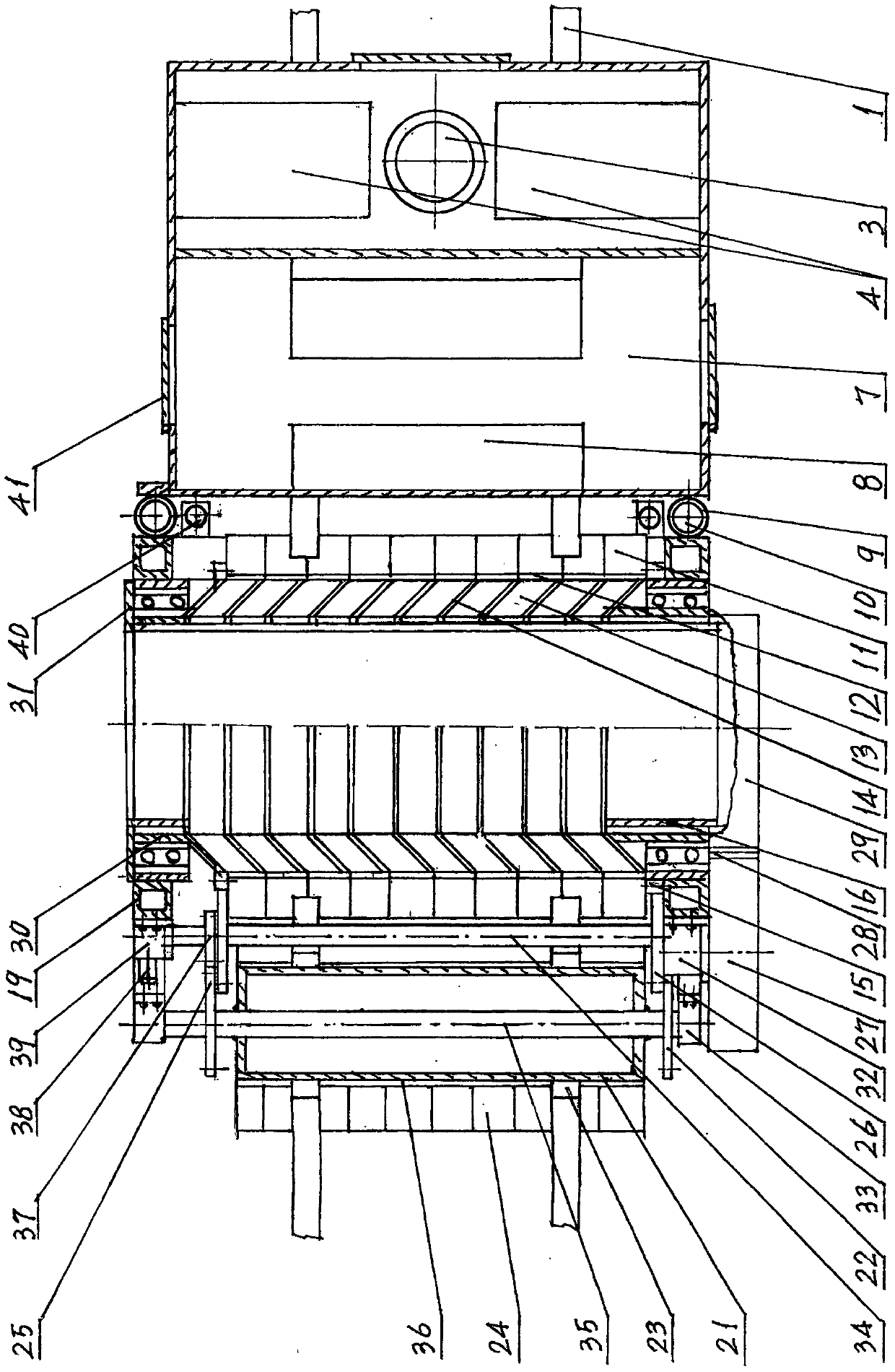

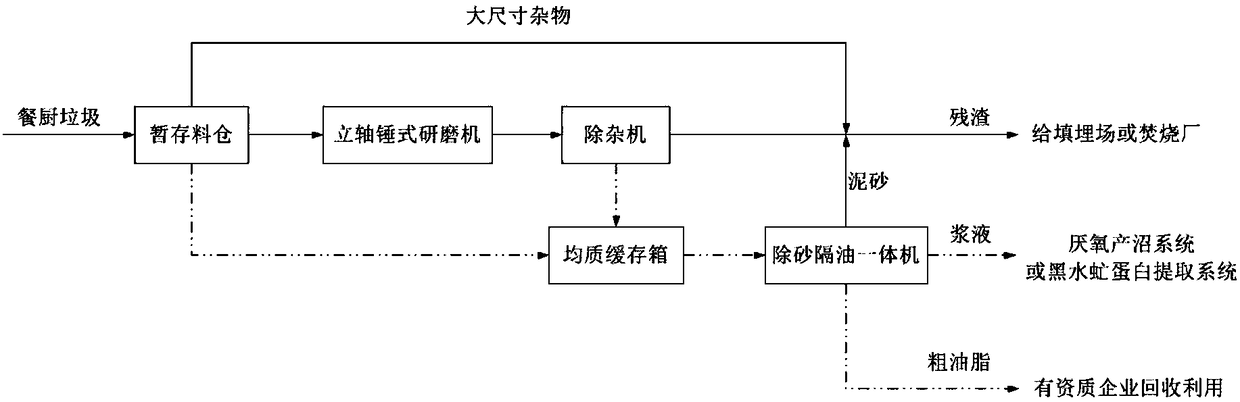

Kitchen waste mechanical pretreatment system and pretreatment process thereof

ActiveCN108580516AAchieve purificationGood quality effectSolid waste disposalOil separationProcess engineering

The invention discloses a kitchen waste mechanical pretreatment system and a pretreatment process for the kitchen waste mechanical pretreatment system. The mechanical pretreatment system comprises a temporary storage material bin, double non-shaft screw conveyors, a vertical shaft hammer type grinding machine, an impurity removal machine, a homogenizing cache box and a sand removal and oil separation integrated machine. By means of the kitchen waste mechanical pretreatment system and the pretreatment process for the kitchen waste mechanical pretreatment system, kitchen waste with complex composition is taken as raw materials, high-purity organic slurry is produced, aftertreatment material inlet requirements for dry or wet anaerobic fermentation or black gadfly breeding and the like are met, sorted residue meets various heat treatment technology material inlet heat value requirements for incineration, gasification and the like, separation and purification of the kitchen waste are realized, the technical bottleneck of existing kitchen waste mechanical pretreatment being long in process chain, low in organic matter separation efficiency and high in impurity content and energy consumption is broken through, and a more optimized, more suitable and more reliable mechanical pretreatment technology is provided for a city classified kitchen waste treatment project.

Owner:BEIJING ENVIRONMENT ENG TECH CO LTD

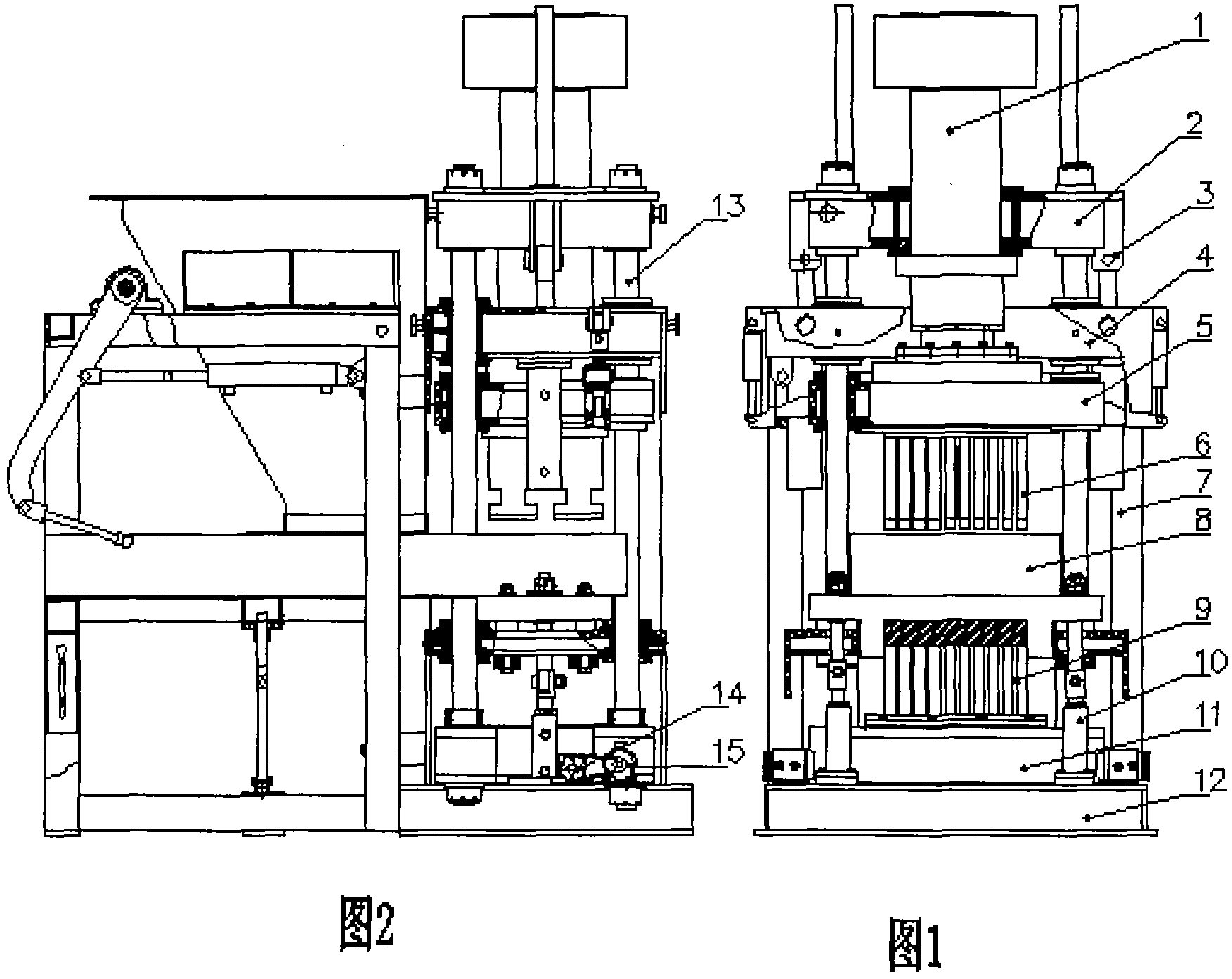

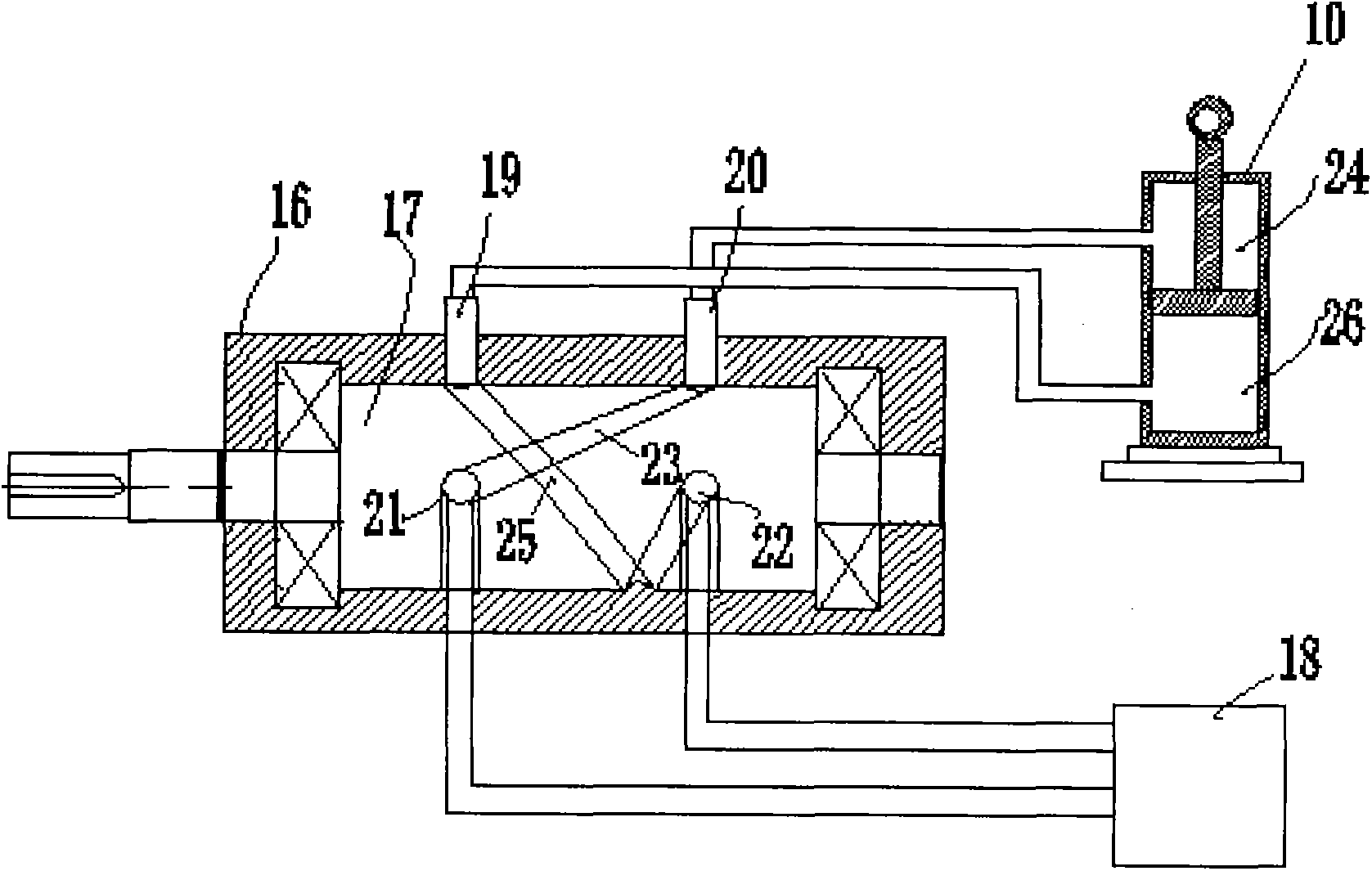

Intelligent single-cylinder dual-pressure forming equipment

InactiveCN103358389AAchieving bi-directional pressureImprove compactnessCeramic shaping apparatusMachine partsPetroleum engineering

The invention discloses intelligent single-cylinder dual-pressure forming equipment. The equipment comprises a machine frame, an upright post assembly, an oil cylinder assembly, a die assembly and a vibration assembly, wherein the upright post assembly comprises upright posts, an upper beam, an intermediate beam and an underbeam, the upper parts of the upright posts are fixed with the upper beam, the lower parts of the upright posts are fixed with the underbeam, and the intermediate beam conducts reciprocating movement up and down, with guiding of the four upright posts; the oil cylinder assembly comprises a main oil cylinder and a return oil cylinder, the main oil cylinder is connected with the intermediate beam, the return oil cylinder is positioned on a top beam and drives the intermediate beam to conduct return motion, and the main oil cylinder and the return oil cylinder are connected through an oil circuit of a hydraulic station; the vibration assembly comprises a vibration oil cylinder, a shockwave device and a motor. By adopting the structure, the dual-pressure purpose is achieved through one main pressure oil cylinder; meanwhile, as the shockwave device is arranged, hydraulic mode vibration is realized, the vibration noise is low and the machine parts are subject to small damage.

Owner:山东宏发科工贸有限公司

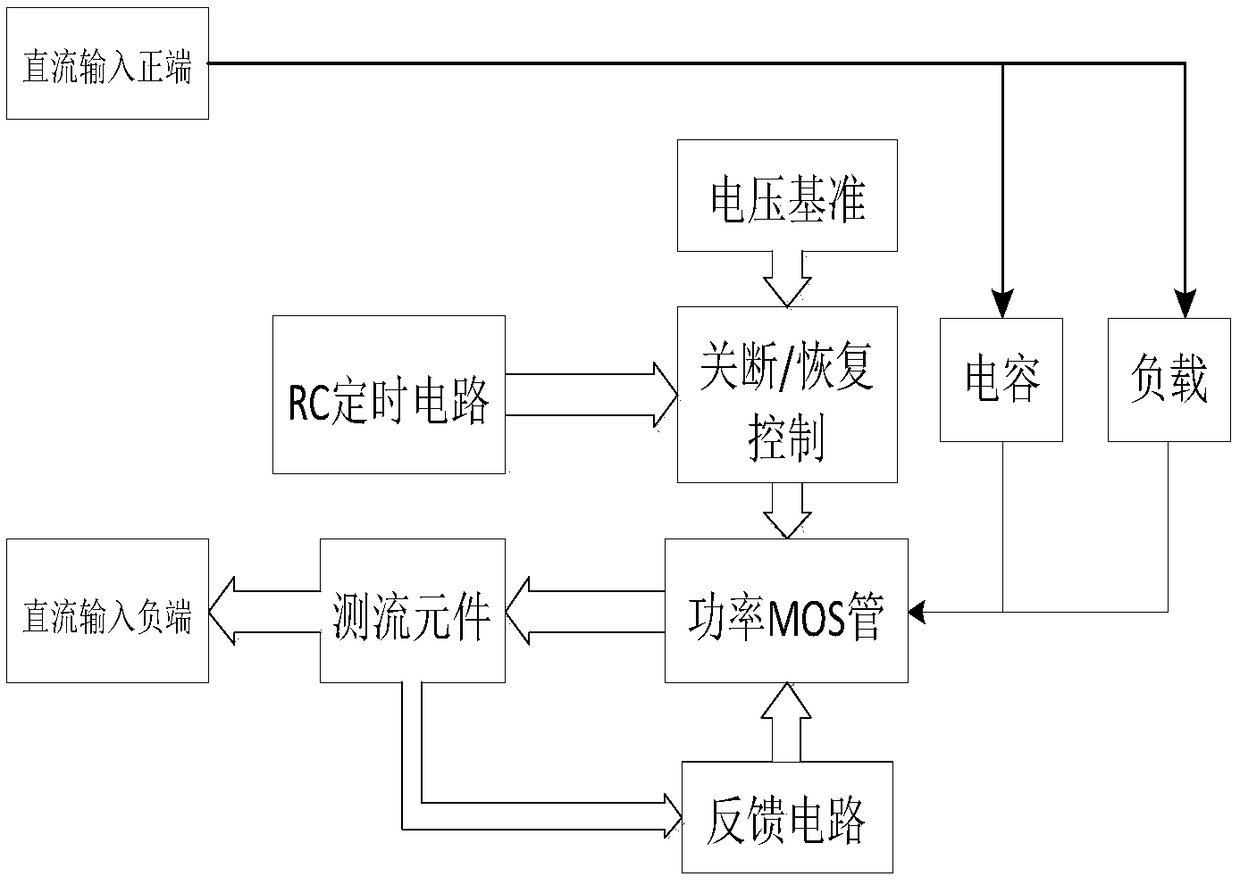

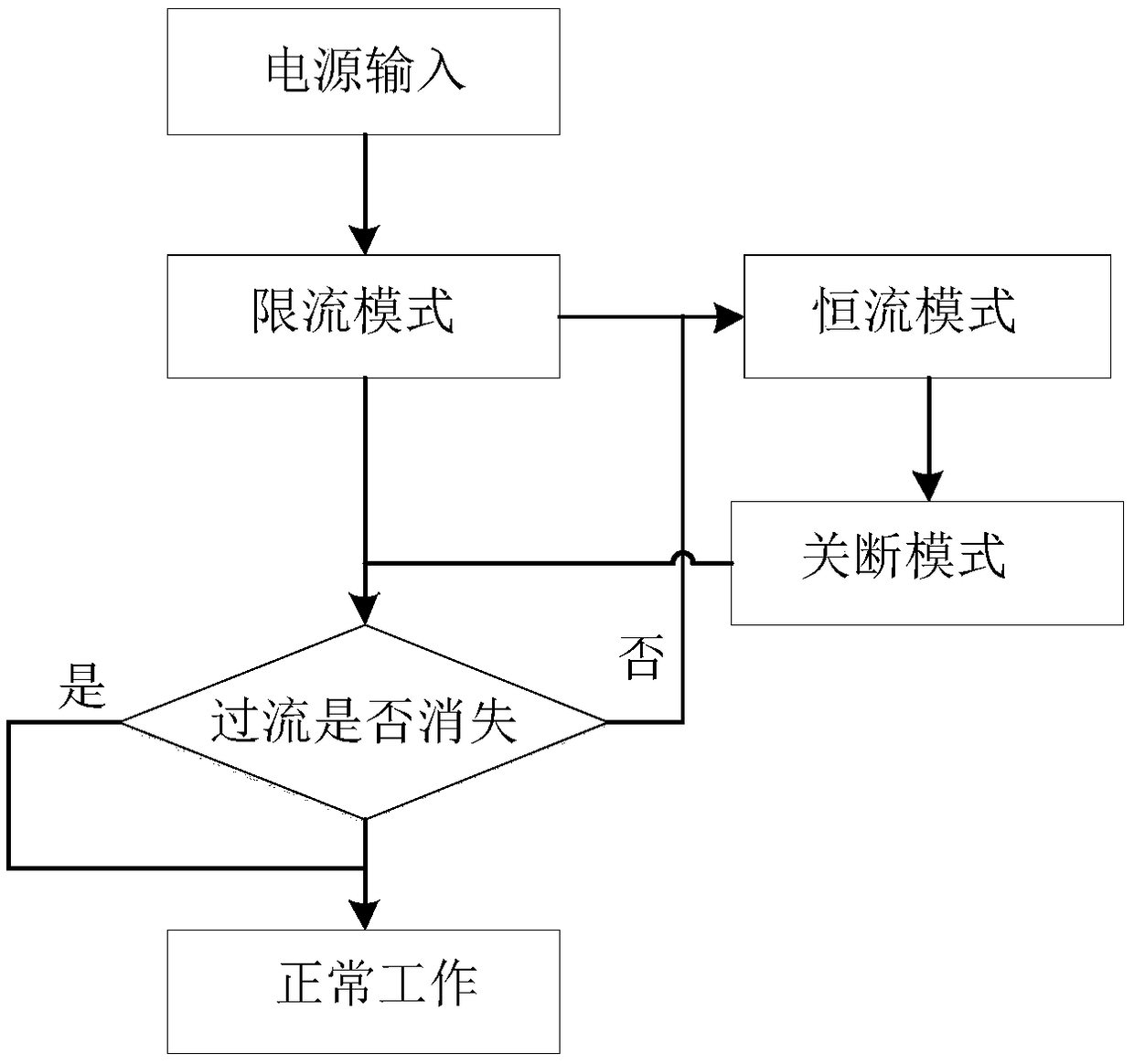

Surge current suppressor

ActiveCN108963999AAdvanced principleReliable function implementationArrangements responsive to excess currentEmergency protective arrangements for limiting excess voltage/currentCurrent limitingEngineering

The invention relates to the field of airborne electronic equipment power electronics, in particular to a surge current suppressor. The surge current suppressor is connected to the circuit of the input power supply in series and comprises a power MOS tube connected in series in the circuit of a direct-current input negative end; a current measuring element connected in series in the circuit of thedirect-current input negative end and used for inputting the current of the power supply circuit and converting the current into a voltage; a feedback circuit connected with the current measuring element and the power MOS tube, when the voltage value detected by the current measuring element is larger than or equal to the first preset value, the power MOS tube is enabled to be in a current limiting state. The surge current suppressor is advanced and reliable in principle and can achieve a startup surge suppression function, and compared with the traditional mode, the function realization is simple and reliable, and the power consumption is low, the cost is low, the occupied area of the printed board is small, and the weight is light.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

Method for reconstructing a current block of an image and corresponding encoding method, corresponding devices as well as storage medium carrying an images encoded in a bit stream

ActiveUS9159141B2Low costAdvanced principleImage codingCharacter and pattern recognitionMotion vectorBitstream

Owner:INTERDIGITAL MADISON PATENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com