Blind plug type liquid cooling module

A blind insertion and liquid cooling technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of electromagnetic compatibility performance, heat dissipation performance, quick disassembly performance rejection, and module vibration and shock resistance. Strong, weak anti-salt spray ability and other problems, to achieve the effect of strong resistance to mechanical environment, reduce professional skill requirements, and improve rapid response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

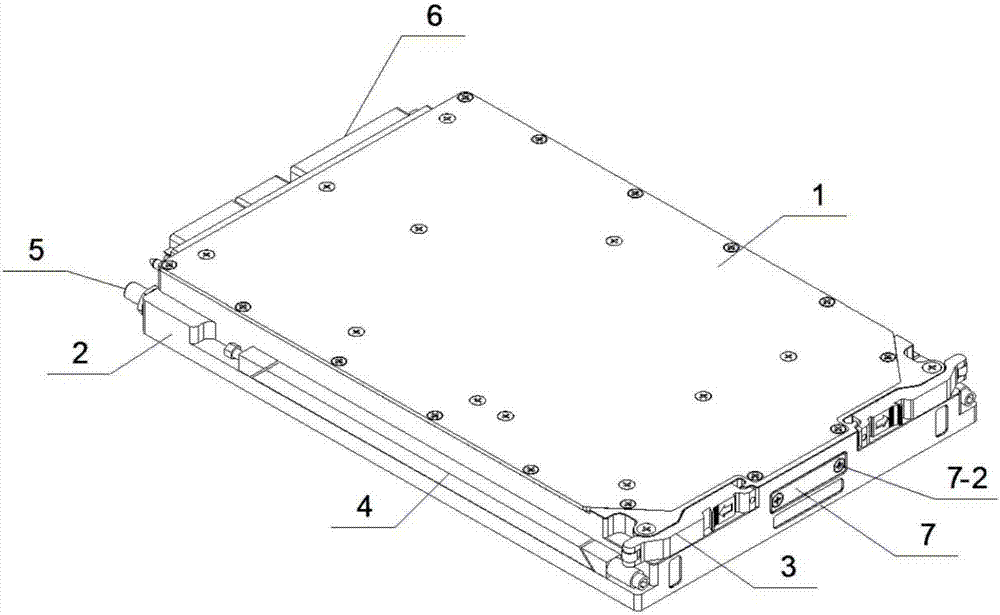

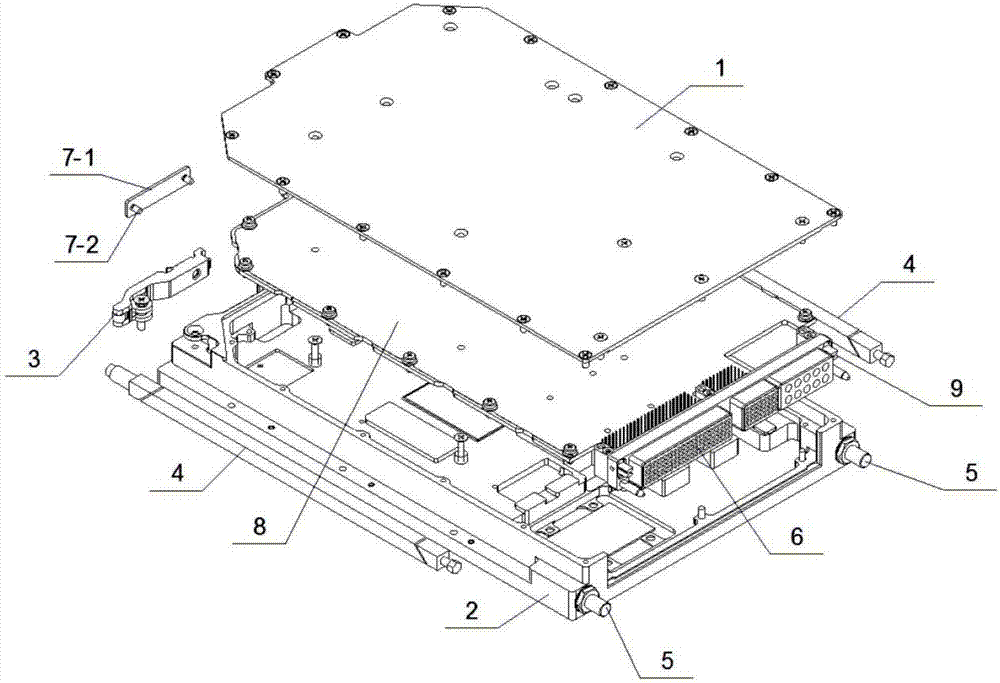

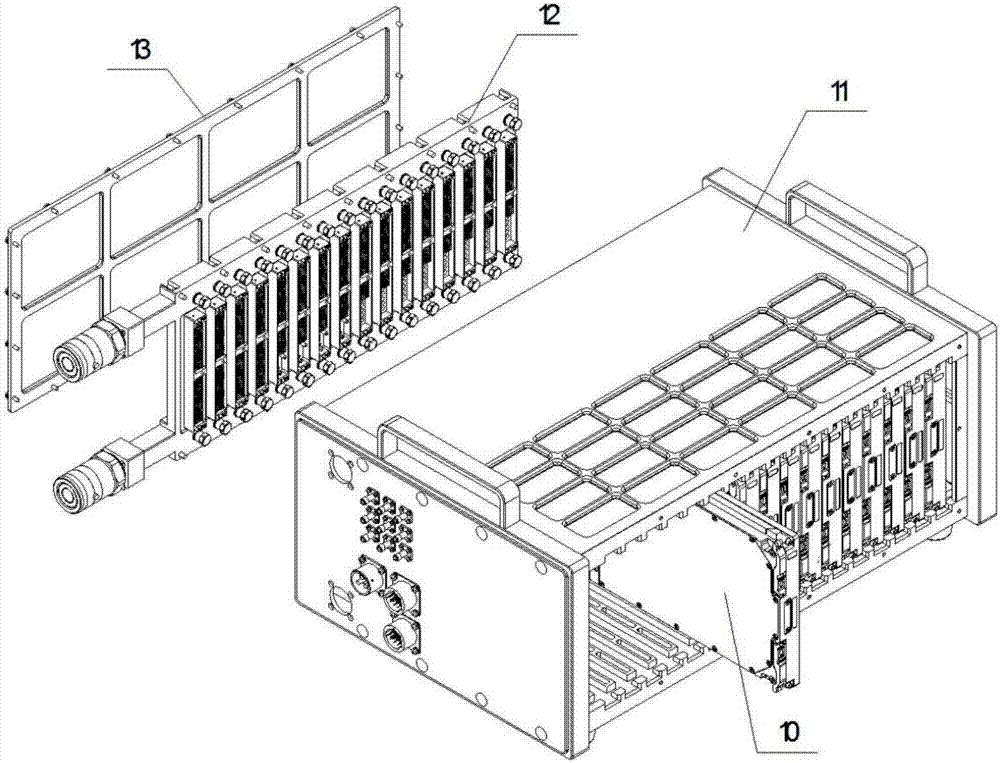

[0047] (1) If figure 1 , figure 2 , image 3 Shown is an embodiment of the present invention. In this embodiment, the functional module is transformed into a type that can realize fast plug-in and unplug capability, ultra-high heat dissipation capability, electromechanical-hydraulic collaborative blind plug capability, radio frequency blind plug capability, high electromagnetic shielding capability, Blind plug-in liquid cooling module with strong anti-vibration and shock ability, strong anti-salt spray ability, friendly man-machine interface, beautiful appearance, convenient operation and meeting the requirements of military environment.

[0048] The entire module adopts a modular design idea, and the cover plate 1, the puller 3, the locking ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com