Patents

Literature

247results about How to "Easy to debug and maintain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

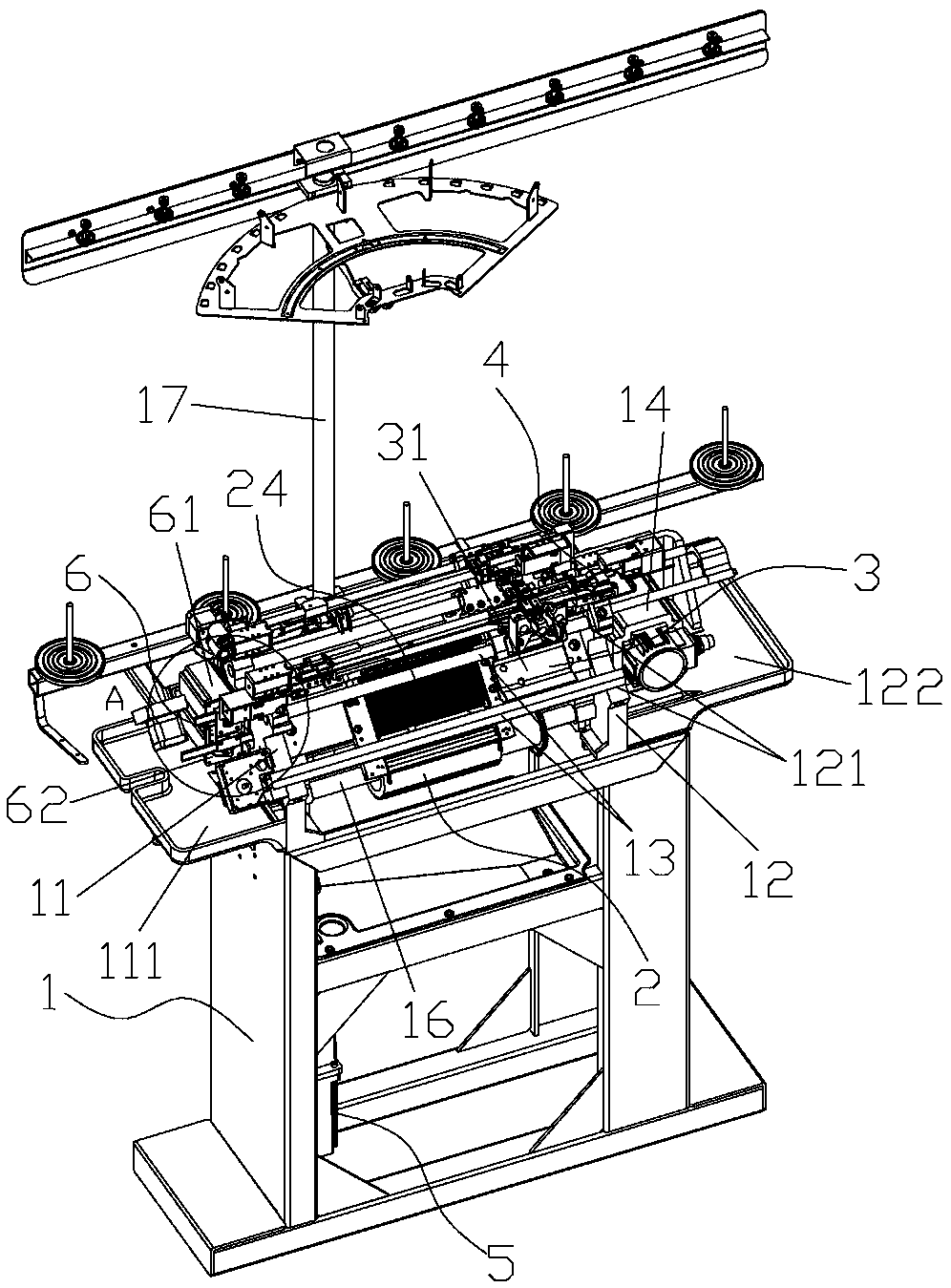

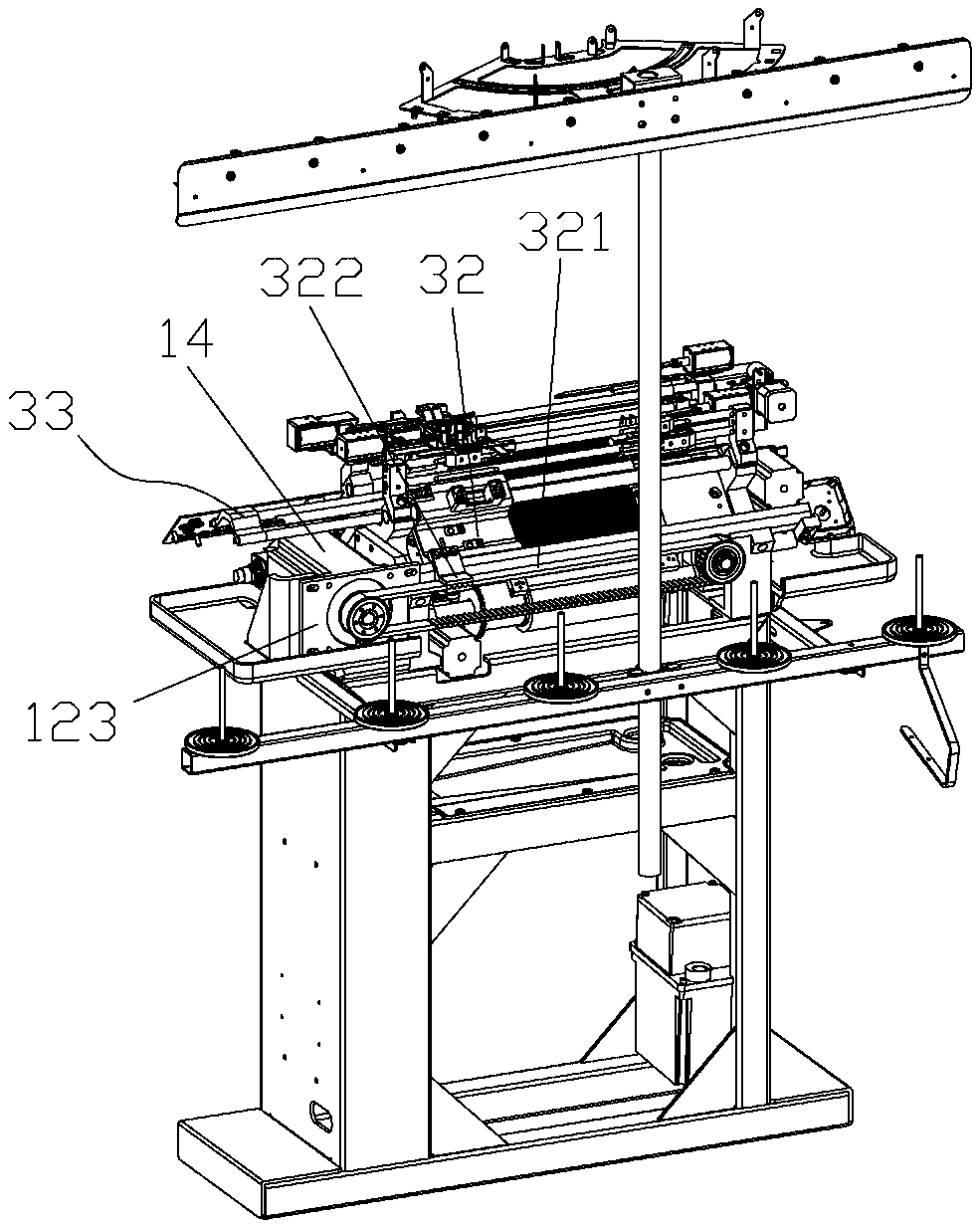

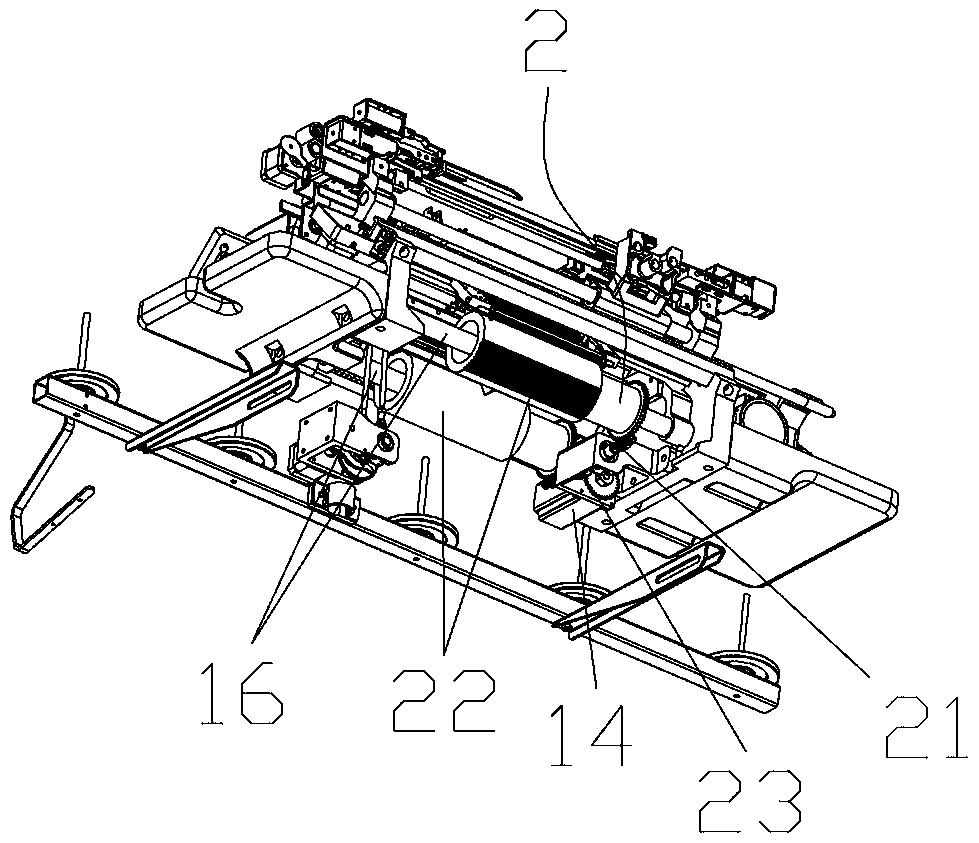

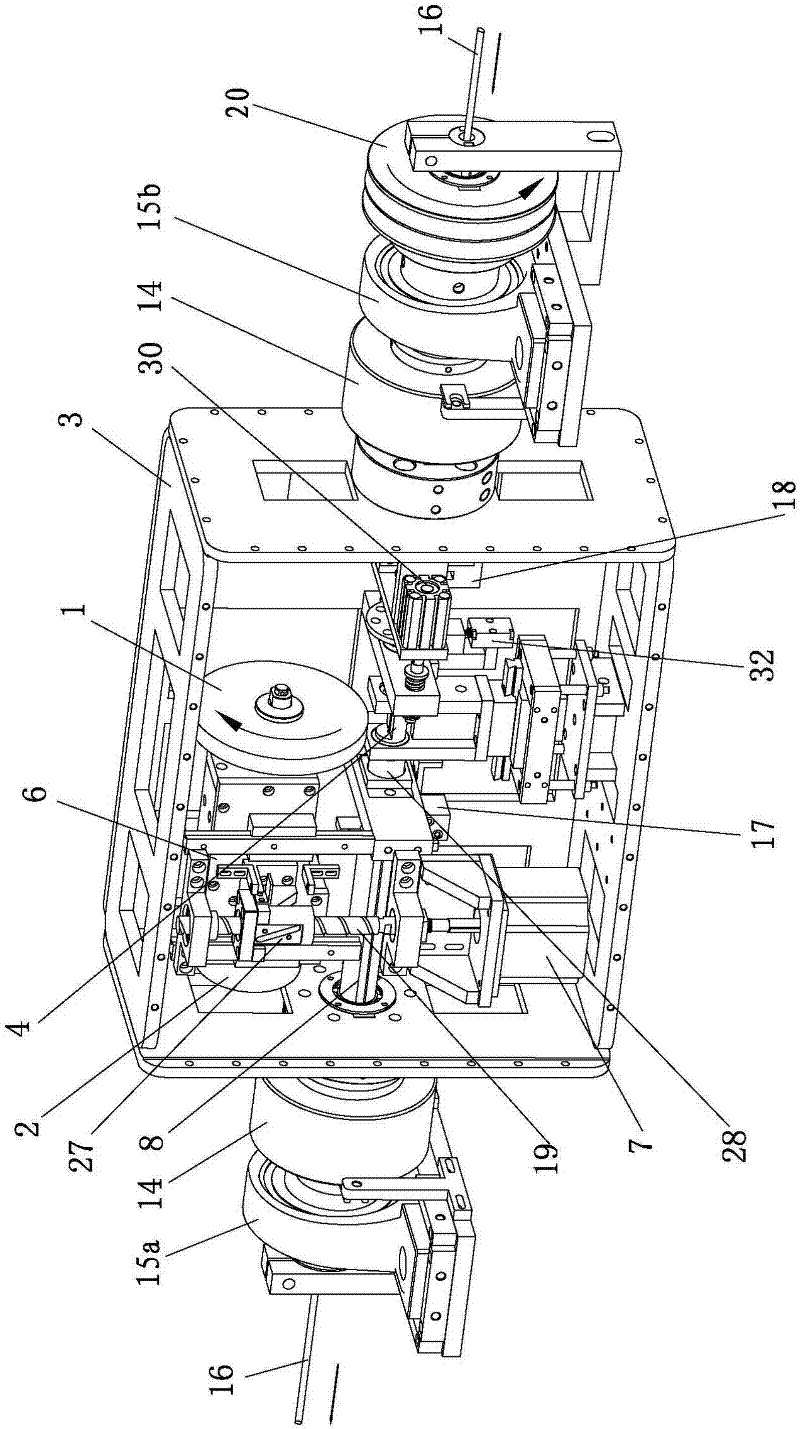

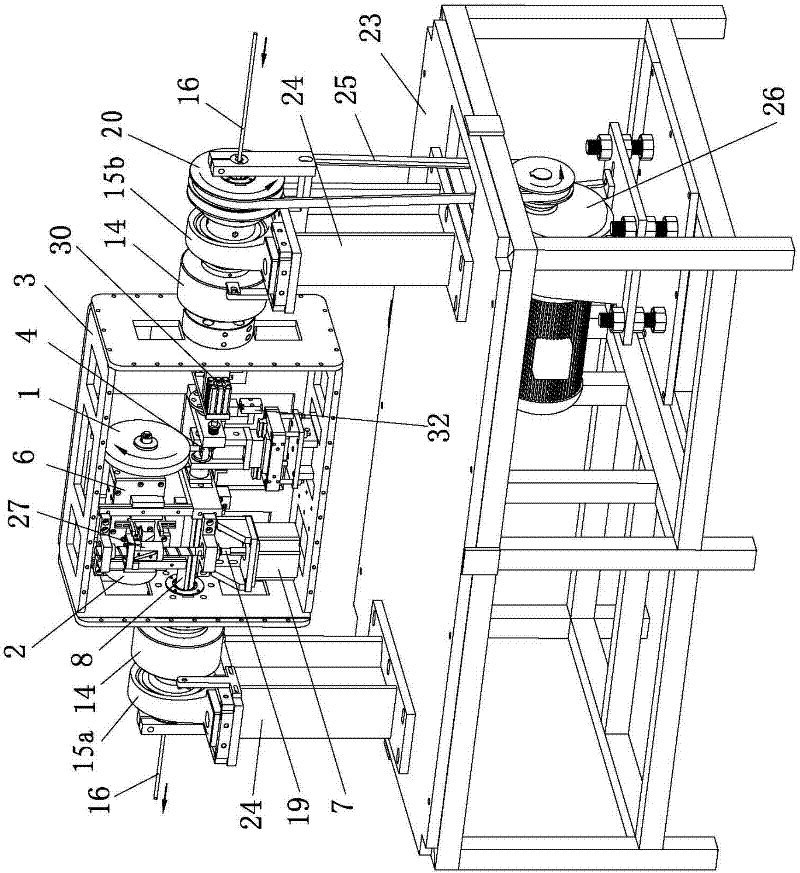

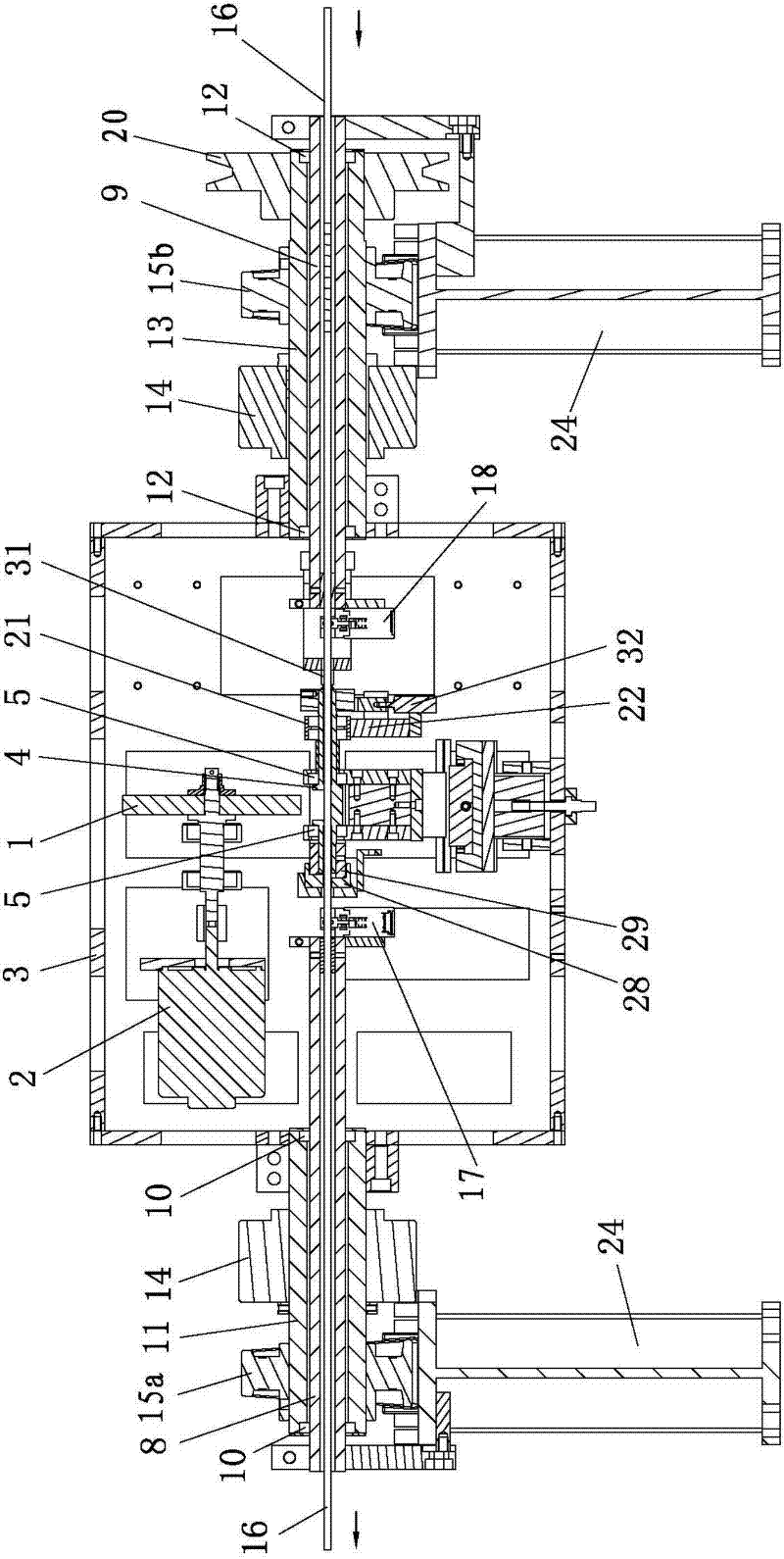

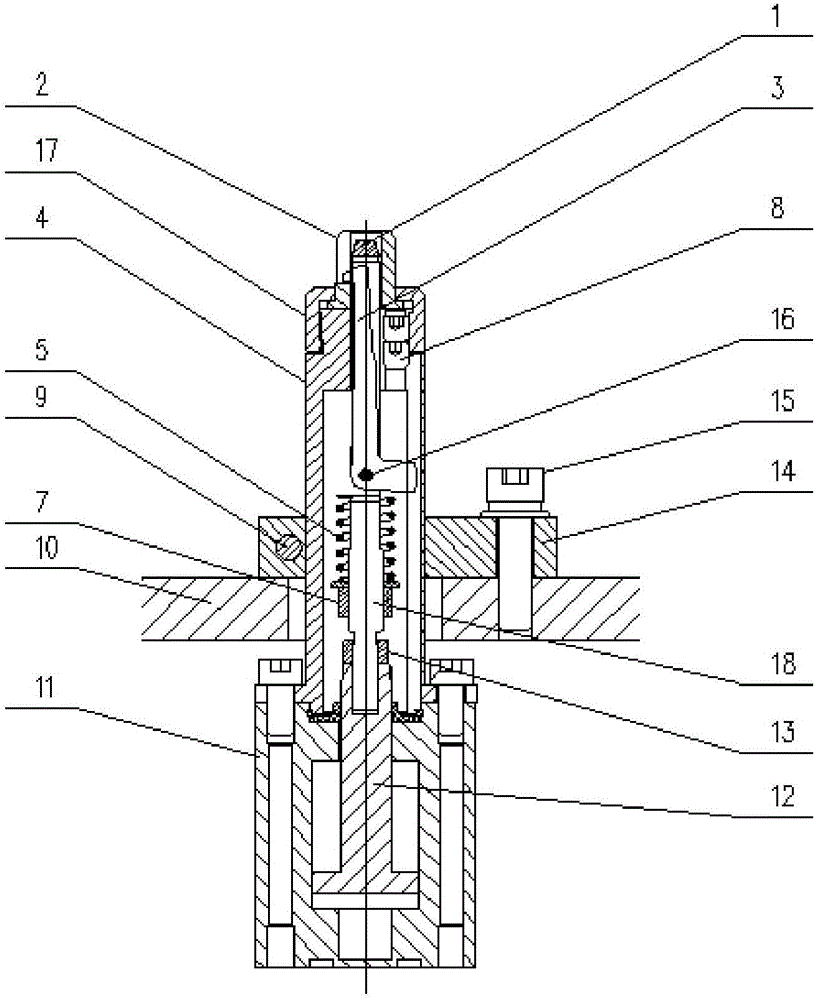

Sliding plate conveying system with accompanied lifting function

InactiveCN102390677AIngenious structureRealize plane transportationControl devices for conveyorsMechanical conveyorsSlide platePhysics

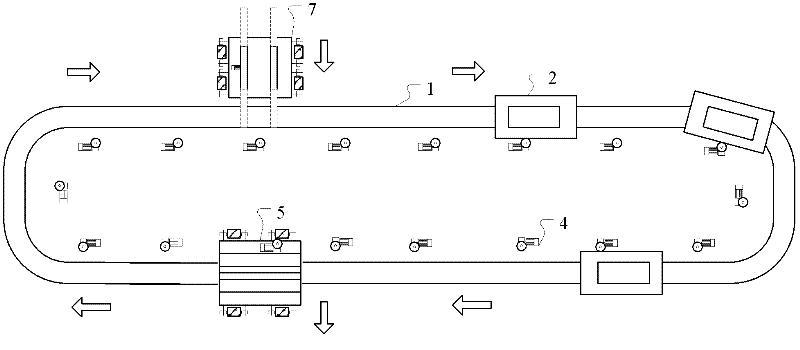

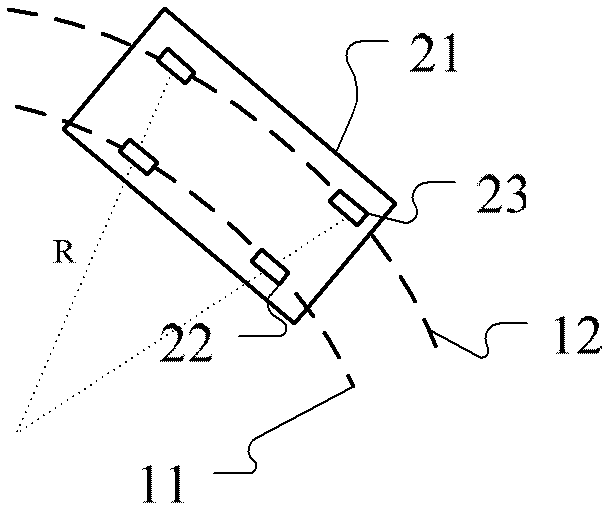

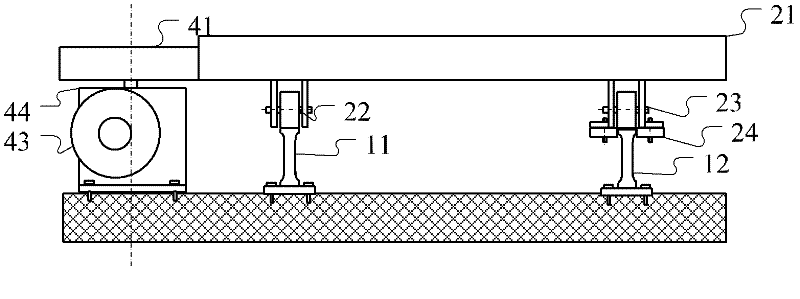

The invention relates to a sliding plate conveying system with an accompanied lifting function. The sliding plate conveying system with the accompanied lifting function comprises a railway, sliding plate devices, friction wheel drive devices, a piece-down lifting table device and a piece-up lifting table device, wherein the plurality of sliding plate devices are arranged on the railway and can travel along the railway; the sliding plate devices are used for loading workpieces; the plurality of friction wheel drive devices are arranged along the line of the railway and are used for driving the sliding plate devices; the piece-down lifting table device and the piece-up lifting table device are respectively arranged along the line of the railway; the piece-up lifting table device is used for placing the workpieces on the sliding plate devices; and the piece-down lifting table device is used for taking the workpieces from the sliding plate devices. The sliding plate conveying system with the accompanied lifting function has an ingenious structure, strong functions, high flexibility, a wide application range, and high working reliability. The sliding plate conveying system with the accompanied lifting function cannot only realize the plane conveying of the workpieces on the ground or in the air, but also realize full-space three-dimensional conveying of the workpieces among the ground, the air and the railway; and simultaneously the system can realize station identification and workpiece online lifting functions, reduce labor intensity and improve efficiency.

Owner:MIRACLE AUTOMATION ENG CO LTD

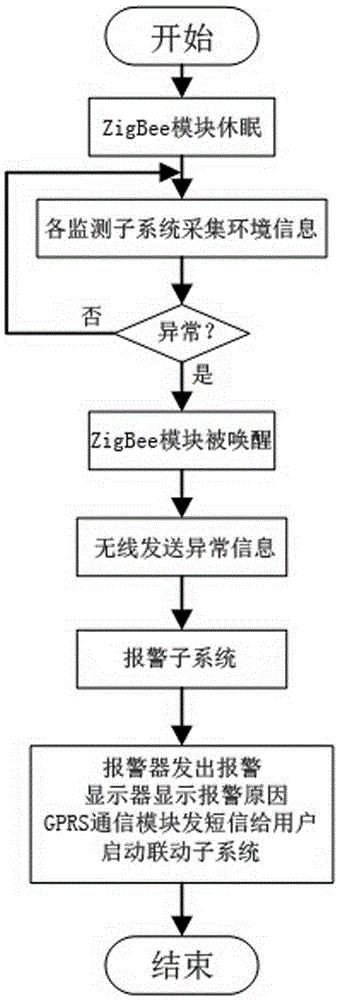

Smart home safe guard system and control method thereof

ActiveCN105336090AAchieve wireless connectionEnhanced cropabilityAlarmsHome environmentControl system

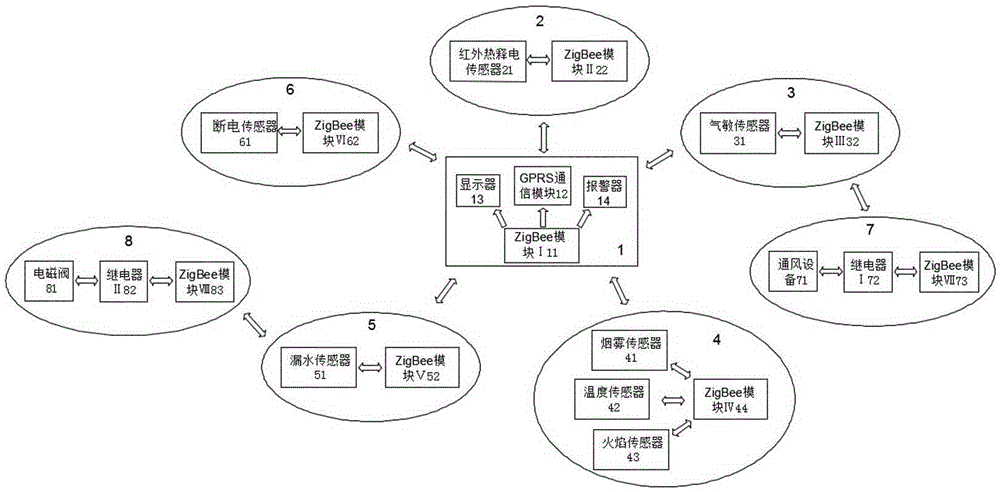

The invention discloses a smart home safe guard system. The smart home safe guard system comprises an alarm subsystem and multiple monitoring subsystems. The alarm subsystem comprises a ZigBee module I and a GPRS communication module, a display and an alerter which are connected with an output end of the ZigBee module I, each monitoring subsystem is internally provided with a monitoring sensor and a ZigBee module, and each monitoring subsystem is in communication connection with the ZigBee module I of the alarm subsystem through the corresponding ZigBee module in the corresponding system. According to the safe guard system, wireless automatic networking can be achieved, debugging and maintenance are easy, convenient and rapid, the cost performance is high, installation is easy, the space is saved, attractiveness is achieved, real-time monitoring of various home environments can be achieved, the good home environment is guaranteed, the stability of the system is high, and the situation of global paralysis caused by failure of a central control system can be effectively avoided.

Owner:QUFU NORMAL UNIV

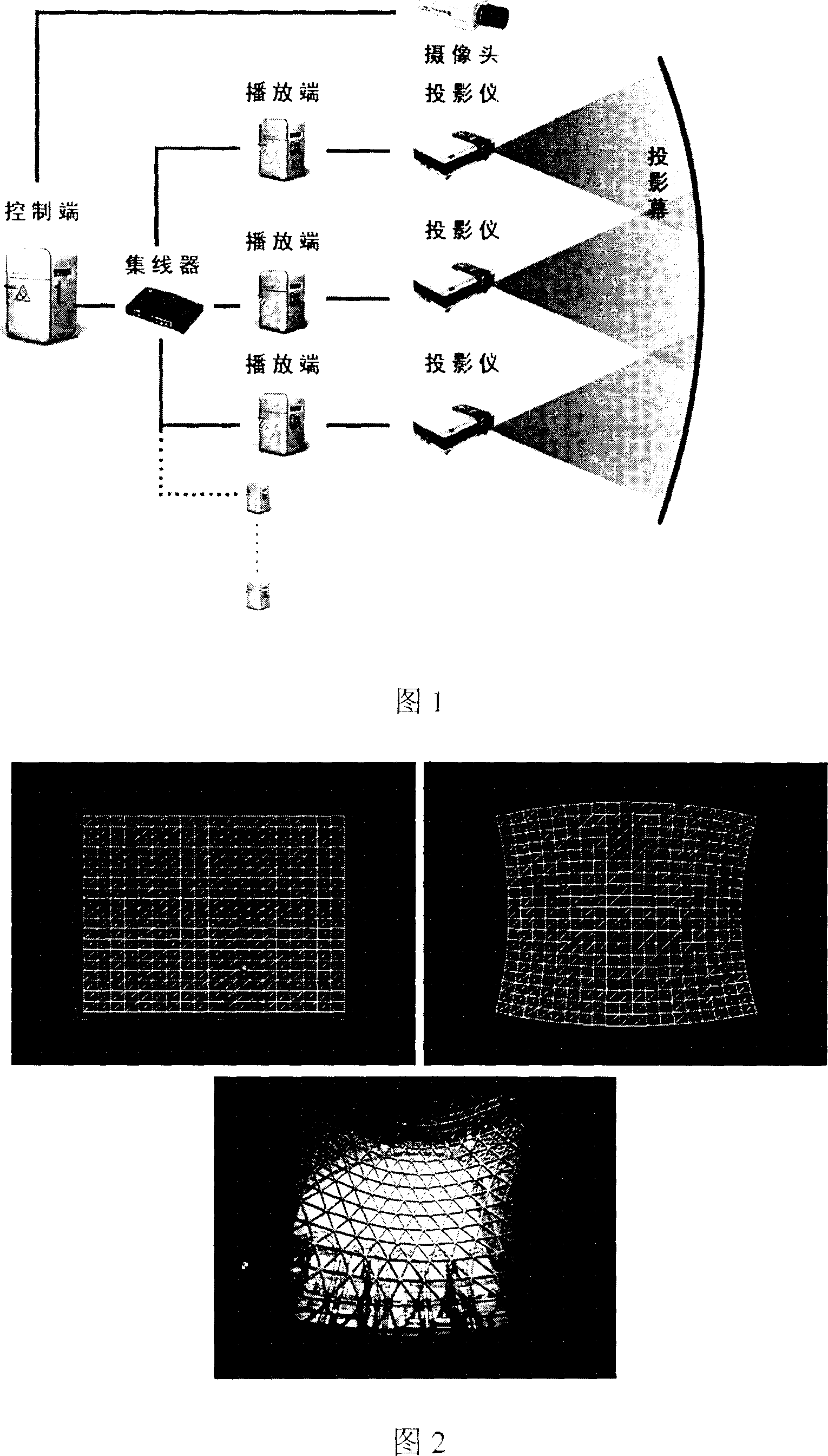

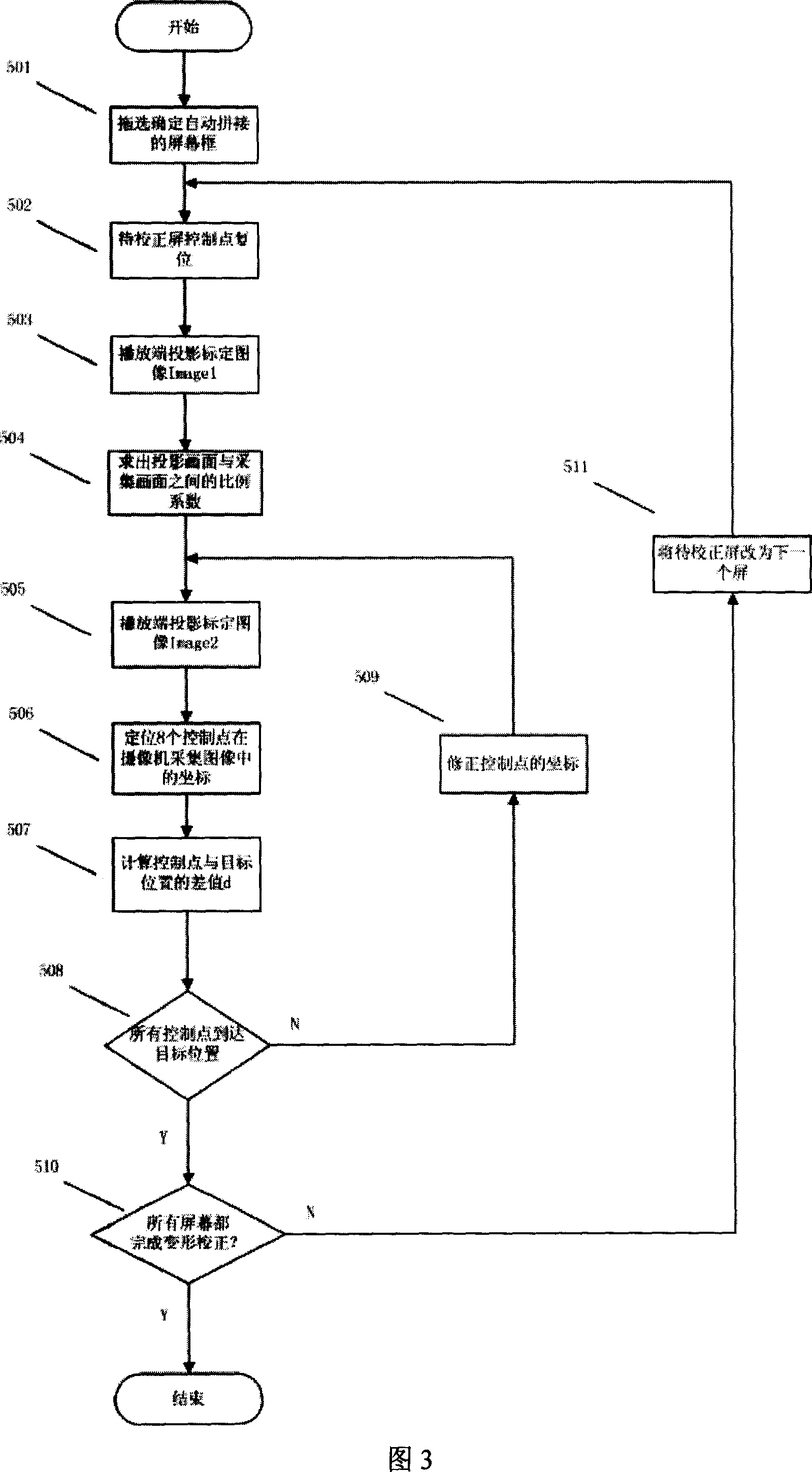

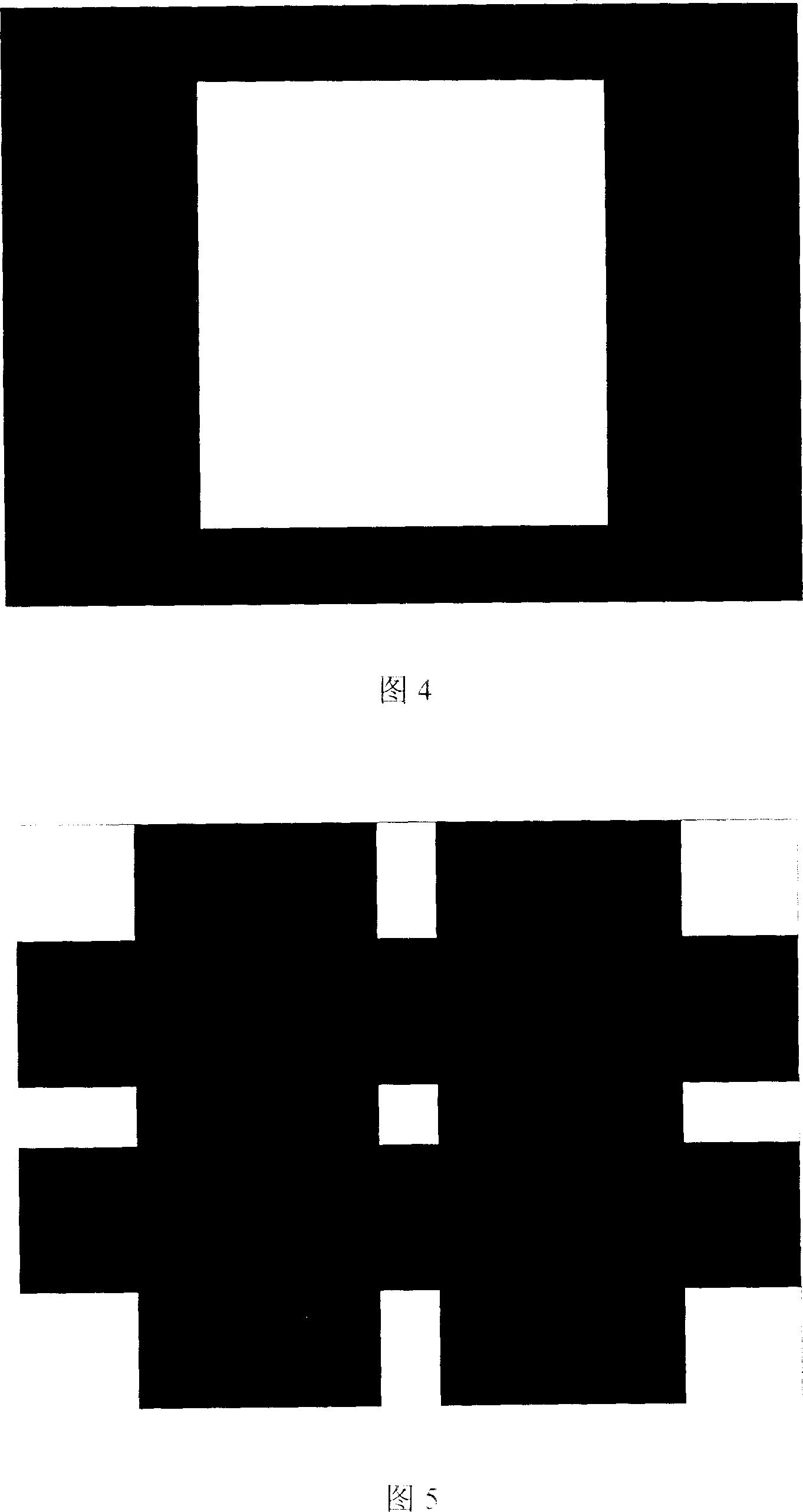

Correction method for deformation of multiscreen playing suitable for irregular screen

InactiveCN101017316AIncrease the number ofLow costImage enhancementTelevision system detailsComputer scienceCorrection method

This invention relates to one multi-screen play deformation correction method for irregular screen, which comprises the following steps: firstly processing deformation on multi-screen picture to make the projection suitable for irregular screen; then through control end for correction of multiple screens to fulfill multi-screen picture automatic matching; finally melting the picture edge; in playing process, through control end to process simultaneous control.

Owner:上海水晶石视觉展示有限公司

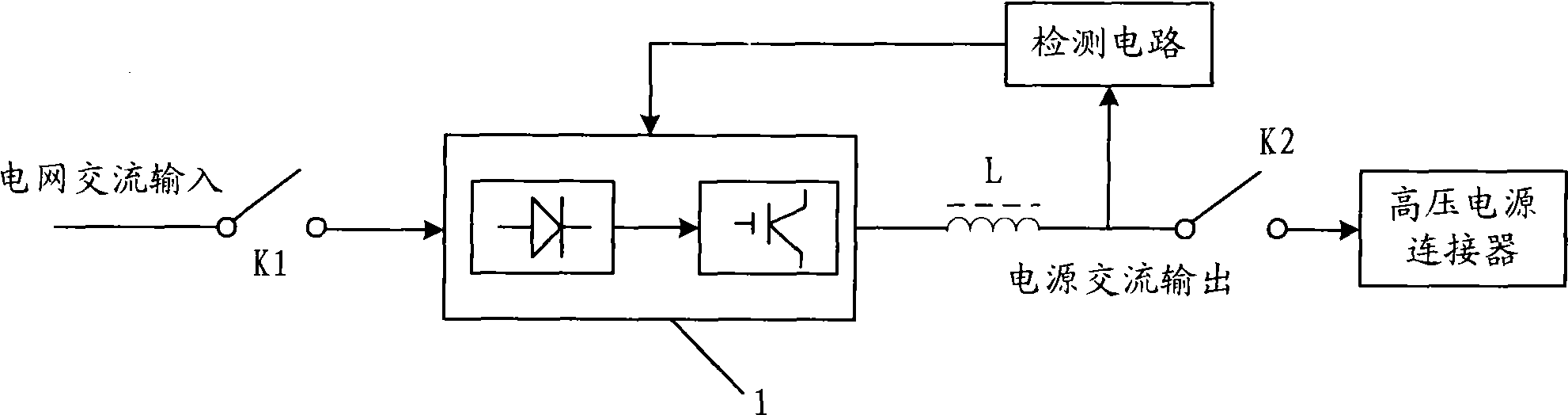

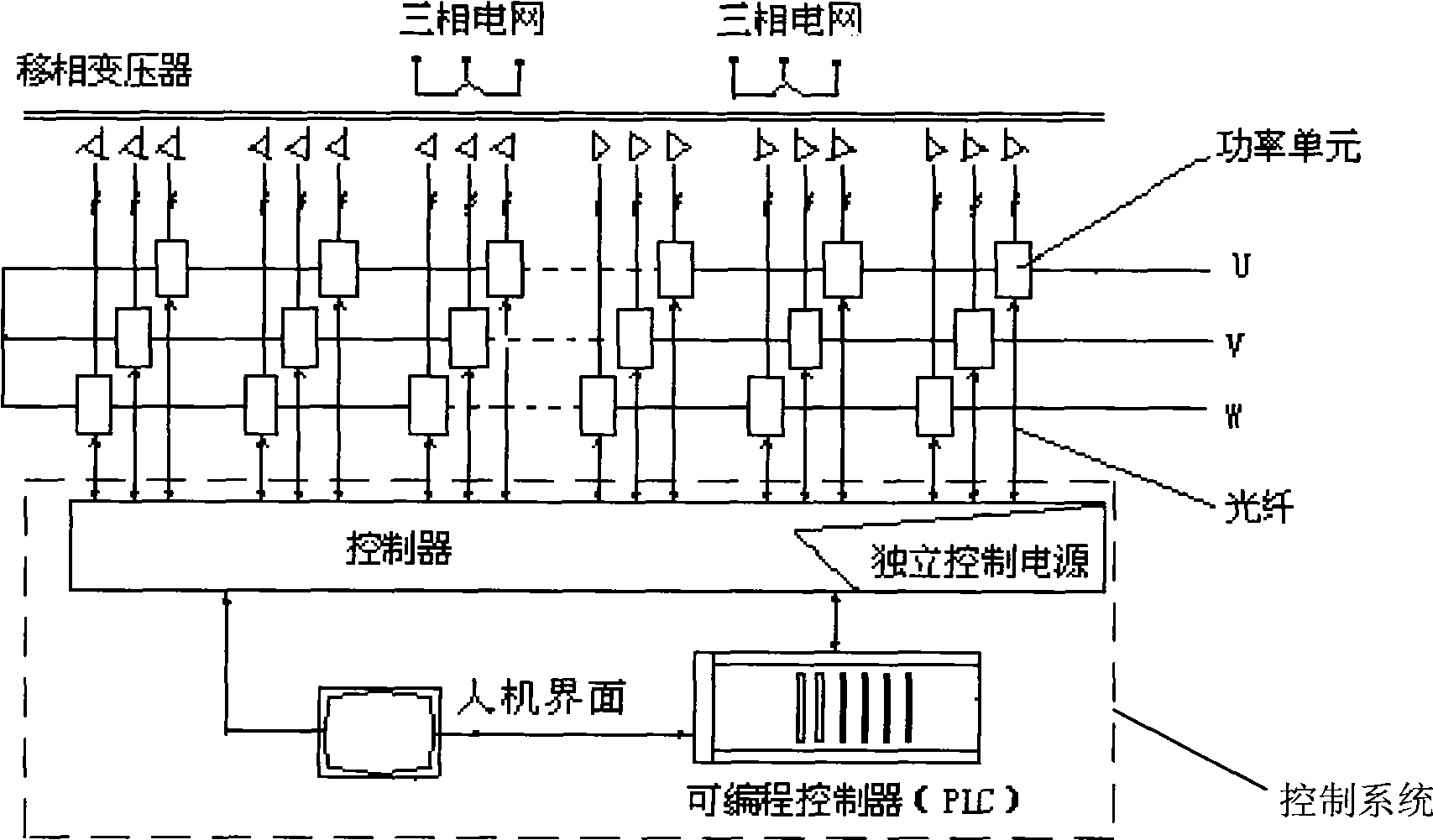

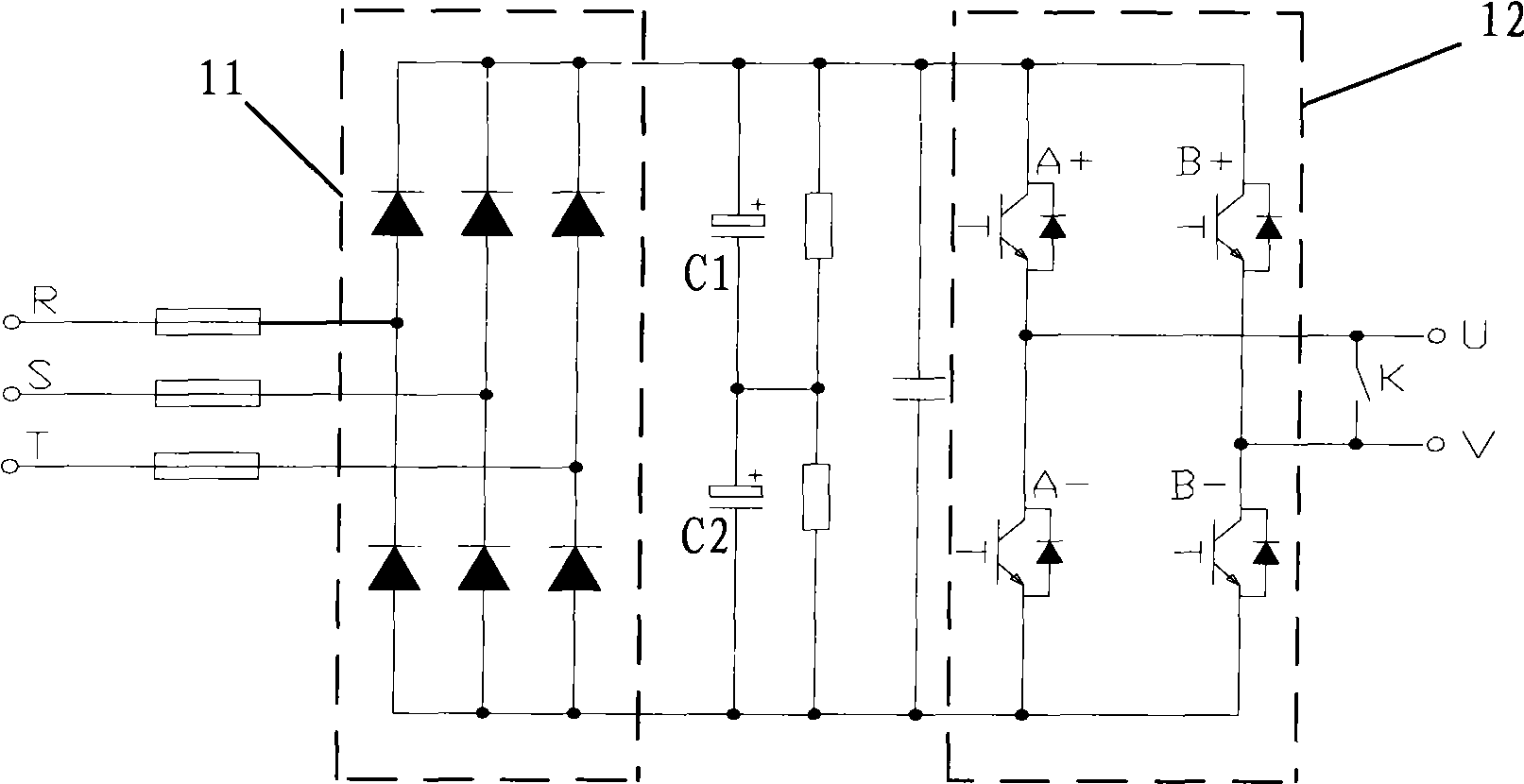

Large power ship shore electric power

InactiveCN101488720AReduce lossReduce volumeAc-ac conversionDc-ac conversion without reversalElectricityPower factor

The invention discloses a high-power marine shore power supply which comprises electric fence high pressure three phase AC input, power supply high pressure three phase AC output and an inverter system; wherein, the inverter system is a high pressure inverter system which directly rectifies and inverts high tension electricity of the electric fence three phase AC input and then outputs high pressure three-phase alternating current, thus reducing the intermediate transforming links as well as improving the power factor of the power supply and the reliability of the products.

Owner:青岛创统科技发展有限公司

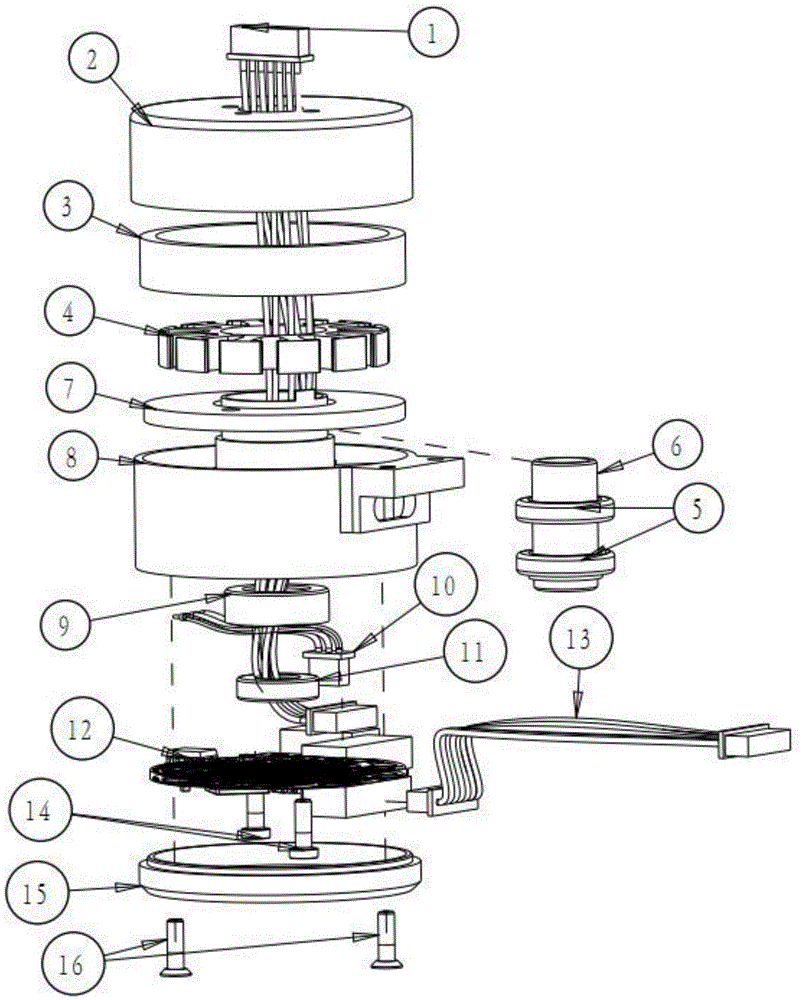

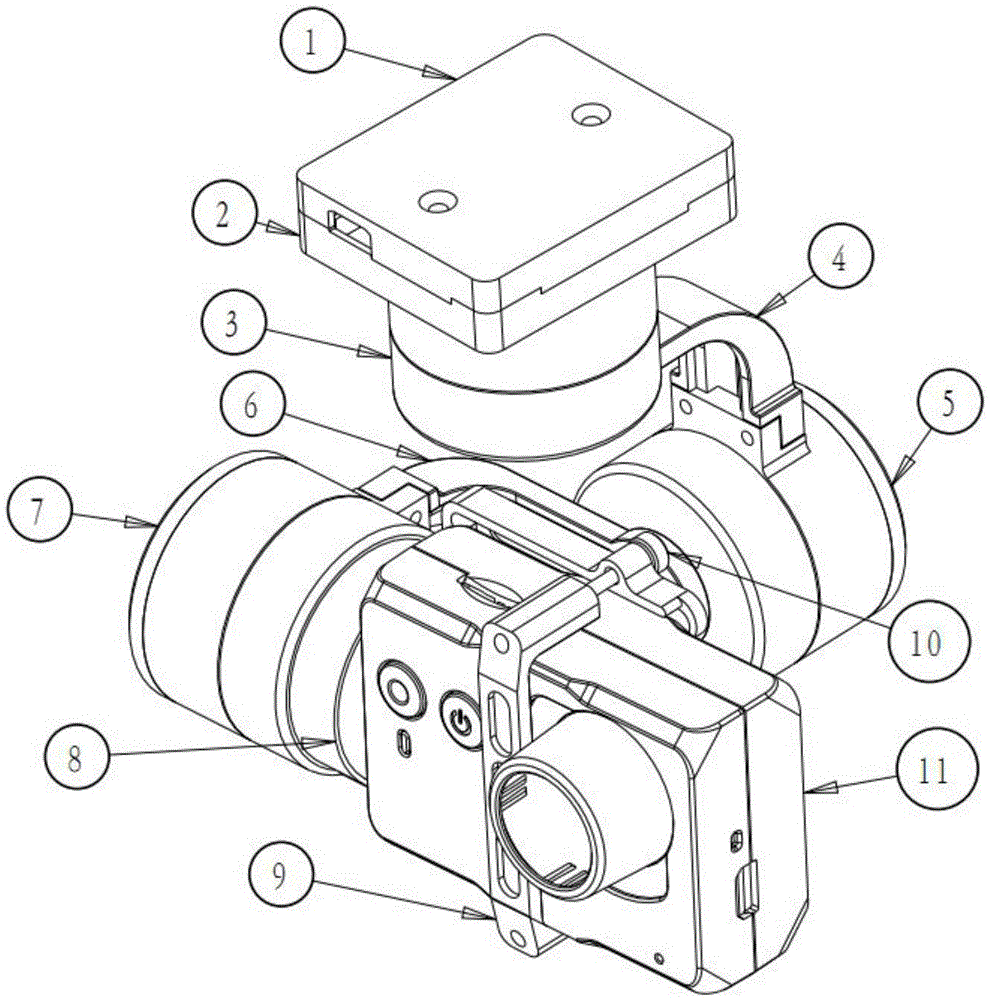

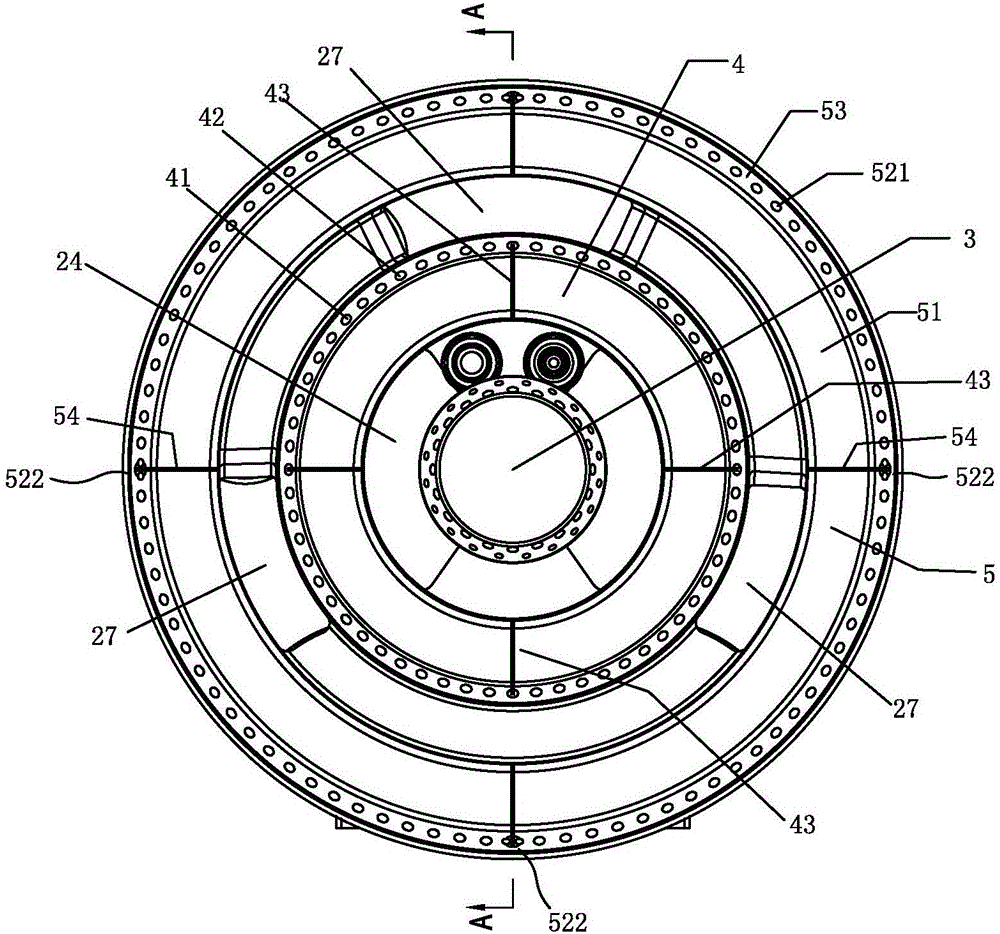

Servo assembly for aerial camera stability-increasing cradle head and stability-increasing cradle head with same

PendingCN105584637AEasy to assembleEasy to debug and maintainAircraft componentsAssociation with control/drive circuitsElectric machineMachine

The invention discloses a servo assembly for an aerial camera stability-increasing cradle head and the stability-increasing cradle head with the same. A rotor iron core, a magnet ring, a stator iron core, a power transfer board, bearings and a hollow rotating shaft are sequentially installed in a machine shell, a flexible flat cable A penetrates through the rotor iron core, the magnet ring, the stator iron core and the hollow rotating shaft to be connected with the power transfer board and connected with a flexible flat cable C outside the machine shell, a three-phase winding wire of a motor is connected with a flexible flat cable B through the power transfer board, the flexible flat cable B is connected with a magnetic grain and connected to an electron speed regulator module through a terminal, and the electron speed regulator module is connected with the flexible flat cable C. According to the servo assembly for the aerial camera stability-increasing cradle head and the stability-increasing cradle head with the same, assembly, maintenance and debugging are convenient, the electron speed regulator module, the magnetic grain and the servo motor are integrated into a whole, under the protection of the machine shell and the hollow shaft of the motor, the problems that the servo module is damaged and the cable is broken due to the fact that the cradle head is impacted are avoided, and the reliability of cradle head products is greatly improved.

Owner:SHENZHEN HUBSAN TECH

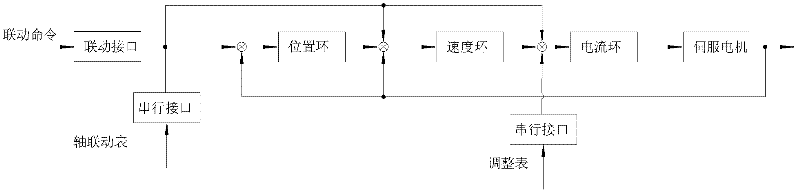

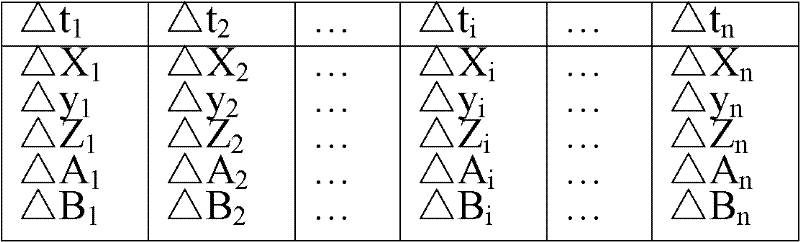

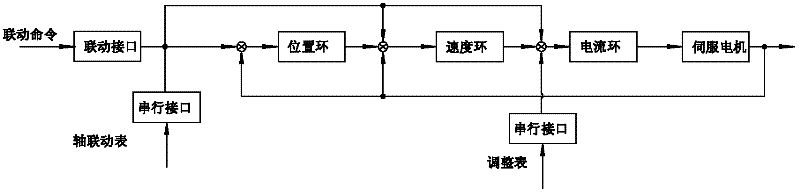

Motion control system and position control method thereof

InactiveCN102354146AEasy to debug and maintainImprove reliabilityNumerical controlPosition controlStandardization

The invention provides a fully-open standardized motion control system and a position control method thereof for an open numerical control system. In the invention, a communication cycle is not required to be set, and a real-time communication interface is extremely simple, therefore, huge amounts of real-time computing resources are saved, operations of maintenance and debugging are simple and convenient, and the reliability of the motion control system is remarkably increased. Through using a linkage interface and a shaft linkage table file in the invention, real-time computing resources are significantly saved, therefore, the defects such as long sampling period and complex algorithm and the like in a feed-forward link are overcome, and favorable conditions for researching and developing new algorithms are created. For dynamic lags and position errors generated by the certainty changes of loads, a current feed-forward control is set in a current loop of the invention, thereby providing a new technical means for controlling dynamic lags.

Owner:数驱技术有限公司

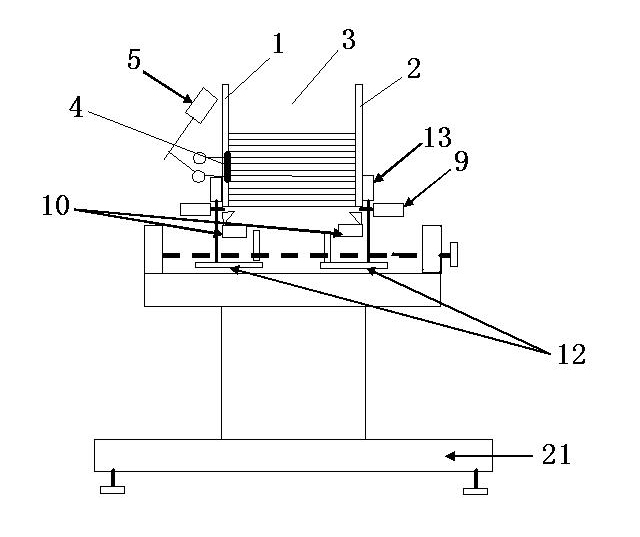

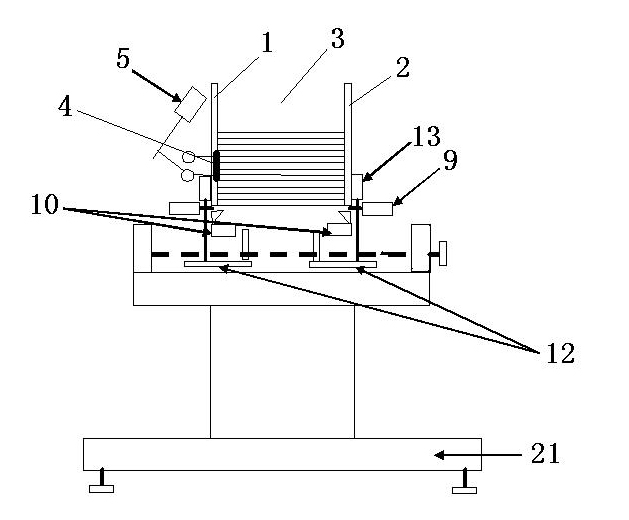

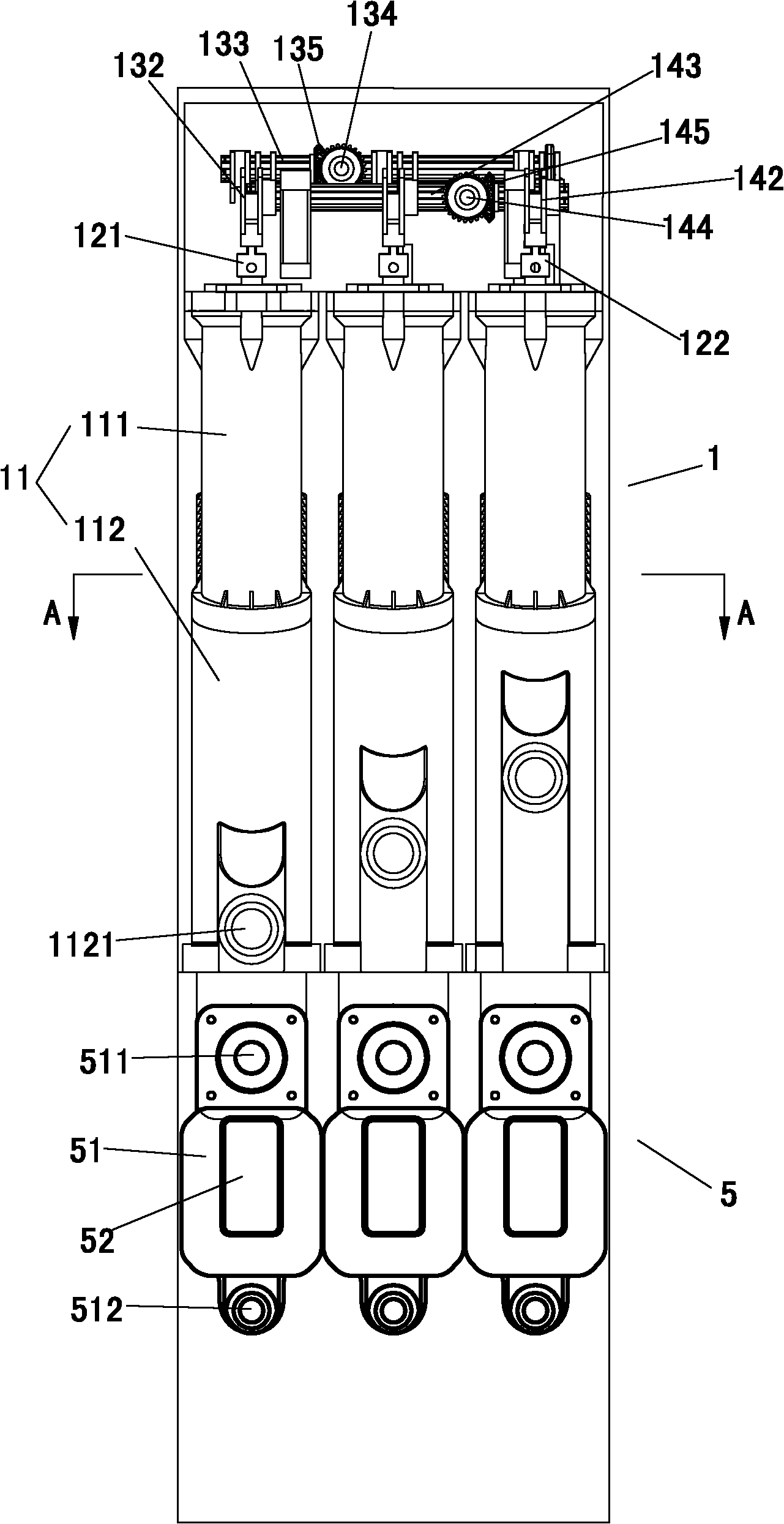

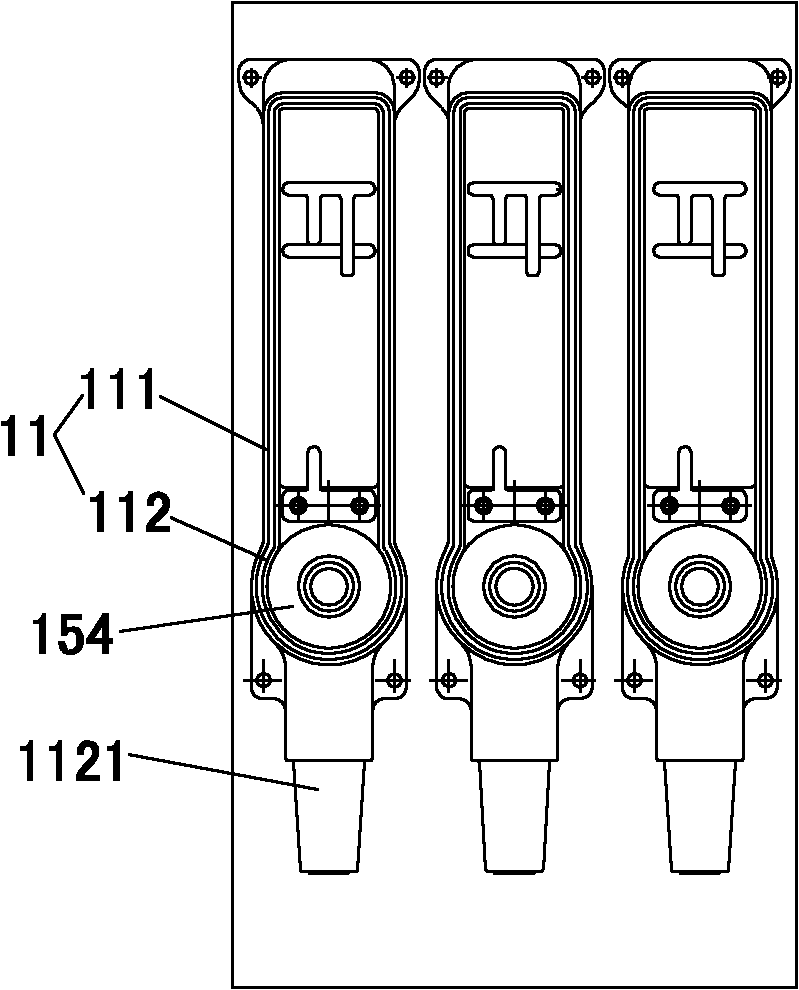

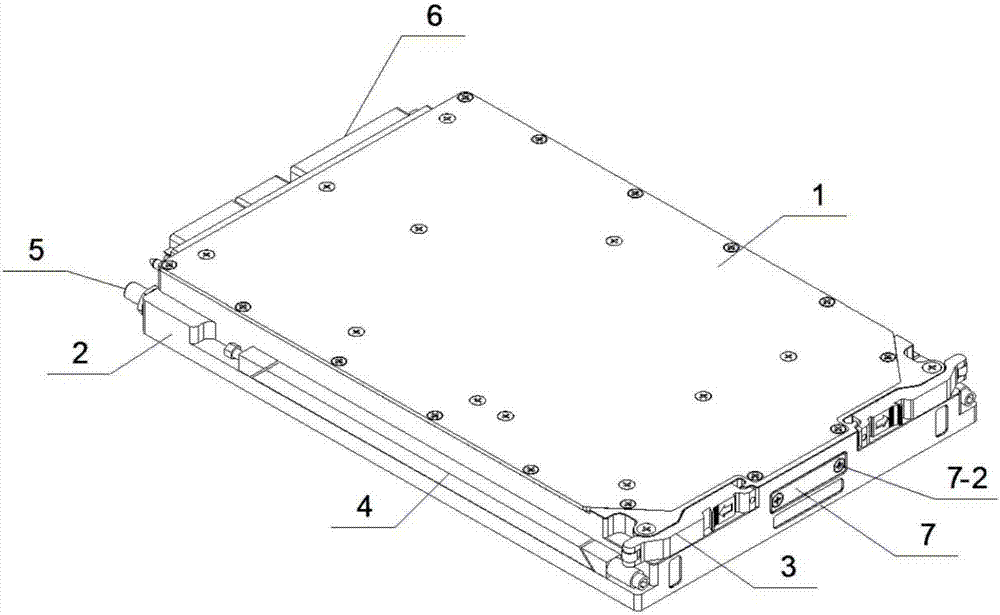

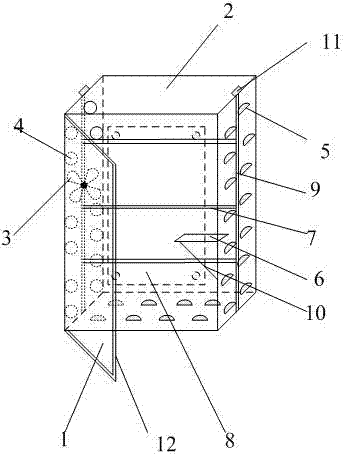

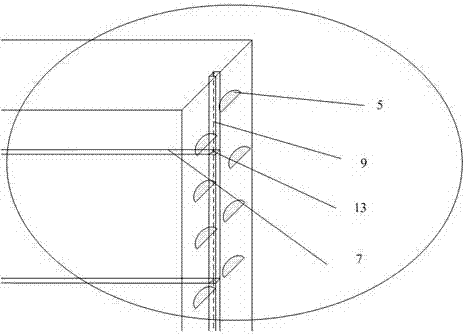

Board feeding machine for printed circuit board (PCB) production line

ActiveCN102001523ASimple structureEasy to debug and maintainConveyor partsProduction lineEngineering

The invention discloses a board feeding machine for a printed circuit board (PCB) production line, which comprises a left trough plate (1) and a right trough plate (2), wherein both the lower parts of the left trough plate (1) and the right trough plate (2) are respectively provided with a clamping block (4) capable of clamping the downmost PCB, the clamping block (4) is connected with a clamping cylinder (5) driving the clamping block to act; both the lower parts of the left trough plate (1) and the right trough plate (2) are respectively provided with a board bearing platform (6), and the distance between the two board bearing platforms (6) is slightly smaller than the distance between two lamination channels (3); a stripper gap (7) is arranged between the board bearing platform (6) and the corresponding left trough plate (1) or between the board bearing platform (6) and the corresponding right trough plate (2), and one end of the stripper (8) is located in the stripper gap (7) while the other end thereof is connected with a stripper cylinder (9); and the lower part of the board bearing platform (6) is provided with a transmission guide rail (10) for feeding the fell PCBs in the production line, and the lower part of the transmission guide rail (10) is provided with a supporting plate (12) connected with a supporting plate cylinder (13). The board feeding machine in the invention has simple structure, short board transmission distance and safety and reliability.

Owner:NANJING PANDA ELECTRONICS MFG

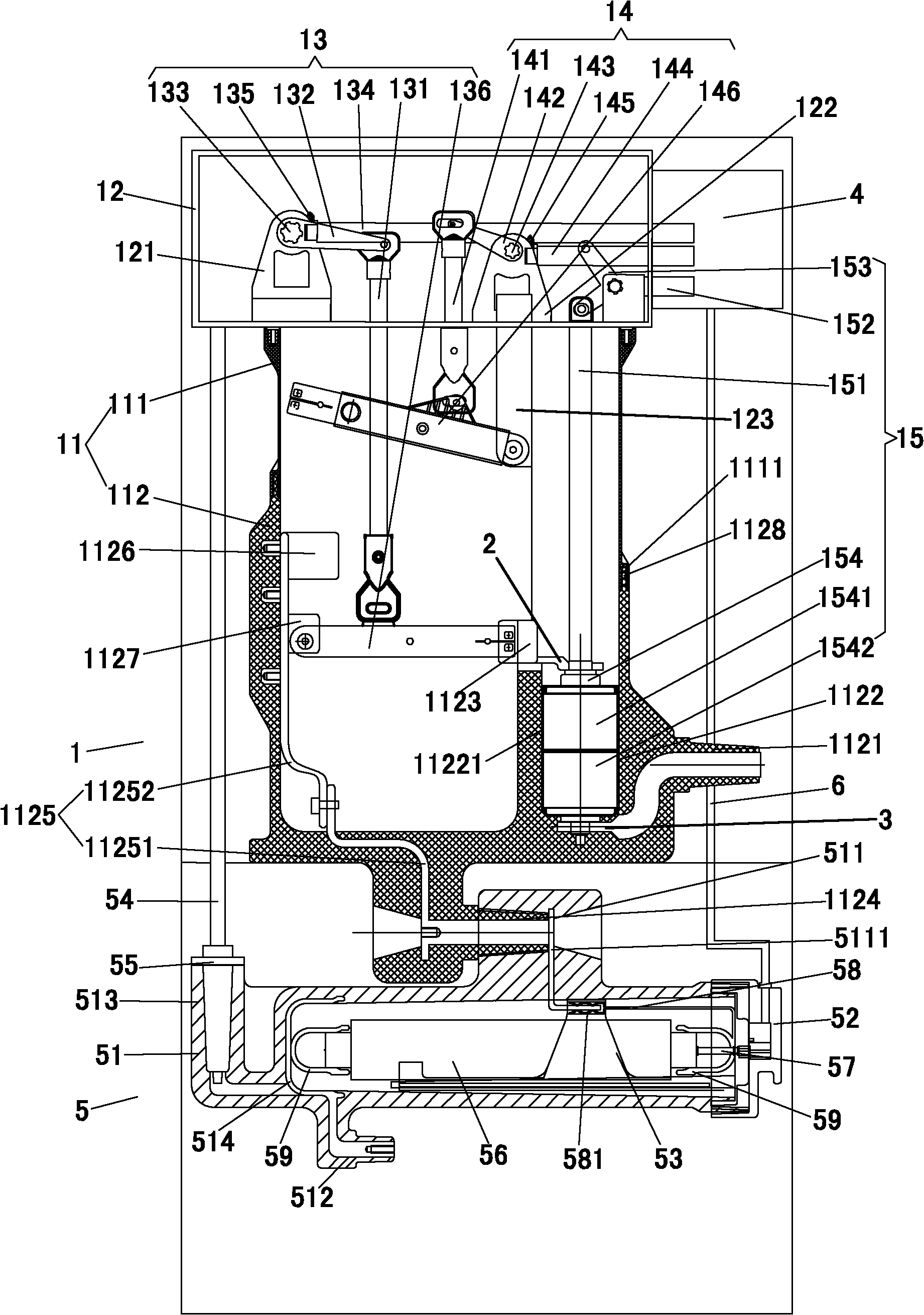

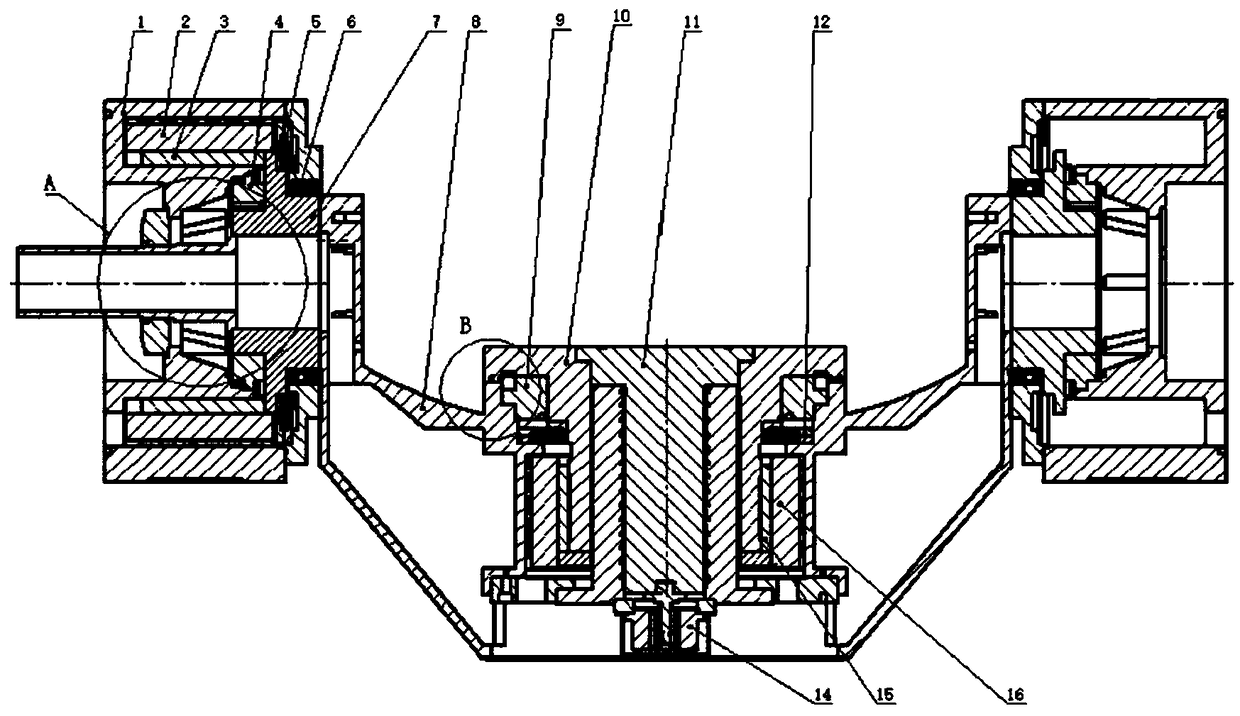

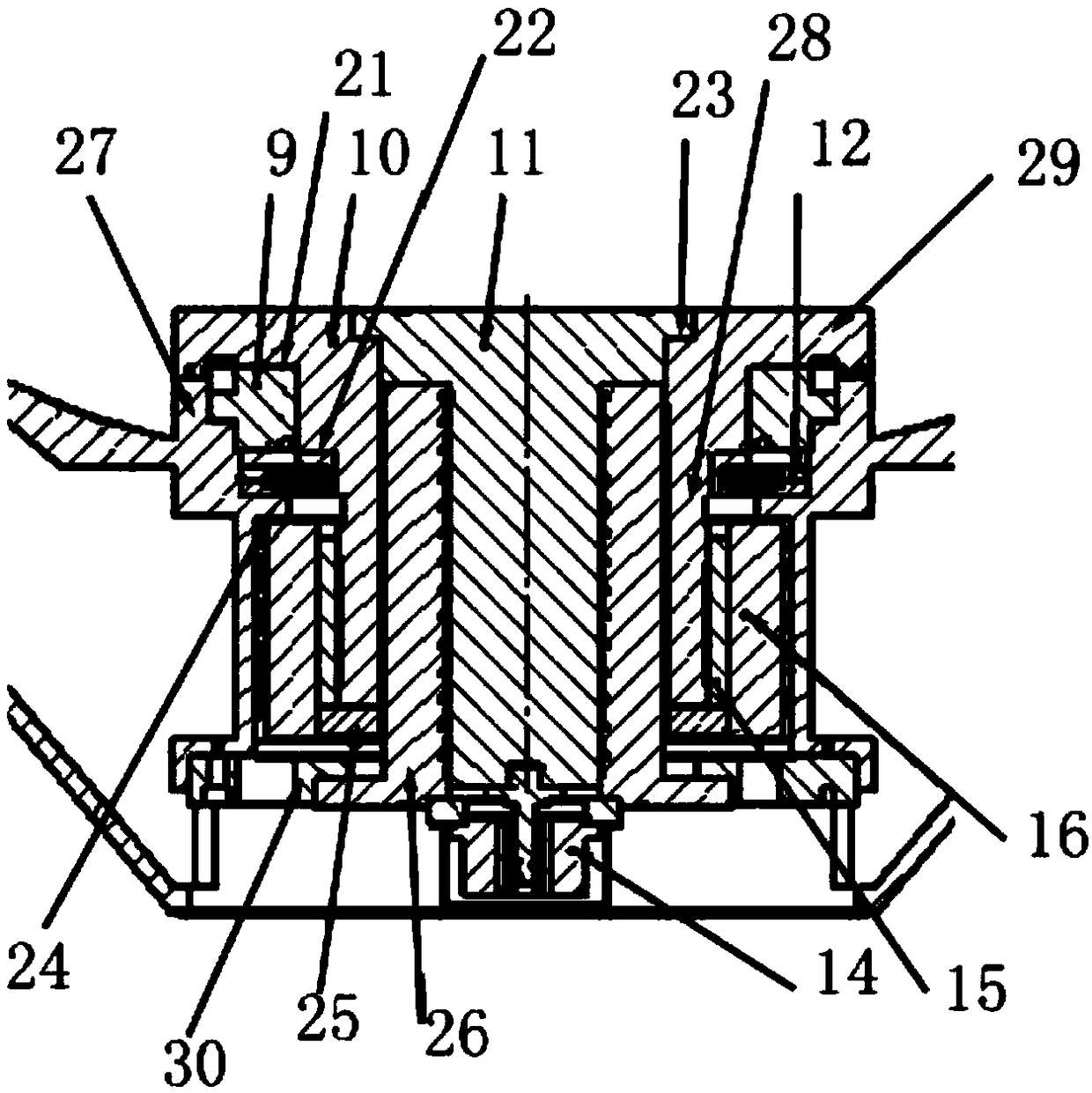

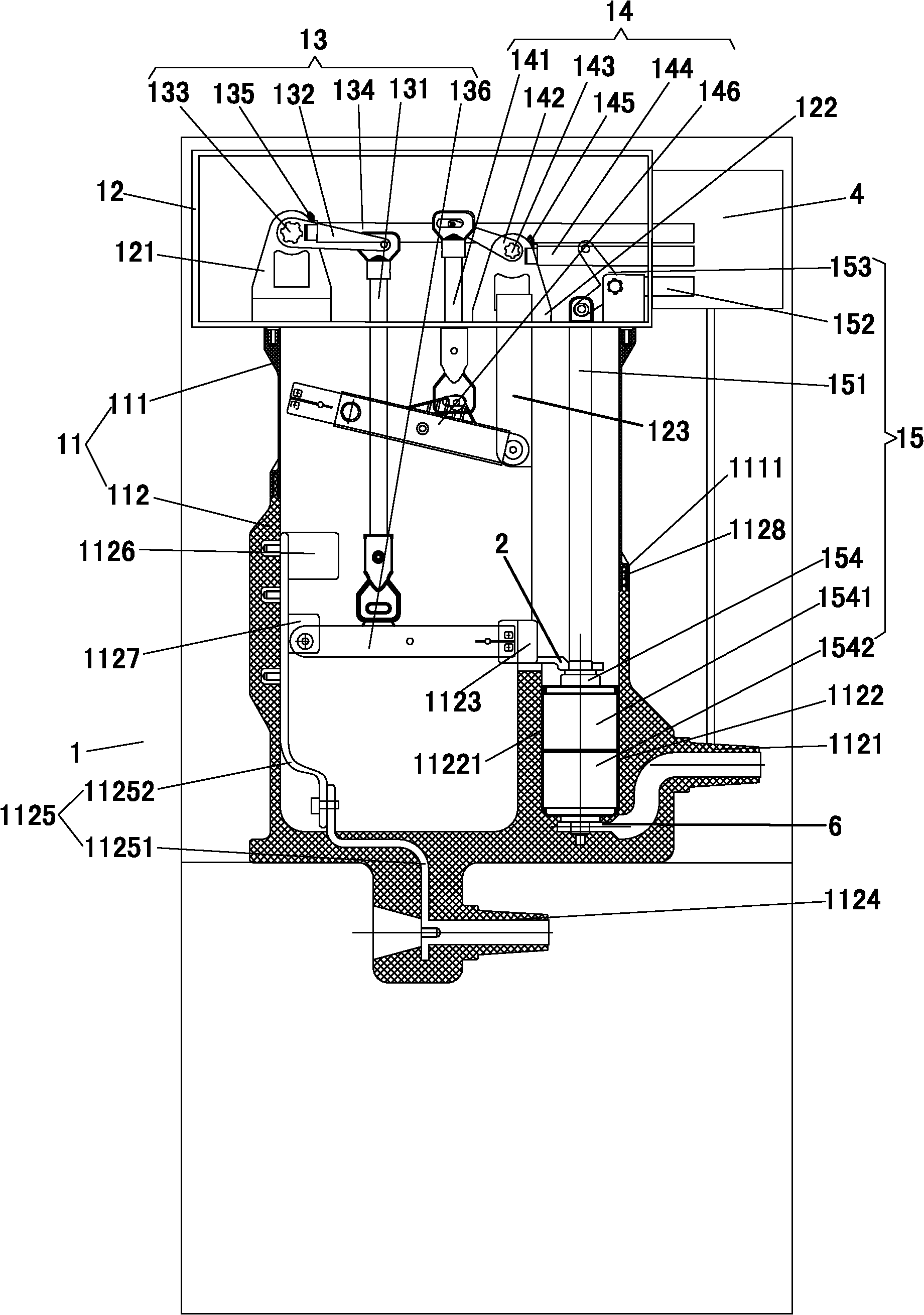

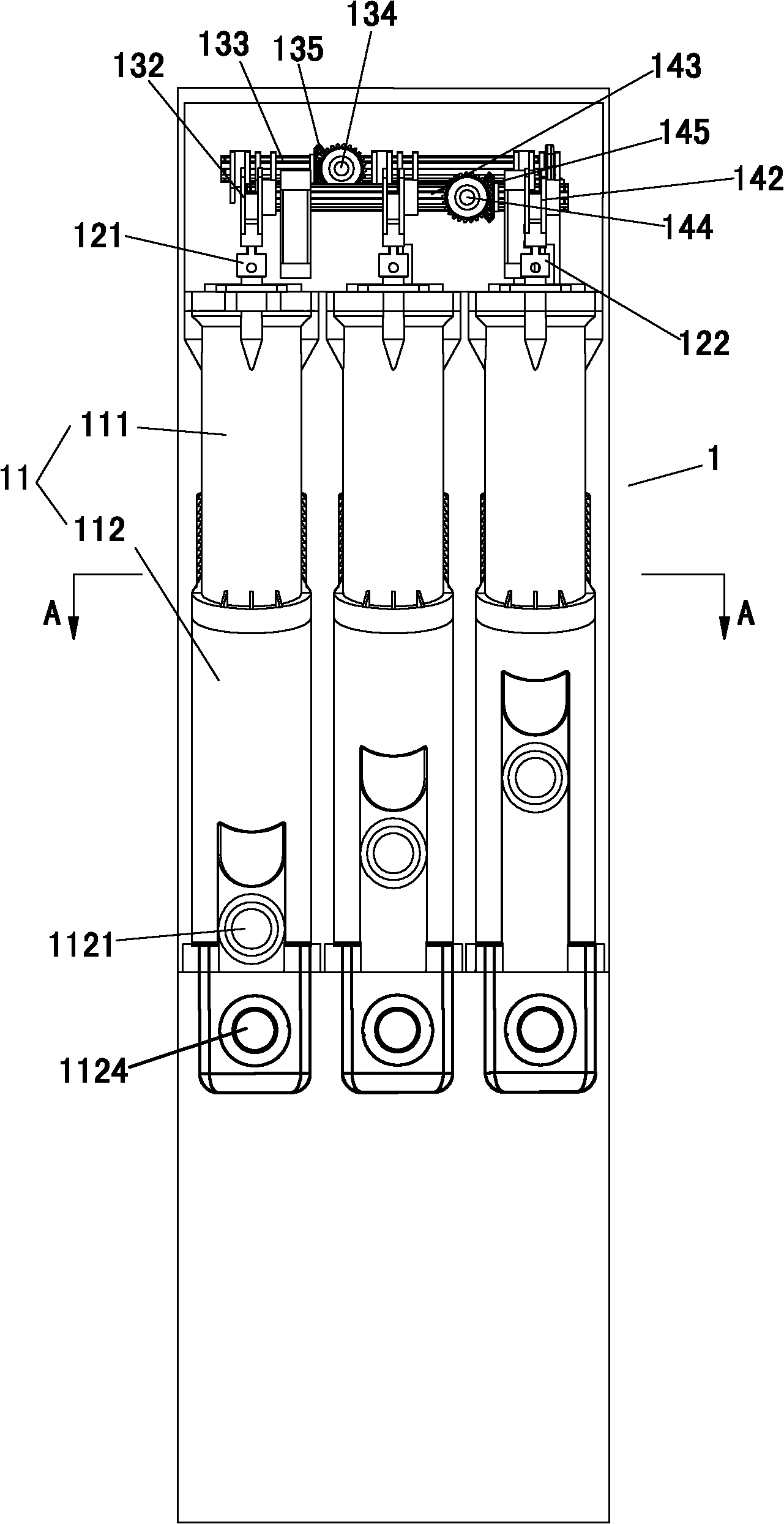

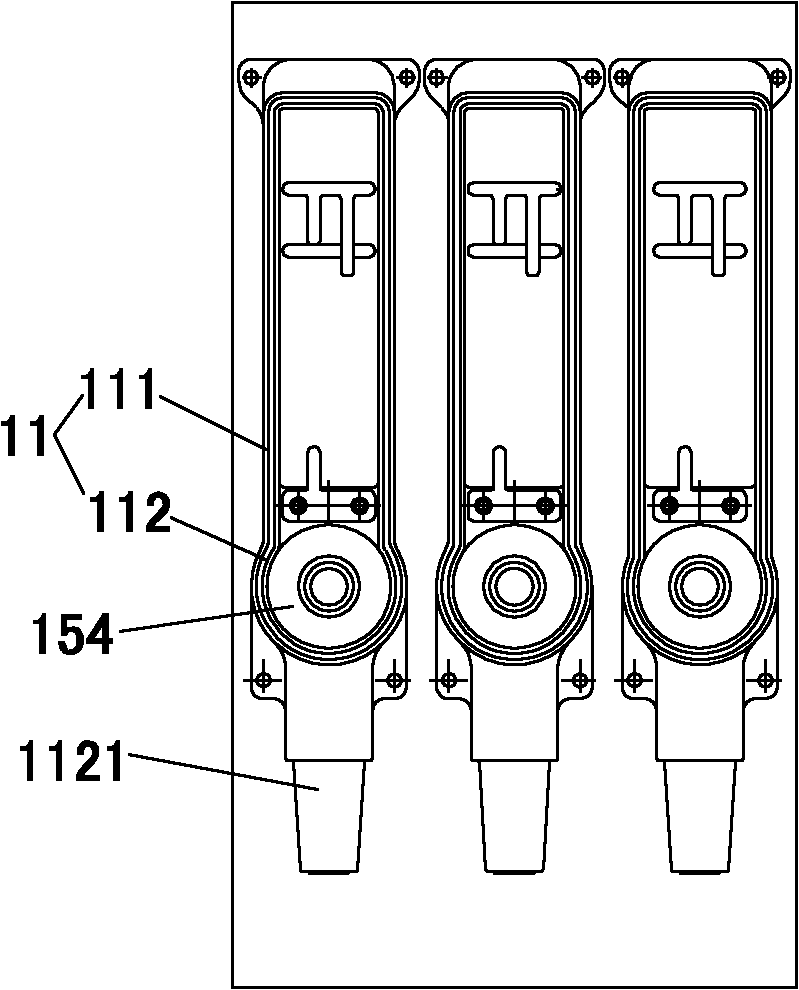

24kV solid insulated fully-closed switch combined electrical appliance

ActiveCN101847838AExtended service lifeEasy to replaceSwitchgear arrangementsSubstation/switching arrangement boards/panels/desksThree-phaseAlternating current

The invention discloses a 24kV solid insulated fully-closed switch combined electrical appliance, which is applied to an alternating current trunk line or an alternating current distribution network and comprises three phases of high-voltage load switch units and a fuse protector unit; each phase of high-voltage load switch unit comprises a switch insulated hood fixed in a box body, a driving hood, an isolating switch, an earthed switch and a vacuum switch; the upper parts of the three phases of switch insulating hoods are connected with the driving hood which is formed by connecting an upper half cylinder and a lower half cylinder; the isolating switch, the earthed switch and the vacuum switch are arranged in the switch insulating hood and the driving hood; and the fuse protector unit is arranged below the high-voltage load switch unit. The invention has the advantages of compact structure, low cost, safe use, easy maintenance and debugging and long service life.

Owner:BEIJING SOJO ELECTRIC

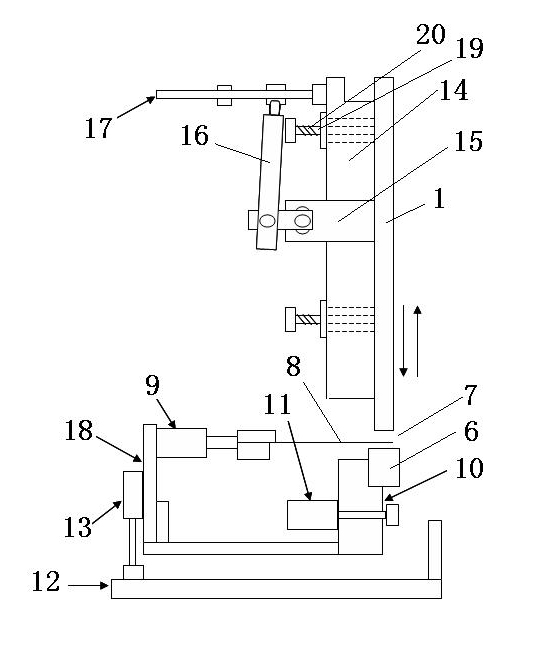

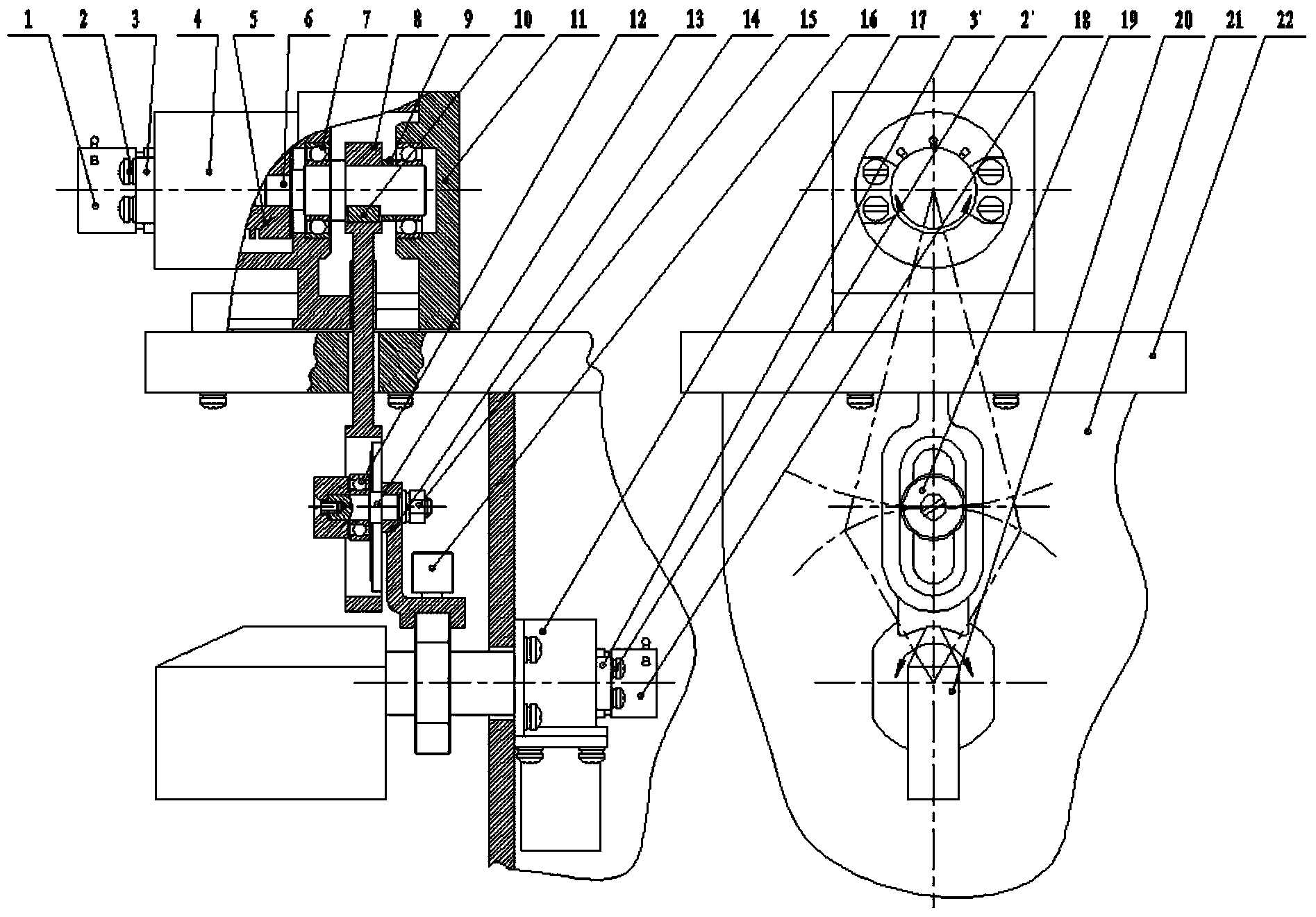

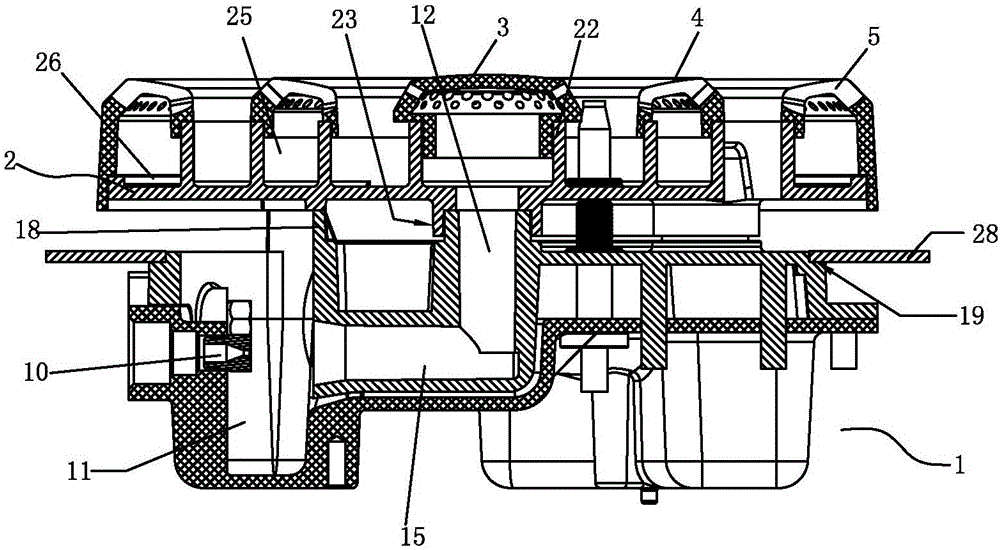

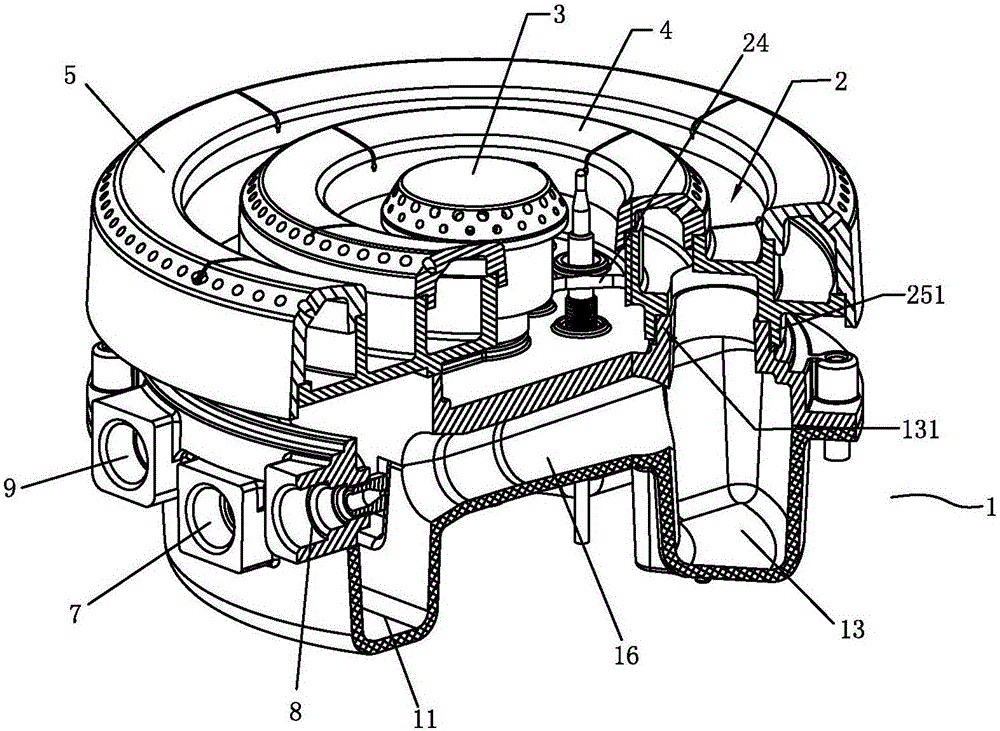

Double-rotation-shaft precision workbench

PendingCN108620898ARealize processingHigh positioning accuracyLarge fixed membersRotary stageRotational axis

The invention relates to a double-rotation-shaft precision workbench. The double-rotation-shaft precision workbench comprises a rotation workbench capable of rotating along a B axis, the lower portionof the rotation workbench is arranged in a swinging basket body, and the two ends, away from the rotation workbench, of the swinging basket body are fixed to an A-axis main shaft capable of rotatingalong an A axis. The outer edge of the A-axis main shaft is connected with a first torque motor, wherein the first torque motor can drive the A-axis main shaft to rotate, and accordingly the swingingbasket body can be driven to do the rotation movement along the A axis. The outer side of a rotation shaft of the rotation workbench is connected with a second torque motor, wherein the second torquemotor can drive the rotation shaft to rotate, and accordingly the rotation workbench can be driven to do the rotation movement along the B axis. The double-rotation-shaft workbench is arranged along the A axis and the B axis, the torque motors are adopted for direct drive, the rotation coordinate axis of a horizontal machining center has high positioning precision, and since the torque motors areadopted for direct drive, the inner space can be sufficiently utilized, the height of a rotation table is reduced, and the whole rotation table structure is more compact.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

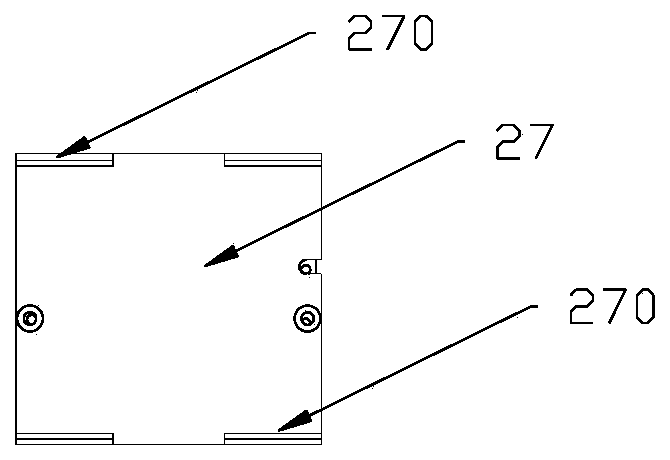

24kv solid insulated fully-closed switch equipment

ActiveCN101847839AEasy to debug and maintainEasy to installSwitchgear arrangementsEarthing arrangementsThree-phaseEngineering

The invention discloses 24kV solid insulated fully-closed switch equipment, which is applied to an alternating current trunk line or an alternating current distribution network and comprises a three phases of high-voltage load switch units; each phase of high-voltage load switch unit comprises a switch insulated hood fixed in a box body, a driving hood, an isolating switch, an earthed switch and a vacuum switch; the upper part of the three phases of switch insulating hoods are connected with the driving hood which is formed by connecting an upper half cylinder and a lower half cylinder; and the isolating switch, the earthed switch and the vacuum switch are arranged in the switch insulating hood and the driving hood. The invention has the advantages of compact structure, low cost, safe use and easy maintenance and debugging.

Owner:BEIJING SOJO ELECTRIC

Non-contact ultrasonic flow velocity meter and non-contact flow velocity detection method

InactiveCN105181997AImprove stabilityImprove accuracyFluid speed measurementNon-contact ultrasoundWater flow

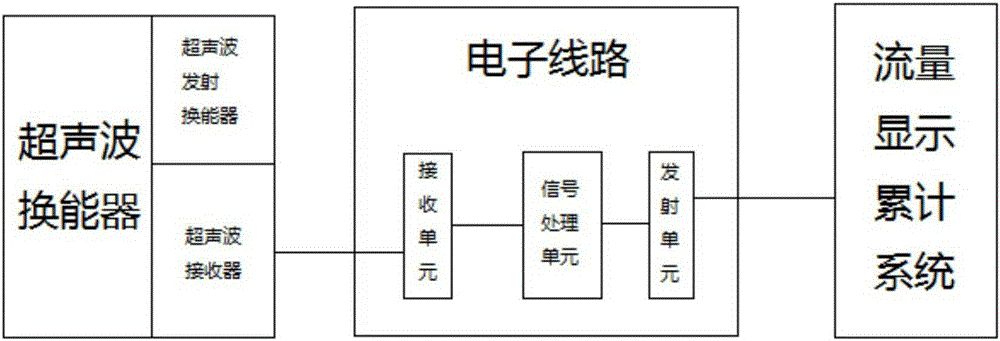

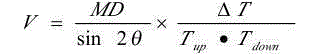

The invention discloses a non-contact ultrasonic flow velocity meter. The non-contact ultrasonic flow velocity meter comprises an ultrasonic transducer, an electronic circuit and a flow display and accumulation system, wherein the ultrasonic transducer comprises an ultrasonic emission transducer and an ultrasonic receiver; the ultrasonic emission transducer is used for converting electric energy into ultrasonic energy, and emitting the ultrasonic energy to the detected flow; the ultrasonic receiver is used for receiving ultrasonic signals and sending the ultrasonic signals to the electronic circuit; the electronic circuit comprises an emission unit, a receiving unit and a signal processing unit; the receiving unit is used for receiving the ultrasonic signals sent from the ultrasonic receiver and sending the ultrasonic signals to the signal processing unit to process the signals; and the emission unit sends the signals processed by the signal processing unit to the flow display and accumulation system. As the non-contact ultrasonic flow velocity meter installs the ultrasonic emission transducer and the ultrasonic receiver on the outer wall of a pipeline to be detected, flow detection when the water flow is opened wide can be performed, and no detection elements are required to be installed in the flow while the flowing state of the flow is not changed.

Owner:TIANJIN ZHONGZHONG SCI & TECH CO LTD

Standard combined acceleration output device

InactiveCN104019830ACompact layoutImprove structural strengthMeasurement devicesEngineeringOutput device

The invention discloses a standard combined acceleration output device based on a swing arm centrifuge and an electromagnetic vibrating table, which is used for generating standard combined acceleration formed by combining linear stable acceleration and sinusoidal acceleration. The device comprises the swing arm centrifuge and the electromagnetic vibrating table arranged at the tail end of a swing arm of the swing arm centrifuge, wherein the linear stable acceleration is generated by the swing arm centrifuge; the sinusoidal acceleration is generated by the electromagnetic vibrating table. According to the device, the metering and testing requirements of an acceleration meter under the condition of combination of the stable acceleration and the sinusoidal acceleration are met; the vibrating table is independently arranged at the tail end of the swing arm of the centrifuge, and the problem of deviation of a movable ring of the electromagnetic vibrating table under a centrifugal force field is solved by a reverse electromagnetic coil additionally arranged in the vibrating table; the device is compact in structure; standard components are adopted, so that the device can be flexibly mounted and dismounted, and is convenient to debug and maintain.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

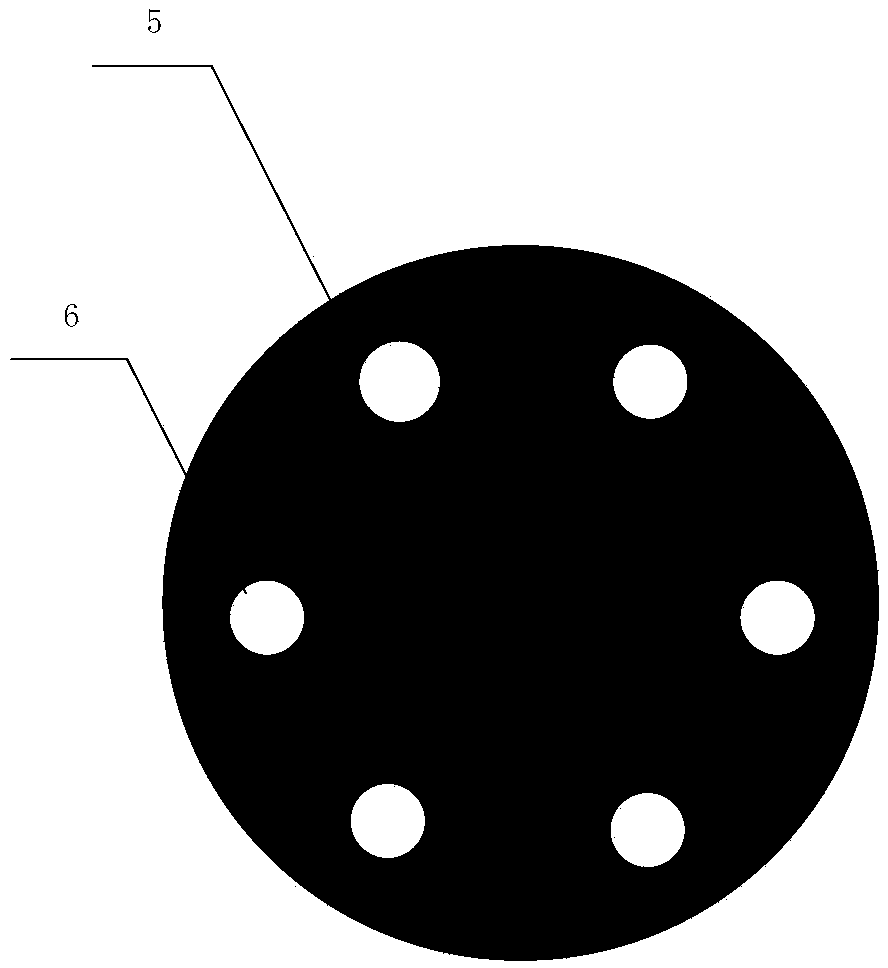

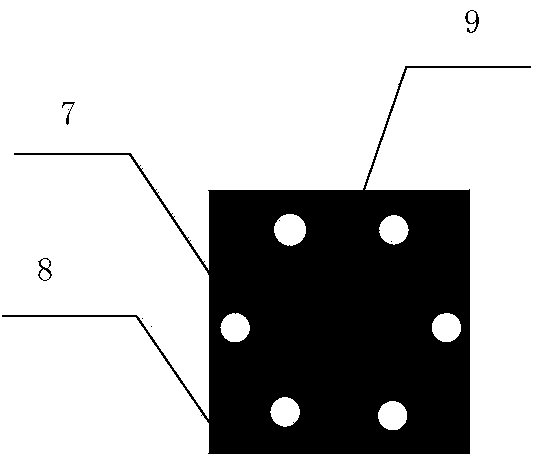

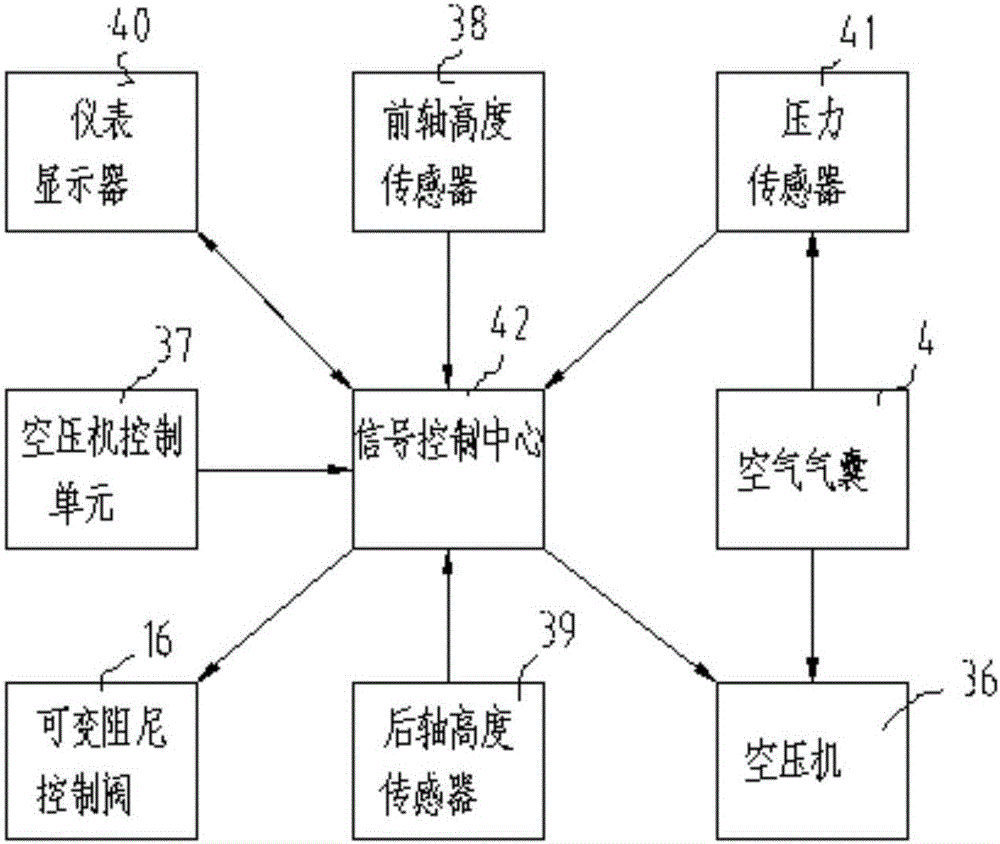

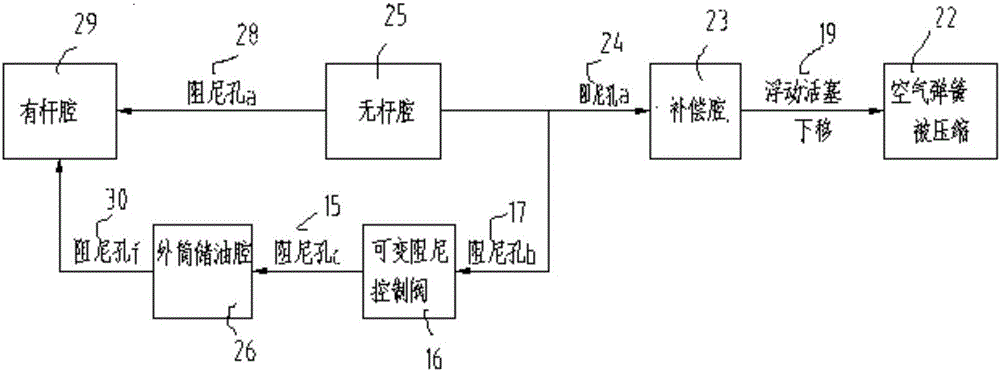

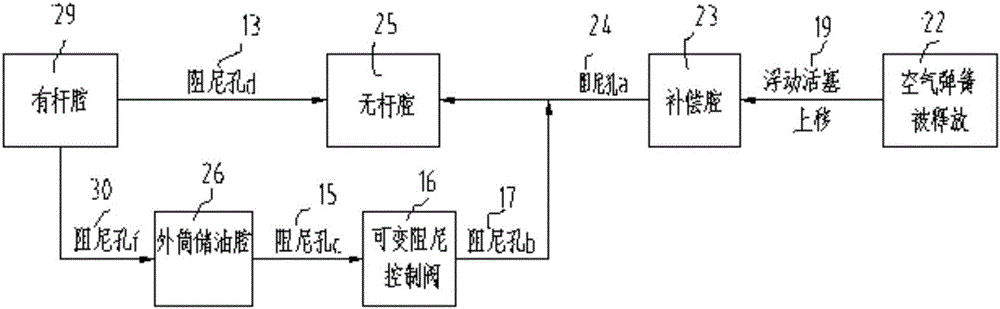

Variable damping automobile hydraulic buffer provided with height adjusting system

InactiveCN106090111ALimit rate of changeEasy to chargeSpringsResilient suspensionsCylinder headAir compressor

The invention provides a variable damping automobile hydraulic buffer provided with a height adjusting system. The hydraulic buffer comprises a buffering system and the height adjusting system. The buffering system comprises a piston rod, a piston head, a spring assembly, an inner barrel, an outer barrel and a variable damping control valve. The height adjusting system comprises an air compressor, an air compressor control unit, a front axle height sensor, a rear axle height sensor, a pressure sensor, a signal control center, an air cylinder head, an air sac and a cylinder barrel. The inner barrel is partitioned into a rod cavity and a rodless cavity by the piston head. The outer barrel is partitioned into an outer barrel oil storage cavity and a floating piston oil storage cavity by an inner barrel lower end cover. Two oil ports of the variable damping control valve communicate with the outer barrel oil storage cavity and the rodless cavity correspondingly. A floating piston separates oil liquid from an air spring chamber. The oil liquid circuits between the rodless cavity and the rod cavity through the variable damping control valve and a series of damping holes, and is matched with the height adjusting system for making corresponding height compensation while the buffer is compressed or stretched. A good buffering effect and riding comfort can be obtained.

Owner:JIANGSU UNIV

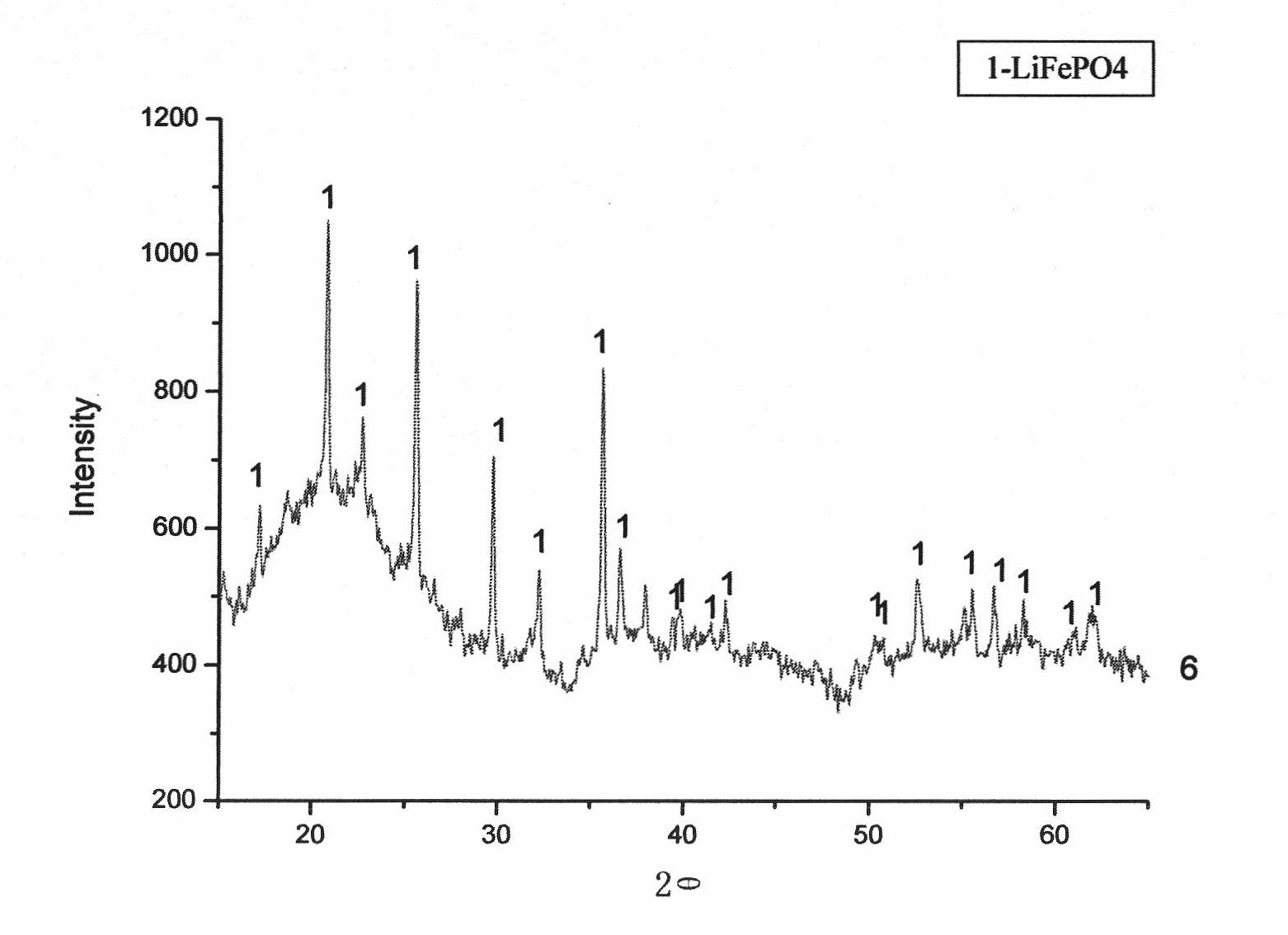

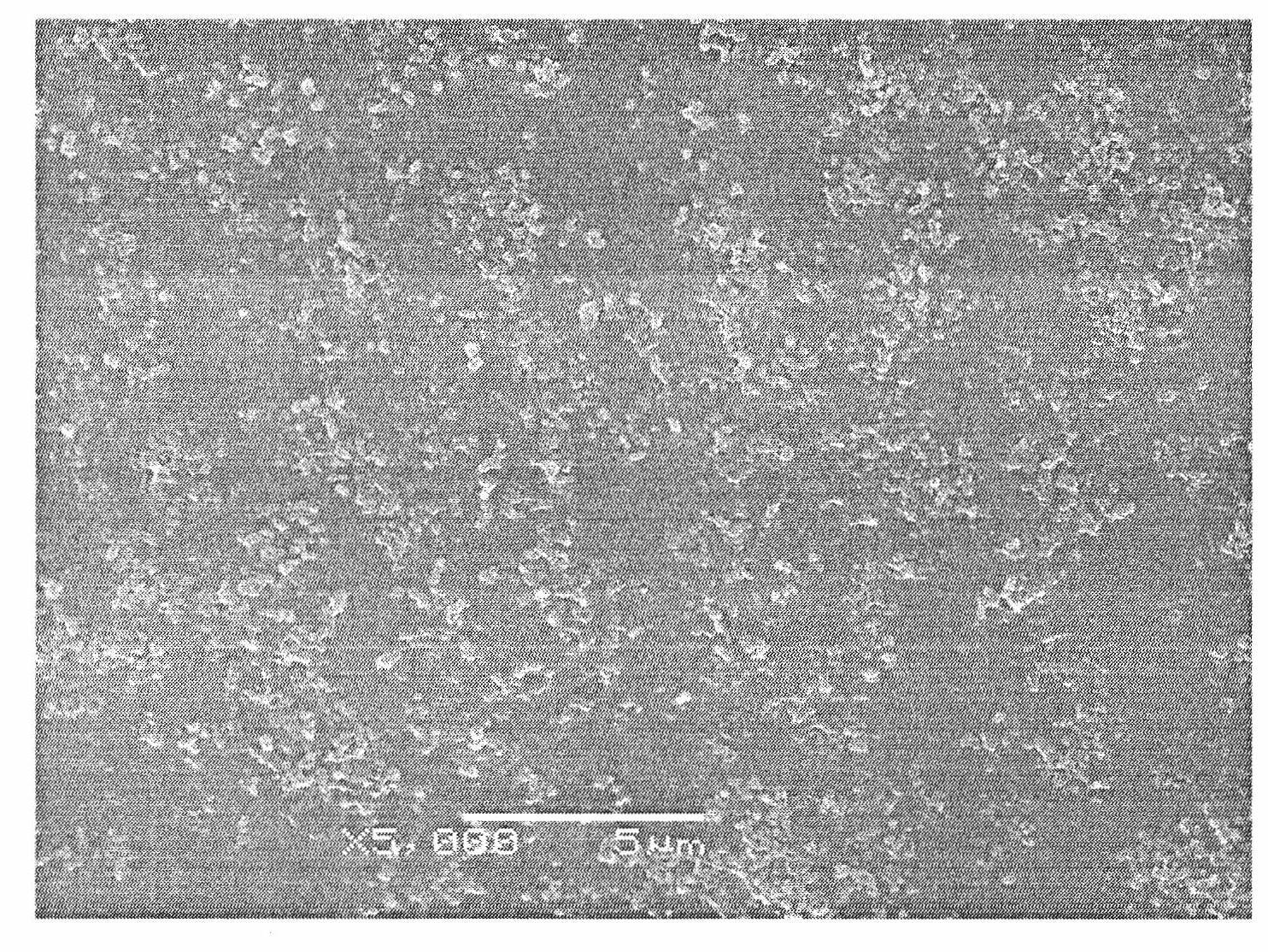

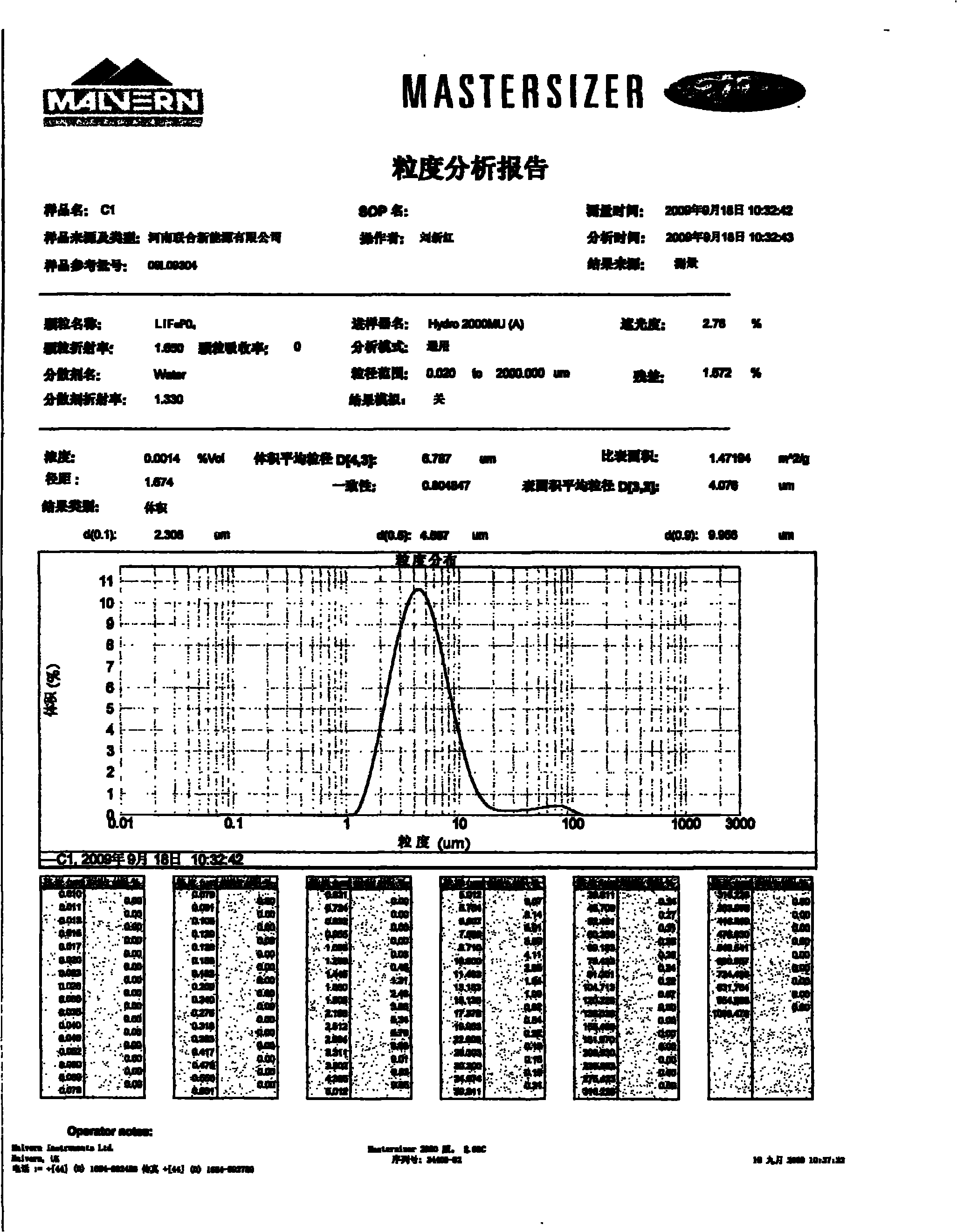

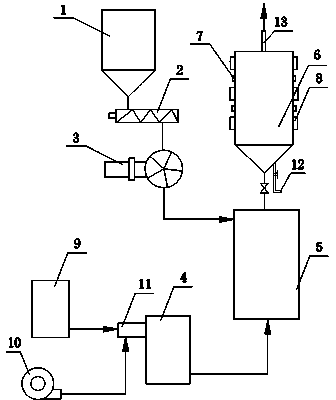

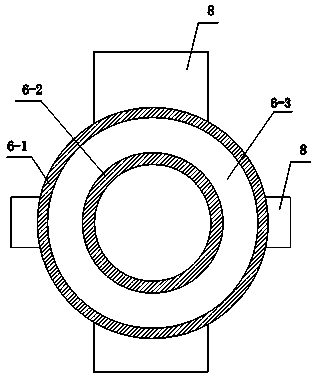

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

Air steering engine rudder piece angle and electrical angle overlapping zeroing execution mechanism

ActiveCN104111021ASimple structureLow costAngles/taper measurementsElectrical testingPosition angleAngular degrees

The invention discloses an air steering engine rudder piece angle and electrical angle overlapping zeroing execution mechanism. When zeroing is carried out, a rudder piece begins to be in oscillating motion under an acting force, the rudder piece drives a fixed shaft to be in synchronous oscillating motion through a shift fork, a rolling bearing II rolls up and down in a waist-shape groove to force an oscillating bar to oscillate, the oscillating bar drives a rotation shaft to rotate, and meanwhile, drives an angle sensor I to rotate synchronously through an elastic coupler, and thus the angle of the rudder piece is collected. When the oscillating bar stops oscillating, the rudder piece is in the zero position; and at the moment, if error appears between the zero position angle collected by the angle sensor I and the angle of an angle sensor II, a pressing plate II and a screw II on the steering engine are loosened, the angle sensor II is rotated to enable the angle sensor II to be overlapped with the zero position angle of the angle sensor I, and a screw II on the steering engine is then fastened. The execution mechanism is simple in structure, low in cost and convenient to assemble, maintain and debug, and meets the requirement that the overlap degree of the electrically-controlled angle of the steering engine and the mechanical angle of the rudder piece is guaranteed to be in graded precision.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

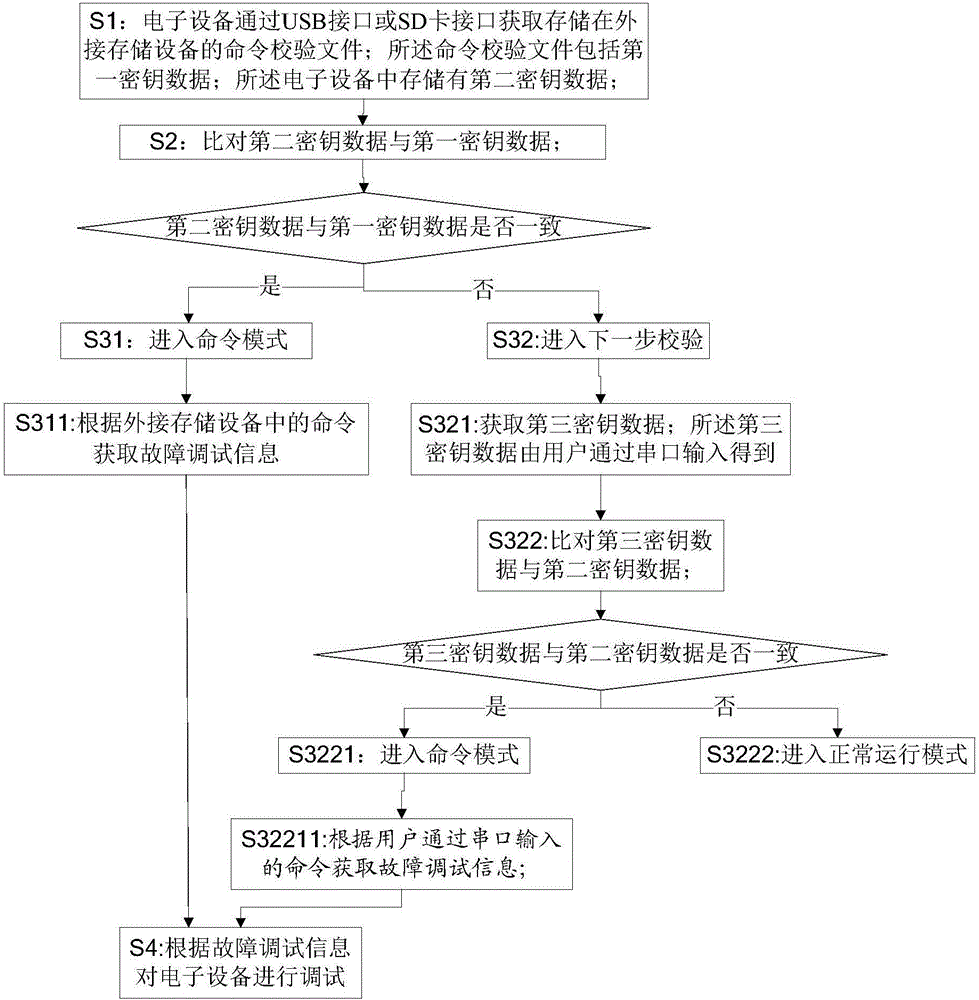

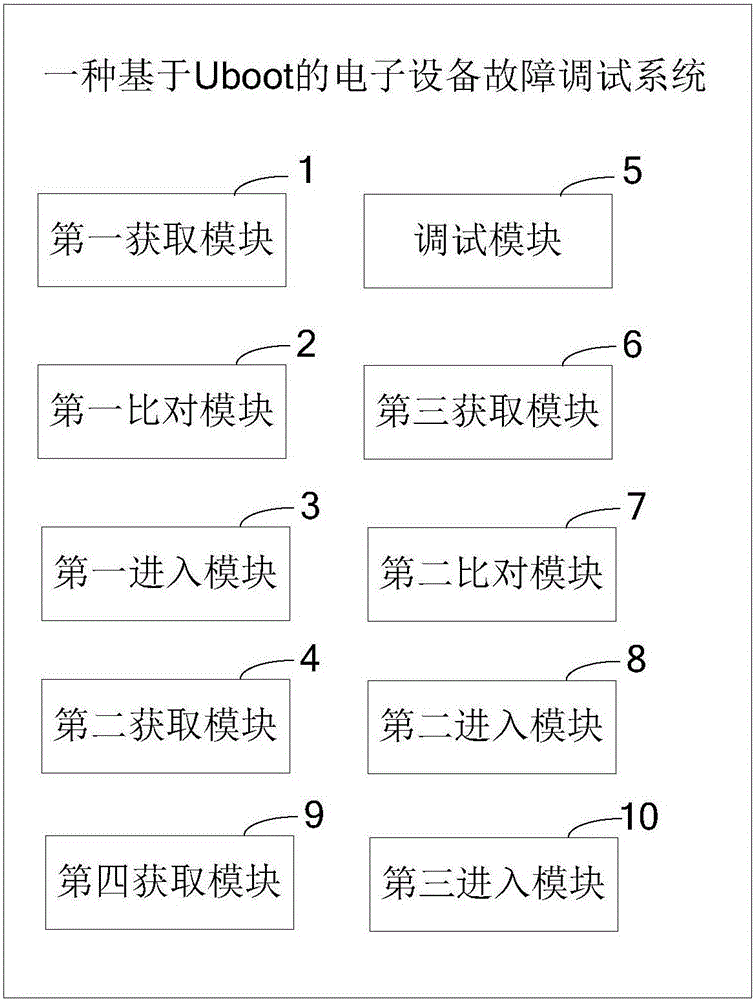

Method and system for debugging failures of electronic products based on Uboot

ActiveCN106776308AImprove convenienceImprove efficiencySoftware testing/debuggingDigital data authenticationSerial portCommand pattern

The invention relates to the field of maintenance of electronic products, in particular to a method and a system for debugging failures of electronic products based on Uboot. The method for debugging the failures of the electronic products based on Uboot comprises the following steps: using electronic equipment to acquire a command verification file, stored in an external storage device, by means of a universal serial bus (USB) interface or a secure digital (SD) card interface, wherein the command verification file comprises first secret key data; comparing second secret key data with the first secret key data; if the second secret key data is consistent with the first secret key data, entering a command mode; using the electronic equipment to acquire failure debugging information by means of the USB interface or the SD card interface according to the command stored in the external storage device; debugging the electronic equipment according to the failure debugging information. A fast and safe failure debugging method is provided for the electronic equipment, especially for the electronic equipment without a serial port.

Owner:FUZHOU GAOTU INFORMATION TECH

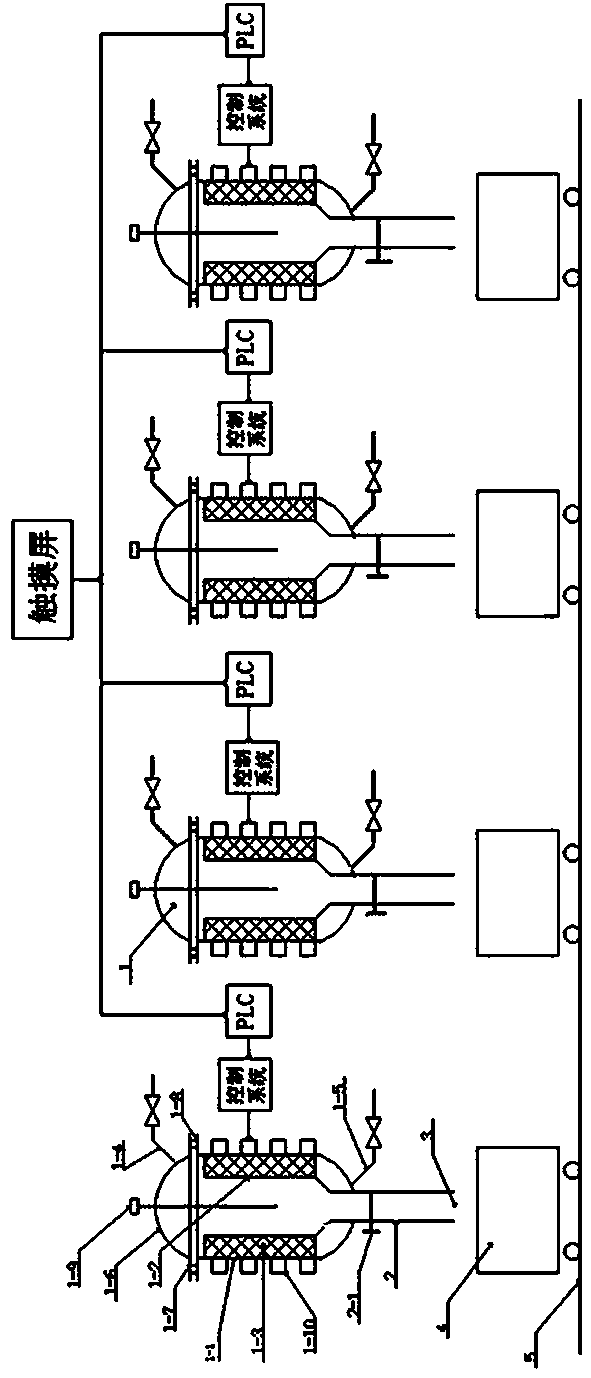

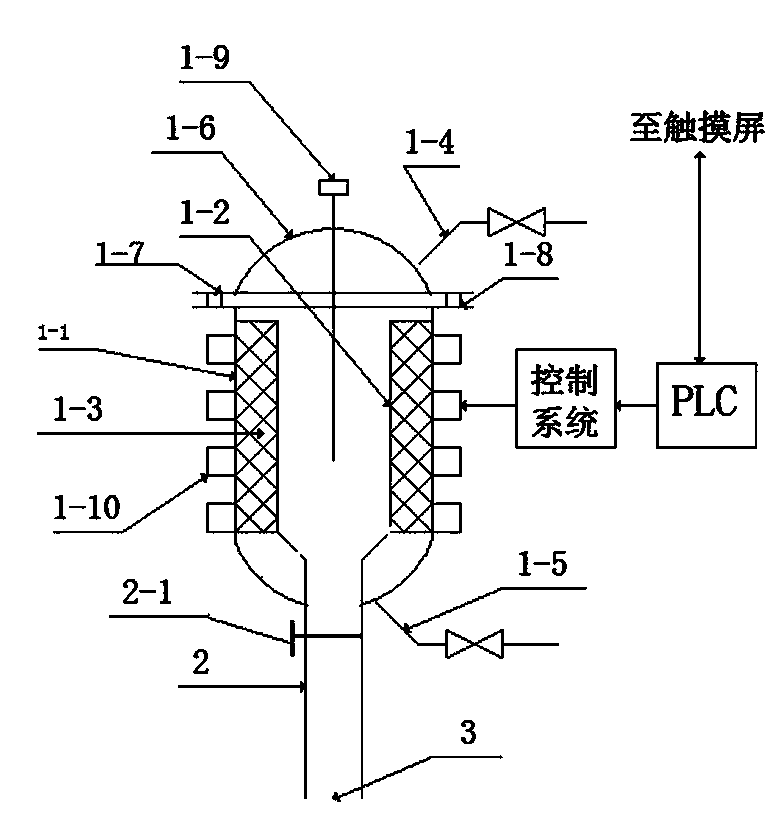

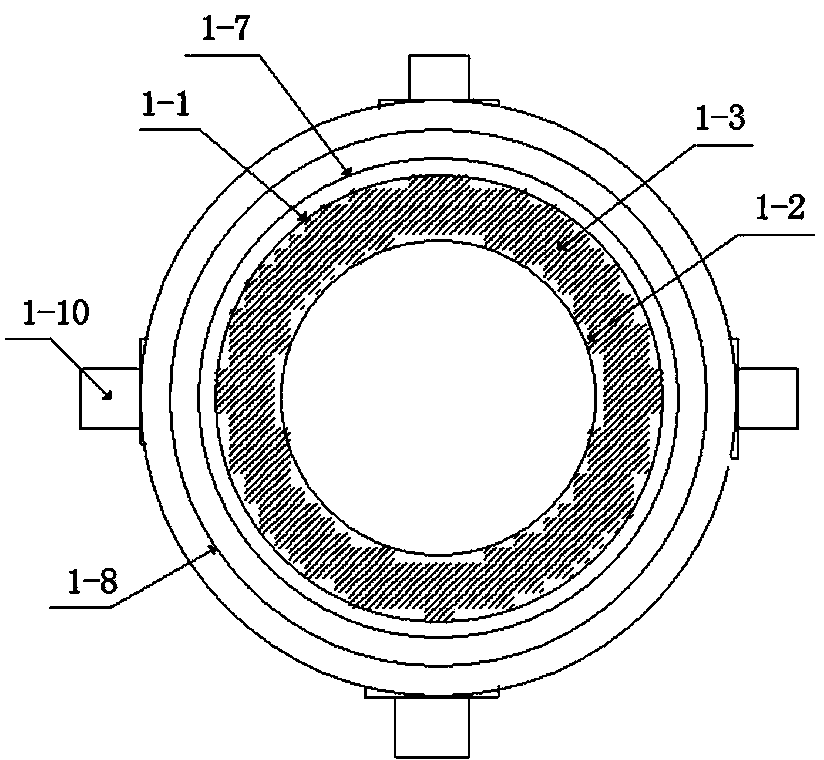

Magnesite/dolomite microwave light-burning device and method

Owner:山东派智新能源科技有限公司

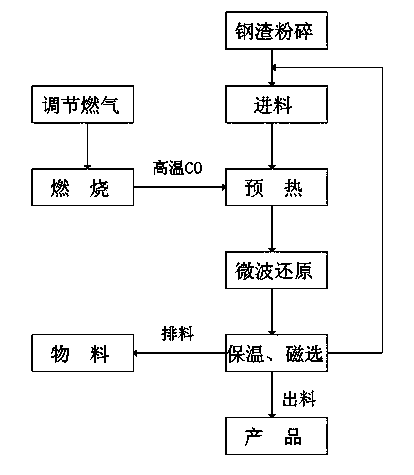

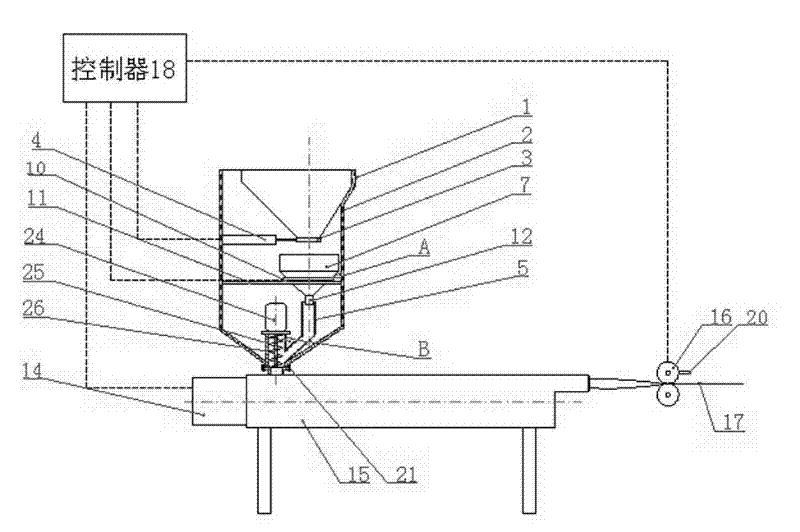

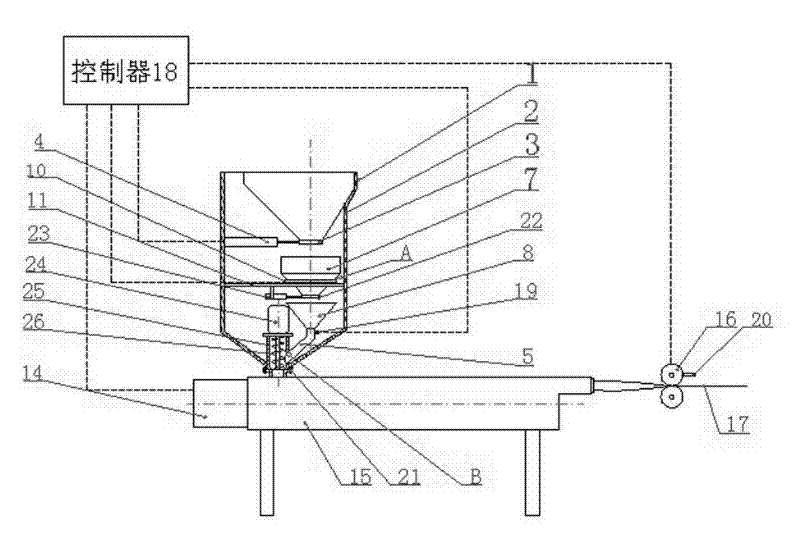

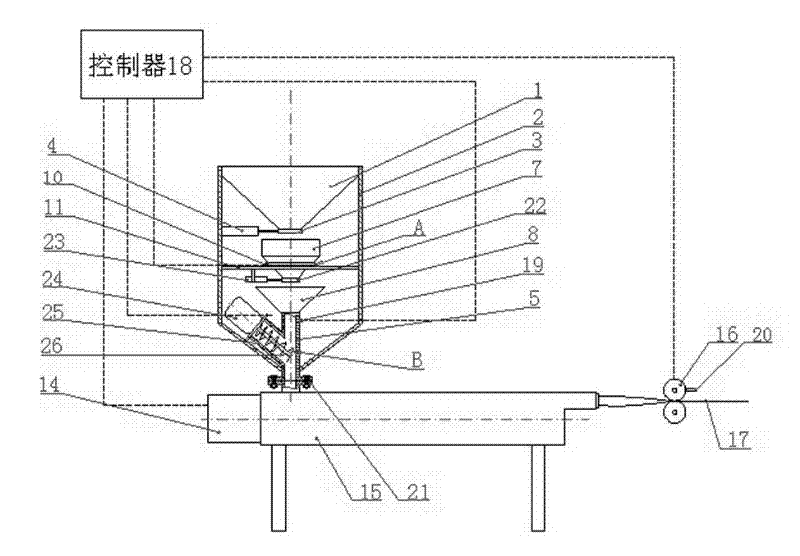

Magnetic separation device and method for reducing hematite-containing material by utilizing microwave

The invention relates to a device and a method for reducing hematite-containing materials by utilizing microwave heat treatment and carrying out magnetic separation. The device comprises a material bin, a screw feeder, a star type feeding machine, a preheating reacting furnace and a microwave magnetic separator. When the magnetic separation is carried out, the materials are crushed and then added to the material bin, powdery materials enter the preheating reacting furnace through the screw feeder and the star type feeding machine for preheating, and the preheated powdery materials enter the microwave magnetic separator through an air inlet pipe for the microwave heat treatment and the magnetic separation; products subjected to the magnetic separation are discharged through an ore discharge pipe from a discharge port, and other materials are discharged through an outlet pipe from the discharge port. The device disclosed by the invention can be used for reducing the weak magnetic Fe2O3 contained in the materials into strong magnetic Fe3O4 through the microwave heating and separating the iron ore concentrates through the magnetic separation, integrally and simultaneously carries out the reduction and the magnetic separation, has the advantages of small investment, low energy consumption, large treatment quantity, water saving, no air pollution, wide application range and relatively popularization prospect, is simple in equipment, and can be used for treating multiple hematite-containing materials which include ores, such as steel slag, low-grade limonite and iron ores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Automatic control device for uniform discharge of extruder

The invention relates to a novel application of a refining device on a device for automatically controlling an extruder to discharge material uniformly, wherein the device for automatically controlling an extruder to discharge material uniformly comprises a controller, a raw material hopper, a rack, a feed hopper and a weighing device, wherein the raw material hopper and the feed hopper are respectively arranged on the upper end and the lower end of the rack, and a lower outlet of the feed hopper is connected with a feed port of the extruder; a lower outlet of the raw material hopper is provided with an automatically controlled raw material gate; an input end of the controller is connected with the weighing device, an output end of the controller is connected with a motor of an extruding screw of the extruder or a driving motor of a traction roll, and an upper surface of the feed port of the extruder is connected with a material blending device. The invention has the advantages that a structure is simplified, the manufacturing cost is reduced, a control principle is simple, the operation is easy, the precision can meet production needs, the maintenance and the debugging are easy; and the uniformity of length, color and thickness of products is greatly improved.

Owner:王根乐

Horizontal knitting machine

The invention mainly relates to a horizontal knitting machine. The horizontal knitting machine comprises a main rack, a needle selection system, a sliding rail assembly, a machine head part, a shuttlepart, a yarn cutting device and a finger splitting system, wherein the needle selection system comprises a roller mechanism, two rollers of the roller mechanism are driven by an independent driving device, the sliding rail assembly is arranged above the needle selection system, the machine head part is arranged on the sliding rail assembly, the machine head part comprises a front machine head assembly and a rear machine head assembly, the driving device is in linkage connection with the front machine head assembly and the rear machine head assembly through a transmission assembly, so that thefront machine head assembly and the rear machine head assembly achieve horizontal reciprocating motion on the sliding rail assembly, the upper end of the machine head part is provided with a shuttleassembly, the shuttle assembly is intermittently driven by the machine head part, the yarn cutting device is connected with the independent driving device for driving, and the finger splitting systemcomprises a fork knife part and a scissors part. The horizontal knitting machine has the advantages that the structure is simple, the horizontal knitting machine is portable and flexible, the operating load is low, the energy consumption is low, the transmission and weaving efficiency is improved, and the maintenance and debugging are convenient, and economic benefits of enterprises is increased.

Owner:ZHEJIANG RUIFENG INTELLIGENT TECH CO LTD

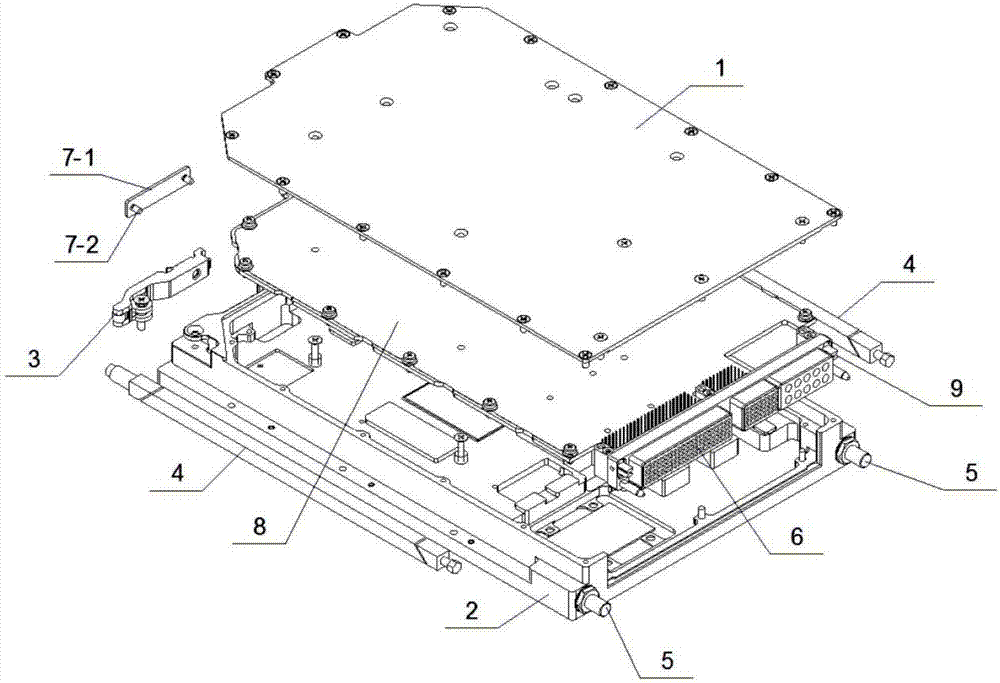

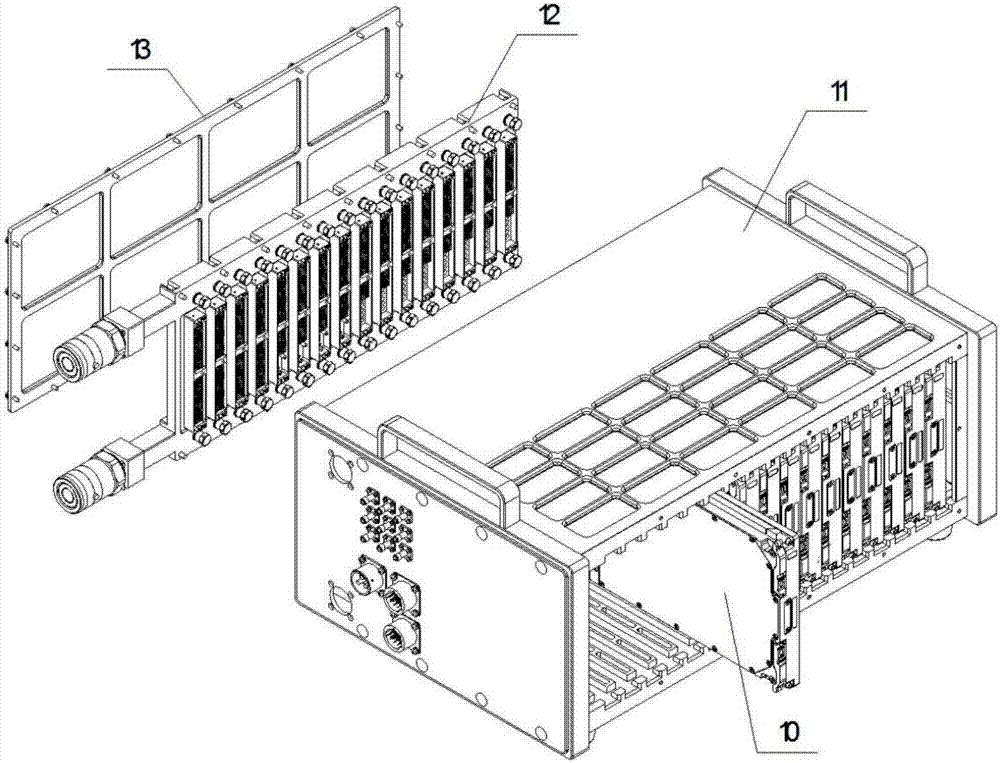

Blind plug type liquid cooling module

InactiveCN107172863AEasy to debug and maintainQuick changeCooling/ventilation/heating modificationsCooling channelMechanical engineering

A blind plug type liquid cooling module comprises a liquid cooling cavity which is composed of a cavity, a built-in flow channel, and fluid. A puller is arranged in the front of the liquid cooling cavity. A floating blind plug connector is arranged in the rear of the liquid cooling cavity. A plurality of printed boards or devices are arranged in the middle. Locking strips are arranged at both sides. A cover plate is arranged at least above. The cover plate, the liquid cooling cavity and the floating blind plug connector constitute an isolated chamber which provides electromagnetic shielding and salt fog isolation for the printed boards or the devices. A blind plug liquid cooling joint is arranged in the rear of the liquid cooling cavity. A cooling channel is formed between the blind plug liquid cooling joint and the built-in flow channel of the liquid cooling cavity. Cooling liquid circulates in the cooling channel to cool the printed boards or the devices.

Owner:叶发亮

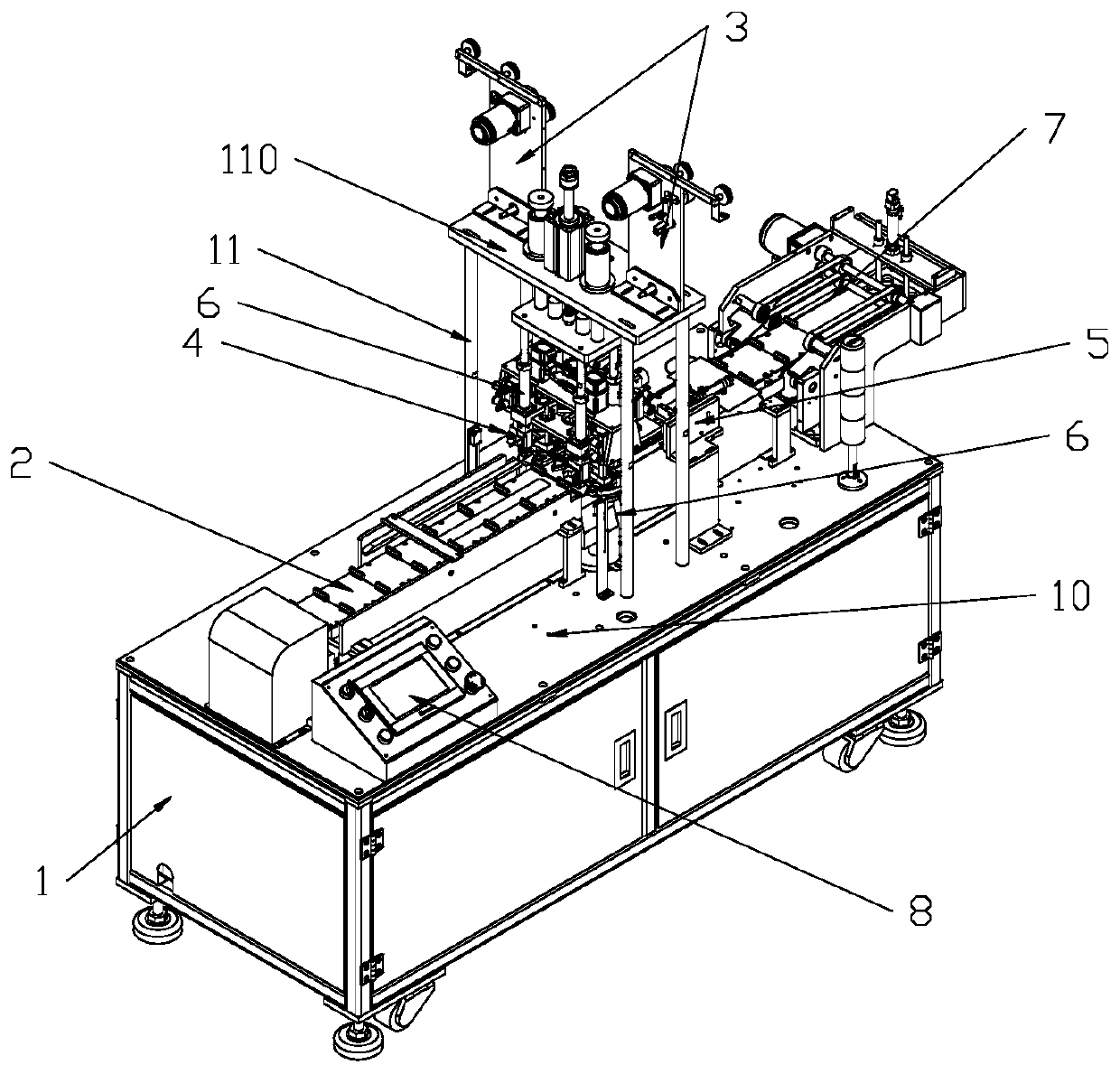

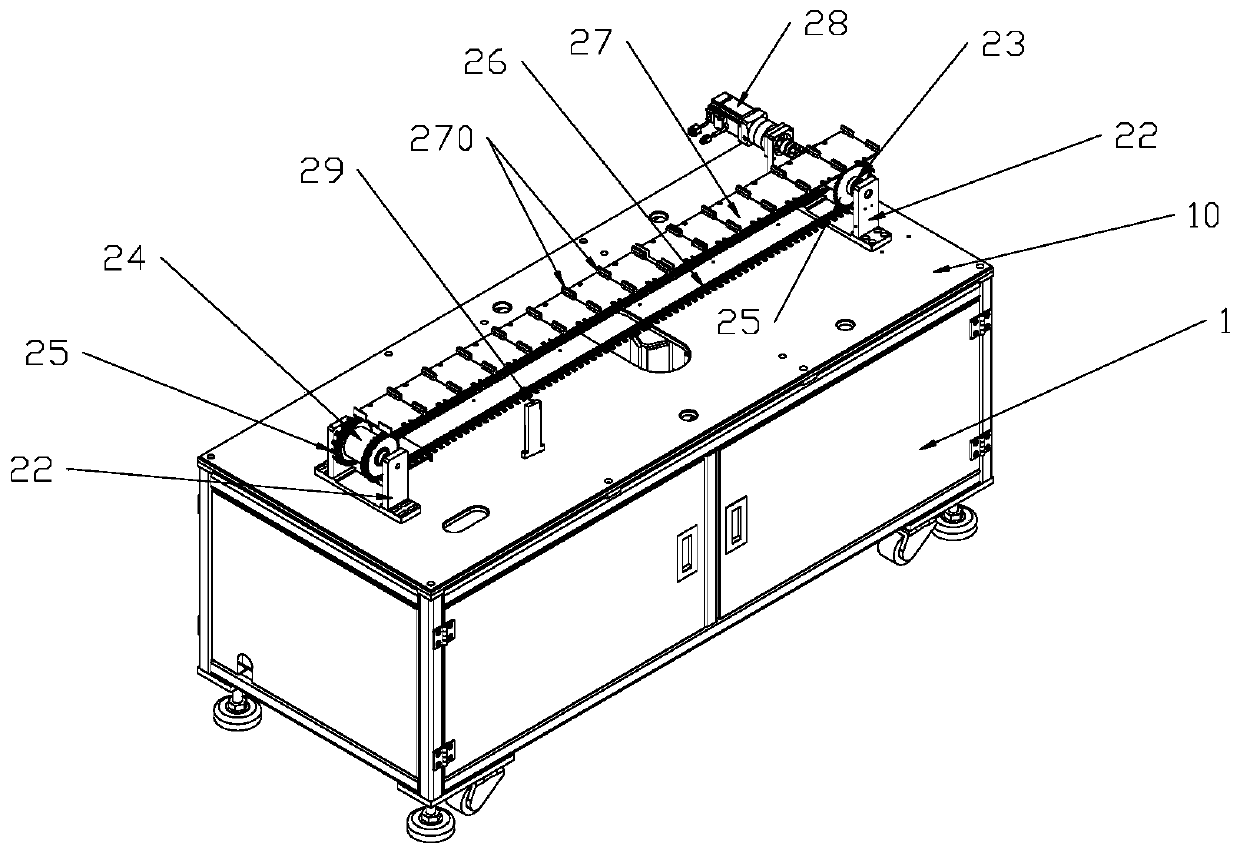

Automatic welding machine for ear straps of face mask

PendingCN111590904AImprove efficiencyImprove pass rateDomestic articlesProtective garmentWinding machinePalletizer

The invention discloses an automatic welding machine for ear straps of a face mask. The automatic welding machine for the ear straps of the face mask comprises a rack. An equipment platform is arranged on the rack, a mask conveying mechanism, a thread feeding mechanism, a thread winding mechanism, a thread shearing mechanism, a welding mechanism, a stacking mechanism and a controller are arrangedon the equipment platform, and the thread feeding mechanism, the thread winding mechanism, the thread shearing mechanism and the welding mechanism are arranged above the mask conveying mechanism. Thestacking mechanism is arranged at the output end of the mask conveying mechanism, the mask conveying mechanism comprises two chain wheel supports, a driving double-chain wheel and a driven double-chain wheel, two parallel and tensioned chains are arranged between the driving double-chain wheel and the driven double-chain wheel, and the two chains are both located on the surface of the equipment platform. A plurality of flat plate type mask carriers are transversely and evenly laid on the two chains. The automatic welding machine for the ear straps of the face mask has the beneficial effects that the conveying positioning precision is high, the average transmission ratio is accurate, the transmission is stable, the efficiency is high, the transmission power is high, the overload capacity ishigh, the high-speed performance is excellent, and maintenance and debugging are convenient.

Owner:HUIZHOU HAPPY VAPING TECH LTD

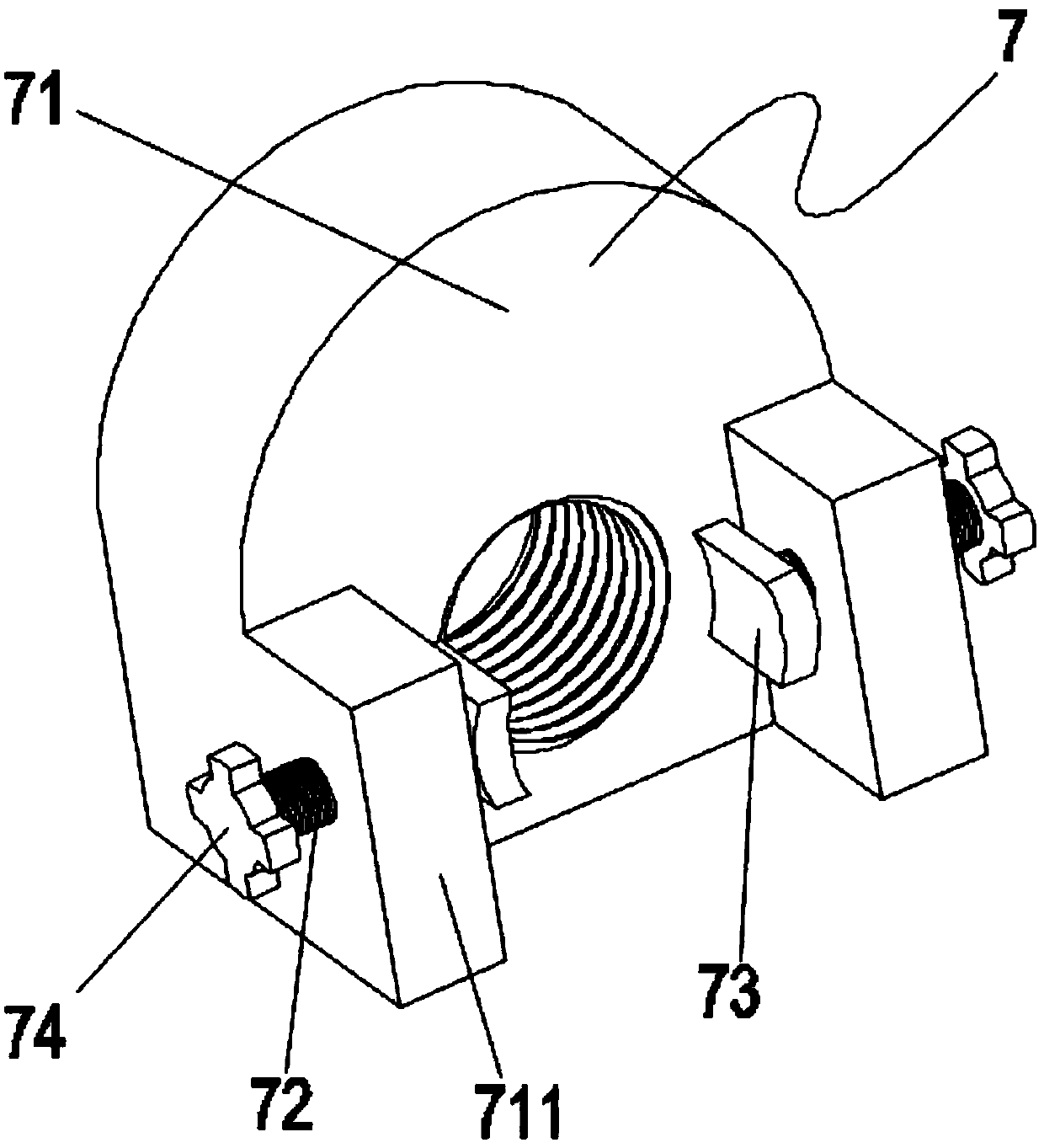

Wire grinding mechanism

ActiveCN102225519ASmooth rotationImprove grinding accuracyRevolution surface grinding machinesEngineeringGrinding wheel

The invention discloses a wire grinding mechanism. Controlled by a digital control circuit, a wire to be grinded is fixed in the grinding mechanism, a sand wheel rotation motor 2 drives the rotation of a sand wheel, a revolution motor 26 drives the revolution of the sand wheel around the wire to grind the surface of the outer circle of the wire, and simultaneously, a radial feed motor 7 drives the radial movement of the sand wheel so as to grind at a depth on the wire. Compared with the prior art, the mechanism of the invention is stable in rotation, durable and wearable, high in grinding precision, low in working noise, high in grinding efficiency, and convenient in maintenance and debugging.

Owner:深圳乐扬电线电器有限公司

Power distribution cabinet

InactiveCN104332860AEasy to liftImprove cooling effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringElectrical equipment

The invention discloses a power distribution cabinet, relating to the field of electrical equipment. The power distribution cabinet comprises a power distribution cabinet body with a cabinet door and a top cover. The top cover is detachably connected to the power distribution cabinet. The power distribution cabinet body also comprises a fan and heat radiating slotted holes. The fan and the heat radiating slotted holes are arranged at the left side face of the power distribution cabinet. The right side face and the bottom face are provided with a plurality of air inlet holes. The power distribution cabinet is internally provided with a working table and cross bars which are slidingly connected to the power distribution cabinet. The front of the power distribution cabinet is provided with a plastic baffle plate which is fixed on the power distribution cabinet through screws and nuts. The power distribution cabinet has the advantages of good heat radiating performance, good insulation performance and convenient debugging and repair.

Owner:SUZHOU SHIJIJINGYUAN OPTIC

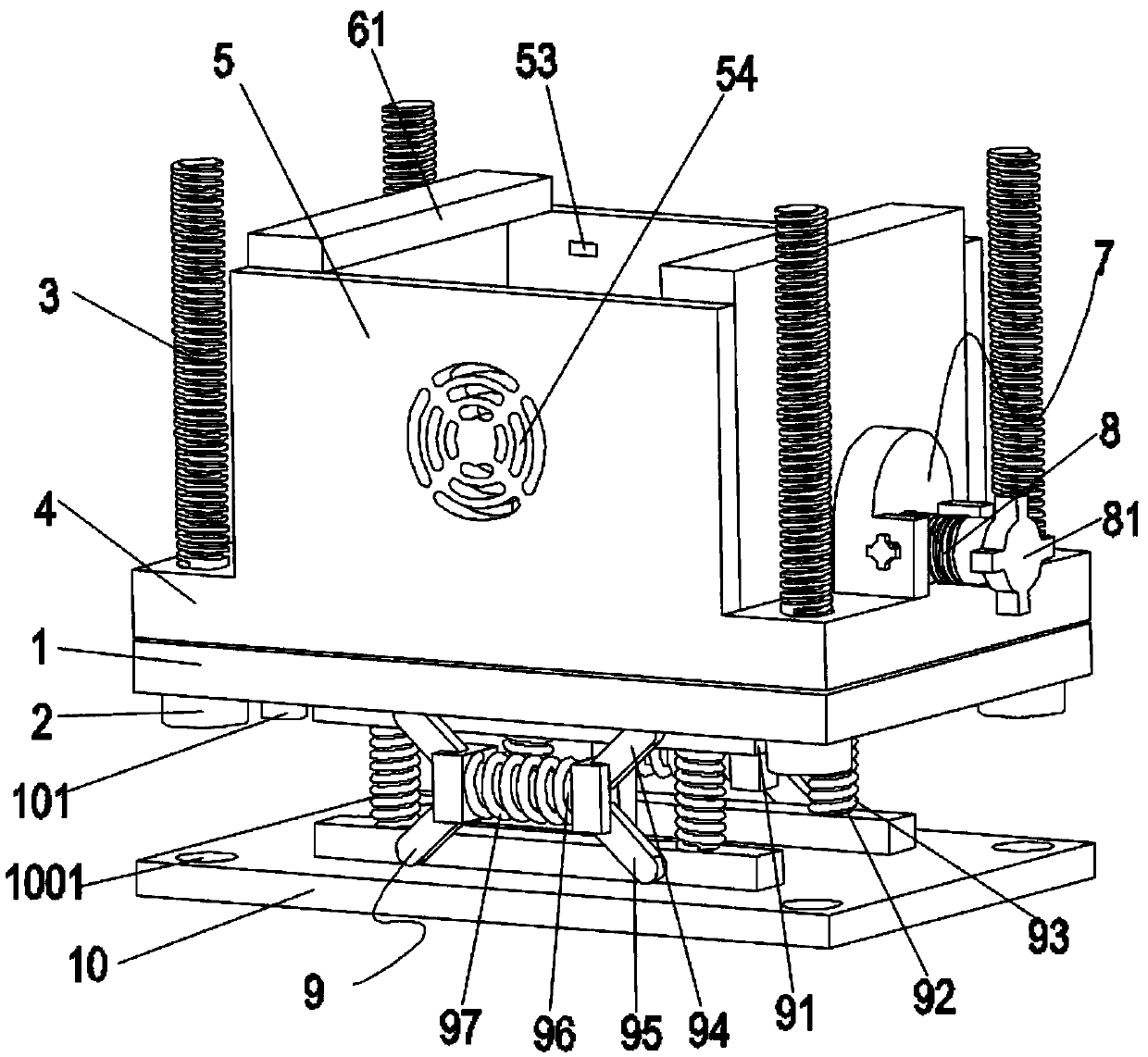

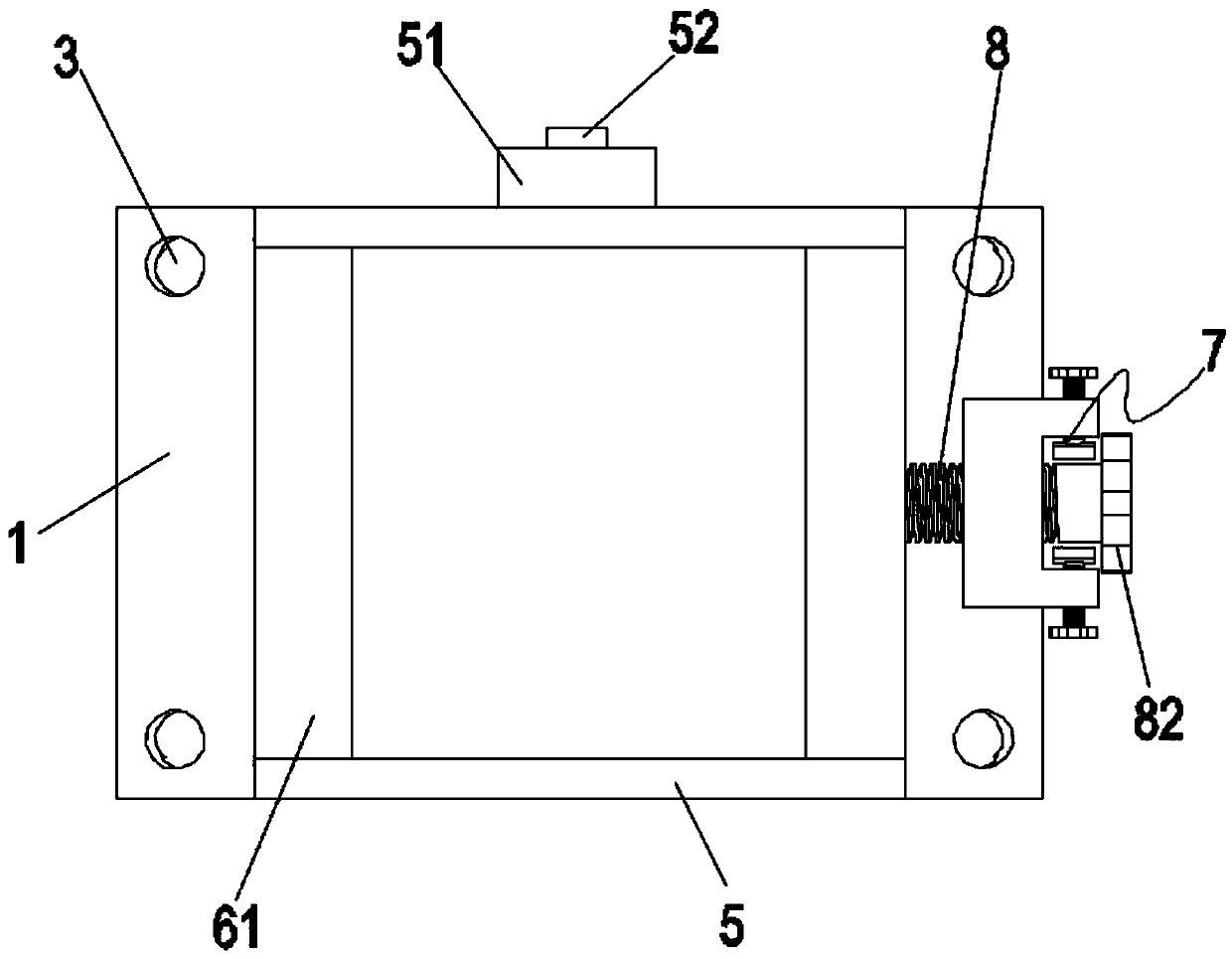

New energy vehicle distribution box with stable installation

InactiveCN109524897AEasy to disassembleSimple and fast operationSubstation/switching arrangement cooling/ventilationAnti-seismic devicesNew energyRoad surface

The invention relates to the technical field of new energy vehicles and particularly relates to new energy vehicle distribution box with stable installation. The new energy vehicle distribution box comprises a lifting platform, motors, four screws 1, a support plate, two fixed plates, a clamping plate, a fixed table, a screw 2, a shock absorbing mechanism and a bottom plate. The bottom end of theleft side of the lifting platform is provided with a control switch, the motors are arranged at four corners of the bottom end of the lifting platform. The bottom end of each of the four screws 1 is fixedly connected to a motor power output end, the top end of each of the four screws 1 is threadingly connected to a corner of the support plate to extend to the outside, the two fixed plates are front and back symmetrically arranged at the top end of the support plate, an outer wall of the front fixed plate is provided with a fan and a controller, and an inner wall of the front fixed plate is provided with a temperature sensor. The new energy vehicle distribution box is provided with the shock absorbing mechanism, the damage to the distribution box due to a bumpy road in driving is reduced, the clamping plate for clamping is set, at the same time, a component group can be lifted, the maintenance and debugging by the staff are facilitated, and the working efficiency is improved.

Owner:合肥众建翔新能源有限公司

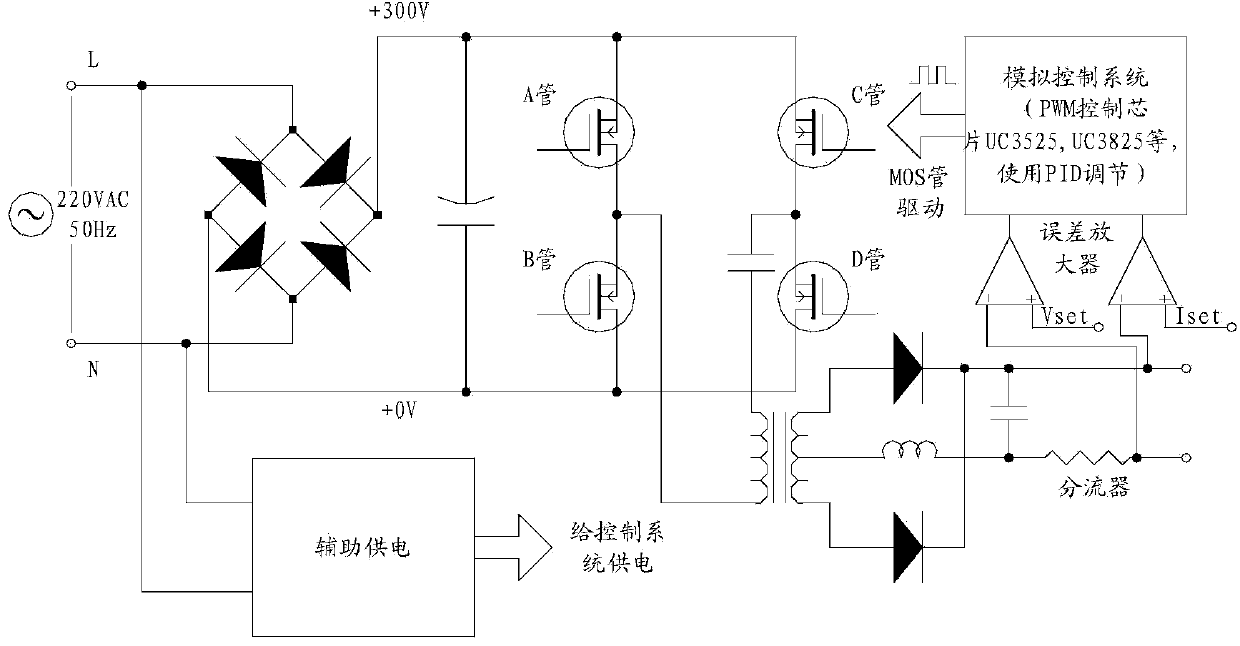

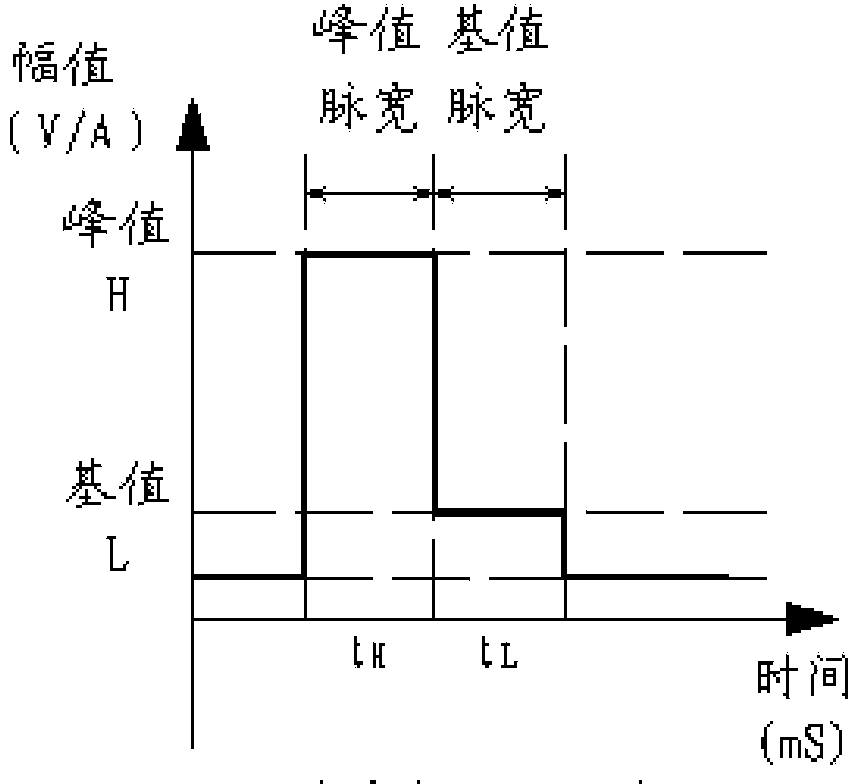

Control system for all-digital single-pulse electroplating power supply

InactiveCN103436932AHigh output pulse width accuracyEnsure consistencyCellsDigital signal processingTransformer

The invention provides a control system for an all-digital single-pulse electroplating power supply, and relates to the technical field of an electronic circuit. The control system comprises an EEROM (electrically erasable read-only memory), a power amplifier board, a secondary temperature detection and protective module, a communication port, an analog amplifier, a PWM (pulse width modulation) signal drive transformer and a display module, wherein the EEROM is connected with a digital signal processing module and used for storing the working parameters of the power supply and storing the control parameters in power failure, the communication port is used for completing communication, the analog amplifier is used for amplifying the feedback voltage and a telecommunication signal, and the display module is used for a power supply state indicator lamp and a buzzer. The control system for the all-digital single-pulse electroplating power supply is high in pulse width precision, and the consistency of products in the metal surface processing and the product quality can be guaranteed.

Owner:KUNSHAN PUYUAN ELECTRONICS TECH

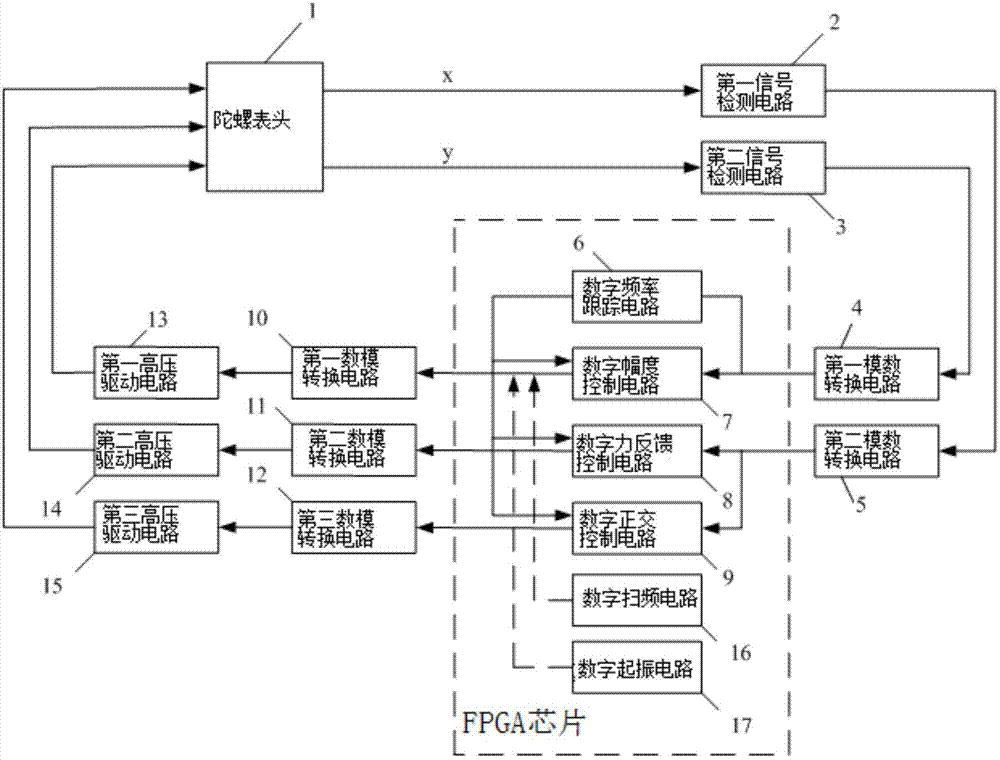

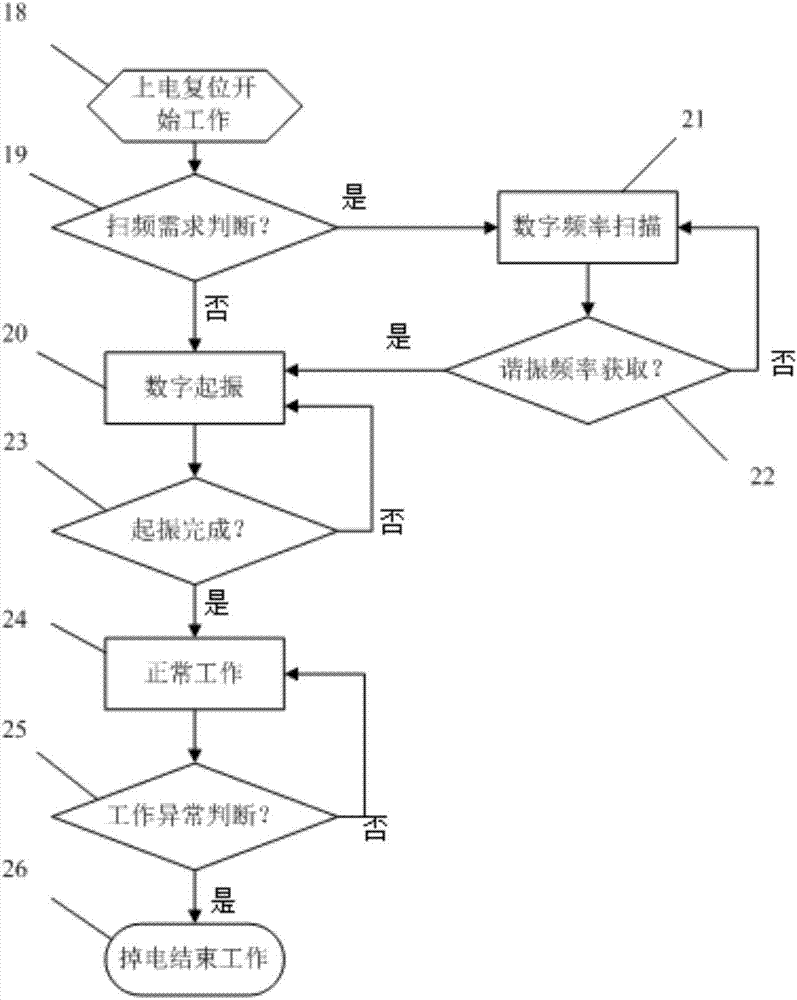

Force balance model-based hemispherical resonant gyro digital control circuit

ActiveCN104515516AReduce the impactSimple designSpeed measurement using gyroscopic effectsTurn-sensitive devicesAmplitude controlHigh pressure

The invention provides a force balance model-based hemispherical resonant gyro digital control circuit comprising a gyro meter header and the like, a first signal detection circuit and a second signal detection circuit are connected with the gyro meter header, a first analog-to-digital conversion circuit and the second signal detection circuit are connected, a second analog-to-digital conversion circuit and the first signal detection circuit are connected, a digital frequency tracking circuit and a digital amplitude control circuit are connected with the first analog-to-digital conversion circuit, a digital force feedback control circuit and a digital orthogonal control circuit are connected with the second analog-to-digital conversion circuit, the first analog-to-digital conversion circuit is connected between a first high voltage drive circuit and a digital amplitude control circuit, and the second analog-to-digital conversion circuit t is connected between a second high voltage drive circuit and a digital force feedback control circuit. The force balance model-based hemispherical resonant gyro digital control circuit can effectively improve the gyro control precision and stability, temperature environment changes have small impact on the digital control circuit precision, and the mass and volume of the control circuit can be reduced.

Owner:SHANGHAI XINYUE METER FACTORY

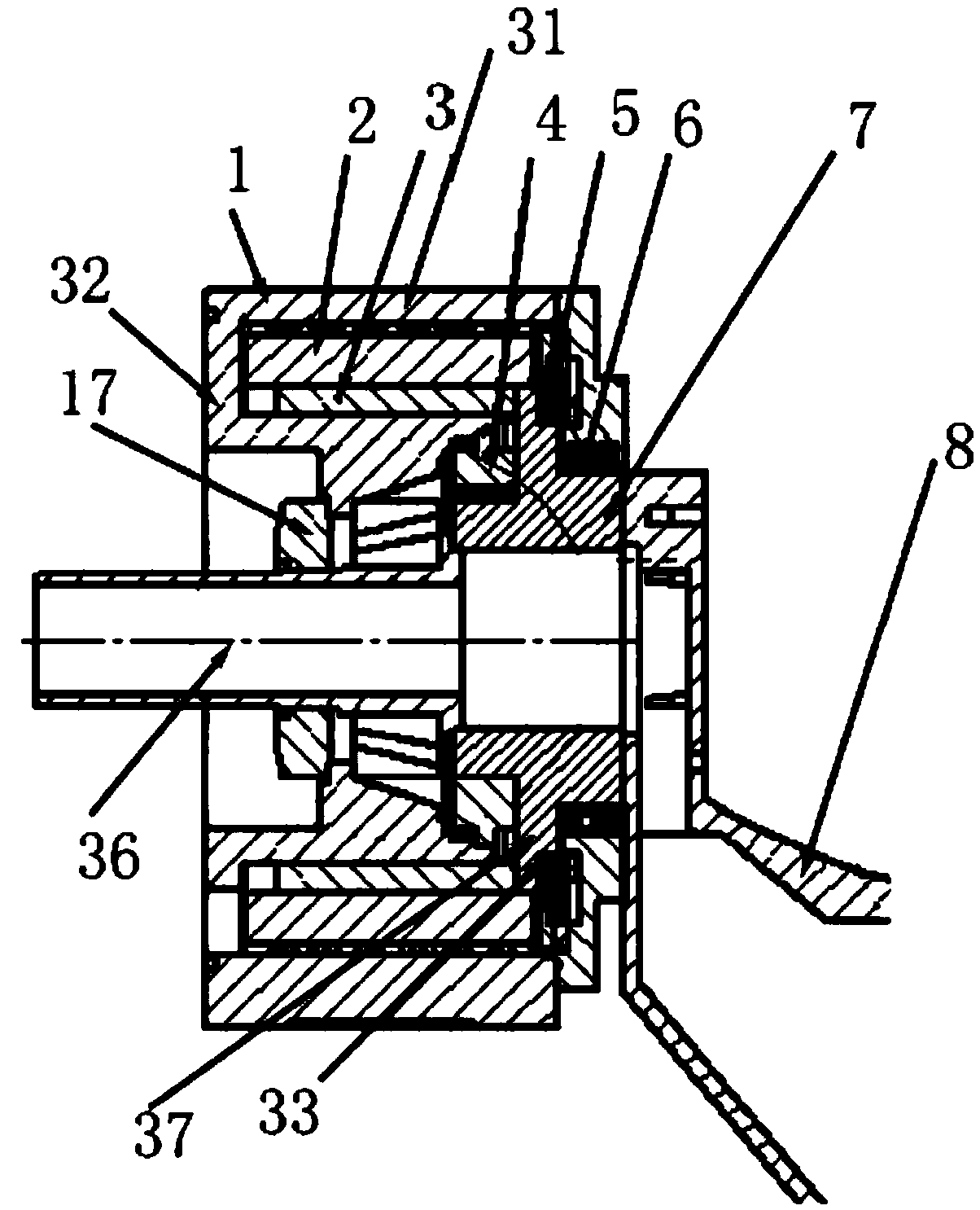

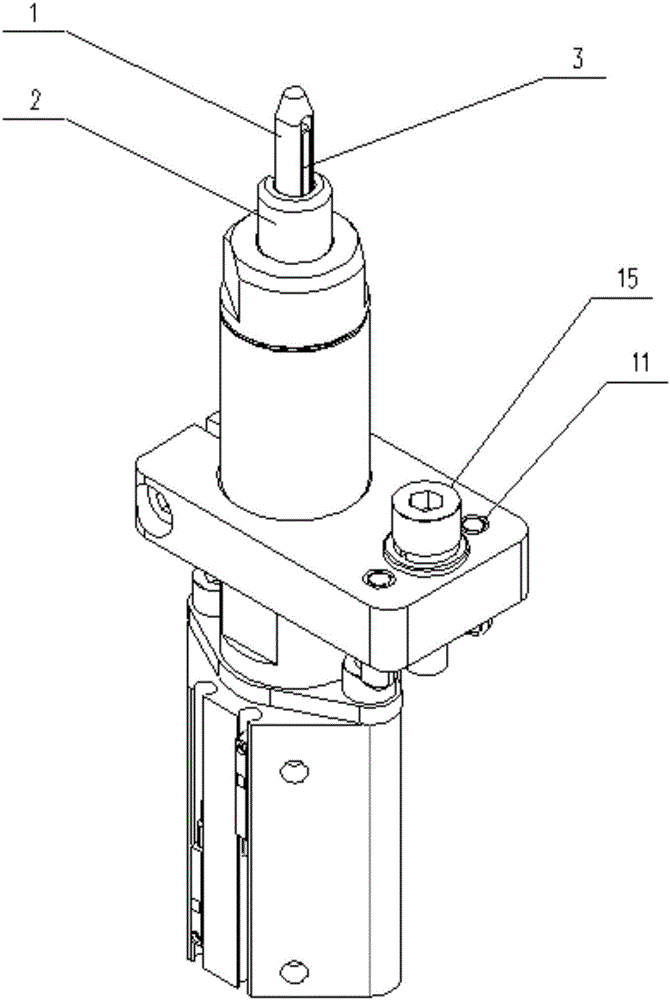

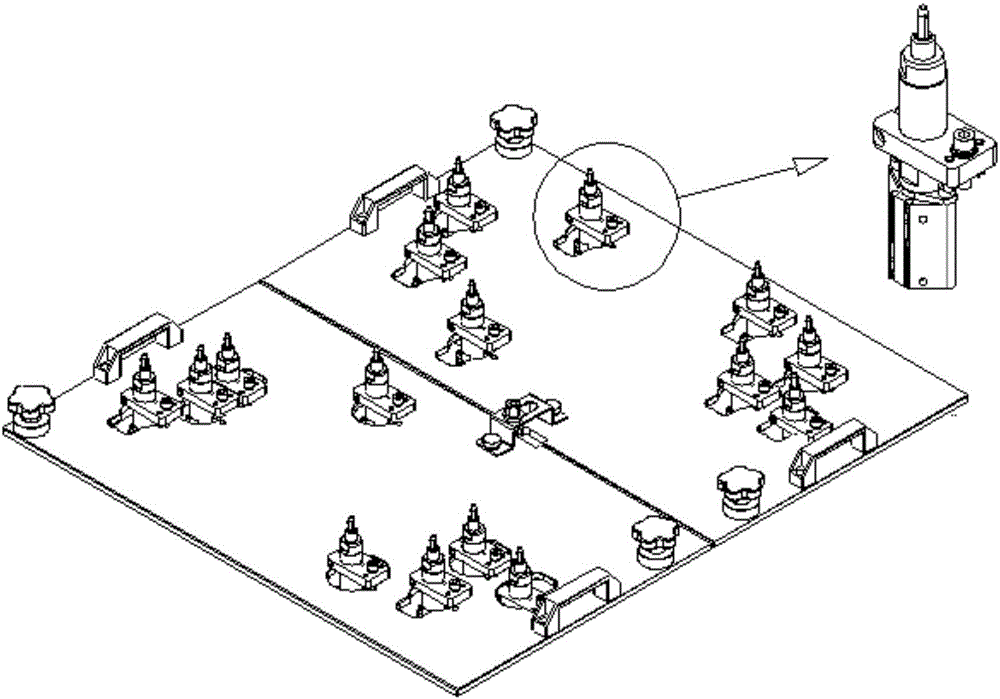

Pneumatic positioning and locking pin hook mechanism.

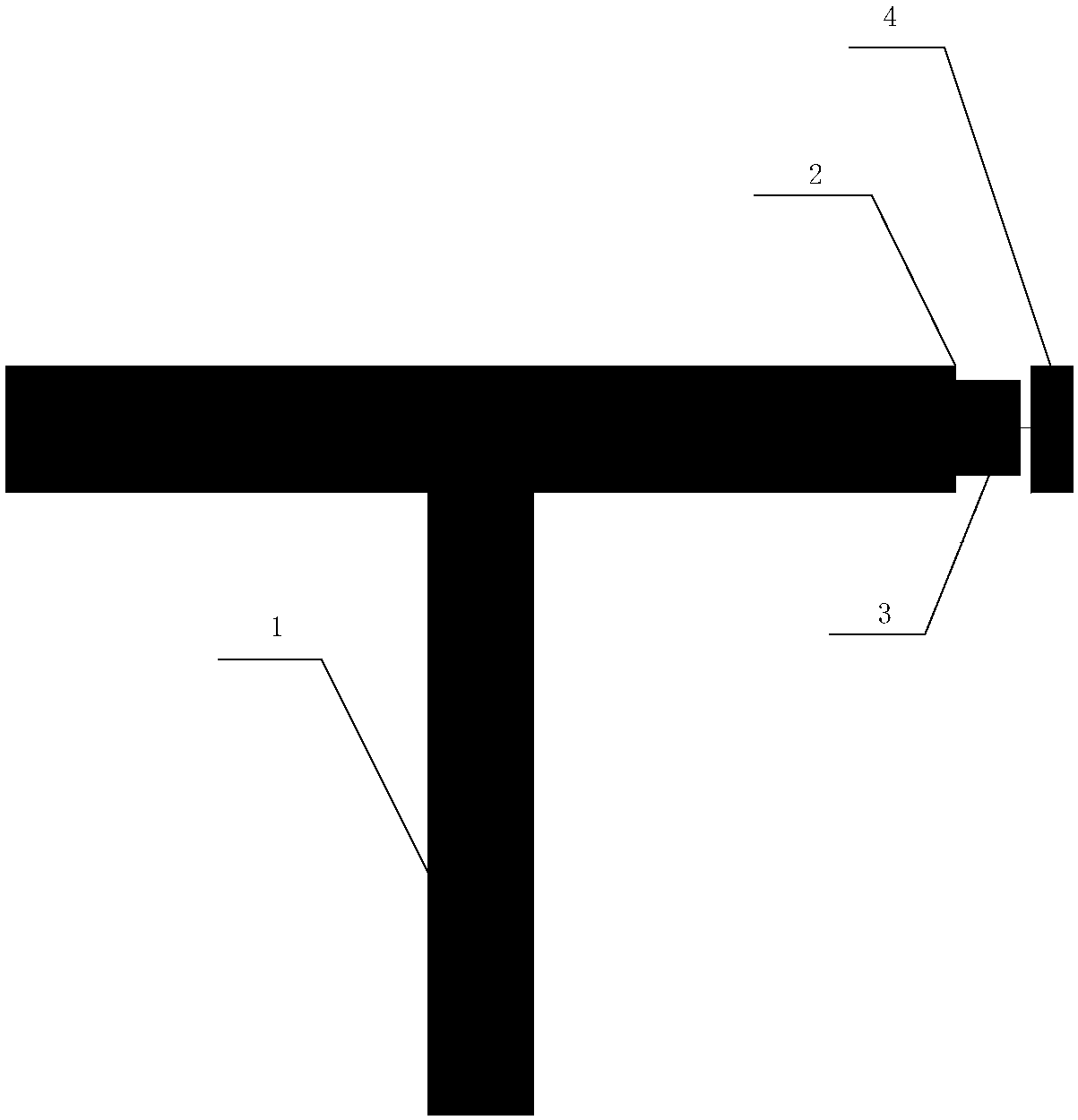

ActiveCN106392440APrecise positioningPrecise clampingLiquid surface applicatorsWelding/cutting auxillary devicesAutomatic controlJackscrew

The invention provides a device facilitating achievement of clamping and positioning of various parts. The device can achieve automatic control easily, and fast switching and positioning locking between various to-be-machined parts can be performed conveniently. The production efficiency can be improved, the product quality can be improved, and the mechanism has the beneficial effects of being easy to operate, convenient to maintain, safe in production and the like and is broad in application prospect. The mechanism comprises a pin 1, a supporting ring 2, a hook 3, a pin body 4, springs 5, spring pre-tightening nuts 7, a jackscrew 8, a pin body locking bolt 9, a clamping fixture installing plate 10, a cylinder 11, a cylinder rod 12, a pin locking nut 13, a pin body fixing plate 14, a pin body fixing plate bolt 15, a cylinder pin 16, a supporting ring gland 17 and a connecting rod 18.

Owner:江西清研扬天科技有限公司

Upside-air-inlet three-fire-ring high-power combustor

ActiveCN106439809ASimple internal structureEasy to debug and maintainGaseous fuel burnerFuel gasCombustor

An upside-air-inlet three-fire-ring high-power combustor comprises a burner, a distributor seat, a central fire cover, an inner-ring fire cover and an outer-ring fire cover, wherein the burner comprises an air and fuel gas pre-mixing cavity, a central gas outlet tube, an inner-ring mixing cavity, an inner-ring gas outlet connector, an outer-ring mixing cavity and an outer-ring gas outlet connector; the air and fuel gas pre-mixing cavity is positioned on the front part and is provided with a top opening; the central gas outlet tube is positioned in the center; the inner-ring mixing cavity is positioned on the right side; the outer-ring mixing cavity and the outer-ring gas outlet connector are positioned on the left side; and the central gas outlet tube, the inner-ring mixing cavity and the outer-ring mixing cavity respectively communicate with the air and fuel gas pre-mixing cavity through a central ejector tube, an inner ejector tube and an outer ejector tube. Because the structure is adopted, the top opening of the air and fuel gas pre-mixing cavity of the burner is positioned in a stove and positioned above a panel; upside air inlet is realized by primary air; an annular supporting table in the peripheral direction of the burner supports the metal panel or a bottom plate of a liquid receiving plate; secondary air enters via a gap between a distributor and the panel of the stove; and air and fuel gas are pressurized and pre-mixed in the burner, and can quickly enter the distributor seat.

Owner:ZHONGSHAN HEME ELECTRICAL APPLIANCES & GAS COOKERS

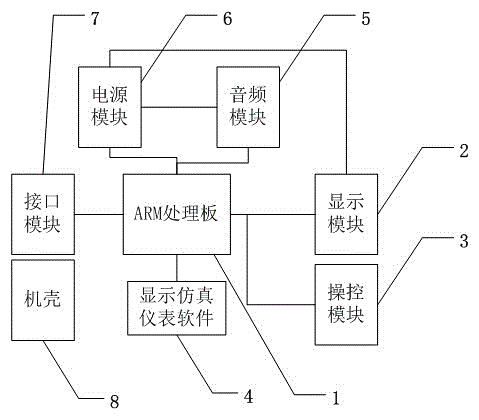

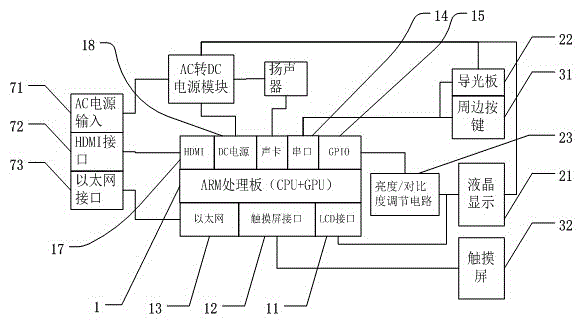

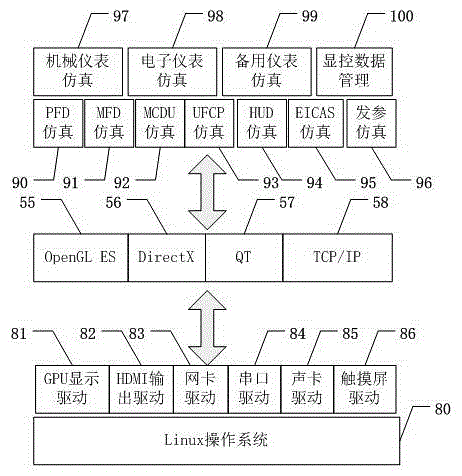

ARM based embedded integrated display simulation instrument

InactiveCN105116756AImprove work efficiencyImprove real-time performanceSimulator controlComputer moduleEmbedded software

The invention relates to an ARM based embedded integrated display simulation instrument. The ARM based embedded integrated display simulation instrument is composed of an ARM processing board, a display module, a control module, an audio module, a power supply module, an interface module, display simulation instrument software and the like. Interconnection of a plurality of integrated display simulation instruments is realized through instrument simulation software architecture. The ARM based embedded integrated display simulation instrument has the characteristics of low cost, high reliability, timeliness, simple interface, convenient debugging and the like, can improve the design and development efficiency of a flight simulator, and reduces the debugging and maintenance difficulty. Meanwhile, the ARM based embedded integrated display simulation instrument has an embedded software and hardware environment, not only can provide functional verification for a POP design, but also can provide verification for performance indexes, data interfaces and the like.

Owner:BEIJING INVENT MEDIATEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com