Double-rotation-shaft precision workbench

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems that it is difficult to meet the high-speed and high-efficiency processing requirements of CNC machine tools, limit the speed of CNC turntables, etc., and achieve simple and elegant appearance , Elimination of backlash, good dynamic performance and the effect of regulating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

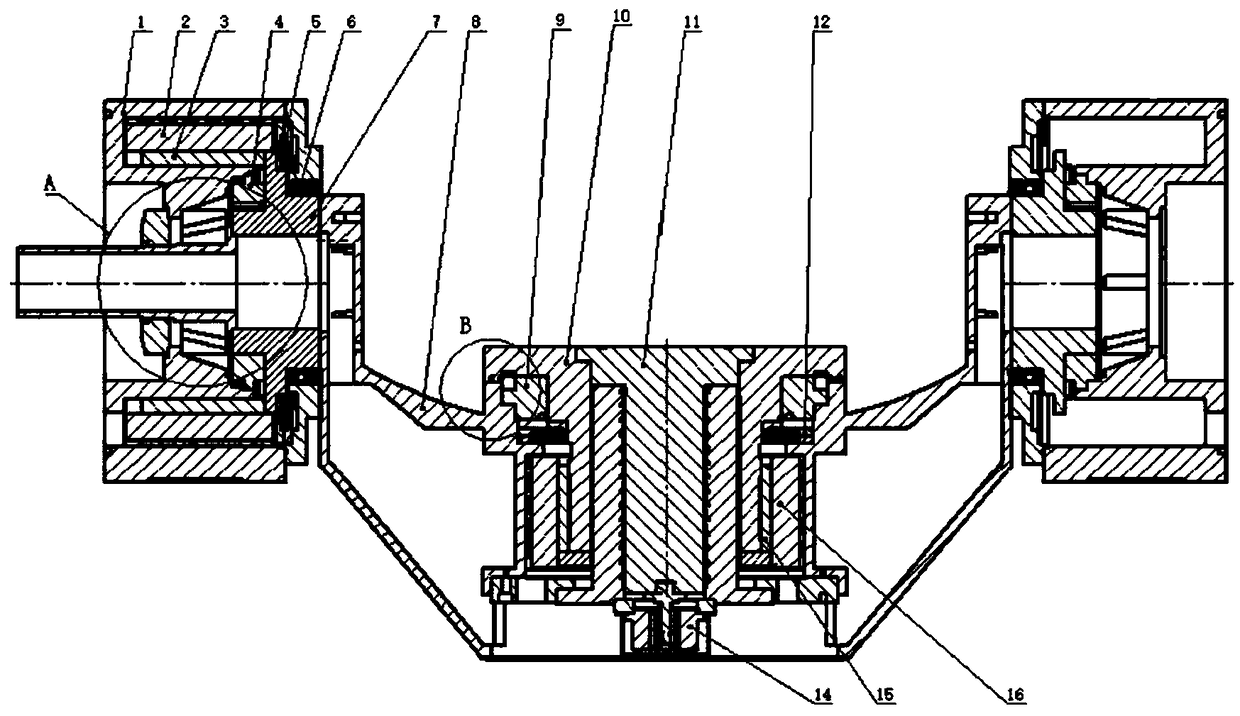

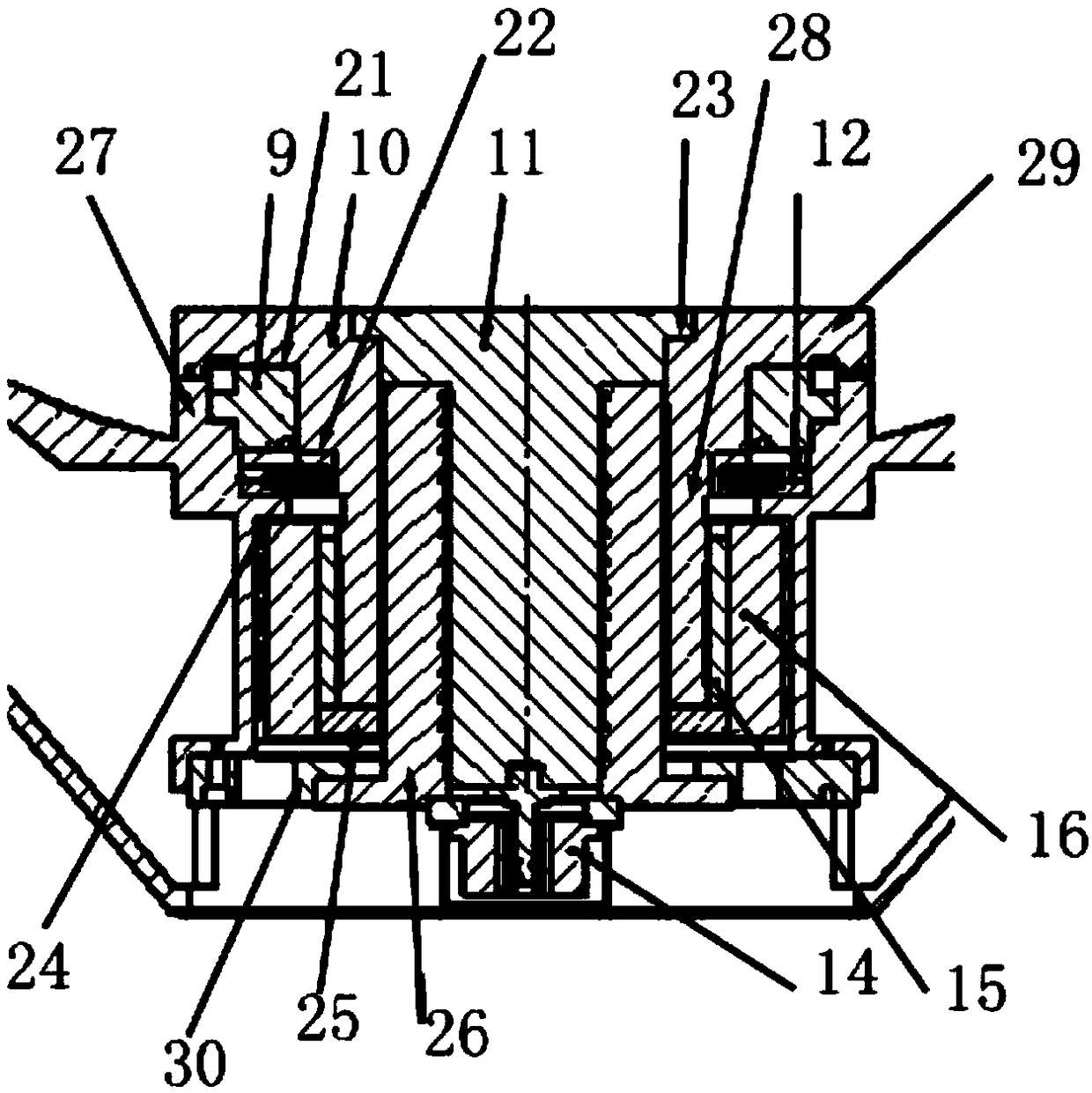

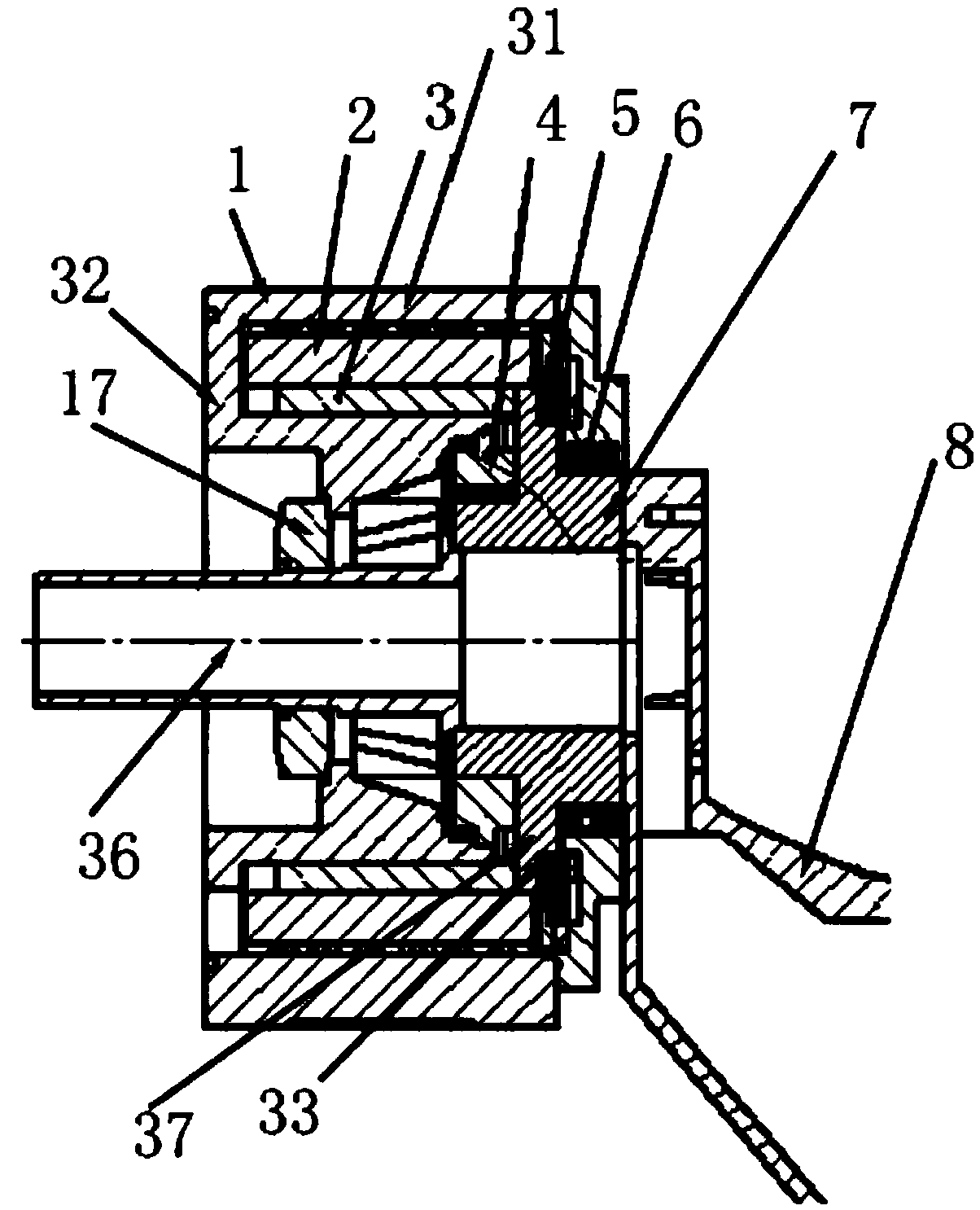

[0029] This embodiment provides a precision workbench with double rotary shafts, see Figure 1-Figure 6 . The double rotary axis precision workbench of the present invention may refer to a workbench capable of rotating along the A axis and the B axis in a horizontal machining center. The dual-axis precision workbench of this embodiment includes a turntable 10 that can rotate along the B axis, and the turntable 10 that rotates along the B axis is used to place workpieces that need to be processed. The bottom of the rotary table 10 is installed in the cradle body 8 . Preferably, the middle of the cradle body 8 is used to install the rotary table 10, and the two ends of the cradle body 8 away from the rotary table 10 are respectively fixed with the A-axis main shaft 7 capable of rotating along the A-axis. Preferably, the cradle body 8 includes a middle cradle base 27 for installing the rotary table 10 and cradle arms located at two ends of the cradle base. Preferably, the crad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com