Patents

Literature

478results about How to "Eliminate backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

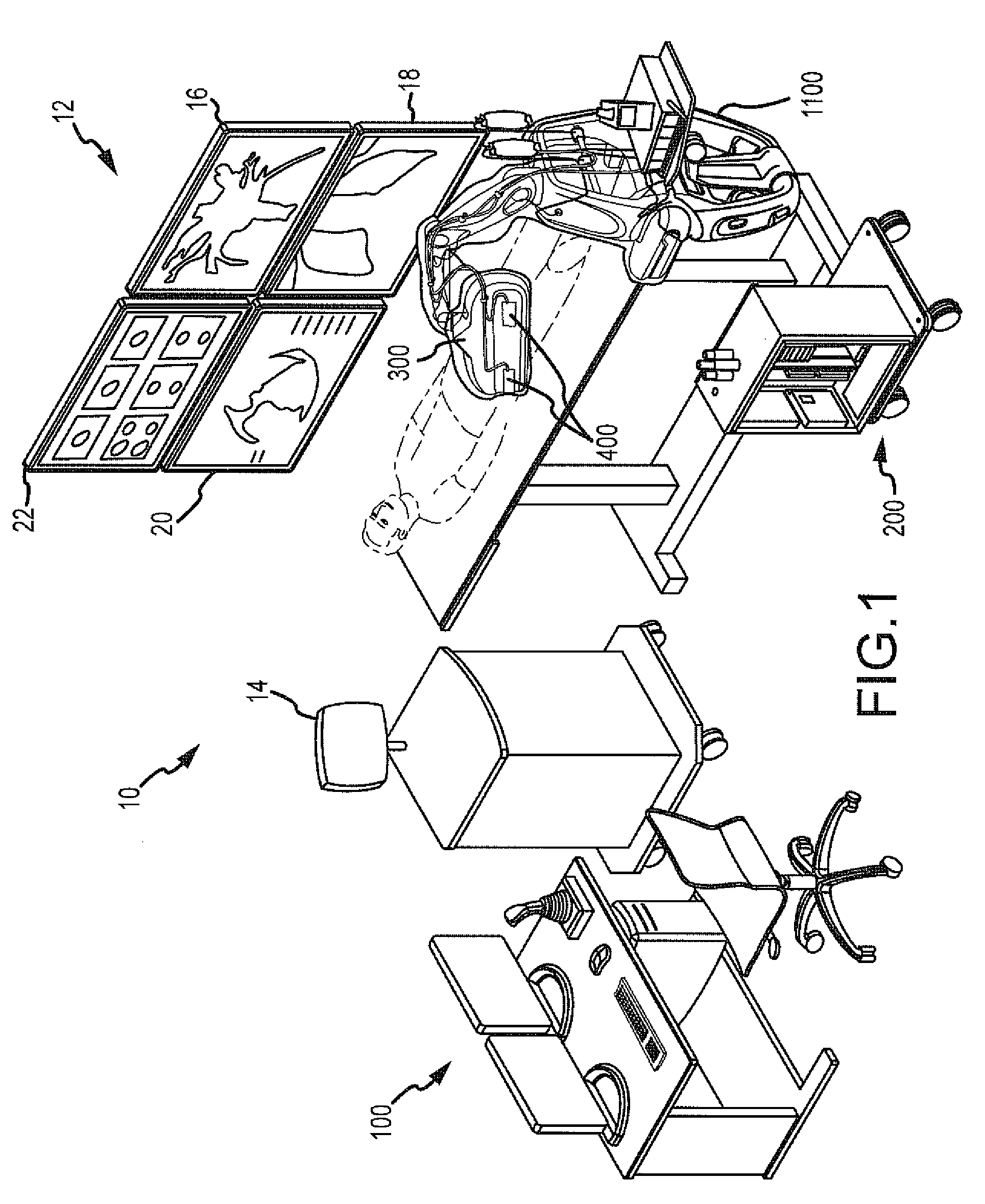

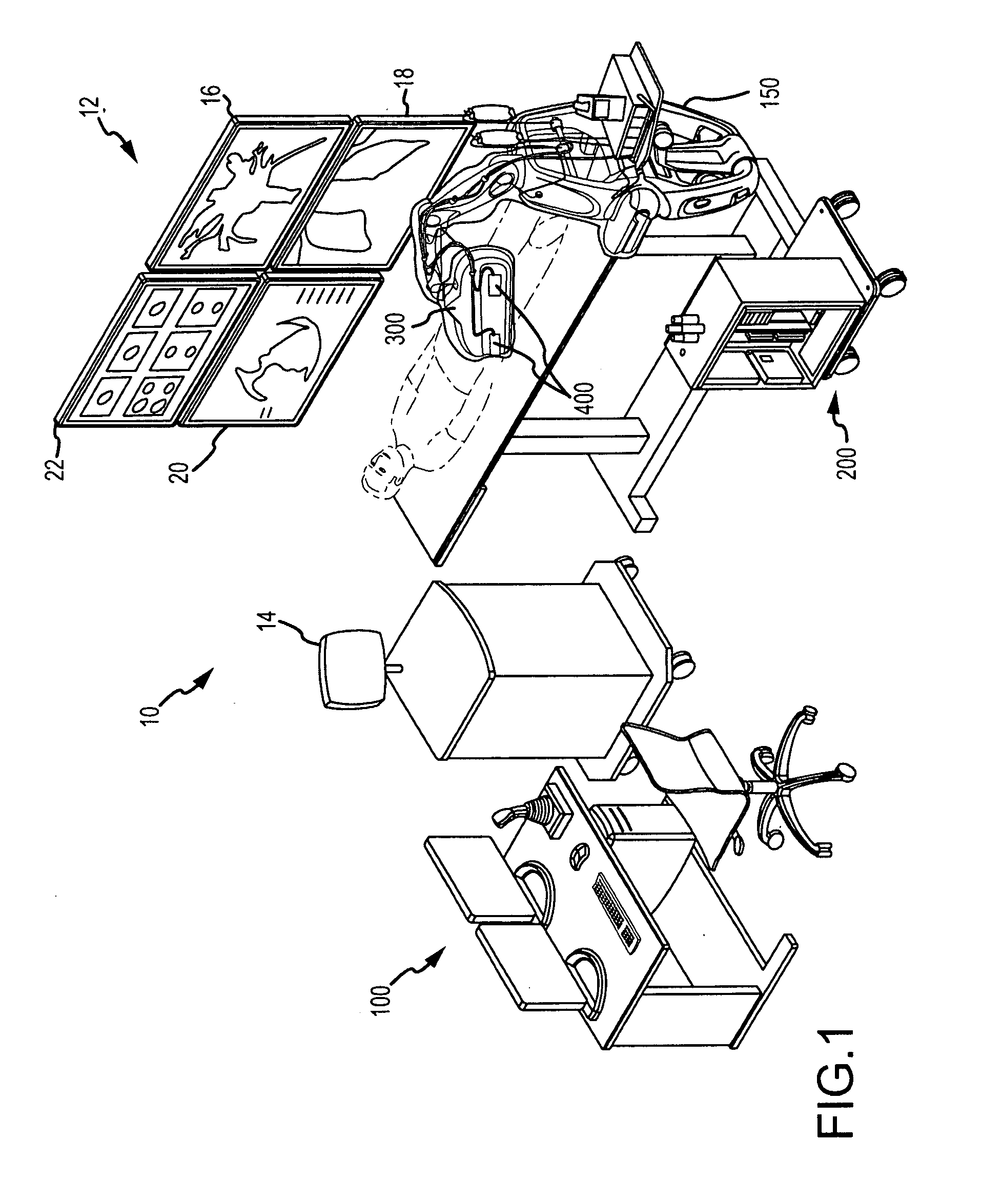

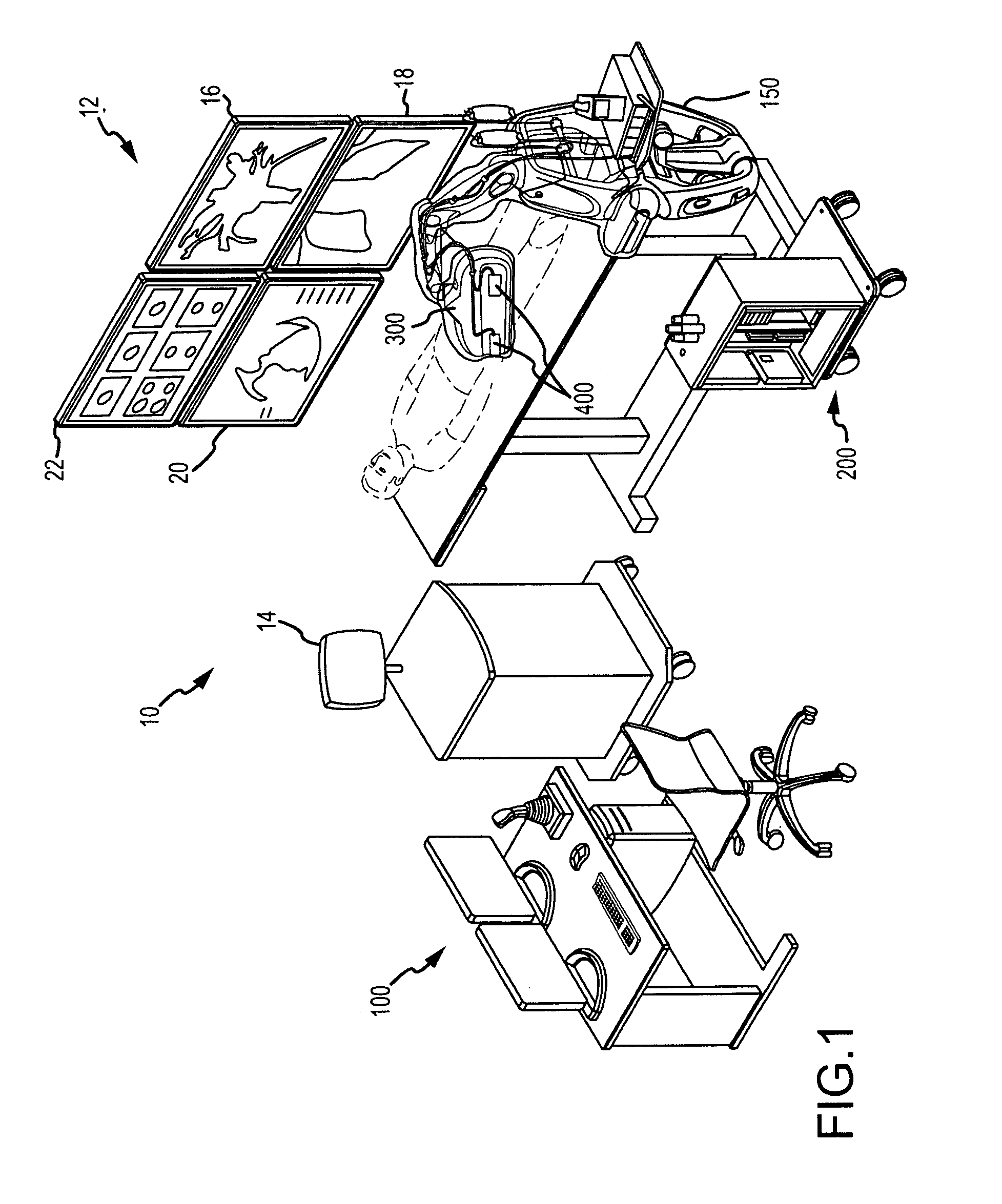

Robotic catheter device cartridge

ActiveUS8684962B2Minimize and eliminate procedural variabilityMinimize and eliminate exposureDiagnosticsSurgical needlesRoboticsSteering wheel

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

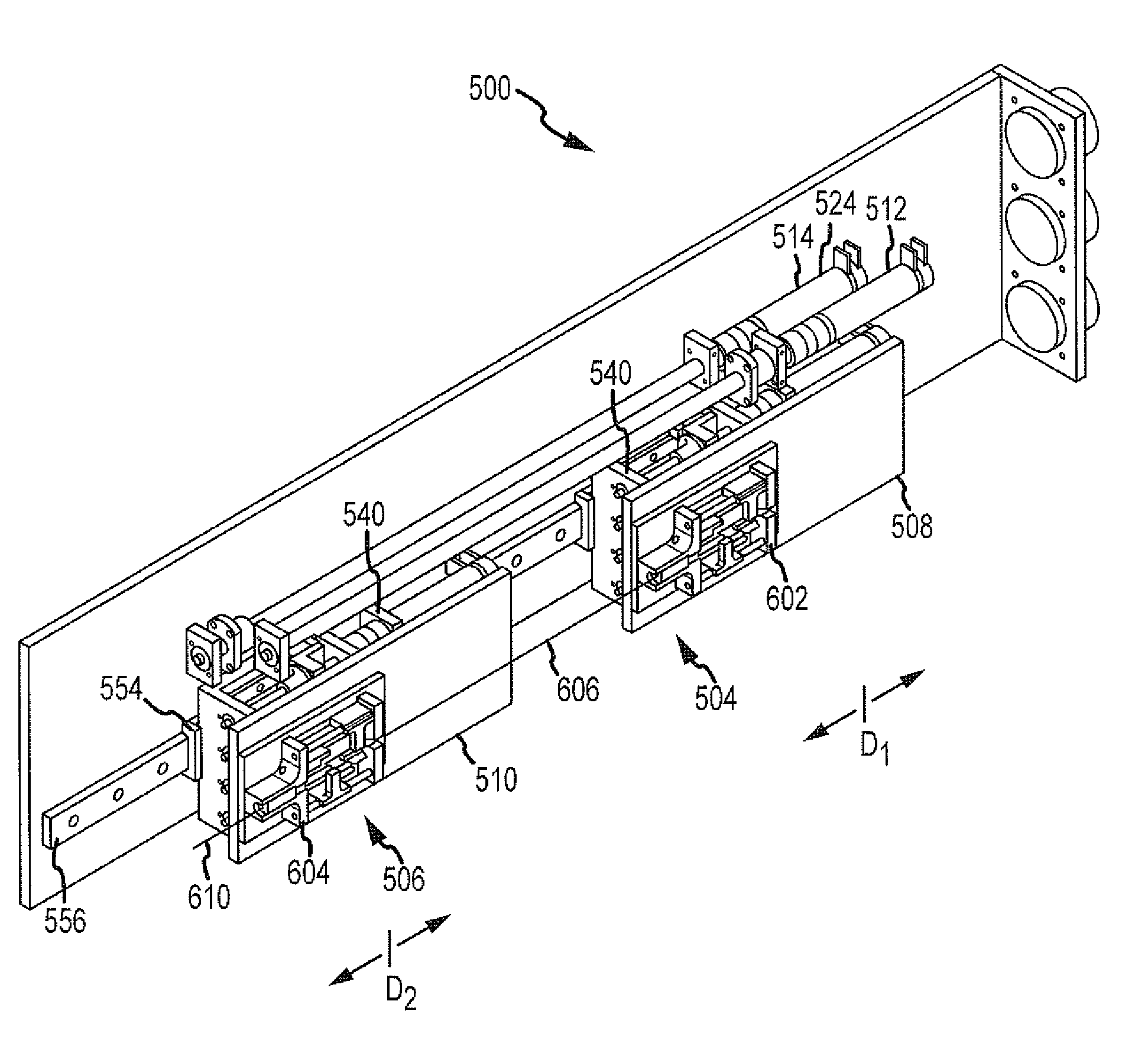

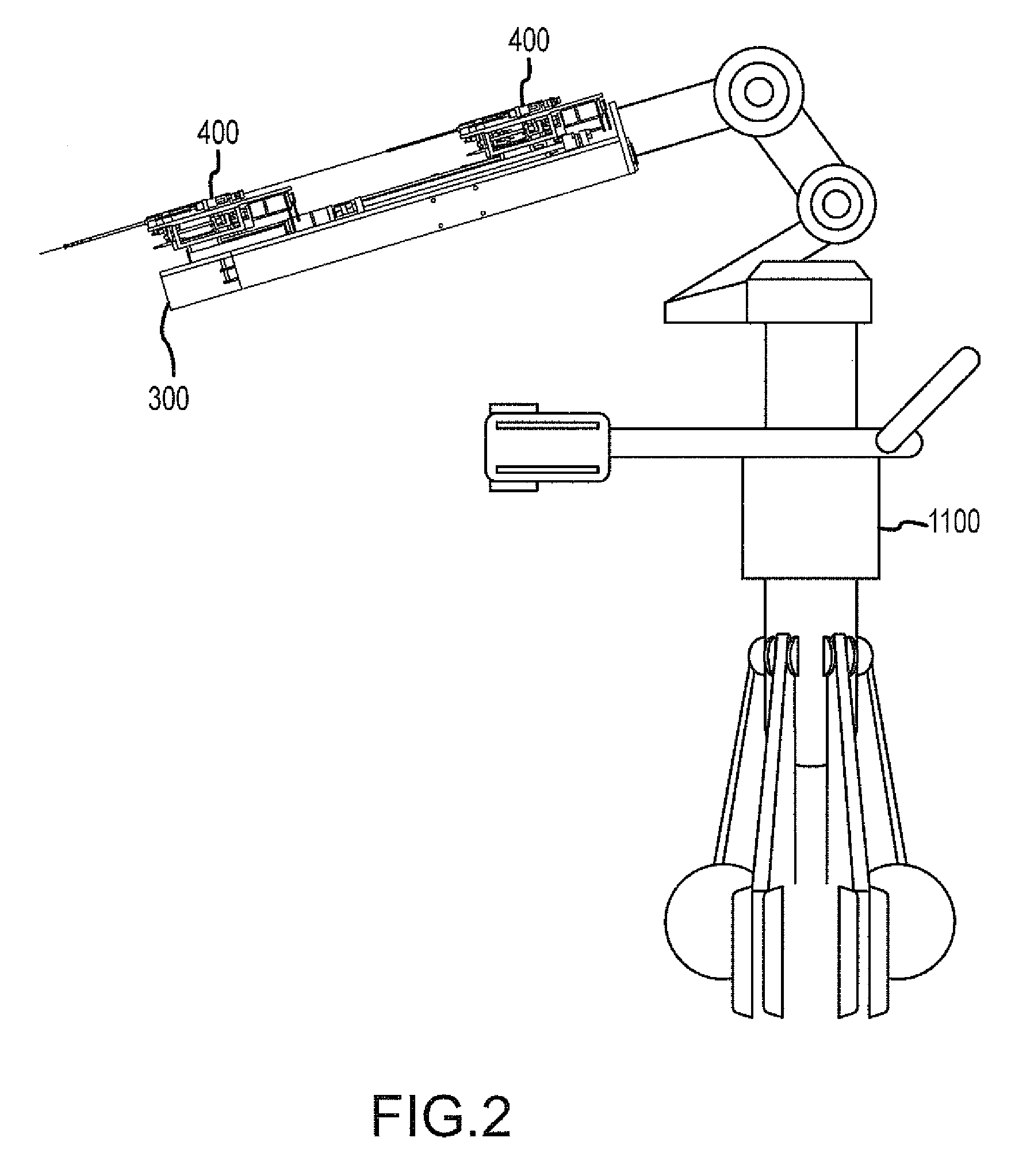

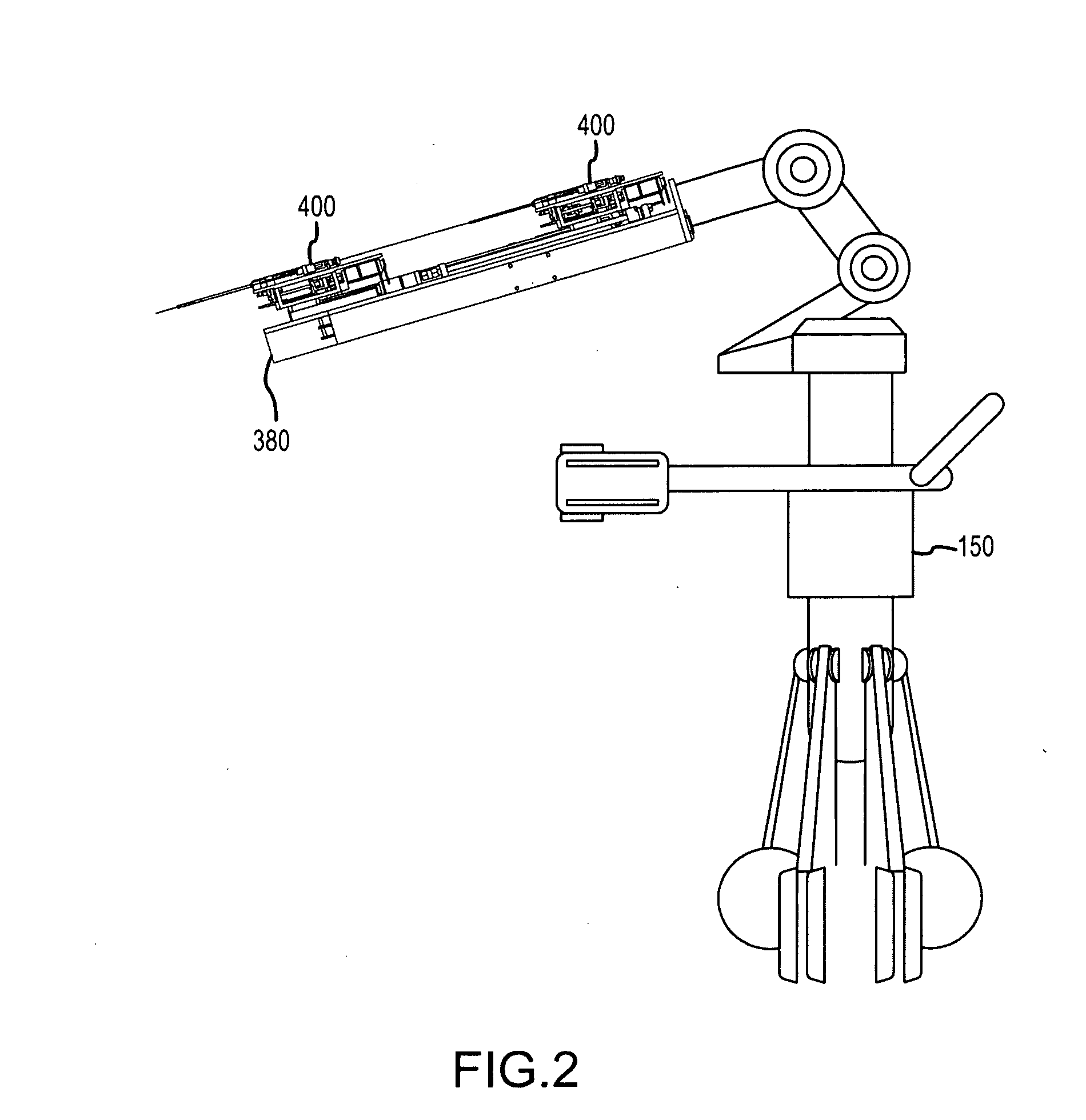

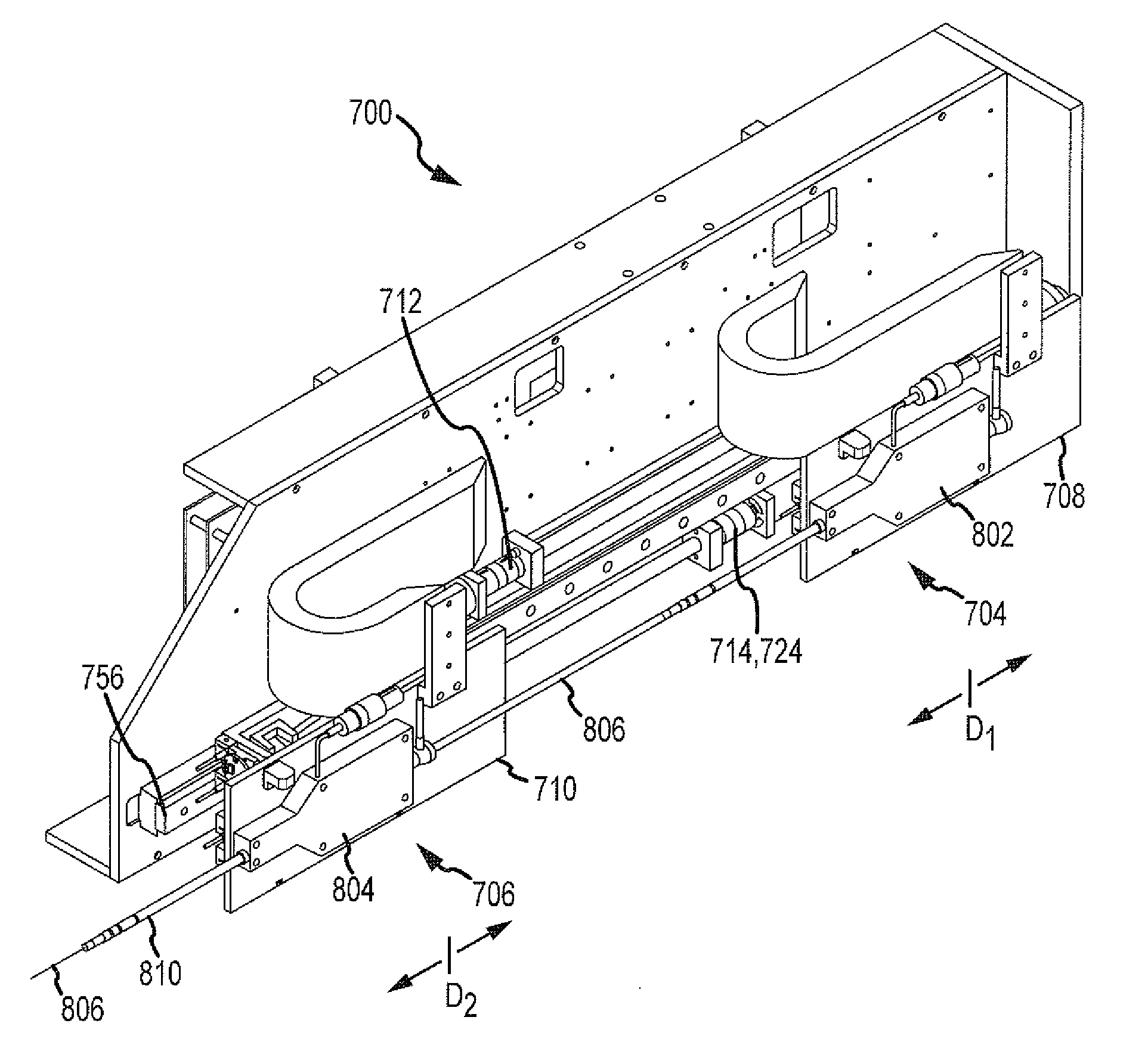

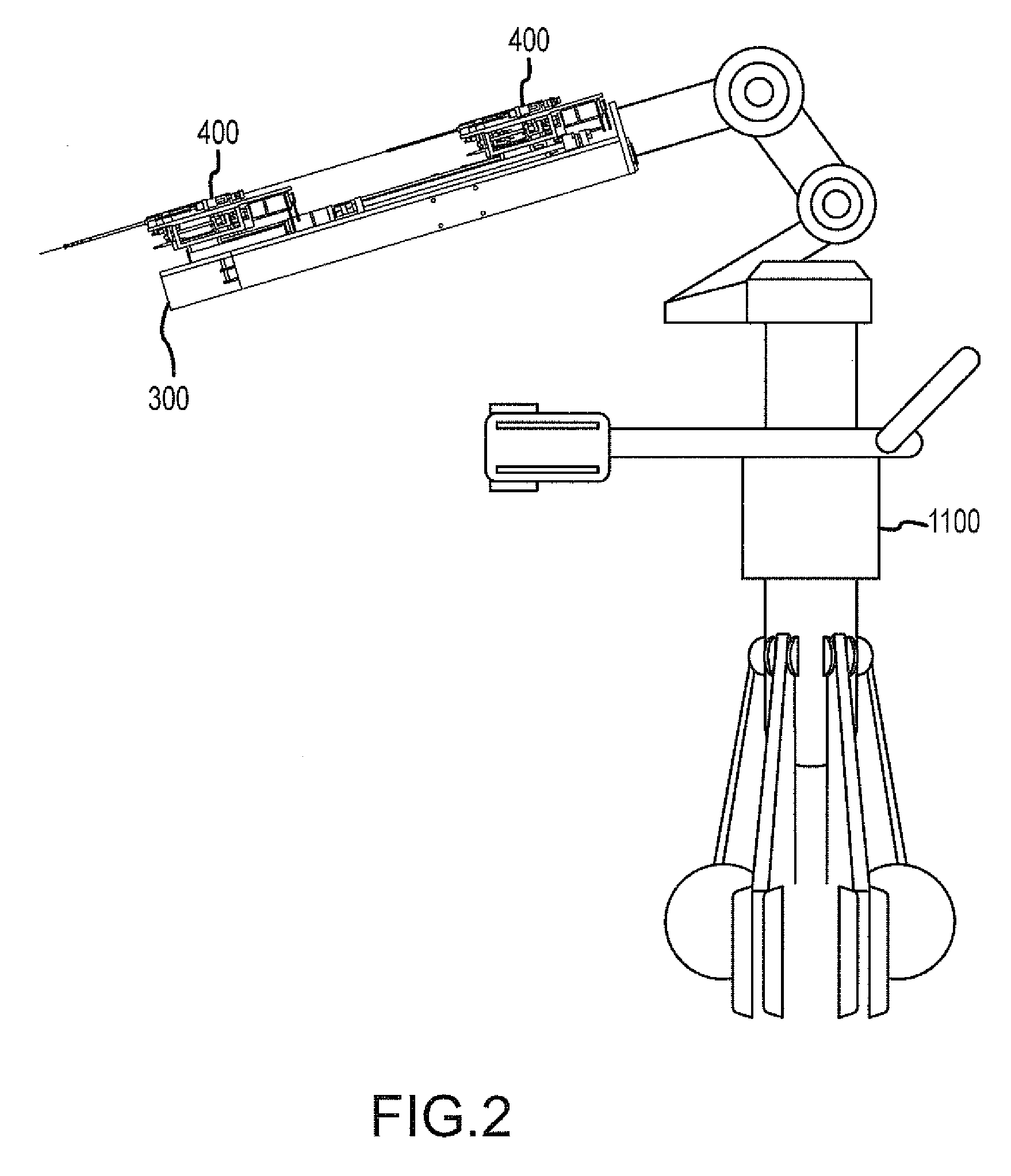

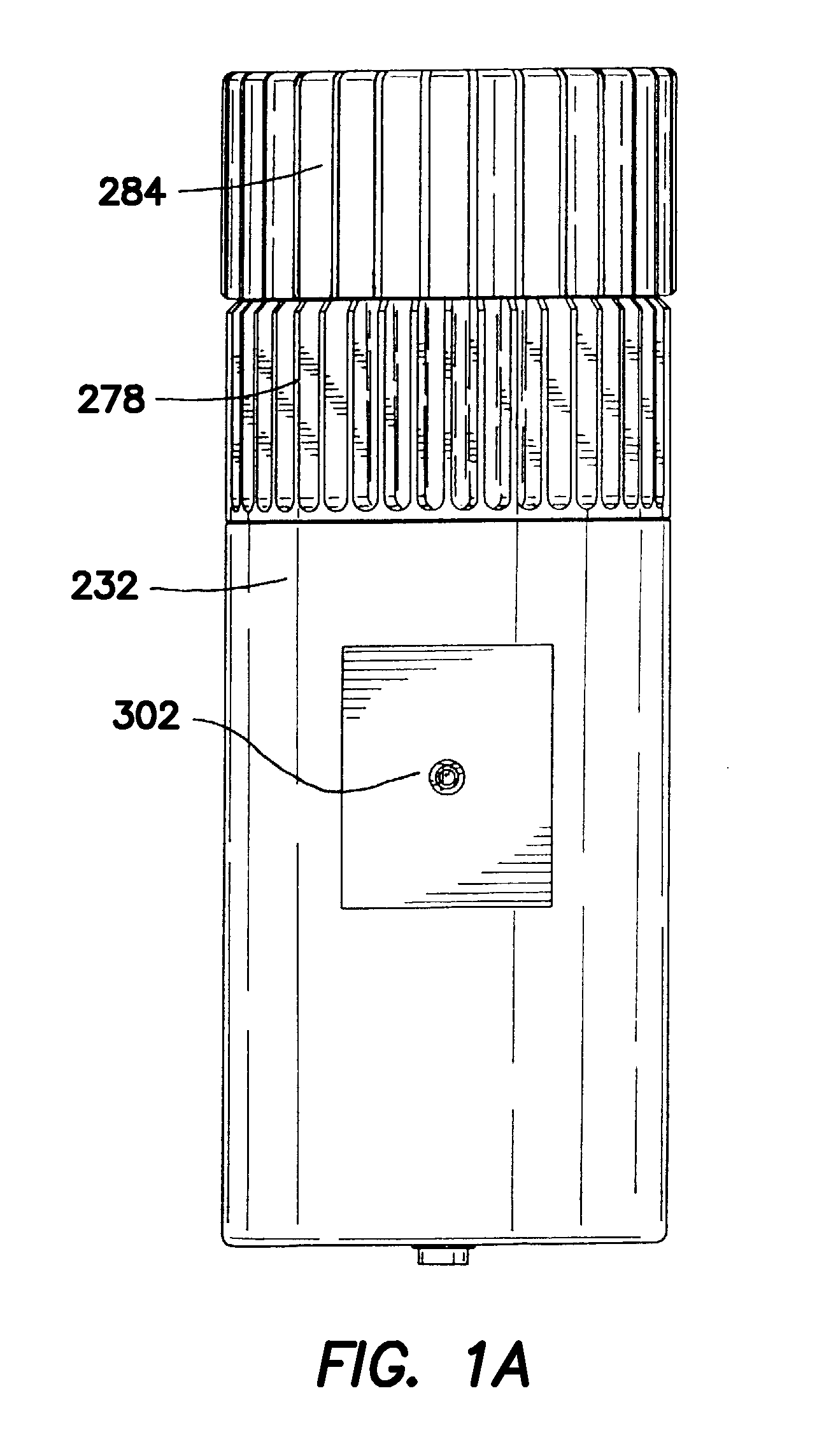

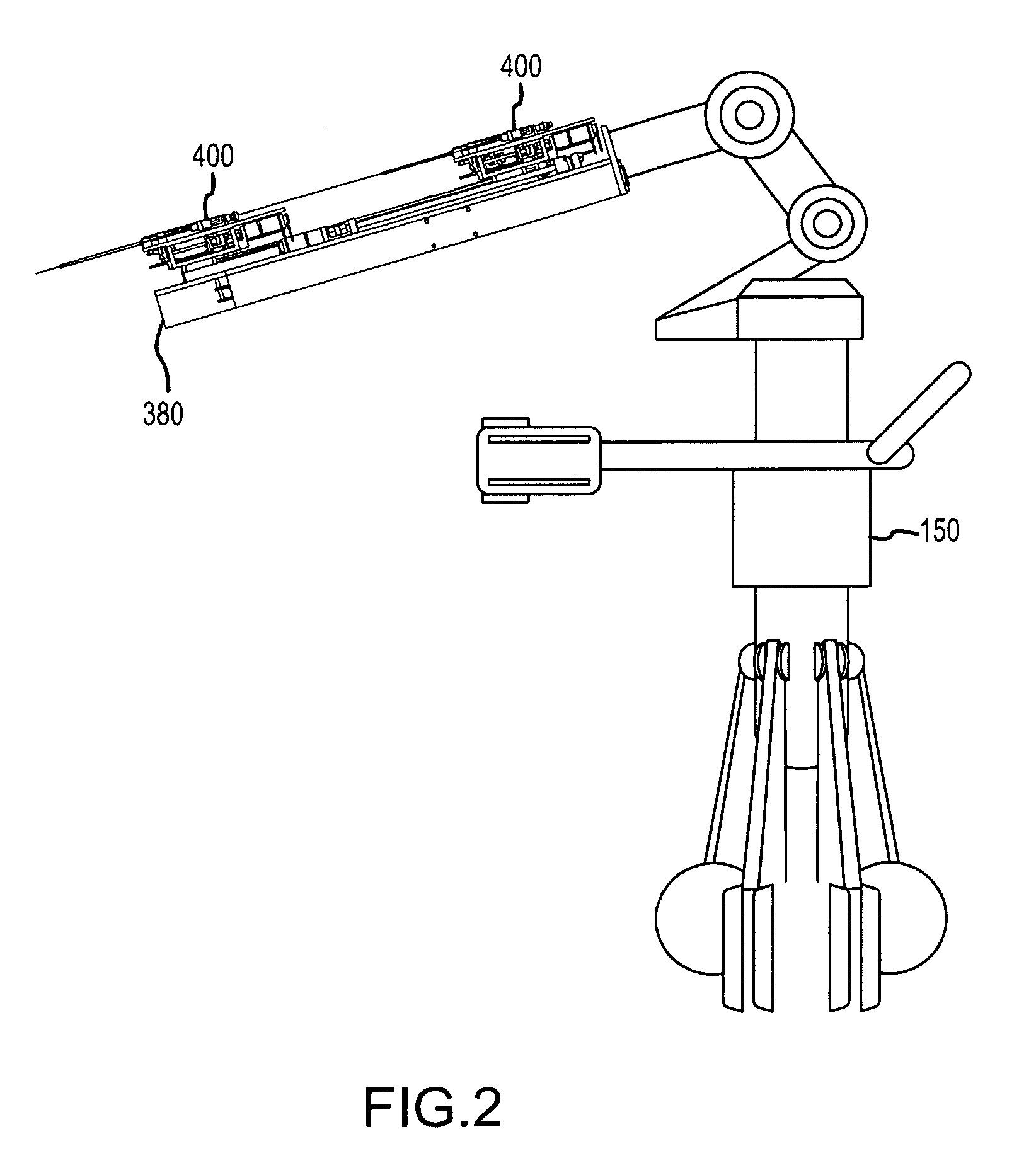

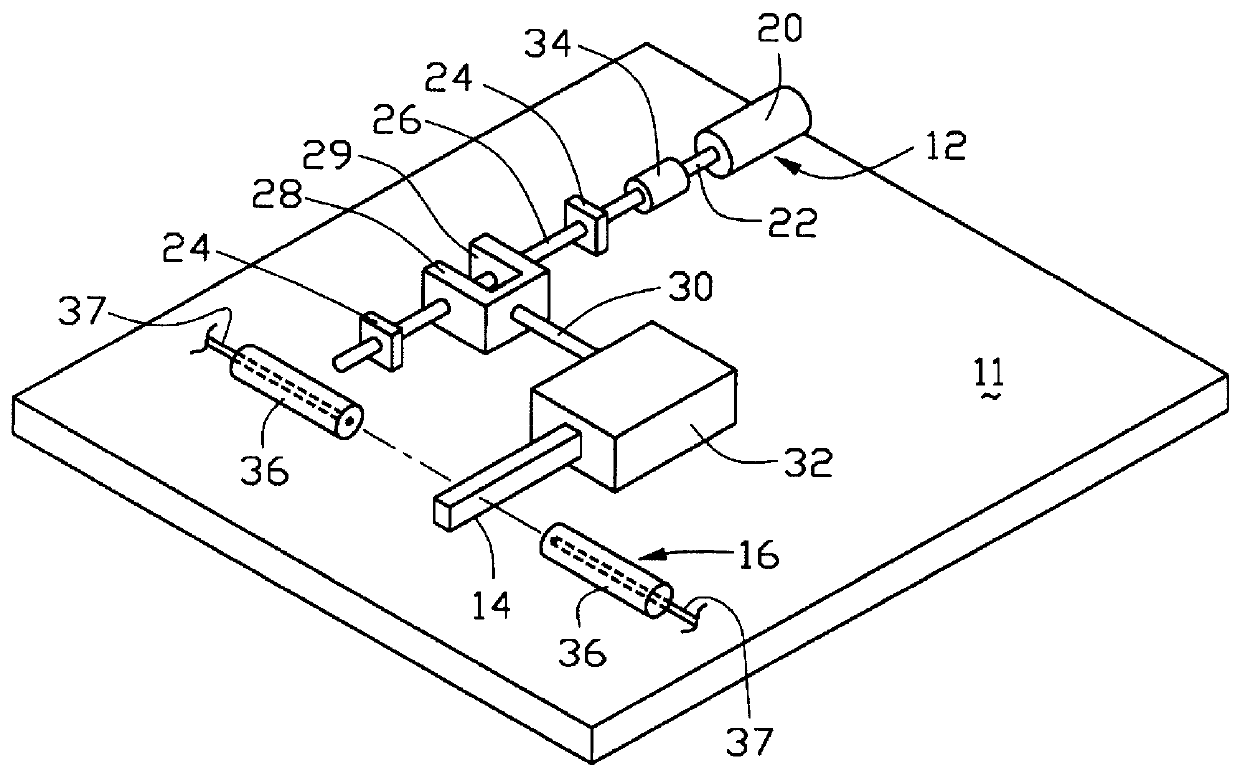

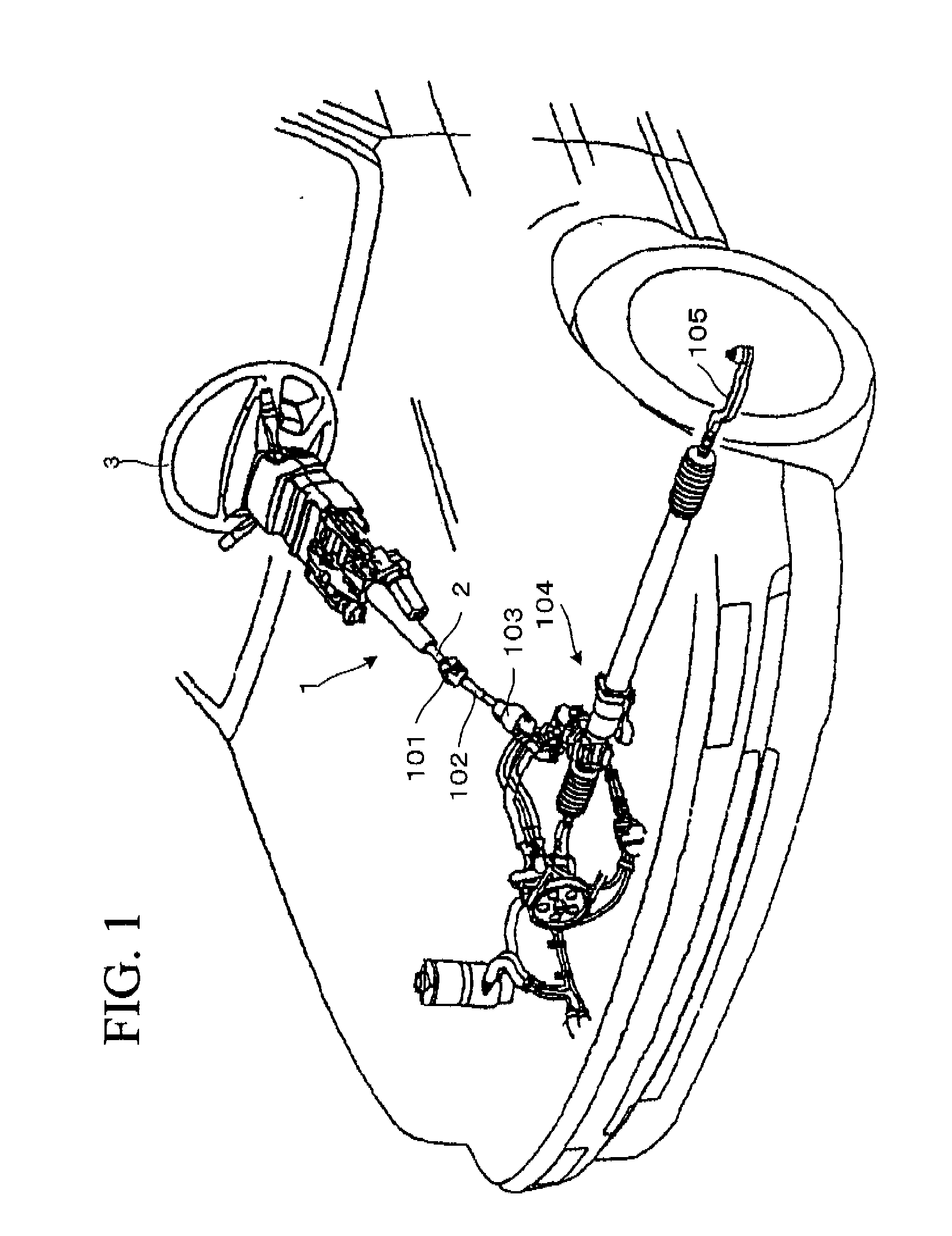

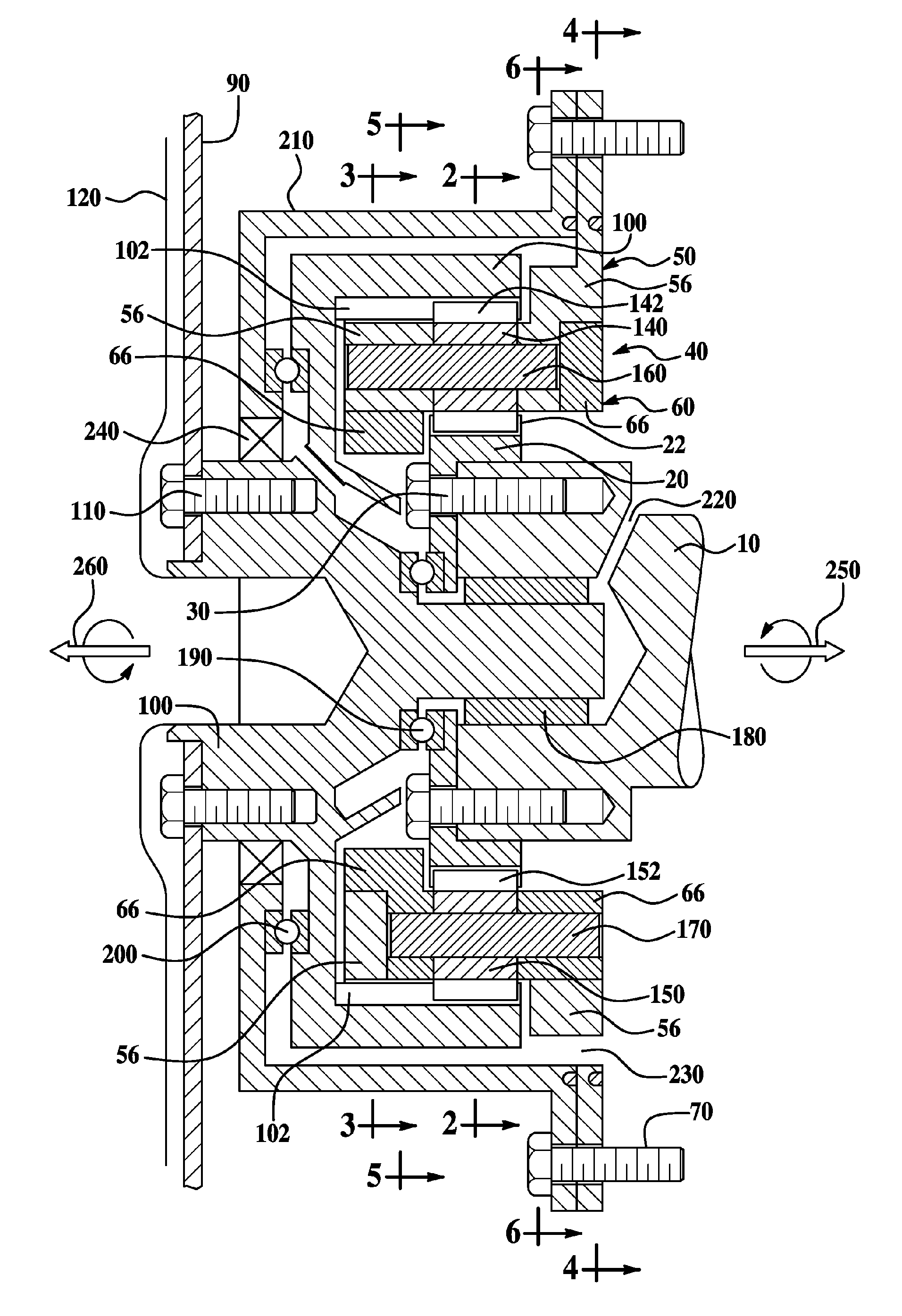

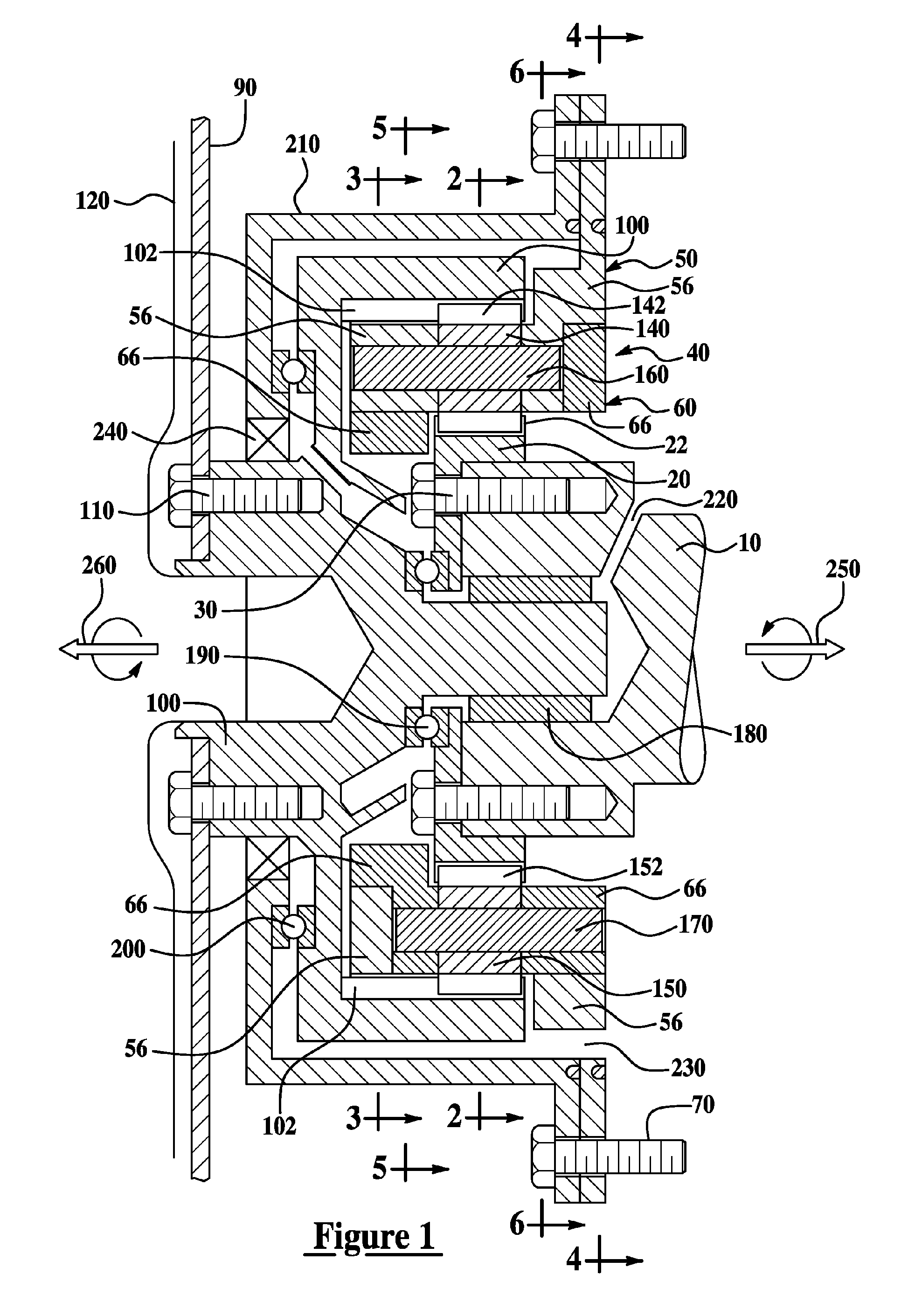

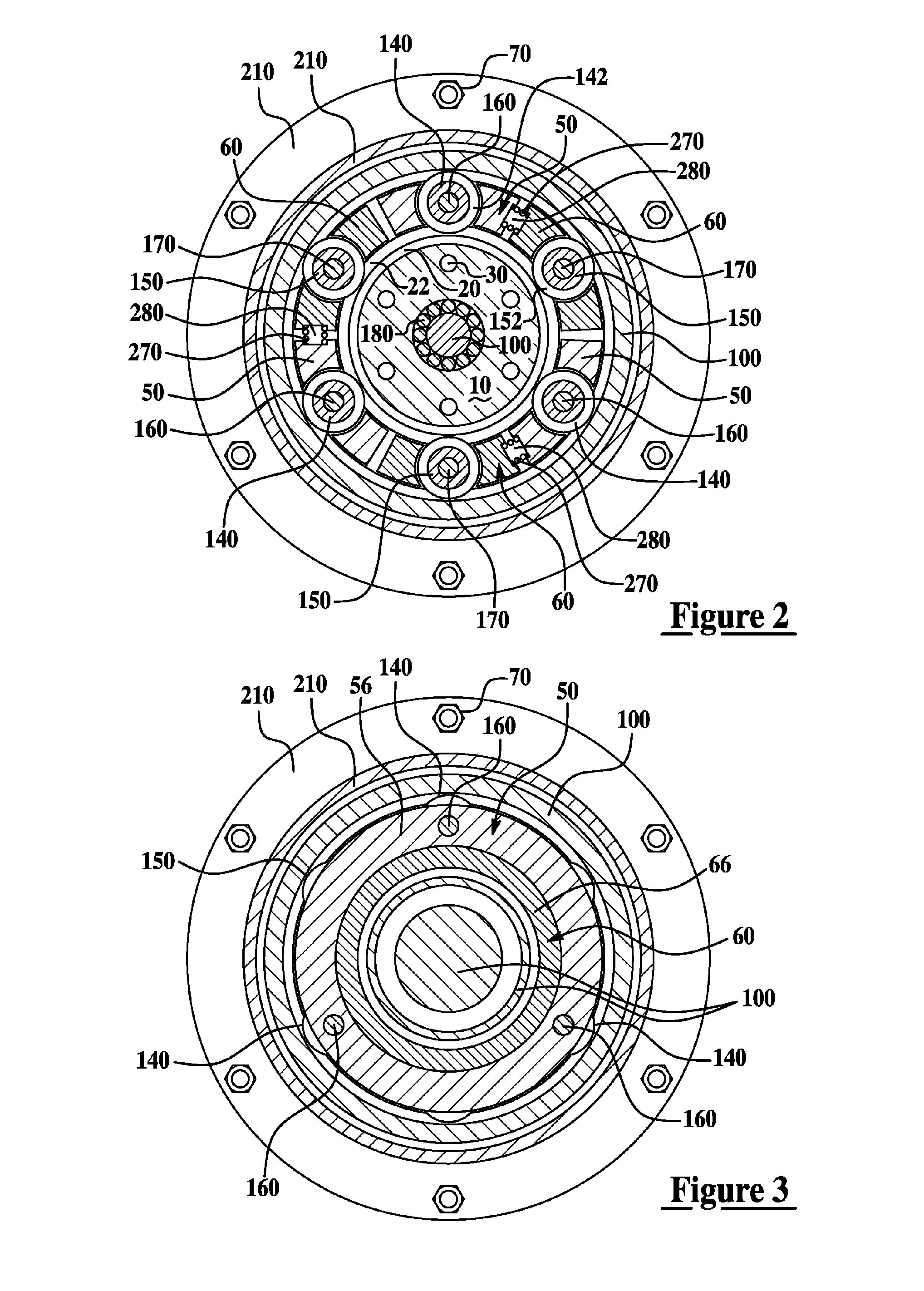

Robotic catheter rotatable device cartridge

InactiveUS20090247944A1Minimize and eliminate procedural variabilityEliminate backlashDiagnosticsMedical devicesEngineeringSteering Wire

A robotic catheter rotatable device cartridge may include a housing member attachable to a drive mechanism for rotating the cartridge and a catheter attached to the cartridge along an axial direction of the catheter. A slider block may be generally slidable relative to the housing and engaged with one or more steering wires for controlling movement of the catheter in a transverse direction relative to the axial direction. The catheter may include the steering wire(s) engaged therewith and movable in the transverse direction when the slider block is linearly driven in a predetermined direction.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

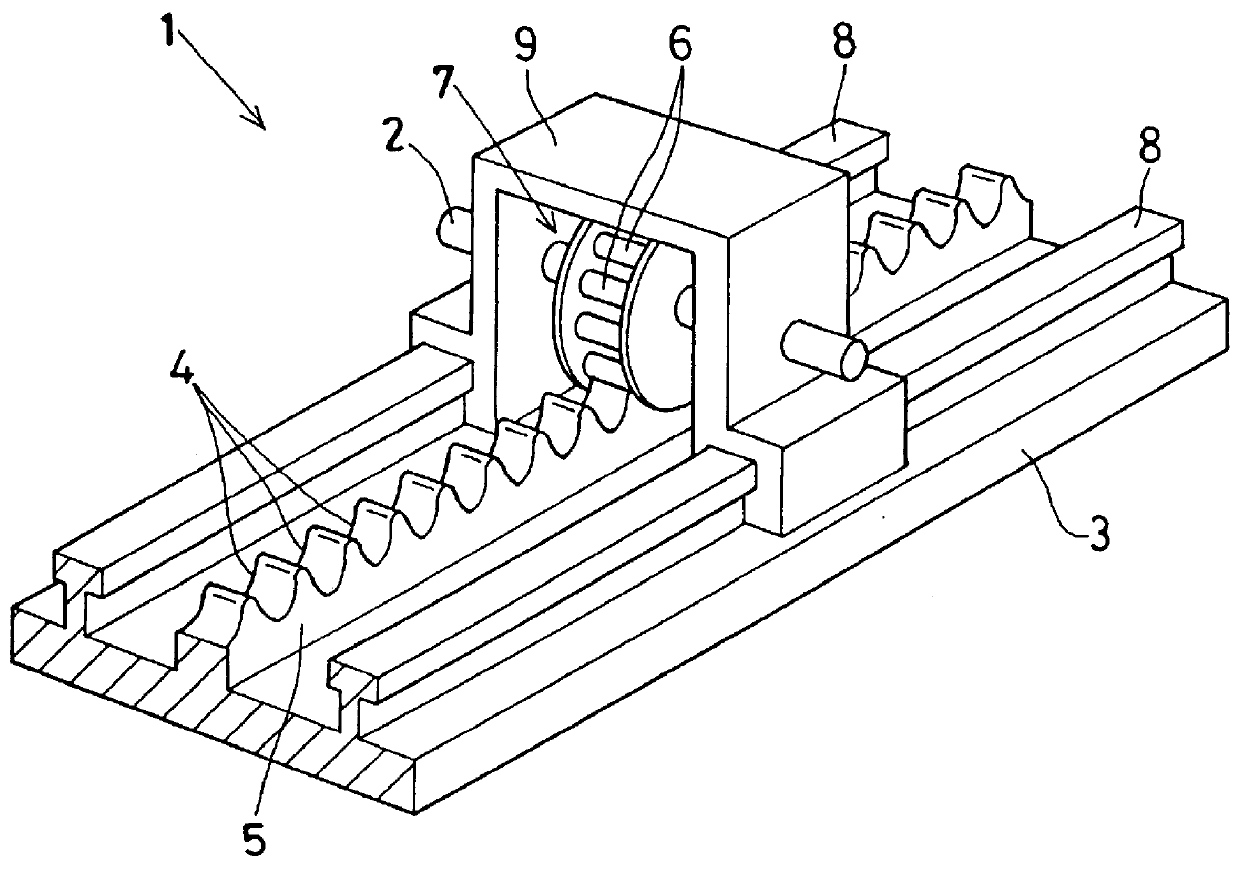

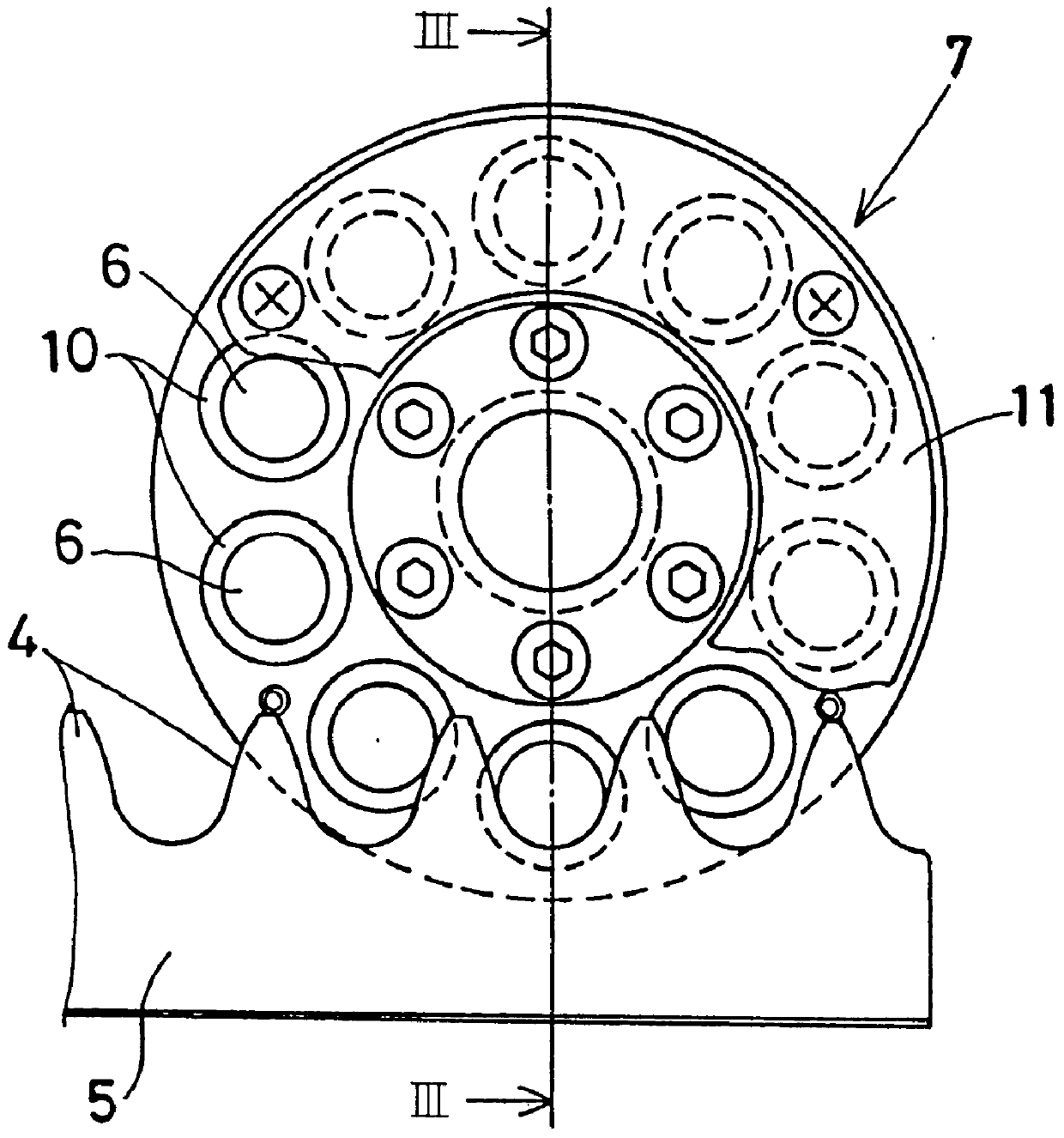

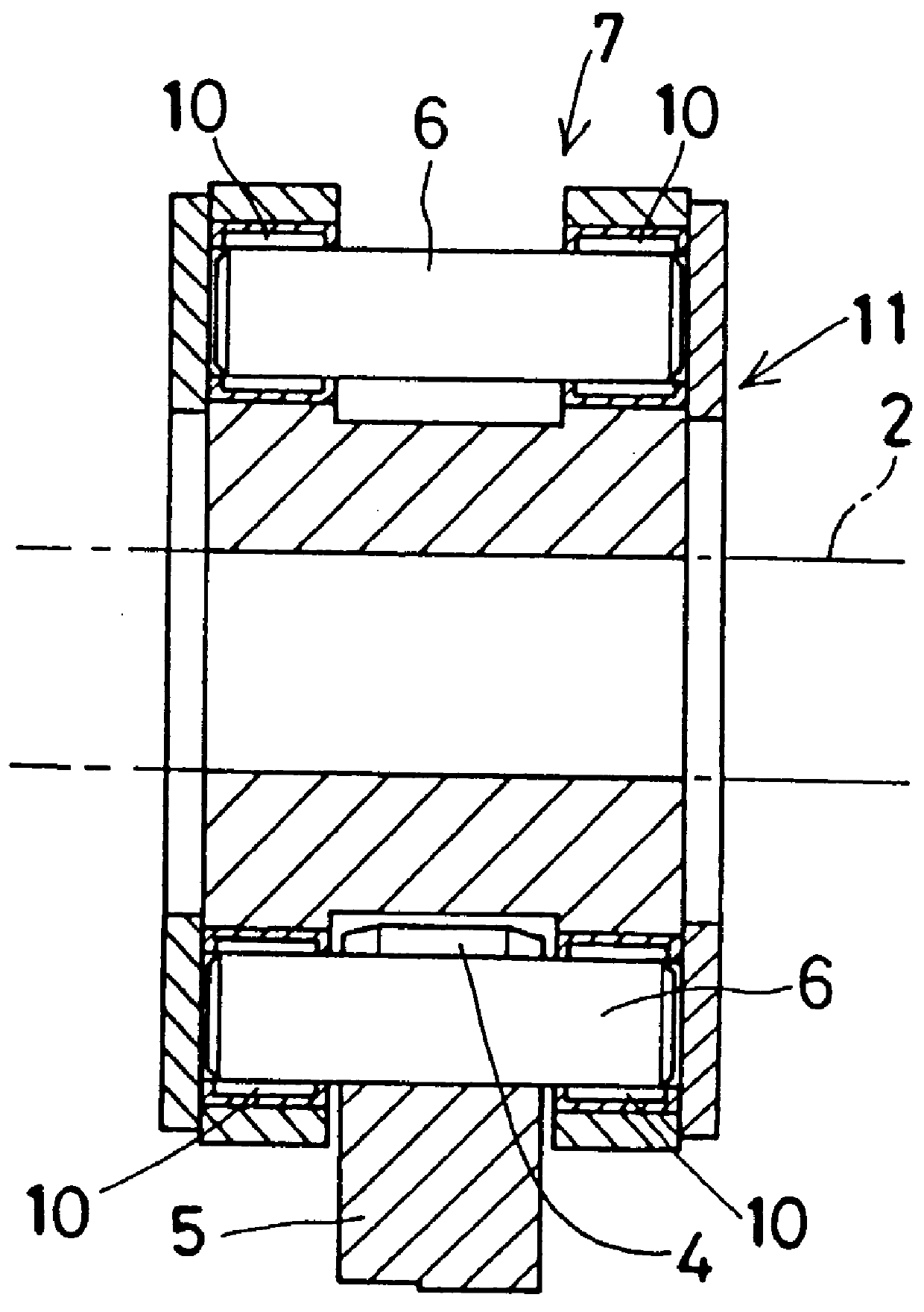

Transmission device for converting a torque between rotary movement and linear movement

InactiveUS6023989ASmooth meshingEliminate fluctuationsToothed gearingsPortable liftingLinear motionGear wheel

A transmission device for converting a torque from rotary to linear movement includes a rack having a plurality of teeth and a pinion having rollers which mesh with the teeth of the rack, with pressurization provided therebetween. The rack has an arcuate tooth flank diametrically greater than each of the rollers of the pinion. The rack also has a tooth face which has an approach profile progressively moving away from the path of contact of each of the rollers along which each of the rollers would otherwise engage with the tooth face. A plurality of each of the rollers of the pinion concurrently mesh with the corresponding teeth of the rack. Another embodiment converts a torque between rotary and linear movement and comprises a pinion having a plurality of teeth and a rack having a plurality of rollers to mesh with the teeth of the pinion. The device achieves reduced transmission resistance, a silent intermeshing movement with no substantial noise and vibration, as well as reduced wear on the teeth and rollers.

Owner:KAMOSEIKO

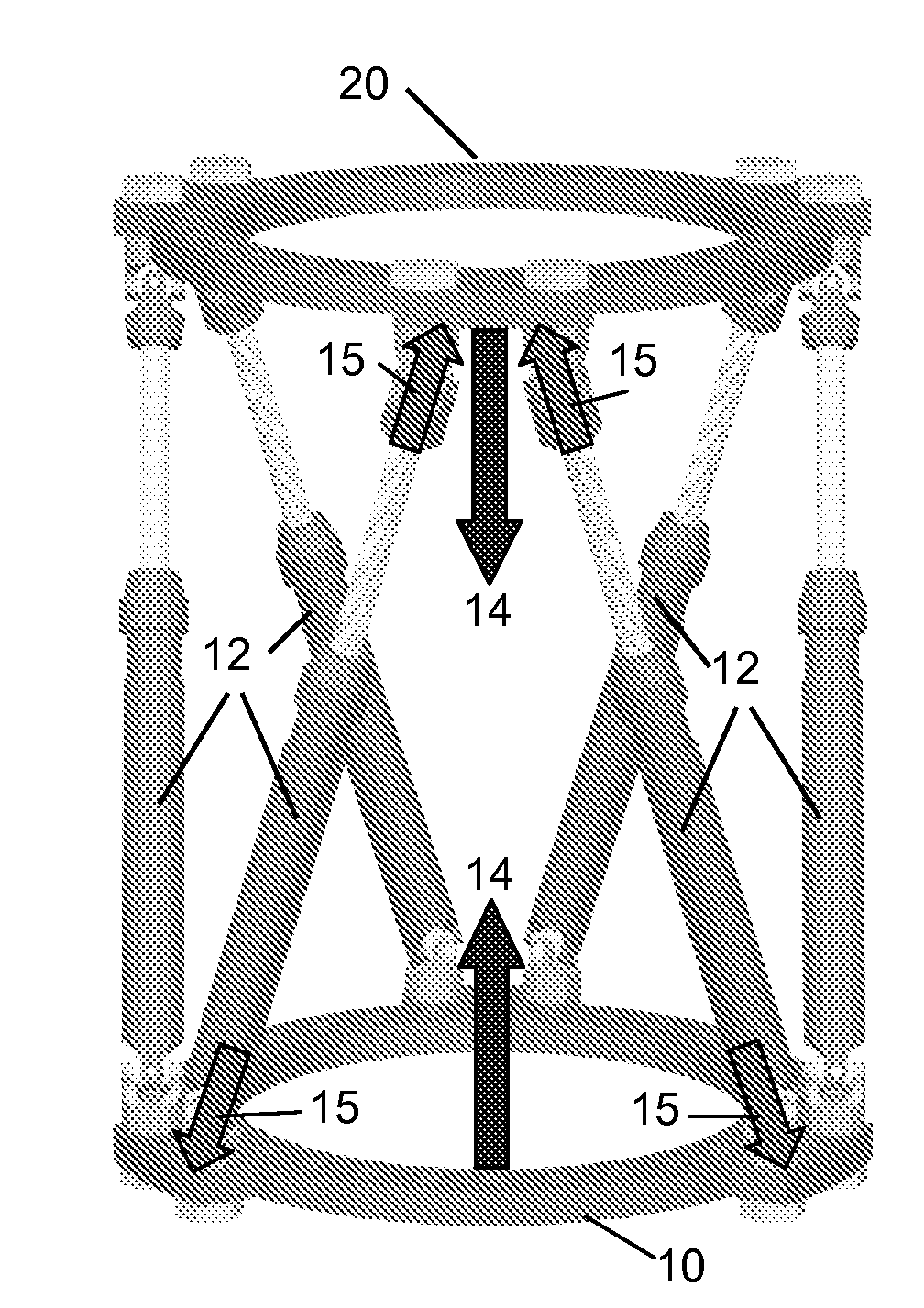

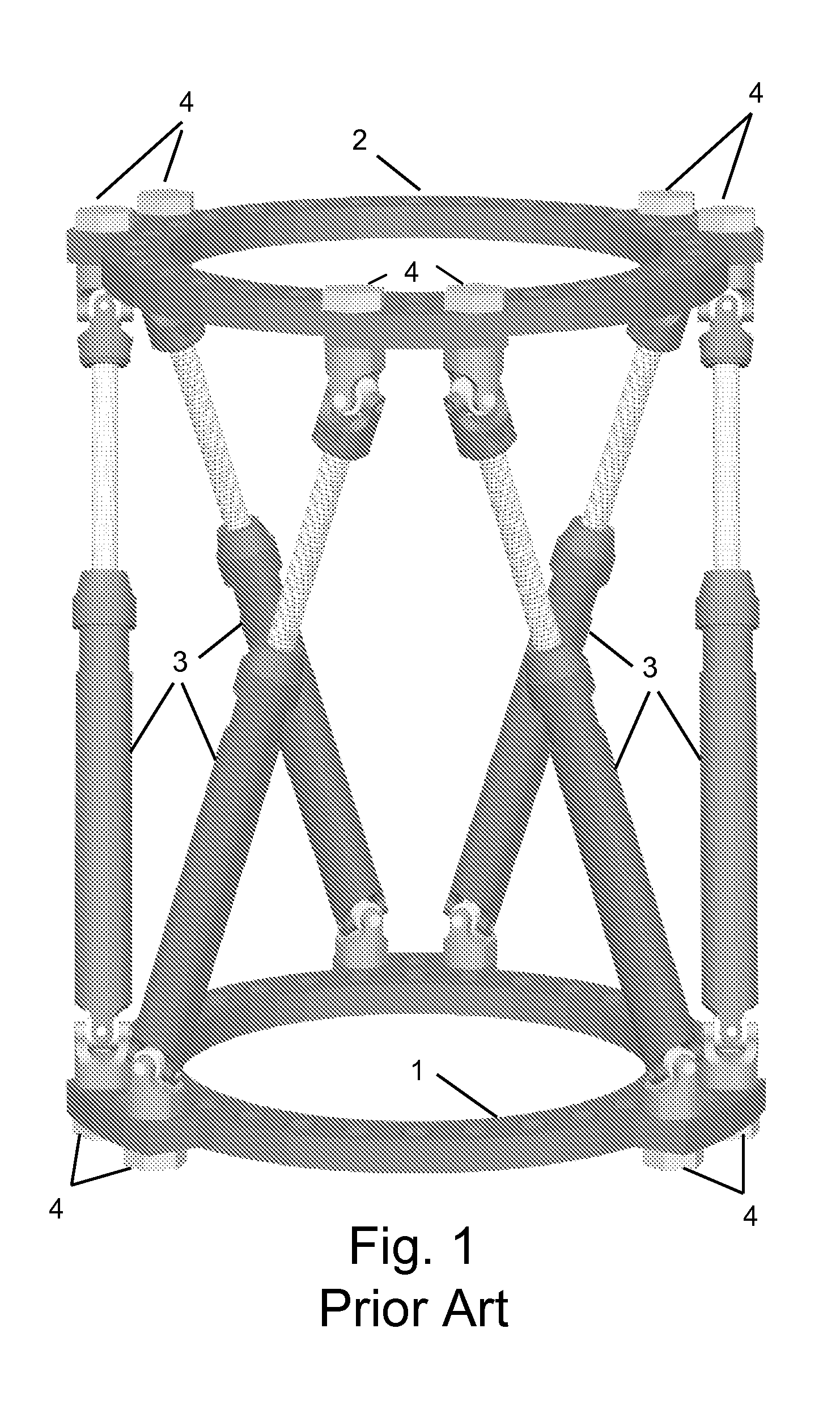

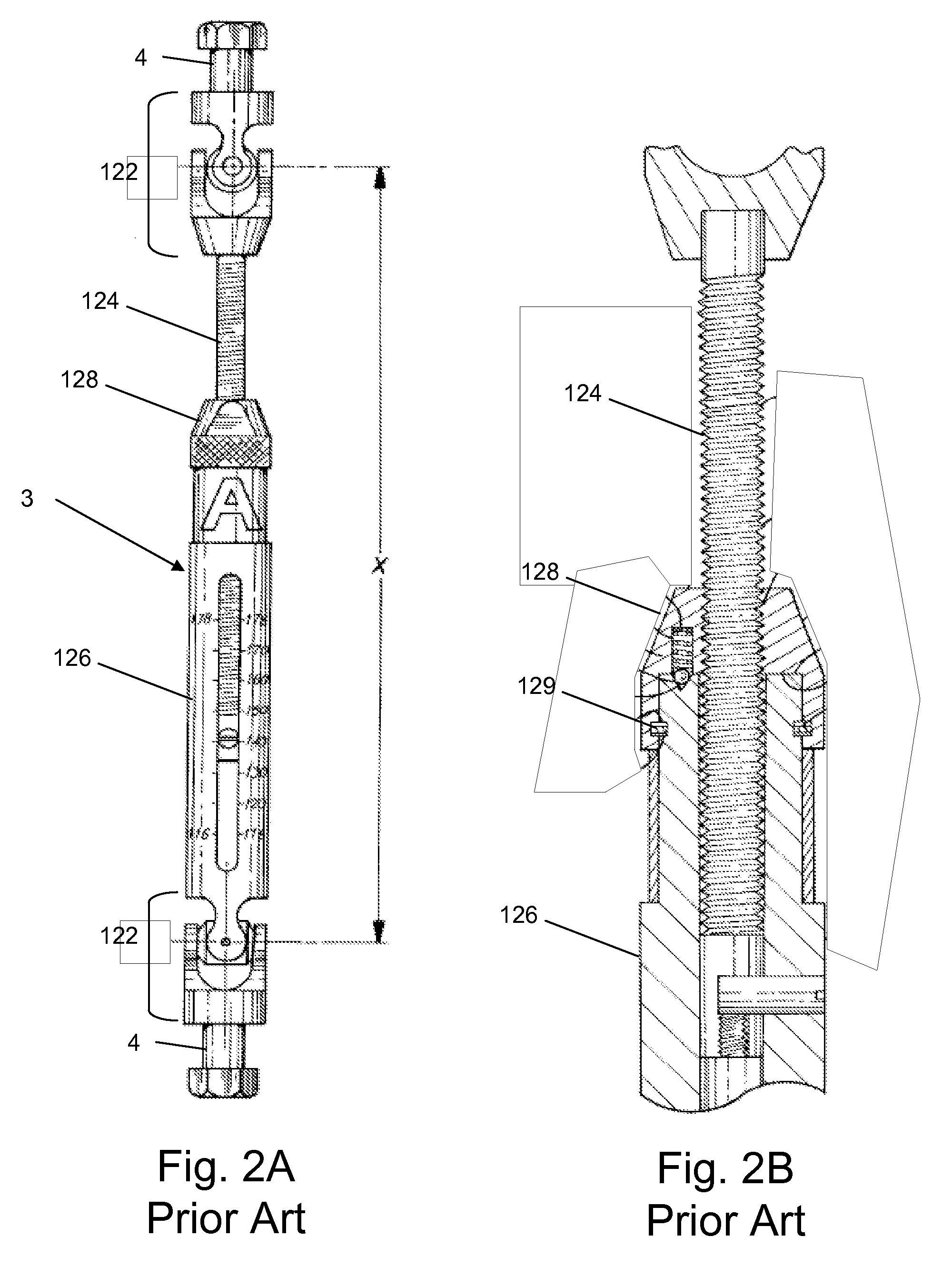

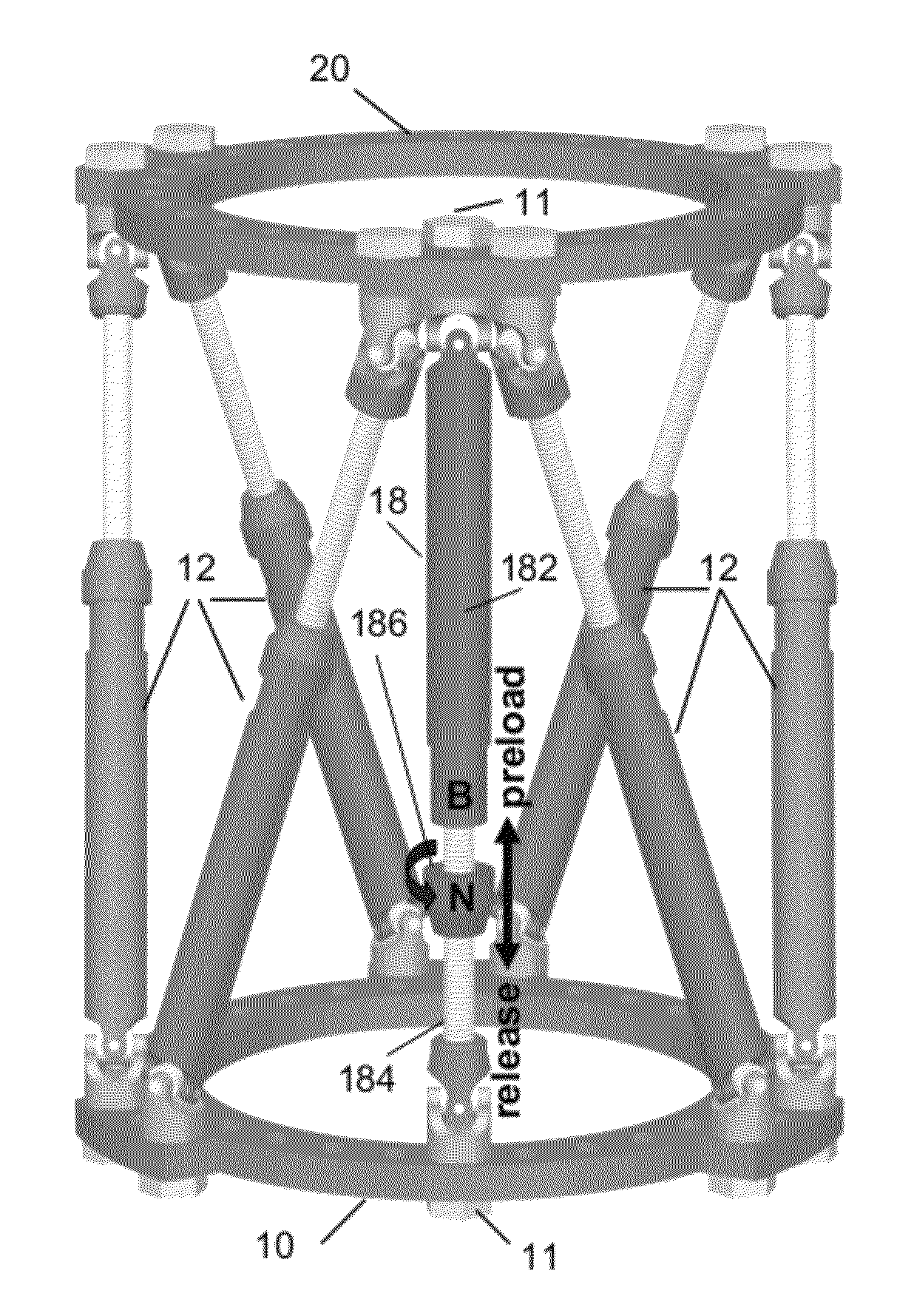

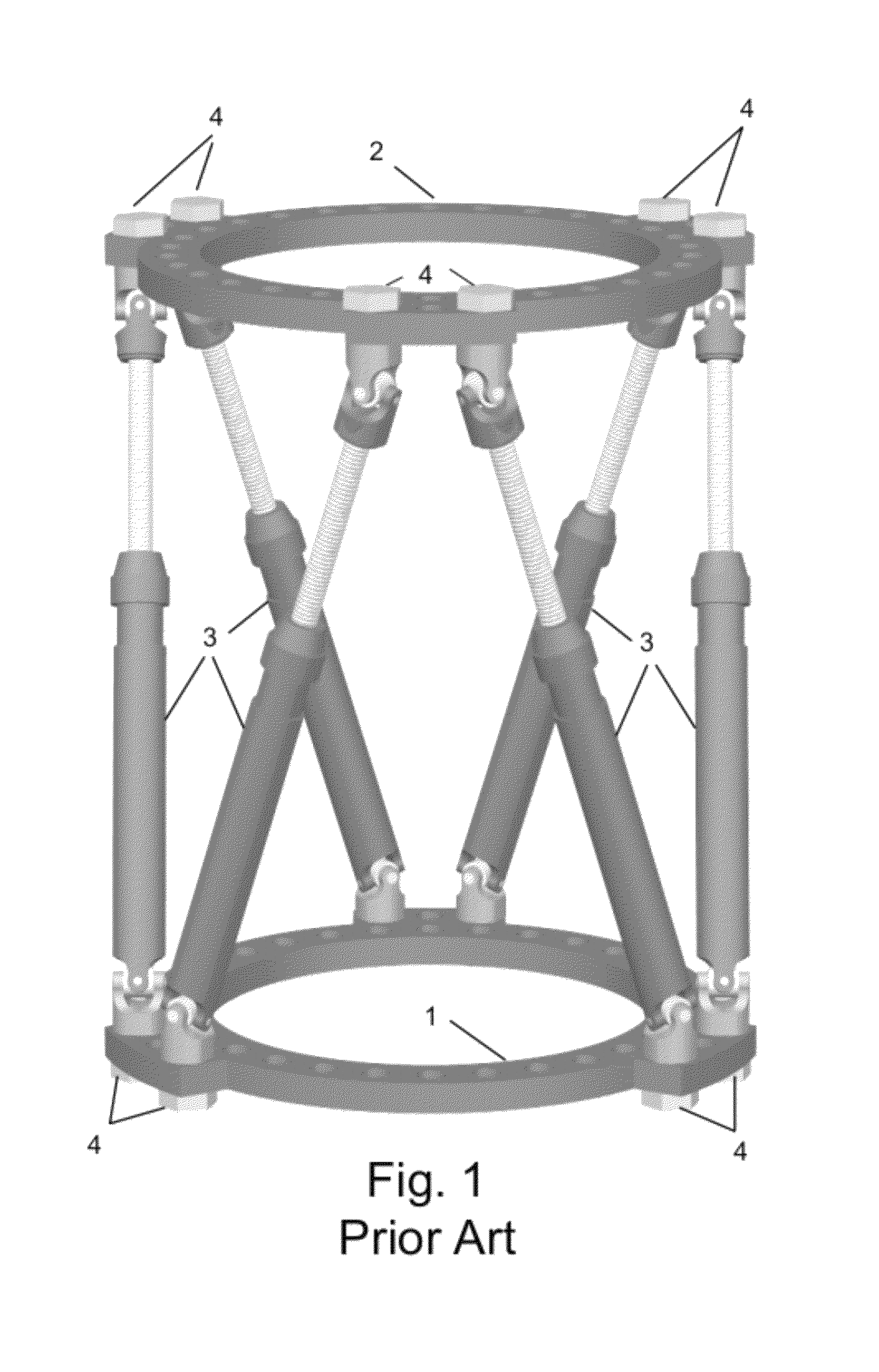

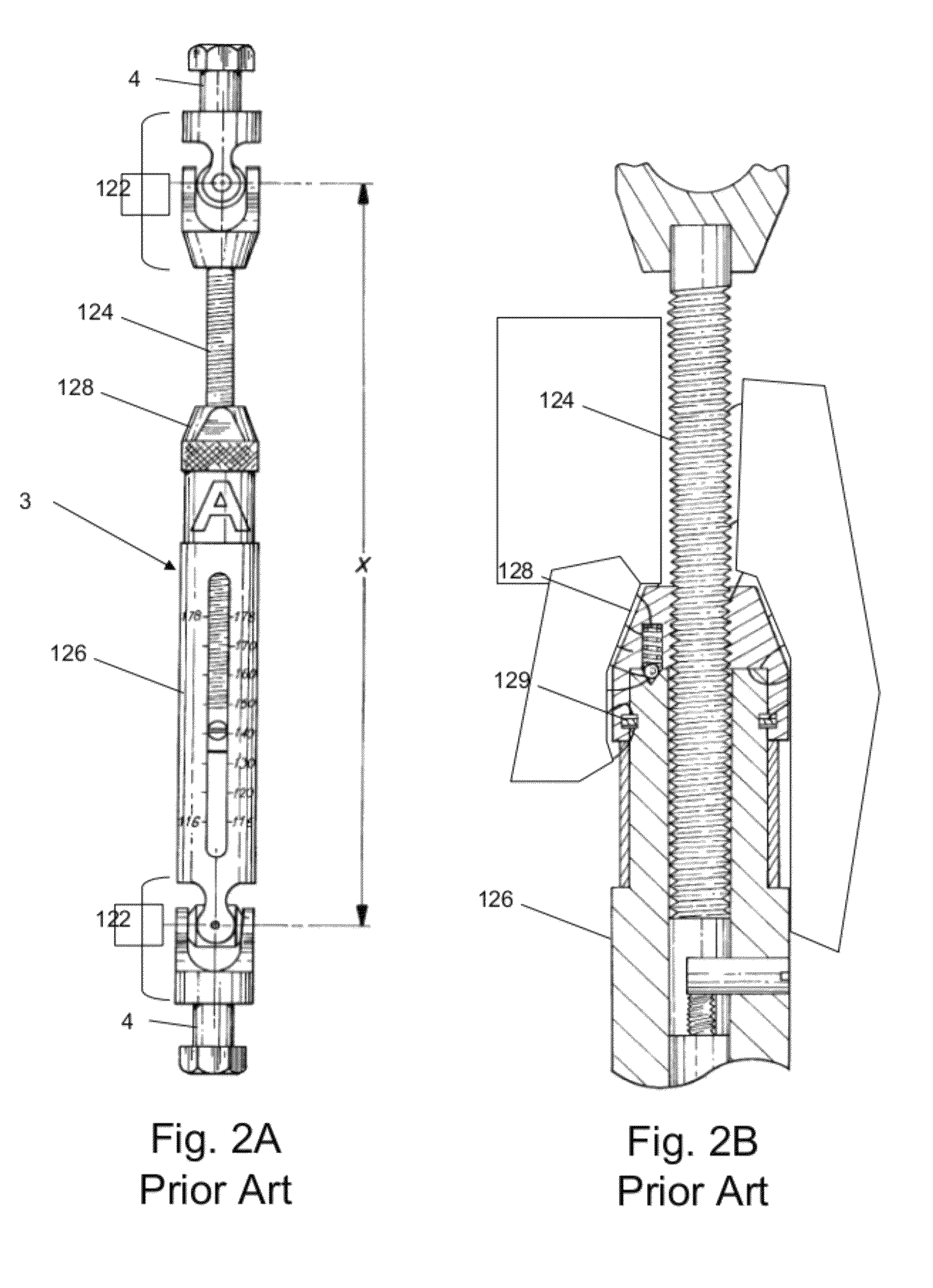

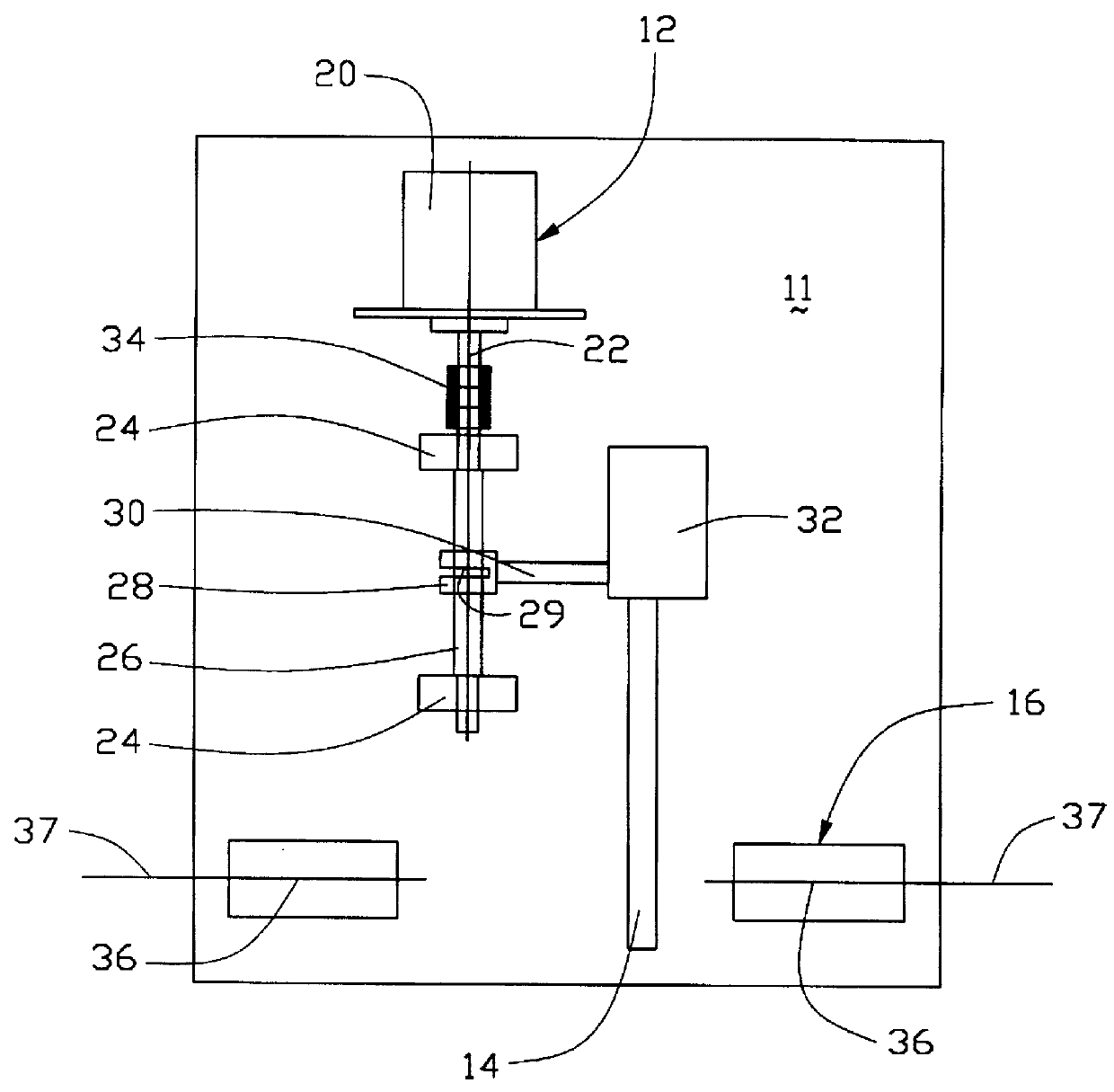

Orthopedic fixation device with zero backlash and adjustable compliance, and process for adjusting same

ActiveUS20080269741A1Eliminate backlashAccurately and securely fixedInternal osteosythesisJoint implantsOrthopedic fixation devicesEffective length

An orthopedic fixator for positioning a first element relative to a second element with precision and with controlled compliance which can be adjusted during the healing process. One embodiment comprises a first frame for attachment to the first element, a second frame attached to the first frame through a plurality of adjustable effective length struts, and a third frame for attachment to the second element, wherein the third frame is compliantly attached to the second frame. A preferred embodiment comprises adjustable length preload elements to apply unidirectional forces between the first and second frames so as preload the adjustable effective length struts and substantially reduce the positional tolerance. An alternative embodiment comprises adjustable spring elements allowing the compliance of the attachment of the third frame to the second frame to be adjusted at various points in the healing process.

Owner:KARIDIS SARA LYNN

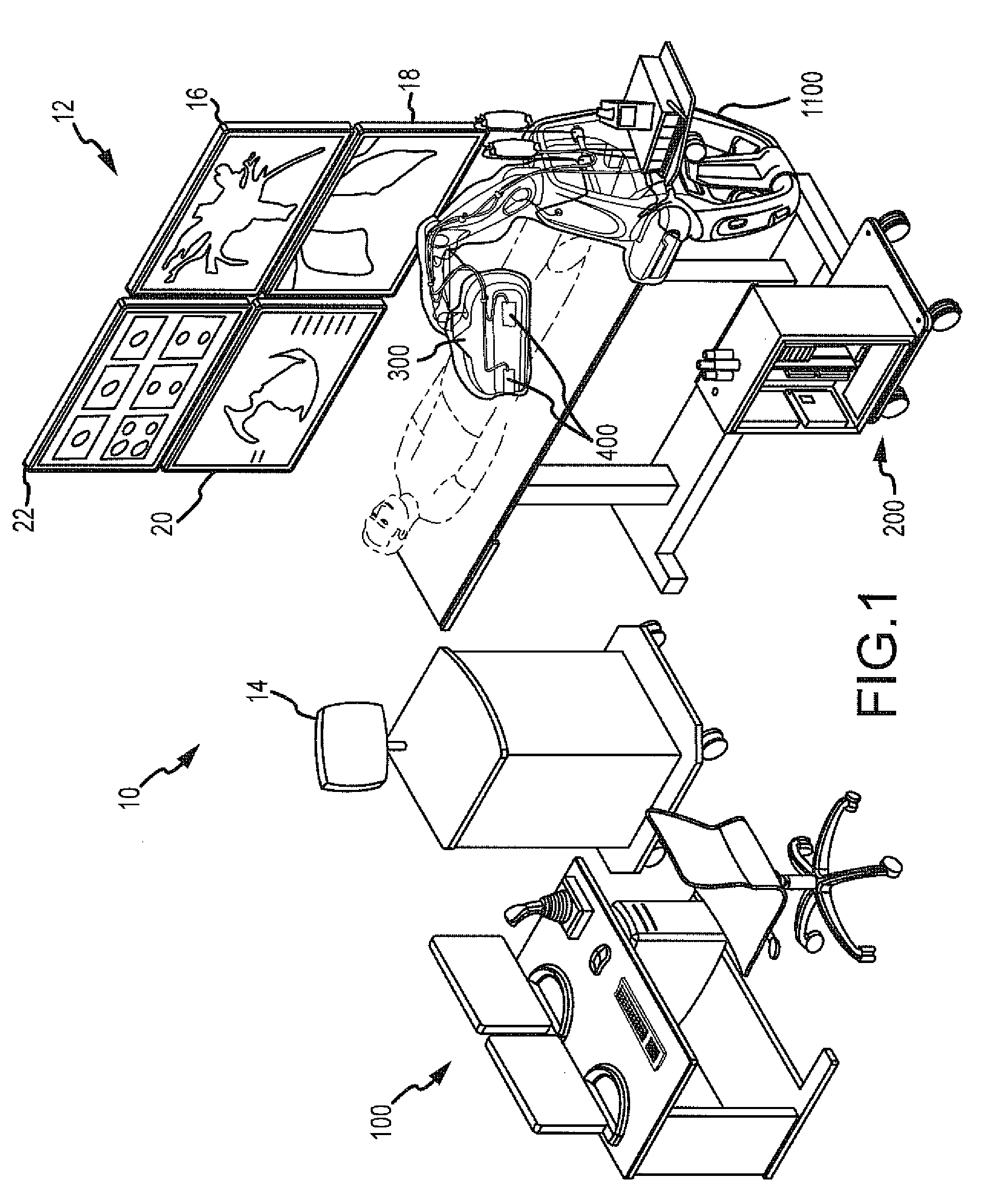

Robotic catheter device cartridge

ActiveUS20090247943A1Minimize and eliminate procedural variabilityMinimize and eliminate exposureDiagnosticsSurgical needlesSteering wheelEngineering

A robotic catheter device cartridge may include a finger or a slider block generally disposed in a channel and engaged with a steering wire. The steering wire may control movement of a component having the steering wire engaged thereto when the finger or the slider block is linearly driven in a predetermined direction. The cartridge may be a transseptal cartridge having a transseptal needle connected thereto, a catheter cartridge having a catheter connected thereto, or a sheath cartridge having a sheath connected thereto.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Orthopedic fixation device with zero backlash and adjustable compliance, and process for adjusting same

ActiveUS8202273B2Eliminate backlashAccurately and securely fixedInternal osteosythesisJoint implantsOrthopedic fixation devicesEffective length

An orthopedic fixator for positioning a first element relative to a second element with precision and with controlled compliance which can be adjusted during the healing process. One embodiment comprises a first frame for attachment to the first element, a second frame attached to the first frame through a plurality of adjustable effective length struts, and a third frame for attachment to the second element, wherein the third frame is compliantly attached to the second frame. A preferred embodiment comprises adjustable length preload elements to apply unidirectional forces between the first and second frames so as preload the adjustable effective length struts and substantially reduce the positional tolerance. An alternative embodiment comprises adjustable spring elements allowing the compliance of the attachment of the third frame to the second frame to be adjusted at various points in the healing process.

Owner:KARIDIS SARA LYNN

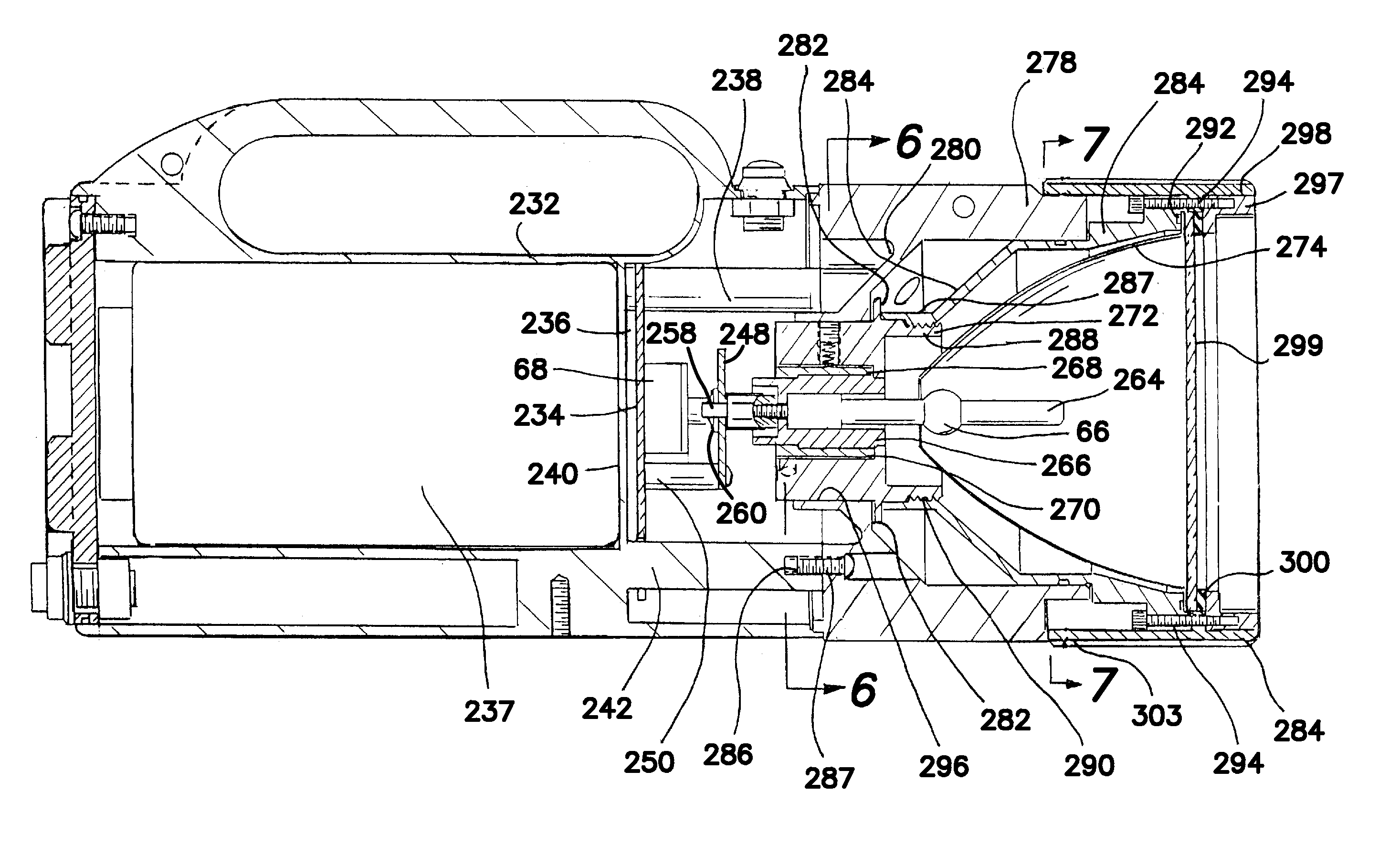

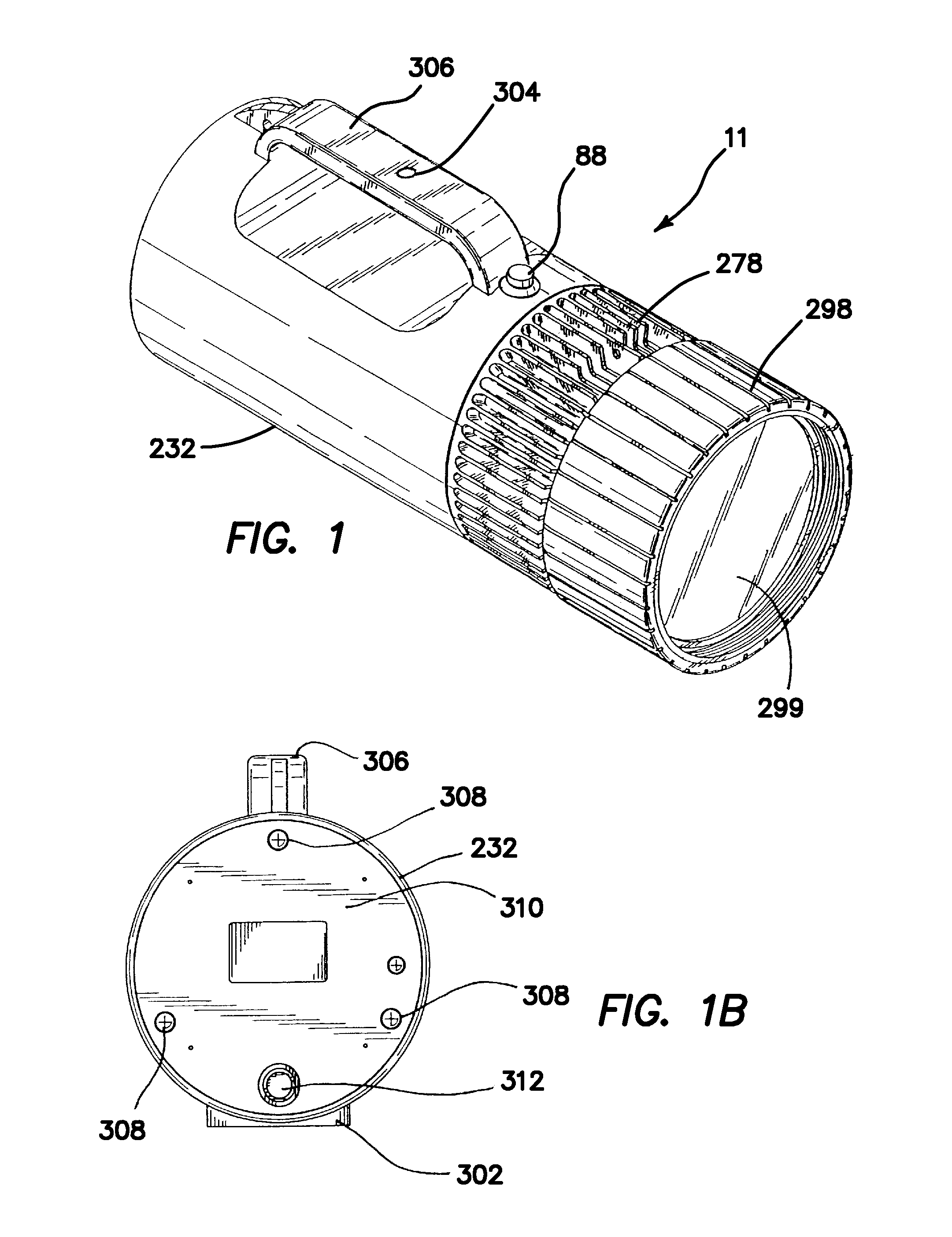

Apparatus and method for operating a portable xenon arc searchlight

InactiveUS20120212963A1Eliminate backlashReduce instabilityWith electric batteriesOptical signallingInstabilityLight beam

An apparatus for producing a high intensity beam of light with high efficiency of conversion of electrical power into light intensity includes an arc lamp, a reflector, a screw drive mechanism coupled between the arc lamp and reflector for positioning the arc lamp relative to the reflector to provide zoom control of the beam of light, and a spring for biasing the screw drive mechanism into a stable configuration to eliminate backlash and instability of the positioning the arc lamp relative to the reflector to provide zoom control of the beam of light. A handheld light includes an IR filter selectively disposable over the aperture of the light so that only infrared light and a circumferential light curtain is interposed between the IR filter and the body so that no there are no light leaks even the IR filter and the body are prevented from fitting closely due to interposed debris.

Owner:SUREFIRE LLC

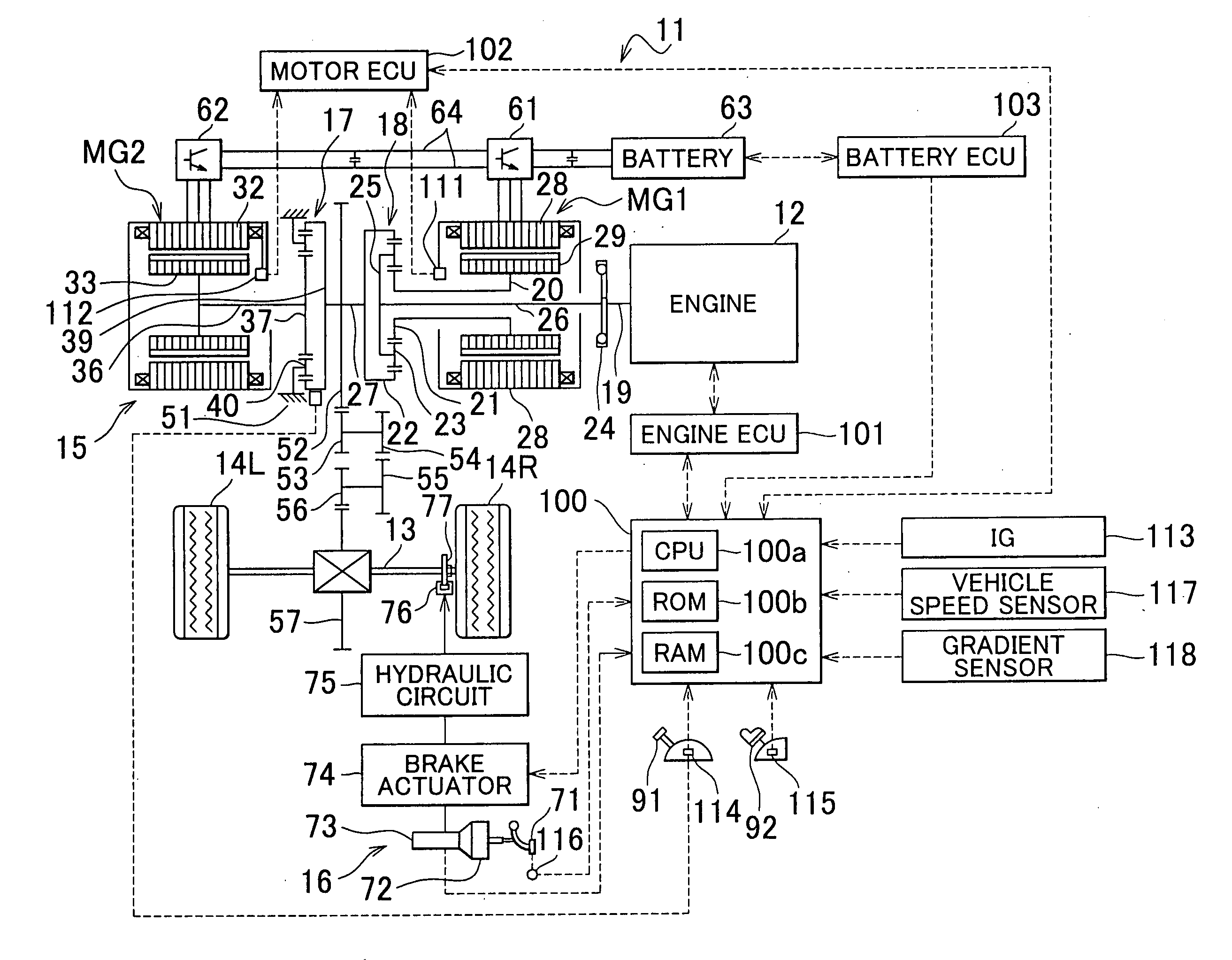

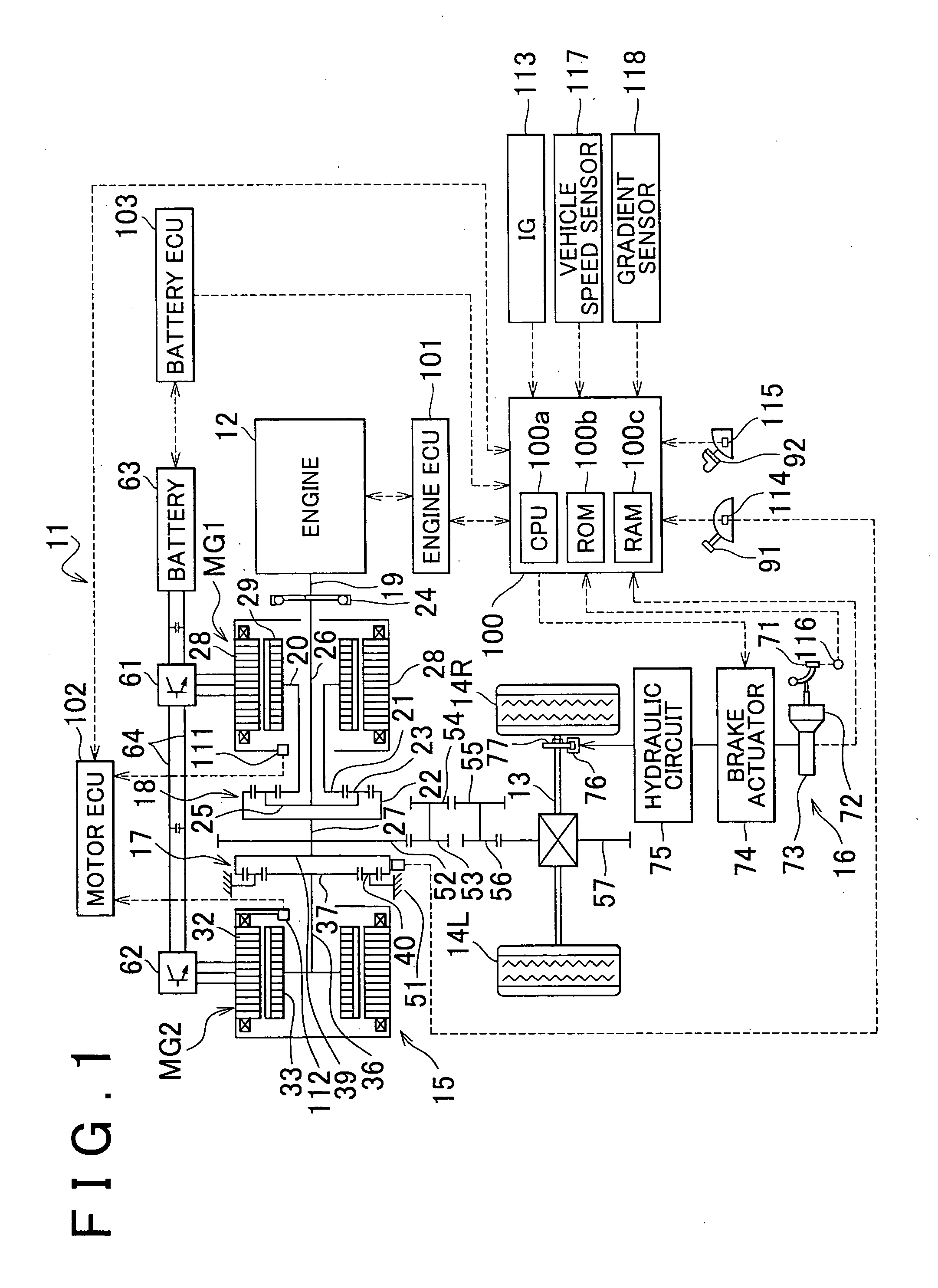

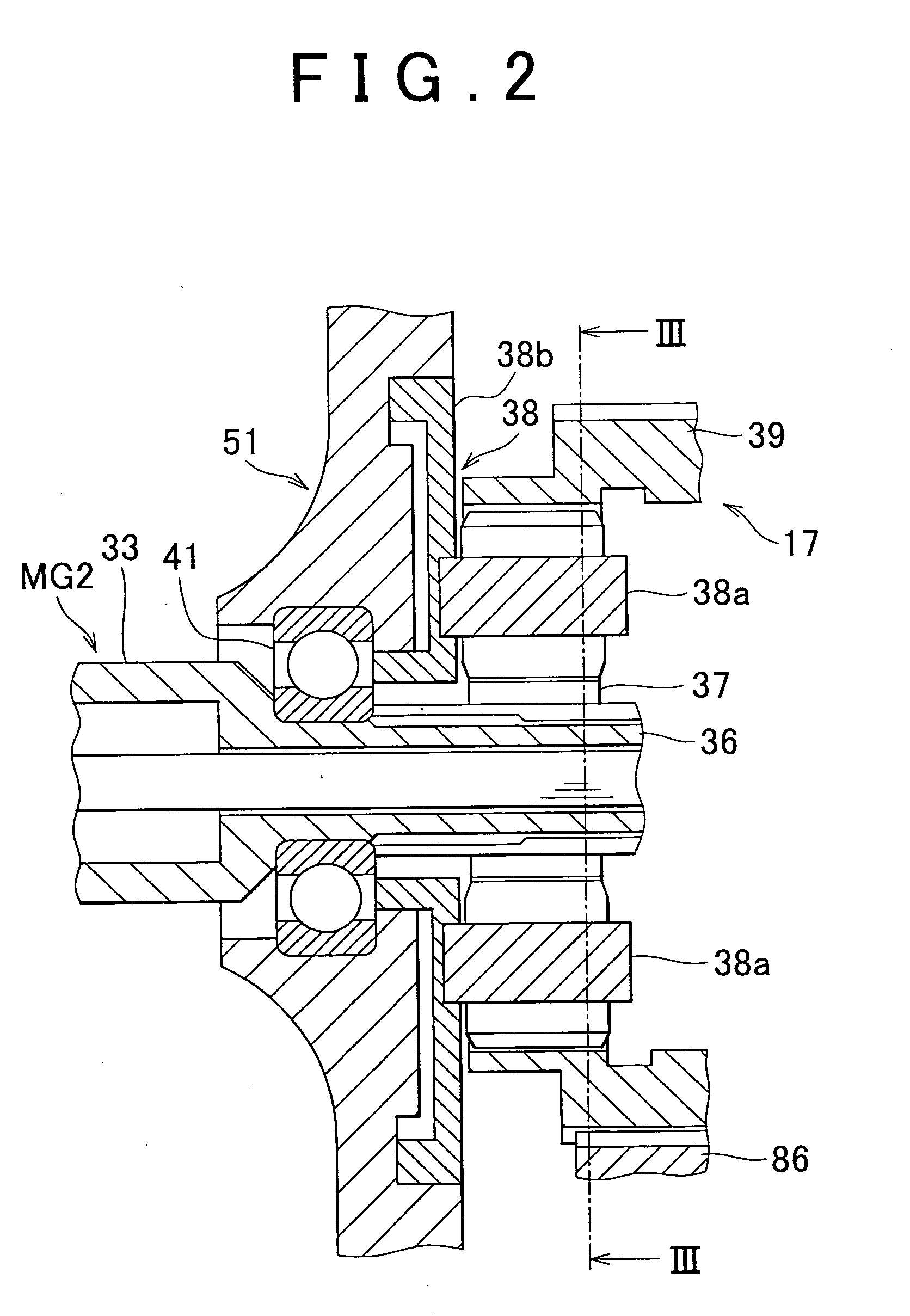

Vehicle control apparatus and method

InactiveUS20090043465A1Improve product durabilityMinimize impactHybrid vehiclesDigital data processing detailsDrive shaftPinion

In a case where, in order to stop a hybrid vehicle on a hill, a brake device is turned on and then the shift lever is shifted to the parking position (“P” position) to lock a parking-lock device and then the brake device is turned off and then the brake device is turned on despite that torsional torque is acting on the drive shaft, a motor generator, which is an inertial object having a large weight, is driven to rotate in a rotational direction corresponding to the direction of gradient of the road, so that the resultant rotational torque is transmitted to a sun gear, to pinions, and to a ring gear.

Owner:TOYOTA JIDOSHA KK

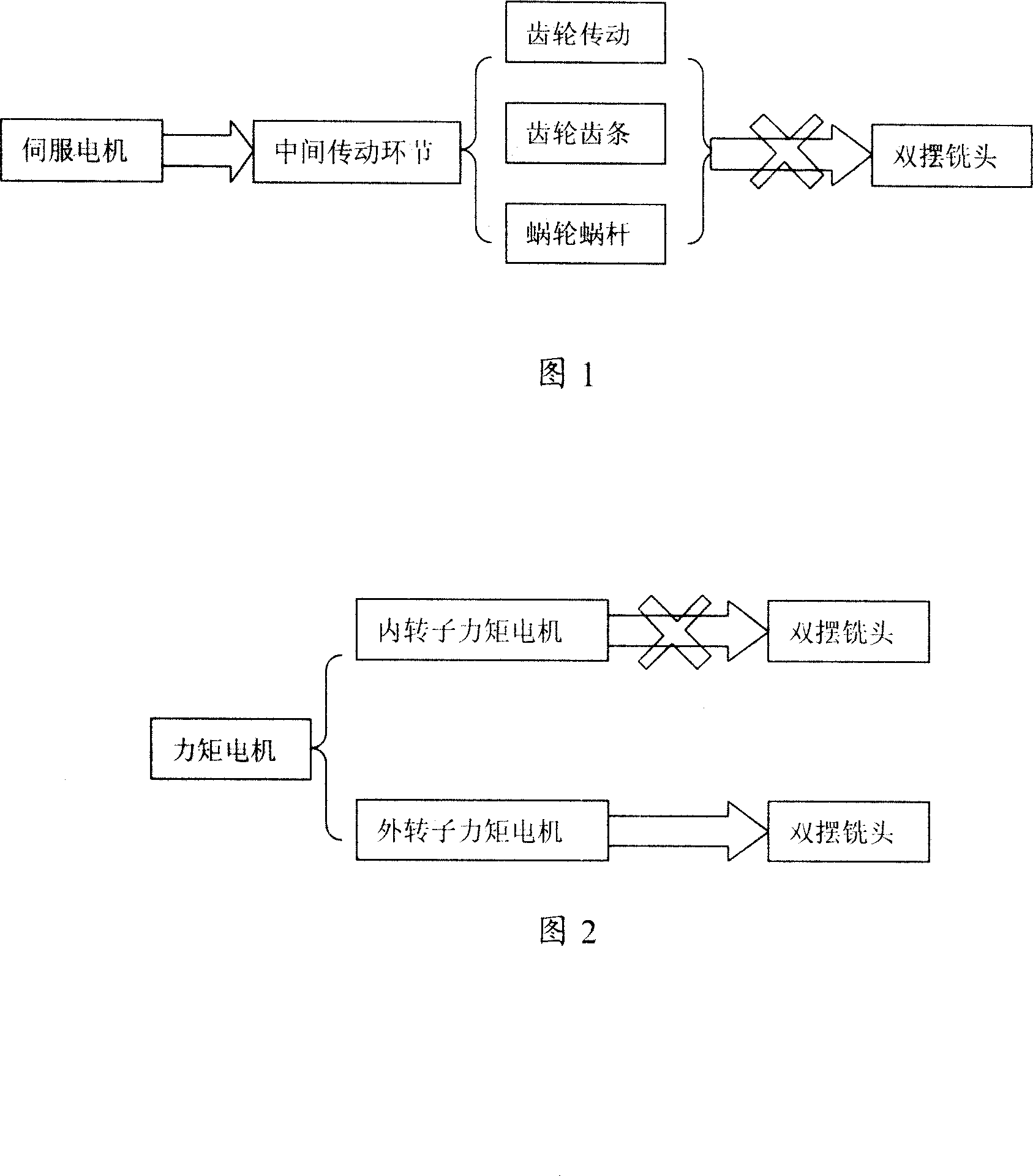

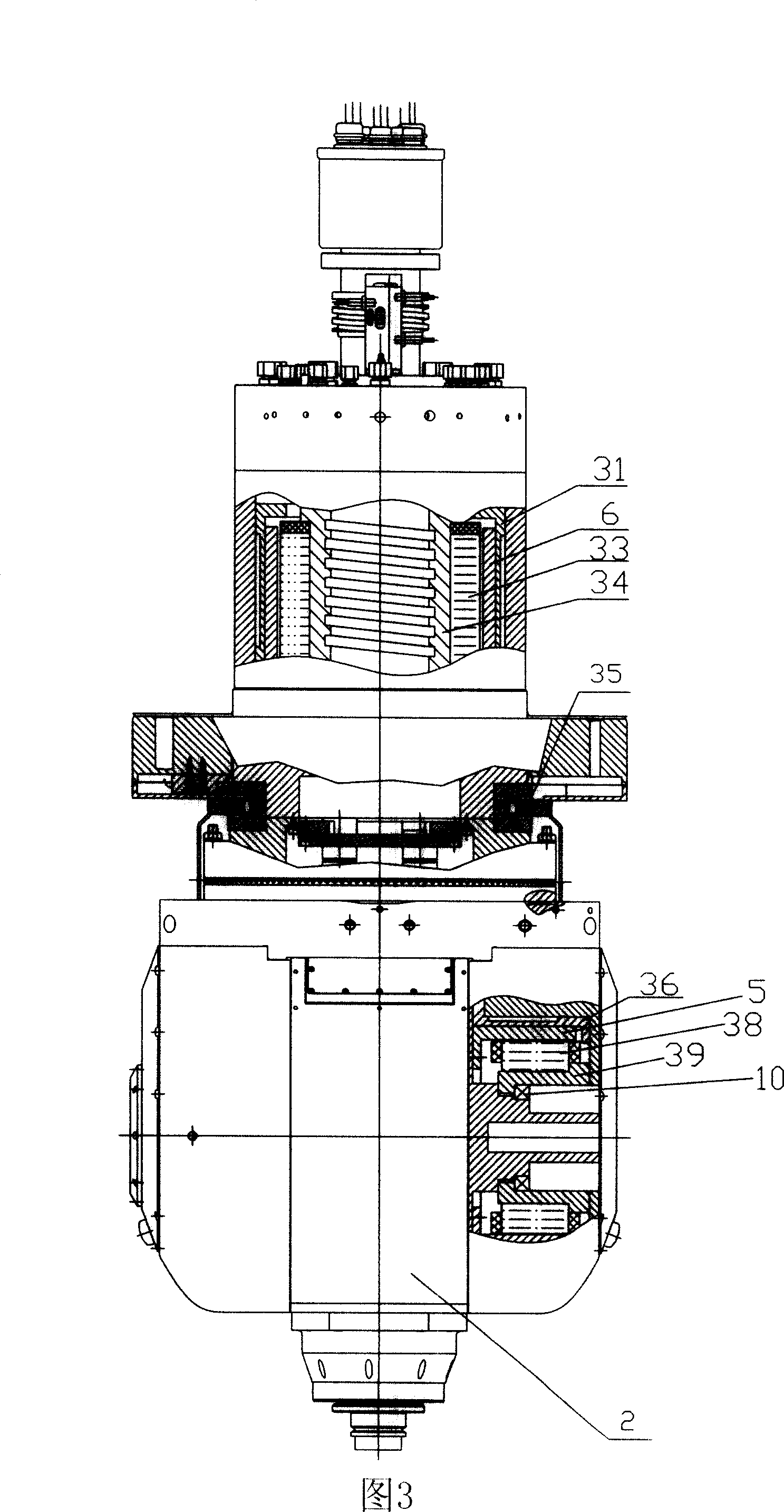

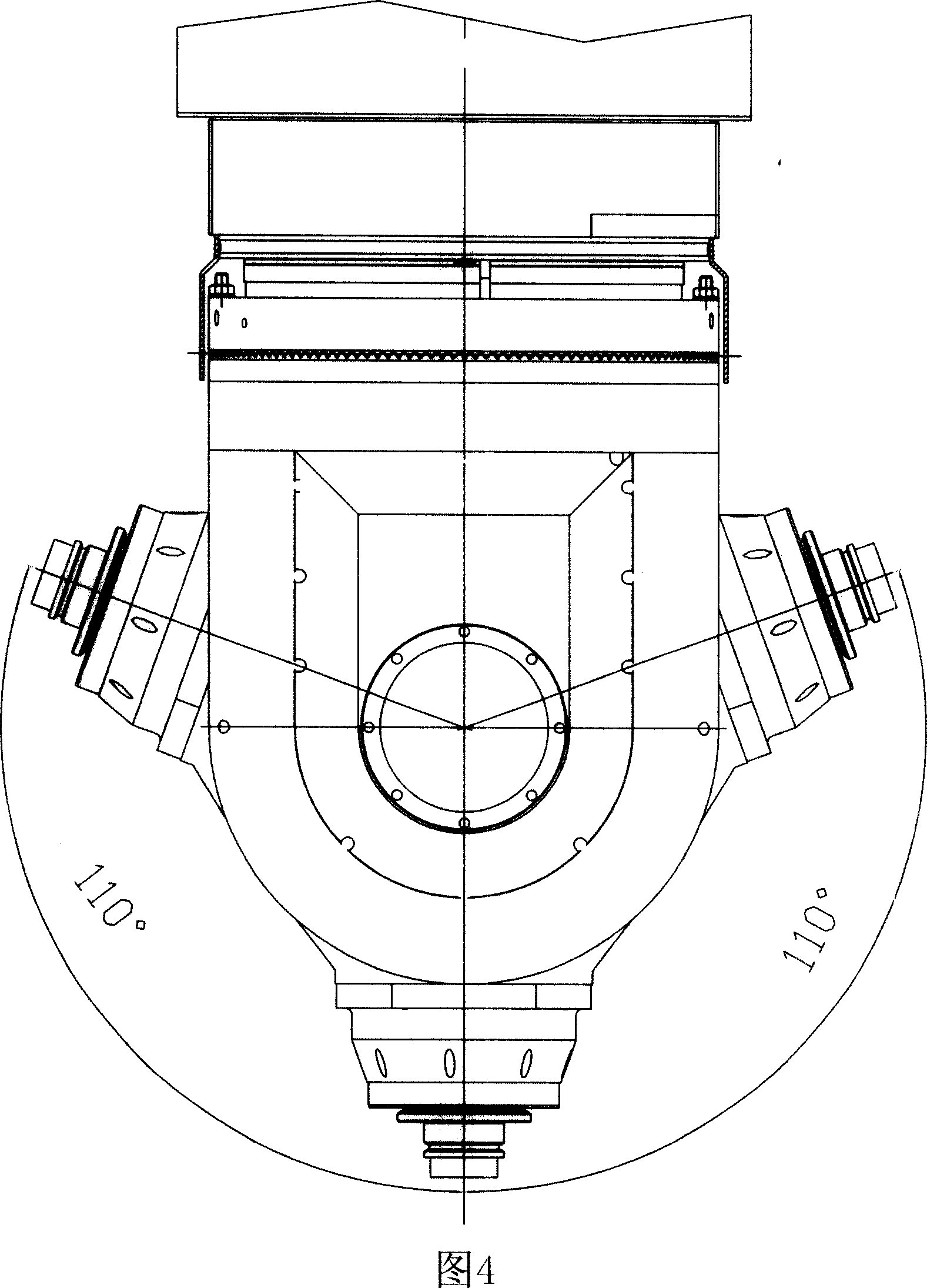

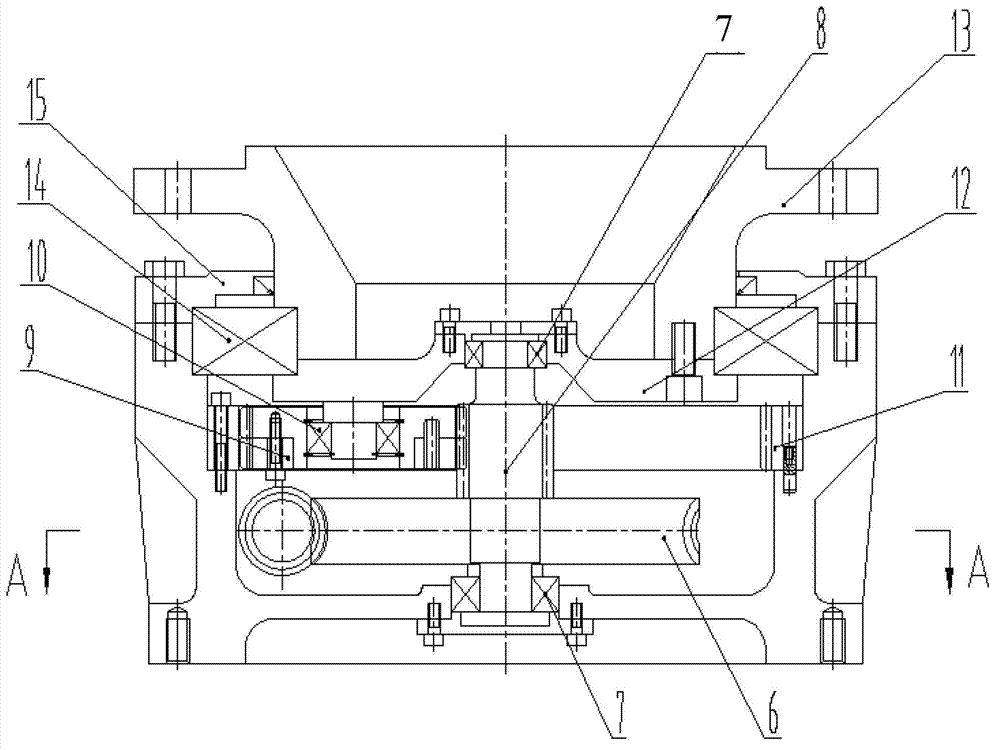

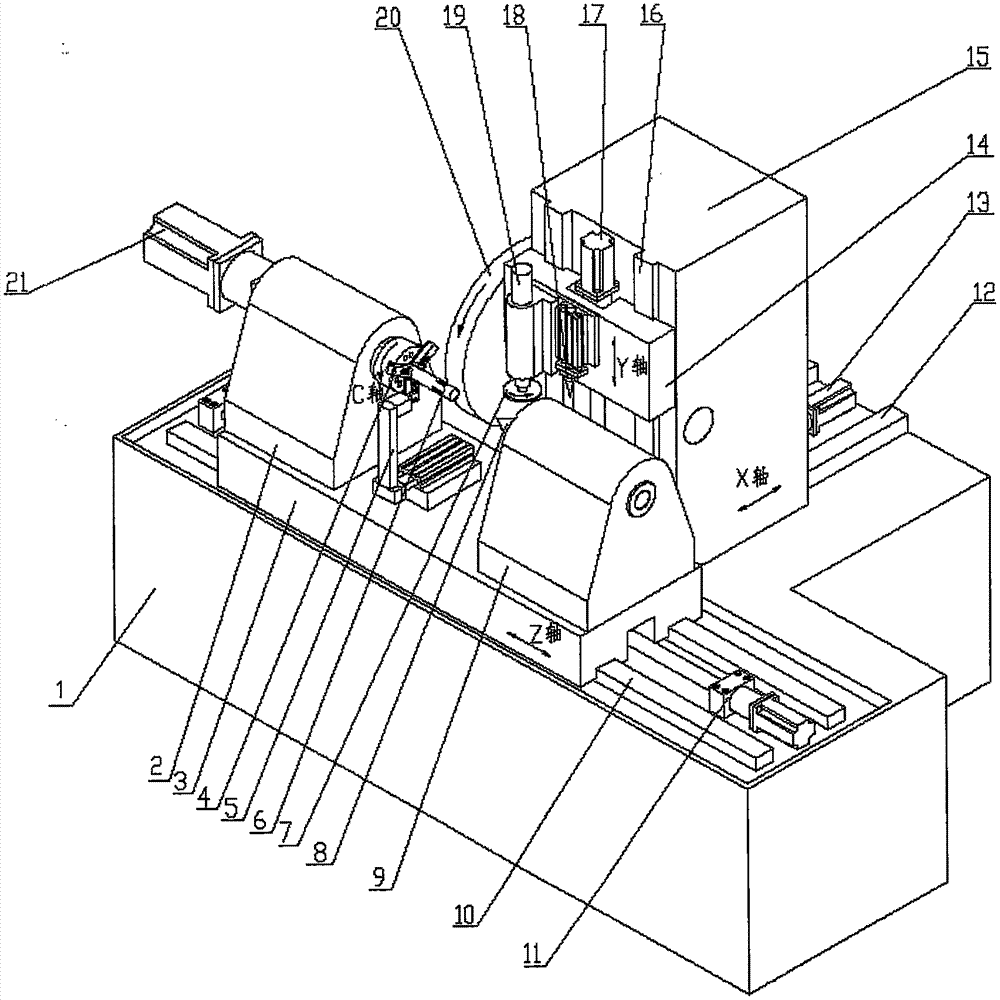

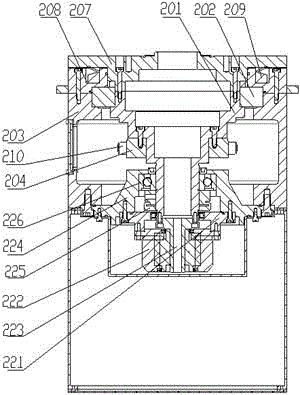

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

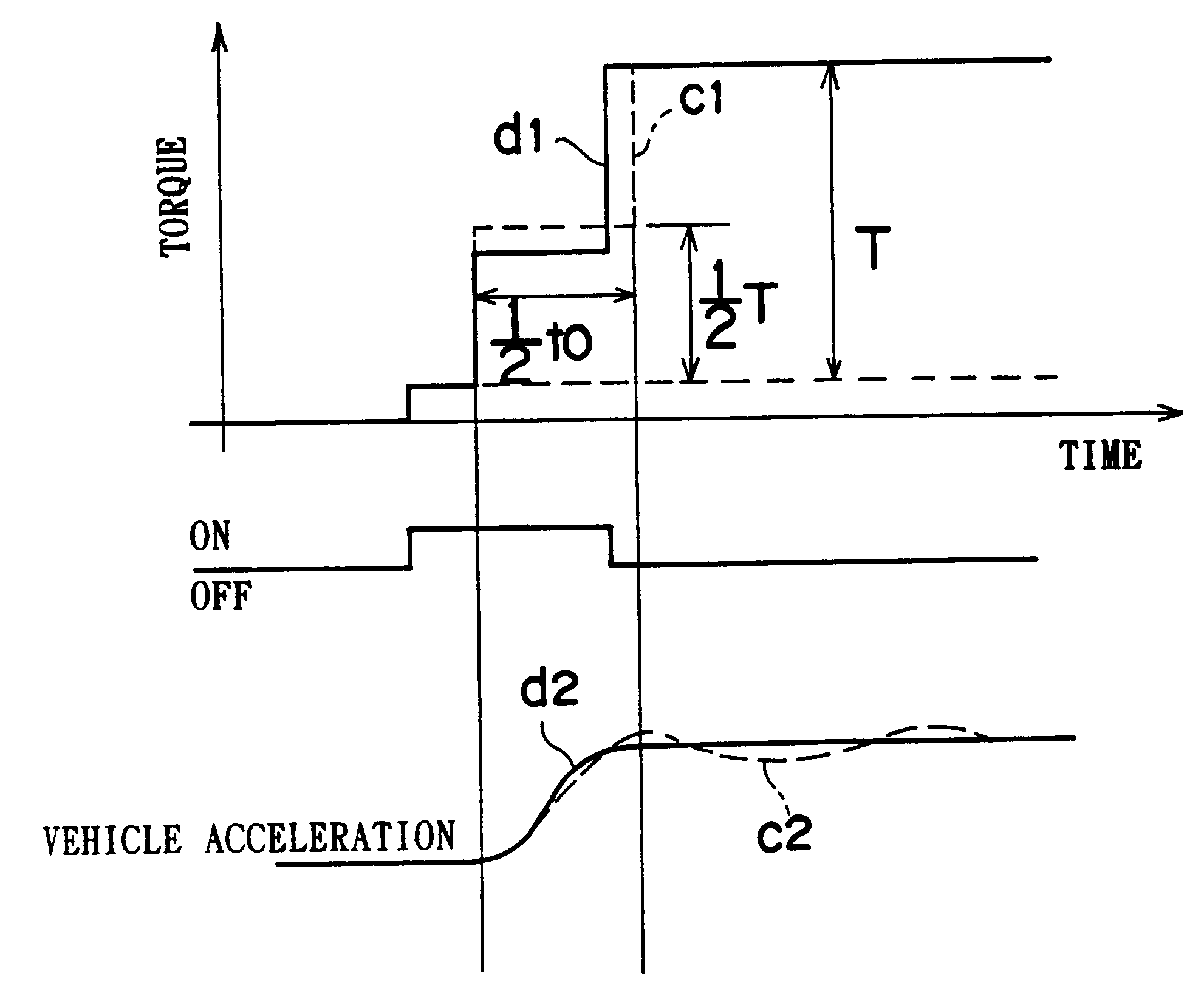

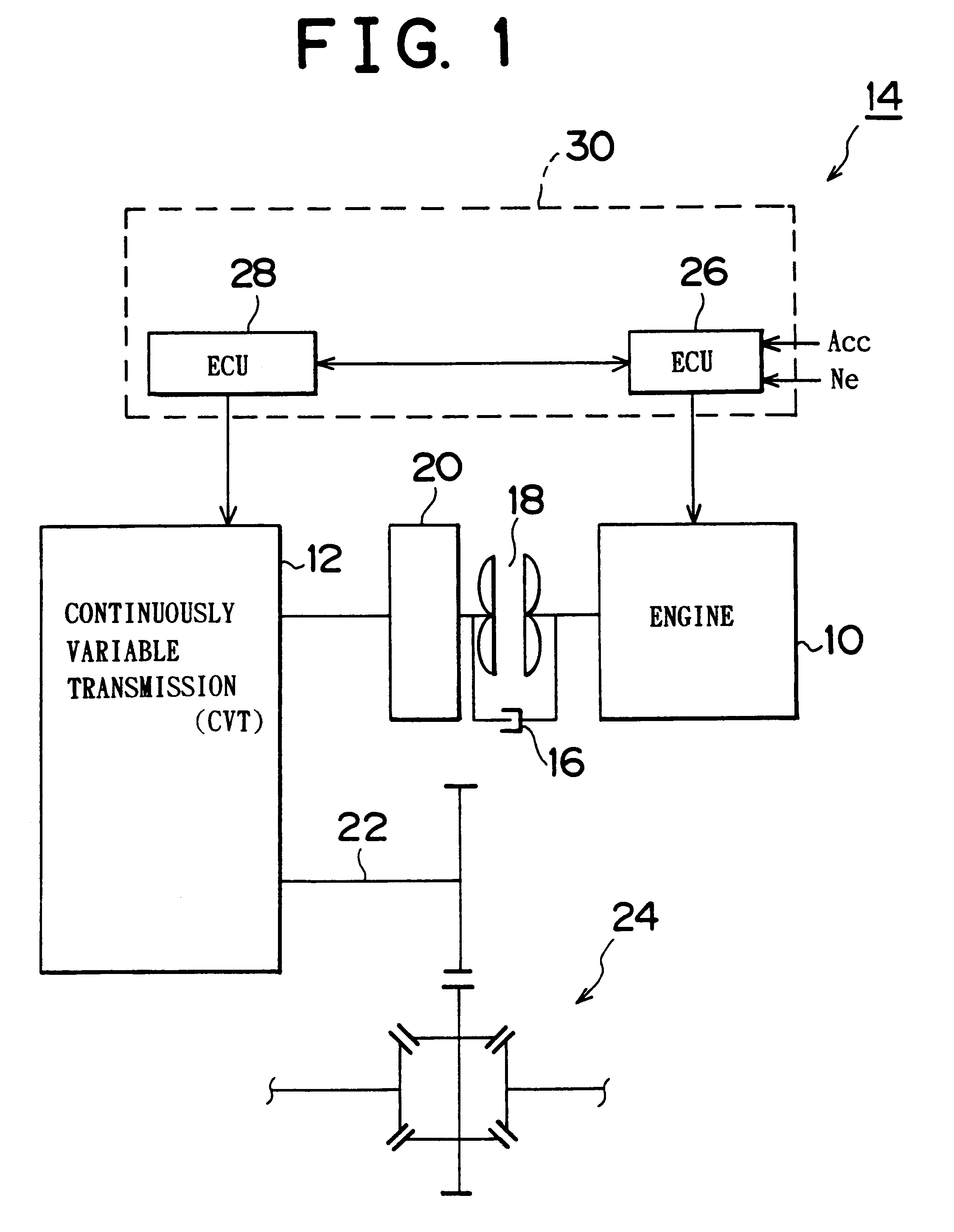

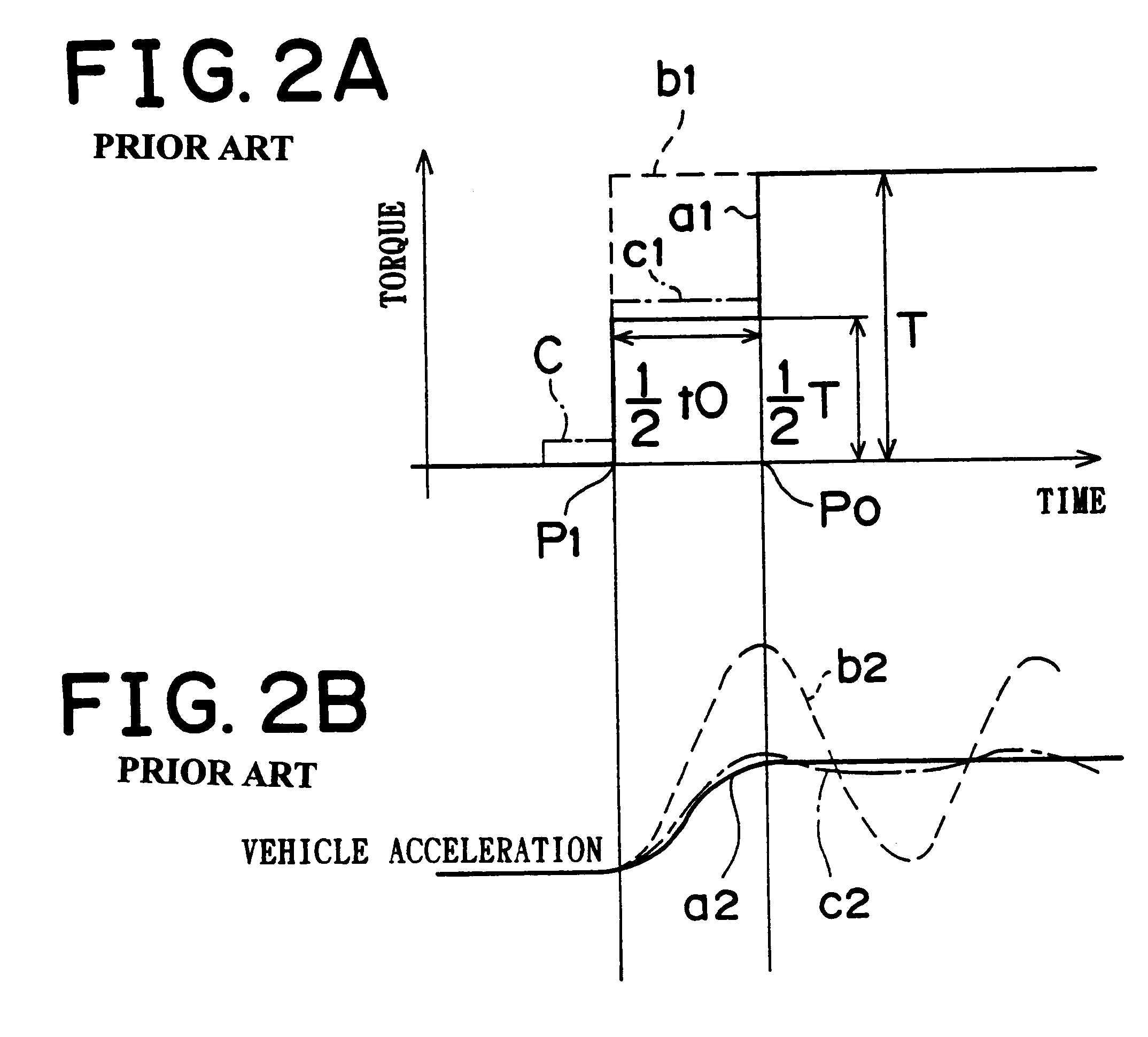

Vehicle control apparatus having power source and continuously variable transmission, and control method of the apparatus

InactiveUS6377882B1Reduce vibrationEliminate backlashHybrid vehiclesElectrical controlControl theoryControl torque

A control apparatus for a vehicle that has a power source and a continuously variable transmission. If a backlash-reducing control execution flag is on, a central control section utilizes an inertia torque produced during a backlash-reducing control as a part of a transient surge-reducing control that follows the backlash-reducing control, by setting at least one of a control duration and a control torque of the transient surge-reducing control to a value that is less than the control duration or torque set for an ordinary transient surge-reducing control. Therefore, the vehicle control apparatus is able to effectively perform the transient surge-reducing control and therefore further reduce vibrations of the vehicle.

Owner:TOYOTA JIDOSHA KK

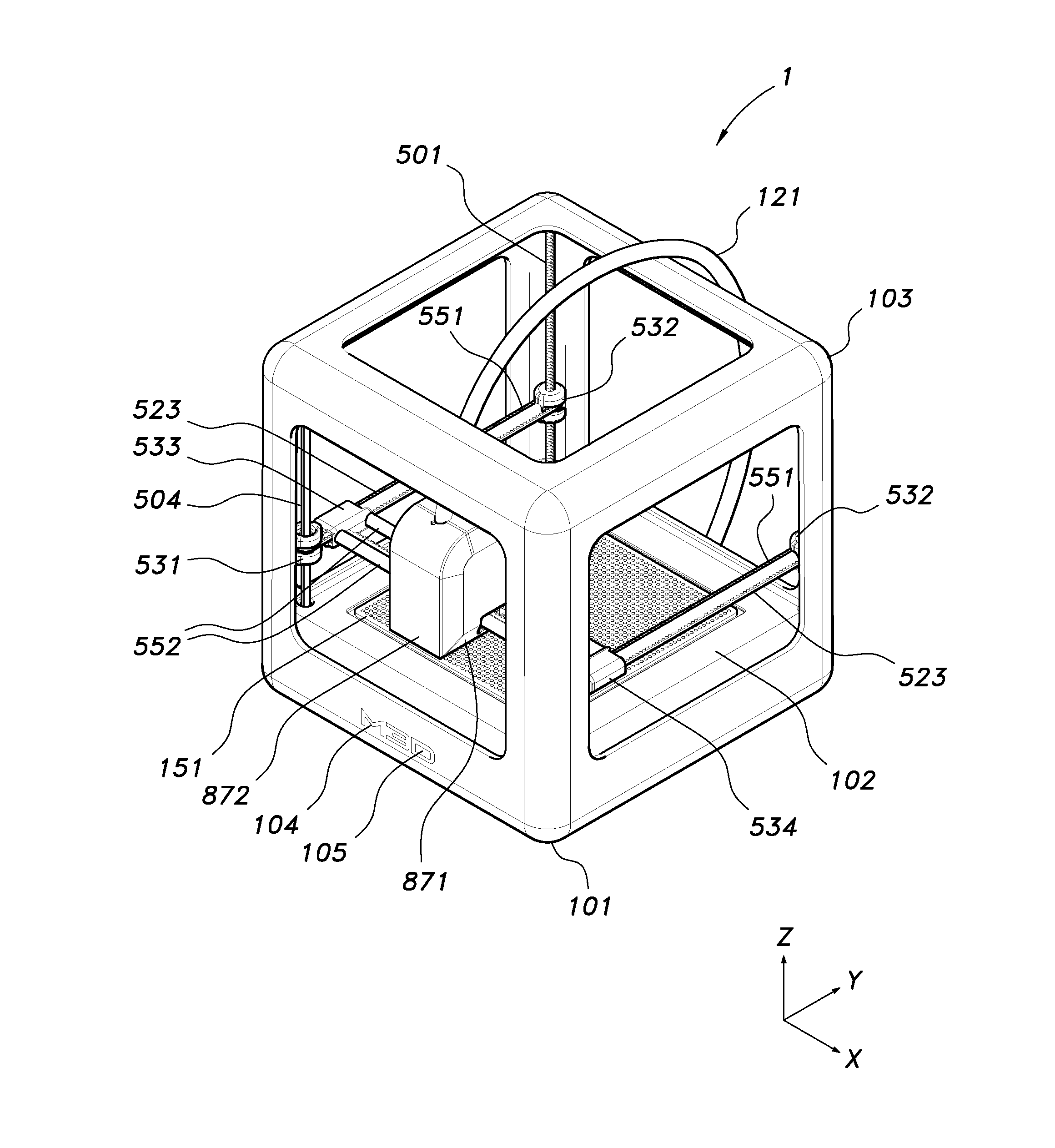

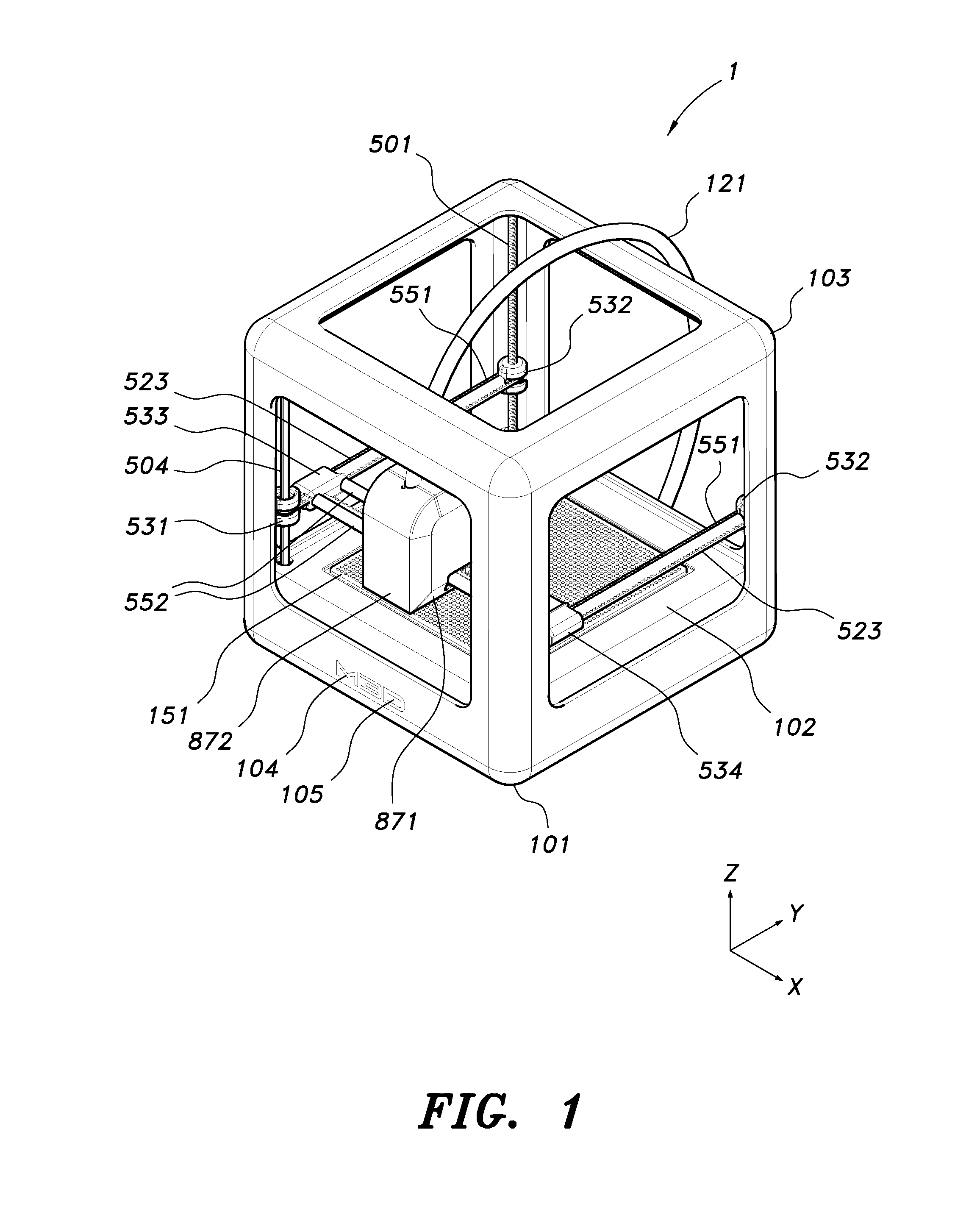

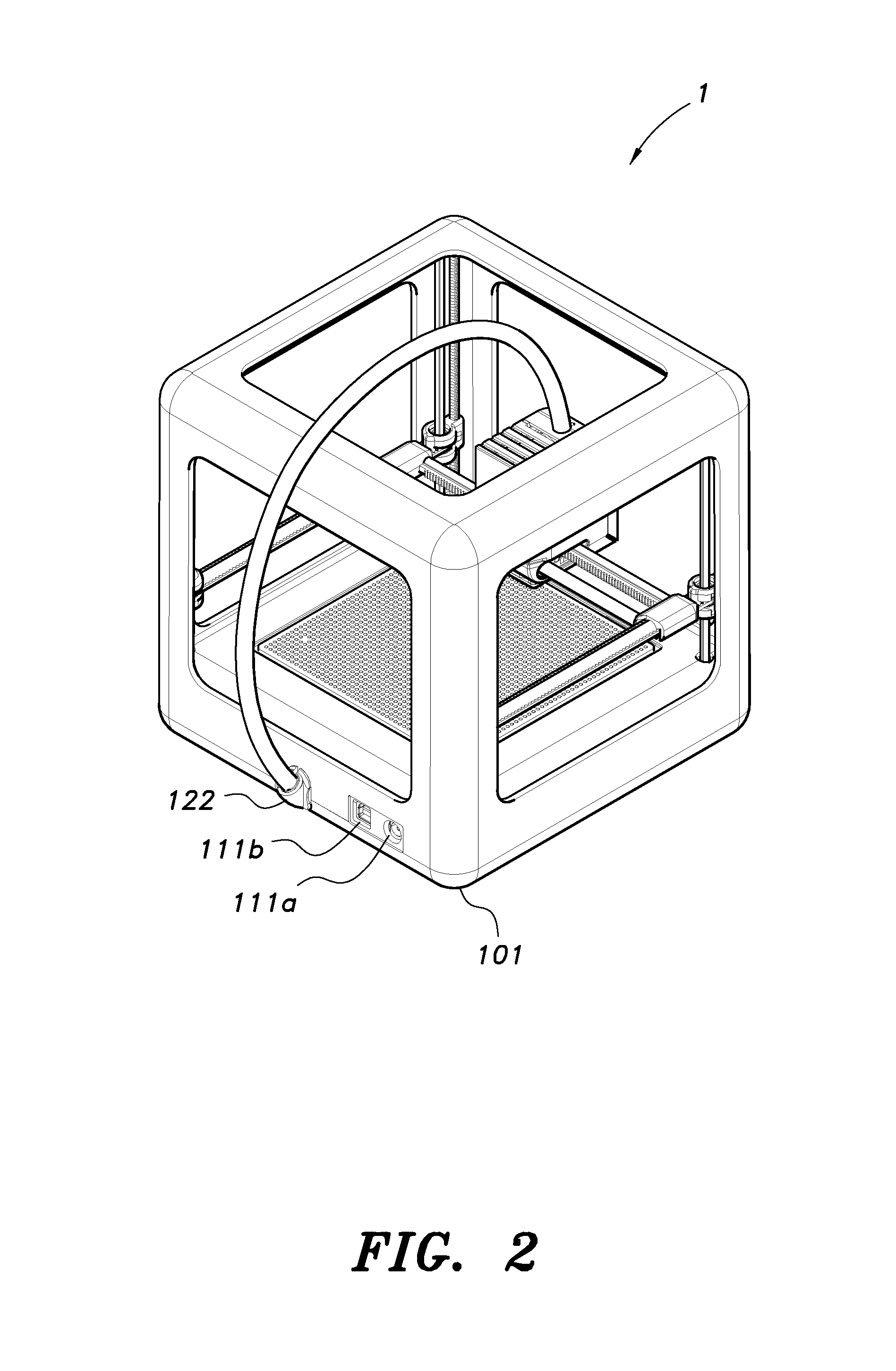

3D printer

InactiveUS20160236409A1Improve space efficiencyImprove energy efficiencyProgramme controlAdditive manufacturing apparatusLow noiseEngineering

A 3D printer has a casing, a nozzle for printing, an extruder, a heating element, and a print bed. The casing encloses a region above and around the print bed to form a printing zone. Further, the 3D printer has features adapted for low-noise operation, and is already suitably quiet enough for use in a low-noise environment because it does not generate loud sounds. Specifically, in a quiet office with 37-38 dB of noise, noise emissions were measured while the present invention constructed a 3D printed model, and at six inches from the extruder on the 3D printer, the noise emissions measured 39-58 dB, at three feet away measured 38-43 dB, and at six feet away measured around 37-40 dB.

Owner:ARMANI MICHAEL DANIEL +1

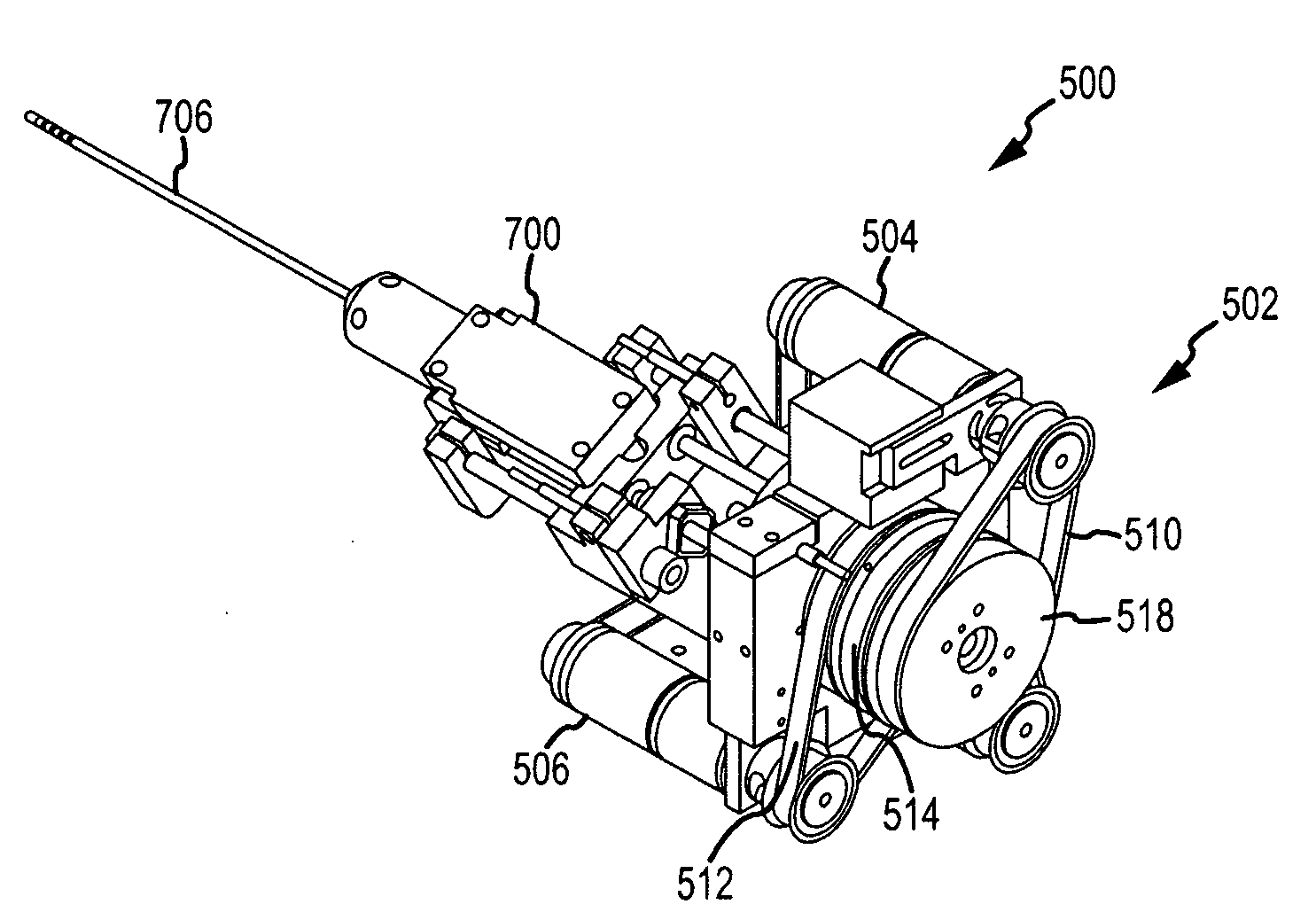

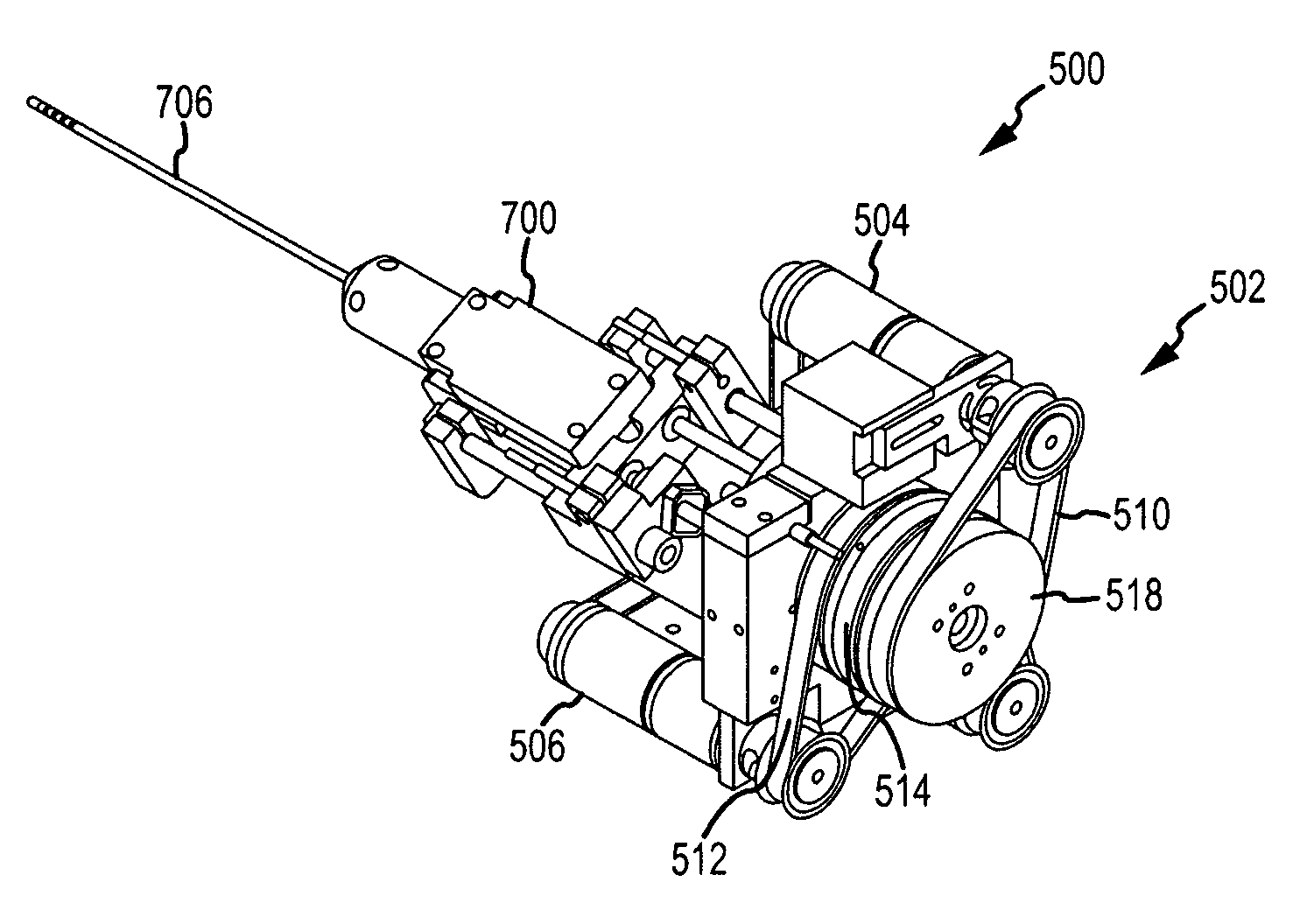

Robotic catheter rotatable device cartridge

InactiveUS8317745B2Minimize and eliminate procedural variabilityEliminate backlashDiagnosticsMedical devicesEngineeringGuide tube

A robotic catheter rotatable device cartridge may include a housing member attachable to a drive mechanism for rotating the cartridge and a catheter attached to the cartridge along an axial direction of the catheter. A slider block may be generally slidable relative to the housing and engaged with one or more steering wires for controlling movement of the catheter in a transverse direction relative to the axial direction. The catheter may include the steering wire(s) engaged therewith and movable in the transverse direction when the slider block is linearly driven in a predetermined direction.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

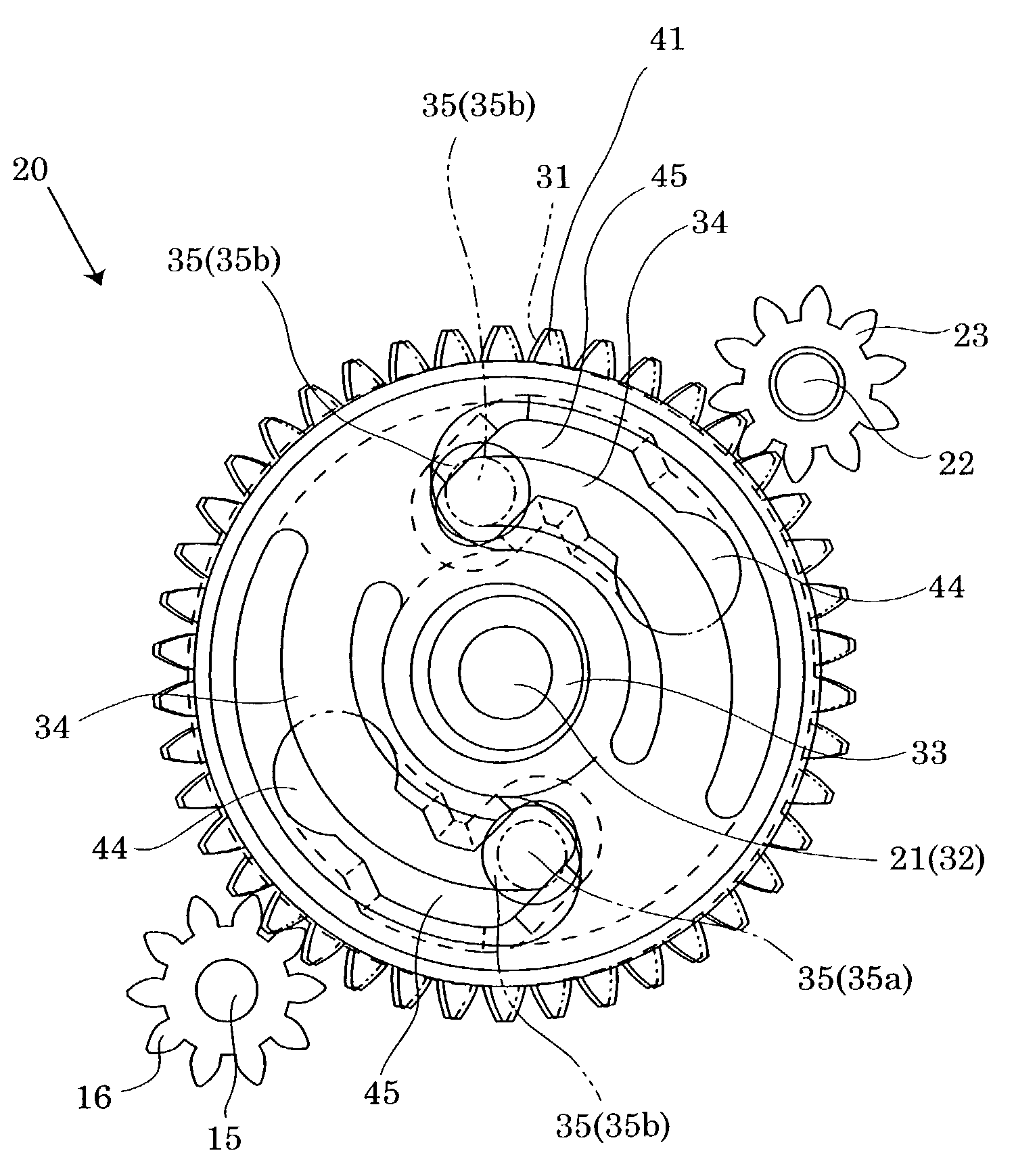

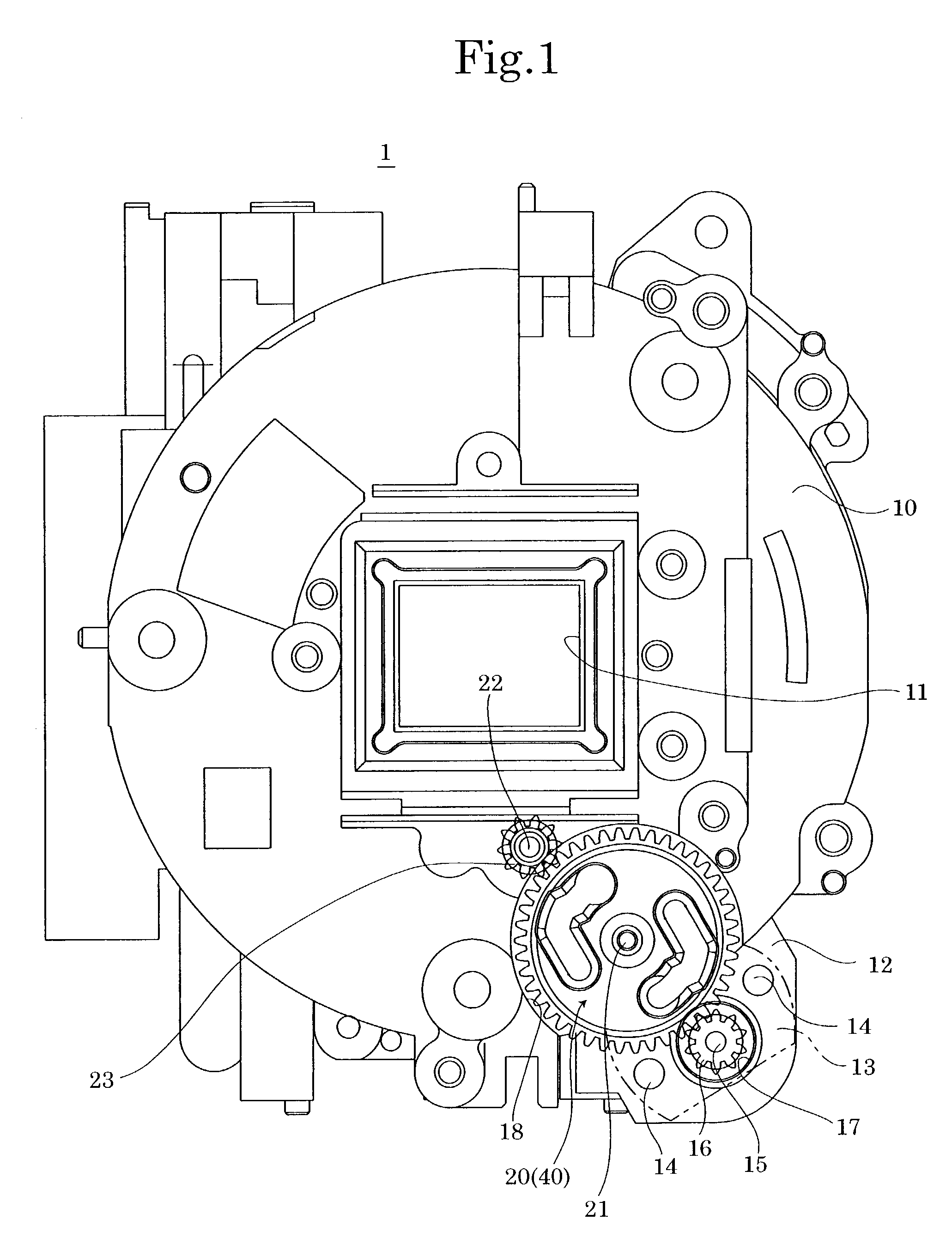

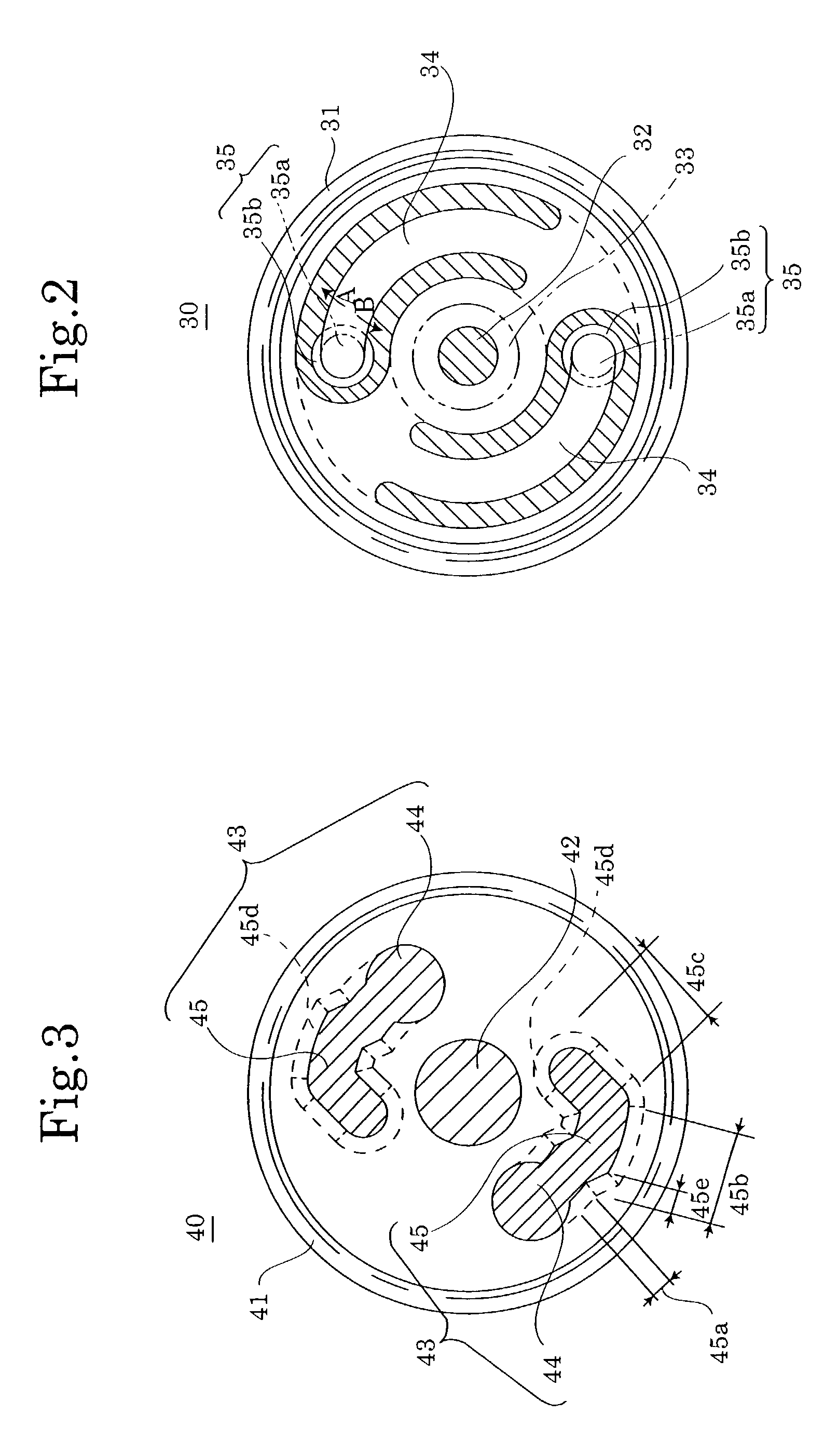

Gear mechanism with an idler gear, a gear mechanism with a device for eliminating backlash between gears, and a motor driving mechanism

InactiveUS6997079B2Eliminate backlashMinimal numberPortable liftingToothed gearingsMotor driveEngineering

A gear mechanism includes a driving gear, a driven gear, and an idler gear which is in mesh with the driving gear and the driven gear, wherein rotation of the driving gear is transferred to the driven gear via the idler gear. The idler gear includes first and second spur gears which are positioned adjacent to each other in an axial direction and are generally centered about a common axis, radial teeth of the first and second spur gears each being the same in shape, pitch and the number of teeth, and the first and second spur gears being biased to rotate in opposite directions. The first and second spur gears are connected so as to be relatively movable in a radial direction normal to the axial direction while maintaining the first and second spur gears in mesh with the driving gear and the driven gear.

Owner:ASAHI KOGAKU KOGYO KK

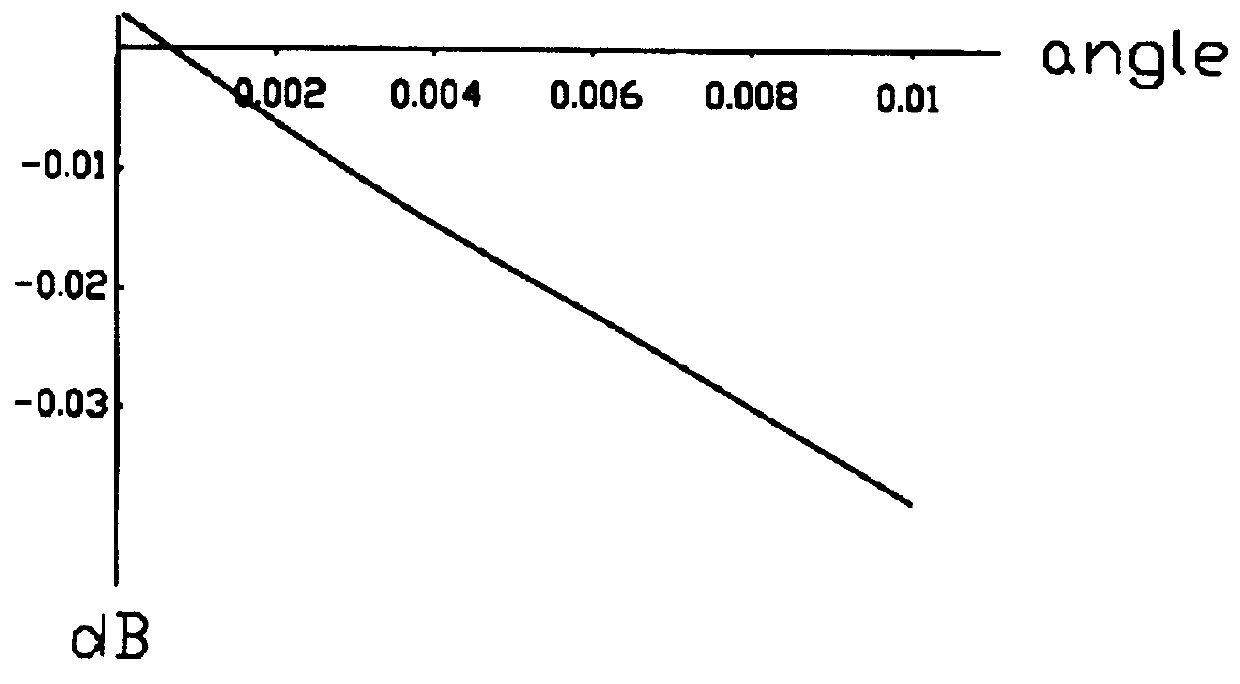

Motor driven optical fiber variable attenuator

InactiveUS6144794ASmooth movementEliminate backlashCoupling light guidesUltrasound attenuationMotor drive

A variable attenuator comprises a motor which actuates a lead screw to move rotatably, and a nut associated with the lead screw to move linearly. A neutral density filter moves along with the linearly moving nut wherein the filter is positioned between two spaced collimators for providing linear attenuation changes of light transmitted therebetween.

Owner:ALLIAN FIBER OPTIC PROD INC

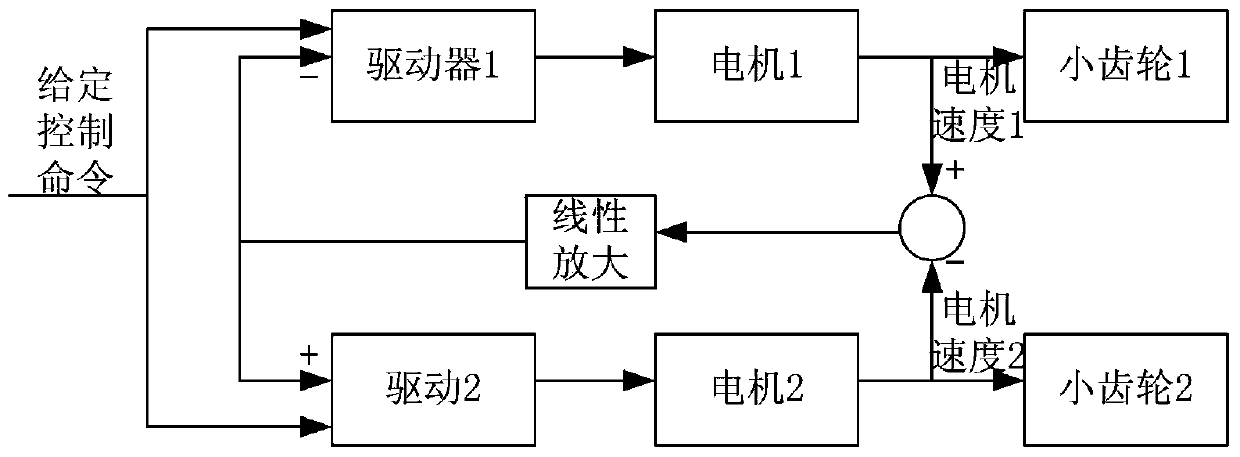

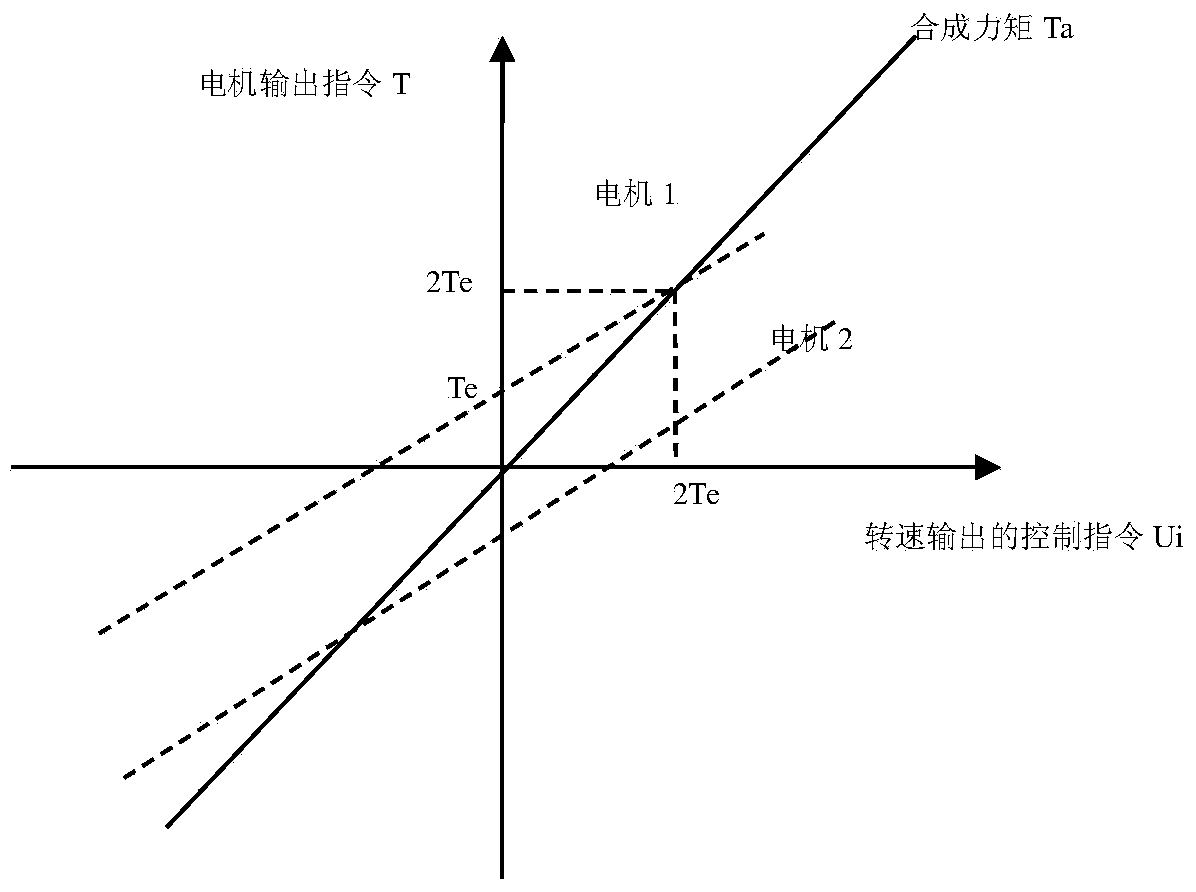

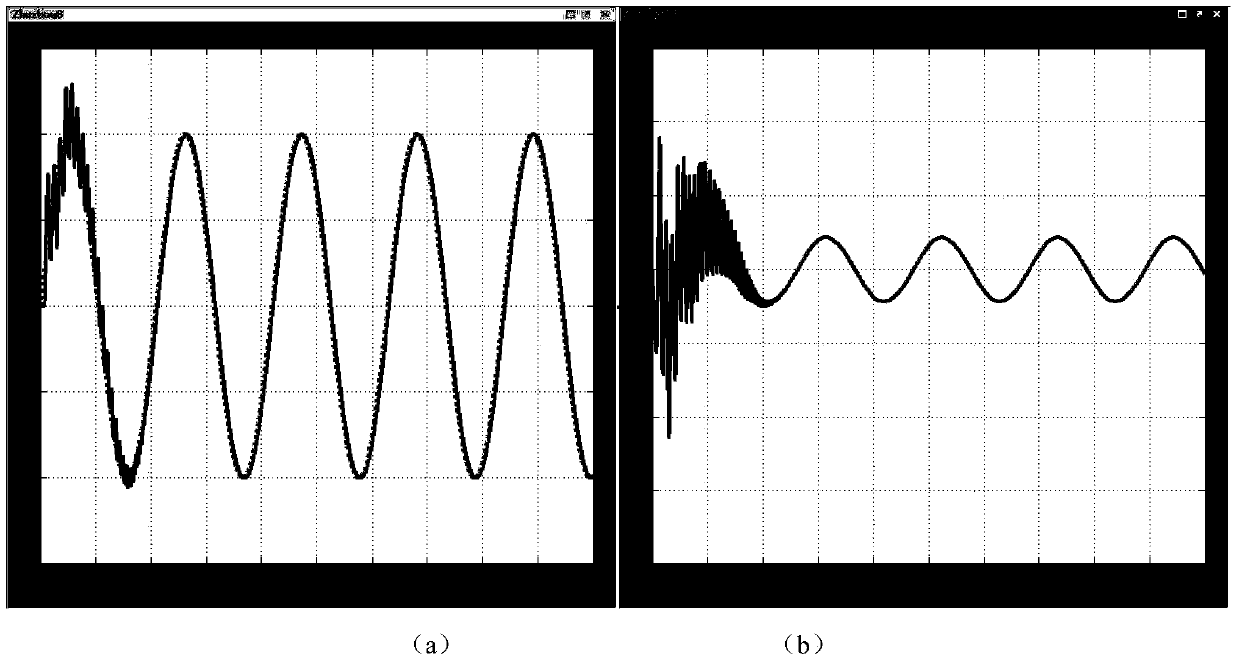

Dual-motor energy-saving anti-backlash control method

InactiveCN103701368AReduce consumptionGuaranteed steady state accuracyMultiple dynamo-electric motors speed regulationLinear systemMotor drive

The invention relates to a dual-motor energy-saving anti-backlash control method and belongs to the technical field of electromechanical control. A nonlinear dual-motor system is changed into an approximate linear system by applying a bias torque and rotating speed negative feedback; in addition, a real-time bias torque is designed to save energy to the greatest extent on the basis of ensuring good tracking effect. A closed-loop control is formed from speed and acceleration feedback of the motor, so that the size of the bias torque changes with the state of the system, namely a large bias torque is applied at the beginning and during the direction changing process, and a small value is needed to keep the state due to no need of the bias torque in stable operation. In order to solve the design problems of the dual-motor system about bias torque parameters and a proportion integration differentiation (PID) controller parameters, a plurality of controller parameters are simultaneously optimized by adopting a particle swarm algorithm. By adopting the dual-motor energy-saving anti-backlash control method, the problem about an optimization design of the controller of the dual-motor drive system is solved, and meanwhile, the effects of quick tracking of an input signal by the system, a small steady state error, synchronization of double motors, backlash removal and reduction of energy consumption are ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

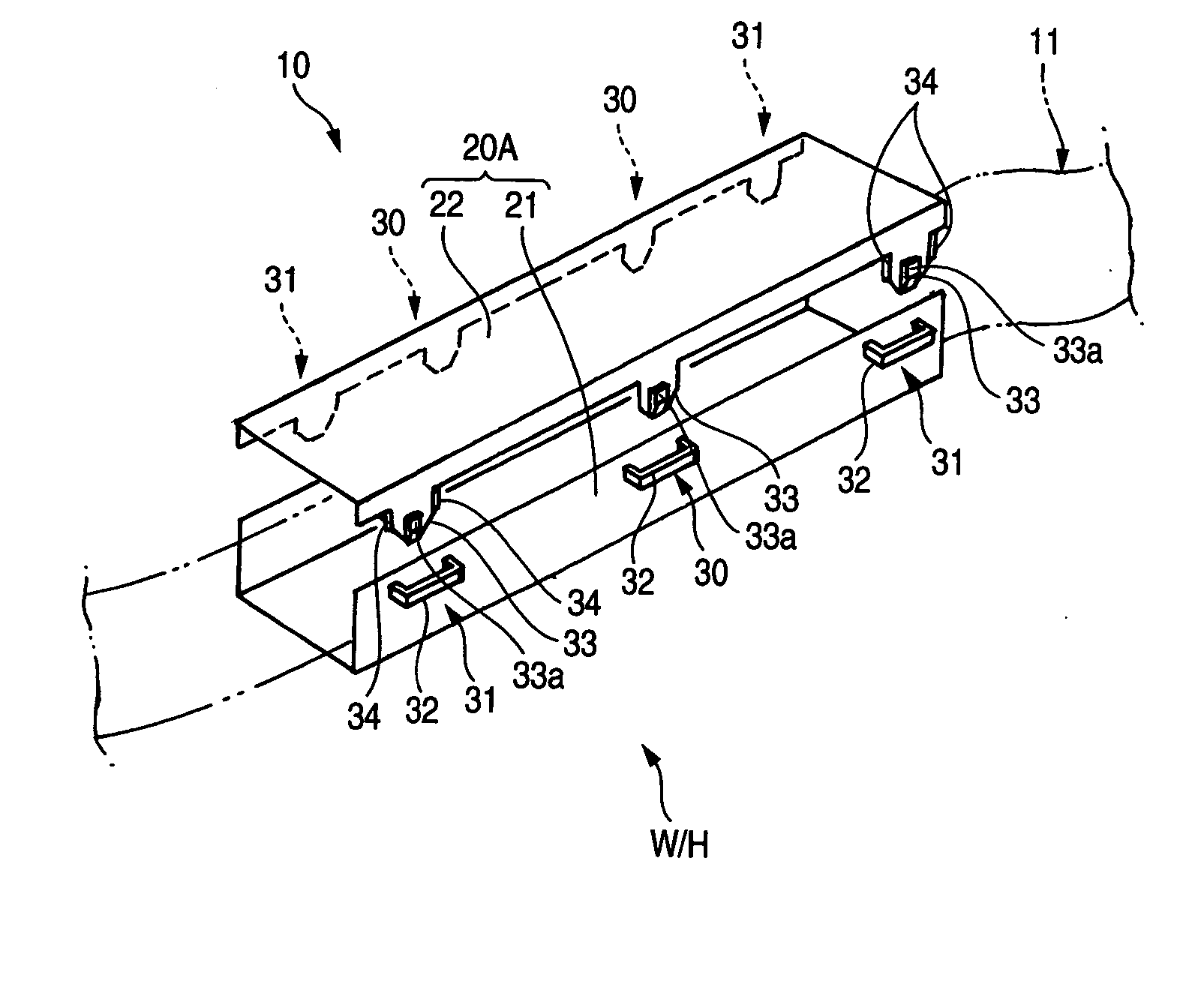

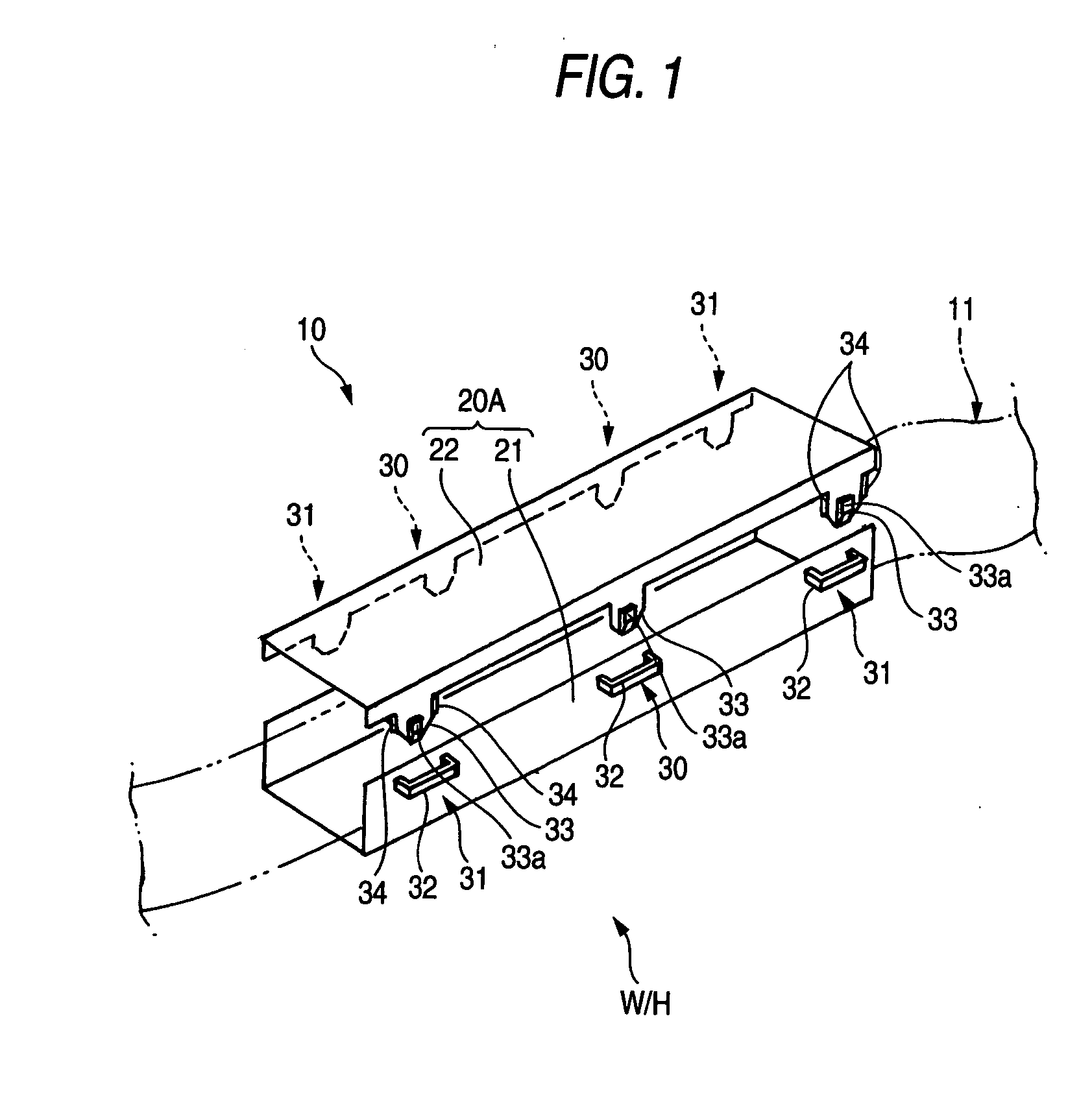

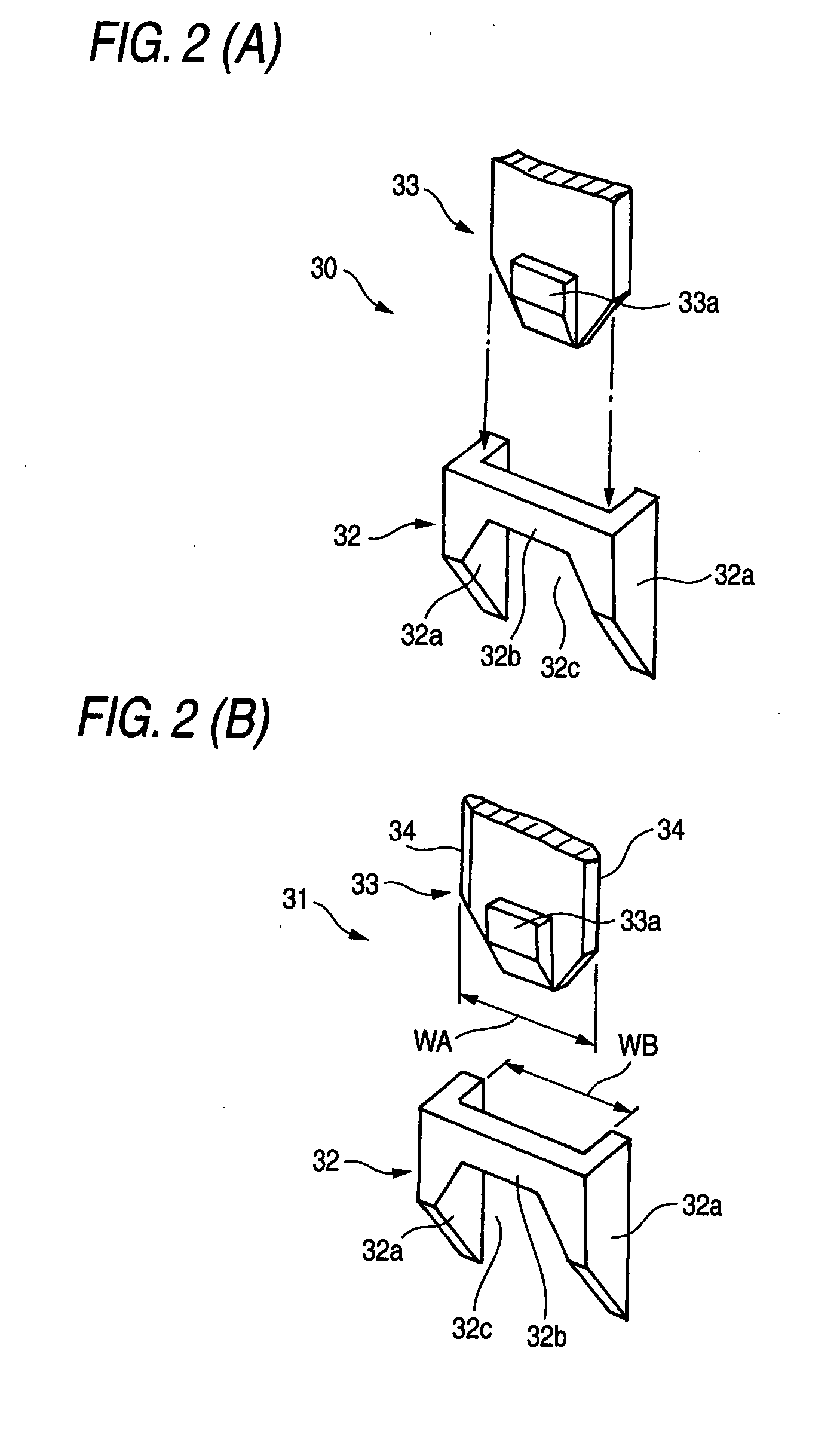

Locking structure for protector and wire harness

ActiveUS20050145410A1Eliminate backlashAvoid distortionExtensible conductorsElectrical apparatus contructional detailsEngineeringElectric wire

Owner:YAZAKI CORP

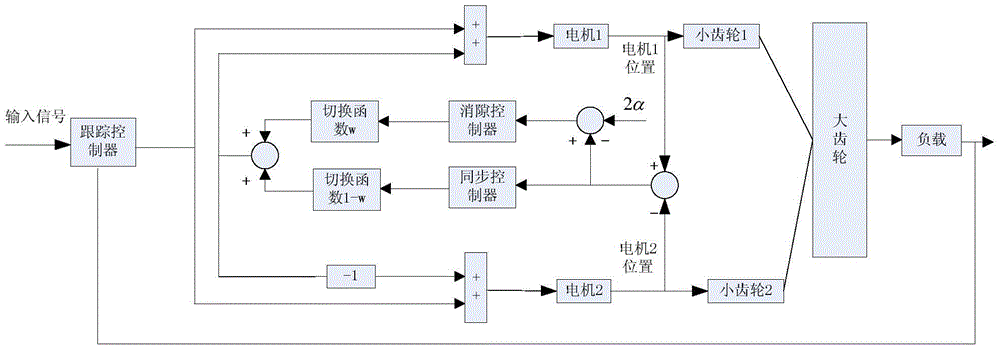

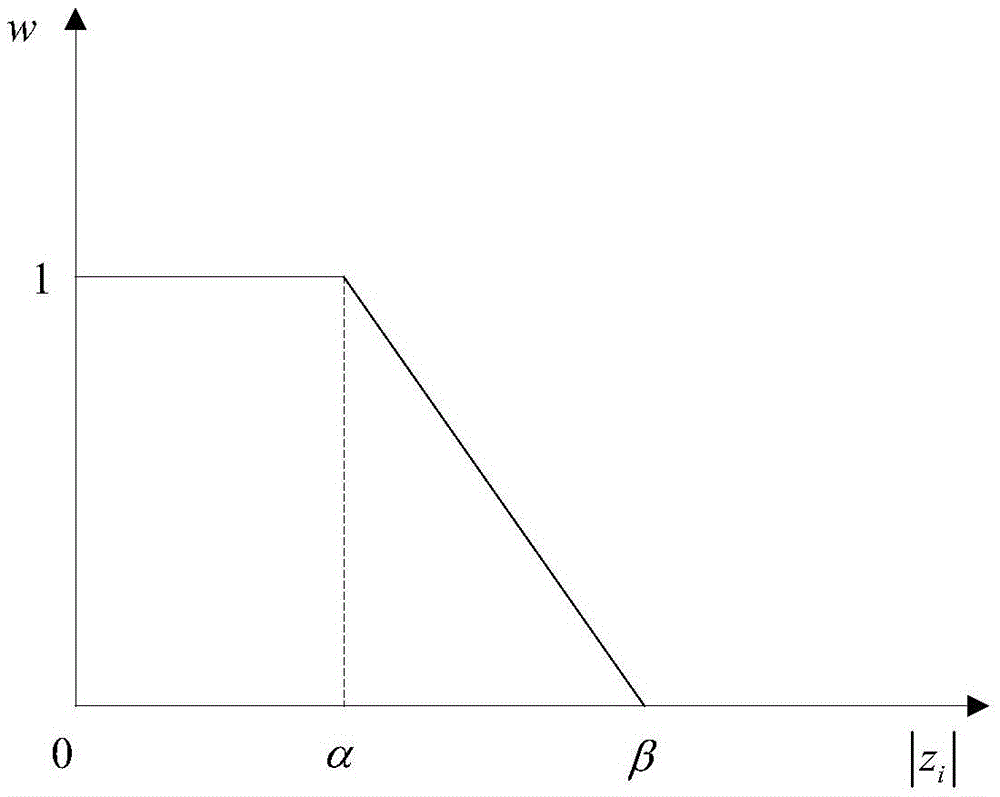

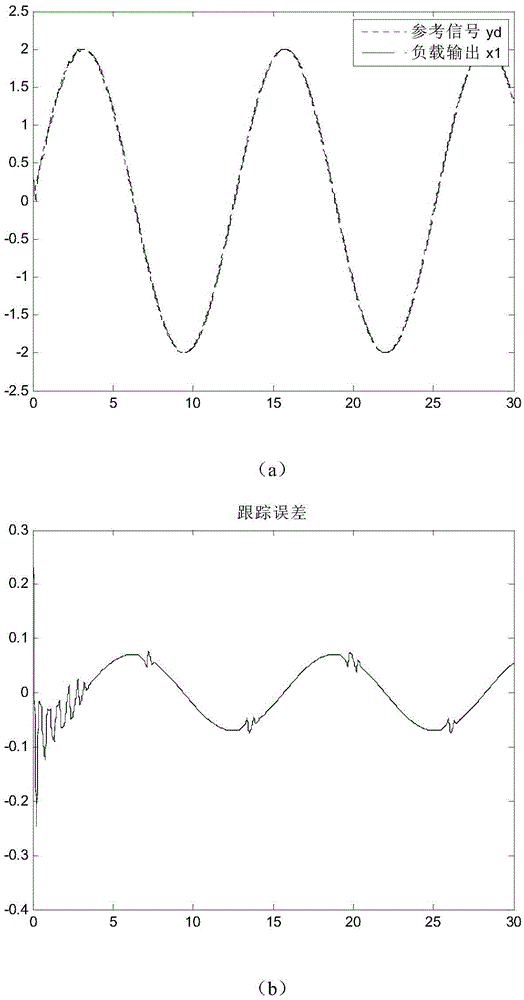

Anti-backlash and synchronization control method for dual-motor servo system

ActiveCN105610350ASimple designGuaranteed tracking effectMultiple dynamo-electric motors speed regulationBacksteppingState space equation

The invention discloses an anti-backlash and synchronization control method for a dual-motor servo system, relating to a tracking, synchronizing and anti-backlash comprehensive control method for a dual-motor servo system and belonging to the technical field of motor control. The implementation method of the invention comprises the following steps: analyzing a dual-motor servo system with backlash; building a state-space equation of the system by using a dead zone model of the backlash; designing a tracking controller by using a robust backstepping control method; respectively designing a synchronization controller and an anti-backlash controller by using the robust backstepping control method based on the tracking controller; and introducing a transfer function for the anti-backlash controller and the synchronization controller, applying the anti-backlash controller to make up for backlash when the backlash is about to appear and carrying out synchronization control when no backlash appears, thus ensuring the tracking, synchronizing and anti-backlash control of the dual-motor servo system. The technical problem to be solved in the invention is to eliminate the influence of backlash nonlinearity and ensure the synchronization of motors under the premise of realizing load tracking.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

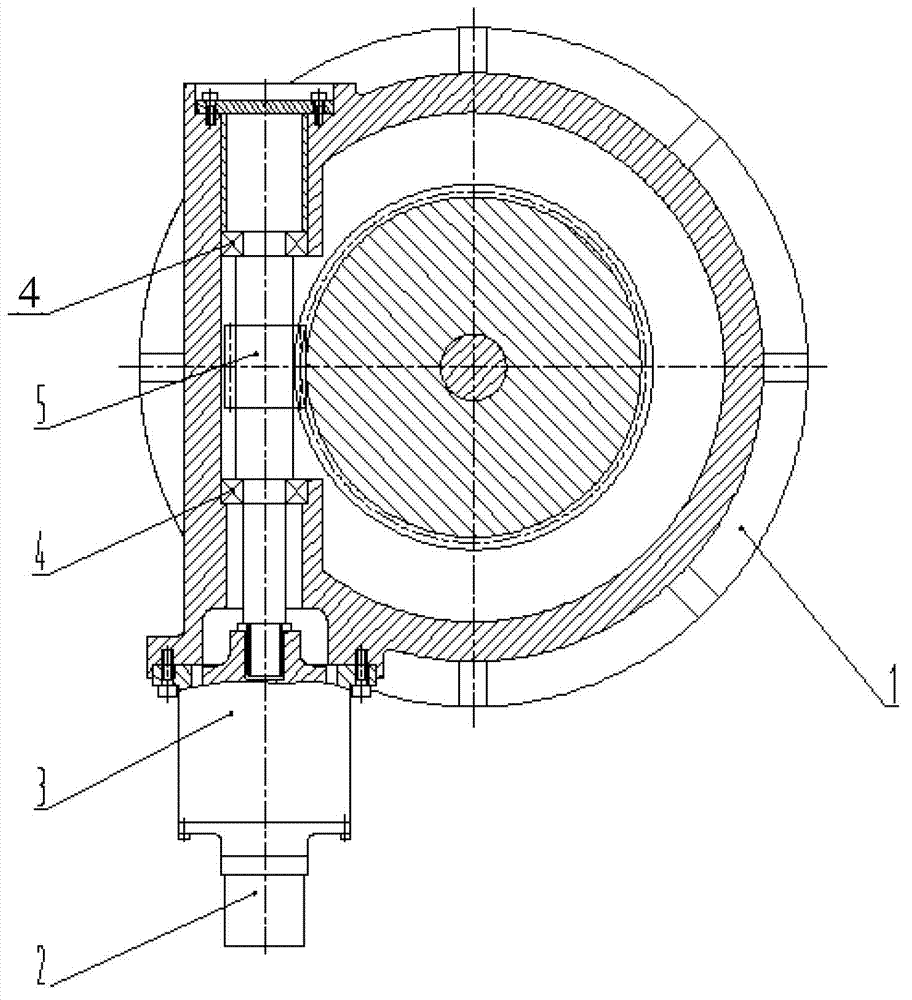

Azimuth transmission device of heliostat

InactiveCN103195875AWith reversible self-lockingReduce output speedToothed gearingsPortable liftingHeliostatDrive motor

The invention discloses an azimuth transmission device of a heliostat. The azimuth transmission device of the heliostat comprises a main box, a worm gear mechanism, a drive motor, an inner gear ring, a planet carrier, a planet gear assembly and an output flange, wherein the worm gear mechanism is arranged inside the main box, an worm gear assembly of the worm gear mechanism is coaxially connected with an output-stage sun gear shaft; the drive motor is connected with the worm shaft of the worm gear mechanism through a speed reduction device; the inner gear ring is arranged inside the main box; the planet carrier is rotatably arranged on the main box and provided with a planet gear shaft, the planet gear assembly is rotataby arranged on the planet gear shaft and is respectively engaged with the inner gear ring and the sun gear on the output-stage sun gear shaft; and the output flange is connected with the planet carrier. The azimuth transmission device of the heliostat avoids the problems of large size, large stress, large abrasion during long-time operation, influence on the positioning accuracy due to the fact that a worm gear pair serves as the output stage.

Owner:CHONGQING GEARBOX

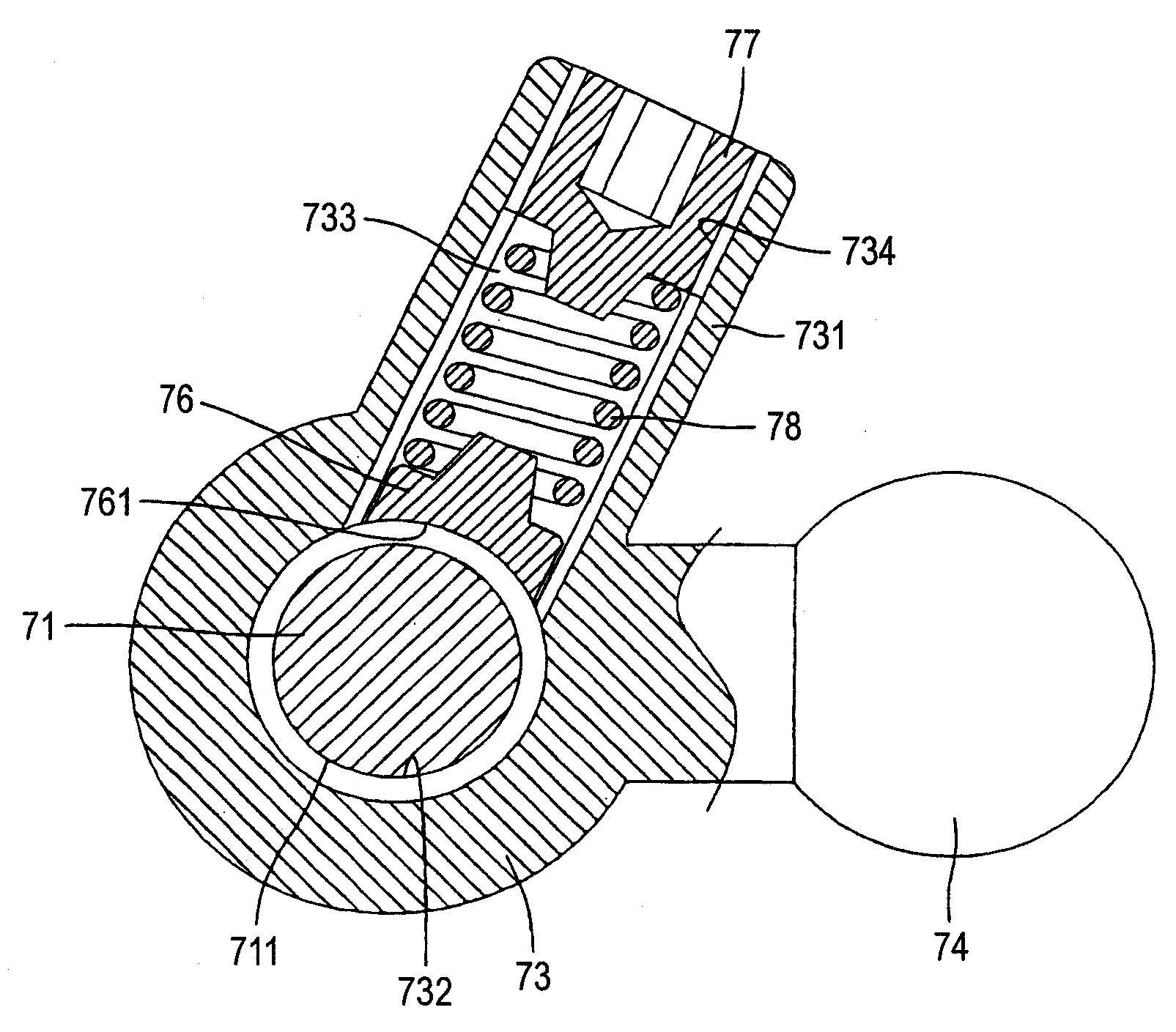

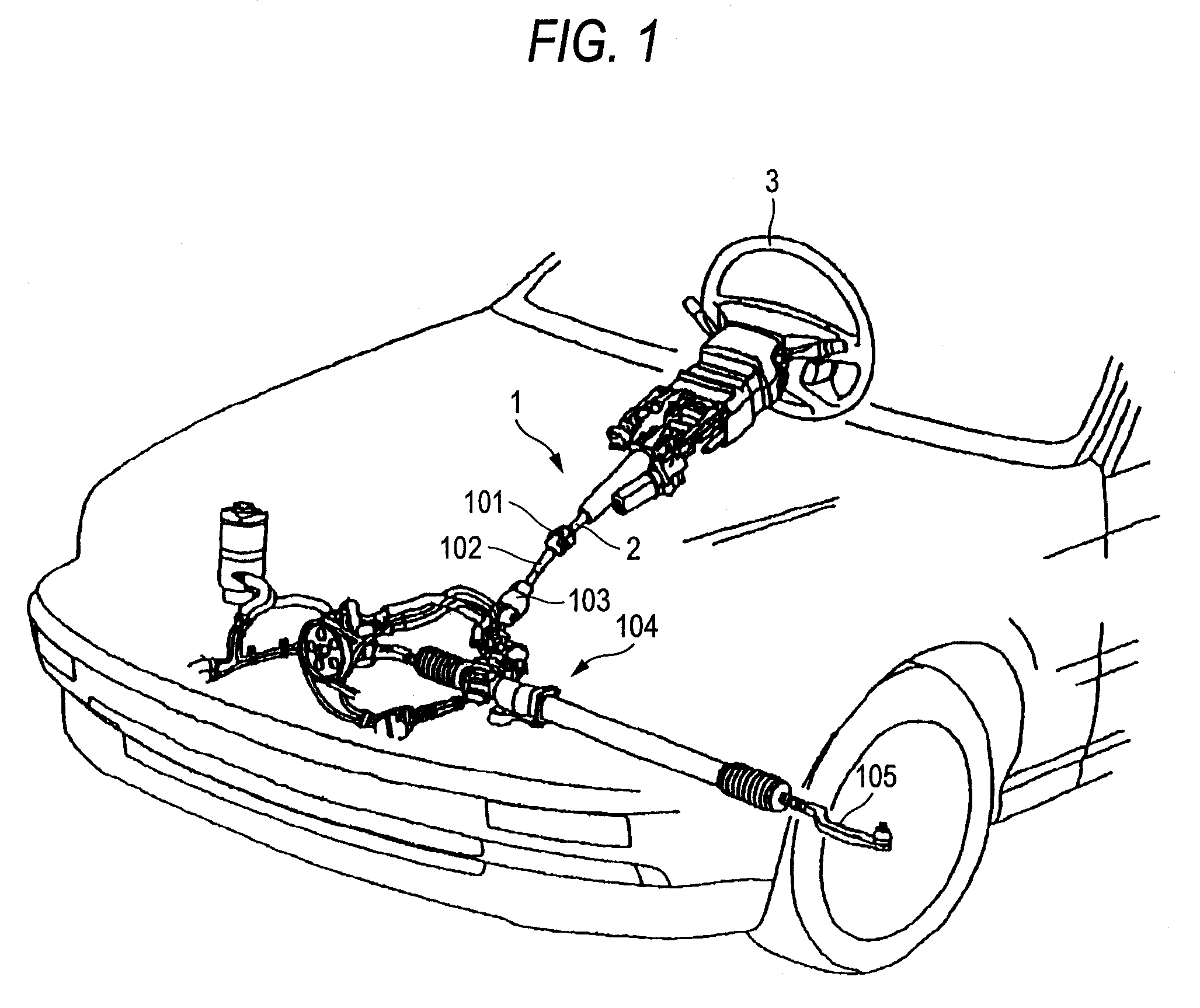

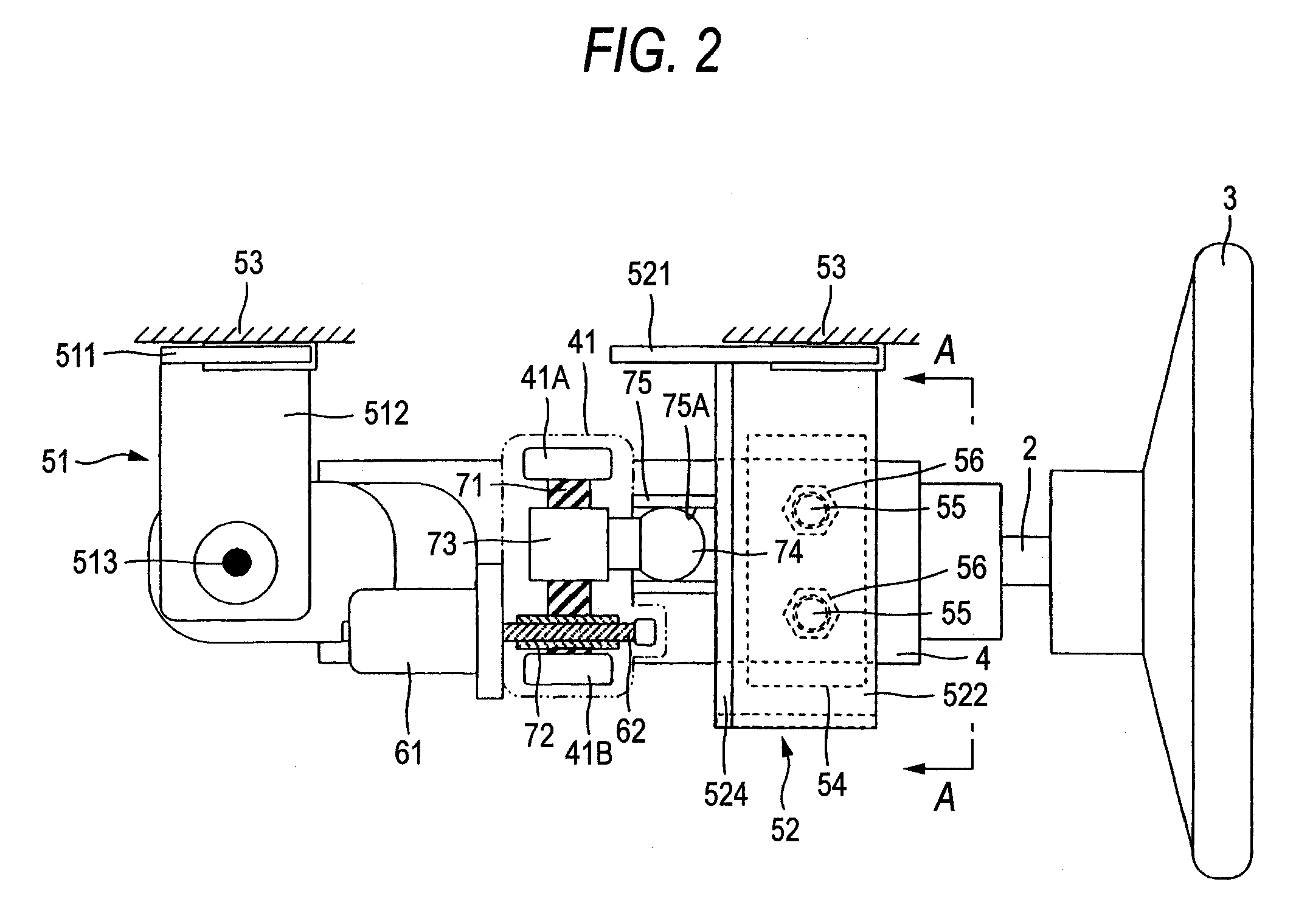

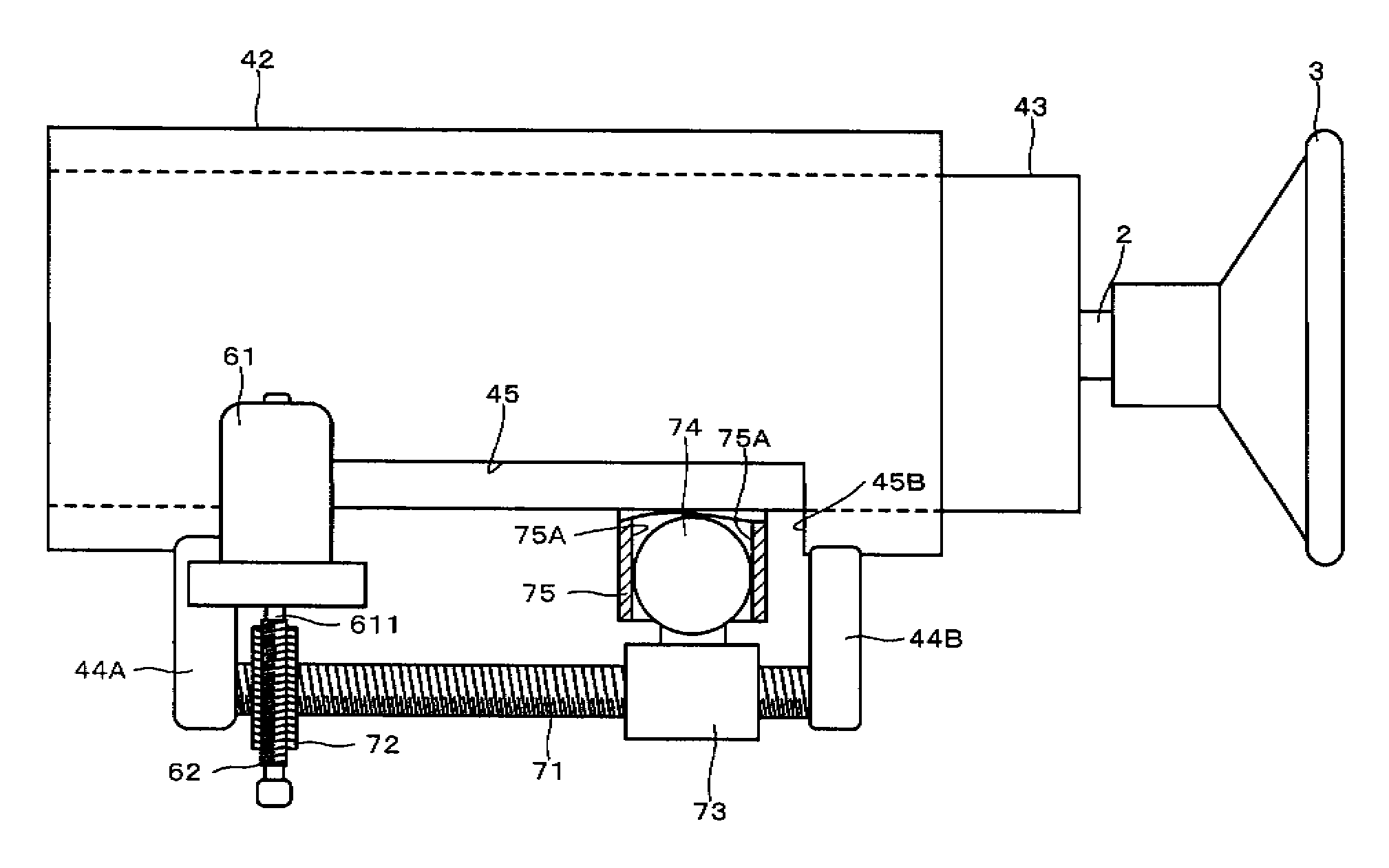

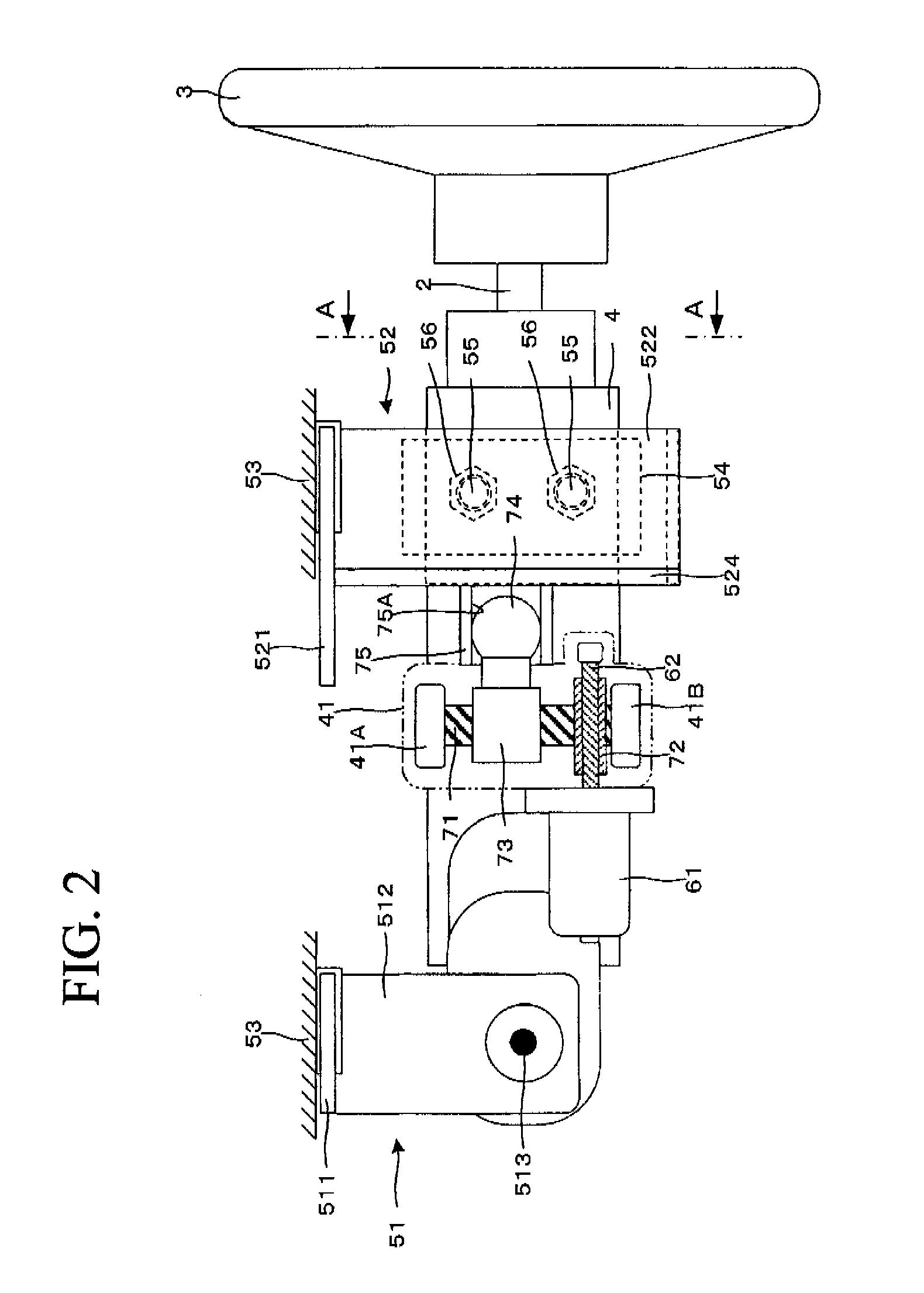

Steering apparatus

InactiveUS20080047382A1Facilitate adjustment of backlashImprove rigidityGearingSteering columnsSteering wheelCoil spring

In the steering apparatus and feed screw mechanism, by properly adjusting the screw-in distance of a pressing force adjusting screw 77, the arc-shaped contact surface 761 of a pressing member 76 can be pressed against the outer diameter portion 711 of a feed screw shaft 71 with a required pressing force due to the biasing force of a compression coil spring 78. As a result of this, a backlash between a feed nut 73 and feed screw shaft 71 can be removed. Therefore, the telescopic position adjustment and tilt position adjustment of a steering wheel 3 can be carried out smoothly, thereby being able to enhance the rigidity of the steering wheel 3 after execution of the position adjustment thereof.

Owner:NSK LTD

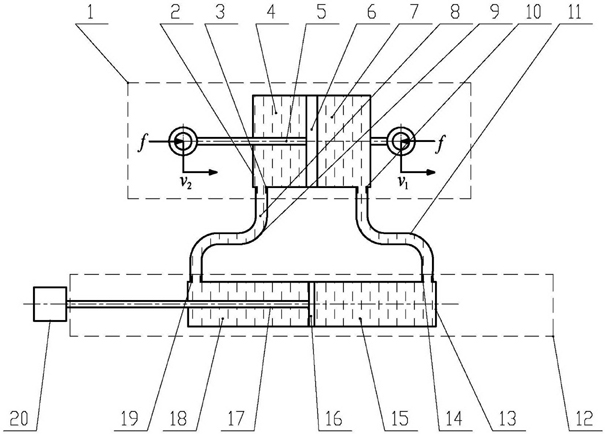

Ultrahigh-precision numerically-controlled non-circular curved surface composite grinder

PendingCN105437032AHigh precisionIncrease productivityGrinding carriagesGrinding drivesSurface grindingEngineering

An ultrahigh-precision numerically-controlled non-circular curved surface composite grinder comprises a grinder bed and an upright post capable of moving forwards and backwards; a workbench is located at the front end of the grinder bed; a headstock, a tailstock and a measuring device are mounted on the workbench; a horizontal-axis grinding wheel disc and a vertical-axis grinding wheel disc are mounted on the movable upright post; a composite grinding function is realized through accurate control of four servo axes, namely an axis X, an axis Y, an axis Z and an axis C; and a workpiece can be subjected to excircle grinding, plane surface grinding, groove grinding, prismatic polyhedron grinding and end surface grinding through one-time clamping, and can also be subjected to non-circular curved surface grinding through linkage differential complement of the axis C and the axis X. The ultrahigh-precision numerically-controlled non-circular curved surface composite grinder has the characteristics of high machining precision, wide application range, high production efficiency and the like.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

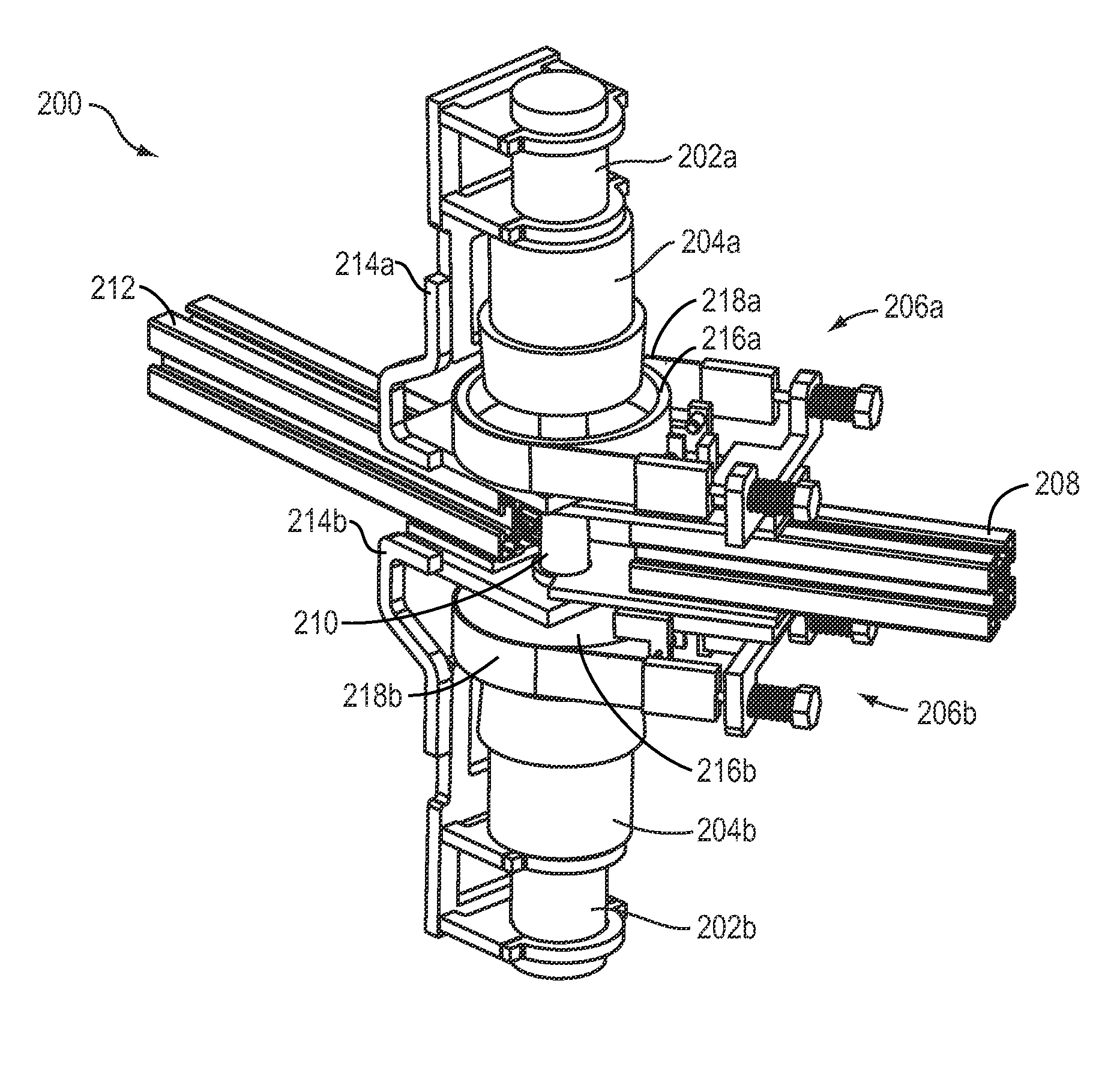

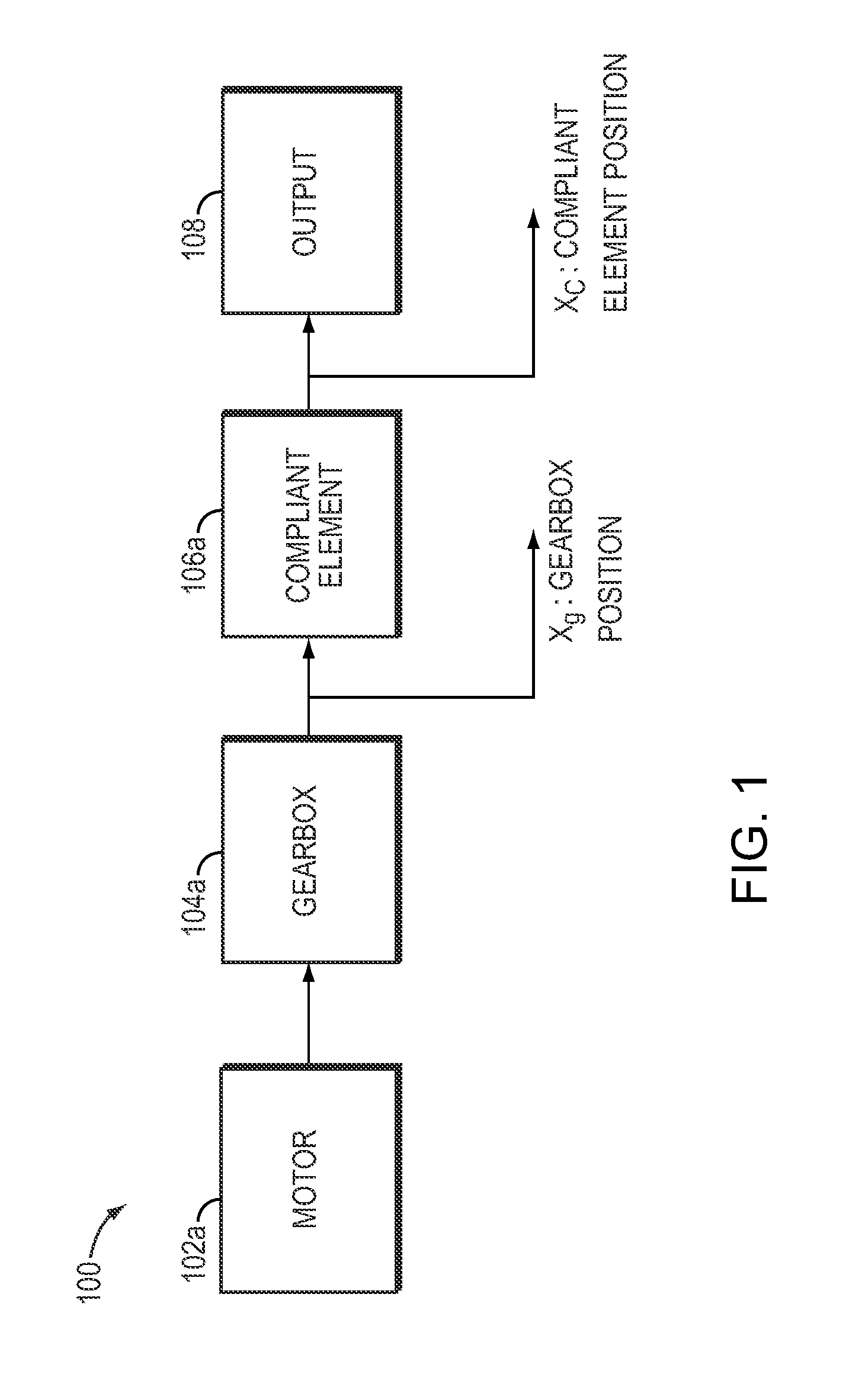

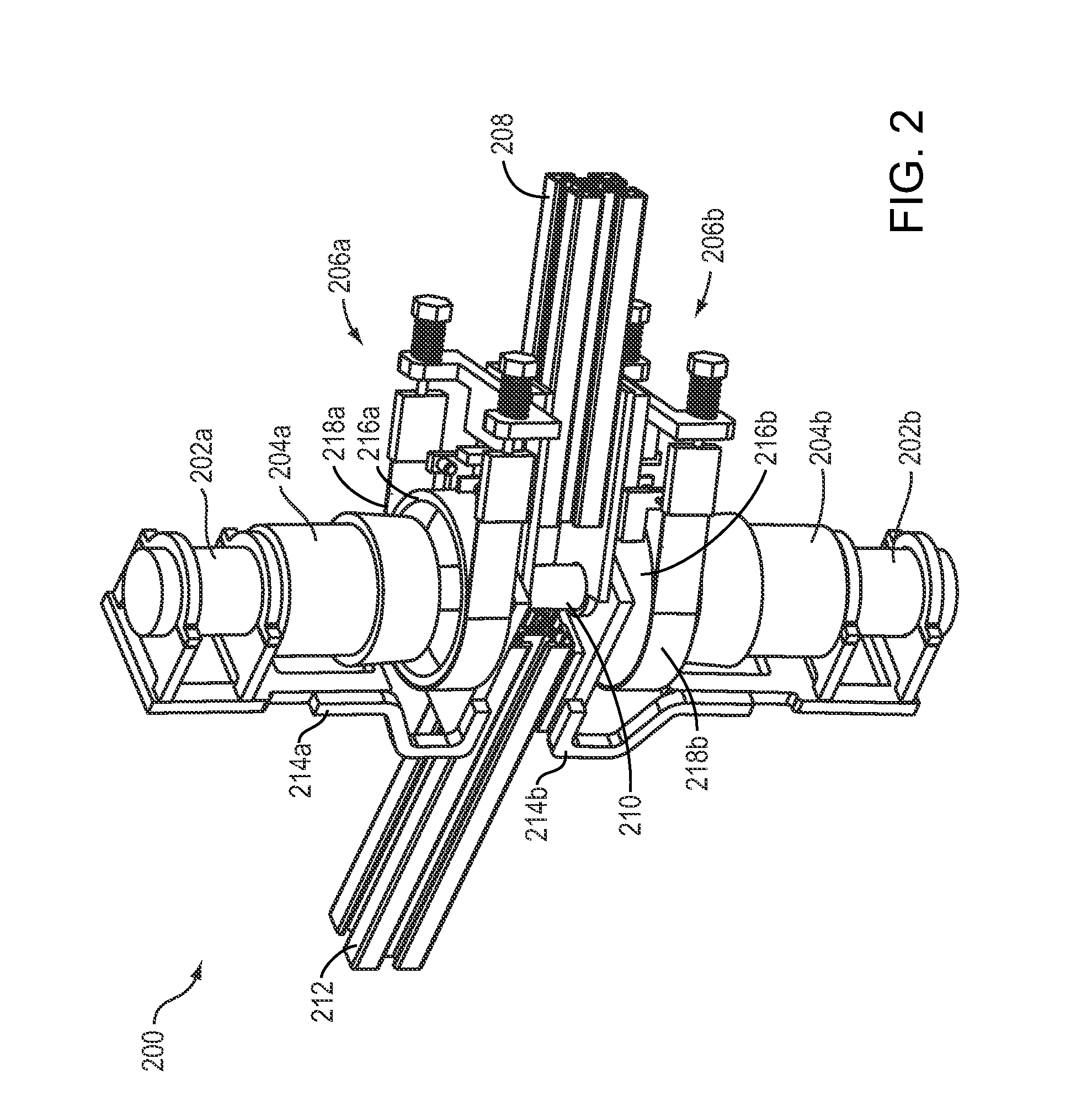

Dual-motor series elastic actuator

ActiveUS20120312114A1Reduce negative effectsEliminate backlashPortable liftingGearing detailsEngineeringActuator

Certain embodiments of a system for reducing backlash include a member geared for rotation in first and second directions. In various implementations, a first motor causes rotation in the first direction with an output biased to preclude space between mating gear components in the first direction, and a second motor, which is mechanically independent of the first motor, causes rotation in the second direction with an output biased to preclude space between mating gear components in the second direction.

Owner:RETHINK ROBOTICS

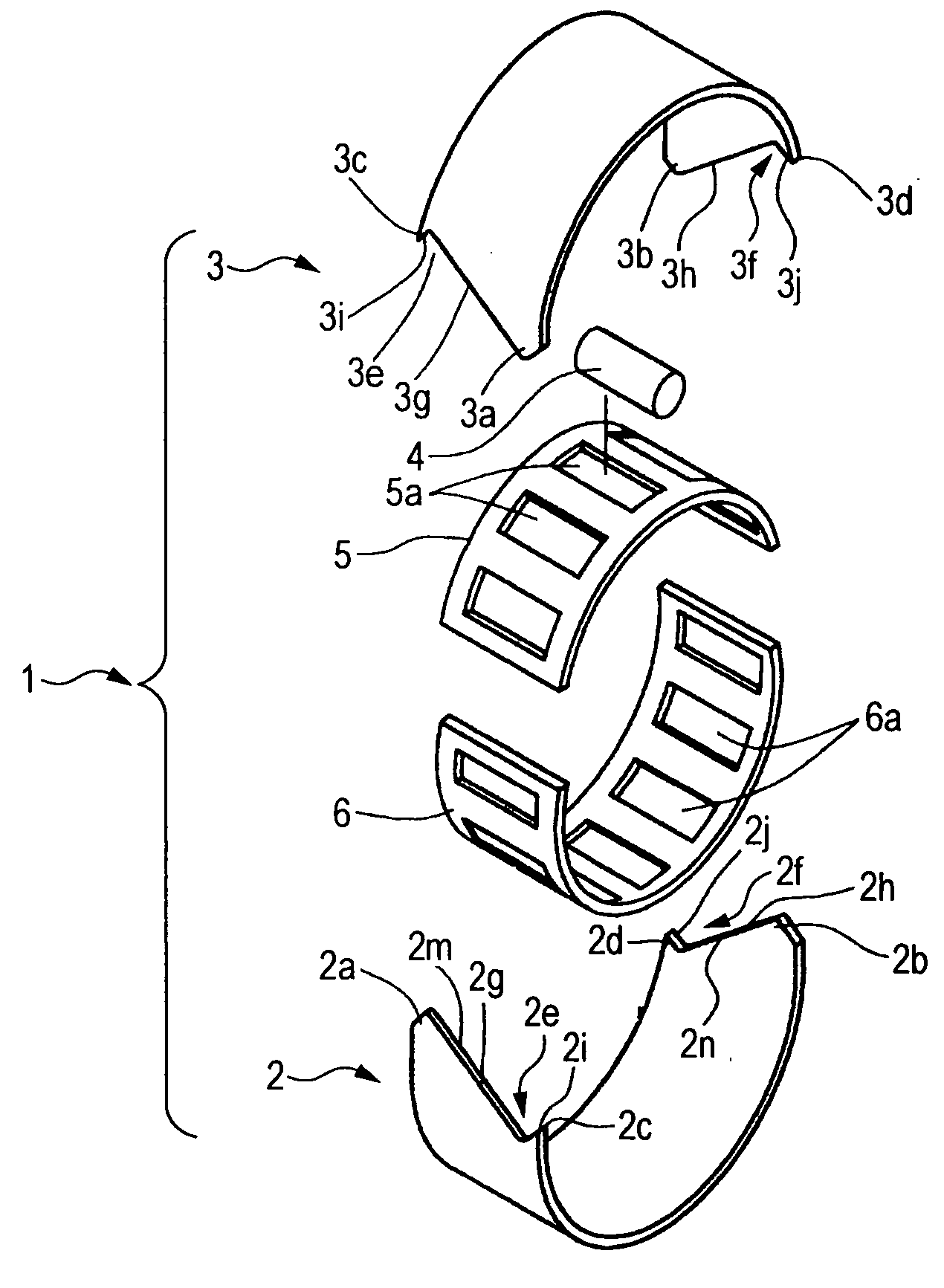

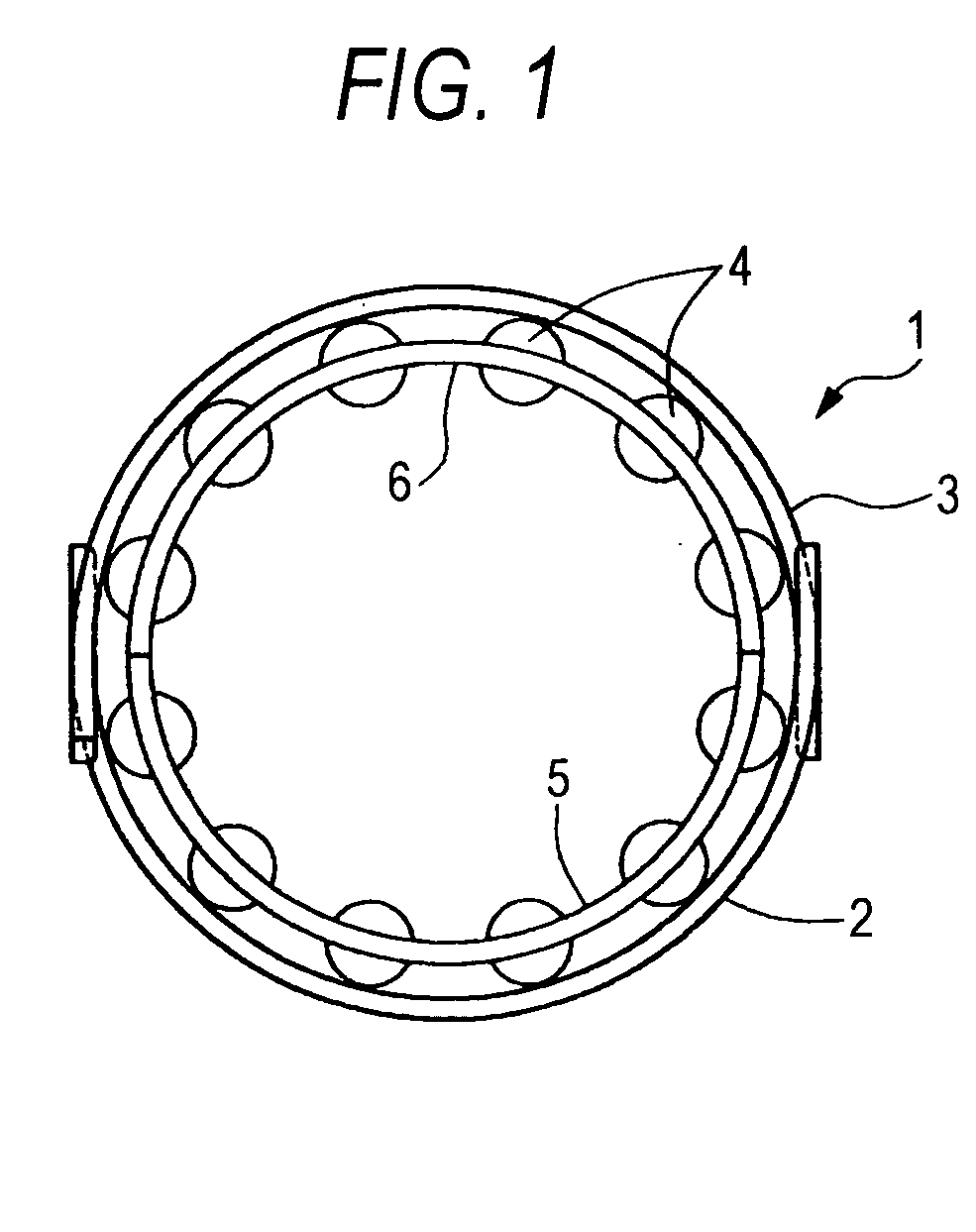

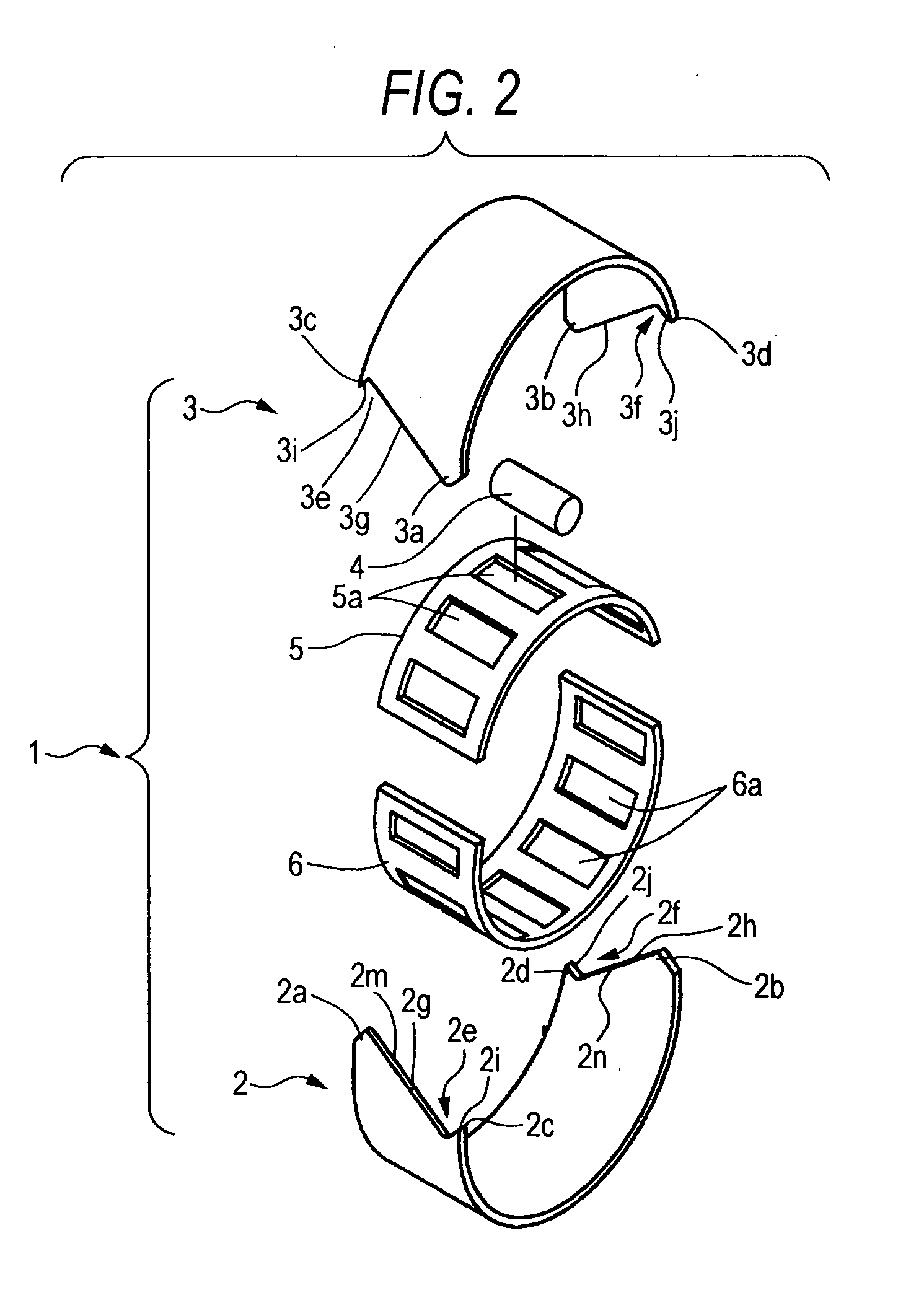

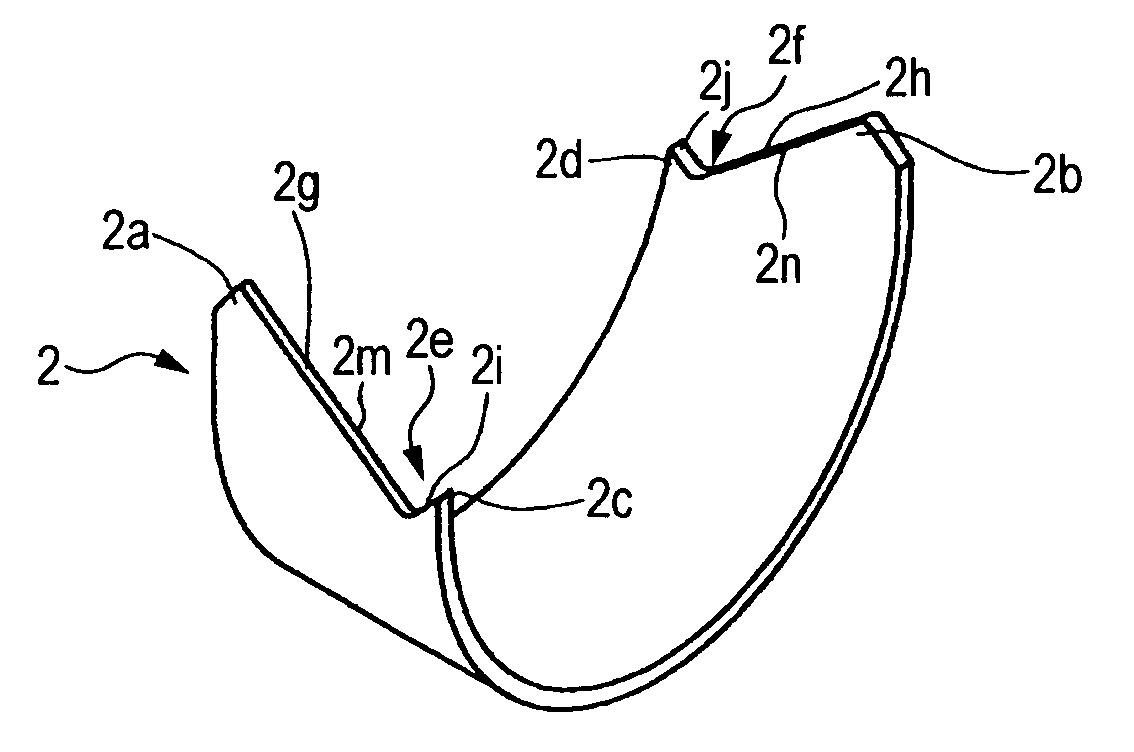

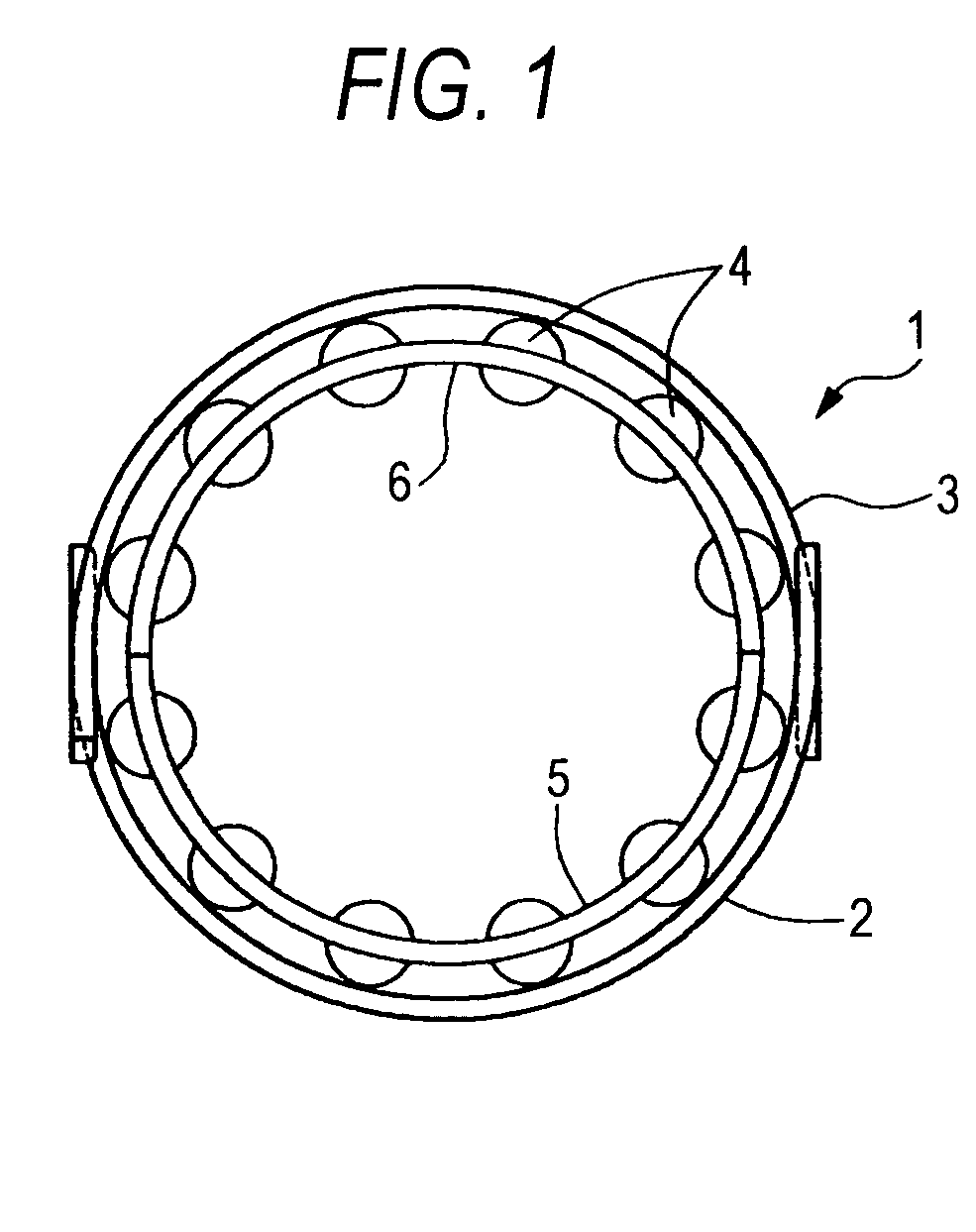

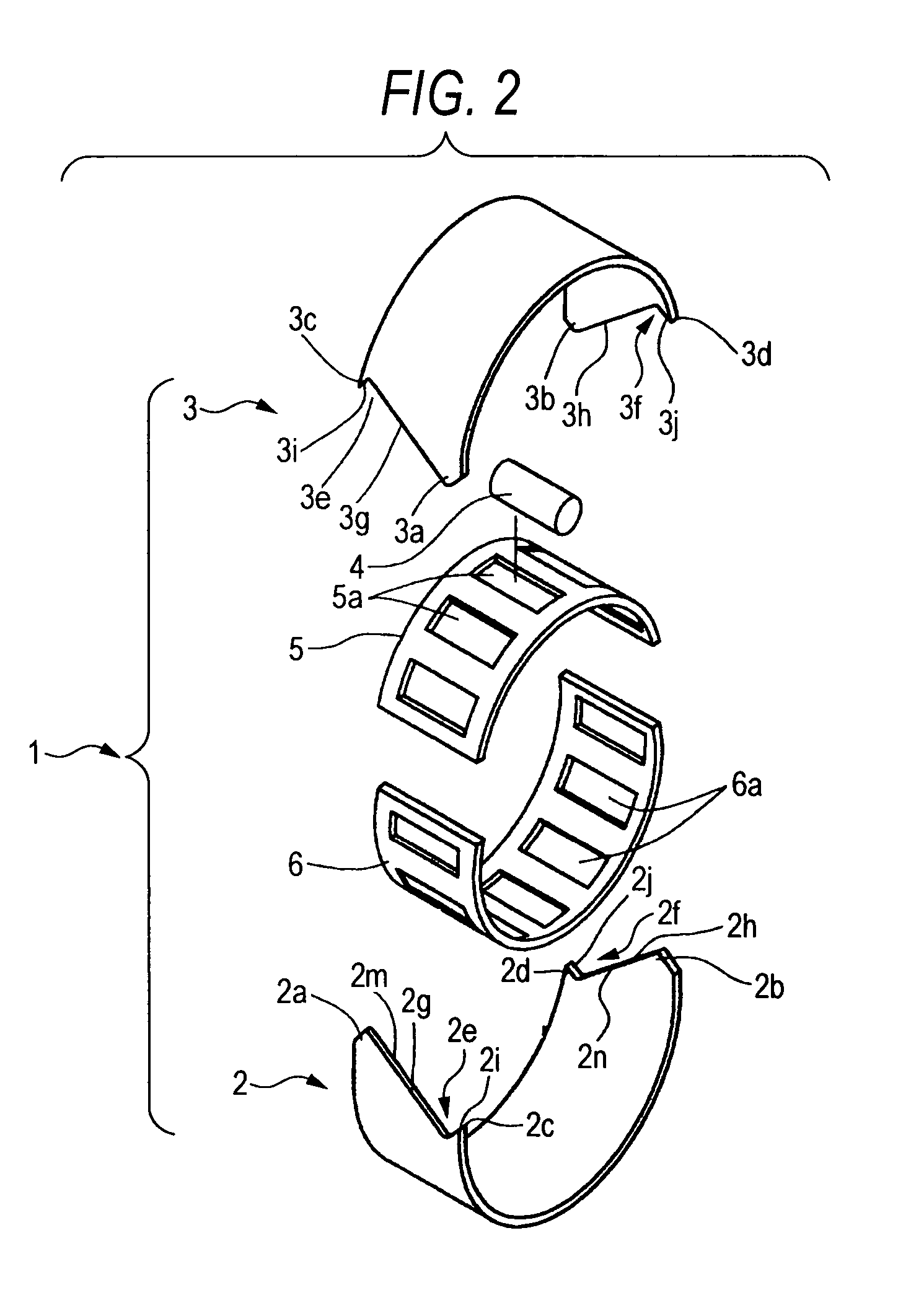

Split outer race, split rolling bearing using same, and manufacturing method for split outer race

ActiveUS20050265644A1Improve accuracyImprove manufacturing yieldConnecting rod bearingsShaftsRolling-element bearingBand shape

Owner:JTEKT CORP

Steering device

InactiveUS20090308189A1Eliminate backlashReduce feeding costsToothed gearingsSteering columnsScrew threadRidge

Provided are a steering device and a feed screw mechanism. The steering device is made so easy in the adjusting work of a backlash that it can eliminate the backlash reliably, even if the precision of the thread of a feed thread shaft or a feed nut is poor, thereby to improve the rigidity and to reduce the manufacturing cost of the feed screw mechanism. An upper-side end portion feed nut is urged upward of FIG. 8 by an upper-side disc spring so that an upper-side flank face of the thread ridge of the upper-side end portion fee nut is brought into close contact with the lower-side flank face of the thread ridge of a feed screw shaft. On the other hand, a lower-side end portion feed nut is urged downward of FIG. 8 by a lower-side disc spring so that a lower-side flank face of the thread ridge of the lower-side end portion fee nut is brought into close contact with the upper-side flank face of the thread ridge of the feed screw shaft. As a result, a feed nut and the feed screw shaft are cleared of the backlashes in the two upward and downward directions of FIG. 8.

Owner:NSK LTD

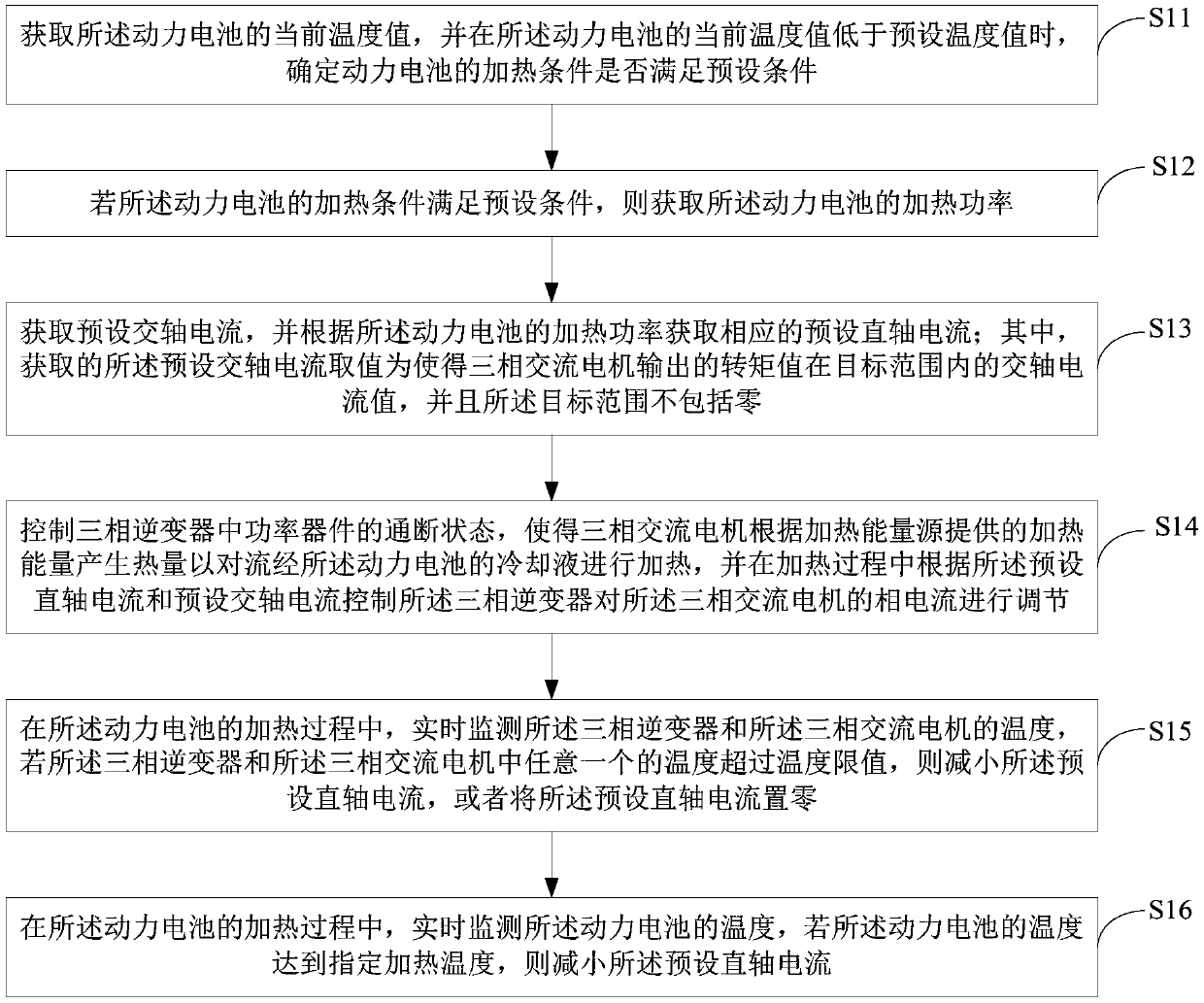

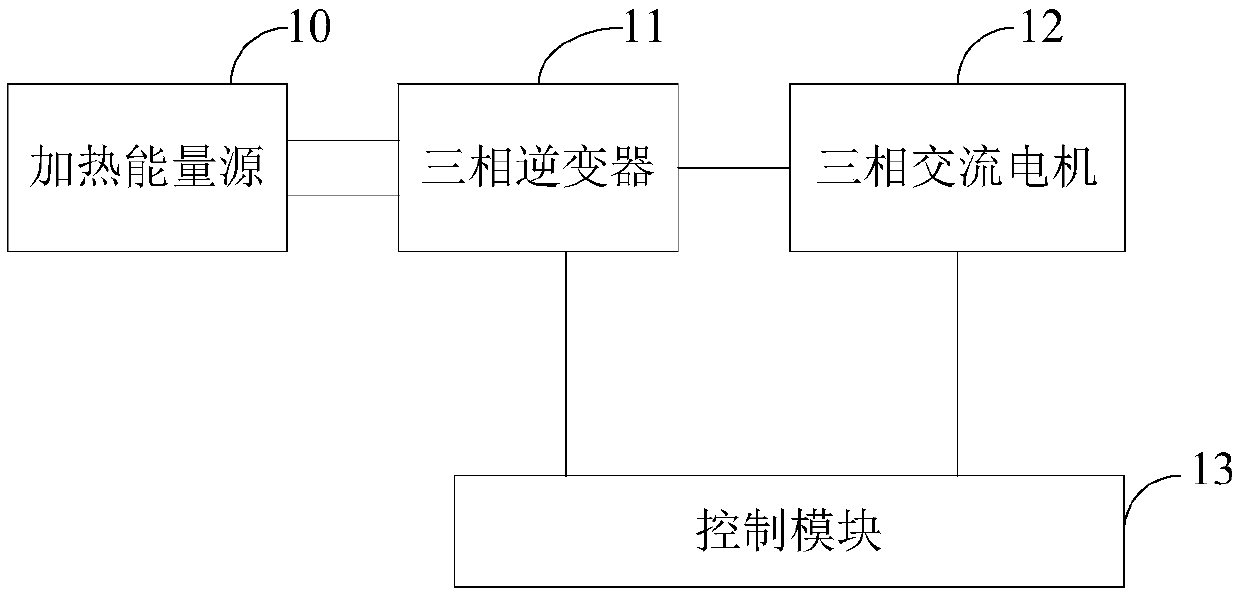

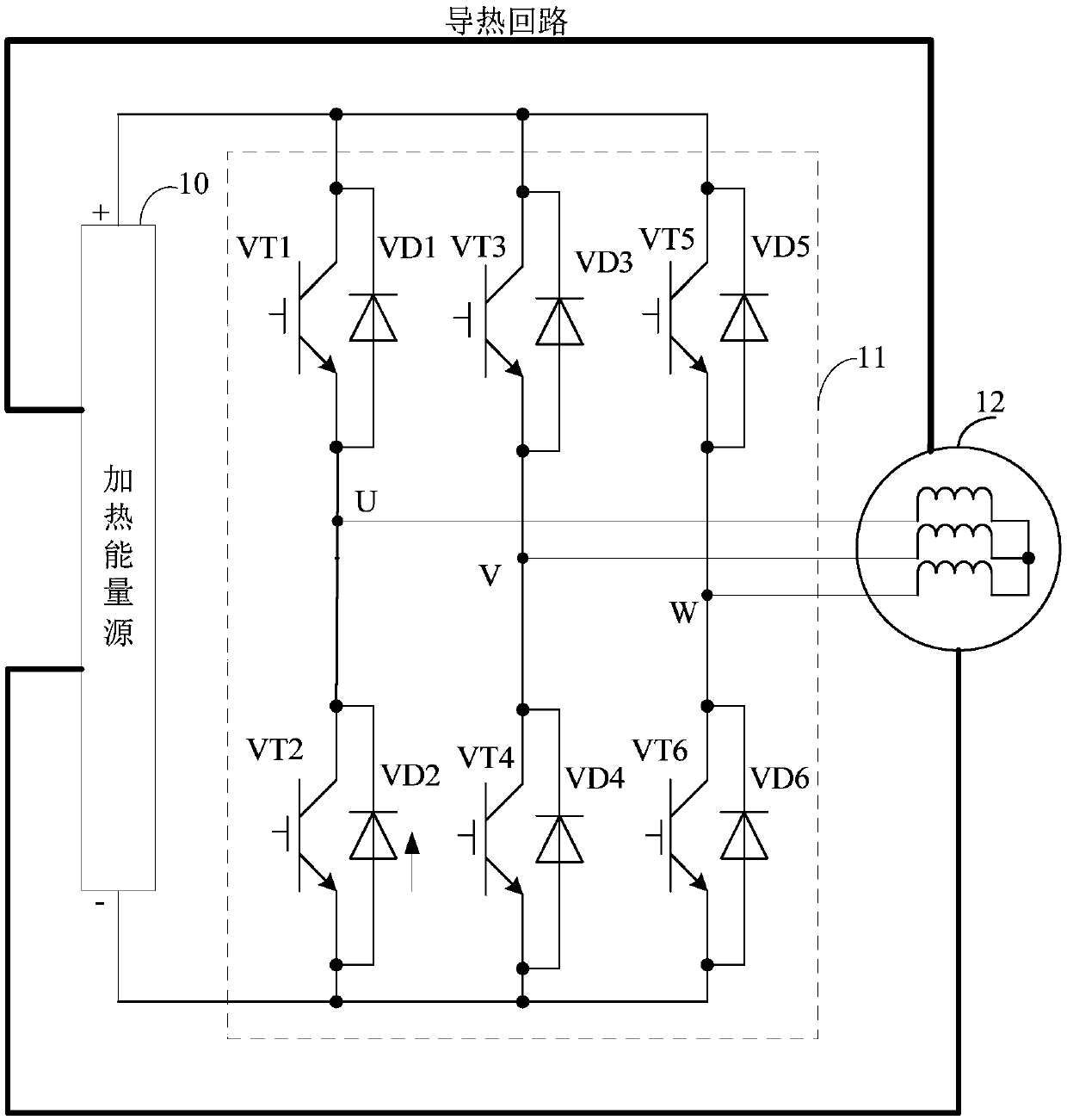

Vehicle and power battery heating device and method thereof

ActiveCN111347935AAvoid jitterEliminate backlashSpeed controllerElectric devicesAutomotive engineeringMotor shaft

The application provides a vehicle and a power battery heating device and method thereof. According to the power battery heating method, when the current temperature value of a power battery is lowerthan a preset temperature value and the heating condition of the power battery meets a preset condition, a three-phase inverter is controlled to enable a three-phase alternating current motor to generate heat according to the heating energy so as to heat cooling liquid flowing through the power battery; a preset quadrature-axis current enabling the torque value output by the motor to be at a proper value is obtained; a corresponding preset direct-axis current according to the heating power of the power battery is obtained; in the heating process, the three-phase inverter is controlled to adjust the phase current of the three-phase alternating current motor according to the preset direct-axis current and the preset quadrature-axis current, so that the motor shaft outputs an electromagnetictorque that has a very small torque value, cannot enable a vehicle to move, does not damage the parts of a vehicle transmission mechanism and only the motor output shaft outputs a pre-tightening forceto the transmission mechanism to eliminate meshing clearances, and thus the vehicle is effectively prevented from shaking.

Owner:BYD CO LTD

System And Method For Reducing Backlash In A Planetary Gear Set

InactiveUS20070093354A1Reduce controlPreclude creationToothed gearingsGearing detailsGear wheelGear tooth

Systems and methods for reducing or eliminating backlash to control gear rattle include a planetary gear set with a planet carrier including a first part that supports at least one forward-torque carrying planet gear that has at least one tooth contacting a drive side of gear teeth of an associated sun gear and ring gear and a second part that supports at least one reverse-torque carrying gear that has at least one tooth contacting a coast side of gear teeth of the associated sun gear and ring gear, the second part of the carrier being rotationally biased relative to the first part to reduce or eliminate effective backlash of the gear set.

Owner:FORD GLOBAL TECH LLC

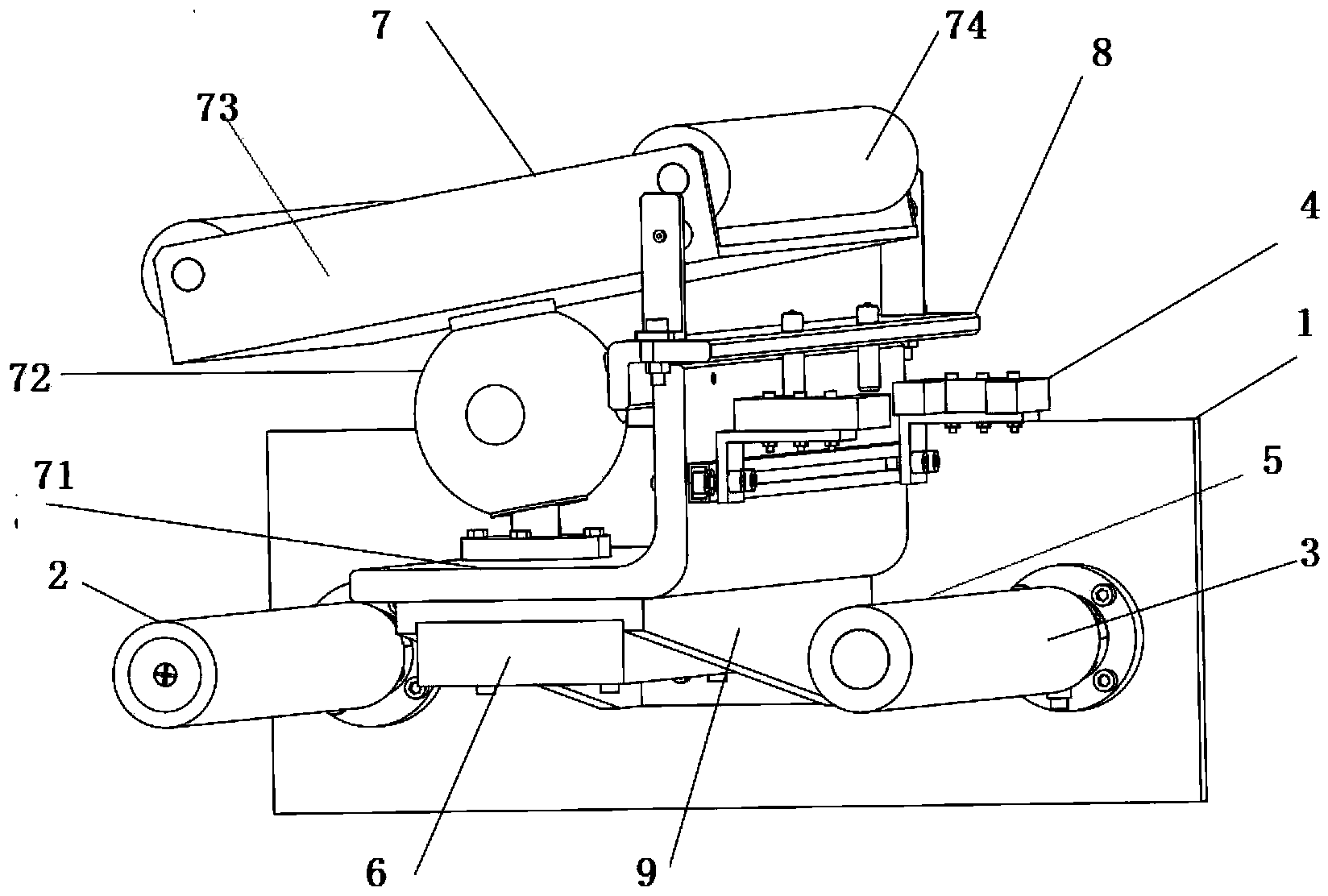

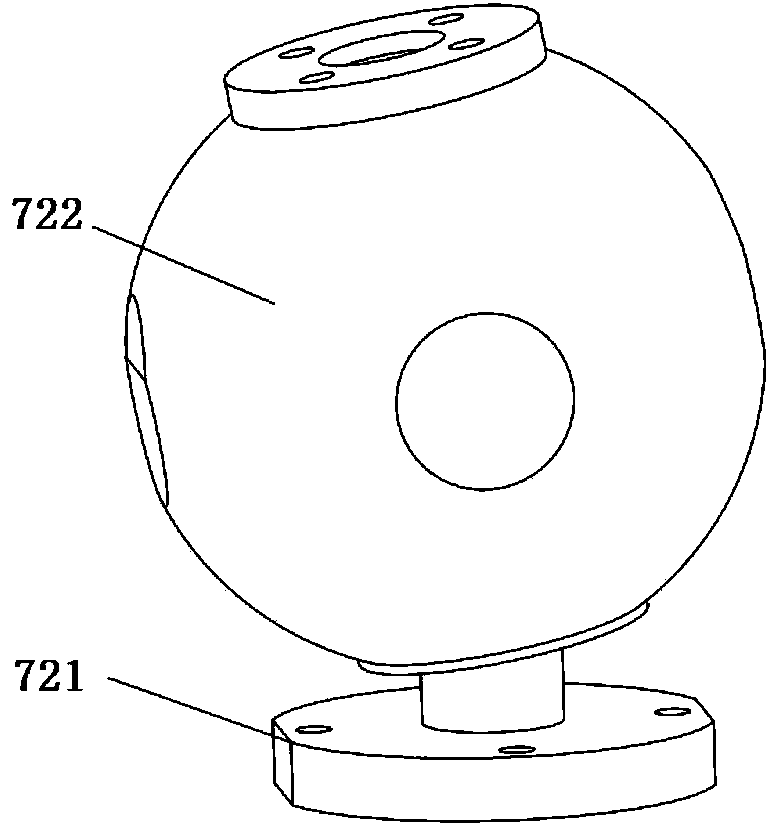

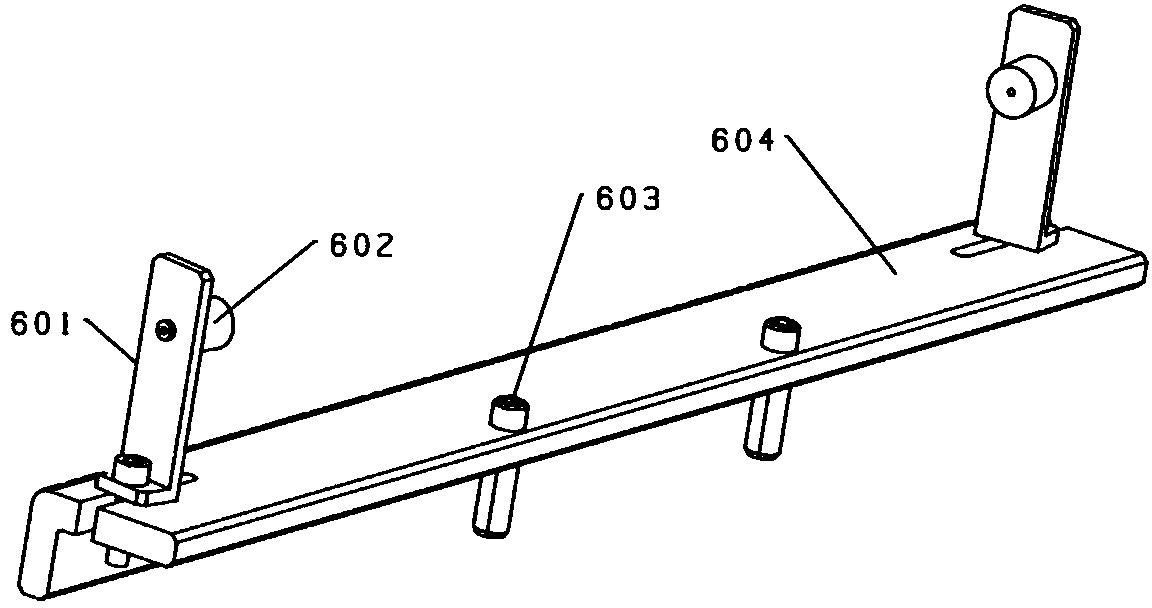

Film conveying deviation-rectifying device combining tension control

The invention provide a film conveying deviation-rectifying device combining the tension control, which comprises a film input guiding roller, an output guiding roller, a deflection detecting mechanism, a tension detecting mechanism, a controller and a deviation-rectifying actuating mechanism, wherein the film input guiding roller and the output guiding roller are used for inputting a film guide into the deviation-rectifying actuating mechanism and outputting the film guide from the deviation-rectifying actuating mechanism; the deflection detecting mechanism is used for detecting whether the film deflects or not; the tension detecting mechanism is used for detecting the film tension; the controller is used for generating deviation-rectification or / and tension control instruction as per the detection information; the deviation-rectifying actuating mechanism comprises a spherical motor, a deflection frame and a deviation-rectification roller; a runner of the spherical motor drives the deflection frame to rotate on a feeding surface of the film; the friction between the rectification roller and the film drives the inverse rotation of the film to realize the deviation-rectification; meanwhile, the runner of the spherical motor drives the deflection frame to rotate on the surface vertical to the feeding surface of the film, so as to tighten or loose the film to realize the tension control. According to the invention, the deviation-rectification and the tension control of the film can be realized simultaneously, the influence of the tension variation on the deviation-rectification is greatly reduced, the structure is simple, and the deviation-rectifying precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydraulic inert container device

The invention relates to a hydraulic inert container device, which comprises a big hydraulic cylinder, a small hydraulic cylinder and a mass block. The two cavities of the big hydraulic cylinder and the two cavities of the small hydraulic cylinder are correspondingly communicated; and the mass block is connected with the end of a piston rod of the small hydraulic cylinder. When external force is applied to the piston rod and the cylinder body of the big hydraulic cylinder along the axial direction of the piston rod, the piston moves linearly relative to the cylinder body and pushes the oil toflow into the small hydraulic cylinder from the big hydraulic cylinder so as to form pressure difference between the two sides of the piston in the small hydraulic cylinder; and the pressure difference drives the piston of the small hydraulic cylinder to move and finally drives the mass block to move so as to obtain the characteristics of the inert container. Force transferring liquid is arrangedin the hydraulic inert container device, and only by adding a proper damping mechanism to the liquid passage, the device can be used as a damping element as well, thereby saving additional special damping element for the system. The invention provides an ideal inert container device capable of bearing big load and serving as a damping element for a vibration system.

Owner:JIANGSU UNIV

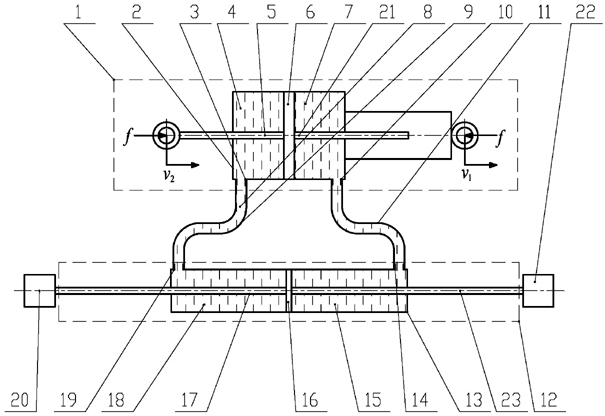

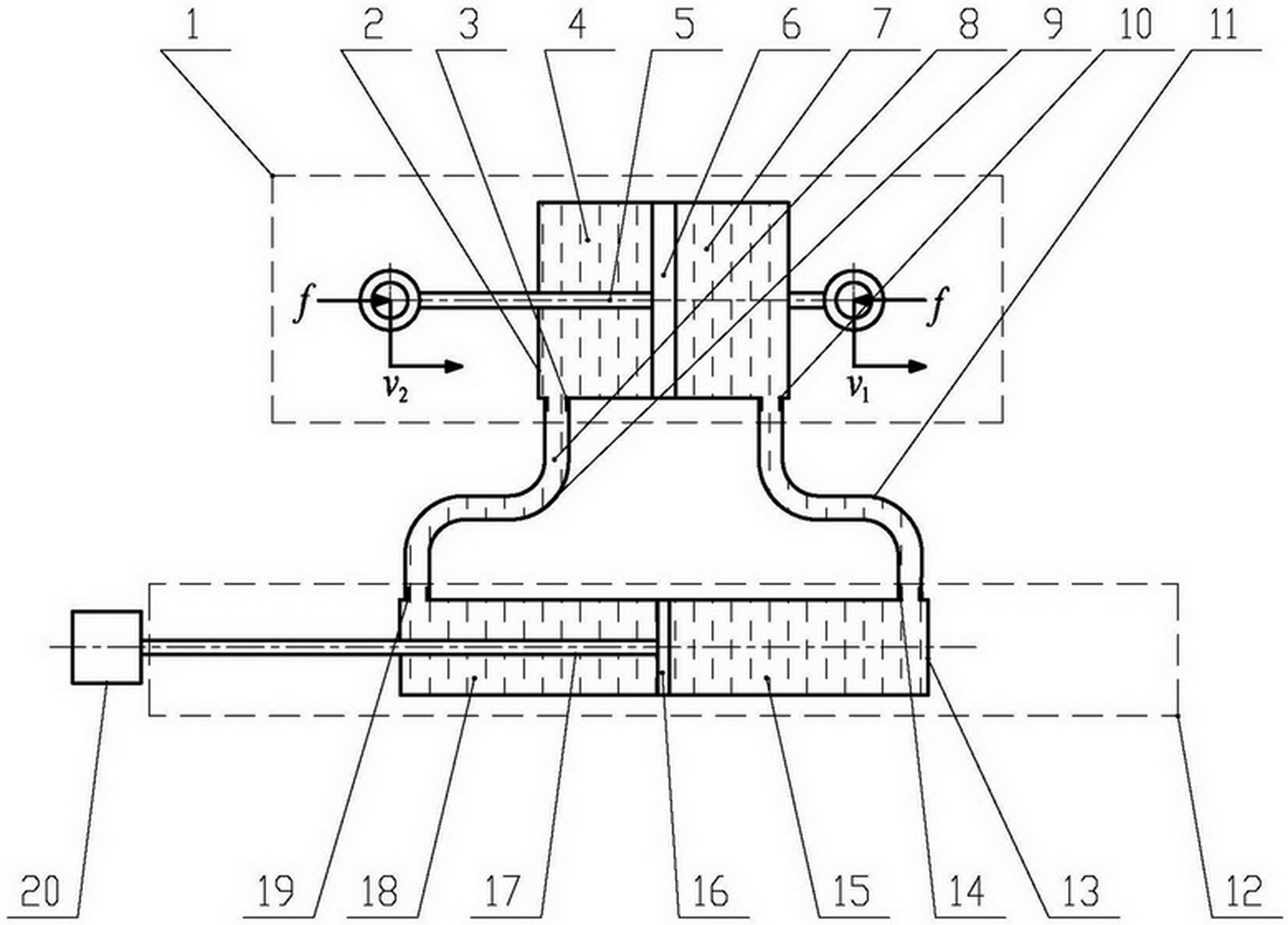

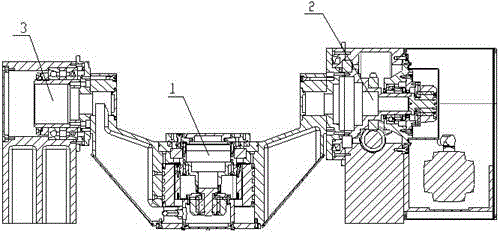

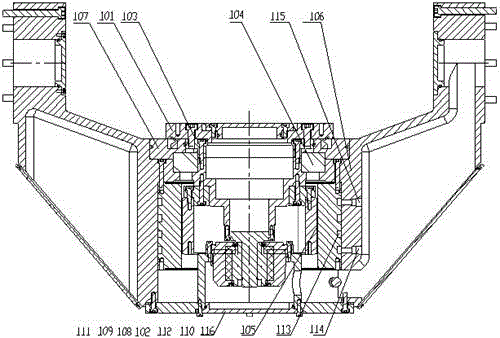

Effective high-precision double-rotating working table of vertical machining center

ActiveCN104476213AHigh precisionCompact structureFeeding apparatusLarge fixed membersNumerical controlTorque motor

The invention discloses an effective high-precision double-rotating working table of a vertical machining center. The effective high-precision double-rotating working table of the vertical machining center comprises a rotating table part, a right cradle part and a left cradle part, the rotating table part is arranged between the right cradle part and the left cradle part, one end of the left cradle part is firmly connected with the rotating table part, one end of the right cradle part is firmly connected with the rotating table part, and a rotating servo motor is arranged in the right cradle part. The effective high-precision double-rotating working table of the vertical machining center is simple and compact in structure and capable of realizing five-axis linkage and finishing complex curved surface processing after being fixed on a numerical control vertical machine tool, the right cradle part is driven by a rolling worm, the clearance can be adjusted through a left eccentric sleeve and a right eccentric sleeve so as to provide a large torque and a high rotating speed, the rotating table part uses a torque motor to directly drive the working table, the reverse clearance is eliminated, the locating precision is higher, and the rotating speed is high; a first cross roller bearing is capable of simultaneously bearing radial force and axial force, and the precision of the working table is reinforced.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD +1

Split outer race, split rolling bearing using same, and manufacturing method for split outer race

ActiveUS7270484B2Suppress and prevent and noiseSuppress and prevent vibrationConnecting rod bearingsShaftsRolling-element bearingEngineering

Owner:JTEKT CORP

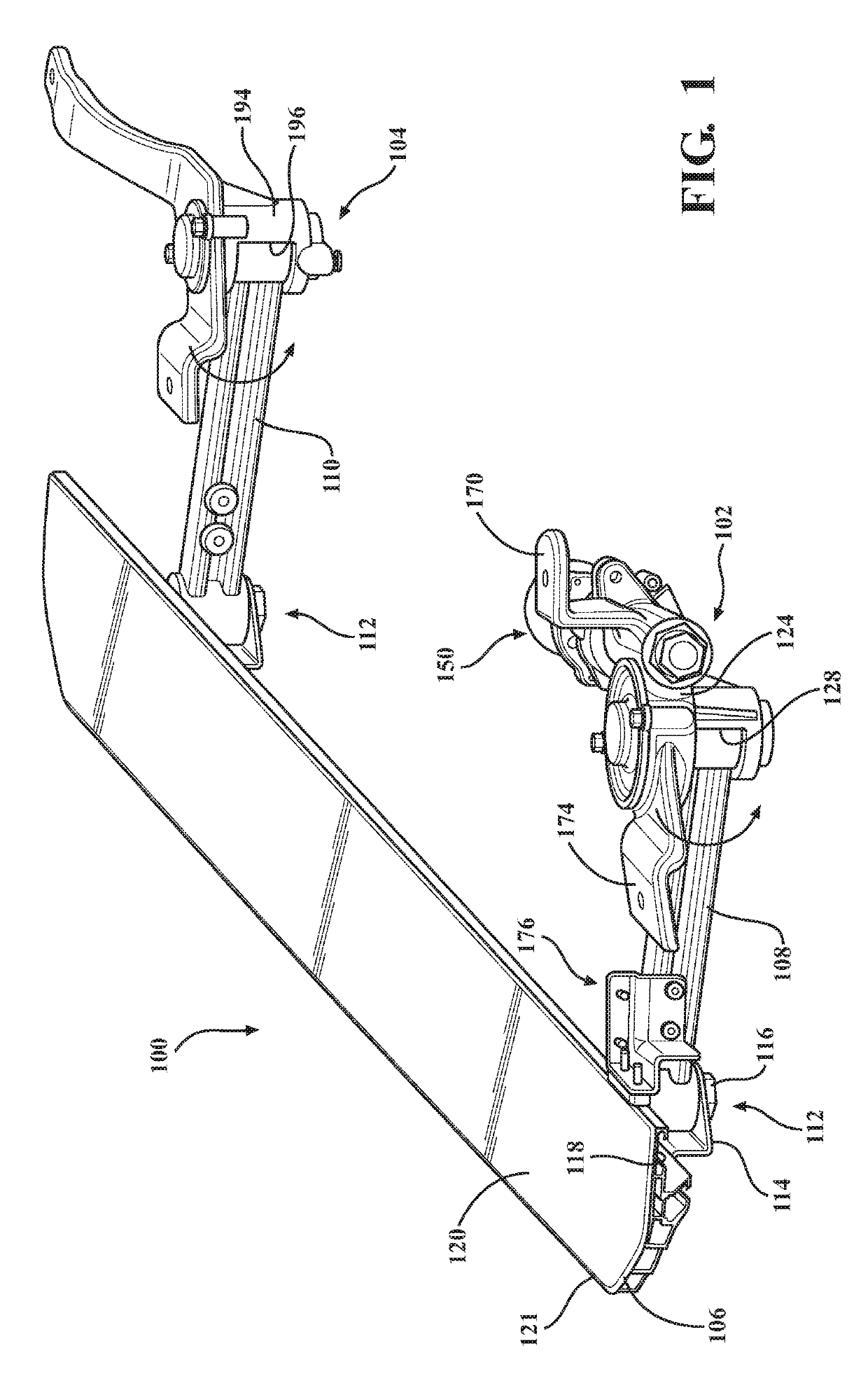

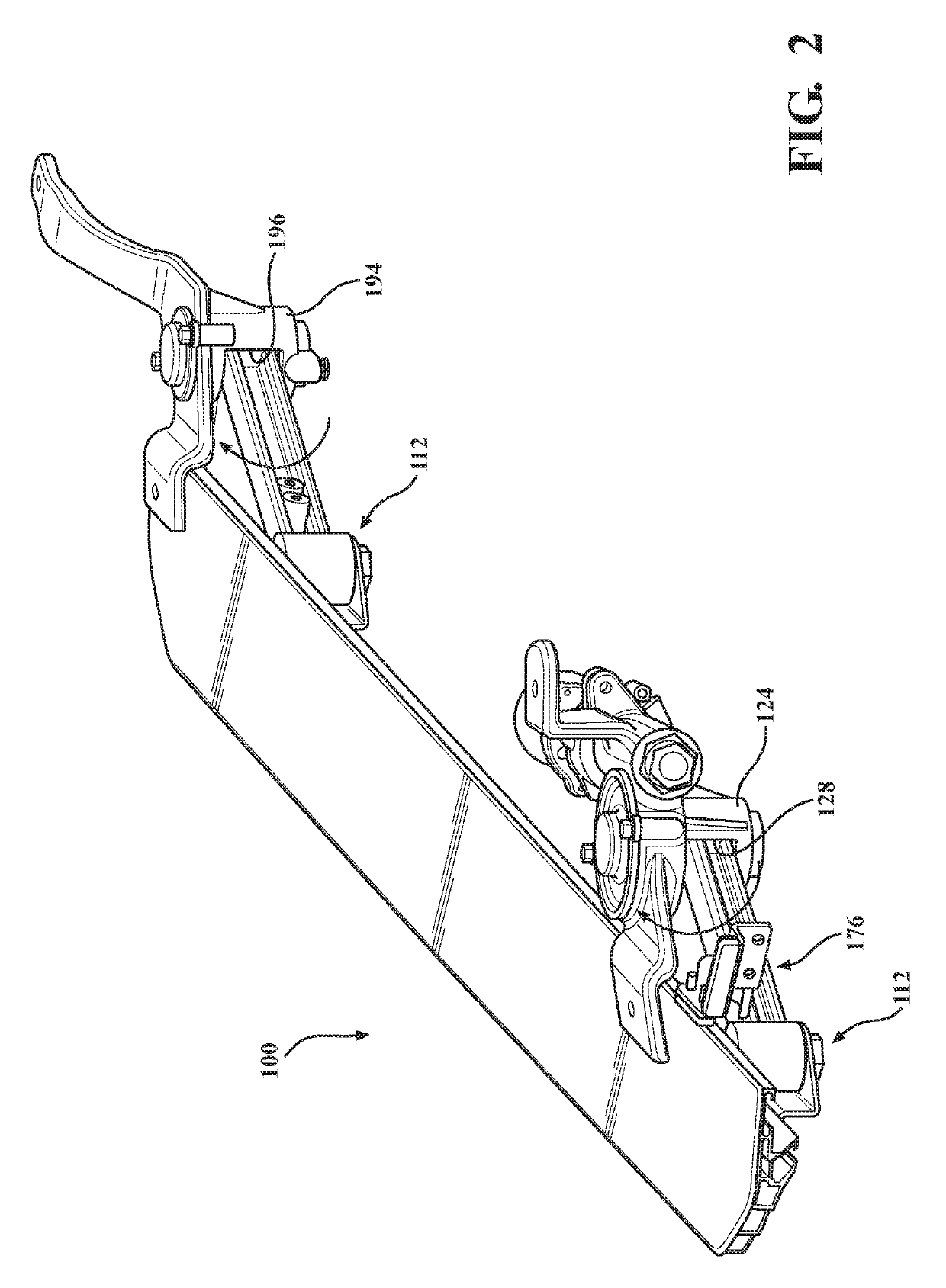

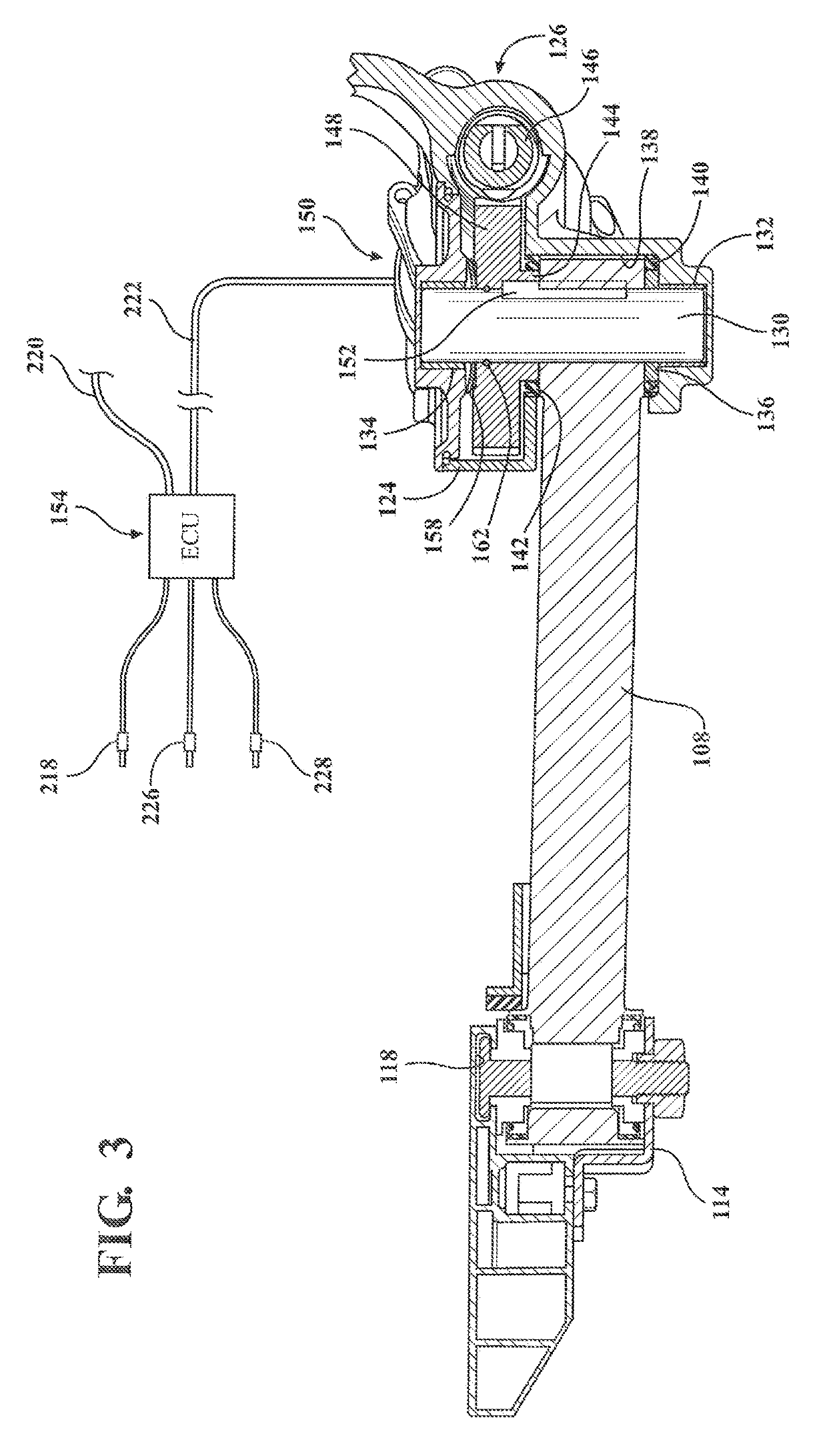

Compact power running board

ActiveUS10343610B2Reduce weightGood conditionRailway componentsSteps arrangementActuatorControl theory

A compact deployable / retractable running board assembly for a motor vehicle including a running board, linkage coupled to the running board, and a motor assembly coupled to an actuator, the running board moveable between at least one stowed position and at least one deployed position. The linkage includes a drive arm connected to a pivot shaft within a housing at a location on the pivot shaft between two bushings that are coupled to the pivot shaft within the housing. The linkage also includes an idler arm connected to a pivot shaft within an idler housing. The actuator is operably coupled to the linkage to cause rotation of the linkage to move the running board between the at least one stowed position generally under the motor vehicle and at least one deployed position to provide a step surface for a user.

Owner:MAGNA INTERNATIONAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com