Dual-motor energy-saving anti-backlash control method

A control method and dual-motor technology, applied in the direction of speed regulation of multiple motors, can solve the problems of exponential explosion, low calculation efficiency of enumeration method, and poor robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

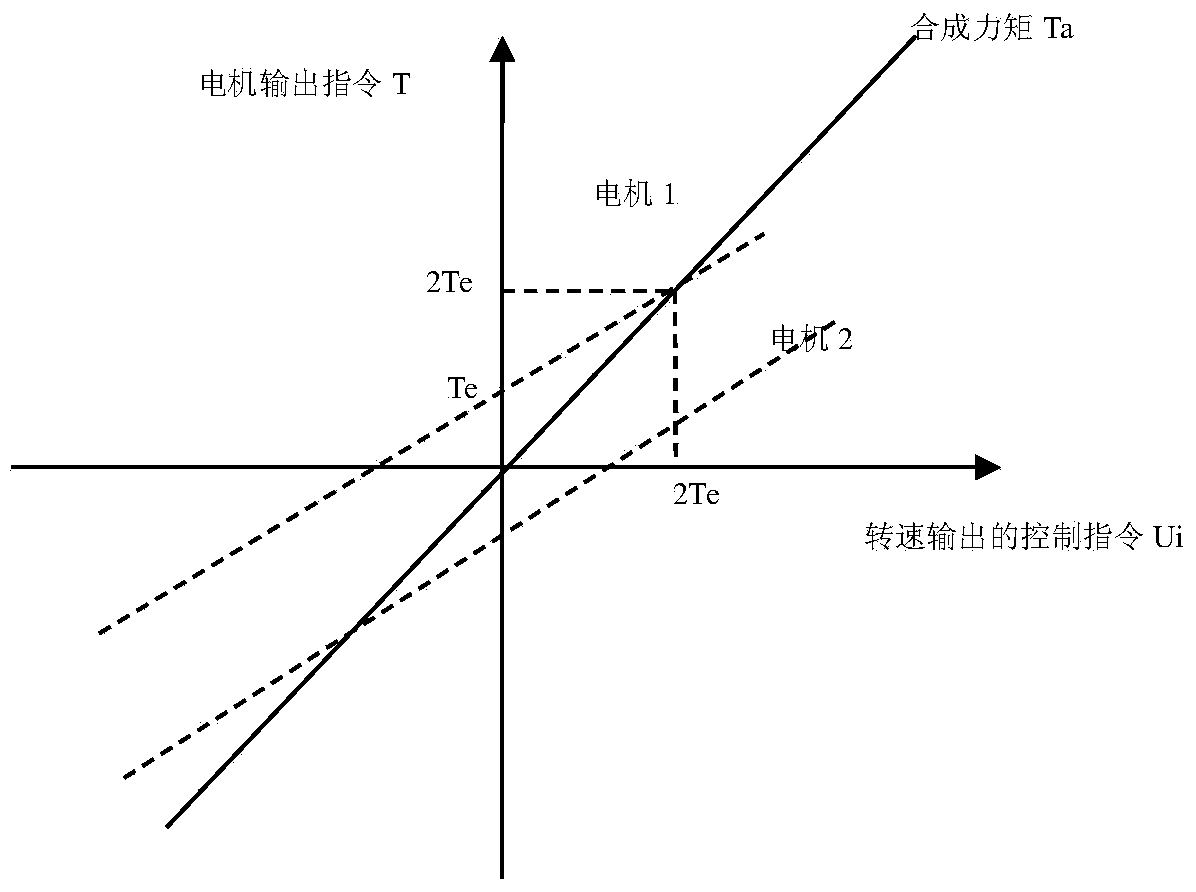

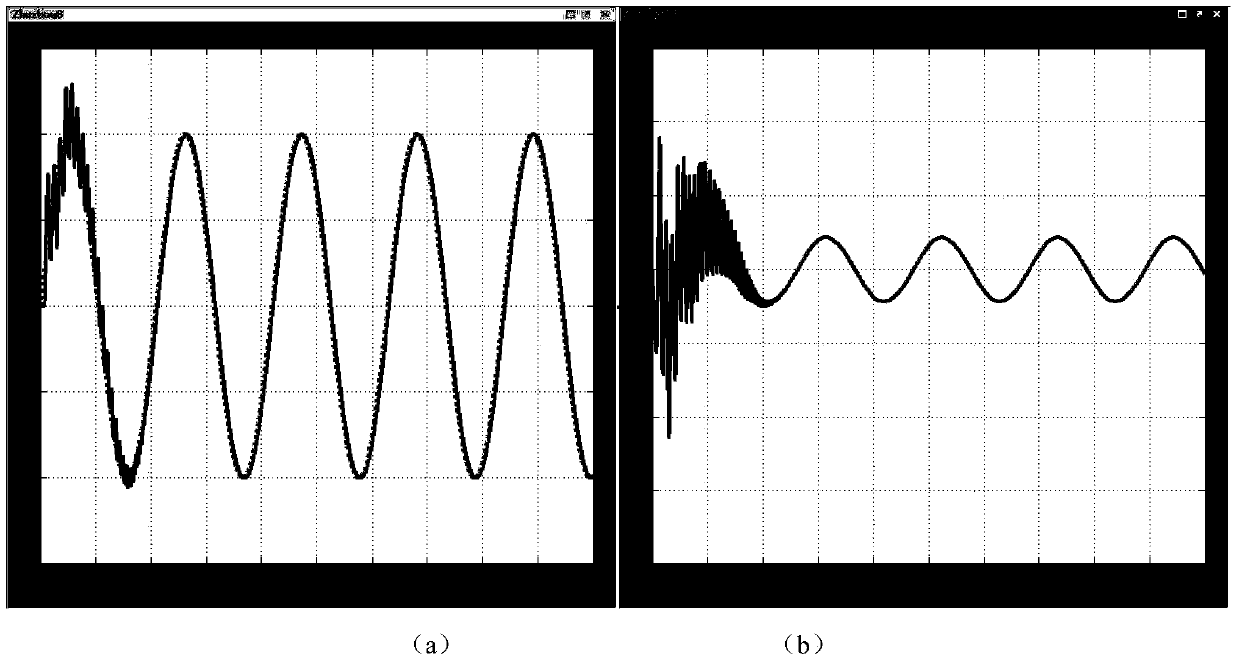

[0058] In this embodiment, an energy-saving and anti-backlash control system is designed according to the method described in the content of the invention, and the problem of tuning parameters of the multi-coupling controller in the dual-motor controller is solved by using the particle swarm optimization algorithm. The objective function with error and energy consumption as the performance index is selected, and the controller parameters and bias torque parameters of the dual-motor drive system are optimized simultaneously.

[0059] The dual-motor optimal control method based on the particle swarm method is mainly divided into the following steps:

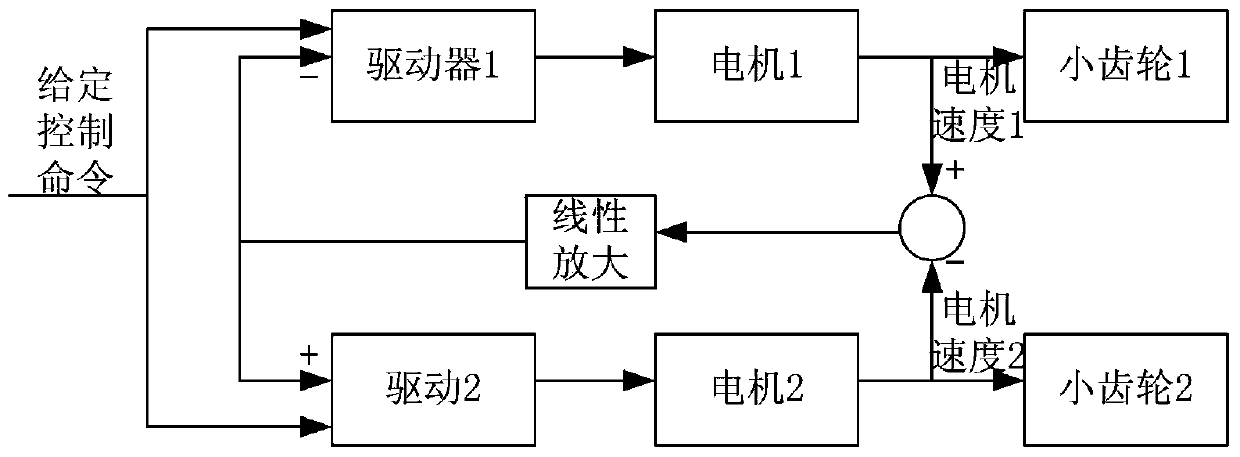

[0060] The first step: Design differential negative feedback control to achieve the purpose of synchronizing two small motors. The speed difference of the two motors is taken, and after being linearly amplified, it is respectively negatively fed back to the current loop input ends of the two motors. The principle of differential n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com