Patents

Literature

204results about How to "Reduce output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

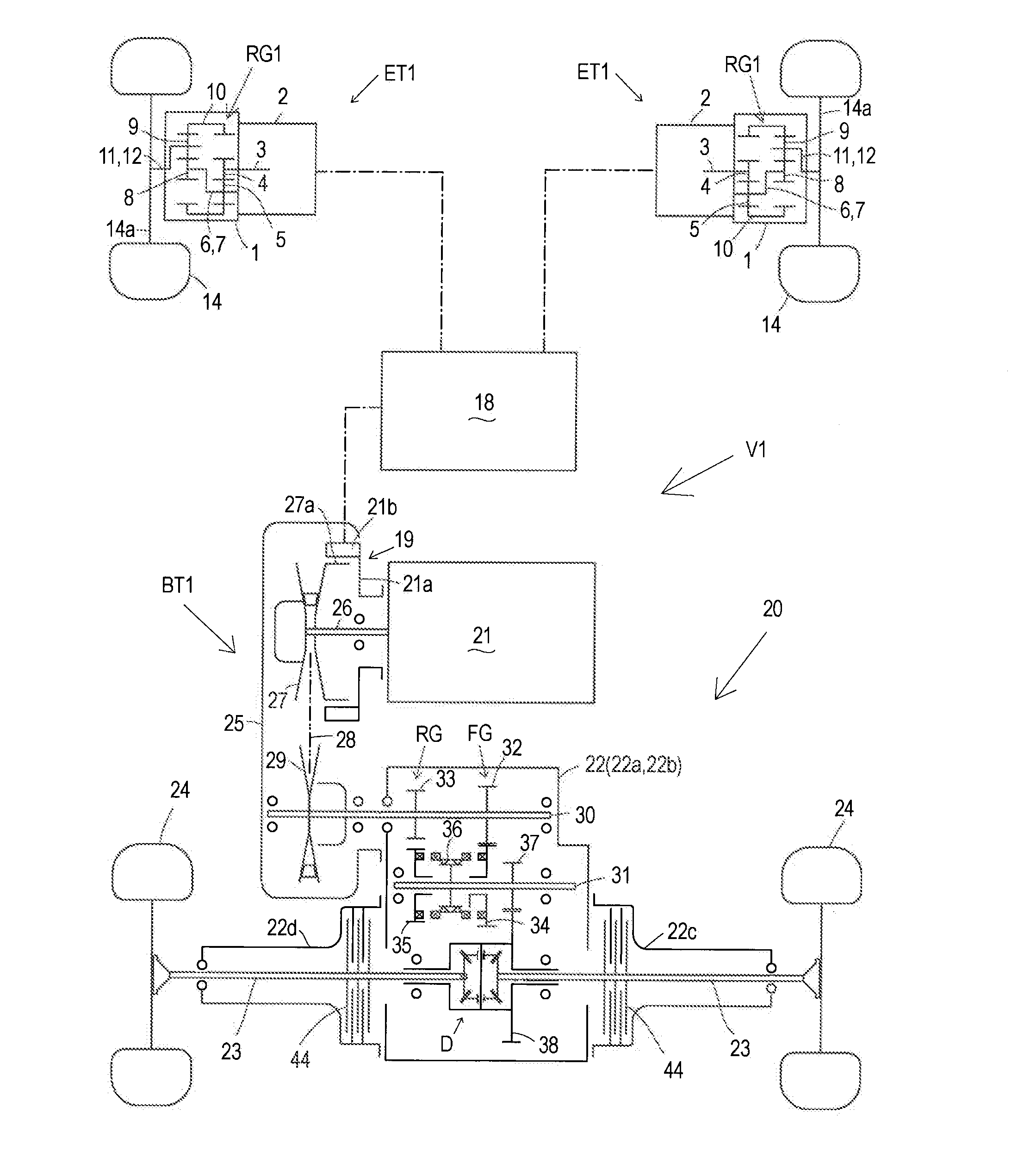

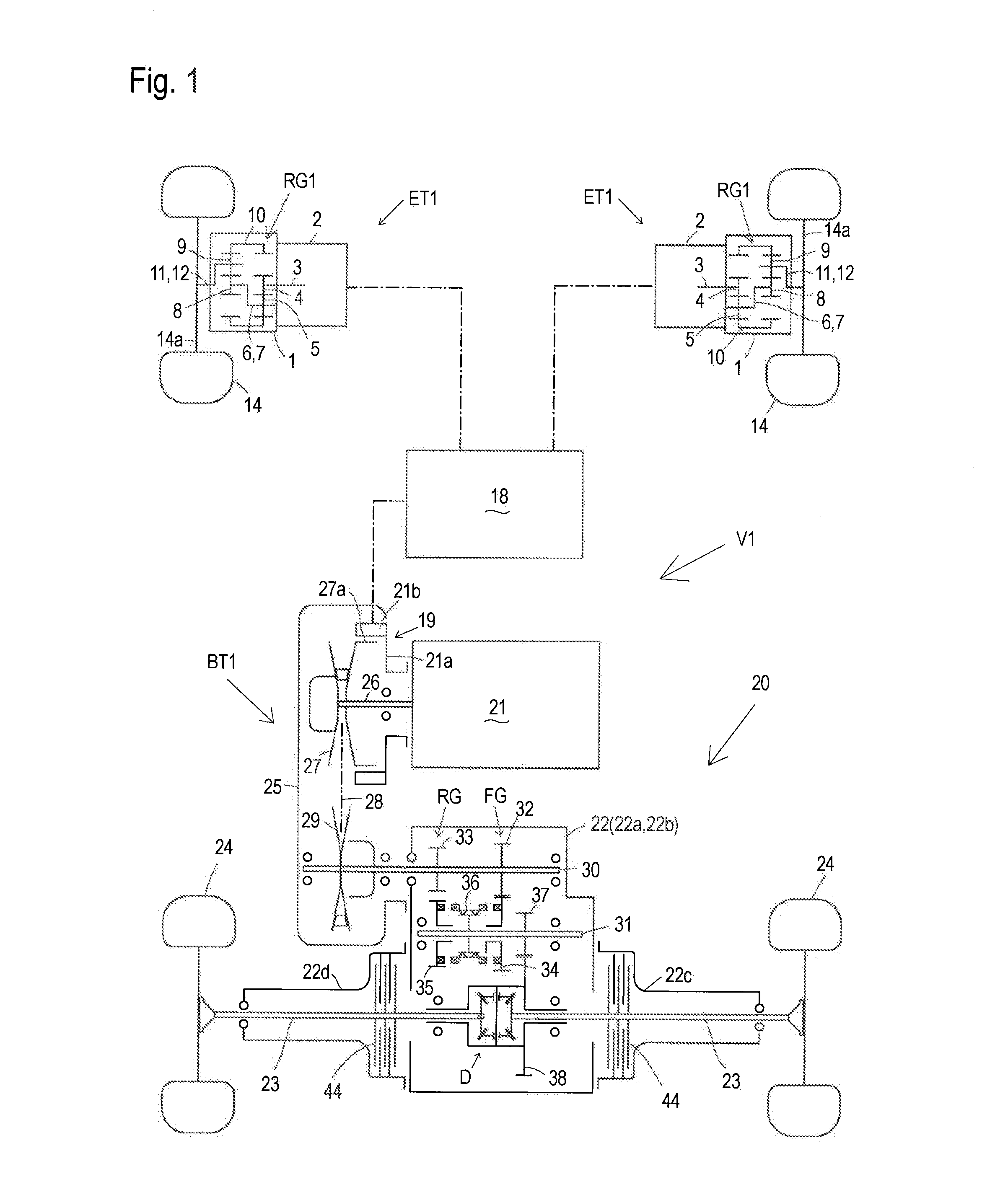

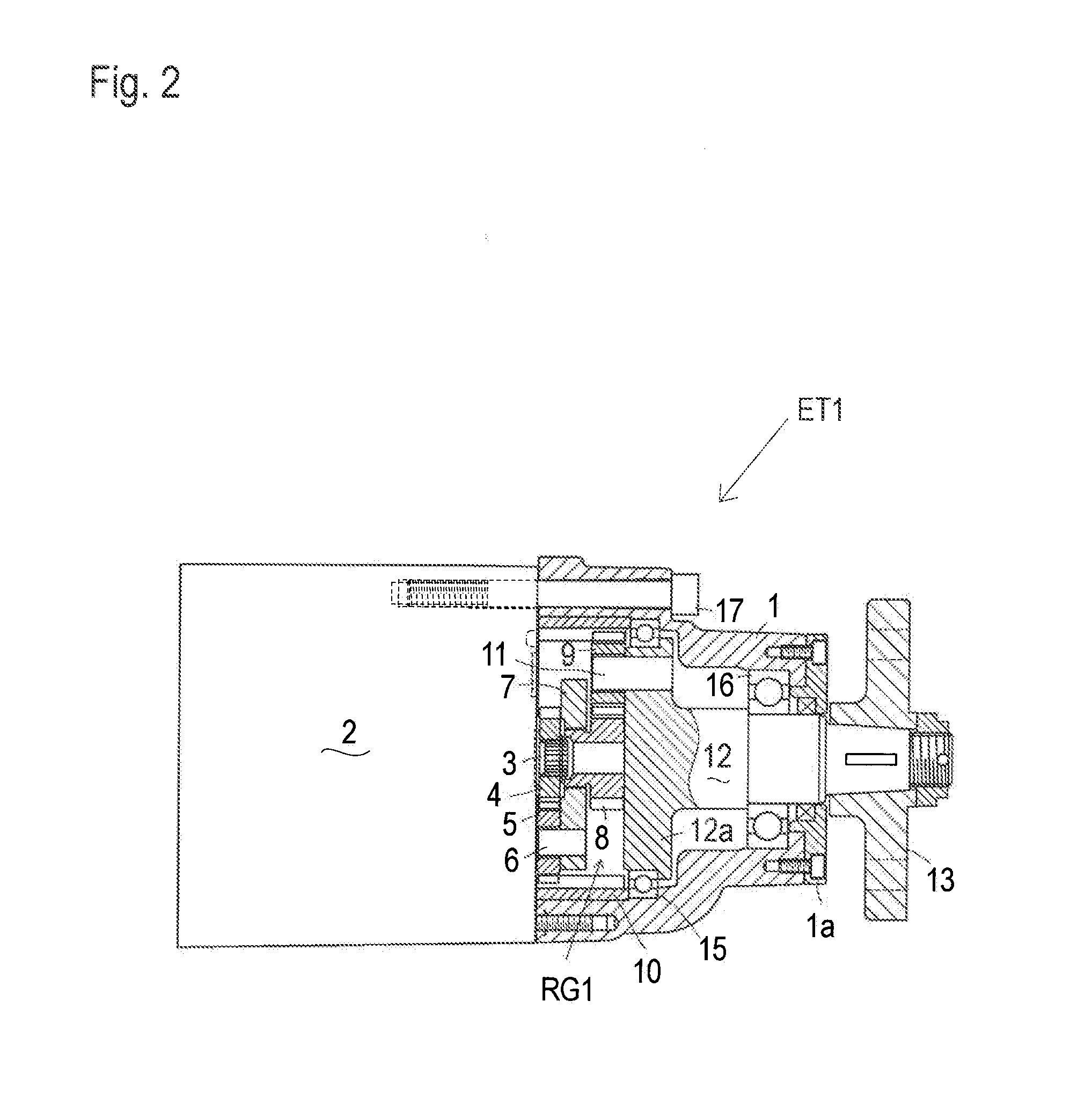

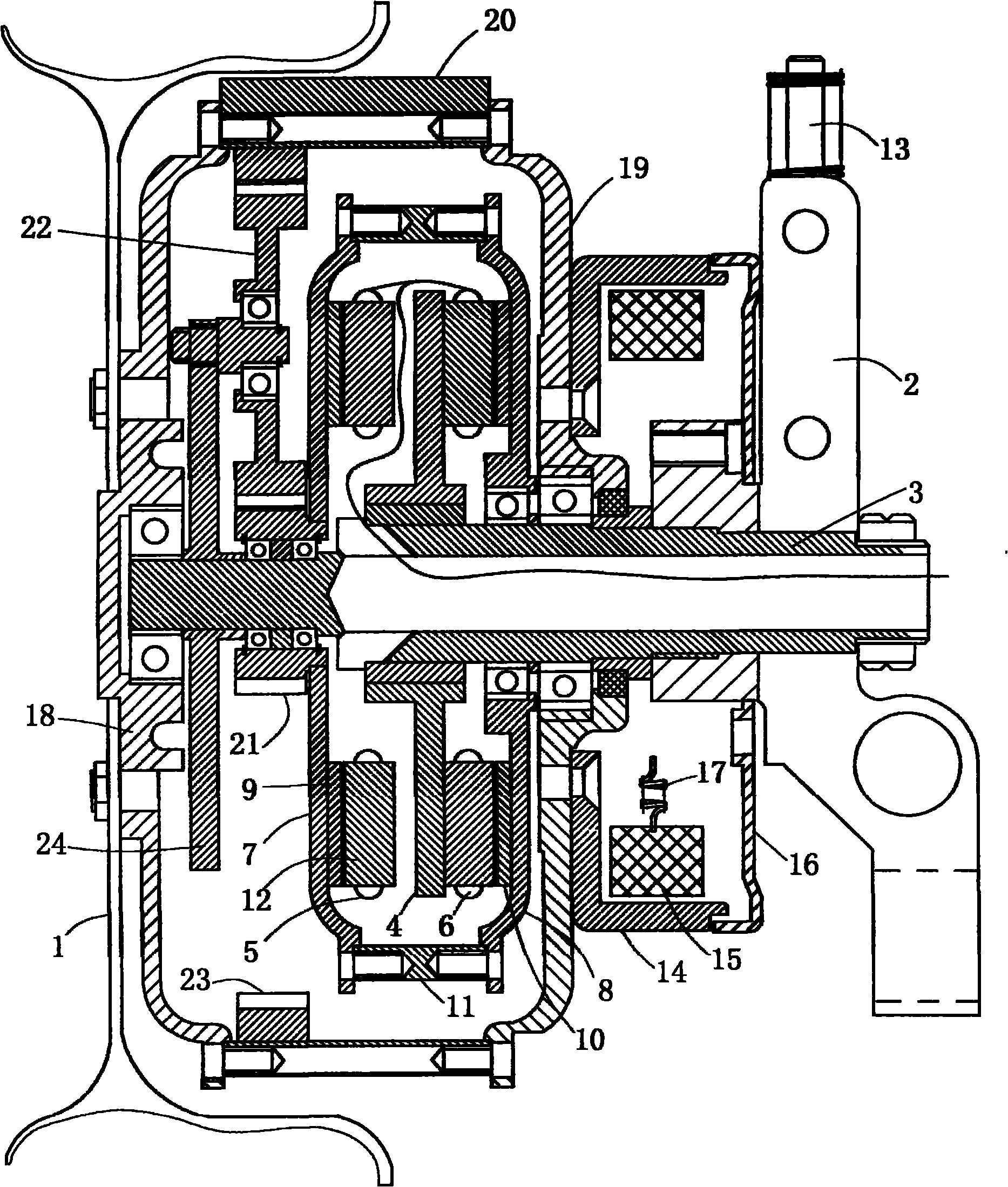

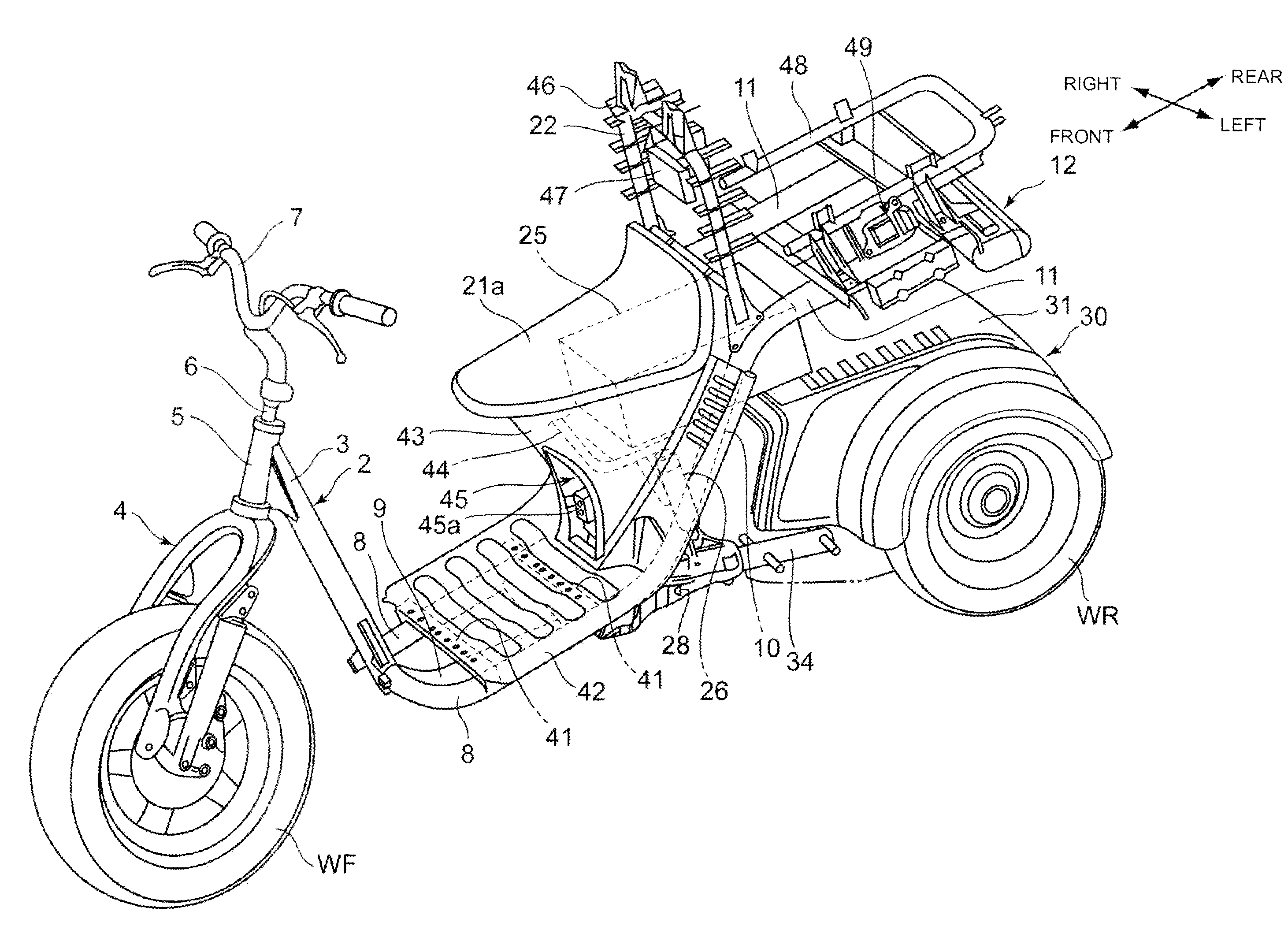

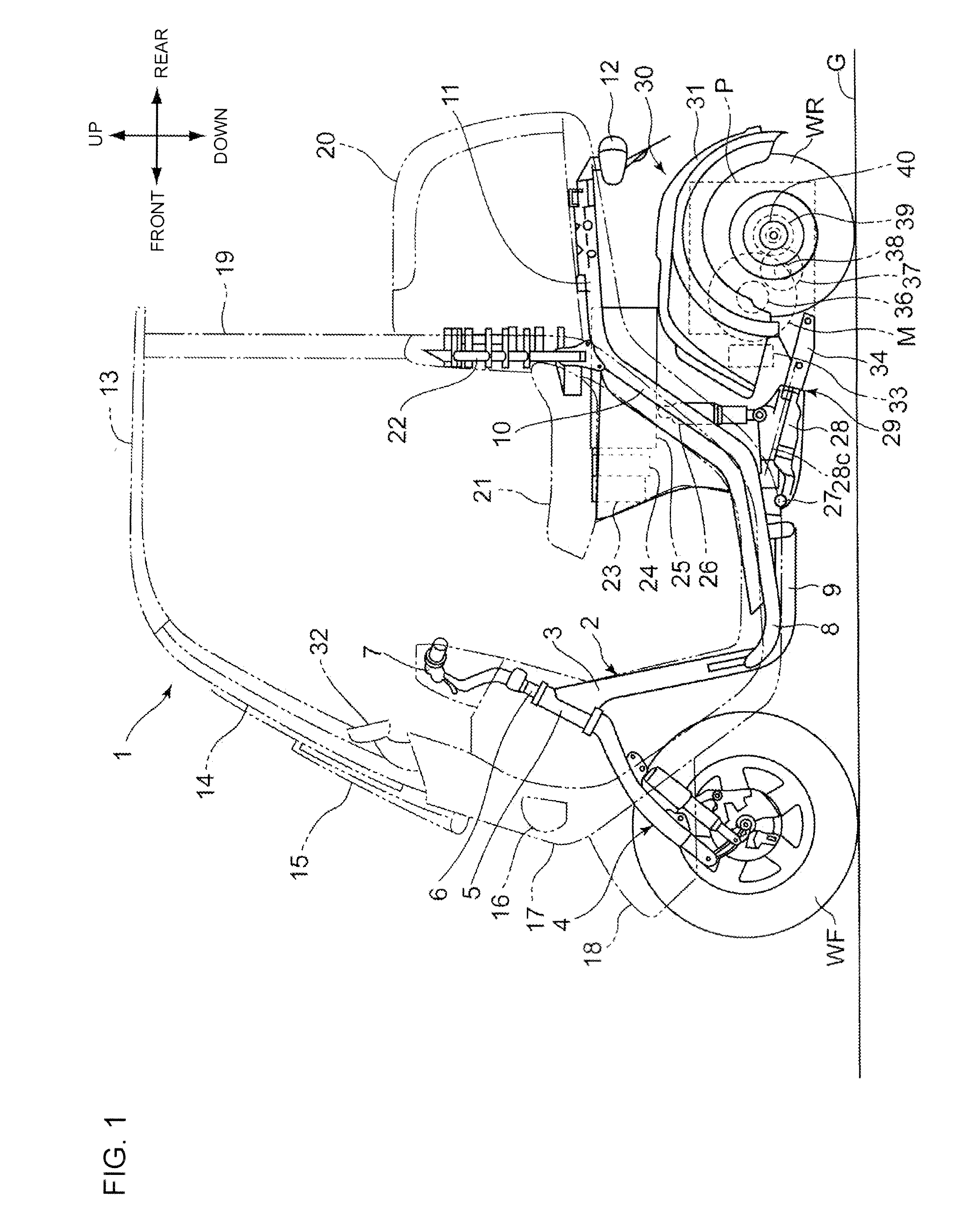

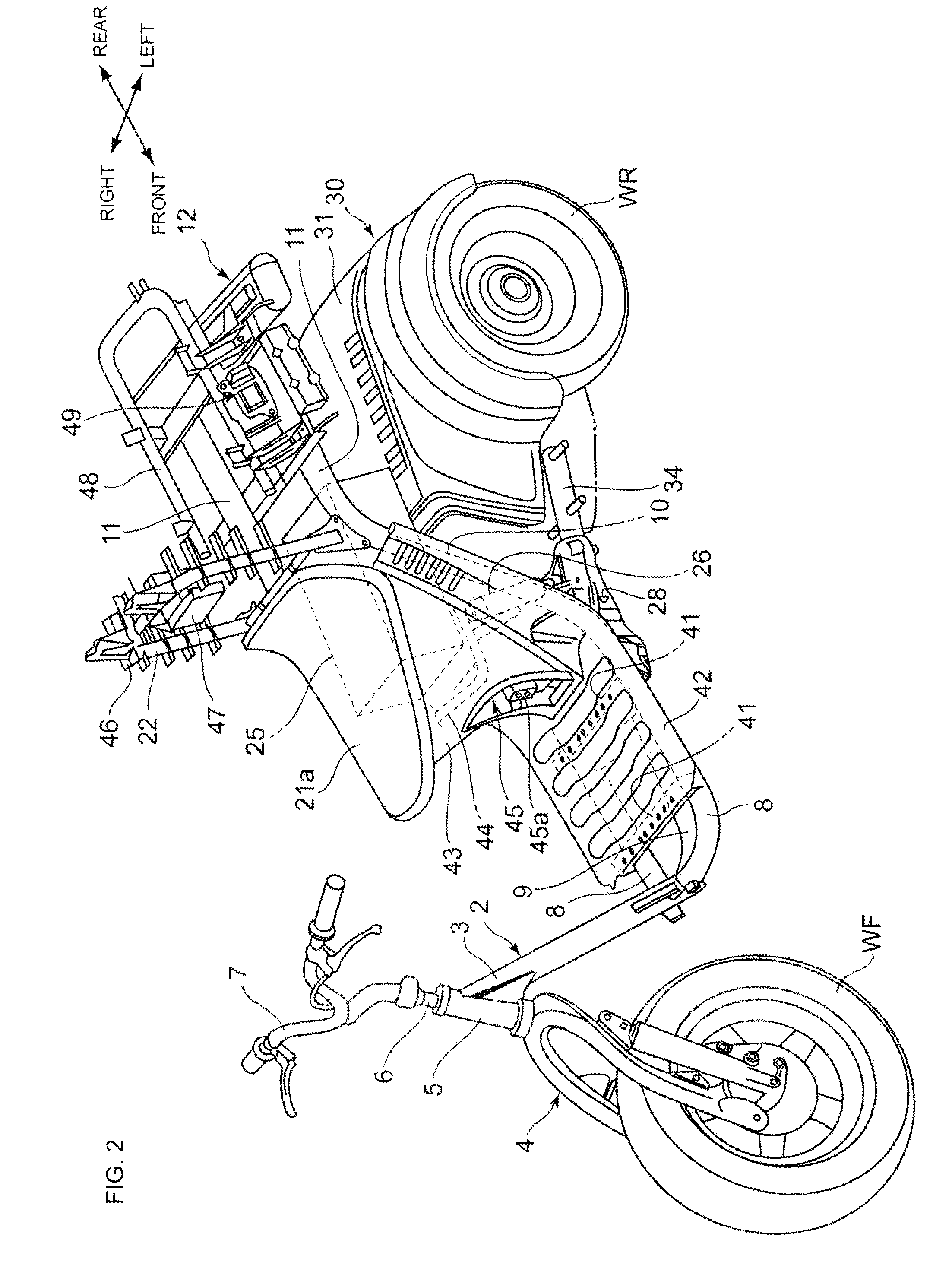

Vehicle With Electric Transaxle

ActiveUS20130075183A1Increase torqueSimplified and economized in structureElectric propulsion mountingGearingElectrical batteryEngineering

A vehicle comprises a transaxle, a battery and a load carrying bed. The transaxle includes a casing incorporating a drive train and supporting an axle and includes an electric motor mounted on the casing to drive the axle via the drive train. The battery is provided for supplying electric power to the electric motor. The transaxle and the battery are disposed below the load carrying bed so as to overlap the load carrying bed when viewed in plan.

Owner:KANZAKI KOKYUKOKI MFG

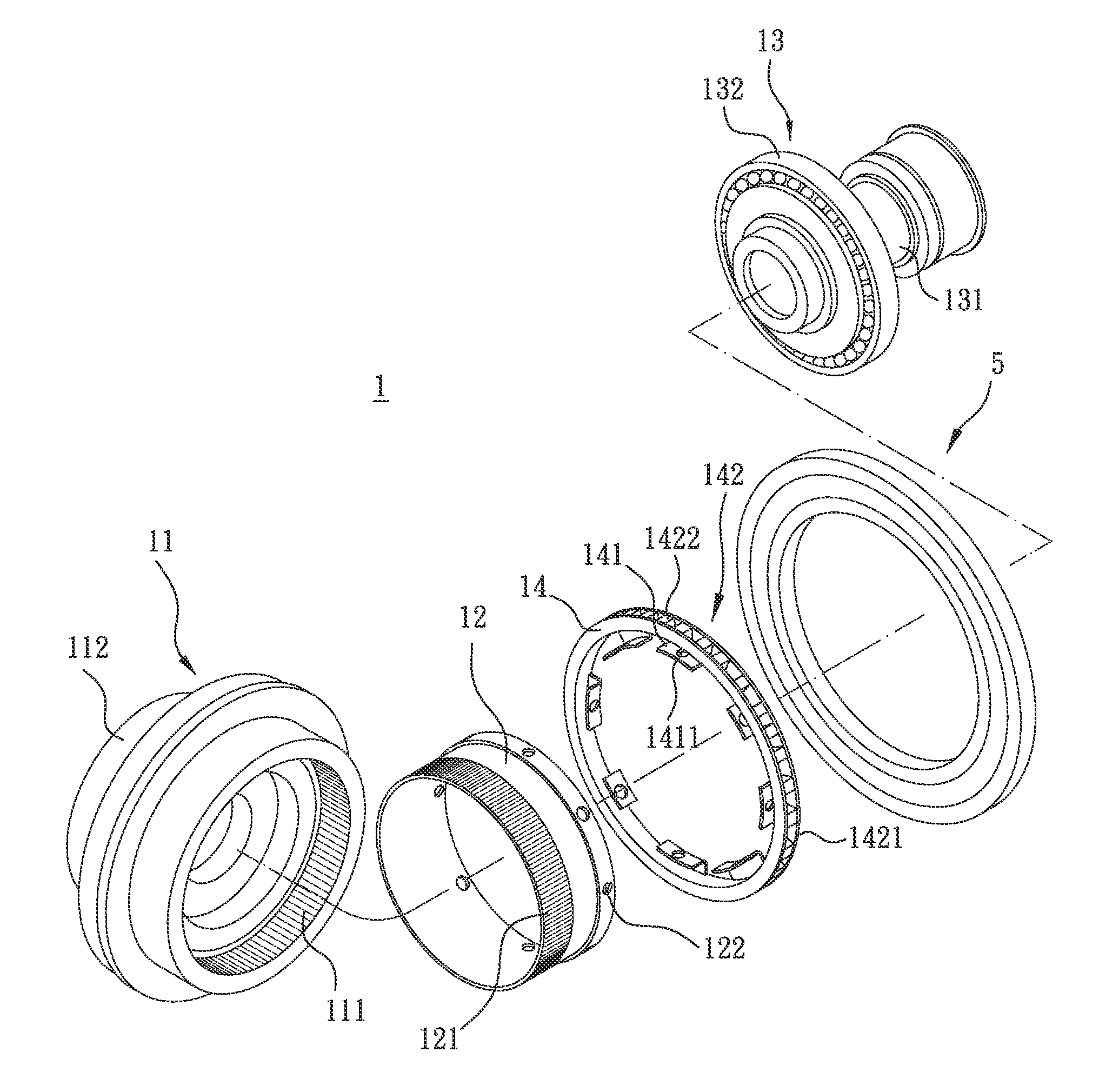

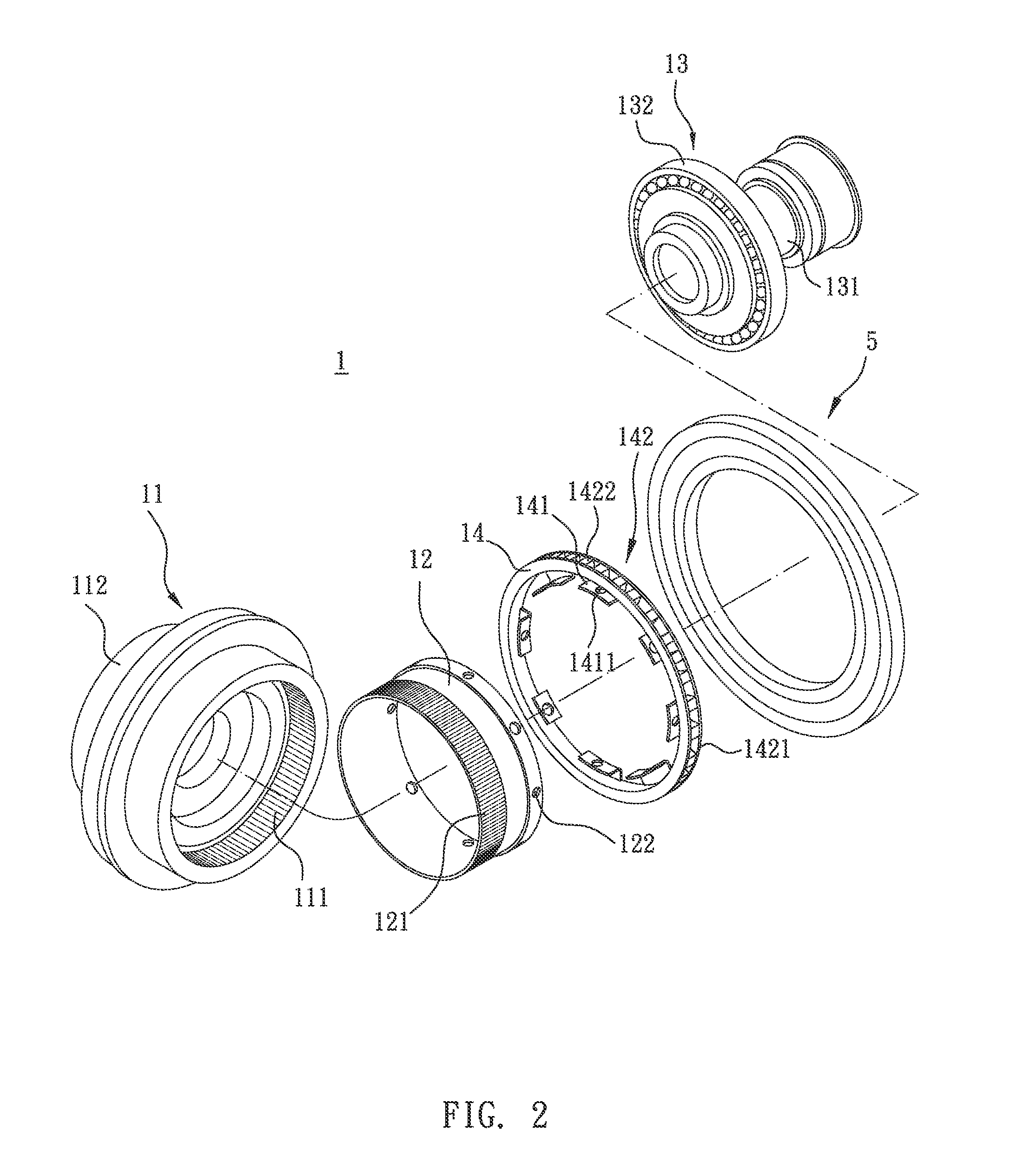

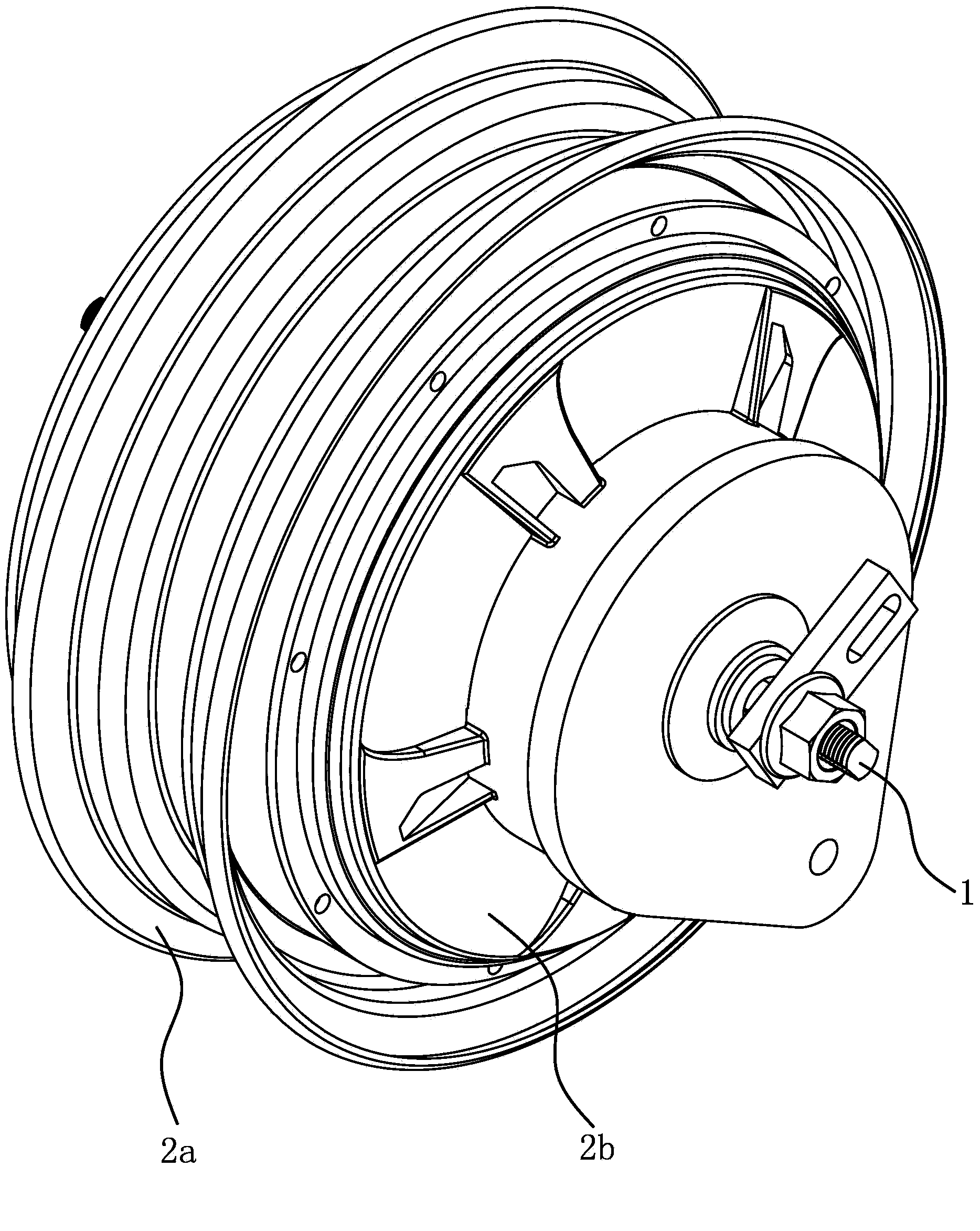

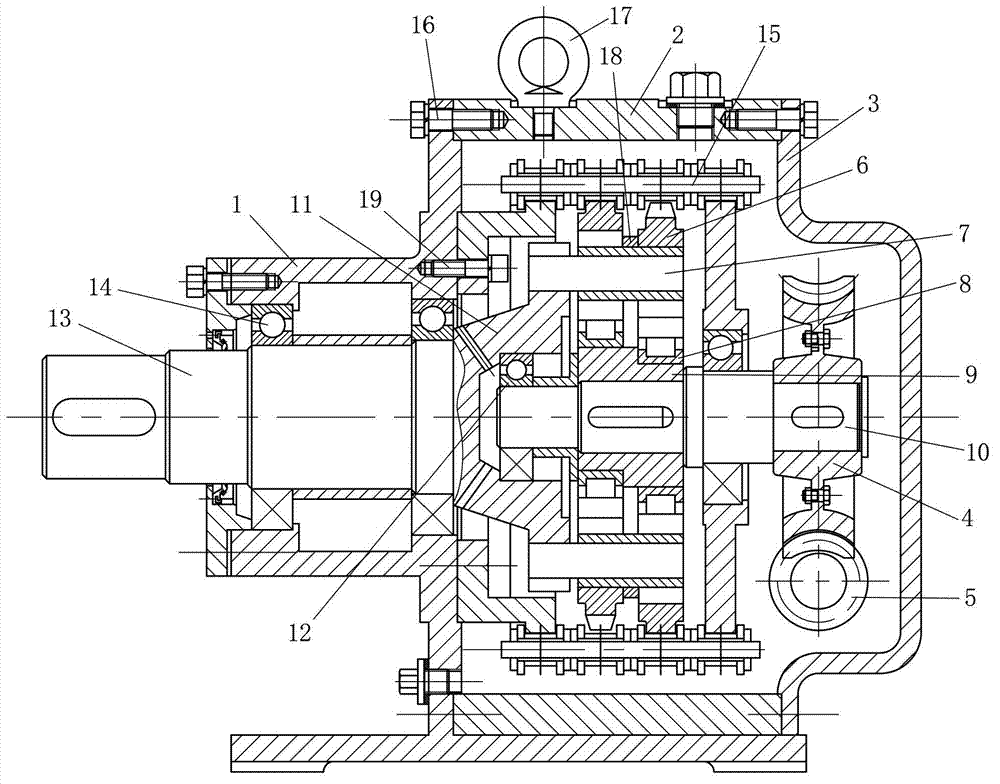

Hub assembly of disc type variable-speed motor of electric vehicle

InactiveCN102142749AReduce output speedIncrease output powerMagnetic circuit rotating partsElectric machinesEngineeringElectric vehicle

Owner:WEIFANG SHUAIKE NEW ENERGY VEHICLE TECH

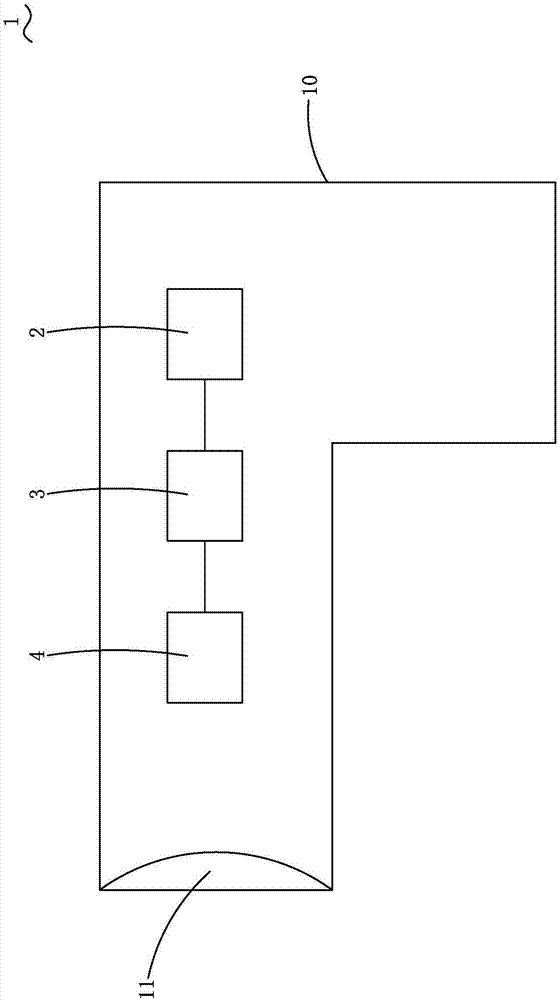

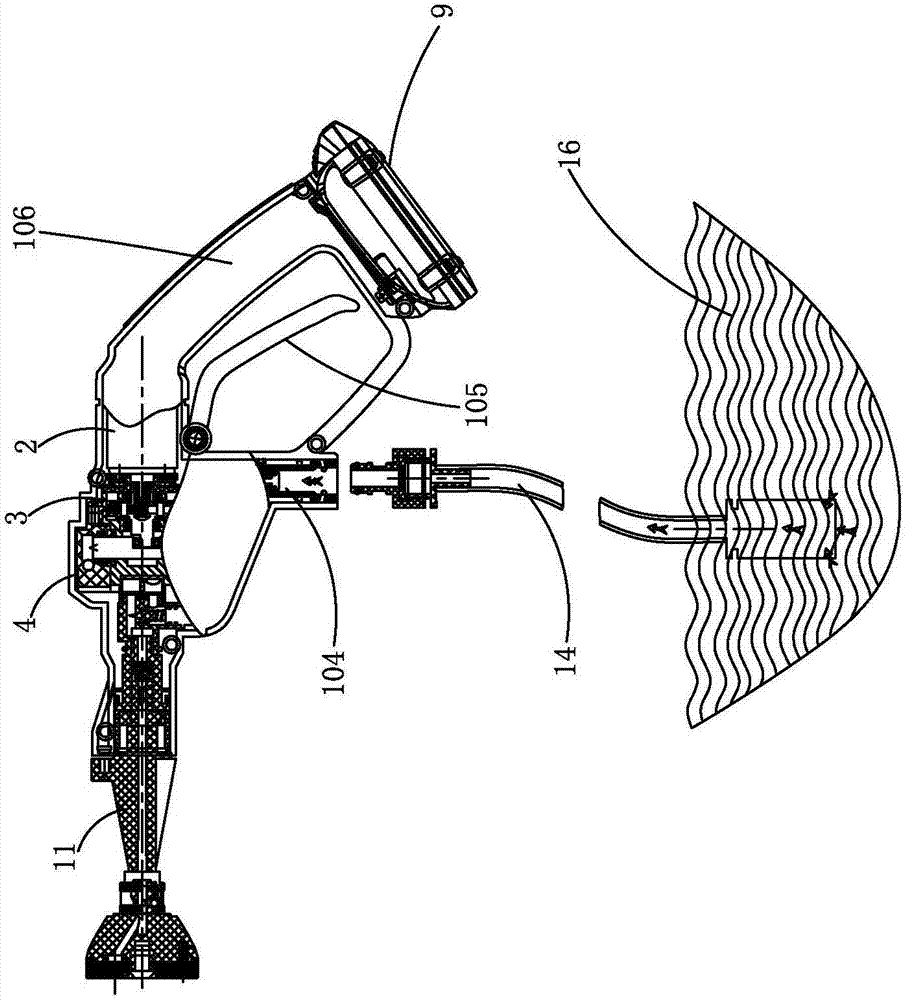

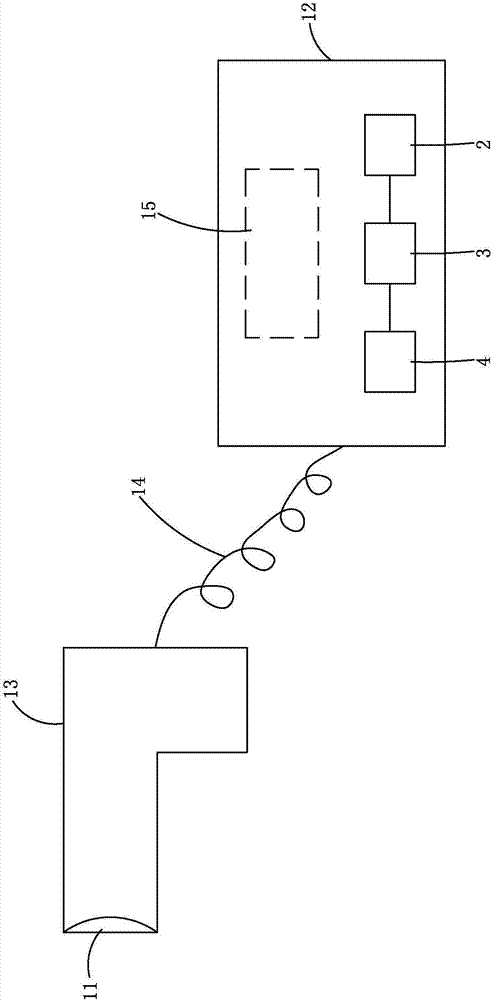

Pump unit and hand-held type high-pressure cleaning machine

PendingCN107061213AReduce volumeSimple structurePositive displacement pump componentsRotary piston pumpsReciprocating motionEngineering

The invention relates to a pump unit applied to a high-pressure cleaning machine. The pump unit comprises water inlet chambers, water outlet chambers and a central chamber, wherein the central chamber communicates with the water inlet chambers and the water outlet chambers. The pump unit further comprises a plunger and an eccentric mechanism, wherein the plunger is arranged in the central chamber, and the eccentric mechanism is connected with the plunger; and the plunger is driven by the eccentric mechanism to perform reciprocating motion in the central chamber.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

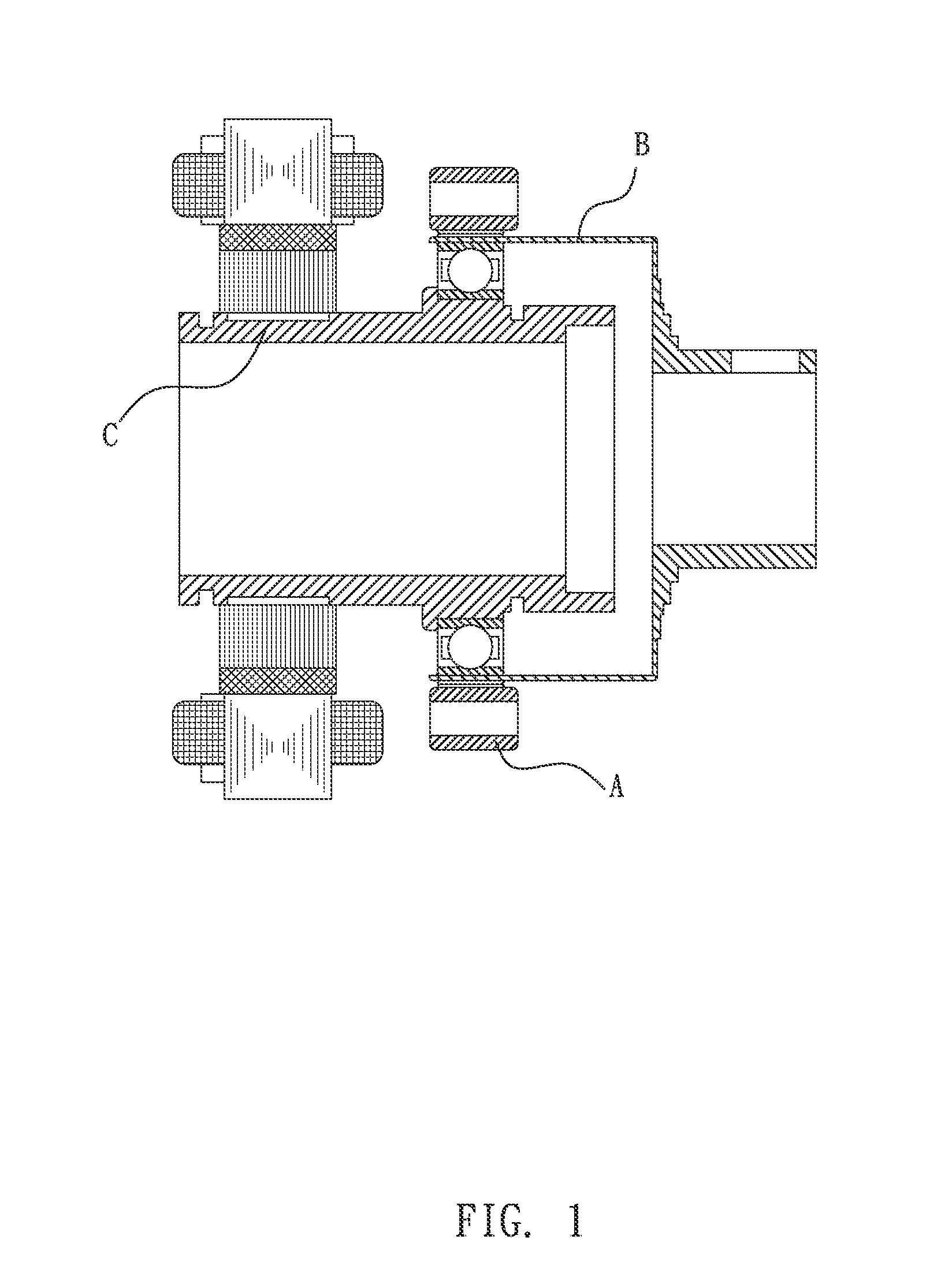

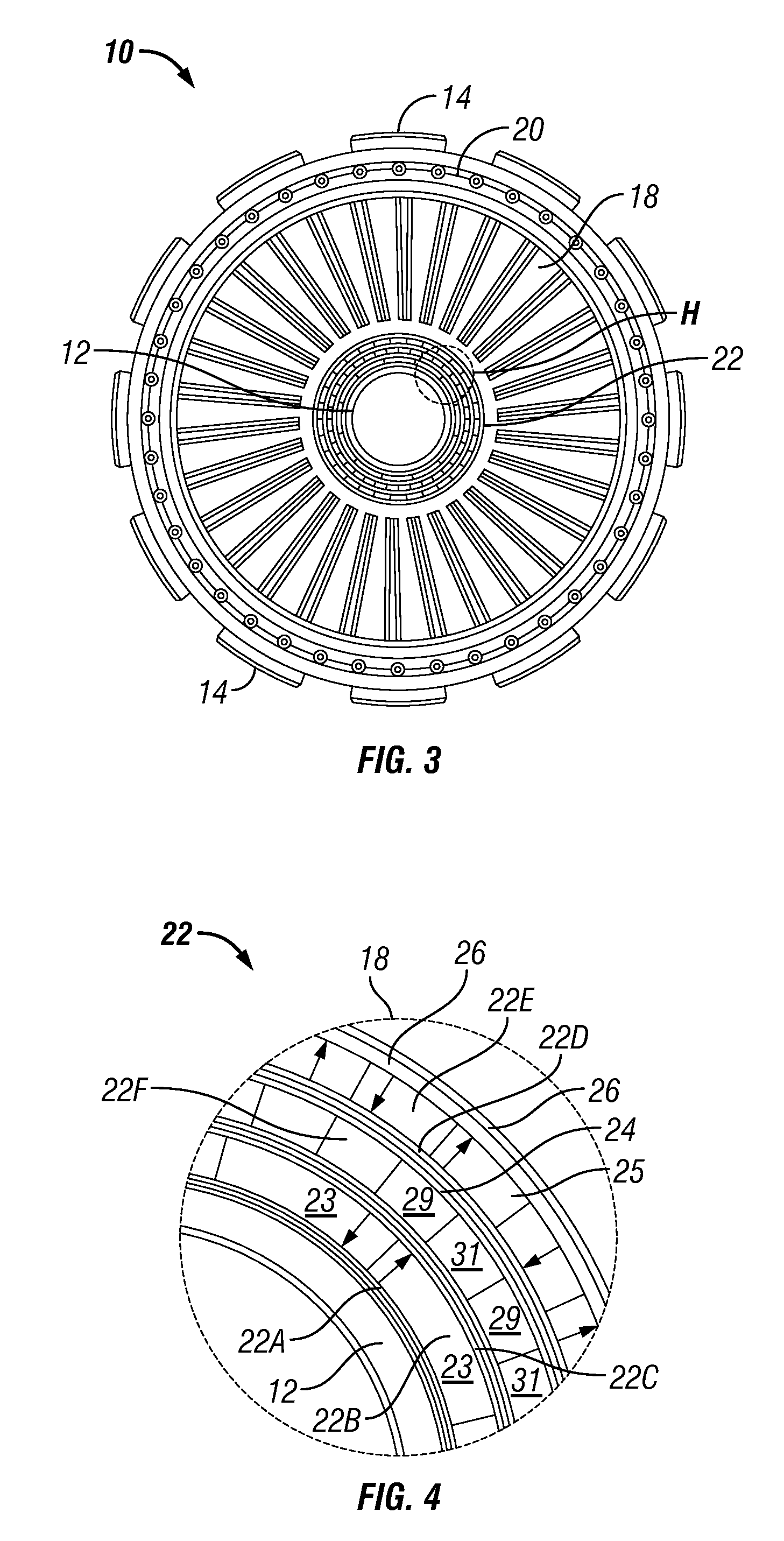

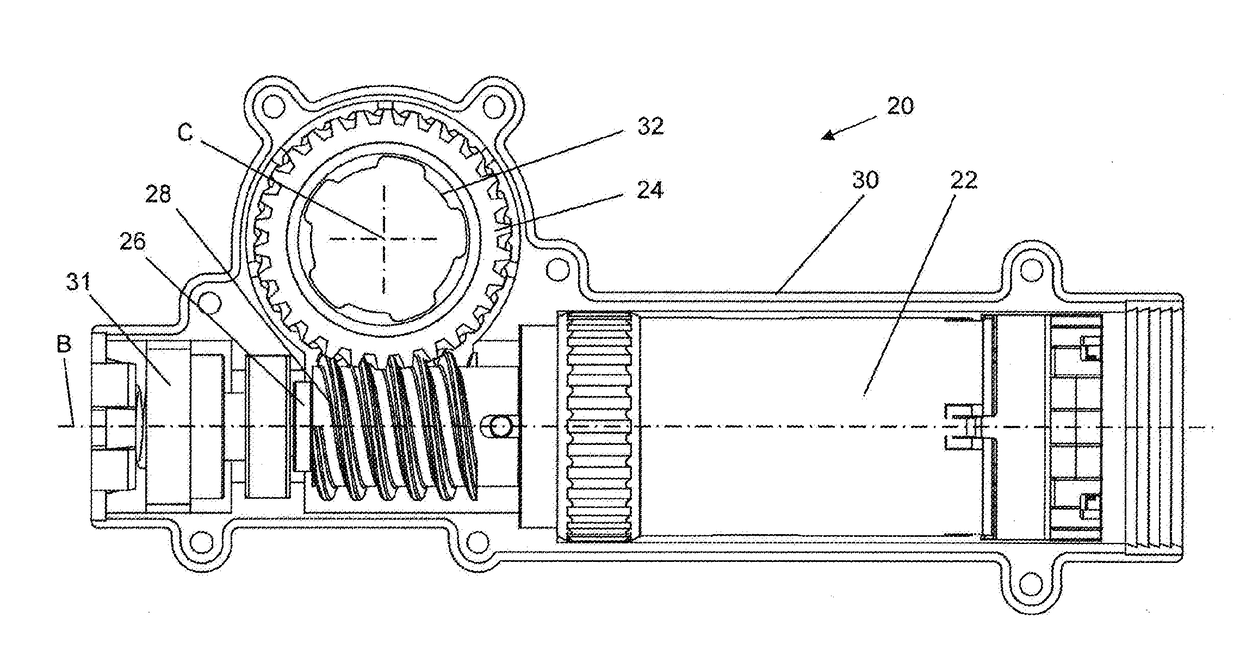

Harmonic reducer with clutch function

ActiveUS20140083245A1Overcomes drawbackReduce usageToothed gearingsFreewheel clutchesHarmonicEngineering

A harmonic reducer with clutch function includes a circular spline, a mounting base, a flexspline and a wave generator. When a power source drives the wave generator to rotate in a first direction, a one-way clutch engages to lock the mounting base so as to deform the flexspline and hence rotate the circular spline in the first direction. When an external force is applied to the output shaft in the first direction, the mounting base is driven by the flexspline so the one-way clutch disposed thereon is disengaged by a force in a second direction. At this moment, the rotation speed of the wave generator is equal to zero relative to the flexspline, so the wave generator can be driven by the circular spline to rotate along with the flexspline, and the central axel of the wave generator can be driven to rotate as well.

Owner:YEH CHUN SHEN

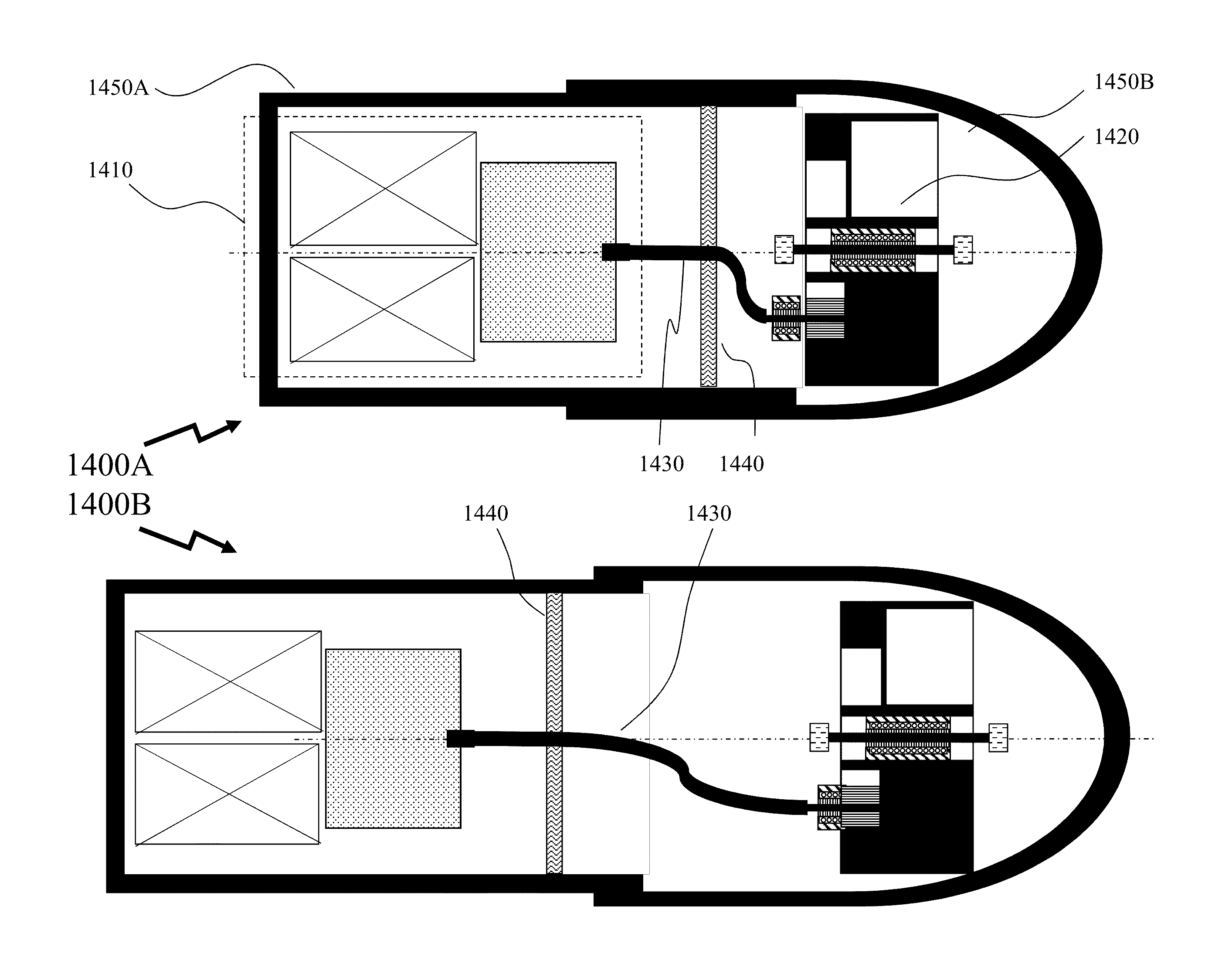

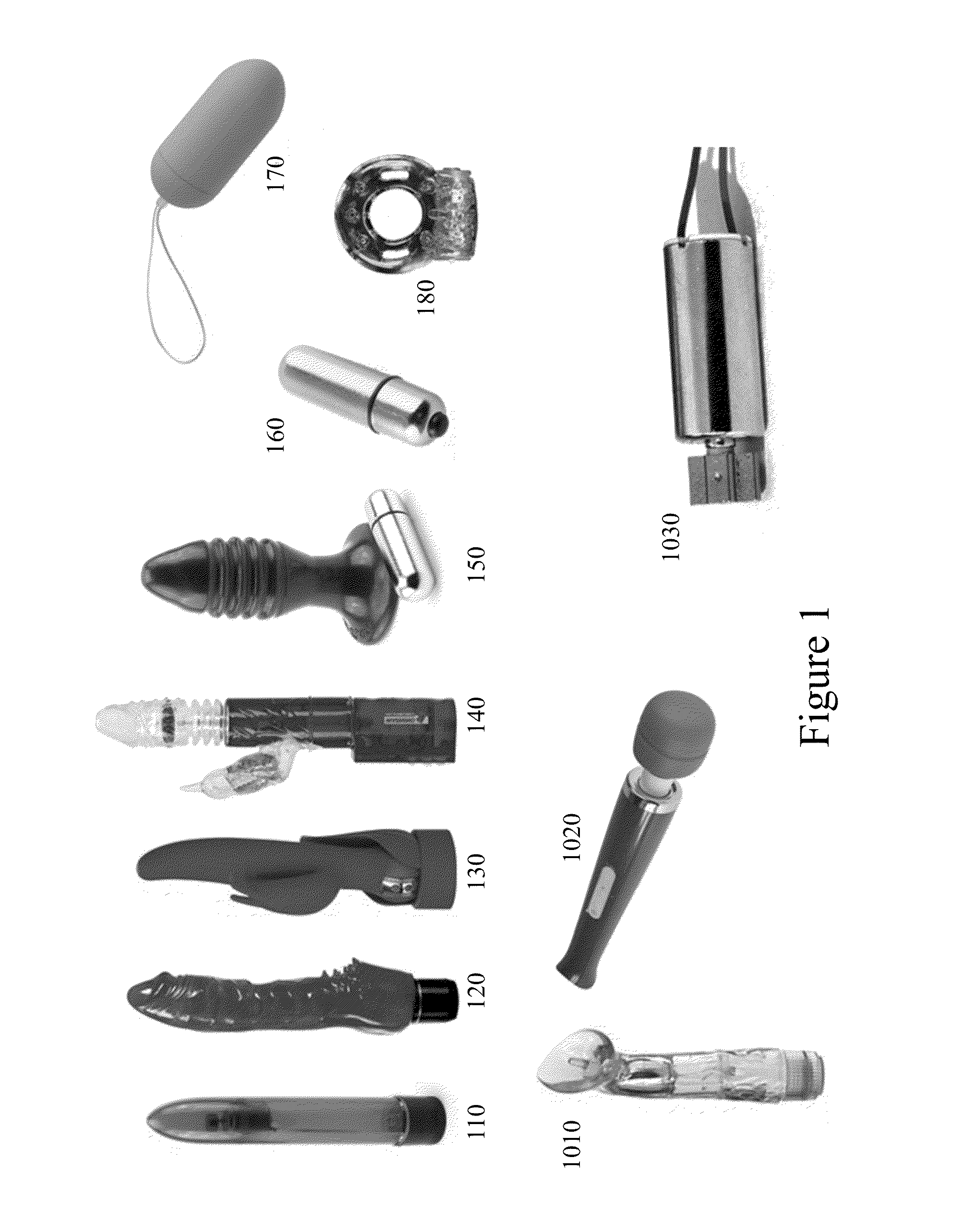

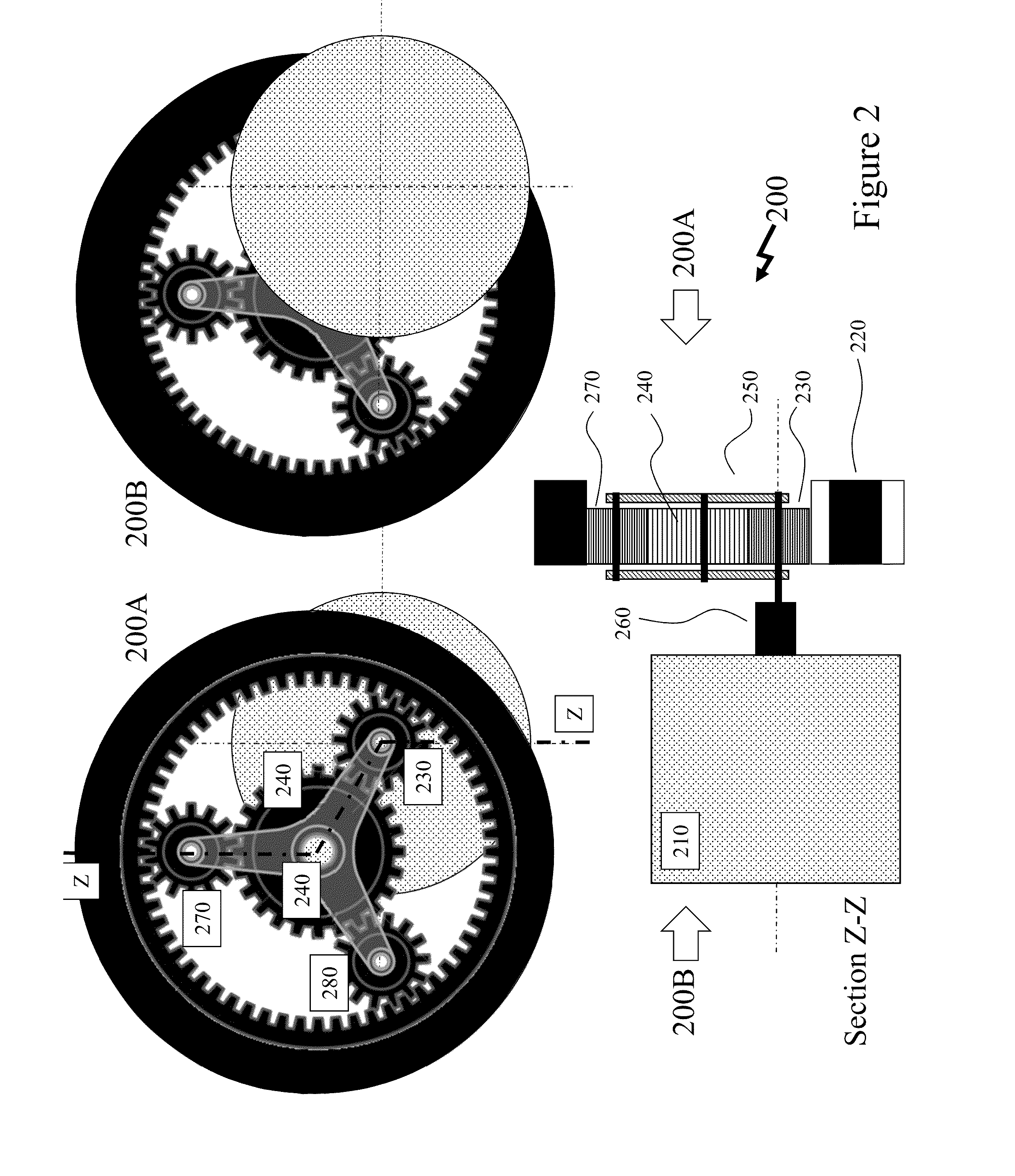

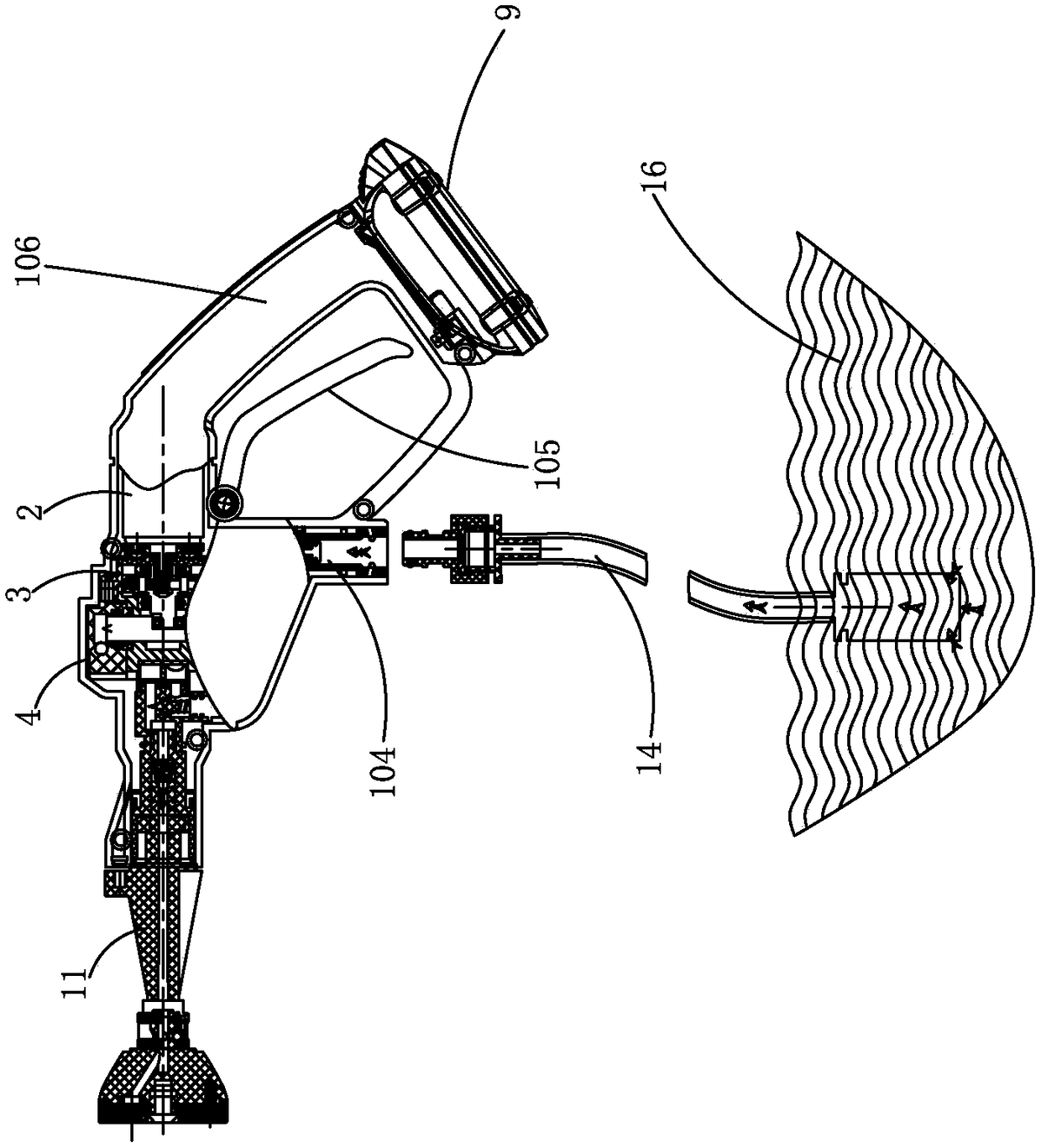

Methods and devices relating to vibratory impact adult devices

ActiveUS20160015596A1Low costHigh amplitude vibrationVibration massageNon-surgical orthopedic devicesEngineeringFrequency characteristic

Small high efficiency motors in order to produce large amounts of power must be operated such that they are running at high speed outside the desired vibration range for sexual stimulation. Accordingly, designs allowing for the appropriate gearing to allow heavy weights to be spun with small diameter and high efficiency whilst not increasing the outer diameter of an adult device are disclosed. Beneficially embodiments of the invention provide users with adult devices providing high impact (amplitude) vibration in a range of physical geometries compatible with providing internal and / or external stimulation which can also be offered at low cost and / or low manufacturing cost with extended operating life. Additionally, design flexibility via axial designs, non-axial designs, flexible drive designs, aperiodic drive designs, and linearly driven designs provide design solutions for implementing vibrators with low cost, high impact, targeted frequency characteristics, increased efficiency, and increased power.

Owner:OBOTICS INC

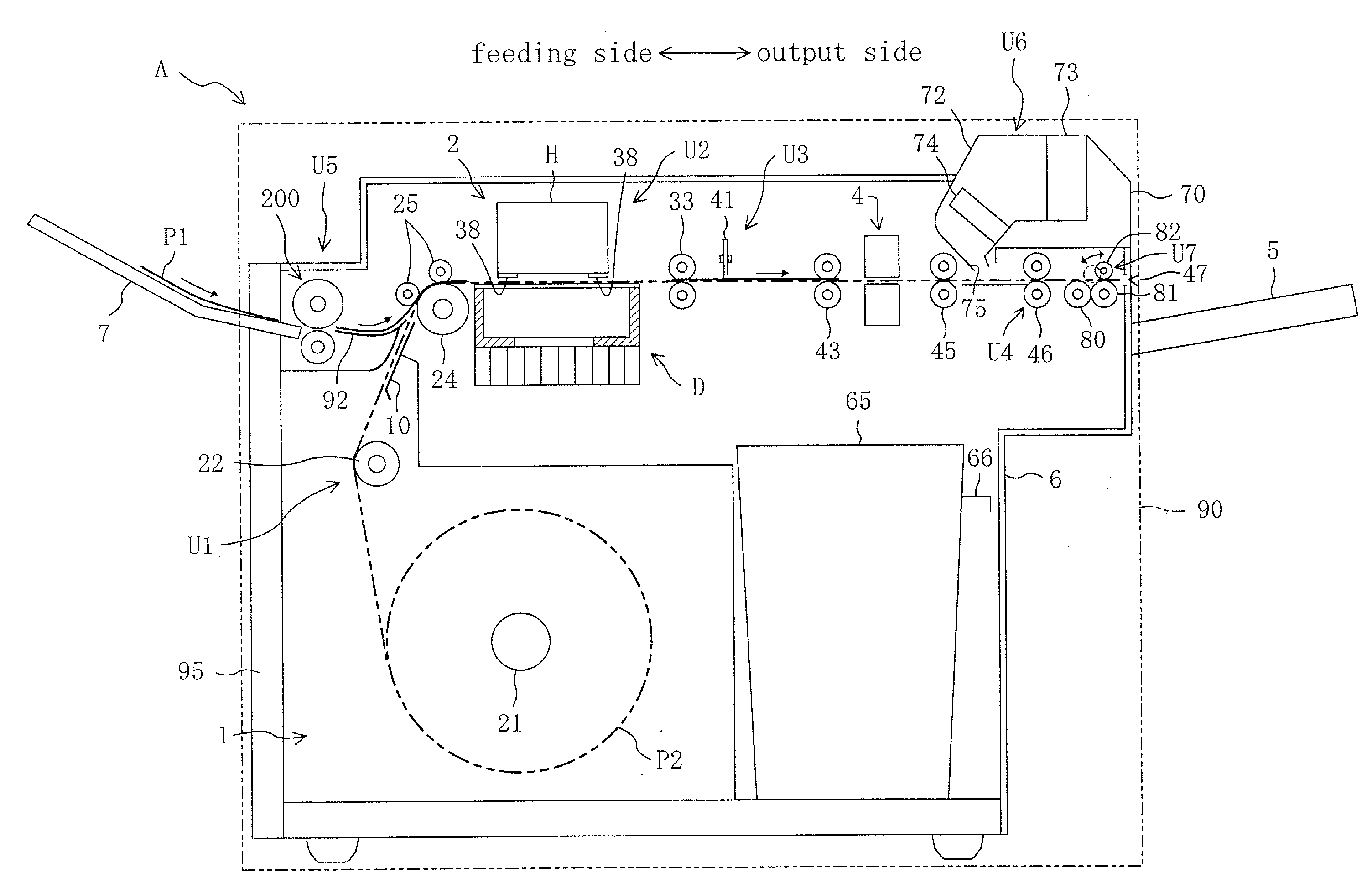

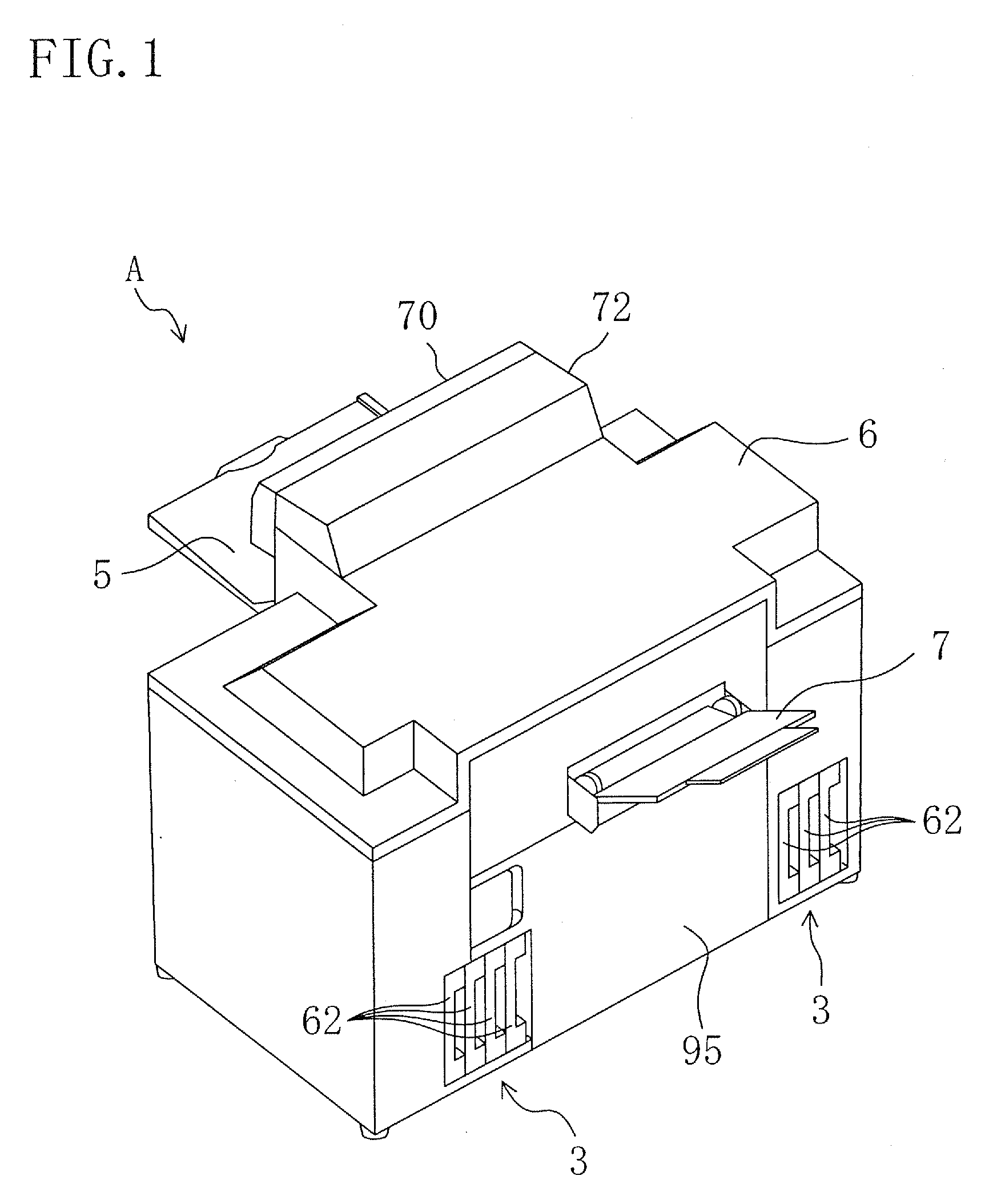

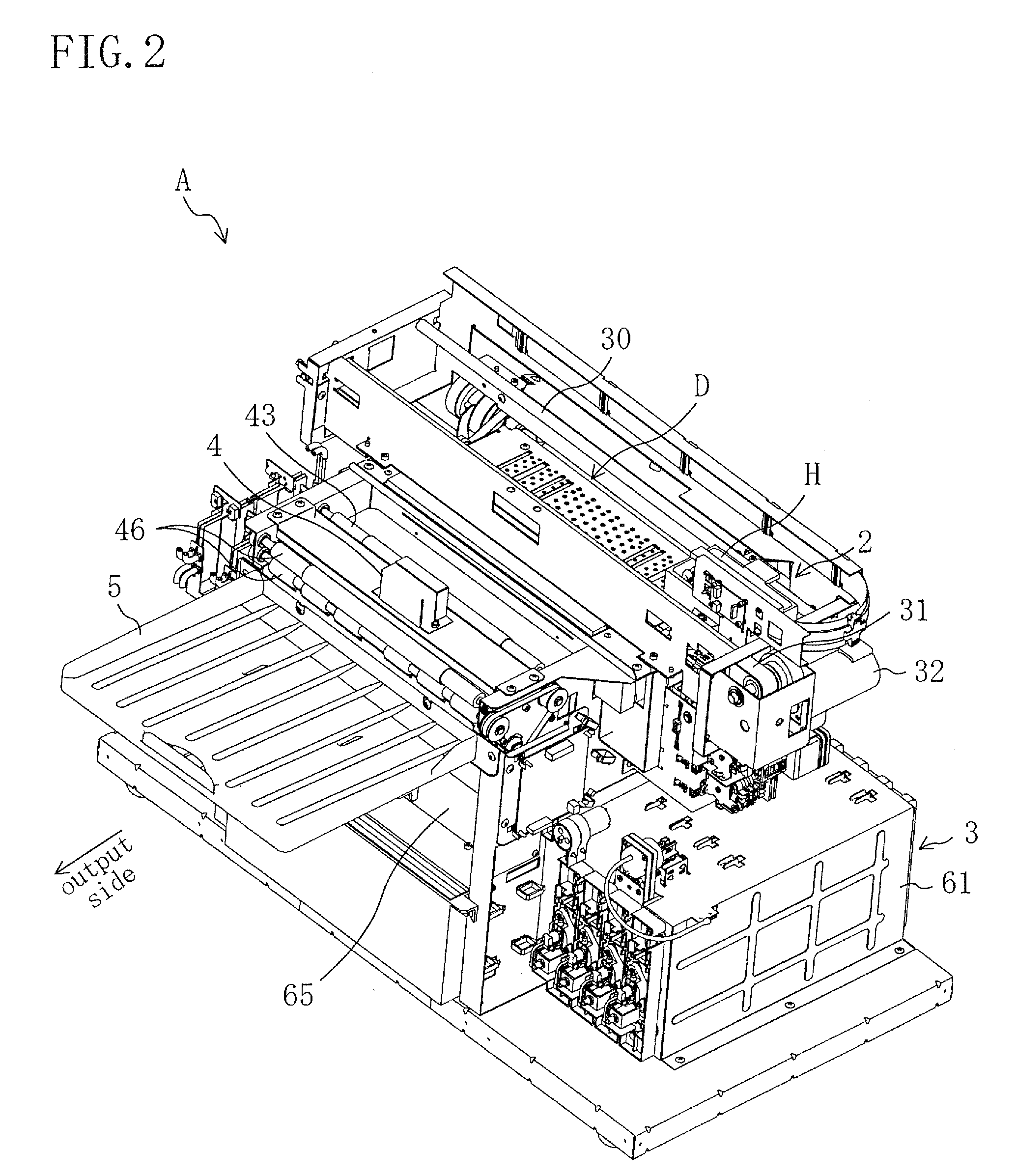

Paper output mechanism

InactiveUS20090189337A1Improve variationIncrease the output speedElectrographic process apparatusArticle deliveryPulp and paper industryActuator

A paper output mechanism includes: a roller pair composed of a first roller and a second roller travelable around the first roller and configured, when the second roller is in a first position, to output a piece of paper to a paper placement part by pinching the piece of paper between the first and second rollers and driving at least one of the first and second rollers into rotation with an actuator; and a roller position changing mechanism for switching the second roller between the first position and a second position located closer to the paper output side than the first position. When the trailing edge of the piece of paper is sent out to the paper placement part, the roller position changing mechanism changes the second roller from the first position to the second position.

Owner:NORITZ CORP

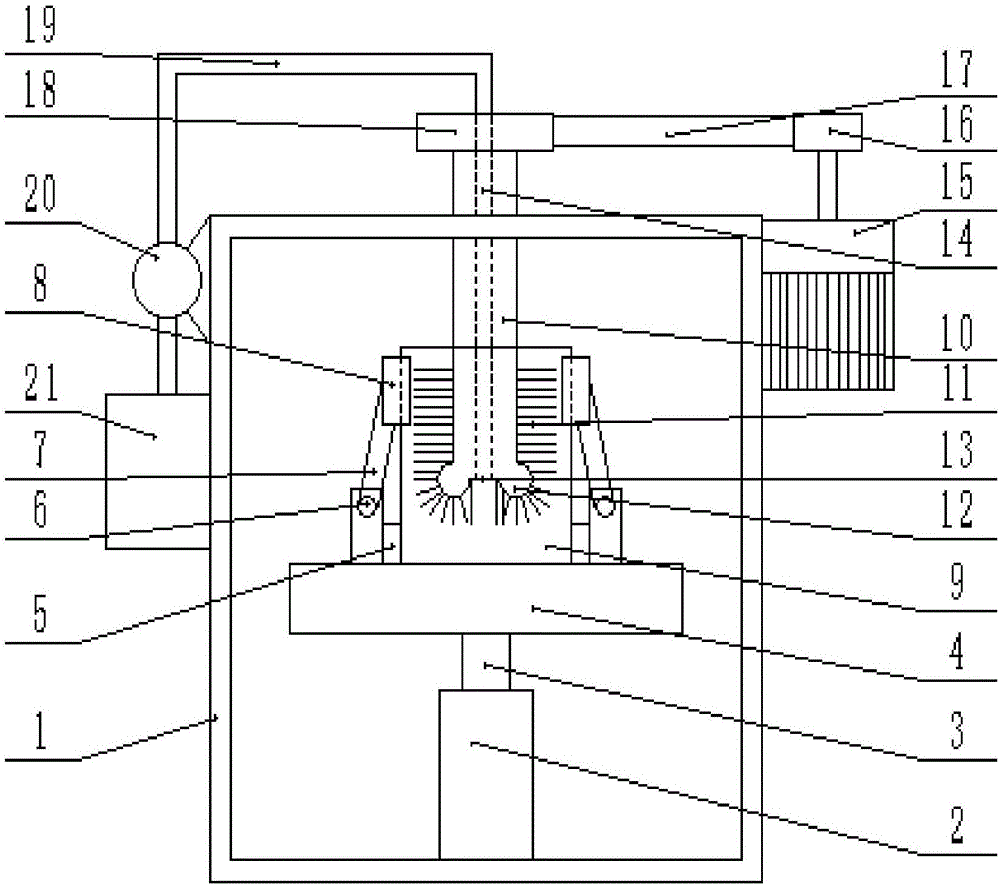

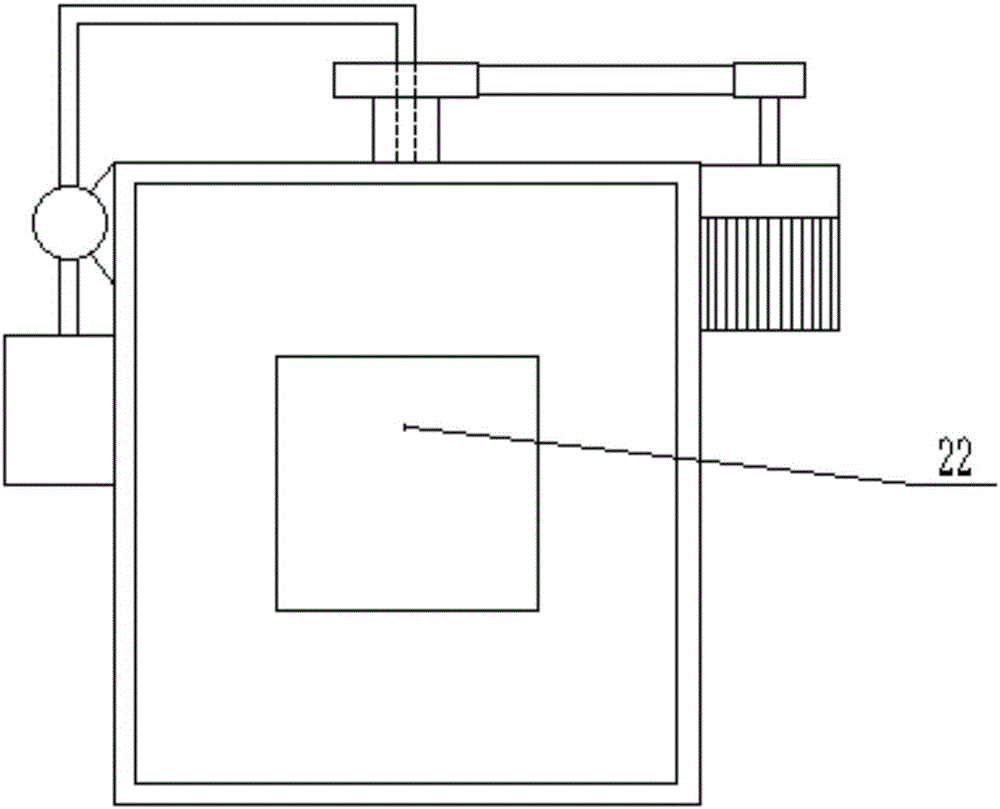

Cup cleaning device

InactiveCN106670196AAchieve cleaningGuaranteed cleaning effectHollow article cleaningEngineeringElectric motor

Owner:茹朝贵

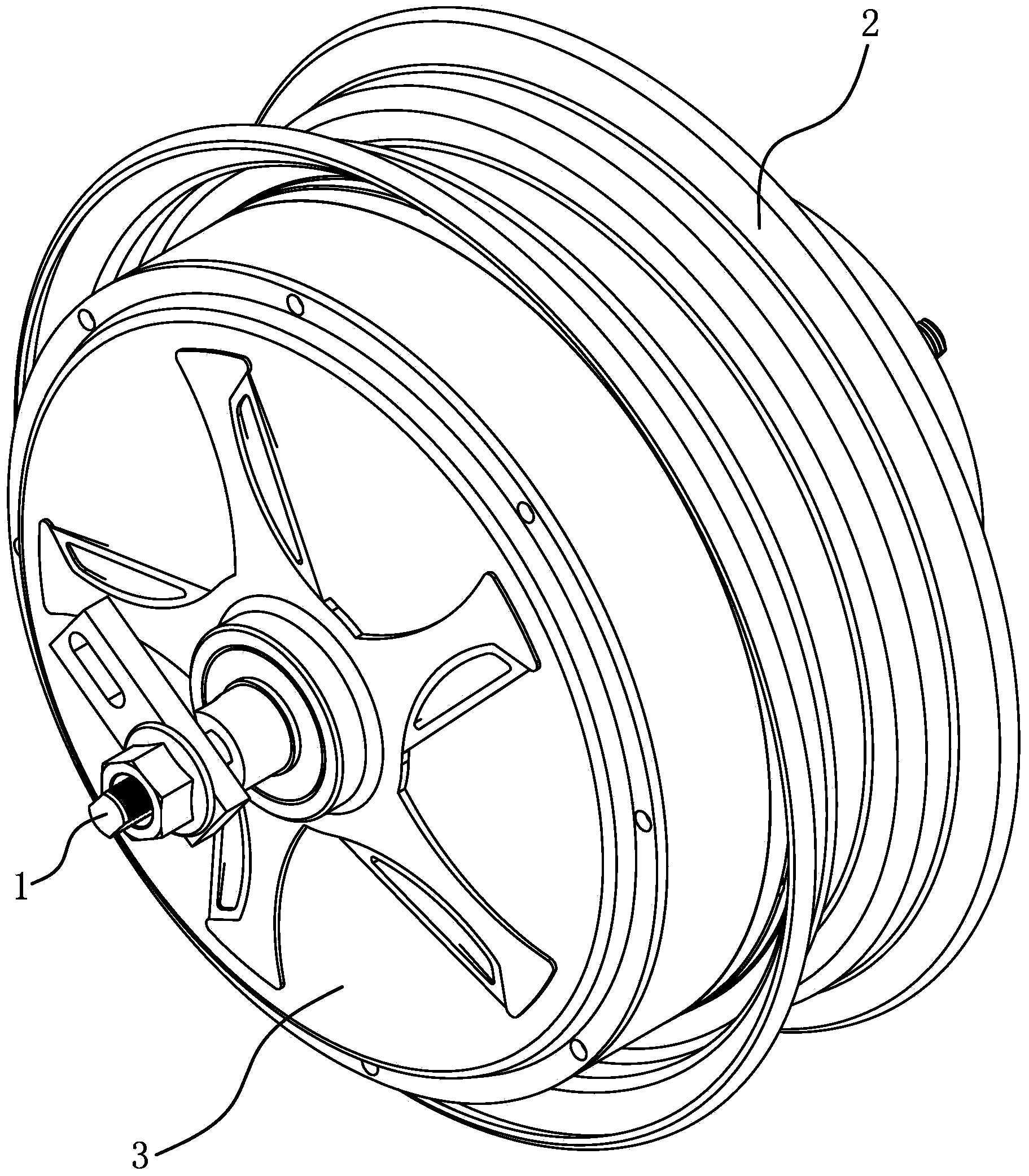

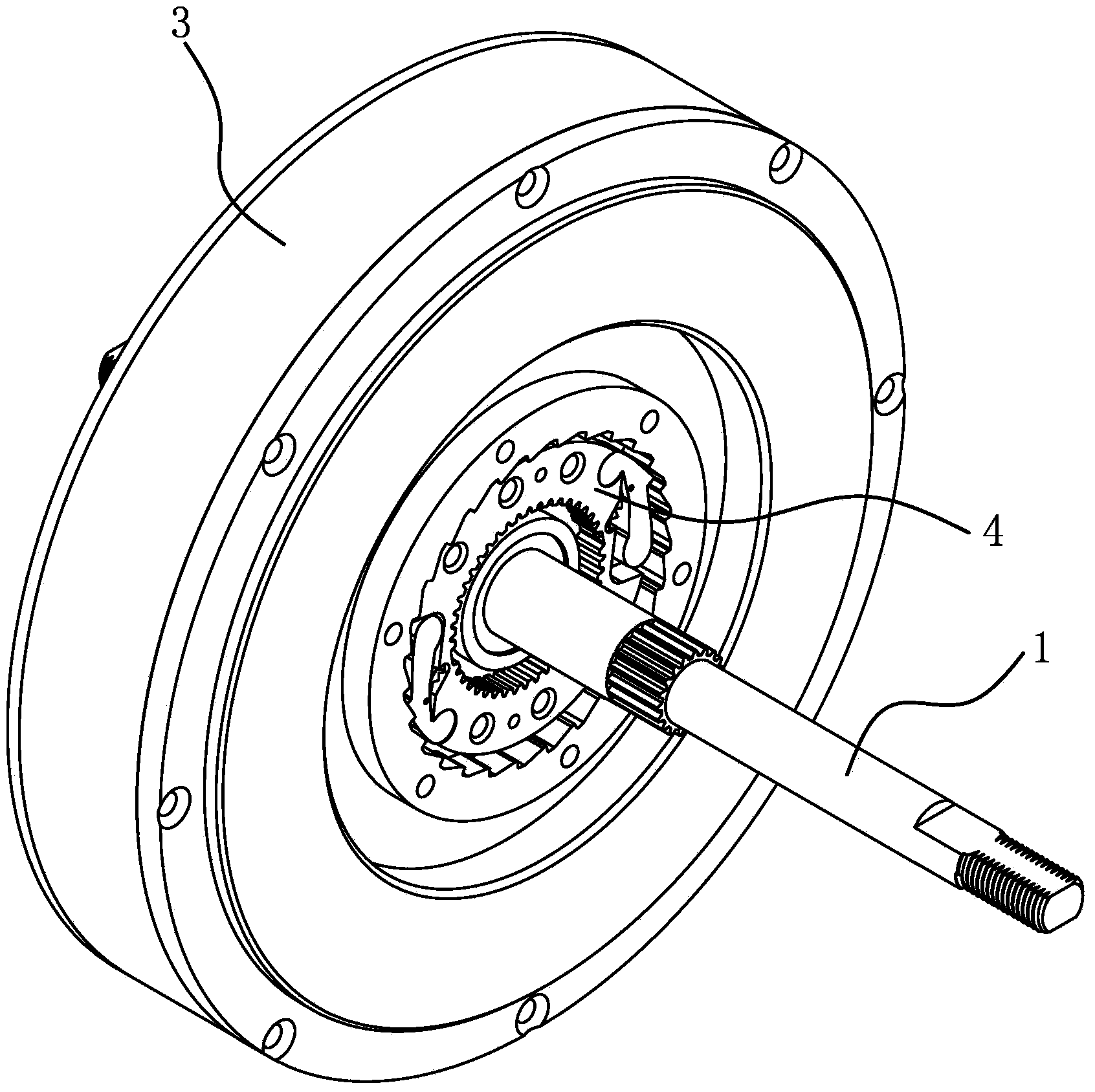

Electric vehicle variable speed drive hub

ActiveCN103840604AAvoid enteringEasy to installSpeed controllerElectric devicesMechanical engineering technologyReducer

The invention provides an electric vehicle variable speed drive hub, and belongs to the technical field of machine engineering. The electric vehicle variable speed drive hub solves the problem that an existing electric vehicle variable speed drive hub is poor in heat dissipation performance, loud in noise and low in output efficiency. The electric vehicle variable speed drive hub comprises a fixing shaft, a hub steel ring, a motor and a speed reducer, wherein the hub steel ring is positioned on the fixing shaft; the speed reducer is located in the hub steel ring, and the motor is located on one side of the speed reducer and located outside the hub steel ring; the motor is composed of a stator and a rotor, the stator is fixedly connected with the fixing shaft, and the rotor is positioned on the fixing shaft; the speed reducer comprises a box body, an input gear shaft, an output gear shaft and an overrun clutch, the box is fixedly connected with the fixing shaft, the input gear shaft is connected with the rotor, and the output gear shaft is fixedly connected with the hub steel ring; the rotor and the hub steel ring are connected through the overrun clutch. The electric vehicle variable speed drive hub has the advantages of being good in heat dissipation effect, high in universality and low in noise.

Owner:临海赫士利电动科技有限公司

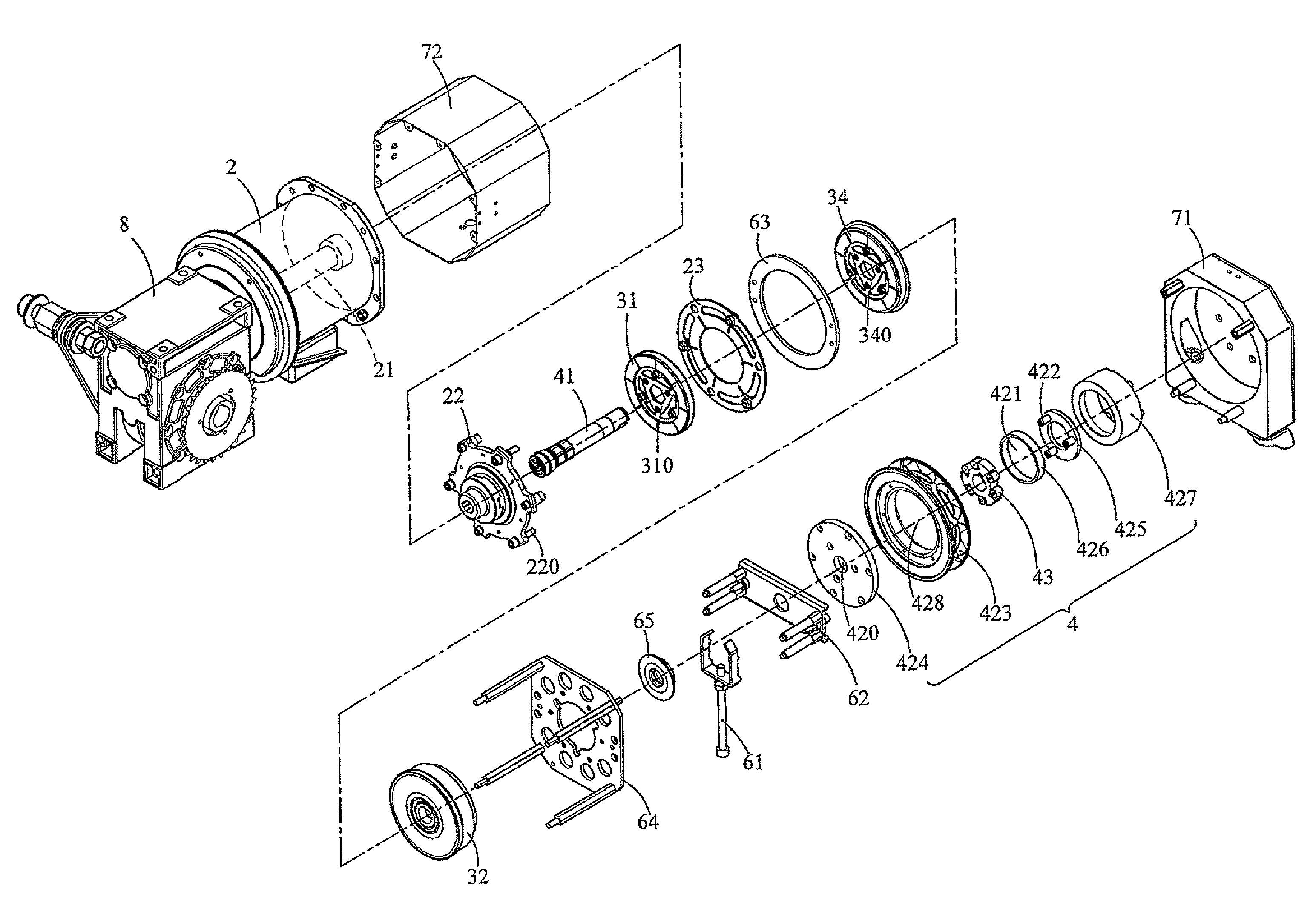

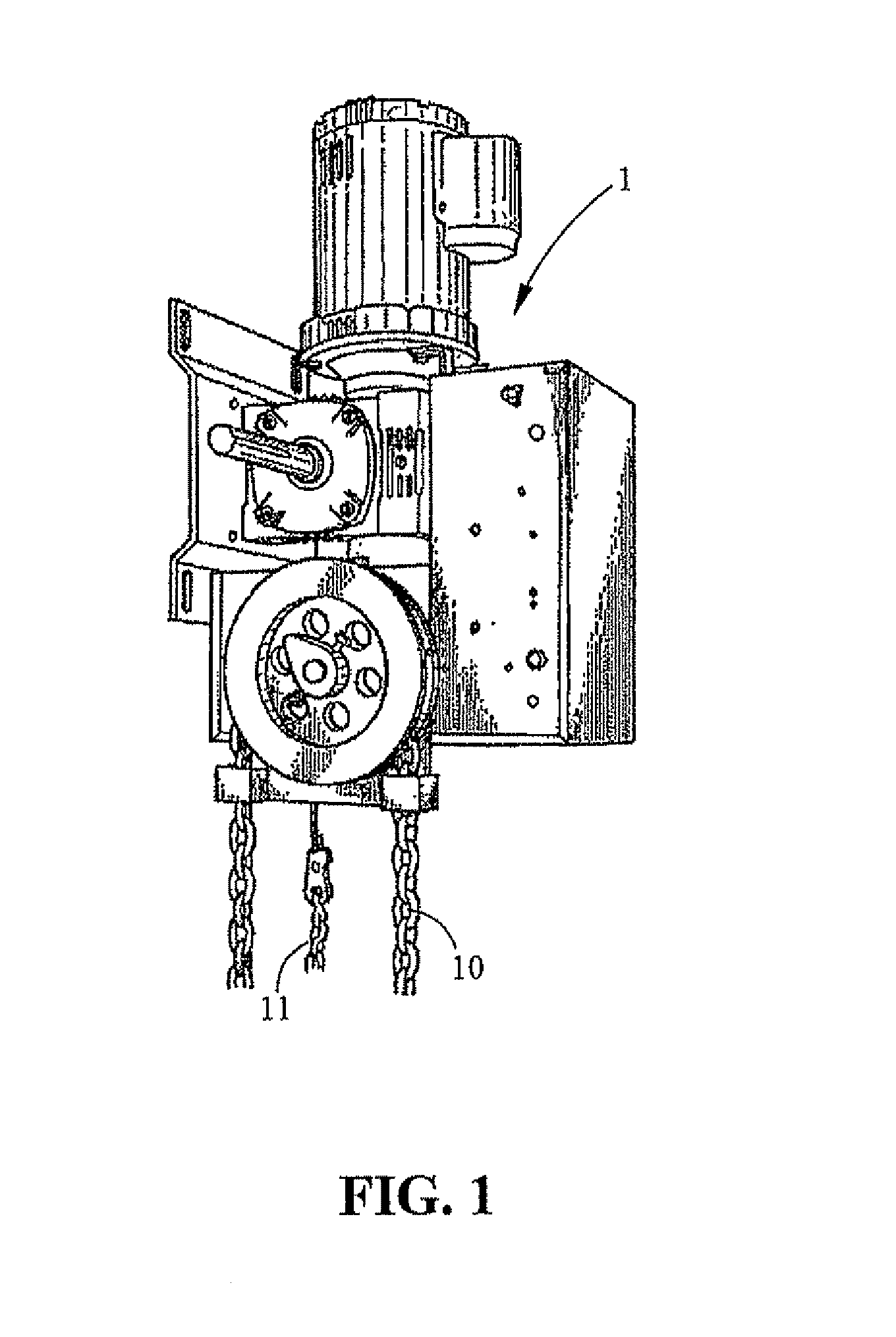

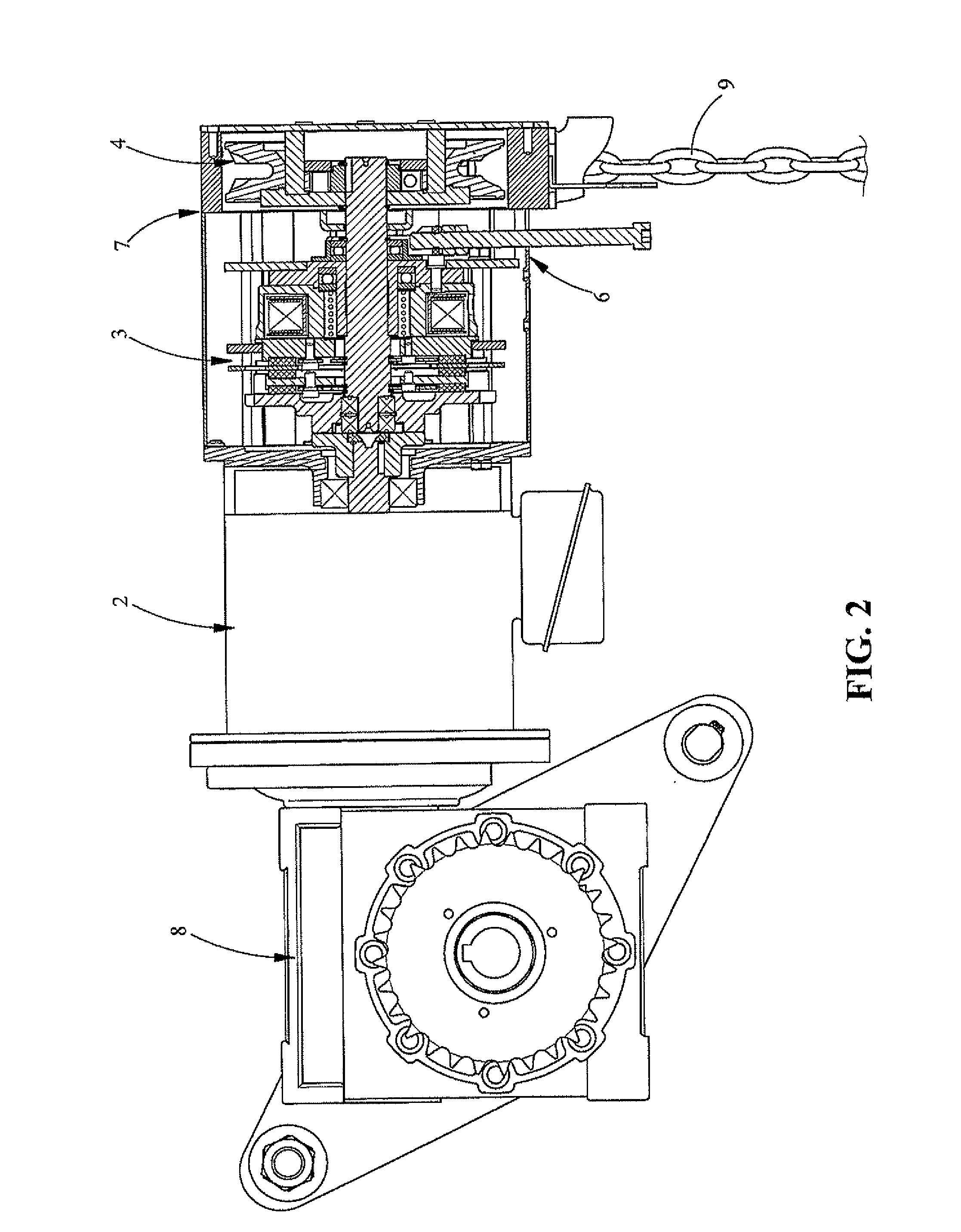

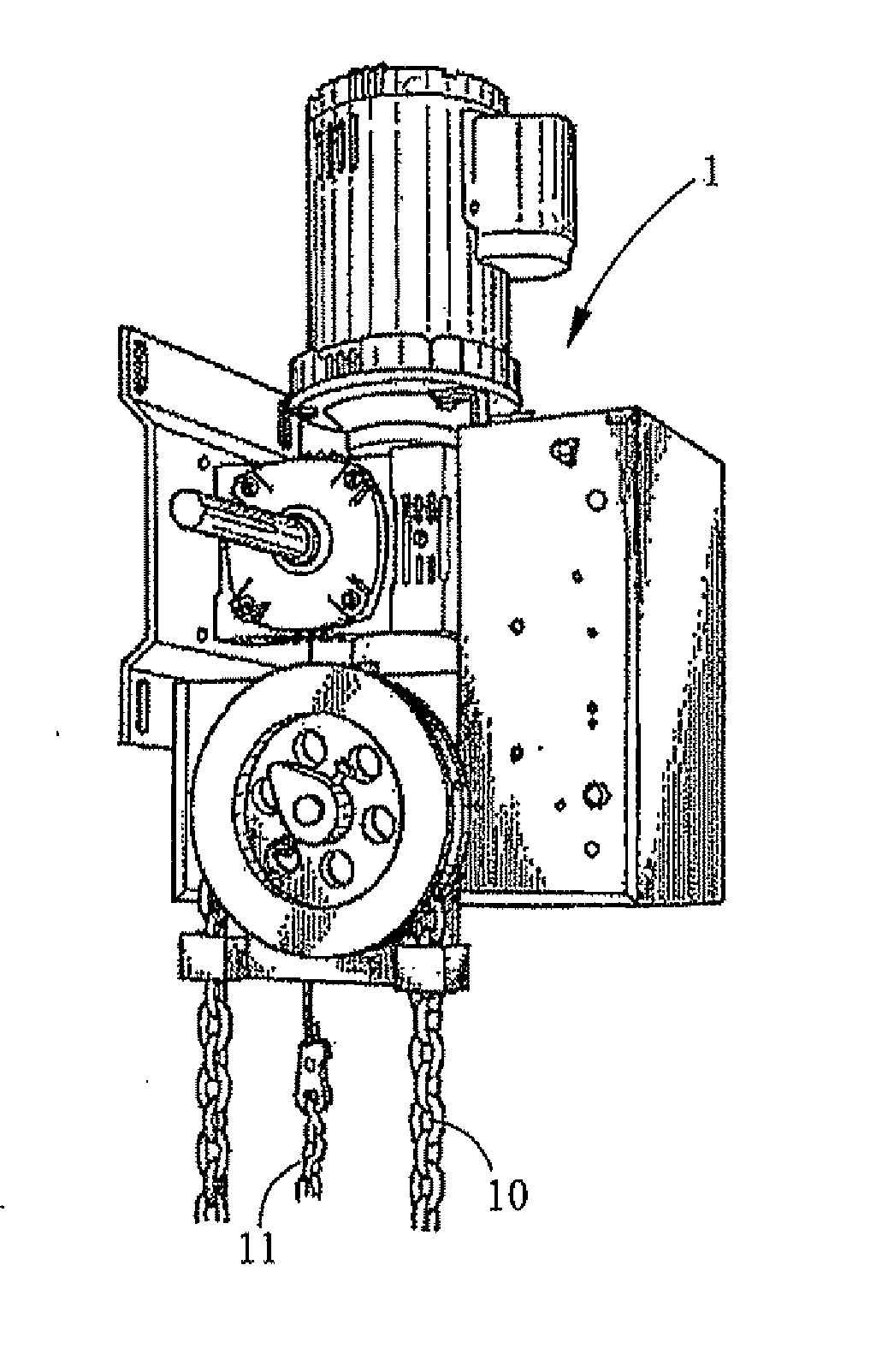

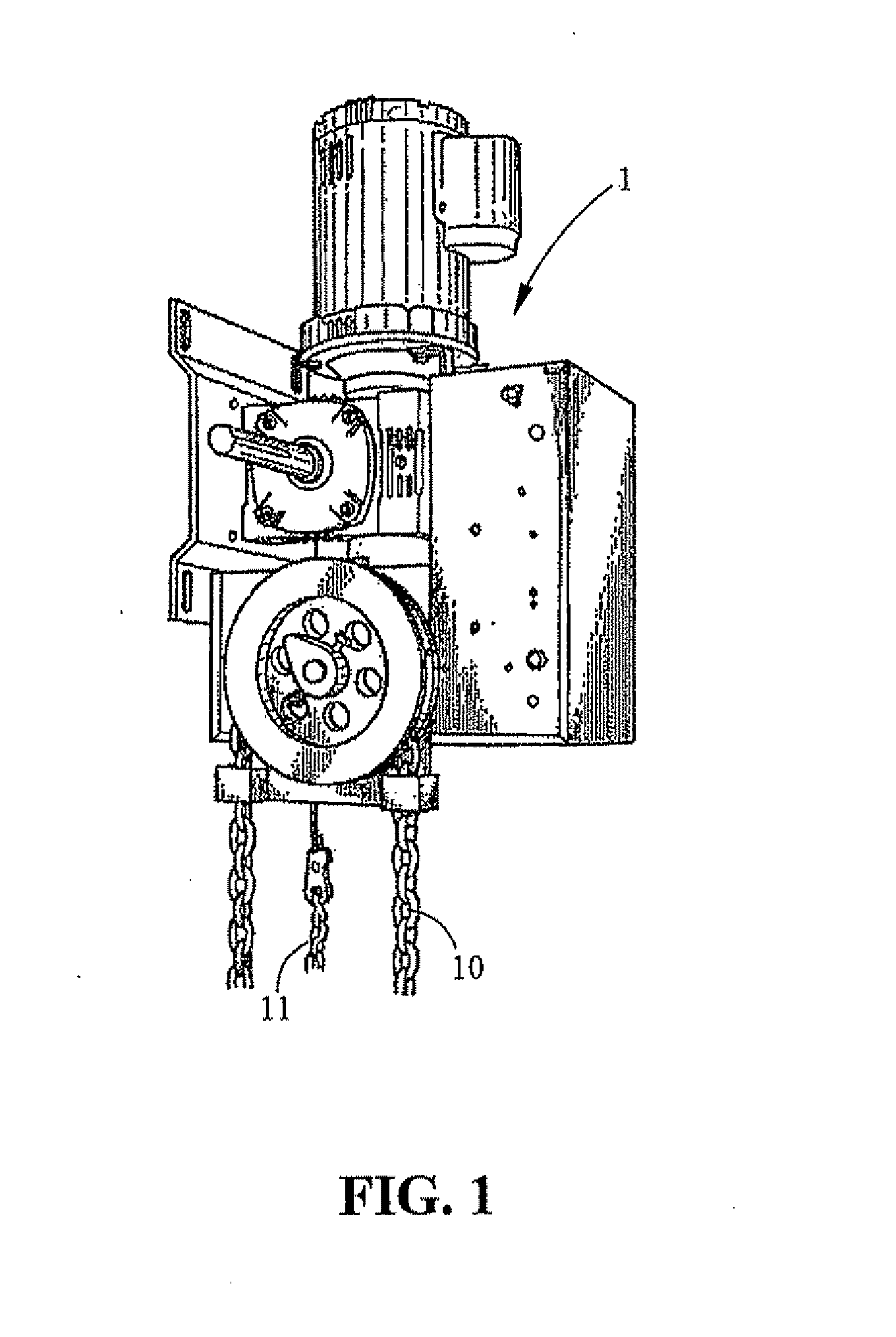

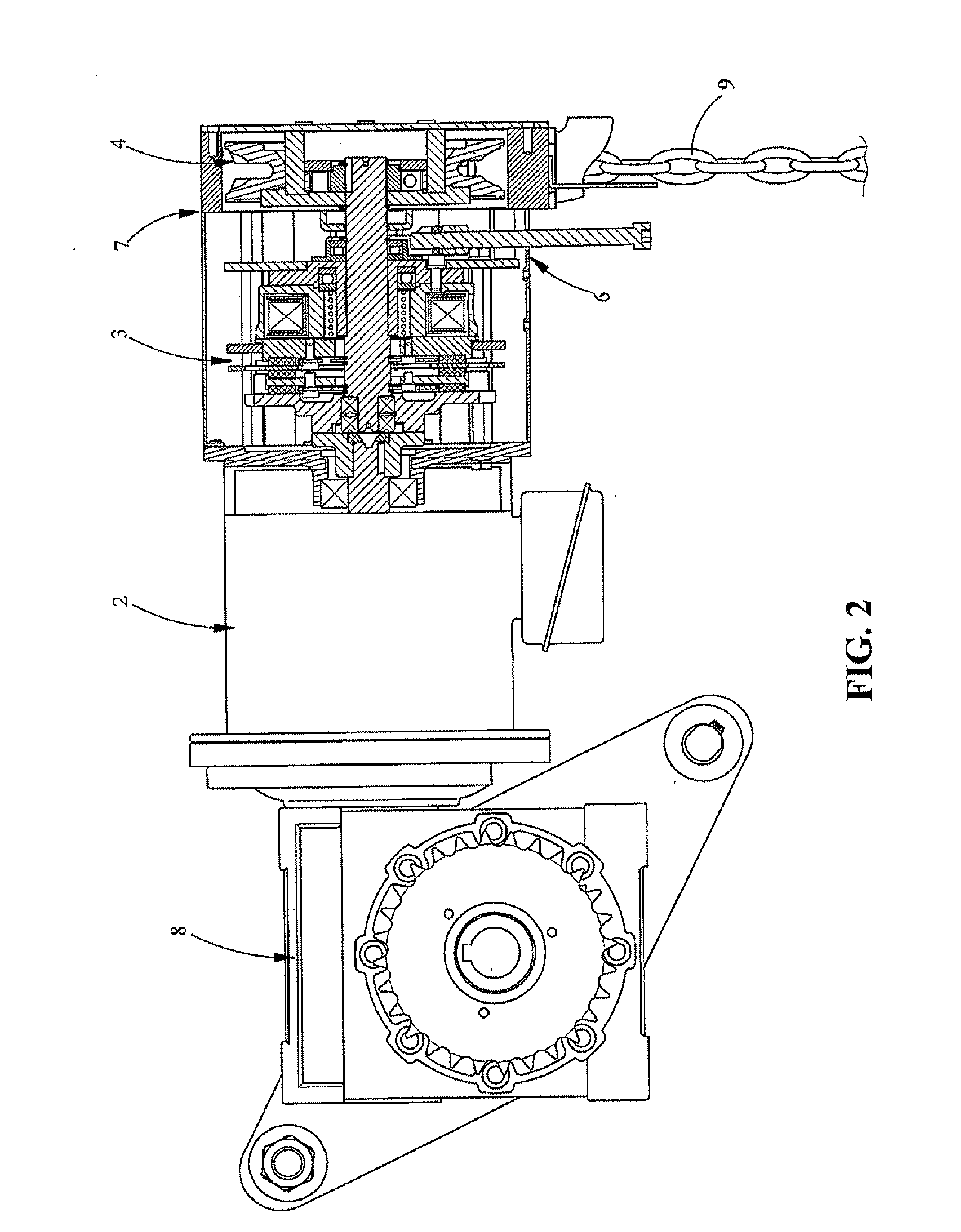

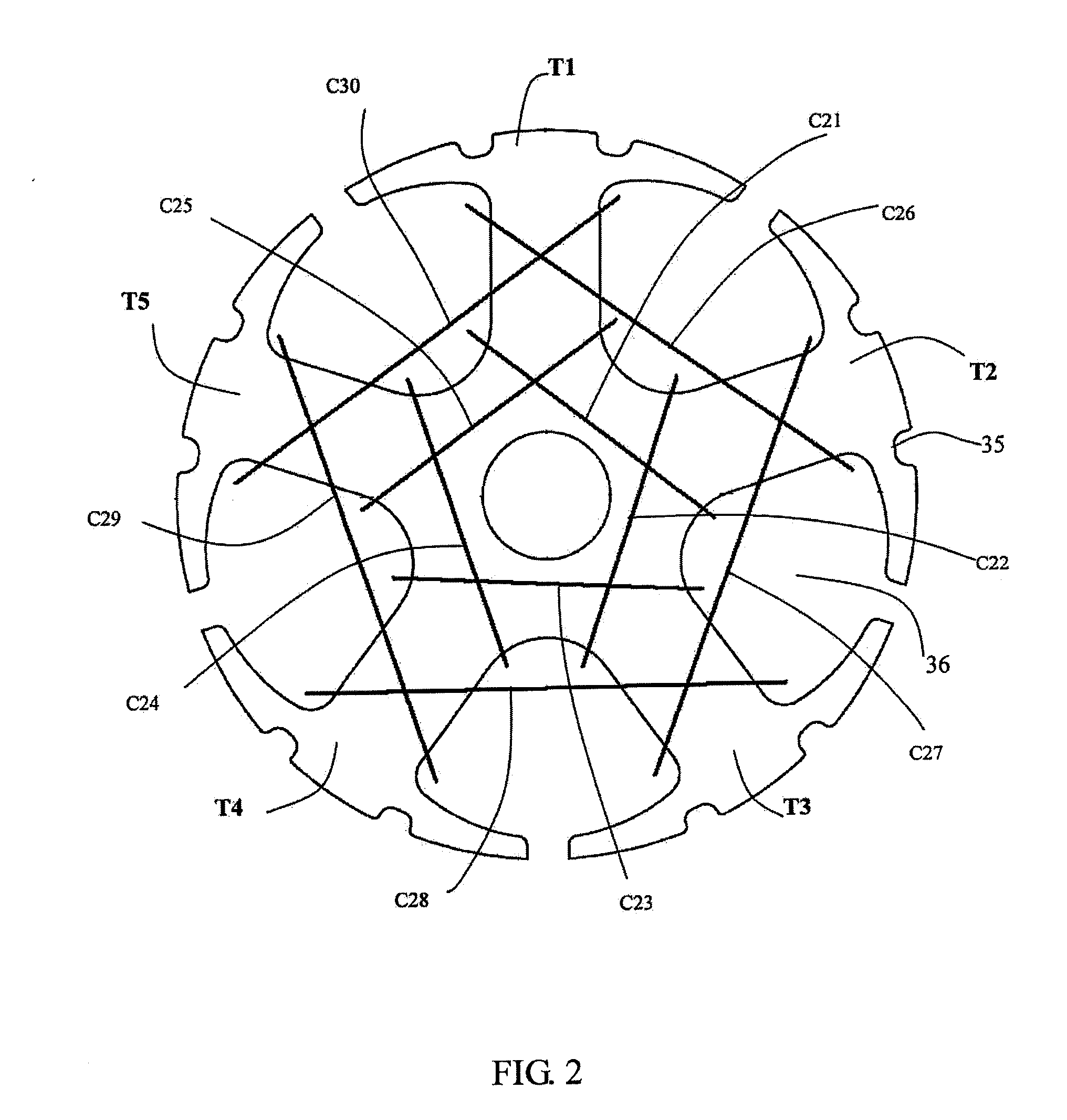

Door machine having chain disk locking mechanism

ActiveUS8657096B2Extend your lifeLow costOperating means/releasing devices for valvesDoor/window protective devicesLocking mechanismCost savings

A door machine having an electric motor and a chain disk locking mechanism. The chain disk locking mechanism includes a chain disk, an engaging rotary block, a stationary shaft and a plurality of moving pins. When the chain disk is pulled to rotate, the fixed pins of the chain disk press the moving pins so as to push the engaging rotary block to rotate with the stationary shaft together. When the stationary shaft is pulled to rotate, the engaging rotary block prohibits the moving pins from rotation. When the chain disk is pulled manually, the rolling door can be rolled upward or downward; when cease pulling the chain disk, braking is immediately effected so as to prevent the rolling door from moving upward or downward. Hence, the clutch mechanism can be omitted for cost saving and the structure of the mechanism can be simplified.

Owner:HSIEH CHUNG HSIEN

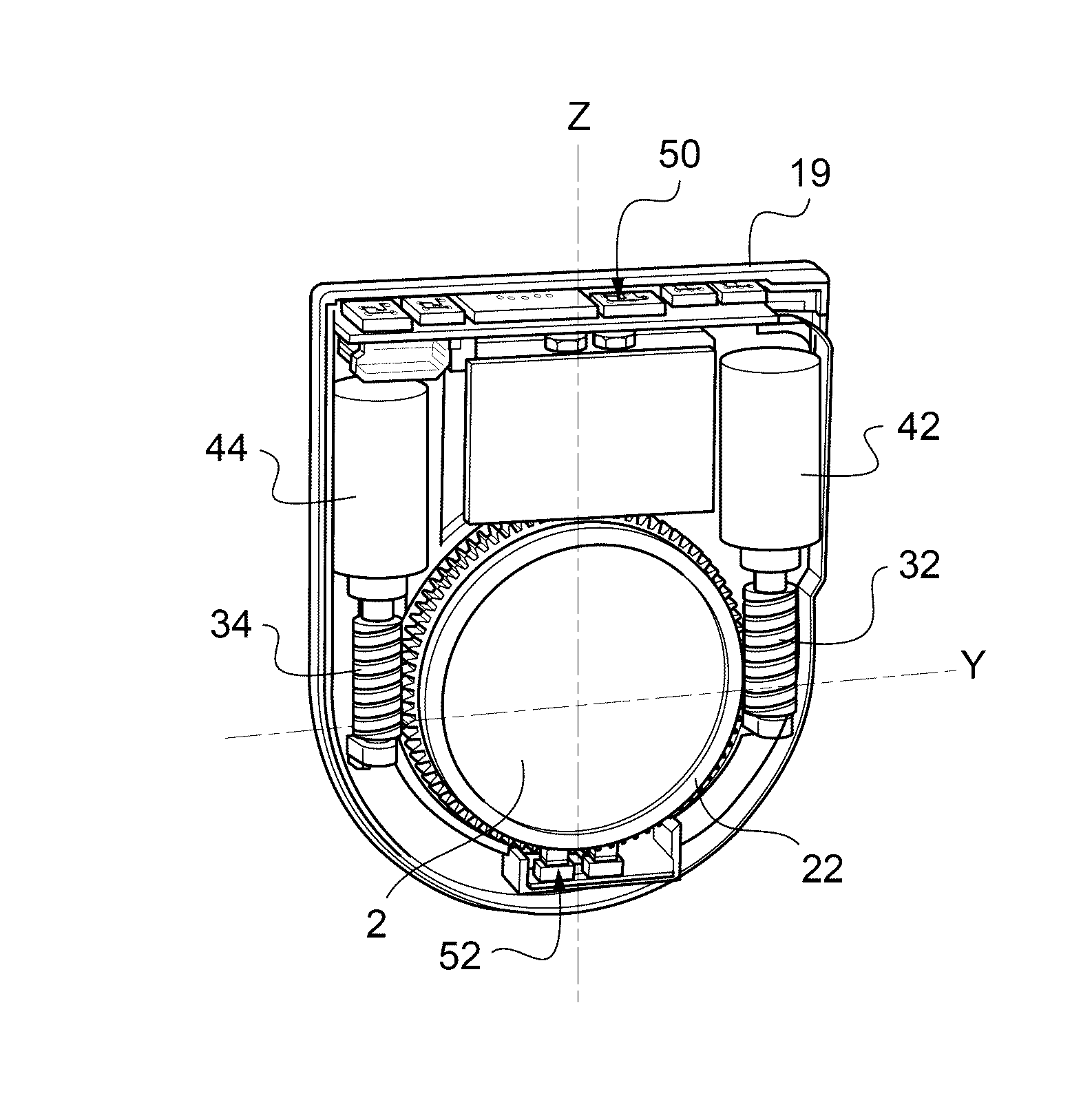

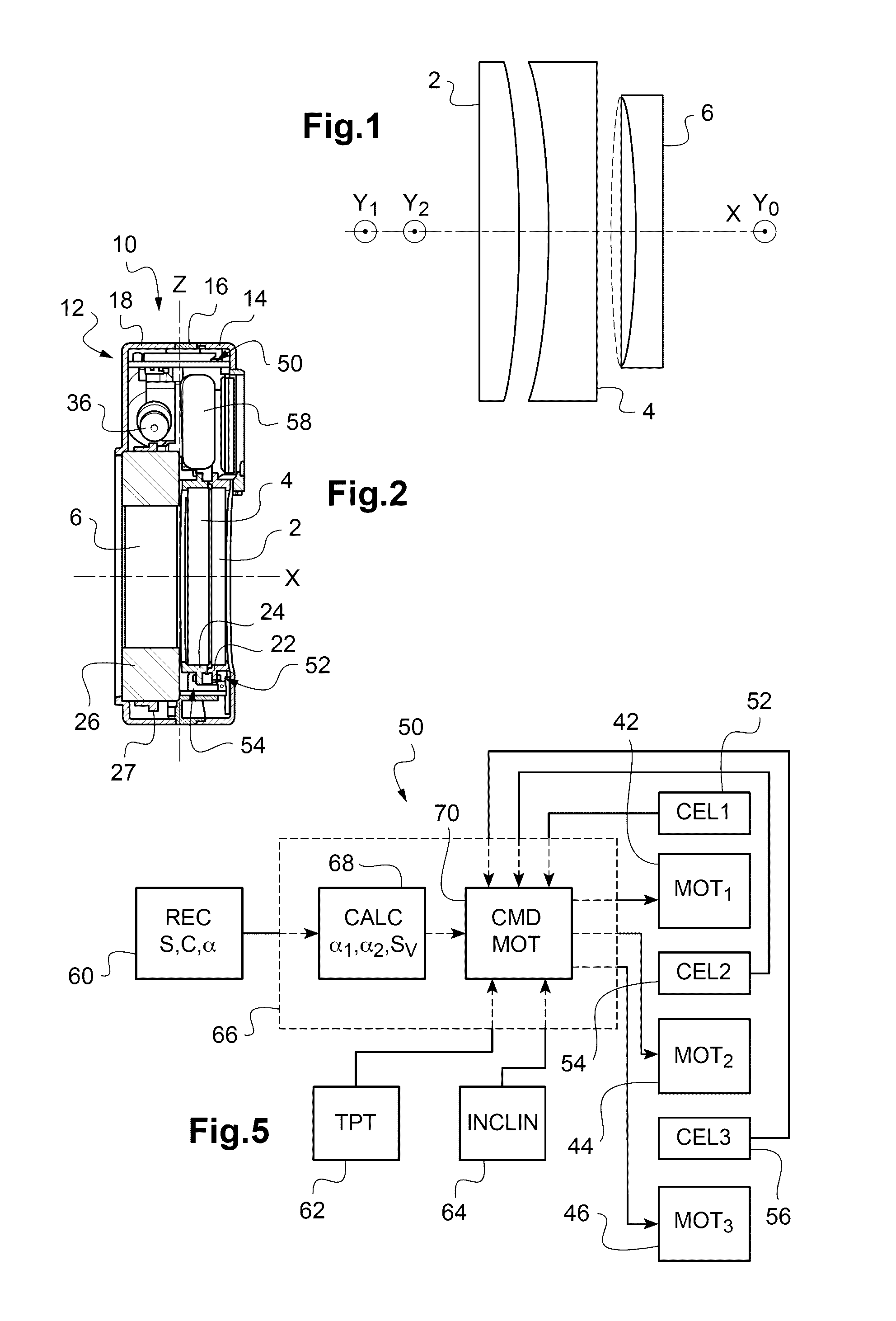

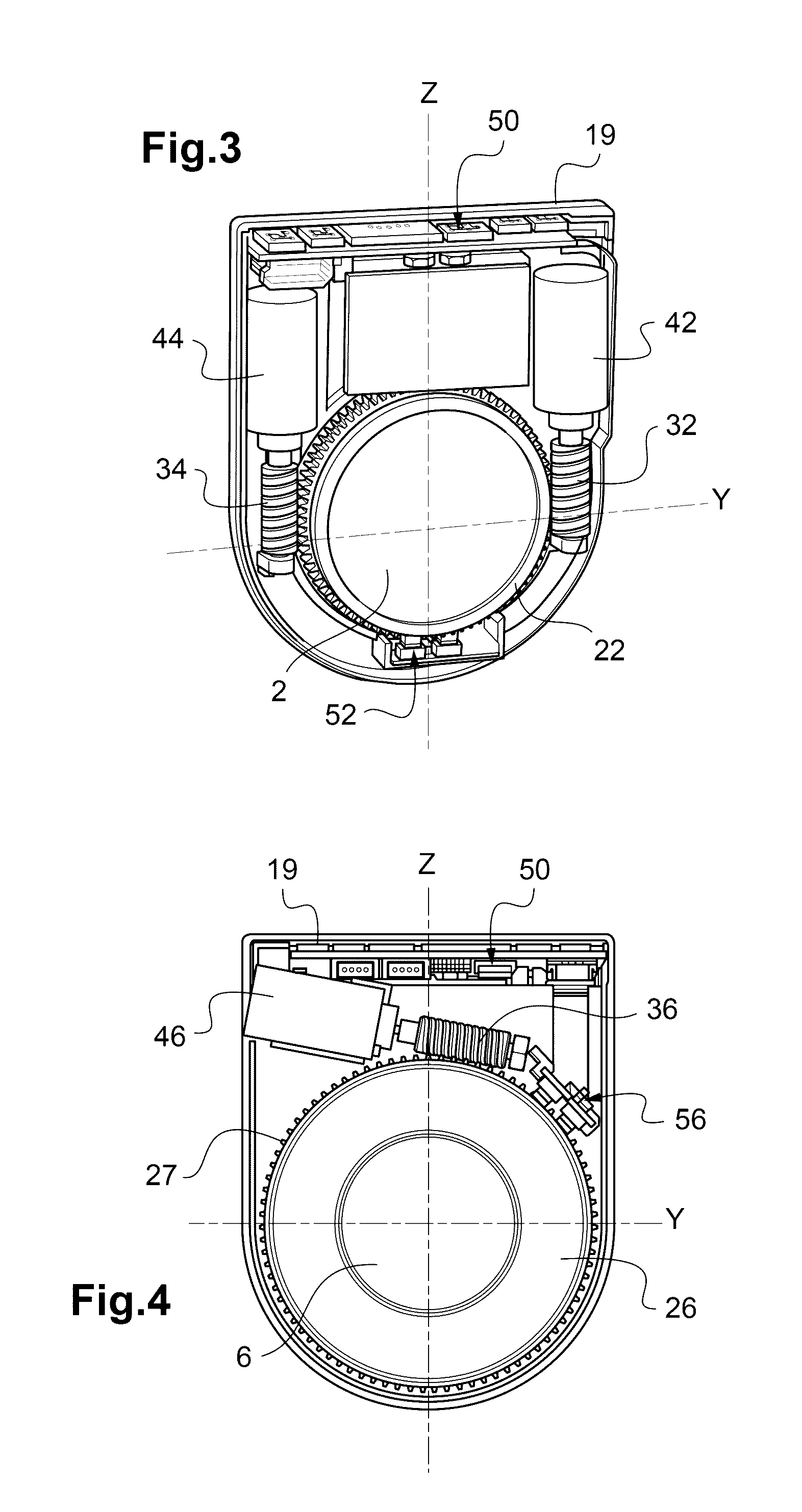

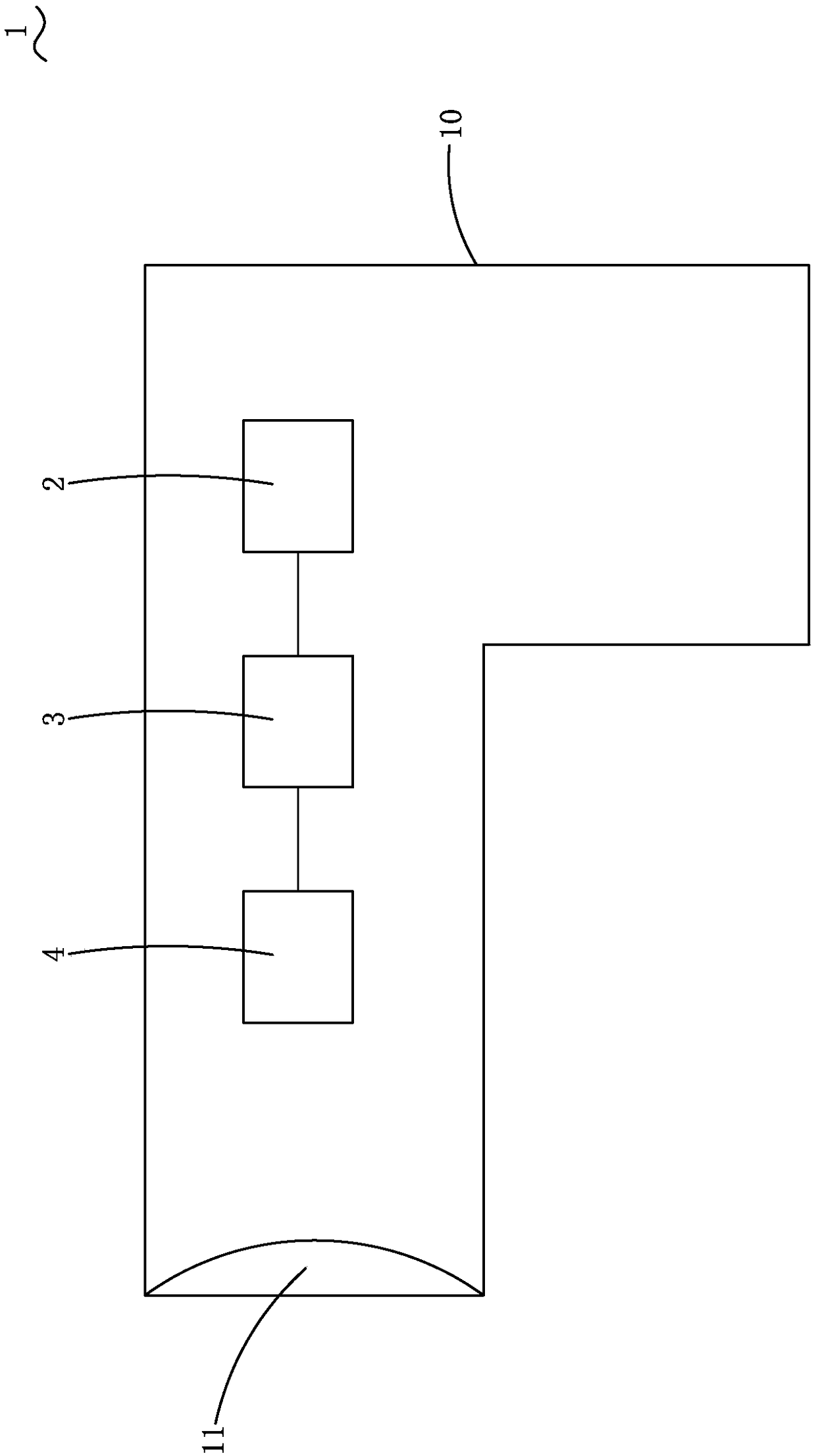

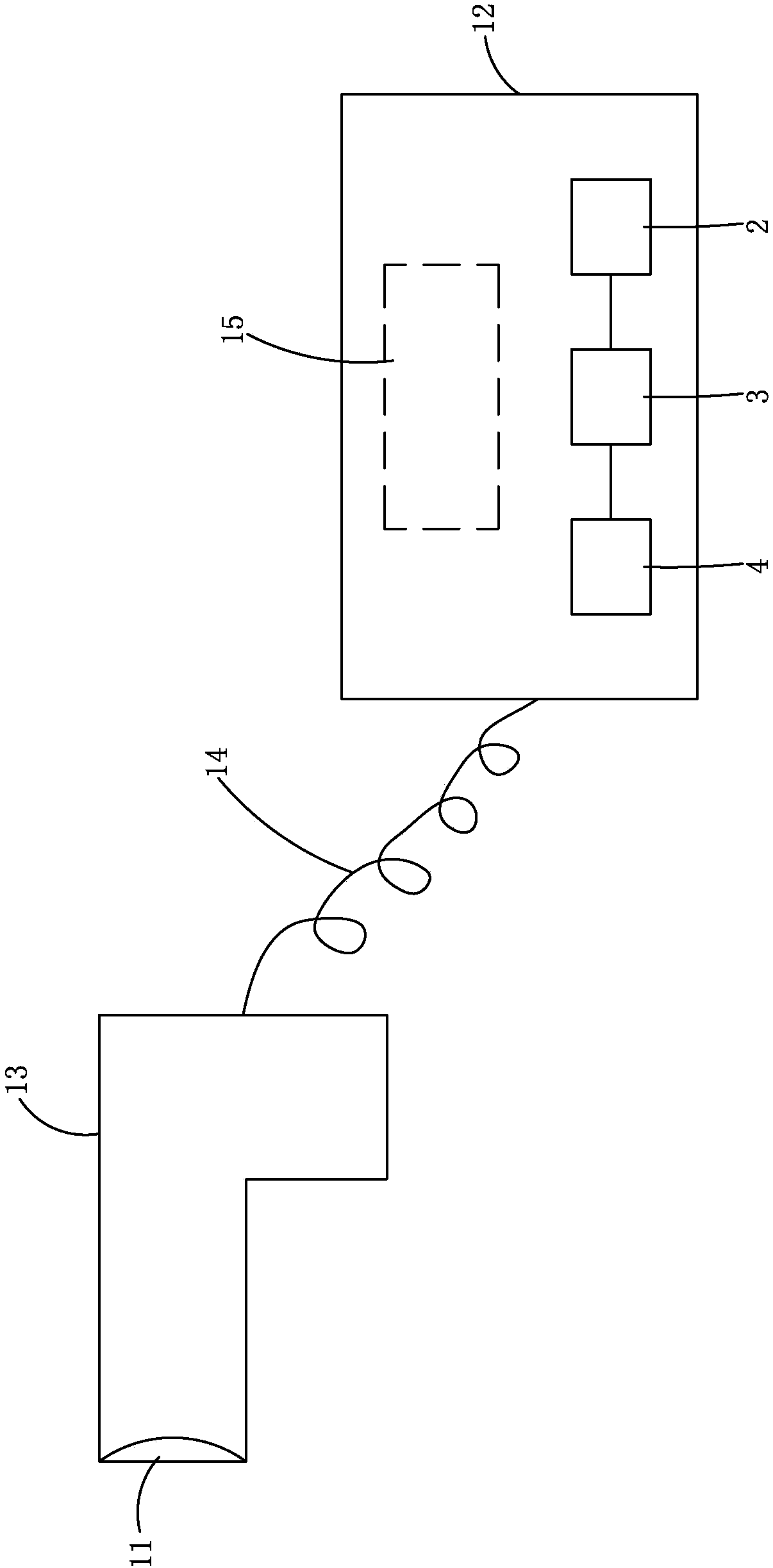

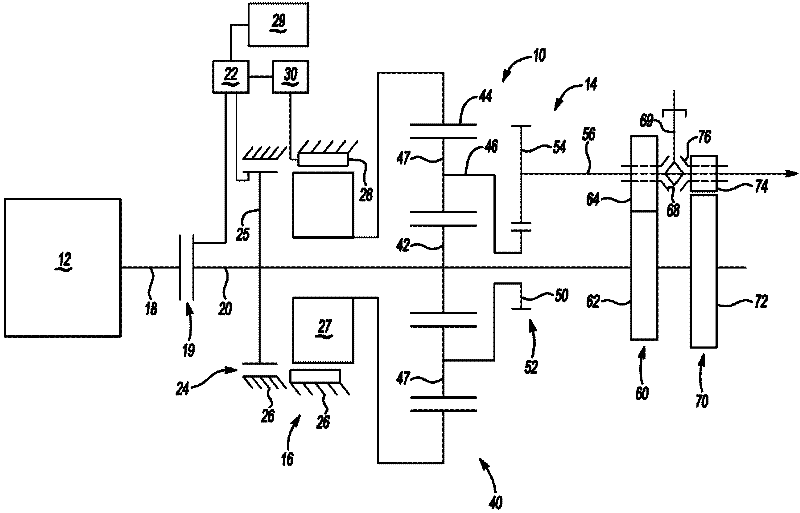

Visual compensation system and optometric binocular device

A visual compensation system (10) enabling observation, with variable optical power correction, along an optical observation axis (X) includes:—a first rotatable optical element (2) centered on the optical axis (X) and having a first cylinder power along the optical axis (X); —a second rotatable optical element (4) centered on the optical axis (X) and having a second cylinder power along the optical axis (X); and—a lens (6) having the optical axis (X) as the axis thereof, and moreover having variable sphere power.

Owner:ESSILOR INT CIE GEN DOPTIQUE

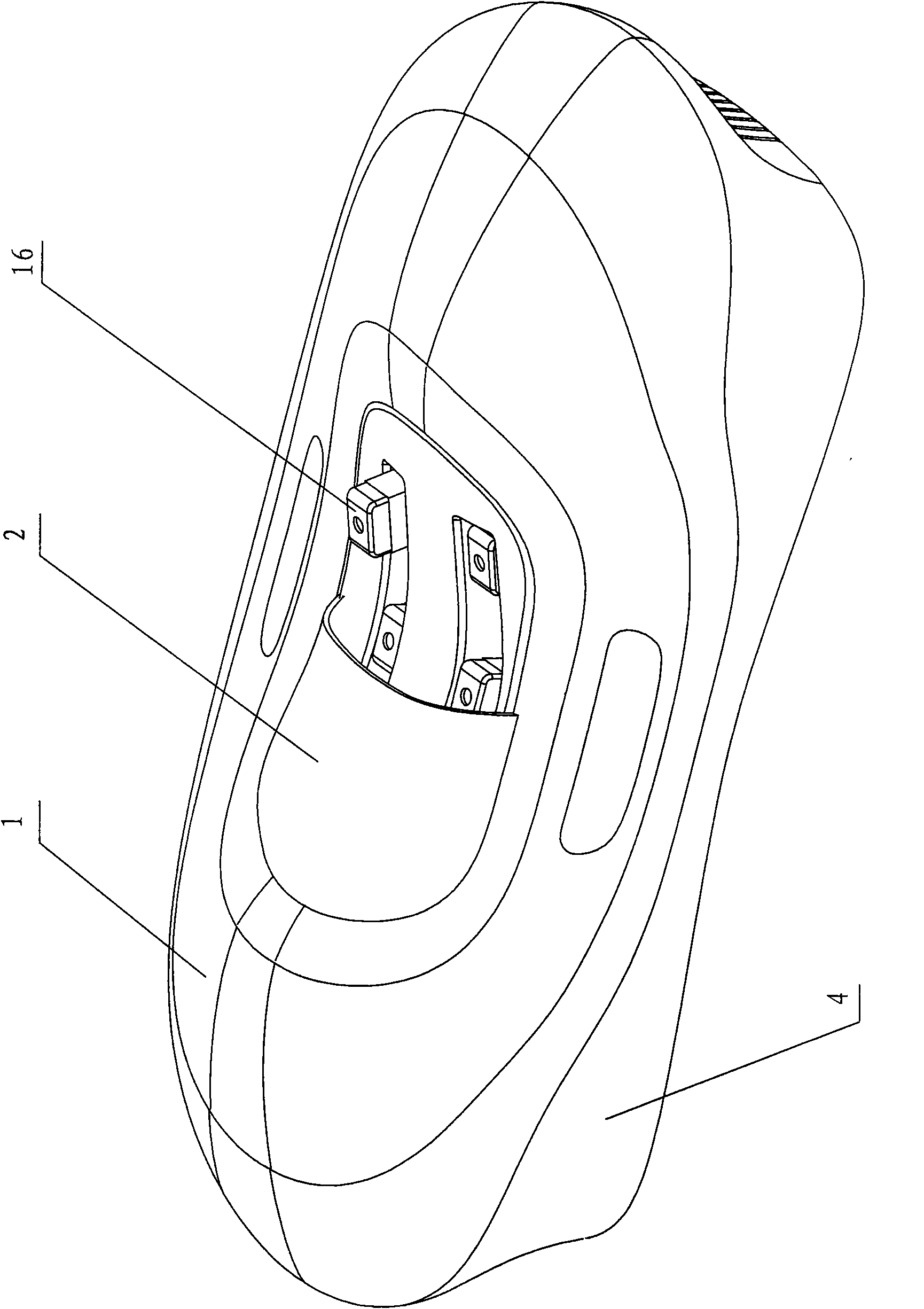

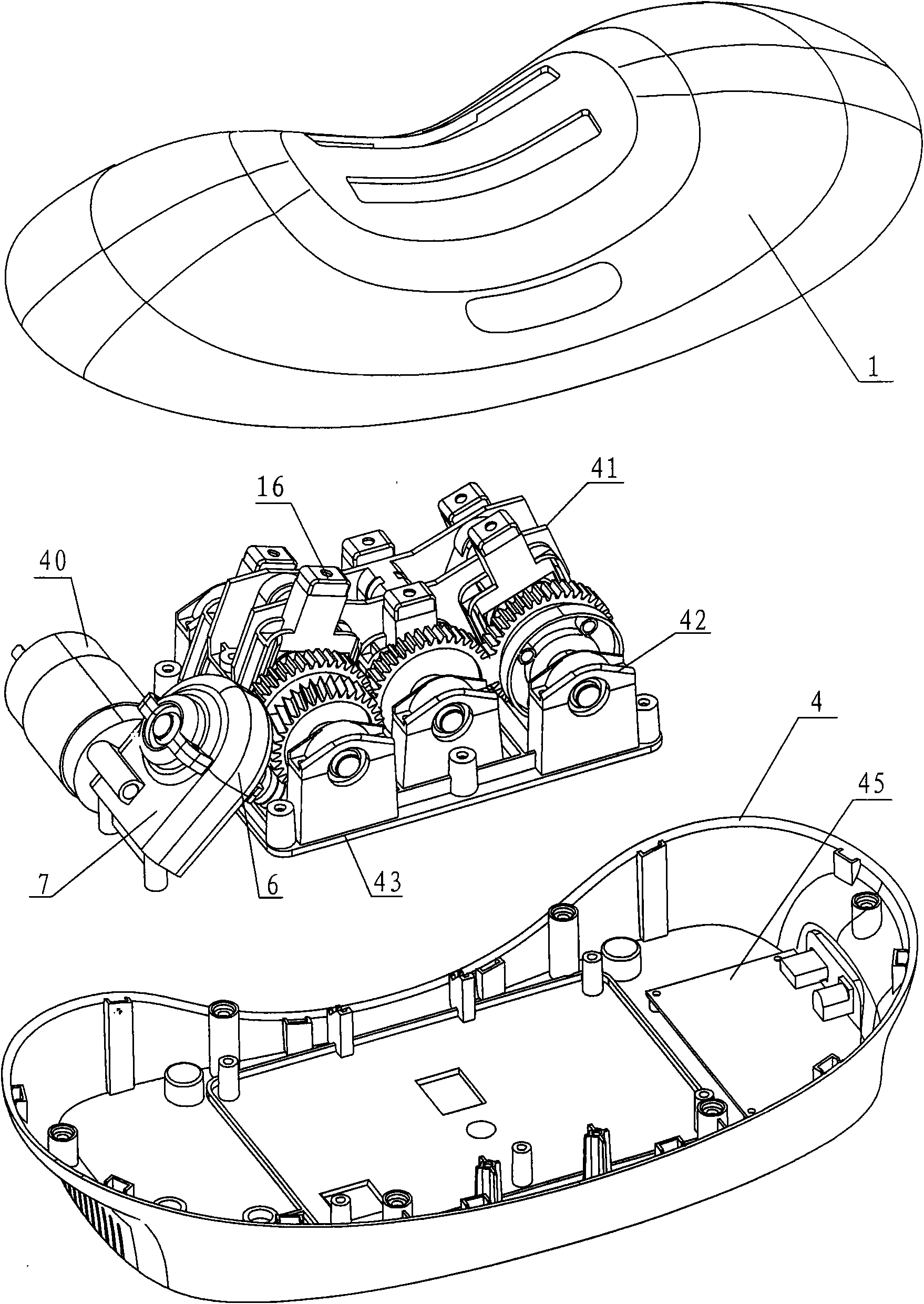

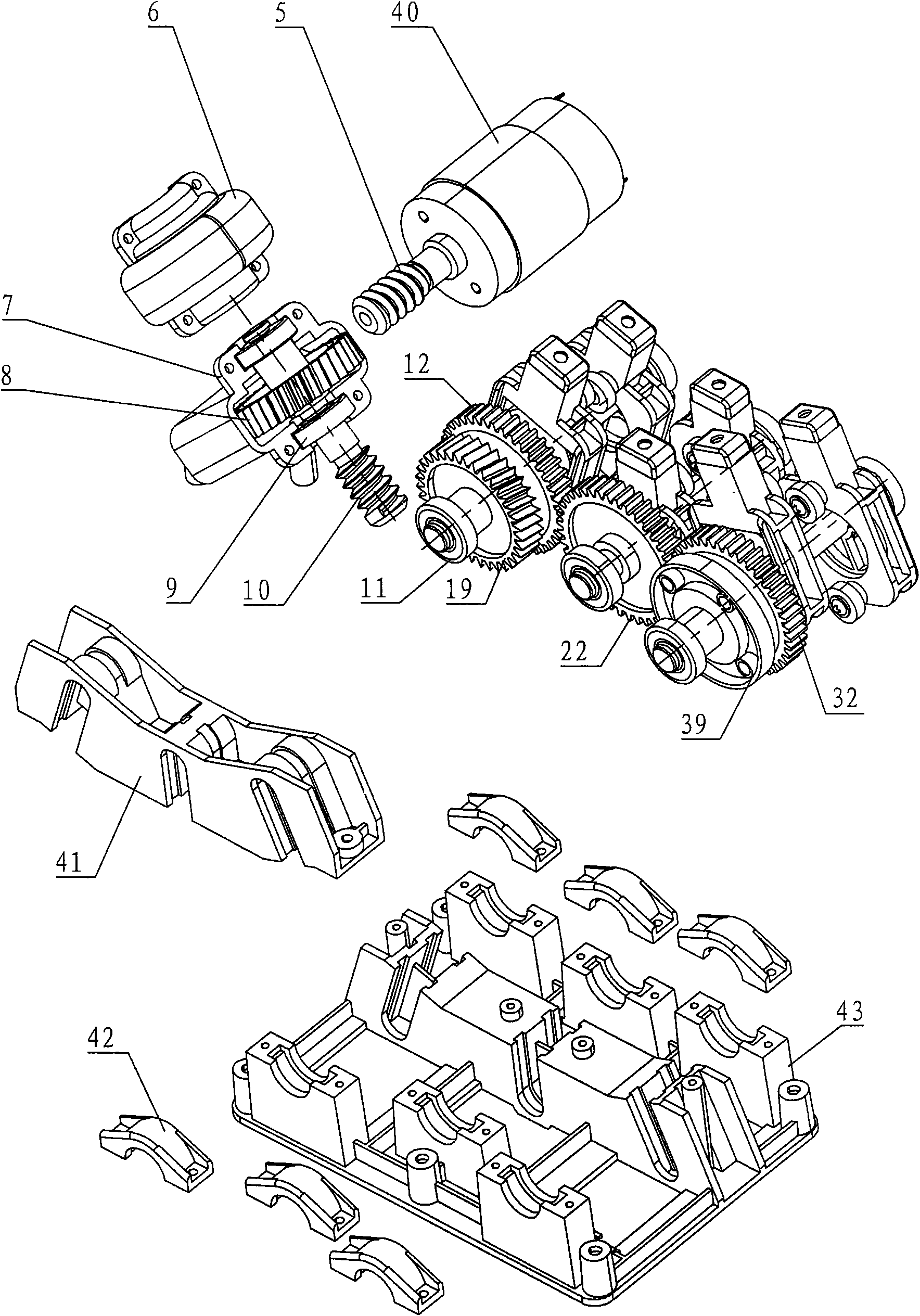

Head and neck massage pillow

InactiveCN101642406AReduce output speedSoft top pressurePillowsSuction-kneading massageNeck muscleEngineering

The invention relates to a head and neck massage pillow, which comprises a pillow-like machine case, wherein a motor and a driving mechanism are arranged in the machine case. The head and neck massagepillow is characterized in that a machine cover of the pillow-like machine case is provided with a strip hole for exposing a power output end of a massaging head, and an elastic laying cloth for sealing; six sets of eccentric wheel sliding block combined mechanisms driven by the driving mechanism are arranged in the machine case; and a sliding block exposed on the end face of the machine cover isprovided with rubber massaging heads. The head and neck massage pillow performs gravity traction massage by using the gravity of a human head, the massaging heads move up and down by turns to resistand press corresponding acupuncture points of the head and the neck, the resisting and pressing force is gentle, and the motion frequency of the massaging heads is changed by adjusting the rotating speed of the motor, so a person can have a comfort feeling. The head and neck massage pillow is characterized by scientific design, reasonable and simple structure, and convenient, comfort and safe use,can meet the requirements of different age groups on massage therapy of the head and the neck, increases the blood circulation of a human head, and relieves the fatigue of neck muscles.

Owner:河北路德医疗器械有限公司

Door machine having chain disk locking mechanism

ActiveUS20130074409A1Low costSimplified mechanical componentDoor/window protective devicesPower-operated mechanismLocking mechanismEngineering

A door machine having an electric motor and a chain disk locking mechanism. The chain disk locking mechanism includes a chain disk, an engaging rotary block, a stationary shaft and a plurality of moving pins. When the chain disk is pulled to rotate, the fixed pins of the chain disk press the moving pins so as to push the engaging rotary block to rotate with the stationary shaft together. When the stationary shaft is pulled to rotate, the engaging rotary block prohibits the moving pins from rotation. When the chain disk is pulled manually, the rolling door can be rolled upward or downward; when cease pulling the chain disk, braking is immediately effected so as to prevent the rolling door from moving upward or downward. Hence, the clutch mechanism can be omitted for cost saving and the structure of the mechanism can be simplified.

Owner:HSIEH CHUNG HSIEN

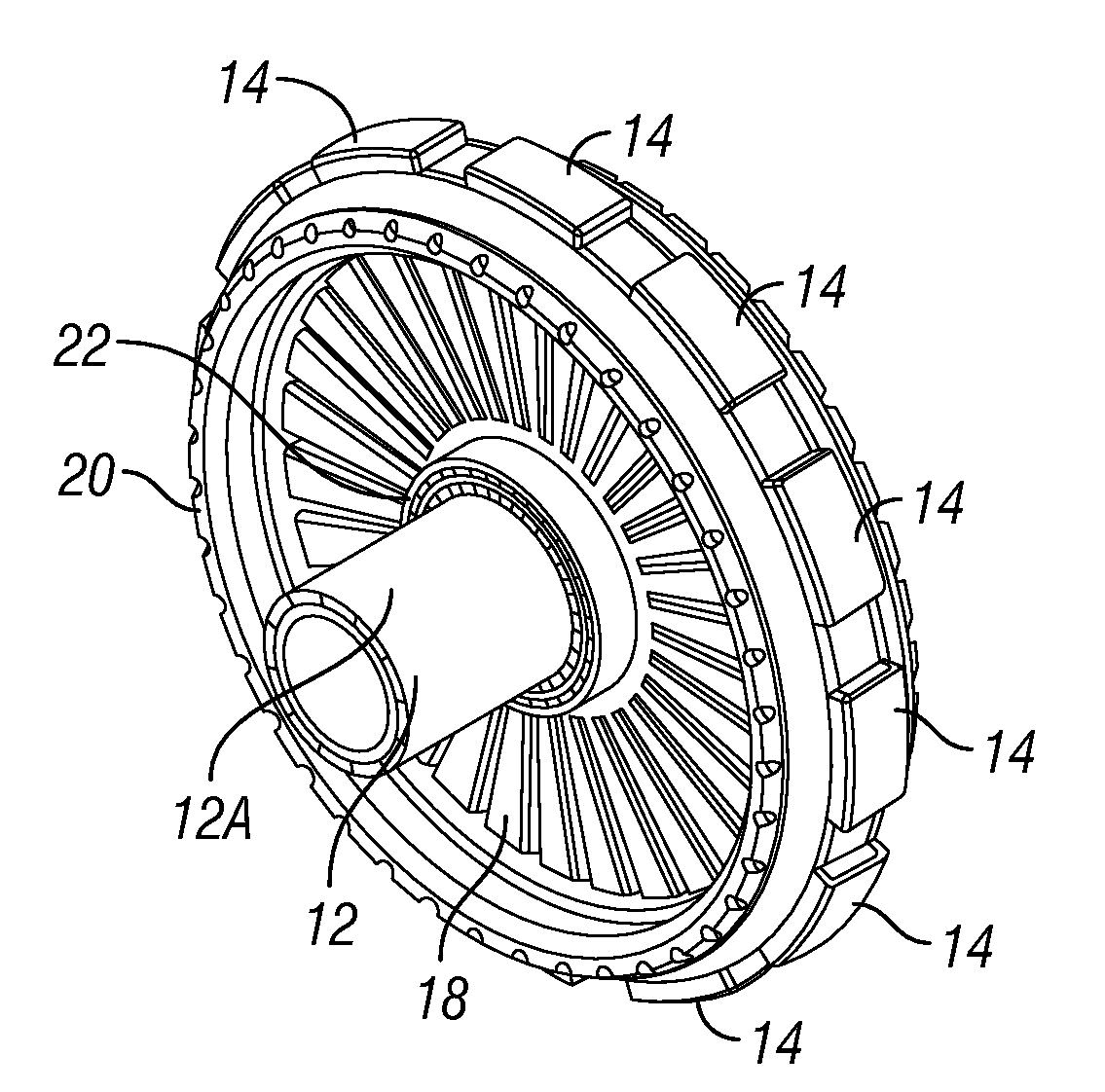

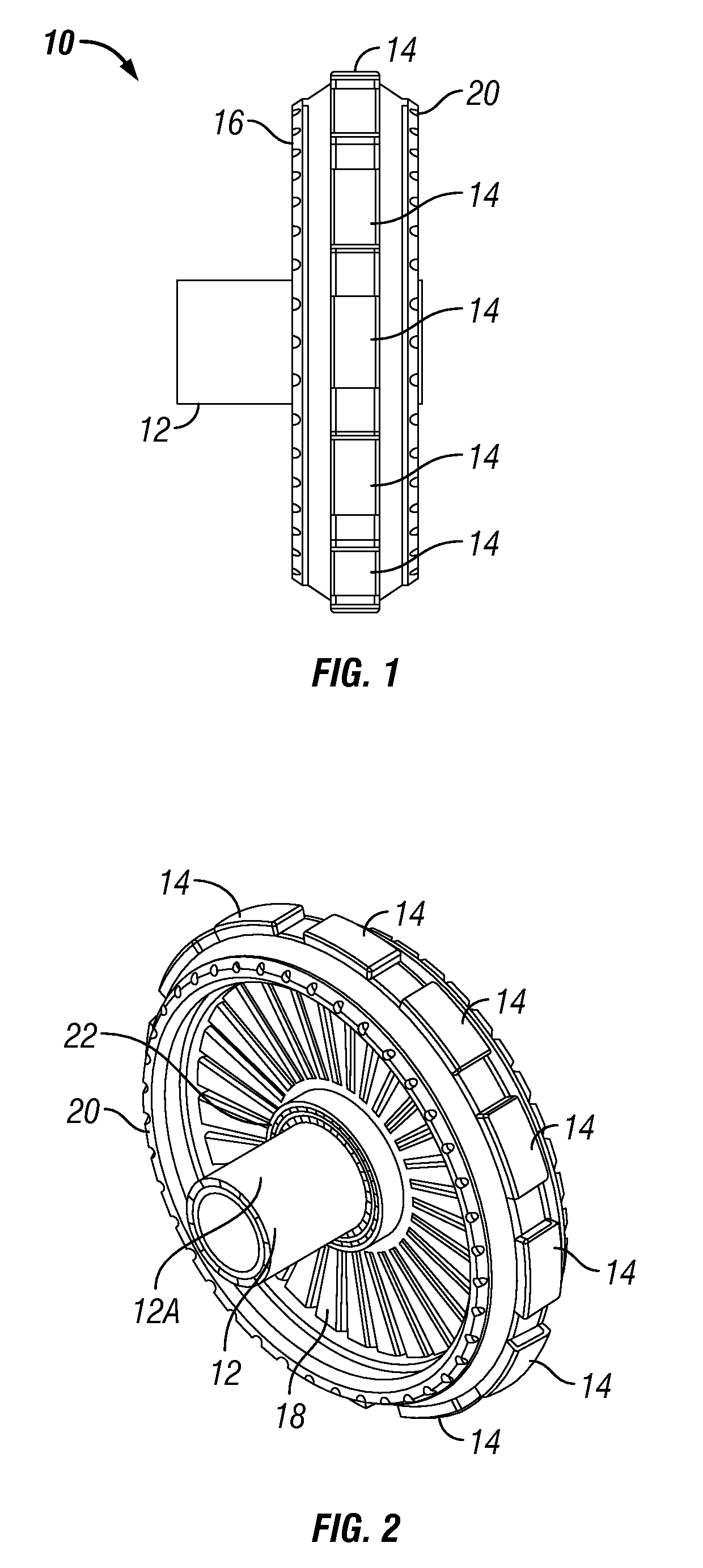

Turbine generator having direct magnetic gear drive

InactiveUS20100032952A1Increase rotation speedReduce output speedDynamo-electric brakes/clutchesHydro energy generationRotation velocityEngineering

A turbine operated electric generator includes a turbine and a magnetic gear unit rotationally coupled at an input thereof to at least one of an inner rim of the turbine and an outer rim of the turbine. An output of the magnetic gear unit is configured to operate an electric generator. The magnetic gear unit includes magnets configured to at least one of increase a rotation speed at the output with respect to the input speed and inversely change a torque at the output with respect to the input and decrease the output speed with respect to the input speed and inversely change the torque.

Owner:DEXTER MAGNETIC TECH

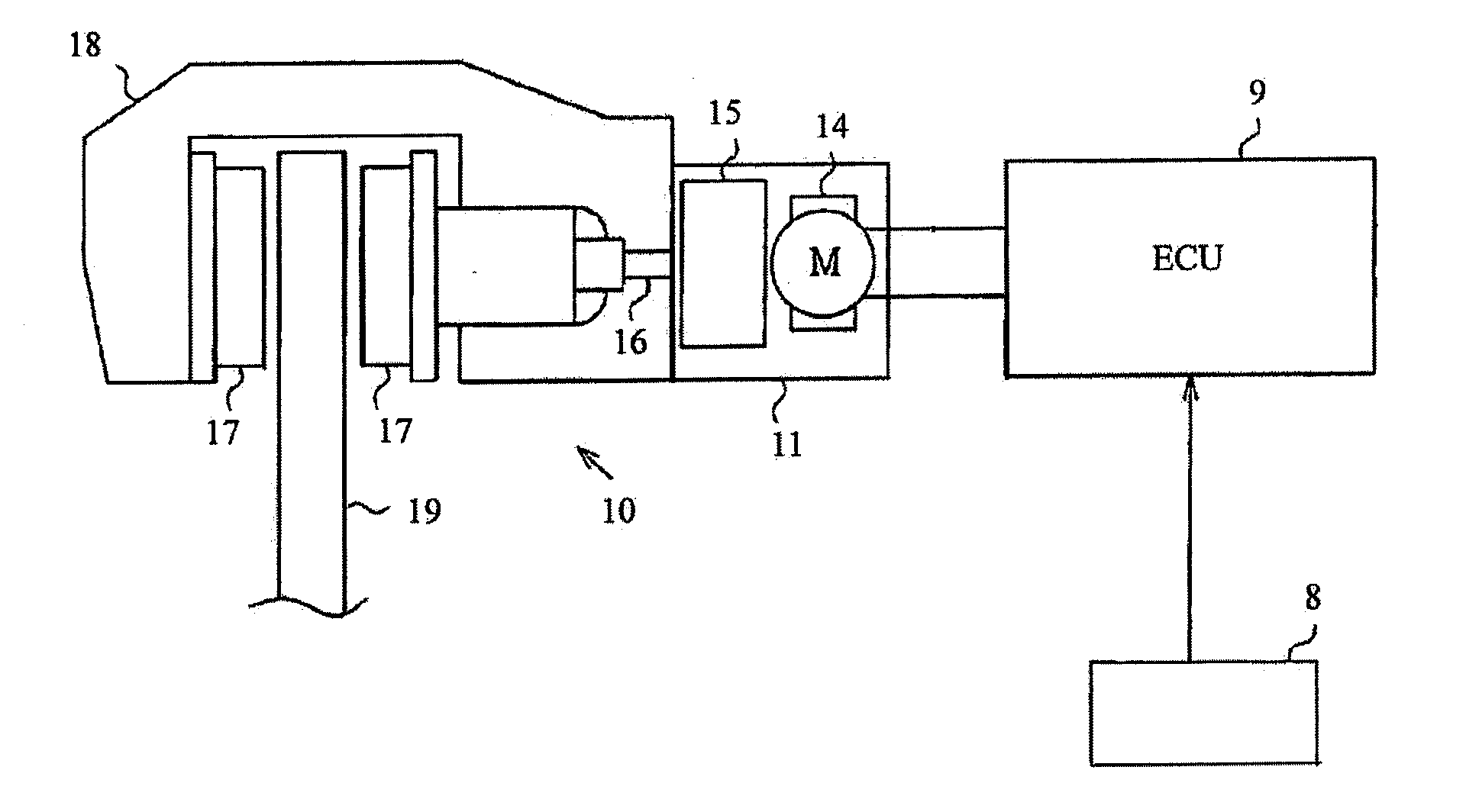

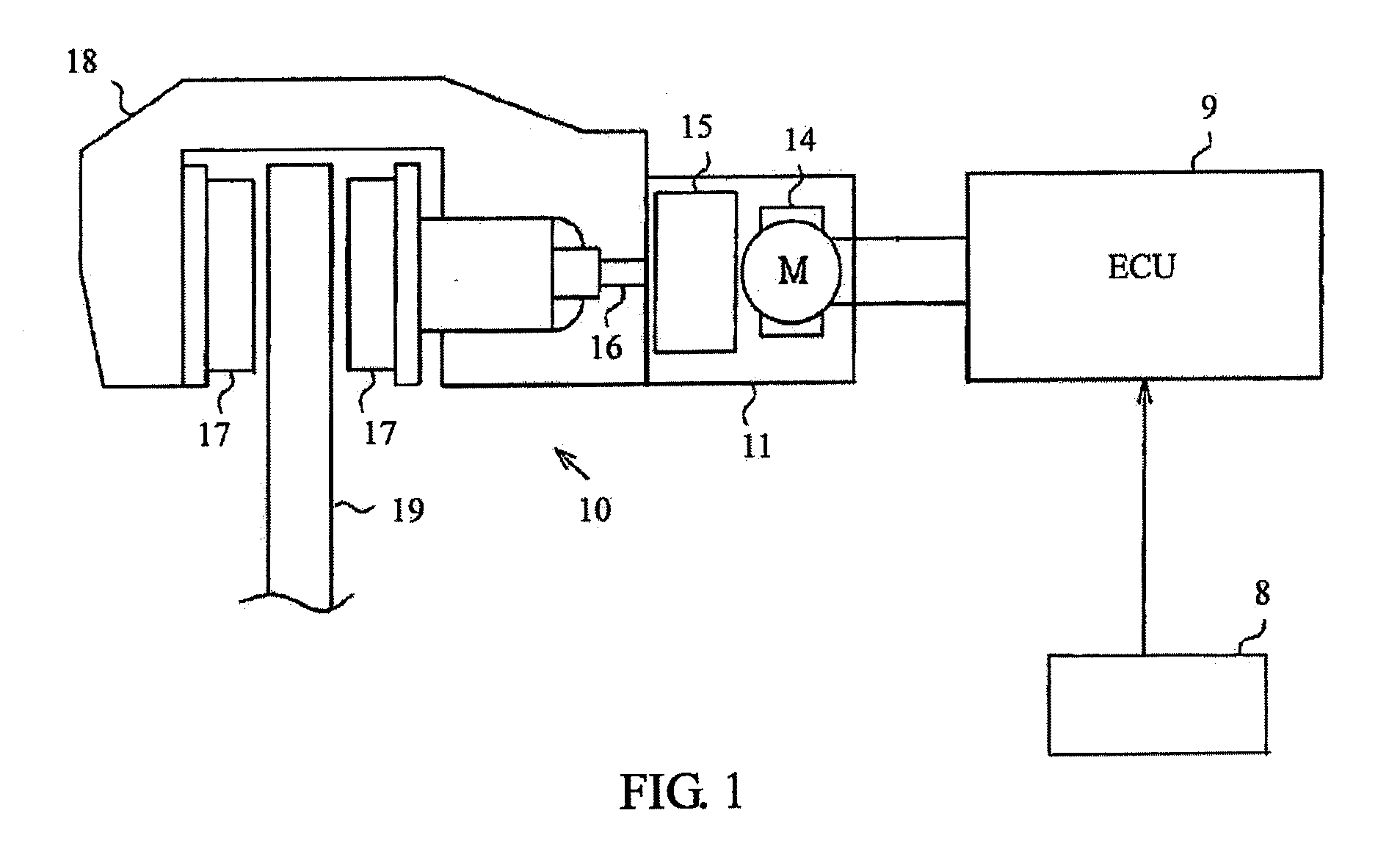

Motor and electric parking brake system

ActiveUS20110147144A1Reduce output speedBraking action transmissionMagnetic circuitElectricityElectric parking brake

A motor for actuating brake members of an electric parking (EPB) system, comprises a stator and a rotor rotatably mounted to the stator. The rotor comprises a shaft, a commutator, a rotor core fixed to the shaft, and rotor windings wound about teeth of the rotor core and electrically connected to segments of the commutator. The rotor windings comprise a plurality of winding units, each of the wining units comprising at least two coils. The coils of each winding unit are wound about the same teeth and connected to a same pair of segments.

Owner:JOHNSON ELECTRIC SA

Electric vehicle

ActiveUS20120247855A1Increase output powerReduced dimensionCyclesElectric propulsion mountingEngineeringElectric vehicle

In an electric three-wheeled vehicle, a centrifugal clutch transmits rotary driving power to a counter shaft when the revolution speed of a motor exceeds a prescribed value. The clutch is coaxially located at one end of a motor output shaft. A counter shaft is located inside the outside diameter of the motor in a side view of the vehicle. The motor output shaft, counter shaft, and axles are arranged from a vehicle forward side in the order of mention. The axis center of the counter shaft is located below a line connecting the axis center of the motor output shaft and the axis center of the axle in a side view of the vehicle.

Owner:HONDA MOTOR CO LTD

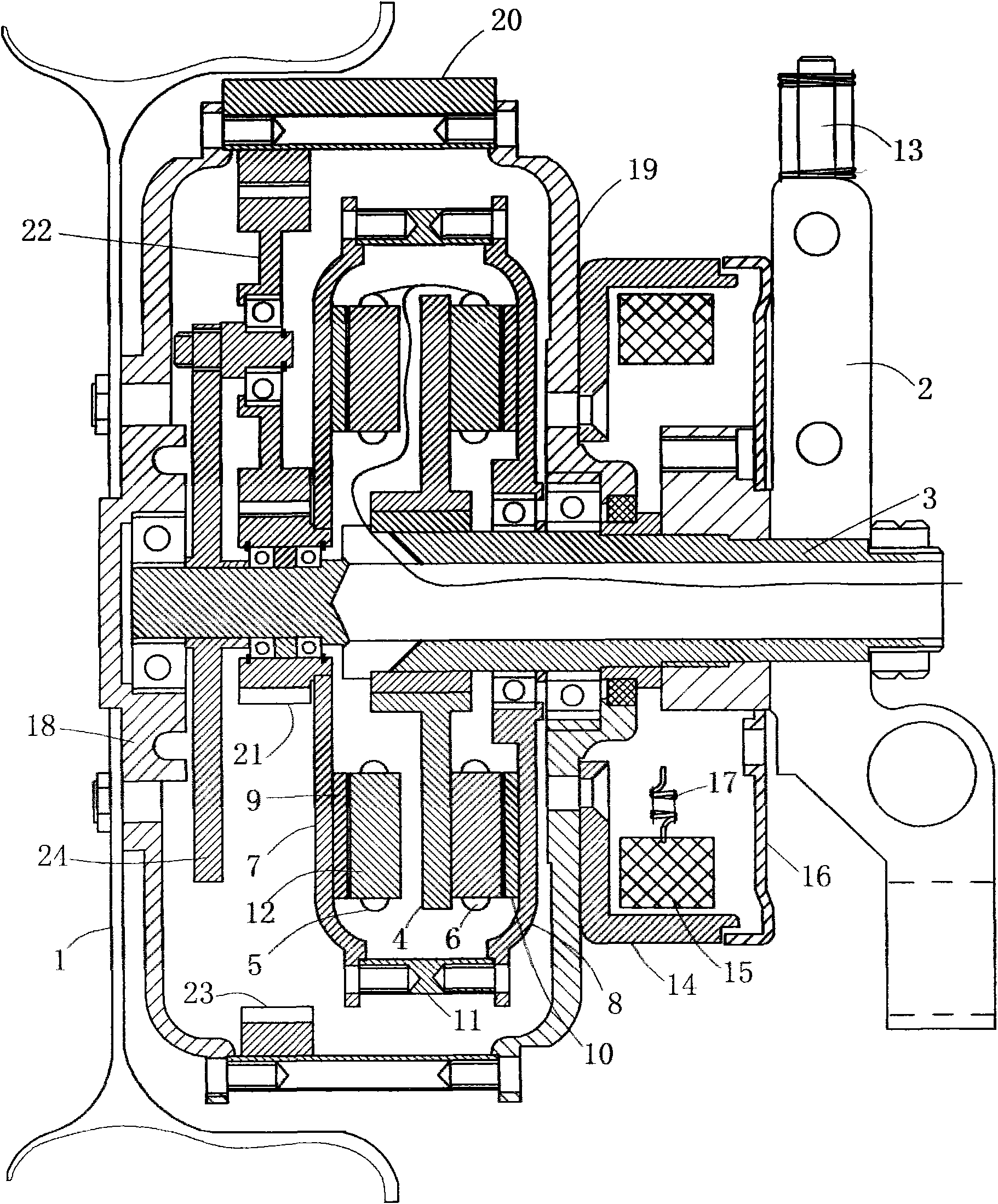

Speed reducer

InactiveCN103206491AReduce output speedCompact structureToothed gearingsGearing detailsReduction driveEngineering

The invention discloses a speed reducer which comprises a shell. The speed reducer further comprises a small teeth difference planetary drive mechanism and a worm drive mechanism which are both arranged inside the shell, and a worm gear of the worm drive mechanism is fixedly mounted an input shaft of the small teeth difference planetary drive mechanism. When the speed reducer is used for power drive, rotary motion is inputted from the worm drive mechanism and outputted from an output shaft of the small teeth difference planetary drive mechanism, and is totally subjected to double reductions which are reduction carried out by the mutually meshed worm and worm gear and reduction carried out by the small teeth difference planetary drive mechanism respectively, so that drive ratio and bearable load are increased significantly by the aid of the speed reducer. Besides, the worm drive mechanism and the small teeth difference planetary drive mechanism are arranged inside the same shell, and accordingly, the speed reducer is compact in structure, small in size and lightweight.

Owner:XINJIANG GOLDWIND SCI & TECH

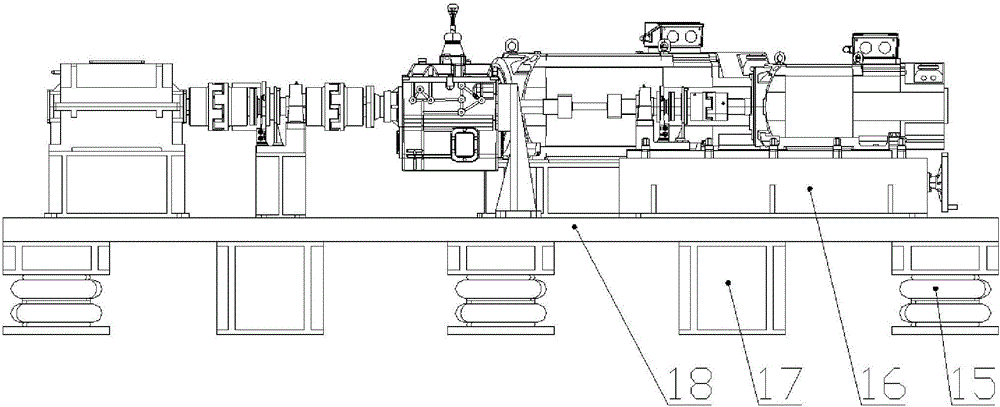

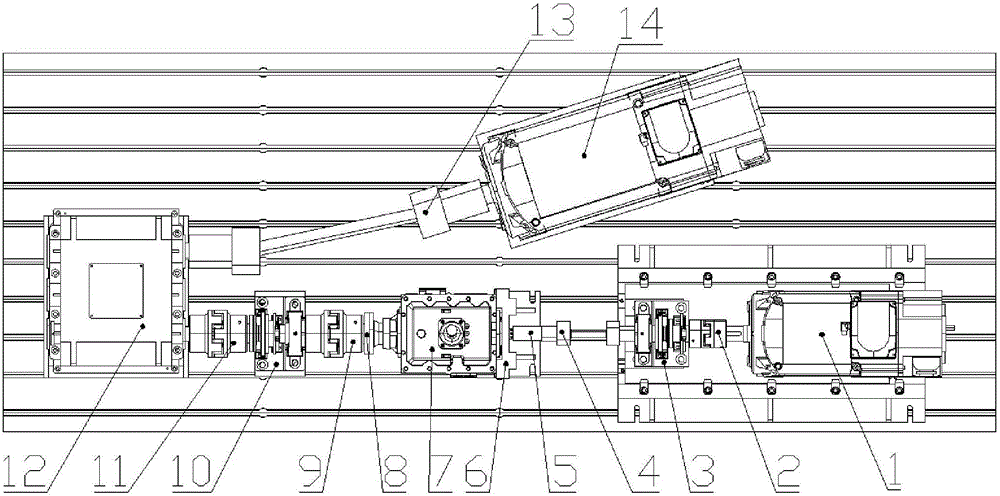

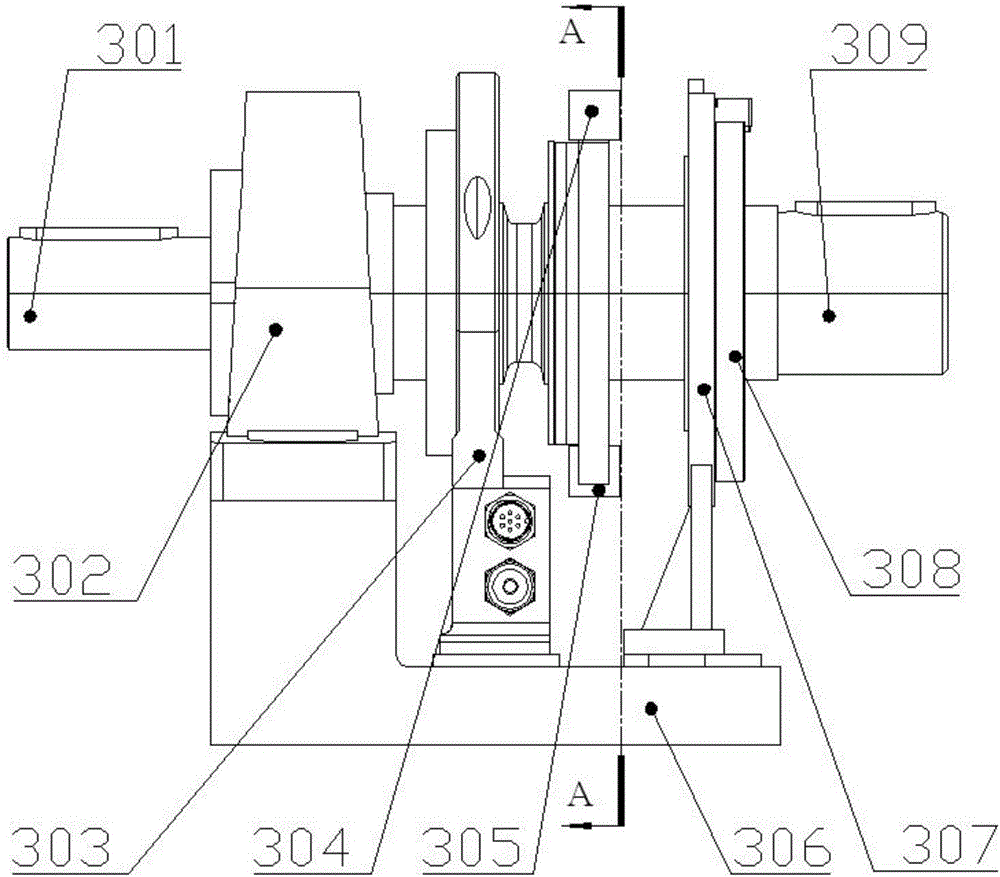

RWD automobile gearbox transmission error detection test bench and comprehensive testing method

InactiveCN105928700AShorten the lengthTake advantage ofMachine gearing/transmission testingCombined testCoupling

The invention relates to an RWD automobile gearbox transmission error detection test bench and a comprehensive testing method, and belongs to the technical field of automobile gearbox detection. The test bench comprises a test bench device and an adjustment and supporting device. The test bench device comprises an AC drive motor, an input end elastic shaft coupler, an input end transmission error comprehensive detection device, an input end cv-joint synchronous universal shaft coupler, a gearbox input spline shaft, a tested gearbox, a gearbox output flange shaft, a first output end elastic shaft coupler, an output end transmission error comprehensive detection device, a second output end elastic shaft coupler, a two-gear reduction gearbox, an output end cv-joint synchronous universal shaft coupler, and an AC loading motor. The test bench is advantageous in that the device employs a U-shaped layout and reduces the area of an occupied land; the test bench can measure the static and dynamic transmission errors of the gearbox at the same time; the test bench employs the two-gear reduction gearbox and a sliding table mechanism, can meet the testing requirements of different types of gearboxes, and improves the universality of the test bench.

Owner:JILIN UNIV

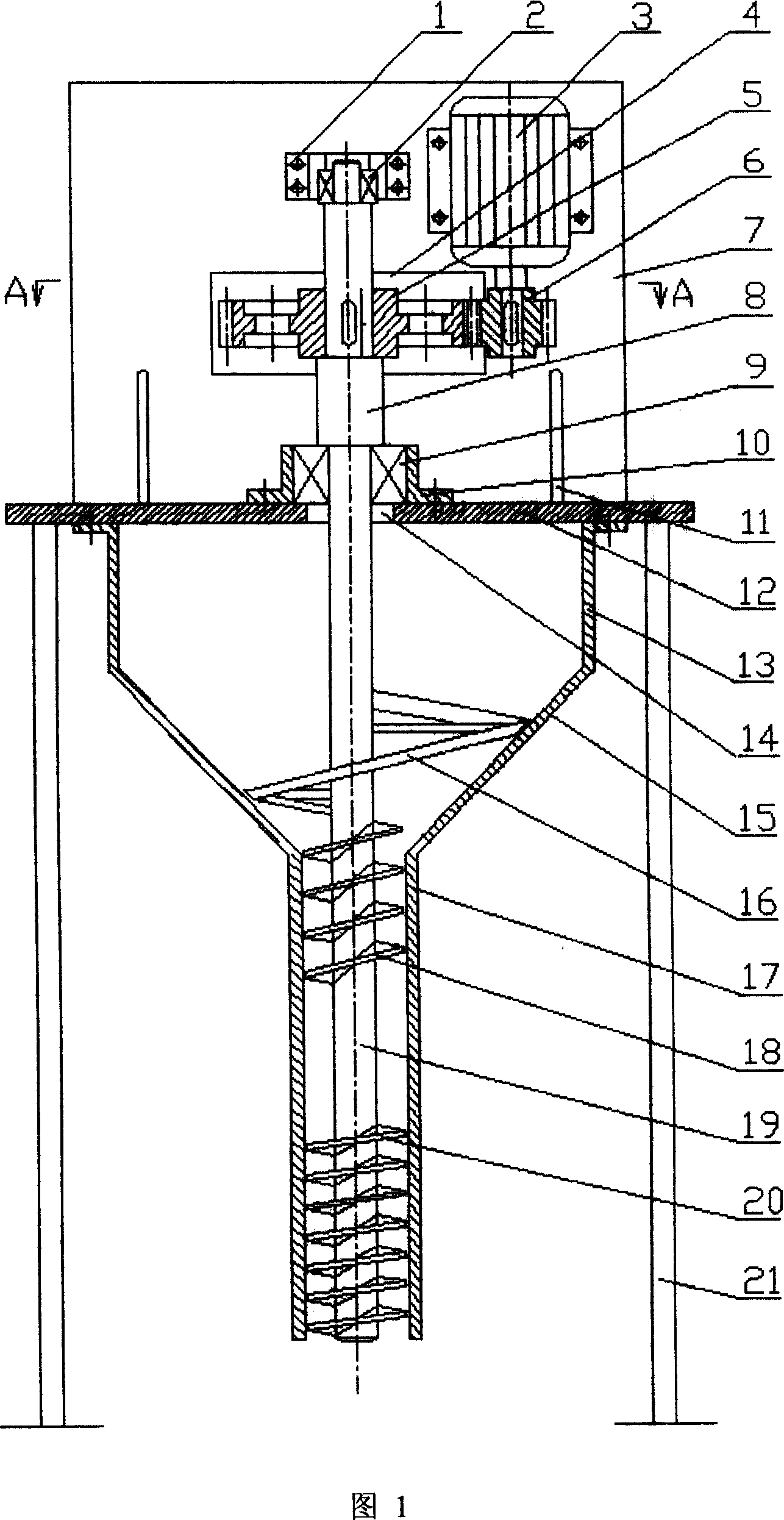

Pressurization trace quantity helix powder feeding equipment

InactiveCN101012031AGuaranteed normal rotationTo achieve the purpose of sealed deliveryToothed gearingsPackagingColloidEngineering

The pressurized micro spiral powder feeder drives the screw shaft through drive mechanism by generators, hopper and material outlet pipe integrated under the lower surface of the support platform, featuring in its being load bore by support platform and positioned by the middle up shaft bearing, vertically going through the insert hopper of the round hole, the lower end sticking to the material output pipe in arm shape, blender at the screw shaft of the corresponding position of the conical sectional hopper, intermittently fixing two sections spiral vanes with different pitches, lower spiral vane pitch smaller than the pitch of the upper spiral vane, leaving a section of emptiness between the spiral shaft of the spiral vanes. It is simple and compact in structure, adjustable in feeding quantity, even and stable in pressurized transportation.

Owner:UNIV OF SCI & TECH OF CHINA

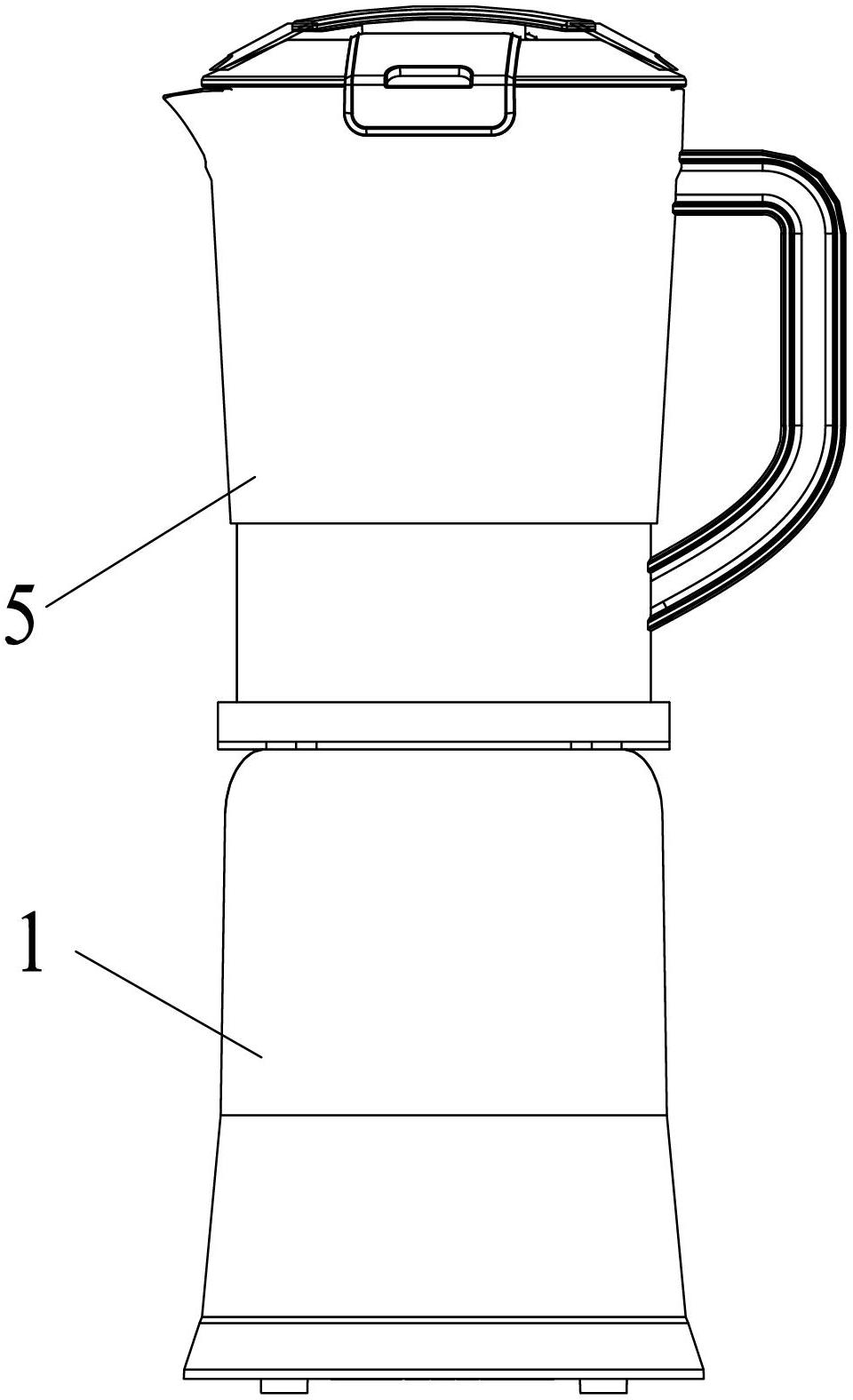

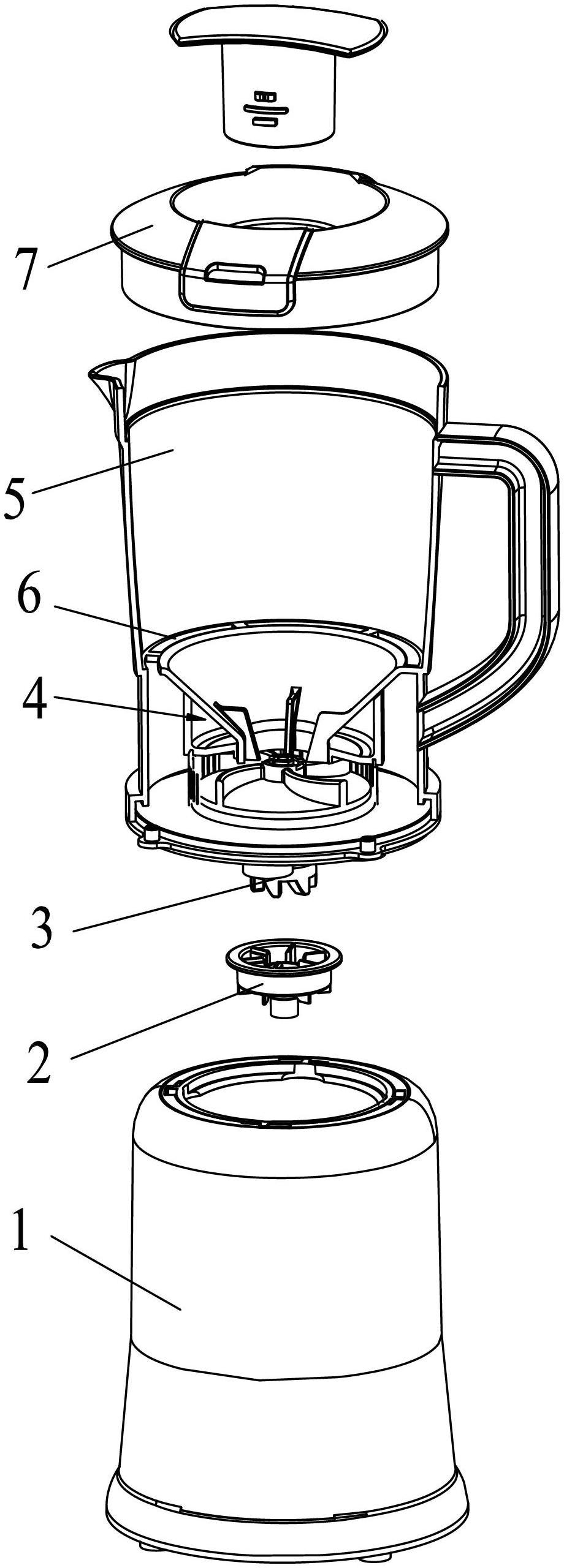

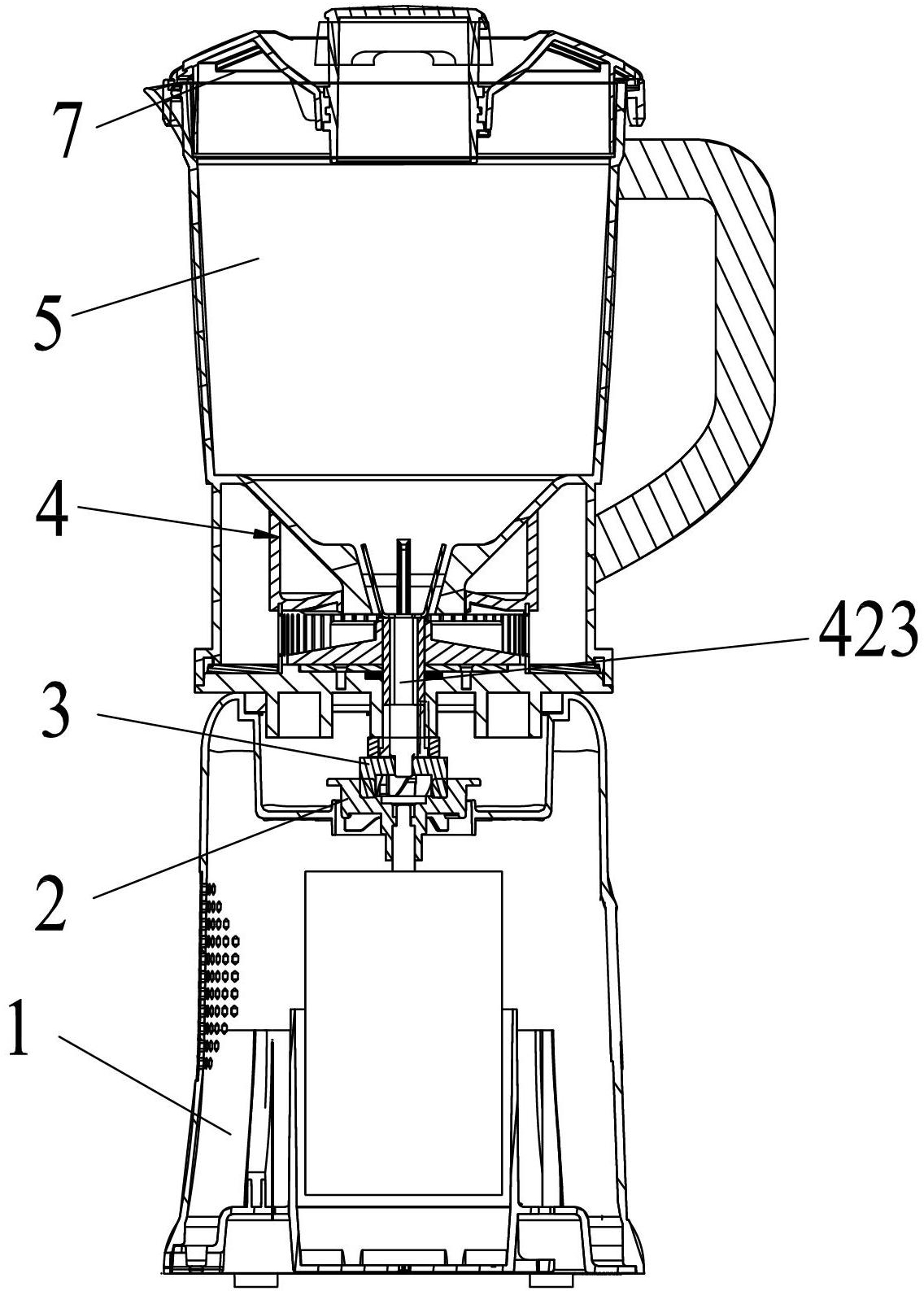

Agitator

The invention discloses an agitator. The agitator comprises a main unit (1) which provides power input, an agitation cup (5) and an agitator mill structure (4) which is arranged in the agitation cup (5); an output shaft of the main unit (1) penetrates through the bottom of the agitation cup (5) and is connected with the agitator mill structure (4); the agitator mill structure (4) comprises a filtering assembly and a knife assembly which is matched with the filtering assembly; the filtering assembly comprises a feed port (411), a filter screen (412) and a knife holder (413); the feed port (411) is positioned at the upper end of the filtering assembly; the knife holder (413) is arranged at the lower end of the filtering assembly; the filter screen (412) is connected between the feed port (411) and the knife holder (413) in a close fit way; and the knife assembly is arranged on the knife holder (413) and is positioned in the filter screen (412). The agitator can achieve a good crushing effect in the working state of low rotation speed, and greatly increasing food processing universality.

Owner:MIDEA GRP CO LTD

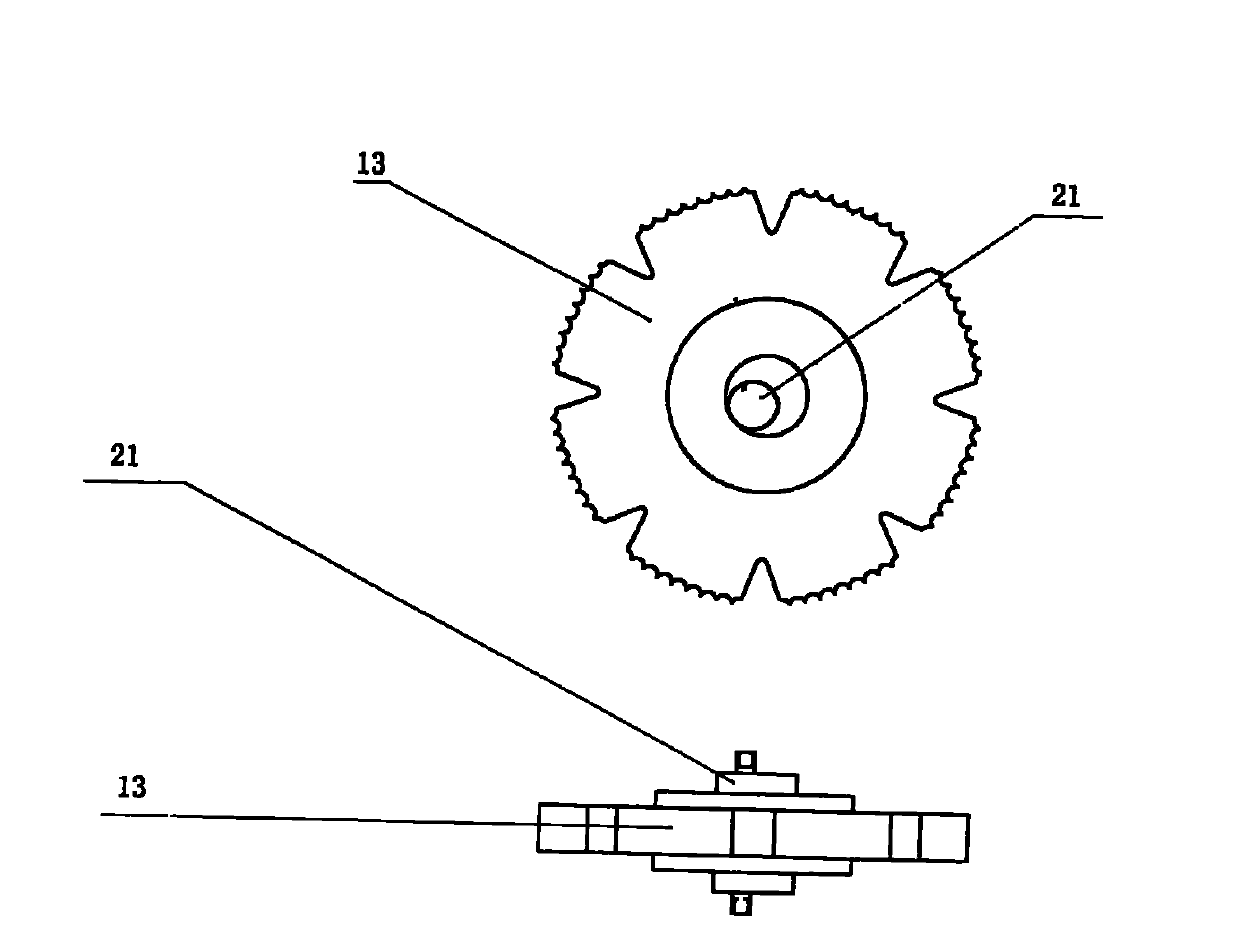

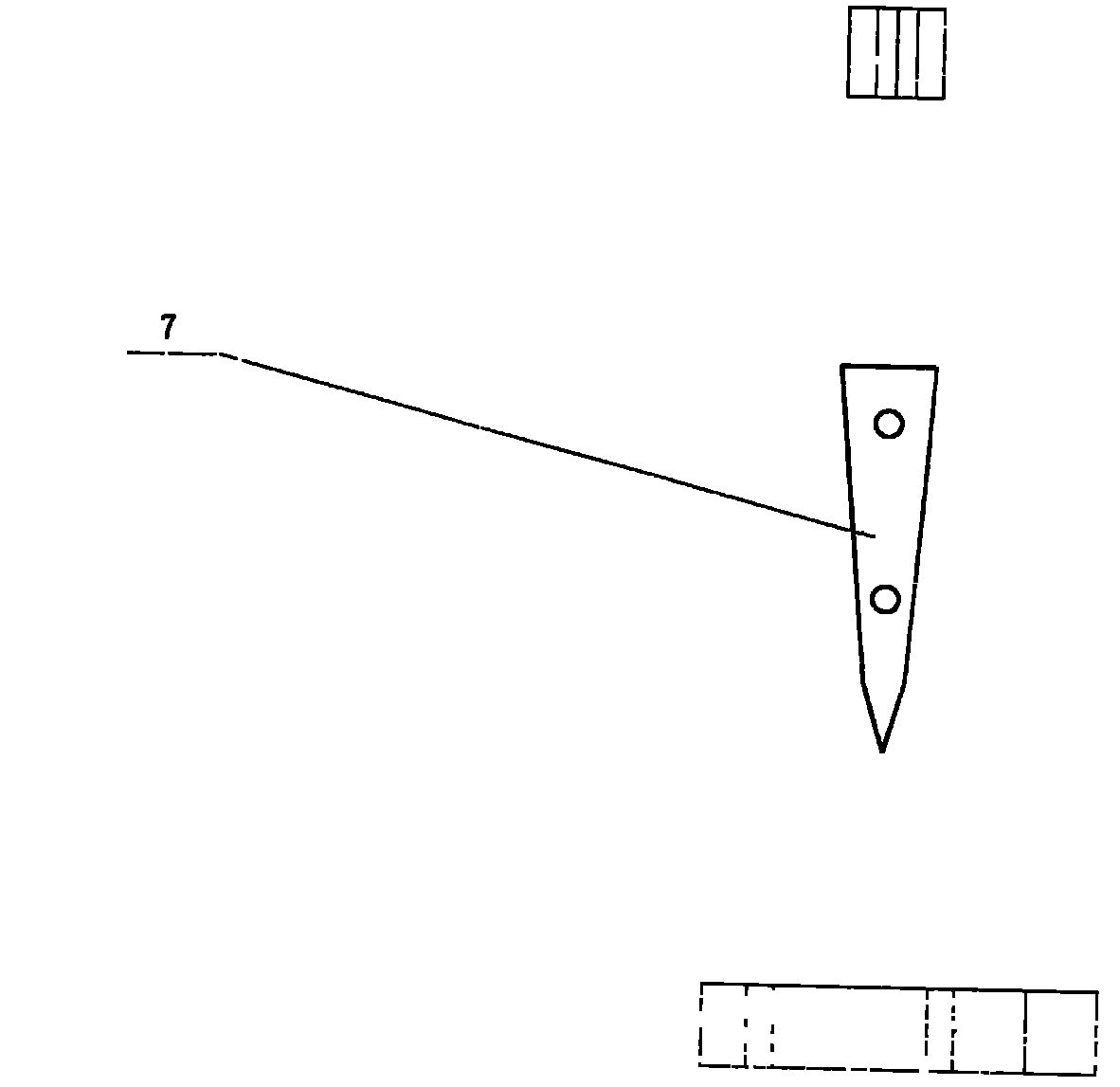

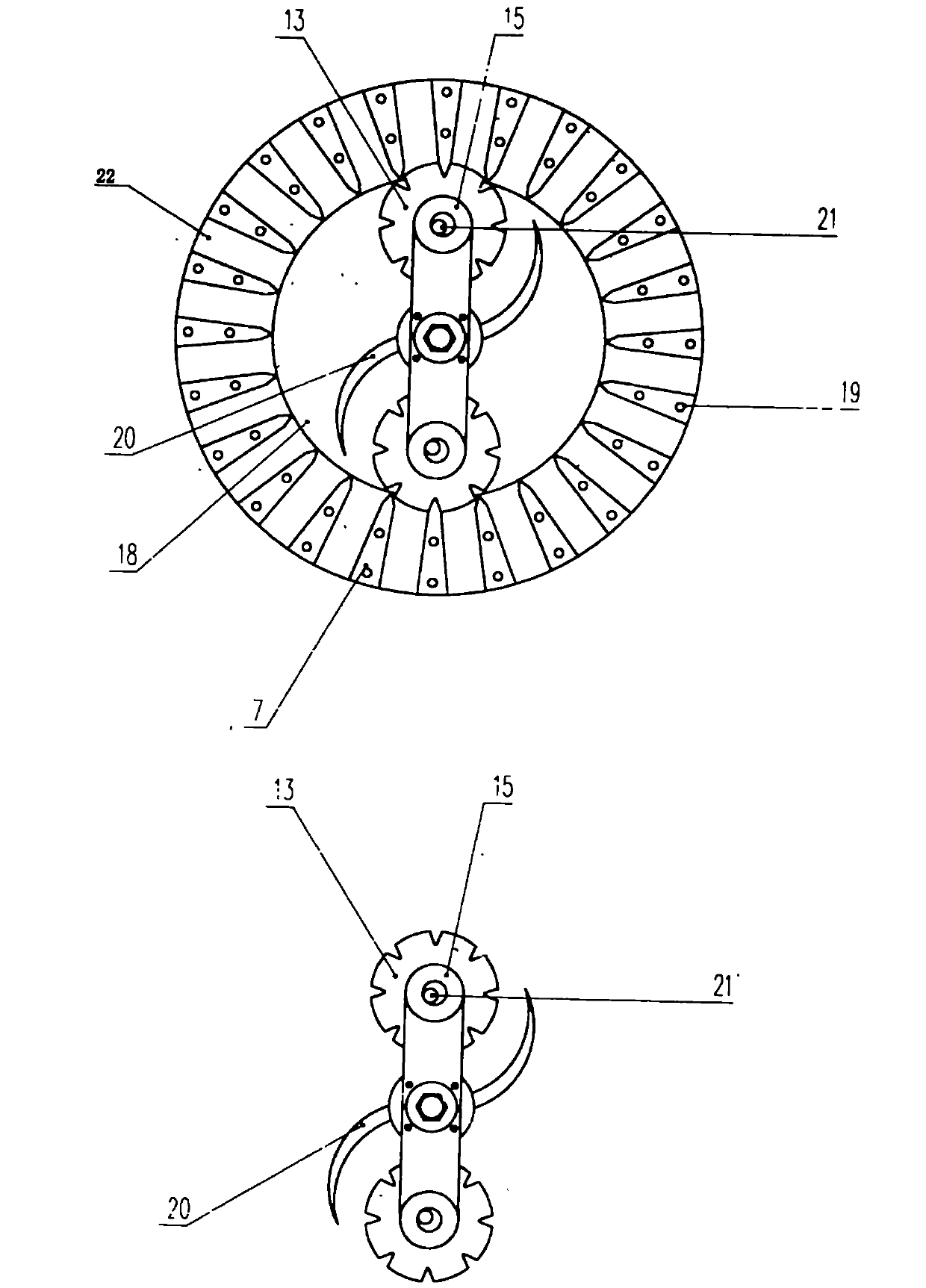

Biomass molding machine with annular tooth-shaped mold

InactiveCN102310578AImprove performanceReduce sensitivityShaping pressMolding machineInjection molding machine

The invention discloses a biomass molding machine with an annular tooth-shaped mold. When a biomass raw material enters a molding cavity, a tooth-shaped pressure roller and the annular tooth-shaped mold synchronously and relatively rotate, so that the raw material entering the molding cavity is fed into a molding mold hole under the mutual clamping action of the tooth-shaped pressure roller and the annular tooth-shaped mold instead of being extruded freely into the molding mold hole; a tooth-shaped pressure roller point is used for further pushing the raw material into the molding mold hole; the discharging speed of the raw material entering a molding mold under the forced pushing action of the pressure roller tooth point is not decreased, and hole blocking and machine halt are avoided; and the idle rotating time of the raw material which rotates along with the tooth-shaped pressure roller is reduced. The raw materials are pressed into the molding mold hole at any time, so that the characteristics of various raw materials and the sensitivity of the molding machine to the raw materials are lowered relatively, reactive loss is reduced, the abrasive degree is lowered, the suitability of the molding machine with the annular tooth-shaped mold for various raw materials is enhanced, the overall performance of the molding machine is enhanced greatly, and the technical defects of the conventional molding machine are overcome remarkably.

Owner:萧钠 +1

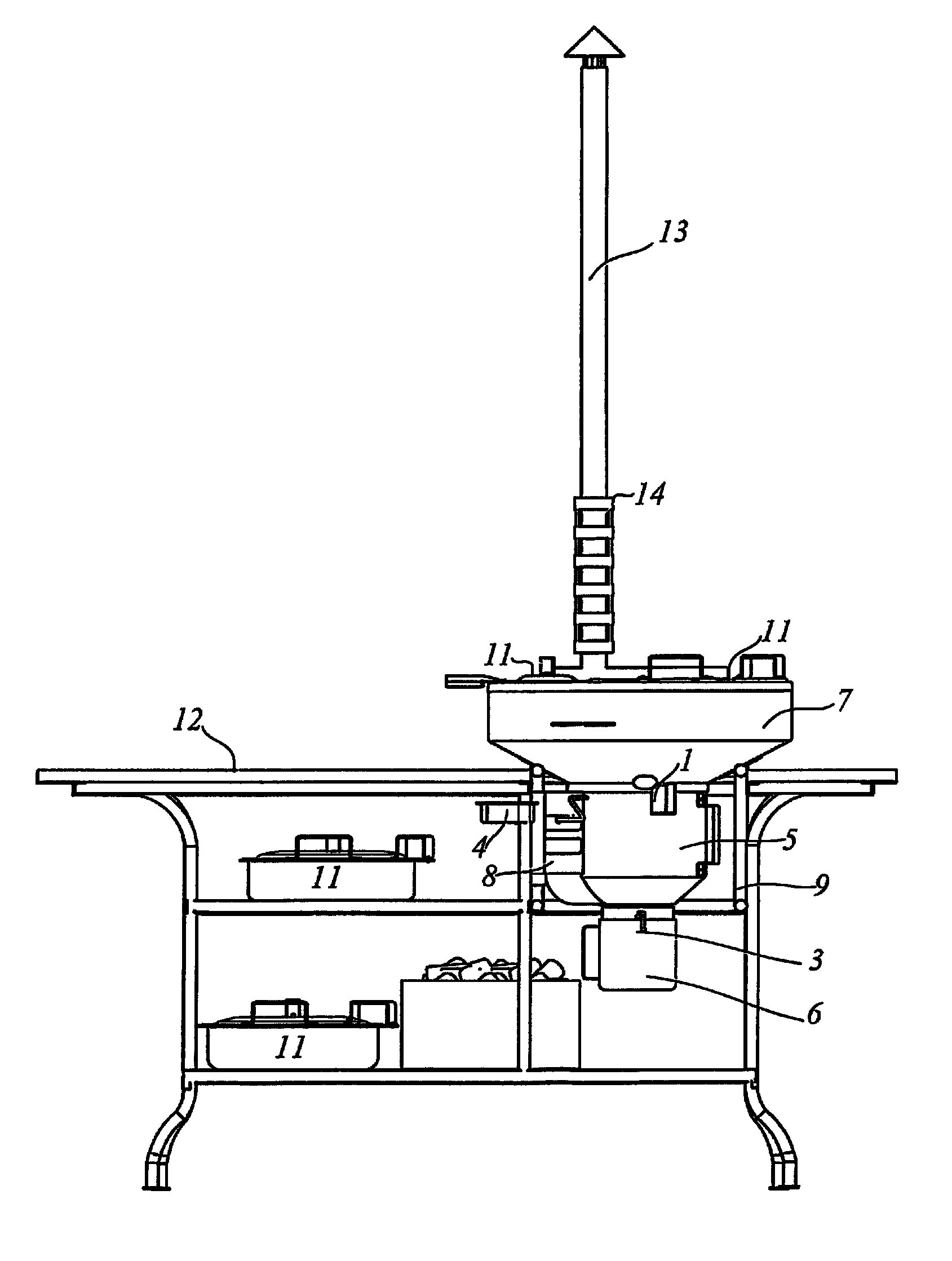

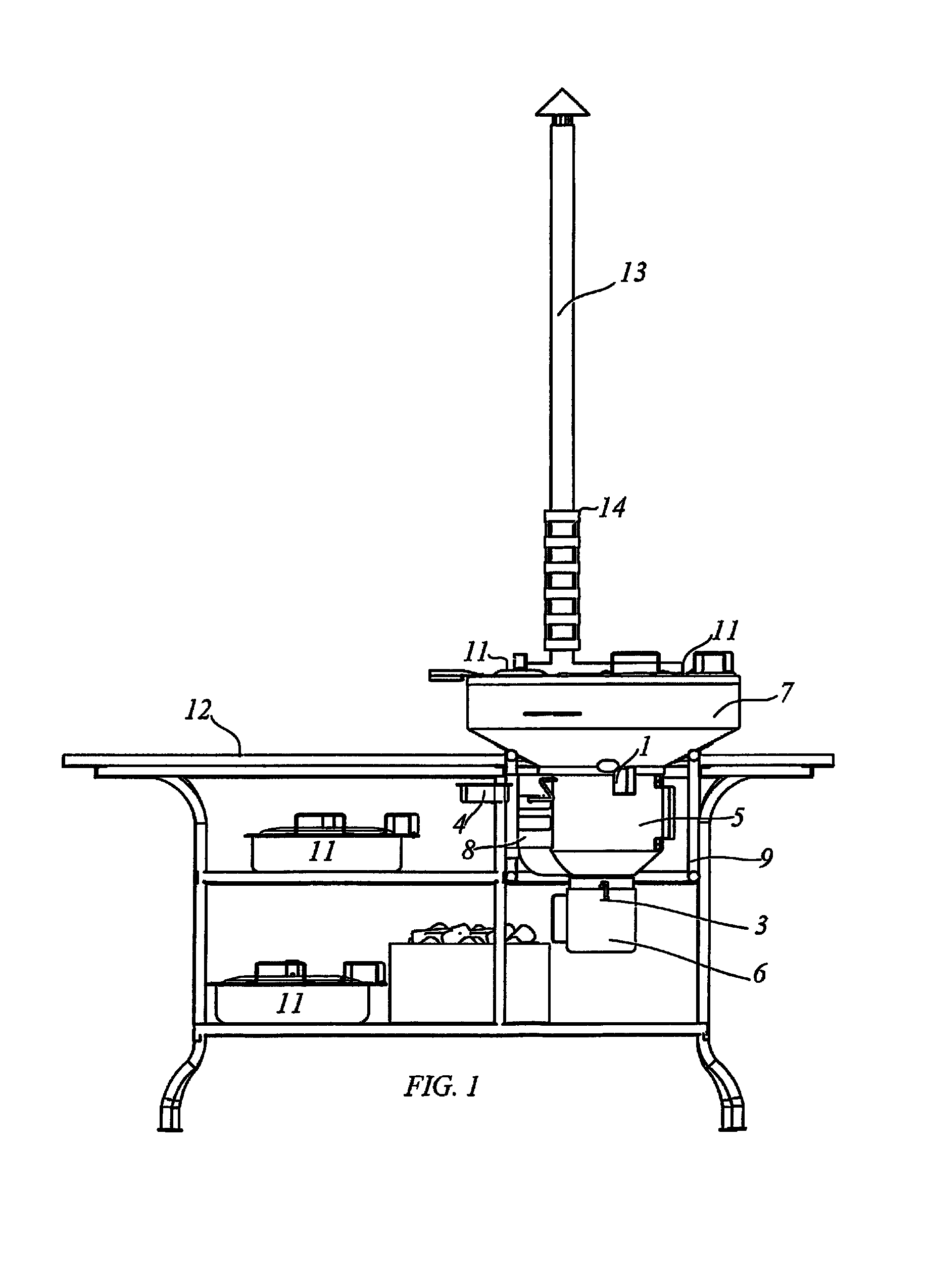

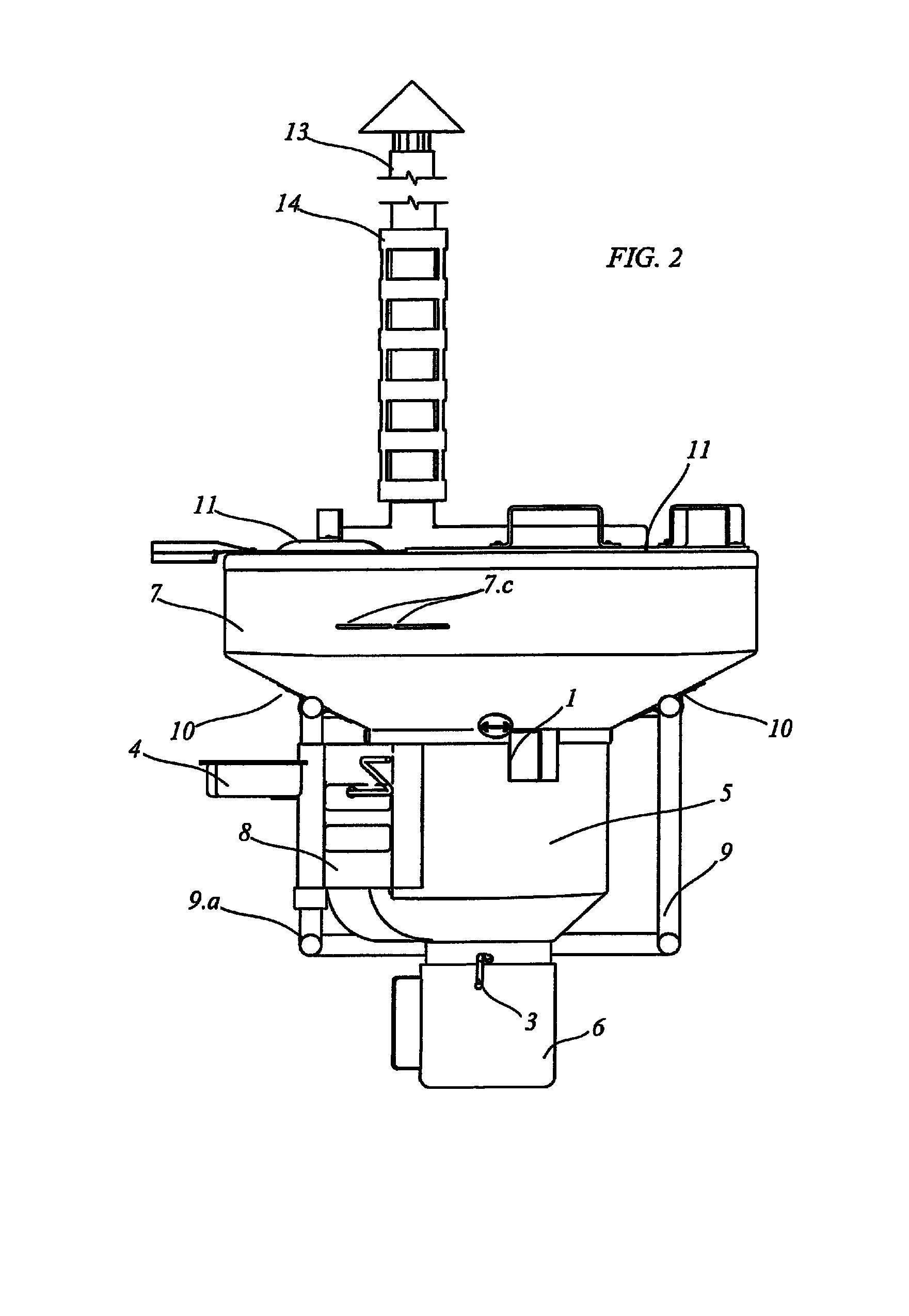

Heating device and method

ActiveUS8479720B1Reduce output speedImprove efficiencyCombustion-air/flue-gas circulation for stovesGaseous fuel burnerThermodynamicsCombustion chamber

A new and useful heating device is provided, that is particularly characterized by the efficient way it provides combustion of a carbon based fuel (e.g. wood). A vertically oriented combustion chamber is configured with a relatively narrow, lower portion, a relatively wider upper portion, and a vertically oriented wall structure defining the combustion chamber.

Owner:FIGUEROA OSCAR ENRIQUE

Pump unit and hand-held high-pressure washer

InactiveCN108087226AReduce volumeSimple structurePiston pumpsCleaning using liquidsReciprocating motionEngineering

The invention relates to a pump unit applied to a high-pressure washer. The pump unit comprises a water inlet cavity, a water outlet cavity, and a central cavity communicating with the water inlet cavity and the water outlet cavity; and the pump unit further comprises a plunger disposed in the central cavity and an eccentric mechanism connecting with the plunger, and the eccentric mechanism drivesthe plunger to reciprocate in the central cavity.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

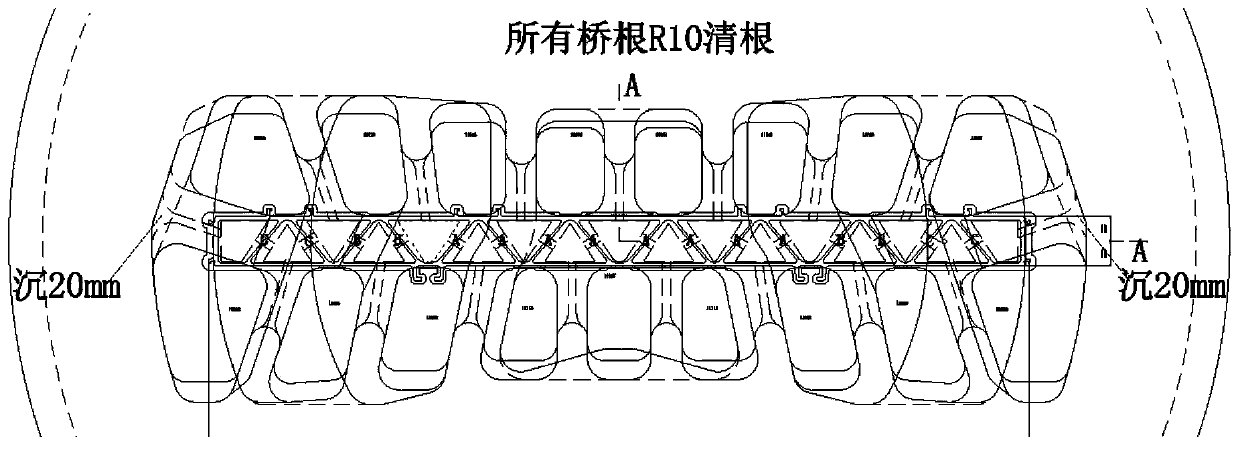

Aluminium alloy large broad width thin-wall rail car body floor profile extrusion technology

InactiveCN111069321AReduce the number of welds and welding defectsReduce processing costsExtrusion control devicesThin walledProcess systems

The invention belongs to the technical field of aluminium profile processing technology and relates to an aluminium alloy large broad width thin-wall rail car body floor profile extrusion technology.An aluminium alloy cast ingot comprises the following components in percentage by mass: 0.60-0.70% of Si, equal to or less than 0.25% of Fe, 0.03-0.08% of Cu, 0.20-0.30% of Mn, 0.45-0.55% of Mg, 0.10-0.20% of Cr, equal to or less than 0.10% of Zn, equal to or less than 0.05% of Ti, 0.30-0.50% of Mn+Cr, 0.03-0.05% of Zr, equal to or less than 0.05% of a single impurity, equal to or less than 0.15%of total amount of impurities, and the balance of Al. A thin-wall profile with the width being 1000 mm is produced through selecting reasonable alloy components and extruding equipment, innovating diedesign, optimizing die structure and controlling a key extruding process system, and the problems that the floor profile is non-uniform in flow rate and has waves and twisting are solved, so that thedimensional accuracy, the surface quality and the physical and chemical property of the profile can reach the standard of the technical protocol, and stable mass production of the large broad width thin-wall floor profile is realized.

Owner:CHINA ZHONGWANG

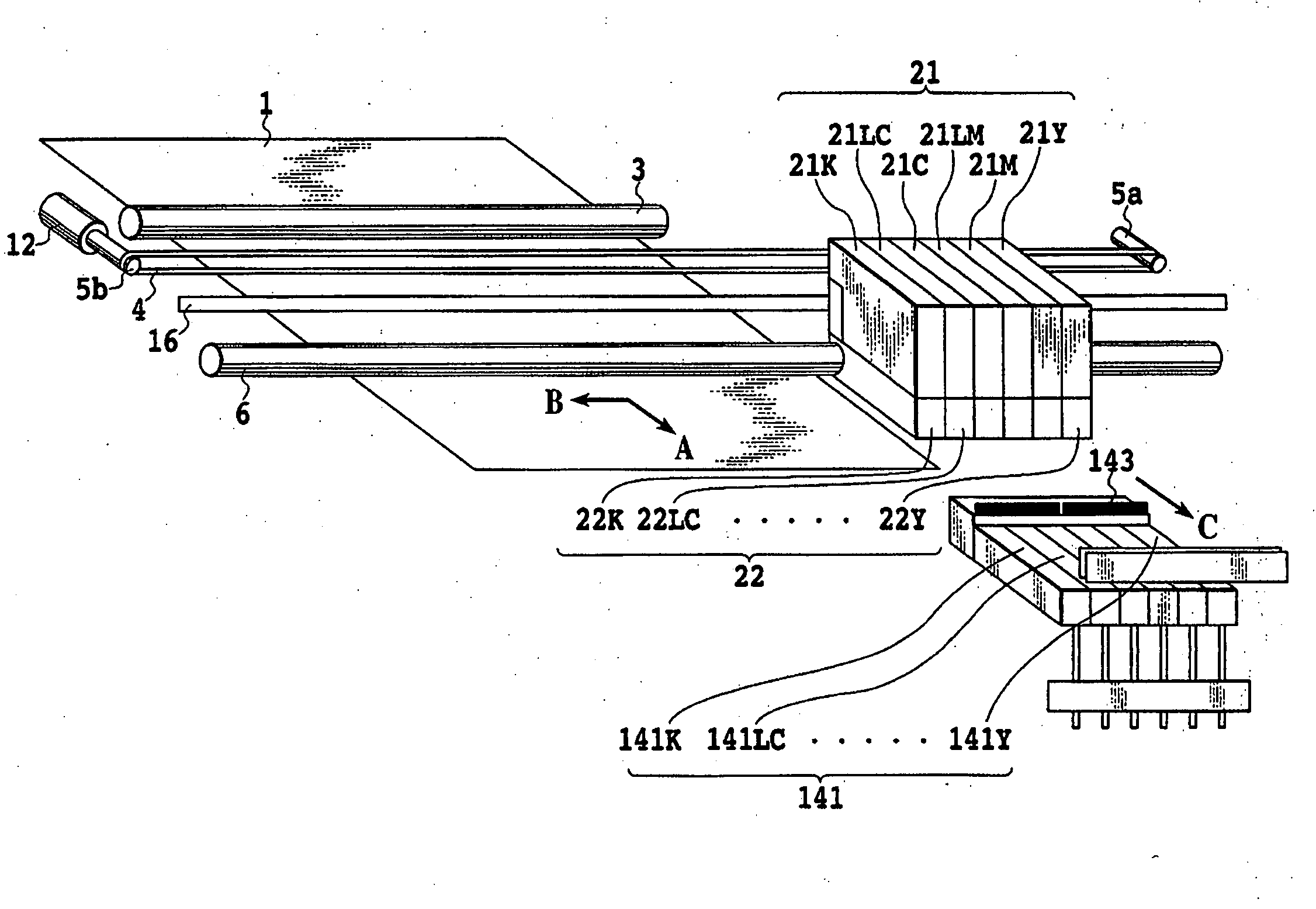

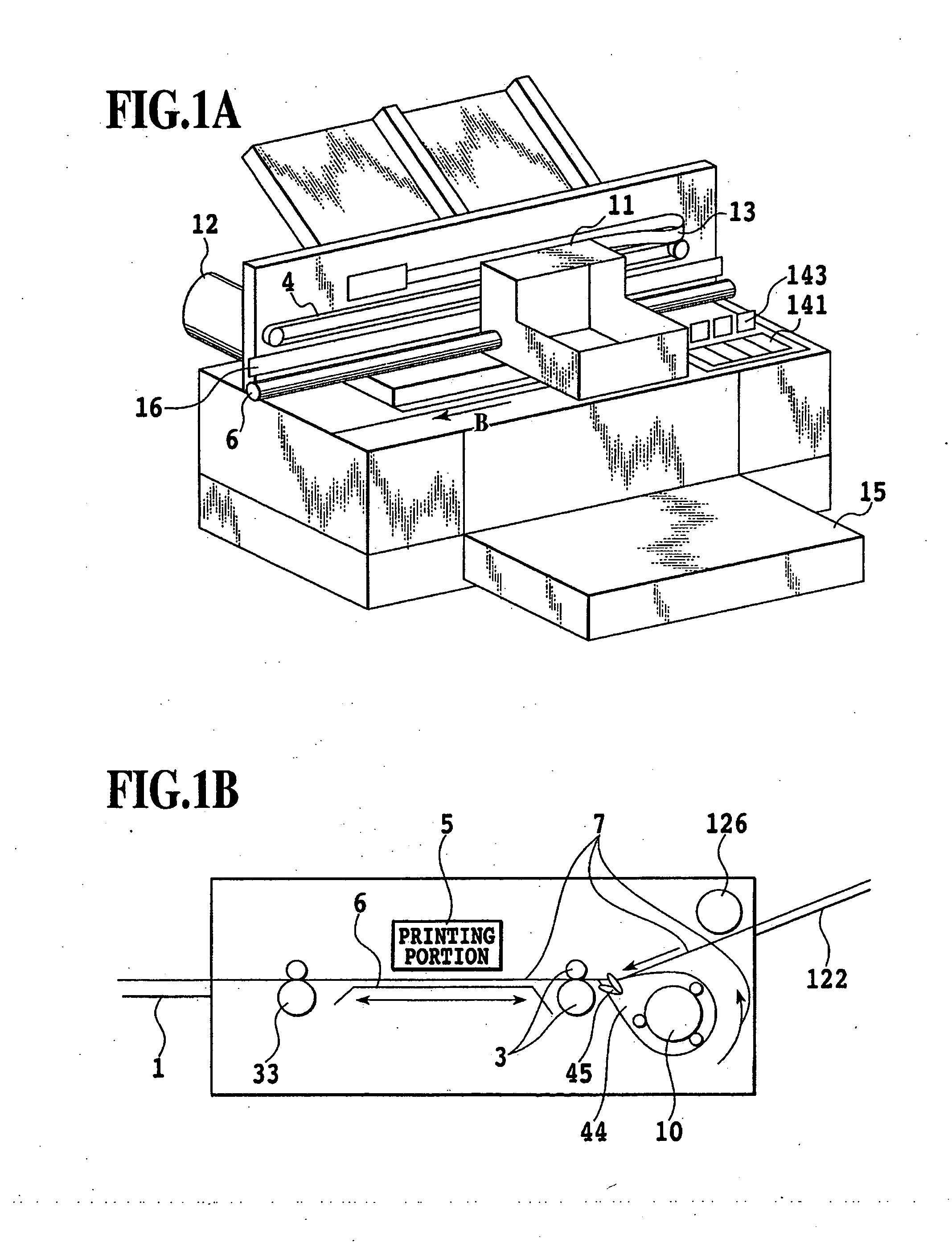

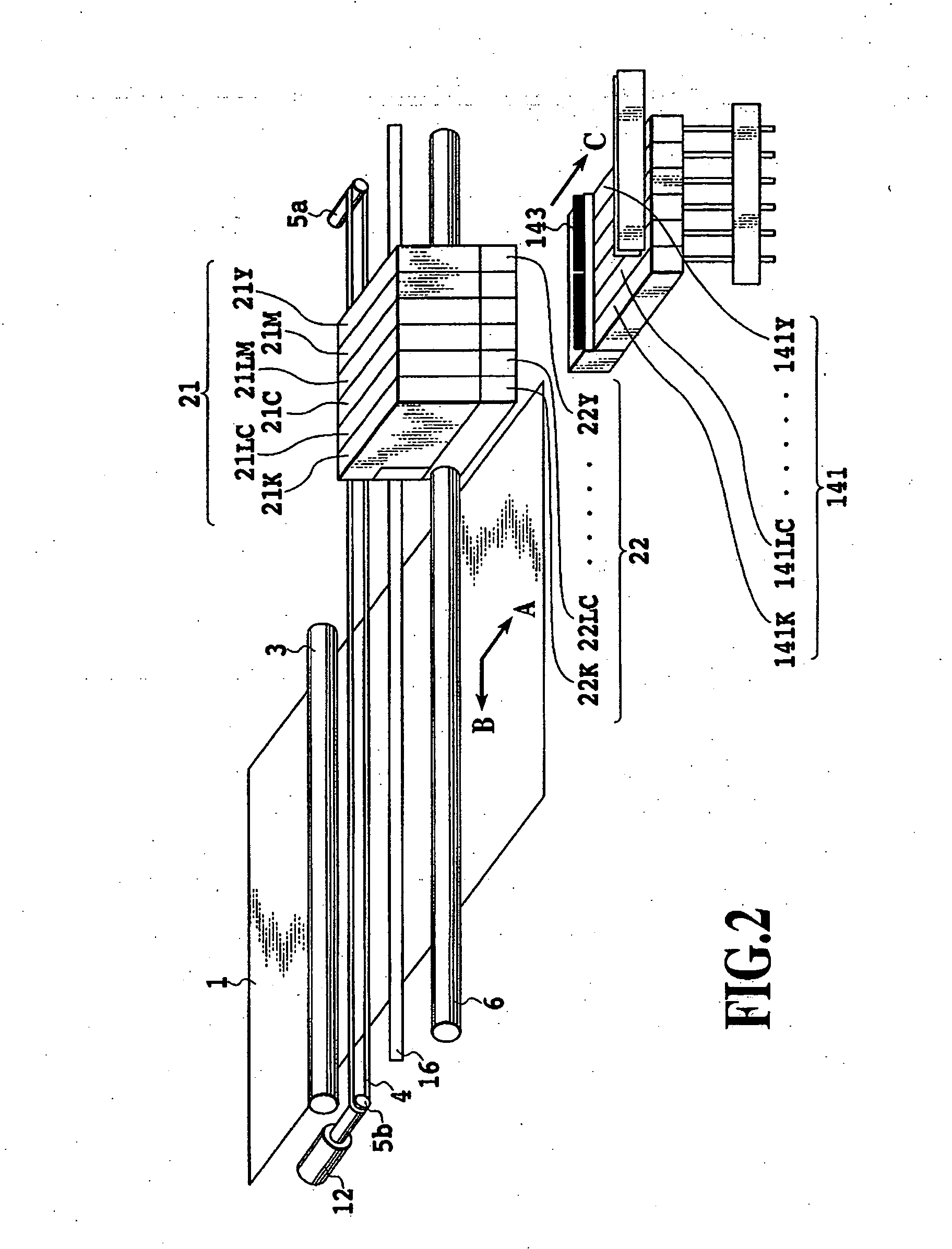

Inkjet printing apparatus and inkjet printing method

InactiveUS20060279587A1Reduce output speedSuppression problemSpacing mechanismsOther printing apparatusElectrical and Electronics engineeringInkjet printing

In a serial inkjet printing apparatus mounting a plurality of kinds of inks which have different properties and are arranged in parallel, high-speed bidirectional printing is realized without causing an influence of fixing period to prolong output time more than necessary. In order to realize the high-speed bidirectional printing, an order of executing forward print scanning and backward print scanning is controlled so as to further reduce a sum of time required to form an image and time required to wait for the formed image to be fixed. Thus, also in the bidirectional printing, between a forward direction and a backward direction, print scanning in a direction having shorter fixing period is set prior to that in the other direction. Consequently, total time required for image output can be further reduced.

Owner:CANON KK

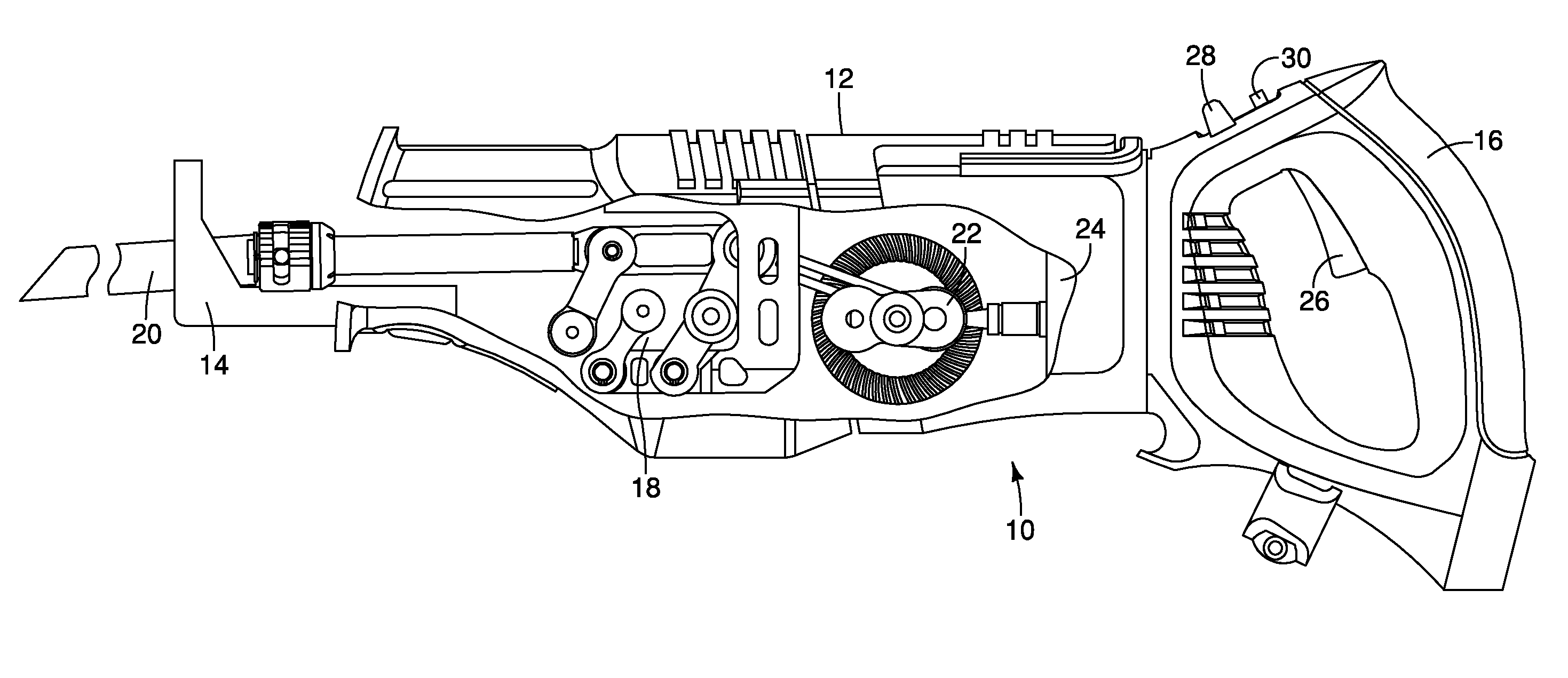

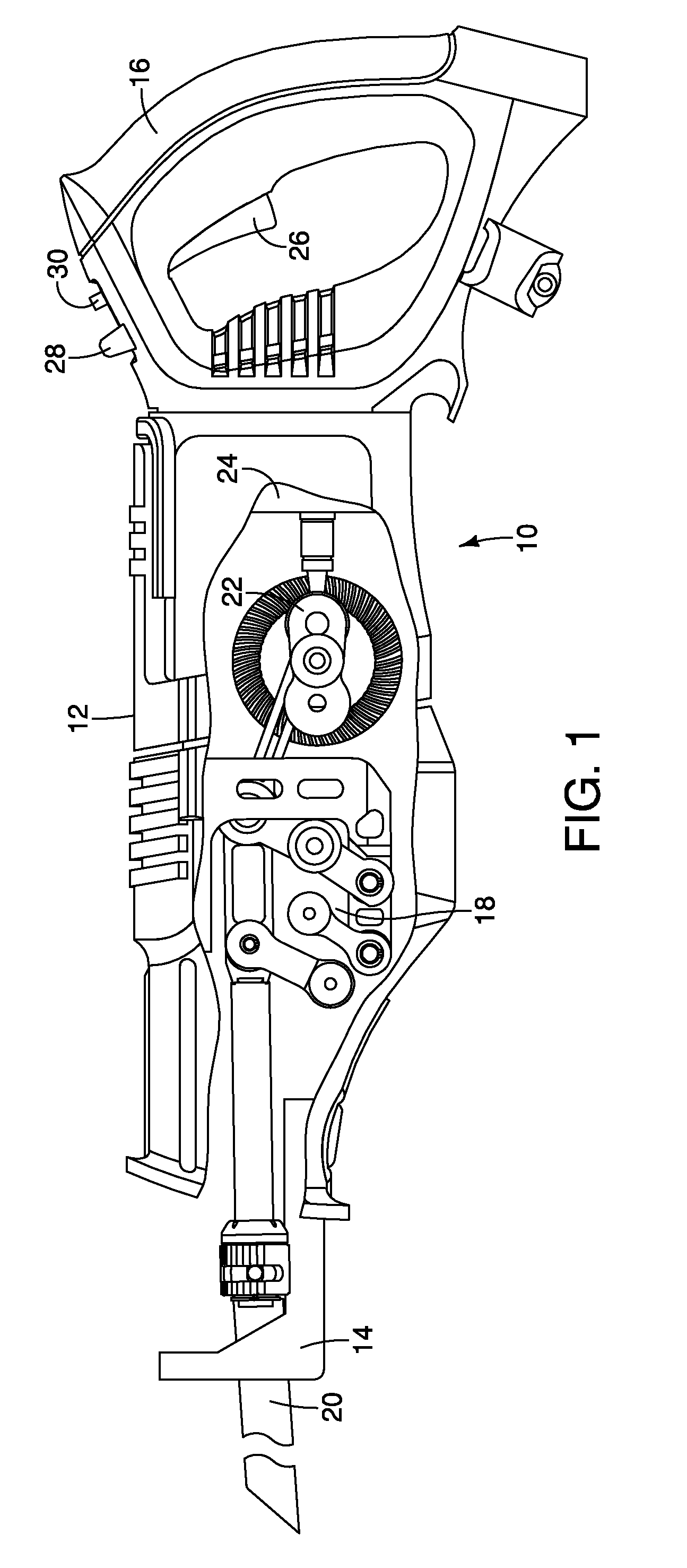

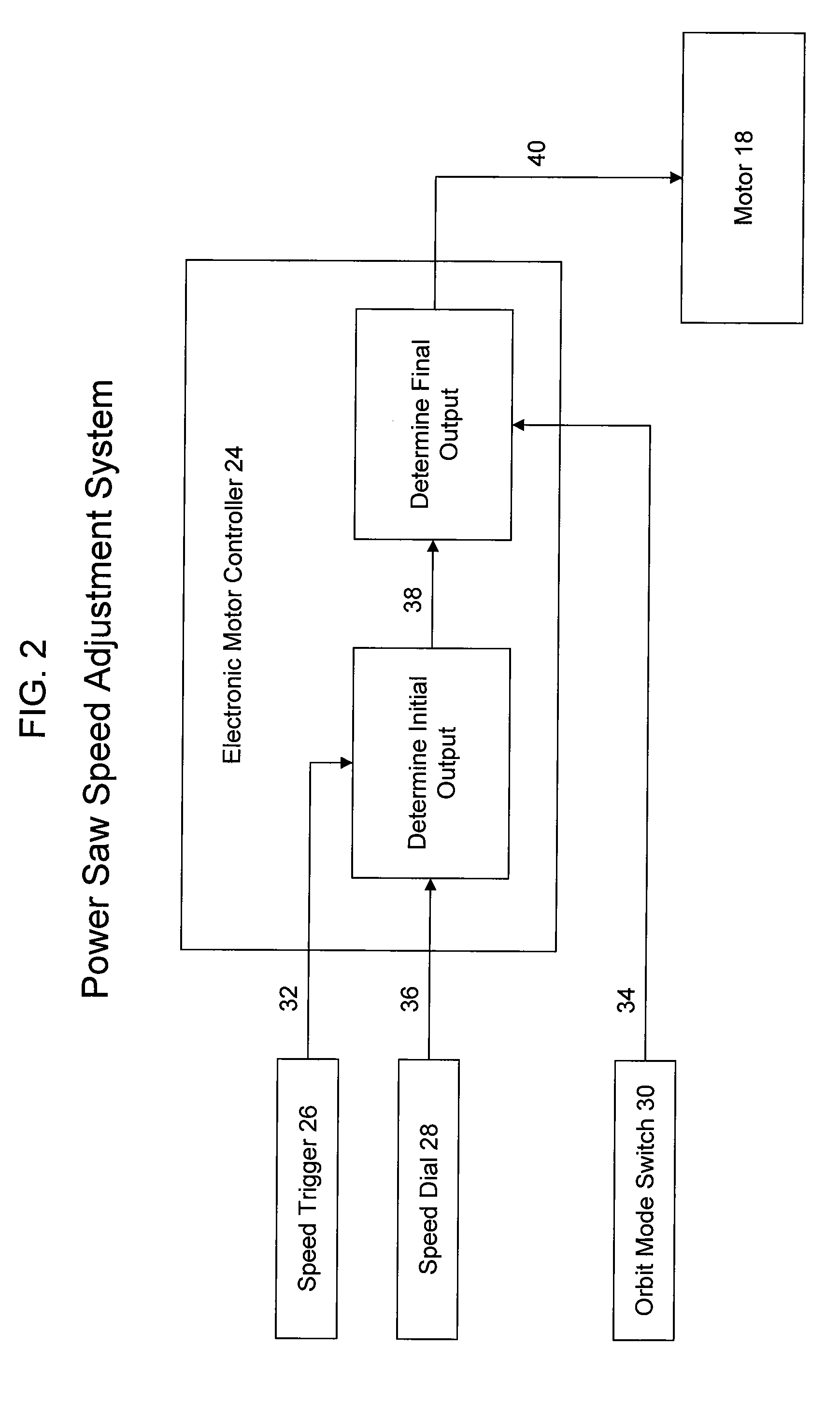

Electronic orbit control for saws

ActiveUS8653764B2Reduce output speedDC motor speed/torque controlDrilling rodsElectronic controllerOrbit

A power saw having a reciprocating blade, including a housing having a handle portion for holding the saw; a variable speed motor in the housing for driving the reciprocating blade; a mechanism configured to move the reciprocating blade in a non-linear path; an electronic controller for controlling the operation of the motor; a trigger switch configured to provide an electrical signal to the controller that is proportional to the amount of travel that the switch is moved, wherein the signal causes the controller to operate the motor through a range of operating speeds; and a mode switch operatively connected to the controller and including a first mode providing normal operating speeds responsive to the trigger switch being selectively moved through its range of travel, and a second mode wherein the operating speeds are within the range of about 50% to about 80% of the normal operating speeds.

Owner:CREDO TECH CORP +1

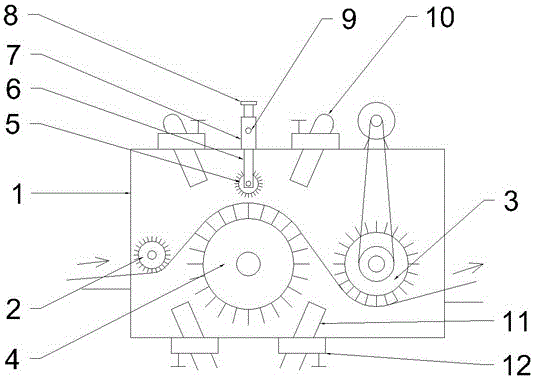

Non-woven carding dust-removing device

InactiveCN106498647AReduce output speedIncrease frictionMechanical cleaningPressure cleaningEngineeringNonwoven fabric

The invention provides a non-woven carding dust-removing device. The non-woven carding dust-removing device comprises a dust-removing box, wherein a cloth inlet is formed in one end of the dust-removing box and a cloth outlet is formed in the other end of the dust-removing box; a cloth inlet steering roller is arranged at the cloth inlet and in the dust-removing box; a cloth outlet steering roller is arranged at the cloth outlet and in the dust-removing box; a carding roller is arranged in the dust-removing box; a cloth pressing roller is arranged over the roller surface of the carding roller and is arranged at the bottom of an adjusting shaft; an upper dust-absorbing pipe is arranged on each of the two sides of the cloth pressing roller; the upper dust-absorbing pipe passes through the top of the dust-removing box and extends to be above the carding roller; a lower dust-absorbing pipe is arranged below the carding roller and in the dust-removing box. By adoption of the scheme, the non-woven carding dust-removing device has a simple structure, good speed-controlling effect and low use cost and can remove dust.

Owner:湖州盛世杰制衣有限公司

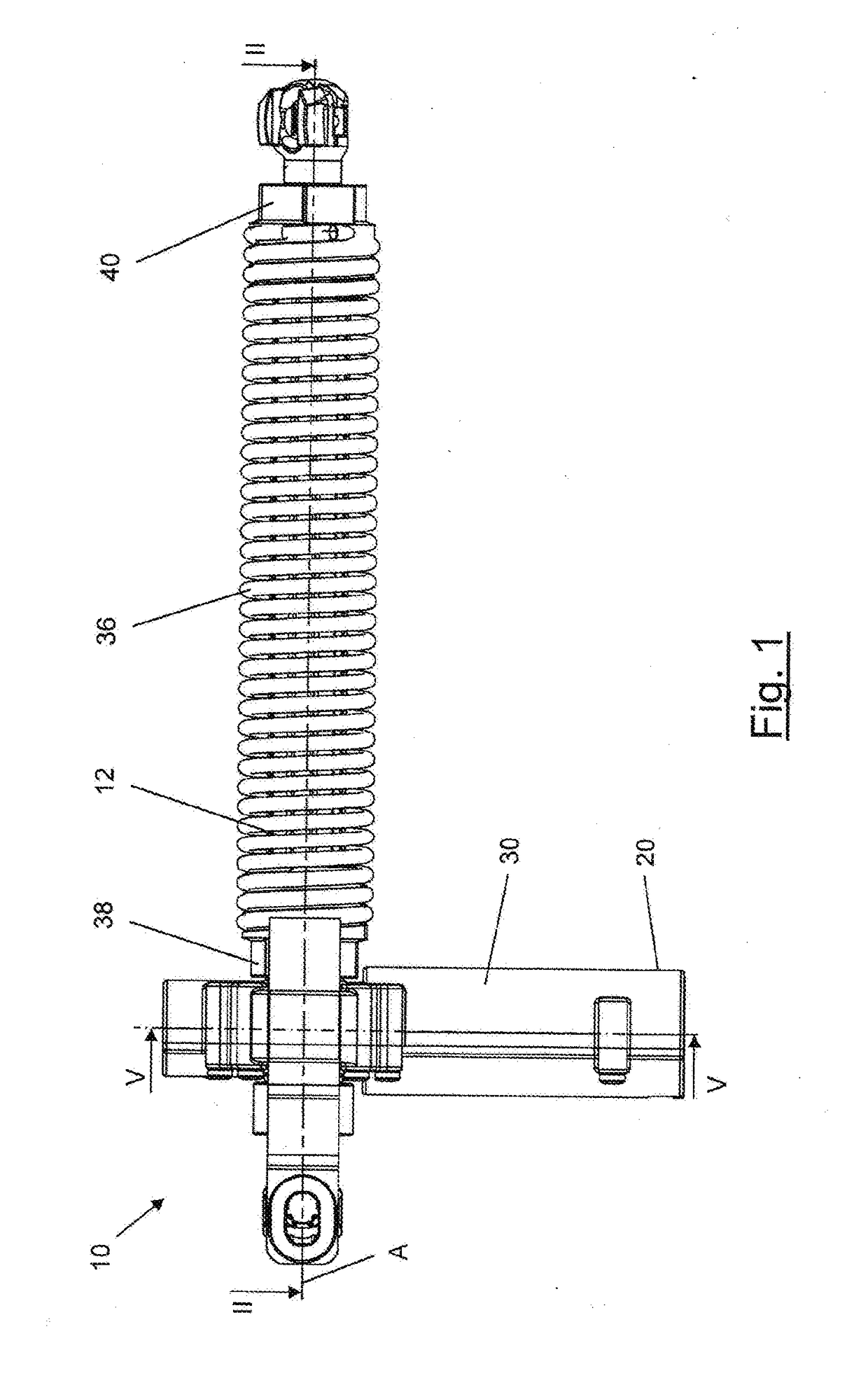

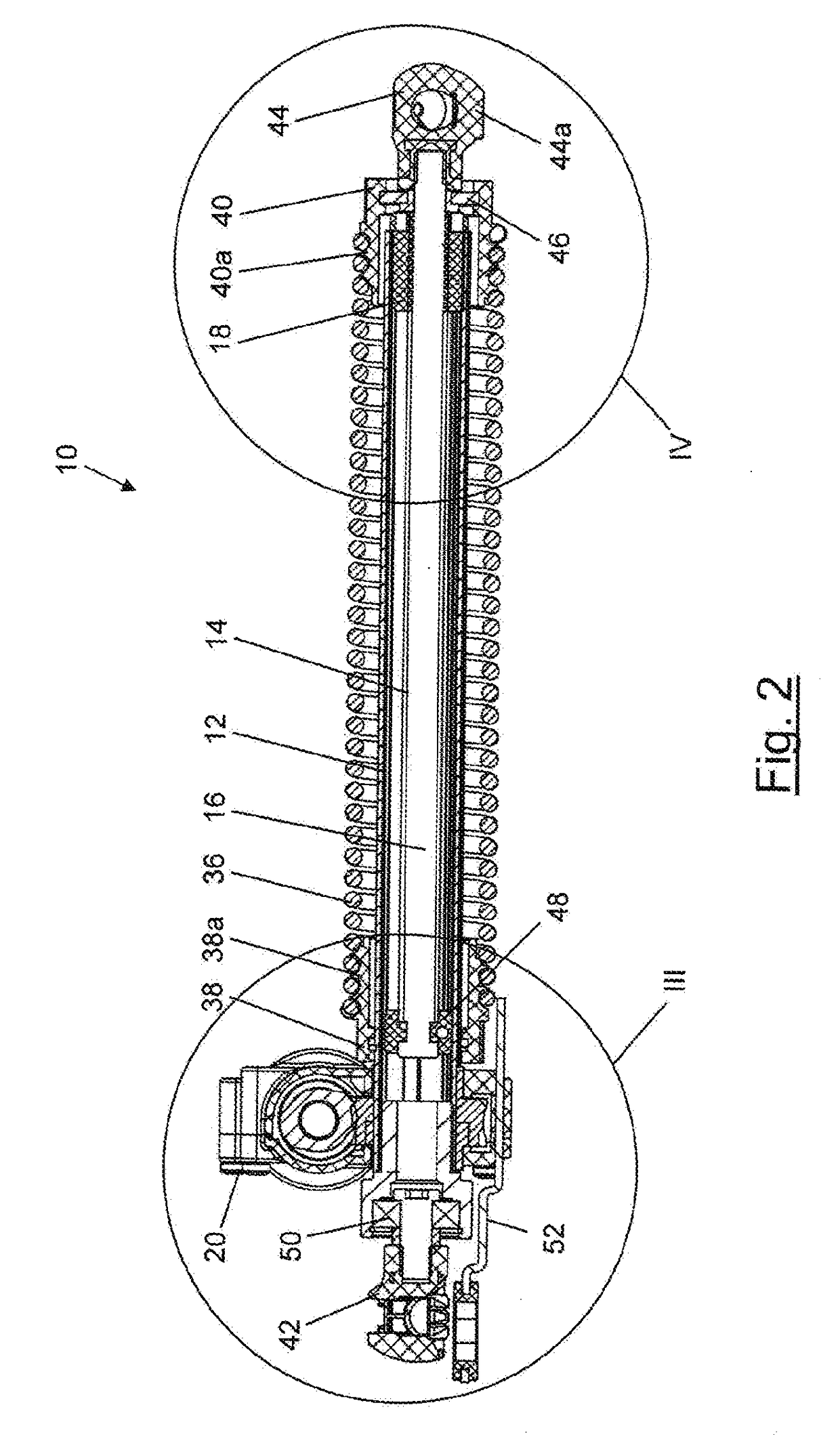

Spindle drive apparatus

ActiveUS20180080532A1Easy to assembleReduce output speedPower-operated mechanismWing openersEngineeringDriven element

A spindle drive apparatus includes a guide tube having a connection unit for connecting the spindle drive apparatus to a superordinate assembly, the connection unit fastened to the guide tube for rotation relative thereto, an externally threaded spindle housed at least in part in the guide tube, a further connection unit rotationally fixed to the end of the spindle for connecting the spindle drive apparatus to a further superordinate assembly, a spindle nut is fastened to the guide tube in threaded engagement with the spindle, and a drive assembly has a drive unit, wherein a drive element that is driven by the drive unit surrounds the guide tube and is rotationally fixable thereto, and wherein the drive unit is supported on one of the superordinate assemblies or on an element connected thereto.

Owner:STABILUS

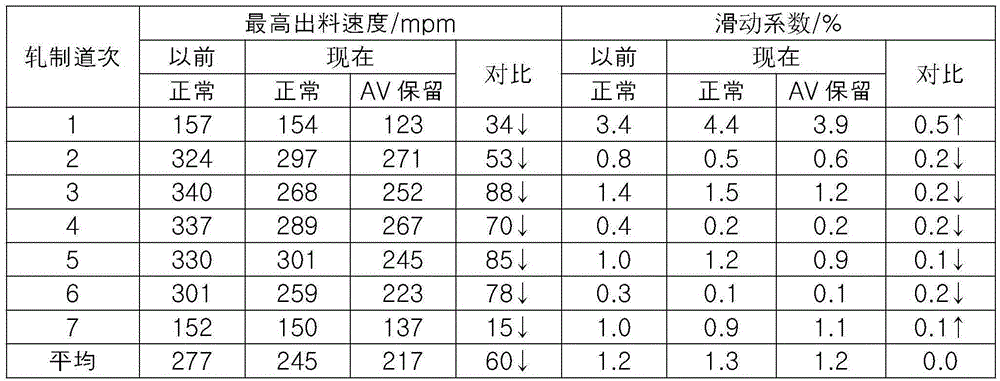

Method for preventing steel band from sliding in reversible cold rolling process of 400-series steel plate

InactiveCN105327947AIncrease production capacityIncrease productionTension/compression control deviceMetal rolling arrangementsReduction rateSheet steel

The invention discloses a method for preventing a steel band from sliding in the reversible cold rolling process of a 400-series steel plate. The method comprises the steps that firstly, rollers with the diameters ranging from 75 mm to 105 mm are selected for rolling, the surface roughness of the rollers in first three rolling gates ranges from Ra0.4 to Ra0.6, the front tension of the steel band is controlled to be 40-60 ton in the rolling process, the rear tension of the steel band is smaller than the front tension of the steel band by 2-3 ton except the first gate, the discharging speed of the steel band is controlled to be 500-600 mpm, and the reduction rate of each gate is smaller than or equal to 28%.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

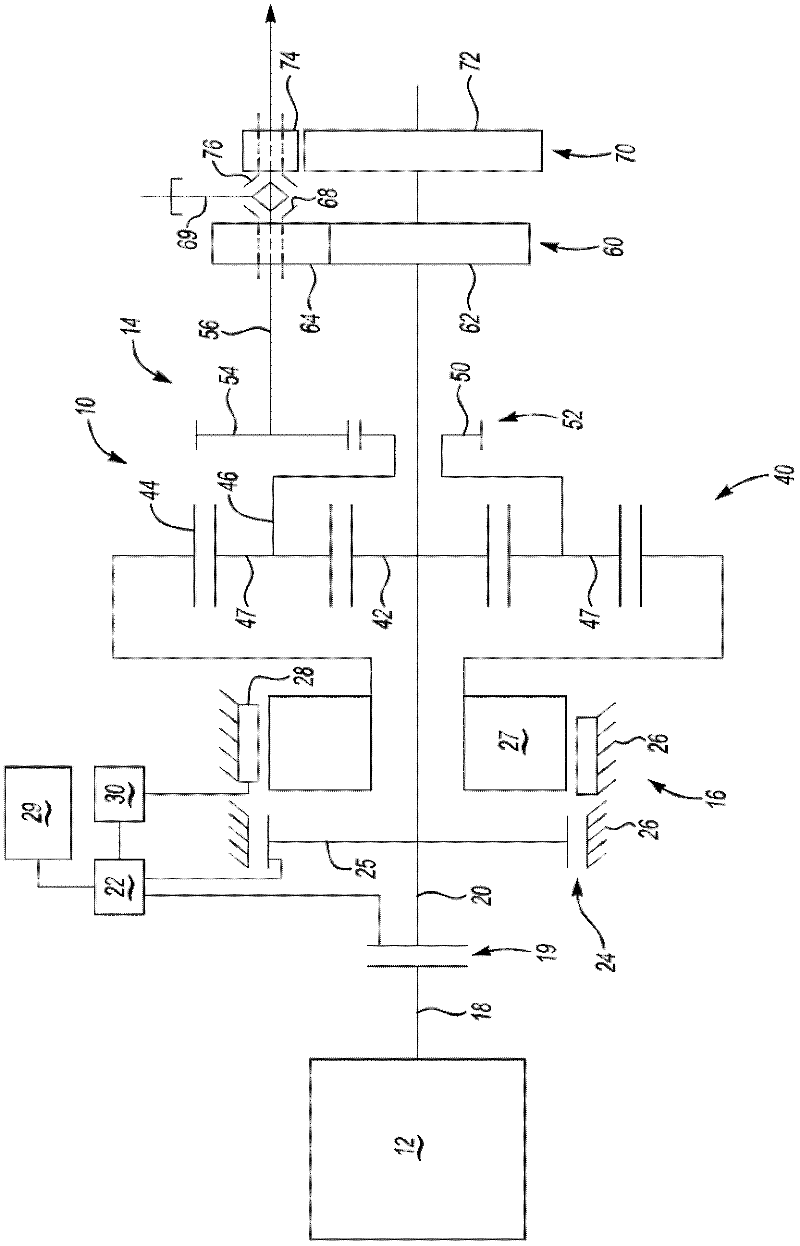

Motor-assisted transmission

ActiveCN102537232AReduce output speedImprove economyGas pressure propulsion mountingToothed gearingsFixed ratioControl theory

A powertrain has an engine with a crankshaft. The powertrain includes a planetary gear set having a first, a second, and a third member. The first member is connected for common rotation with an input member. A first clutch is selectively engageable to operatively connect the crankshaft with the input member. A second clutch is selectively engageable to ground the input member with a stationary member. An electric motor / generator has a rotor operatively connected for common rotation with the second member. An output member is provided, with a set of intermeshing gears configured to transfer torque from the third member to the output member. A first gear pair and a second gear pair are operable by engagement of a first synchronizer and a second synchronizer, respectively, to provide two different fixed ratios between the input member and the output member.

Owner:GM GLOBAL TECH OPERATIONS LLC

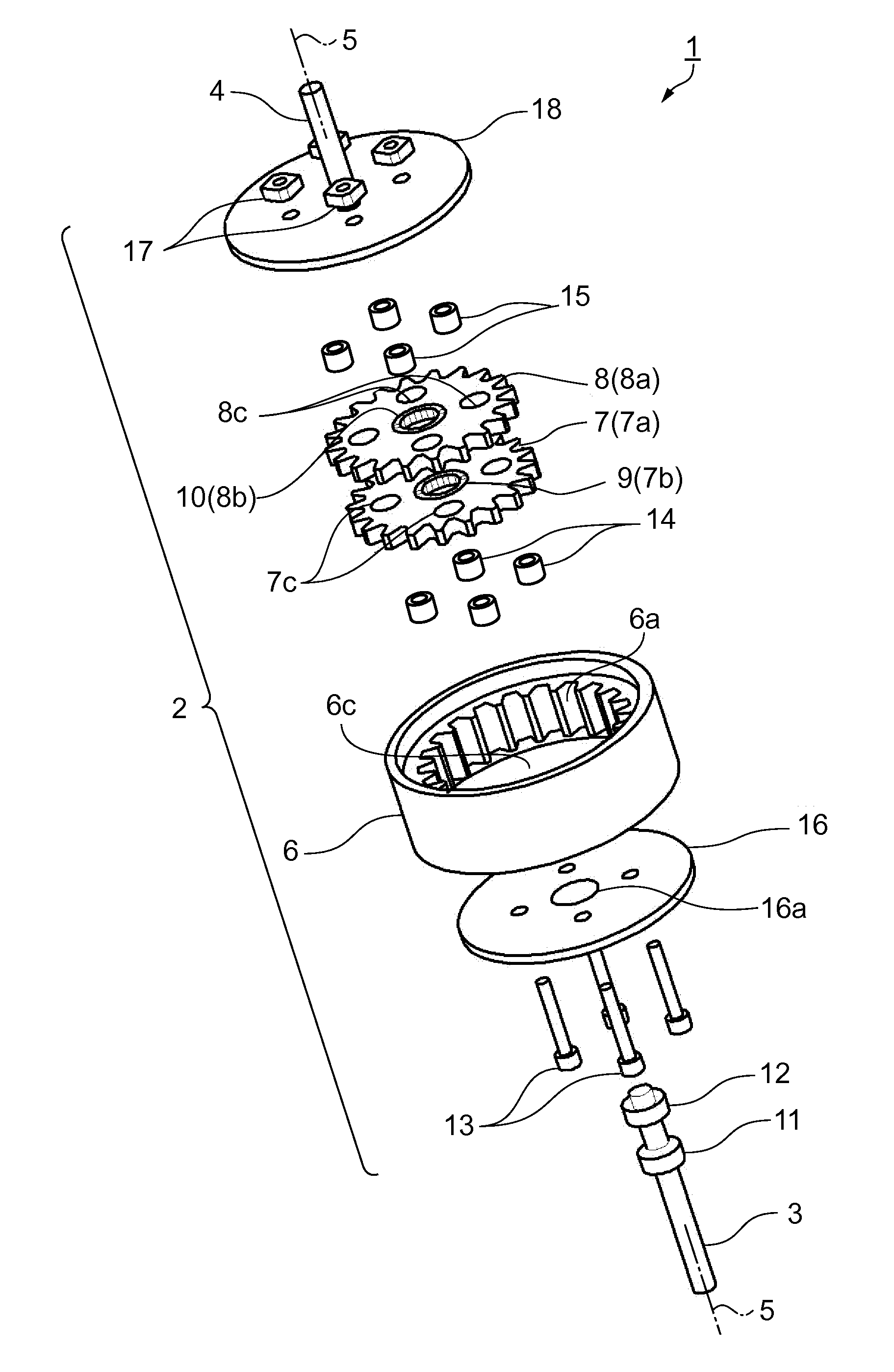

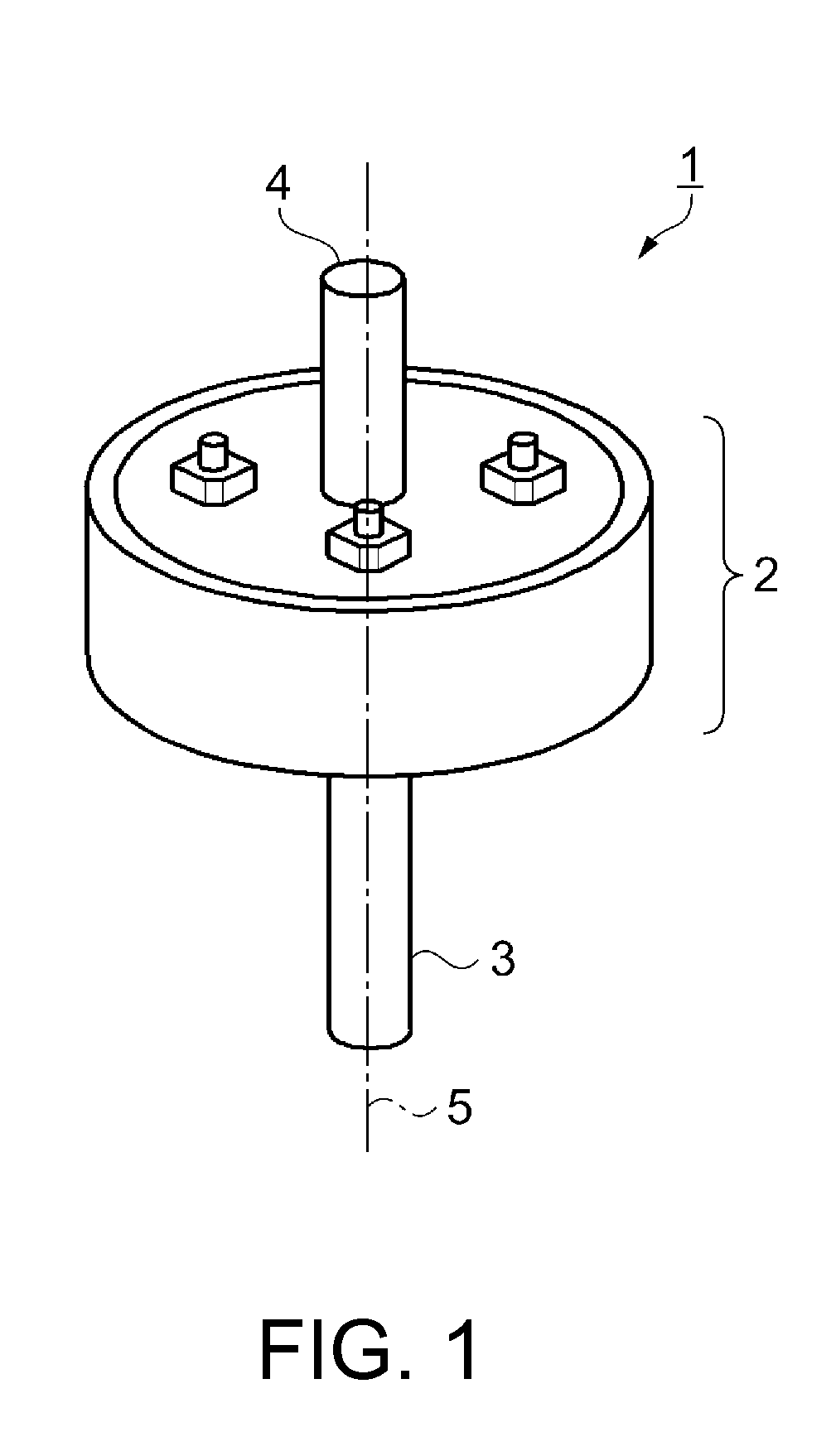

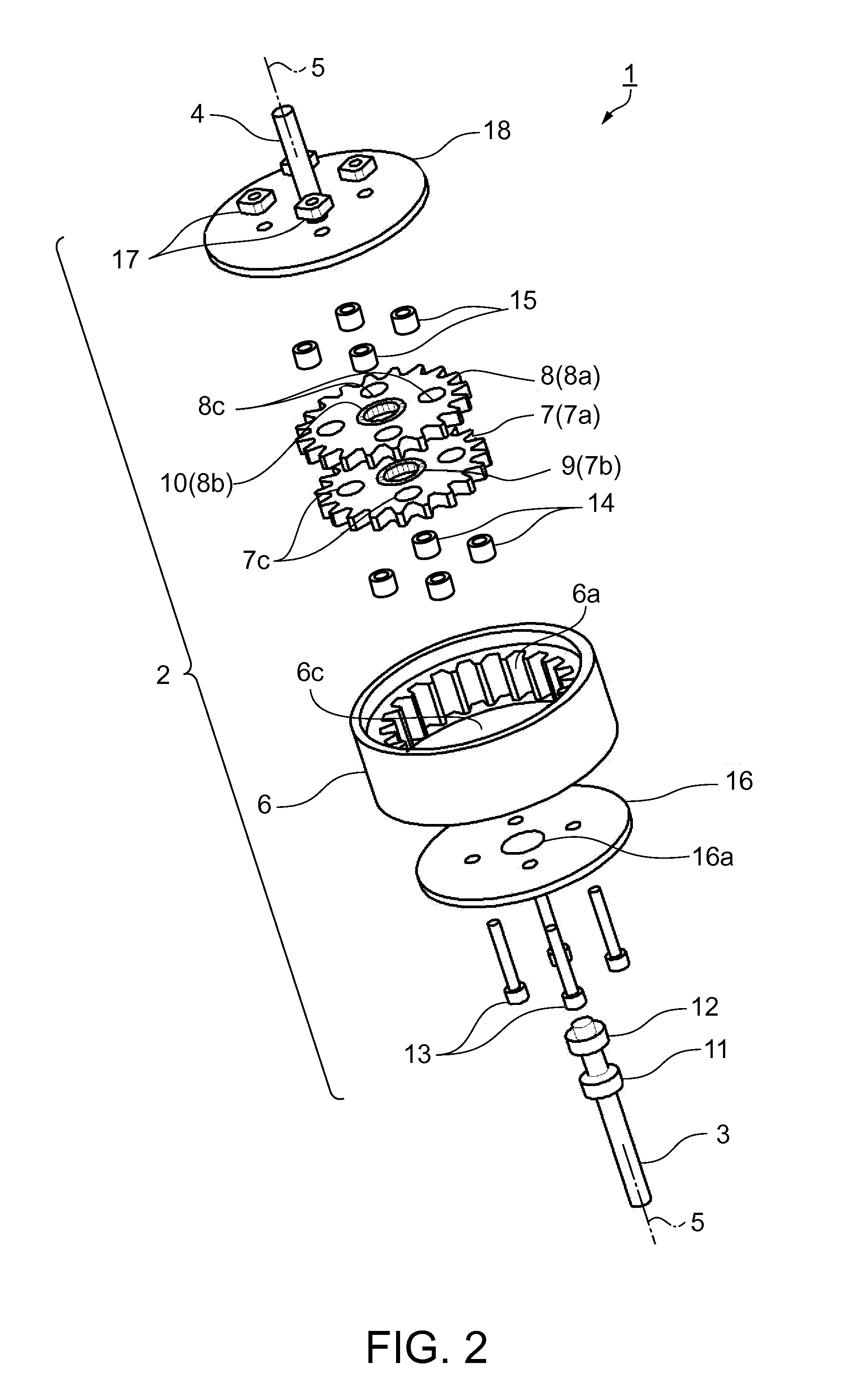

Speed reducer, robot, and robot hand

InactiveUS20120325040A1Prevent and avoid occurrenceReduce output speedProgramme-controlled manipulatorJointsRobot handReducer

A speed reducer includes a ring gear having internal gear teeth, a revolving gear meshing with the ring gear, an eccentric cam relatively rotatably provided in a center of the revolving gear, a first rotating shaft in the eccentric cam, the first rotating shaft driving the revolving gear by rotating the eccentric cam, a through pin inserted into a through hole in the revolving gear, a second rotating shaft connected to the through pin and outputting rotation obtained by the rotation of the revolving gear, and an elastic section between the through hole and the through pin, the elastic section having a greater area of contact with the through pin than with the through hole.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com