Patents

Literature

597results about How to "Increase the output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

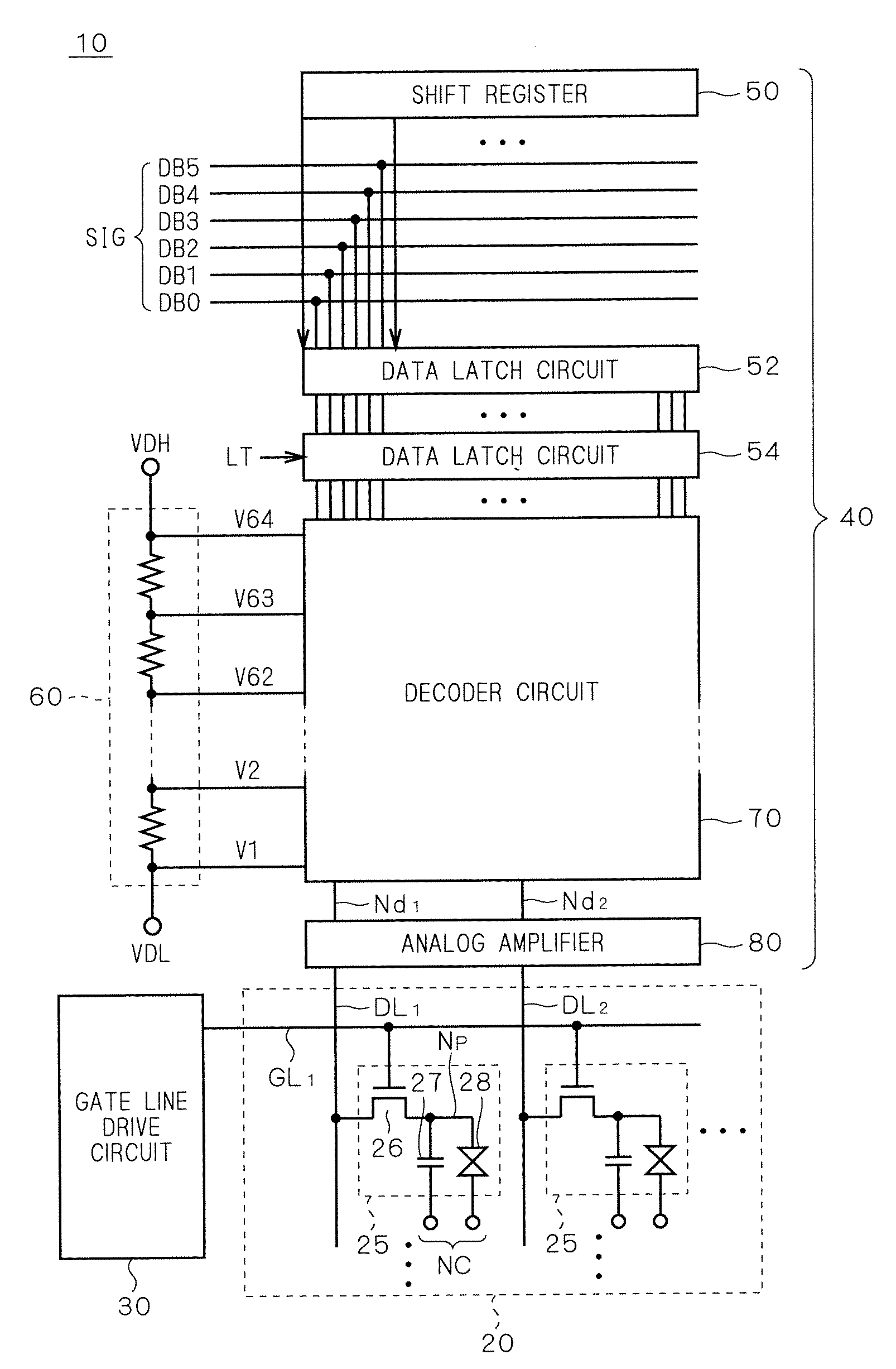

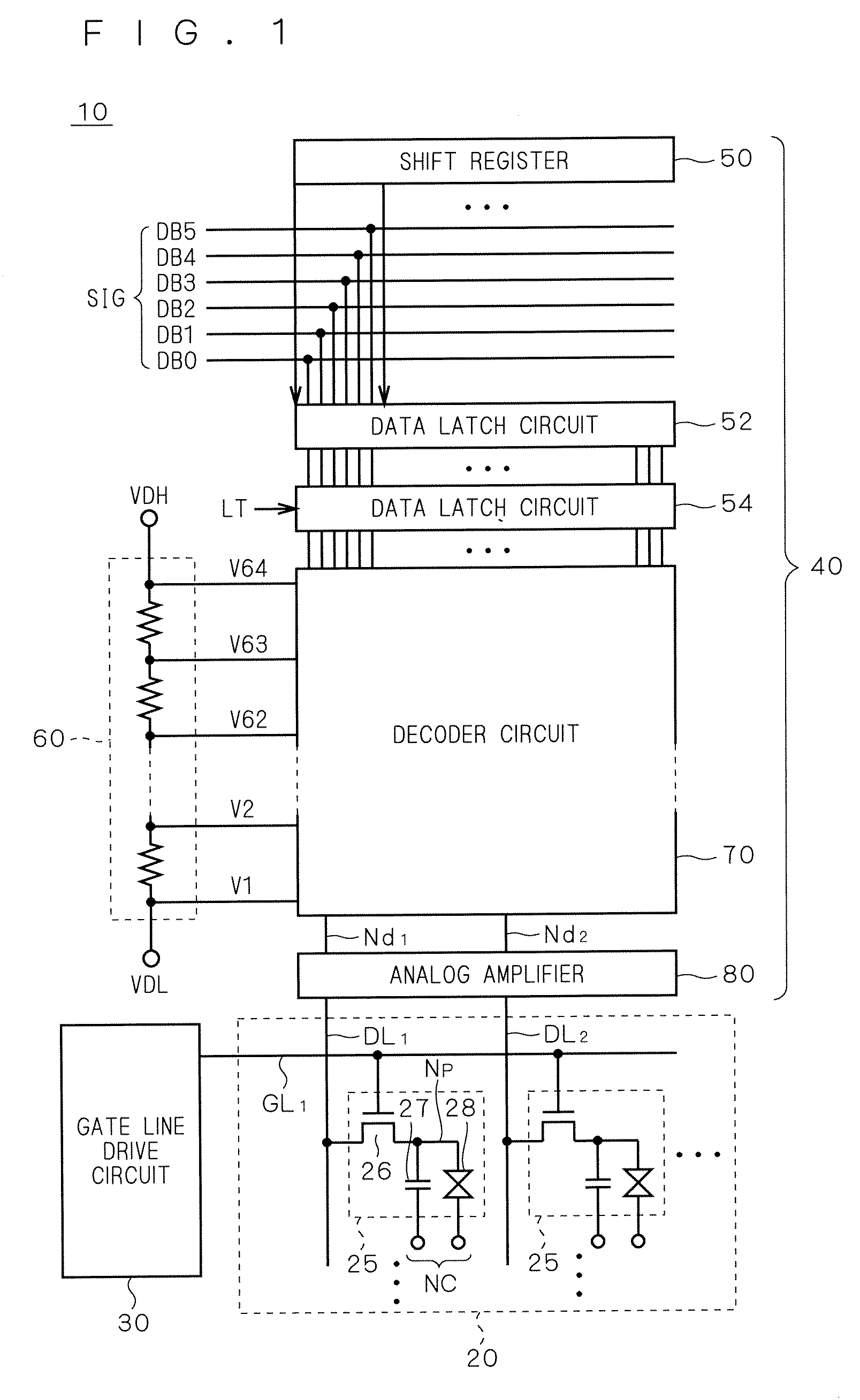

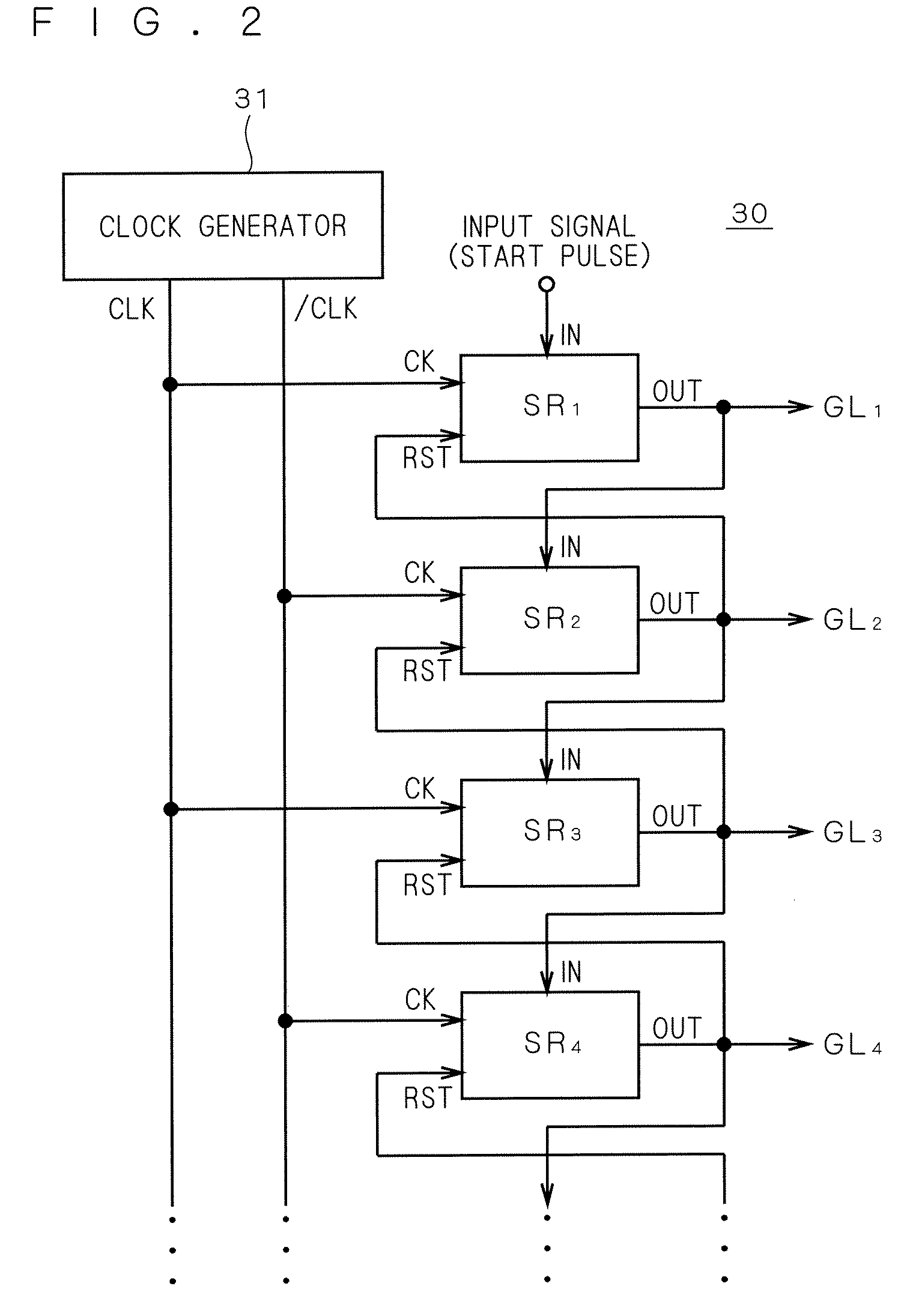

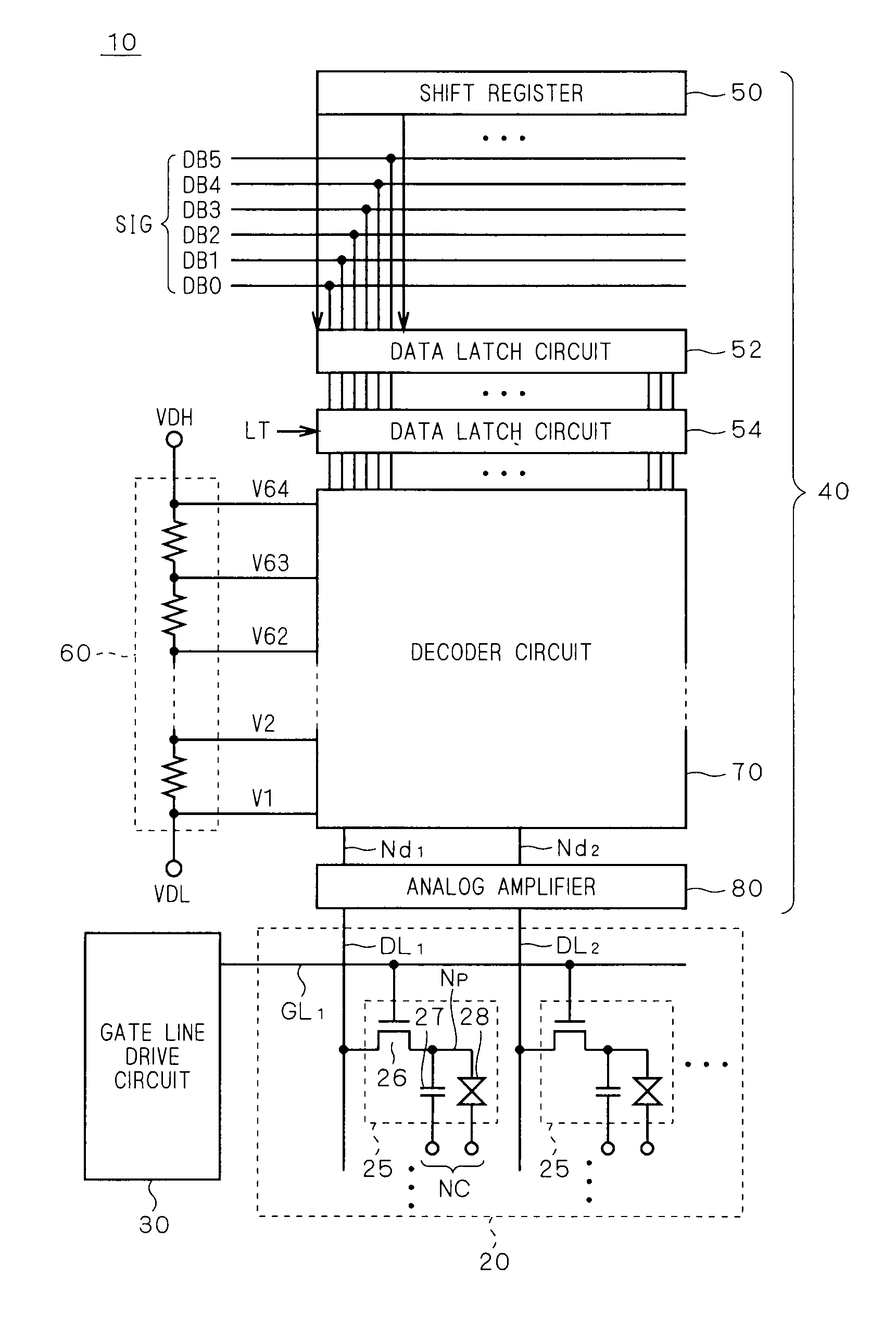

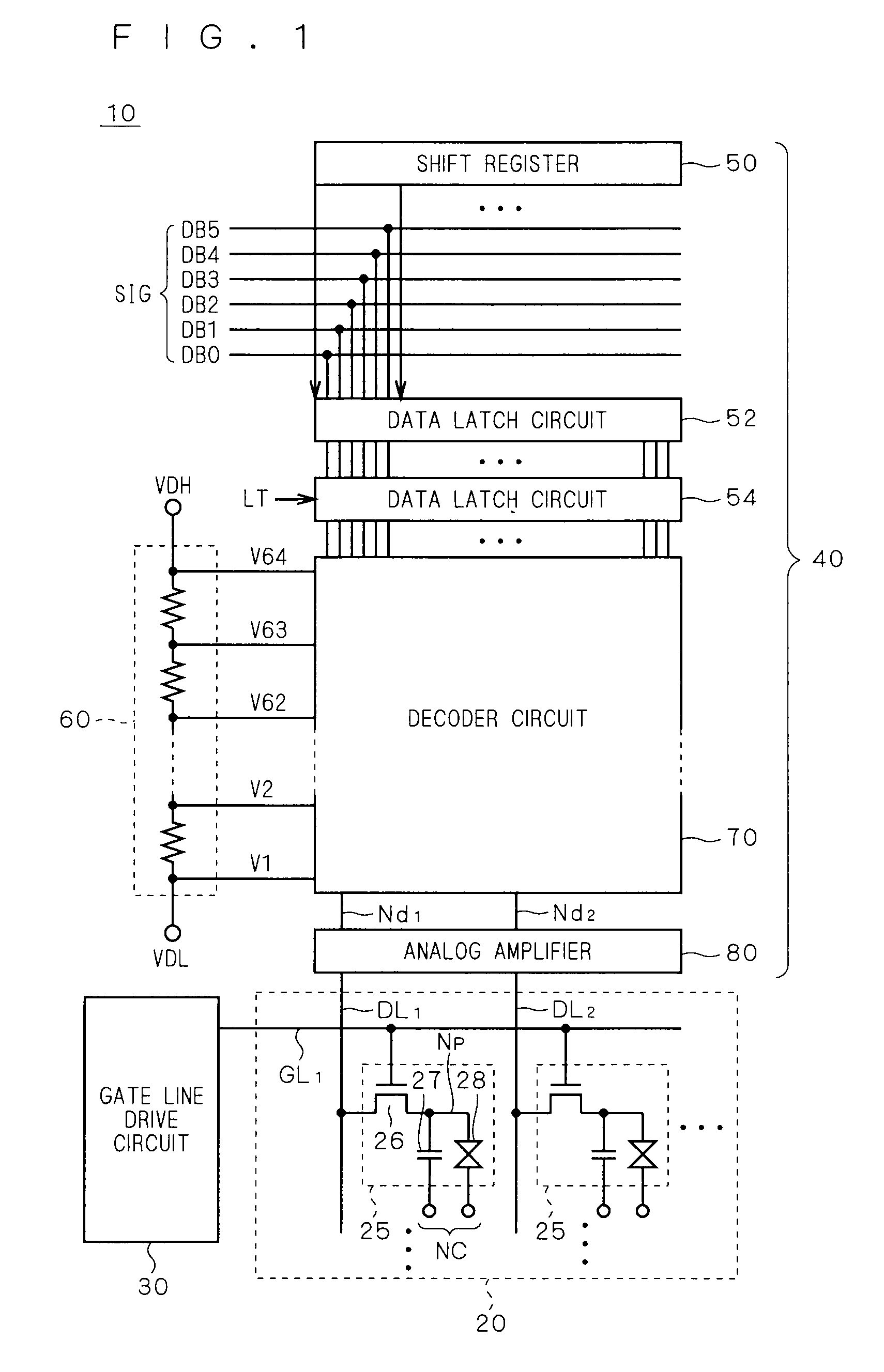

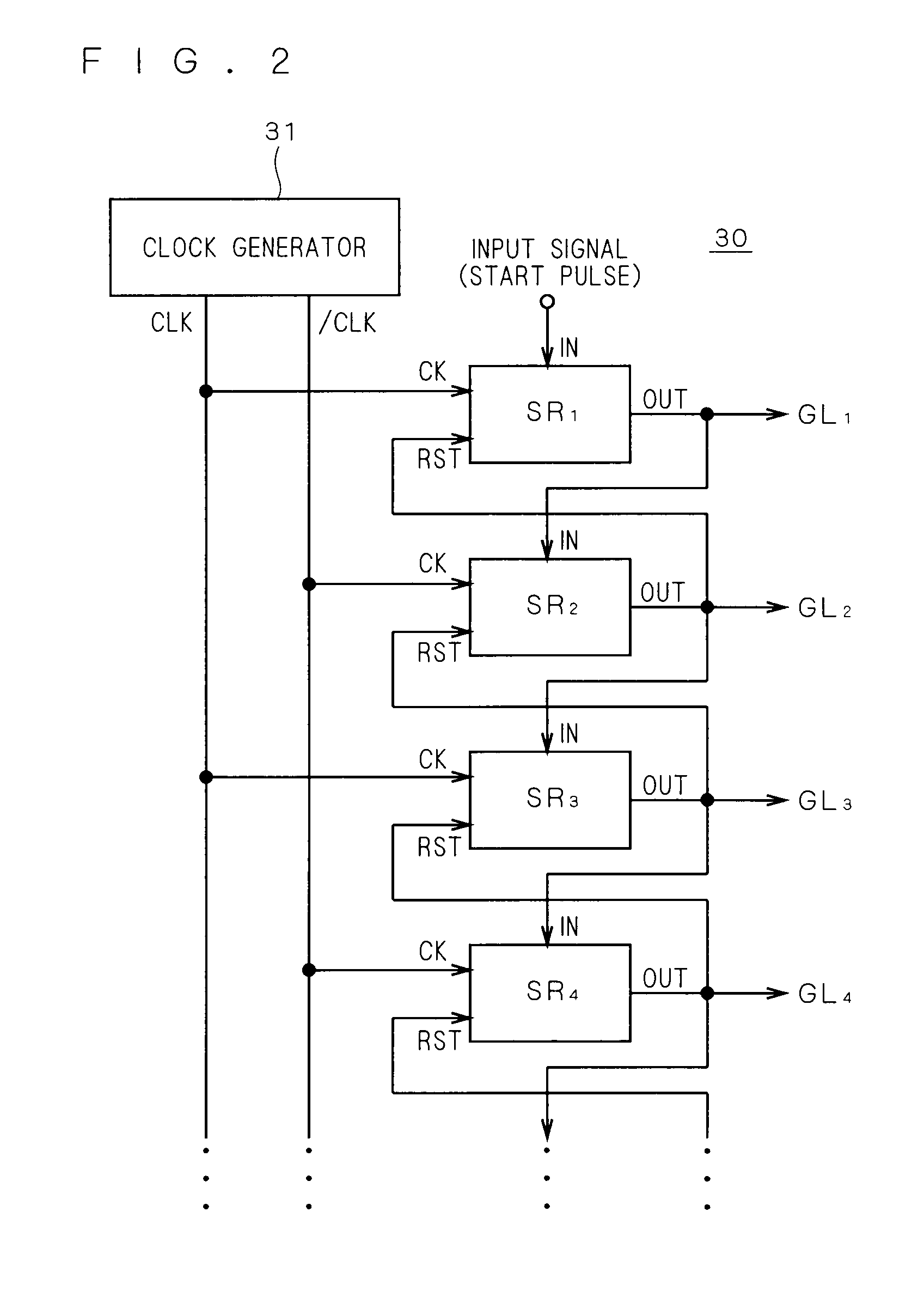

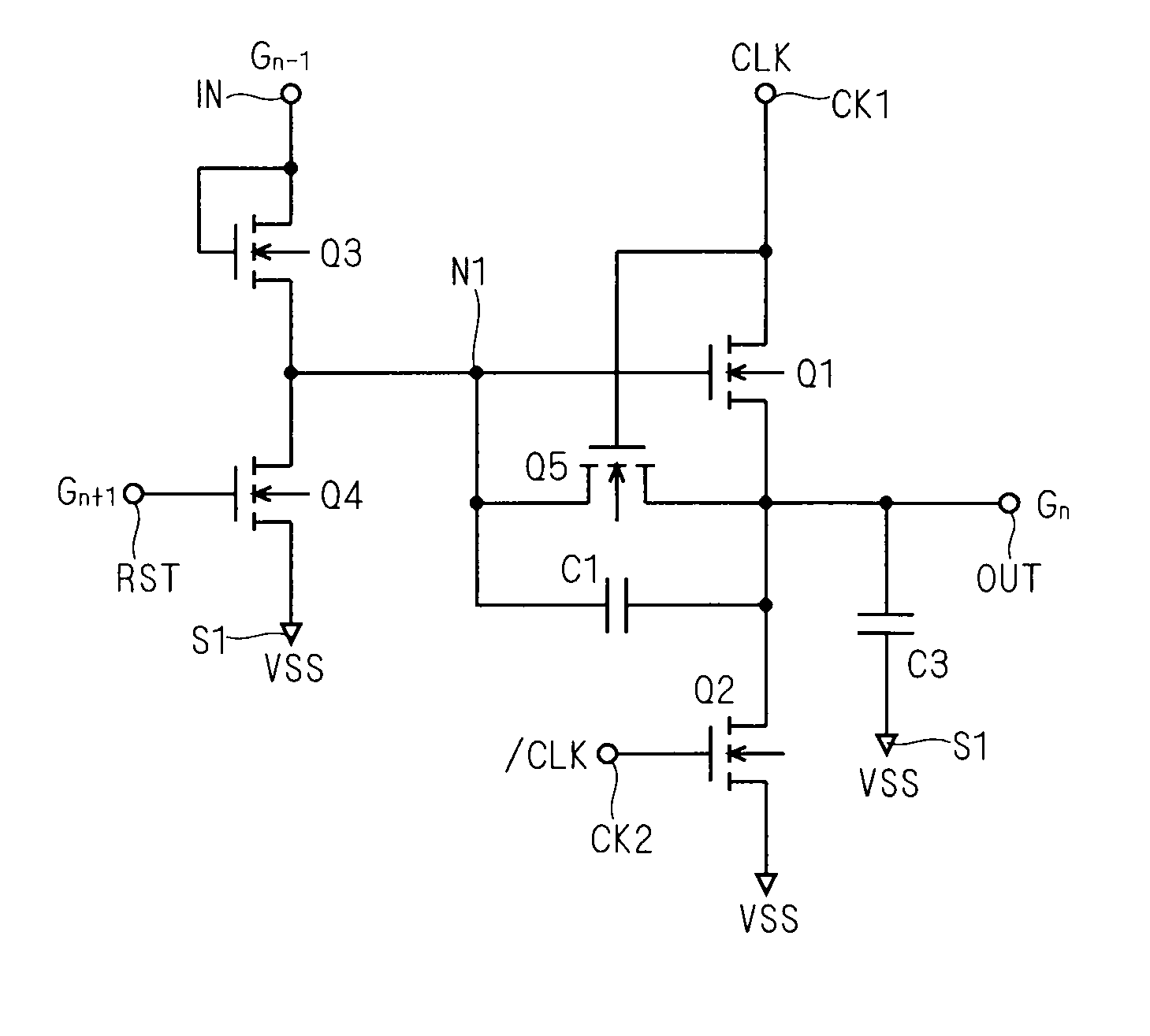

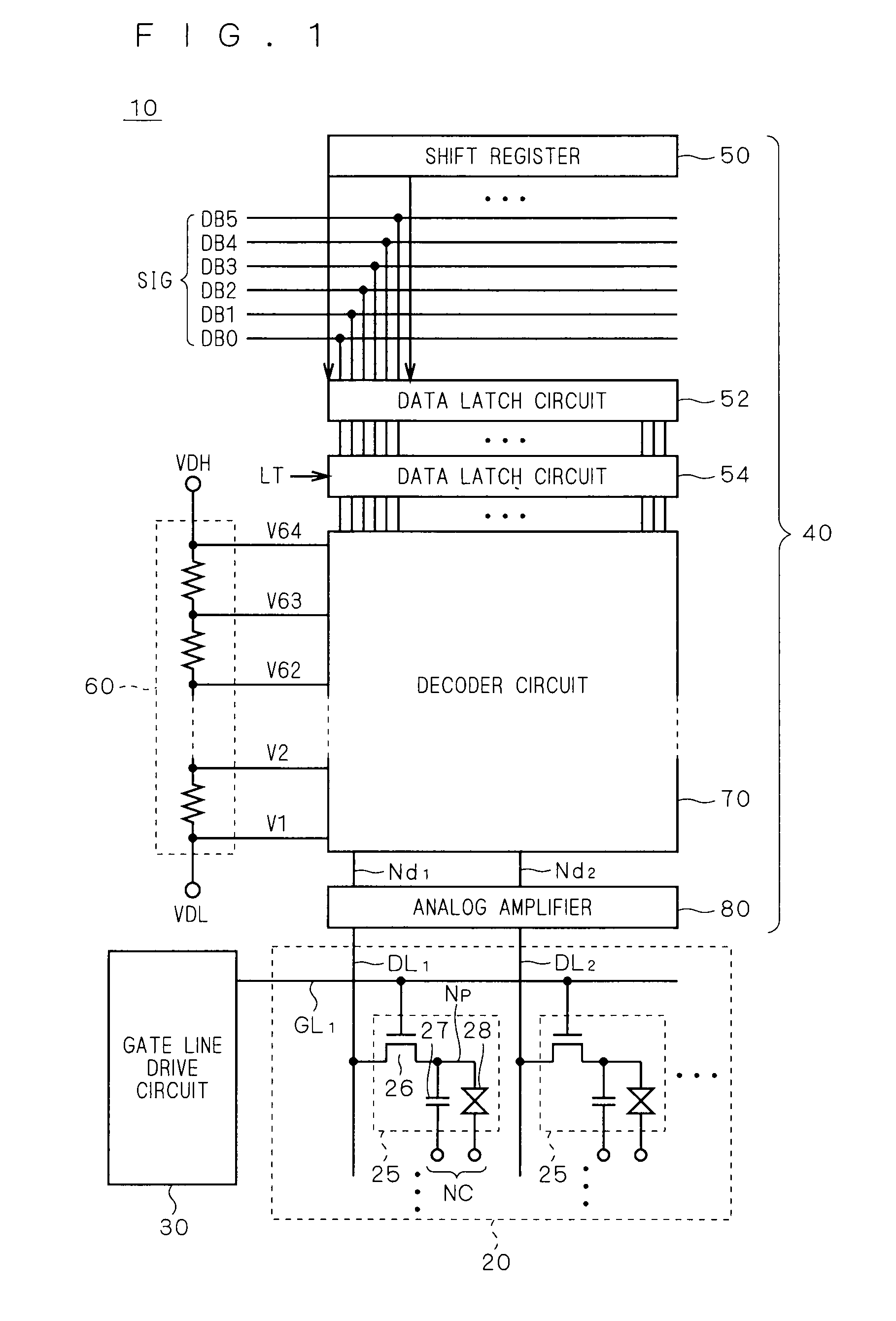

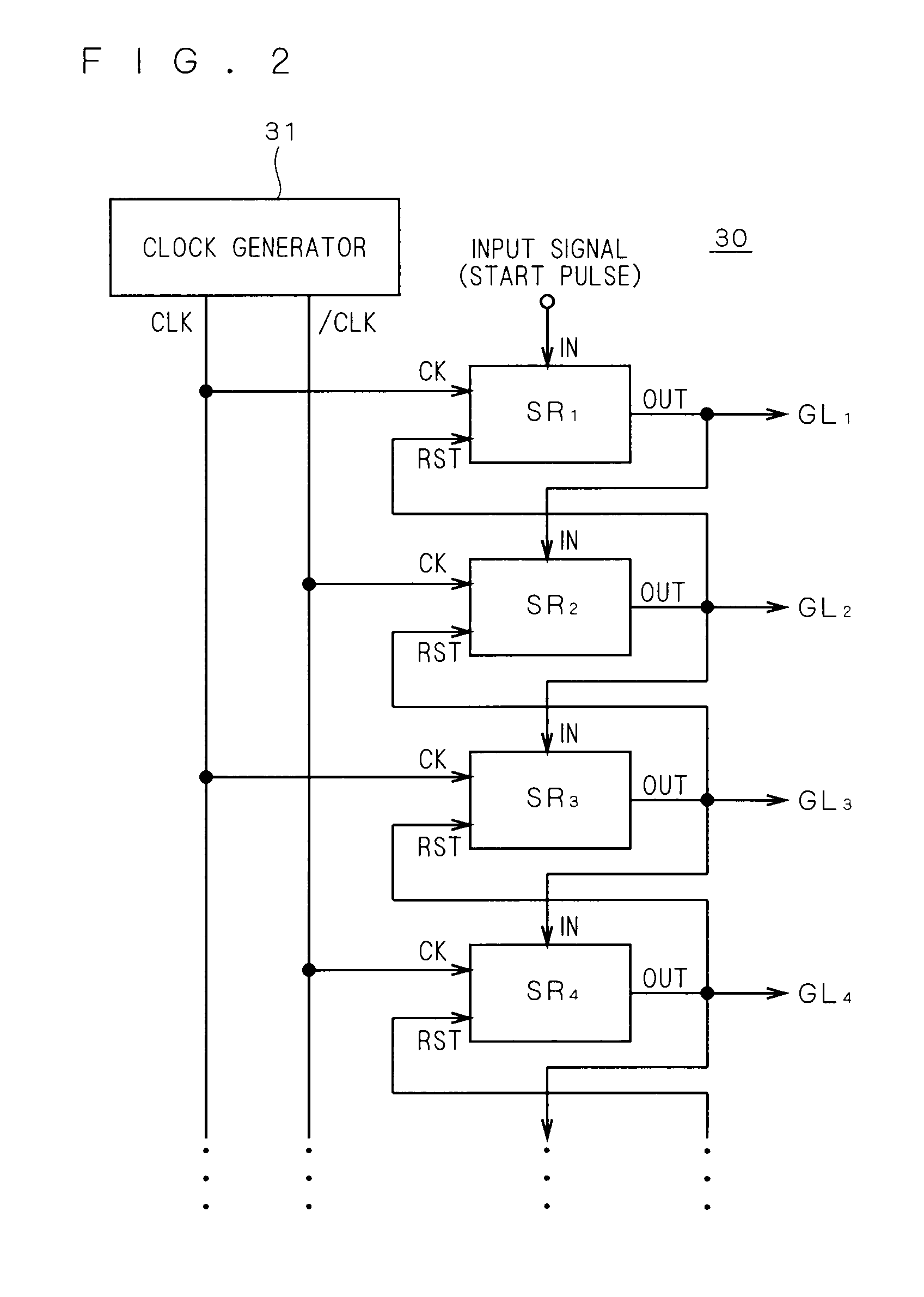

Shift register circuit and image display comprising the same

InactiveUS20070247932A1Defective operation is preventedDrive capability is prevented being loweredStatic indicating devicesDigital storageShift registerProcessor register

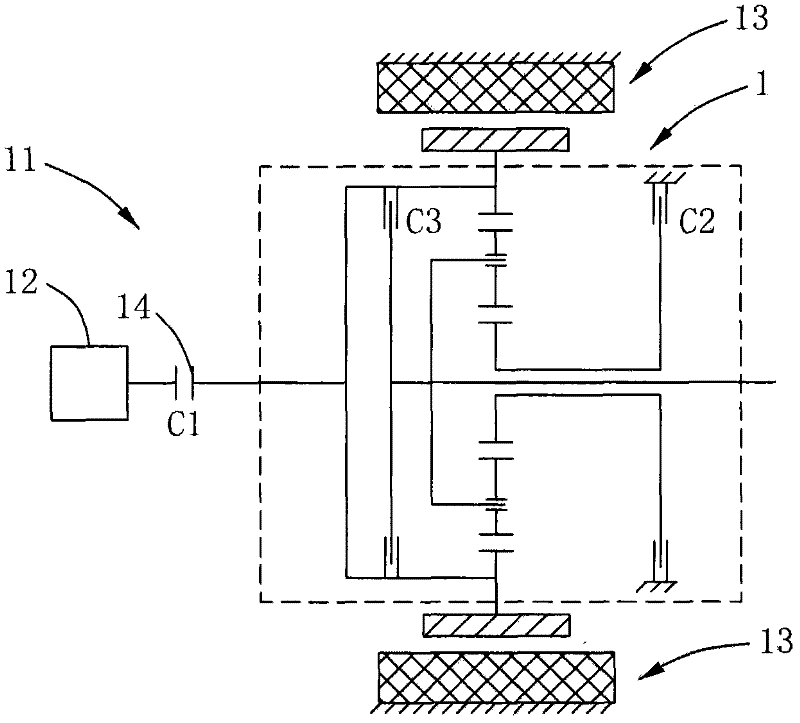

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:MITSUBISHI ELECTRIC CORP

Shift register circuit and image display comprising the same

ActiveUS8493309B2Lower capability requirementsImprove driving abilityStatic indicating devicesDigital storageShift registerProcessor register

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:TRIVALE TECH

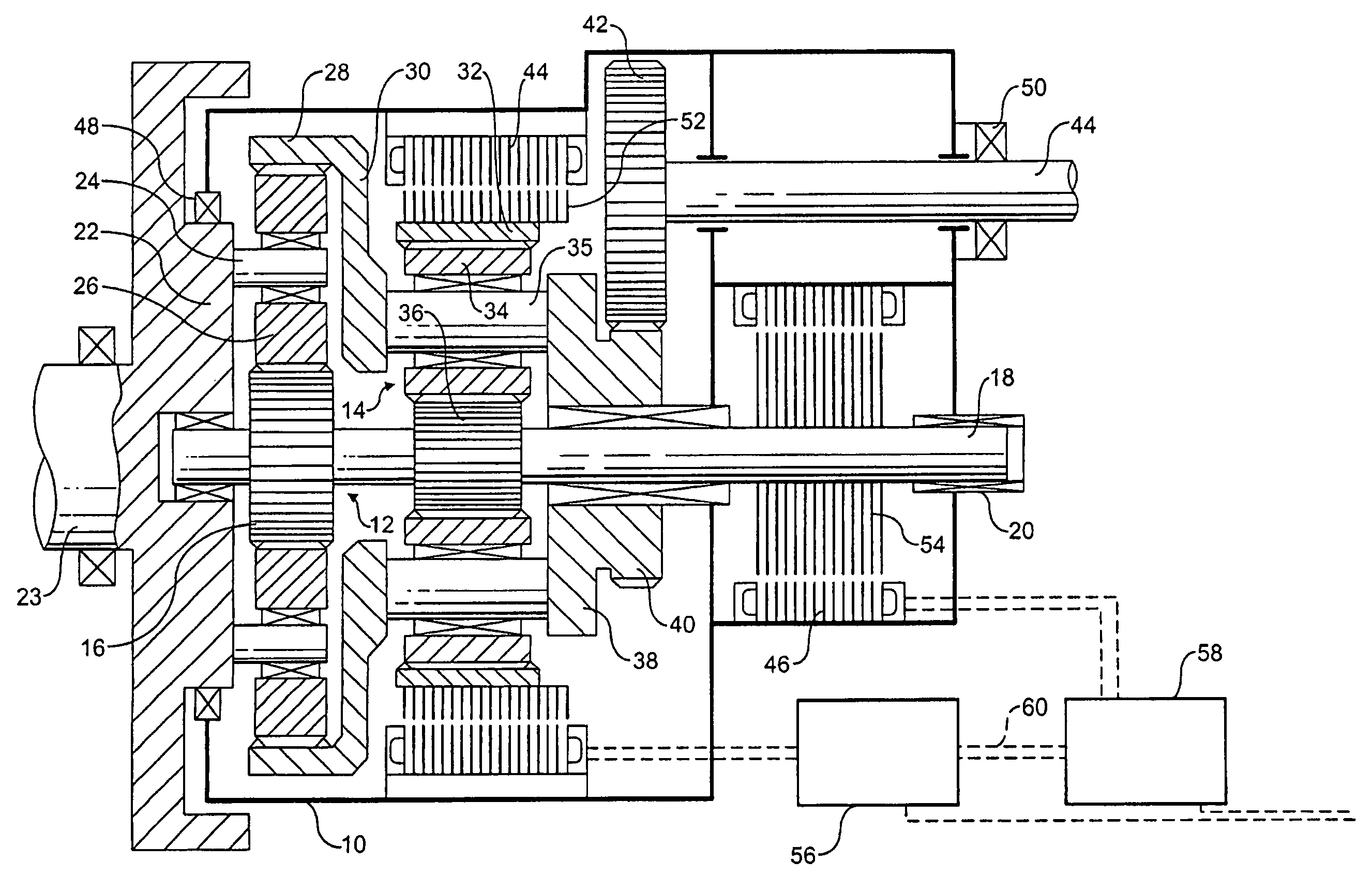

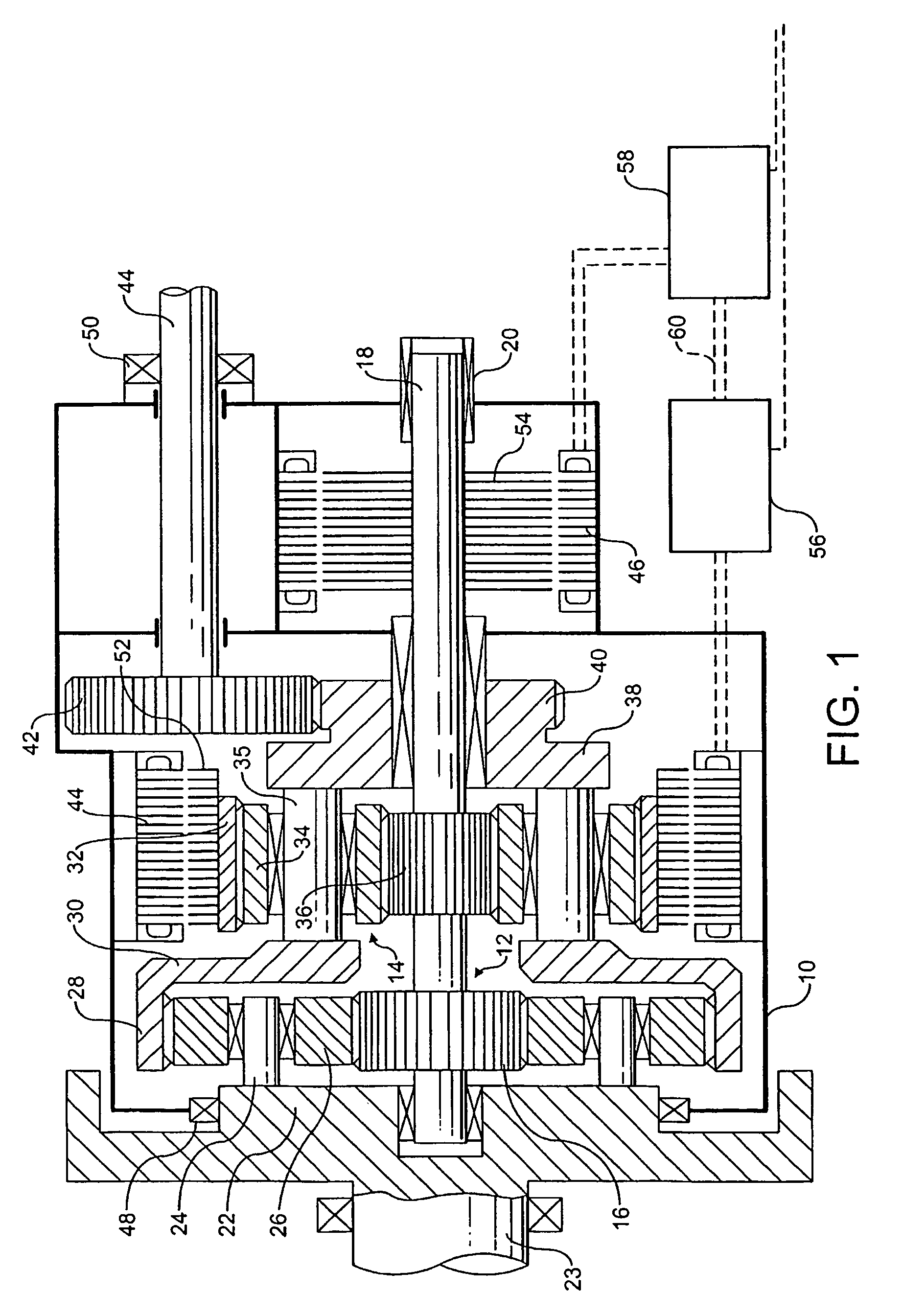

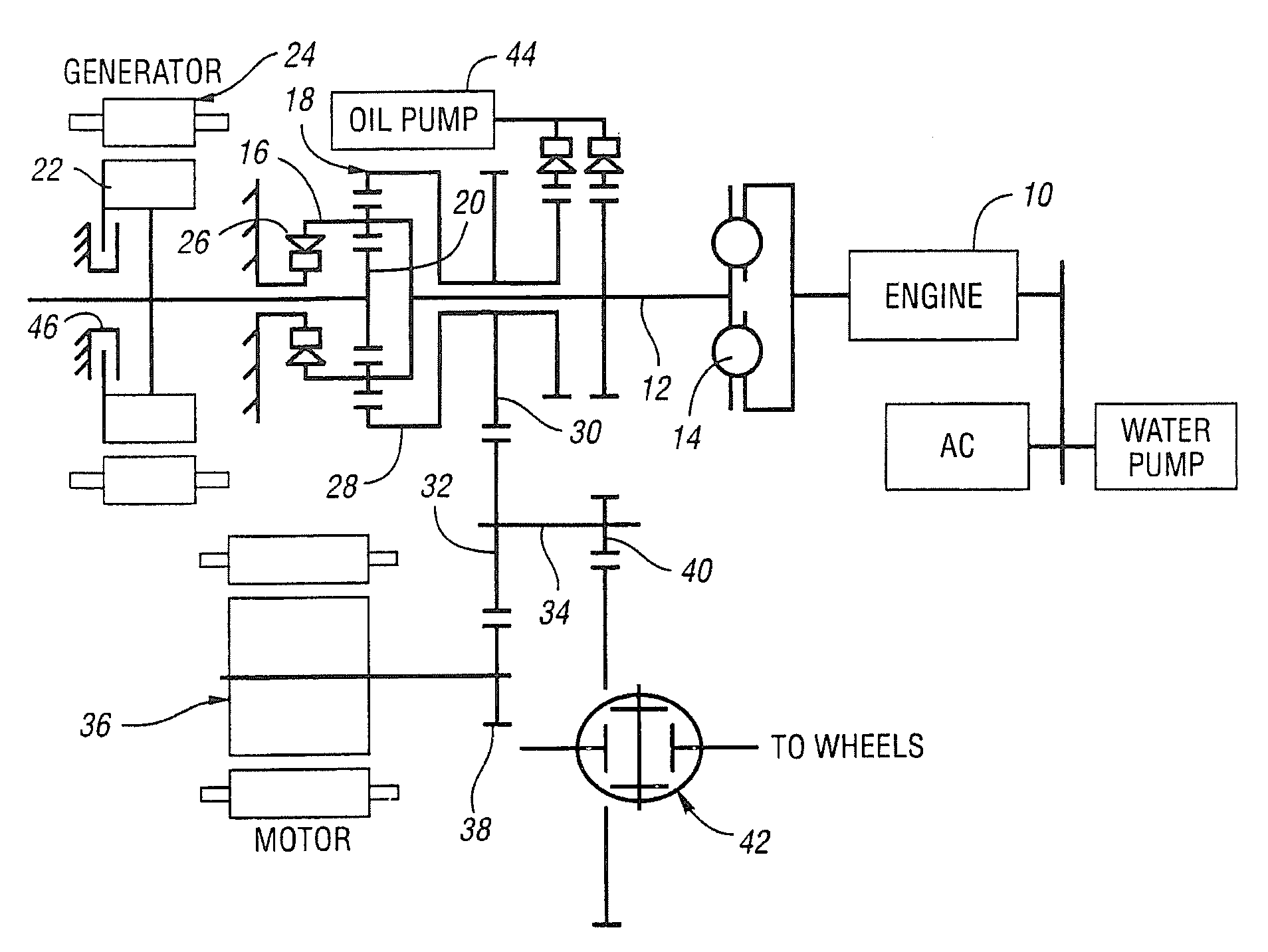

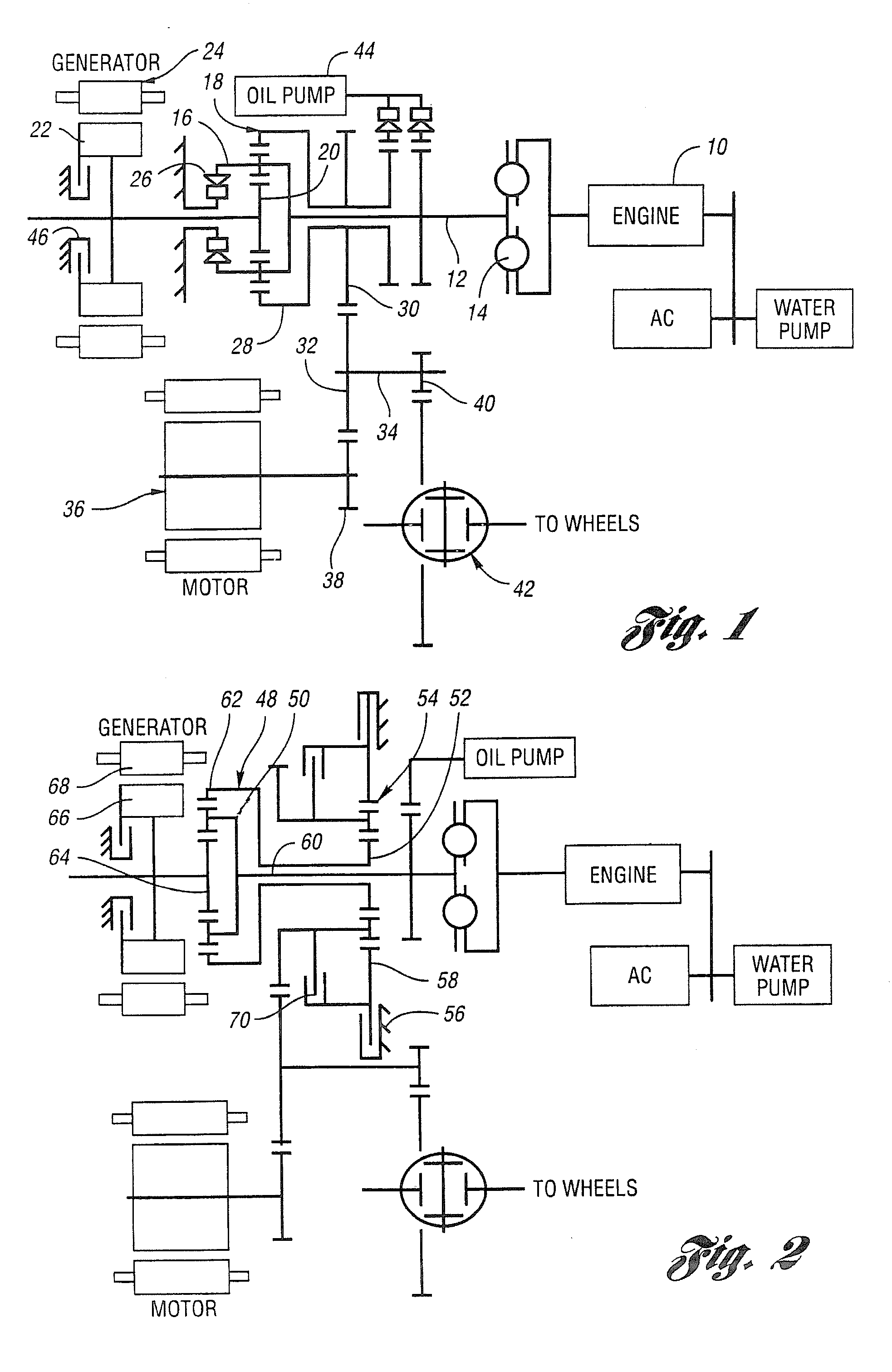

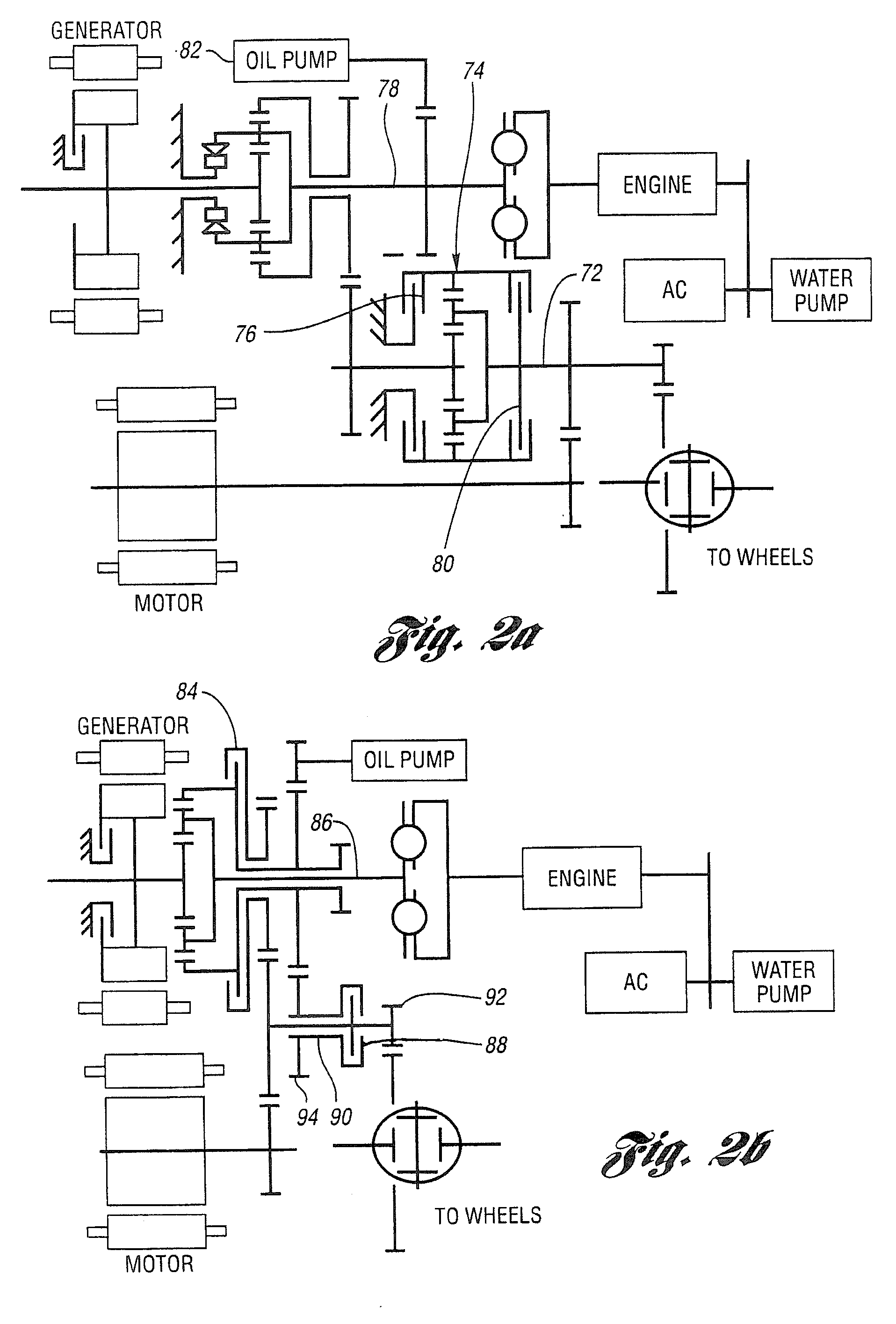

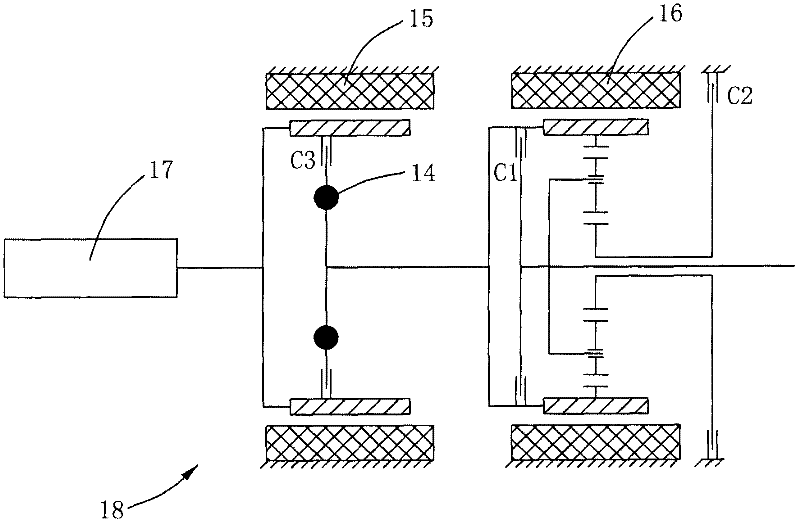

Automotive vehicle transmission systems

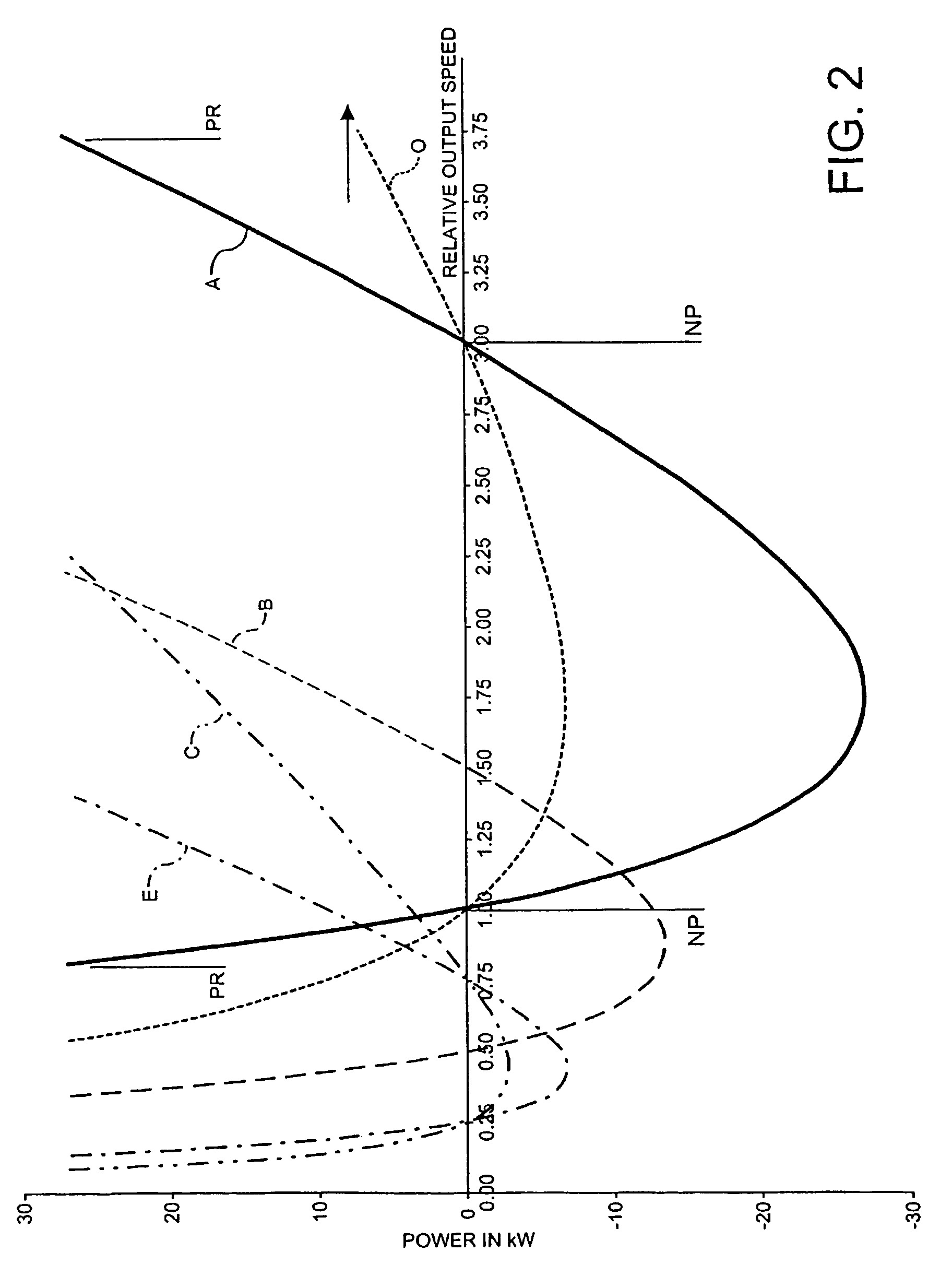

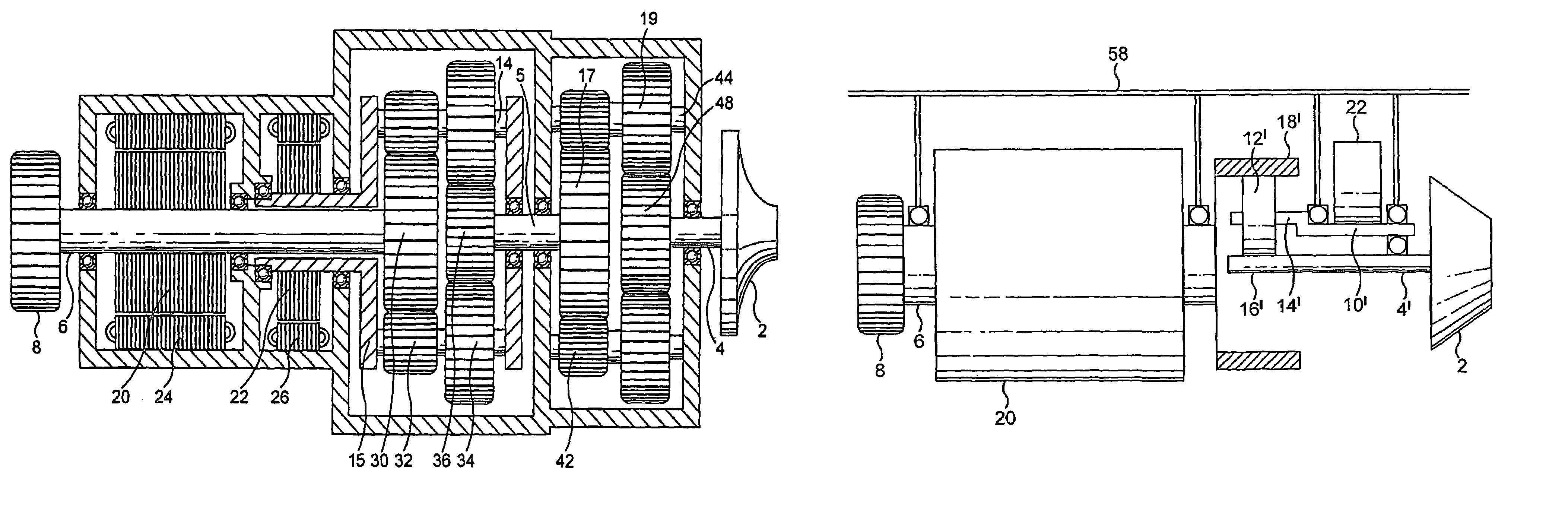

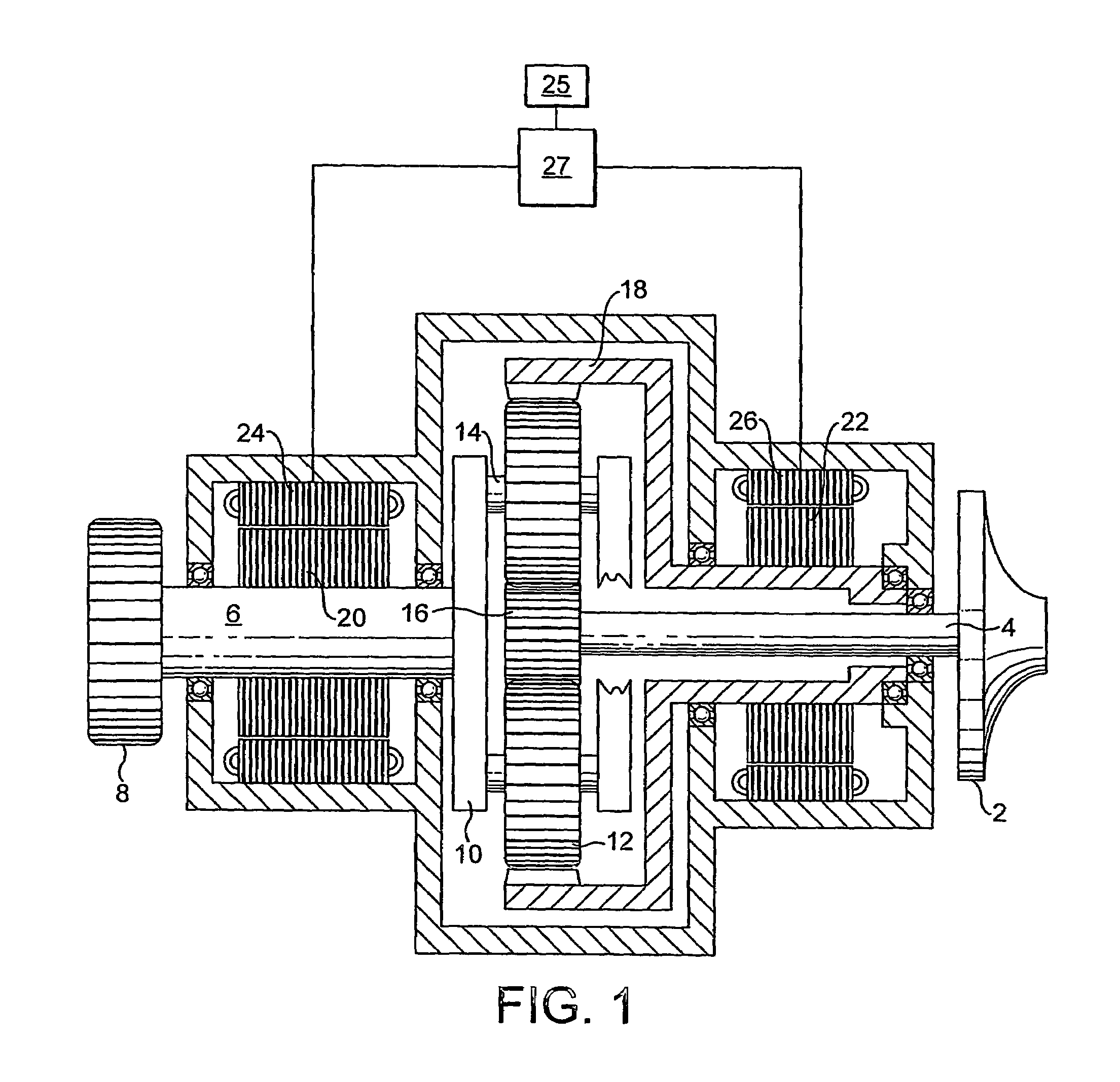

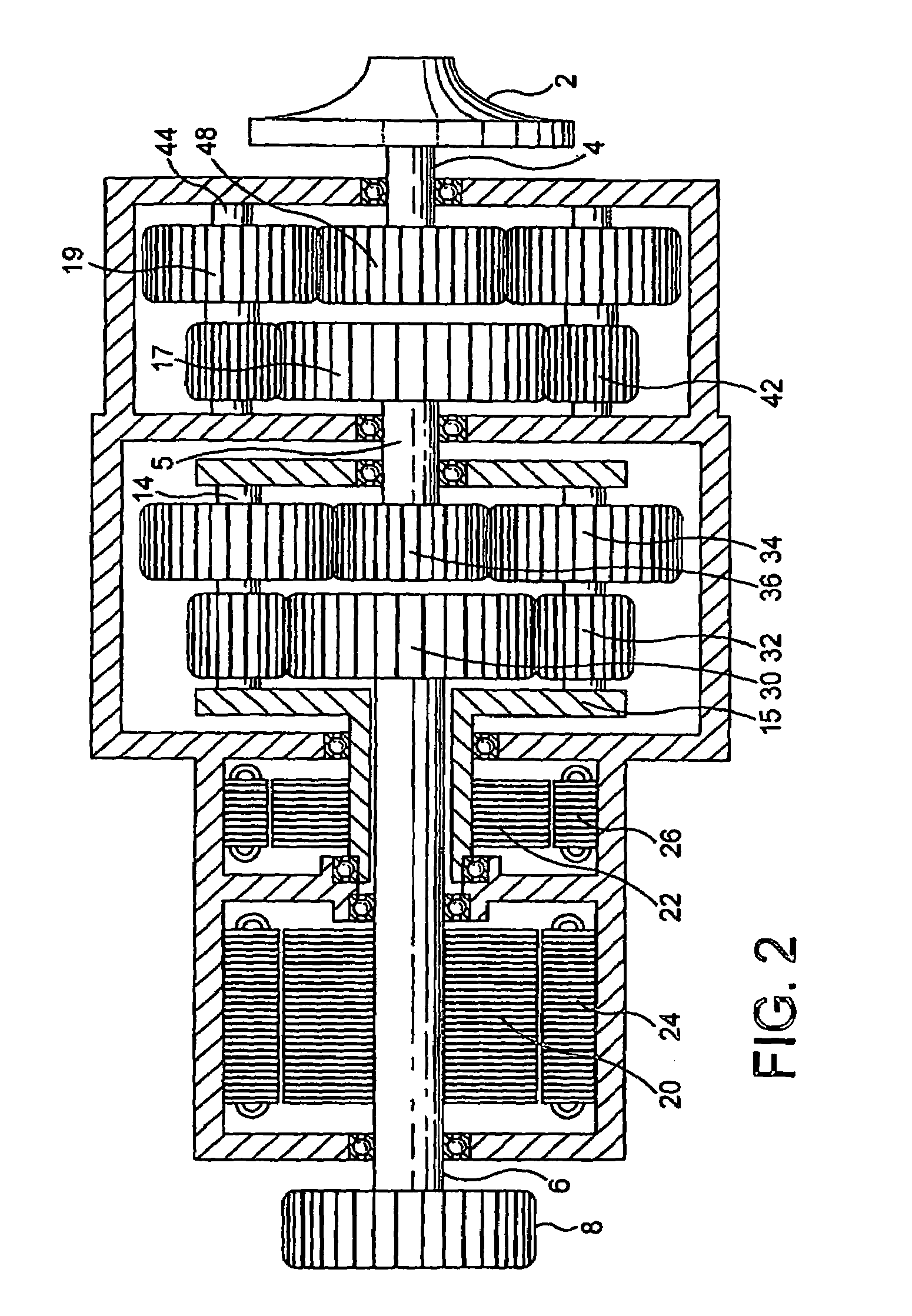

InactiveUS7172524B2Avoid inefficiencyIncrease the output speedHybrid vehiclesDigital data processing detailsMobile vehicleElectricity

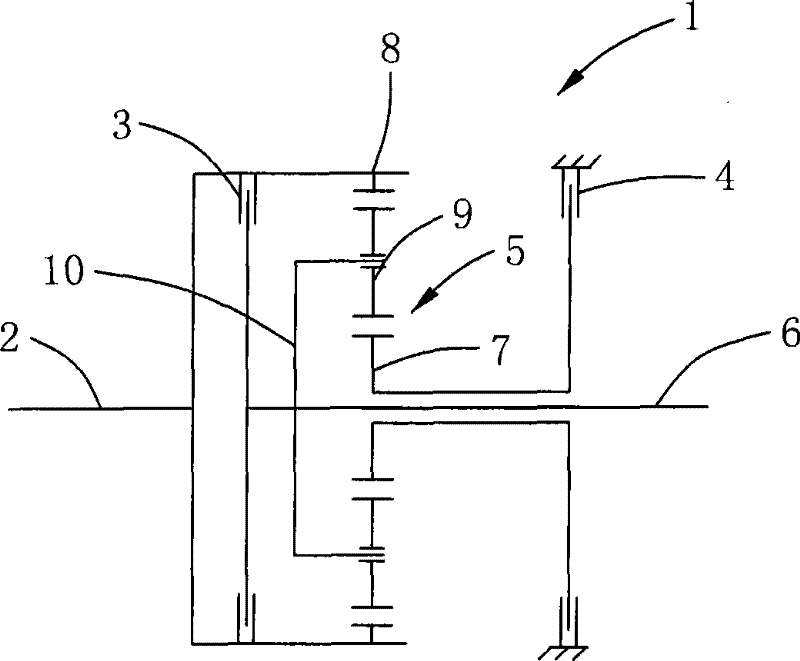

An automotive vehicle transmission system has two epicyclic gearsets and a first and second electrically connected motor / generator. Components of the epicyclic gearsets and the motor / generators are connected such that, when the transmission system is in use, electrical power is transferred between the first and second motor / generators.

Owner:DRIVETEC (UK) LTD

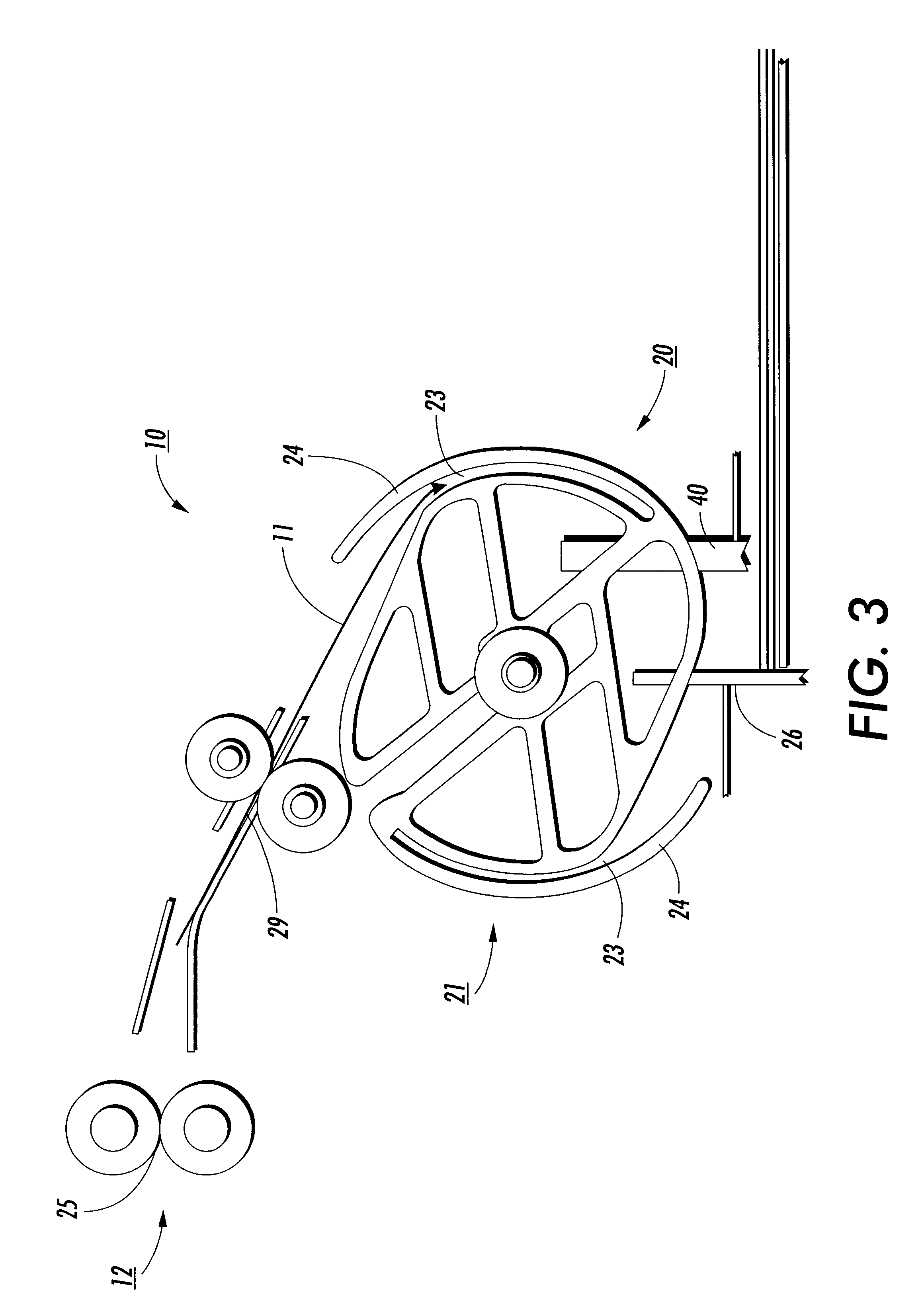

Automotive air blowers

InactiveUS7703283B2Maximise efficiency of blowerLow costGearboxesCombustion enginesImpellerElectricity

An automotive air blower, in particular a supercharger, comprises an air pump, such as an air impeller (2) connected to the output shaft (4) of a transmission system, the input shaft of which is connected, in use, to the engine of a motor vehicle. The input and output shafts (6, 4) are connected to respective branches of a three-branch epicyclic differential gearset. The third branch of the gearset and the input shaft (6) are connected to the rotor (20, 22) of respective electrical machines, the electrical connections of the stators (24, 26) of which machines are connected together via a controller (27) arranged to control the flow of electric power between them.

Owner:DRIVETEC (UK) LTD +1

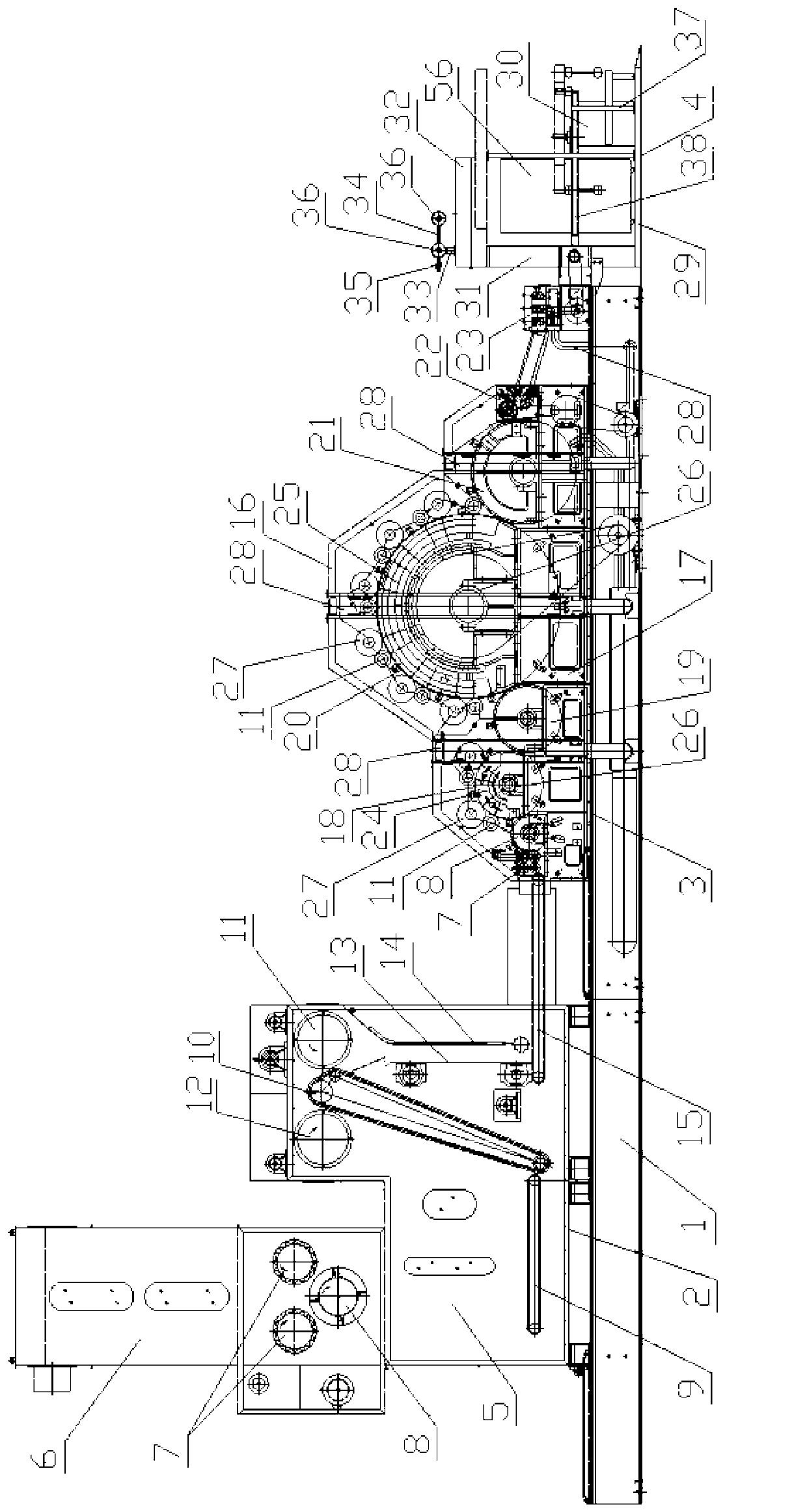

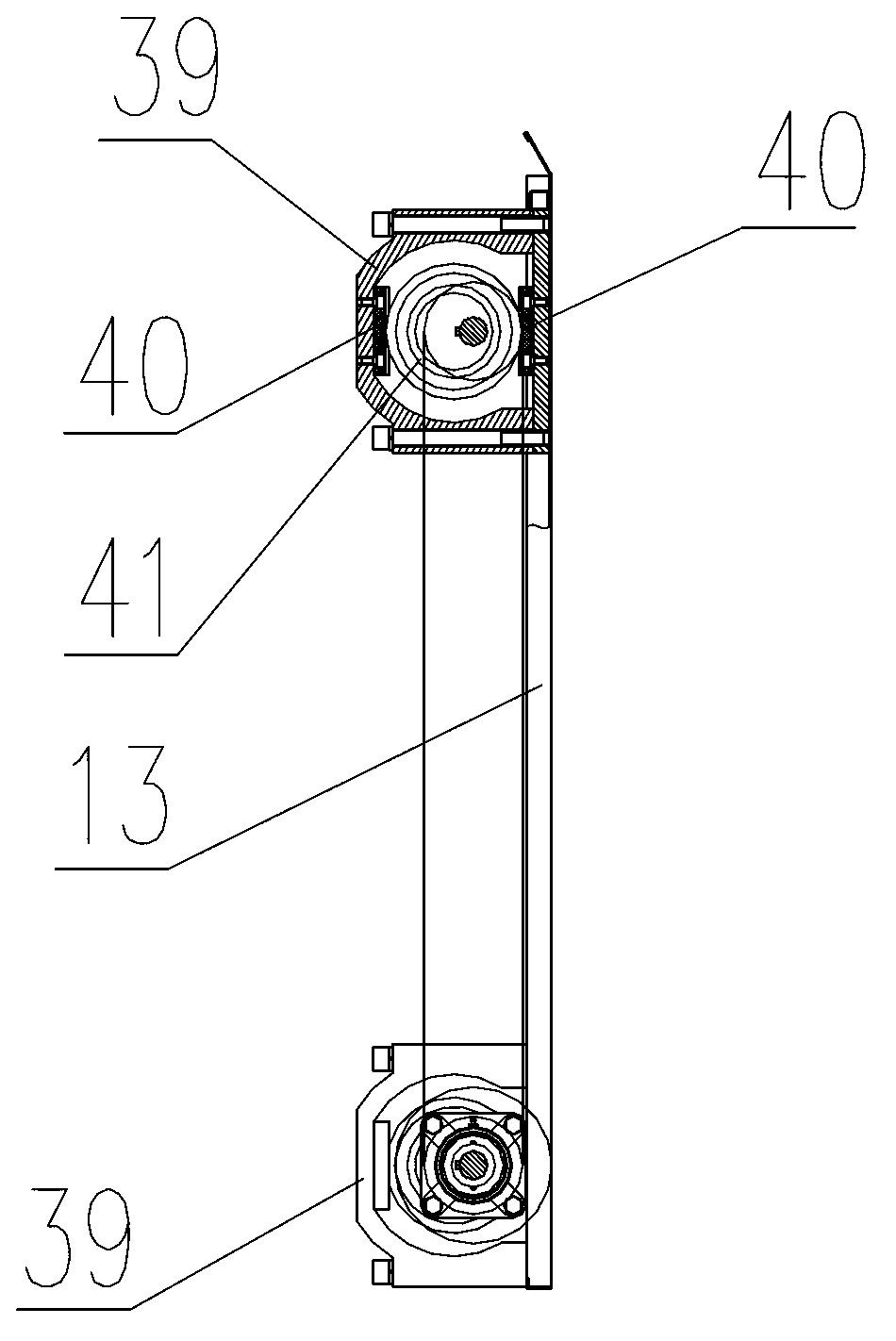

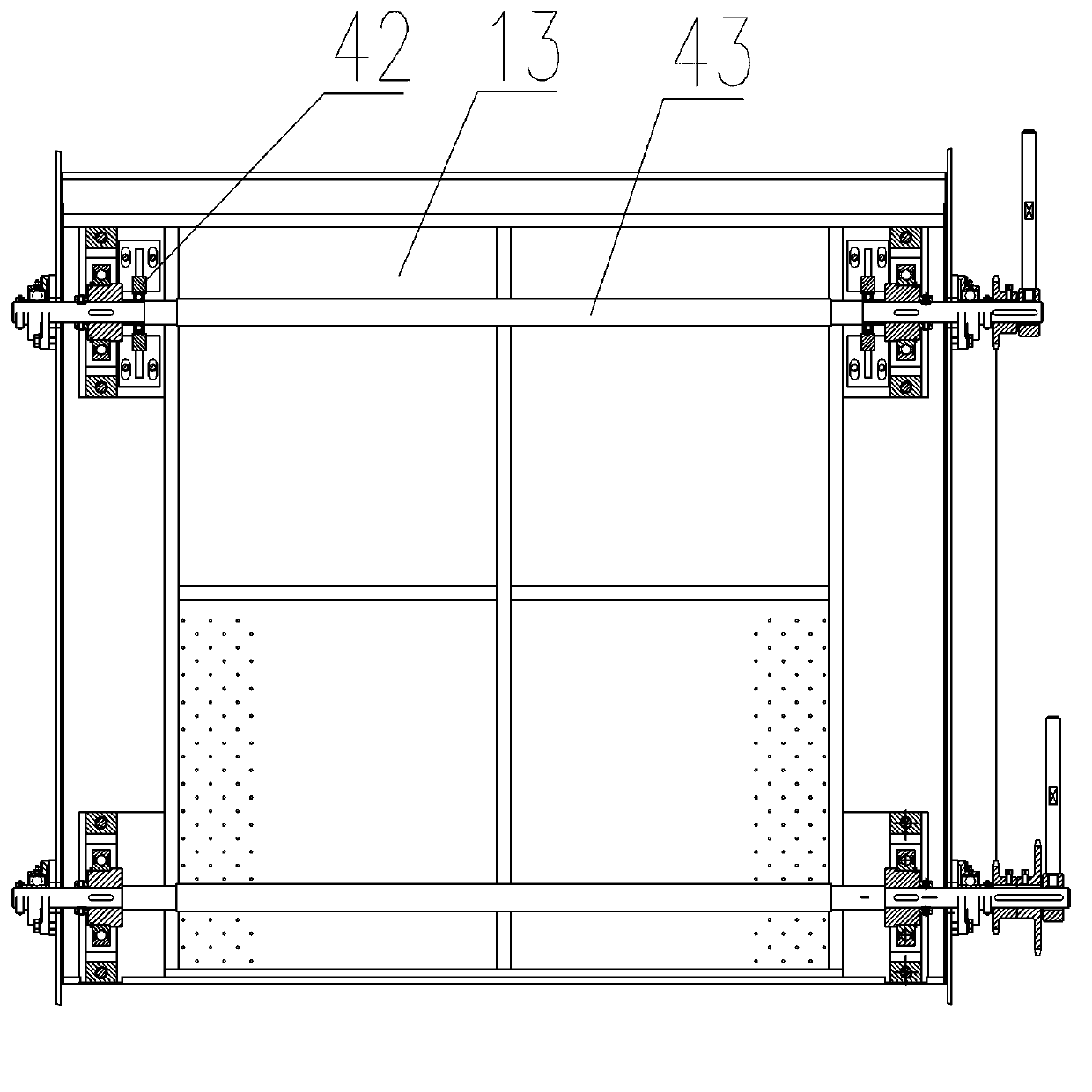

High-speed carding machine

InactiveCN102995167AGuaranteed stabilityGuaranteed speedCarding machinesEngineeringUltimate tensile strength

A high-speed carding machine comprises a base and a vibration wool feeding machine, a high-speed carding device and an automatic three-position barrel changing device which are connected with one another sequentially. The vibration wool feeding machine in the high-speed carding machine utilizes a translational vibration plate and a baffle to push textile raw materials uniformly, and moreover, the falling and outputting speeds of the textile raw materials are increased. A shaft seat of the high-speed carding machine is arranged on a breast cylinder wallboard and a large cylinder wallboard, so that the phenomenon that the positions of a breast cylinder and a large cylinder are changed relatively to the positions of a working roller and a wool stripping roller due to the high-speed rotation is avoided, the production quality is ensured, a suction pipe is arranged to suck the textile raw materials and reduce air flow which is generated by high-speed rotation, and the operation stability and high speed of the carding machine are ensured. The automatic three-position barrel changing device can control rotating wheels to change collection barrels, so that the high-speed carding machine is simple in structure and the labor intensity of the working personnel is reduced; and a U-shaped guardrail can ensure that the operation tracks of the collection barrels are stable when the collection barrels are changed, so that the whole barrel changing operation is carried out stably, and the collection barrels are prevented from tipping over during the barrel changing process.

Owner:青岛诚利佳机械有限公司

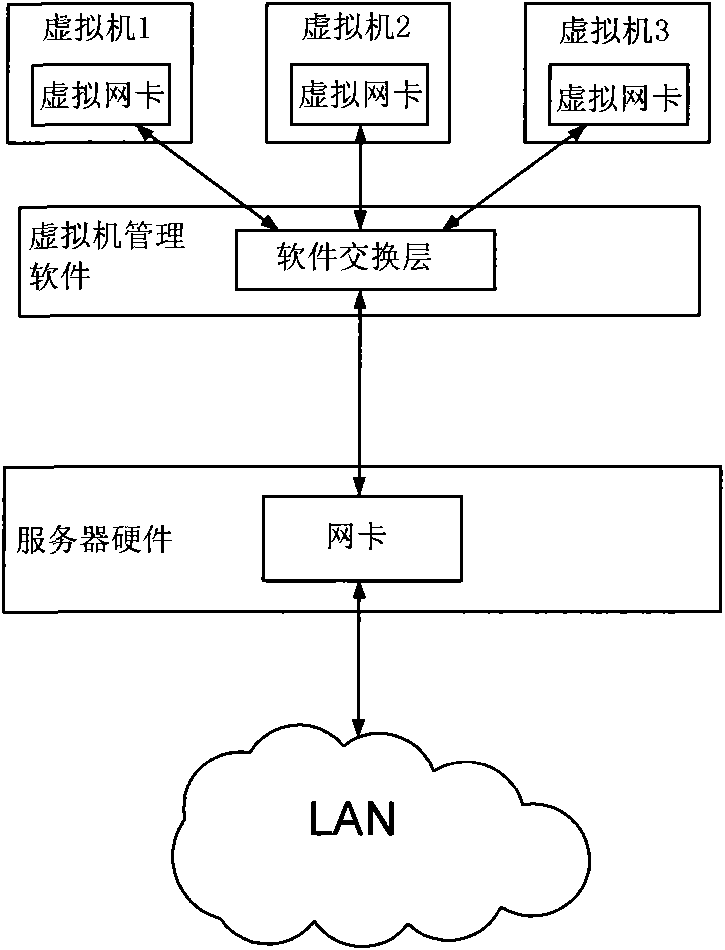

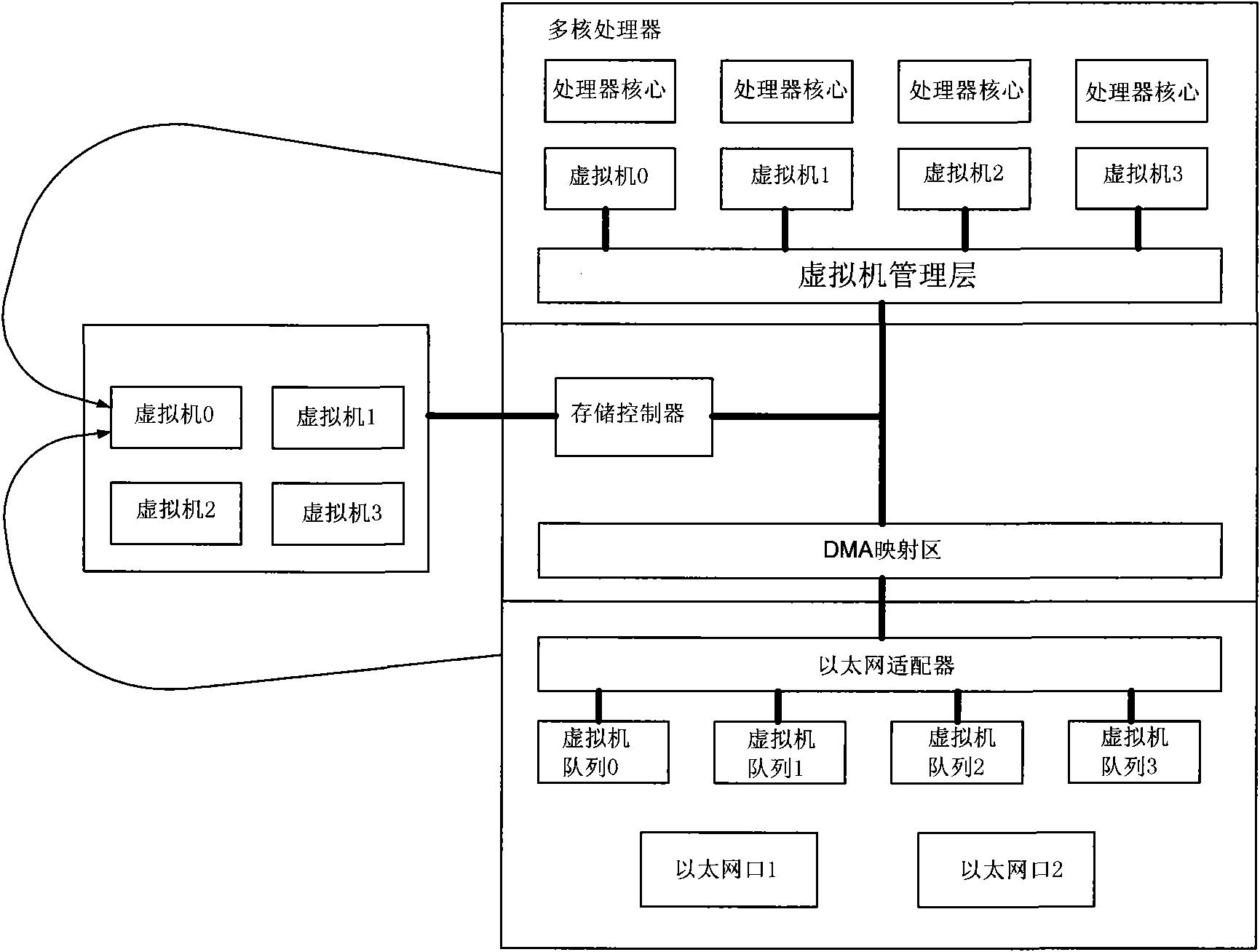

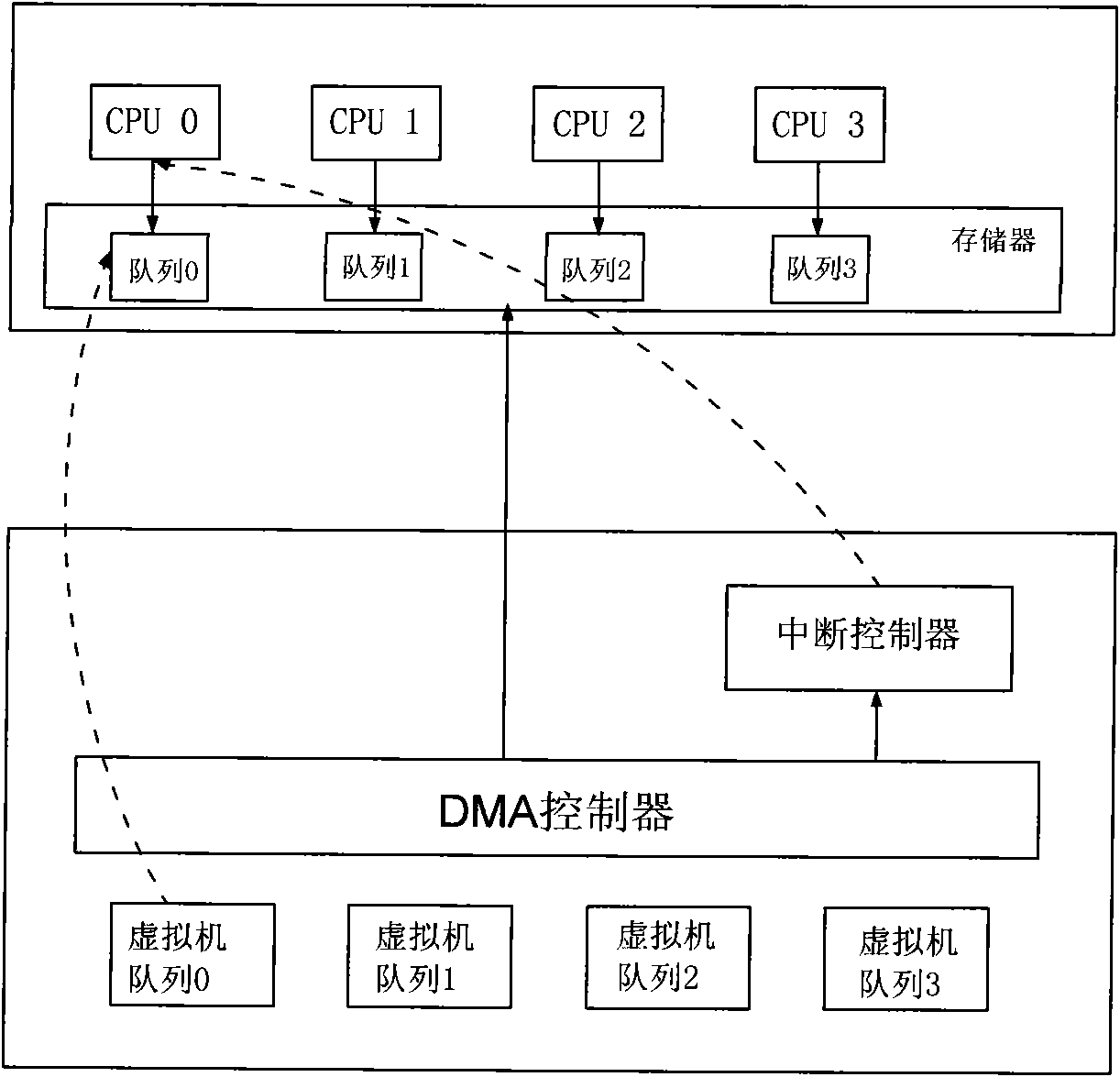

Network card interrupt control method for a plurality of virtual machines

ActiveCN101620551AImplement interrupt handlingImprove throughput speedProgram initiation/switchingVirtualizationNetwork interface controller

The invention relates to a virtual network card interrupt control method for a plurality of virtual machines, which comprises the following steps: reading a descriptor of a data packet firstly to obtain information of a DMA source address, a destination address, length, and the like when a network card receives or transmits the data packet; then, executing DMA operation, back writing the descriptor after the operation is completed; counting by a counter corresponding to a virtual machine queue; transmitting an interrupt request when a numerical value of the counter reaches a preset time threshold value; carrying out the counting operation of the counter when the counter operates; when the numerical value of the counter reaches a preset time threshold value, judging whether the data packetcompletes the operation or not, if completing the operation, transmitting the interrupt request, otherwise, transmitting the interrupt request after the data packet completes the operation, and setting immediate interrupt operation without being restrained by the two threshold values as required. The network card interrupt control method completes the interrupt operation of the original software layer by hardware, completely releases the CPU and reduces the utilization ratio of the CPU, and meanwhile, because the processing speed of the hardware is greatly higher than the processing speed of the software, the data processing speed is greatly increased.

Owner:DAWNING INFORMATION IND BEIJING +1

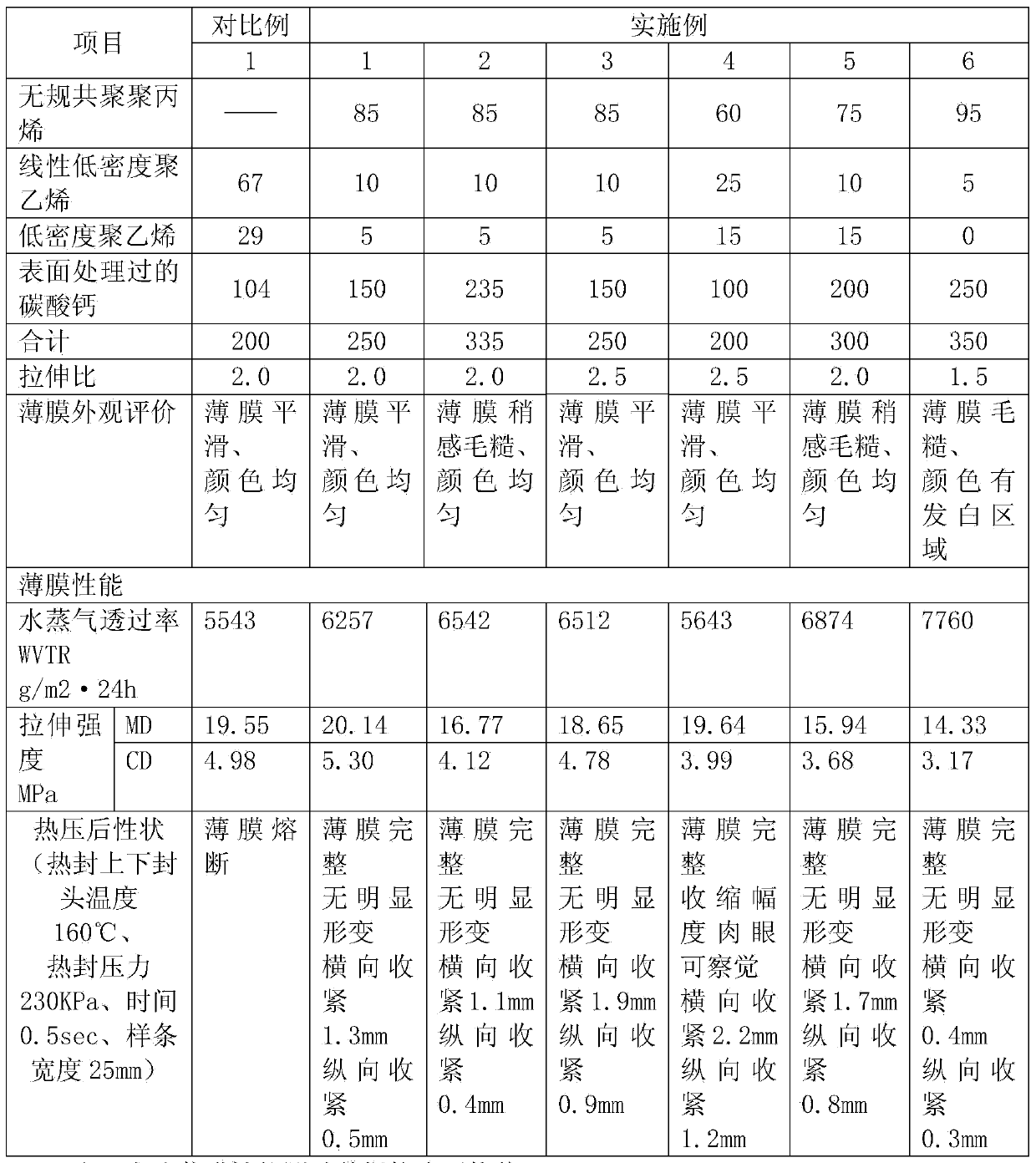

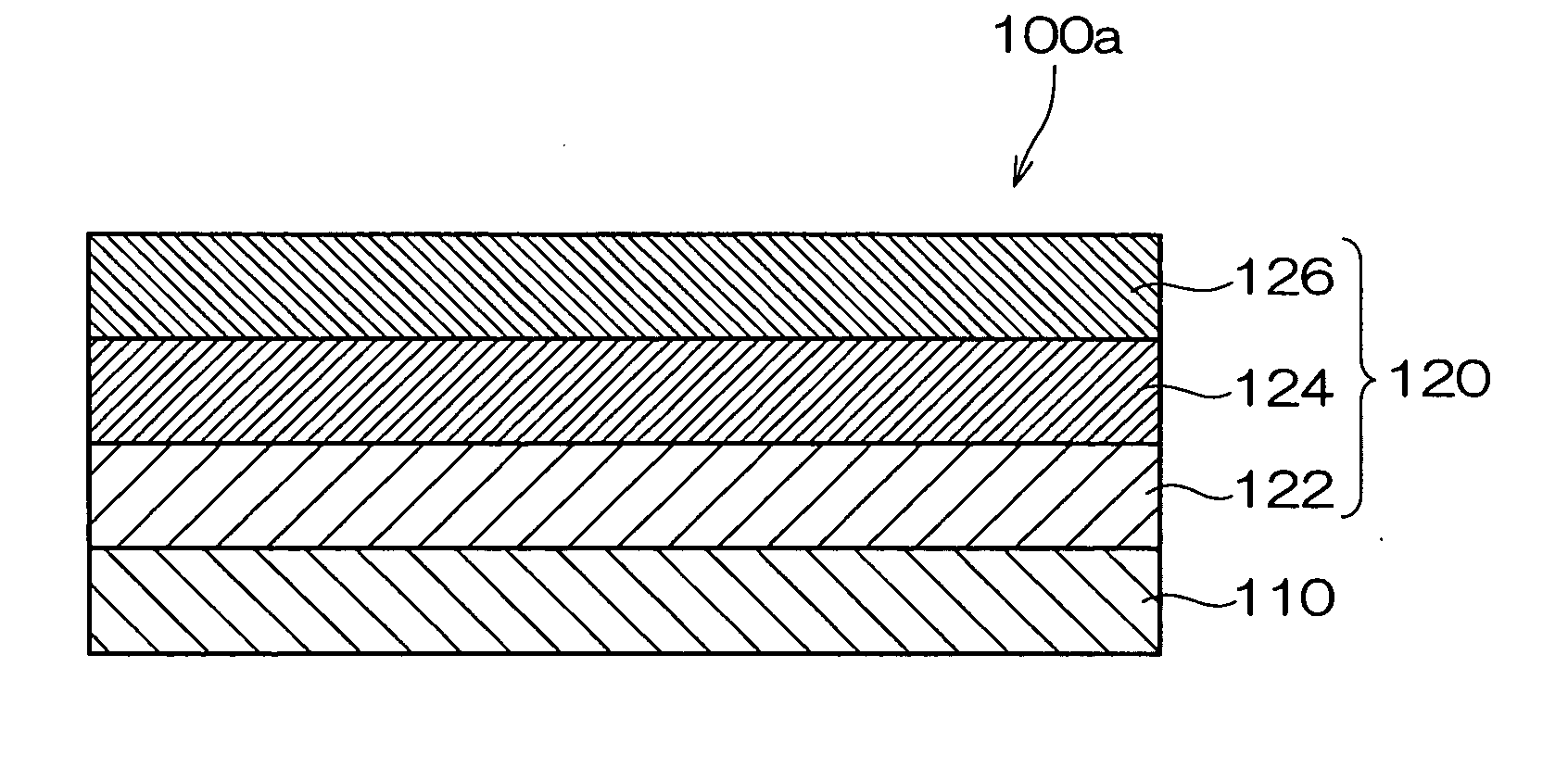

Polyolefin microporous air-permeable membrane and preparation method thereof

ActiveCN103739962AImprove process rangeDoes not affect processing performancePolymer sciencePolyolefin

The invention discloses a polyolefin microporous air-permeable membrane and a preparation method thereof. The microporous air-permeable membrane is prepared from a polyolefin substrate filled with a calcium carbonate filler with processed surface by means of casting extruding, stretching, and heat setting and film-forming. During the preparation, the polyolefin and the calcium carbonate filler with the processed surface are blended, extruded and pelletized, so as to prepare air-permeable particles; the air-permeable particles are extruded and molten by a casting extruder; the melt temperature is kept at 240-255 DEG C; the melt is continuously extruded to form a film through a die lip clearance of a T-shaped die head of a casting machine; the film is subjected to one-step or two-step stretching in a uniaxial manner; the draw ratio is controlled to be 1.5-2.5; the film obtained in the stretching manner is subjected to heat setting treatment at the heat setting temperature of 70-85 DEG C. The polyolefin microporous air-permeable membrane disclosed by the invention can ensure high air permeability and mechanical property of the microporous air-permeable membrane, meanwhile, the processing performance of the product is not affected, and the resistance to high temperature and high pressure of the film is also improved.

Owner:SHANGHAI ZIHUA FILM TECH CO LTD

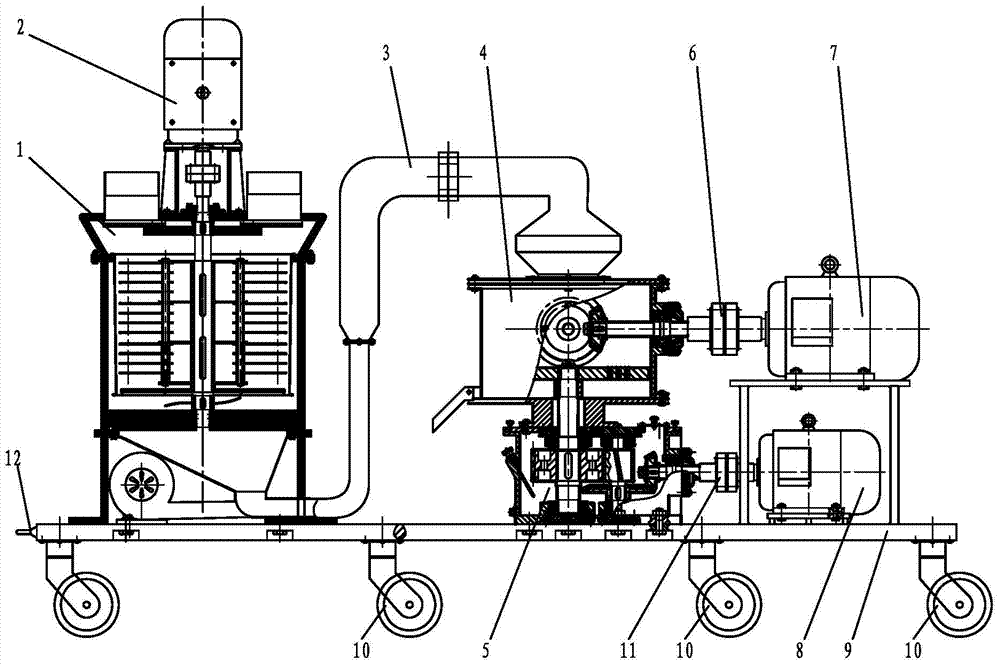

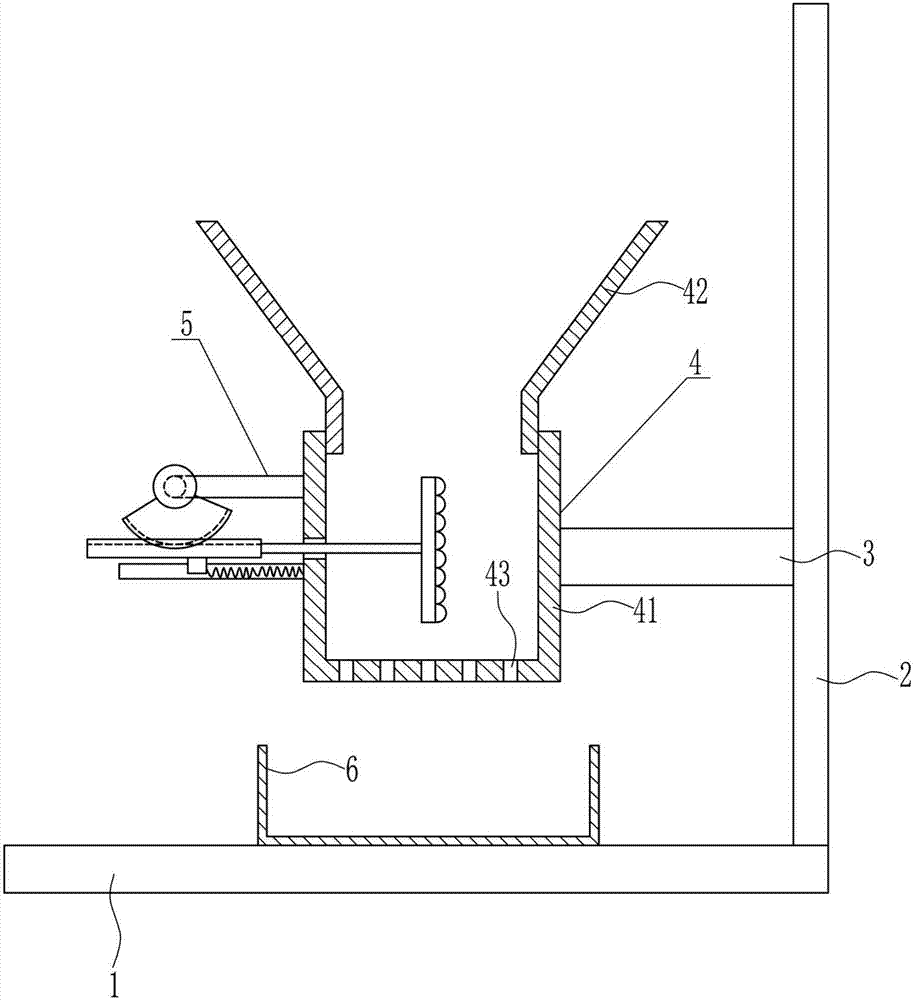

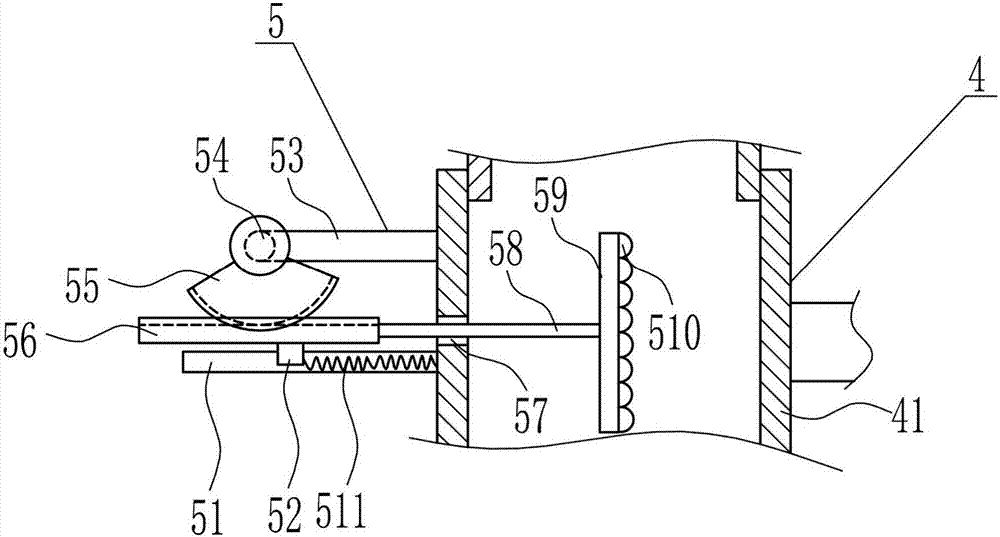

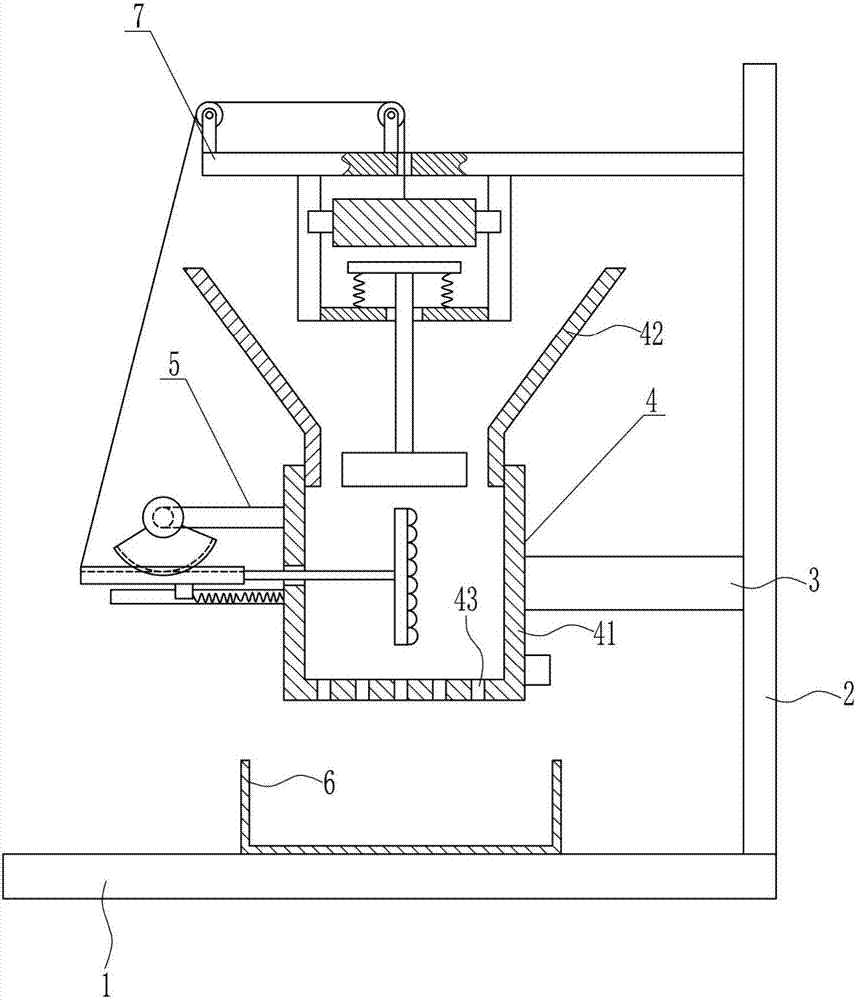

Biomass straw smashing and forming all-in-one machine

InactiveCN103495484ABig hitImprove crushing efficiencyGranulation by pressingGrain treatmentsWork cycleAir blower

The invention provides a biomass straw smashing and forming all-in-one machine, and relates to a straw smashing and forming device. The biomass straw smashing and forming all-in-one machine solves the problems that in an existing straw forming fuel production process, the straw smashing procedure and the compressing and compacting forming procedure are independently completed through a smashing device and a squeezing forming device respectively, the power consumption is high, the logistics cost is high, and the working cycle is long. The vertical smashing device and the squeezing forming device are arranged on a walking plate in parallel from front to back, walking wheels are arranged below the walking plate, a blade is arranged at the bottom of a feed port of the vertical smashing device, a main shaft of the smashing machine is sleeved with a sleeve, hammer carrier plates are arranged on the sleeve from top to bottom, a hammer set is arranged between every two adjacent hammer carrier plates in an annular mode, hammers of each hammer set are evenly arranged in the vertical direction, each hammer is of a multi-tooth-edge rectangular structure, an air blower is arranged at the bottom of a machine shell and communicate with a material storage hopper, and the material storage hopper is communicated with an inlet of the squeezing forming device through an air duct. The biomass straw smashing and forming all-in-one machine is used for smashing and forming biomass straw.

Owner:NORTHEAST FORESTRY UNIVERSITY

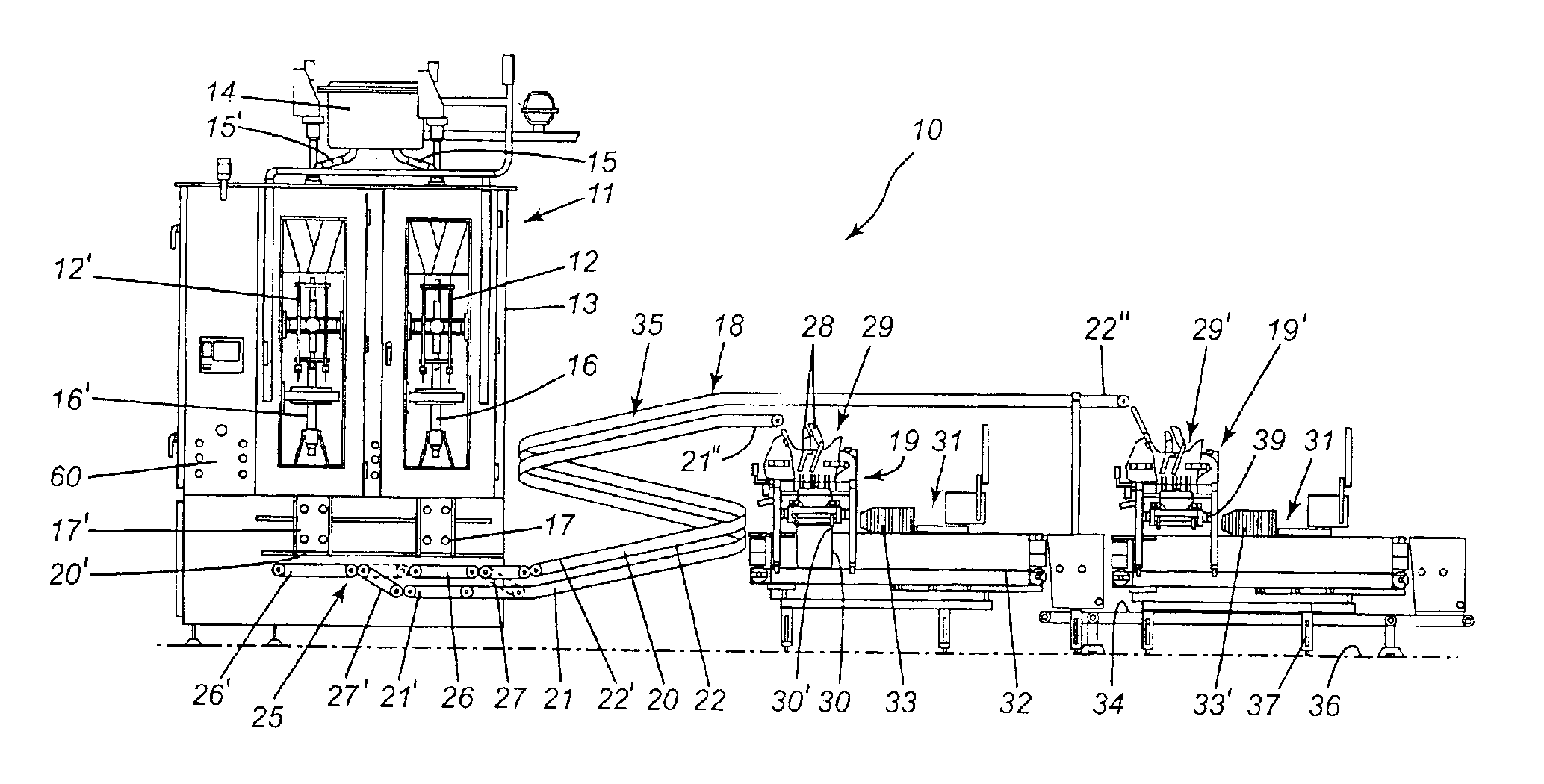

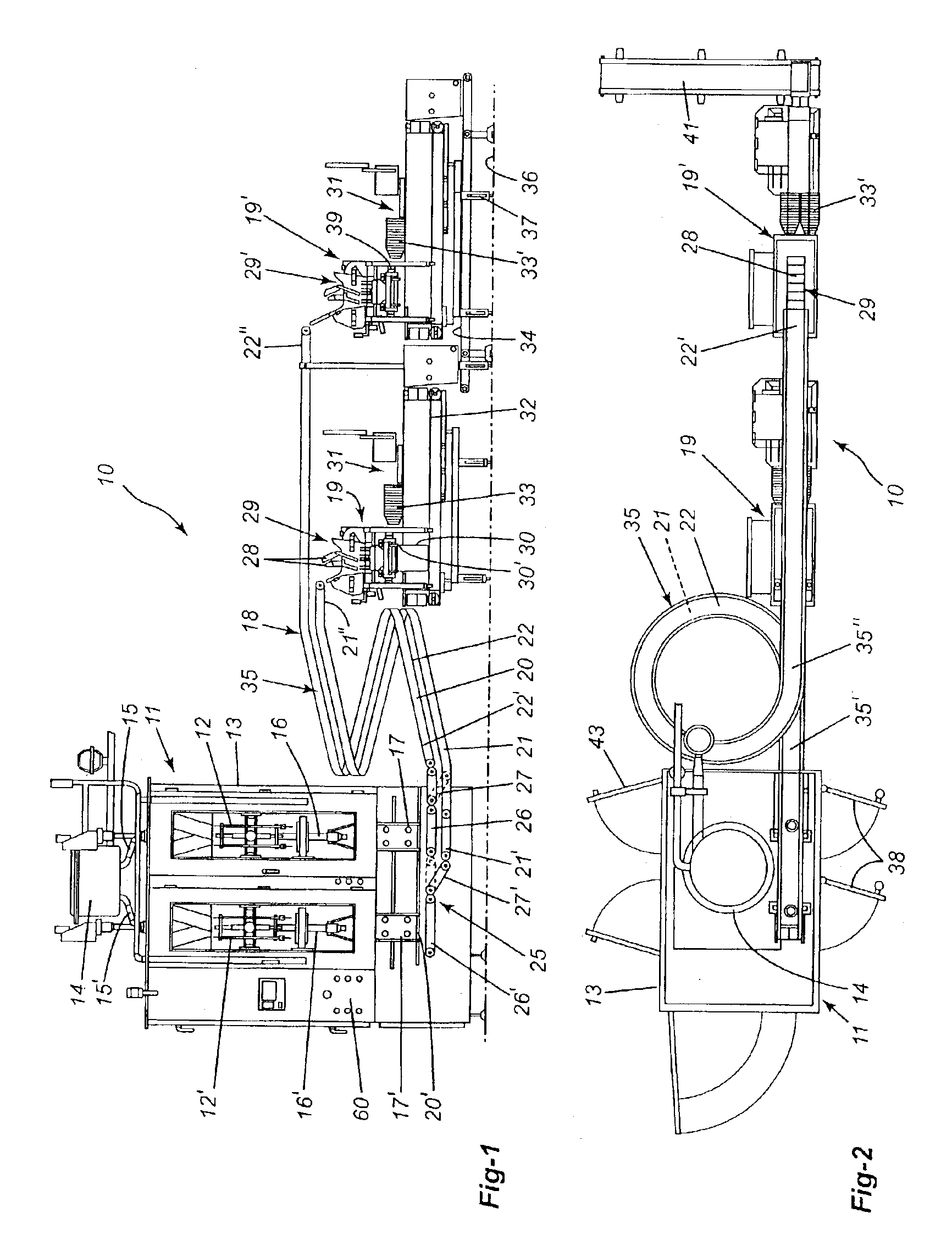

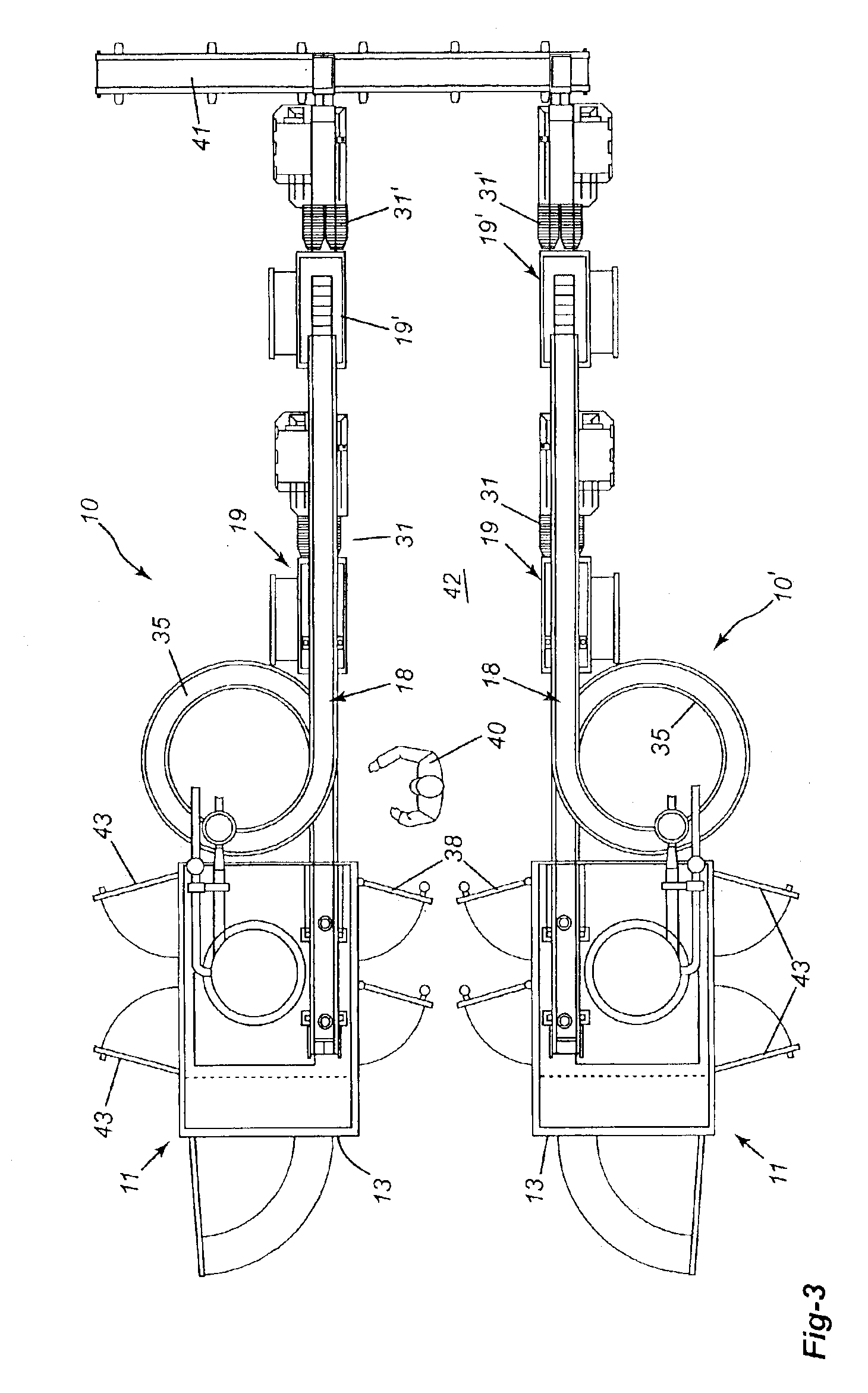

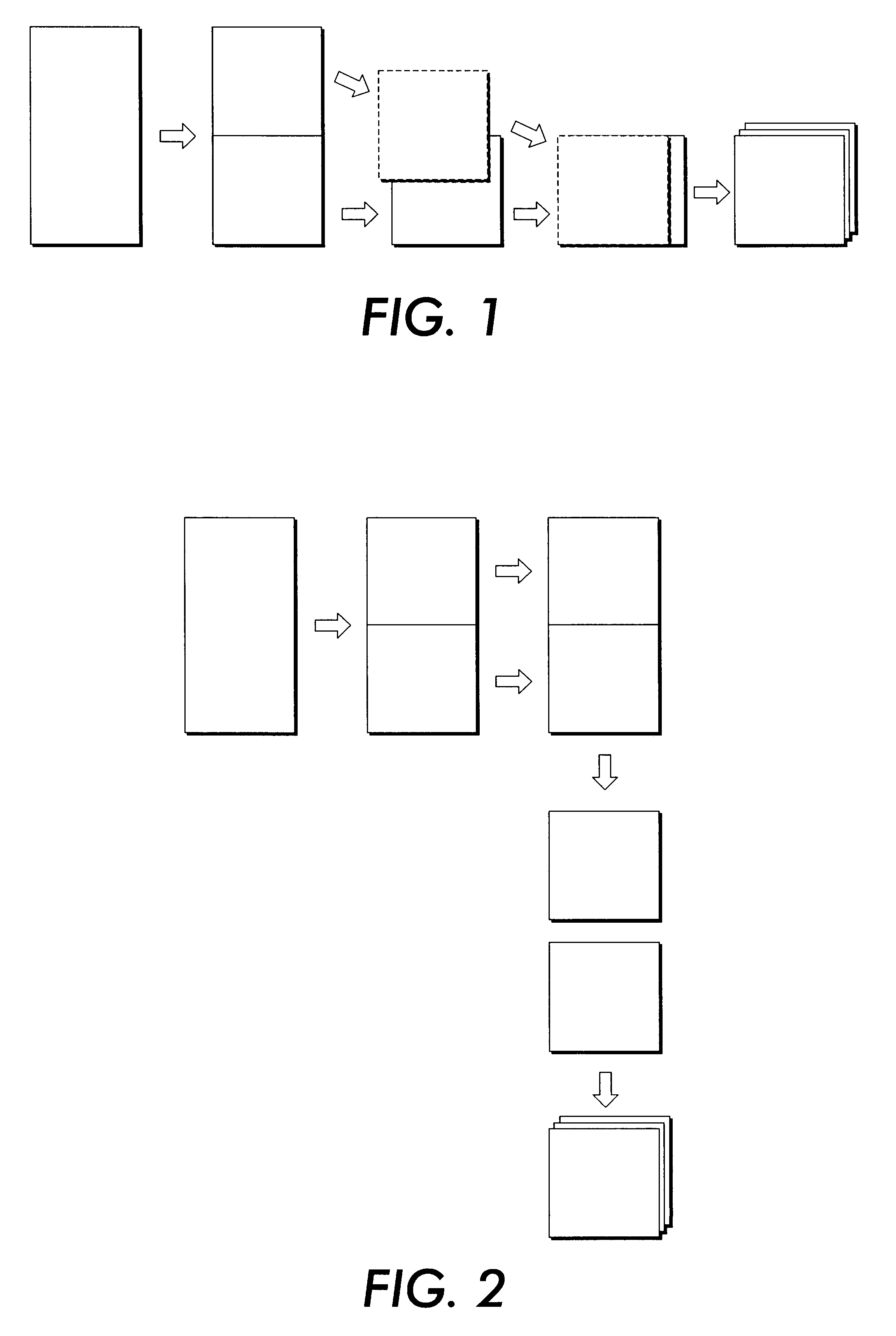

High speed bagging system and method

InactiveUS6874299B2Increase the output speedHigh outputWrapping material feeding apparatusMultiple wrapper applicationLiquid productWork cycle

A high speed bagging system and a method for placing a liquid product into a bag and placing at least two of these bags into a pouch is described. The system comprises at least two bag fillers housed in a common filler housing and operating simultaneously to place the liquid product in respective bags on a continuous basis during a working cycle. Filled bags are simultaneously conveyed on a two lane conveyor system. The two-lane conveyor is configured to optimize floor space area. Each conveyor belt has an outlet end associated with a respective bagging machine at a bagging station. The bagging machines are adapted to place at least two of the bags into a pouch on a continuous basis during the working cycle. The bagging machines feed a respective pouch closure device to close a mouth opening of the pouches which are then discharged on a discharge conveyor.

Owner:GLOPAK INC

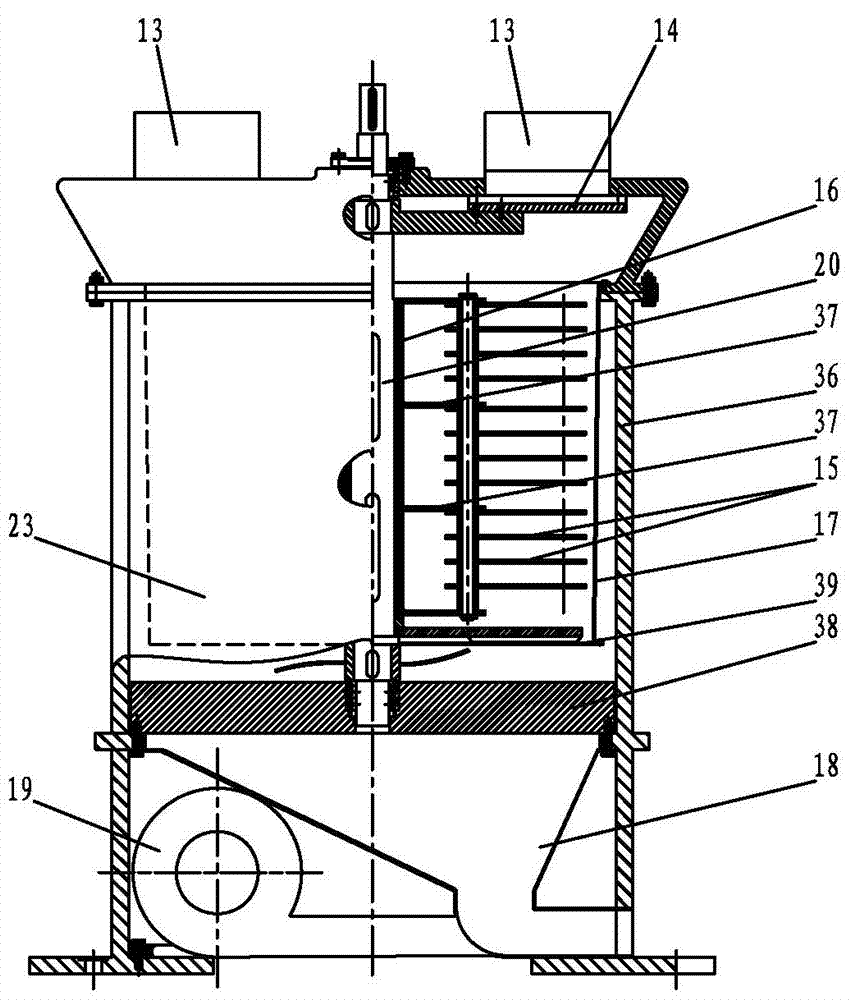

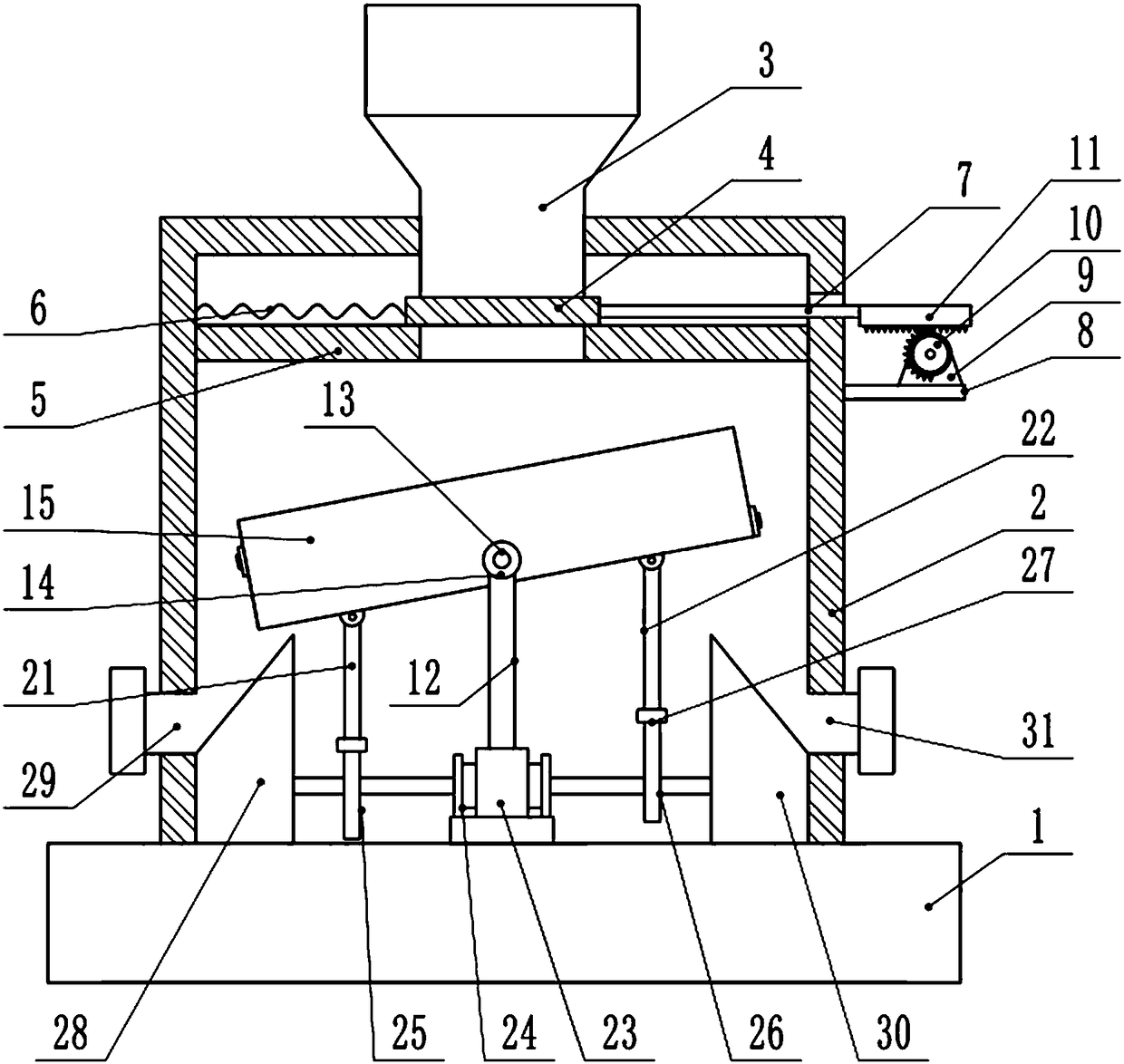

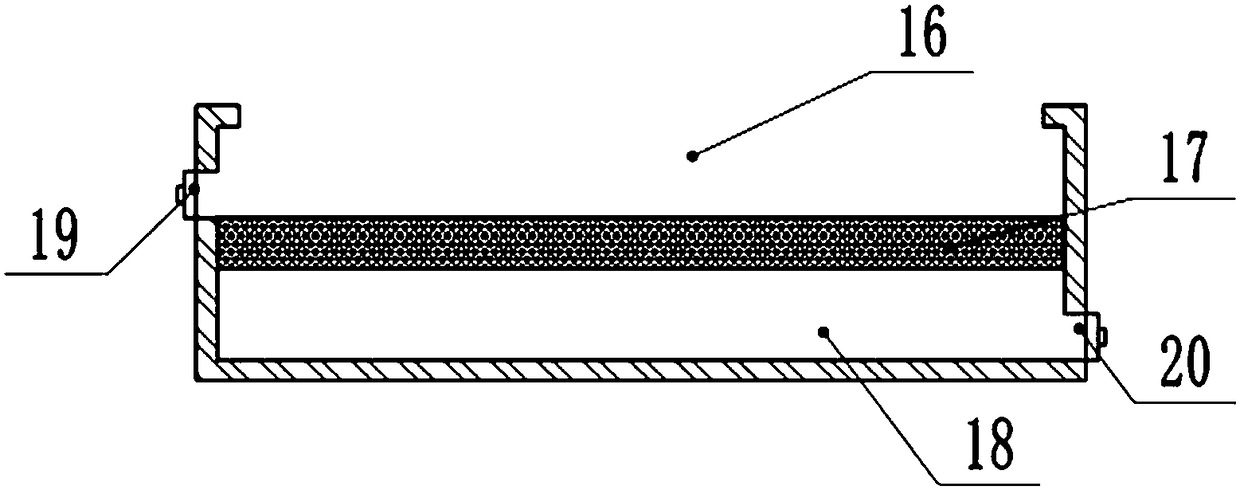

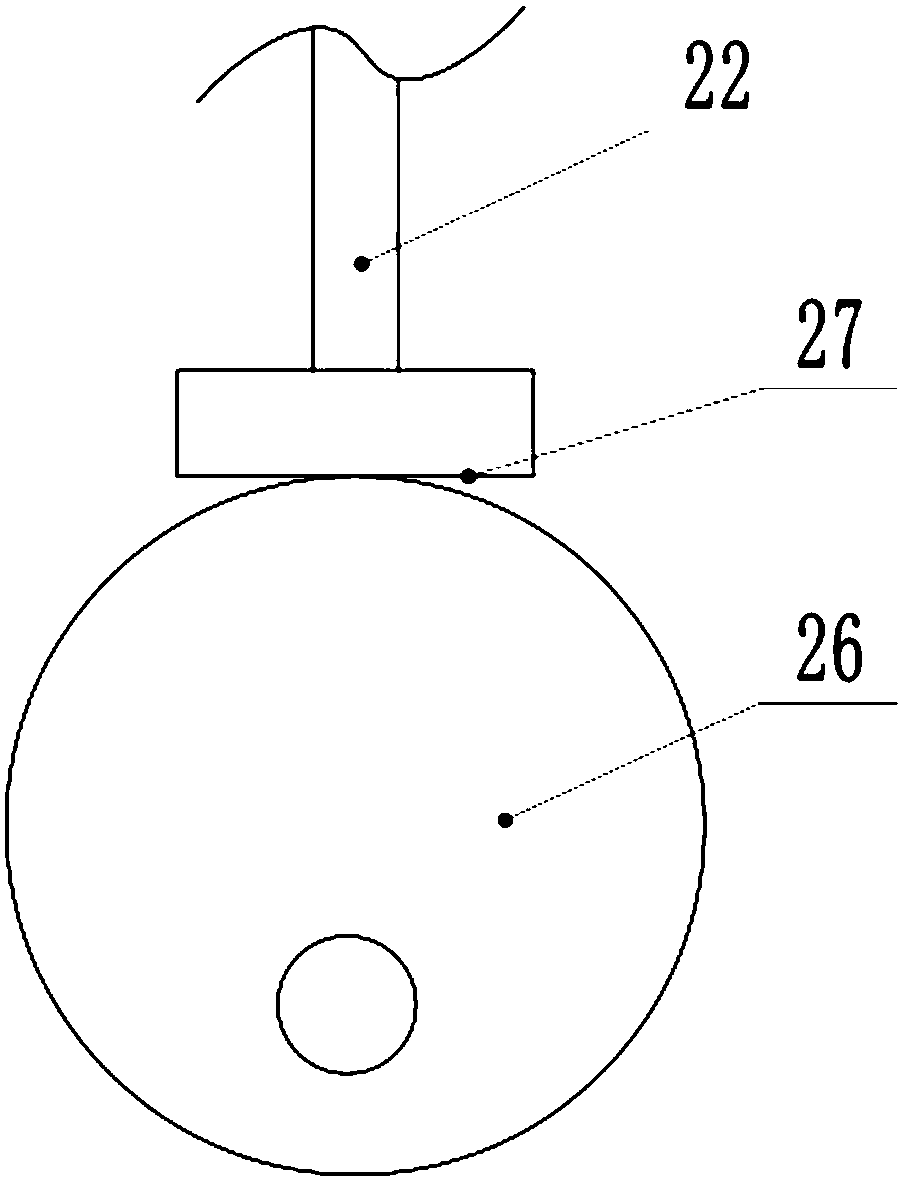

Superfine natural pearl powder screening device with convenient discharging function

ActiveCN108097572APrevent clogging of the screenCauses clogging of the screenSievingScreeningInterference fitEngineering

The invention discloses a superfine natural pearl powder screening device with a convenient discharging function. The superfine natural pearl powder screening device comprises a base and a screening tank, wherein the screening tank is arranged on the base; a blocking plate is arranged on the lower side of a feeding hopper; a screening slot is rotationally mounted on a swinging shaft; a driving motor is fixedly mounted on a bracket; and a left cam and a right cam are mounted on output shafts positioned at the left and right ends of the driving motor in an interference fit manner, and correspondingly get in contact with ejector blocks positioned at the lower ends of a left ejector rod and a right ejector rod. Through the arrangement of an intermittent discharging disc, the intermittent quantitative dropping operation can be achieved when pearl powder drops into the screening slot for being screened, thereby preventing the circumstance that too much pearl powder drops at a time, the screening pressure is excessive, and then a screening mesh is blocked by the pearl powder; through the swinging screening action of the screening slot, the pearl powder screening operation on the screeningmesh inside the screening tank can be accelerated; and through the left and right inclination of the screening tank, the pearl powder discharging speed can be improved, the residue of the pearl powder inside the screening tank can be avoided, and then the relatively simple cleaning operation can be achieved.

Owner:安徽正特机电科技有限公司

Single/double sheet stacker

InactiveUS6575461B1Increase speedDoubles output speedFunction indicatorsElectrographic process apparatusEngineeringStacker

Owner:XEROX CORP

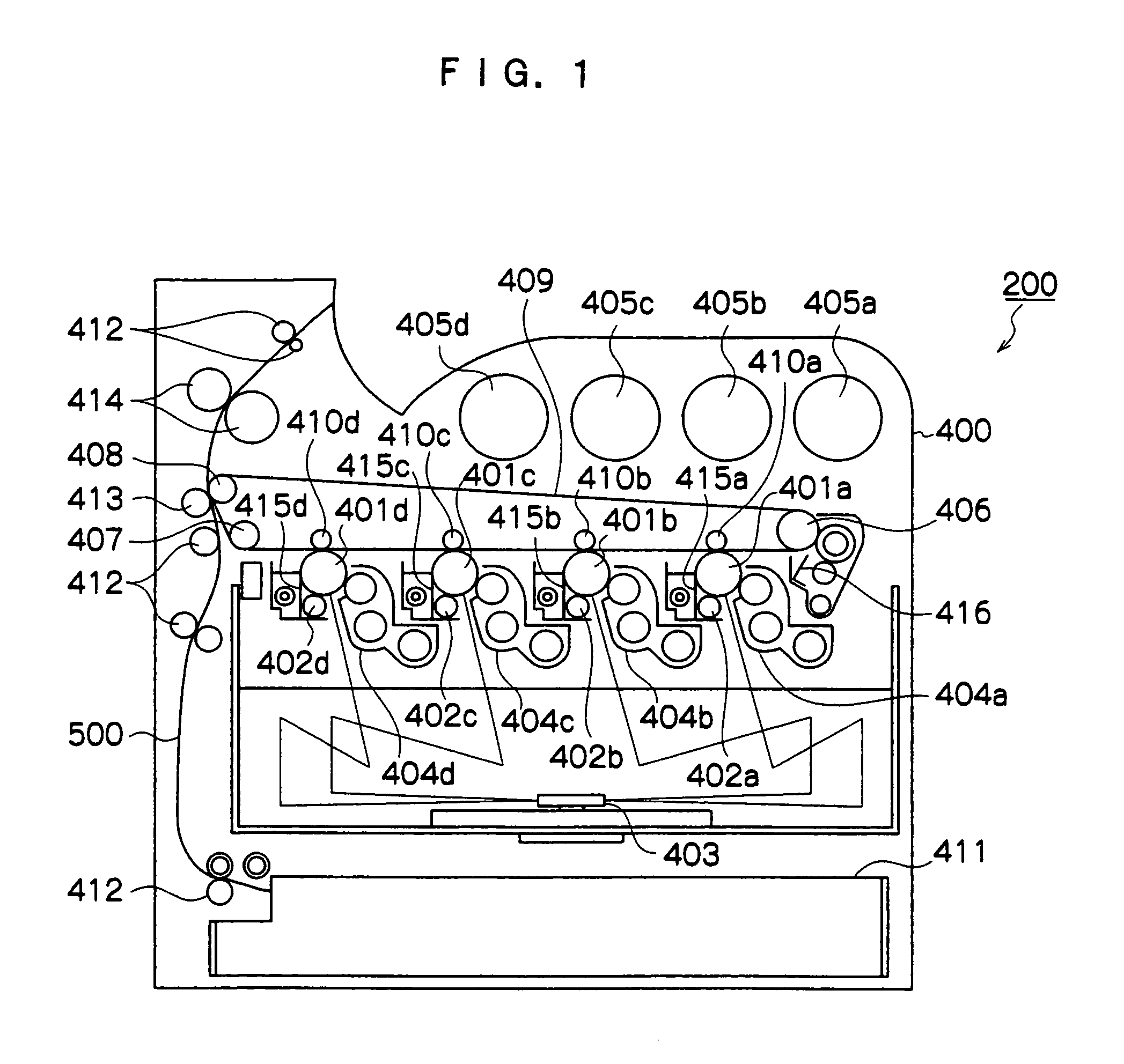

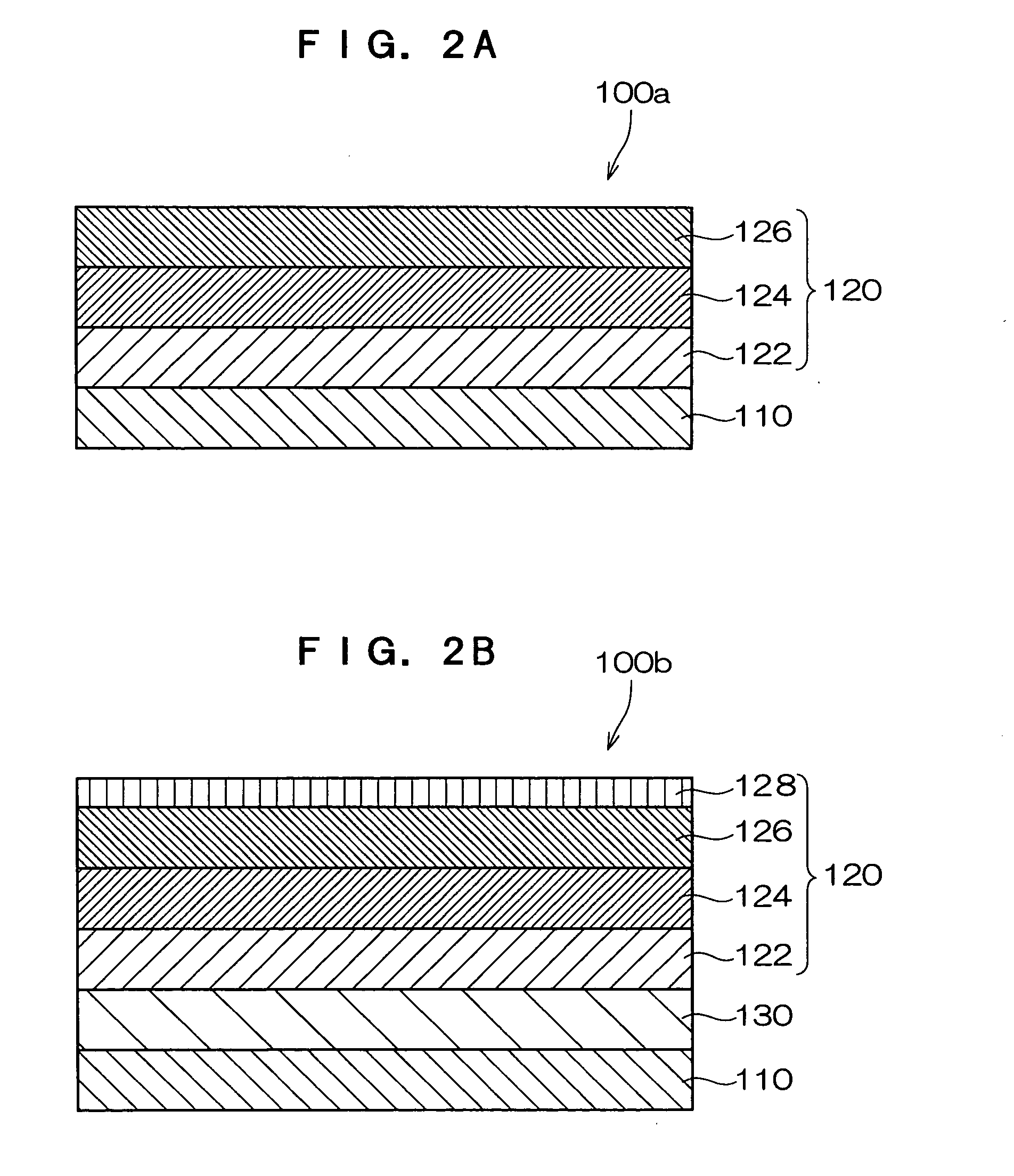

Method of forming composite color image

ActiveUS20070172748A1Improve image qualityPrevent image quality defectElectrographic process apparatusElectrographic processes using charge patternEngineeringYoung's modulus

Owner:FUJIFILM BUSINESS INNOVATION CORP

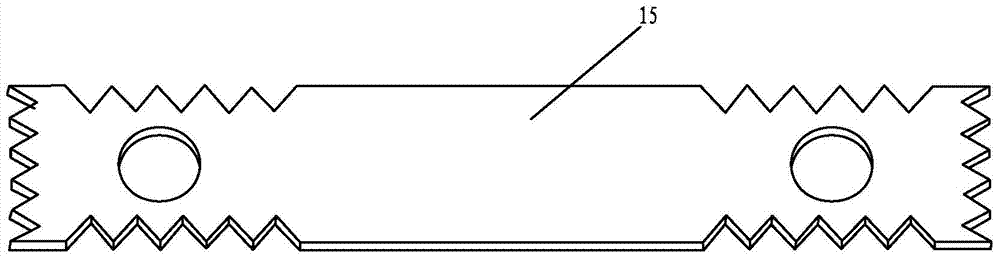

Fruit ice cream machine

InactiveCN103168908AChange the setting directionIncrease the output speedFrozen sweetsReduction driveElectric machinery

The invention provides a fruit ice cream machine, belongs to the technical field of food equipment, and solves the problems of the existing fruit ice cream machine that the discharging speed is low and residual food remains in a stirring cavity. The fruit ice cream machine comprises a machine base, an abrasive disc and an electric motor arranged inside the machine base, wherein the electric motor is connected with the abrasive disc through a speed reducer; the abrasive disc can be driven to rotate through the electric motor; a material containing bin is further arranged above the machine base; the material containing bin consists of a cylindrical feeding barrel and a conical gland; a discharging port is formed in the gland; a plurality of strip-shaped serrated blades are uniformly fixed on the outer circular conical surface of the abrasive disc; each blade is arranged along the rotation direction of the same abrasive disc relative to the straight edge line of the outer circular conical surface of the abrasive disc according to the same inclined angle; and a concave material storage groove is formed in the outer circular conical surface of the abrasive disc between two adjacent blades. According to the fruit ice cream machine, the discharging speed can be increased, and residual ice-cream-shaped food inside the stirring cavity is reduced.

Owner:马剑峰

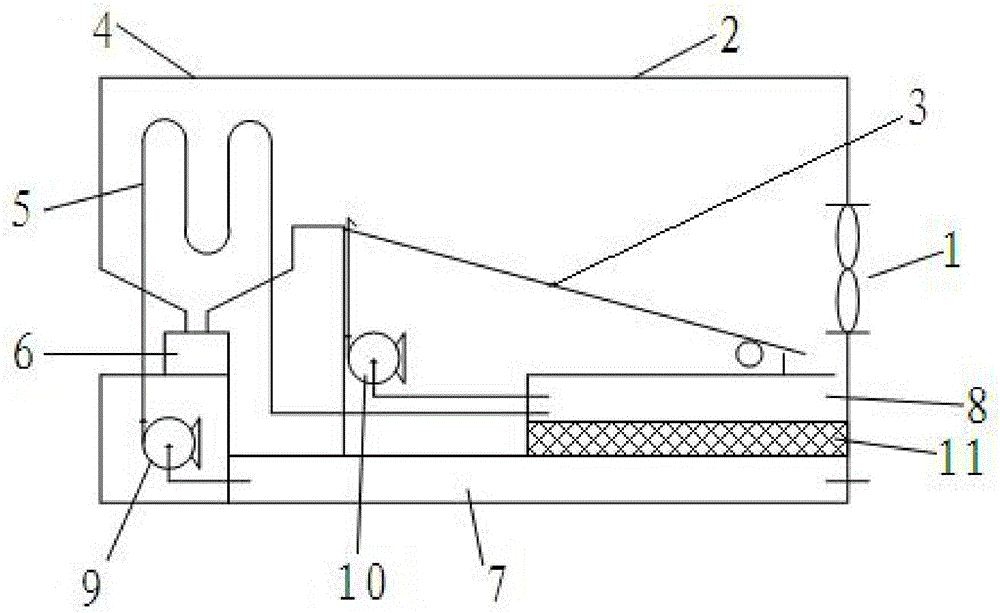

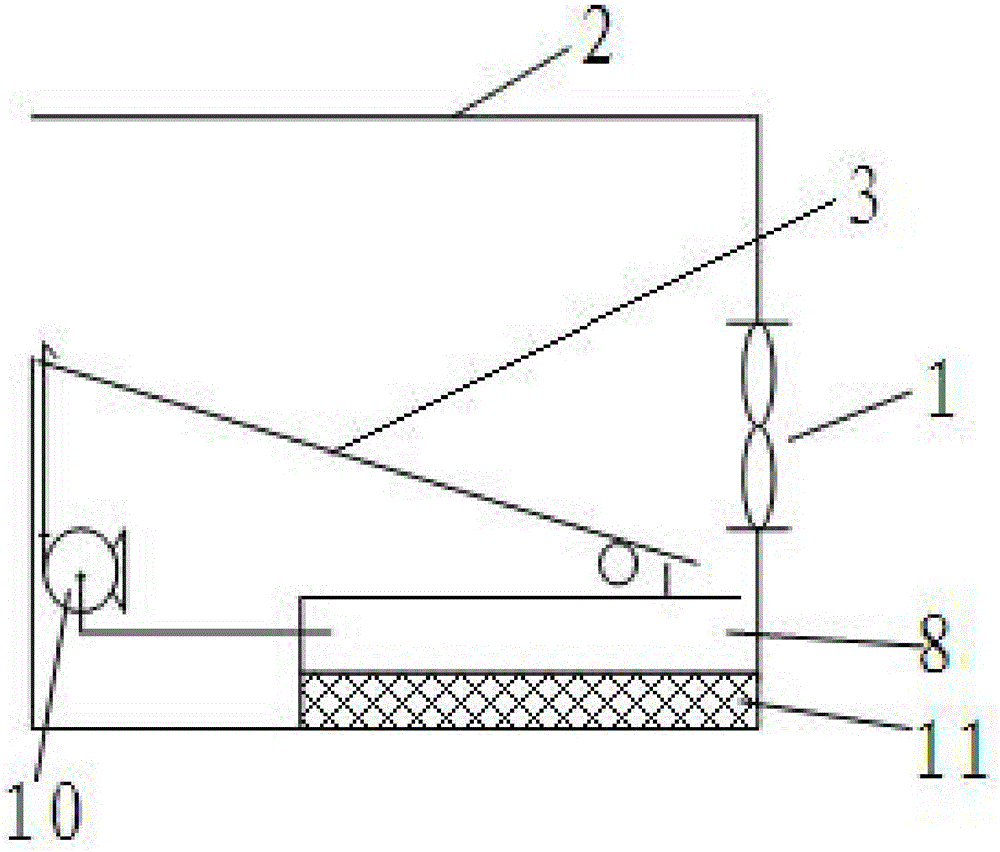

Structure compact type seawater desalination device

ActiveCN105936522AFast evaporationIncrease the output speedGeneral water supply conservationSeawater treatmentSeawaterEvaporator

The invention discloses a structure compact type seawater desalination device, which includes an evaporator (2). The middle part of an evaporator (2) side wall is provided with a wind inlet, the middle and upper part of an evaporator (2) side wall opposite to the wind inlet is provided with a damp and hot steam outlet, the internal bottom of the evaporator (2) is provided with a concentrated seawater tank (8), the upper surface of the concentrated seawater tank (8) is provided with a vertical telescopic rod, the top of the telescopic rod is provided with a rotating pair, the top of the rotating pair and bottom of the damp and hot steam outlet are connected by a heating plate (3), and the bottom of the damp and hot steam outlet is higher than the top of the rotating pair. The water outlet of the concentrated seawater tank (8) is connected to a cold seawater inlet through a concentrated seawater pump (10), and the cold seawater inlet is disposed on the upper end top surface of the heating plate (3). The structure compact type seawater desalination device provided by the invention is used for seawater desalination, and can guarantee residents' drinking water supply in coastal water-deficient areas.

Owner:HOHAI UNIV CHANGZHOU

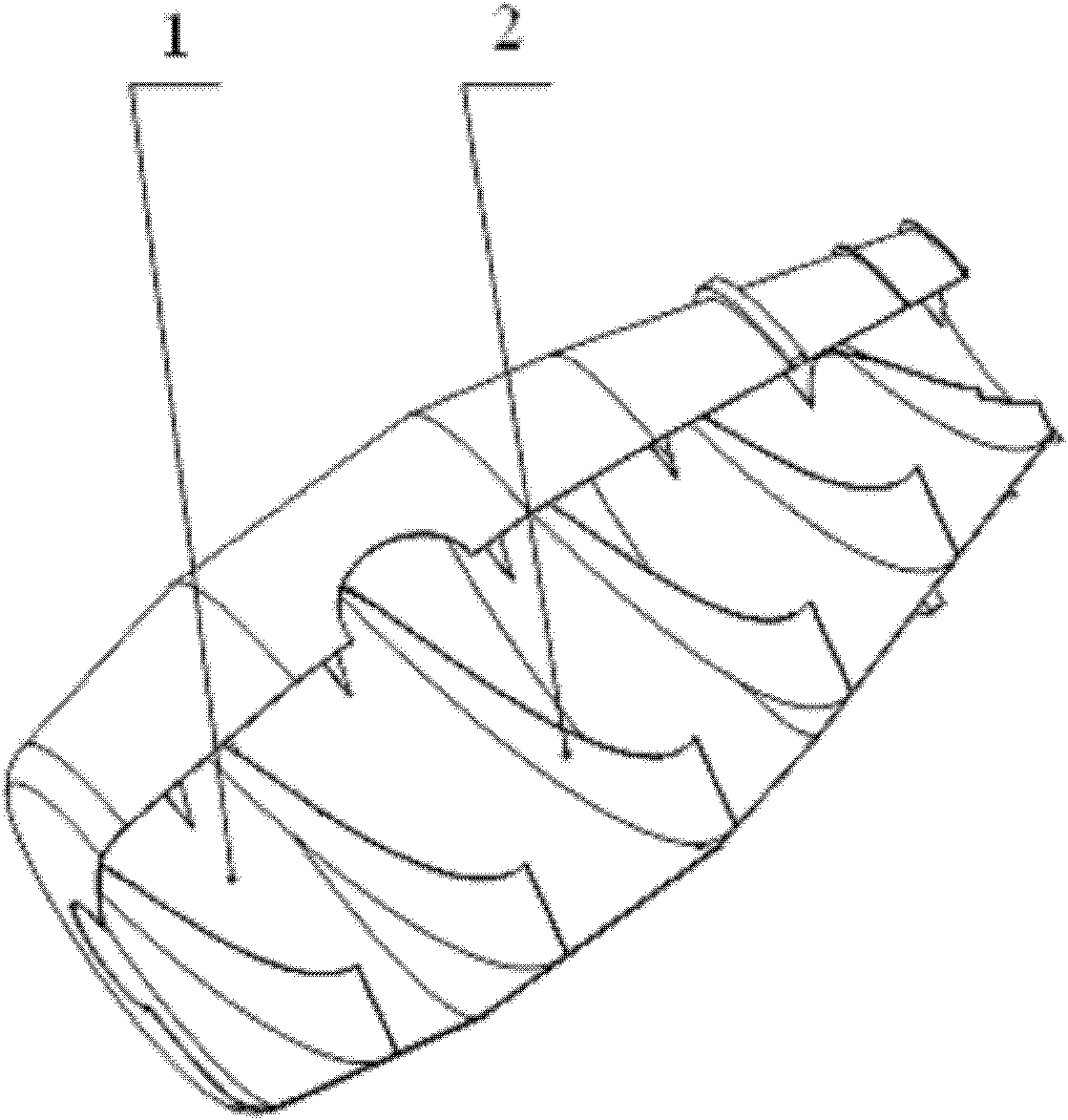

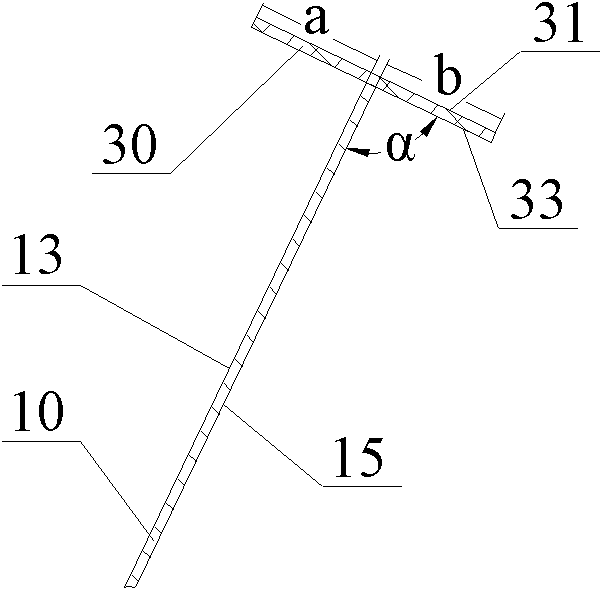

Concrete mixing truck as well as mixing drum and mixing drum blade structure thereof

The invention provides a mixing drum blade structure and mixing drum of a concrete mixing truck as well as the concrete mixing truck. The mixing drum blade structure comprises a first blade part which is connected to the inner wall of the mixing drum and a second blade part which is intersected with the first blade part. According to the mixing drum blade structure provided by the invention, the first blade part and the second blade part are intersected with each other, so that the strength of the whole mixing drum blade structure is enhanced, the mixing drum blade structure can better adapt to the concrete mixing, the mixing effect is optimized, the mixing becomes more uniform, and the segregation phenomenon is prevented from occurring in a mixing process. The mixing drum provided by the invention has the mixing drum blade structure, so that the mixing drum has the advantages of better abrasion resisting property, better flow-guiding effect, prolonged service life, more uniform mixing effect and increased feeding and discharging speeds. Besides, the concrete mixing truck which is provided with the mixing drum provided by the invention can be used for maintaining the excellent quality of the concrete which is transported.

Owner:ZOOMLION HEAVY IND CO LTD

Transmission arrangements for hybrid electric vehicles

InactiveUS20060116231A1Lower ratioIncrease gear ratioHybrid vehiclesTransmission elementsEngineeringBattery electric vehicle

A geared, power transmission mechanism for a hybrid electric vehicle wherein multiple power flow paths are established between an engine and vehicle traction wheels and between an electric motor and the vehicle traction wheels. At least one of the power flow paths is characterized by at least two ratios.

Owner:FORD GLOBAL TECH LLC

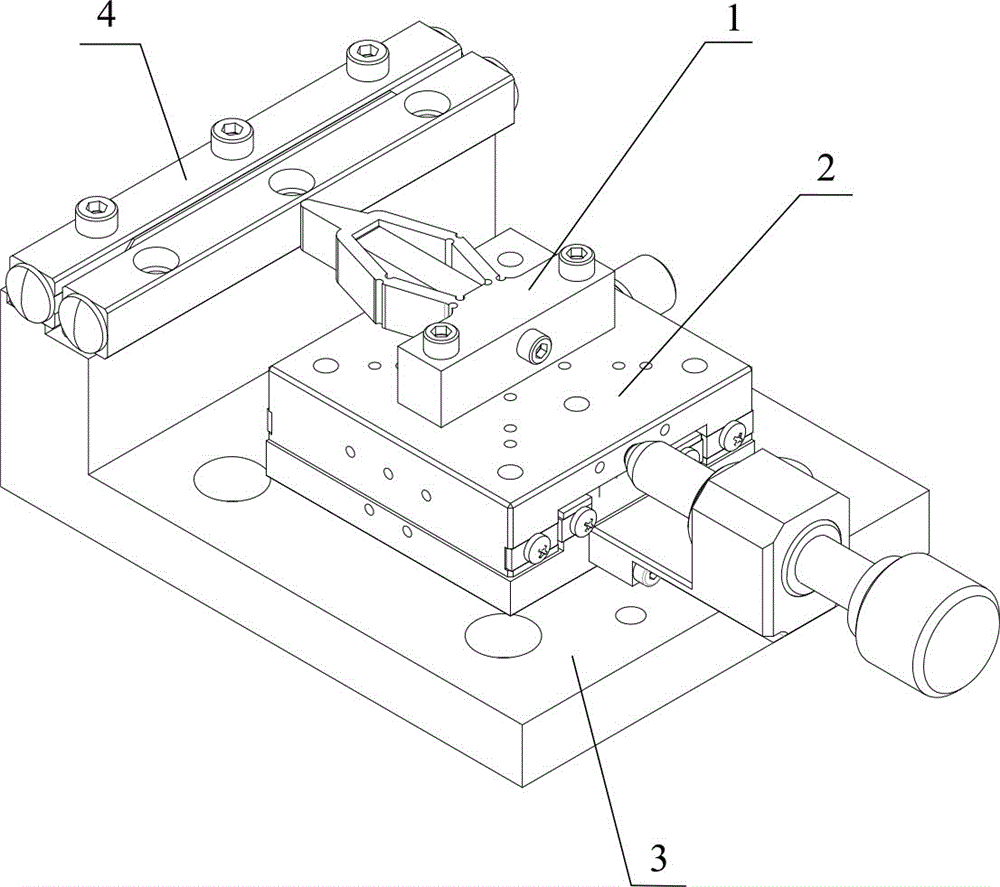

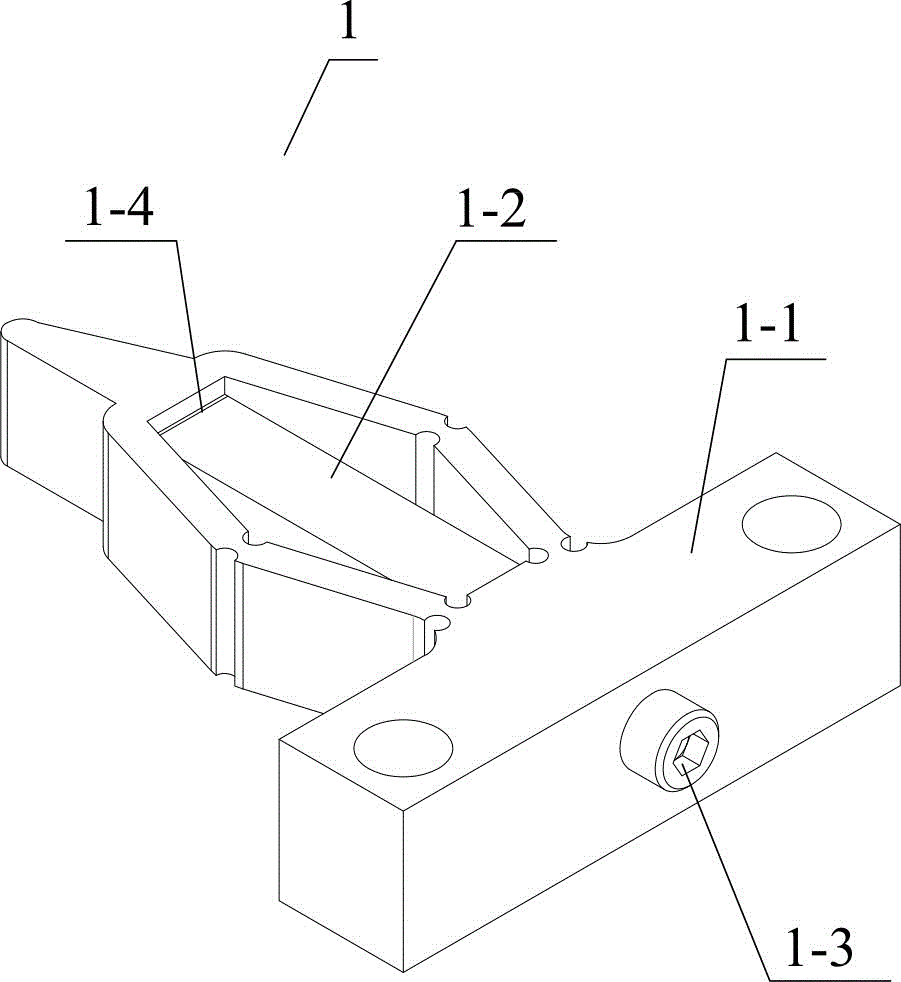

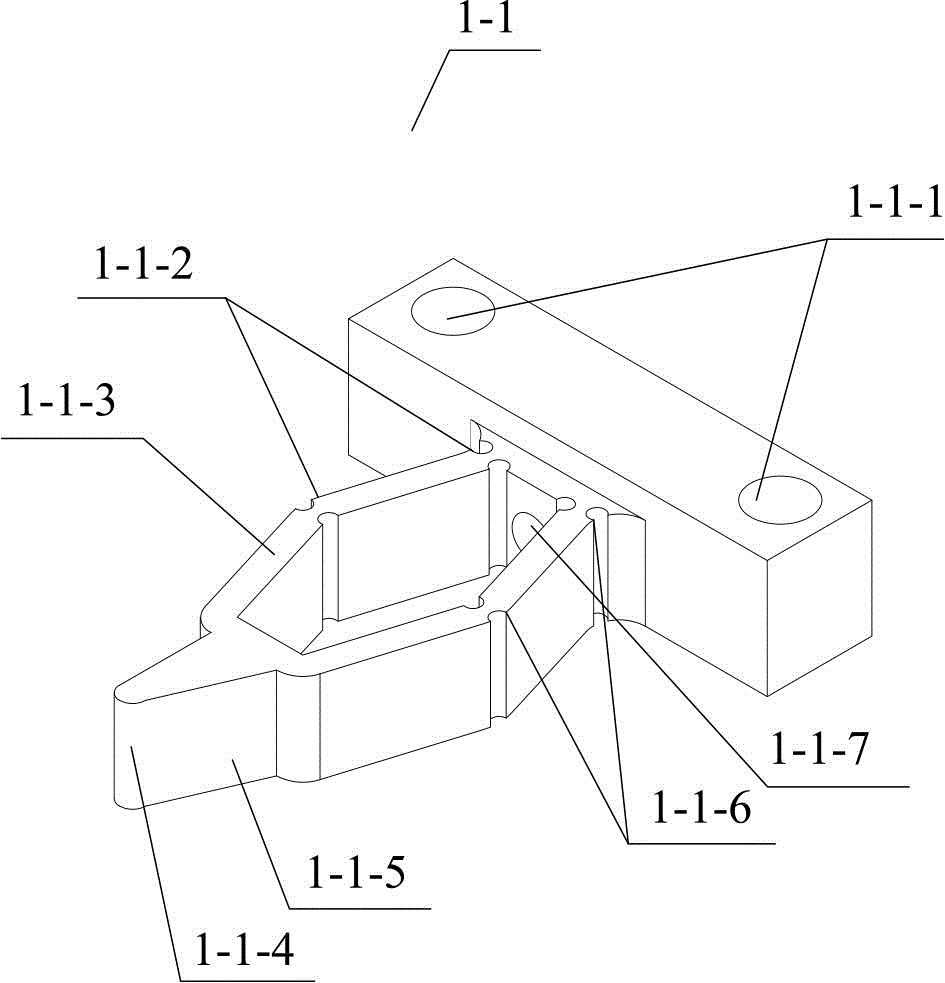

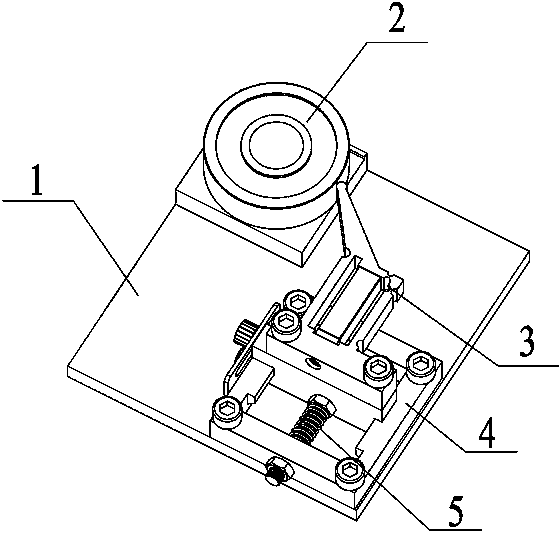

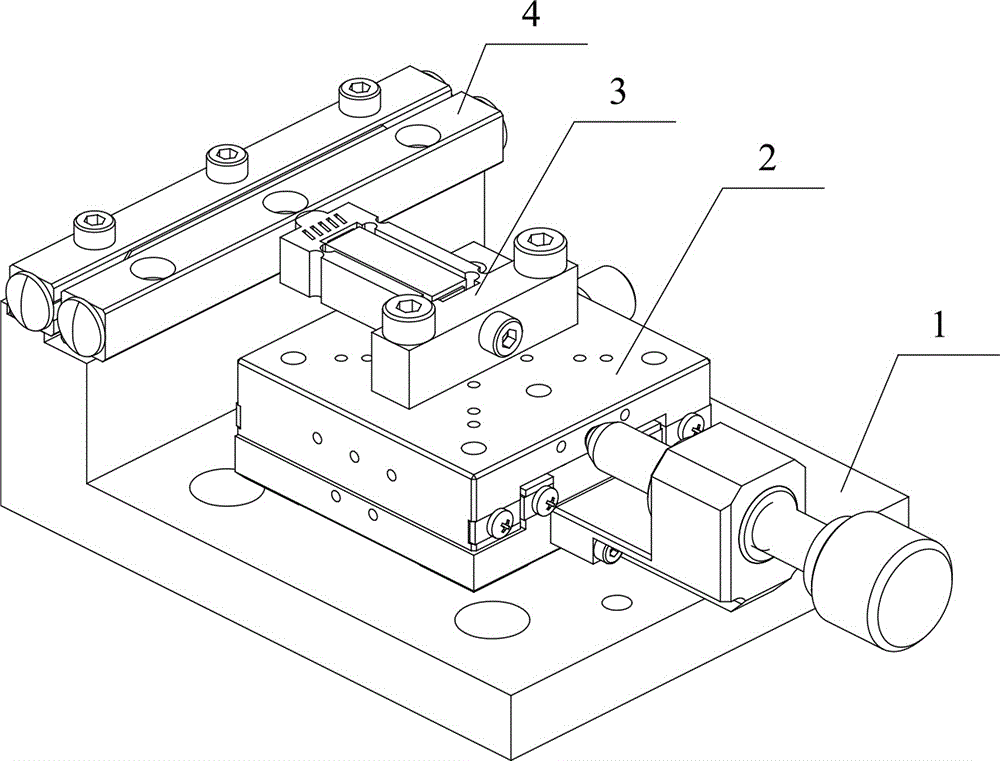

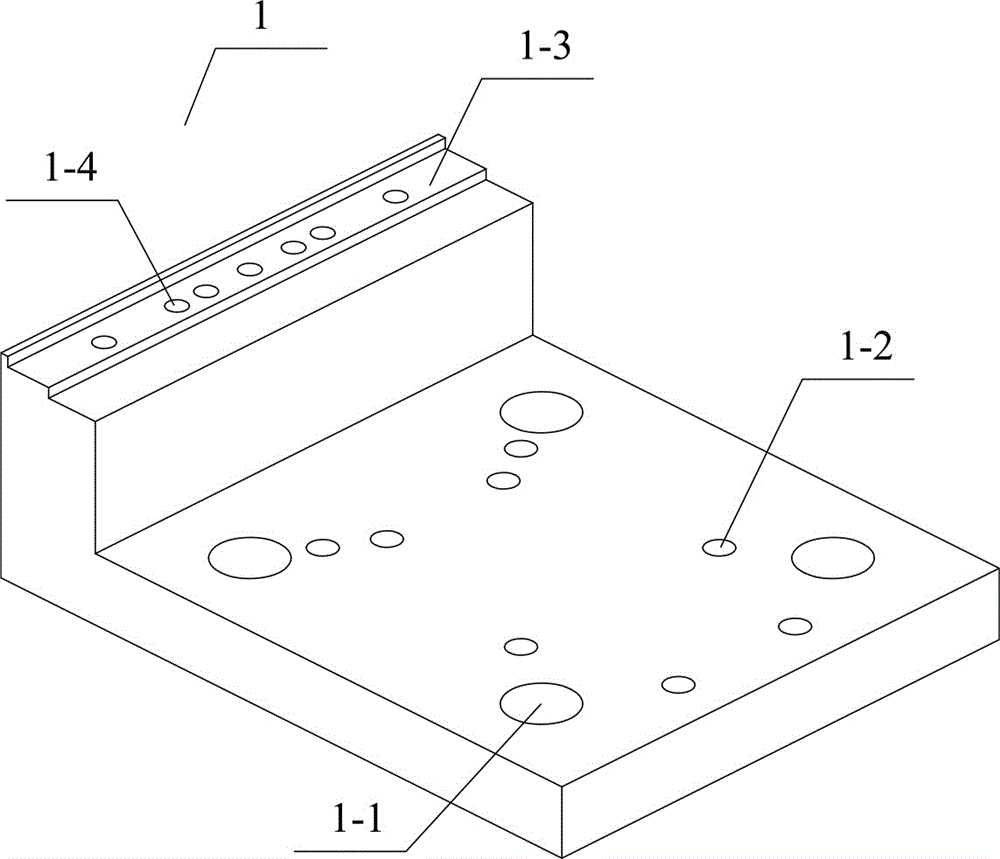

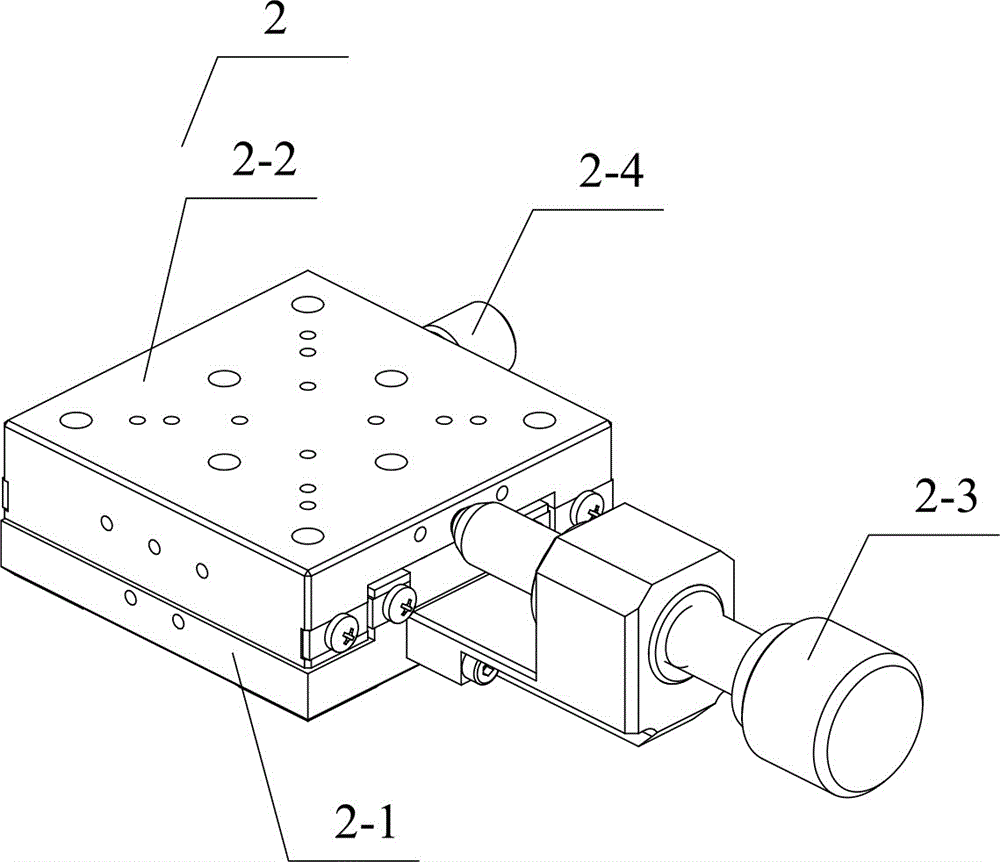

Rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor and composite excitation method thereof

ActiveCN105827143AIncrease frictionIncreased frictional driving forcePiezoelectric/electrostriction/magnetostriction machinesMicro nanoFriction force

The invention provides a rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor and a composite excitation method thereof to solve the problem that in an existing piezoelectric stick-slip linear motor, the mechanical output property is limited due to the fact that comprehensive regulation on friction force is difficult. The rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor is composed of an oblique-wedge stator, a preloading device, a mounting support and a rotor; the oblique-wedge stator adopts asymmetrical hinges of a wedged structure, lateral displacement is generated through an oblique-wedge rhombus motion converter and the ununiform axial rigidity distribution characteristic of a stator drive foot, the friction drive force is increased, and the friction resistance is decreased; meanwhile, friction regulation waves are overlapped into sawtooth drive waves in the rapid deformation stage of the stator, comprehensive regulation on the friction force is achieved, and the mechanical output characteristic of the piezoelectric stick-slip linear motor is significantly promoted. The rhombus oblique-wedge quadratured drive type piezoelectric stick-slip linear motor has the advantages of being simple in structure, high in precision, large in stroke and the like and has the good application prospect in the fields of micro-nano precise driving and positioning such as machining of precise medical instruments, optical precise instruments and semiconductors.

Owner:CHANGCHUN UNIV OF TECH

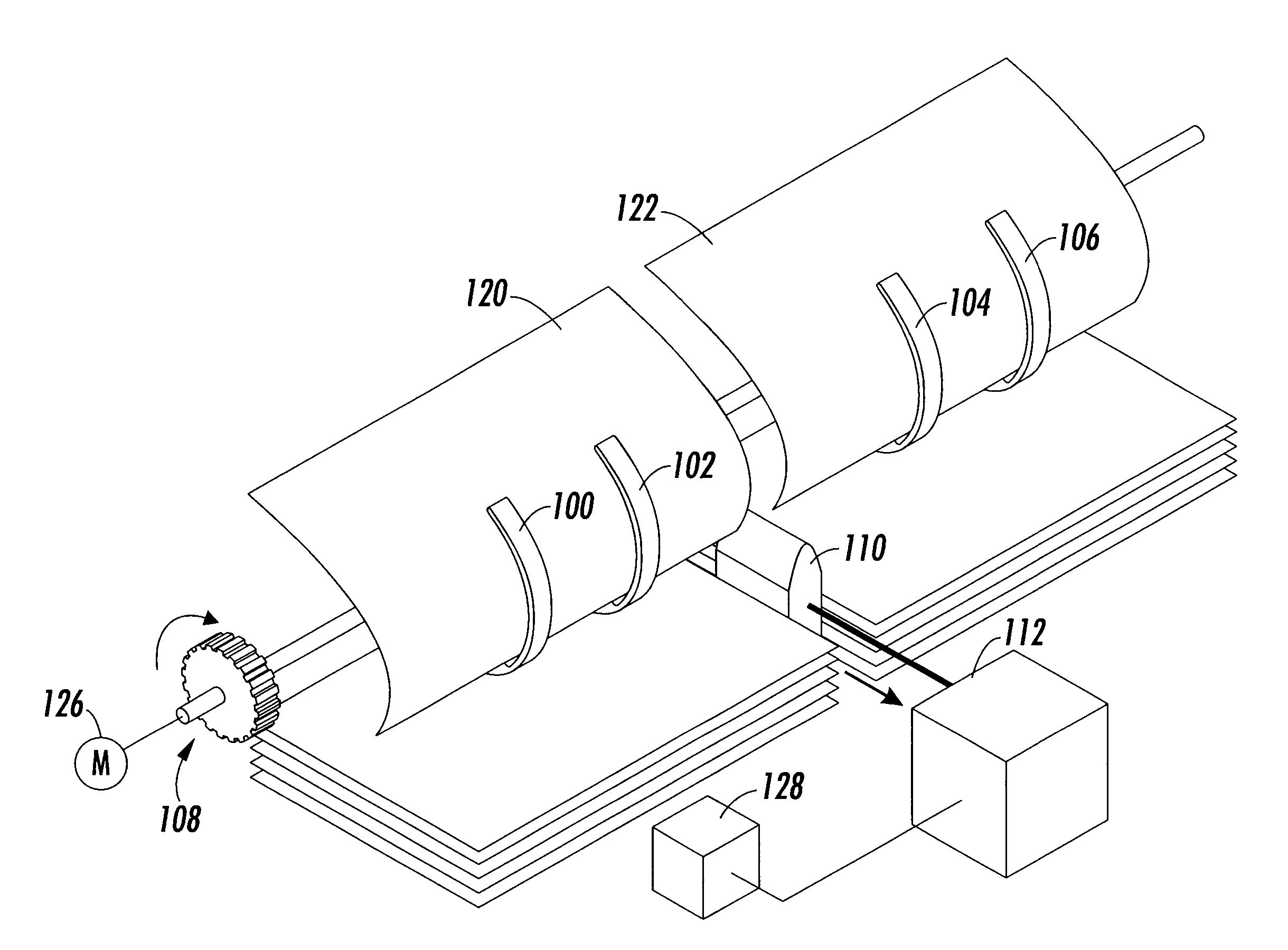

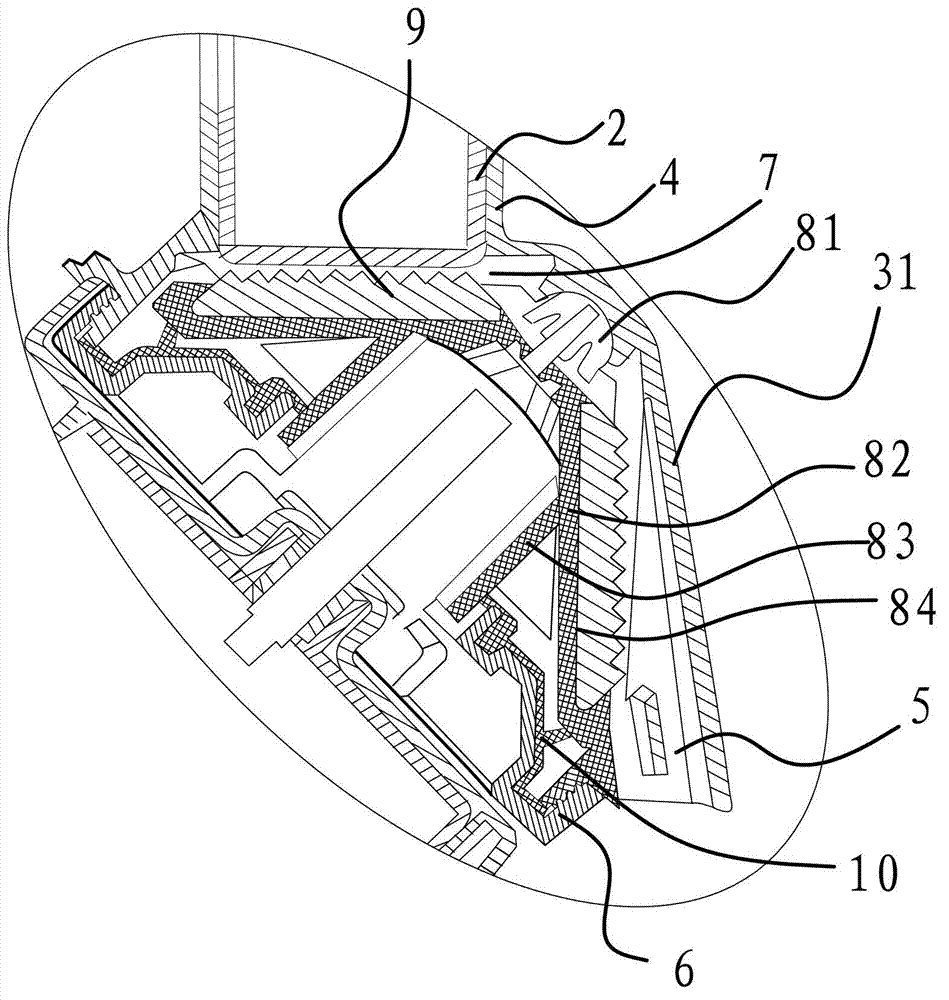

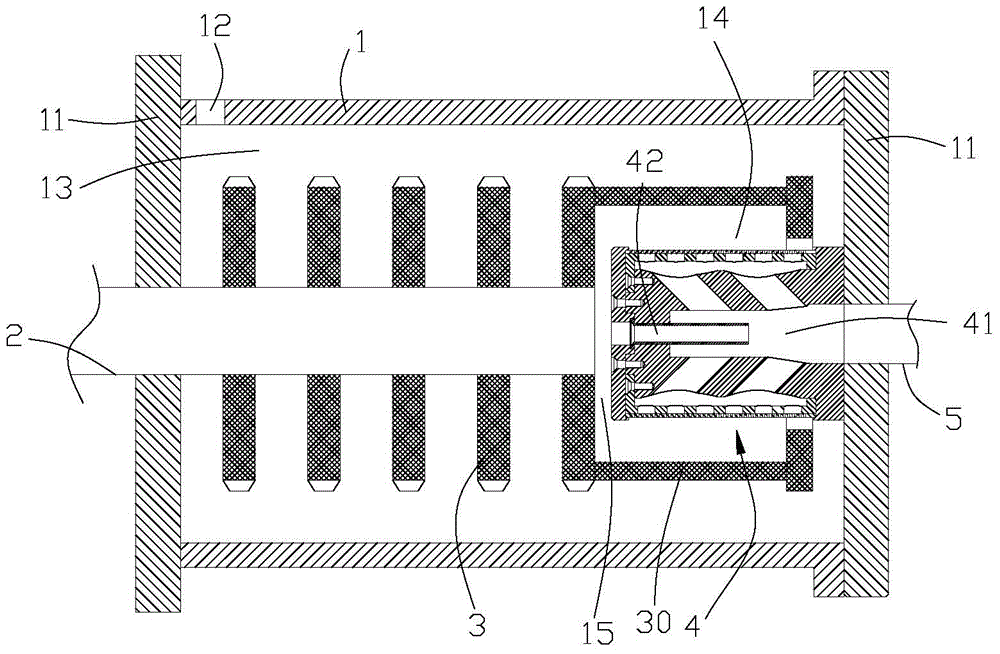

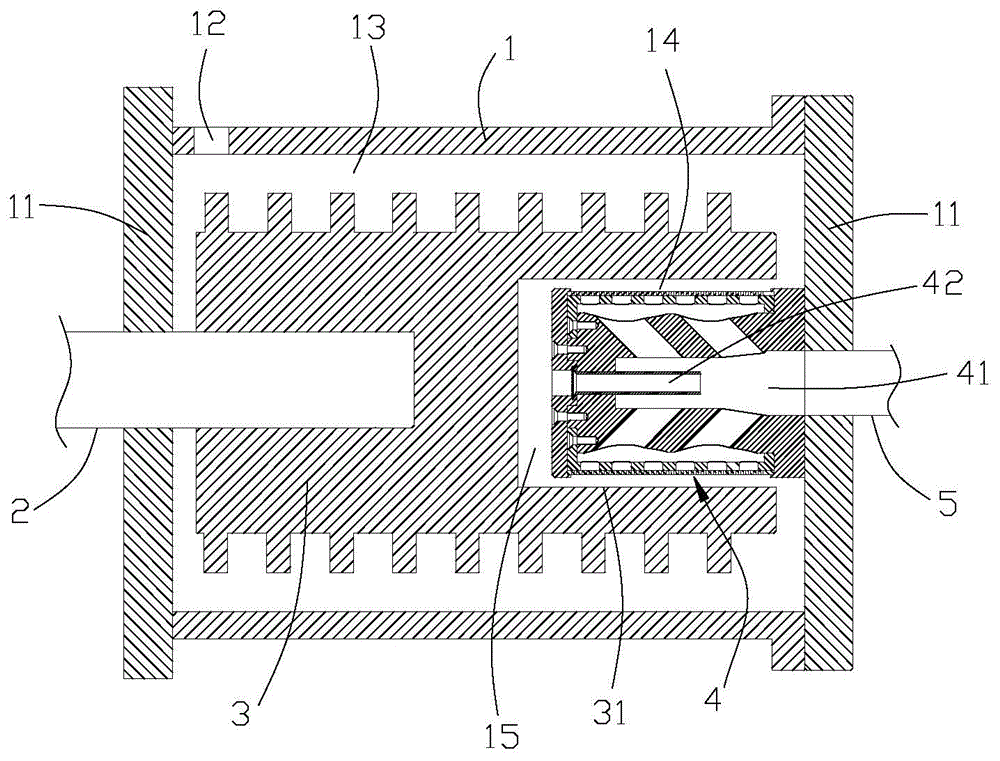

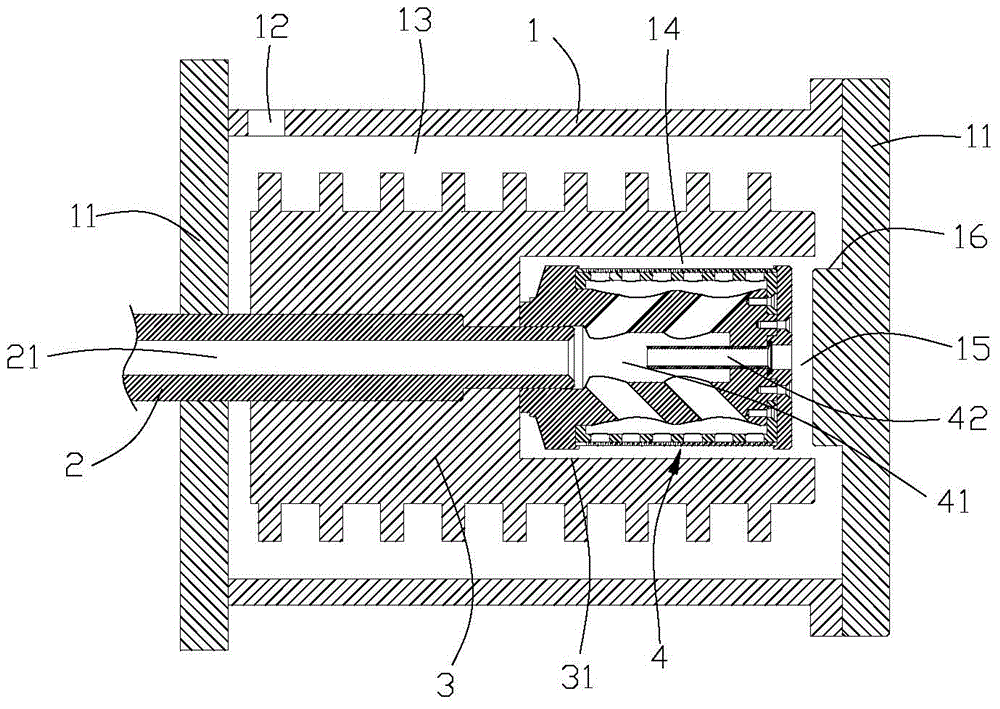

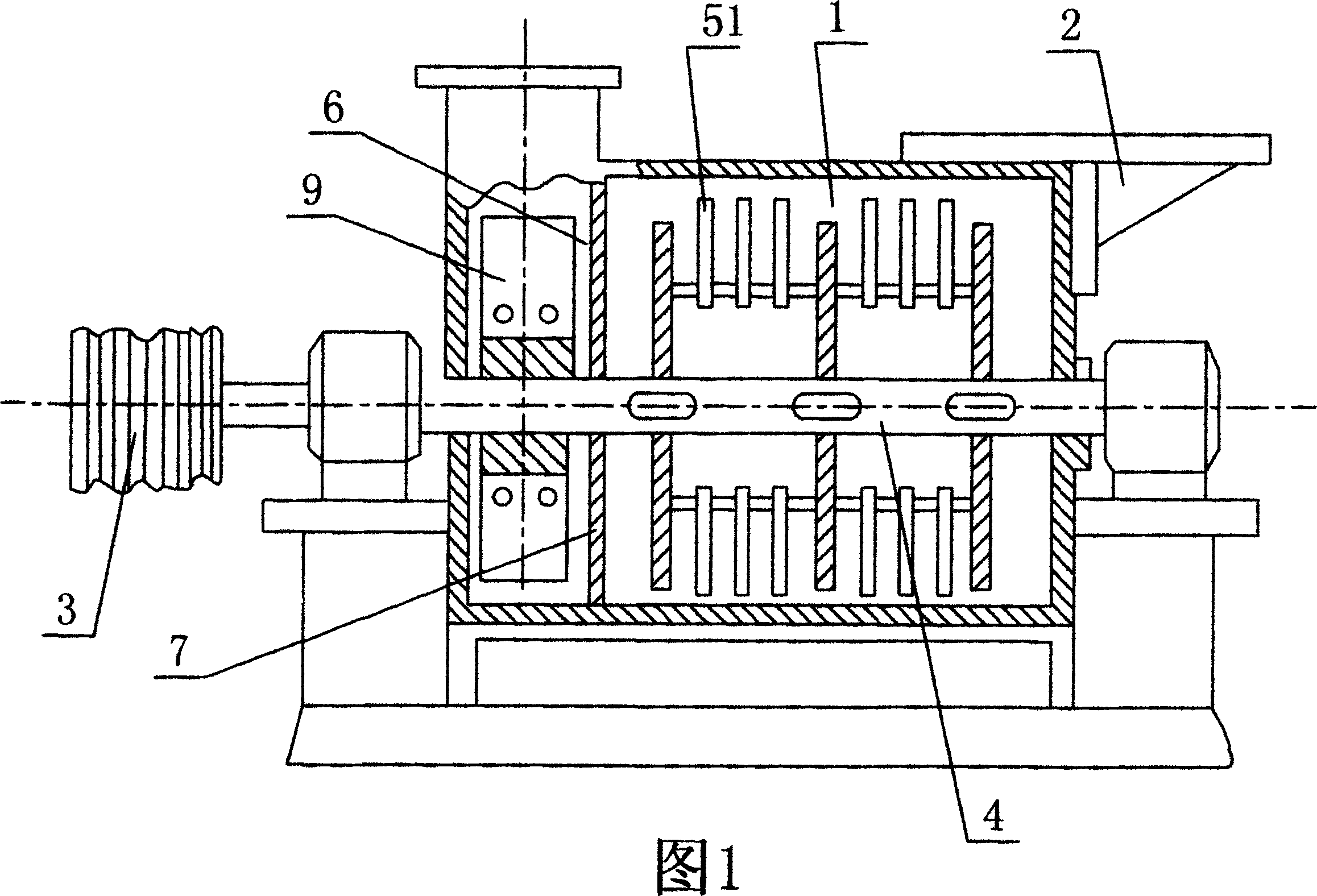

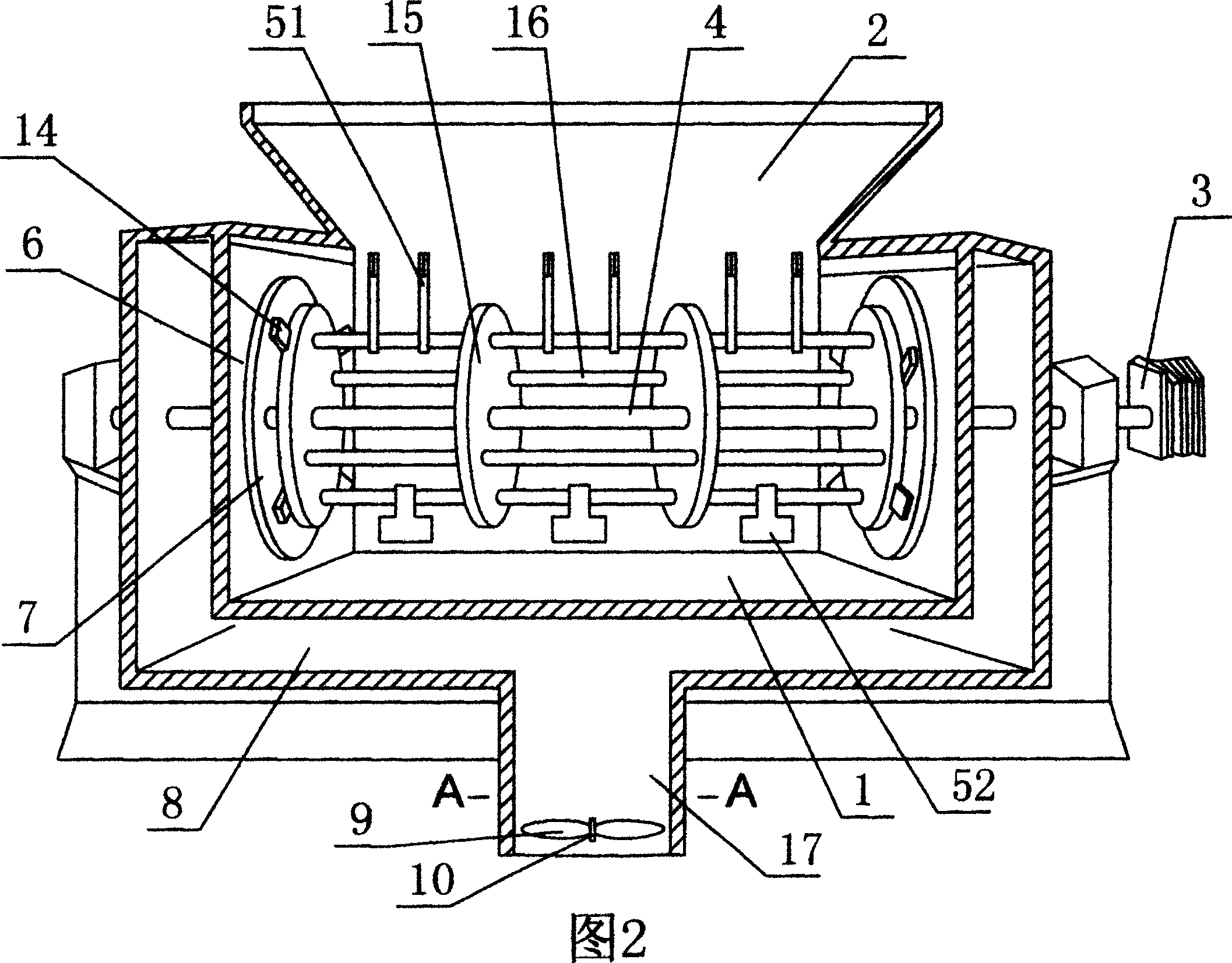

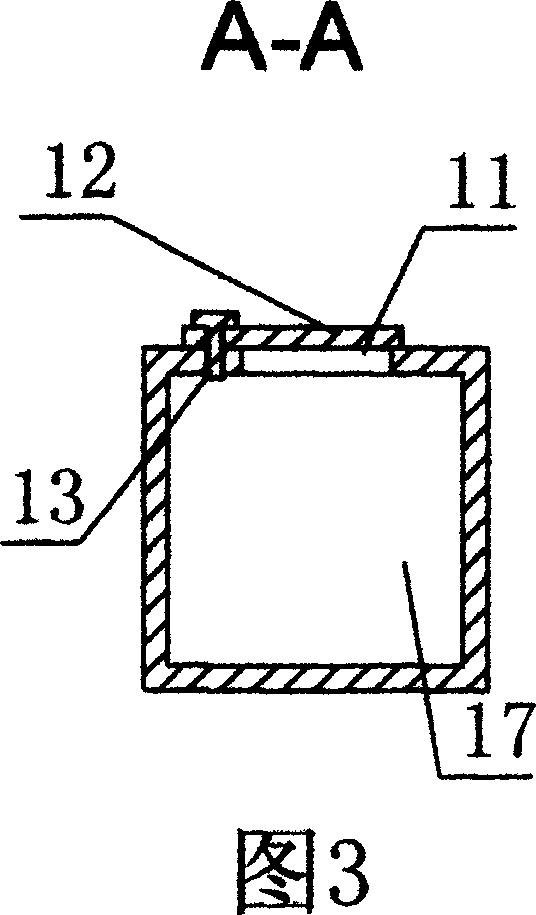

Super sand mill with double-separation system

The invention relates to a sand mill, and particularly relates to a super sand mill with a double-separation system. The super sand mill comprises a horizontal grinding barrel with two ends being sealed by virtue of end covers, wherein a feeding opening is formed in the grinding barrel, a rotating main shaft stretches into the grinding barrel from one end cover, a grinding area and a separation area are formed in the grinding barrel, a grinding rotor installed on the rotating main shaft and rotating along with the rotating main shaft is arranged in the grinding area, a discharging separator is arranged in the separation area, a vacuum area formed by the relative movement of two sides of an axial clearance is formed in the grinding barrel, and the separator is provided with an exhaustion passage communicating a separator discharging cavity and the vacuum area in the axial direction. The separator is provided with the exhaustion passage, when the grinding rotor rotates, two sides of the axial clearance make relative movement to form a vacuum area, so that bubbles generated in the grinding barrel can be discharged from the exhaustion passage, and the discharging speed can be increased.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

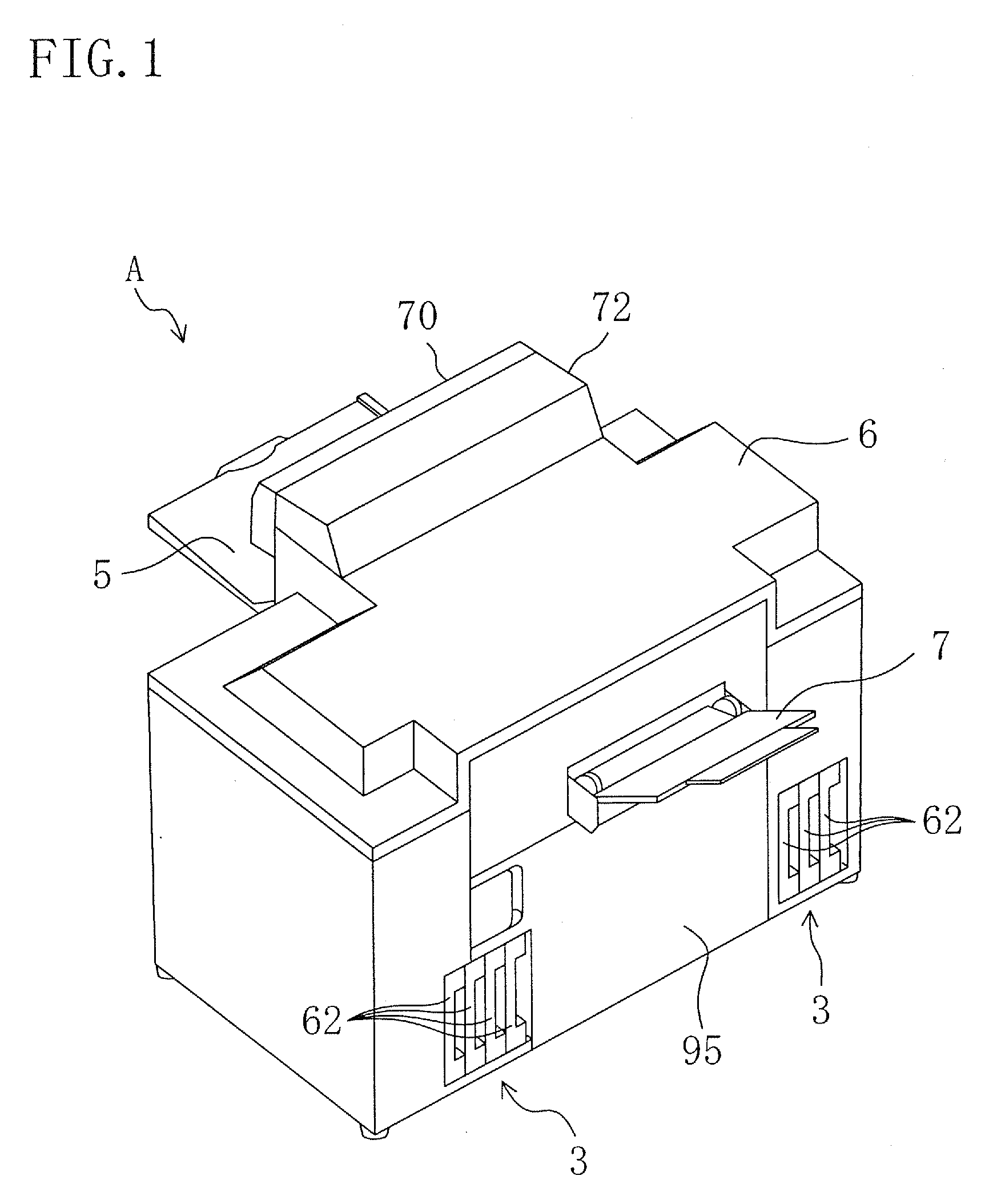

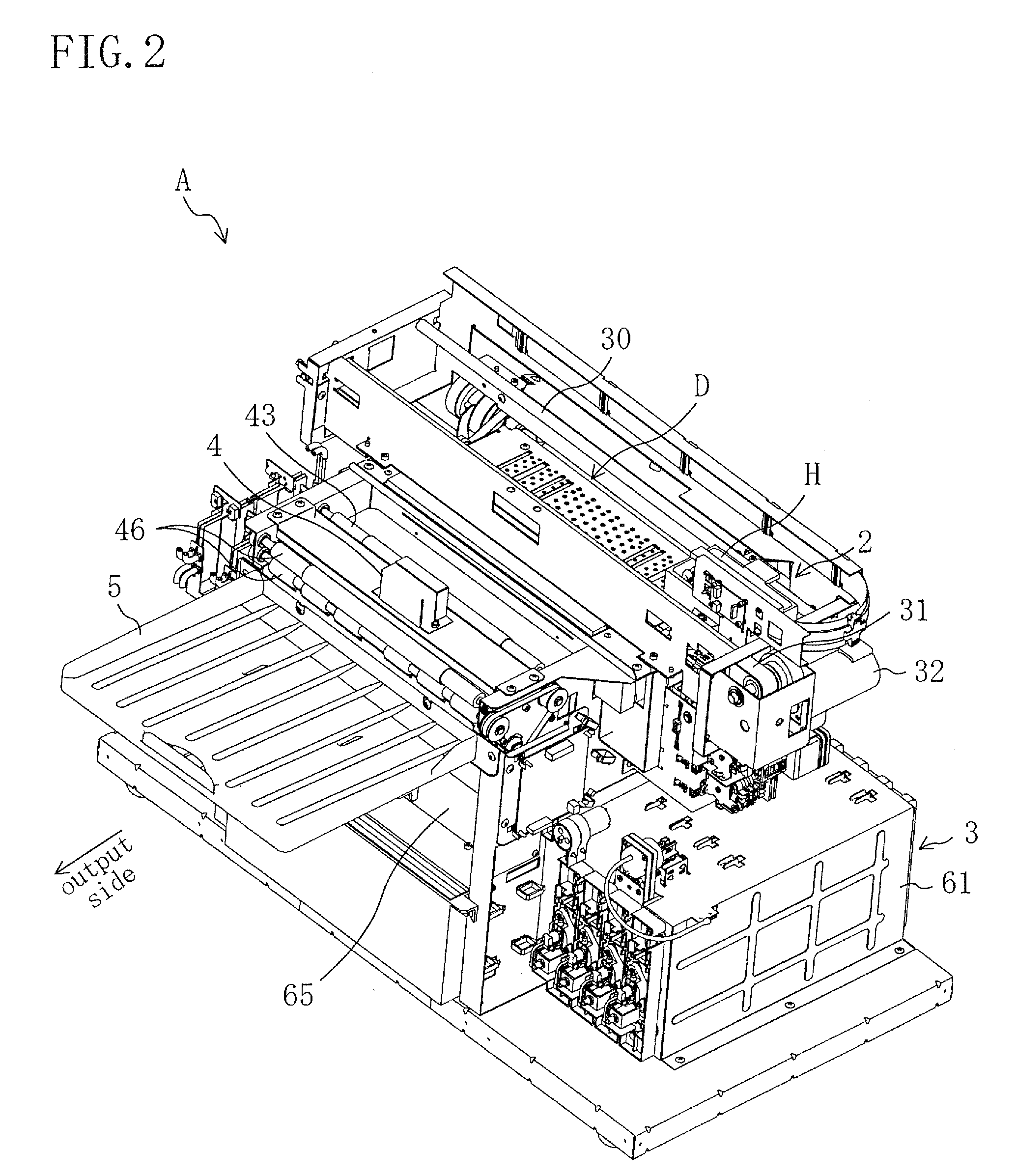

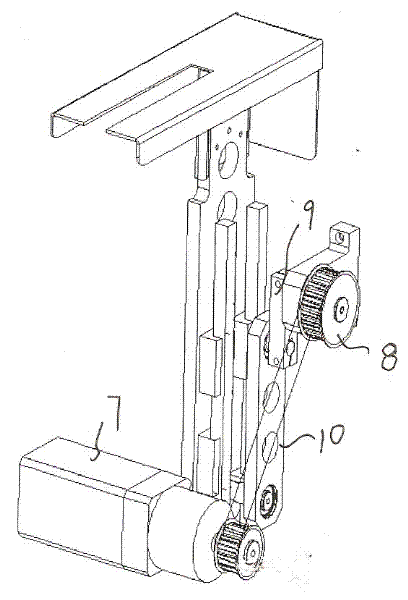

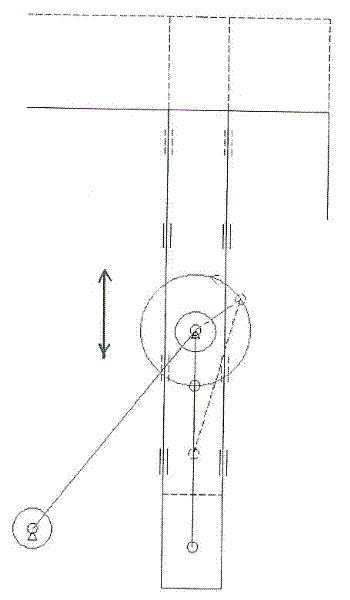

Paper output mechanism

InactiveUS20090189337A1Improve variationIncrease the output speedElectrographic process apparatusArticle deliveryPulp and paper industryActuator

A paper output mechanism includes: a roller pair composed of a first roller and a second roller travelable around the first roller and configured, when the second roller is in a first position, to output a piece of paper to a paper placement part by pinching the piece of paper between the first and second rollers and driving at least one of the first and second rollers into rotation with an actuator; and a roller position changing mechanism for switching the second roller between the first position and a second position located closer to the paper output side than the first position. When the trailing edge of the piece of paper is sent out to the paper placement part, the roller position changing mechanism changes the second roller from the first position to the second position.

Owner:NORITZ CORP

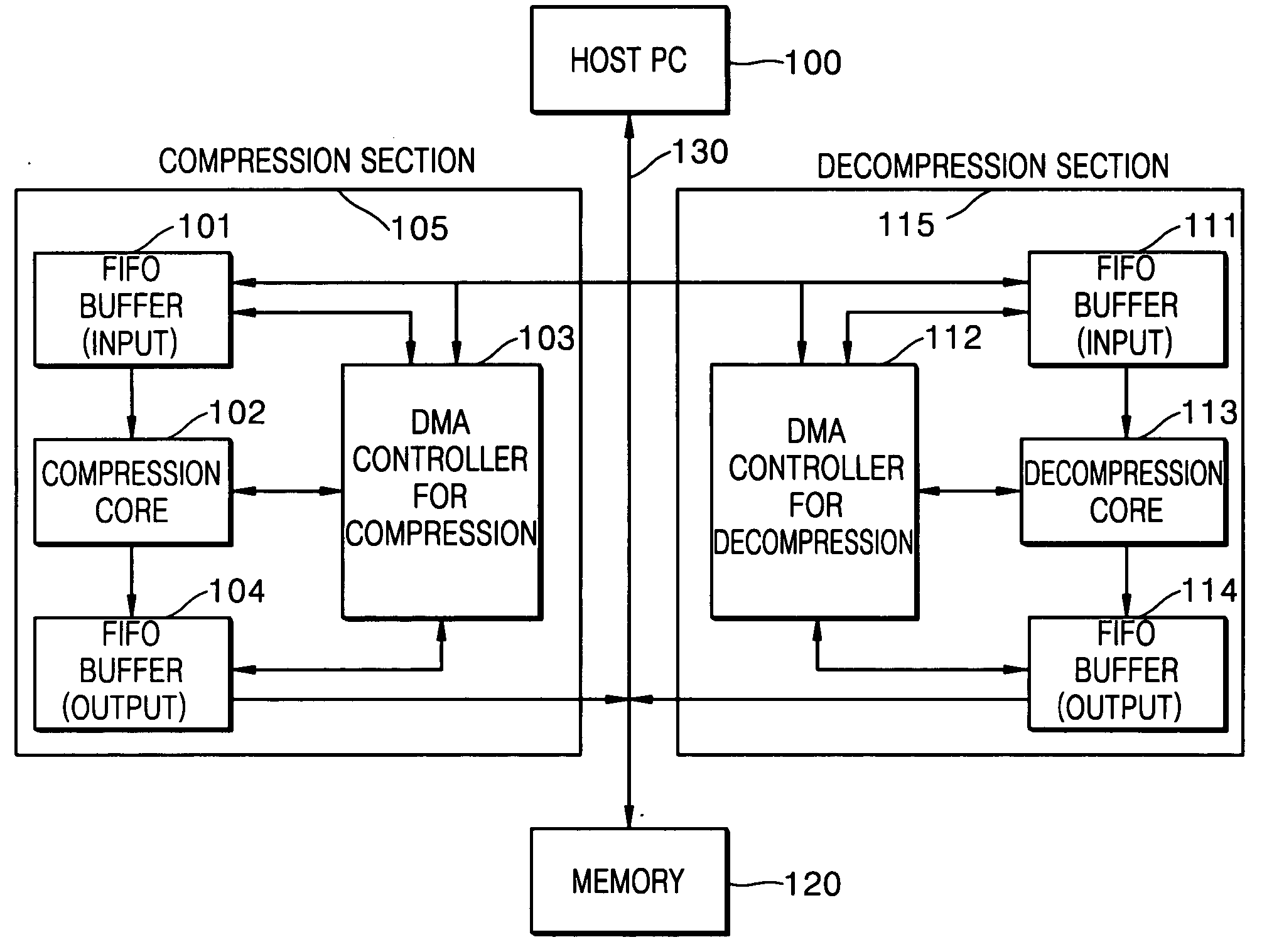

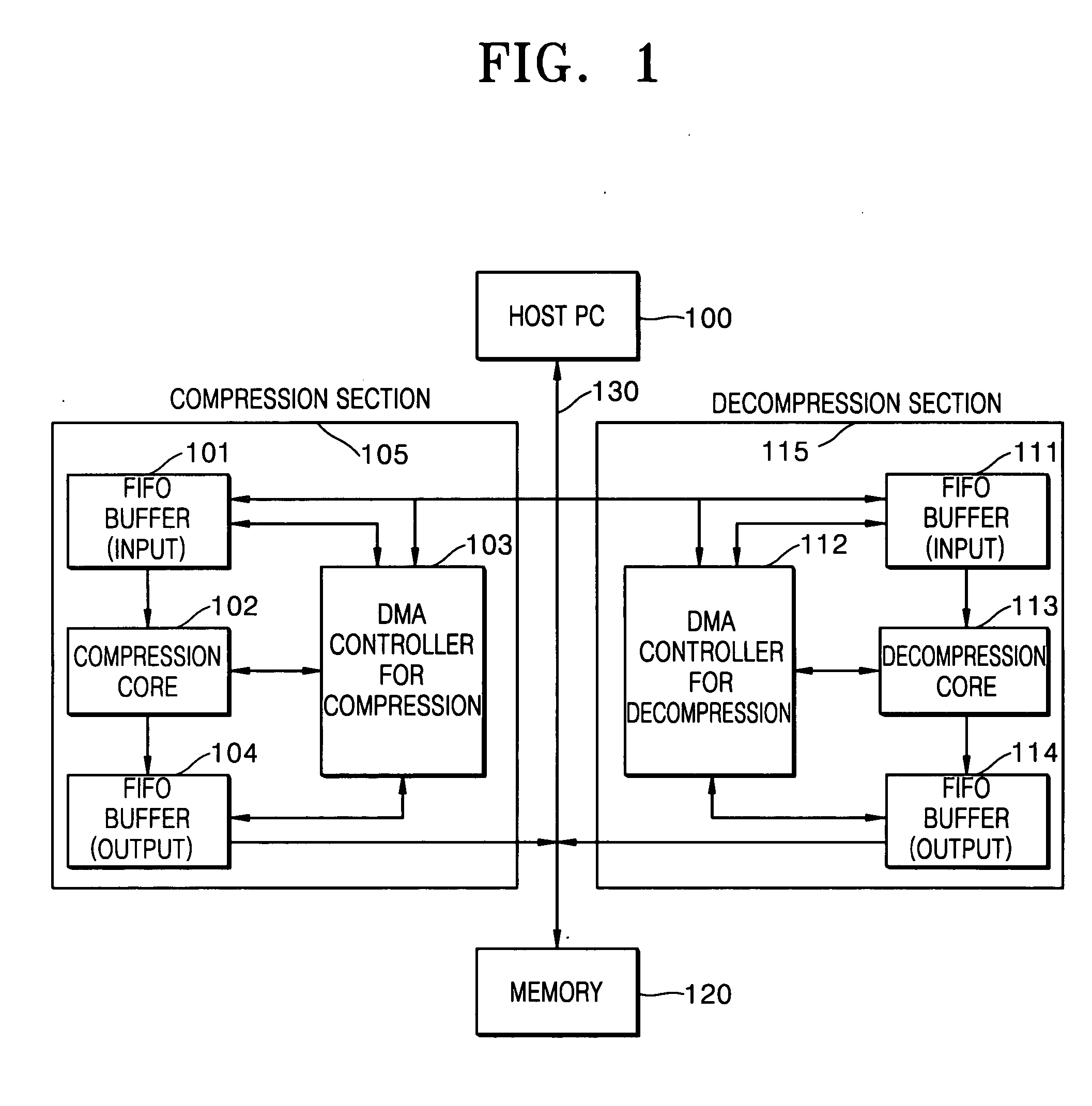

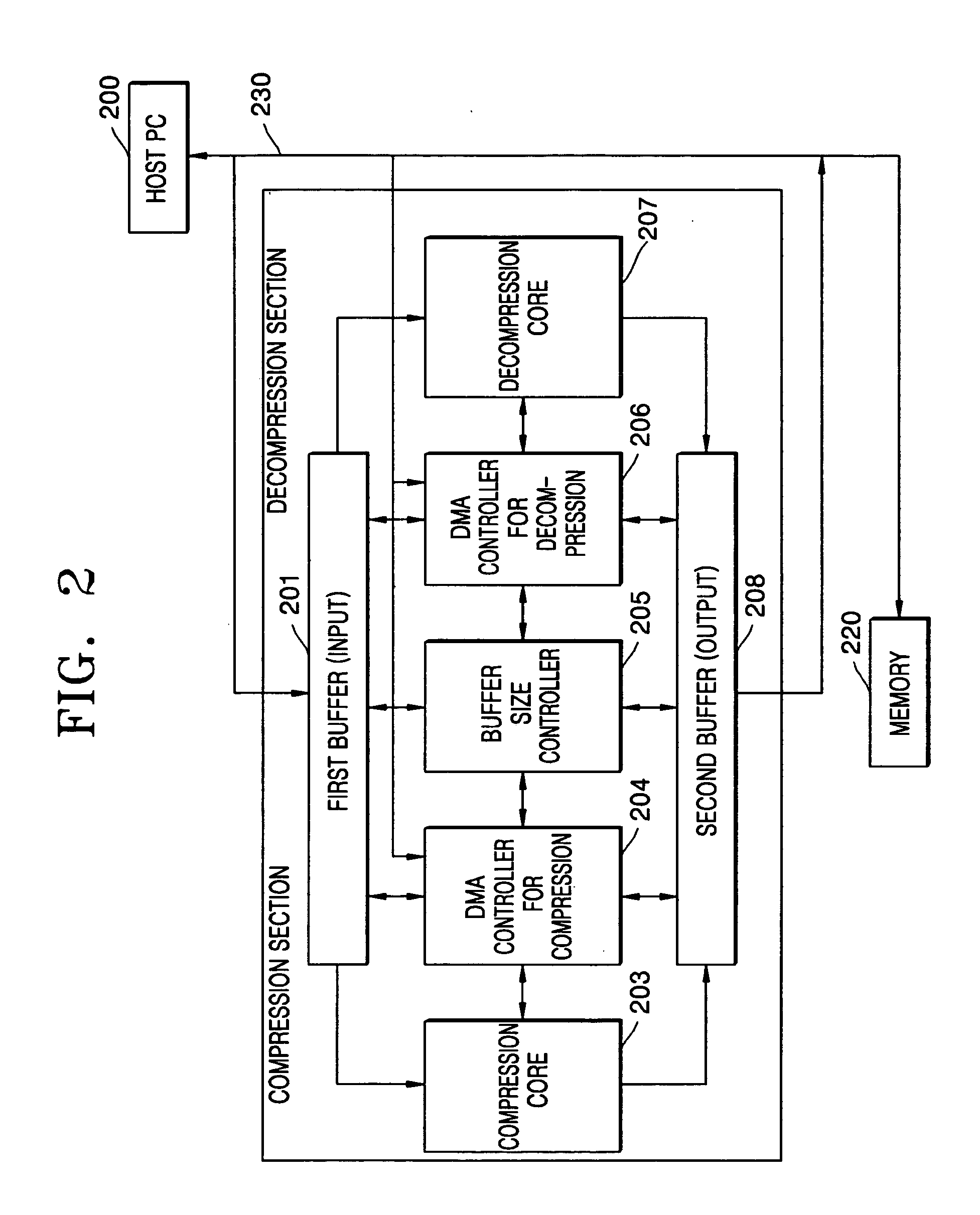

Data compression and decompression unit

InactiveUS20050105125A1Improve data throughputIncrease in sizeDigital computer detailsVisual presentationData compressionParallel computing

A data compression and decompression unit that can enhance a data throughput during compression and decompression of data by dynamically allocating the sizes of the input and output buffers to the compression and decompression sections in accordance with a compressibility of data. The data compression and decompression unit includes a compression section that receives bit map data from a terminal, compresses the bit map data with a predetermined compressibility, and generates compressed data, and a decompression section that decompresses the compressed data into an original format, and generates decompressed data. The data unit further includes a memory section that stores the bit map data, the compressed data, and the decompressed data, and a control section that controls the compression and decompression in accordance with the predetermined compressibility.

Owner:S PRINTING SOLUTION CO LTD

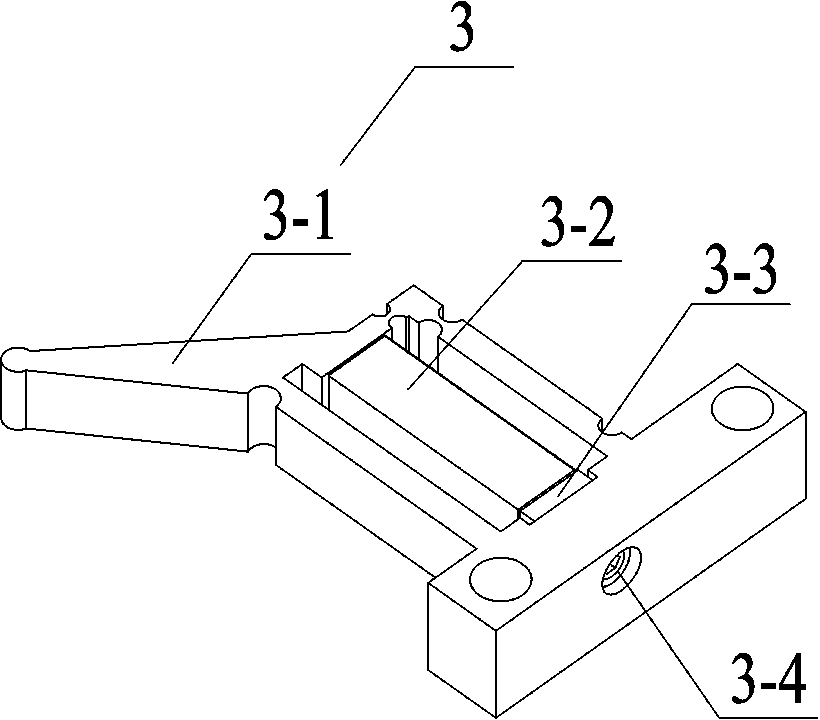

External stirring type rotary piezoelectric stick-slip driver and driving method thereof

ActiveCN108322090AIncrease frictionReduce frictional resistancePiezoelectric/electrostriction/magnetostriction machinesMicro nanoEngineering

Owner:CHANGCHUN UNIV OF TECH

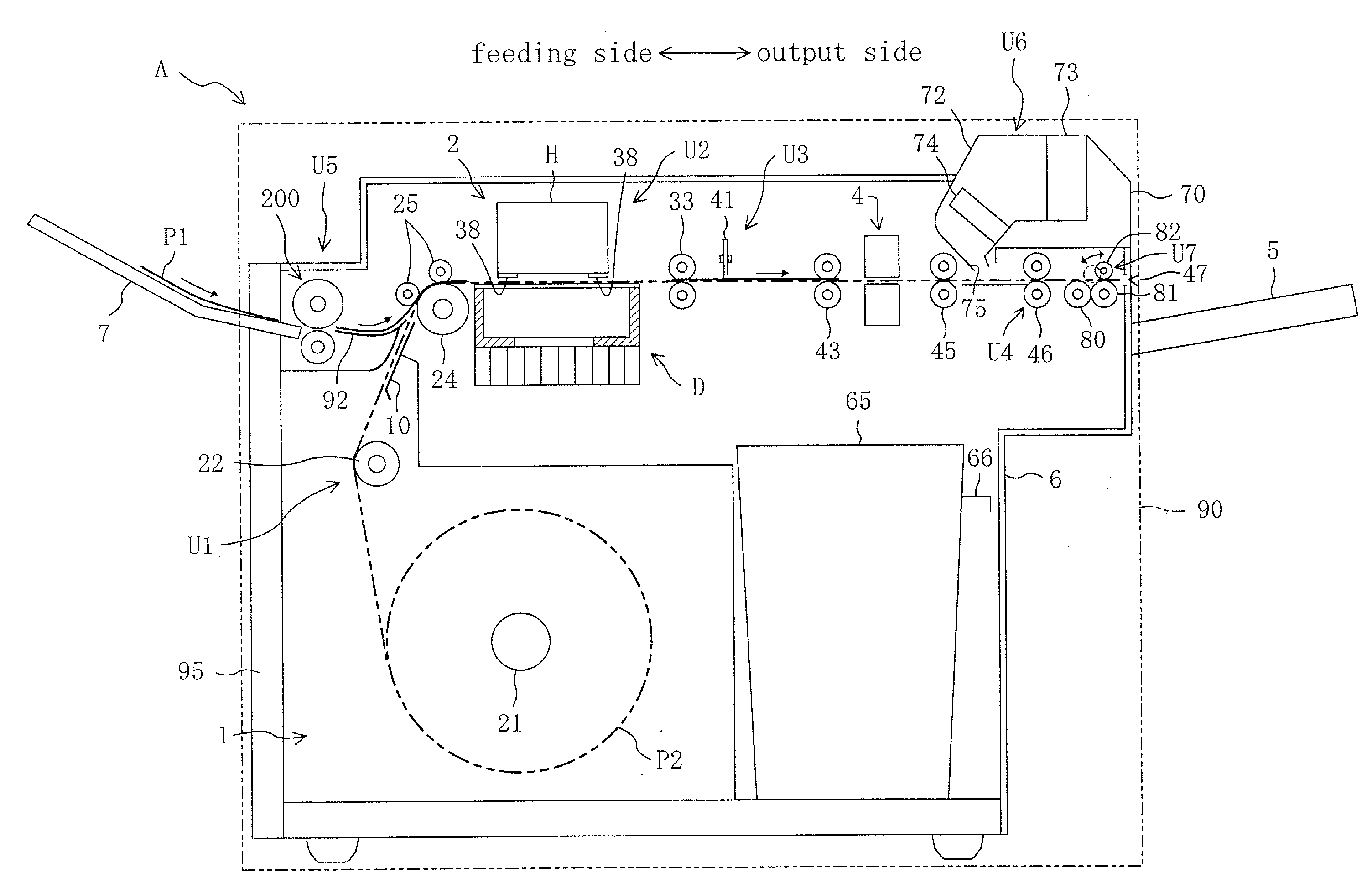

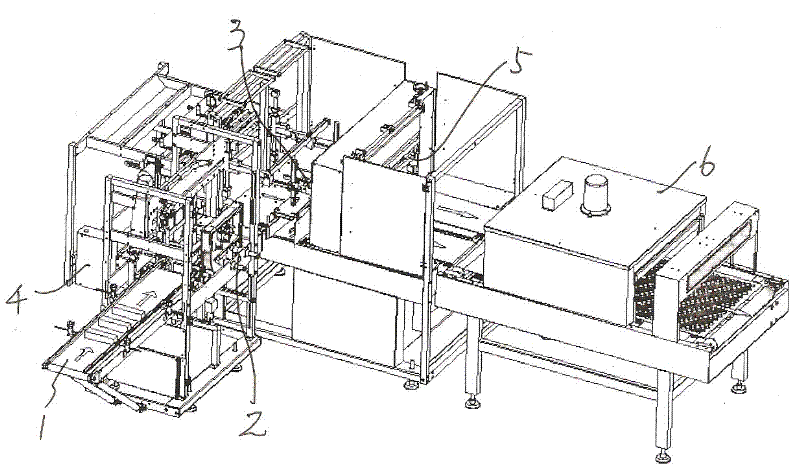

Fully-automatic packaging machine for heat shrinkable film

ActiveCN102501996AAccelerateGood effectWrapping material feeding apparatusWrappingFully automaticPackaging machine

The invention discloses a fully-automatic packaging machine for a heat shrinkable film, comprising a feeding conveyor belt, wherein a stacking and package scraping mechanism is arranged above the feeding conveyor belt; a wrapping and conveying mechanism is arranged at the back of the stacking and package scraping mechanism; a film conveying mechanism is arranged at the back of the wrapping and conveying mechanism; a film covering mechanism is arranged at the back of the film conveying mechanism; and a drying oven is arranged at the back of the film covering mechanism. The fully-automatic packaging machine is reasonable in structure; double servo systems, a pre-stacking mechanism, a film drawing mechanism and the like are adopted; and compared with a general shrinkable film packaging machine on the market, the fully-automatic packaging machine for the heat shrinkable film has the characteristics of higher speed, more stability, better heat shrinkable surface effect, more convenience inoperation and maintenance and the like.

Owner:NANTONG UNIVERSAL MACHINERY

Crusher

InactiveCN1974019AIncrease the output speedLow power consumptionGrain treatmentsPulverizerPower unit

The crusher includes one material crushing chamber with feeding port in the upper part, one spindle driven with power unit inside the crusher, one crushing cutter capable of rotating in the plane perpendicular to the main axis, and at least one discharging port with strainer. It features the suction chamber communicated with the discharging port and the induced draft fan in the outlet of the suction chamber with driving shaft not connected to the spindle. The present invention has increased outwards discharging suction force, no chocking of the strainer and high discharging speed and output.

Owner:李福全

Transmission, driving system with transmission, and control method for driving system

ActiveCN102678846AWork quicklyEasy to controlHybrid vehiclesToothed gearingsSpur gearTransmission system

The invention provides a transmission, a driving system with the transmission, and a control method for the driving system. The transmission comprises a first shaft, a first clutch, a second clutch, a planetary gear mechanism and a second shaft which are coaxial, wherein the planetary gear mechanism comprises a sun gear, a gear ring, a planetary gear and a planetary carrier; the planetary gear can rotate on the planetary carrier and rotate around the sun gear and the gear ring; a driving disc of the first clutch, the first shaft and the gear ring are integrally arranged; the sun gear and a driven disc of the second clutch are integrally arranged; and the planetary carrier, a driven disc of the first clutch and the second shaft are integrally arranged. Through the arrangement, a multi-shaft design is avoided, the number of gears is reduced, the design, manufacturing and assembly of a transmission system are greatly simplified through a group of planetary gear mechanism and a few clutches, cost is reduced, the total weight of equipment is reduced, and the requirement on driving devices such as a motor and an engine is reduced.

Owner:SHANGHAI E PROPULSION AUTO TECH

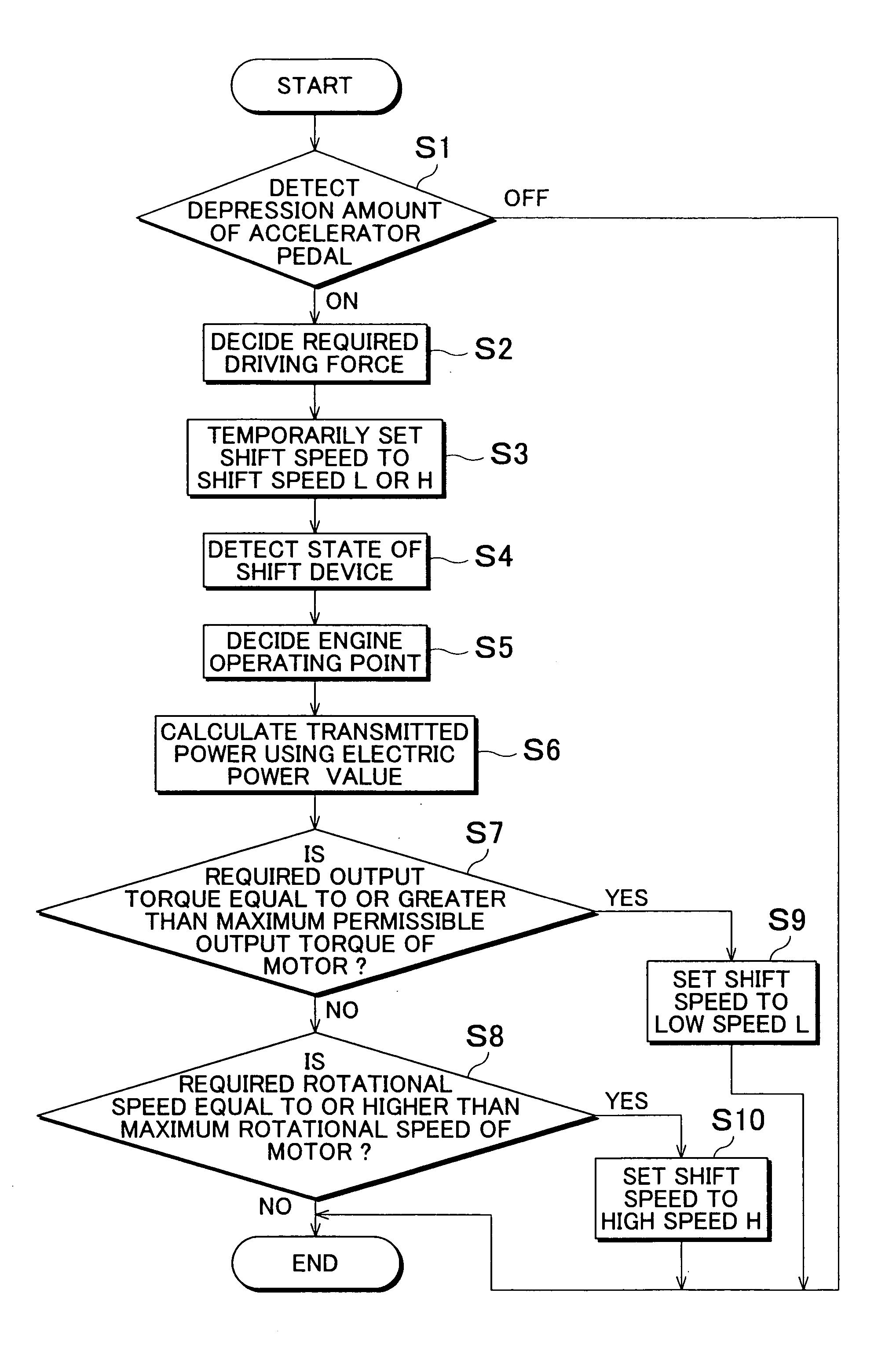

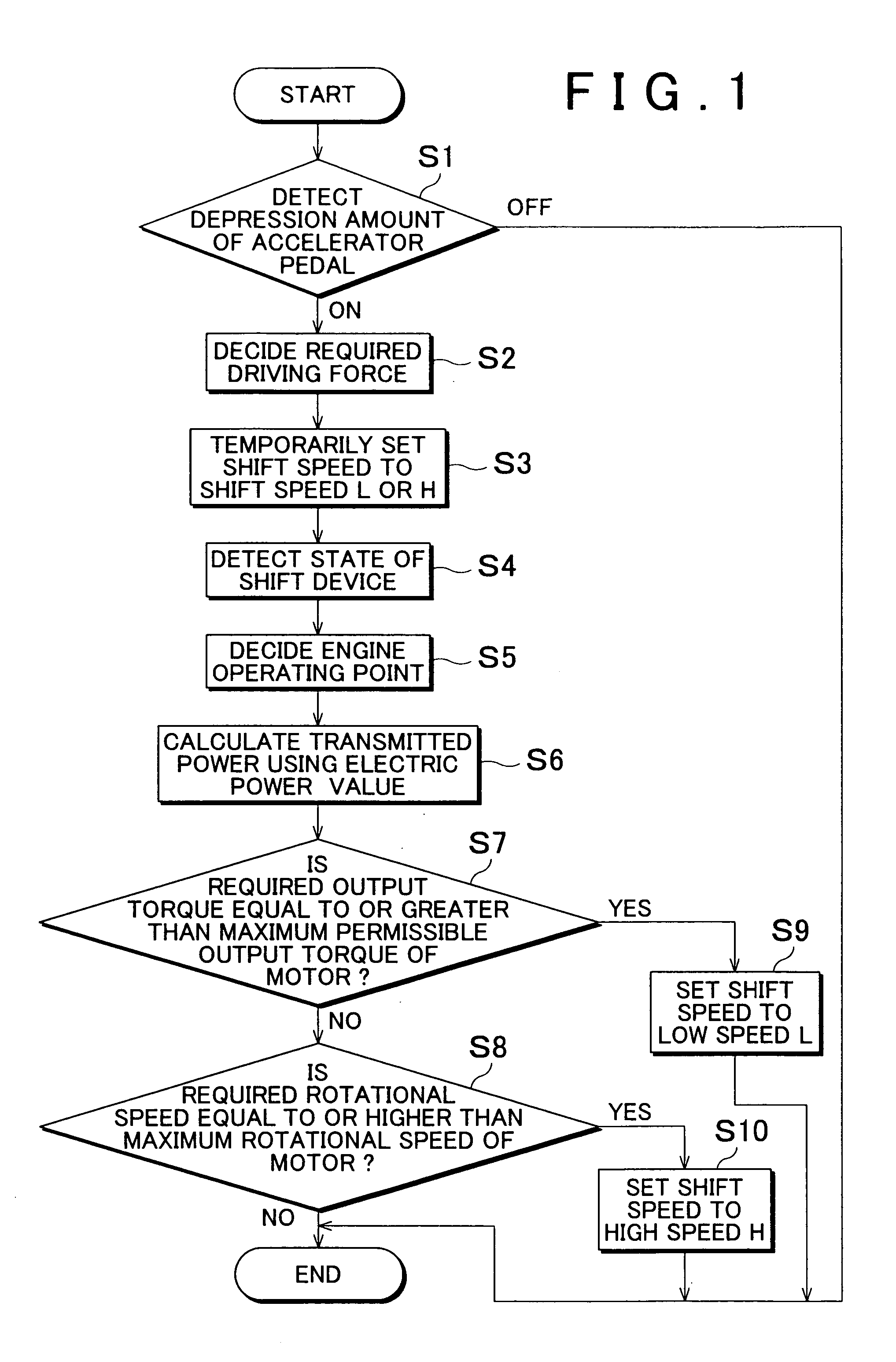

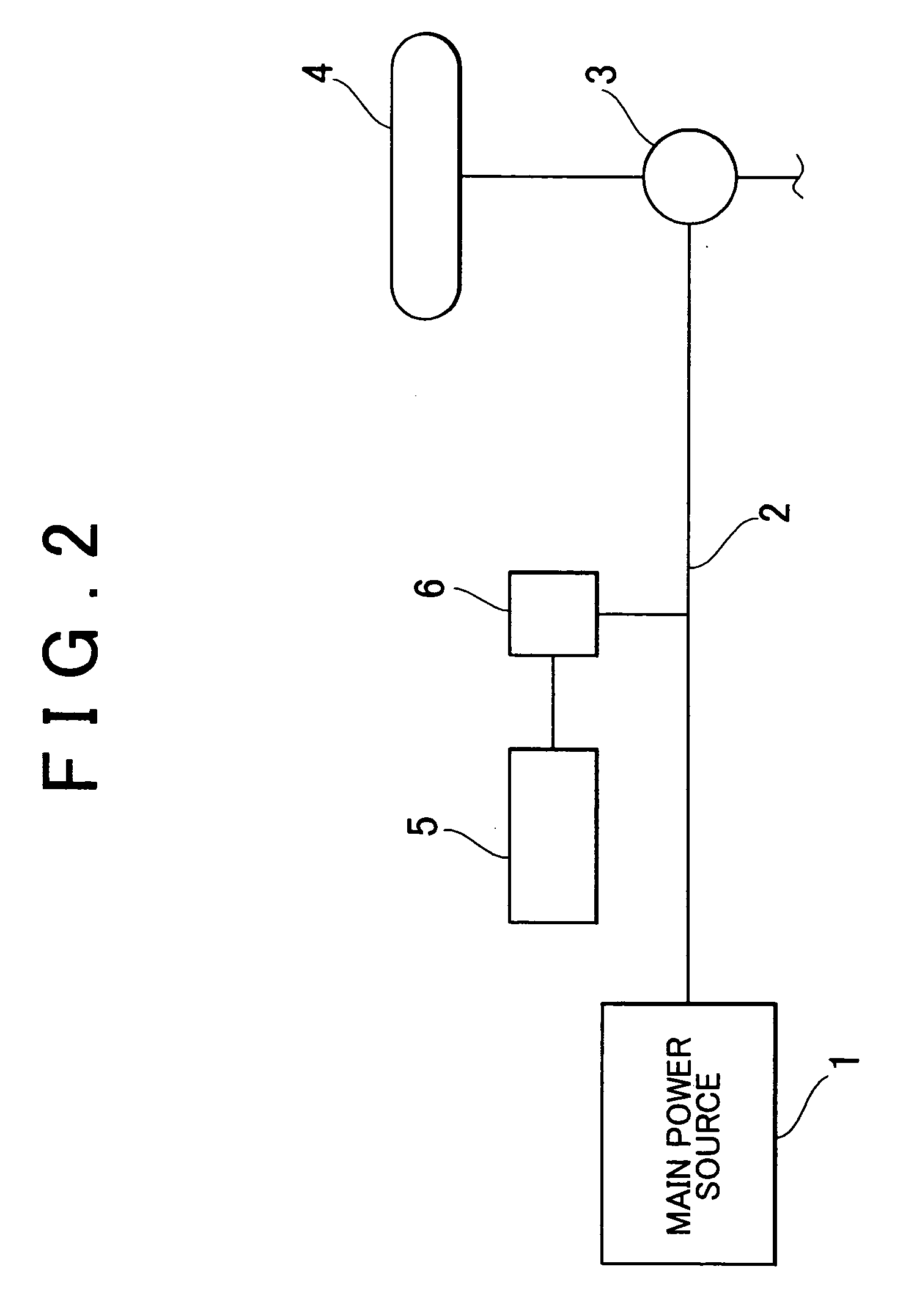

Control apparatus and control method for hybrid vehicle

ActiveUS20050203678A1Increase rotation speedSmall sizeHybrid vehiclesDigital data processing detailsHybrid vehicleControl theory

A control method for a hybrid vehicle which includes an engine, a first motor / generator, a second motor / generator, and a manual changing device that changes a driven state of an output member of the engine that depends on a driving state of the engine and a driving state of the second motor / generator, includes the steps of detecting required driving force of the vehicle; detecting required output torque of the second motor / generator based on the required driving force when a change in a rotational speed of the engine is detected; comparing the detected required torque to the maximum permissible torque of the second motor / generator, and increasing a gear ratio when it is determined that the required output torque is greater than the maximum permissible torque.

Owner:TOYOTA JIDOSHA KK

Shift register circuit and image display comprising the same

ActiveUS20110182399A1Lower capability requirementsImprove driving abilityStatic indicating devicesDigital storageElectricityShift register

In a shift register circuit, a defective operation while an output signal is not outputted and a drive capability lowering while the output signal is outputted are prevented. A unit shift register comprises a first transistor for supplying a clock signal inputted to a first clock terminal to an output terminal, and the first transistor is driven by a drive circuit. A second transistor is connected between the gate of the first transistor and the output terminal and has a gate connected to the first clock terminal. The second transistor connects the gate of the first transistor to the output terminal based on the clock signal when the gate of the first transistor is at L (Low) level.

Owner:TRIVALE TECH

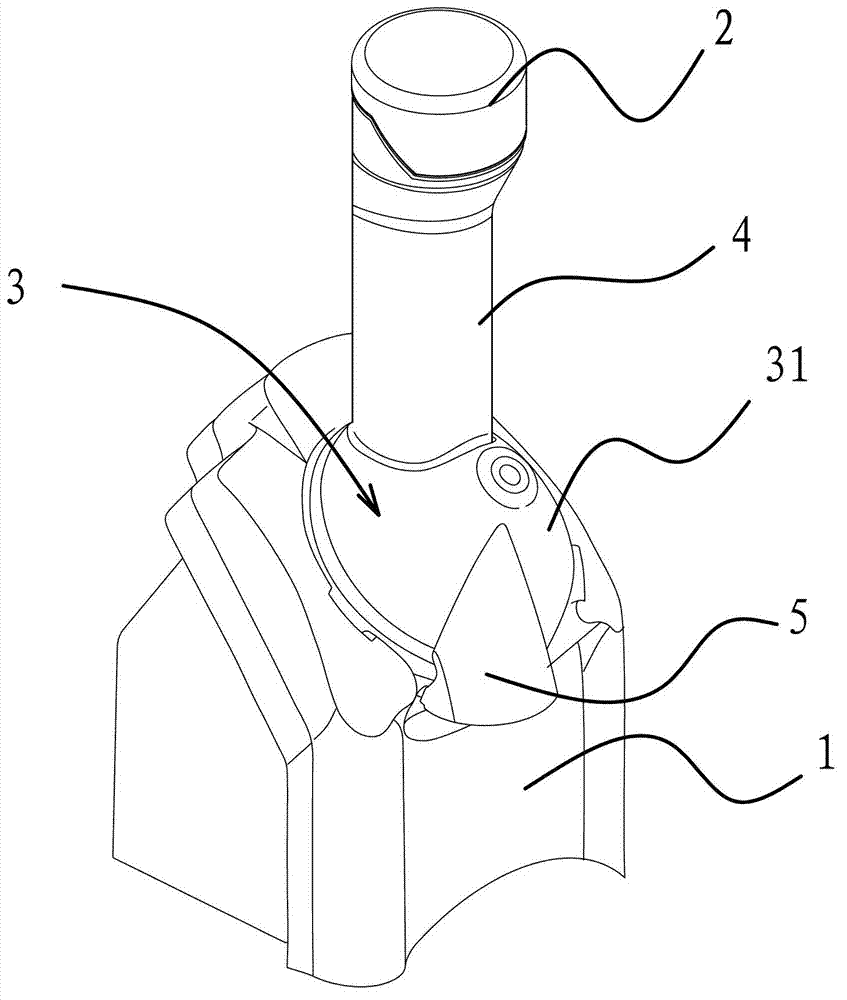

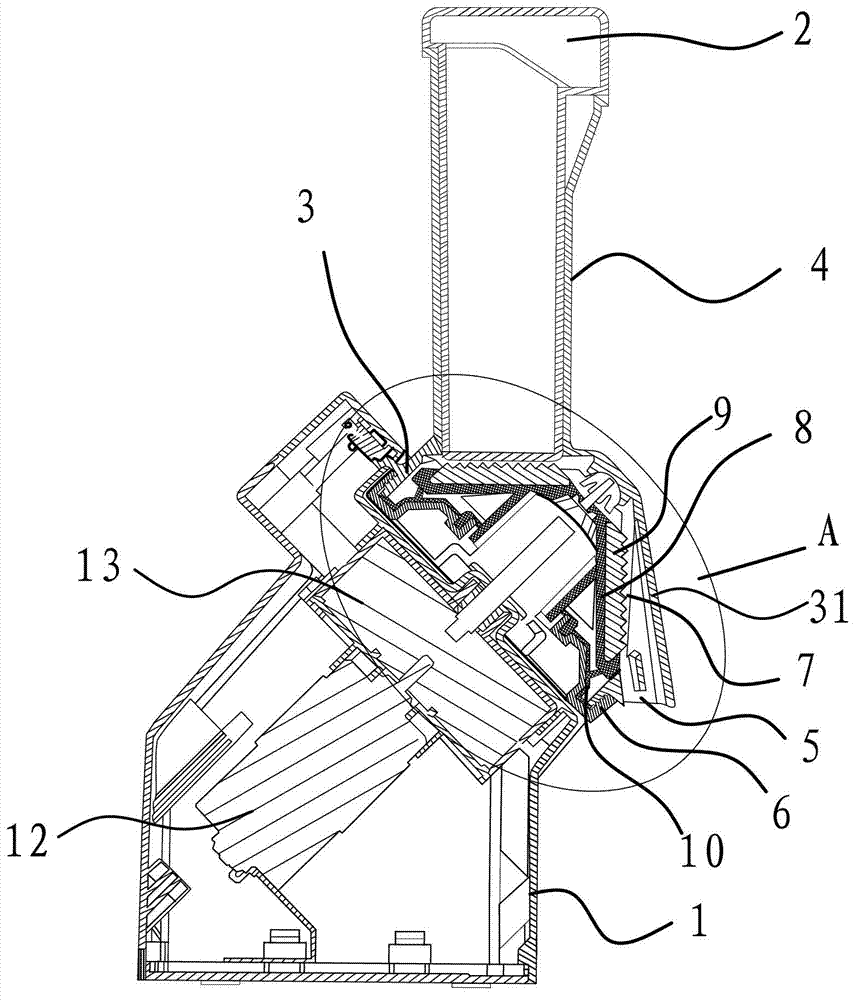

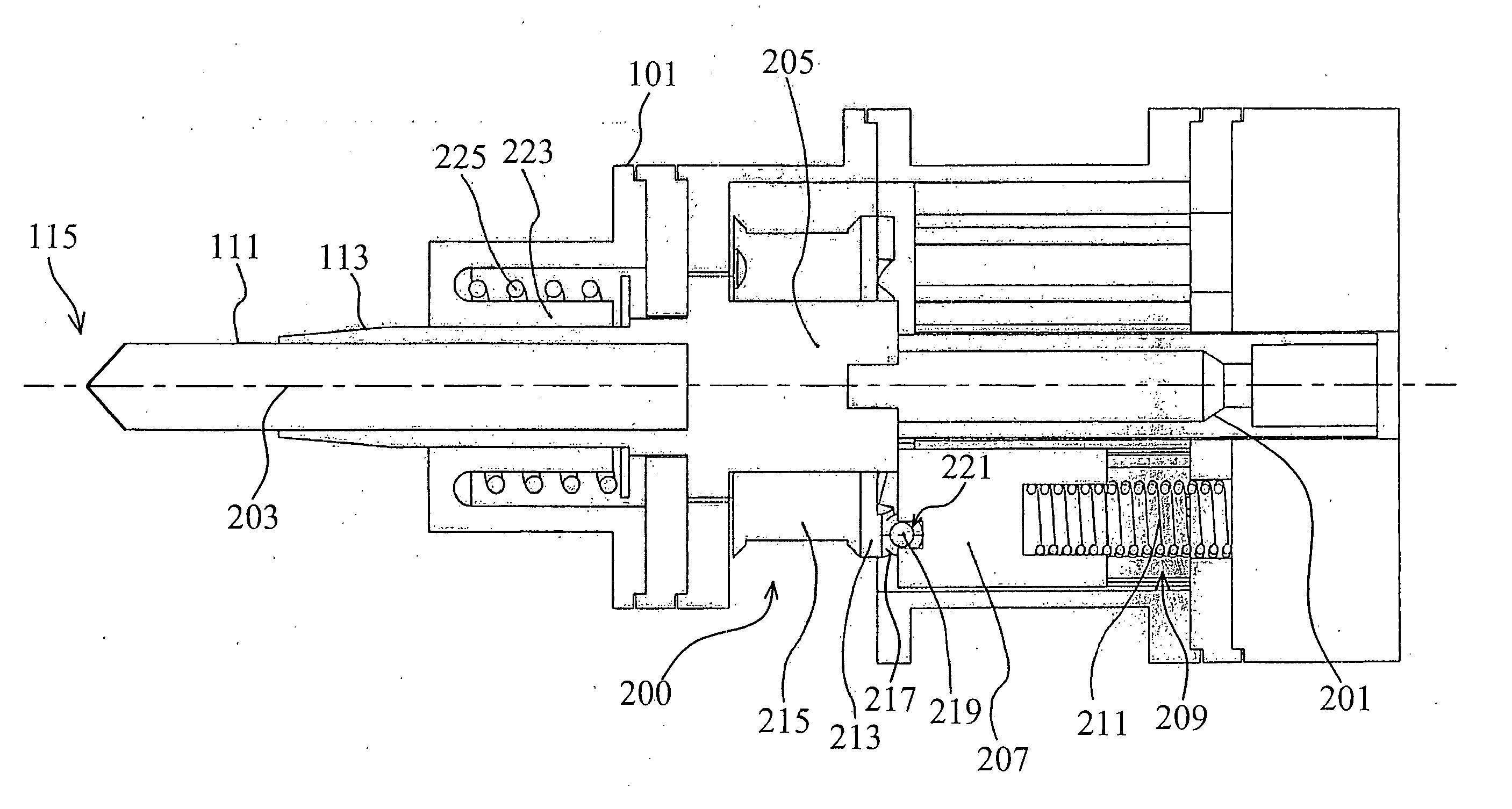

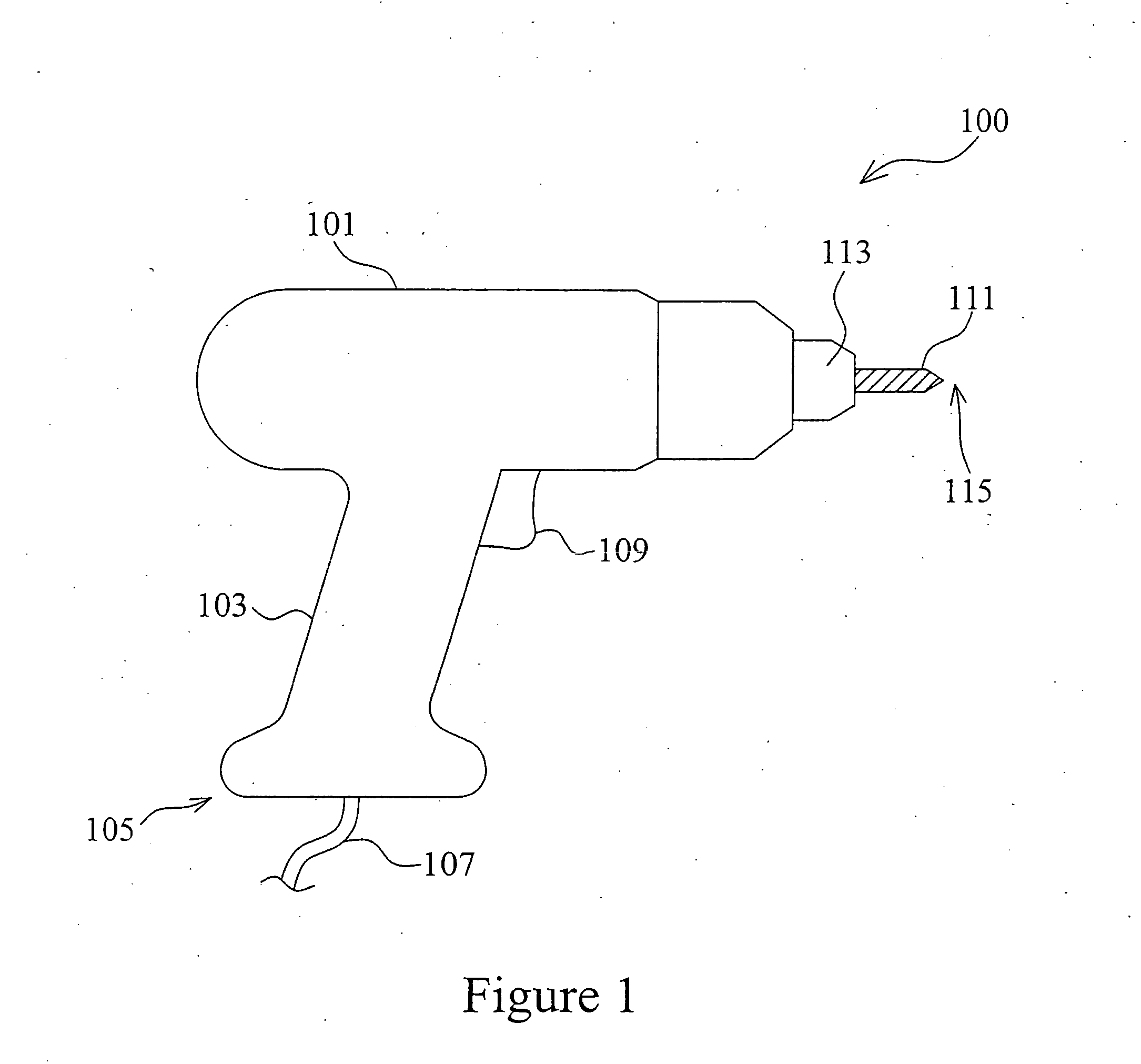

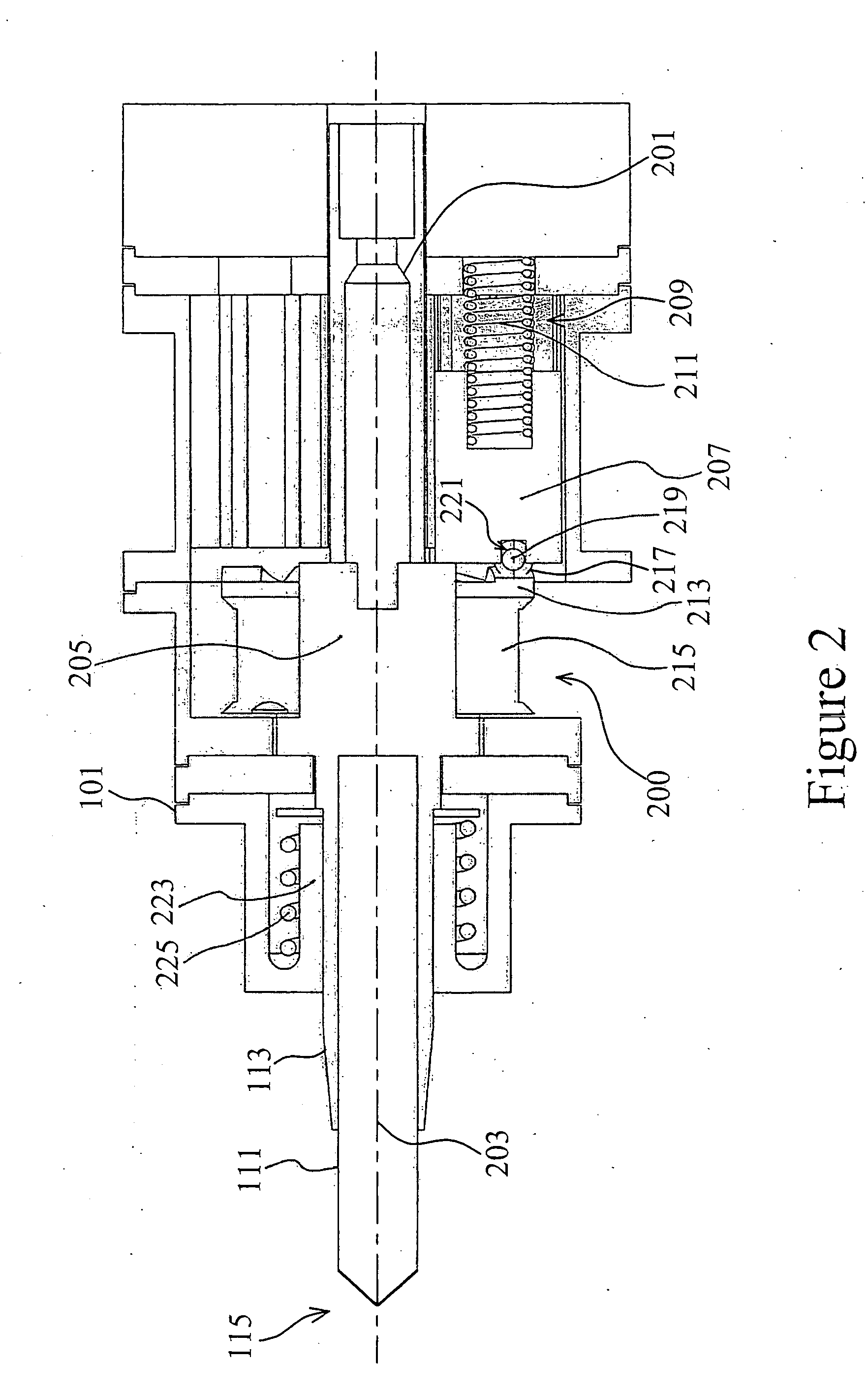

Impact mechanism for a hammer drill

ActiveUS20060102364A1Increase the output speedDrilling rodsConstructionsReciprocating motionEngineering

An impact mechanism for a hammer drill, which has a housing and a drill bit protruding outside the housing, is provided. The mechanism includes firstly an impact platform within the housing; the impact platform is in connection with the drill bit for receiving impact forces and for transferring the impact forces to the drill bit. The mechanism also has a plurality of cams within the housing, and the plurality of cams are angularly spaced apart and arranged about an axis of rotation. The mechanism further includes a plurality of hammers placed within the housing and interactable with both the impact platform and the plurality of cams. The plurality of hammers are angularly spaced apart and arranged about the axis of rotation, and each hammer is capable of reciprocating along the axis for exerting the impact forces on the impact platform. Each of the plurality of cam is driven to interact with each of the plurality of hammers alternatively such that the plurality of hammers are driven to reciprocate along the axis so as to generate the impact forces.

Owner:THE HONG KONG POLYTECHNIC UNIV

Efficient crushing device for petroleum coke

InactiveCN106964418APromote fragmentationImprove crushing effectSievingScreeningPetroleum cokeBolt connection

The invention relates to a crushing device for petroleum coke, in particular to an efficient crushing device for petroleum coke and aims at achieving the technical purpose of providing the efficient crushing device for petroleum coke, wherein the efficient crushing device for petroleum coke is easy to operate, capable of saving time and labor, good in crushing effect and high in work efficiency. To achieve the above technical purpose, the efficient crushing device for petroleum coke is provided and comprises a bottom plate and the like. The top of the bottom plate is provided with a collecting frame and a support. The collecting frame and the support are connected with the top of the bottom plate in a bolt connection manner. The collecting frame is located on the left side of the support, the support is vertically arranged, and lower portion of the left side face of the support is connected with a transverse plate in a bolt connection manner. A discharging device is arranged on the left side of the transverse plate and provided with a first crushing device. According to the crushing device, a crushing plate and a crushing block are adopted for repeatedly crushing the petroleum coke, and the crushed petroleum coke can pass through discharging holes to fall into the collecting frame.

Owner:汪新新

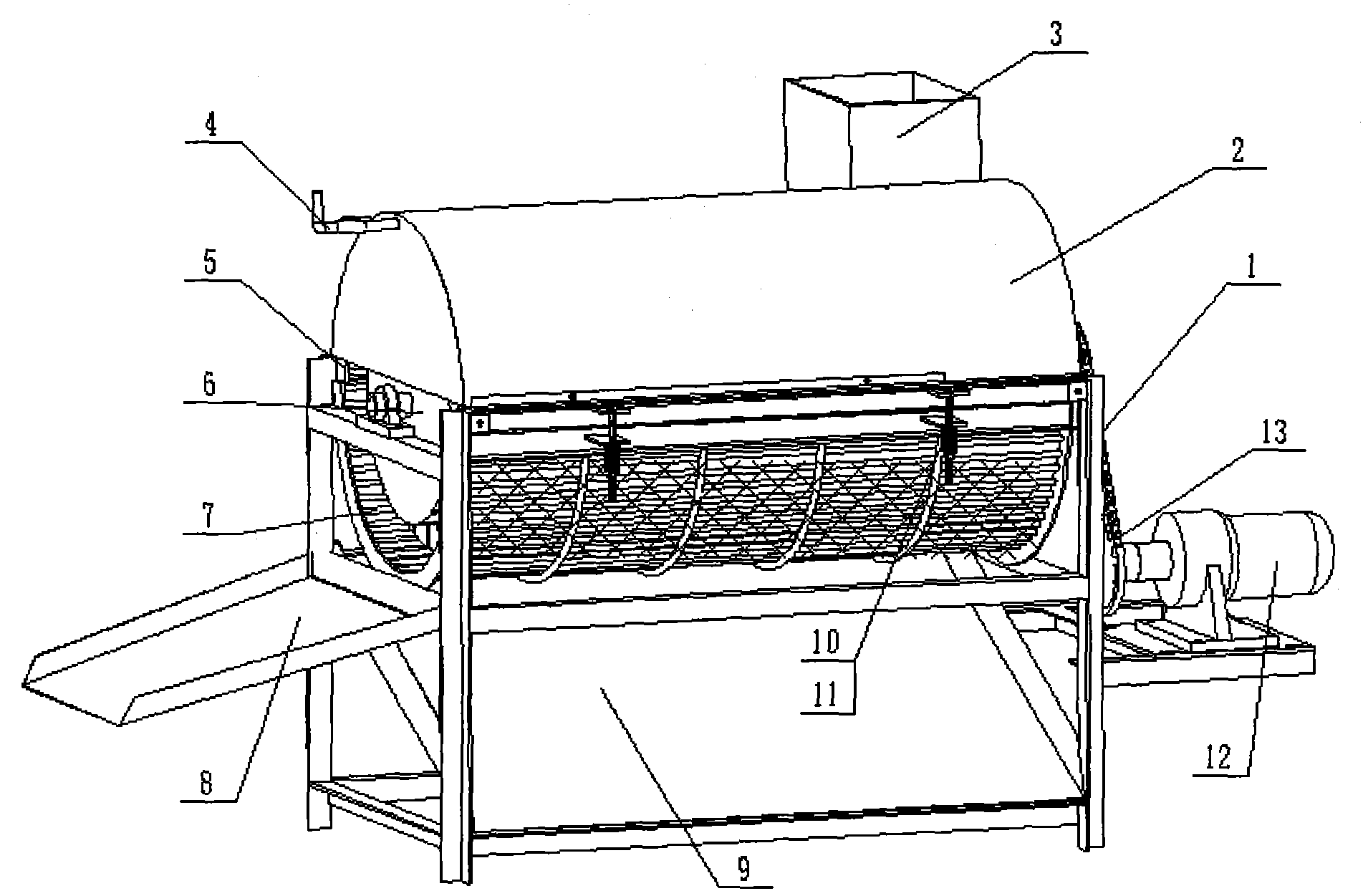

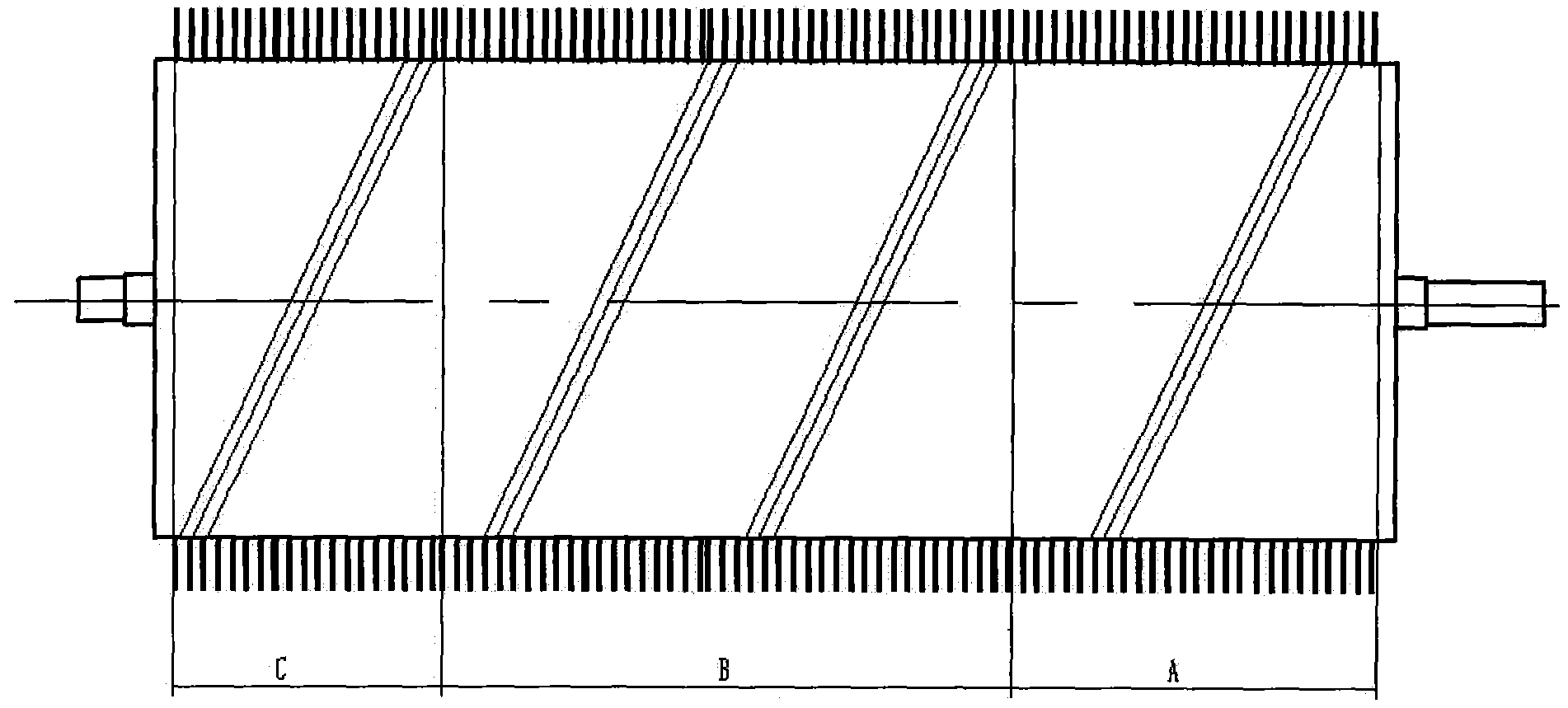

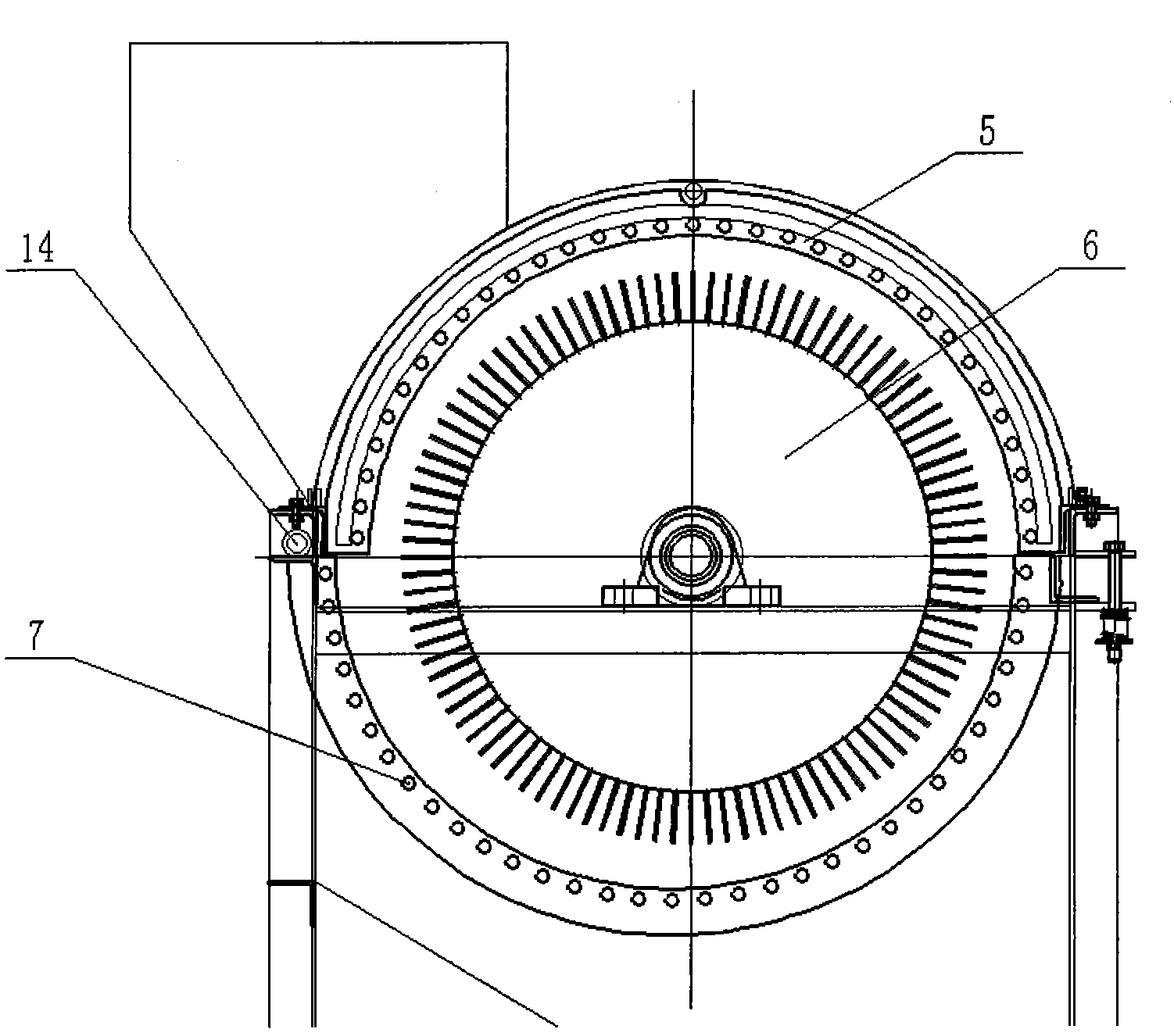

Green walnut peeling machine

The invention relates to a green walnut peeling machine. The green walnut peeling machine comprises a machine body, a machine cover, a feeding hopper, a spraying water pipe, a peeling unit, a discharging hopper, a peel discharging slide plate, a motor, and a pin roll, wherein the motor is installed at one end of the machine body, power of the motor is transmitted to a spiral brush roller of the peeling unit through a transmission mechanism, the spiral brush roller is horizontally fixed on the machine body through a bearing with a seat, an upper grid plate and a lower grid plate are in a half arc shape, square steel wire screens are welded in the grid plates, the upper grid plate is fixed on the machine body, the upper grid plate and the spiral brush roller are concentrically installed, one side of the lower grid plate is connected with the machine body through the pin shaft, the other side of the lower grid plate is connected with the machine body through a spring and a bolt, the upper grid plate and the lower grid plate form a peeling rotary drum, the feeding hopper is located above one end of the motor, the discharging hopper is located at the other end of the machine body, the peel discharging slide plate is located below the peeling unit and fixed on the machine body, the spraying water pipe is located above the upper grid plate, half shafts are installed on two sides of a brush body of the spiral brush roller, and a brush is axially spirally arranged and sequentially divided into an A thick steel wire section, a B think steel wire section and a C nylon brush section from a power input side. The green walnut peeling machine is capable of simultaneously peeling and cleaning green walnuts and high in peeling efficiency.

Owner:陕西省农业机械研究所有限公司

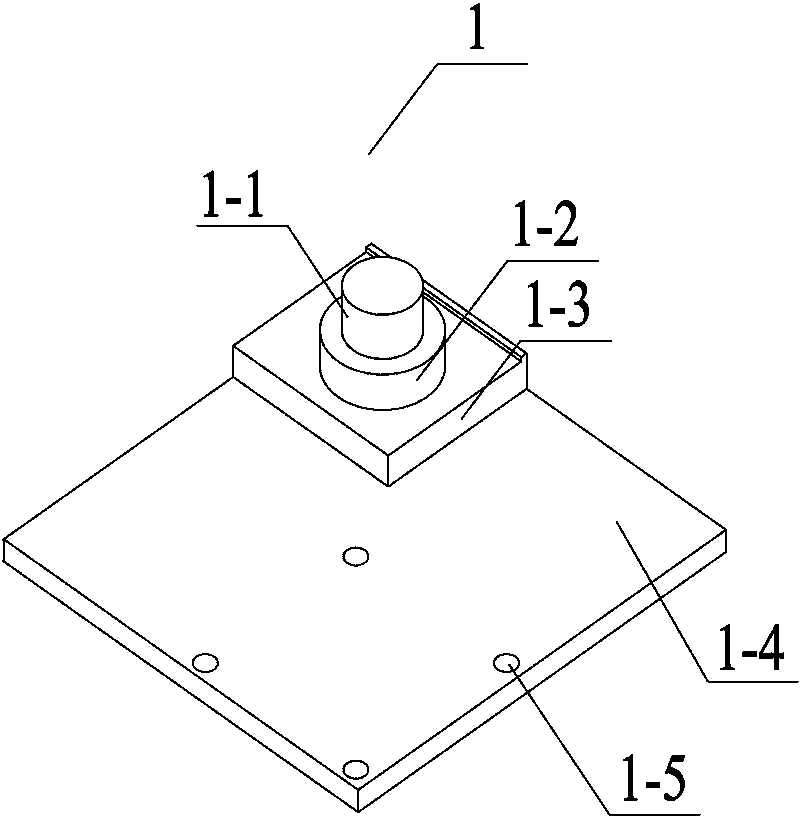

Slanted-slot type precise piezoelectric stick-slip linear motor and driving method thereof

ActiveCN105827140AReduce frictional resistanceImprove mechanical output characteristicsPiezoelectric/electrostriction/magnetostriction machinesMicro nanoStator

Provided are a slanted-slot type precise piezoelectric stick-slip linear motor and a driving method thereof. The problem that for a current piezoelectric stick-slip linear motor, due to the fact that comprehensive regulation of friction force is difficult, the mechanical output characteristic is limited is solved. The motor is composed of a base, a pre-pressure adjustment mechanism, a slanted-slot type stator and a slanted-slot type rotor, the stator adopts a symmetric flexible hinge structure to produce displacement amplification, due to the fact that rigidity distribution of slanted slots and a semicircular drive foot in the axial direction is nonuniform, lateral displacement is produced, friction drive force is increased, and frictional resistance is reduced; meanwhile, a friction regulation wave is compositely overlaid in a sawtooth drive wave in the rapid deformation stage of the stator, the frictional resistance between the staror and the rotor in the rapid deformation stage is reduced, comprehensive regulation of the friction force is achieved, and the mechanical output characteristic of the piezoelectric stick-slip linear motor is significantly improved. The slanted-slot type precise piezoelectric stick-slip linear motor has the advantages of being simple in structure, high in precision, large in stroke and the like, and an excellent application prospect in the micro-nano precision driving and positioning fields such as aerospace, optical precision instruments and semiconductor processing is achieved.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com