Crusher

A pulverizer and pulverizing chamber technology, applied in grain processing, etc., can solve the problems of fire, fan speed reduction, material change performance, etc., to achieve the effect of expanding the processing range, reducing power consumption, and reducing raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

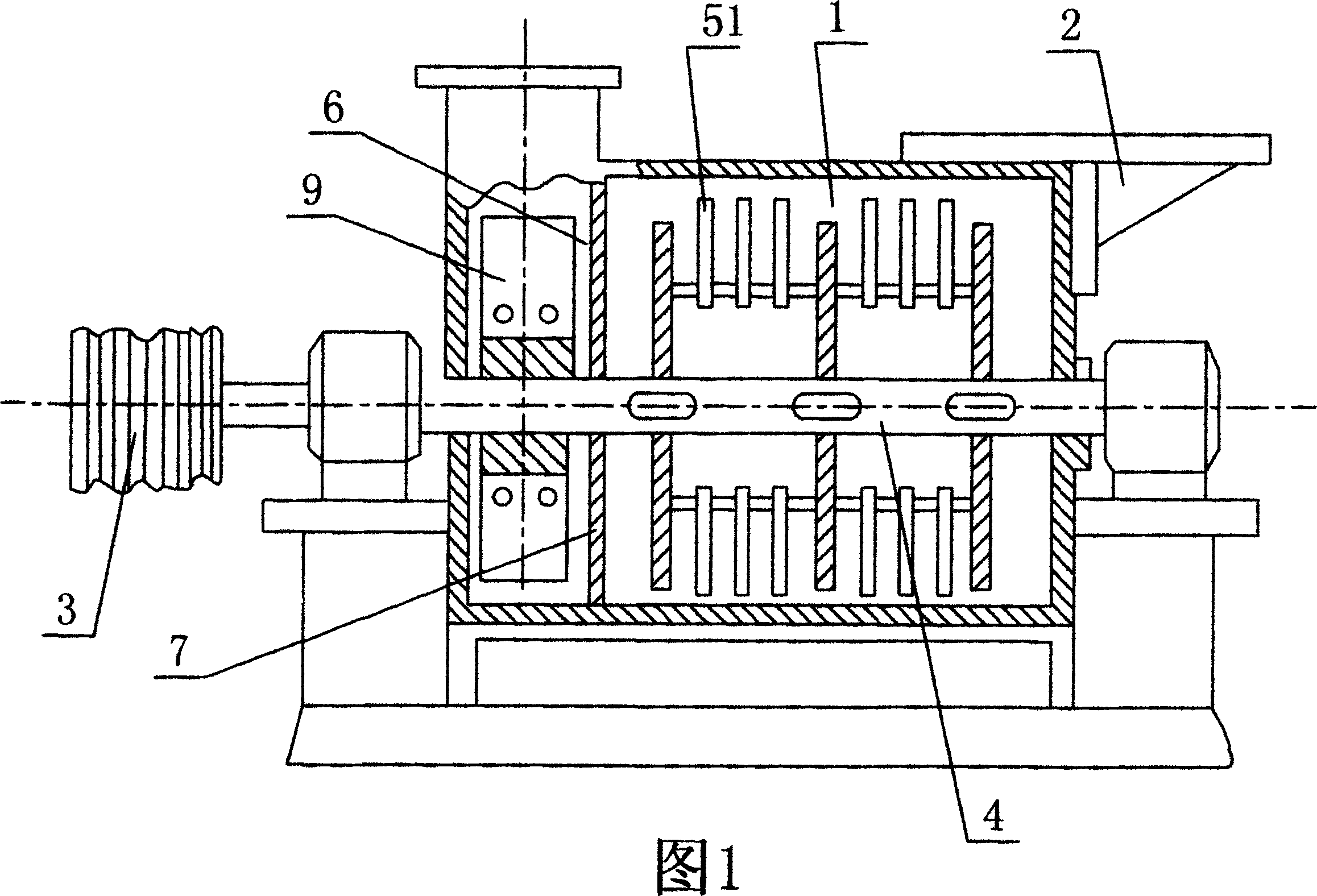

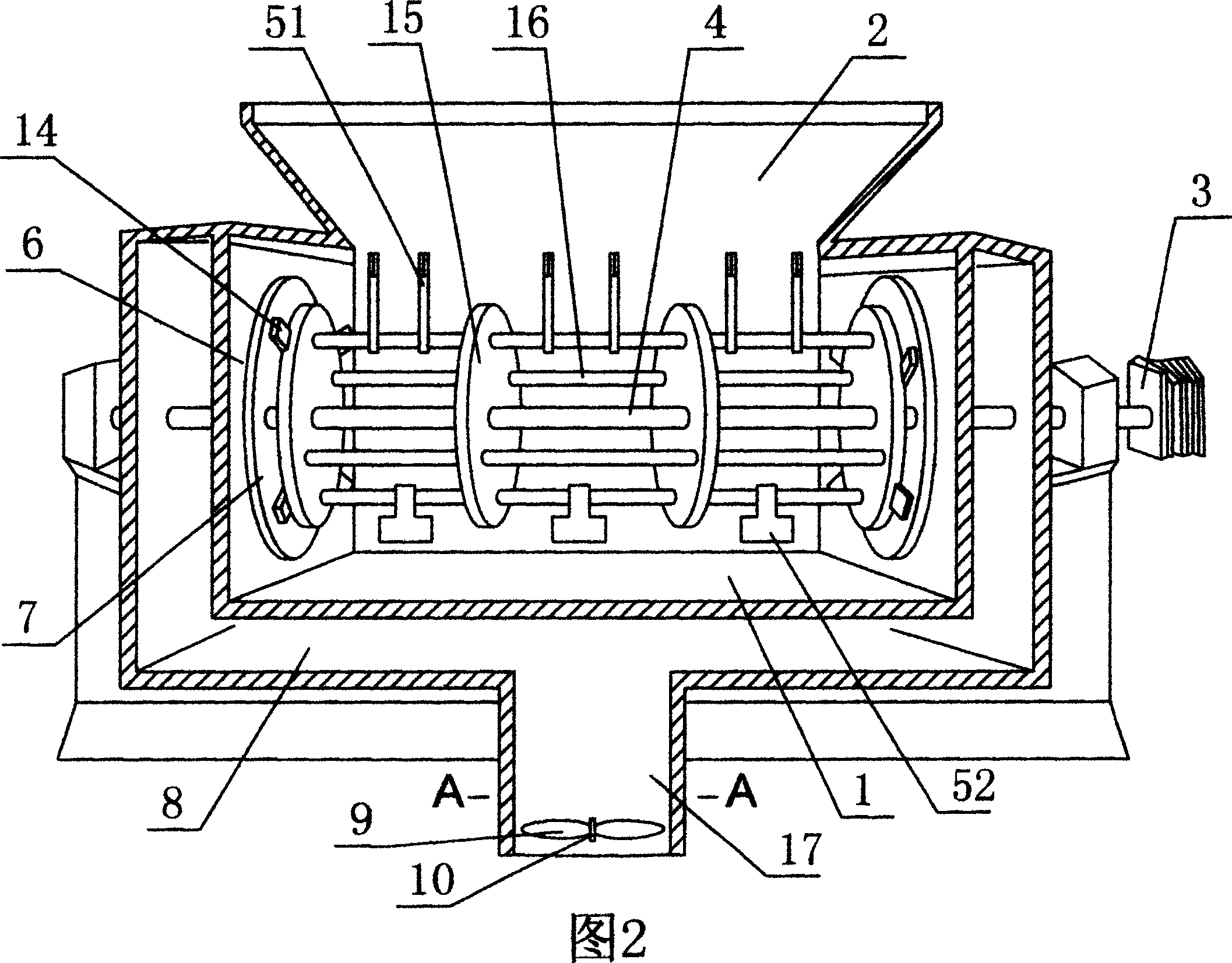

[0019] The specific embodiment of the present invention includes a material crushing chamber 1, a feed inlet 2 is arranged above the crushing chamber, a main shaft 4 driven by a power device 3 is provided in the chamber of the crushing chamber, and the main shaft can be driven to rotate in a plane perpendicular to the axis of the main shaft. The pulverizing cutter 51 or 52, at least one of the two axial ends of the pulverizing chamber is provided with a discharge port 6, and a screen 7 is provided on the discharge port, and it is characterized in that: the periphery of the pulverizing chamber is also provided with a discharge port. The mouth is connected to the suction chamber 8, and the outlet 17 of the suction chamber is provided with an induced fan 9, and the power shaft 10 of the induced fan is not connected with the main shaft 4 for transmission.

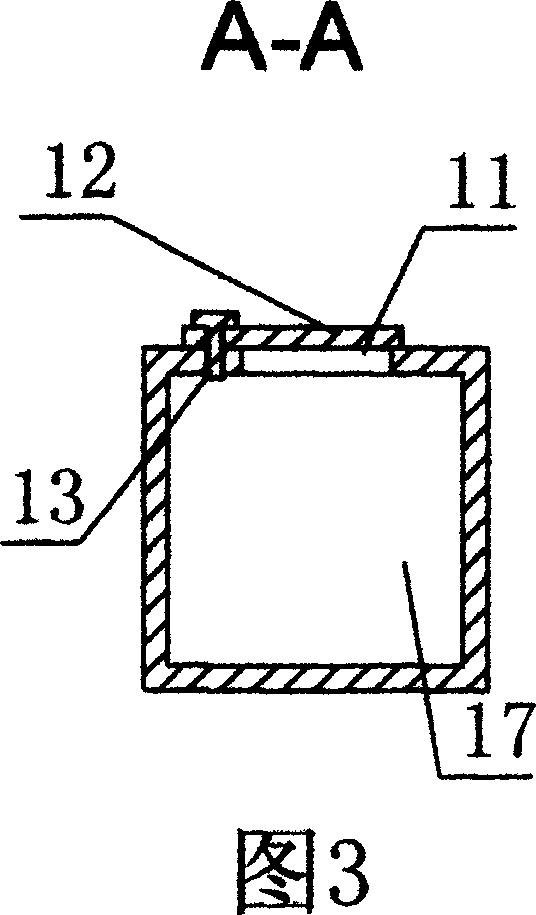

[0020] The side wall of the outlet of the suction chamber is provided with an air introduction port 11 and an adjustable dampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com