Patents

Literature

1012results about How to "Good peeling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

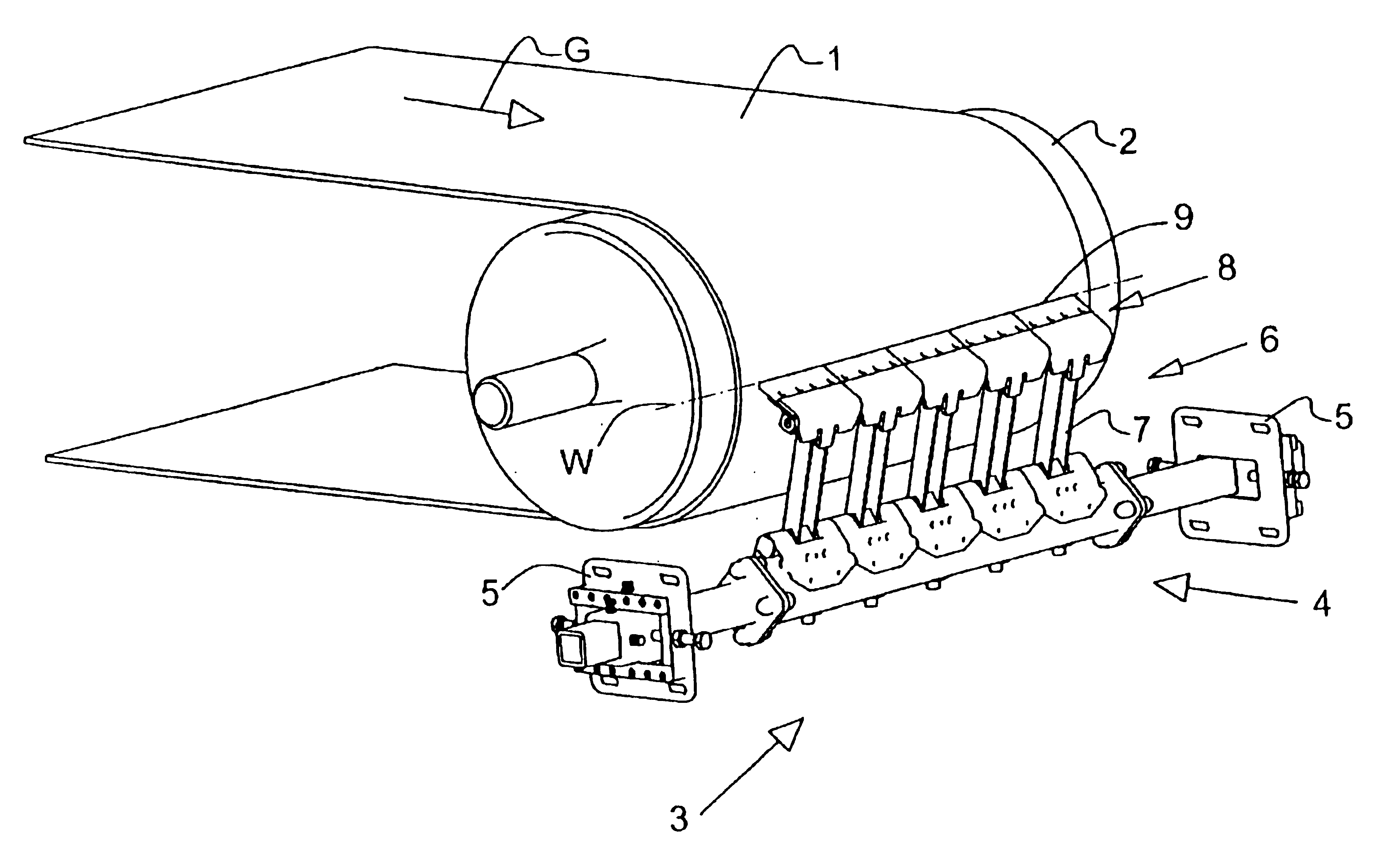

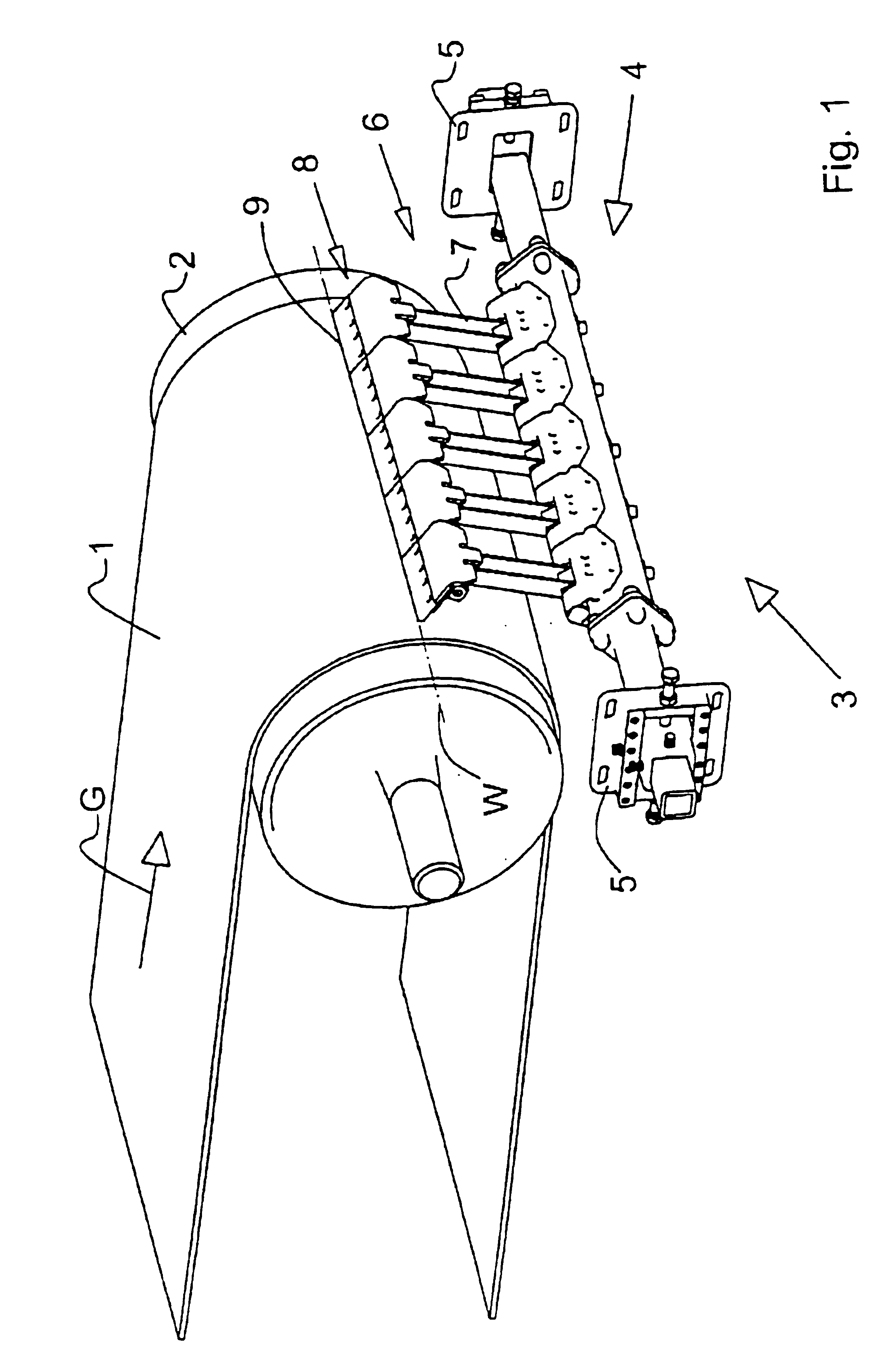

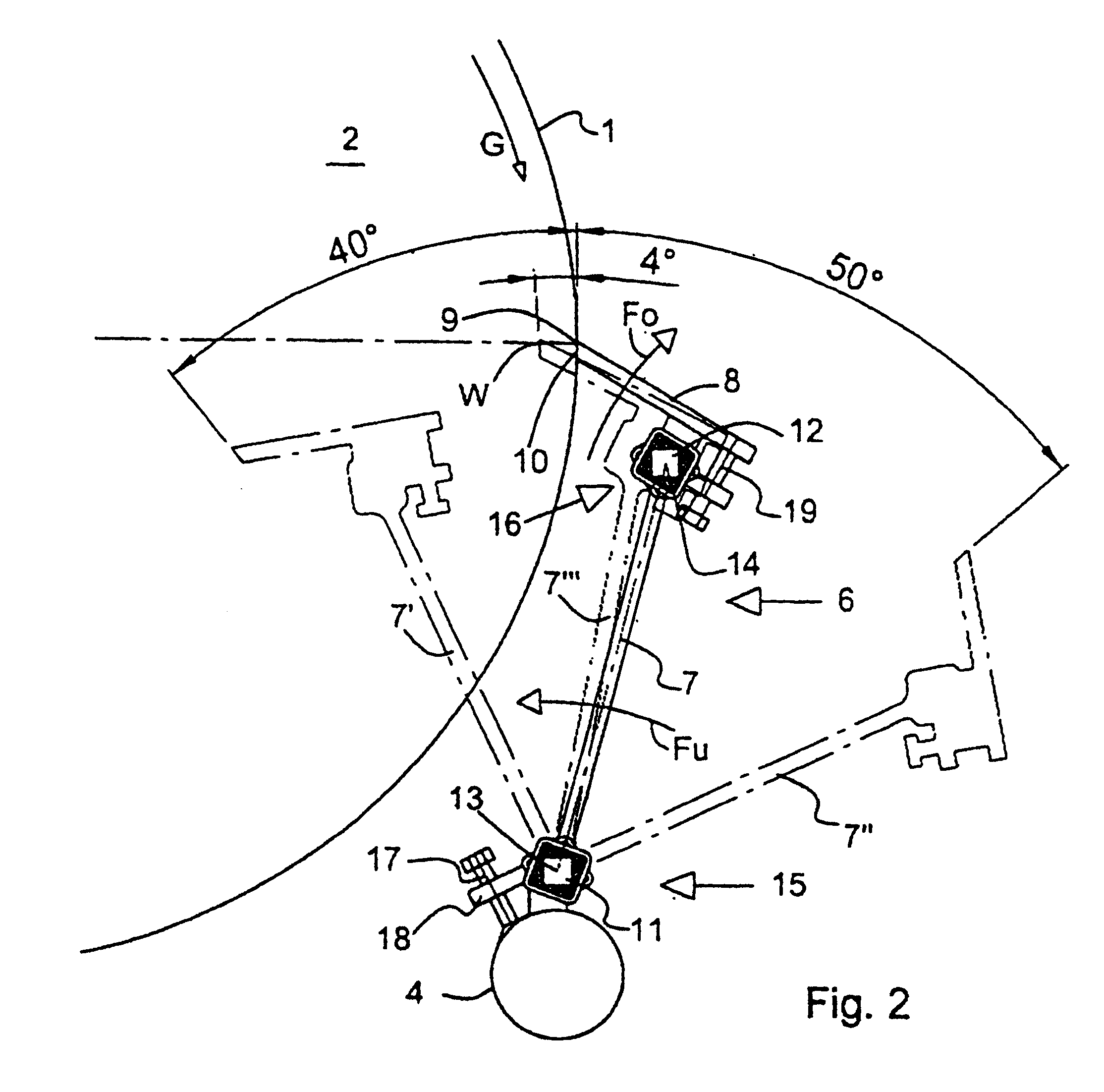

Stripping device for the return run area of conveyor belts

Apparatus for stripping a belt in conveyor belt assemblies includes a stripping element on a system carrier, the stripping element having a stripping lamella on a lamella holder, the stripping lamella contacting the belt in a peeling position, wherein the stripping element has a swivel mount coupled to the lamella holder and a swivel axis parallel to a plane of the belt, a spring for pressing the stripping lamella against the belt such that the lamella holder in the peeling position is swiveled about the horizontal axis, and when obstructions adhering to the belt impact the stripping lamella, the lamella holder deflects and returns a working position, wherein the stripping lamella is swivel mounted at the lamella holder by a swivel mount having an axis parallel to a plane of the belt and is held and spring biased by a top spring is counter to the bottom swivel mount spring.

Owner:KILL FRECH CORNELIA

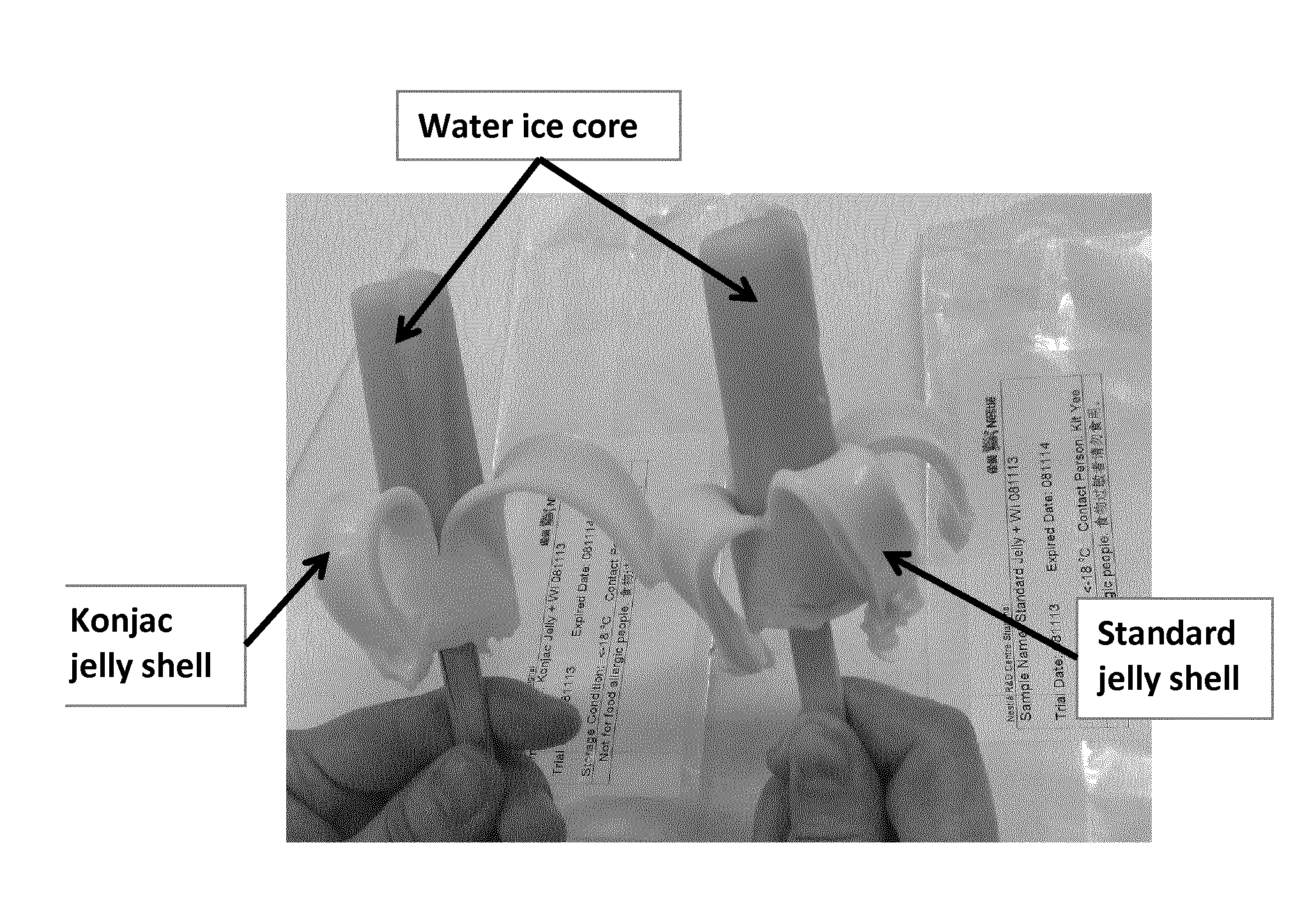

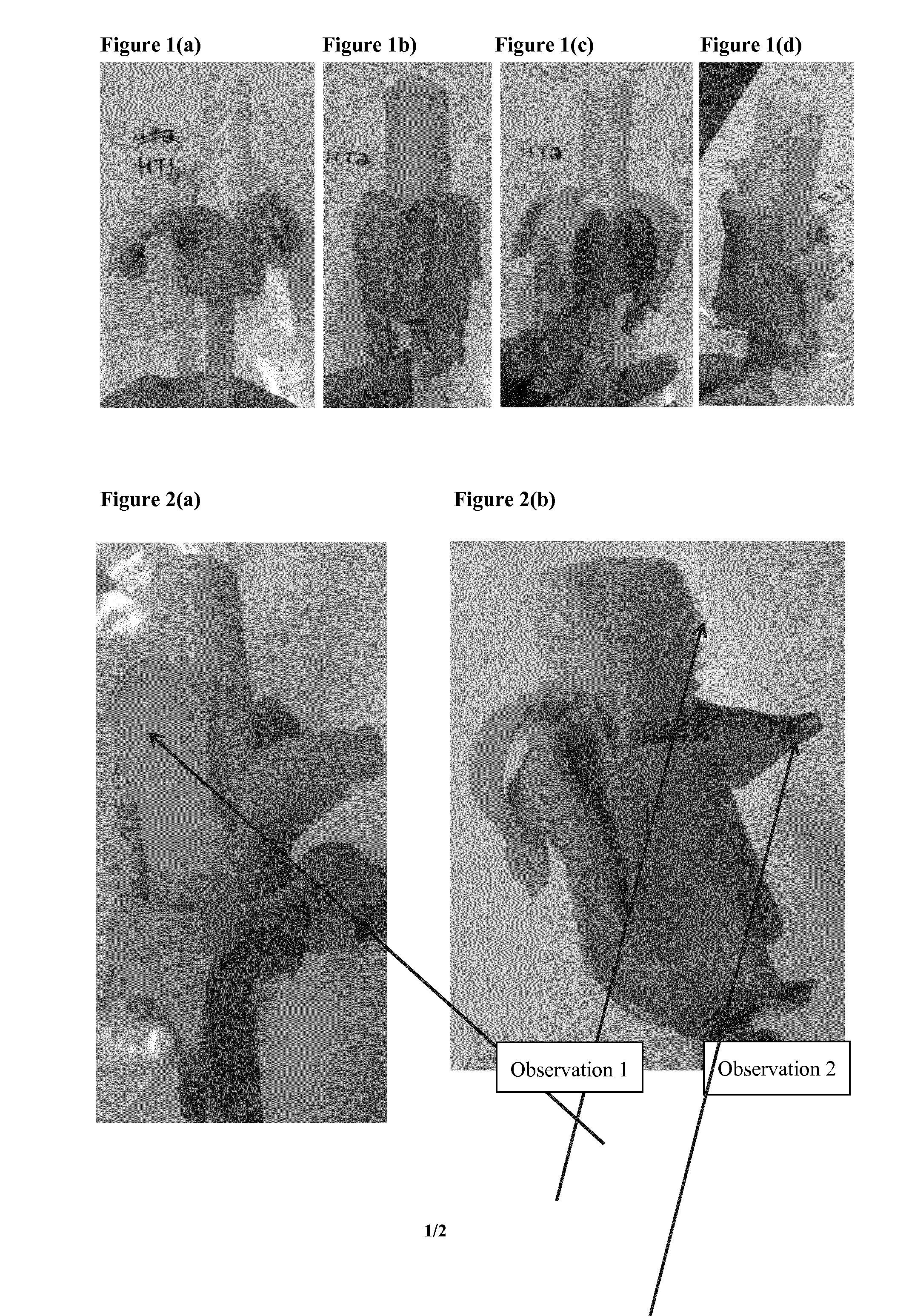

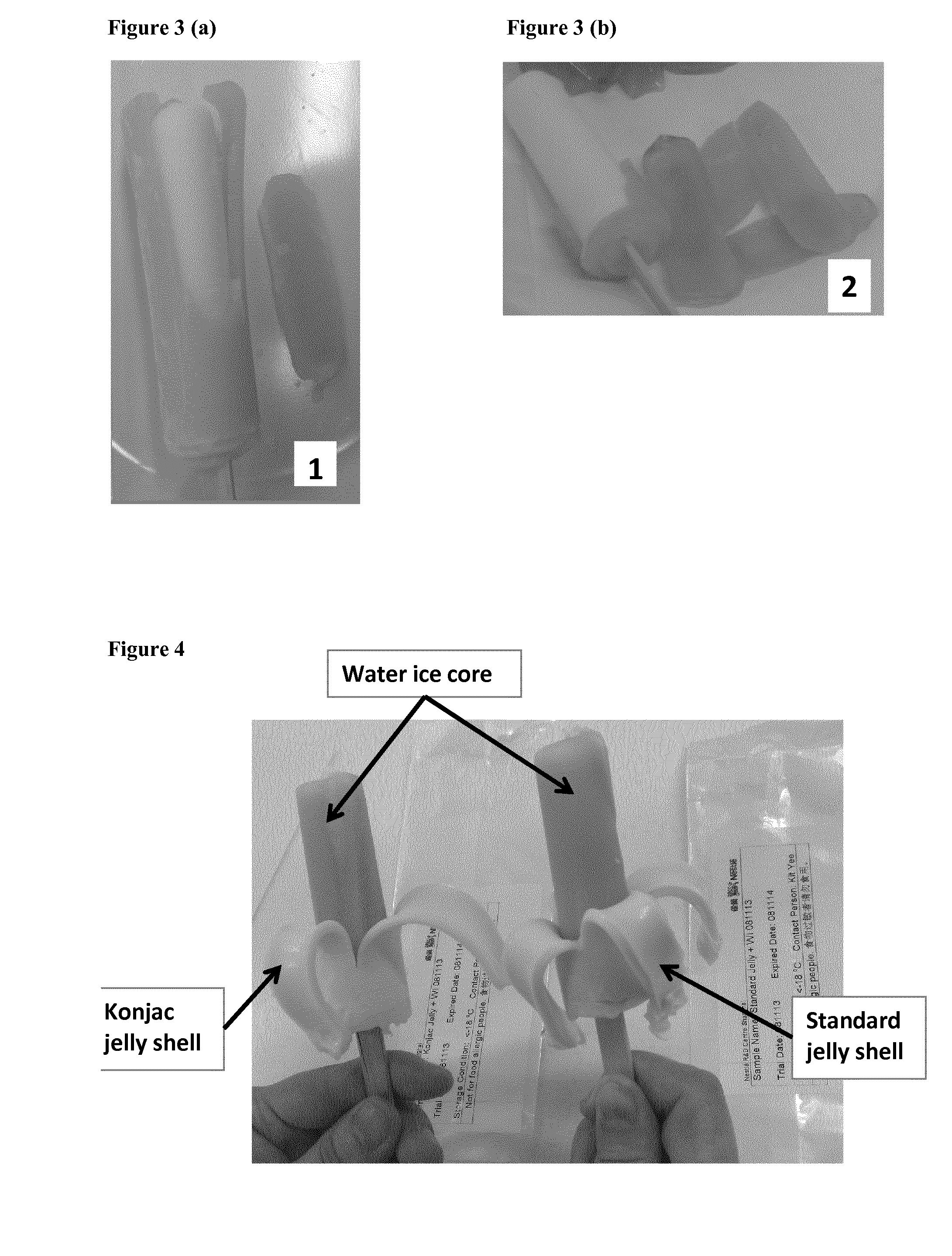

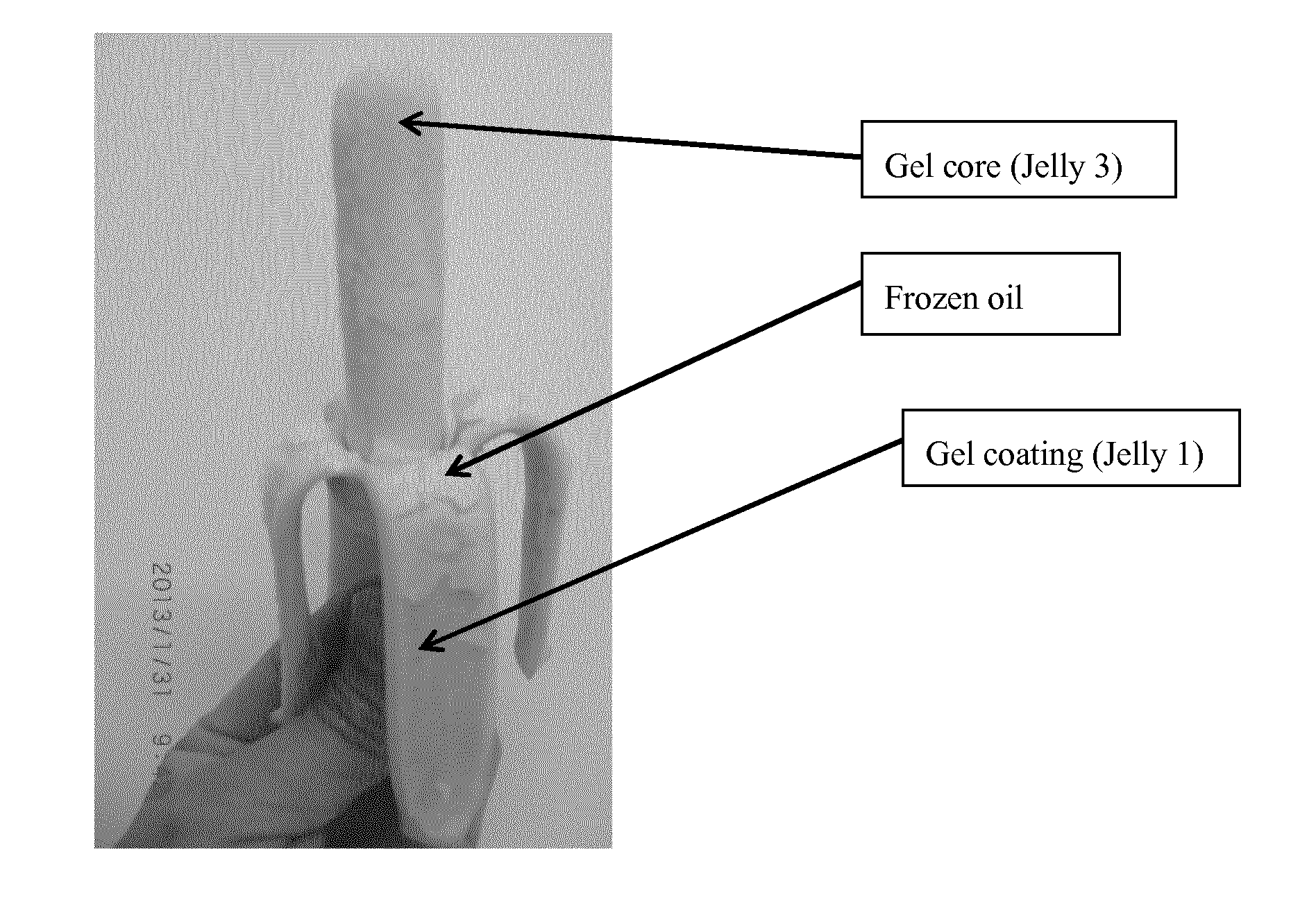

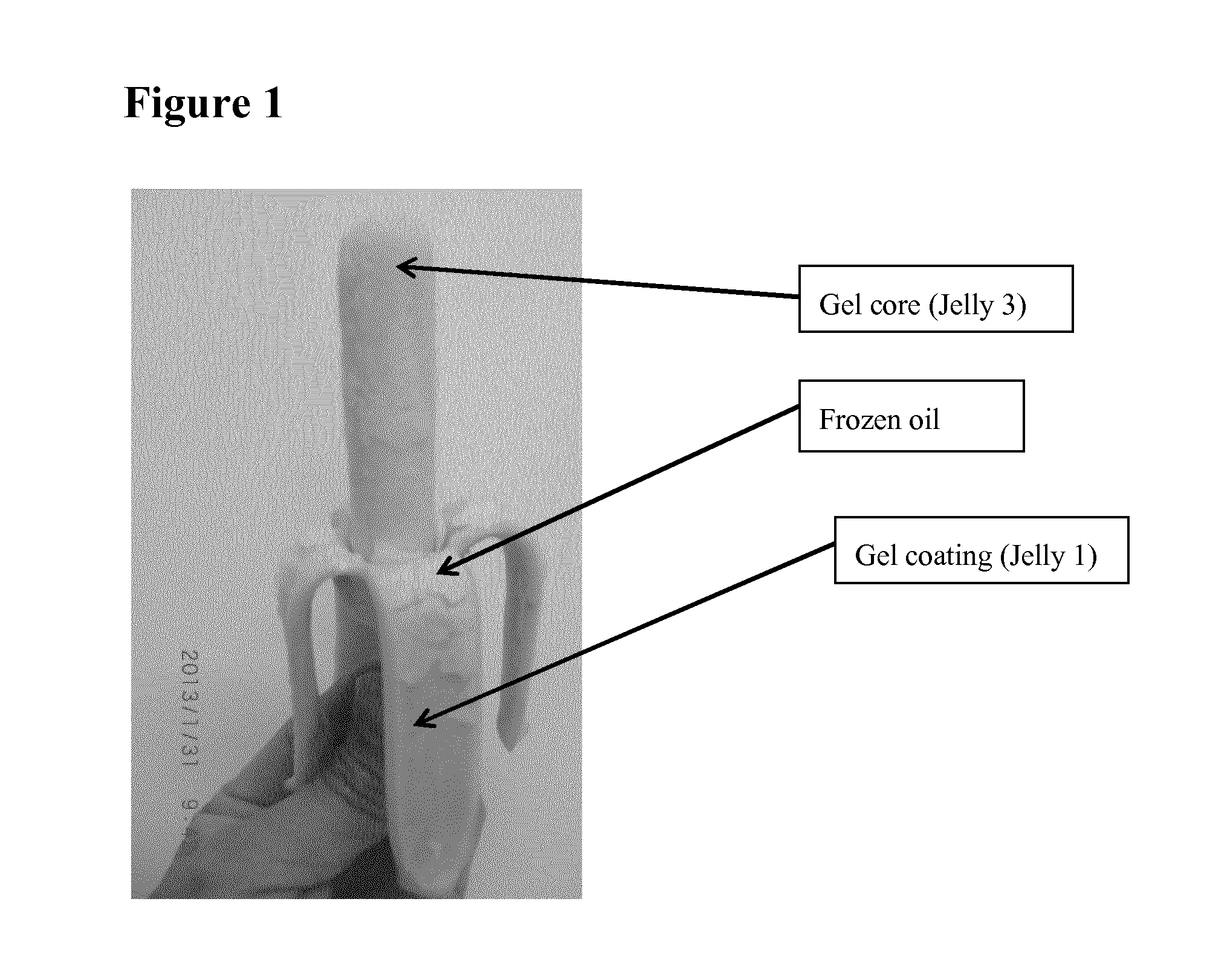

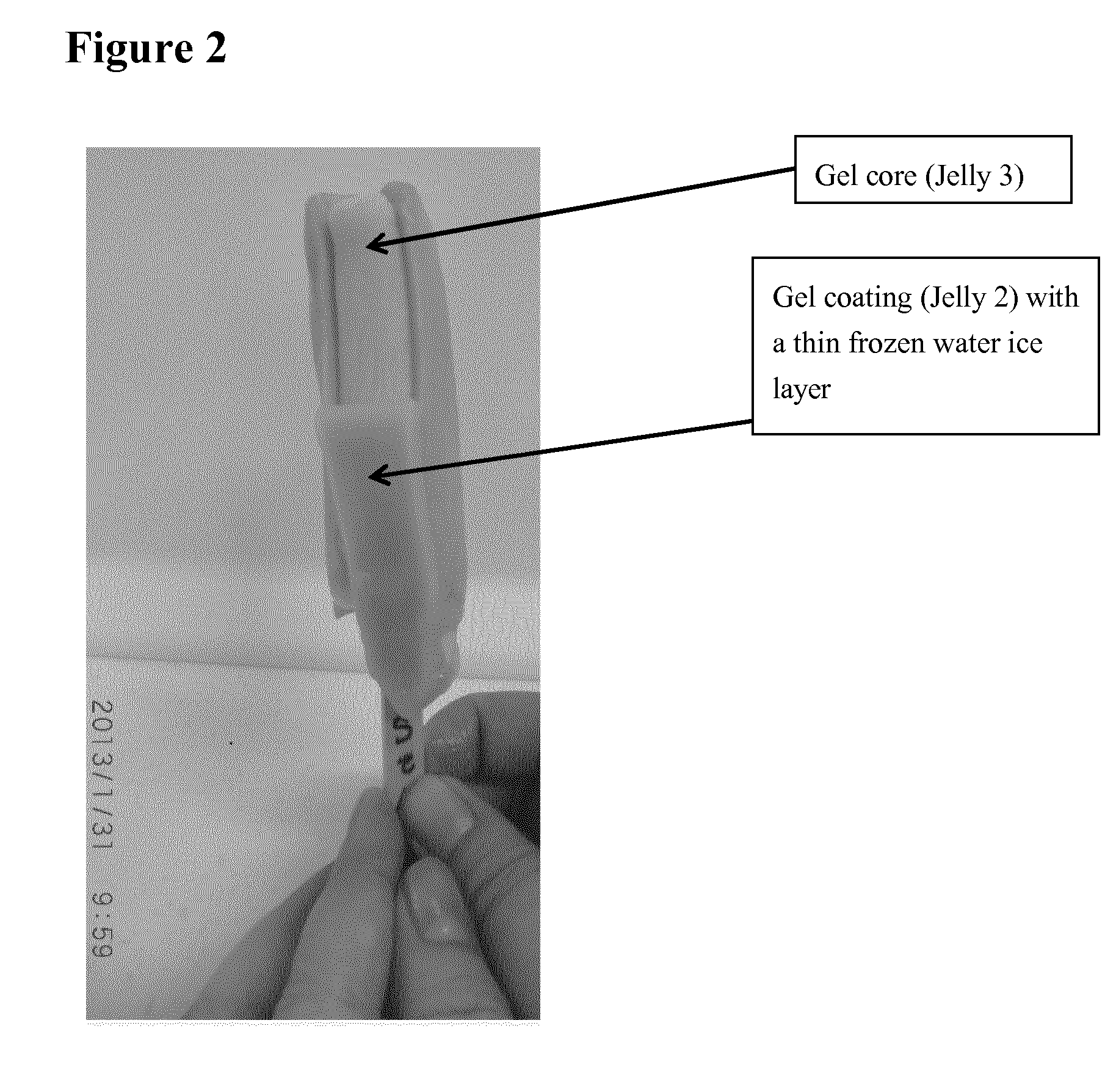

Frozen confectionery product with an easy peelable gel coating and a method for manufacturing same

The invention relates to a frozen confectionery product comprising a core of a frozen confection, which is at least partially coated with a gel coating, characterized in that the gel coating has a layer of frozen liquid on the surface of the gel coating that originates from syneresis of the gel. Furthermore, the invention relates to a method for making such a frozen confectionery product.

Owner:NESTEC SA

Frozen confectionery product with an easy peelable gel coating and a method for manufacturing same

The invention relates to a frozen confectionery product comprising a core of a frozen confection, which is at least partially coated with a gel coating, characterized in that the gel coating is at least partly coated with a barrier coating of frozen liquid facilitating the peeling of the gel coating. The invention also relates to a method for making such a frozen confectionery product.

Owner:NESTEC SA

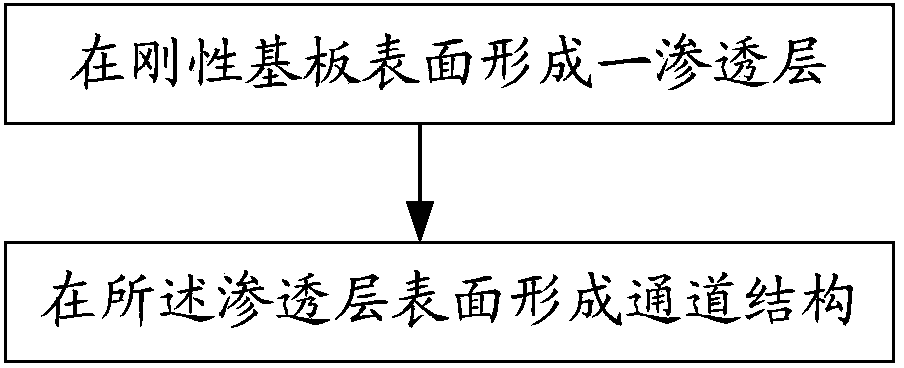

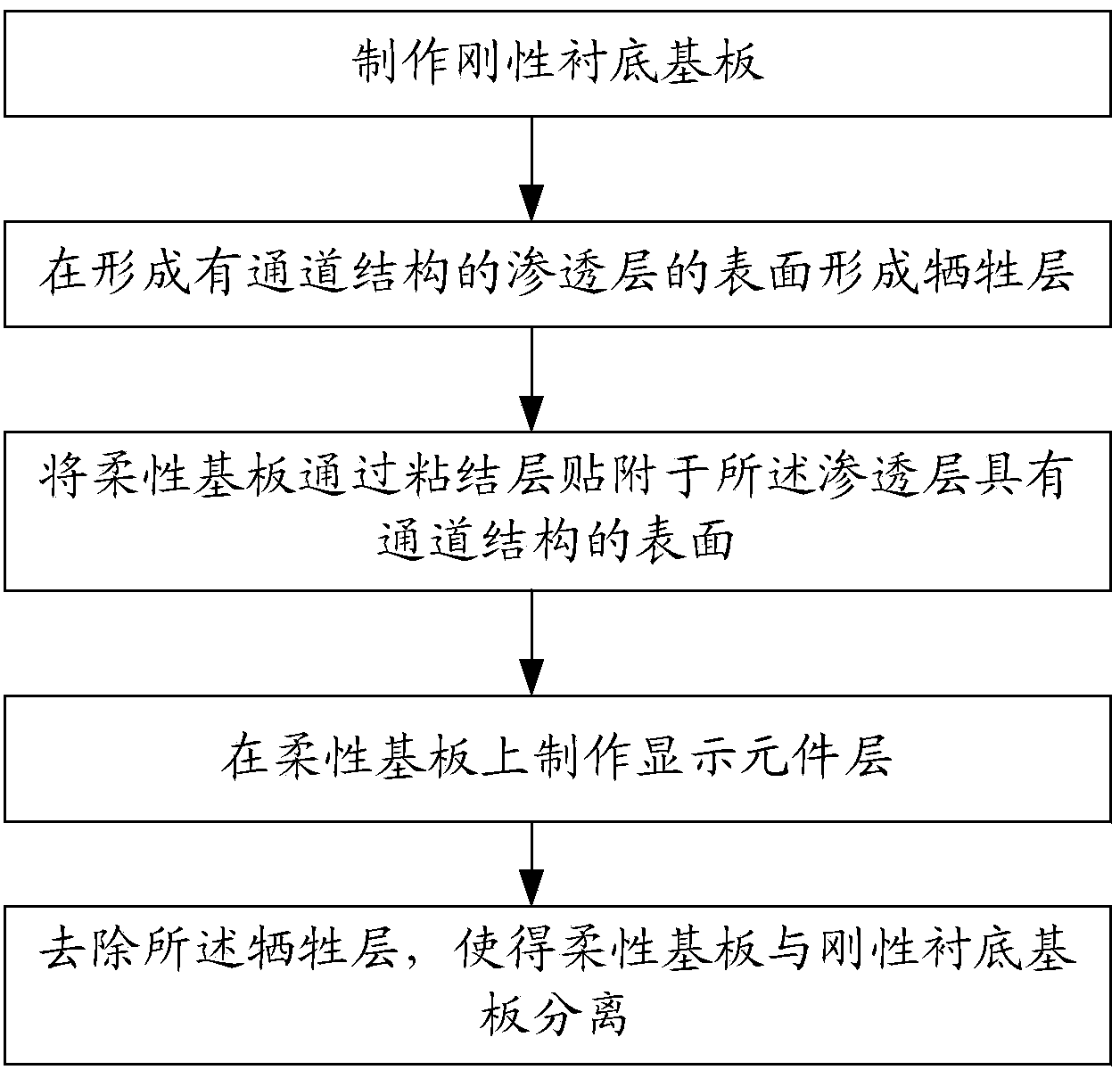

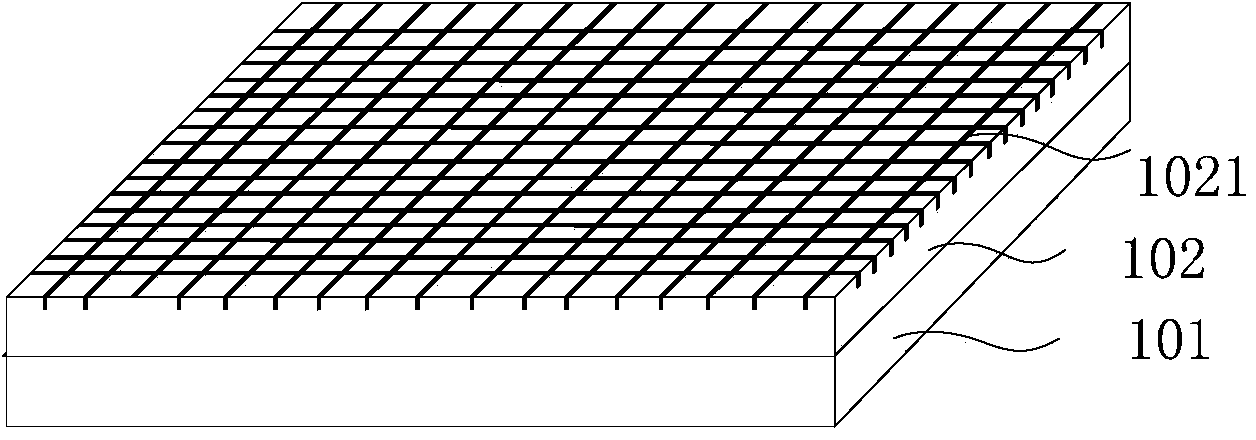

Manufacturing method for rigid substrate and flexible display device and rigid substrate

ActiveCN103682176AReduce etch timeGood peeling effectFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention relates to a manufacturing method for a rigid substrate and a flexible display device and the rigid substrate. The manufacturing method for the rigid substrate used for manufacturing the flexible display device includes the following steps that a permeable layer is formed on the surface of the rigid substrate, and channel structures are formed in the surface of the permeable layer. The manufacturing method for the rigid substrate and the flexible display device has the advantages of shortening the etching time of a sacrificial layer and improving the stripping effect of a flexible substrate.

Owner:BOE TECH GRP CO LTD

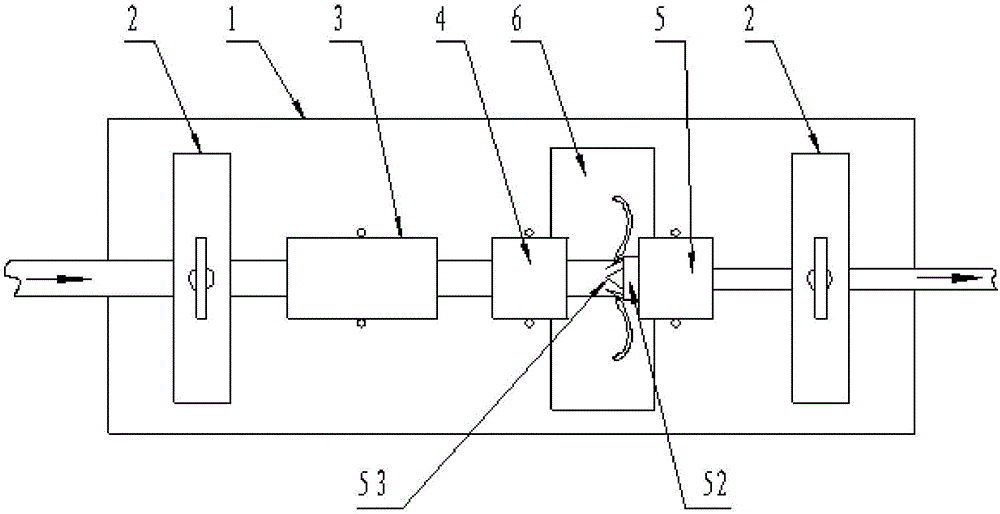

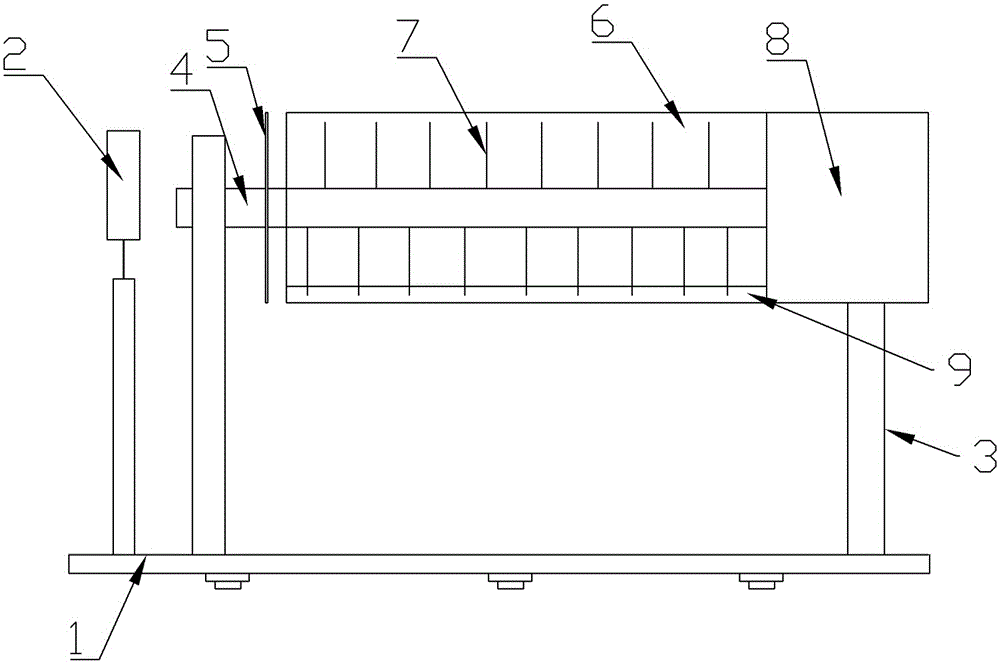

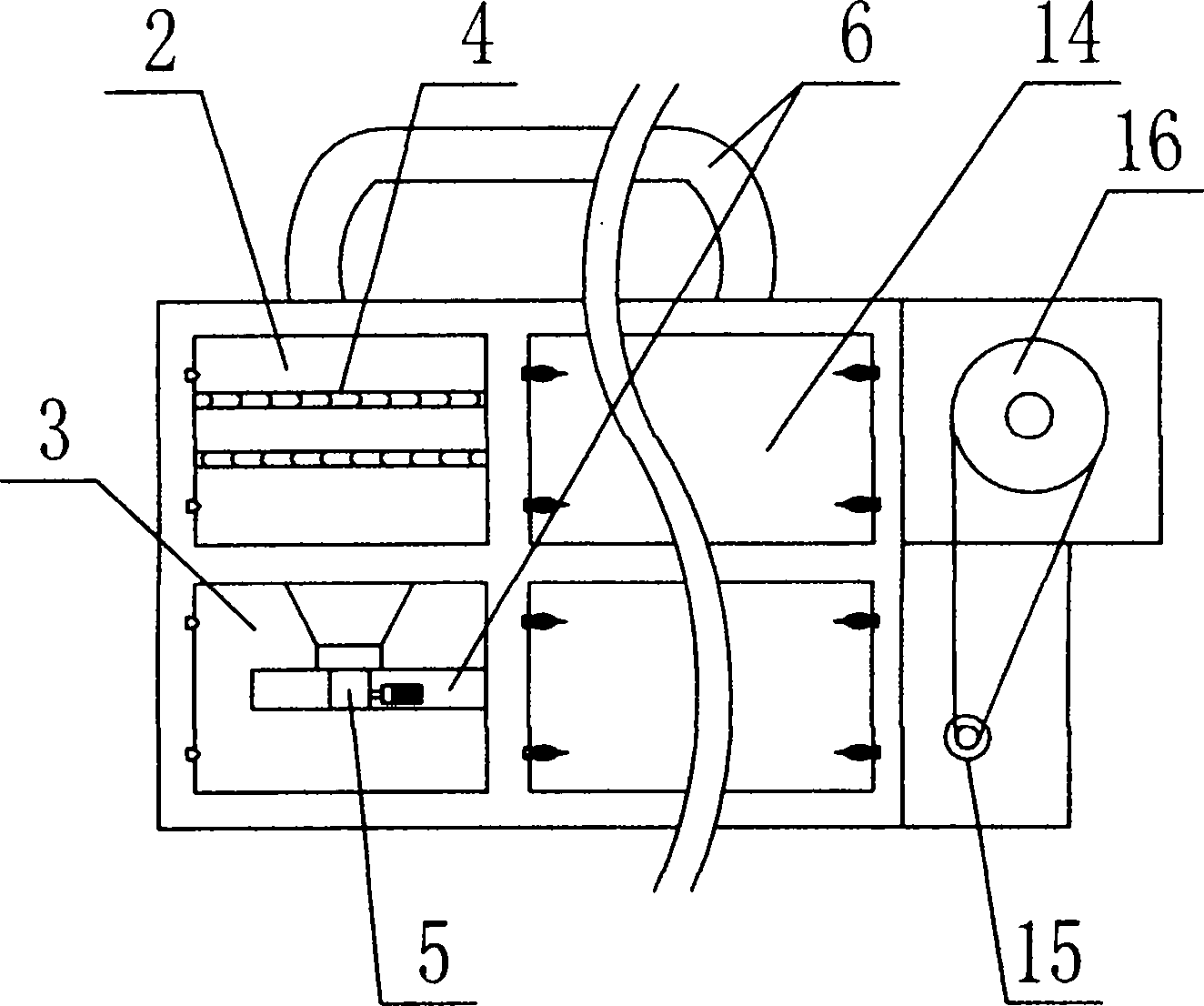

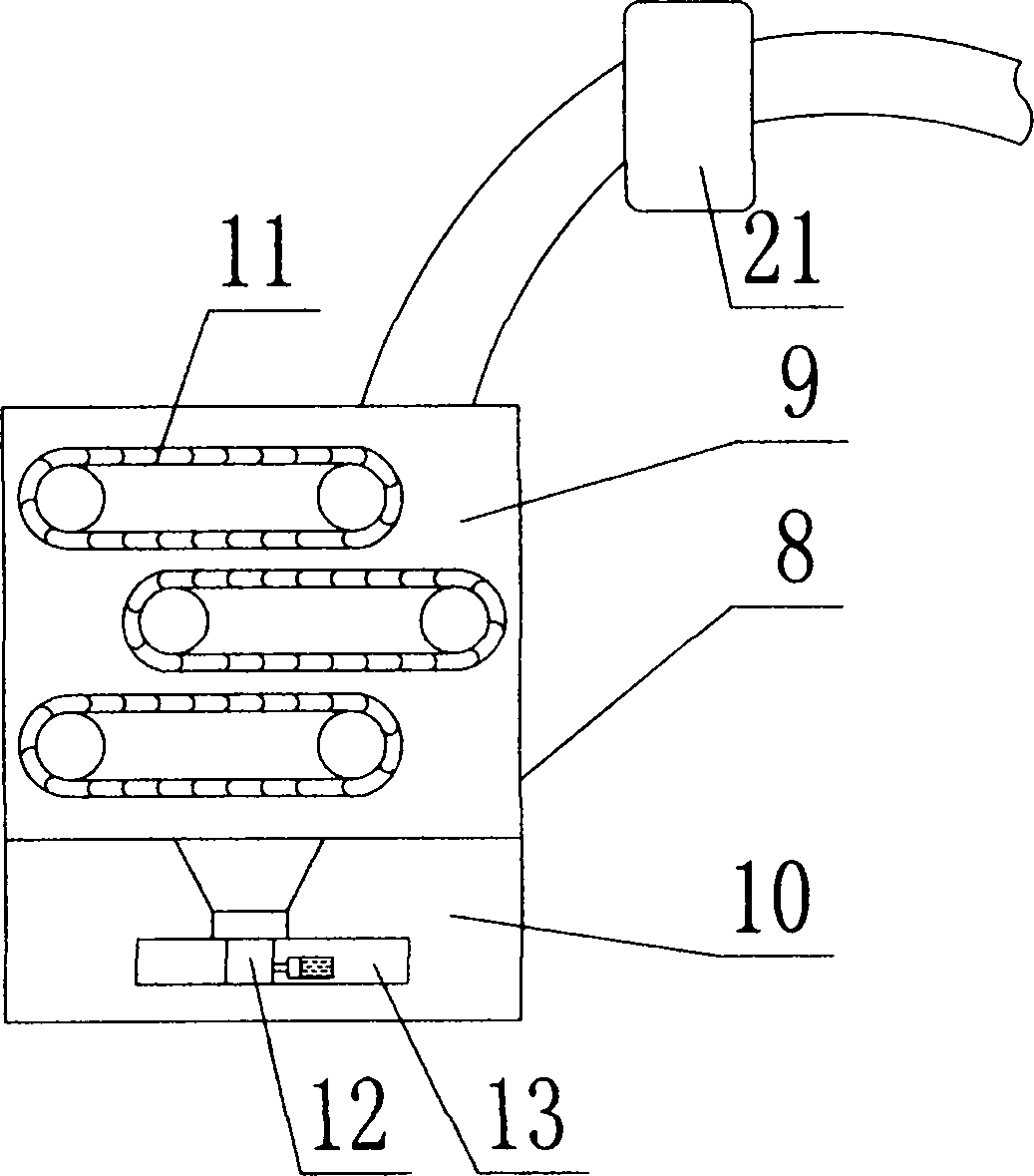

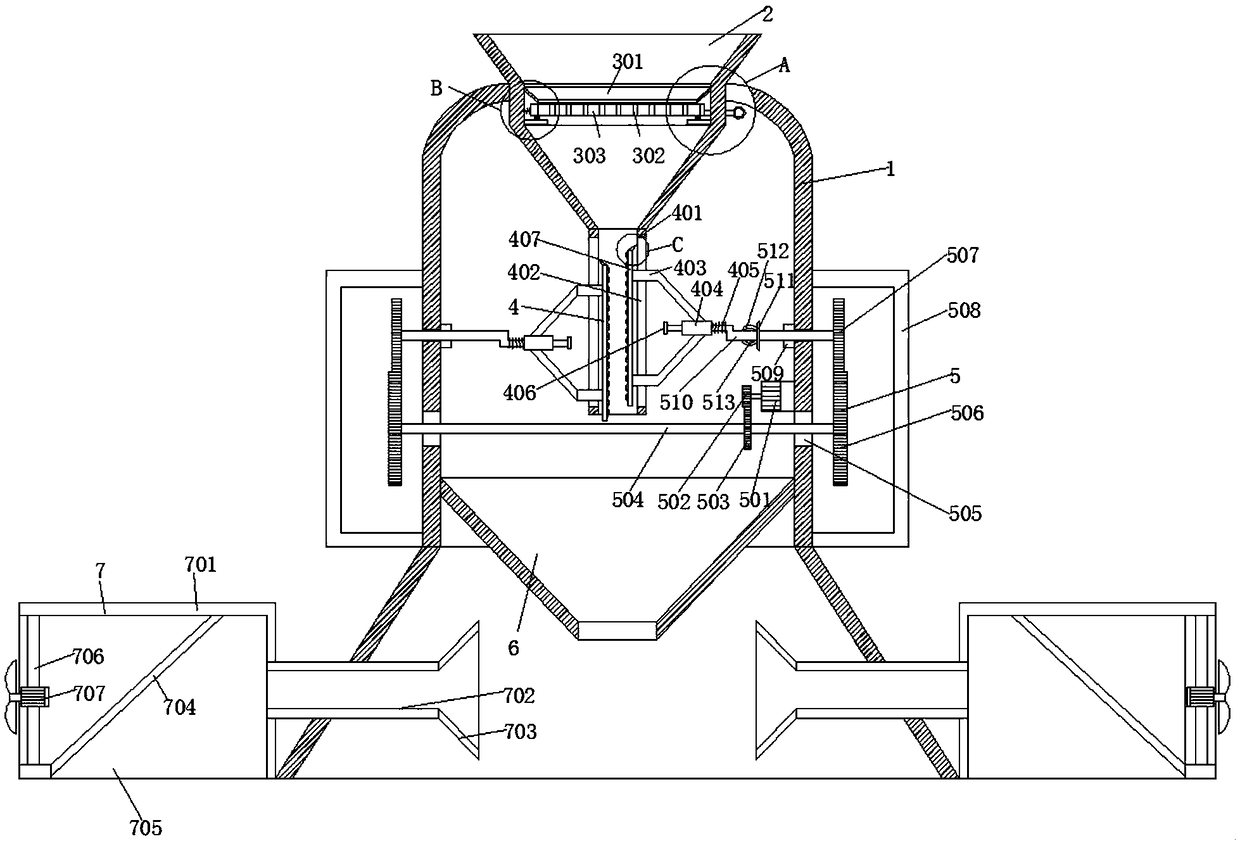

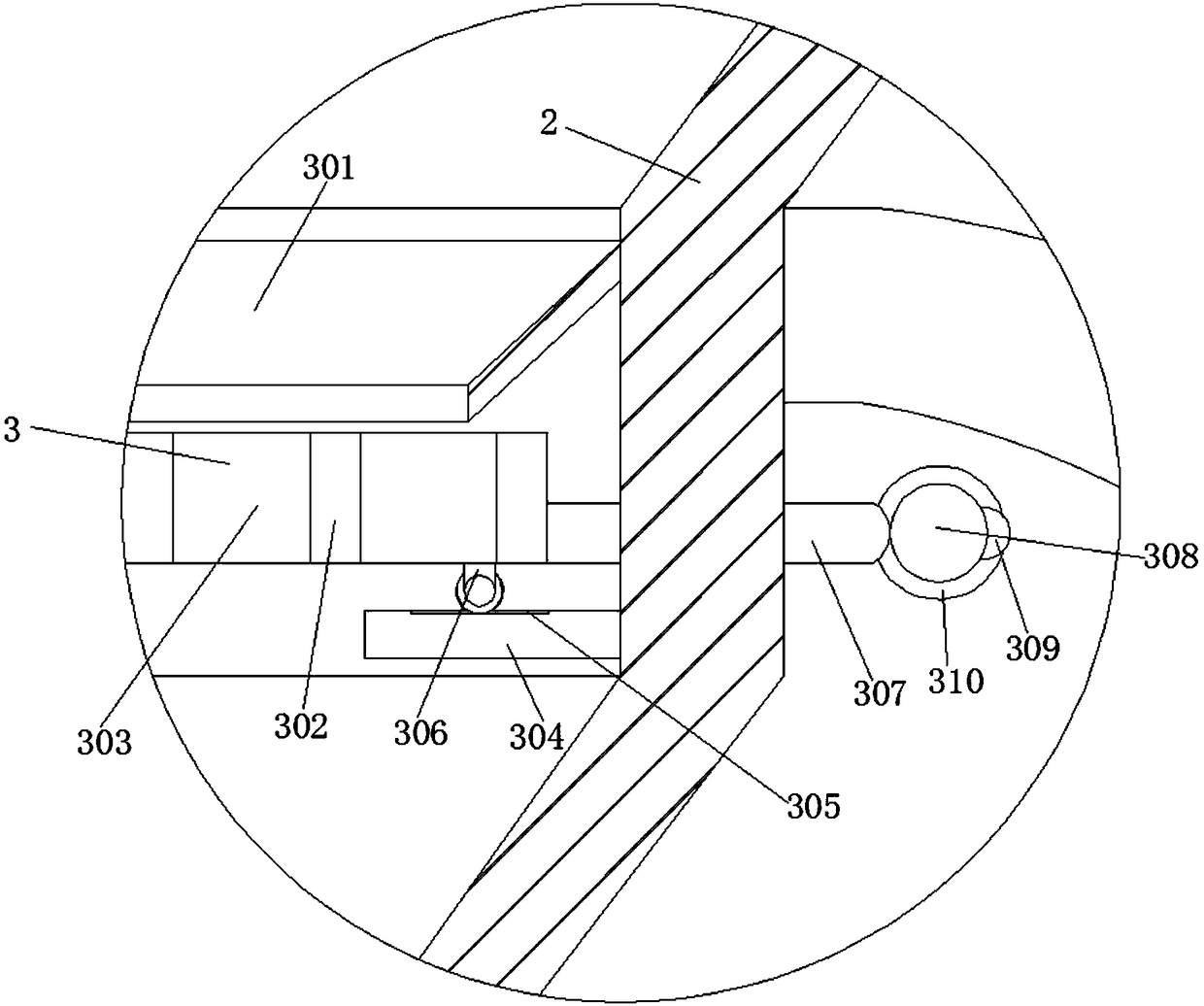

Operation method of electric peeling device for protective cores of waste cables

ActiveCN106329410AReduce labor intensitySave labor costsApparatus for removing/armouring cablesEngineeringProtective relay

Provided is an operation method of an electric peeling device for the protective cores of waste cable. Clamping mechanisms are arranged at the two ends on an operation table. A heater, a cutting mechanism and a stripping mechanism are sequentially arranged along the running direction of cables between the two clamping mechanisms. An insulating layer collection hole is arranged between the cutting mechanism and the stripping mechanism. The operation method comprises the following steps: adjusting the height of the telescopic rods on the clamping mechanisms; adjusting the distance between the blade of a cutter on the cutting mechanism and the inner core of a cable and the distance between the blade of a separator on the stripping mechanism and the inner core of the cable; adjusting the centers of the mechanisms to the same axis line; and heating, cutting and stripping the insulating layer of a to-be-processed cable in sequence. The device has a simple structure. The operation method is simple. The use effect is good. Operation by workers is facilitated. The labor intensity of workers is reduced greatly. The stripping effect is good, and the production efficiency is high. The method is suitable for stripping the rubber sheaths of all kinds of cables. High cable core recovery efficiency is achieved.

Owner:HUATONG CABLE INC

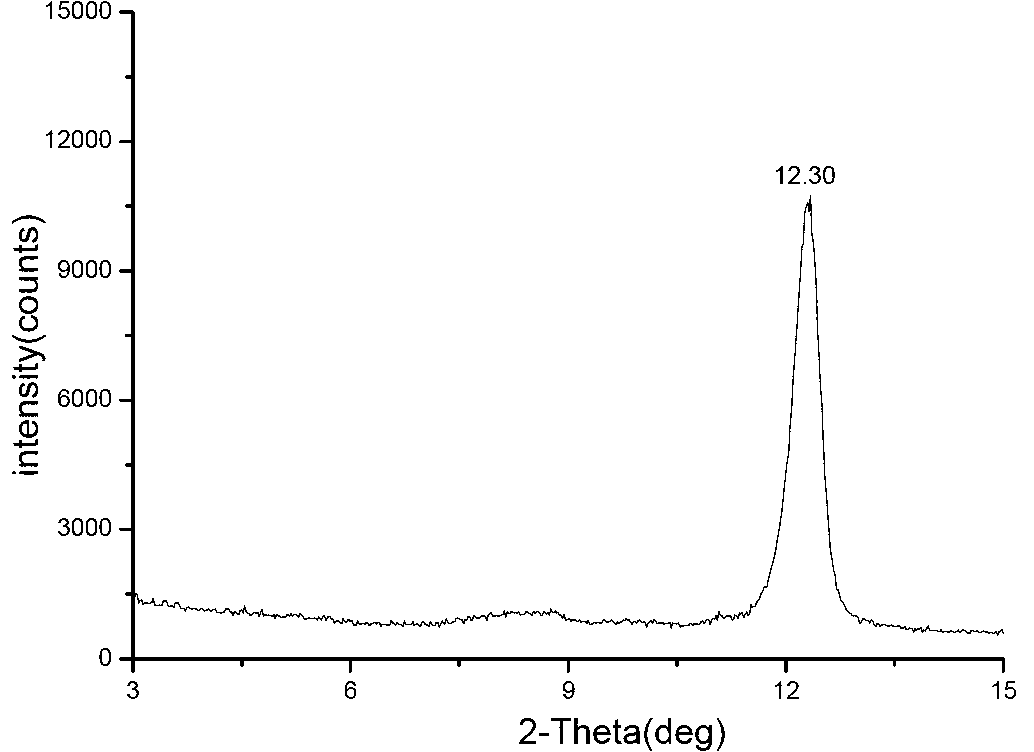

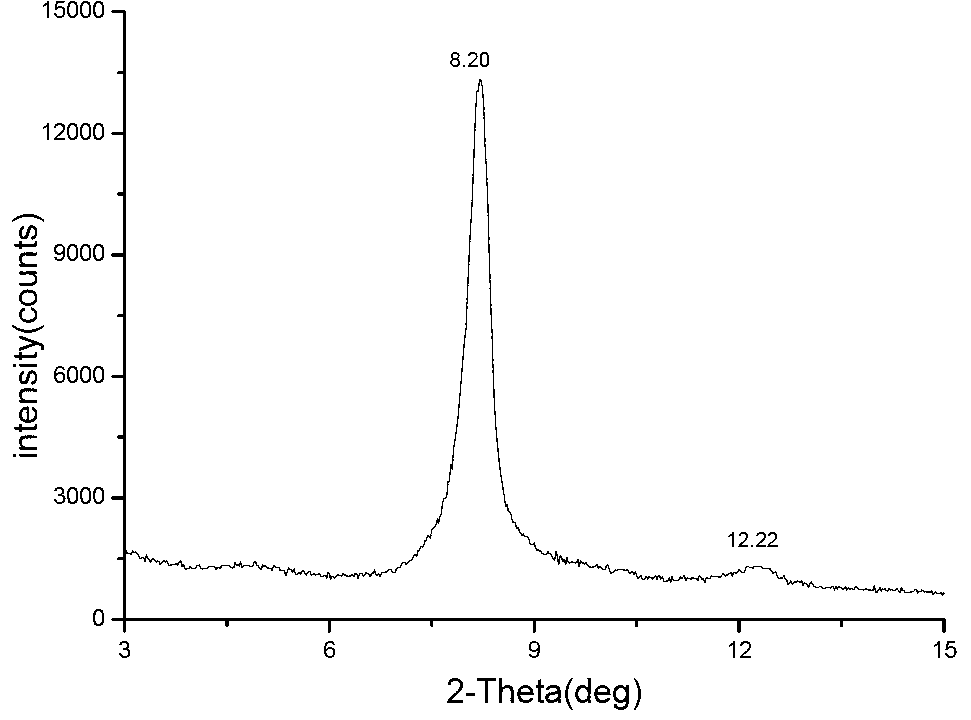

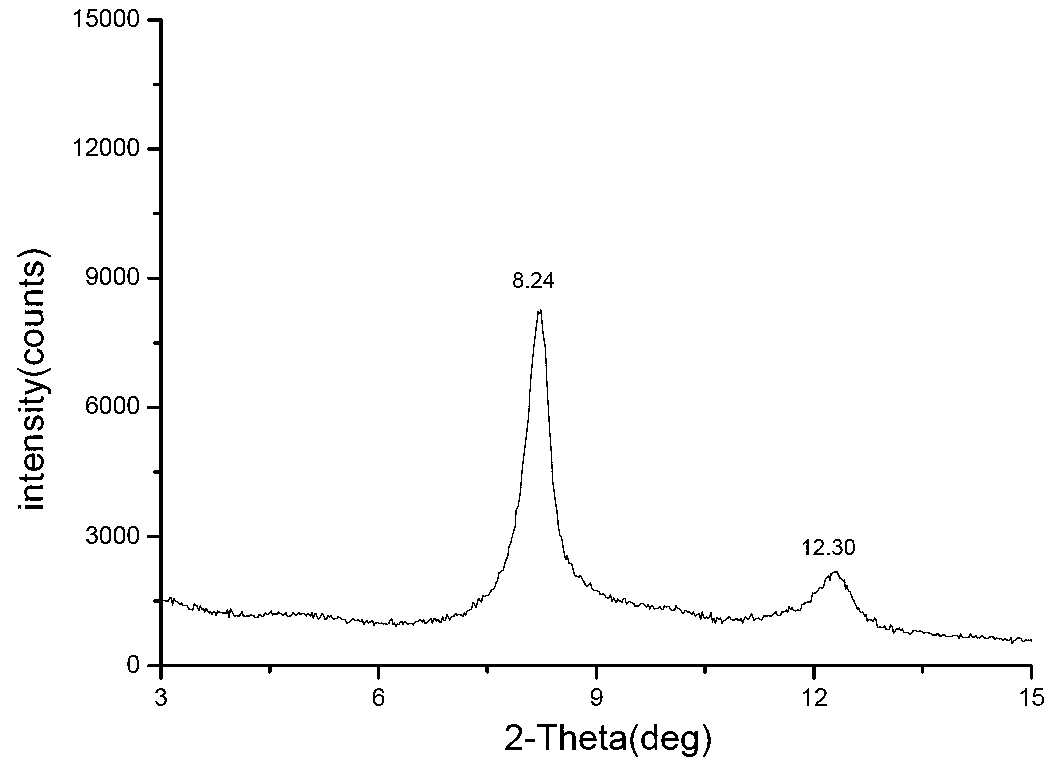

Method for preparing graphene through liquid-phase stripping method

The invention discloses a method for preparing graphene through a liquid-phase stripping method. The preparation method comprises the following steps: S1, performing expanding treatment on a graphite raw material through an expanding method; S2, dispersing the expanded graphite into an aqueous solution containing a surfactant to obtain a mixture, performing ultrasonic treatment on the mixture, centrifuging the mixture, and drying the mixture for later use; S3, adding the dried graphite into an organic solvent, a mixed solution of an organic solvent and a surfactant or a mixed solution of an organic solvent and substances with surface energy similar to that of the graphene, performing ultrasonic treatment and suction filtration, drying, and repeating the step S3 for 1-10 times, thereby obtaining graphene. Compared with the prior art, the method disclosed by the invention can be used for greatly shortening the ultrasonic treatment time, improving the stripping efficiency and obtaining high-quality graphene under low-power ultrasonic treatment.

Owner:SHENZHEN MINDKING TECH

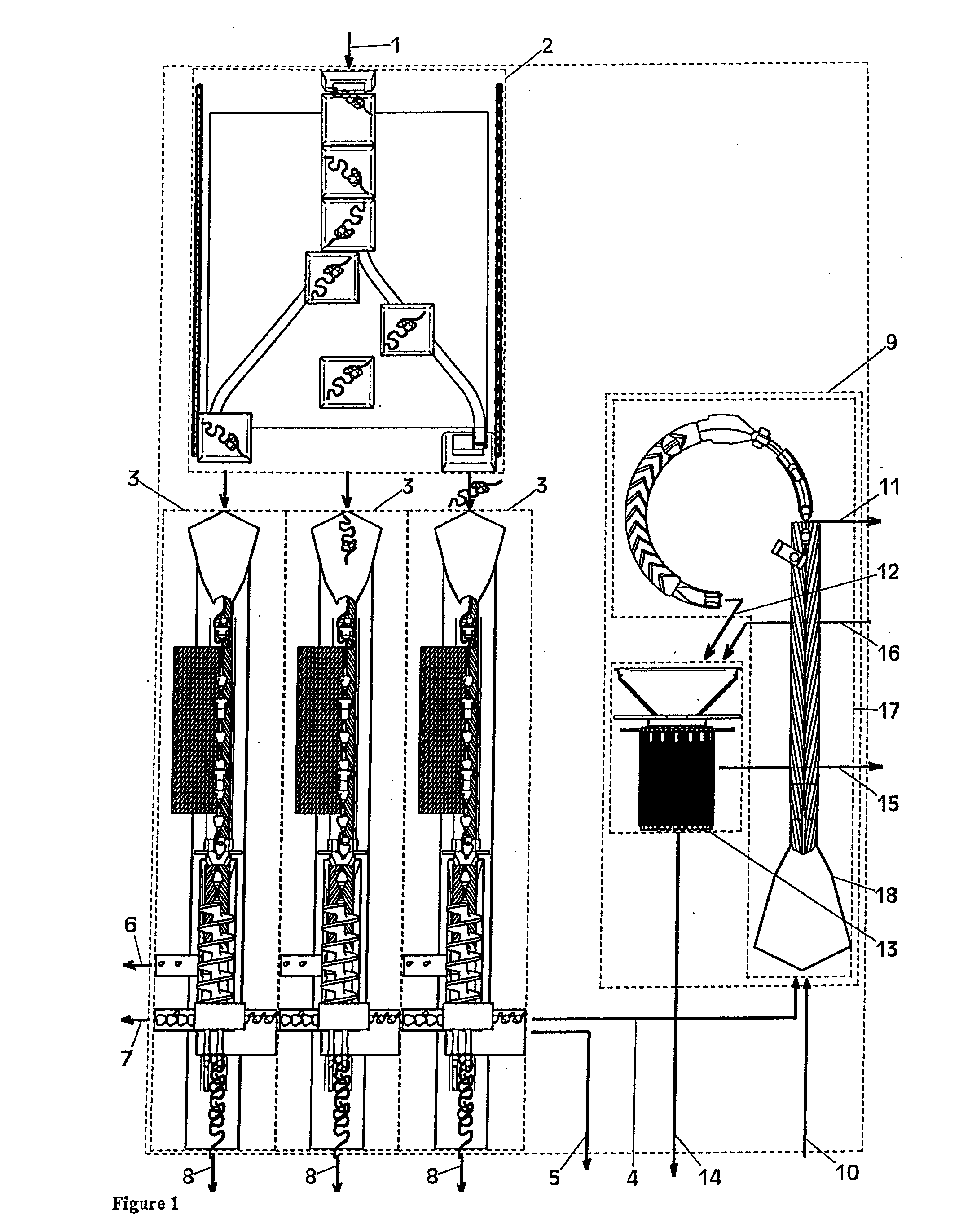

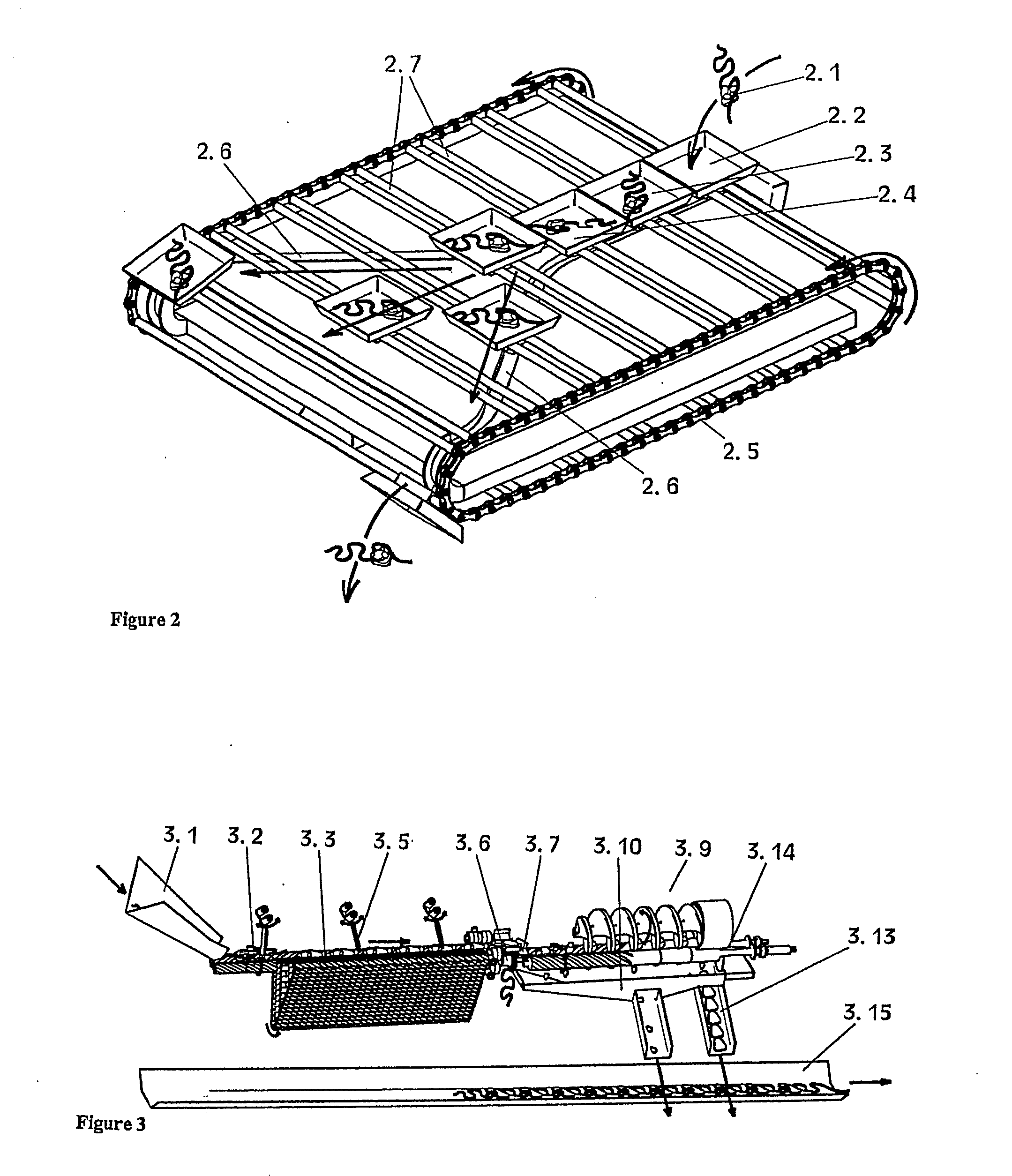

Method and Apparatus For Mechanically Processing an Organ or Organs Taken Out From Slaughtered Poultry

InactiveUS20090239457A1Efficient executionEfficient workAnimal stomach clearanceAnimal intestines working-upSurgeryOrgan of Corti

Method and apparatus are provided for mechanically processing an organ or organs taken out from slaughtered poultry in a processing device or processing line, which organ or organs form part of an organ package and wherein said organ or organs are separated from the organ package. The organ package is spatially oriented by the processing device without notably breaking tissue connections in the package, and in a preselected order so as to cause harvesting of organs from the package to occur in a preselected sequence that depends on the location of the organ package in the processing device or processing line.

Owner:MEYN FOOD PROCESSING TECH

Preparation method of superfine modified kaolin

The invention relates to a preparation method of superfine modified kaolin, which is characterized in that the preparation method comprises the following steps that (1), kaolin powder and carbamide are uniformly mixed in an open container, and fully absorb moisture in air to form a mixture; (2), the mixture is heated, and reacts at 70-120 DEG C; a kaolin-carbamide intercalation compound is prepared; an intercalation rate is 80%-98%; (3), the compound is placed into a ball mill; a certain amount of dispersing agent and water is added; wet grinding is conducted; the content of ground kaolin with a particle size less than 2 micrometers is above 90%; a kaolin mud cake is obtained through suction filtration and dehydration; (4) a certain amount of silane coupling agent and water is added into the kaolin mud cake, and stirred at 50-80 DEG C; a coupling reaction happens; the modification is achieved; and (5) the modified kaolin is dried, and the finished superfine modified kaolin is prepared. According to the preparation method, the intercalation rate is high; the influence on a crystal structure of the kaolin is small; a peeling effect is good; and the prepared superfine modified kaolin is particularly applicable to rubber and plastic materials and oil paint.

Owner:中国高岭土有限公司

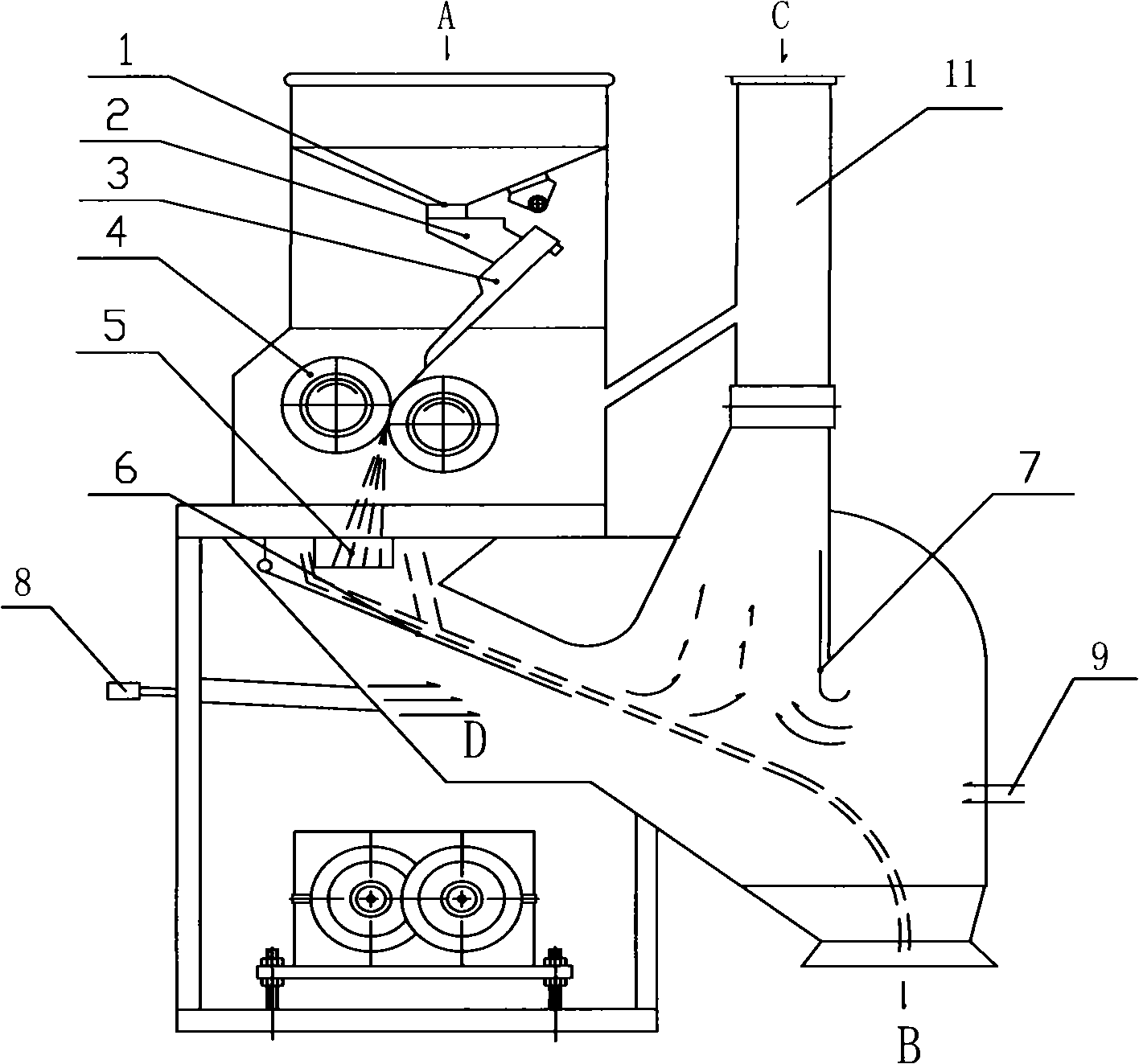

Oat barking equipment and barking method

ActiveCN101264459AShort preparation timeFragrant smellGrain huskingGrain polishingNutritive valuesSkin effect

The invention discloses an oat pelt puller and the skinning method. The pelt puller comprises a frame, a feeding assembly, a propeller, a sand drum assembly and a power unit; which is characterized in that: the whole components are arranged on the frame; the propeller is arranged in the feeding assembly, the propeller is connected with the momentum output terminal of the power unit, the lower end of the propeller passes through the exit end of the feeding assembly and is connected with the sand drum assembly, a sand plate is correspondingly arranged on the periphery of the sand drum assembly, a skinning chamber forms between the sand plate and the sand drum assembly, the distance between the sand plate and the sand drum assembly is 1 to 10mm, the lower end of the skinning chamber is a discharge opening. The pelt puller has the advantages of simple combination, high efficiency, good skinning effect, and no damage to oat grain, the obtained oat without peel has the advantages of ability to be used for cooked congee, rice steaming, short process time, ability to direct edible, moderate mouthfeel, fragrant odor, high nutritive value, suitability for traditional food habits of Asian, satisfaction for the diversification requirements for oats food edible mood.

Owner:SANZHULIANG ZAOZHUANG FOOD BEVERAGE CO LTD

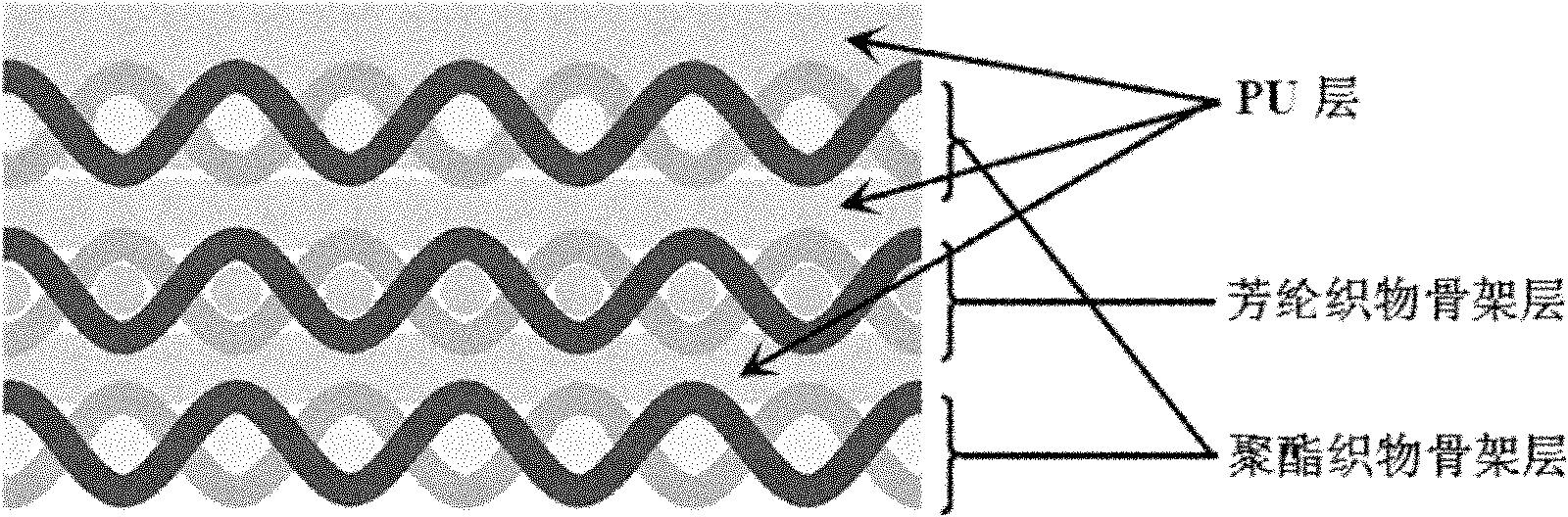

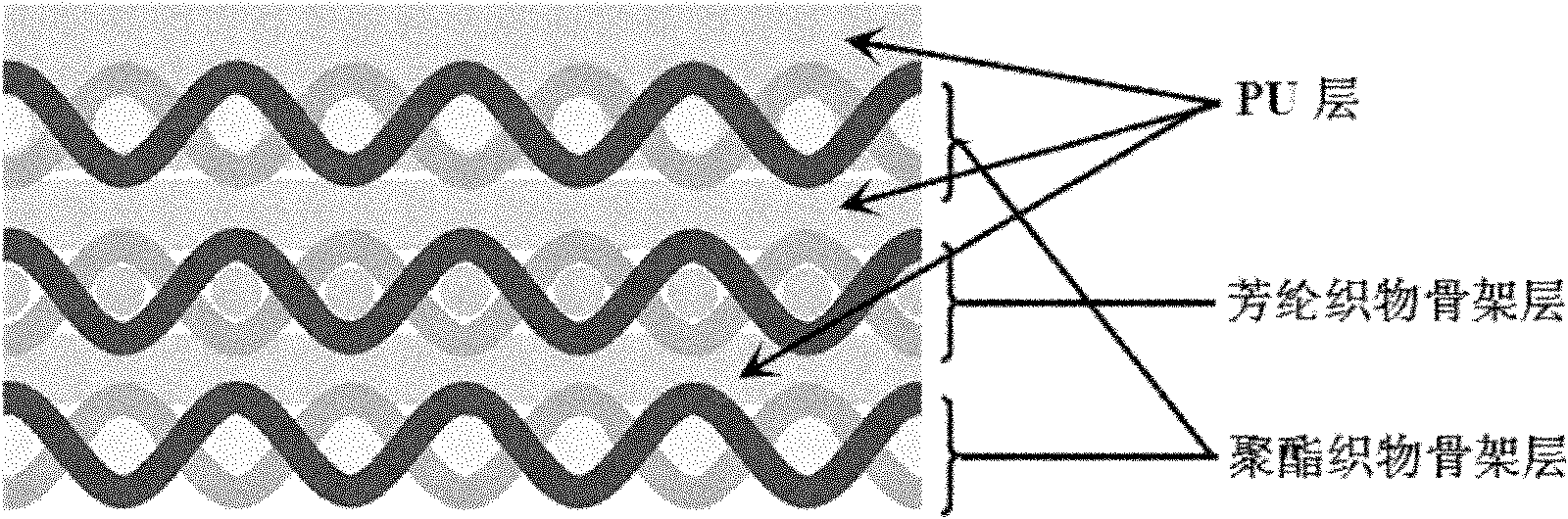

Light conveying belt and preparation method thereof

ActiveCN101979283AHigh warp strengthQuality assuranceConveyorsSynthetic resin layered productsPolyesterEngineering

The invention relates to a light conveying belt and a preparation method thereof. The conveying belt comprises a Kevlar woven fabric, polyester woven fabrics and a polyurethane covering adhesive layer, wherein the Kevlar woven fabric is used as a middle framework layer; two layers of the polyester woven fabrics are used as a framework material of an upper framework layer and a framework material of a bottom framework layer; and three framework layers are respectively laminated with conductive polyurethane so as to obtain the three-fabric three-adhesive light conveying belt. The preparation method comprises the following steps of: (1) adopting Kevlar as warps of the Kevlar woven fabric and adopting ultra low shrink polyester multifilament yarns as weft yarns of the Kevlar woven fabric, wherein the basic weave is plain weave; (2) gluing the fabric and then sizing the glued fabric; and (3) coating the materials. The conveying belt of the invention has high strength. The integral tensile strength and the peel strength of the conveying belt are greatly improved. The preparation method is simple, has low cost and is suitable for industrial production.

Owner:DONGHUA UNIV

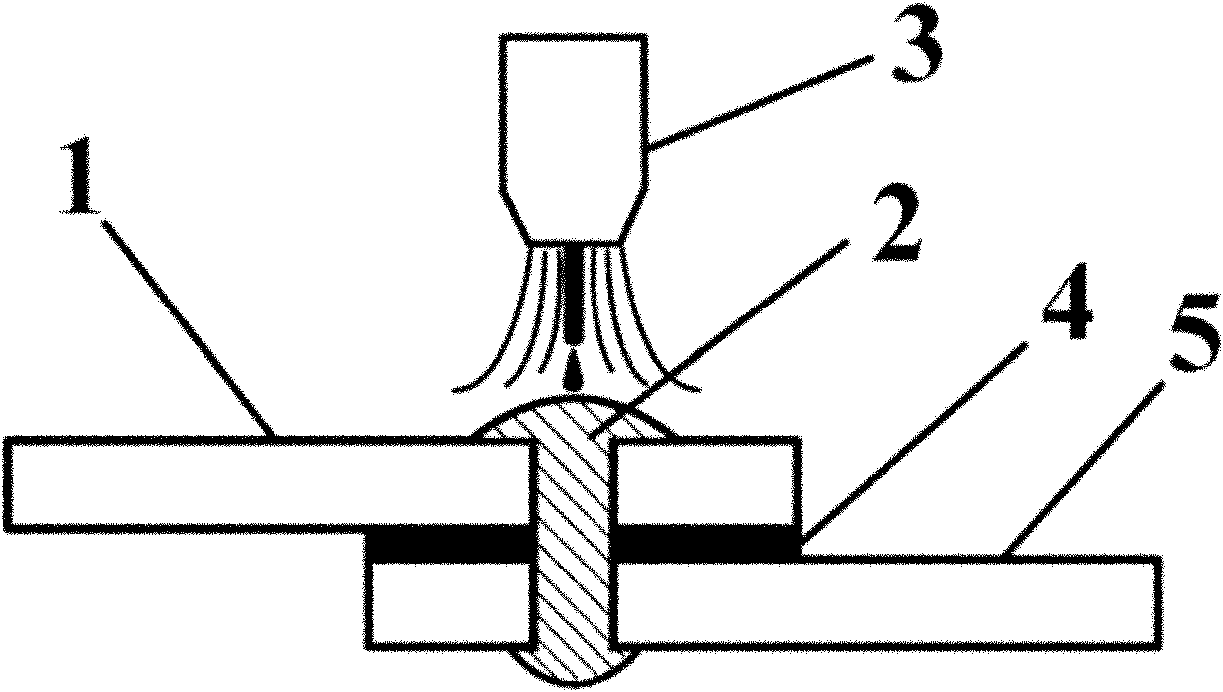

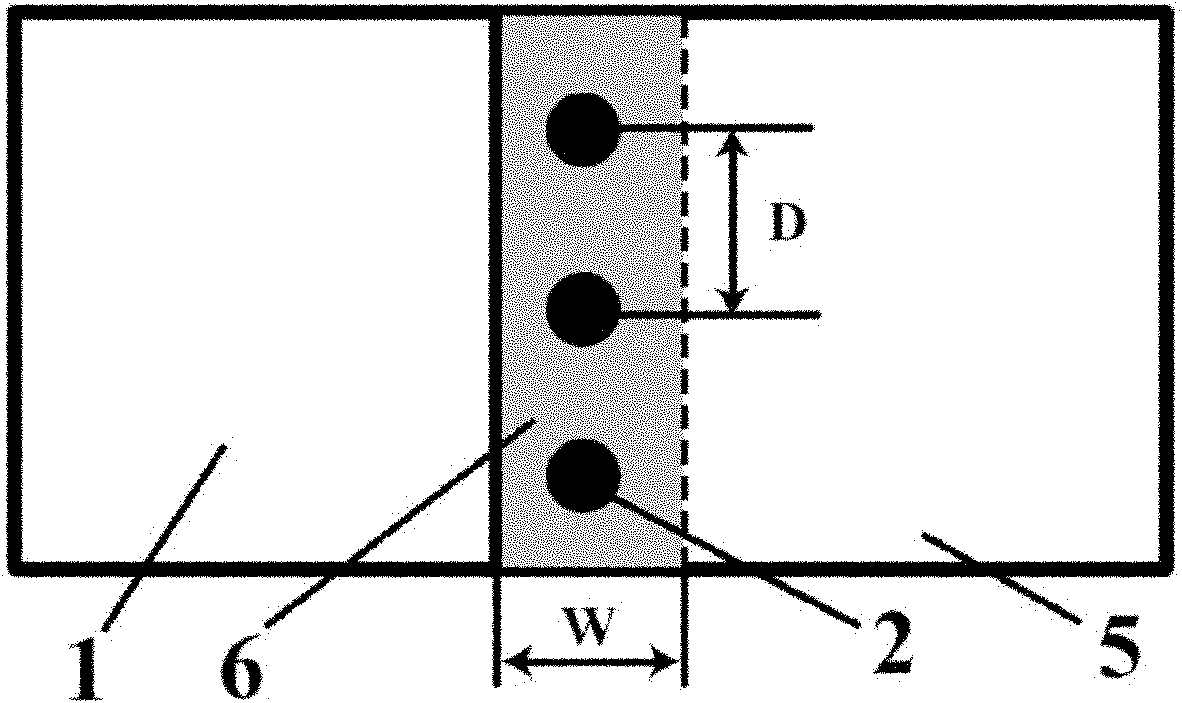

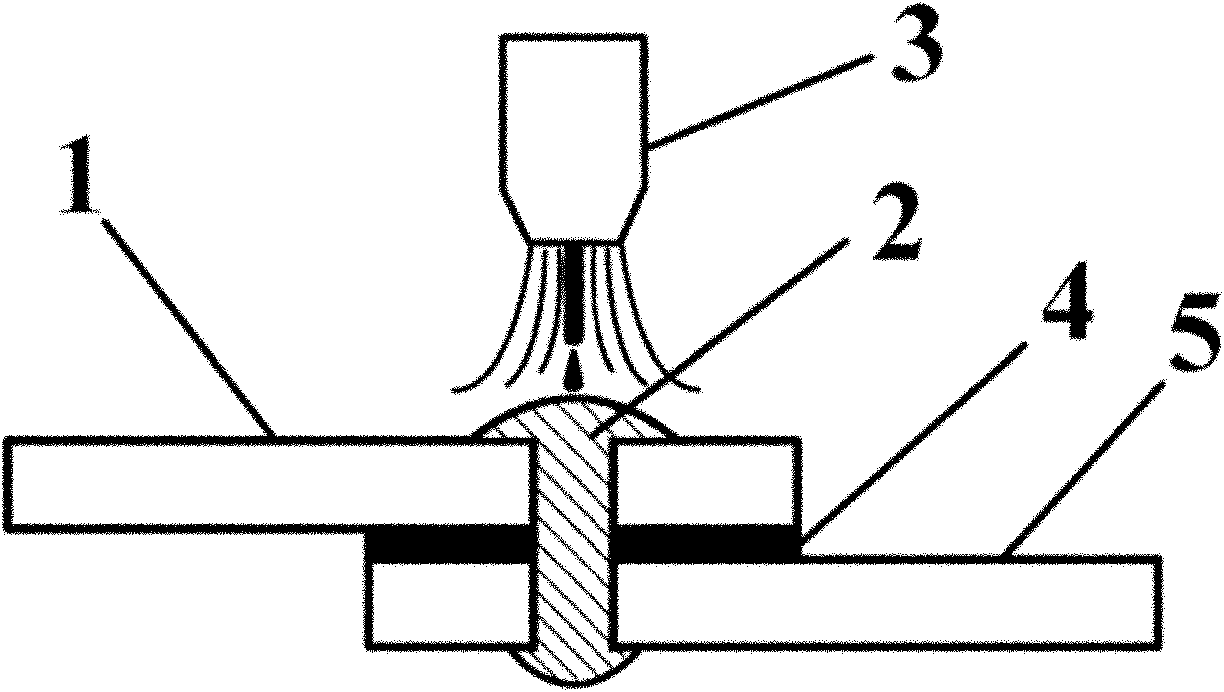

Adhesive jointing and electric arc spot welding combined connection method for metals

InactiveCN102059460AHigh solder joint strengthImprove stabilityArc welding apparatusJoint surfaceElectric arc

The invention belongs to the technical field of material engineering and relates to a connection technique for metals, in particular to a welding and adhesive jointing combined connection technique for metals, which comprises: applying adhesive for structural curing on the joint surfaces of materials to be welded; jointing the materials; and welding. The technique is characterized in that: an adhesive layer which is 0.02 to 1 millimeter thick is uniformly applied between the jointing surfaces of the materials to be connected; after joining, through holes with an aperture of 3 to 10 millimeters are formed on a jointed part at 15 to 50 millimeter intervals along a joint, and performing double-sided filler wire spot welding at the holed part with an arc weld; and heating the jointed parts between which a glue layer is applied to 50 to 500 DEG C before welding and after welding, and keeping the temperature for 10 to 180 minutes. The method can increase the strengths of the welded spots, avoid surface collapse caused by other adhesive bonding, improve the bearing load, fatigue strength and shearing performance of difficult-to-weld welded structure made of one kind of metal and different kinds of metals, and meet actual engineering needs.

Owner:DALIAN UNIV OF TECH

Plant functional polyester filament and preparation method thereof

InactiveCN110863252AHigh mechanical strengthImprove wear resistanceMonocomponent polyesters artificial filamentSynthetic polymer filament chemical after-treatmentPolyesterFiber

The invention discloses a plant functional polyester filament and a preparation method thereof. The plant functional polyester filament comprises 0.1-1.5% of plant extract. The preparation method includes a step of plant functional polyester master batch preparation, and the step of plant functional polyester master batch preparation includes: slicing PET, heating to melt, adding an antioxidant and a dispersing agent, and stirring; then, adding a protecting agent and the plant extract, and mixing at a high speed; finally, adding a modifying agent, well mixing to obtain a mixture, and extrudingfor granulation. The plant functional polyester filament integrates high mechanical strength of polyester fibers and the anti-mite and antibacterial performance of the plant extract and has advantages of antibacterial and deodorizing effects, high wear resistance, high elasticity, comfort in hand feeling and less proneness to pilling and fouling.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

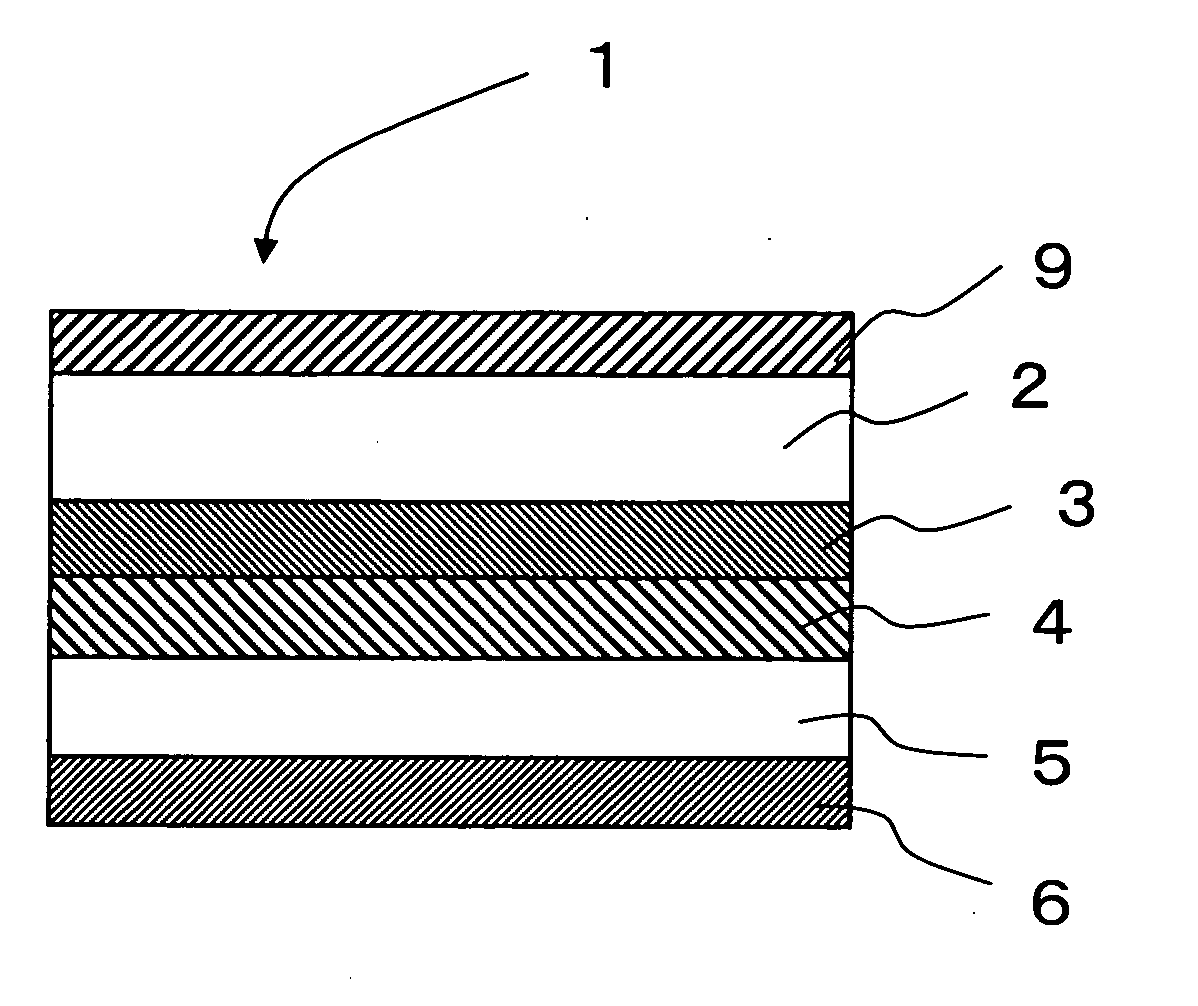

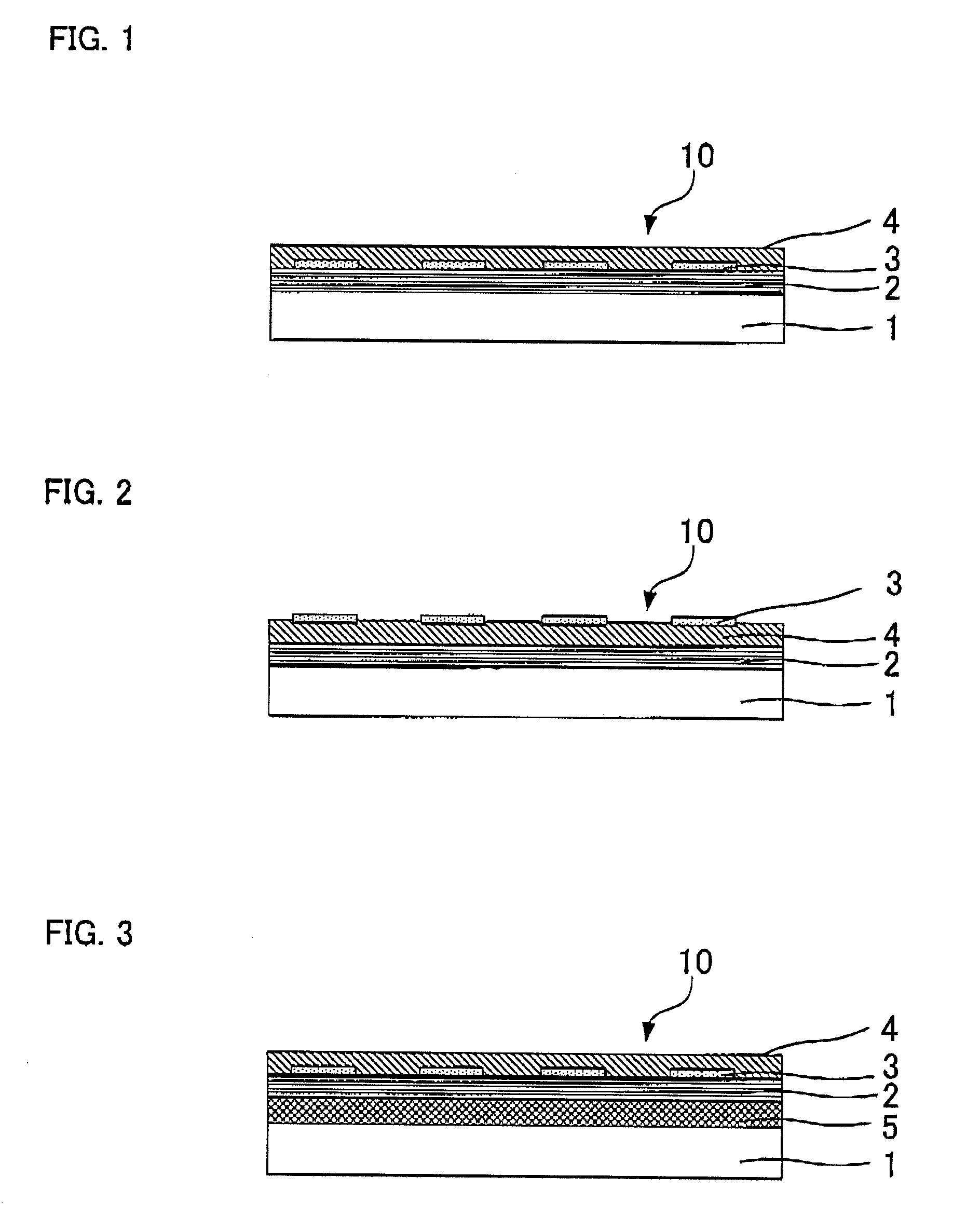

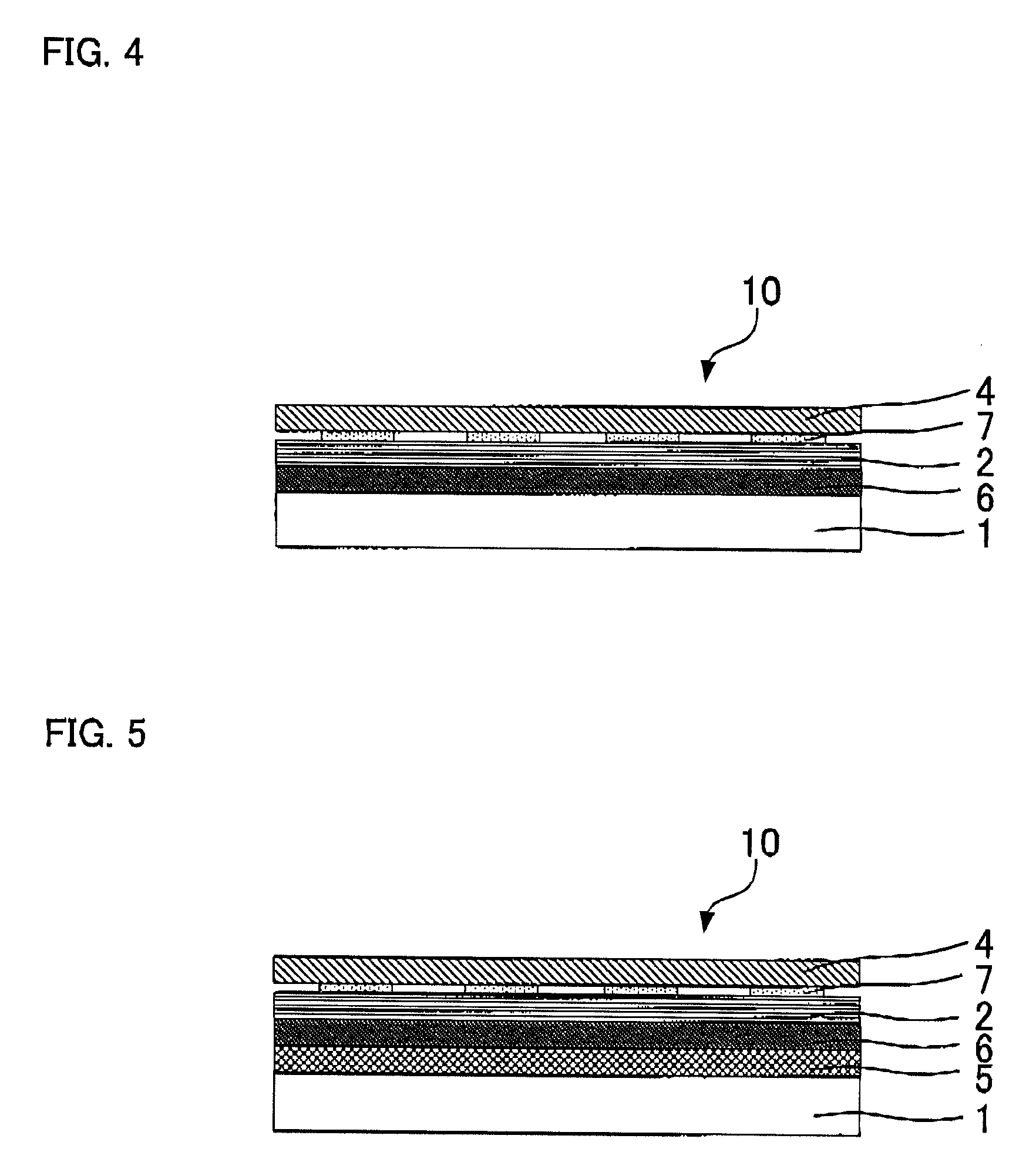

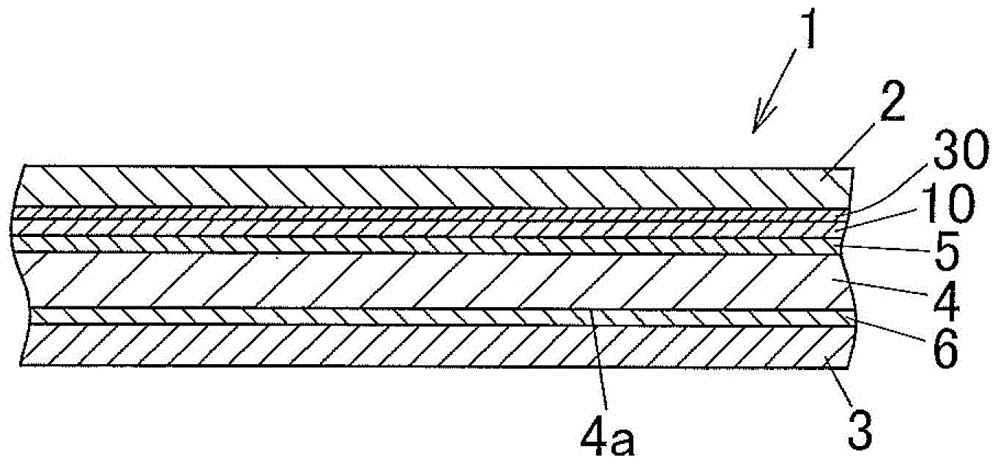

Hologram transfer sheet and intermediate transfer recording medium

ActiveUS20060127623A1Avoid crackingAvoid layeringLayered productsDecorative surface effectsChemical structureTotal solid content

It is an object of the invention is to provide a hologram transfer sheet comprising: at least, a peelable layer; a relief formation layer having a relief; and a metal thin layer, which are sequentially formed on a substrate, capable of preventing a crack or discoloration of the metal thin layer which may be caused by heat or stress when a transfer layer is aligned with and transferred onto a transfer receiving body or preventing a disfigurement of the external appearance which may be caused by a crack mark of the metal thin layer following the thermal deformation of the substrate when performing an entire surface transfer by means of a heat roller. Such a hologram transfer sheet (1) comprising: at least, a peelable layer (3); a relief formation layer (4) having a relief; and a metal thin layer (5), which are sequentially formed on a substrate (2), is characterized in that the peelable layer (3) is made of a norbornene-based resin having a chemical structure containing a norbornene structure at least. The peelable layer preferably contains a resin incompatible with such a norbornene-based resin at a ratio from 5 to 30% by weight relative to a total solid content.

Owner:DAI NIPPON PRINTING CO LTD

Photoresist stripper and application thereof

InactiveCN105116696AEasy to prepareAnti-foaming effectPhotosensitive material processingPotassiumAlkali metal

The invention provides a photoresist stripper comprising components in percentage by mass as follows: 1%-5% of inorganic base, 3%-12% of alkali metal salt, 4%-10% of organic base, 3%-10% of an organic solvent, 1%-10% of a high-molecular polymer, 0.1%-2% of a chelating agent, 0.1-3% of a corrosion inhibitor and the balance of deionized water, wherein the high-molecular polymer is polyethylene glycol and / or polypropylene glycol, the chelating agent contains potassium or sodium, and the corrosion inhibitor contains sodium benzoate. The stripper is basically free of bubbles and has a bubble inhibition effect during usage; the stripper is a uniform solution at the room temperature but can be layered at the usage temperature, stripped photoresist films can float on supernatant liquids, are prevented from sinking to the bottom and being pumped by a circulating pump and cannot block a filter net and a filter element, the service life can be prolonged, and the film stripping efficiency can be improved. The stripper has the high stripping rate at the usage temperature, enables products to have better cleanliness and does not corrode ITO (indium tin oxide) circuits and substrates.

Owner:LENS TECH CHANGSHA

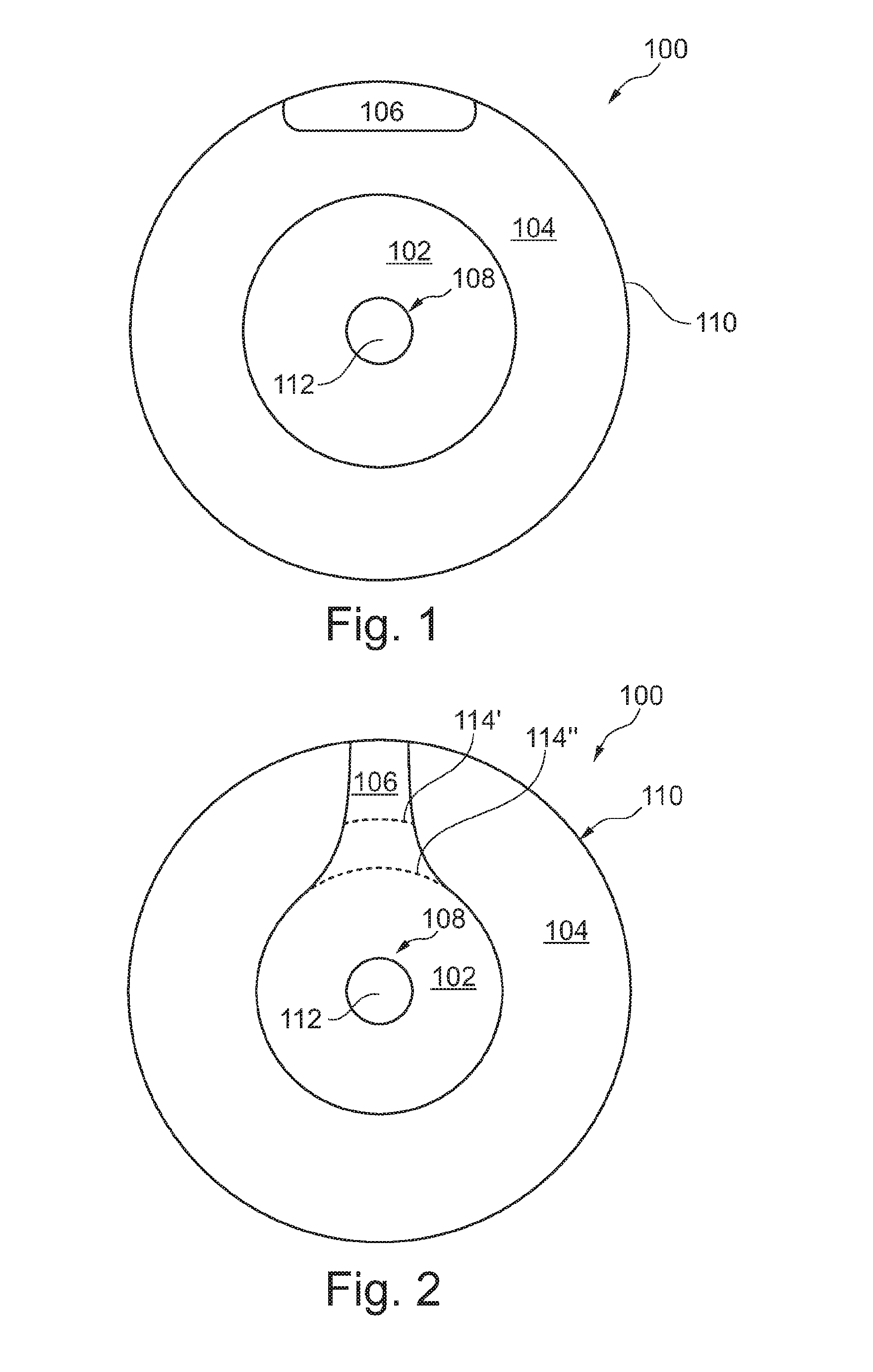

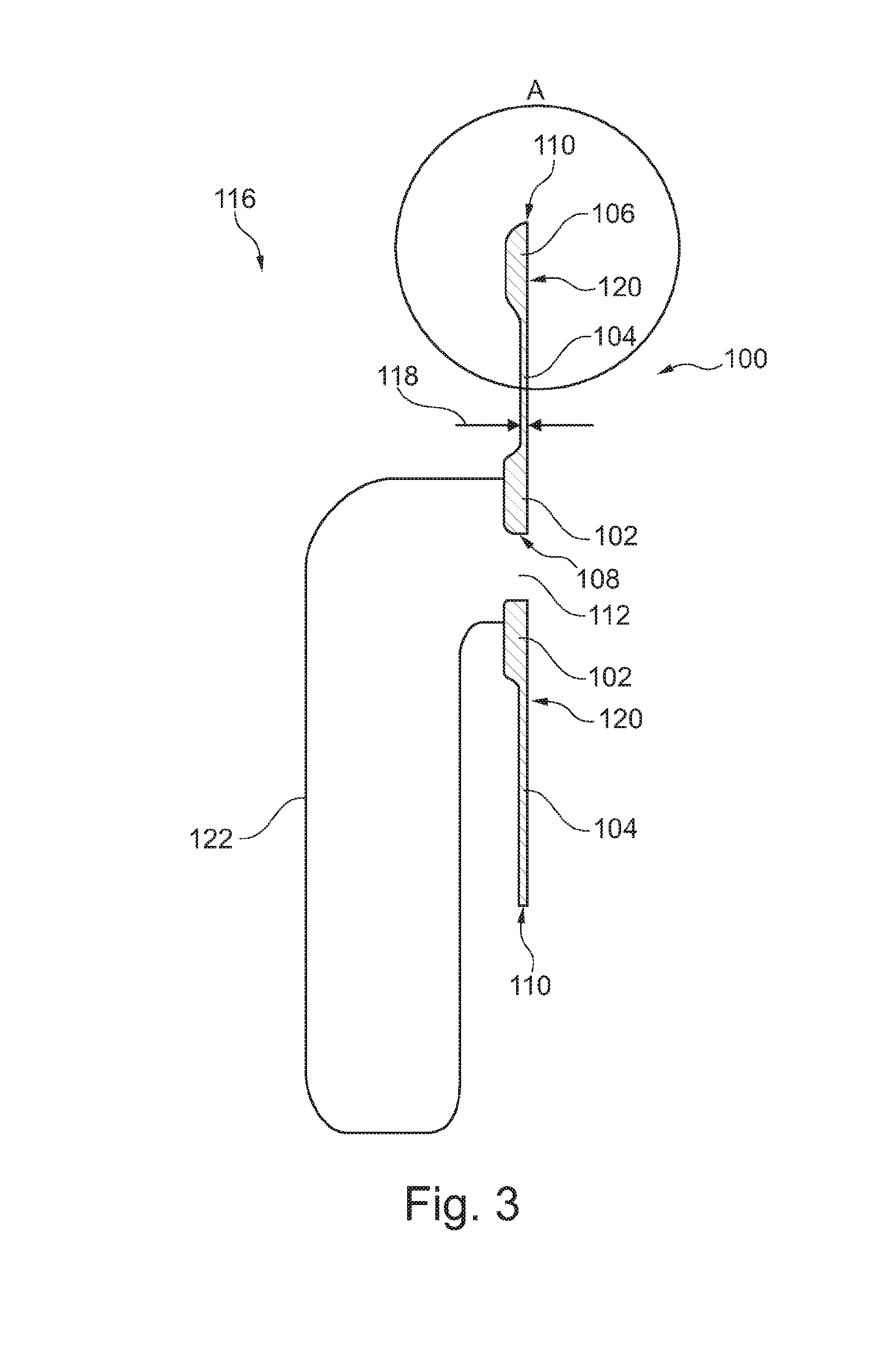

Ostomy appliance

InactiveUS20140128826A1Good peeling effectEasy to peelNon-surgical orthopedic devicesBodily discharge devicesEngineeringOstomy appliances

Owner:COLOPLAST AS

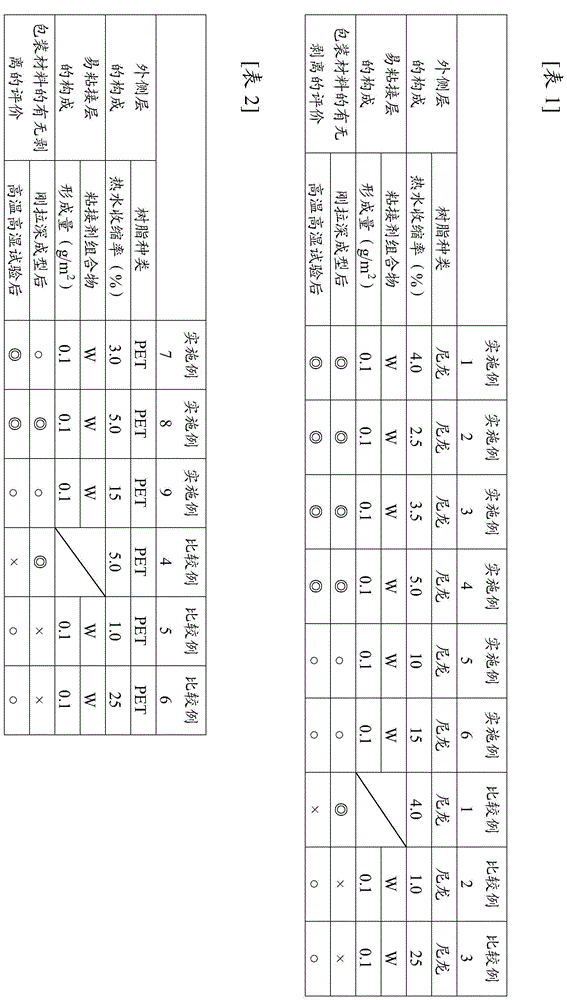

Double-sided pressure sensitive adhesive tape for computer embroidery and preparation method thereof

ActiveCN101602919AHigh peel strengthGood peeling effectFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates a double sided pressure-sensitive adhesive tape for computer embroidery and a preparation method thereof. The double-sided pressure sensitive adhesive tape comprises base material, a pressure-sensitive adhesive layer coated on the two sides of the base material and a release paper layer; wherein, the pressure sensitive adhesive layer is prepared by being coated with pressure sensitive adhesive which is prepared by the following components according to the parts by weight: 80.0-100.0 parts of 2-ethylhexyl acrylate, 8.0-15.0 parts of butyl acrylate, 3.0-7.5 parts of acrylic acid, 8.0-15.0 parts of vinyl acetate, 1.0-7.5 parts of hydroxy-ethyl acrylate, 0.20-1.0 part of benzoyl peroxide, 120.0-200.0 parts of main solvent, 5.0-30.0 parts of auxiliary solvent and 2.0-6.0 parts of crosslinking and curing agent solution. In the formula design of the invention, the molecular weight design dispersion coefficient is designed to be a little smaller, the molecular weight is not too large and the soft monomer is increased so as to improve the peeling strength, thus reaching the aim that the adhesive tape has high peeling performance and can be pasted repeatedly.

Owner:永大(中山)有限公司

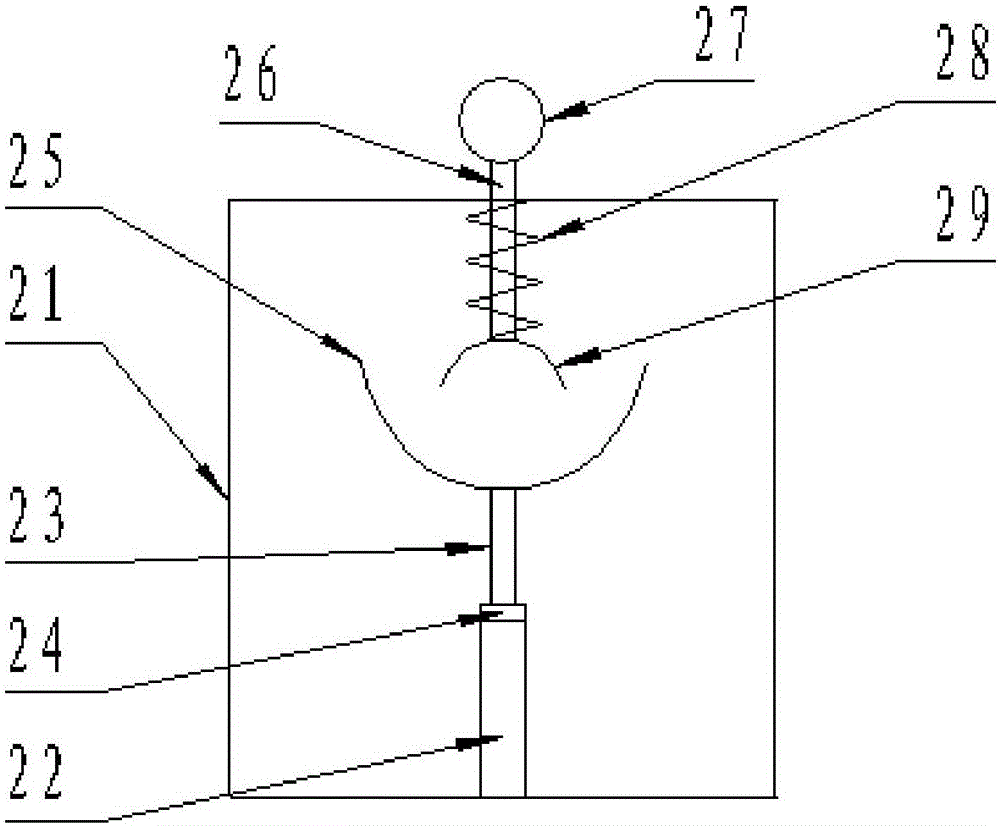

Orange skin dividing device

InactiveCN103653198AGood peeling effectExtended service lifeVegetable peeling'Orange peel' skinInsertion stent

The invention relates to an orange skin dividing device which is composed of a sleeve, supports, suspension arms, a spring, arc knives and knife points. The sleeve and the knives move downwards relative to an orange, the six arc knives form a spherical cavity, and the spring enables the cavity to be soft to some extent, so that the cavity is adaptive to oranges of different sizes and in different shapes. The knives move downwards along with the sleeve, when an orange enters the spherical cavity, the protruding knife points start to cut open the orange skin, the knives continue to move downwards to divide the orange skin into six pieces, and automatic orange skin dividing is achieved.

Owner:HUAZHONG AGRI UNIV

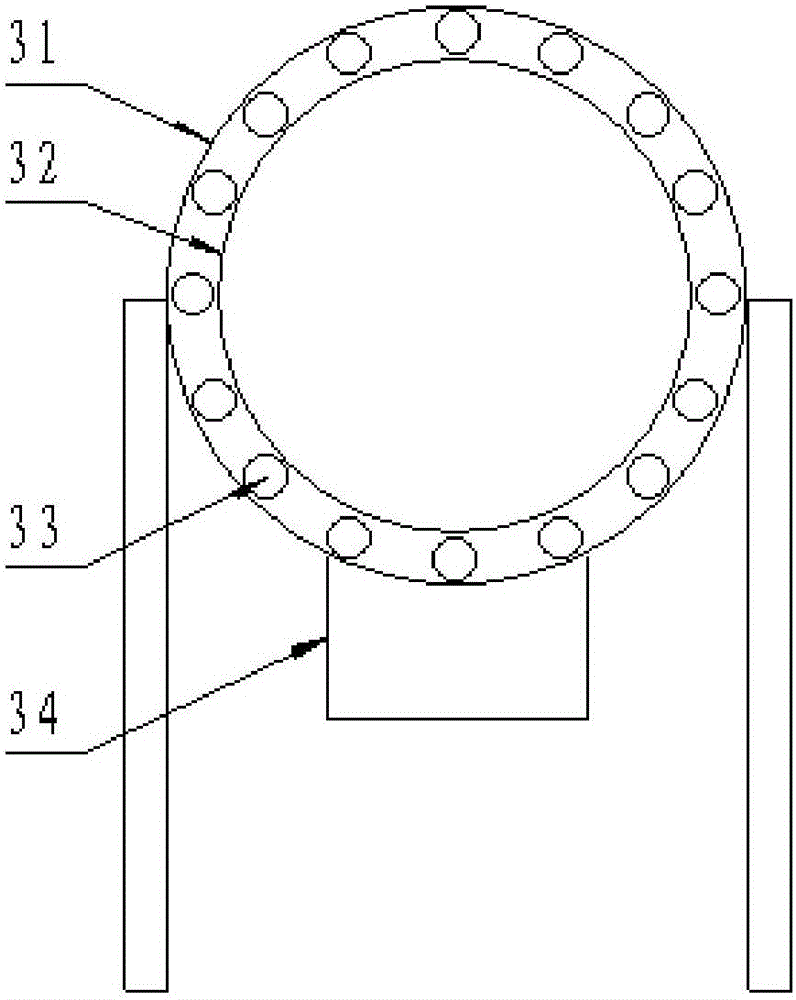

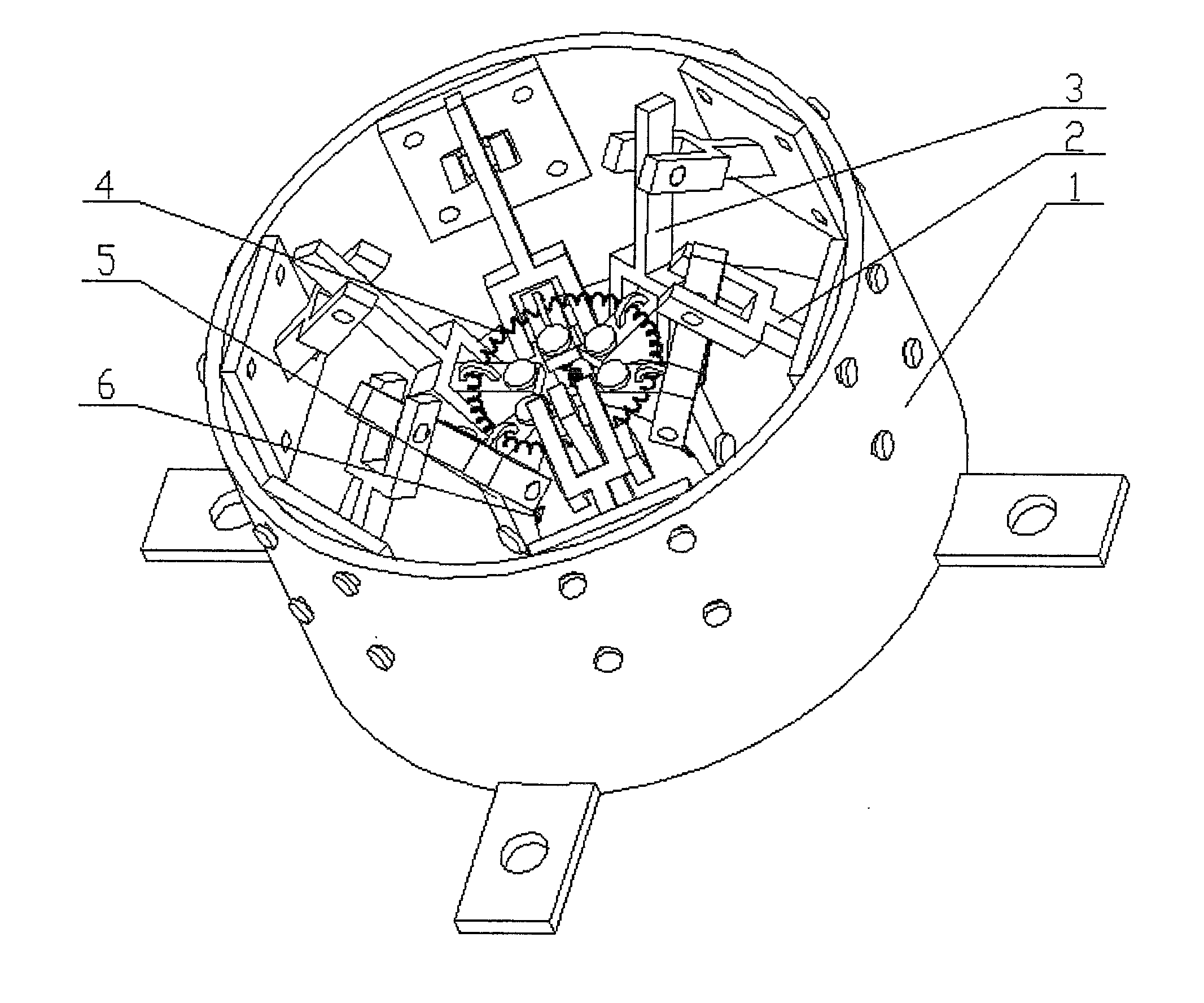

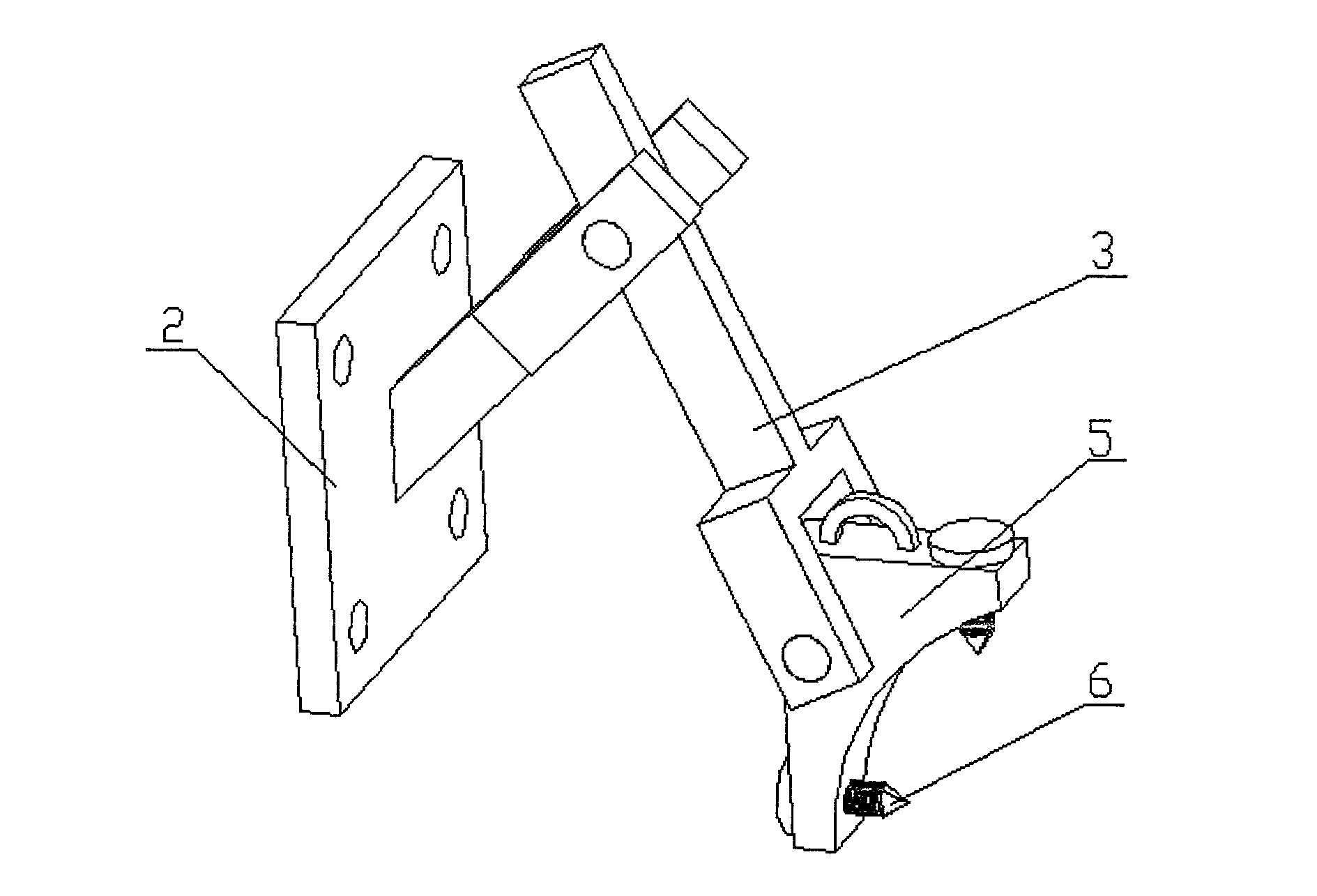

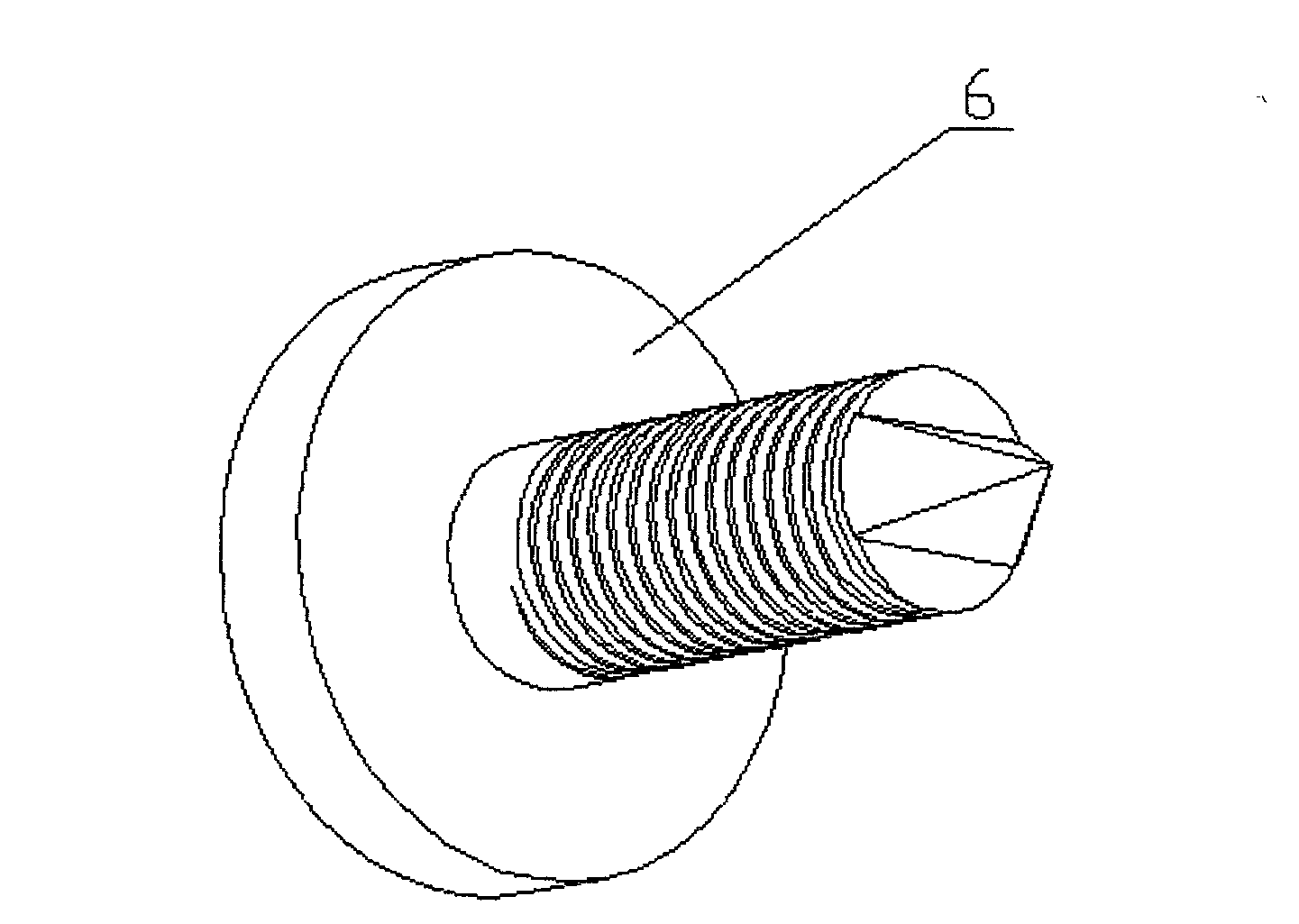

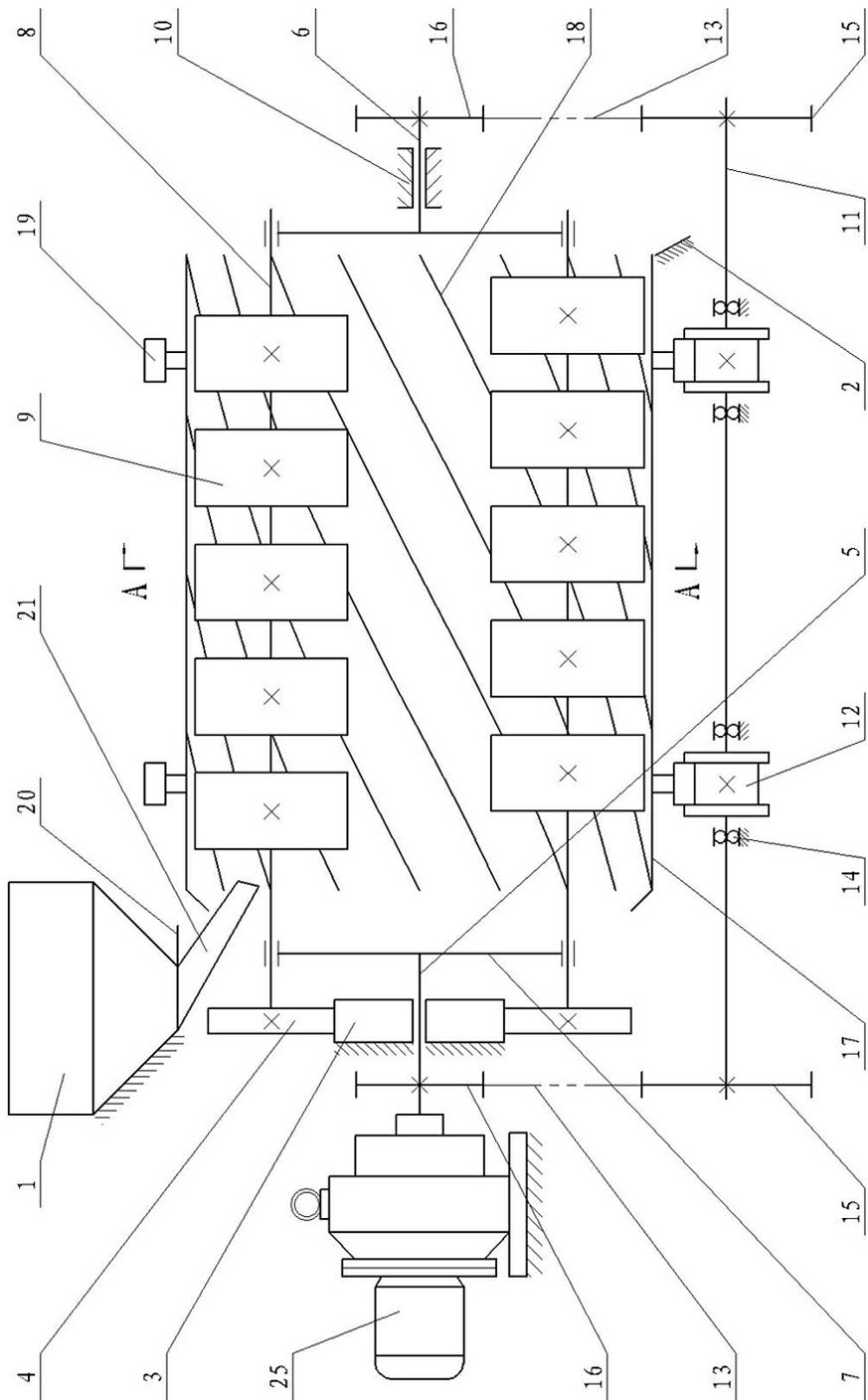

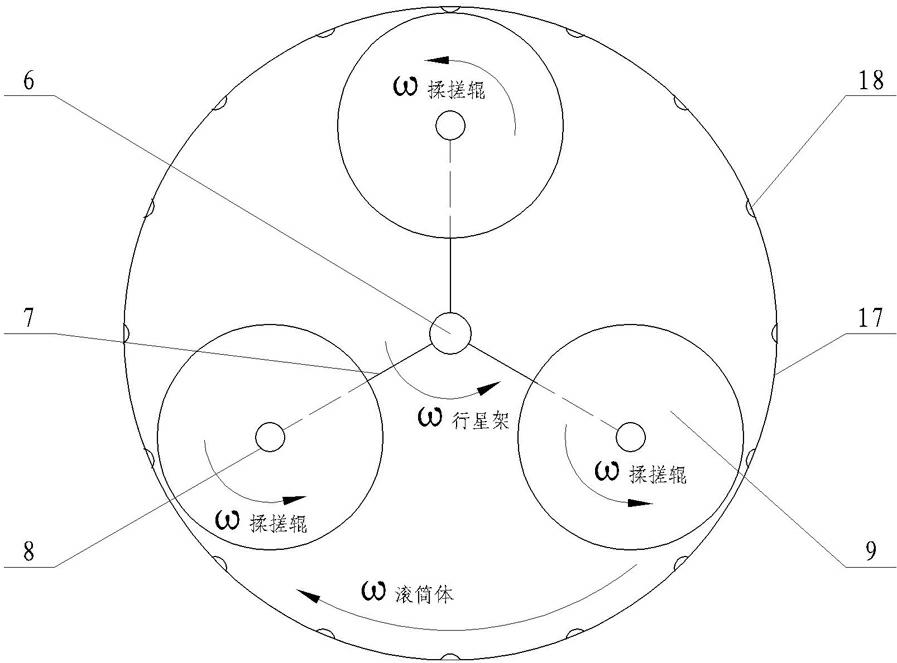

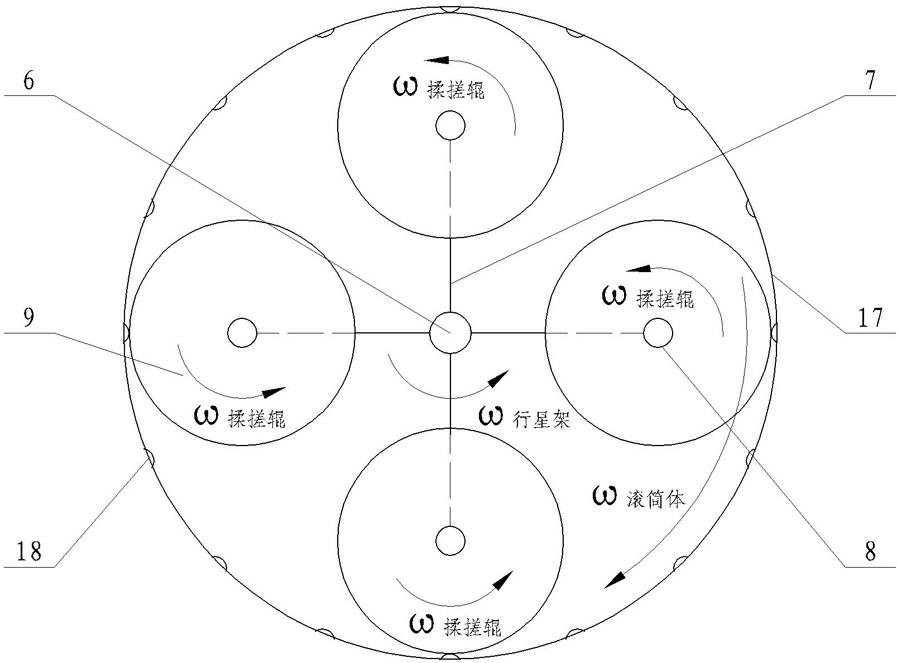

Spiral kneading type pea huller

InactiveCN102318883AMeet production requirementsGood peeling effectFood treatmentDrive shaftSprocket

The invention provides a spiral kneading type pea huller, which is characterized in that: drive shafts and driven shafts respectively support in the central hole of a sun gear and a hole of a bearing I, the outer ends of the drive shafts are connected with a drive device, the centers of two planet carriers are respectively fixed at the inner ends of the drive shafts and the driven shafts, planet pinion shafts respectively penetrate through the holes on one planet carrier, the ends of the planet pinion shafts, which are close to the drive device, are assembled with a planet gear which is meshed with the sun gear, the other ends of the planet pinion shafts support in the holes on the other plant carrier, kneading rollers are fixed on the planet pinion shafts, two drive shafts respectively support in the holes of bearings II, carrier rollers are fixed among the bearings II, a chain wheel I is respectively fixed on the two ends of the two drive shafts, two chain wheels II are respectivelyfixed at the outer ends of the drive shafts and the driven shafts, and are connected with the chain wheels I through chains, ledges are arranged on the inner surface of a rotary drum body, the two ends of the excircle are born on the carrier rollers through rollers, a feed hopper is positioned at the feed end of the rotary drum, and a discharge port is arranged at the other end of the rotary drum. The spiral kneading type pea huller can realize a plurality of times of kneading, has a good hulling effect, and has a simpler and more reliable structure.

Owner:SHANDONG UNIV OF TECH

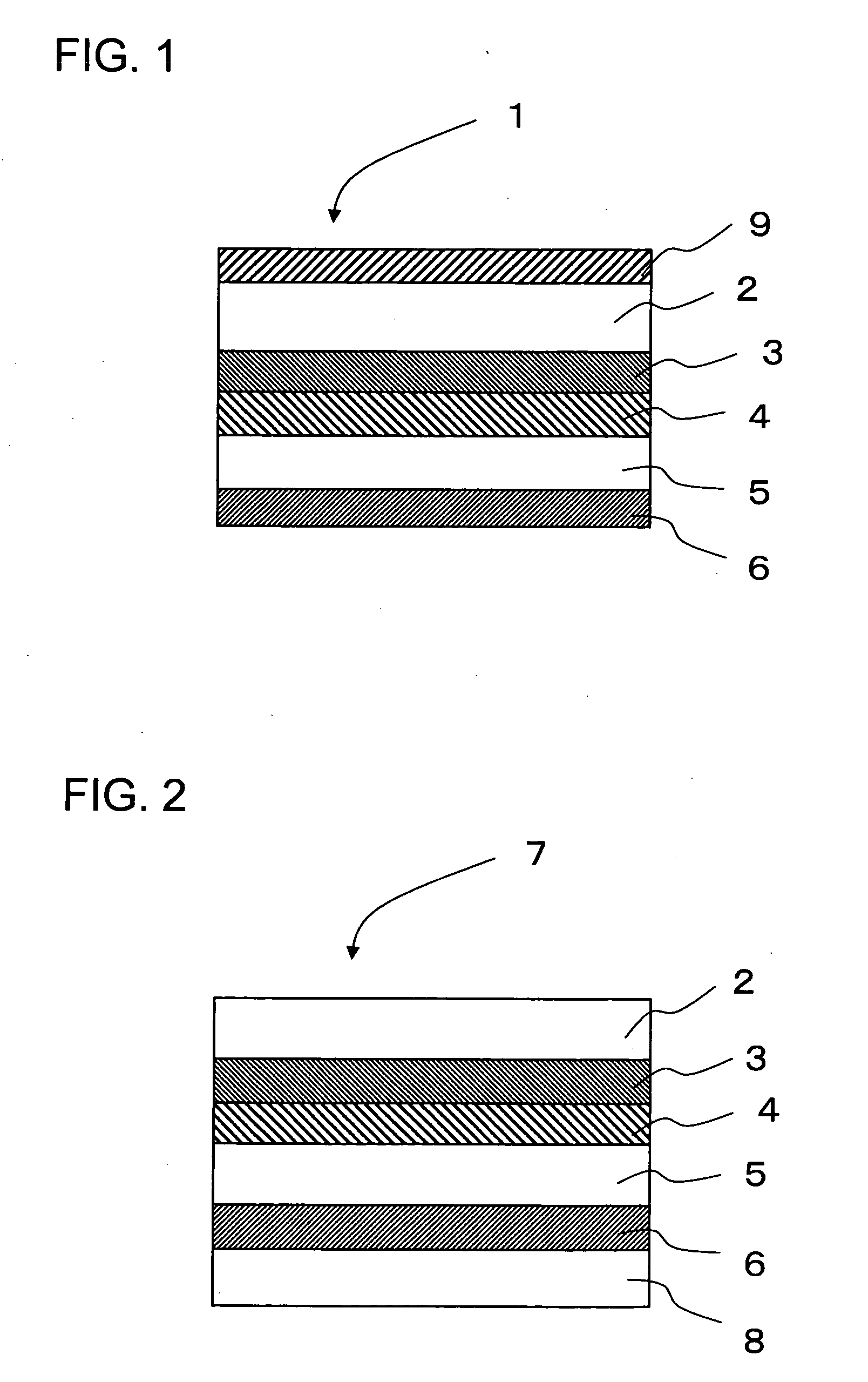

Volume hologram transfer foil, volume hologram laminate, and production method thereof

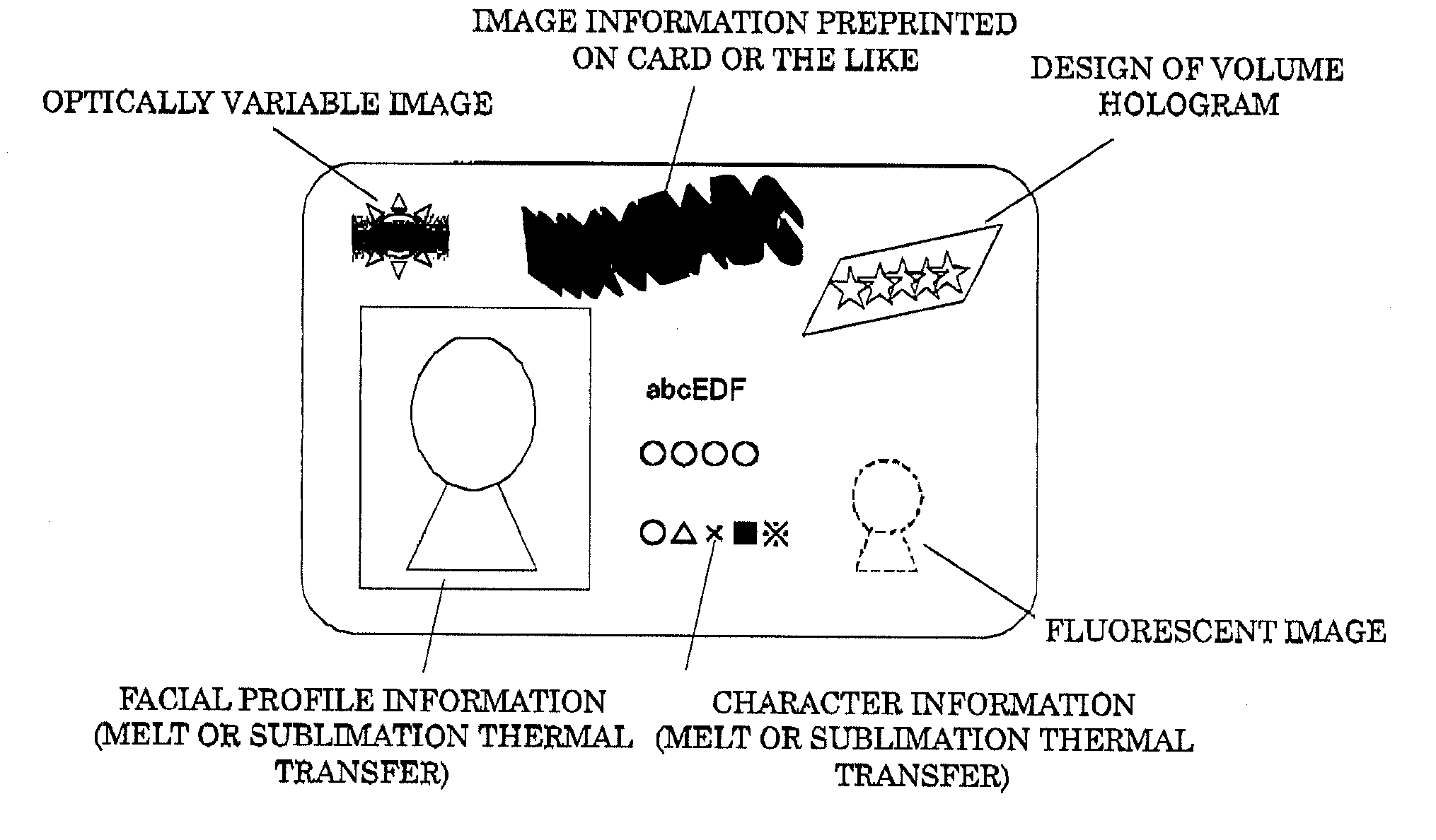

ActiveUS20080316556A1Improve anti-counterfeiting functionGood peeling effectOther printing matterDecorative surface effectsImage formationReflective layer

A major object of the present invention is to provide a volume hologram transfer foil that gives a volume hologram laminate higher in antiforgery function,The present invention achieves the object by providing a volume hologram transfer foil comprising: a substrate, a volume hologram layer carrying a recorded volume hologram that is formed on the substrate, and an image forming layer carrying a formed image and a heat seal layer containing a thermoplastic resin that are formed on the volume hologram layer, and comprising no reflective layer having a function to reflect light.

Owner:DAI NIPPON PRINTING CO LTD

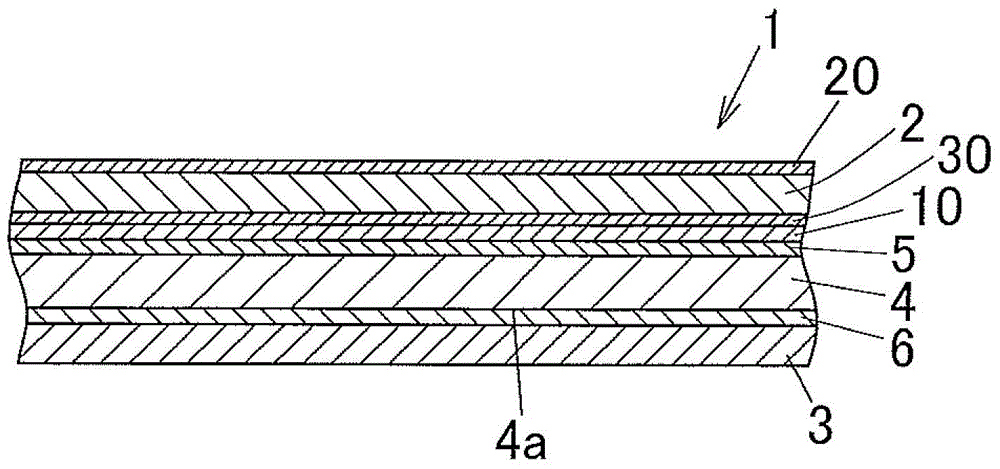

Packaging material and molded case

InactiveCN104339765AWon't peel offGood formabilityBattery isolationLaminationMetallic foilPolymer science

A packaging material 1 includes a heat resistant resin stretched film layer 2 as an outer layer, a thermoplastic resin layer 3 as an inner layer, a metal foil layer 4 arranged between these layers, and a colored ink layer 10 arranged between the metal foil layer 4 and the heat resistant resin stretched film layer 2. As the heat resistant resin stretched film, a heat resistant resin stretched film having a hot water shrinkage rate of 2% to 20% is used, and the heat resistant resin stretched film layer 2 and the colored ink layer 4 are integrally laminated via an easily adhesive layer 30. In this packaging material, at the time of forming and sealing, and even being used in a somewhat severe environment such as high-temperature and humid environment, the colored ink layer will not be detached from the heat resistant resin stretched film layer.

Owner:SHOWA DENKO PACKAGING CO LTD

Peanut peeler

The invention relates to the technical field of refining processing of peanuts, particularly to a peanut peeler having a good peeling effect. The peanut peeler comprises a rotating shaft and a fan, wherein a roller is arranged on the rotating shaft, a movable plate in dismountable connection is axially arranged on the side wall of the circumference of the roller, and two end surfaces of the roller adopt a network structure; the fan can blast towards the inner part of the roller; an electrical heated tube is also arranged between the roller and the fan on the rotating shaft, and a suction blower is arranged on the other end surface of the roller; stirring teeth are also arranged in the roller on the rotating shaft. According to the peanut peeler disclosed by the invention, heat of the electrical heated tube is brought into the roller by the fan, so that hot air is generated in the roller, and peanut kernels in the roller are heated; the coats of the peanut kernels are scorched when being heated, so that the coats are easy to come off. The roller rotates and the stirring teeth in the roller stir, so that the peanut kernels are uniformly heated, and the peanut kernels are impacted each other in the roller; under the impact, the coats of the peanut kernels come off, and the suction blower suck in the coats which come off, so that the purpose of peeling is realized.

Owner:CHONGQING SHUANGEN AGRI MACHINERY MFG

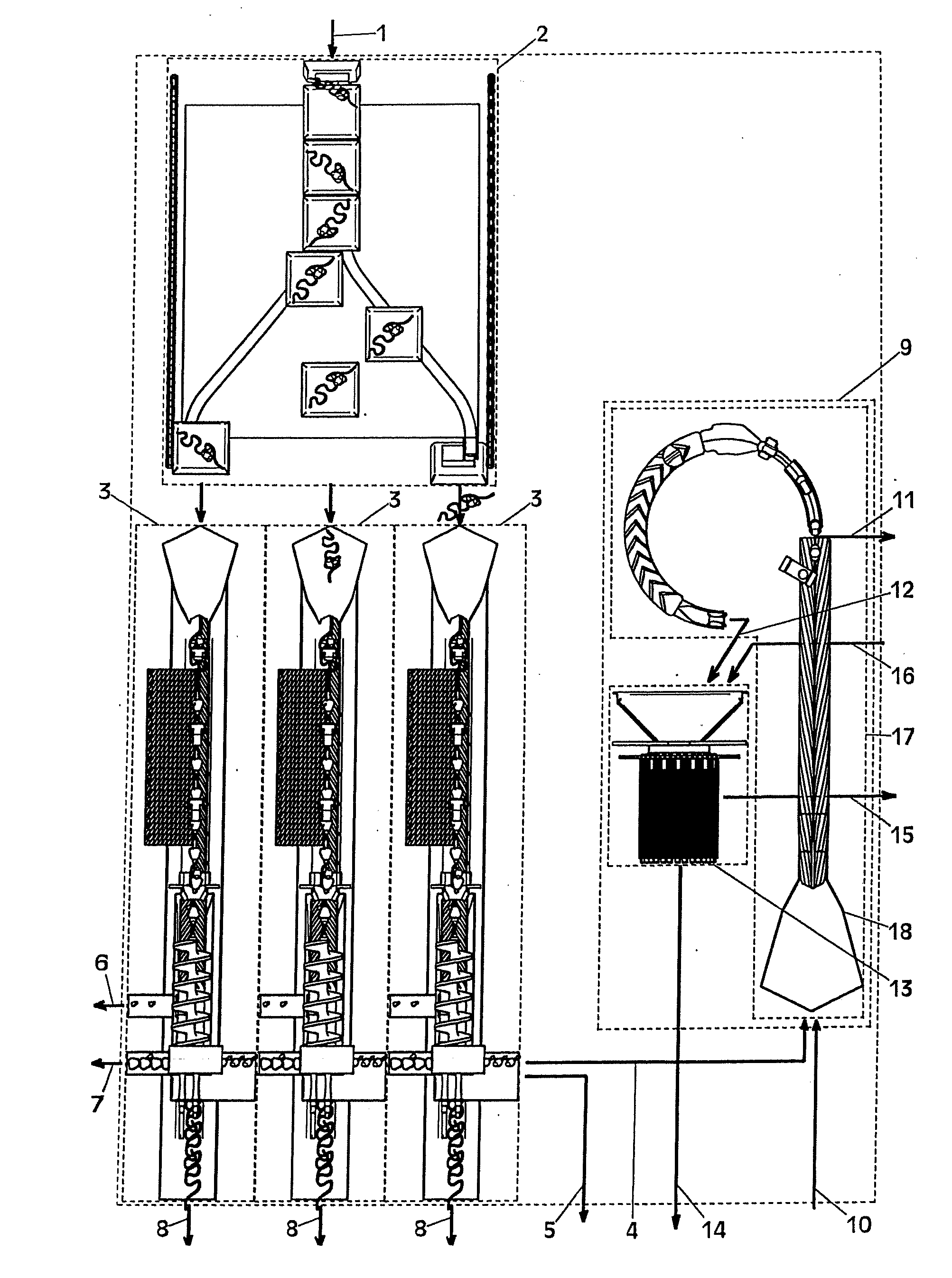

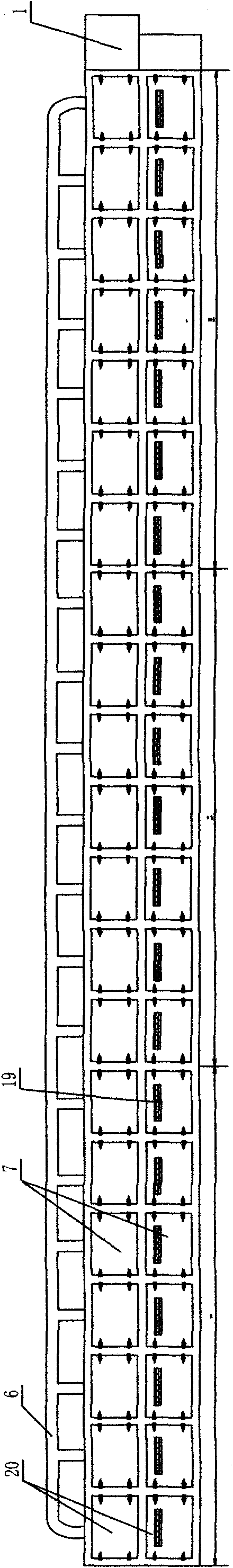

Device and process for removing red skin of peanuts by partitioned temperature control quick cooling at low temperature

The invention relates to a device for removing the red skin of peanuts by partitioned temperature control quick cooling at low temperature, which comprises a baking device and a cooling device connected with the baking device, wherein the baking device is connected with a hot source; the cooling device is connected with a cold source; the baking device comprises a power box and three groups of ovens which are connected together; a humidification box is arranged in the front of each group of oven; and the humidity in the humidification box is constant, and a humidity sensor and a peanut conveying belt are arranged in the humidification box. In the device, the peanuts are baked at the low temperature, so the grease quality of the peanuts is not damaged, and the quality guarantee period is not shortened; after being baked, the peanuts are cooled at the low temperature quickly, so that the peanuts can be separated from the skin quickly; the peeling rate of the peanuts is more than or equal to 99 percent, the valve breaking rate of the peanuts is 0 percent, the peanuts are easy to peel, the peeling effect is good, the influence of the peeling process on peanut protein, and a peroxidating value is less than 0.45 mmol / kg; and the automaticity of equipment is high, the working condition of relevant equipment can be adjusted automatically according to the detected equipment state, the work efficiency is improved greatly, and the operation is simple.

Owner:青岛秋润食品有限公司

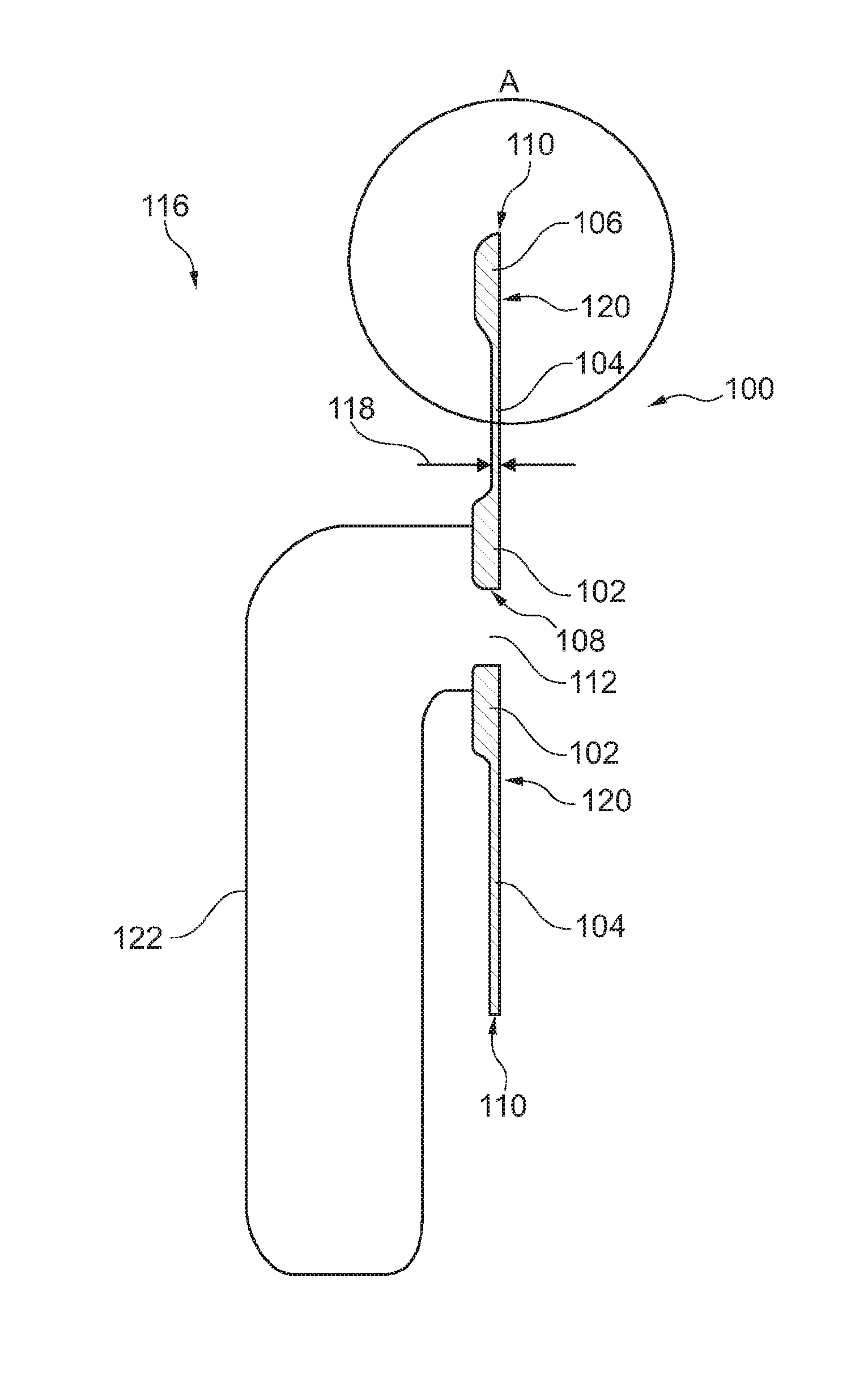

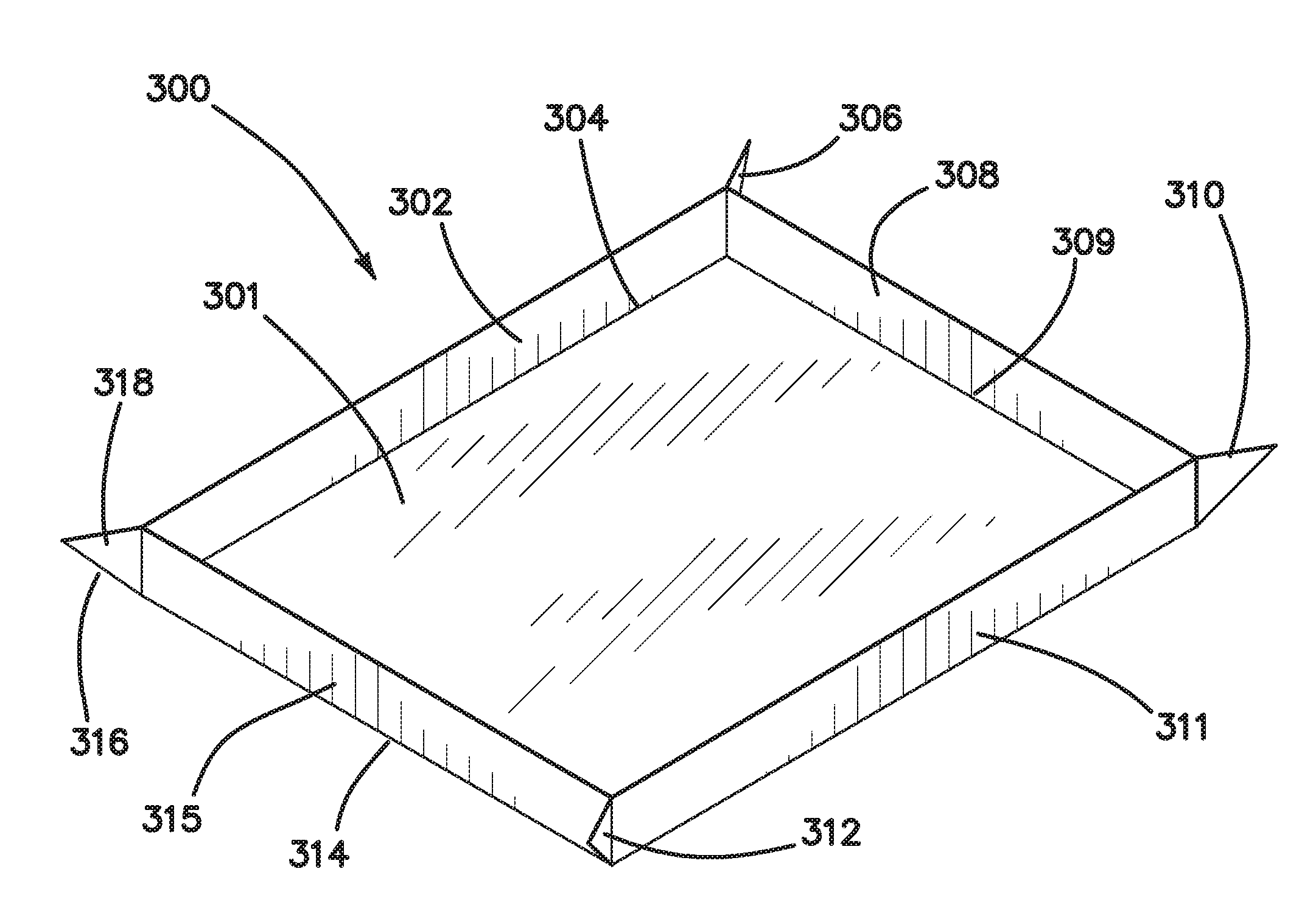

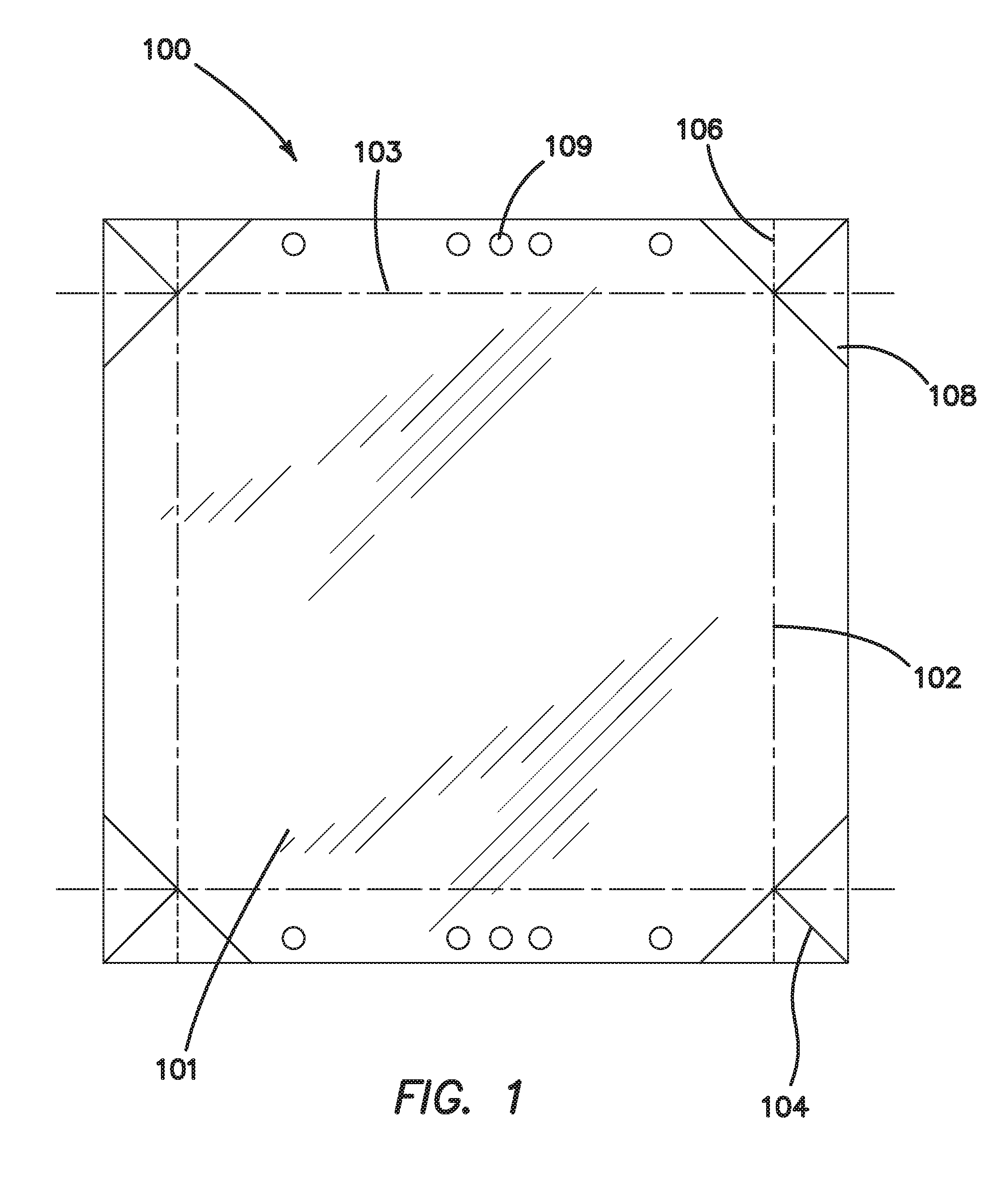

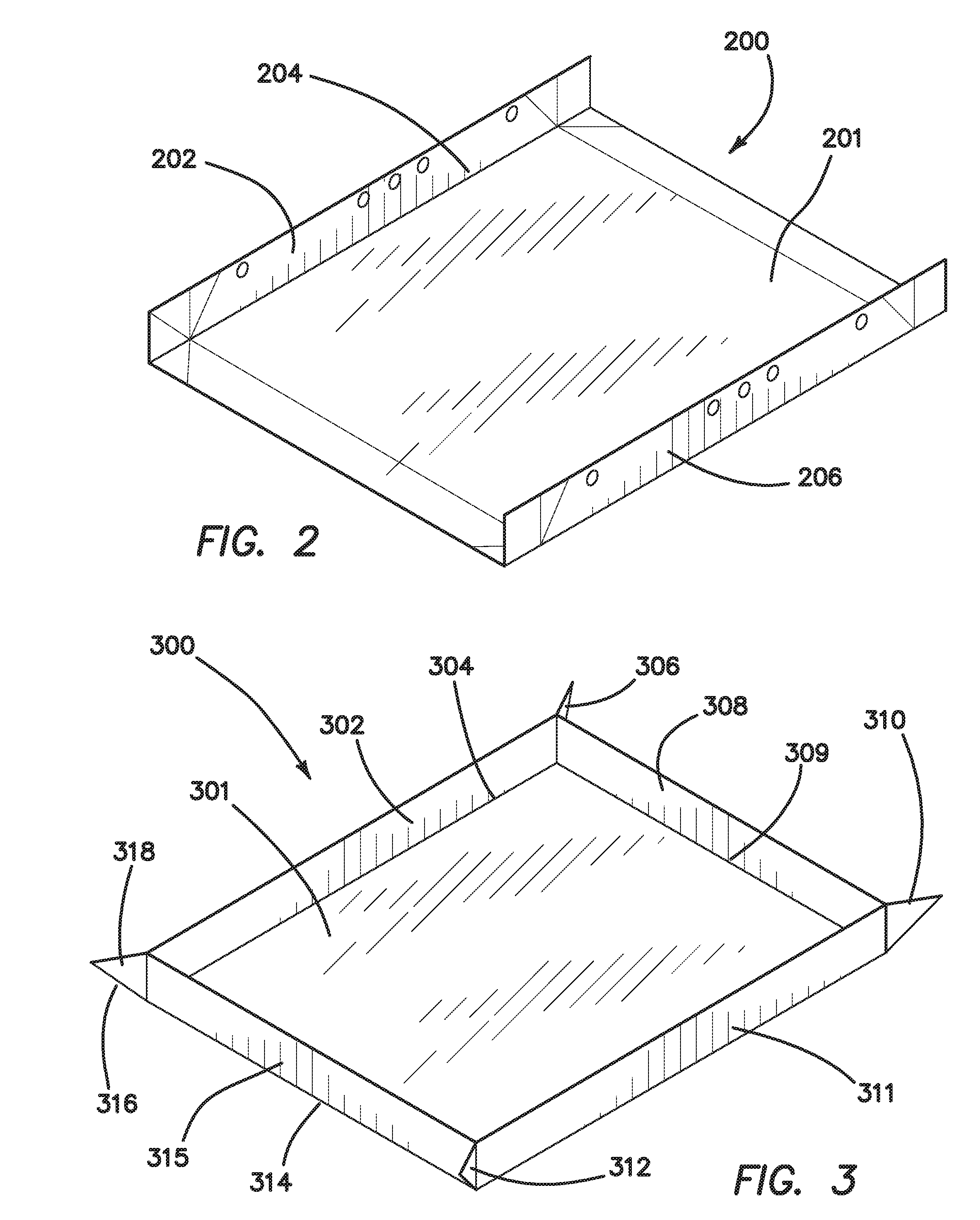

Release liner/layer, system and method of using the same with additive manufacturing

InactiveUS20160176112A1Easy to removeEasy to replaceManufacturing platforms/substratesLayered productsPolyolefinThermoforming

Release liner forming structures and methods of making and using the same. The methods of making the release liner include thermoforming and sheet bending. The flexible release liner may be used in conjunction with a rigid, transparent supporting surface. The release liner may be developed from a flexible sheet formed into a deformable resin fluid vat. A release layer, and additional structure if desired, can be formed of or include plastic, such as polyolefin or fluoropolymer. In some instances, the polyolefin is, or includes, polymethylpentene or a fluropolymer is fluorinated ethylene propylene. The optical and other properties of the release layer can be altered with treatments and other materials to, for example, reduce over-penetration of a light beam or deform a release layer.

Owner:FULL SPECTRUM LASER

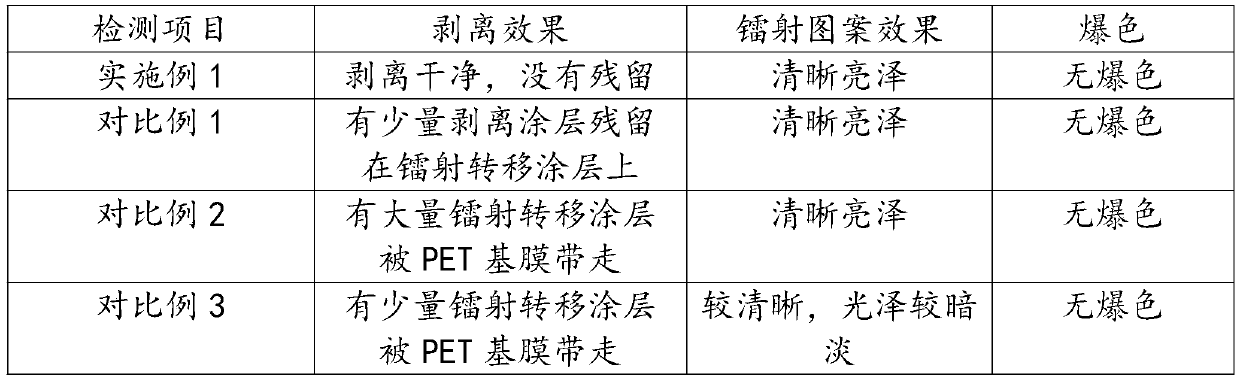

Laser transfer paper, and production technology thereof

ActiveCN110284372AReduce hydrophilicityReduce the number of hydroxyl groupsFlexible coversWrappersLaser patterningPaper based

The invention discloses laser transfer paper and production technology thereof. The laser transfer paper comprises a laser transfer coating layer, laser patterns printed onto the laser transfer coating layer, an aluminizing layer used for coating the laser transfer coating layer through plating, a protective rubber layer which is used for coating the aluminizing layer and protecting a part of the aluminizing layer, and a zinc sulfide dielectric layer which is used for coating the protective rubber layer through plating; and the zinc sulfide dielectric layer is bonded with a paper base through a transfer glue. According to the laser transfer paper, the laser patterns with hollowing out effect are formed, so that the appearance effect of the laser transfer paper as packing paper is improved; the bonding capacity of a peeling coating layer with a tackifying bottom coating layer is increased, so that the stability of laser transfer film in subsequent processing process is ensured; at the same time, the surface tension of the coating layer after curing is reduced, the coating layer peeling effect is improved, and light transmission and white exposure caused by peeling of a part of the laser transfer coating layer are prevented; in laser transfer coating layer preparation process, resin system light transmission effect is improved, so that the reflective effect of the laser patterns is improved.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

Coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading

InactiveCN108433120AReduce wasteReduce manufacturing costGas current separationHuskingEngineeringPeanut kernel

The present invention provides a coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading, and relates to the field. The coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading comprises a machine shell. The top part of the machine shell communicates with a material feeding funnel; the inside of the material feeding funnel isprovided with a stable material conveying device; a coat-removing device is arranged in the machine shell and connected with the material feeding funnel; two transmission devices are connected with the coat-removing device; a material discharging funnel is arranged inside the machine shell and fixedly connected with the lower sides of the transmission devices; and two peanut coat separation devices are arranged on the both sides of the machine shell. In the coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading, the operations of the transmission devices can drive two kneading plates to move up and down repeatedly; besides, the movement directions of the two kneading plates are opposite; and the opposite movement direction of the two kneading plates is similar to that of hand kneading, can ensure that the peanuts are not damaged and improves the integrity of the peanut kernels.

Owner:赵从琴

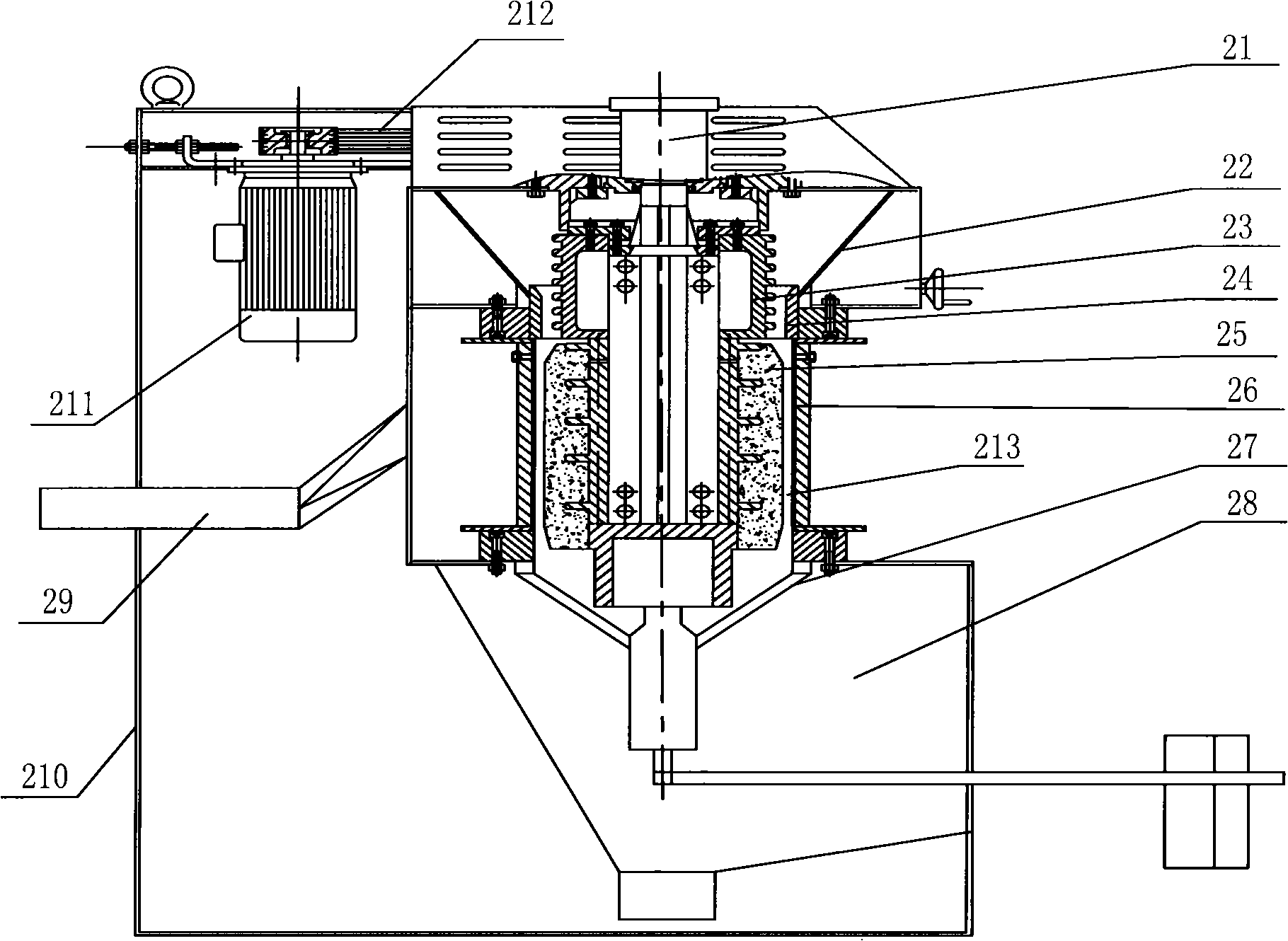

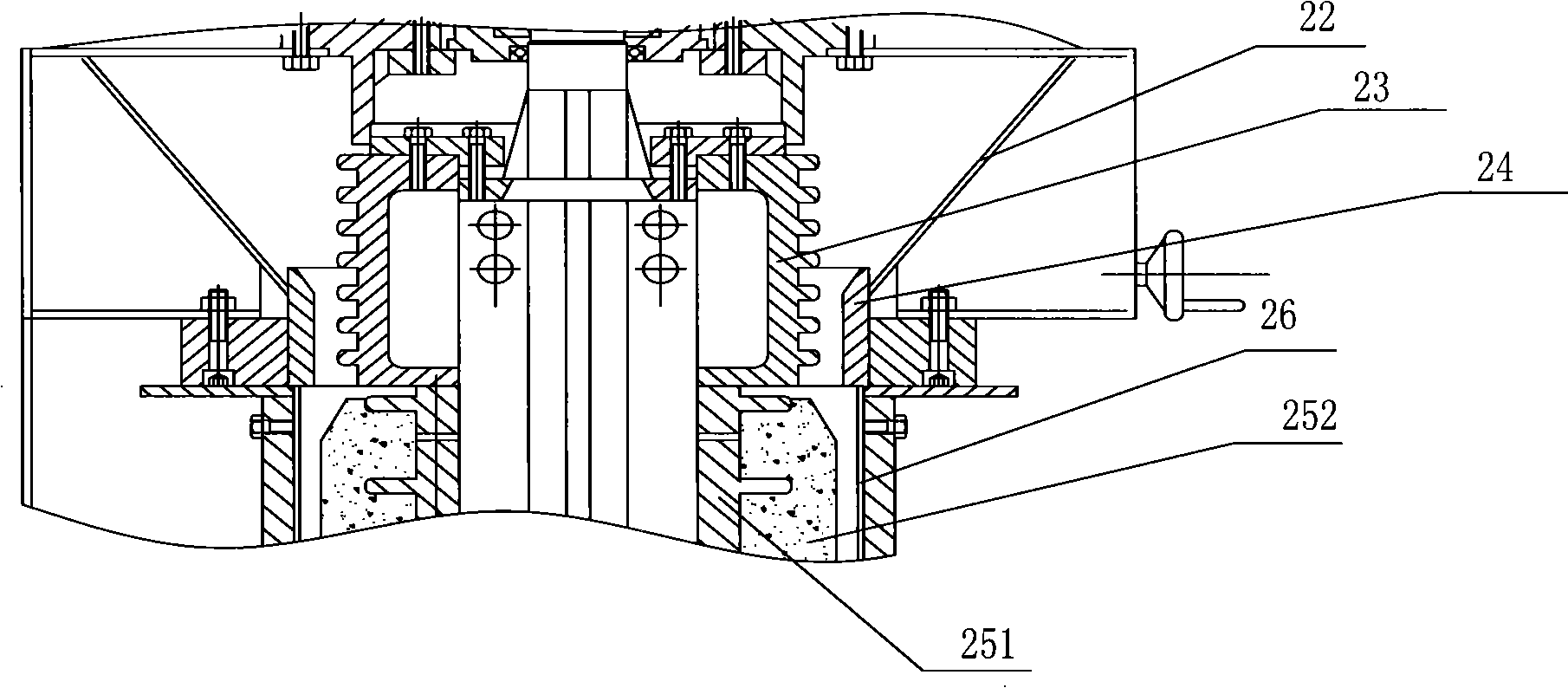

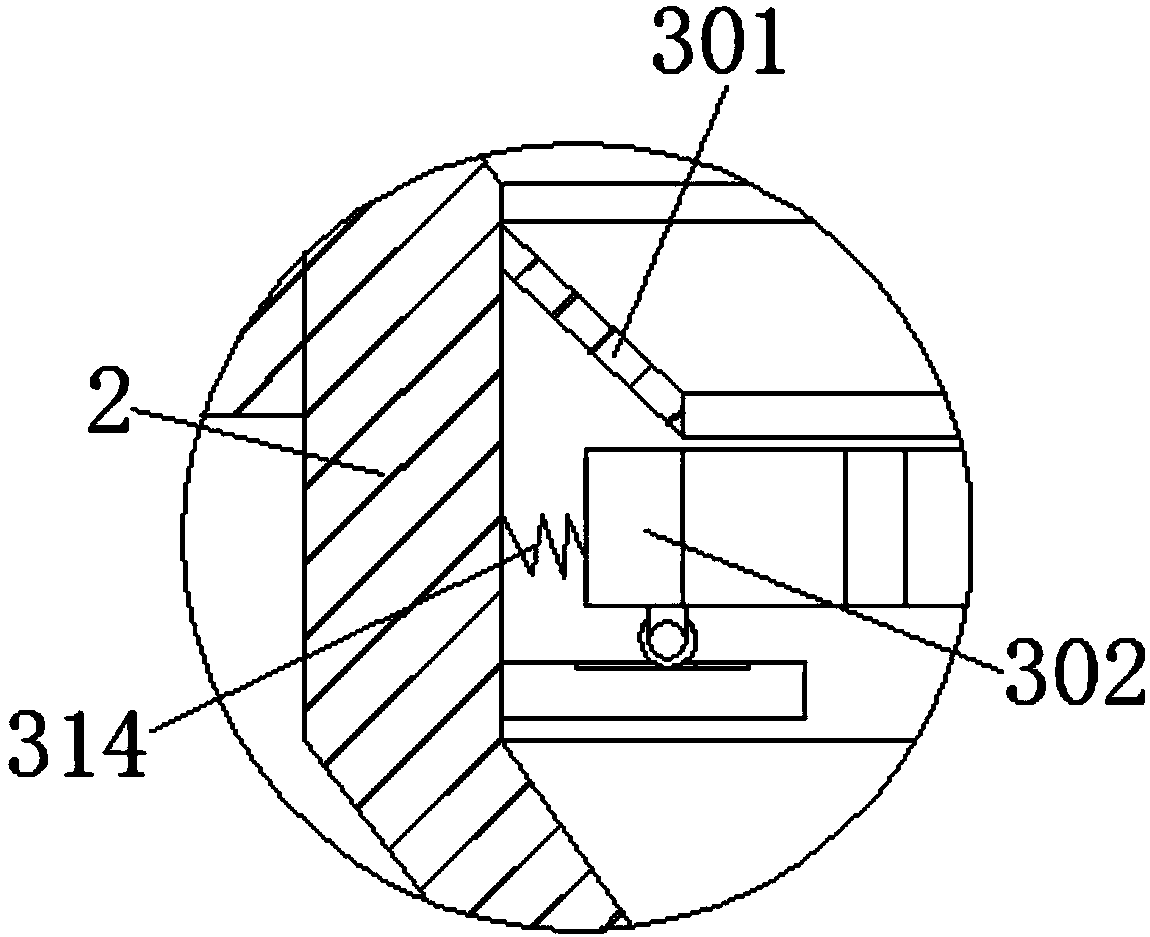

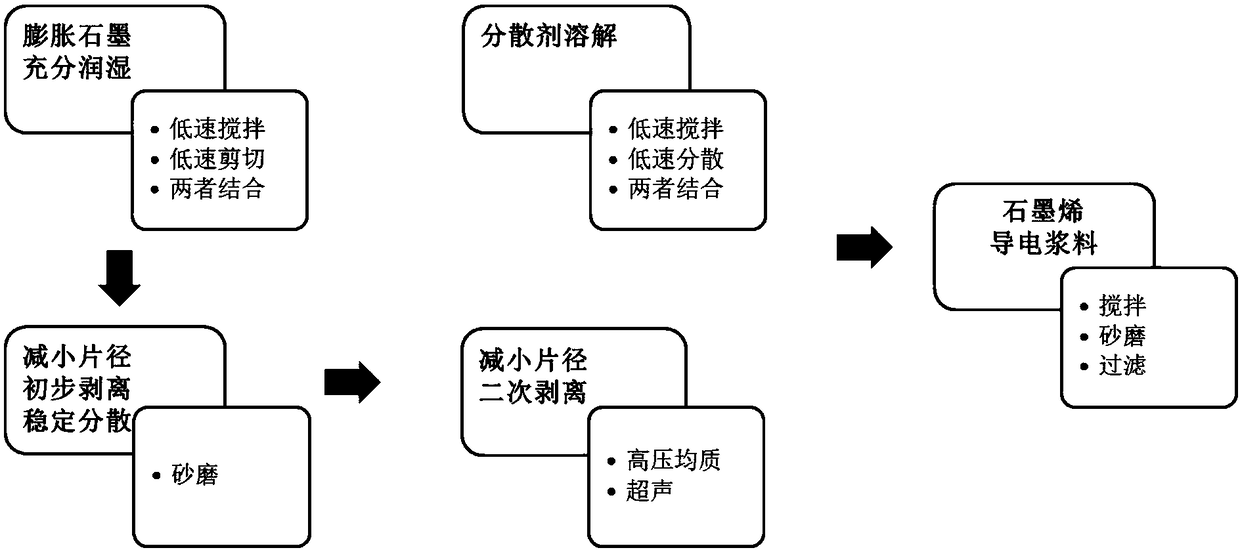

Method and device for massively producing graphene conductive slurry and prepared graphene conductive slurry

ActiveCN108630338AExcellent physical and chemical propertiesEvenly dispersedNon-conductive material with dispersed conductive materialCable/conductor manufactureHigh concentrationGraphite

The invention provides a method and a device for massively producing a graphene conductive slurry and a prepared graphene conductive slurry. The method comprises the following steps of a) mixing graphite and a solvent, carrying out at least one low-speed mixing processing or / and low-speed shearing processing and acquiring a graphite dispersion liquid; b) carrying out at least one sanding processing on the graphite dispersion liquid and acquiring a preliminary stripped graphene dispersion liquid; c) carrying out at least one high pressure homogenization processing or / and ultrasonic processing on the preliminary stripped graphene dispersion liquid, and acquiring a single layer or a small layer of graphene dispersion liquid; d) dissolving a dispersing agent in a solvent to obtain a dispersantsolution; and e) mixing the single layer or the small layer of graphene dispersion liquid and the dispersant solution, carrying out at least one sanding processing, and acquiring the graphene conductive slurry. By using the method, under the condition of environmental protection, the stable and uniformly-dispersed graphene conductive slurry with a high concentration is acquired. And the device issuitable for the continuous automatic production of the high-concentration and high-stability graphene conductive slurry.

Owner:北京地泽科技有限公司

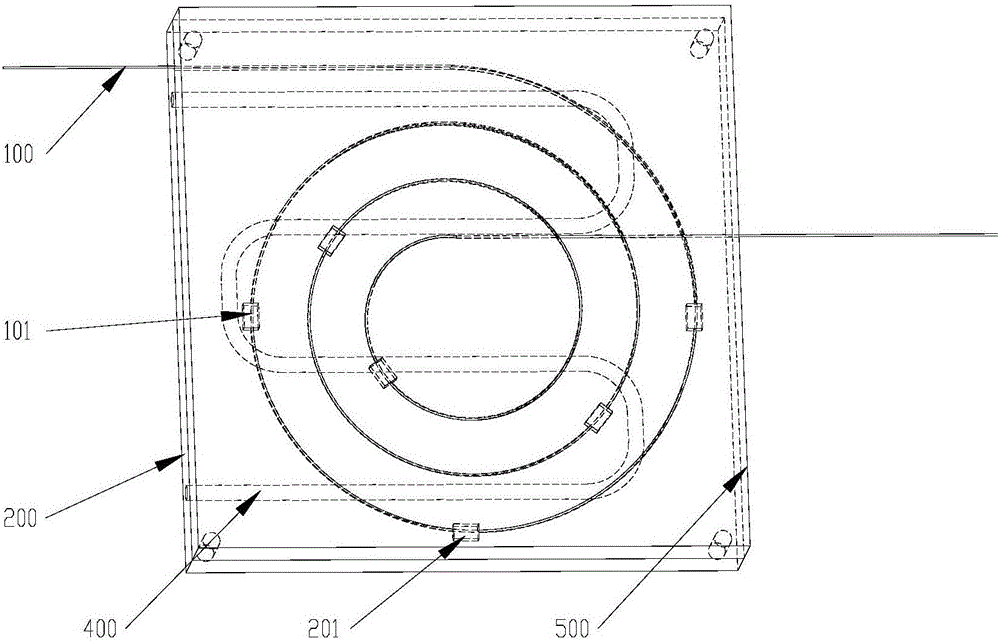

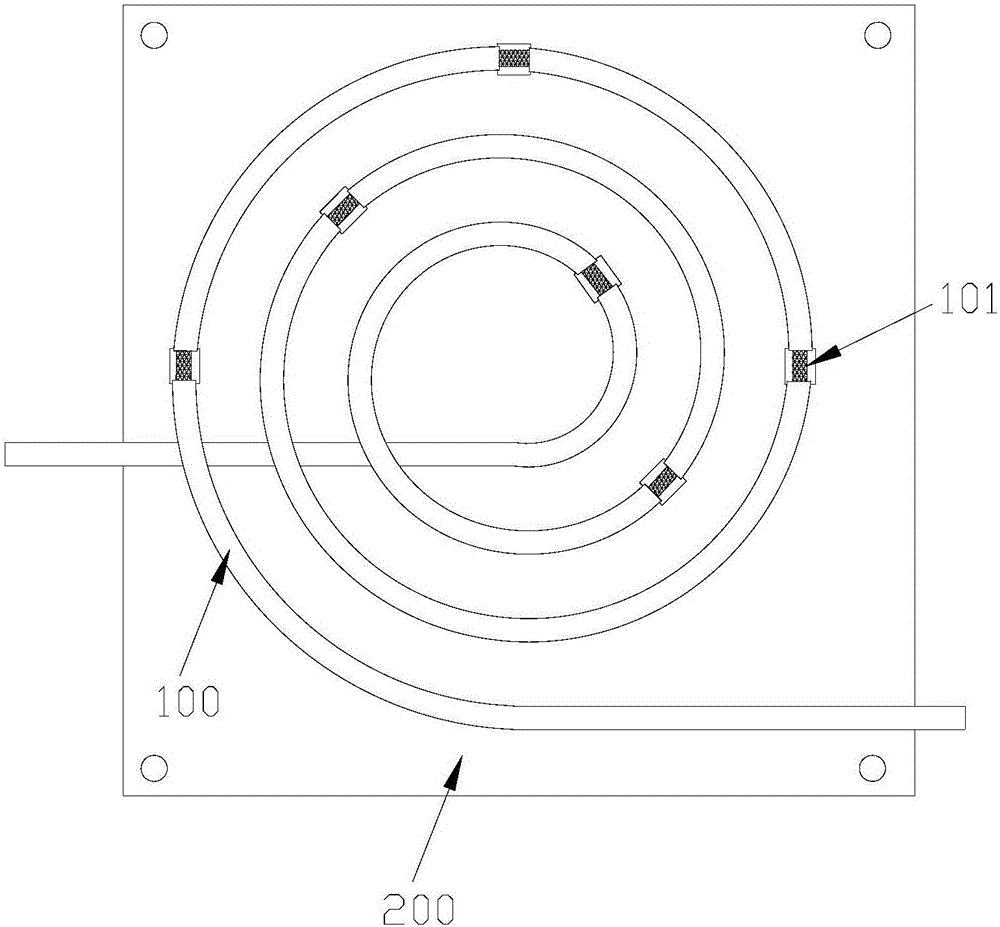

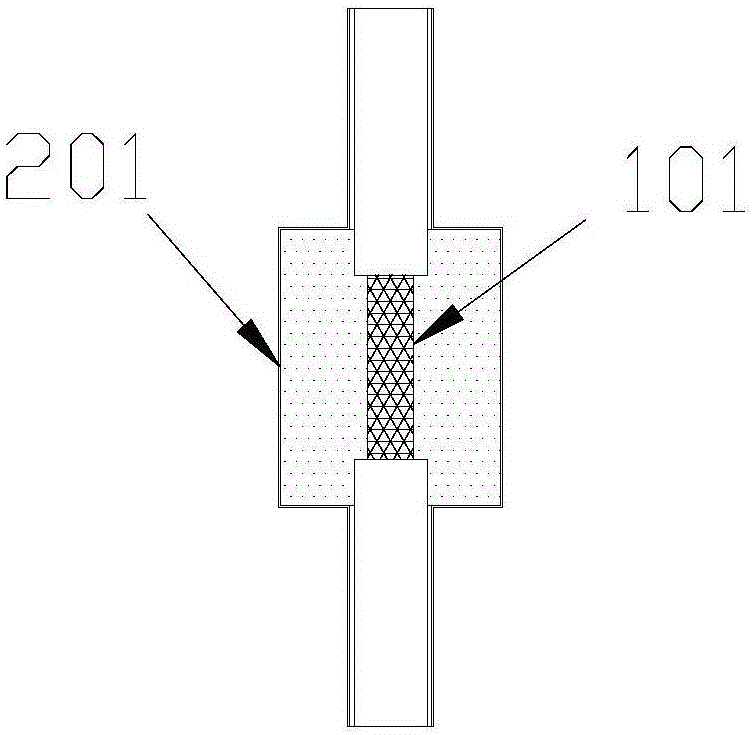

Cladding power stripper for removing high-order mode laser and manufacturing method of cladding power stripper

ActiveCN106405737AControl stripping efficiencyAvoid Concentration LeakageOptical fibre with multilayer core/claddingActive medium shape and constructionDouble-clad fiberHeat conducting

The present invention relates to a cladding power stripper for removing high-order mode laser and a manufacturing method of the cladding power stripper. The cladding power stripper is structured in the following manners that: an optical fiber is coiled in an annular groove of a heat sink; an annular water cooling channel is coiled in the annular groove of the heat sink; a plurality of heat sink recessed grooves are arranged in the annular groove of the heat sink; the surfaces of optical fiber segments suspended on the heat sink recessed grooves are etched so as to form irregular V-shaped groove structures; and the heat sink recessed grooves are filled with a heat-conducting medium; the heat conducting medium completely coats the etched optical fiber segments; and a shell cover plate enables encapsulation protection for the heat sink. According to the cladding power stripper of the present invention, the coating layer of the double-cladding optical fiber is stripped off at intervals, and an exposed inner cladding layer is mechanically etched into the irregular V-shaped grooves so as to be adopted as the dipping openings of cladding light; leaked cladding power is absorbed by the heat conducting medium; heat is transferred to the heat sink and then is taken away by cooling water; the optical fiber is bent into an annular shape, so that the stripping efficiency of high-order mode cladding light can be increased, and light beam quality can be improved.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

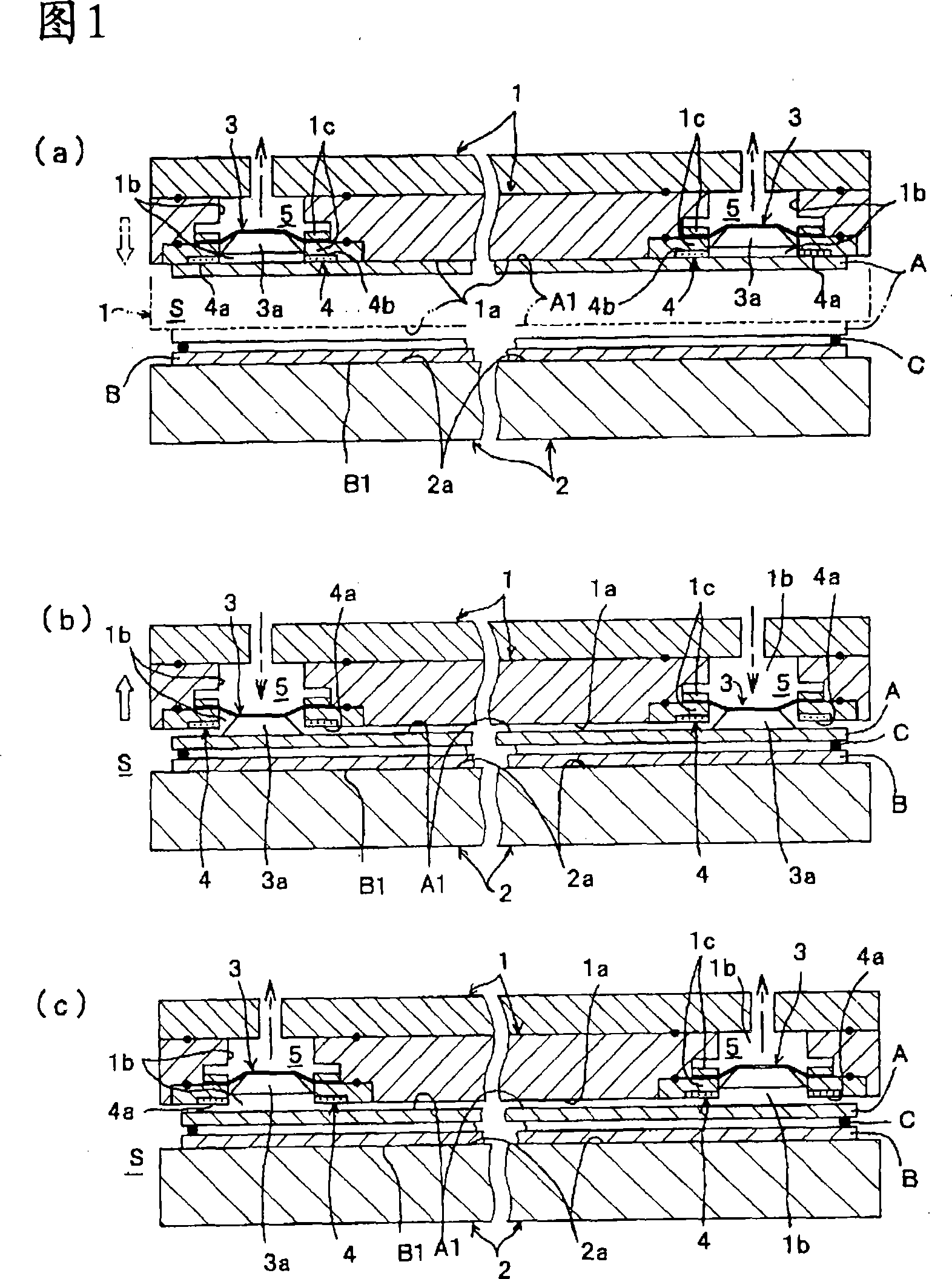

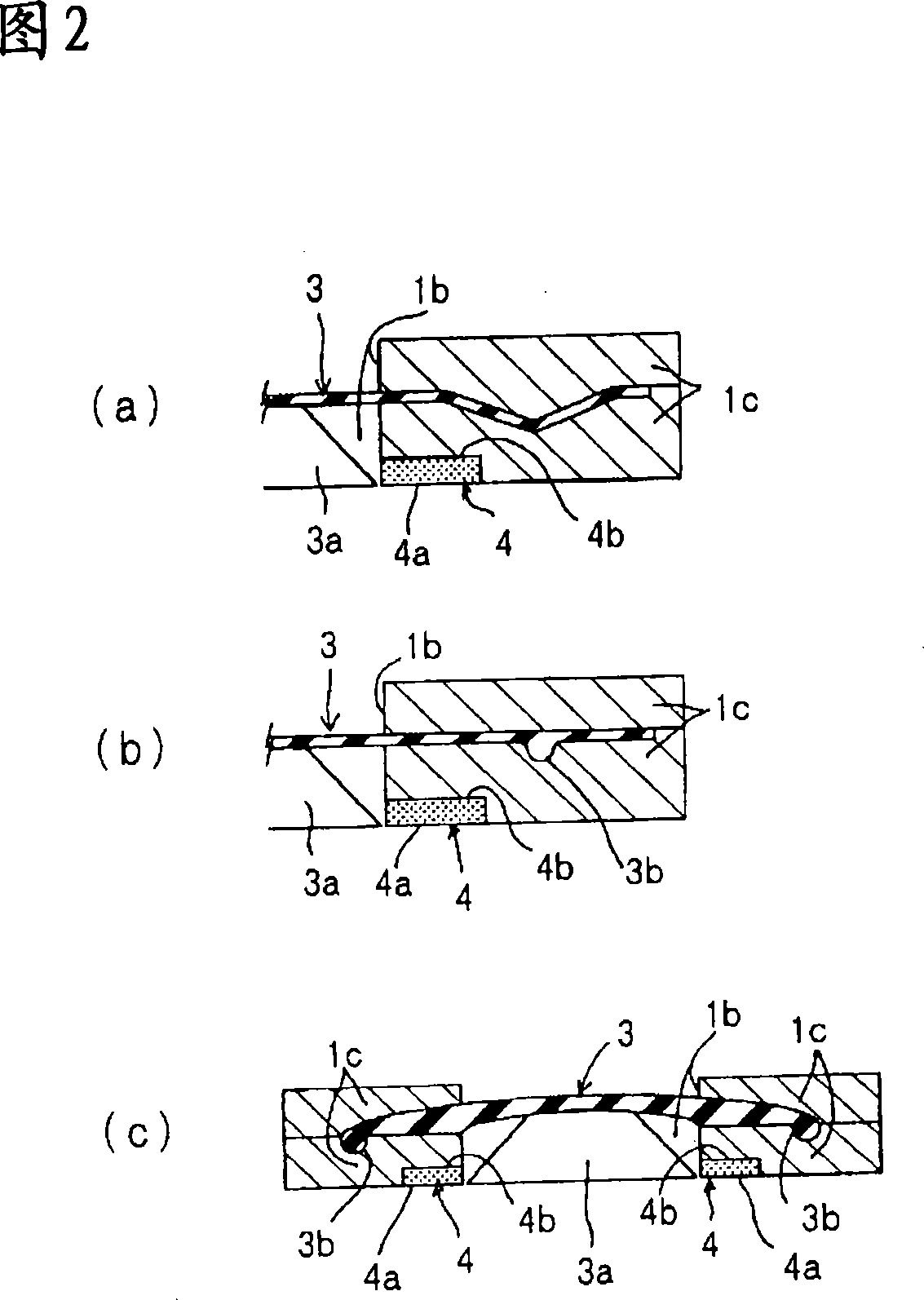

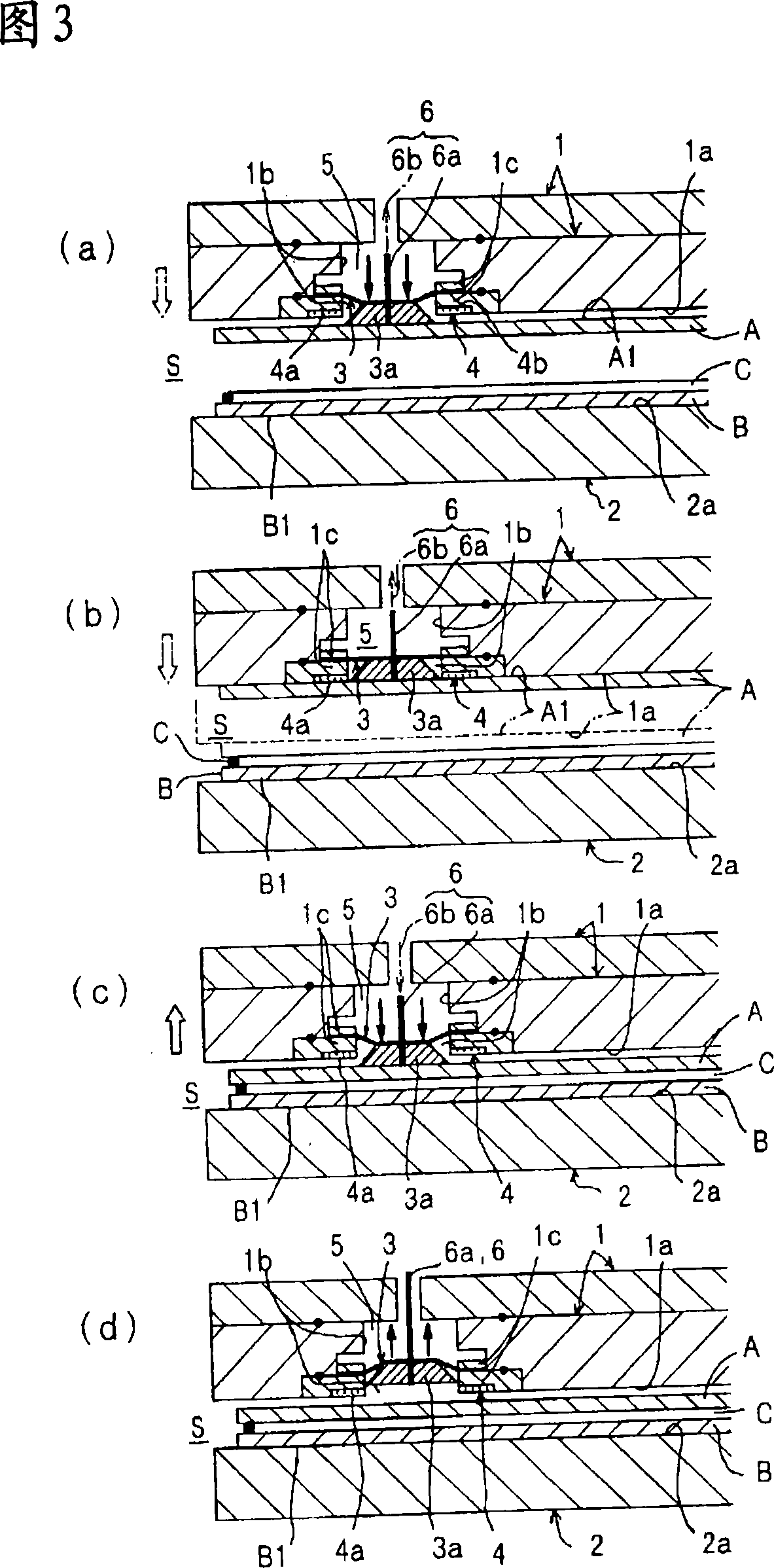

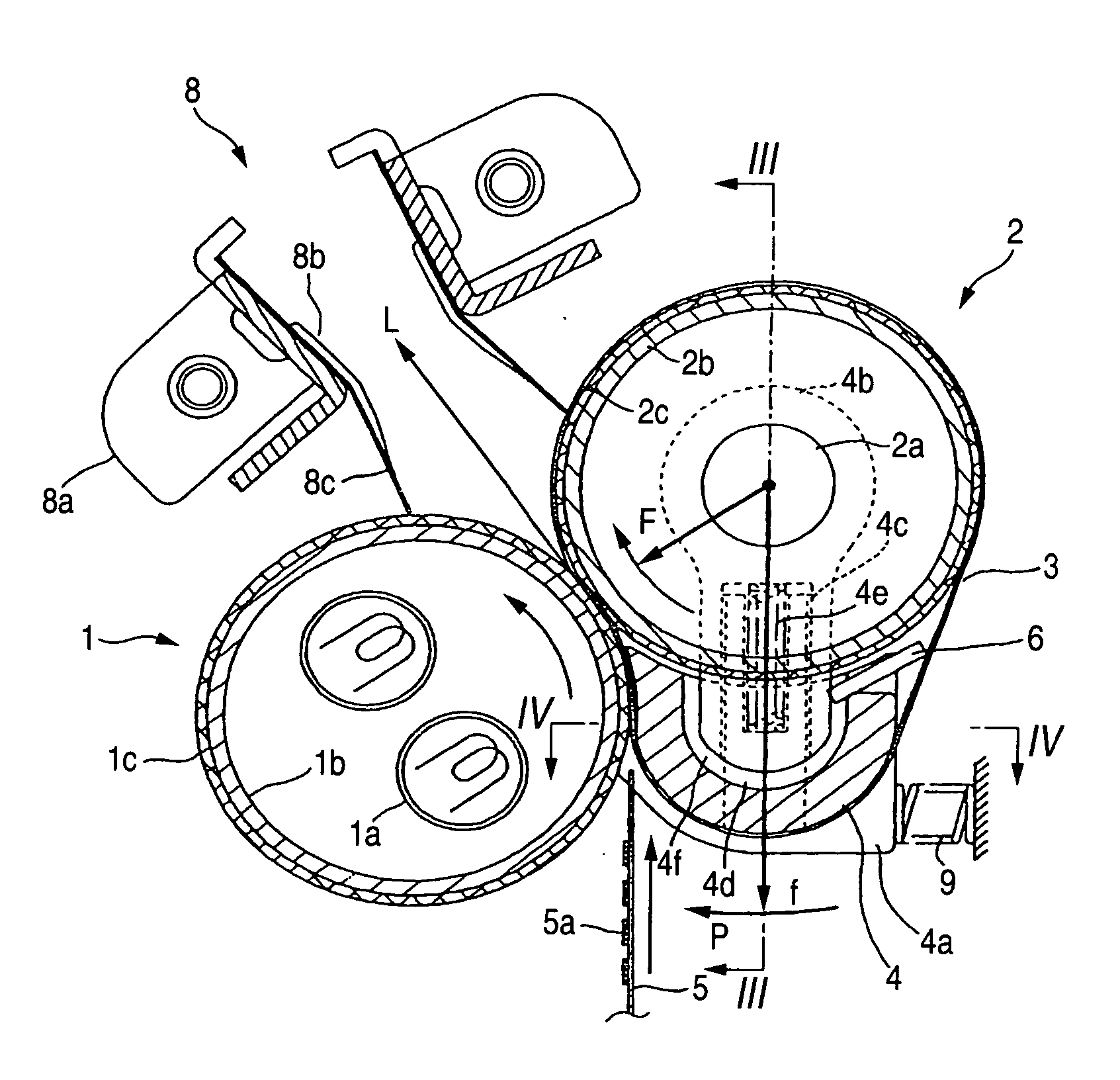

Adhesive chuck device

InactiveCN1985288ASimple peeling structureReduce failure rateNon-linear opticsIdentification meansEngineeringMechanical engineering

The invention aims to surely mount and remove a board by a pneumatic mechanism having a simple structure. On a board side of a holding board (1), a movable film (3) which can be deformed in a direction intersecting with a board side plane (1a) in an opening part (1b) provided on the board side plane (1a), and an adhesive member (4) for holding a board (A) by adhesion by facing the board are provided. By reciprocating the movable film (3) by a pressure difference between a primary side space (5) and a secondary side space (S) of the movable film (3), an adhesive surface (4a) of the adhesive member (4) is permitted to abut to the board (A) to hold the board by adhesion, the adhesive surface and the board are forcibly separated and the board (A) is smoothly peeled from the adhesive surface (4a) of the adhesive member (4).

Owner:SHIN ETSU ENG

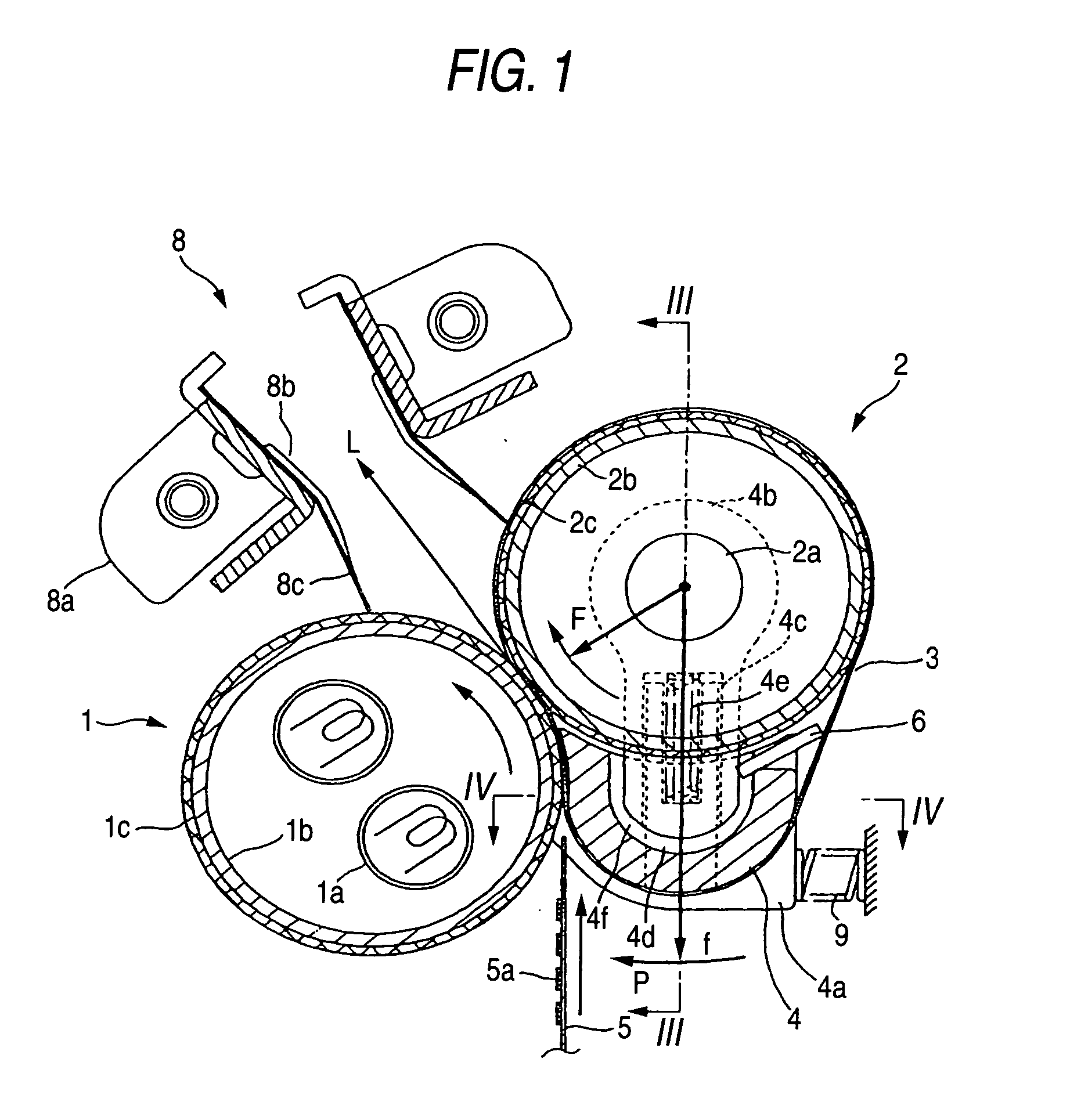

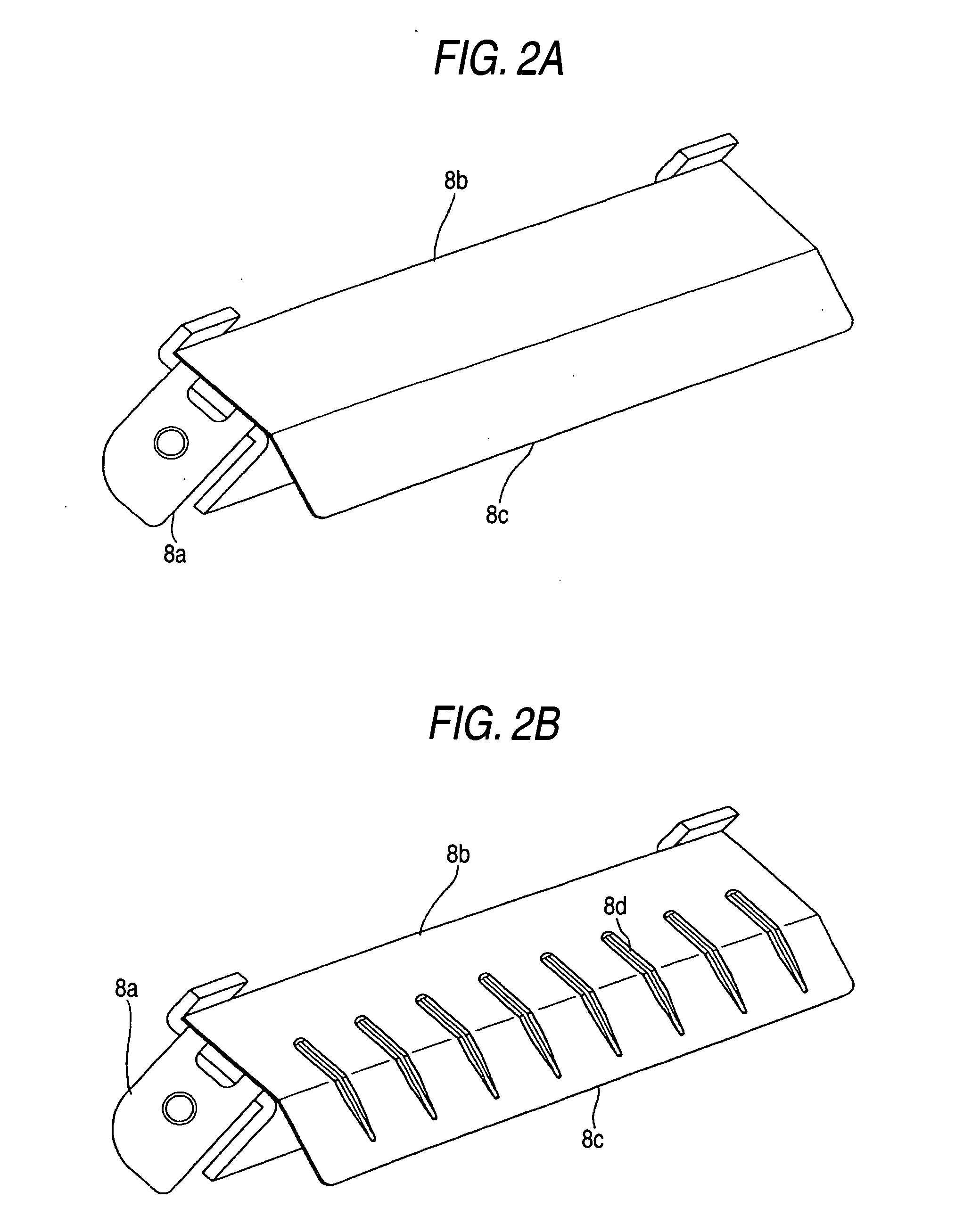

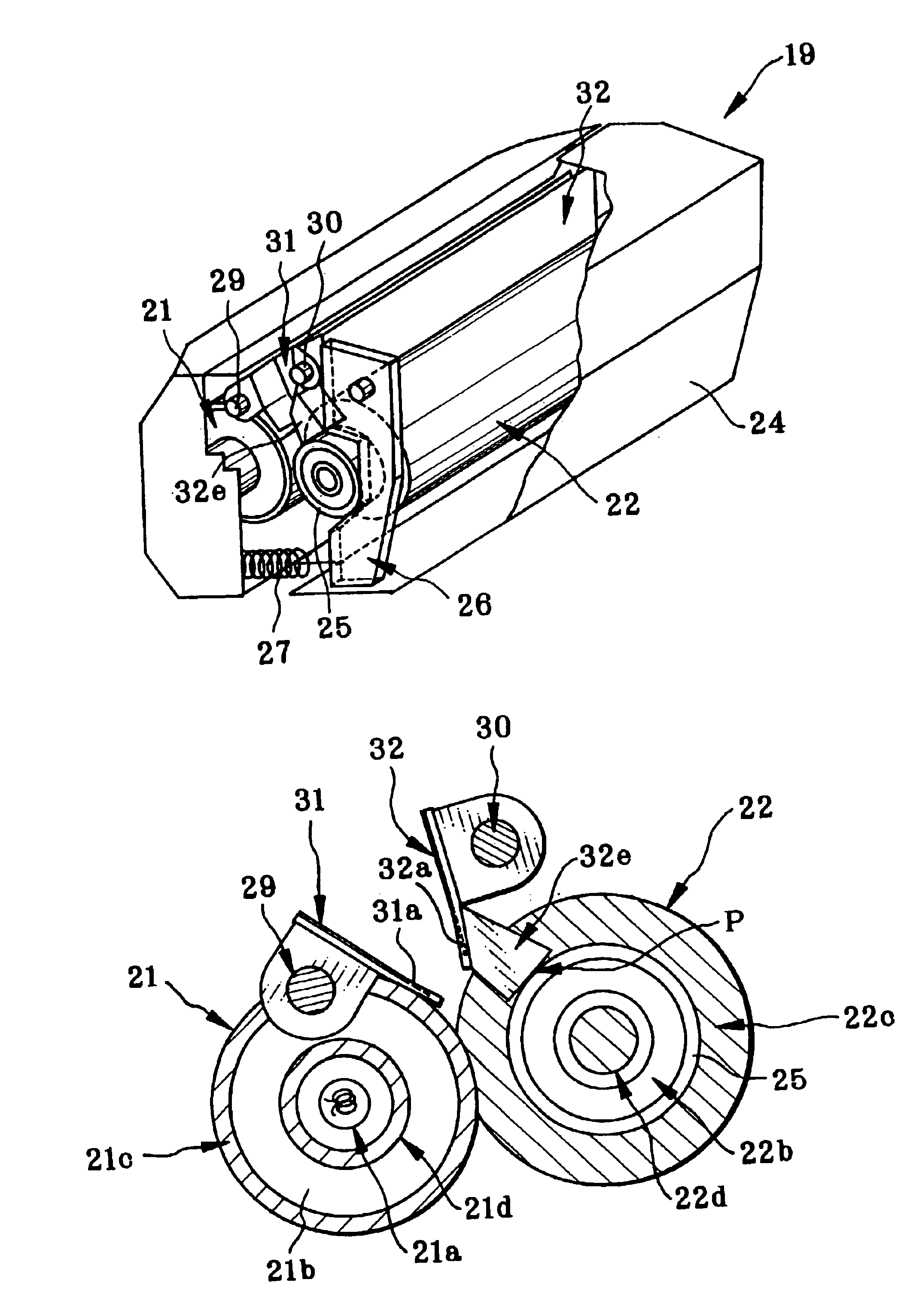

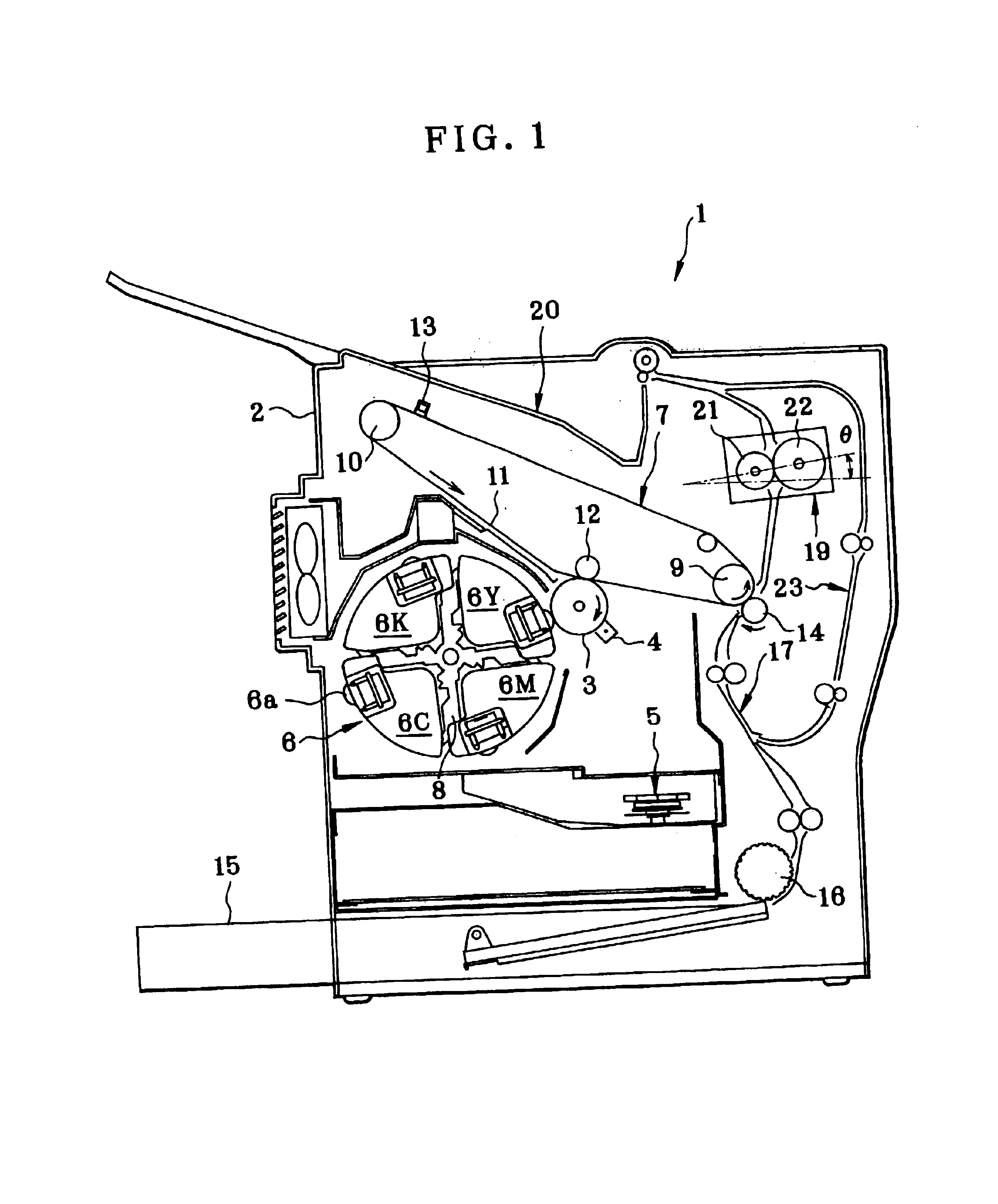

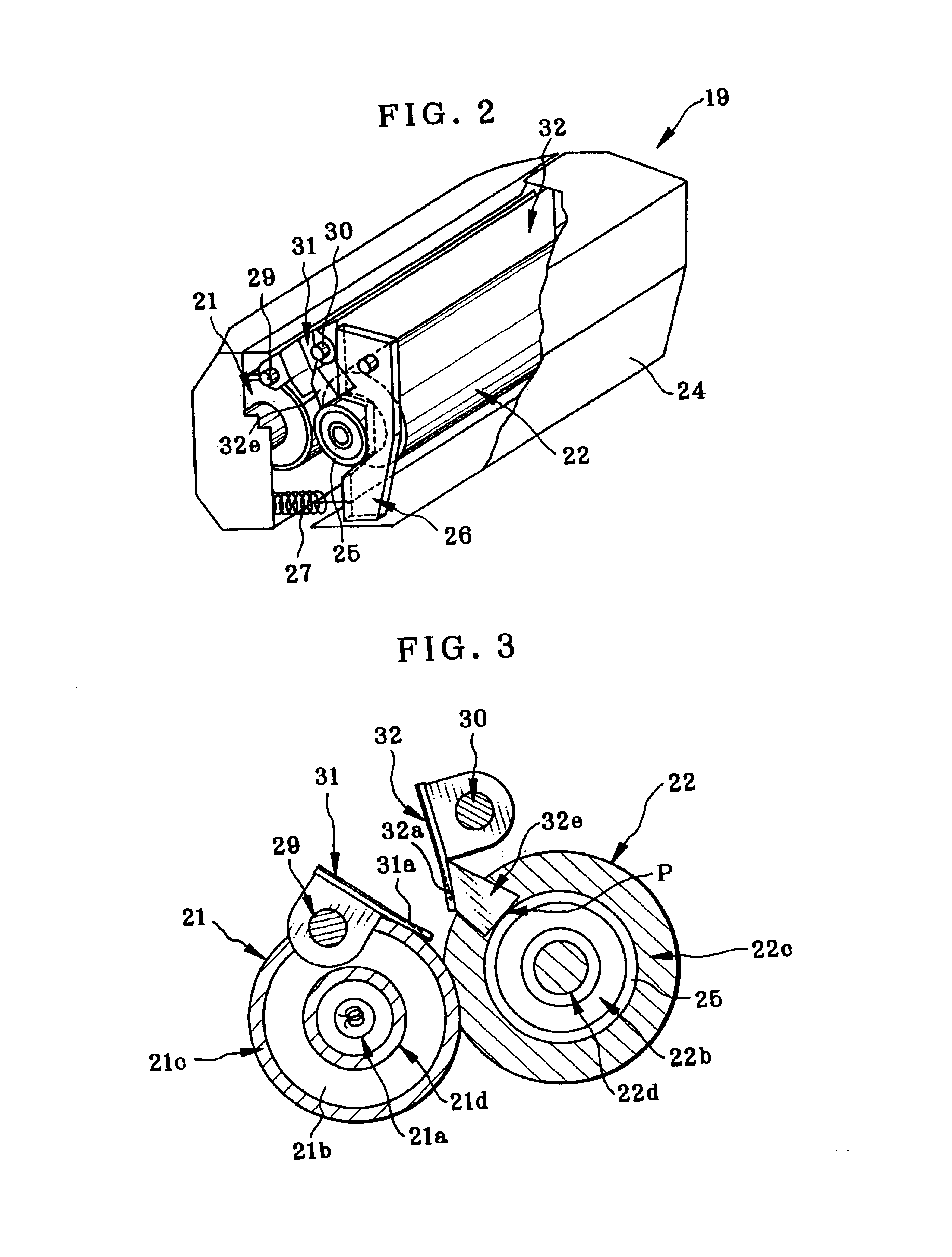

Fixing device and image forming apparatus incorporating the same

InactiveUS20050123328A1Prevent surfaceImage can be preventedOhmic-resistance heatingElectrographic process apparatusImage formationContact position

In a fixing device for fixing a toner image onto a recording medium, a healing roller is provided with an elastic layer formed on an outer periphery thereof. An endless belt is adapted to be circulated. A press member presses a part of the endless belt against the heating roller so as to deform the elastic layer, thereby forming a fixing nip portion through which the recording medium it passed. A guide member has a slope portion extended so as to close to a tangential line defined at a press contact position between the heating roller and the press member, as is being away from the exit of the fixing nip portion. A fixing pressure generated at the exit of the fixing nip portion is greater than a fixing pressure generated at an entrance of the fixing nip portion.

Owner:SEIKO EPSON CORP

Fixing device

InactiveUS6839537B2Good peeling effectAvoid it happening againElectrographic process apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com