Adhesive jointing and electric arc spot welding combined connection method for metals

A connection method and metal-to-metal technology, applied in the field of material engineering, can solve problems such as difficult to achieve effects, affect mechanical properties, and large failure loads, and achieve the effects of meeting actual engineering needs, improving material utilization, and increasing fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1. Welding magnesium / aluminum dissimilar metals by the method of the present invention.

[0017] The size of the overlapping part of the plate is 15×300mm, and the thickness of the plate is 1.5mm. The welding steps are as follows:

[0018] 1. Clean the sample with acetone before welding to remove oil stains on the surface, and clean the lap surface to remove the oxide film after drying.

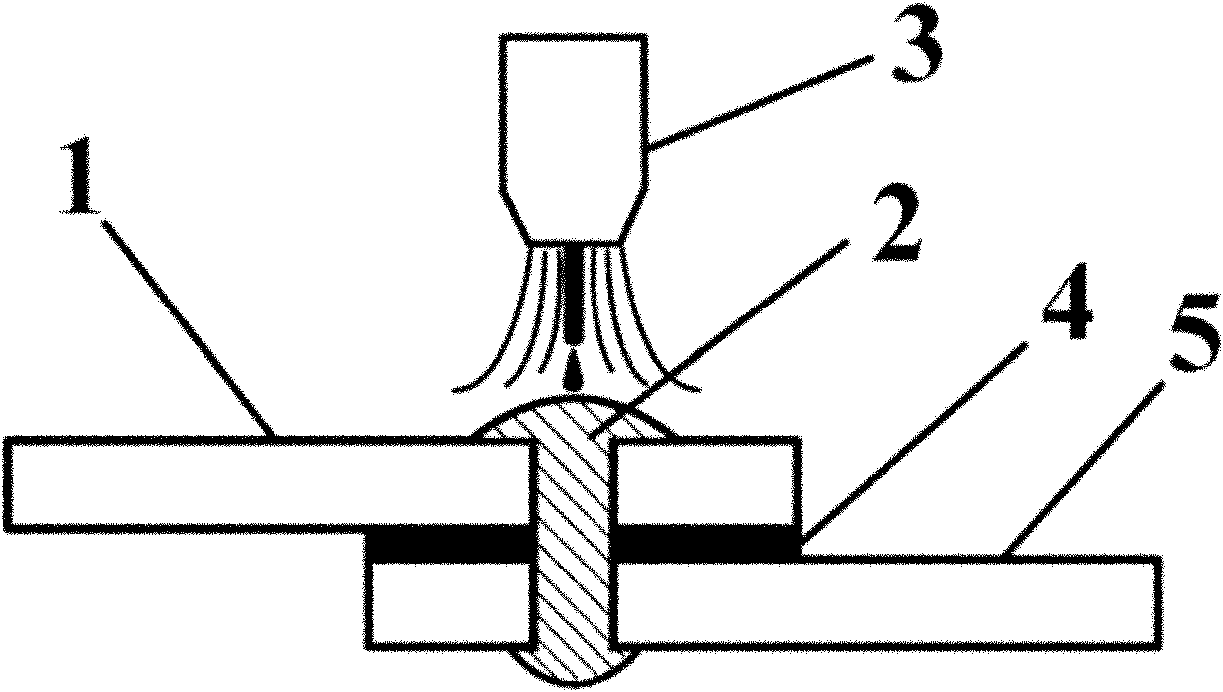

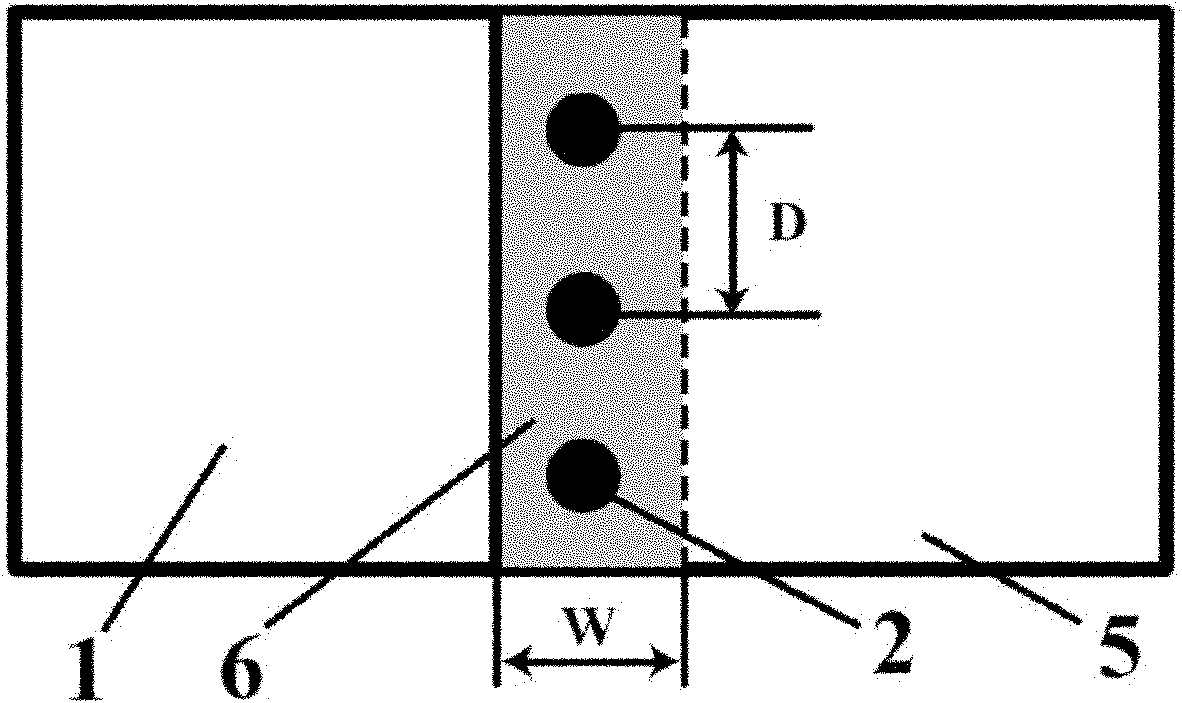

[0019] 2. Such as figure 1 , figure 2 As shown, the glue layer 4 is coated between the overlapping parts 6 of the materials 1 and 5 to be welded, the overlapping width W is 15 mm, the total thickness of the glue layer is 0.1 mm, and the glue layer adopts an epoxy resin structural adhesive.

[0020] 3. Use a welding fixture to press the plates 1 and 5 tightly, and open a row of through holes 2 with a diameter of 3mm along the seam direction at the lap joint. The distance between each through hole is D=25mm.

[0021] 4. Adopt the molten extremely inert gas shielded welding process to per...

Embodiment 2

[0024] In Example 2, the magnesium alloy was welded by the method of the present invention.

[0025] The size of the overlapping part of the plate is 20×300mm, and the thickness of the plate is 1.5mm. The welding steps are as follows;

[0026] 1. The pre-welding treatment is the same as in Example 1.

[0027] 2. The lapped surface of the material to be welded is coated with a glue layer, the lap width is 20mm, the total thickness of the glue layer is 0.15mm, and the phenolic resin structural adhesive is used.

[0028] 3. Use a welding fixture to press the overlapped part tightly, and open a row of through holes with a diameter of 4mm along the seam at the overlapped place, and the distance between each through hole is 45mm.

[0029] 4. Using tungsten gas shielded welding process, single-sided wire-filled spot welding is performed on the through hole, and then the test piece is turned over to perform wire-filled spot welding on the other side of the through hole. The welding process par...

Embodiment 3

[0032] In Example 3, Q235 steel was welded by the method of the present invention.

[0033] The size of the overlapping part of the plate is 35×300mm, and the thickness of the plate is 2.0mm. The welding steps are as follows:

[0034] 1. The pre-welding treatment is the same as in Example 1.

[0035] 2. The lapped surface of the material to be welded is coated with an adhesive layer, the lap width is 35mm, the total thickness of the adhesive layer is 0.5mm, and the urea-formaldehyde resin structural adhesive is used.

[0036] 3. Use a welding fixture to press the overlapped part tightly, and open a row of through holes with a diameter of 6mm along the seam at the overlapped place, and the distance between each through hole is 50mm.

[0037] 4. Using plasma arc welding process, single-sided wire-filled spot welding is performed on the through hole, and then the test piece is turned over to perform wire-filled spot welding on the other side of the through hole. Arc current is 180A, dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com