Patents

Literature

584 results about "Appliance component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

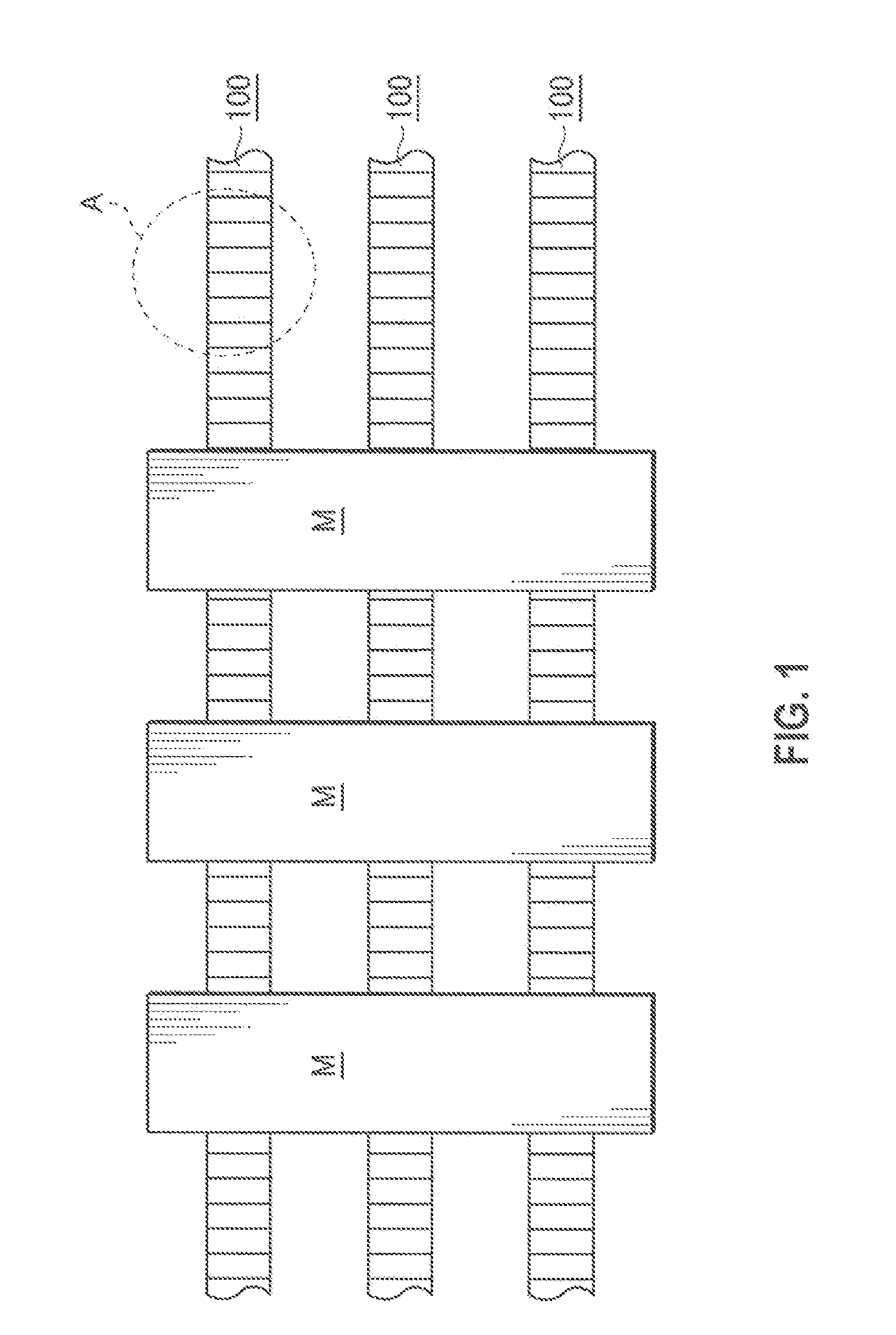

Computer rack heat extraction device

InactiveUS6412292B2More revenueExcessive coolingDucting arrangementsDigital data processing detailsAppliance componentEngineering

An air conditioning cooling apparatus and method which includes the steps of supplying cooling air generated from a cooling apparatus into an air passageway formed below a floor; guiding the cooling air within the air passageway into an equipment assembly disposed on the floor through an opening located in the floor; communicating the cooling air introduced into the equipment assembly into a plenum and introducing the air released from within the equipment into the plenum and communicating the released air through the cooling apparatus for cooling the released air. The method permits temperature differential between the air supplied to the air passageway and the air introduced into the plenum from the equipment assembly to be 45.degree. F. to substantially 40.degree. F. so as to reduce the power necessary for operating on the fan of the blowing apparatus. The equipment assembly utilizes an air flow control mechanism so as to substantially evenly distribute cooling air to the equipment.

Owner:EATON INTELLIGENT POWER LIMITED

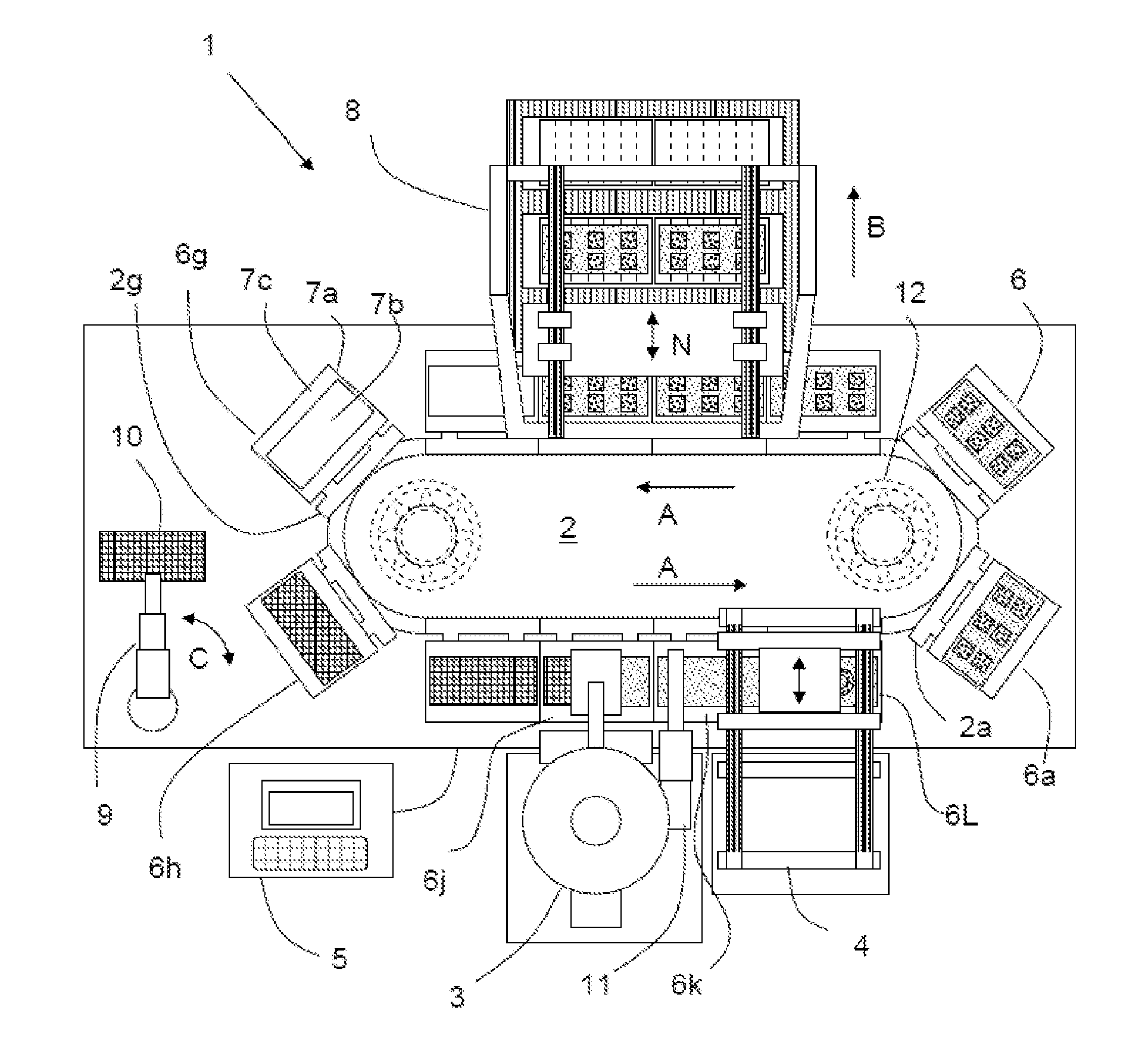

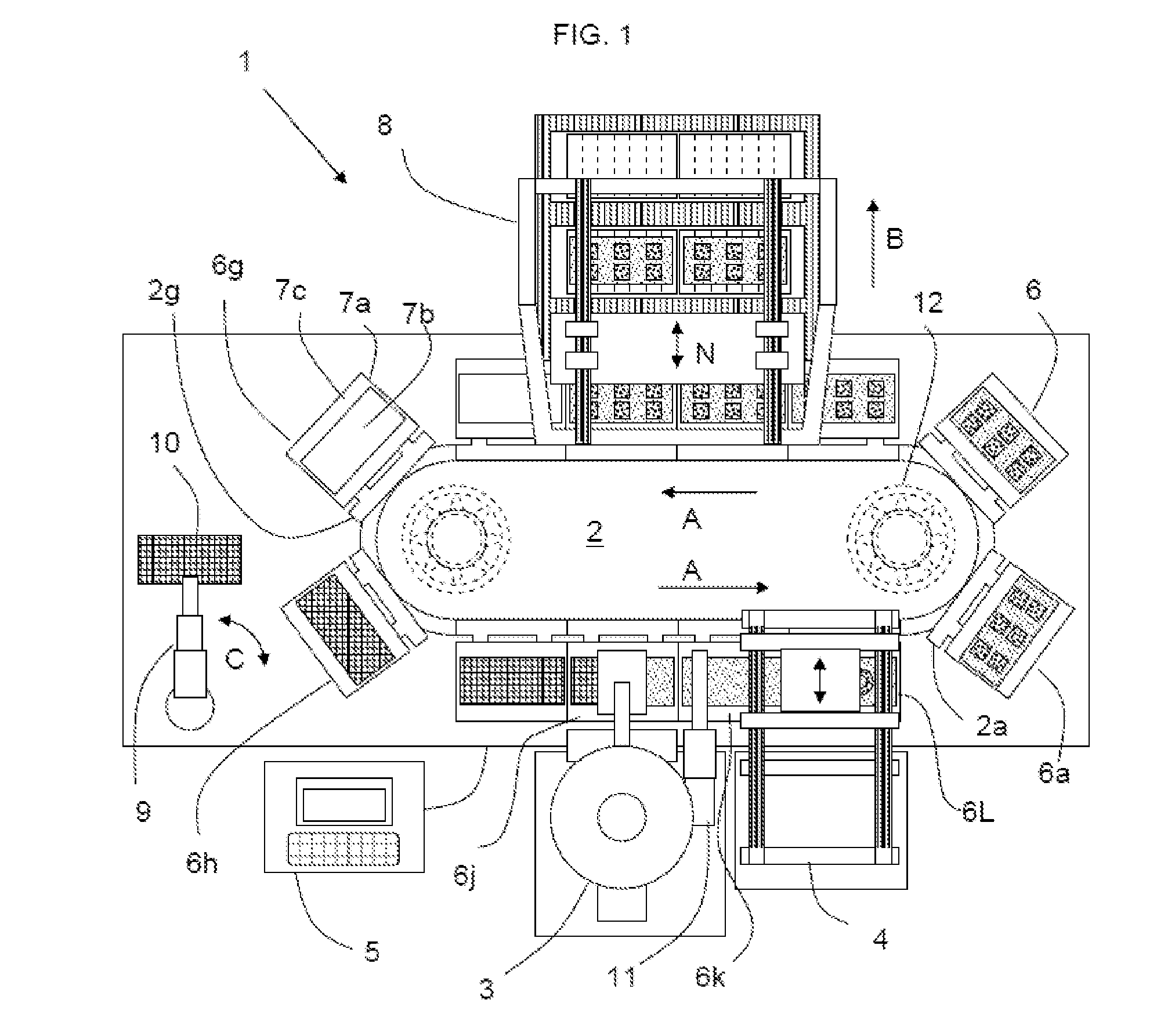

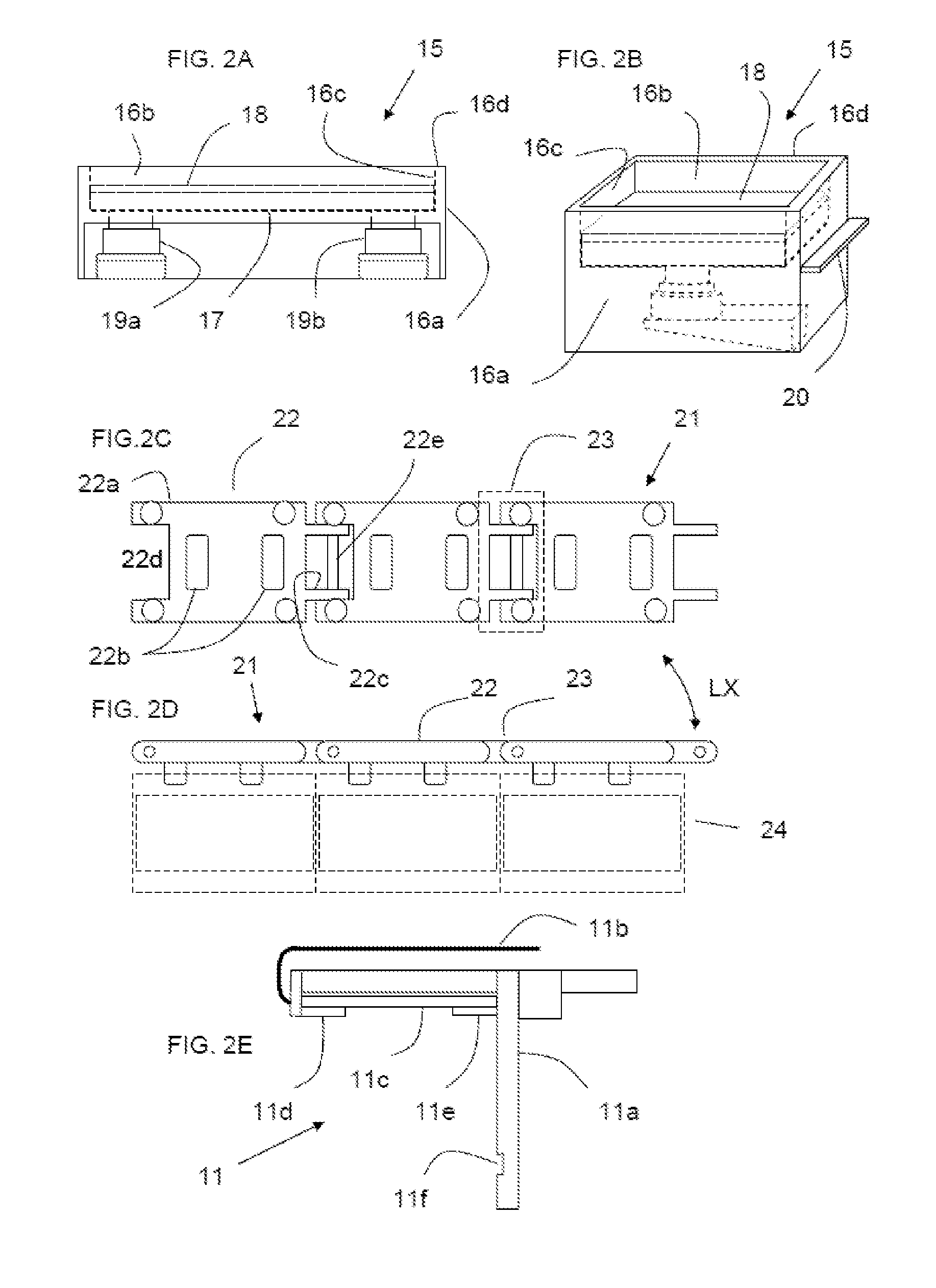

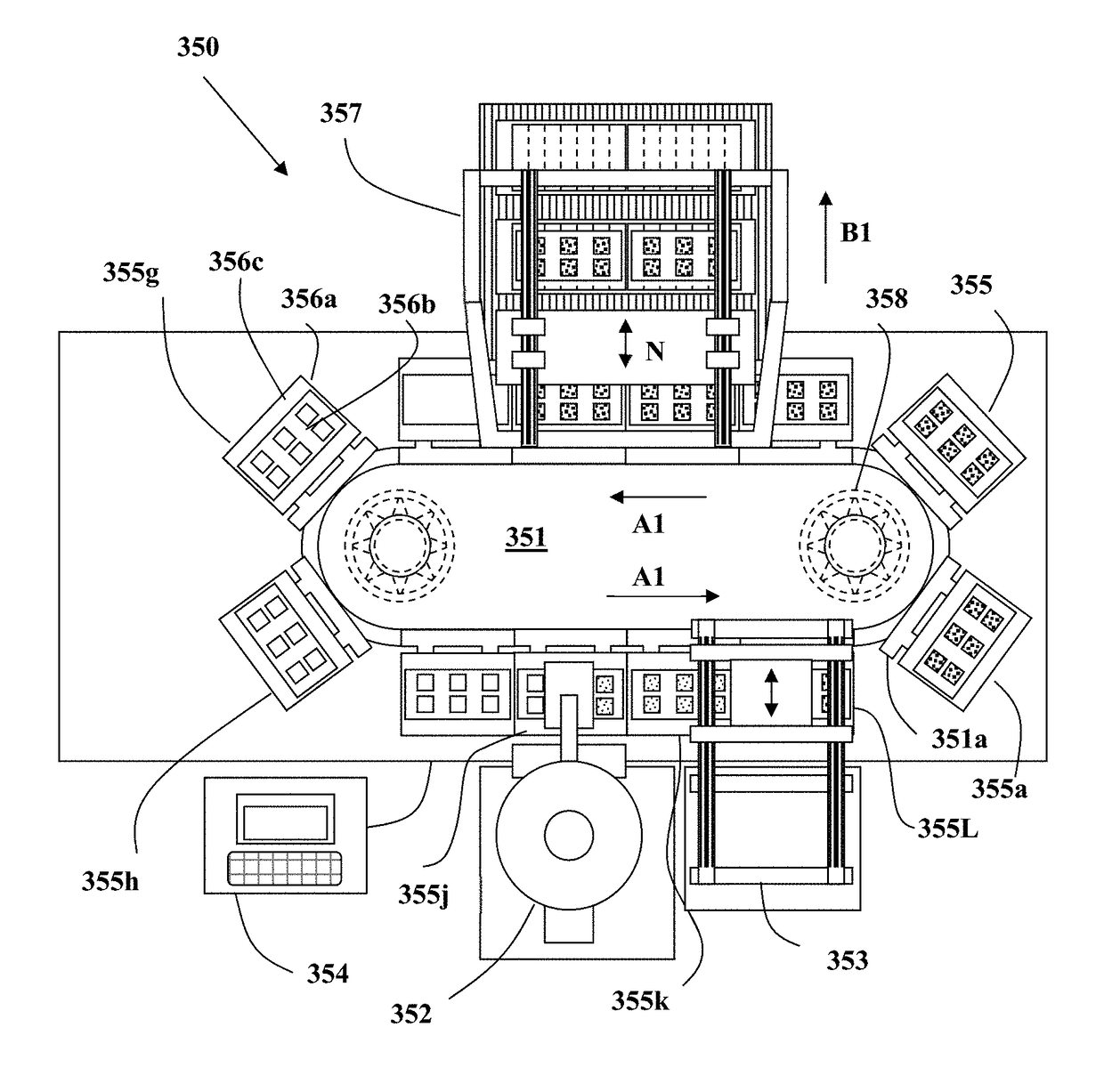

Three-dimensional printing system and equipment assembly

ActiveUS8888480B2Loss of productionImprove efficiencyManufacturing platforms/substratesConfectioneryDevice Subassembly3 dimensional printing

Owner:APRECIA PHARMA LLC

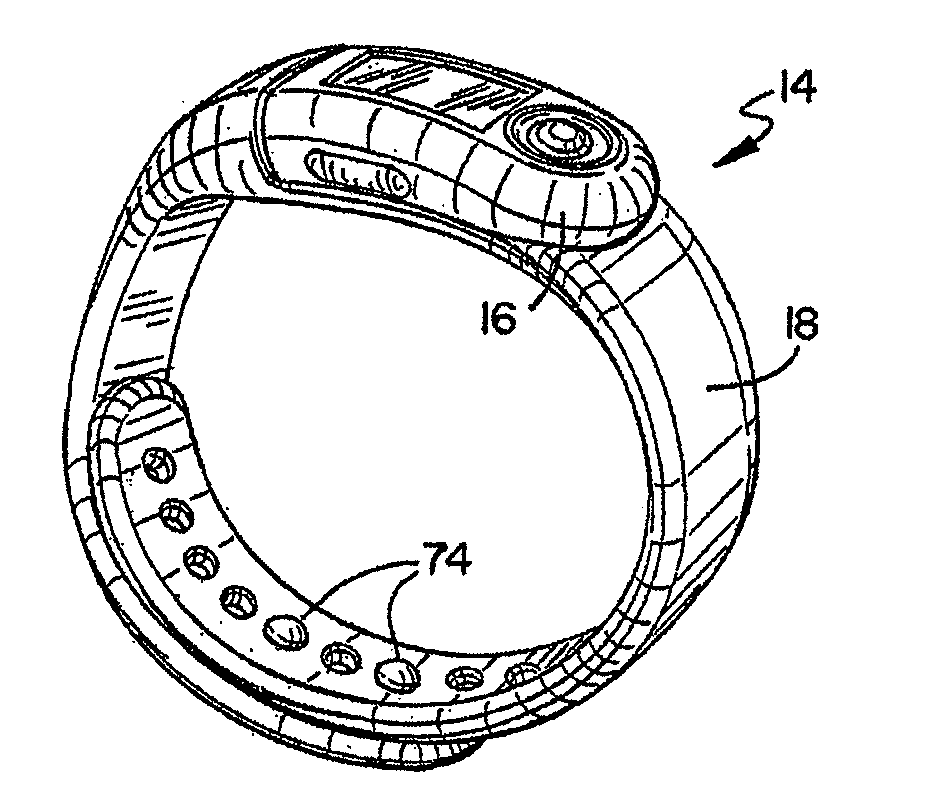

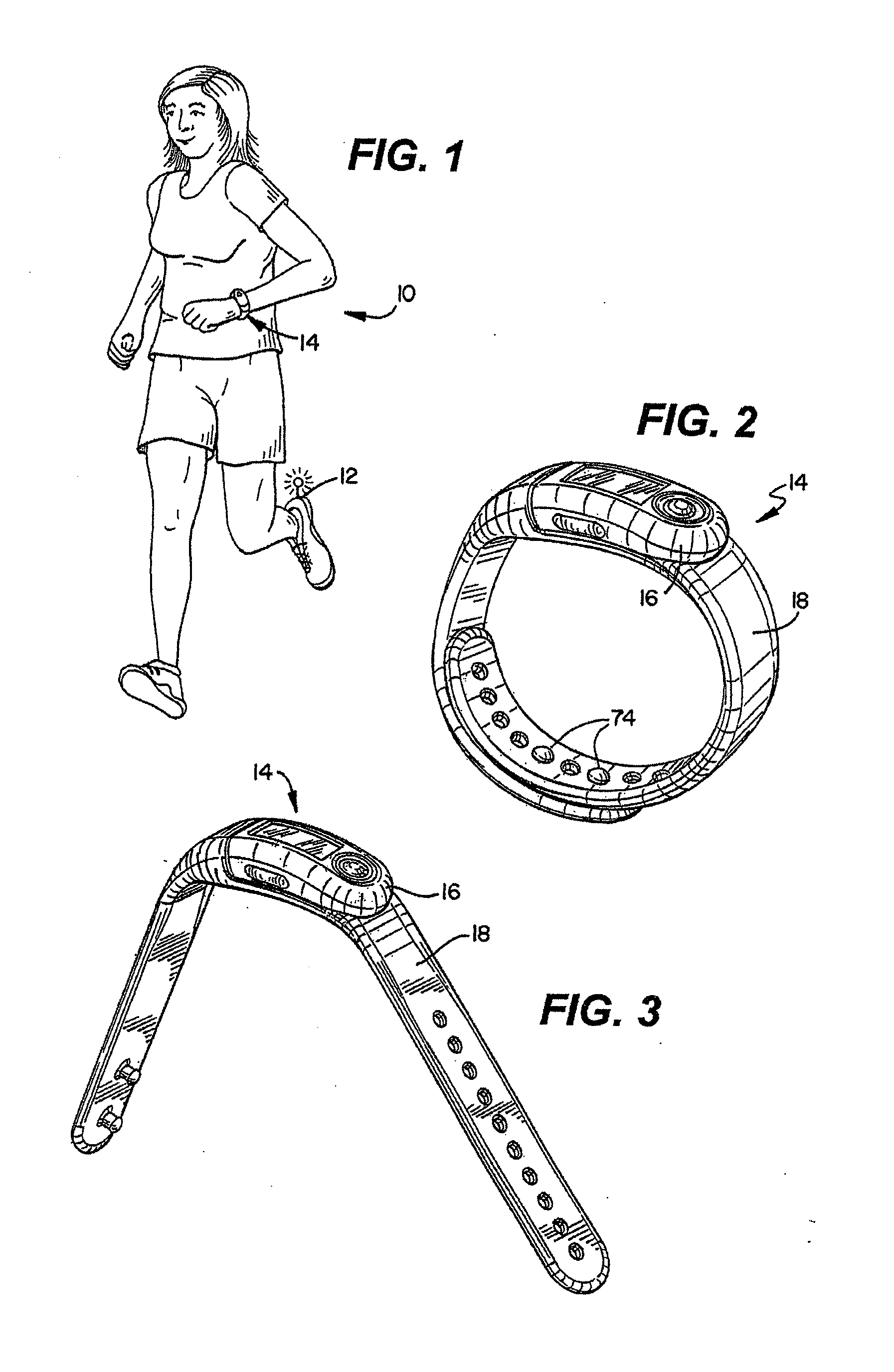

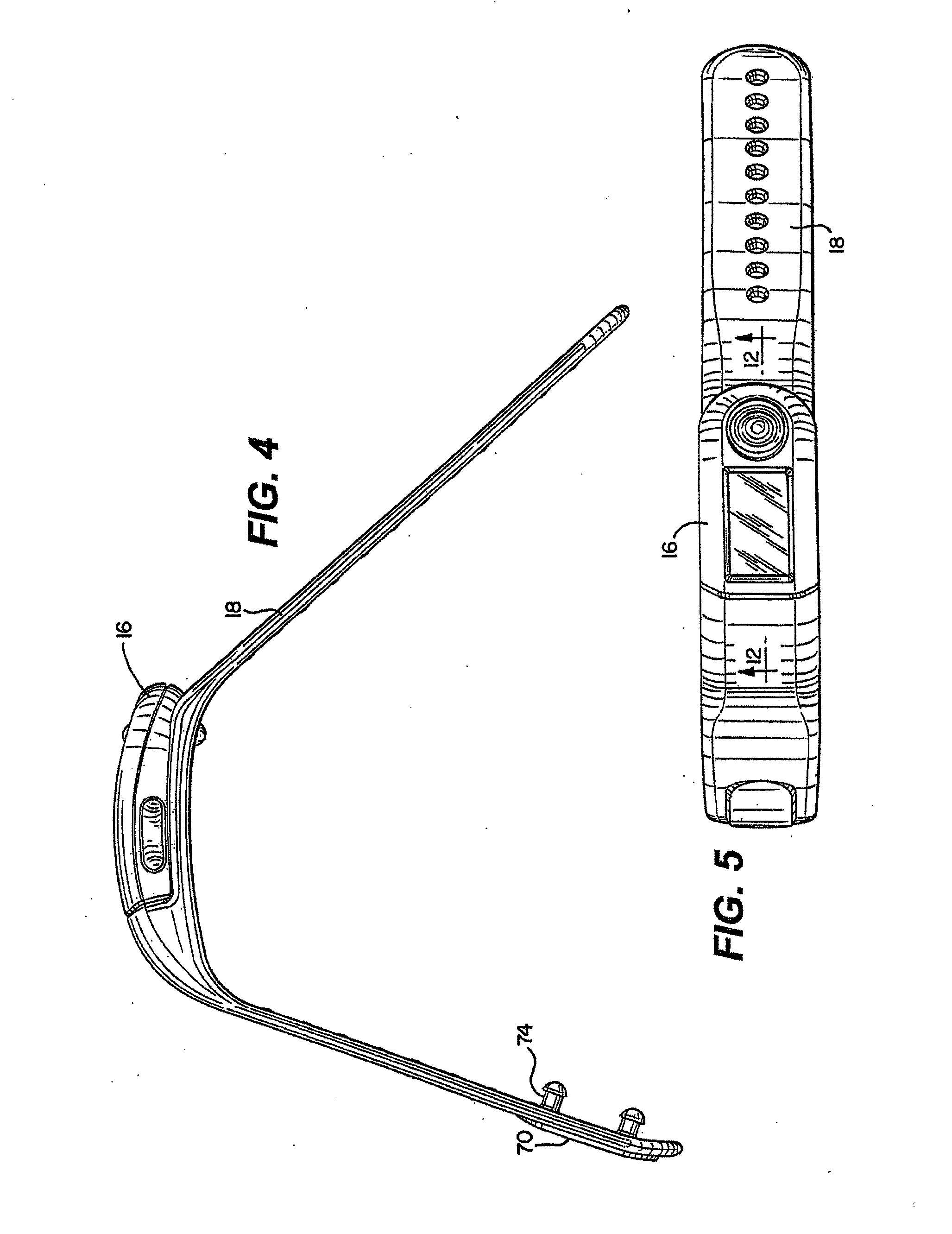

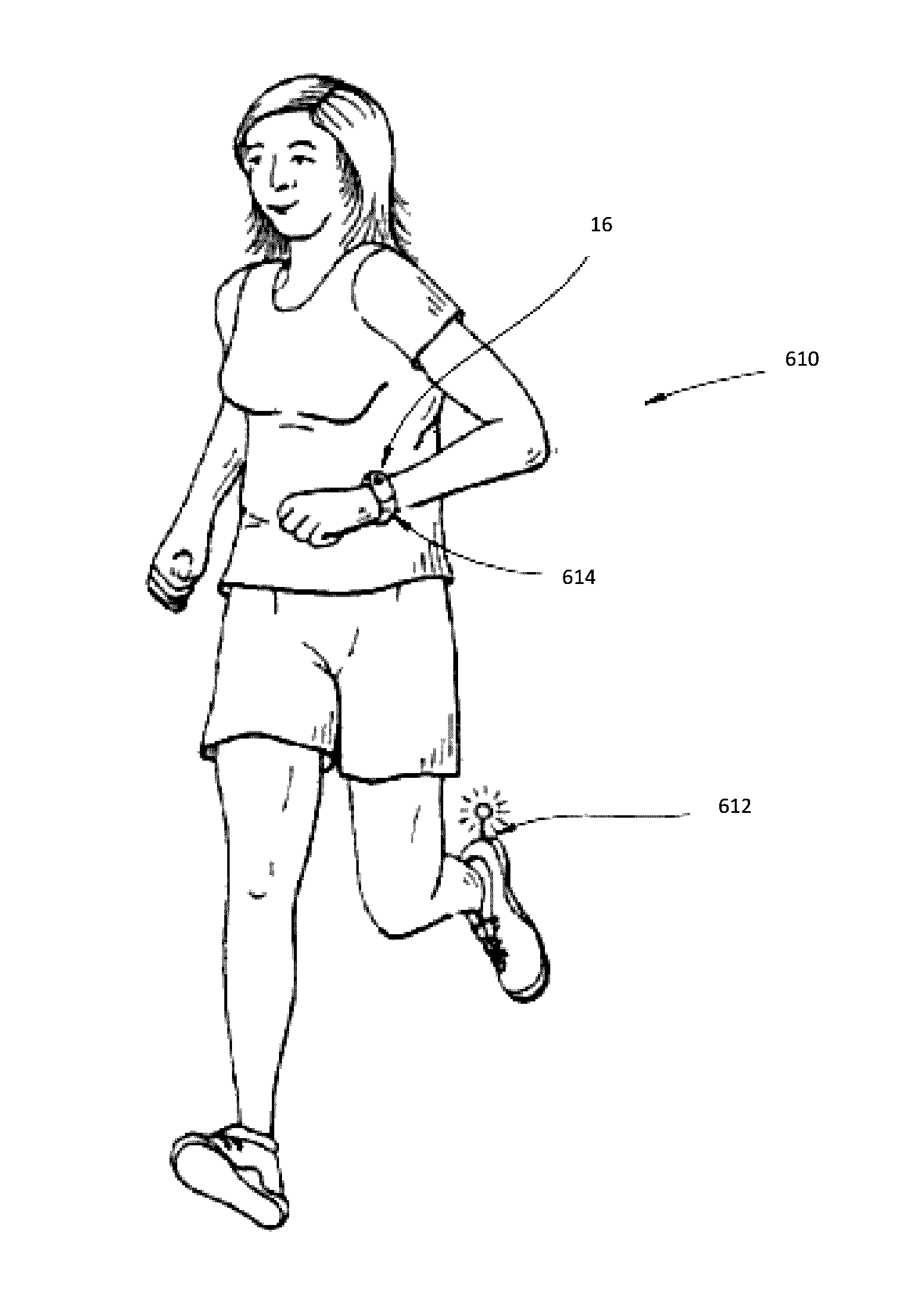

Wearable Device Assembly Having Athletic Functionality

ActiveUS20100311544A1Function increaseImprove accuracyGymnastic exercisingDigital computer detailsAppliance componentMotor function

A wearable device has a carrier having an aperture. A device has a USB connection and a protrusion wherein the protrusion is received in the aperture to connect the device to the wristband. The device is a USB type device having athletic functionality. The device may further be configured to receive calibration data such that a measured distance may be converted to a known distance based on athletic activity performed by a user.

Owner:NIKE INC

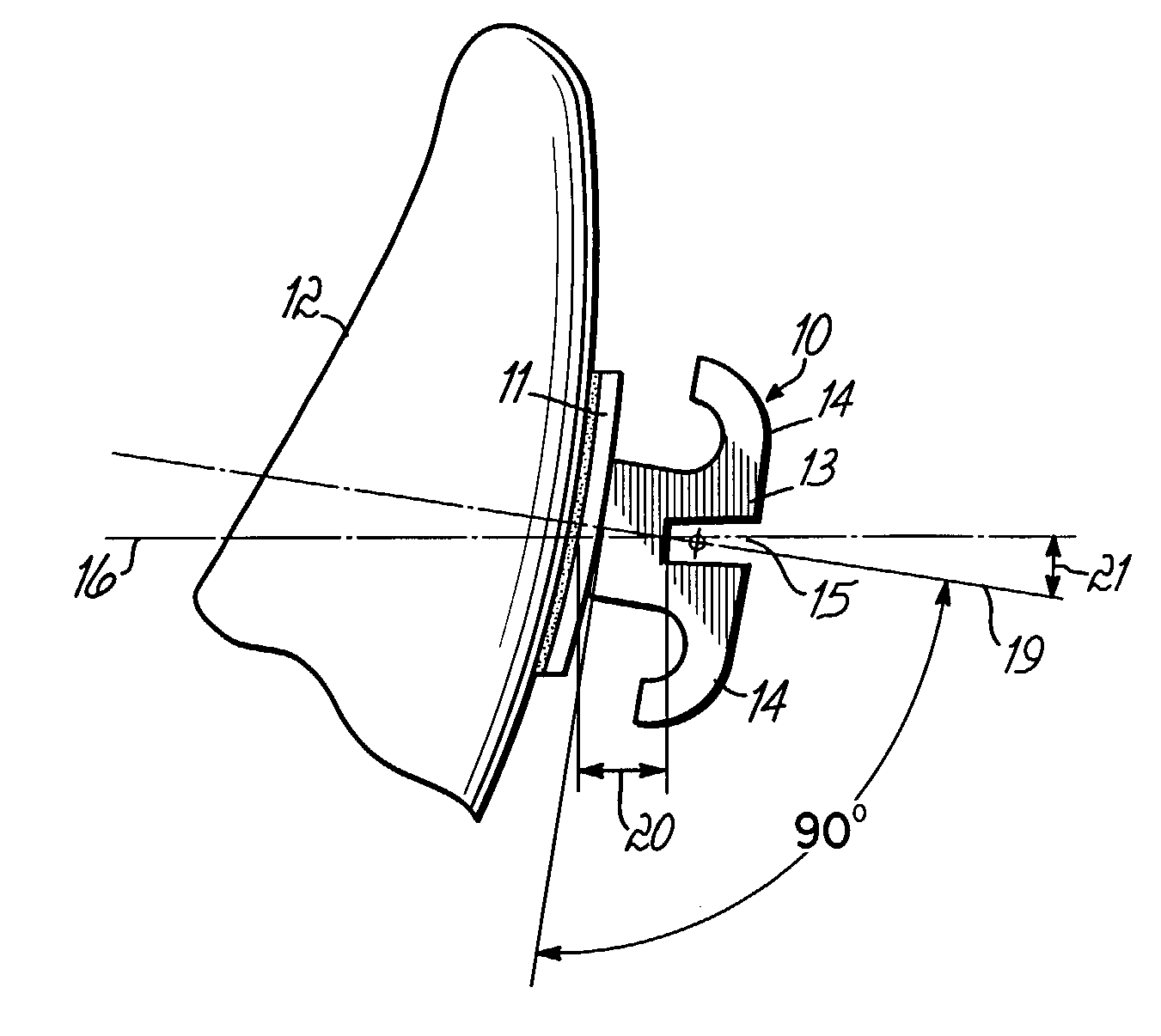

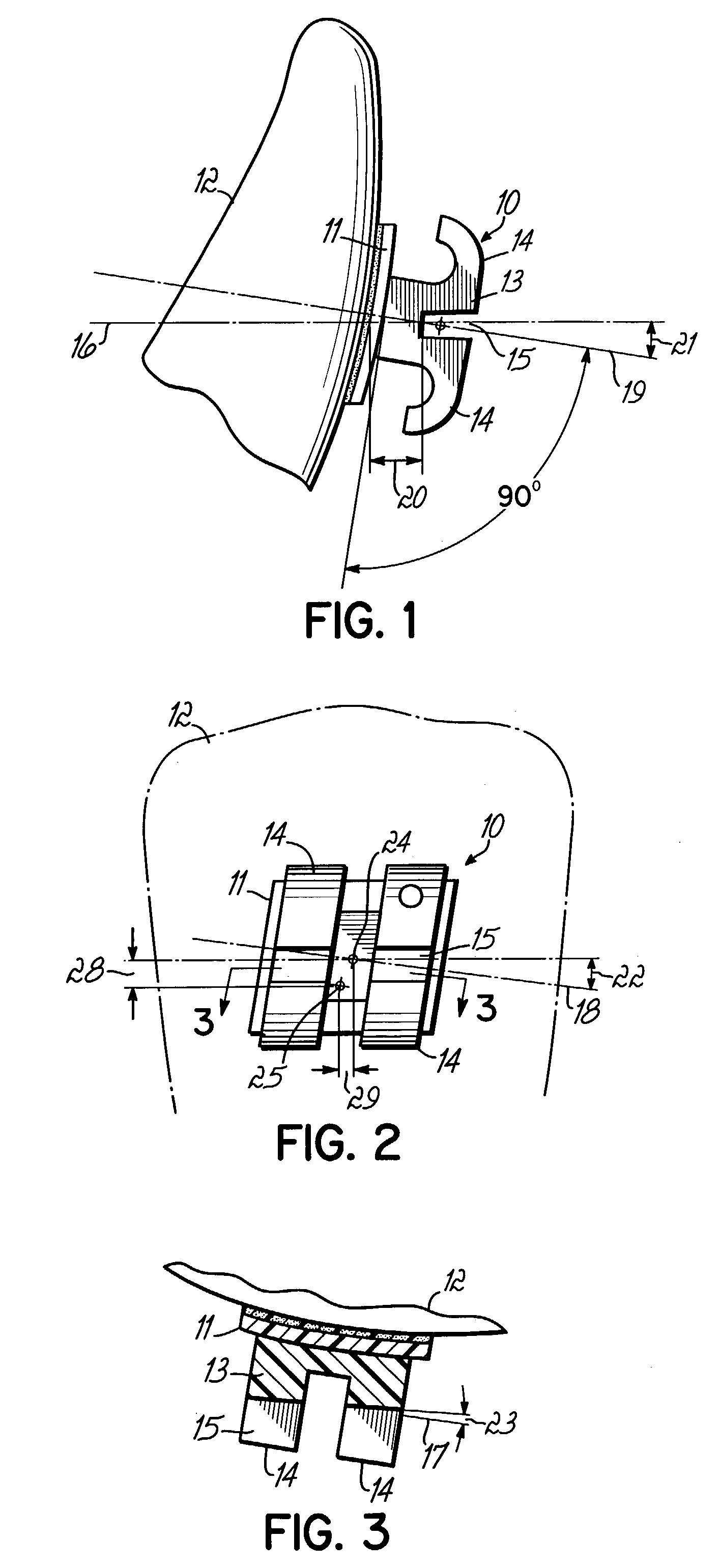

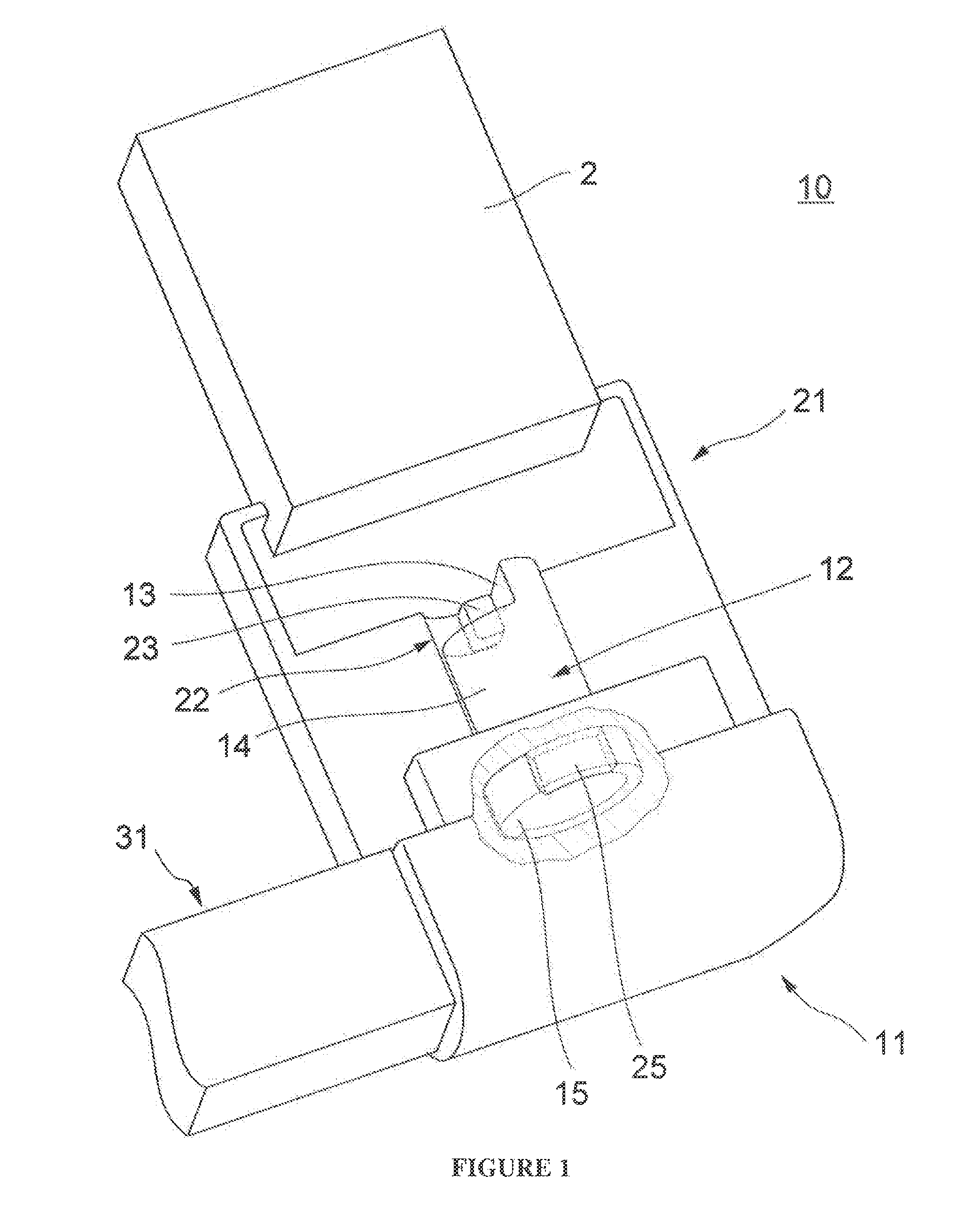

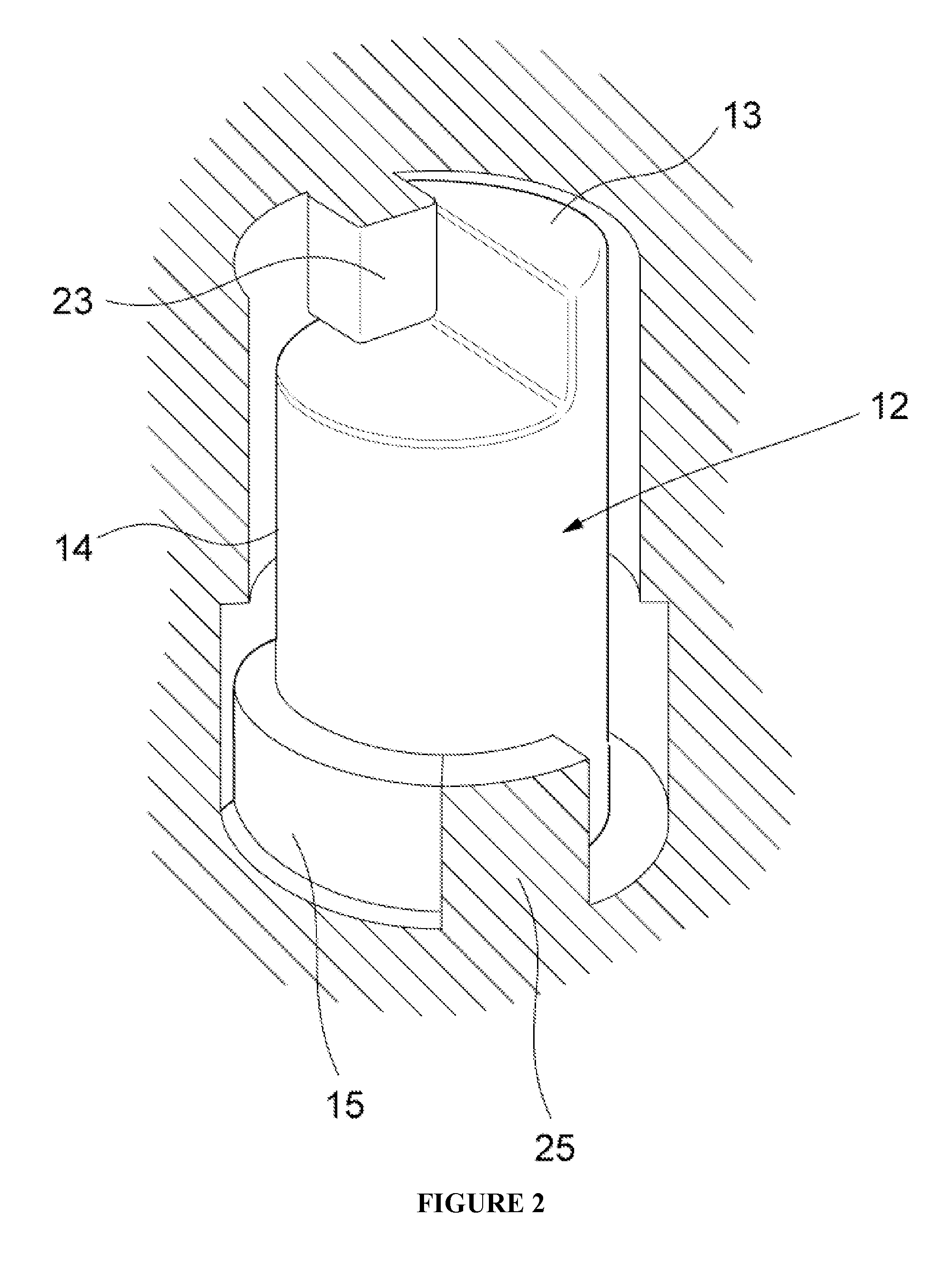

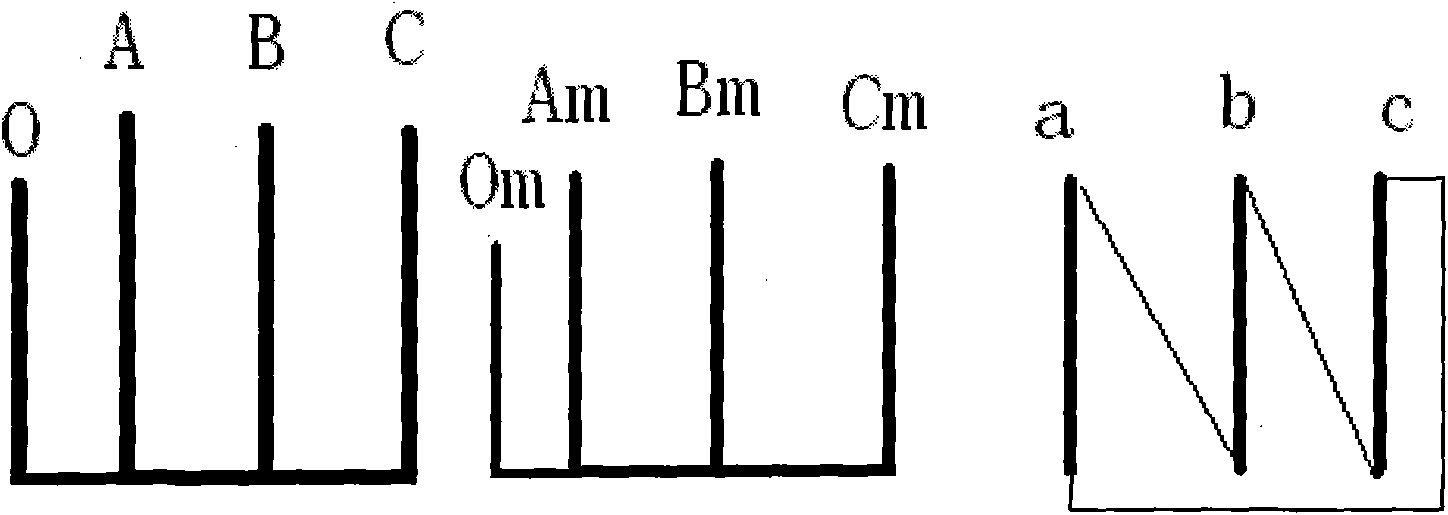

Providing custom orthodontic treatment with appliance components from inventory

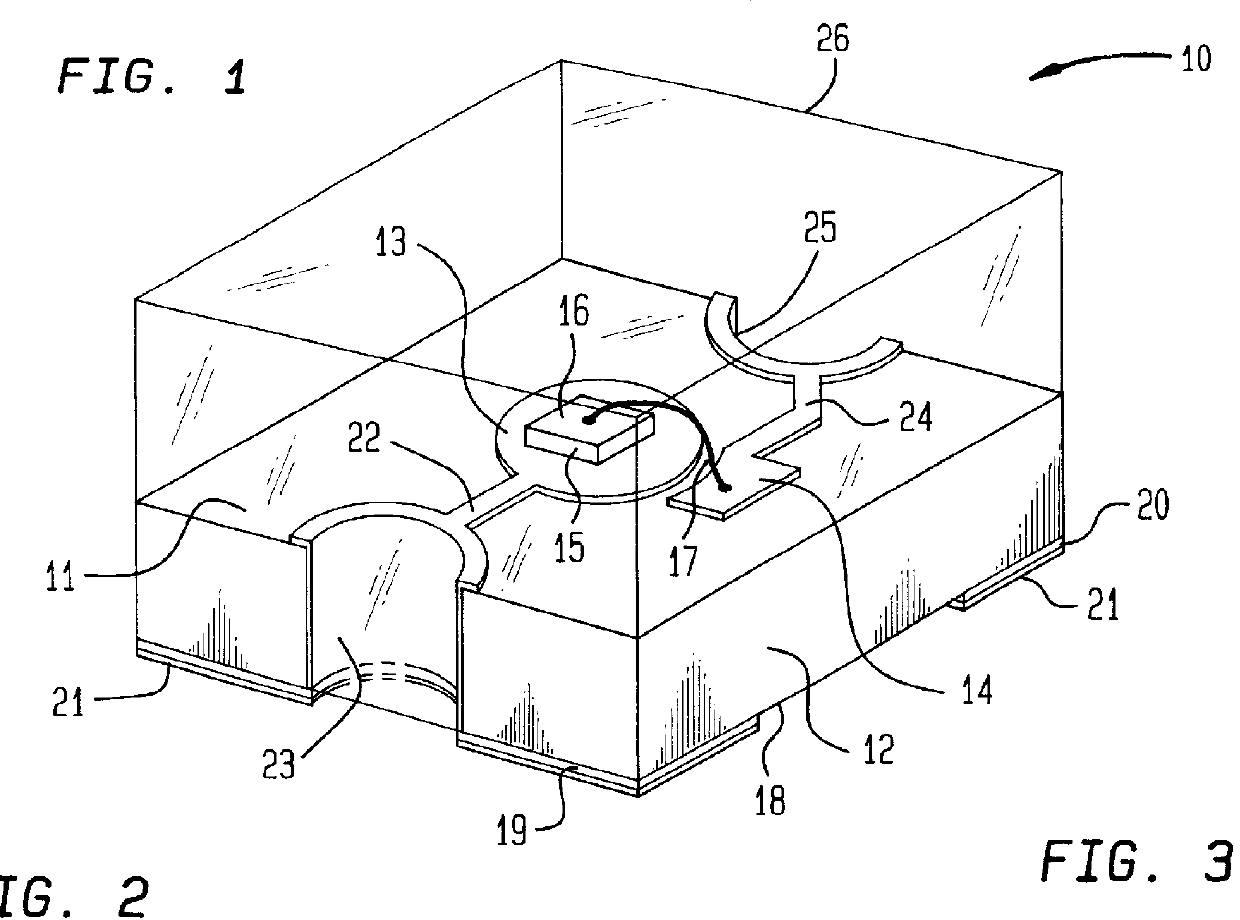

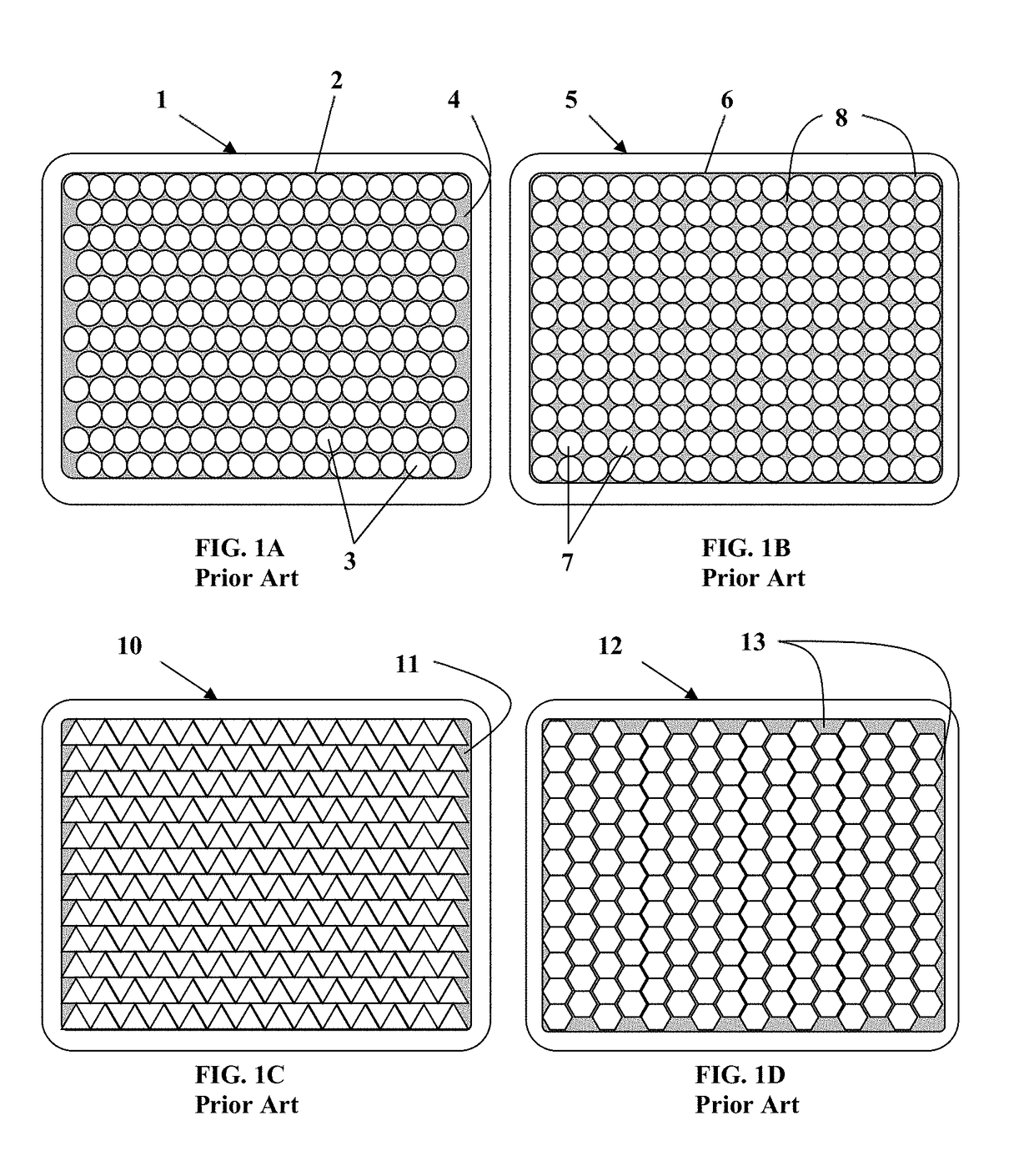

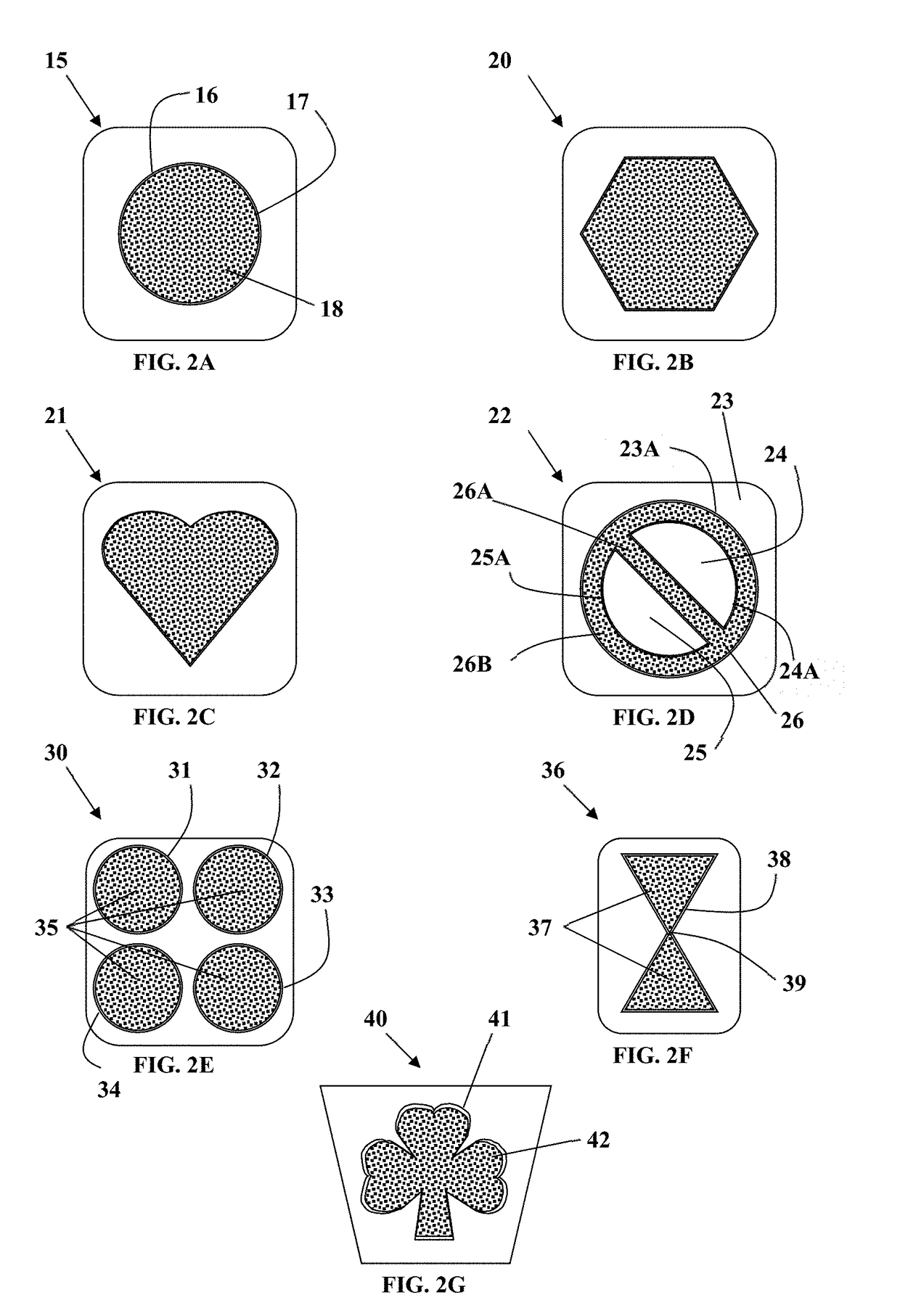

Computer analysis is made of individual patient related data in order to select standard or pre-manufactured orthodontic appliances or appliance components (10) that are most likely to provide orthodontic treatment suitable for the individual patient. This analysis can be made by the software of a custom orthodontic appliance designing system, without actually manufacturing the custom appliance. Geometric parameters (21-24, 28, 29) of a custom designed appliance may be compared with corresponding parameters of alternative standard appliances or appliance components so that the closest standard component can be used. The custom appliance can be designed to accommodate the geometries of one or more appliance components. Where custom mounting instructions that modify otherwise standard installation of an appliance or component will render the standard component more compatible with a custom appliance design, such instructions are provided to the orthodontist along with the selection. The invention is most useful in selecting orthodontic brackets, or combinations of standard brackets and standard archwires.

Owner:ORMCO CORP

Modular surface mount component for an electrical device or LED's

InactiveUSRE36614E1Reduce manufacturing costHighly suitablePrinted circuit assemblingDischarge tube luminescnet screensEpoxySurface mounting

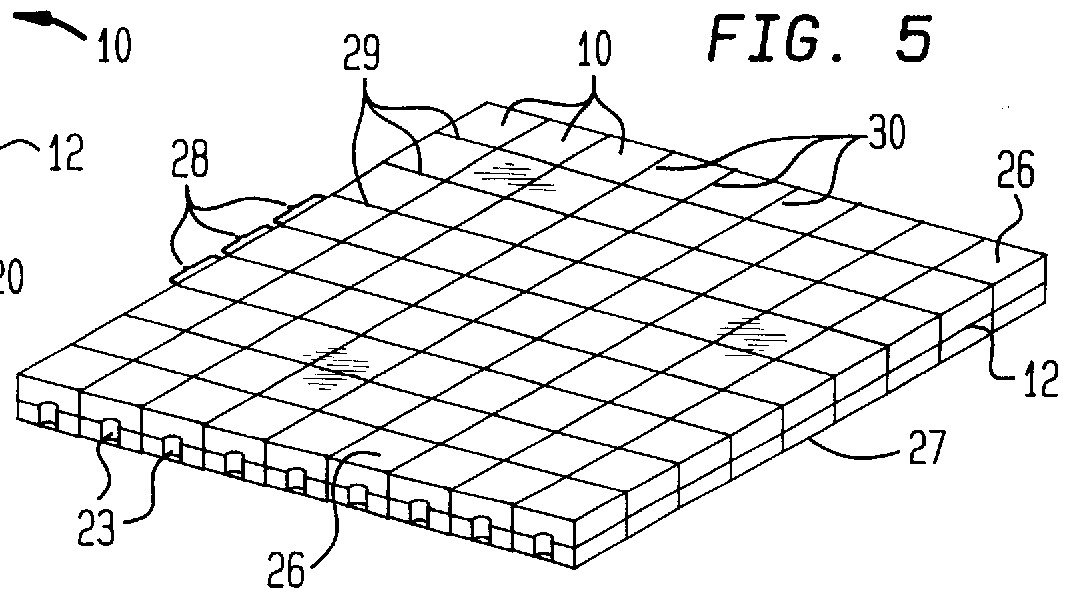

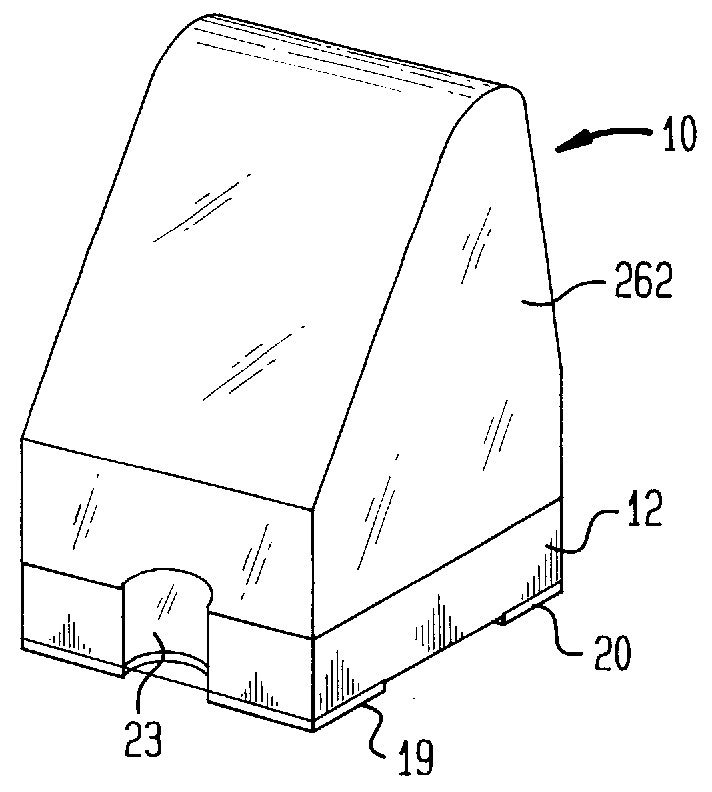

Processing techniques for various surface mount modular components provide various structures for single device components (10) and multiple device components (FIGS. 6 and 7) suitable as character displays. The technique beings with a slab of substrate material 12 patterned on both sides. Plated through holes (33, 43) connecting back side terminals (19, 20) to front side connective strips (22, 24) are formed. Devices (15, 16) are mounted to land areas (13, 34) and wire bonded to connecting pads (14). The front side is coated with epoxy to encapsulate the devices in a layer having an outer surface formed into optional lenses (262, 263). The slab is then separated to provide the modular components.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG +1

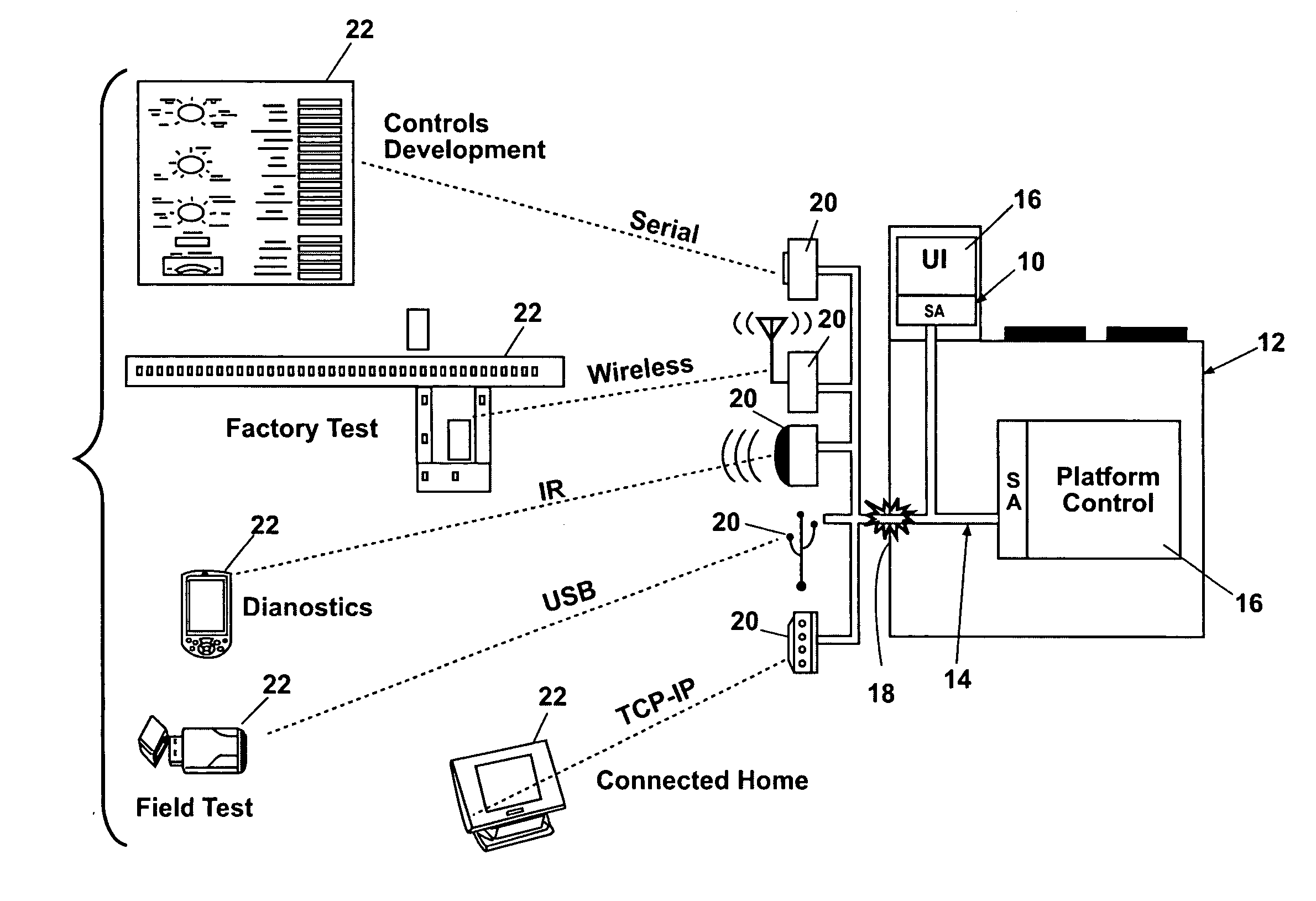

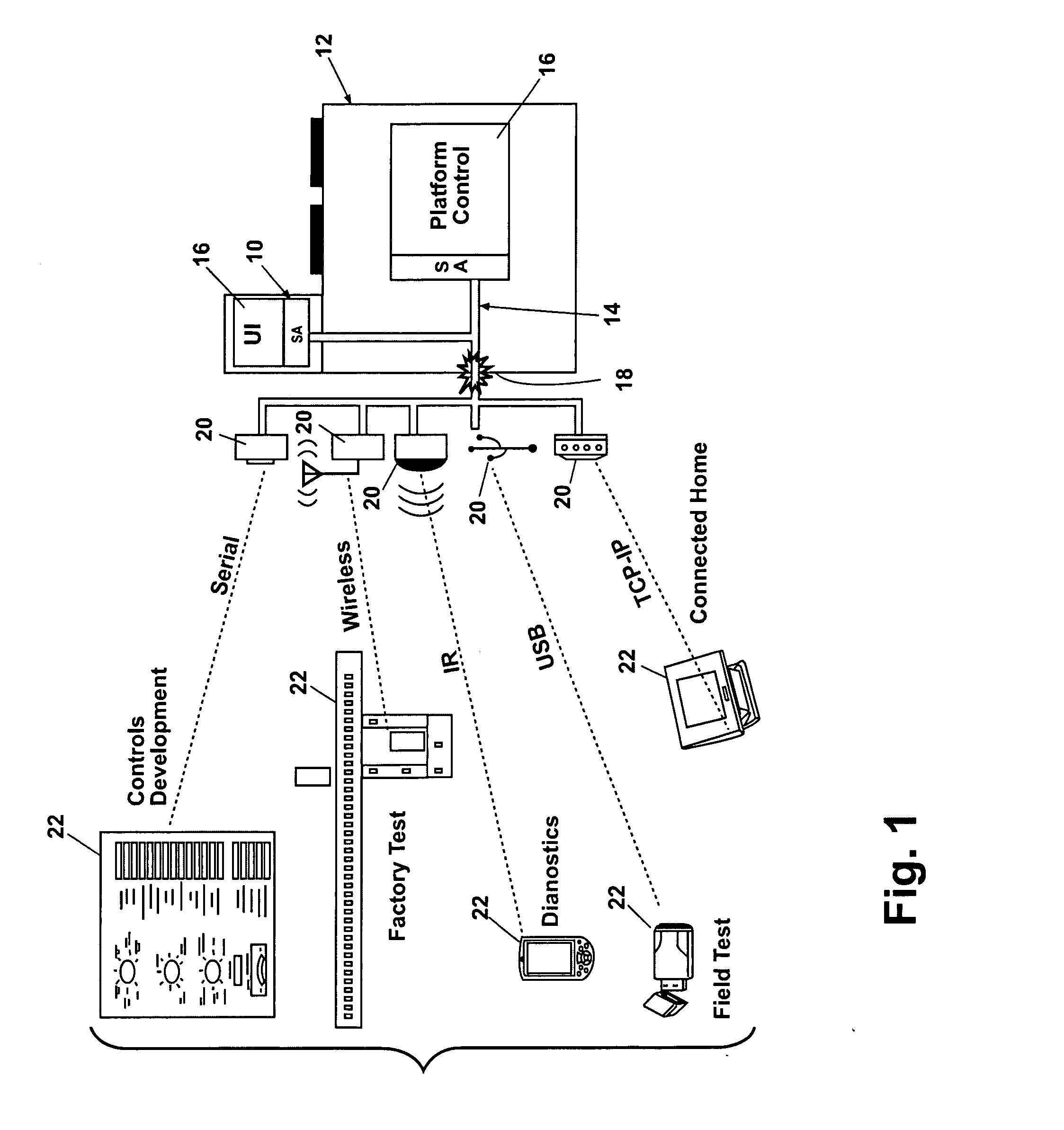

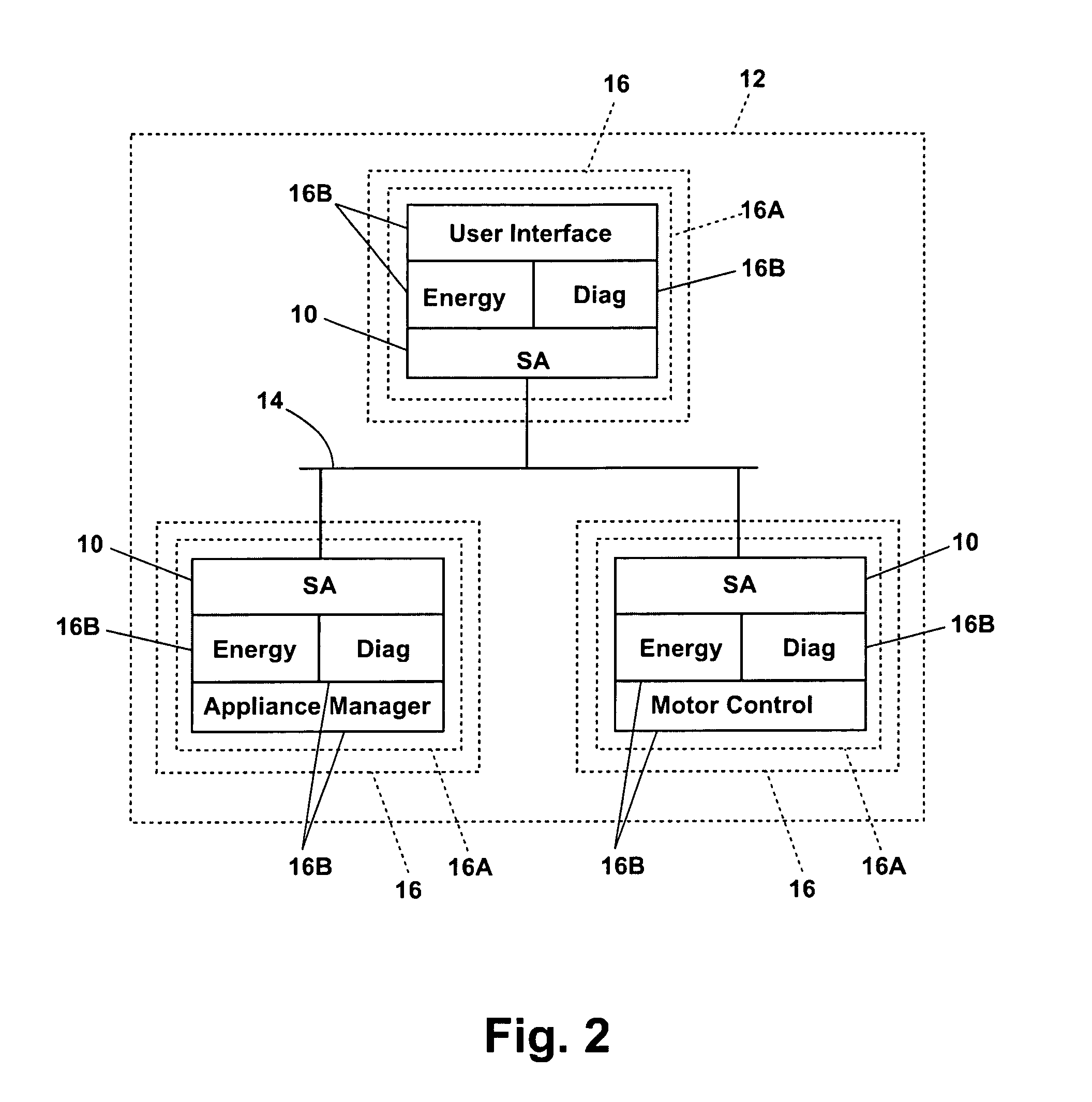

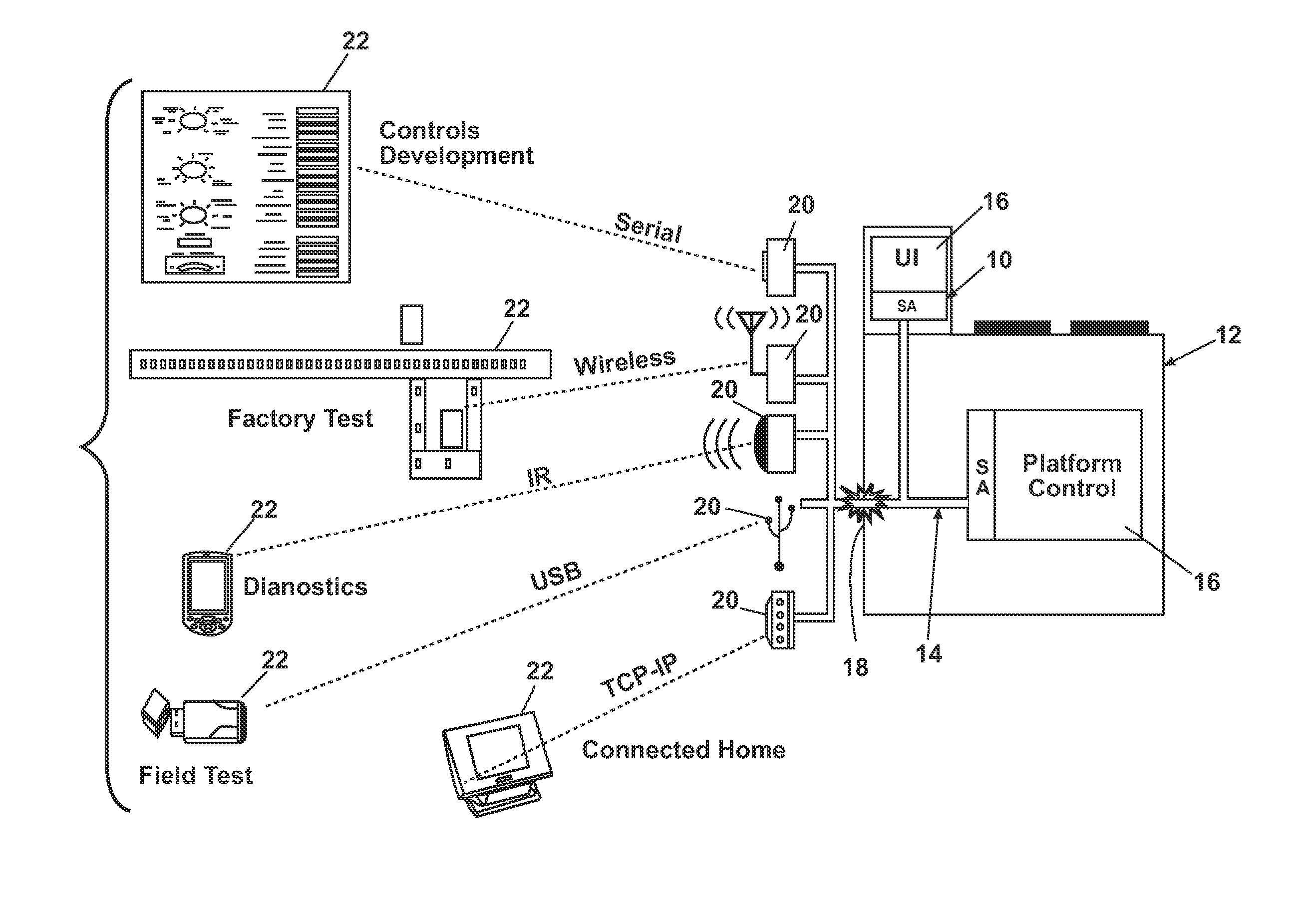

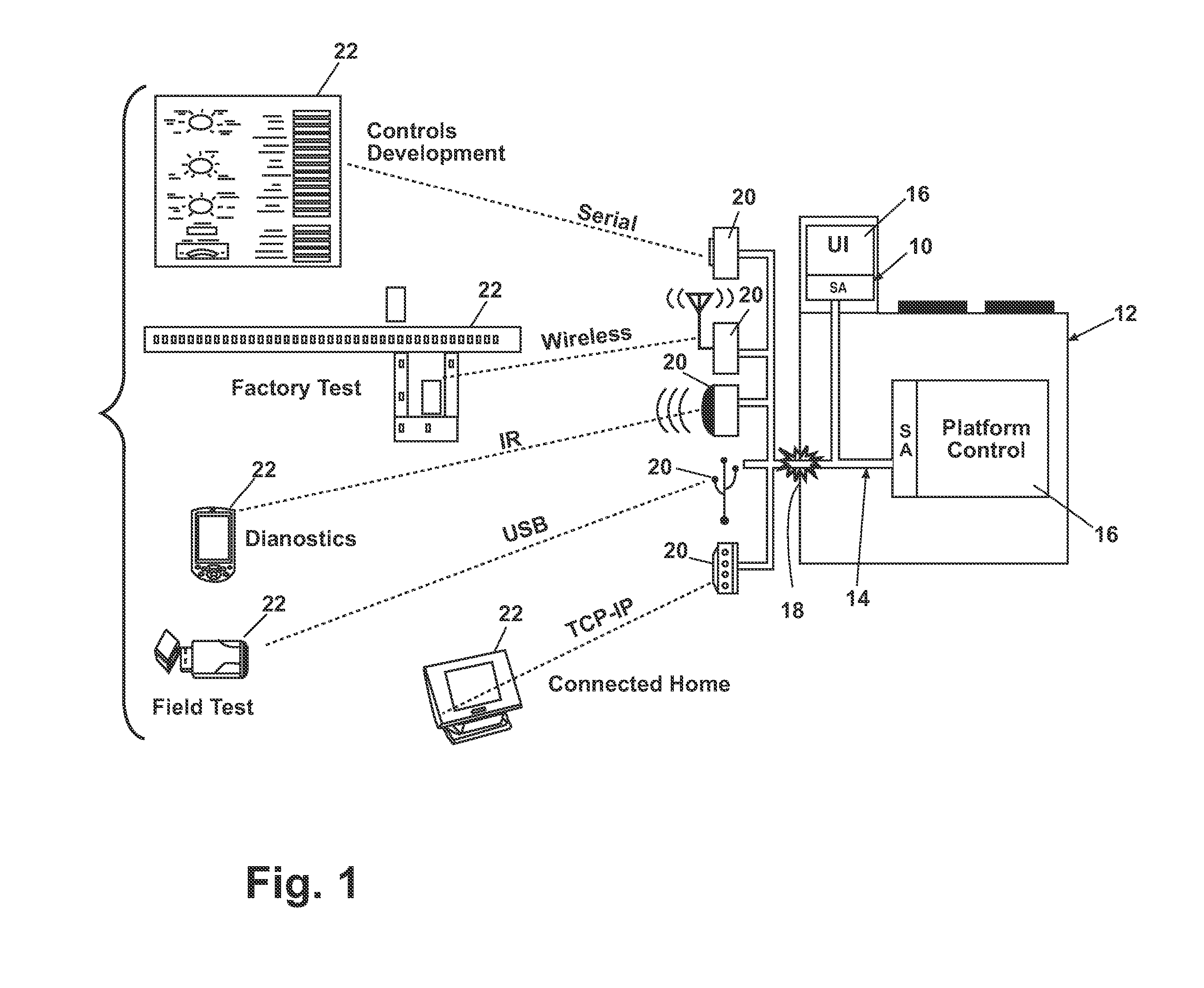

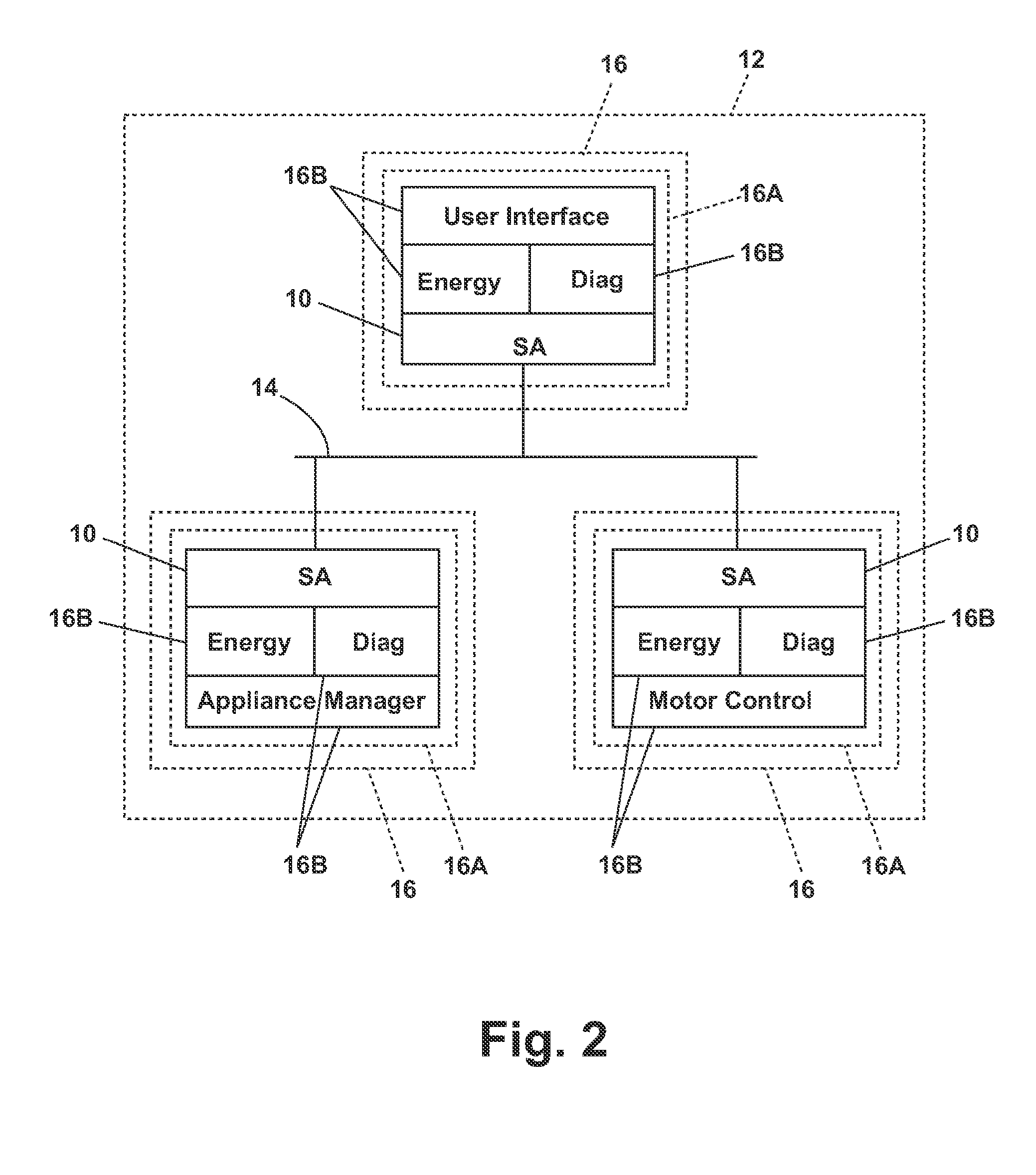

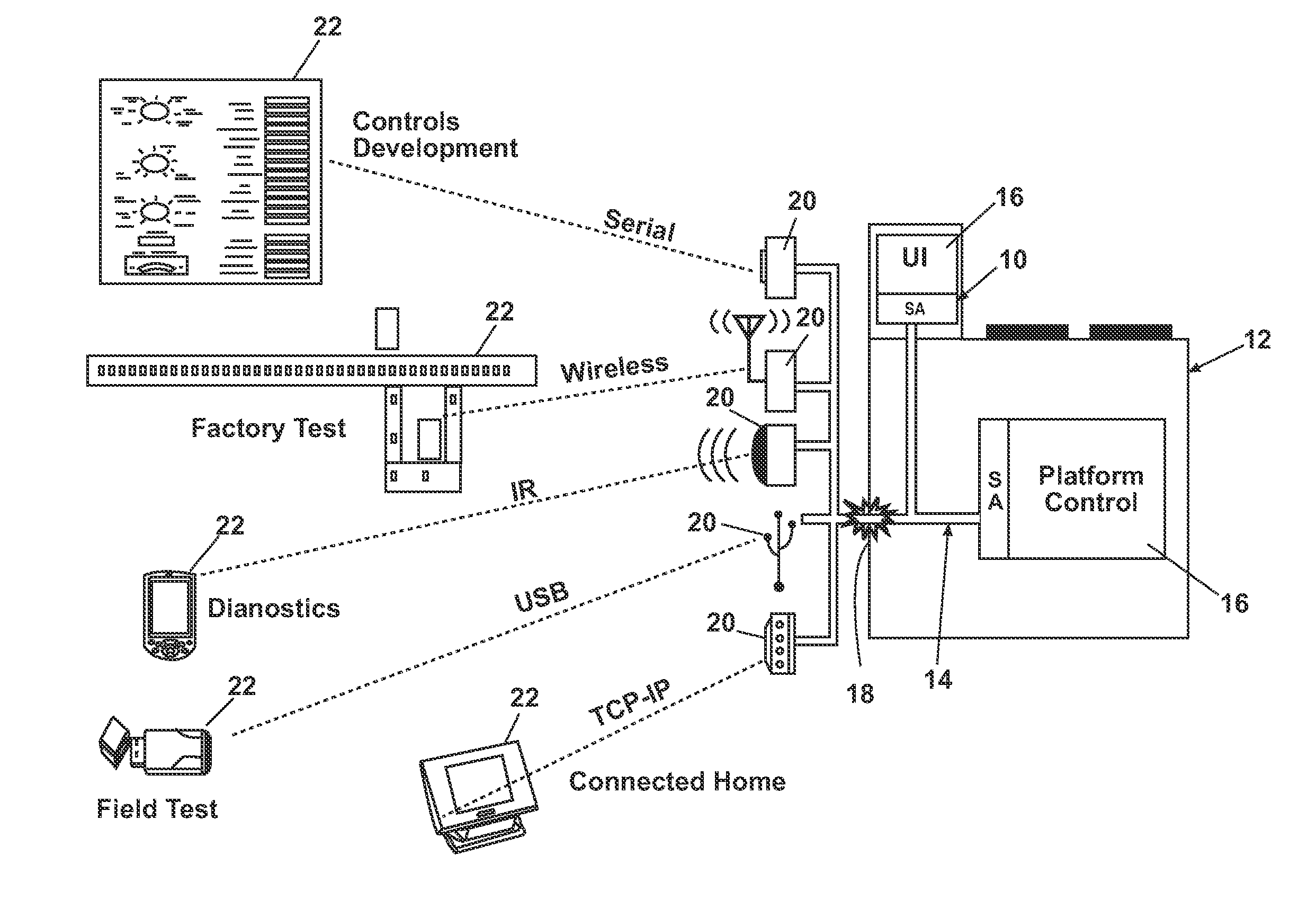

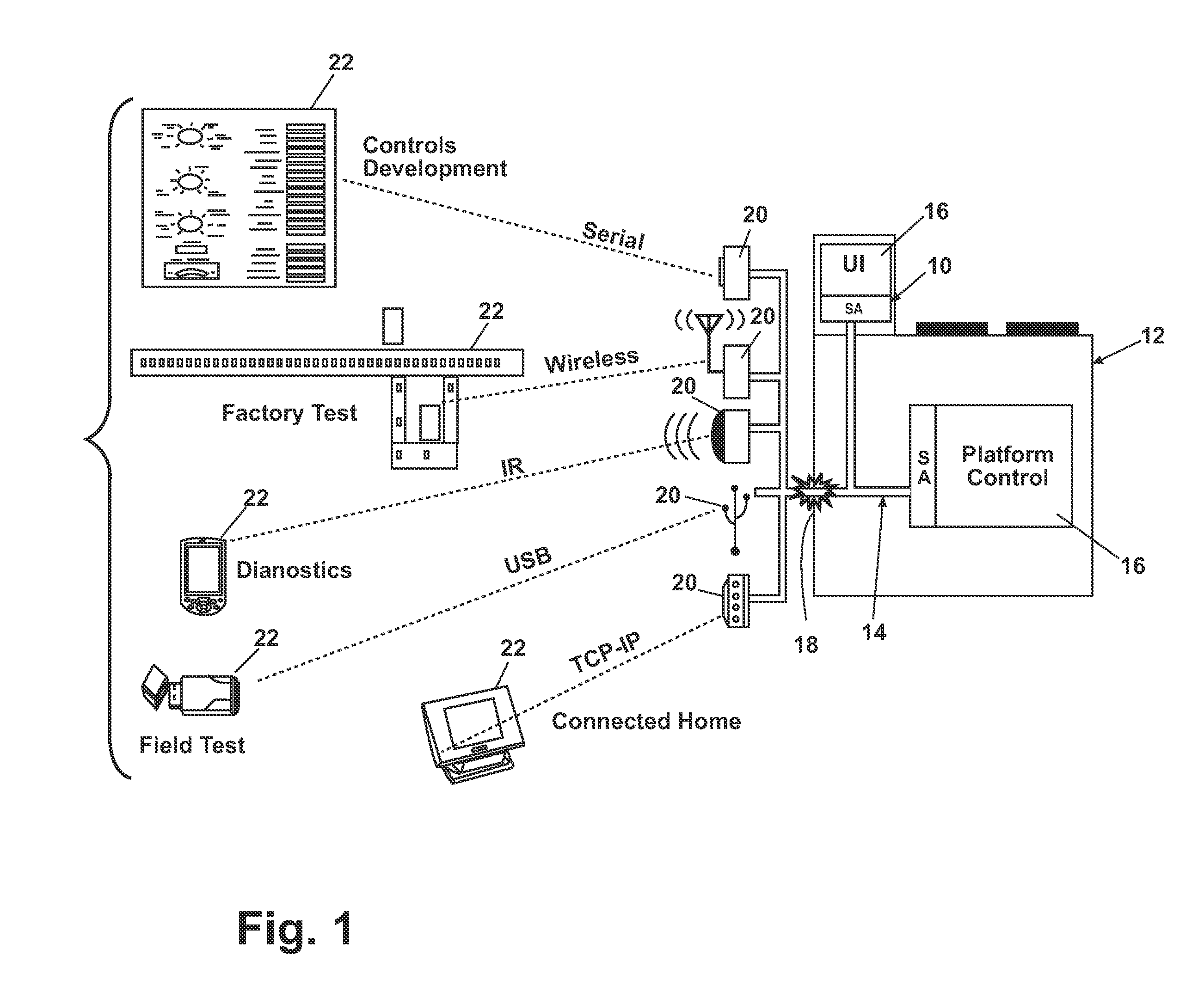

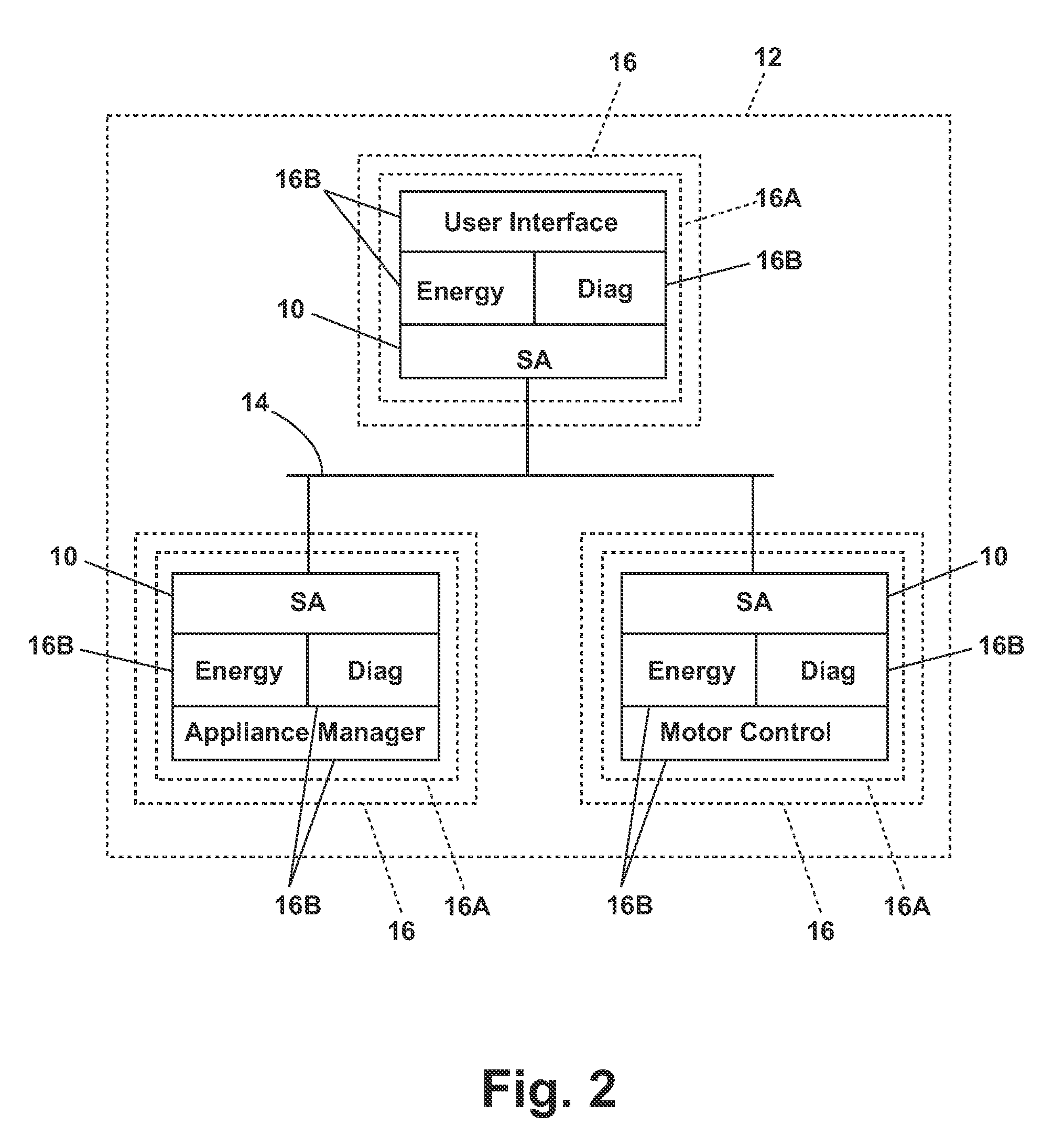

Software architecture system with embedded virtual router

ActiveUS20080104212A1Facilitate communicationEnergy efficient ICTWashing controlling processesSoftware architectureAppliance component

The invention relates to a network system of at least two appliances, each appliance configured to perform a cycle of operation on an article, and each appliance having its own software architecture. An embedded virtual router enables communication among appliance components independent of the architecture of the software.

Owner:WHIRLPOOL CORP

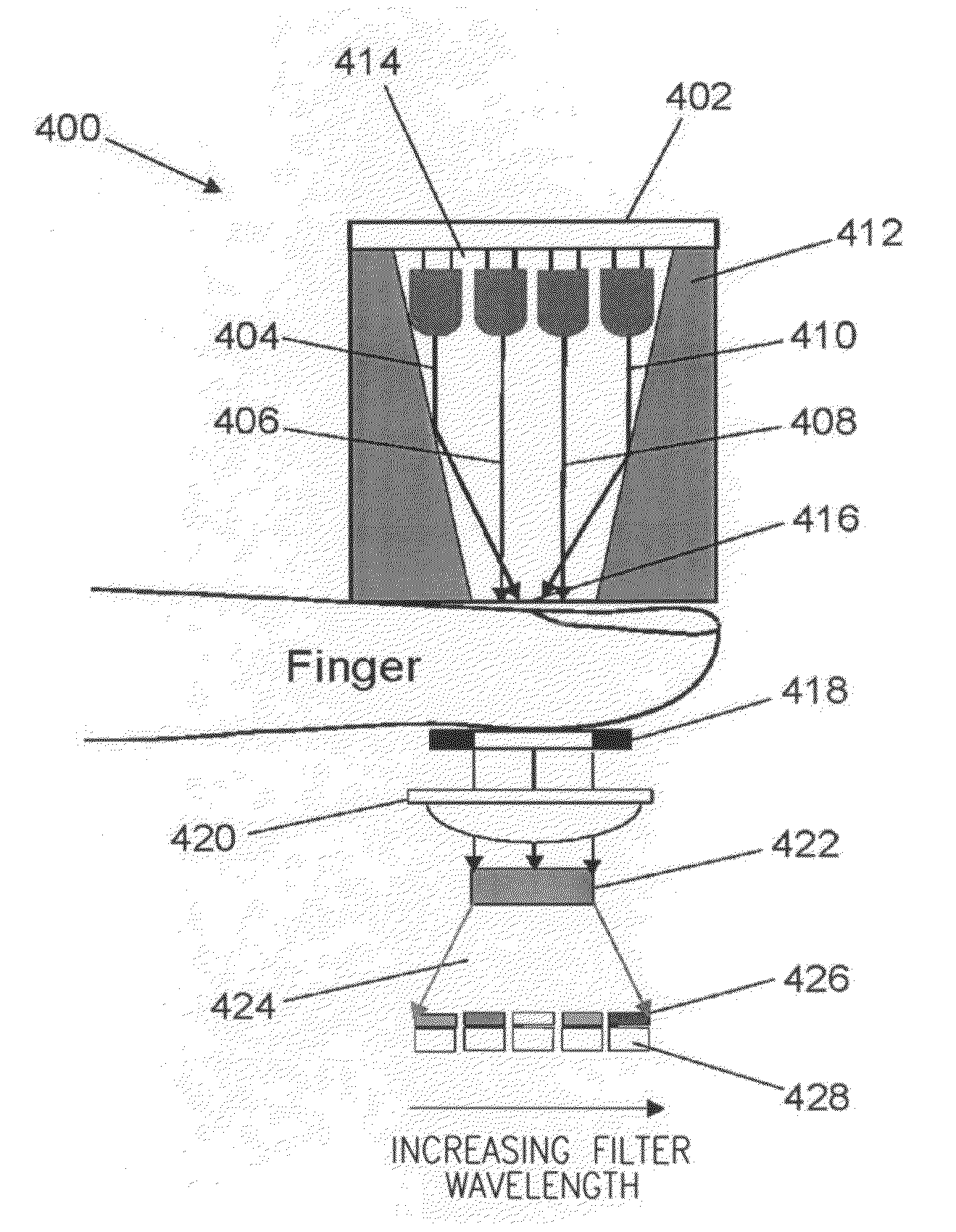

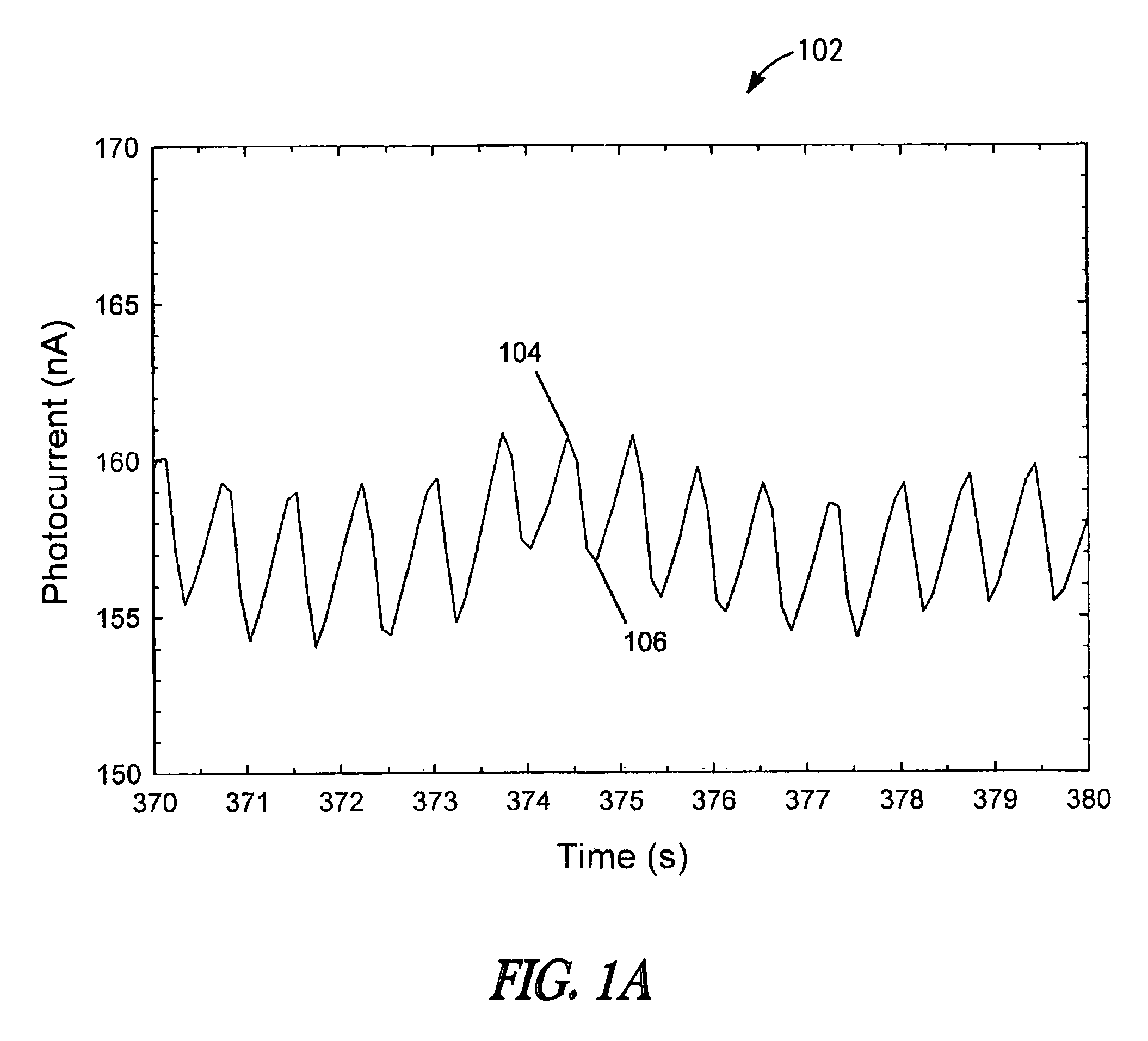

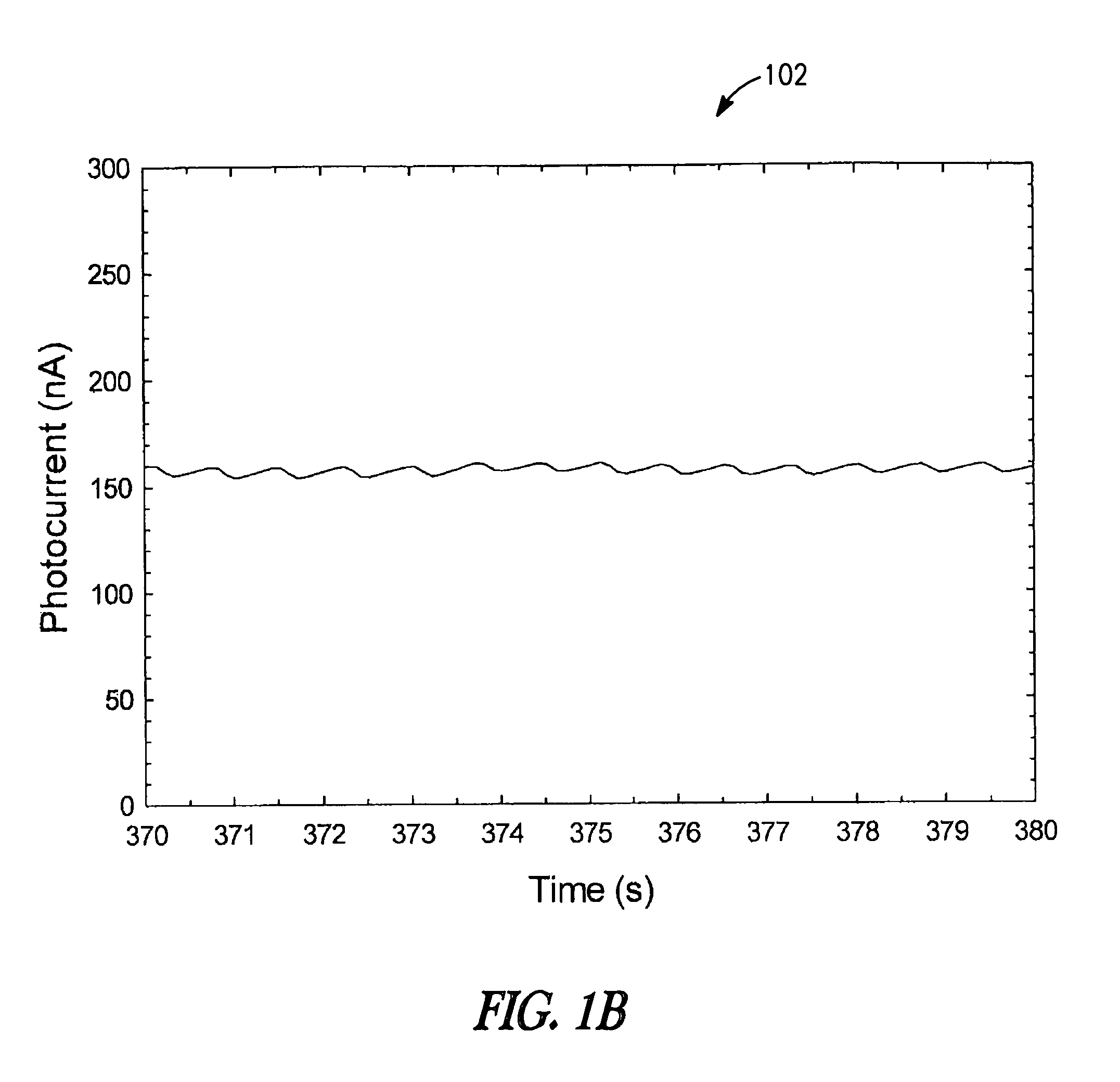

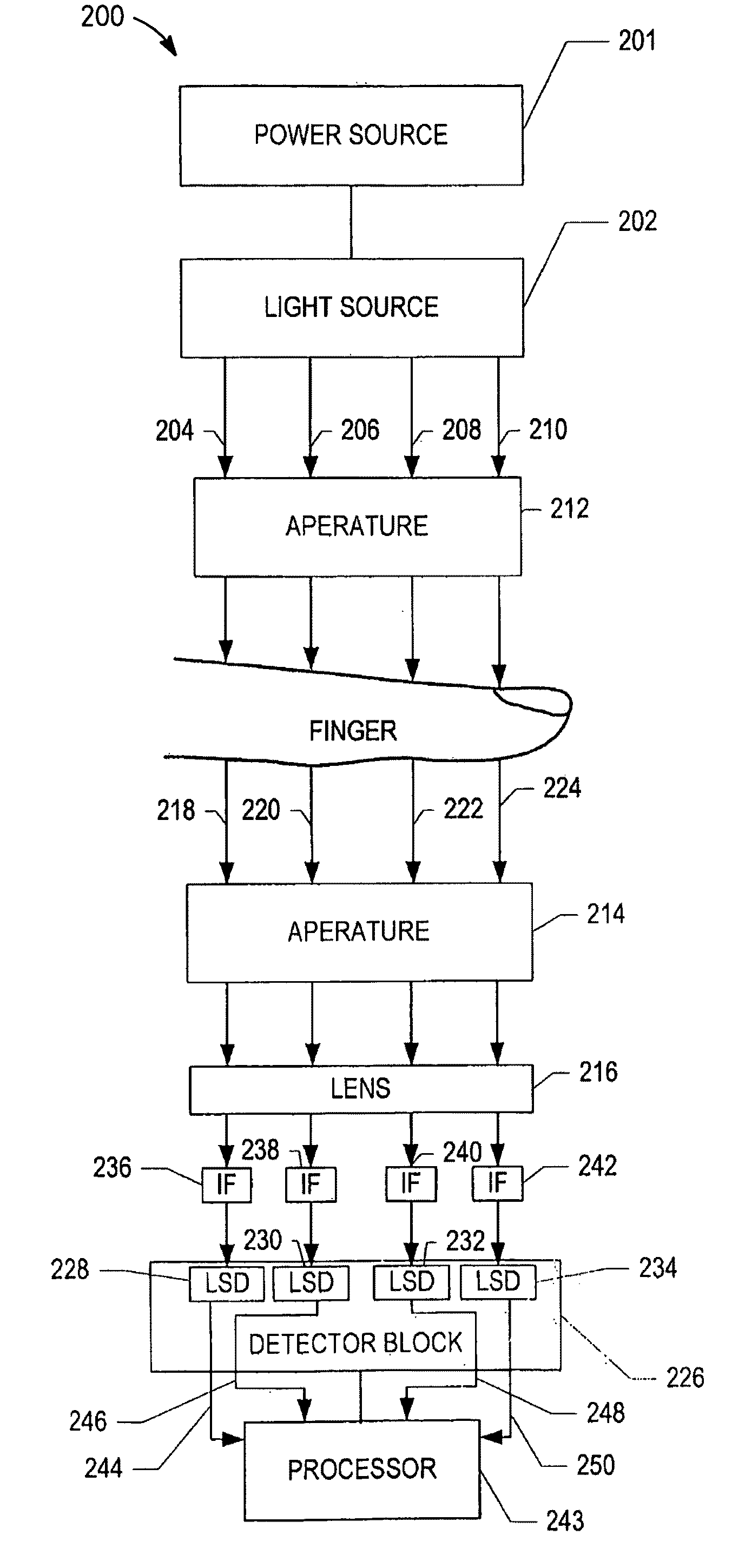

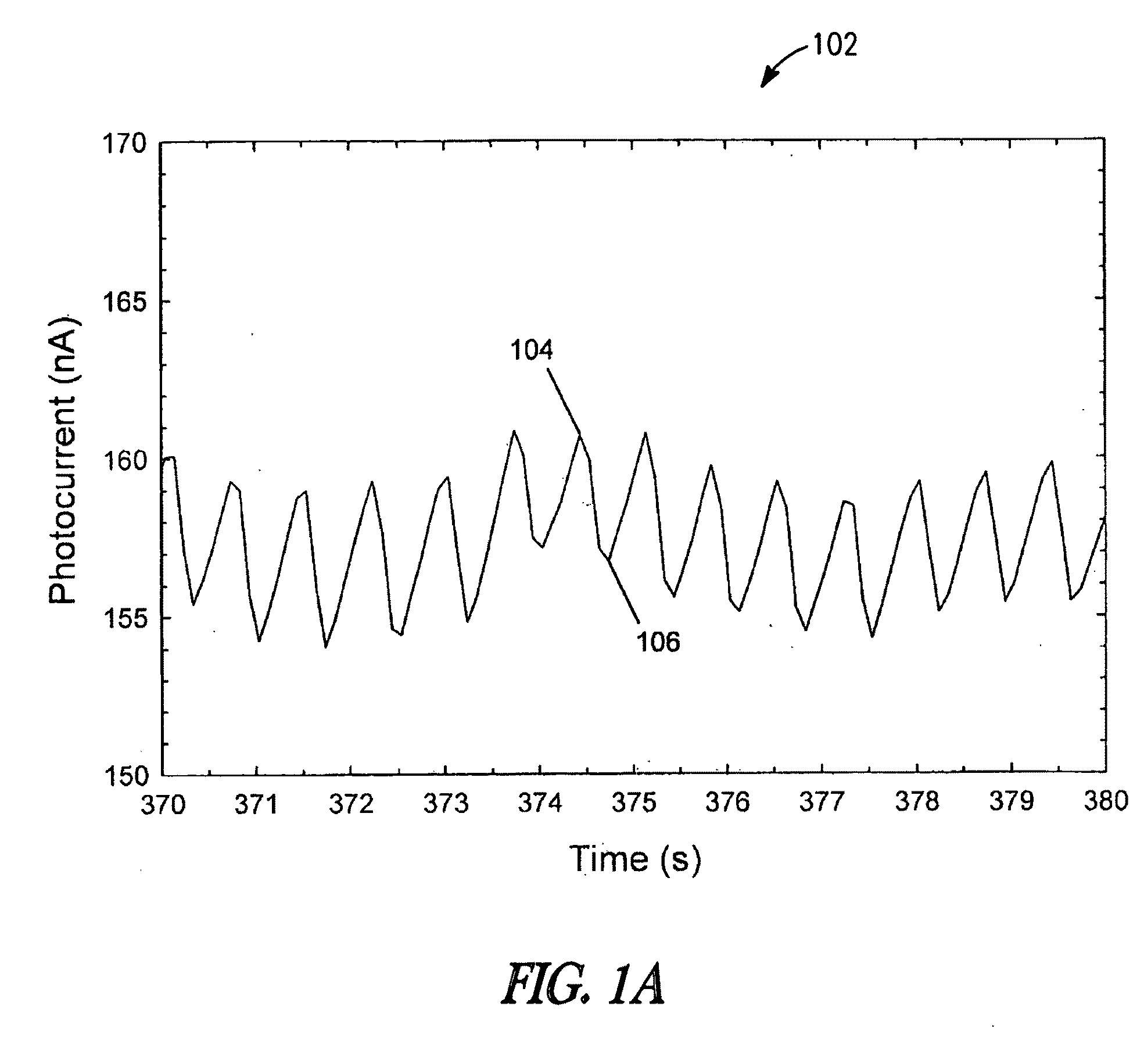

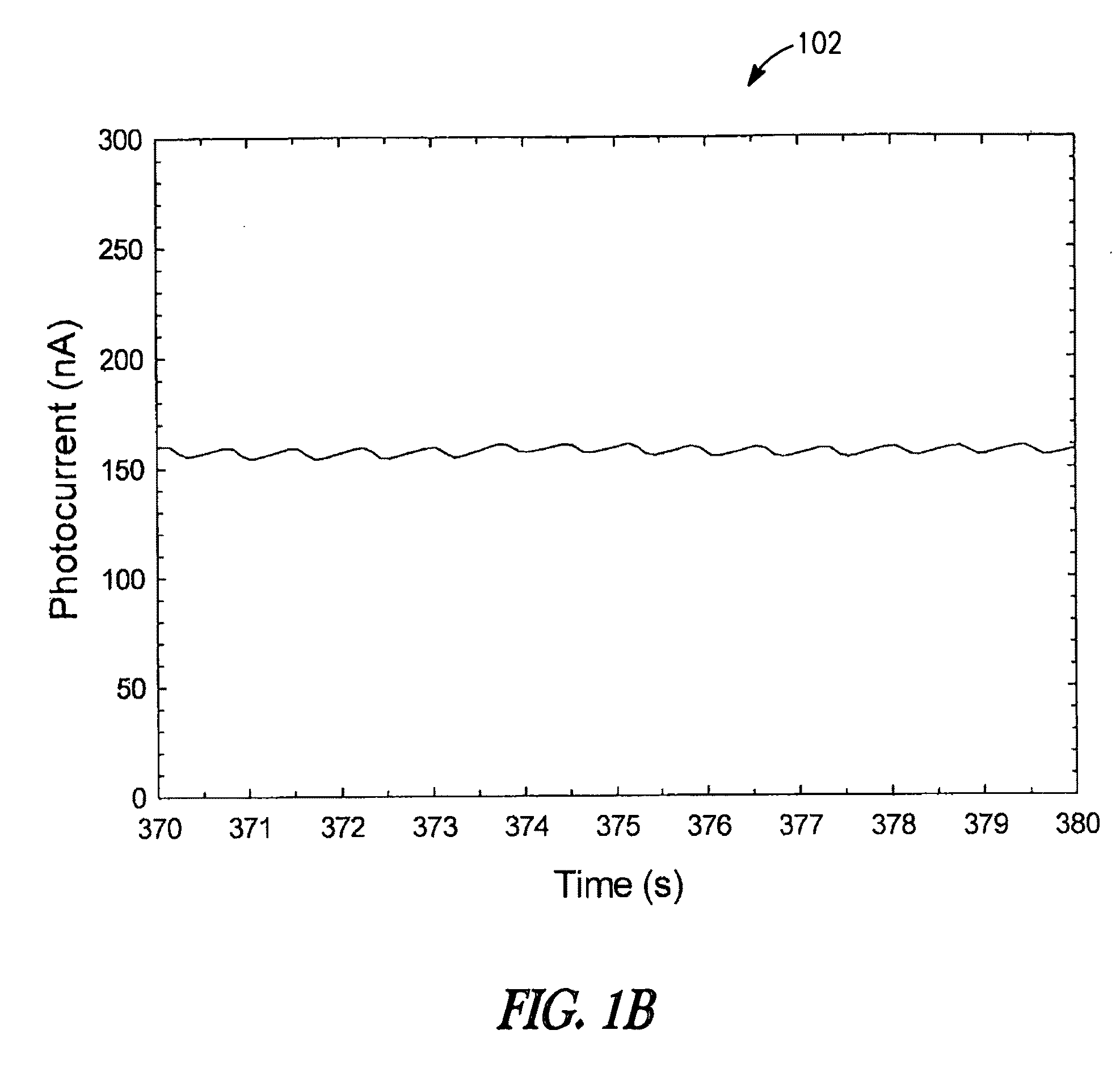

Optical device components

ActiveUS7809418B2Material analysis by optical meansDiagnostic recording/measuringLight sensingLight beam

Embodiments of the invention relate to an apparatus including a light source to generate a plurality of light beams with each of the plurality of light beams having a different wavelength range. The apparatus also includes a light funnel to direct the plurality of light beams to the target area, an aperture to direct the plurality of light beams emitting from the target area to a lens, the lens configured to collect the light beams emitting from the target area. Further, the apparatus includes a detector including a plurality of light-sensing devices each configured to detect a light beam and configured to generate an output signal indicative of an intensity of light detected and a processor for determining the blood characteristic as a function of each generated output signal.

Owner:ST LOUIS MEDICAL DEVICES INC

Software Architecture System with Embedded Virtual Router

ActiveUS20080109830A1Facilitate communicationWashing controlling processesEnergy efficient ICTSoftware architectureAppliance component

The invention relates to a network system of at least two appliances, each appliance configured to perform a cycle of operation on an article, and each appliance having its own software architecture. An embedded virtual router enables communication among appliance components independent of the architecture of the software.

Owner:WHIRLPOOL CORP

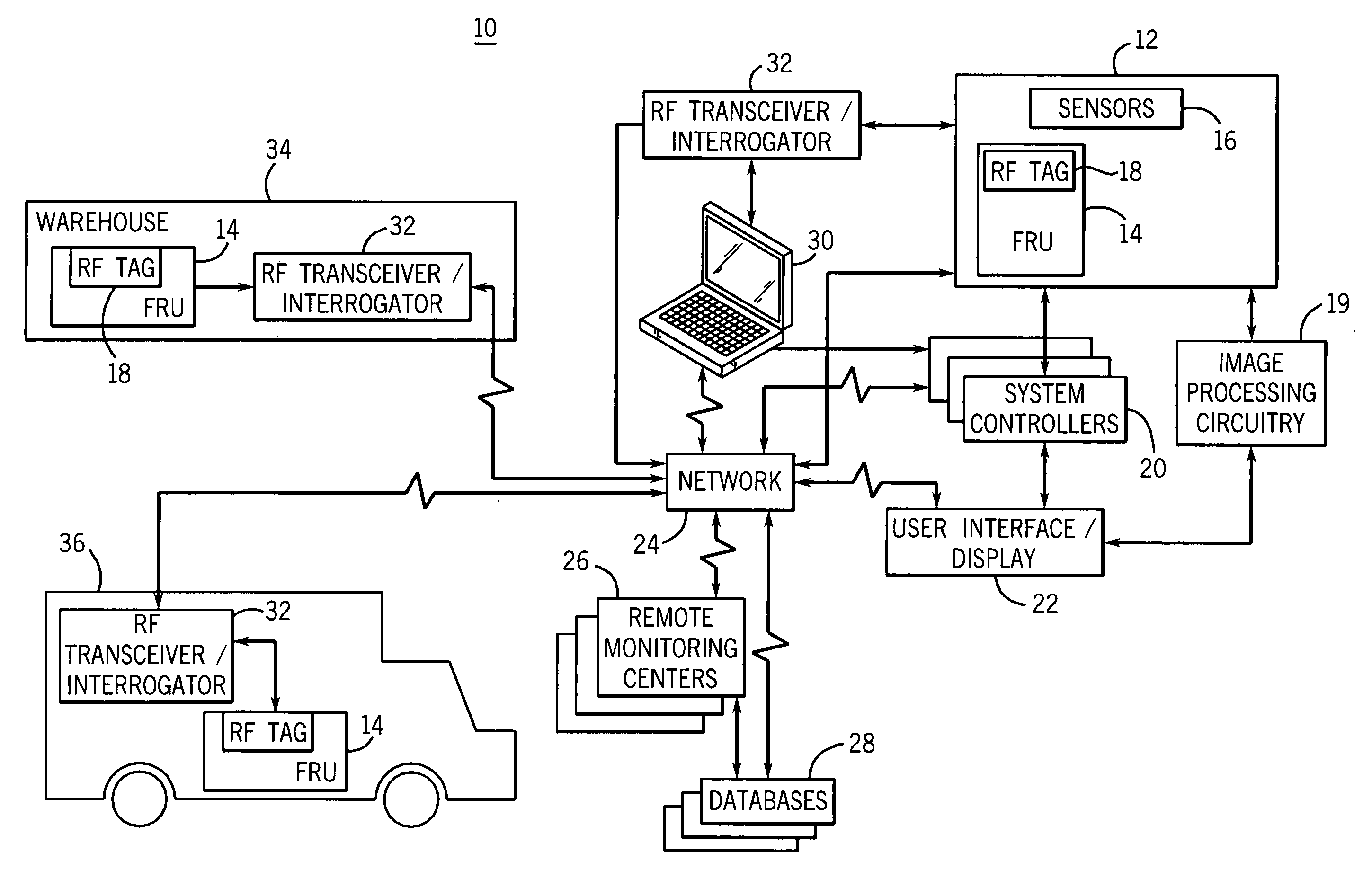

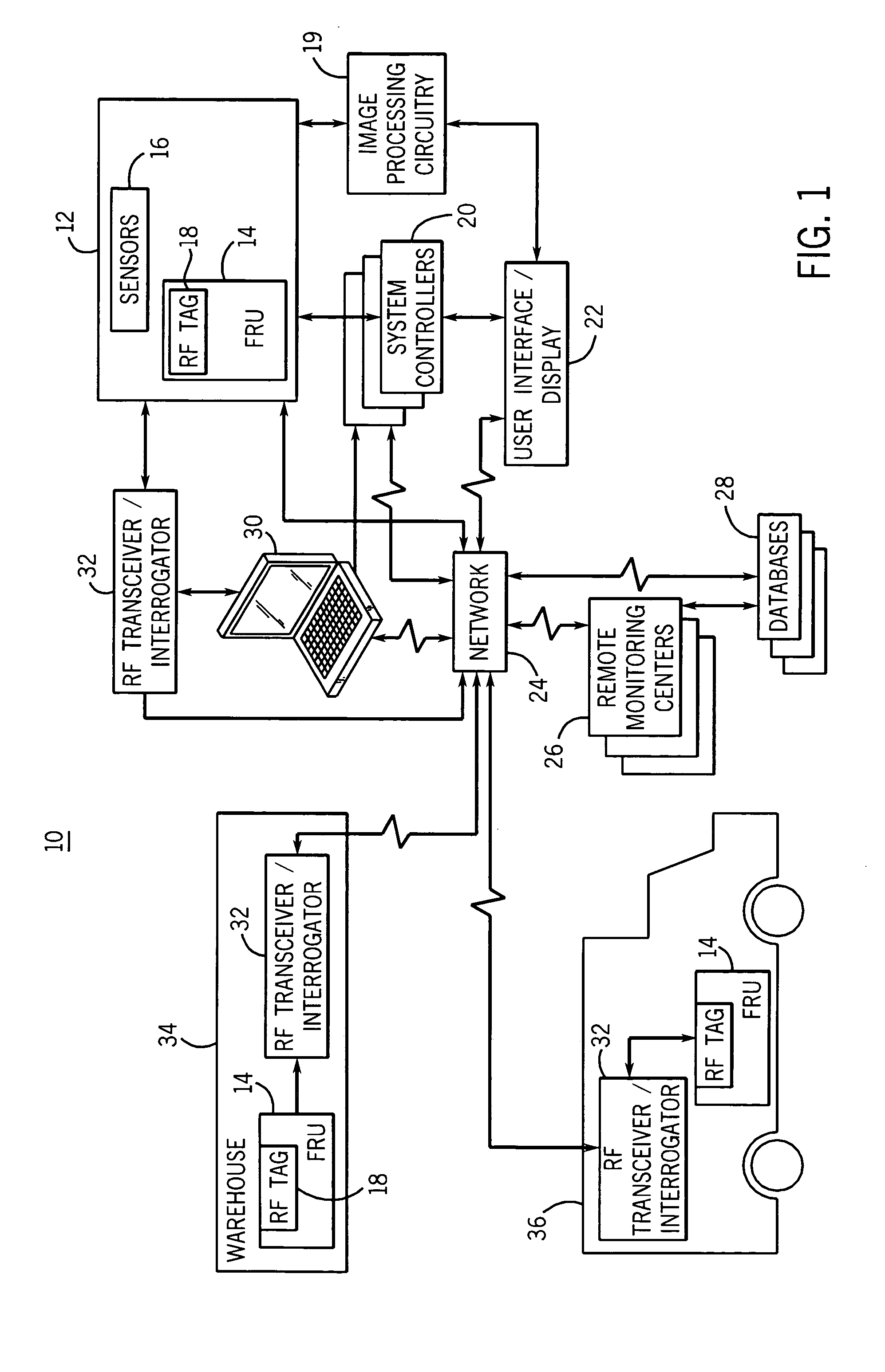

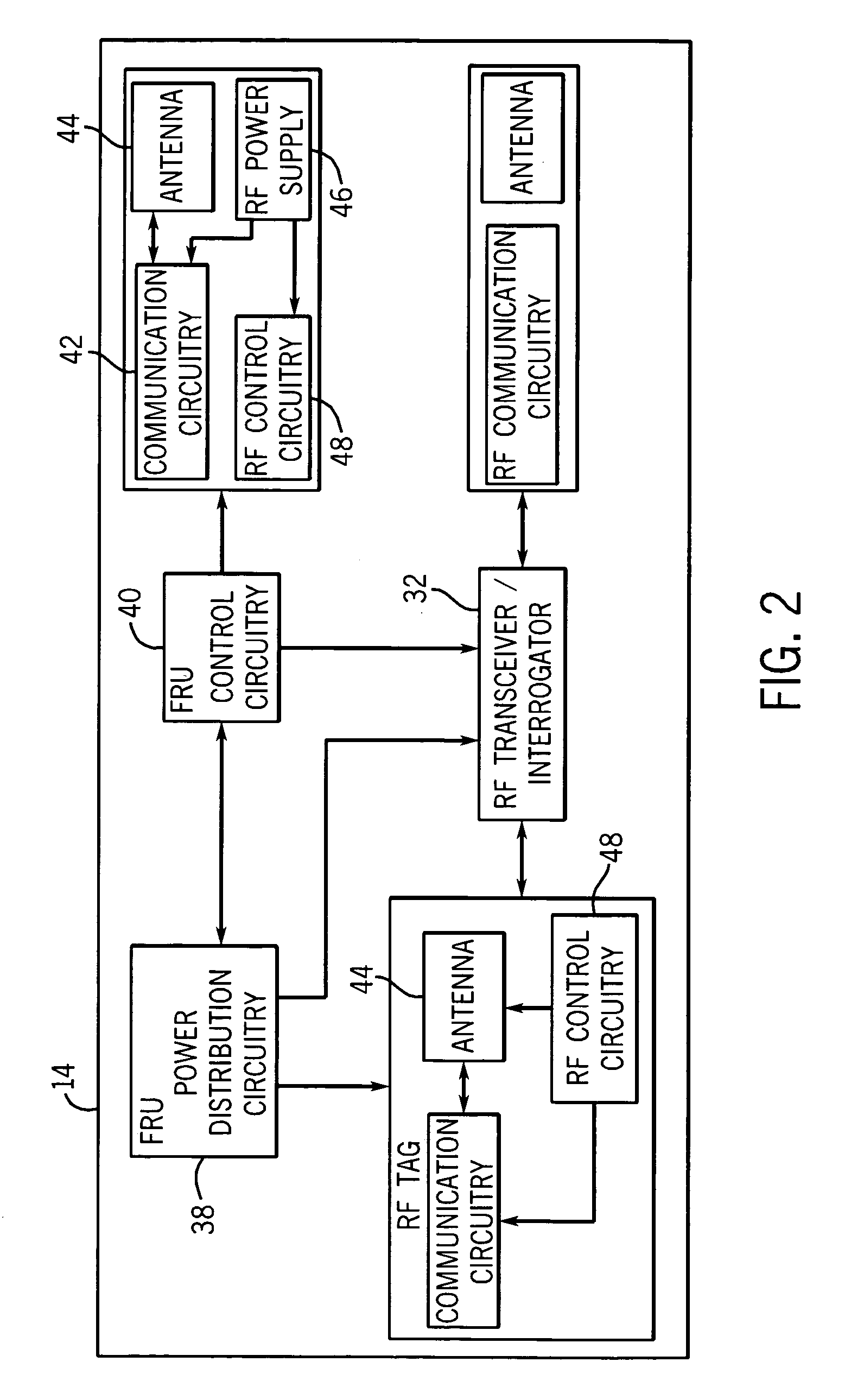

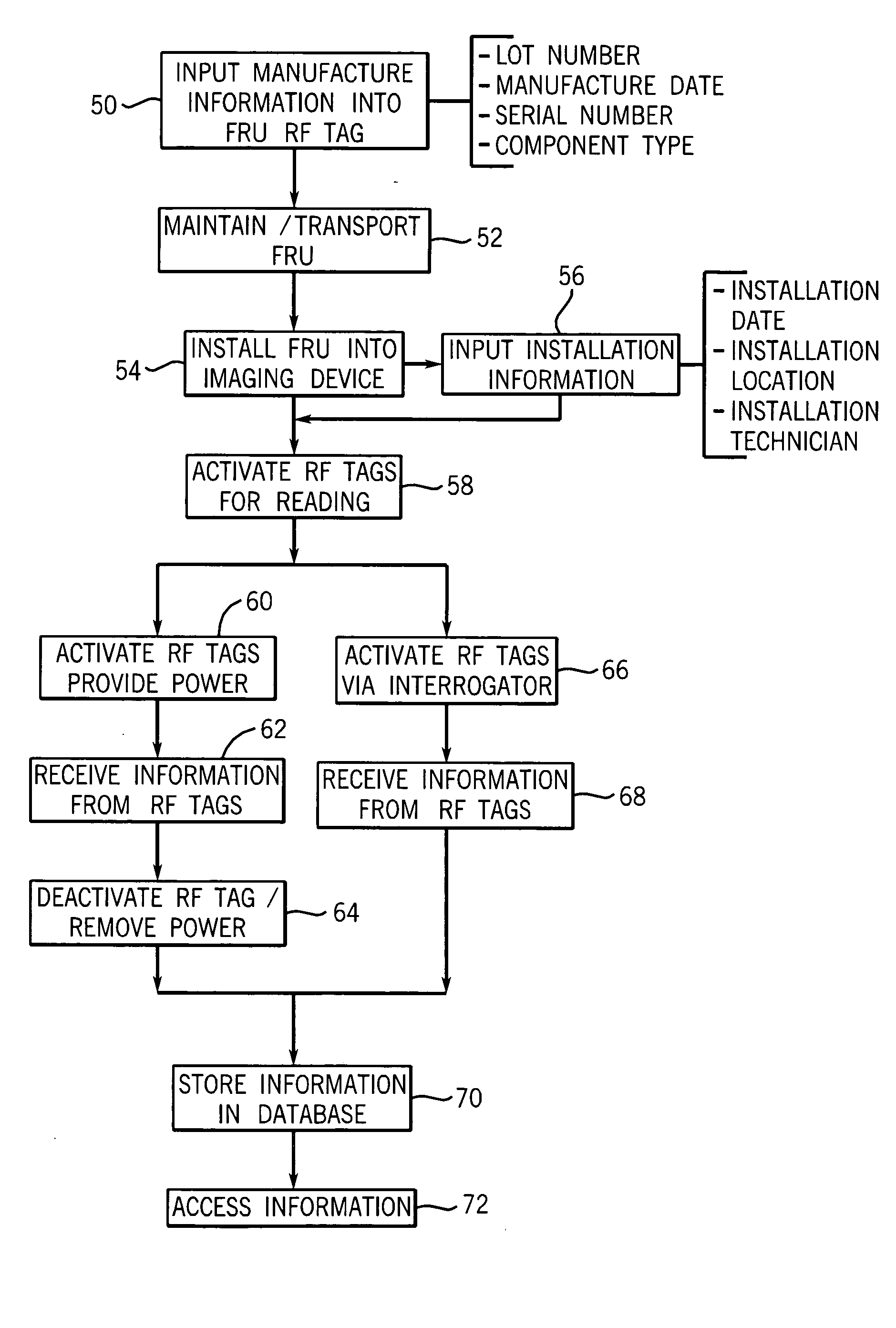

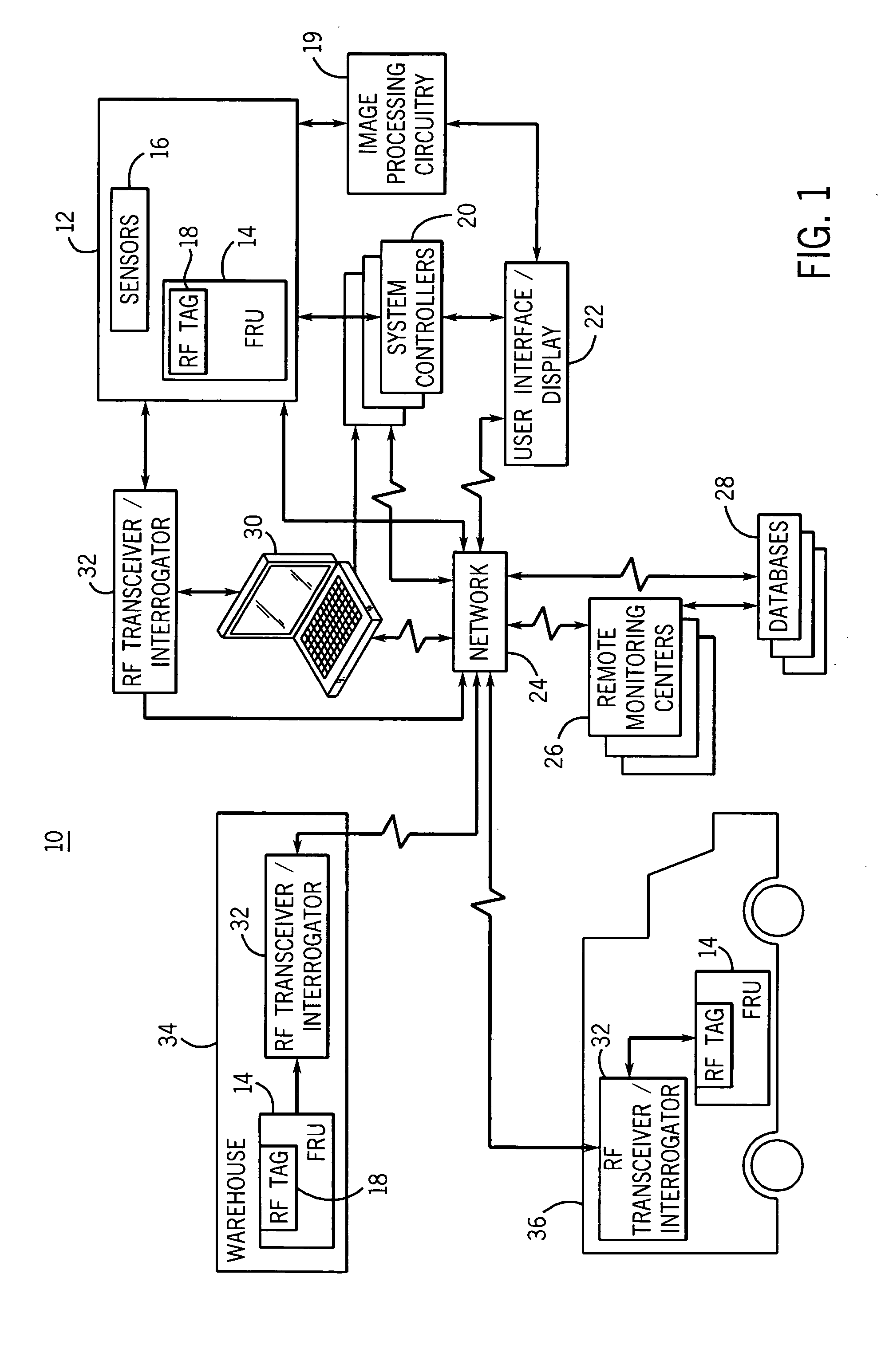

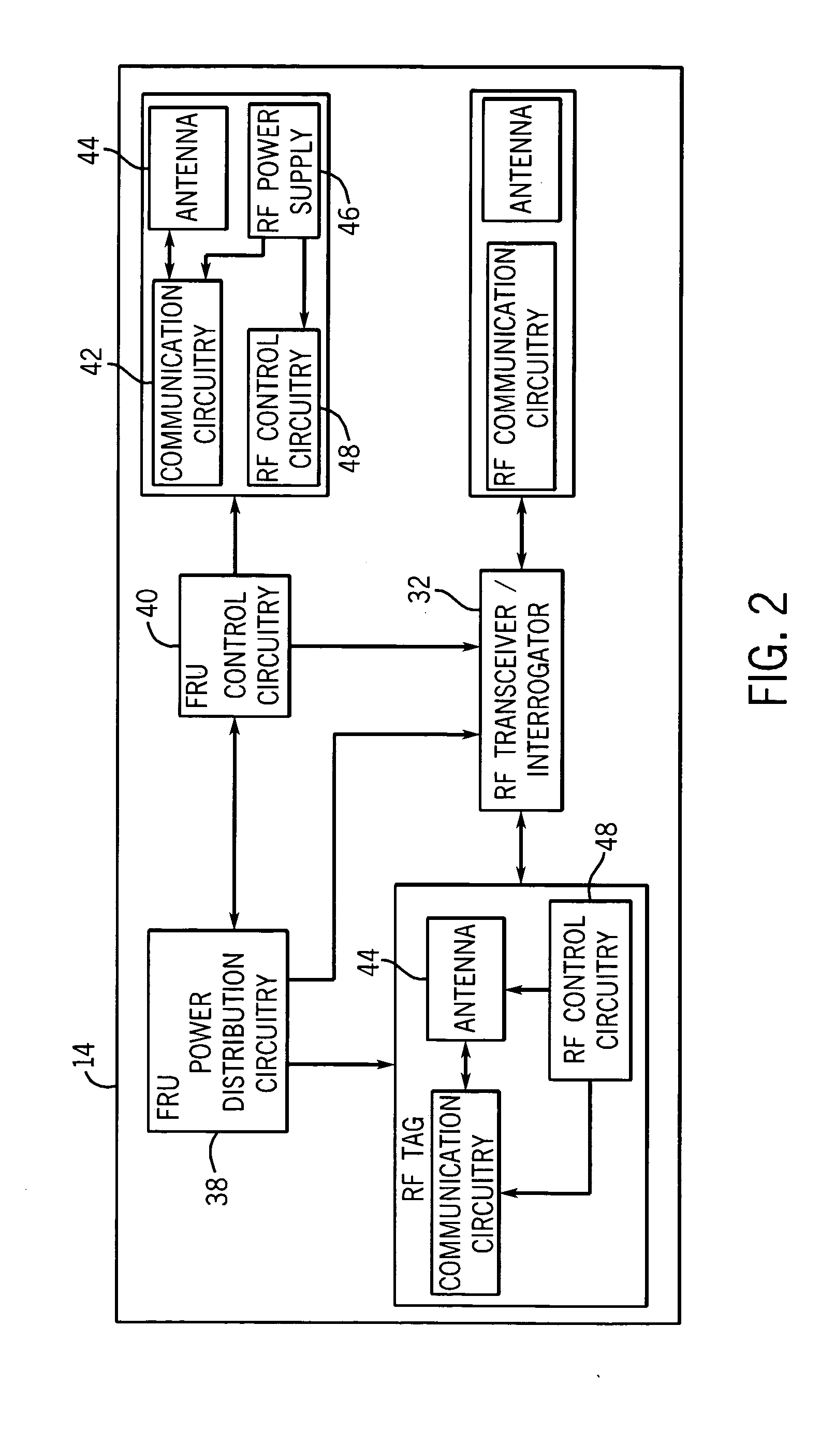

Method and system for determining hardware configuration of medical equipment using RF tags

Owner:GE MEDICAL SYSTEMS INC

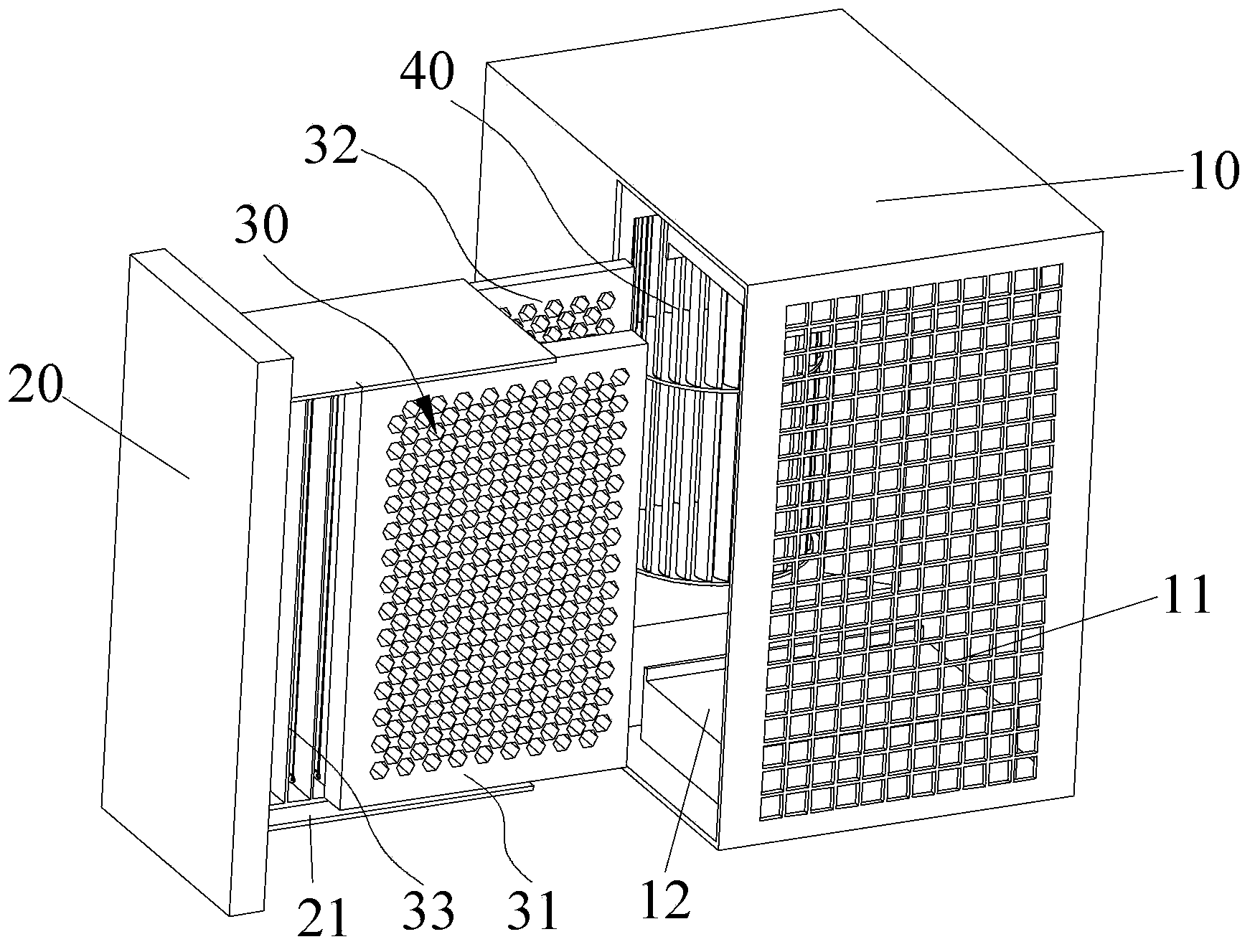

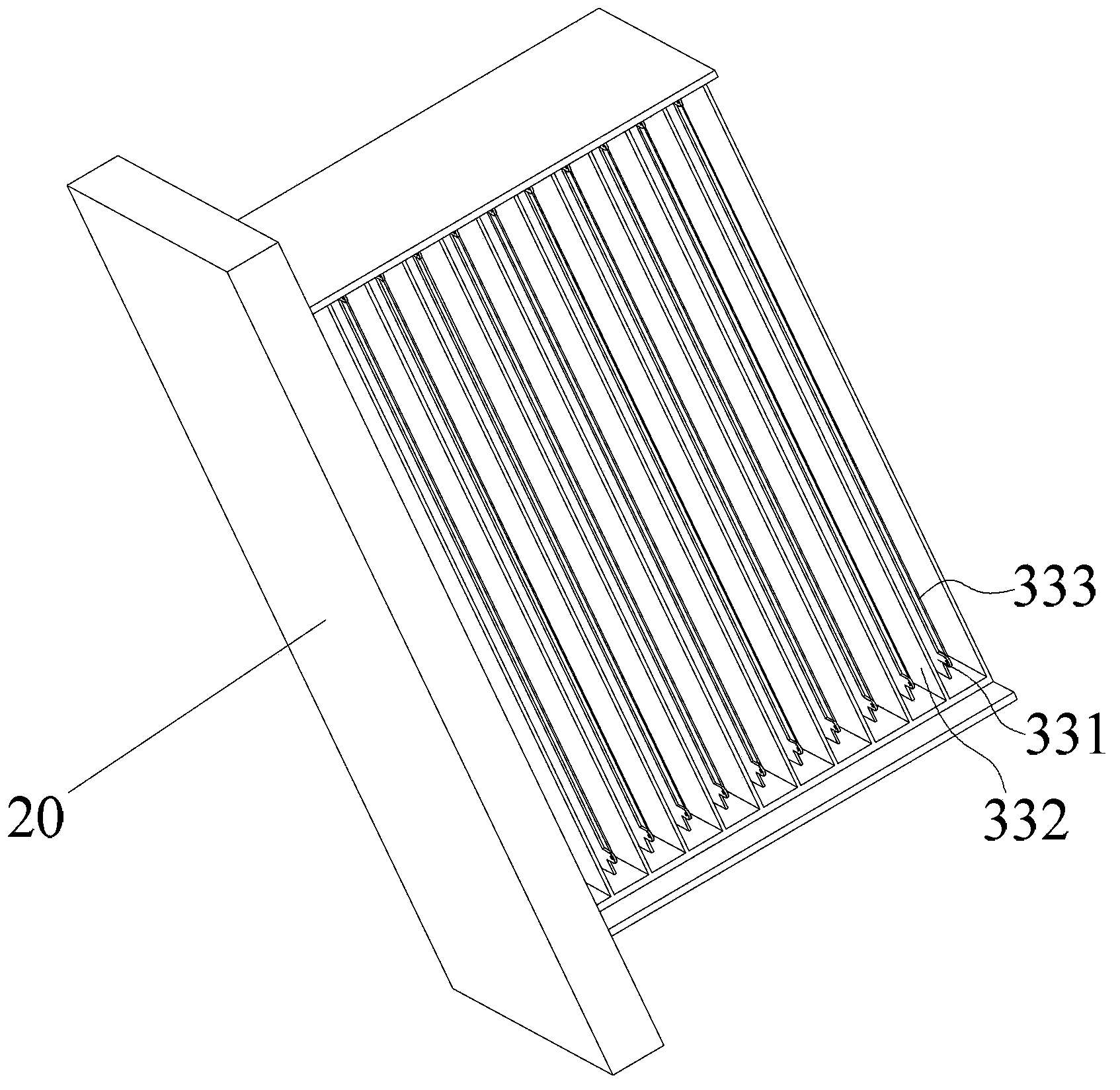

Air purifier

ActiveCN103629752AAffect performanceAvoid bumping or even damageLighting and heating apparatusSpace heating and ventilation detailsAppliance componentAir purifier

The invention provides an air purifier. The air purifier comprises a shell (10) and a purification component (30) arranged in the shell (10). The air purifier further comprises a movable lateral wall (20) fixedly connected with the purification component (30). The air purifier effectively resolves the problems that in the cleaning, assembly and disassembly process of an air purifier in the prior art, as an electric appliance component in the air purifier is damaged easily, the performance of the whole air purifier is affected.

Owner:GREE ELECTRIC APPLIANCES INC

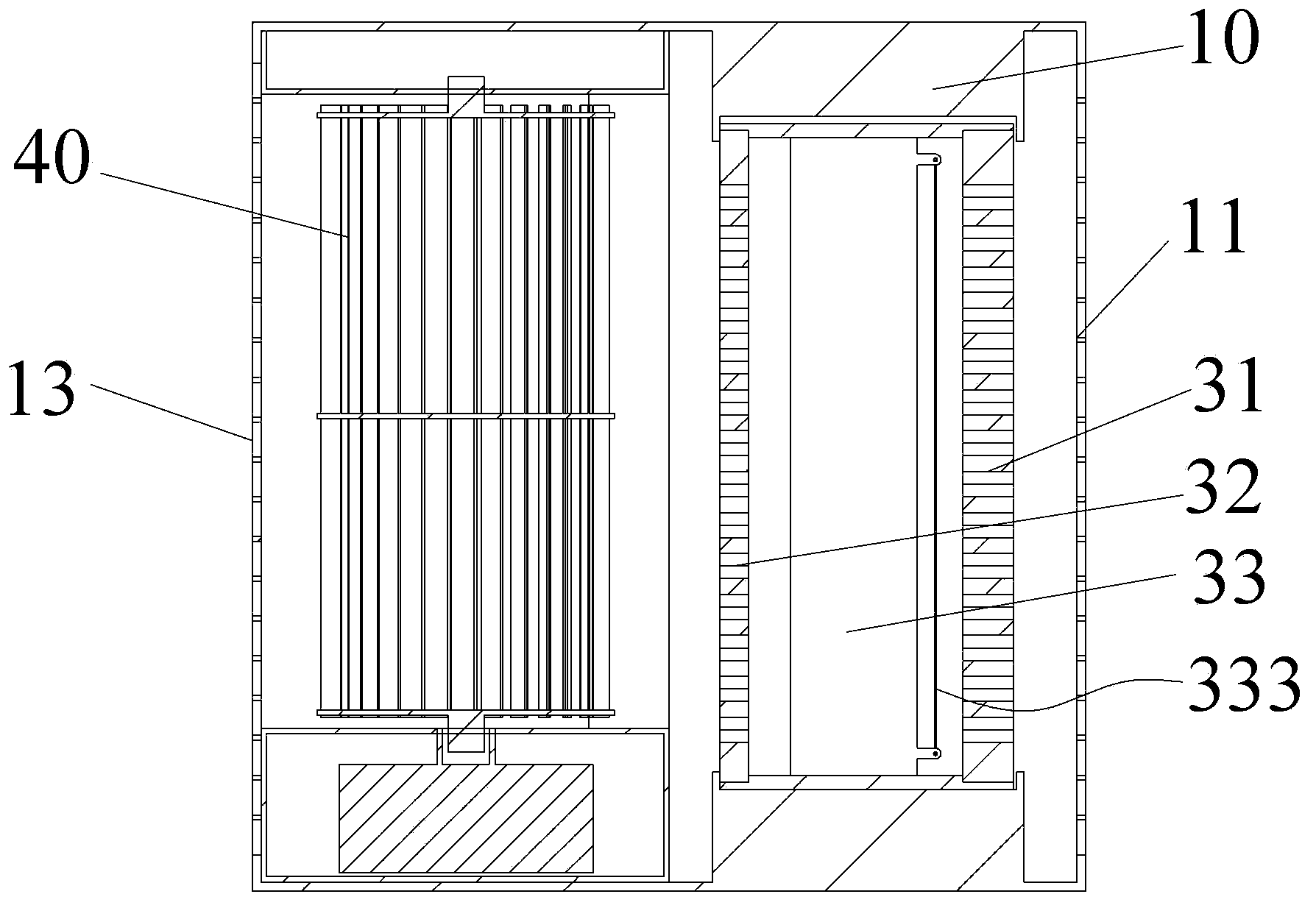

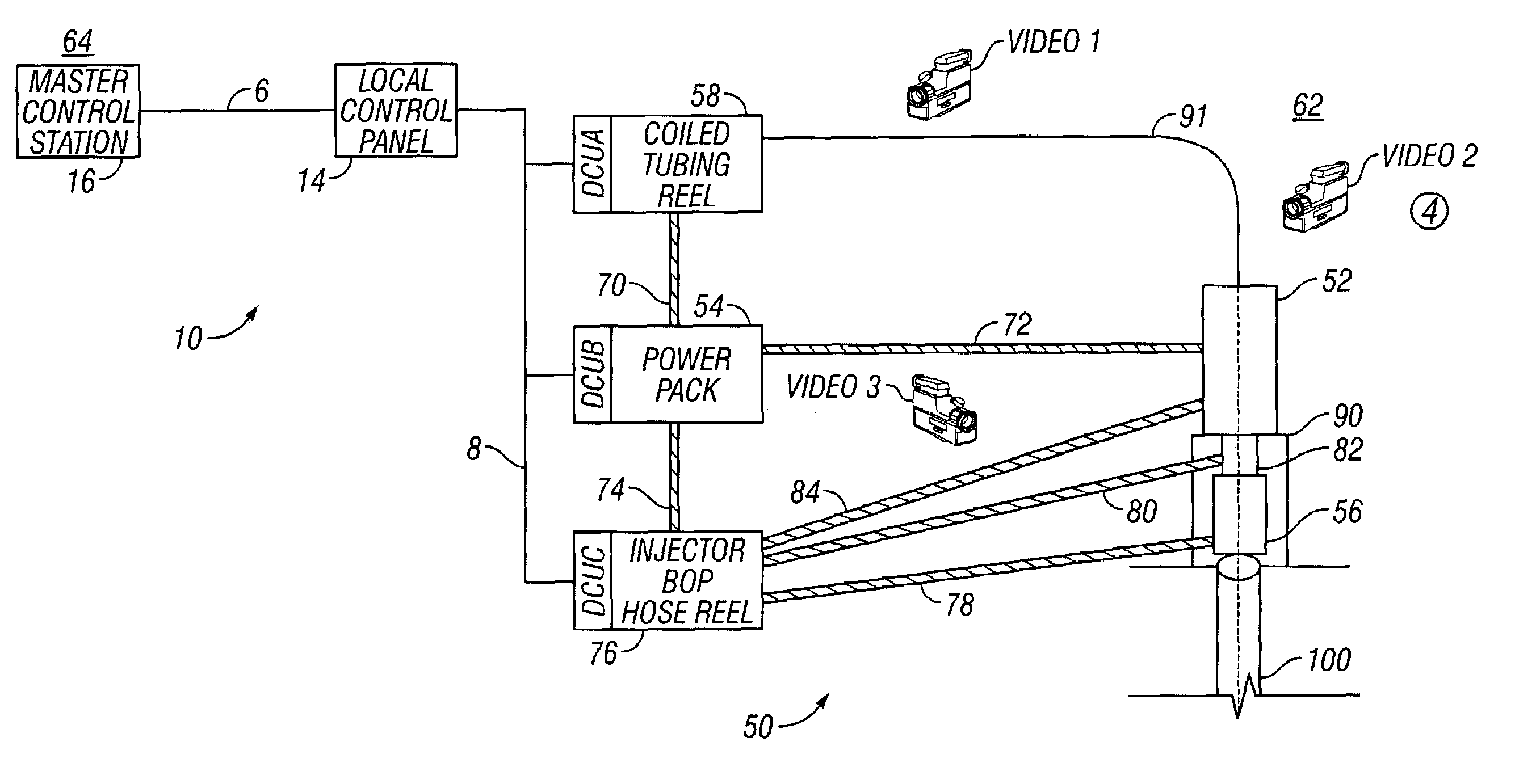

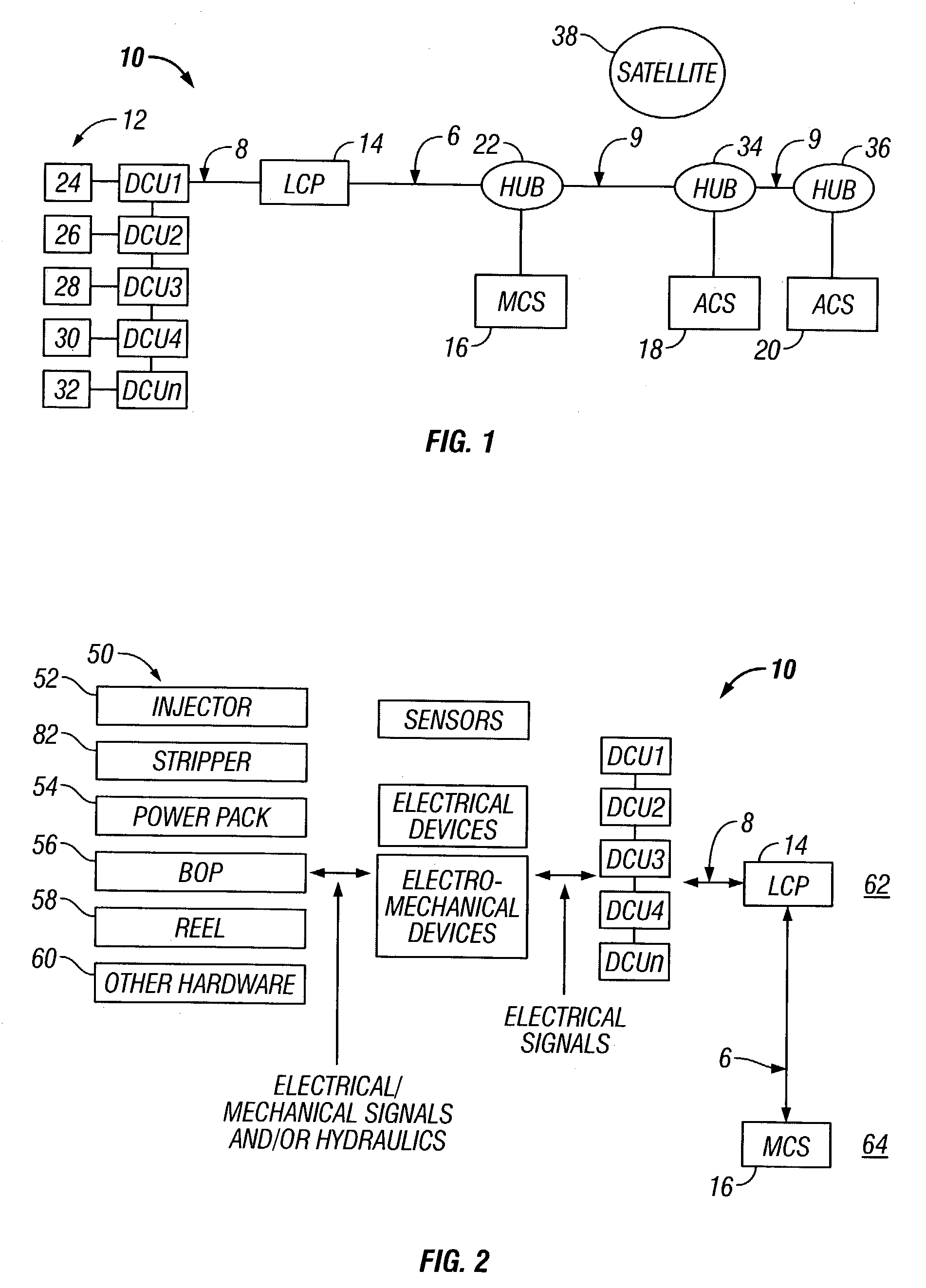

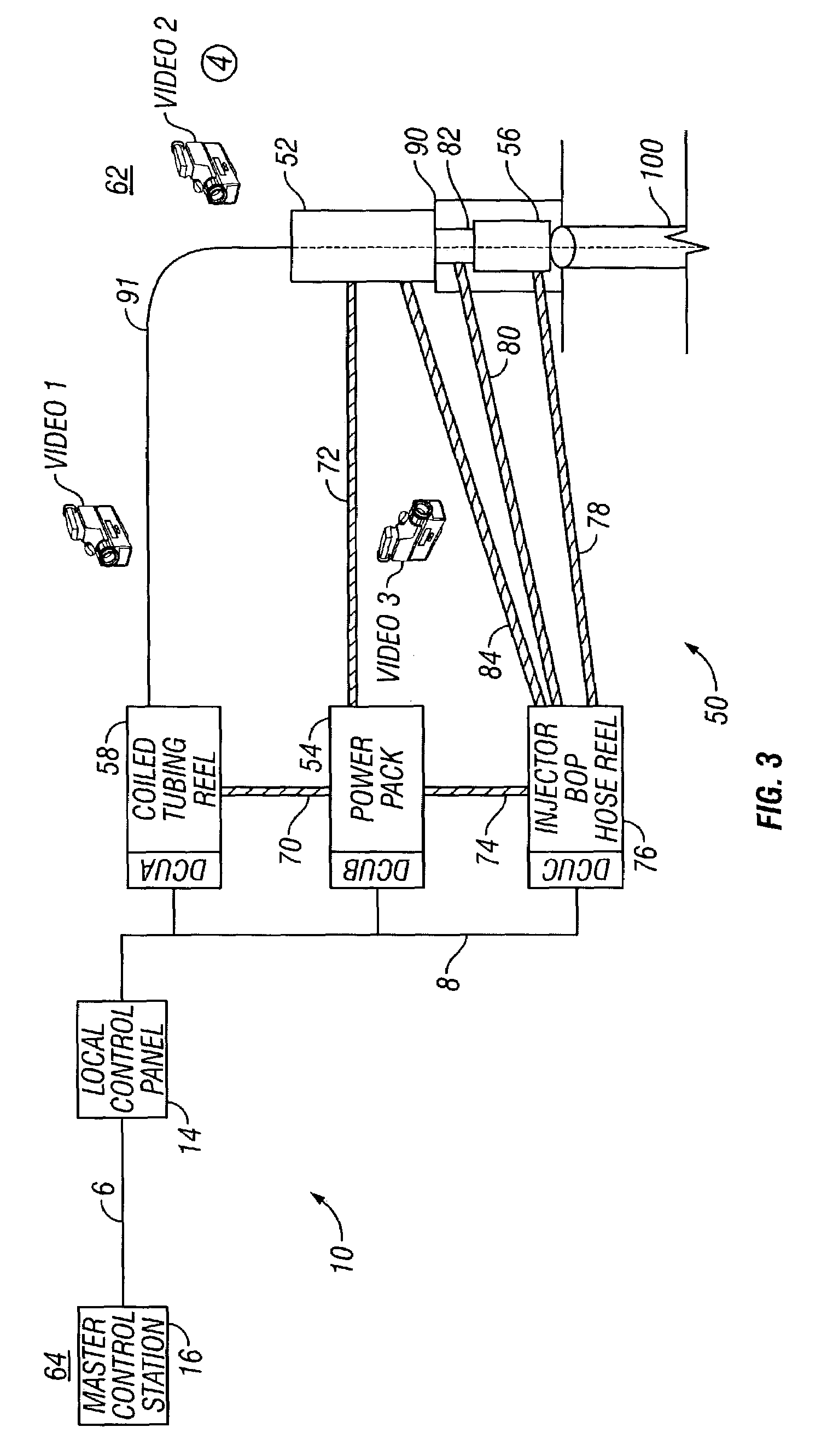

Distributed control system

InactiveUS6968905B2Improve securityLow skill levelDrilling rodsDigital data processing detailsNon real timeArea network

A distributed control system for local or remote control of equipment. The distributed control system provides a communication bridge through a local control panel between a non-real-time network, and a real-time network, such as a controller area network. Both soft real-time and hard real-time networks are suitable, but hard real-time is preferred. Multiple distributed control units are used to control various equipment components. The distributed control system may be applied in any environment. The distributed control system may be applied to a skid-mounted coiled tubing unit.

Owner:SCHLUMBERGER TECH CORP

Optical device components

ActiveUS20090105565A1Material analysis by optical meansDiagnostic recording/measuringLight sensingLight beam

Embodiments of the invention relate to an apparatus including a light source to generate a plurality of light beams with each of the plurality of light beams having a different wavelength range. The apparatus also includes a light funnel to direct the plurality of light beams to the target area, an aperture to direct the plurality of light beams emitting from the target area to a lens, the lens configured to collect the light beams emitting from the target area. Further, the apparatus includes a detector including a plurality of light-sensing devices each configured to detect a light beam and configured to generate an output signal indicative of an intensity of light detected and a processor for determining the blood characteristic as a function of each generated output signal.

Owner:ST LOUIS MEDICAL DEVICES INC

Method and system for determining hardware configuration of medical equipment using RF tags

According to one embodiment, the present technique provides a medical device component having an RF tag that is configured to provide information regarding the medical device component. Particularly, the RF tag may contain and provide information regarding maintenance, installation, and manufacture of the medical device component. Indeed, the exemplary embodiment of the present technique may facilitate the development of an “as built” or hardware configuration of the medical device through the use of RF tags. Advantageously, the medical device may be surveyed by activating the RF tags, which contain and transmit information regarding the various components in the medical device.

Owner:GE MEDICAL SYSTEMS INC

Network System with Message Binding for Appliances

InactiveUS20080137670A1Avoid it happening againError detection/correctionInterprogram communicationAppliance componentNetworked system

A network system for an appliance has communication among components with a message protocol that includes a flag set to bind individual messages together for a complete snapshot of the state of an appliance component.

Owner:WHIRLPOOL CORP

Three-dimensional printing system and equipment assembly

ActiveCN104640686AManufacturing platforms/substratesIncreasing energy efficiencyPharmaceutical drugAppliance component

Owner:APRECIA PHARMA LLC

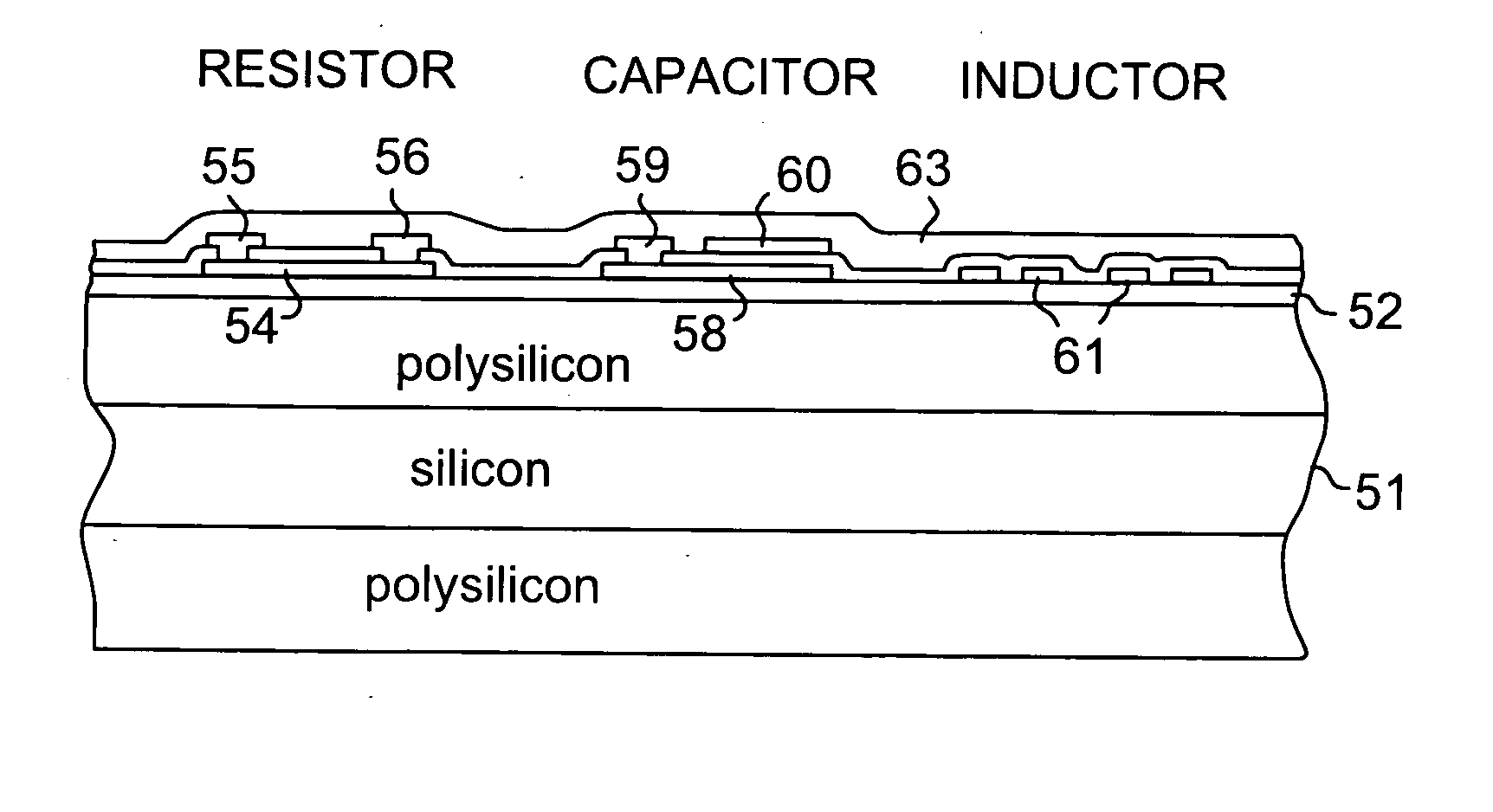

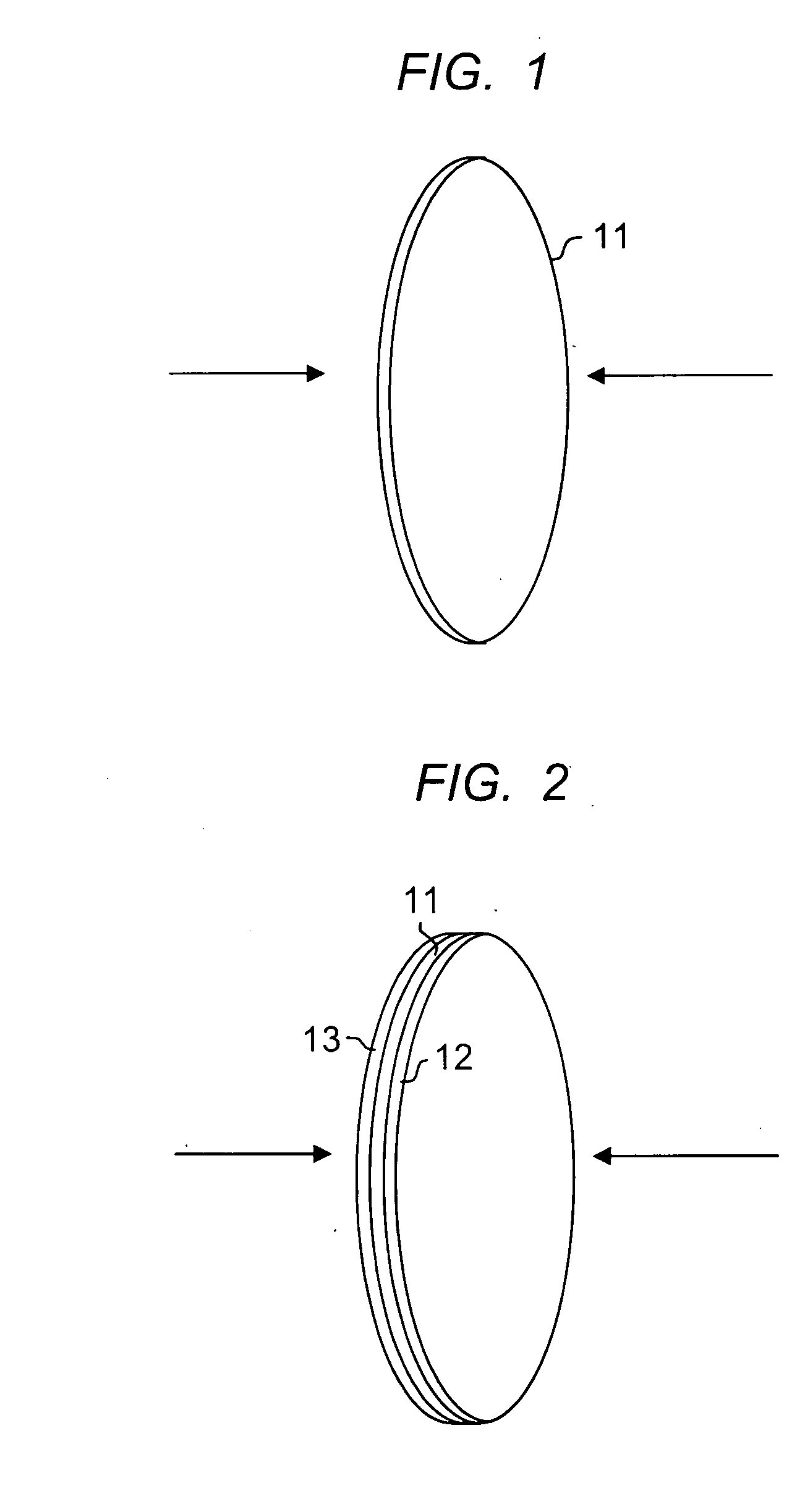

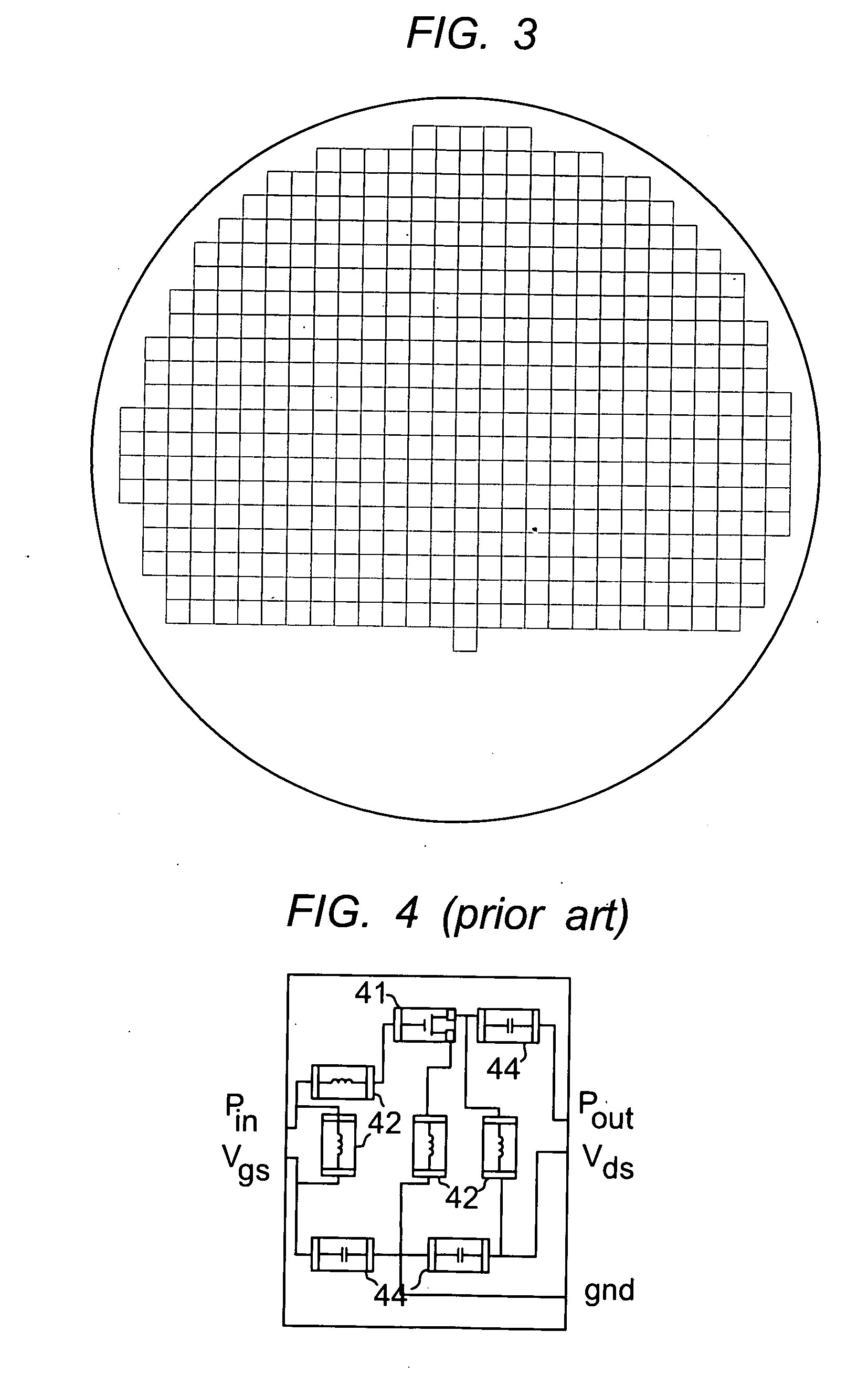

Integrated passive devices

InactiveUS20050253257A1Reduce interactionReduces rf interactionSemiconductor/solid-state device detailsSolid-state devicesElectrical interactionInductor

The specification describes a multi-chip module (MCM) that contains an integrated passive device (IPD) as the carrier substrate (IPD MCM). Parasitic electrical interactions are controlled at one or both interfaces of the IPD either by eliminating metal from the interfaces, or by selective use of metal in parts of the MCM that are remote from the sensitive device components. The sensitive device components are primarily analog circuit components, especially RF inductor elements. In the IPD layout, the sensitive components are segregated from other components. This allows implementation of the selective metal approach. It also allows parasitic interactions on top of the IPD substrate to be reduced by selective placement of IC semiconductor chips and IC chip ground planes. In preferred embodiments of the IPD MCM of the invention, the IPD substrate is polysilicon, to further minimize RF interactions. The various methods of assembling the module may be adapted to keep the overall thickness within 1.0 mm.

Owner:SYCHIP

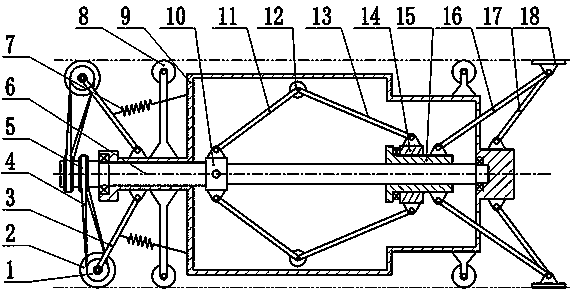

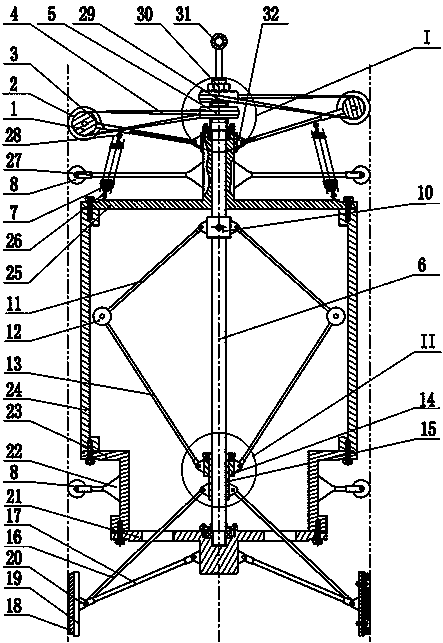

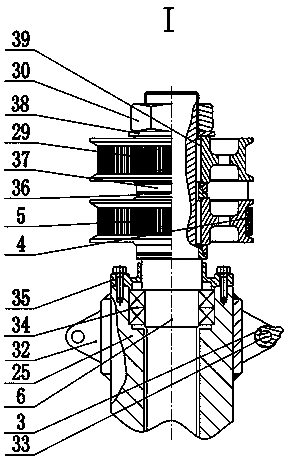

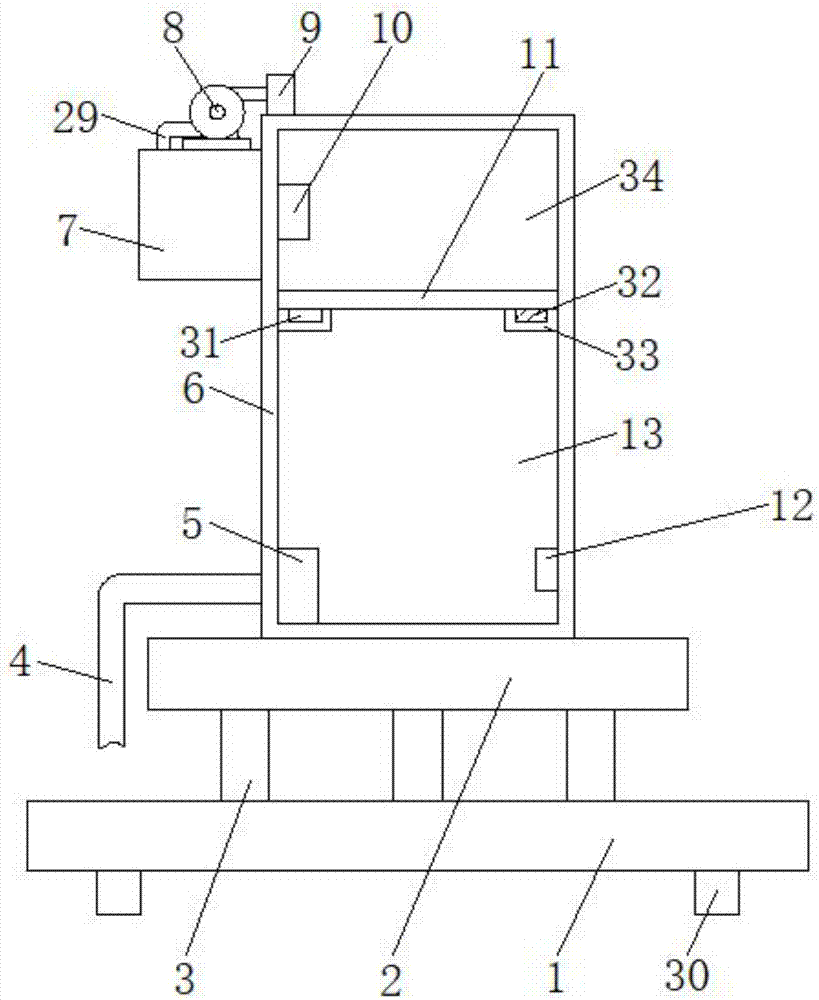

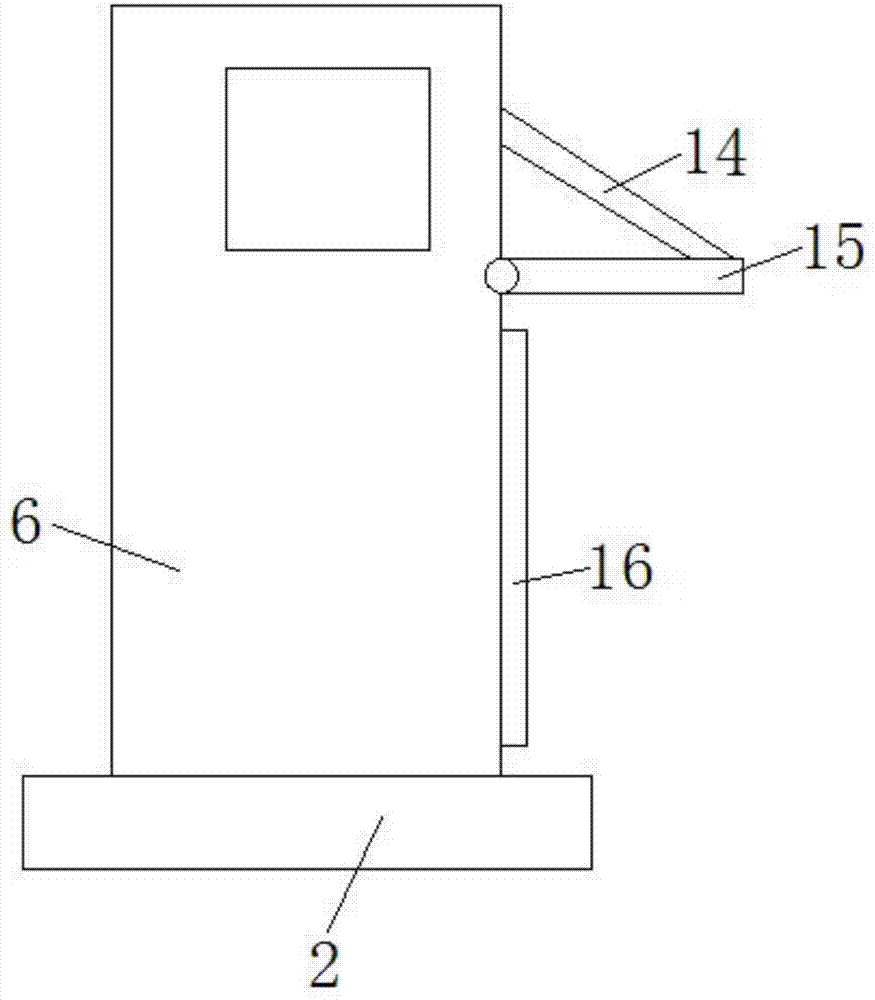

Mechanical tube cleaner speed controller

InactiveCN103551350ATo overcome the shortcomings of excessive delay of the speed controllerAdapt to speed changesHollow article cleaningAppliance componentEngineering

The invention relates to a mechanical speed controller used for controlling running speed of a tube cleaner and a defect detection device in a pipe cleaning and defect detection process of natural gas pipes on active service and a pressure test and discharging process of pipelines under construction. The controller can control the speed of the tube cleaner to be in a certain range and solve the problem that the existing tube cleaner is impacted due to the fact that the speed cannot be controlled and a detector is inaccurate in detection due to the fact that the speed is too high. Four support wheels are arranged at two ends of a barrel body respectively, and two speed collection wheels are symmetrically arranged on two sides of the barrel body through support rods and connected through a spring. A belt wheel A is coaxially installed on the speed collection wheels and connected with a belt wheel B on the end portion of a central shaft through a belt. A sleeve is installed in the middle section of the central shaft, a fixed barrel is installed on the tail section, and a rotating barrel is sleeved on the outside of the fixed barrel. One end of a connection rod A and one end of a connection rod B are hinged to a mass block, the other ends of the connection rod A and the connection rod B are connected with the sleeve and the rotating barrel respectively, a connection rod C is connected with the end portion of the fixed barrel and a friction block, and a connection rod D is connected with the end portion of the barrel body and a friction block. The speed controller is simple in structure, free of delaying, safe and reliable and has no electric appliance components.

Owner:SOUTHWEST PETROLEUM UNIV

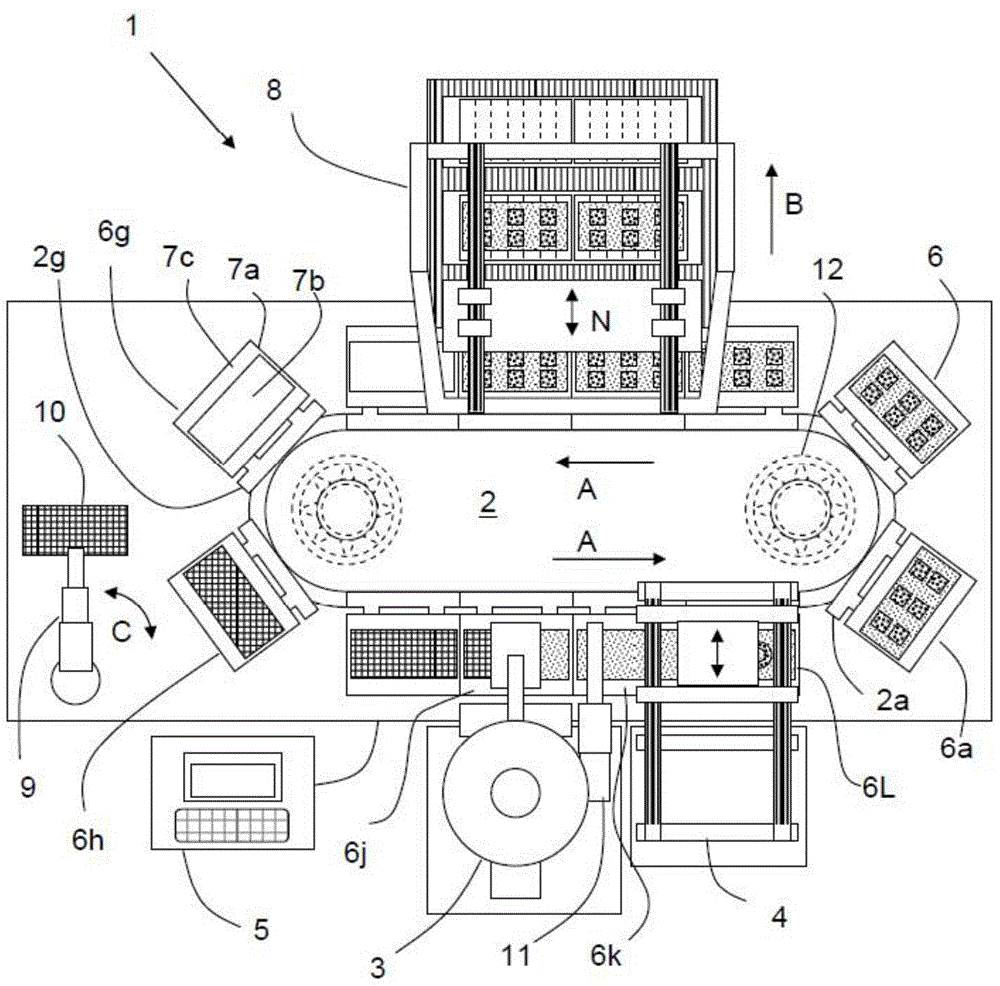

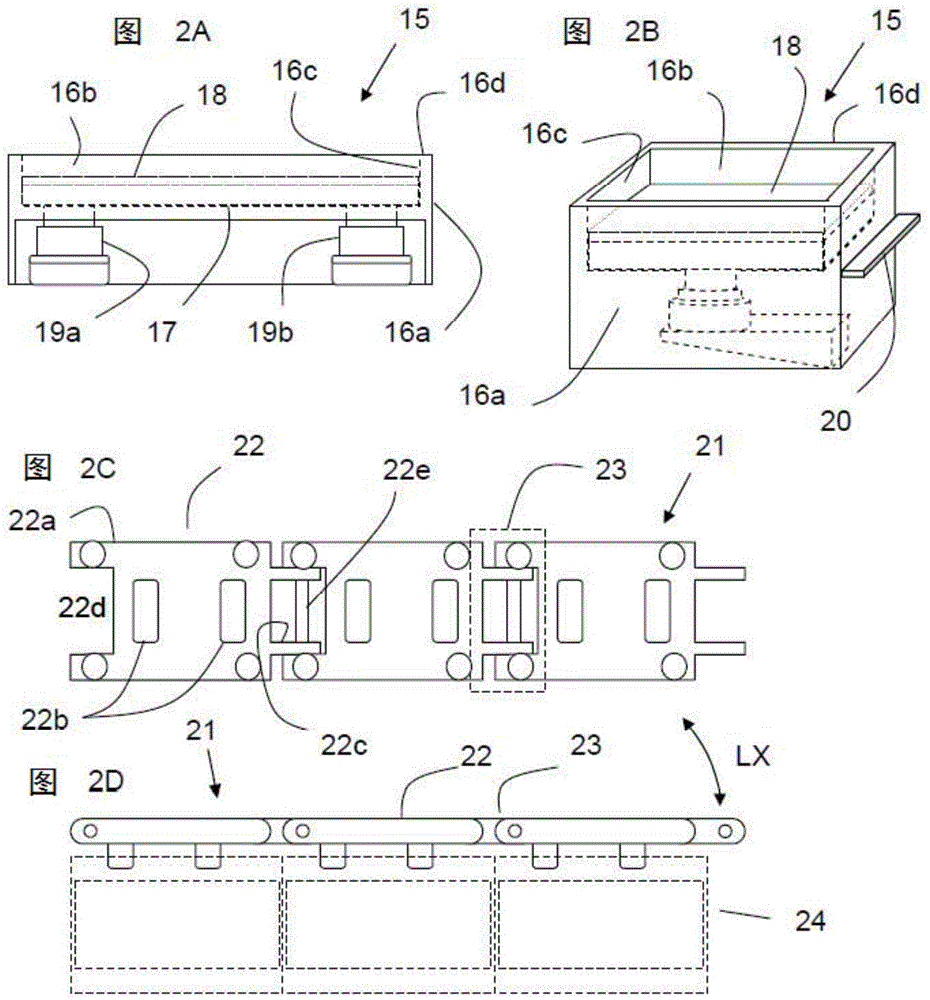

Three-dimensional Printing System and Equipment Assembly

ActiveUS20180141275A1Minimal product lossImprove efficiencyManufacturing platforms/substratesPowder deliveryPharmaceutical drugAppliance component

A three-dimensional printing system and equipment assembly for the manufacture of three-dimensionally printed articles is provided. The equipment assembly includes a three-dimensional printing build system, an optional liquid removal system and an optional harvester system. The build system includes a conveyor, plural build modules and at least one build station having a powder-layering system and a printing system. The equipment assembly can be used to manufacture pharmaceutical, medical, and non-pharmaceutical / non-medical objects. It can be used to prepare single or multiple articles.

Owner:APRECIA PHARMA LLC

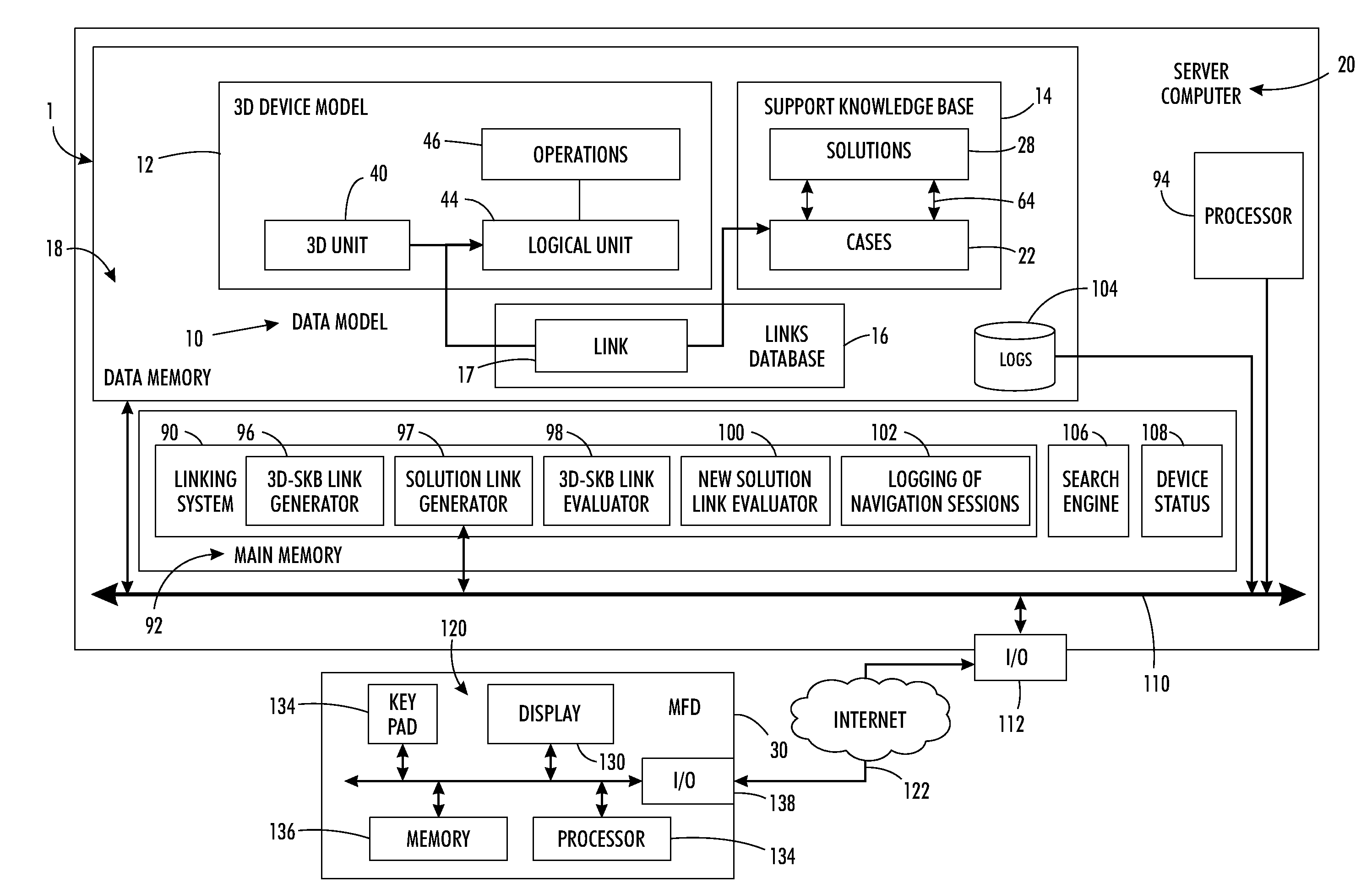

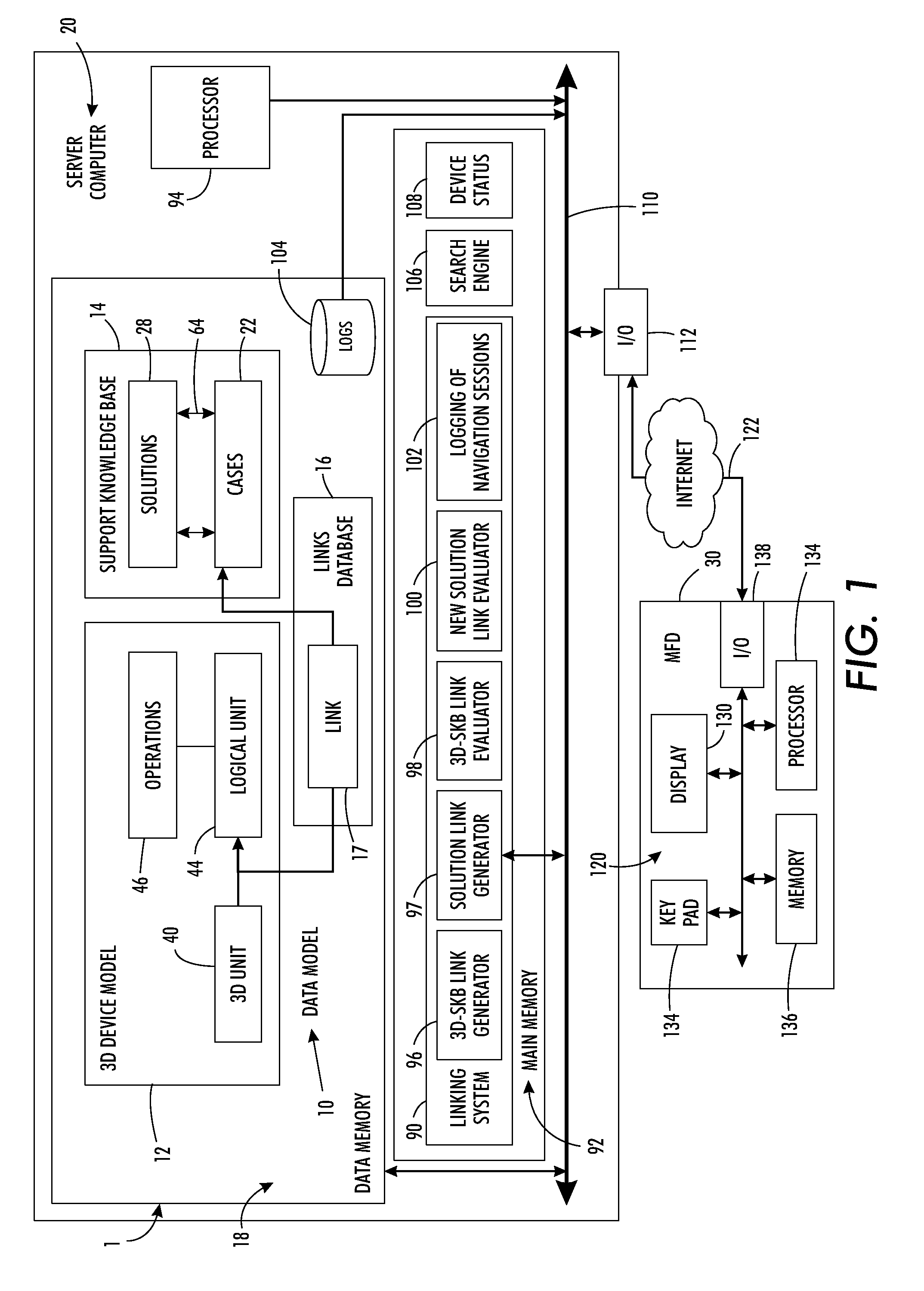

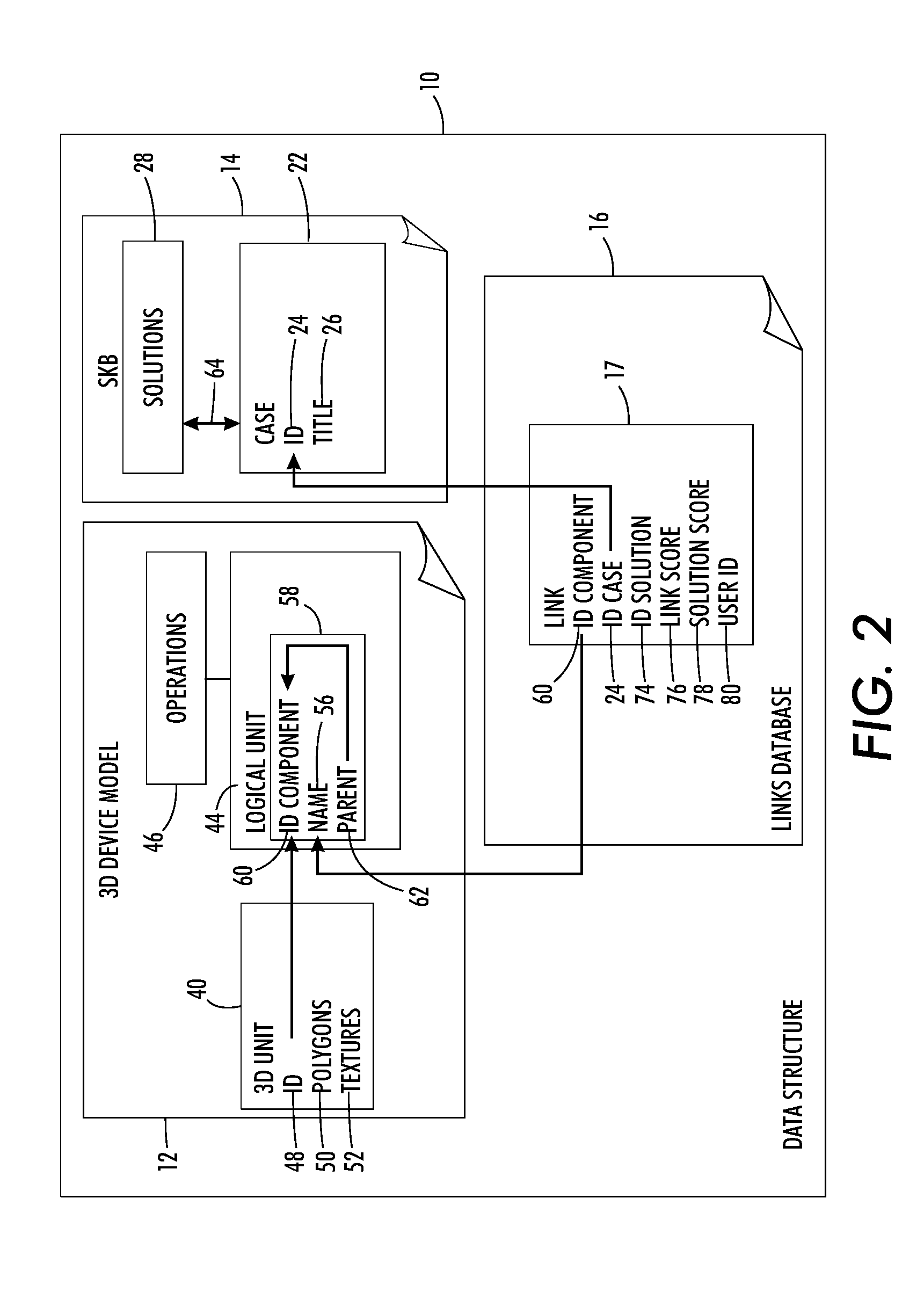

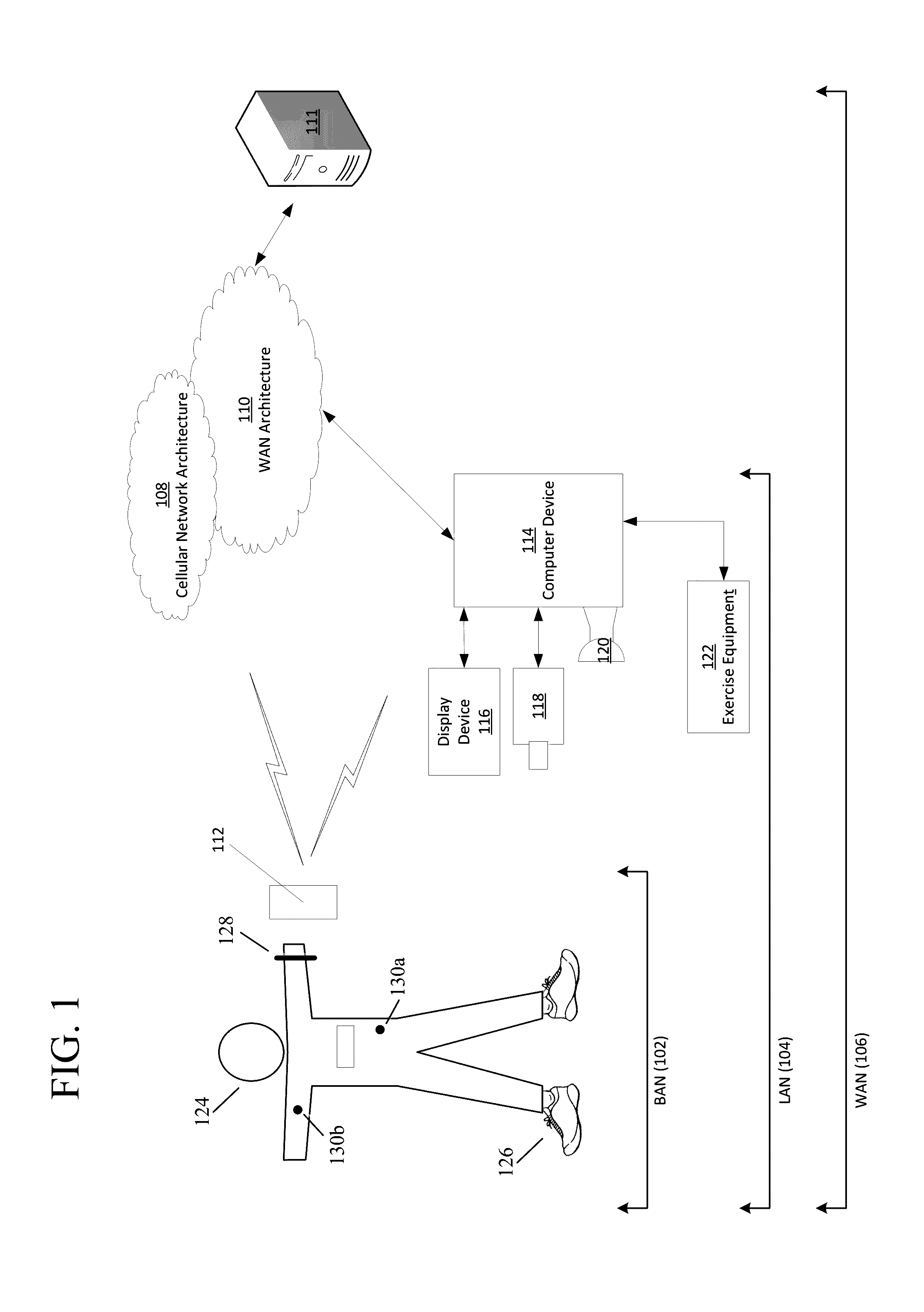

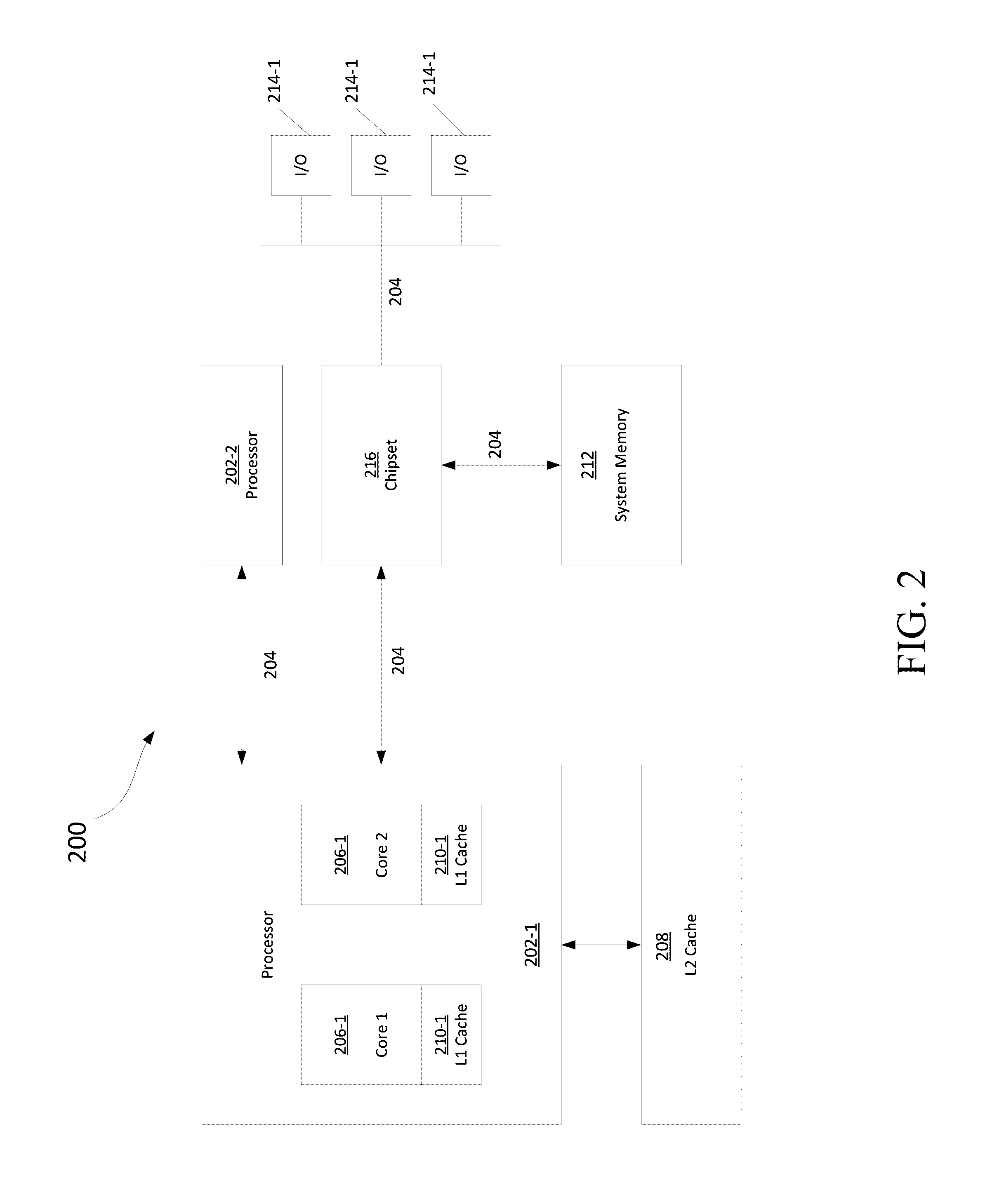

Collaborative linking of support knowledge bases with visualization of device

A system and method which may be implemented at least partly by a computer, are provided for developing a support system. A virtual representation of a device is generated for display on a user interface. Links between components of the virtual representation, which represent components of the device, and corresponding cases in a searchable knowledge base (SKB) are stored. Users can navigate the SKB in search of a solution to a problem with the device with the assistance of the virtual representation which enables actuation of the existing links. The users are able to create new links, each new link linking a component of the virtual representation with a case in the SKB which the user identifies as providing a solution to the problem with the device which is related to the component. The new link is stored for future use by the user or by other users.

Owner:XEROX CORP

Wearable USB device assembly

ActiveUS20160346609A1Easy to operateSub-station arrangementsGymnastic exercisingExercise performanceAppliance component

Tracking and monitoring athletic activity offers individuals with additional motivation to continue such behavior. An individual may track his or her athletic activity by utilizing a wearable device assembly configured to monitor various aspects of athletic performance. In some embodiments, the wearable device assembly may comprise a USB-type device having athletic functionality and configured to transmit to and / or receive data from an external computing device.

Owner:NIKE INC

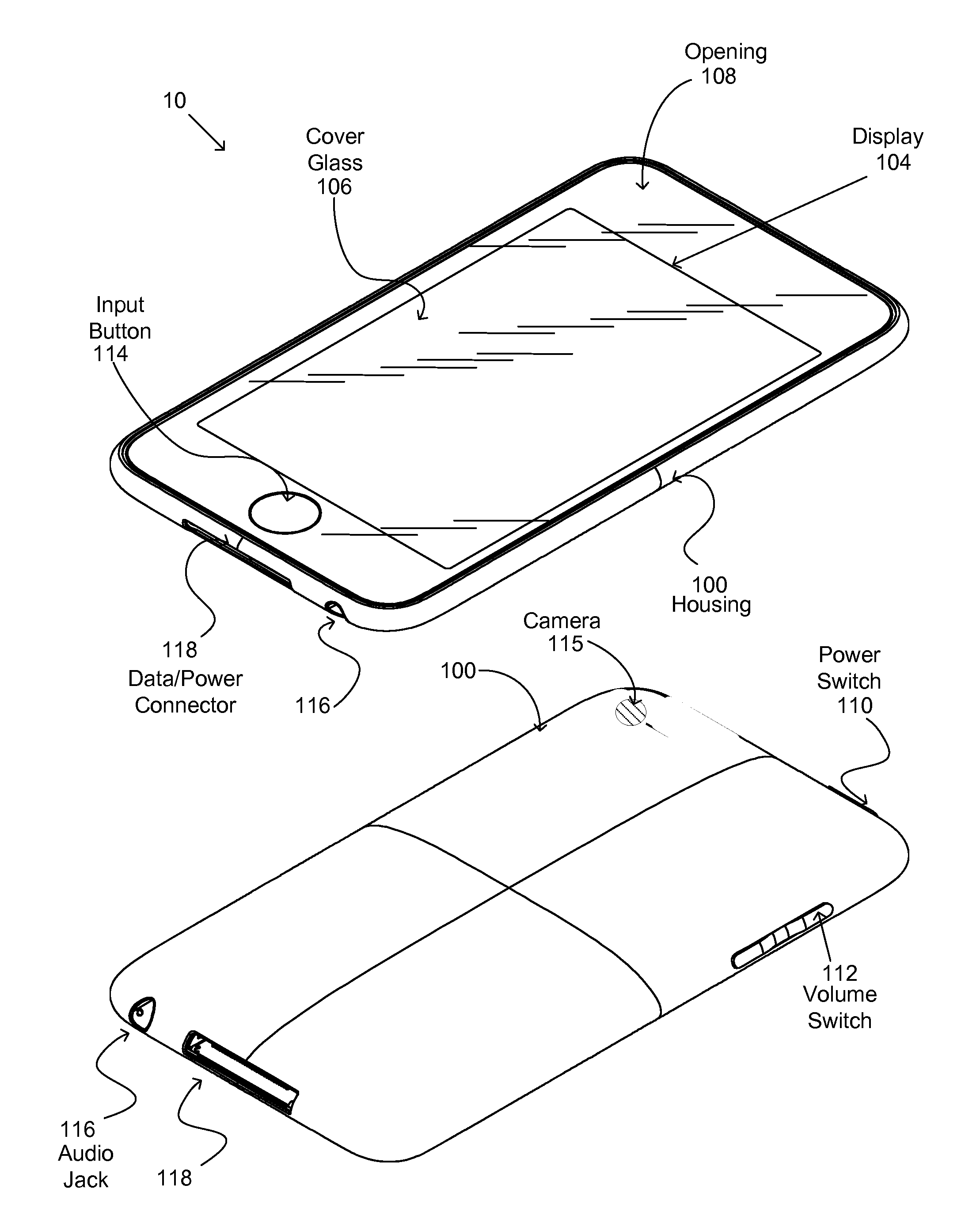

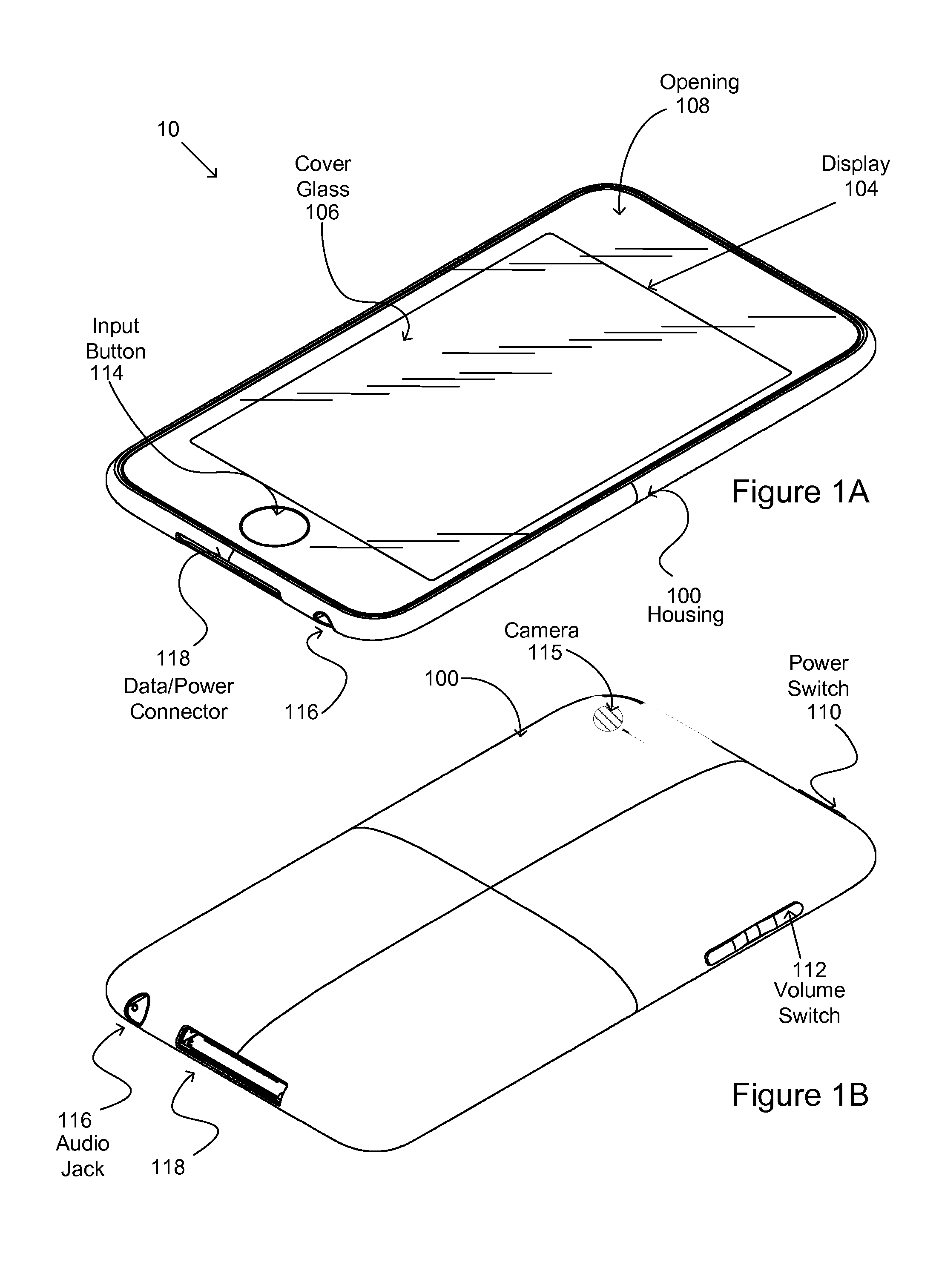

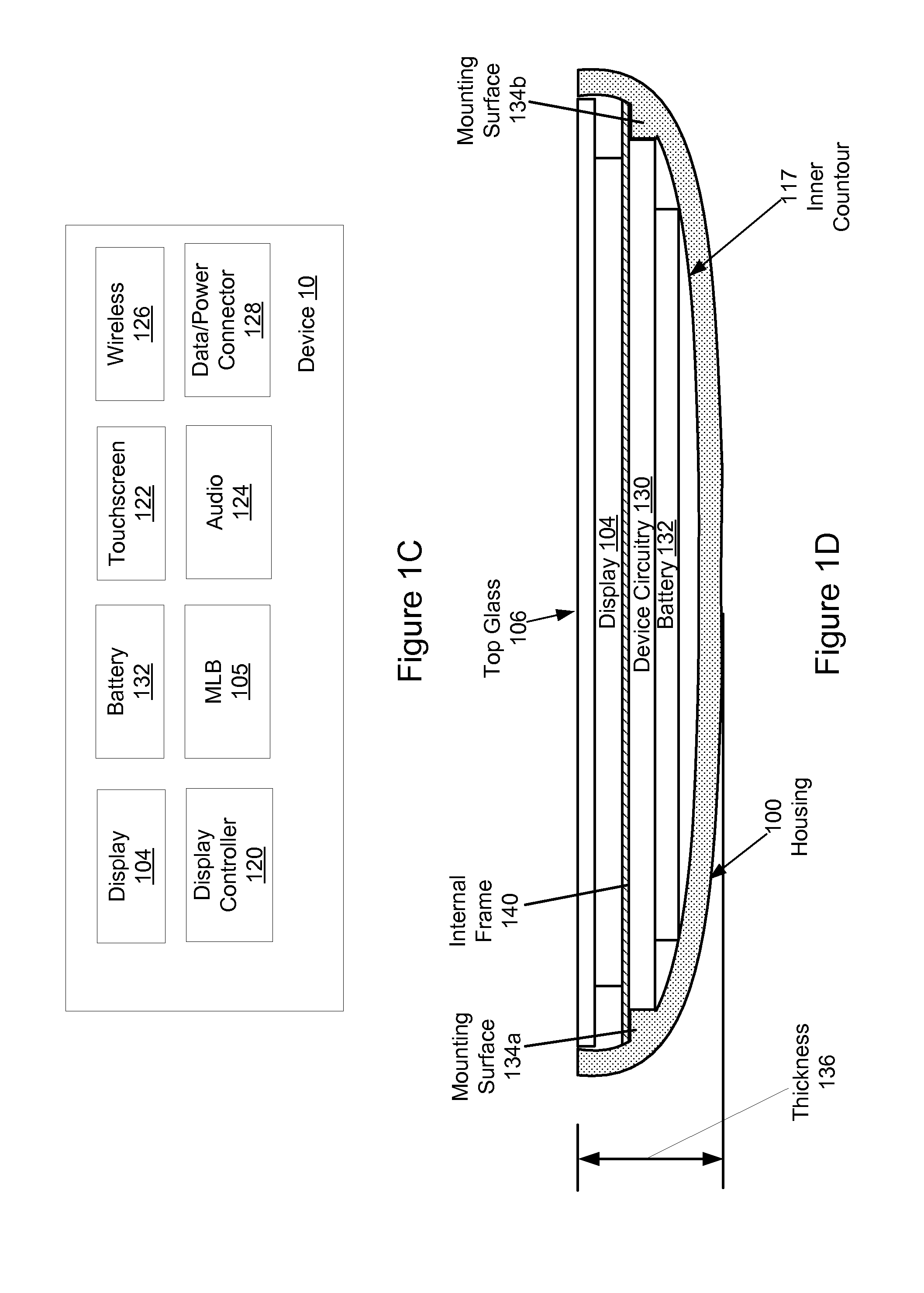

Internal frame optimized for stiffness and heat transfer

InactiveUS20130141870A1Excellent characteristicsHigh strengthDigital data processing detailsSubstation equipmentMetal frameworkDisplay device

A thin portable electronic device with a display is described. The components of the electronic device can be arranged in stacked layers within an external housing where each of the stacked layers is located at a different height relative to the thickness of the device. One of the stacked layers can be internal metal frame. The internal metal frame can be configured to act as a heat spreader for heat generating components located in layers adjacent to the internal frame. Further, the internal metal frame can be configured to add to the overall structural stiffness of the device. In addition, the internal metal frame can be configured to provide attachment points for device components, such as the display, so that the device components can be coupled to the external housing via the internal metal frame.

Owner:APPLE INC

Peripheral device with limited relative angular movement

The present invention provides a peripheral device with limited relative angular movement. The peripheral device is configured for detachable operative interconnection with a computing device and comprises a first portion, a second portion, and an operatively connected peripheral device component. The first portion includes a first hinge portion, which defines an axis of rotation, and comprises a first protrusion and a second protrusion. The first protrusion is disposed axially separated at a predetermined distance from the second protrusion. The second portion includes a second hinge portion, which is operatively interconnected with the first hinge portion to allow the first portion and the second portion to rotate relative to one another about the axis of rotation between a first angle and a second angle. The peripheral device component provides one or more peripheral device functions. The first angle and the second angle at least in part are defined by the first protrusion and the second protrusion.

Owner:NETGEAR INC

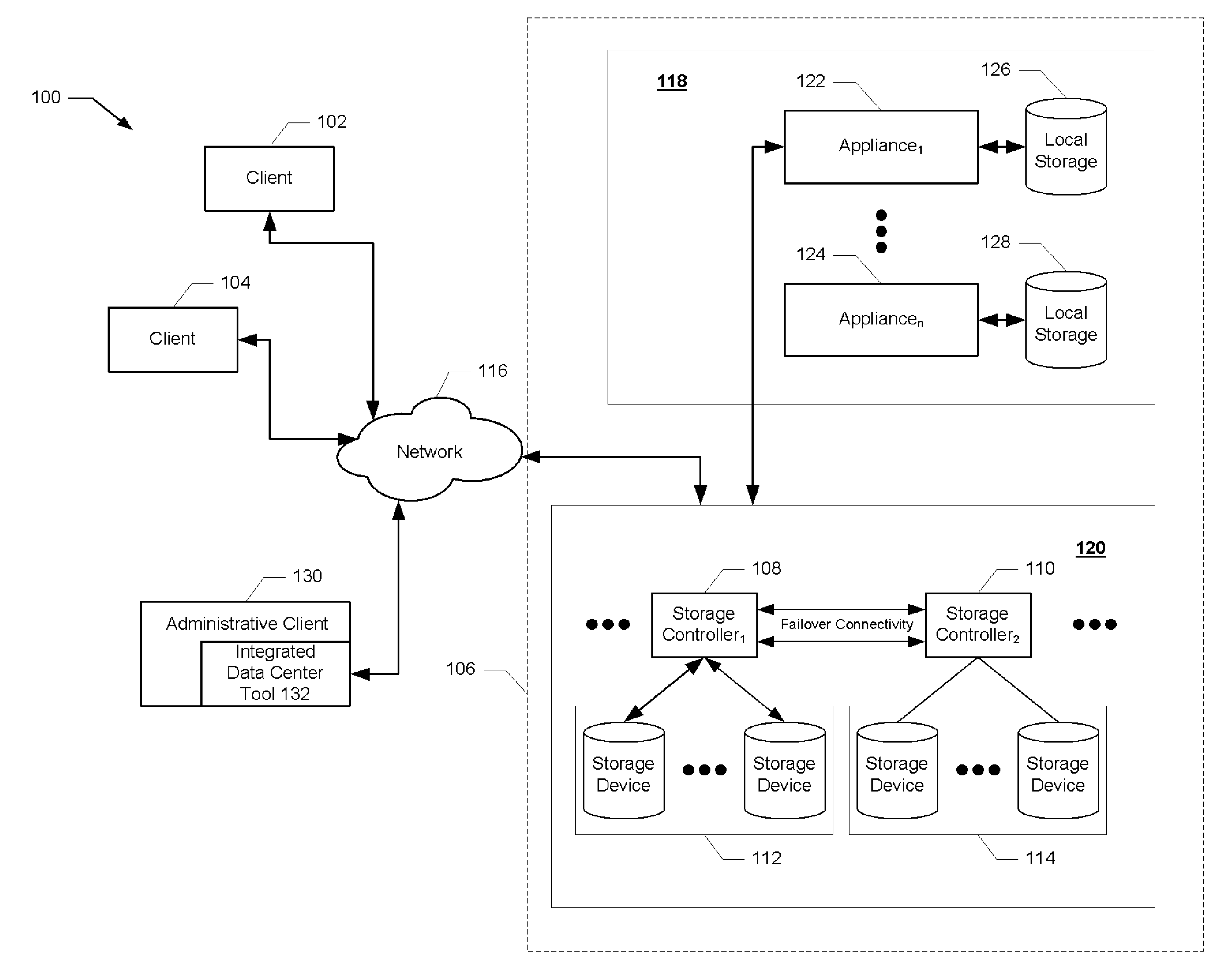

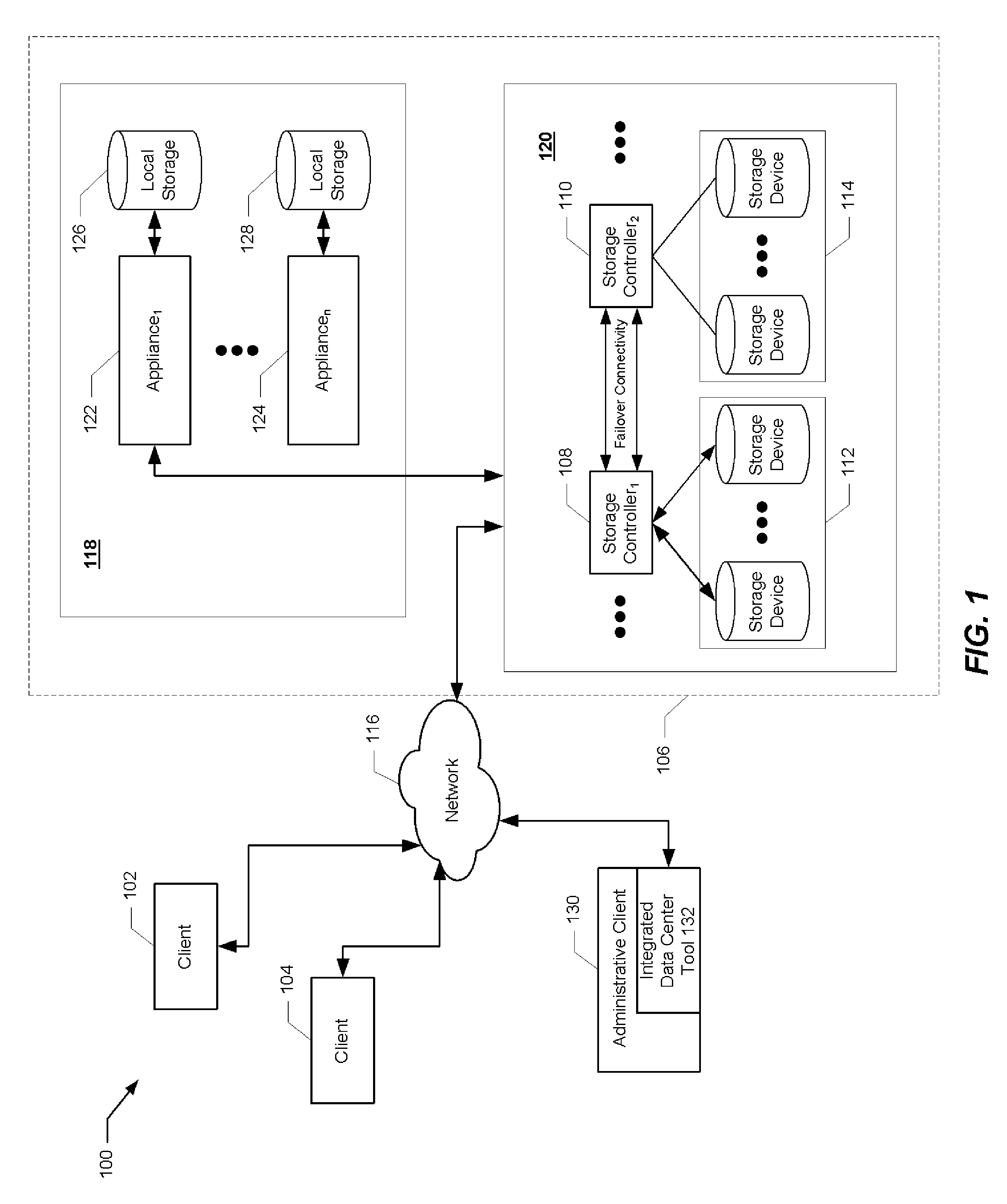

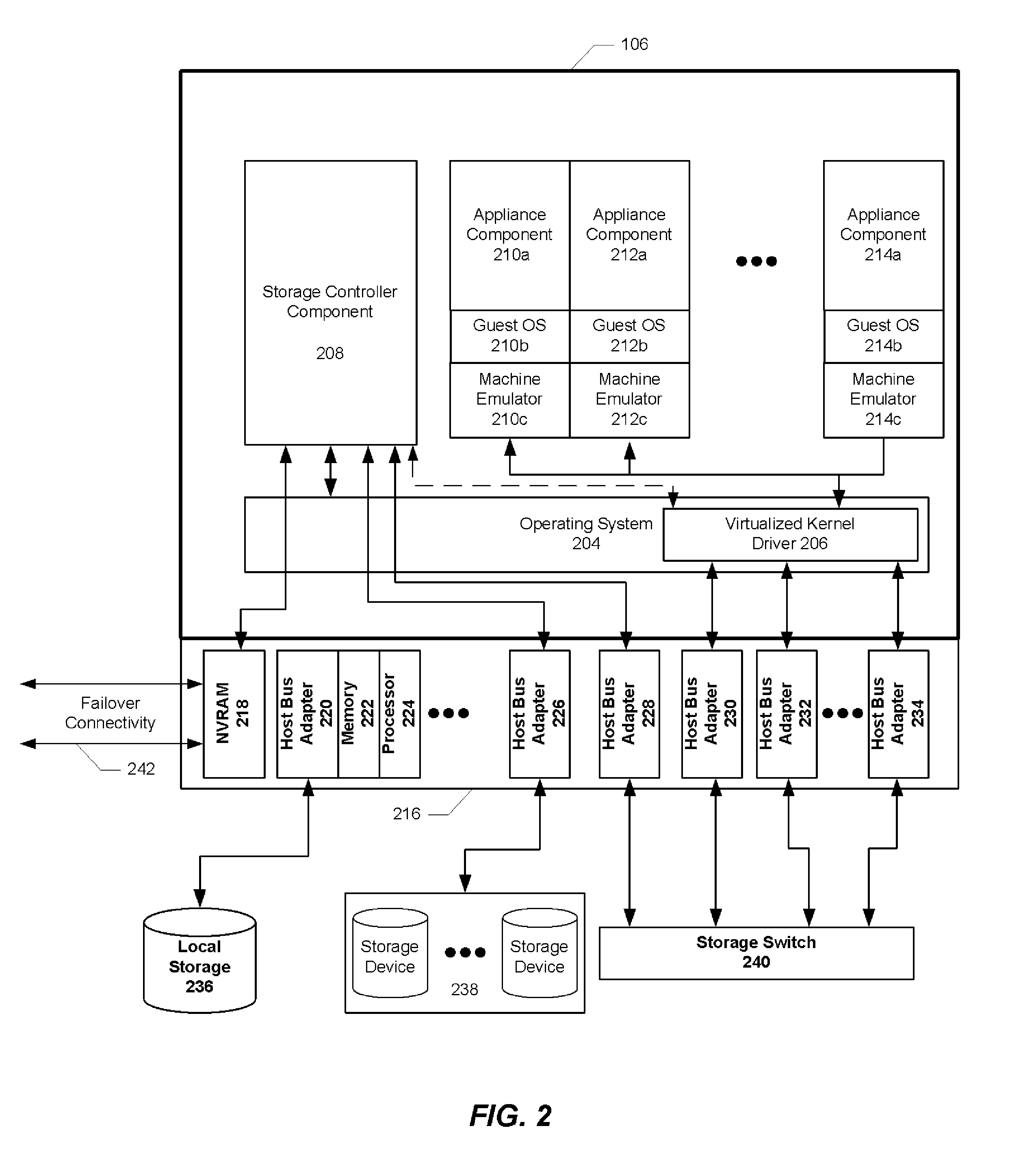

Integrated storage controller and appliance method and system

InactiveUS20110271062A1TransmissionSoftware simulation/interpretation/emulationVirtualizationData center

An integrated data center method and system combines a storage controller and one or more appliances onto a computer platform. Storage controller component executes on the hardware of a computer platform and has exclusive access to a first storage controller host bus adapter coupled to a storage shelf having one or more storage devices. The method and system provisions a virtualized instance of the hardware from the computer platform to deliver application services from an appliance component. The appliance component may share the processing resources from the computer platform through multiple different virtual machines. With respect to storage, aspects of the present invention exclusively associates an appliance host bus adapter from the computer platform to the appliance component. In addition, aspects of the present invention also provide control of the appliance host bus adapter to the appliance component passing through the virtualized instance of the hardware. To access the storage devices, the appliance host bus adapter and corresponding appliance component are coupled with a second storage controller host bus adapter associated with the storage controller component. Aspects of the present invention enable the access to the storage controller component and storage devices from each appliance host bus adapter. This enables applications associated with the appliance component to perform storage operations on the storage devices at a high throughput even though the applications are executing within a virtualized instance of the hardware.

Owner:NETWORK APPLIANCE INC

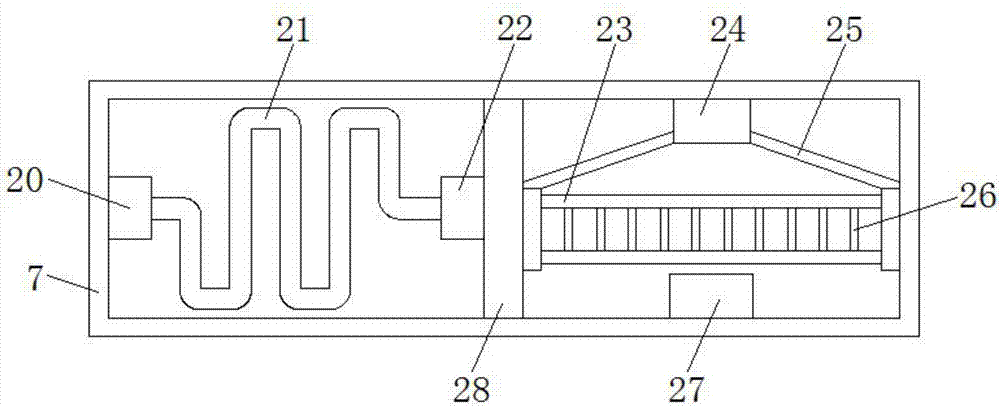

Durable power distribution automatic cabinet

InactiveCN107425448AReduce the temperaturePrevent affecting operationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsAppliance componentEngineering

The invention discloses a durable power distribution automatic cabinet, which comprises a cabinet body, wherein the bottom of the cabinet body is provided with a supporting plate; the middle of the upper surface of the supporting plate is provided with a placement groove adaptive to the cabinet body; the bottom end of the cabinet body is arranged in the placement groove; the bottom of the supporting plate is fixedly provided with supporting rods which are evenly distributed; the bottom of the supporting rod is fixedly provided with an embedding plate; the bottom of the embedding plate is fixedly provided with spacing columns which are in annular array distribution; and a division plate is fixedly installed in the cabinet body and independently segments the inner cavity of the cabinet body into a first wiring chamber and a second wiring chamber. One side of the cabinet body is provided with a regulation box, so that temperature in the cabinet body can be lowered when the durable power distribution automatic cabinet is used, heat generated in the working process of an electric appliance component in the cabinet body is emitted, and a situation that the operation of equipment is affected since the heat is accumulated in the cabinet body is avoided so as to be favorable for prolonging the service life of the equipment.

Owner:宁波智正伟盈信息科技有限公司

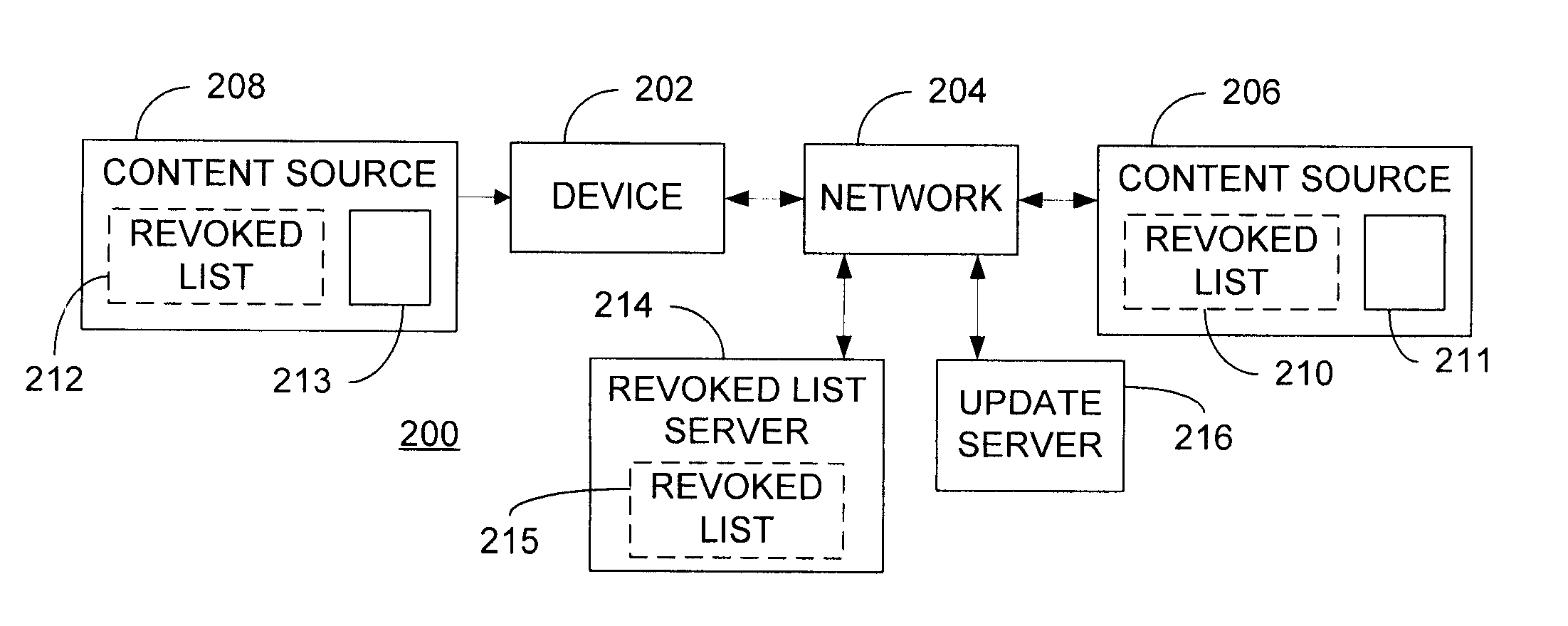

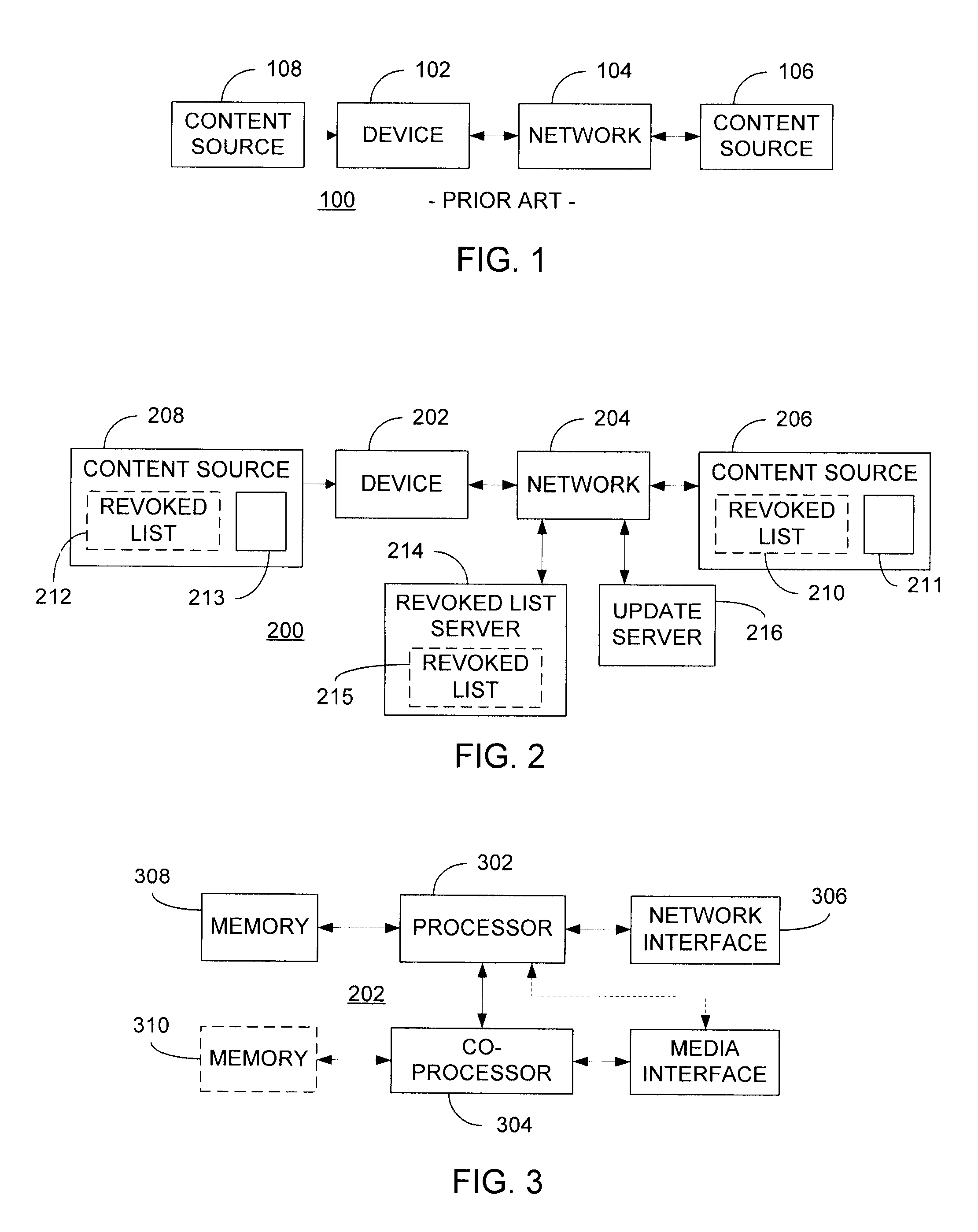

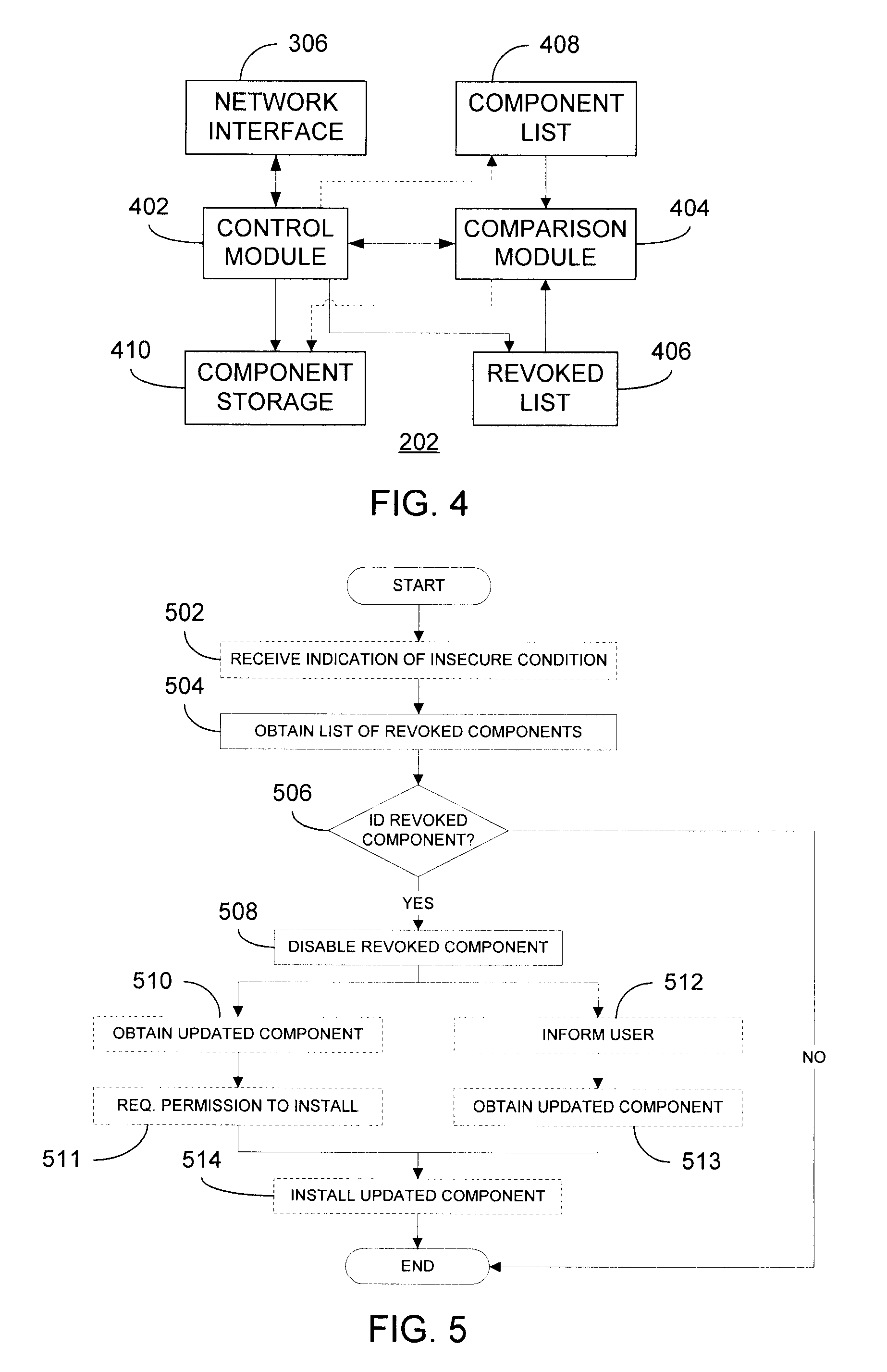

Notification of Revocation in a Device Offering Secure Playback of Content

InactiveUS20080072077A1Unauthorized memory use protectionHardware monitoringComputer hardwareDevice Subassembly

A device, suitable for playback of content, identifies components, installed on the device, to be used during playback of the content. Additionally, the device obtains a list of revoked components, which it compares with the identified device components. If one or more of the device components matches one or more entries in the list of revoked components, the identified revoked components are disabled such that they are prevented from playing back any pre-existing or future content. In a presently preferred embodiment, the device can automatically obtain an updated component corresponding to the revoked component and thereafter install the updated component so as to reinstate a secure environment. In this manner, user experiences regarding play back capabilities of devices may be improved and the overall security of the system is increased.

Owner:ATI TECH INC

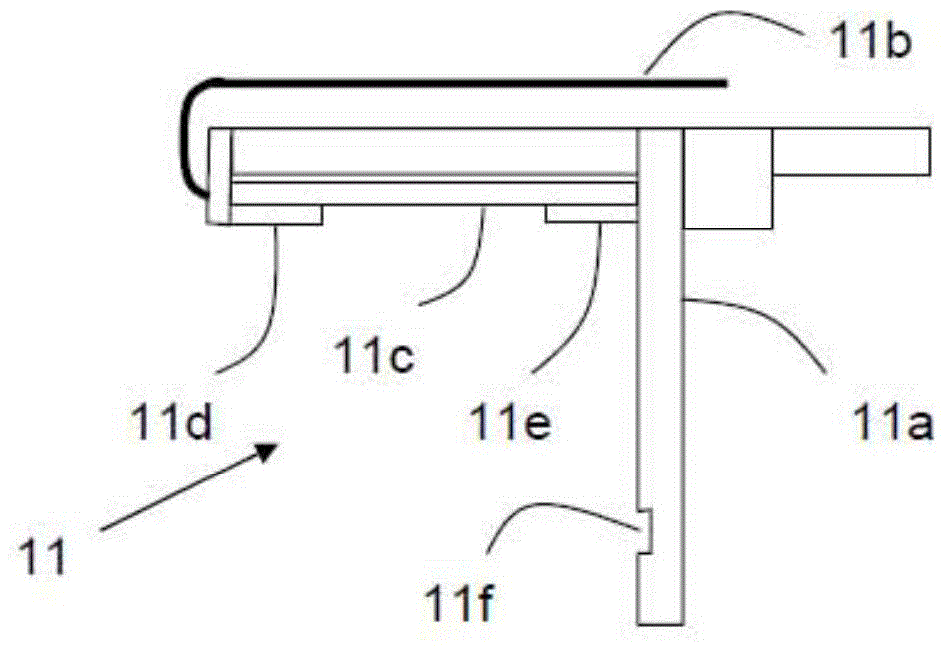

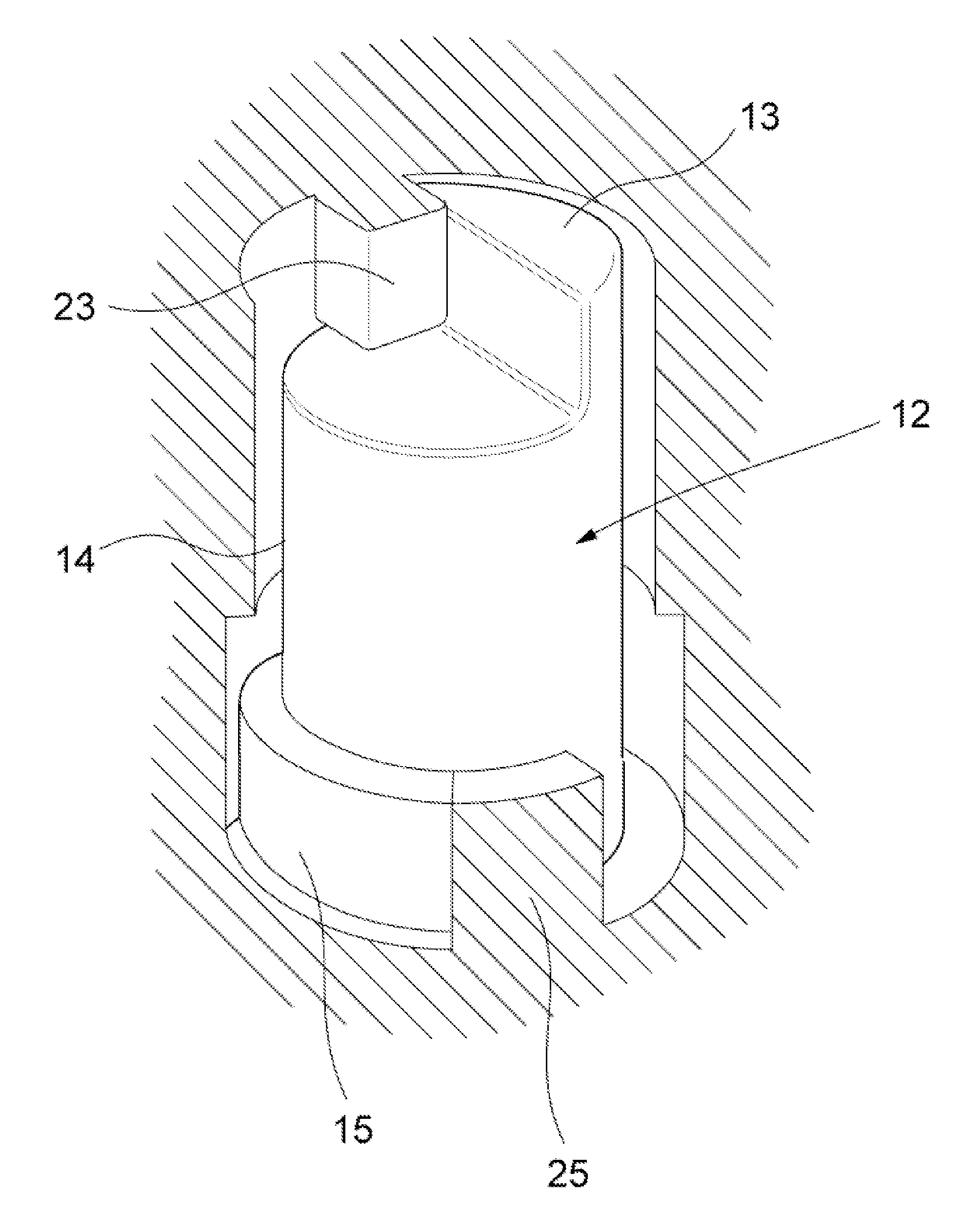

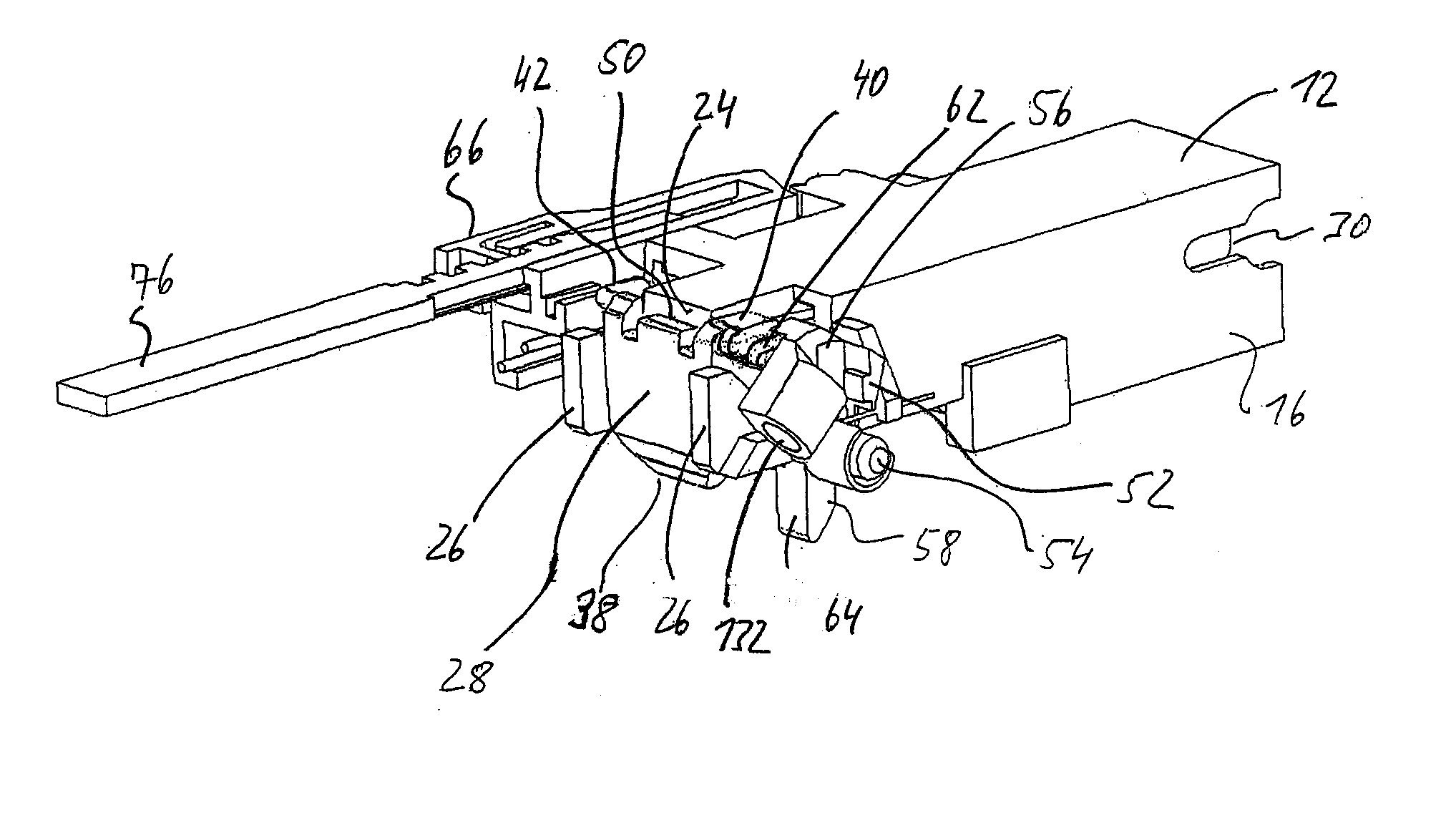

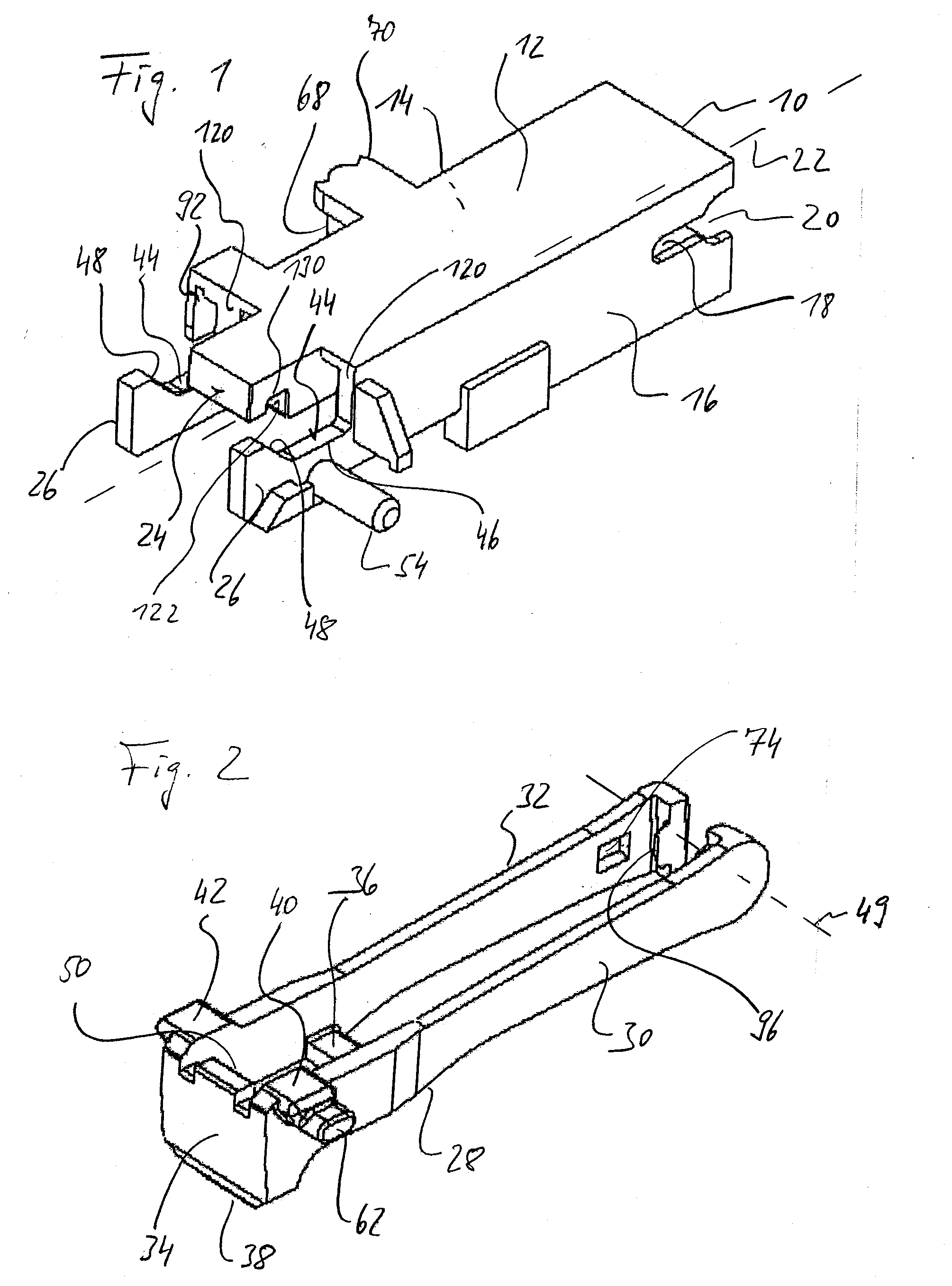

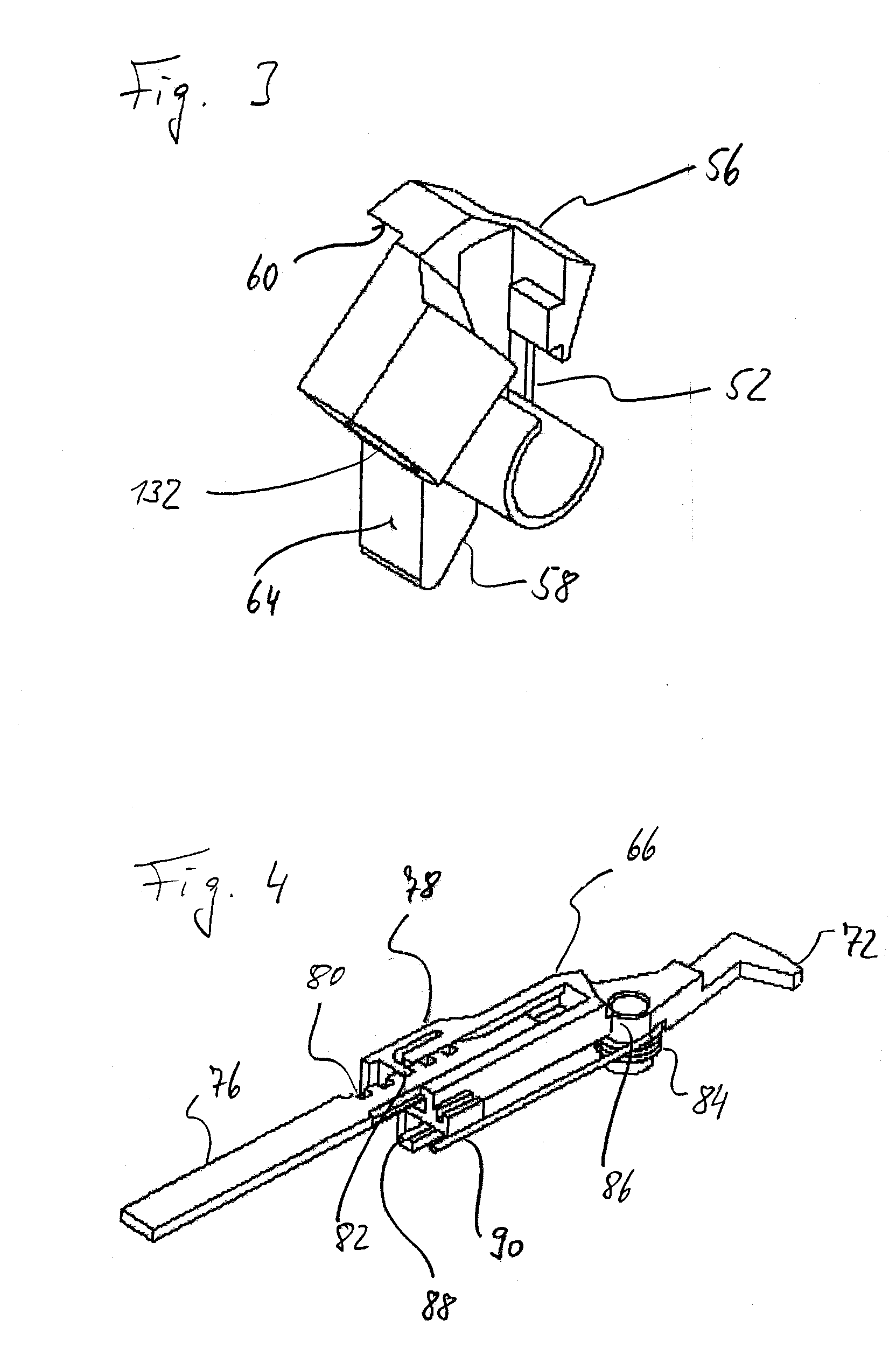

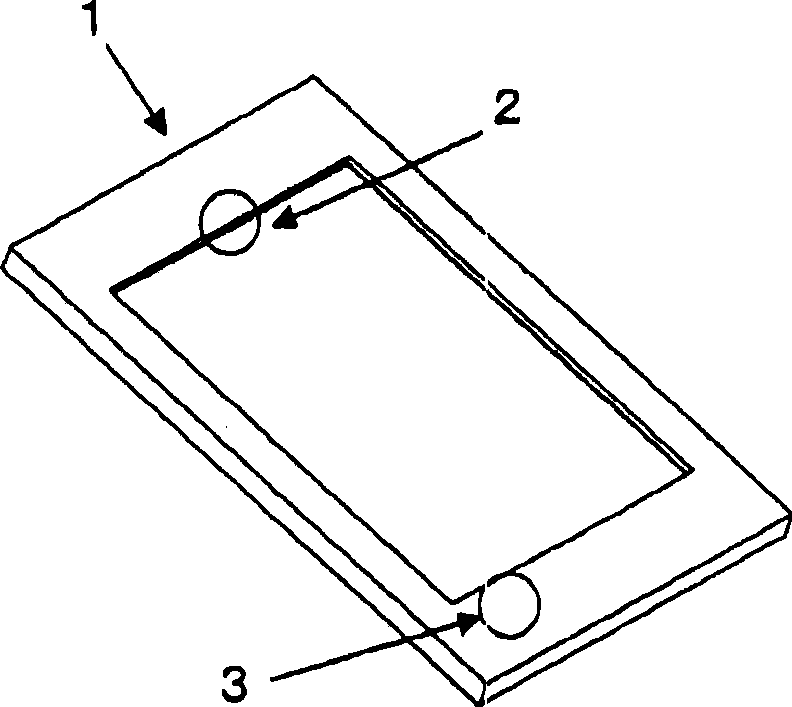

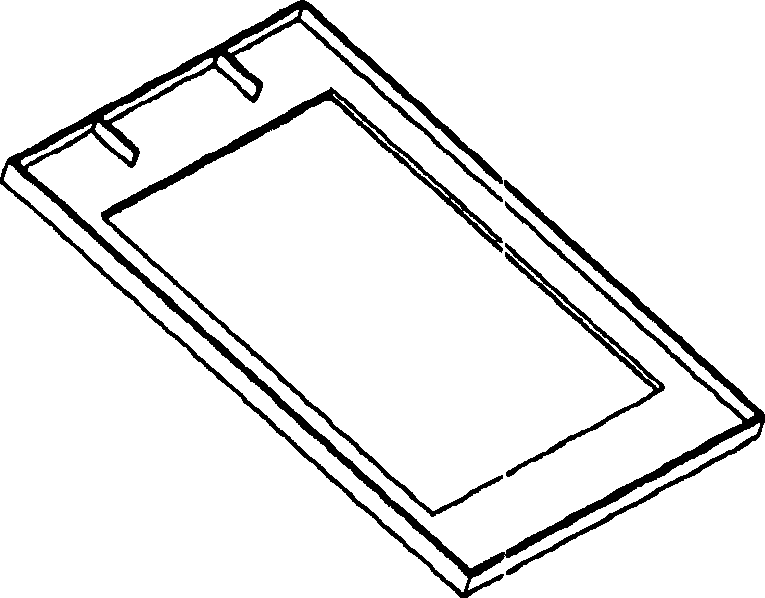

Door latch device for a domestic appliance, in particular for a dish washer

ActiveUS20080042447A1Little strengthTight closing of the doorWing fastenersTableware washing/rinsing machinesImpact systemAppliance component

A door latch device for a domestic electrical appliance, in particular for a dishwasher, has a frame (10) provided or to be provided on a first component of the domestic appliance, a latching unit (28) arranged so it can be displaced relative to the frame between an open position and a latched position for engagement with a closure system of a second component of the domestic appliance that can be moved relative to the first appliance component and is to be locked with respect thereto, and a latching spring assembly that pre-tensions the latching unit and which in the open position of the latching unit forces the unit into engagement with a blocking surface (24) that blocks relaxation of the latching spring assembly. According to one aspect of the invention a control member (52) that is separate from the latching unit and arranged so it can be moved relative thereto is provided, comprising an application system (64) for an actuating portion of the second appliance component and comprising an impact system for a block-cancelling effect on the latching unit. According to a further aspect the latching unit is formed by a one-piece latching body on which, in addition to a latching system (38) for engagement with the closure system of the second appliance component and a blocking system (50) for engagement with the blocking surface (24), supporting surfaces for the latching spring assembly are also arranged.

Owner:EMZ HANAUER

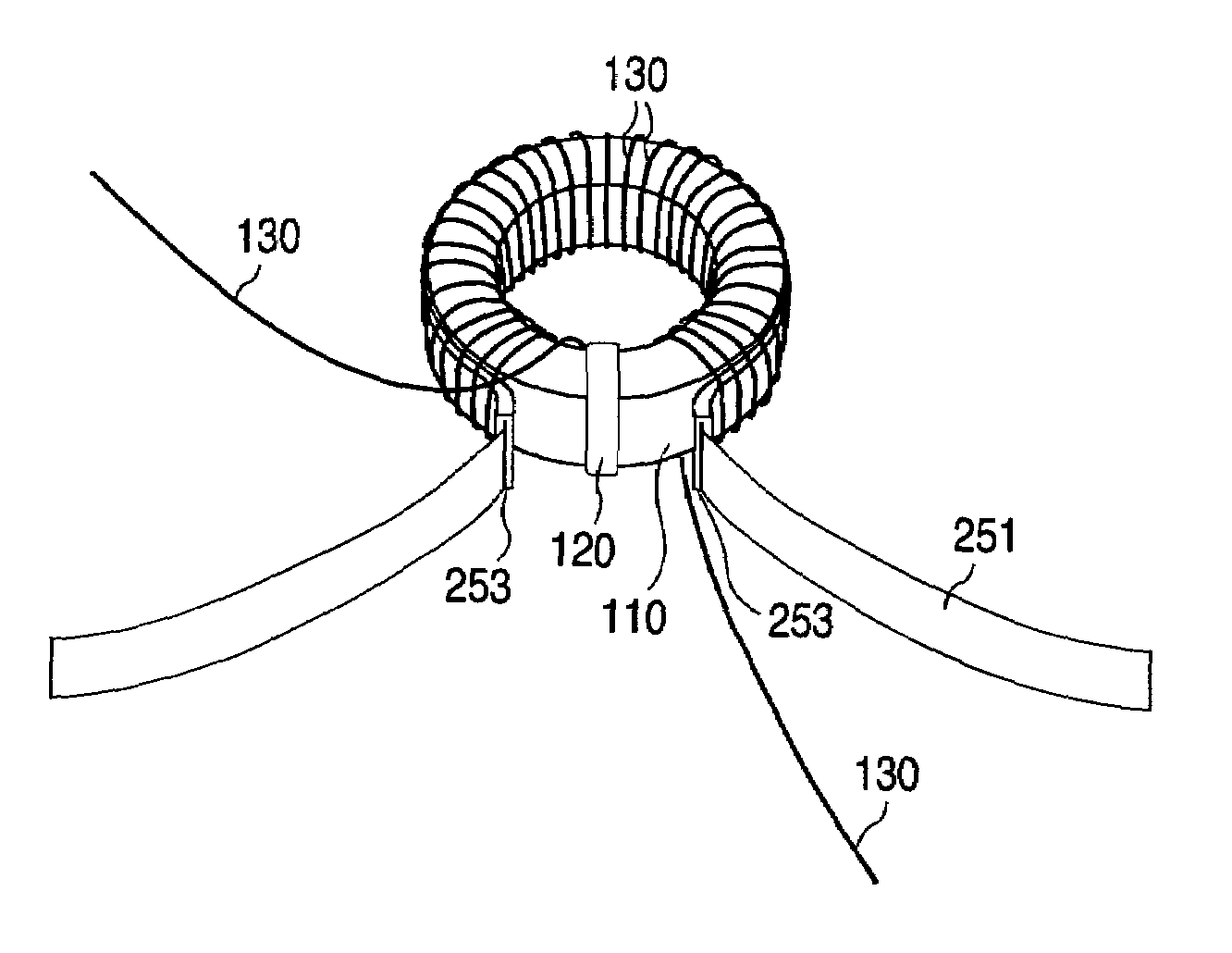

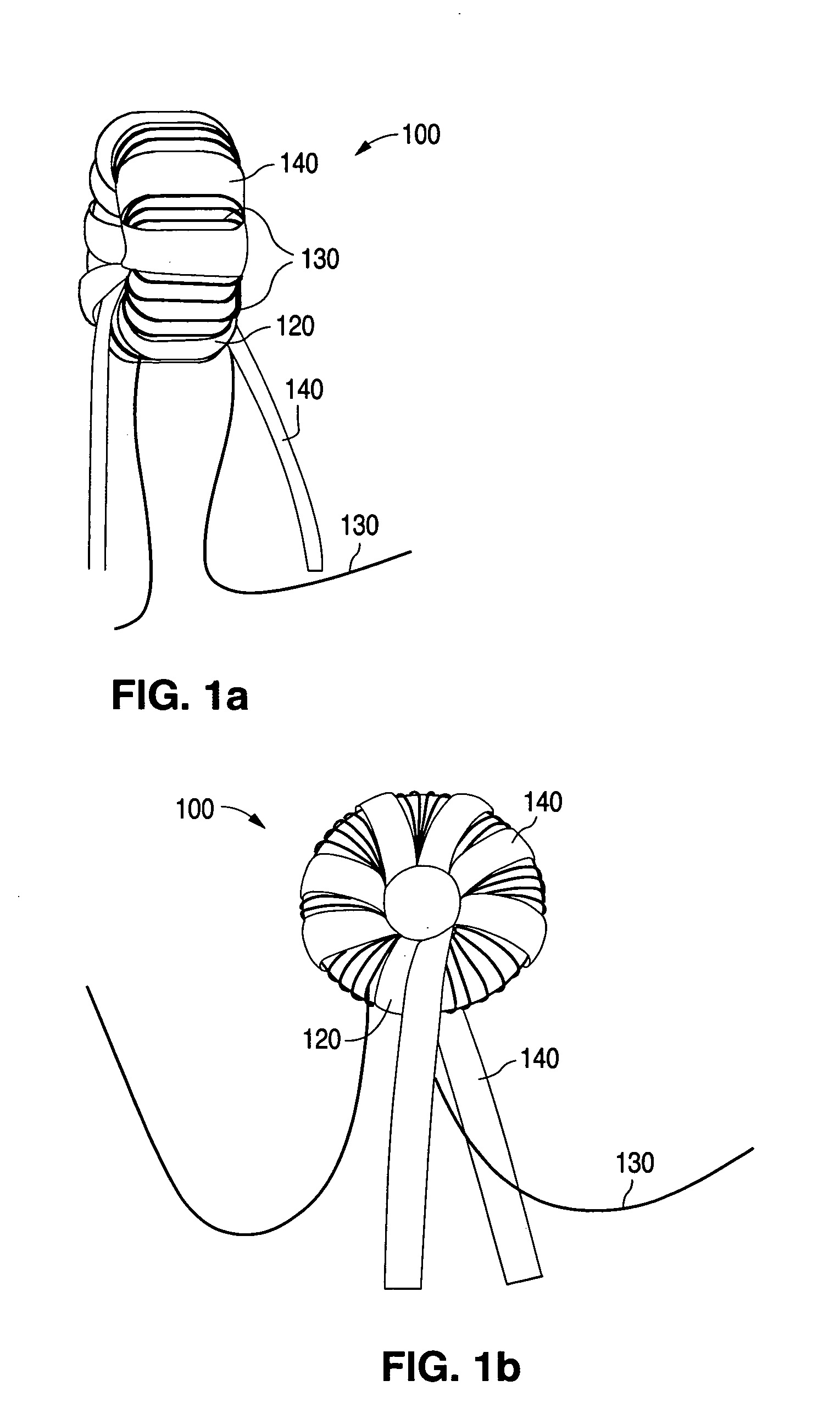

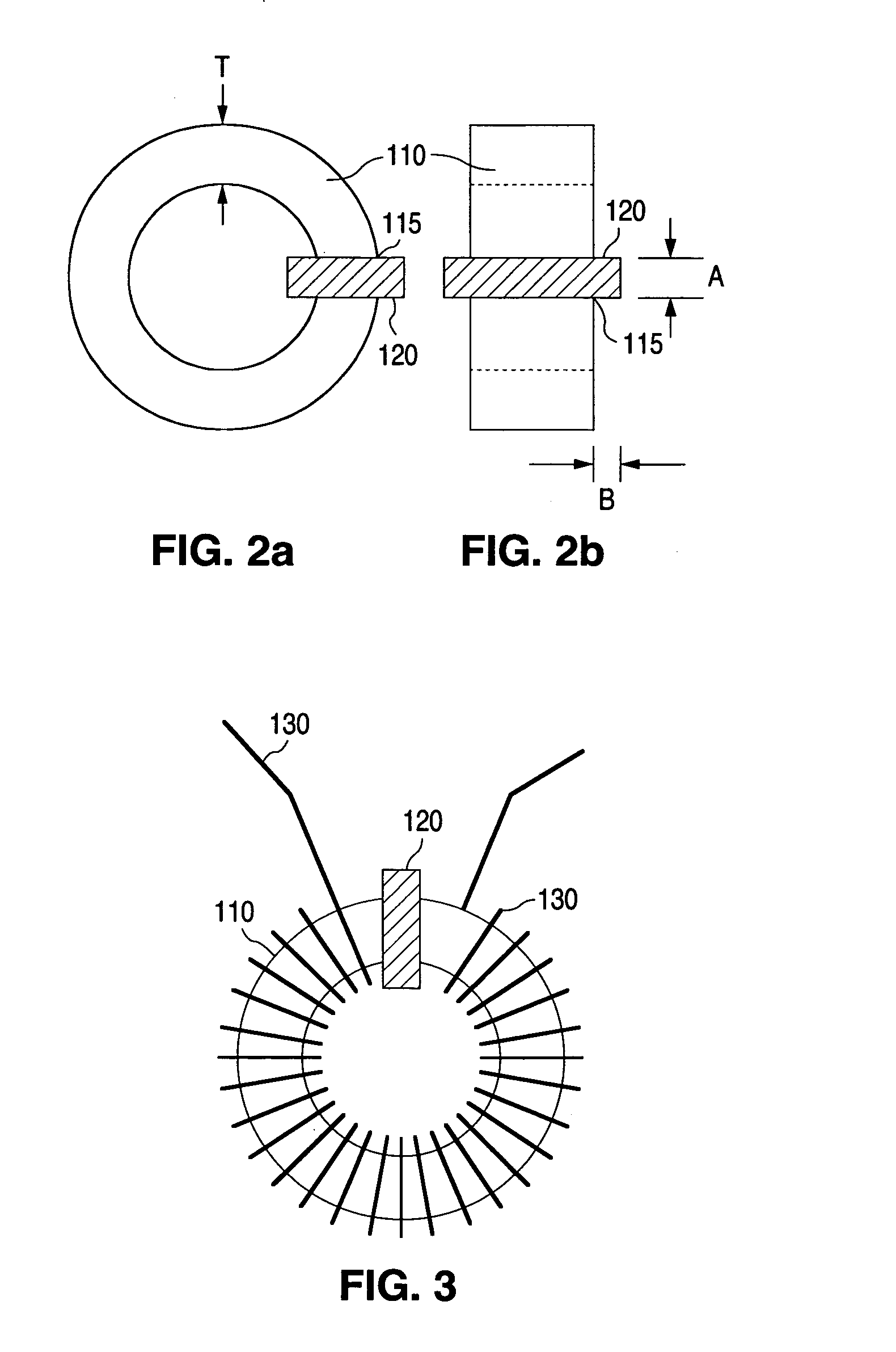

Insulation and integrated heat sink for high frequency, low output voltage toroidal inductors and transformers

InactiveUS7142085B2Improve thermal efficiencyImprove power densityTransformers/inductances coolingTransformers/inductances coils/windings/connectionsCopper wireTransformer

Toroidal transformer and inductor configurations are described that allow for greater heat transfer away from internal device components. The inventive transformer allows for higher thermal and electrical efficiency, as well as for more efficient use of expensive components, such as copper wire. In one embodiment, a toroidal transformer provides access for cooling air by forming the primary winding from a single layer of thick wire and a secondary winding of few turns such that most of the primary winding is exposed to air flow. In another embodiment, a heat sink is positioned between the core and primary windings to conduct heat away from the transformer.

Owner:ASTEC INT LTD

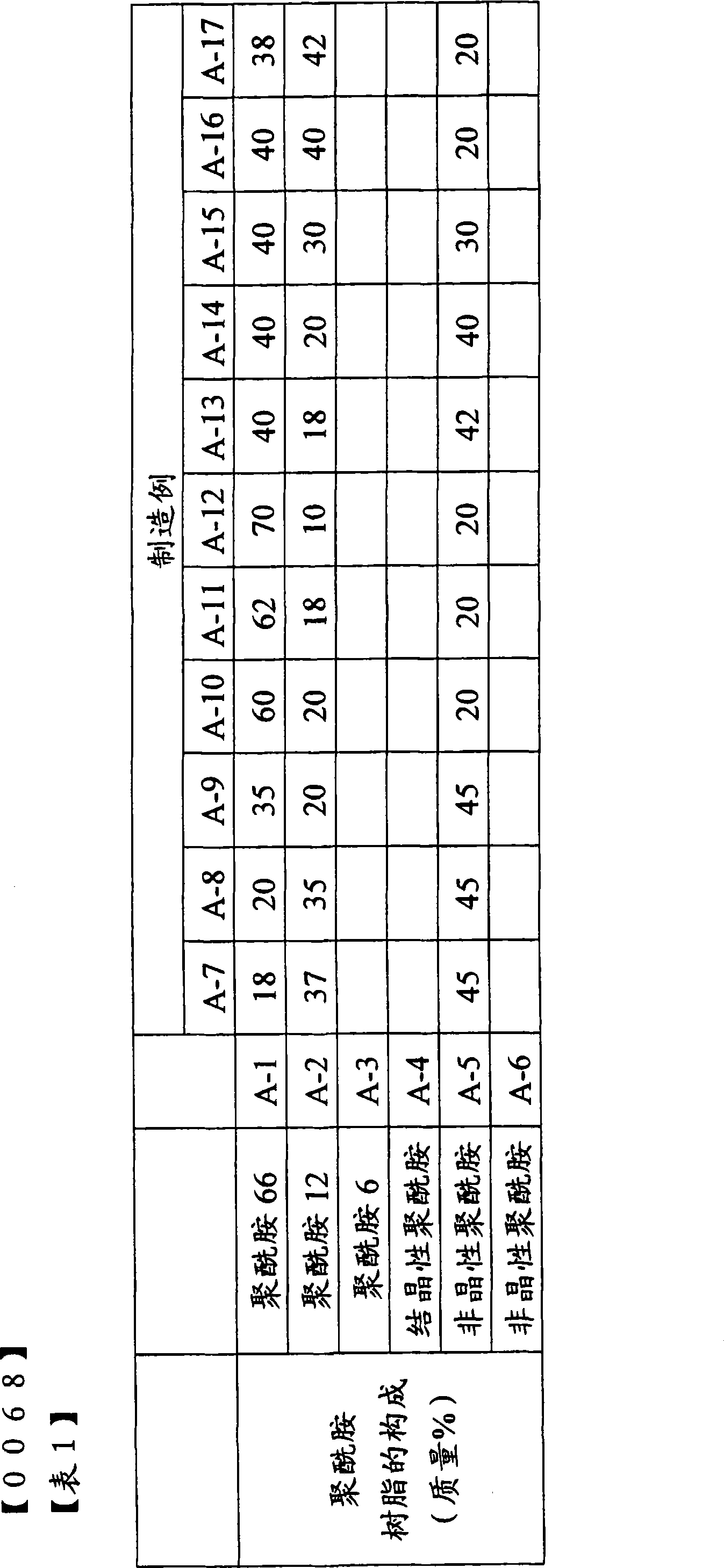

Glass fiber reinforced polyamide resin composition

InactiveCN101508839AGuaranteed liquidityReduce the temperatureElectrical apparatus casings/cabinets/drawersGlass fiberElastomer

The invention provides a glass fiber reinforced daiamid resin composition, which has excellent thin-wall forming property and surface appearance, and is applied to thin-wall portable electronic appliance components or computer frame components. The glass fiber reinforced daiamid resin composition is formed in combined with 50 to 150 parts of glass fiber by weight relative to 100 parts of daiamid resin composition by weight containing 90% to 99% of daiamid resin by weight and 1% to 10% of acid modified styrene elastomer by weight, the daiamid resin is combined with 20% to 60% of daiamid 66 resin by weight, 20% to 40% of daiamid 12 resin and 20% to 50% of amorphous daiamid resin by weight, and the total dose is 100% by weight.

Owner:UNITIKA LTD

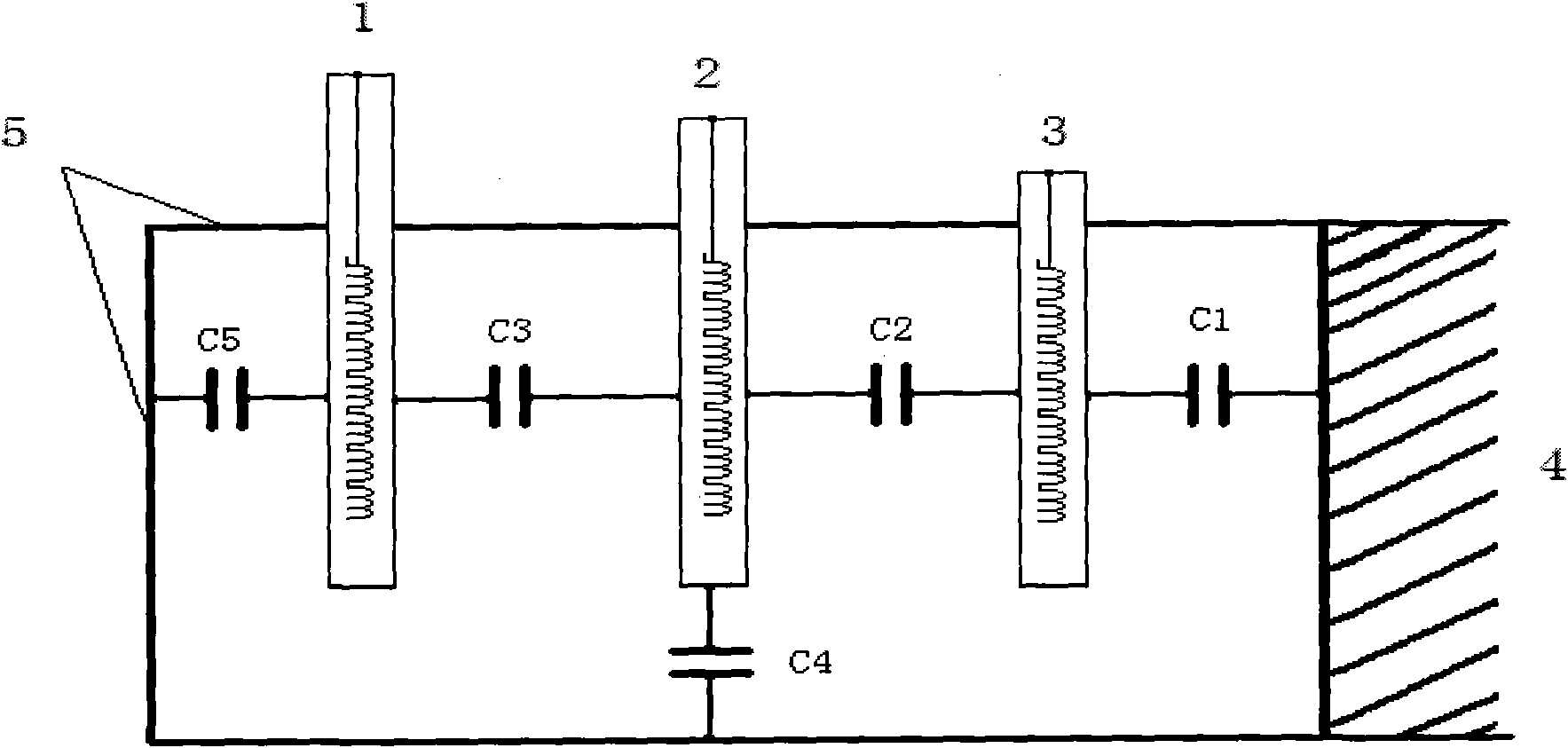

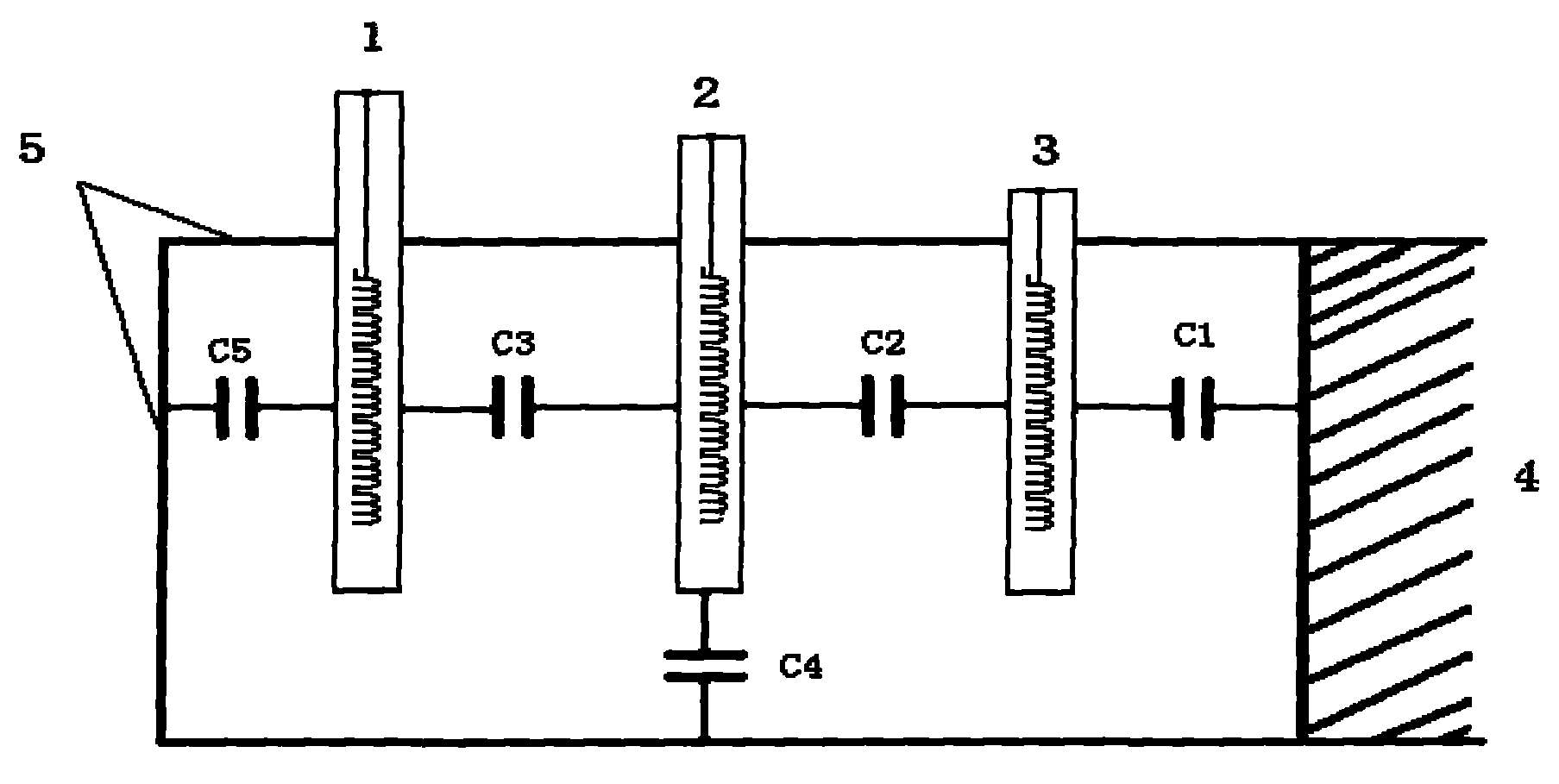

Dielectric-capacitance testing method of deformation degree of transformer winding

InactiveCN101776435AGuaranteed safe operationImprove the quality of workResistance/reactance/impedenceElectrical/magnetic solid deformation measurementQuality of workDielectric loss

The invention provides a dielectric-capacitance testing method of the deformation degree of a transformer winding, belonging to the technical field of test of electric appliance components. The deformation degree of the transformer winding is judged by testing the variation of the dielectric loss and capacitance of the transformer winding. The invention has the advantages that shortage of the prior art is overcome, the deformation degree of the transformer winding is judged by testing the variation of the dielectric loss and capacitance of the transformer winding, the deformation degree of the transformer winding can be accurately judged by an overall dielectric-capacitance method or an interphase dielectric-capacitance method or by complementation and confirmation therebetween so that the repair the operating state of the transformer can be timely and accurately monitored, normal and safe operation of the transformer is ensured, and the working quality and the efficiency of the transformer are improved. The method is particularly suitable for testing the deformation degree of the transformer winding with the voltage of 110kV or above.

Owner:HEBEI ELECTRIC POWER RES INST

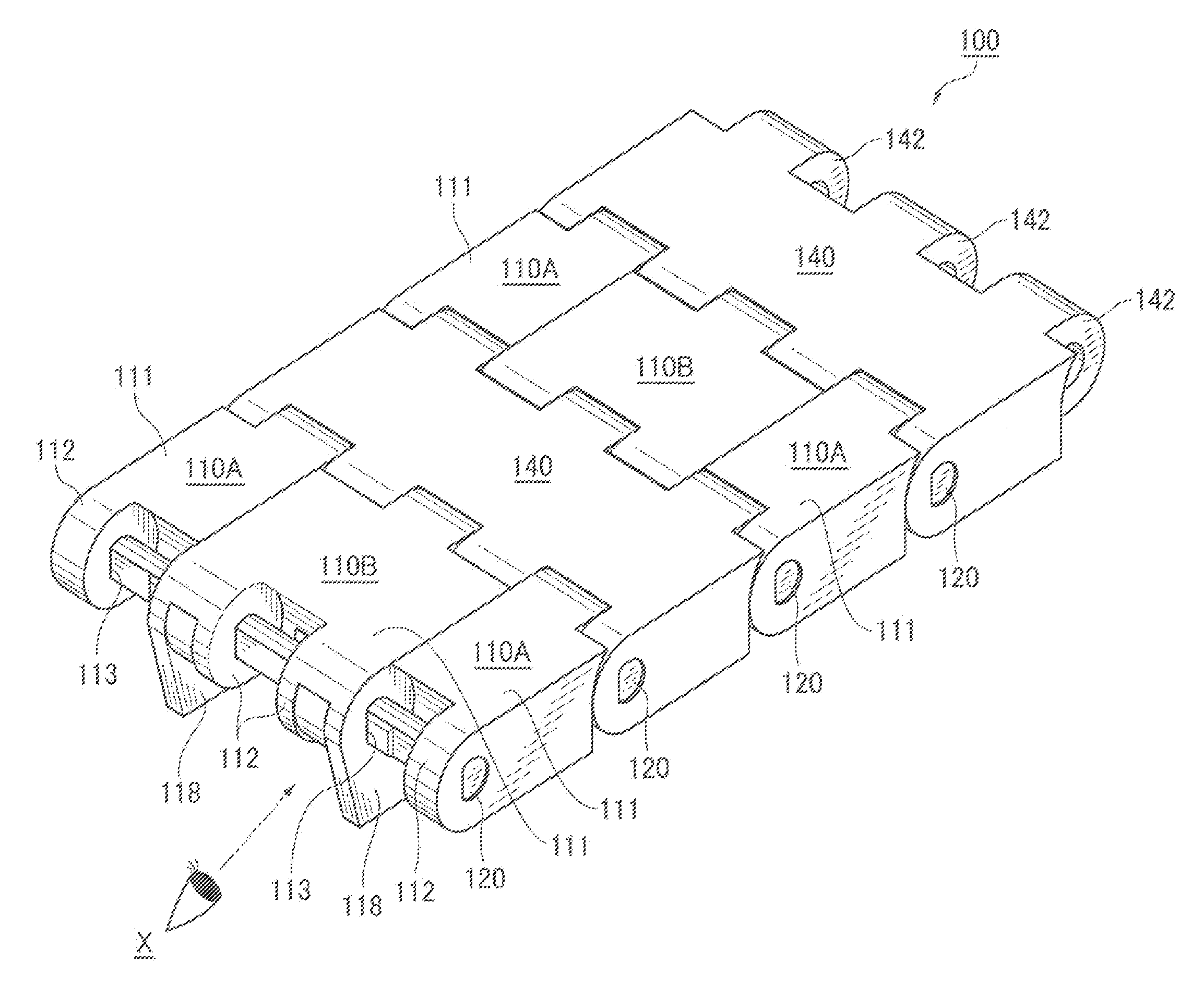

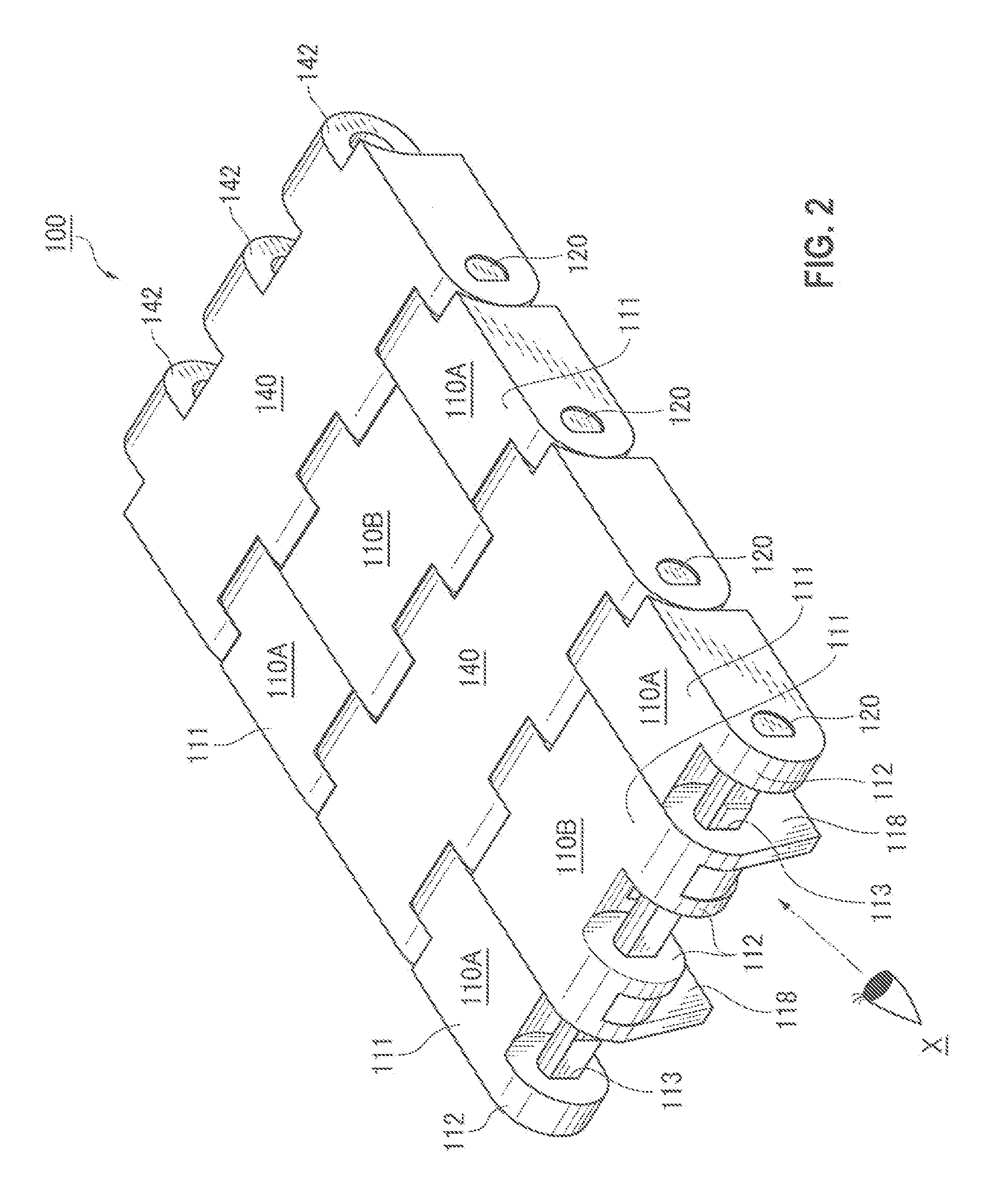

Conveyor chain

ActiveUS20120073938A1Easy to fixDrive stabilityConveyorsSupporting framesAppliance componentSynthetic resin

A conveyor chain that enables magnet pieces for attracting and retaining articles conveyed on the chain. The magnet pieces are incorporated into synthetic resin link modules without changing a predetermined chain width and dimensioning of other device components. A large number of link rows consisting of a number of synthetic resin link modules are connected together so as to have a predetermined chain width W. At least some of the synthetic resin link modules have magnet storing blind holes which open in the chain width direction from link side surfaces such that a magnet piece can be insertably stored in the magnet storing blind hole and securely enclosed by the link side surface of an adjacent synthetic resin link module in the chain width direction.

Owner:TSUBAKIMOTO CHAIN CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com