Modular surface mount component for an electrical device or LED's

a technology of leds and modules, applied in the direction of sustainable manufacturing/processing, identification means, instruments, etc., can solve the problems of large cost of interface devices such as displays, increasing the cost of displaying information, so as to achieve a significant reduction in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

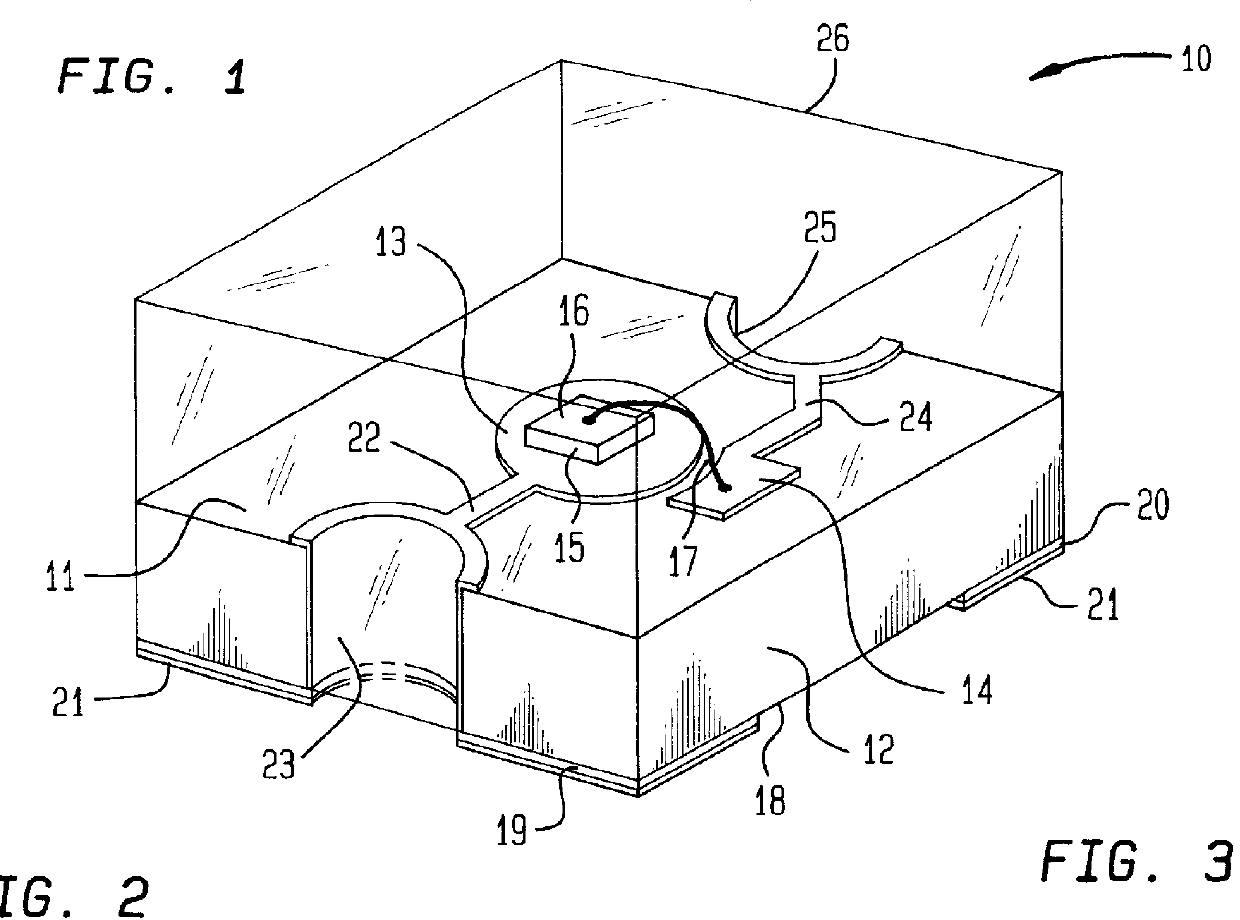

FIG. 1 demonstrates the construction of a typical modular component 10 that may be manufactured according to the present invention. Deposited onto the upper side 11 of a flat substrate 12 of an electrically insulating material, for instance synthetic plastic material or the like, is a conductive pattern of highly conductive material such as copper. The conductive pattern deposited onto the upper side 11 defines a land area 13 and a connection pad 14. A light emitting diode 15 is mounted on the land area 13 so that its terminal on the underneath or back side is electrically and mechanically coupled to the land area 13. The upper side of the light emitting diode 15 is provided with a terminal 16 which is electrically conductive and connected with the connection pad 14 via a bonding wire 17.

Deposited onto the rear of back side 18 of the flat substrate 12 is a second conductive pattern of highly conductive material such as copper. This second conductive pattern defines a first terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com