Patents

Literature

33results about How to "Low skill level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

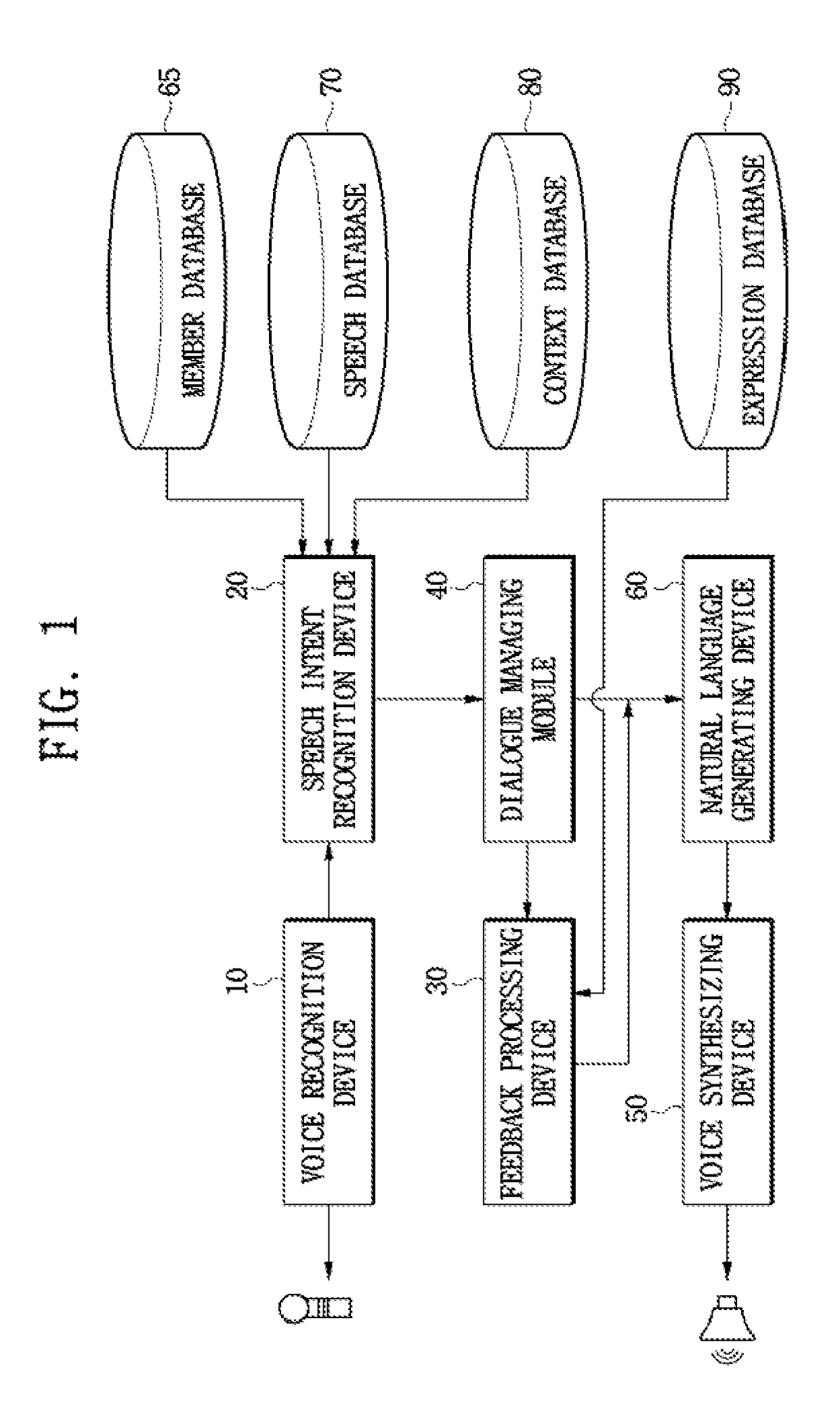

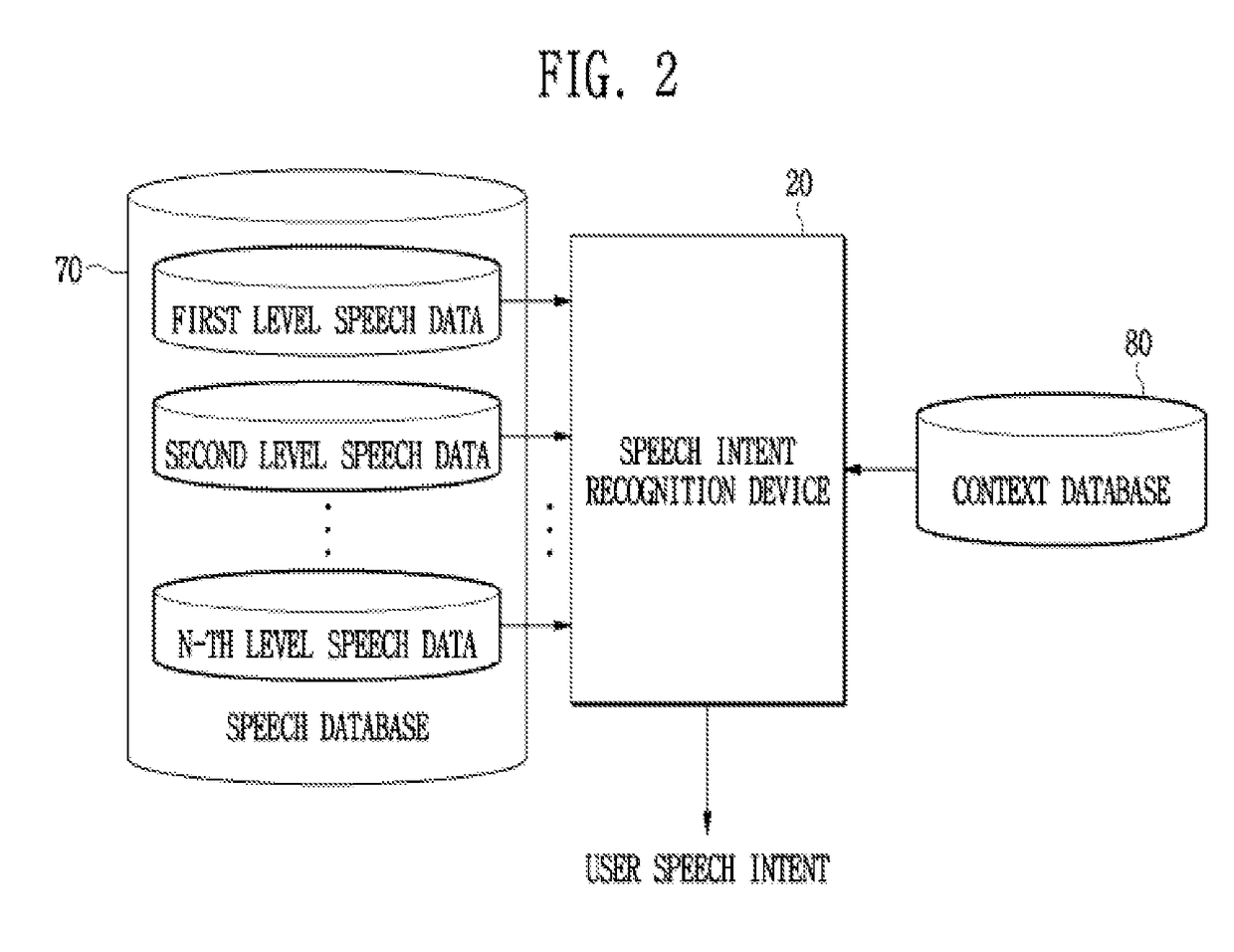

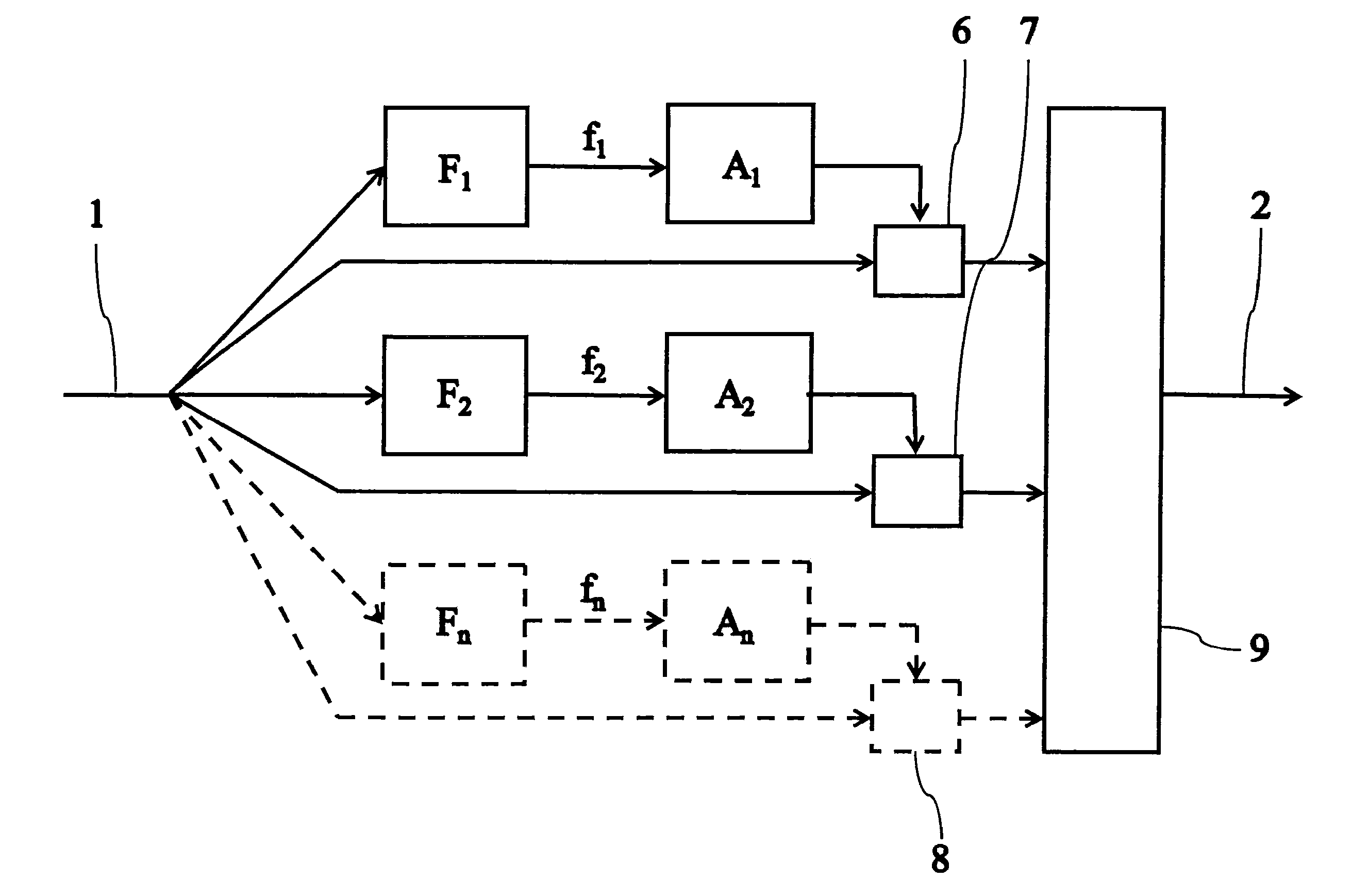

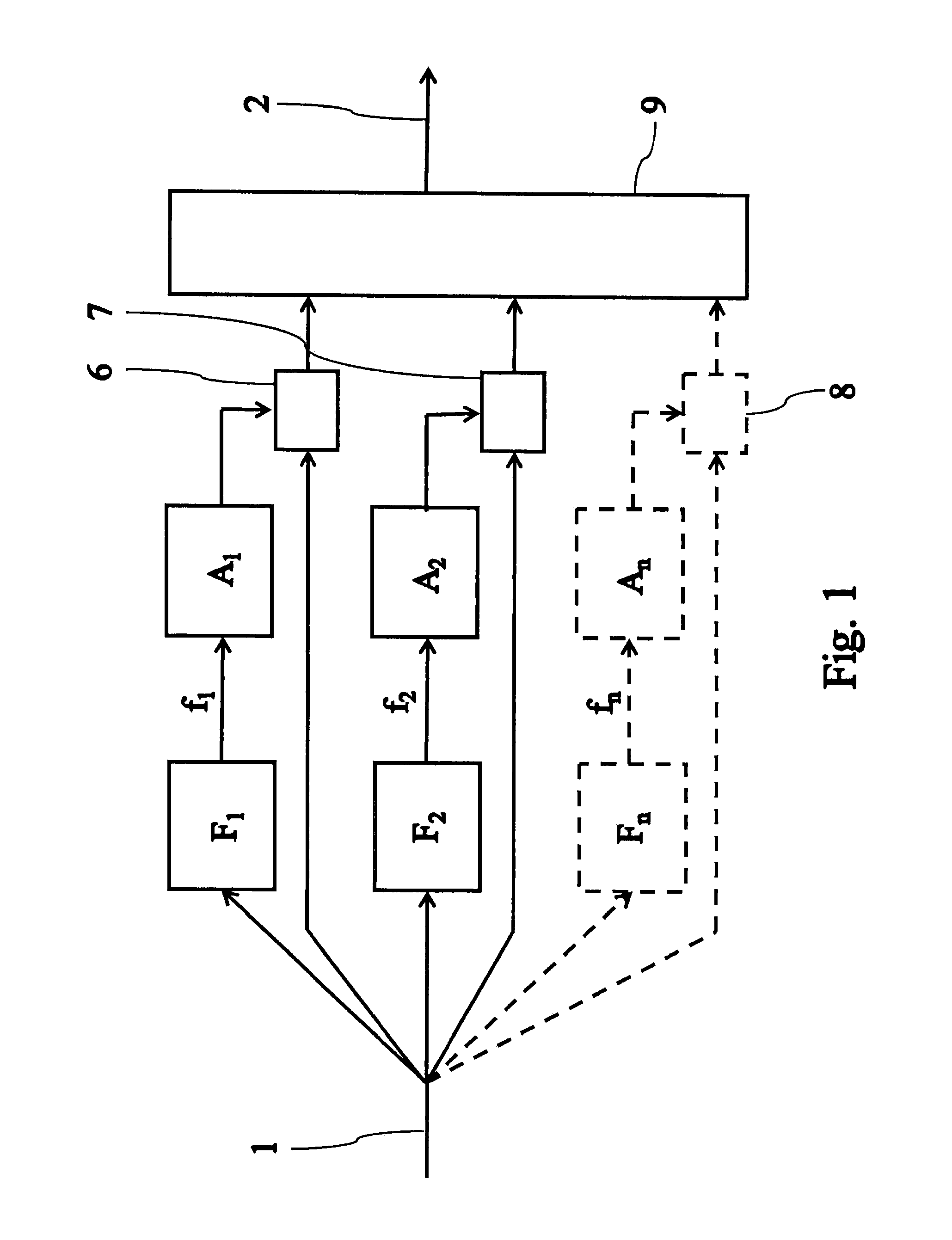

Apparatus and method for foreign language study

ActiveUS20120290300A1Low skill levelSpeech recognitionTeaching apparatusSpeech identificationIntent recognition

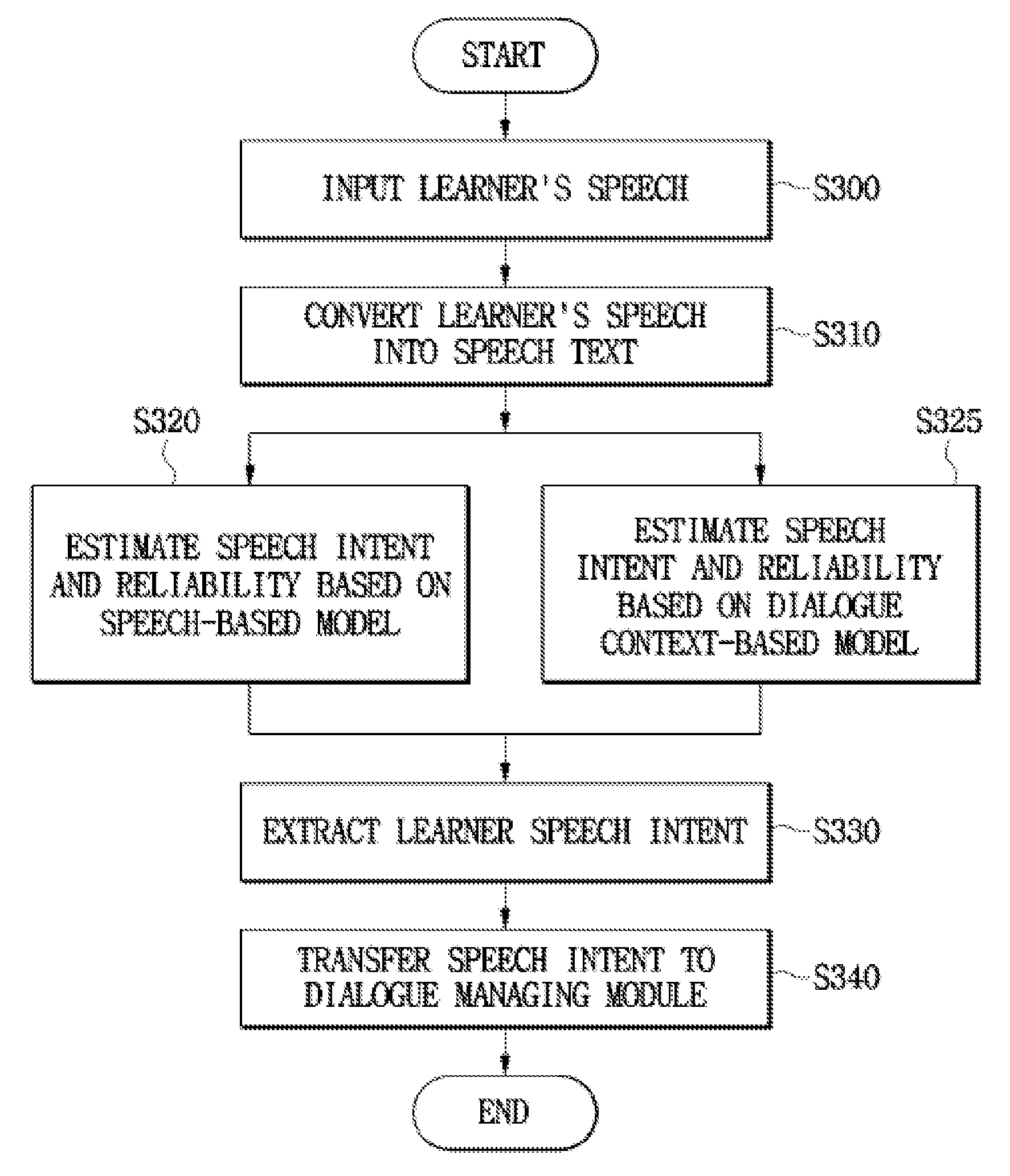

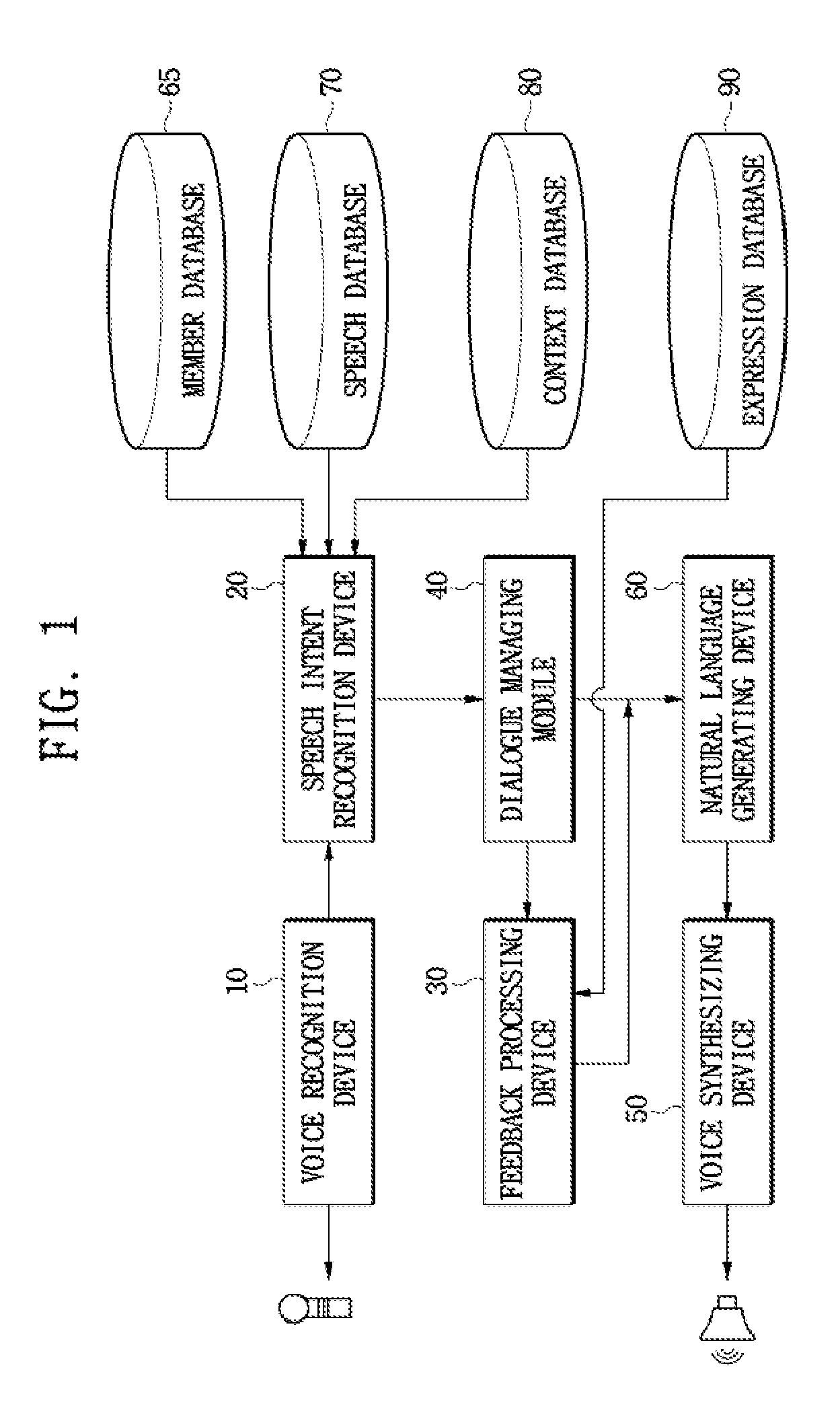

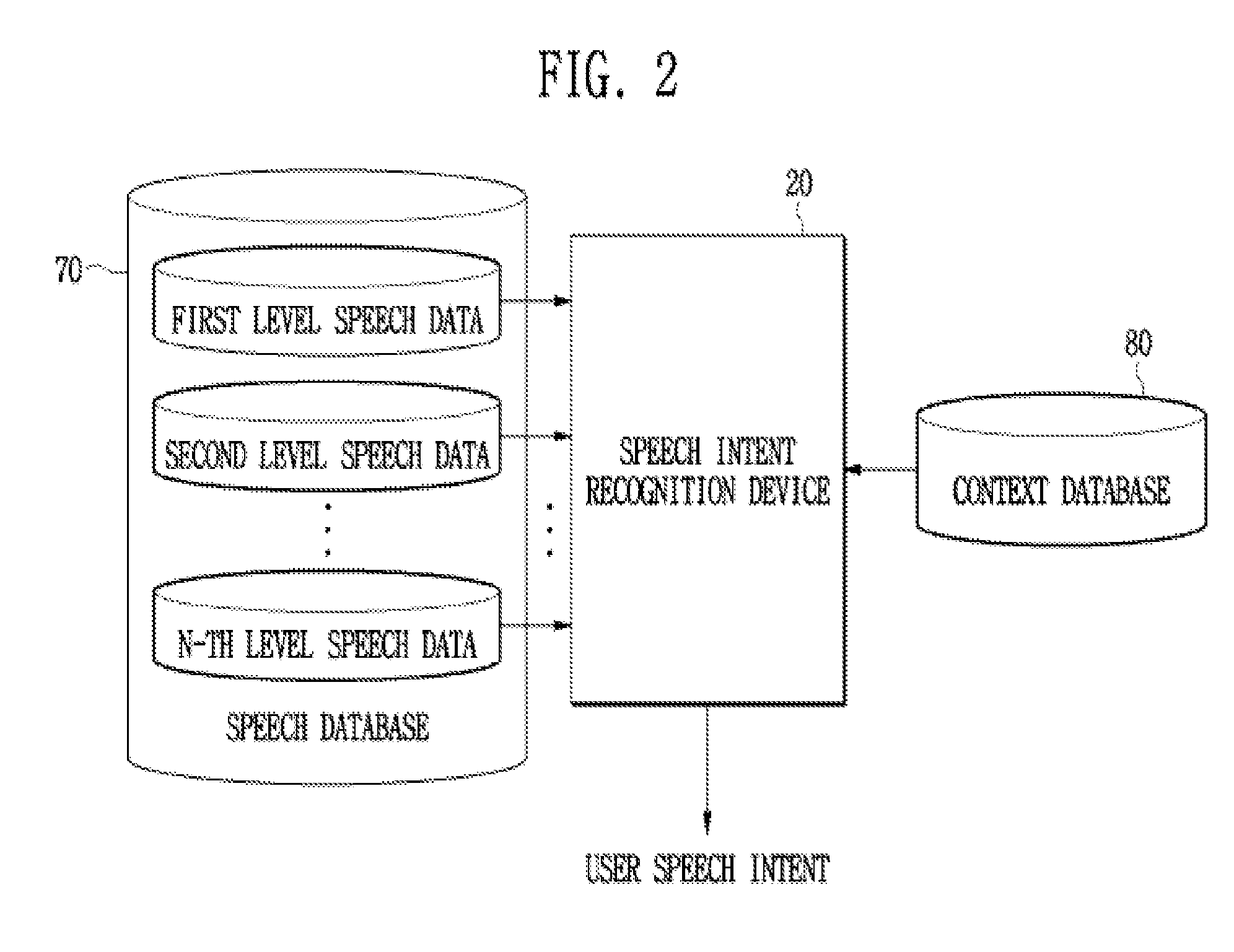

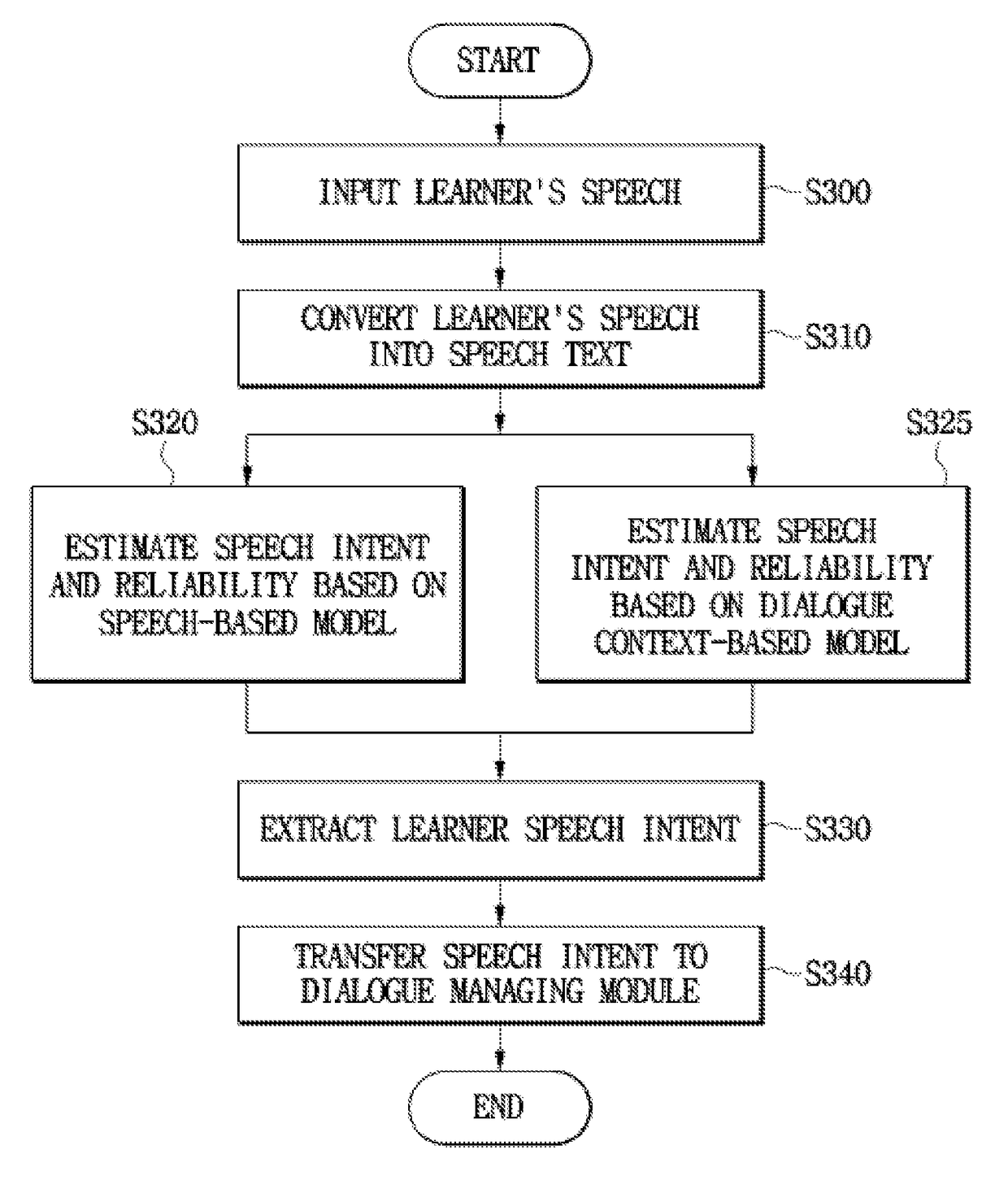

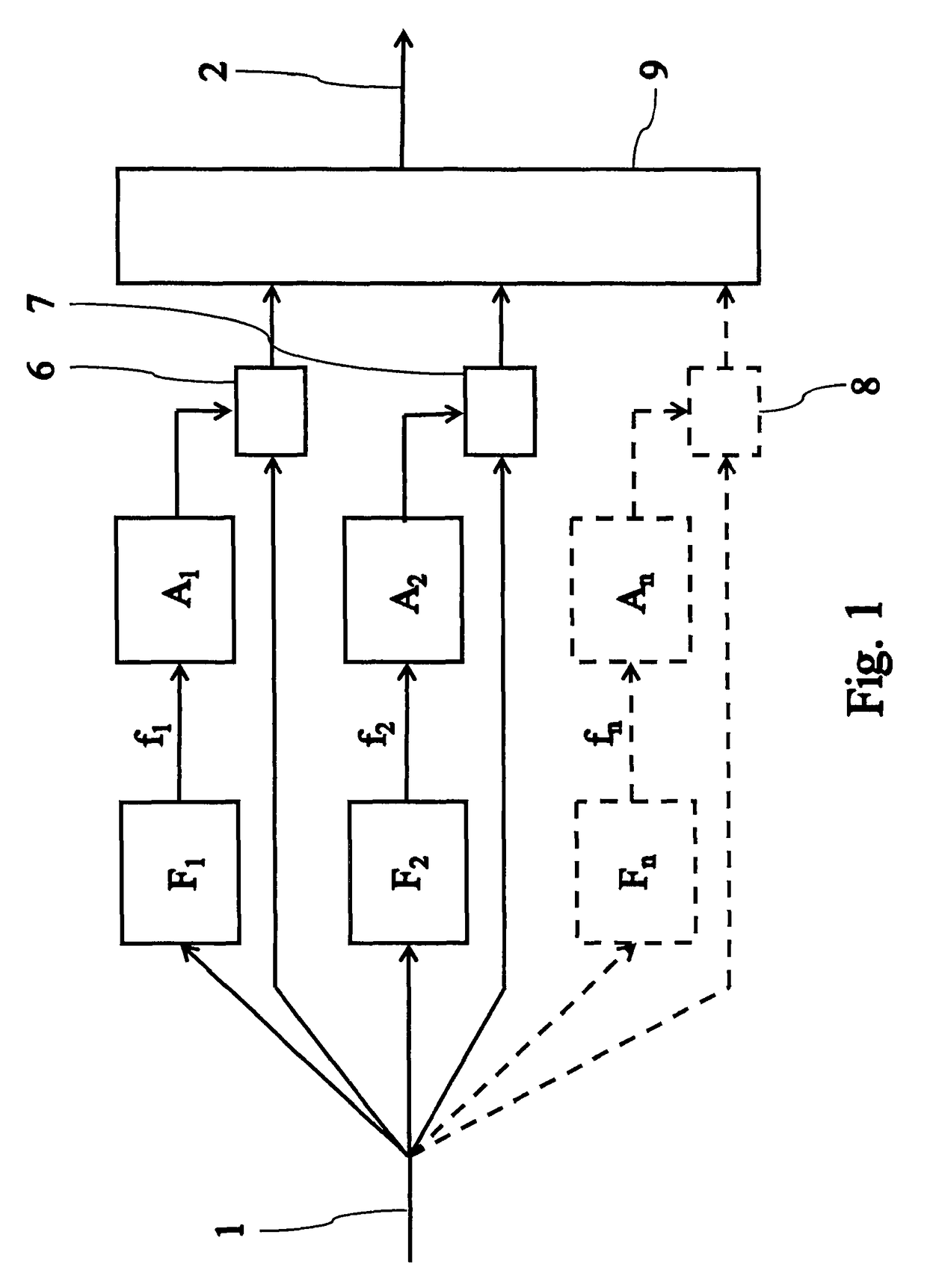

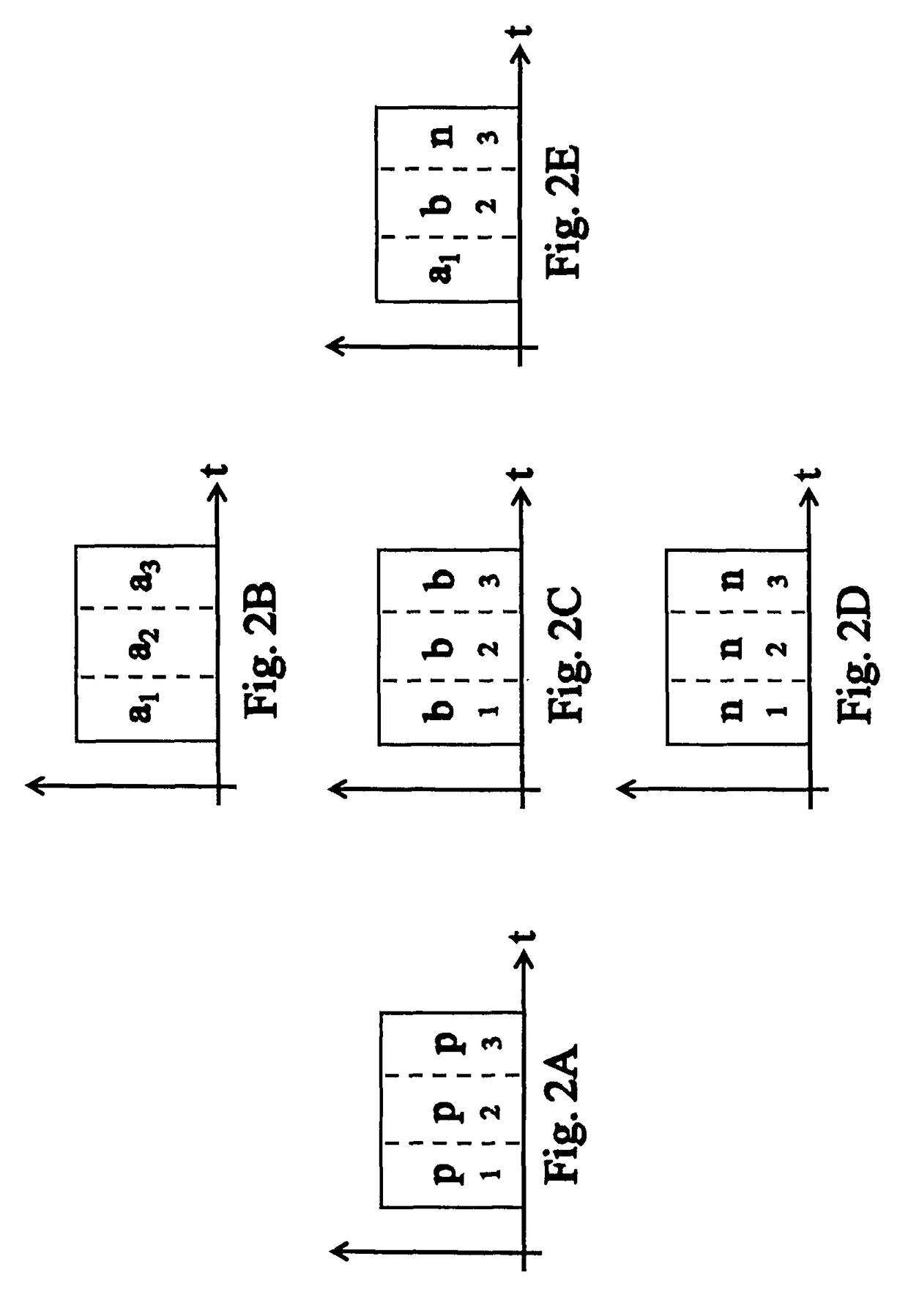

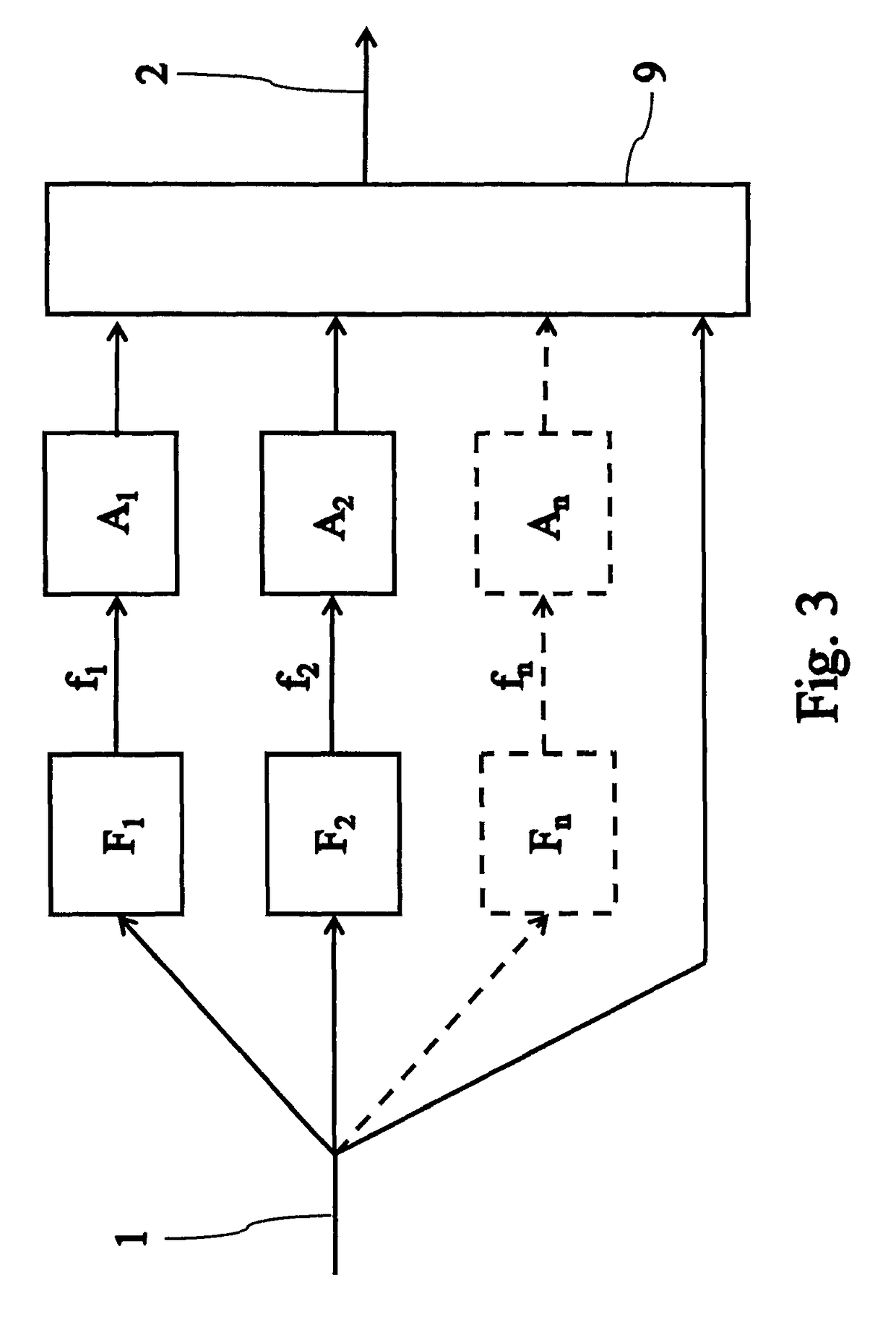

The apparatus for foreign language study includes: a voice recognition device configured to recognize a speech entered by a user and convert the speech into a speech text; a speech intent recognition device configured to extract a user speech intent for the speech text using skill level information of the user and dialogue context information; and a feedback processing device configured to extract a different expression depending on the user speech intent and a speech situation of the user. According to the present invention, the intent of a learner's speech may be determined even though the learner's skill is low, and customized expressions for various situations may be provided to the learner.

Owner:POSTECH ACAD IND FOUND

Apparatus and system for speech intent recognition

Owner:POSTECH ACAD IND FOUND

Hydrochloric acid-extraction method for preparing rutile titanium white

The invention discloses a hydrochloric extraction method to prepare rutile-type titan white, which comprises: decomposing the ilmenite with hydrochloric acid and iron powder to reduce high-valence ferrum; separating titanium tetrachloride with solvent extraction to form water liquid with given concentration; adding macromolecular organics for thermal hydrolyzation; filtering, bleaching, and obtaining high-pure fine grain of metatitanic acid; treating with salt, microwave drying, calcining at 900Deg, screening, and obtaining the product. This method needs low energy consumption, and fits to low or rich grade material.

Owner:陈泽安

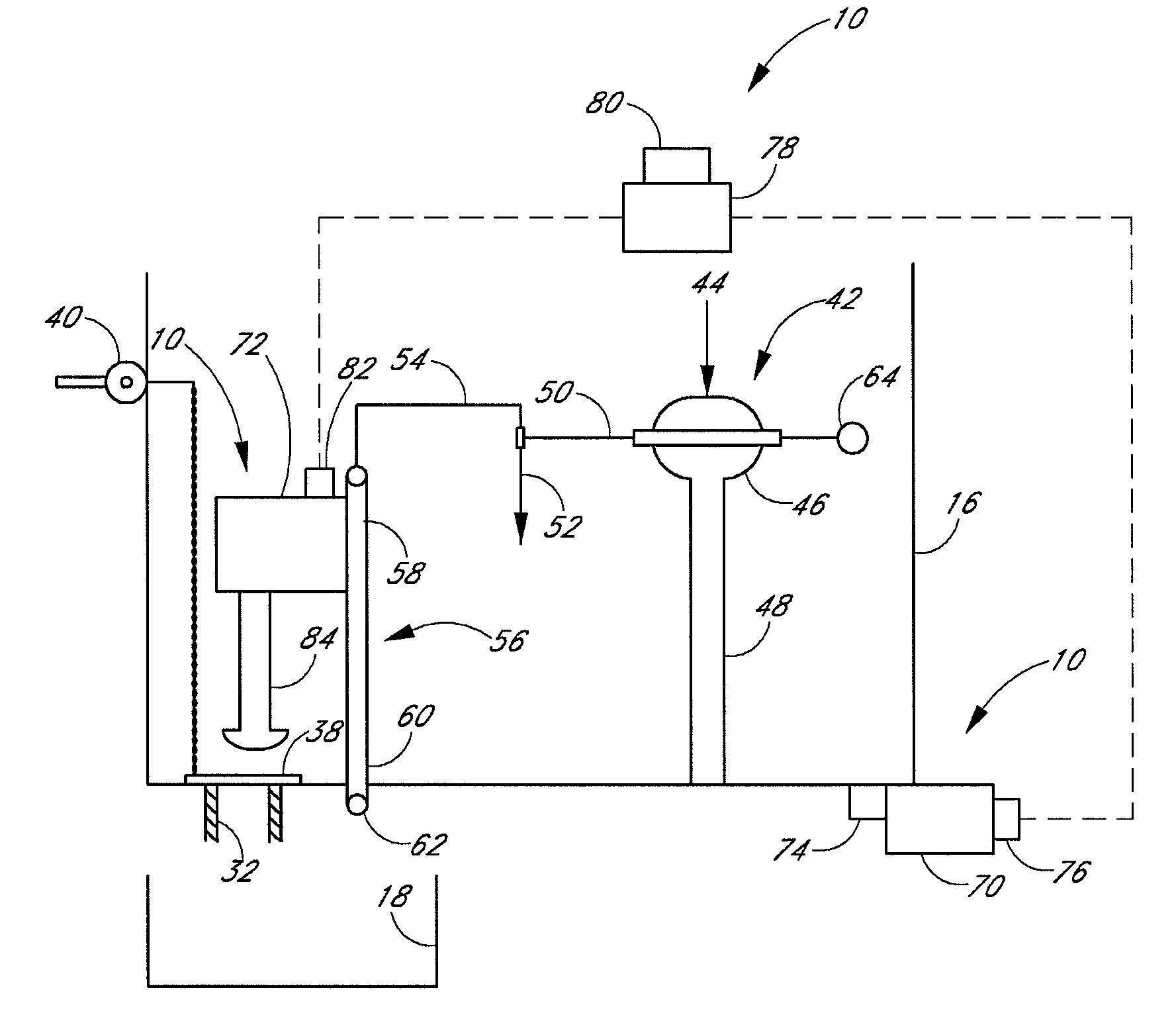

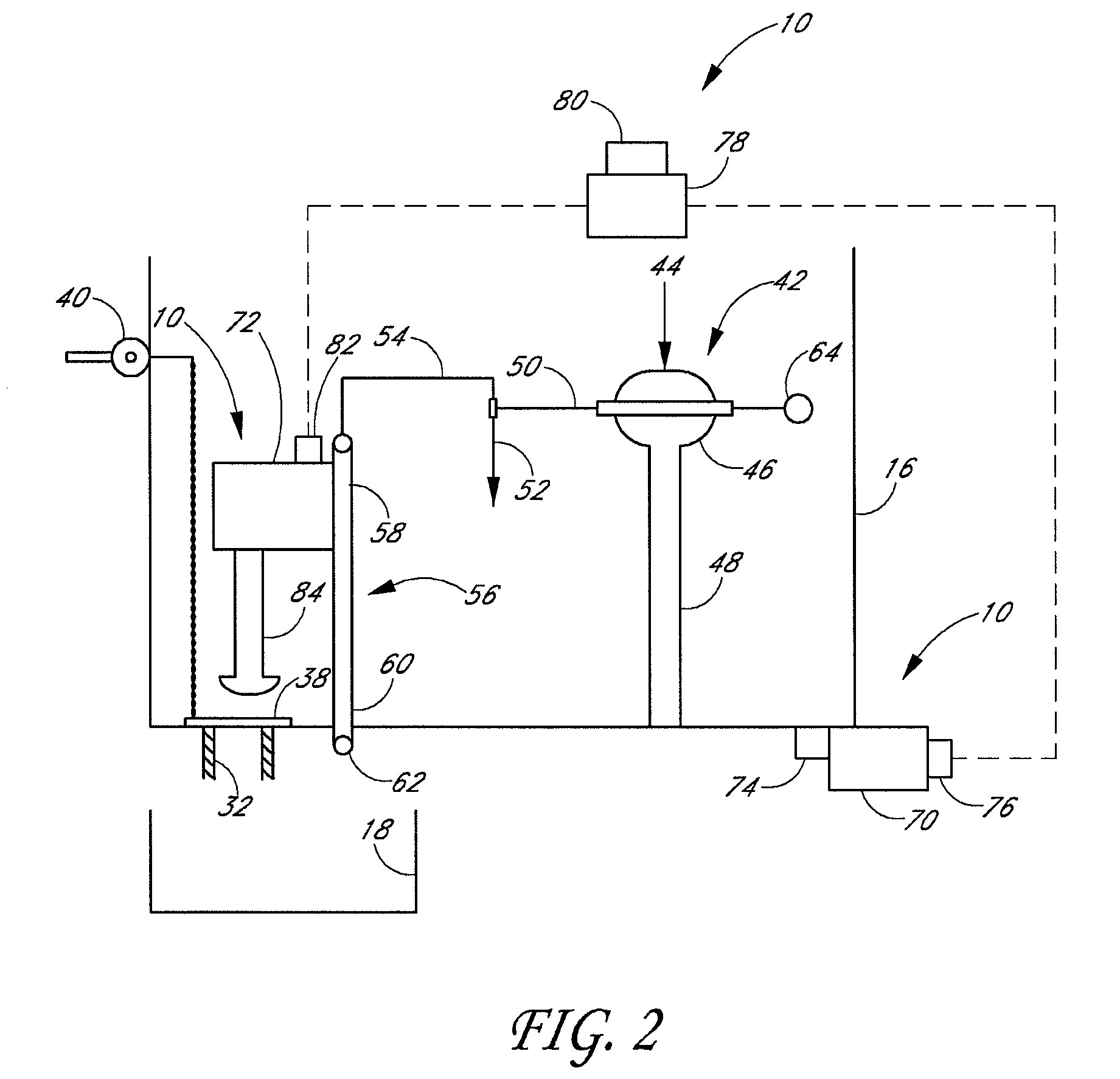

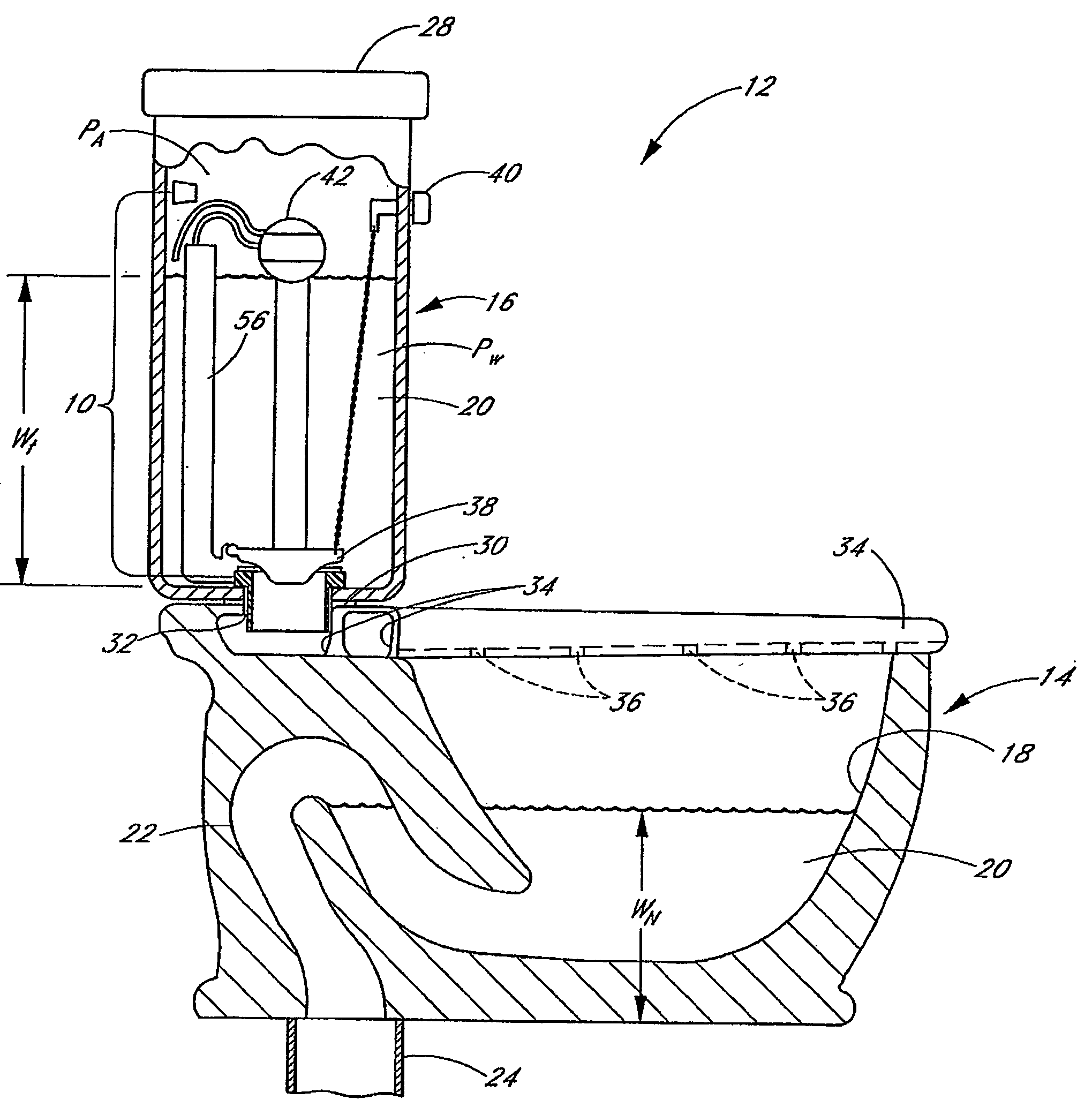

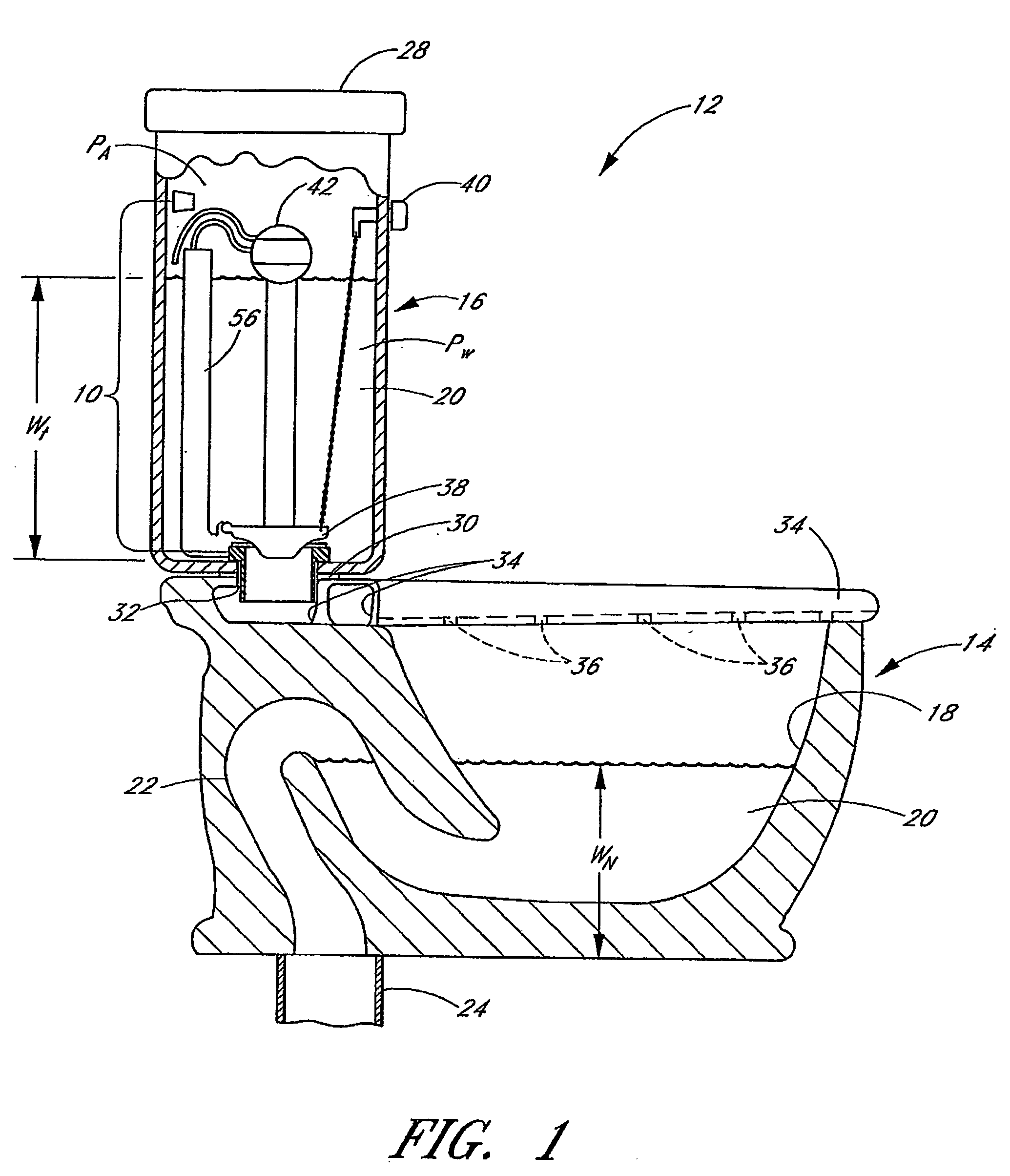

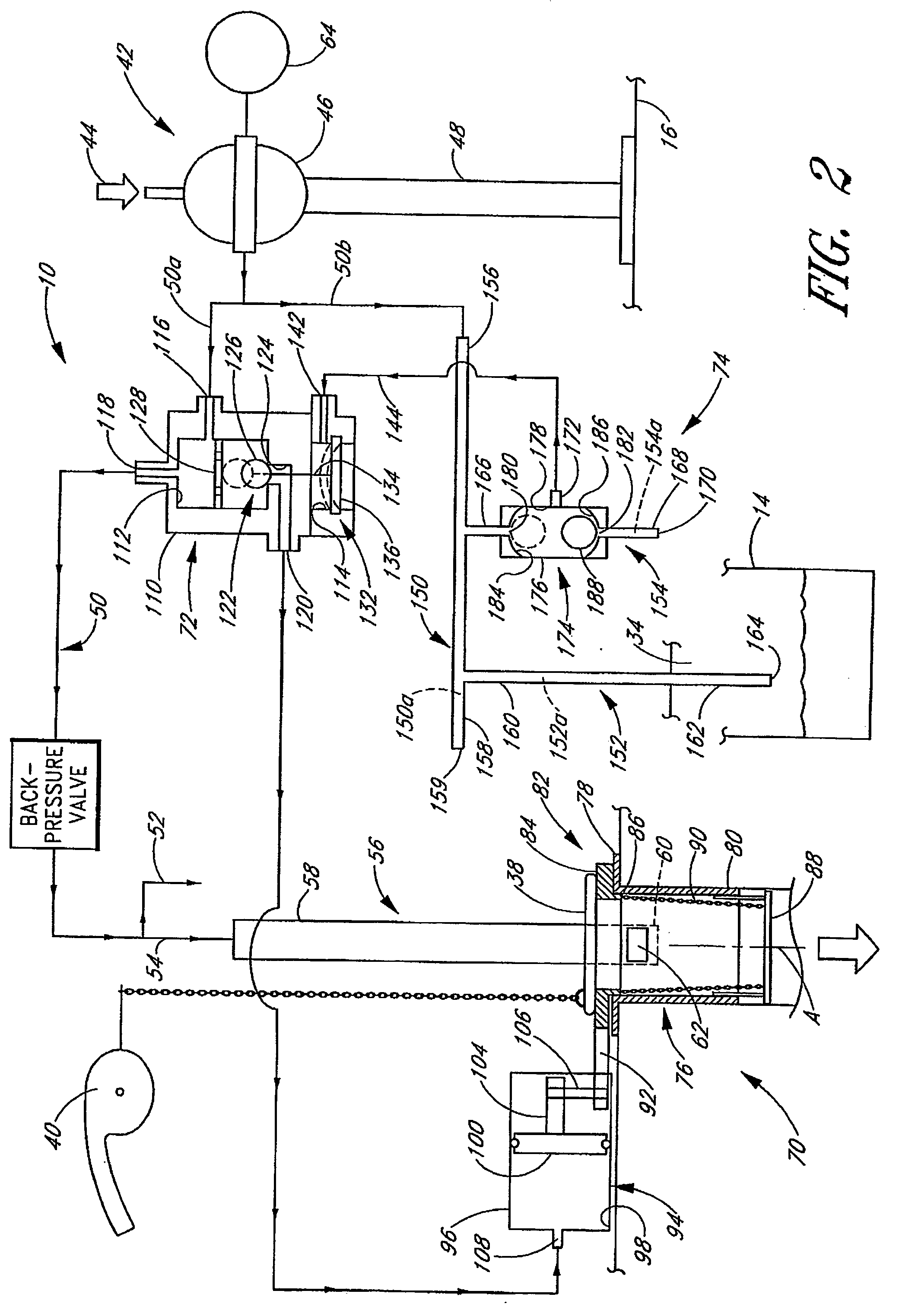

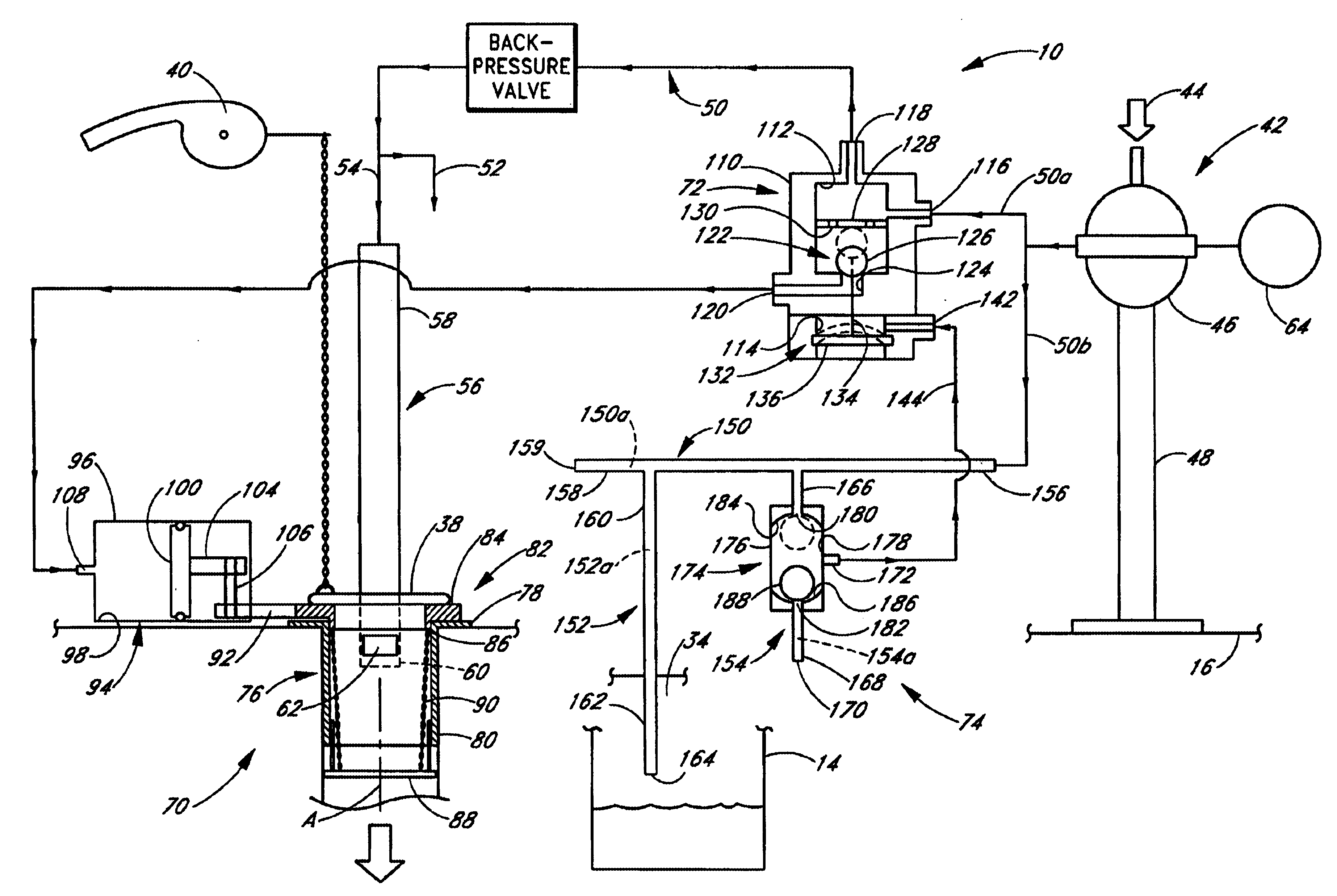

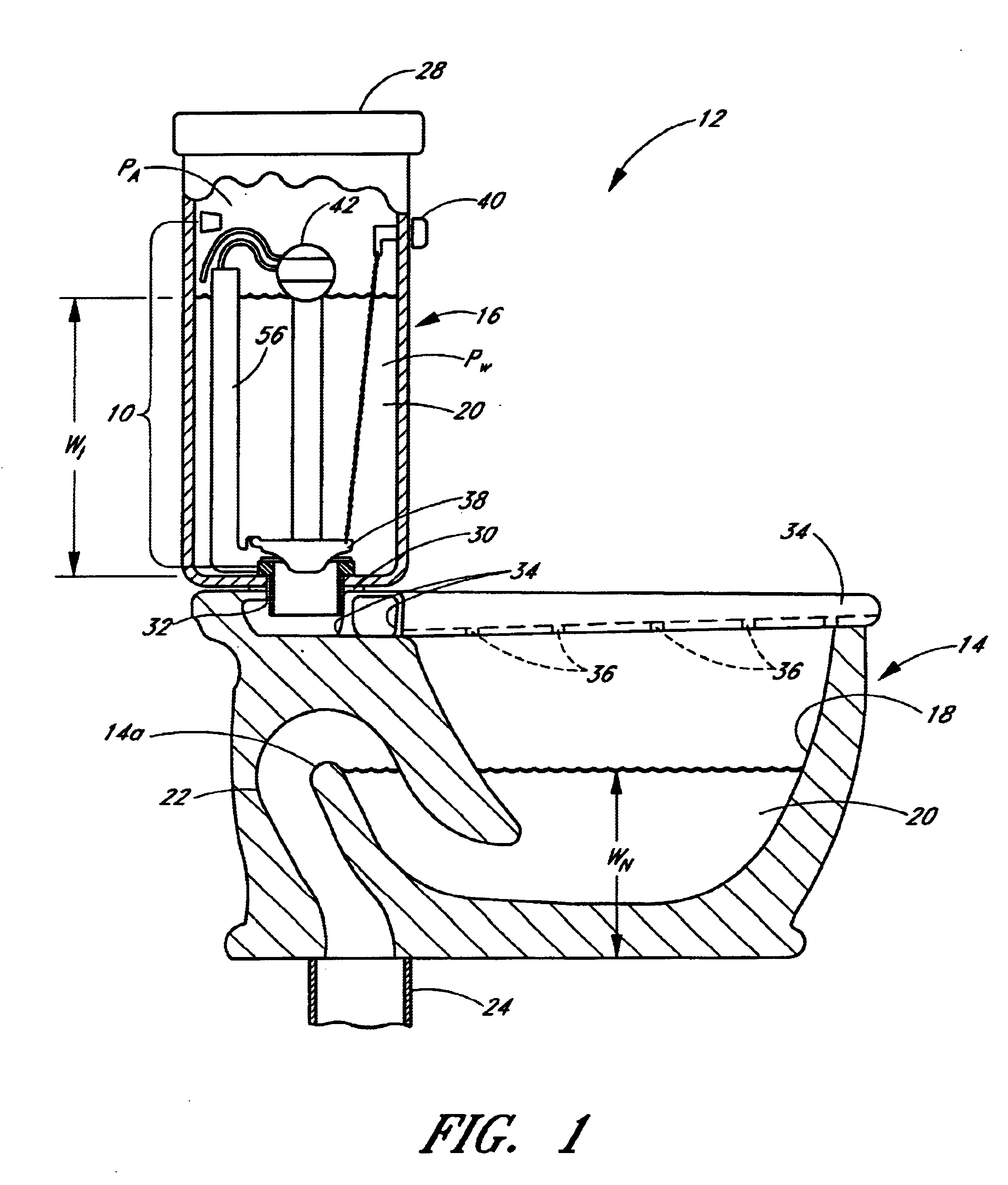

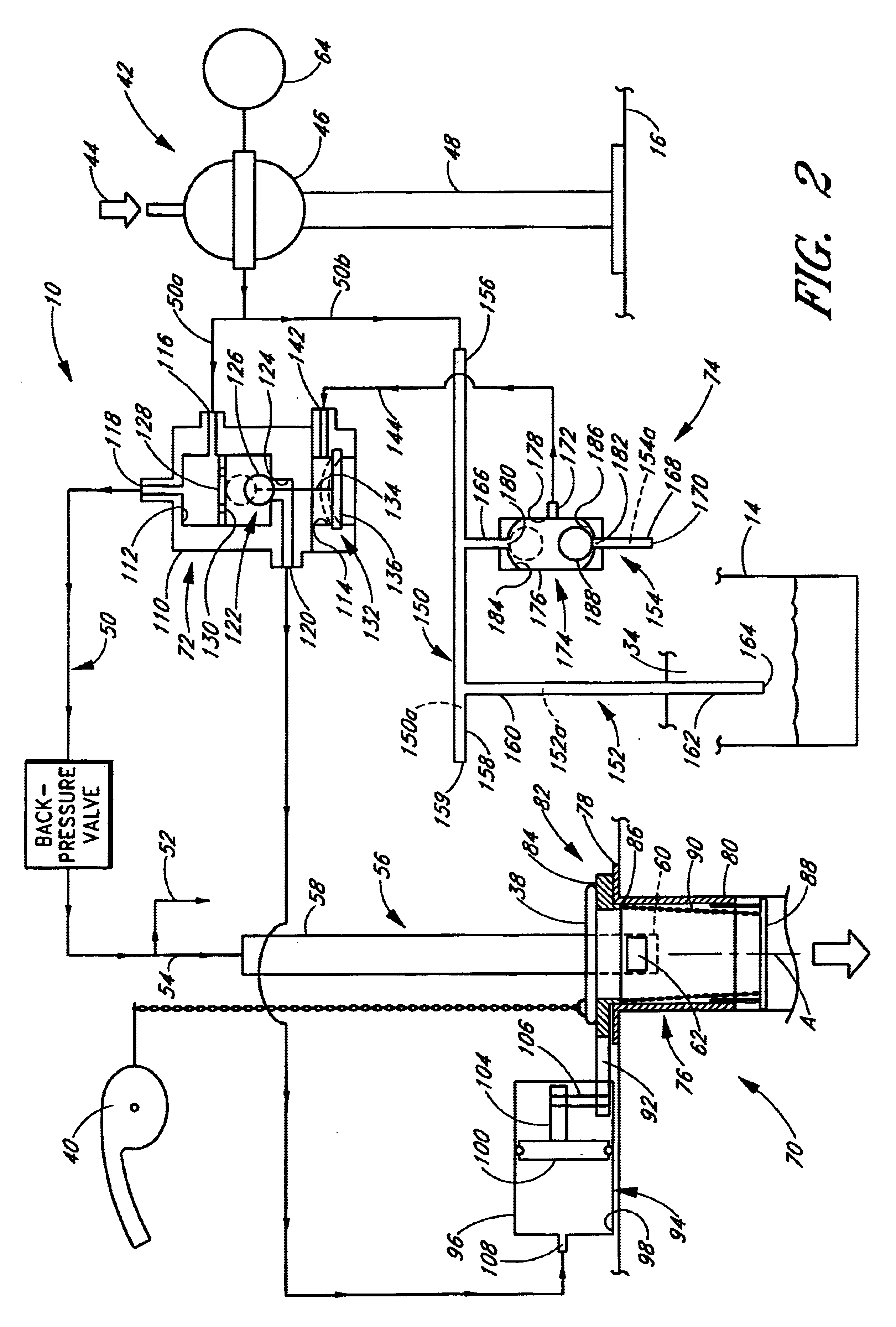

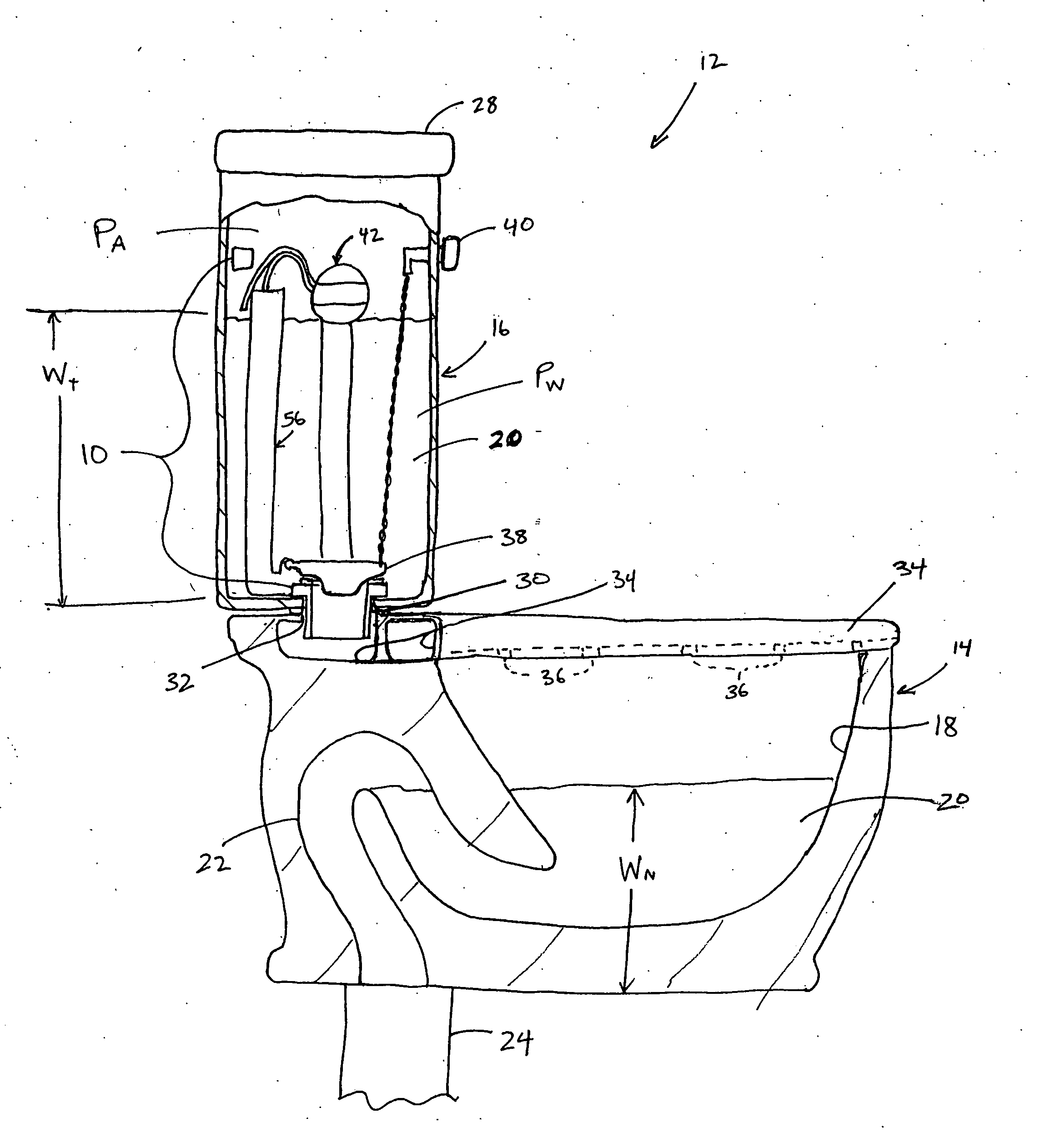

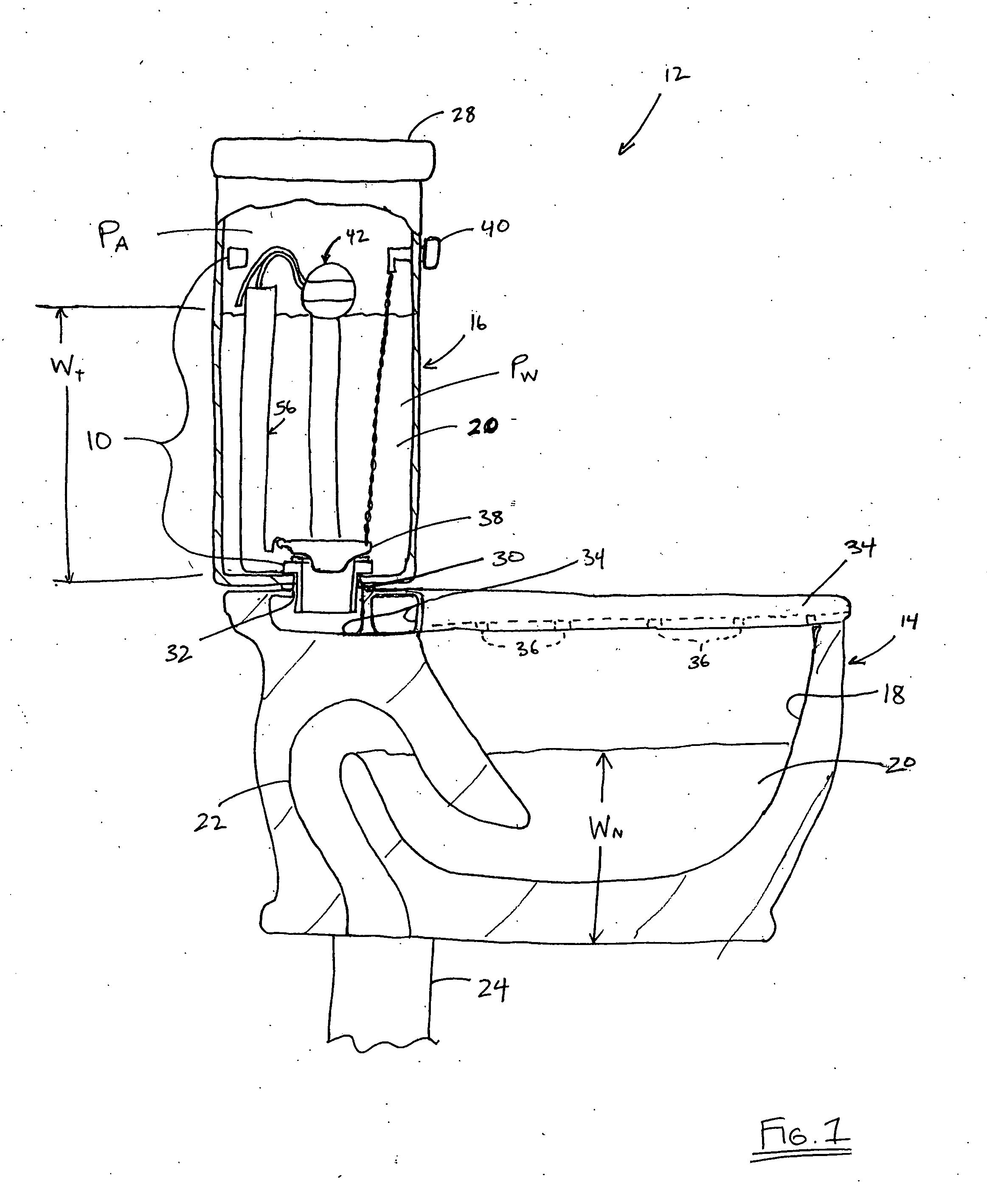

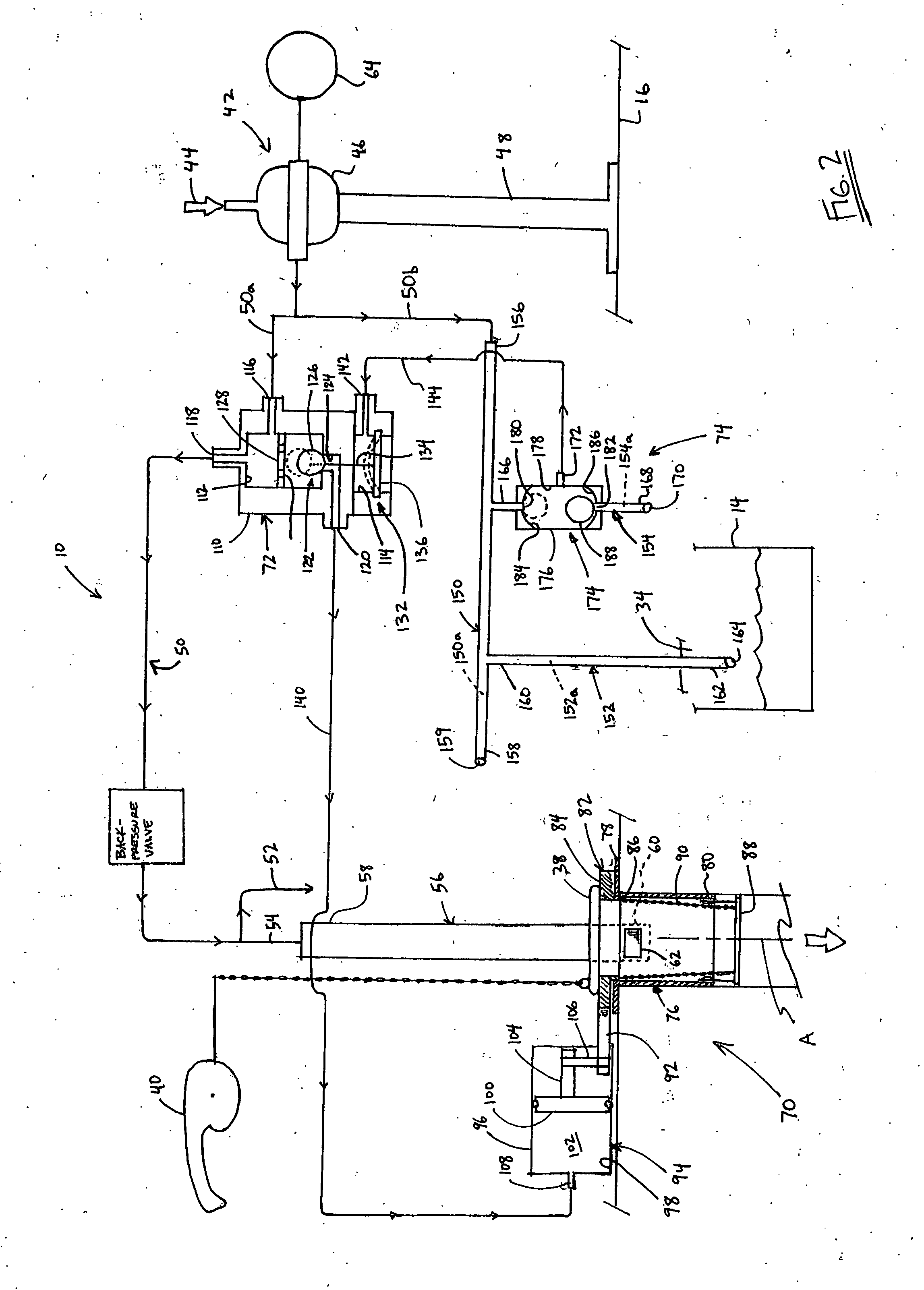

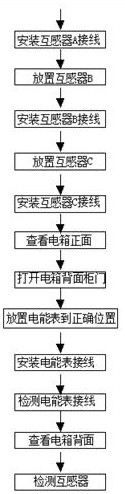

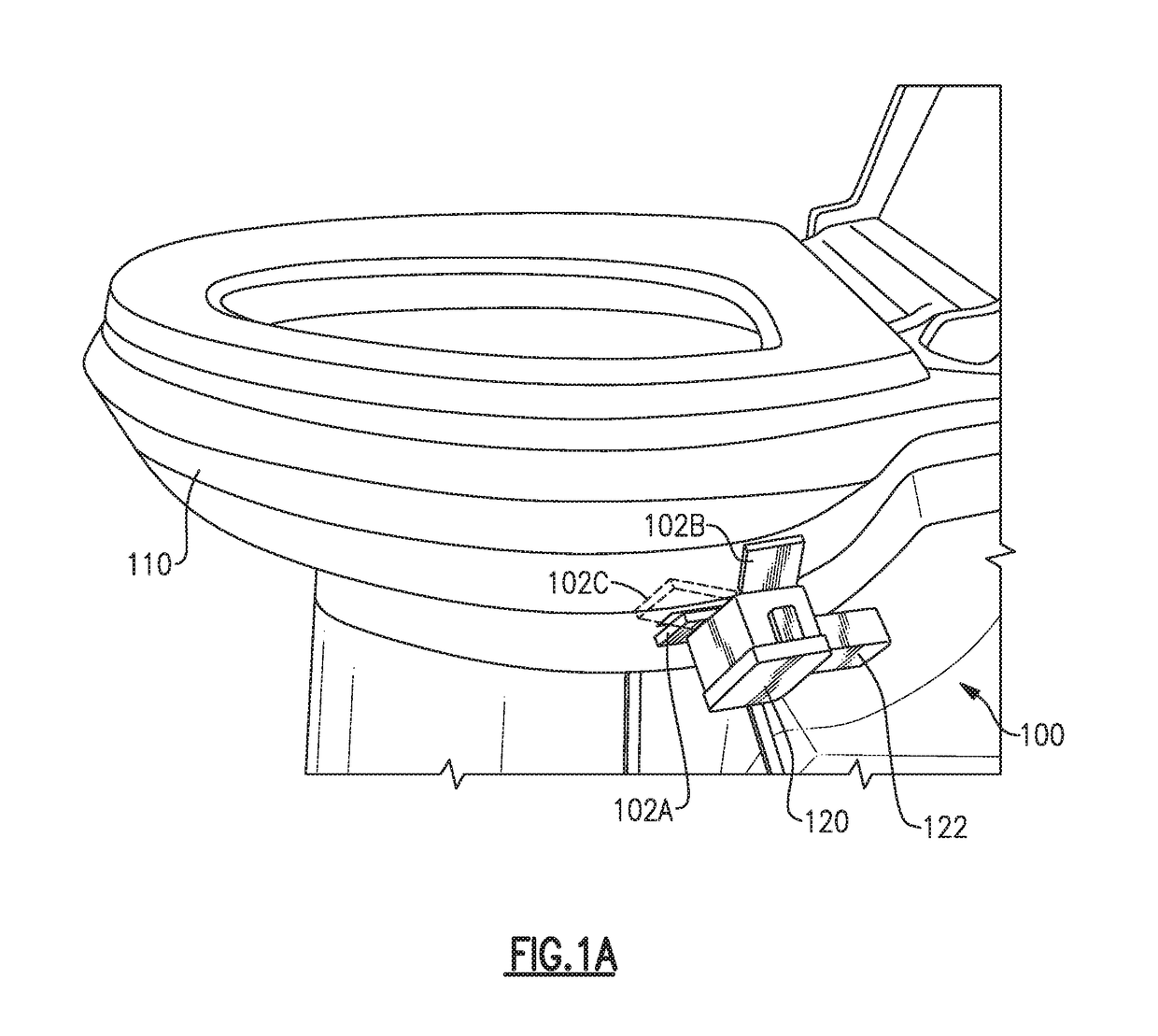

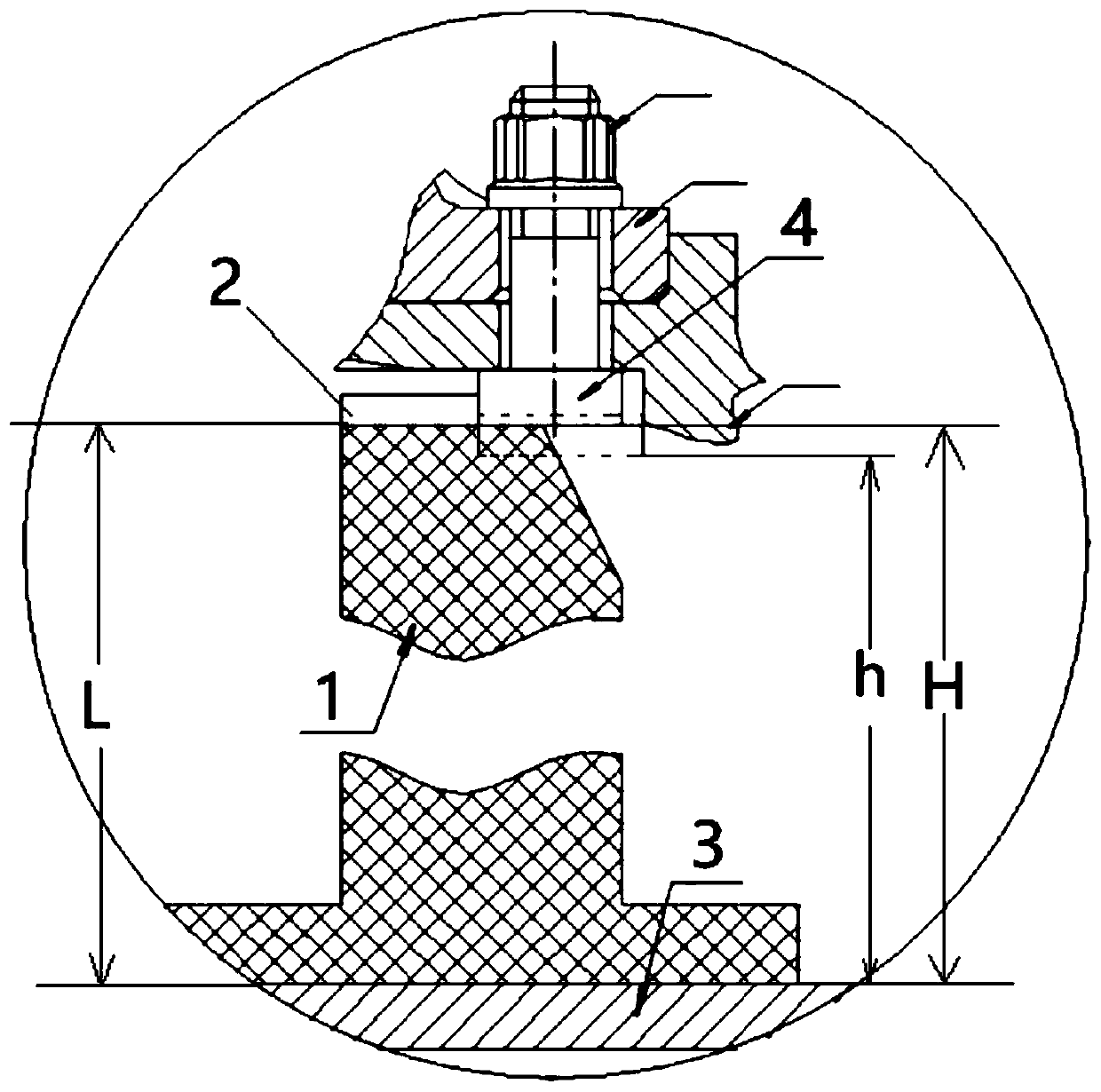

Toilet overflow prevention system and method

ActiveUS7636959B2Cost-effective and reliableLow skill levelWater closetsTesting/calibration apparatusEngineeringActuator

Owner:LIMIT

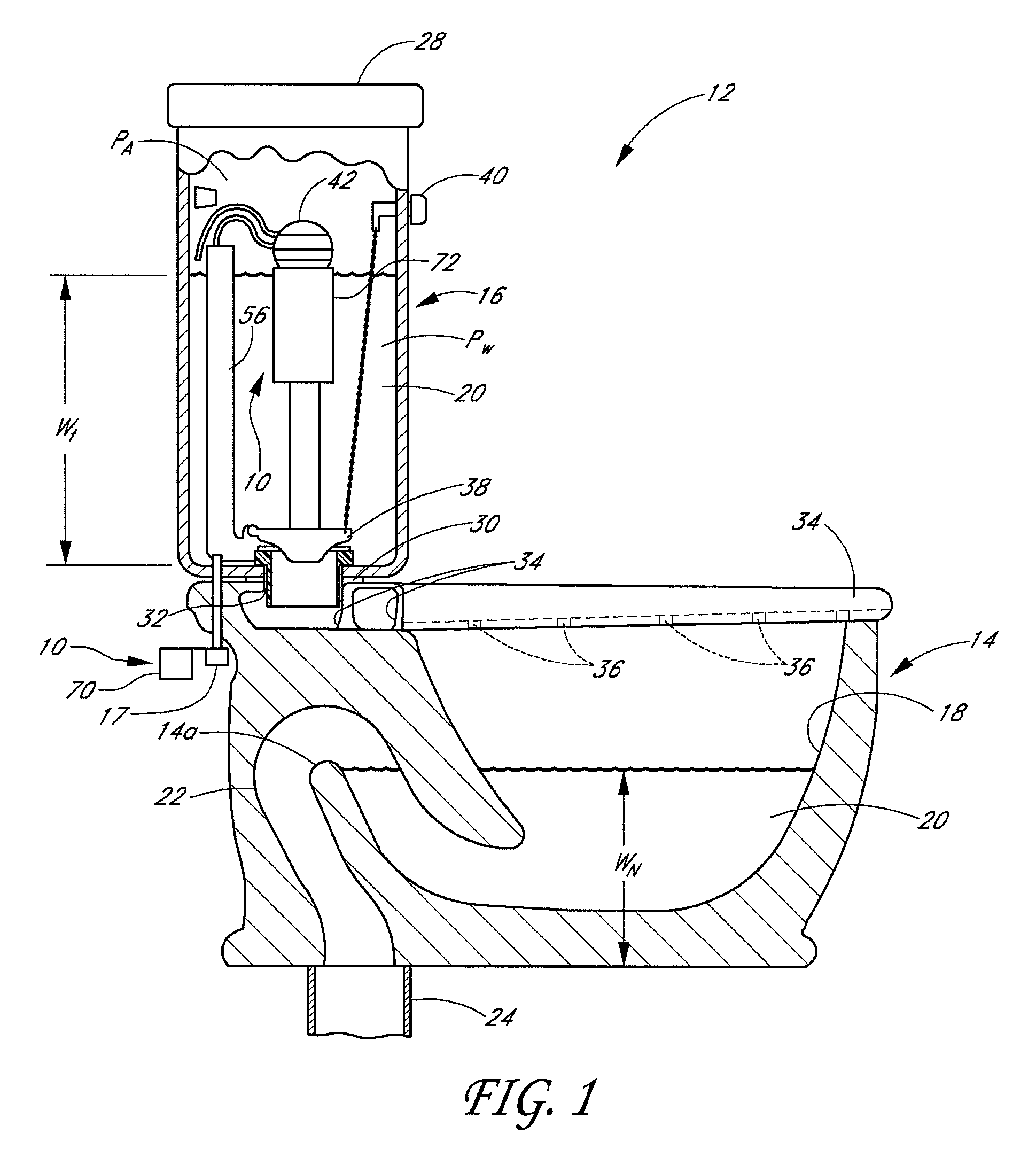

Toilet overflow prevention device

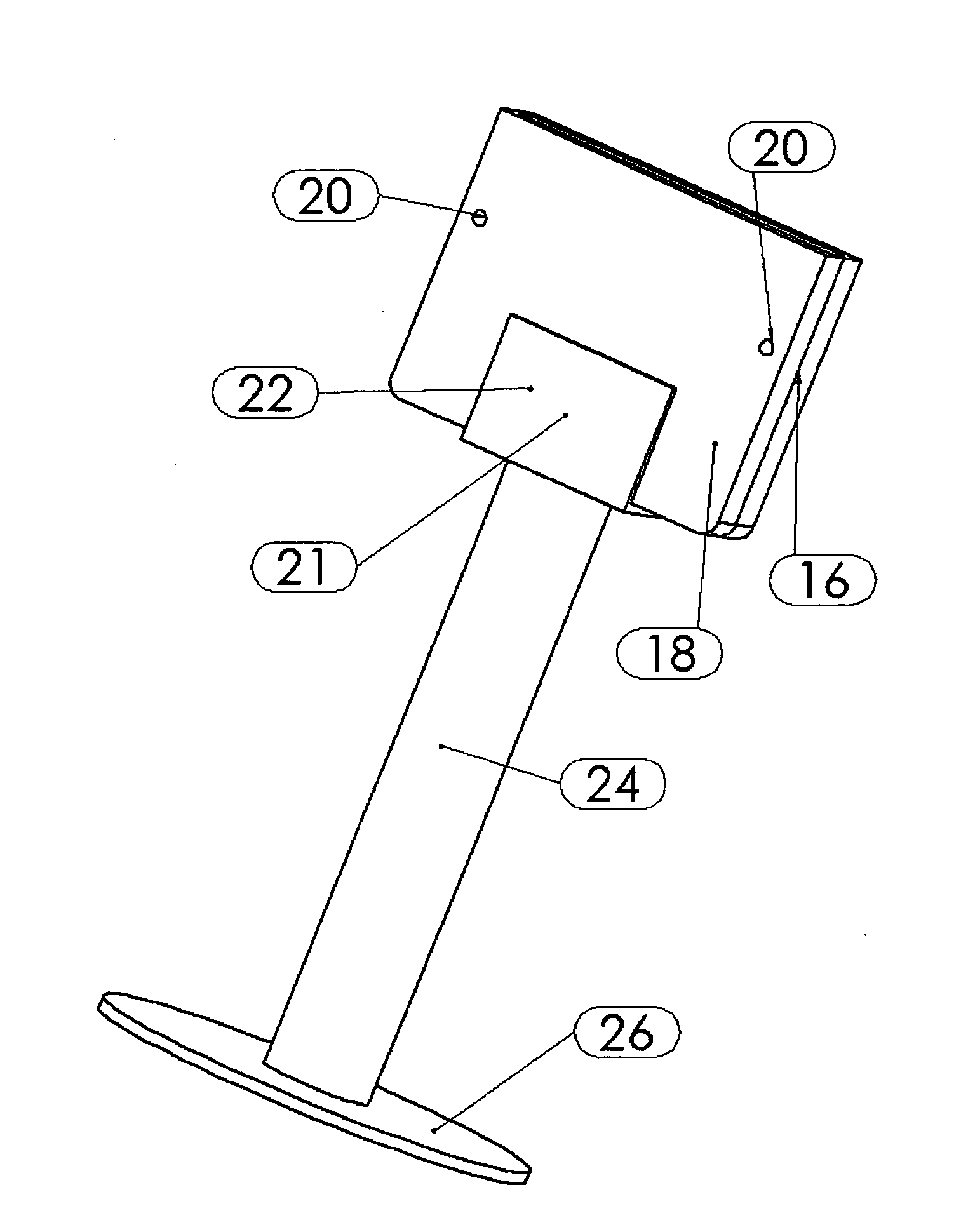

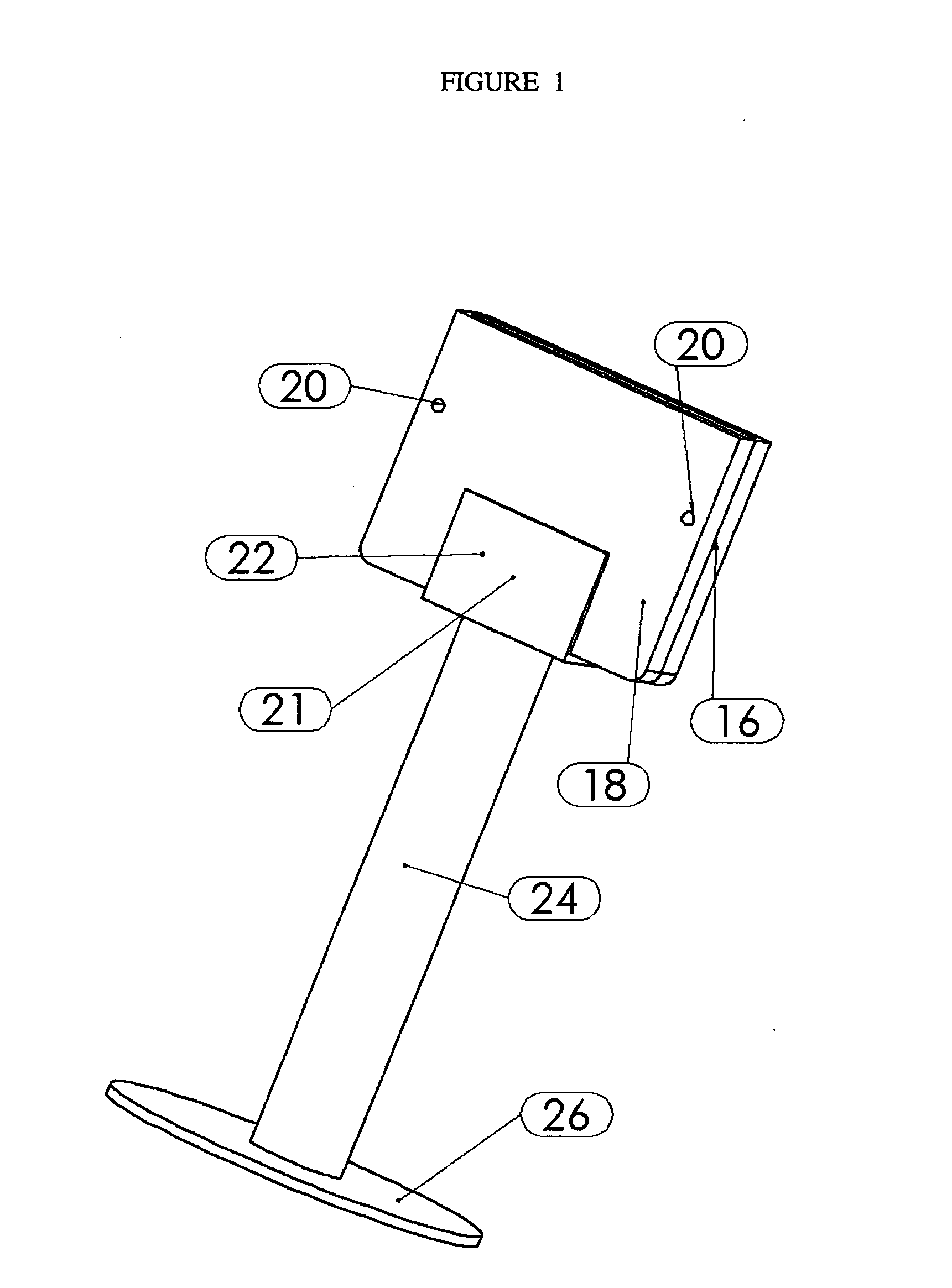

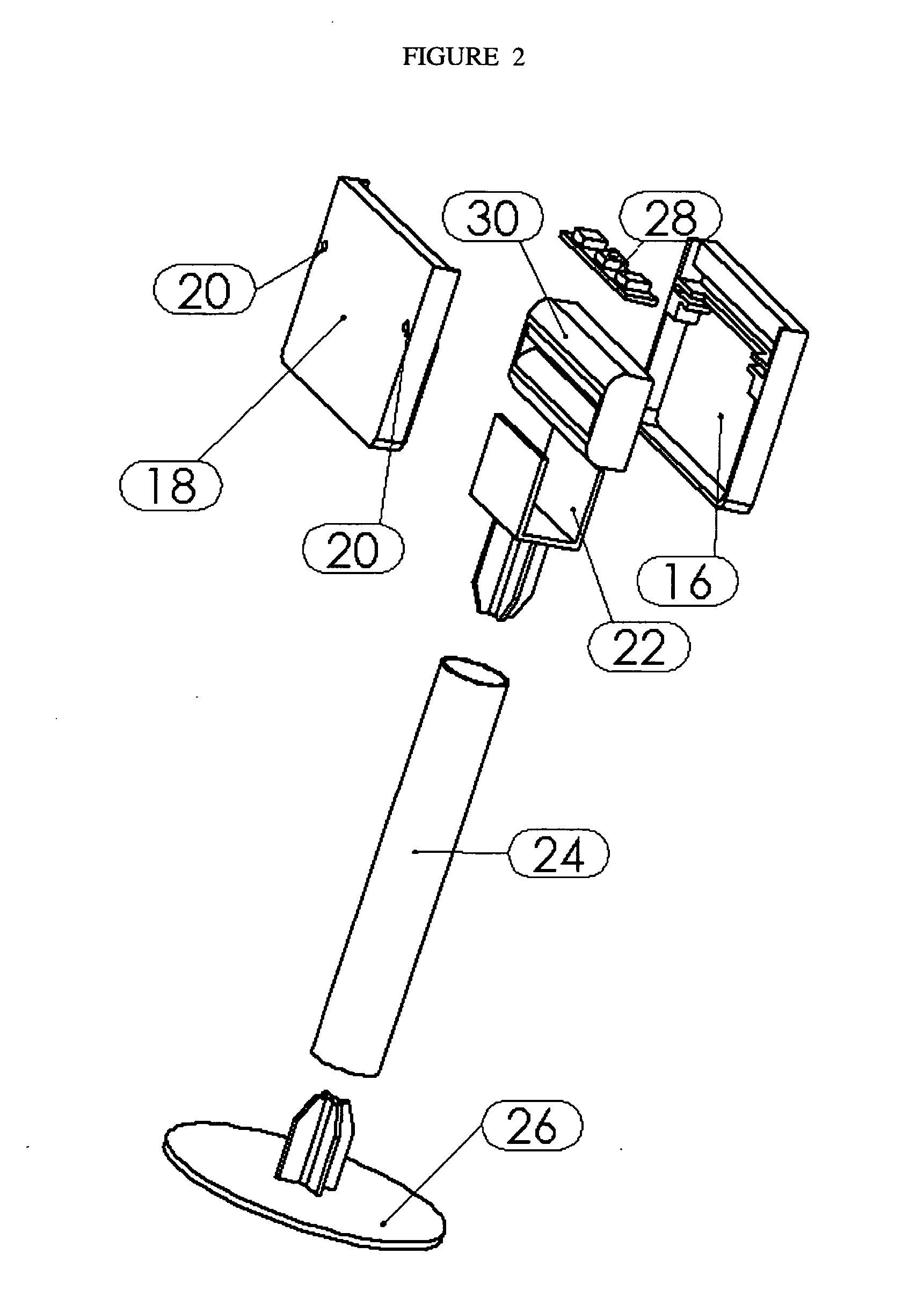

ActiveUS20050132482A1Cost-effective and reliableLow skill levelOperating means/releasing devices for valvesWater closetsControl signalEngineering

A toilet overflow prevention device including an overflow valve assembly, a control valve and a water level sensor. The overflow valve assembly is configured to selectively permit a flow of water through the valve assembly from the tank to the bowl of an associated toilet. The water level sensor is configured to provide a control signal in response to detecting an above-normal water level within the bowl of the toilet. The control valve is configured to actuate the overflow valve assembly in response to a control signal from the water level sensor. Preferably, the overflow valve assembly is separate from the primary flush valve of the toilet and is located between the primary flush valve and the bowl of the toilet.

Owner:LIMIT

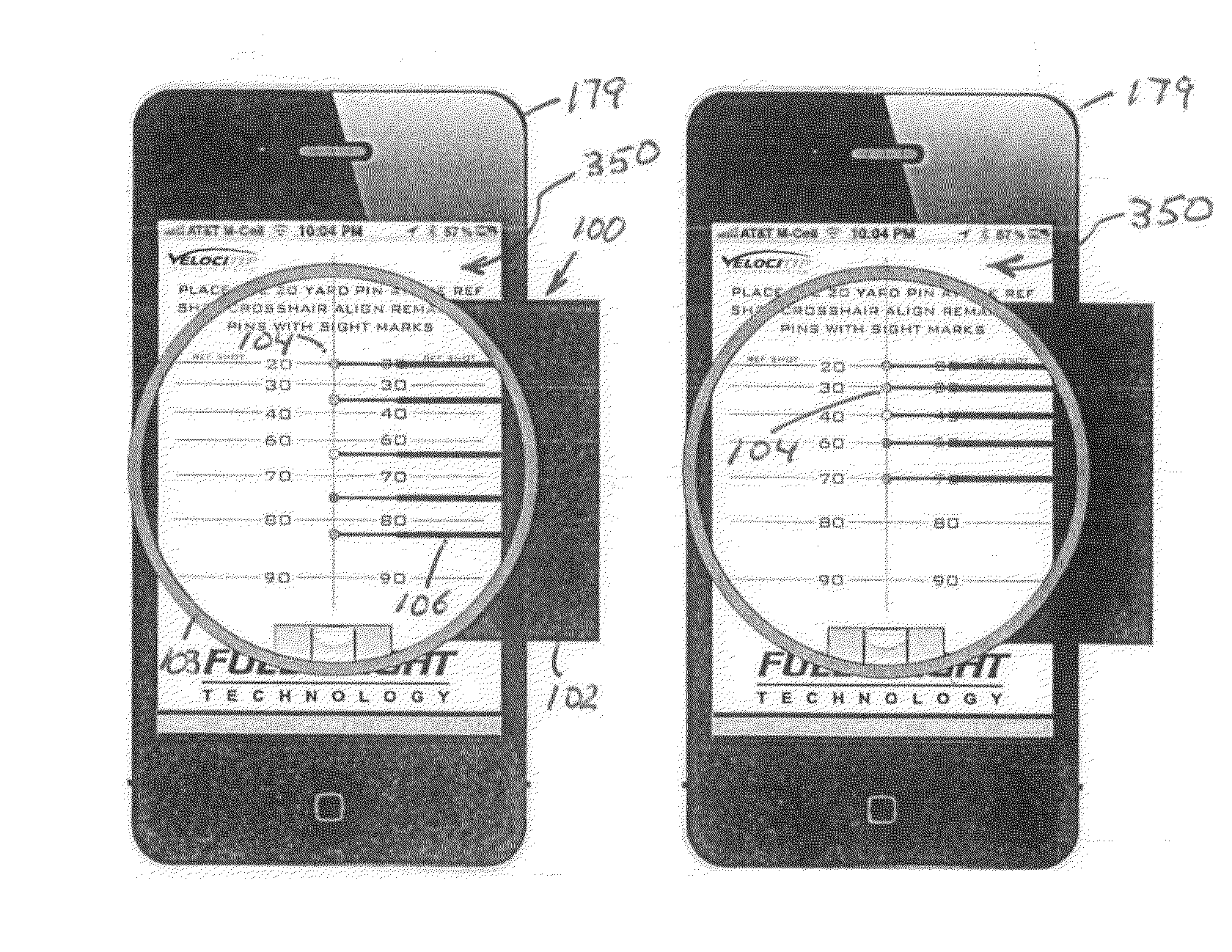

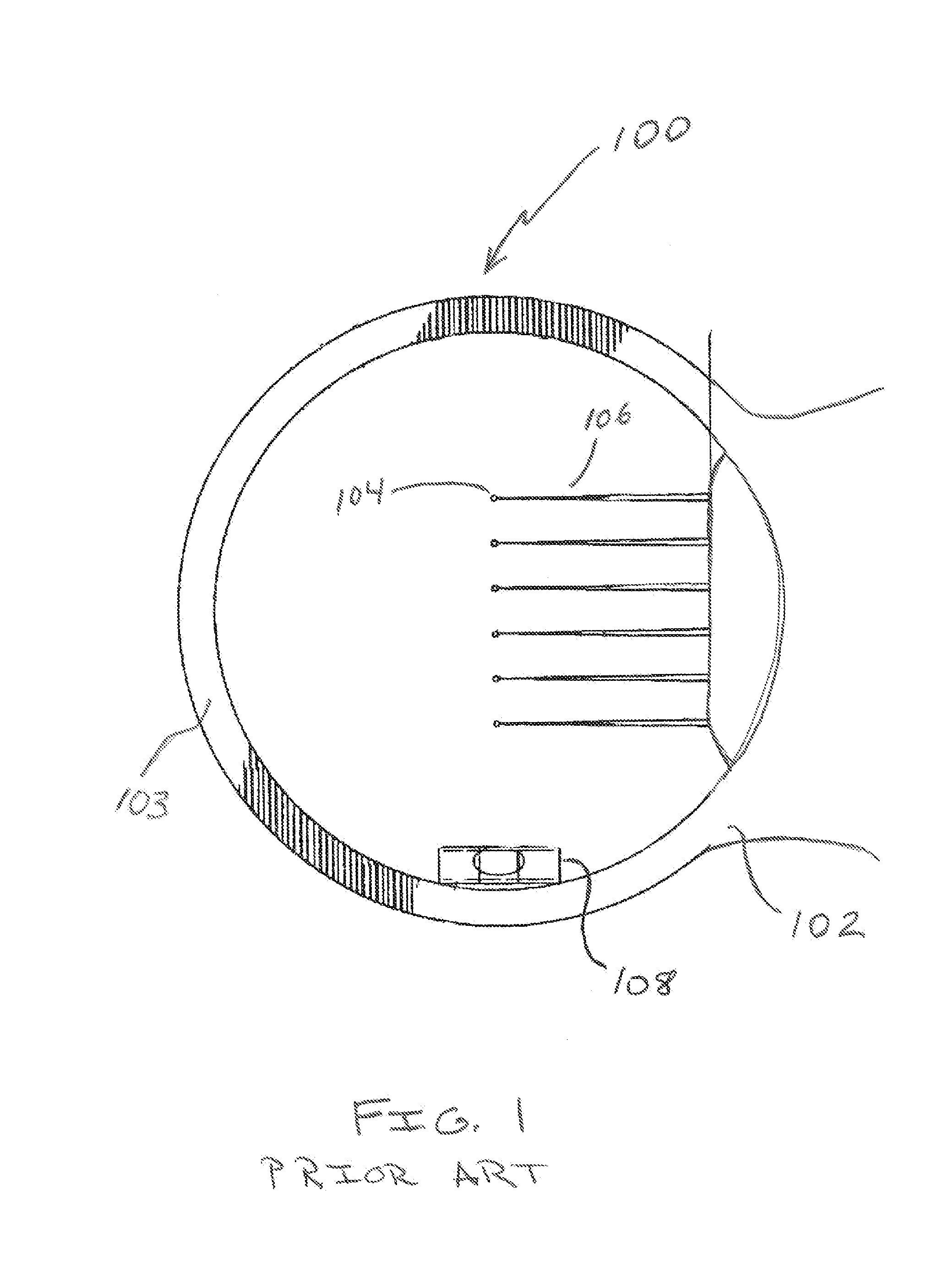

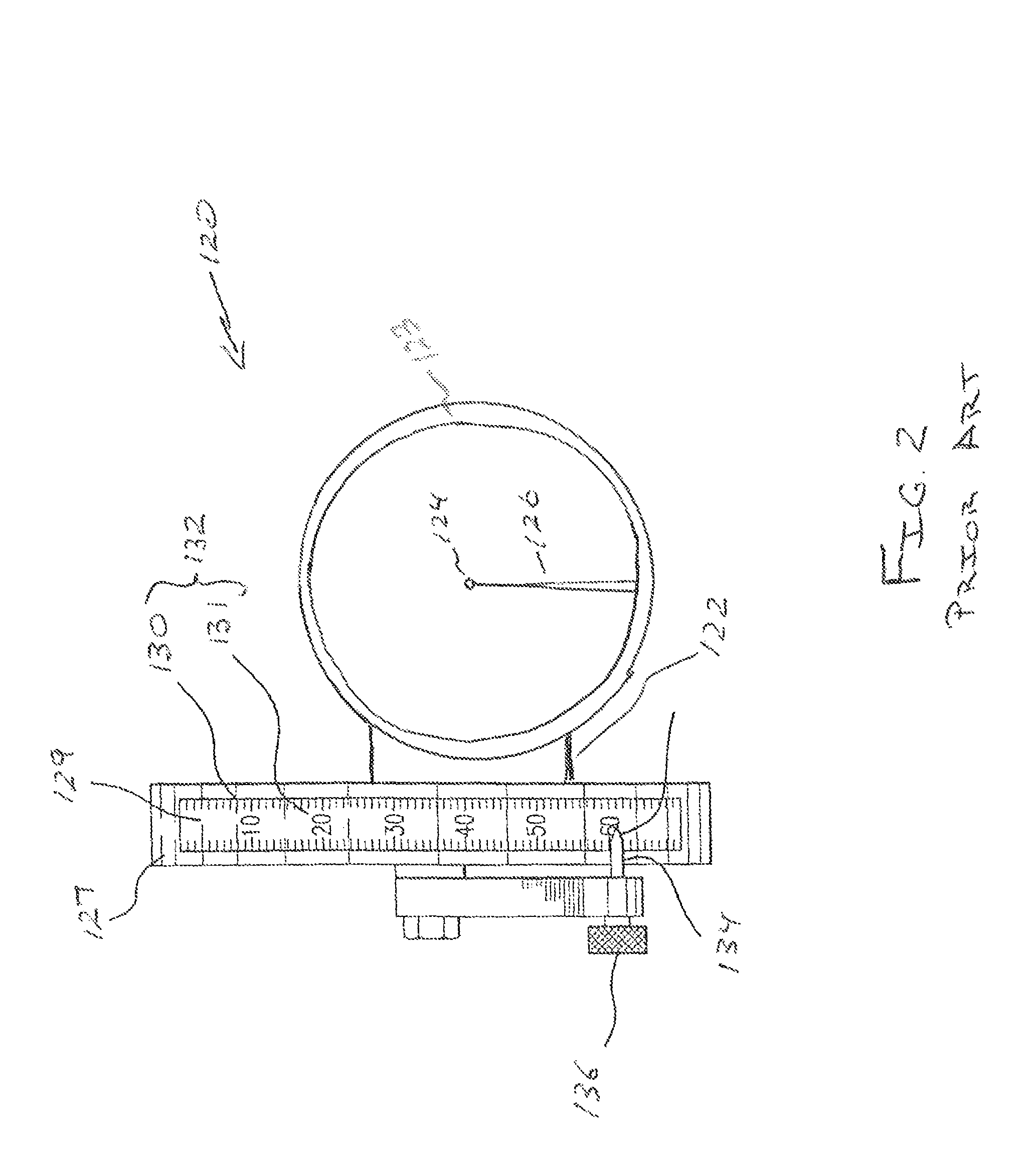

Apparatus, system and method for archery sight settings

ActiveUS9441913B1Easy transferShorten the timeSighting devicesInput/output processes for data processingGraphicsGraphical user interface

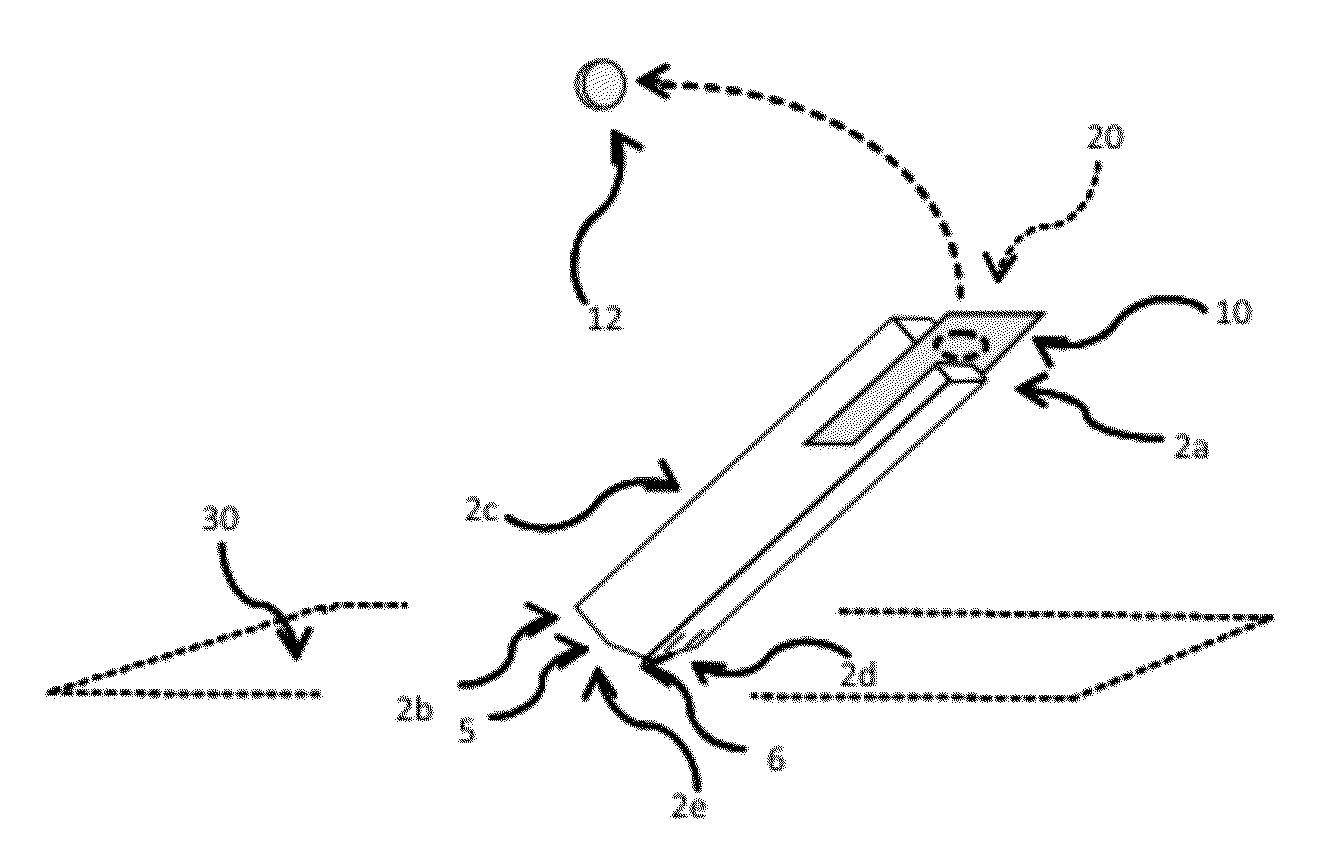

A non-transitory computer-readable medium whose contents cause a processing device including a touch screen display to perform a method for generating an archery sight setting, the method including acts of rendering a graphical user interface in the touch screen display, receiving a first input to the graphical user interface to select at least one archery parameter, and presenting a plurality of sight marks in the graphical user interface including at least a first sight mark and a second sight mark, the plurality of sight marks scaled within the graphical user interface to provide a 1:1 ratio between a first distance separating the first sight mark and the second sight mark in the graphical user interface and a second distance separating a first sighted-in position and a second sighted-in position in an archery sight including at least one mechanically-adjusted sight pin.

Owner:FULL FLIGHT TECH

Toilet overflow prevention device

ActiveUS6961966B2Cost-effective and reliableLow skill levelWater closetsOperating means/releasing devices for valvesControl signalWater flow

A toilet overflow prevention device including an overflow valve assembly, a control valve and a water level sensor. The overflow valve assembly is configured to selectively permit a flow of water through the valve assembly from the tank to the bowl of an associated toilet. The water level sensor is configured to provide a control signal in response to detecting an above-normal water level within the bowl of the toilet. The control valve is configured to actuate the overflow valve assembly in response to a control signal from the water level sensor. Preferably, the overflow valve assembly is separate from the primary flush valve of the toilet and is located between the primary flush valve and the bowl of the toilet.

Owner:LIMIT

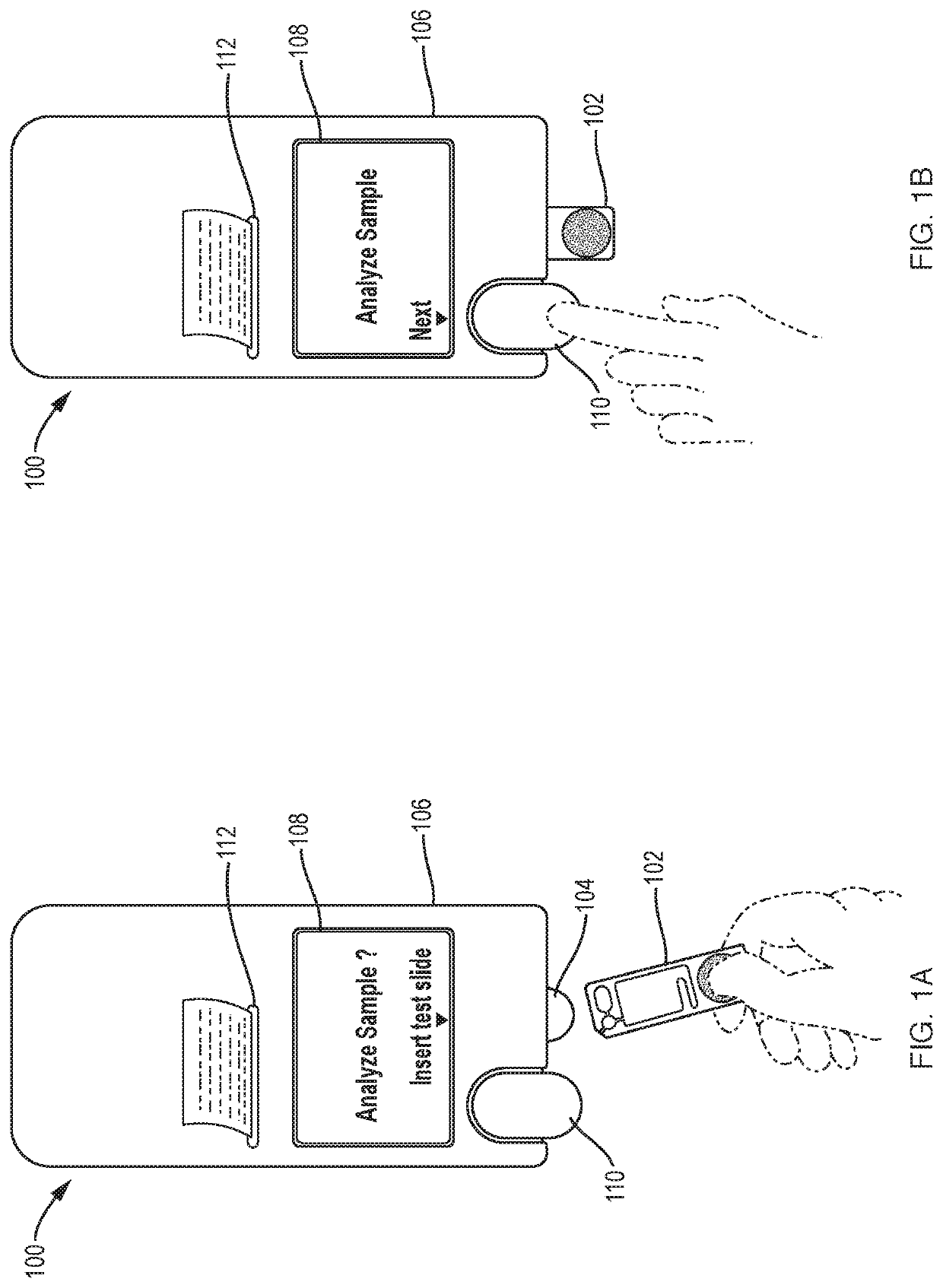

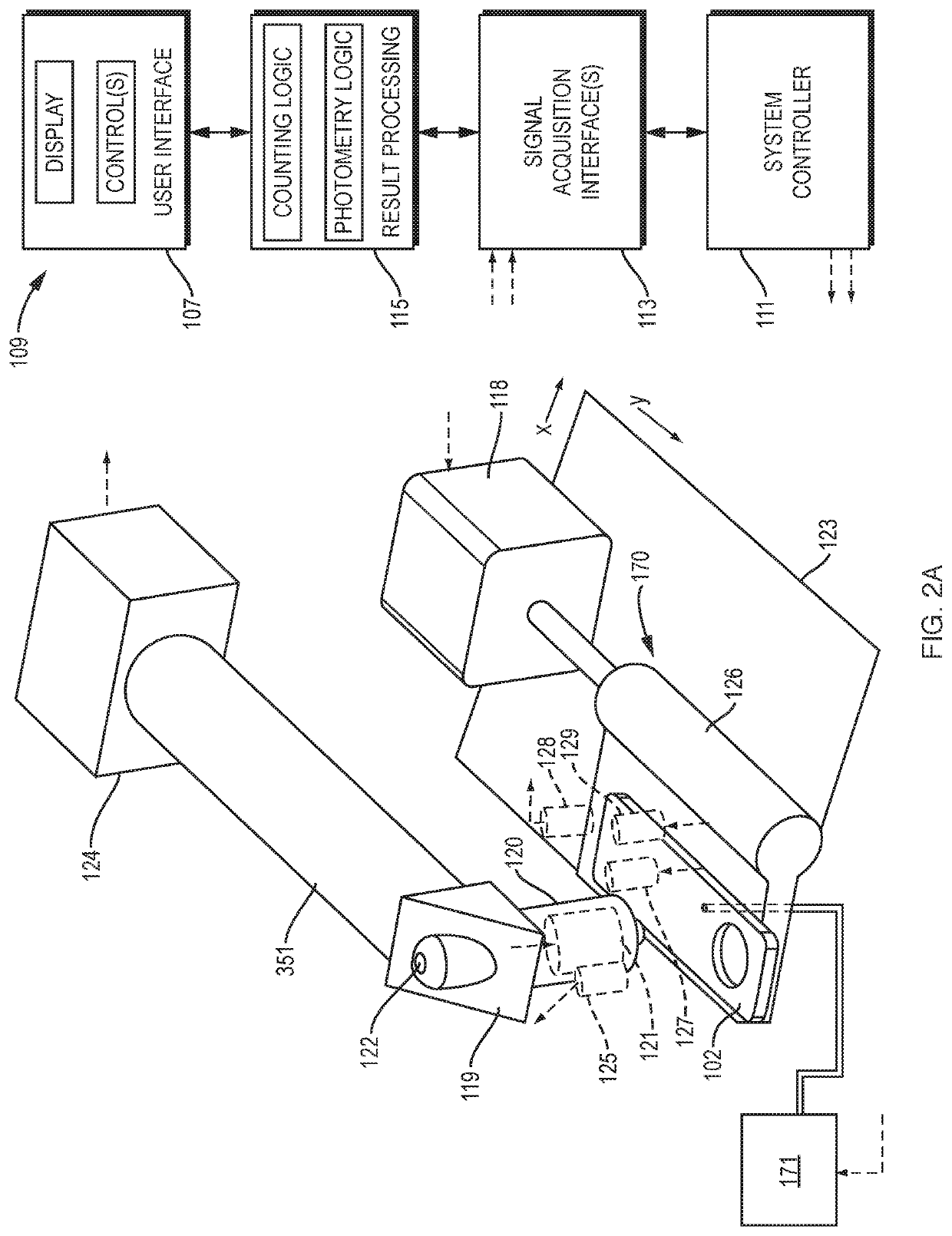

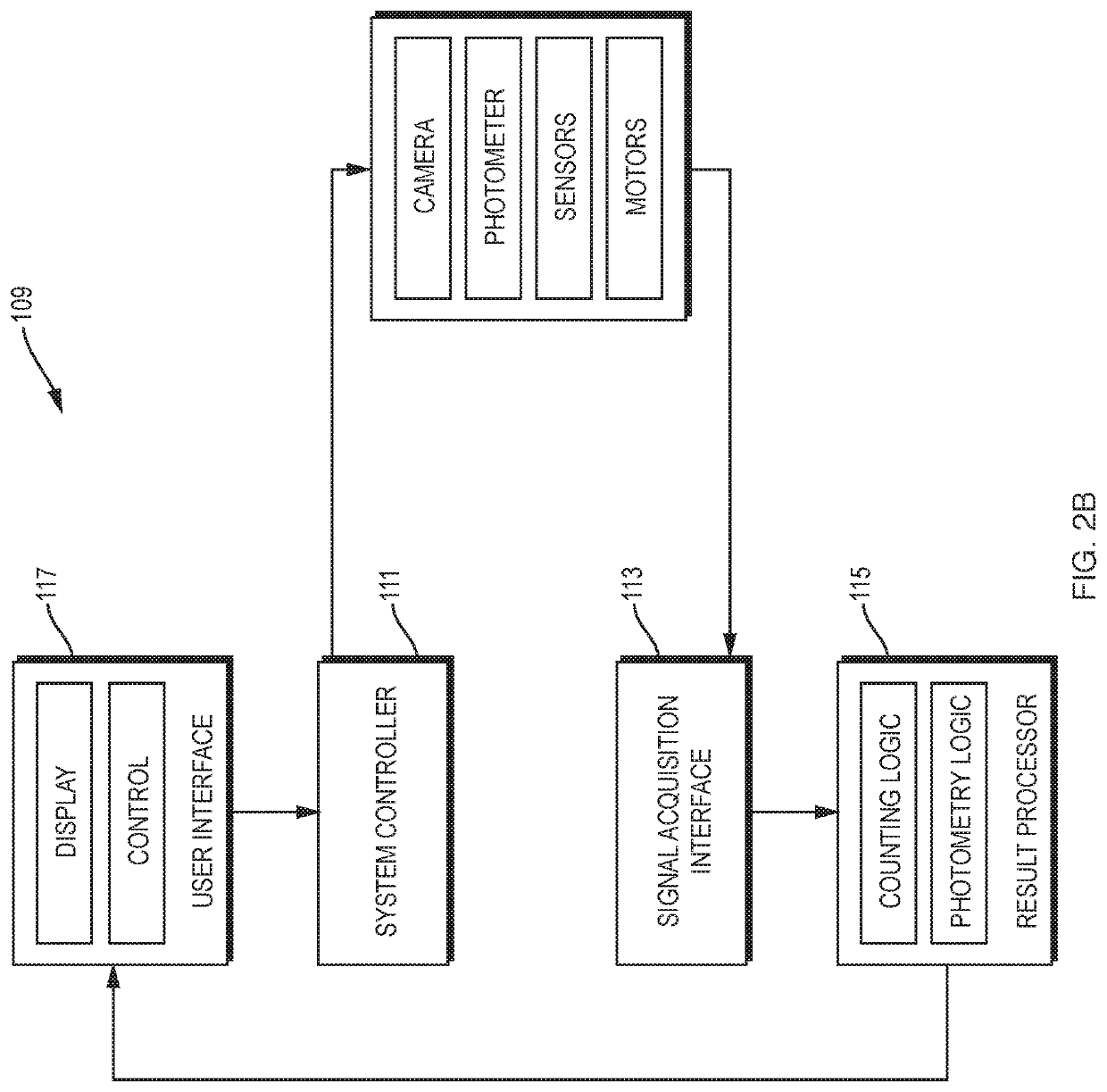

Automated microscopic cell analysis

ActiveUS11480778B2Minimizing any bubblingEliminate Bubble ProblemsPreparing sample for investigationBiological particle analysisWhite blood cellBiology

Disclosed in one aspect is a method for performing a complete blood count (CBC) on a sample of whole blood by metering a predetermined amount of the whole blood and mixing it with a predetermined amount of diluent and stain and transferring a portion thereof to an imaging chamber of fixed dimensions and utilizing an automated microscope with digital camera and cell counting and recognition software to count every white blood cell and red blood corpuscle and platelet in the sample diluent / stain mixture to determine the number of red cells, white cells, and platelets per unit volume, and analyzing the white cells with cell recognition software to classify them.

Owner:MEDICA CORP

Method and Apparatus for Measuring Blood Pressure

ActiveUS20140316288A1Easy to adjustMinimize complexityEvaluation of blood vesselsCatheterPeripheral pulsesDiastolic phase

Embodiments of the present invention provide an improved transformation method whereby the peripheral pulse waveform is filtered to separate different phases which make up the waveform. The separate phases are transformed before being re-combined to provide an estimated intra-arterial transfer function. For example, in one embodiment the peripheral pulse waveform is filtered by a first high pass filter, and a copy of the peripheral pulse waveform filtered by a second high pass filter, having a different cut-off frequency. The two filtered waveforms may then be further processed, for example by being added back to original wave-form, and are then multiplexed together in a time division manner to provide a final waveform. For example, the part of the first filtered waveform corresponding to the systolic phase may be combined with the part of the second filtered waveform corresponding to the diastolic phase to produce the final waveform, and the respective filter cut-off frequencies may be chosen to extract characteristics of the respective phases of the heart.

Owner:SUNTECH MEDICAL

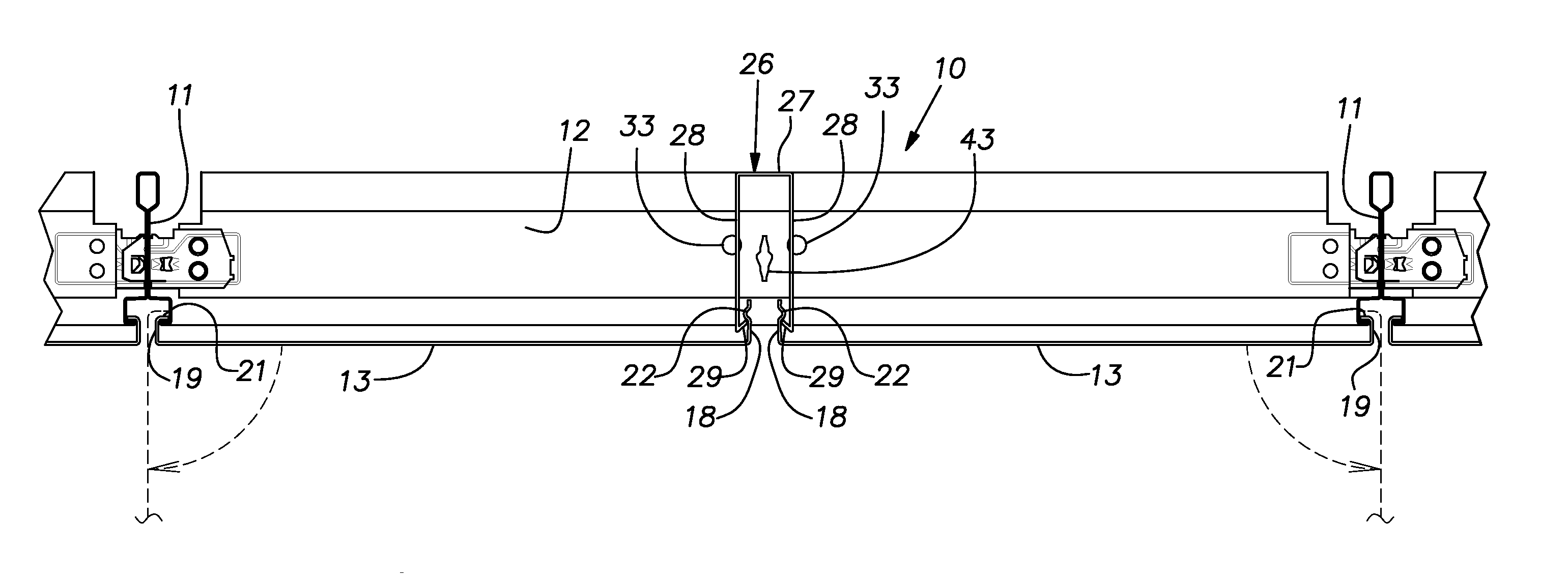

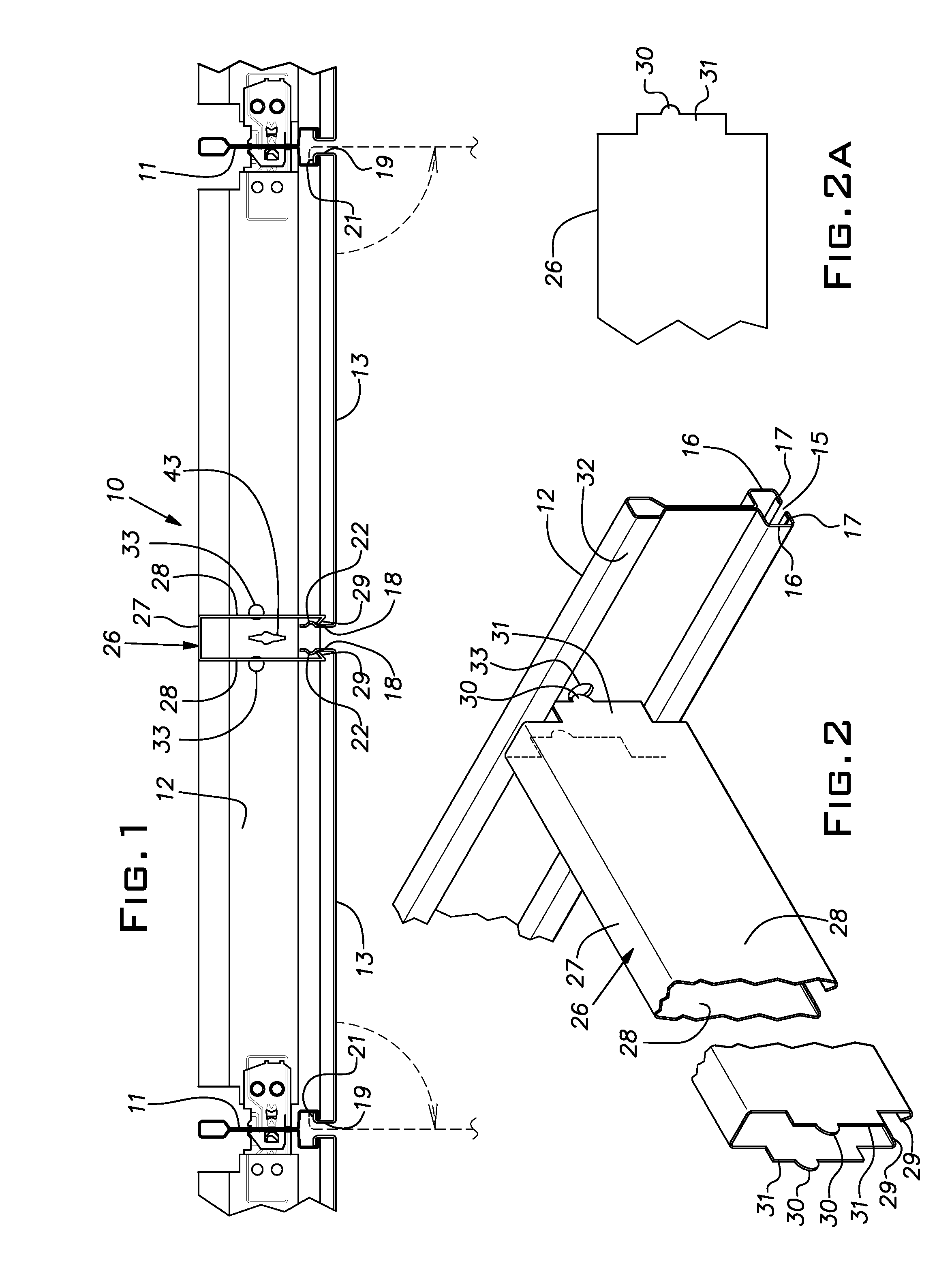

Self aligning three dimensional support structure for a roof constructed with prefabricated components

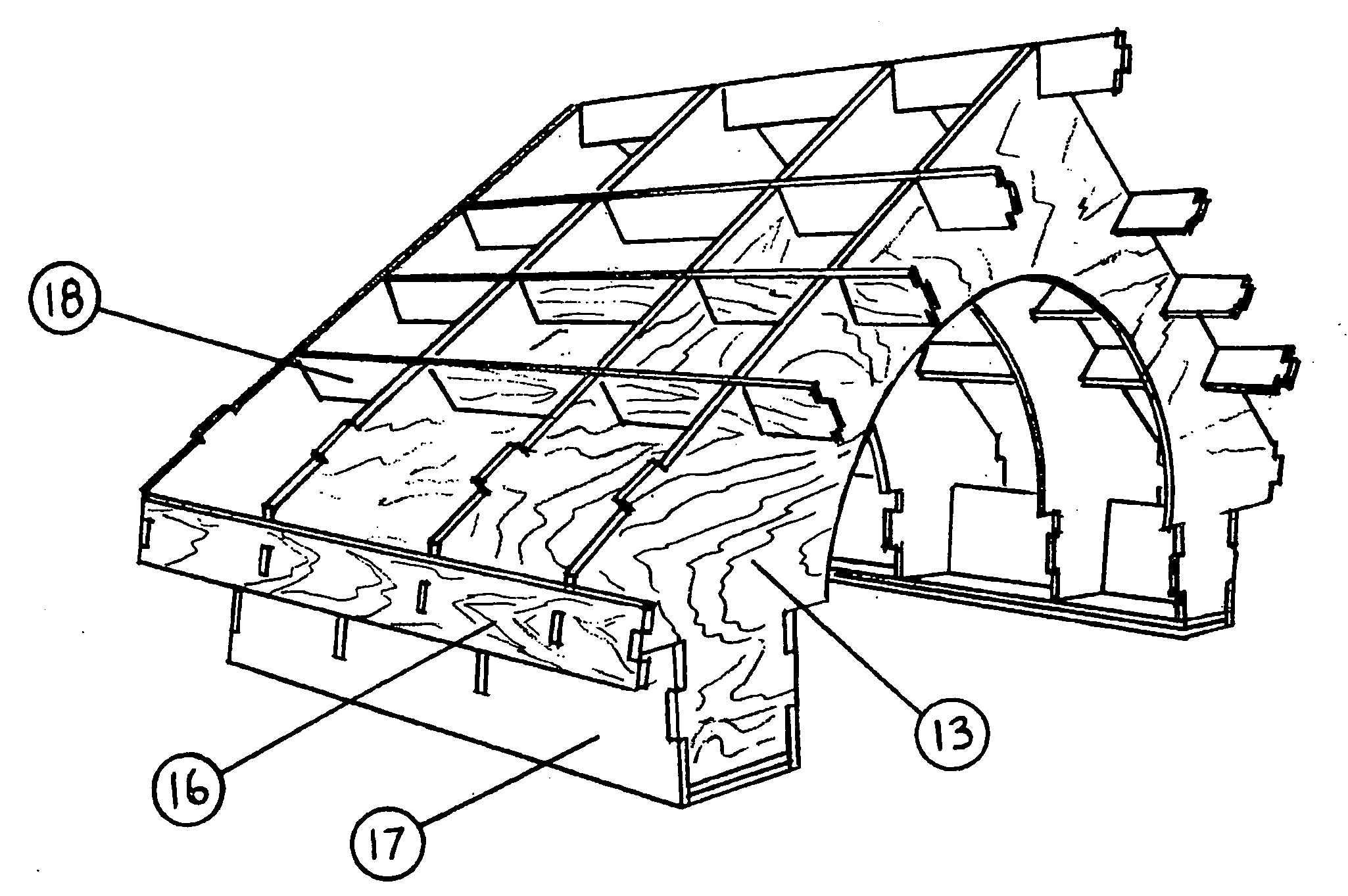

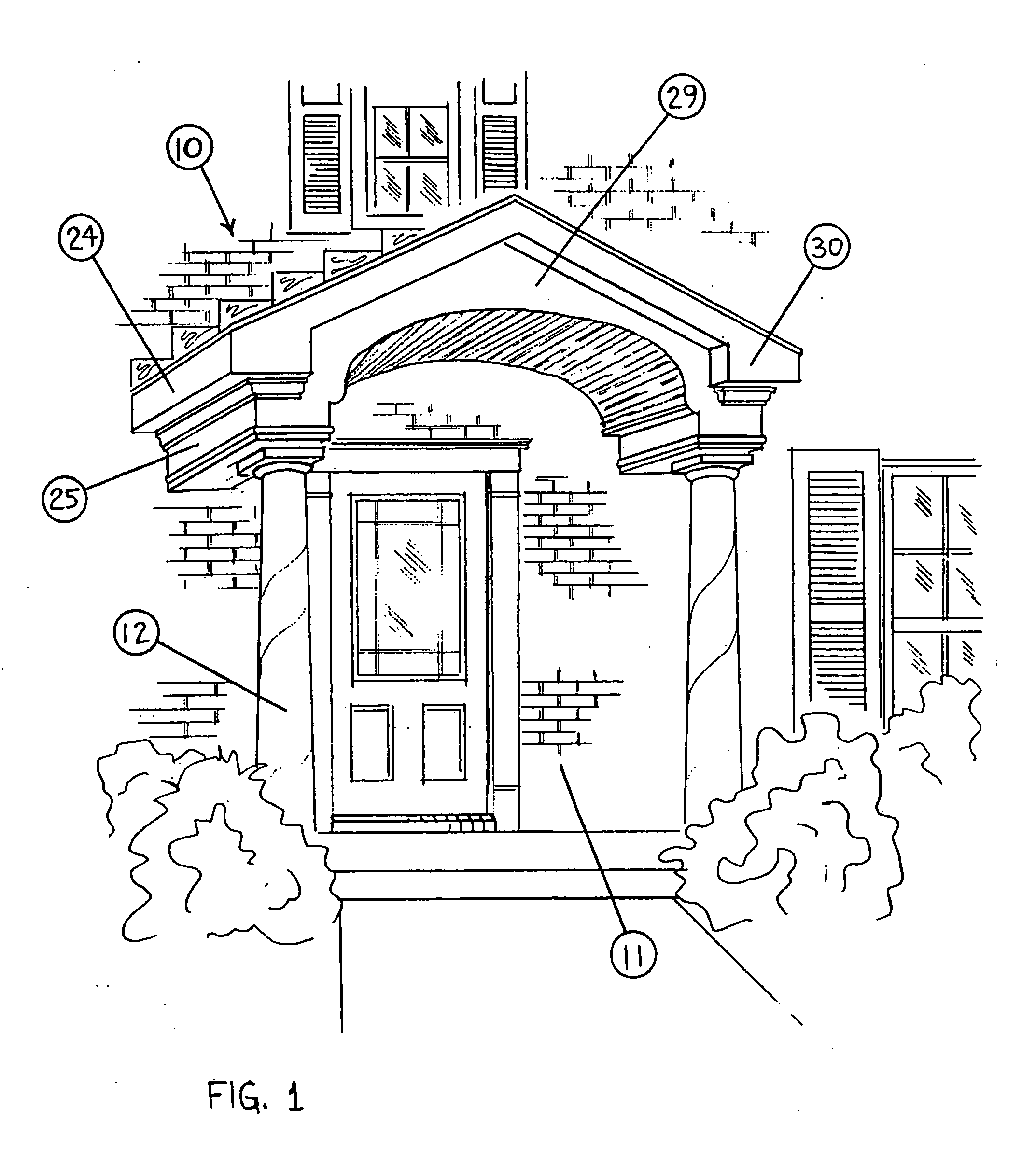

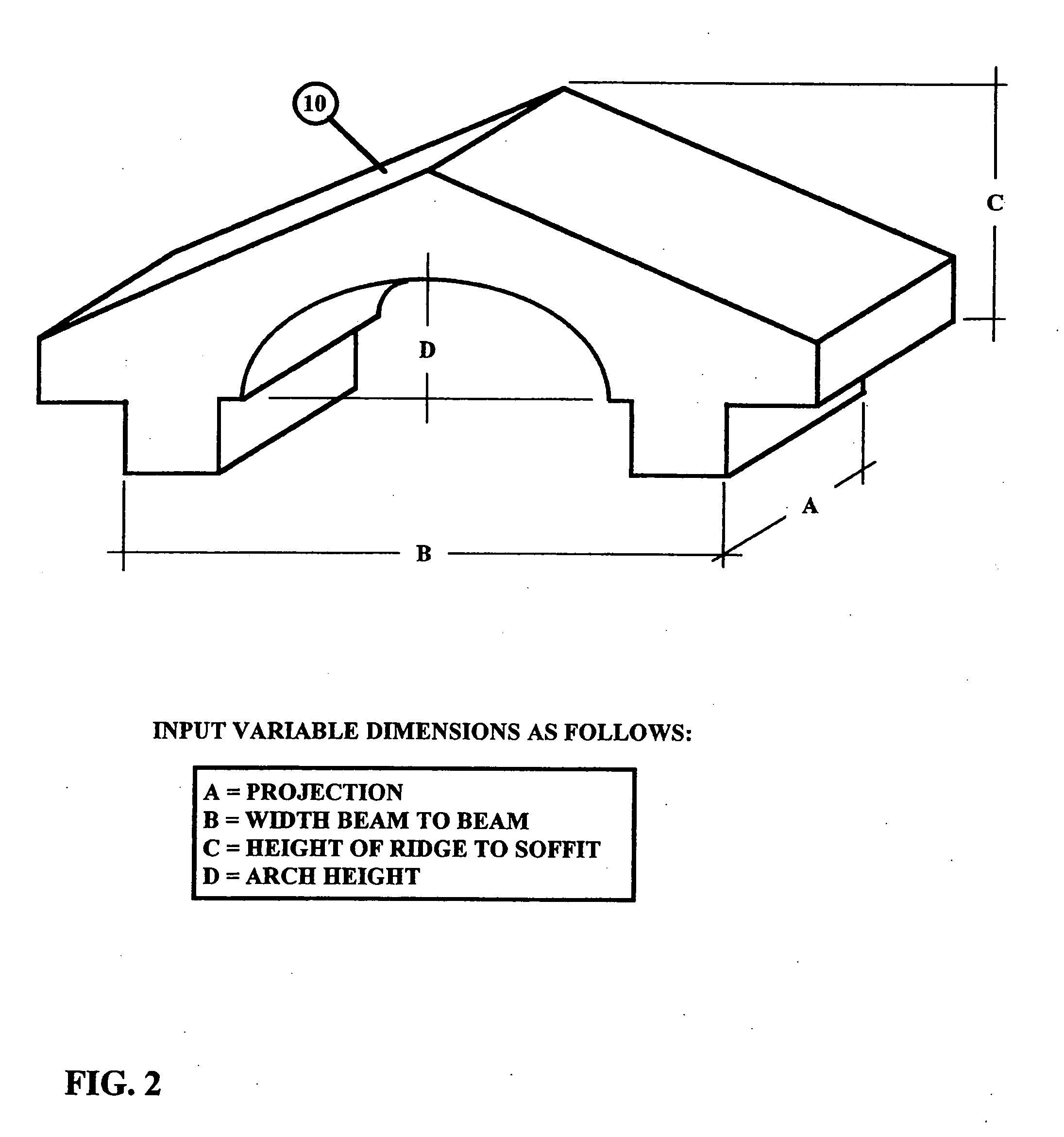

The invention provides a method for easy prefabrication of a self aligning three dimensional roof support and roof structure, such as a dormer or porch roof, which is fully constructed of sheet goods with tab and slot interconnecting components. The roof support structure is constructed of a parallel aligned space series of substantially rigid sheet truss members and a parallel aligned space series of substantially rigid purlin members running perpendicular to the truss members and interlocked with the truss members with opposing interlocking slots to form a self- aligning three dimensional support structure whereby the flush upper sheet ends provide support for roof sheathing. The roof sheathing and additional side fascia members are fit to the substructure with inter-engaging tabs and slots.

Owner:VIVIANO ROBERT P

Toilet overflow prevention device

ActiveUS20050132483A1Low skill levelCost-effective and reliableOperating means/releasing devices for valvesWater closetsControl signalEngineering

A toilet overflow prevention device including an overflow valve assembly, a control valve and a water level sensor. The overflow valve assembly is configured to selectively permit a flow of water through the valve assembly from the tank to the bowl of an associated toilet. The water level sensor is configured to provide a control signal in response to detecting an above-normal water level within the bowl of the toilet. The control valve is configured to actuate the overflow valve assembly in response to a control signal from the water level sensor. Preferably, the overflow valve assembly is separate from the primary flush valve of the toilet and is located between the primary flush valve and the bowl of the toilet.

Owner:LIMIT

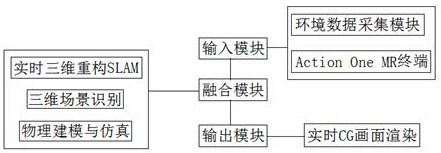

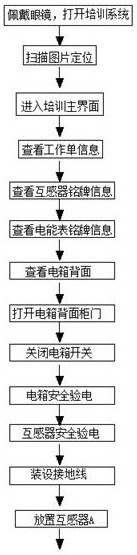

Electric power meter installation and connection practical training system based on mixed reality technology

PendingCN111724486AReduce follow-up expensesIncrease interest in learningInput/output for user-computer interactionCosmonautic condition simulationsMixed realityData acquisition

The invention discloses an electric power meter installation and connection practical training system based on a mixed reality technology. The system comprises a metering cabinet, a mutual inductor, an electric energy meter, an input module, a fusion module and an output module. The metering cabinet, the mutual inductor and the electric energy meter are all virtual models. The input module, the fusion module and the output module are connected in sequence, the input module comprises an environmental data acquisition module and an ActionOne MR terminal, and the fusion module comprises an SLAM unit for implementing three-dimensional reconstruction, a three-dimensional scene recognition unit and a physical modeling and simulation unit. According to the invention, a mixed reality experience mode is adopted, content of practical training operation is experienced in a scenarized manner, each experiencer can experience the field operation process of meter installation and power connection atthe first perspective, students can personally experience the learning content through the mixed reality experience system, the practical training safety can be improved, the skill level of themselvescan also be improved, modernization, standardization and science and technology of education training are promoted to a large extent, and intelligent teaching is truly achieved.

Owner:重庆鑫泺源智能科技有限公司

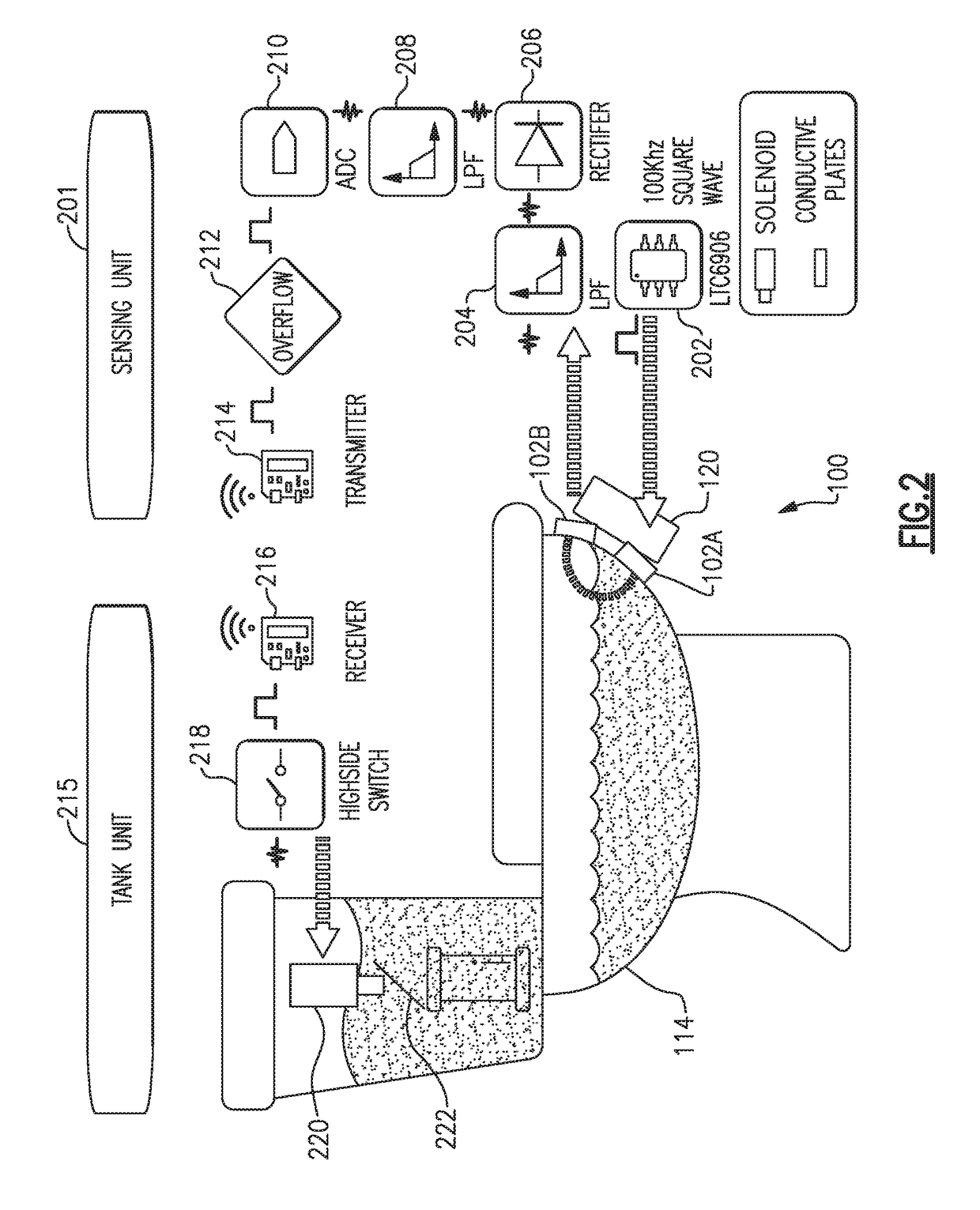

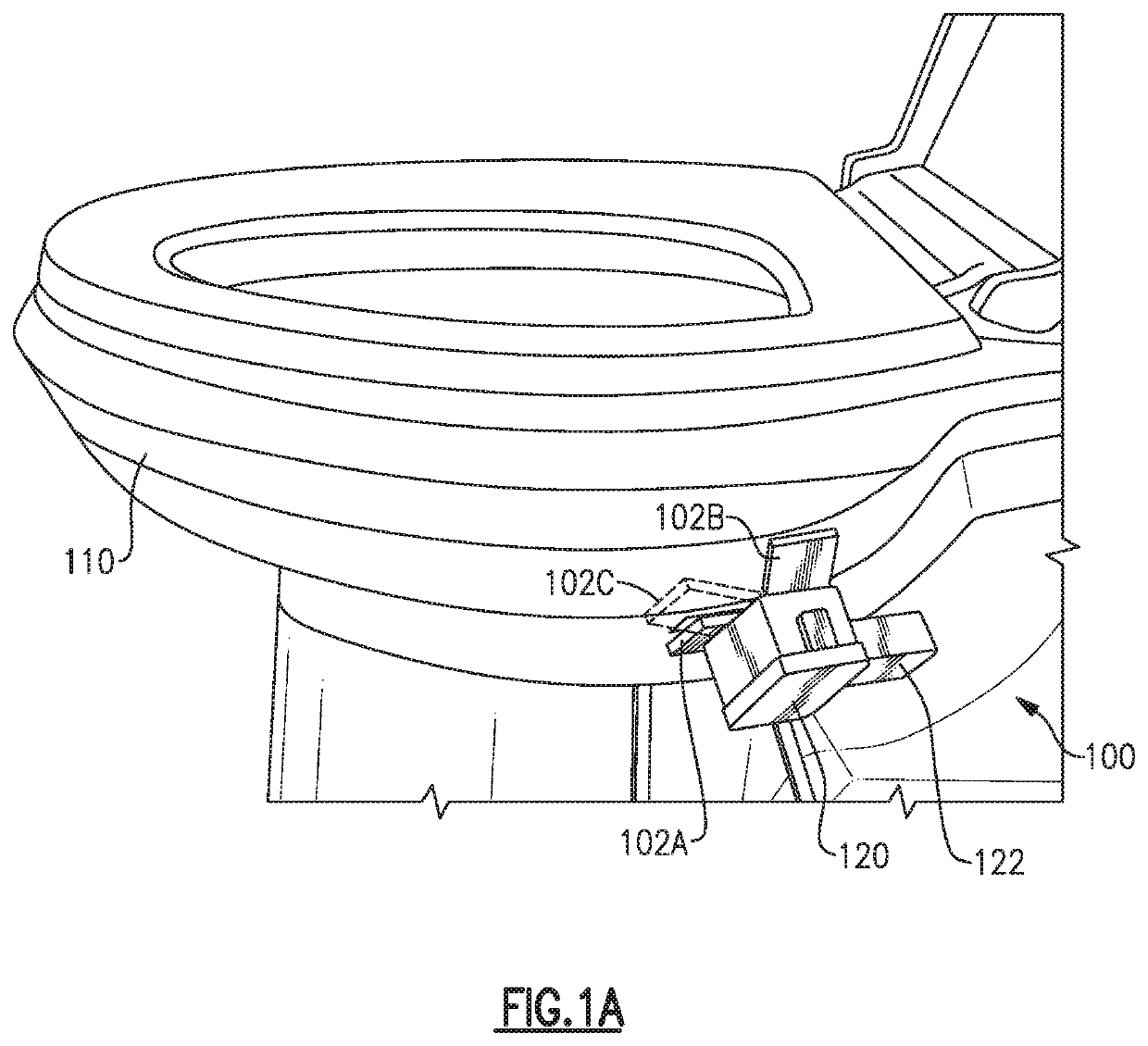

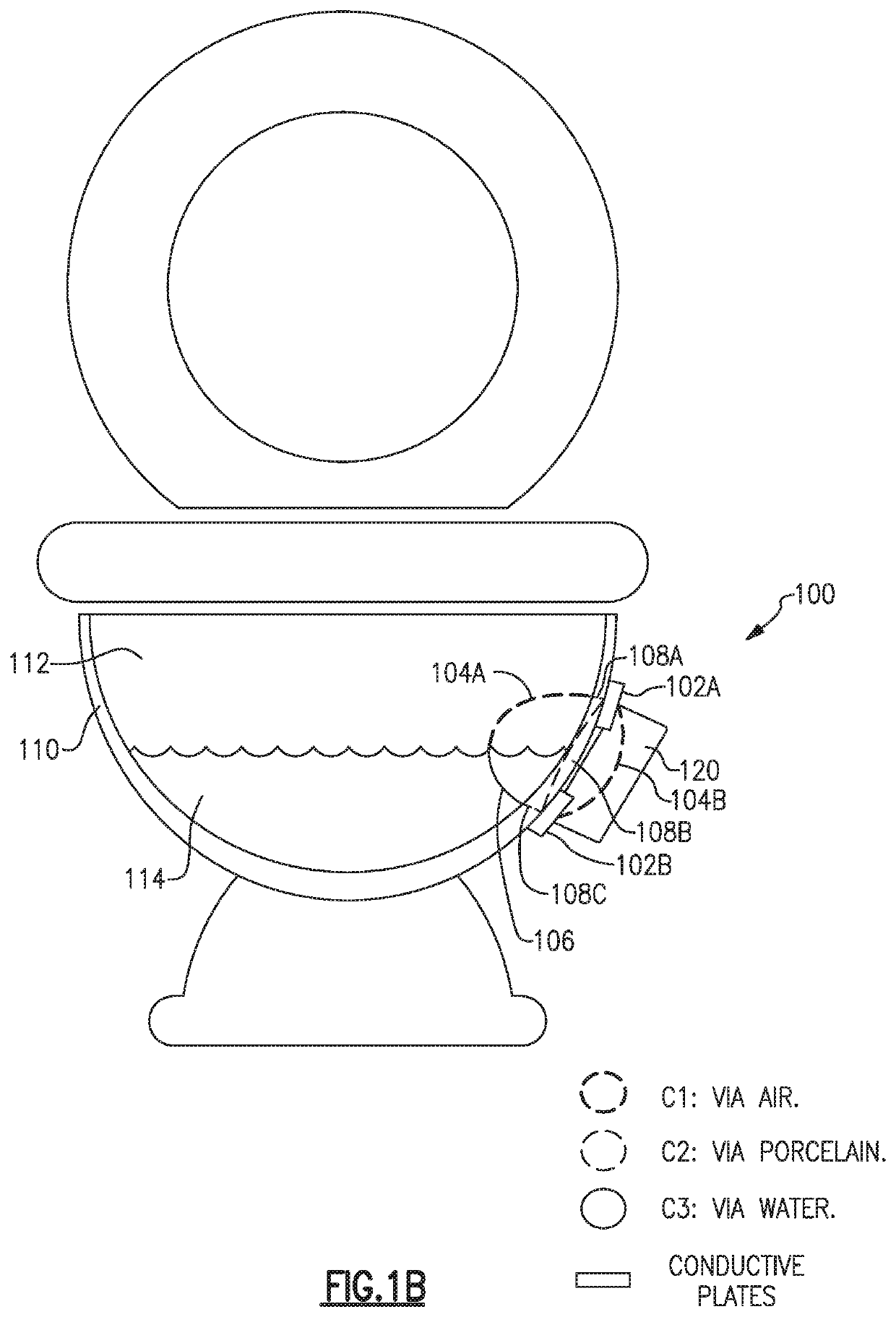

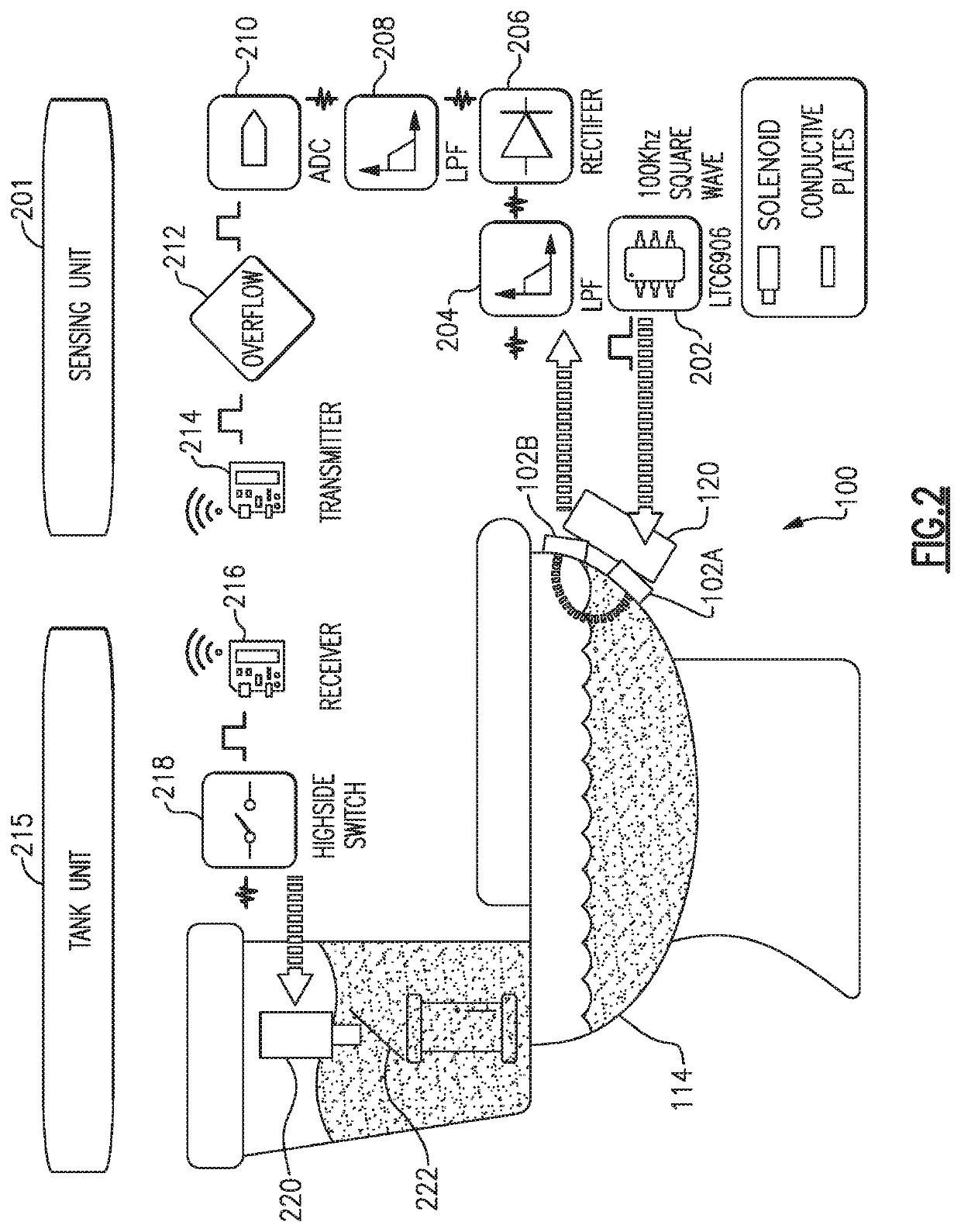

Toilet overflow prevention system and method

ActiveUS20180371734A1Cost-effective and reliableLow skill levelWater closetsClimate change adaptationTime rangeEngineering

A system for preventing overflow of a toilet includes a capacitance sensor arrangement as in combination with certain features (e.g., flap valve disablement). The system can detect an overflow flush condition of a toilet by sensing the value of a parameter of one or more normal flush cycles of the toilet and establishing a normal range for the value of the parameter using the sensed value. The system can also store the normal range in a memory for comparison to a value of the parameter during subsequent flush cycles. The system can perform sensing over a predetermined timeframe. The system can include the time frame being sufficient to include the entire push cycle of the toilet.

Owner:LIMIT

Toilet overflow prevention system and method

ActiveUS10697166B2Cost-effective and reliableLow skill levelWater closetsClimate change adaptationTime rangeControl engineering

Owner:LIMIT

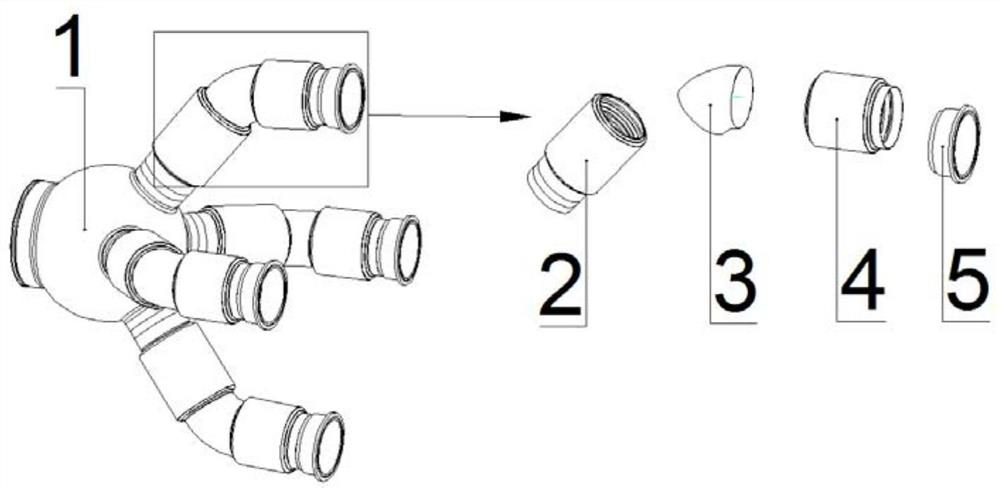

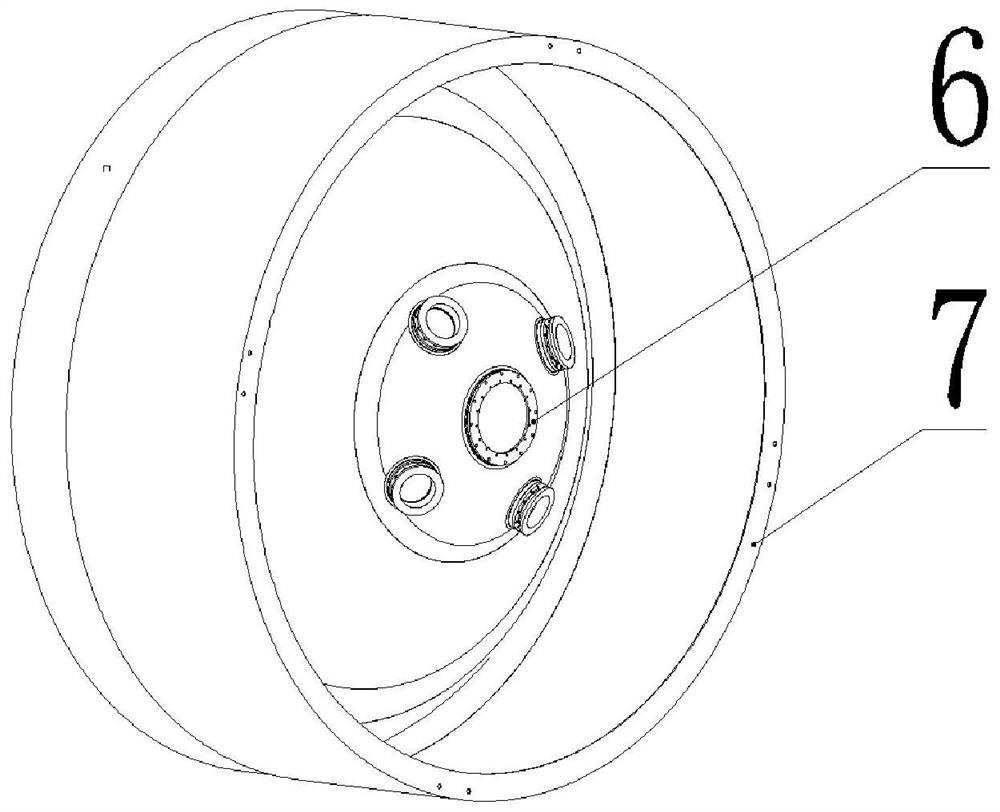

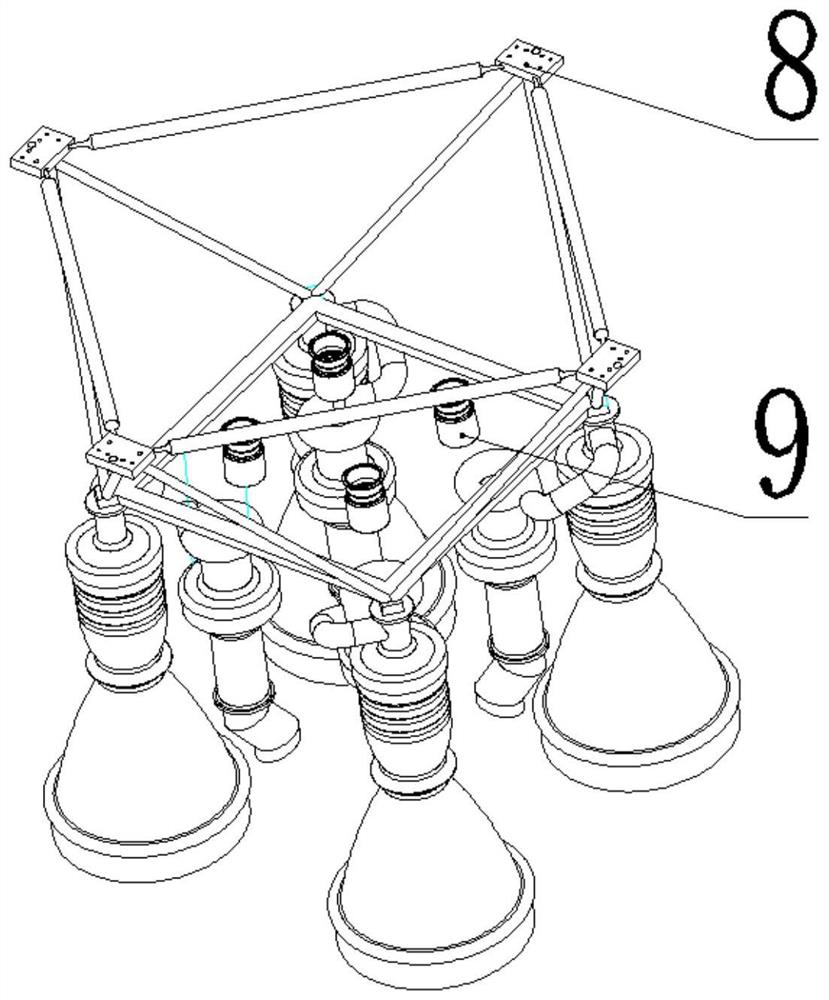

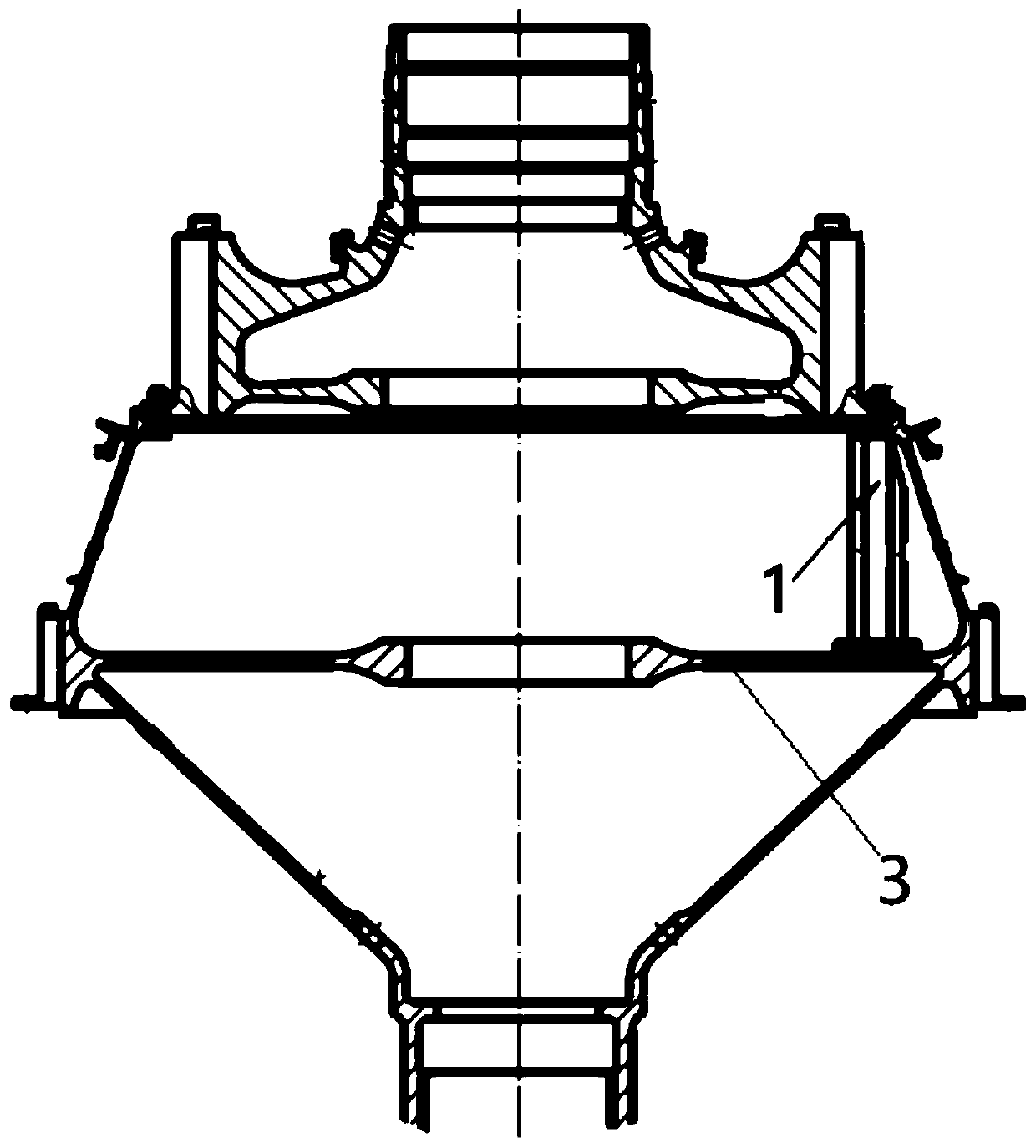

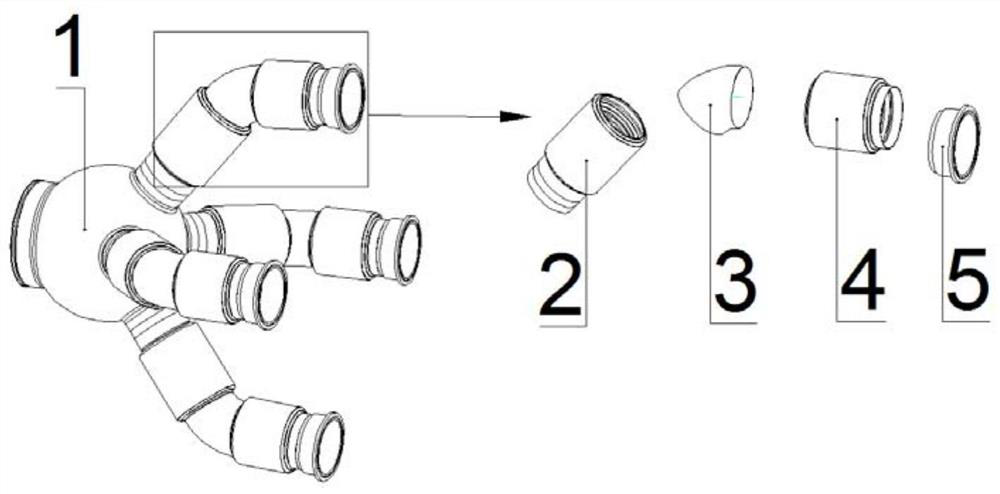

Digital assembling and manufacturing method for tailor-welded pipeline

ActiveCN113334047AFast and accurate boundary feature measurementLow skill levelMetal working apparatusManufacturing computing systemsData modelingControl engineering

The invention discloses a digital assembling and manufacturing method for a tailor-welded pipeline. Basic data of digital sampling are obtained through measurement of a laser tracker, calculation of virtual boundary conditions of a pipeline is completed through modeling, and manufacturing of parts is completed according to model data. Compared with the prior art, the method has the positive effects that a laser tracker measurement system is adopted for data measurement, the measurement precision is high, real-time and rapid effects are achieved, the operation is simple and convenient, and pipeline boundary characteristic measurement can be rapidly and accurately carried out; a pipeline assembly space is copied to a part production workshop, the operation environment is single, the space is large, and the risk of instrument damage is avoided; the waiting time for manufacturing the tailor-welded pipeline of a spacecraft assembly is eliminated; and the data of the actual assembly space positions of the two ends of the pipeline are obtained through measurement for production and manufacturing, excessive dependence on manual experience is eliminated through data support, and the production quality and the assembly precision of the pipeline are improved.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

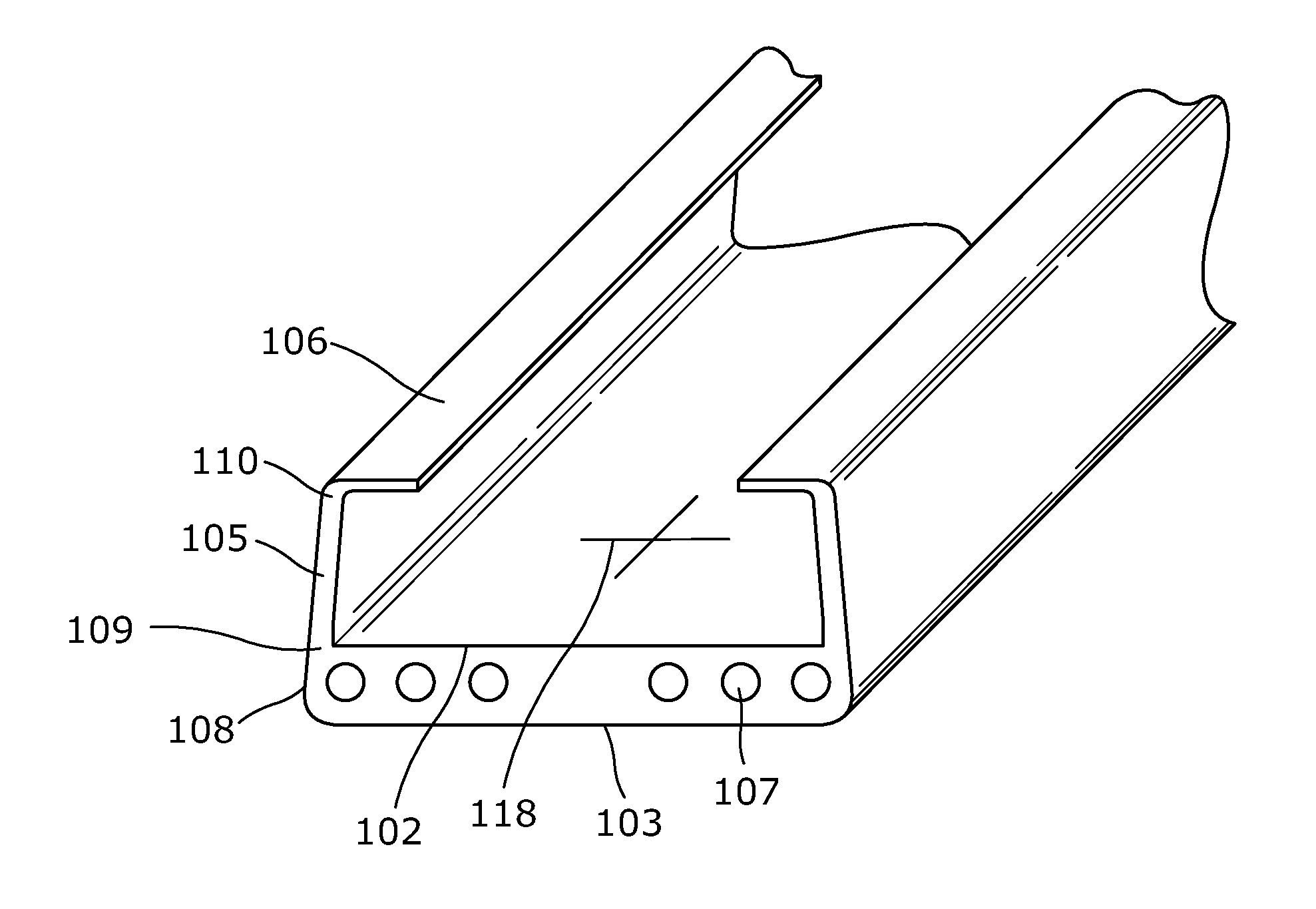

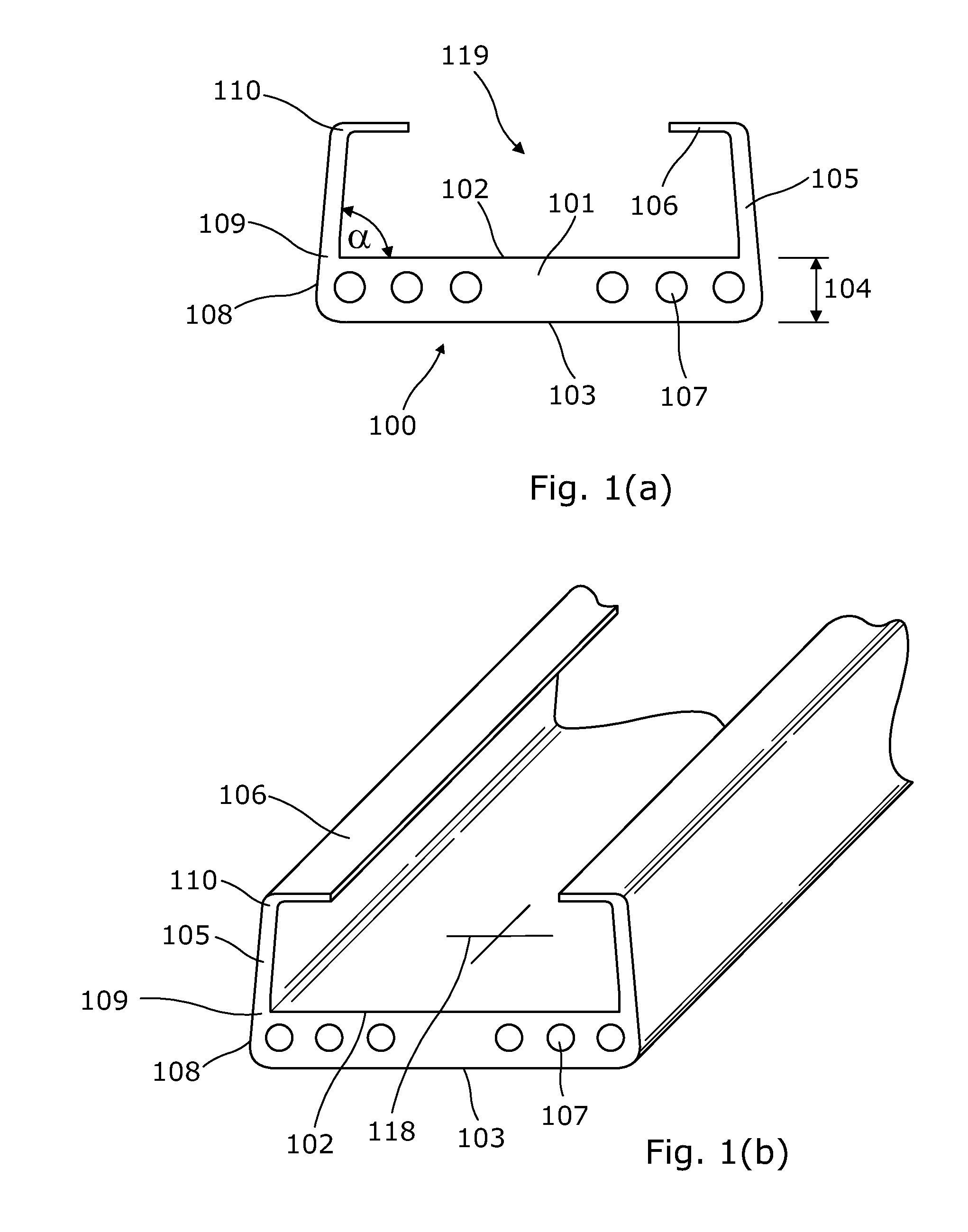

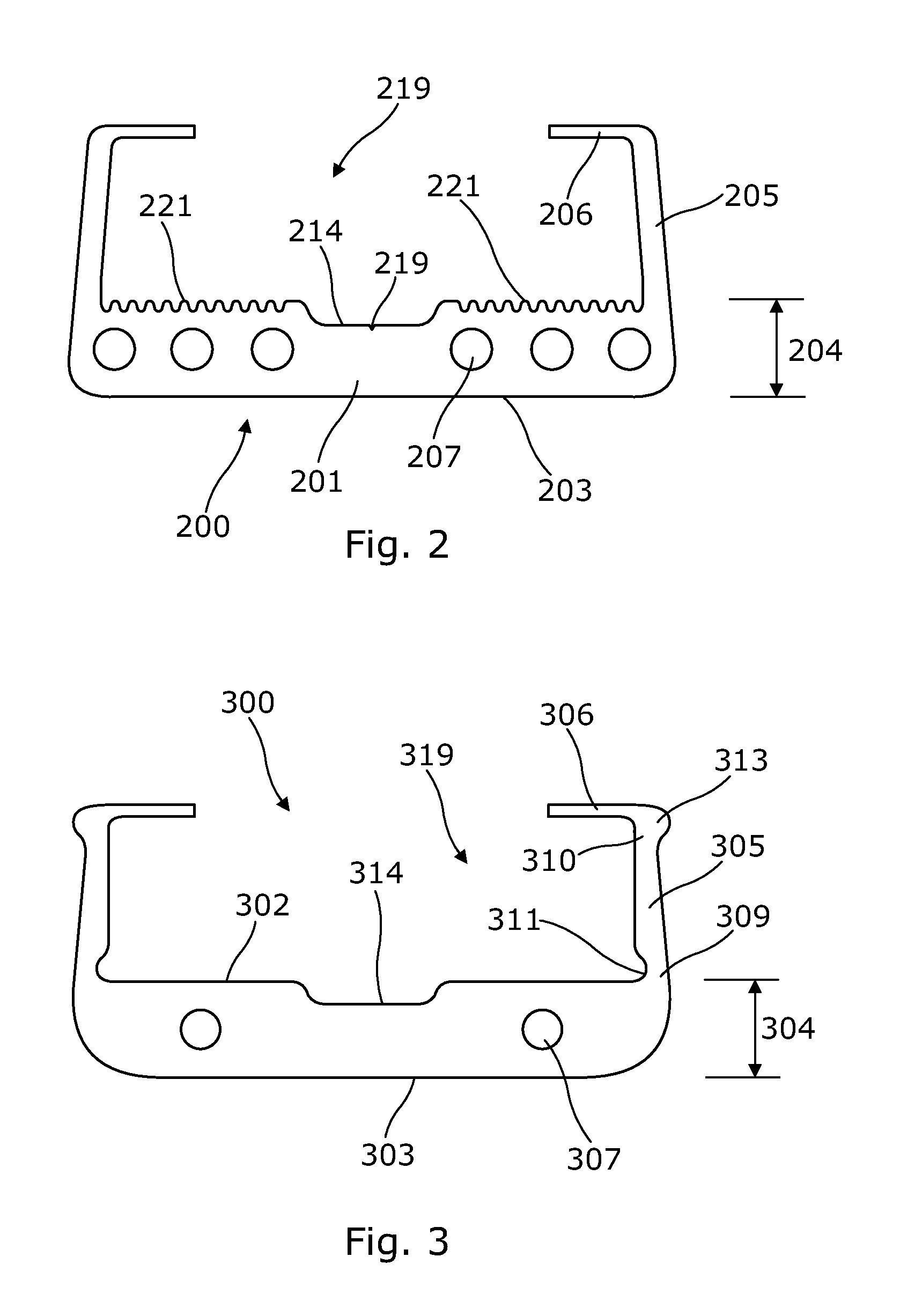

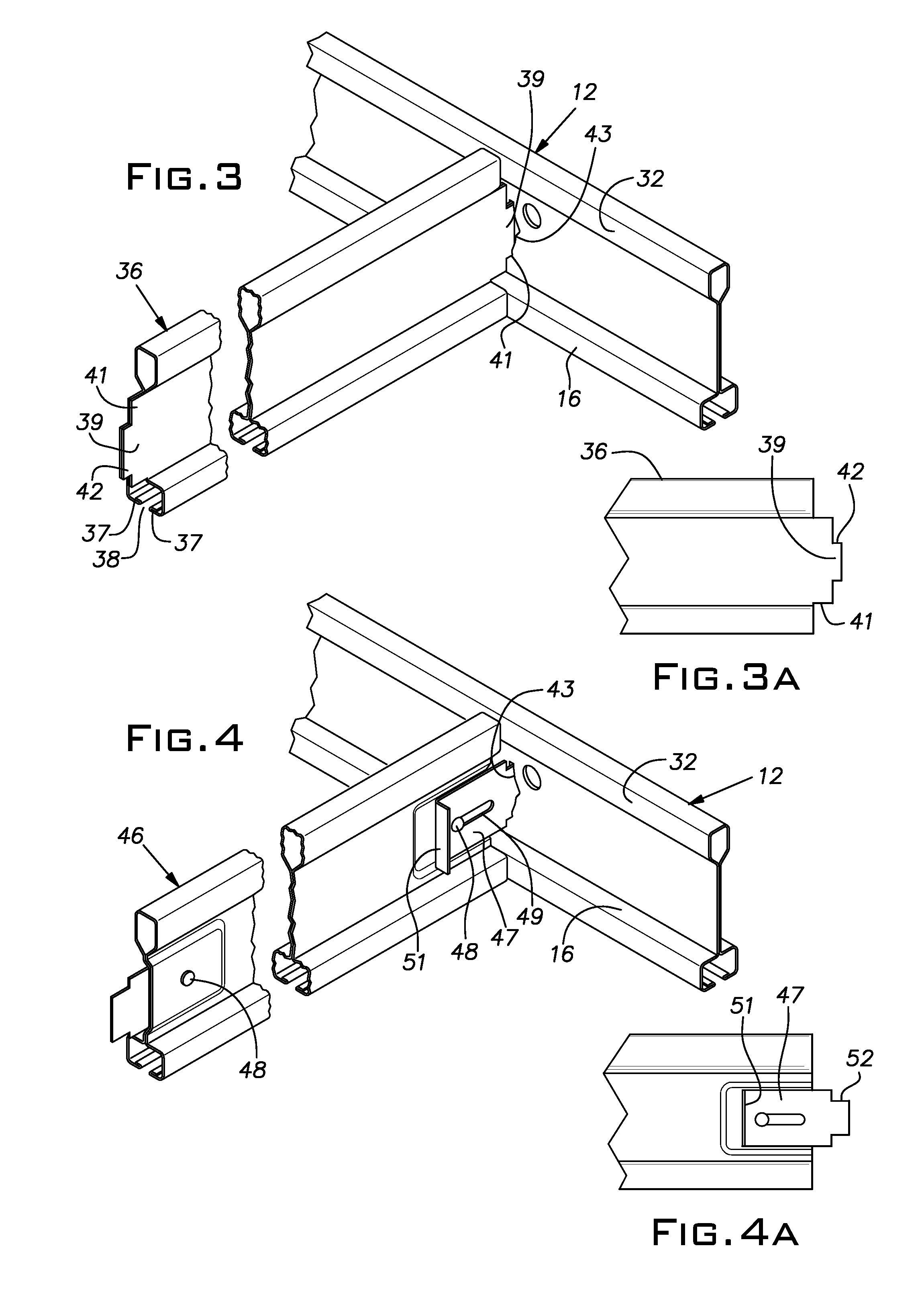

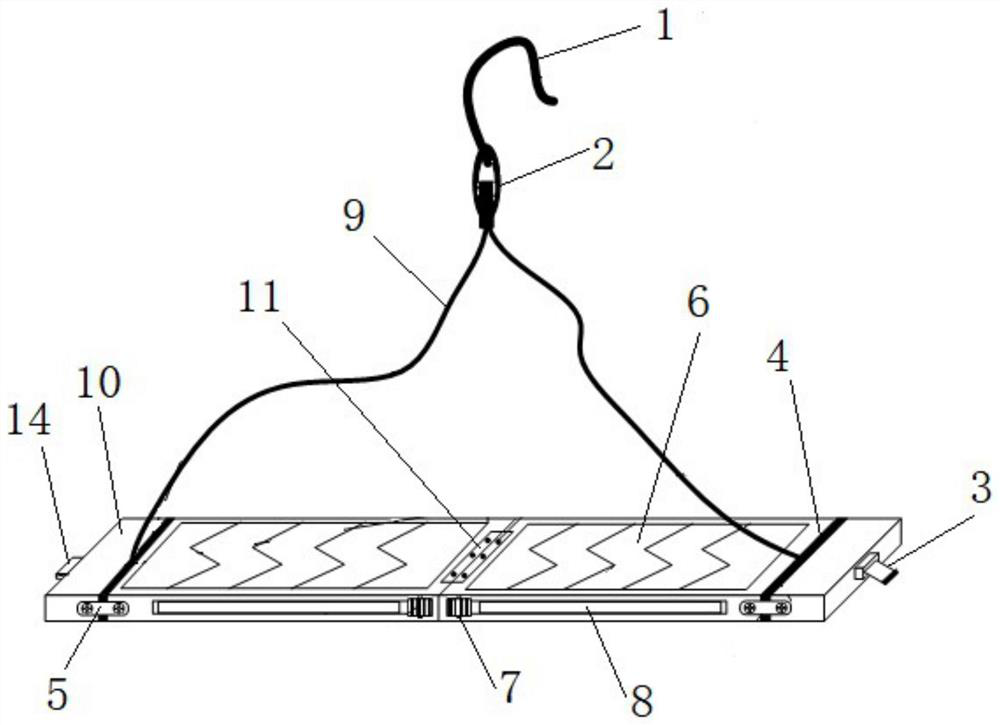

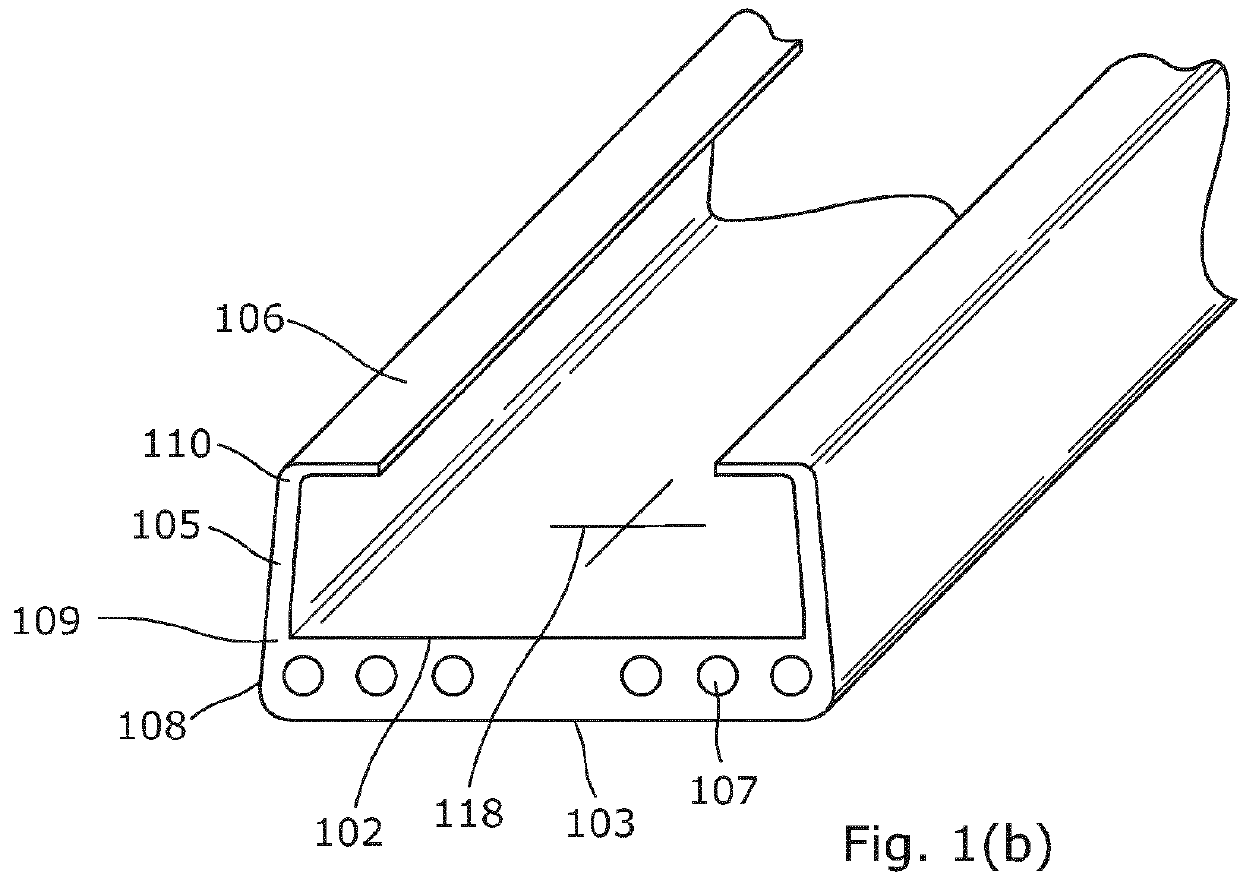

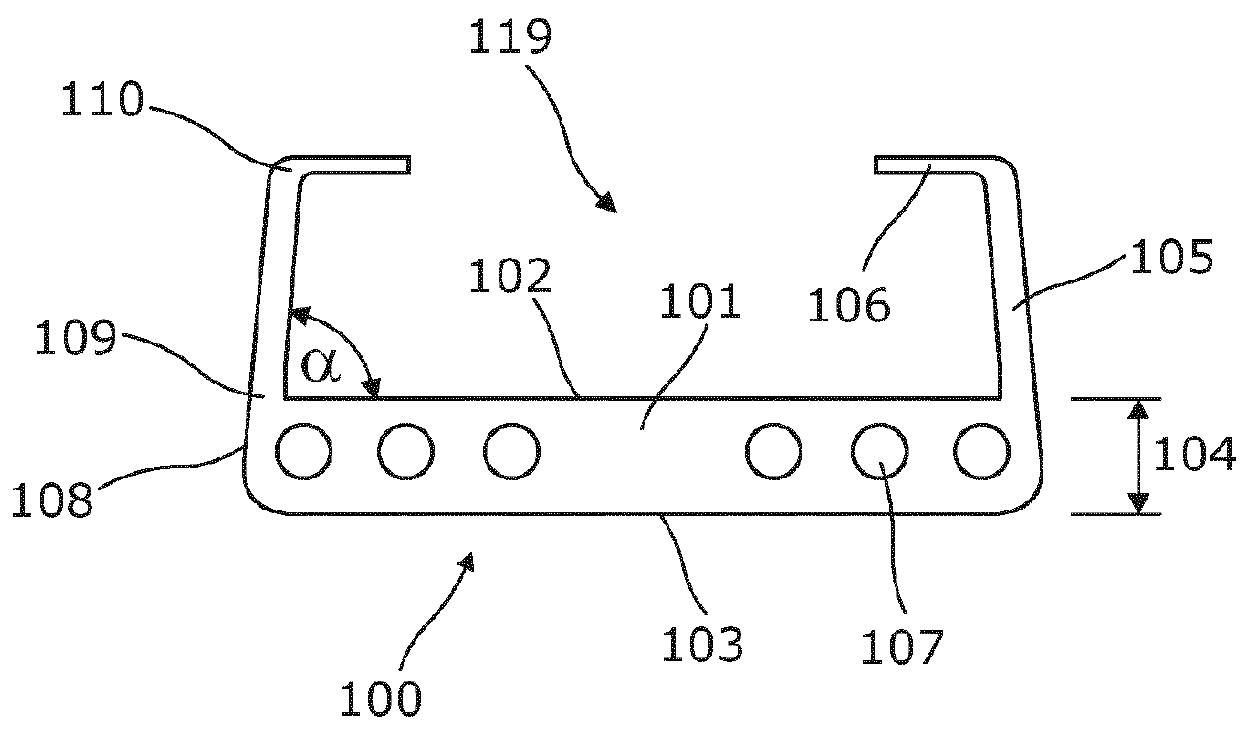

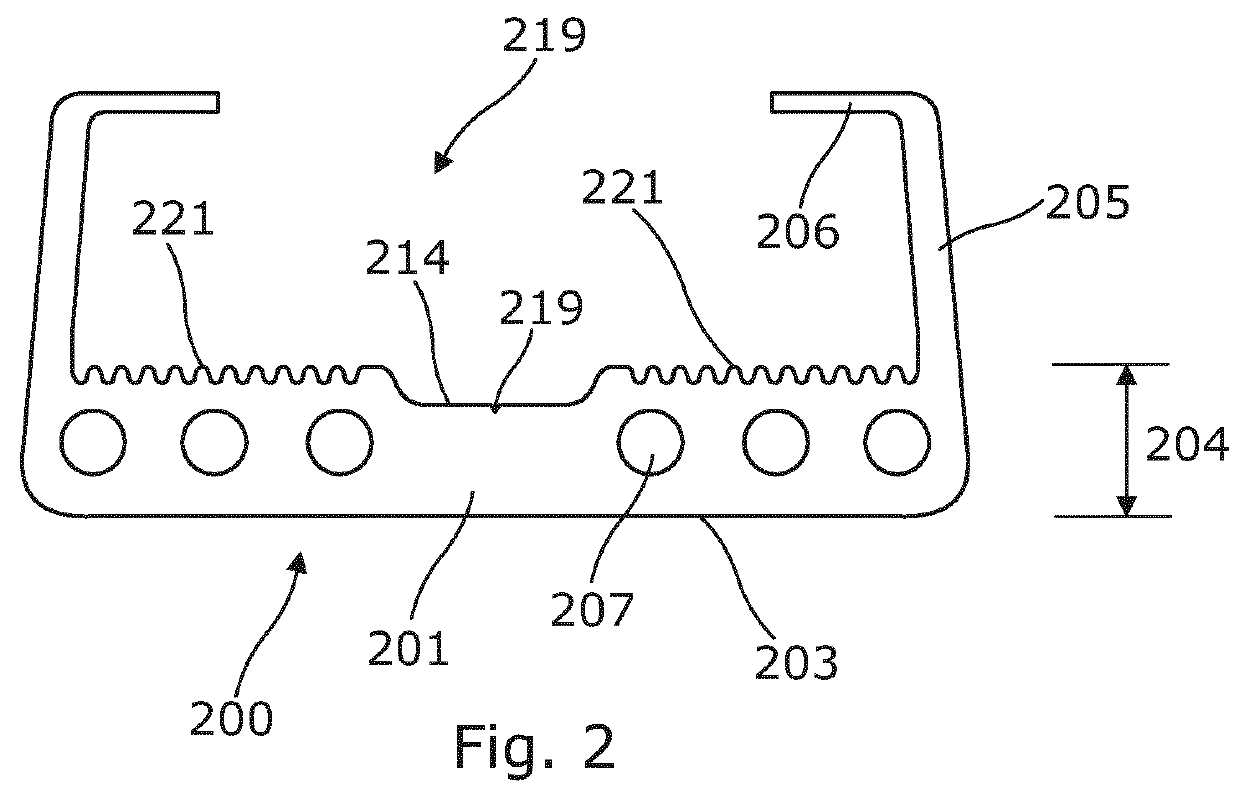

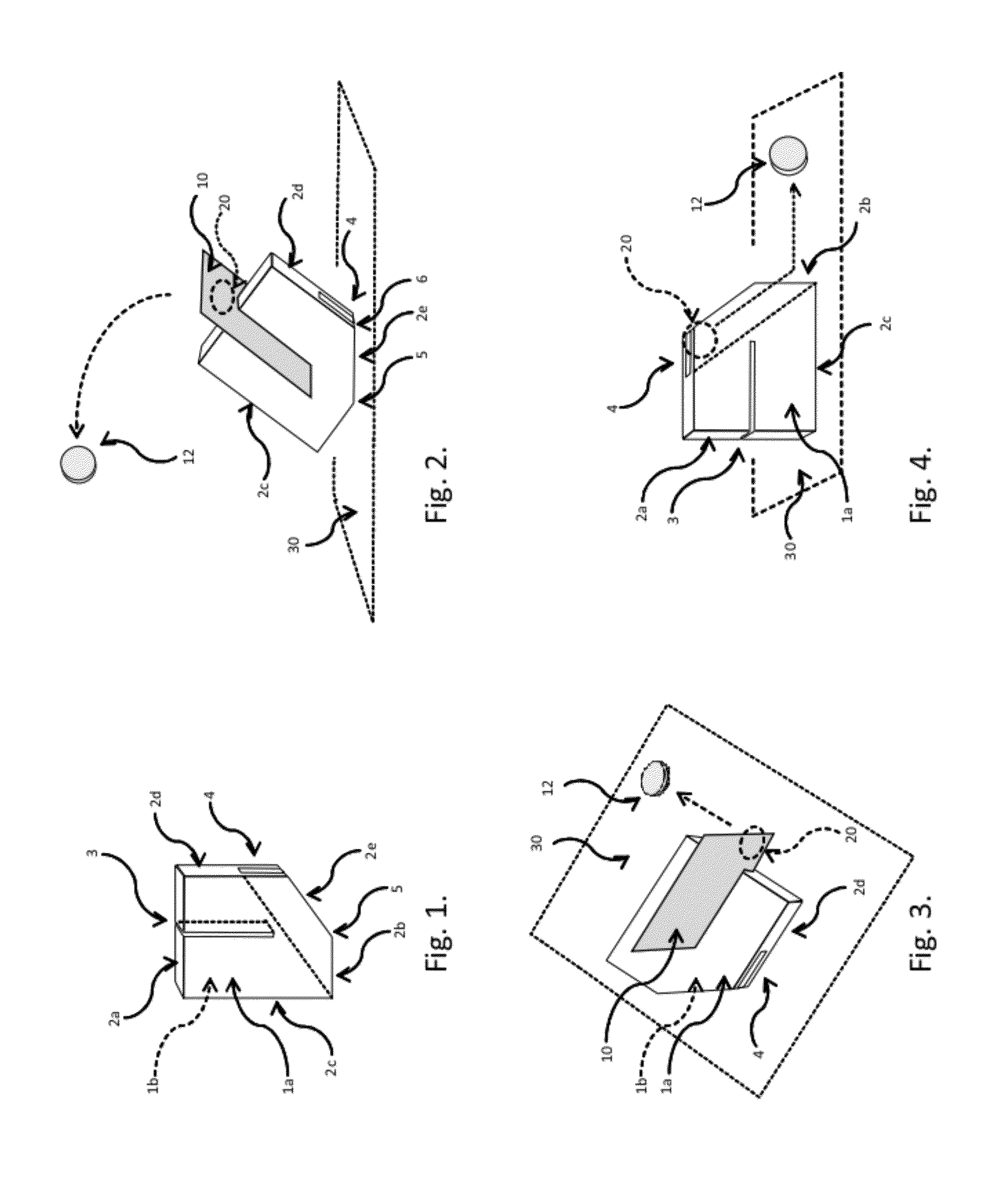

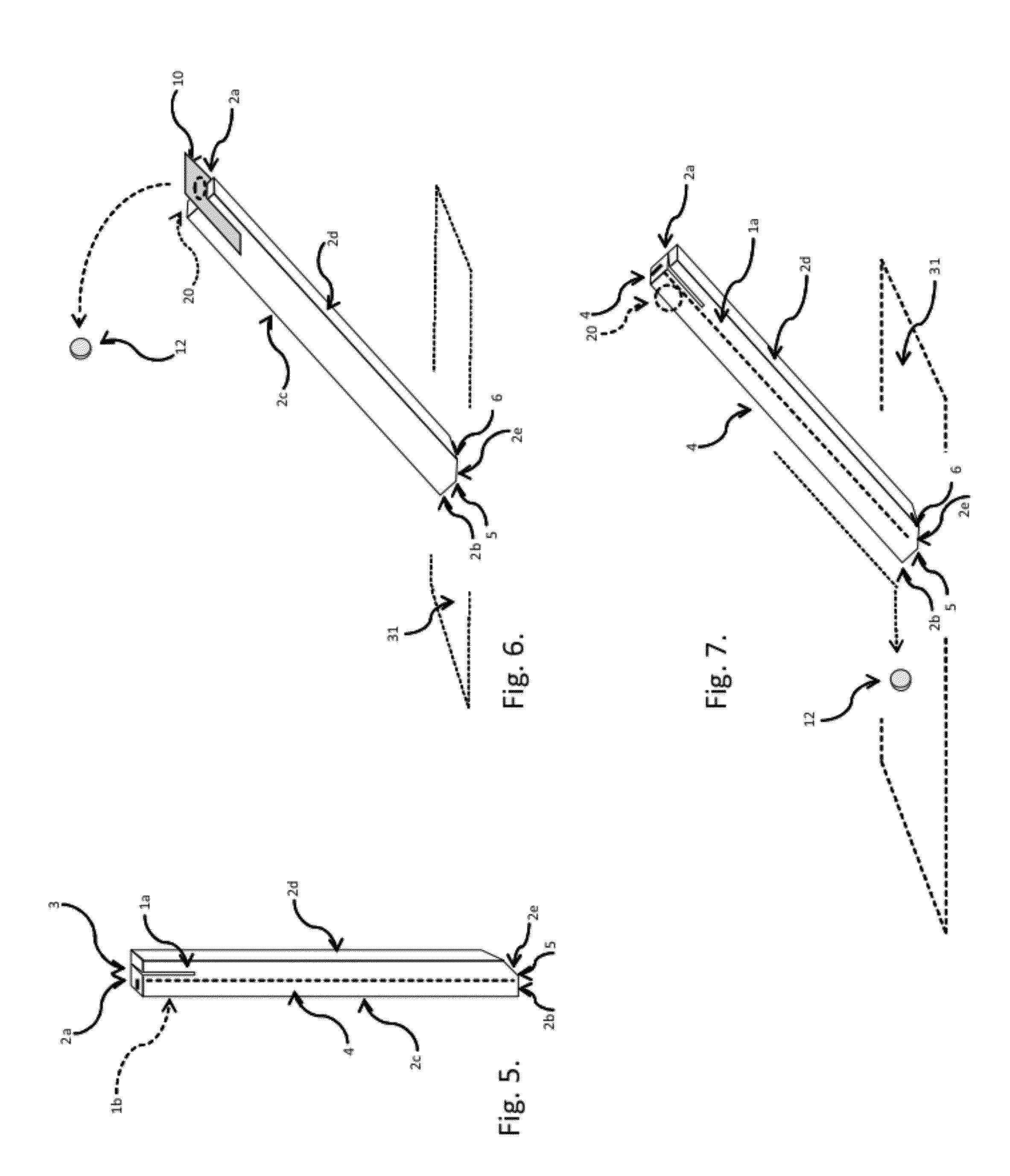

Acoustic dampener

ActiveUS20150013244A1Reduce acoustic energy transmissionLow installation skill levelElectrical transducersRecord carriersEngineering

An acoustic dampener (100) comprising a base member (101) having a first surface (102) and a second surface (103), the first surface (102) and the second surface (103) are spaced apart from each other defining a thickness (104) therebetween. The acoustic dampener (100) further comprising a pair of side arms (105), each having a first end (109) and a second end (110). Each side arm (105) is attached to the base member (101) at its first end (109) at a predetermined angle. The side arm (105) extends from the base member (101) to form a channel formation (119) to receive a batten. A flange (106) extends substantially orthogonally from the second end (110) of each side arm (105) for retaining a batten within the channel formation (119).

Owner:JAMES HARDIE TECH LTD

Automated microscopic cell analysis

ActiveUS20200174241A1Minimizing any bubblingEliminate Bubble ProblemsPreparing sample for investigationBiological particle analysisWhite blood cellBiology

Disclosed in one aspect is a method for performing a complete blood count (CBC) on a sample of whole blood by metering a predetermined amount of the whole blood and mixing it with a predetermined amount of diluent and stain and transferring a portion thereof to an imaging chamber of fixed dimensions and utilizing an automated microscope with digital camera and cell counting and recognition software to count every white blood cell and red blood corpuscle and platelet in the sample diluent / stain mixture to determine the number of red cells, white cells, and platelets per unit volume, and analyzing the white cells with cell recognition software to classify them.

Owner:MEDICA CORP

Bi-parting accessible ceiling system

A suspended ceiling comprising a grid formed of intersecting grid runners and snap-up panels supported on the grid runners, the grid runners dividing a ceiling area into standard modules, the pans being formed of sheet material and each having its sides sized to cover the module size while leaving a space at visible faces thereof between adjacent panels when in an installed position on the grid, at least one adjacent pair of panels being displaceable from their installed positions, the gap between a pair of displaceable panels being closed by a removable runner or the displaceable panels so that when the displaceable panels are displaced from their installed position and any removable runner is removed, an access opening of twice the standard module is made available for accessing the area above the ceiling while adjacent panels at longitudinal ends of the gap between the displaceable panels can remain in respective installed positions.

Owner:USG INTERIORS INC

Enhanced Cake Topper

InactiveUS20150062881A1Low skill levelHigh level of perceivedPoint-like light sourceElectric circuit arrangementsEngravingLight pipe

One aspect of the invention uses a sealed housing and using a battery of sufficient voltage / power to continue the a light source projected for at least eight hours into the display. This light is directed onto a clear or translucent acrylic sheet or other material of similar properties using the described sheet as a light pipe. Any engraving in the surface of the material is highlighted and gives the appearance of a neon style light display. An illuminated display that is customizable, attractive, durable and easily cleaned. Accordingly, Additional features, advantages, and embodiments of the invention may be set forth or apparent from consideration of the following detailed description, drawings, and claims. Moreover, it is to be understood that both the foregoing summary of the invention and the following detailed description are exemplary and intended to provide further explanation without limiting the scope of the invention as claimed.

Owner:MAHONEY SR MICHAEL ROBERT

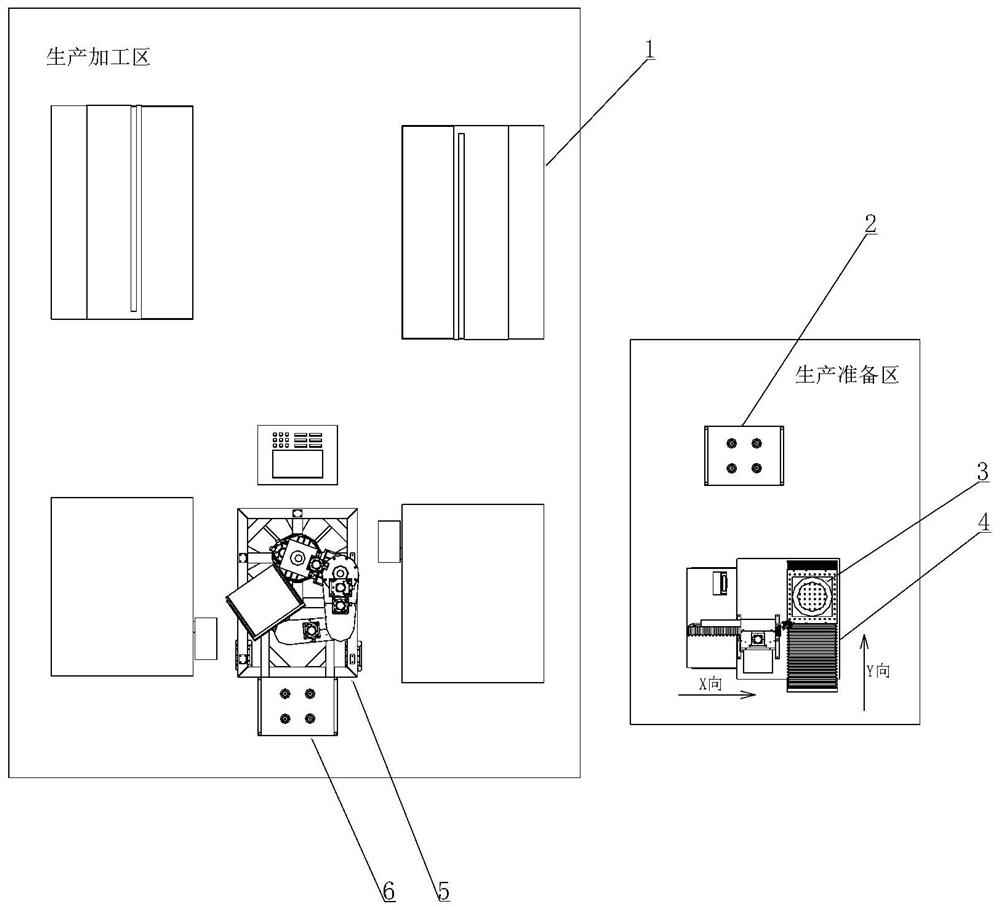

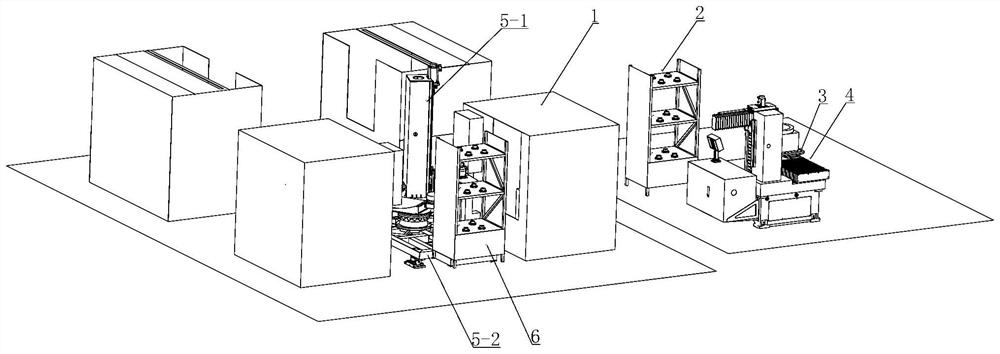

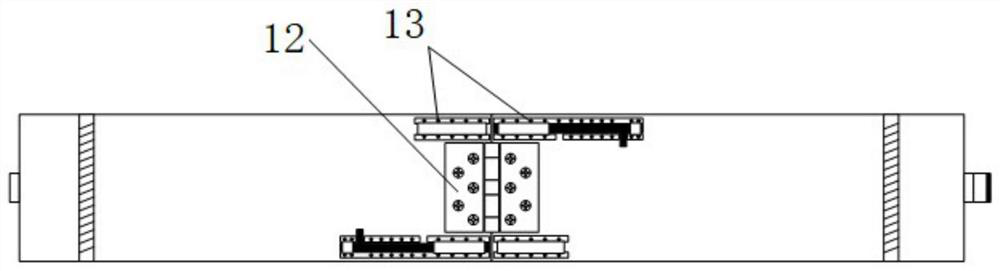

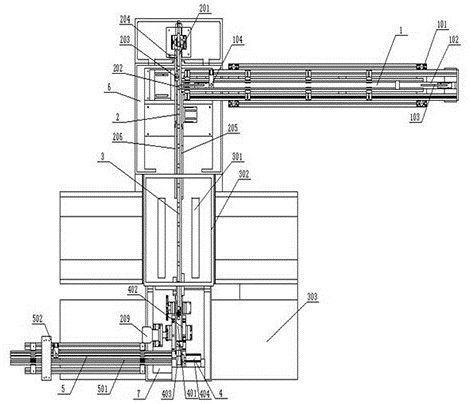

A flexible manufacturing unit for multi-variety and small-batch box parts

ActiveCN110842623BIncrease productivityEasy to carryPositioning apparatusMetal working apparatusControl systemElectrical control

The invention relates to a flexible manufacturing unit for multi-variety and small-batch box parts, which comprises a zero point positioning module, an external alignment module, a loading and unloading robot module, a workpiece storage module, a numerical control processing equipment module and an electrical control module; The alignment module outside the machine is set in the production preparation area, including the measurement alignment unit, workpiece clamping unit and supporting PLC control unit; the loading and unloading robot module is set in the production processing area, including industrial handling robots and mobile robot platforms; workpiece storage The module is composed of a fixed silo and a mobile silo. The fixed silo is set next to the alignment module outside the machine in the production preparation area; the mobile silo is fixed on the movable robot platform; the CNC processing equipment module is set in the production The processing area includes CNC machining center equipment and safety door control system; the zero point positioning module is a dynamic combination module that is transferred synchronously with the workpiece production; the electrical control module is connected with the PLC of other modules. The invention satisfies the need for multi-variety and small-batch box-like parts and improves production efficiency.

Owner:TIANJIN NAVIGATION INSTR RES INST

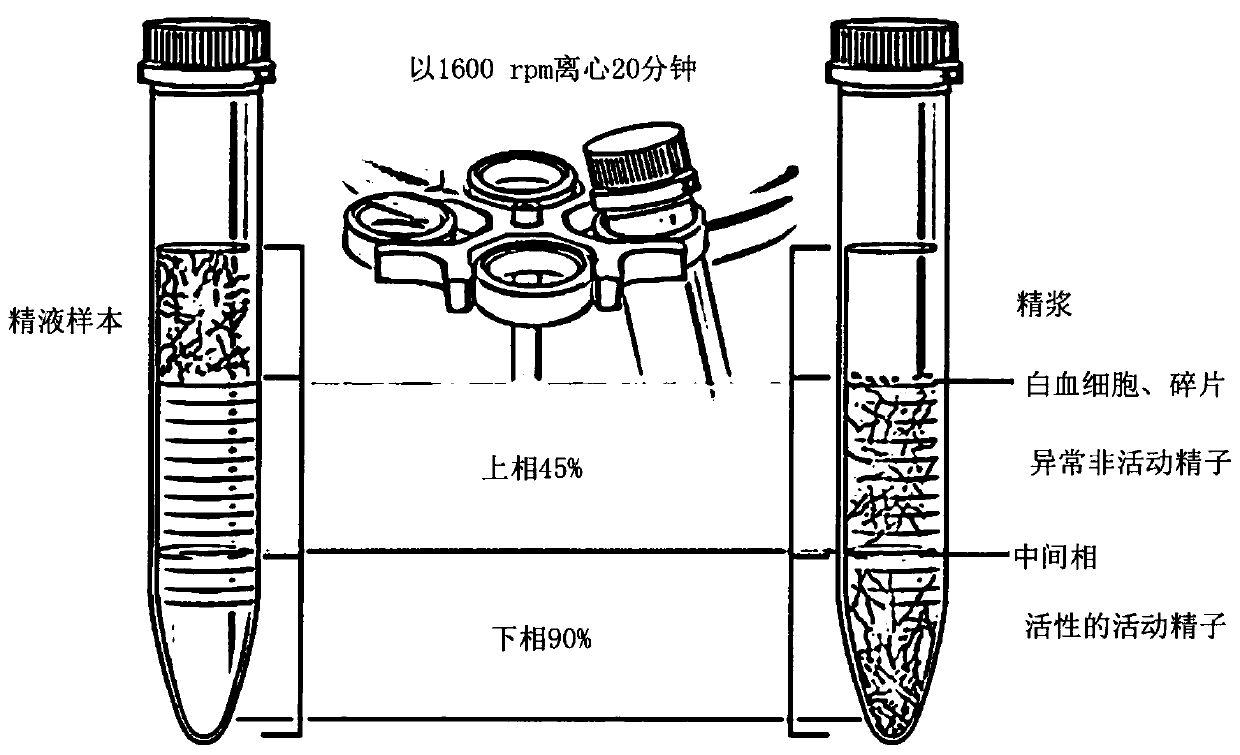

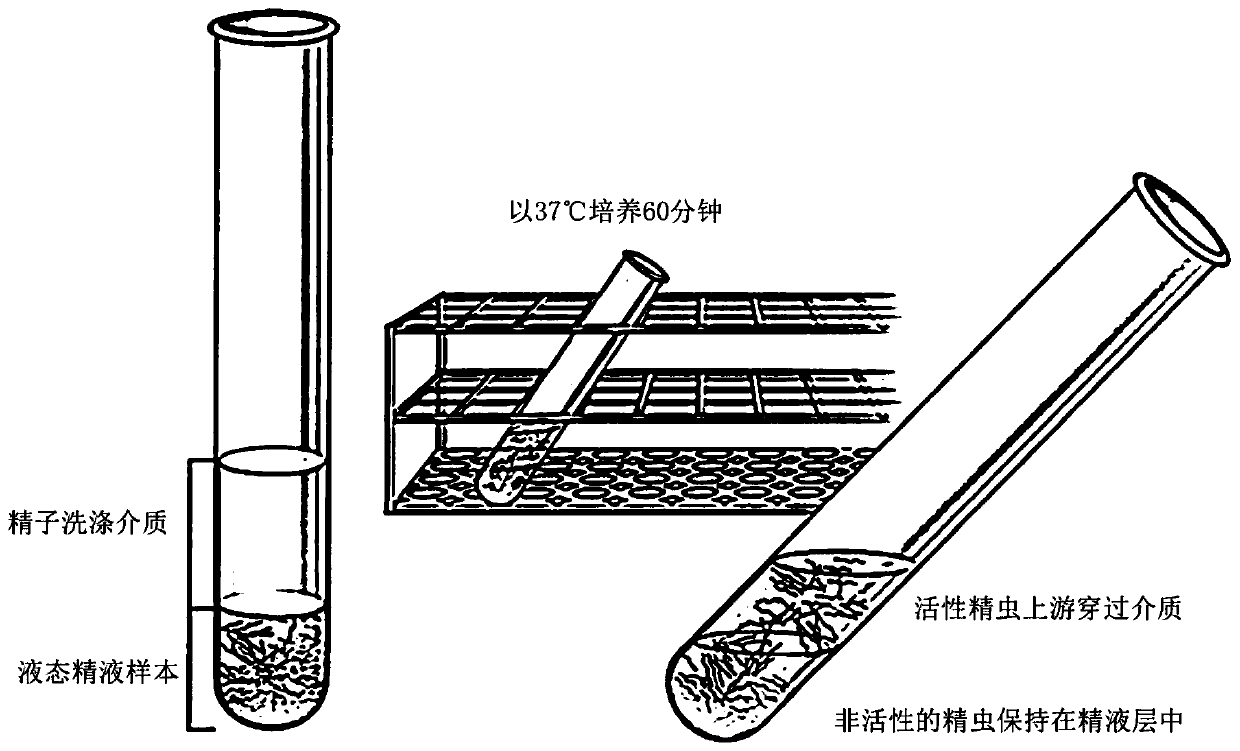

Method and system for processing biological sample

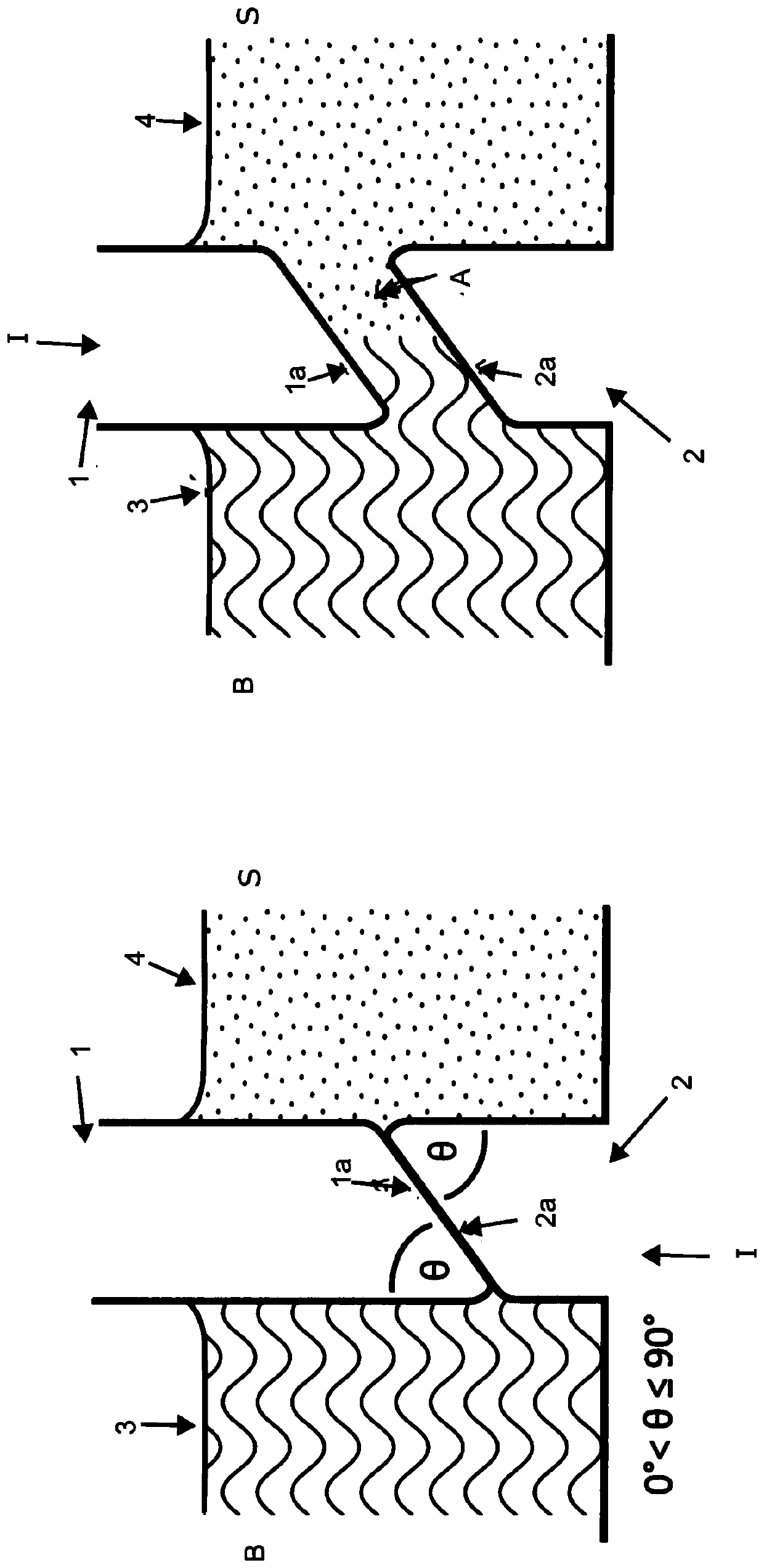

PendingCN110475848AIncreased ability to concentrate motile spermShort swim distanceBioreactor/fermenter combinationsAnimal reproductionBuffer solutionComputer science

The present invention is directed to the processing of a biological sample into its constituent components for use in ART and includes introducing a sample into a first volume disposed adjacent a second volume comprising buffer solution; wherein the first and second volumes are adapted for fluid communication therebetween; selectively separating the first volume from the second volume with a movable closure member disposed therebetween; wherein the step of selectively separating the first volume from the second volume comprises moving the closure member so that a fluid communication aperture is formed by one or a combination of the closure member or the closure member in combination with the first and second volumes to allow fluid communication between the first volume and the second volume such that motile cells migrate from the sample in the first volume to the buffer solution in the second volume.

Owner:GENEA IP HLDG PTY LTD

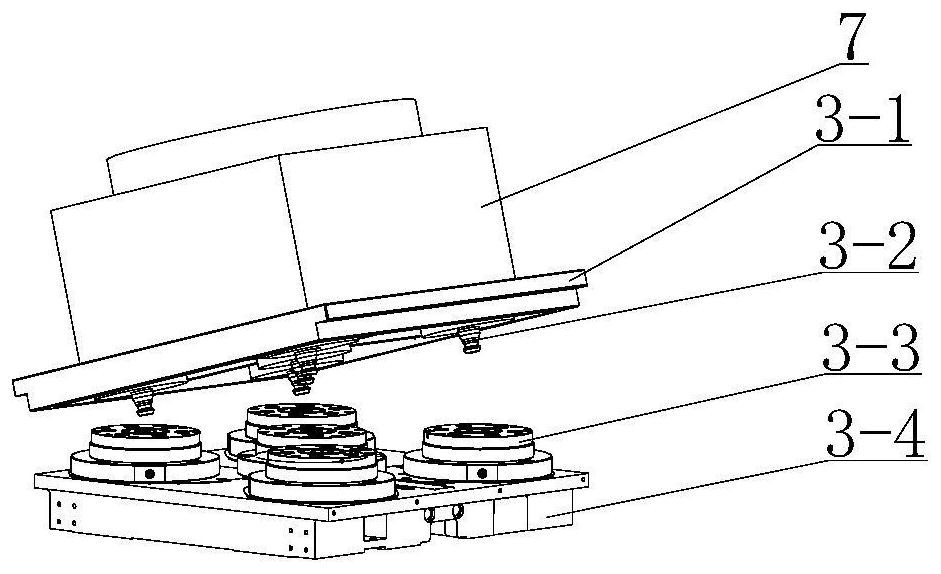

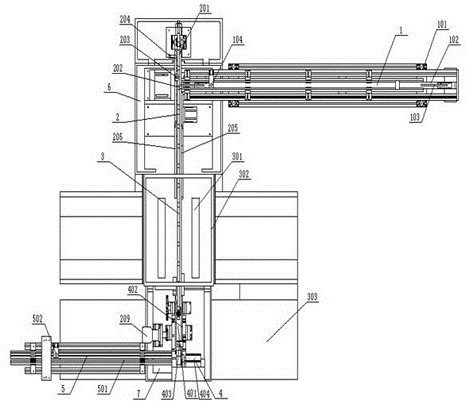

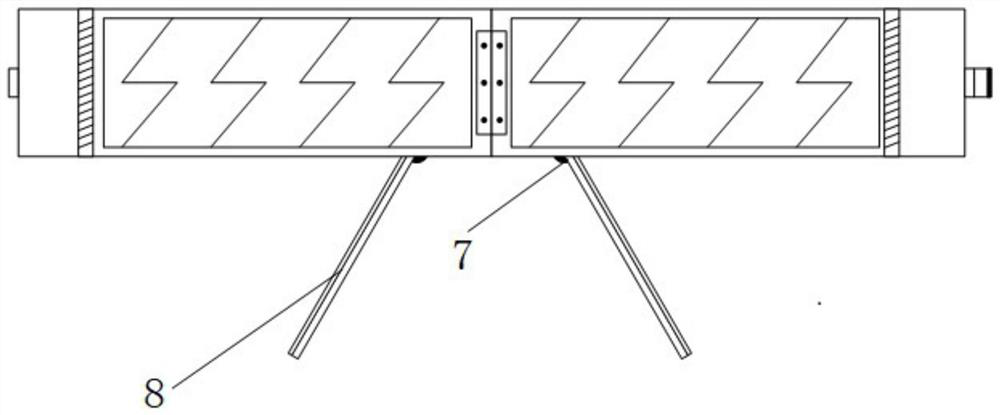

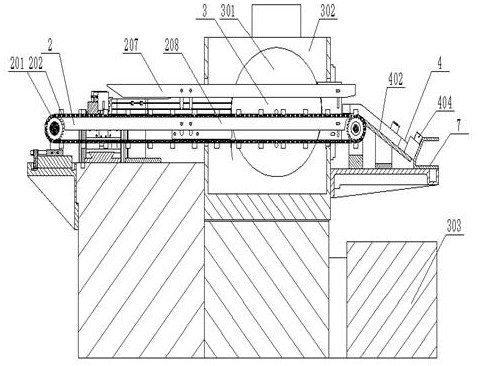

A high-efficiency slider special grinding machine and grinding method

ActiveCN108081047BRealize intelligenceAchieve modularityGrinding feedersPlane surface grinding machinesHydraulic motorEconomic benefits

The invention discloses a special grinding machine for high-efficiency sliders and a grinding method. The special grinding machine for high-efficiency sliders includes a rodless cylinder-driven feeding system, a feeding system, a grinding system, a pushing system and a feeding system; A high-efficiency grinding method for a slider includes the steps of loading, feeding, processing, pushing and unloading. The special grinding machine for the slider of the present invention adopts automation technology, and the loading, grinding, and unloading are all automatically completed. Compared with the traditional processing method, the efficiency is increased by 10-12 times; the grinding system adopts high-strength grinding wheels and a brand-new hydraulic motor chain. Grinding is completed in a free state by the type driving mode, and the rough and fine grinding is completed at one time. At the same time, the surface roughness of the finished product is higher, the precision is higher, and the yield rate is higher. The double improvement of efficiency and quality is really realized. The processing efficiency is improved, the number of machines is reduced, and the one-time investment is saved, so the economic benefits are greatly improved.

Owner:日照金泰机械制造有限公司

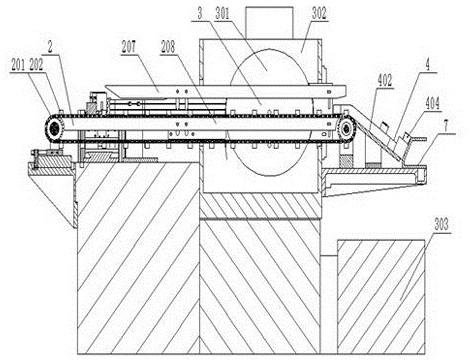

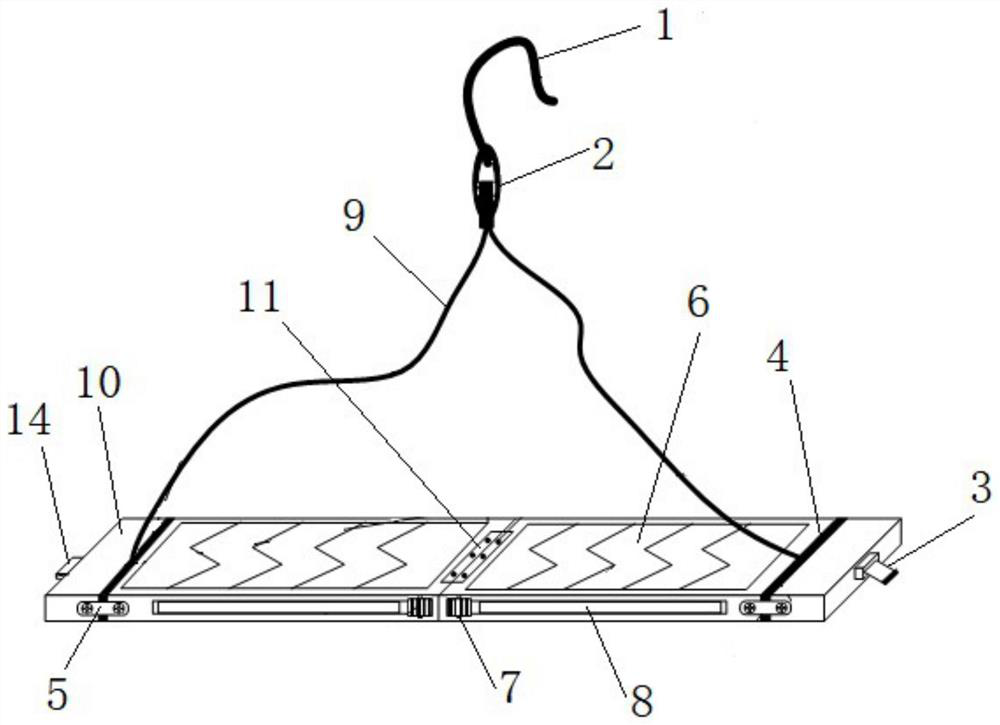

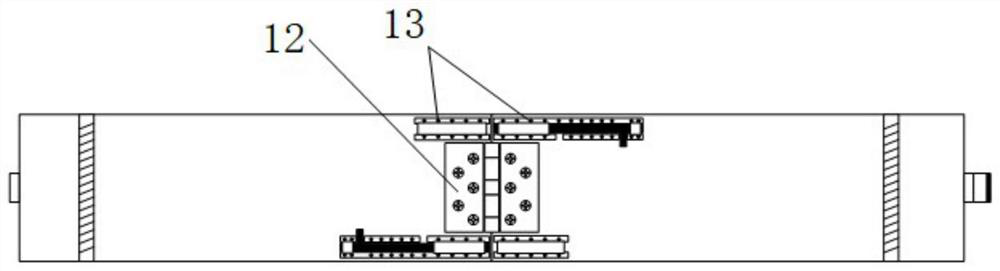

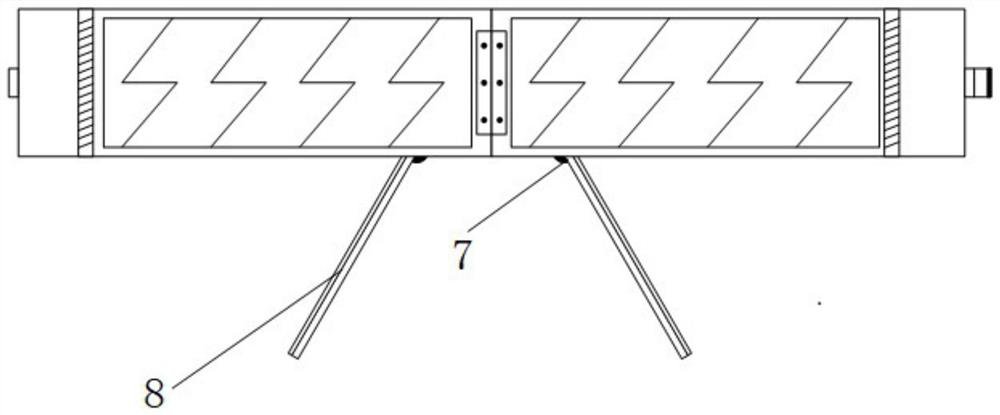

A portable foldable anti-swing climbing board

ActiveCN113694486BPrevent shaking from side to sideExpand the scope of workClimbingClassical mechanicsControl theory

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

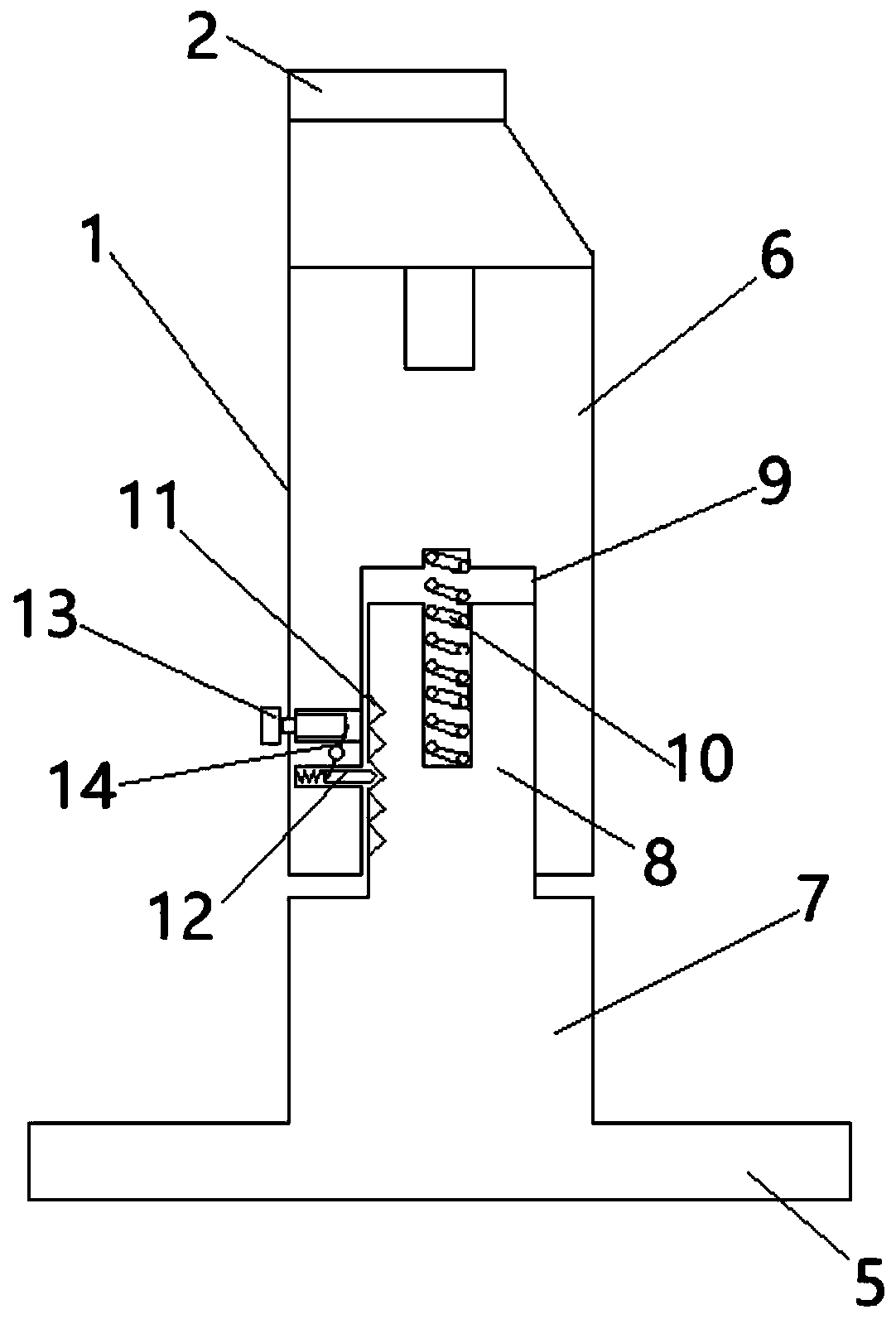

Device and method for mounting D bolt in blind cavity of rotating part

ActiveCN111360762AThe problem of preventing falling and turningSolve technical problems of damageMetal-working hand toolsStructural engineeringMinimal contact

The invention discloses a device and method for mounting a D bolt in the blind cavity of a rotating part. The device comprises a support adjustment column, wherein a rectangular through groove is formed in the upper end of the support adjustment column; the width of the rectangular through groove is greater than the length of the straight side of a D bolt; the height between the bottom of the rectangular through groove of the support adjustment column and the bottom of the support adjustment column is not less than the distance between the end face of the head of the D bolt and a rotator bodydisc web when the head of the D bolt is in contact with the minimum contact surface of a motion-stopping surface; and the length between the bottom of the rectangular through groove of the support adjustment column and the bottom of the support adjustment column is less than the distance between the mounting fastening back end face of the D bolt and the rotator disc web. The D bolt is positioned and supported by the support adjustment column with the rectangular adjustment column at the upper end, so that the problems of falling and rotating of the D bolt during mounting and disassembly are solved; the technical problem of damage to the motion-stopping side of a rotator is solved; no particular person is required to support the D bolt; the labor cost is lowered; and the skill level of operating personnel is lowered. The device has the advantages of simple and lightweight structure, reliable positioning, and high economical efficiency.

Owner:AECC AVIATION POWER CO LTD

Acoustic dampener

ActiveUS9249584B2Reduce transmissionLower component costsSound proofingFlooring insulationsEngineeringShock absorber

An acoustic dampener (100) comprising a base member (101) having a first surface (102) and a second surface (103), the first surface (102) and the second surface (103) are spaced apart from each other defining a thickness (104) therebetween. The acoustic dampener (100) further comprising a pair of side arms (105), each having a first end (109) and a second end (110). Each side arm (105) is attached to the base member (101) at its first end (109) at a predetermined angle. The side arm (105) extends from the base member (101) to form a channel formation (119) to receive a batten. A flange (106) extends substantially orthogonally from the second end (110) of each side arm (105) for retaining a batten within the channel formation (119).

Owner:JAMES HARDIE TECH LTD

Method and apparatus for measuring blood pressure

ActiveUS10159445B2Low skill levelSuitable for useEvaluation of blood vesselsSensorsPeripheral pulsesEngineering

Embodiments of the present invention provide an improved transformation method whereby the peripheral pulse waveform is filtered to separate different phases which make up the waveform. The separate phases are transformed before being re-combined to provide an estimated intra-arterial transfer function. For example, in one embodiment the peripheral pulse waveform is filtered by a first high pass filter, and a copy of the peripheral pulse waveform filtered by a second high pass filter, having a different cut-off frequency. The two filtered waveforms may then be further processed, for example by being added back to original wave-form, and are then multiplexed together in a time division manner to provide a final waveform. For example, the part of the first filtered waveform corresponding to the systolic phase may be combined with the part of the second filtered waveform corresponding to the diastolic phase to produce the final waveform, and the respective filter cut-off frequencies may be chosen to extract characteristics of the respective phases of the heart.

Owner:SUNTECH MEDICAL

Efficient grinding machine special for sliding blocks

ActiveCN112338670ARealize intelligenceAchieve modularityGrinding feedersPlane surface grinding machinesMachineGrinding wheel

The invention discloses an efficient grinding machine special for sliding blocks. The efficient grinding machine special for the sliding blocks comprises a rodless air cylinder driving feeding system,a feeding system, a grinding system, a pushing system and a discharging system. The efficient grinding method for the sliding blocks comprises the steps of feeding, conveying, machining, pushing anddischarging. According to the grinding machine special for the sliding blocks, the automation technology is adopted, feeding, grinding and discharging are all completed automatically, and compared with a traditional machining mode, the efficiency is improved by 10-12 times; the grinding system adopts a high-strength grinding wheel, grinding and rough and fine grinding are completed at a time in afree state in a brand-new hydraulic motor chain type driving mode, meanwhile, the surface roughness of a finished product is higher, the precision is higher, the yield is higher, the efficiency and quality are truly improved, meanwhile, due to the fact that the machining efficiency is greatly improved, the number of machines is reduced, the one-time investment is saved, and the economic benefit isgreatly improved.

Owner:青岛祥银传动设备有限公司

Portable foldable anti-swing climbing plate

ActiveCN113694486APrevent shaking from side to sideExpand the scope of workClimbingStructural engineeringControl theory

The invention relates to the technical field of climbing tools, in particular to a portable foldable anti-swing climbing plate which comprises a hook, a lifting rope, an anti-swing support and two pedals. The first ends of the two pedals are pivoted through a hinge; the two ends of the lifting rope are connected with the second ends of the two pedals correspondingly; the hook is arranged in the middle of the lifting rope; grooves matched with the anti-swing supports are formed in the side faces of the two pedals; the anti-swing support is retracted into the pedals through the groove; and the anti-swing support is rotationally connected with the pedals. The two pedals can be unfolded to be in a horizontal state through rotation, the pedals are hung at a high position through the hooks, the anti-swing support is stretched to make the anti-swing support make contact with and abut against an electric pole or other equipment in the environment, the effect of fixing the pedals is achieved, and the phenomenon that the pedals shake left and right is prevented advantageously; the technical problem that an operation acting point is not horizontal due to the fact that climbing is conducted only through climbers at present is solved; and meanwhile, carrying is convenient, and the requirement for the pole climbing skill level of workers can be lowered.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

A method for digitally assembling and manufacturing tailor-welded pipelines

ActiveCN113334047BFast and accurate boundary feature measurementLow skill levelMetal working apparatusManufacturing computing systemsData modelingControl engineering

The present invention disclosed a digital assembly manufacturing method of welding pipelines. The basic data of digital sampling is obtained through laser tracking measuring, the modeling completes the solution of the virtual boundary conditions of the pipeline, and the manufacturing of parts is completed according to the model data.Compared with the existing technology, the positive effect of the present invention is: the present invention uses the laser tracking meter measurement system for data measurement, the measurement accuracy is high, the real -time fast, the operation is simple, and the pipeline boundary feature measurement can be performed quickly and accurately; the invention is replicated by the present invention.The pipeline assembly space to the parts of the parts, the operating environment is single and the space is large, which avoids the risk of damage instruments; eliminates the time when the spacecraft's assembly needs to be waited for the manufacturing of the welding pipeline;The data of the space location is produced and manufactured. The data supports excessive dependence on artificial experience and improves the quality and assembly accuracy of pipeline production.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com