Self aligning three dimensional support structure for a roof constructed with prefabricated components

a three-dimensional support structure and prefabricated technology, applied in the field of self-aligning three-dimensional support structures for roofs, can solve the problems of labor intensive, high labor intensity, waste of materials, etc., and achieve the effects of low assembly skill level, low labor intensity, and affordable shipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

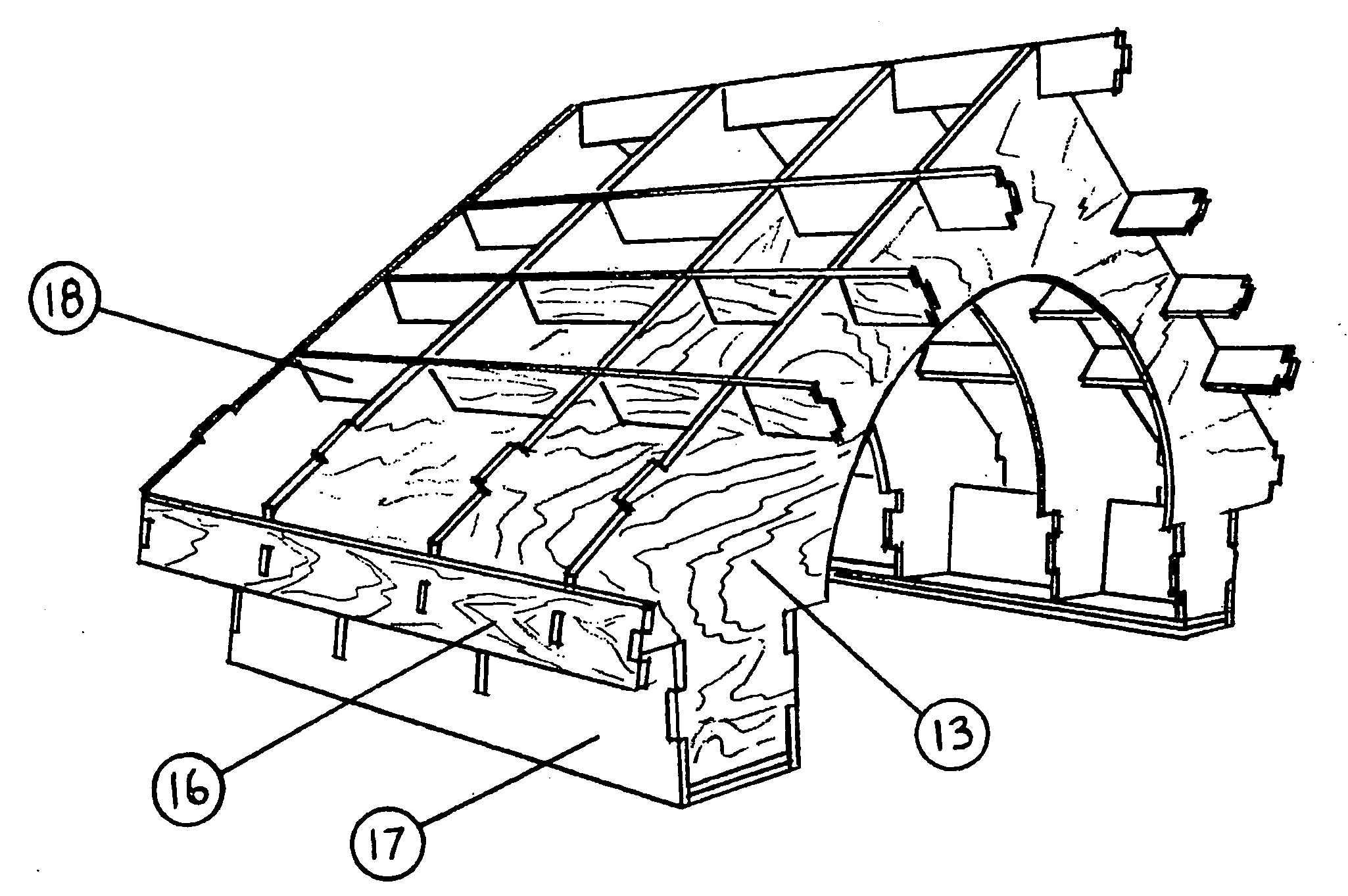

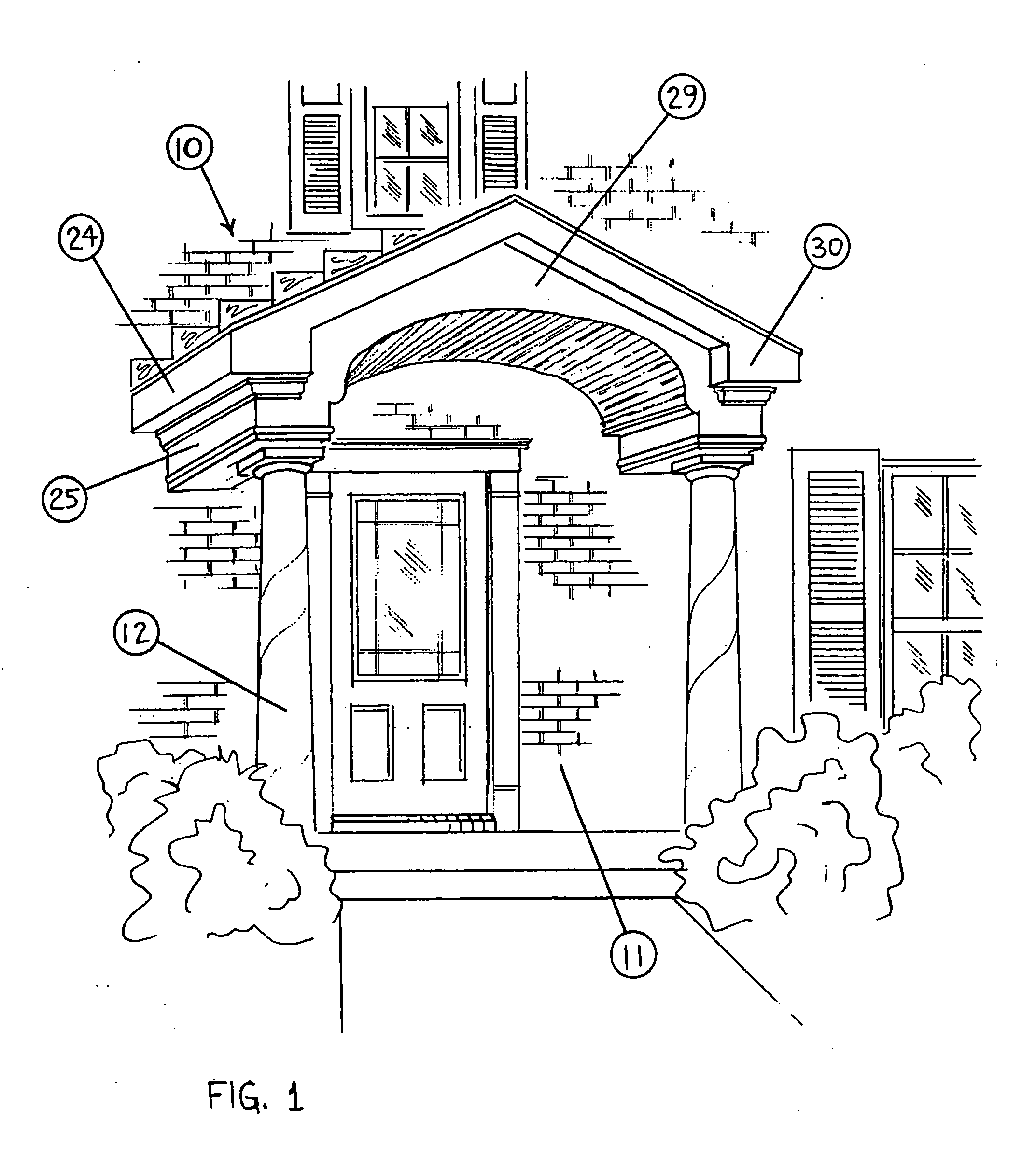

[0017]A completed embodiment of a porch roof structure manufactured with tab and slot self aligning three dimensional construction in accordance with the teachings of this present invention is illustrated in FIG. 1. In this example a porch roof structure 10 is illustrated at the front entrance of a building 11 and is supported with columns 12. While a porch roof is here illustrated, the principals of the present invention are equally applicable to the construction of a dormer.

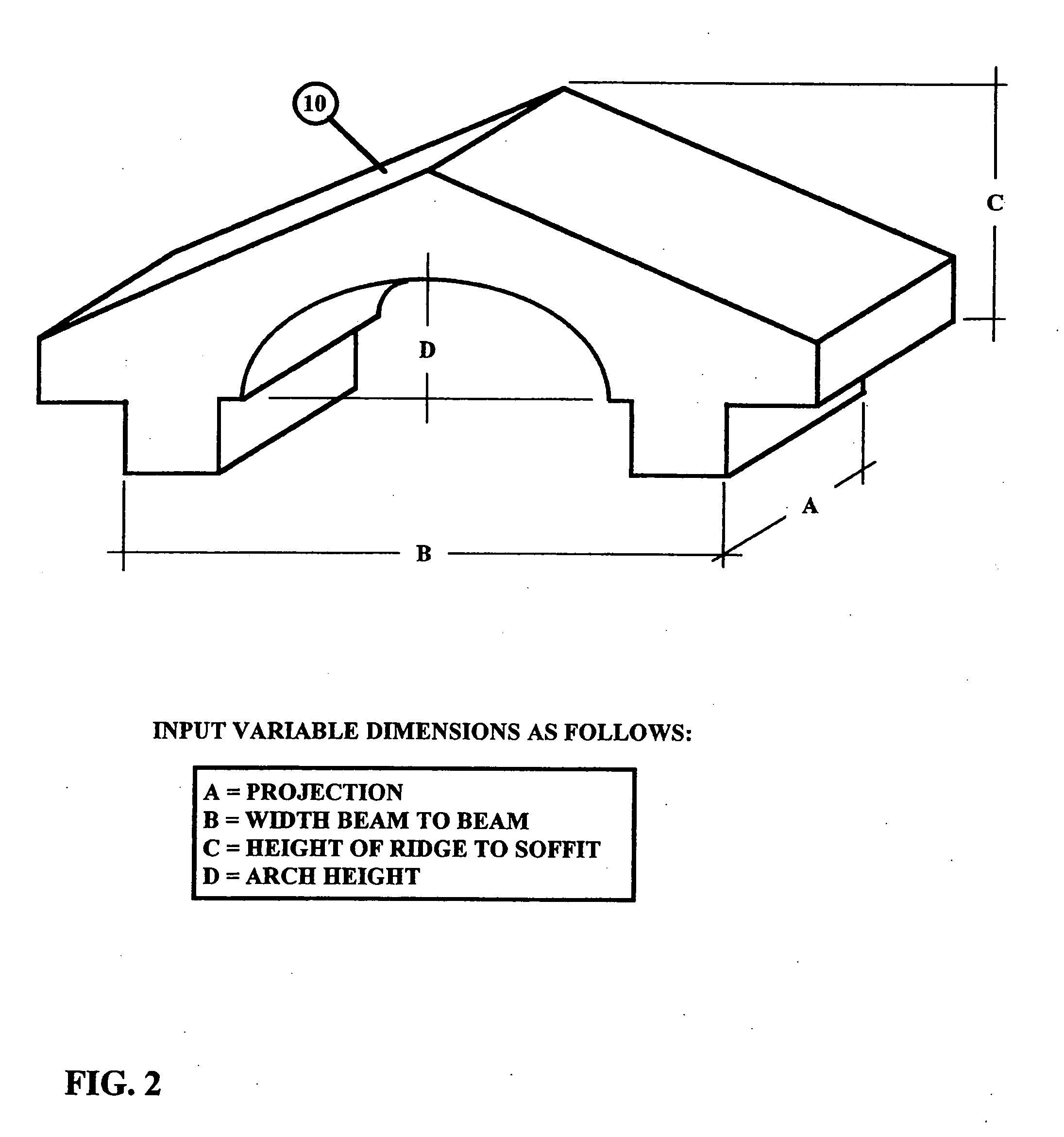

[0018]The porch roof structure 10 is constructed fully of sheet goods, such as plywood, for the subassembly and weather impervious PVC sheet goods for the exposed trim, by the utilization of a CNC router machine and the use of computer spread sheets for the variables. As is illustrated in FIG. 2, the only variables which need to be inserted into the CNC machine are the dimension A for projection, the dimension B for width between beams and the dimension C for height from ridge to soffit. If an arch is also inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com