Patents

Literature

947 results about "Metatitanic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanic acid is a general name for a family of chemical compounds of the elements titanium, hydrogen, and oxygen, with the general formula [TiO x ... Some older literature including Brauer's Handbook refers to TiO 2 as titanic acid. Metatitanic acid (H 2 TiO 3), Orthotitanic acid (H 4 TiO 4).

Method for recycling titanium dioxide in waste SCR (Selective Catalytic Reduction) denitration catalyst

ActiveCN103130265AQuality assuranceAvoid overdoseTitanium dioxideChemical recyclingSolubilityPhosphorous acid

The invention relates to a method for recycling titanium dioxide in a waste SCR (Selective Catalytic Reduction) denitration catalyst. The method comprises the following steps of: firstly removing dust from the waste denitration catalyst, pulverizing, then adding concentrated sulfuric acid so as to carry out acid hydrolysis on the waste denitration catalyst to obtain a concentrated titanyl sulfate solution, and adding water for dilution; adding a non-ionic emulsifier serving as a flocculating agent and a sulfonate surface active agent or a polycarboxylate surface active agent as a coagulant aid, and adding water-solubility methyl silicone oil; pumping into a plate-and-frame filter press for filter pressing, carrying out vacuum concentration on filtrate, then heating to 90 DEG C to 98 DEG C, and maintaining for 5.5 hours so as to hydrolyze the filtrate; cooling a hydrolysis product to 40 DEG C, and carrying out vacuum filtration so as to sediment out metatitanic acid; rinsing with sand-filtered water and deionized water, and adding potassium carbonate or phosphorous acid to obtain metatitanic acid filter cakes; and drying the filter cakes, calcining at 500-800 DEG C, and then pulverizing to obtain a titanium dioxide finished product. The method has the advantages of being capable of reducing disposal amount of the waste denitration catalyst, recycling the waste denitration catalyst and reducing the production cost of the waste denitration catalyst.

Owner:江苏万德环保科技有限公司

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

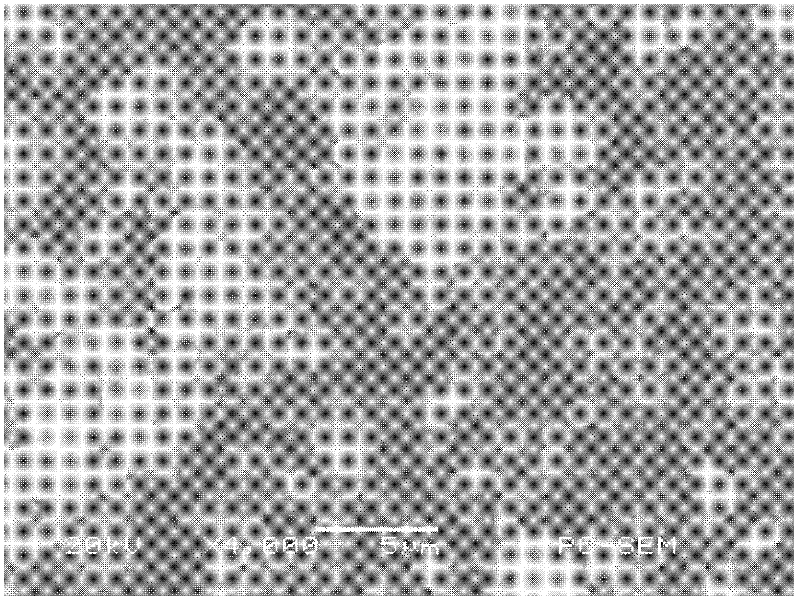

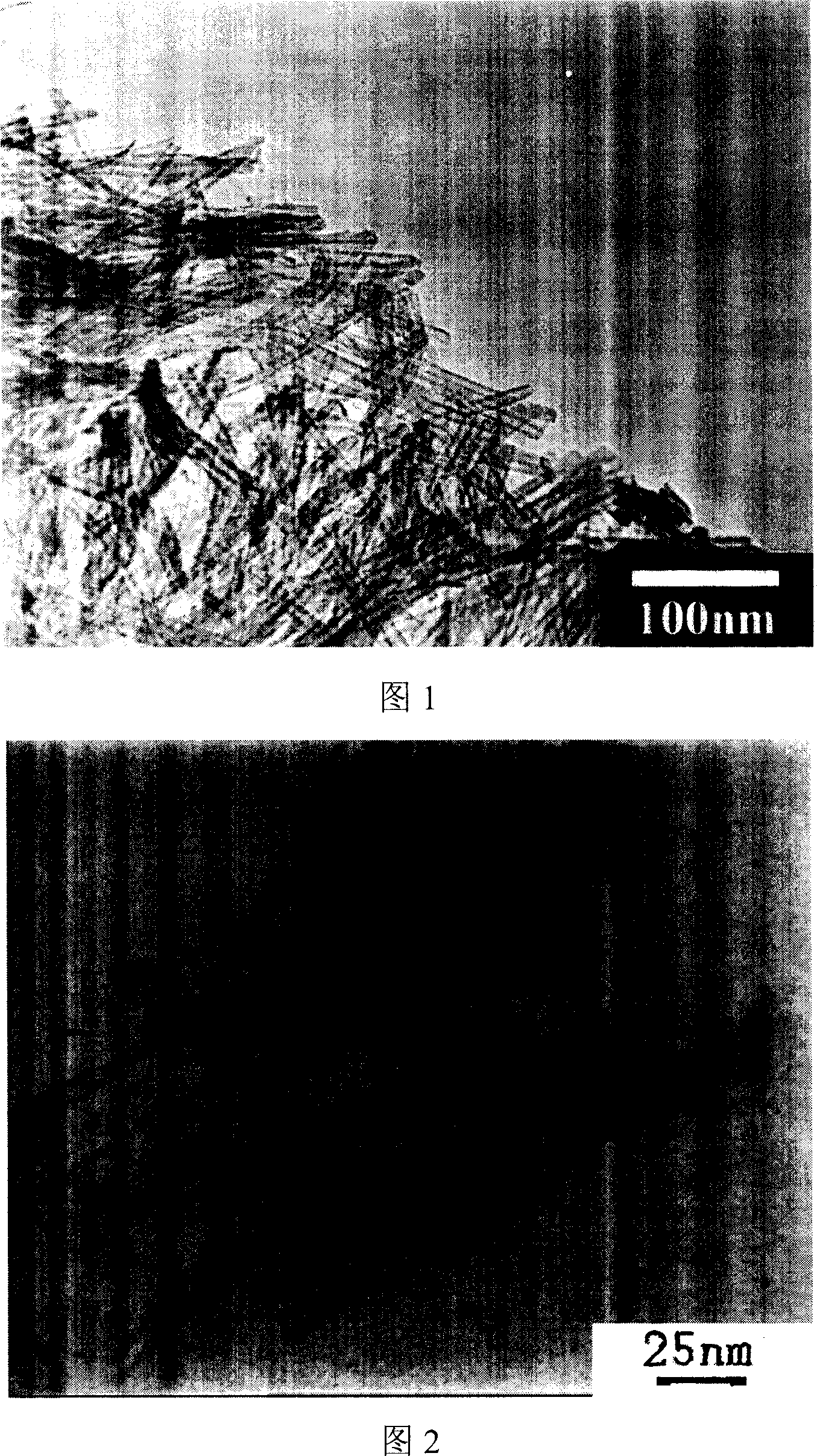

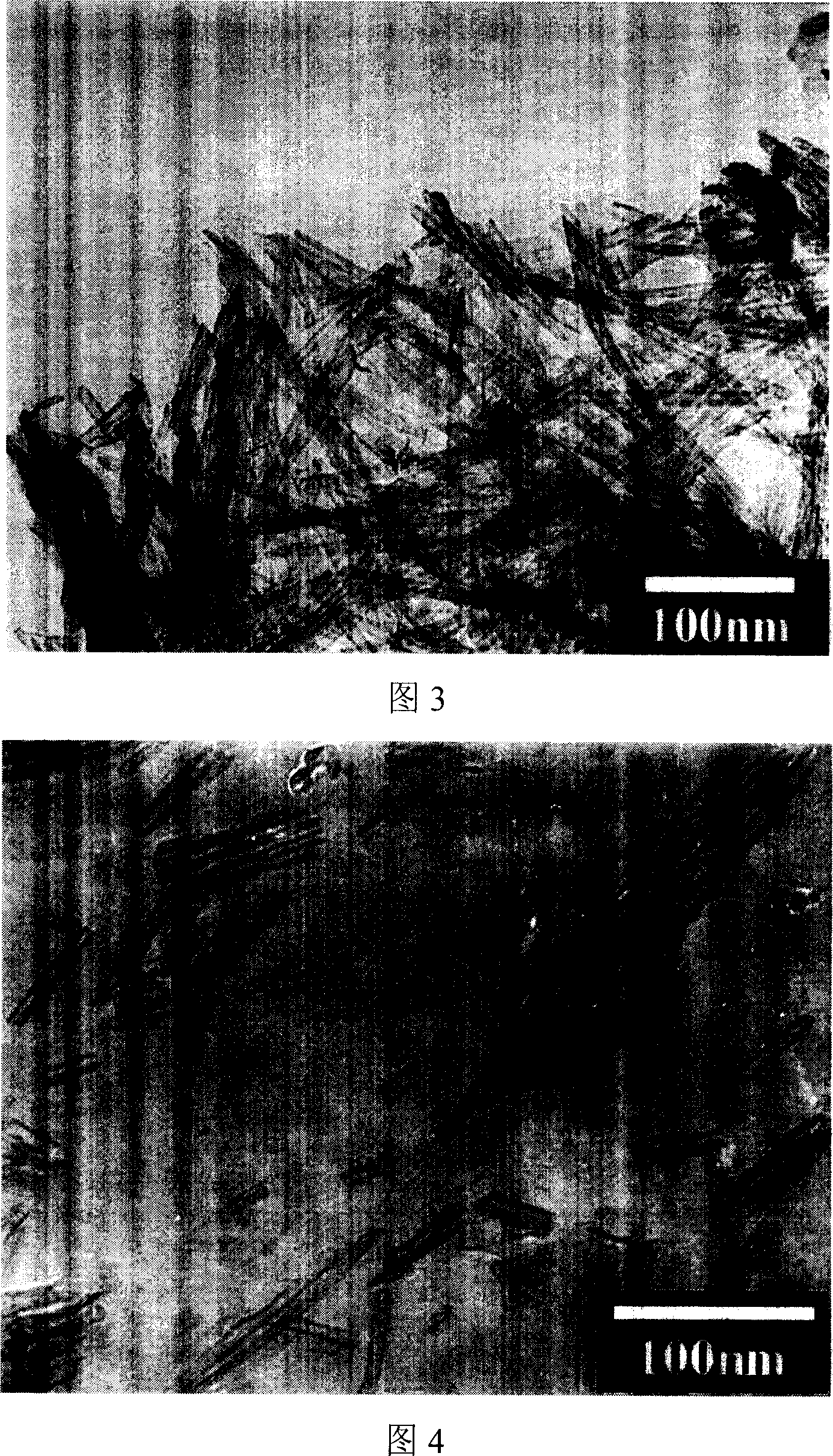

Process for preparing hydrated sodium titanate and nano titanate tube series

InactiveCN1378977AWith ion exchangeLarge specific surface areaTitanium compoundsSodium titanateThermal stability

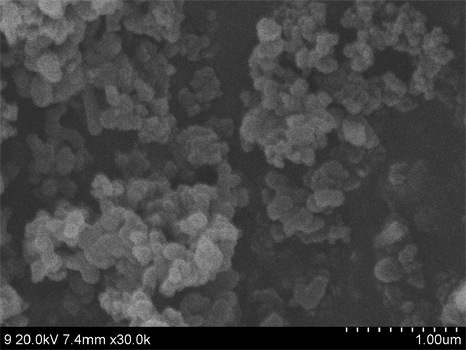

A process for preparing the nanometre tubes of hydrated sodium titanate and titanate series includes such steps as hydrothermal reaction of TiO2 or metatitanic acid to obtain the nanometre tubes of hydrated sodium titanate, mixing them with the solution containing one or two kinds of metal ions to convert them to the nanometre tubes of hydrated titanate or composite hydrated titanates of the saidmetal ions, and thermal dewatering to obtain the nanometre tubes of corresponding titanate or composite titanates. Its advantages are uniform shape, large specific surface area, high thermal stability and regulatable catalytic performance.

Owner:TSINGHUA UNIV

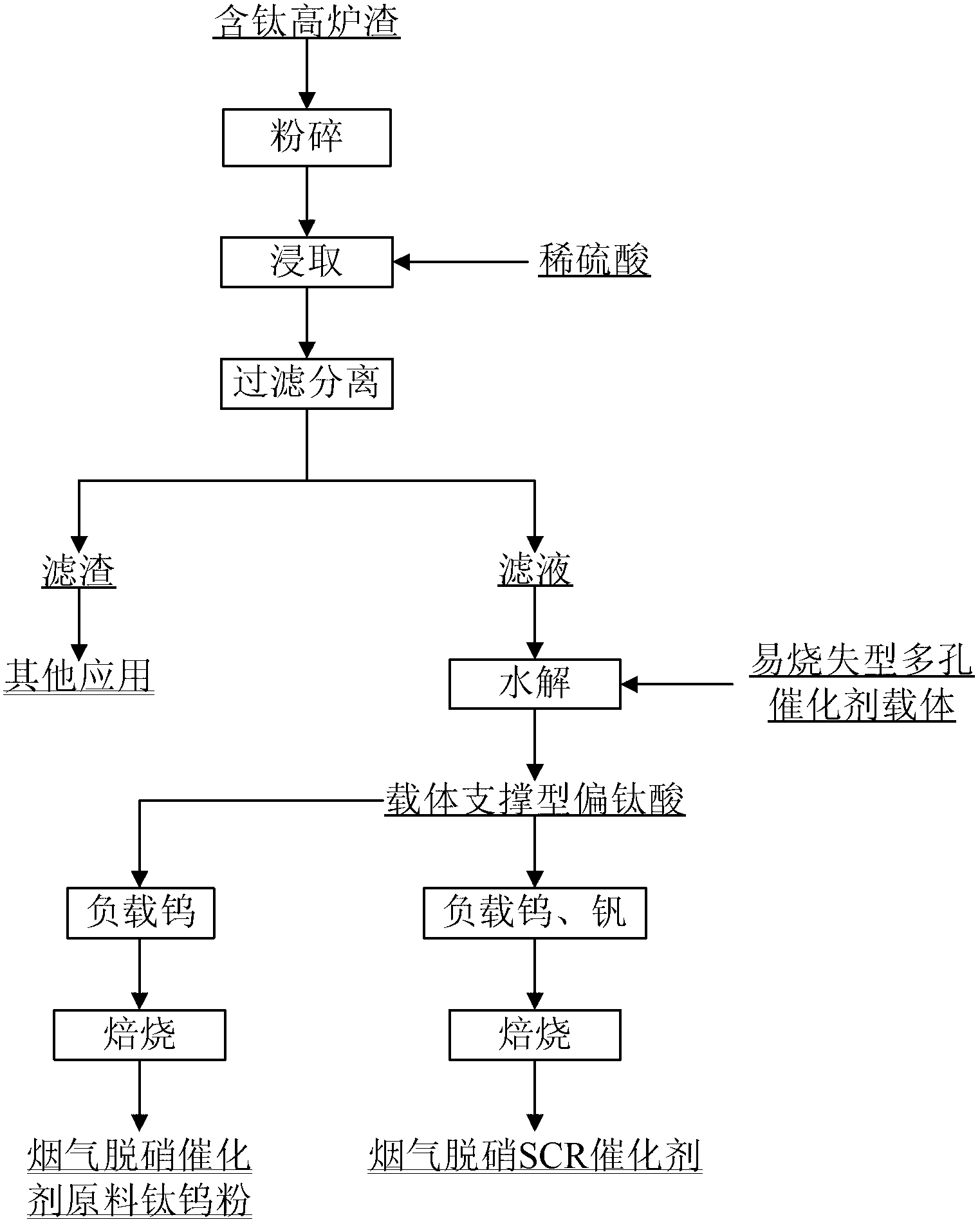

Method for preparing selective catalytic reduction SCR flue gas denitration catalyst and method for preparing raw material titanium-tungsten powder of SCR flue gas denitration catalyst

ActiveCN102698737AReduce manufacturing costAlleviate the pricey situationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPorous catalystSlag

The invention relates to a method for preparing a selective catalytic reduction SCR flue gas denitration catalyst and a method for preparing a raw material titanium-tungsten powder of the SCR flue gas denitration catalyst. The method for preparing the SCR flue gas denitration catalyst comprises the followings: smashing titanium-bearing blast furnace slag, leaching TiO2 in the smashed titanium-bearing blast furnace slag with dilute sulphuric acid, filtering and separating the mixture to obtain residues and titanium solution, adding a porous catalyst carrier which is easy to be burnt off into the titanium solution and hydrolyzing the mixture; filtering, washing and drying the hydrolyzed product to obtain a carrier supported metatitanic acid, and further loading tungsten and vanadium on the metatitanic acid, and baking the obtained product to obtain a vanadium-tungsten-titanium SCR denitration catalyst. The method not only effectively utilizes valuable elements in blast furnace slag, solves the problems that the titanium dioxide product is extracted, separated and purified difficultly from the blast furnace slag, and the quality of the product cannot meet the standard easily, and also greatly reduces the production cost of the vanadium-tungsten-titanium SCR denitration catalyst and has a broad application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing titanium dioxide product for high-specific surface area denitrating catalyst

InactiveCN101318697AImprove performanceWill not polluteCatalyst carriersDispersed particle separationFiltrationHigh surface

The invention relates to a method for preparing titania raw materials with high specific surface area used by denitration catalyst, which relates to the chemical product preparation technical field. The method comprises the following steps that: a metatitanic acid produced by adoption of the sulfuric acid method is processed by an organic surfactant and then modified so as to reduce the viscosity of the metatitanic acid; and loose titania products with high specific surface area and high surface chemical activity used by the denitration catalyst are prepared through filtration and calcination of the processed metatitanic acid. The method has a simple technique for processing the metatitanic acid and has low cost; and added organic substances are fully decomposed during the calcining stage, thereby impurities can not be brought into the final products and the environmental pollution can not be caused.

Owner:四川华铁钒钛科技股份有限公司

Rare-earth doped low-temperature denitration catalyst and preparation method thereof

ActiveCN103055848ALow running costLow retrofit costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthSlurry

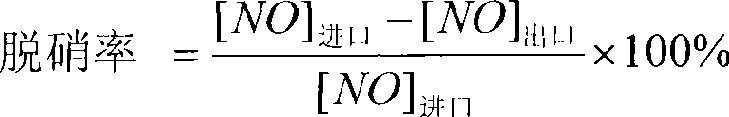

The present invention relates to a rare-earth doped low-temperature denitration catalyst and a preparation method thereof. The main active component of the catalyst is manganese oxide, the carrier is titanium oxide, and cerium oxide and iron oxide are used as cocatalysts. The preparation method includes the following steps: adding solutions of various metal nitrates into a metatitanic acid slurry, then adjusting the pH of the mixture to obtain complete precipitation by using concentrated ammonia, stirring for a while, and performing centrifugal filtration to the resulting suspension, and drying and calcining at a temperature to obtain the rare-earth doped low-temperature denitration catalyst; wherein the molar ratio of each element is as follows: Mn: Fe: Ce: Ti = 5: (0 ~ 2): 4:20. In the temperature range of 140-180 DEG C, the denitration activity of the metal oxide low temperature catalyst of the present invention can reach 80-98%, and the catalyst has a relatively excellent water and sulfur resistance performance.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

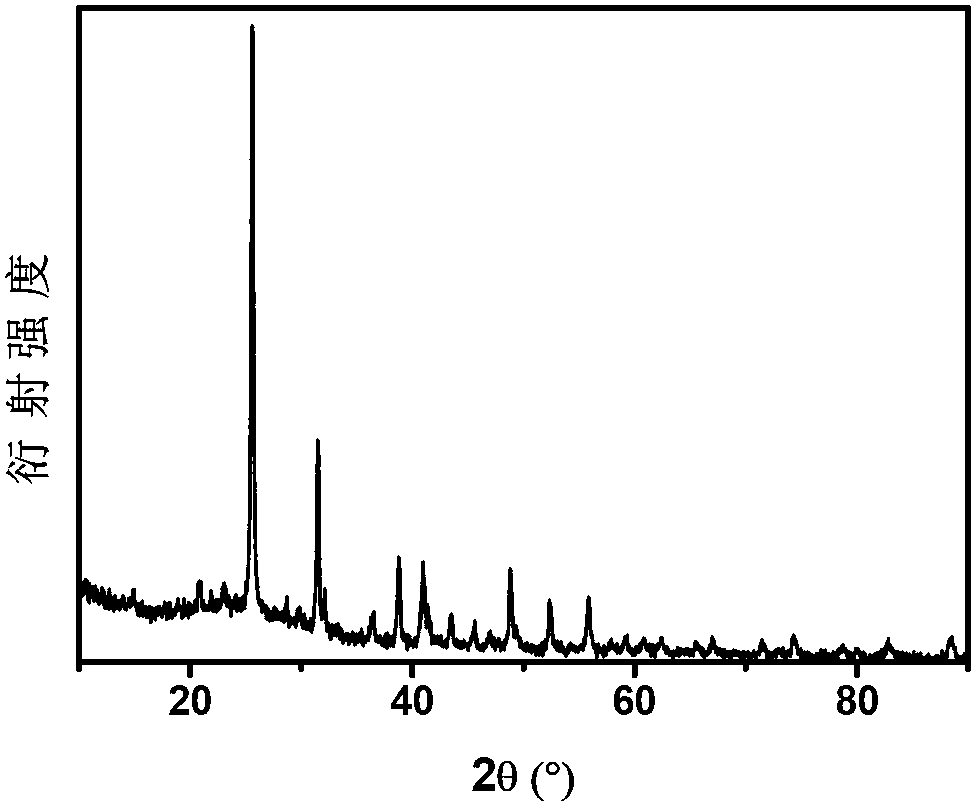

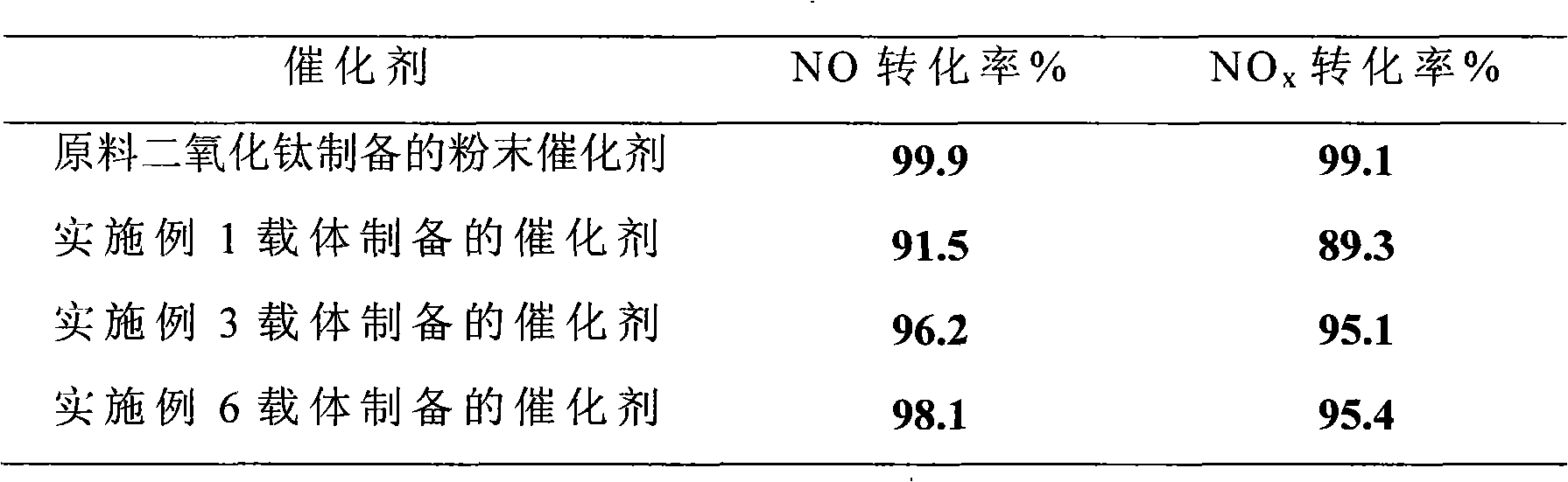

Method for preparing denitration catalyst

InactiveCN102357359AImprove conversion rateGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystTungstate

The invention discloses a preparation method of a denitration catalyst. The method comprises the following steps: (1) with an intermediate product of metatitanic acid from a titanium dioxide factory as a raw material, washing with dilute nitric acid, weak aqua ammonia, deionized water respectively to remove impurity ions so as to prepare metatitanic acid slurry; (2) orderly adding ammonium tungstate, ammonium molybdate and ammonium metavanadate into the metatitanic acid slurry, beating the mixture by ultrasonic wave, adjusting the pH of the slurry to 4.0-6.5 by an acid; (3) allowing the mixed slurry to stand, drying to obtain the catalyst powder; (4) compacting and molding the catalyst powder into honeycomb by a mold, performing heat treatment at 200-600 DEG C for 4-10 hours to obtain the denitration catalyst of the invention. The method for preparing the denitration catalyst of the invention has low cost and simple process, and the denitration catalyst can increase the conversion rate of NO. The denitration catalyst of the invention can realize a conversion rate of NO in power plant flue gas flue gas components of up to above 97% at a reaction temperature of 350 DEG C.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of titanium pigment used in ship paint

ActiveCN102226043AGood dispersionGood weather resistancePigment treatment with organosilicon compoundsSilicon oxideSlurry

The invention discloses a preparation method of titanium pigment used in ship paint. The method comprises the following steps that: a. metatitanic acid is calcined, such that a titanium pigment crude product is obtained, the titanium pigment crude product is prepared into TiO2 slurry, and sodium hexametaphosphate is added to the slurry; b. the slurry is heated, a silicon-containing compound is added to the slurry, and the slurry is homogenized; c. the pH value of the TiO2 slurry is regulated to 0.8 to 4; d. after the slurry is slaked, an organic dispersant is added to the slurry, an aluminum-containing compound is added to the slurry, and the mixture is homogenized; e. the pH value of the TiO2 slurry is regulated to 4 to 8; f. the TiO2 slurry is slaked; g. the TiO2 slurry is filtered, such that the resistivity of the filter cake is greater than or equal to 100 [omega]M; and the filter cake is dried and heat treated; h. an organic surface conditioning agent is added to the filter cake, and the filter cake is crushed, such that the finished product is obtained. According to the present invention, nano-sized silicon oxide sol and alumina sol are prepared sequentially. Through physical adsorption and chemical absorption, a compact coating layer is formed on the surface of the TiO2 particles. Then, the coating layer is firmly attached to the surface of the TiO2 particles through chemical deposition. With the coating layer, the product provided by the present invention possesses good dispersibility, weatherability and corrosion resistance. Meanwhile, according to the method provided by the present invention, the raw materials are easy to obtain, the processes are smooth and are easy to control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

Preparation method of diatomite ceramic particles or ceramic plates

InactiveCN102093033AIncrease contentImprove adsorption capacityClaywaresExpanded clay aggregateVegetable fibers

The invention relates to a preparation method of diatomite ceramic particles or diatomite ceramic plates. The preparation method of the diatomite ceramic particles comprises the following steps: grinding diatomite, adding cosolvent, mineral powder and vegetable fiber powder to mix evenly and grind; and adding water to mix, shaking to obtain diatomite ceramic particles, and roasting to obtain the finished diatomite ceramic particles. The preparation method of the ceramic plates comprises the following steps: using evenly mixed powder to perform dry pressing with a pressure forming machine, or using mud with the water content of 15-25wt% to perform extrusion forming; and roasting to obtain the diatomite ceramic plates. The formed and dried diatomite ceramic plates or diatomite ceramic particles are soaked in slurry prepared from anatase titanium dioxide nanometer powder or metatitanic acid powder and then dried and roasted to obtain diatomite ceramic particles or diatomite ceramic plates with photochemical activity. In the invention, the low temperature sintering method is adopted to prepare the diatomite diatomite ceramic plates and ceramic particles which have high diatomite content and good adsorption property and water resistance and can be combined with various functional components on the surface. The diatomite ceramic products in the invention are convenient to use and have simple production technology and cheap and easy available raw materials.

Owner:JILIN UNIV +1

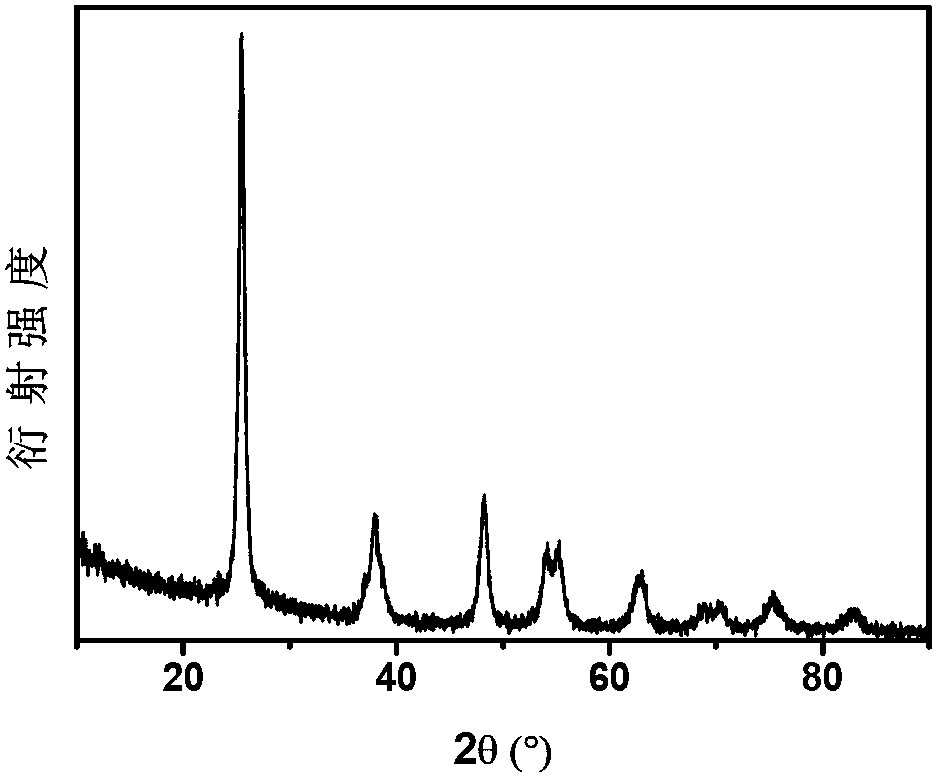

Preparation method for titanium dioxide group catalyst carrier

InactiveCN101513620AGood formabilityImprove catalytic performanceCatalyst carriersDispersed particle separationTitanium tetrachlorideMetatitanic acid

The invention provides a preparation method for a titanium dioxide group catalyst carrier with excellent moldability, high strength and high specific surface. The method comprises the following steps: using titanium dioxide or metatitanic acid prepared by hydrolyzation and neutralization of precipitate with titanium tetrachloride as the raw material; by weight portions, mixing and grinding 60-85% of titanium dioxide or dried metatitanic acid powder (counted as titanium dioxide), 1-10% of temporary adhesive and 1-5% of pore-forming material into uniform powder; adding 5-35% of constitutive adhesive, 0.5-2% of molding adhesion promoter, 1-10% of extrusion aid and water followed by evenly mixing and making into mud; extruding for molding after the mud decays; seasoning the extrudate at room temperature; baking and dehydrating at a temperature below 80 DEG C; and then iglossing at 400-600 DEG C to obtain the titanium dioxide group carrier. After molding, the specific surface of the carrier is 80-150m / g, and the pressive strength thereof is 15-100N / mm. The carrier is mainly used for selective catalytic reduction (SCR) to remove nitrogen oxide.

Owner:NANJING UNIV

Method for preparing supported nano TiO2 composite photocatalysis material by microwave

InactiveCN101485978AImprove abilitiesHigh activityMetal/metal-oxides/metal-hydroxide catalystsMicrowaveSulfate

The invention relates to a method for preparing a load type nanometer TiO2 composite photocatalysis material by microwave, and belongs to the technical field of nanometer functional materials. The solved technical problem is to seek a method for preparing the load type nanometer TiO2 composite photocatalysis material with easy preparation, low cost and high efficiency. In the method, pretreated nonmetallic minerals are used as a carrier, added in an organic solution dissolved with tetrabutyl titanate or titanyl sulfate or industrial metatitanic acid and subjected to microwave treatment and calcination to prepare the nanometer TiO2 composite photocatalysis material. The method has the advantages of simple process and low cost, and the nanometer TiO2 composite photocatalysis material prepared by the method has high photocatalysis efficiency; moreover, the method can also improve the practical capability of the photocatalyst in treating waste water and lay a solid foundation for gradual industrialized production of the photocatalysis materials.

Owner:XIHUA UNIV

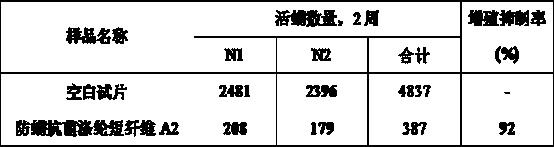

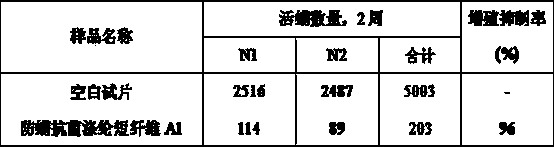

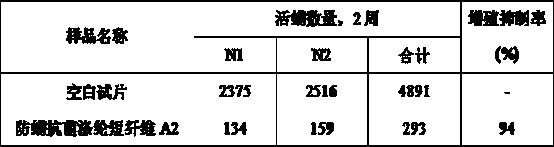

Anti-mite antibacterial polyester staple fiber and preparation method thereof

The invention relates to insoluble inorganic anti-mite antibacterial polyester staple fiber which is prepared from micron-scale heat accumulation anti-mite ceramic powder and silver-loaded nano titanium dioxide composite antibacterial powder through an esterification polymerization spinning mode or prepared by making the powder into masterbatch and mixing with polyether slices and spinning, wherein the micron-scale heat accumulation anti-mite ceramic powder is prepared from 2-6 parts of Tai Chi stone, 5-12 parts of boric acid, 8-30 parts of clayed soil and 3-8 parts of silicic acid by mass by grinding, tabletting, calcining and high-temperature compounding; the silver-loaded nano titanium dioxide composite antibacterial powder is prepared from 1-1.5 parts of silver nitrate and sodium chloride and 3-5 parts of metatitanic acid by mass by precipitation, suction filtration, washing, drying and calcining; the anti-mite antibacterial polyester staple fiber obtained by spinning has a relatively strong antibacterial effect on staphylococcus aureus and escherichia coli, wherein the antibacterial rate is greater than or equal to 95%, and the mite proliferation inhibition rate is greater than 92%.

Owner:SHANGHAI DEFULUN CHEM FIBER

Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

InactiveCN101396656ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateSlurry

The invention belongs to the chemical material field, in particular to an SO3 poisoning resisting power plant flue gas SCR denitrification catalyst and a preparation method thereof. Tungsten doped titanium pigment which is synthesized from domestic metatitanic acid slurry and ammonium paratungstate oxalic acid solution is adopted by the catalyst as a carrier. Vanadium is used as a main catalyst, and oxide of germanium or zinc is added as additive for lowering the oxidization of the vanadium on SO2. Through drying, calcining and sieving, the catalyst is obtained. The catalyst comprises 80-95wt percent of TiO2, 3-15wt percent of WO3, 1-8wt percent of V2O5 and 1-8wt percent of GeO2 or ZnO2. The preparation method has the advantages of simple preparation process, easy operation, low cost and good denitrification effect. The SCR catalyst prepared by the method is tested to prove high denitrification efficiency and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

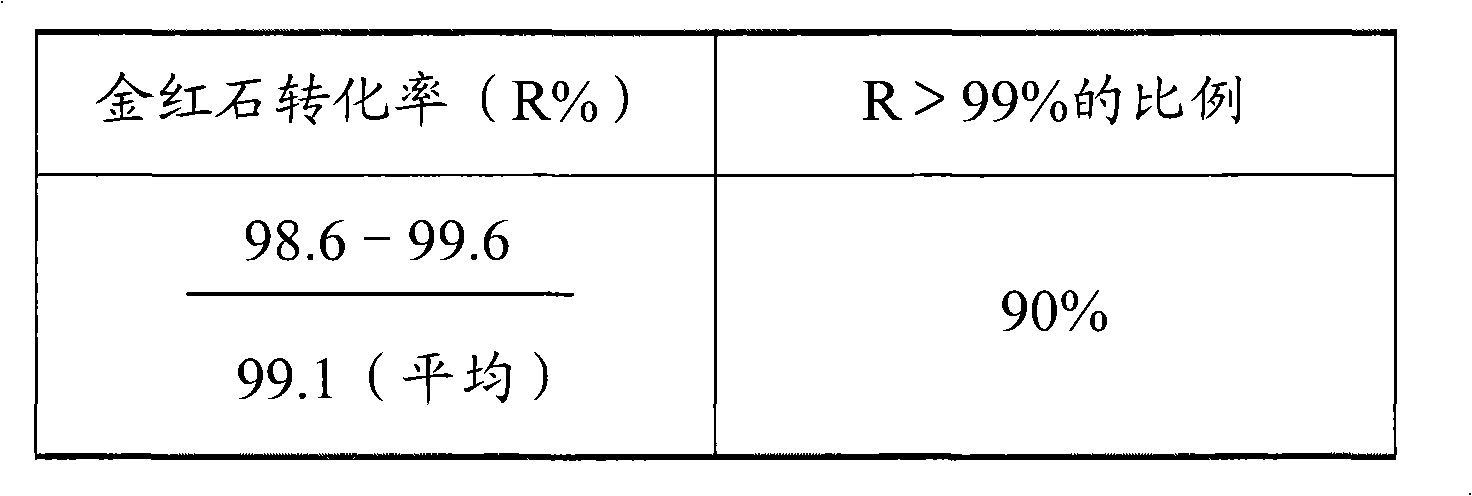

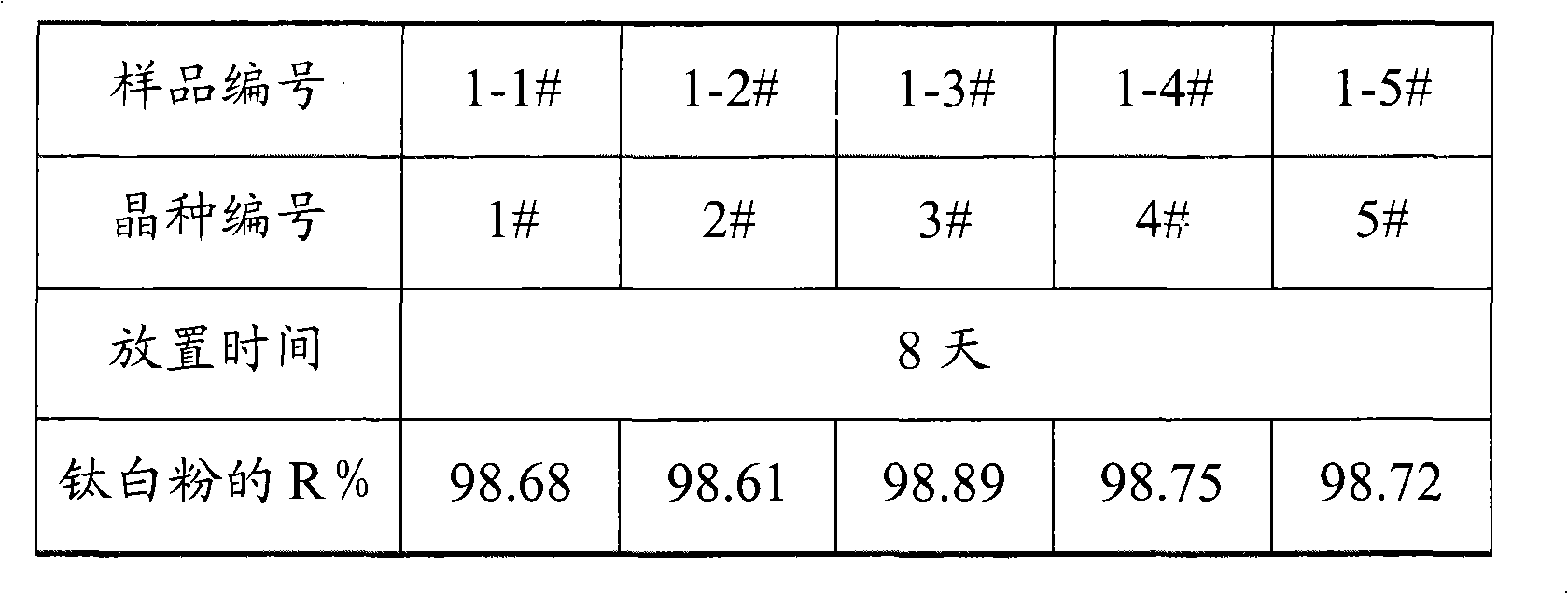

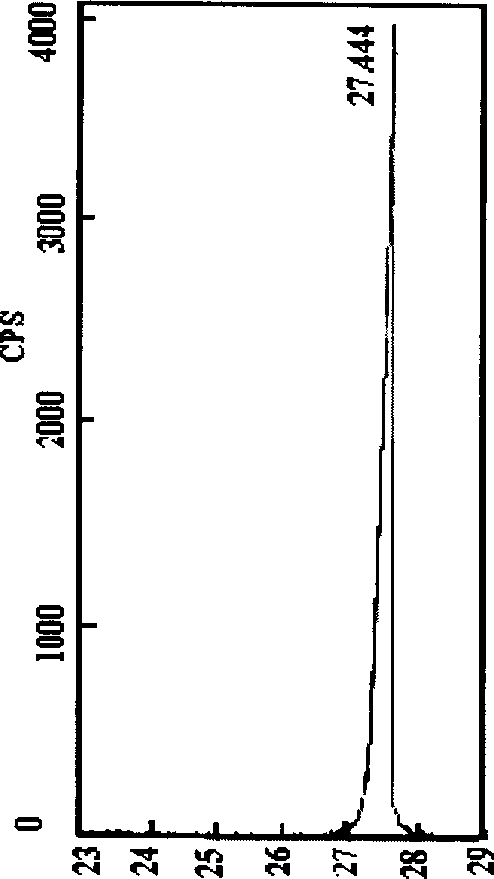

Preparation method of rutile type calcining seeds with high activity and high stability

The invention discloses a preparation method for a rutile type calcination crystal seed with high activity and high stability, which comprises the following steps: (1) metatitanic acid and alkali liquid are respectively preheated and according to the ratio of 1.3:1-1.65:1 of alkali and titanium, the metatitanic acid is added into the alkali liquid in 30 to 55min to prepare ortho-titanate; (2) the obtained titanate is cooled and then washed in water with the temperature of 40 to 55 DEG C and changed into ortho-titanic acid; (3) the ratio of titanium and acid is controlled between 0.35 and 0.55, and hydrochloric acid is added into the ortho-titanic acid in two times, then PH value, temperature raising speed are controlled and the curing is carried out so as to obtain the rutile type calcination crystal with high activity and high stability. The method of the invention has obvious effect on inducing the metatitanic acid to be transformed into the rutile type when calcination is carried out, and the rutile transformation ratio of crystal seed is more than 99 percent; the rutile transformation ratio (R) of the obtained titanium powder is more than or equal to 98.7 percent; after crystal seed is placed for 6 to 10 days, the rutile transformation ratio (R) of the obtained titanium powder is still more than or equal to 98.6 percent.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

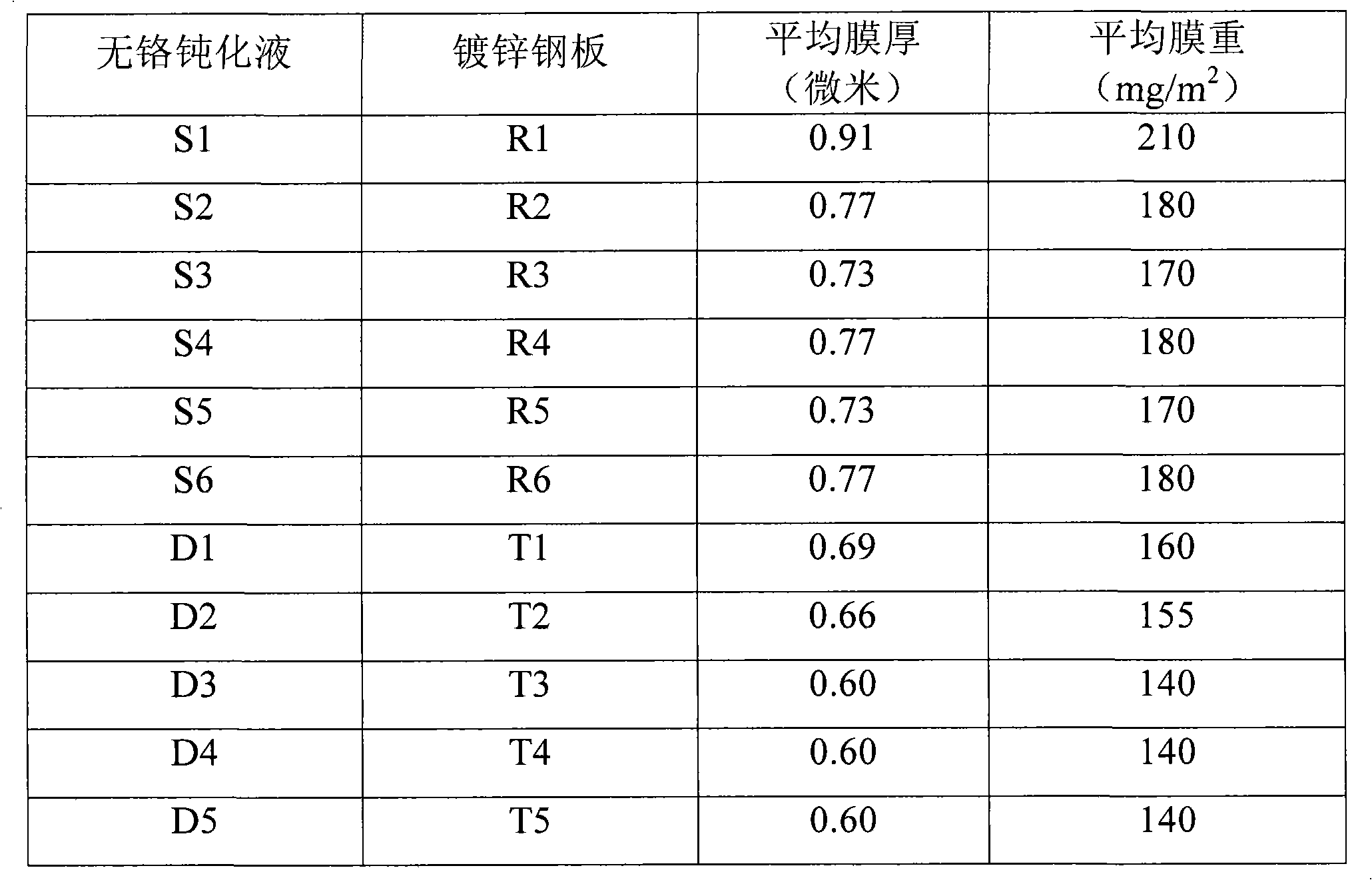

Chromium-free passivation solution and hot-dip galvanized metal material

InactiveCN102373453AImprove corrosion resistanceImprove water resistanceHot-dipping/immersion processesChromium freeSilanes

The invention relates to a chromium-free passivation solution and a hot-dip galvanized metal material. The chromium-free passivation solution is prepared from a raw material mixture through uniform mixing. The raw material mixture contains one or more silane coupling agents and water. The chromium-free passivation solution is characterized in that the raw material mixture also contains one or more titanium compounds, one or more inorganic silicon compounds, one or more water-soluble film-forming agents and tannic acid or phytic acid, wherein the one or more titanium compounds are selected from hexafluorotitanic acid, ammonium hexafluorotitanate, potassium hexafluorotitanate, metatitanic acid and titanyl sulfate and the one or more inorganic silicon compounds are selected from nanoscale silica powder, silica sol and sodium silicate. The chromium-free passivation solution has good corrosion resistance, good water resistance, good heat resistance, good fingerprint resistance and excellent roller coating performances. A passivation method adopting the chromium-free passivation solution can greatly shorten treatment time, can be utilized for passivation plate production in a spray mode or a roller coating mode, and also can avoid an oiling process in galvanized plate production.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

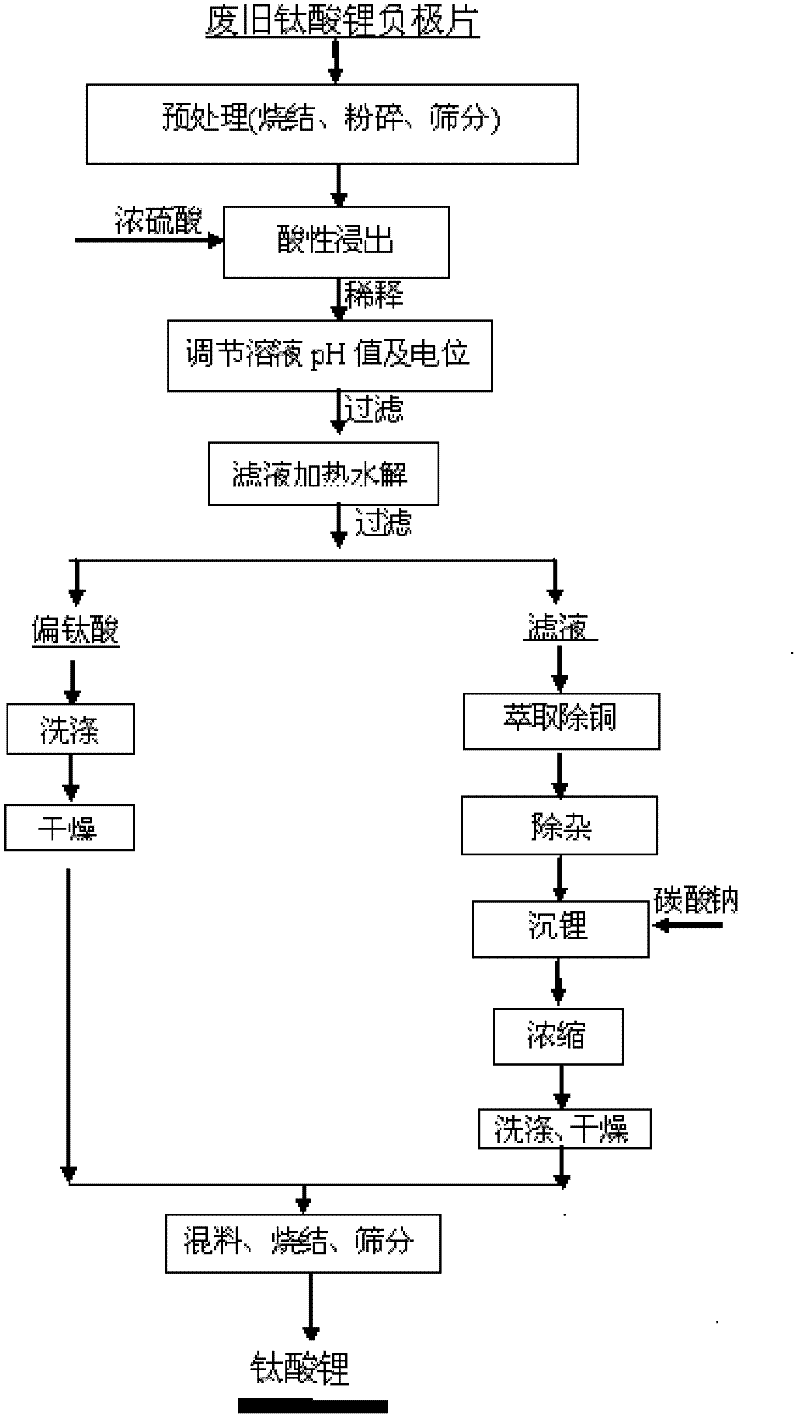

Method for regenerating lithium titanate serving as anode material of waste lithium ion battery

ActiveCN102390863AImprove electrical performanceAchieve recyclingTitanium compoundsBattery recyclingLithium carbonatePhysical chemistry

The invention discloses a method for regenerating lithium titanate serving as an anode material of a waste lithium ion battery. The method comprises the following steps of: pretreating the anode material of the waste lithium ion battery and acid-leaching the pretreated anode material; diluting leachate; adjusting the pH value of the leachate; performing oxidation-reduction potential; filtering the leachate; heating filtrate to hydrolyze the filtrate, and filtering after complete hydrolysis; washing and drying the obtained residue to prepare metatitanic acid; performing impurity removal, concentration and lithium precipitation on the obtained filtrate, washing and drying to prepare lithium carbonate; and mixing the metatitanic acid and the lithium carbonate according to a stoichiometric ratio, and sintering to prepare the lithium titanate anode material. By the method, cyclic regeneration of waste lithium titanate is realized; the lithium titanate has the characteristics of low environmental pollution, high recycling rate, convenience for industrialization and the like; the synthesized lithium titanate has higher electric performance and can meet a market requirement.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

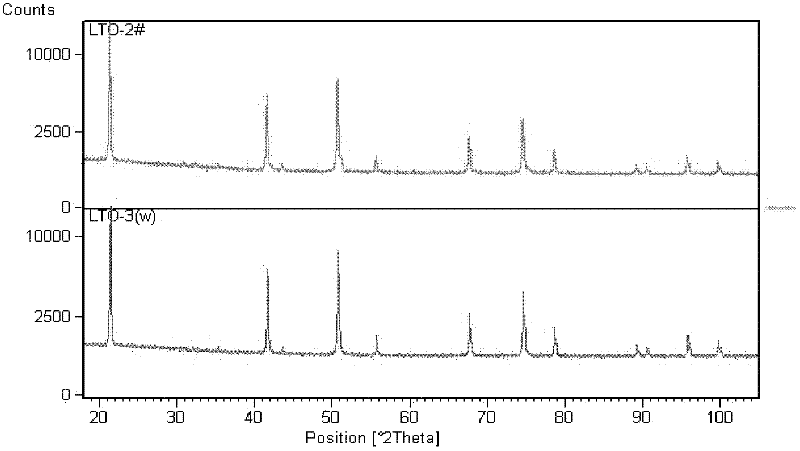

Methods for preparing and using crystal seeds of rutile in high activity

This invention relates to a process for producing rutile-type titanium dioxide powder, especially a method for preparing high-activity rutile seed crystal for titanium dioxide powder production. The method comprises: (1) adding 50-70 deg.C metatitanic acid into 80-100 deg.C NaOH solution at a ratio of 1:(1.2-2.5), and dissolving; (2) cooling, washing with water, preparing into 100-250 g / L slurry, and adding HCl to adjust the pH value to 2.0-3.1; (3) hydrolyzing under stirring for 2-24 h; (4) controlling the electric conductivity of the washing solution less than or equal to 400 mu.S / cm, or pNa greater than or equal to 2.5 for washing during titanic acid hydrolysis process; (5) adding HCl at an acid / titanium ratio of (0.19-0.35):1 for dissolution at 50-70 deg.C; (6) adding water to dilute, and cooling to a seed crystal concentration of 90-110 g / L. This invention has such advantages as high rutile seed crystal activity, high titanium dioxide powder rotary kiln productivity, high titanium dioxide powder quality, and high titanium dioxide powder production efficiency.

Owner:朱贤荣 +2

Preparation method of high dispersing rutile product

ActiveCN102391689AReduce dosageLow costTitanium dioxidePigment treatment with macromolecular organic compoundsPhysical chemistryWater soluble

The invention discloses a preparation method of a high dispersing rutile product; the preparation method comprises the following steps of: adopting a sulfuric acid process which sequentially comprises steps of acidolysis reaction, hydrolyzing generation of metatitanic acid, salt treatment, calcining, wet grinding, then sanding, coating and aerating powder to obtain titanium white, washing rutile titanium dioxide crude product obtained by calcining so as to reduce the content of water-soluble sale thereinto, and then adding a dispersing agent to the washed rutile titanium dioxide for wet grinding; the alkyd resin series of a rutile product prepared by the method has the dispersiveness of 20 degrees and gloss of more than 120; if the rutile crude product is not washed, the alkyd resin series of the rutile product prepared by the same after-treatment method has the dispersiveness of 20 degrees and gloss of up to 120; and the usage quantity of the dispersing agent is greatly reduced in the wet grinding process, thereby saving the cost and greatly increasing the dispersion performance of the product.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

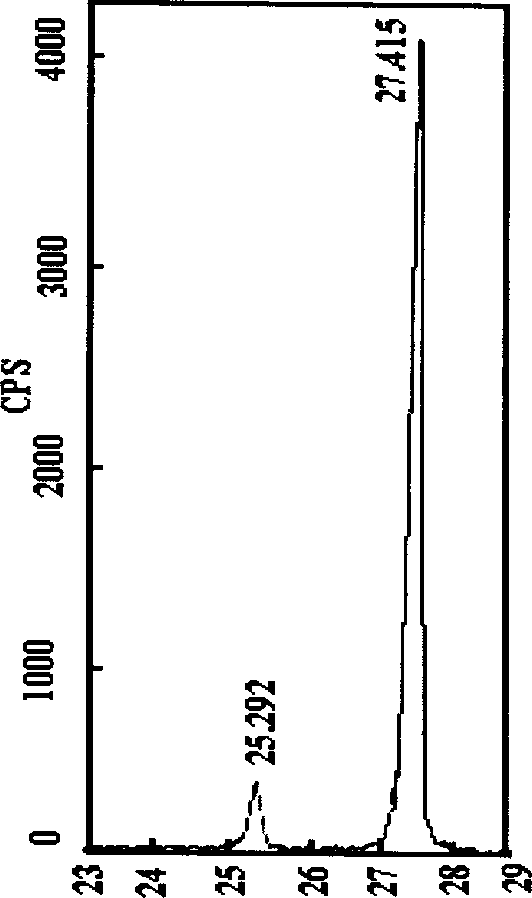

Method for producing rutile type white titanium pigment by using crystal seed method of double action

InactiveCN1415548APhase change low temperature fastImprove migration speedTitanium dioxideDual effectTitanium

A process for preparing rutile-type titanium pigment powder by dual-effect crystal seed method includes such steps as preparing dual-effect crystal seeds, hydrolyzing titanium liquid while adding the crystal seeds while plays the role of crystal nucleus of hydrolized metatitanic acid particle, and calcining where it plays the role of the crystal nucleus for rutile-type phase change. Its advantages are low calcining temp, low cost and high output.

Owner:NANKAI UNIV

mc nylon nano conductive composite material and preparation method thereof

The invention discloses a methyl cellulose (MC) nylon nano conductive composite material and a preparation method thereof. The material comprises the following chemical components by weight percent: 85%-100% of MC nylon and 0%-15% of conductive filling material, wherein the conductive filling material is one or two or more than two of natural crystalline flake graphite, expanded graphite, conductive carbon black, carbon fiber and carbon nano tube; and the conductive filling material is treated with a modifier, the use amount of the modifier is 0-10% of the use amount of the conductive fillingmaterial, and the modifier is one or two or more than two of gamma-trimethoxypropylsilane coupling agent, gamma-aminopropyltrimethoxysilane coupling agent, gamma-aminopropyltriethoxysilane coupling agent, gamma-aminopropylmethyldimethoxysilane coupling agent, metatitanic acid coupling agent, phosphate coupling agent, aluminate coupling agent and organic acid chromium compound. The MC nylon nano conductive composite material has the advantages of good comprehensive performance and use property.

Owner:NANJING UNIV OF SCI & TECH

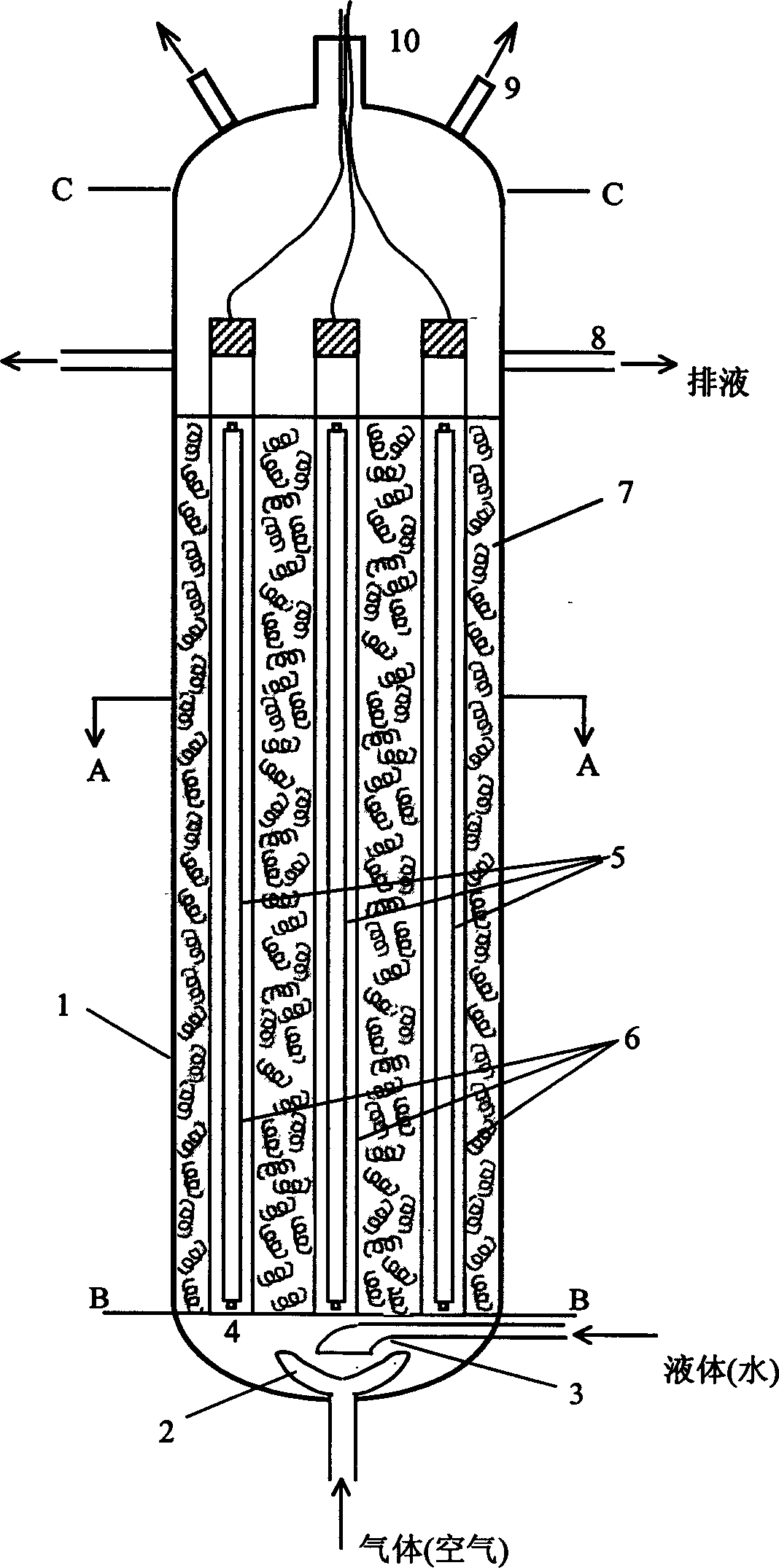

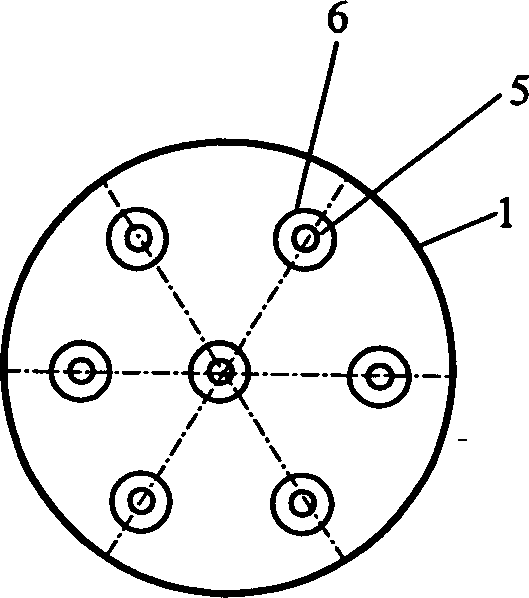

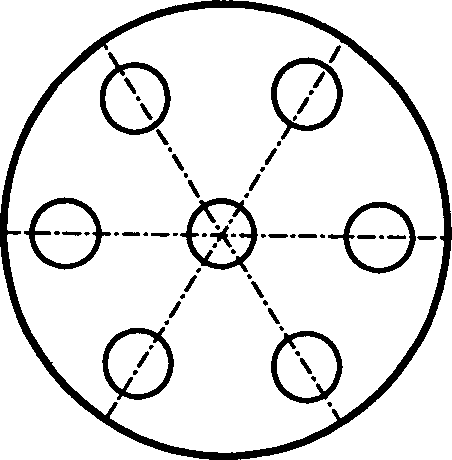

Visible photoactivating photo catalyst and light-column type packed bed reaction unit

InactiveCN1528513AEffective absorptionReduce the temperatureWater/sewage treatment by irradiationCatalyst activation/preparationFixed bedUltraviolet lights

The invention relates to a nitrogen-doped visible photosensitized TiO2 photocatalyst making method as well as its light-array type filling-fixed-bed photocatalysis fluid processing method and device. It evenly produces water and ammonia at the same time in the system by ammonium bicarbonate thermolysis, to make titanium tetrachloride carry out even hydrolysis and ammonolysis reactions to produce nitrogen-doped metatitanic acid fore body, which is treated at the nitrogen atmosphere under low temperature to obtain visible photosensitized nitrogen-doped nano TiO2 film or powder. The glass-tube ultraviolet light cannulas are uniformly distributed in the light-array type reactor, where the load-type photocatalyst is filled in the huddling mode in the air gap between the cannulas. It has advantages of moderate reacting condition, low heat treating temperature, etc. The photocatalysis reactor has advantages of continuous running, convenient operation, high efficiency, etc; can be applied to sewage treatment, drinking water's deep purification, waste gas treatment, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

Honeycombed catalyst for low-temperature synergic denitrification, dioxin removal and mercury removal and preparation method thereof

ActiveCN107952449ALow investment costLow running costGas treatmentHeterogenous catalyst chemical elementsRare earthPalygorskite

The invention discloses a honeycombed catalyst for low-temperature synergic denitrification, dioxin removal and mercury removal and a preparation method thereof. The honeycombed catalyst employs metatitanic acid and sulfated palygorskite as carriers, copper oxides, manganese oxides and vanadium oxides as active ingredients and rare-earth metal oxides as active aids. The honeycombed catalyst hereincan provide synergic denitrification, dioxin removal and mercury removal at the low temperature of 80-300 DEG C; under the action of the honeycombed catalyst, NOx and dioxin are selectively catalytically reduced into N2, HCl, CO2 and CO; the produced HCl is suitable for serving as a mercury removal aid; elemental mercury, CO, hydrocarbons and alkenes are thoroughly oxidized into mercury oxide andCO2; the honeycombed catalyst has denitrification rate of 95% and above and dioxin removal rate and mercury removal rate of 90% and above.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

Method for preparing denitration catalyst carrier TiO2-WO3 composite powder

InactiveCN102327783AImprove performanceEasy to processCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses a method for preparing denitration catalyst carrier TiO2-WO3 composite powder, which comprises the following steps of: pulping and dispersing a metatitanic acid raw material; adjusting until the concentration of the slurry, calculated in terms of the titanium dioxide TiO2, is 15-25% by mass; adding ammonium paratungstate to the slurry according to a proportion, wherein calculated by the mass of tungsten trioxide WO3, the additive proportion of the ammonium paratungstate is 4.0%-10.0% of the sum of the TiO2 and the WO3; adding ammonia water to the slurry to adjust the pH to 6.5-9.0; filtering and dewatering to obtain a blocky filter cake; crushing the filter cake mechanically; drying and roasting the crushed filter cake at 200 DEG C to 580 DEG C for 6 hours; and crushing the roasted material falling in the kiln to obtain a TiO2-WO3 composite powder product serving as the denitration catalyst carrier. The method disclosed by the invention is low in manufacturing cost and simple in process; and the prepared product has the advantages of high specific surface area, high surface chemical activity, high catalytic efficiency and good processability.

Owner:四川华铁钒钛科技股份有限公司

Preparation method of tio2-wo3 composite powder used as catalyst carrier

InactiveCN102294273AImprove performanceEasy to processCatalyst carriersDispersed particle separationPtru catalystAmmonium metatungstate

The invention discloses a preparation method for TiO2-WO3 composite powder used as a catalyst carrier. The method comprises the following steps: dispersing the raw material metatitanic acid through beating, and adjusting the concentration of obtained slurry to be 15 to 25% on the basis of the mass percentage of TiO2; adding ammonia liquor into the slurry and adjusting the pH value of the slurry to be 6.5 to 9.0; filtering the slurry to obtain a solid phase filter cake; beating the solid phase filter cake again, and adjusting the concentration of obtained slurry to be 24 to 30% on the basis ofthe mass percentage of TiO2; adding an ammonium metatungstate solution in proportion, wherein, the proportion of addition amount of ammonium metatungstate is 4.0% to 10.0% with the mass of titanium dioxide as reference; directly pumping the slurry treated in the previous steps into a drying calcination apparatus for drying and calcining, and crushing blanking materials of a calcination kiln to obtain a finished product. The preparation method has the characteristics of low manufacture cost and a simple process; the prepared product has the advantages of a high specific surface area, high surface chemical activity, high catalysis efficiency and good processing performance.

Owner:四川华铁钒钛科技股份有限公司

TiO2-WO3-SiO2 composite powder used as catalyst carrier and preparation method thereof

InactiveCN102553655AHigh catalytic efficiencyHigh strengthCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses and provides a preparation method of TiO2-WO3-SiO2 composite powder used as a catalyst carrier. The method sequentially comprises the following steps: dispersing a metatitanic acid raw material into the slurry through beating, and regulating the concentration of the slurry having the mass fraction of 10 percent to 20 percent and counted with titanium dioxide; respectively adding ammonium paratungstate and white carbon black into the slurry; adding ammonia water and regulating the pH value to be within the range of 5.5 to 8.5; filtering and dehydrating the slurry to obtain a blocky filter cake; mechanically grinding the blocky filter cake obtained after filtering and dehydrating, drying the ground filter cake for 2.5 hours at a temperature of 200 DEG C to 380 DEG C and calcining the dried filter cake for 4.5 hours at a temperature of 380 DEG C to 680 DEG C; and obtaining the TiO2-WO3-SiO2 composite powder after grinding calcined falling materials. The method disclosed by the invention has the advantages of low manufacturing cost, simple process, high specific surface area of a product, high surface chemical activity, and good processing performance. A denitration catalyst prepared from the product has the advantages of high strength, long service life, high catalytic efficiency and the like.

Owner:四川华铁钒钛科技股份有限公司

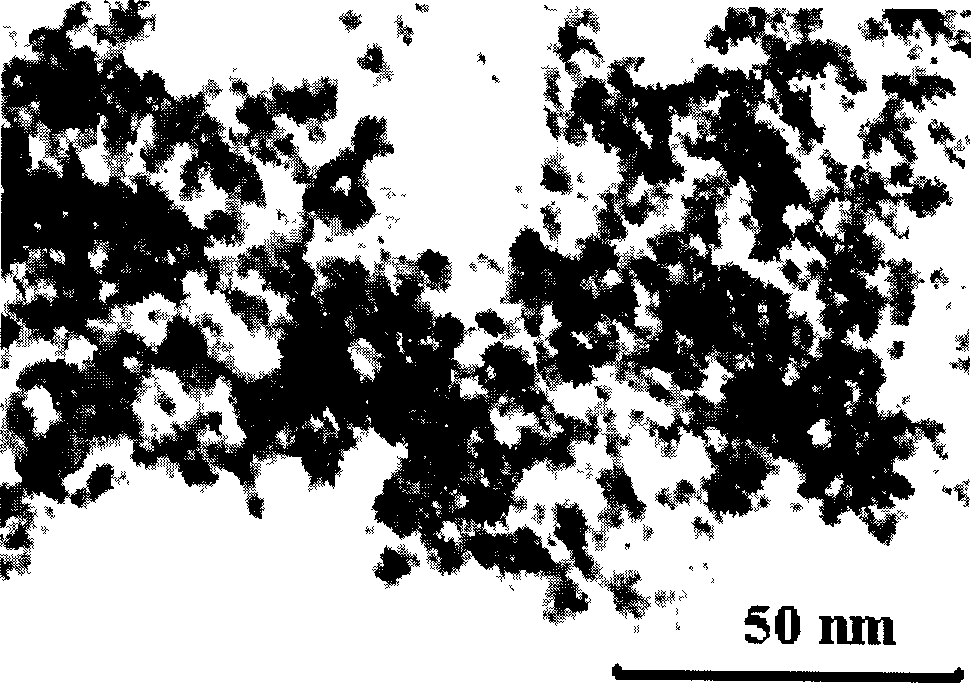

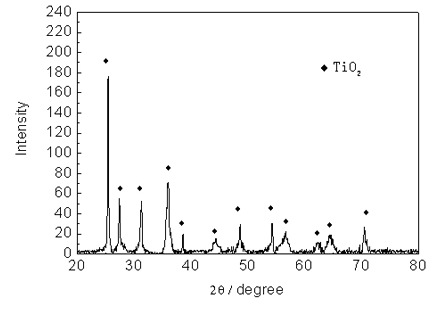

Nano titanium dioxide (TiO2) for flue gas denitration catalyst and preparation method thereof

InactiveCN102198397ASmall grainUniform grainDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingLattice defects

The invention provides a special nano titanium dioxide (TiO2) for a high-performance denitration catalyst and a preparation method thereof. The nano-TiO2 comprises the following components in mass percentage: 80-95% of TiO2 and 5-20% of SiO2; and the nano-TiO2 is prepared by a precipitation method, and precipitated precursors comprise TiOSO4 solution and silica sol. The preparation method comprises the following steps: dissolving metatitanic acid used as raw material with concentrated sulfuric acid to obtain titanyl sulfate solution; precipitating titanyl sulfate and the silica sol by the precipitation method to obtain metatitanic acid slurry; and washing the metatitanic acid slurry with de-ionized water, drying and baking to finally obtain the special nano-scale TiO2 for the denitration catalyst. The preparation method has the following advantages: (1) the TiO2 obtained by the precipitation method has the characteristics of small and uniform crystal particles, large specific surface area and more surface lattice defects so that the TiO2 and active components of the catalyst such as vanadium and tungsten interact strongly so as to improve properties of the catalyst; and (2) the cheap silica sol is utilized as an additive, which improves surface acidity and specific surface area of the nano-TiO2 and causes no toxic or harmful substances after the silica sol is baked.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

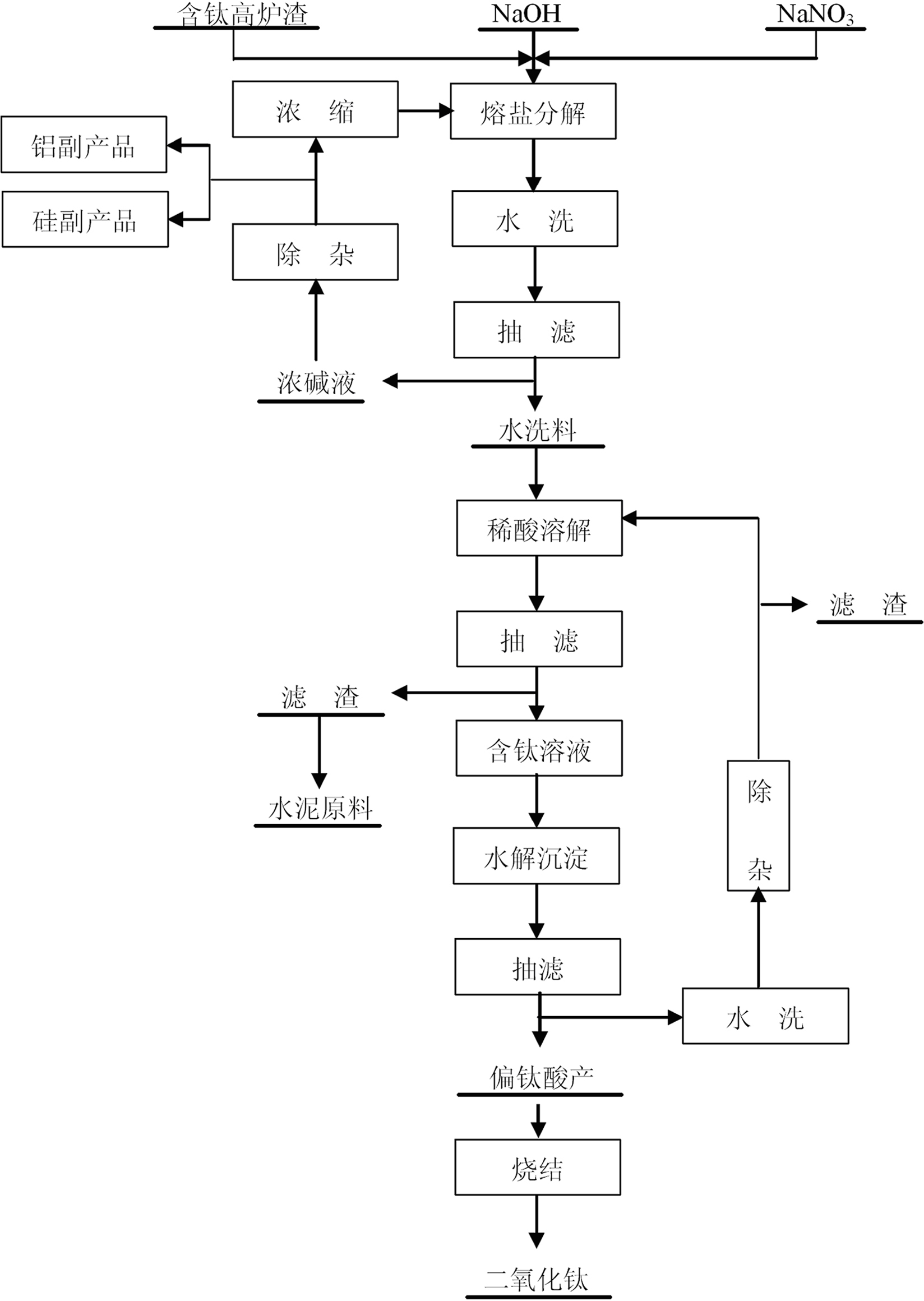

Method for producing titanium dioxide by using titanium-containing blast furnace slag

InactiveCN101994012AEasy to operateLow reaction temperatureProcess efficiency improvementSlagSodium titanate

The invention relates to a comprehensive utilization technology of blast furnace slag, in particular to a method for producing titanium dioxide by using titanium-containing blast furnace slag. The technical scheme comprises the following steps of: crushing, ball milling and screening titanium-bearing blast furnace slag, and placing in a molten salt system containing NaOH and NaNO3; washing the intermediate product in water at 60-75 DEG C, and filtering; removing impurities of a NaOH and NaNO3 alkaline solution containing sodium silicate and sodium metaaluminate, concentrating, and returning to the NaOH and NaNO3 molten salt system; dissolving the washing material containing solid phase sodium titanate by using an inorganic acid, adding a reducing agent for a reduction reaction, and then filtering; filtering the titanium-containing solution to obtain an inorganic acid filtrate and a metatitanic acid product; and calcining the metatitanic acid product at 600-1300 DEG C to obtain the final product of titanium dioxide powder. The invention realizes high conversion rate of titanium, and furthest reduces environmental pollution at the same time.

Owner:NORTHEASTERN UNIV

Method for preparing Nano tube of titanate

InactiveCN101003385ALarge specific surface areaImproved electrical and catalytic propertiesPolycrystalline material growthTitanium compoundsCopper nitrateSodium titanate

This invention discloses a method for preparing titanate nanotubes. The method comprises: uniformly mixing nitrate and power of sodium titanate nanotubes at a mol ratio of (5-100):1, performing melt-reaction at 50-450 deg.C for 3-48 h, cooling, washing to remove unreacted nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, and drying to obtain titanate nanotubes. The nitrate is lithium nitrate, potassium nitrate, rubidium nitrate, cesium nitrate, silver nitrate, nickel nitrate, thallium nitrate, copper nitrate, zinc nitrate or cobalt nitrate. The precursor of sodium titanate nanotubes is prepared by: reacting titanium dioxide, metatitanic acid or titanate ester in 20-80 wt. % NaOH aqueous solution at 100-140 deg.C for 12-72 h, washing with water, filtering and drying. This invention can prepare titanate nanotubes with large specific surface area by melt-exchange method.

Owner:HENAN UNIVERSITY

Preparation method for denitration catalyst carrier nano titanium dioxide

InactiveCN104667901AReduce manufacturing costSimple processCatalyst carriersDispersed particle separationCatalyst supportTitanium dioxide

The invention discloses a preparation method for a denitration catalyst carrier nano titanium dioxide. According to the method, an intermediate metatitanic acid for preparing titanium dioxide with a sulfuric acid method is used as a raw material; an ammonium salt is added to adjust the pH value; and the steps of washing, filtering, drying and roasting are carried out to obtain the denitration catalyst carrier nano titanium dioxide product. Compared with the prior art, the method disclosed by the invention has low manufacturing cost and a simple process; and the prepared product has the advantages of large specific surface area, high dispersion degree, uniform particle morphology, narrow grain diameter distribution, small grain diameters of aggregates and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Synthesis method of lithium extraction adsorbent

InactiveCN110975795AImprove the phenomenon that it is difficult to mix evenlyDry fastOther chemical processesWater contaminantsPhysical chemistryLiquid lithium

The invention discloses a synthesis method of a lithium extraction adsorbent. The preparation method comprises the following steps: dissolving a lithium source in a solvent containing a certain amountof additive, then adding a titanium source into the solvent to be uniformly mixed to form a solid-liquid mixed state, and carrying out drying treatment to assist synthesis, so that the raw materialsare rapidly dried, fully mixed and calcined to obtain a lithium-ion sieve precursor Li2TiO3 with uniformly distributed particle sizes. A metatitanic acid type lithium ion sieve H2TiO3 obtained after acid pickling and lithium removal of the precursor Li2TiO3 has a remarkable adsorption effect. The method is simple and easy to implement, and the lithium ion sieve H2TiO3 is mainly used for extractinglithium from salt lake brine, oil field brine, seawater and other water bodies and has huge potential in the aspect of liquid lithium extraction.

Owner:NANJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com