Method for regenerating lithium titanate serving as anode material of waste lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery recycling, chemical instruments and methods, titanium compounds, etc., can solve the problem of no recycling method, achieve good electrical performance, meet market requirements, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

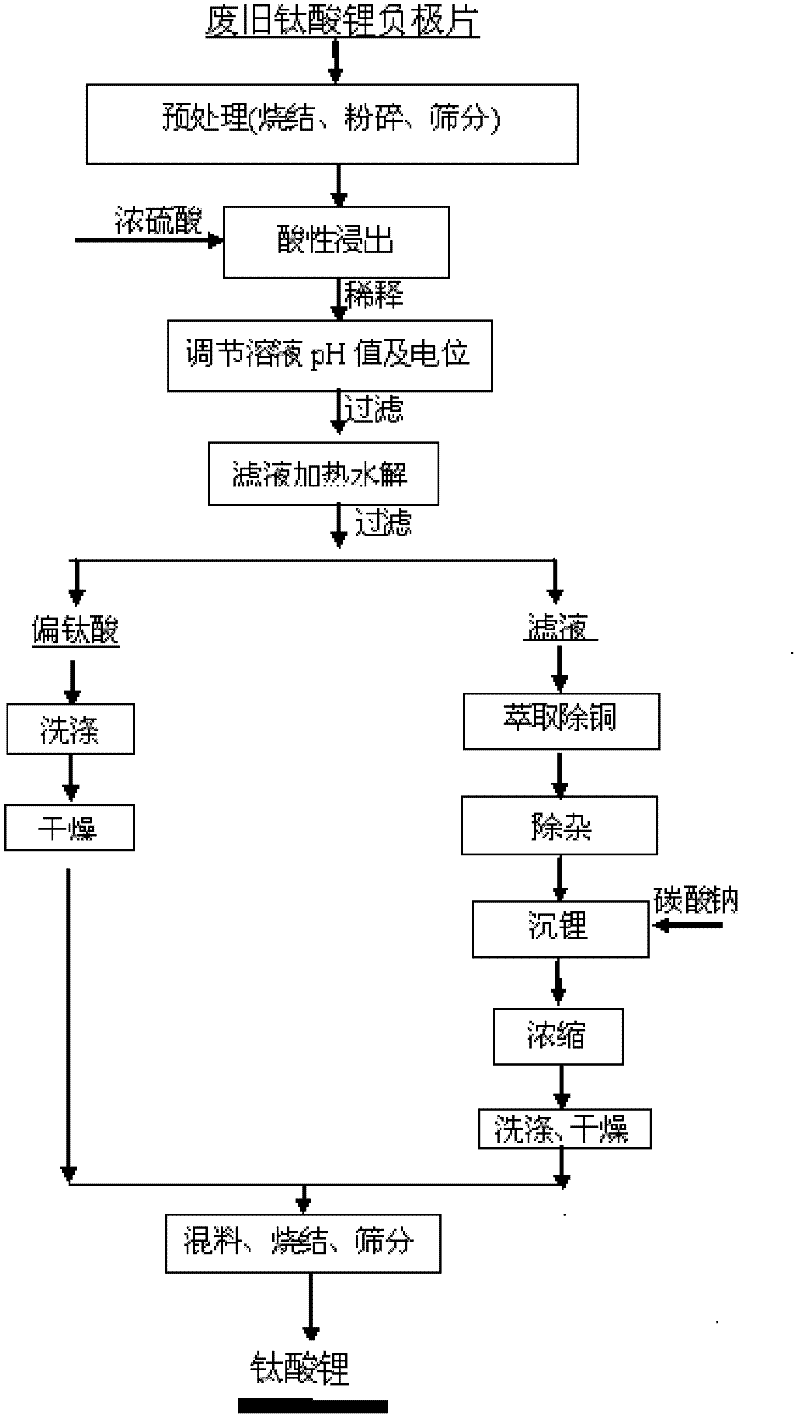

Method used

Image

Examples

Embodiment 1

[0026] Take 500 g of the lithium titanate negative electrode sheet of the waste lithium-ion battery, and its chemical composition is shown in Table 1 after testing.

[0027] Table 1 Chemical composition of waste lithium titanate negative electrode sheet before pretreatment

[0028] detection element

Ti

Cu

Li

Fe

Ca

Mg

other

Mass percentage (%)

36.27

18.20

4.22

0.01

0.01

0.01

41.28

[0029] Put the negative electrode sheet into a muffle furnace and sinter at 500°C for 30 minutes to remove organic matter. The sintered negative electrode sheet was pulverized by a pulverizer and passed through a 60-mesh sieve to obtain 462 g of under-sieve material. The chemical composition is shown in Table 2.

[0030] Table 2 Chemical composition of waste lithium titanate negative electrode sheet after pretreatment

[0031] detection element

Embodiment 2

[0033] Take 400g of the above-mentioned undersize, add 700mL of 96% sulfuric acid, stir with air, react for 3 hours, add to 1000mL aqueous solution after aging for 2 hours, filter after stirring for 0.5h, and dilute the filtrate to 2000mL. The detected components are shown in Table 3. The main reactions that occur are as follows:

[0034] Li 4 Ti 5 o 12 +12H 2 SO 4 (concentrated)→5Ti(SO 4 ) 2 +2Li 2 SO 4 +12H 2 o

[0035] Cu+2H 2 SO 4 (concentrated)→CuSO 4 +SO 2 ↑+2H 2 o

[0036] Cu+H 2 SO 4 (concentrated)→CuO+SO 2 ↑+H 2 o

[0037] Table 3 Filtrate Components

[0038] detection element

Embodiment 3

[0040] Add ammonia water to the above filtrate to adjust the pH value to 2.0, then add sodium sulfite to adjust the reduction potential of the solution to 0.35V, raise the temperature of the solution to 80°C, add an appropriate amount of dilute sulfuric acid to maintain the pH value of the solution at about 2.0, stir for 3 hours, and filter to obtain Metatitanic acid and filtrate. After the metatitanic acid was washed with a small amount of water, it was placed in a blast drying oven and dried at 100°C for 5 hours to obtain 320.76 g of metatitanic acid, the composition of which is shown in Table 4:

[0041] Table 4 Main components of metatitanic acid

[0042] detection element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com