Patents

Literature

267results about How to "Meet market requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

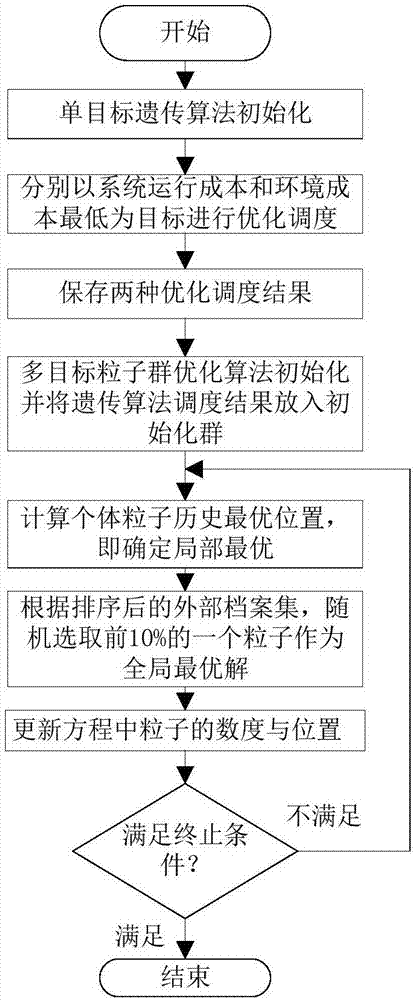

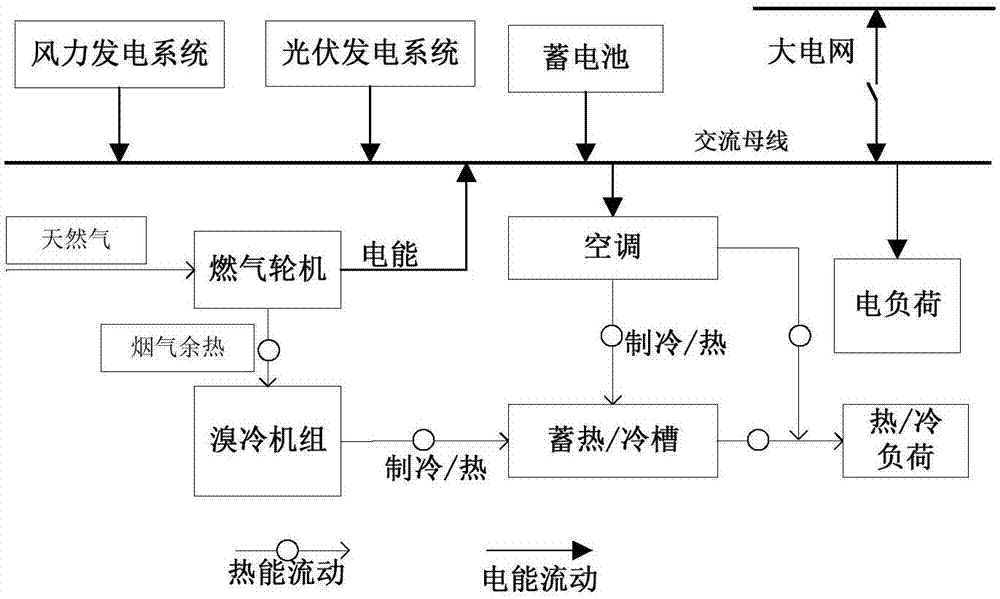

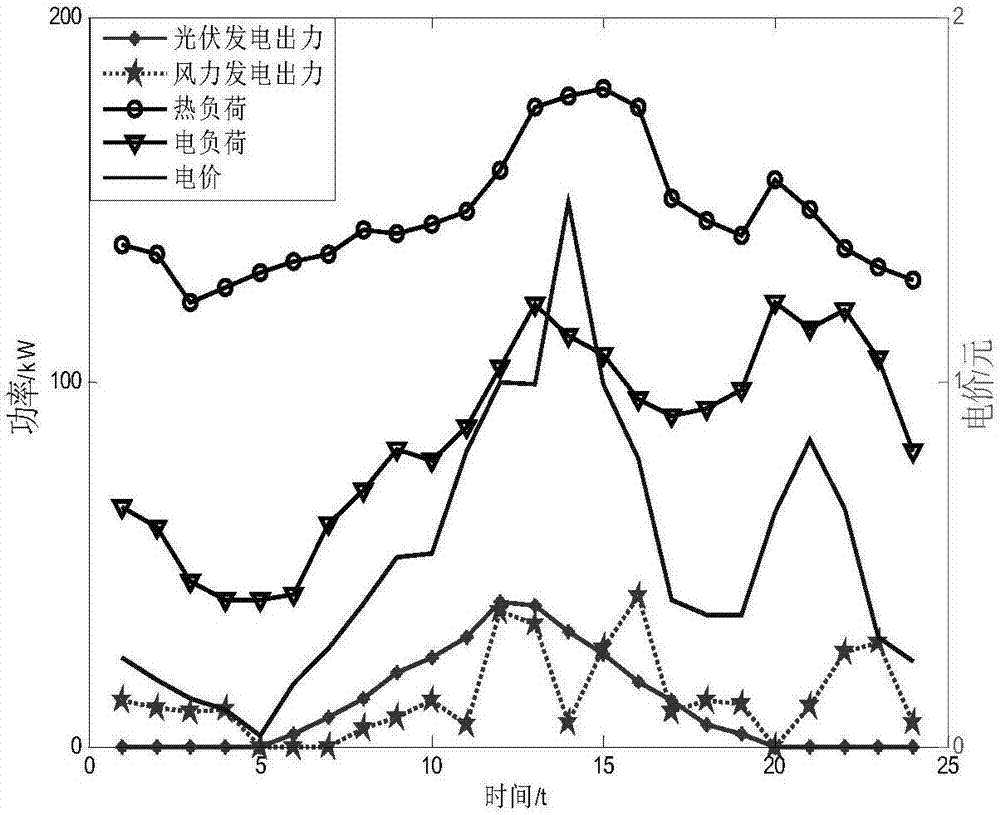

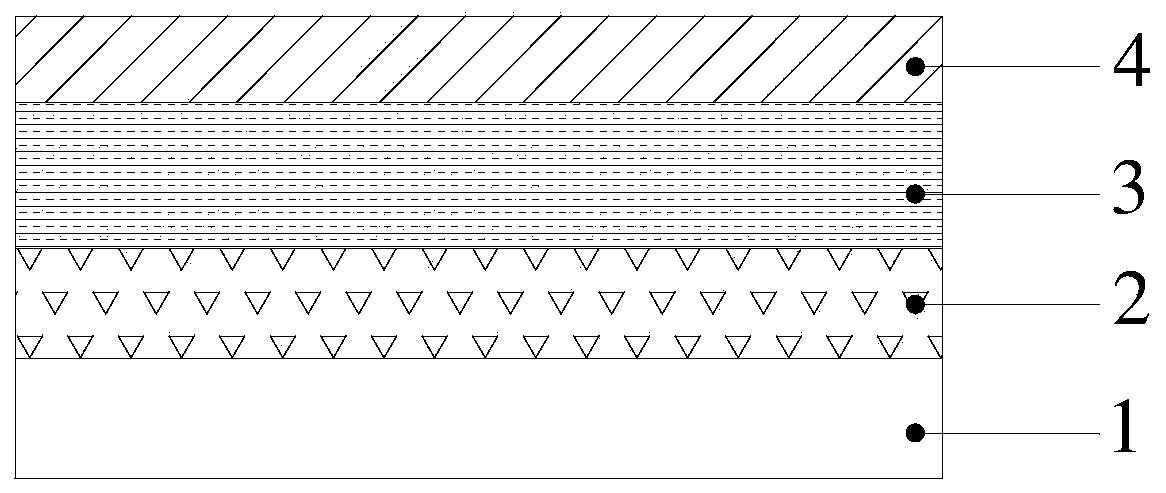

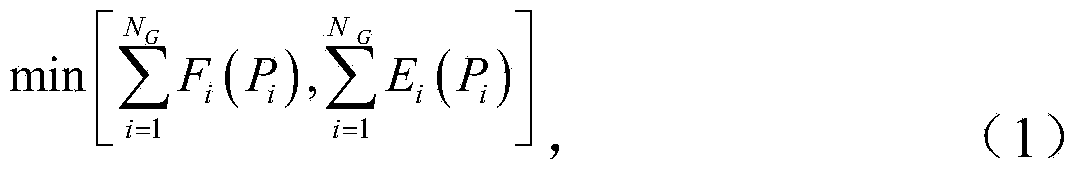

Combined cold heat and power supply microgrid multi-objective dynamic optimal operation method

ActiveCN107482638ASolve the problem of connecting to the large power gridSolve the problems that arisePower network operation systems integrationSingle network parallel feeding arrangementsMicrogridMathematical model

The invention discloses a combined cold heat and power supply microgrid multi-objective dynamic optimal operation method; characteristics of translatable electrical load are firstly considered in an optimization process, then schedulability of source side and energy storage system are considered, contribution in each period in three kinds of controllable units serves as optimization variables, minimum system operation cost and minimum pollutant emission control expense serve as optimal operation targets, and a mathematical model of current multi-objective optimal operation problem is established; an excellent particles leading multi-objective particle swarm optimization algorithm is adopted to solve the optimization problem, that is, a single objective genetic algorithm is utilized to respectively find two points including minimum system operation cost and minimum pollutant emission control expense, and the two points serving as excellent particles is utilized to lead an optimal direction of the multi-objective particle swarm algorithm; the invention provides an effective multi-objective dynamic optimal operation method, and the method is significant for improving energy source comprehensive utilization efficiency of a multiple energy coupled system and promoting renewable energy source development.

Owner:HANGZHOU DIANZI UNIV

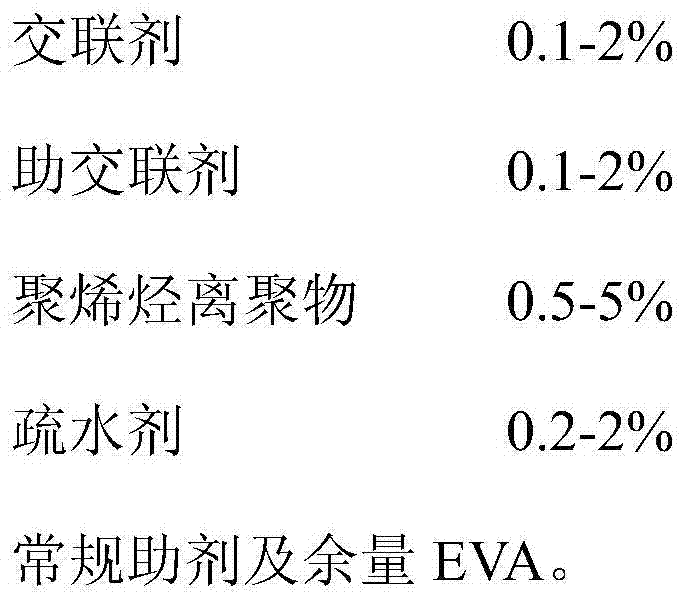

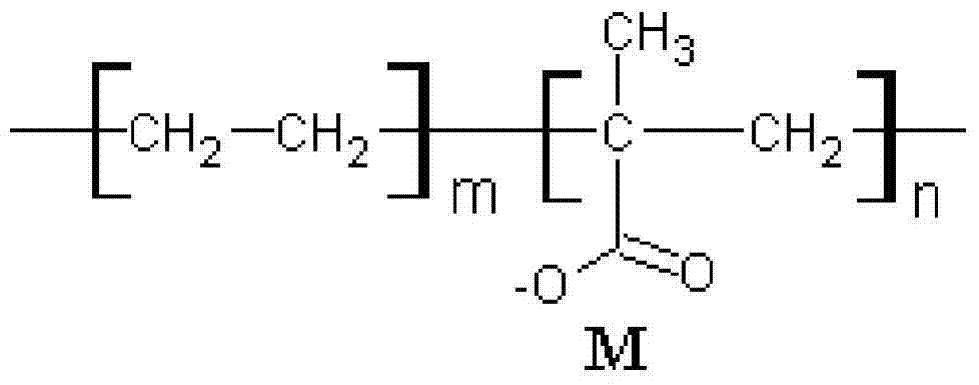

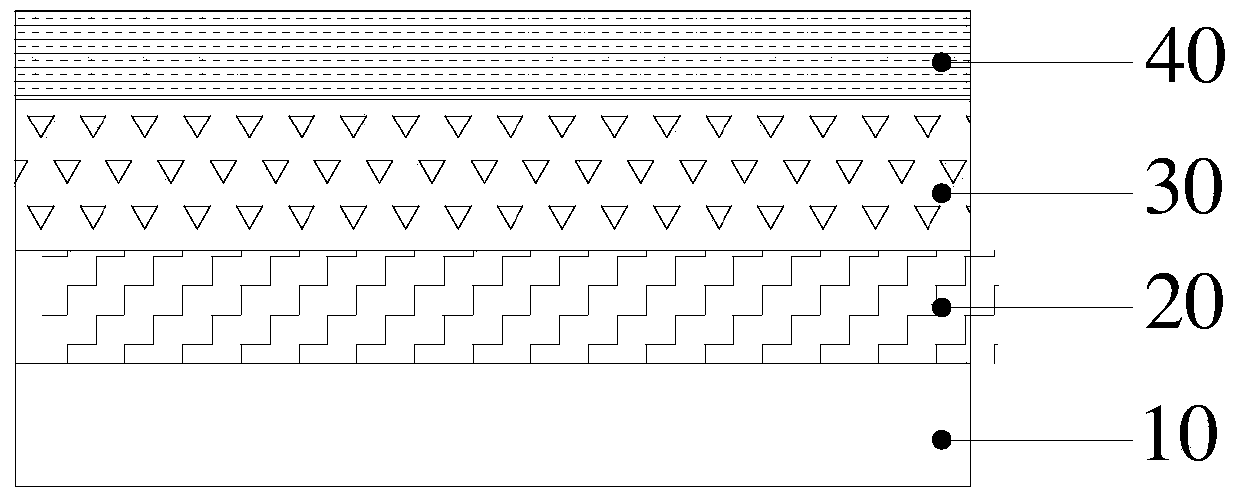

Photovoltaic EVA film resisting PID

ActiveCN103525321ALow costImprove performanceNon-macromolecular adhesive additivesFilm/foil adhesivesPolyolefinEngineering

The invention relates to a photovoltaic EVA film resisting PID. The photovoltaic EVA film resisting the PID comprises the following components, by mass fraction, 0.05-5% of cross-linking agents, 0.05-5% of assistant crosslinker agents, 0.2-10% of polyolefin ionomer, 0.1-5% of hydrophobing agents, normal additives and the balance EVA. The photovoltaic EVA film resisting the PID is low in cost and high in performance, has no selectivity on battery pieces, the PID resistance performance is lasting and stable, and the photovoltaic EVA film resisting the PID can pass the PID standard test of IEC, has identical lasting PID resistance performance in a photovoltaic system, thoroughly eradicates the PID problem of components in an EVA level, and meets the demands of current and future component markets.

Owner:CSI SOLAR POWER GROUP CO LTD +2

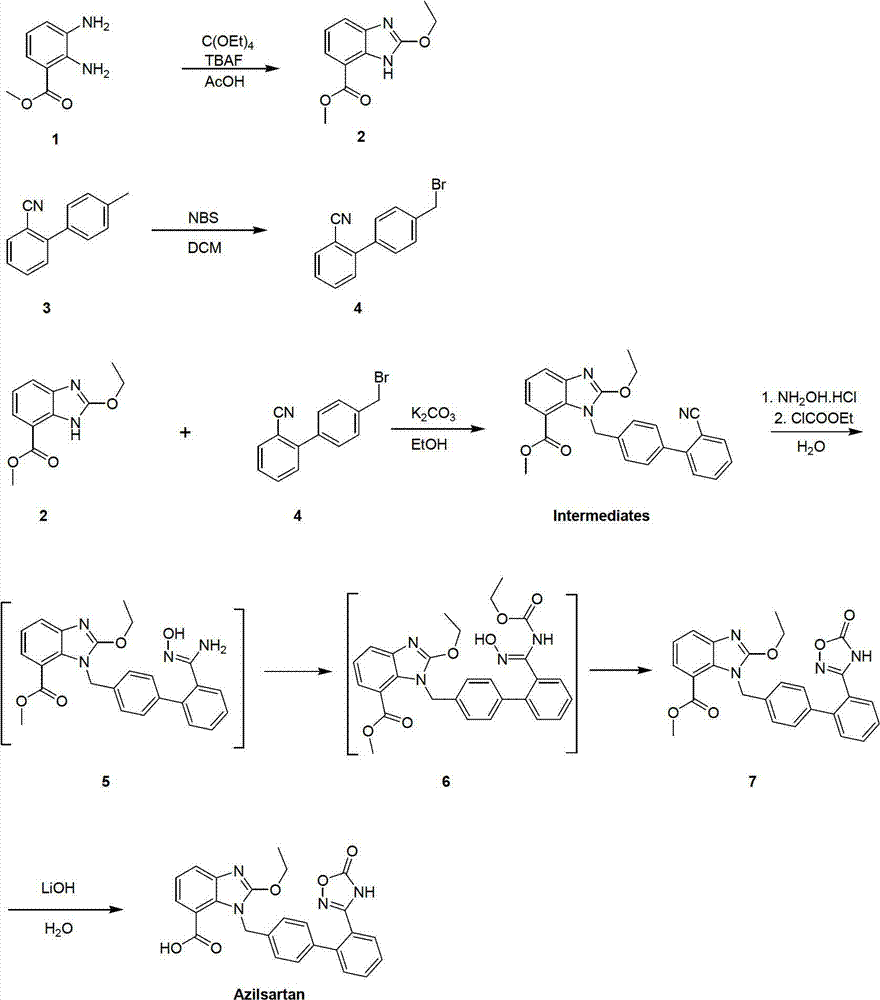

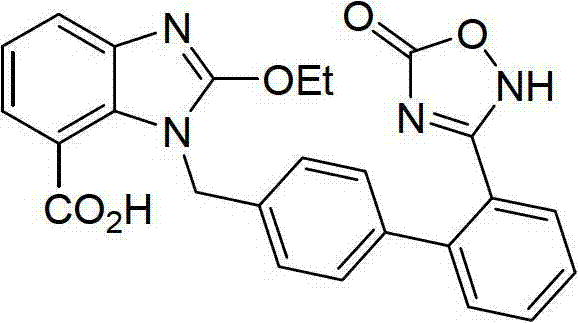

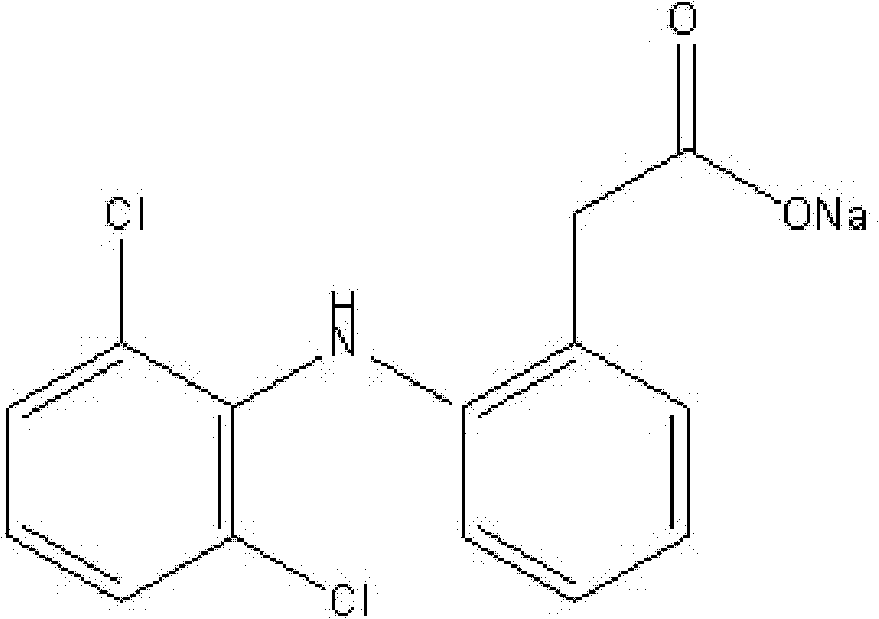

Preparation method of azilsartan

InactiveCN102766138AReduce usageEmission reductionOrganic chemistryEthyl chloroformateCarboxylic salt

The invention relates to a preparation method of azilsartan, comprising the following steps of: (1) preparing ethoxybenzimidazole-7-methyl carboxylate; (2) preparing 2-cyan-4'-bromomethyl biphenyl; (3) dissolving the ethoxybenzimidazole-7-methyl carboxylate and the 2-cyan-4'-bromomethyl biphenyl into ethanol; adding potassium carbonate to react to obtain 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate; (4) suspending the 1-[(2'-cyan diphenyl-4-yl)methyl]-2-ethoxybenzimidazole-7-methyl carboxylate in water; adding hydroxylamine hydrochloride, sodium hydroxide and tetrabutylammonium fluoride; heating and reflowing, and then cooling; adding the sodium hydroxide and ethyl chloroformate, heating and reflowing to obtain azilsartan methyl ester; and (5) hydrolyzing the azilsartan methyl ester to obtain a product. The preparation method of the azilsartan, disclosed by the invention, has the advantages of being short in process route, high in yield, and safe and reliable; and the purity of the azilsartan obtained by using the method is high.

Owner:WENZHOU PEOPLES HOSPITAL

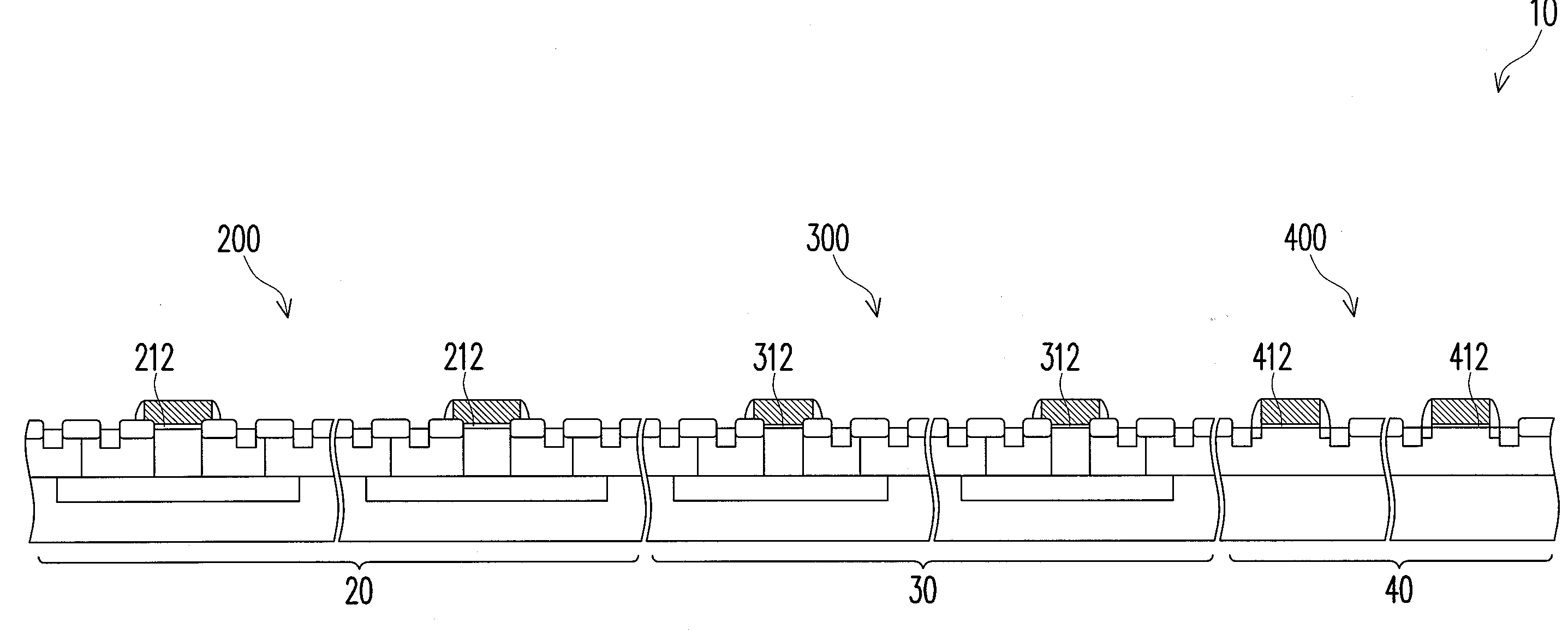

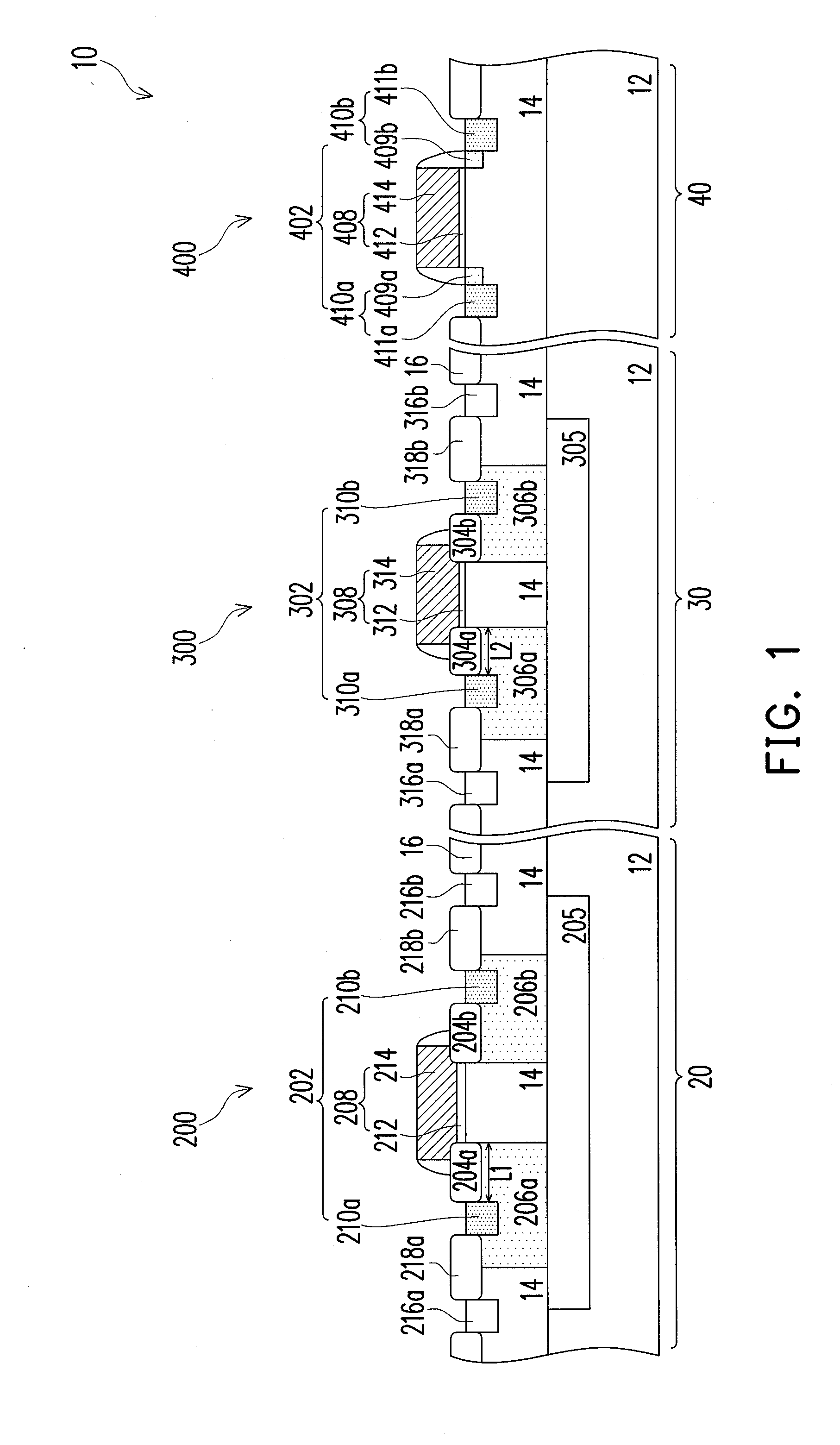

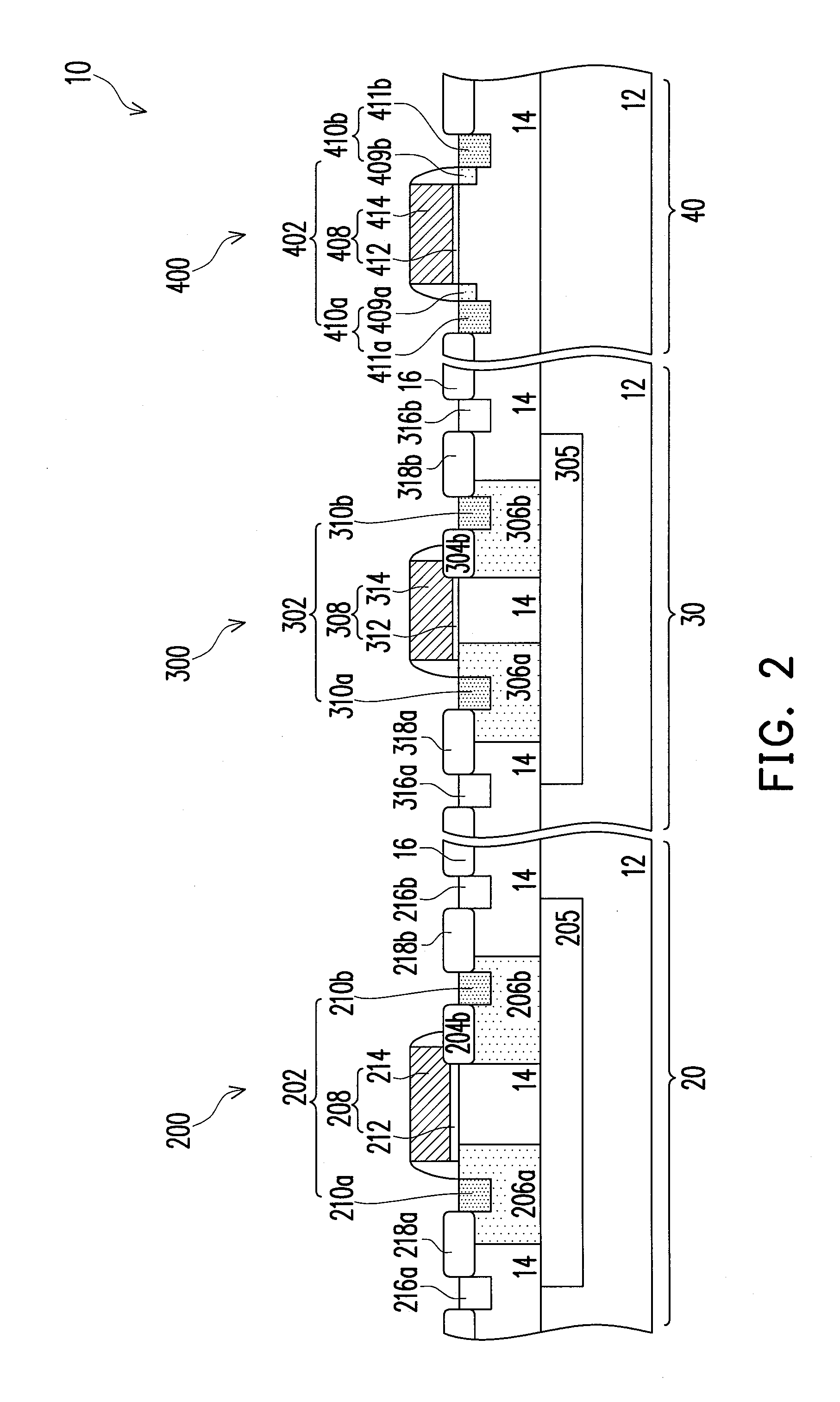

Semiconductor device and method of fabricating the same

ActiveUS20100096702A1Higher saturated currentImprove performanceTransistorSolid-state devicesLow voltage circuitsGate dielectric

A semiconductor device including a substrate, a high voltage device, a medium voltage device and a low voltage device is provided. The substrate includes a high voltage circuit area, a medium voltage circuit area and a low voltage circuit area. The high voltage device, the medium voltage device and the low voltage device are respectively disposed in the high voltage circuit area, the medium voltage circuit area and the low voltage circuit area. The medium voltage device and the high voltage device have the same structure while the medium voltage device and the low voltage device have different structures. Further, the high voltage device, the medium voltage device and the low voltage device respectively include a first gate dielectric layer, a second gate dielectric layer and a third gate dielectric layer, and the thickness of the second gate dielectric layer is smaller than that of the first gate dielectric layer.

Owner:UNITED MICROELECTRONICS CORP

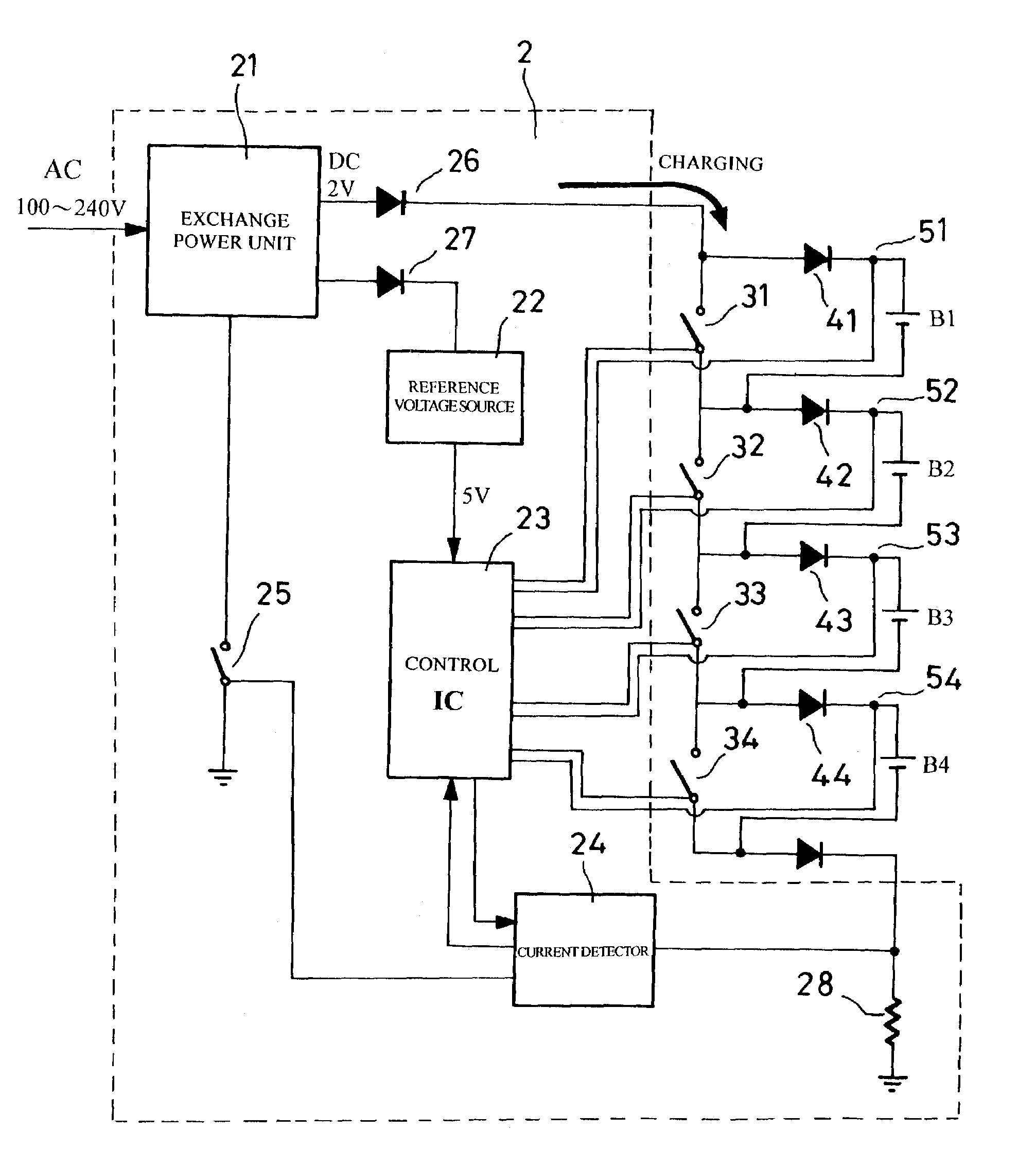

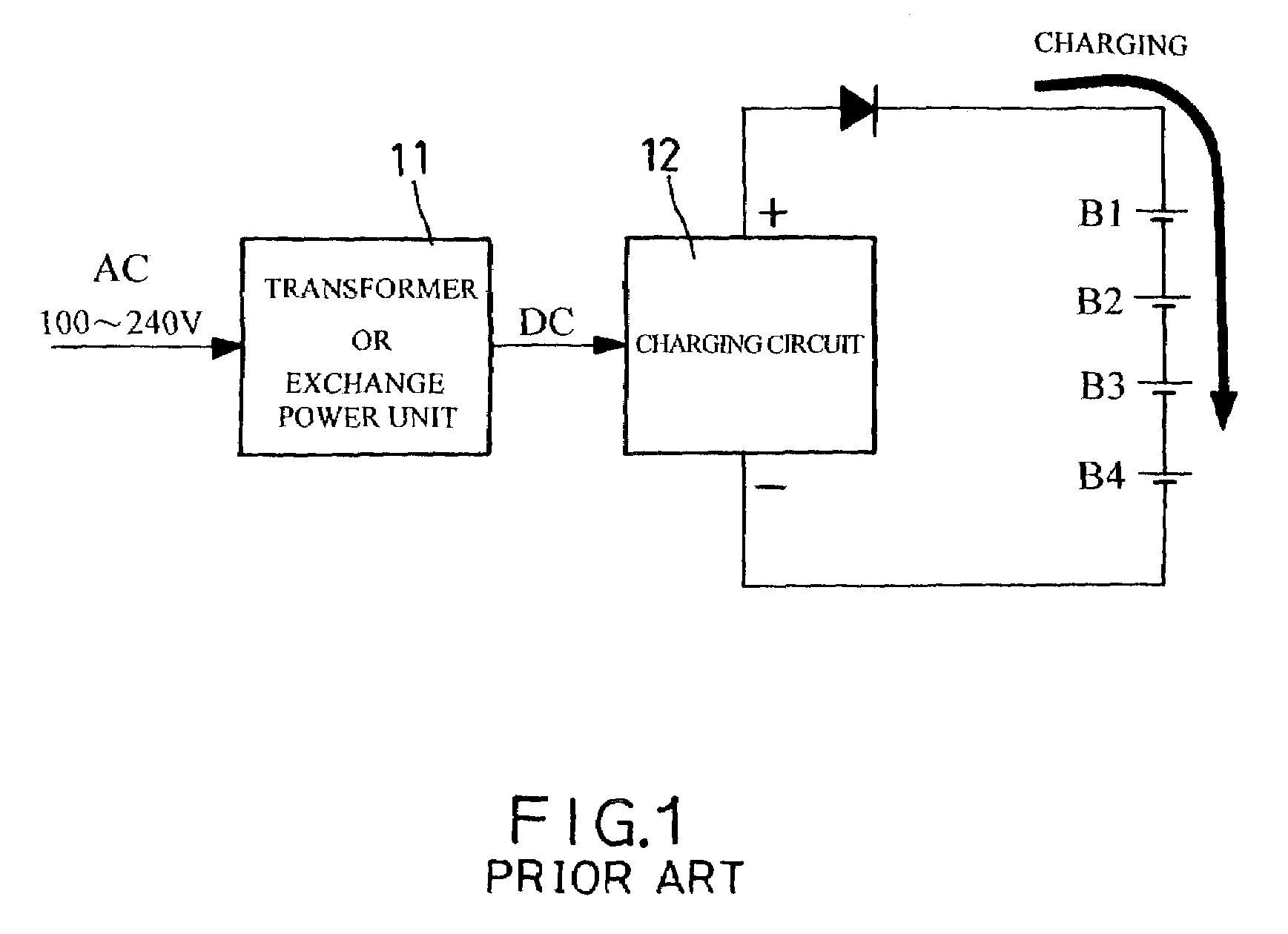

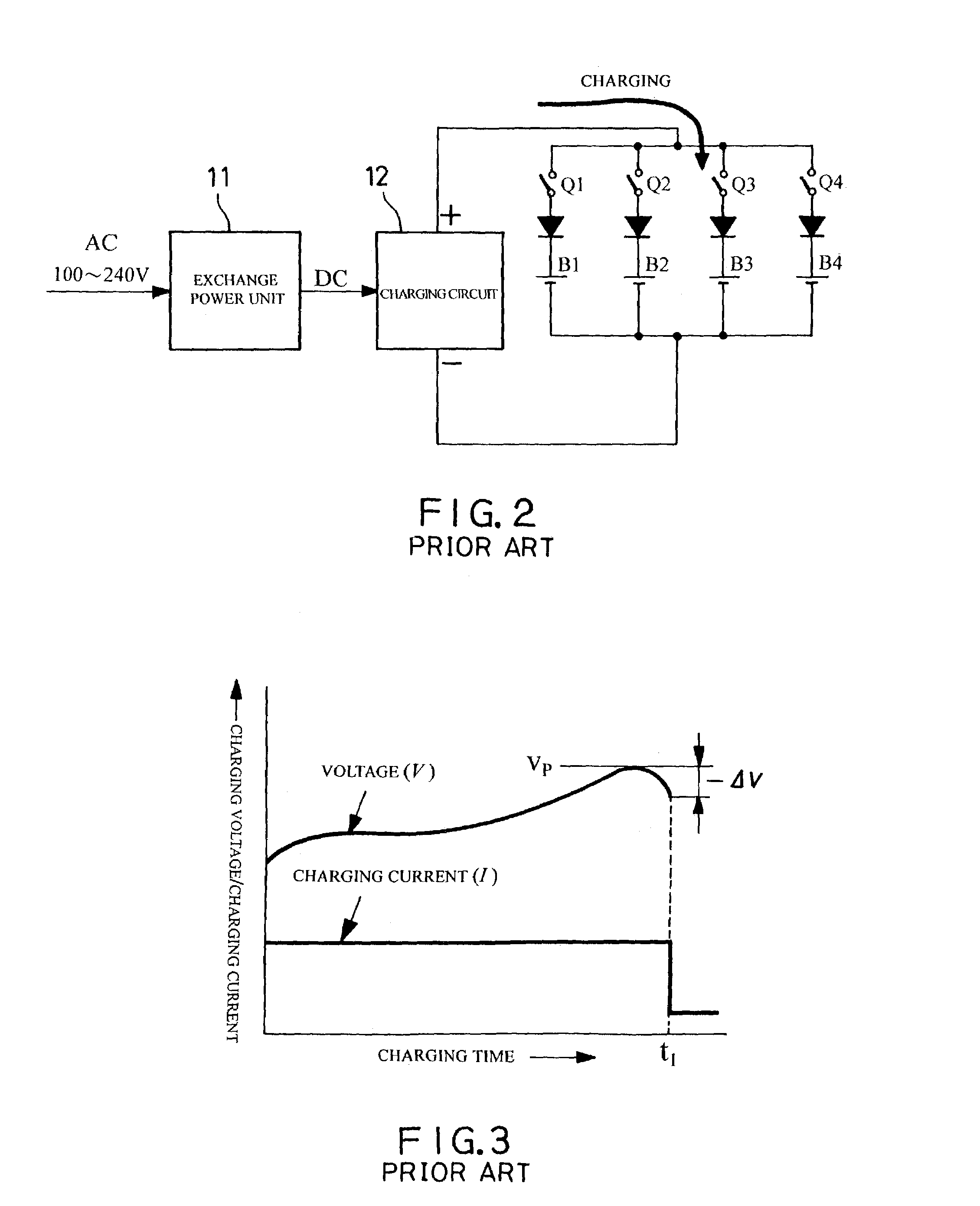

Series charger with separate detection of batteries (battery set)

InactiveUS7068011B2Fast chargingHigh use safetyCharge equalisation circuitElectric powerElectricityCharge current

The present invention relates to a series charger with separate detection of batteries which includes a charging control device for converting the inputted AC power into DC power so as to charging four batteries in series connection. The charging control device further provides a reference voltage source to a control IC which is connected with a current detector for measuring the current value of the batteries. Each of the series-connected batteries is parallel-connected with a switch element. A one-way diode is interposed between the positive end of the batteries and each of the switch elements. Besides, the control IC provides −ΔV to the positive terminal of the respective charging circuit of the batteries for detecting the end-point voltage thereof. When each of the batteries is fully charged, the respective switch element is switched in a close circuit so that the charging current continues to flow downward for further charging operation. Moreover, after all batteries are fully charged one after another, the current detector is used to regulate the charging current or the switch-on time of the switch elements is controlled for proceeding with supplementary charging procedure.

Owner:YANG FU I

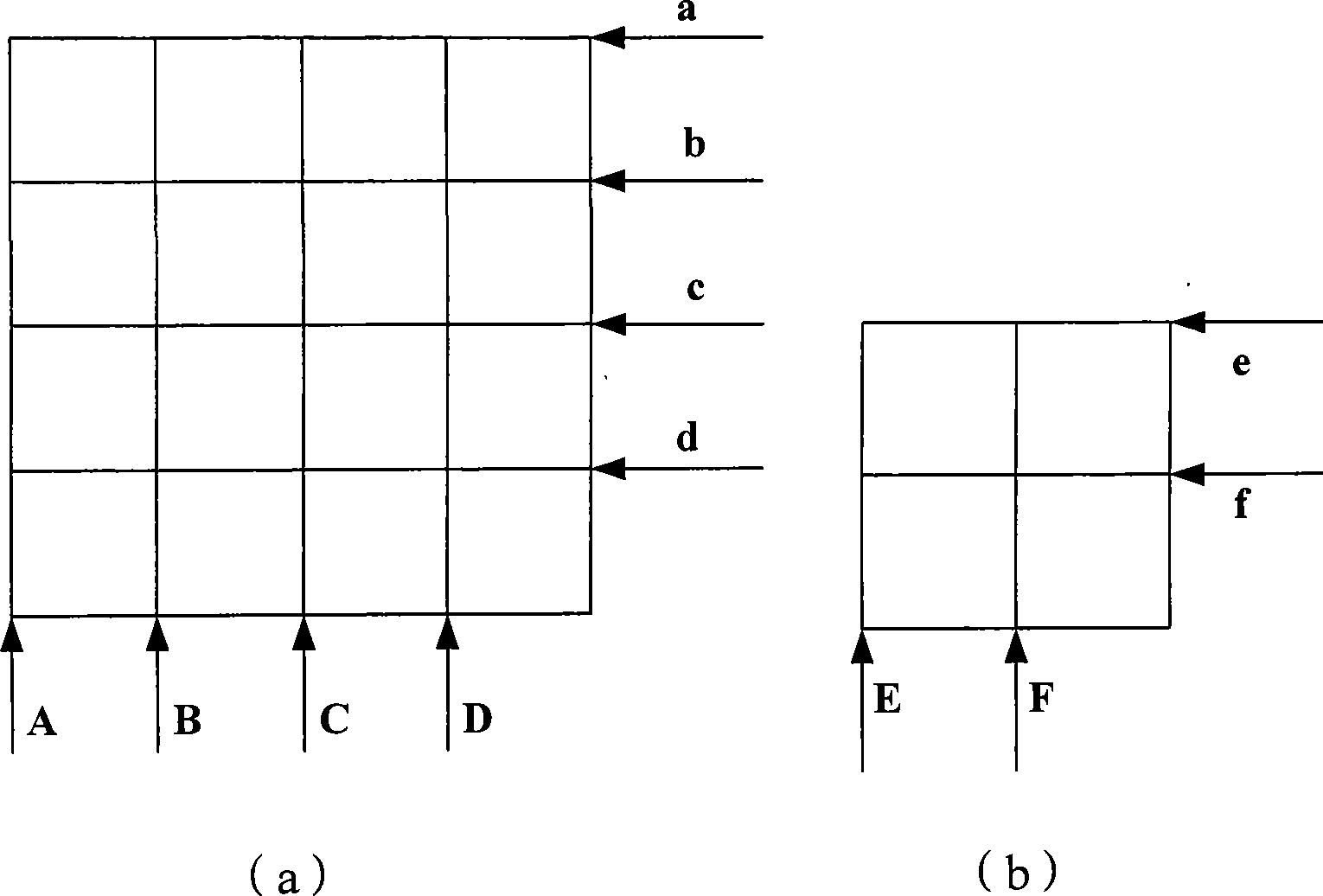

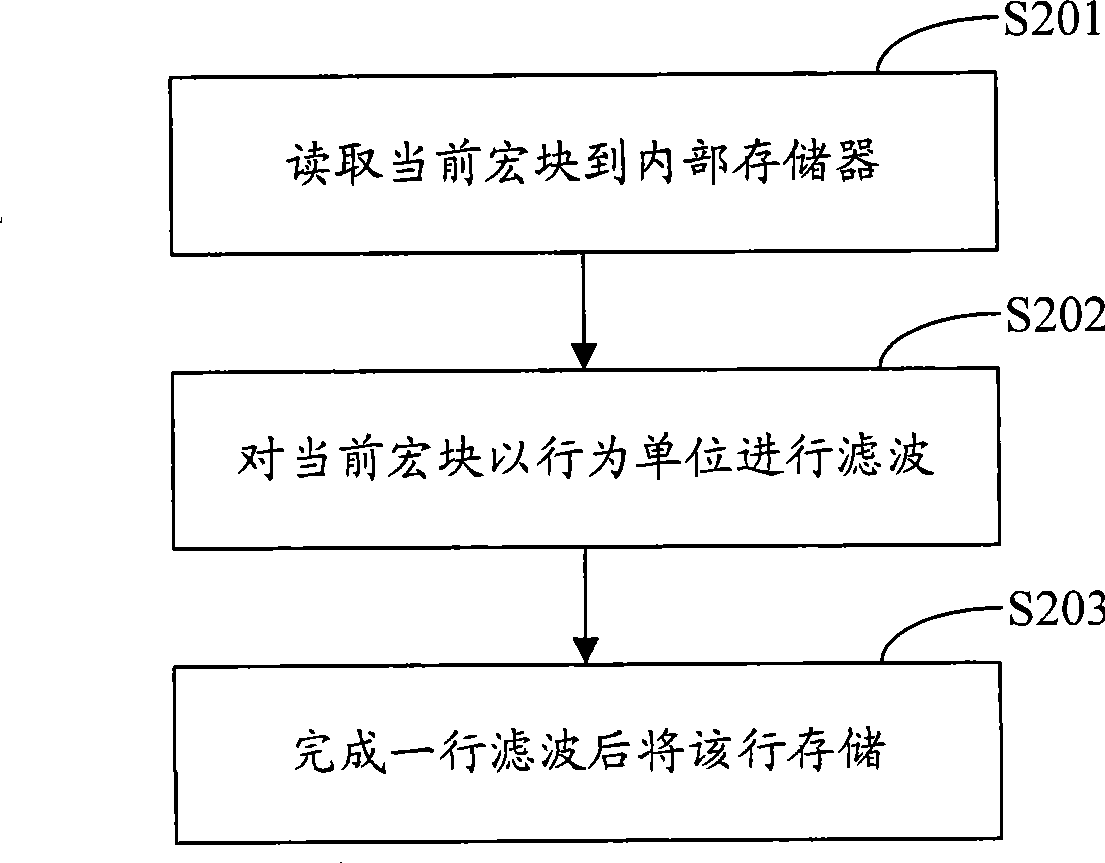

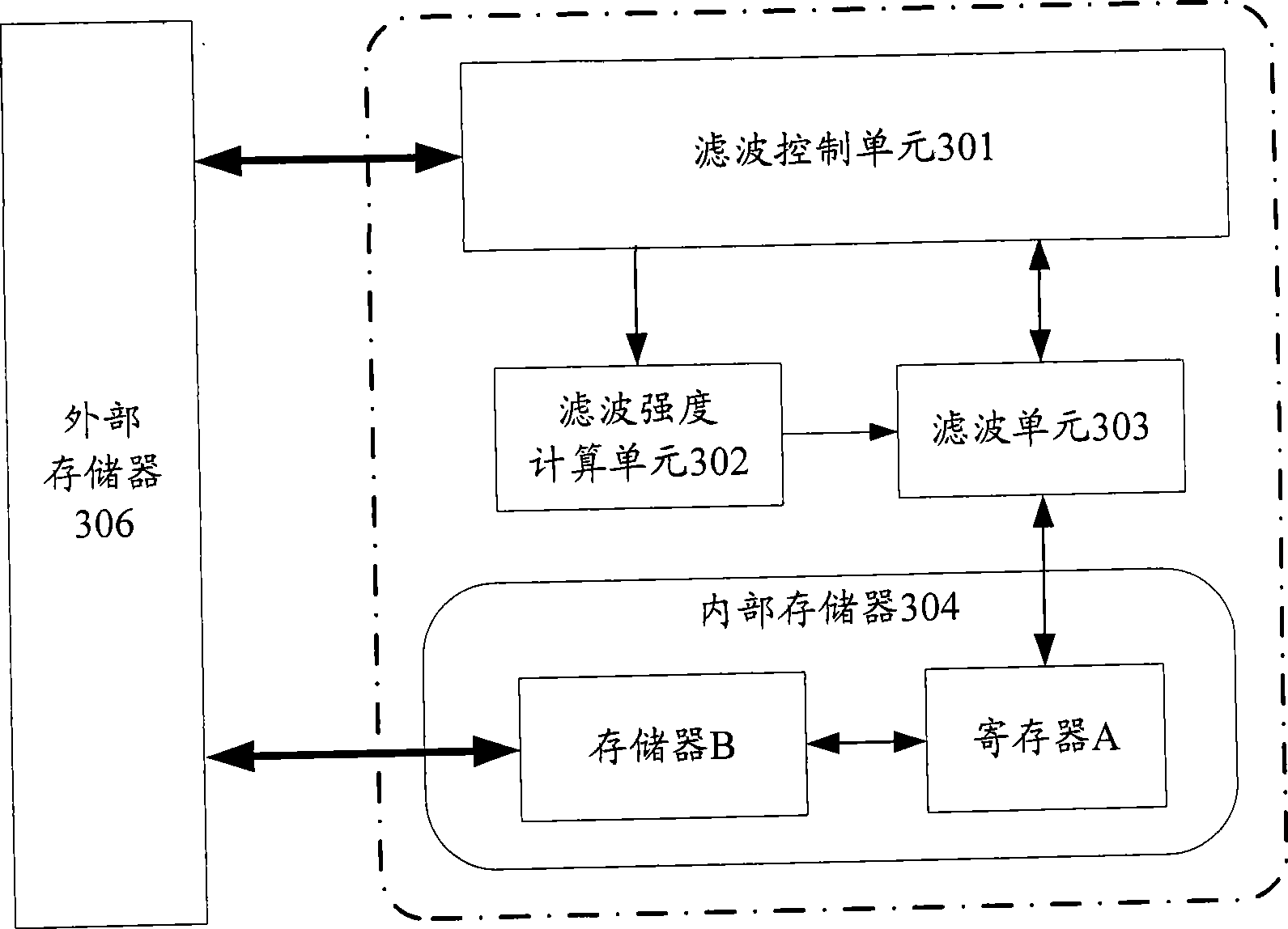

Method, system and filter for filtering de-block

ActiveCN101472173ASave spaceShorten the timeColor television with pulse code modulationTelevision systemsInternal memoryComputer architecture

The invention is applicable to the field of the video decoding based on blocks, and provides a method, a system, and a filter for realizing the de-blocking filer. The invention is characterize in that a video and an image frame are divided into a plurality of 16*16 macro blocks; each block is divided into sixteen 4*4 subblocks; the macro blocks are divided into four lines in the way that four blocks are arranged on one line; and the upper boundary and the left boundary of each block in the macro blocks are filtered. The filtering method comprises the following steps: reading the current macro blocks to an internal memory; filtering the current macro blocks by taking a line as a unit; and storing the line where one-line filtering is finished. After the image information of 16*16 macro blocks is read to the internal memory, the horizontal filtering is conducted on the vertical boundary of one line, the vertical filtering is conducted on the horizontal boundary of the line, the filtering is conducted on the next line in sequence, the judgment of whether or not the line is involved in the subsequent filtering process should be conducted after one-line filtering is finished, the image information obtained by filtering the line and the upper line is stored in the internal memory or the external memory according to the judgment result.

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

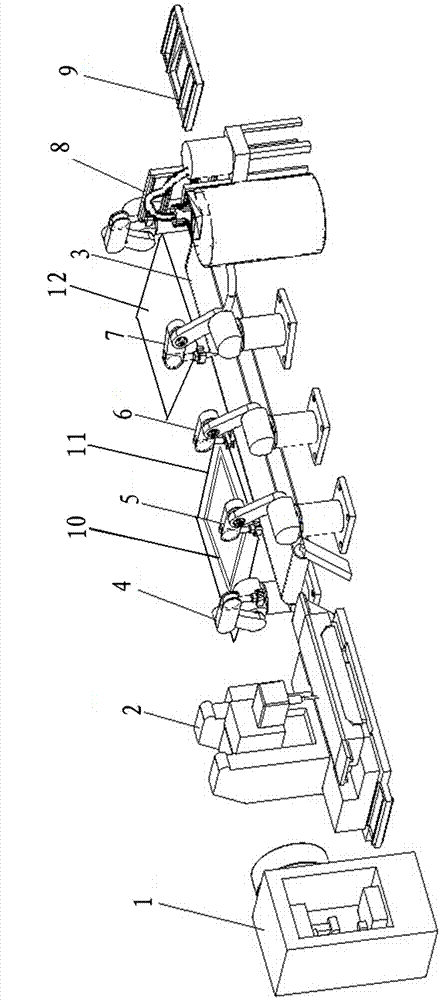

Assembling line for glass-fiber reinforced plastic windows

InactiveCN102756281AReduce workloadImprove work efficiencyAssembly machinesOther manufacturing equipments/toolsProduction lineGlass fiber

Owner:SHANGHAI DIANJI UNIV

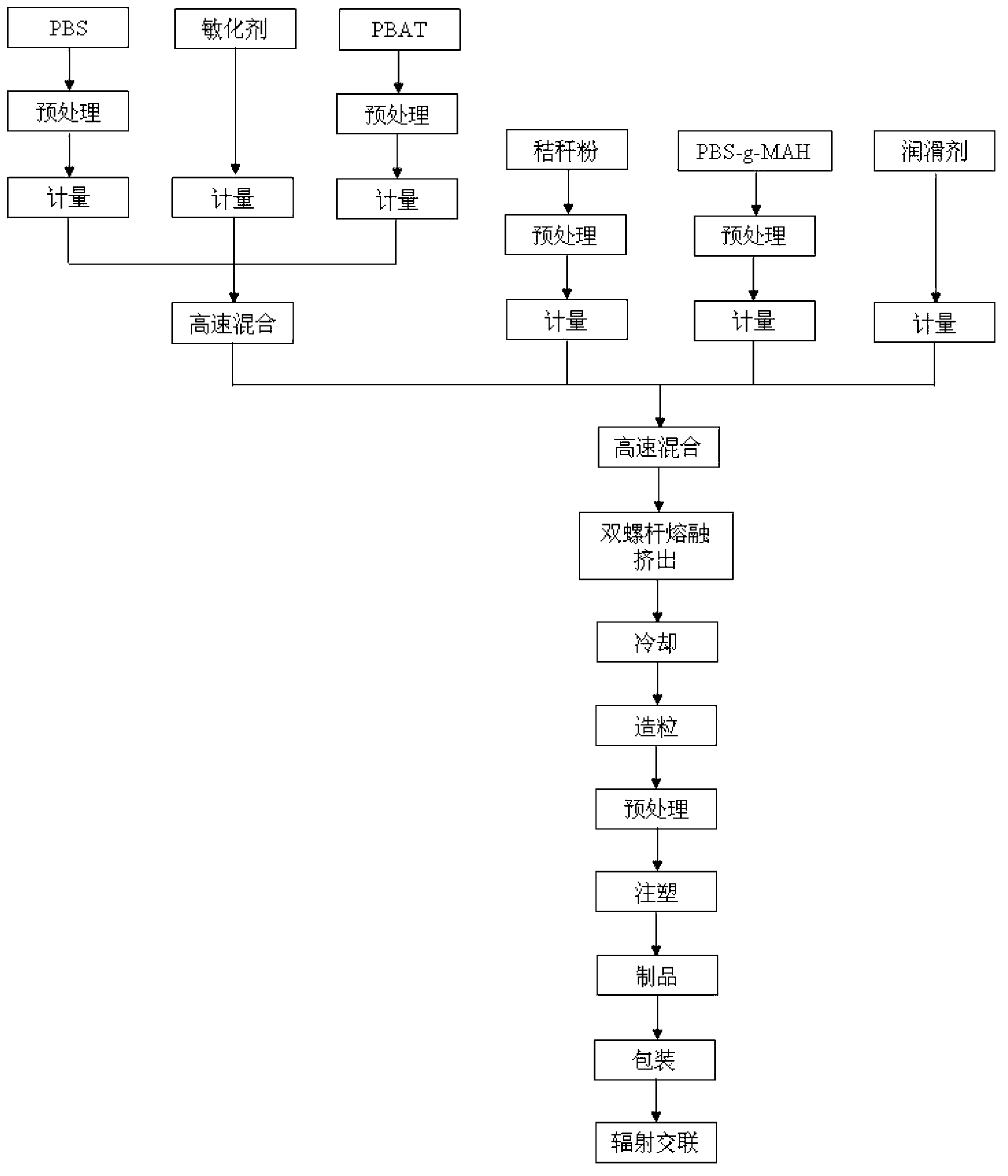

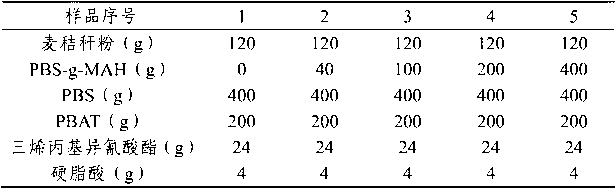

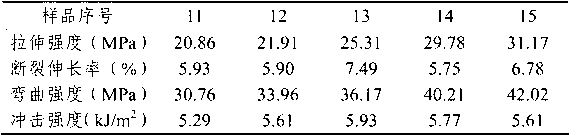

Straw fiber/PBS(poly butylene succinate)/PBAT (propylene adipate and polybutylene terephthalate) composite and preparation method thereof

InactiveCN103265716ALow costGood water resistance and heat resistanceWeather resistancePolybutylene terephthalate

The invention discloses a straw fiber / PBS(poly butylene succinate) / PBAT (propylene adipate and polybutylene terephthalate) composite and a preparation method thereof. The preparation method comprises the following steps: mixing the pre-treated PBS, straw powder, PBS-g-MAH, PBAT, compatibilizer, lubricant, radiation sensitizer according to a certain proportion, then melt blending and extruding through double screw, and then processing the obtained particles on an injection molding machine to form an injection product, and performing the radiation reinforcing crosslinking on the obtained injection product. The prepared straw fiber / PBS / PBAT ternary composite material is a high-tenacity, high-strength and high performance composite material capable of being completely degraded; compared with the pure PBS product, the straw powder in low cost is added in the composite material, the cost is greatly lowered and close to the general plastic product on the market; and furthermore, the composite material product is good in weather resistance, water resistance and heat resistance and capable of satisfying the market demand.

Owner:河南省科学院同位素研究所有限责任公司

Hydrogenation combined method for diesel oil

ActiveCN101724457ADeep modificationReduce cokingTreatment with hydrotreatment processesHydrogenCombined method

The invention discloses a hydrogenation combined method for diesel oil, which comprises the following steps: dividing a straight-run diesel oil raw material and / or a coking diesel oil raw material into two parts of materials, performing hydro-upgrading reaction on one part of the material after being mixed with a catalytically cracked diesel oil raw material, and performing hydro-refining reaction on the other part of the material. The hydro-refining reaction and the hydro-upgrading reaction share a set of hydrogen recycling system. The combined method of the invention meets the requirement of products with different amounts and quality by flexibly adjusting raw oil ratio of two reaction zones, reduces operating severity of a hydro-upgrading reaction zone and prolongs the operation cycle at the same time. In addition, the method of the invention simplifies the process flow, can decrease equipment and reduces investment and operation cost. The method is suitable for hydro-processes of various inferior-quality distillate raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Blanking manufacturing method of capacitance touch screen

InactiveCN103699286AImprove visual enjoymentChanging the vanishing structureInput/output processes for data processingCapacitanceIndium tin oxide

The invention belongs to the technical field of capacitance touch screens, particularly relates to a blanking manufacturing method of a capacitance touch screen. The method includes adopting vacuum magnetic-control continuous plating to deposit a silica film on a glass substrate to serve as a bottom layer; depositing an indium tin oxide film on the silica film through magnetic-control sputtering to serve as an electroconductive film layer; plating a silicon nitride film on the indium tin oxide film to serve as a blanking layer. Indium tin oxide is arranged on the glass substrate, sheet resistance value of indium tin oxide can be easily controlled to be within a preset range, and parameters of the silicon nitriode film are adjusted according to sheet resistance of indium tin oxide and film forming effect, so that lines on indium tin oxide are enabled to be nonobvious, excellent blanking effect is realized, visual enjoyment of a user is improved, the problem that the capacitance touch screen cannot balance the sheet resistance value of indium tin oxide and the blanking effect, and the capacitance touch screen meets market requirements and is high in market competitiveness.

Owner:SHENZHEN LEAGUER OPTRONICS

High-strength alkali-free glass fibre direct roving sizing agent for optical cable strengthening core

The invention discloses a size of high-strength alkali-free glass fibre direct yarn used for a reinforced core of an optical cable, comprising coupling agent, lubricant, film forming agent A, film forming agent B, film forming agent C and a pH value regulator; the solid weight of all the materials accounts for 5 to 10 percent, the rest of materials is water, and the content of the water accounts for 90 to 95 percent of the total weight of the size; the coupling agent adopts silane coupling agent and accounts for 3 to 10 percent of the solid weight of the size; the lubricant adopts unsaturated olein lubricant and accounts for 1 to 10 percent of the solid weight of the size; the film forming agent A, the film forming agent B and the film forming agent C respectively adopts one of epoxy emulsion, polyester emulsion and polyvinyl acetate emulsion, wherein, the film forming agent C selects compound with low degree of polymerization, the combination of the film forming agent A and the film forming agent B accounts for 80 to 85 percent of the solid weight of the size, the film forming agent C accounts for 1 to 5 percent of the solid weight of the size, the pH value regulator adopts acid and accounts for 1 to 5 percent of the solid weight of the size and the pH value of the size is 2 to 8. The size has good compatibility with vinyl resin and epoxy resin and can lead the strength of the glass fibre reinforced plastic of the product to be improved.

Owner:JUSHI GRP CO

Brainstorming-based thermal power plant economic environment scheduling method

ActiveCN104037757ARealize the solutionScheduling is simpleAc network circuit arrangementsMathematical modelBrainstorming

The invention discloses a brainstorming-based thermal power plant economic environment scheduling method. The method includes the following steps of: determining mathematical models of thermal power plant environmental economic scheduling problems; step 2, obtaining various parameters in the models; step 3, obtaining an initial feasible scheduling set of the thermal power plant environmental economic scheduling problems; step 4, evaluating the feasible scheduling set; step 5, updating the feasible scheduling set; step 6, judging whether entire feasible scheduling is updated completely; step 7, updating a non-inferior scheduling solution set in an external archiving set; step 8, performing iterative output of a final feasible scheduling scheme, and the method terminates. According to the brainstorming-based thermal power plant economic environment scheduling method of the invention, a thermal power plant is adopted as a power supply system, and solutions to thermal power plant economic scheduling problems which are required by comprehensive environmental protection can be realized through collection and analysis of data of a power system and the thermal power plant and a brainstorming optimization algorithm based clustering and variation ideas.

Owner:XIAN UNIV OF TECH

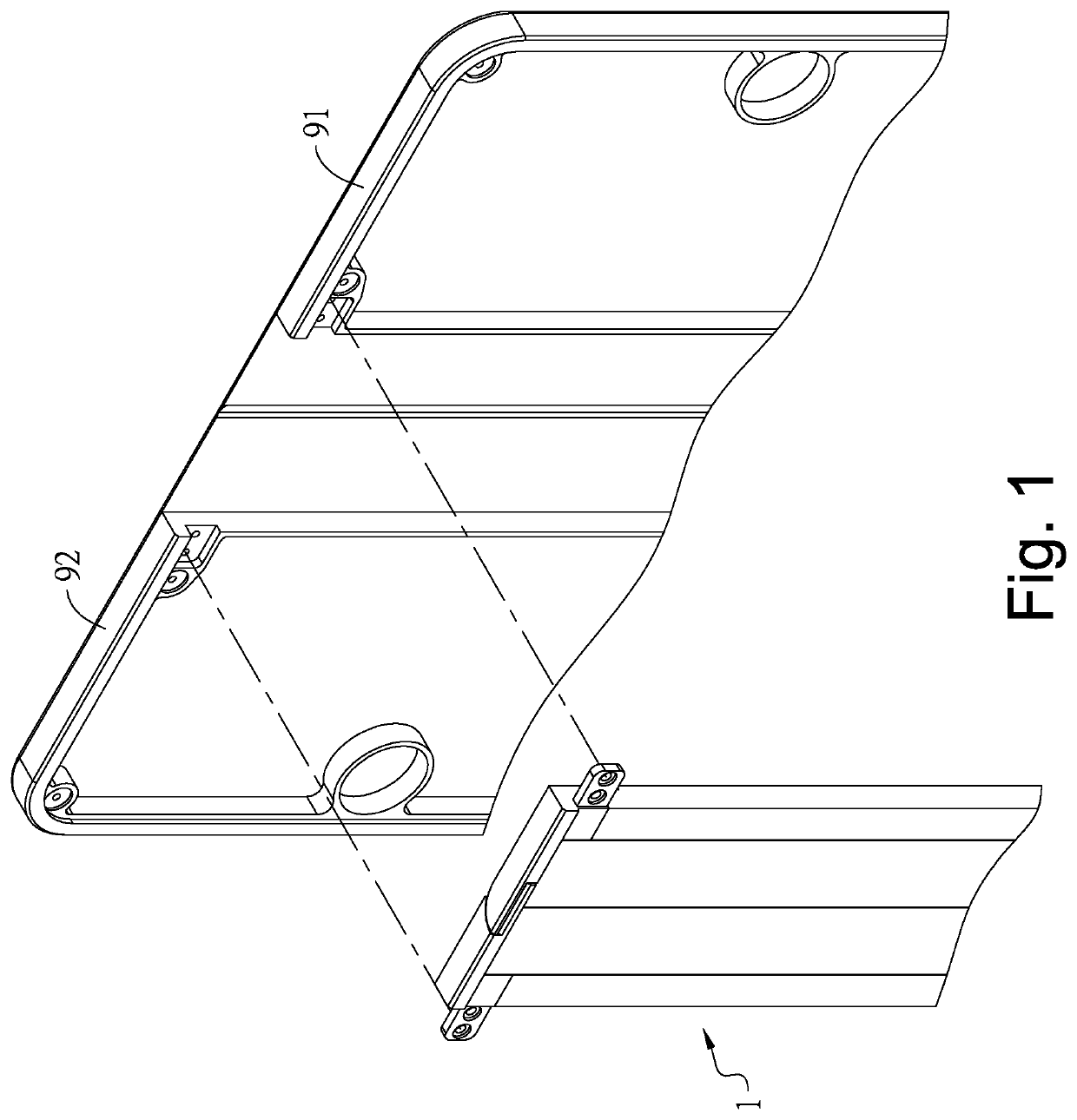

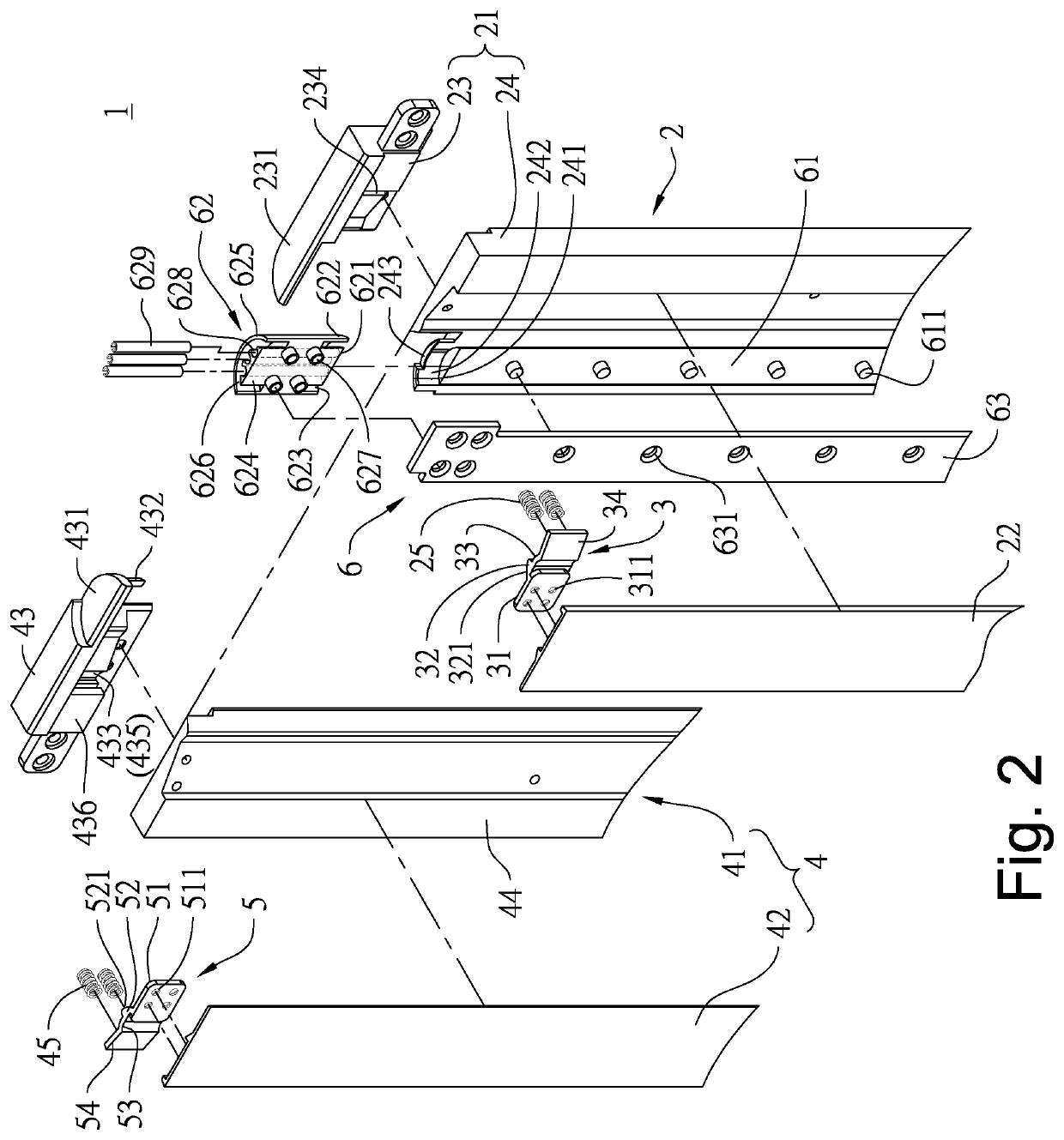

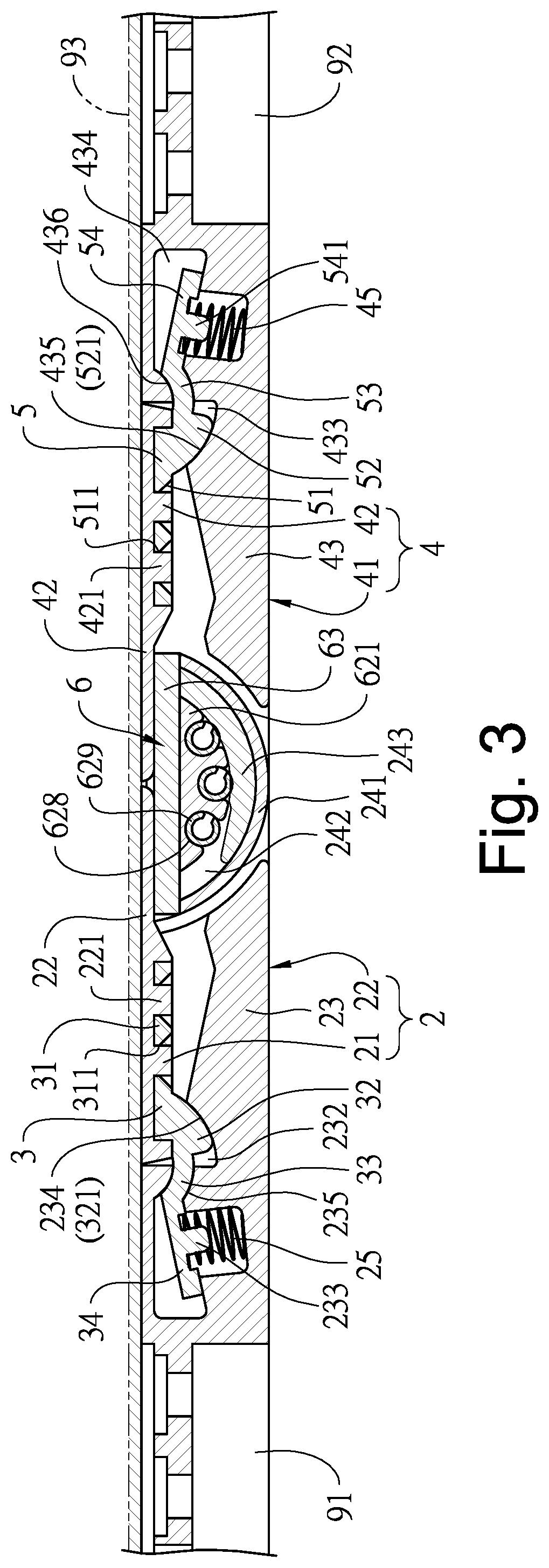

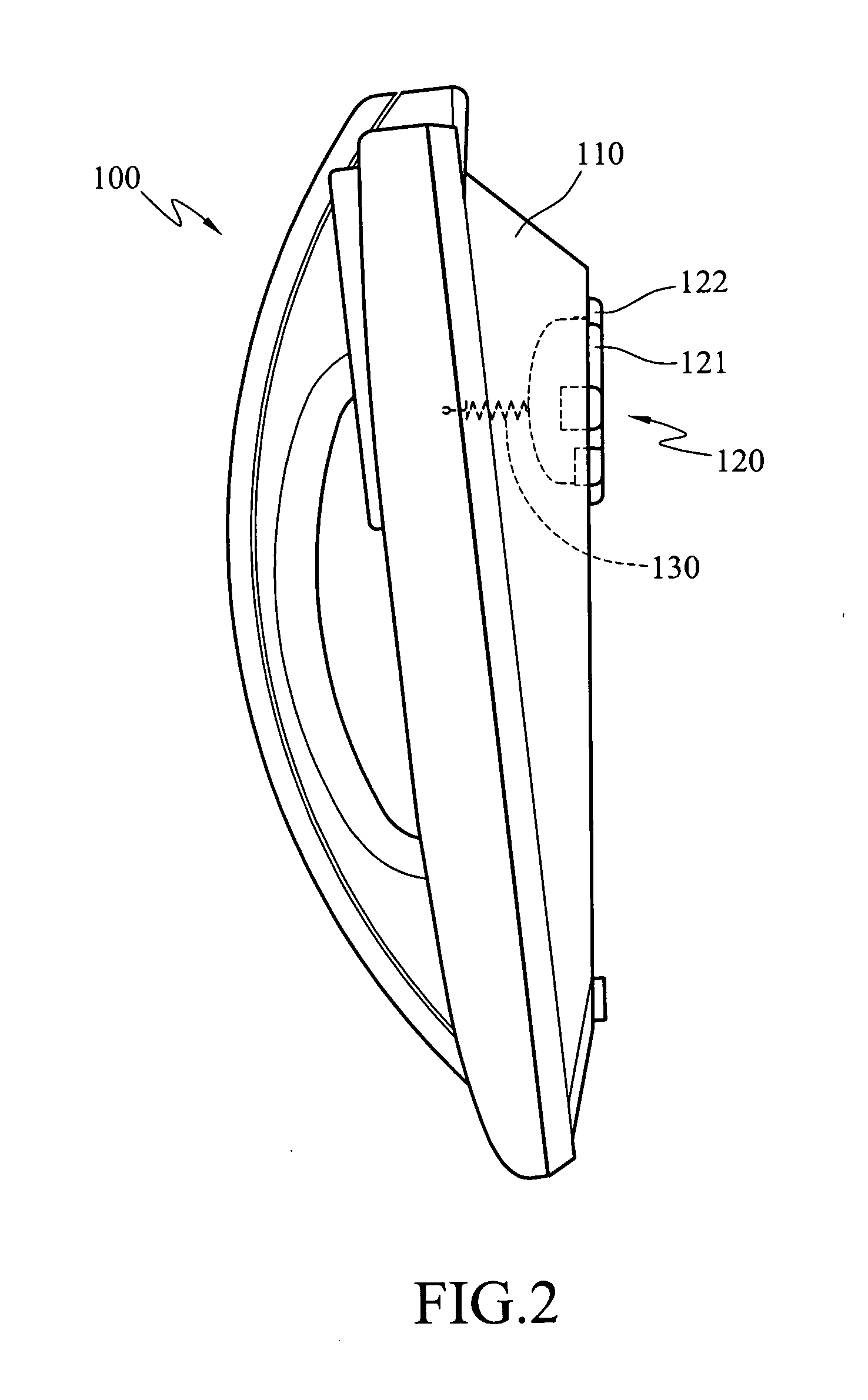

Hinge module for a foldable type device

ActiveUS20190390703A1Reduce spaceNot conducive to overall designWing accessoriesDetails for portable computersEngineeringMechanical engineering

Owner:JARLLYTEC CO LTD

Method for extracting high-purity nobiletin from citrus peels

ActiveCN102875509AEasy to realize industrial productionHigh purityOrganic chemistryReflux extractionOrganic solvent

The invention discloses a method for extracting high-purity nobiletin from citrus peels. The method comprises the following steps: 1, carrying out reflux extraction of crushed dry citrus peels for 2 to 4 times, combining the filtrate after filtration, and concentrating under reduced pressure to obtain a concentrated solution; 2, adding water into the concentrated solution, then adding an acidic solution or an alkaline solution till the pH value of the system ranges from 3 to 9, standing for removal of the supernatant to obtain a sediment, settling and washing the sediment, centrifuging, and collecting solid to acquire a polymethoxylated flavonoids crude product; 3, conducting ungrease treatment; 4, using an organic solvent to achieve reflux dissolution of the polymethoxylated flavonoids crude product which is subject to ungrease treatment, then adding activated charcoal for reflux decoloration, filtering, standing the concentrated filtrate for crystallization, and filtering the crystallized filtrate to obtain a nobiletin crude product; and 5, recrystallizing to obtain the high-purity nobiletin of which the quality purity is not less than 98 percent. The method provided by the invention has the characteristics of simplicity, feasibility, short production period, no need of expensive production equipment, low cost and the like, and is easy for realizing industrial production of high-purity nobiletin.

Owner:SHAANXI HUIKE BOTANICAL DEV CO LTD

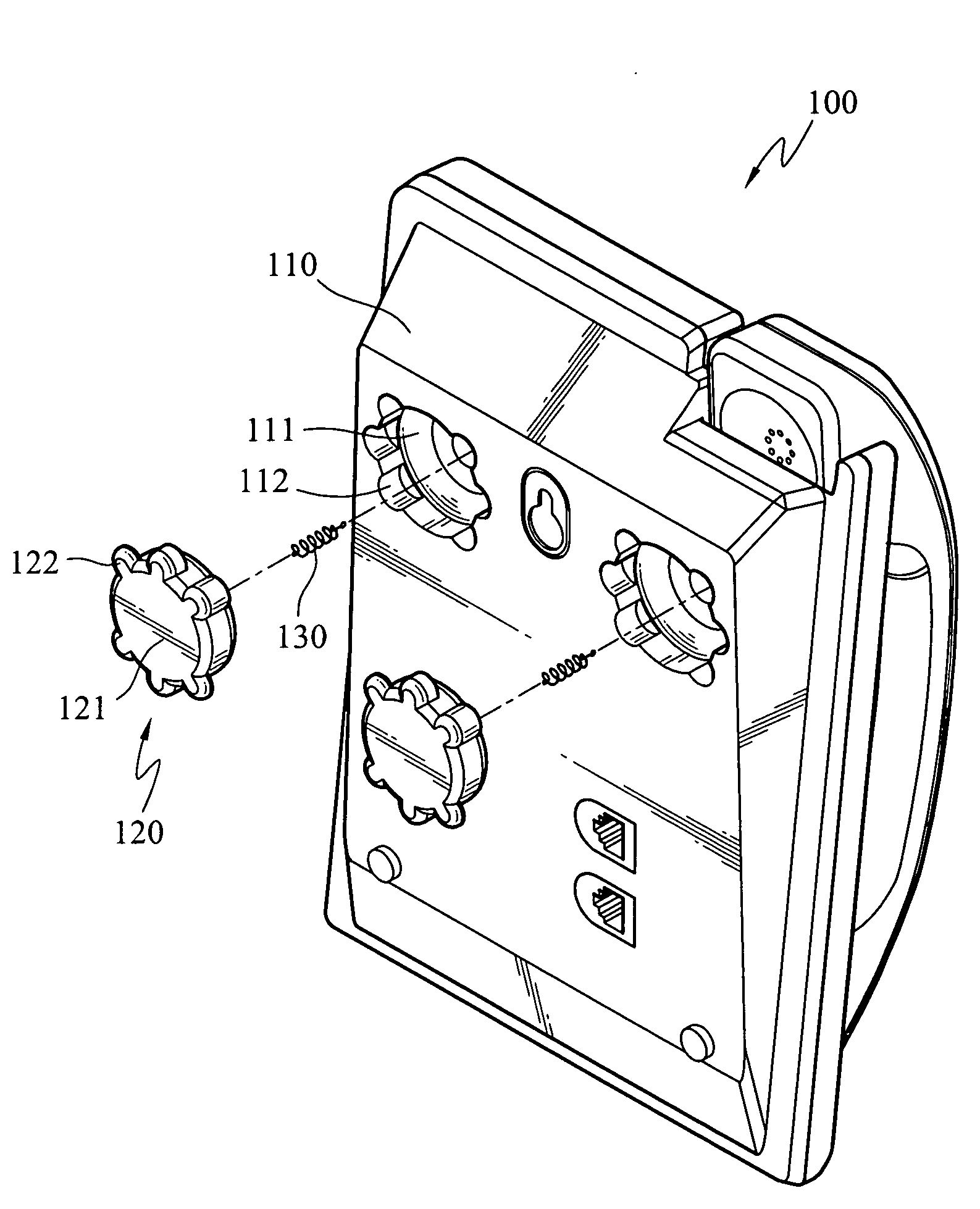

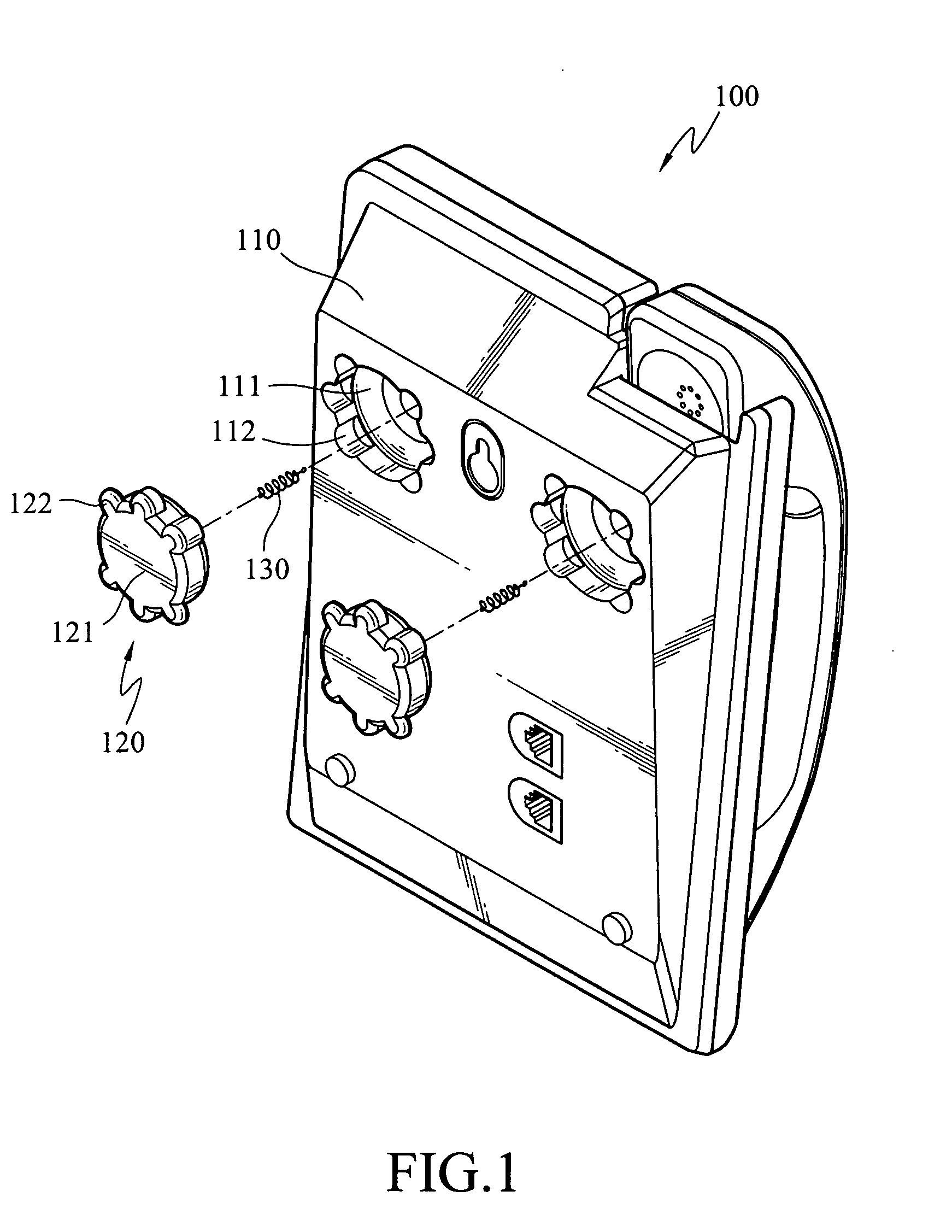

Electronic device with pad height adjustable

InactiveUS20080029664A1Improve disadvantagesQuick and accurate adjustmentMachine framesStands/trestlesEngineeringElectronic equipment

Owner:INVENTEC MULTIMEDIA & TELECOM

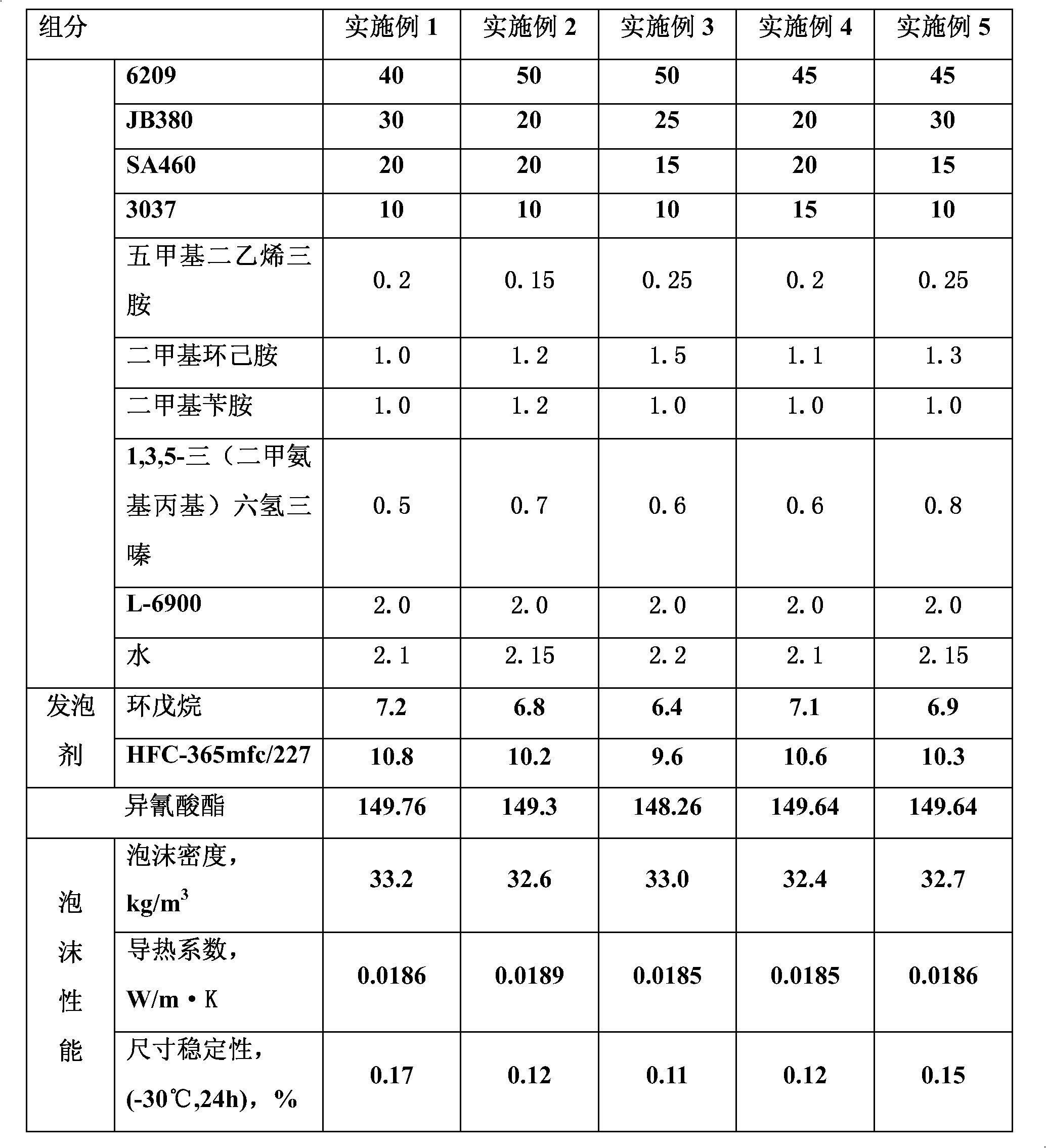

Polyurethane rigid foam composite polyether

The invention relates to polyurethane rigid foam composite polyether and belongs to the technical field of polyurethane foam plastic. The polyurethane rigid foam composite polyether consists of the following raw materials in part by weight: 100 parts of polyether polyol, 0.1 to 0.5 part of catalyst I, 0.5 to 1.5 parts of catalyst II, 1.0 to 1.5 parts of catalyst III, 0.5 to 0.8 part of catalyst IV, 1.5 to 2.5 parts of silicone oil, 1.5 to 2.5 parts of water and 15 to 20 parts of mixture consisting of cyclopentane and 365mfc / 227, wherein the polyether polyol adopts four kinds of different polyols. The heat conductivity coefficient of foam prepared from the composite polyether and isocyanate is obviously lower than that of cyclopentane foam. In the reaction process of the isocyanate and the composite material, a wider operating range can be achieved. Sensitivity of parameters such as the reaction materials, moulds, environmental conditions and the like is reduced.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

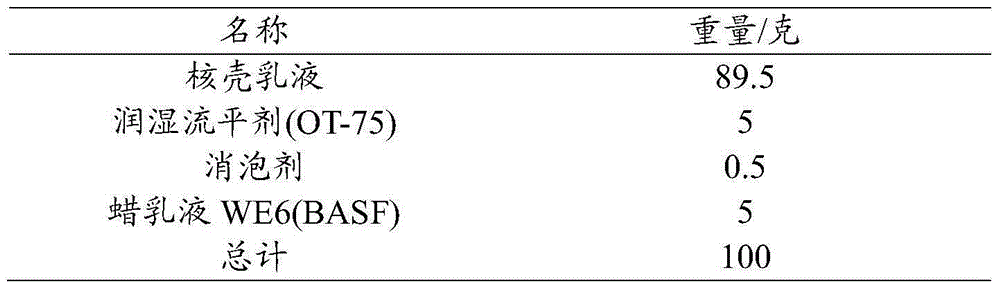

Water-based environment-friendly film-forming material applied in steel fastener surface, and preparation method and application thereof

ActiveCN105175615AImprove adhesionImprove water resistanceAnti-corrosive paintsPhosphoric Acid EstersFunctional monomer

The invention provides a water-based environment-friendly film-forming material applied in steel fastener surface, and a preparation method and application thereof. Specifically, the preparation method for the water-based environment-friendly film-forming material applied in the steel fastener surface comprises synthesis of a shell emulsion and synthesis of a core-shell emulsion, wherein the shell emulsion is firstly prepared from a vinyl monomer I composed of olefinic carboxylic acid, a crosslinking functional-group monomer and acrylate (C1-C10) alcohols; and then the core-shell emulsion is synthesized from the above-mentioned shell emulsion, and a vinyl monomer II composed one or a mixture of more than two selected from the group consisting of the acrylate (C1-C10) alcohols, phosphate functional monomers and styrene; thus, the water-based environment-friendly film-forming material applied in the steel fastener surface is obtained. The water-based environment-friendly film-forming material applied in the steel fastener surface has high adhesive force to a substrate and is corrosion-resistant, oxidation-resistant and wear-resistant.

Owner:GUANGZHOU HENGLONGYU CHEM SCI & TECH

Diclofenac sodium sustained-release tablet and its preparation process

ActiveCN102274200AAvoid condensationReduce usageOrganic active ingredientsAntipyreticDiclofenacAdhesive

The invention relates to the technical field of medicine, in particular to diclofenac sodium sustained release tablets and a preparation process thereof. The diclofenac sodium sustained release tablets provided by the invention comprise the following components in percentage by mass: 16.5 to 39.0 percent of diclofenac sodium, 10.0 to 35.5 percent of sustained release agent, 33.5 to 65.0 percent of filling agent, 2.01 to 8.0 percent of glidant, 0 to 2.5 percent of lubricating agent, and 0 to 8.0 percent of adhesive. According to the diclofenac sodium sustained release tablets and a whole-powder direct tabletting method thereof provided by the invention, by changing the components and the preparation method, the production process is simplified, the production cost is reduced, the production efficiency is improved, the yield is improved to 98.0 to 100 percent, granule condensation is avoided, the surface of the tablets is smooth, meanwhile, consumption of high-concentration alcohol is avoided, and the potential safety hazard in the production process is reduced.

Owner:SINOPHARM GRP ZHIJUN SHENZHEN PINGSHAN PHARMA CO LTD

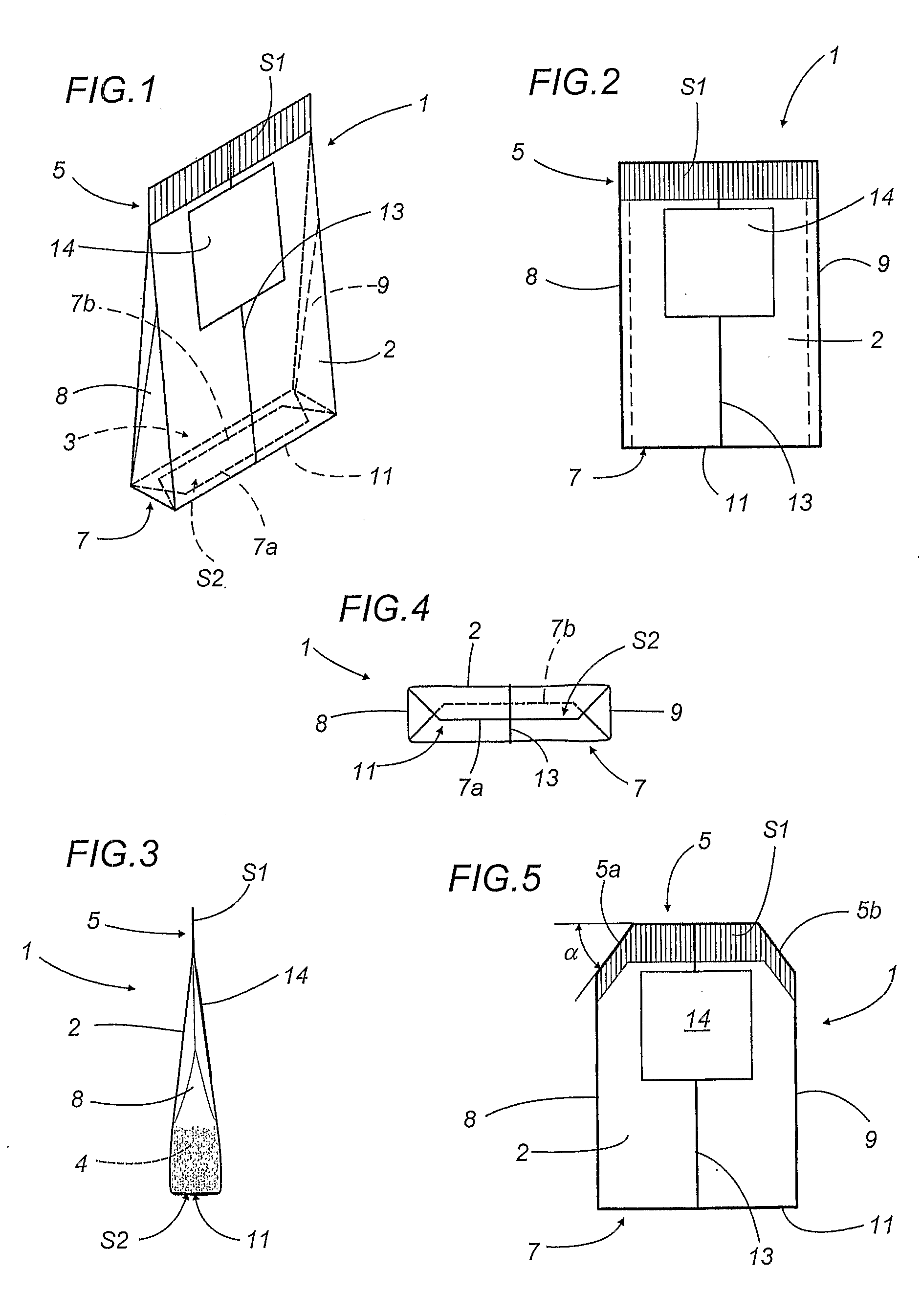

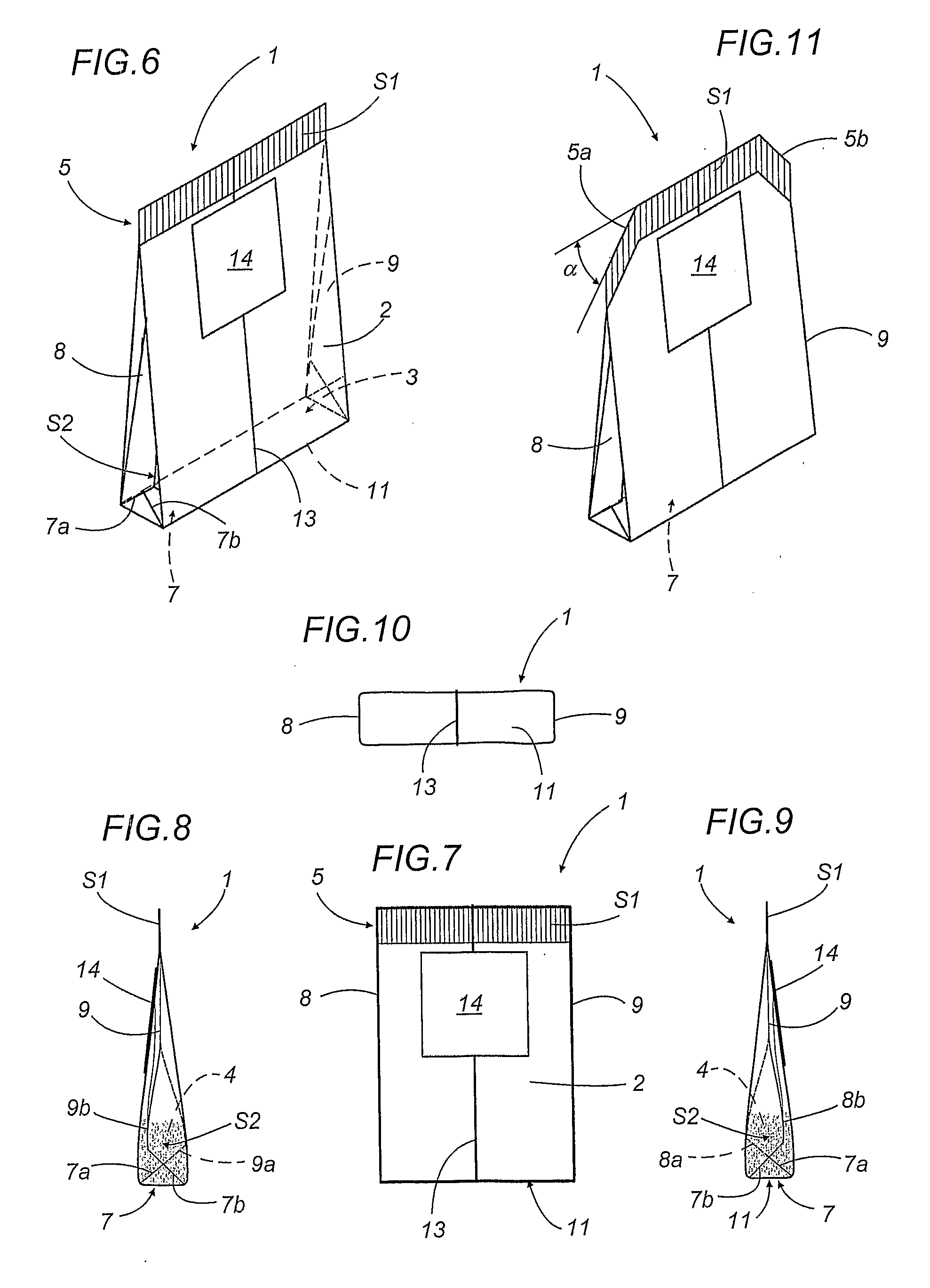

Single-lobe filter bag for infusion products

InactiveUS20090263546A1Quality improvementOvercome disadvantagesPackaging foodstuffsSINGLE LOBEEngineering

A single-lobe filter bag for infusion products comprises a length (2) of filter material forming a chamber (3) containing a charge (4) of the infusion product. The length (2) comprises: a first closed top end (5) formed by a first join (S1) between two first end edges of the length (2); a second closed bottom end (7) and two sides (8, 9) connecting the two ends (5, 7) of the length (2); the two sides (8, 9) connecting the first and second edges (5, 7) are at least partly folded onto each other to form a fold towards the inside of the chamber (3) and the second bottom end (7) of the filter bag (1) is closed by second join (S2) designed to form a rigid flat bottom surface (11) of the filter bag (1) such as to define a stable base, with a substantially triangular cross section, for supporting the filter bag (1).

Owner:IMA FLAVOUR

SMT no-lead tinol

InactiveCN101088695AOvercoming lead problemsLead issues comply withWelding/cutting media/materialsSoldering mediaOrganic acidSuccinic acid

The SMT no-lead tinol includes solvent, thixotropic agent, adhesive, composite activating agent, surfactant and antioxidant, and the composite activating agent consists of methyl succinic acid, organic acid and halogen salt. The SMT no-lead tinol has the features of high wettability, good printing performance, homogeneous and fine paste, light color of the soldered residue, low corrosion and high storage stability, and is suitable for use in twice reflux soldering of double-sided circuit board in electronic industry.

Owner:SHENZHEN UNIBRIGHT TECH

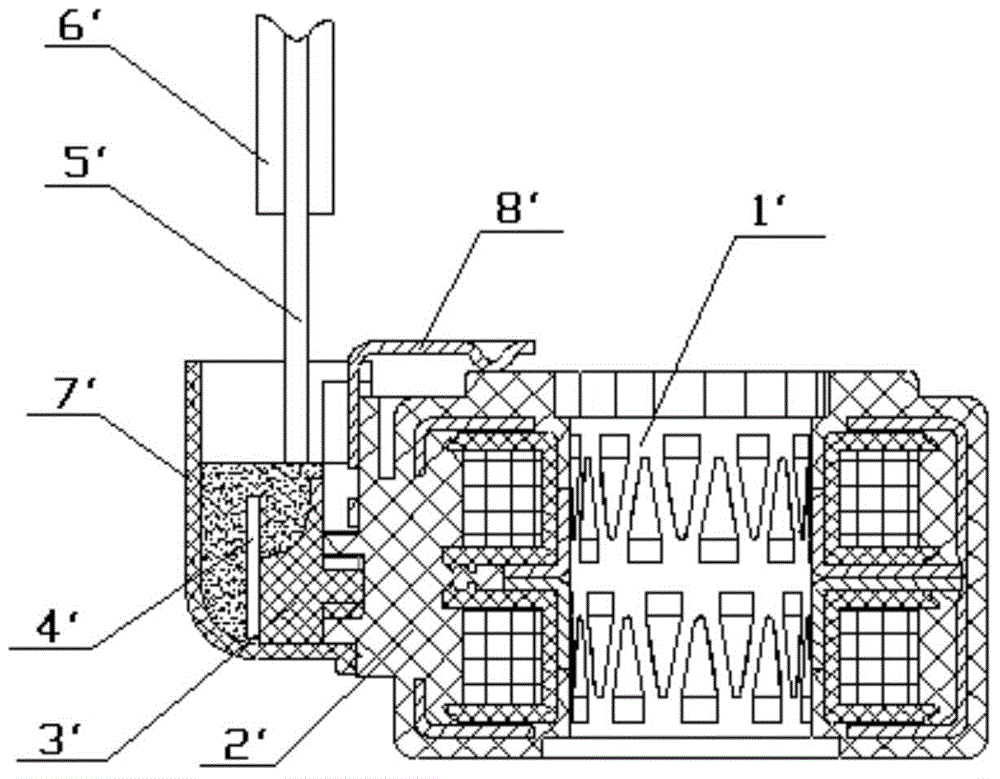

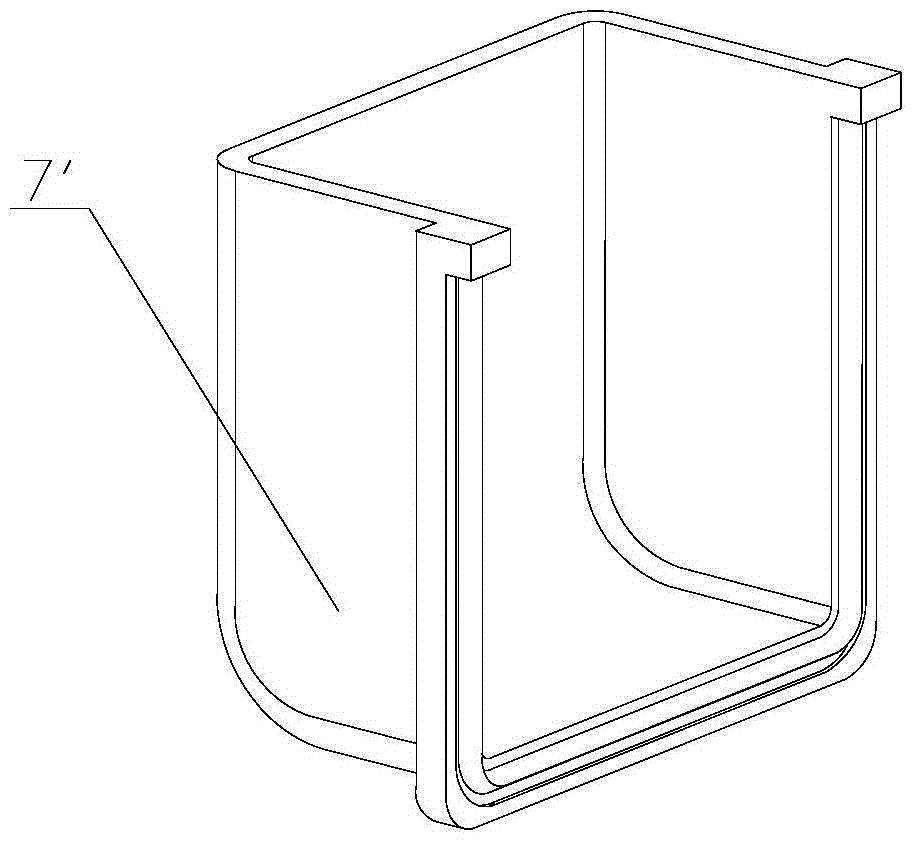

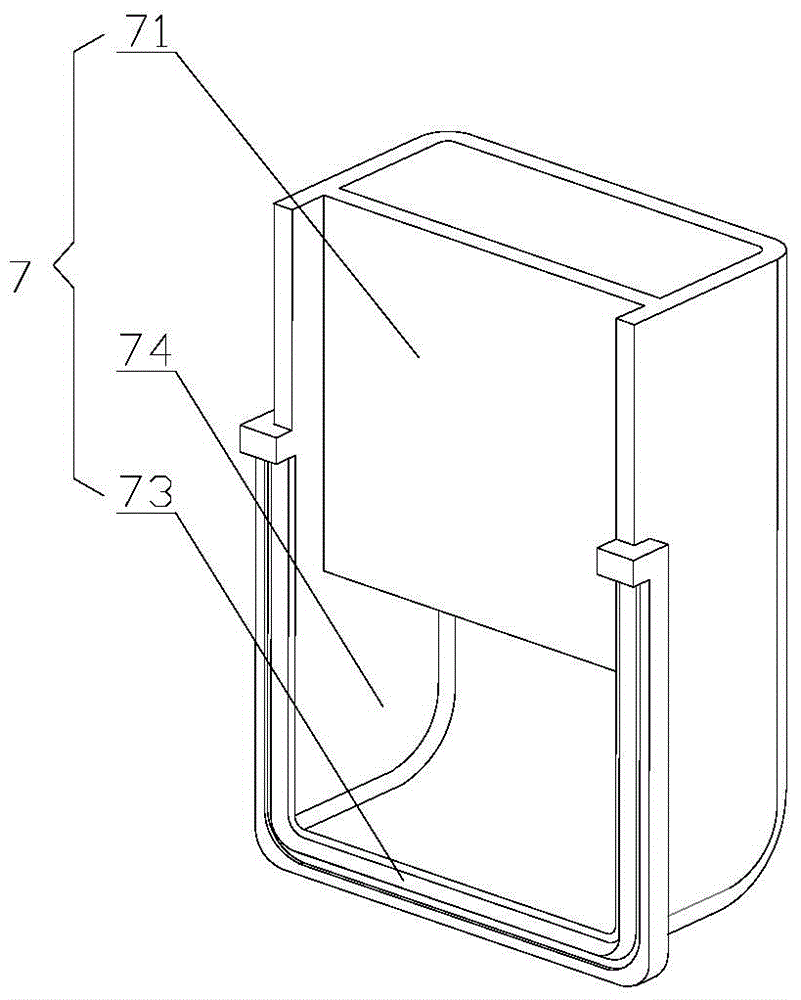

Explosion-proof coil, electronic expansion valve and machining method of explosion-proof coil

ActiveCN106151646AImprove explosion-proof performanceMeet certification requirementsOperating means/releasing devices for valvesEfficient regulation technologiesElectronic expansion valveMachining

The invention discloses an explosion-proof coil which comprises a winding (1) and a winding shell (2). A cable mounting part (3) and a circuit board (4) are arranged on the winding shell (2). A leading wire (5) is installed on the circuit board (4). A protection sleeve (6) is arranged outside the leading wire (5). A housing (7) is further fixedly connected outside the winding shell (2). The top end of the housing (7) is higher than the bottom end of the protection sleeve (6). The housing (7), the cable mounting part (3), the circuit board (4), the leading wire (5) and part of the protection sleeve (6) are formed into a whole through encapsulation. Compared with the prior art, encapsulation of the bottom end of the protection sleeve (6) is achieved through the explosion-proof coil, the electric insulation performance of the joint of the circuit board (4) is guaranteed, the explosion-proof performance of the explosion-proof coil is improved, the explosion-proof coil is made to meet the national certification requirements for explosion-proof coils, and meanwhile, market requirements for the explosion-proof coil of an electronic expansion valve can also be met. The invention further provides the electronic expansion valve with the explosion-proof coil applied and a machining method of the explosion-proof coil.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

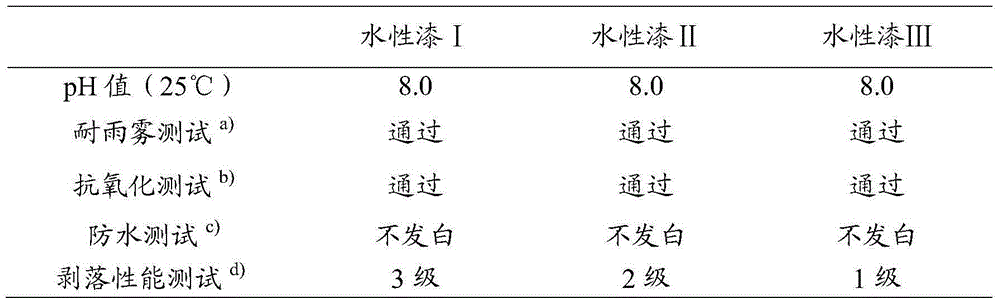

Nano sterilizing anionic double-component aqueous wood paint

InactiveCN101880500ANo pollutionWon't hurtAntifouling/underwater paintsPaints with biocidesAcrylic resinLacquer

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano sterilizing anionic double-component aqueous wood finishing paint and a preparation method thereof. The nano sterilizing anionic double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano sterilizing anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, strong sterilization and mildew prevention, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

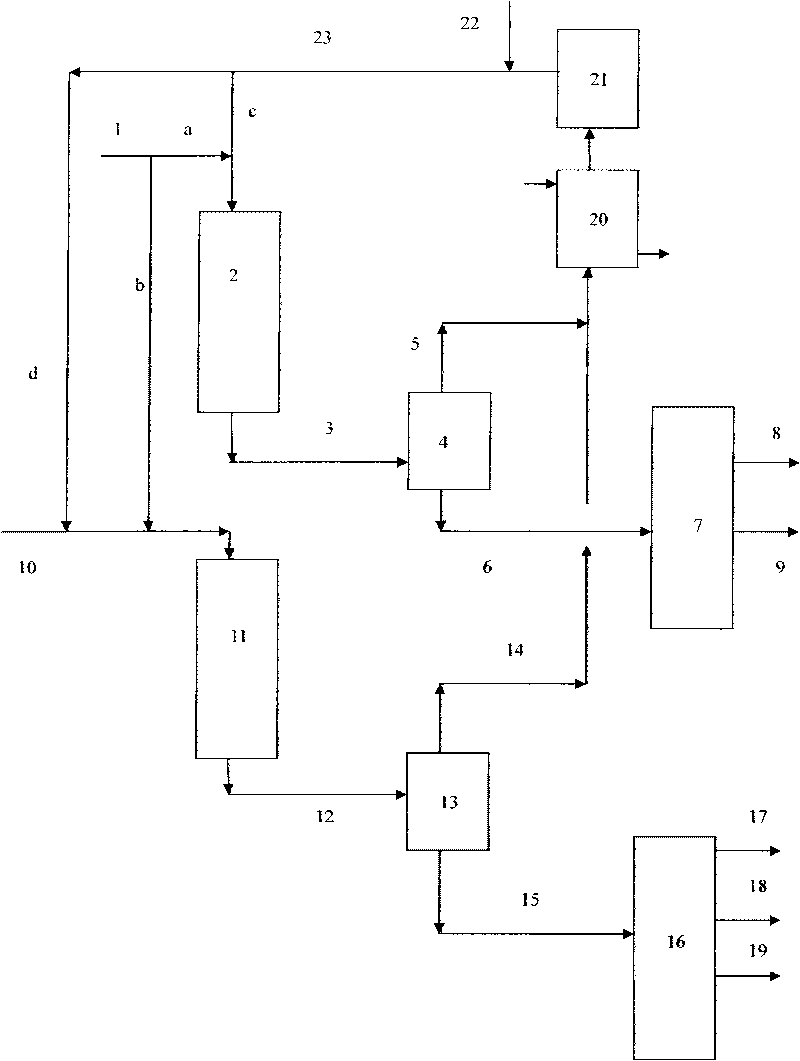

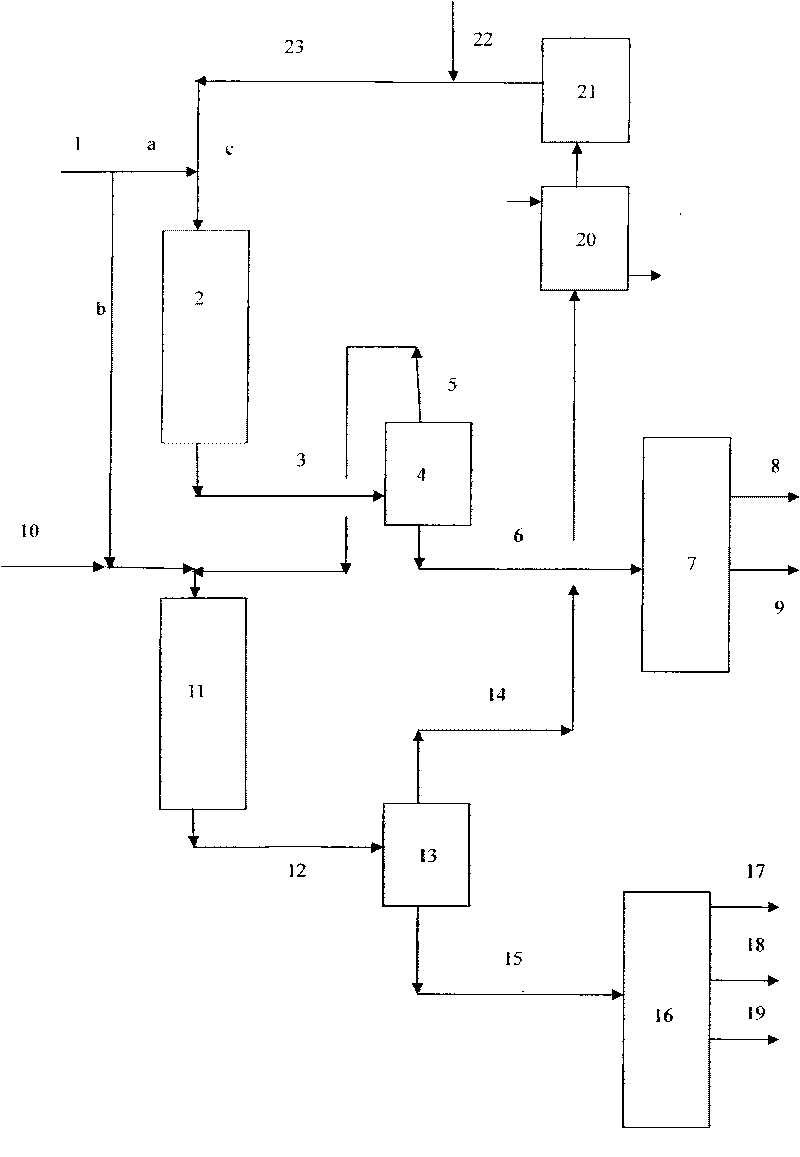

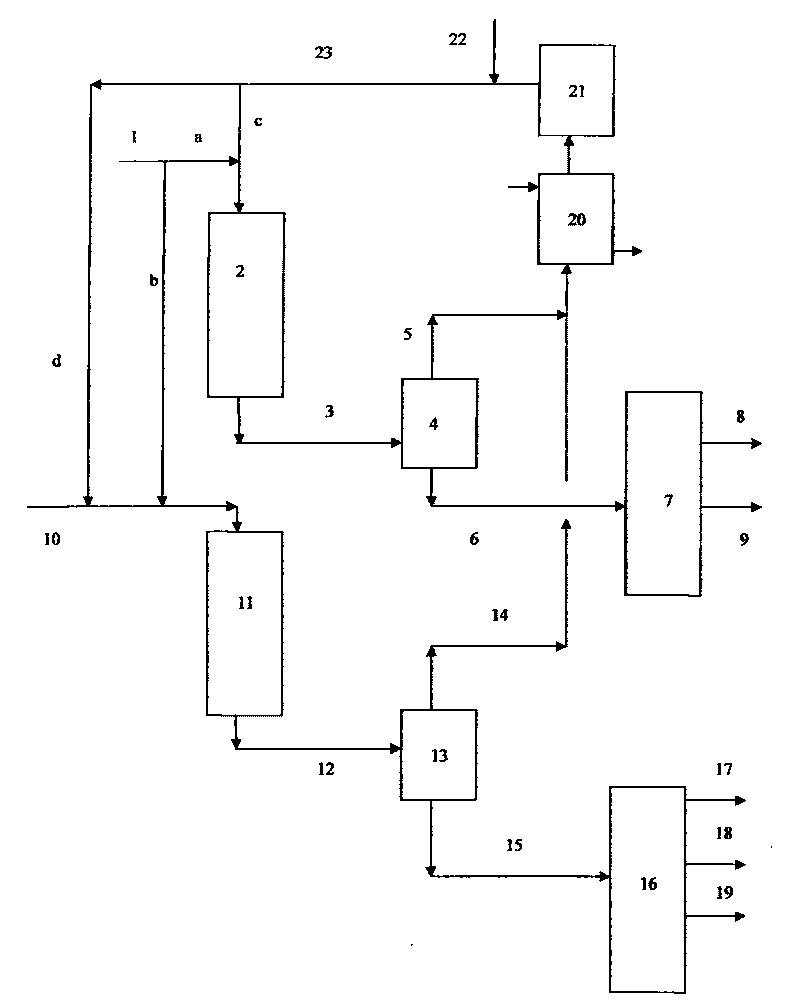

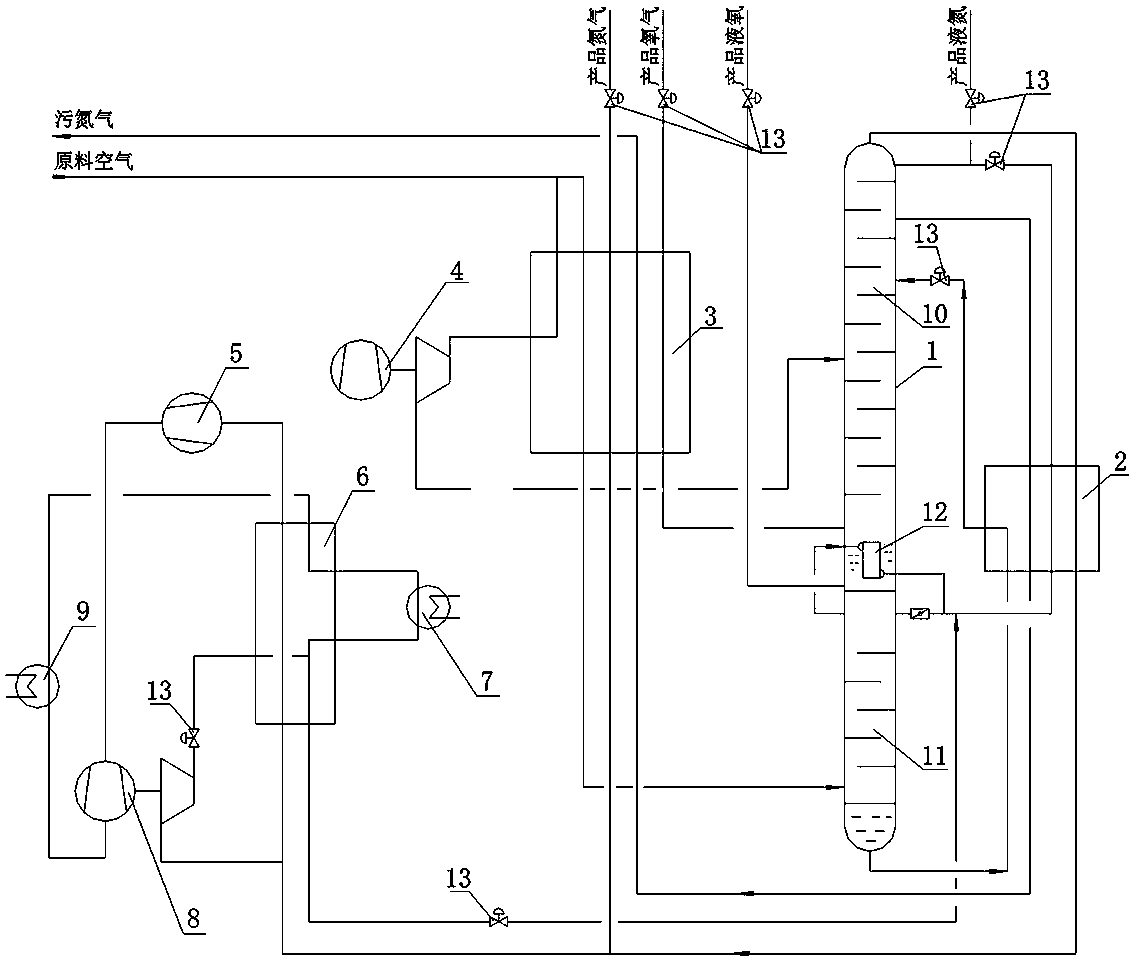

Novel liquid air-separating device and novel liquid air-separating process

ActiveCN103062990AGuaranteed outputGuaranteed puritySolidificationLiquefactionLiquid productAir conditioning

The invention discloses a novel liquid air-separating device. The novel liquid air-separating device comprises a rectifying tower (1), the rectifying tower (1) comprises an upper tower body (10), a lower tower body (11) and a main condensing evaporator (12), one channel of a product nitrogen outlet of the upper tower body (10) is sequentially connected with a main heat exchanger (3) and a product nitrogen output pipe, and another channel of the product nitrogen outlet of the upper tower body (10) is sequentially connected with a liquefied heat exchanger (6), a circulating nitrogen compressor (5), a boosting end of a boosting expansion machine (8), a booster aftercooler (9), the liquefied heat exchanger (6), a low-temperature air conditioning unit (7) and the liquefied heat exchanger (6). The novel liquid air-separating device has the advantages that the device is organically combined with air-separating rectification and heat exchange devices, and accordingly device investment is reduced, and yield and purity of liquid products are guaranteed; product liquid oxygen quantity can be decreased or increased by increasing or decreasing product liquid nitrogen extraction quantity, and oxygen yield is increased or decreased; and continuous production and variable-load production of the device are achieved, energy consumption is lowered, and product quality is stable and guaranteed.

Owner:四川蜀道装备科技股份有限公司

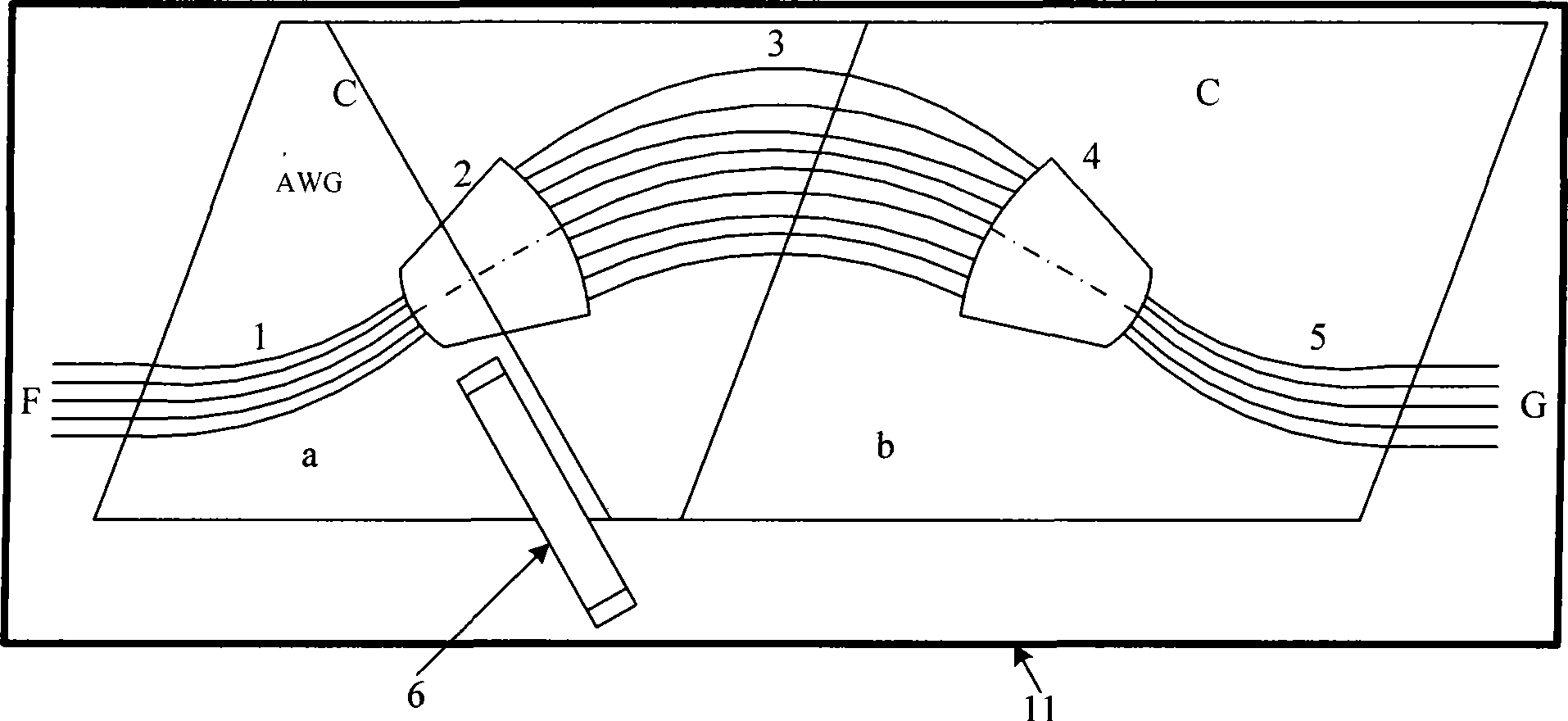

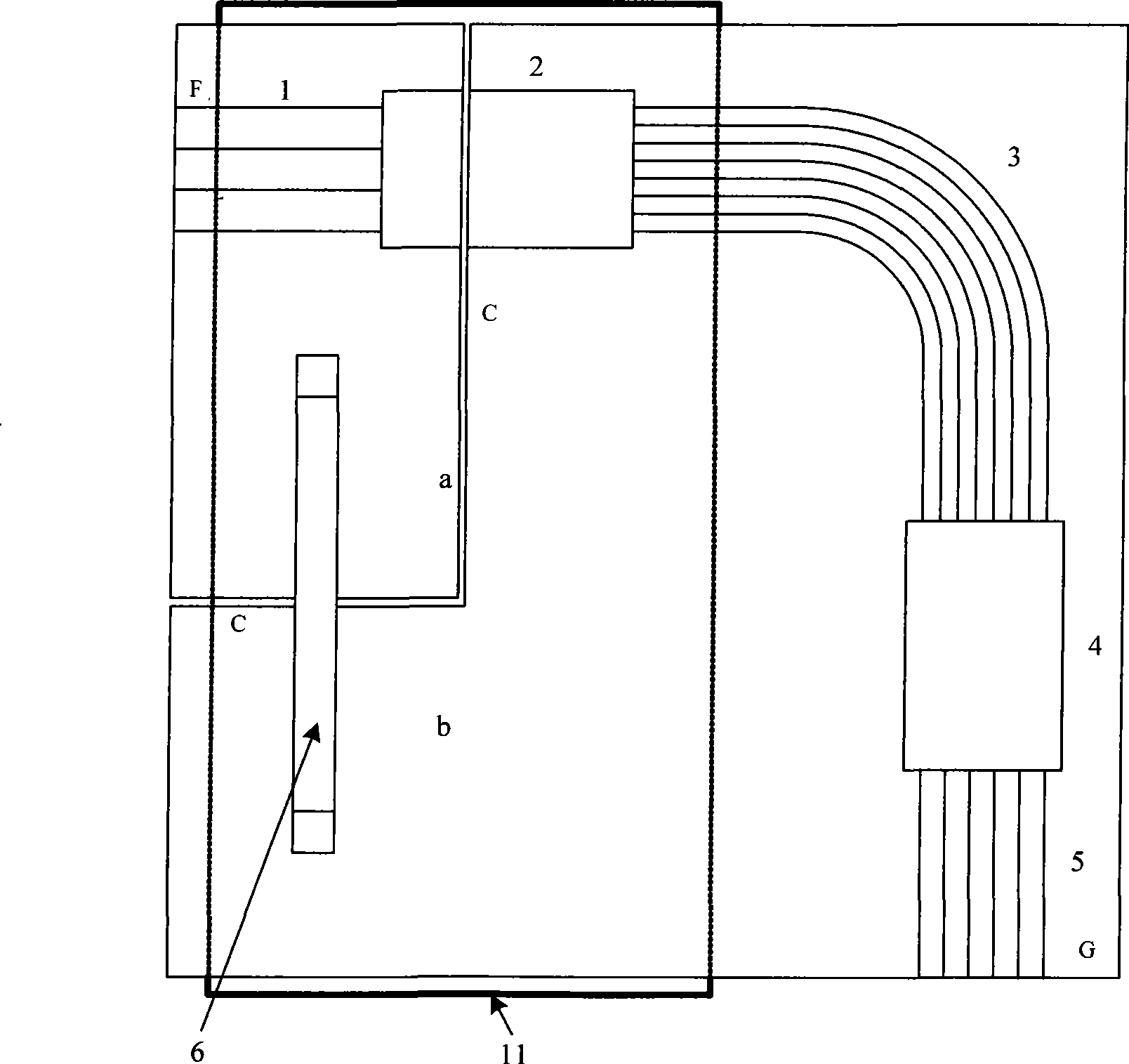

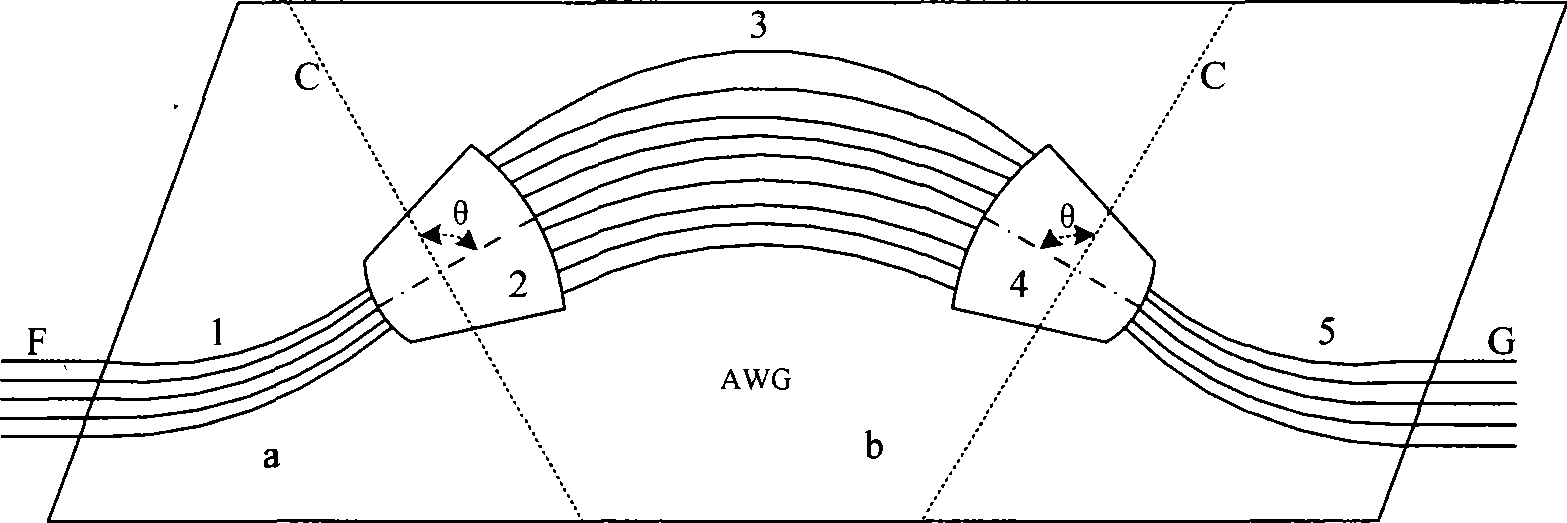

Method for manufacturing afebrile array wave-guide grating based on flat-plate wave-guide movement

ActiveCN101419313ALower device costReduce device sizeCoupling light guidesEngineeringWaveguide grating

The invention discloses a method for manufacturing an afebrile array wave-guide grating based on flat-plate wave-guide movement, which comprises the following steps that a common silicon-based silica array wave-guide grating chip is divided into a first part and a second part along a cutting line for inputting a flat-plate wave guide or a cutting line for outputting the flat-plate wave guide on the array wave-guide grating chip; a temperature compensating rod spans the cutting line of the array wave-guide grating chip and is fixed with the surfaces of the first part and the second part of the array wave-guide grating chip; and the expansion and contraction of the temperature compensating rod drive the first part and the second part to move relatively, so as to compensate wavelength shift caused by the temperature and manufacture the afebrile array wave-guide grating. The method doses not adopt a substrate. The first part a and the second part b are placed on a six-axes precision fine tuning bracket to be fully and freely adjusted in six directions; the device cost is reduced; the processing steps are simplified to the maximum degree so that the manufacture of the device is easy to implement; deterioration of the performance of the device is reduced to the maximum degree; and the stability is strong.

Owner:GUANGXUN SCI & TECH WUHAN

Method for preparing shikimic acid from folium ginkgo extraction waste liquor

ActiveCN109593034AReasonable process designHigh purityCarboxylic compound separation/purificationOrganic solventHydrolysate

The invention relates to the field of extraction and purification of plant effective components, in particular to a method for preparing shikimic acid from folium ginkgo extraction waste liquor. The method comprises the following steps: carrying out enzymolysis on the folium ginkgo extraction waste liquor; and collecting an enzymatic hydrolysate, filtering by an organic membrane, carrying out adsorption elution by an anion exchange resin column, concentrating, crystallizing and drying. The method is simple to operate, economical and practical and proper to popularize, and does not need an organic solvent. Moreover, the obtained shikimic acid is high in purity and good in appearance condition, and the mass content is greater than 99%.

Owner:GUILIN NATURAL INGREDIENTS CORP

Method for producing high-strength Q690D steel plate with thickness of 4 mm on wide and thick plate mill

ActiveCN105921514ASolve the technical problems that cannot produce thin gauge productsExpansion of rolling productionMetal rolling arrangementsThick plateChemical composition

The invention relates to a method for producing a high-strength Q690D steel plate with thickness of 4 mm on a wide and thick plate mill. A technological path is as follows: material selecting-cogging heating-descaling-cogging rolling-cooling-cogged ingot finishing (including inspecting and breaking)-hybrid welding (composite blanks)-inspecting-warehousing; and reheating of the composite blanks-descaling-rolling (finished product rolling)-cooling-finishing (including cutting the steel plate into an upper part and a lower part)-heat treatment-cooling-appearance inspecting-sampling- physical and chemical inspecting-judging-warehousing. Reasonable Q690D chemical component blanks are selected, thicknesses and lengths of rolled pieces are selected scientifically, the blanks are welded in a hybrid manner, and then are heated, rolled, subjected to heat treatment and finishing, checked and inspected, the delivery state of production is Q+T / Q, and the thickness of a finished product is 4.0 mm; and the performance, size and surface quality of the product can completely meet the standard requirement of the GB / T16270 product. The product can stop a gap that domestic and foreign wide and thick plate mills cannot roll thin steel plate products.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

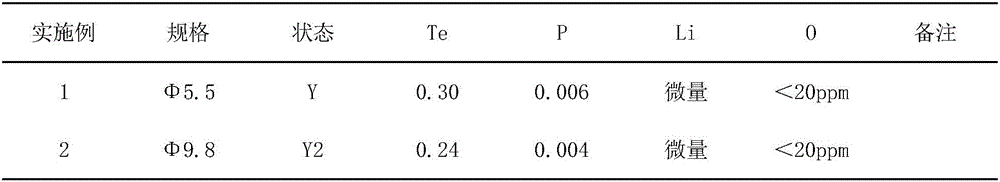

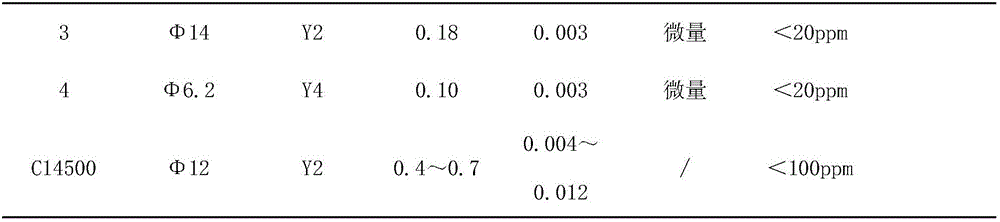

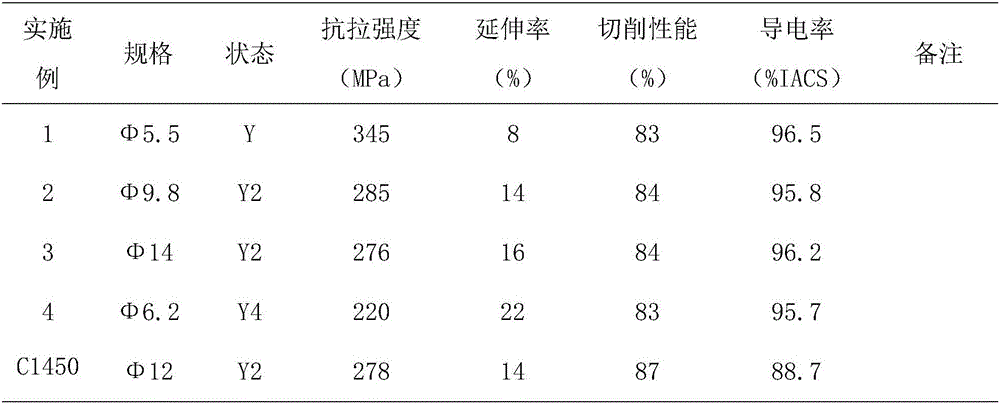

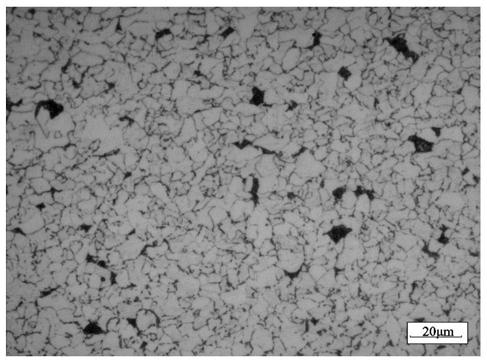

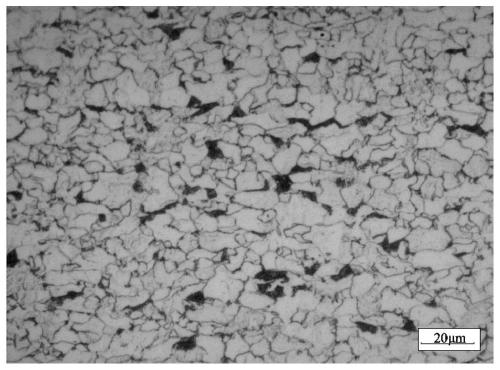

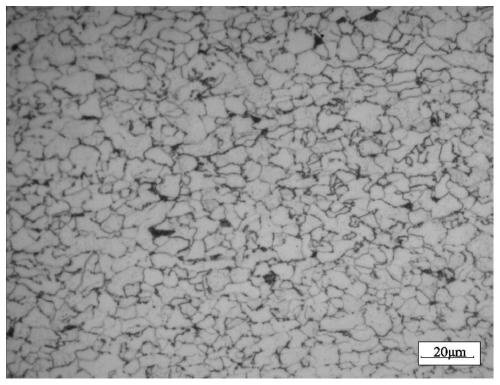

Ultrahigh-conductivity leadless free-cutting copper alloy material, and preparation method and application thereof

The invention discloses an ultrahigh-conductivity leadless free-cutting copper alloy material, and a preparation method and application thereof. The material is characterized by comprising the following chemical components by weight: 0.10 to 0.30% of Te, 0.003 to 0.009% of P and 99.70 to 99.90% of Cu, wherein the total amount of impurities is less than 0.1%. The preparation method adopts melting, extruding and drawing technology and cooperatively uses a phosphorus-lithium composite deep deoxidation method; and the prepared has oxygen content of less than 20 ppm, reaching the level of oxygen-free copper TU1, and has electrical conductivity of greater than 95% IACS, obviously higher than C14500 conductivity standard (greater than 85% IACS). The material has excellent machinability, electrical conductivity and heat conductivity and resistance to corrosion and electrical ablation, and can be extensively applied to electronic and electrical connection devices, integrated circuit lead frames, welding high-grade gun nozzles, electromotors, switch components and the like with ultrahigh requirements on electrical conductivity.

Owner:CECEP INDAL ENERGY CONSERVATION +1

450-MPa-grade hot-radical spangle-free high-strength galvanized plate for pre-engineered metal buildings and production method of 450-MPa-grade hot-radical spangle-free high-strength galvanized plate

InactiveCN109797346AMeet market requirementsObvious cost advantageHot-dipping/immersion processesElectromagnetic inductionRaw material

The invention belongs to the technical field of steel production, and relates to a method for producing a hot-radical spangle-free galvanized plate for pre-engineered metal buildings based on a hot rolled strip production line and an acid plating continuous production line, in particular to a 450-MPa-grade hot-radical spangle-free high-strength galvanized plate for the pre-engineered metal buildings and a production method of the 450-MPa-grade hot-radical spangle-free high-strength galvanized plate. According to the production method, galvanizing raw materials with the thickness being 1.0-2.0mm are provided by the full headless hot rolled strip production line, then a hot-galvanized coiled plate is produced through straightening, phosphorus breaking, acid pickling, flattening, heating, galvanizing, finishing, passivating, tensile straightening and rolling by the continuous acid pickling galvanizing production line, that is, through processes such as flattening before galvanizing (a roughening process), electromagnetic induction heating (the in-furnace time is 20-50 s), finishing after galvanizing, dual tensile straightening, and roller coating surface treatment, thin-specification450-MPa-grade hot-radical spangle-free high-strength steel for cars can be produced, and the effect that cold rolling is replaced with hot rolling is achieved.

Owner:RIZHAO STEEL HLDG GROUP

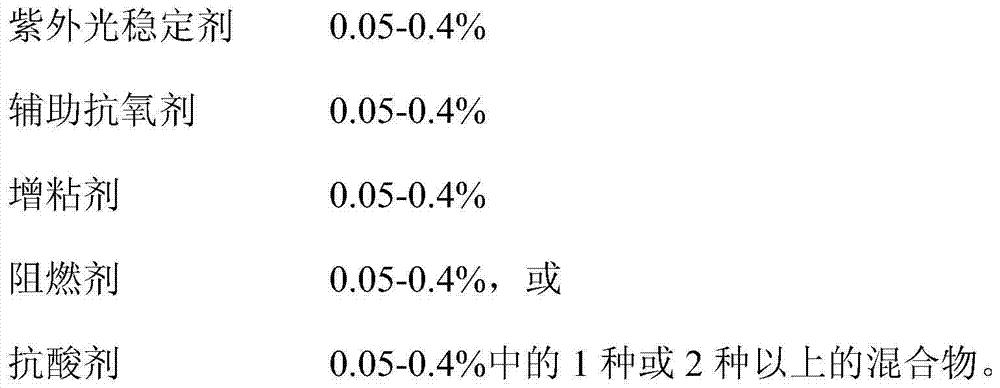

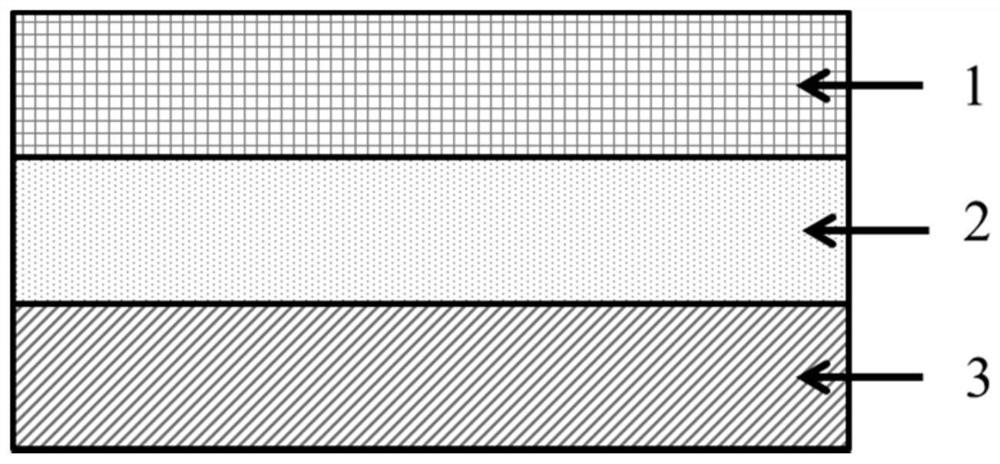

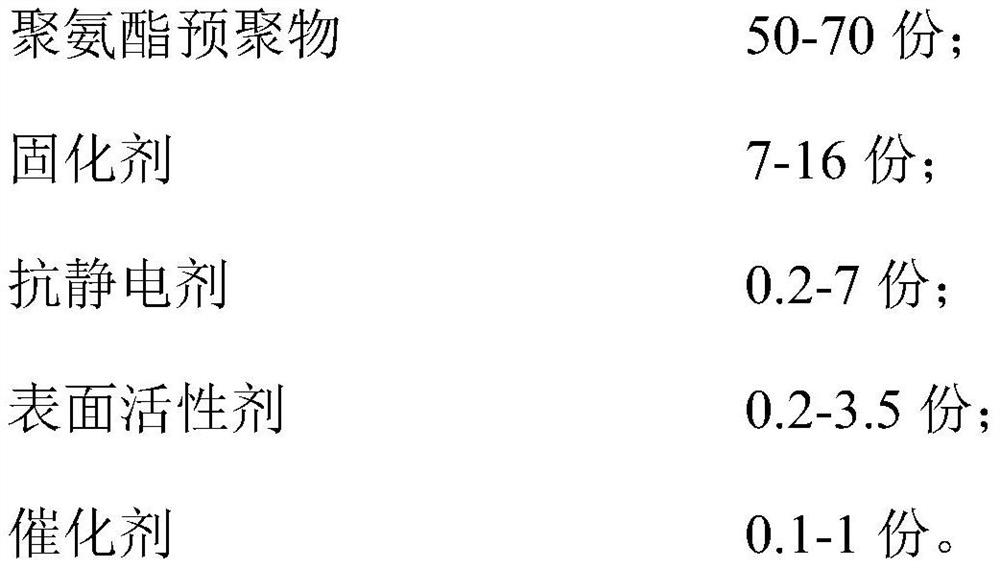

Polyurethane adhesive, PU protective film and preparation method and application of PU protective film

InactiveCN112251184ALow tearing voltageNot easy to precipitateNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolyurethane adhesive

The invention provides a polyurethane adhesive, a PU protective film as well as a preparation method and application of the PU protective film. The polyurethane adhesive is prepared from the followingcomponents in parts by weight: 50-70 parts of a polyurethane prepolymer, 7-16 parts of a curing agent, 0.2-7 part of an antistatic agent, 0.2-3.5 parts of a surfactant and 0.1-1 part of a catalyst. The PU protective film comprises a base material layer and a polyurethane adhesive layer which are attached to each other, and the polyurethane adhesive layer is formed by the polyurethane adhesive. The preparation method of the PU protective film comprises the following steps: (1) mixing a polyurethane adhesive with a solvent to obtain a mixed solution; and (2) coating the mixed solution obtainedin the step (1) on a base material layer, and drying and curing the mixed solution to obtain the PU protective film. The PU protective film provided by the invention has the advantages of low film tearing voltage, low viscosity and no residual glue, and meets the market use requirements.

Owner:CYBRID TECHNOLOGIES INC

Ultrahigh strength thermal shock resistance corundum/mullite product and manufacture method thereof

The invention relates to an ultrahigh strength thermal shock resistance corundum / mullite product and a manufacture method thereof. The manufacture method comprises steps of stirring 8-mesh white corundum, 80-mesh white corundum, 320-mesh tabular corundum, 24-mesh capacitance synthetic mullite, 36-mesh capacitance synthetic mullite, 280-mesh andalusite, 180-mesh sillimanite, 800-mesh aluminum oxide powder, 200-mesh kaolin and yellow dextrin for 1-3 hours, then adding 8% water so as to wring, stacking and ageing for 10 days, stirring for 15 minutes again, then molding through jolt-squeeze, naturally drying in shade, then firing for 6-8 hours at 1600 DEG C-1620 DEG C so as to obtain the ultrahigh strength thermal shock resistance corundum / mullite product. According to the manufacture method, the raw material chemical components and granularity ratio are optimized, the product is sintered fully, and the prepared corundum / mullite product has low porosity, large volume density, good strength, good thermal shock resistance, good integrated quality, and long service life up to 4-6 months.

Owner:长兴宏业高科高温耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com