Single-lobe filter bag for infusion products

a filter bag and single-chamber technology, applied in the field of single-chamber filter bags for infusion products, can solve the problems of poor infusion quality and longer infusion time, lack of three-dimensional or volumetric properties, and misshapen surface of filter bags, so as to improve the overall quality of infusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

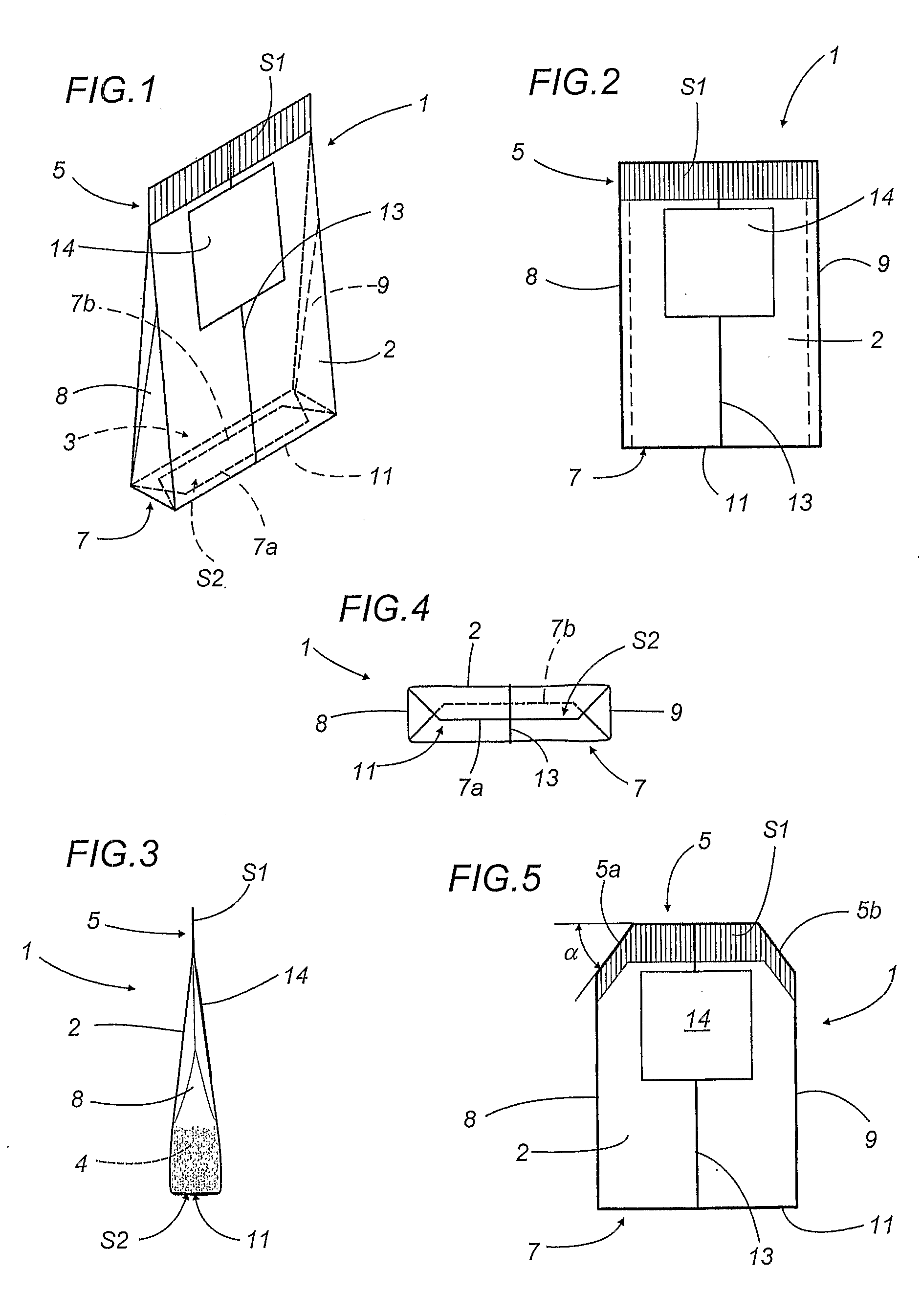

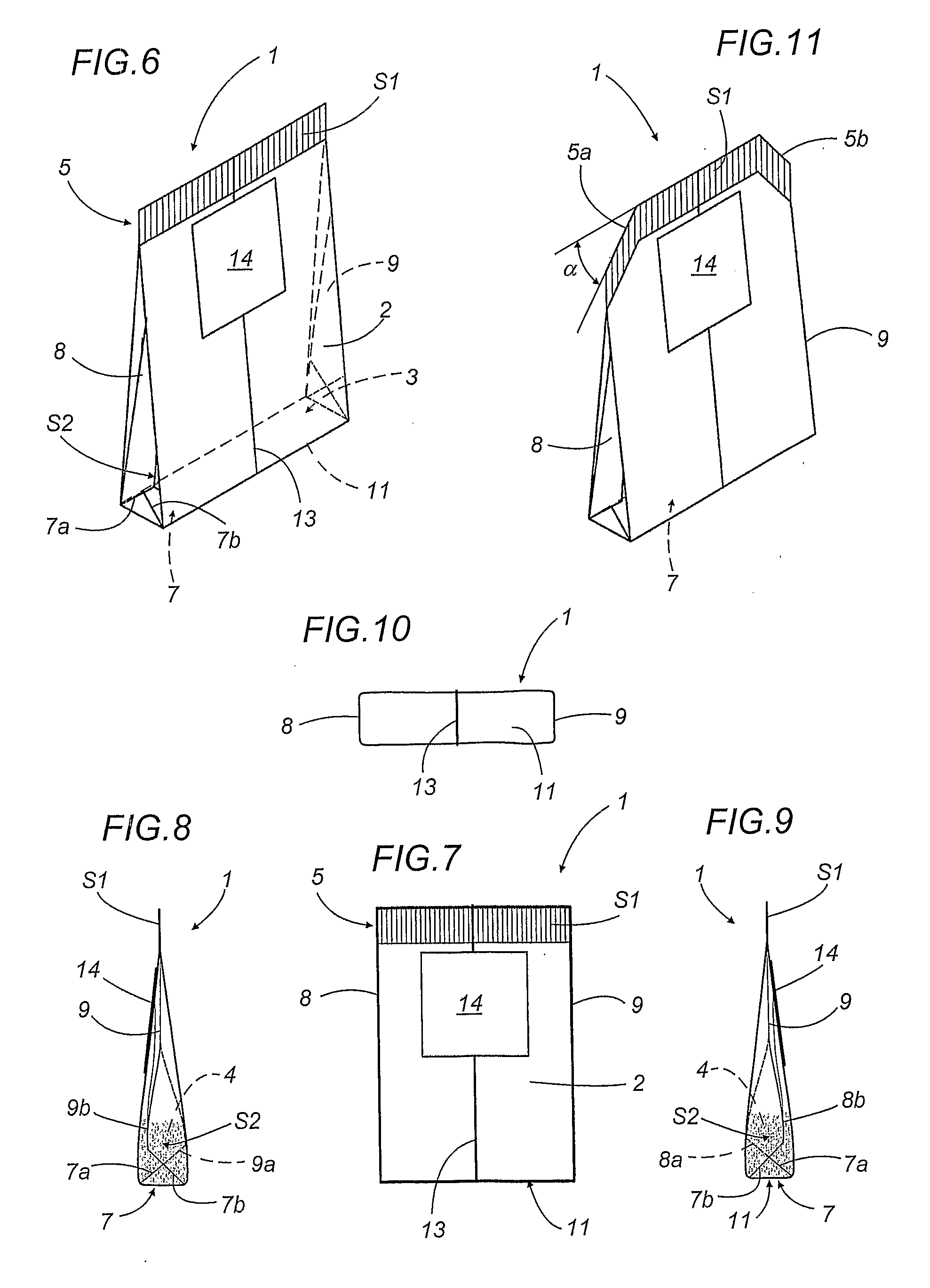

[0035]More specifically, in the first embodiment illustrated in FIGS. 1 to 4, the ends of each of the two second edges 7a and 7b closer to the sides 8 and 9 are partially folded towards the inside of the chamber 3 to form a bevelled shape and are flattened on the corresponding area of the other edge 7a or 7b in such a way as to create the stiff supporting base 11 at the second end 7.

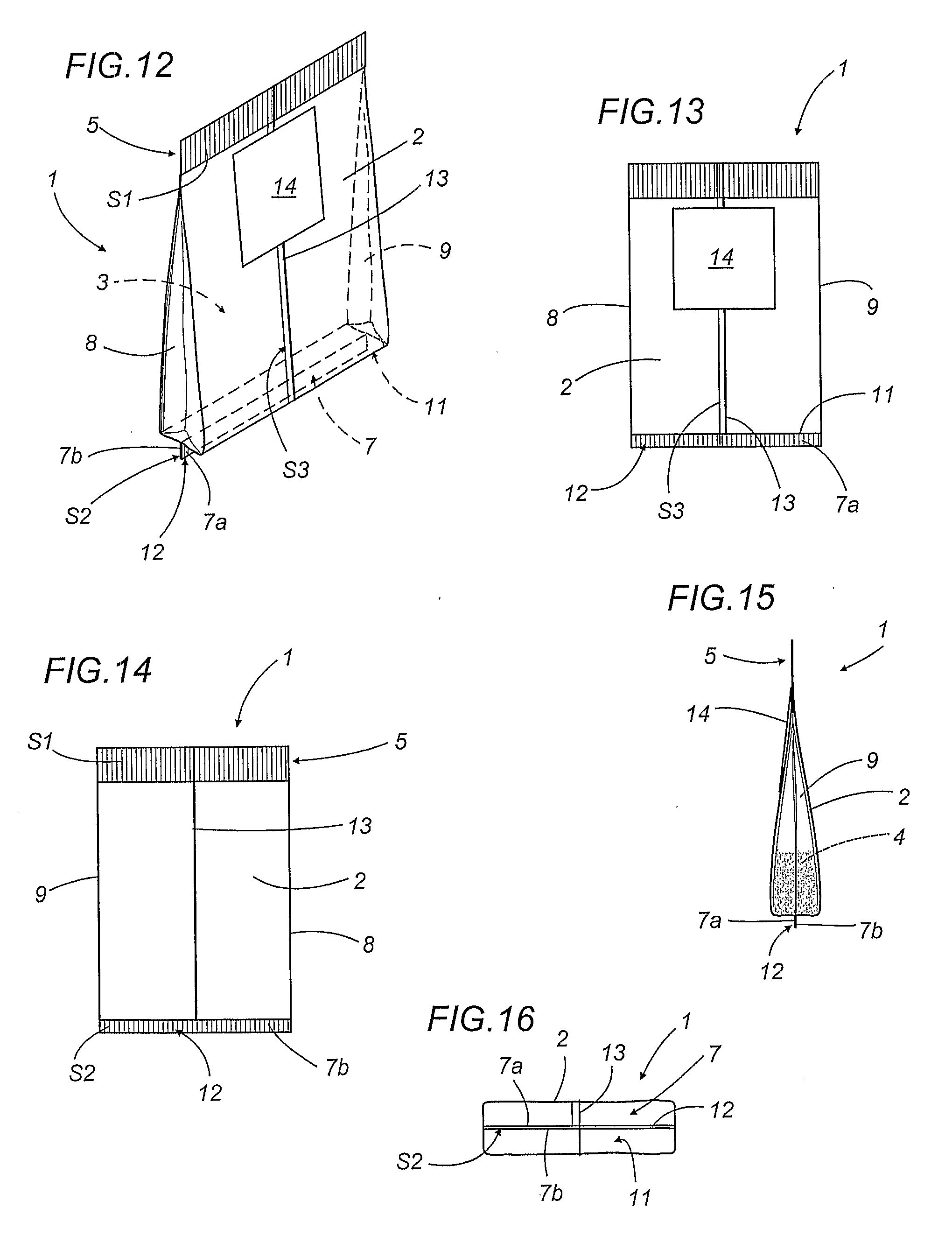

[0036]In the third embodiment (see FIGS. 12 to 16), the second edges 7a and 7b define a central extension of the second bottom end 7. The second edges 7a and 7b are folded face to face onto each other and joined in such a way as to form a tab 12 protruding from the bottom supporting base 11 that is elastically compliant in such a way as to be folded onto the bottom base 11 to increase its stiffness.

[0037]Alternatively, the tab 12 may be folded and joined stably by a seal S4 to the bottom supporting base 11, thus forming a larger, stiff longitudinal area (see FIGS. 17 to 20).

second embodiment

[0038]In the second embodiment illustrated in FIGS. 6 to 10, the two ends of each of the second edges 7a and 7b are folded towards the first end 5, which is placed over the respective end of the other edge 7a or 7b and at the respective bottom ends 8a, 8b and 9a, 9b of the connecting sides 8 and 9 (initially open) of the length 2 in such a way as to form a bevelled shape.

[0039]Each pair of ends of the second edges 7a and 7b is reciprocally joined by a seal S2 at the respective bottom areas of the connecting sides 8 and 9: this creates a stiff lateral area of the length 2 in order to form wide supporting shoulders for the closed bottom supporting base 11 of the filter bag 1.

[0040]In this specific case, the seal S2 is simultaneously made also on the substantially central area of each side 8, 9 in order to also join the latter which, as stated, are initially open, in the configuration in which they are folded towards the inside of the chamber 3.

[0041]In addition to the above, the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com