Straw fiber/PBS(poly butylene succinate)/PBAT (propylene adipate and polybutylene terephthalate) composite and preparation method thereof

A composite material and straw fiber technology, which is applied in the radiation-strengthened cross-linked straw fiber/PBS/PBAT ternary composite material and its preparation, and in the field of straw fiber plastic, can solve the problems of reducing the tensile strength and limitation of composite materials, and improve the Impact toughness, easy control, and the effect of improving interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

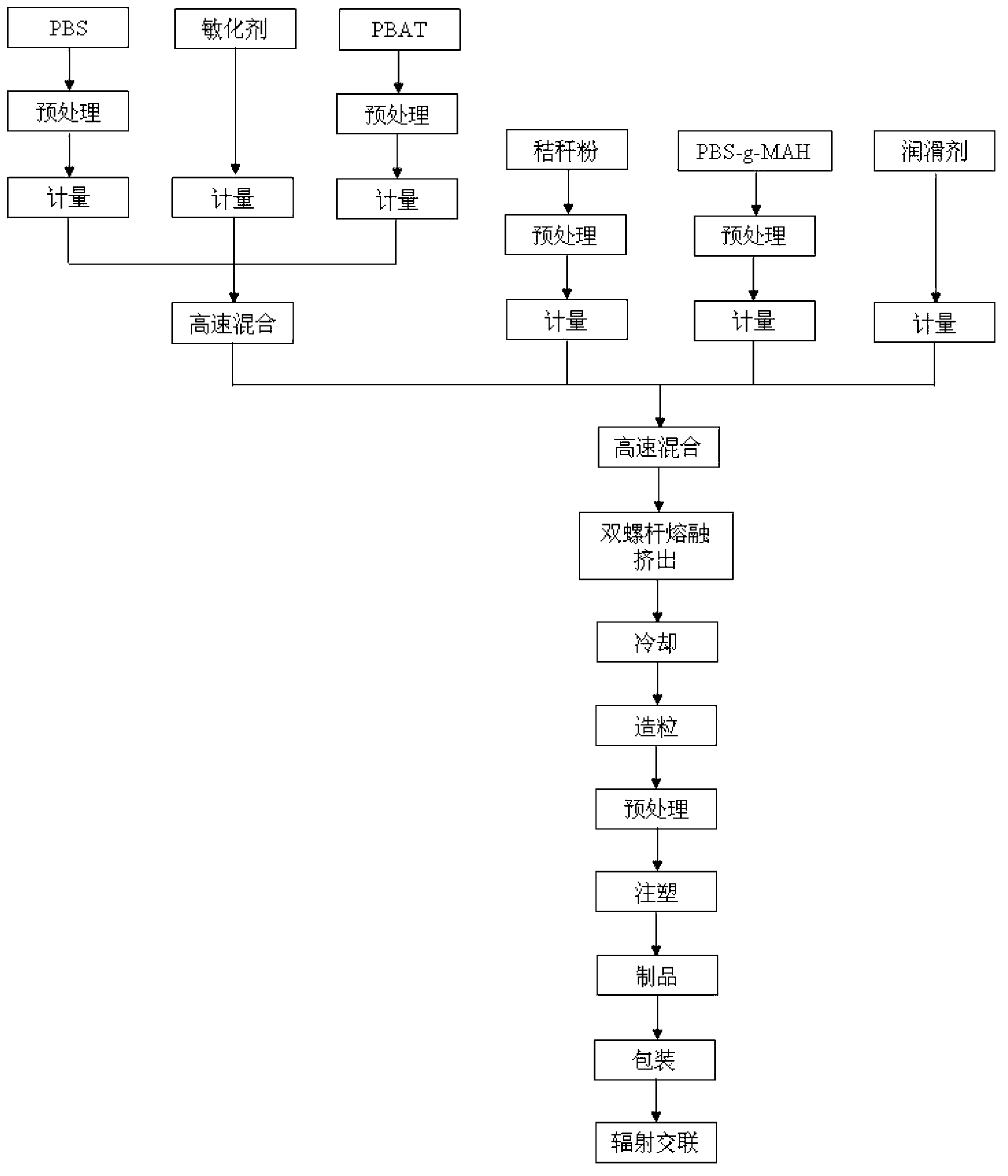

[0044] figure 1Shown is the preparation process flow chart of the radiation-enhanced cross-linked straw fiber / PBS / PBAT ternary composite material provided by the present invention. Mainly include the following process steps:

[0045] (1) Raw material pretreatment

[0046] ① Place PBS, straw powder, PBS-g-MAH, and PBAT in a vacuum drying oven at 60°C for 48 hours;

[0047] ② First mix PBS, PBAT, and radiation sensitizer triallyl isocyanate according to the ratio in Table 1 in a high-speed mixer at room temperature for 3 minutes, then add straw powder and compatibilizer PBS-g- according to the ratio in Table 1. MAH and stearic acid were stirred for 5 minutes at room temperature in a high-speed mixer.

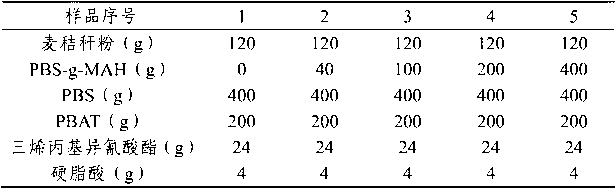

[0048] Table 1 Straw fiber / PBS / PBAT composites with different compositions

[0049]

[0050] (2) Twin-screw melt blending extrusion

[0051] ③Put the mixed raw materials into a twin-screw extruder to melt and mix them evenly and extrude and granulate. The extrusion conditi...

Embodiment 2

[0063] figure 1 Shown is the preparation process flow chart of the radiation-enhanced cross-linked straw fiber / PBS / PBAT ternary composite material provided by the present invention. Mainly include the following process steps:

[0064] (1) Raw material pretreatment

[0065] ① Place PBS, straw powder, PBS-g-MAH, and PBAT in a vacuum drying oven at 80°C for 24 hours;

[0066] ② Firstly mix PBS, PBAT, radiation sensitizer triallyl isocyanate according to the ratio in Table 3 in a high-speed mixer at room temperature for 2 minutes, then add straw powder and compatibilizer PBS-g- according to the ratio in Table 3 MAH and zinc stearate were stirred in a high-speed mixer at room temperature for 3 minutes.

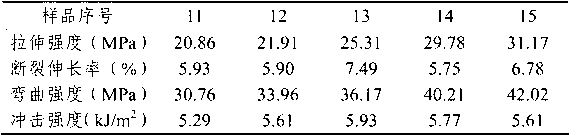

[0067] Table 3 Straw fiber / PBS / PBAT composites with different compositions

[0068]

[0069] (2) Twin-screw melt blending extrusion

[0070] ③Put the mixed raw materials into a twin-screw extruder to melt and mix them evenly and extrude and granulate. The extrusion conditio...

Embodiment 3

[0082] figure 1 Shown is the preparation process flow chart of the radiation-enhanced cross-linked straw fiber / PBS / PBAT ternary composite material provided by the present invention. Mainly include the following process steps:

[0083] (1) Raw material pretreatment

[0084] ① Place PBS, straw powder, PBS-g-MAH, and PBAT in a vacuum drying oven at 100°C for 12 hours;

[0085] ② First mix PBS, PBAT, and radiation sensitizer trimethylolpropane trimethacrylate according to the ratio in Table 5 in a high-speed mixer at room temperature for 3 minutes, then add straw powder according to the ratio in Table 5 to increase volume The agent PBS-g-MAH and calcium stearate were stirred in a high-speed mixer at room temperature for 4 minutes.

[0086] Table 5 Straw fiber / PBS / PBAT composites with different compositions

[0087]

[0088] (2) Twin-screw melt blending extrusion

[0089] ③Put the mixed raw materials into a twin-screw extruder to melt and mix evenly and extrude and granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com