Patents

Literature

1079 results about "Poly(butylene succinate)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polybutylene succinate (PBS) (sometimes written polytetramethylene succinate) is a thermoplastic polymer resin of the polyester family. PBS is a biodegradable aliphatic polyester with properties that are comparable to polypropylene.

Biodegradable bicomponent fibers with improved thermal-dimensional stability

InactiveUS6953622B2Improve wettabilityImprove bindingConjugated synthetic polymer artificial filamentsYarnFiberPolyester

A biodegradable hydrophilic binder fiber. These fibers may be produced by co-spinning an aliphatic polyester material in a side-by-side configuration with a polylactide polymer to obtain a fiber with improved material attributes. A multicarboxylic acid may be incorporated into either or both components of the fiber. The aliphatic polyester polymer may be selected from a polybutylene succinate polymer, a polybutylene succinate-co-adipate polymer, or a blend of these polymers. The biodegradable bicomponent fiber exhibits substantial biodegradable properties, yet has improved thermal stability and has significantly reduced shrinkage. The bicomponent fiber may be used in a disposable absorbent product intended for the absorption of fluids such as body fluids.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Preparation of polybutane diacid butanediol ester

A process for preparing butanediol polysuccinate able to be fully biodegradated includes such steps as adding butanediol and butanedioic acid to reactor, esterifying reacting at 150-200 deg.C, and vacuum polycondensating at 200-280 deg.C under the existance of catalyst. It is a thermoplastic resin with 100,000 of mass average molecular weight and better mechanical performance.

Owner:中科启程新材料科技(海南)有限公司

Material capable of completely biodegrading and preparation method thereof

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

Full-biodegradable polylactic acid composite material and preparation method thereof

The invention discloses a full-biodegradable polylactic acid composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 40-93 parts of polylactic acid, 5-40 parts of flexibilizer, 1-10 parts of plasticizer, 1-30 parts of vegetable fibre, 0.1-2 parts of antioxygen and 0.1-1 part of silane coupling agent. In the invention, the vegetable fibre composite polylactic acid is modified, which can enhance the mechanical property and the heat resistance of the polylactic acid material, and moreover, the polylactic acid material can be fully degraded, and the raw materials of the polylactic acid material are renewable and abundant; a lateral feed mode is applied to the fiber, therefore, the damage of a screw to the fibre is smaller, the strengthening and toughening effects of the fibre are better. Polydiethylene glycol sebacate (PBS), grafted with a polylactic acid copolymer, serves as the flexibilizer, which not only greatly improves the compatibility of the PBS and the polylactic acid but also can improve the toughness and the heat resistance of the composite material.

Owner:CHERY AUTOMOBILE CO LTD

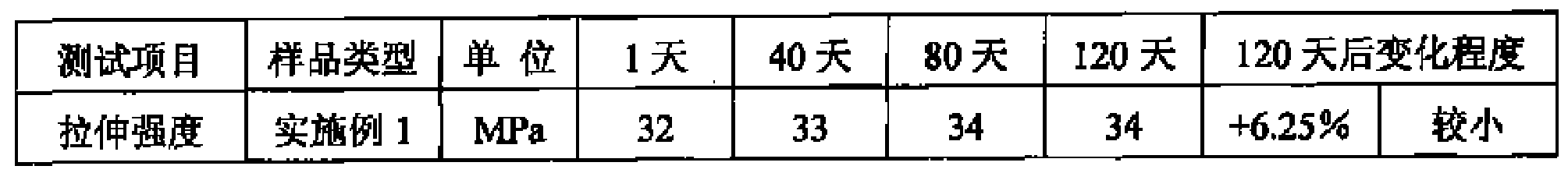

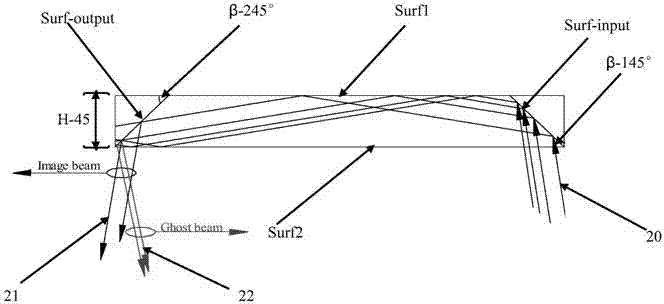

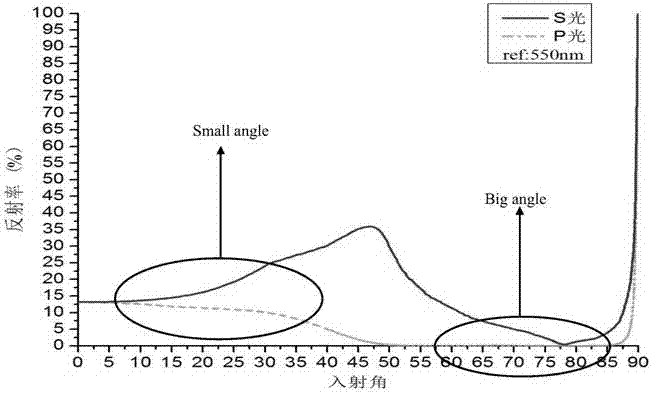

Polarization light guide planar waveguide optical display device

ActiveCN104503087ACompact structureThin structurePlanar/plate-like light guidesLight guideDisplay device

The invention provides a polarization light guide planar waveguide optical display device which comprises an image display light source, a collimating lens assembly, a PBS (poly butylene succinate) polarization beam splitter assembly, a planar light guide transmission substrate, a polarization conversion light guide substrate and a small-angle coupling output surface. The image display light source is used for emitting a display light wave for displaying a needed image, the collimating lens assembly is used for collimating light waves emitted by the light source, the PBS polarization beam splitter assembly is used for correspondingly splitting the light waves, the planar light guide transmission substrate is used for performing reflection propagation for coupled-into light waves to form total-reflection light waves, the polarization conversion light guide substrate is used for converting polarization states of the light waves, and the small-angle coupling output surface is mainly used for coupling the light waves out of the substrate and enlarging viewing fields. The polarization light guide planar waveguide optical display device has the advantages that the device is compact in structure, light and large in viewing field, an optical design and machining process is simple and easy to implement, and the device can be used for the fields such as wearing display, 3D (three-dimensional) naked eye display, automobile navigation and wild map instruction.

Owner:SHANGHAI RAYPAI PHOTONIC CRYSTAL LTD

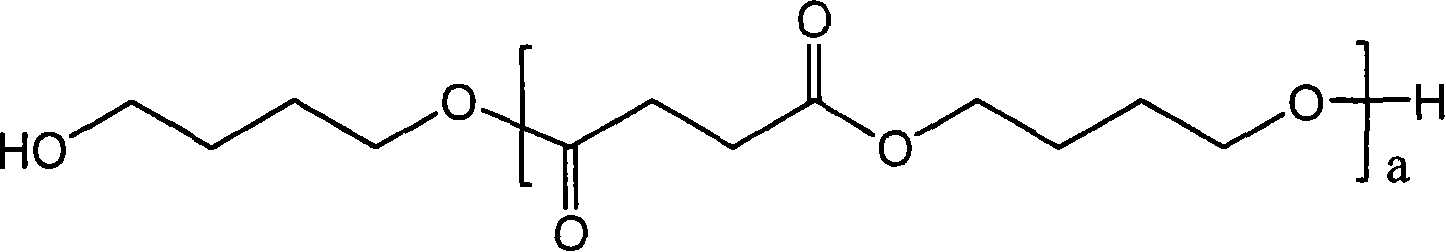

High molecular weight poly(butylene succinate) and preparation method thereof

ActiveCN101077905AHigh molecular weightNarrow molecular weight distributionPolymer scienceButanediol

The present invention relates to one kind of high molecular weight polybutanediol succinate and its preparation process, and features that bihydroxy terminated butanediol succinate, especially low molecular weight bihydroxy terminated butanediol succinate, as the pre-polymer and diisocyanate as the chain extender in 0.1-13 % are molten and reacted to prepare polybutanediol succinate with low cost, great molecular weight, narrow molecular weight distribution and excellent mechanical performance. The polybutanediol succinate has number average molecular weight greater than 5.5x10<4>, molecular weight distribution of 1.4-1.8, tensile strength of 39-58 MPa, and elongation at break of 300-700 %.

Owner:SICHUAN UNIV

Continuously-produced full-degradable starch-based plastic alloy and preparation method thereof

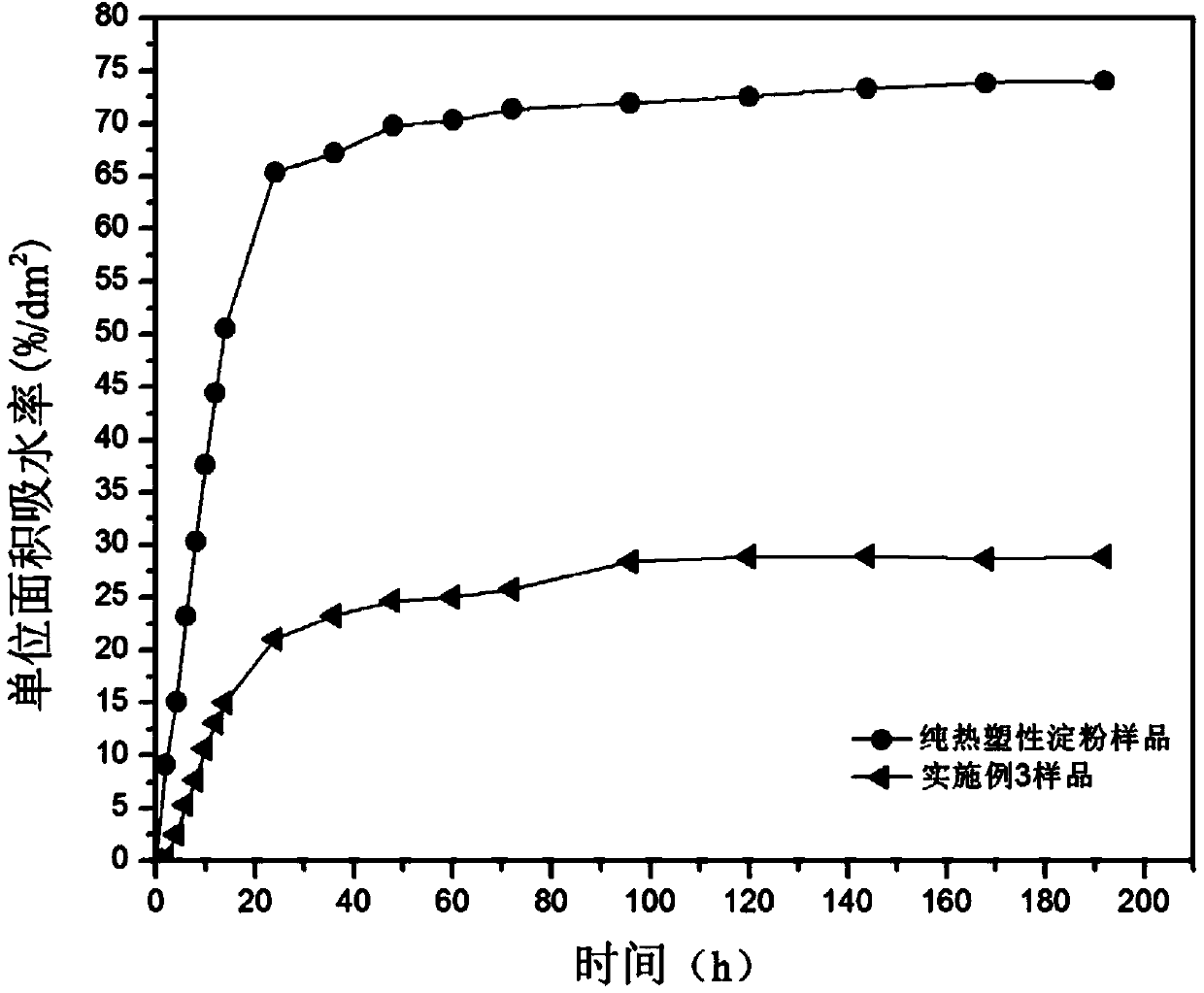

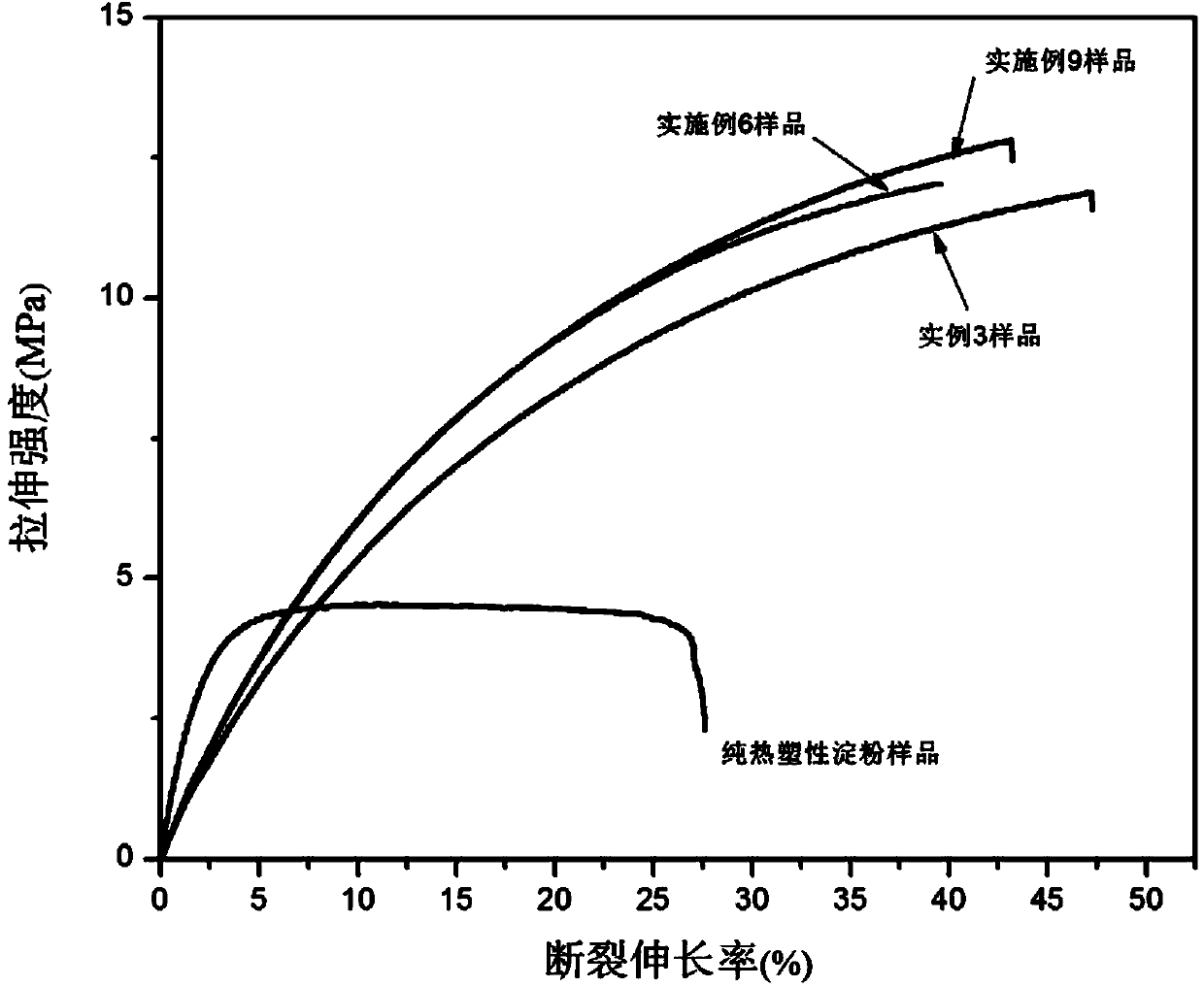

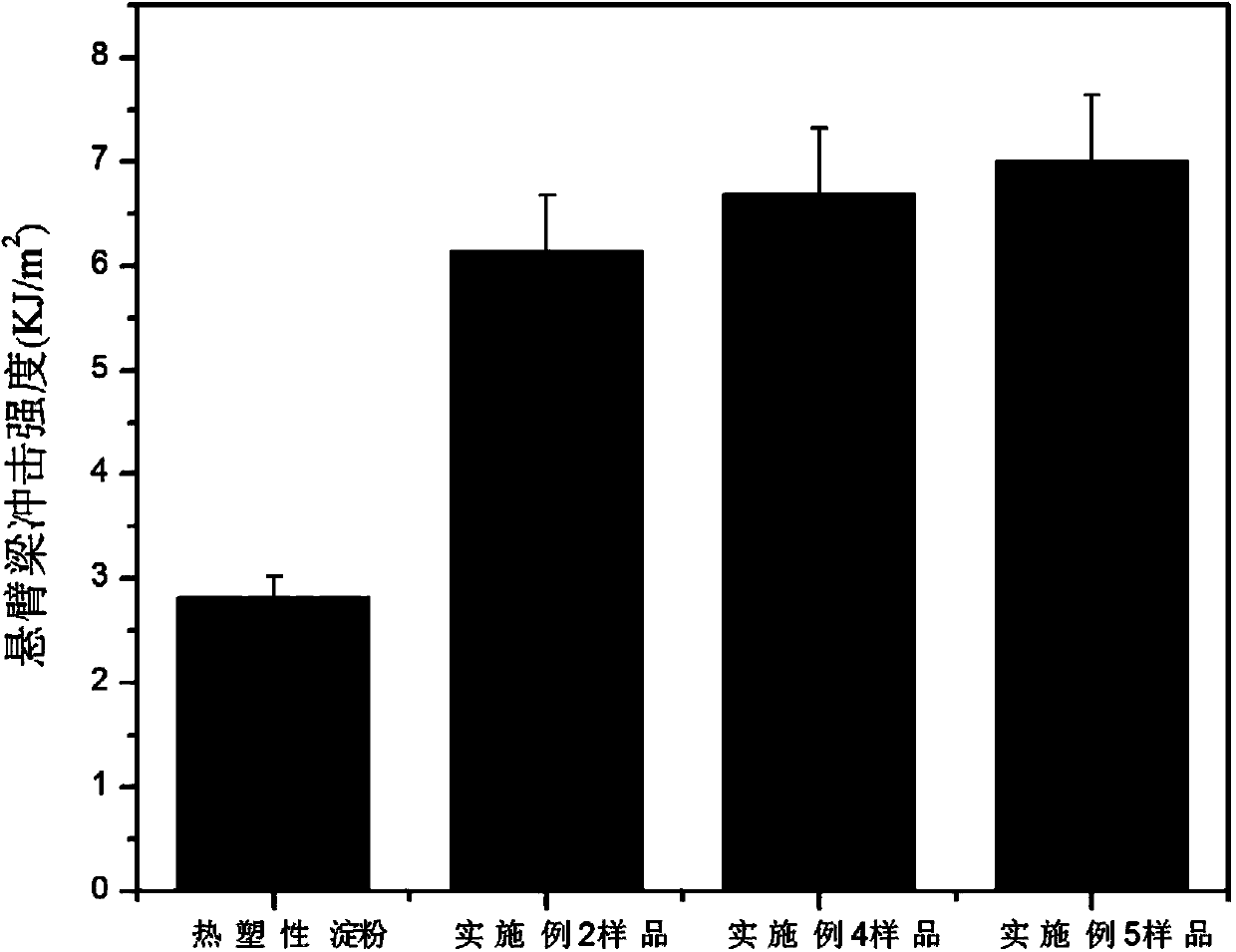

The invention discloses a continuously-produced full-degradable starch-based plastic alloy and a preparation method thereof. The starch-based plastic alloy contains the following components in parts by weight: 40-90 parts of starch, 5-60 parts of poly(butylene succinate), 5-60 parts of polylactic acid, 10-40 parts of plasticizer, 0.1-10 parts of compatibilizer and 1-10 parts of processing acid. The preparation method comprises the steps of mixing starch, plasticizer and part of processing aid, and extruding to obtain thermoplastic starch particles; then, mixing the thermoplastic starch particles with poly(butylene succinate), polylactic acid, compatibilizer and the residual processing aid, and extruding to obtain the starch-based plastic alloy. The starch-based plastic alloy disclosed by the invention is favorable in hydrophobicity and strength, good in component compatibility, favorable in thermoplastic processability, capable of realizing continuous production and processing as well as simple and feasible in technical process.

Owner:EAST CHINA UNIV OF SCI & TECH

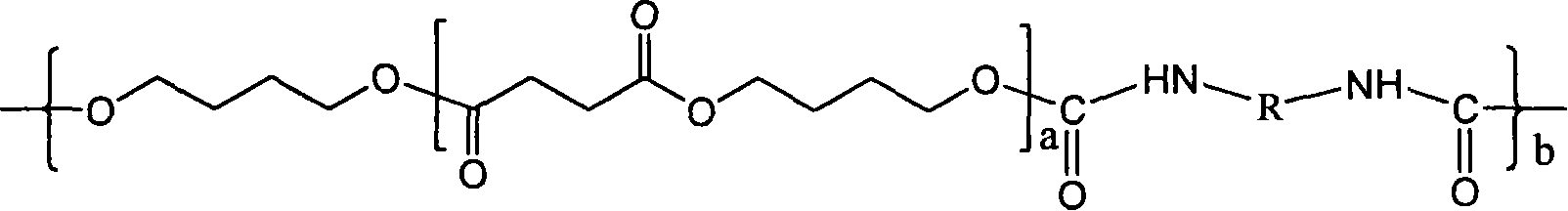

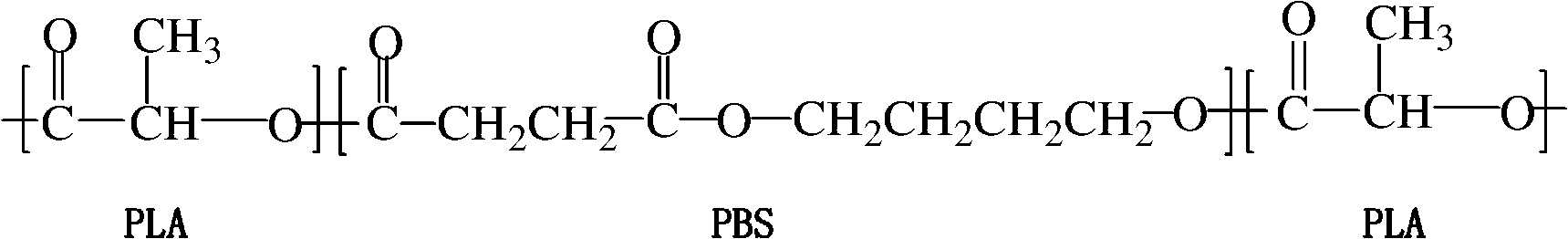

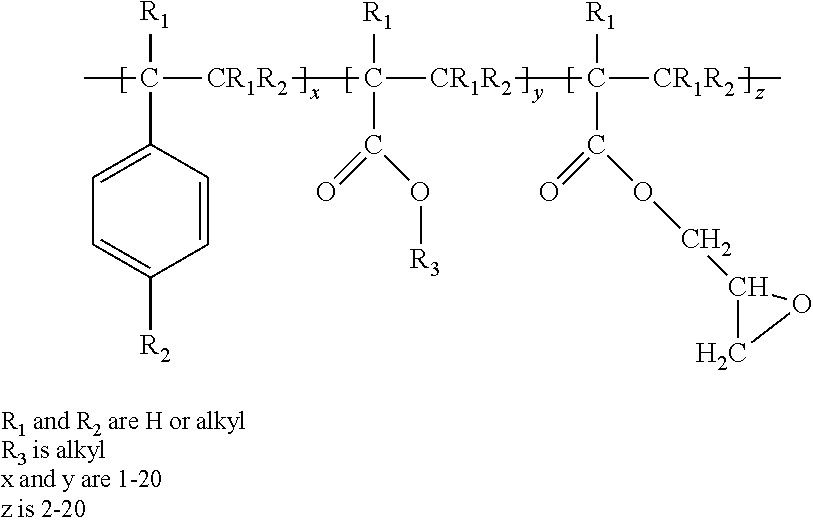

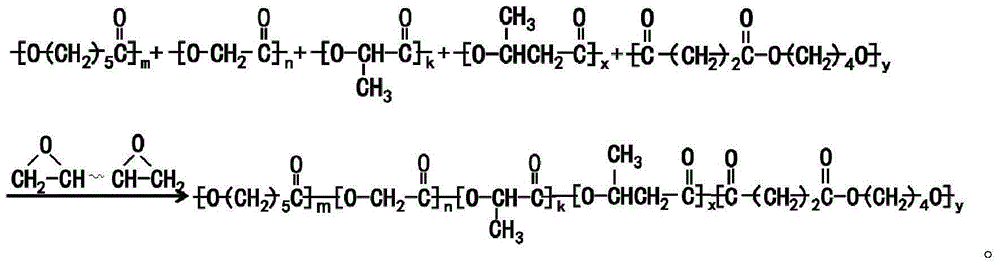

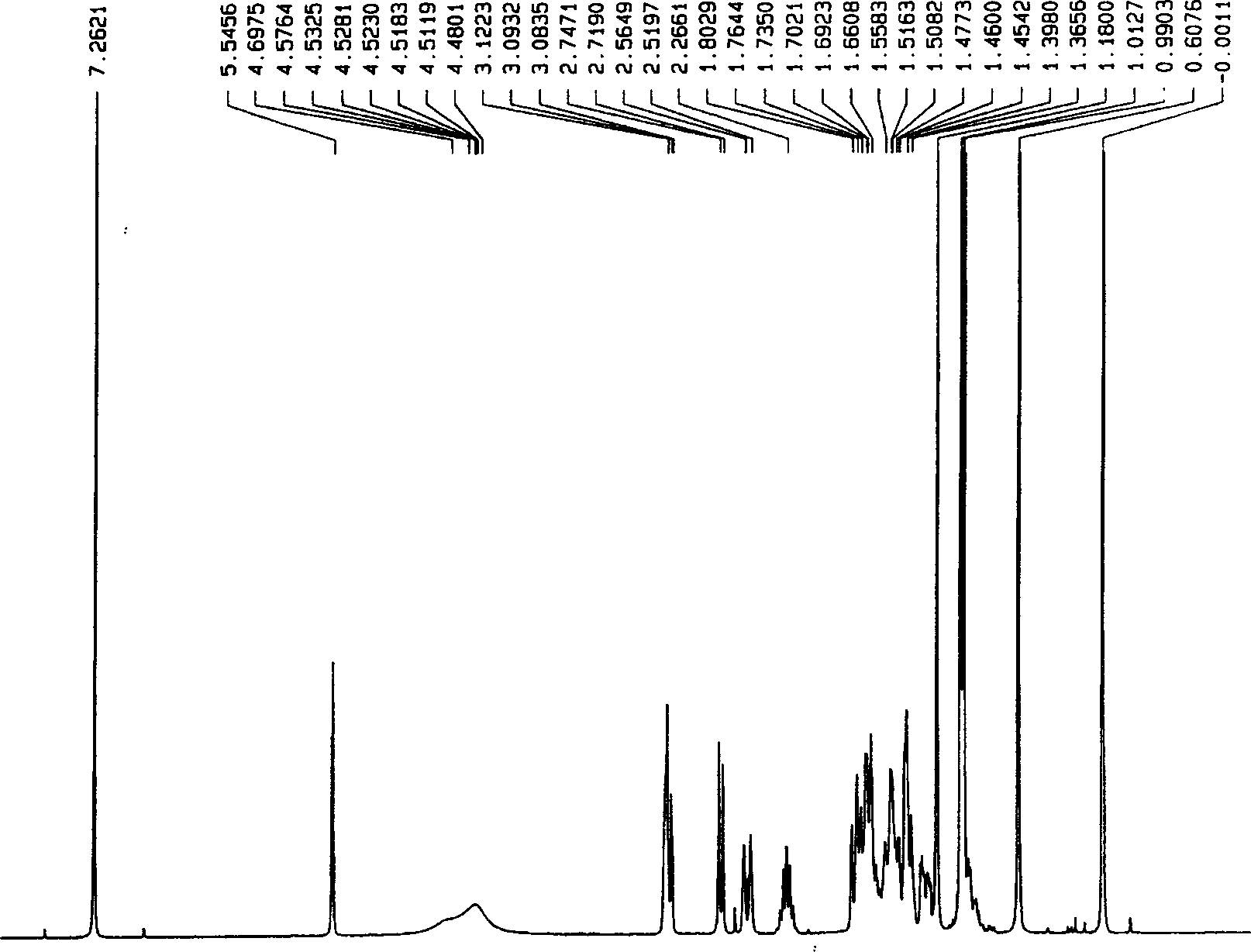

Polylactic acid toughening modifier and preparation method thereof

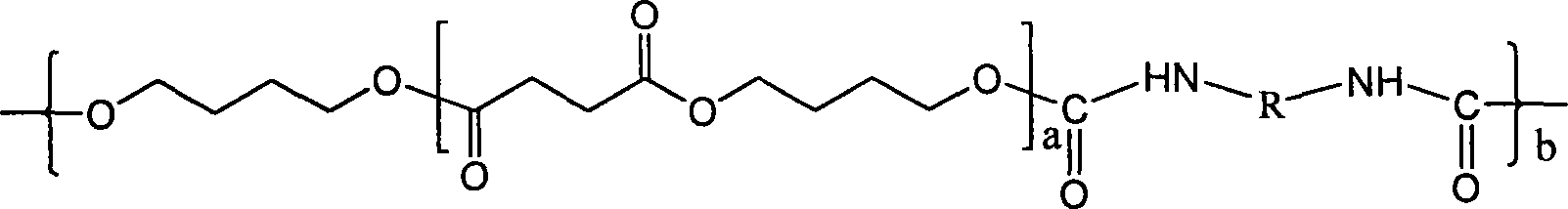

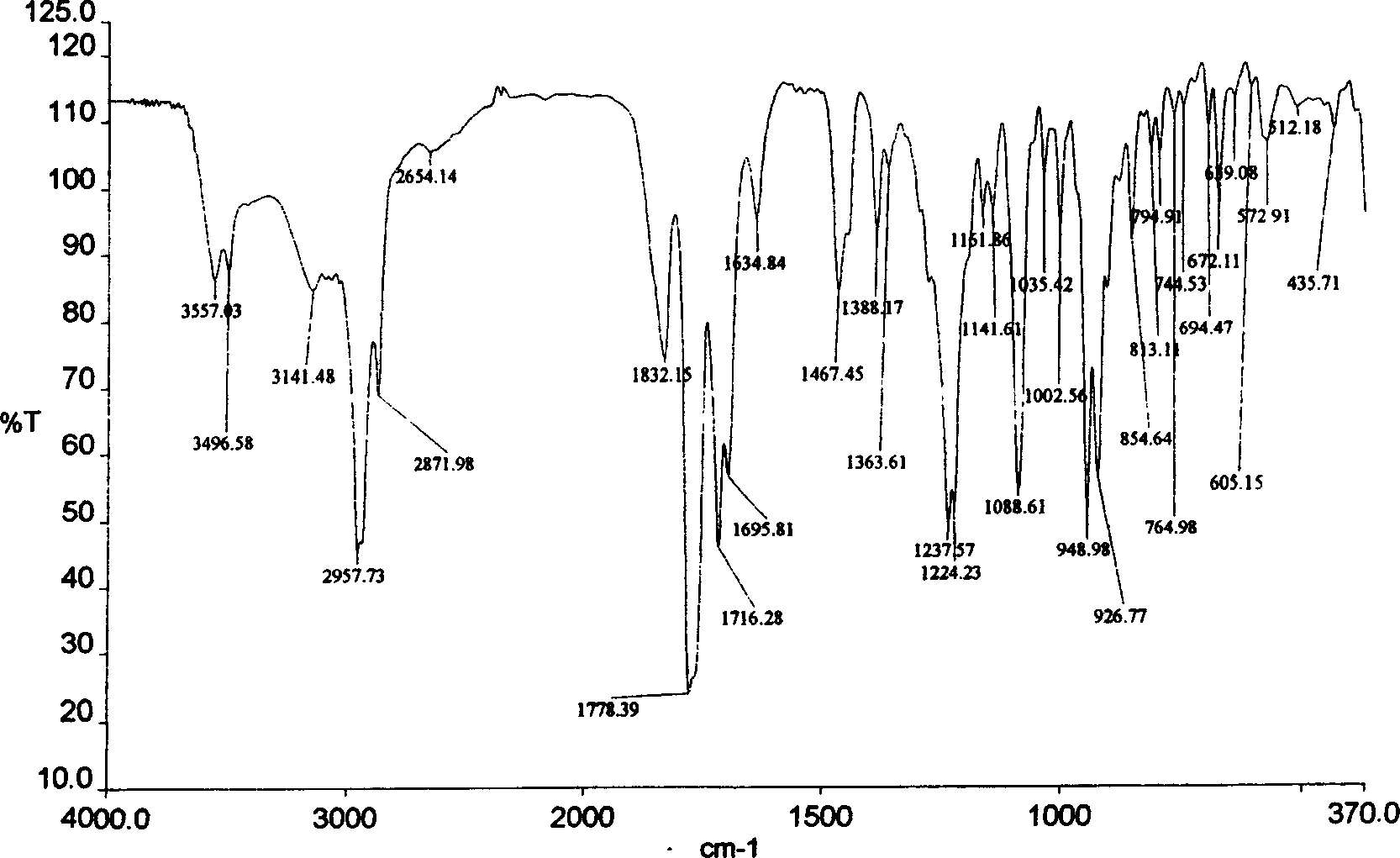

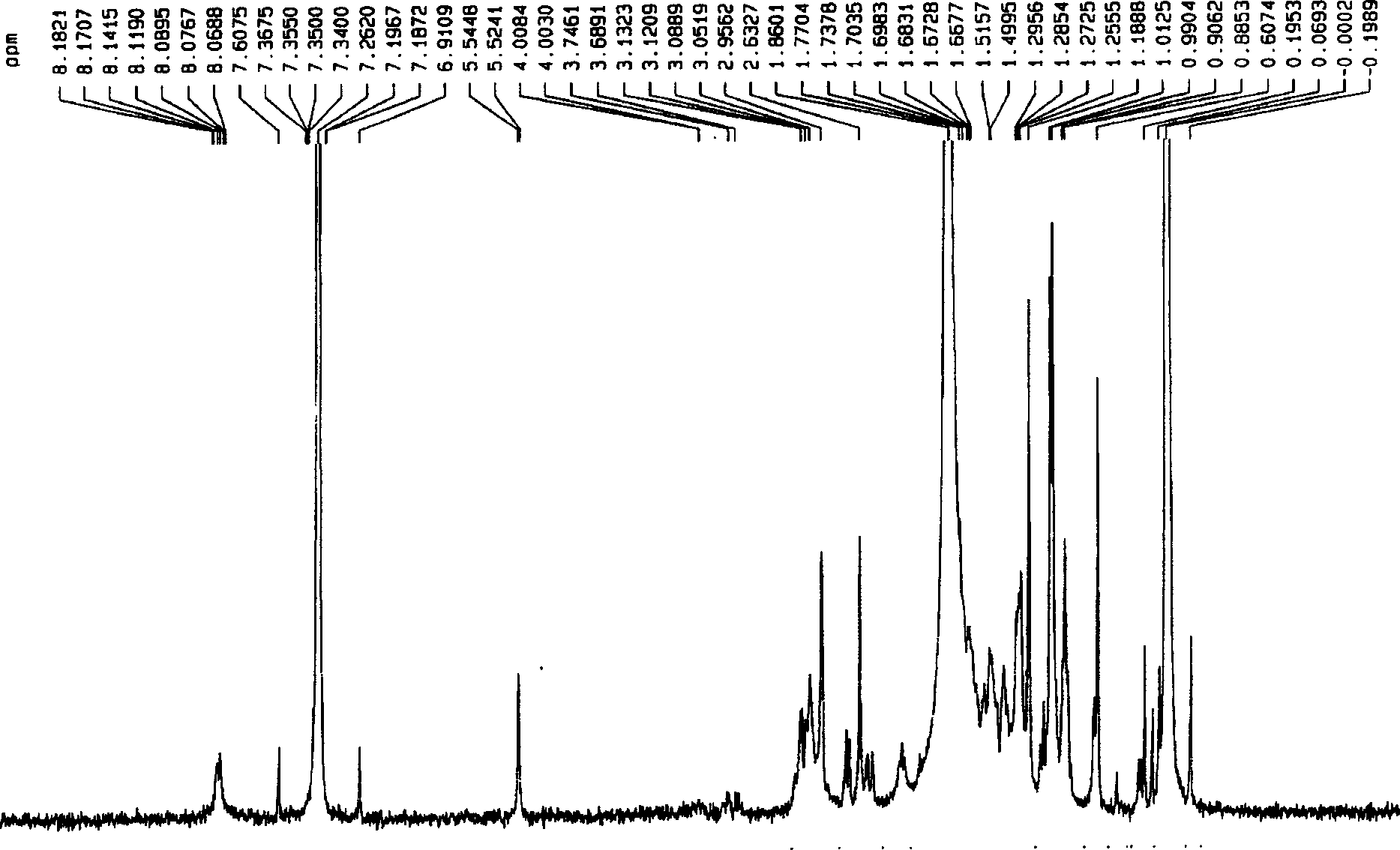

The invention relates to a polylactic acid toughening modifier in the technical field of high polymer material and a preparation method thereof. Lactide ring-opening polymerization is initiated on the terminal hydroxyl of poly (butylene succinate), and purification is carried out, thus obtaining the polylactic acid toughening modifier, the chemical structural formula is as follows. The modifier of the invention prepared by adopting degradable material can solve transport phenomenon and diosmose in the prior art.

Owner:SHANGHAI JIAO TONG UNIV

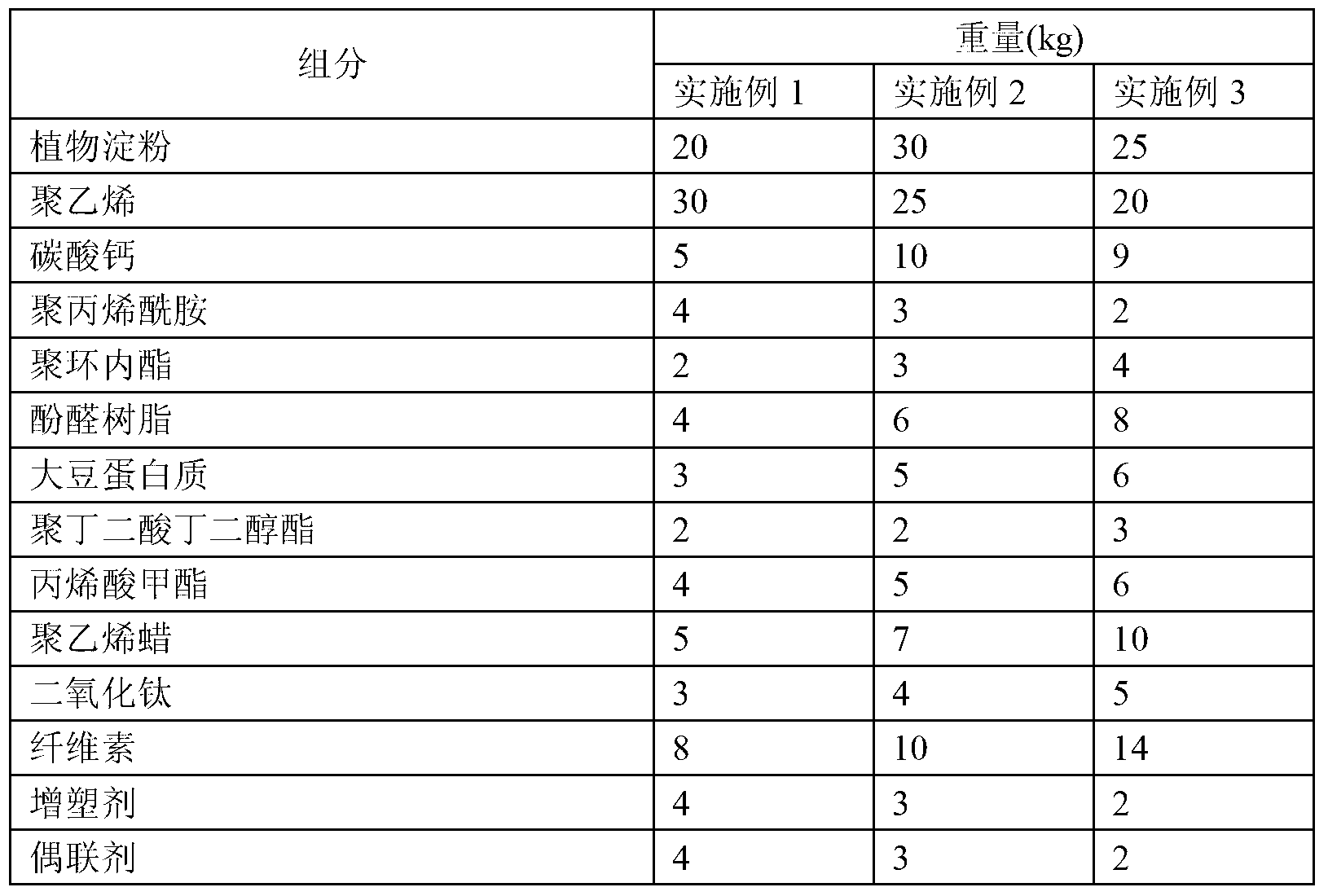

Degradable film containing starch and preparation method of degradable film

The invention provides an agricultural film material and particularly relates to a degradable film material containing starch serving as a raw material, belonging to the technical field of high molecular materials. The degradable film comprises the following raw materials in parts by weight: 20-30 parts of plant starch, 20-30 parts of polyethylene, 5-10 parts of calcium carbonate, 2-4 parts of polyacrylamide, 2-4 parts of poly cyclic lactone, 4-8 parts of phenol aldehyde resin, 3-6 parts of soybean protein, 2-3 parts of polybutylene succinate, 4-6 parts of methyl acrylate, 5-10 parts of polyethylene wax, 3-5 parts of titanium dioxide, 8-14 parts of cellulose, 2-4 parts of plasticizer and 2-4 parts of coupling agent. The degradable film provided by the invention has excellent strength, the tensile strength of the degradable film can be higher than 16MPa, the light transmittance can be higher than 88%, and the degradable film can be generally degraded within 4-6 months.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Completely-biodegradable mulching film material and mulching film

InactiveCN103937179ANo residueTo increase productionClimate change adaptationPlant protective coveringsPlastic mulchPoly(butylene succinate)

The invention discloses a completely-biodegradable mulching film material which contains one kind or several kinds of compounds which are selected from a group consisting of polyhydroxy alkanoates, polylactic acid, poly(butylene adipate-co-terephthalate), poly(butylene-scuccinate / adipate) and poly(butylene-scuccinate). By adopting the completely biodegradable mulching film material, the yield of crops can be greatly improved, the mulching film material can be completely biodegradable without residues of a mulching film, and the yield of crops can be continuously increased.

Owner:山东省意可曼科技有限公司

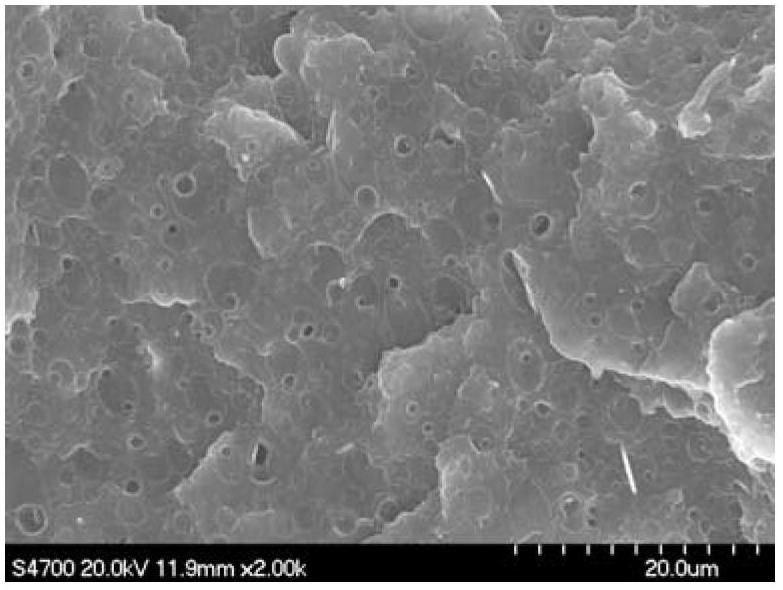

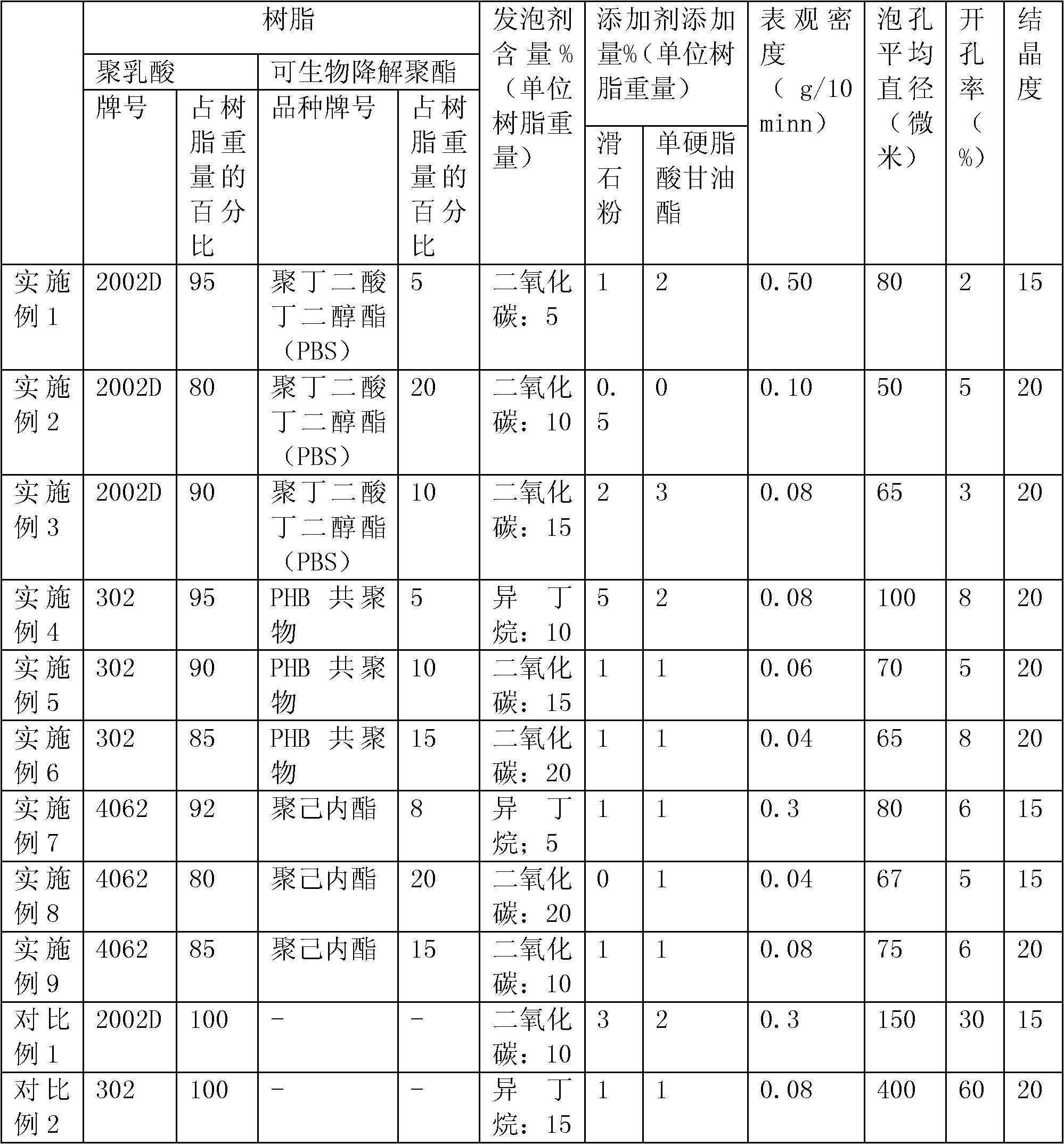

Polylactic acid foamed material and preparation method thereof

The invention relates to a polylactic acid foamed material and a preparation method thereof. The invention solves the technical problems of large pore size, nonuniformity and high porosity in the existing product. The polylactic acid foamed material is prepared by an extrusion foaming method. The polylactic acid foamed material comprises polylactic acid, at least one biodegradable polyester (selected from poly(butylenes succinate), polyhydroxybutyrate, polycaprolactone and copolymer or blend thereof), a physical foaming agent, and at least one processing assistant for foaming. The apparent density of the microporous foamed sheet is 0.05-0.5g / cm<3>, the average pore diameter is not greater than 100 micrometers, and the porosity is not greater than 10%. The invention is mainly used in the fields of food packaging, automobile industry and the like.

Owner:BEIJING UNIV OF CHEM TECH

Large molecular nucleating agent for poly butylenes succinate and copolyester of poly butylenes succinate and application thereof

The invention relates to a large molecular nucleating agent for poly butylenes succinate and a copolyester of the poly butylenes succinate and an application thereof. The large molecular nucleating agent is polyvinyl acetal, and the nucleating performance of the polyvinyl acetal is regulated and controlled by blending the polyvinyl acetal with the poly butylenes succinate and the copolyester of the poly butylenes succinate in an in-site polymerization way or in an adding way in a processing process. The large molecular nucleating agent is non-toxic, odorless, non-corrosive and dispersible. By taking the polyvinyl acetal as the large molecular nucleating agent, the peak crystallization temperatures of the poly butylenes succinate and the copolyester of the poly butylenes succinate can be raised remarkably, crystallization degree and crystallization speed are increased remarkably, a crystallization period is shortened remarkably, and the mechanical property of resin is enhanced remarkably.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Starch-based biodegradable material composition

ActiveUS20090075346A1Overcomes drawbackSugar derivativesHydrolasesCopolyesterPoly(butylene succinate)

A starch-based biodegradable material composition includes: an enzyme-hydrolyzed starch; and a biodegradable polyester selected from at least one of an aliphatic polyester of polybutylene succinate and an aliphatic-aromatic copolyester. The enzyme-hydrolyzed starch is prepared by hydrolyzing a native starch using a starch-hydrolyzing enzyme. The starch-hydrolyzing enzyme has an activity unit ranging from 15000 to 40000.

Owner:GRACE BIOTECH CORP

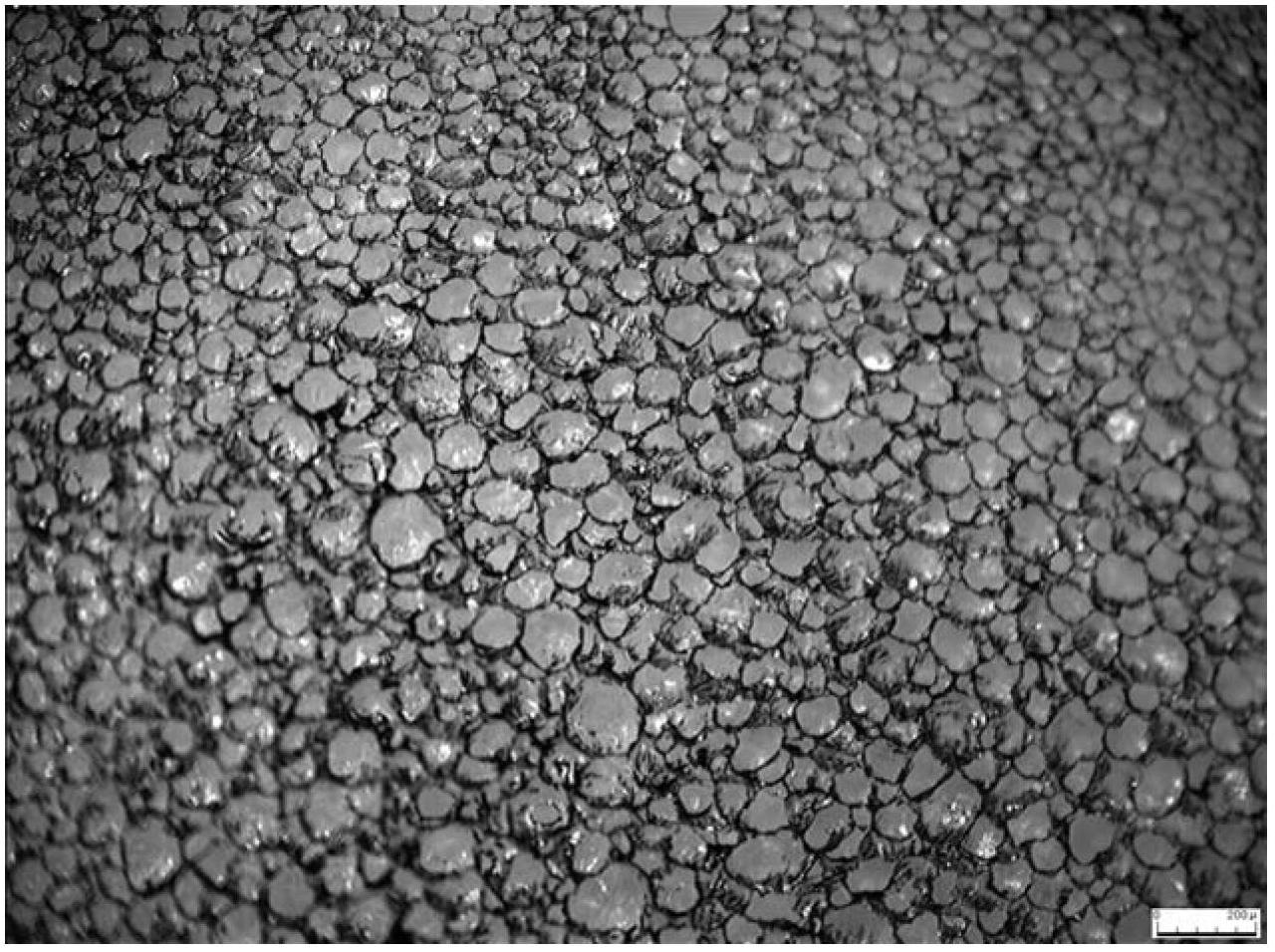

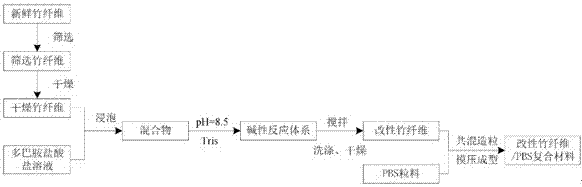

Technique for improving interfacial compatibility of bamboo fiber and polybutylene succinate based on polydopamine bionic interfacial modification modifier

InactiveCN107459830ALow priceGood dimensional stabilityBiocompatibility TestingPoly(butylene succinate)

The invention discloses a method for preparing a bionic modified bamboo fiber reinforced polybutylene succinate (PBS) composite material. The method comprises the following steps: (1) screening a bamboo fiber, keeping the length less than 380mu m, and performing soaking treatment with a dopamine hydrochloride solution; 2) putting trismetyl aminomethane (Tris) into the soaked mixed system to adjust the pH value to alkalescence, stirring at normal temperature and normal pressure, filtering, and drying so as to obtain a polydopamine modified bamboo fiber of which the water content is less than 1%; and 3) uniformly mixing the modified bamboo fiber with PBS granules in a mass ratio of 1:1 in a high-speed mixing machine, pelletizing in a double-screw extruder, performing compression molding on mixed granules in a hot press, naturally cooling in a cold press, and demolding, thereby obtaining a modified bamboo fiber / PBS composite material. According to the method disclosed by the invention, dopamine has biocompatibility, the fiber is slightly damaged, no complex container is needed in the modification process, the production method is simple and convenient and safe and environmentally friendly, and the mechanical properties of the composite material are remarkably improved.

Owner:BEIJING FORESTRY UNIVERSITY

Process for preparing thermal resistant easy processed polylactic resin

The invention belongs to a manufacturer method for thermal resistant easy to machined poly lactic acid resin that is made up from poly lactic acid, thermal resistant material, high molten mass speed polymers material aliphatic polyester and antioxidant. The process includes mixing in blending machine, and extruding at 160-185 degree centigrade. The resin could be used to make film, panel, sheet material, sparkle, and plastic components. The products have excellent thermal resistance capability, mechanical property and machine property.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Completely biodegradable polyhydroxyalkanote / poly(butylene succinate) blending alloy

The invention discloses a full biodegradable N-poly-ester / poly butylene succinate blending alloy, which is characterized in that the blending alloy is prepared from N-poly-ester, poly butylene succinct, starch, filler and the other auxiliary agents. The blending alloy uses the heat resistance, good processing and forming property, higher crystallizing property, good tensile strength and impact toughness of the poly butylene succinate to improve the defects of poor heat resistance, serious processing and forming viscous, slow crystallization and lower mechanical strength of the N-poly-ester, and reduce the cost and widen the application range, the obtained blending alloy has good comprehensive performance, and can be applied in the fileds of blowing film, extruding sheets, injecting one-off environmental supplies and medical treatment.

Owner:山东省意可曼科技有限公司

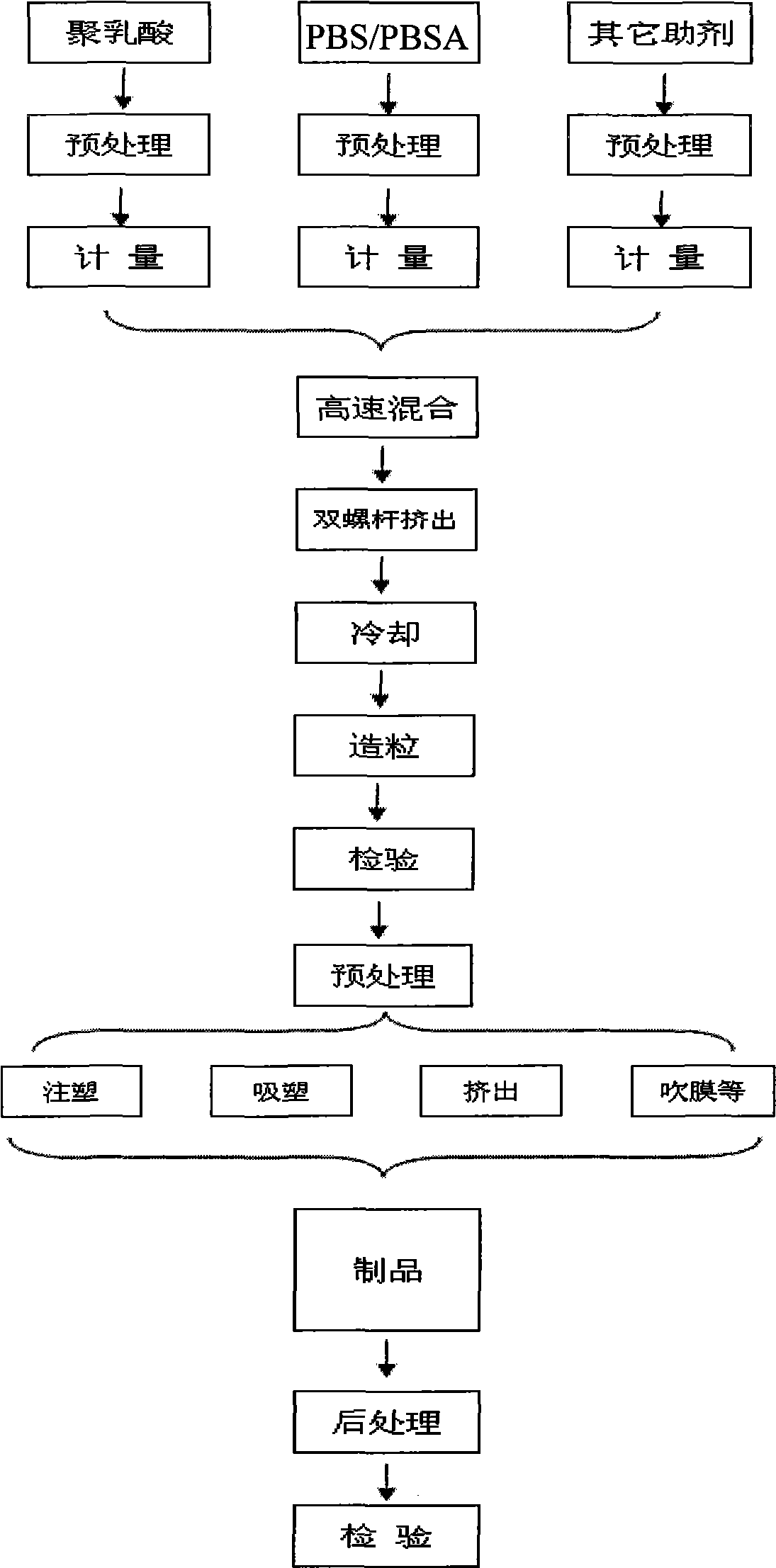

Preparation method of completely biodegradable plastic resin and film products thereof

The invention relates to a preparation method of a completely biodegradable plastic resin and film products thereof. The preparation method is realized through the following steps: conducting surface treatment on starch with content controlled to be 90% by taking corn starch, sweet potato starch, tapioca, konjac starch, poly(butylene succinate) (PBS), various plastic additives and the like as raw materials, and blending the starch with biodegradable synthetic resin (PBS, PLA (polylactic acid)) for modification; and adopting film blowing, extrusion and other technologies to obtain corresponding products. The preparation method has the beneficial effects that on the premise of maintaining the product to be completely biodegradable, the tensile strength and elongation at break of the product can be improved, so that the product truly conforms to the market demand.

Owner:上海可伊实业有限公司

Catalyst for preparing polybutylene succinate and copolyesters thereof and preparation method thereof

The invention provides a catalyst for preparing polybutylene succinate and copolyesters thereof and a preparation method thereof. The preparation method comprises the following steps: (1) adding titanium alkoxides, silica-alkoxides, dibastic alcohol and a metal cocatalyst into solution for reaction at a temperature of between 80 and 180DEG C, and separating and removing unreacted substances and micromolecular products in a reaction system; and (2) adding a complexing agent for continuous reaction and collecting the catalyst in reaction products. Or the preparation method comprises the following steps: (1) adding titanium alkoxides, dibastic alcohol and a metal cocatalyst into solution for reaction at a temperature of between 80 and 180DEG C, and separating and removing unreacted substancesand micromolecular products in a reaction system; and (2) adding silica-alkoxides and a complexing agent for continuous reaction and collecting the catalyst in reaction products. The catalyst has high catalytic activity, low addition volume, good product quality, no reaction when meeting water at normal temperature, easy long-term storage and good industrial application prospect and value.

Owner:SHANGHAI HUAMING HI TECH GRP

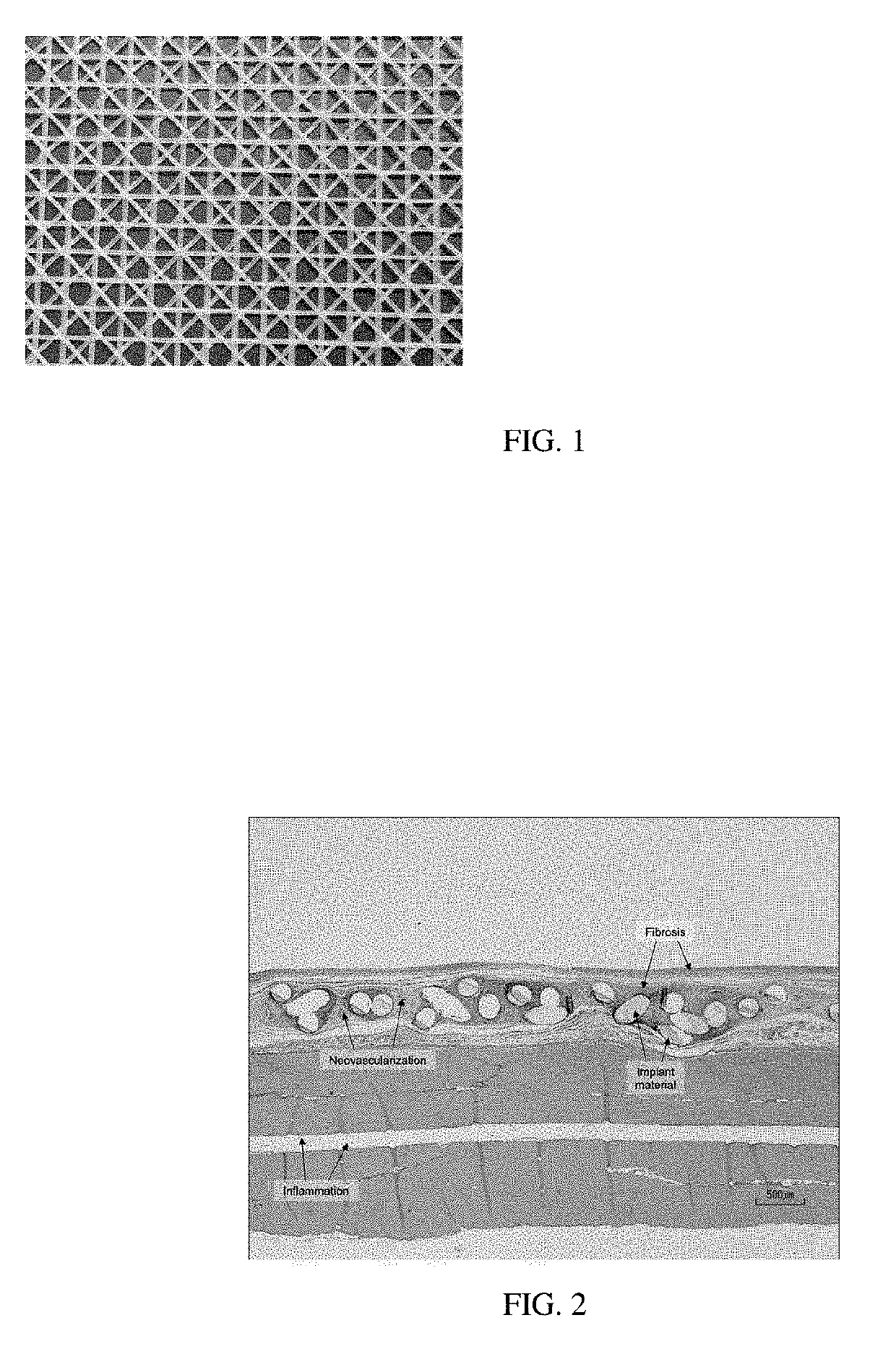

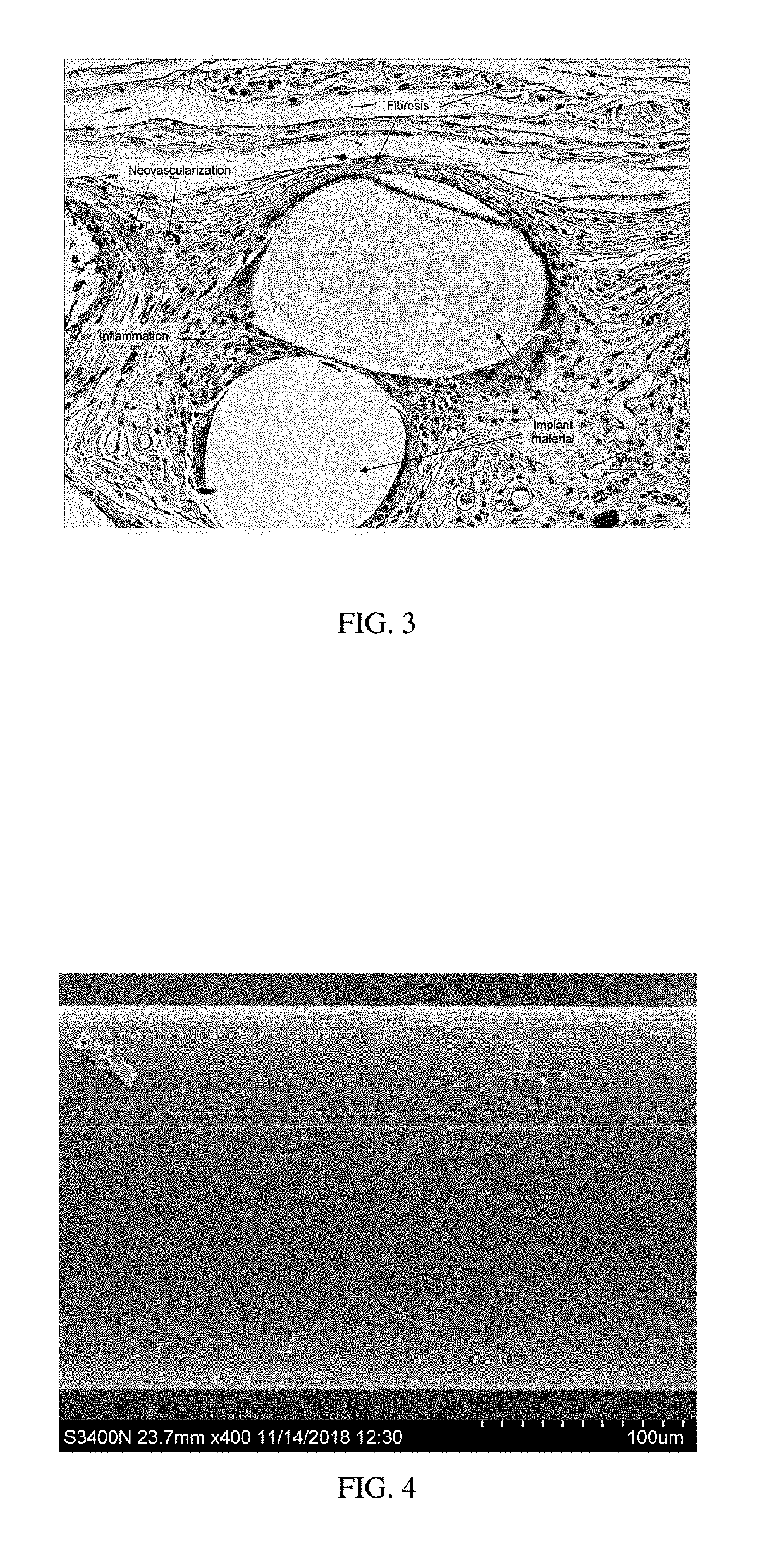

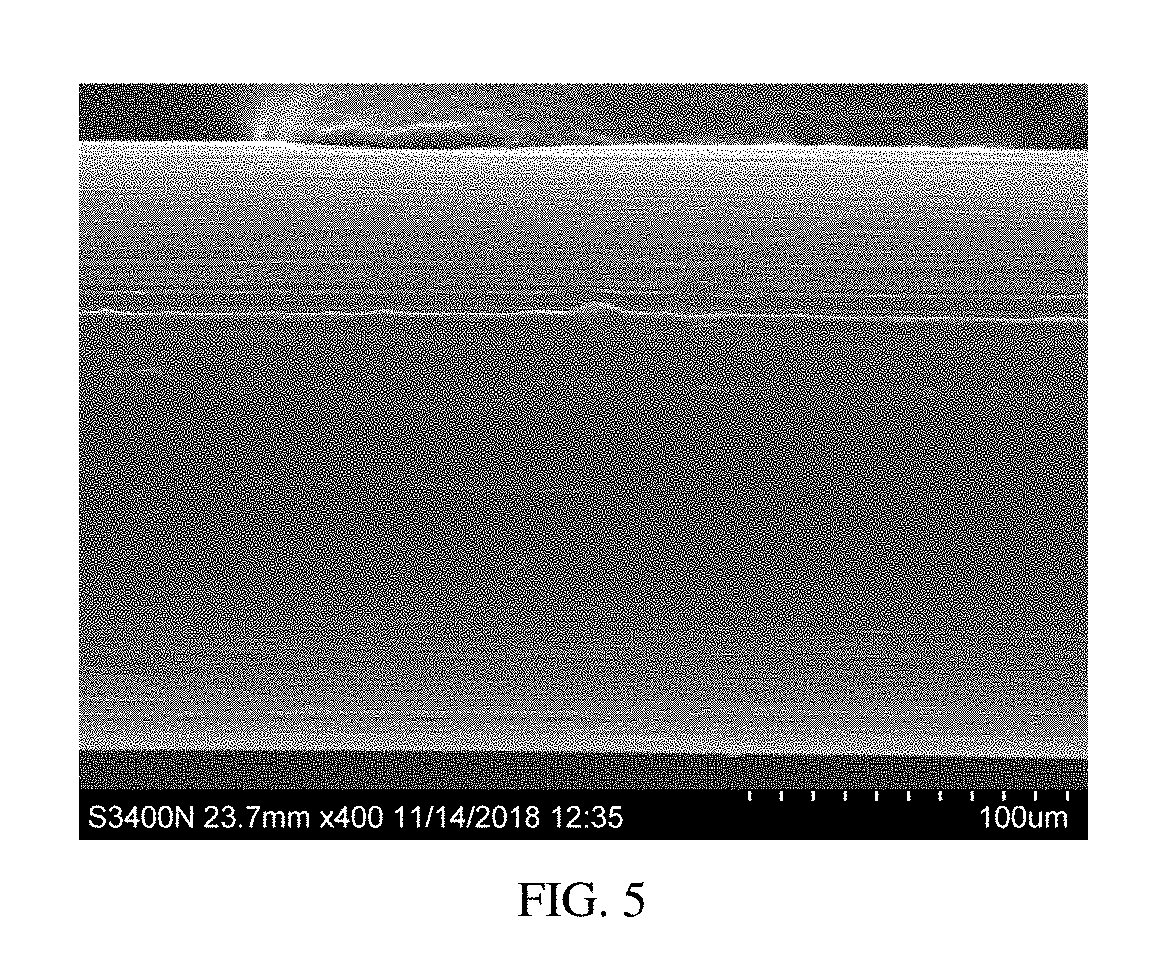

Surgial mesh implants containing poly(butylene succinate) and copolymers thereof

PendingUS20190269817A1Inhibition of colonizationReduce and prevent occurrenceSuture equipmentsMammary implantsFiberLimulus amebocyte lysate

Resorbable implants comprising poly(butylene succinate) and copolymers thereof have been developed. The implants implants are preferably sterilized, and contain less than 20 endotoxin units per device as determined by the limulus amebocyte lysate (LAL) assay, and are particularly suitable for use in procedures where prolonged strength retention is necessary, and can include one or more bioactive agents. The implants may be made from fibers and meshes of poly(butylene succinate) and copolymers thereof, or by 3d printing, and the fibers may be oriented. Coverings and receptacles made from forms of poly(butylene succinate) and copolymers thereof have also been developed for use with cardiac rhythm management devices and other implantable devices. These coverings and receptacles may be used to hold, or partially / fully cover, devices such as pacemakers and neurostimulators. The coverings and receptacles are made from meshes, webs, lattices, non-wovens, films, fibers, and foams, and contain antibiotics such as rifampin and minocycline.

Owner:TEPHA INC

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Low Glass Transition Polyhydroxyalkanoates for Modification of Biodegradable Polymers

ActiveUS20150147929A1Improve propertiesHigh strengthWoven fabricsNon-woven fabricsPolytetramethylene terephthalateVitrification

Compositions of biobased polymer blends of polymers of polybutylene succinate (PBS) or polybutylene-adipate-terephthalate (PBAT) and a polyhydroxyalkanoate copolymer are described. In certain embodiments, the copolymer is a multiphase copolymer blend having one phase a glass transition temperature of about −5° C. to about −50° C. Methods of making the compositions of the invention are also described. The invention also includes articles, films and laminates comprising the compositions.

Owner:CJ CHEILJEDANG CORP

Biodegradable material, and preparation method and application thereof

The invention provides a biodegradable material which is prepared from the following raw materials in percentage by weight: 10-35% of 3-hydroxybutanoic acid-4-hydroxybutanoic acid copolymer, 10-35% of poly(butylene succinate), 0-50% of polylactic acid, 5-25% of vegetable oil, 1-10% of plasticizer and 0.02-5% of reaction promoter. The invention also provides a preparation method of the biodegradable material and application of the biodegradable material in preparation of a biodegradable film. The biodegradable material, which is a degradable biological material, has the advantages of excellent elongation at break, high tensile strength, favorable transparency and excellent comprehensive properties. The preparation method provided by the invention has the advantages of simple technique, strong operability and low production cost, and is easy to control; and the biodegradable material can be prepared into a biodegradable film after being subjected to simple processing, and thus, the invention can easily implement industrial production and has favorable economic benefit and wide application prospects.

Owner:ECOTA ENVIRONMENTAL TECH

Preparation of high molecular weight poly(butylene succinate)

The invention relates to a method for preparing high molecular weight poly(butylenes succinate), which is characterized in that: the method adopts a cerium salt-ethylene glycol antimony binary catalytic system and solves the problems that the poly (butylenes succinate) in the prior art has low molecular weight and poor hue and so on. The prepared poly(butylenes succinate) has high molecular weight, good color and luster, and good mechanical property, improves the output and the quality of polyester products, decreases the content of stibium in the polyester products, and improves the post-processing spinnability. The weight average molecular weight of the poly(butylenes succinate) prepared by the method can reach between 5.6x10<4> and 12.5x10<4>, the rupture strength is between 35 and 55MPa, and the breaking elongation rate is between 200 and 420 percent. The method can ensure that the whole synthesis period is shortened, thereby reducing cost.

Owner:NANJING UNIV OF TECH

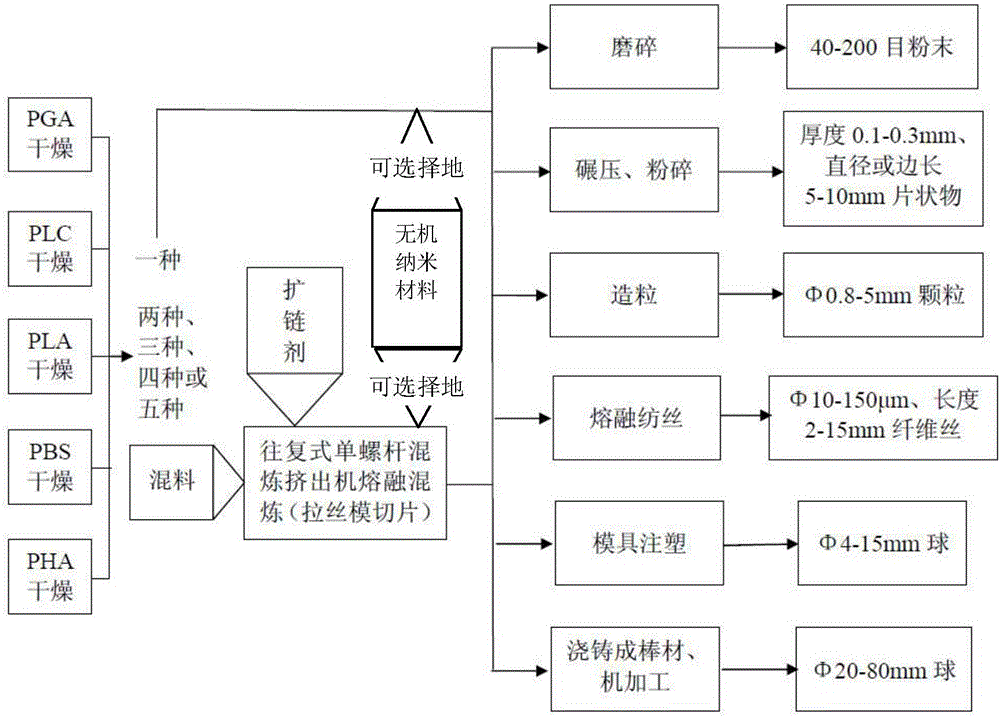

Degradable material for oil and gas field operation and preparation method thereof

InactiveCN105295321ALess intrusiveReduce harmFluid removalDrilling compositionAcid fracturingPoly-3-hydroxybutyrate

The invention provides a degradable material for oil and gas field operation and a preparation method thereof. The preparation method of the degradable material for oil and gas field operation comprises the step of carrying out melting mixing reaction on two, three, four, or five polymers of polyglycolic acid, polycaprolactone, polylactic acid, poly butylene succinate and poly-3-hydroxybutyrate and a chain extender, so as to obtain resin alloy, namely, the degradable material for oil and gas field operation. The degradable material for oil and gas field operation can be prepared into shapes such as pieces, powder, particles and balls, or can be prepared from one of polyglycolic acid, polycaprolactone, polylactic acid, poly butylenes succinate and poly-3-hydroxybutyrate into shapes such as pieces, powder, particles and balls through the method, is used for temporary plug and filtration reduction for protecting a reservoir, and temporarily plugging shot holes, constructed layer sections, and the like during various operation (drilling, well completion, well repair and acid fracturing) in the oil and gas field, and has the advantages of being completely degradable and harmless to the stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

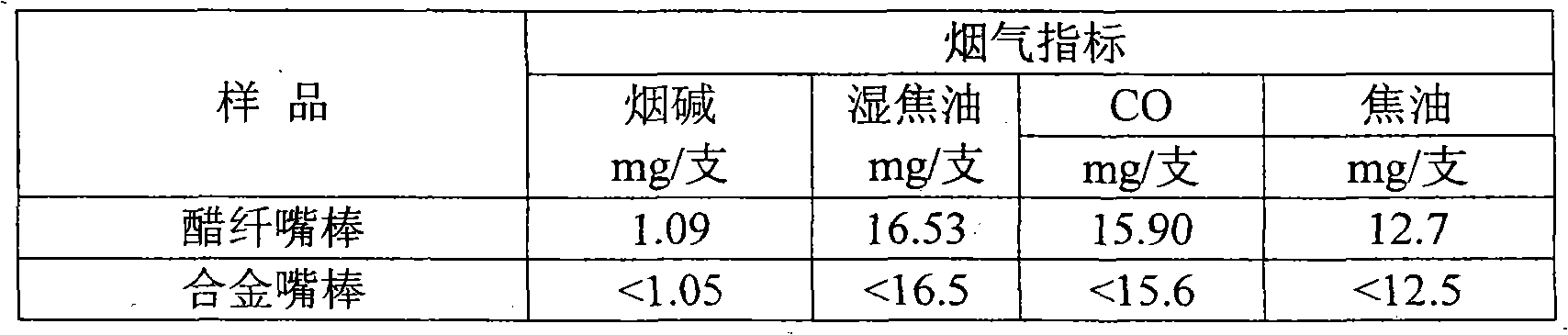

Biodegradable cigarette fiber material and cigarette filter

ActiveCN102080278ABiodegradableImprove adsorption capacityTobacco smoke filtersMelt spinning methodsFiberPolymer science

The invention provides a biodegradable cigarette fiber material and a cigarette filter. The biodegradable cigarette fiber material comprises the following raw materials of 1-99wt percent of poly(butylene succinate) polymer, 1-99wt percent of polylactic acid polymer and 0-3wt percent of stabilizing agent, and the cigarette fiber material is prepared by processing the raw materials with a melting spinning process. The poly(butylene succinate) polymer and the polylactic acid polymer can be respective homopolymers of the two polymers per se and can also be copolymers containing other monomer materials, which do not exceed 30 percent of the total quantity of respective molecular chain segments of the two polymers. The invention also provides a biodegradable cigarette filter rod prepared from the cigarette fibre material through sizing processing, and a cigarette product. The provided cigarette filter has a property equivalent to the property of the traditional general cigarette filter, a cigarette end discarded by a smoker can be decomposed within shorter time in the natural environment, and the pollution of the cigarette waste to the environment is avoided at present while the requirement of cigarette production is met.

Owner:海南海福新材料有限公司

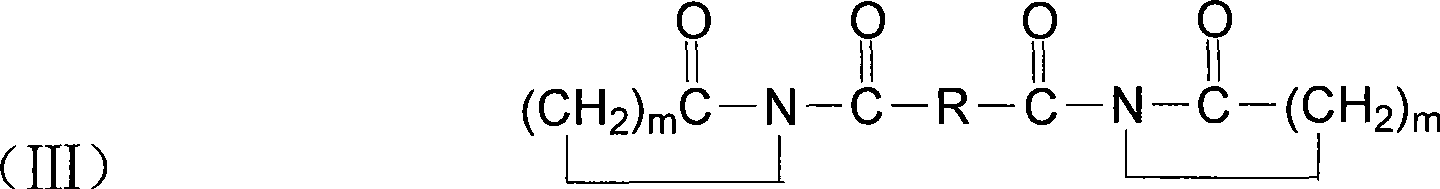

Method for preparing high molecular weight biodegradable polyester by combined chain extension

The invention relates to a method for preparing biodegradable polyester. Firstly, melt polycondensation is conducted through diol and dicarboxylic acid and a low molecular weight polyester prepolymer with number average molecular weight between 2, 000 and 20, 000 or intrinsic viscosity below 0.64dL / g is prepared; binary oxadiazoline and diacyl bis-caprolactamate are combined to extend chain, and chain extension is carried out at a certain temperature; and the biodegradable polyester is obtained. The number average molecular weight of polybutylene adipate (PBA) can reach up to 39, 000 and the intrinsic viscosity to 1.13dL / g. For poly (butylene succinate) (PBS) with relatively high melting point, the intrinsic viscosity after chain extension is up to 0.99dL / g.

Owner:BEIJING UNIV OF CHEM TECH

Modified butanediol ester poly succinic acid and synthetic method

InactiveCN1796435AImproved crystallization behaviorSlow crystallization ratePolymer scienceSynthesis methods

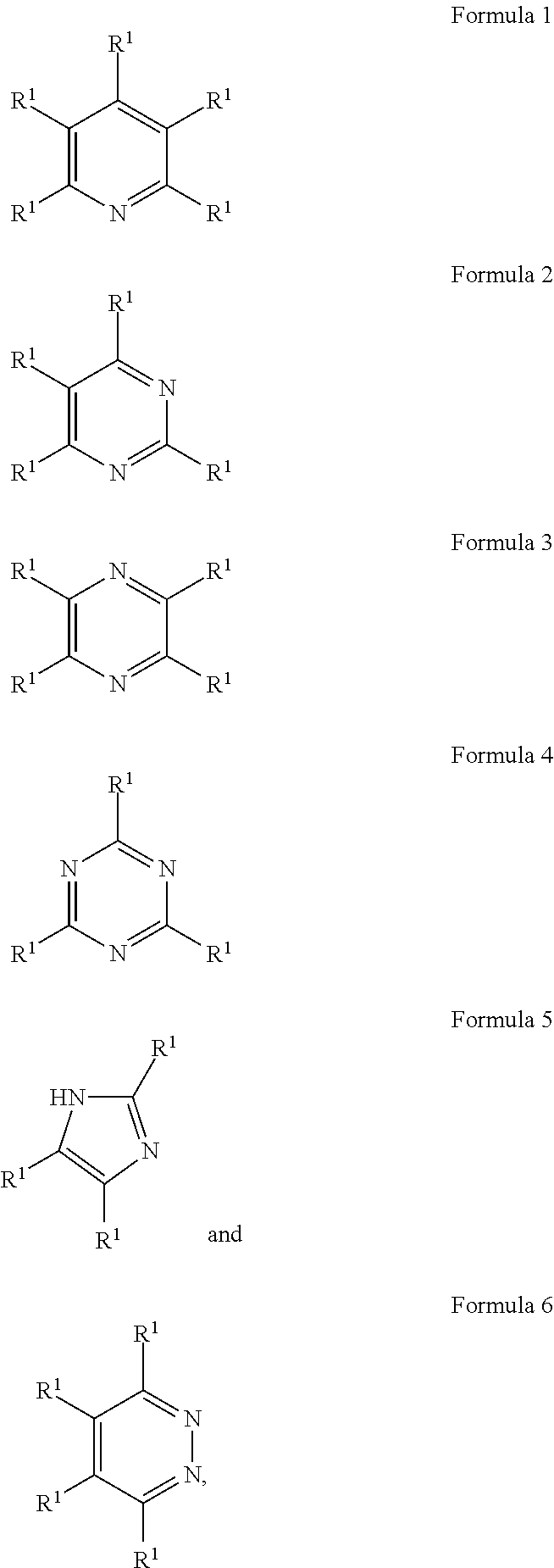

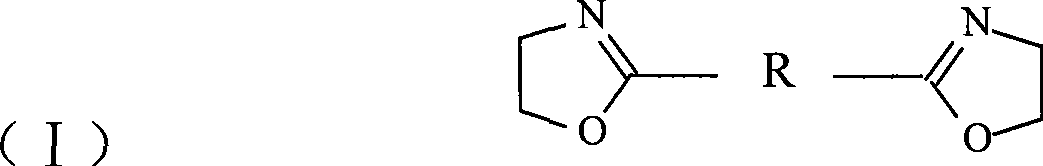

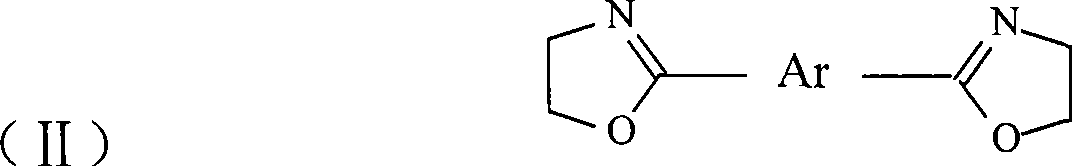

This invention relates to a cyclic compound, especially poly (butylenes succinate) modified by copolymerization with maleopimaric anhydride and its synthesis method. Succinic acid, 1,4-butanediol are mixed at a mole ratio of 1:1~4, and 4~20g maleopimaric imine dicarboxylic ester oligomers are added per 163g succinic acid / 1,4-butanediol mixture. The system is stirred at a temperature of 160~200 deg.C in the presence of inert gas, and cadmium acetate, zincum acetate, stibium oxide, butyl titanate or their optional combinations are added as catalysts at a mass fraction of 0.1~3% for a polymerization at a temperature of 230~280 deg.C and a pressure of 5~10Pa to produce modified poly(butylenes succinate) with a following structure. Such an environmentally friendly polymer performs a good elongation rate at break, impact-resistance strength and bending strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

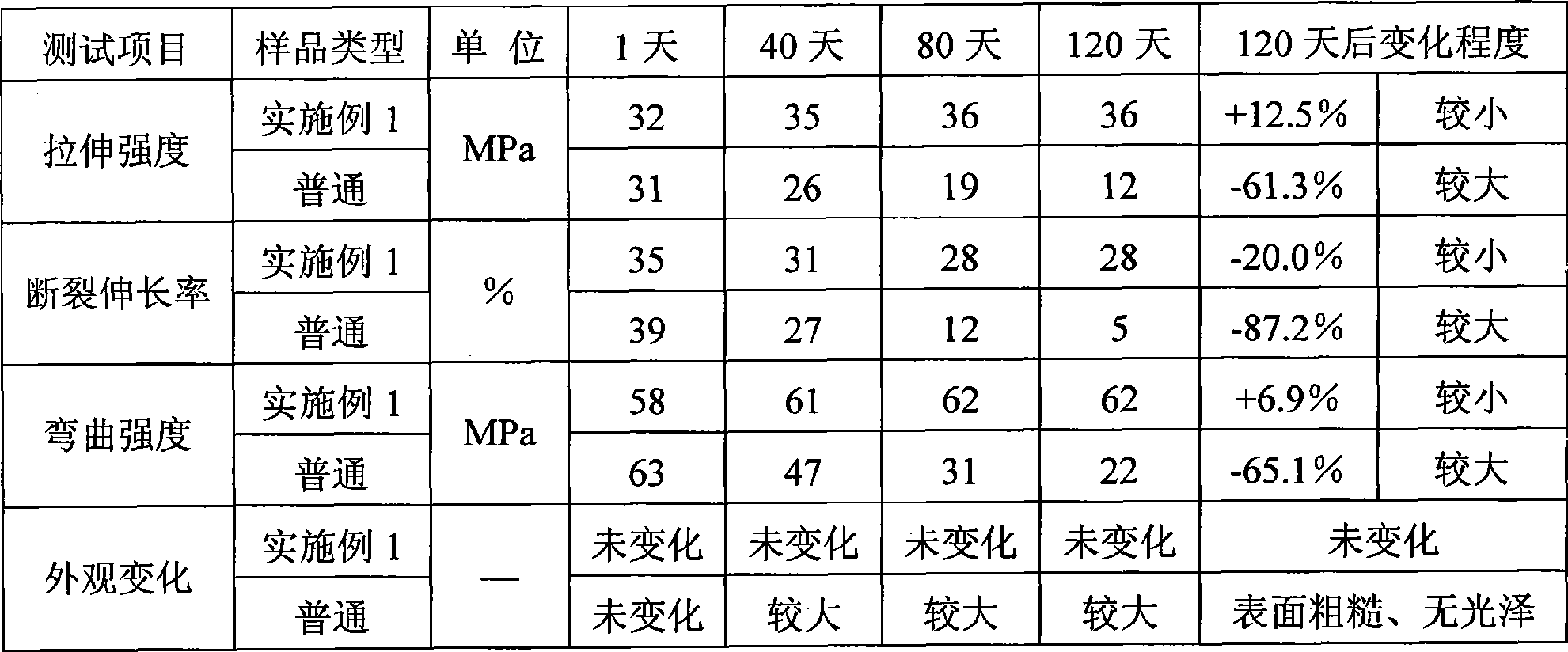

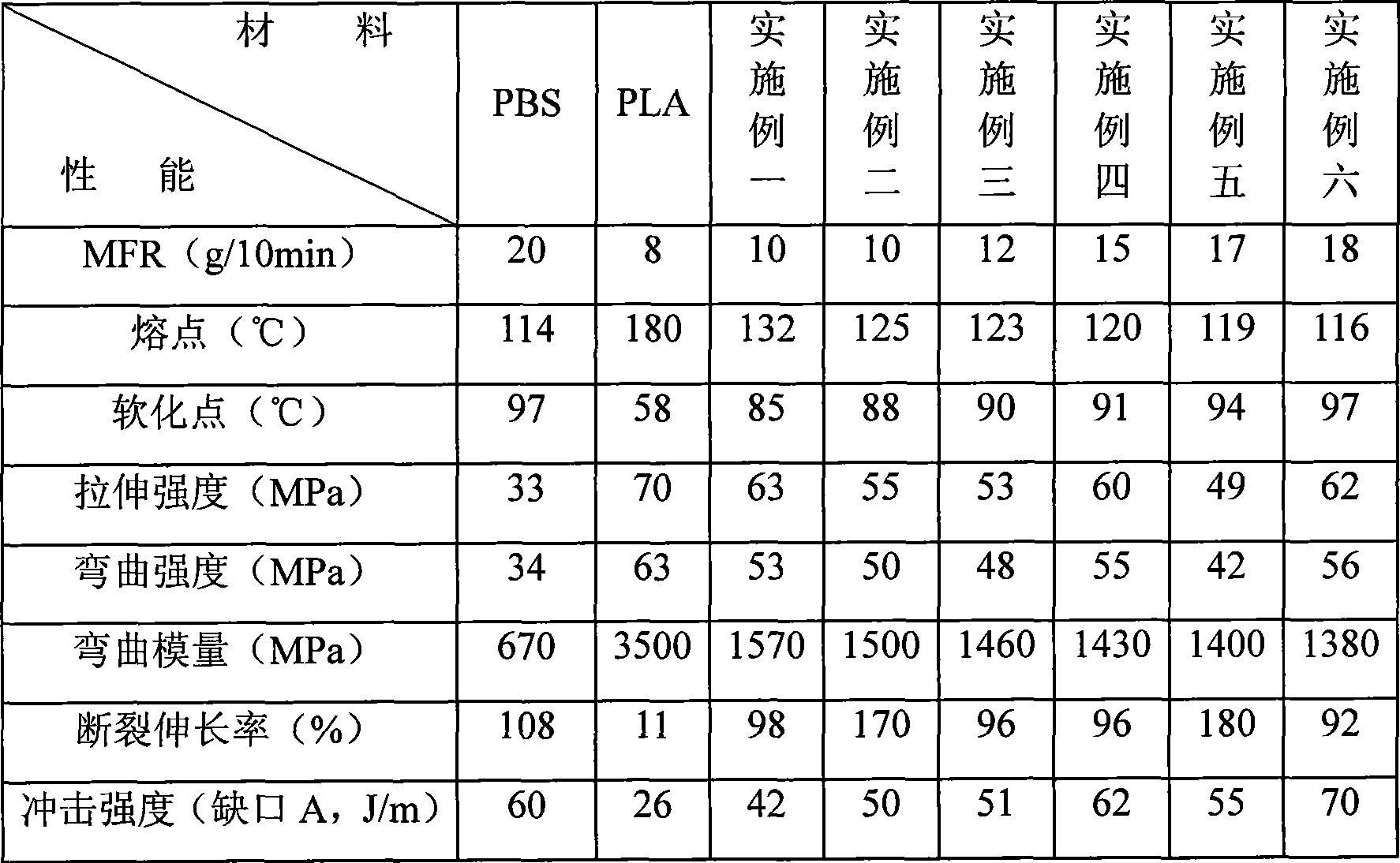

Full-biodegradation high-tenacity heat-resistant type polylactic resin and preparation method thereof

ActiveCN101824211AGood mechanical propertiesImprove heat resistanceGlycidyl methacrylatePoly(butylene succinate)

The invention discloses full-biodegradation high-tenacity heat-resistant type polylactic resin and a preparation method thereof. The polylactic resin comprises polylactic resin, polybutylene succinate, dicumyl peroxide and glycidyl methacrylate; and the weight-average molecular weight of the polylactic resin is 8-13 ten thousand, and the weight-average molecular weight of the polybutylene succinate is 7-11 ten thousand. In parts by weight, the total amount of the polylactic resin and the polybutylene succinate is 100 parts, wherein the polylactic resin accounts for 70-90 parts, the polybutylene succinate accounts for 10-30 parts, the dicumyl peroxide accounts for 0.1-1 part, and the glycidyl methacrylate accounts for 1-10 parts. Compared with the prior art, the full-biodegradation high-tenacity heat-resistant type polylactic resin has good biodegradation property, mechanical property and heat-resisting property; and the preparation method has simple technique process, excellent processing performance and low cost, and can realize large-scale industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Biodegradable polyester composition

The invention discloses a biodegradable copolyester compound which comprises the components with the weight percentage as follows: 45 percent to 90 percent of poly butylene succinate, 5 percent to 50 percent of poly lactic acid, 1 percent to 2 percent of plasticizer and 1 percent to 5 percent of filling, wherein, the plasticizer is at least one of dimethyl phthalate and diethyl phthalate; and the filling is at least one of talcum powder, bamboo powder, nanometer calcium carbonate and nanometer titanium-silicon complexing agent. The biodegradable copolyester compound integrates the advantages of various biodegradable materials to ensure that the biodegradable copolyester compound not only has good heat resistance, mechanical performance, processability and aging resistance but also reduces the production cost and develops the application field of the biodegradable material under the precondition of not changing the biodegradability.

Owner:马世金

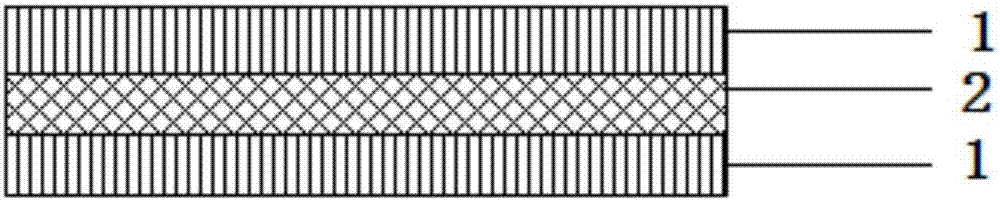

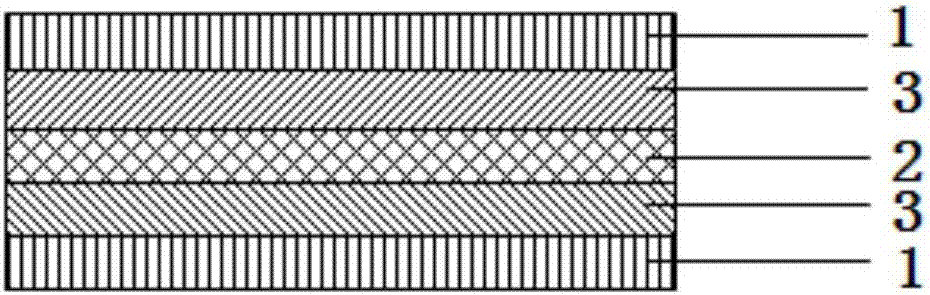

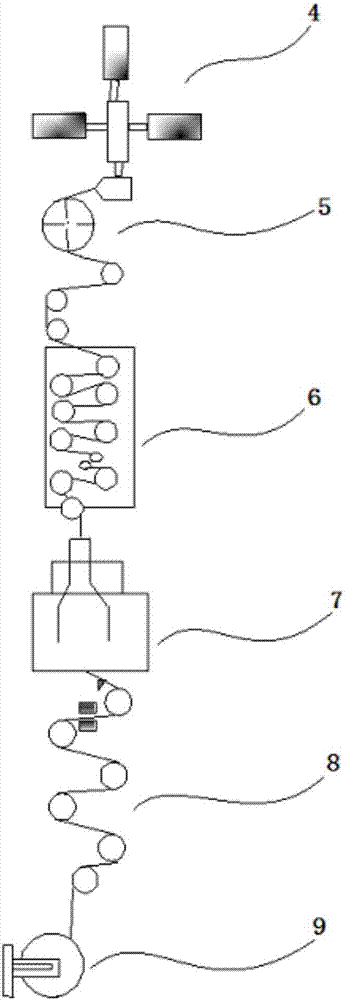

Biodegradable multilayer co-extrusion material and preparation method thereof

ActiveCN107031153APromote degradationWith natural propertiesSynthetic resin layered productsFlat articlesPolybutyleneMedical product

The invention provides a biodegradable multilayer co-extrusion material. The material is characterized by comprising two surface functional layers and a middle layer located between the two surface functional layers, components of the surface functional layers and the middle layer include biodegradable materials, and the biodegradable materials refer to one or more of polybutylene succinate, polylactic acid, polyhydroxyalkanoate and polybutylene adipate-polybutylene terephthalate. The invention further discloses a preparation method of the material. The biodegradablity of four selected master batches of the multilayer co-extrusion material is good, and adopted inorganic minerals are natural, so that the co-extrusion material has completely biodegradable properties and can be widely used in various types of food packages, medical products, environmental protection labels, advertisements and all kinds of environmental-protection products.

Owner:齐庆德

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com