Patents

Literature

47results about How to "Improved crystallization behavior" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blended foam material based on polycaprolactone (PCL) and modified polylactic acid (PLA) and preparation method thereof

The invention discloses a blended foam material based on PLC and modified PLA and a preparation method thereof, and belongs to the foam material field. The foam material comprises, by weight, 60-90 parts of PLA, 1-25 parts of PCL, 2-10 parts of reinforcing agents, 1-3 parts of nanometer nucleating agents, 4 parts of foaming agents, 0.1-1 part of a blowing promoter, 1-3 parts of environment-friendly flame retardants and 0.5-1 part of a surfactant. According to the foam material and the preparation method thereof, composite foamed plastics with good mechanical properties and superior surface quality can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

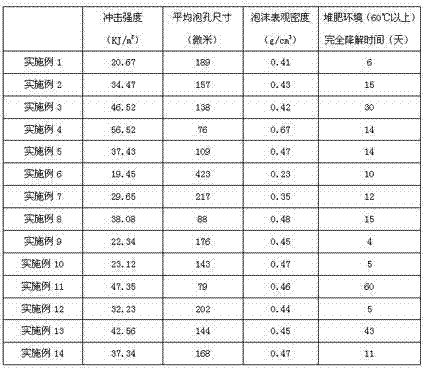

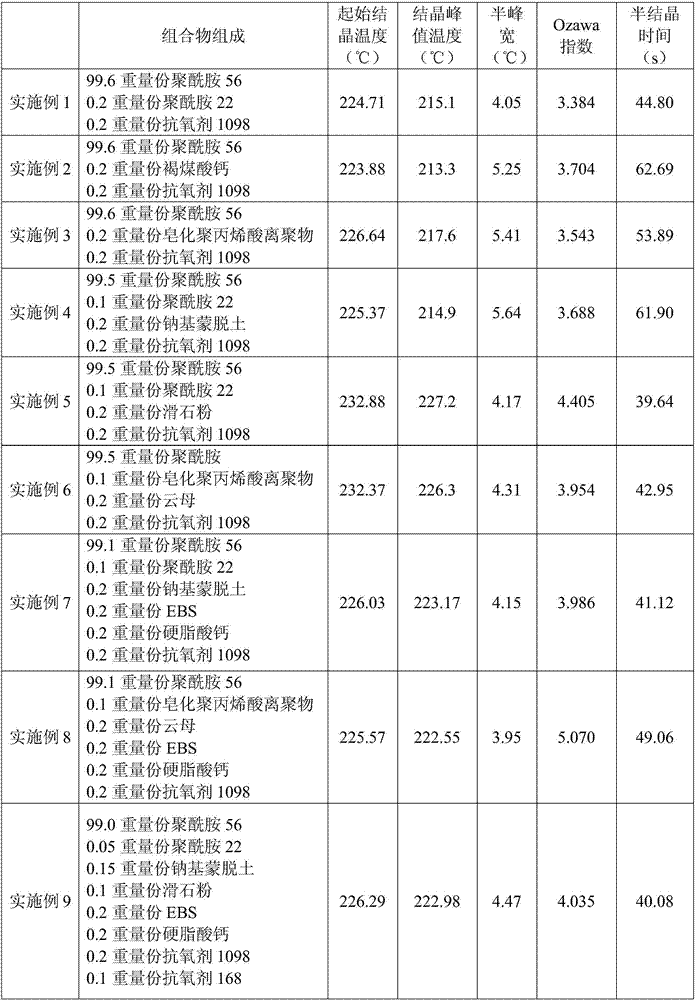

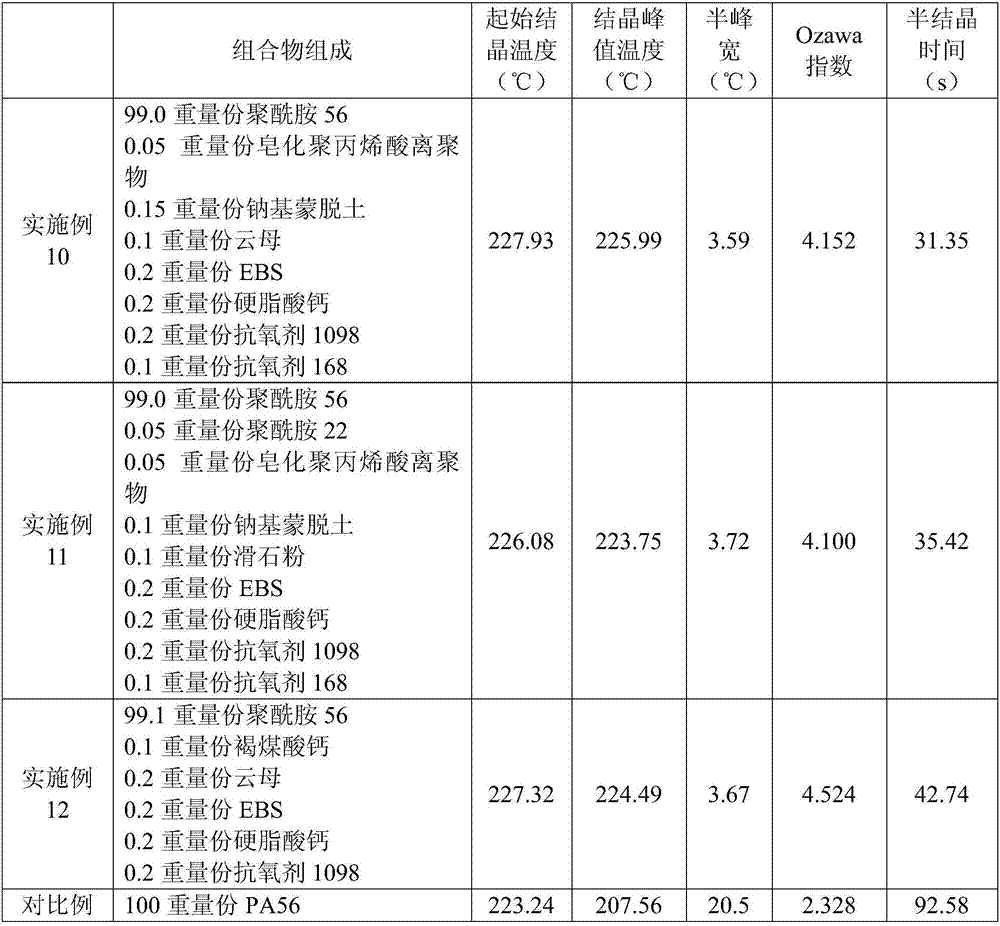

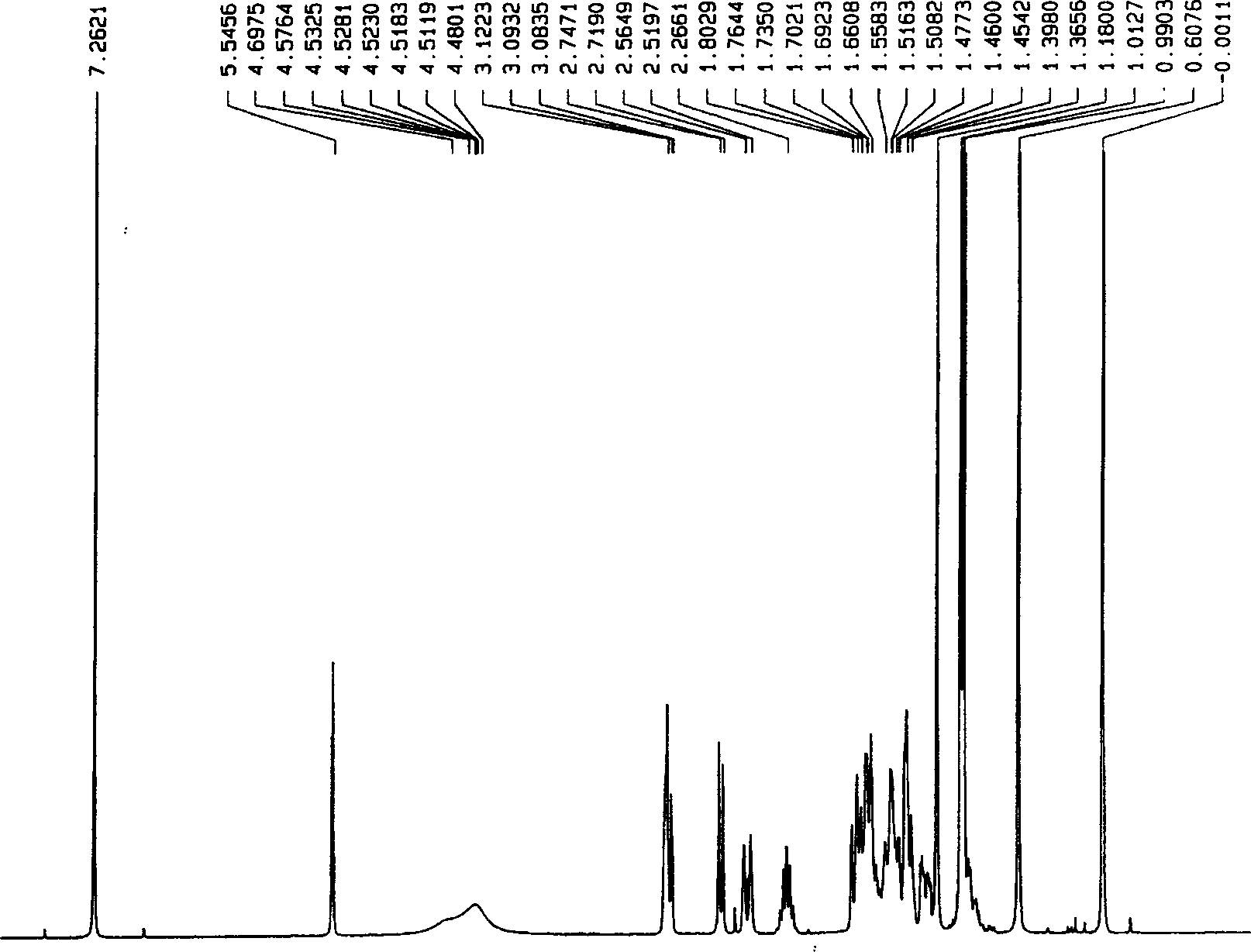

Polyamide composition for quick injection molding and preparation method thereof

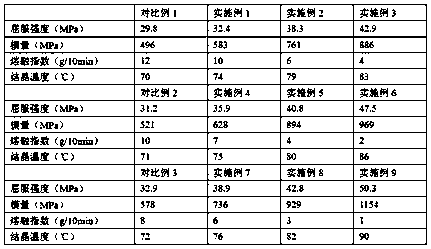

InactiveCN106867250AImproved crystallization behaviorGood dimensional stabilityPolymer sciencePolyamide

The invention provides a polyamide composition for quick injection molding and a preparation method thereof. The polyamide composition comprises 95-100 weight parts of polyamide resin and below 0.5 weight part of a nucleating agent, preferably, 0.005-0.5 weight part, and optimally, 0.005-0.03 weight part, wherein the polyamide resin includes polyamide 5X resin. The preparation method for the polyamide composition for quick injection molding comprises the following steps: (1) uniformly mixing the components of the polyamide resin composition, thereby obtaining a mixture; and (2) extruding and granulating the mixture, thereby obtaining the polyamide composition. The crystallizing speed of the polyamide composition prepared according to the invention is obviously increased, so that the purposes of shortening the manufacturing and molding period and increasing the size stability of the quick injection molding product can be achieved.

Owner:CATHAY R&D CENT CO LTD +1

Modified butanediol ester poly succinic acid and synthetic method

InactiveCN1796435AImproved crystallization behaviorSlow crystallization ratePolymer scienceSynthesis methods

This invention relates to a cyclic compound, especially poly (butylenes succinate) modified by copolymerization with maleopimaric anhydride and its synthesis method. Succinic acid, 1,4-butanediol are mixed at a mole ratio of 1:1~4, and 4~20g maleopimaric imine dicarboxylic ester oligomers are added per 163g succinic acid / 1,4-butanediol mixture. The system is stirred at a temperature of 160~200 deg.C in the presence of inert gas, and cadmium acetate, zincum acetate, stibium oxide, butyl titanate or their optional combinations are added as catalysts at a mass fraction of 0.1~3% for a polymerization at a temperature of 230~280 deg.C and a pressure of 5~10Pa to produce modified poly(butylenes succinate) with a following structure. Such an environmentally friendly polymer performs a good elongation rate at break, impact-resistance strength and bending strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

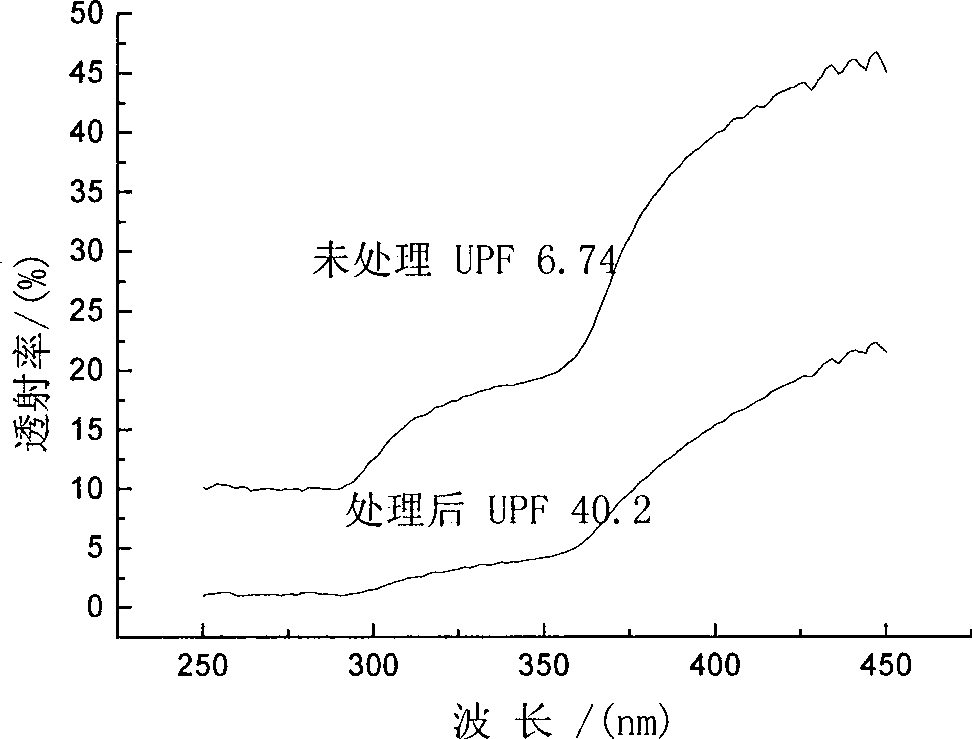

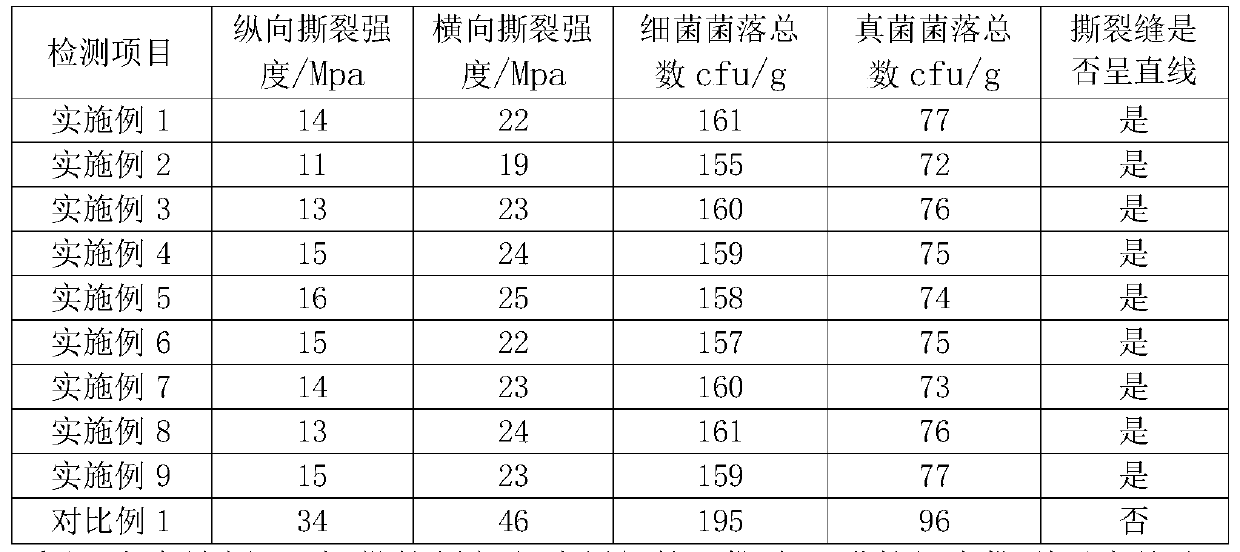

Method for adhering sericin and nanometer material on real silk fabric

ActiveCN101446036AImproved crystallization behaviorLow water solubilityBiochemical fibre treatmentAnimal fibresAntibiosisSaline solutions

The invention discloses a method for adhering sericin and nanometer materials on real silk fabrics; at first, partial degumming treatment is carried out on the real silk fabrics to obtain the real silk fabrics containing 10 to 15 percent of the sericin; then the method of dipping, padding or spraying is adopted to carry out treatment on the real silk fabrics in soluble metal saline solution with a concentration of 0.1 to 0.5mol / L; then real silk products with various nanometer functions like antibiosis, UV resistance and static resistance are obtained by treating the real silk fabrics in alkali vapors of 60 to 80 DEG C for 30 to 120 minutes. The process of the method is simple, saves energy, protects environment, can be carried out on the traditional dyeing device, has high working efficiency and is extremely easy to be popularized and applied.

Owner:JIANGSU NADN SCI TECH CO LTD

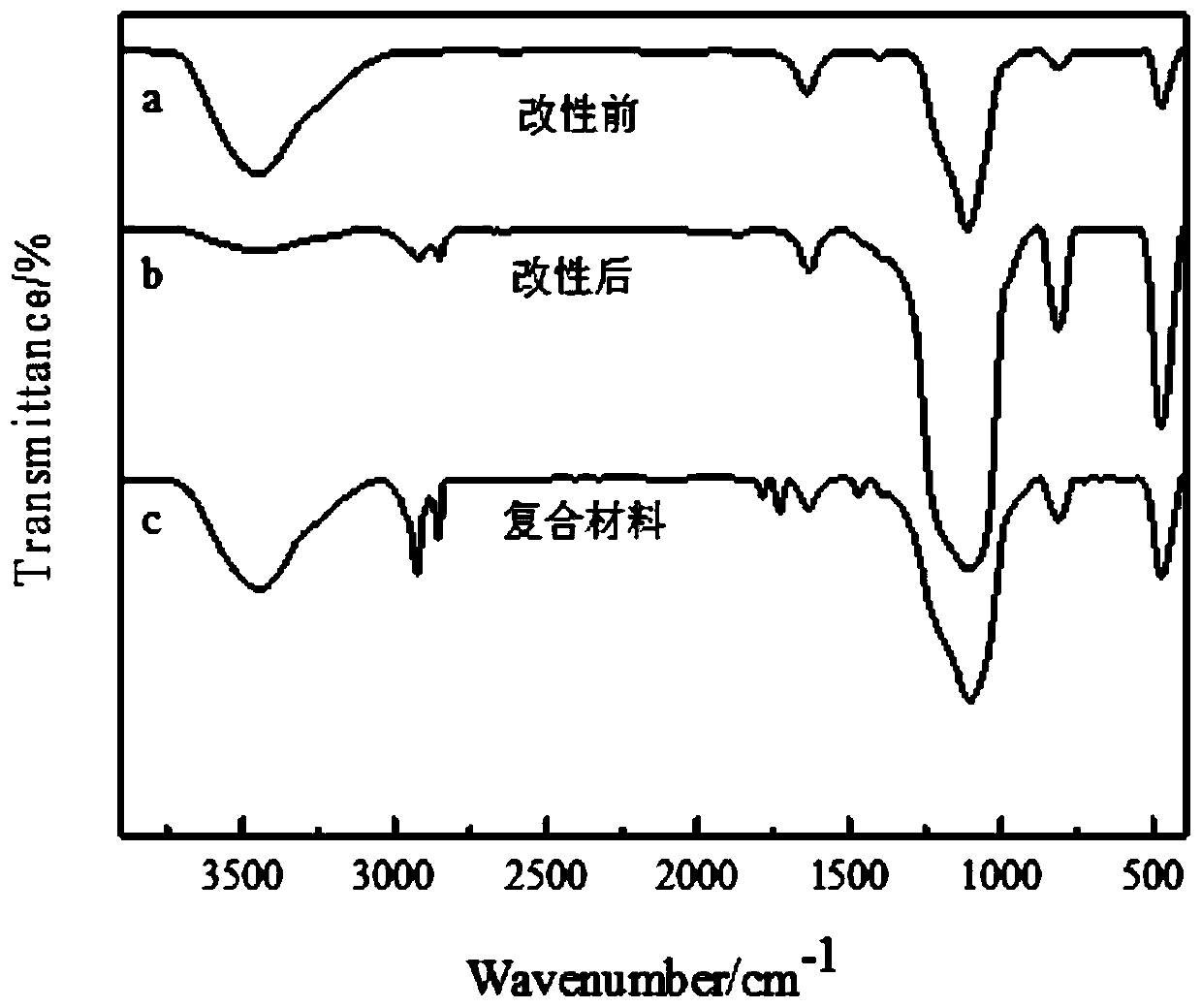

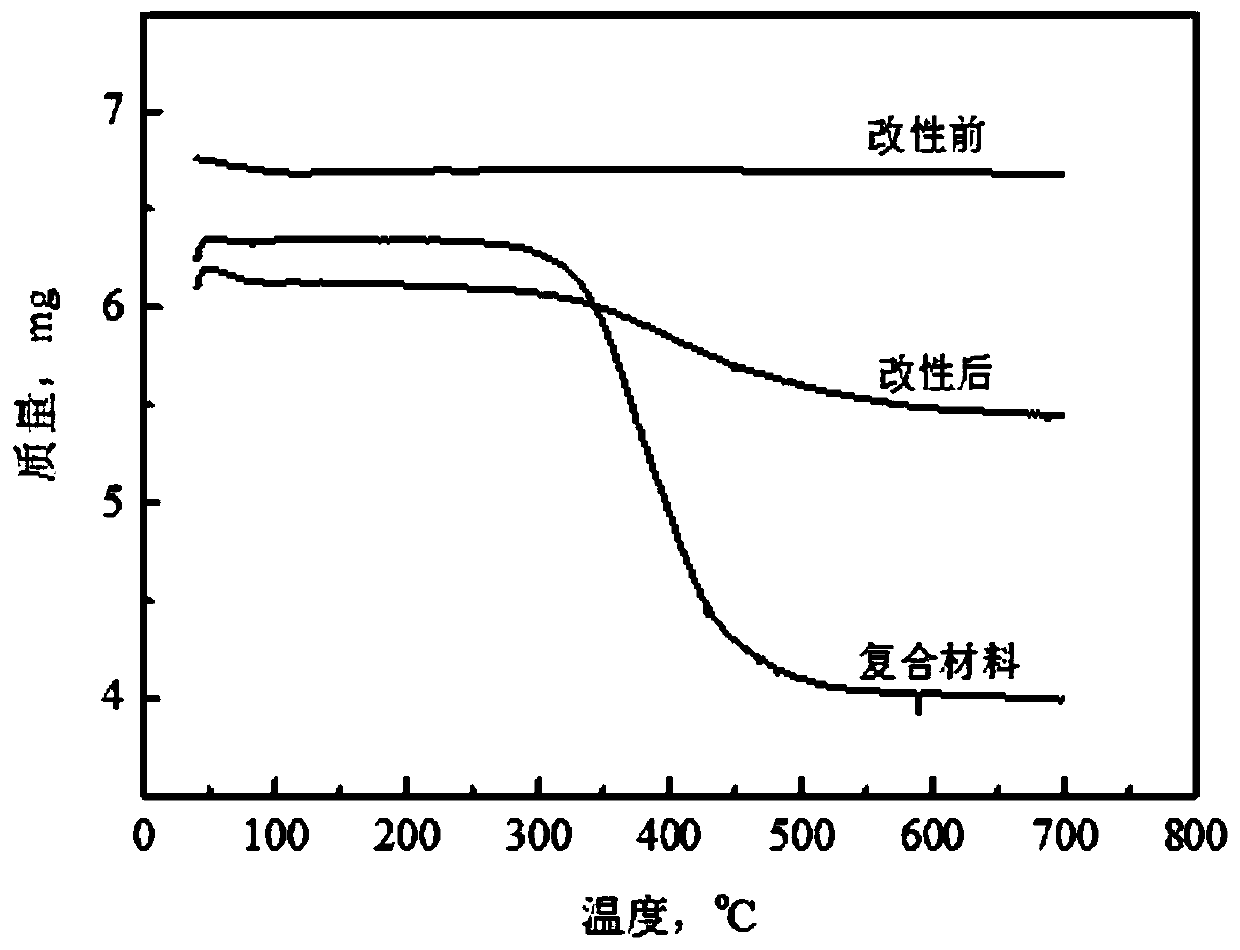

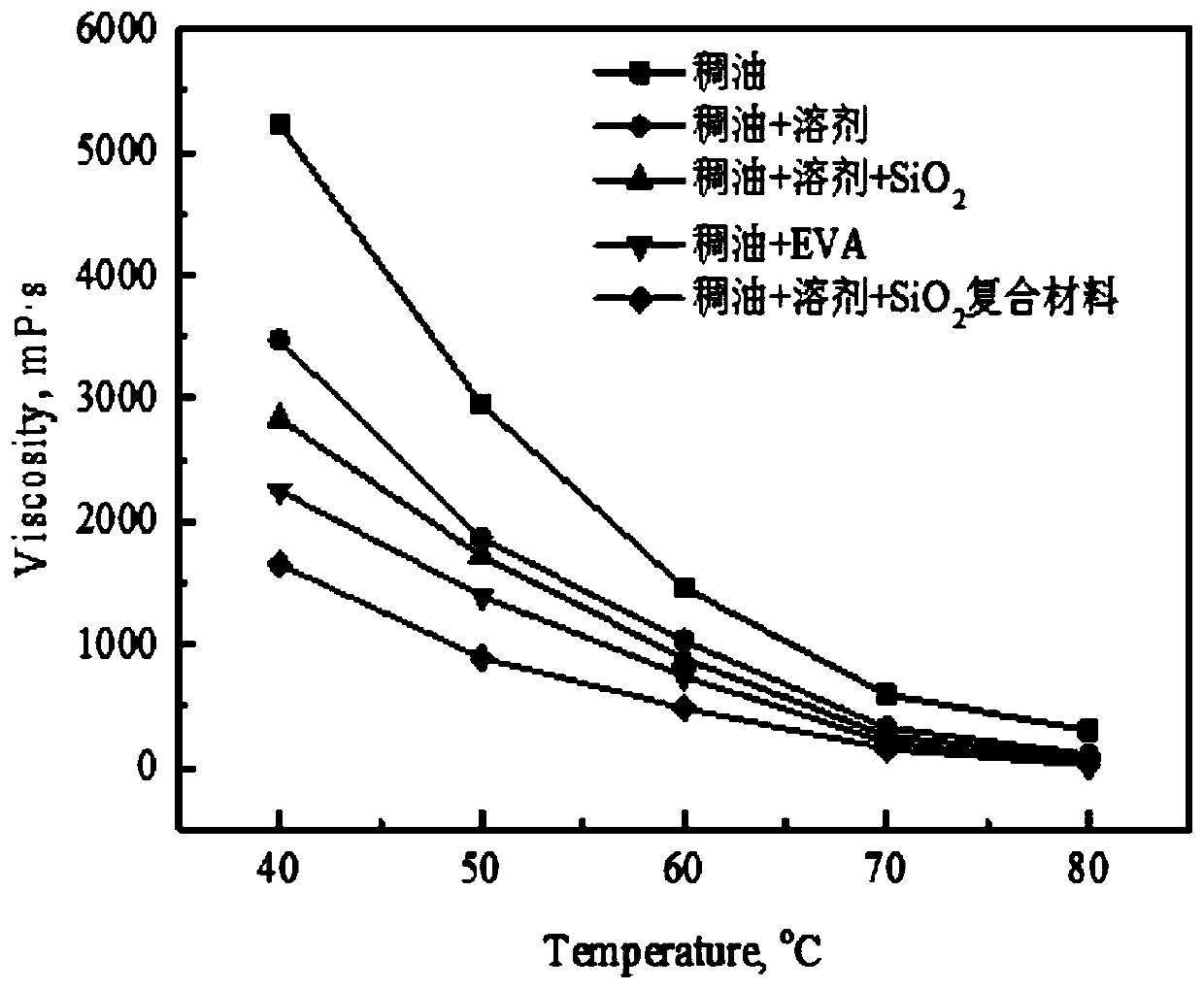

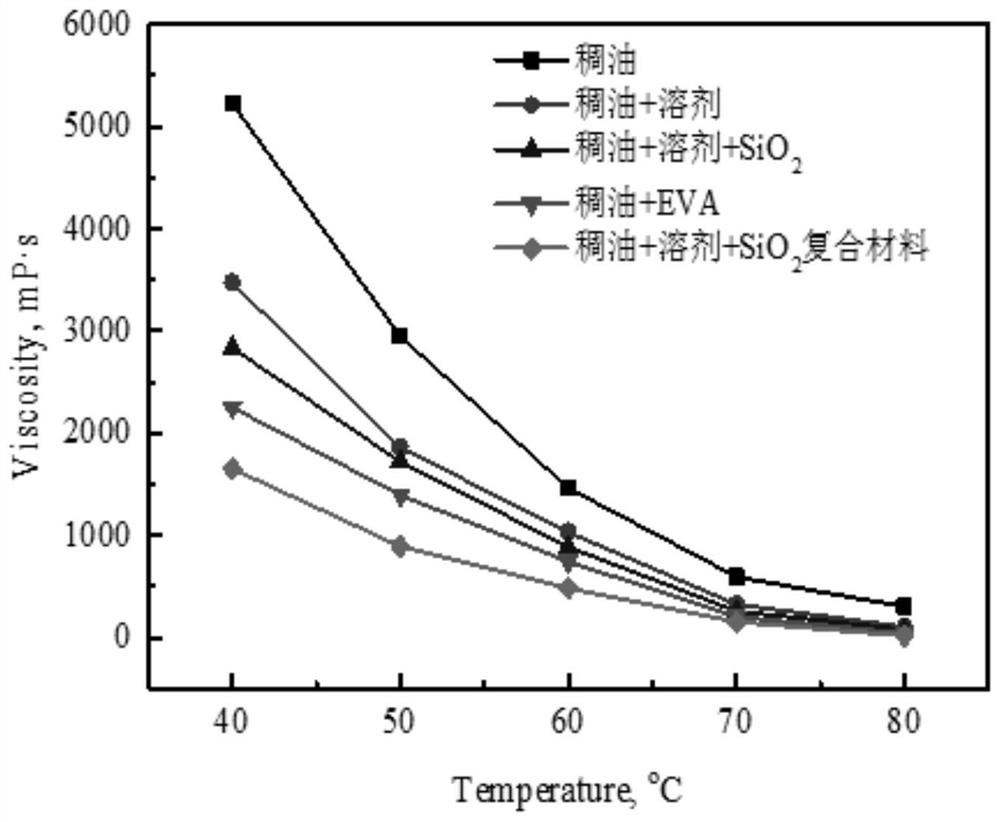

Nano-composite material high-wax thick oil pour point-depressing and viscosity-reducing agent and preparation method thereof

ActiveCN110922955AImprove low temperature fluidityEasy accessDrilling compositionPolymer sciencePolymer chemistry

The invention provides a nano-composite material high-wax thick oil pour point-depressing and viscosity-reducing agent and a preparation method thereof. The pour point-depressing and viscosity-reducing agent comprises nano-silica, a silane coupling agent, octadecyl methacrylate, maleic anhydride, styrene and acrylamide; a mass / volume ratio of the nano-silica to the silane coupling agent is (2-3):1g / mL, and a molar ratio of octadecyl methacrylate to maleic anhydride to styrene to acrylamide is (3-8):1:2:1; and a mole / volume ratio of octadecyl methacrylate to the silane coupling agent is (3-8):1 mol / mL. The invention also provides a preparation method of the pour point-depressing and viscosity-reducing agent. The pour point-depressing and viscosity-reducing agent has the advantages of pourpoint depressing and viscosity reducing effects, good effects, improvement of the low-temperature fluidity of crude oil, simple and easily controlled production processes, effectiveness in solving ofthe problems that a pour point depressant and a viscosity reducer cannot be considered at the same time and the low-temperature fluidity of thickened oil is poor, and wide application prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Quickly molded high density polyethylene composition and preparation method thereof

ActiveCN104558747AFast crystallization temperatureRapid prototyping High crystallization temperatureMasterbatchPolymer science

The invention relates to a quickly molded high density polyethylene composition and a preparation method thereof and belongs to the technical field of macromolecular materials. The composition is characterized by being prepared from polyethylene A and polyethylene B with different densities and melt quality flow rates by adding an additive masterbatch to blend and granulate, wherein the composition is prepared from the following components in parts by weight: 75-90 parts of polyethylene A, preferably 80-85 parts, 10-25 parts of polyethylene B, preferably 15-20 parts, and 0.06-0.15 part of the additive masterbatch, and the additive masterbatch is a mixed extrudate of low density polyethylene, nano calcium carbonate and talc powder in a mass ratio of 3: 2: 1. During granulation, three groups of matching kneading blocks with different included angles are used to extrude and granulate at 210-220 DEG C. The composition provided by the invention is high in crystallization temperature and short in crystallization time, the product is fast in molding speed during production and good in dimensional stability, and the components are relatively low in price.

Owner:CHINA PETROLEUM & CHEM CORP

Wet spinning device applying regulable magnetic field and method

InactiveCN101781804AAchieve reconstructionGood orientationArtificial filament physical treatmentWet spinning methodsFiberEngineering

The invention relates to a wet spinning device applying regulable magnetic field and method, and a method thereof. The device comprises a wet spinning device and a controllable magnetic field generation device. The device is characterized in that: a pair of brackets in the controllable magnetic field generation device is arranged on the two sides of the spinning device respectively; and each bracket has a structure that: a third copper rod capable of moving up and down is horizontally arranged between a first copper rod and a second copper rod which are arranged in parallel; and a magnetic field generator horizontally slides on the third copper rod so as to ensure the application of the magnetic field to different spinning lines. A novel concept in the device and the method is that the regulable magnetic field is applied in sections in the whole spinning process from the preparation of a spinning stock solution to the package and collection of fibers, so that the reconstruction of an aggregative structure of a polymer is realized and the orientation and crystallization of the polymer are improved.

Owner:SHANGHAI UNIV

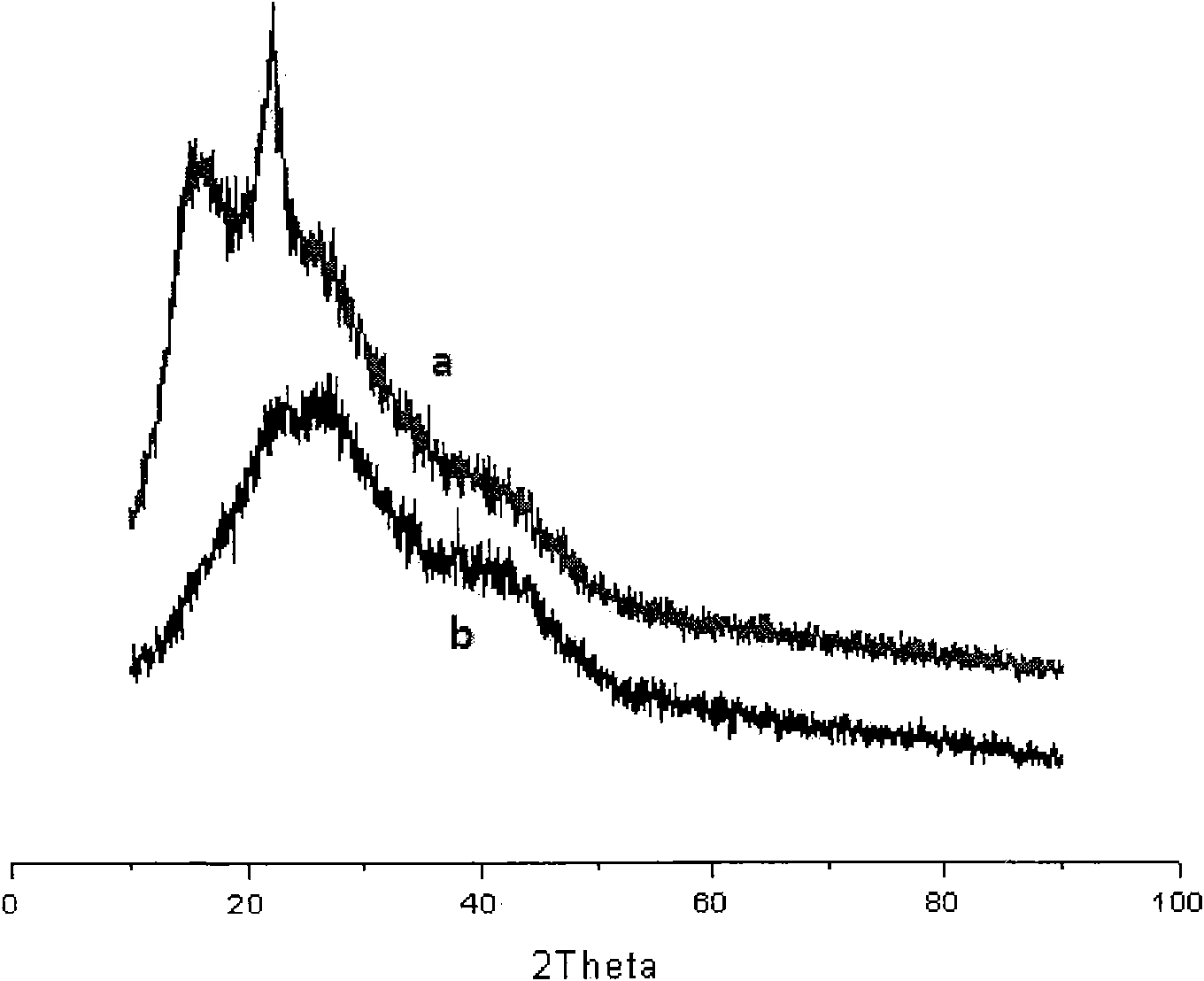

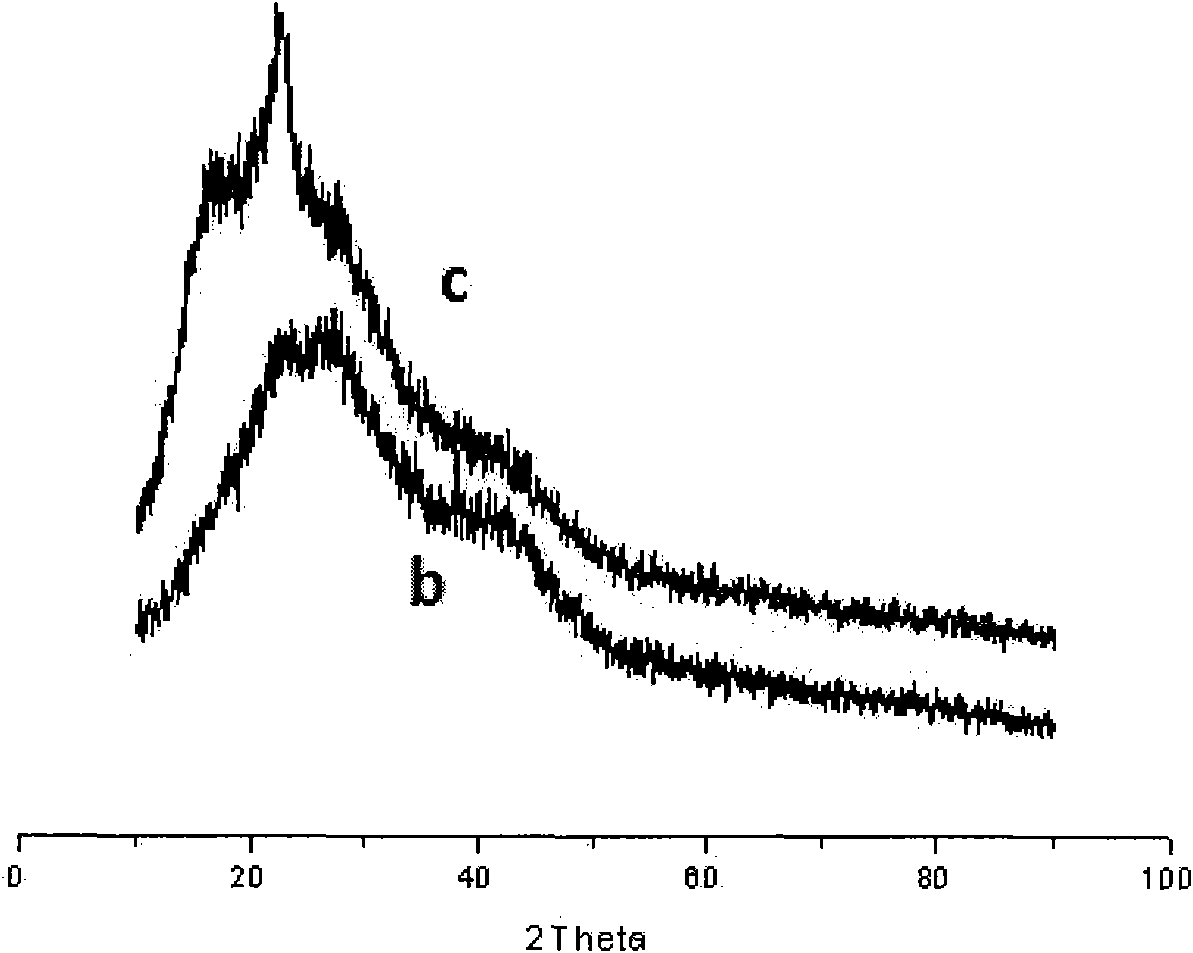

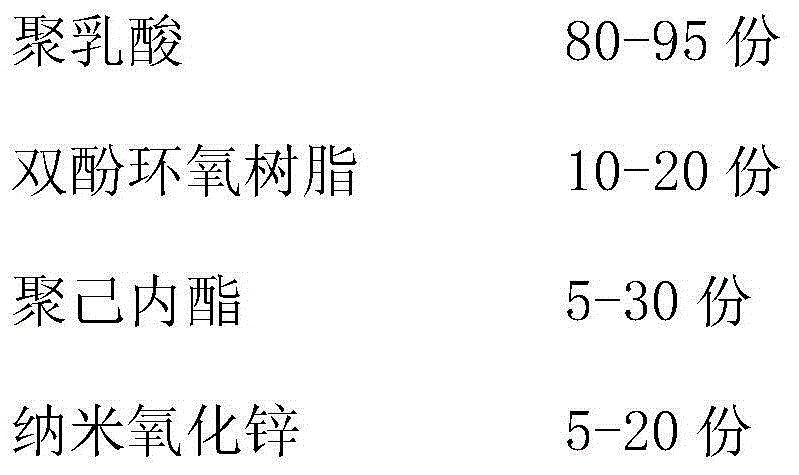

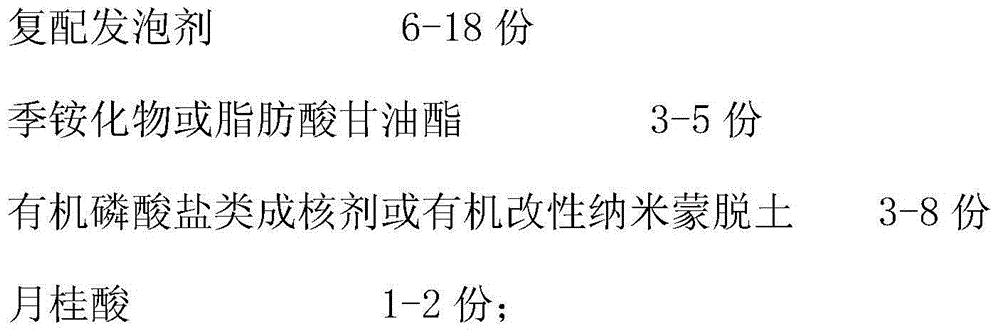

Nano zinc oxide modified foaming material and preparation method thereof

InactiveCN104861602AConductiveImprove mechanical propertiesAmmonium compoundsFatty acid glycerol esters

The invention discloses a nano zinc oxide modified foaming material. The nano zinc oxide modified foaming material comprises components in parts by weight as follows: 80-95 parts of polylactic acid, 10-20 parts of bisphenol epoxy resin, 5-30 parts of polycaprolactone, 5-20 parts of nano zinc oxide, 6-18 parts of a compound foaming agent, 3-5 parts of a quaternary ammonium compound or fatty glyceride, 3-8 parts of an organic phosphate nucleating agent or organically modified nano-montmorillonite and 1-2 parts of lauric acid. According to the nano zinc oxide modified foaming material, the process is simple and easy, and the polylactic acid based composite foaming conductive material with excellent conductivity and general mechanical performance, good heat resistance and controllable density can be prepared economically and effectively.

Owner:周末

High-barrier thin film modified by nano rare earth nucleating agent

ActiveCN104354411AHigh tensile strengthHigh elongation at breakSynthetic resin layered productsPolymer scienceThin membrane

The invention relates to a high-barrier thin film modified by a nano rare earth nucleating agent. The thin film comprises a surface layer 1, a core layer and a surface layer 2 and is characterized in that the surface layer 1 contains 10-30 percent of MXD6, 63-84.9 percent of PA6, 2-4 percent of anti-sticking master batch, 3-8 percent of a compatilizer and 0.1-5 percent of the nano rare earth nucleating agent; the core layer contains 95-99.9 percent of MXD6 and 0.1-5 percent of the nano rare earth nucleating agent; the surface layer 2 contains 10-30 percent of MXD6, 63-84.9 percent of PA6, 2-4 percent of anti-sticking master batch, 3-8 percent of the compatilizer and 0.1-5 percent of the nano rare earth nucleating agent. The tensile strength and the haze of the modified high-barrier film are better improved.

Owner:厦门长塑实业有限公司

Dry unilateral-stretching production technology of lithium battery separator

InactiveCN111391267AHigh crystallinityHigh tensile strengthCell component detailsPhysical chemistryPolypropylene

The invention relates to the technical field of lithium battery separators and provides a dry unilateral-stretching production technology of a lithium battery separator. The dry unilateral-stretchingproduction technology of the lithium battery separator solves the problem that the hole size distribution of a lithium battery separator produced in the prior art is uneven. The dry method unilateralstretching production technology of the lithium battery separator comprises the following steps of (1) preparing materials, wherein polypropylene and ethylene-propylene copolymer are used as raw materials, pre-dried respectively and then put into a high-speed mixer to be stirred to uniform; (2) conducting melt extrusion, wherein the evenly mixed raw materials are fed into an extrusion machine andplastified into uniform melt, and the uniform melt is extruded from a slit die; (3) conducting tape casting film formation, wherein the melt undergoes tape casting and then forms a polypropylene basefilm, and the polypropylene base film undergoes traction and coiling; (4) conducting annealing treatment, wherein the coiled polypropylene base film is placed in a drying box to undergo annealing treatment; (5) conducting unilateral stretching, wherein the annealed polypropylene base film undergoes cold stretching and hot stretching; and (6) conducting heat setting, wherein heat setting is conducted on the polypropylene base film completing unilateral stretching, and after cooling and coiling, the lithium battery separator is obtained.

Owner:石狮申泰新材料科技有限公司

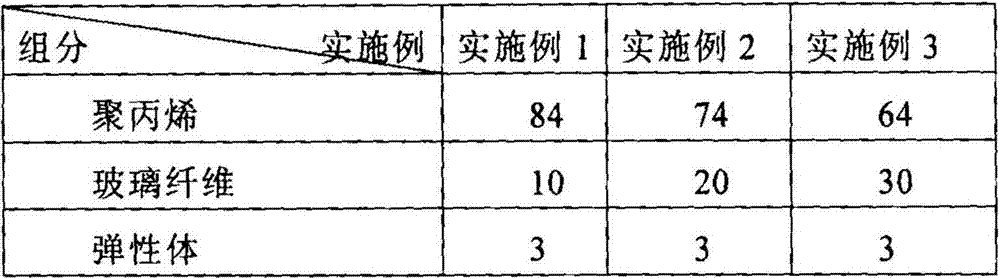

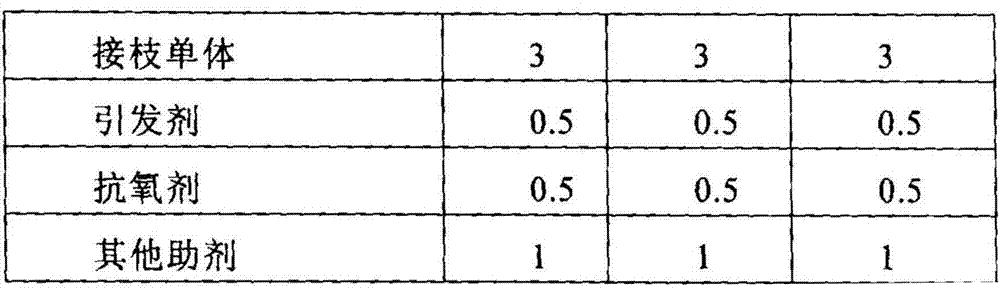

Low-fiber-floating glass-fiber-reinforced toughening polypropylene composite material and preparation method thereof

The invention relates to a low-fiber-floating glass-fiber-reinforced toughening polypropylene composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 30-80 parts of polypropylene, 10-60 parts of glass fiber, 3-12 parts of elastomer, 1-5 parts of grafted monomer, 0.2-1 part of initiator, 0.2-1 part of antioxidant and 0.2-2.0 parts of other assistant. Compared with the prior art, the invention prepares a polypropylene material having high strength, high rigidity and stable size under the reinforcing action of glass fiber on a high polymer material; the glass fiber has action of accelerating the crystallization of the high polymer material, and the high polymer material is quick to crystallize and cool; and the glass fiber is difficult to constrain and cover, and the elastomer can disturb the crystallization action of the polypropylene, thus preparing the low-fiber-floating reinforced toughening polypropylene composite material having high shock strength.

Owner:上海日之升科技有限公司

Preparation method of phase change composite material with high phase change enthalpy

InactiveCN108219752AHigh phase change enthalpyEasy accessHeat-exchange elementsPhase change enthalpyCross-link

The invention discloses a preparation method of a phase change composite material with a high phase change enthalpy. The preparation method comprises the following steps: (1) synthesizing nano-flower-shaped mesoporous organic silicon; and (2) preparing shape-stabilized the phase change composite material by taking the nano-flower-shaped mesoporous organic silicon as a carrier. The preparation method disclosed by the invention has the advantages that the nano-flower-shaped mesoporous organic silicon is taken as the carrier for fixing PEG (polyethylene glycol) to prepare the shape-stabilizedphase change composite material, so that the crystallization behavior of PEG molecules is improved, and the phase change enthalpy of the shape-stabilized phase change composite material is increased; the PEG modified by GO forms a cross-linked network, so that the stability of the phase change composite material is increased; and interior of the network of the PEG is filled with the GO to form afilled structure, so that the thermorheological behavior and the crystallization behavior of the phase change composite material are effectively improved.

Owner:ZHEJIANG OCEAN UNIV

Poly-hydroxyalkanoate degradable composite material containing carbon nanomaterial and preparation method

ActiveCN102964789AHigh thermal conductivityImprove thermal conductivityNucleationCarbon nanomaterials

The invention relates to a poly-hydroxyalkanoate degradable composite material containing a carbon nanomaterial and a preparation method thereof. The composite material is constructured by introducing a high thermal conductive carbon nanomaterial into a poly-hydroxyalkanoate matrix to form an efficient thermal conductive network in the composite material to accelerate dissipation of heat discharged by crystals. The carbon nanomaterial is used as a nucleating agent at the same time to promote nucleation and crystallization of the poly-hydroxyalkanoate matrix. The carbon nanomaterial is further used as a flexibilizer to strengthen the obtained composite material. The mass ratio of the poly-hydroxyalkanoate matrix to the carbon nanomaterial is 10:1 to 2000:1. Compared with the prior art, the carbon nanomaterial has the advantages of high machining property, high mechanical property and high thermal property, low production cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Tearable packaging film and preparation method thereof

The invention relates to a tearable packaging film and a preparation method thereof, and belongs to the technical field of cast films. The raw materials for preparing the tearable packaging film include, by weight, LDPE, LLDPE, HDPE, PP, metallocene polyethylene, a lubricant, a dispersant, an antibacterial agent and a crystallization nucleating agent, wherein the antibacterial agent comprises teapolyphenols and chitin fibers; and the crystallization nucleating agent comprises dibenzylidene sorbitol, p-hydroxybenzoic acid and poly(phenyl 4-methoxyl-4'-acryloyloxybenzoate). The invention also discloses the preparation method of the tearable packaging film. The preparation method comprises the following steps: S1, mixing, and extrusion plasticizing; S2, extrusion casting; S3, calendering setting; and S4, corona, trimming and rolling. The packaging film is convenient to tear.

Owner:天津登峰卫生用品材料有限公司

Heat-resistant impact-resistant polypropylene composition and preparation method thereof

InactiveCN110760126AImprove impact toughnessImprove heat resistancePolypropylene compositesPolymer science

The invention discloses a heat-resistant impact-resistant polypropylene composition and a preparation method thereof, and belongs to the technical field of polypropylene materials. The polypropylene composite is characterized by comprising the following components in parts by weight: 100 parts of a polypropylene resin powder, 0.03-0.3 part of a hyper-branched polymer powder, 0.02-0.1 part of an inorganic nucleating agent, 0.05-0.3 part of an antioxidant, 0.02-0.1 part of an acid absorbent, and 0.03-1.0 part of an antistatic agent, wherein the polypropylene resin is a homo-polymerized polypropylene resin powder, a melt mass flow rate of the homo-polymerized polypropylene resin under the conditions of 2.16 kg and 230 DEG C is 20-60 g / 10 min, the isotacticity of polypropylene is 95% or more,and Mw / Mn is 4-12. Through the synergistic effect of a small amount of hyper-branched polyethylene and a small amount of nano-scale white carbon black added in the composition, the rigidity and toughness balance of a product is achieved, the crystallization speed is increased, and the crystallization behavior of polypropylene is improved, so that the size of resin crystals is finer and denser, thescattering and refraction of an incident light are reduced, and the glossiness of the product is increased.

Owner:CHINA PETROLEUM & CHEM CORP

High tenacity one-dimensional titanium dioxide nanowire modified PP material and preparation method thereof

The invention provides a high tenacity one-dimensional titanium dioxide nanowire modified PP material and a preparation method thereof, and belongs to the field of high polymer materials. The PP material is prepared from the following components in parts by weight: 50-80 parts of polypropylene, 5-40 parts of modified one-dimensional TiO2 nanowire, 1-2 parts of an antioxidant, 1-2 parts of a lightstabilizer and 5-10 parts of a fire retardant; the modified one-dimensional TiO2 nanowire is obtained by adding one-dimensional TiO2 nanowire into a surfactant for surface modification, the diameter of the modified one-dimensional TiO2 nanowire is 10-200nm, and the length is 50nm-5micron. The invention further provides the preparation method of the high tenacity one-dimensional titanium dioxide nanowire modified PP material. The material has the high tenacity.

Owner:芜湖万隆新材料有限公司

Laser two-dimensional code ear tag modification material special for breeding stock and preparation method

ActiveCN102181146AGood weather resistanceGood compatibilityAnimal husbandryEar tagWeather resistance

The invention discloses a laser two-dimensional code ear tag modification material special for breeding stock. The modification material is characterized by comprising the following materials in part by weight: 97 to 99 parts of polyurethane, 1.5 to 2.5 parts of antimony trioxide, 0.01 to 0.03 part of dispersant and 0.05 to 0.09 part of coupling agent. By using the advantages of the thermoplasticpolyurethane such as oil resistance, toughness, abrasion resistance, ageing resistance and the like and adding a photo-oxidation stabilizing auxiliary agent, the weather resistance of the material isimproved, and the problems of ageing, brittleness, breakage, drop and the like under the actions of air, sunlight and oxygen after an ear tag is worn for long time are solved; and by adding a modifying material into the polyurethane, the laser processing performance of a thermoplastic polyurethane elastomer is enhanced, and batch production of laser processing on the thermoplastic polyurethane elastomer material is realized. Tested by the applicant, the drop, breakage or fracture rate of the ear tag made of the modification material does not exceed 2 percent when the ear tag is worn by the breeding stock in three years.

Owner:贵阳维隆塑胶有限公司

High temperature modification treatment method of electrolytic aluminium liquid

InactiveCN1804137AImprove the internal structure of the meltImproved crystallization behaviorAluminium alloyMetal

The pyrometamorphism treatment method to add mixed rare-earth with Ce as main into the high-temperature electrolytic aluminum solution can improve the fused mass inner structure effectively, eliminates the low-strength on high-temperature phenomena, further improves the crystallization behavior, has important meaning for casting high-performance aluminum alloy, and thereby brings great economic and social benefits.

Owner:苏州有色金属研究院有限公司

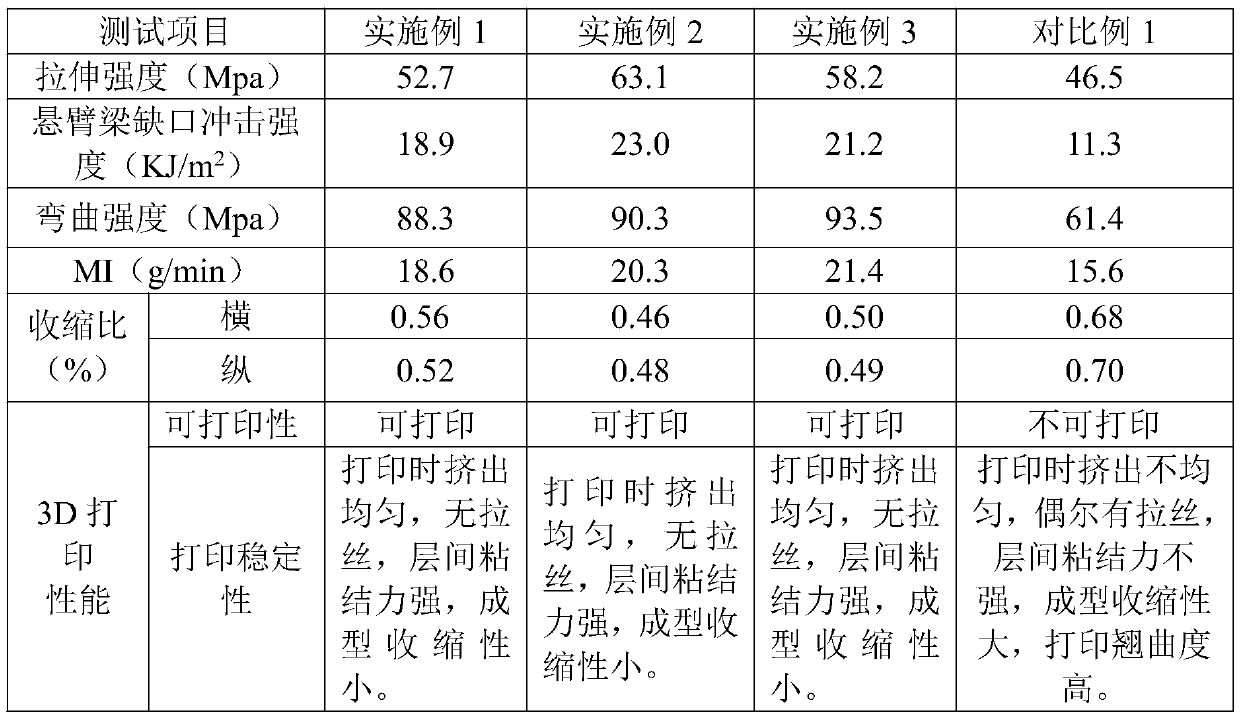

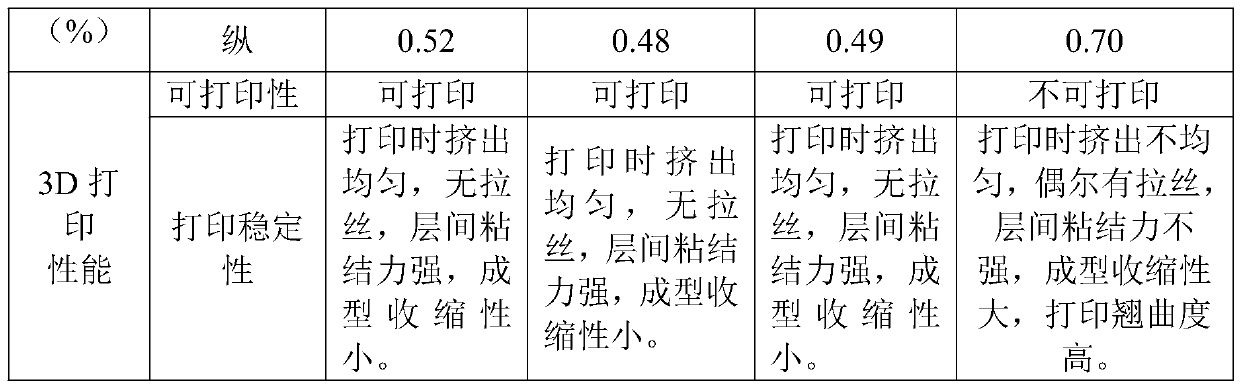

Method for preparing recycled regenerated plastic for 3D printing

InactiveCN110698806AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a method for preparing a recycled regenerated plastic for printing. The recycled and regenerated plastic for 3D printing, which is disclosed by the invention, comprises 60-70 parts of a recycled plastic, 5-20 parts of glass fibers, 3-10 parts of graphenoid, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, recycled and regenerated plastic may also comprise 10-60 parts ofEVA (ethylene vinyl acetate), and the content of VA (vinyl acetate) of EVA is 20-55%. The graphenoid is one of silicene, germanene and molybdenum disulfide surface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and an acrylonitrile-butadiene-styrene copolymer. The recycled and regenerated plastic is one or more of ABS (acrylonitrile butadiene styrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

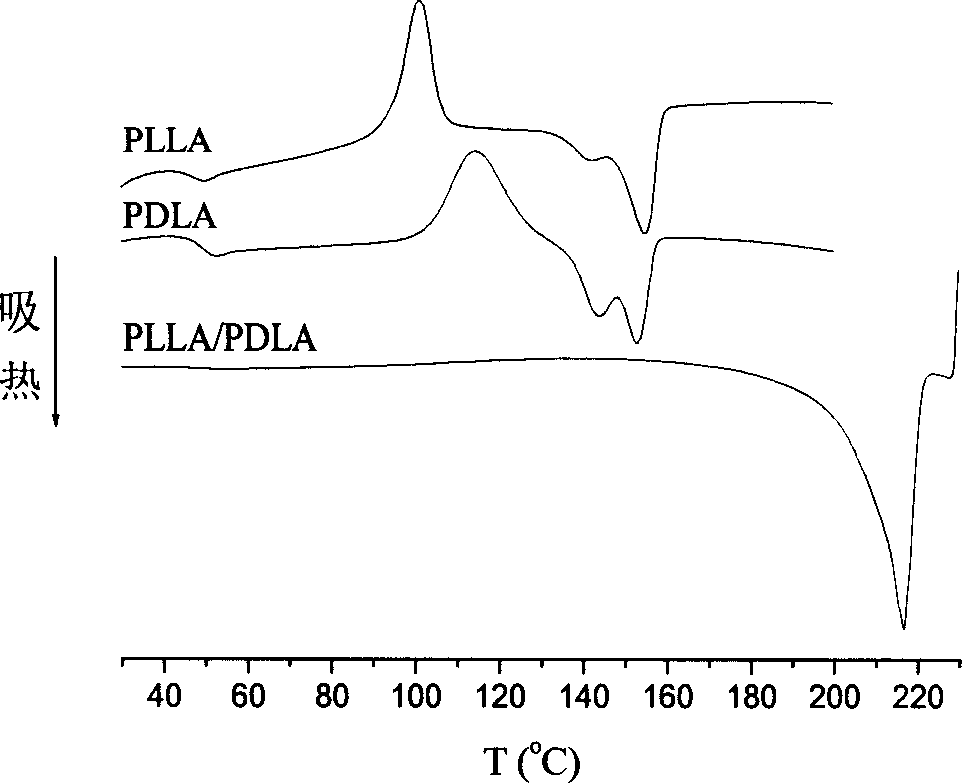

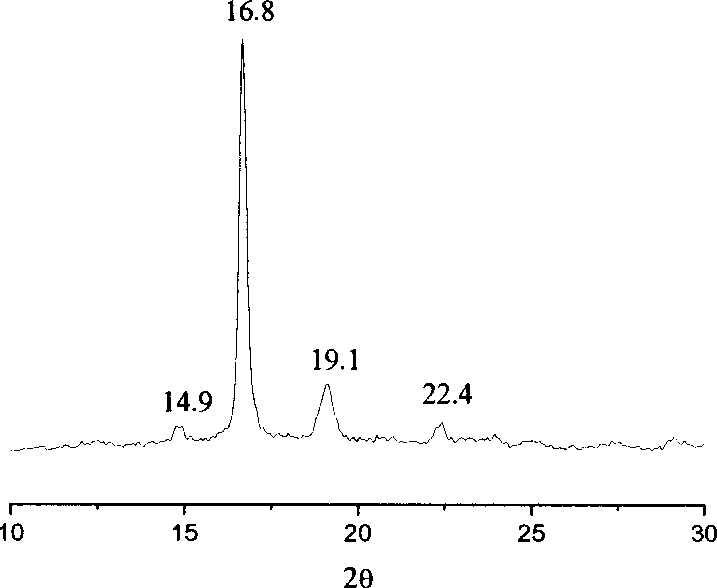

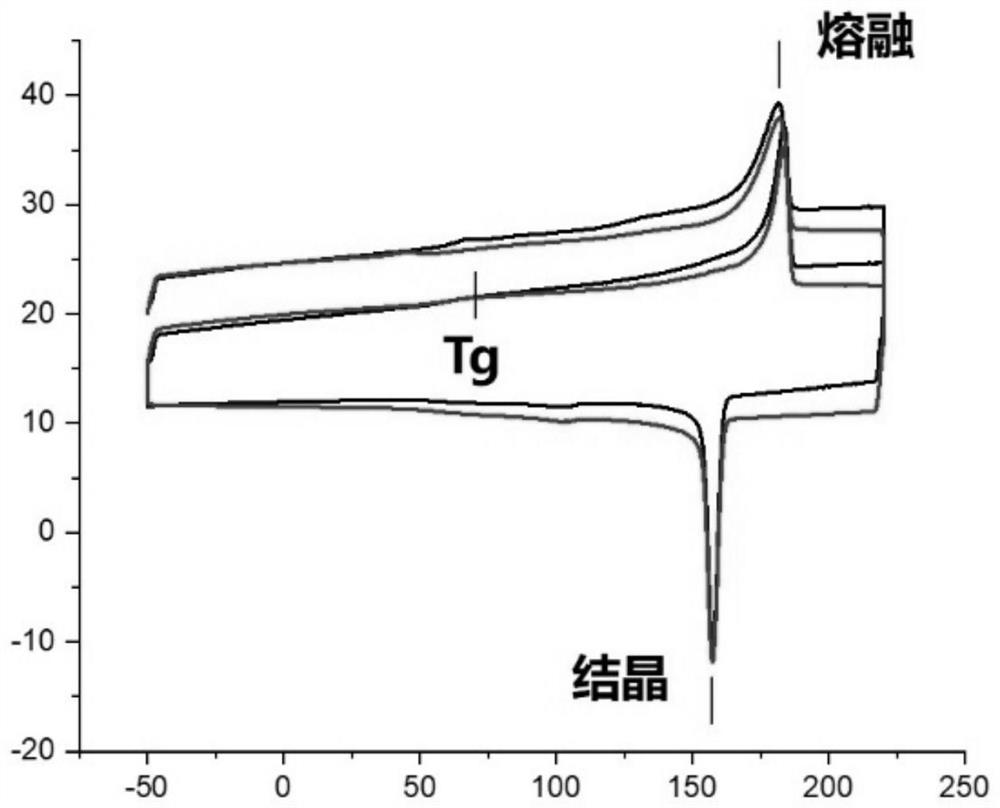

Method for improving heat property and crystallization behavior of polylactic acid and its multiple blocked copolymer

The invention discloses a modified polylactic acid and multi-block copolymer heat property and crystallization behavior method, which comprises the following steps: (1) dissolving L-polylactic acid and multi-block copolymer and D-polylactic acid and multi-block copolymer in the carrene or chloroform at 1:1 rate; stirring the mixture liquid until dissolving evenly; (2) pouring the blending liquid on the culture dish; evaporating naturally for 1-3 days at indoor temperature; extracting into vacuum; storing the polylactic acid composition at indoor temperature. The invention adopts composite modified polymerization crystallization behavior to avoid adding out-phase nucleation agent, which improves the heat-durability in the final manufacturing course.

Owner:DONGHUA UNIV

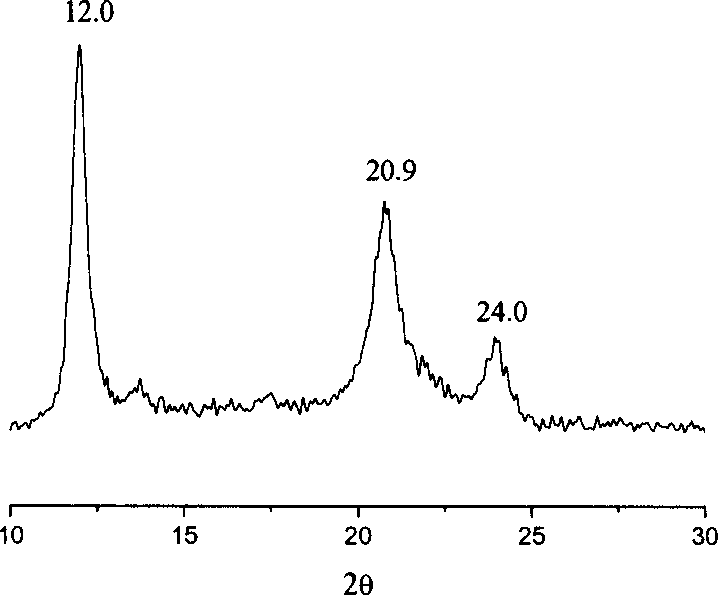

Preparation method for halloysite, ultrafine inorganic powder and PTFE micro-nano composite material

ActiveCN104987633AImproved crystallization behaviorImprove mechanical propertiesMicro nanoHalloysite

Provided is a preparation method for a halloysite, ultrafine inorganic powder and PTFE micro-nano composite material, and the method relates to the technical field of preparation of PTFE micro-nano composite materials. The method comprises steps of: firstly, preparing a uniform mixing of PTFE and inorganic powder through mechanical high speed blending; then shaping the obtained mixed powder through cold pressing, and performing mold releasing to obtain a sheet-like sample; and finally placing the sample in a muffle furnace, raising the temperature to 370-380 DEG C at a rising rate of 150-200 DEG C / h, keeping the temperature for 2 hours, and then cooling the sample to the room temperature along with the furnace, thereby obtaining a PTFE micro-nano composite material. According to the method provided by the invention, the crystallization behavior of the PTFE is improved through filling with inorganic micro-nano particles; excellent mechanical properties of the PTFE are maintained by regulating interfacial adhesion between the micro-nano particles and the PTFE; meanwhile, the PTFE is endowed with excellent wear resistance and creep resistance.

Owner:安徽桑瑞泰粉末材料有限公司

Recycled regenerated plastic for 3D printing and preparation method of recycled regenerated plastic

InactiveCN110698807AImproved crystallization behaviorImprove mechanical propertiesPolymer sciencePolyethylene terephthalate glycol

The invention relates toa recycled regenerated plastic for 3D printing. The recycled regenerated plastic comprises 60-70 parts of recycled regenerated plastic, 5-20 parts of glass fiber, 3-10 parts ofa graphene-like material, 1-10 parts of a toughening agent, 2-3 parts of a dispersant, 1-15 parts of biochar, 1-5 parts of a compatibilizer, 0.1-2 parts of a chain extender, 0.5-1 part of a lubricant, 0.1-5 parts of a foaming agent and 1-8 parts of other additives. In addition, the recycled regenerated plastic may also comprise 10-60 parts of EVA (an ethylene-vinyl acetate copolymer), and the content of VA (vinyl acetate) inEVA is 20-55%. The graphene-like material is one of silicene, germanene and molybdenum disulfide which are subjected tosurface activity treatment. The chain extender is one or more of pyromellitic dianhydride, dicumyl peroxide and acrylonitrile-butadiene-styrene copolymer grafted oxazoline. The recycled regenerated plastic is one or more of ABS (acrylonitrile butadienestyrene), polypropylene and PET (polyethylene terephthalate).

Owner:泉州龙晟轻工有限公司

Biodegradable PLA film and preparation method thereof

The invention discloses a biodegradable polylactic acid film and a preparation method thereof. The biodegradable polylactic acid film comprises the following components: 70-95 parts of polylactic acid (PLA), 4-29 parts of poly (butyl carbonate) (PBC), 0.1-1 part of a chain extender epoxy acrylic copolymer, 0.1-10 parts of a plasticizer tung oil anhydride, 0.1-1 part of a heat stabilizer zinc stearate and 0.1-5 parts of a nucleating agent phenyl phosphonic acid loaded calcium carbonate powder. The preparation method comprises the steps of uniformly mixing the raw materials in proportion, carrying out melt blending by a twin-screw extruder to obtain the modified polylactic acid film blowing special resin, and carrying out blow molding by a film blowing machine to form the film. The PLA film prepared by the method has high tensile strength, good opening performance and good transparency.

Owner:SINOCHEM QUANZHOU ENERGY TECH CO LTD

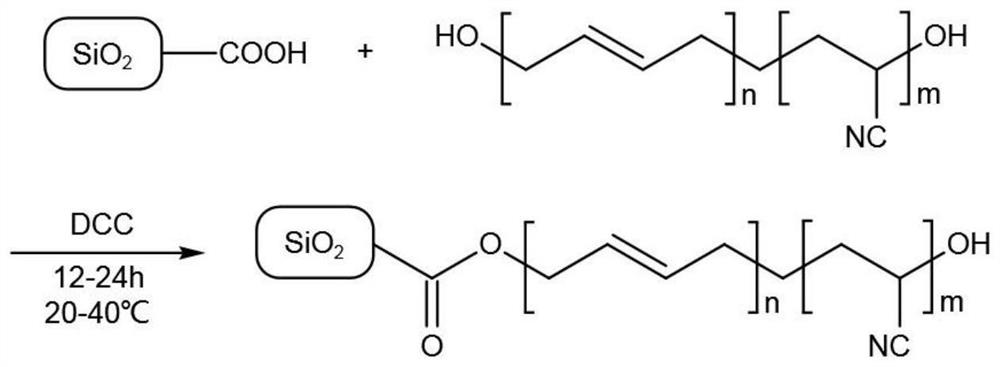

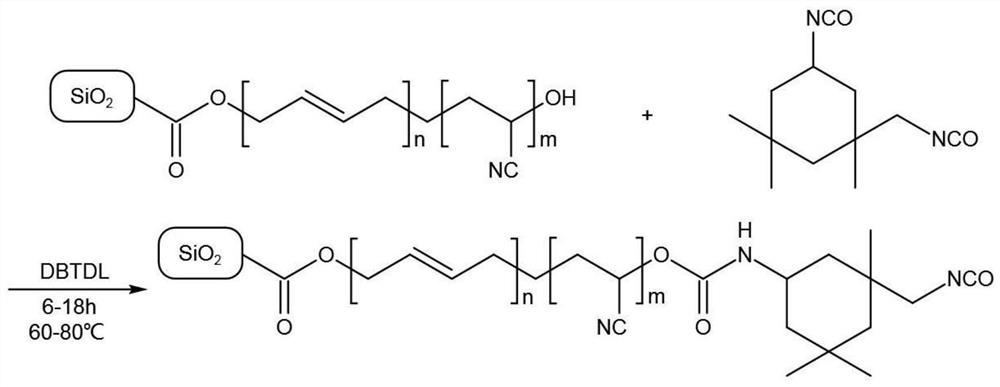

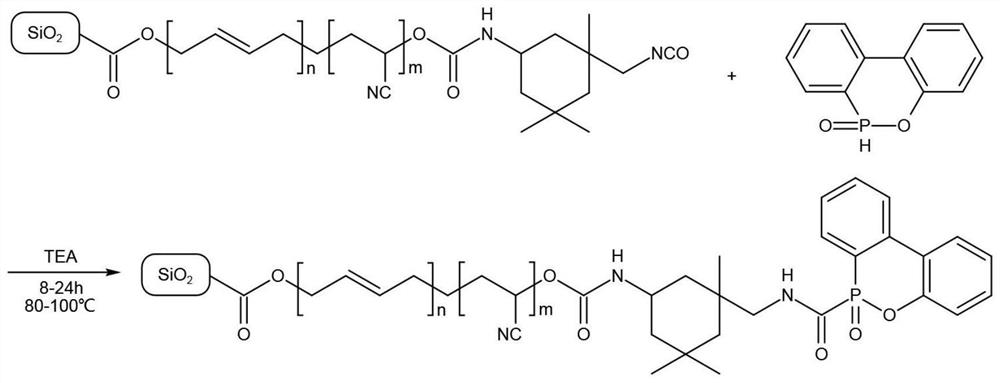

Functional modified silicon dioxide flame-retardant modified polylactic acid composite fiber and preparation method thereof

InactiveCN113373536AImprove functionalityInhibit sheddingFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceNitrile rubber

The invention relates to the technical field of new materials, and discloses a functional modified silicon dioxide flame-retardant modified polylactic acid composite fiber. Silicon dioxide reacts with adipic acid to obtain carboxylated silicon dioxide; the carboxylated silicon dioxide reacts with hydroxyl-terminated butadiene-acrylonitrile rubber to obtain hydroxyl-terminated butadiene-acrylonitrile rubber modified silicon dioxide; the hydroxyl-terminated butadiene-acrylonitrile rubber modified silicon dioxide reacts with isophorone diisocyanate to obtain isocyanate butadiene-acrylonitrile rubber modified silicon dioxide; the isocyanate butadiene-acrylonitrile rubber modified silicon dioxide further reacts with 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to obtain phosphaphenanthrene-based butadiene-acrylonitrile rubber modified silicon dioxide; the phosphaphenanthrene-based butadiene-acrylonitrile rubber modified silicon dioxide is mixed with polylactic acid; and melt spinning is performed to obtain the functional modified silicon dioxide flame-retardant modified polylactic acid composite fiber. Butadiene-acrylonitrile rubber and nano silicon dioxide can absorb and disperse stress energy, a phosphaphenanthrene group can generate oxyacid of phosphorus when being combusted to promote carbon formation of a matrix and form a carbon protection layer, and the nano silicon dioxide is deposited on the surface of a carbon layer to enhance the barrier effect, so that the flame retardant property of the composite fiber is enhanced.

Owner:南陵县麒霆新材料科技有限公司

Polybutylene succinate composite material and preparation method thereof

InactiveCN108219391AImprove mechanical propertiesImproved crystallization behaviorTwo stepPoly(butylene succinate)

The invention relates to a polybutylene succinate composite material and a preparation method thereof. The stereo-composite polylactic-acid reinforced polybutylene succinate composite material is prepared from the raw materials: 100 parts (by weight) of polybutylene succinate copolymer and 10-40 parts (by weight) of stereo-composite polylactic acid, wherein the stereo-composite polylactic acid isprepared from 30-70 parts (by weight) of polylevolactic acid and 30-70 parts (by weight) of polyparalactic acid. Through blending the stereo-composite polylactic acid and polybutylene succinate, the mechanical properties of pure polybutylene succinate resin are enhanced. According to the polybutylene succinate composite material and the preparation method thereof, the raw materials are readily available, and the process is simple; by adopting a two-step melting and blending method, the introduction of non-degradable materials such as a chain extender is avoided, and other non-degradable substances are not introduced while the mechanical properties of the pure polybutylene succinate resin are enhanced, so that the formed polybutylene succinate composite material has excellent biodegradability.

Owner:HUBEI GUANGHE BIO TECH

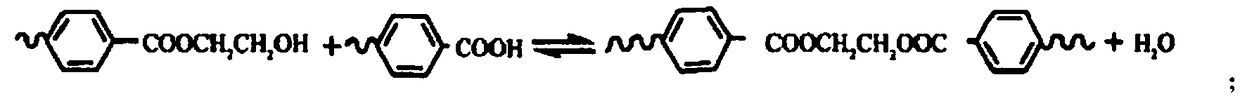

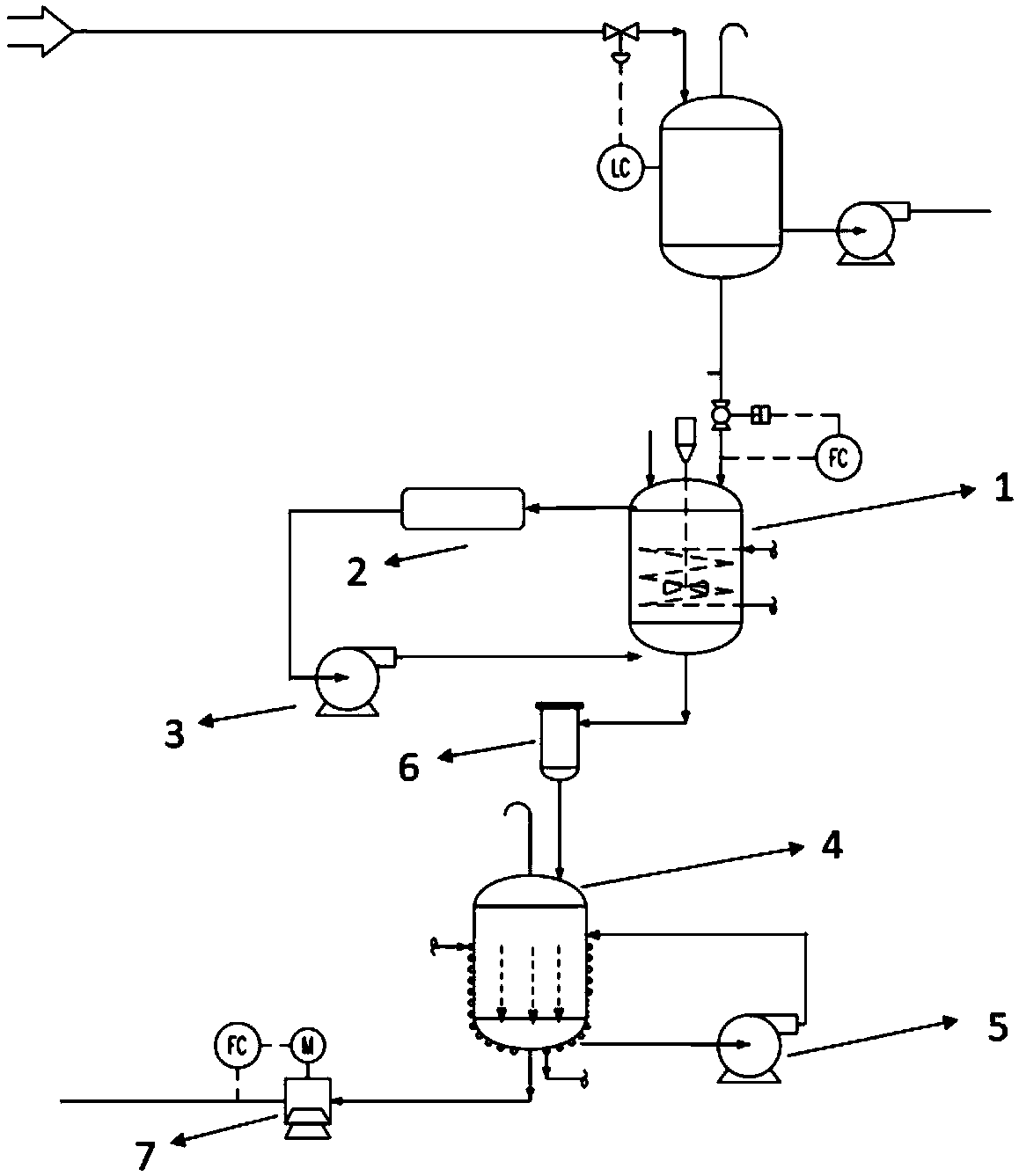

Homogeneous hyper-viscous polyester and preparation method thereof

The invention relates to homogeneous hyper-viscous polyester and a preparation method thereof. The method comprises the following steps of: controlling the mechanism of adding a catalyst during a synthesis process to obtain low-viscous polyester with an intrinsic viscosity of 0.300-0.500 dL / g, and then performing solid phase thickening on the low-viscous polyester to obtain the homogeneous hyper-viscous polyester with an intrinsic viscosity of 0.85-1. 15dL / g, an intrinsic viscosity deviation less than or equal to 0.02dL / g and a molecular weight distribution index of 2.5, wherein the catalyst is added when the average polymerization degree of an intermediate product in a polymerization reaction reaches 8-17; the pre-reaction of the solid-phase thickening is divided into four stages which are a first stage, a second stage, a third stage, and a fourth stage, the corresponding temperatures are 190-195 DEG C,195-210 DEG C, 210-220 DEG C and 220-230 DEG C respectively. The preparation methodof the homogeneous hyper-viscous polyester obviously reduces the content of oligomer in a product, and the prepared polyester has high quality and excellent popularization value.

Owner:ZHEJIANG UNIFULL IND FIBER +1

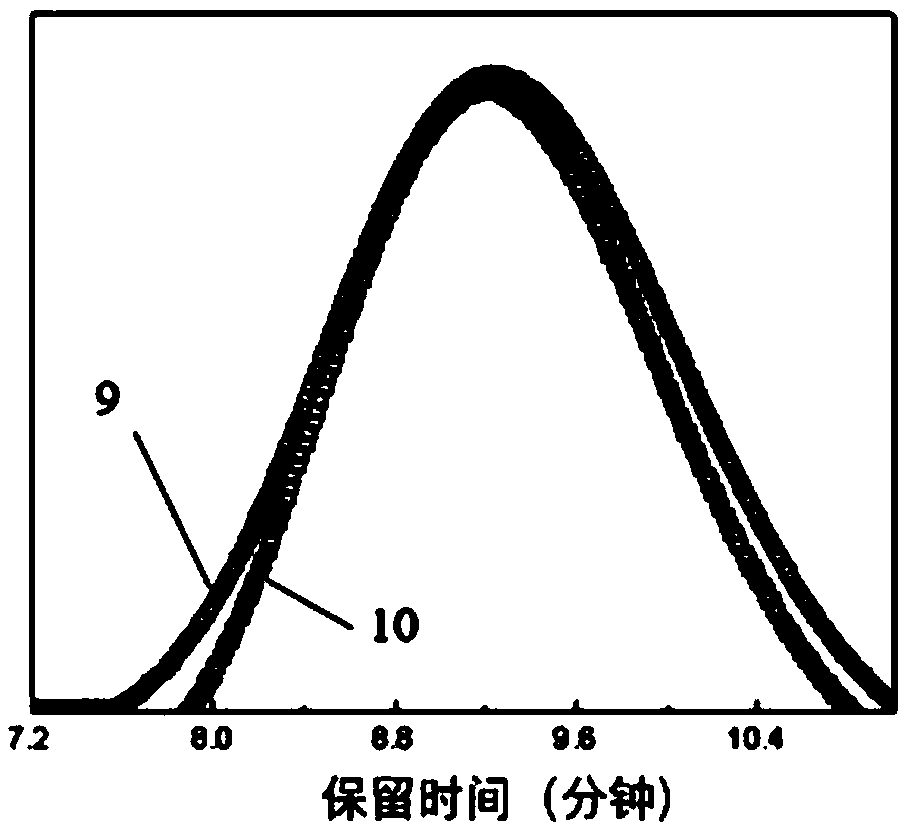

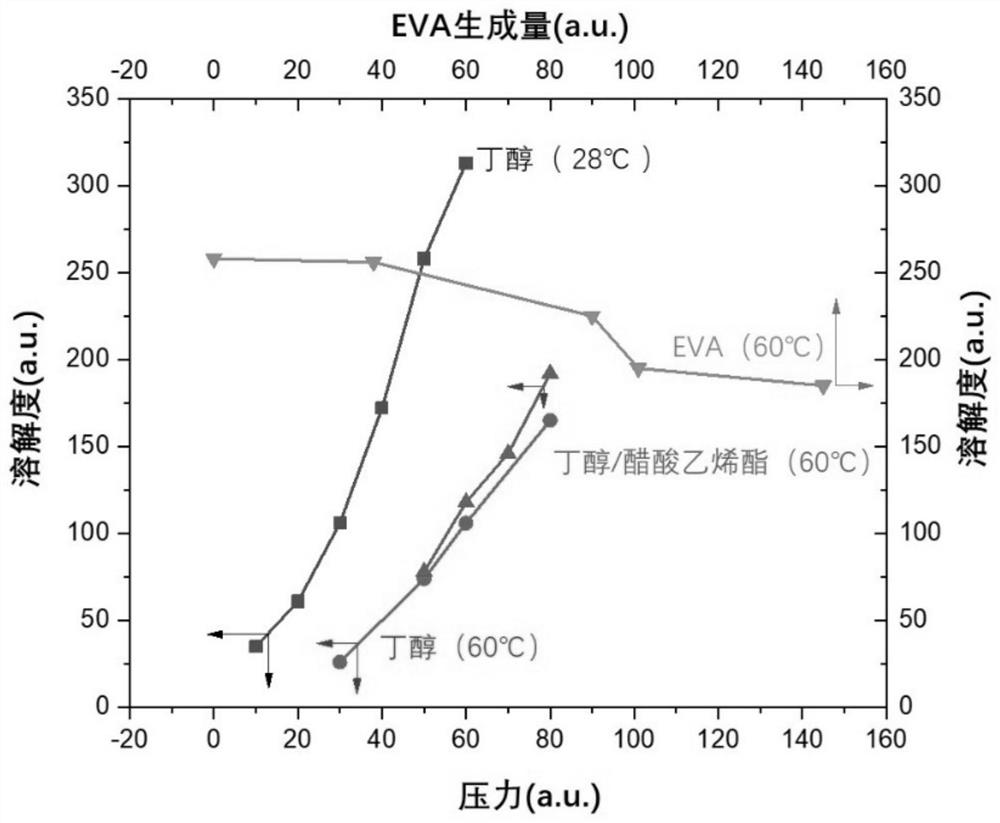

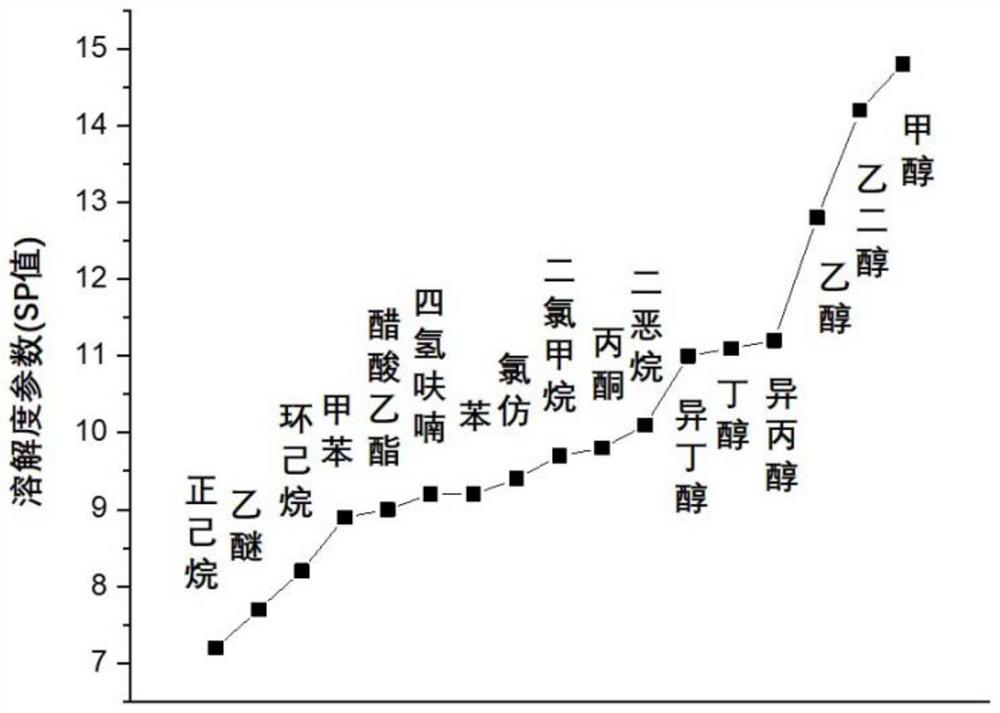

Regulation and control method and synthesis method for EVA synthesis with controllable branching degree, EVOH resin and synthesis method thereof

The invention provides EVOH resin. The weight-average molecular weight of the EVOH resin is greater than or equal to 9 kg / mol. The molecular weight distribution PDI of the EVOH resin is less than 2.0. Based on the response relationship between the reaction pressure and the polymer structure, the invention provides the method for regulating, controlling and synthesizing the EVA with the controllable branching degree according to the difference of solubility, partition coefficient and initiation efficiency of different initiators in different solvent systems, and the method is realized by compounding an initiator, compounding a solvent and regulating the reaction pressure, and has the characteristics of strong controllability, mild conditions, simple operation and large-scale synthesis prospects. EVOH resin with high molecular weight and narrow distribution can be obtained through alcoholysis reaction of the EVA prepared by the method.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polyethyleneimine functionalized carbon nanotube modified polyformaldehyde composite material and preparation method thereof

The invention provides a preparation method of a polyethyleneimine functionalized carbon nanotube modified polyformaldehyde composite material. The preparation method comprises the following steps: A)mixing carbon nanotube with an acid to obtain carboxylated carbon nanotube; b) mixing and reacting the carboxylated carbon nanotube and polyethyleneimine in the presence of a condensing agent to obtain a polyethyleneimine functionalized carbon nanotube product; and C) reacting polyformaldehyde with the polyethyleneimine functionalized carbon nanotube product, and molding to obtain the product. According to the method disclosed by the invention, the polyethyleneimine functionalized carbon nanotubes can be uniformly dispersed in the polyformaldehyde matrix, and the interface bonding force between the carbon nanotubes and the polyformaldehyde is improved; therefore, the thermal stability of the polyformaldehyde composite material is improved, the crystallization behavior and the mechanical property are improved, and the polyformaldehyde composite material can be widely applied to the fields of automobiles, electronic appliances, machinery, precise instruments, building materials and thelike.

Owner:HENAN UNIVERSITY

A nano-composite high-wax heavy oil pour point and viscosity depressant and preparation method thereof

ActiveCN110922955BImprove low temperature fluidityEasy accessDrilling compositionNanocompositeMaterials science

Owner:SOUTHWEST PETROLEUM UNIV

Poly-hydroxyalkanoate degradable composite material containing carbon nanomaterial and preparation method

ActiveCN102964789BHigh thermal conductivityImprove thermal conductivityNucleationCarbon nanomaterials

The invention relates to a poly-hydroxyalkanoate degradable composite material containing a carbon nanomaterial and a preparation method thereof. The composite material is constructured by introducing a high thermal conductive carbon nanomaterial into a poly-hydroxyalkanoate matrix to form an efficient thermal conductive network in the composite material to accelerate dissipation of heat discharged by crystals. The carbon nanomaterial is used as a nucleating agent at the same time to promote nucleation and crystallization of the poly-hydroxyalkanoate matrix. The carbon nanomaterial is further used as a flexibilizer to strengthen the obtained composite material. The mass ratio of the poly-hydroxyalkanoate matrix to the carbon nanomaterial is 10:1 to 2000:1. Compared with the prior art, the carbon nanomaterial has the advantages of high machining property, high mechanical property and high thermal property, low production cost and the like.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com