Wet spinning device applying regulable magnetic field and method

A technology of wet spinning and spinning device, which is applied in the field of wet spinning device with adjustable magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

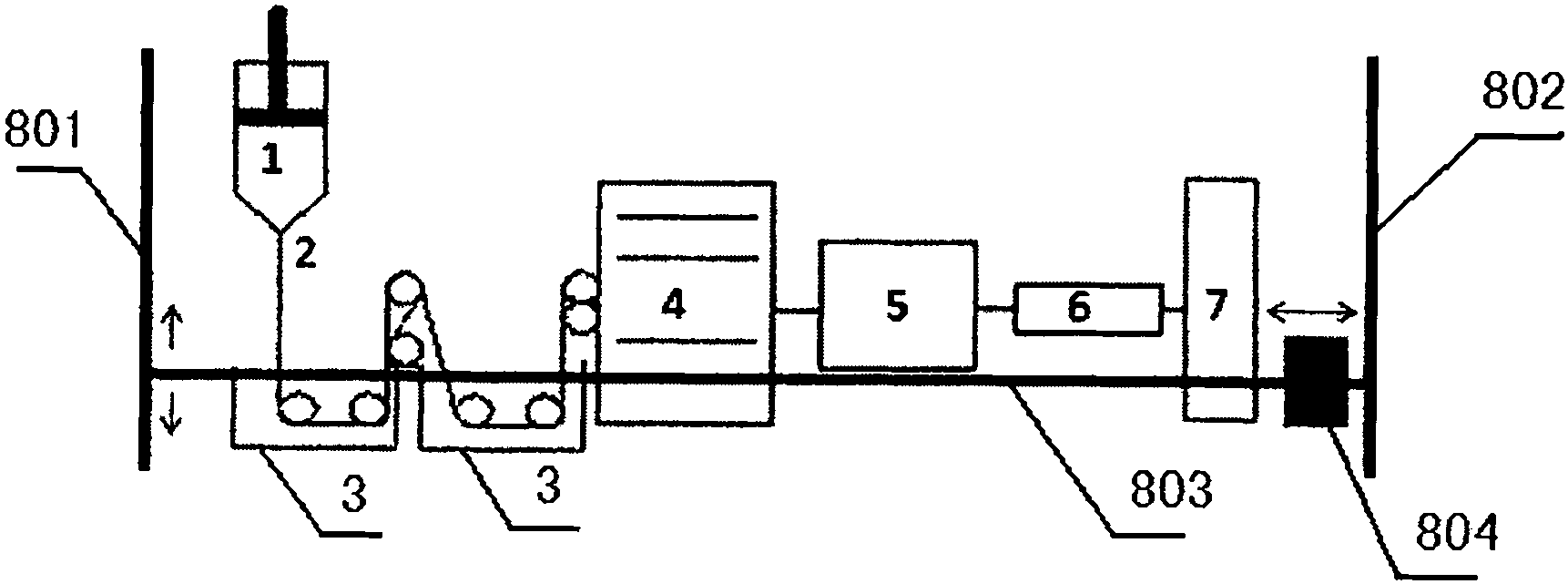

Method used

Image

Examples

Embodiment 1

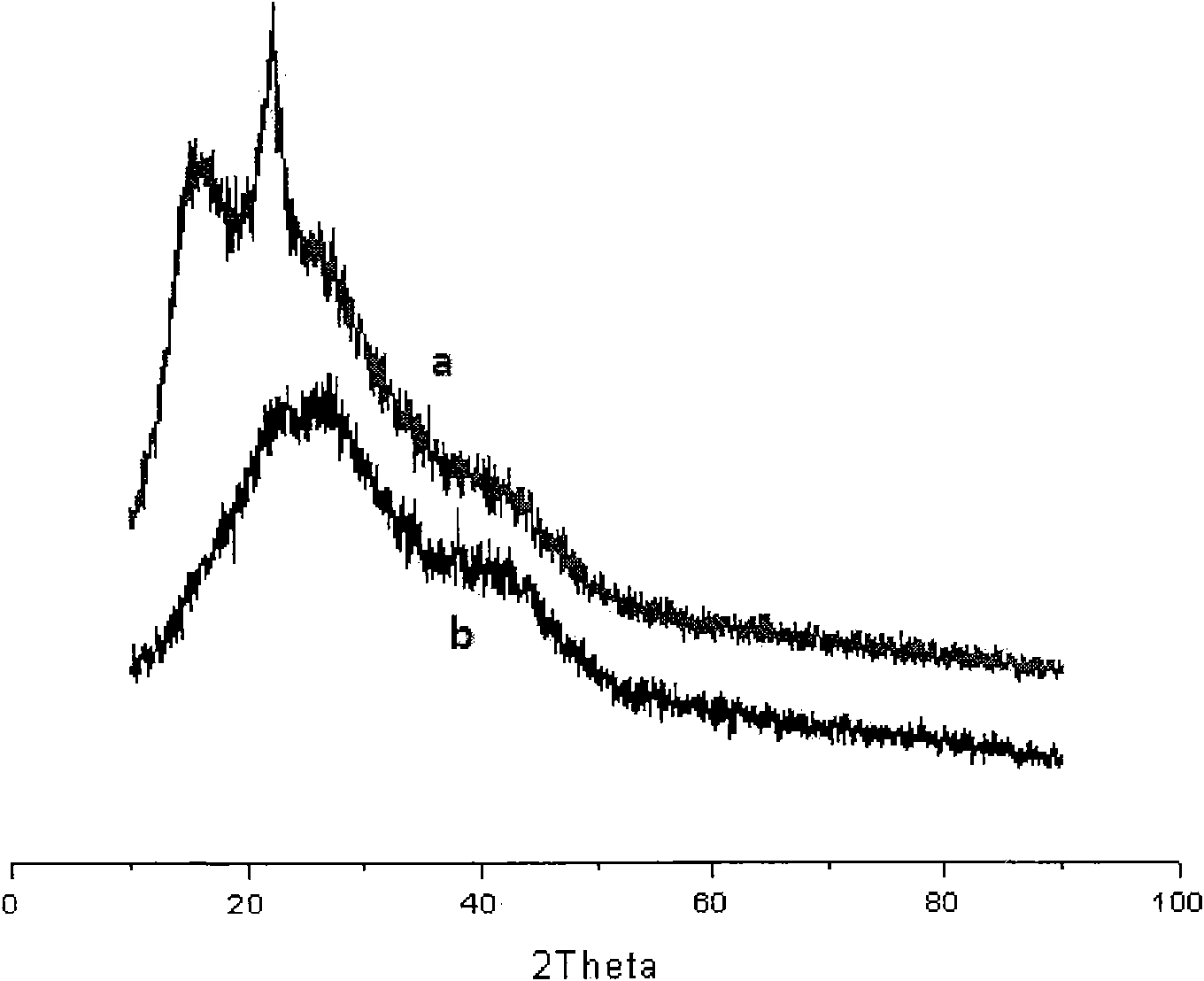

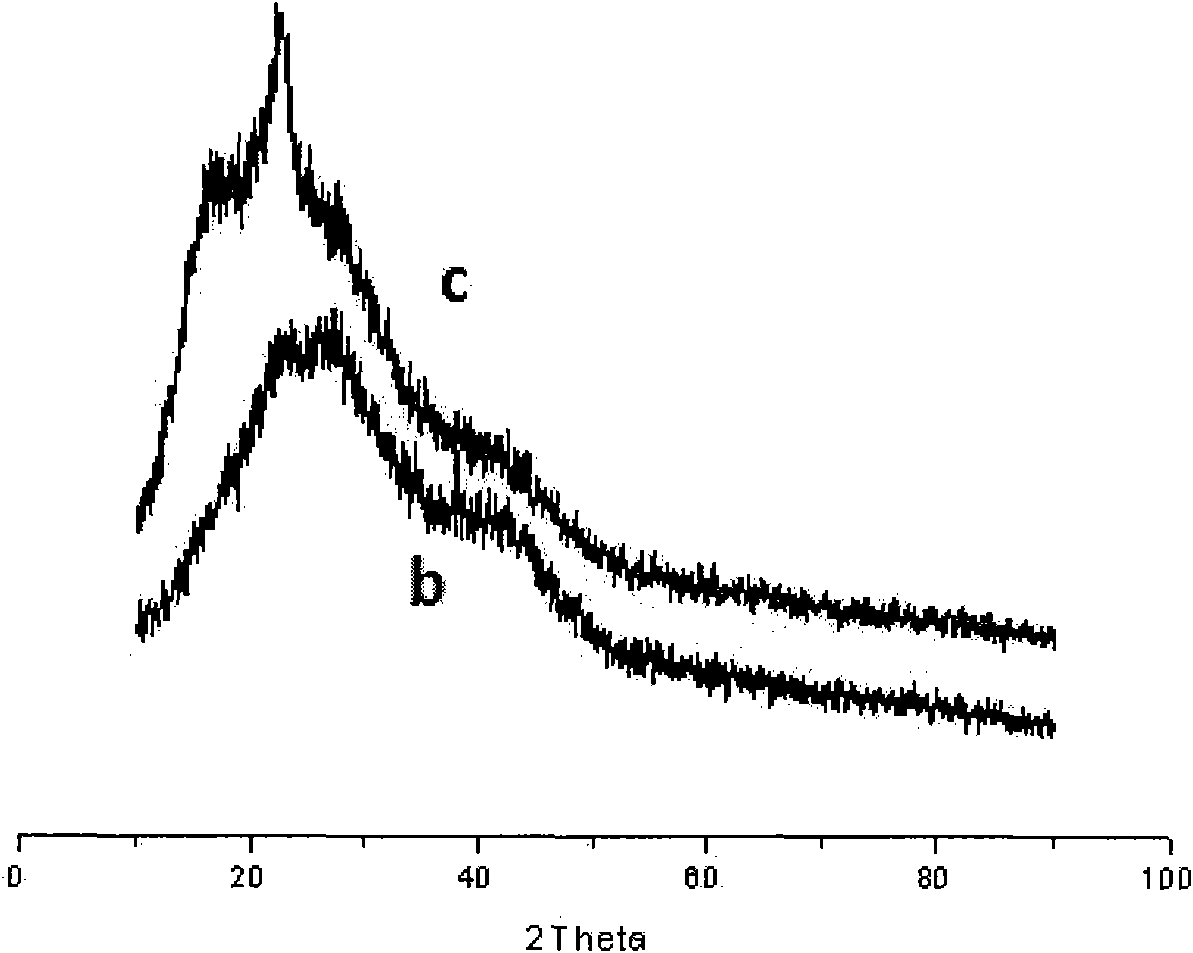

[0023] Embodiment 1: A certain amount of PSA-DMF spinning stock solution with a concentration of 16% is placed in the polymer delivery mechanism 1 for degassing. The coagulation bath 3 sets vertically, the coagulation bath is a mixed solution of DMF and water, the temperature of the coagulation bath is 45°C, and the concentration of DMF is 52%. The cured fibers enter the washing tank 4, the solvent DMF is removed, and the washed fibers enter the drying process. The box 5 is dried, and the temperature of the drying box is set at 160°C to remove residual solvent and water. The dried fibers are stretched through the drafting device 6, and the drafting temperature is set at 270°C, and finally collected by the winding shaft Finished fiber, the rotation speed of the winding shaft is set to 2m / min. The crystallization properties of the obtained fibers are shown in figure 2 (b) and image 3 (b).

Embodiment 2

[0024] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that the adjustment magnetic field generator 804 is placed at the coagulation bath 3 . The magnetic field intensity measured with a magnetometer is 0.5T, and the crystallinity of the fiber obtained is shown in figure 2 (a).

Embodiment 3

[0025] Embodiment 3: This embodiment is basically the same as Embodiment 2, the difference is that the magnetic field generator 804 is adjusted at the drafting device 6 . The magnetic field intensity measured with a magnetometer is 0.5T, and the crystallinity of the fiber obtained is shown in image 3 (c).

[0026] Through the above experimental comparison of polysulfone amide wet spinning with and without magnetic field, combined with figure 2 and image 3 , it can be found that, compared with the traditional wet spinning device, the crystallization property of the fiber obtained by using the wet spinning device of the present invention is obviously improved. It is found by calculation that compared with the fiber obtained in Example 1, the crystallinity of the fiber obtained in Example 2 and Example 3 is increased by 34.2% and 25.7% respectively. The above description of the examples is to facilitate those of ordinary skill in the art to understand and apply the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com