Probe type online three-dimensional imaging detection system and probe type online three-dimensional imaging detection method

A technology of three-dimensional imaging and detection system, which is applied in the direction of analyzing materials and instruments, and can solve the problems of weak image processing function and unsatisfactory image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

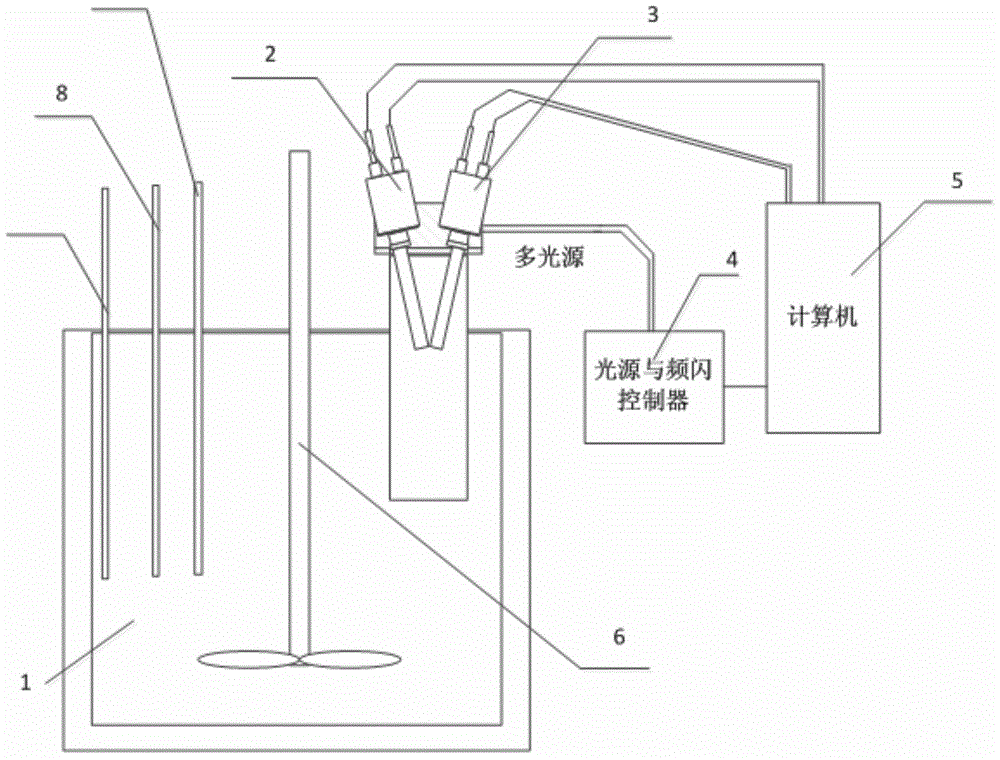

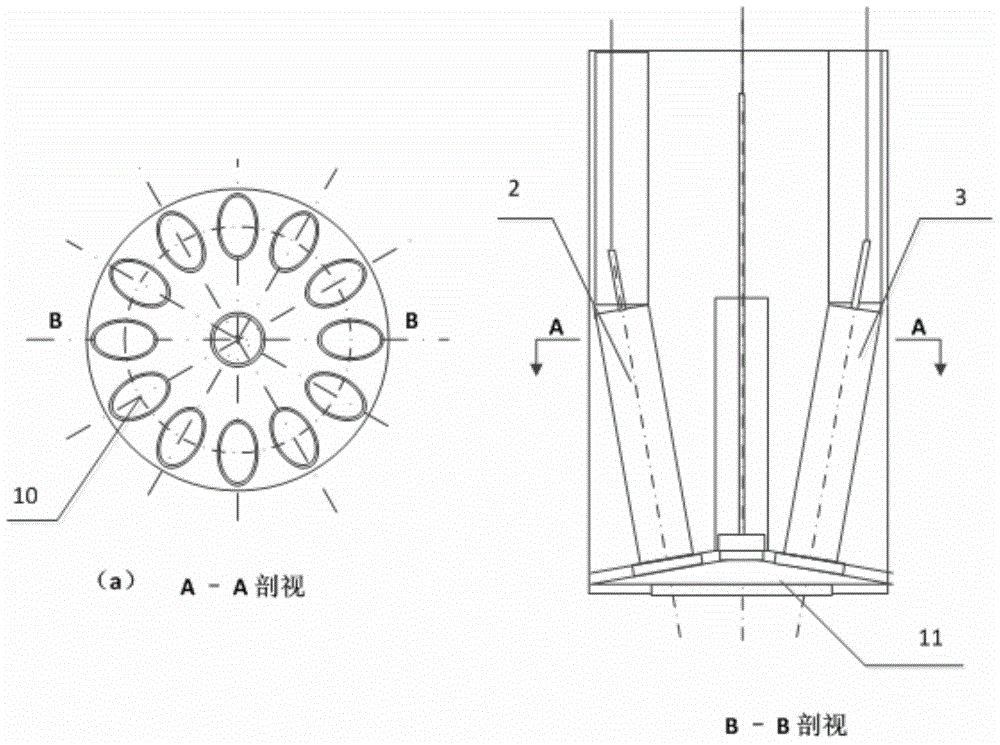

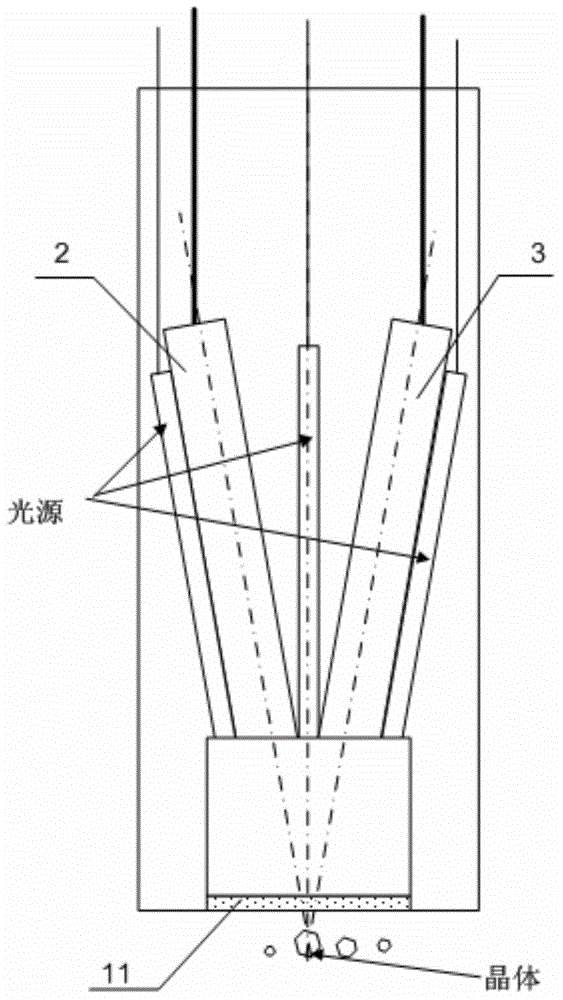

[0112] like figure 1 , 2 , shown in 3, a kind of probe-type online stereoscopic imaging detection system, comprises the crystal growth reactor 1 that the crystal to be measured is housed, is arranged on the three-dimensional imaging probe inside the crystal reactor, wherein the three-dimensional imaging probe comprises a fixed solid angle Two cameras 2, 3 and a light source, the lenses of the cameras 2 and 3 are central telescopic lenses, and the imaging is clearer; the blade stirrer 6 is arranged in the crystal growth reactor; the system also includes a light source and a strobe control for controlling the work of the light source 4, a computer 5 for processing the image collected by the three-dimensional imaging probe and a display connected to the computer, the light source is connected with the strobe controller 4 and the computer 5, wherein the three-dimensional imaging probe is used to obtain the 2D image of the crystal sample Transmission to the computer 5, the compute...

Embodiment 2

[0115] like Figure 4 , 5 , the present embodiment has the same structure as embodiment 1 except the following features:

[0116] like Figure 4 A reflective disc 12 is arranged under the glass window 11 of the three-dimensional imaging probe, and the gap between the reflective disc 12 and the glass window 11 forms a slurry flow channel 13 . For fast-moving crystals and when the concentration of crystals in the reactor is high, the slurry flow channel can "rectify" the crystals in the solution, and the crystals pass through the slurry flow channel in sequence, which can improve the quality of the collected 2D images.

Embodiment 3

[0118] like Figure 5 , the present embodiment has the same structure as embodiment 1 except the following features:

[0119] The bottom of the three-dimensional imaging probe is provided with a tapered end 13 . In order to facilitate the insertion of the probe into the small size crystallization reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com