Patents

Literature

225 results about "Grain number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Popular Answers (1) ASTM grain size number(n) is related with the number of grains that you can count in 100X magnification (N) by the relation, N=2 (n-1). So ASTM grain size number increases with decreasing grain size. For more information you can check the link.

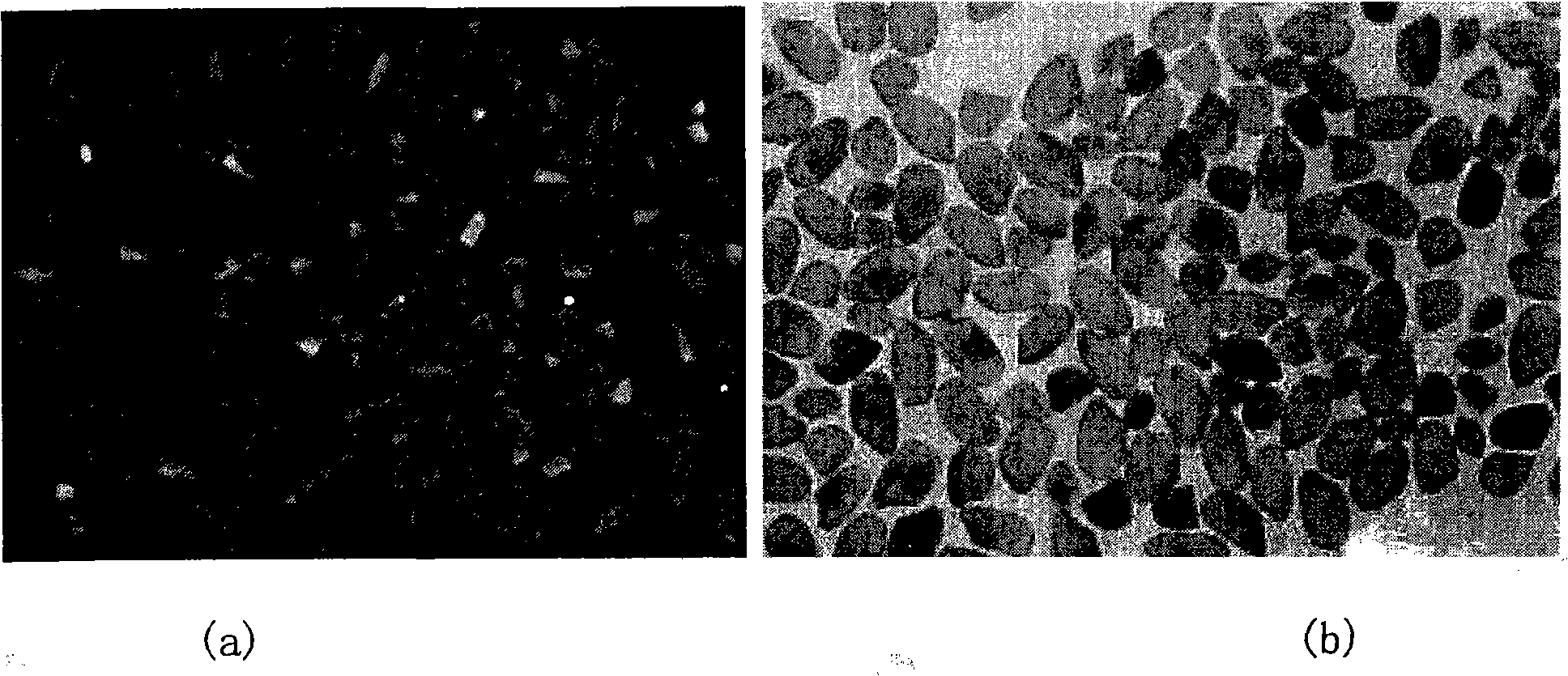

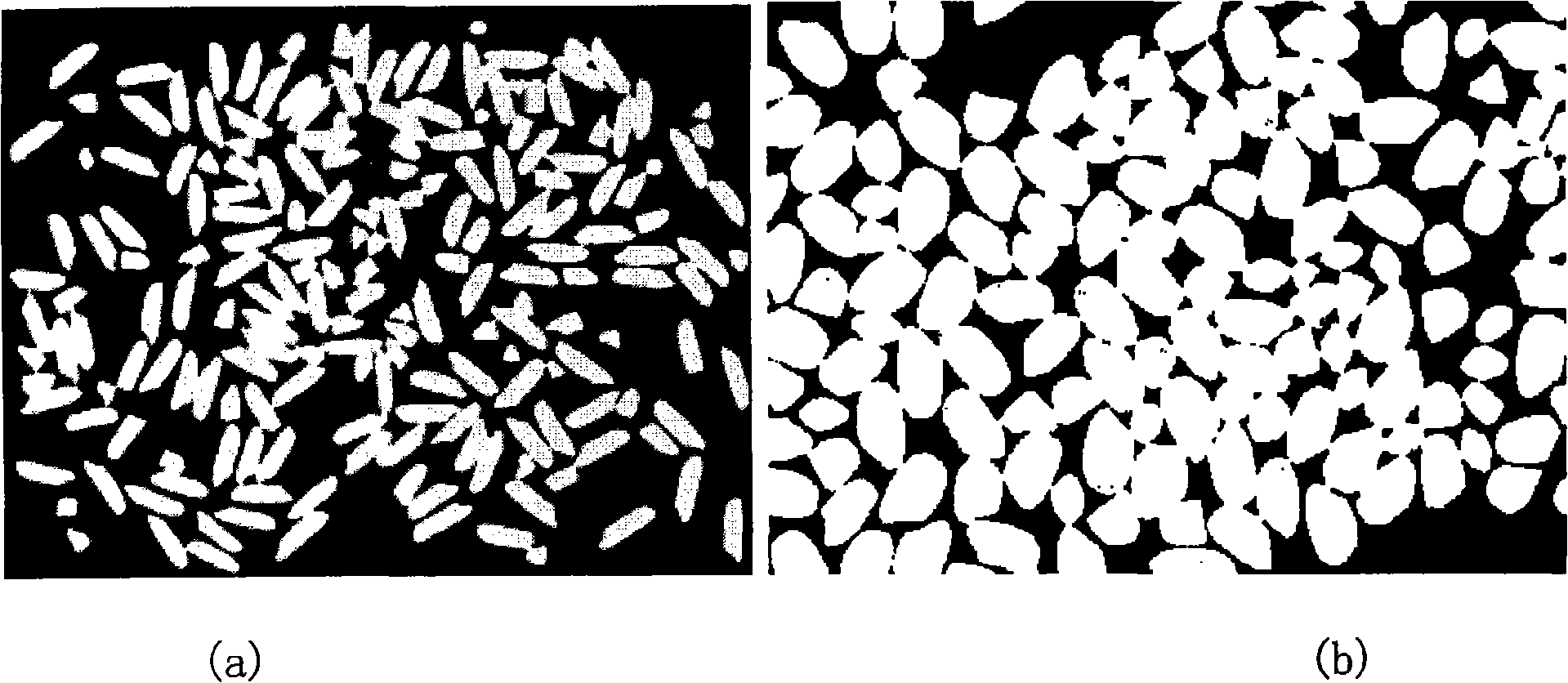

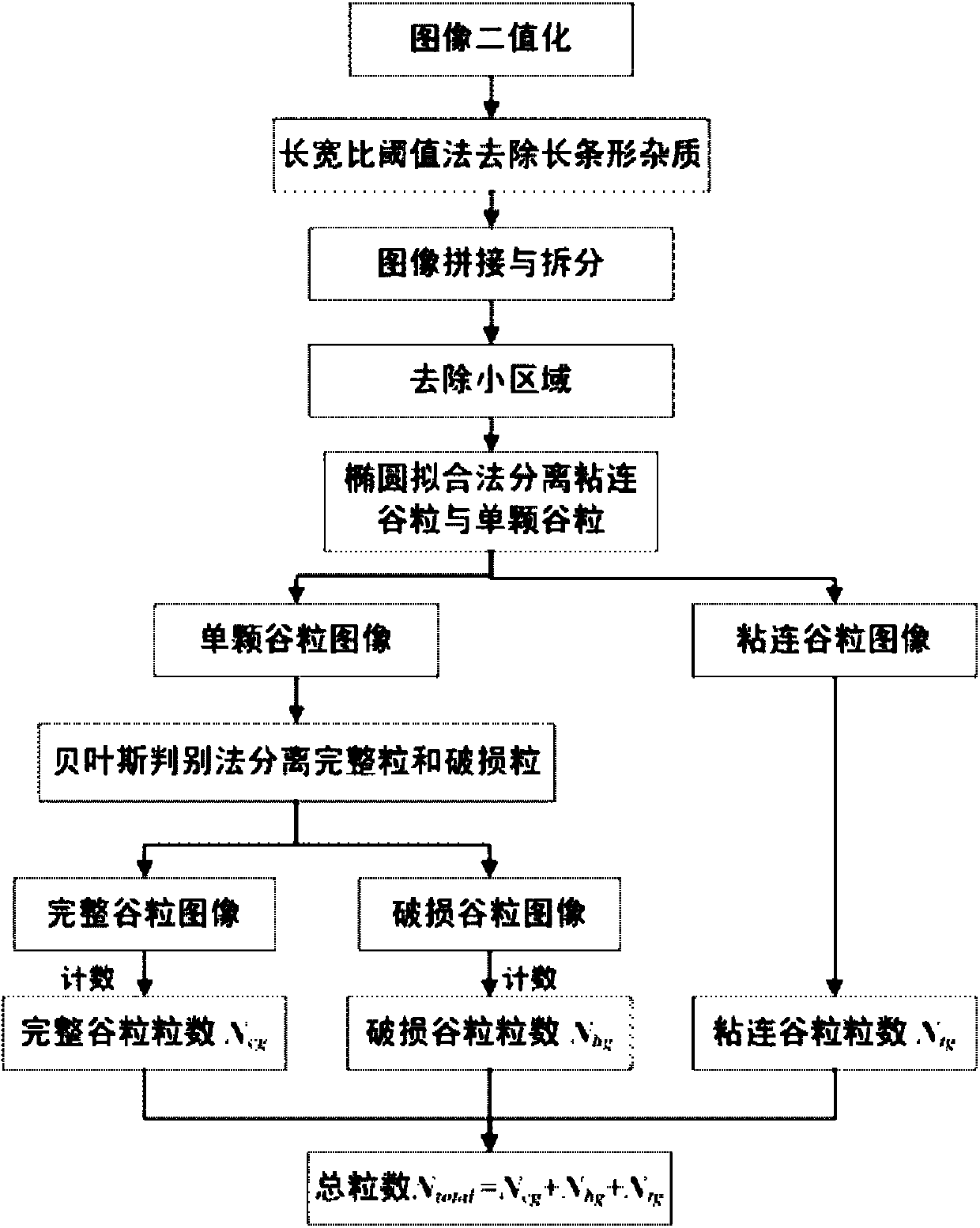

Image type automatic analysis method for mesh adhesion rice corn

InactiveCN101281112AOvercoming problems that are difficult to analyze automaticallyRemove the restriction of non-stick placementImage analysisMaterial analysis by optical meansAutomatic segmentationSplit lines

The invention discloses an image automatic analysis method for reticulate adhesion rice. The method firstly images rice under the grade of a reference backlight, and enables the reticulate adhesion rice to belong to the different local regions separately through an automatic segmentation. Secondly, the automatic segmentation includes that fat circular rice is carried on a distance transformation and a watershed transformation to be divided, as well as to use a circular template to get the concave angle point of long rice after the long rice is carried out watershed transformation, and the separation line can be determined and the wrong separation line can be removed according to the concave angle point. Different colors is using to color complete polished rice, broken rice and the rice whose length is in the critical region and to color background and chalkiness so as to figure out the grain number, the length, the width and the length to width ratio of each grain, finally, and the entire polished rice rate, the broken rice rate, the chalkiness degree and the chalkiness grain rate, and to form an analysis report. The invention overcomes the problem that the reticulate adhesion rice is difficult to be carried on automated analysis, and removes the limit of the request analysis sample is not in adhesion placing.

Owner:ZHEJIANG SCI-TECH UNIV

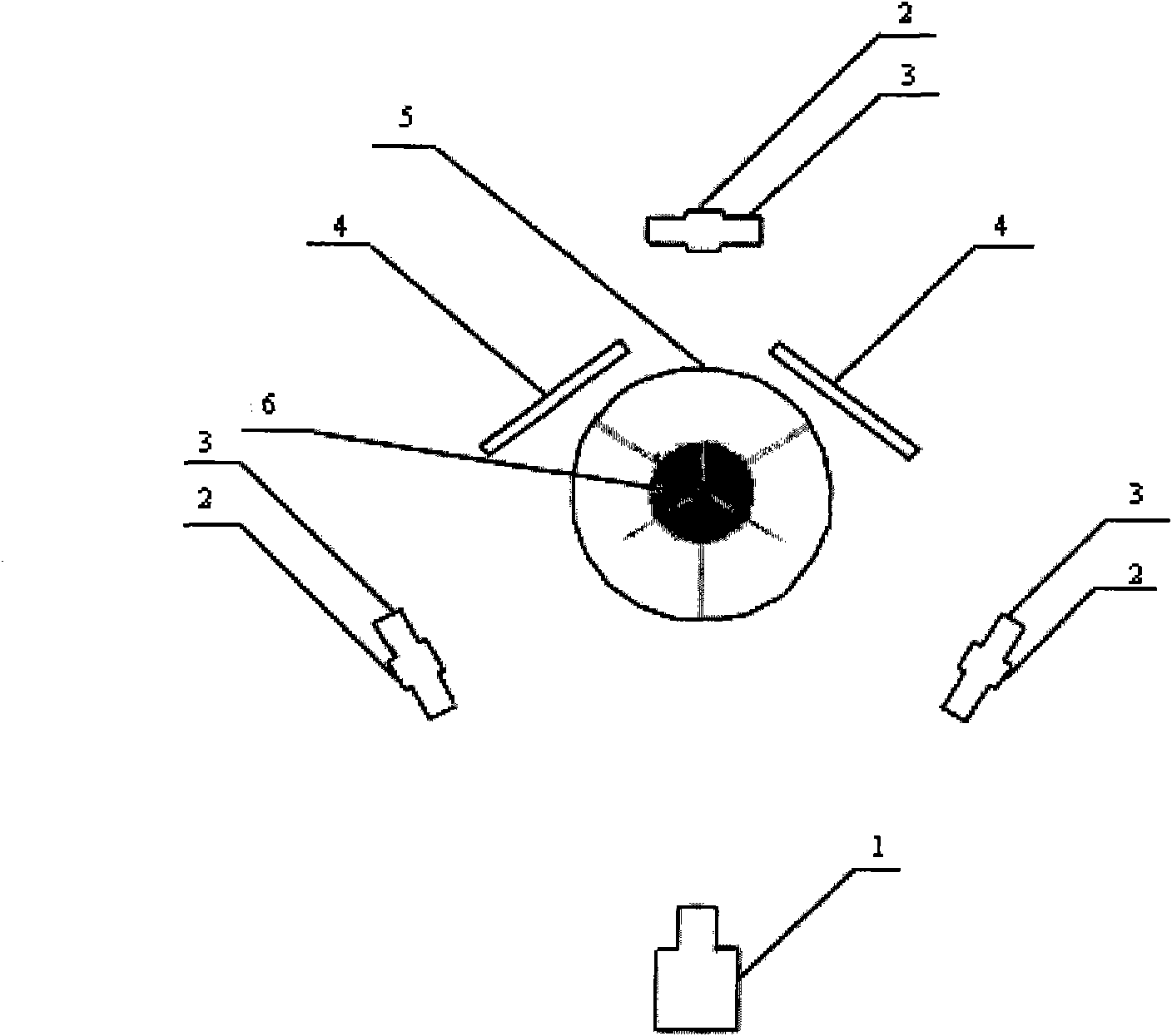

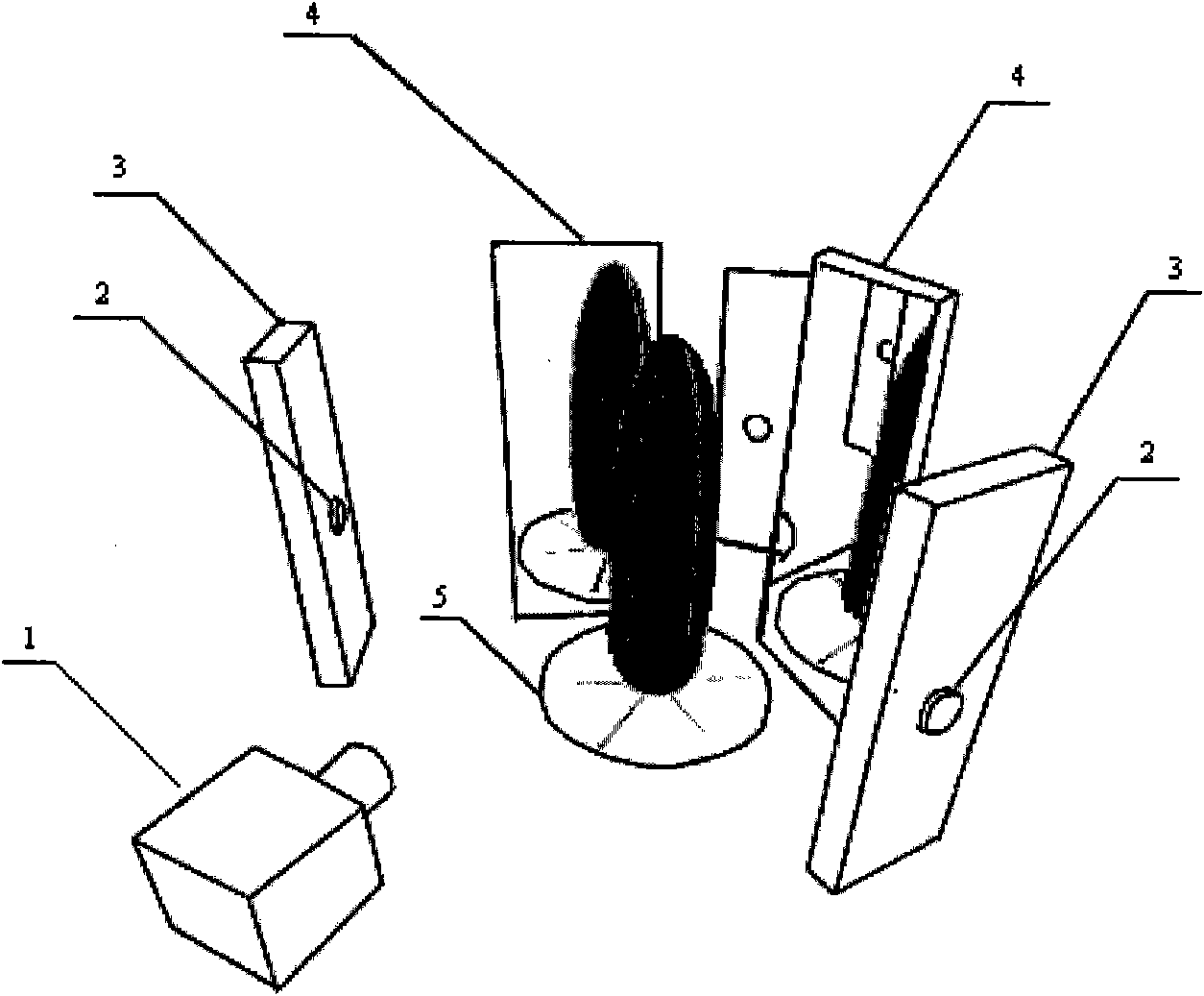

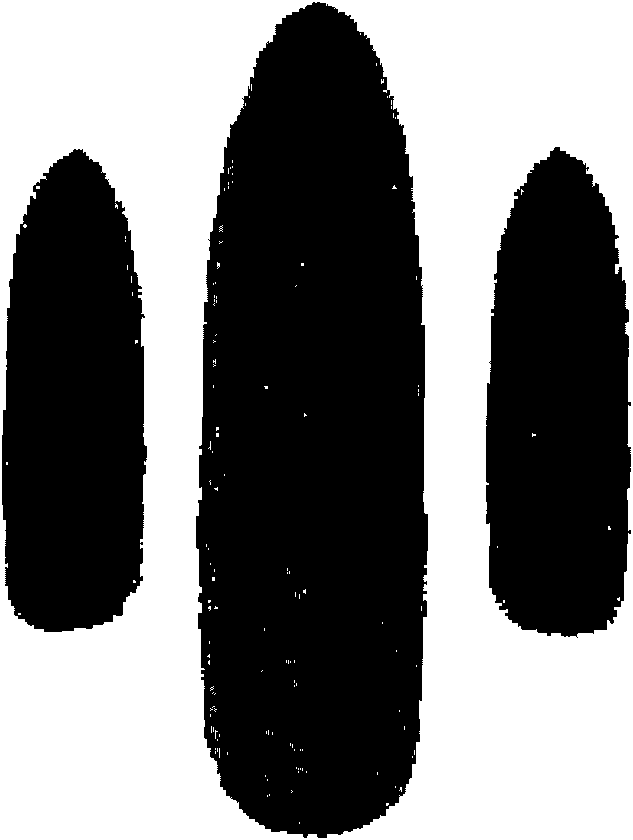

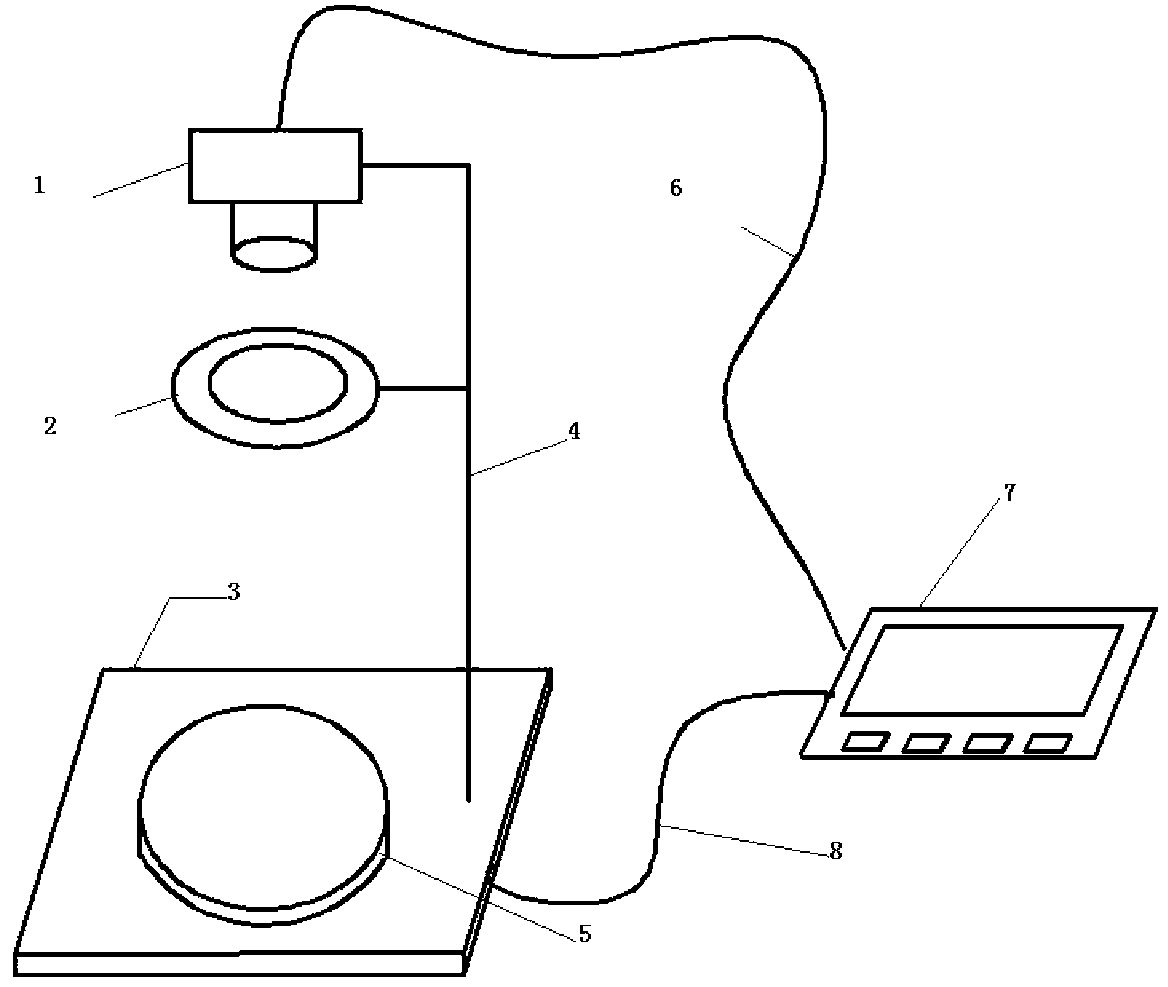

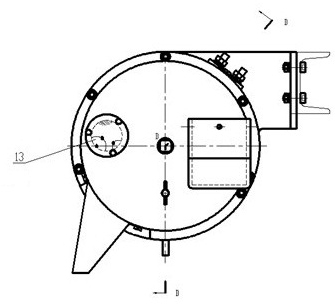

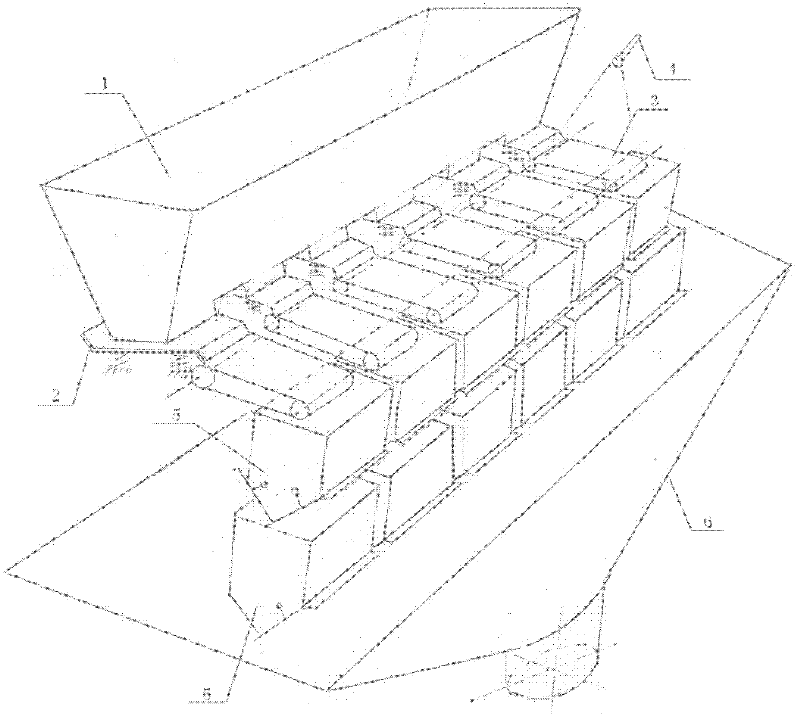

Corn seed investigating device based on machine vision

ActiveCN101933417AImprove the many disadvantages of manual testSeed and root treatmentPhotographyMachine visionLaser light

The invention discloses a corn seed investigating device based on machine vision, comprising an object stage, an image collection unit and two reflectors. The image collection unit is opposite to the object state; the two reflectors are placed at the other side of the object stage opposite to the image collection unit and are arranged in the position where the two reflectors can image the part of the corn ear part to be tested, which can not be directly collected by the image collection unit. The device has the advantages of time and labor saving, rapidness, high efficiency, and the like; images at three sides of the corn ear can be imaged at one time through two reflectors; the object stage has the weighing function without other auxiliary weighing instruments; three linear laser light sources can be used for distinguishing the boundary of the corn overlapping part; the collected picture can be used for extracting multiple appearance parameters of progeny length, progeny row, progeny grains, grain number of each row, bald length, bald rate, and the like; and the defects for artificial seed investigation at present is improved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

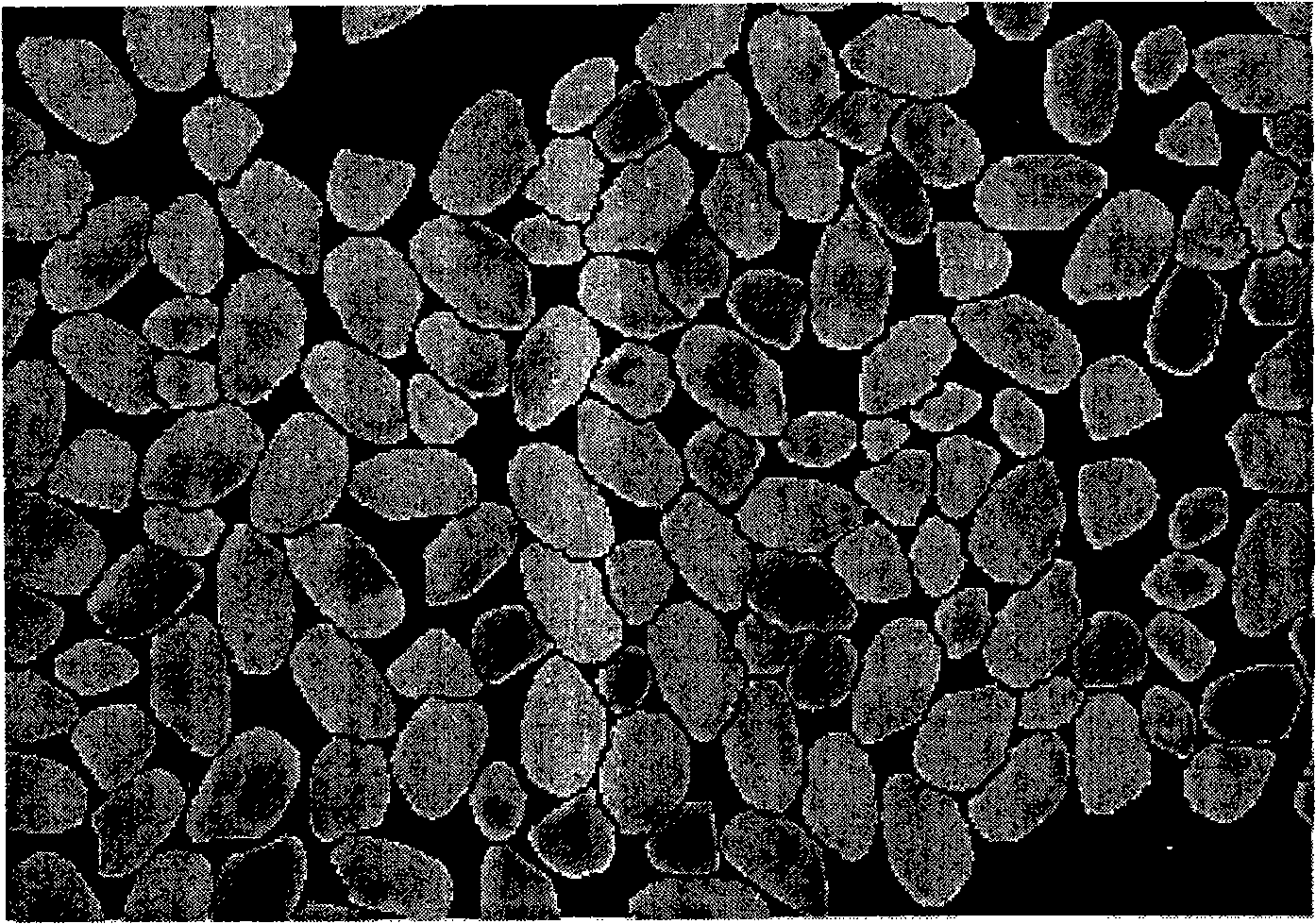

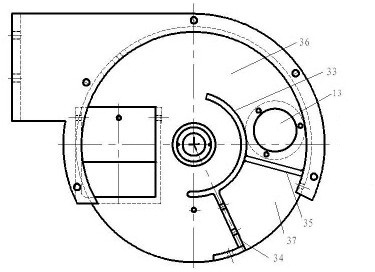

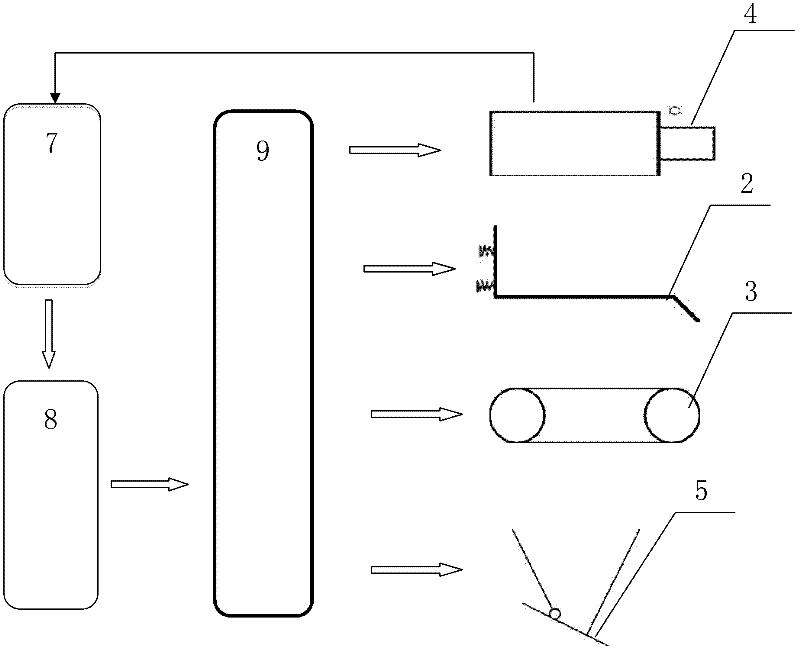

Digitalized paddy rice seed testing machine

ActiveCN101905215AEvenly dispersedSolve adhesionGas current separationIndividual particle analysisAgricultural scienceRice grain

The invention relates to an online non-destructive testing method which is suitable for automatically measuring and recording the total grain number, the filled grain number, the maturing rate, the grain lengths, the grain widths and the length-width ratio of a single plant or single-batch paddy rice in the paddy rice seed testing process for agricultural scientific research personnel. The digitalized paddy rice seed testing machine mainly comprises six functional modules of a bar code recognizer, a grain transfer device, an air separation device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. The digitalized paddy rice seed testing machine can be used for separating filled grains and empty and shriveled grains by utilizing the air separation device, dynamically acquiring grain parameters by utilizing a machine vision technology and simultaneously measuring the total grain number and the filled grain number of the paddy rice, thereby overcoming a bottleneck that the traditional testing measure can not simultaneously acquire the total grain number and the filled grain number and realizing the detection to the grain-size parameters of the paddy rice at the same time of calculating the paddy rice grain number. The invention can be also widely applied to the seed testing work of other grain crops.

Owner:HUAZHONG UNIV OF SCI & TECH

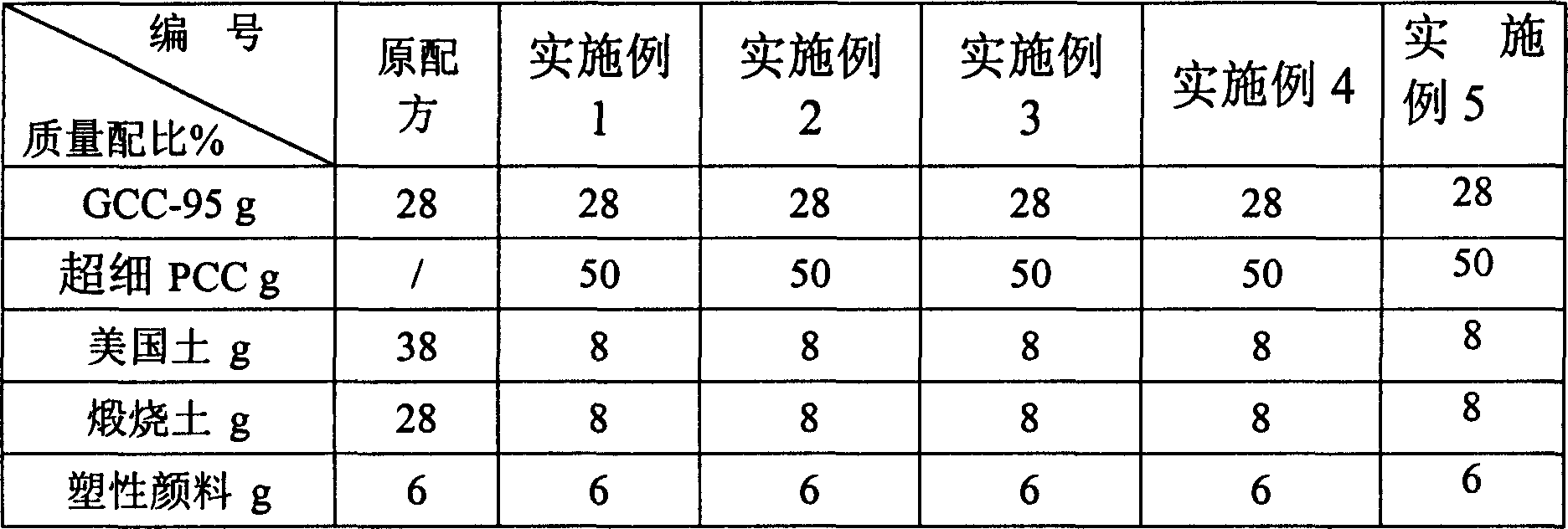

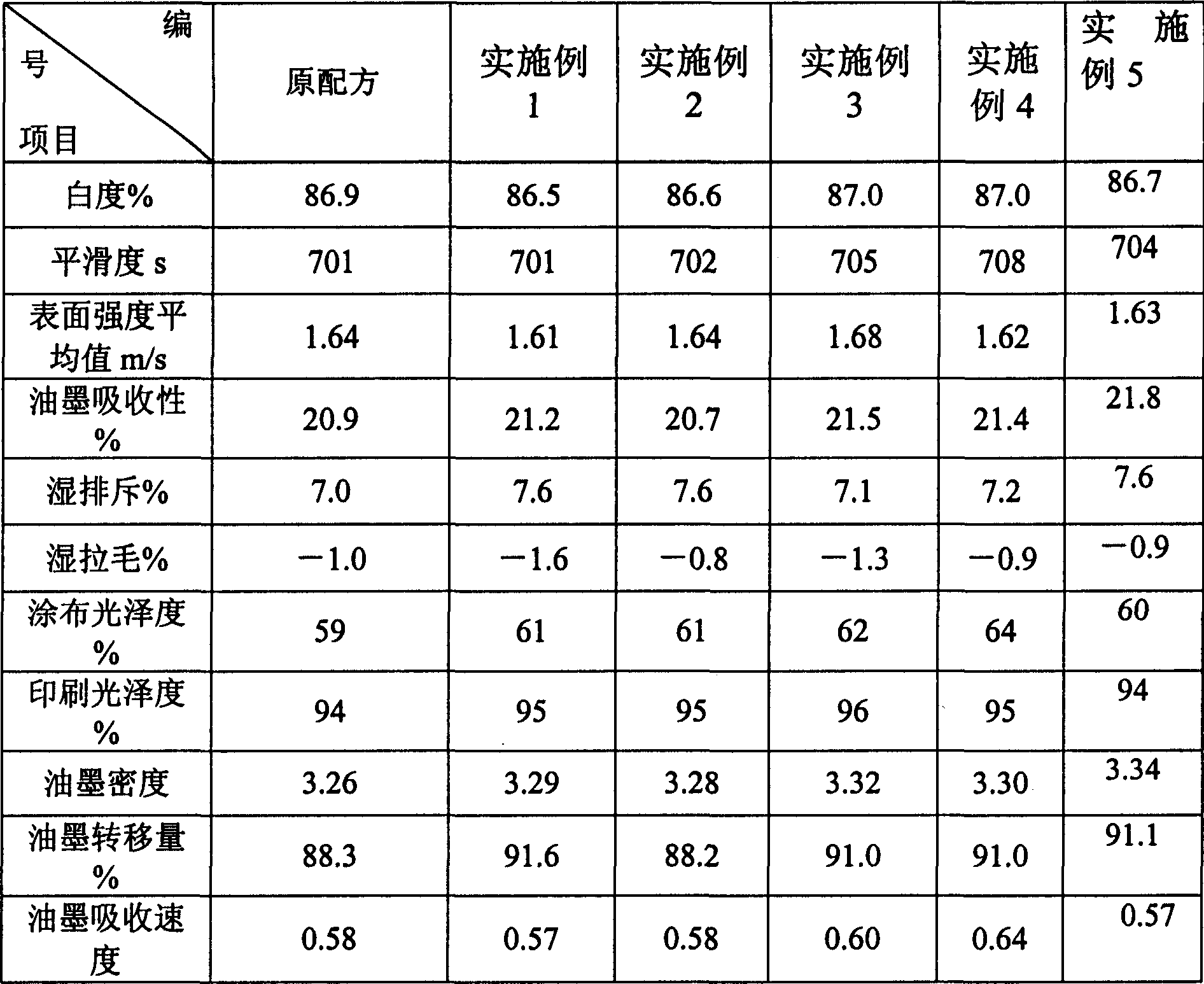

Process for preparing superfine light calcium carbonate

ActiveCN1884085AHigh whitenessReduce manufacturing costCalcium/strontium/barium carbonatesCoatings with pigmentsPhosphatePyrophosphate

The invention discloses a preparing method of super-fine lightweight calcium carbonate, which comprises the following steps: adding disperser in the calcium hydroxide slurry; sending the slurry to the grinding equipment; inputting carbon dioxide from bottom of grinding equipment to carbonize; synchronizing grinding and carbonizing. The disperser is one or two of phosphate, sodium polyacrylate, triethanolamine, sodium pyrophosphate, sodium polyphosphate or hexametaphosphate. The even grain size of super-fine calcium carbonate is 0.2-2.0 mum with 60-100 percent grain number with less than 2 mum grain size, which is fit for paper making filler or paper coating dye.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

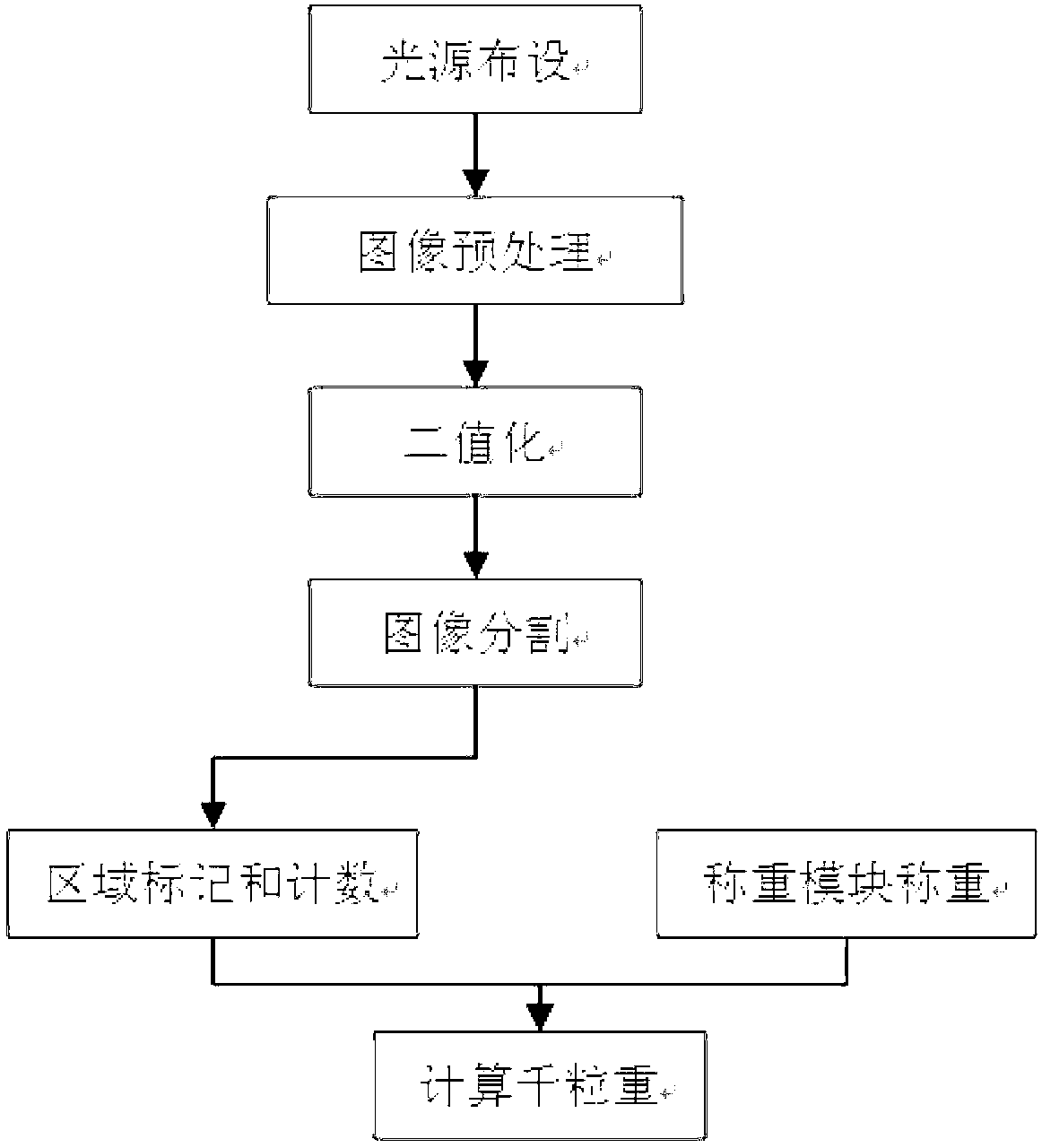

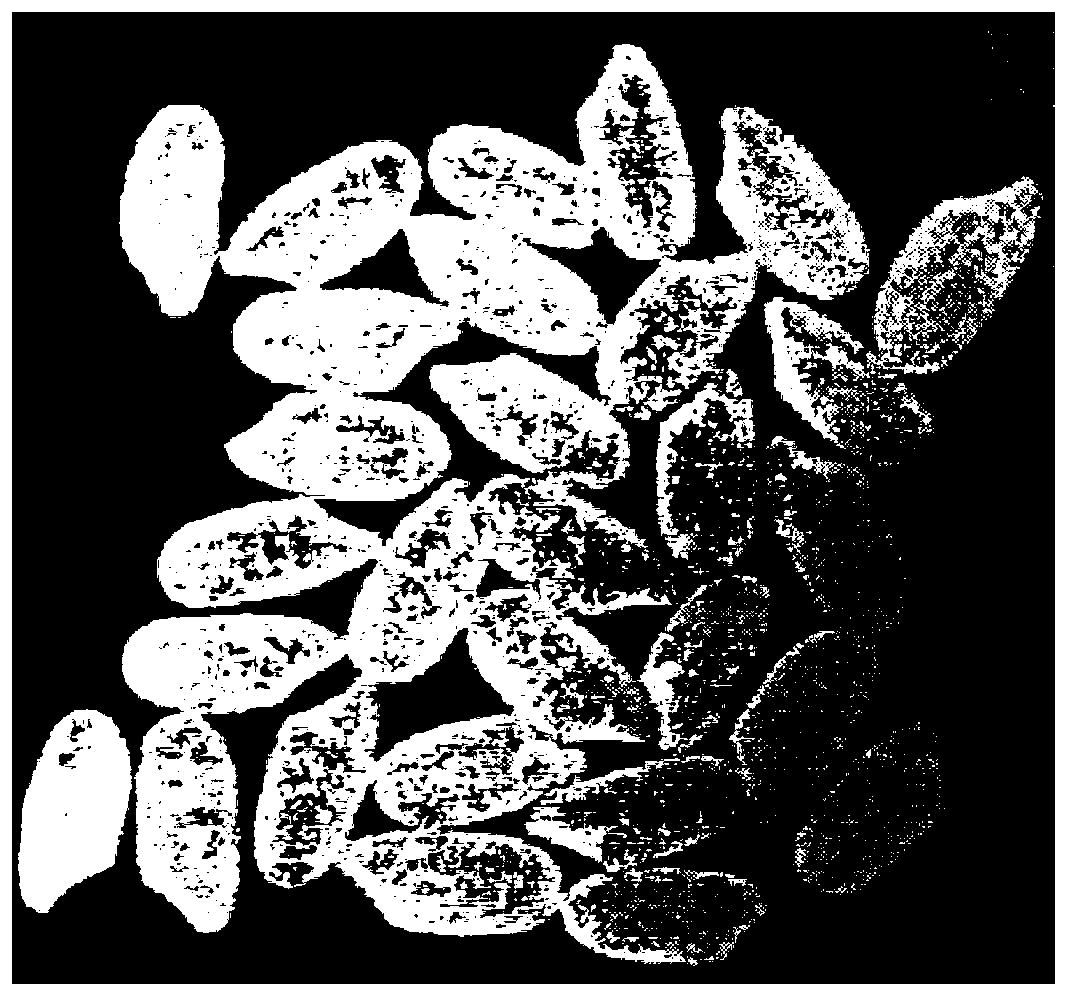

Method and device for measuring weight of thousand of seeds

The invention discloses a method for measuring the weight of one thousand of seeds. The method comprises the following steps of: 1) paving a plurality of seeds to be detected and collecting an image and the weight of the seeds; 2) converting the image into a gray level image and carrying out filtering treatment on the gray level image; 3) carrying out binarization treatment on the gray level image which is subjected to the filtering treatment to obtain a binarized image; 4) extracting the outlines of the seeds in the binarized image and dividing according to the outlines and communication regions; selecting a characteristic point of the outline in each communication region and matching characteristic point pairs and establishing dividing lines between the two characteristic point pairs, wherein the dividing lines are used for dividing each communication region into a plurality of sub-regions; 5) counting the quantity of the sub-regions of all the communication regions to obtain the quantity of the seeds; 6) calculating the weight of one thousand of seeds according to the grain quantity and the weight of the seeds. The invention further discloses a device for measuring the weight of one thousand of seeds. The device disclosed by the invention is simple in structure, convenient to operate and high in measurement precision.

Owner:ZHEJIANG UNIV

Ridge-covering and trench-sowing cultivation and fertilization technology of dryland winter wheat

InactiveCN101803514APromote formationIncrease number and thousand kernel weightFertilising methodsHorticultureBand shapeEvaporation

The invention relates to a ridge-covering and trench-sowing cultivation and fertilization technology of dryland winter wheat, which comprises the following steps of: preparing land, applying a base fertilizer, forming ridges with the widths of 35-40cm and covering a white plastic film on the ridges; preserving a ridge width of 30-35cm between two ridges; sowing wheat in grooves with a row distance of 15-20cm and a rowing amount of 150-225 kg / ha; uncovering the film during the total growth fertility period of the wheat so as to keep the strip film covering the soil surface; ditching and topdressing a nitrogen fertilizer of 30-45 kg / hm between wheat rows when the soil starts to defrost in spring and the wheat starts to turn green; milling in time after topdressing the fertilizer; keeping the plastic film covering the ridges after wheat is harvested; and returning all straws to be covered in grooves among the ridges for stimulating the rainfall infiltration in summer and lessening the water evaporation loss of the soil. The invention can stimulate the formation and the transferring of dry substances to grains, remarkably improves the ear grain number and the thousand grain weight and remarkably increases the wheat yield.

Owner:NORTHWEST A & F UNIV

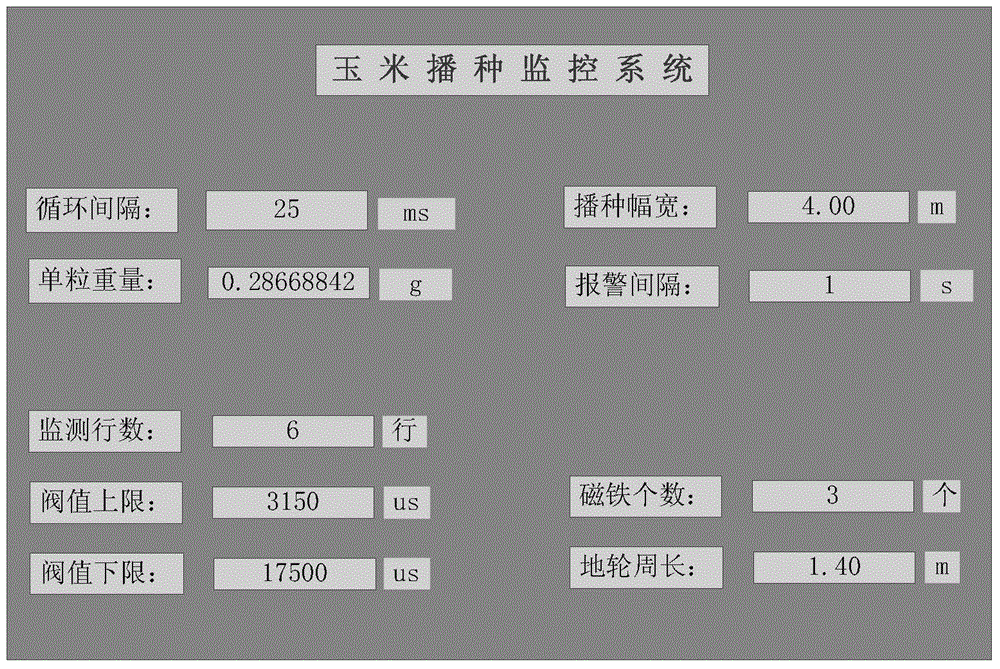

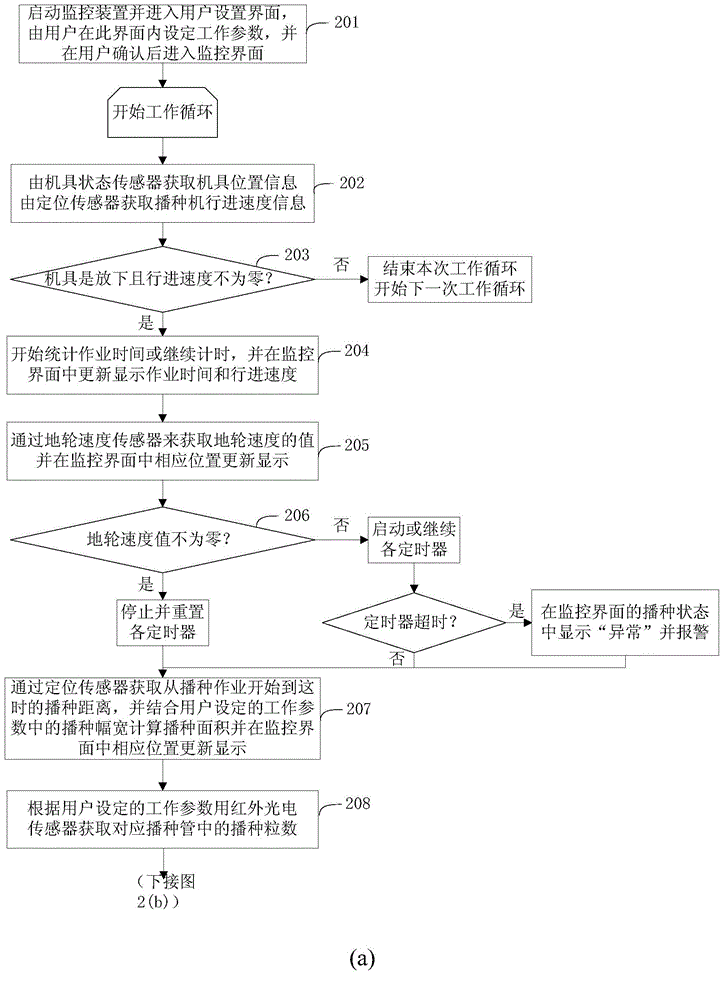

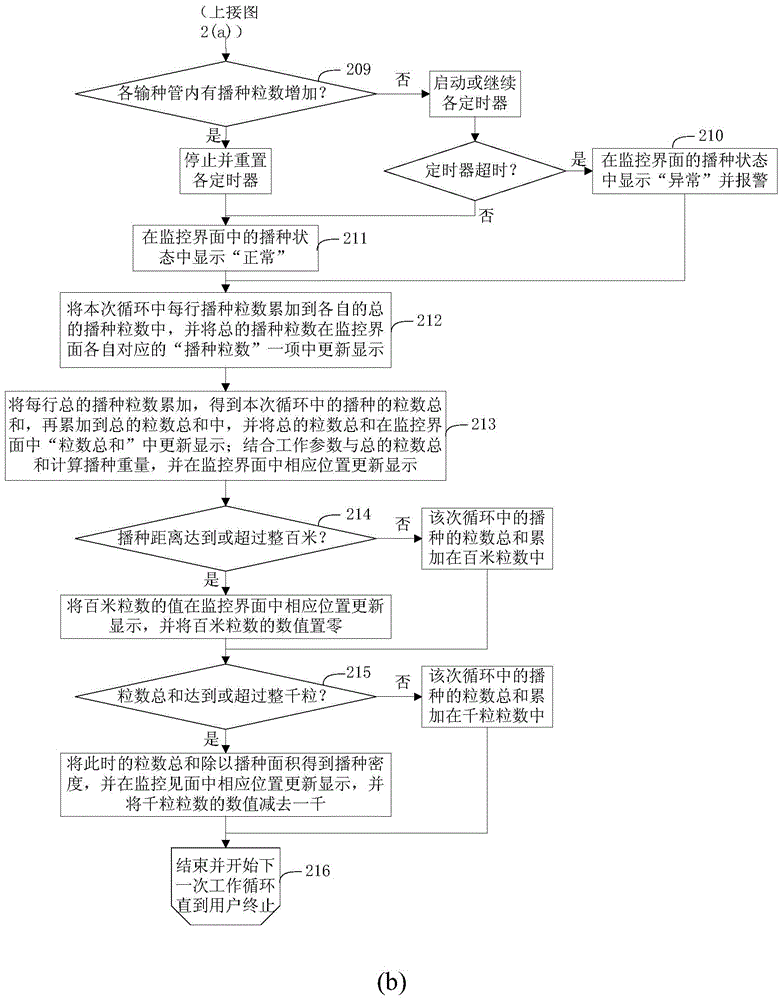

Device and method for monitoring corn precision seeding operation

ActiveCN103605307AReal-time monitoring of seeding grain numberBest fault alarm sensitivityProgramme controlComputer controlState parameterEngineering

The invention relates to the field of agricultural engineering, and particularly relates to a device and a method for monitoring corn precision seeding operation. The device particularly comprises a microprocessor, input and output devices facing users, an infrared photoelectric sensor, a signal acquisition circuit and an alarm device. The method particularly comprises that: after operation parameters are set by the users on a setting interface, an operation monitoring scanning cycle is started; a signal indicating the state of seeding operation is firstly acquired, then the signal indicating the state of seeding operation is computed with combination of the operation parameters so that parameters indicating the state of seeding operation are obtained and outputted and displayed to the users in real time; then whether the seeding state is normal is judged via the operation state parameters, and alarm is performed to the users if the seeding state is abnormal through judgment; and finally the scanning monitoring process is repeated via returning to the operation monitoring scanning cycle till the users terminate. Seeding grain numbers in corn precision seeding operation are monitored in real time by the device and the method, and great fault alarm sensitivity is achieved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

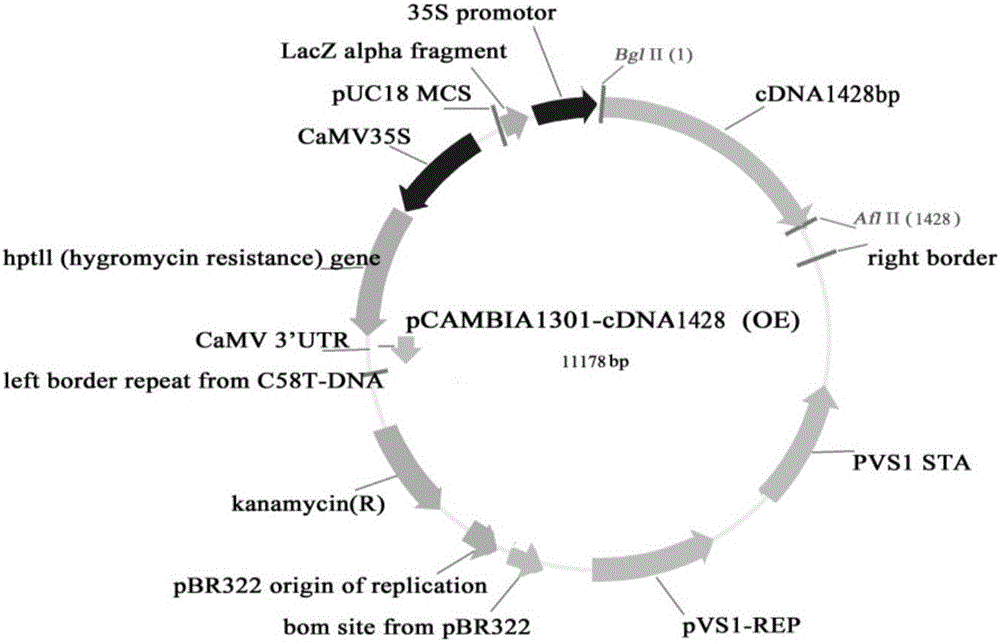

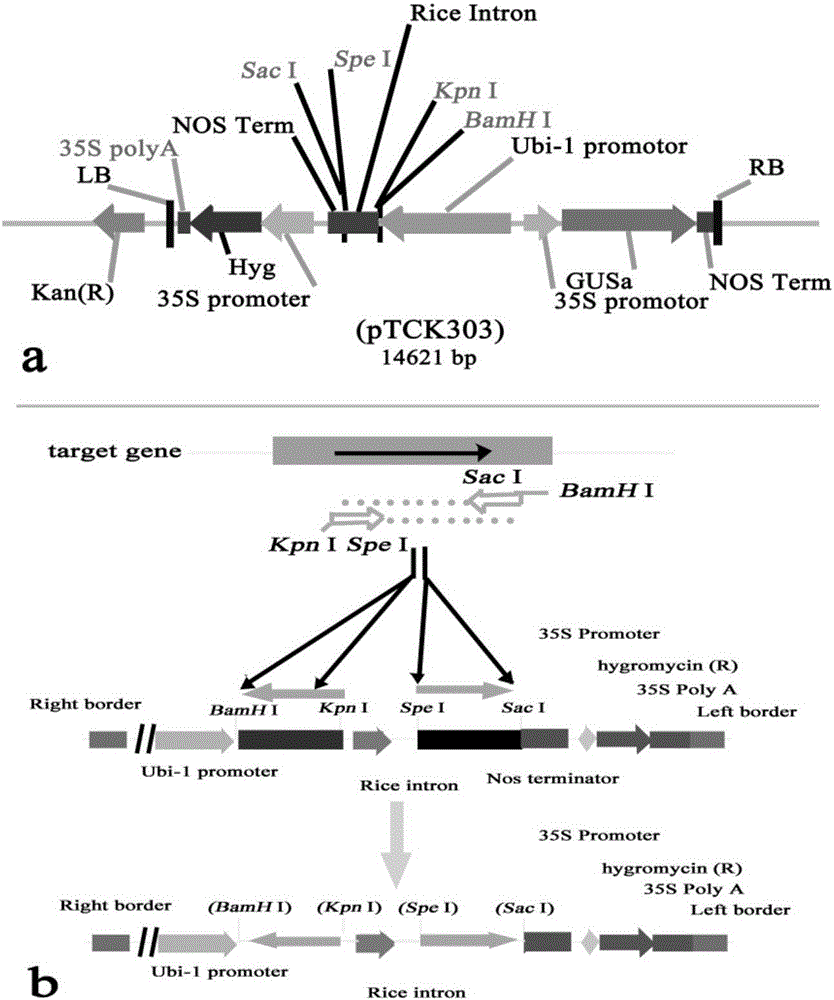

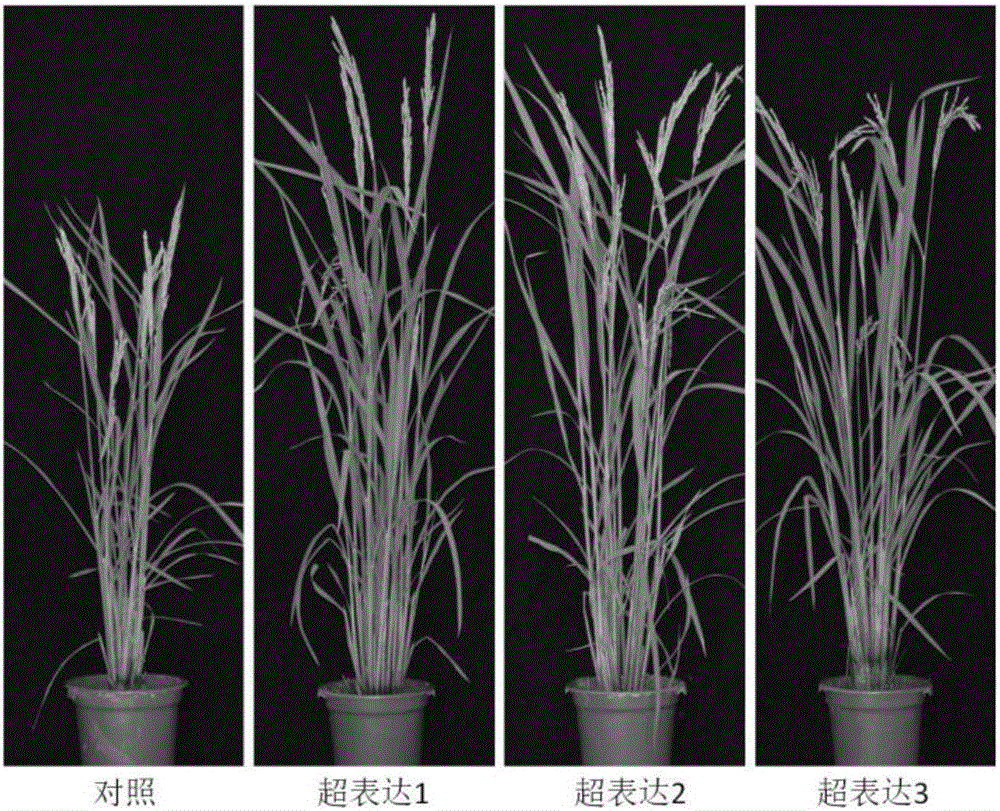

Gene OsPTR10 for improving nitrogen utilization efficiency and yield of rice and applications of gene OsPTR10

ActiveCN106119262AImprove utilization efficiencyIncrease the number of tillersMicrobiological testing/measurementPlant peptidesPlant genetic engineeringMutant

The invention relates to the field of plant genetic engineering, and provides a rice nitrogen transporter gene OsPTR10, wherein the protein sequence of the rice nitrogen transporter gene OsPTR10 is shown as SEQ ID No.1, and the cDNA sequence of the rice nitrogen transporter gene OsPTR10 is shown as SEQ ID No.2. According to the rice nitrogen transporter gene OsPTR10, through the excessive expression of the OsPTR10 gene, the normal efficiency in absorbing nitrogenous fertilizer of the rice is improved, the content of soluble protein of plants is increased, further, the tiller number is increased, the ear length and filling grain number are increased, and finally, the yield is improved; through the RNAi technology, the expression quantity of the OsPTR 10 gene is reduced, and the functions of the gene are verified in the OsPTR10 target gene mutant. The gene has the significant application values on the aspects of the statement on the influences of the nitrogen element on the growth and development of the plants and on the aspects of the efficient utilization for the nitrogen fertilizer of the rice and the improvement on the yield of the rice.

Owner:WUHAN INST OF BIOENG

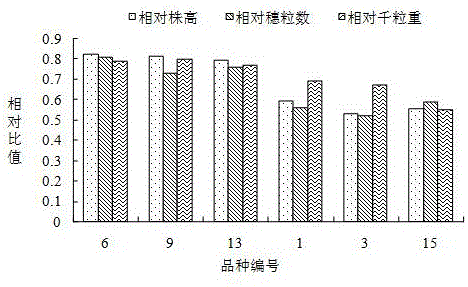

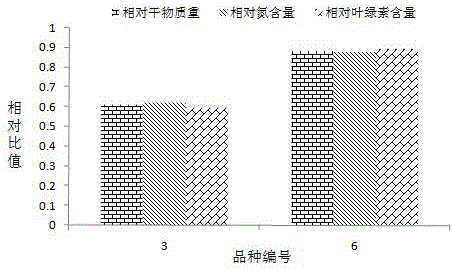

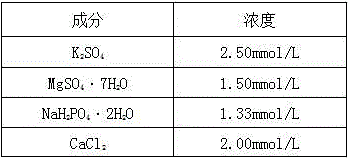

Method for screening varieties with high utilization rate of nitrogen from multiple wheat varieties

InactiveCN106576728AEasy to operateImprove nitrogen use efficiencyFertilising methodsPlant cultivationBiological propertyRelative strain

Provided is a method for screening varieties with the high utilization rate of nitrogen from multiple wheat varieties. The method comprises following steps: selecting wheat varieties with grains of the same size, placing the wheat varieties into a culture dish till the grains germinate to become rooted seedlings; selecting seedlings with growth uniformity from seedlings, dividing them into two groups and utilizing nutrition liquid with different nitrogen concentrations to pour till wheat become mature; testing and calculating relative strain height, relative grain number and relative thousand seed weight of each variety; making comprehensive comparisons and selecting several wheat varieties with three highest integrated indices as varieties with the high utilization rate of nitrogen; becoming re-screening seedlings through germination, taking re-screening seedlings with uniform growth, diving them into two groups, utilizing nutrition liquid with different nitrogen concentrations for water culture and testing and calculating relative dry matter weight, relative nitrogen content and relative chlorophyll content of each variety; and making comprehensive comparisons and selecting one wheat variety with three highest integrated indices as the variety with relatively higher utilization rate of nitrogen. The method for screening varieties with the high utilization rate of nitrogen from multiple wheat varieties has following beneficial effects: wheat varieties finally screened by the method provide material for further improvement of existing varieties and research of biological characteristics and physiochemical mechanisms.

Owner:GANSU AGRI UNIV

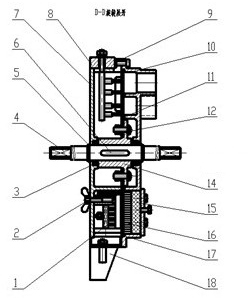

Pneumatic hole seed sowing device

ActiveCN102349376AAccurately control and adjust the seeding numberAdapt to the requirements of precision hole sowingSowingEngineeringGrain number

The invention discloses a pneumatic hole seed sowing device, which comprises a seed discharging assembly, a seed sowing shaft, a seed sowing housing, a seed clearing assembly, an air sucking housing, a seed sucking tray and a seed guiding pipe; the seed sowing housing, the seed sucking tray and the air sucking housing are arranged in the axial direction of the seed sowing shaft; the seed sowing shaft drives the seed sucking tray to rotate; connecting devices are distributed along the circumference on the seed sowing housing and the air sucking housing, so that the seed sowing housing and the air sucking housing are connected to form a shell in which a cavity is formed; the seed discharging assembly, a seed discharging port and the seed guiding pipe are arranged below the internal space ofthe seed sowing housing; the seed clearing assembly is arranged on the side wall of the upper left part of the seed sowing housing; the middle part of the cavity of the seed sowing housing is provided with a rectangular seed inlet, and the exterior of the seed sowing housing is provided with a seed inlet passage; an air sucking nozzle and an air blowing nozzle are respectively arranged at the upper part and the lower part of the exterior of the air sucking housing to form negative pressure airflow and positive pressure airflow respectively; and seeds are adsorbed on the seed sucking tray, andthe seeds on the seed sucking tray are blow into the seed discharging port and enter the seed guiding pipe. The pneumatic hole seed sowing device can be used for accurately controlling and adjusting the sowing grain number of each hole, and has seed clearing and anti-blocking functions.

Owner:SOUTH CHINA AGRI UNIV

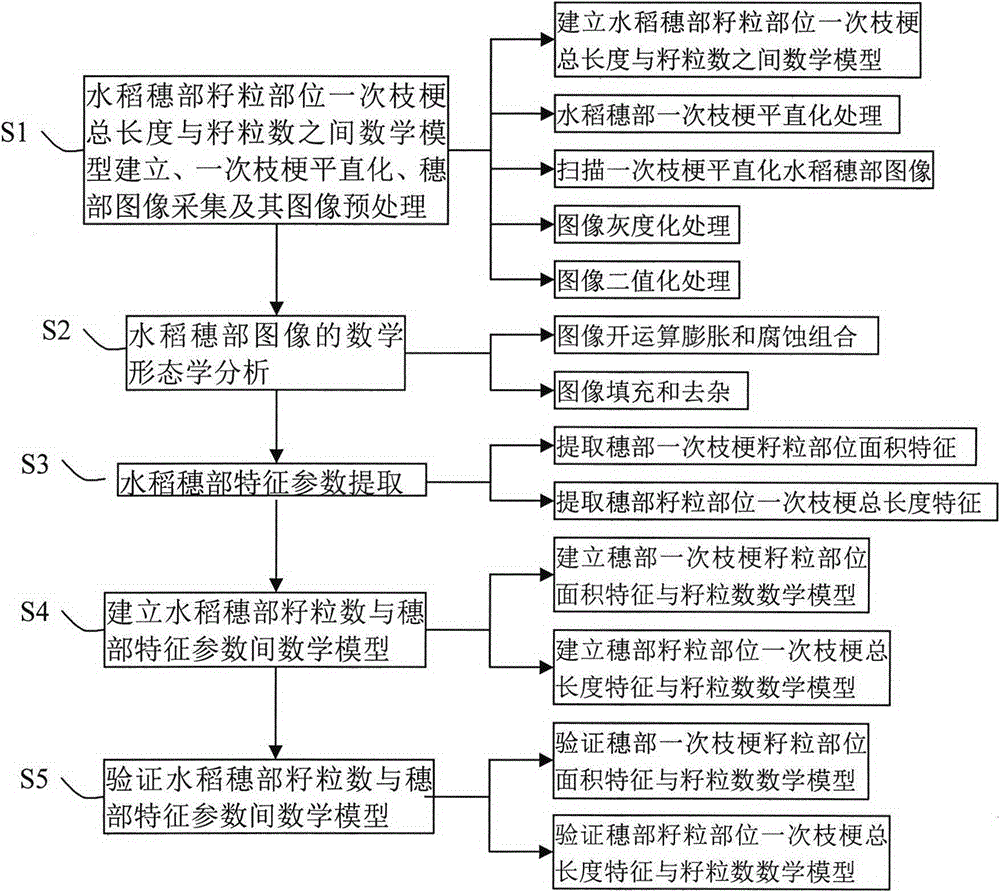

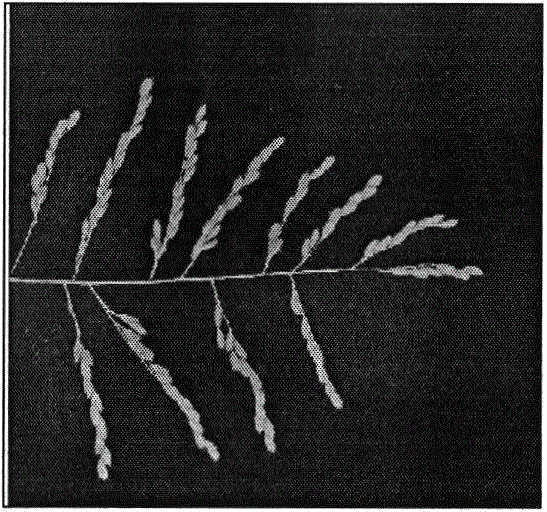

Grain counting method for spike of single rice based on digital image processing technology

InactiveCN104021369AEnsure practicalityEnsure effectivenessImage analysisCharacter and pattern recognitionMathematical modelCounting efficiency

The invention discloses a grain counting method for a spike of a single rice based on digital image processing technology. The method comprises the steps that S1) the correlation between a characteristics parameter and the grain number of the spike of the rice is established, a first branch of the spike is straightened, a spike image is obtained via a scanner, and the spike image is preprocessed; S2) mathematic morphological processing is carried out on the preprocessed spike image to remove part which is low in structural element, and a hole filling operation is carried out to remove all non-target objects; S3) characteristic parameters of the area and the total first-branch length of the grain part of the spike image are extracted; S4) mathematic models between the characteristic parameters and the grain number are established; and S5) the mathematic model between the characteristic parameters and the grain number are verified. The grain counting method based on digital image processing technology can be used to count grains of the spike accurately, rapidly and objectively, and the grain counting efficiency of the spike is improved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for increasing yield of gleying paddy soil at lake paddy area

InactiveCN103250607APromote growthIncrease productionFertilising methodsRice cultivationSurface layerPotassium

A method for increasing the yield of gleying paddy soil at a lake paddy area comprises the steps: fertilizing oxygen fertilizer and silicon fertilizer to gleying paddy fields with the soil type being the gleying paddy soil, wherein the fertilization amount of the oxygen fertilizer per acreage is 1.6kg-2.4kg, the fertilization amount of the silicon fertilizer per acreage is 12kg-18kg, growth of paddy rice can be effectively promoted, the paddy yield can be greatly improved by 20.8%-37.4%, the total grain number of each hole is increased by 17.6%-24.9%, the thousand seed weight is increased by 3.7%-4.4%, the total amount of reducing substances of the soil after the paddy rice is harvested is remarkably reduced by 21.3%-46.8%, organic matter in the soil is improved by 4.2%-10.4%, rapid available phosphorus is improved by 2.9%-5.3%, rapidly available potassium is improved by 2.1%-6.2%, and total nitrogen is improved by 2.2%-5.2%. The method has the advantages of being good in effect of improving the yield of the paddy rice, simple in operation, wide in application range, and particularly suitable for being widely popularized and applied in the gleying paddy soil in the mild surface layer at the lake paddy area.

Owner:JIANGXI INST OF REO SOIL

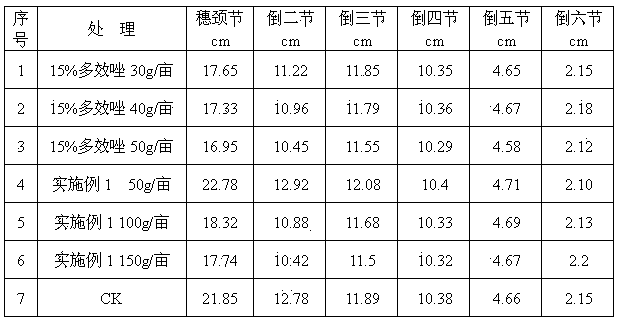

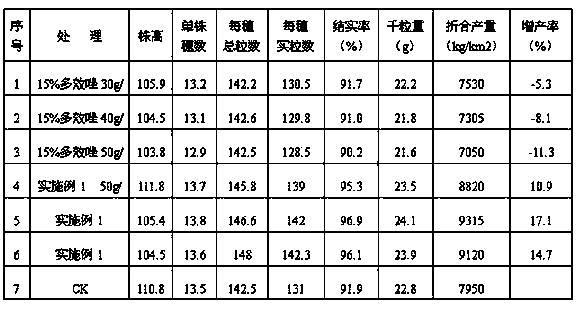

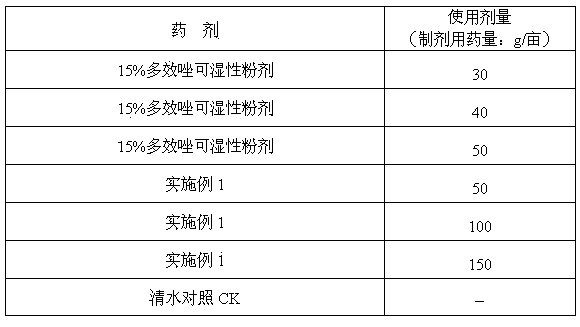

Rice overgrowth-controlling, lodging-resistant and yield-increasing agent and application thereof

InactiveCN103951519ASolve the problem of controlling prosperity and resisting lodgingDoes not affect safety Qi SuiFertilising methodsFertilizer mixturesPhosphatePanicle

The invention discloses a rice overgrowth-controlling, lodging-resistant and yield-increasing agent and an application thereof. The rice overgrowth-controlling, lodging-resistant and yield-increasing agent mainly comprises a plant growth regulator and a fertilizer, wherein the regulator is brassinolide and paclobutrazol or uniconazol, and the fertilizer is one or combination of more than two of substances containing N / P / K / B / Zn / Ca / Cu / Fe / Mn / Mo / Me / S / Cl / Si and other elements, such as urea, potassium dihydrogen phosphate, diammonium phosphate, calcium carbonate, potassium nitrate, silicon fertilizer, zinc sulfate, ferrous sulfate, potassium chloride, boric acid, borax, copper sulfate, ferrous sulfate, molybdenum fertilizer, magnesium sulfate, potassium sulfate, manganese sulfate and rare earth fertilizer. The rice overgrowth-controlling, lodging-resistant and yield-increasing agent has good safety and can effectively shorten the length between neck-panicle nodes and top second nodes of rice and enhance lodging resistance of rice; simultaneously, the rice overgrowth-controlling, lodging-resistant and yield-increasing agent can not affect safe dates of full heading and the grain number per spike of rice, prolong the service life of functional leaf of rice, improve the seed setting rate and the 1000-grain weight of rice and significantly affect the yield of rice. The rice overgrowth-controlling, lodging-resistant and yield-increasing agent is suitable for various types of rice, including conventional rice, hybrid rice and super hybrid rice, and has the advantages of low cost and high performance-price ratio.

Owner:兰永权

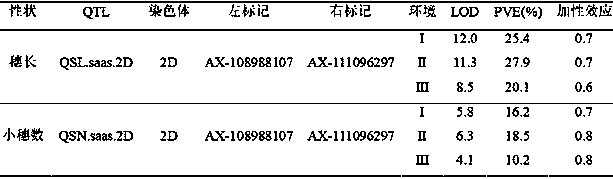

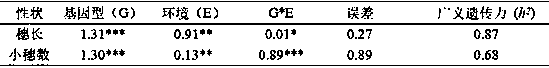

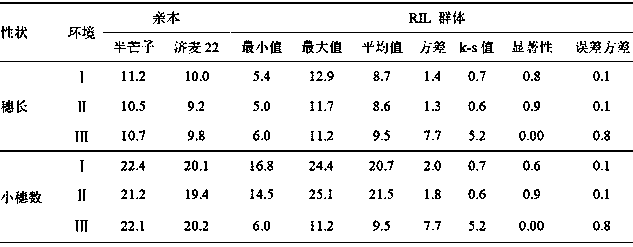

Major QTL (Quantitative Trait Loci) capable of influencing wheat ear length and application thereof

ActiveCN109402284AMicrobiological testing/measurementDNA/RNA fragmentationTriticeaeCandidate Gene Association Study

The invention belongs to the field of wheat genetic breeding, and provides major QTL (Quantitative Trait Loci) capable of influencing the wheat ear length. The major QTL are located on a 2D (Two-Dimensional) chromosome short arm, and are located between a left marker AX-108988107 and a right marker AX-111096297 of an SNP (Single Nucleotide Polymorphism) marker; the major QTL can affect the spikelet number at the same time; the QTL have a candidate gene for encoding IAA (Indoleacetic Acid)-amino acid hydrolase; phenotypic variation explanation rates of the QTL on the ear length and the grain number per ear are respectively 27.9 to 20.1 percent and 18.5 to 10.2 percent; positive allelic variation of the QTL are sourced from parent varieties-Banmangzi, and the QTL have huge application valuein wheat breeding.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

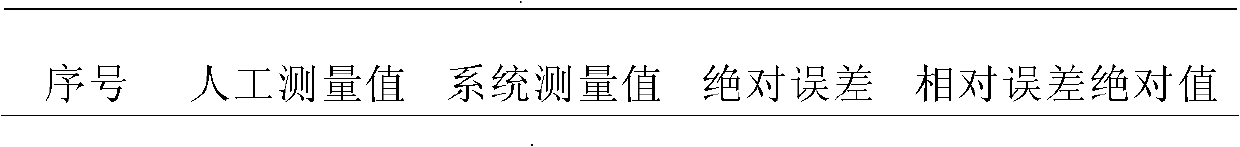

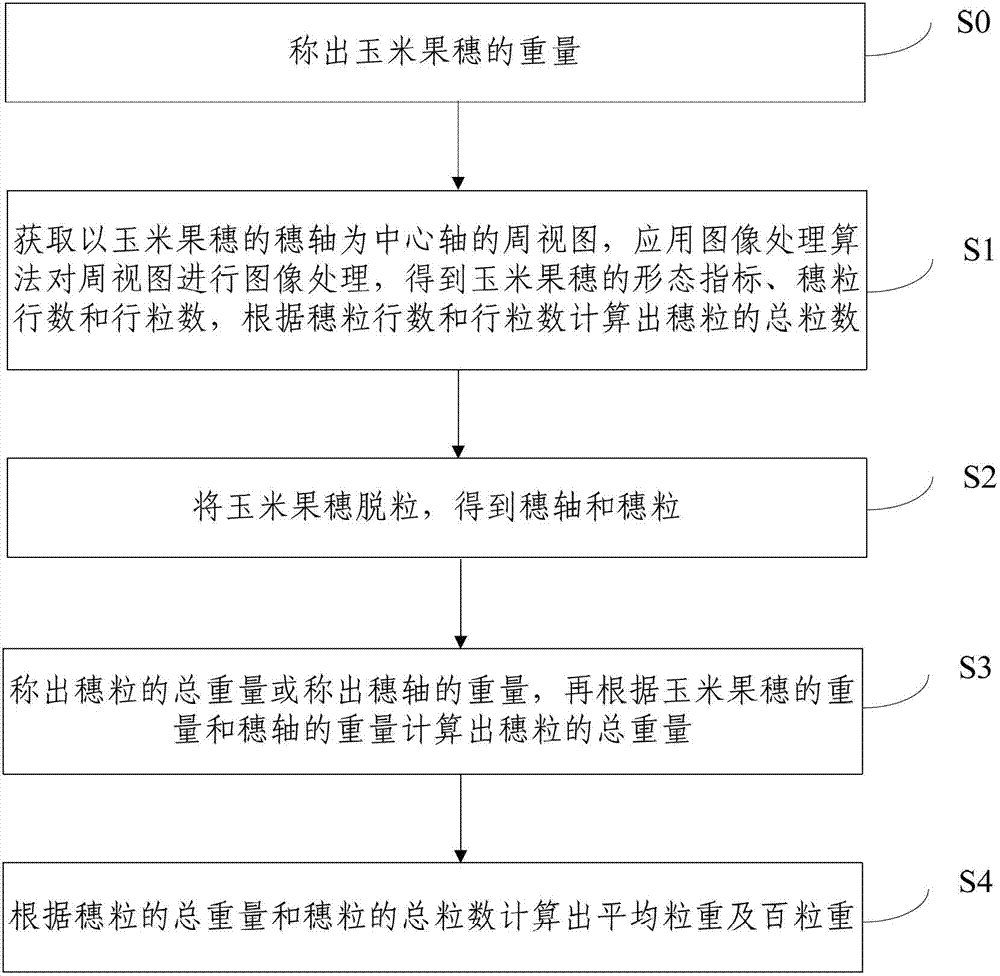

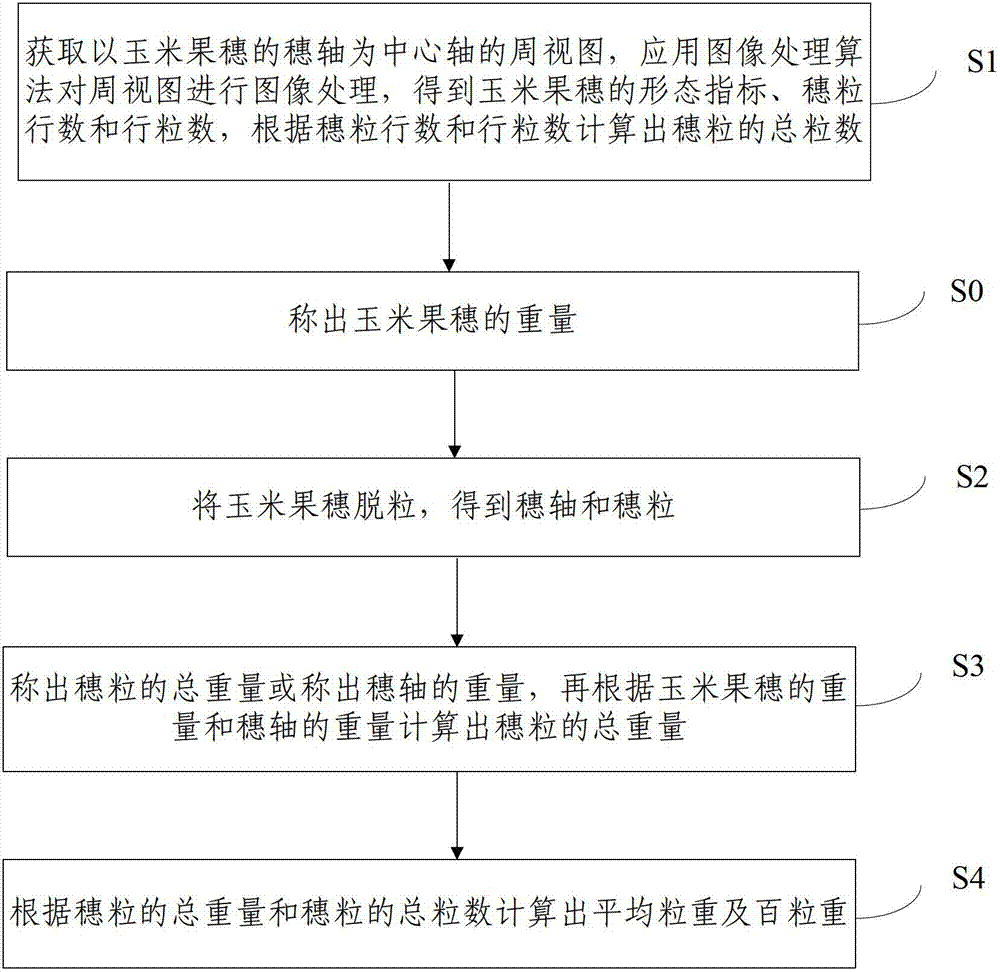

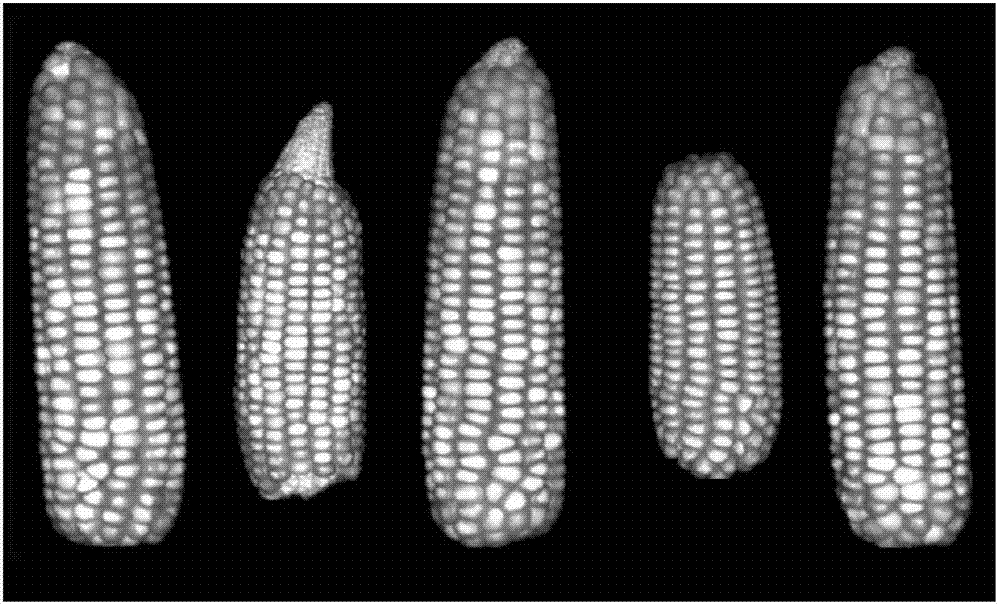

Method and device for performing high-precision determination of corn ear variety based on images

The invention discloses a method and a device for performing high-precision determination of corn ear variety based on images. A corn ear week view using cob as central axis is established and the week view is processed by image processing algorithms to obtain data of morphological index, ear grain row number and per row grain number, and the total grain number of ear grains is calculated based on the ear grain row numbers and the per row grain numbers; the corn ears are threshed to produce a cob and ear grains; the total weight of the ear grains or the weight of the cob is measured, and the total weight of the ear grains is calculated based on the weight of the corn ear and the weight of the cob; and the mean grain weight and the 100-grain weight are calculated based on the total weight of the ear grains and the total number of the ear grains. Before thresh of the corn ears, the weight of the corn ears is measured by a weighing sensor. With the digital image processing and sensor techniques, after obtaining the one-week ear grain distribution diagram of the corn ears, and the parameters of all the corn ear grains are calculated, including morphological index, ear grain row number, per row grain number, mean grain weight and so on. The precision of determining the variety of the corn ears is improved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

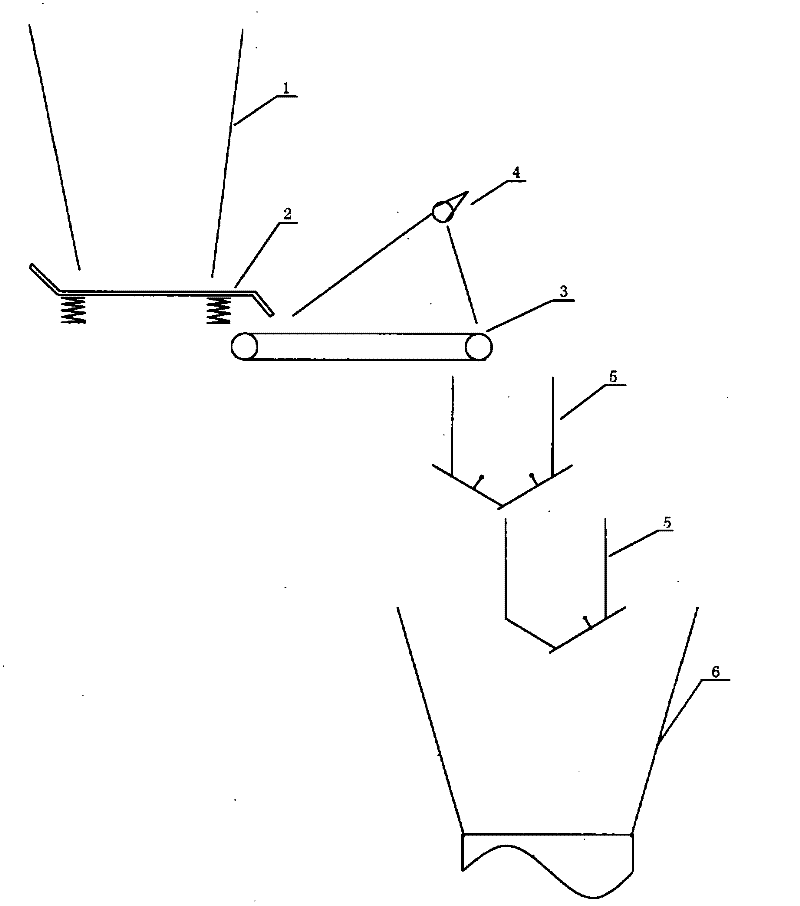

Realizing method for quantitative grain counting and device thereof

InactiveCN102390578ASolid materialPackaging automatic controlProgrammable logic controllerControl system

The invention discloses a realizing method for quantitative grain counting and device thereof, comprising a control system, a feeder, a conveyor, a camera, a memory hopper and a retainer, wherein said control system comprises an image processor, a combined calculation processor and PLC (programmable logic controller); said feeder feeds material to the conveyor in scattered way; at least one layer of memory hopper is set below the conveyor; the camera and the image processor performs image data collection and analysis and grain calculation on material on the conveyor, and delivers the material to the corresponding memory hopper, wherein the material grain number is corresponding to the memory hopper; the combined calculation processor performs combined calculation on the material amount in the memory hopper and compares it with the preset target grain number, and selects the memory combination with a grain number which is closest to the target grain number within allowed deviation range, and discharges the material in the memory hopper. The invention combines the batch CCD grain counting technology with uncontrollable grain number with combined calculation technology to largely raise the precision and speed on quantitative grain calculation.

Owner:SHANGHAI CHAOYANG MACHINERY & ELECTRICITY

Foliage biological organic fertilizer

InactiveCN104478608AIncrease profitFertilization method is simpleAmmonium salt fertilisersFertilizer mixturesMinor elementSuccinic acid

The invention belongs to the technical field of synthetic fertilizer, and particularly relates to a foliage biological organic fertilizer. The foliage biological organic fertilizer comprises boric acid, potassium carbonate, epsilon-polylysine, humic acid, polyacrylamide, ammonium molybdate, chitin, ferric sulfate, methylene succinic acid, diethylaminoethanol hexanoate, water and a composite microbial inoculant. The fertilizer can increase the chlorophyl component in crops and enhance the stress tolerance of the crops. The fertilizer has promotion actions on the growth development and various physiological processes of the crops. Multiple minor elements can promote the growth of seedlings and increase the grain number in the later period, thereby enhancing the yield and improving the quality. The fertilizer has the advantages of scientific proportioning of raw materials and low production cost, and prevents the nutrients from being immobilized or converted in soil, so that the nutrients are directly supplied to the crops for absorption. The utilization ratio of the fertilizer is enhanced. The fertilizer application method is simple and easy to implement, and has obvious economic benefit.

Owner:HEZE BAIHUA BIOTECH

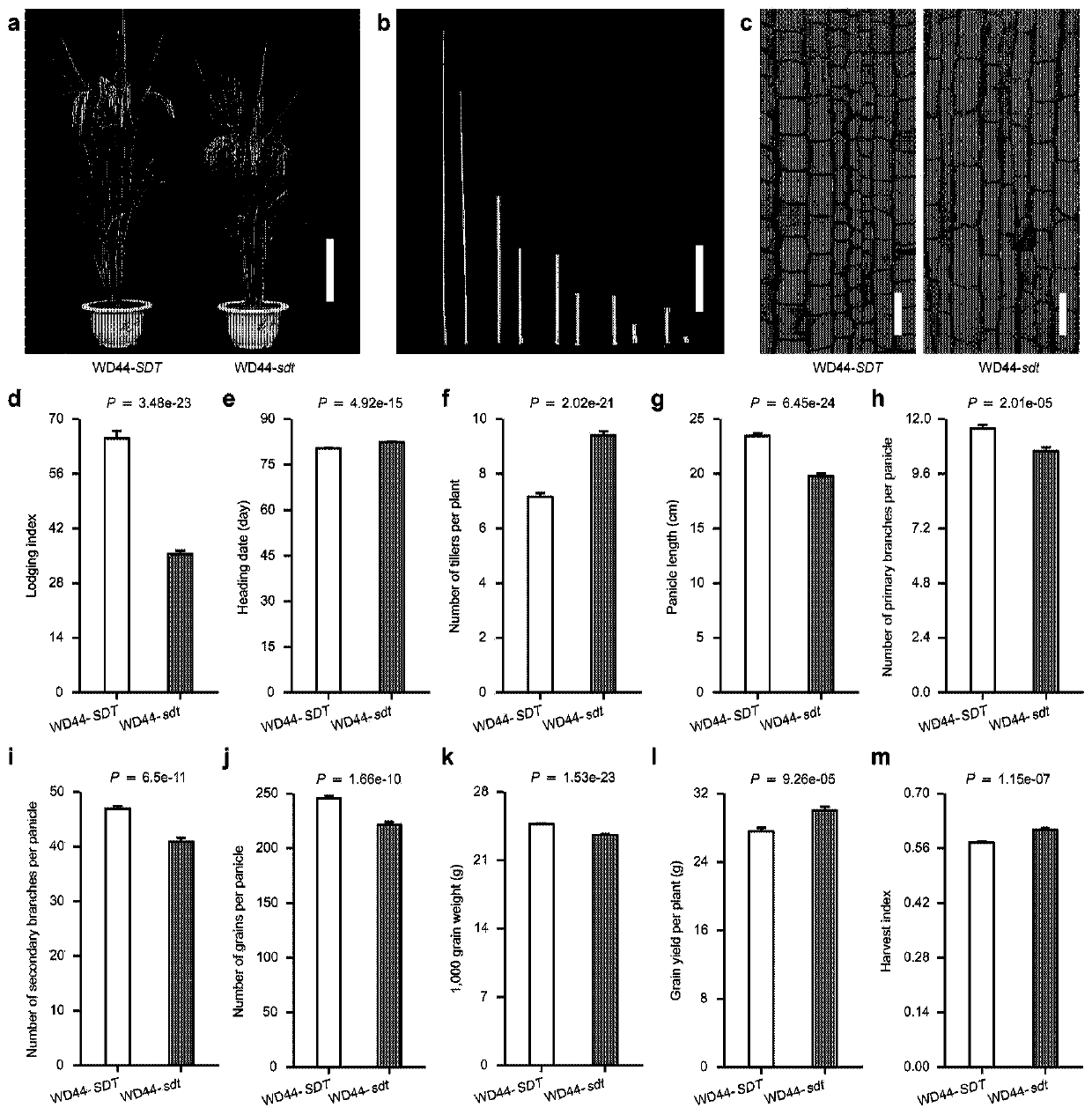

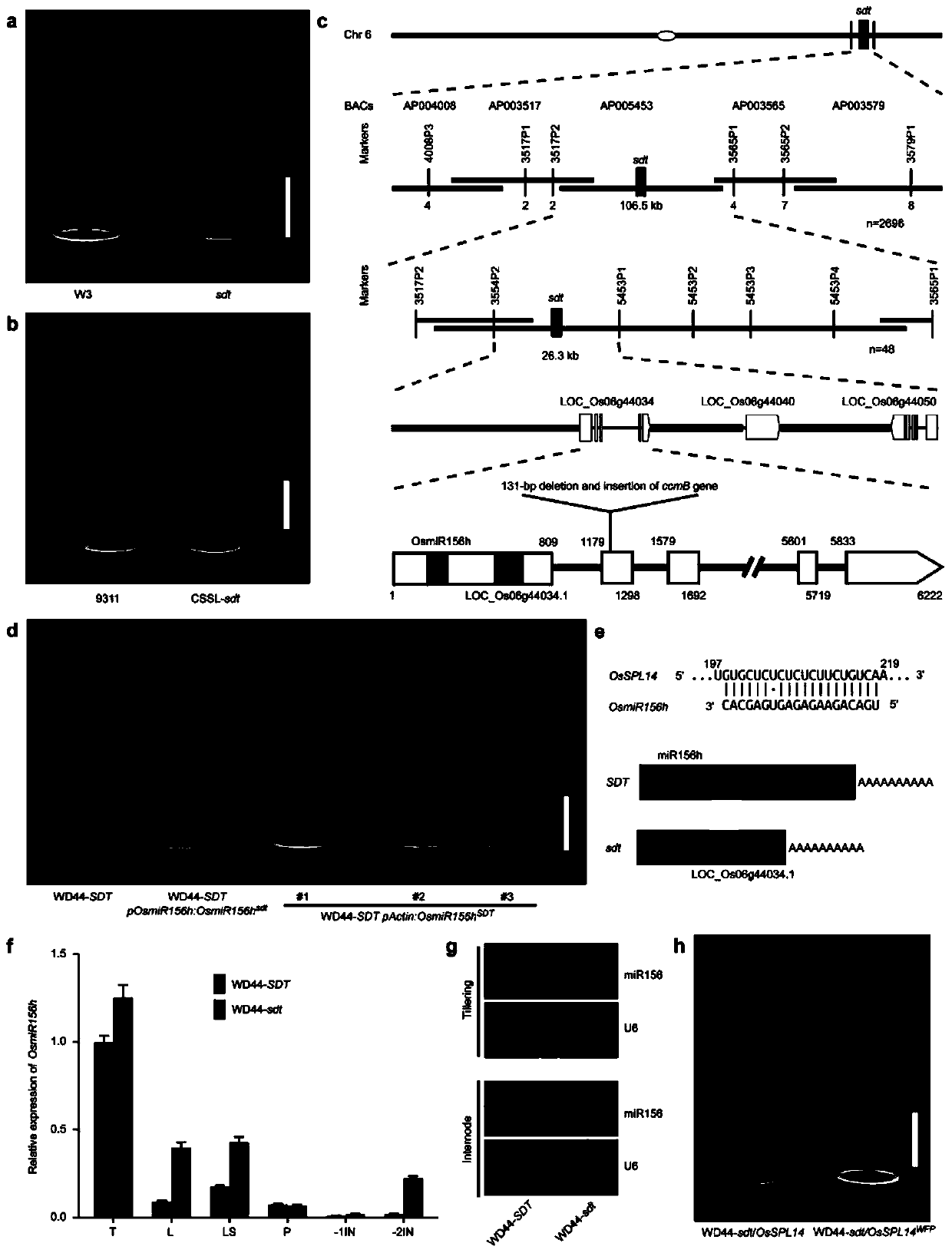

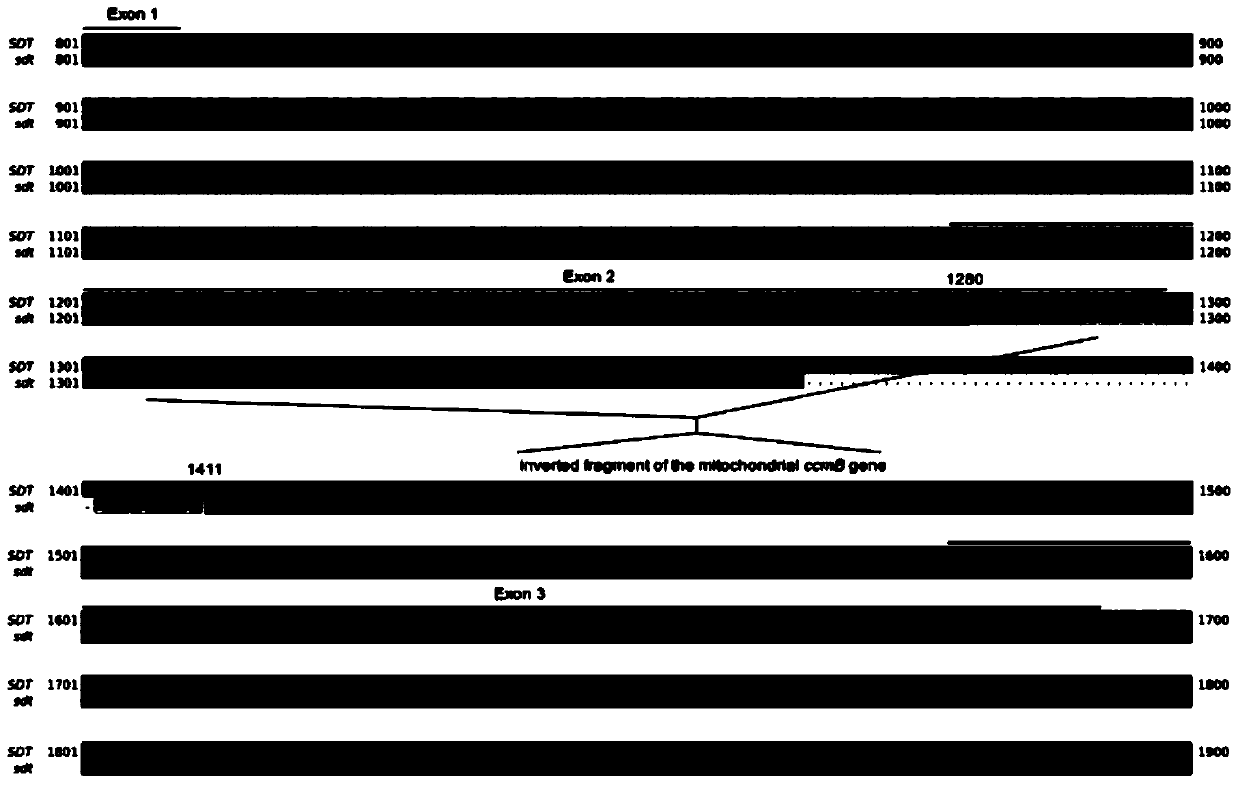

Gene for controlling Oryza sativa plant height, enhancing lodging resistance, increasing effective tiller number and yield and its application

The invention discloses an SDT (semi dwarf and high-tillering) gene for decreasing Oryza sativa plant height, enhancing lodging resistance, increasing tiller number and yield, and its application. The SDT gene coding is OsmiR156h. In semi dwarf and high-tillering SDT Oryza sativa mutant, the length of the mRNA 3'-UTR transcribed from the SDT gene is shorter than that of the 3'-UTR transcribed from a wild type SDT gene, resulting in high SDT gene transcription level than expression level of the wild type SDT gene. Genetic analysis shows that SDT is a semidominant mutation, which can inhibit longitudinal splitting of stem cells to control the internode length and plant height, thereby improving the lodging resistance of Oryza sativa; at the same time, the SDT gene can increase effective tiller number of Oryza sativa, thereby improving grain number and yield per spike. The present invention for the first time improves that the control on the length of 3'-UTR of mRNA transcribed from the OsmiR156h gene can change the expression level of gene, thereby realizing the application prospect of the cultivation of excellent varieties of Oryza sativa.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

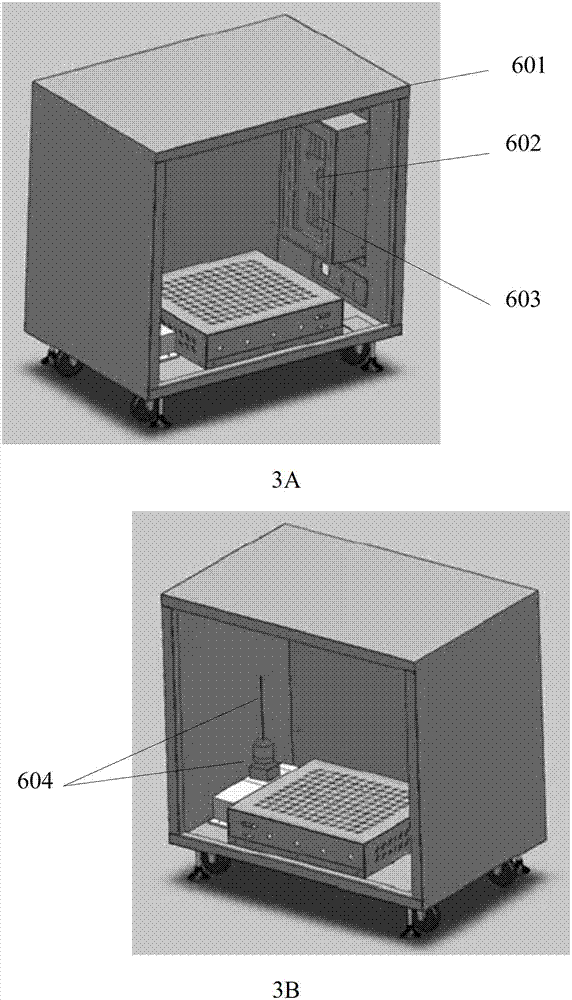

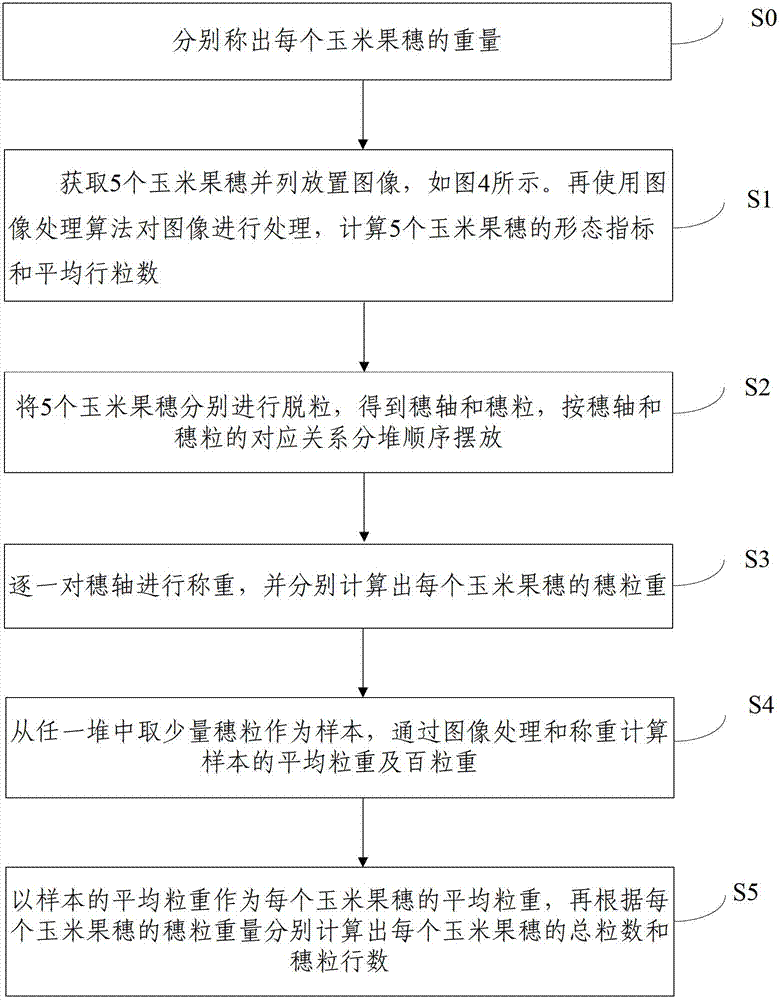

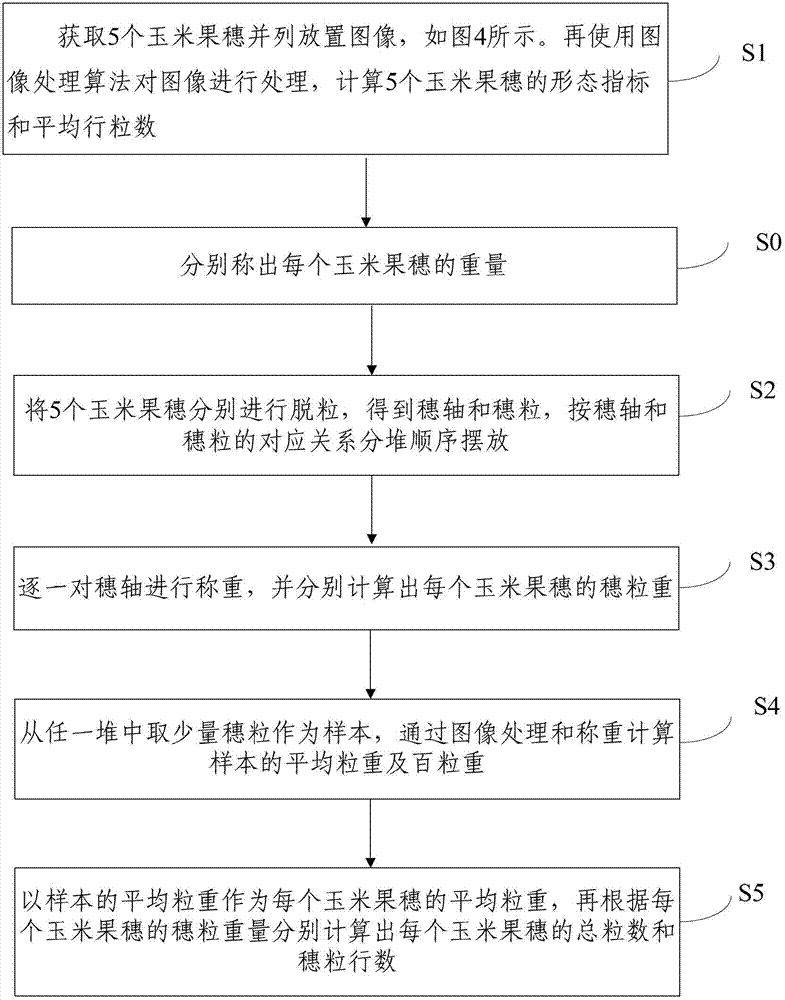

High-efficiency corn ear seed test method and device based on image

ActiveCN103026823AImprove the efficiency of test workSeed and root treatmentImaging processingGrain weight

The invention discloses a high-efficiency corn ear seed test method and a device based on an image. The method comprises the following steps that an image of N corn ears placed in parallel is obtained and processed by an image processing algorithm; the shape indexes and average line number of the N corn ears are calculated; the N corn ears are threshed; cobs and grains are obtained; the cobs are weighed one by one, and the grain weight of each corn ear is calculated; a few grains are taken from any pile as samples; the average grain weight and hundred-grain weight are calculated by image processing and weighing; the average grain weight of the samples serves as the average grain weight of each corn ear; and the total grain number and the grain line number of each corn ears are calculated according to the grain weight of each corn ear. Multiple corn ears are subjected to seed test simultaneously by a digital image processing and sensor technology, and the efficiency of the corn seed test is improved greatly.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

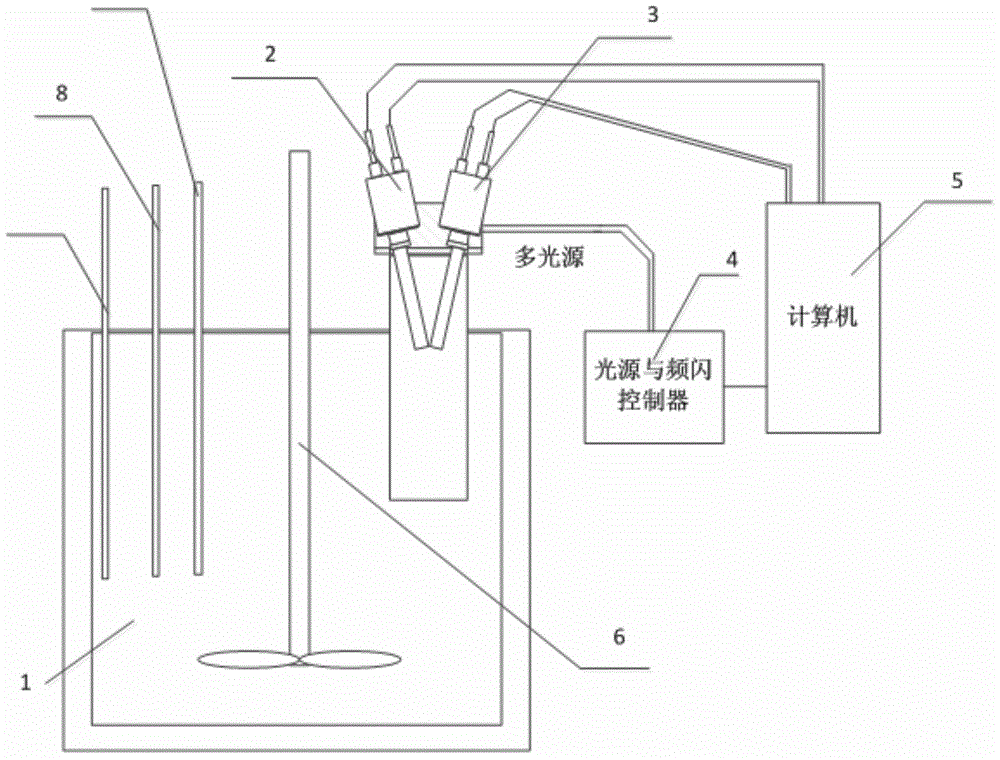

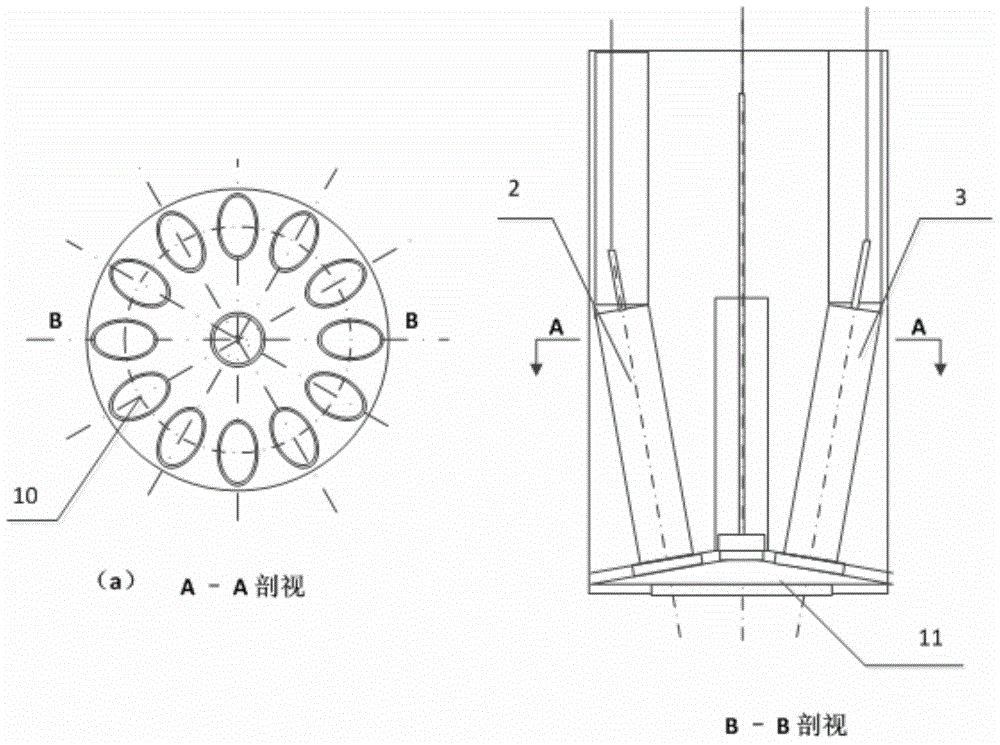

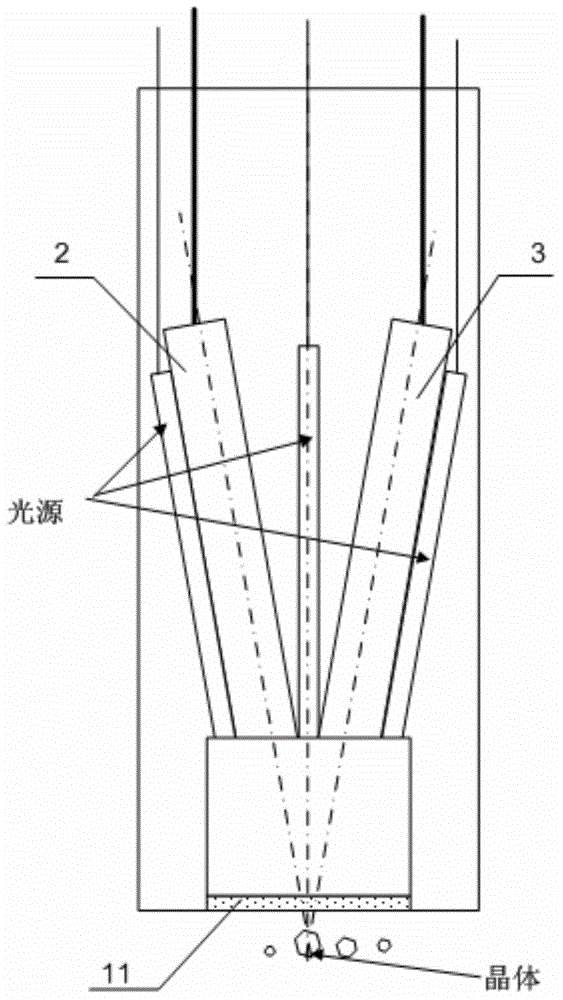

Probe type online three-dimensional imaging detection system and probe type online three-dimensional imaging detection method

ActiveCN103558129APromote crystallizationCrystallization process control and scale-upMaterial analysisProbe typeImaging processing

The invention discloses a probe type online three-dimensional imaging detection system which comprises a crystal growth reactor, a three-dimensional imaging probe, a light source and a strobe controller, a computer for processing an image, and a display, wherein the three-dimensional imaging probe is used for transmitting a 2D image to the computer; the computer is used for firstly deleting a background by using a splitting technology and then identifying corresponding points and lines from the 2D image by using an angle / edge / line detection technology; for few angles / lines which are detected difficultly, indistinct angles / lines are predicted / estimated by using molecule modeling and a crystal shape model on the basis of the obtained angles and lines, 3D image reconstruction is realized by using the determined points and lines, then particle description characteristics of 3D crystals are obtained by combining with solution parameters measured online, and finally, the control and the amplification of a crystallization process in a reactor are realized by using a crystalline form grain number balancing model and computational fluid mechanics. The system and the method provided by the invention are capable of directly acquiring the image from the solution and realizing the reconstruction of the 3D crystalline form, and are high in image processing speed.

Owner:PHARMAVISION QINGDAO INTELLIGENT TECH LTD

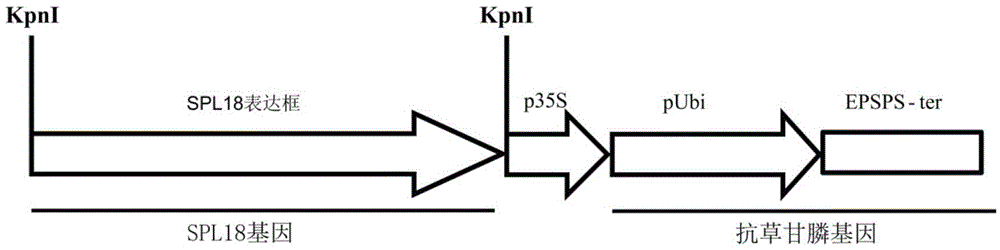

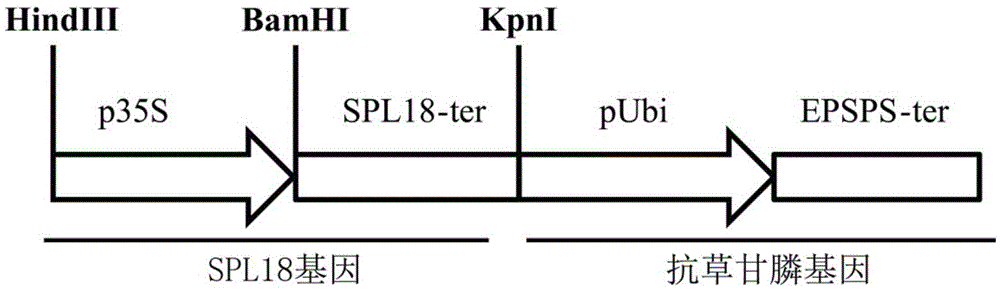

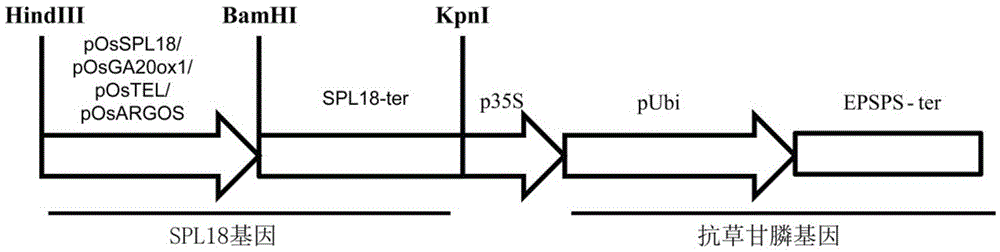

Application of SPL18 gene in enhancing plant yield

ActiveCN105624188AConvenient branchIncrease productionPlant peptidesFermentationBiotechnologyGrain weight

The invention discloses application of an SPL18 gene in enhancing plant yield. The SPL18 gene is derived from corn, rice, sorghum, wheat, barley, rye, millet, soybean, rape or sunflower. For the first time, the invention provides a method for enhancing grain number per spike or / and grain weight by promoting spike branching by using the SPL18 gene. The SPL gene is overexpressed in the crop, thereby effectively promoting spike branching, enhancing the grain number per spike or / and grain weight by 3% or above, and increasing the yield by 5% or above. The technique can effectively enhance the individual yield and yield per unit area, thereby enhancing the grain productivity and providing a new idea for national grain safety.

Owner:ZHEJIANG UNIV

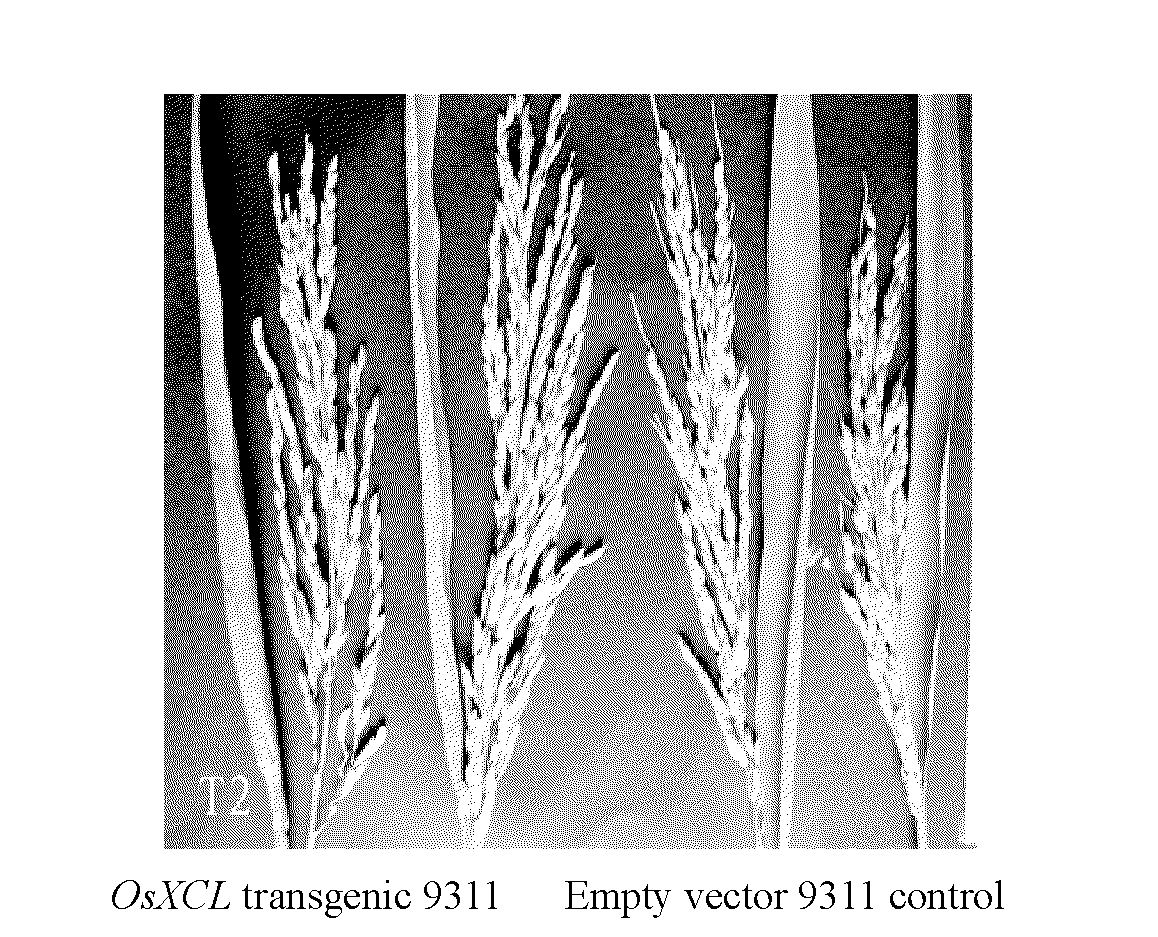

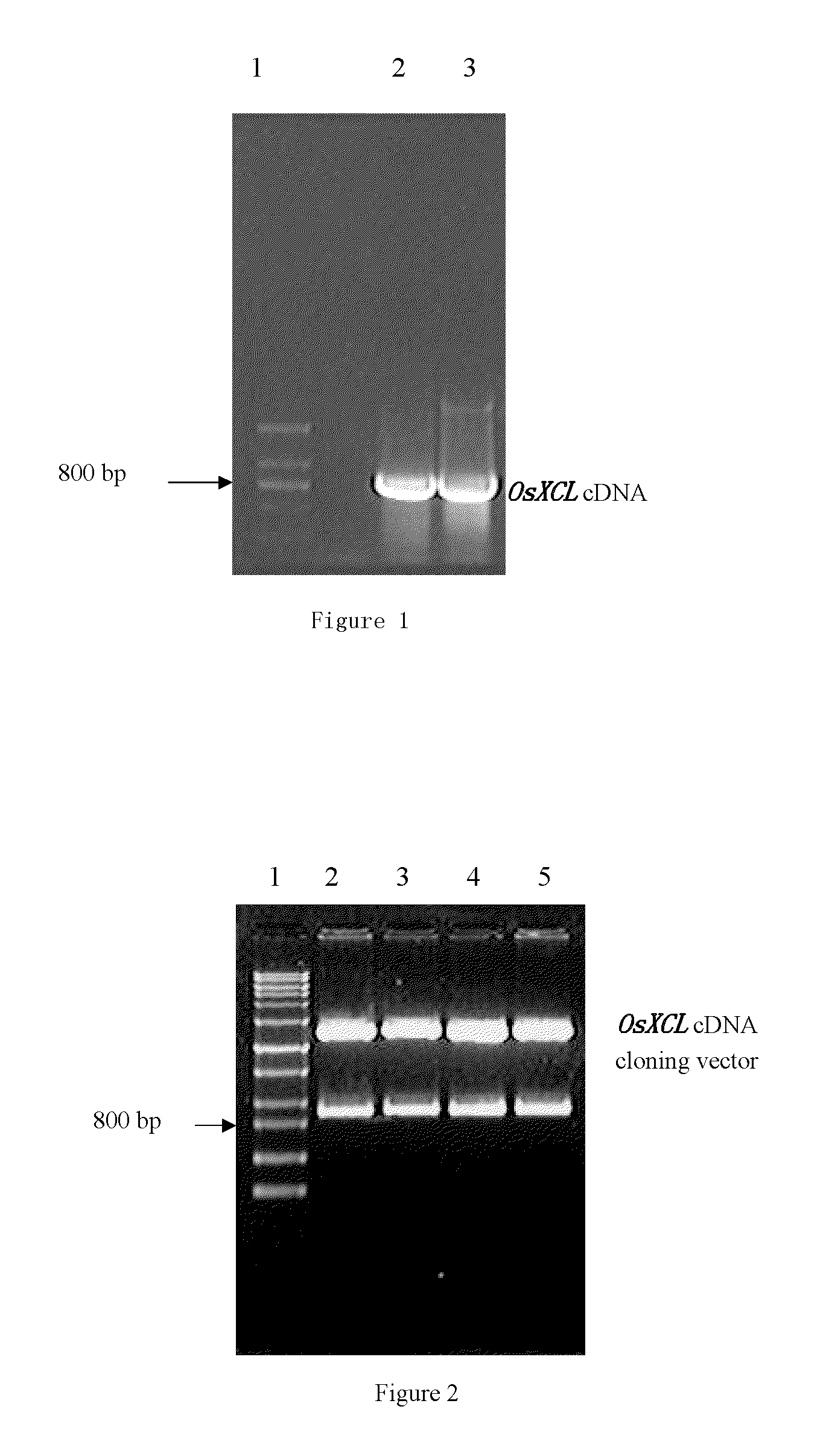

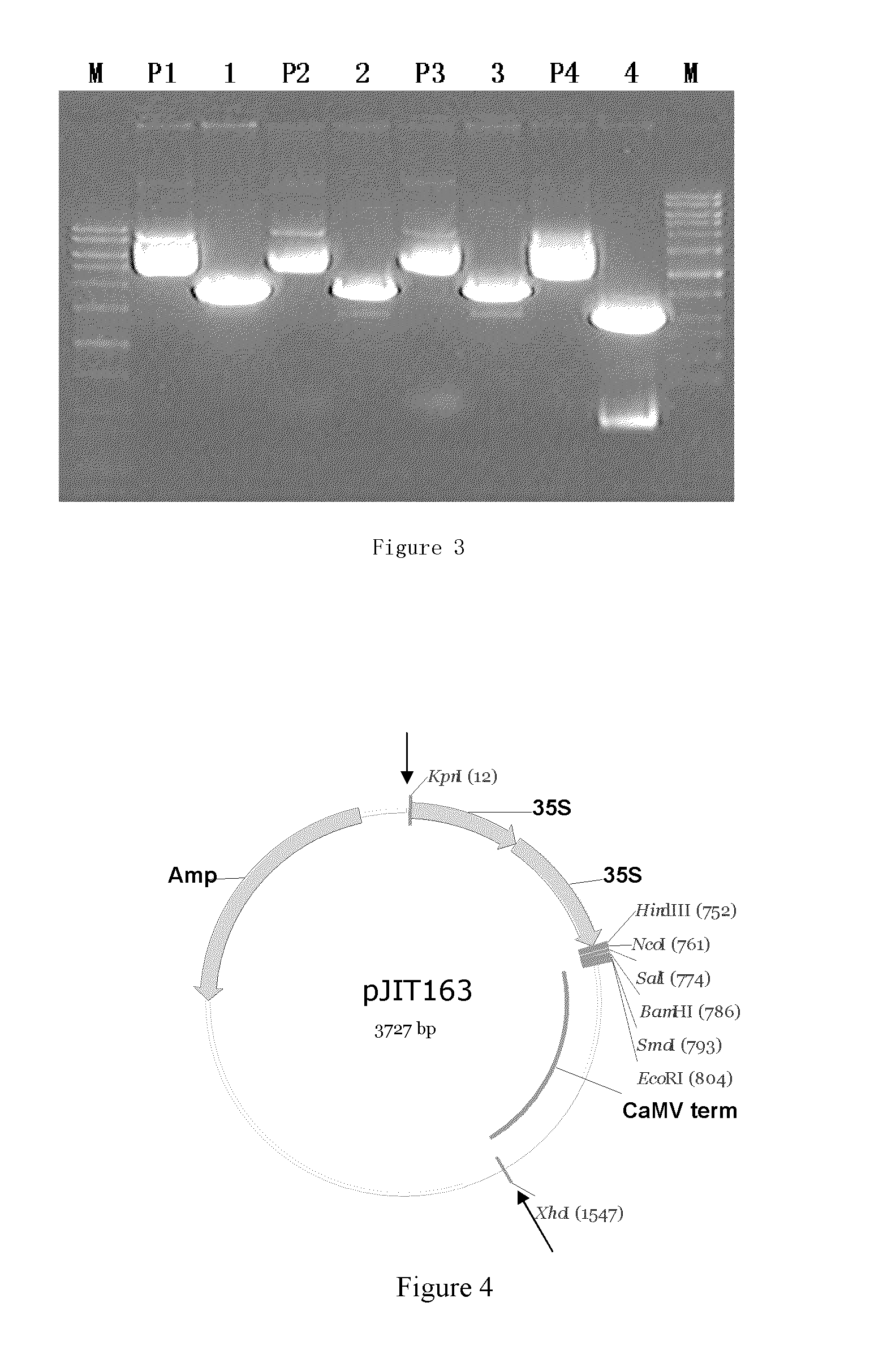

Proteins relating to grain shape and leaf shape of rice, coding genes and uses thereof

ActiveUS20120240292A1Increase grain weightIncreased grain lengthBacteriaImmunoglobulinsGenetically modified riceOryza

The present invention provides a protein OsXCL relating to grain shape and leaf shape of rice, its derived proteins and their coding genes. Transgenic rices over-expressing OsXCL gene present phenotypes as increase of grain length, grain weight and number of grains per panicle, and leaf rolling and so on. The present invention also provides the method for obtaining transgenic plants by transforming the coding genes of OsXCL or its derived proteins into objective plants.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

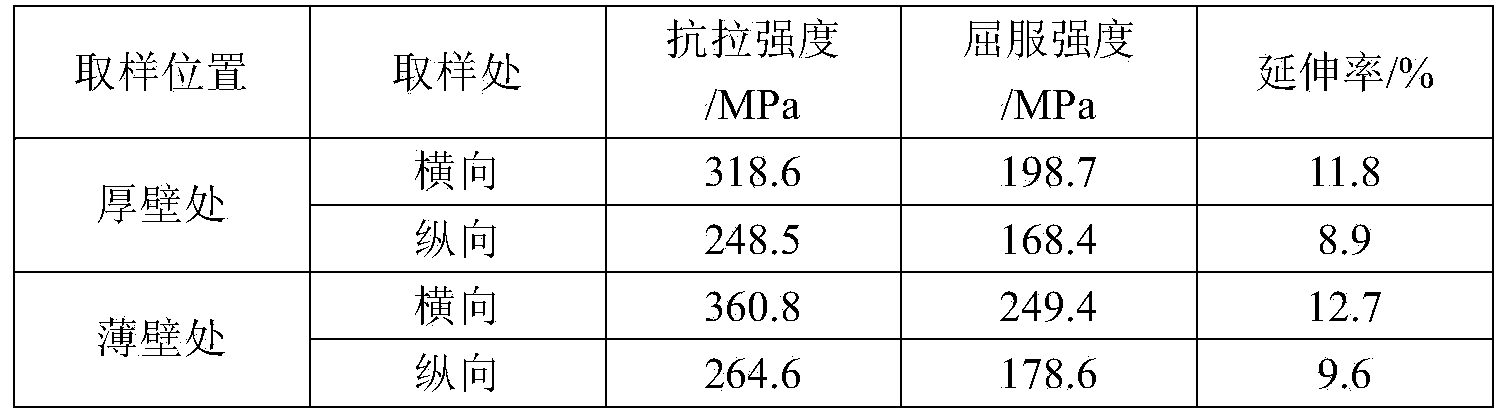

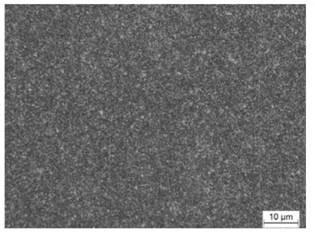

Isothermal die forging technique of large-sized magnesium alloy component

ActiveCN103447432AEvenly distributedReduce difficulty of deformationMetal-working apparatusProject areaCooling down

The invention relates to an isothermal die forging technique of a large-sized magnesium alloy component and belongs to the technical field of magnesium alloy materialmachining. According to the implementation scheme of the invention, the isothermal die forging technique comprises the following steps of heating to 380-430 DEG C after a large-sized magnesium alloy forged disc is machined to be a blank according to a designed blank size; carrying out once isothermal die forging formation at 380-430 DEG C after preserving the temperature for 3-6h to obtain a forged piece; taking out the forged piece and cooling down to obtain a finished-product, wherein the average crystal size of the large-sized magnesium alloy forged disc is smaller than or equal to 15 microns, and the ratio of equiaxed grain number to total crystal grain number of the large-sized magnesium alloy forged disc is equal to or larger than 0.95; in the isothermal die forging process, the downstream speed when the die is fed is 0.05-0.2mm / s, the downstream time when the die is fed is 10-30min, the pressure is 35,000-80,000kN, and the pressure preservation time after the die is formed is 30-40min. According to the isothermal die forging technique of the large-sized magnesium alloy component, which is disclosed by the invention, the magnesium alloy die forged piece with the diameter of 680-1,000mm, the wall thickness of 30-100mm and the maximum horizontal projected area of equal to or larger than 0.4m<2> can be prepared; the preparation technique is simple, the production period is short and the precision and the performance of the obtained forged piece are higher than the precision and the performance of a common die forged piece.

Owner:CENT SOUTH UNIV

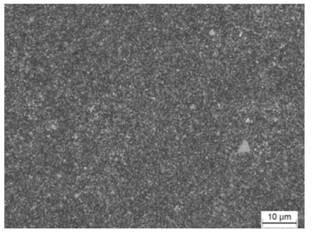

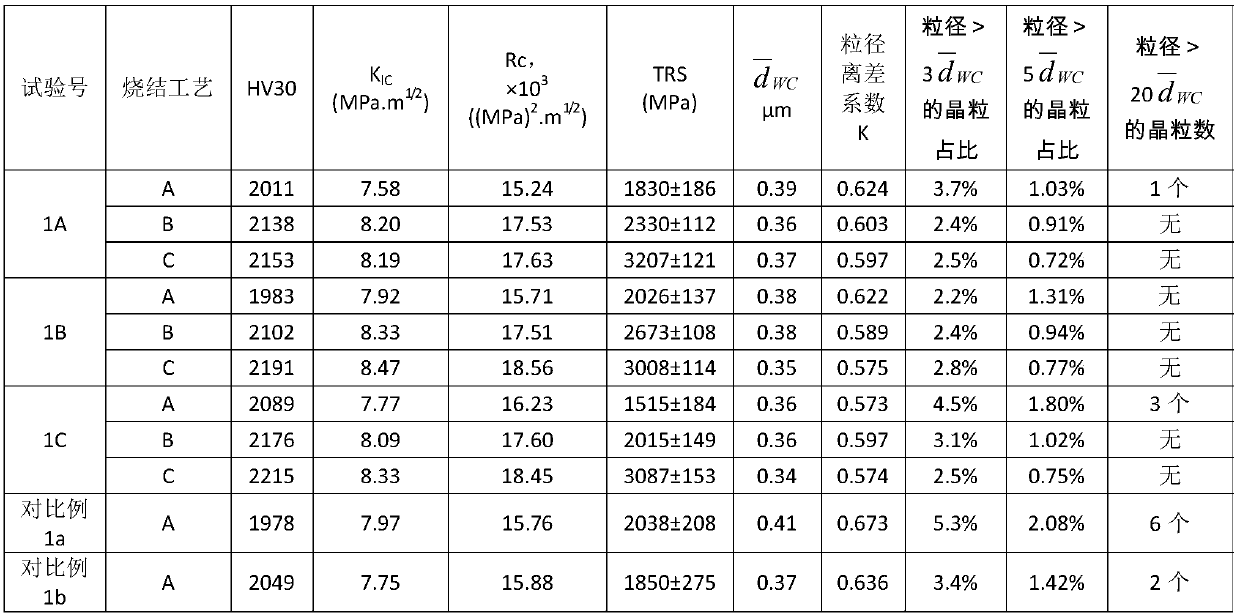

Ultra-fine grain hard alloy and preparing method thereof

The invention relates to an ultra-fine grain hard alloy which comprises WC, a binding phase and a grain growth inhibitor. The weight percentage content of the WC is 83%-96%, the average grain size is(0.2-0.6) micron, the WC grain size deviation coefficient K is larger than or equal to 0.54 and smaller than or equal to 0.61, the grain number percentage of the WC with the grain size larger than 3 times and smaller than 5 times is smaller than or equal to 5%, and the grain number percentage of the WC with the grain size larger than 5 times is smaller than or equal to 1.1%; and the binding phaseis Co, the content of Co in percentage by weight is 3%-15%, and the grain growth inhibitor comprises Cr3C2, VC, TiC and / or Ti (C, N). The invention further relates to a preparation method of the superfine hard alloy. An end mill or a drill bit manufactured by adopting the ultrafine grain hard alloy has excellent use performance in high-speed or high-efficiency cutting machining of difficult-to-machine materials such as stainless steel, a titanium alloy, PCBs, acrylic, glass fibers, hardwood, resin and CFRP.

Owner:ZIGONG CEMENTED CARBIDE CORP

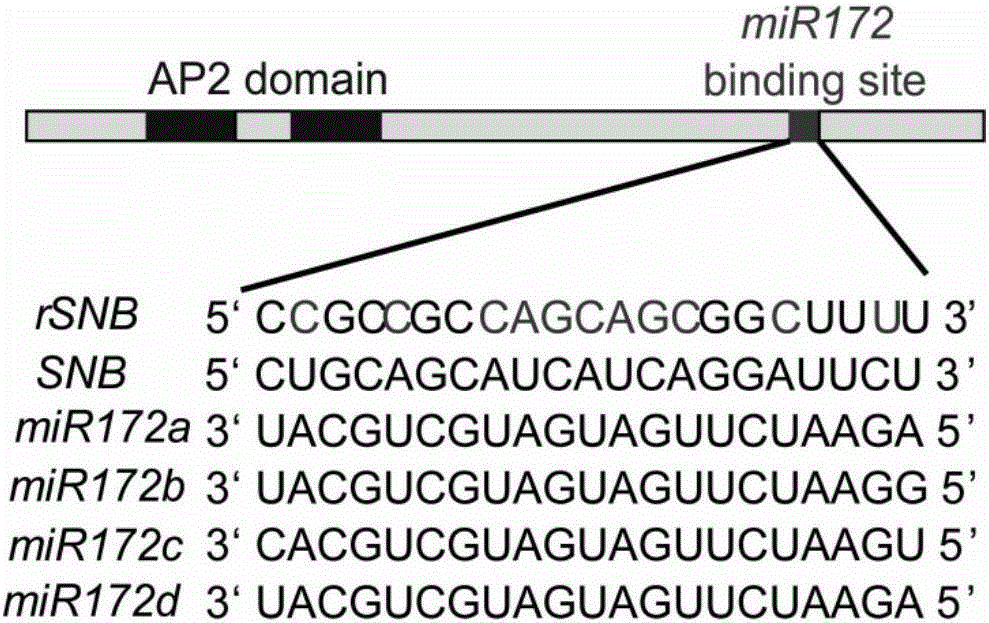

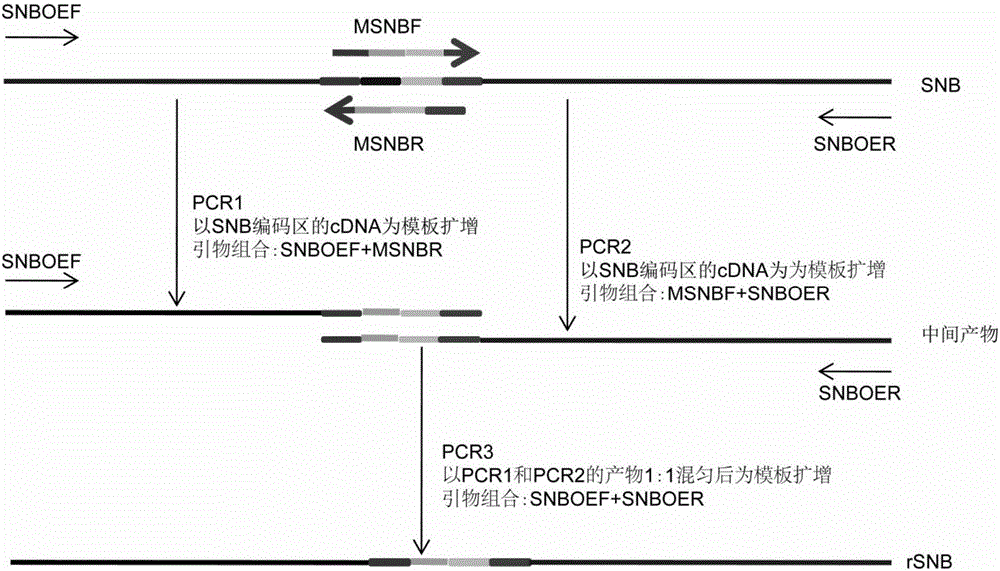

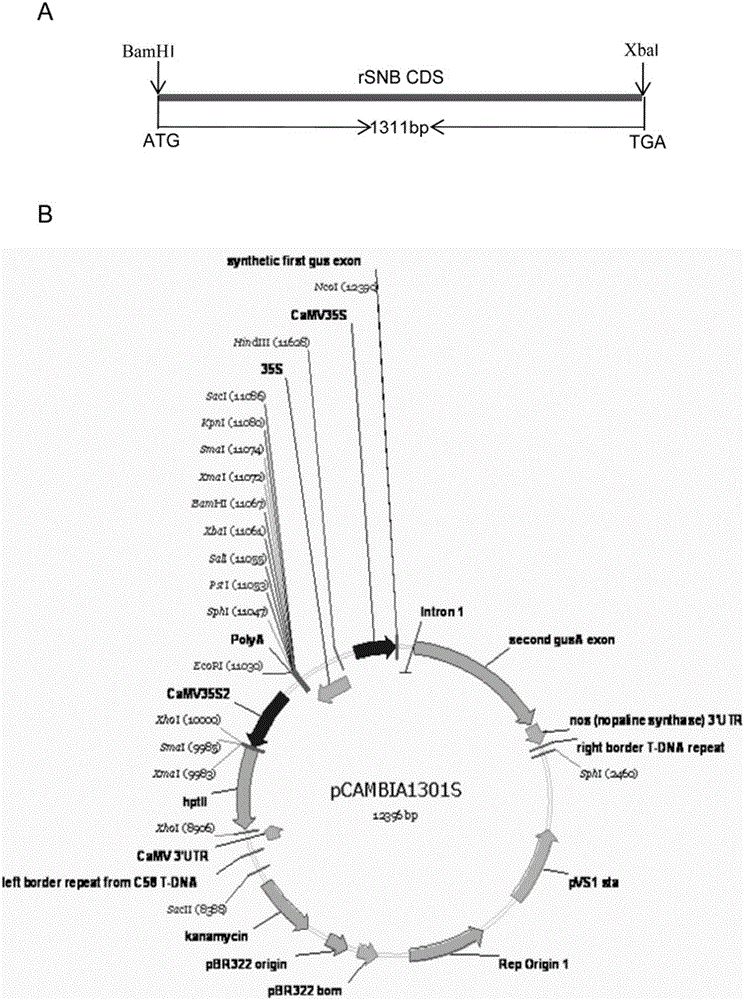

Method for increasing grain number per ear and reducing plant height by use of rice SNB genes

InactiveCN106701778AIncrease grain countReduce plant heightPlant peptidesFermentationNucleotideBinding site

The invention relates to the technical field of plant gene engineering, in particular to a method for increasing the grain number per ear and reducing plant height by use of rice SNB genes. The nucleotide sequence of SNB genes is shown as SEQ ID NO:1. Artificially mutant rSNB genes are obtained by changing the binding site of microRNA172 in the SNB genes, the nucleotide sequence of the rSNB genes is shown as SEQ ID NO:2, and the sequence of protein encoded by the rSNB genes is shown as SEQ ID NO:3. The grain number per ear of rice is remarkably increased and the plant height of the rice is notably reduced through overexpression of rSNB, and further studies prove that SNB encoded protein has the activity of a transcription suppressor. The functions of the SNB genes on increasing the grain number per ear of the rice and reducing the plant height of the rice are disclosed, and a novel rice genetic improvement method is also provided.

Owner:HUAZHONG AGRI UNIV

Novel anti-pest seed coating agent for waxy corn

InactiveCN101647337AGood control effectAchieve the dual purpose of killing insects and bacteriaCoatingsSeed coating/dressingCypermethrinDisease

The invention provides a seed coating agent of waxy corn, which comprises the following components in percentage by weight: 1 to 2 percent of polyvinyl alcohol, 3 to 8 percent of gum arabic, 0.1 to 1percent of surfactant, 2 to 5 percent of antifreezing agent, 0.1 to 1 percent of defoaming agent, 1 to 2 percent of warning color, 0.5 to 1 percent of thiamethoxam, 0.5 to 2 percent of cypermethrin, 1to 2 percent of carboxin, 0.1 to 1 percent of fludioxonil, 0.1 to 2 percent of chitosan, 1 to 2 percent of potassium fertilizer, and the balance of water. The seed coating agent achieves effective control efficiency to soil insects (cutworms, grubs and the like), stem rot, head smut and aphids, generates obvious control efficiency to diseases and insect damages, and has low dosage. The germination speed of waxy corn seeds is increased by 0.5 day, seedlings grow robustly, the dry fresh weight is increased, and the comprehensive control efficiency of plant diseases and insect pests reaches 90.80 percent; and at the harvest time, the spike length, the spike thickness and the spike grain number are improved compared with a contrast, and the yield of the corn is improved by 10 to 15 percent.

Owner:上海农业科技种子有限公司

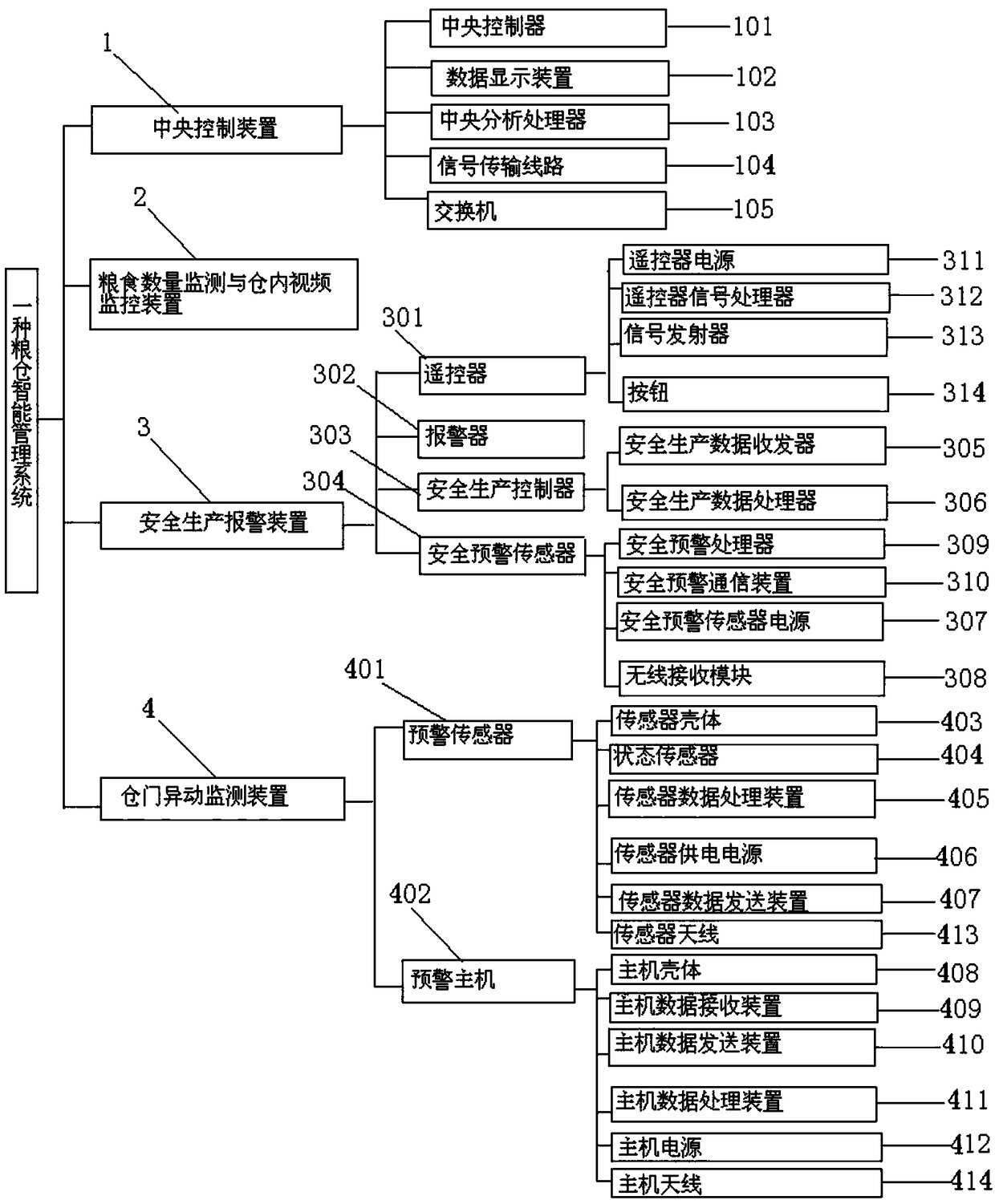

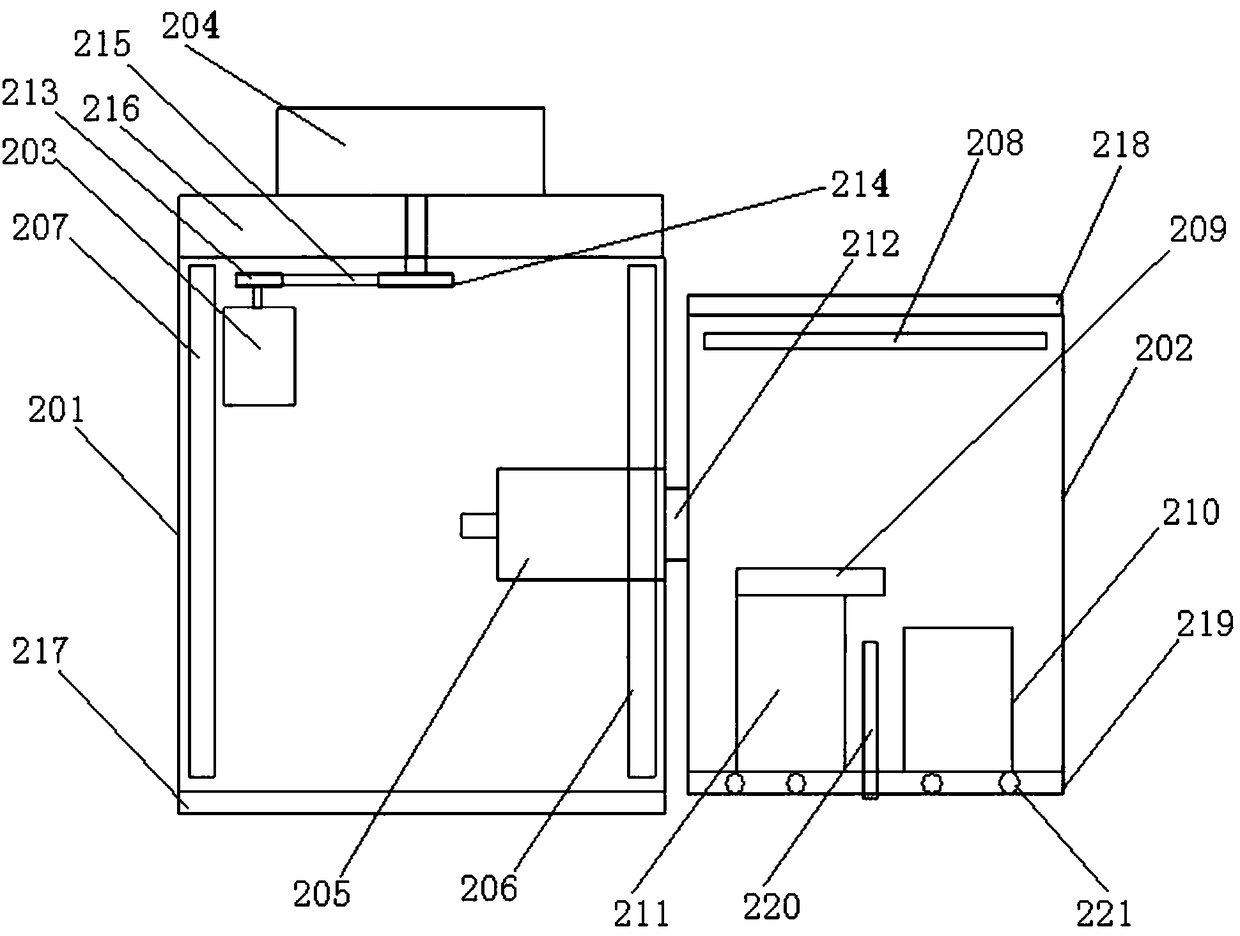

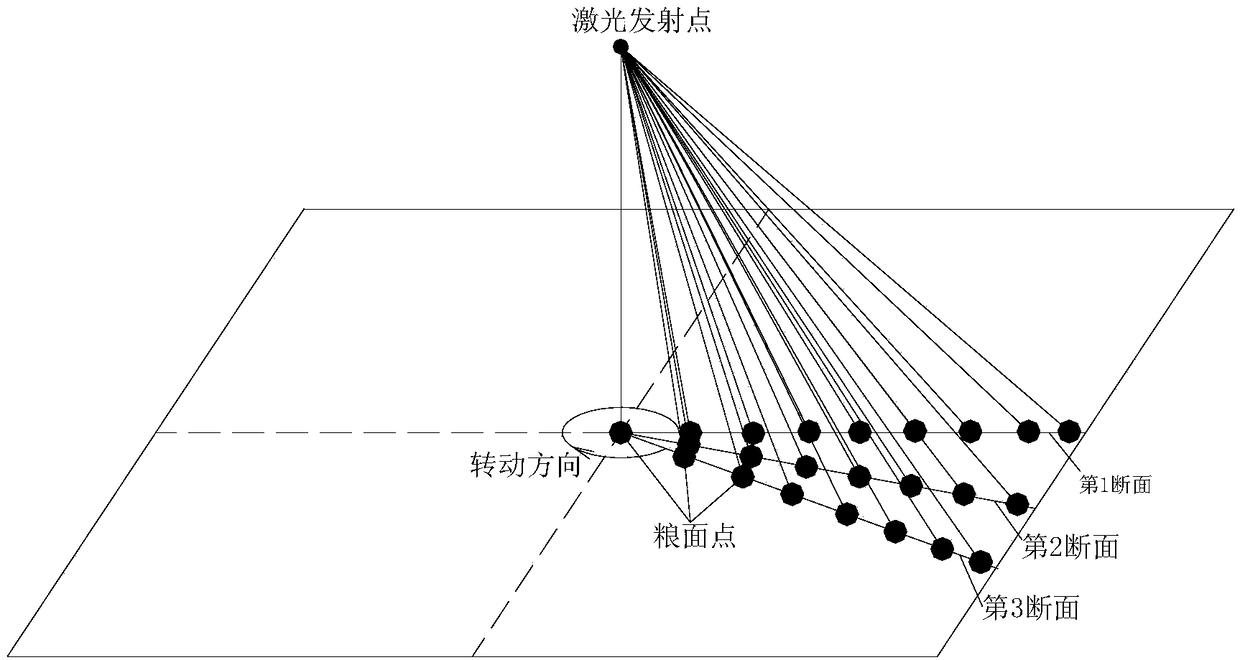

Intelligent granary management system

PendingCN108345285AAccurate measurementSimple structureMeasurement devicesTransmission systemsVideo monitoringTime information

The invention discloses an intelligent granary management system which comprises a central control device, a grain number monitoring and warehouse-in video monitoring device, a warehouse door abnormal-action monitoring device and a safety production alarm device. According to the intelligent granary management system, the grain inventory quantity can be measured accurately in real time, the full-color high-definition frame can be obtained in a dark warehouse-closed environment, and the real scene in the warehouse can be comprehensively monitored by 360 degrees without dead corners and withoutpeople entering into; meanwhile, the positioning is accurate, so that the personnel outside the warehouse can arrive at the accident site in time to rescue the personnel in the warehouse in time, andthe safety of grain production is guaranteed; the opening state of the warehouse door of the granary can be monitored in real time, and whether a person enters the granary is determined; and the timeinformation of the warehouse door opening can be obtained, so that the safety of the grain storage is guaranteed.

Owner:郑州工大粮安科技有限公司

Water-saving and high-yield cultivation method for dry land wheat

InactiveCN103392469AIncrease productionReduce the risk of waiting for rain topdressingFertilising methodsHorticultureWater savingRoot shoot ratio

The invention discloses a water-saving and high-yield cultivation method for dry land wheat, and relates to cultivation methods of crops. The water-saving and high-yield cultivation method for the dry land wheat comprises the following steps of fertilizing, farming, variety selecting, flat planting, group controlling and intertillage weeding and suspension of soil conservaton drought-resisting. According to the water-saving and high-yield cultivation method for the dry land wheat, downward tying probability of a root before winter is increased through early deep applying of fertilizer, root shoot ratio is increased so as to enable a root system to sufficiently absorb moisture and nutrient of soil at a deep layer, even-row flat planting is adopted to increase the dry land wheat group, strong seedlings are bred, and a reasonable group management strategy is adopted to increase the dry land wheat yield through synchronous improvement of grain number and thousand seed weight on the foundation of a large group. Risk of dressing waiting for rain in the late growth stage of wheat is reduced, and effort and labor are reduced.

Owner:QINGDAO AGRI UNIV

Molybdenum blank preparing method

InactiveCN101966585ALower sintering temperatureShorten the sintering timeGranularityVolumetric Mass Density

The invention discloses a molybdenum blank preparing method, and relates to a method for preparing a pure molybdenum blank with the grain number of 5,000 to 20,000 / mm<2> and the grain size of 300 to 800nm. The molybdenum blank preparing method is characterized in that: in the preparation process, submicron-scale molybdenum powder with the granularity of 0.5 to 1um is taken as a raw material and is pretreated, molded and sintered into a molybdenum blank. In the molybdenum blank preparing method, the molybdenum powder is taken as a raw material, and the molybdenum blank with fine grains can be prepared by reducing sintering temperature and shortening the sintering time, and has the density of 9.8 to 10.0, the grain number of 5,000 to 20,000 / mm<2> and the grain size of 300 to 800nm. The submicron-scale molybdenum powder is taken as the raw material for preparing the molybdenum blank with fine grains, special requirements on production equipment are absent, and the method is suitable for industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Matrimony vine sheet produced by stack delaminated pressing and preparation method thereof

Belonging to the field of health products, the invention in particular relates to matrimony vine sheets produced by stack delaminated pressing and a preparation method thereof. The matrimony vine sheets comprise 40-60 wt% of a matrimony vine submicron powder and 40-60 wt% of a Lycium ruthenicum submicron powder. The preparation method is as below: first respectively drying the matrimony vine and the Lycium ruthenicum to moisture no more than 8%; respectively carrying out superfine grinding on the matrimony vine and the Lycium ruthenicum, so as to obtain powders with no more than 2000 mesh for standby; then according to the proportion, respectively preparing the powders into particles with a same grain number for standby by a dry method; and finally respectively adding the two kinds of particles into two different hoppers of a stack tablet press, and carrying out pressing to obtain the product. The matrimony vine sheets provided by the invention contain abundant proteins, fats, 22 amino acids, and vitamin A1, B1, B2, C, and elements of calcium, magnesium, copper, zinc, manganese, iron, lead, nickel, cadmium, cobalt, chromium, potassium and sodium, which have important effects in maintaining normal physiological effects of human body. The product prepared by the method provided by the invention has good mouthfeel, abundant nutrition and low cost; and the process flow is simple for operation.

Owner:QINGHAI RUIYUAN PHARM RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com