Process for preparing superfine light calcium carbonate

A technology of light calcium carbonate and equipment, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, addition of inorganic compounds, etc., can solve the problems affecting the application of light calcium carbonate, large particle size, wide particle size range, etc. , to achieve the effect of fine particle size, high whiteness and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

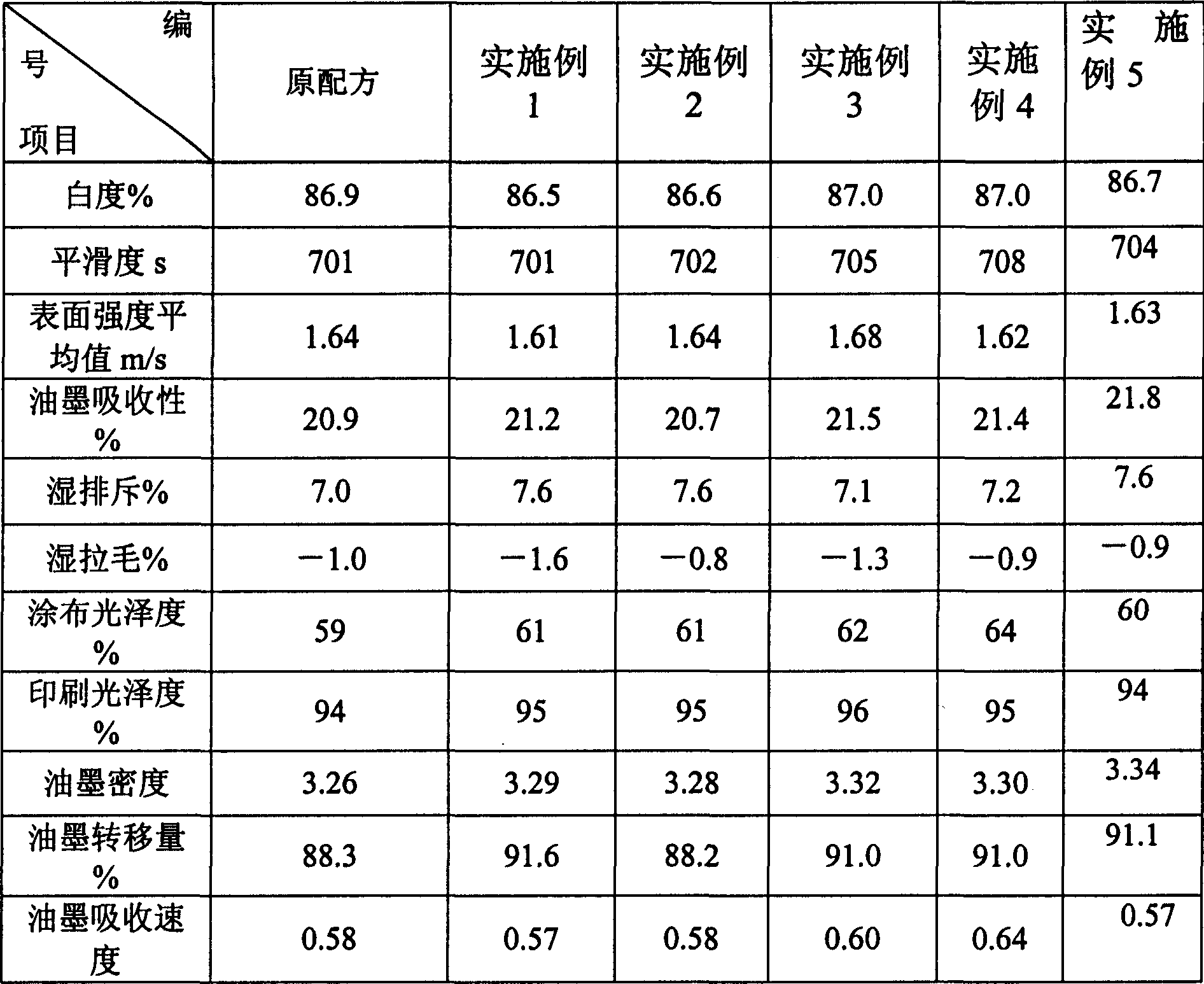

Embodiment 1

[0017] In the calcium hydroxide (average particle diameter is 10 μ m) water slurry that weight concentration is 20%, add the phosphate ammonium salt that is 1% of superfine calcium hydroxide dry weight and contain 12 carbon atoms, add simultaneously as hydrogen 0.3% sodium polyacrylate of calcium oxide dry weight, the calcium hydroxide slurry is sent into 5 vertical sand mills of 80 liters in series with a pneumatic diaphragm pump, and the feed flow rate is 8 liters / minute. At the same time, pass pure carbon dioxide gas from the bottom of each sand mill, the flow rate of carbon dioxide is 50 liters per minute, and turn on the sand mill to make grinding and carbonization proceed simultaneously. The slurry discharged from the fifth sand mill is completely carbonized, the pH of the slurry is 6.7, and the carbonization temperature is 45°C. The average particle size of the obtained ultrafine calcium carbonate is 0.4 μm, and the particles smaller than 2 μm account for the total numbe...

Embodiment 2

[0019] In the calcium hydroxide (average particle diameter is 5 μm) water slurry that weight concentration is 5%, add the sodium polyacrylate that is 0.8% of calcium hydroxide dry weight, calcium hydroxide slurry is sent into two sides with pneumatic diaphragm pump. A series of 300 liter vertical sand mills with a feed flow rate of 15 liters / min. At the same time, pass pure carbon dioxide gas from the bottom of each sand mill, the flow rate of carbon dioxide is 90 liters per minute, and turn on the sand mill to make grinding and carbonization proceed simultaneously. The slurry discharged from the second sand mill is completely carbonized, the pH of the slurry is 7.0, and the carbonization temperature is 70°C. The average particle size of the obtained ultrafine calcium carbonate is 0.5 μm, and the particles smaller than 2 μm account for the total number of particles. 98% of.

Embodiment 3

[0021] In the common calcium hydroxide (average particle diameter is 5 μ m) water slurry that weight concentration is 25%, add the phosphate potassium salt that is 2% of calcium hydroxide dry weight and contain 14 carbon atoms, calcium hydroxide slurry Feed into a stirring mill of 3 cubic meters, pass the mixed gas containing 25% carbon dioxide volume concentration from the bottom of the stirring mill, open the stirring mill, stir and grind carbonization for 8 hours with 80 rpm, the pH of the water slurry is 6.7, the carbonization temperature is 30°C, and the gas flow rate of the mixed gas is 300 liters / minute. The average particle size of the obtained superfine calcium carbonate is 0.5 μm, wherein particles smaller than 2 μm account for 93% of the total particle number.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com