Patents

Literature

129results about How to "Shorten the sintering time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of microwave processing ceramics and microwave hybrid heating system for same

InactiveUS20070023971A1Shorten the sintering timeOhmic-resistance heating detailsFurnace typesMicrowave ovenSusceptor

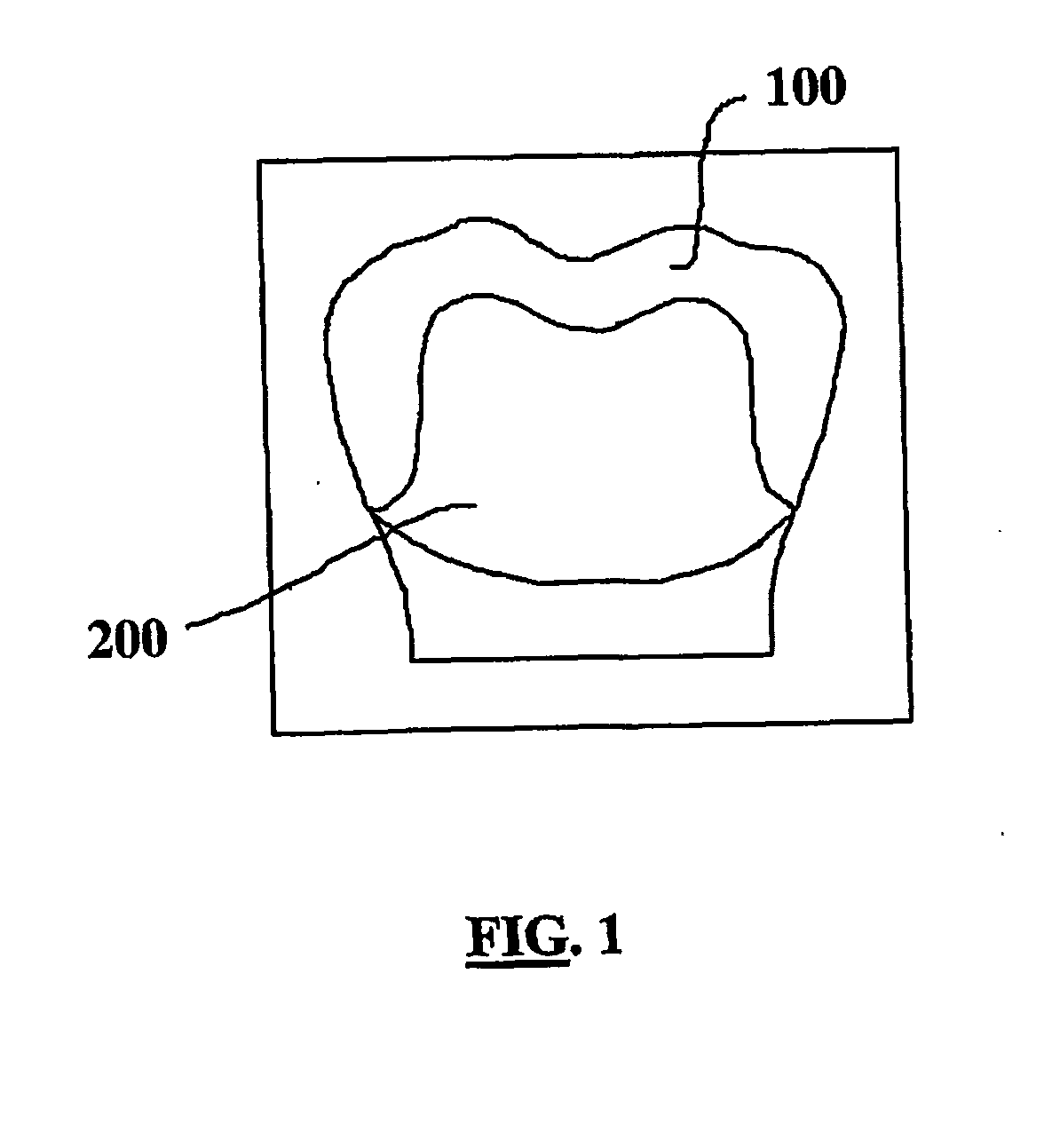

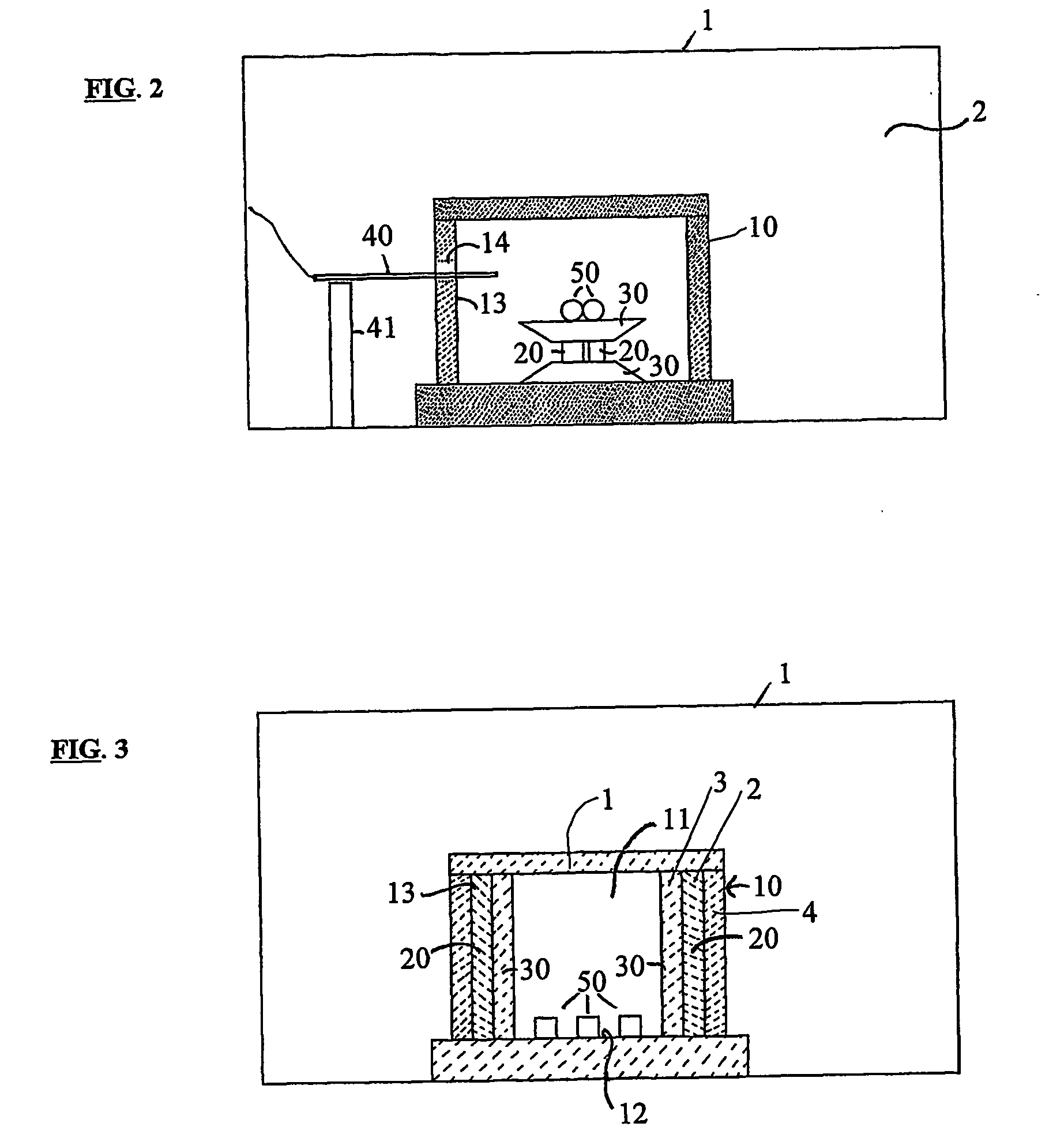

A method for sintering ceramic materials using a microwave hybrid heating system includes the steps of providing a ceramic member to be sintered, providing a microwave furnace, providing a thermal containment box comprising a material that is virtually transparent to microwave energy, providing at least one susceptor comprising a material that directly couples to microwave energy at room temperature substantially immediately within the thermal containment box, positioning the ceramic member within the thermal containment chamber proximate the susceptor, and irradiating the thermal containment box with microwave energy. The susceptor couples to the microwave energy and generates heat within the thermal containment box and the temperature of the ceramic member increases to the microwave coupling-trigger temperature, at which time the ceramic member couples directly to the microwave energy and is directly sintered by the microwave energy in cooperation with radiant energy from the one susceptor.

Owner:ALFRED UNIVERSITY

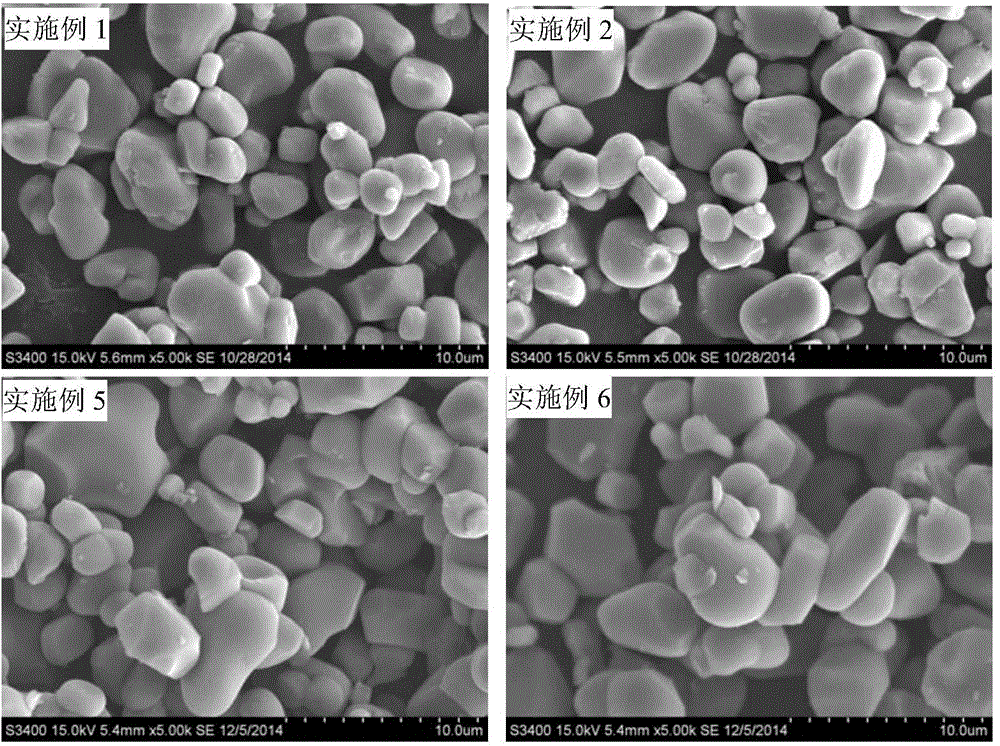

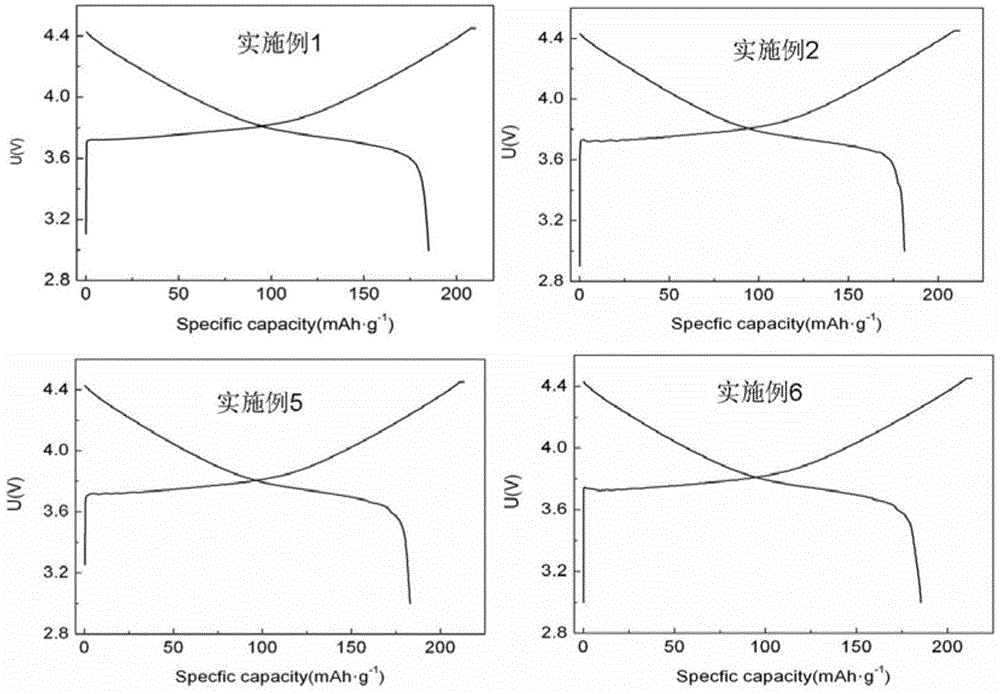

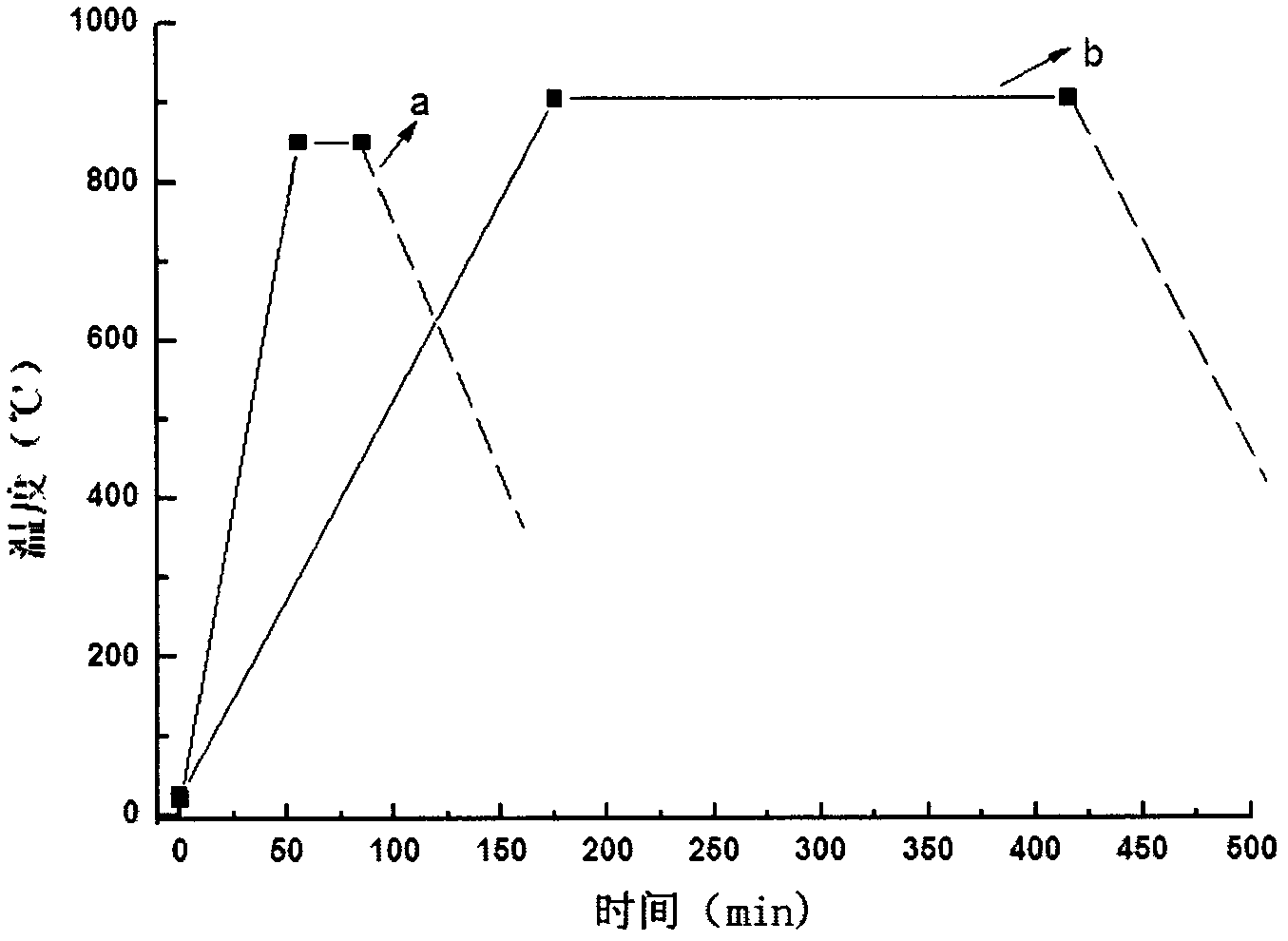

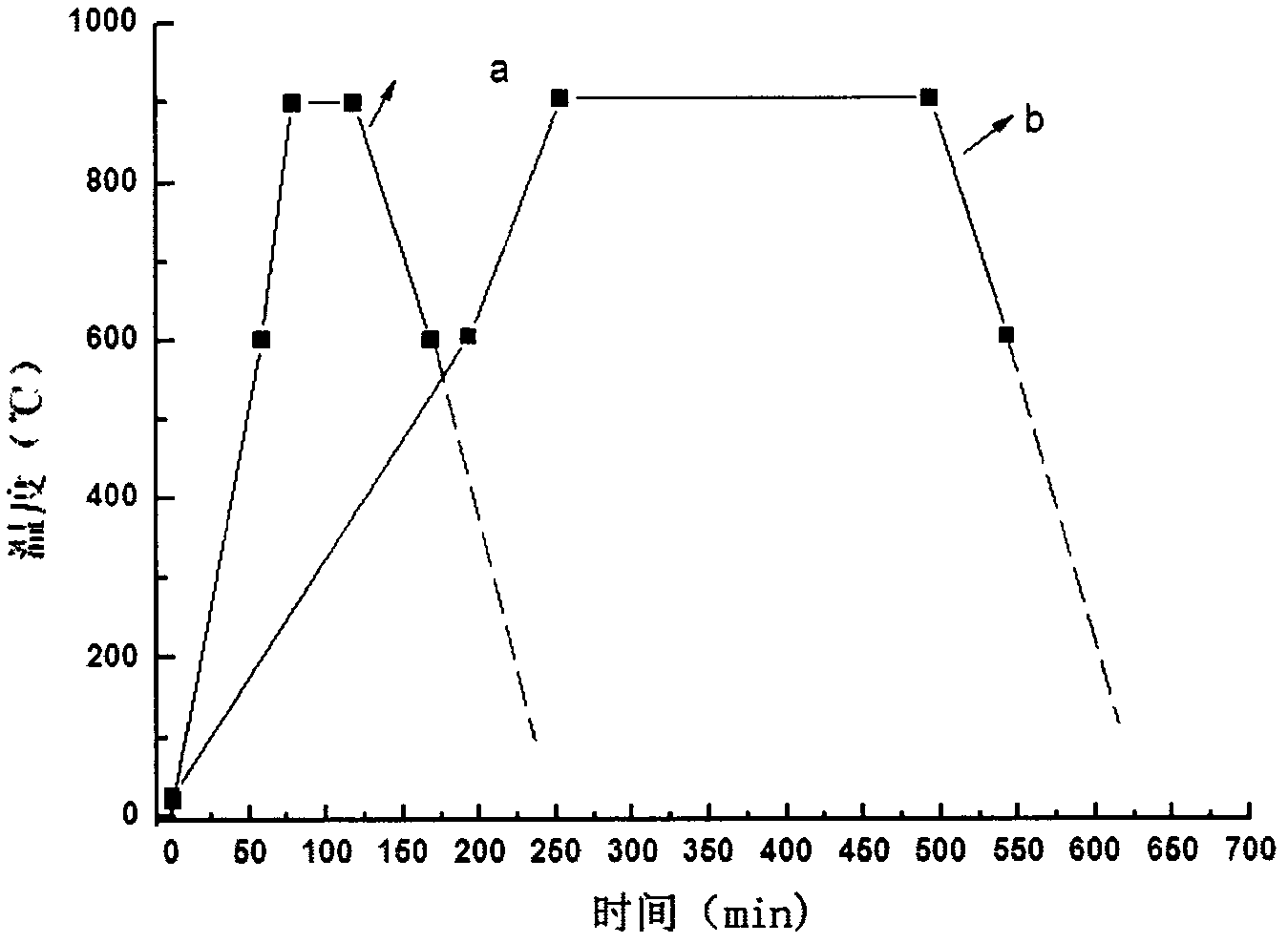

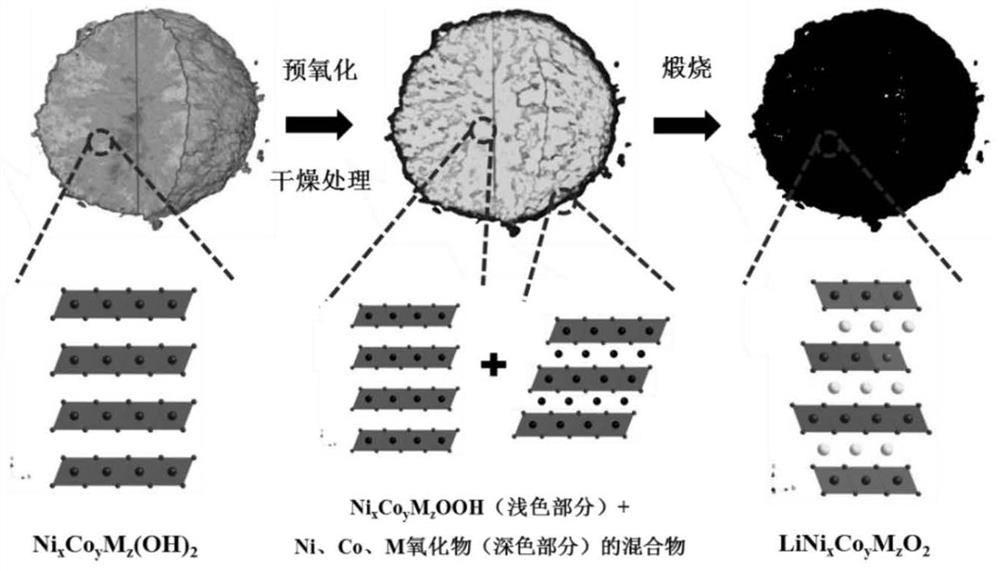

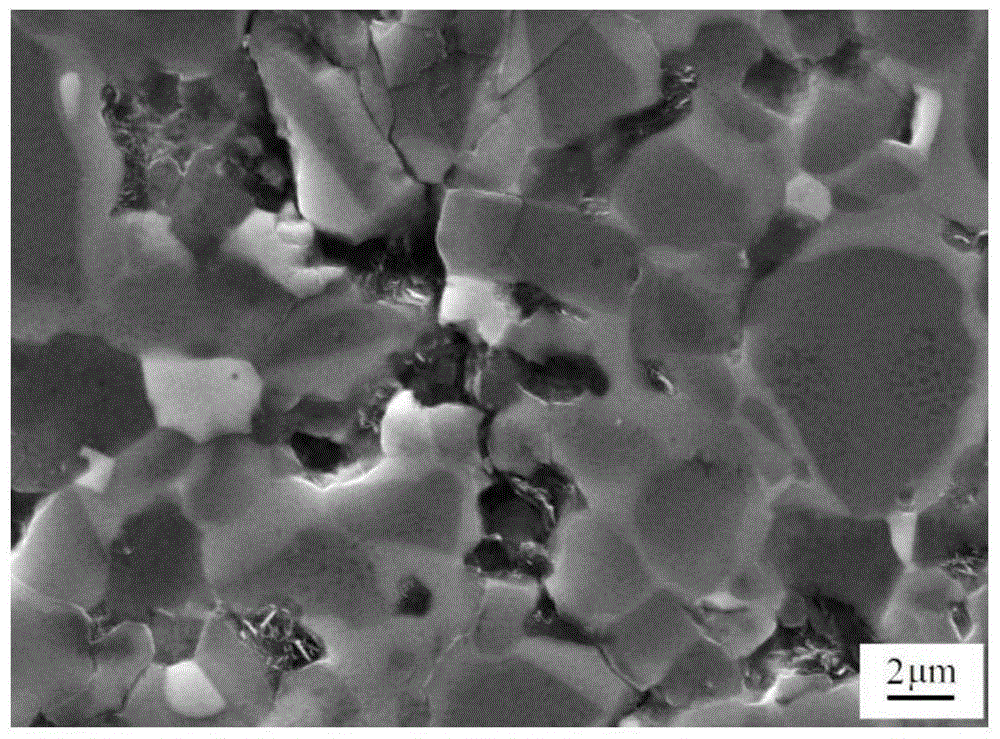

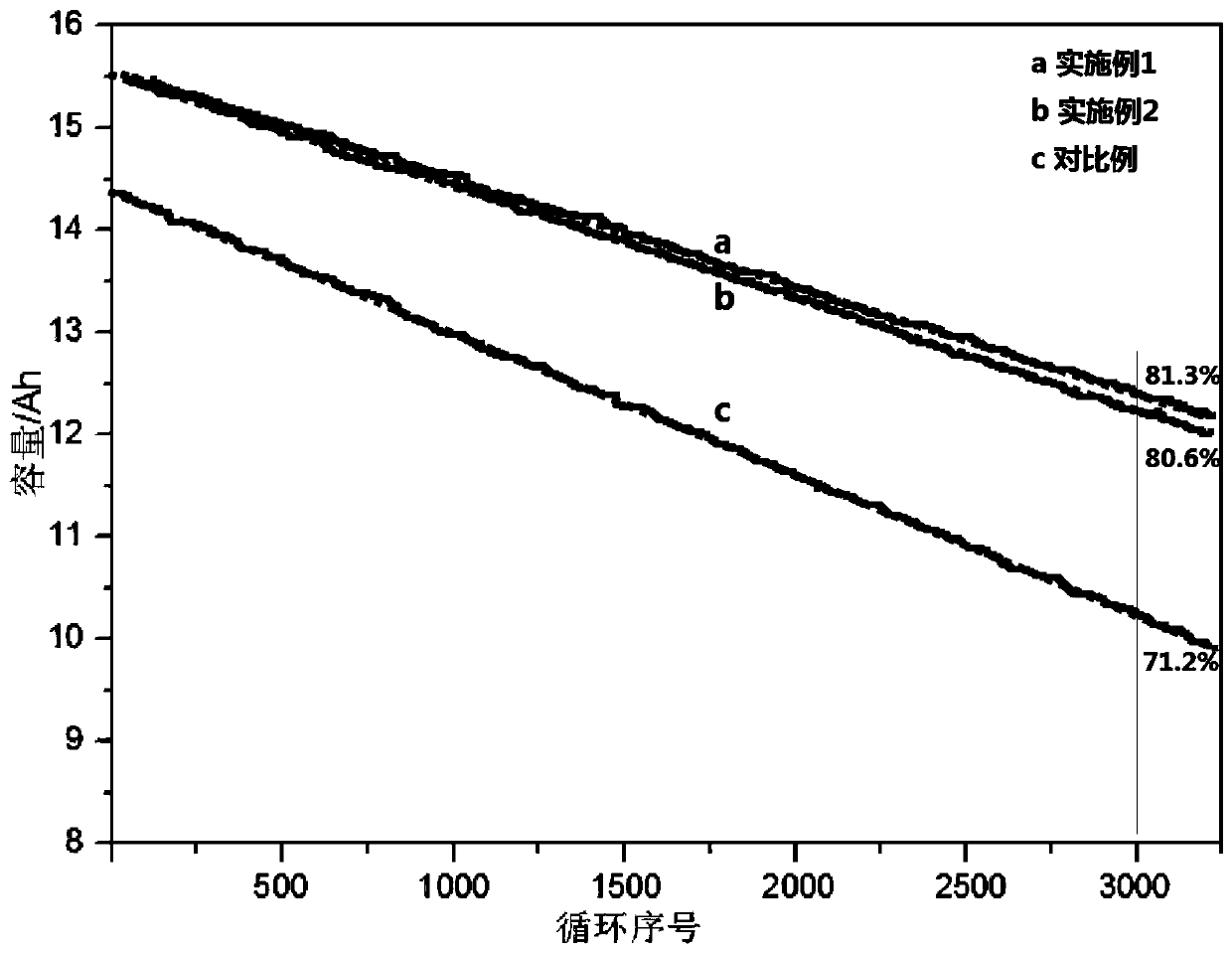

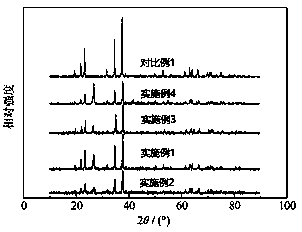

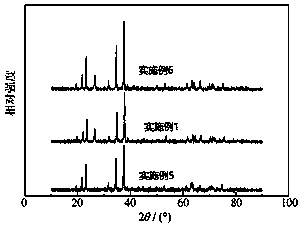

Monocrystal-like lithium battery ternary cathode material and preparation method thereof

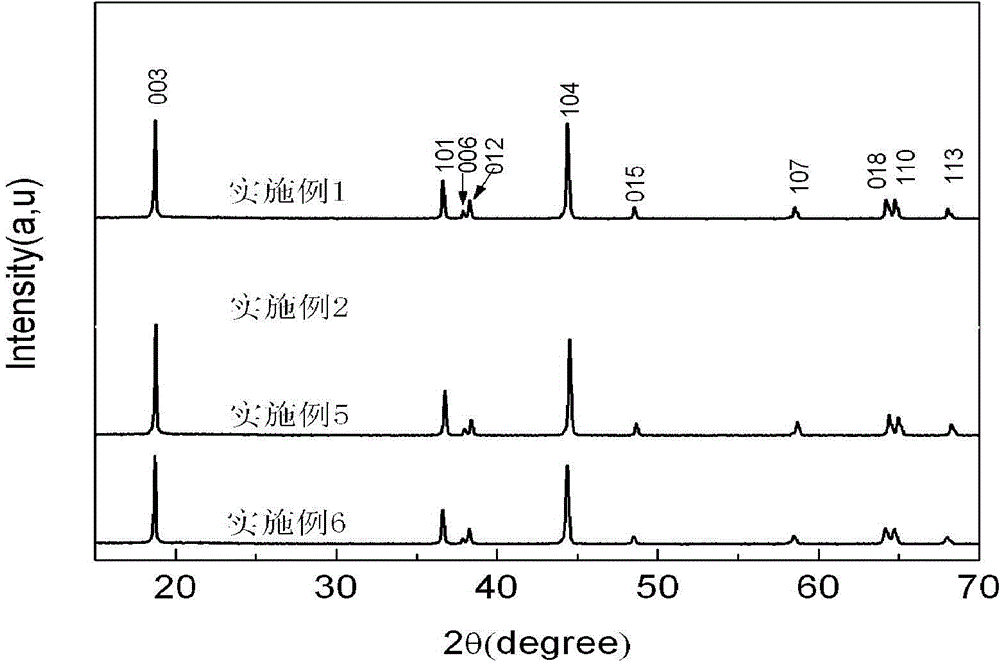

The invention relates to a monocrystal-like lithium battery ternary cathode material and a preparation method thereof. The chemical formula of the cathode material is LiNi(1-x-y-z)CoxMnyMzO2, wherein x is larger than 0 and smaller than or equal to 0.65, y is larger than 0 and smaller than or equal to 0.3, z is larger than or equal to 0 and smaller than or equal to 0.05, and M is one or more of Mg, Ca, Ti, Zn, Cr, Fe, Zr, Co, Cu and Ru. The preparation method of the cathode material comprises the following steps of 1 precursor synthesizing; 2 material mixing, wherein a fluxing agent is added in the material mixing process; 3 sintering and the like. According to the method, the melting point of the material is lowered by adding the fluxing agent, therefore, precursors and lithium salts are in a molten environment, dispersion of metal ions is accelerated, and crystal grains start to grow and development at low temperature, break limitation of precursor aggregates after growing to a certain degree to be dispersed into monocrystal grains and finally grow into the cathode material with the monocrystal morphology; the sintering frequency and the sintering time in the existing monocrystal material synthesizing process are decreased, and then the production cost is reduced.

Owner:HENAN KELONG NEW ENERGY CO LTD

Low-temperature sintered microwave dielectric ceramic and sintering method thereof

The invention discloses low-temperature sintered microwave dielectric ceramic and a sintering method thereof. The low-temperature sintered microwave dielectric ceramic comprises Li2MTi3O8 and N, wherein an M element is Zn, Ni, Co or Mg, and N is B2O3, V2O5, CuO or Bi2O3. The performance of a product prepared by adopting a microwave sintering method disclosed by the invention is superior to that of a traditional solid-phase sintered product, the high-frequency dielectric constant (epsilonr) of the product reaches 20 to 30, a Q*f value reaches up to 6000 to 59000GHz, and the temperature coefficient (tauf) of a resonance frequency is small. Moreover, the presintering time and the sintering time can be shortened, and the sintering temperature is decreased, so that the requirements of LTCC (Low Temperature Co-fired Ceramic) production can be met, the performance of the product is improved, energy sources are saved, the production cost is lowered, the low-temperature sintered microwave dielectric ceramic can be used for the manufacture of microwave devices, such as an LTCC system, a multilayer dielectric resonator, a microwave antenna, a filter and the like, the volatilization of low-melting-point substances is inhibited, the environment is protected, and the low-temperature sintered microwave dielectric ceramic has an important industrial application value.

Owner:GUANGXI NEW FUTURE INFORMATION IND

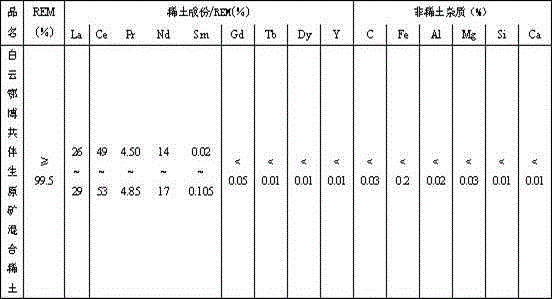

Rare earth permanent magnet prepared from bayan obo accompany raw ore misch metal and preparation method of rare earth permanent magnet

ActiveCN104700973ALow priceReduce pollutionInductances/transformers/magnets manufactureMagnetic materialsMisch metalThermal deformation

The invention relates to a rare earth permanent magnet prepared from a bayan obo accompany raw ore misch metal and a preparation method of the rare earth permanent magnet. The rare earth permanent magnet is prepared from the components as shown in the following equation: (PrNd)x(MM)y(Fe(1-a)Aa)zB, wherein x+y is greater than or equal to 2 and is less than or equal to 2.5, z is greater than or equal to 11 and less than or equal to 14, and MM is bayan obo accompany raw ore misch metal. The rare earth permanent magnet can be prepared by using a powder metallurgy process and a rapid-quenching hot-press thermal deformation process. The bayan obo accompany raw ore misch metal is adopted to develop a novel resource-saving rare earth permanent magnet for replacing a conventional rare earth permanent magnet, the rare earth permanent magnet provided by the invention has the advantages of low price and environment pollution reduction, the magnetic energy product of the prepared rare earth permanent magnet ranges from 25-45 MGOe, and the blank of the application range of ferrite and SmCo rare earth permanent magnets can be well made up.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

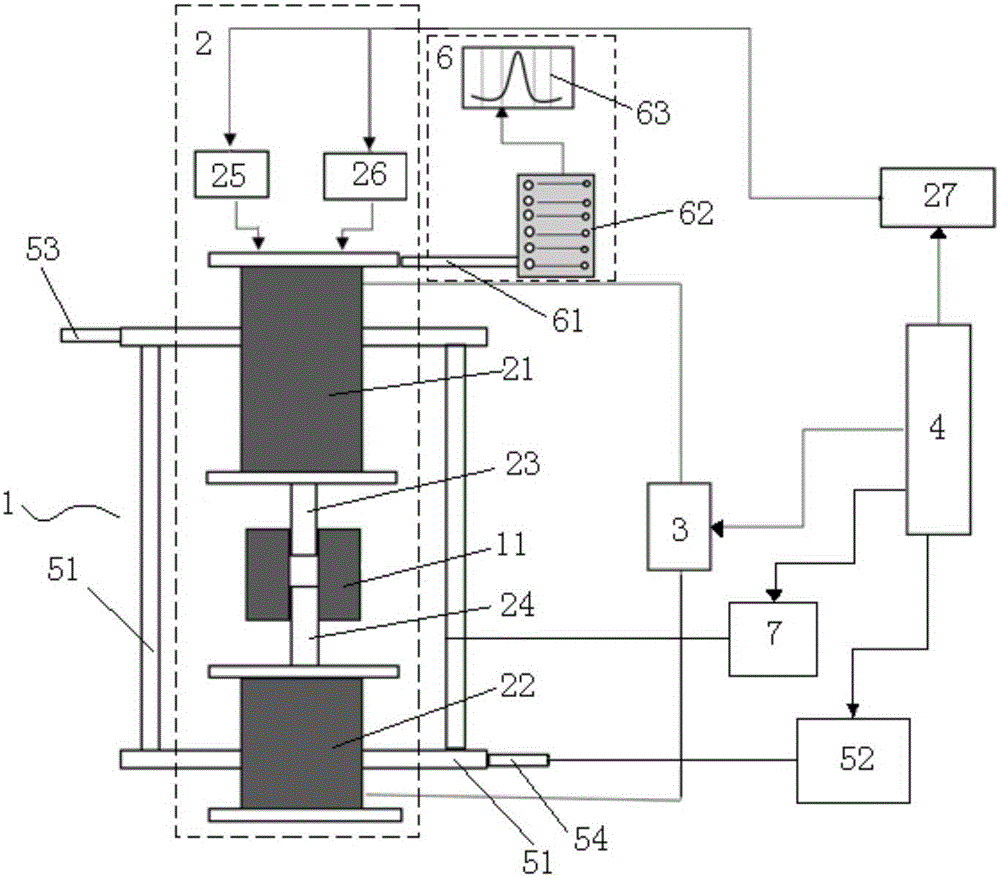

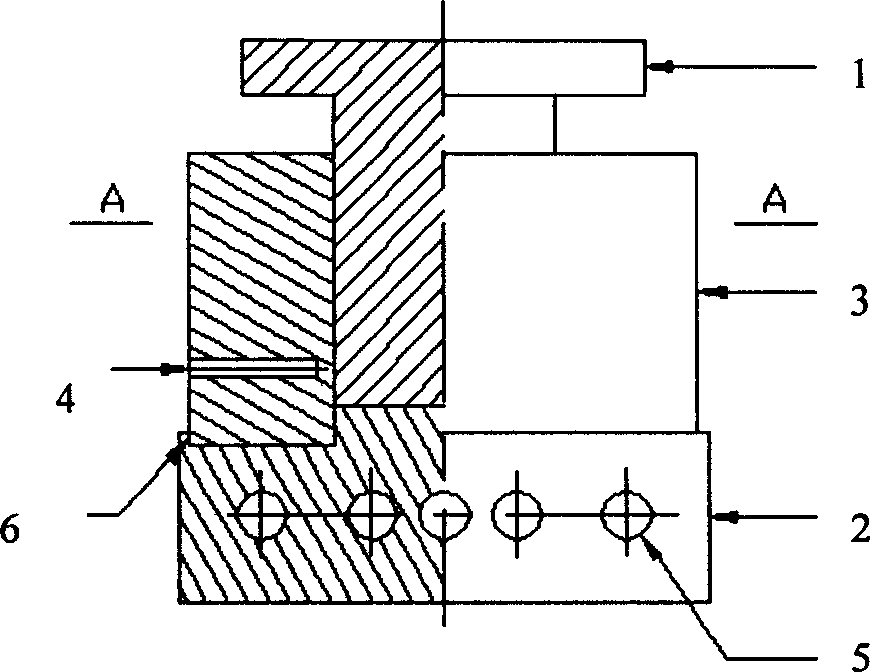

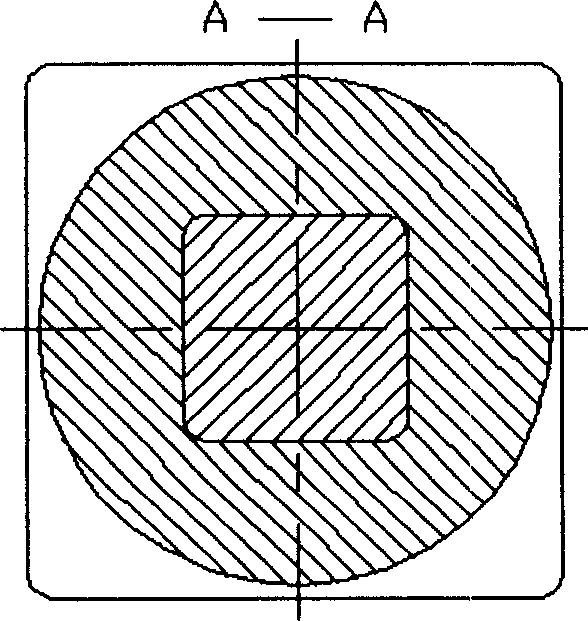

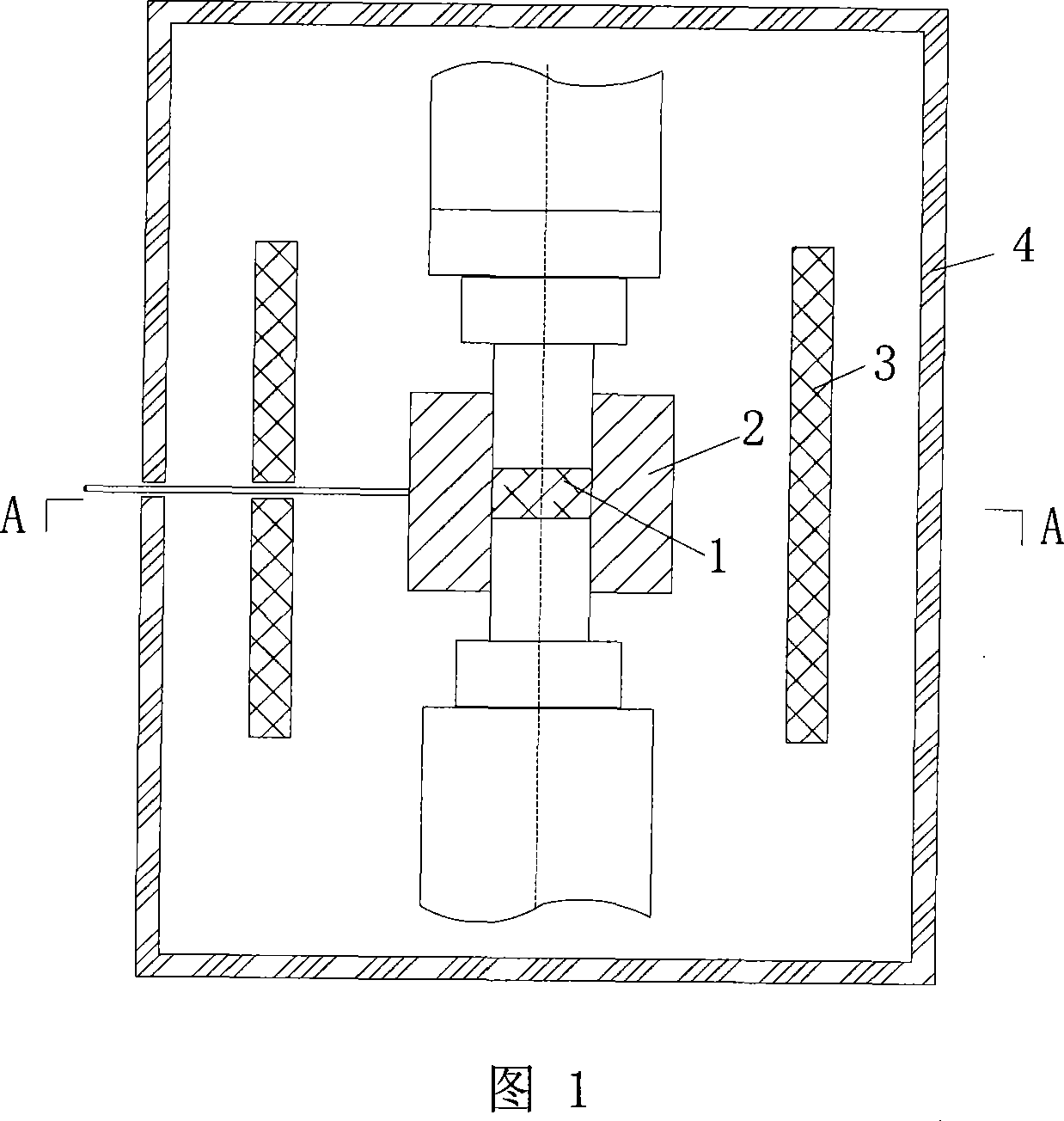

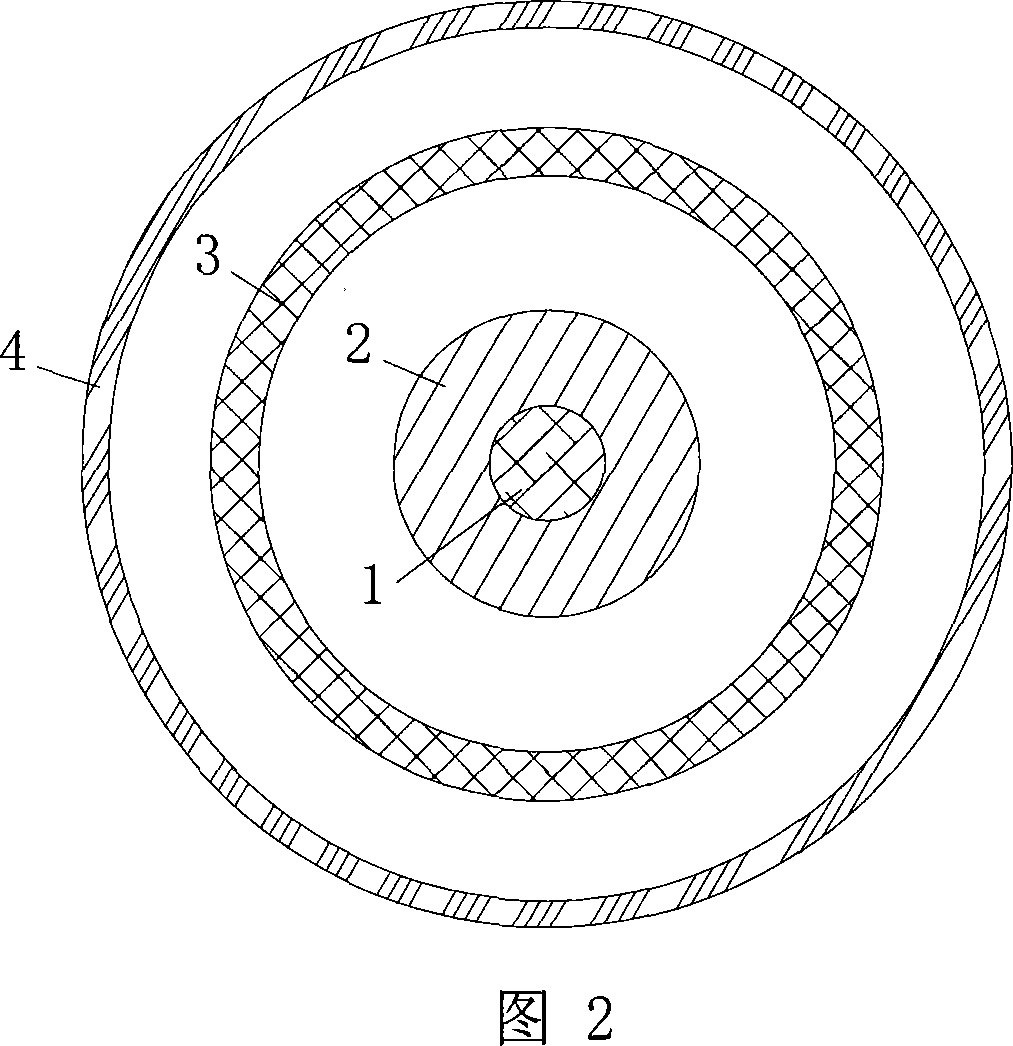

Dynamic pressure electric pulse double-field control sintering furnace and sintering method

ActiveCN105135873ALower sintering temperatureShorten the sintering timeMuffle furnacesMaintainance of heating chambersElectrical impulseDynamic pressure

The invention relates to a dynamic pressure electric pulse double-field control sintering furnace and a sintering method. The sintering furnace comprises a furnace body, a dynamic pressure system, a pulse current generator and a sintering controller. The furnace body is connected with the dynamic pressure system and the pulse current generator. The dynamic pressure system and the pulse current generator are both connected to the sintering controller. A die is arranged in the furnace body. The dynamic pressure system comprises an upper press head electrode, a lower press head electrode, an upper press head, a lower press head, a constant pressure control module, a dynamic pressure control module and a pressure master control module. The dynamic pressure system is connected with the sintering controller. The pulse current generator is connected with the upper press head electrode and the lower press head electrode and connected with the sintering controller as well. The sintering controller controls the dynamic pressure system and the pulse current generator to generate the adjustable dynamic pressure for a material to be sintered and conduct plasma pulse current sintering on the material to be sintered. The dynamic pressure electric pulse double-field control sintering furnace and the sintering method can be widely applied to sintering of the high-performance material.

Owner:TSINGHUA UNIV

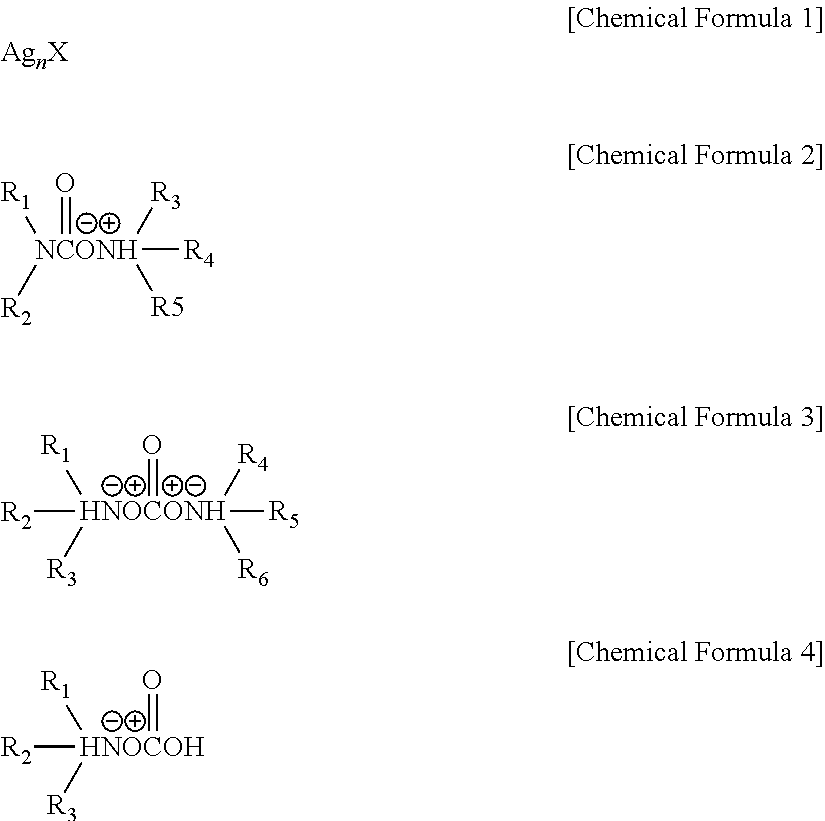

Silver ink composition

ActiveUS20140026782A1Improve stabilityImprove conductivityAntifouling/underwater paintsInksSilver inkPhysical chemistry

The present invention relates to a silver ink composition comprising: silver complexes obtained by reacting one or more silver compounds selected from chemical formula 1 with one or more ammonium carbamate-based compounds or ammonium carbonate-based compounds selected from chemical formula 2 to chemical formula 4; and oxime-based compounds.

Owner:INKTEC CO LTD

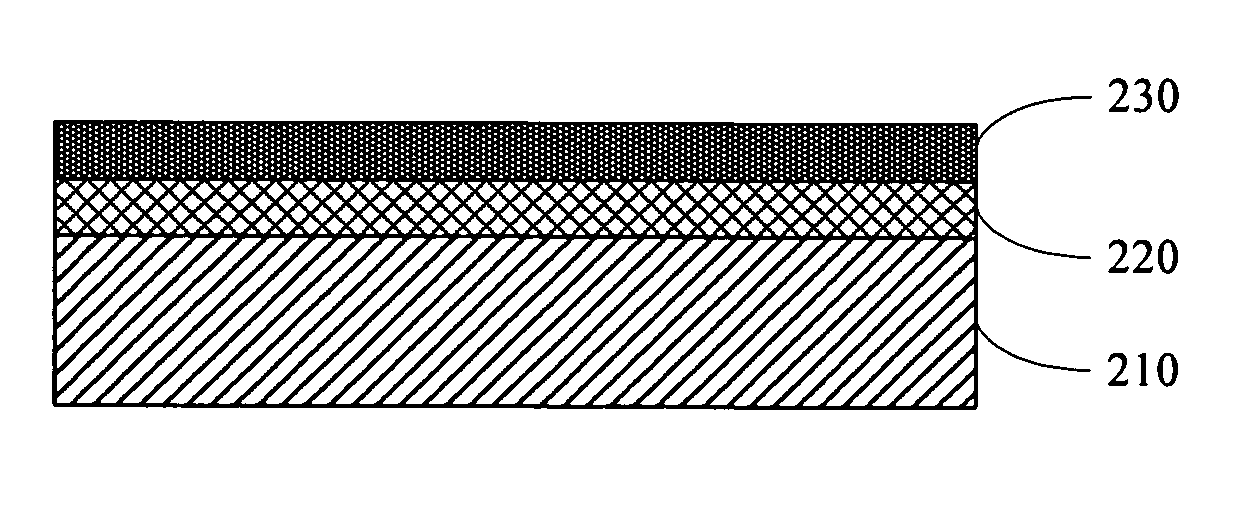

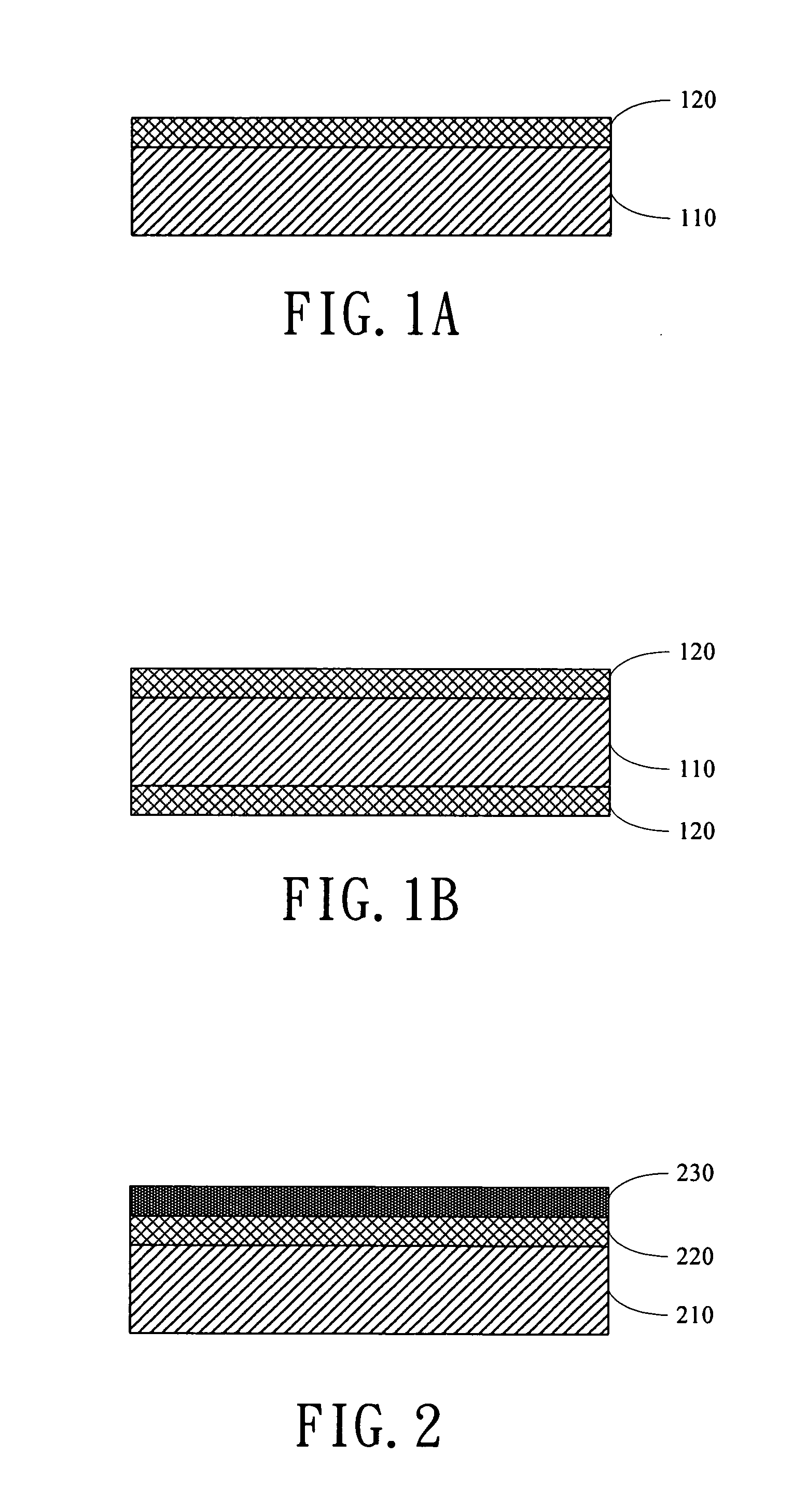

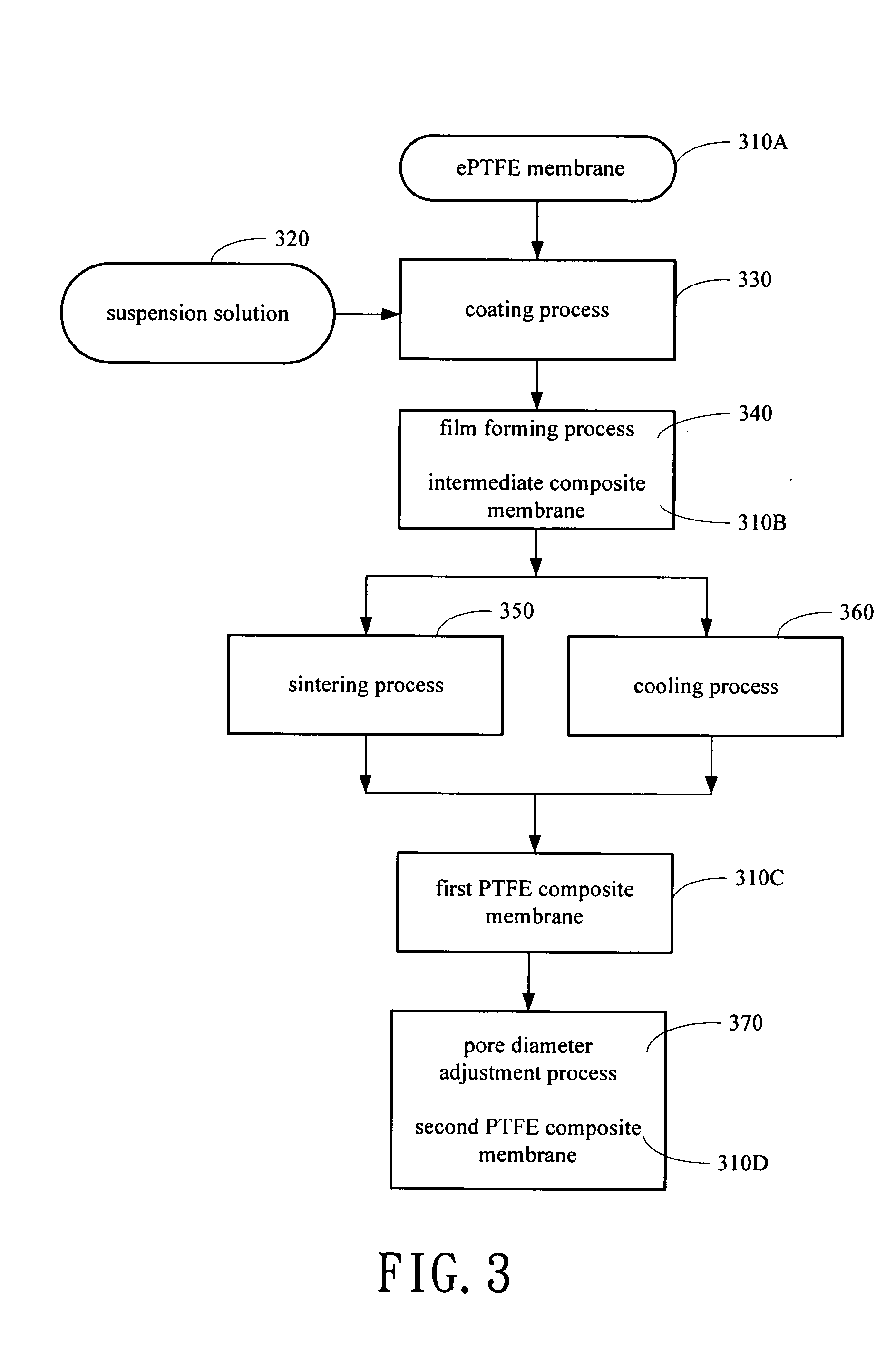

Composite membrane and method for forming the same

ActiveUS20060269735A1Shorten the sintering timeBroaden applicationMembranesSemi-permeable membranesExpanded PTFEMembrane configuration

The present invention discloses discloses a composite PTFE membrane comprising an expanded PTFE membrane as substrate and a sintered porous PTFE membrane on top of it. The porous PTFE membrane on top has porous structure with interconnected channels formed with a sintering process that fuses the PTFE fine powders coated on the ePTFE membrane. Furthermore, the present invention discloses a method for forming the composite PTFE membrane.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Rare-earth permanent magnet material mixed with bayan obo co-existence and associated crude ores and method for manufacturing rare-earth permanent magnet material

InactiveCN104637643ALow priceReduce pollutionInorganic material magnetismInductances/transformers/magnets manufactureThermal deformationAlloy

The invention relates to a rare-earth permanent magnet mixed with bayan obo co-existence and associated crude ores and a method for manufacturing the rare-earth permanent magnet. Compositions of the rare-earth permanent magnet are shown as a following formula of MM<x>Fe<y>A<z>B, the x is larger than or equal to 2 and is smaller than or equal to 2.5, the y is larger than or equal to 11 and is smaller than or equal to 14, the z is larger than or equal to 0 and is smaller than or equal to 0.6, the MM represents rare-earth mixed with the bayan obo co-existence and associated crude ores, and the A represents nanometer auxiliary alloy which includes one type of Nd elements, Pr elements, Al elements and Cu elements or a plurality of types of the Nd elements, the Pr elements, the Al elements and Cu elements. The rare-earth permanent magnet can be manufactured by the aid of a powder metallurgy technology and rapid quenching and thermal pressure and thermal deformation technologies. The rare-earth permanent magnet and the method have the advantages that the novel resource-saving rare-earth permanent magnet which is developed from the rare-earth mixed with the bayan obo co-existence and associated crude ores can replace the traditional rare-earth permanent magnet and is low in cost, and environmental pollution can be reduced; the magnetic energy product scope of the magnet ranges from 20MGOe to 40MGOe, and applicable scope gaps of ferrites and SmCo rare-earth permanent magnets can be effectively filled.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

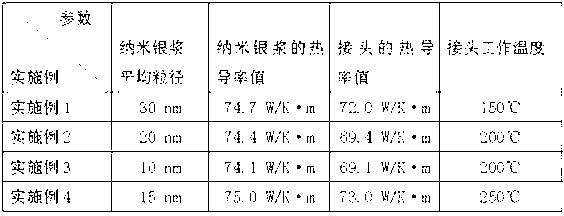

Nano silver paste for chip mounting and method for preparing nano silver paste

ActiveCN102935518ANo pollution in the processLower sintering temperatureMaterial nanotechnologyFlocculationSilver paste

The invention provides a method for preparing a nano silver paste. The method includes step A, a reducing agent and a dispersing agent are dropwise added in a silver nitrate solution and stirred; step B, the solution obtained through the step A is subjected to centrifugation to obtain nano silver particles with upper layers as mixed solutions and lower layers as sedimentation; step C, the nano silver particles separated through the step B is cleaned by deionized water and subjected to flocculation by a electrolyte solution, and nano silver particles capable of being subjected to centrifugation are re-precipitated; step D, the nano silver particles are subjected to cleaning, flocculation and centrifugation for a plurality of times to obtain a water-soluble nano silver paste; and step E, the nano silver paste is applied to a chip and a substrate surface to be interconnected, and the interconnected chip and substrate surface is heated in a hot air work bench or a stove to form a sintering joint.

Owner:深圳市先进连接科技有限公司

Process for preparing magnesium alloy and its composite material

The present invention relates to preparation process of magnesium alloy and its composite material, and is a breakthrough in powder metallurgical technology. The preparation process includes smelting magnesium alloy ingot, ball milling to produce powder, hot pressing and sintering, hot rolling treatment, etc. The present invention combines powder pressing and powder sintering to raise the strength of composite material, improve the toughness, lower the sintering temperature, reduce the sintering time and lower the power consumption. During the operation, no protective gas is added, and the material does not be oxidized, resulting in simple and reliable apparatus, low cost and high practicability.

Owner:TONGJI UNIV

Process for sintering ceramic powder or ceramic base composite powder

The invention provides a process for sintering ceramic powder or ceramic base composite powder which comprises, subjecting ceramic powder or ceramic base composite powder to heating, pressurizing, compound sintering with sparks with the sintering being controllable, i.e. air or vacuum or argon or nitrogen atmosphere. The invention realizes the effects of short time and low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

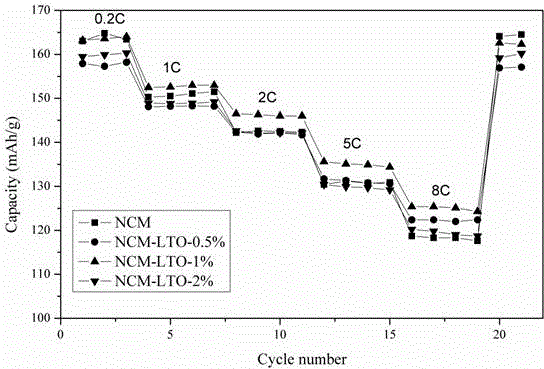

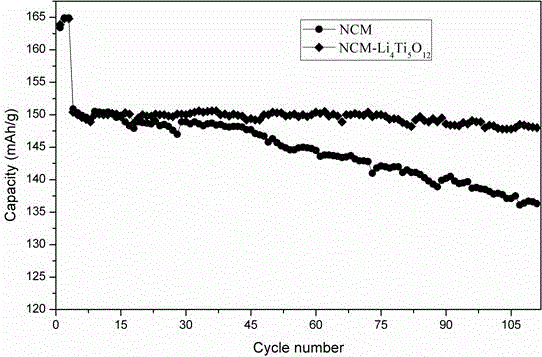

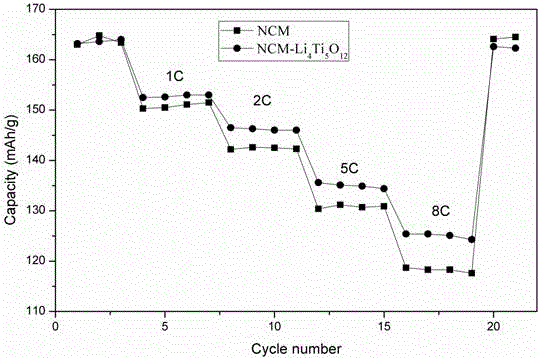

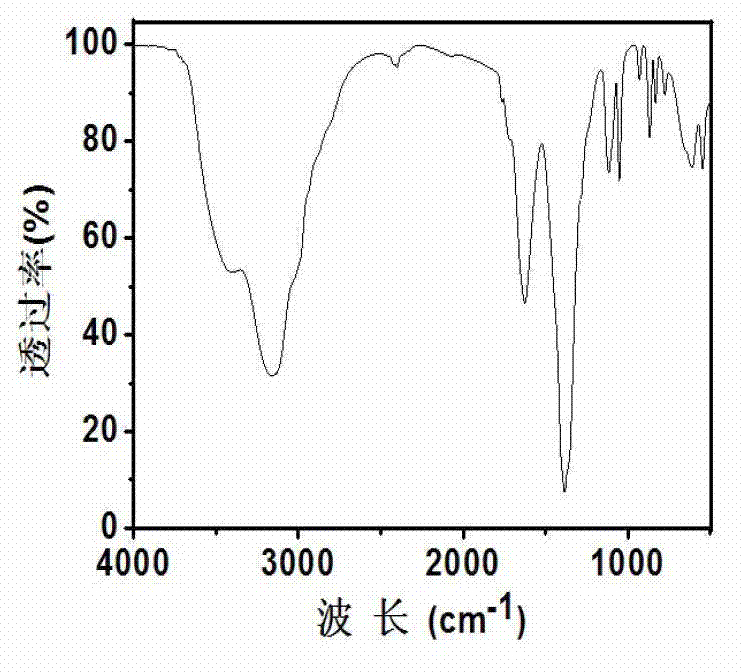

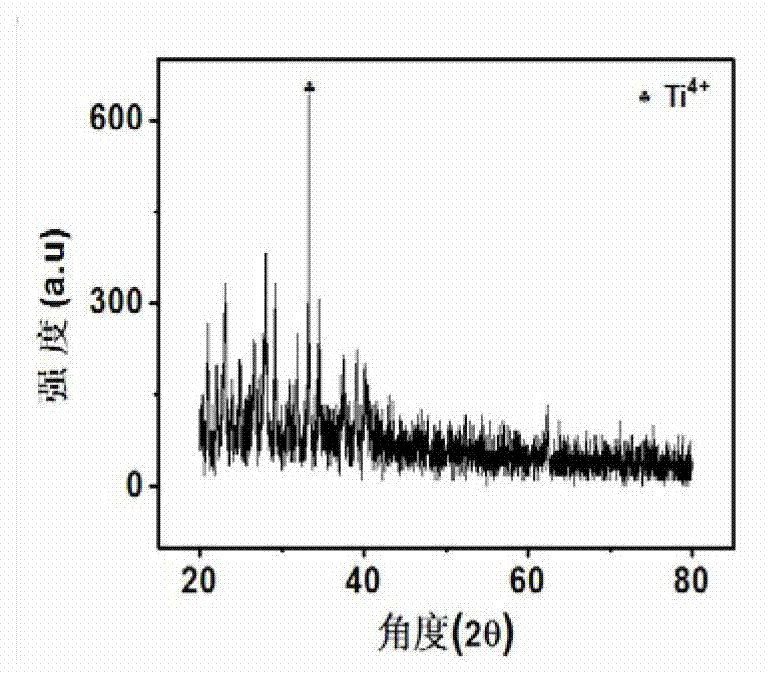

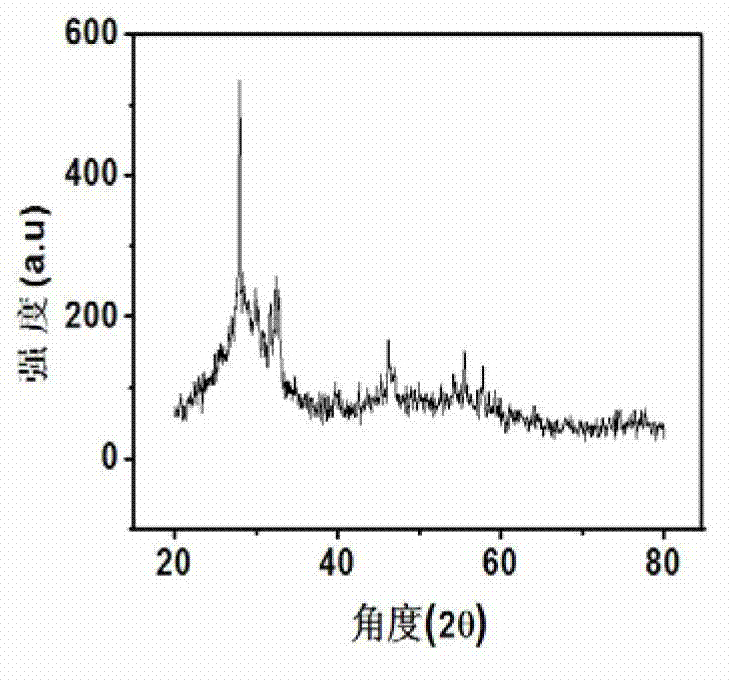

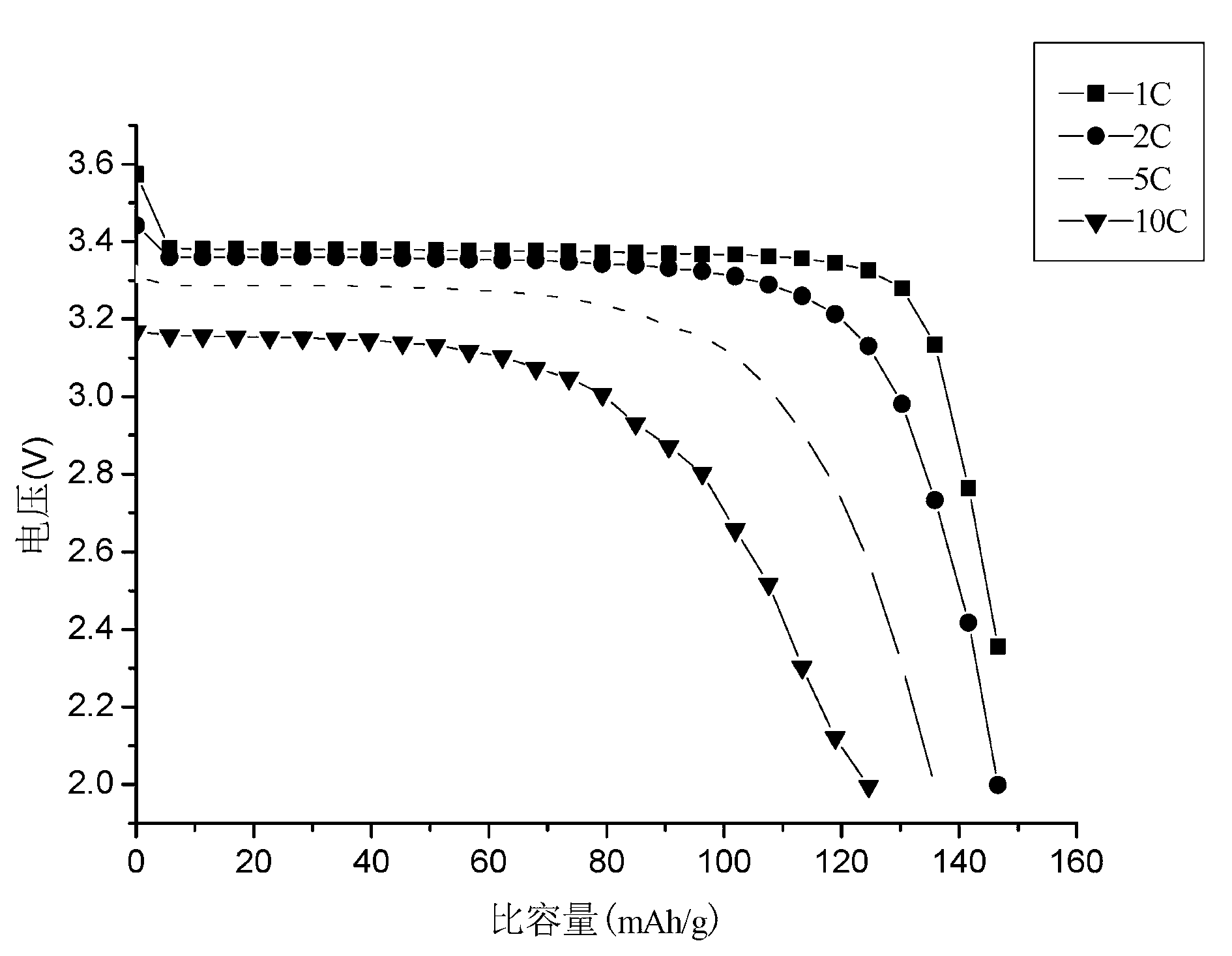

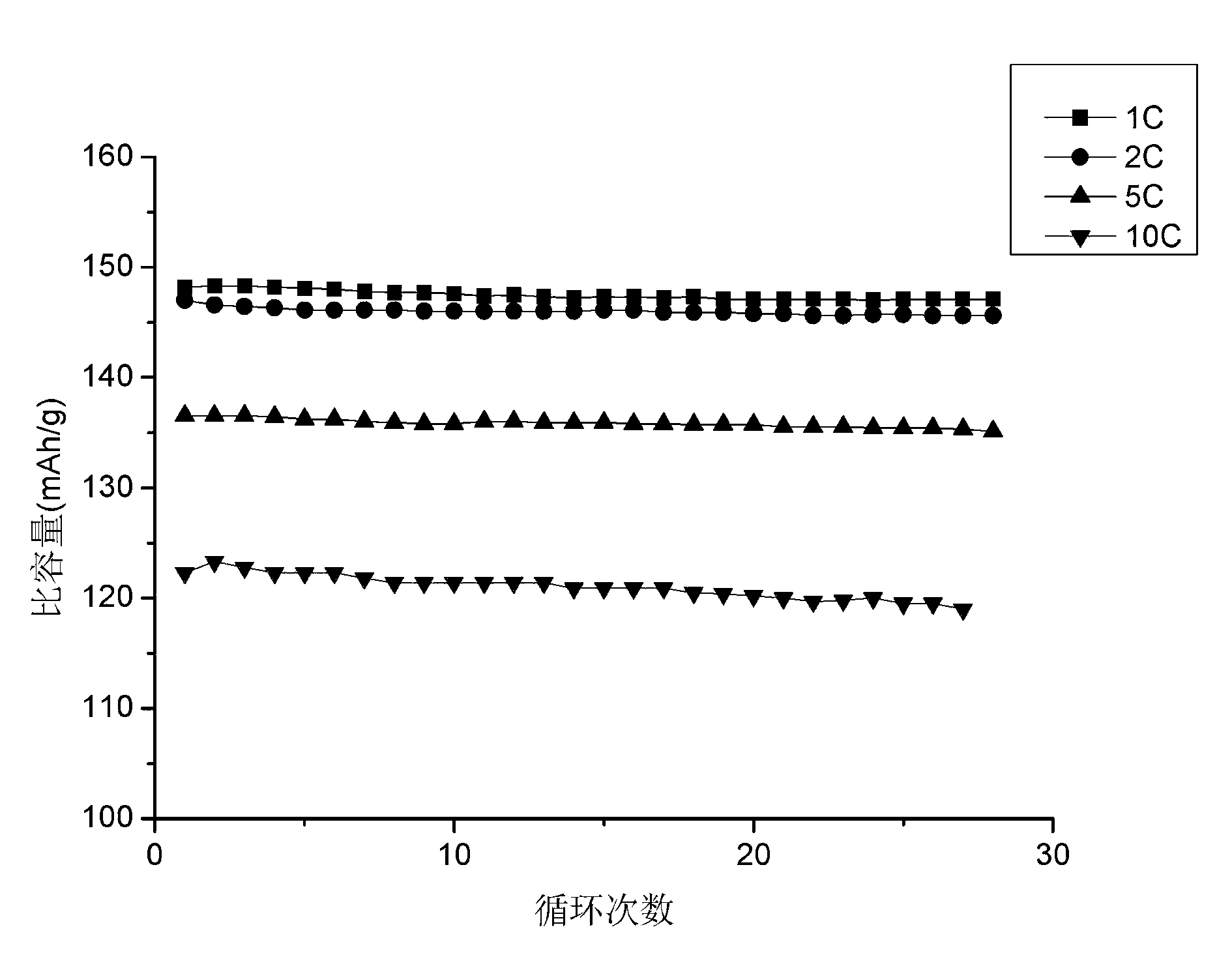

Preparation method of lithium titanate coated lithium ion battery nickel cobalt manganese cathode material

InactiveCN105789606AImprove cycle stabilityImproved magnification performanceCell electrodesBatteriesManganeseCobalt

The invention relates to the technical field of battery materials, in particular to a preparation method of the lithium titanate coated lithium ion battery nickel cobalt manganese cathode material. According to the method, the existing preparation process of the lithium ion battery cathode material is improved, a lithium titanate nanomaterial is synthesized via a sol-gel method and then dipped on a nickel cobalt manganese ternary material via a solution method, so that the composite material high in safety, good in cycling stability and high in initial coulomb efficiency is obtained. The method is simple, feasible, high in production efficiency and suitable for large-scale production, production procedures are reduced, sintering temperature is lowered, sintering time is shortened, and production cost is saved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Environment-coordinating method for preparing titanate piezoelectric ceramic powder

InactiveCN102898147AAvoid defectsGo greenPiezoelectric/electrostrictive/magnetostrictive devicesSpontaneous combustionElectricity

The invention discloses an environment-coordinating method for preparing titanate piezoelectric ceramic powder, and the method is characterized in that lactic acid is chelating agent, swelling agent and pore-forming agent, sol is prepared under the normal temperature by utilizing a sol-gel method, after the pH value is adjusted, the sol is vacuum concentrated or removed with solvent under constant pressure to obtain gel, the gel is processed through unique swelling process and spontaneous combustion way under the temperature of 180 DEG C to 200 DEG C to obtain a nano pyrophoric material, and the pyrophoric material is pre-burned to obtain nano powder under the temperature of 550DEG C to 600DEG C; and the powder is processed through procedures such as granulating, tabletting, plastic releasing and the like to obtain a green sheet, the green sheet is sintered for 1 to 2h under the condition of 950DEG C to 1025DEG C to obtain a ceramic sheet, and the ceramic sheet is polarized in normal-temperature silicon oil to obtain the titanate piezoelectric ceramic powder after standing. The method has important practical significance for traditional piezoelectric ceramic production process to realize high quality, low energy consumption, low cost and environmental friendliness; and meanwhile, an important innovation effect for the titanate compound application field seeking no conglobation and having ultra-large specific surface area can be achieved.

Owner:CHINA WEST NORMAL UNIVERSITY

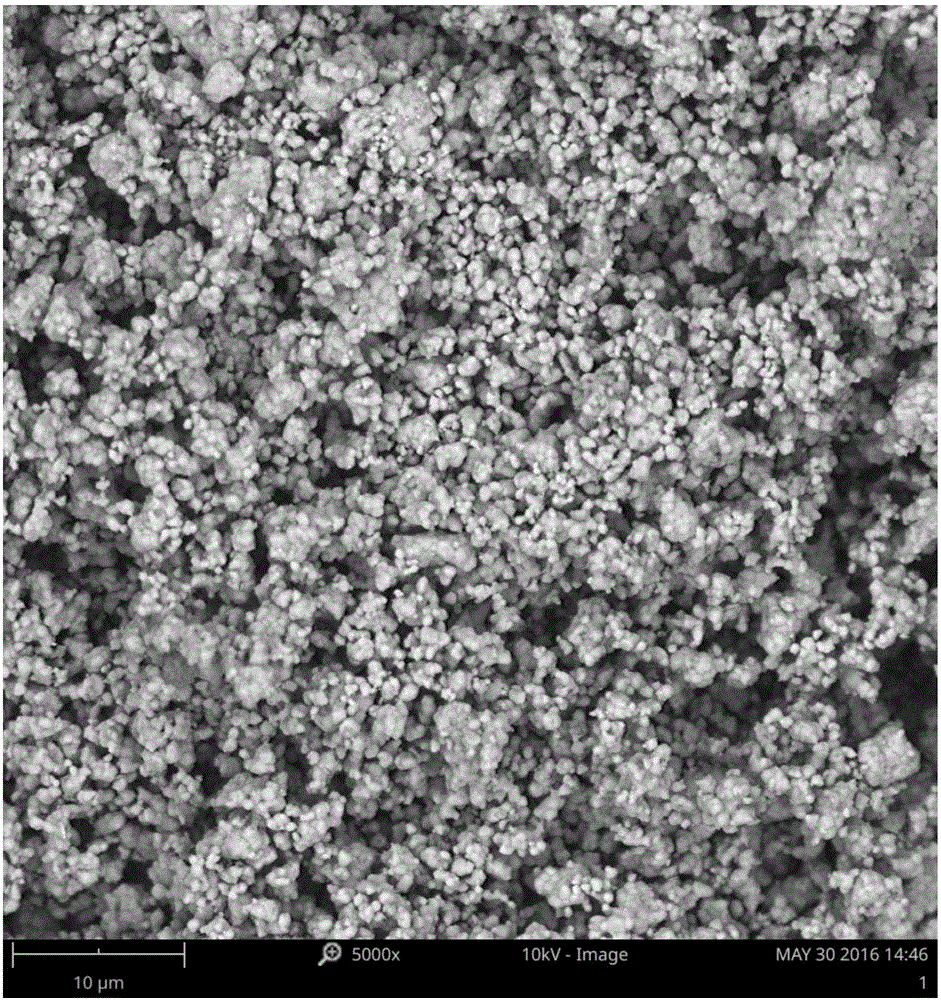

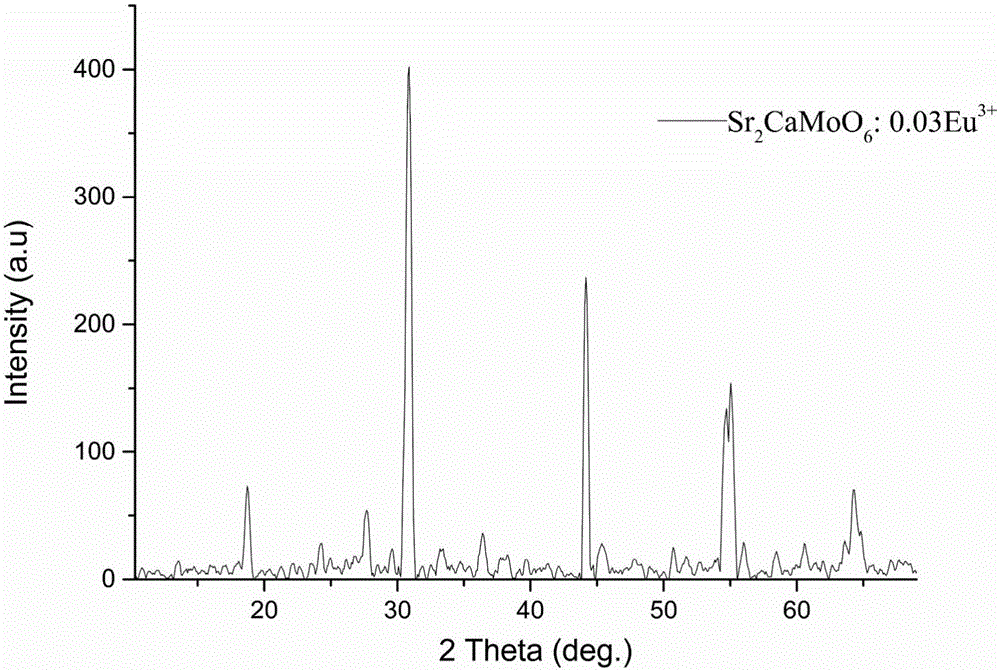

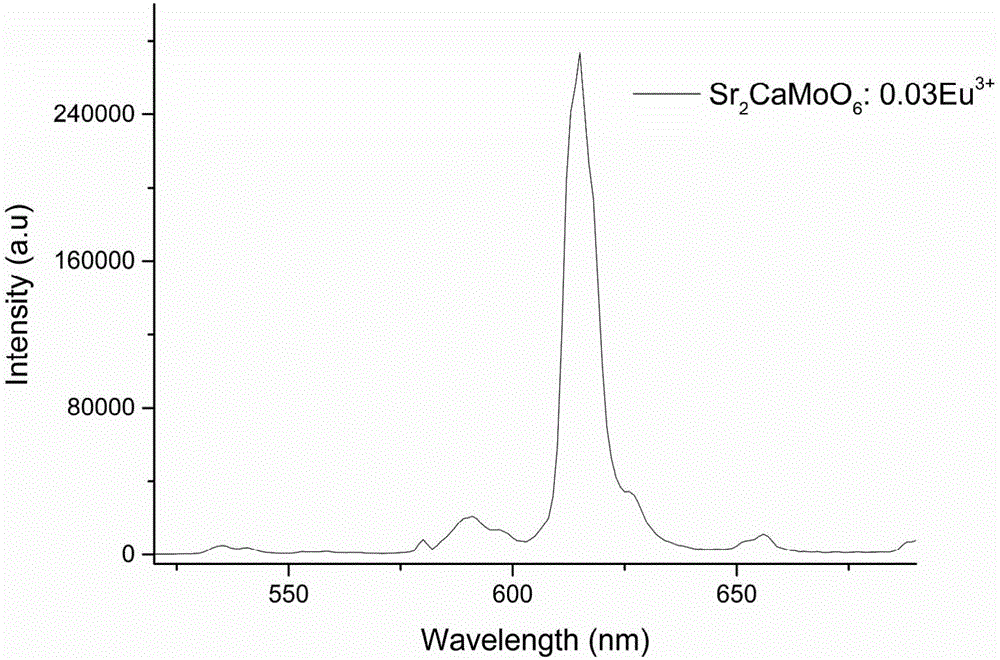

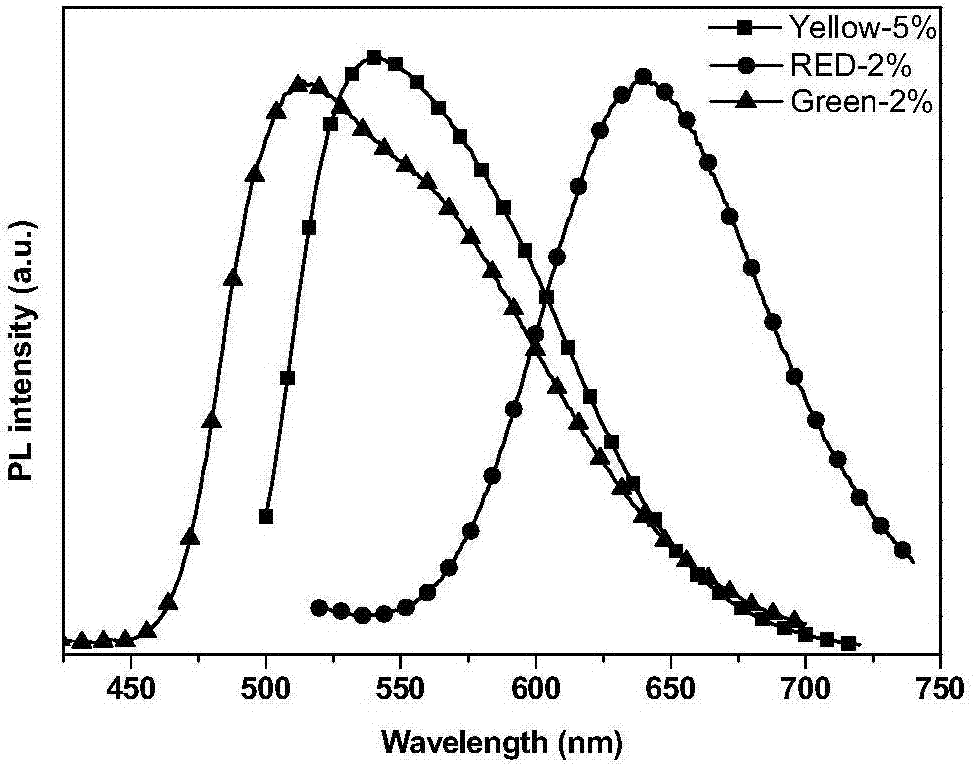

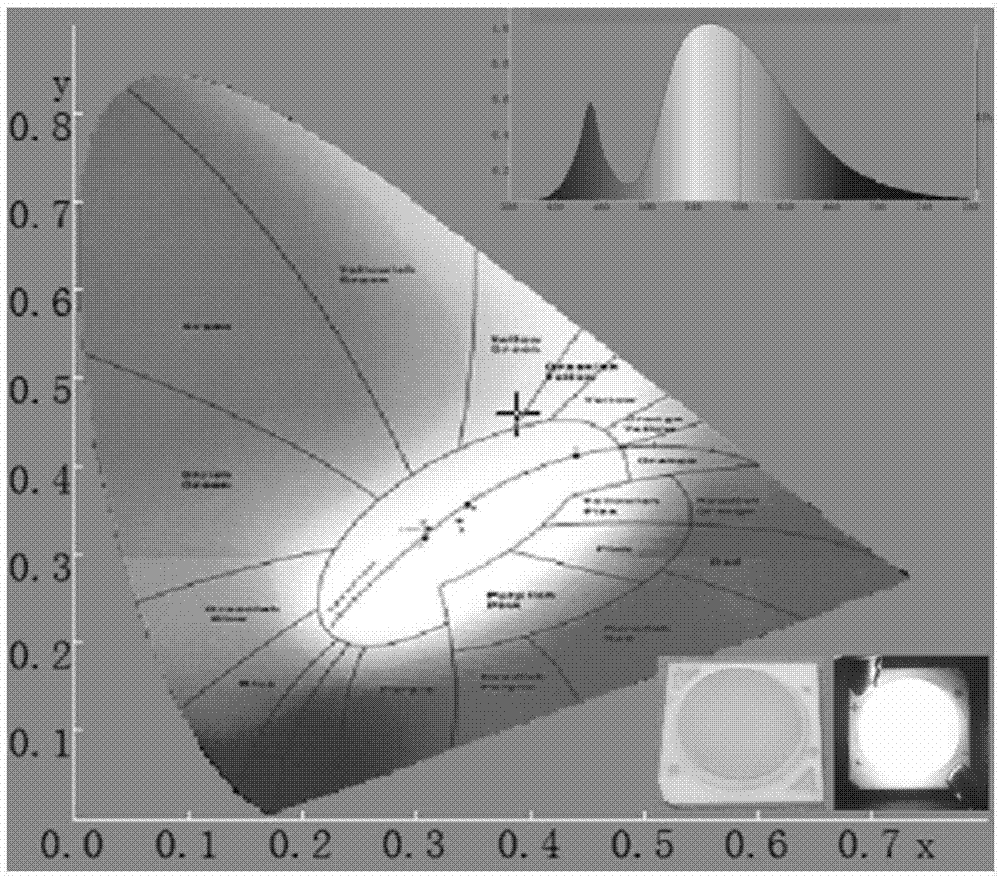

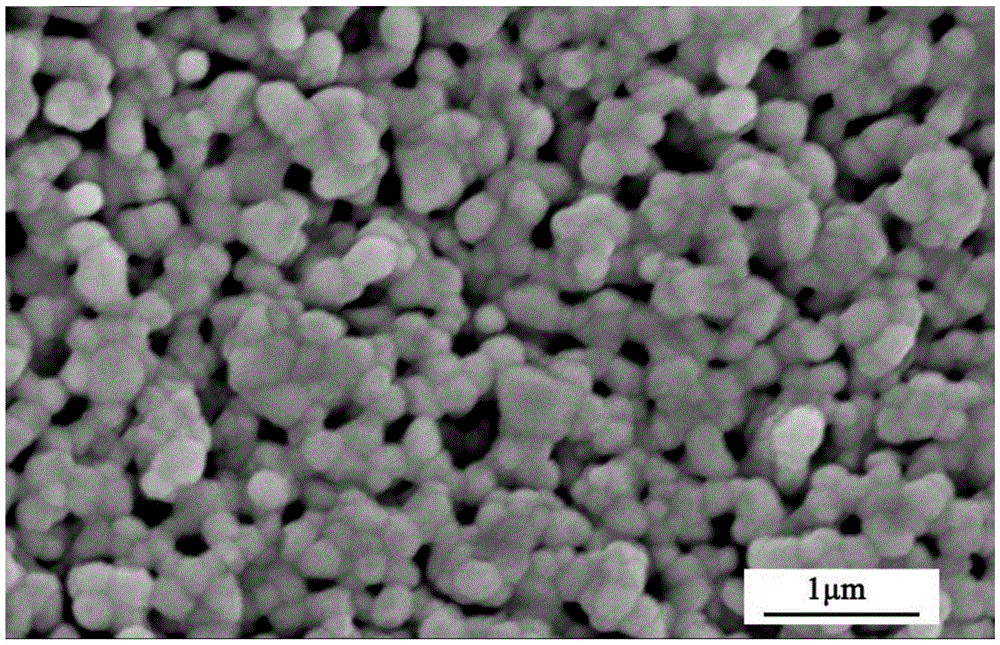

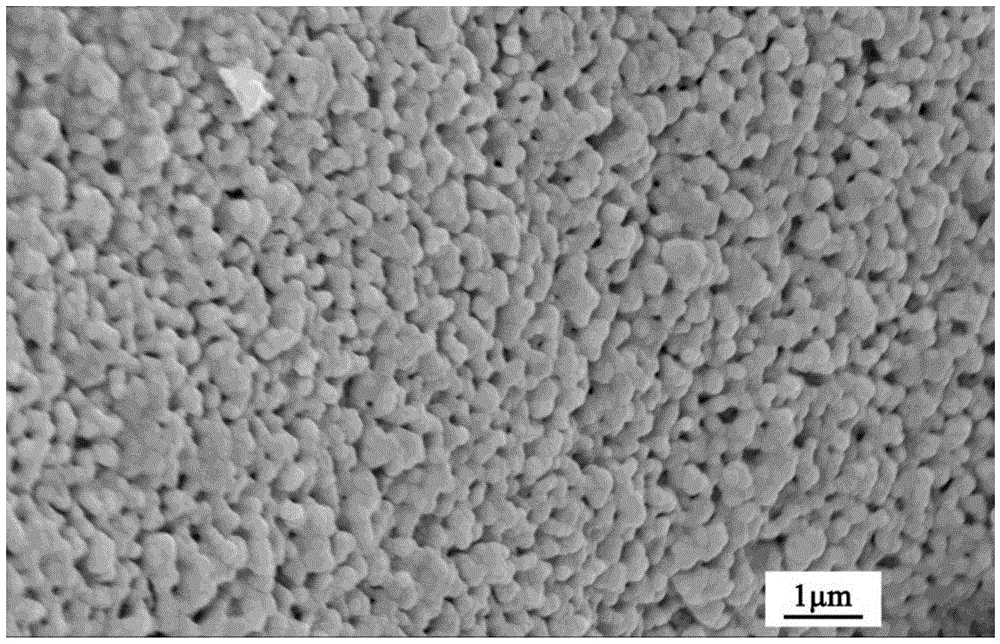

Preparation method of Eu<3+> doped molybdate red fluorescent powder used for white light LED (Light Emitting Diode)

InactiveCN106190119AReduced sinteringShort sintering timeEnergy efficient lightingLuminescent compositionsMolybdateMicrowave

The invention discloses a preparation method of Eu<3+> doped molybdate red fluorescent powder used for a white light LED (Light Emitting Diode). A chemical formula of the red fluorescent powder is Sr2CaMoO6:xEu<3+>, wherein x is greater than or equal to 0.01 and less than or equal to 0.15. Raw materials are weighed according to a stoichiometric ratio, the raw materials and a fluxing agent are fully and evenly mixed, and a mixture is added into double crucibles made of corundum, wave absorbent is arranged between the double crucibles, the double crucibles are loaded into a microvan, temperature is quickly raised to 750 to 950DEG C, the mixture is sintered in an oxidation environment, and heat preservation time is 0.5 to 4h; finally, cooling, grinding, washing and drying are carried out to obtain the red fluorescent powder used for the white light LED. During microvan sintering, the fluxing agent is added to accelerate the formation and growth of molybdate polycrystal, the sintering degree of the fluorescent powder is obviously lowered, sintering time is obviously shortened, a powder body is loose and does not need to be mechanically smashed, in addition, the shapes of aluminate fluorescent powder particles are effectively controlled, and the particles with a small particle diameter and even distribution are obtained, wherein the appearance of the particles is similar to a sphere.

Owner:SHANGHAI INST OF TECH

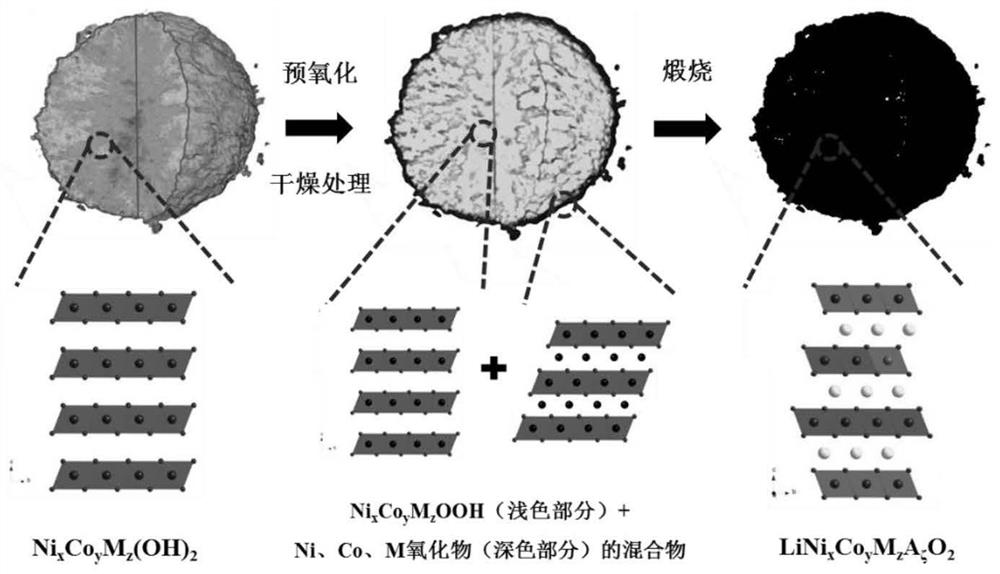

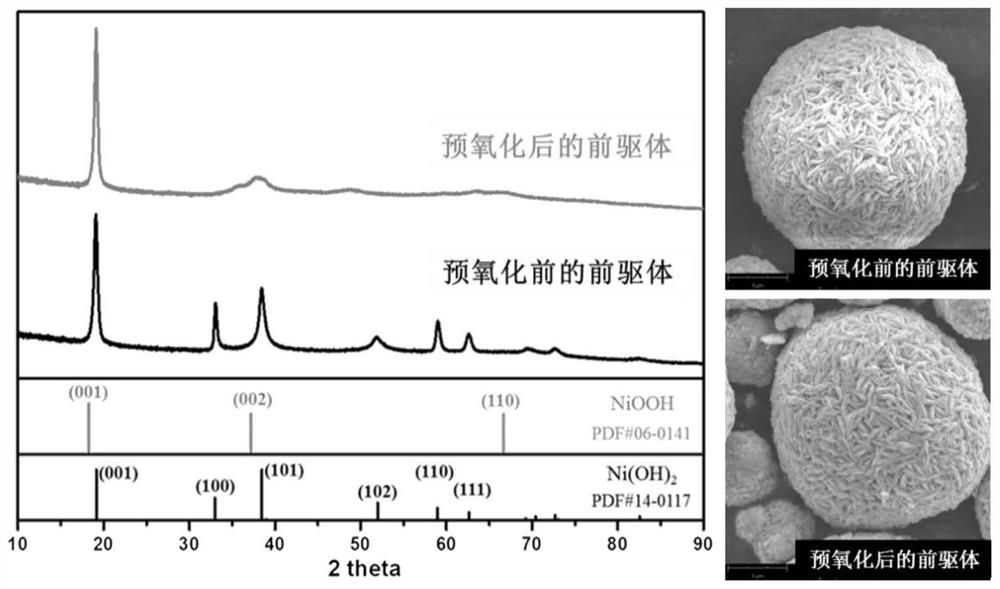

Preparation method of lithium ion battery high-nickel cathode material

ActiveCN111834631AReduce complex processNo releaseSecondary cellsPositive electrodesSlurryCrystallinity

The invention belongs to the technical field of lithium ion battery cathode materials, and specifically relates to a preparation method of a lithium ion battery high-nickel cathode material. An oxidizing agent is added into precursor alkaline slurry prepared through a coprecipitation method for precursor pre-oxidation, then the pre-oxidized precursor is converted into a polycrystalline mixture byadjusting a drying process, and then the polycrystalline mixture and a lithium source are mixed in air or a low-oxygen-concentration mixed atmosphere to be sintered at a time to obtain a target product. According to the preparation method disclosed by the invention, alkali liquor can be recycled to realize precursor pre-oxidation, the sintering time and temperature are shortened, the residual alkali value is reduced, and the crystallinity of the material is improved. In the calcining process, oxygen demand is low, safety is good, and the method is more suitable for industrial large-scale production.

Owner:WANHUA CHEM GRP CO LTD

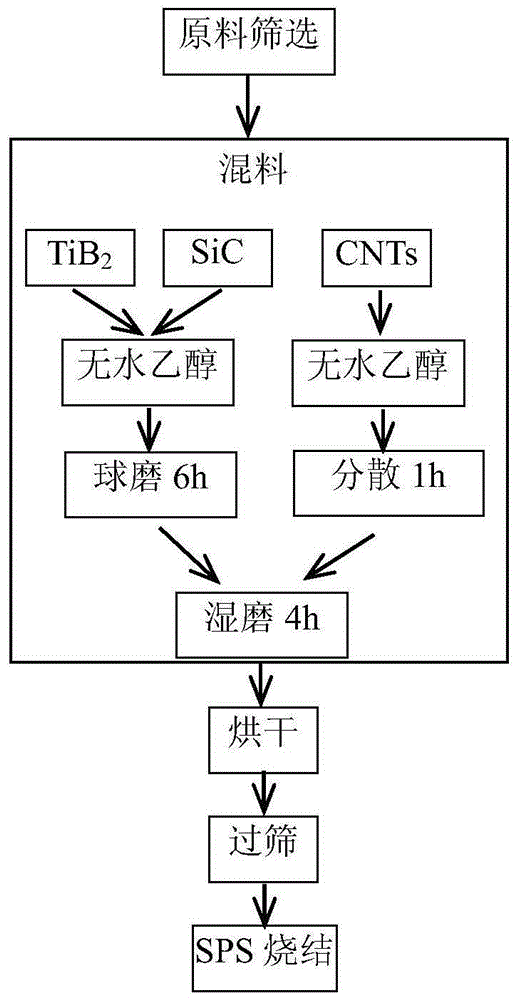

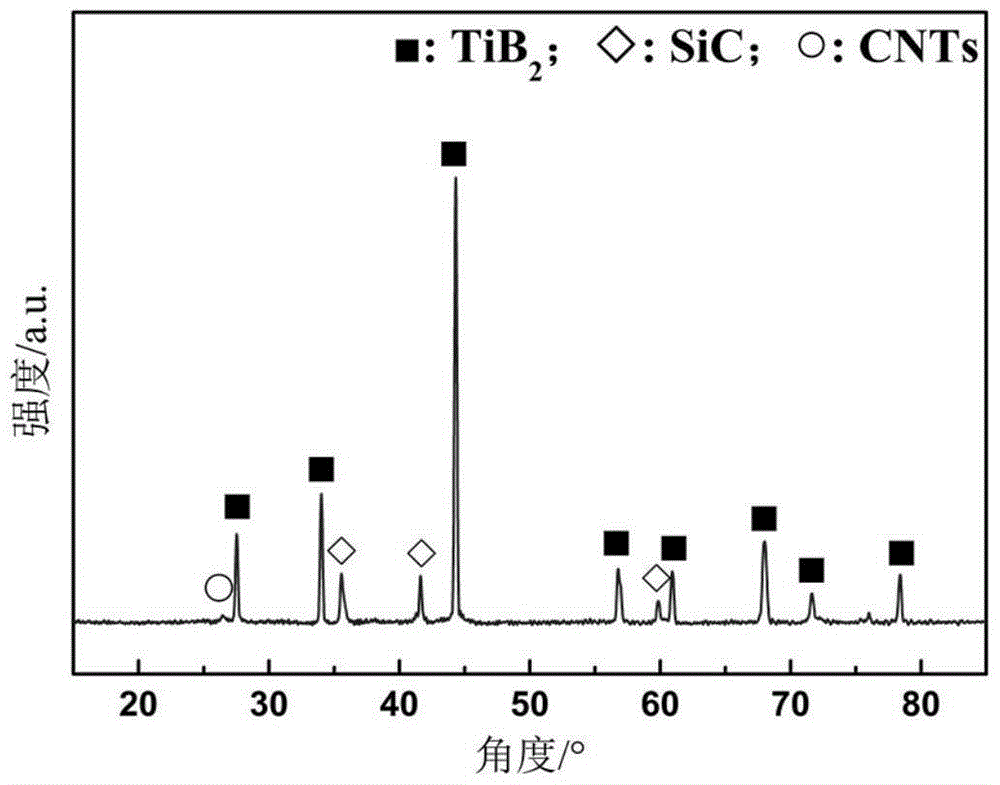

Ultra-temperature CNTs/TiB2-SiC ceramic composite material and preparation method thereof

The invention provides a preparation method of an ultra-temperature CNTs / TiB2-SiC ceramic composite material. The method comprises the following steps of mixing, drying and grinding titanium diboride powder, silicon carbide powder and carbon nanotube powder to obtain mixed powder of titanium diboride, silicon carbide and carbon nanotube; then sintering the mixed powder through a spark plasma sintering moulding process to obtain the fast SPS (Spark Plasma Sintering) CNTs / TiB2-SiC ceramic composite material. The CNTs / TiB2-SiC ceramic composite material is a high-toughness thermal protection material with high temperature resistance, ablation resistance and thermal shock resistance, and can meet the demand of thermal protection materials of key parts of a hypersonic cruise vehicle.

Owner:XIAMEN UNIV OF TECH

Molybdenum blank preparing method

InactiveCN101966585ALower sintering temperatureShorten the sintering timeGranularityVolumetric Mass Density

The invention discloses a molybdenum blank preparing method, and relates to a method for preparing a pure molybdenum blank with the grain number of 5,000 to 20,000 / mm<2> and the grain size of 300 to 800nm. The molybdenum blank preparing method is characterized in that: in the preparation process, submicron-scale molybdenum powder with the granularity of 0.5 to 1um is taken as a raw material and is pretreated, molded and sintered into a molybdenum blank. In the molybdenum blank preparing method, the molybdenum powder is taken as a raw material, and the molybdenum blank with fine grains can be prepared by reducing sintering temperature and shortening the sintering time, and has the density of 9.8 to 10.0, the grain number of 5,000 to 20,000 / mm<2> and the grain size of 300 to 800nm. The submicron-scale molybdenum powder is taken as the raw material for preparing the molybdenum blank with fine grains, special requirements on production equipment are absent, and the method is suitable for industrial production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Lithium iron phosphate positive electrode material, preparation method thereof and lithium ion battery

InactiveCN111082011APromote growthImprove compaction performanceCell electrodesSecondary cellsElectrical batteryLithium electrode

The invention discloses a lithium iron phosphate positive electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of uniformly stirring deionized water, iron phosphate, lithium carbonate and glucose to obtain mixed slurry; carrying out primary grinding on the mixed slurry to obtain coarse grinding slurry, and then carrying out secondary grinding to obtain fine grinding slurry; carrying out centrifugal spray drying on the finely ground slurry to obtain a dry material, and mixing the dry material with lithium titanate to obtain a lithium iron phosphate precursor; carrying out solid-phase sintering on the lithium iron phosphate precursor in a nitrogen atmosphere to obtain a lithium iron phosphate sintered body; and carrying out air jet pulverization and grading on the lithium iron phosphate sintered body to prepare the lithium iron phosphate positive electrode material. The lithium iron phosphate positive electrode material prepared by the method has relatively high compaction density and excellent cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY CO LTD CO LTD

Dual heating mode flash sintering method combining current heating with radiant heating

InactiveCN101050121AThe actual promotion and application value is highShorten the sintering timeMaterials scienceRadiation heating

This invention relates to a method for preparing block material from powdery material by sintering. The method is a rapid sintering method by combination of electric heating and radiation heating. The electricity / radiation power ratio is (5-30):1. The radiation heater / mold height ratio is (1-3):2. Samples with diameters greater than 30 mm are heated through combination of electric heating and radiation heating at a heating rate of 100-800 deg.C / min; the heat preservation time is 3-15 min. After heat preservation, electric heating and radiation heating terminated, and the samples are naturally cooled. The method can be used to prepare samples with uniform inner structure and diameters greater than 30 mm, and has such advantages as short sintering time and low energy consumption.

Owner:WUHAN UNIV OF TECH

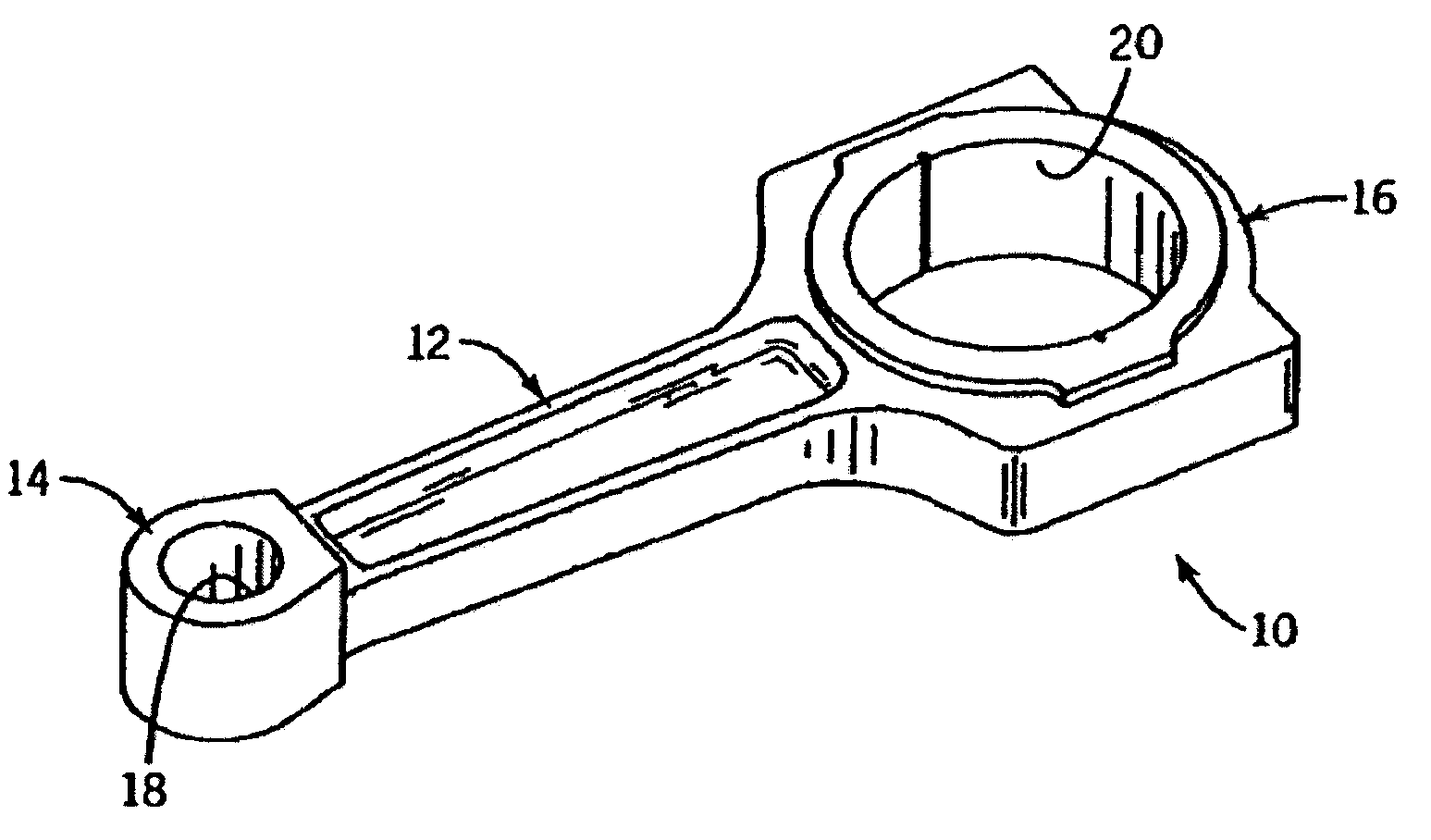

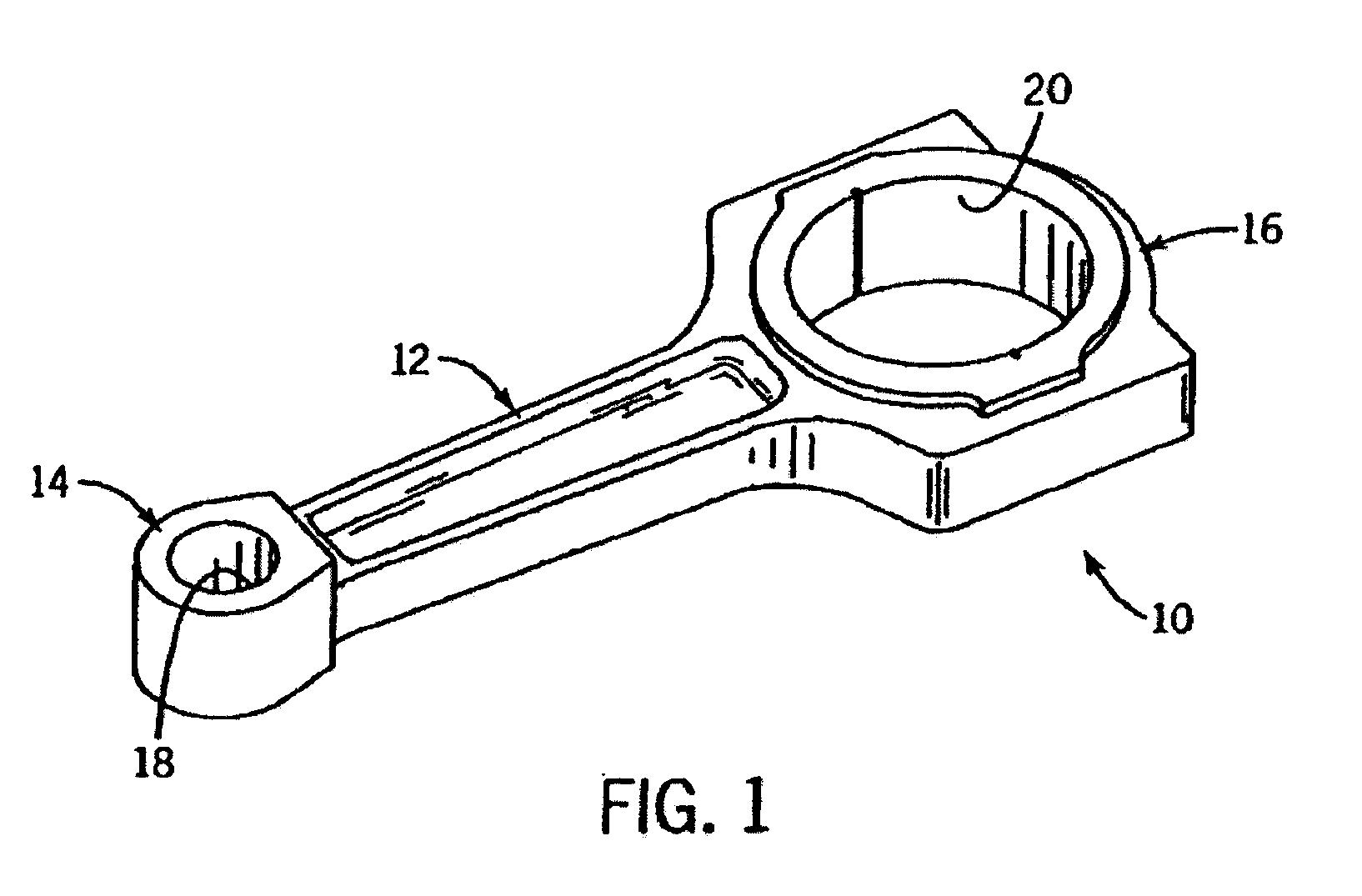

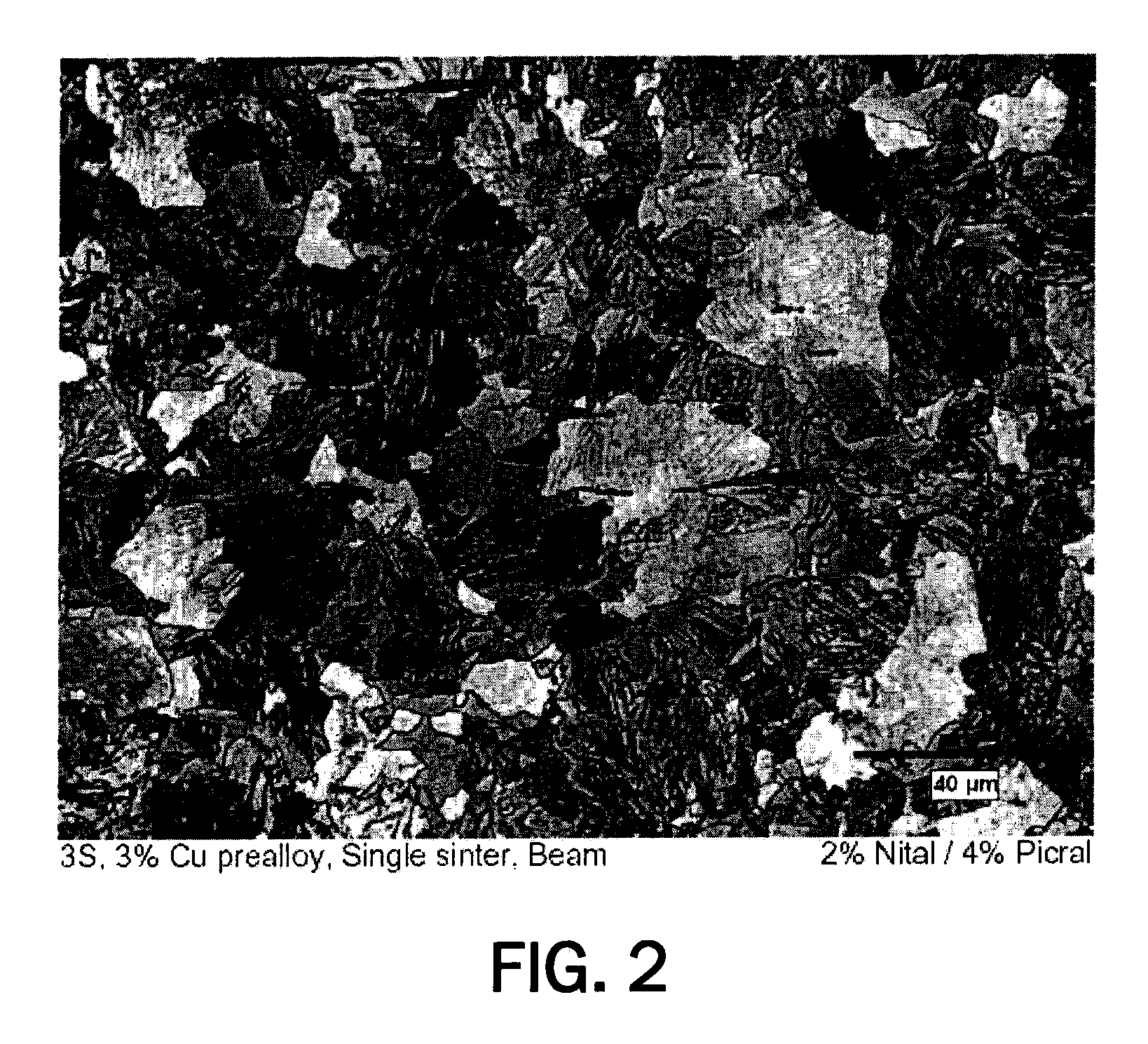

Prealloyed copper powder forged connecting rod

A process for manufacturing connecting rods is provided which comprises the steps of compacting, sintering, and powder forging a powder metal comprising a carbon source and a prealloyed powder consisting essentially of iron and copper. The connecting rods made from this process have sufficient hardness and strength to be used in an engine and do not require any additional quenching or tempering.

Owner:SKN SINTER METALS LLC (US)

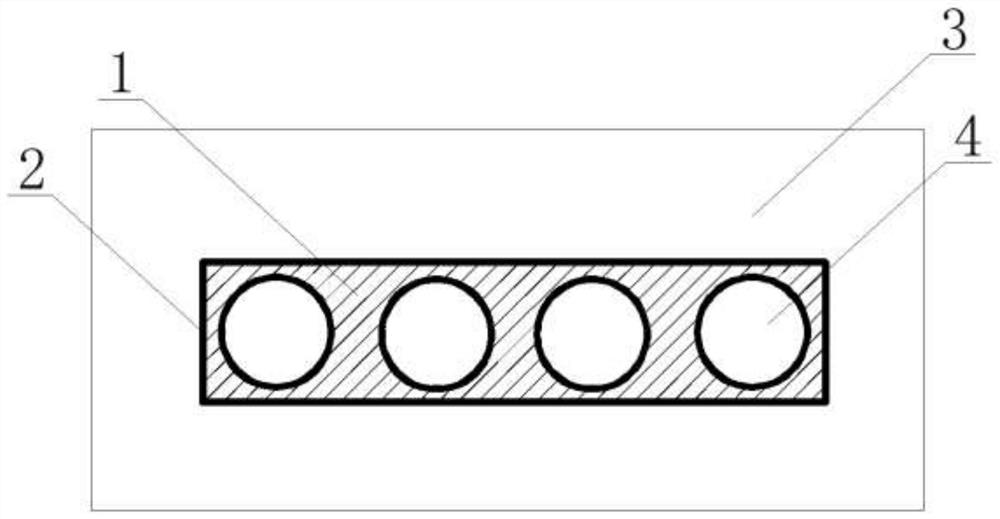

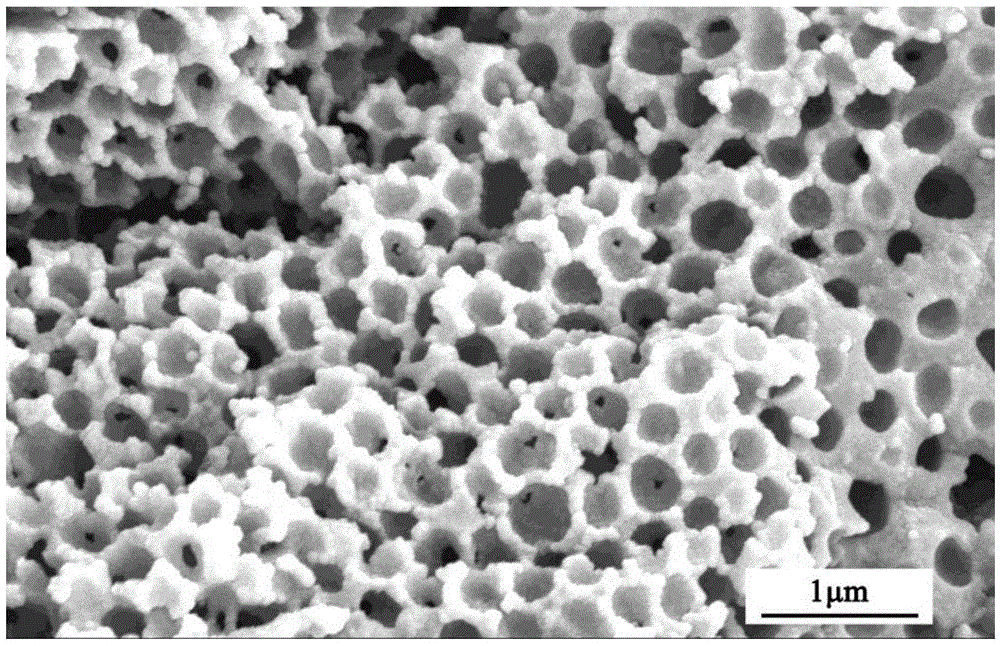

Ceramic filter membrane prepared from red mud, and preparation method thereof

ActiveCN112028608AImprove performanceLow costMembranesSemi-permeable membranesPlasticizerMicrosphere

The invention discloses a ceramic filter membrane prepared from red mud. The ceramic filter membrane comprises a matrix and a membrane layer, and the matrix is prepared from, by weight, 60-80 parts ofred mud microspheres, 7-15 parts of granite powder, 5-12 parts of plastic clay, 4-7 parts of a plasticizer and 1-2 parts of a lubricant; the membrane layer is prepared from, by weight, 60-80 parts ofthe red mud microspheres, 7-15 parts of the granite powder, 5-12 parts of the plastic clay and 0.1-0.5 part of a dispersing agent; the sphere diameter of the red mud microspheres in the matrix preparation raw material is 45-60 [mu]m; and the sphere diameter of the red mud microspheres in the raw materials for preparing the membrane layer is 10-20 [mu]m. The ceramic filter membrane can be producedin the invention, the pore diameter ranges from 70 nm to 100 nm, the bending strength ranges from 20 MPa to 30 MPa, and the pure water flux ranges from 25 m<3> / m<2>.d to 30 m<3> / m<2>.d.

Owner:SHANDONG UNIV OF TECH

Hydroxyapatite-based fluorescent ceramic material and preparation method thereof

The invention relates to a hydroxyapatite-based fluorescent ceramic material and a preparation method thereof. The hydroxyapatite-based fluorescent ceramic material is prepared from the following raw materials in percentages by weight: 95-99% of hydroxyapatite matrix and 1-5% of fluorescent powder. The preparation method comprises the steps of mixing the hydroxyapatite matrix with the fluorescent powder evenly; loading the mixed raw materials into a graphite mold, putting the graphite mold into a spark plasma sintering furnace, sintering in a vacuum environment to obtain transparent ceramic; and finally grinding and polishing to obtain the hydroxyapatite-based fluorescent ceramic material. By adopting hydroxyapatite nano powder, the sintering temperature of the fluorescent ceramic is effectively reduced, the sintering time of the fluorescent ceramic is effectively shortened, the luminescence characteristic of fluorescent powder can be effectively reserved; meanwhile, by adopting the ceramic as the matrix, the thermal conductivity of an LED packaging material can be significantly improved, and the heat resistance and the stability of the fluorescent ceramic material are effectively improved; the preparation technology is simple and convenient; and the hydroxyapatite-based fluorescent ceramic material can be directly used as a packaging material to replace a traditional organic polymer or silica gel packaging material, and has a good application prospect.

Owner:台州优瑞精工科技有限公司

Ceramic for ceramic LED lamps

The invention discloses a ceramic for ceramic LED lamps. The ceramic is formed through grinding components and firing the ground components, and the components comprise 50-60 parts of aerated aluminum powder, 60-70 parts of aluminum nitride, 30-45 parts of mica powder, 40-50 parts of calcite powder, 6-8 parts of lead trioxide, 8-10 parts of samarium oxide, 8-10 parts of boron nitride, 12-15 parts of born carbide, 20-25 parts of silicon micro-powder, 25-35 parts of molybdenite powder, 5-8 parts of nanometer magnesium oxide, 8-10 parts of titanium dioxide, 8-10 pars of zirconium dioxide and 12-15 parts of silicon nitride. The ceramic for ceramic LED lamps can effectively solve the problems of firing fracture, deformation and high defective index of present ceramics, can shorten the pre-burning and sintering time, reduces the sintering temperature , greatly saves energy, reduces energy consumption, is environmentally-friendly and reduces the production cost, grains of sintered products are fine and uniform and have high density, the fracture toughness of the ceramic material is effectively improved, sintering deformation is well controlled, the sintered ceramic material is integrally balanced, wastes are greatly reduced, and the quality of the products is improved.

Owner:YANCHENG SILU INFORMATION TECH SERVICE CO LTD

Method for electric-field-assisted low-temperature fast sintering of porous ceramics

The invention relates to a method for electric-field-assisted low-temperature fast sintering of porous ceramics. The temperature of a porous ceramics body is raised to a proper temperature, and fast sintering of the ceramics can be achieved through proper electric field intensity. Different electric field intensity conditions can be selected according to different porous ceramic materials. In the transmission process of matter excited by electric field energy, the particle activity is improved, the diffusion migration speed is increased, ceramics particles are rapidly sintered, sintering temperature can be effectively lowered, and sintering time can be effectively shortened. By means of the method for electric-field-assisted low-temperature fast sintering, the porous ceramics which is high in strength and high in porosity can be acquired.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing anode material of lithium ion battery by spray refrigeration

InactiveCN1431729AEasy to operateFew control conditionsActive material electrodesLi-accumulatorsIonElectrochemistry

Based on the molecular formula of the material of positive electrode of the lithium ion battery, the proportioning materials are prepared. The mechanical ball milling method is utilized to mix the materials evenly. With the deionized water being added, the said dmixture is stirred up to obtain the solution of the materials. Spraying the prepared solution to the refrigerating medium in liquid state with being stired up obtains the refrigeration object. With being filtered, the refrigeration object is quickly moved to the desiccator, which is freezed by liquid nitrogen in advance, so as to obtain the predecessor in fine crystal caused by vacuum drying. Nano anode material of lithium ion battery is obtained by sintering the predecessor in 3-10 hours at 500-1000 deg.C.

Owner:张文魁 +4

Ultra-thin alumina ceramic substrate preparation method

The invention relates to the technical field of alumina ceramics, particularly to an ultra-thin alumina ceramic substrate preparation method. A purpose of the present invention is to solve the problemof too high sintering temperature of the alumina ceramic substrate in the prior art. The method comprises: (1) carrying out surface modification on aluminum oxide powder; (2) preparing a slurry; (3)carrying out casting molding; (4) stamping, wherein the billet tape obtained in the step (3) is stamped to obtain a billet sheet; (5) discharging glue, wherein the billet sheet is placed into a glue discharge furnace, and is subjected to first glue discharge under a nitrogen atmosphere, heating is performed to a temperature of 450-550 DEG C at a heating rate of 0.8-2 DEG C / min, thermal insulationis performed for 35-60 min, second glue discharge is performed in an air atmosphere, heating is performed to a temperature of 180-250 DEG C at a heating rate of 2-5 DEG C / min, and thermal insulation is performed for 80-120 min; and (5) sintering, wherein the billet sheet after the glue discharge in the step (5) is placed into a sintering furnace, and is sintered for 12-20 h at a sintering temperature of 1550-1600 DEG C.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

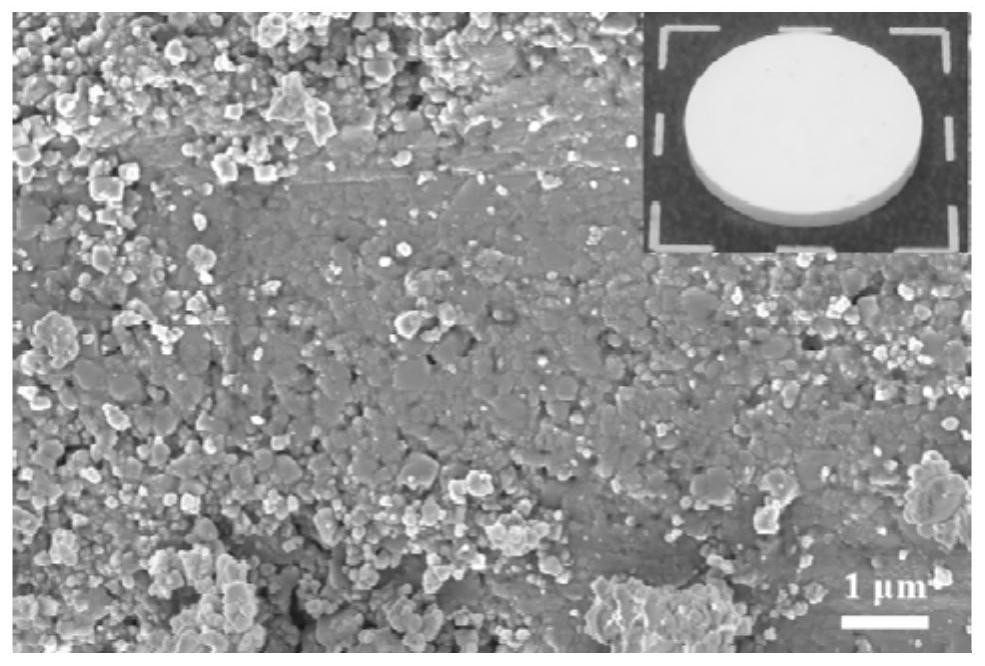

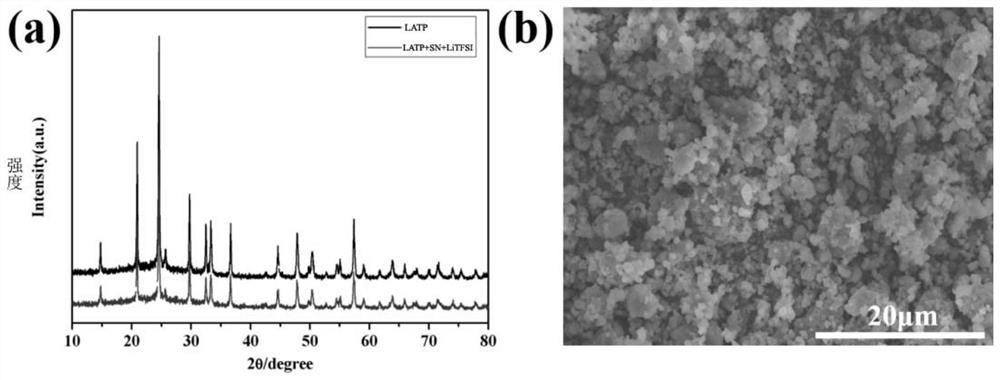

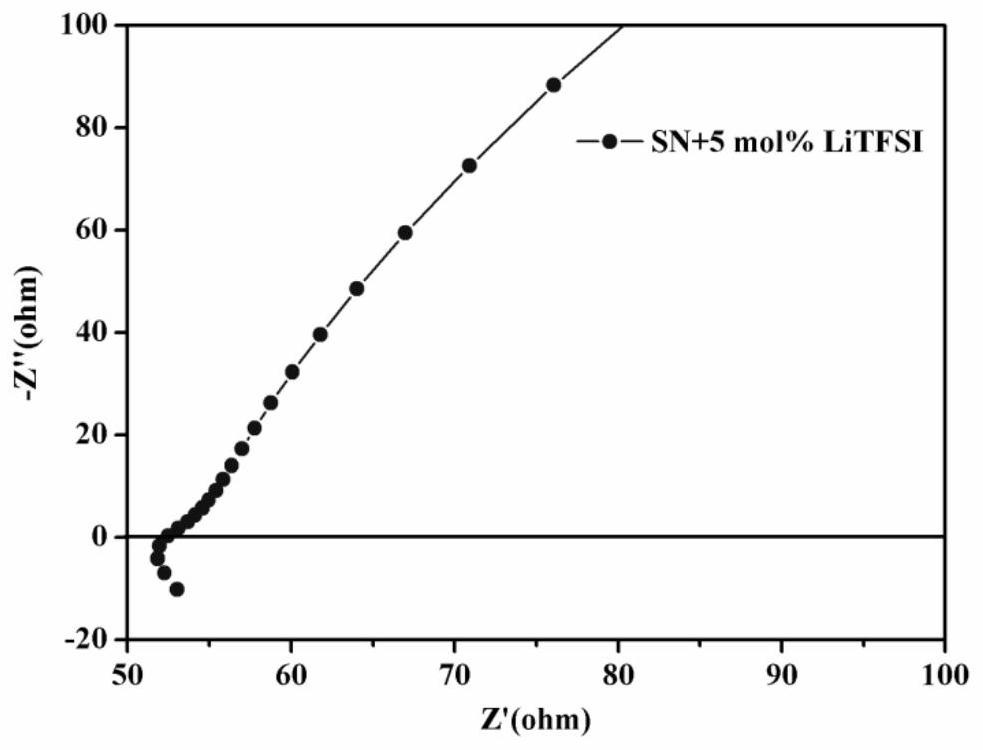

Plastic crystal-ceramic composite solid electrolyte and low-temperature hot-pressing preparation method thereof

InactiveCN112531204APrevent decomposition reactionHigh mechanical strengthFinal product manufactureLi-accumulatorsOxide ceramicPlastic crystal

The invention discloses a plastic crystal ceramic composite solid electrolyte and a low-temperature hot-pressing preparation method thereof. The method comprises the following steps of step 1, weighing oxide ceramic powder and the plastic crystal solid electrolyte, and uniformly mixing to obtain mixed powder; the plastic crystal solid electrolyte comprising a plastic crystal and a lithium salt, step 2, putting the mixed powder into a mold, and flattening the mixed powder; 3, the mixed powder being subjected to compression molding, meanwhile, the mixed powder being subjected to heat treatment,the heating temperature being lower than 600 DEG C, and the plastic crystal solid electrolyte absorbing heat to be molten; and then reducing the temperature to solidify and mold the plastic crystal solid electrolyte to obtain the plastic crystal ceramic composite solid electrolyte. According to the method, densification of the solid electrolyte can be realized at a relatively low temperature, thesolid electrolyte has relatively high ionic conductivity, and the processing time, energy loss and volatilization of a lithium element at a high temperature are greatly reduced.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Microwave synthesis method of boron carbide ceramics

The invention discloses a microwave synthesis method of boron carbide ceramics, and belongs to the technical field of preparation of ceramic materials. According to the microwave synthesis method, a microwave sintering process is used, alumina with a mass fraction of 3% is added as a sintering aid, the sintering temperature, the thermal insulation time and other process parameters are optimized, and the boron carbide ceramic material is prepared at a relatively fast heating rate. According to the present invention, the prepared boron carbide ceramic has advantages of high density, high porosity, high hardness and good toughness; and the preparation method has advantages of simpleness, convenience, low requirement on equipment, substantially-reduced sintering time, substantially-reduced sintering temperature, high production efficiency and less energy consumption, and is suitable for industrial production.

Owner:DONGGUAN UNIV OF TECH

Method for preparing lithium iron phosphate in batch-type high-vacuum dynamic sintering mode

ActiveCN102856551AFully heatedShorten the sintering timeCell electrodesPhosphorus compoundsHeating timeRotary furnace

The invention discloses a method for preparing lithium iron phosphate in a batch-type high-vacuum dynamic sintering mode. The method includes: adopting a batch-type rotary furnace to heat a precursor of the lithium iron phosphate, performing sealing treatment on a furnace head and a rotary portion through a sealing pad and high-temperature-resisting vacuum fat, vacuumizing the rotary furnace during heating, and pumping oxidizing gases and steam generating in the sintering process quickly, wherein the vacuum degree is kept to be 10<2>-10<12> pa, the furnace body is rotated continuously, the heating temperature is 300-900 DEG C, the heating hour is 5-15h; stopping a vacuum pump and a pumping valve after heating is finished, leading in inert gases into the rotary furnace, and taking the product out after cooling. The prepared precursor of the lithium iron phosphate is fed into the batch-type rotary furnace for vacuum sintering, the high-vacuum state is kept by fast vacuumizing the furnace body through the multi-stage vacuum pump during the whole process, and powder materials rotate along with the furnace body to achieve the aim of dynamic sintering, so that the method for preparing lithium iron phosphate in the batch-type high-vacuum dynamic sintering mode is suitable for preparing lithium ion positive pole materials in industrial mode.

Owner:徐剑晖

Full fly ash building brick and its manufacturing method and special additive

A flyash brick for building is prepared from the flyash (90-96 wt.%) and the composite additive (4-10 wt%) containing water glass, alkaline oxide or the alkaline compounds, bentone, and iron oxide. Its advantages are high strength and low cost.

Owner:山西民兴实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com