Preparation method of Eu<3+> doped molybdate red fluorescent powder used for white light LED (Light Emitting Diode)

A molybdate, white light technology, applied in the field of physics, can solve problems such as poor performance of phosphors, and achieve the effects of improving luminous intensity and thermal stability, reducing synthesis temperature and loosening powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1Sr 2 CaO 6 :0.03Eu 3+ The synthesis method is as follows:

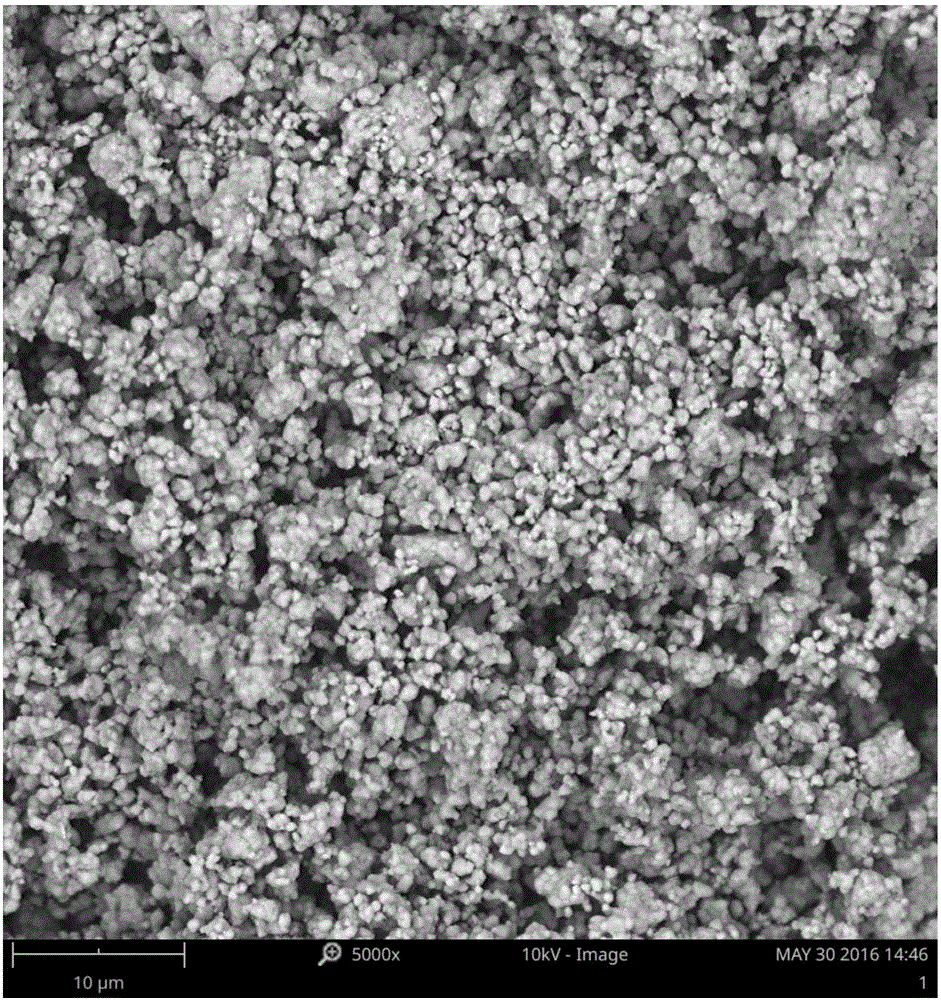

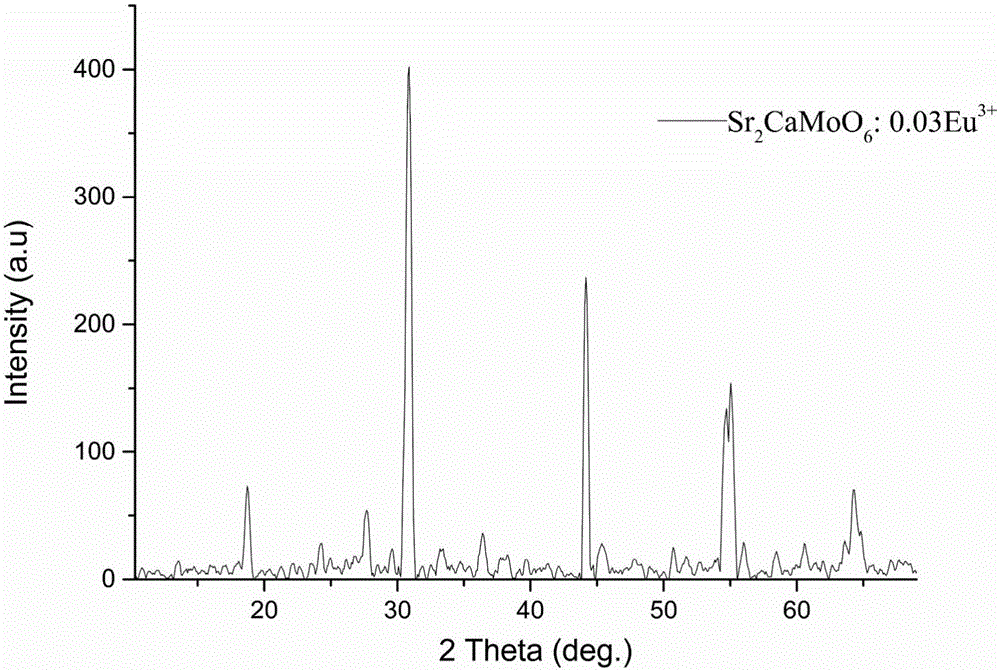

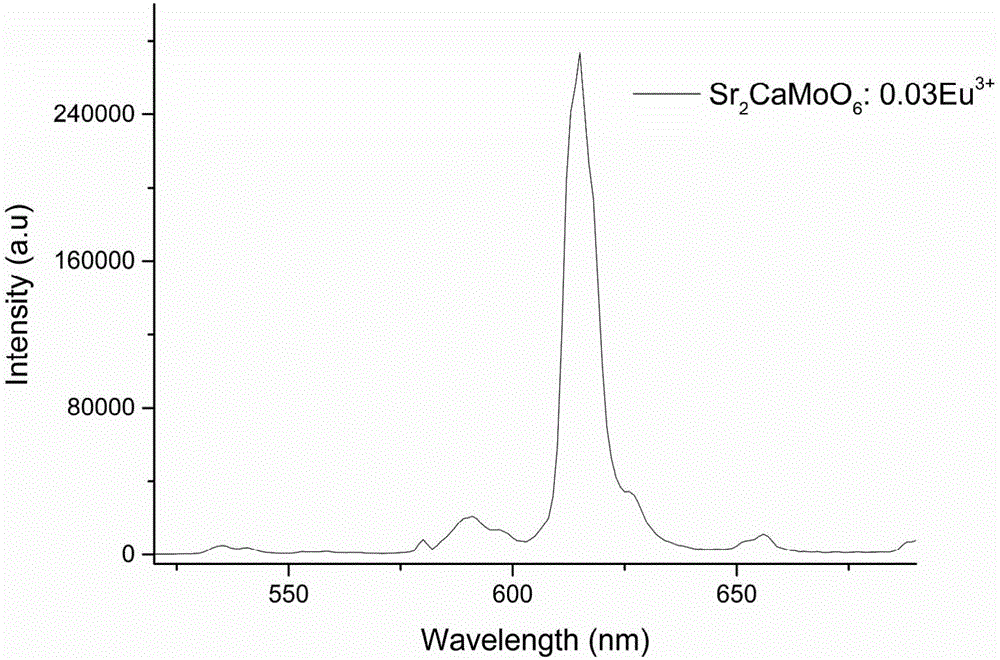

[0027] With the chemical formula Sr 2 CaO 6 :0.03Eu 3+ The stoichiometric ratio in weighs an appropriate amount of SrCO 3 、Eu 2 o 3 , CaCO 3 and MoO 3 As a raw material, take Li by weighing 3% of the total reactant mass. 2 CO 3 , and use it as a flux, then put the raw material and flux in an agate mortar, mix and grind; put the ground raw material into a corundum crucible, put the crucible into Al 2 o 3 Sagger, while placing SiC auxiliary heat material on the outer wall of the sagger; Al 2 o 3Put the sagger in the heat preservation bucket, and fill the insulation cotton between the sagger and the heat preservation bucket, and then put the heat preservation bucket into the microwave oven; by adjusting the power, heat it to 600°C under normal pressure at a heating rate of 50°C / min. Keep warm for 3 hours, then heat to 900°C at the same heating rate, and keep warm for 3 hours; after the reac...

Embodiment 2

[0029] Example 2Sr 2 CaO 6 :0.05Eu 3+ The synthesis method is as follows:

[0030] With the chemical formula Sr 2 CaO 6 :0.05Eu 3+ The stoichiometric ratio in weighs an appropriate amount of SrCO 3 、Eu 2 o 3 , CaCO 3 and MoO 3 As a raw material, weigh LiF according to 1% of the total reactant mass, and use it as a flux, then put the raw material and flux in an agate mortar, mix and grind; put the ground raw material into a corundum crucible , put the crucible into Al 2 o 3 Sagger, while placing SiC auxiliary heat material on the outer wall of the sagger; Al 2 o 3 Put the sagger in the heat preservation bucket, and fill the insulation cotton between the sagger and the heat preservation bucket, and then put the heat preservation bucket into the microwave oven; by adjusting the power, heat it to 600°C under normal pressure at a heating rate of 50°C / min. Keep warm for 3 hours, then heat to 950°C at the same heating rate, keep warm for 3 hours, turn off the microwave ...

Embodiment 3

[0031] Example 3Sr 2 CaO 6 :0.15Eu 3+ The synthesis method is as follows:

[0032] With the chemical formula Sr 2 CaO 6 :0.15Eu 3+ The stoichiometric ratio in weighs an appropriate amount of SrCO 3 、Eu 2 o 3 , CaCO 3 and MoO 3 As a raw material, weigh NaF according to 10% of the total reactant mass, and use it as a flux, then put the raw material and flux in an agate mortar, mix and grind; put the ground raw material into a corundum crucible , put the crucible into Al 2 o 3 Sagger, while placing SiC auxiliary heat material on the outer wall of the sagger; Al 2 o 3 Put the sagger in the heat preservation bucket, and fill the insulation cotton between the sagger and the heat preservation bucket, and then put the heat preservation bucket into the microwave oven; by adjusting the power, heat it to 600°C under normal pressure at a heating rate of 50°C / min. Keep it warm for 3 hours, then heat it to 750°C at the same heating rate, keep it warm for 3 hours, turn off the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com