Patents

Literature

46 results about "Tungstate ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a tungstate is a compound that contains an oxoanion of tungsten or is a mixed oxide containing tungsten. The simplest tungstate ion is WO 2 ...

Ion-exchange separation method for tungsten and molybdenum in tungstate and molybdate mixed solution

InactiveCN102162030AEasy to parsePromote regenerationMolybdeum compoundsProcess efficiency improvementTungstate ionMOLYBDATE ION

The invention discloses an ion-exchange separation method for tungsten and molybdenum in a tungstate and molybdate mixed solution, technically characterized by comprising the following steps of: adjusting the pH of the tungstate and molybdate mixed solution by mineral acid to be appropriate, so that the tungstate ions in the solution are polymerized into paratungstate ions, while molybdenum still exists in the form of tungstate ions; adjusting the concentration of Cl<-> in the solution to be appropriate, enabling the solution to flow through ion exchange columns loaded with macroporous strong base anion exchange resin, so that the tungsten in the solution is absorbed firstly, thereby separating the tungsten from the molybdenum; rinsing a small amount of MoO4<2-> ions absorbed by the resin in the ion exchange columns by a solution with an appropriate concentration of Cl<->; and finally resolving the tungsten absorbed on the resin by using an alkali solution with an appropriate concentration of Cl<-> as a resolving agent to regenerate the resin.

Owner:CENT SOUTH UNIV

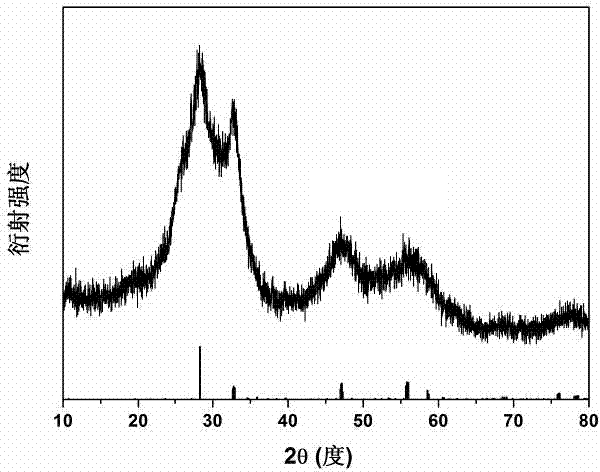

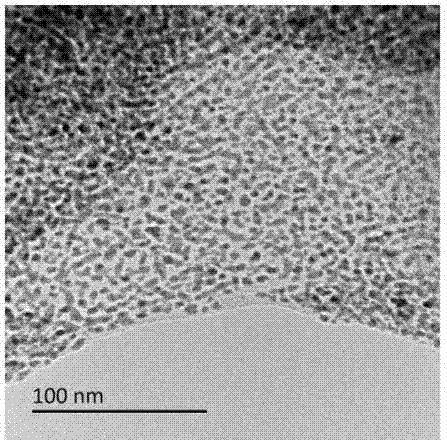

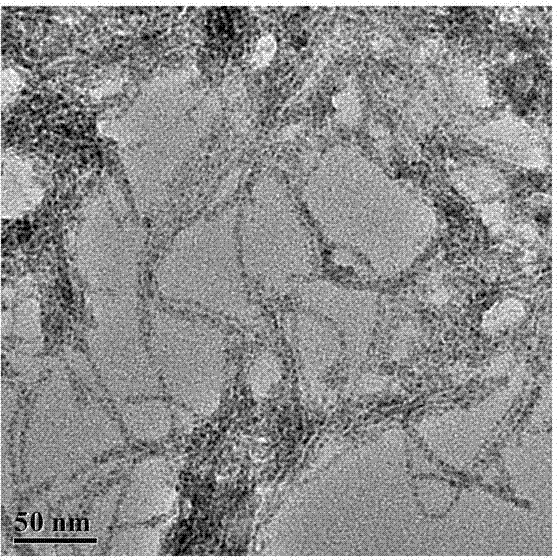

Preparation method of bismuth tungstate quantum dot and preparation method of bismuth tungstate quantum dot-graphene composite material

InactiveCN102963934AImprove photocatalytic activityImprove stabilityCarbon compoundsLuminescent compositionsTungstate ionEmulsion

The invention relates to a preparation method of a bismuth tungstate quantum dot and a preparation method of a bismuth tungstate quantum dot-graphene composite material. The preparation method of the bismuth tungstate quantum dot comprises the steps: a, dissolving a soluble bismuth salt and sodium oleate in water, stirring for more than 1 hour to form a first emulsion-like precursor solution containing bismuth ions, wherein the molar concentration of the sodium oleate in the first precursor solution is smaller than 0.3mol / L; b, dissolving the soluble bismuth salt in water, and stirring and ultrasonically dispersing to form a uniform second precursor solution containing tungstate ions; and c, mixing the first precursor solution and the second precursor solution, and carrying out hydro-thermal synthesis for more than 12 hours at 120-180 DEG C. According to the bismuth tungstate quantum dot and the bismuth tungstate quantum dot-graphene composite material, prepared by using the methods provided by the invention, the bismuth tungstate quantum dot is about 3nm in dimension,not only has extremely high photocatalytic activity, but also has extremely high stability. The preparation methods disclosed by the invention do not special equipment and rigor conditions, are simple in process, strong in controllability and easy for realization of scale production and have practicability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Deep purification method for removing micro-tungsten from high-concentration molybdenate solution

A method for completely cleaning high concentration molybdate solution by removing trace tungsten comprises the steps of pre-adjusting pH value of molybdate solution containing trace tungsten, allowing tungstate ions to completely polymerize to form polytungstate ions, and performing selective adsorption of tungsten with adsorption bed filled with macroporous weak base anion exchange resin, so as to completely remove tungsten from molybdate solution.

Owner:CENT SOUTH UNIV

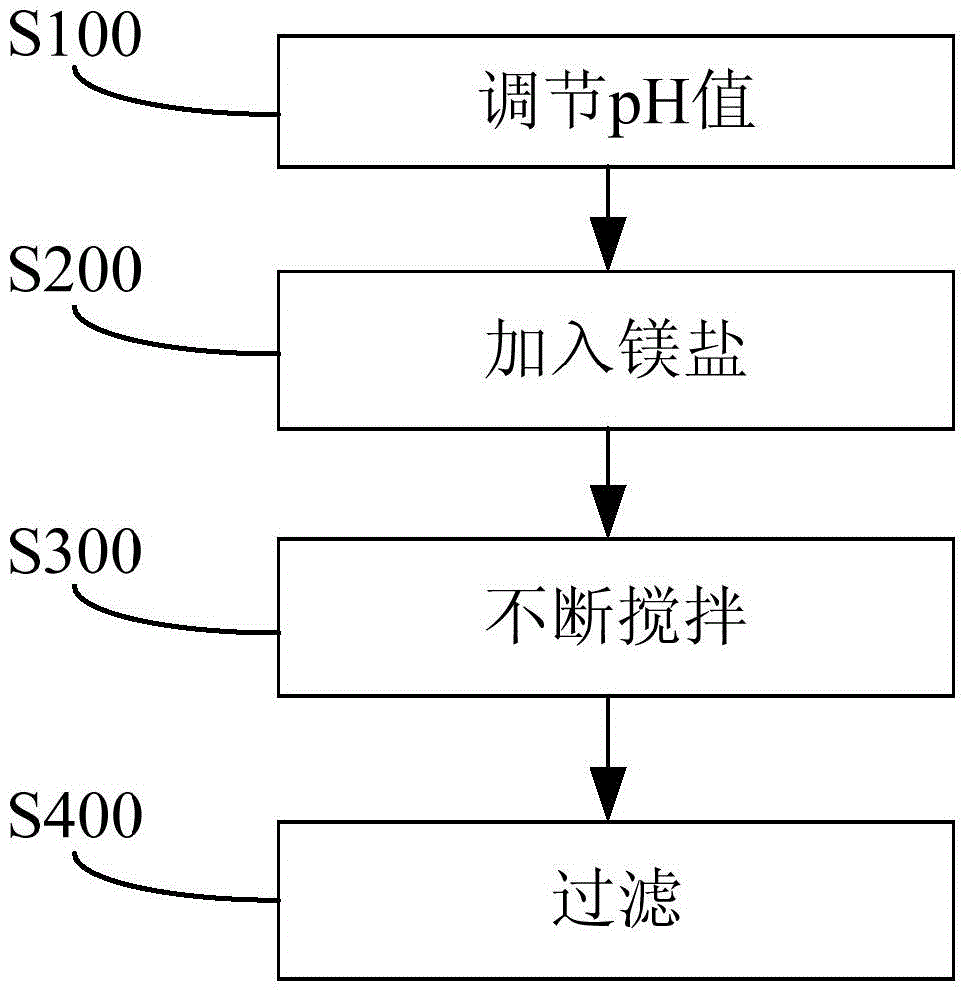

Method used for purifying sodium tungstate solution

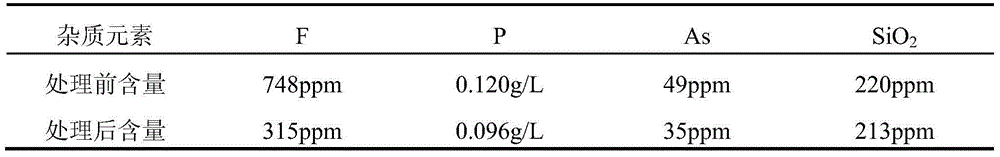

InactiveCN104973628AReduce contentReduce manufacturing costTungsten compoundsTungstate ionAfter treatment

The invention discloses a method used for purifying a sodium tungstate solution. The method comprises following steps: at 50 to 100 DEG C, pH value of the sodium tungstate solution is adjusted so as to realize silicon precipitation and obtain a first sodium tungstate mixed solution containing silicon precipitates; a magnesium salt is added into the first sodium tungstate mixed solution so as to obtain a second sodium tungstate mixed solution; at a temperature of 50 DEG C or higher, stirring is carried out continuously so as to obtain a third sodium tungstate mixed solution containing precipitates; and the third sodium tungstate mixed solution is subjected to filtration so as to obtain a filtrate, wherein the filtrate is the purified sodium tungstate solution. According to the method, solid salts are adopted for purification and processing, so that comprehensive removing of fluorine, phosphorus, arsenic, and silicon can be realized, and influences on tungstate ion exchange and product purity caused by introducing of impurity negative ions and positive ions are avoided. After treatment, content of impurities, such as fluorine, phosphorus, arsenic, and silicon, in the sodium tungstate solution is reduced greatly.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

Colored conversion layers on metal surfaces

InactiveUS20060173099A1Solid state diffusion coatingMetallic material coating processesTungstate ionChromium free

Chromium-free conversion coating treatment solutions and processes for depositing a colored layer on zinc or galvanized steel, aluminum, magnesium or their alloys, are provided comprising: hexafluorotitanate and / or hexafluorozirconate ions; molybdate and / or tungstate ions; one or more chelating complex formers; and a copolymer of alkylene phosphonic or alkylene phosphinic acid and one or more unsaturated carboxylic acids.

Owner:HENKEL KGAA

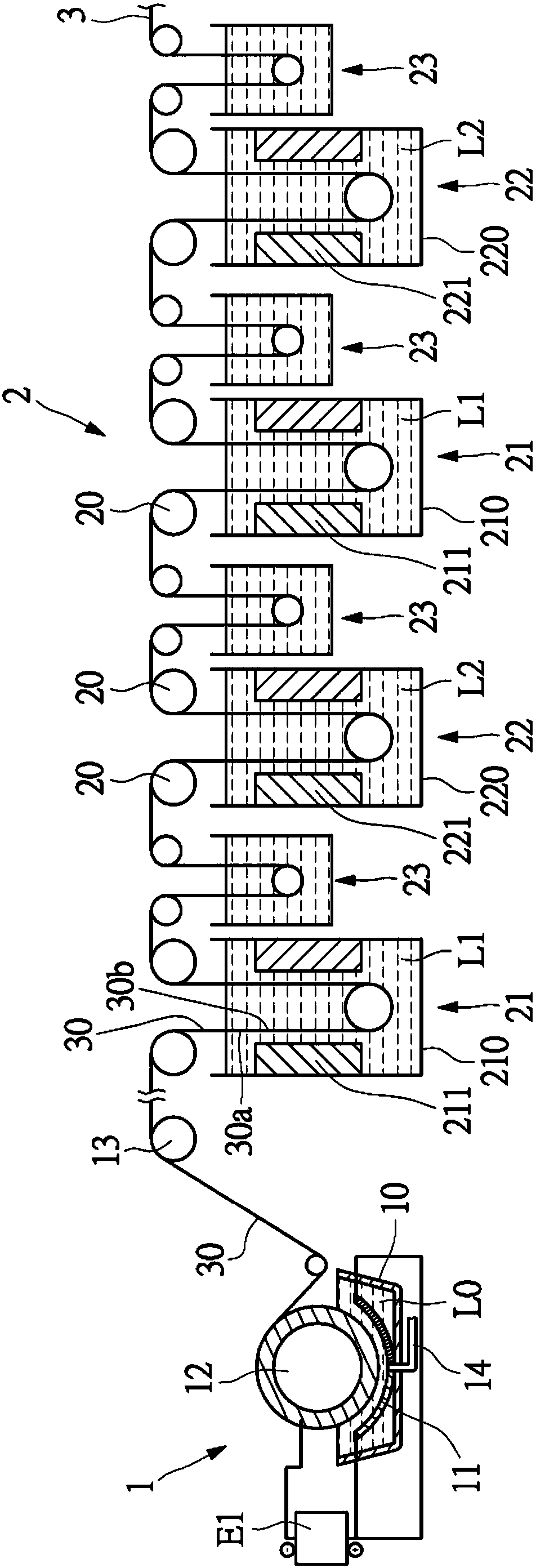

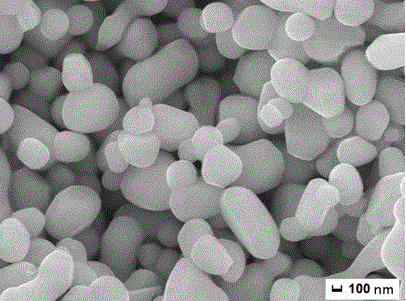

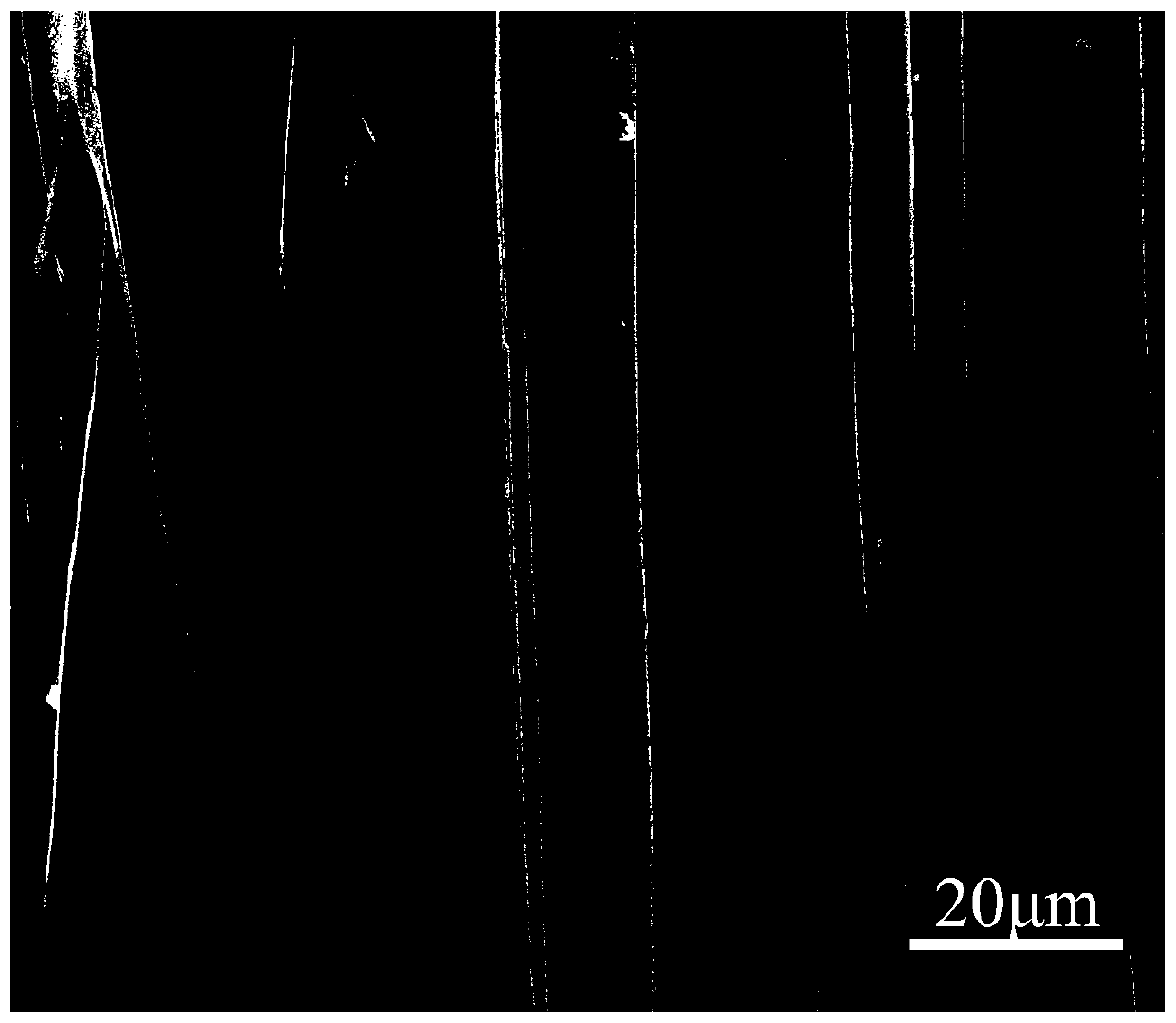

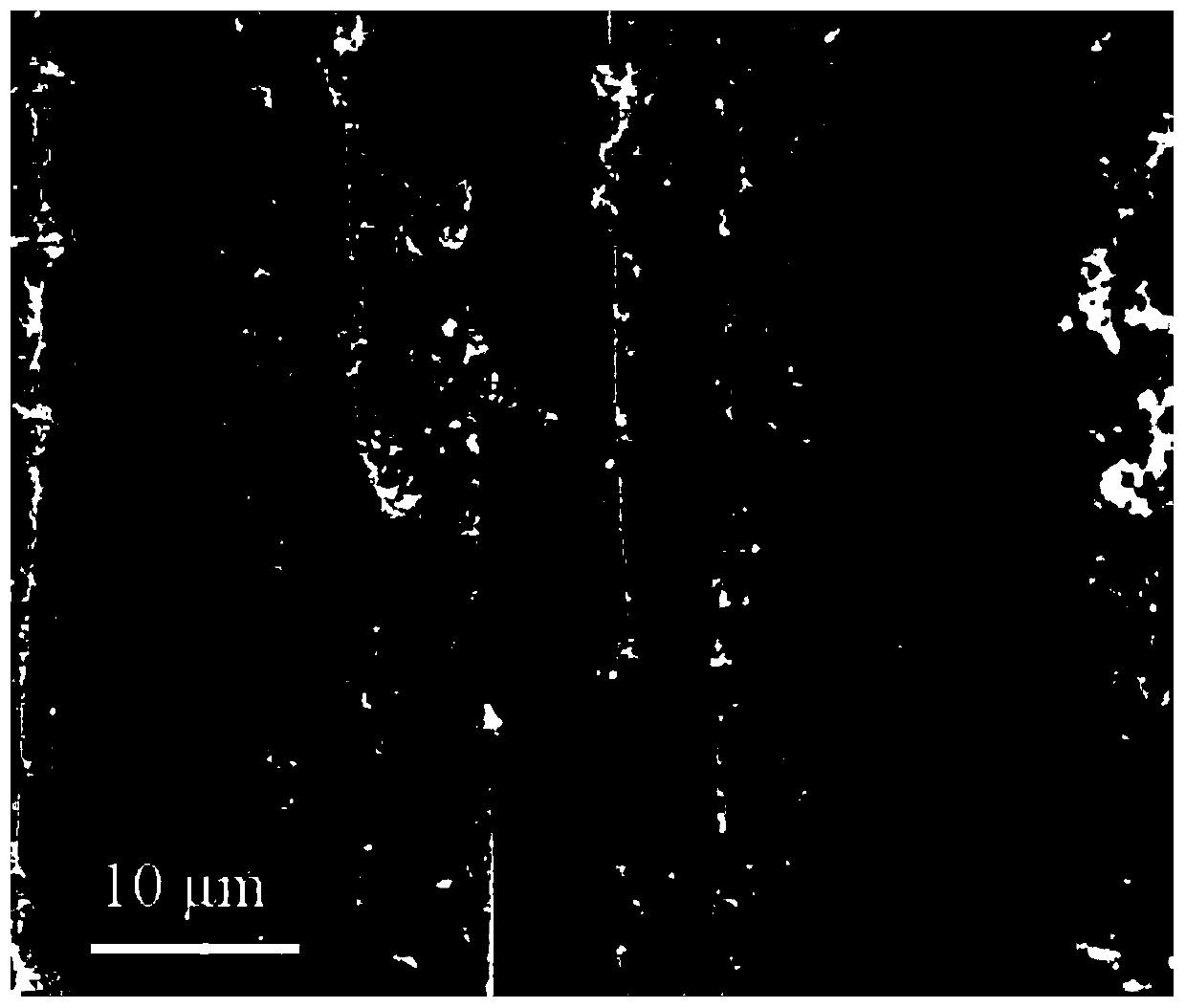

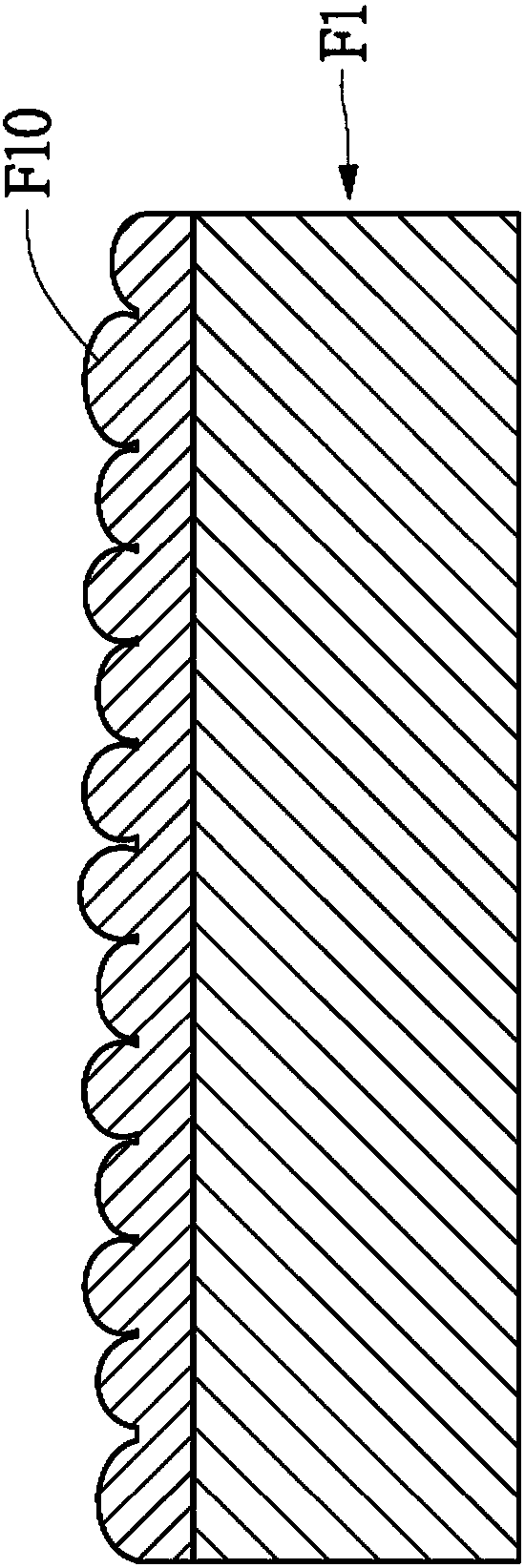

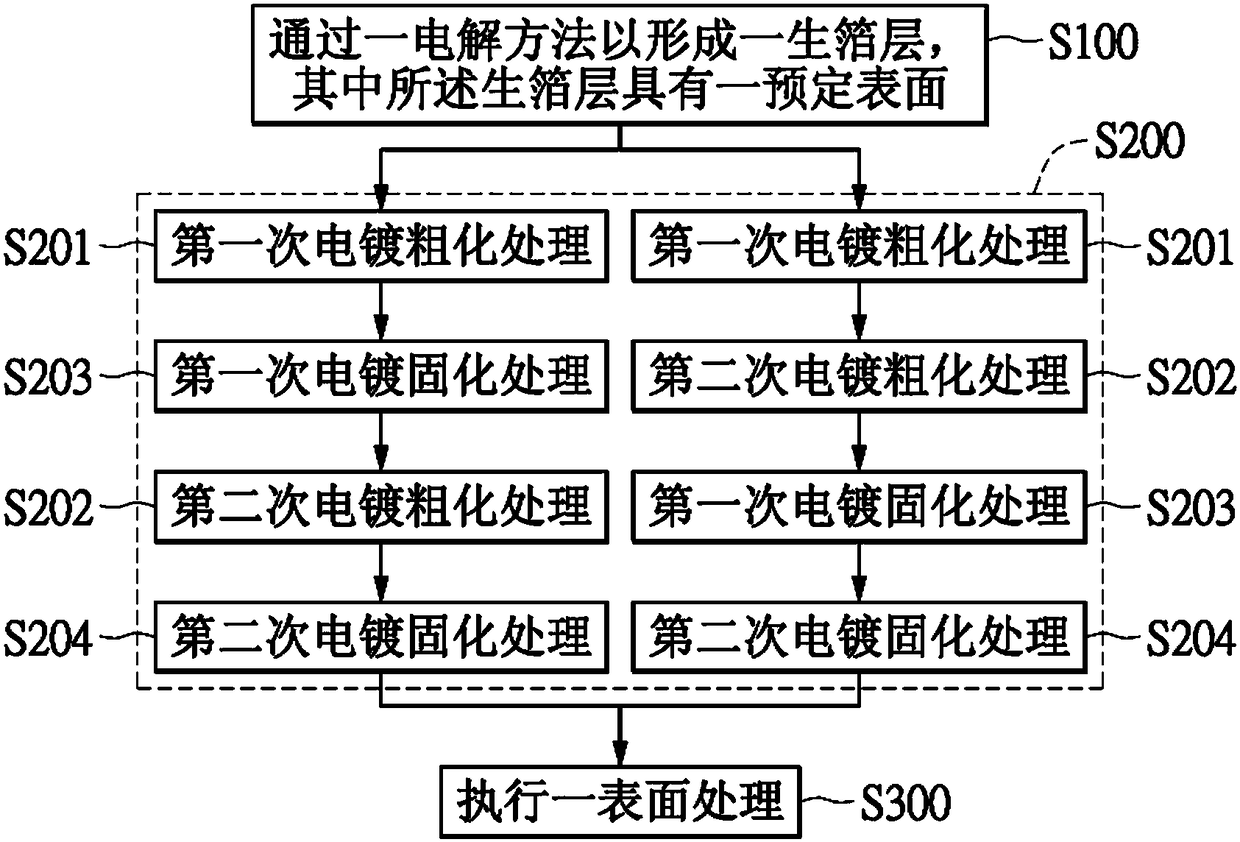

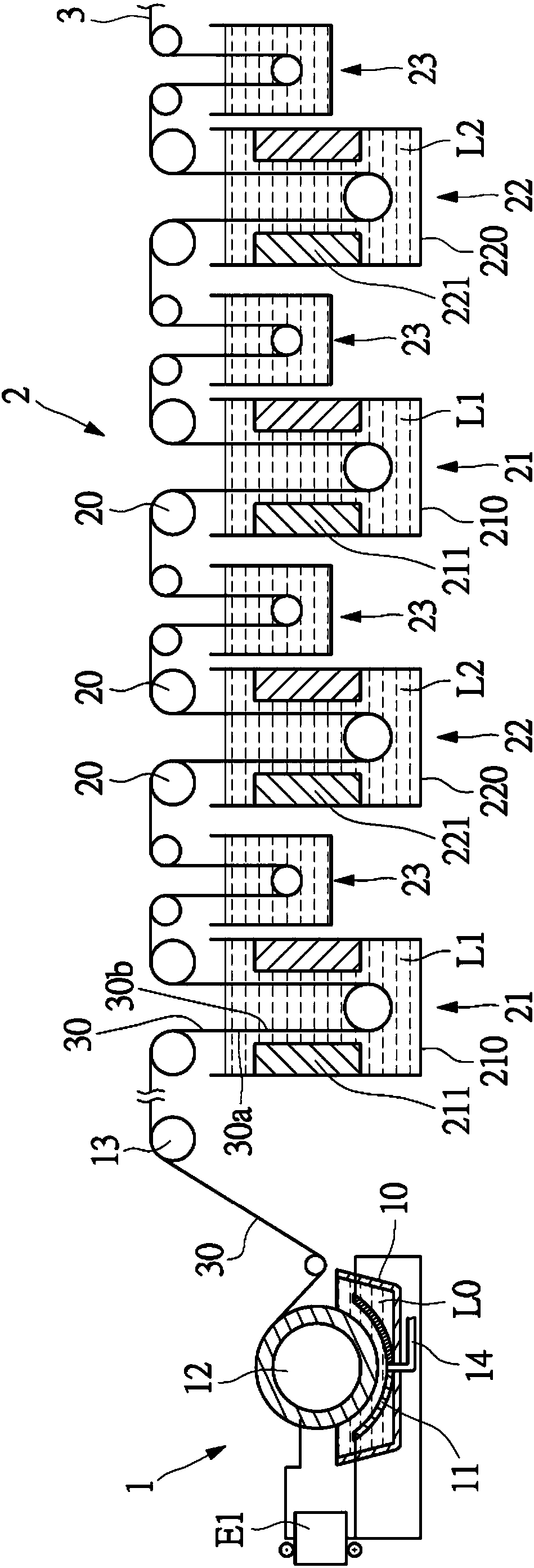

Manufacturing methods of electrolytic copper foil having football-shaped copper particles and circuit board assembly

PendingCN108505075AIncrease contact areaHigh peel strengthPrinted circuit aspectsElectroforming processesTungstate ionElectrolysis

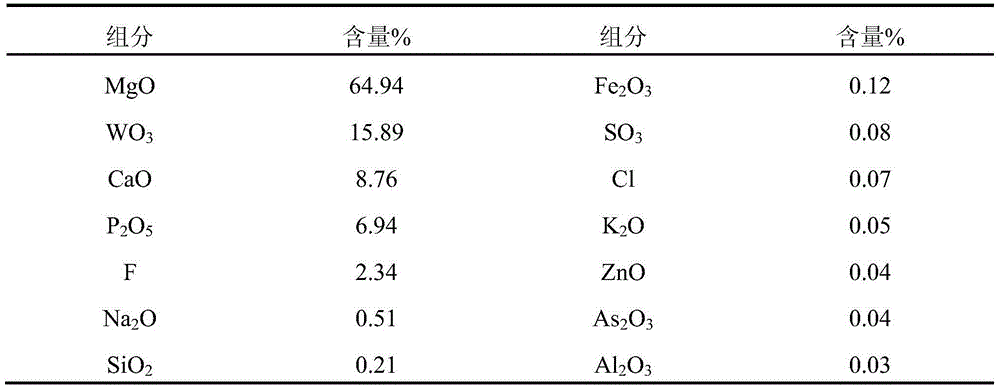

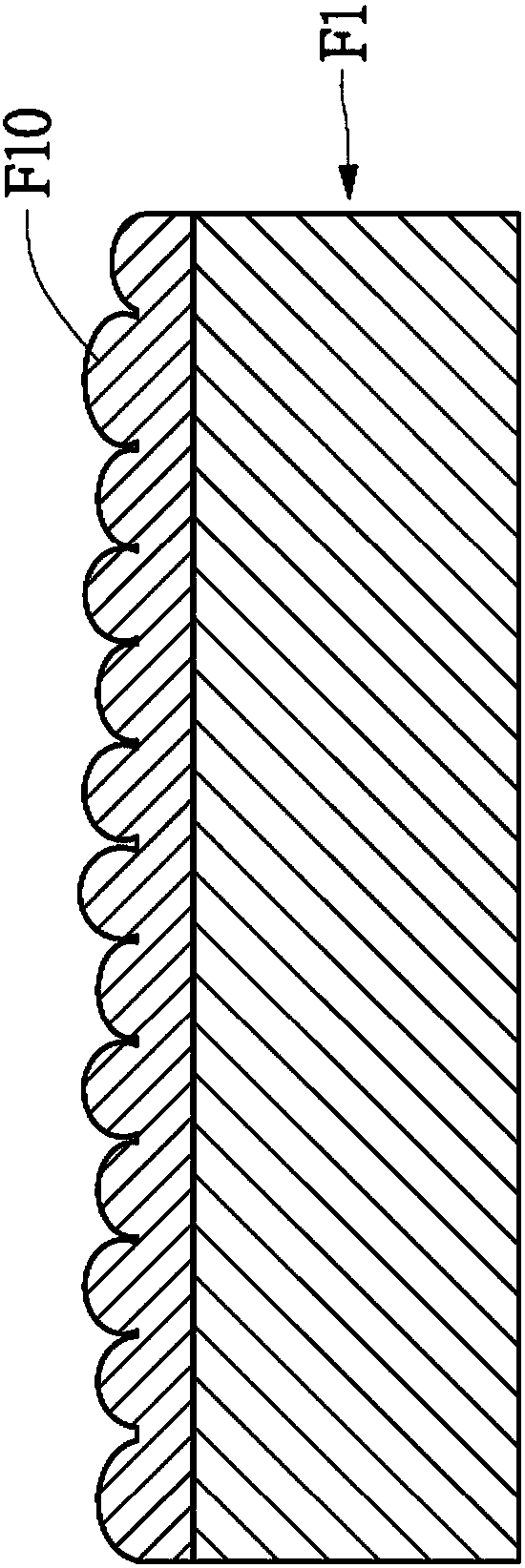

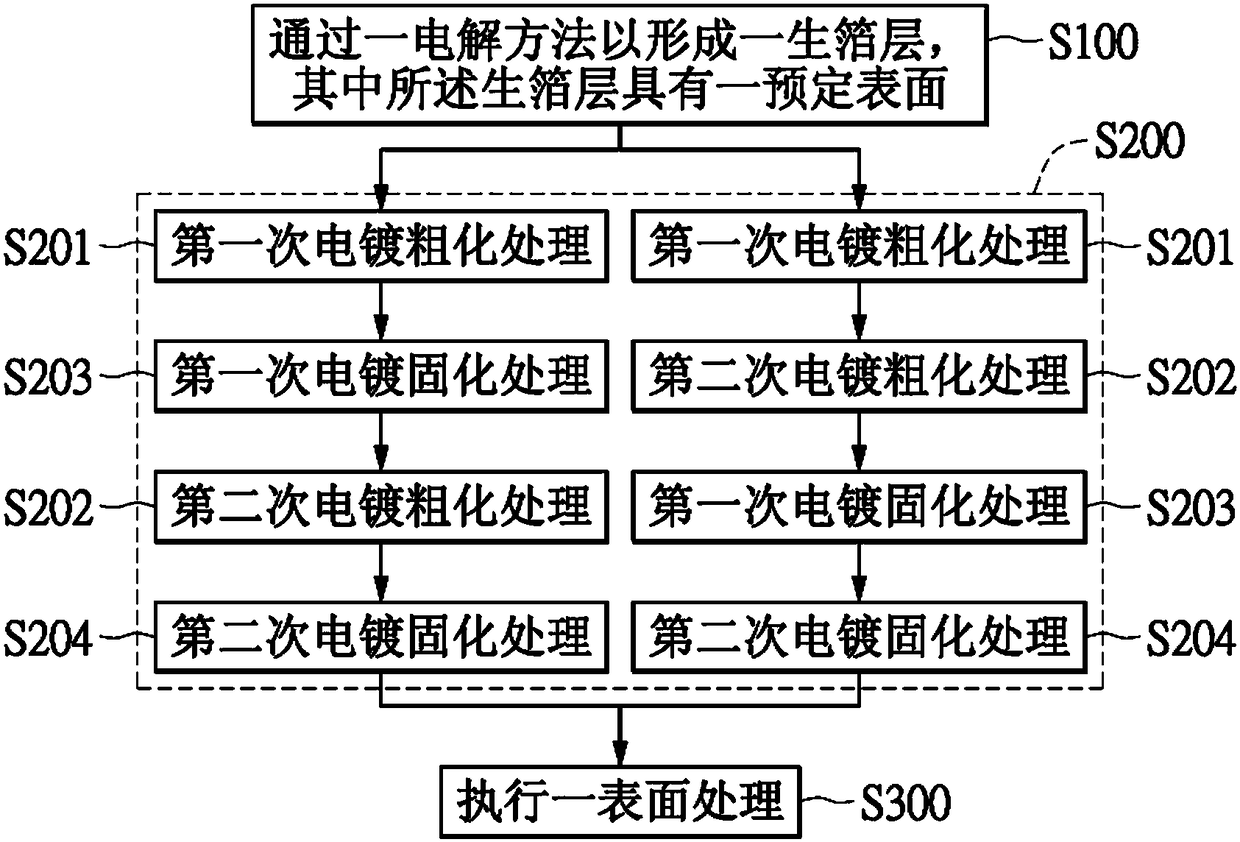

The invention discloses manufacturing methods of an electrolytic copper foil having football-shaped copper particles and a circuit board assembly. The manufacturing methods of an electrolytic copper foil having football-shaped particles include forming a copper foil by an electrolyzing process, wherein the foil layer has a predetermined surface. Then, a roughening treatment layer is formed on thepredetermined surface of the copper foil to form an electrolytic copper foil having football-shaped protrusions on a surface layer. The roughening treatment layer includes a plurality of football-shaped copper particles, and a funnel-shaped arrangement space exists between two adjacent football-shaped copper particles. The steps of forming the roughening treatment layer further includes performinga first electrolytic roughening treatment and a first electrolytic curing treatment, in which a first electrolyte solution used in the first electrolytic roughening treatment includes copper ions, sulfuric acid, arsenic trioxide, and tungstate ions, in which the copper concentration ranges from 3 to 40 g / L, the sulfuric acid concentration ranges from 100 to 120 g / L, the arsenic trioxide concentration is not more than 20 ppm, and the tungstate ion concentration ranges from 5 to 20 ppm. Thus, since the surface layer has the electrolyte copper foil having the football-shaped structure and has alarger contact area with a resin substrate, higher peeling strength can be achieved.

Owner:NANYA PLASTICS CORP

Colored conversion layers on metal surfaces

Chromium-free conversion coating treatment solutions and processes for depositing a colored layer on zinc or galvanized steel, aluminum, magnesium or their alloys, are provided comprising: hexafluorotitanate and / or hexafluorozirconate ions; molybdate and / or tungstate ions; one or more chelating complex formers; and a copolymer of alkylene phosphonic or alkylene phosphinic acid and one or more unsaturated carboxylic acids.

Owner:HENKEL KGAA

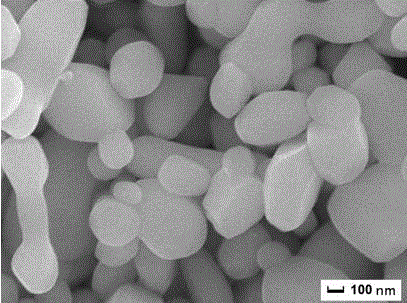

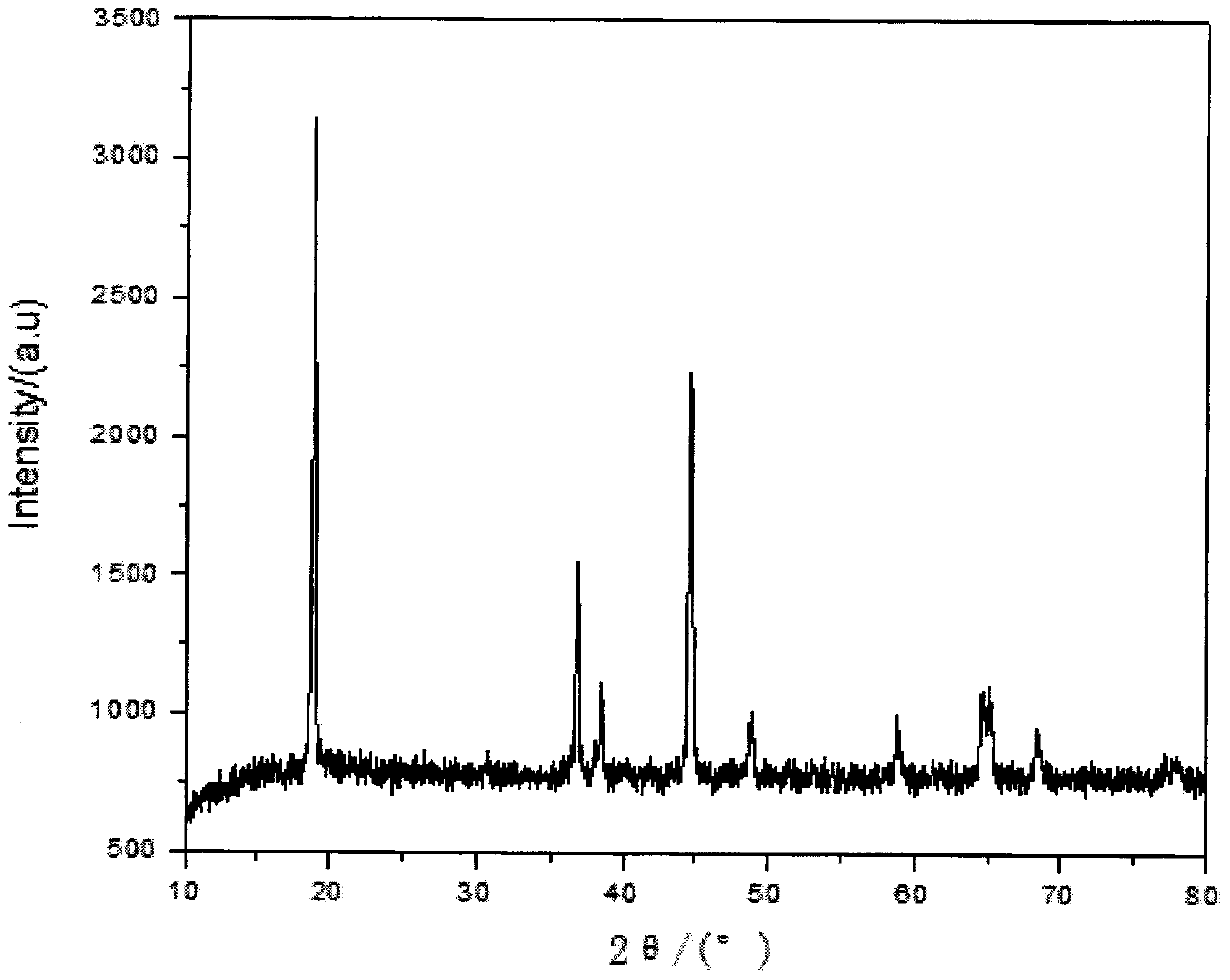

Method for preparing nanometer tungsten powder by organizing sodium tungstate

ActiveCN106623962AOvercoming the phenomenon of high temperature agglomerationReduce the temperatureTransportation and packagingMetal-working apparatusTungstate ionSalicylic acid

The invention relates to a preparation method of nanometer tungsten powder, which is mainly used for preparing the nanometer tungsten powder by organizing tungsten. The method comprises the following steps: organizing sodium tungstate into tungsten salicylate, wherein the molar ratio of the sodium tungstate to sulfuric acid to salicylic acid is 1:(0.8-1.2):(0.8-1.2), and the molar concentration of tungstate ions in the prepared aqueous solution is 1 to 2 mol / L; performing thermal decomposition on the tungsten salicylate to obtain nanometer tungsten oxide, wherein the temperature is 200 to 340 DEG C and is preserved for 0.5 to 8 hours; and performing hydrogen reduction on the nanometer tungsten oxide to obtain the nanometer tungsten powder. The tungsten salicylate with low boiling point is formed by organizing the tungsten and then is subjected to thermal decomposition at 200 to 300 DEG C to form the nanometer tungsten oxide, the nanometer tungsten oxide is subjected to hydrogen reduction to obtain the nanometer tungsten powder with uniform granularity, the granularity of the nanometer tungsten powder is 20 to 40 nm, the purity of the nanometer tungsten powder is 99.99 percent, and the yield of the nanometer tungsten powder exceeds 99 percent. The method has the prominent advantages of simplicity in operation, cleanness and environmental friendliness.

Owner:湖南省华京粉体材料有限公司

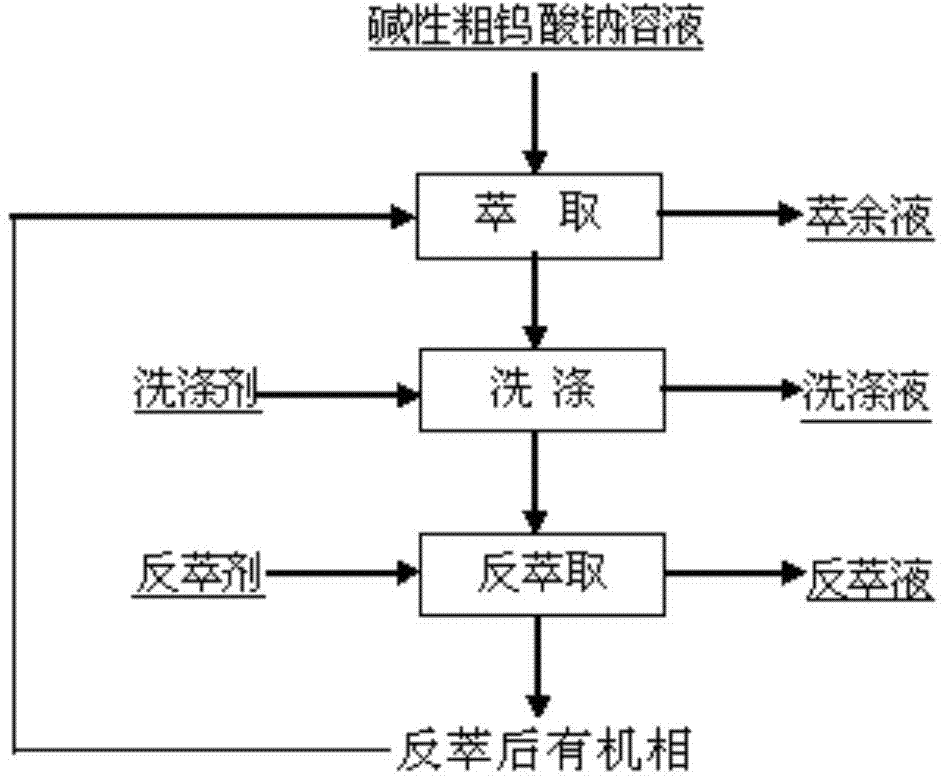

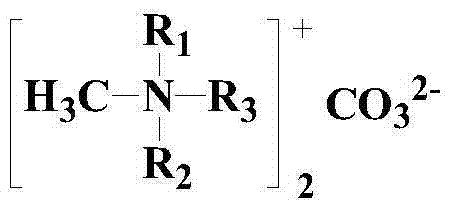

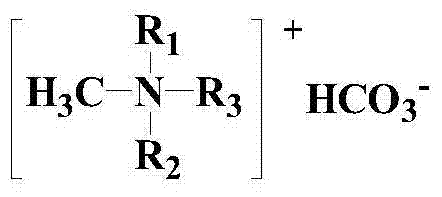

Method for extracting tungsten from alkaline crude sodium tungstate solution without renewable recyclable extracting system

ActiveCN103572075AAchieve complete extractionEfficient extractionProcess efficiency improvementTungstate ionDiammonium carbonate

The invention discloses a method for extracting tungsten from alkaline crude sodium tungstate solution without a renewable recyclable extracting system. The method is characterized in that the hydrocarbonate containing methyl trialkyl ammonium and an organic phase of the hydrocarbonate composite extracting agent are used for carrying out multilevel countercurrent extraction of alkaline crude sodium tungstate solution, the obtained load organic phase is processed in multilevel countercurrent back extraction by utilizing a mixed aqueous solution of ammonium bicarbonate and ammonium carbonate after being washed by water to obtain ammonium tungstate solution, and the organic phase after the back extraction is directly returned to the extraction process to be recycled. By adopting the method, the tungstate ions in the alkaline crude sodium tungstate solution are selectively extracted to prepare the ammonium tungstate, so that the tungstate ions can be effectively separated from the impurity ions such as phosphorus, arsenic, silicon and the like, the extracting agent can be directly reused without being regenerated, the process flow is shortened, the consumption of chemical reagent is reduced, the emission of waste water is reduced, and the industrialized production can be favored.

Owner:CENT SOUTH UNIV

High-efficiency corrosion inhibitor for sea water desalinization first-level reverse osmosis producing water

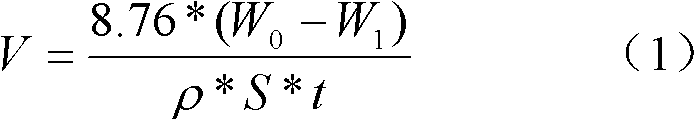

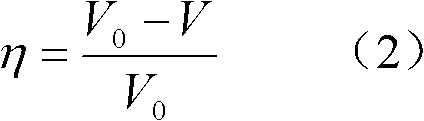

InactiveCN102010075AImprove protectionPitting corrosion mitigationScale removal and water softeningTungstate ionWater desalination

The invention relates to a high-efficiency corrosion inhibitor for sea water desalinization first-level reverse osmosis producing water. One liter of high-efficiency corrosion inhibitor comprises 3 to 20 milligrams of sodium silicate (based on silicon dioxide (SiO2)), 30 to 50 milligrams of sodium hexametaphosphate, 2 to 4 milligrams of zinc sulfate (based on zinc ions (Zn<2+>)), 4 to 10 milligrams of sodium tungstate (based on tungstate ions (WO4<2->) and 2 to 5 milligrams of benzotriazole or methyl benzotriazole. By the high-efficiency corrosion inhibitor, the corrosion rates of the metal materials commonly used in a heat-engine plant, such as carbon steel, red copper and the like in the sea water desalinization first-level reverse osmosis producing water are reduced from 1.14007 mm / a to 0.04282 mm / a and from 0.06173 mm / a to 0.00606 mm / a respectively; the corrosion inhibition rates of the high-efficiency corrosion inhibitor on the carbon steel and the red copper are over 96.24 percent and 90.18 percent respectively; the corrosive action of the first-level reverse osmosis producing water on the materials is greatly relieved; and the tendency of the metal surface pitting is reduced, so that the service life of each of pipelines and equipment is greatly prolonged.

Owner:WUHAN UNIV

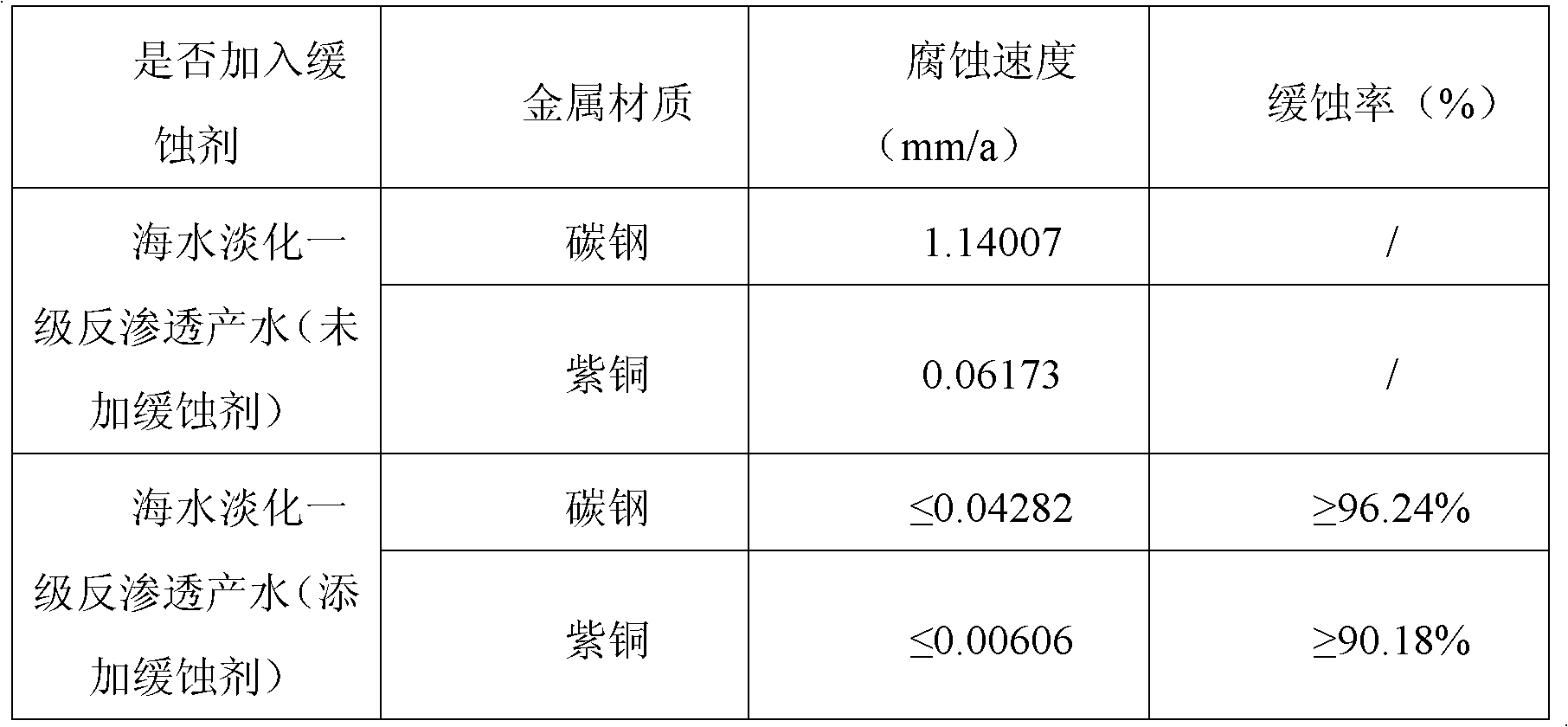

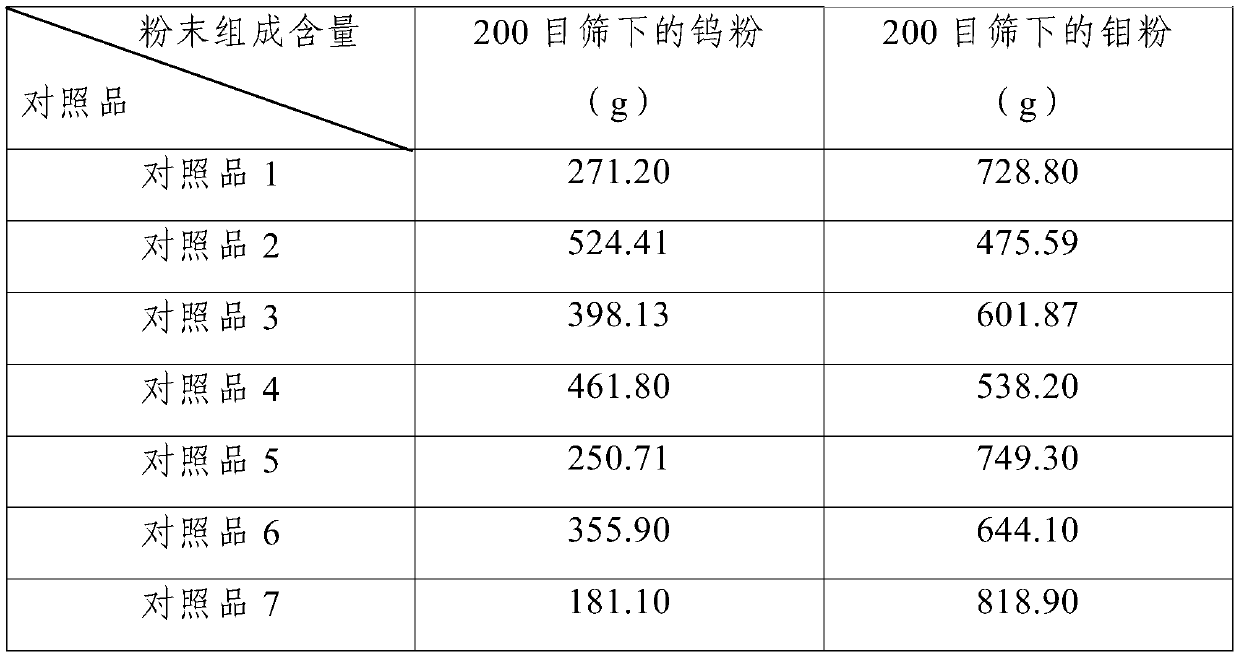

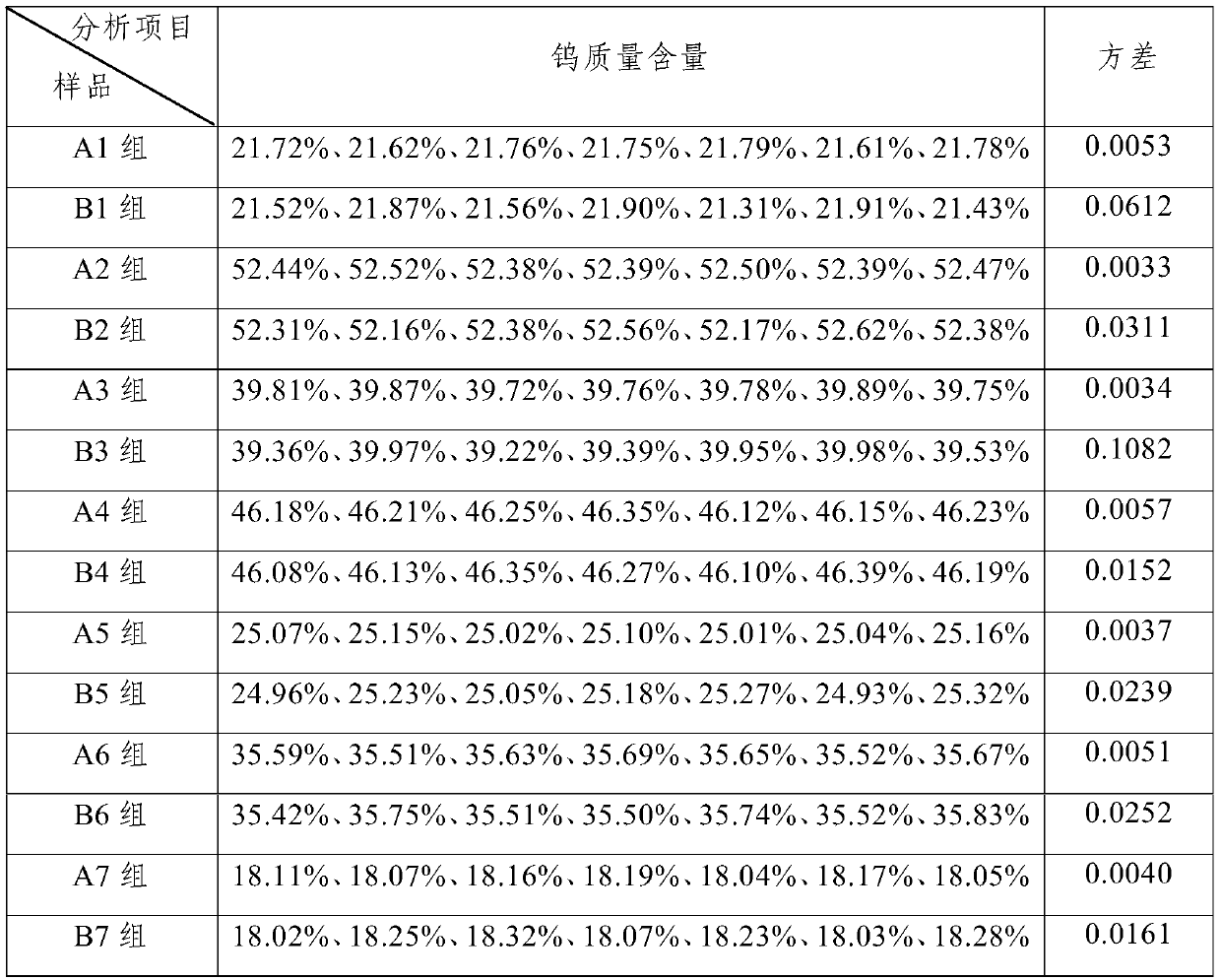

Preparation method of molybdenum-tungsten alloy powder

The invention discloses a preparation method of molybdenum-tungsten alloy powder. The method comprises the steps that firstly, molybdenum trioxide and tungstic acid are added into diluted ammonia water to be dissolved to obtain an ammonium molybdate and ammonium tungstate mixed solution; secondly, the ammonium molybdate and ammonium tungstate mixed solution is sprayed and dried to obtain a molybdenum-tungsten composite oxide precursor; thirdly, the molybdenum-tungsten composite oxide precursor is subjected to roasting decomposition under the temperature gradient condition to obtain a molybdenum-tungsten composite oxide; fourthly, the molybdenum-tungsten composite oxide is subjected to first-stage reduction under the hydrogen condition to obtain a molybdenum-tungsten low-valence oxide; andfifthly, the molybdenum-tungsten low-valence oxide is subjected to second-stage reduction under the hydrogen condition to obtain the molybdenum-tungsten alloy powder. The molybdenum-tungsten alloy powder is prepared by fully mixing molybdate ions and tungstate ions and conducting roasting and reduction, so that size and mass differences of molybdenum particles and tungsten particles are small, hybrid power is high, the uniformity of the molybdenum-tungsten alloy powder is improved, and the problem of insufficient uniformity caused by mechanical mixing of molybdenum powder and tungsten powder is eliminated.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Aluminum Treatment Composition

InactiveUS20090242081A1Improved metal protectionImprove protectionSolid state diffusion coatingWelding/cutting media/materialsAluminum IonTungstate ion

Owner:MACDERMID INC

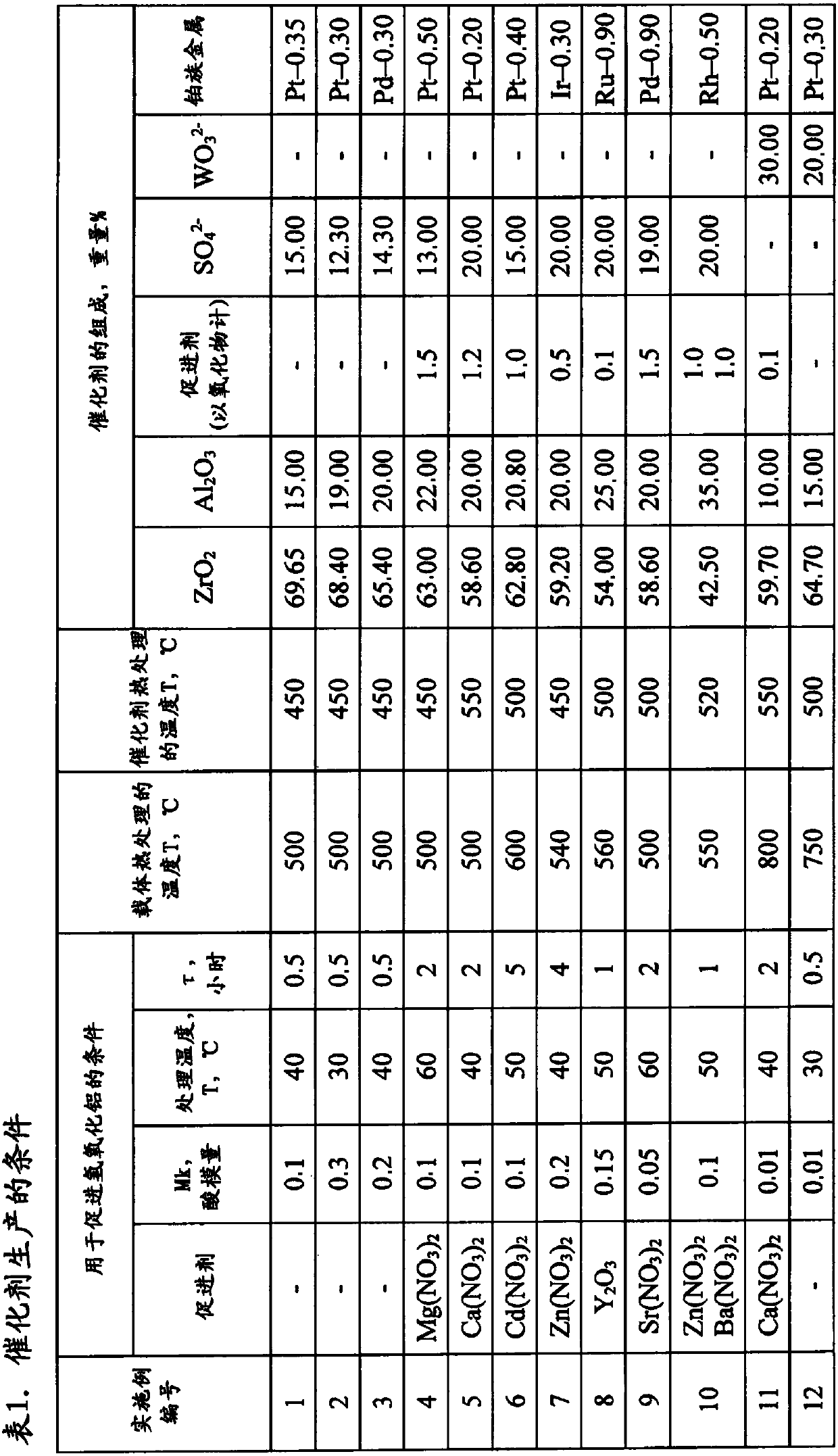

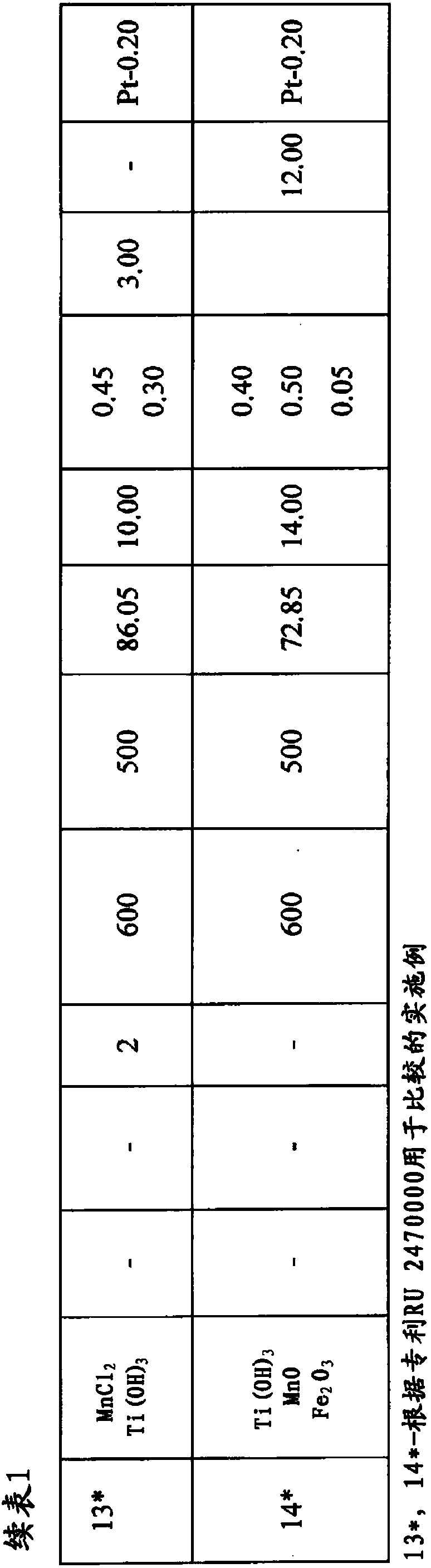

Catalyst for isomerisation of paraffin hydrocarbons and method of preparation thereof

ActiveCN107735174AImprove thermal stabilityReduced sinteringHydrocarbon by isomerisationCatalyst activation/preparationTungstate ionAluminium hydroxide

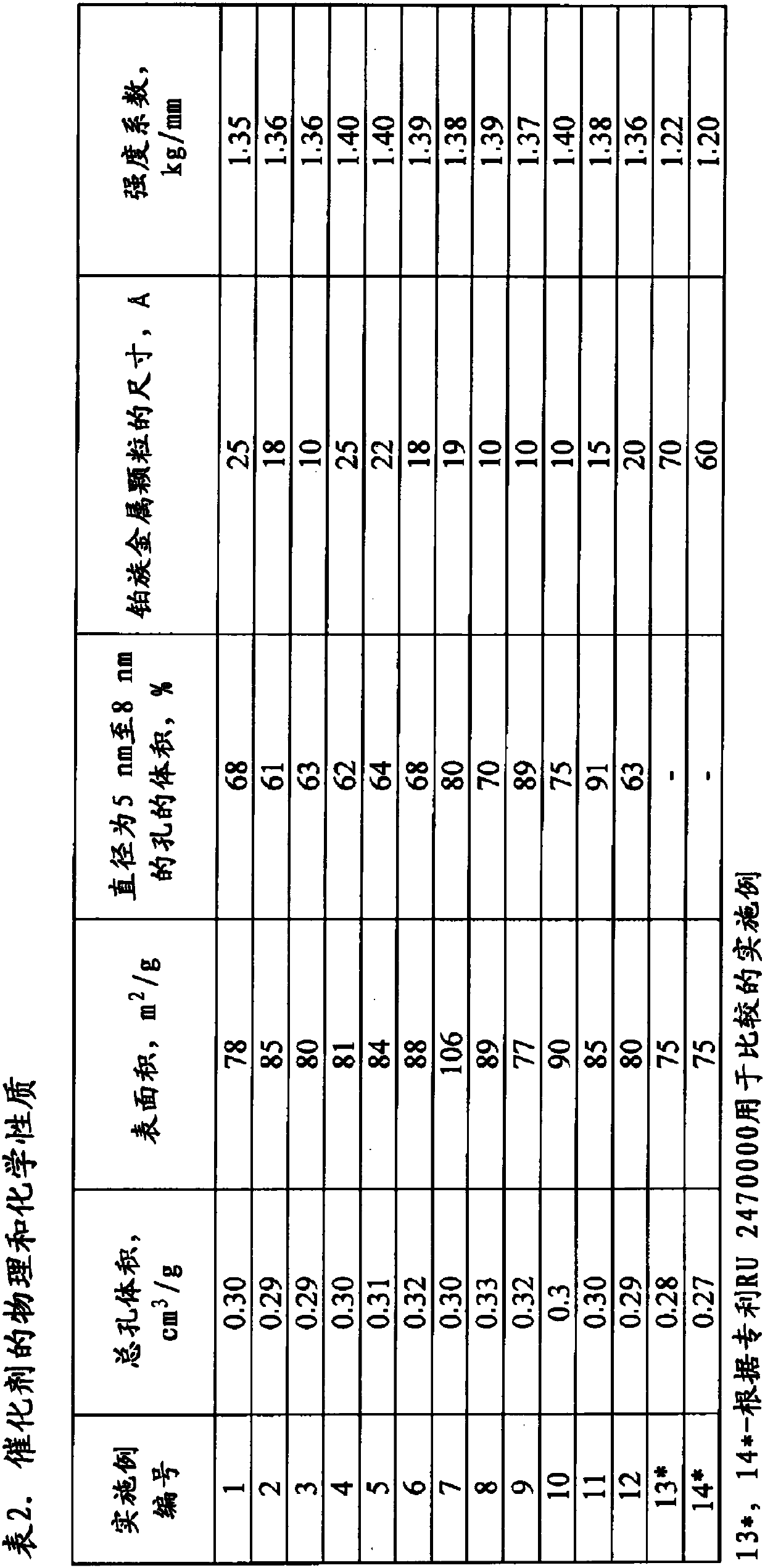

The catalyst comprises a platinum group metal supported on a carrier consisting of a mixture of aluminium oxide, zirconium oxide, and a sulphate ion or tungstate ion. Aluminium hydroxide, the aluminium oxide precursor, is pre-treated using only organic or inorganic acids with an acid module of 0.01-0.3, or in combination with at least one metal compound selected from the group consisting of: yttrium, magnesium, zinc, calcium, barium, cadmium, and strontium, to yield the catalyst wherein the percentage (by volume) of pores with a diameter of 5-8 nm constitutes more than 60% of the total pore volume. The technical result of the invention is the increased activity, selectivity and durability of the produced catalyst for isomerisation of hydrocarbons.

Owner:AKTSIONERNOE OBSHCHESTVO SPETSIALNOE KONSTRUKTORSKO TEKHNOLOGICHESKOE BJURO KATALIZATOR

Preparation method of sulfo-molybdate for separating molybdenum from tungstate solution

InactiveCN102181637ALow costReduce manufacturing costProcess efficiency improvementTungstate ionVulcanization

The invention discloses a preparation method of sulfo-molybdate for separating molybdenum from tungstate solution. Phosphorus pentasulfide serves as vulcanizing agent; after the vulcanizing agent is added into molybdenum-contained tungstate solution, the vulcanizing agent is hydrolyzed to release sulphur ions; the sulphur ions and molybdate are subject to vulcanization reaction to generate sulfo-molybdate; and tungsten still exists in the form of tungstate ion. The vulcanizing agent used by the method has the advantages of high sulphur content and low price, and the preparation cost of the sulfo-molybdate can be obviously lowered.

Owner:CENT SOUTH UNIV

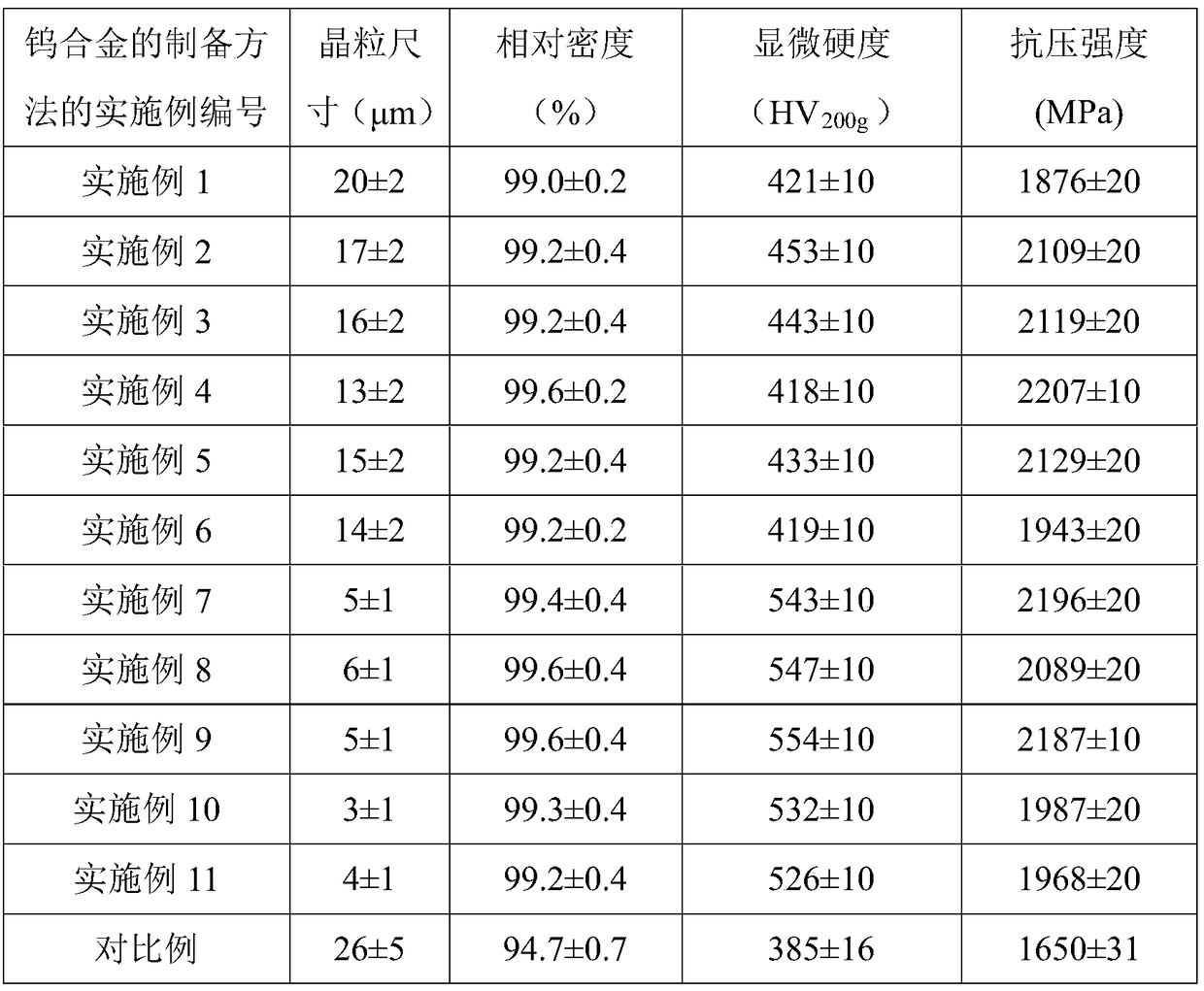

Preparation method of tungsten alloy precursor composite powder, ceramic aluminum oxide enhanced tungsten alloy and preparation method thereof

ActiveCN109182812AImprove wear and erosion resistanceSolve the Coarse Grain of Dispersion Reinforced Tungsten AlloyTungstate ionAluminum Ion

The invention relates to a preparation method of tungsten alloy precursor composite powder, a ceramic aluminum oxide enhanced tungsten alloy and a preparation method of the ceramic aluminum oxide enhanced tungsten alloy, and belongs to the technical field of tungsten alloy. The preparation method of the tungsten alloy precursor composite powder comprises the steps that ammonium metatungstate and amixed solution of soluble aluminum salt are provided, oxalic acid is added into the mixed solution till pH is not larger than 1.5, a complex reaction is carried out, a solvent is removed, and mixed powder is obtained. According to the preparation method, the pH is adjusted through oxalic acid after liquid-liquid mixing, hydrogen ions and tungstate ions in the solution will react to generate tungstate precipitate; oxalate ions and aluminum ions react to generate aluminum oxalate precipitate, serious segregation caused by the mass difference of tungsten atomic nucleuses and aluminum atomic nucleuses can be avoided, the uniformity degree of tungstic acid and aluminum oxalate in the obtained powder is improved, molecular mixing is achieved, and a raw material base is provided for improving high-temperature wear-resisting erosion-resistance performance of tungsten alloy.

Owner:HENAN UNIV OF SCI & TECH

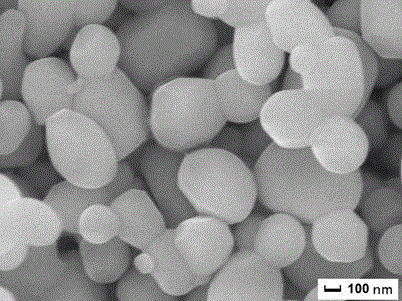

Micro/nano potassium yttrium tungstate near-spherical particles and preparation method thereof

ActiveCN103332748AUniform particle size distributionImprove luminous efficiencyTungsten compoundsTungstate ionMicro nano

The invention discloses micro / nano potassium yttrium tungstate near-spherical particles and a preparation method thereof. The preparation method comprises the following steps: regulating the pH value of a soluble tungstate solution to 7-8.5 and the pH value of Y<3+> of the yttrium ion solution to 5-6.5, mixing according to the tungstate ion:yttrium ion mol ratio of 2:1, regulating the pH value of the mixed solution to 5-7.5, uniformly stirring, adding acetylacetone accounting for 10-20 vol% of the mixed solution, and carrying out ultrasonic vibration to obtain a precursor solution; holding the precursor solution by hydrothermal sealing to obtain a white precipitate, wherein the hydrothermal temperature is 140-180 DEG C, and the holding time is 20-24 hours; and centrifuging the white precipitate, and carrying out heat treatment to obtain the micro / nano potassium yttrium tungstate near-spherical particles. The micro / nano potassium yttrium tungstate near-spherical particles are composed of KY(WO4)2 particles, the particle size is 0.100-1 mu m, and the particle shape is near-spherical. The invention enhances the luminescence efficiency of the powder, can be used as a luminescent material, and can be widely used in the fields of road signs, various energy-saving illuminators, biomedical labels, aviation display devices, various meters and computers, and the like.

Owner:JIANGSU UNIV

Method for recovering and adsorbing tungstate radicals in scheelite beneficiation wastewater

ActiveCN110642335AImprove adsorption capacityEasy to separateWaste water treatment from quariesWater contaminantsTungstate ionElectrolytic agent

The invention relates to a method for recovering tungstate radicals in beneficiation wastewater, and concretely discloses a method for recovering and adsorbing tungstate radicals in scheelite beneficiation wastewater. The invention aims to solve the technical problems of low recovery rate and low recovery rate of tungstate radicals in scheelite beneficiation wastewater in the prior art. The methodcomprises the following steps: a three-electrode system which is composed of a polyaniline / carbon cloth composite electrode material, an Ag / AgCl electrode and a platinum electrode is connected to anelectrochemical workstation, and electro-adsorption is carried out under the condition of electric field force by using the polyaniline / carbon cloth composite electrode material as a working electrode, the Ag / AgCl electrode as a reference electrode, the platinum electrode as a counter electrode and the scheelite beneficiation wastewater to be treated as an electrolyte. The method has a simple andrapid process, and makes the recovery rate of tungstate ions adsorbed for 2 h reach 75%.

Owner:NANCHANG HANGKONG UNIVERSITY

Aluminum treatment composition

InactiveCN102144042AImproved corrosion resistance of metal surfacesImprove corrosion resistanceSolid state diffusion coatingAluminum IonTungstate ion

An aqueous conversion coating composition for treating metal substrates such as aluminum, aluminum alloys, zinc, zinc alloys, magnesium, magnesium alloys and steel to provide a conversion coating thereon. The conversion coating composition comprises a) a source of aluminum ions; b) a fluoro compound; c) at least one pH adjuster; d) a source of Group VIB metal ions selected from the group consisting of tungstate ions and trivalent chromium ions; and e) optionally, a preservative. The conversion coating composition provides a corrosion resistant coating on the metal surface and improves the adhesion of subsequently applied layers.

Owner:MACDERMID INC

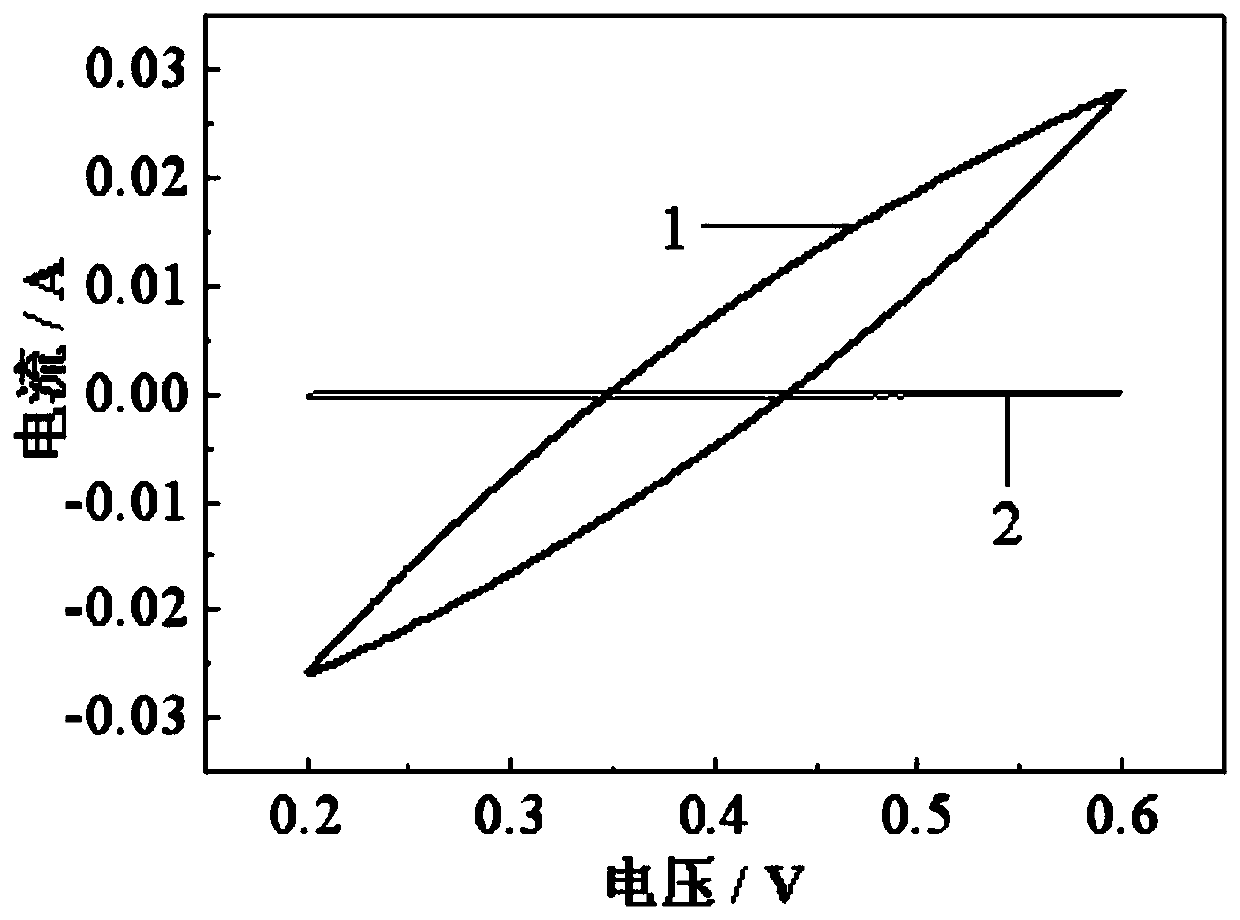

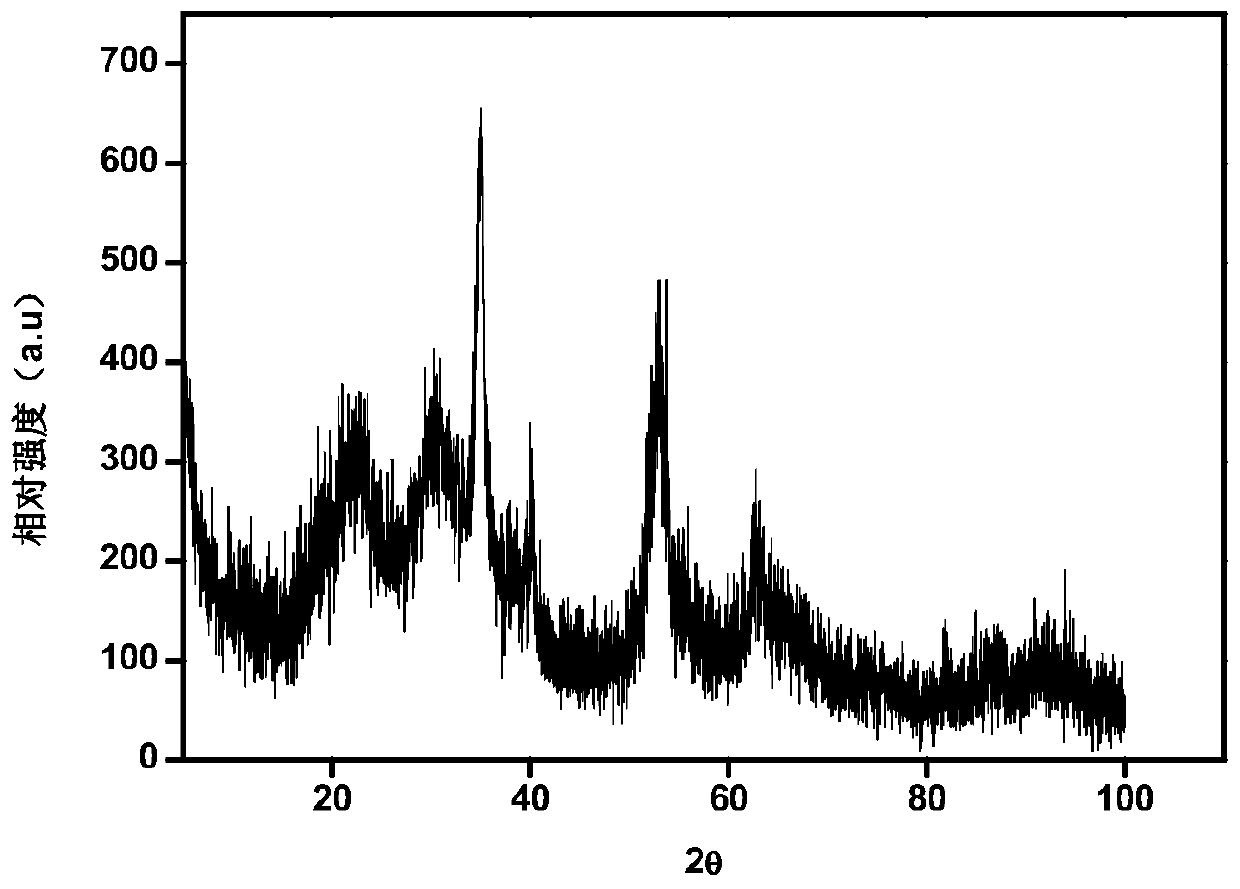

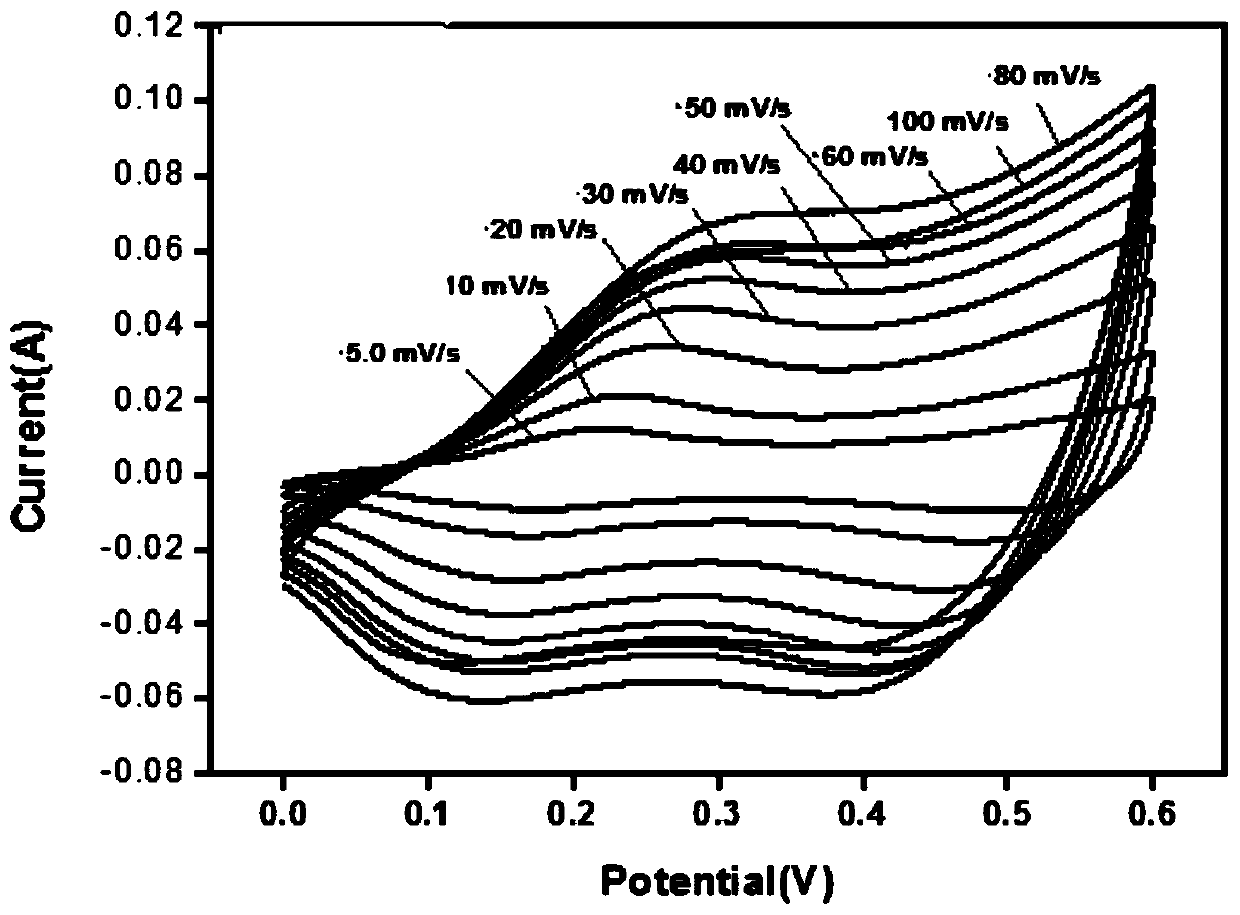

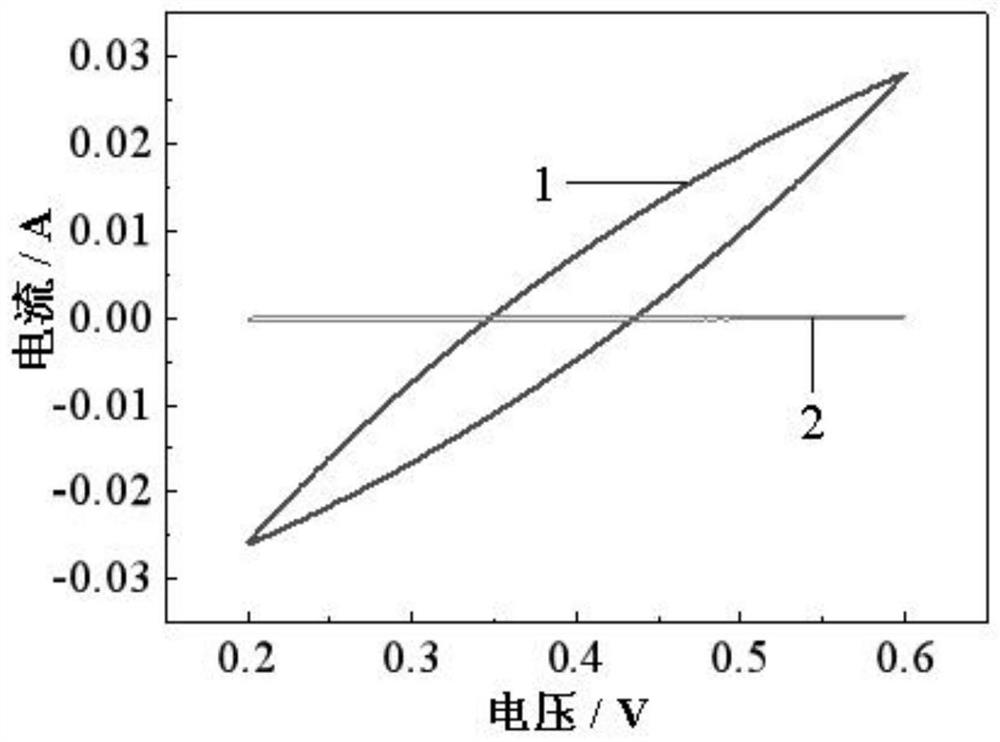

Synthesis method of electrode material cobalt tungstate for supercapacitor

InactiveCN110776016AHigh specific capacitanceImprove Capacitive PerformanceHybrid capacitor electrodesCobalt compoundsTungstate ionCapacitance

The invention provides a synthesis method of an electrode material cobalt tungstate for a supercapacitor. The synthesis method comprises: carrying out mixing dissolving on a cobalt salt and deionizedwater to obtain a solution A, carrying out mixing dissolving on a morphology regulator, a tungstate and deionized water to obtain a solution B, mixing the solution A and the solution B according to avolume ratio of 1:1, carrying out a precipitation reaction, cooling after the precipitation reaction is finished, washing, and drying to obtain cobalt tungstate. According to the invention, based on the high conductivity of the tungstate, the cobalt tungstate prepared by combining cobalt ions and tungstate ions is used as a capacitor electrode material, so that the high reversibility, the excellent cycle performance and the excellent stability can be achieved, and the prepared cobalt tungstate has a coralline-like structure, has a specific surface area, can substantially improve the specific capacitance value of the electrode material, and further has good electrochemical performance.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

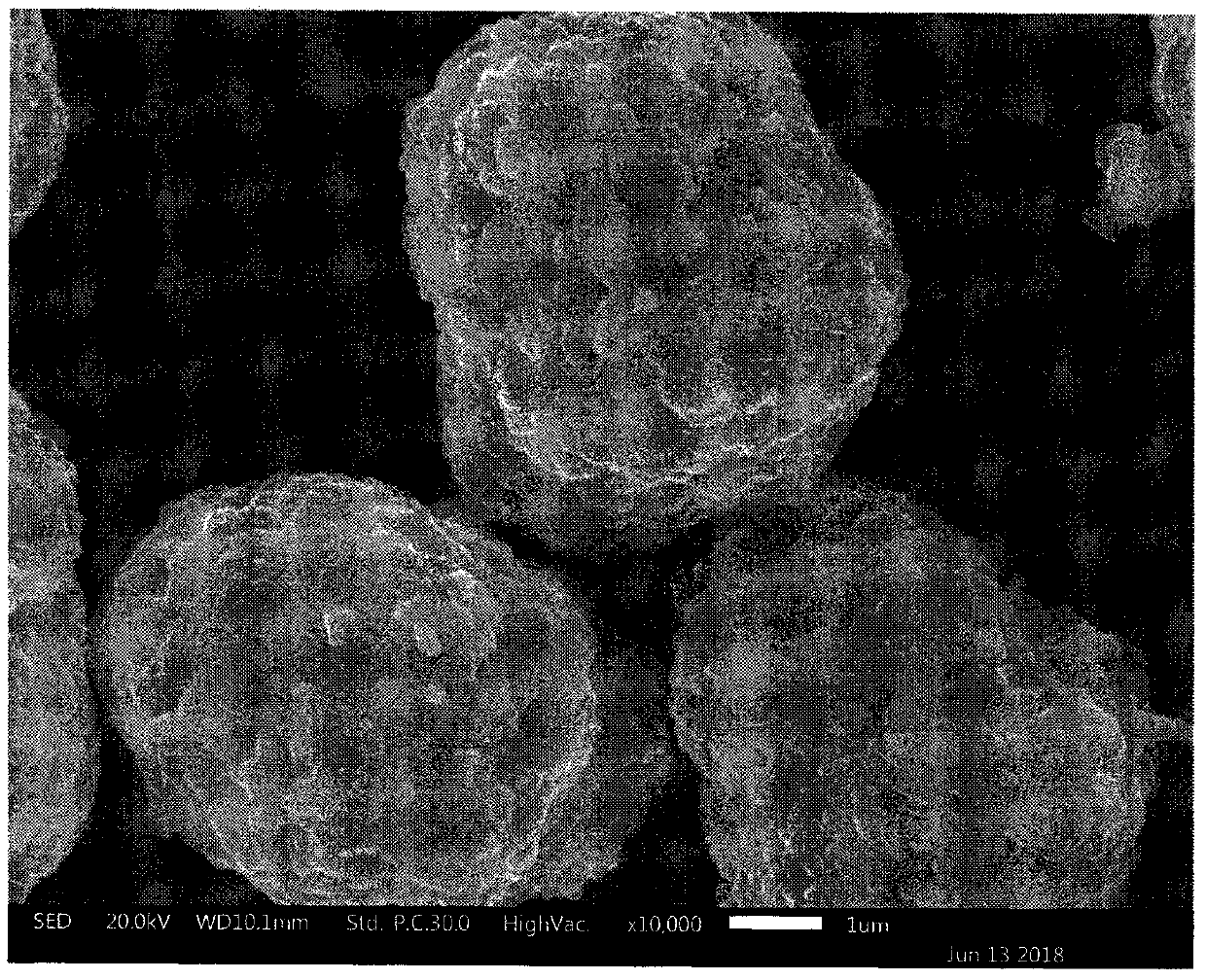

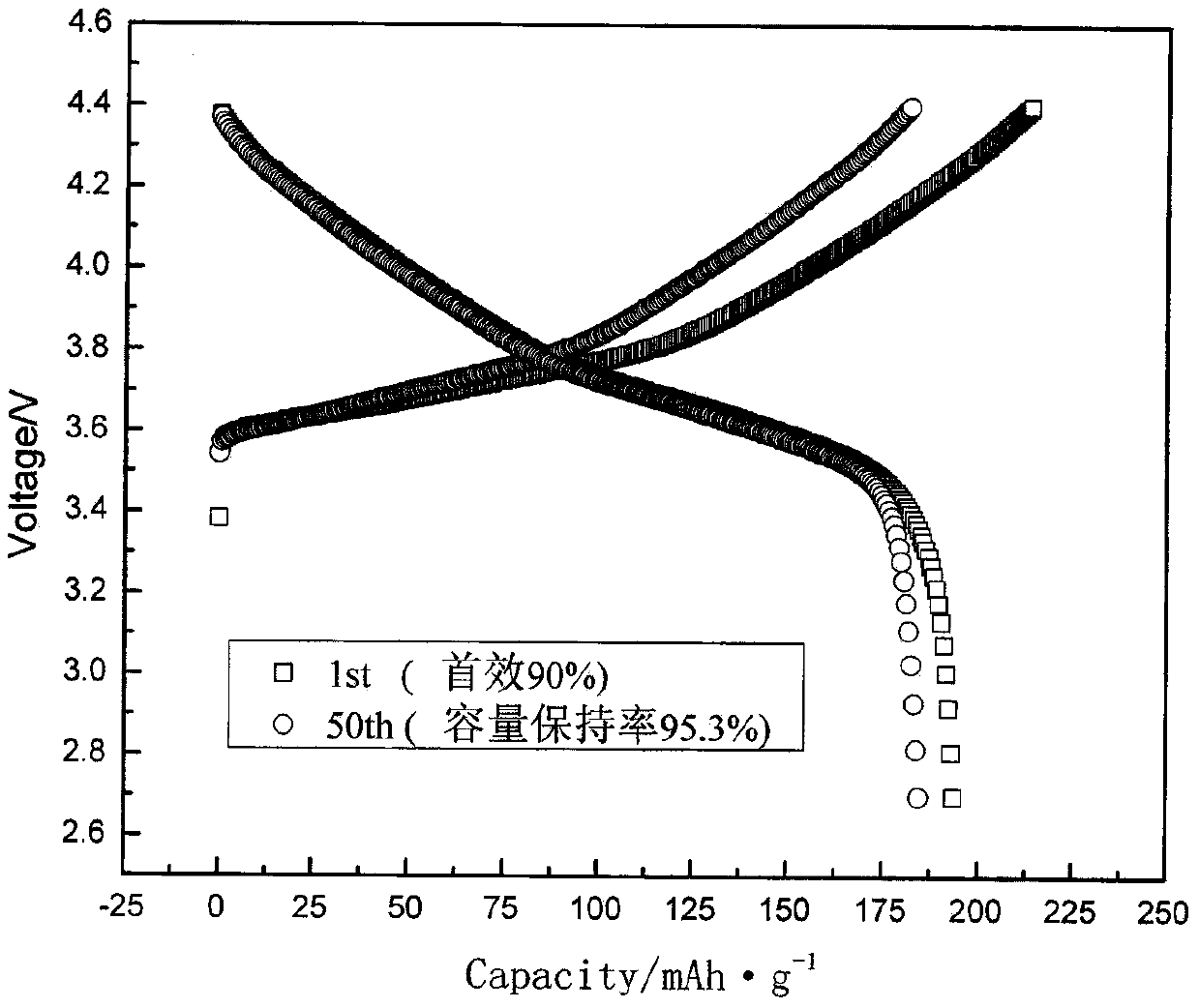

Preparation method of modified LiNi0.6Co0.2Mn0.2O2 ternary positive electrode material, and product and battery

ActiveCN109755524AFacilitated DiffusionImprove charge and discharge performanceCell electrodesSecondary cellsTungstate ionManganese

The invention discloses a preparation method of a modified LiNi0.6Co0.2Mn0.2O2 ternary positive electrode material, and a product and a battery. The preparation method of the ternary positive electrode material comprises the following steps of firstly introducing a magnesium element when preparing a nickel-cobalt-manganese hydroxide precursor, and then adopting an ammonium metatungstate water solution as a complexing agent at the later stage of co-precipitation reaction, wherein the ammonium metatungstate is hydrolyzed in water to show in the forms of ammonia ions and tungstate ions; the ammonia ions are used as the complexing agent to be used for compensating the co-precipitation reaction, and the tungstate ions are partially deposited on the surface of the nickel-cobalt-manganese hydroxide precursor formed in the precipitation reaction stage, so that the in-situ introduction of the tungsten element is realized; and then lithiation treatment is carried out so as to obtain the ternarypositive electrode powder containing the tungsten element on the surface. According to the method, by adding the magnesium element and the surface part in-situ doped tungsten element, the charge and discharge performance, the cycle performance and the like of the obtained modified ternary positive electrode powder are effectively improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Manufacturing methods of electrolytic copper foil having needle-shaped copper particles and circuit board assembly

The invention discloses manufacturing methods of an electrolytic copper foil and circuit board assembly. The manufacturing methods of an electrolytic copper foil having needle-shaped particles includeforming a copper foil by an electrolyzing process, wherein the foil layer has a predetermined surface. Then, a surface treatment layer is formed on the predetermined surface of the copper foil to form an electrolytic copper foil having a needle-shaped structure on a surface layer. The surface treatment layer includes a plurality of needle-shaped copper particles, and a needle-shaped arrangement space exists between two adjacent needle-shaped copper particles. The steps of forming the surface treatment layer further includes performing a first electrolytic roughening treatment and a first electrolytic curing treatment, in which a first electrolyte solution used in the first electrolytic roughening treatment includes copper ions, sulfuric acid, arsenic trioxide, and tungstate ions, in whichthe copper concentration ranges from 3 to 40 g / L, the sulfuric acid concentration ranges from 100 to 120 g / L, the arsenic trioxide concentration is not more than 20 ppm, and the tungstate ion concentration ranges from 5 to 20 ppm. Thus, since the surface layer has the electrolyte copper foil having the needle-shaped structure and has a larger contact area with a resin substrate, higher peeling strength can be achieved.

Owner:NANYA PLASTICS CORP

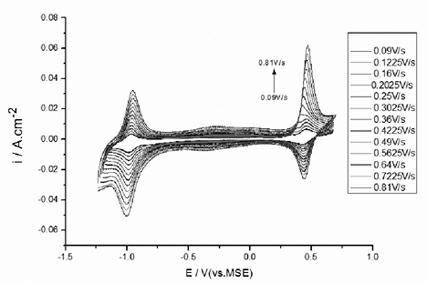

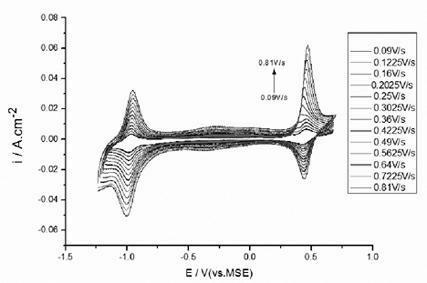

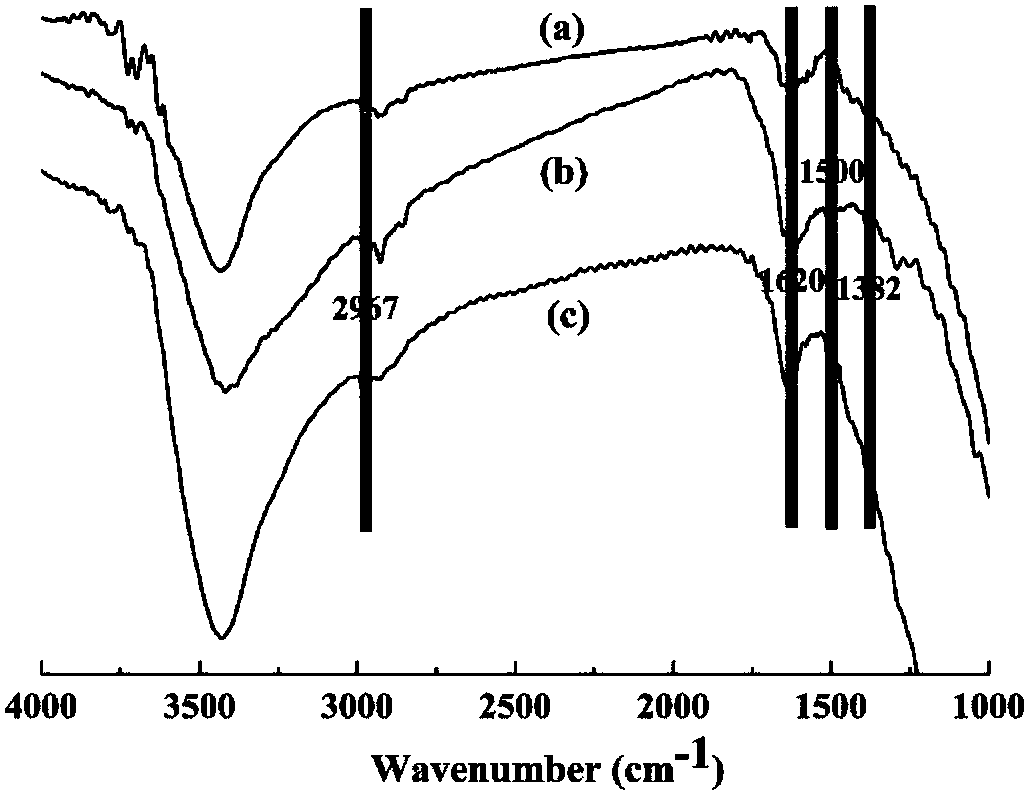

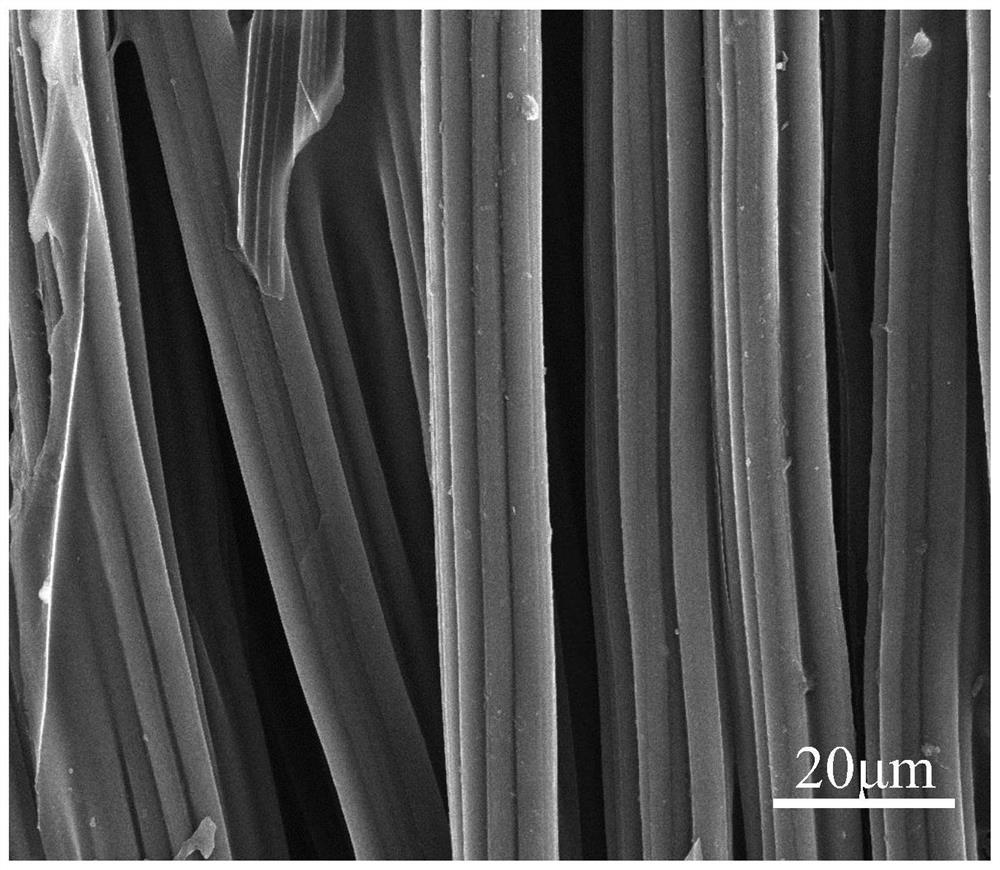

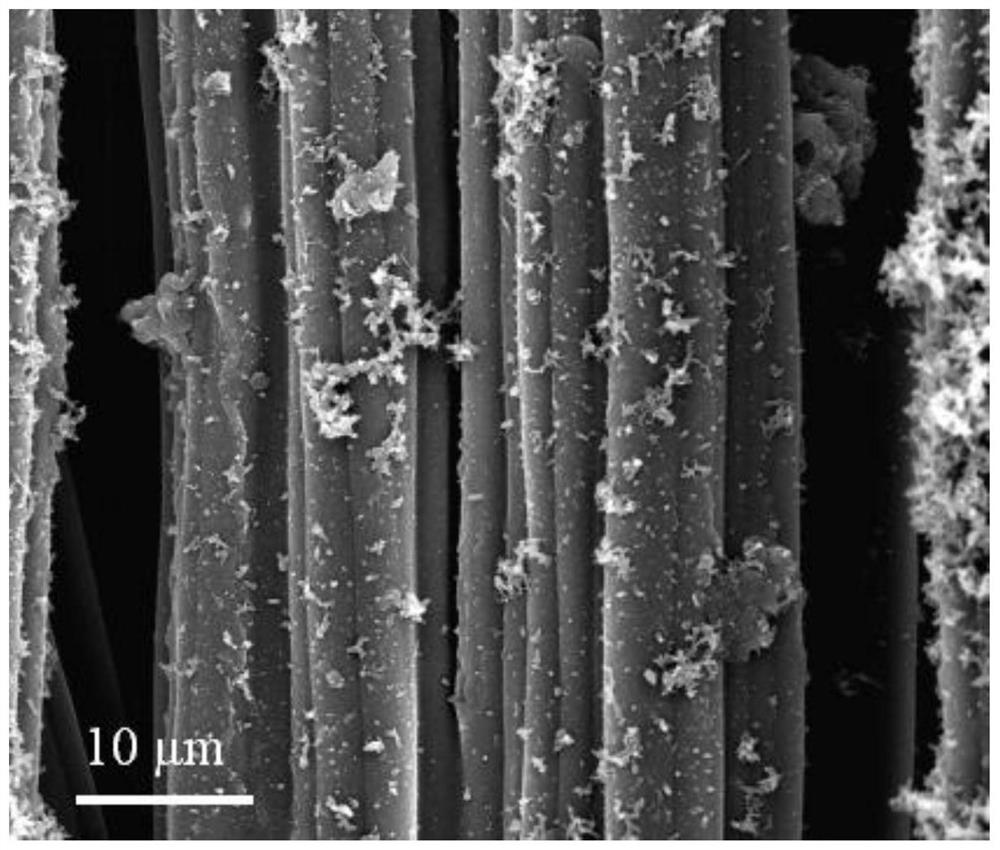

Electrode material for all-vanadium redox flow battery and preparation method thereof

InactiveCN102569815AImprove performanceGood electrochemical reversibilityCell electrodesTungstate ionRedox

The invention discloses an electrode material for an all-vanadium redox flow battery and a preparation method thereof. The preparation method comprises the following steps of: (1) oxidation treatment of acetylene black: carrying out oxidation treatment on acetylene black by use of air or an oxidant; (2) adsorption of tungstic acid by acetylene black: adding oxidized acetylene black into a solution containing tungstate ions, adding an acid liquid to adjust the pH value to acidity, separating out and adsorbing the tungstic acid on the surface of acetylene black, and aging at room temperature, filtering, washing and drying; and (3) calcination: calcining acetylene black adsorbing tungstic acid, and grinding to obtain the acetylene black supported tungstic oxide electrode material. In the method, oxidation treatment is carried out on acetylene black and then tungsten oxide covers on the surface of acetylene black so as to improve the electrochemical reversibility of acetylene black on the redox couple of the all-vanadium redox flow battery.

Owner:SHIJIAZHUANG UNIVERSITY

Composition and process for the treatment of metal surfaces

Owner:MACDERMID INC

Tungsten extraction process and application thereof

ActiveCN113684380AEffective dissolutionHigh dissolution extraction rateProcess efficiency improvementTungstate ionPhysical chemistry

The invention discloses a tungsten extraction process and application thereof. The tungsten extraction process comprises the following steps: mixing a tungsten ore raw material with a tungstate solution under an acidic condition, carrying out heating reaction to dissolve out tungsten, then carrying out solid-liquid separation, and carrying out post-treatment on the filtrate to obtain a tungsten product, wherein the post-treatment at least comprises the following steps: adsorbing cations in the filtrate by adopting cation exchange resin or an extracting agent to obtain a metatungstic acid solution, and then drying or pyrolyzing the metatungstic acid solution to obtain a tungsten elementary substance and / or tungsten oxide product. Tungsten in the tungsten ore raw material is directly and efficiently dissolved out by utilizing the strong self-coordination capability of tungstate ions under the acidic condition, and the dissolution extraction rate is high; and the extraction process flow is more simplified, and the economic value of the obtained tungsten product is higher; and the extraction process is scientific and reasonable in design, high in process controllability, good in economical efficiency and environmental protection property and wide in practical application prospect.

Owner:CENT SOUTH UNIV

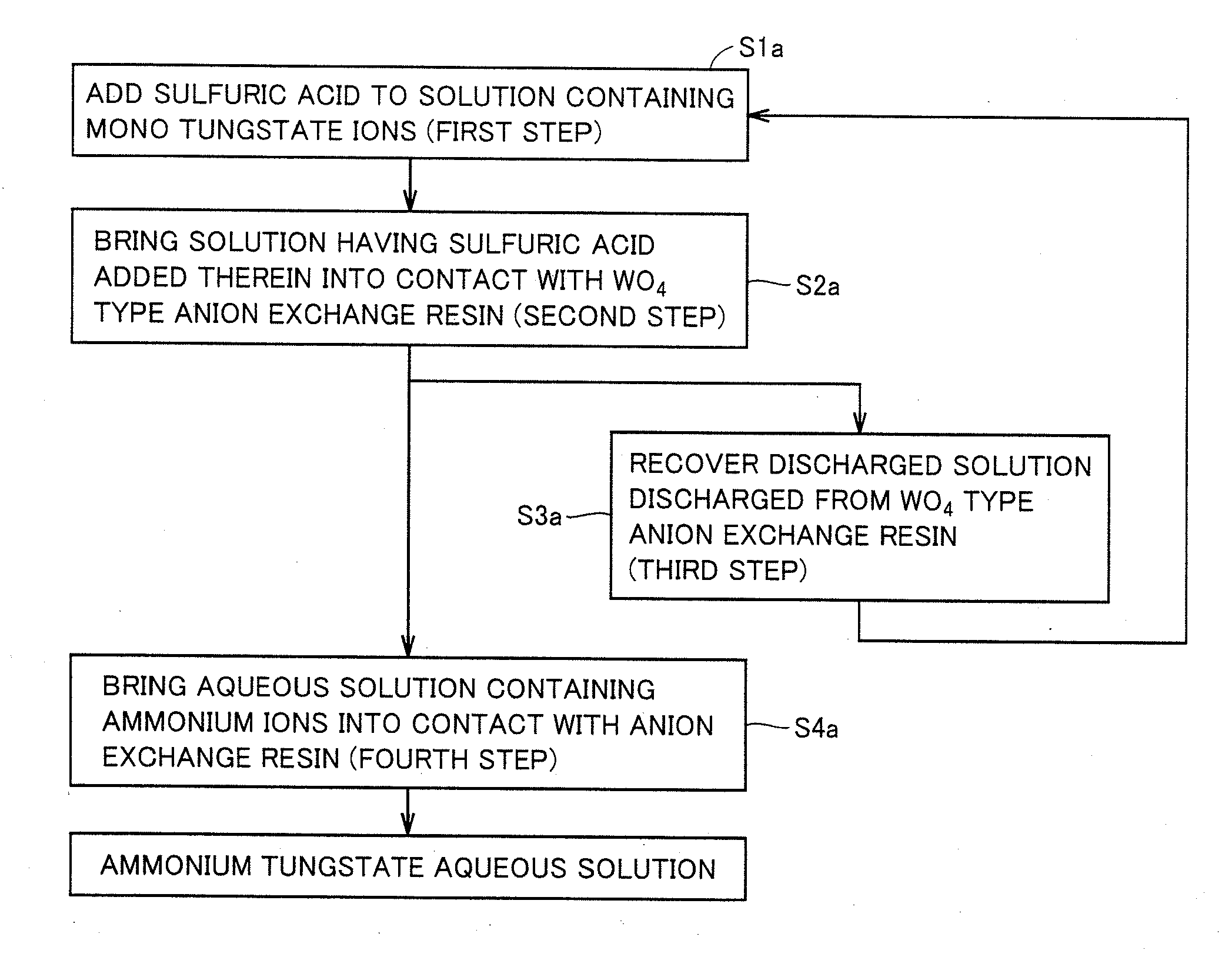

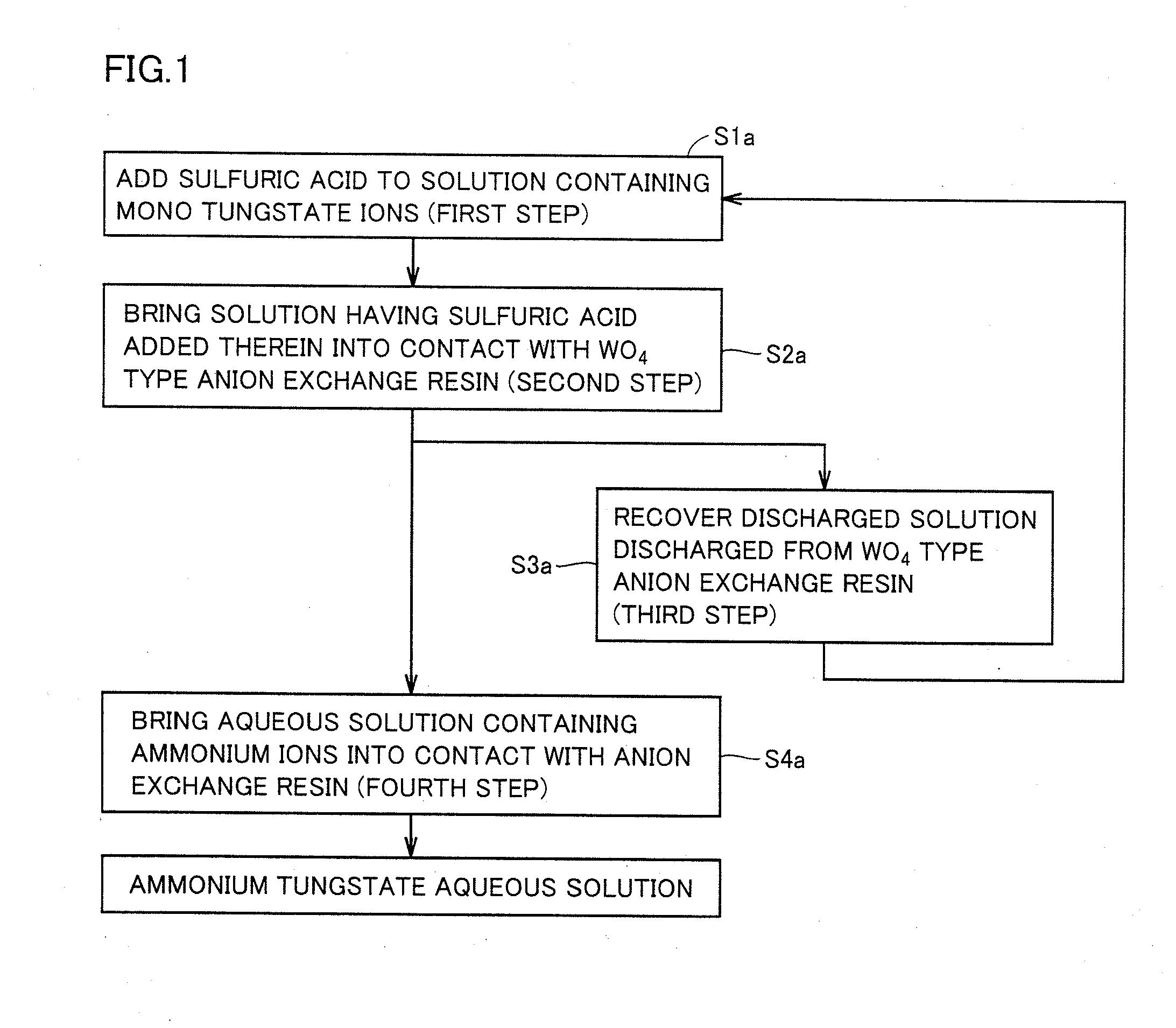

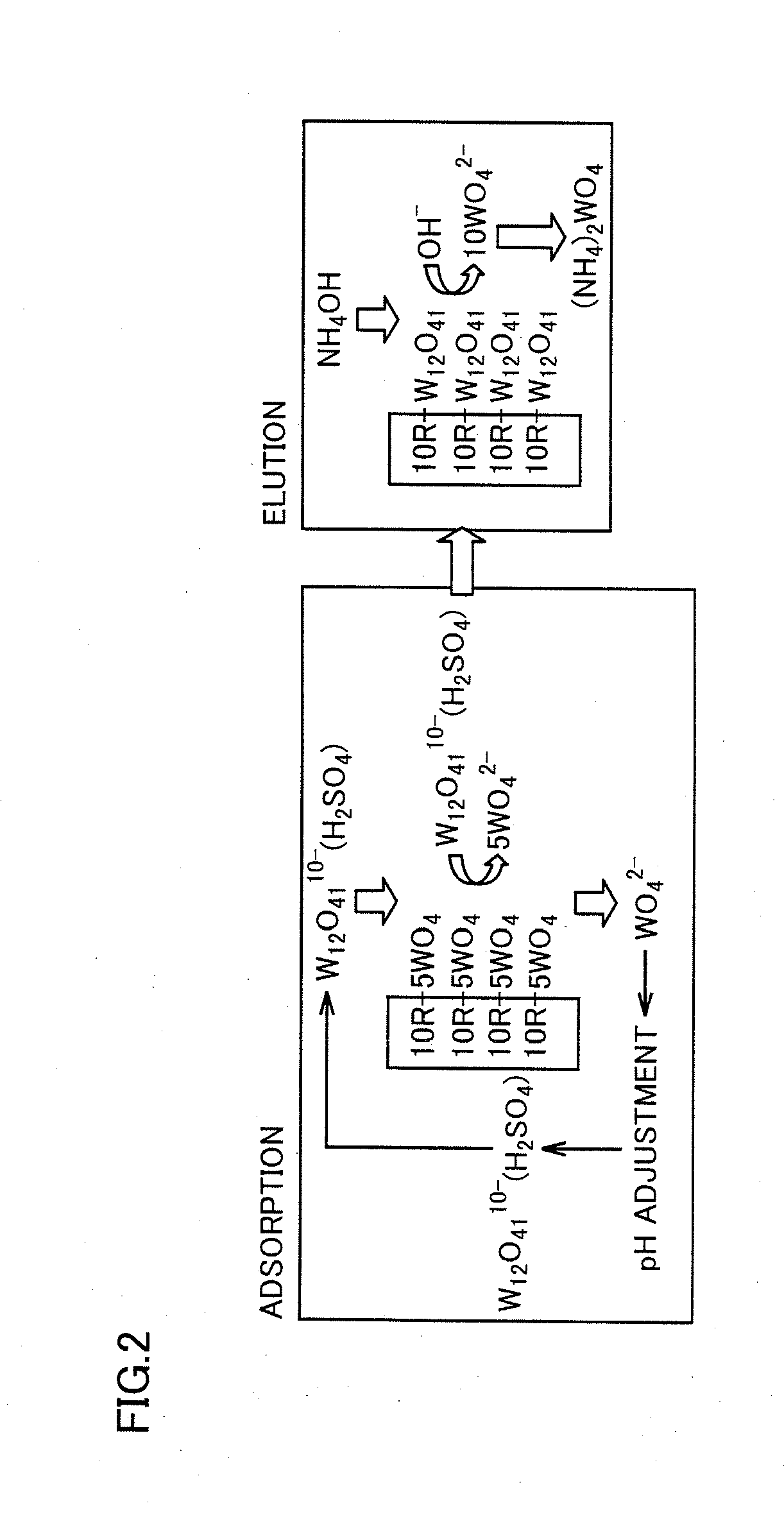

Method for producing ammonium tungstate aqueous solution

InactiveUS20120328506A1Effective recoverySuppress generationTungsten oxides/hydroxidesSpeech recognitionTungstate ionAqueous solution

A method for producing an ammonium tungstate aqueous solution includes the steps of: adding sulfuric acid to a solution containing tungstate ions; bringing the solution having the sulfuric acid added therein, into contact with an anion exchange resin; and bringing the anion exchange resin into contact with an aqueous solution containing ammonium ions.

Owner:ALLIED MATERIAL +2

Processing method of tungsten-containing tin concentrate

The invention discloses a processing method of a tungsten-containing tin concentrate. The processing method comprises the following steps: preparing pulp of the tin concentrate, and mixing the pulp and soluble carbonate to obtain mixed pulp; enabling the mixed pulp to carry out leaching reaction to obtain tungsten-containing leaching residues and a leaching solution; regulating a pH value of the leaching solution to be acid to obtain an acid leaching solution; regulating a pH value of the leaching solution to be alkaline to obtain an alkaline leaching solution; and adding the soluble carbonate in the alkaline leaching solution, and carrying out reaction to obtain artificial scheelite. According to the processing method, tungsten in the tungsten-containing tin concentrate can be converted to tungstate ions depending on the soluble carbonate to enter the leaching solution, thus the method can fully separate tungsten from the tungsten-containing tin concentrate; then, the pH value of the leaching solution is regulated to be acid, thus the tungstate ions in the leaching solution can be removed; while, the pH value of the leaching solution is regulated to be alkaline, full precipitation of the tungstate ions is facilitated, and the artificial scheelite is formed.

Owner:CHINA ENFI ENGINEERING CORPORATION

Processing method of tin concentrate containing tungsten

The invention discloses a processing method of a tungsten-containing tin concentrate. The processing method comprises the following steps: preparing pulp of the tin concentrate, and mixing the pulp and soluble carbonate to obtain mixed pulp; enabling the mixed pulp to carry out leaching reaction to obtain tungsten-containing leaching residues and a leaching solution; regulating a pH value of the leaching solution to be acid to obtain an acid leaching solution; regulating a pH value of the leaching solution to be alkaline to obtain an alkaline leaching solution; and adding the soluble carbonate in the alkaline leaching solution, and carrying out reaction to obtain artificial scheelite. According to the processing method, tungsten in the tungsten-containing tin concentrate can be converted to tungstate ions depending on the soluble carbonate to enter the leaching solution, thus the method can fully separate tungsten from the tungsten-containing tin concentrate; then, the pH value of the leaching solution is regulated to be acid, thus the tungstate ions in the leaching solution can be removed; while, the pH value of the leaching solution is regulated to be alkaline, full precipitation of the tungstate ions is facilitated, and the artificial scheelite is formed.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method of removing arsenic from arsenic-containing nickel sulfate solution

A method of removing arsenic from an arsenic-containing nickel sulfate solution comprises the steps of adding sodium tungstate or sodium molybdate into the arsenic-containing nickel sulfate solution (pH less than or equal to 2) at a molar ratio of arsenic to tungsten or molybdenum of 1:(9-12) for reaction to form a heteropoly acid containing solution, and injecting the solution into an exchange column equipped with large-aperture anion resin to form a solution after ion exchange and the large-aperture anion resin absorbing heteropoly acid. Raw materials used in a whole process can be recycled. A tungstate ion or molybdate anion loss is small (less than or equal to 0.5%); an arsenic content of the final solution after the exchange is less than 0.5 ppm; and industrial production requirements are completely met.

Owner:CENT SOUTH UNIV

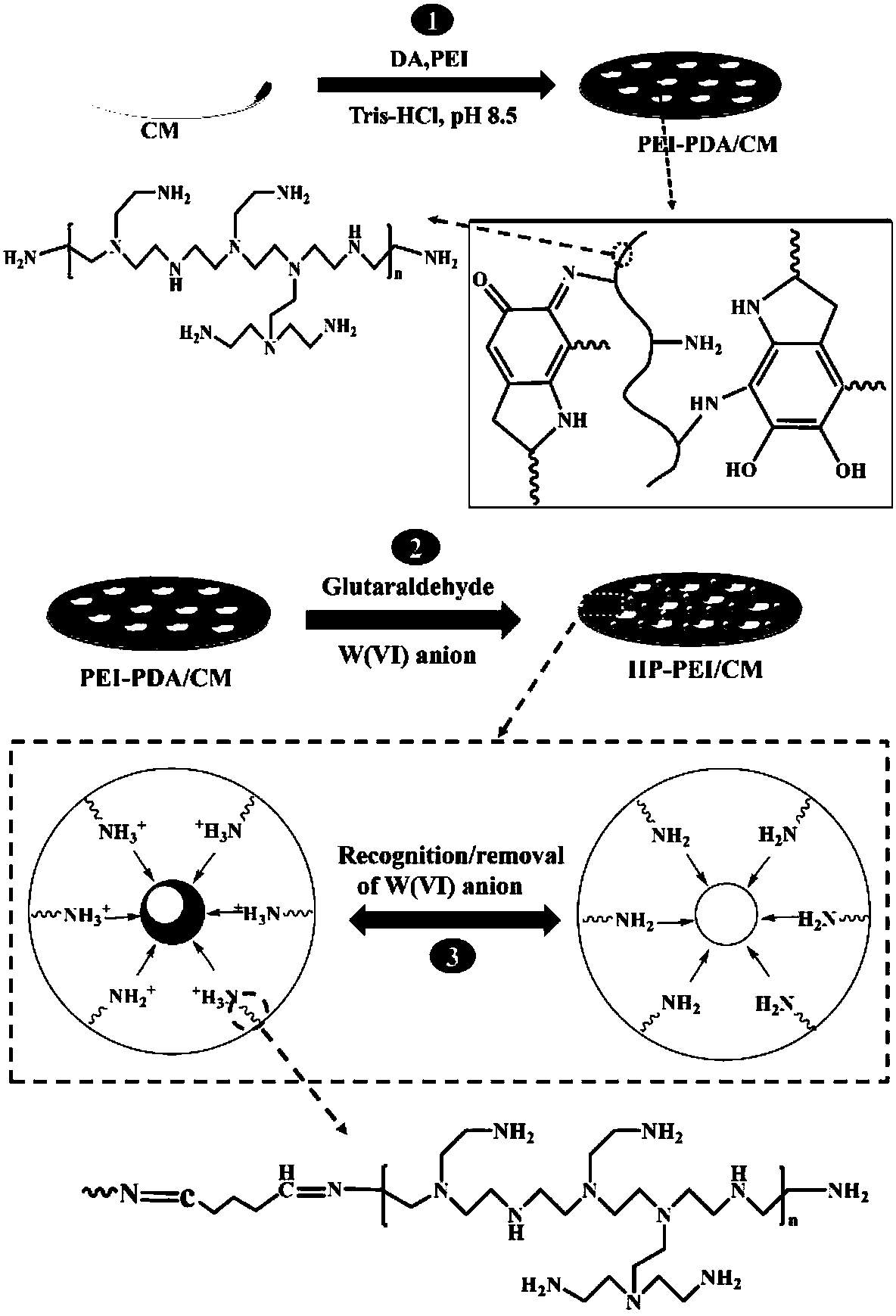

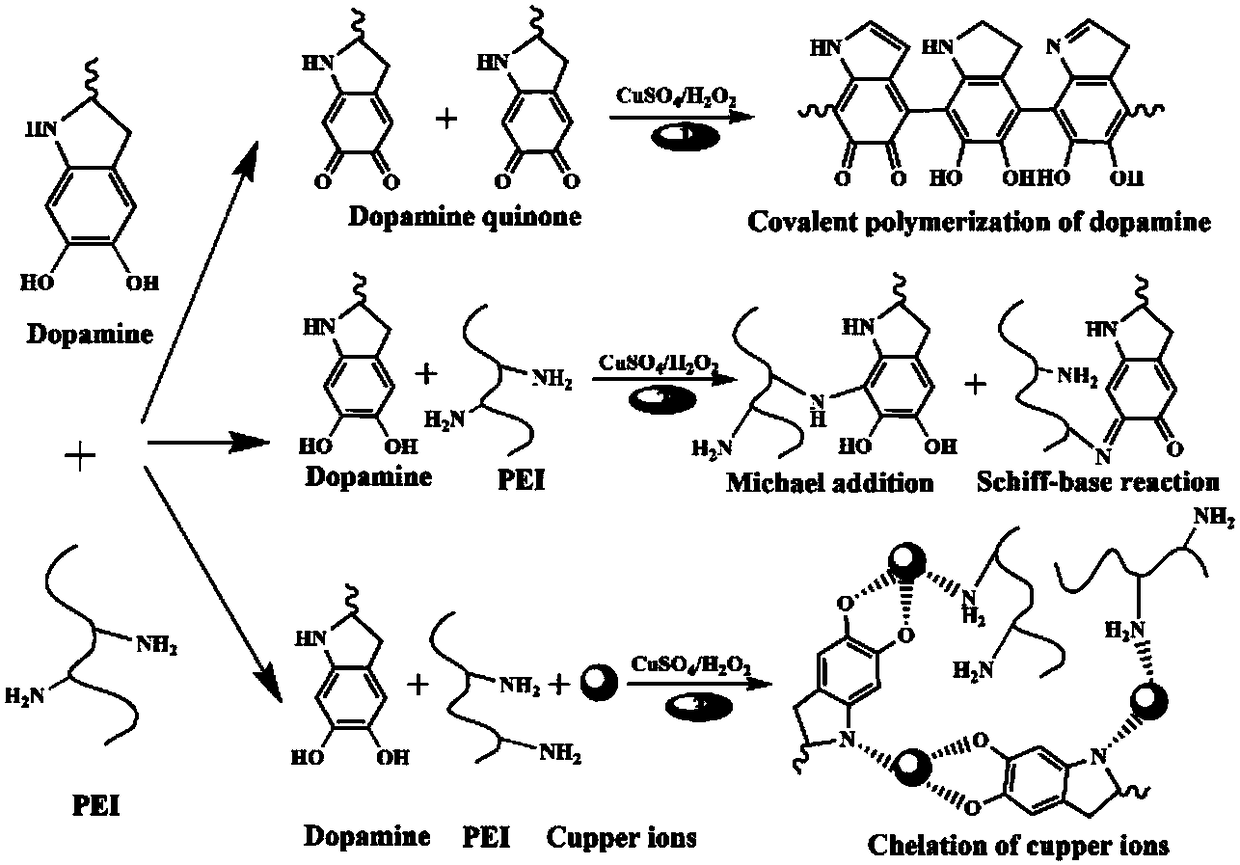

Preparation method of tungstate ion-imprinted ceramic membrane and treatment method of tungsten-containing wastewater

ActiveCN108452779AImprove adsorption capacityHigh reusabilityOther chemical processesWater/sewage treatment by sorptionTungstate ionWastewater

The invention belongs to the technical field of ion imprinting, and particularly relates to a preparation method of a tungstate ion-imprinted ceramic membrane and a treatment method for tungsten-containing wastewater. The preparation method of the tungstate ion-imprinted ceramic membrane comprises the following steps of (1) the preparation method of a codeposition ceramic membrane of polymine andpolydopamine; (2) adsorption reaction between the codeposition ceramic membrane of the polymine and the polydopamine and tungstate ions; (3) immersion of a saturated codeposition ceramic membrane intoan ethanol solution of glutaraldehyde, wherein the vacuum processing is conducted for a predetermined time after the reaction is completed; (4) elution of template ions. The tungstate ion-imprinted ceramic membrane prepared by means of the method not only has high adsorption performance for tungstate ions, but also shows excellent selectivity and ultra-fast adsorption rate, the tungstate ion-imprinted ceramic membrane has stable structural performance, imprinted materials on the surface of the ceramic membrane are uniformly distributed, the combination performance of the imprinted materials and the ceramic membrane is good, the imprinted materials do not easily fall off, and the imprinted ceramic membrane is excellent in recyclability.

Owner:HUNAN UNIV OF SCI & TECH

A recovery and adsorption method for tungstate in scheelite mineral processing wastewater

ActiveCN110642335BImprove adsorption capacityEasy to separateWaste water treatment from quariesWater contaminantsTungstate ionElectrolytic agent

The invention relates to a method for recovering and adsorbing tungstate in scheelite mineral processing wastewater, and relates to a method for recovering tungstate in mineral processing wastewater. The invention aims to solve the technical problems of low recovery rate and slow recovery rate of tungstate in the existing scheelite mineral processing wastewater. The present invention: a polyaniline / carbon cloth composite electrode material, an Ag / AgCl electrode and a platinum electrode constitute a three-electrode system connected to an electrochemical workstation, the polyaniline / carbon cloth composite electrode material is used as a working electrode, and the Ag / AgCl electrode is used as a reference Electrodes, the platinum electrode is the counter electrode, and the scheelite mineral processing wastewater to be treated is used as the electrolyte, which is electrosorbed under the condition of electric field force. The process of the invention is simple and fast, and the recovery rate of tungstate ions adsorbed for 2 hours can reach 75%.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com