Manufacturing methods of electrolytic copper foil having needle-shaped copper particles and circuit board assembly

A technology of electrolytic copper foil and manufacturing method, which is applied in the field of manufacturing electrolytic copper foil and circuit board components, can solve the problems of reducing the peel strength of copper foil and circuit substrate, insufficient peel strength of copper foil, etc., and achieve high peel strength and large contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

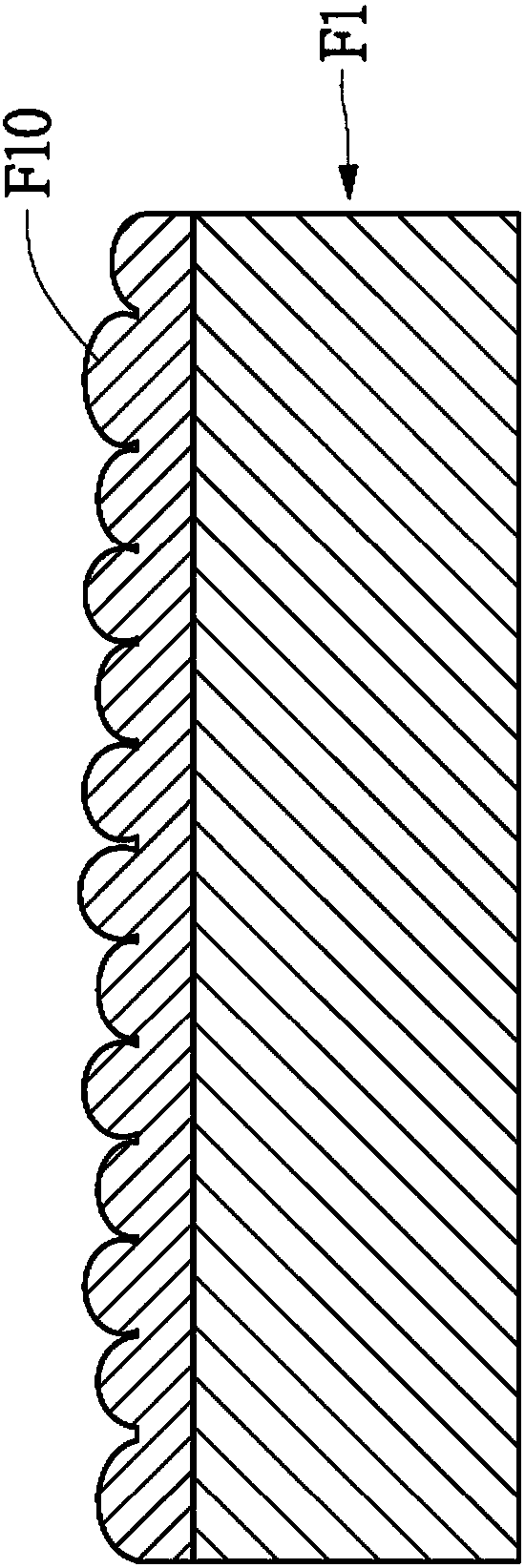

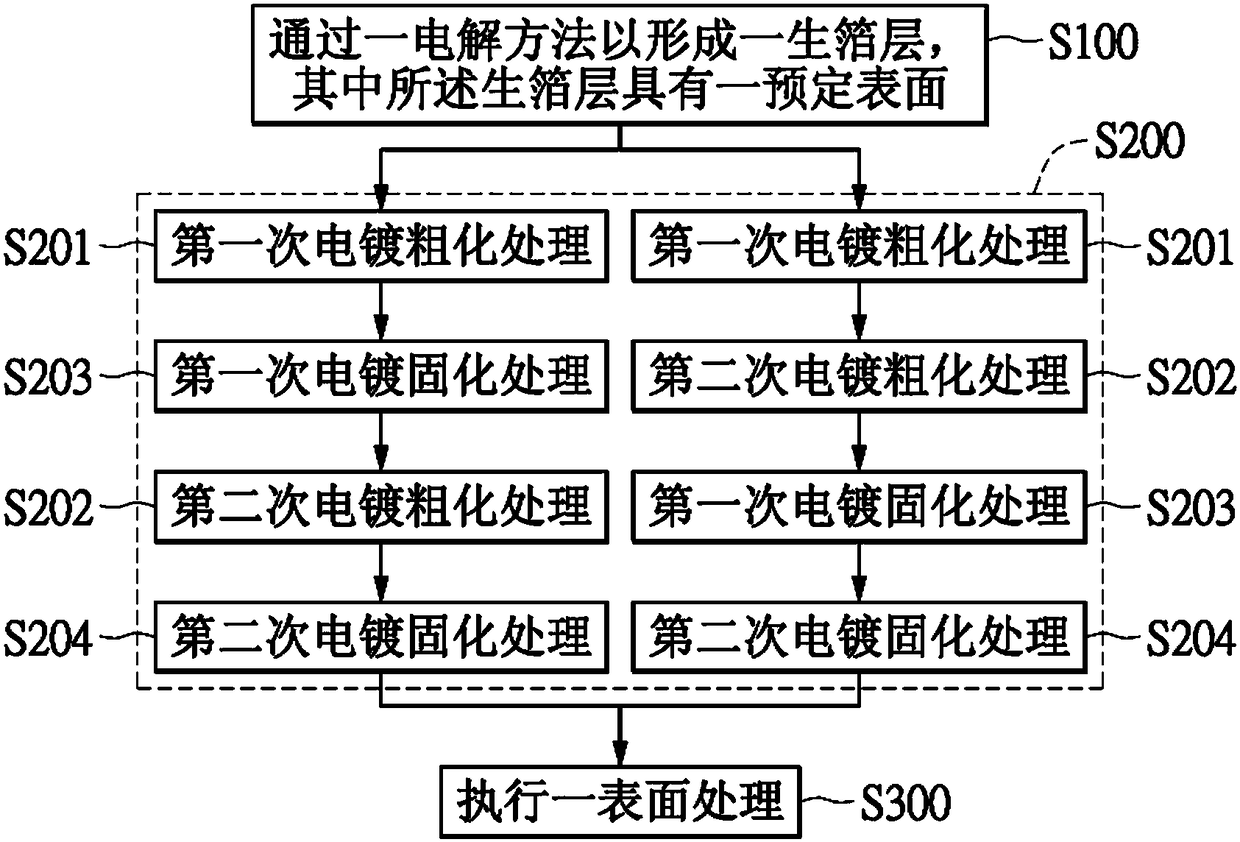

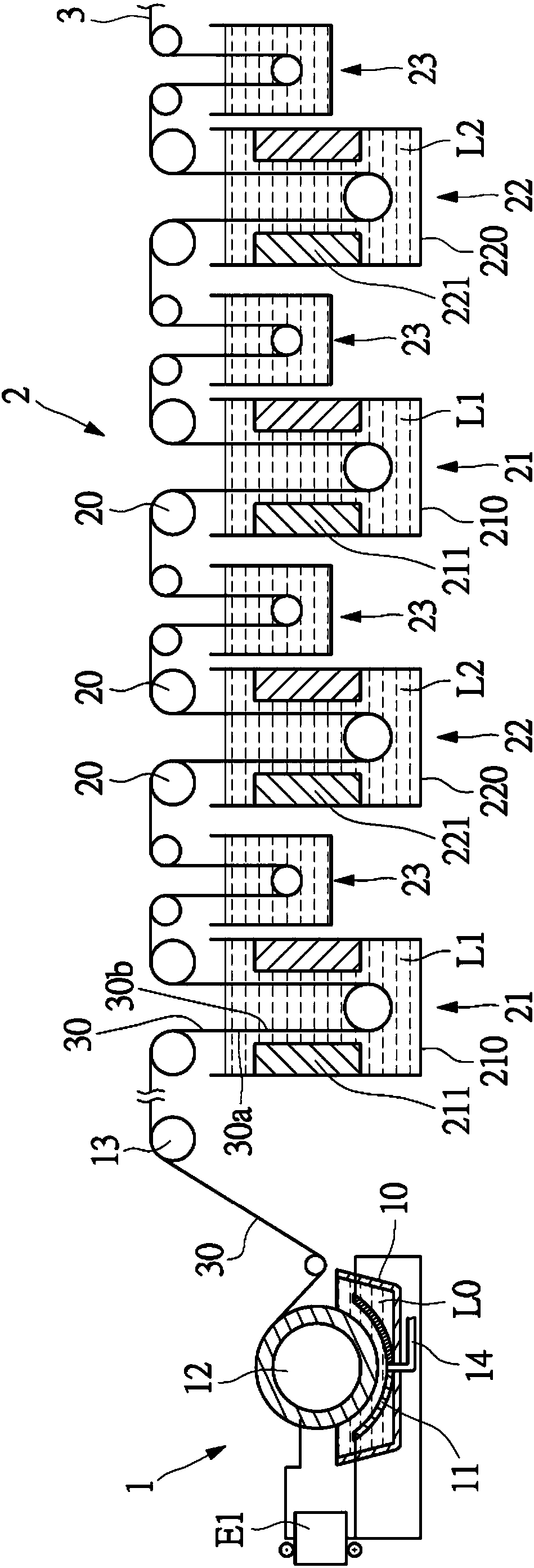

[0035] The following is an illustration of the implementation of the "method for manufacturing an electrolytic copper foil with approximately villous copper nodules and a circuit board assembly" disclosed by the present invention through specific examples. The manufacturing method provided by the embodiment of the present invention can obtain an electrodeposited copper foil with approximately villous copper nodules, which has low roughness and high peel strength. In addition, the circuit board assembly formed by bonding the electrodeposited copper foil with the approximate villi-shaped copper nodules and the resin substrate to each other can be applied to high-frequency signal transmission. Please refer to figure 2 and image 3 . figure 2 A flow chart showing a method for manufacturing an electrodeposited copper foil with approximate villous copper nodules according to an embodiment of the present invention, image 3 for execution figure 2 Schematic diagram of the equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com