Patents

Literature

1571 results about "Needle Shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

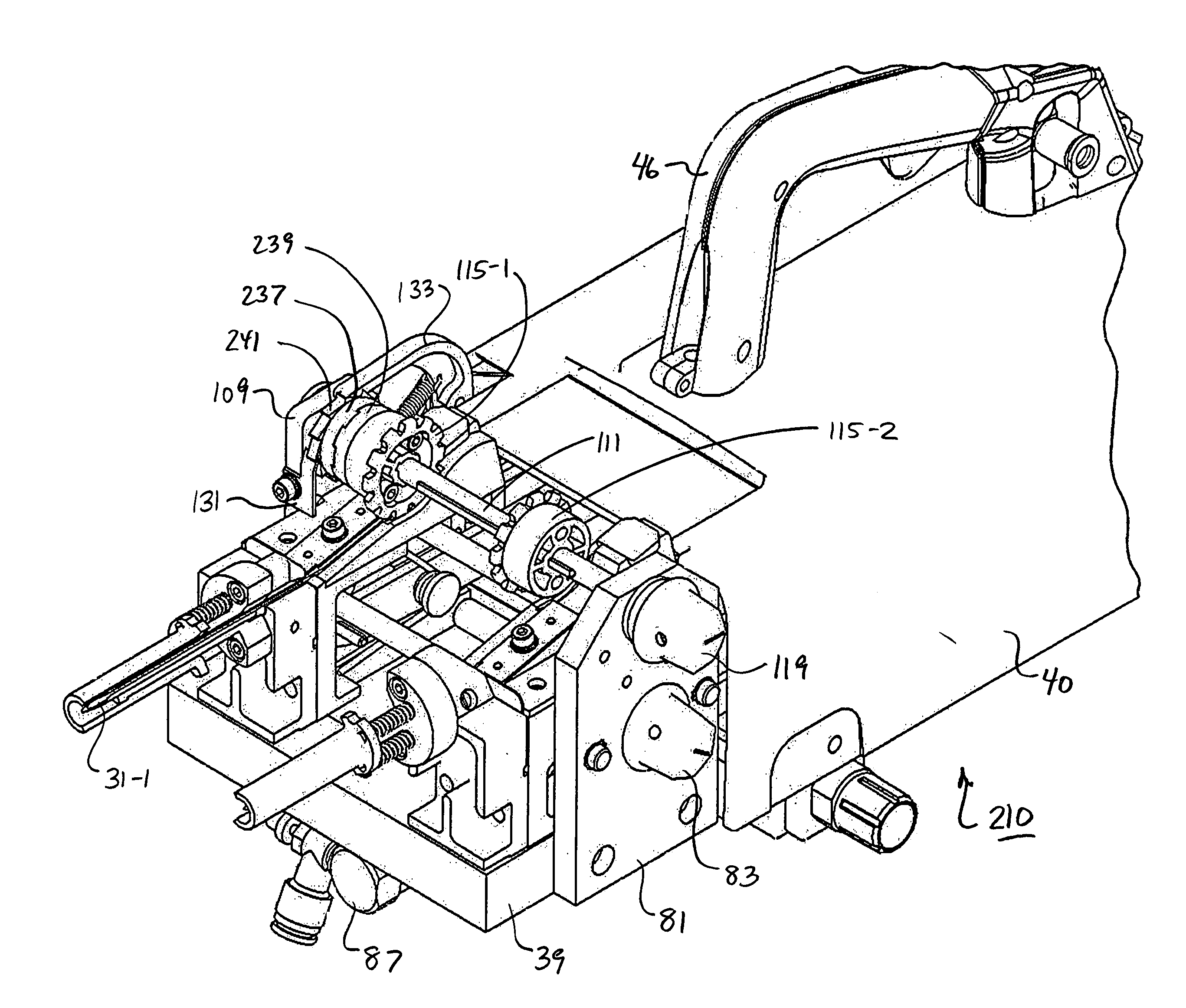

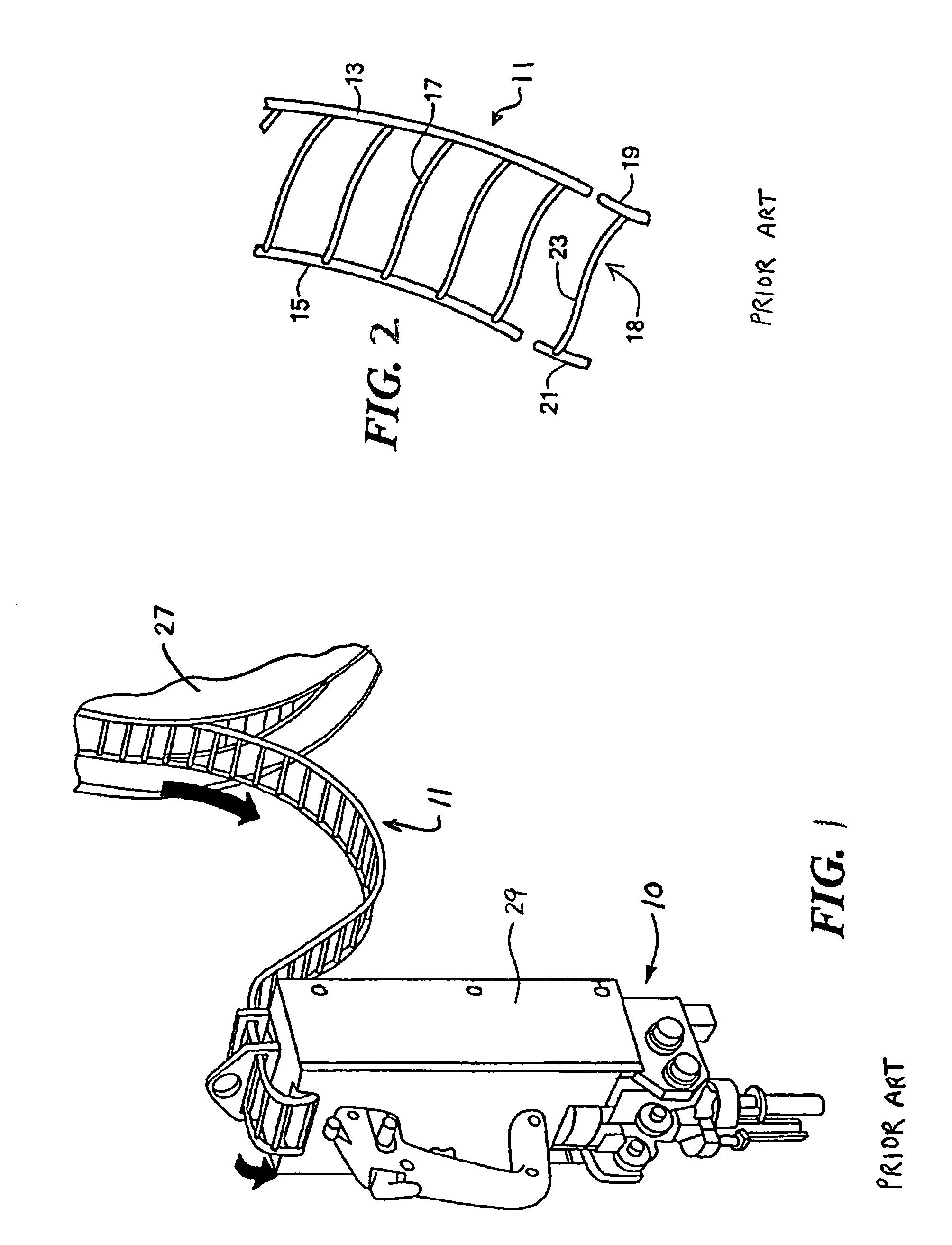

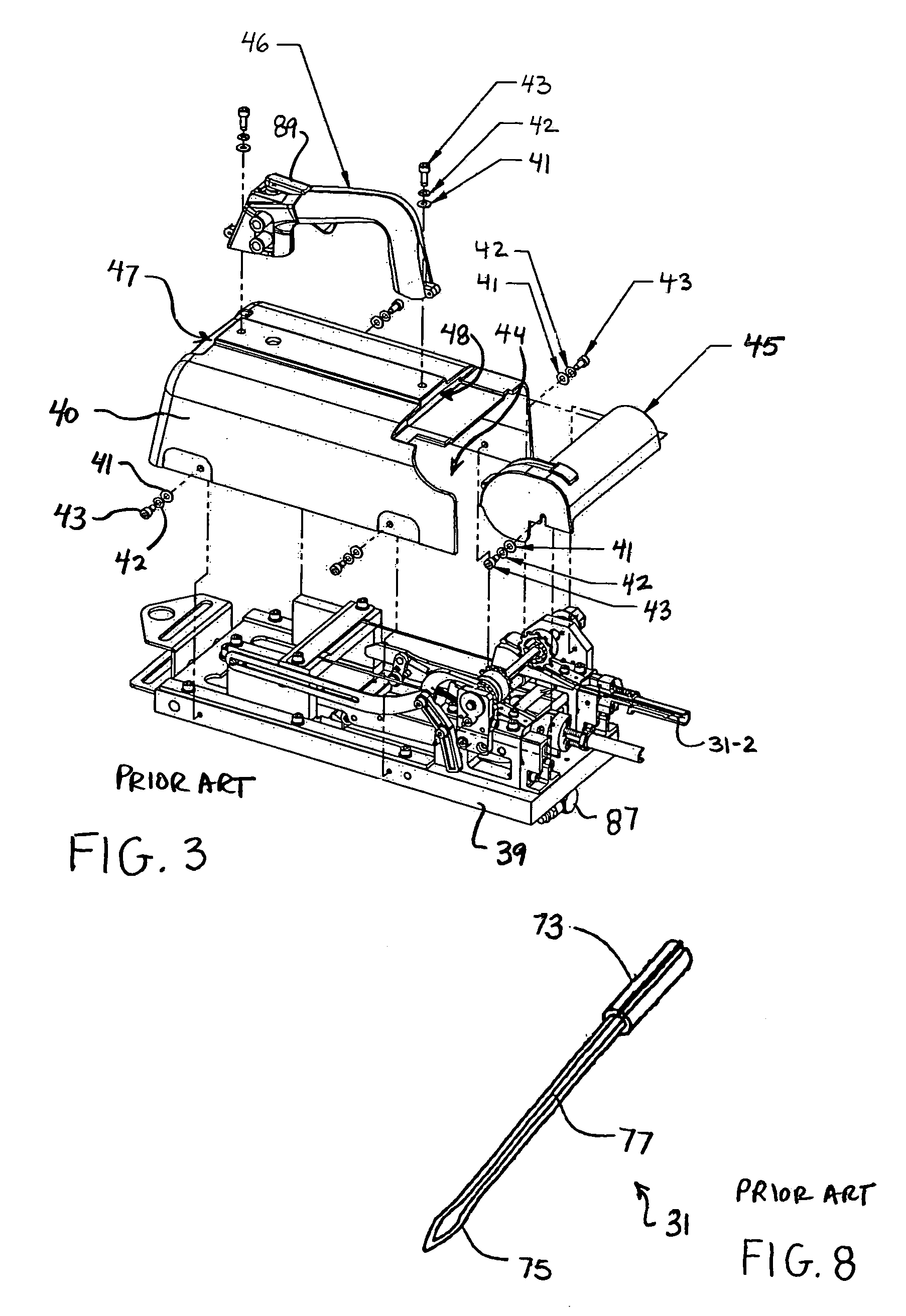

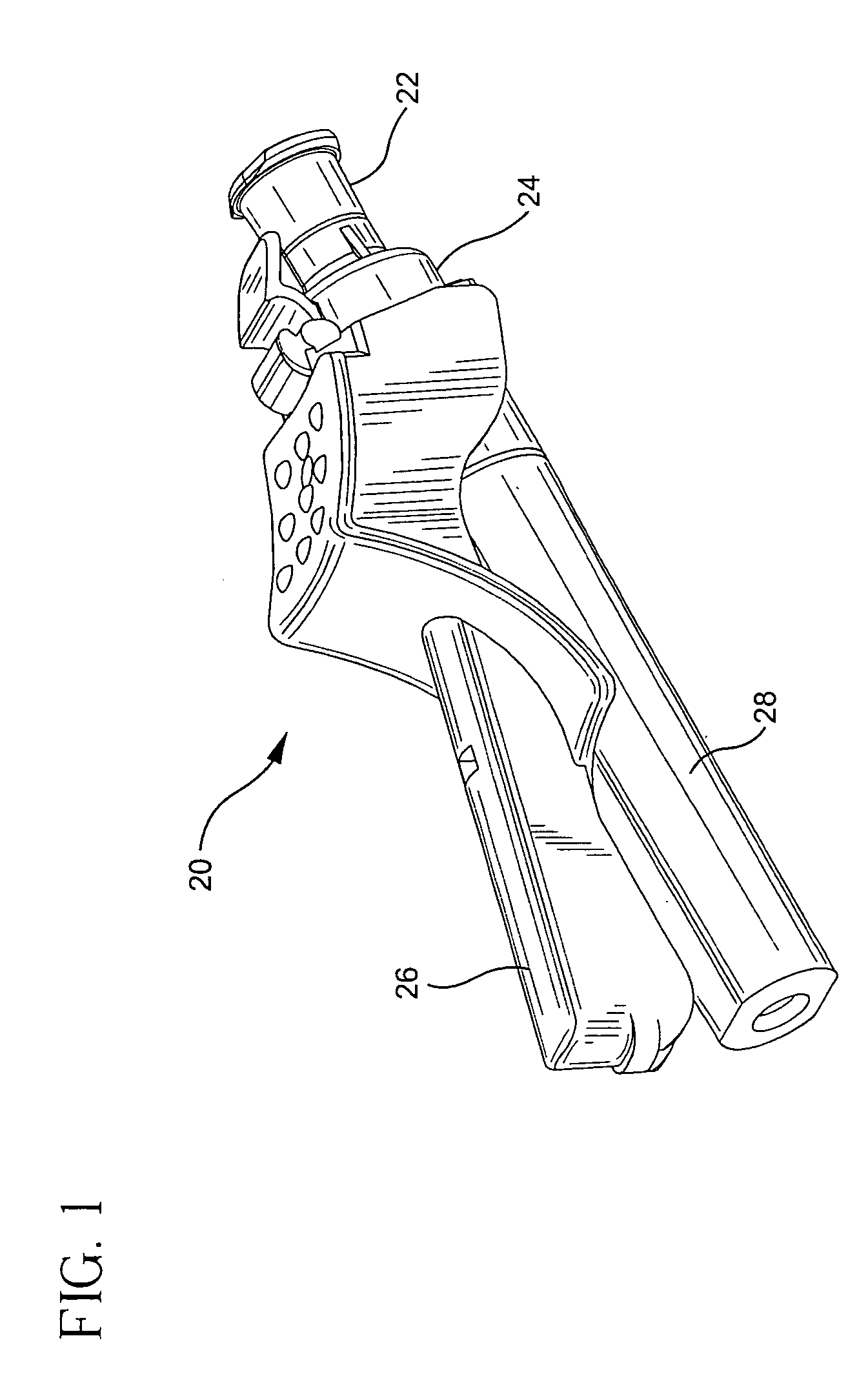

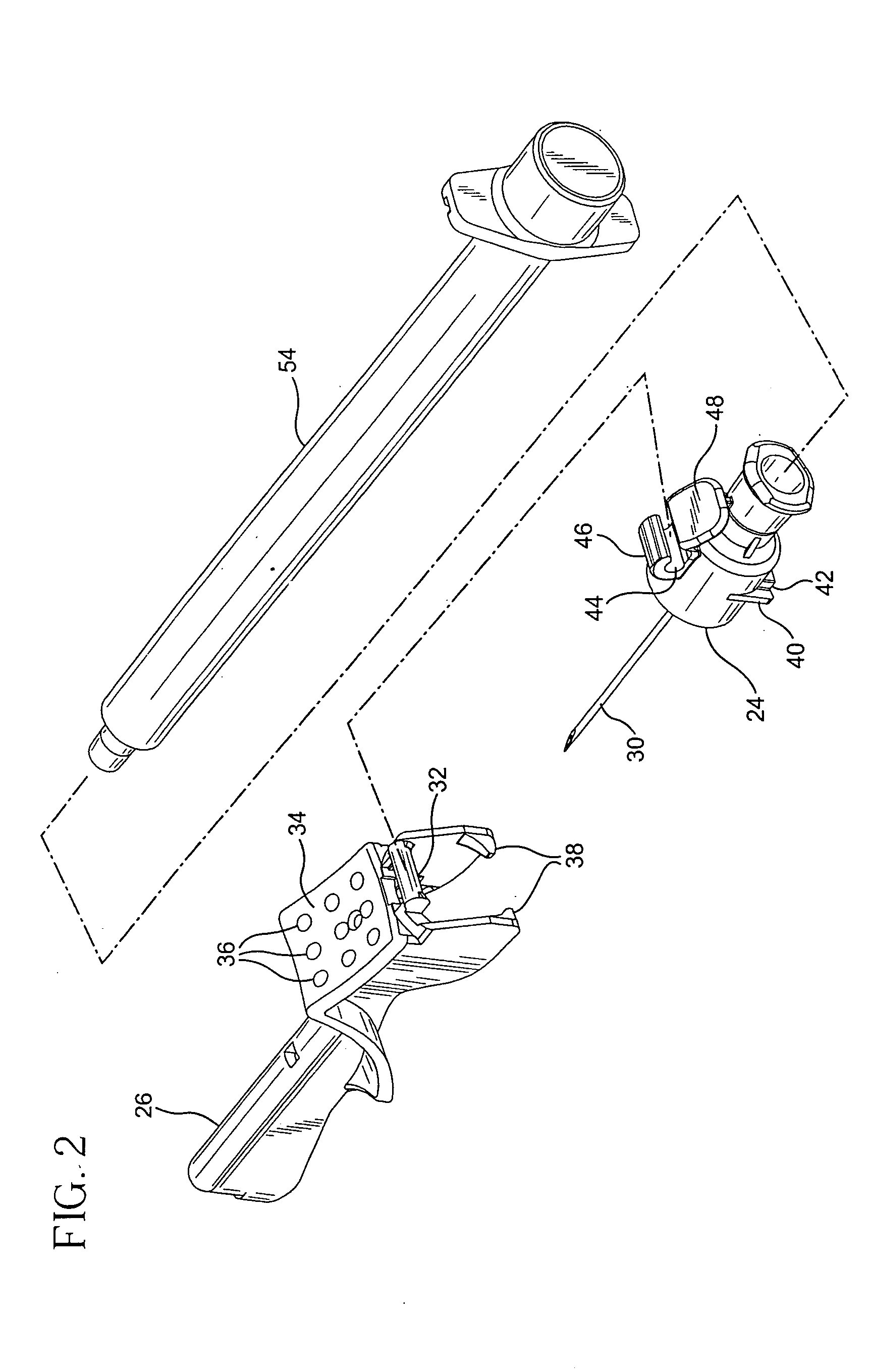

Device for dispensing plastic fasteners

ActiveUS7036680B1Easy to useReduce manufacturing costAffixing tagsCoin-freed apparatus detailsCross-linkEngineering

A device for dispensing an individual plastic fastener from a supply of fastener stock to couple together two or more objects. The supply of fastener stock includes a plurality of equidistantly spaced cross links which are coupled at one end to a continuous side rail. The fastener dispensing device includes a hollowed sharpened needle shaped to define a longitudinal bore and a feed mechanism for advancing the continuous side rail of the fastener stock into direct axial alignment behind the longitudinal bore of the hollowed needle. The feed mechanism includes a rotatably mounted feed shaft, a pair of feed wheels fixedly mounted on the feed shaft, each feed wheel comprising a plurality of sprockets which are sized and shaped to engage the supply of fastener stock, and first and second clutch wheels which are releasably matingly engageable with one another, the first clutch wheel being fixedly mounted on the feed shaft and the second clutch wheel being rotatably mounted on the feed shaft, each of the first and second clutch wheels including a plurality of ratchets. As a feature of the invention, the number of ratchets on each clutch wheel is at most equal to the number of sprockets on each feed wheel.

Owner:AVERY DENNISON CORP

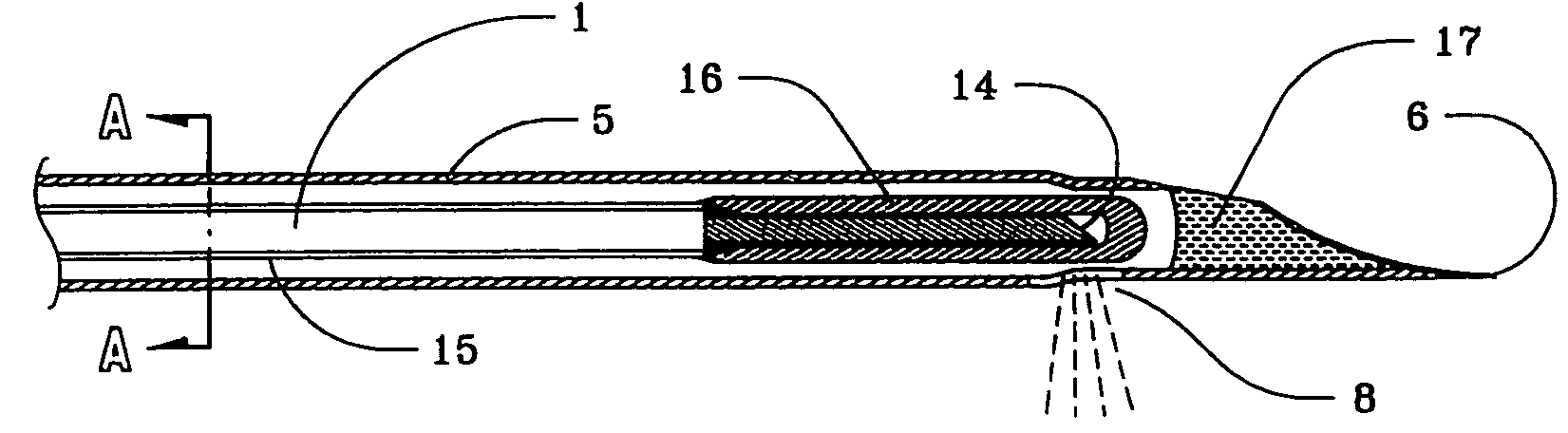

Infusion device

ActiveUS7381200B2Easily inserted into bodyReliably securedInfusion syringesInfusion devicesThree vesselsSurgery

It is an object of the present invention to provide an infusion device that can be easily inserted into the body and that when inserted into a blood vessel reliably ensures the flow of blood. The infusion device is provided with a needle-shaped tube member having a sharp tip in any one lumen of the three lumens provided within a tubular member that can be inserted into the body in such a manner that it can move axially, an extrusion aperture provided in the tubular member through which the needle-shaped tube member is extruded, and a reagent supplier for supplying a predetermined reagent into the needle-shaped tube member. Additionally, recessed portions extending axially are formed in an outer circumferential surface of the tubular member in such a manner that the cross sectional shape perpendicular to the axial direction of the tubular member is a shape in which at least a portion of the outer circumference of an annular shape has been recessed radially inward.

Owner:ASAHI INTECC CO LTD +1

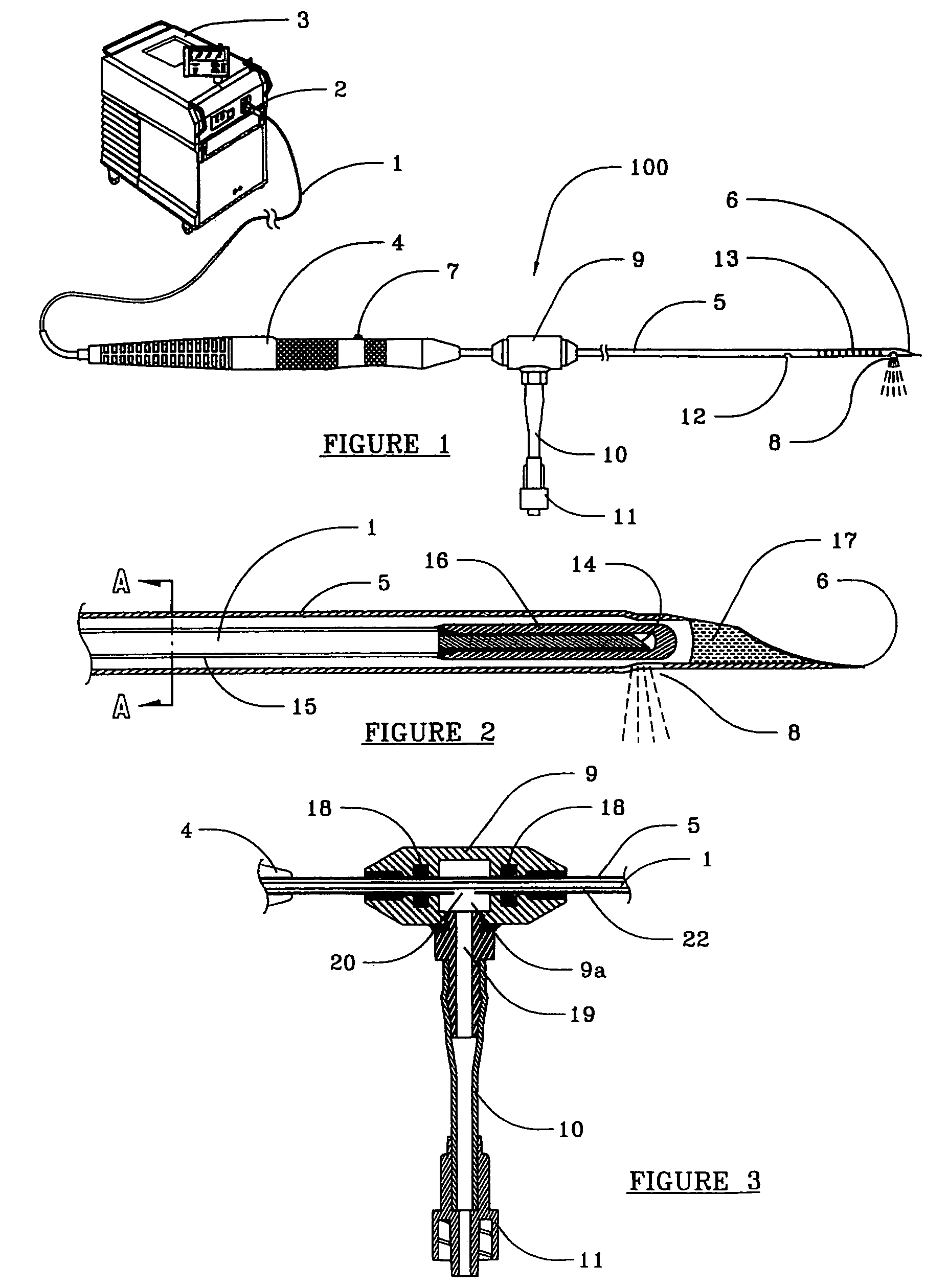

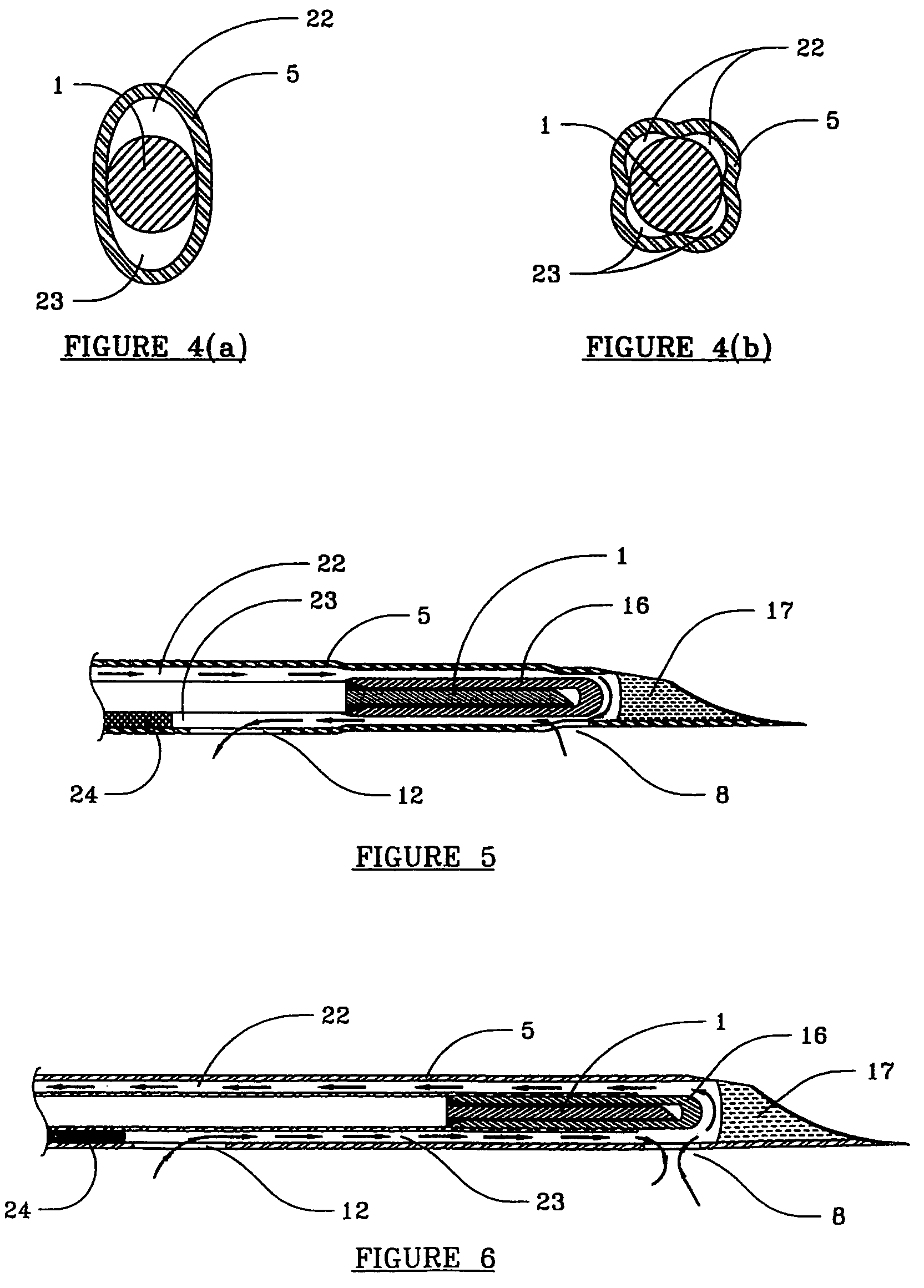

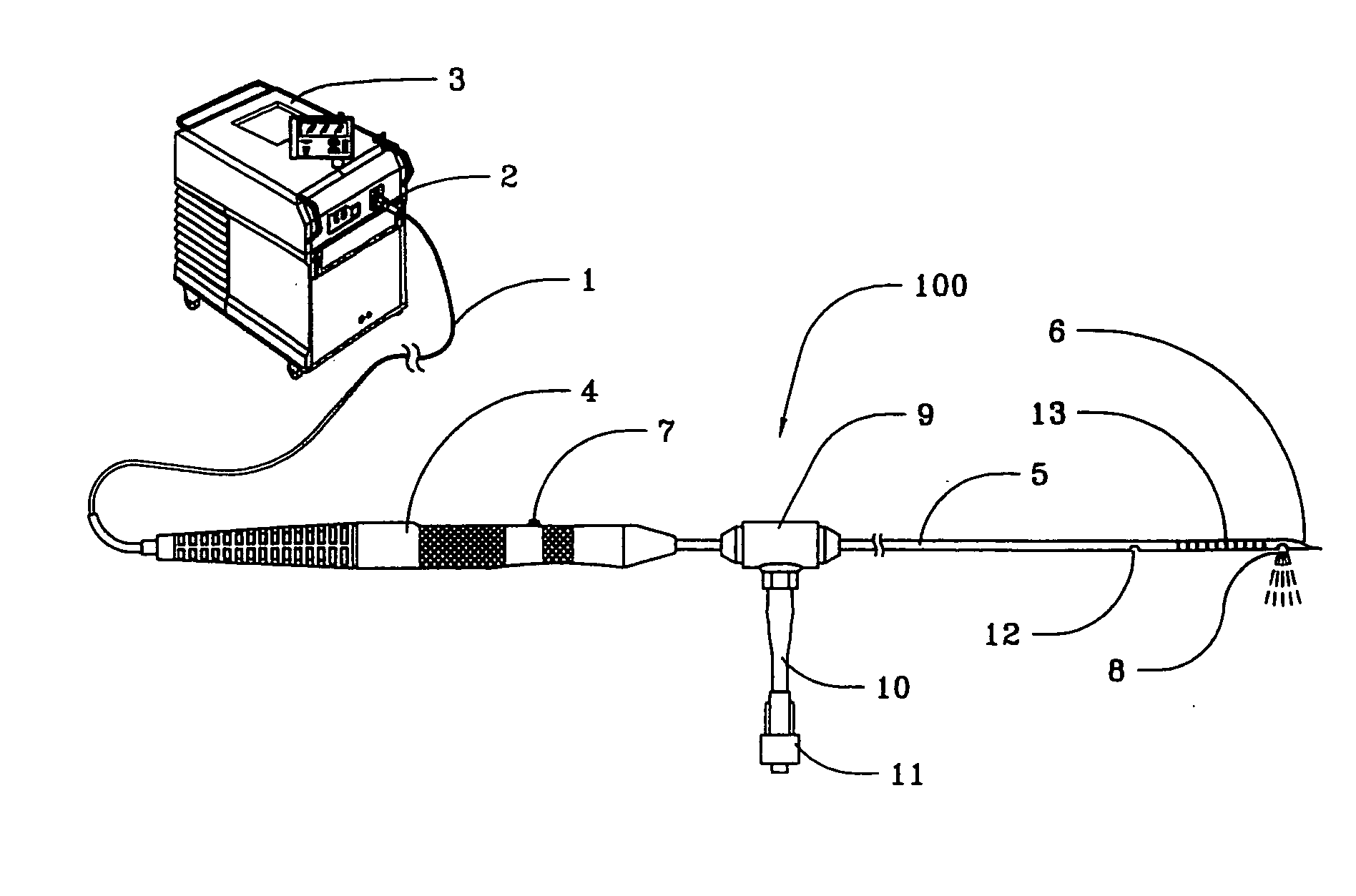

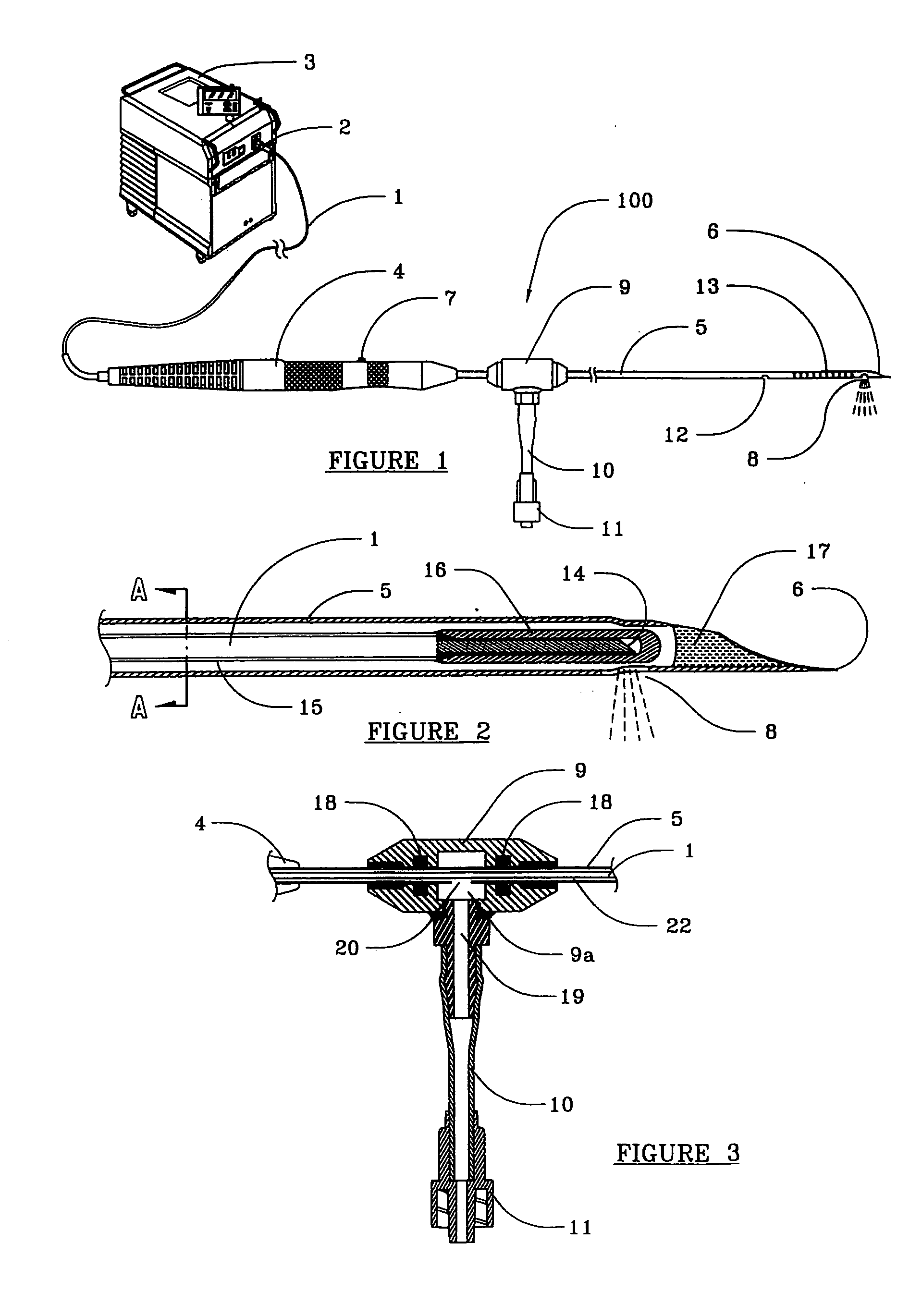

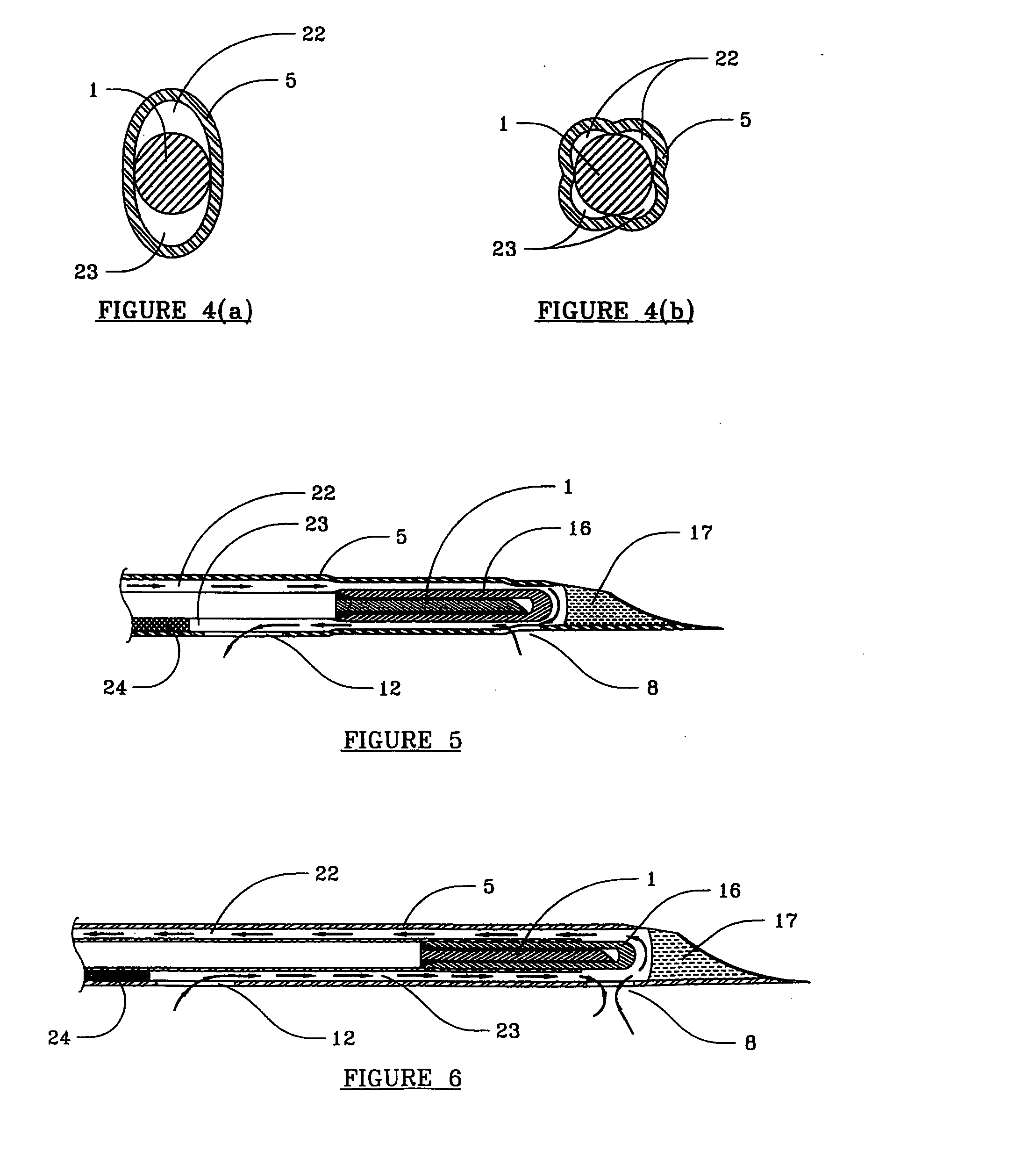

Devices and methods for directed, interstitial ablation of tissue

InactiveUS7306588B2Avoid heat damageExcessive coagulationSurgical needlesSurgical instrument detailsTotal internal reflectionBiomedical engineering

The invention relates to a catheter device including an optical fiber whose distal end is disposed within a hollow tube with a sharp or needle shaped distal end, which can penetrate tissue. The distal end of the optical fiber and the hollow tube are configured so as to emit, by refraction (total internal reflection) or reflection from a metal surface, laser energy at an angle of about 80° to about 90° relative to the longitudinal axis of the optical fiber and hollow tube. The hollow tube is mounted to a housing and may be surrounded by a sheath.

Owner:CATHETER ABLATION SOLUTIONS

Devices and methods for directed, interstitial ablation of tissue

InactiveUS20050131399A1Avoiding excess coagulationFacilitate penetration of tissueSurgical needlesSurgical instrument detailsTotal internal reflectionHollow core

The invention relates to a catheter device including an optical fiber whose distal end is disposed within a hollow tube with a sharp or needle shaped distal end, which can penetrate tissue. The distal end of the optical fiber and the hollow tube are configured so as to emit, by refraction (total internal reflection) or reflection from a metal surface, laser energy at an angle of about 80° to about 90° relative to the longitudinal axis of the optical fiber and hollow tube. The hollow tube is mounted to a housing and may be surrounded by a sheath.

Owner:CATHETER ABLATION SOLUTIONS

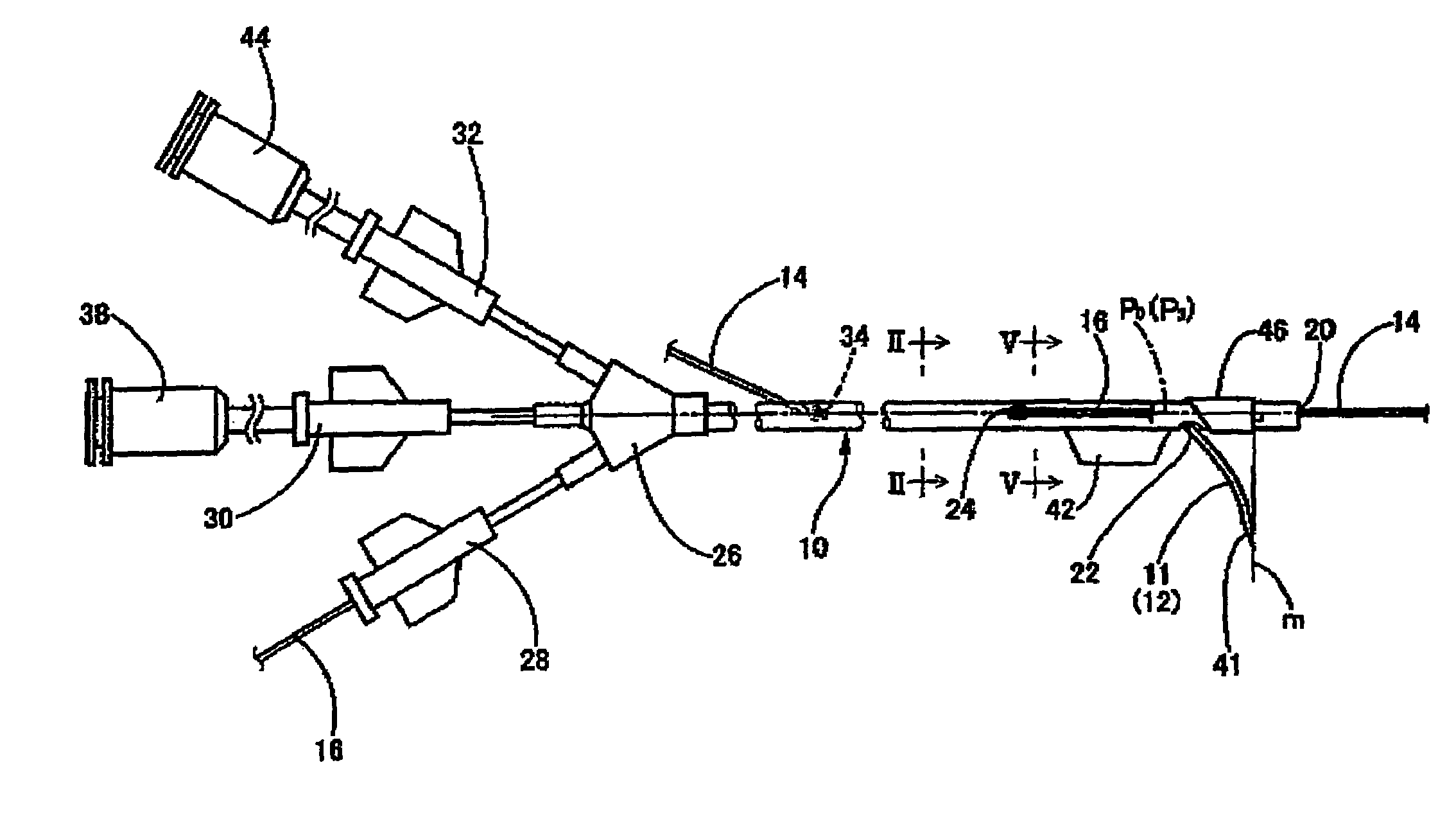

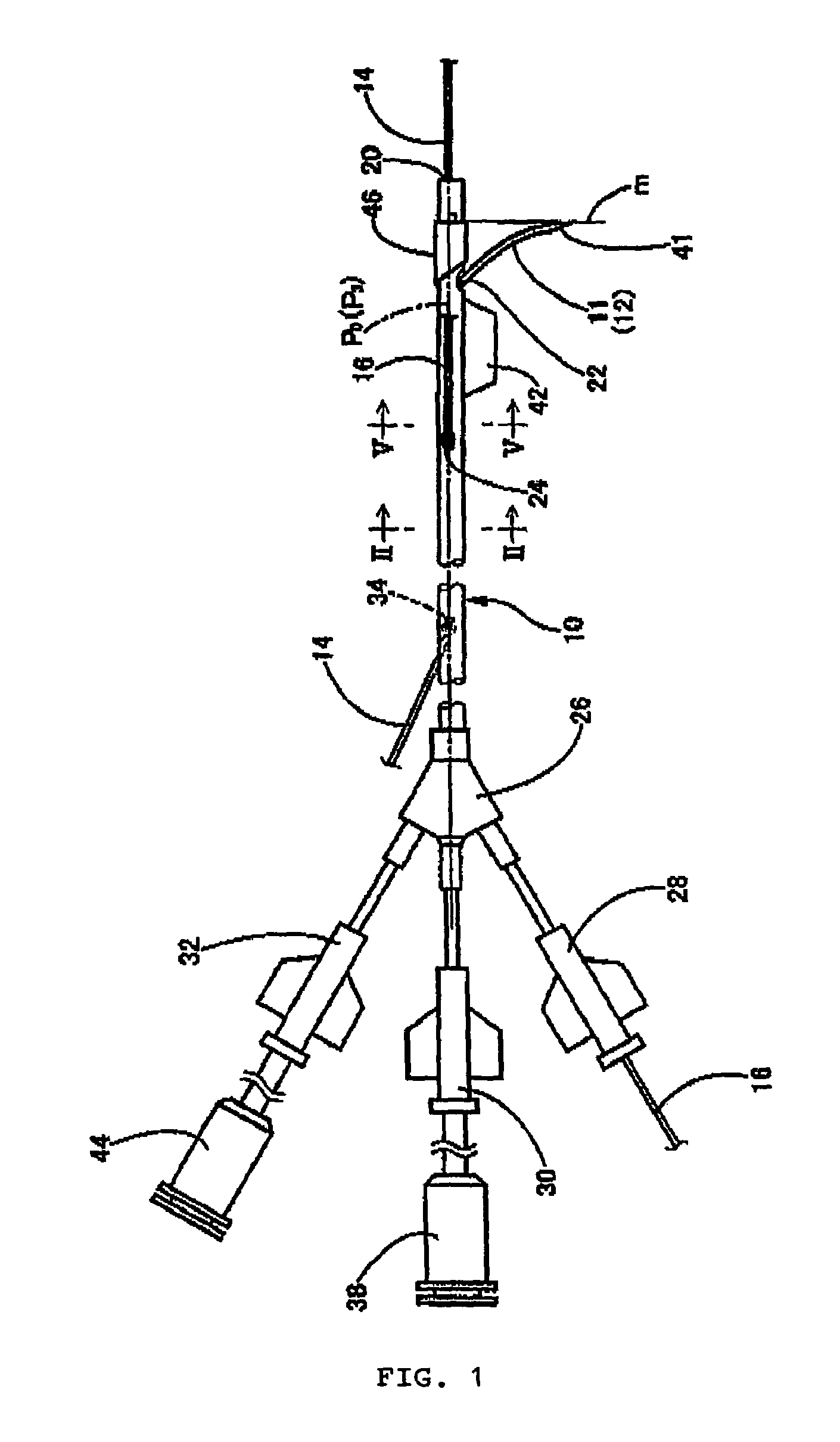

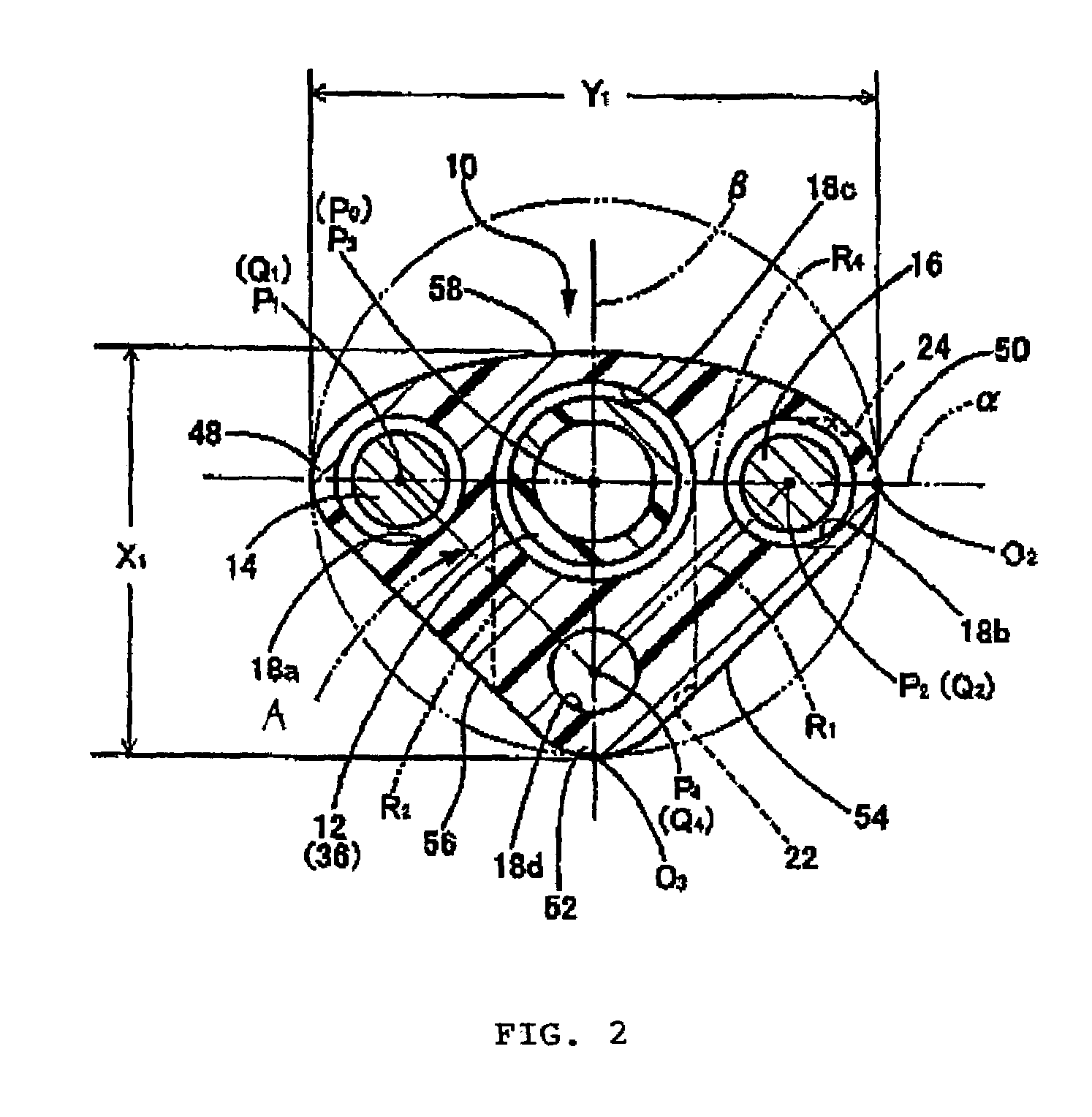

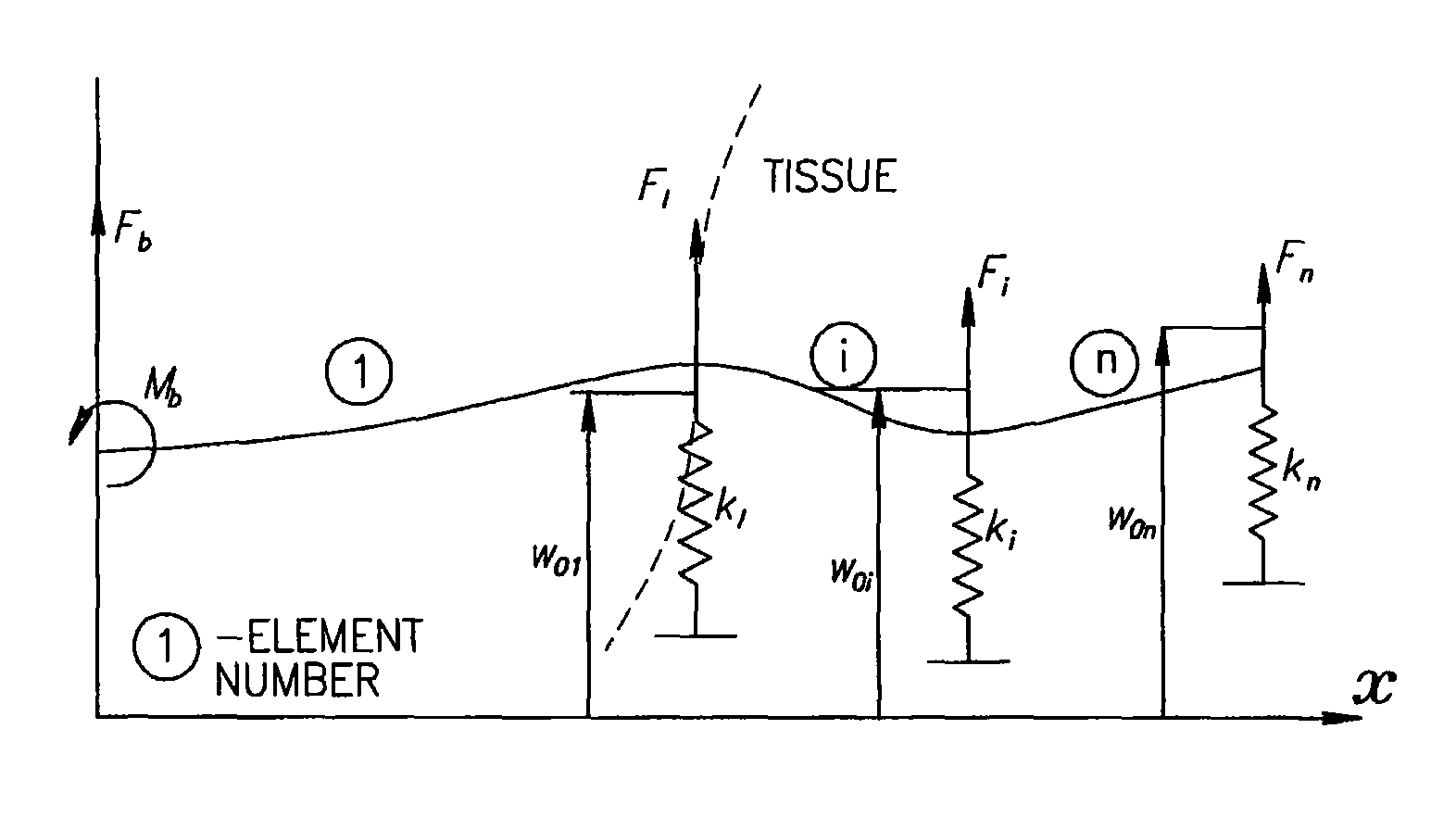

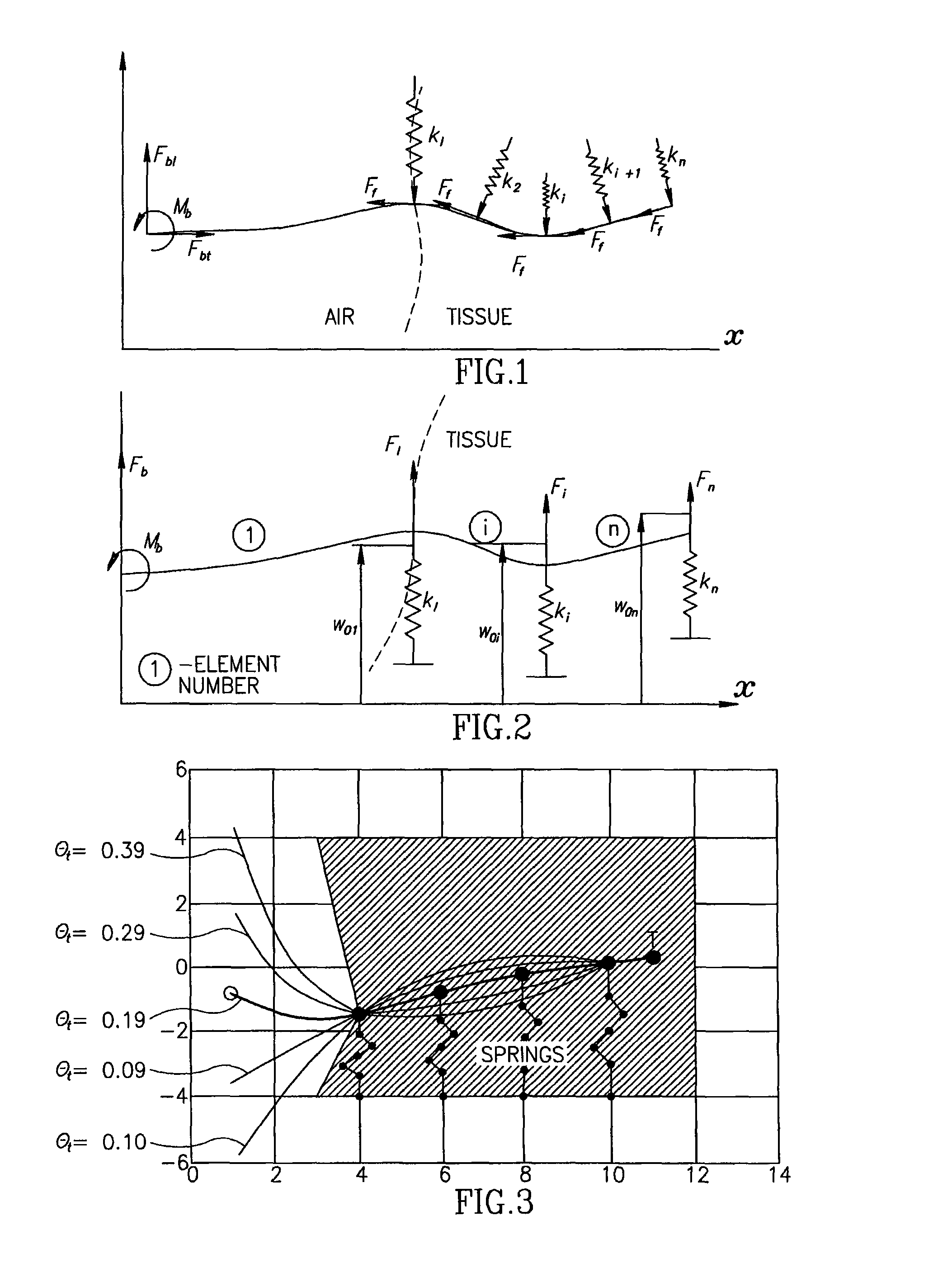

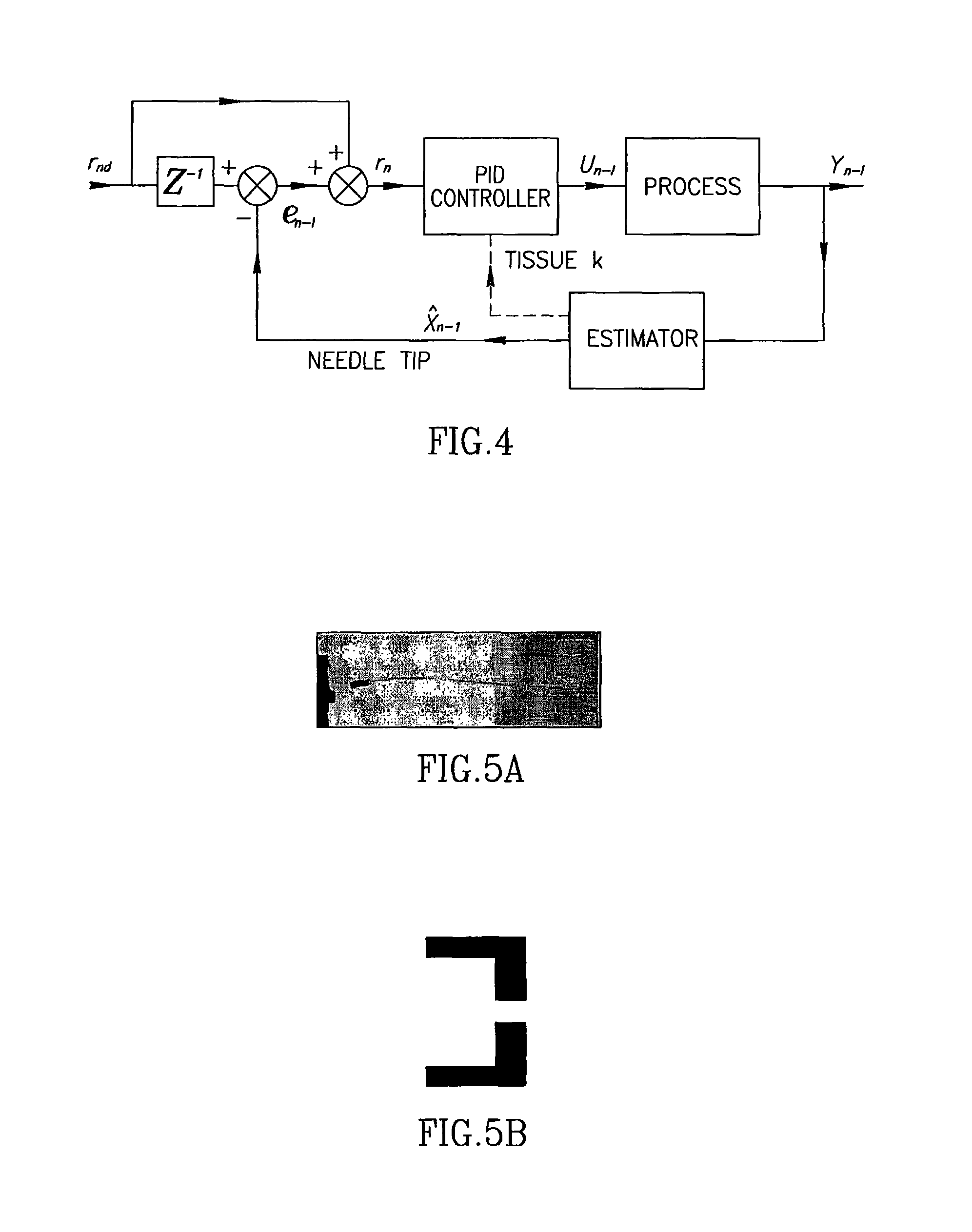

Controlled steering of a flexible needle

ActiveUS20090149867A1Avoid obstaclesReduce in quantitySurgical needlesSurgical navigation systemsStiffness coefficientRobotic systems

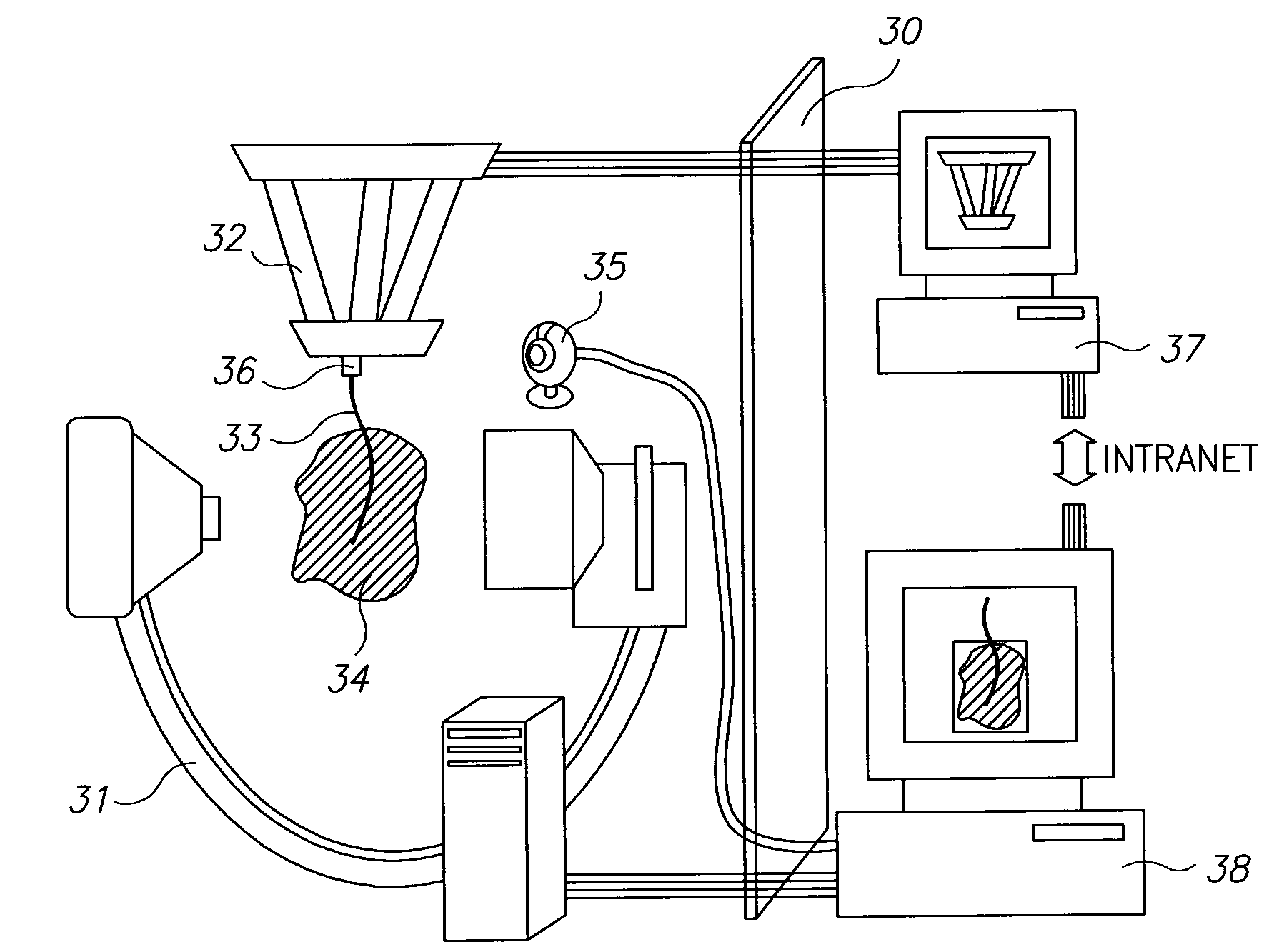

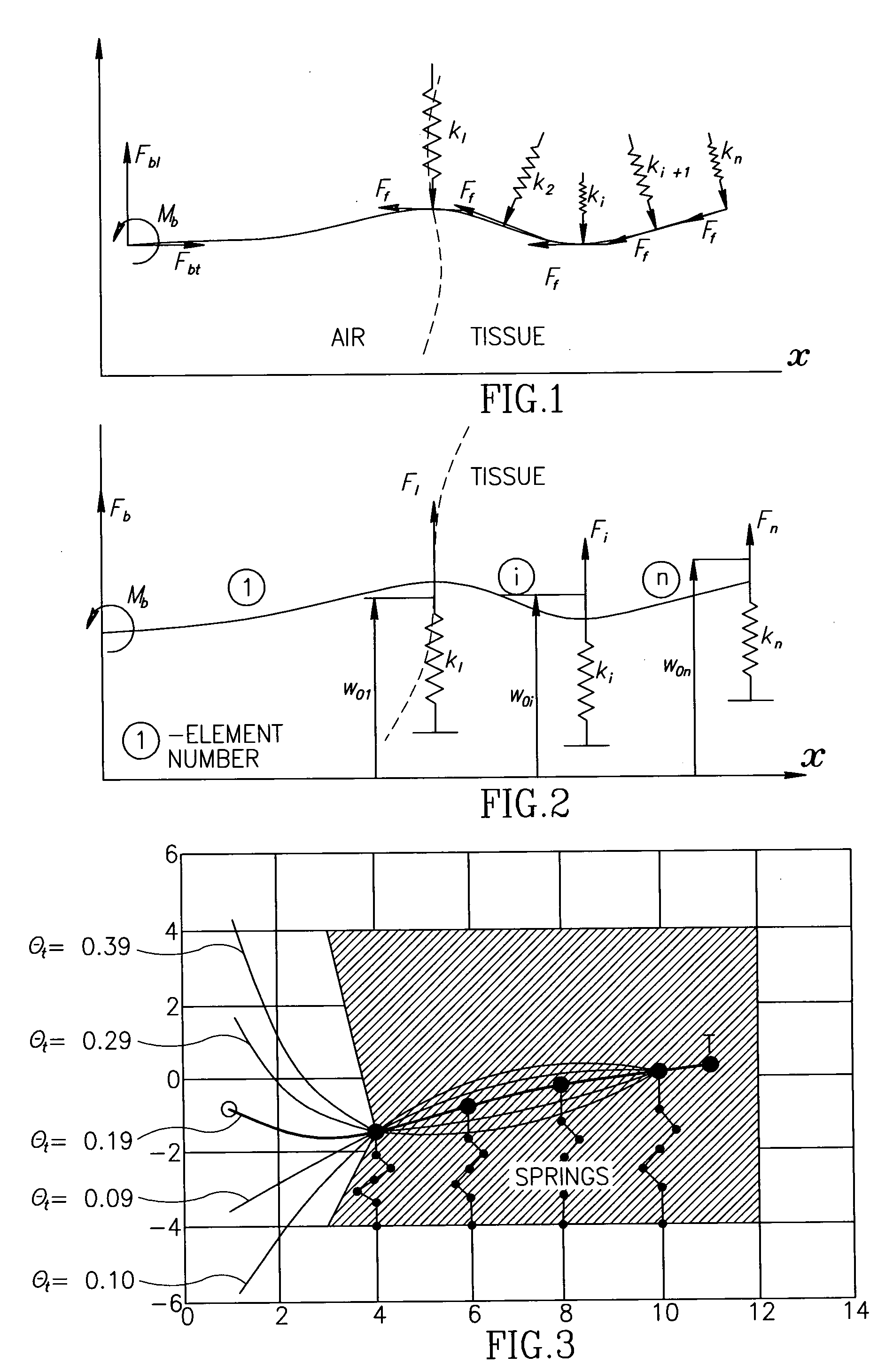

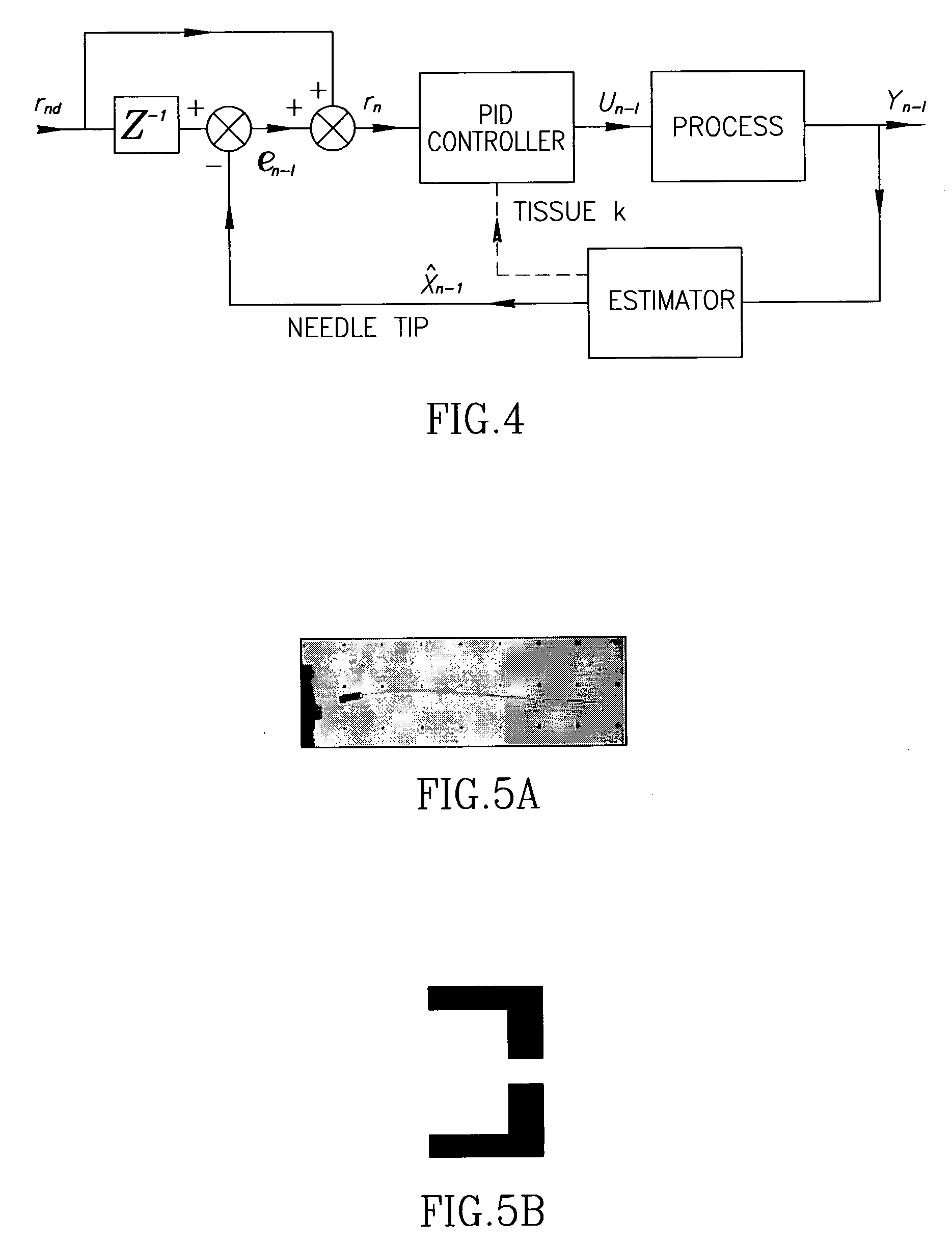

A robotic system for steering a flexible needle during insertion into soft-tissue using imaging to determine the needle position. The control system calculates a needle tip trajectory that hits the desired target while avoiding potentially dangerous obstacles en route. Using an inverse kinematics algorithm, the maneuvers required of the needle base to cause the tip to follow this trajectory are calculated, such that the robot can perform controlled needle insertion. The insertion of a flexible needle into a deformable tissue is modeled as a linear beam supported by virtual springs, where the stiffness coefficients of the springs varies along the needle. The forward and inverse kinematics of the needle are solved analytically, enabling both path planning and correction in real-time. The needle shape is detected by image processing performed on fluoroscopic images. The stiffness properties of the tissue are calculated from the measured shape of the needle.

Owner:TECHNION RES & DEV FOUND LTD

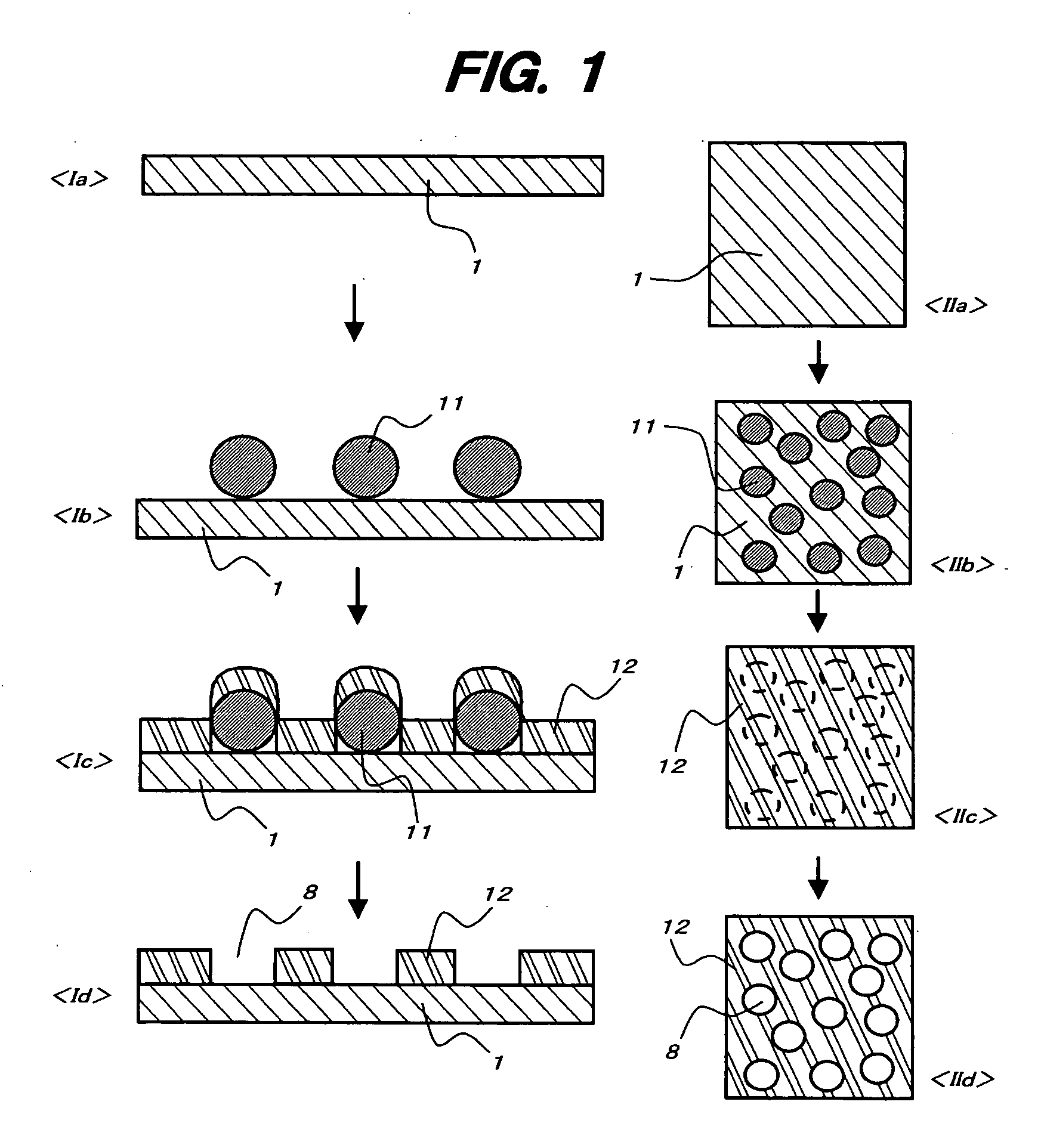

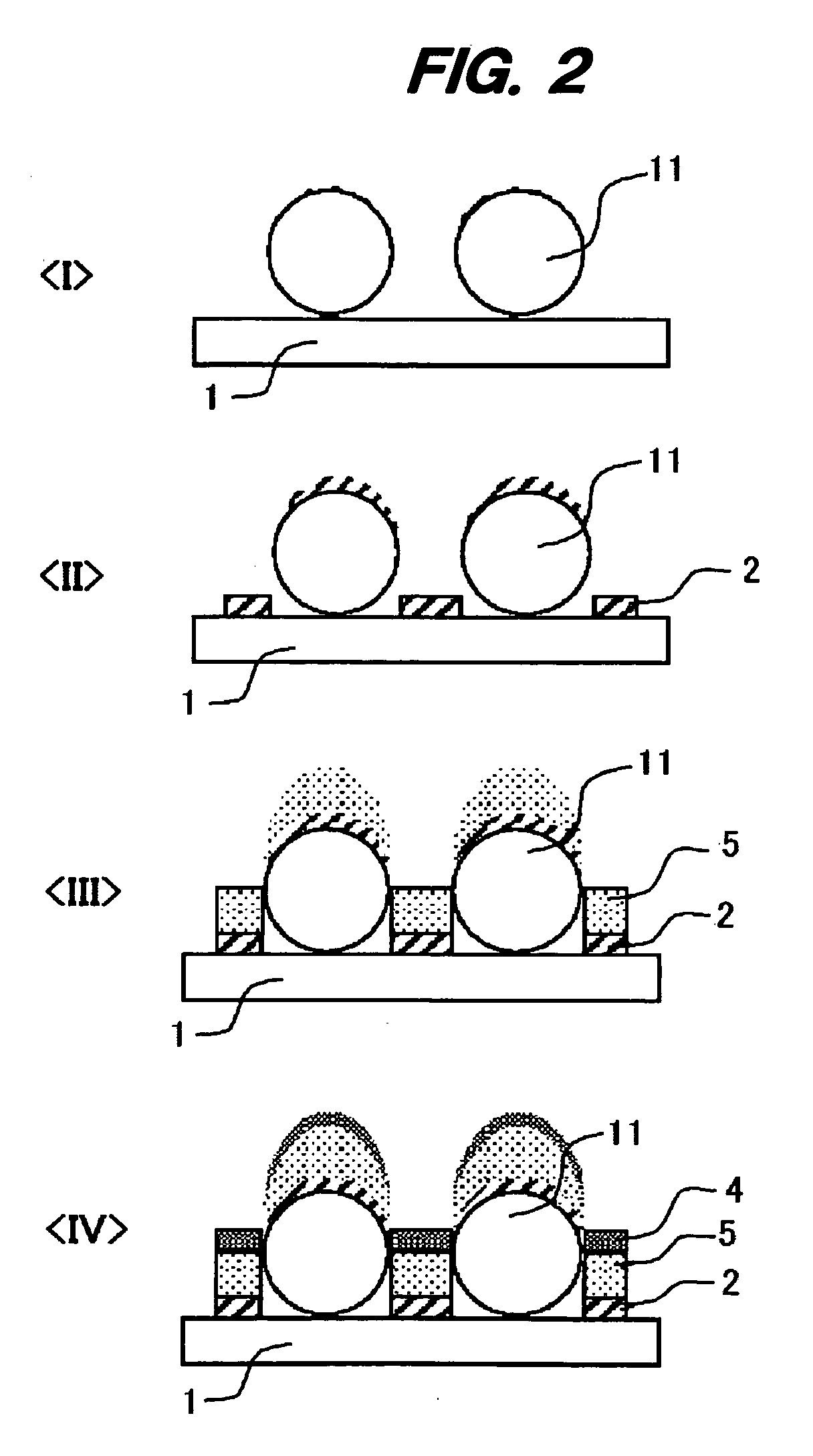

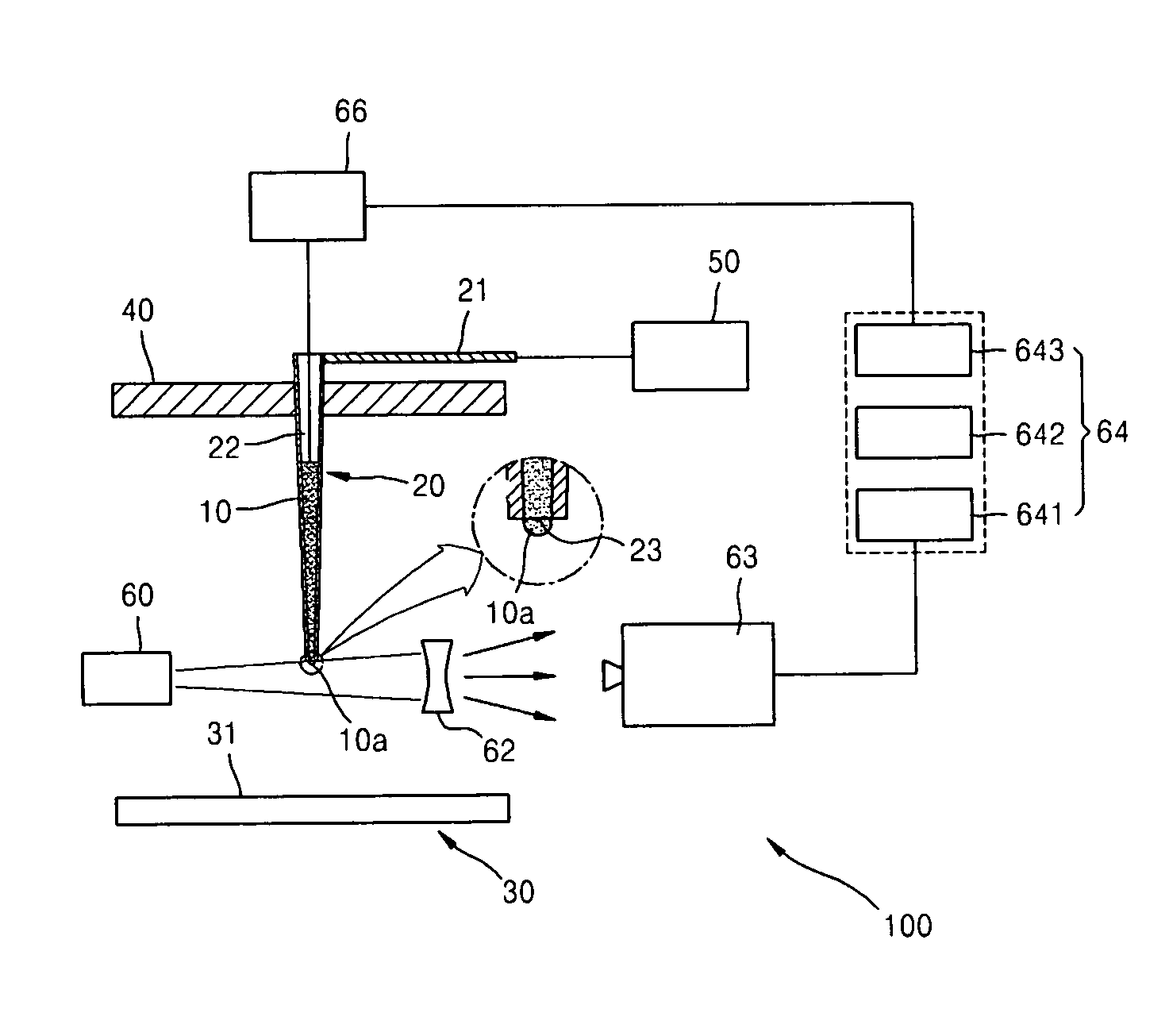

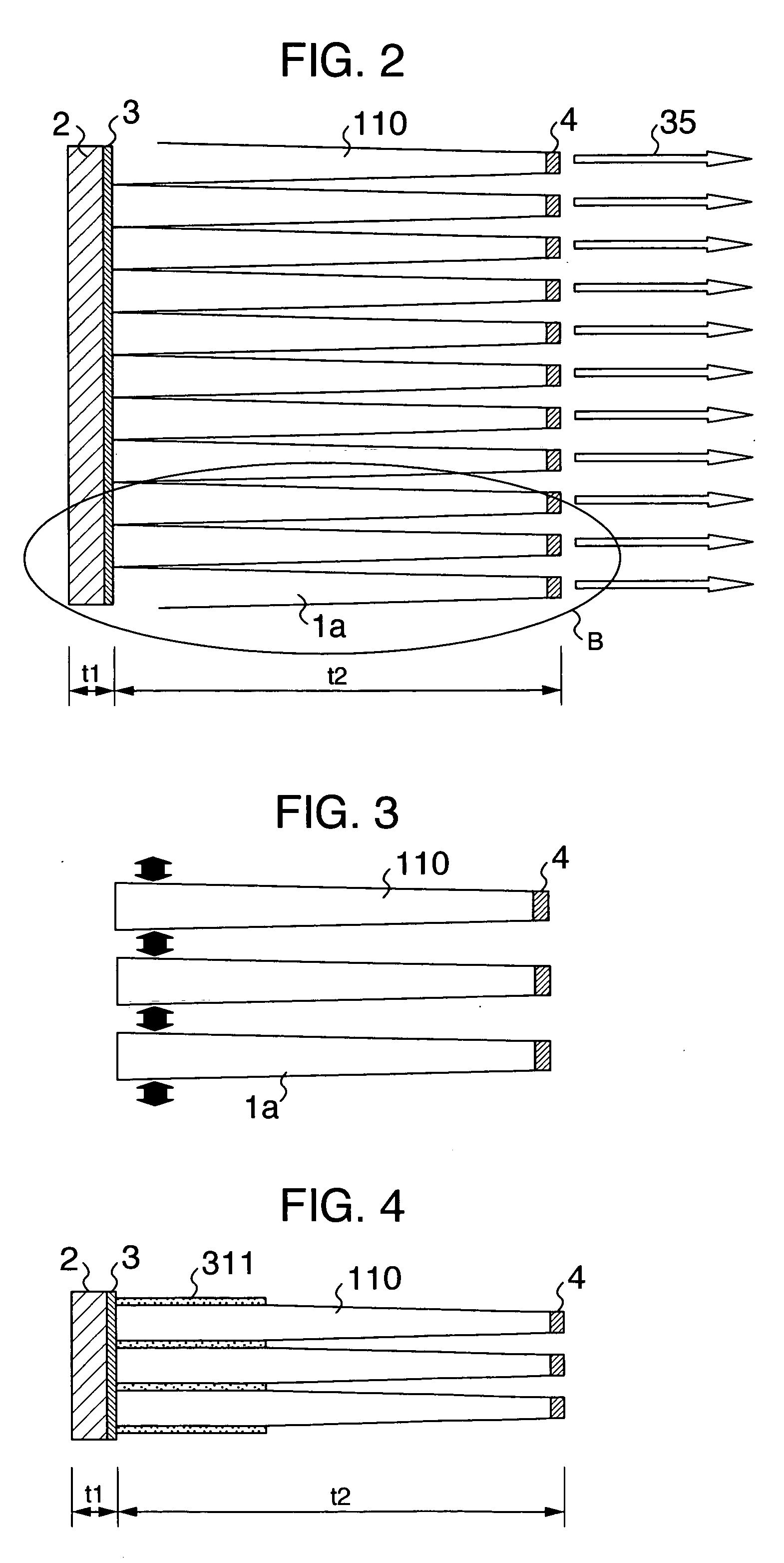

Porous thin-film-deposition substrate, electron emitting element, methods of producing them, and switching element and display element

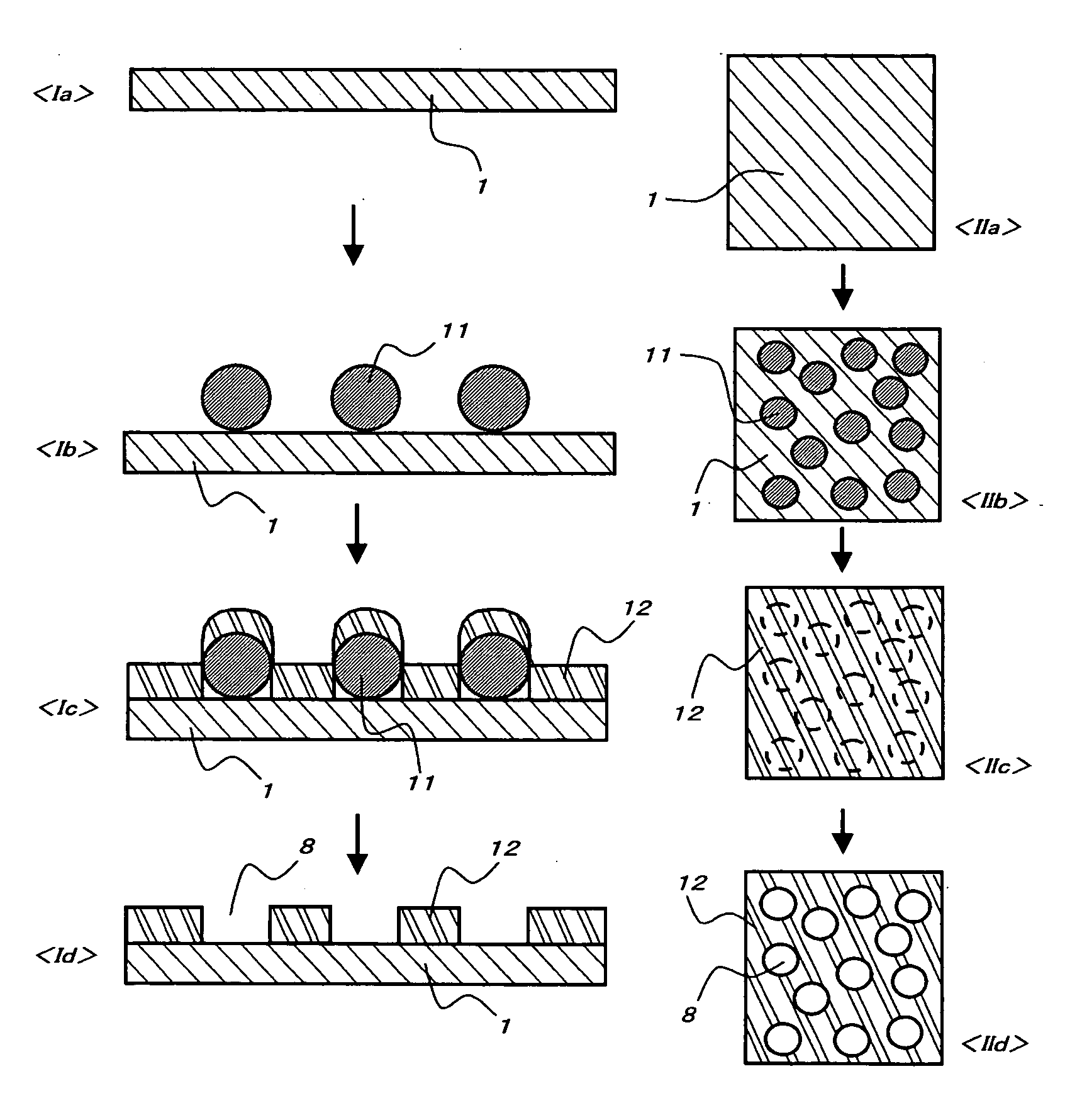

A method of producing a porous thin-film-deposition substrate, which has the steps of: placing onto a substrate that has an electrostatic charge on its surface, fine particles with a surface electrostatic charge opposite to the electrostatic charge of the substrate surface, depositing a thin film on the fine-particle-placed substrate, and then removing the fine particles to form fine pores in the thin film; further, a method of producing an electron emitting element, which has the steps of: adding a catalyst metal on a substrate, placing fine particles onto the catalyst-added substrate, depositing a thin film on the fine-particle-placed substrate, then removing the fine particles to form fine pores in the film, and growing needle-shaped conductors on the catalyst metal that is exposed on a bottom face of the fine pore.

Owner:FUJIFILM CORP

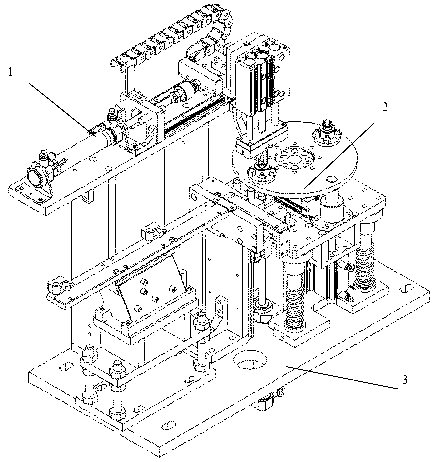

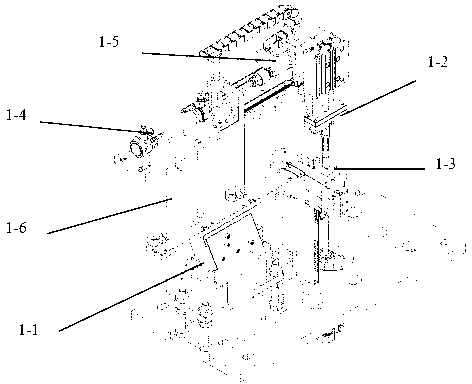

Automatic assembly device and method of O-type sealing ring

InactiveCN103317336ANo damageSmall support ringMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an automatic assembly device of an O-type sealing ring. The automatic assembly device comprises a ring loading and supporting module and a ring moving and releasing module. The ring loading and supporting module forms a feeding station and a ring supporting station, and when a loading device of the O-type sealing ring is located at the feeding station, the O-type sealing ring is delivered to the loading device of the O-type sealing ring by a feeding device of the O-type sealing ring. A loading needle-shaped air cylinder drives the loading device of the O-type sealing ring to move to the ring supporting station, the ring supporting motion is carried out on the O-type sealing ring by a ring supporting device, the O-type sealing ring is delivered to the ring moving and releasing module by the ring supporting device, the ring moving and releasing module enables the supported O-type sealing ring to be delivered to a ring releasing station from the ring supporting station, the ring moving and releasing module breaks away from the supported O-type sealing ring, the supported O-type sealing ring is sleeved at the position of a groove of a workpiece to be assembled, and automatic assembly between the workpiece and the O-type sealing ring is achieved. According to the automatic assembly device, assembly automation of the O-type sealing ring can be achieved, the qualified rate and the assembly efficiency of products are greatly improved, the labor strength is relieved, and the production cost is reduced. The invention further discloses an automatic assembly method of the O-type sealing ring.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

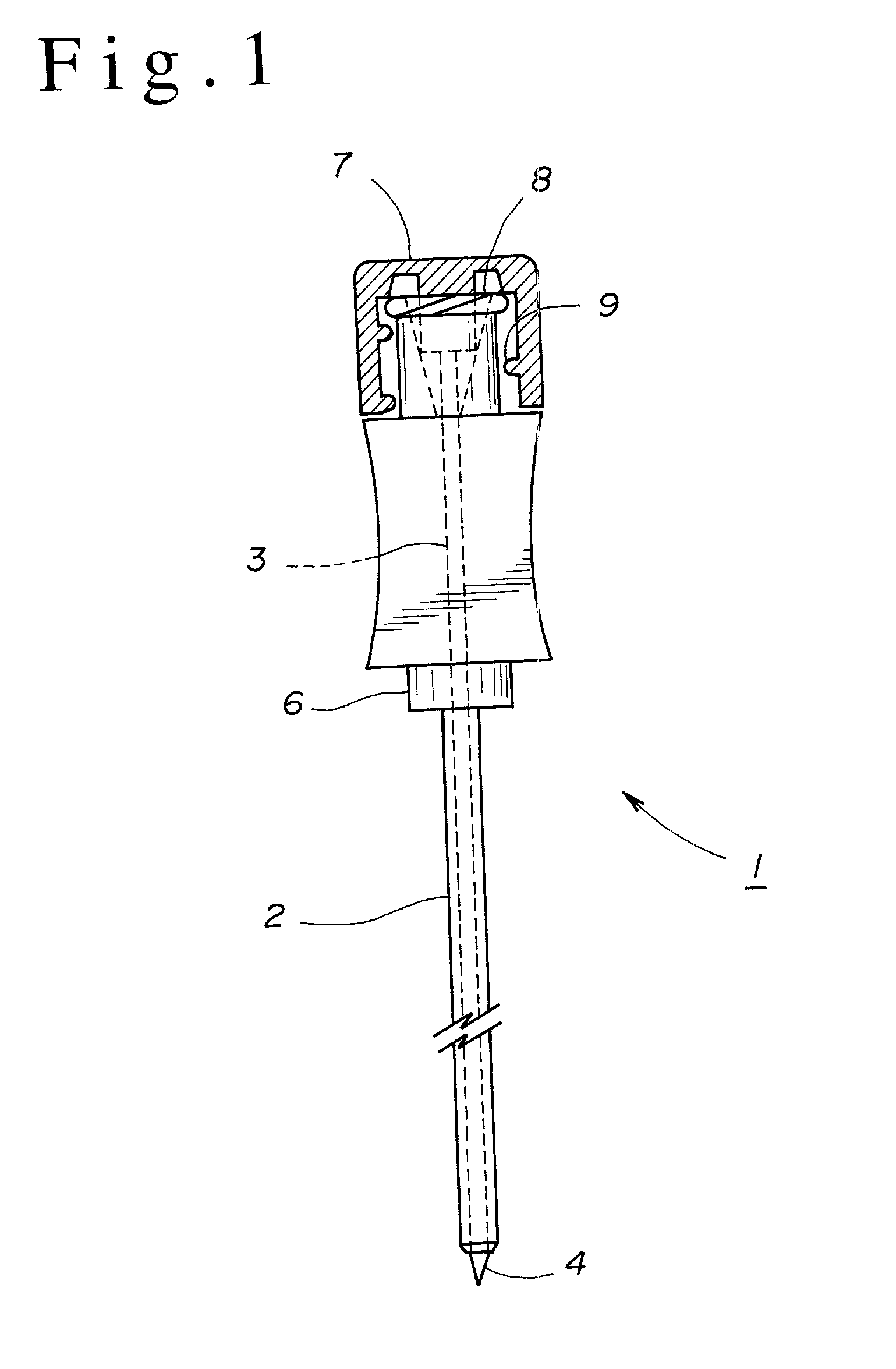

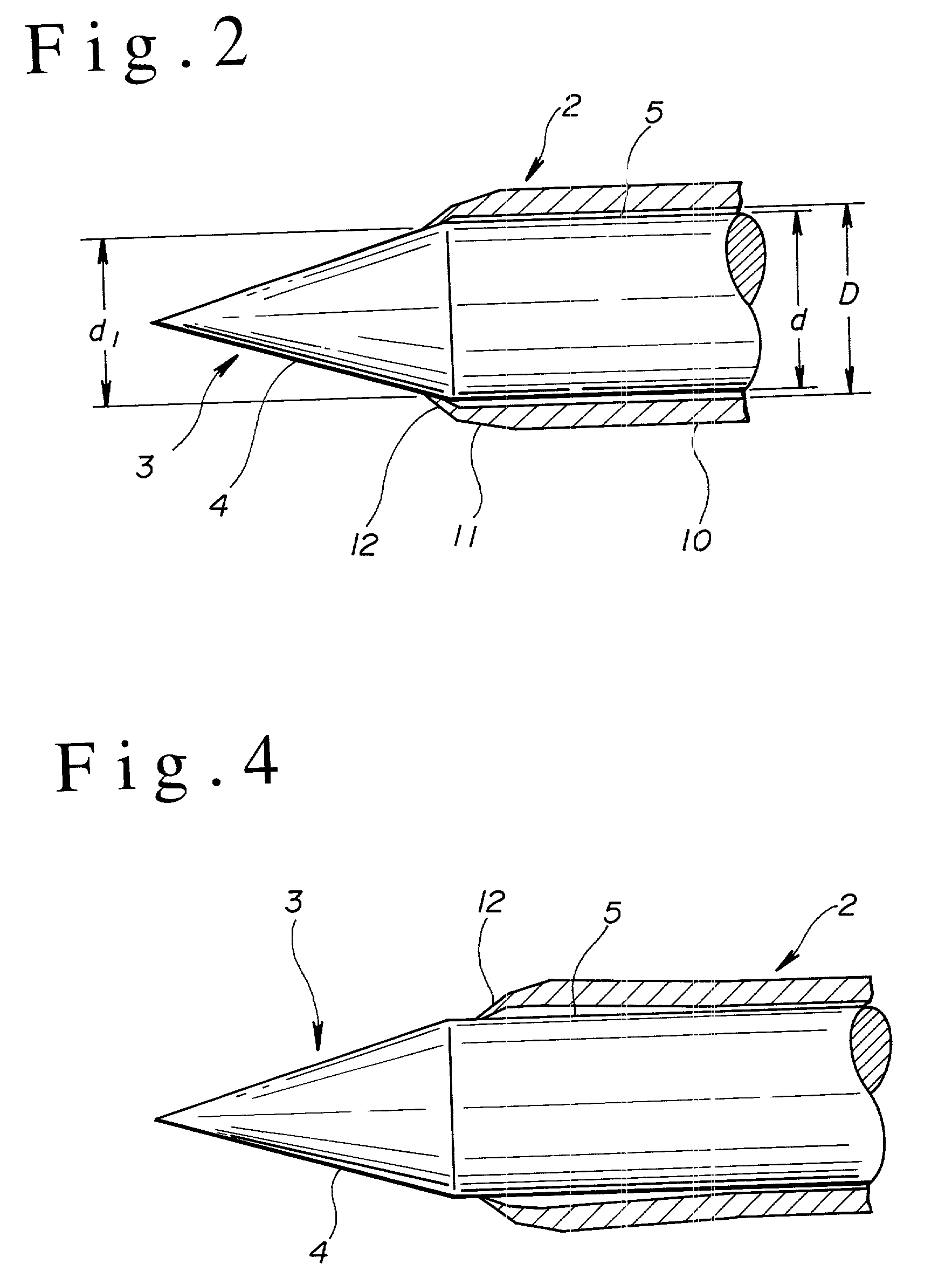

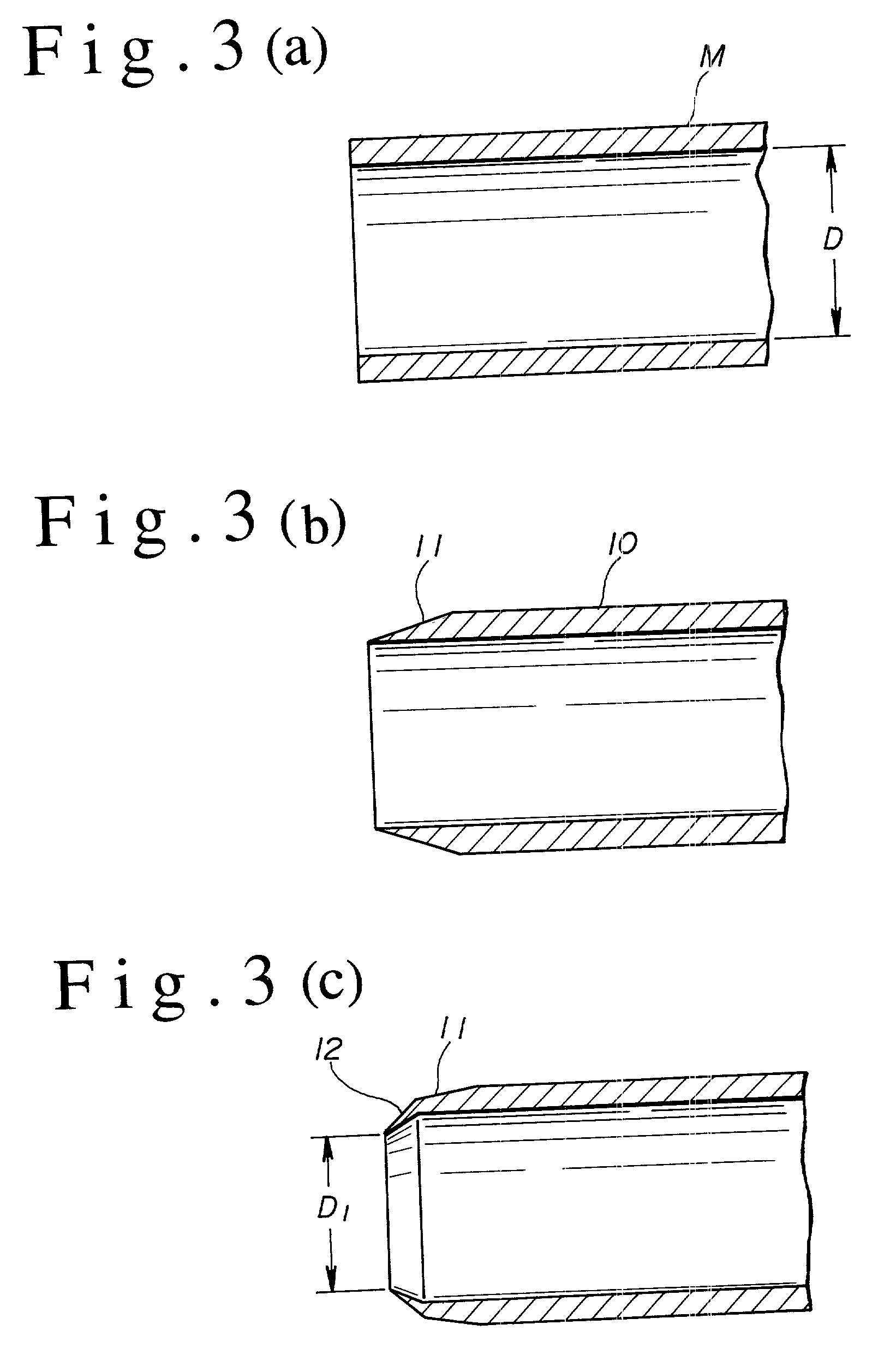

Medical anesthetic needle

A medical anesthetic needle (1) is provided that includes an inner needle (3) of a straight needle shape, having a pencil-pointed tip (4), and an outer needle (2) of a straight tubular shape, having the inner needle inserted thereinto and therethrough from the rear end thereof. A foremost-end part (12) of a hollow, truncated conical shape or the like of the outer needle (2) is formed so that the minimum inner diameter thereof is smaller than the outer diameter of the main body (5) of the inner needle (3). When the inner needle (3) is inserted into and through the outer needle (2), the circumferential fore-end edge of the foremost-end part (12) is in close contact with the circumferential surface of the tip (4) or the main body (5) of the inner needle (3), and no gaps are thus formed therebetween. Therefore, when needled, a patient's nervous tissue is unlikely to be nipped in a gap between the inner and outer needles to cause pain to the patient.

Owner:DR JAPAN

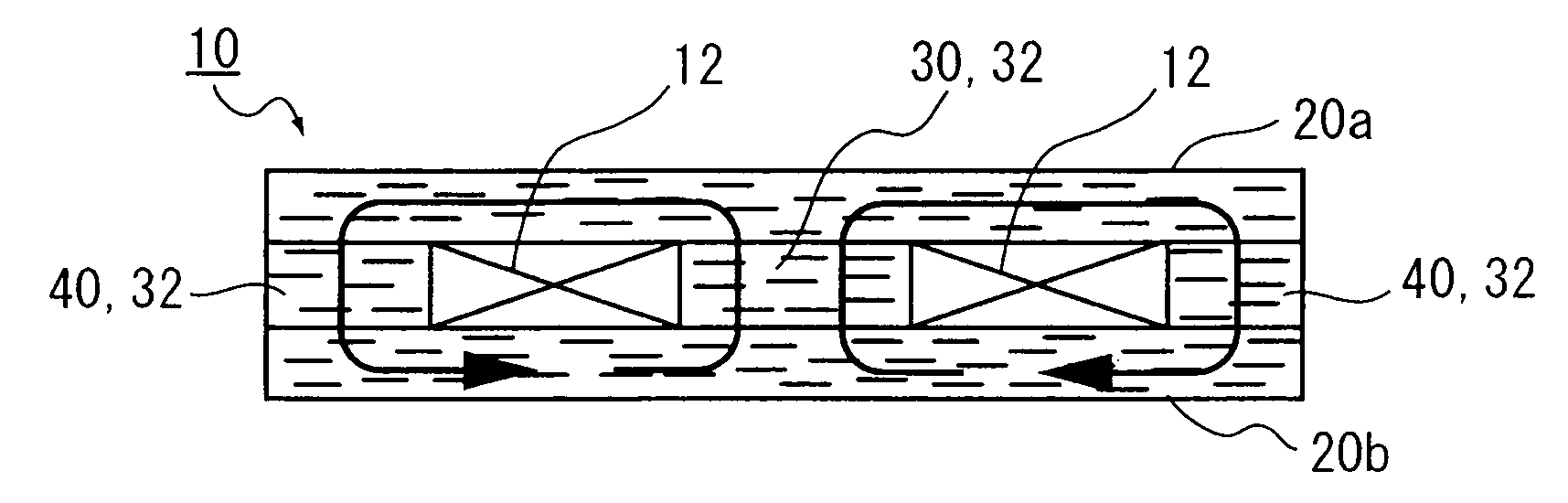

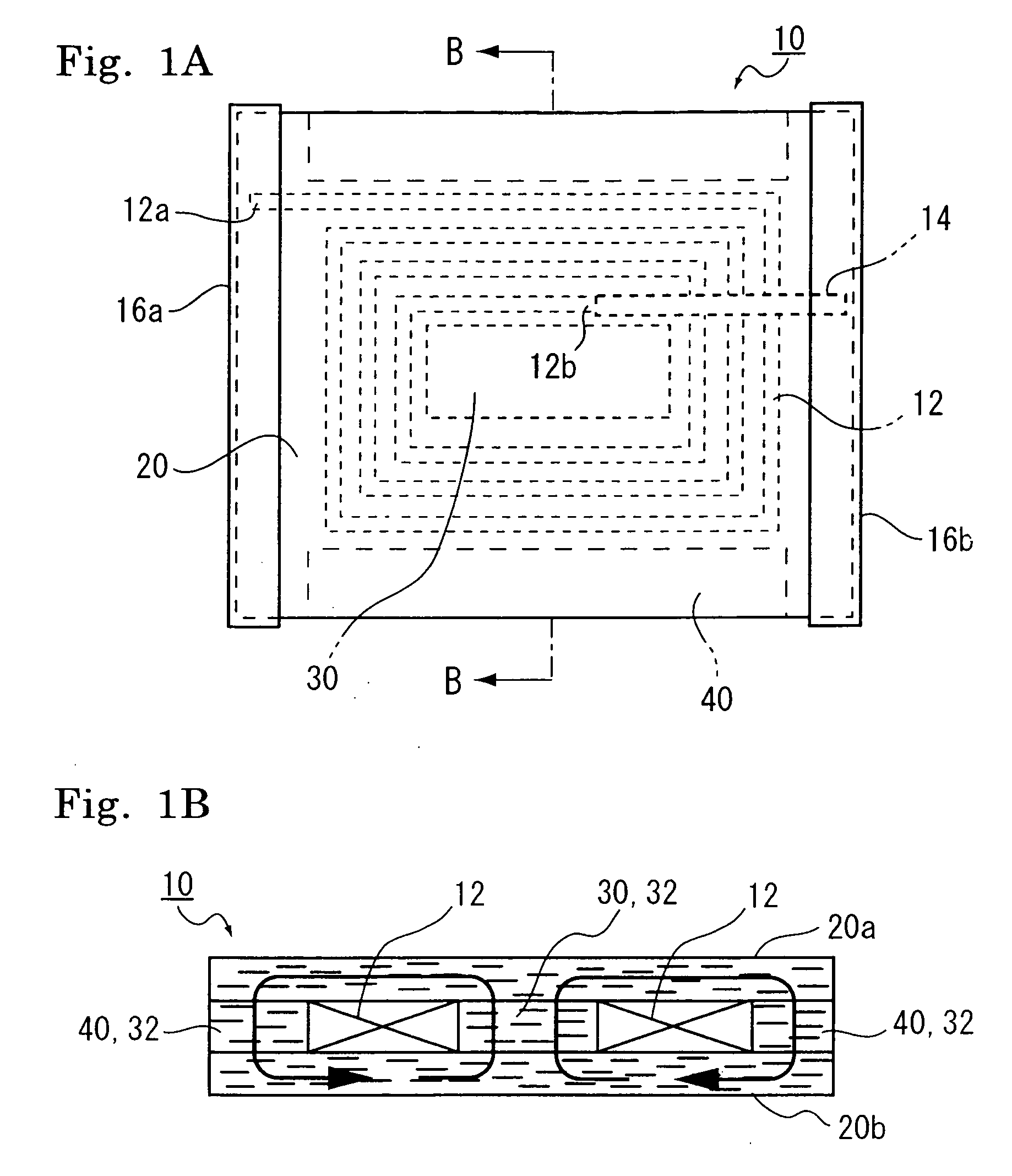

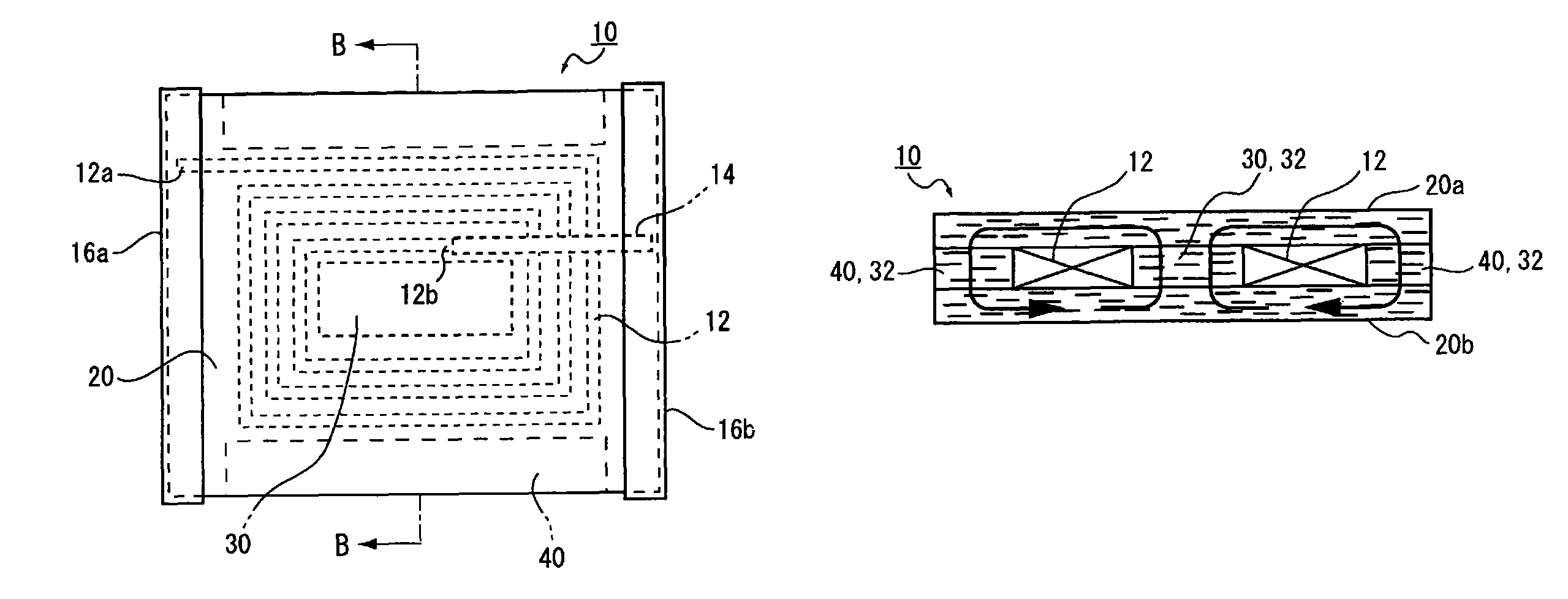

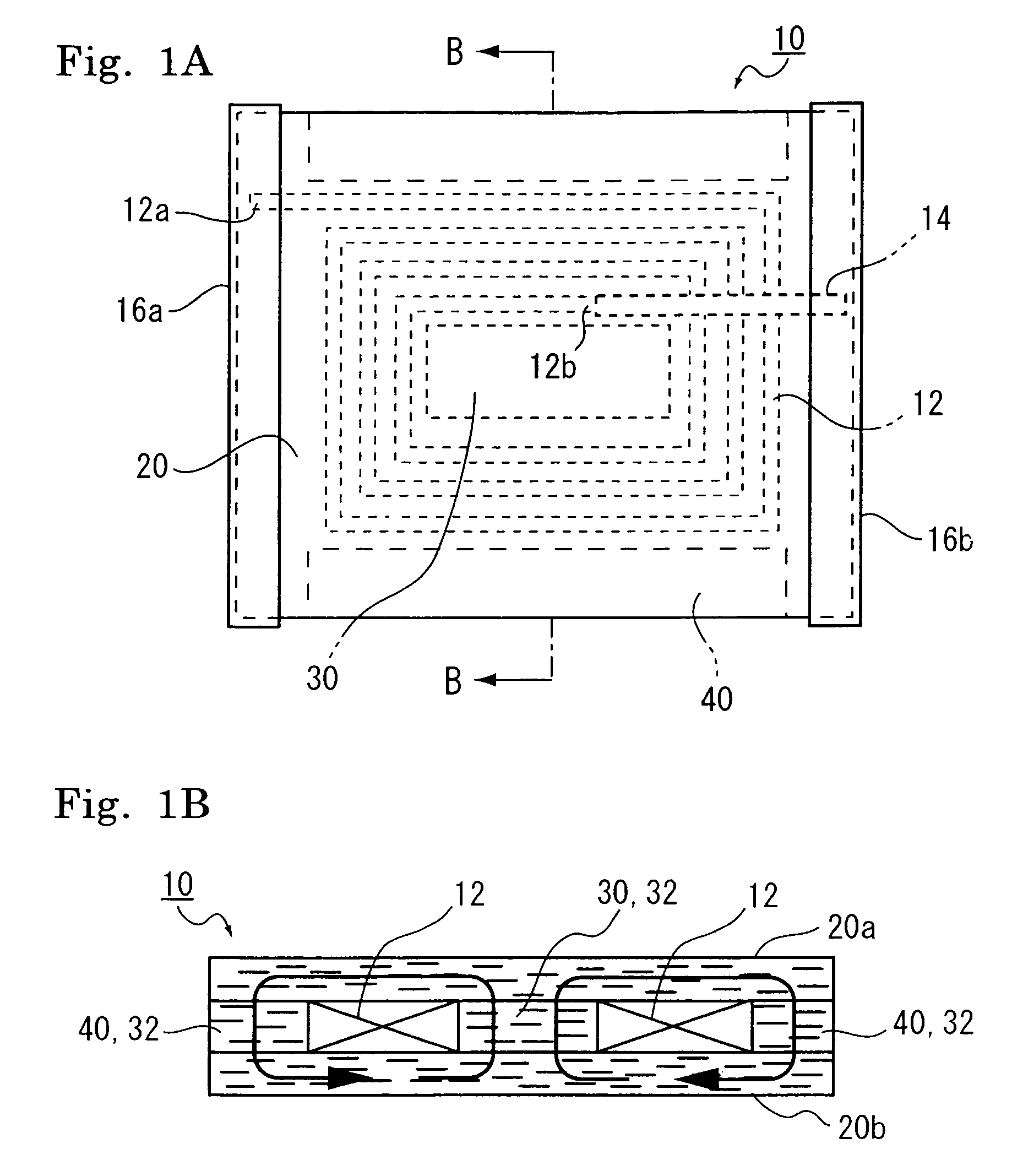

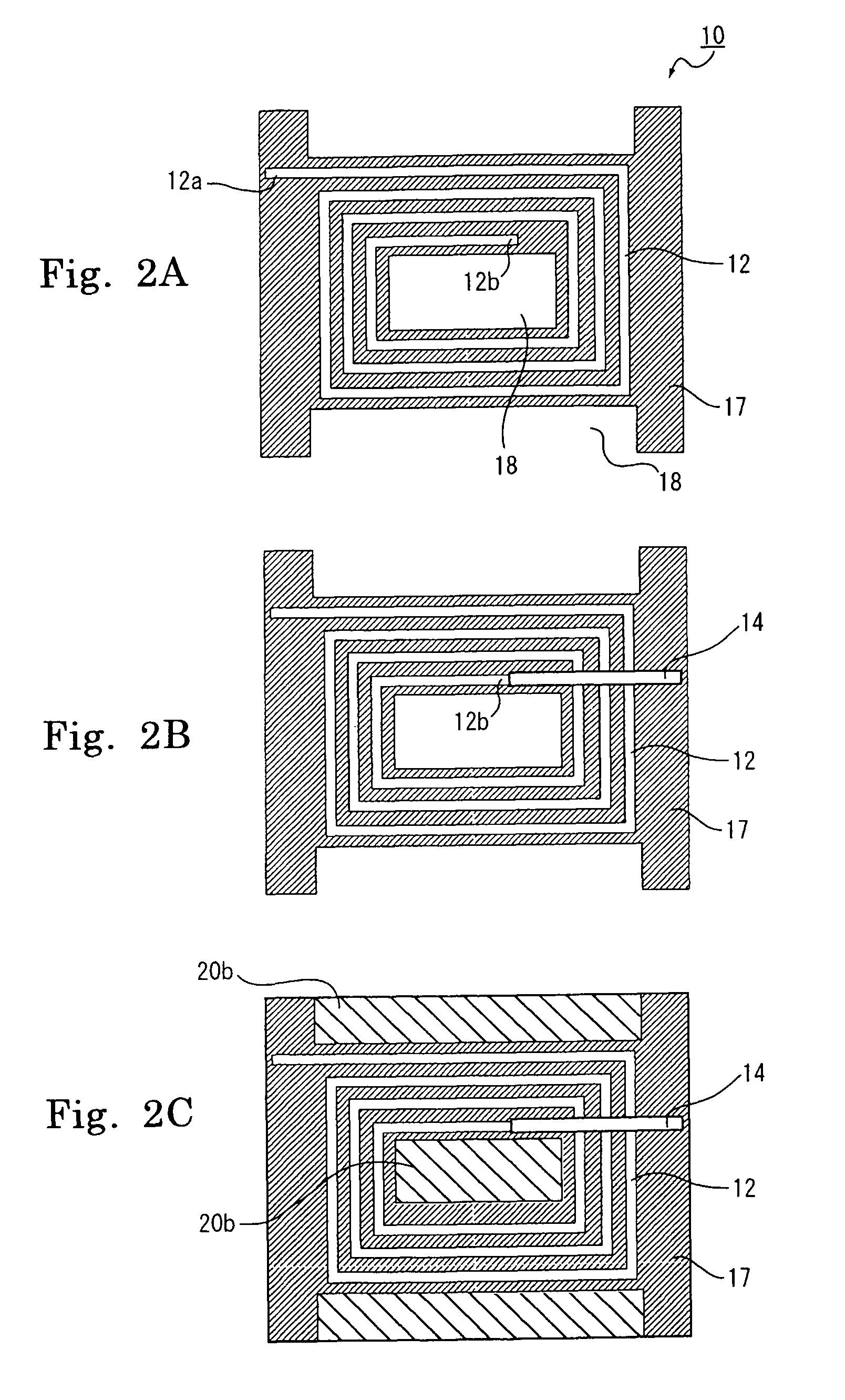

Coil component

ActiveUS20090002117A1Avoid breakingMagnetic permeabilityTransformers/inductances casingsTransformers/inductances magnetic coresIn planeHigh resistance

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

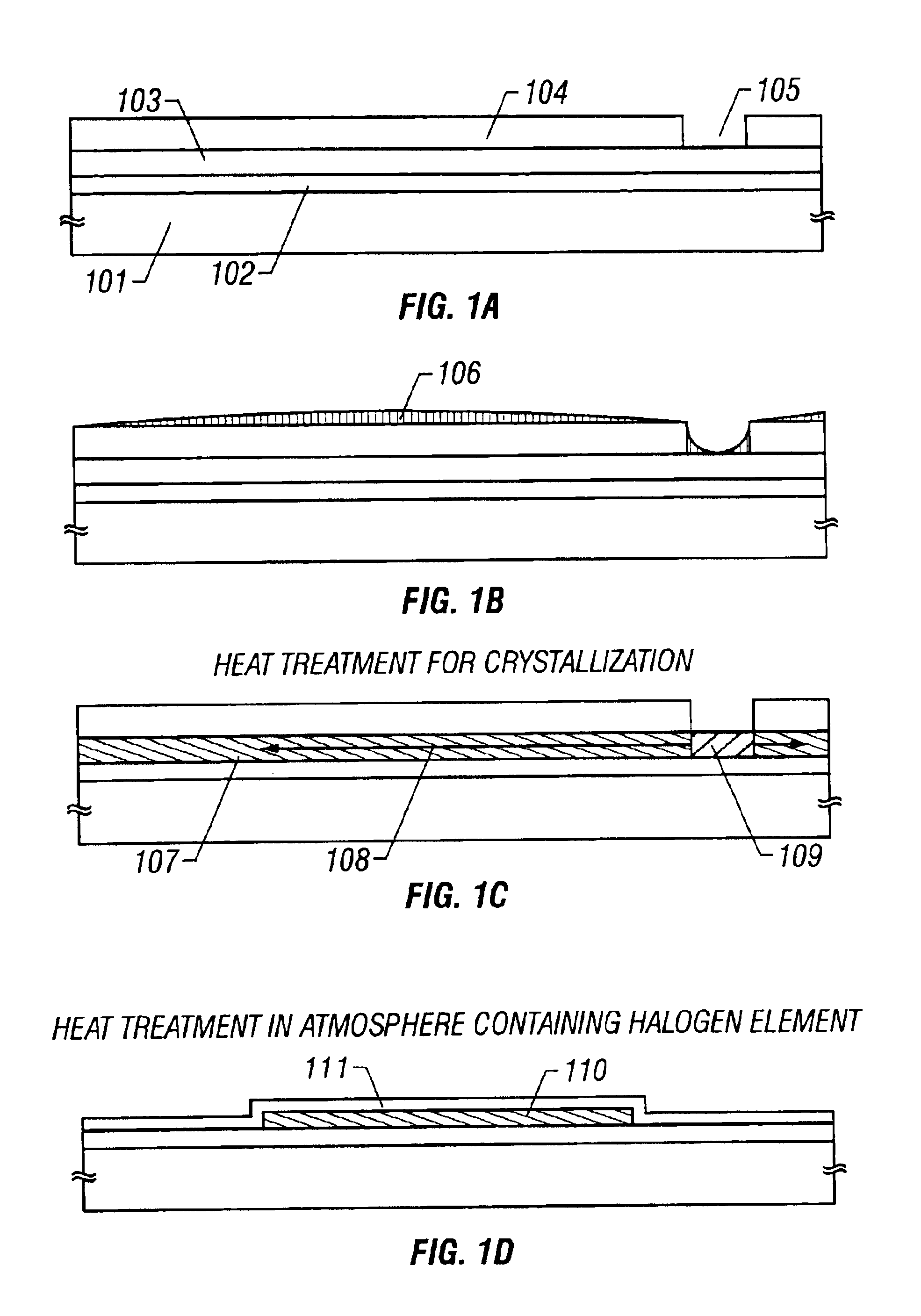

Semiconductor device having crystalline semiconductor layer

InactiveUS7023052B2Improve performanceReduce probabilityTransistorSolid-state devicesMOSFETCrystal structure

Owner:SEMICON ENERGY LAB CO LTD

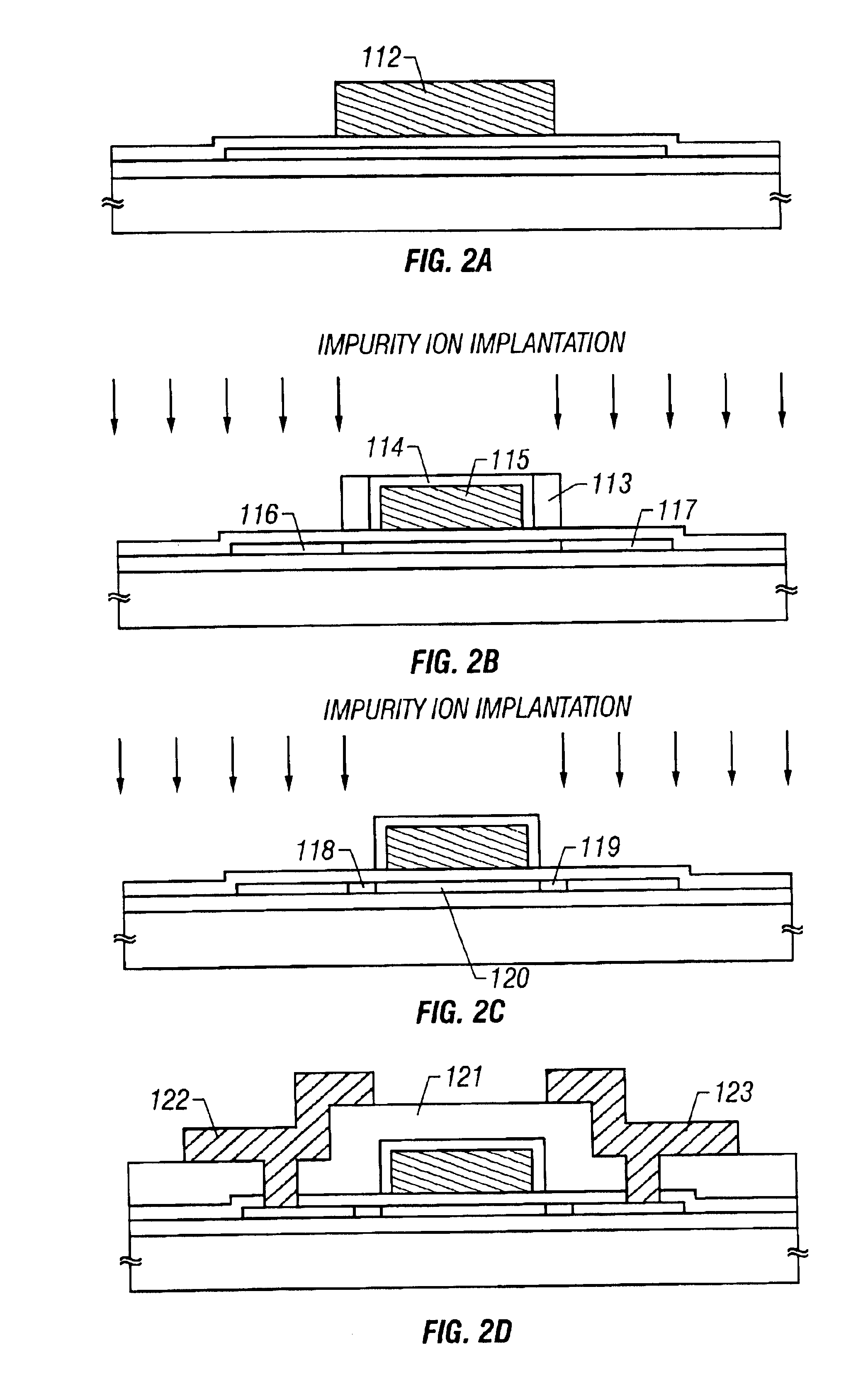

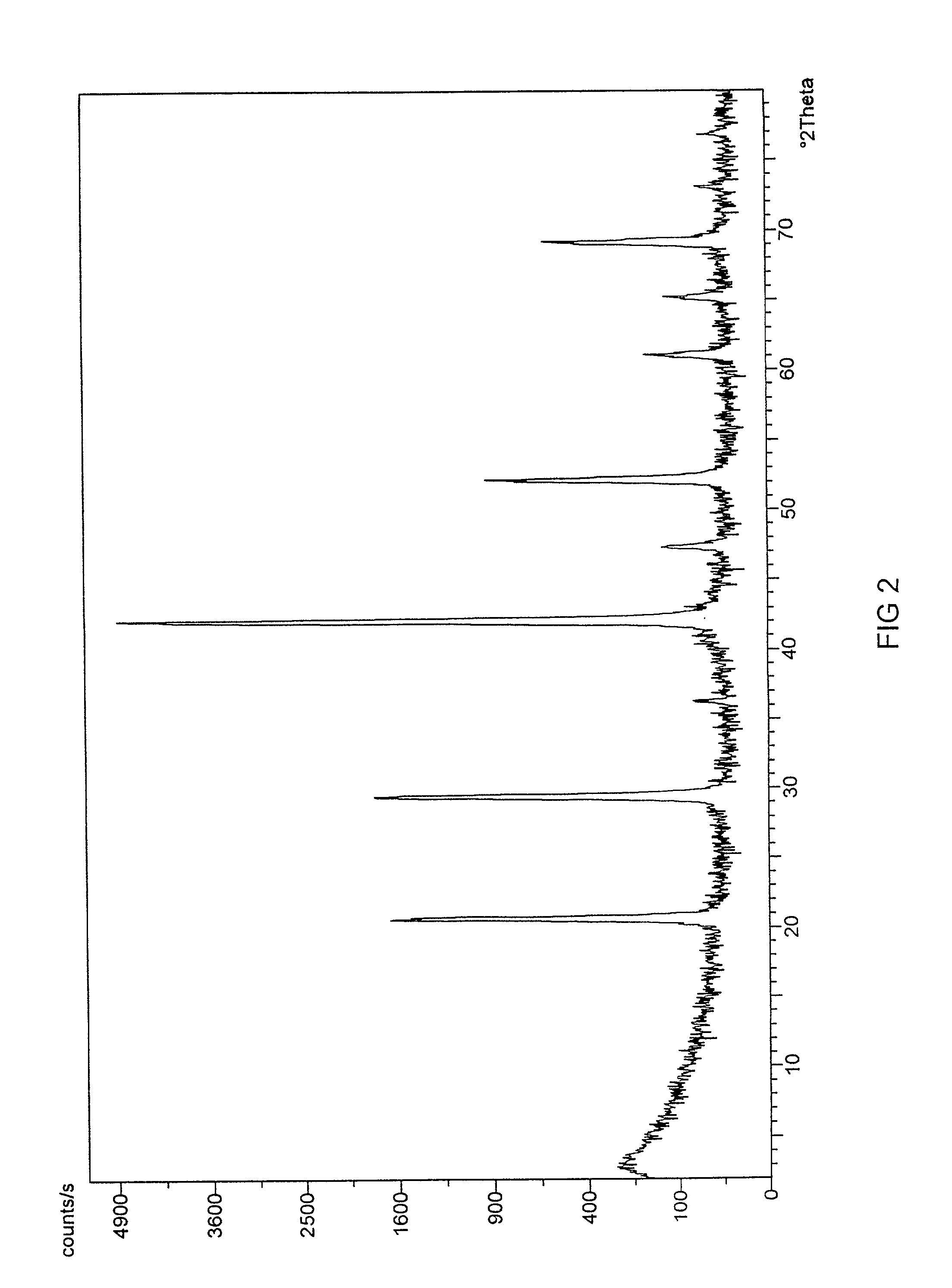

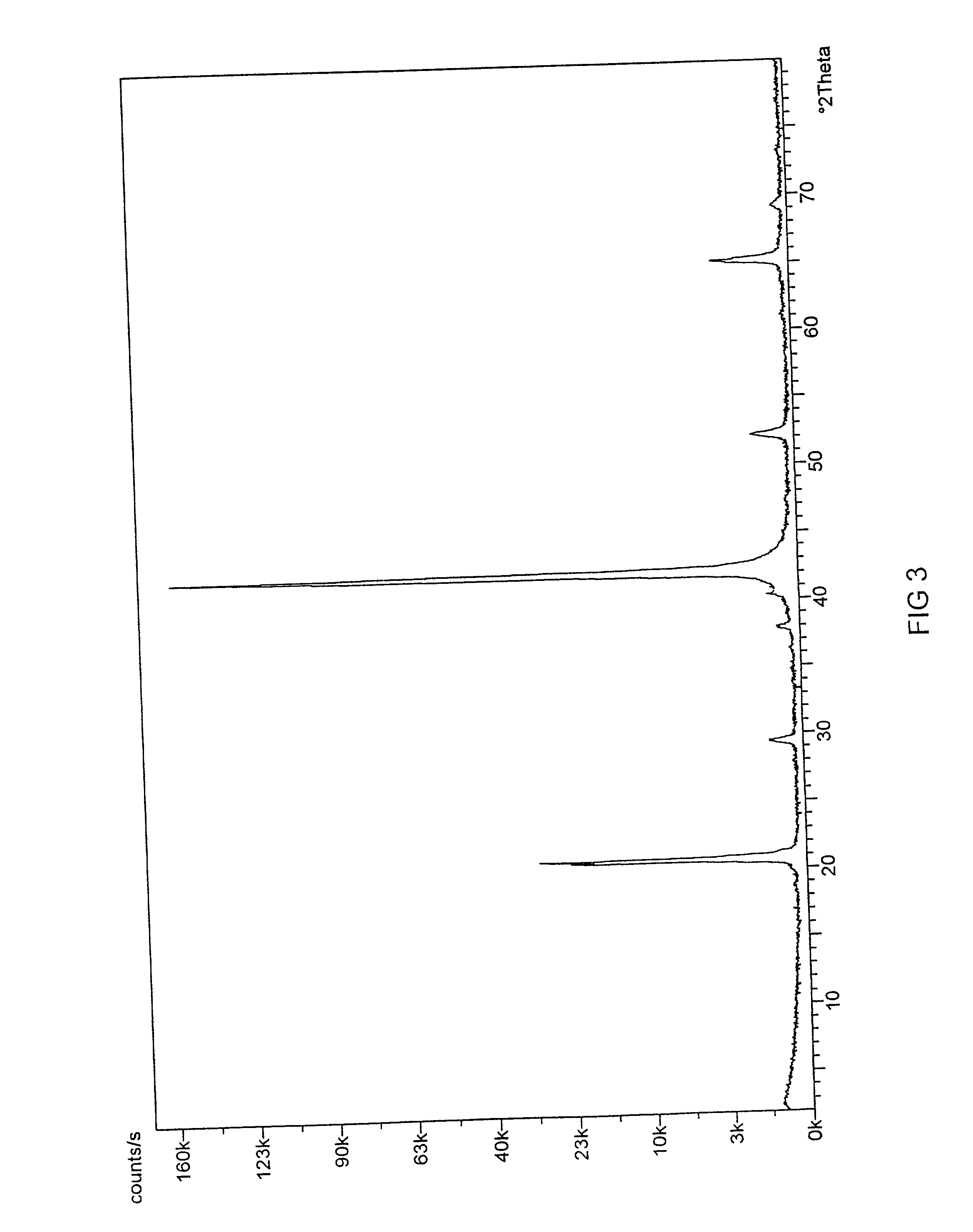

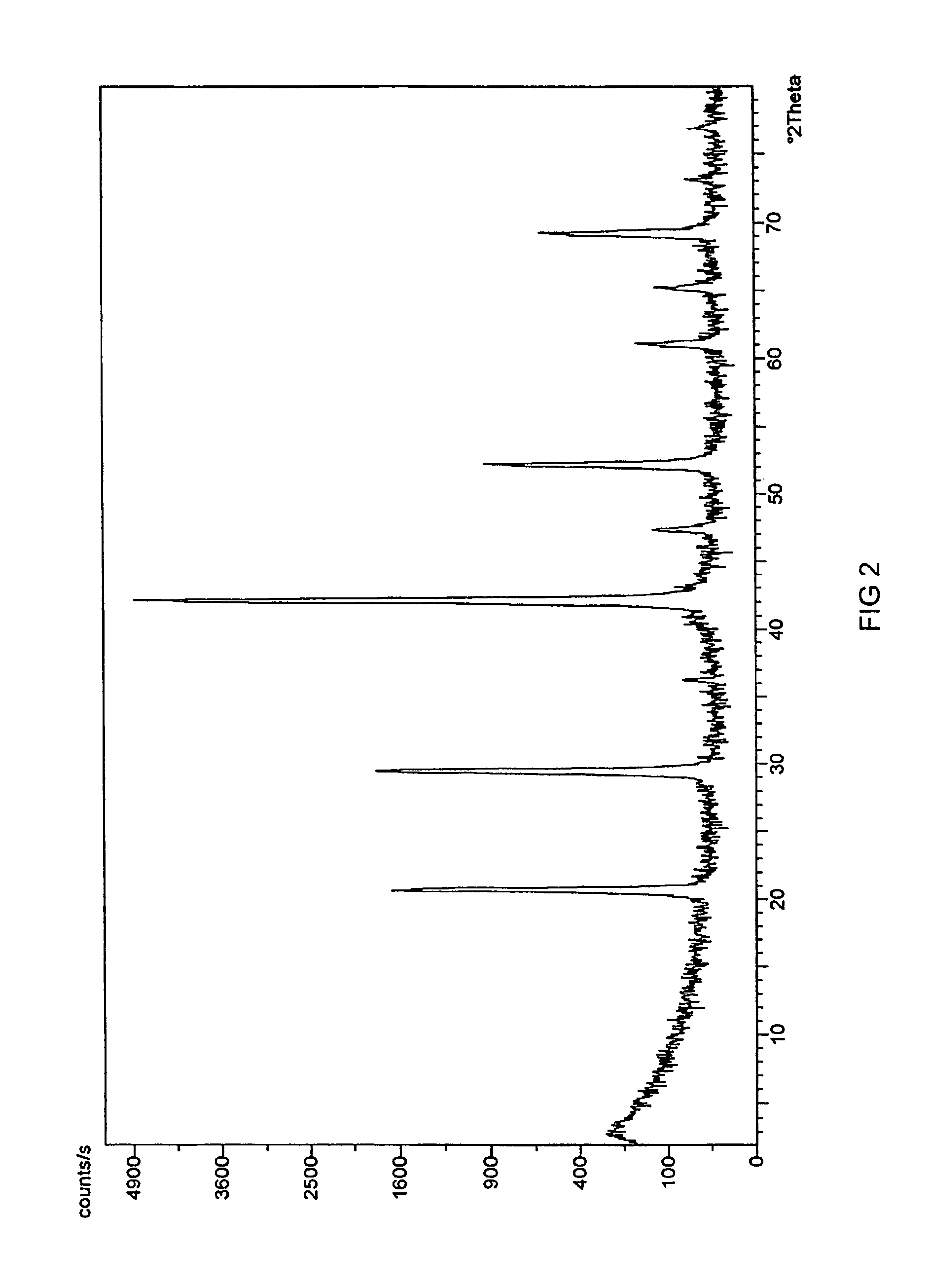

Binderless storage phosphor screen with needle shaped crystals

InactiveUS20010007352A1Improve compromiseImprove clarityX-ray/infra-red processesElectrical apparatusNeedle ShapePhysics

A binderless storage phosphor screen with needle shaped crystals, wherein the phosphor is an alkalihalide phosphor and the needles show high [100] unit cell orientation in the plane of the screen.

Owner:AGFA GEVAERT AG

Controlled steering of a flexible needle

ActiveUS8348861B2Reduce in quantitySurgical needlesSurgical navigation systemsStiffness coefficientRobotic systems

Owner:TECHNION RES & DEV FOUND LTD

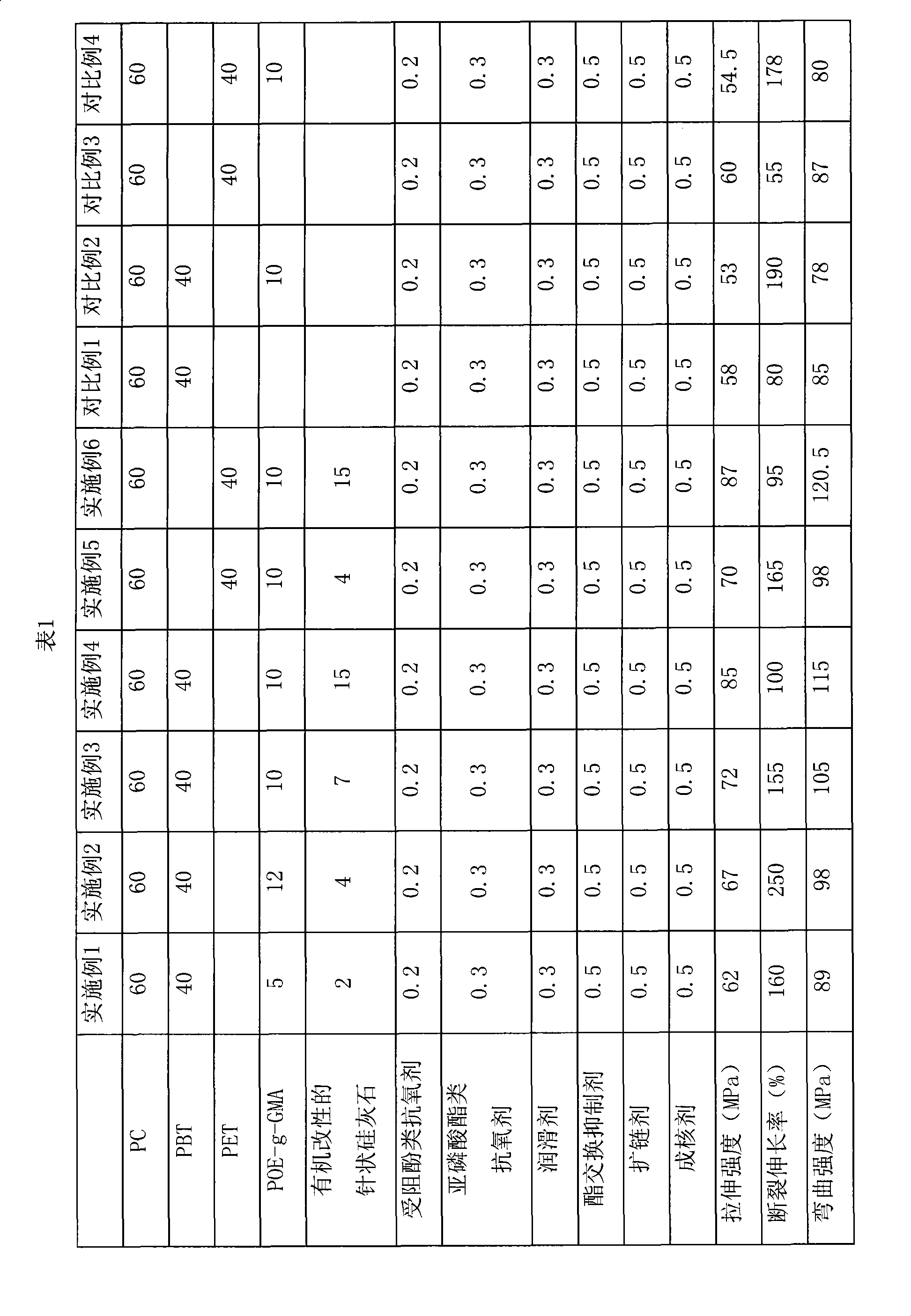

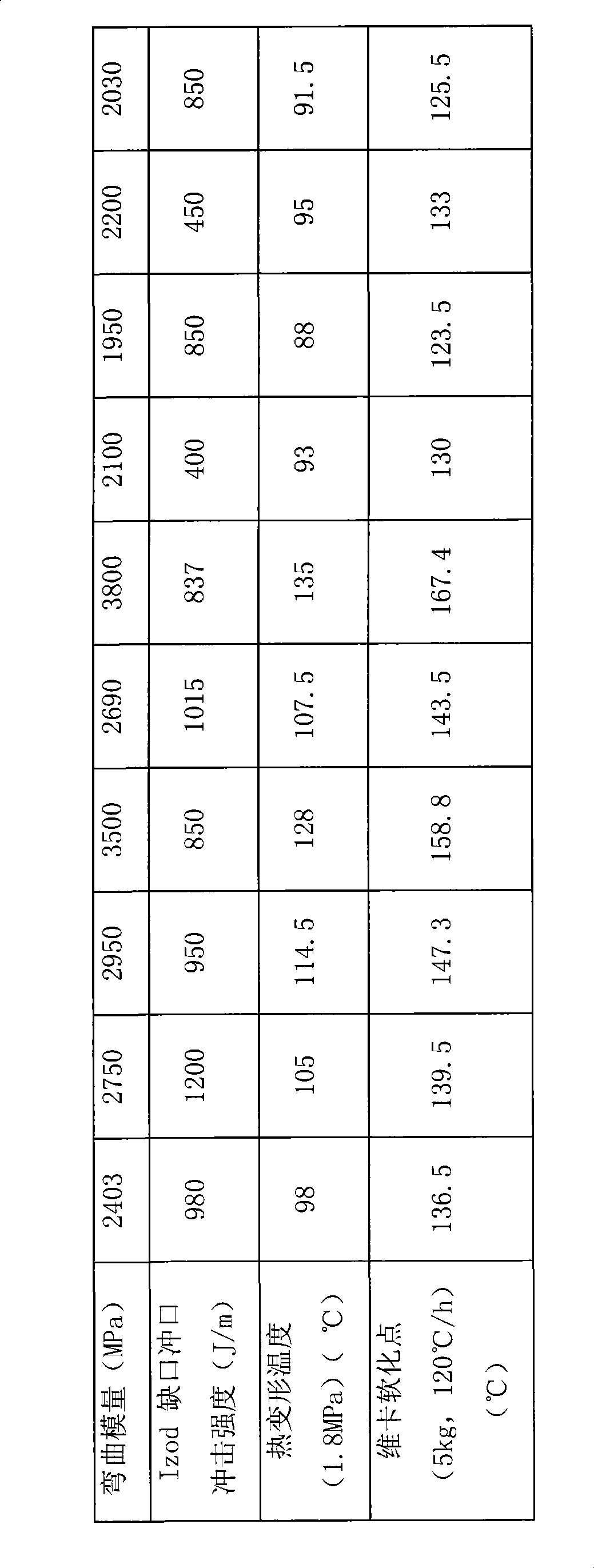

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

Technology for mechanical and clean processing of black tea in different shapes

InactiveCN1792200ARich shapeIncrease color varietiesPre-extraction tea treatmentBlack teaEngineering

A technology for mechanically preparing to black tea with different shapes including needle shape, spiral shape, flat shape and particles is disclosed.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

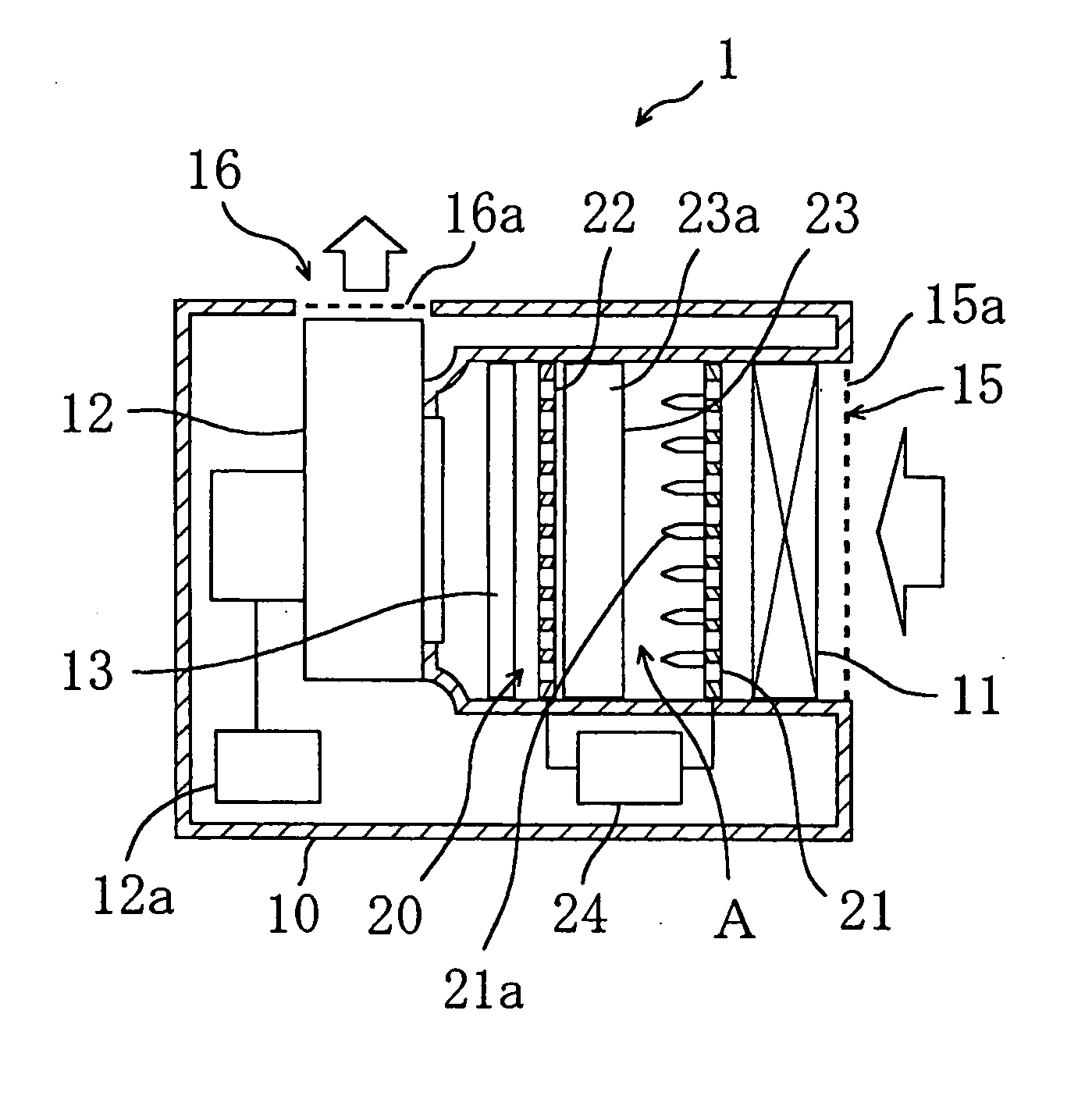

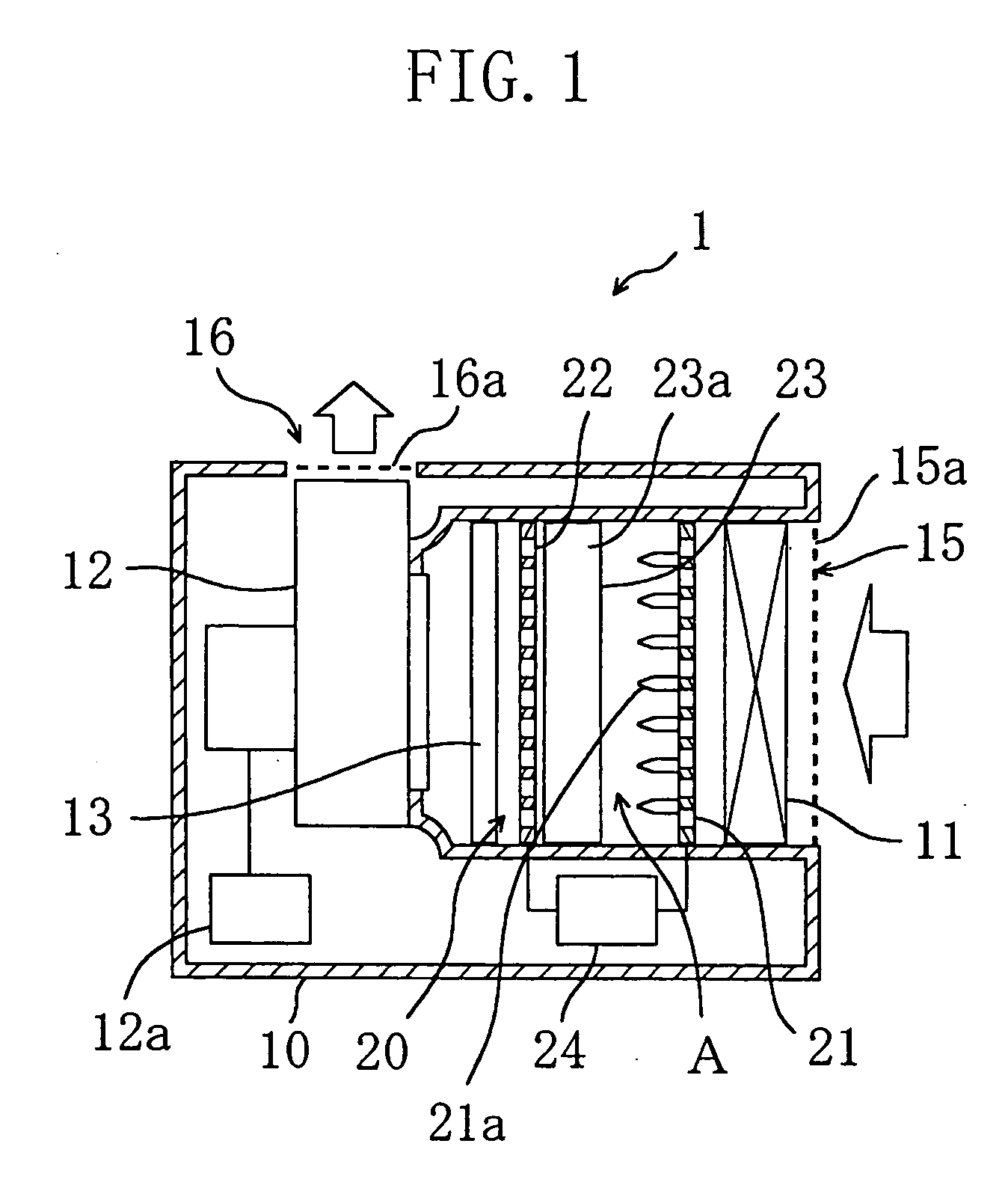

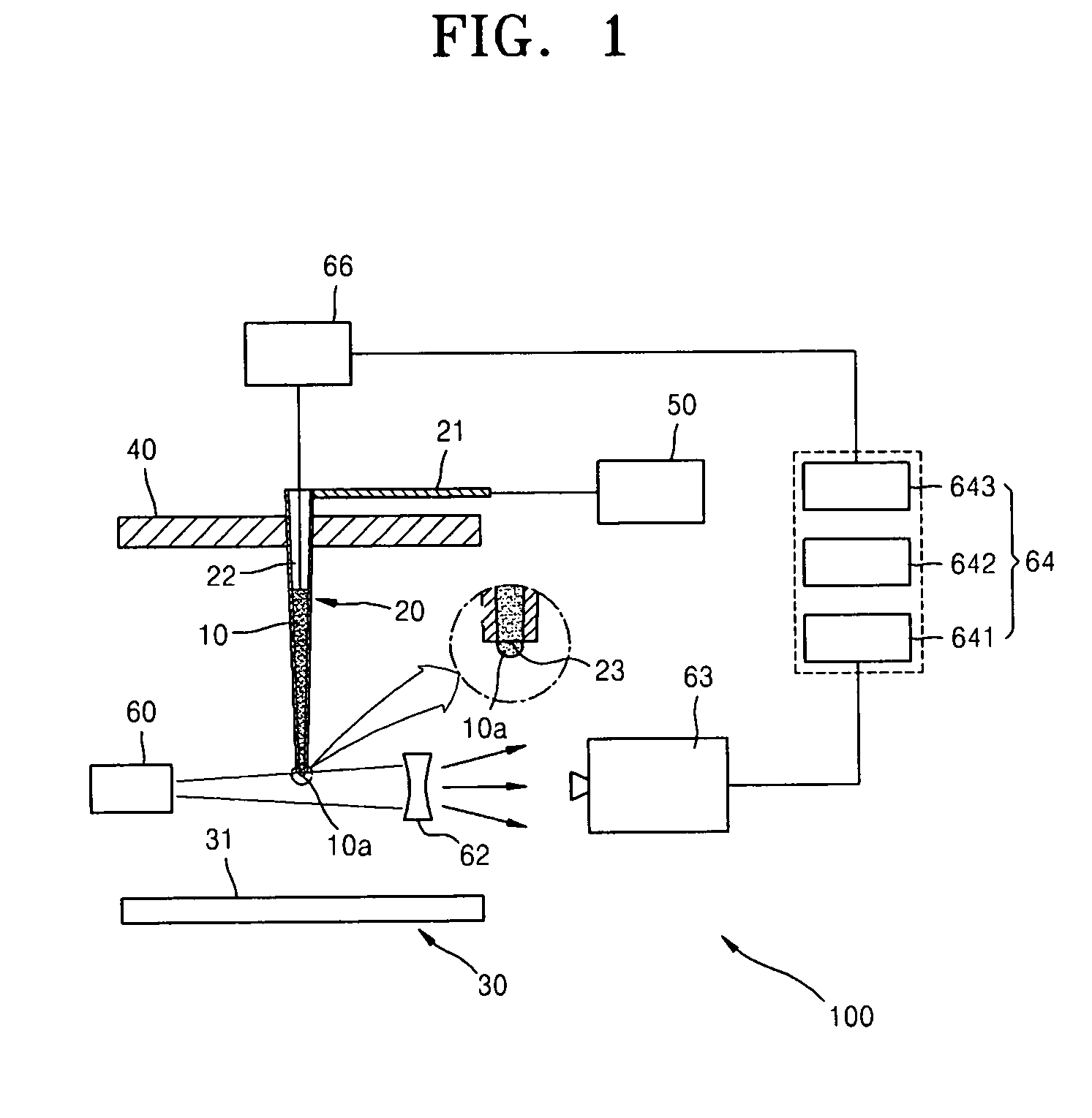

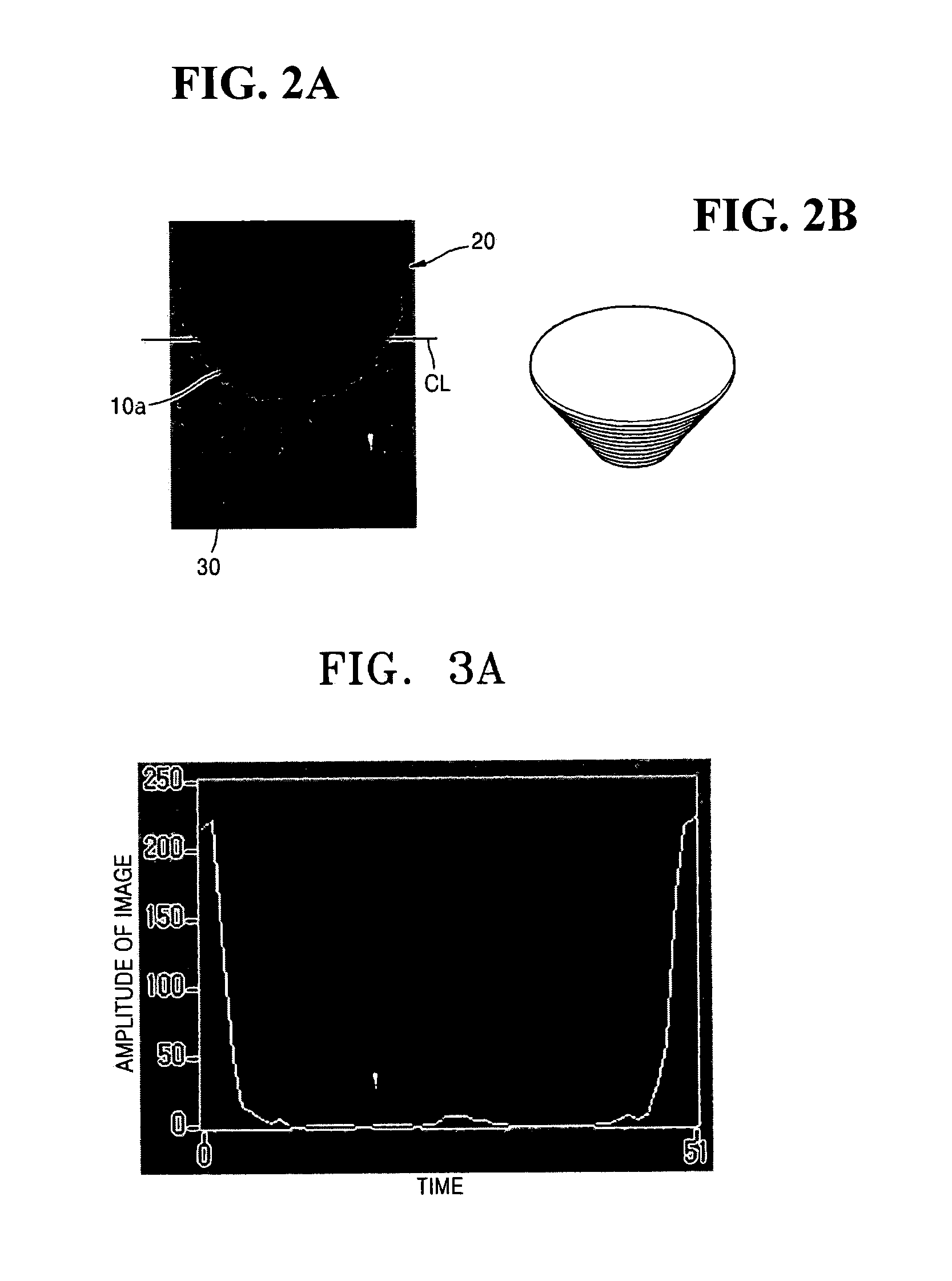

Plasma reactor and purification equipment

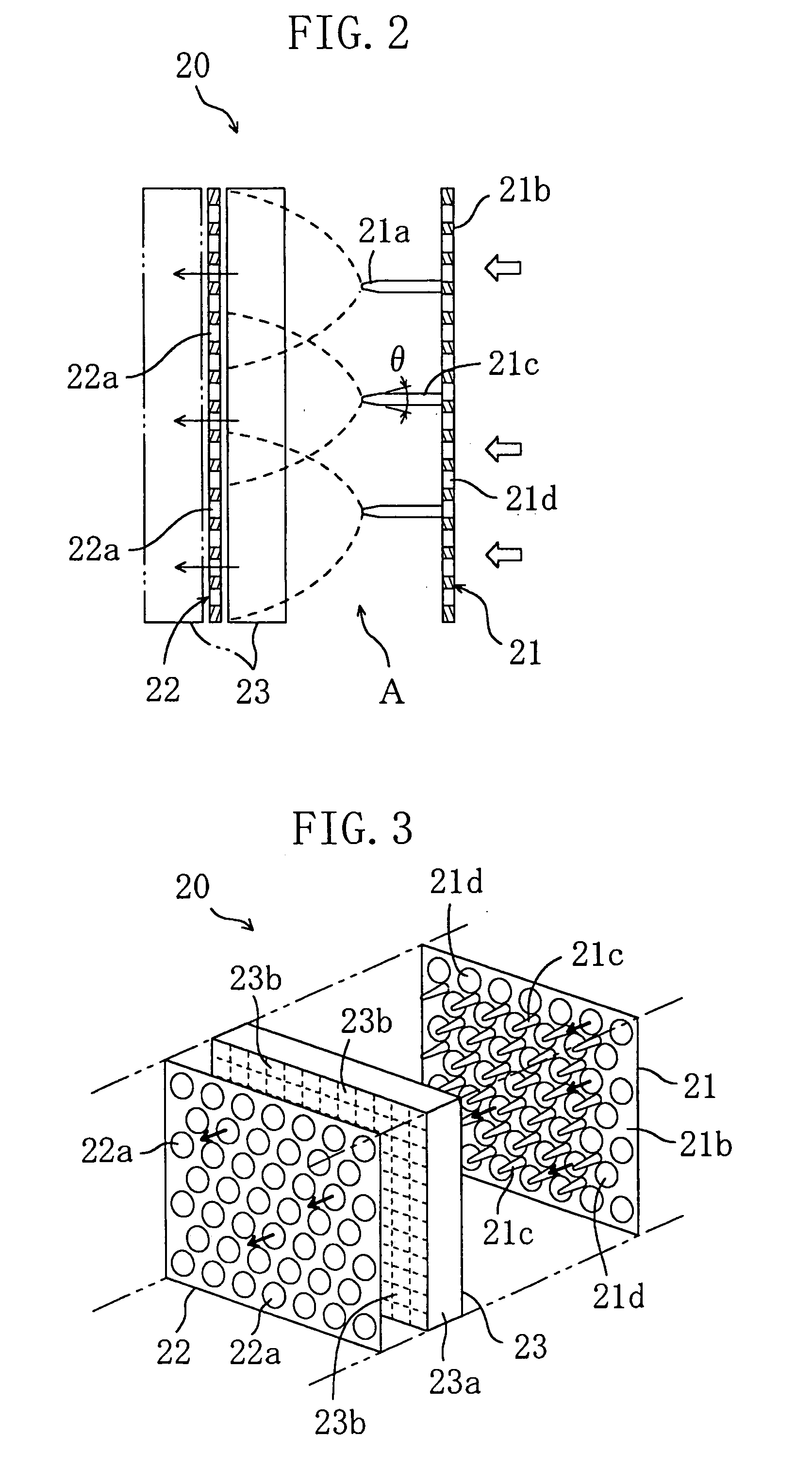

InactiveUS20050174062A1Easily progressGentle fallCombination devicesGas treatmentPlasma reactorNeedle Shape

In the plasma reactor of the present invention, streamer discharge is caused in a wide region so as to increase a plasma generation region without complicating the architecture of the plasma reactor and increasing the cost. In the plasma reactor of the invention, a needle-shaped first electrode and a plate-shaped second electrode are disposed to oppose and to be perpendicular to each other, and the first electrode has a pointed portion as the end thereof on the side of the second electrode and the pointed portion has a point angle θ not less than 30 degrees and not more than 90 degrees, and preferably not less than 60 degrees and not more than 90 degrees.

Owner:DAIKIN IND LTD

Storage phosphor screen having binderless colored layers

InactiveUS20030183777A1Good light stabilityImprove imaging resolutionX-ray/infra-red processesElectrical apparatusPhthalocyanineMetal

A layer arrangement comprising, at least in a binderless layer thereof, one or more vapor deposited pigments like the preferred nanocrystalline beta-Cu-phthalocyanine nanocrystalline dye compound has been disclosed, wherein said layer layer arrangement is, in a preferred embodiment a photostimulable phosphor plate or panel having a binderless needle-shaped photostimulable alkali metal phosphor, and, more preferably, a CsBr:Eu<2+> phosphor, showing besides a high image definition, an excellent preservation of color stability; and wherein the thus produced binderless photostimulable phosphor screen is overcoated with a strong protective layer in order to provide ability for easy transport through a scanning module, without jamming, in a diagnostic radiographic image reading system.

Owner:T2PHARMA GMBH

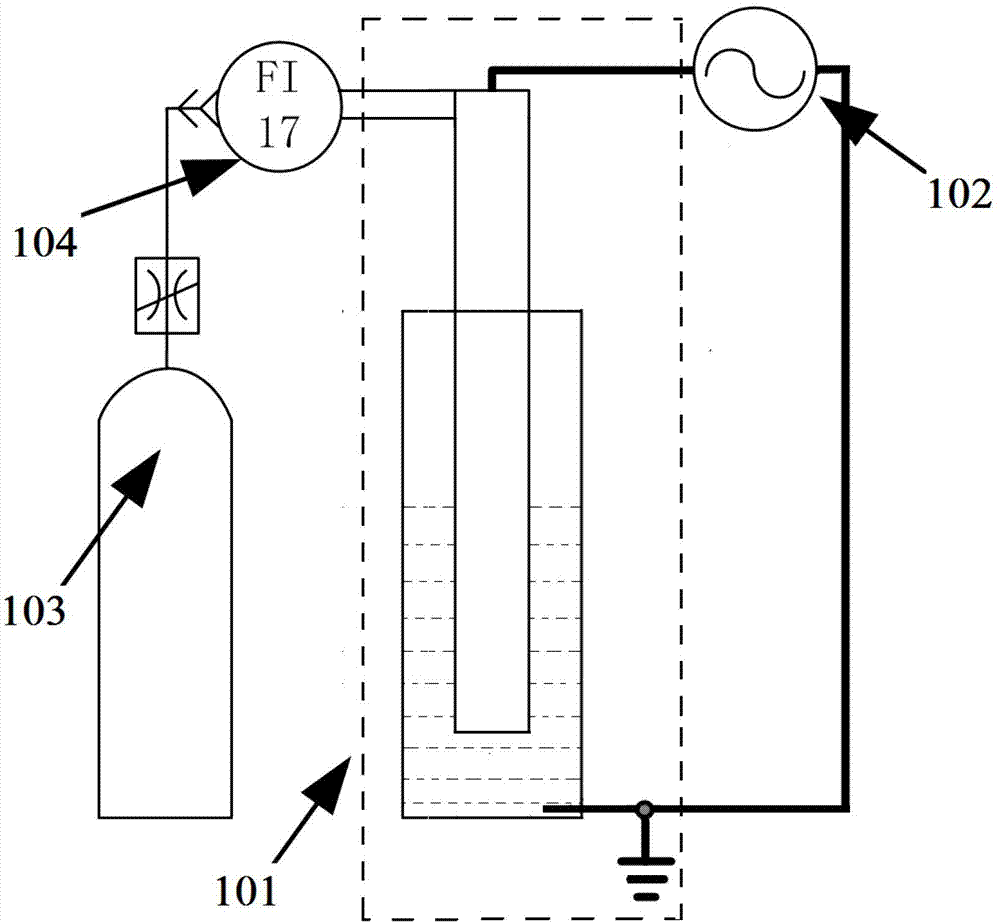

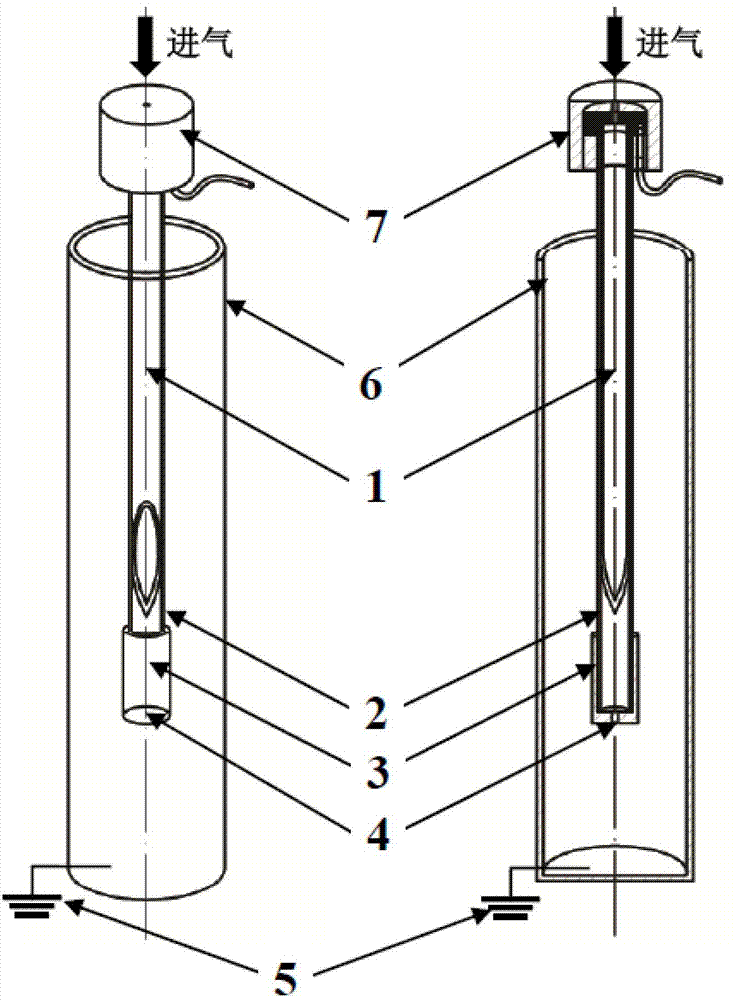

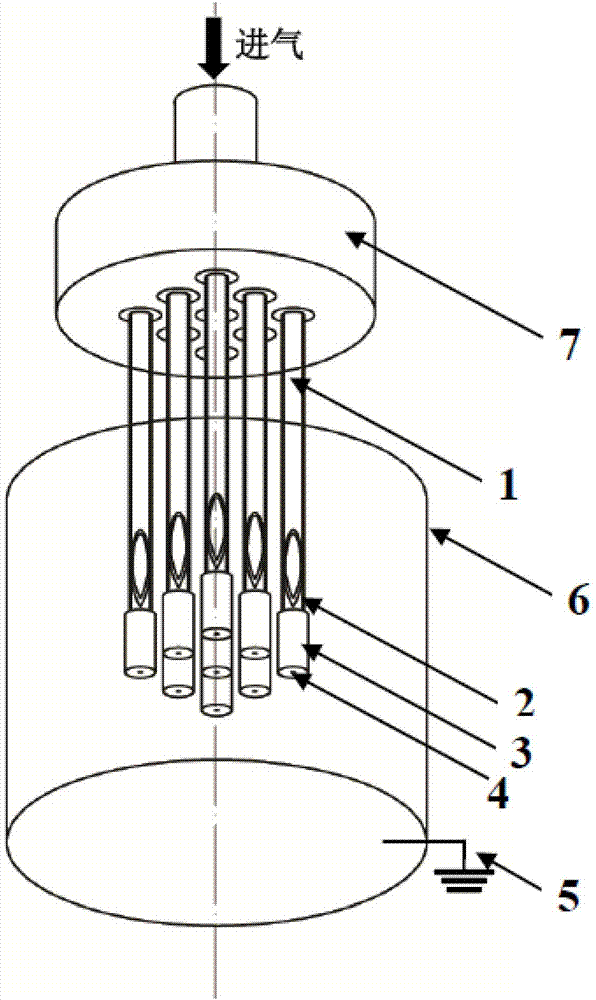

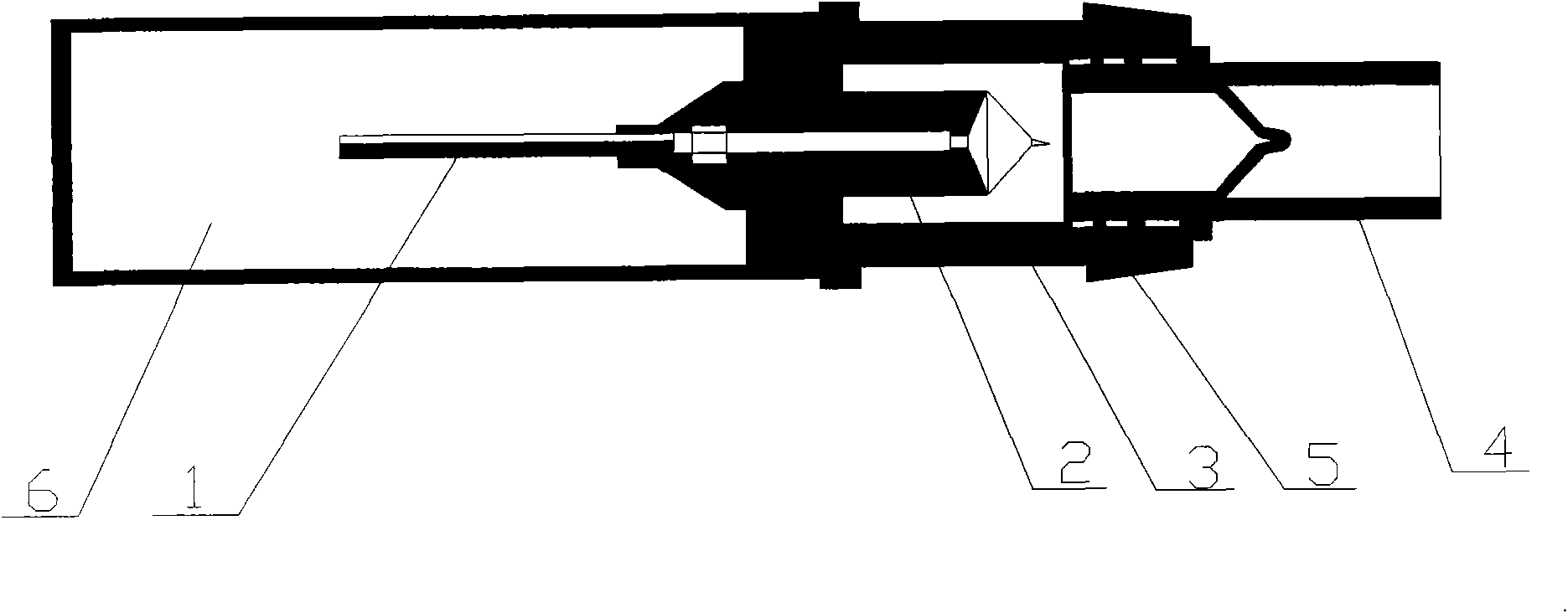

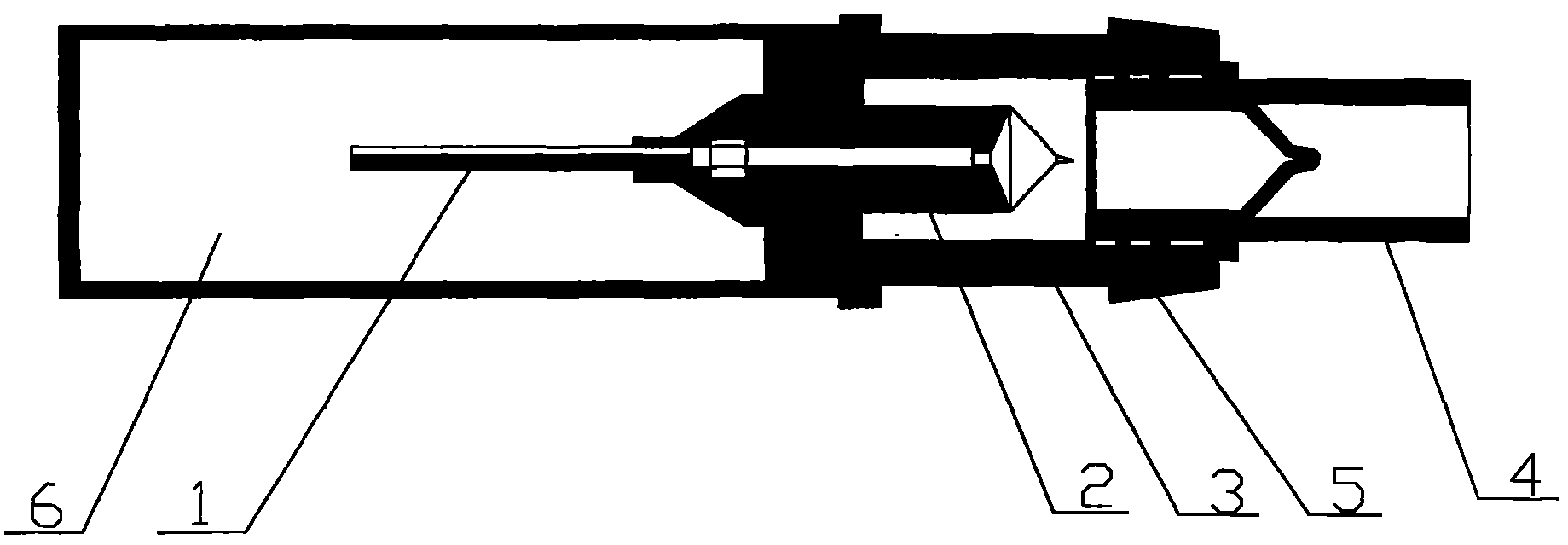

Enhanced-type capillary-needle discharging plasma water treatment device

ActiveCN102897892AAvoid problems with limited depth of actionAvoid lostWater/sewage treatment by irradiationWater/sewage treatment by magnetic/electric fieldsCapillary TubingEngineering

The invention relates to an enhanced-type capillary-needle discharging plasma water treatment device, which belongs to the technical field of the application of low-temperature plasma, and relates to a constant-pressure plasma discharging reaction device for water treatment, and the enhanced-type capillary-needle discharging plasma water treatment device is characterized by comprising a reaction container and a discharging device, wherein the discharging device consists of a metal capillary power electrode, an insulation medium pipe, a metal end cover suspension electrode and an air chamber and is arranged inside the reaction container; working gas enters the metal capillary and the insulation medium pipe through the air chamber, gas discharging plasma is generated inside the insulation medium pipe between a needle-shaped pipe orifice on the lower end of the metal capillary and a metal end cap under the effect of high-voltage power supply, a generated product enters solution to be treated through small holes on the metal end cap, and solution inside the reaction container is purified; and the enhanced-type capillary-needle discharging plasma water treatment device has advantages that the utilization rate of active substances is high, the universality for different solutions to be treated is strong, the stability is good, easiness in integration is realized, and the exciting source requirement of the plasma is reduced.

Owner:TSINGHUA UNIV

Integrated quantitative sampling and reagent adding device

ActiveCN102072949AImprove test accuracyWithdrawing sample devicesPreparing sample for investigationCapillary TubingEngineering

The invention discloses an integrated quantitative sampling and reagent adding device. The device comprises a quantitative capillary tube, a bracket, a kit body, a piston and clamping rings, wherein the quantitative capillary tube is inserted into the bracket; the bracket is integrated with the kit body, the bracket is positioned at one end of the kit body, and the other end of the kit body is provided with the piston; the bracket is provided with capillary tube mounting holes of two diameters; the front end of the bracket is provided with a reaction cup sealing ring, and the tail end of the bracket is provided with a needle; the kit body is provided with an annular protrusion; the tail part of the kit body is provided with the clamping rings of different colors; the piston is provided with an annular protrusion; and the tail part of a reagent chamber in the piston is of a needle shape as same as that at the tail part of the bracket. The integrated quantitative sampling and reagent adding device provided by the invention can be effectively applied to quick detection in the fields of biology, chemistry, medicaments and the like and the industries of food, cosmetics and the like, and greatly improves the test precision in the detection process.

Owner:SHIJIAZHUANG HIPRO BIOTECH

Total artificial method for cultivating cordyceps sinensis

ActiveCN102106235AReduce undue mortalityImprove feathering rateHorticultureInfection rateMortality rate

The invention provides a total artificial method for cultivating the cordyceps sinensis, and belongs to the field of the total artificial cultivation of the cordyceps sinensis. The method comprises the steps of: a. preparing a Chinese hirsutella suspension; b. acquiring, propagating and raising the host insect; c. infecting: taking the hepialus larva obtained by the step b, and soaking the suspension of the step a by a needle-shaped apparatus with the diameter which is less than 0.2mm at one end to prick the hepialus larva to complete the infection; and d. continuously raising. After the method is used, the improper mortality of the chrysalis can be reduced, and the eclosion rate of the hepialus is improved; the mating rate of the hepialus can be improved; and the infection rate of the Chinese hirsutell to the host hepialus larvae can be greatly improved, and the total artificial industrial production of the cordyceps sinensis can be realized.

Owner:四川藏宝虫草生物科技有限公司

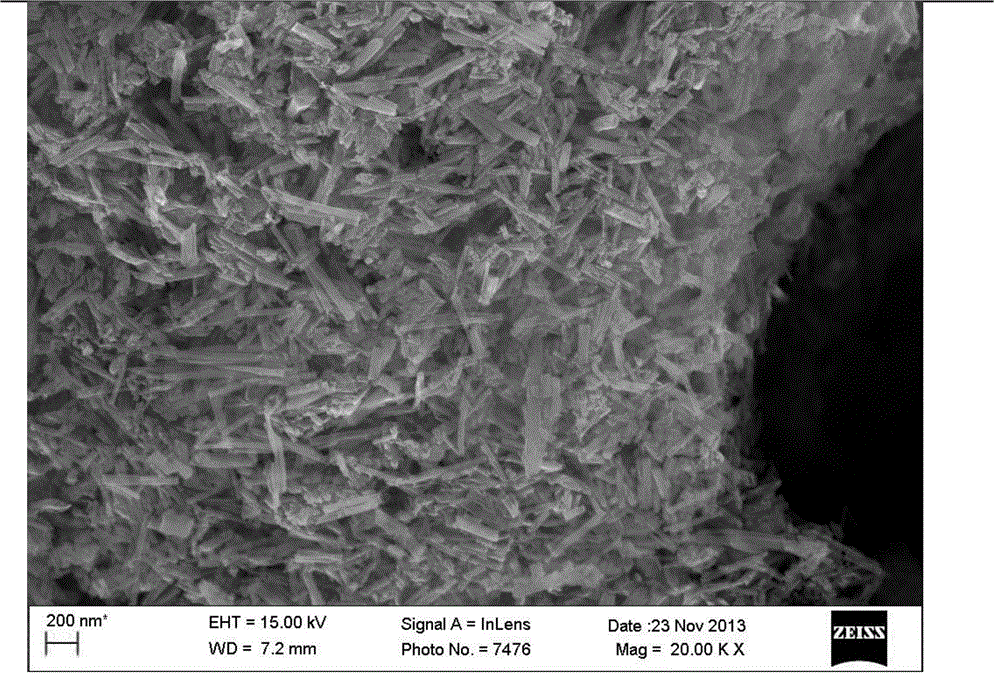

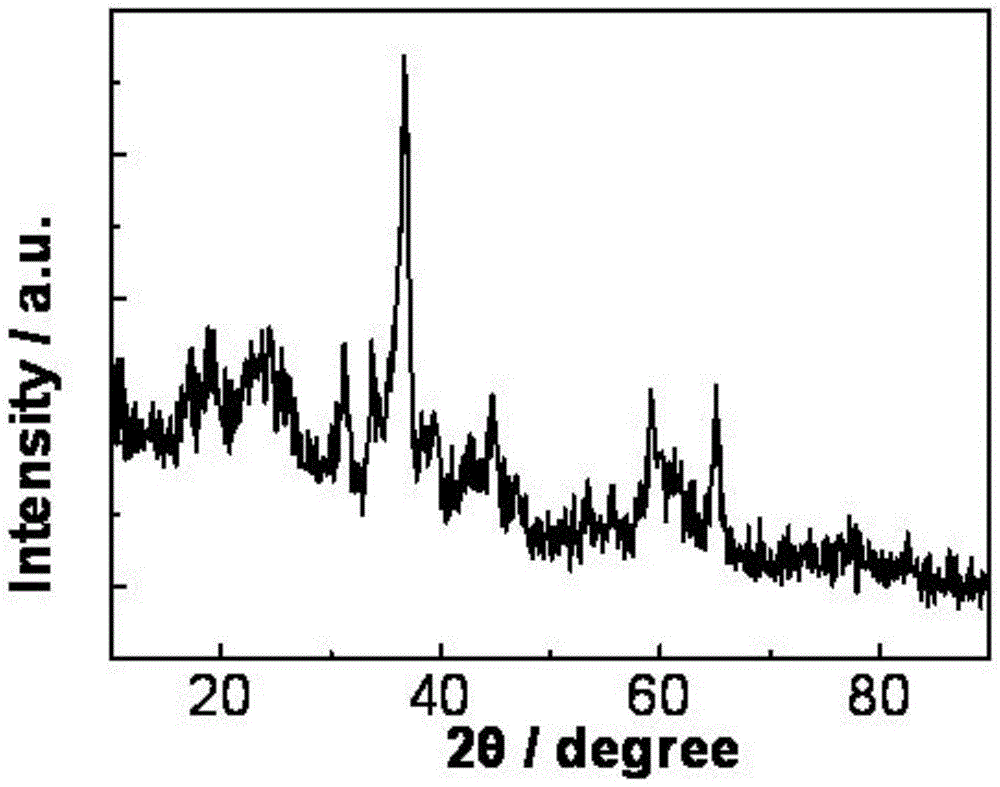

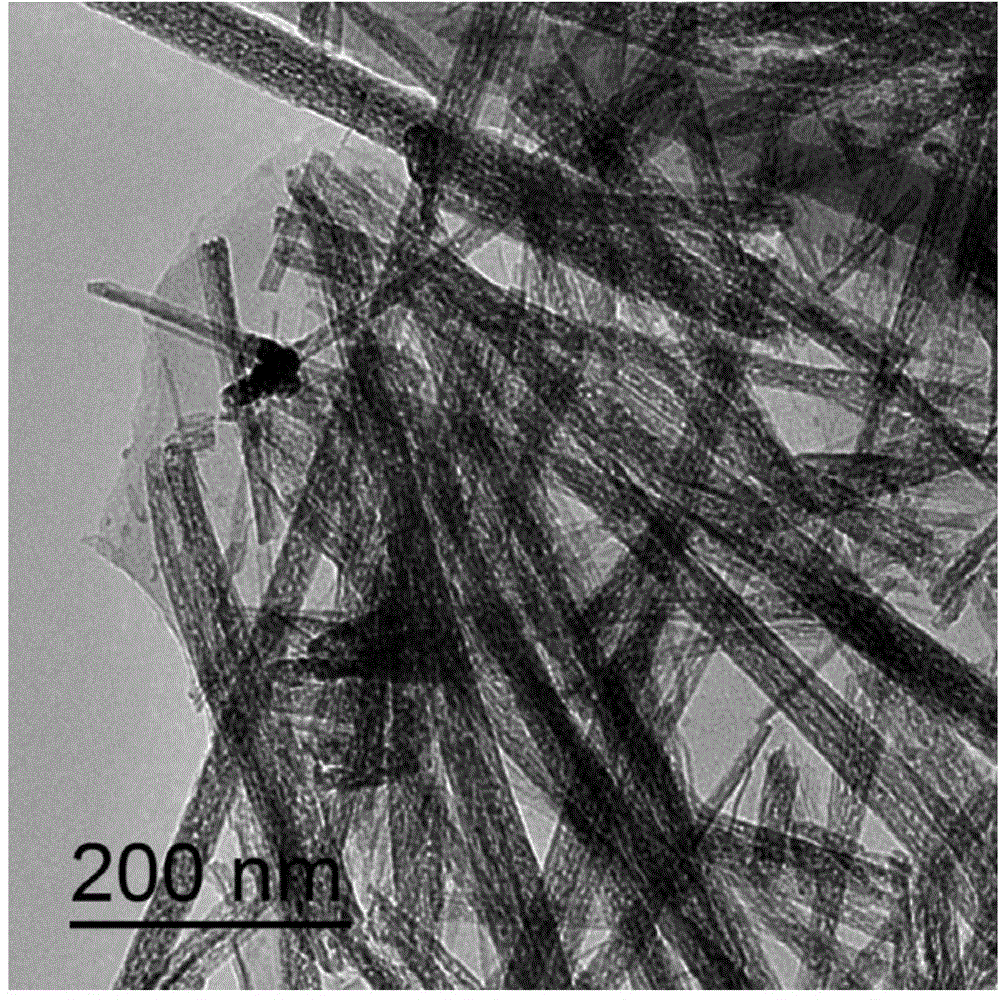

Graphene in-situ load needle-shaped Co3O4 composite electrode material and manufacturing method thereof

InactiveCN103985561AImprove conductivityOptimized areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNano structuring

The invention discloses a graphene in-situ load needle-shaped Co3O4 composite electrode material and a manufacturing method of the graphene in-situ load needle-shaped Co3O4 composite electrode material. Single-layer graphene with needle-shaped Co3O4 growing on the edge or two faces is adopted as a load frame of the composite electrode material, the plane size of a nanosheet layer is one micron to 50 microns, and the manufacturing method comprises the steps that graphite oxide is manufactured through a modified Hummers method, then ultrasonic treatment is carried out to obtain graphene oxide, a precursor of the composite electrode material is manufactured through the graphene oxide, and the precursor is annealed in inert atmosphere to obtain the composite electrode material. The manufacturing method of the composite electrode material is simple and environmentally friendly, according to the typical structure of the composite electrode material, the needle-shaped Co3O4 is combined with the surface or the side face of the graphene, a quasi two-dimensional nano structure is formed, the graphene sheet layer can be loaded with the needle-shaped Co3O4 in situ, the cycle life of the Co3O4 is prolonged, and the specific capacitance and other good electrochemical performance are improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

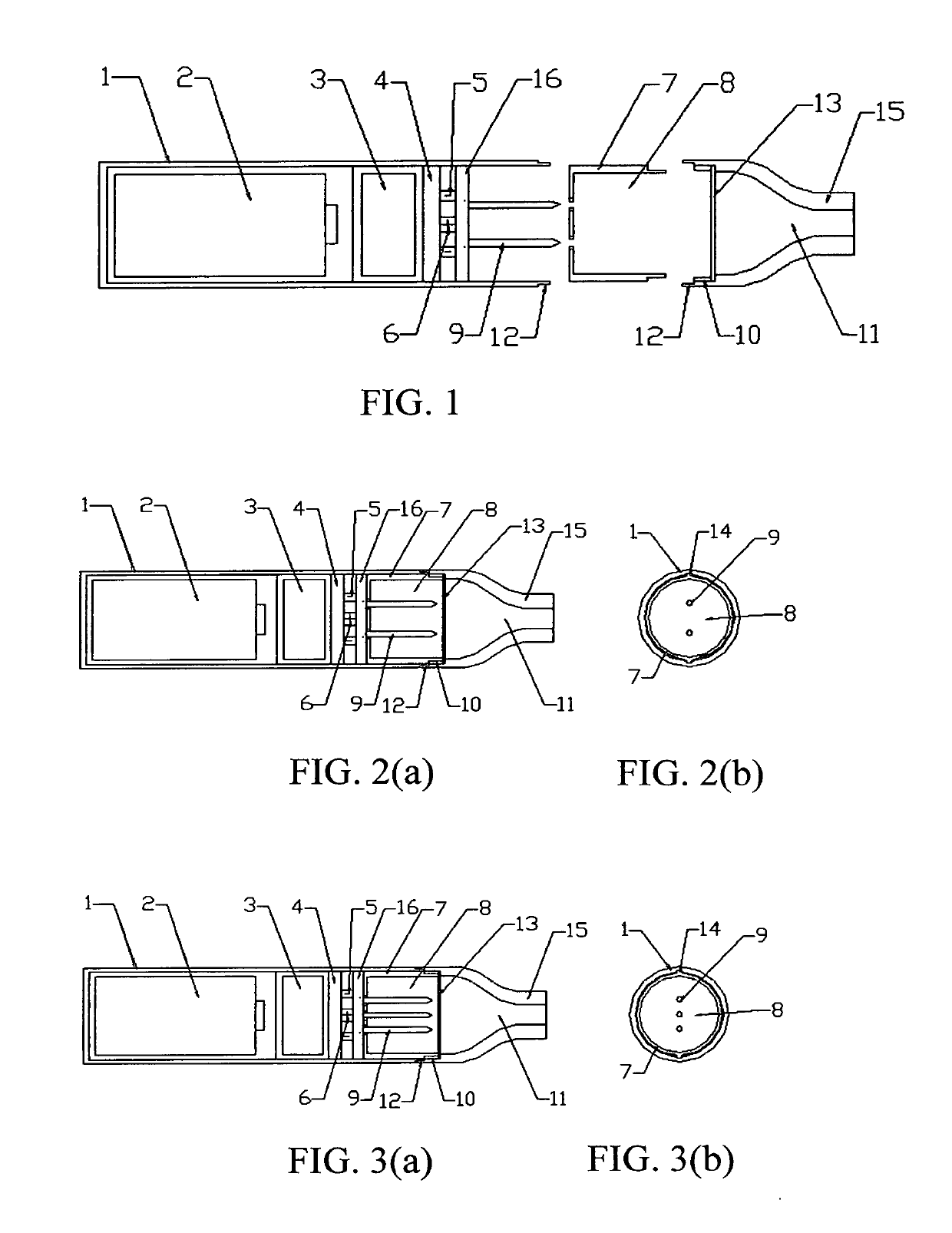

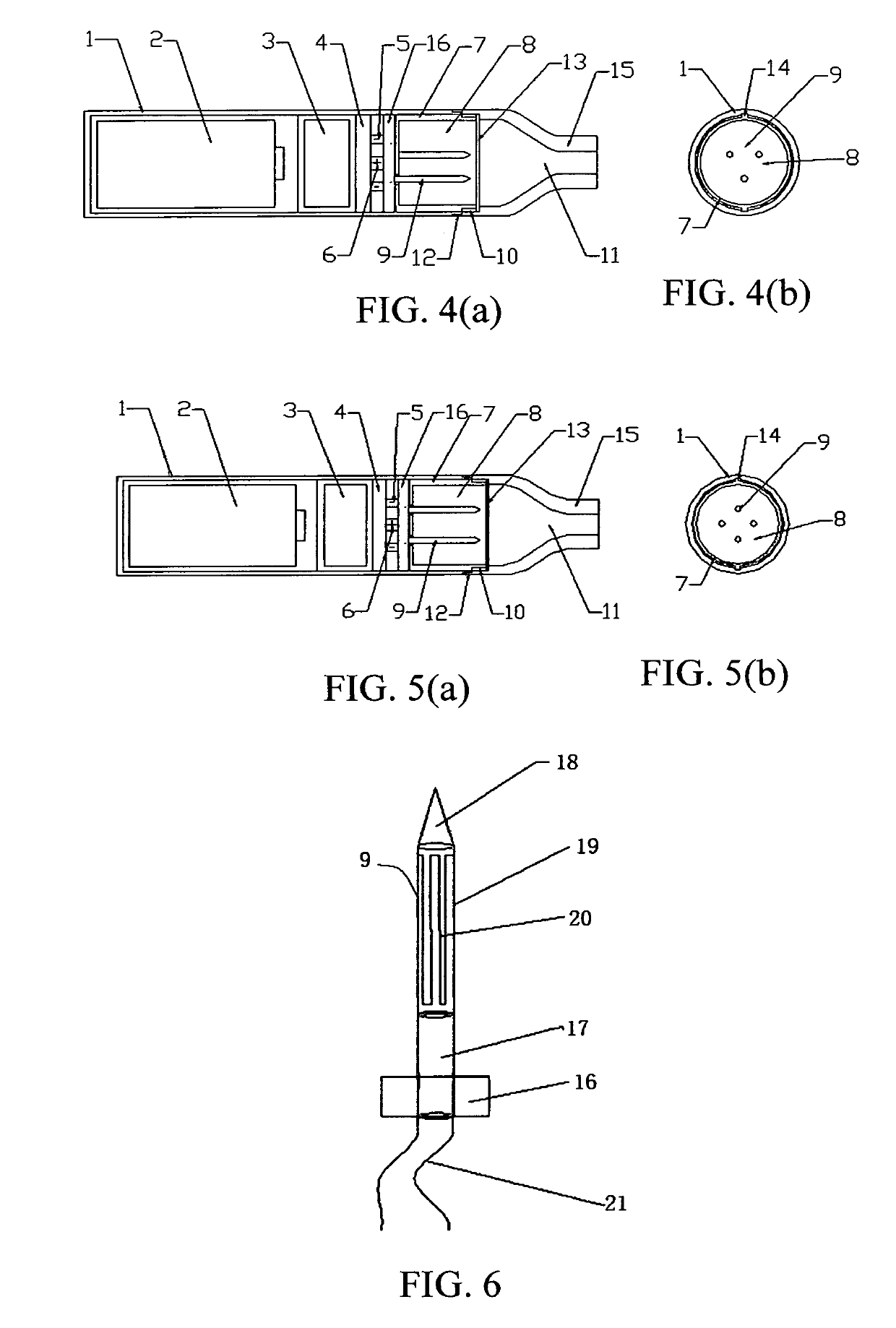

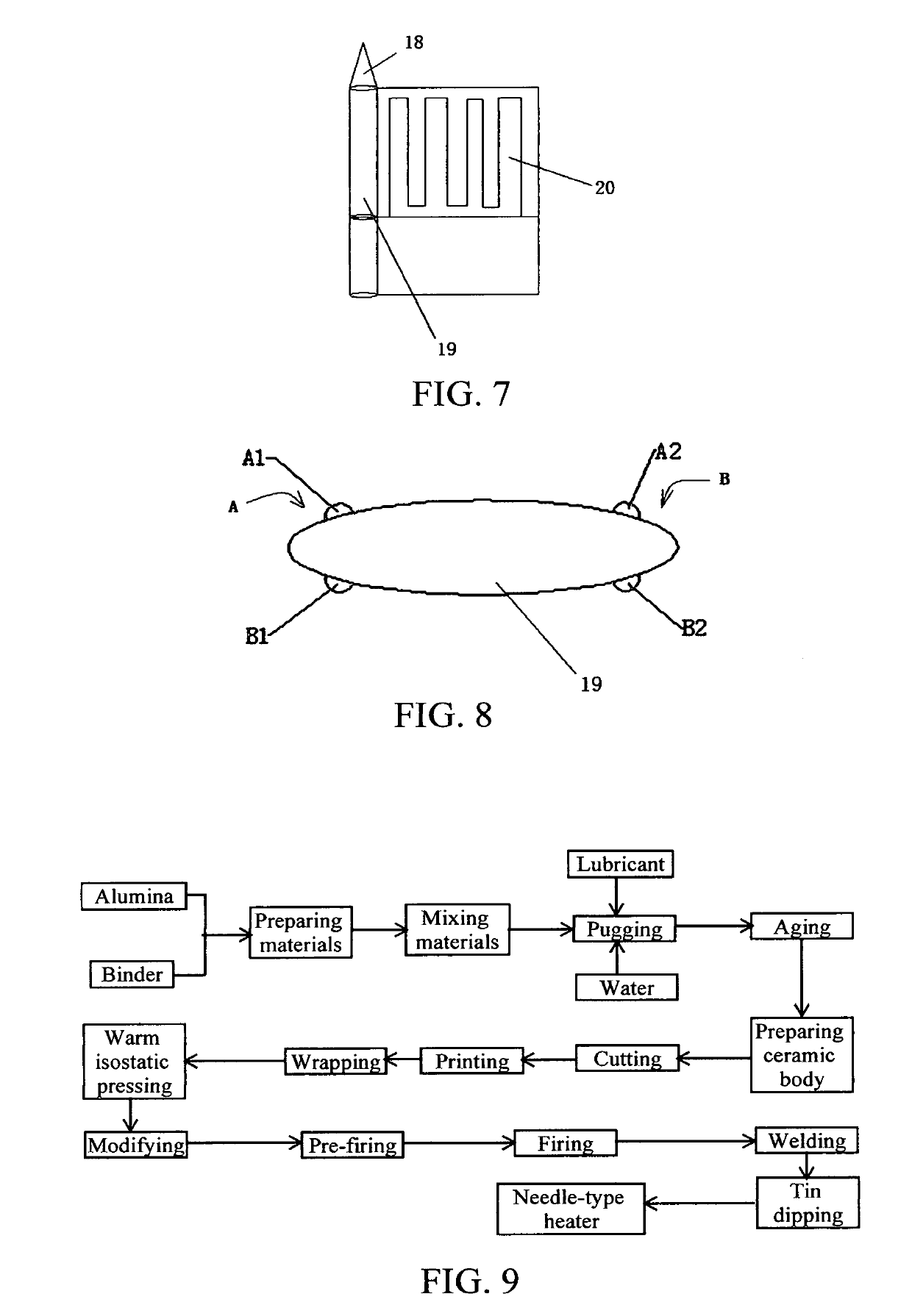

Needle-type heater, production method of needle-type heater, and electrically heated cigarette with needle-type heater

ActiveUS20190320719A1Easy to insertEasy to replaceTobacco treatmentCigar manufactureEngineeringMethods of production

A needle-type heater (9) includes a needle-shaped heating body and a heating element (20), wherein: the needle-shaped heating body includes a tapered cap (18) and a heater substrate (19) connected with a bottom of the tapered cap (18); and the heating element (20) is attached to the heater substrate (19) in a way of coated printing. A production method of the needle-type heater (9) and an electrically heated cigarette with the needle-type heater (9) are also provided. The needle-type heater (9) can fully heat a tobacco product, and the tobacco product is easier to be inserted into a heating cavity (8), so that it is convenient to replace the tobacco product and use.

Owner:HUBEI CHINA TOBACCO IND

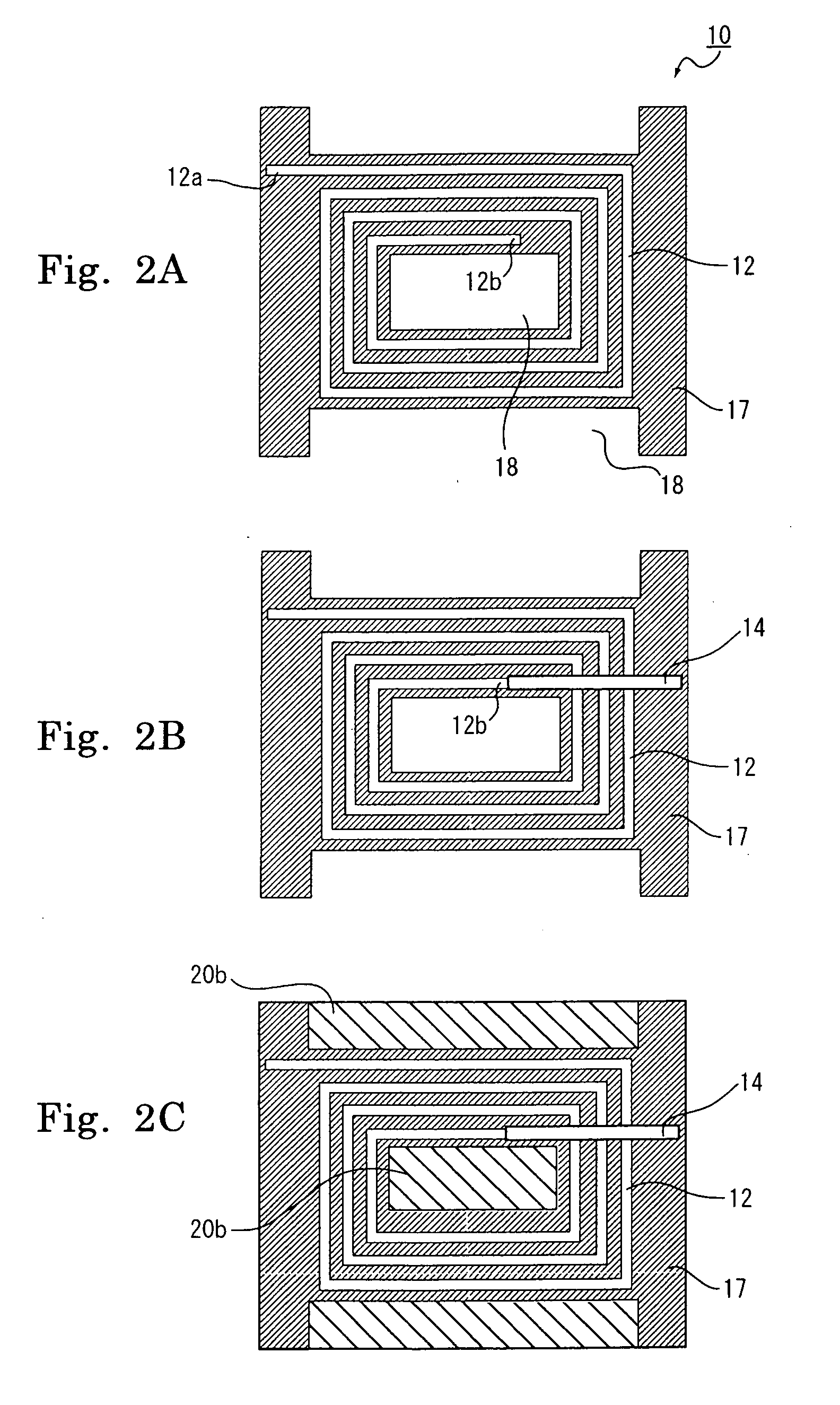

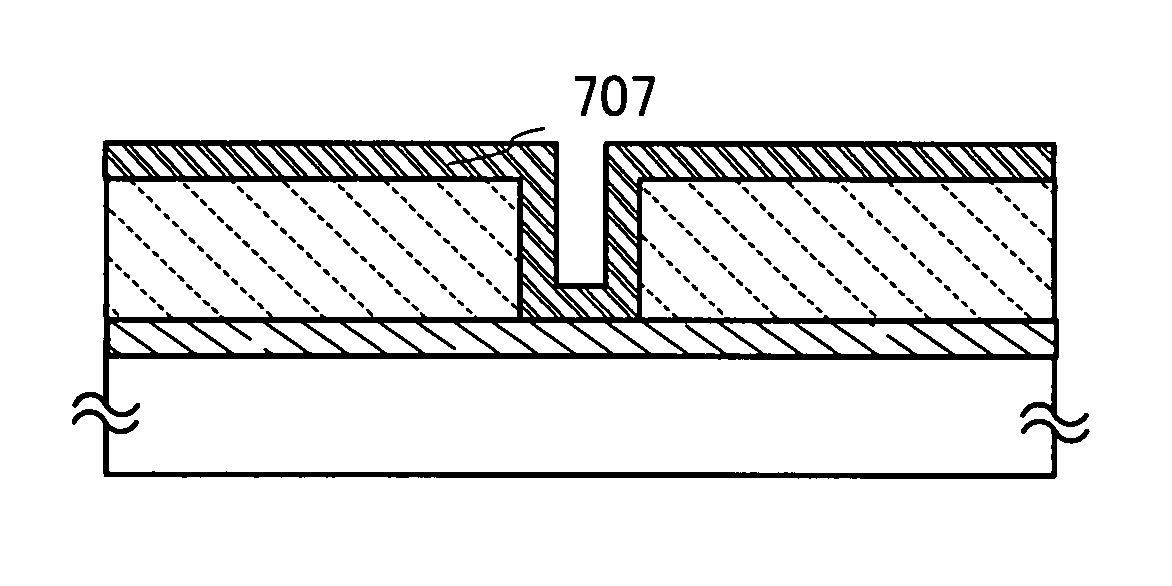

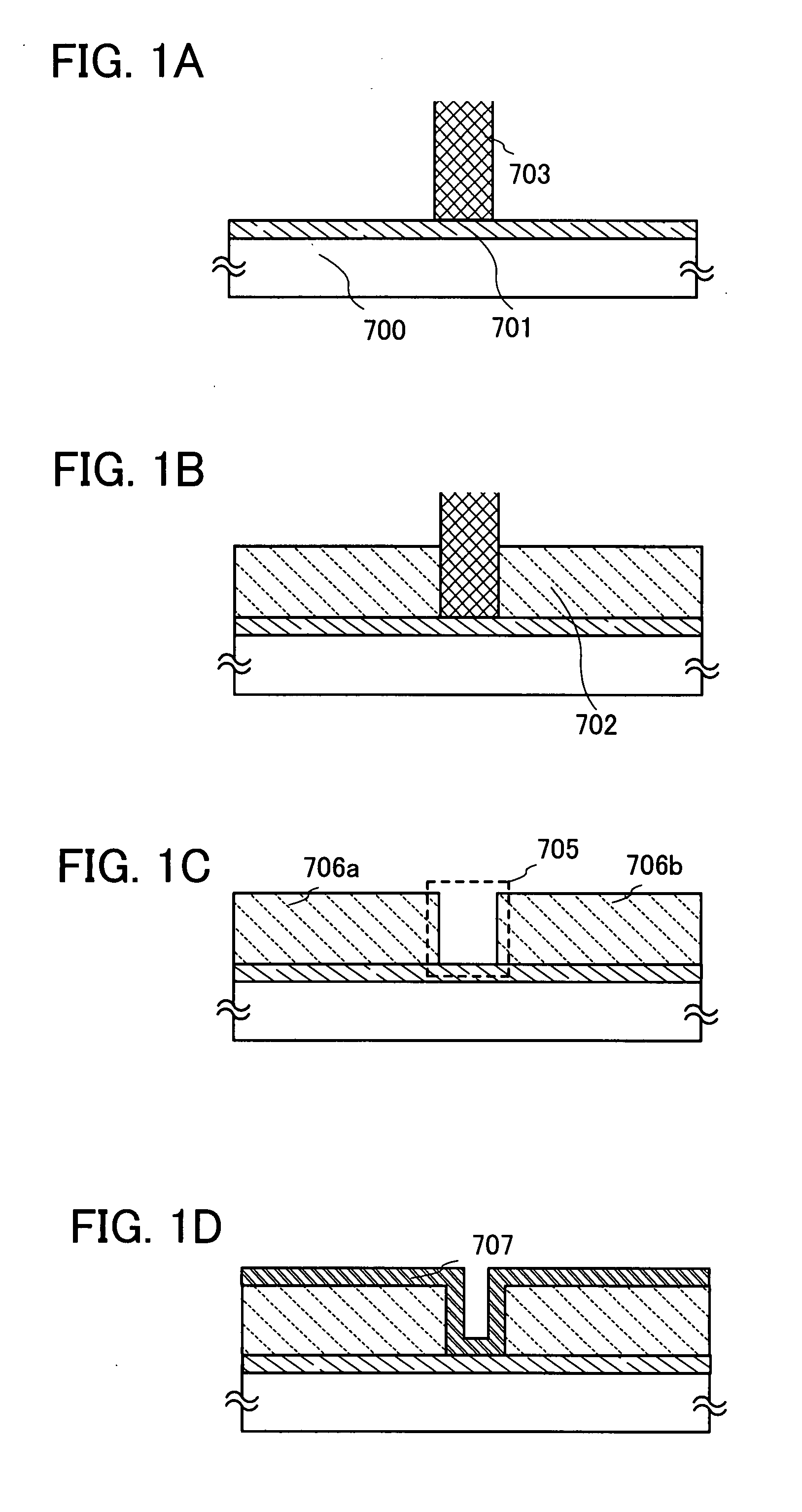

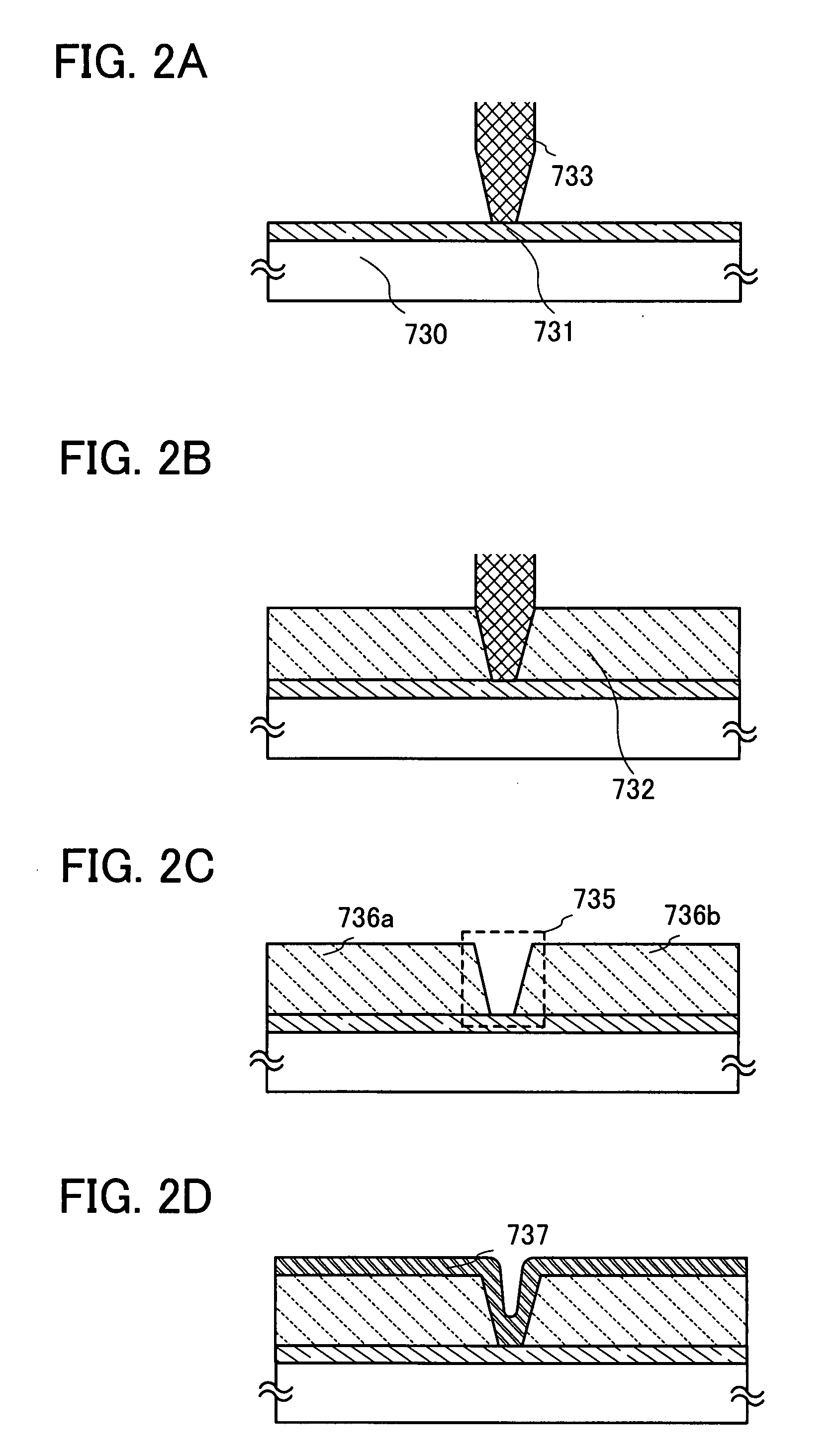

Method of fabricating display device

InactiveUS20080057604A1Reduce in quantityImprove performanceTransistorSolid-state devicesDisplay deviceEngineering

To improve the use efficiency of materials and provide a technique of fabricating a display device by a simple process. The method includes the steps of providing a mask on a conductive layer, forming an insulating film over the conductive layer provided with the mask, removing the mask to form an insulating layer having an opening; and forming a conductive film in the opening so as to be in contact with the exposed conductive layer, whereby the conductive layer and the conductive film can be electrically connected through the insulating layer. The shape of the opening reflects the shape of the mask. A mask having a columnar shape (e.g., a prism, a cylinder, or a triangular prism), a needle shape, or the like can be used.

Owner:SEMICON ENERGY LAB CO LTD

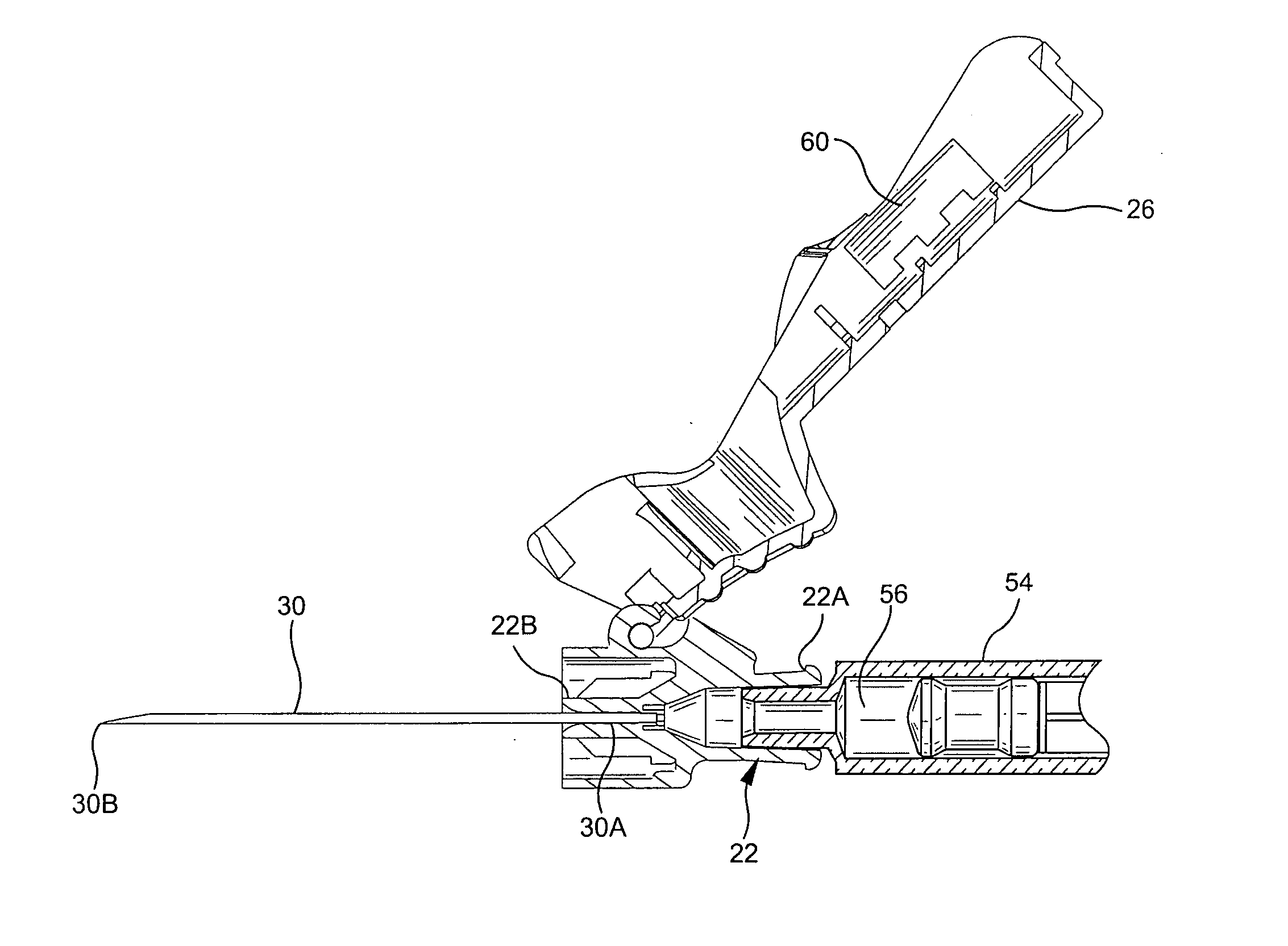

Needle shield assembly having hinged needle shield and flexible cannula lock

InactiveUS20050124944A1Increase deflectionDeflect the end portionInfusion needlesNursing accommodationEngineeringExtremity Part

A needle shield and needle shield assembly are provided for preventing accidental needle sticks. The needle shield includes opposing sidewalls and is pivotable between an open position that allows use of the needle cannula and a closed position that covers at least the tip of the needle cannula. A locking member extends from one of the sidewalls of the needle shield and includes a relatively rigid base portion and a relatively flexible end portion. The needle cannula engages the relatively flexible end portion when entering the needle shield cavity, deflecting it with respect to the base portion. Upon any attempt to move the needle shield from the closed position to the open position, the needle cannula is directed by the locking member towards the relatively rigid base portion, thereby making it very difficult to reuse the needle cannula.

Owner:BECTON DICKINSON & CO

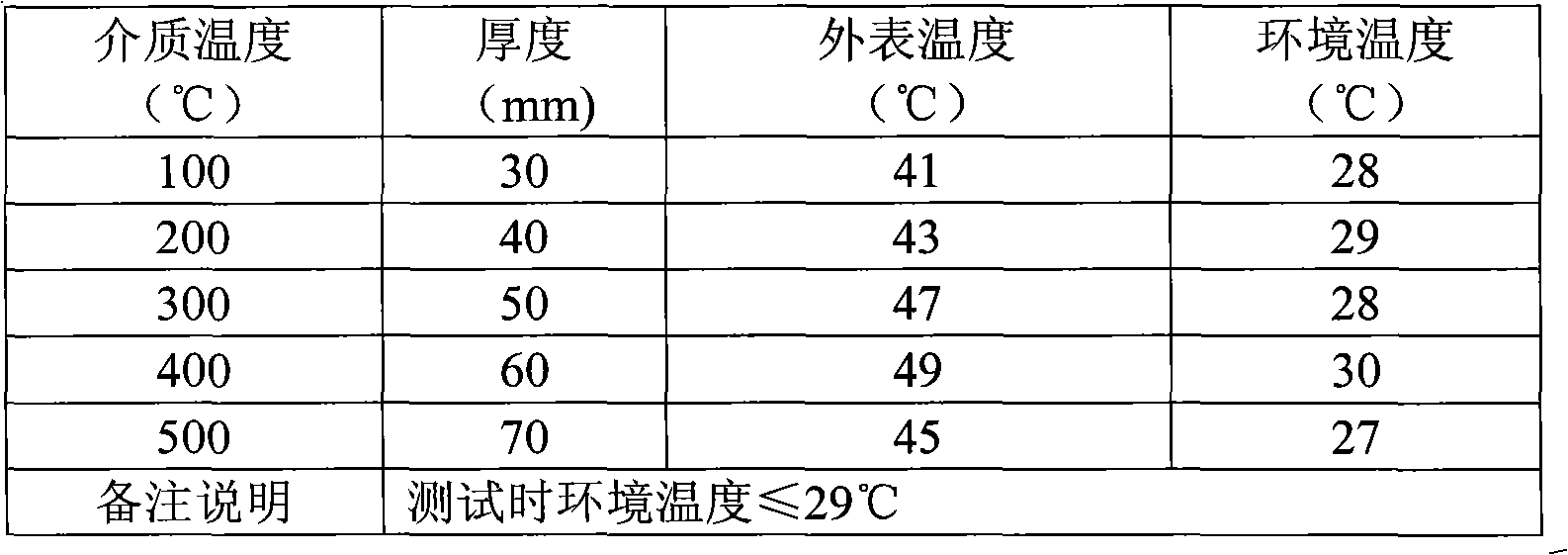

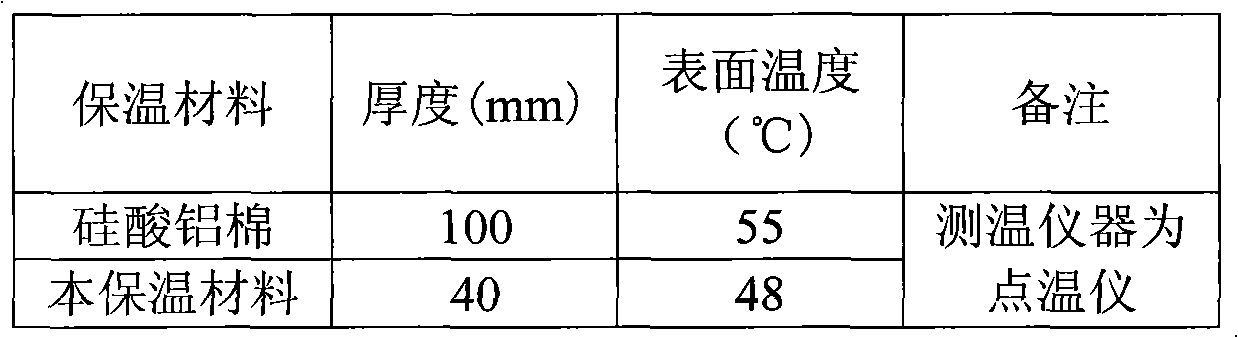

Inorganic heat-insulating material and preparation method thereof

InactiveCN101973750AImprove isolation abilityStrong anti-radiation heat conduction abilitySolid waste managementSodium BentoniteCarbon fibers

The invention relates to an inorganic heat-insulating material and a preparation method thereof. The inorganic heat-insulating material is prepared from the following raw materials in parts by weight: 15-37 parts of basic material, 45-70 percent of pigment and filler and 9-26 parts of auxiliary agent, wherein the basic material comprises the following raw materials in parts by weight: 10-20 partsof phosphoric acid, 3-8 parts of aluminium hydroxide, 2-8 parts of aluminum-silver slurry auxiliary agent, 0.5-5 parts of silicate and 1-5 parts of sodium carboxymethyl cellulose; the pigment and filler is one or a combination of potassium titanate whiskers, expanded perlite, ceramic microspheres, nano-silicon dioxide aerogel, heat-insulating powder, carbon fibers, meerschaum, needle-shaped wollastonite powder and magnesium hydrate; and the auxiliary agent is one or a combination of boron nitride, dichromium trioxide, glass powder, boric acid, nano-zirconia, calcium oxide and calcium-based bentonite. The invention inorganic heat-insulating material has strong insulating capability for solid conductive heat at high temperature (150-500 DEG C) and simultaneously also has strong insulating capability for radiation and flow conductive heat.

Owner:童金荣

Storage phosphor screen having binderless colored layers

InactiveUS6977385B2Good light stabilityImprove imaging resolutionX-ray/infra-red processesElectrical apparatusPhthalocyanineNanocrystal

Owner:T2PHARMA GMBH

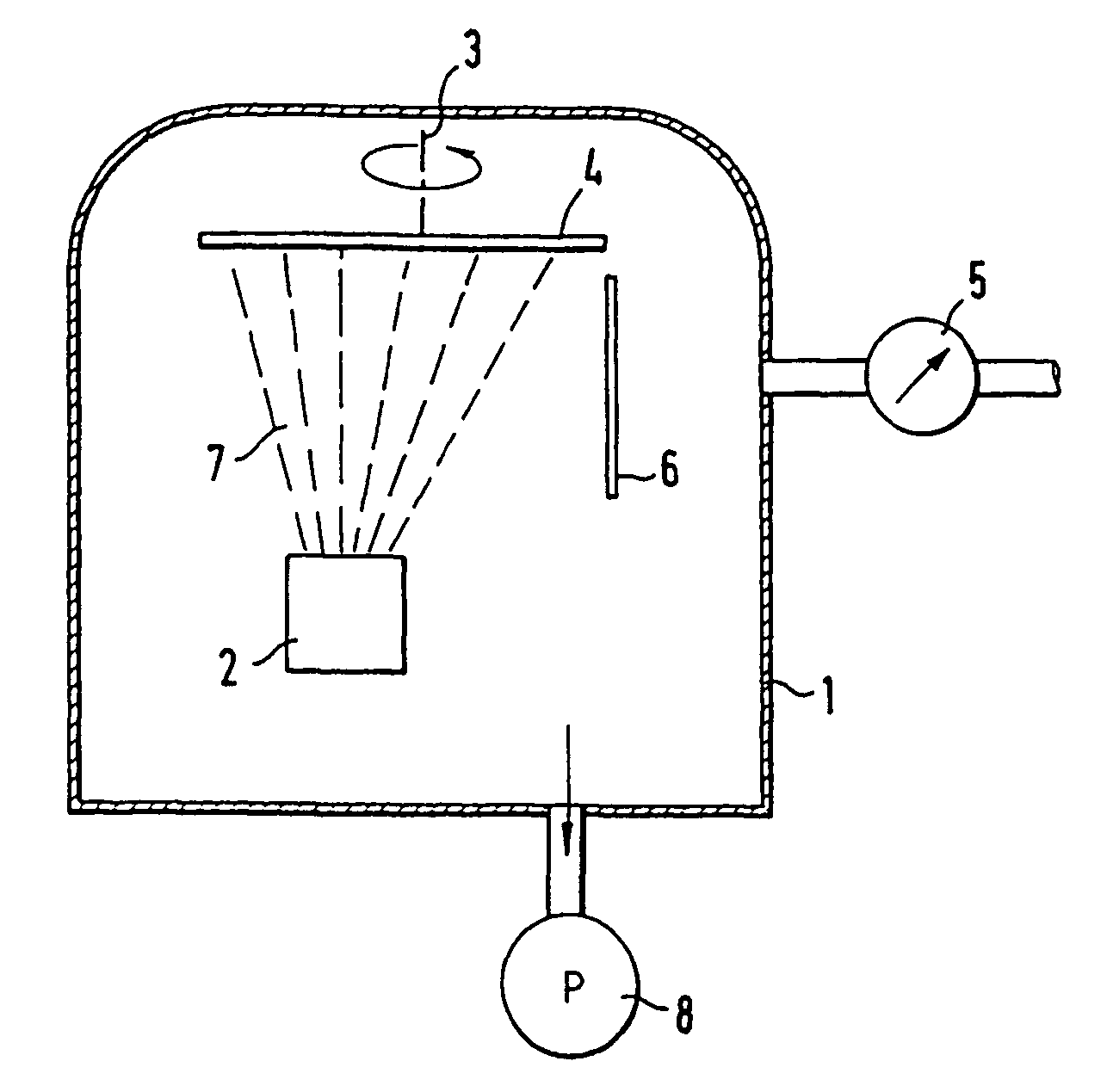

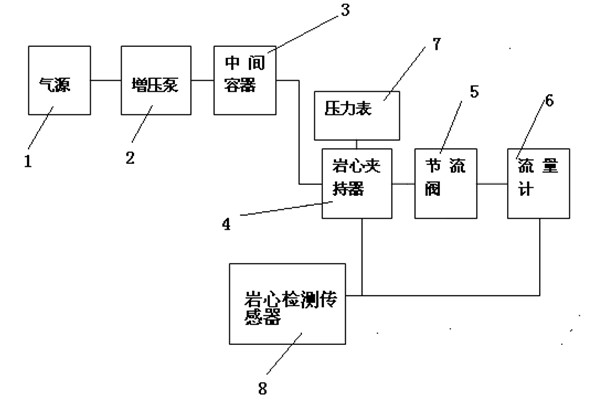

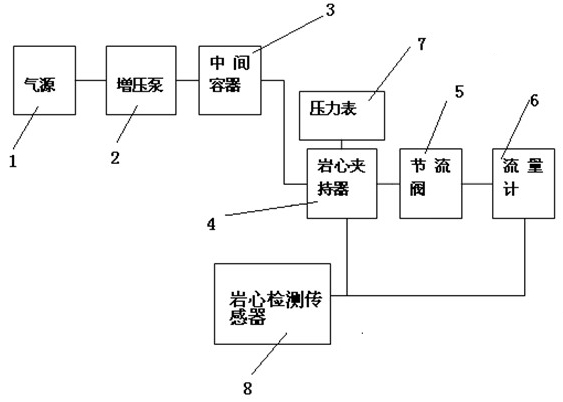

Device and method for testing rock permeability under different pore fluid pressure

InactiveCN102156087AMature processing and production technologyLow costPermeability/surface area analysisRock corePore fluid

The invention belongs to the field of rock permeability test, and discloses a device for testing rock permeability under different pore fluid pressure. The device is characterized by comprising a high-pressure gas source generating device, a back pressure control device and a data detection and display device, wherein the high-pressure gas source generating device is connected with the back pressure control device, and the data detection and display device is connected with the back pressure control device; and the back pressure control device comprises a needle-shaped throttling valve and a rock core holder, wherein the needle-shaped throttling valve is arranged at the outlet end of the rock core holder. The invention also discloses a method for testing the rock permeability under different pore fluid pressure. A back pressure valve in the prior art is replaced by using the needle-shaped throttling valve to adjust the pressure of the rock core in the rock core holder under different pore fluid, the device has good back pressure stabilizing effect, and meanwhile, the processing production technology for the throttling valve is mature and has low cost and strong adaptability.

Owner:SOUTHWEST PETROLEUM UNIV

Coil component

ActiveUS7859377B2Highly resistant against drop shockIncrease the inductance valueTransformers/inductances casingsTransformers/inductances magnetic coresHigh resistanceIn plane

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

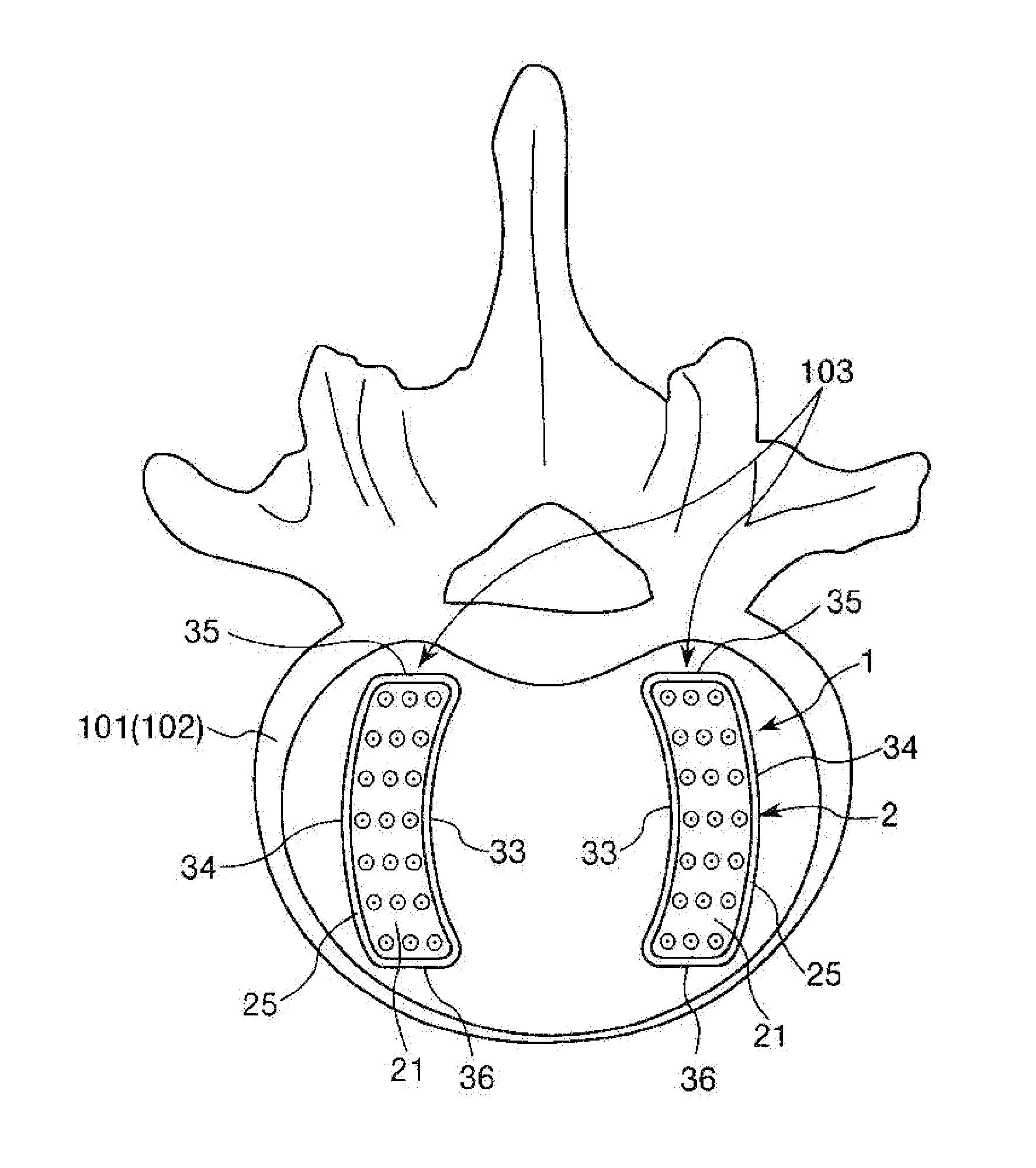

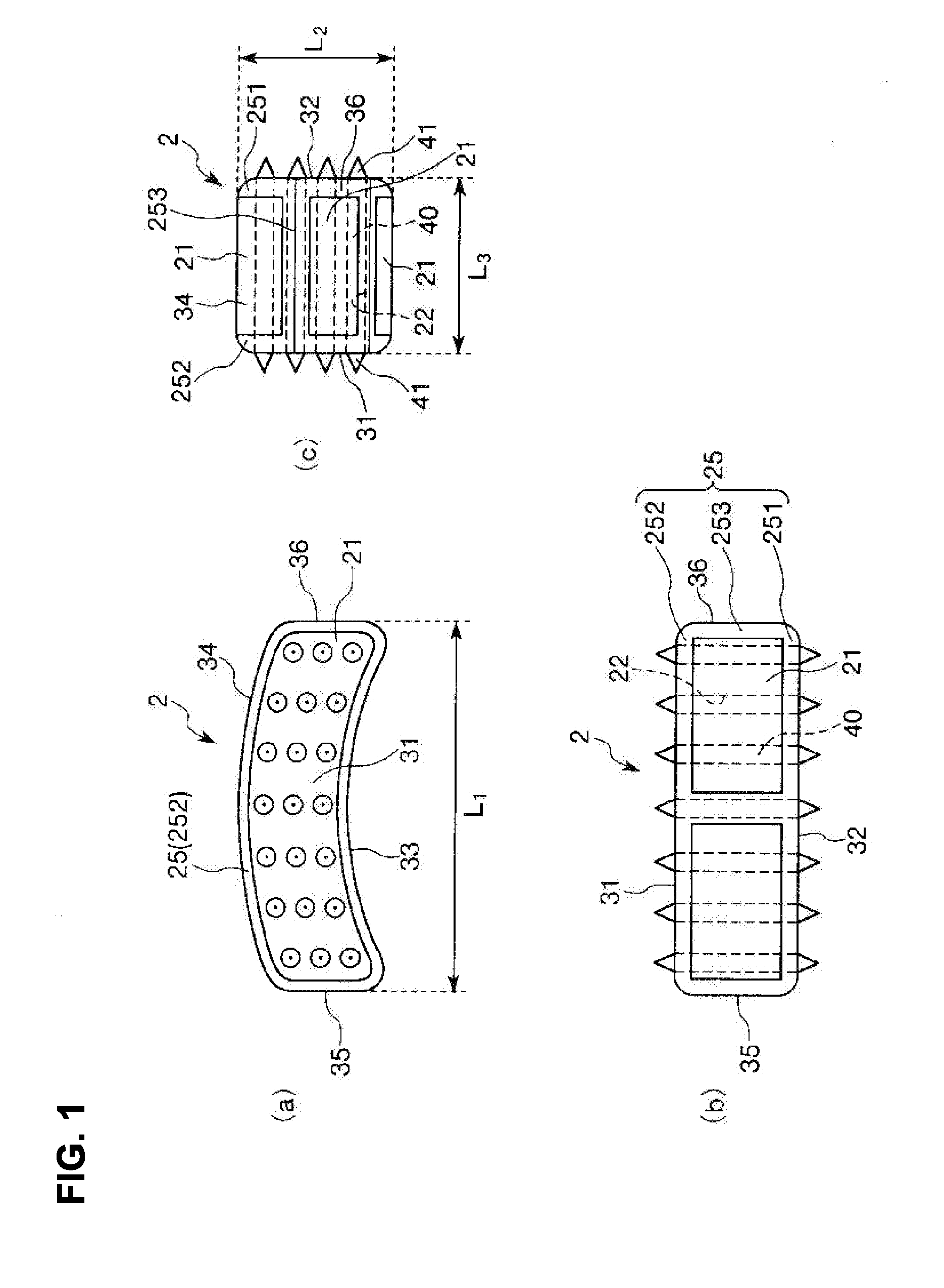

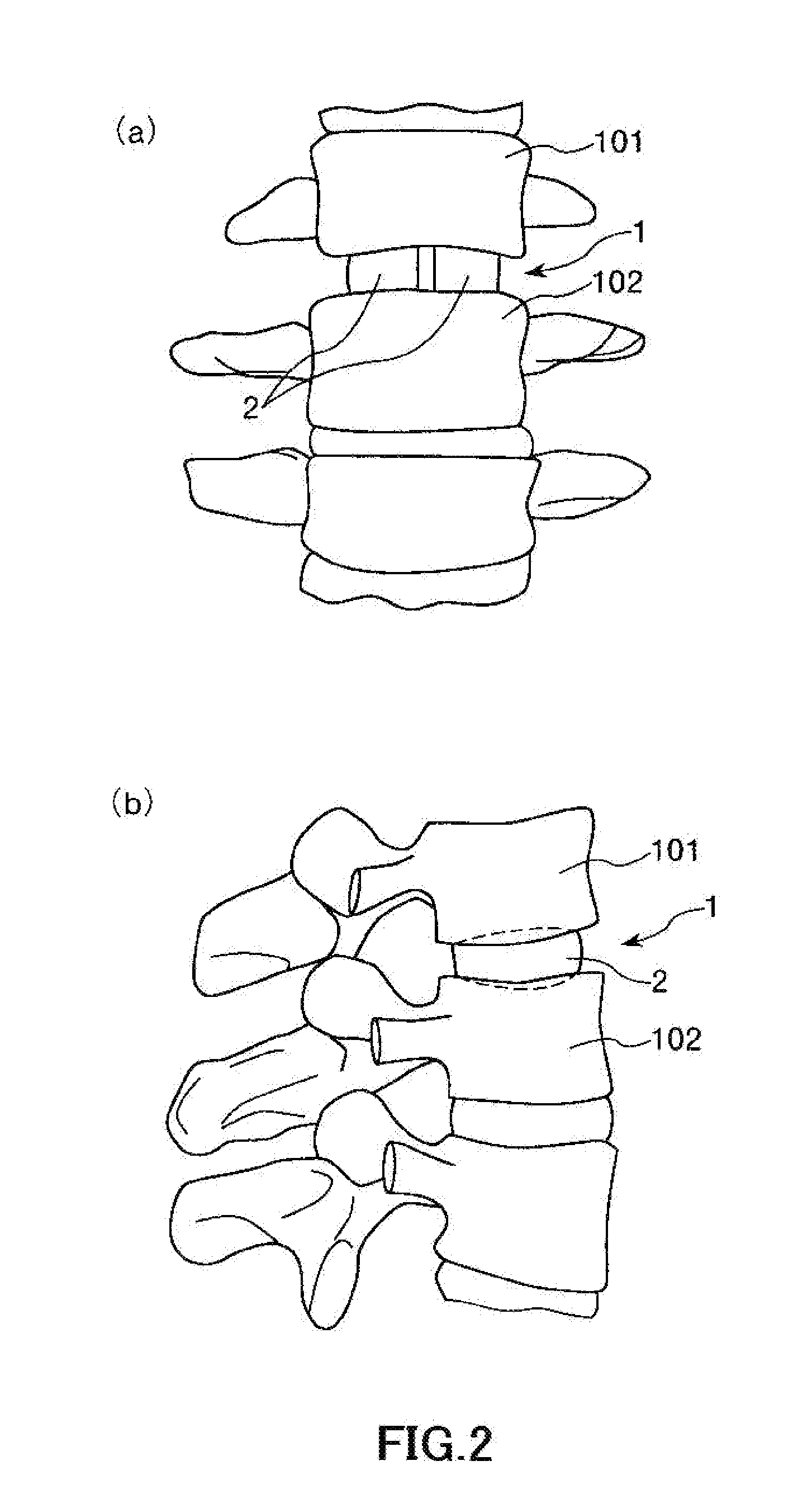

Vertebral body spacer

InactiveUS20130274884A1Small sizeEasy to implementSpinal implantsCoatingsPorosityIntervertebral spaces

A vertebral body spacer of the present invention is used by being inserted between a vertebral body and a vertebral body (intervertebral space). The vertebral body spacer has a block body constituted of titanium or a titanium alloy as a main component thereof, and provided with a pair of contact surfaces to be made contact with the vertebral body and the vertebral body. The block body includes needle parts formed into a needle shape having both end portions and a porous part having through holes passing through the porous part in a thickness direction thereof, and a porosity of at least a surface of the porous part is larger than a porosity of each of the needle parts. The needle parts are inserted into the through holes so that the both end portions are projected from the contact surfaces.

Owner:MITSUBISHI MATERIALS CORP

Device for printing droplet or ink on substrate or paper

ActiveUS7600840B2Constant volumeUniform sizeSequential/parallel process reactionsOther printing apparatusNeedle ShapeControl unit

A device for printing a droplet onto a substrate includes: a droplet generating member which is needle-shaped and comprises a receiving portion disposed vertically to receive a solution, and a discharge hole connected to the receiving portion and formed on a bottom of the receiving portion so that the solution can be discharged from the receiving portion; a substrate disposed below the droplet generating member, the substrate includes a target portion to which the droplet discharged from the discharge hole of the droplet generating member is dropped and attached; a voltage applier applying a voltage to the droplet so that the droplet can be dropped onto the target portion of the substrate; a volume measuring unit measuring the volume of the droplet; and a droplet control unit maintaining the volume of the droplet at a predetermined level based on the measured volume of the droplet.

Owner:SAMSUNG ELECTRONICS CO LTD

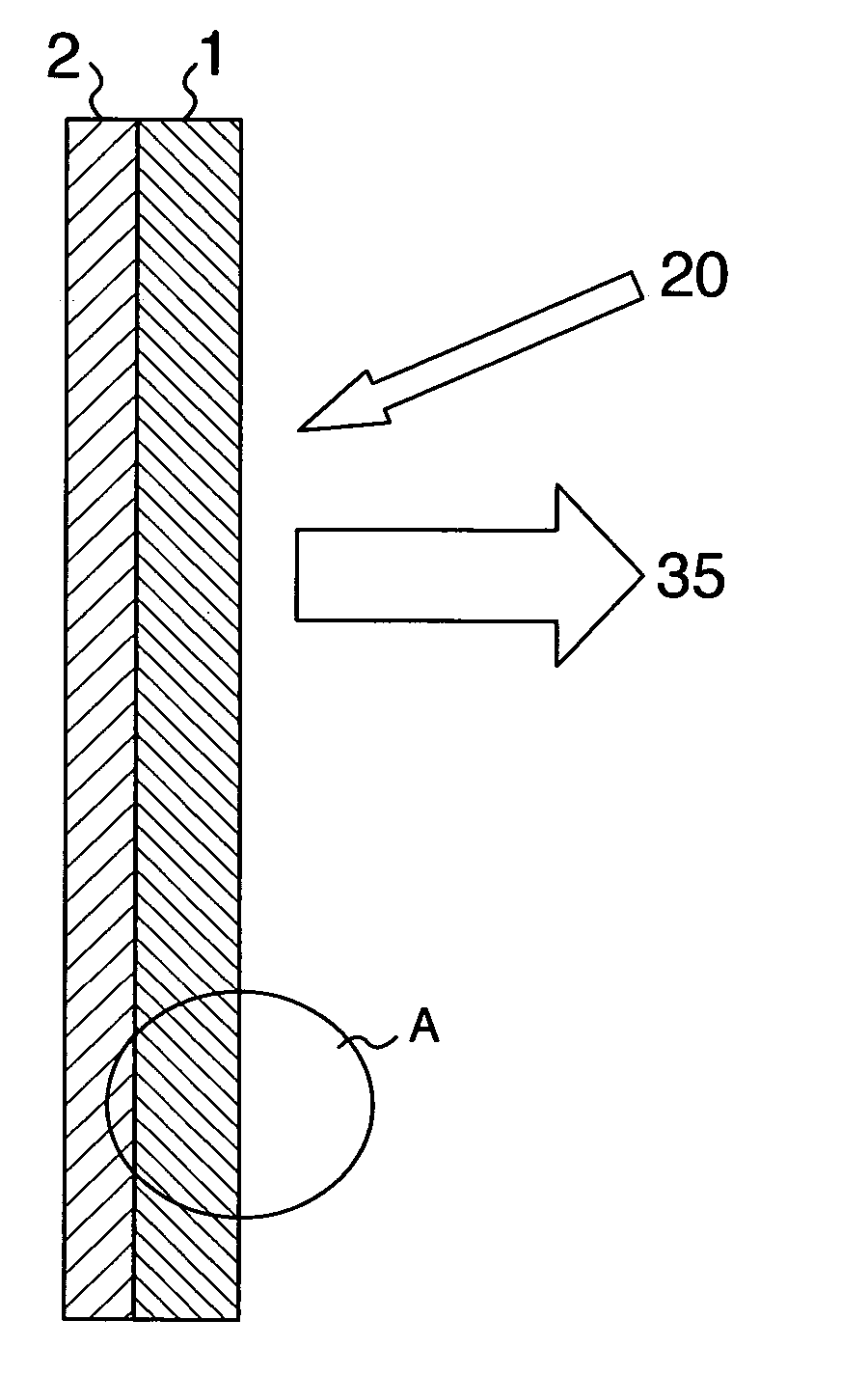

Front plate and display device using same

InactiveUS20050190321A1Improve image qualityReduce fatigueMechanical apparatusIncadescent screens/filtersLight guideDisplay device

Frusto-conical needle-shaped light guide paths are implanted on the surface of a display panel such that output light from display elements propagate through the needle-shaped light guide paths through total reflection, while external light repeats reflections multiple times on wedge-shaped surfaces of the light guide paths, and attenuates. A light absorbing film is coated on the surfaces of he needle-shaped light guide paths to increase a contrast ratio. Thus, a higher contrast can be accomplished in a bright room, and cross-talk between adjacent pixels is reduced, and a reduction in contrast due to display light is also alleviated by employing longer implanted needle-shaped light guide paths, and bringing light incident surfaces of the needle-shaped light guide paths into close contact with the surface of the display panel.

Owner:HITACHI LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com