Patents

Literature

311results about How to "Increase the inductance value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

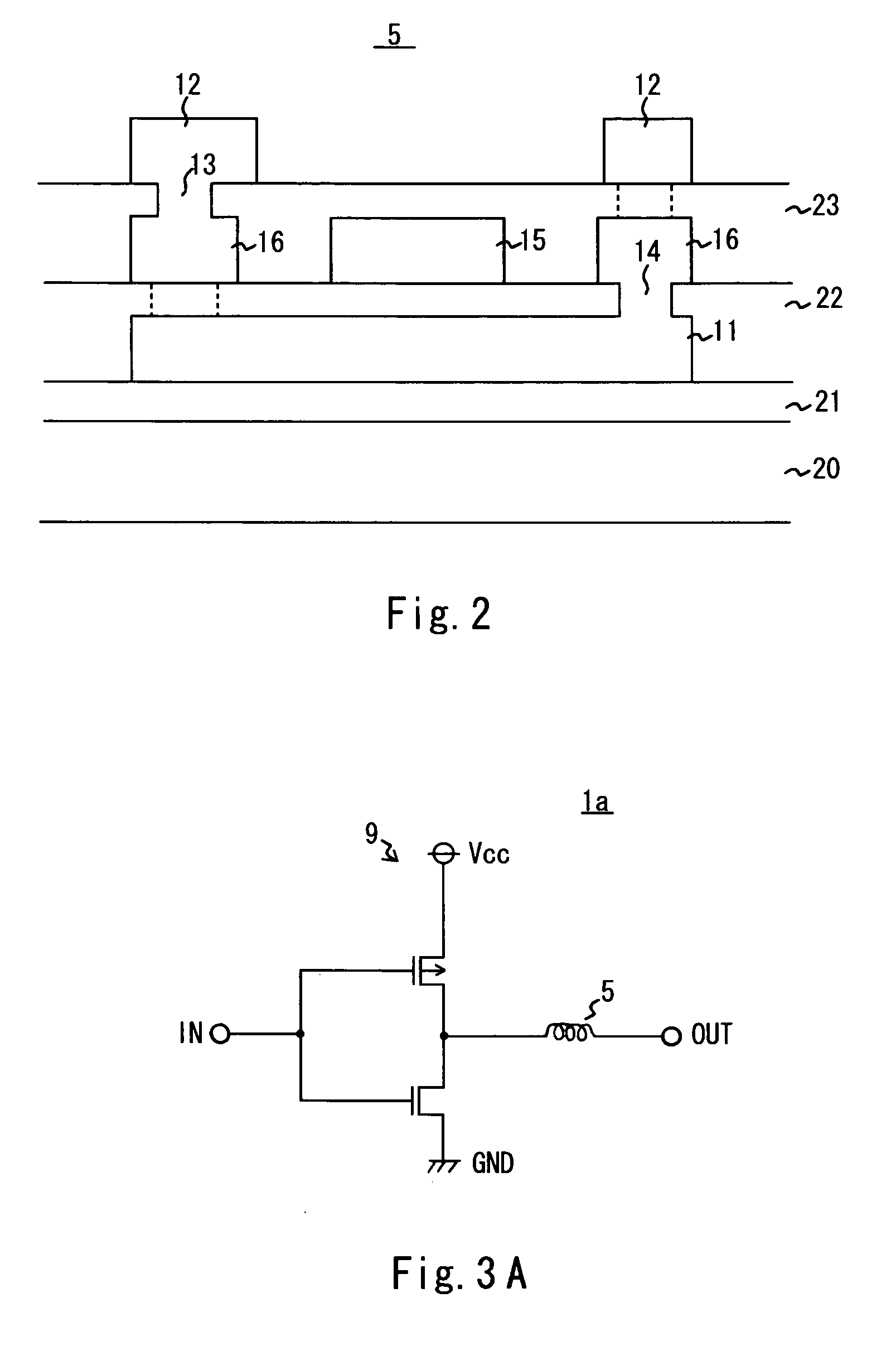

Semiconductor device

InactiveUS6847066B2Increase in the chip areaReduce module sizeTransistorSemiconductor/solid-state device detailsInductorCapacitance

A thin film passive element includes at least one of a capacitance element having a plurality of conductive layers and a dielectric material layer and an inductance element formed of a patterned conductive layer is stacked on a circuit element-forming region of a semiconductor substrate provided with a plurality of connection pads and is connected to the circuit element of the circuit element-forming region.

Owner:OUME ELECTRONICS CO LTD +1

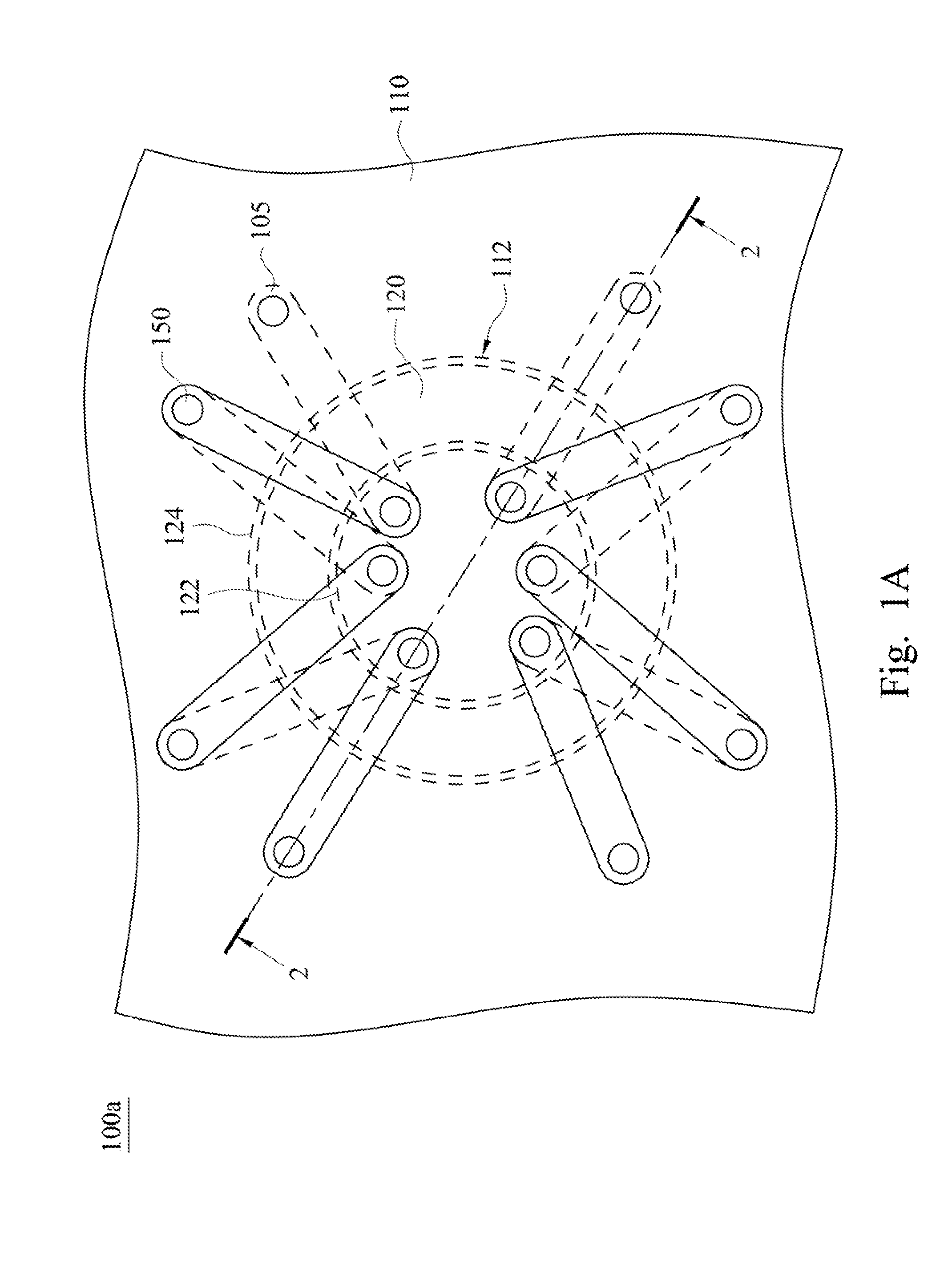

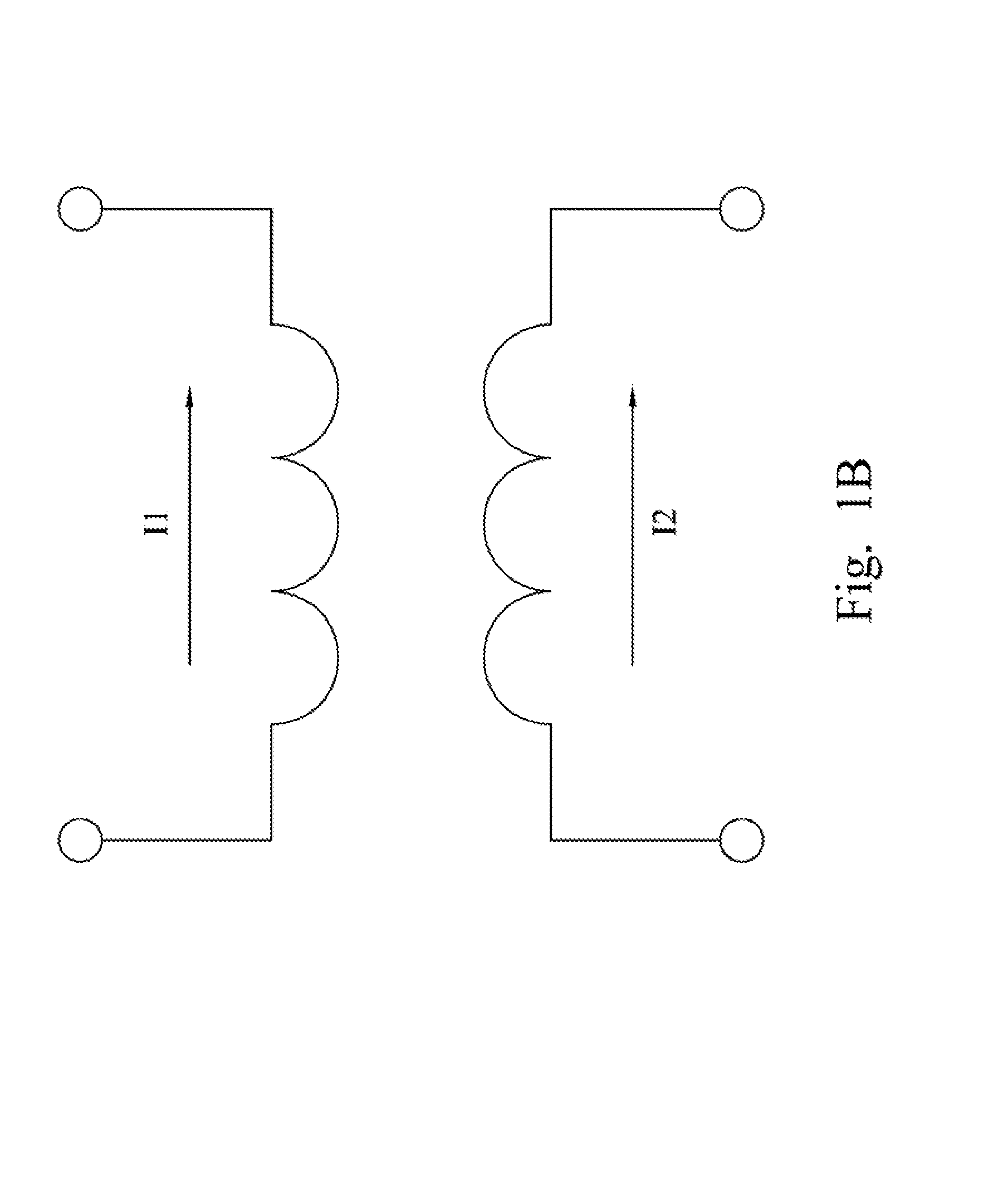

Integrated or printed margarita shaped inductor

InactiveUS20100245011A1Increase the inductance valueArea minimizationMultiple-port networksTransformers/inductances coils/windings/connectionsInductorMagnetic flux

Owner:ARISTOTLE UNIV THESSALONIKI RES COMMITTEE

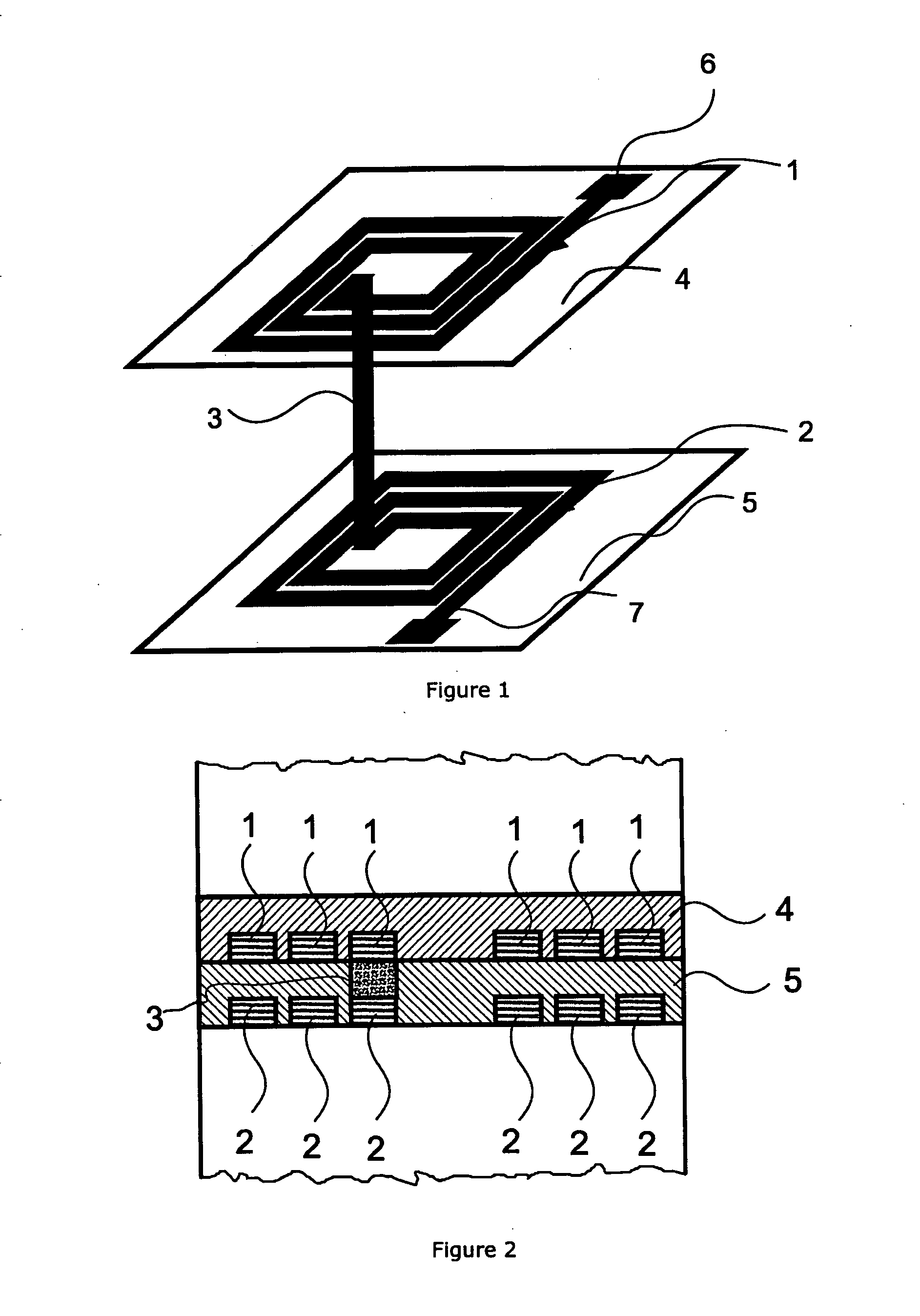

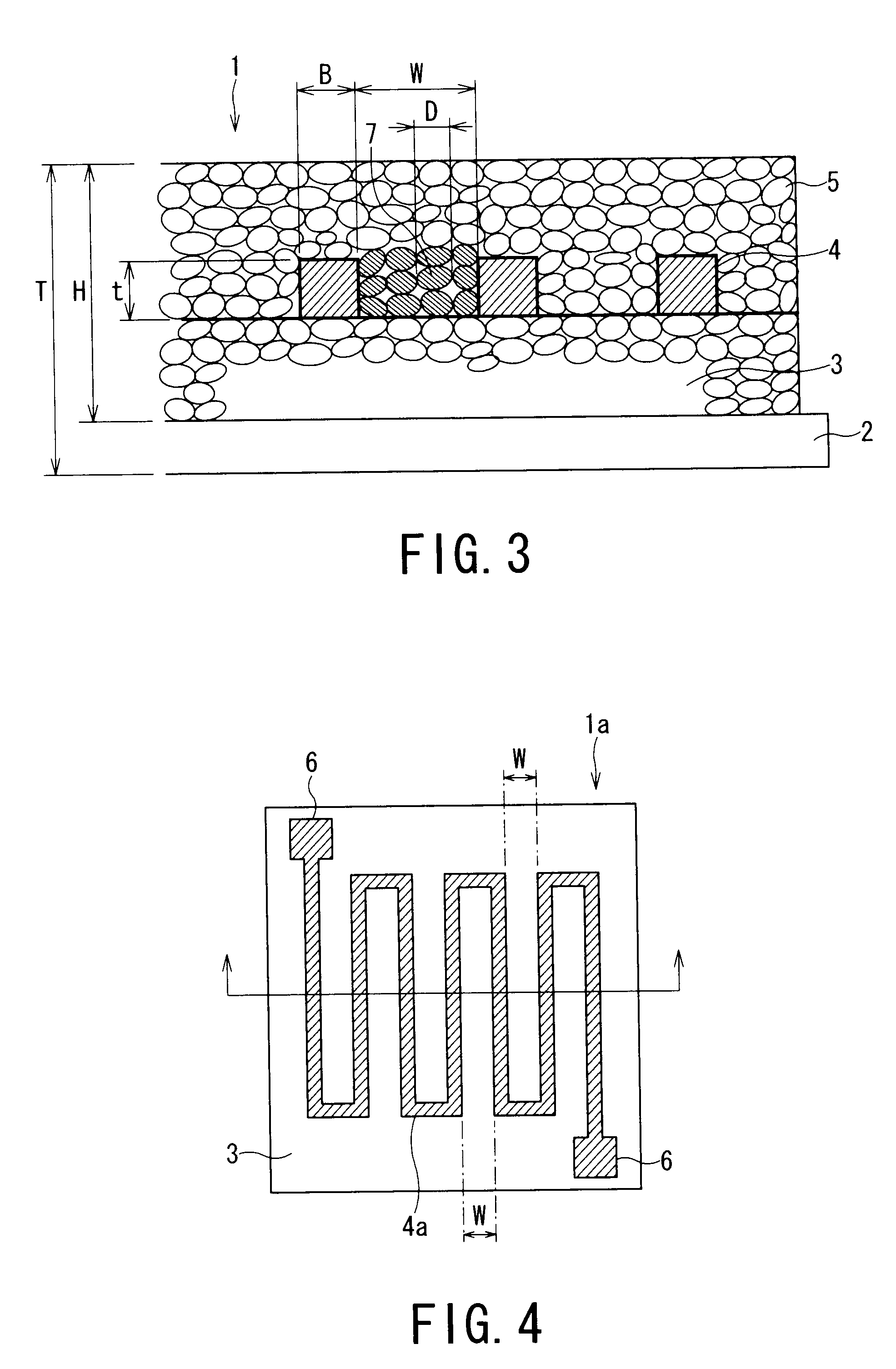

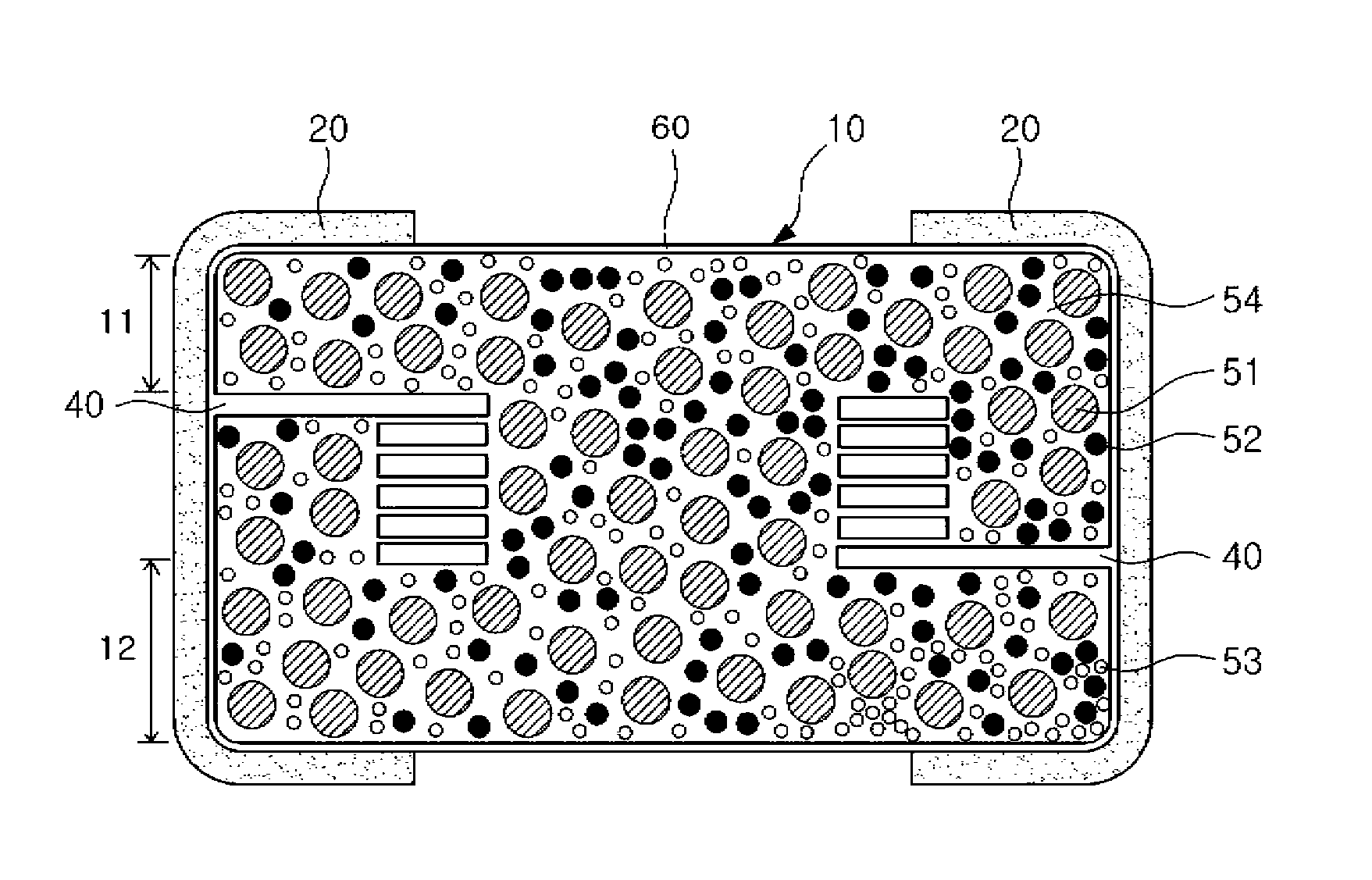

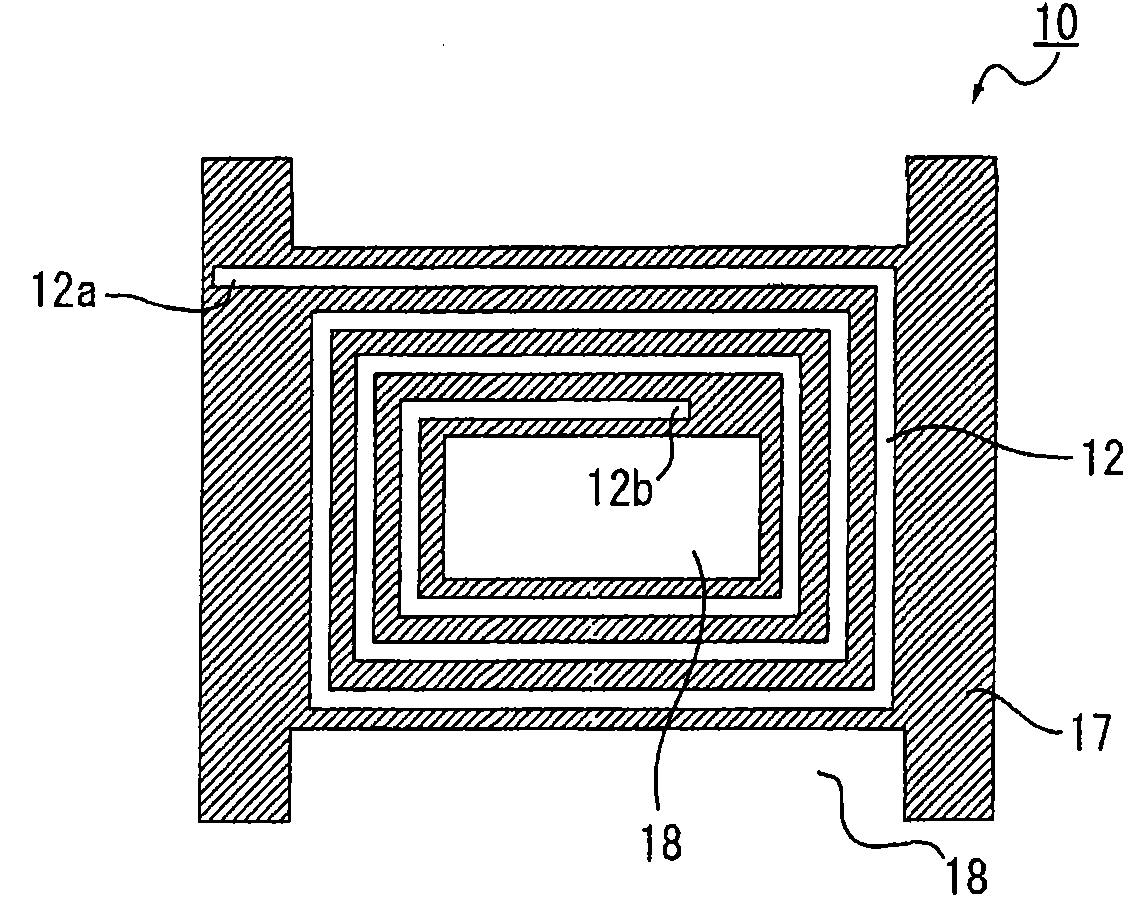

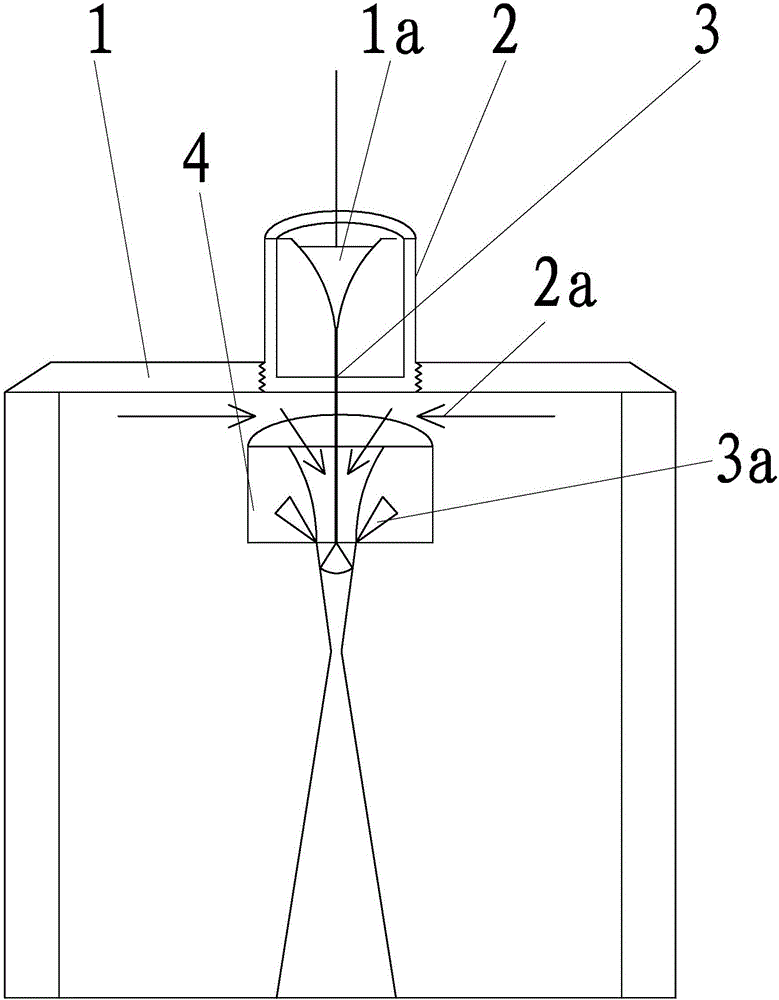

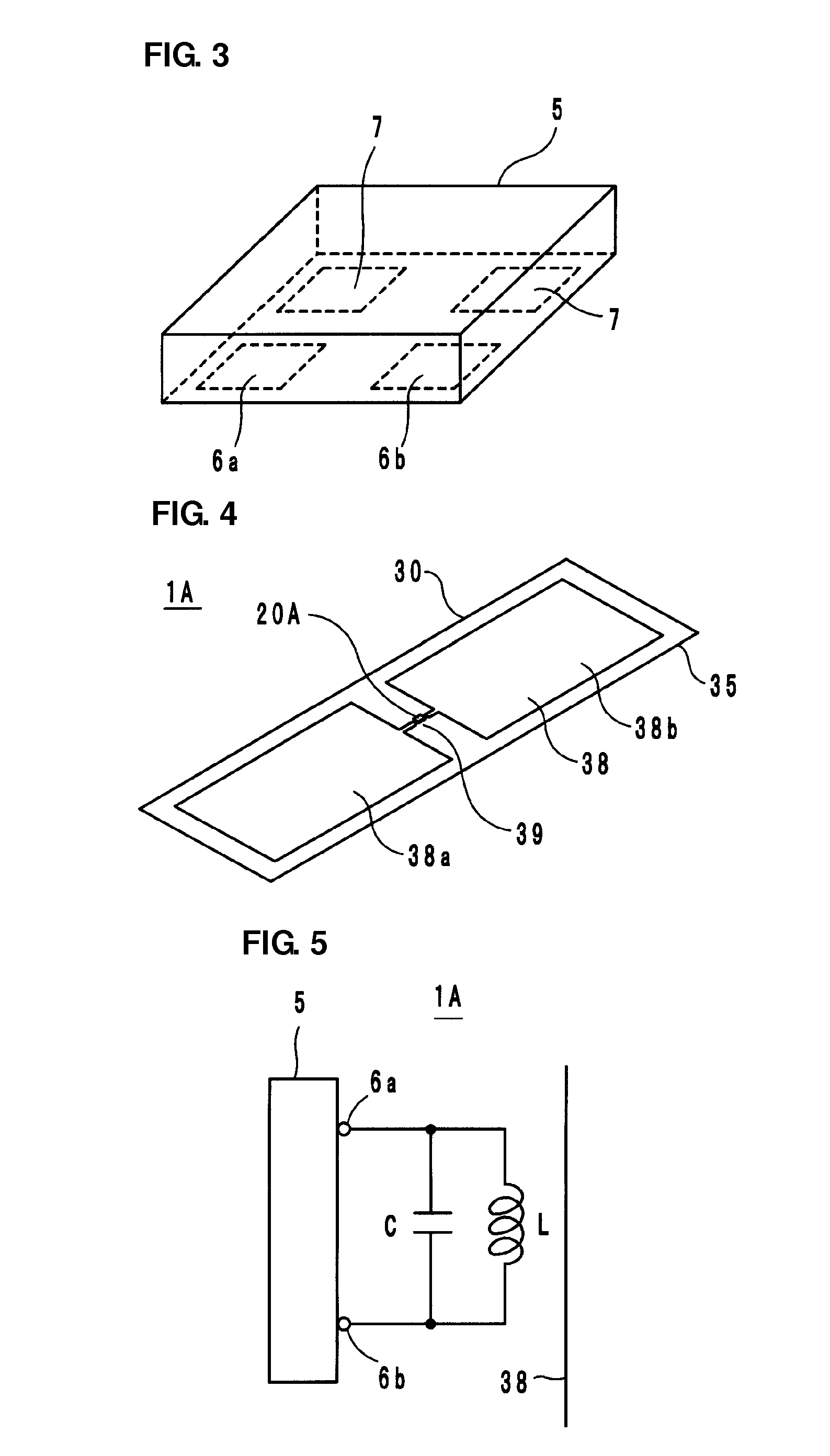

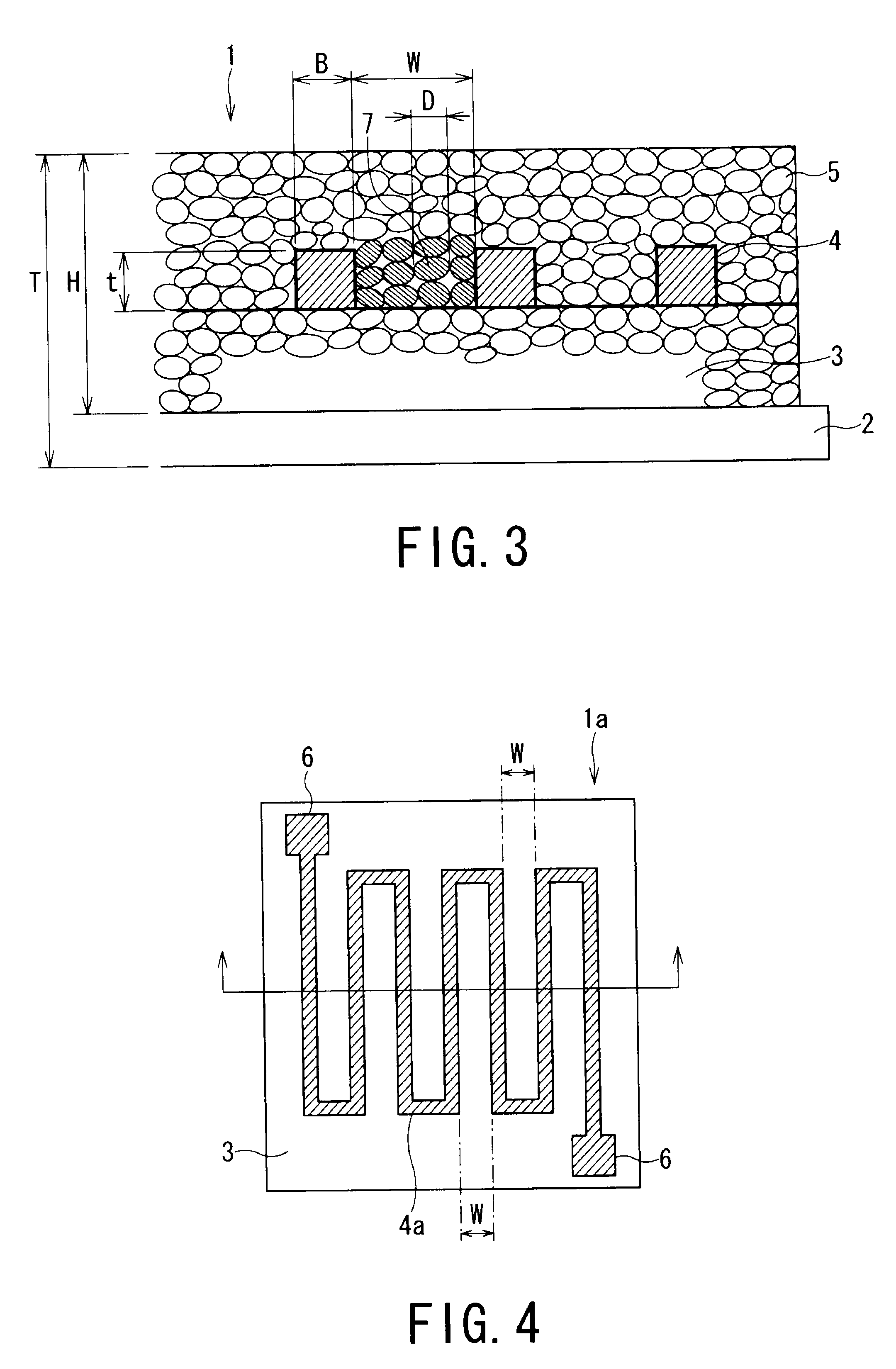

Flat magnetic element and power IC package using the same

ActiveUS20090243780A1Improve permeabilityIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesInductorInductance

A planar magnetic device 1 including a first magnetic layer 3, a second magnetic layer 5, and a planar coil 4 disposed between the first magnetic layer 3 and the second magnetic layer 5, wherein magnetic particles 7 having a shape ratio S / L of 0.7 to 1 when a length of a long axis is L and a length of a short axis orthogonal to the long axis is L are filled in a gap W between coil wirings of the planar coil 4. According to the planar magnetic device 1, it is possible to realize a planar magnetic device such as an inductor reduced in height by using fine particles that enable to effectively obtain a large inductance value.

Owner:KK TOSHIBA +1

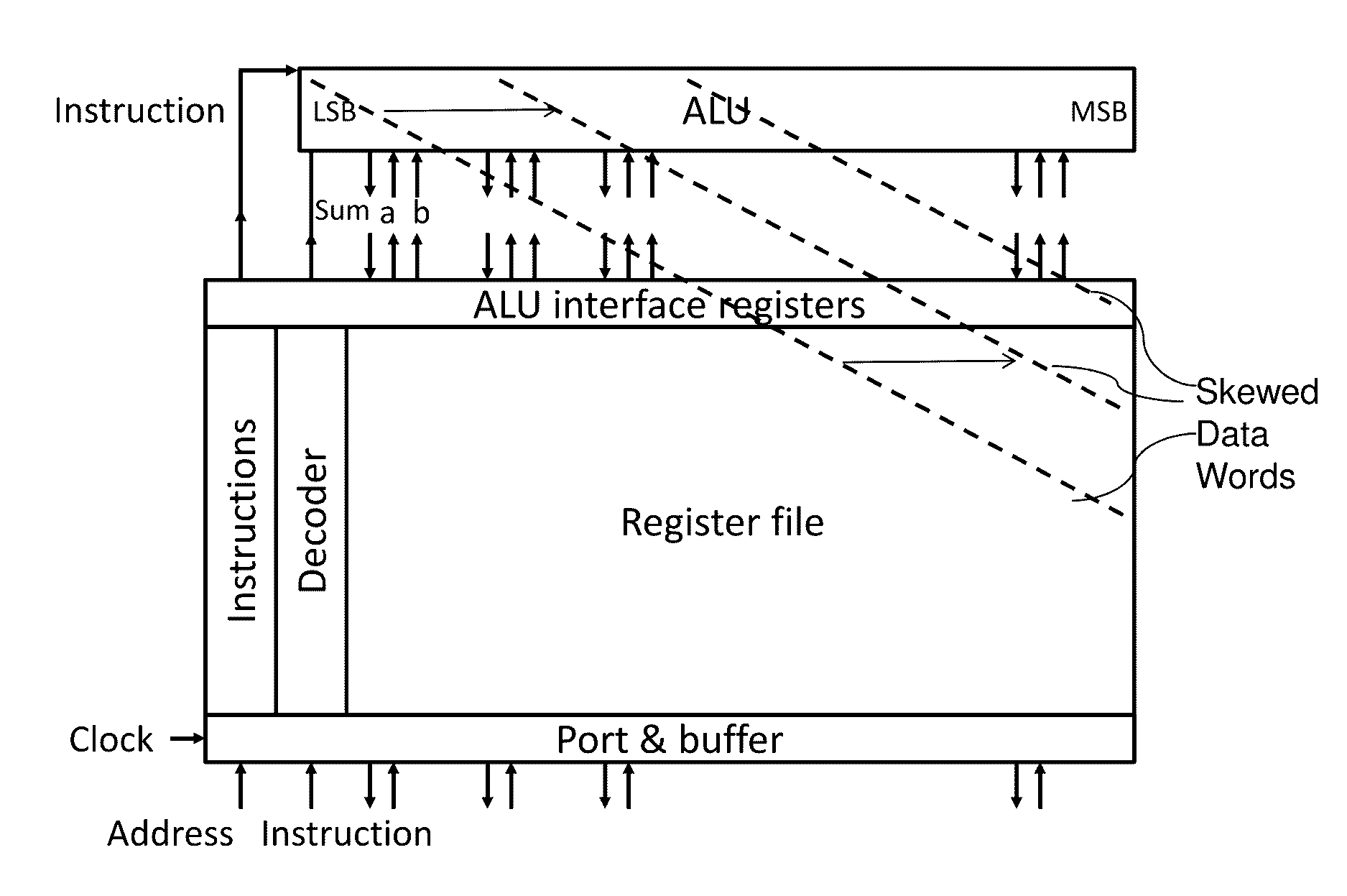

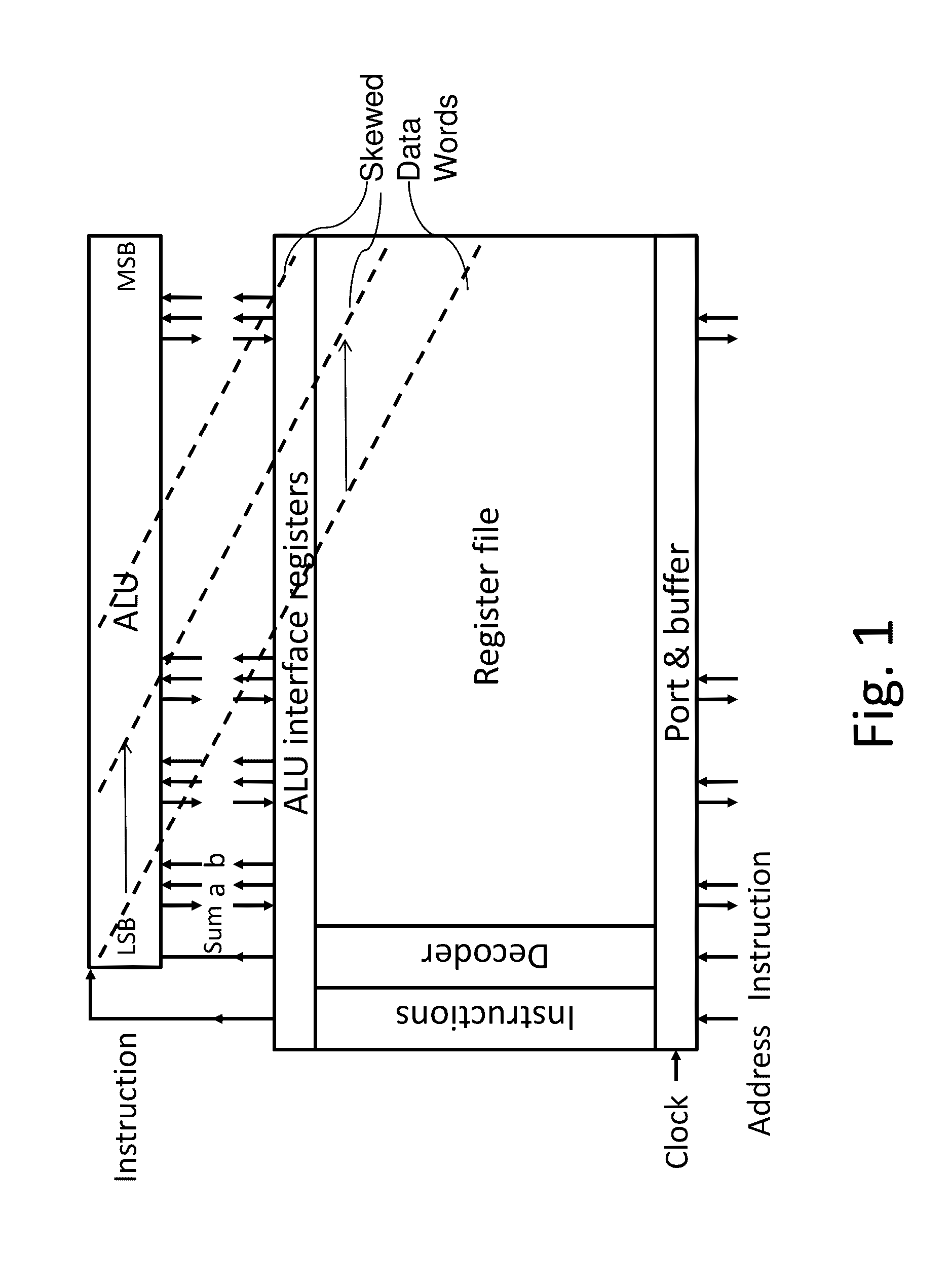

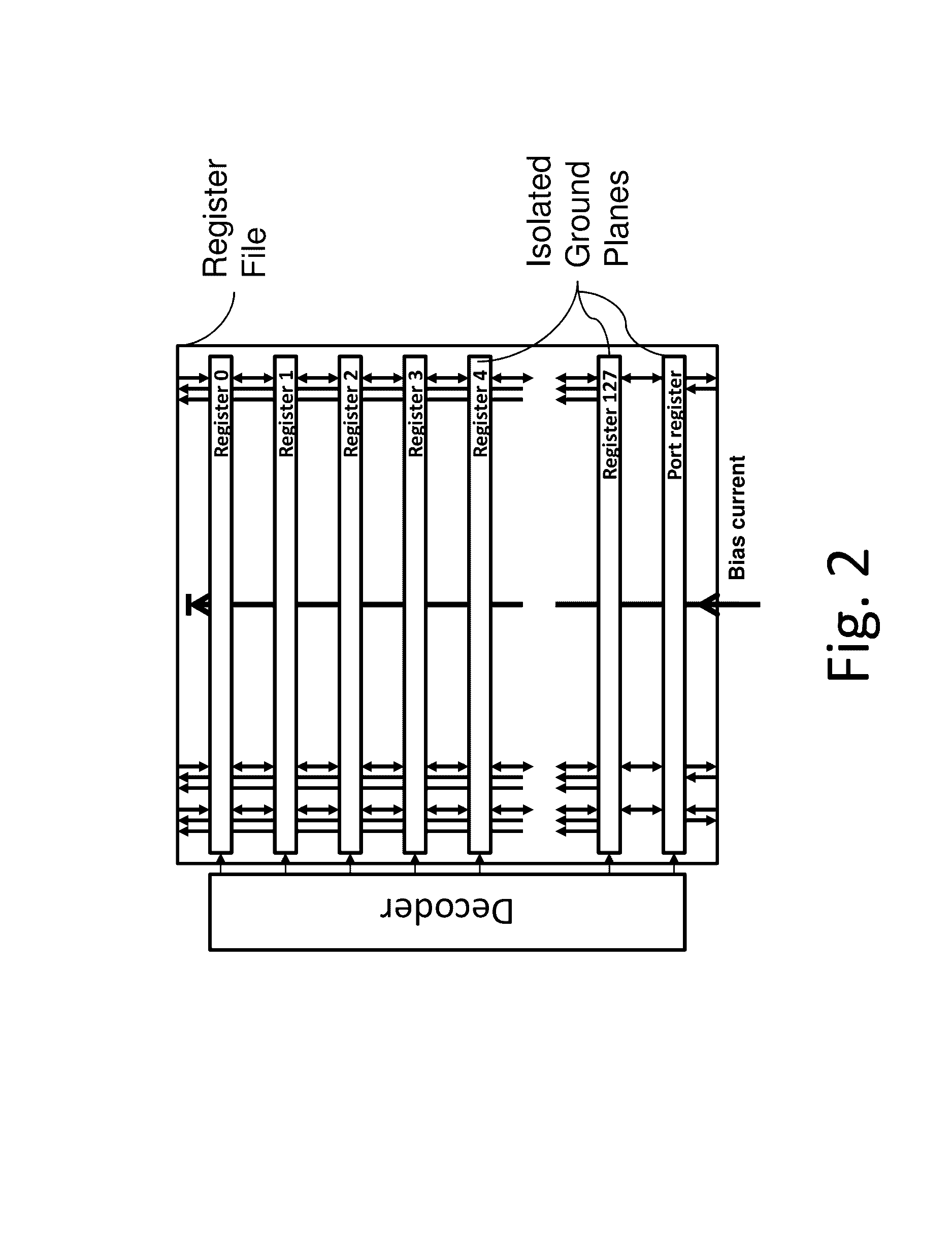

System and method for cryogenic hybrid technology computing and memory

ActiveUS9520180B1Easy to combineTransmission lineCosmetic preparationsQuantum computersLow inductanceDatapath

A system and method for high-speed, low-power cryogenic computing are presented, comprising ultrafast energy-efficient RSFQ superconducting computing circuits, and hybrid magnetic / superconducting memory arrays and interface circuits, operating together in the same cryogenic environment. An arithmetic logic unit and register file with an ultrafast asynchronous wave-pipelined datapath is also provided. The superconducting circuits may comprise inductive elements fabricated using both a high-inductance layer and a low-inductance layer. The memory cells may comprise superconducting tunnel junctions that incorporate magnetic layers. Alternatively, the memory cells may comprise superconducting spin transfer magnetic devices (such as orthogonal spin transfer and spin-Hall effect devices). Together, these technologies may enable the production of an advanced superconducting computer that operates at clock speeds up to 100 GHz.

Owner:SEEQC INC

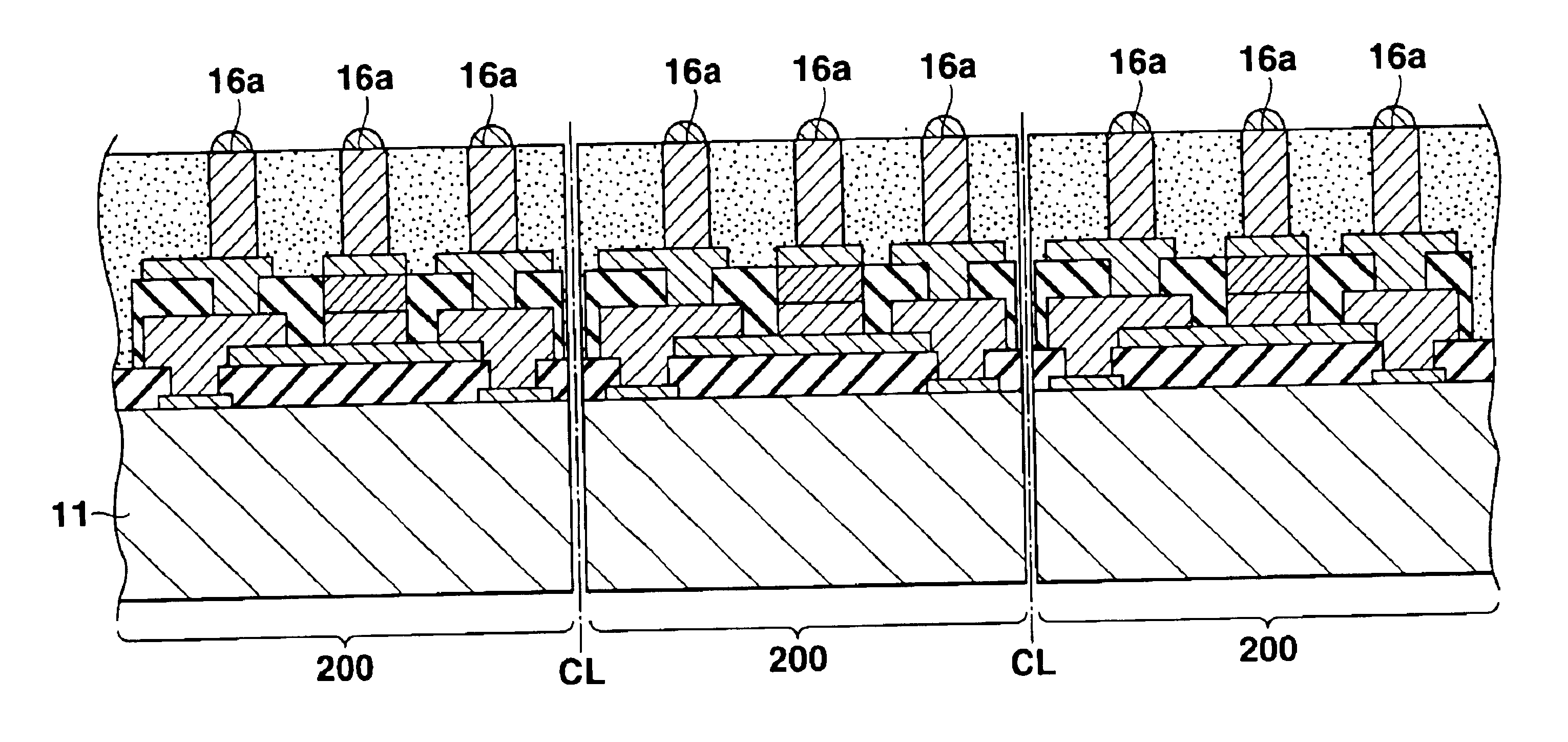

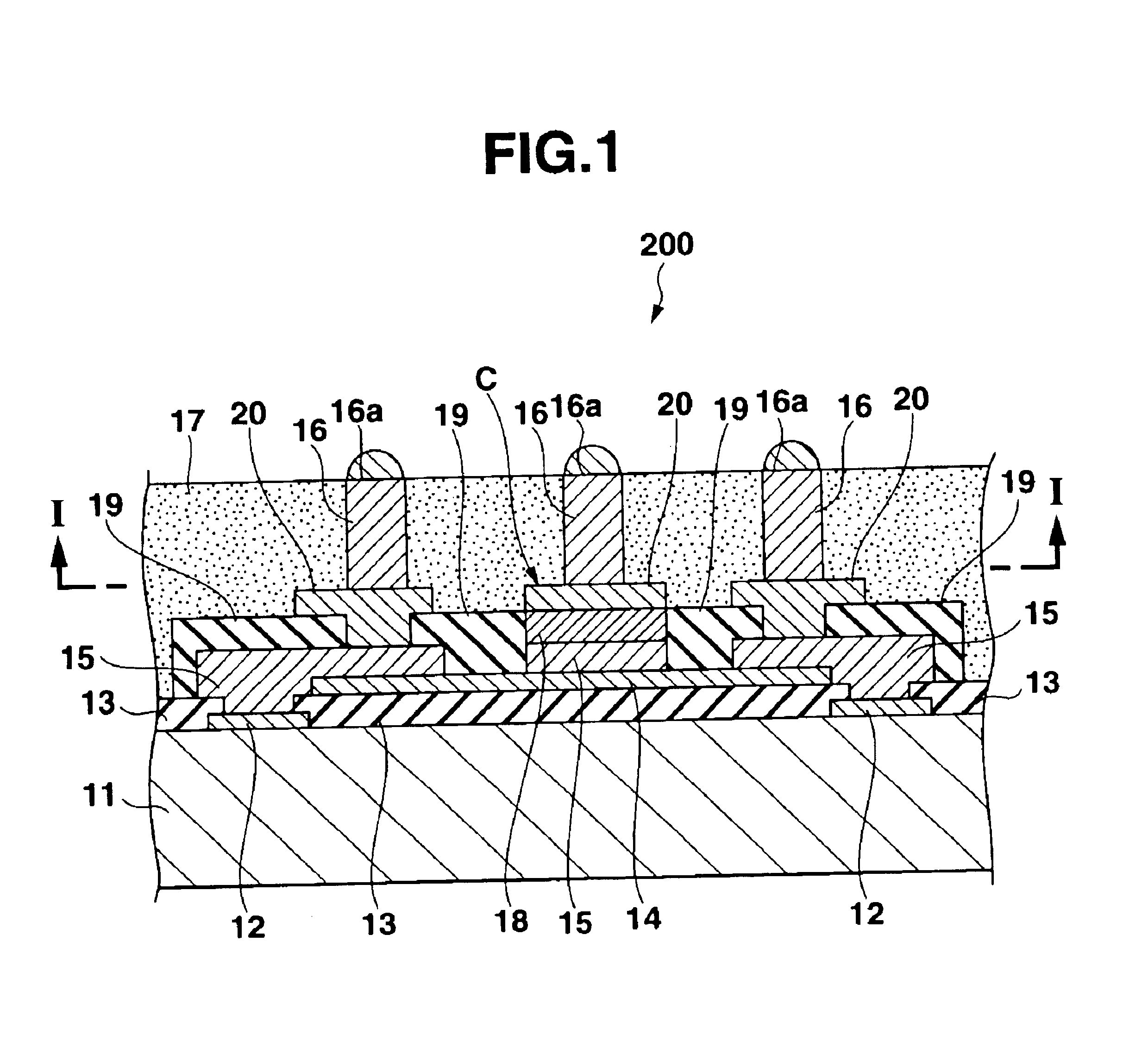

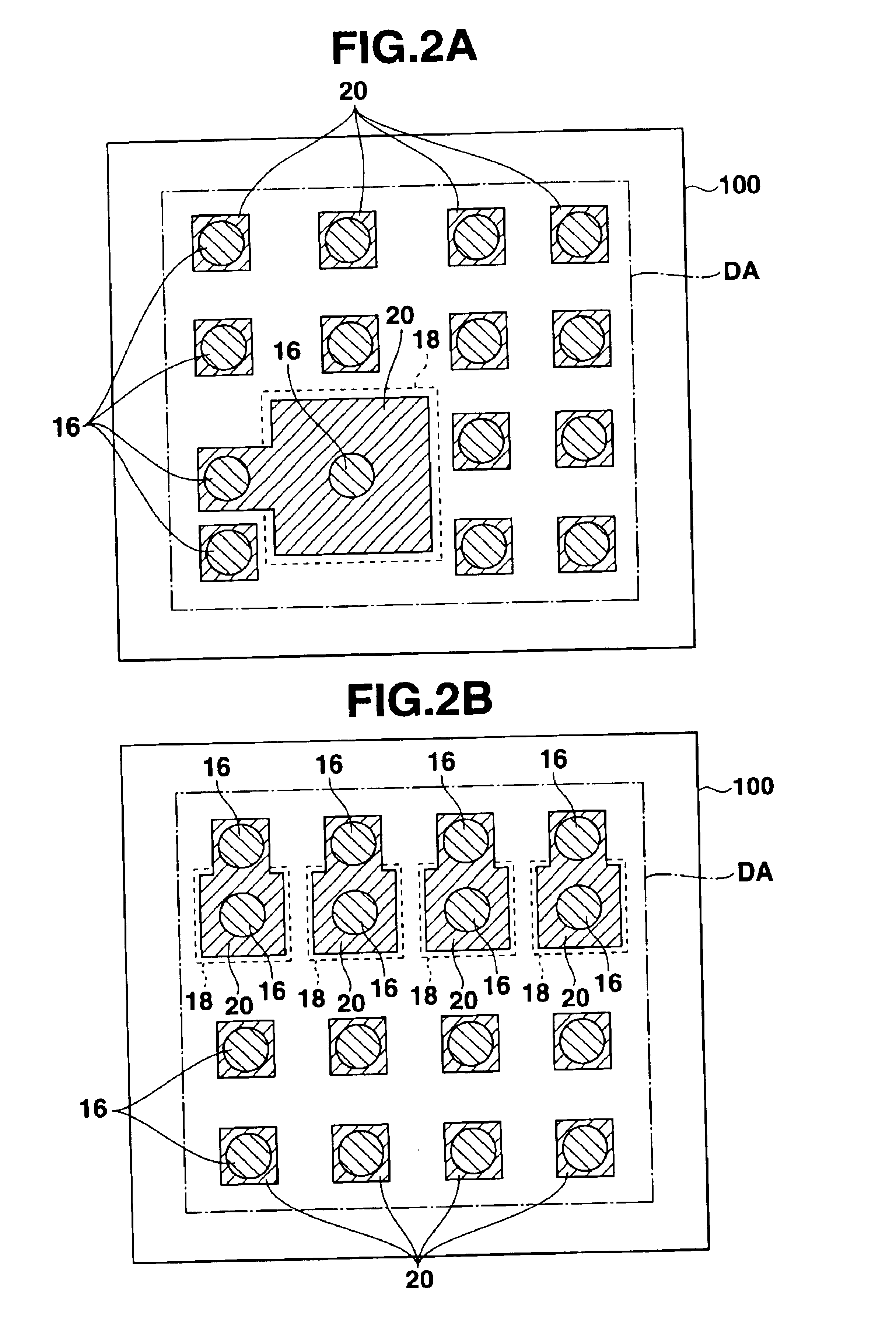

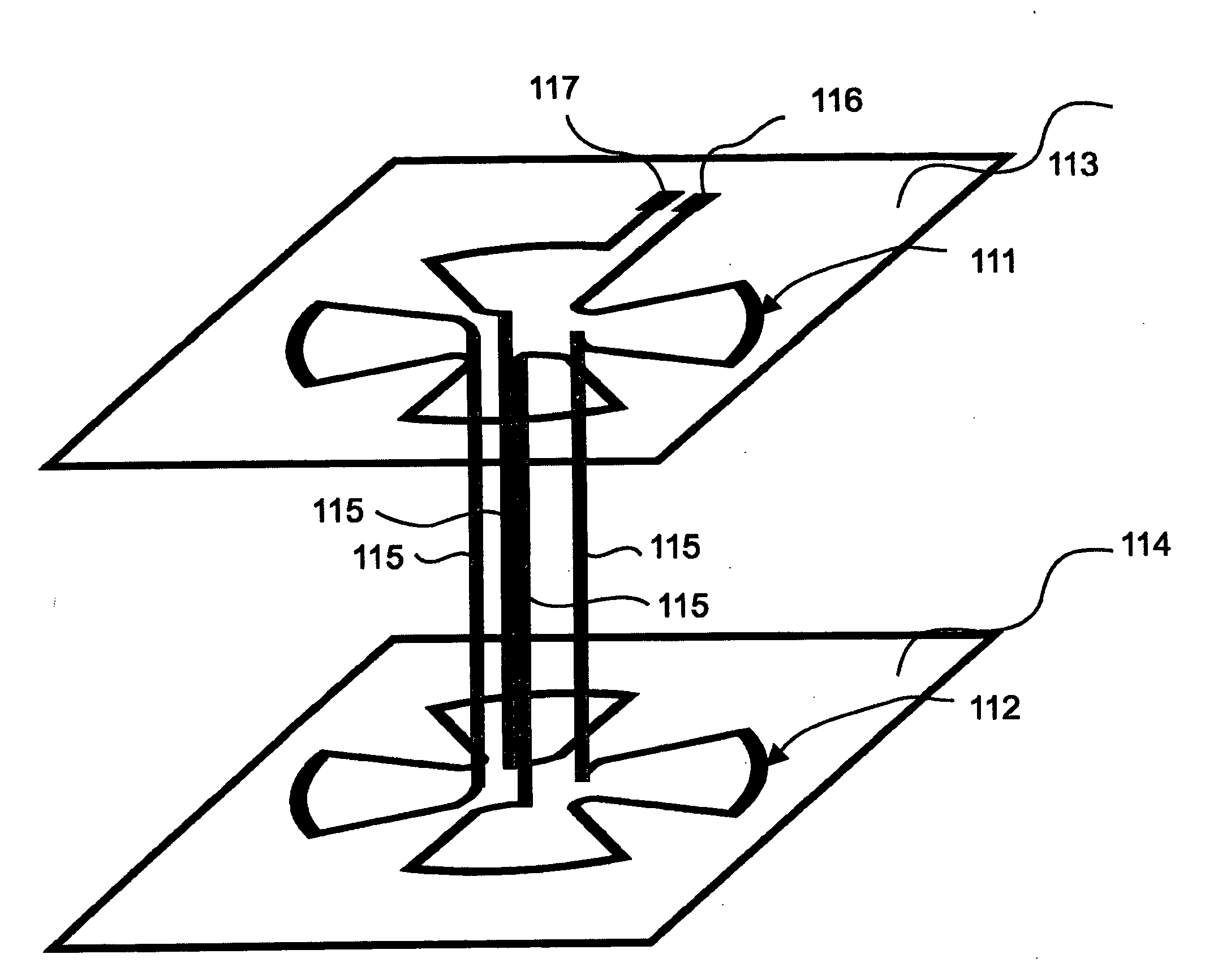

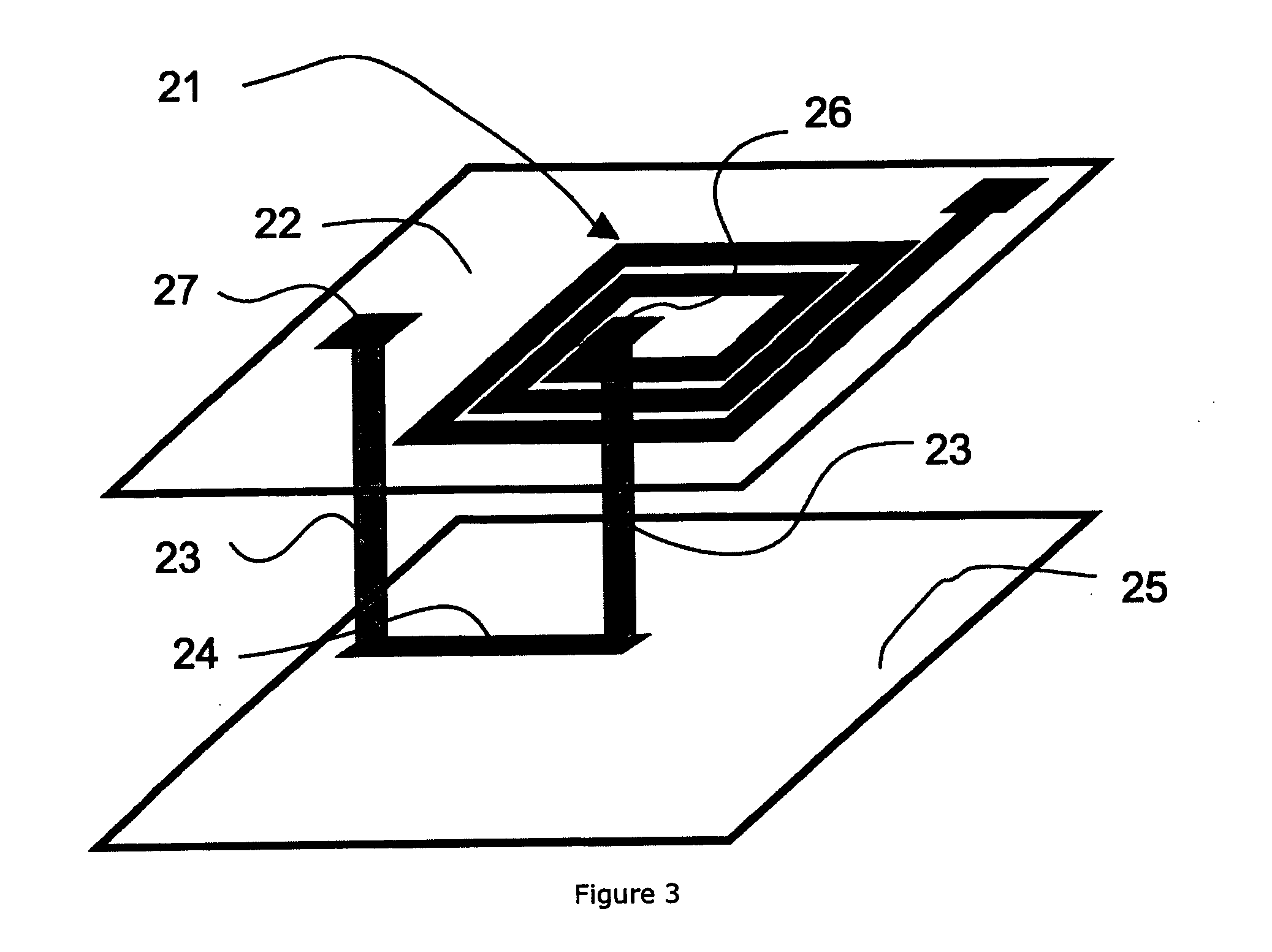

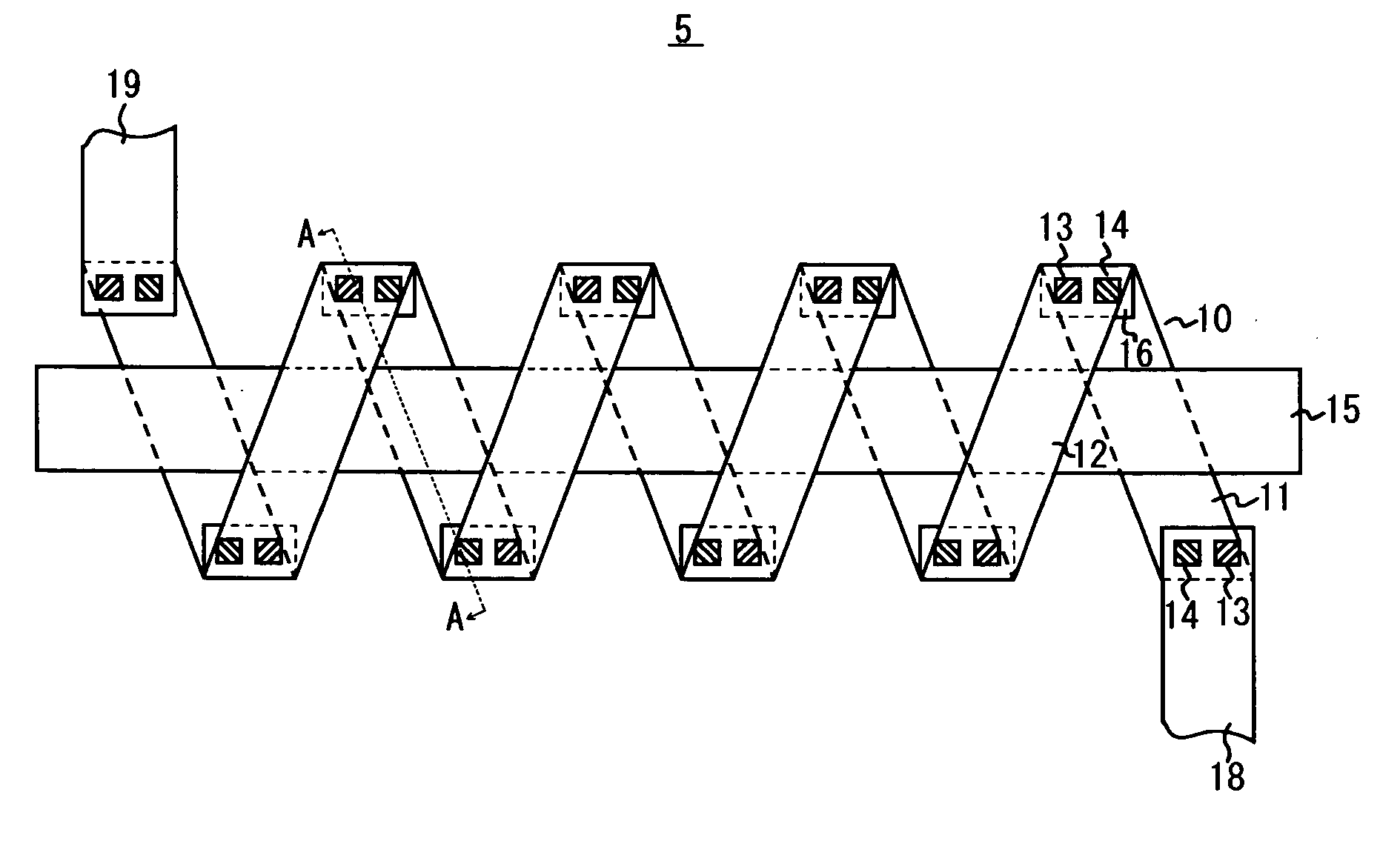

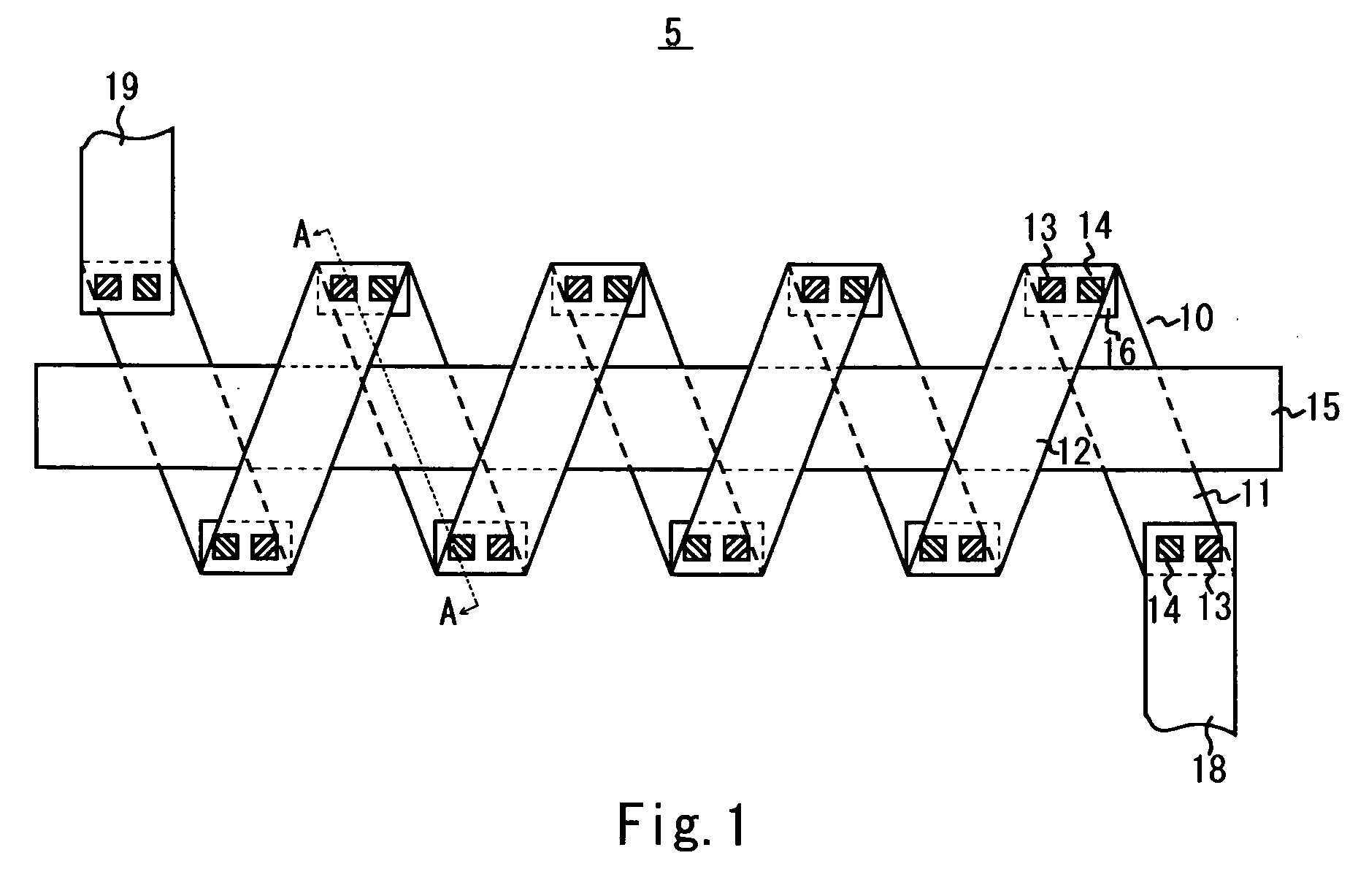

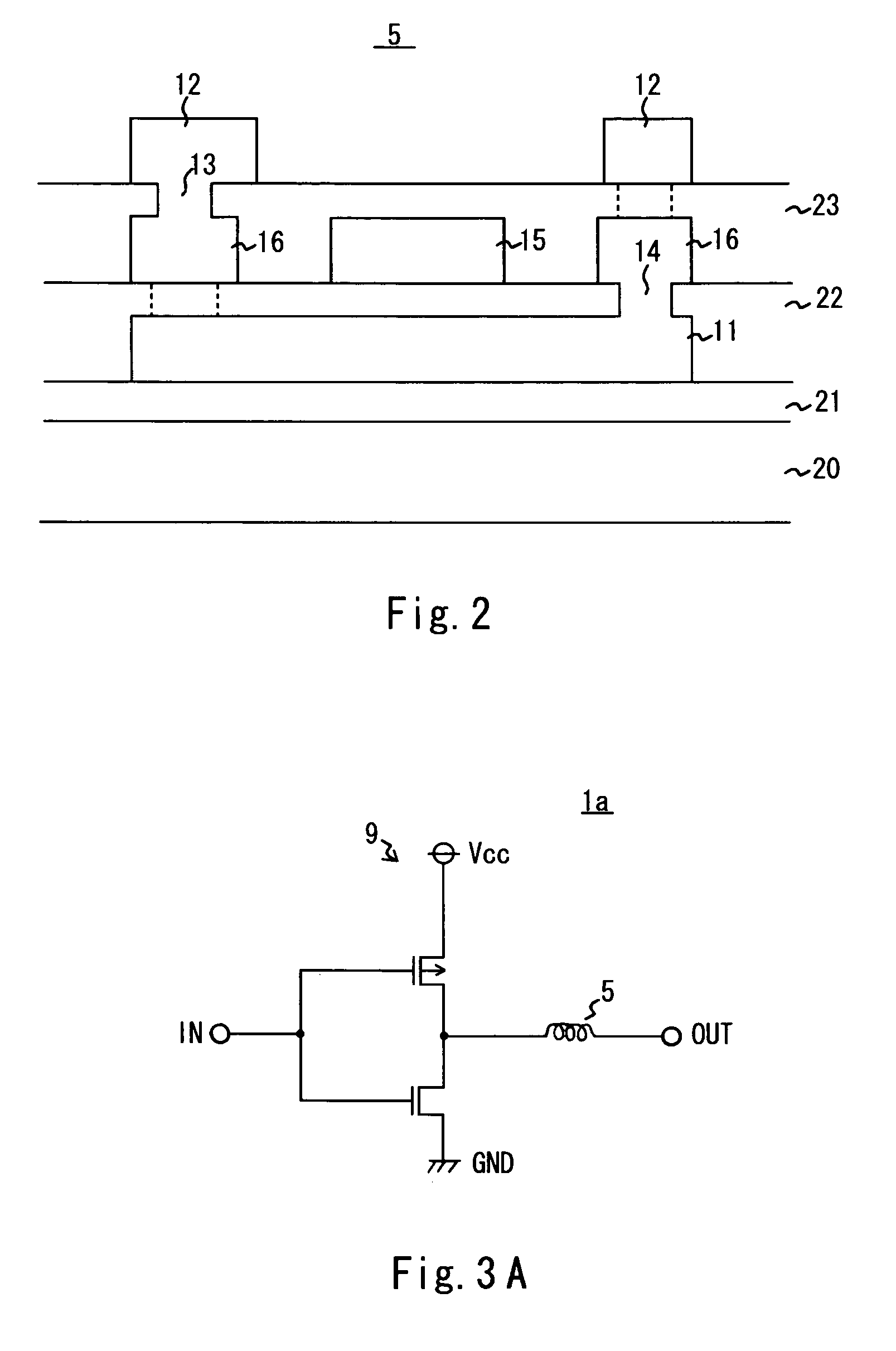

Semiconductor device

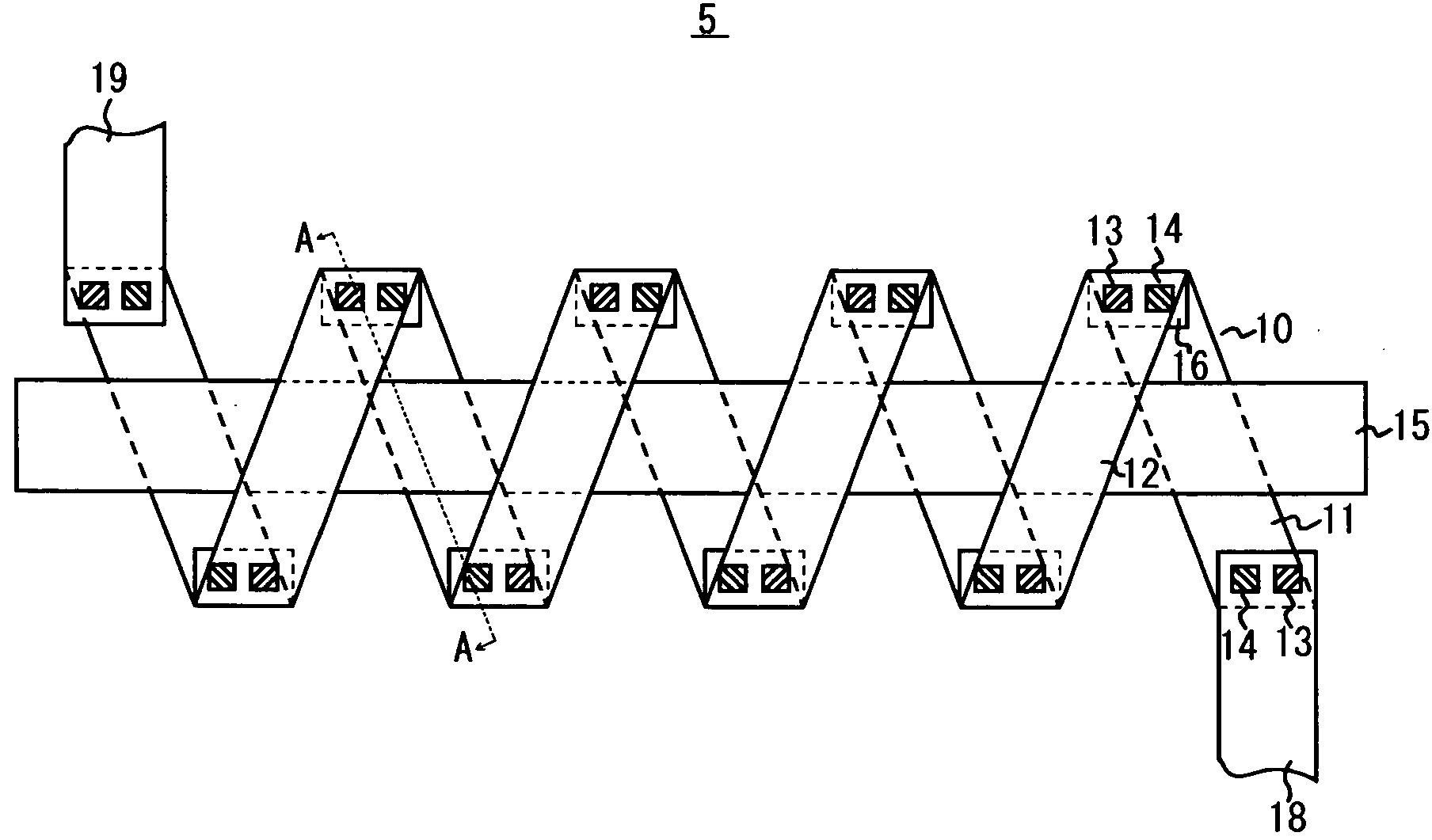

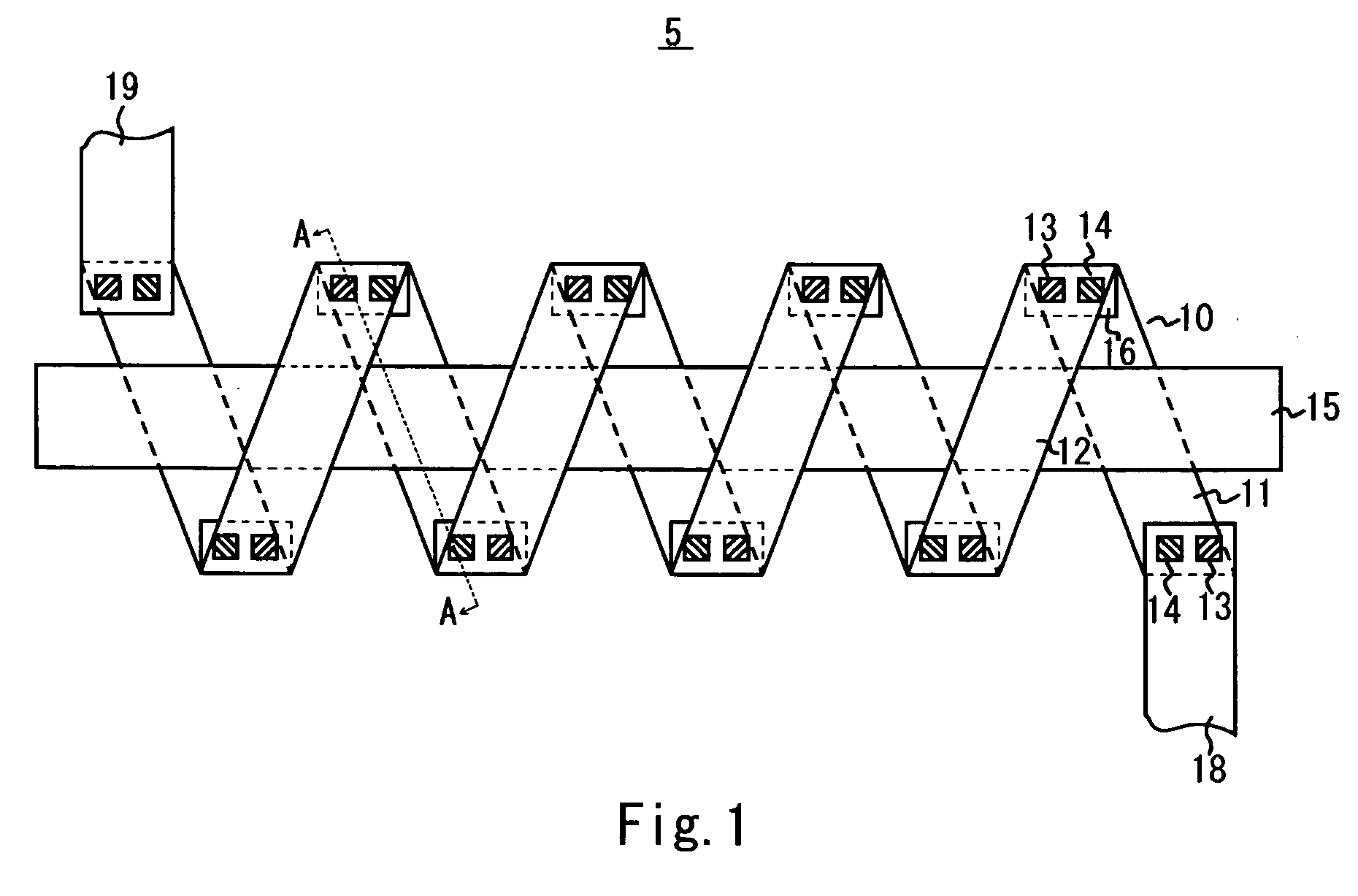

InactiveUS20050088269A1Improve efficiencyIncrease the inductance valueTransformers/inductances casingsSemiconductor/solid-state device detailsHelical lineDevice material

A semiconductor device increases the efficiency of the inductor having a three-dimensional spiral coil and increases the inductance value without requiring any special steps. The semiconductor device includes semiconductor elements and first, second and third metal wire layers to be used for the configuration of the semiconductor elements, a core disposed on the second metal wire layer, and a coil wherein a plurality of pieces of the first metal wire layer and a plurality of pieces of the third metal wire layer connected to the pieces via the connection holes are connected in series to define a spiral surrounding the core.

Owner:ROHM CO LTD

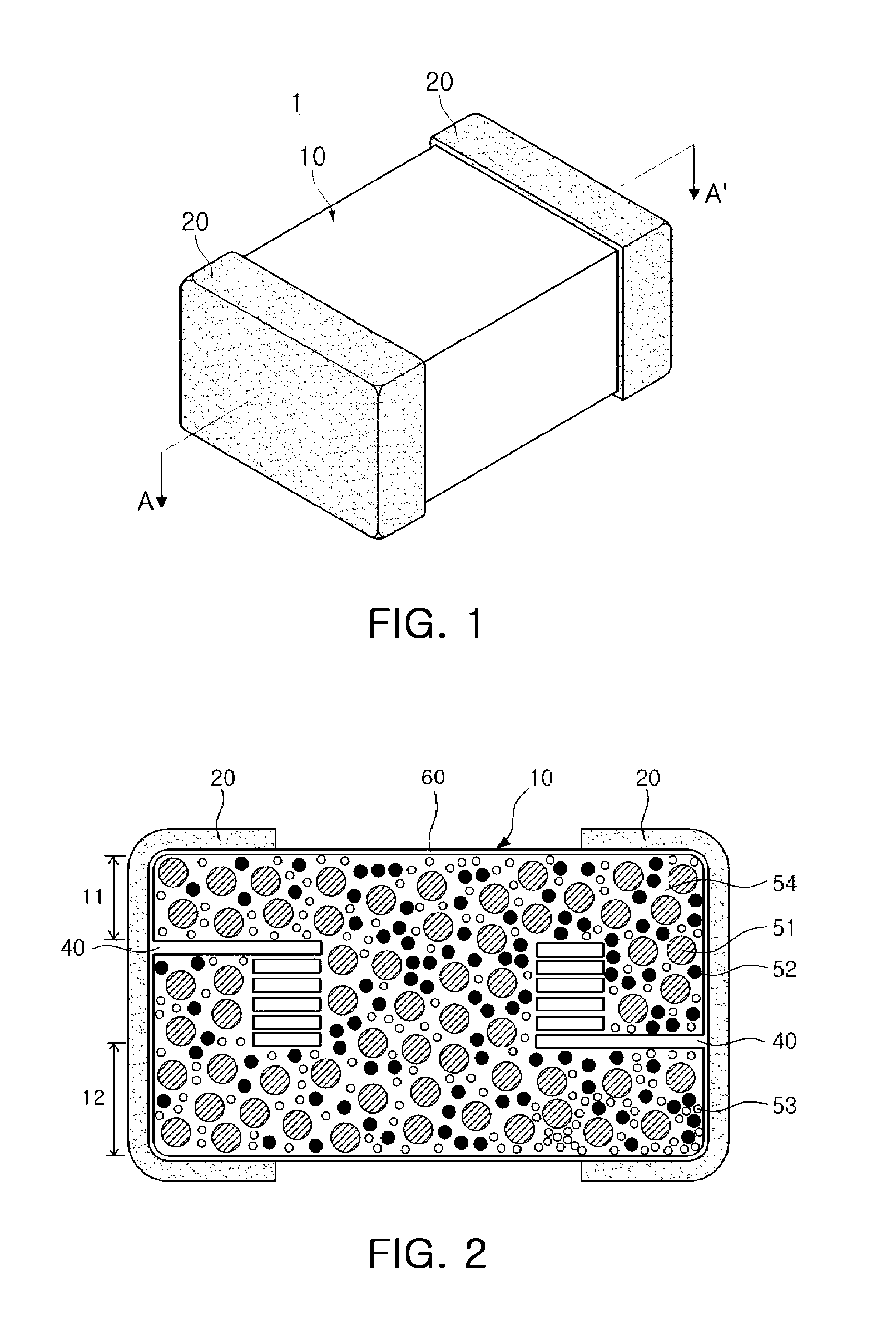

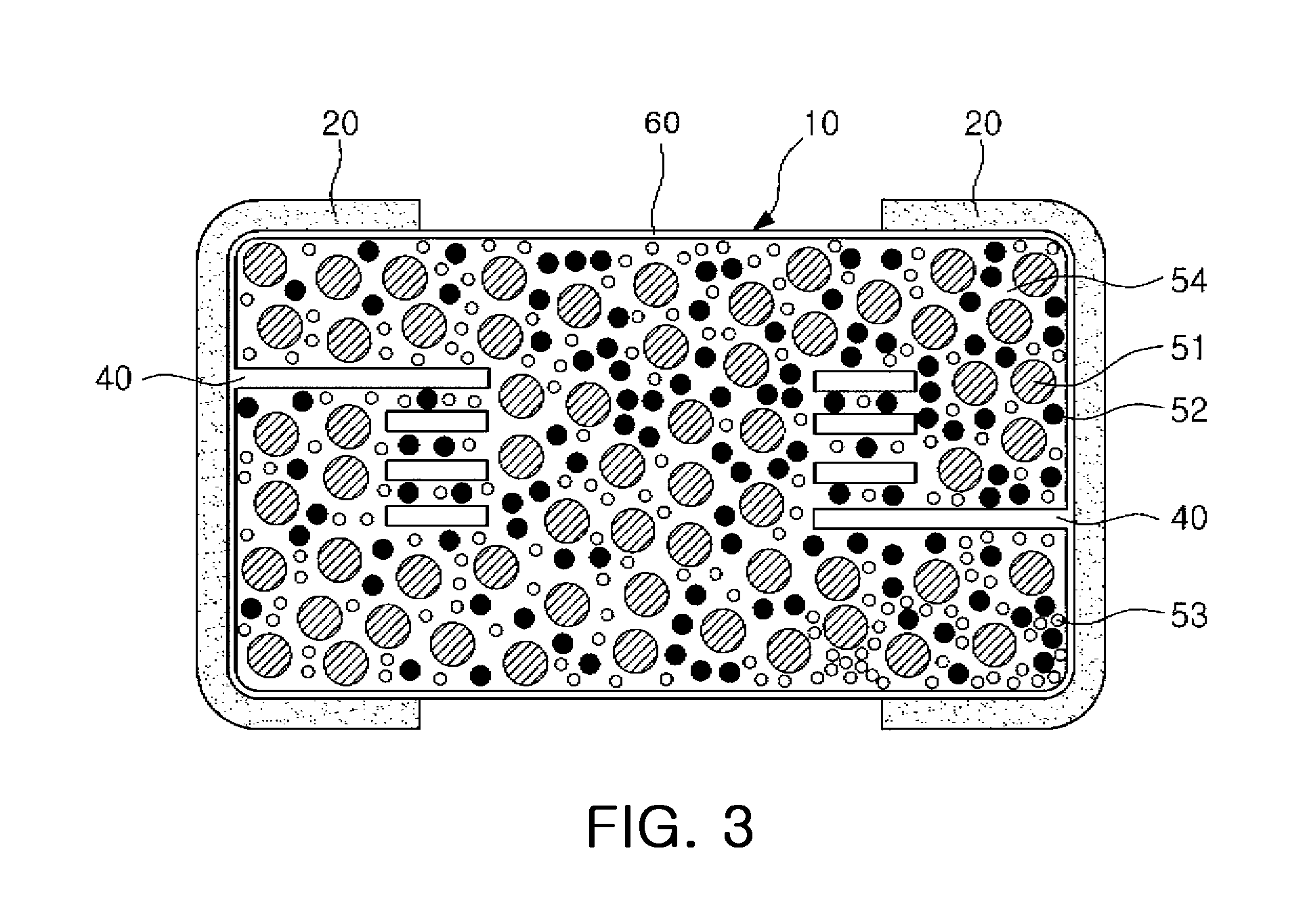

Multilayer inductor and method of manufacturing the same

InactiveUS20130293334A1Increase the inductance valueHigh currentTransformers/inductances coils/windings/connectionsInorganic material magnetismPolymer resinInductor

There is provided a multilayer inductor including: an inductor body formed of a material including metal powder particles, a ferrite, and a polymer resin; a coil part having a conductive circuit and a conductive via formed in the inductor body; and external electrodes formed on ends of the inductor body.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

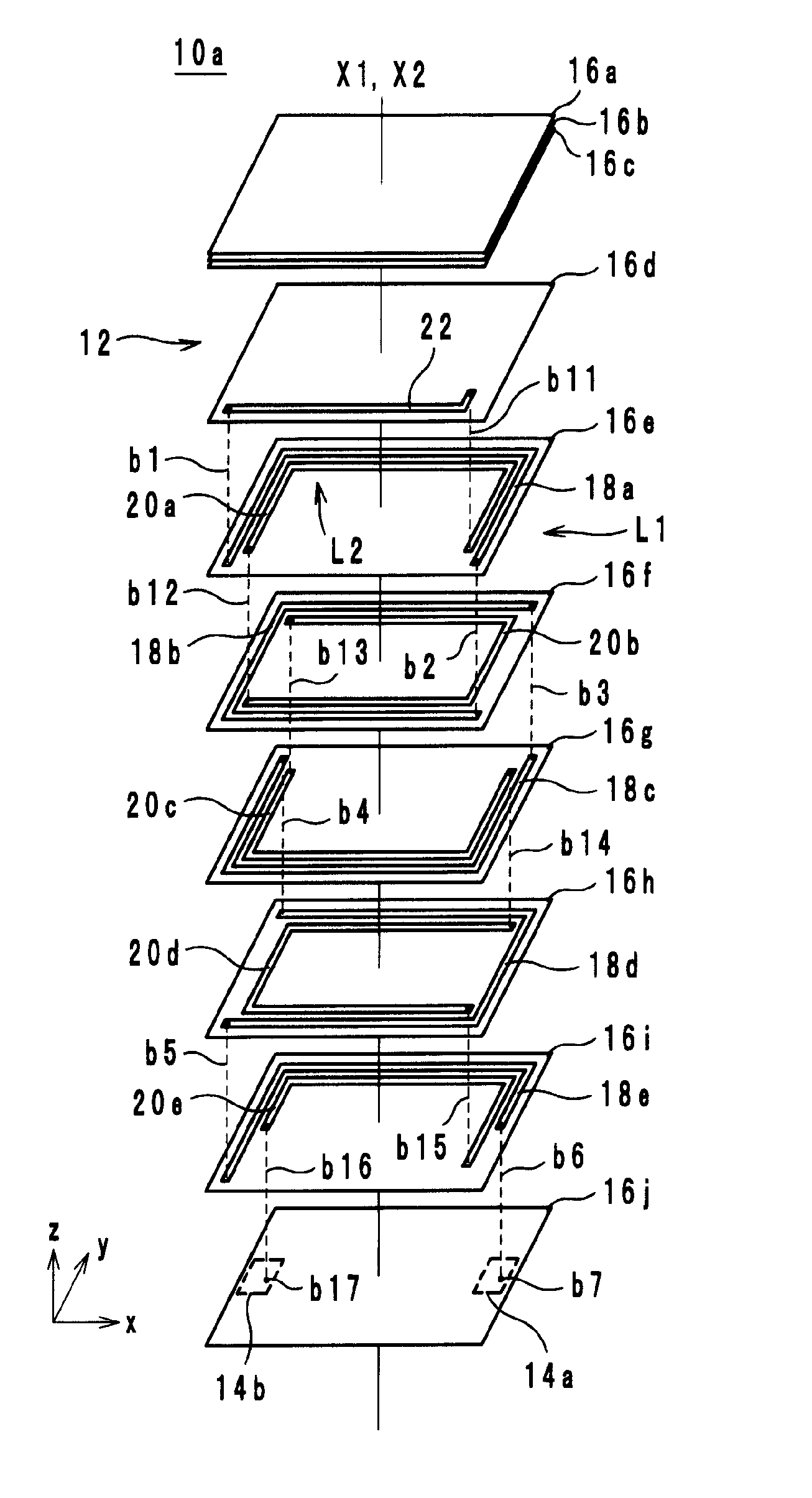

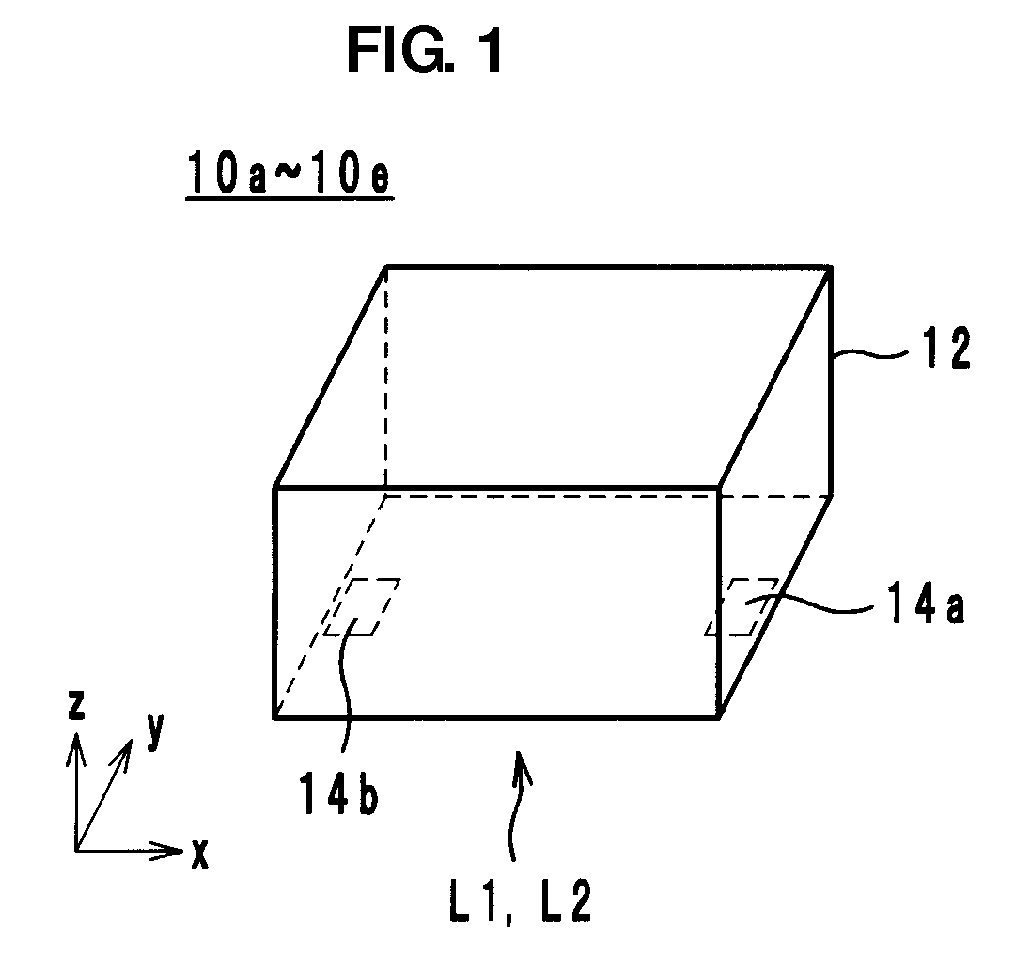

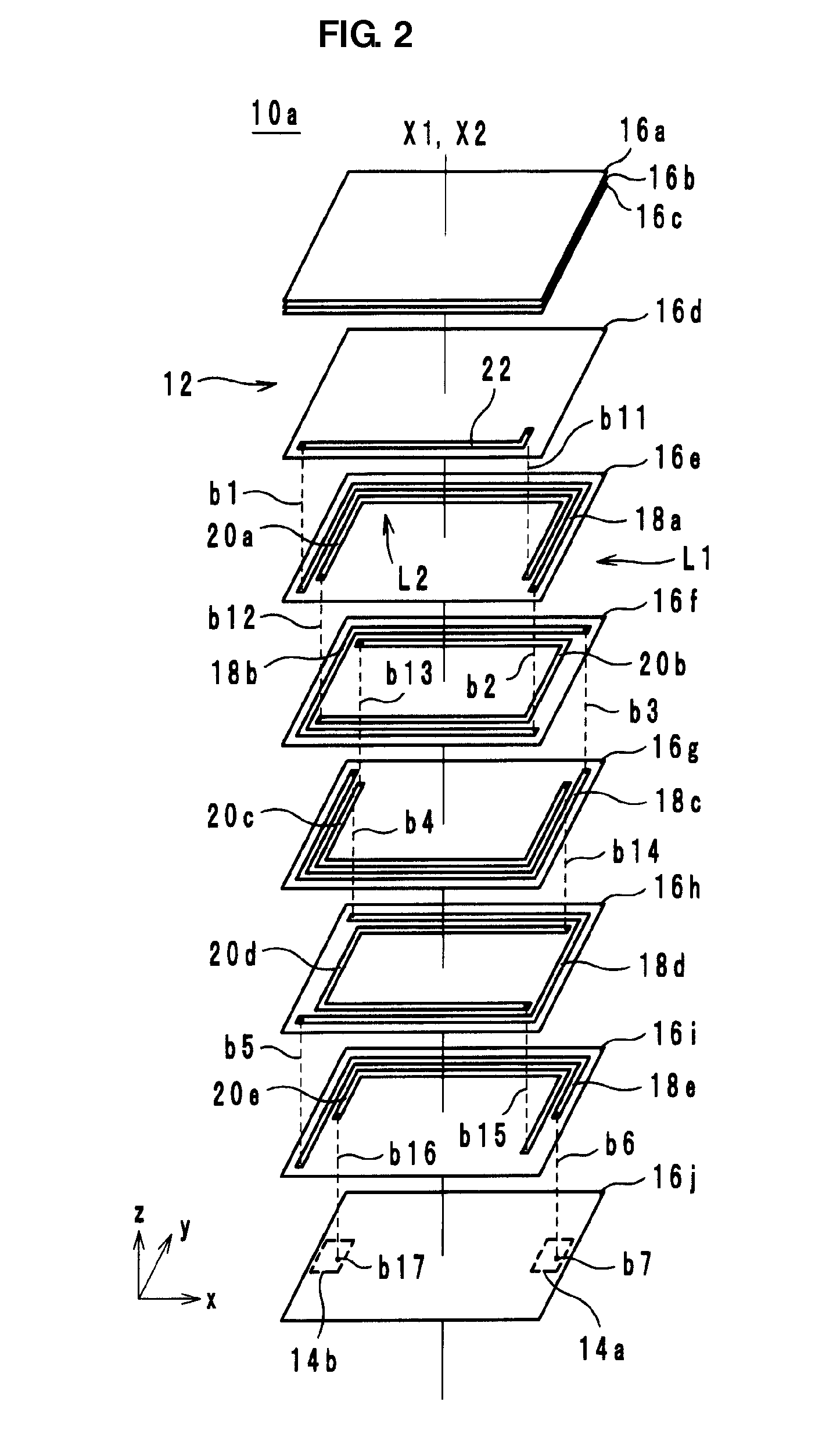

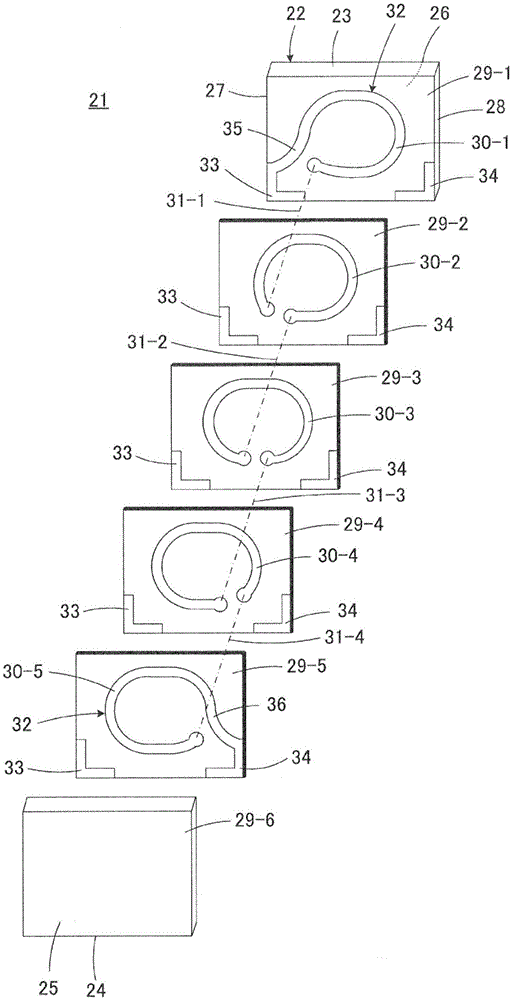

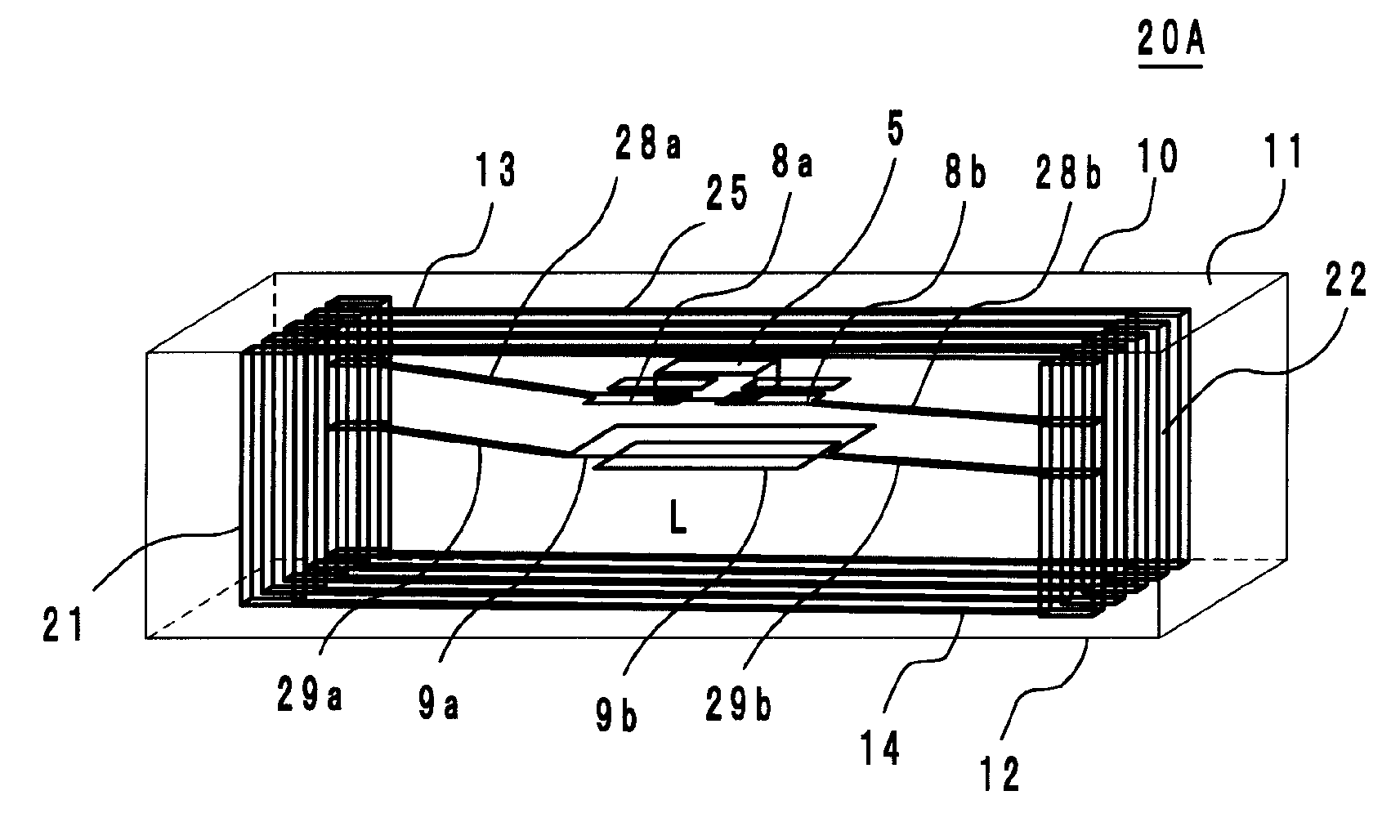

Electronic component

ActiveUS20110102124A1Increase the inductance valueIncrease valueTransformers/inductances detailsPrinted inductancesElectronic component

In an electronic component, a multilayer body includes a plurality of insulator layers stacked on top of one another. A first coil is provided in the multilayer body, includes a first coil axis and extends toward the positive side in the z-axis direction while circling counterclockwise around the first coil axis. A second coil is connected to the first coil, is provided in the multilayer body, includes a second coil axis, and extends toward the negative side in the z-axis direction while circling counterclockwise around the second coil axis. When viewed in plan from the z-axis direction, the first coil axis is disposed inside the second coil and the second coil axis is disposed inside the first coil.

Owner:MURATA MFG CO LTD

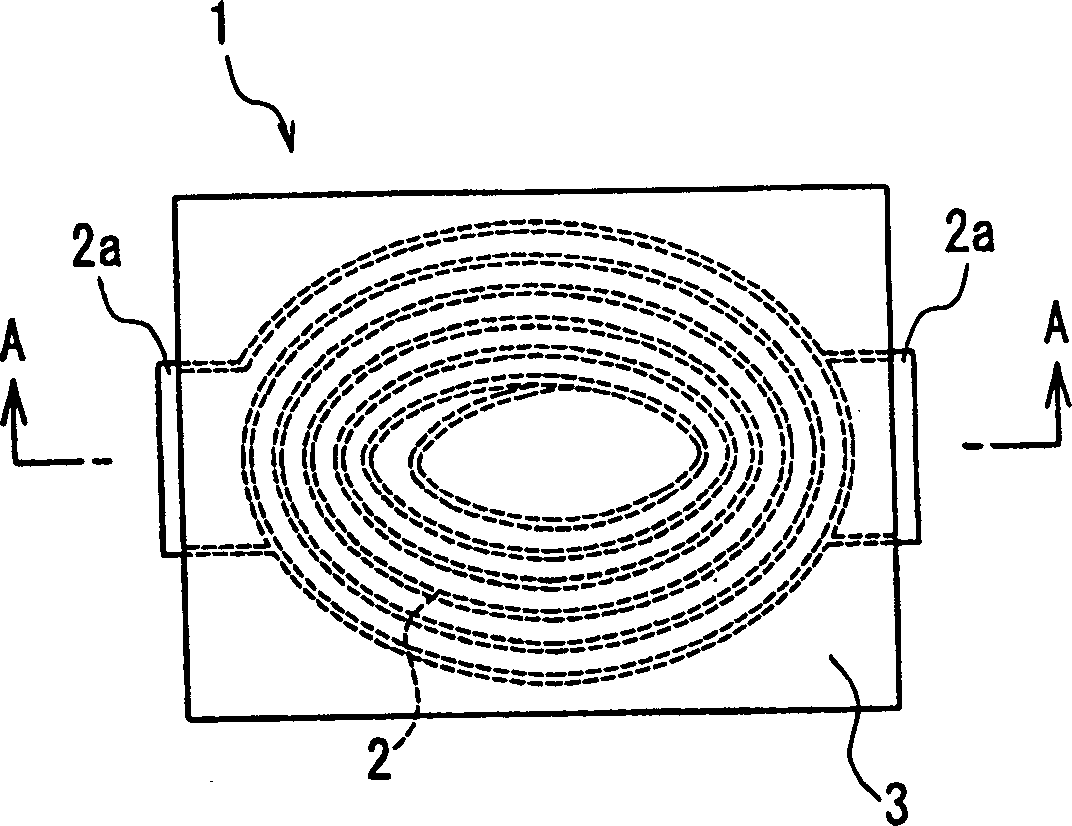

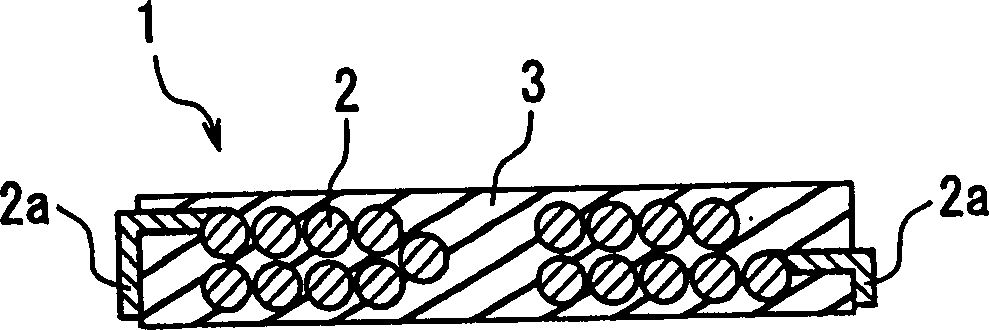

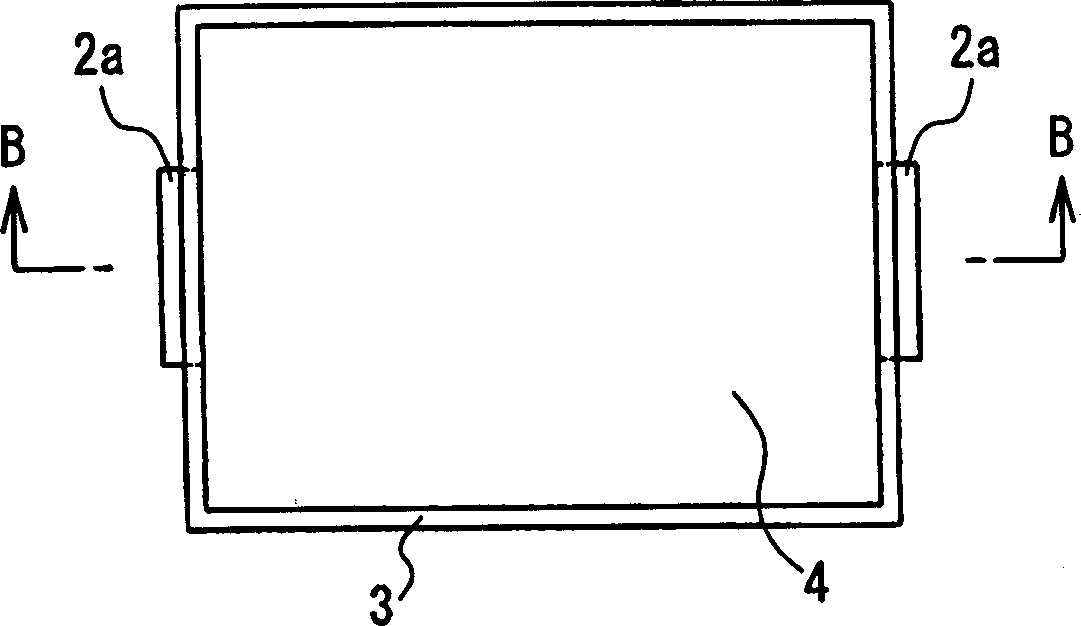

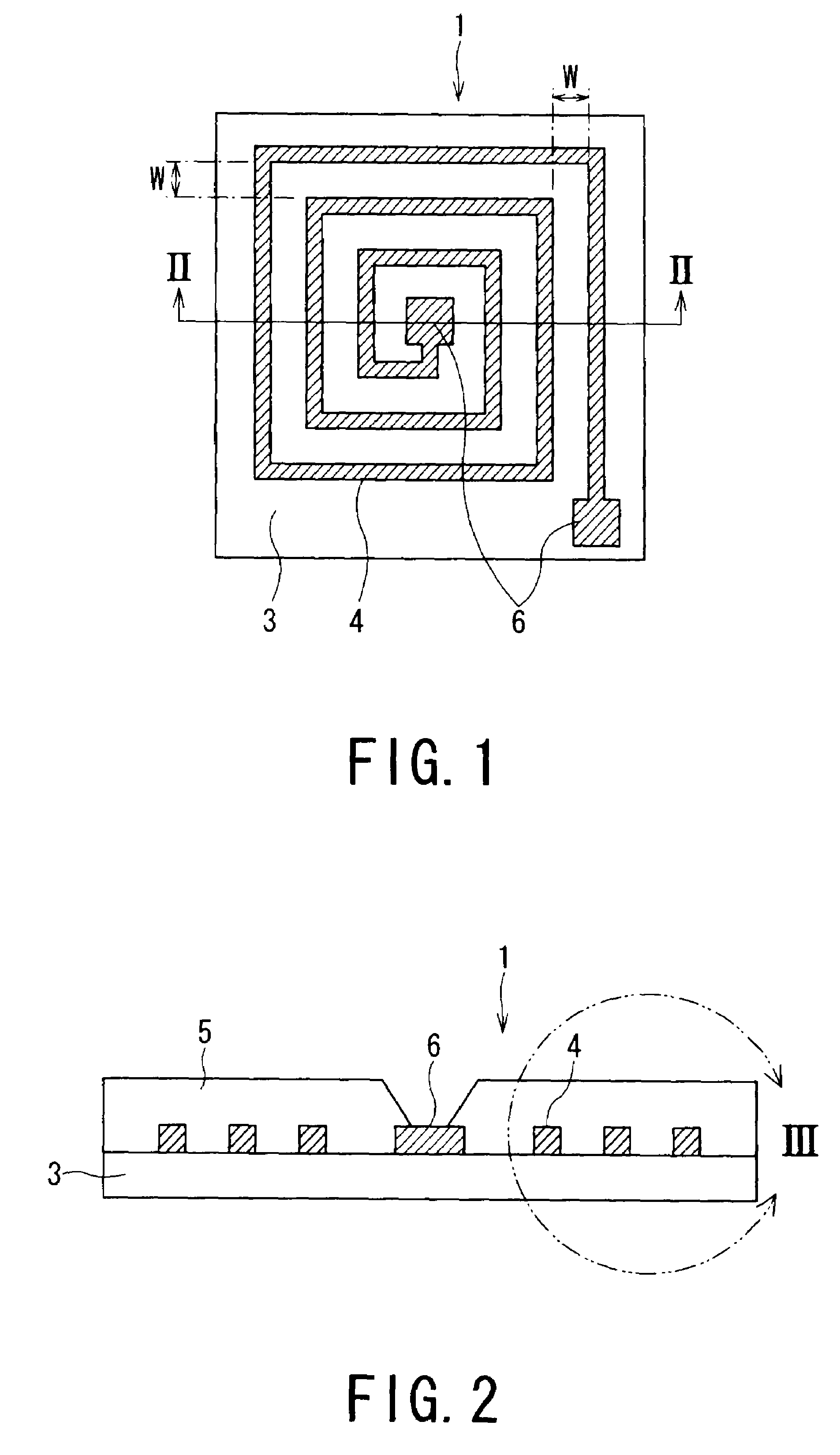

Coil component

ActiveUS7859377B2Highly resistant against drop shockIncrease the inductance valueTransformers/inductances casingsTransformers/inductances magnetic coresHigh resistanceIn plane

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

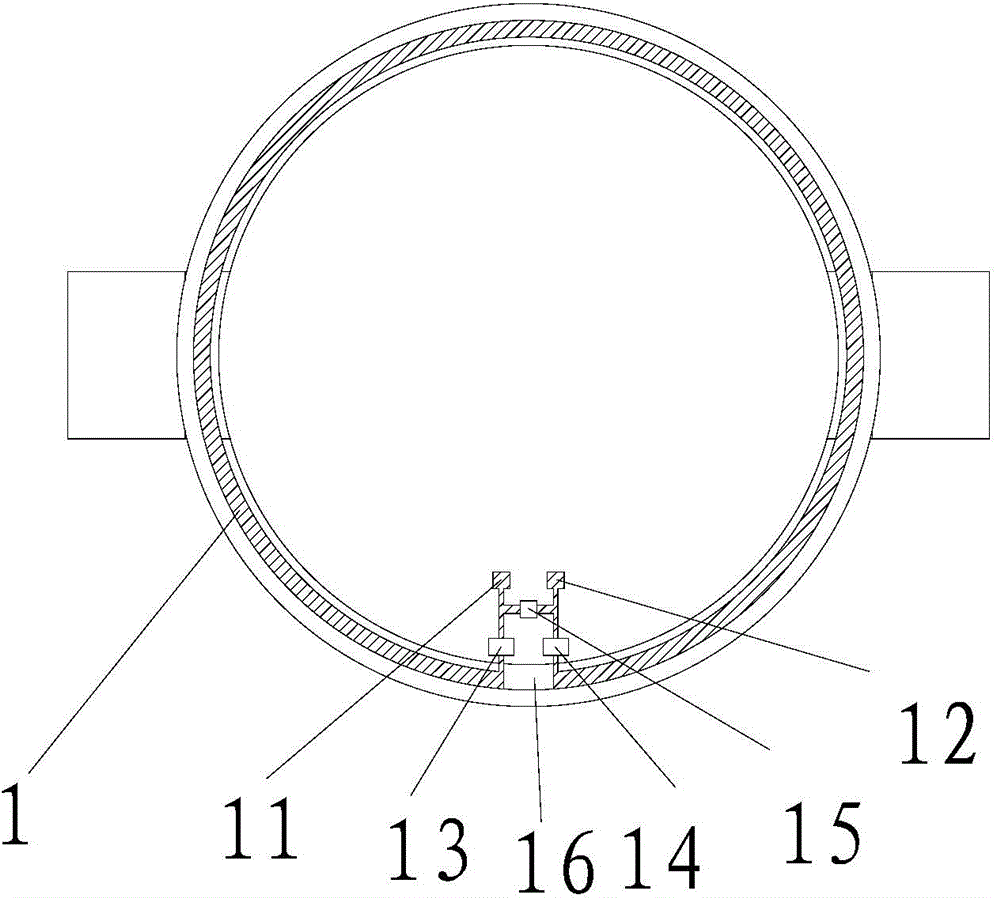

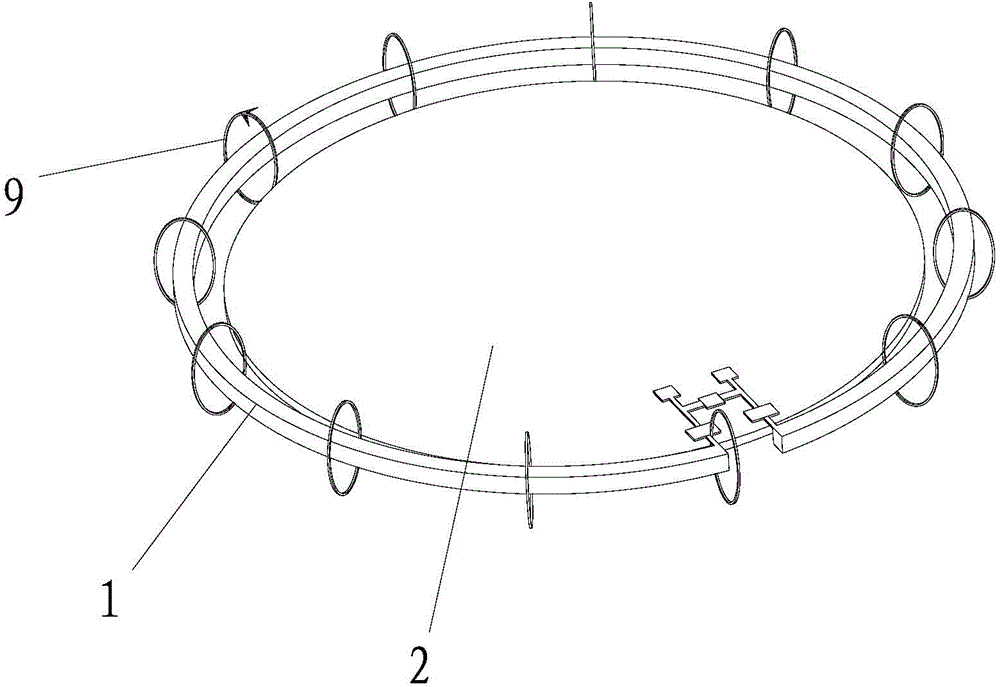

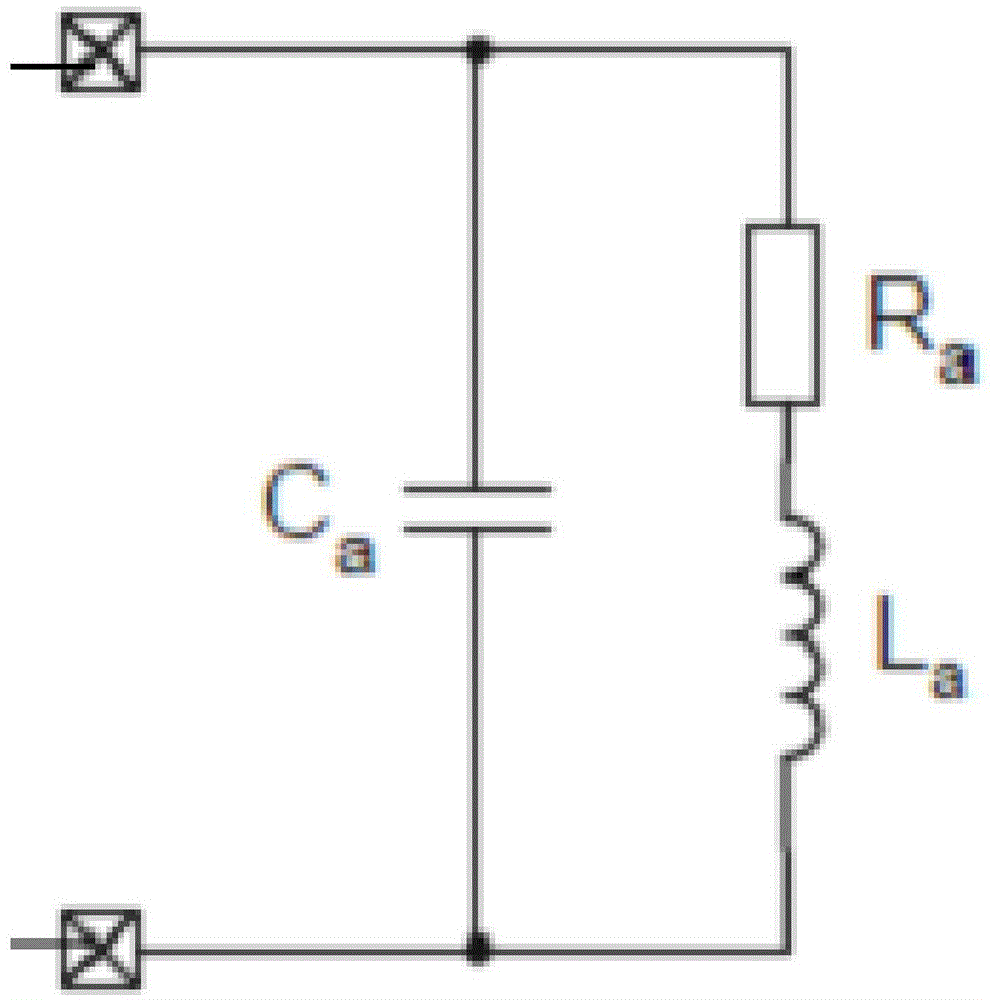

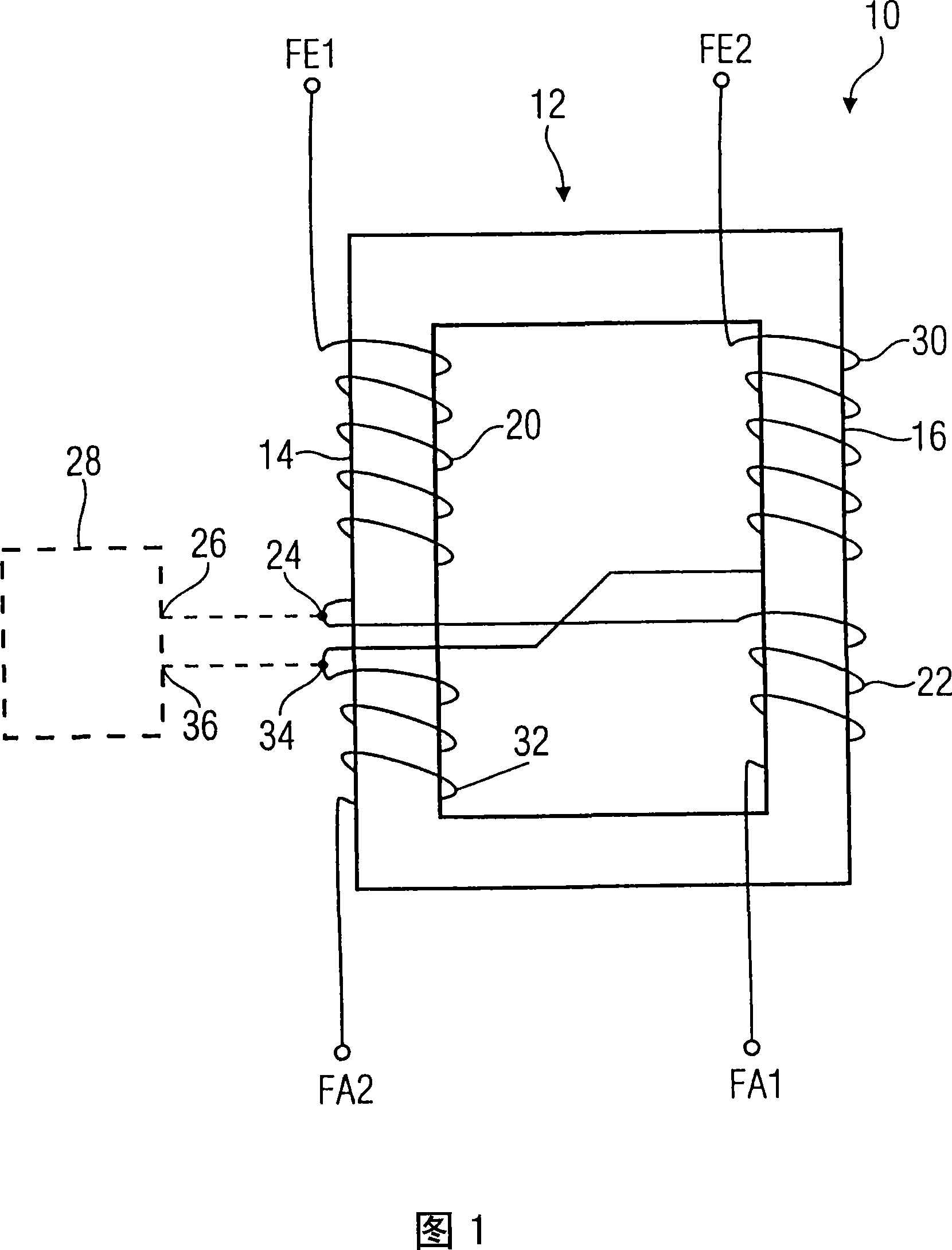

NFC antenna structure applied to wearable device and intelligent watch

InactiveCN104466363ASimple structureSmall footprintAntenna adaptation in movable bodiesRadiating elements structural formsCapacitanceCommunication quality

The invention discloses an NFC antenna structure applied to a wearable device and an intelligent watch. The NFC antenna structure comprises an antenna radiation body, an adjustment circuit assembly, a first feed part and a second feed part, wherein the antenna radiation body is a single-turn metal coil with an opening, and the opening divides the metal coil into a non-closed annular structure; the adjustment circuit assembly comprises a first inductor, a second inductor and a capacitor, and the first inductor and the second inductor are connected in series and then overall connected with the capacitor in parallel. The first inductor and the second inductor connected in series increase the inductance value of the radiation body which is the single-turn non-closed metal coil or metal ring, the capacitor increases the capacitance of the radiation body, the turn number of the metal coil is reduced to one, the occupied space and size of the antenna are small, and communication quality is reliable.

Owner:SHENZHEN SUNWAY COMM

Printed circuit board package structure and manufacturing method thereof

ActiveUS20140266549A1Low costImprove support strengthTransformers/inductances coils/windings/connectionsPrinted circuit aspectsPrinted circuit boardConductive channel

A printed circuit board package structure includes a substrate having a first surface and a second surface, a ring-shaped magnetic element, an adhesive layer, conductive portions and conductive channels. The first and second surfaces respectively have first and second metal portions. A ring-shaped concave portion is formed on a position not covered by the first metal portions of the first surface. The ring-shaped magnetic element is placed in the ring-shaped concave portion. The adhesive layer covers the first metal portions and the ring-shaped magnetic element. The conductive portions are formed on the adhesive layer. The conductive channels penetrate the conductive portions, the adhesive layer, and the substrate, and are respectively located in an inner wall and outside an outer wall of the ring-shaped concave portion. Each of the conductive channels includes a conductive film electrically connects to the aligned conductive portion and second metal portion.

Owner:TRIPOD TECHNOLOGY CORPORATION

Coil component

InactiveCN101615490AFlexibleNo brittle failureTransformers/inductances coils/windings/connectionsPrinted inductancesIn planeHigh resistance

A coil component is provided, and the coil component for an inductor is deformable dependent on flex of a flexible printed board due to elapse of time when mounted thereon, and has high resistance against dropping impact and has an inductance value. The coil component includes an anisotropic compound magnetic sheet which is layered on at least any one or both of the upper surface and the lower surface of an air core coil formed spirally in a plane and which is composed of flat or needle-shaped soft magnetic metal powder, which has a major axis and a minor axis and is dispersed in a resin material, the major axis of which corresponds to an in-plane direction of the air core coil.

Owner:SUMIDA CORP

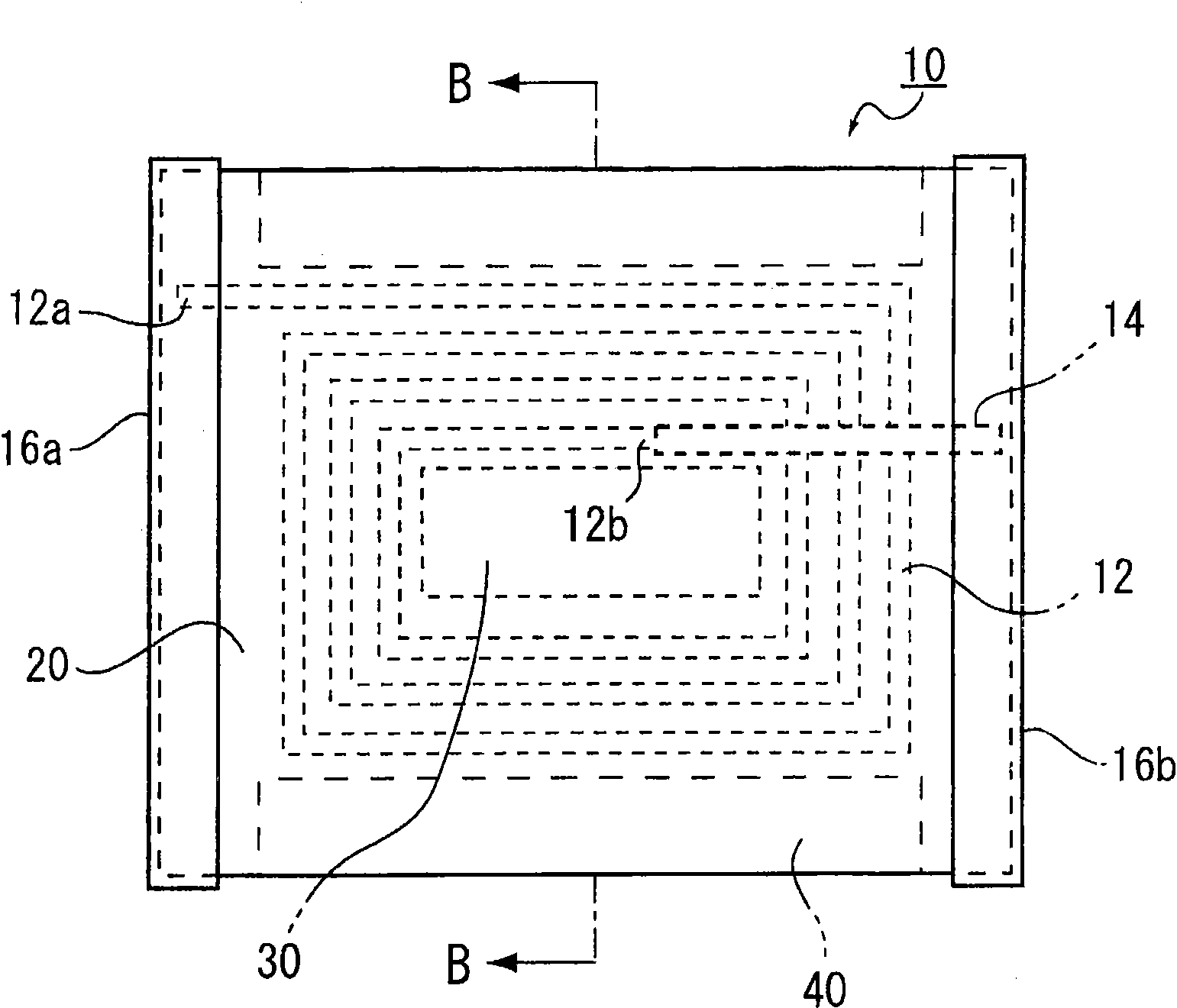

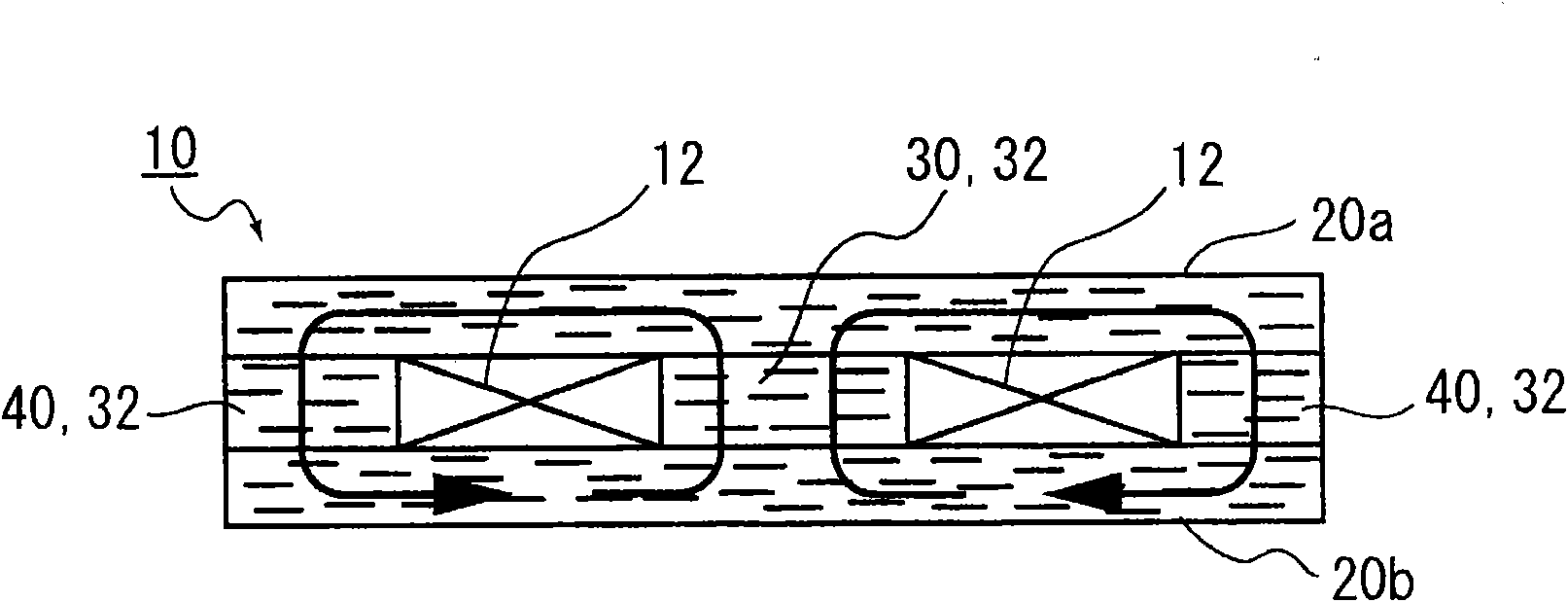

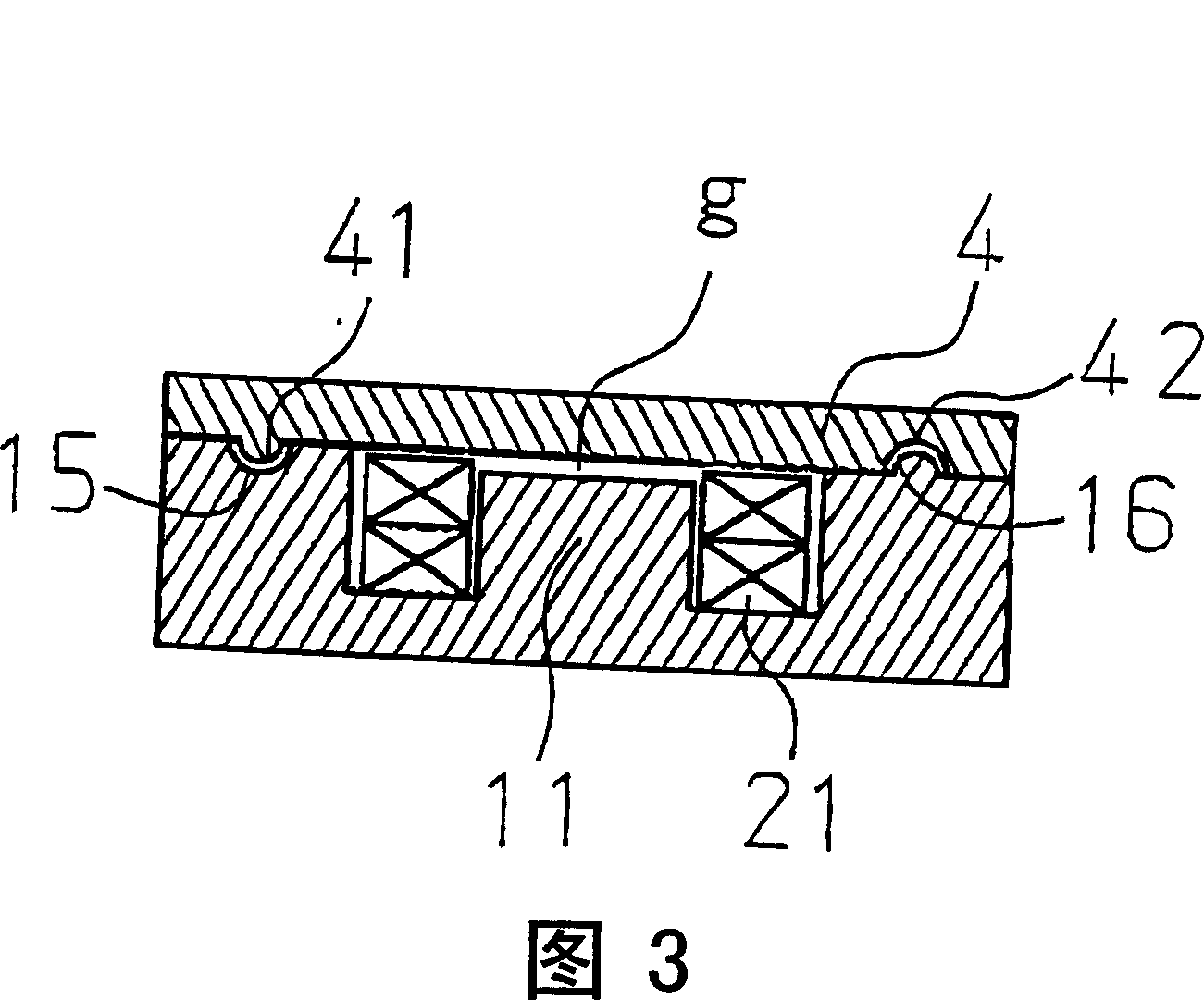

Magnetic element and its manufacture, power supply module therewith

InactiveCN1407564AReduce magnetic lossIncrease the inductance valueTransformers/inductances coils/windings/connectionsEncapsulation/impregnationElectrical conductorComputer module

A magnetic device includes a sheet-type coil including a planar conductive coil and an insulating substance; and a sheet-type first magnetic member disposed on at least one of upper and lower surfaces of the sheet-type coil, where a magnetic permeability of the insulating substance is smaller than a magnetic permeability of the first magnetic member. The magnetic device preferably includes a second magnetic member provided at a predetermined area of the sheet-type coil, the second magnetic member being made of a resin containing a magnetic powder and having a permeability larger than the insulating substance and smaller than the first magnetic member. The predetermined area is at least one position selected from a center portion and a peripheral portion of the sheet-type coil where a conductor constituting the planar conductive coil is not present. Further, a power supply module of the present invention includes the magnetic device according to the present invention.

Owner:PANASONIC CORP

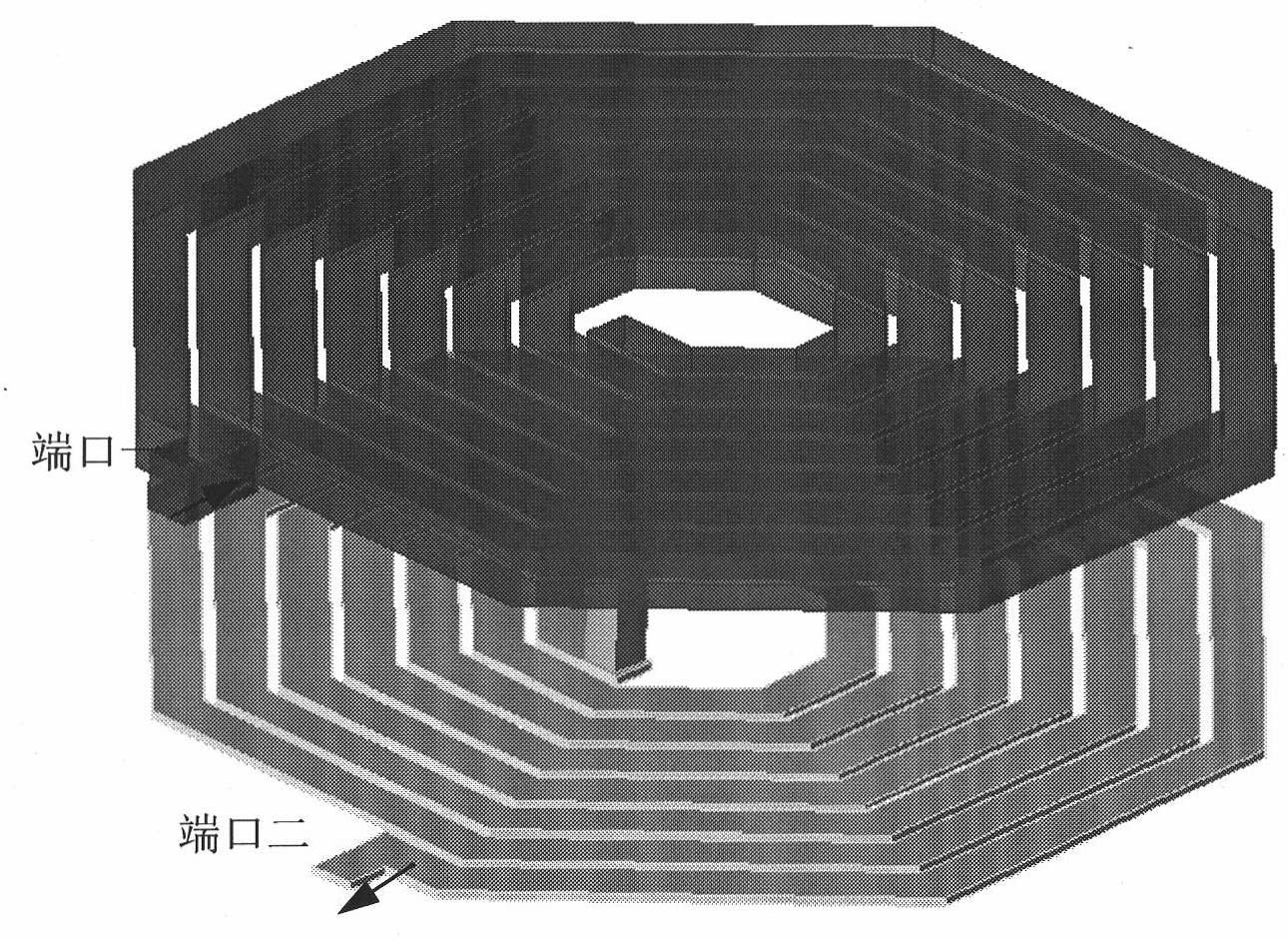

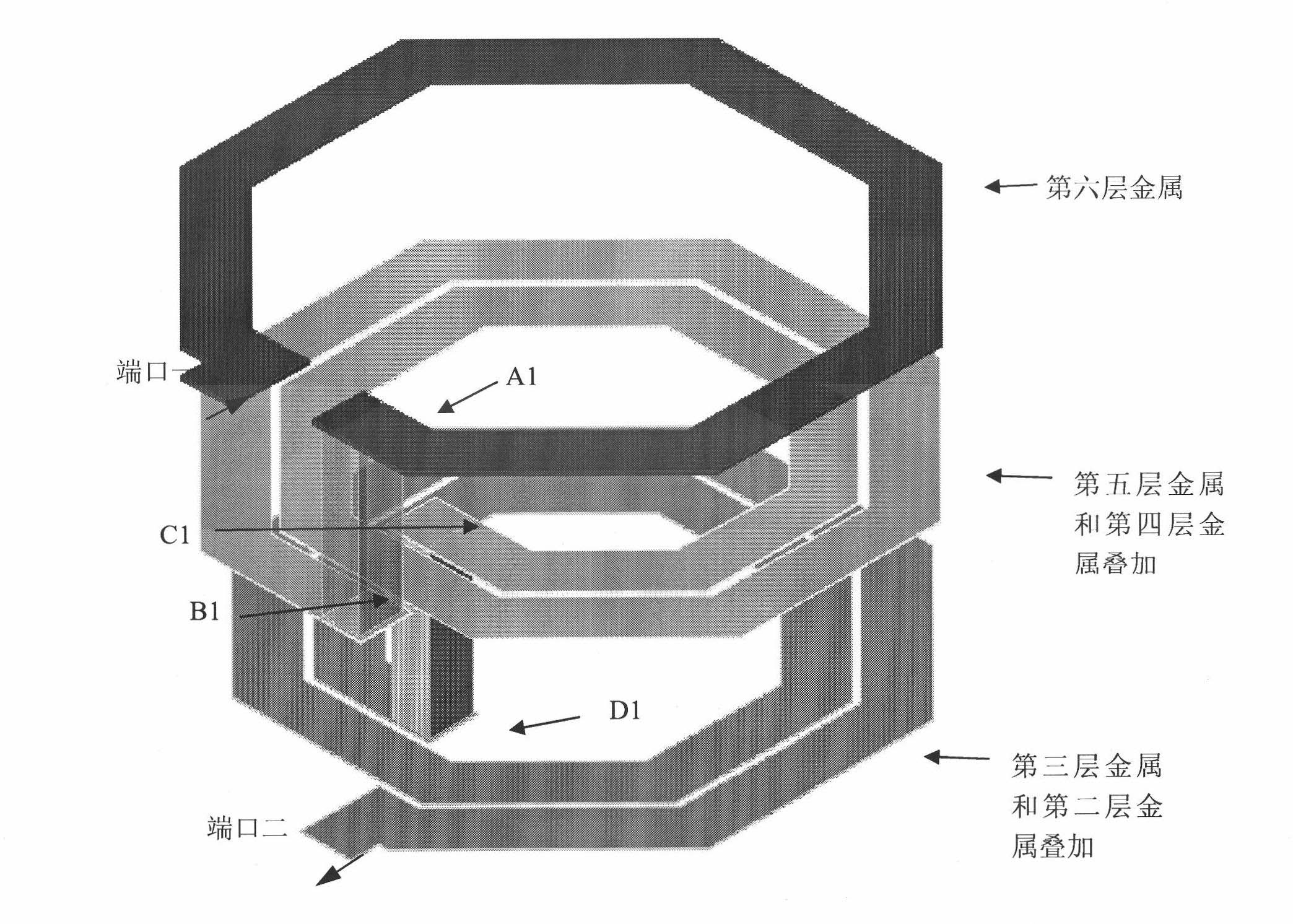

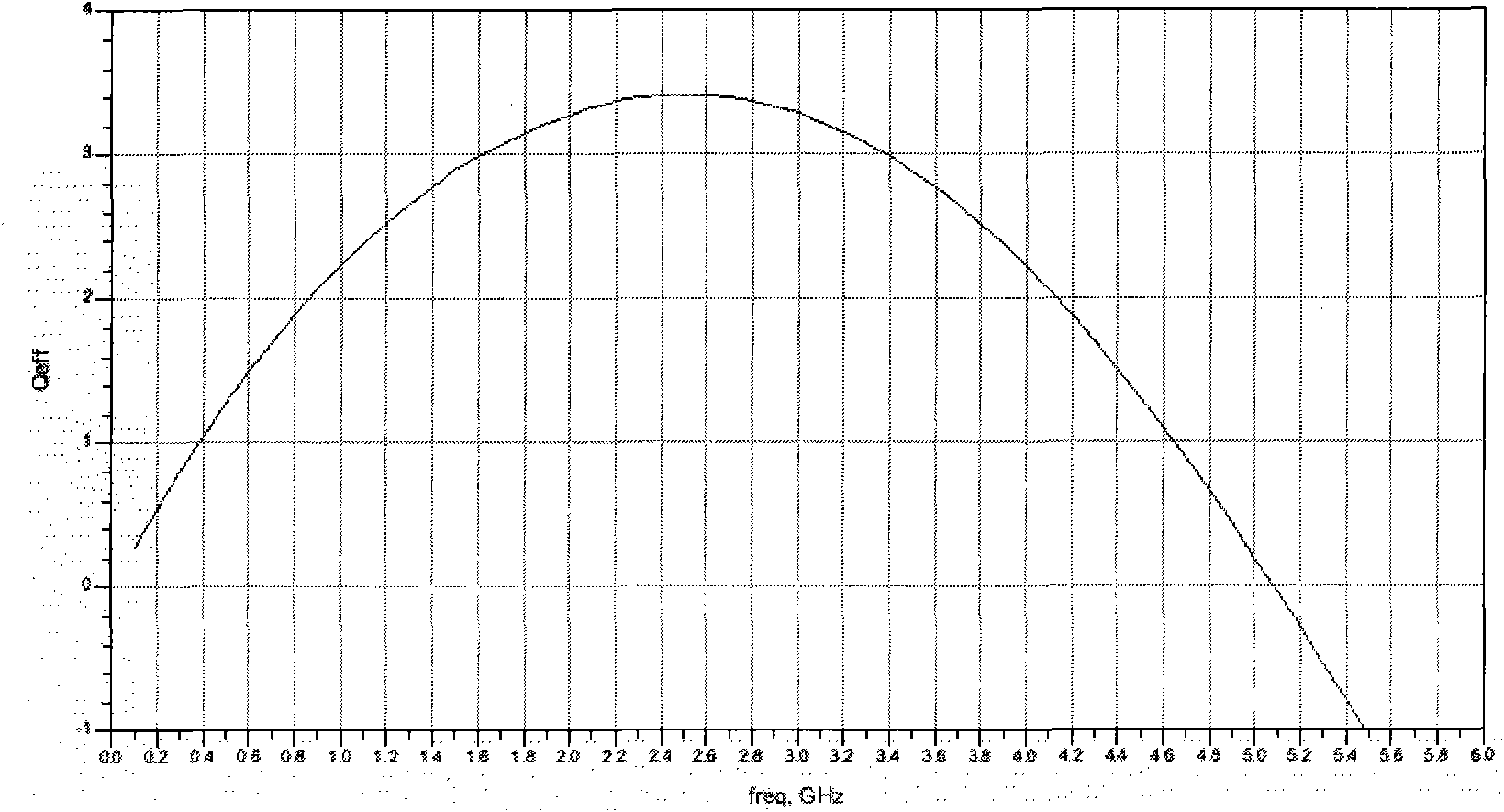

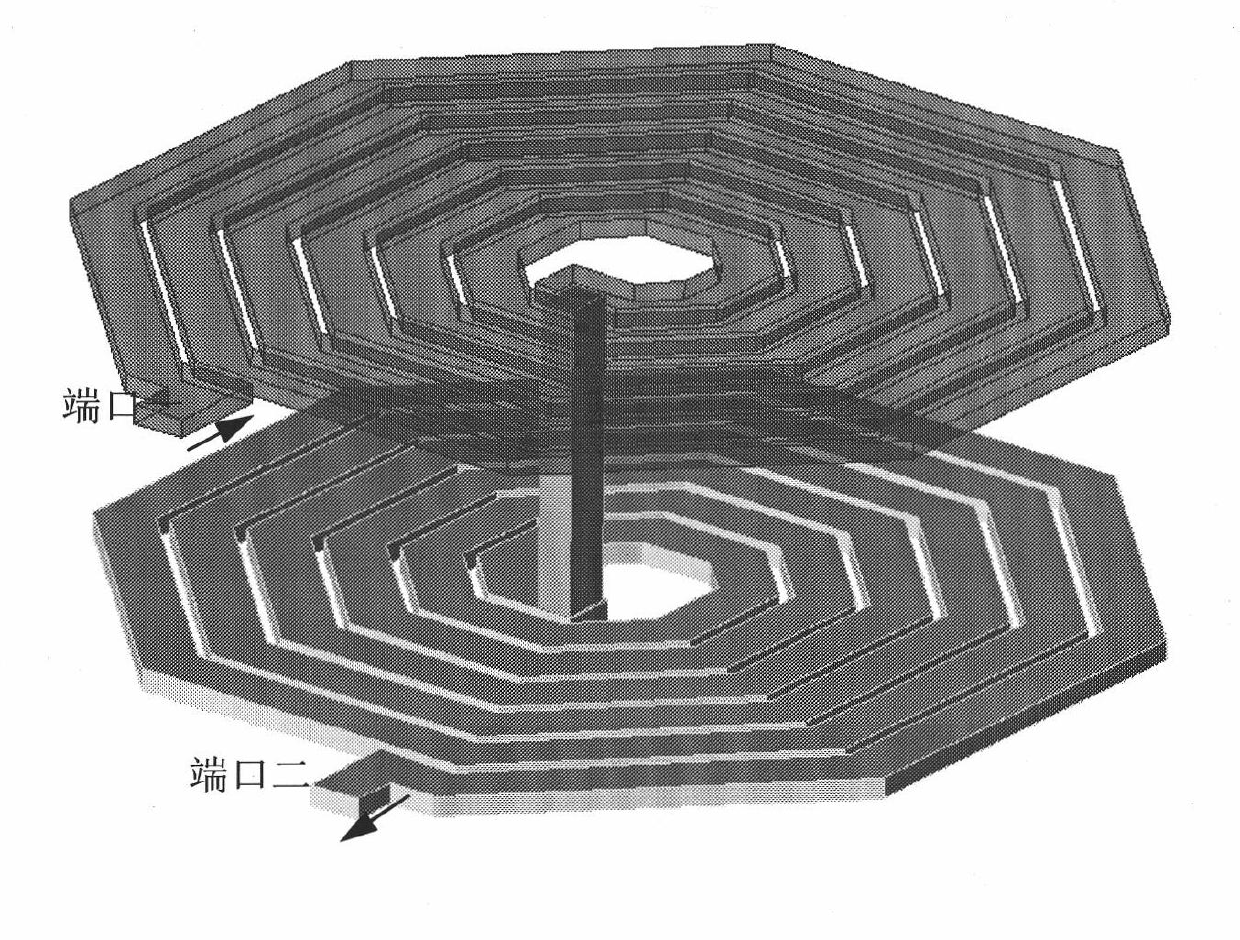

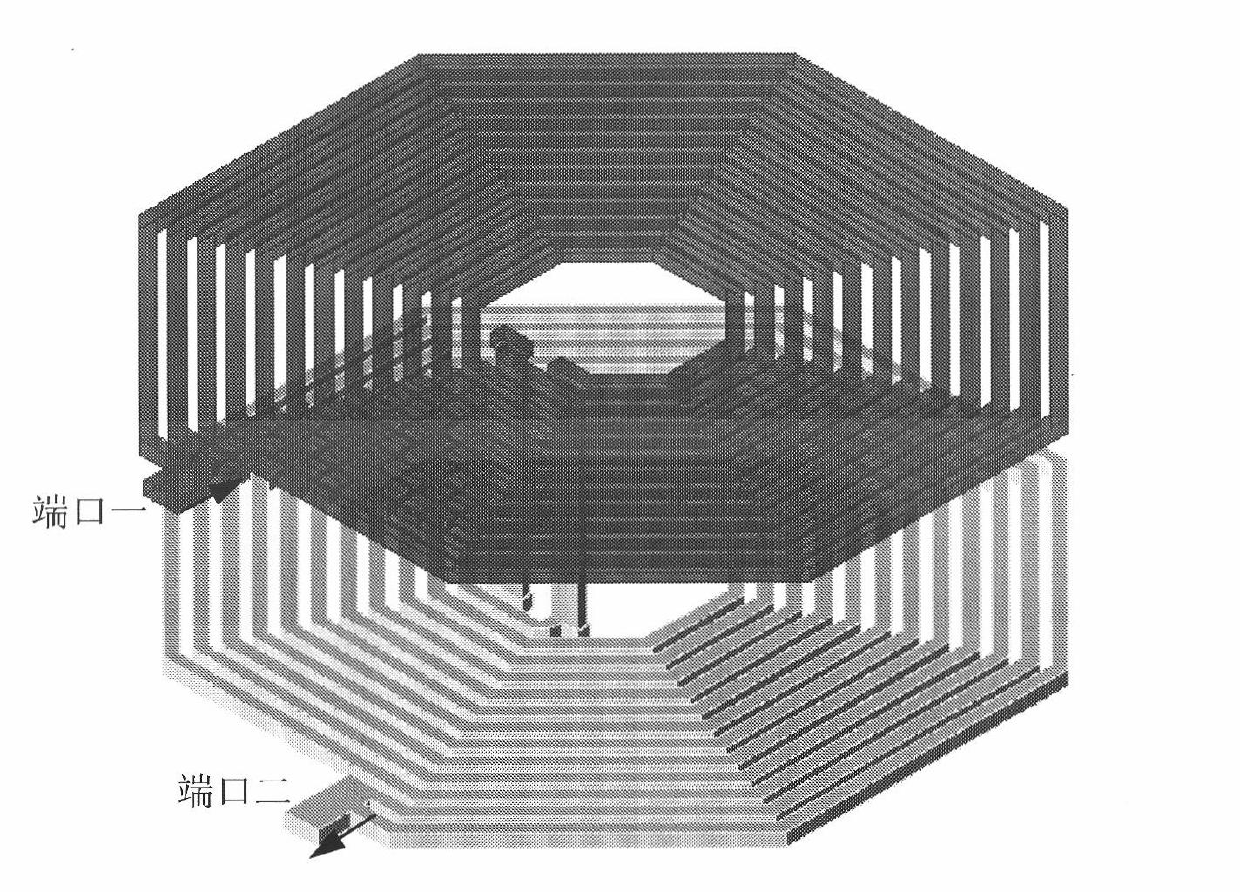

Multilayer stacked inductance utilizing parallel connection of metals

ActiveCN102231313AIncrease the inductance valueHigh inductance figure of meritSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInductanceMetal

The invention discloses a multilayer stacked inductance utilizing parallel connection of metals, which is of a multilayer structure and comprises at least three layers of metal coils from top to bottom, wherein circular slotted parts of the metal coils are aligned; the other lower-layer metal coils except the top-layer metal coil are formed by stacking and connecting multiple metal layers; and the multiple layers of metal coils are interconnected through strip-shaped holes. According to the multilayer stacked inductance provided by the invention, the inductance value under a same area is increased and higher inductance quality factor is effectively maintained by utilizing a method of increasing the effective thickness through stacking lower metals.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

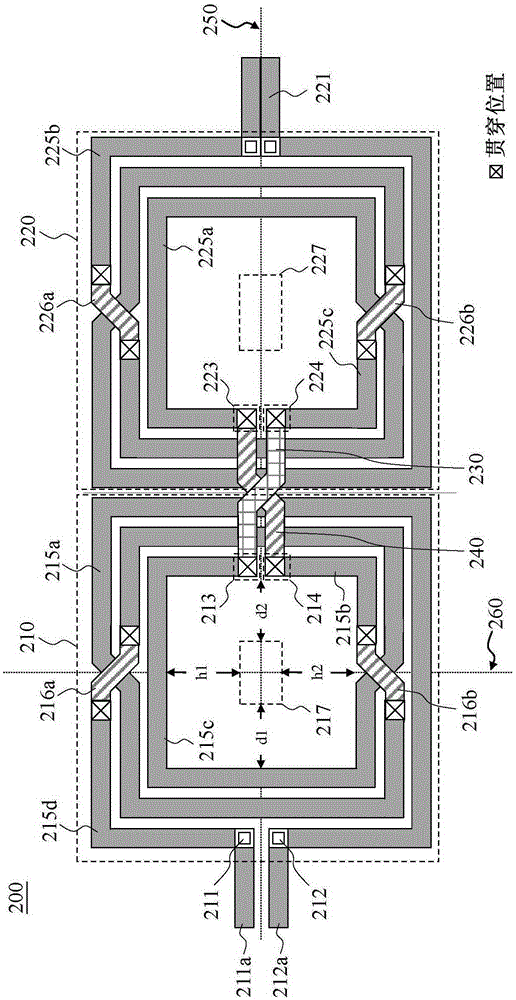

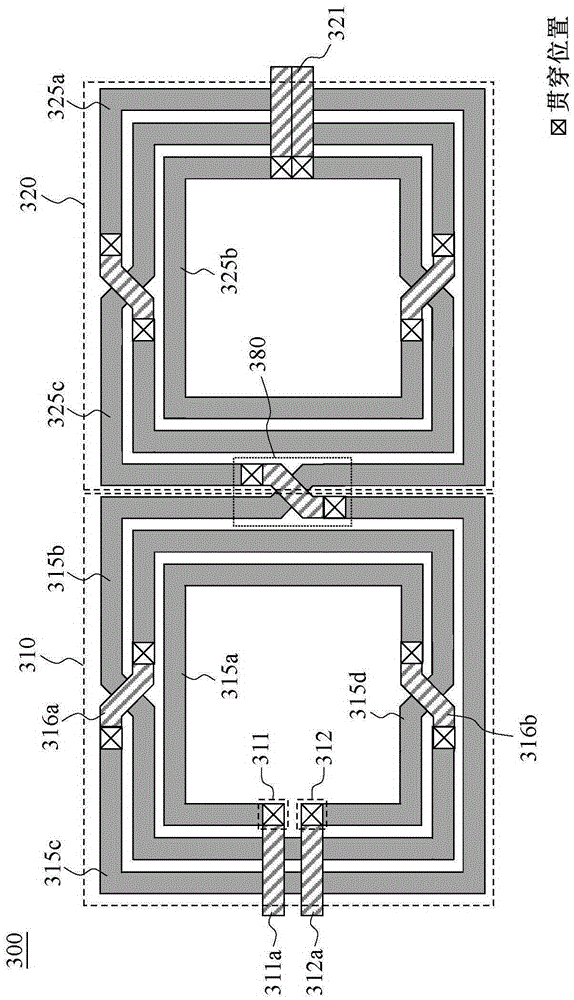

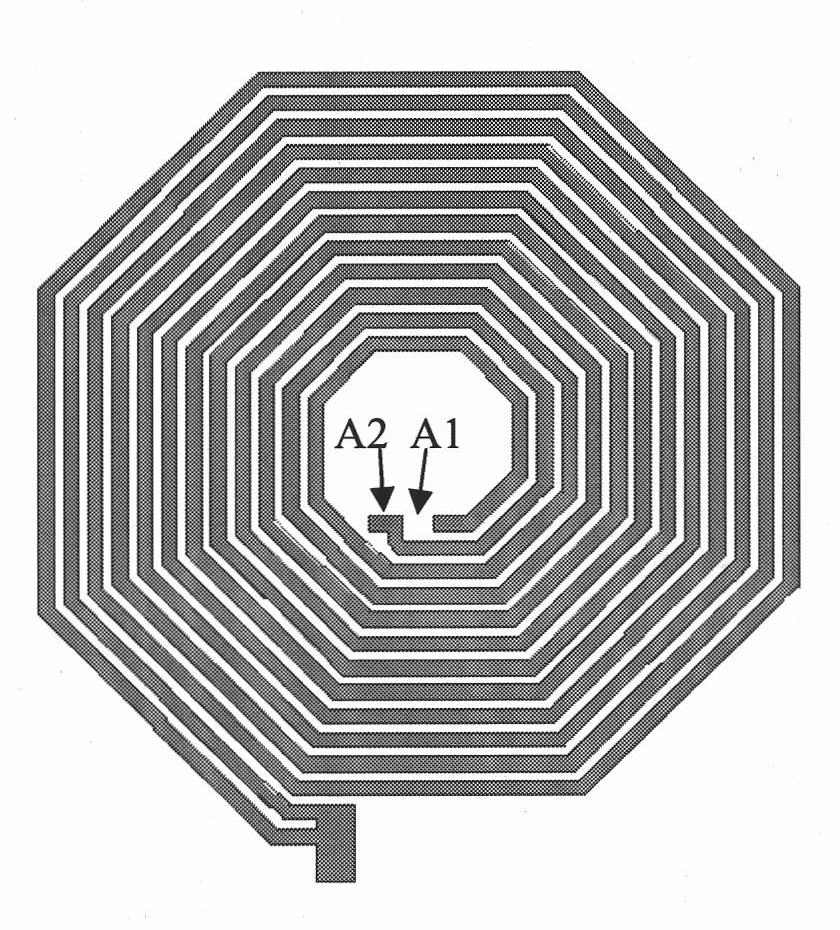

Integrated inductor structure and integrated transformer structure

ActiveCN106571211AGood symmetryIncrease the inductance valueTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses an integrated inductor structure and an integrated transformer structure, and the integrated inductor structure comprises a first spiral coil, a second spiral coil, and a connection line segment. The first spiral coil comprises a plurality of metal line segments and a bridging line segment, and is provided with a first end point, a second end point, a third end point, and a fourth end point, wherein the bridging line segment and the metal line segment are located at different layers, and the bridging line segment is used for connecting the metal line segment. The second spiral coil is provided with a fifth end point and a sixth end point. The connection line segment is connected with the third and fifth end points, and the fourth and sixth end points. The integrated inductor structure takes the first and second end points as the input end and the output end, and the first end point and the third end point are located on a first imaginary line. The first imaginary line passes through the central area of a range surrounded by the first spiral coil, and the bridging line segment and the central area of the range are located on a second imaginary line.

Owner:REALTEK SEMICON CORP

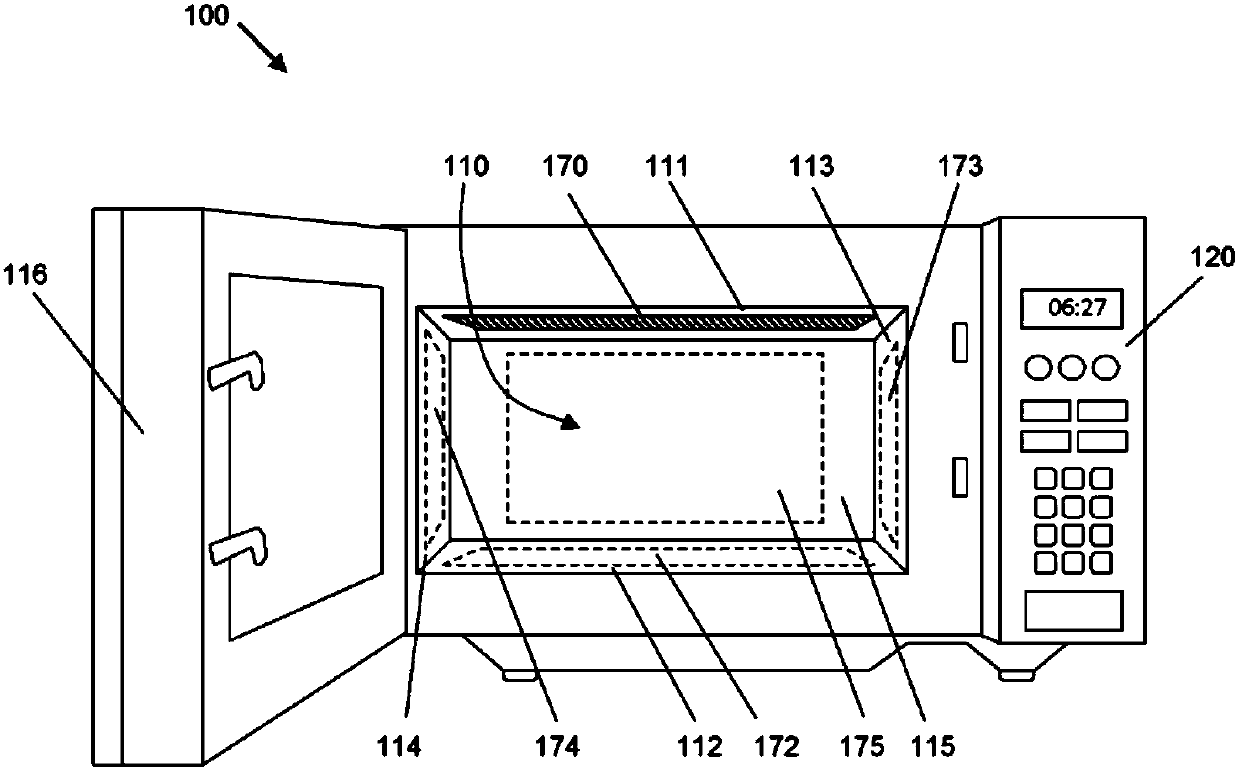

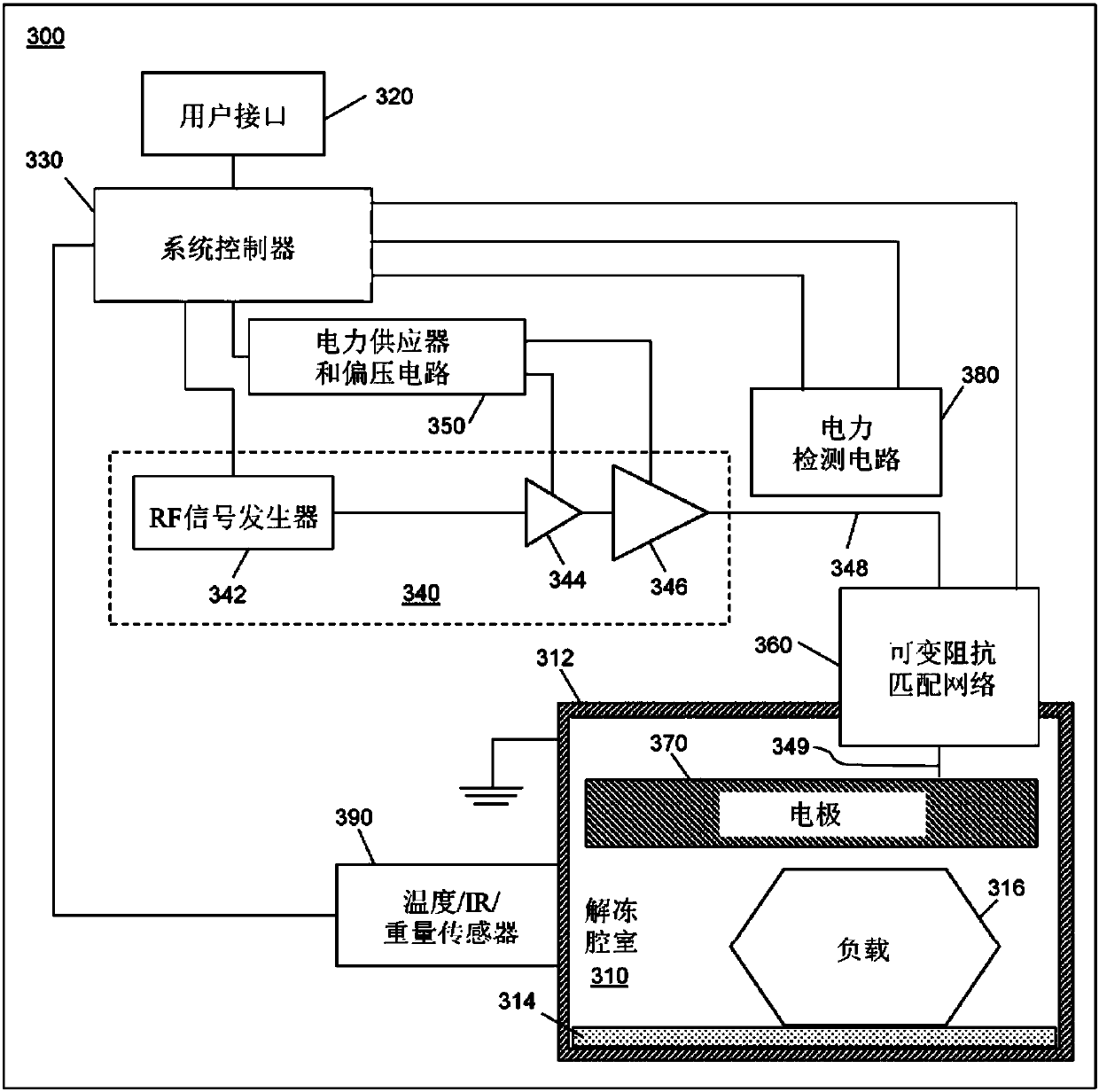

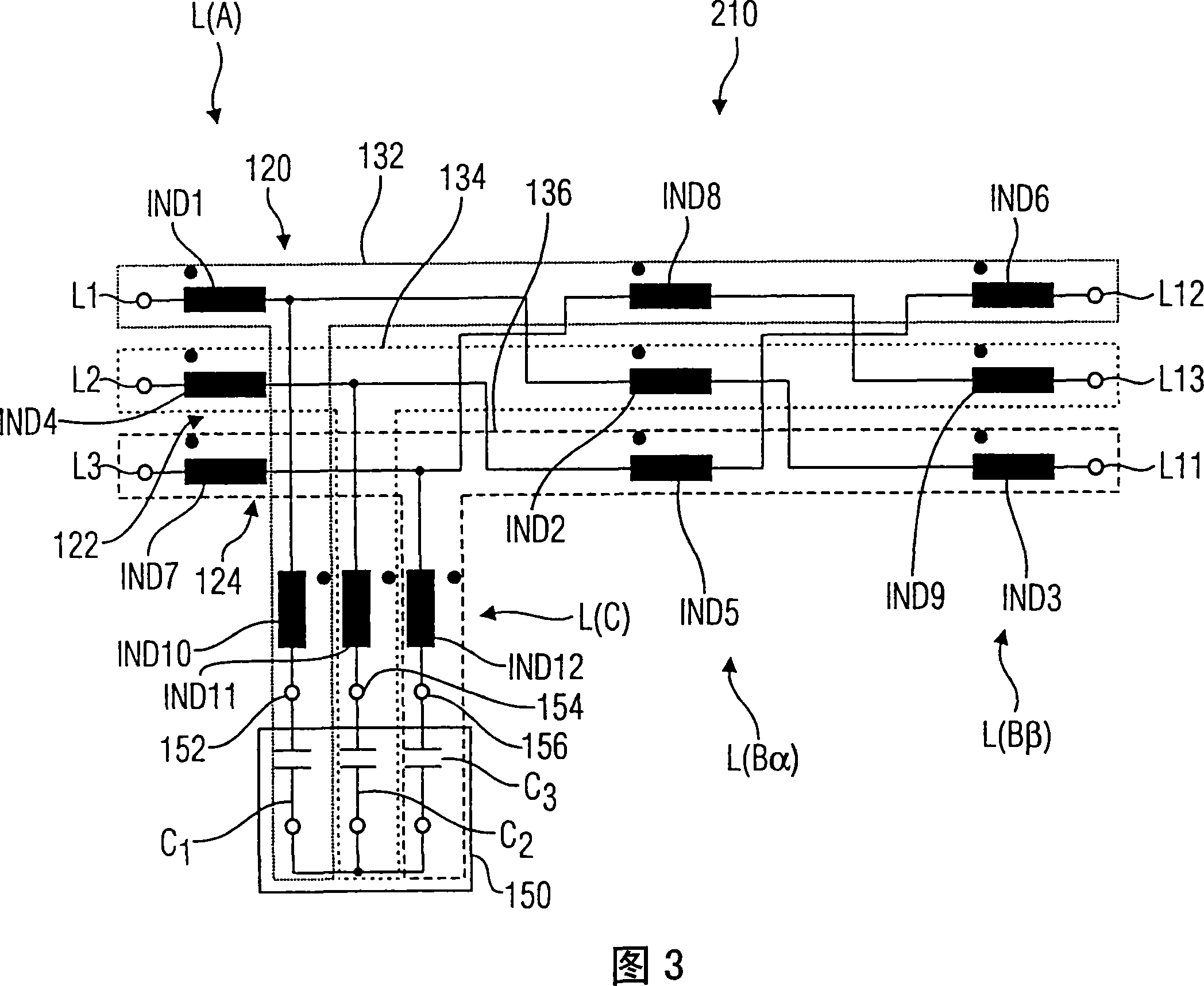

Defrosting apparatus with lumped inductive matching network and methods of operation thereof

ActiveCN107684007AIncrease the inductance valueReduce the inductance valueDielectric heatingMultiple-port networksElectricityProximate

The invention provides a defrosting system which includes an RF signal source, an electrode proximate to a cavity within which a load to be defrosted is positioned, a transmission path between the RFsignal source and the electrode, and an impedance matching network electrically coupled along the transmission path between the output of the RF signal source and the electrode. The system also includes power detection circuitry coupled to the transmission path and configured to detect reflected signal power along the transmission path. A system controller is configured to modify, based on the reflected signal power, an inductance value of the impedance matching network to reduce a ratio of the reflected signal power to the forward signal power. The impedance matching network includes a plurality of fixed-value, lumped inductors positioned within a fixed inductor area.

Owner:NXP USA INC

Semiconductor device

InactiveUS7167073B2Improve efficiencyIncrease the inductance valueSemiconductor/solid-state device detailsSolid-state devicesInductorInductance

A semiconductor device increases the efficiency of the inductor having a three-dimensional spiral coil and increases the inductance value without requiring any special steps. The semiconductor device includes semiconductor elements and first, second and third metal wire layers to be used for the configuration of the semiconductor elements, a core disposed on the second metal wire layer, and a coil wherein a plurality of pieces of the first metal wire layer and a plurality of pieces of the third metal wire layer connected to the pieces via the connection holes are connected in series to define a spiral surrounding the core.

Owner:ROHM CO LTD

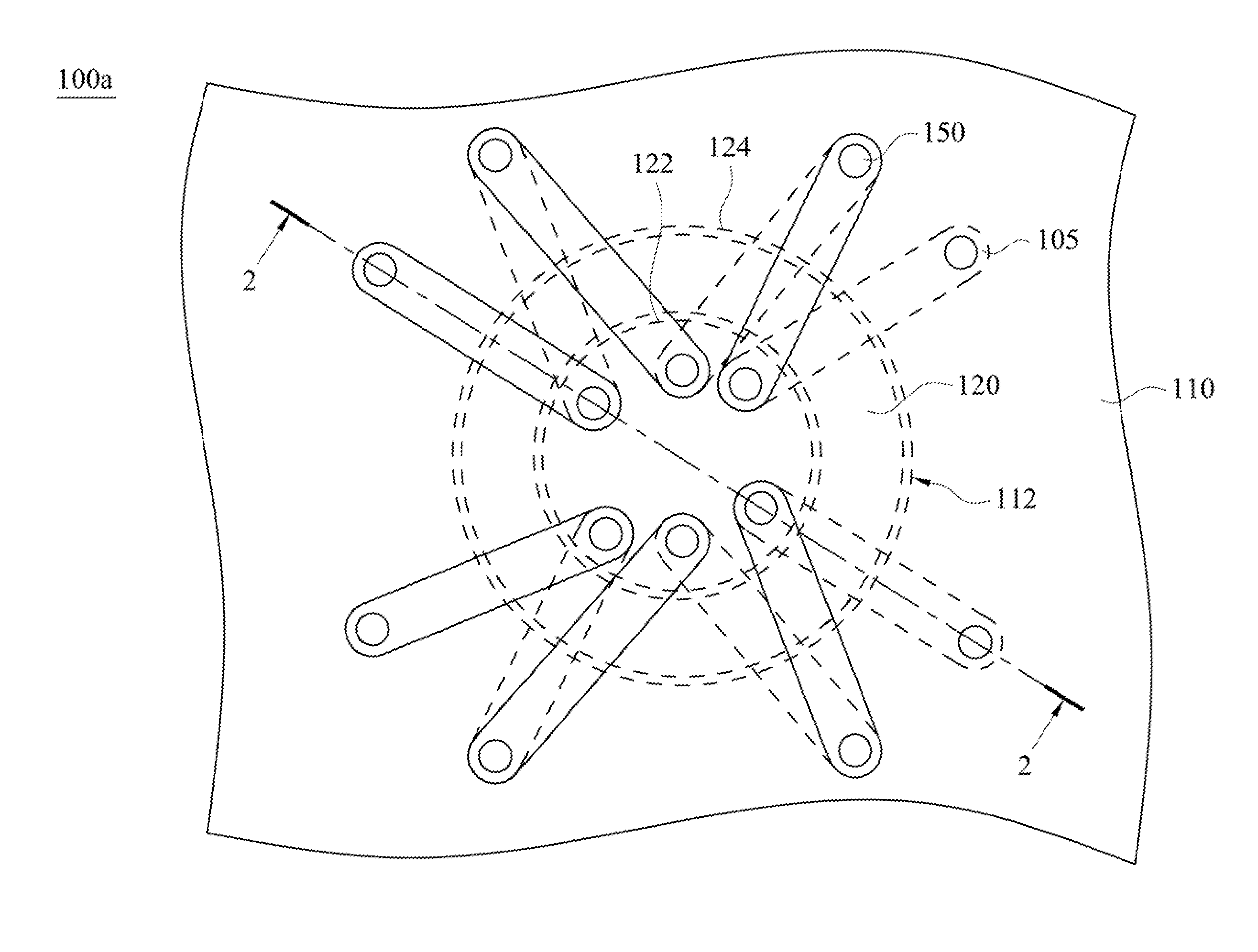

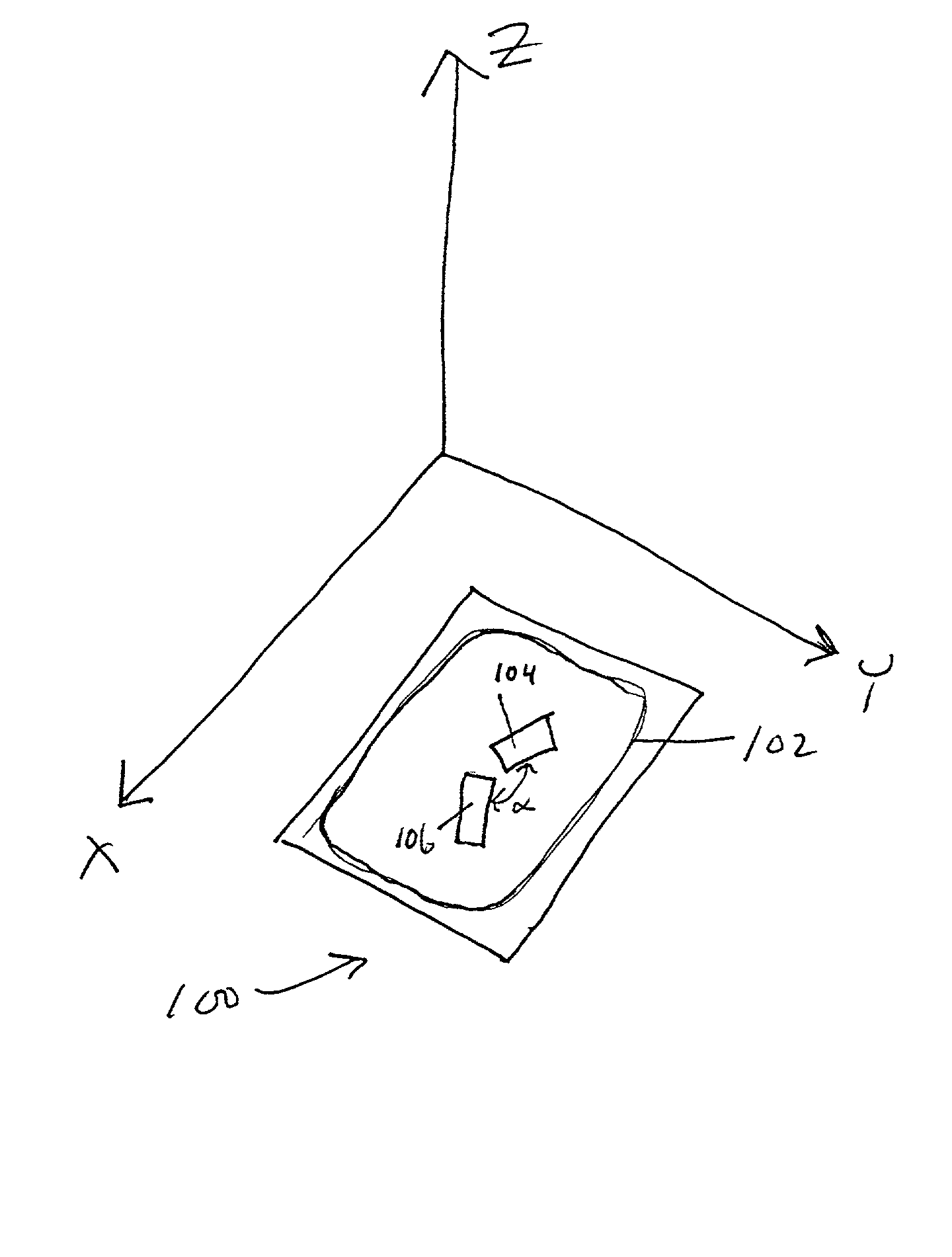

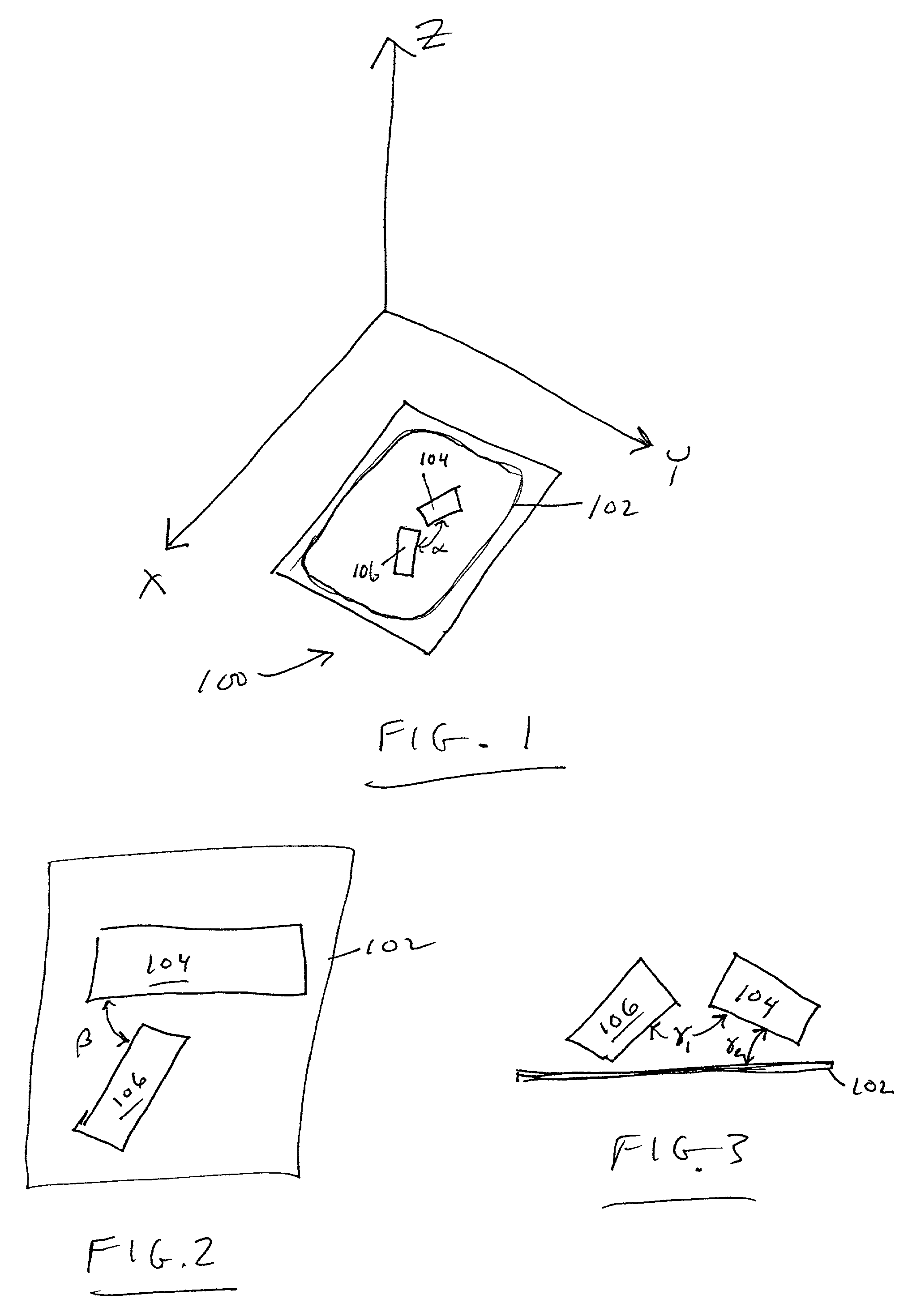

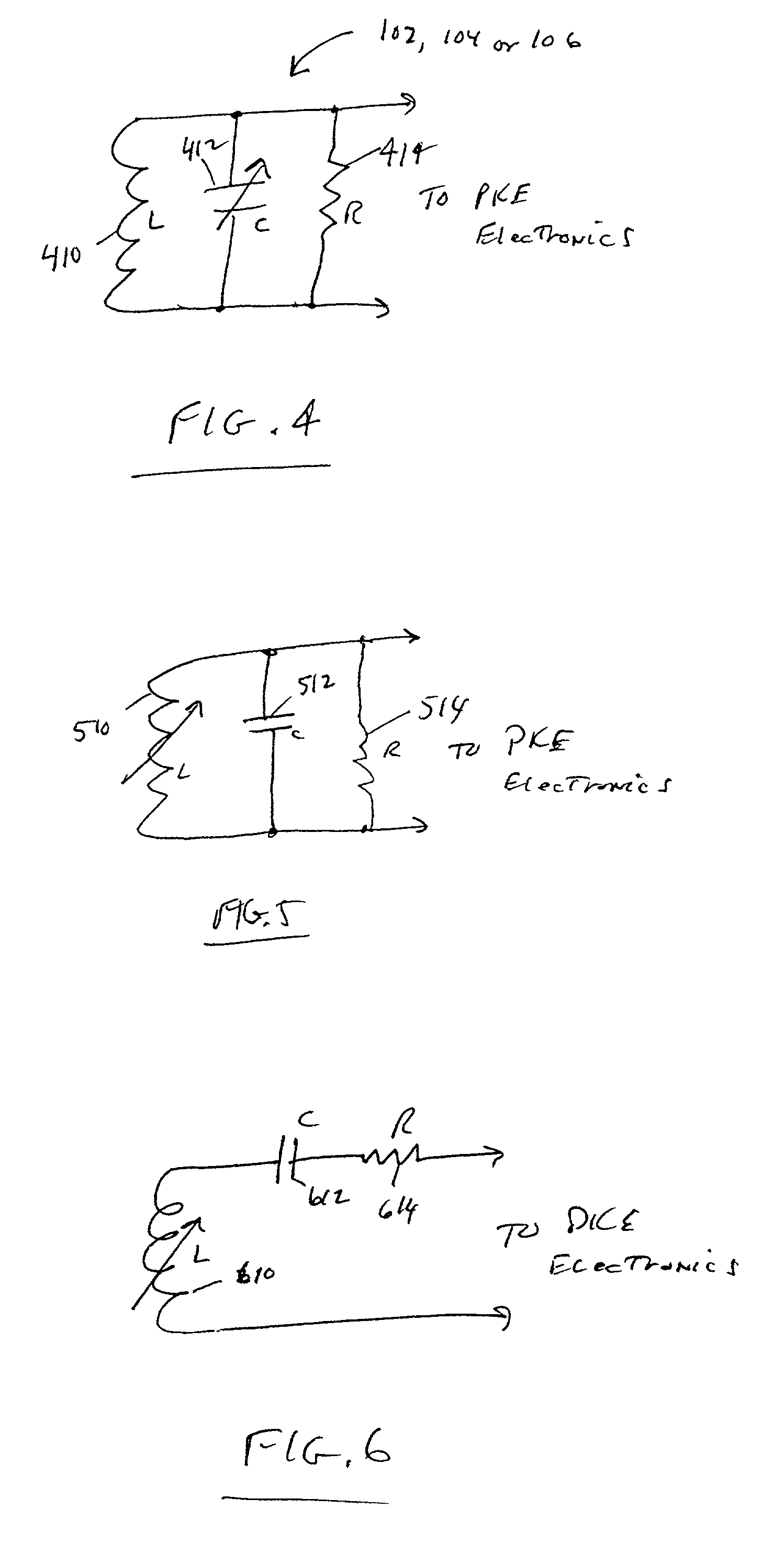

Reducing orientation directivity and improving operating distance of magnetic sensor coils in a magnetic field

InactiveUS20030076093A1Improve permeabilityIncrease the inductance valueAntenna adaptation in movable bodiesIndividual entry/exit registersCouplingResonance

In a passive keyless entry (PKE) system, a PKE key-fob has magnetic sensor coils arranged in non-perpendicular and non-parallel orientations therebetween, resulting in a more uniform omnidirectional pickup pattern when sensing a time varying magnetic field source from an interrogator base station of the PKE system. The magnetic sensor coils may also be stagger tuned to reduce frequency resonance change due to mutual inductance coupling interaction and / or create a desired magnetic field frequency response pickup pattern. Reducing null zones of different orientations of the PKE key-fob results in more uniform and reliable operation of the PKE system, and tuning the magnetic sensors to operate within the correct frequency and bandwidth of the interrogation magnetic signal increases the useful operating range of the PKE key-fob.

Owner:MICROCHIP TECH INC

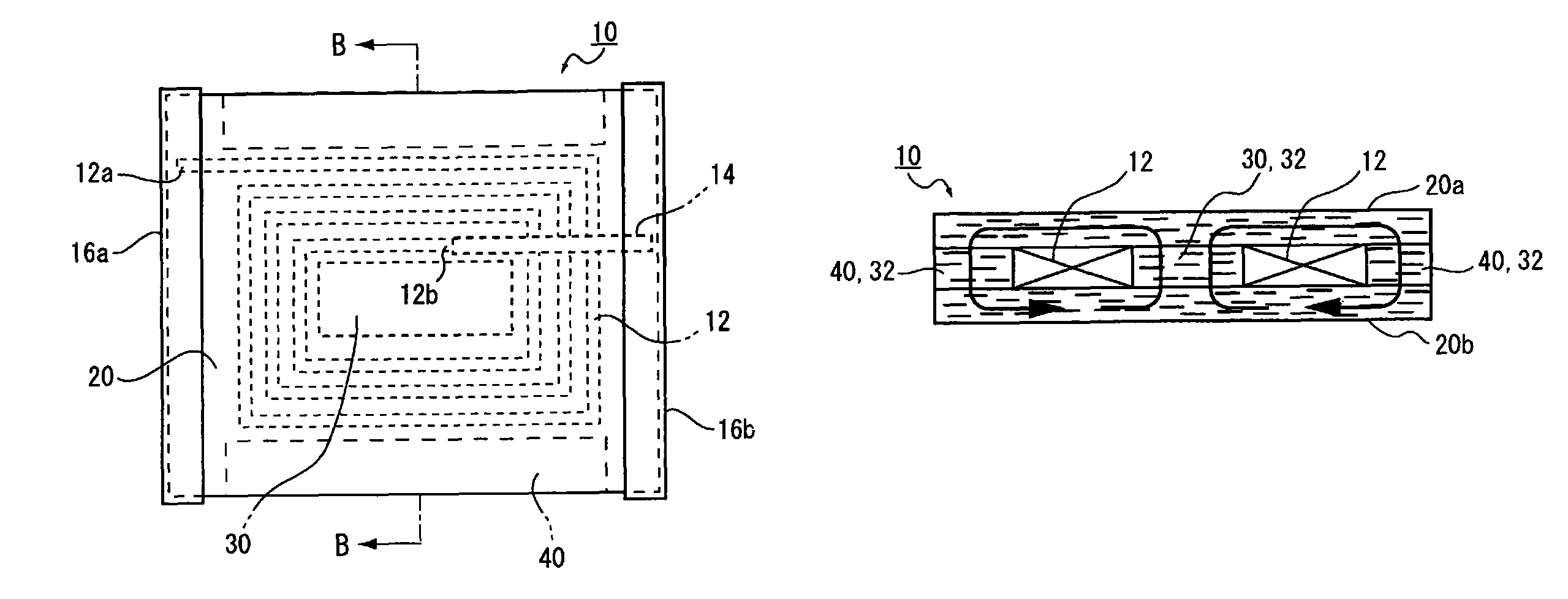

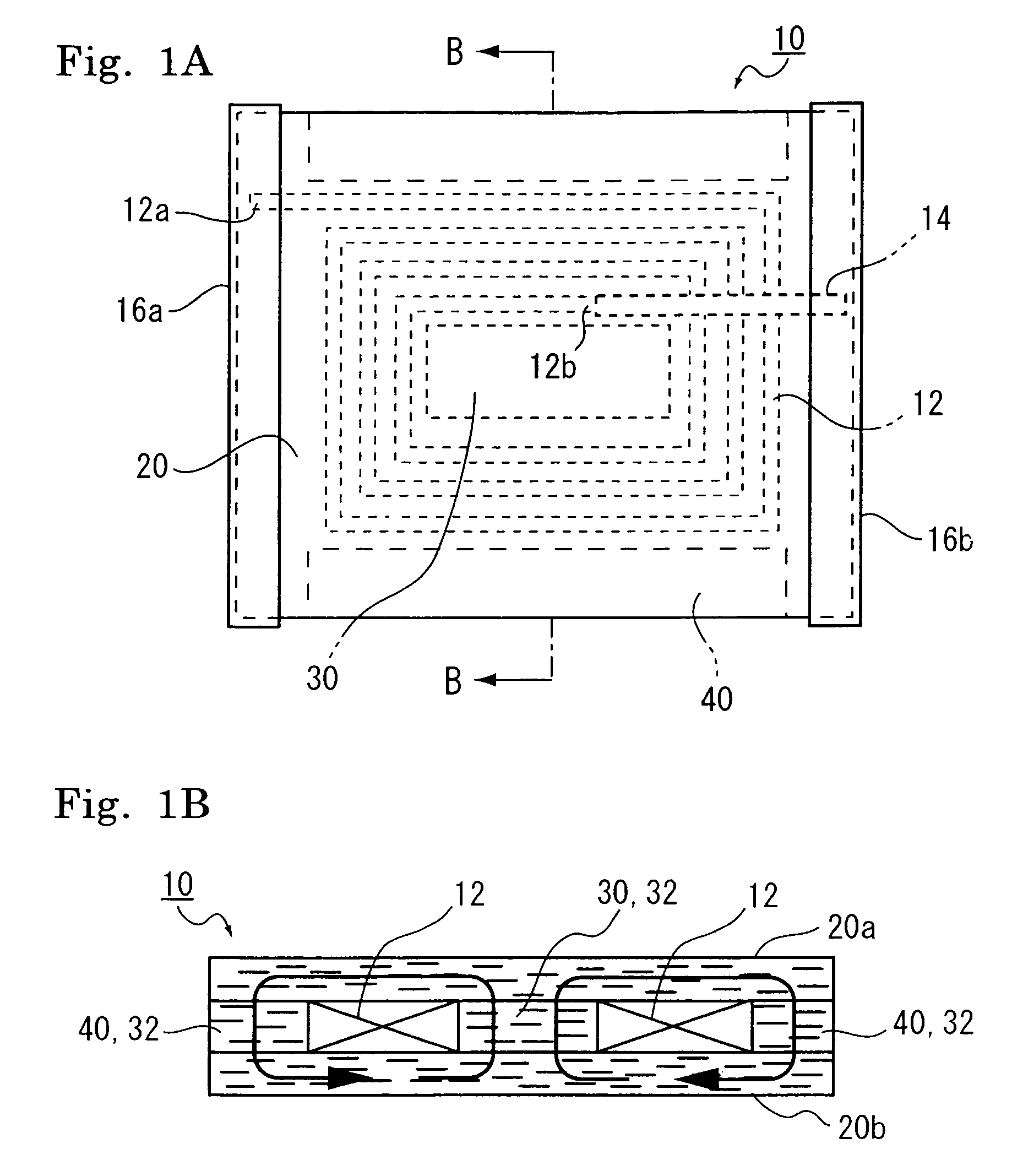

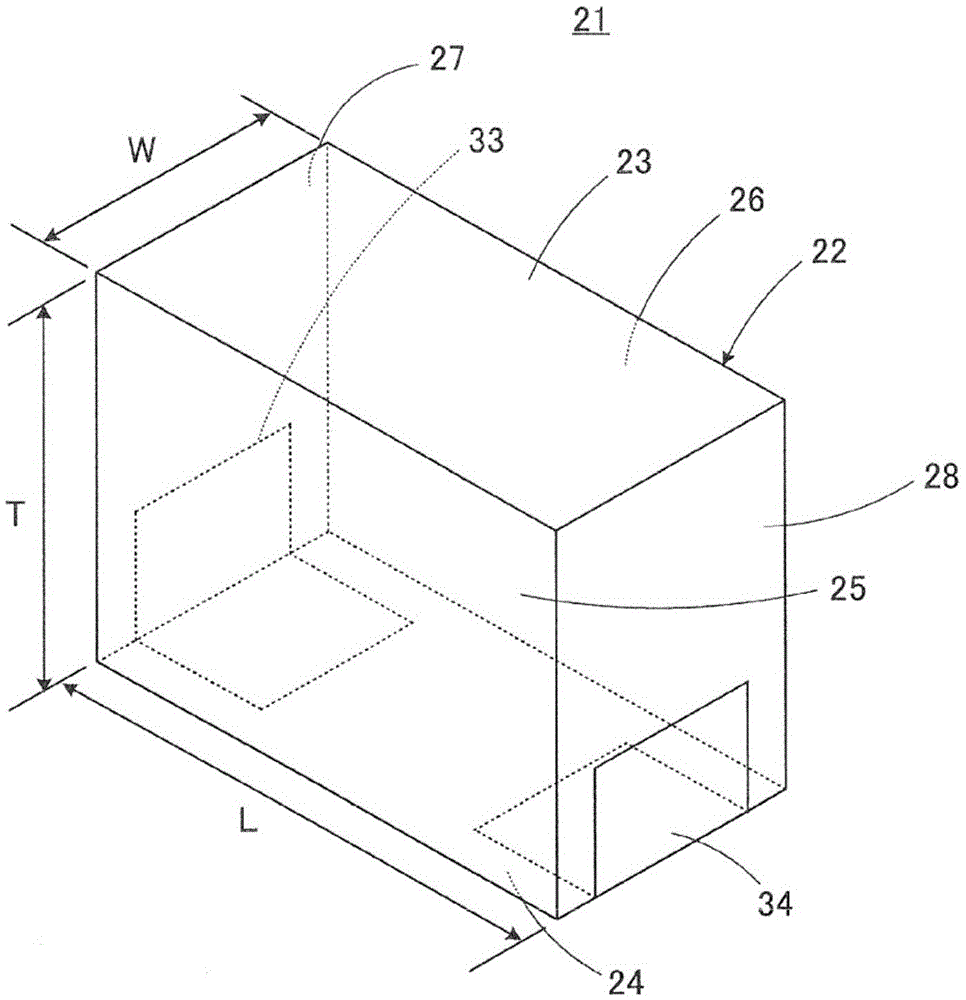

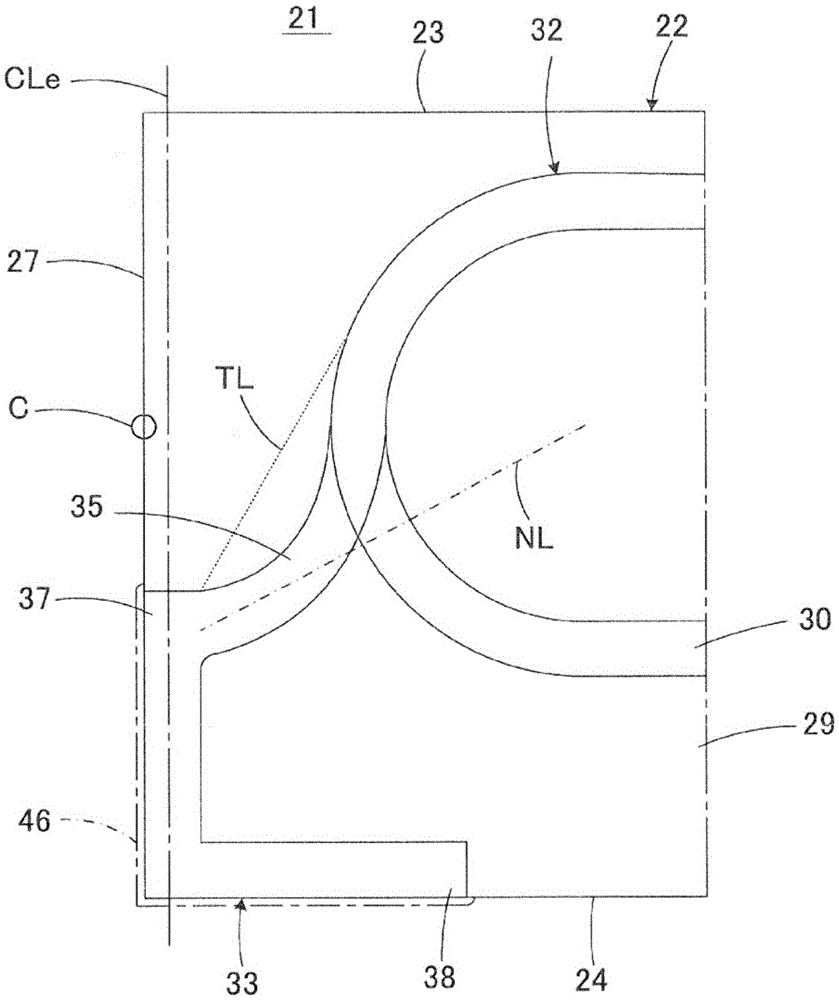

Coil component

ActiveCN106257603AReduce areaIncrease the inductance valueTransformers/inductances coils/windings/connectionsPrinted inductancesElectrical conductorEngineering

The invention provides a coil component in which a coil conductor is built in a laminated structure, and a higher inductance value and a Q value can be obtained. A central axis of the coil conductor (32) is oriented in parallel with a mounting surface. An external terminal electrode (33) is formed so as to extend from the bottom surface (a second main surface) (24) of a member main body (22) in an L-shape to the middle of an end surface (27). An extended conductor layer (35) connecting the external terminal electrode (33) and the coil conductor (32) is pulled out in a direction toward the upper surface (a first main surface) (23) from the end (37) of the external terminal electrode (33) in a state of forming identical end edges, with the distance larger than the distance extending in a normal line direction (NL) with respect to the outer peripheral edge of a circulating conductor layer (30) of the coil conductor (32) and equal to or smaller than the distance extending in a tangent line direction (TL) with respect to the outer peripheral edge of the circulating conductor layer (30), and connects the coil conductor (32) to the external terminal electrode (33).

Owner:MURATA MFG CO LTD

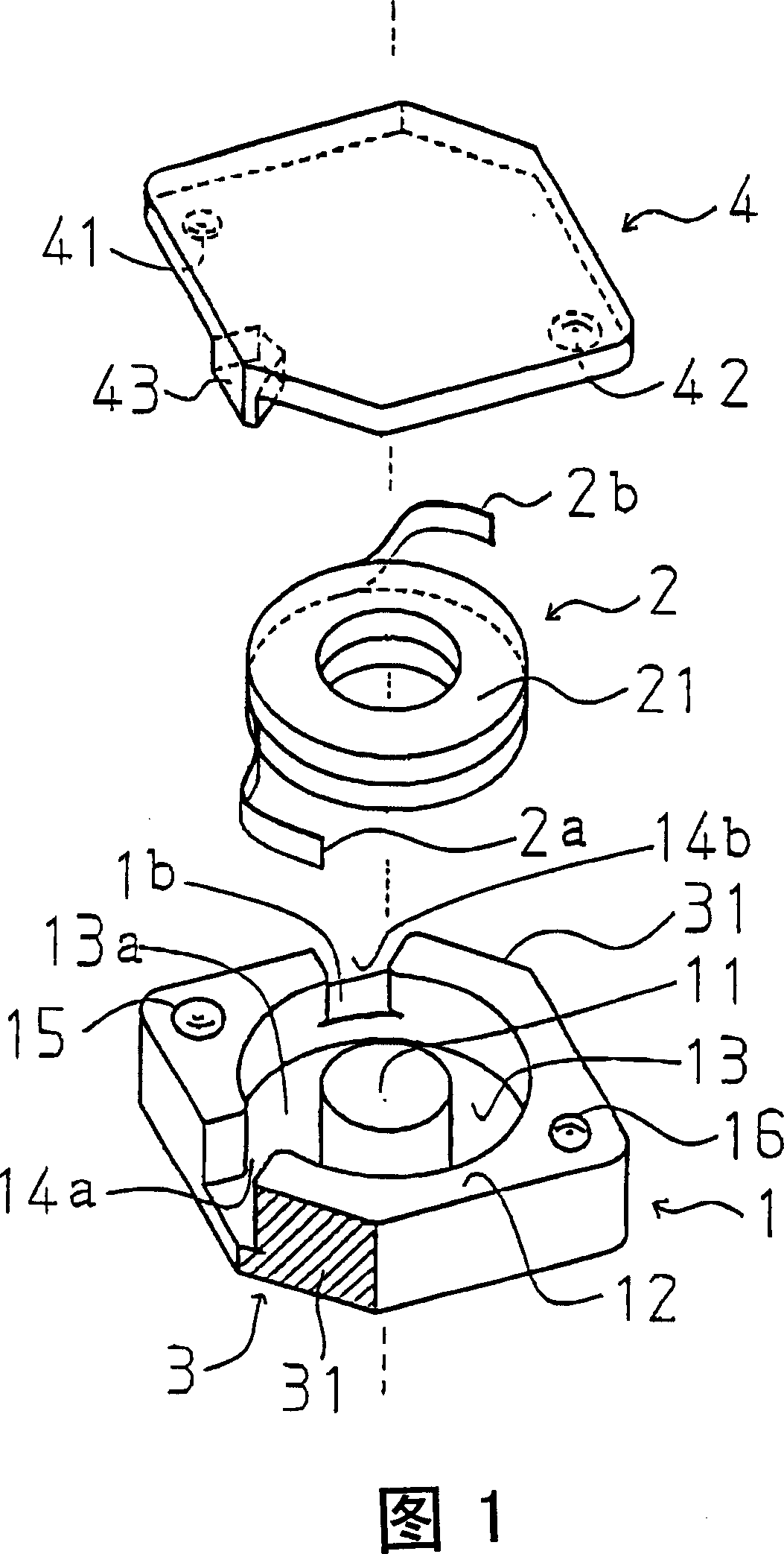

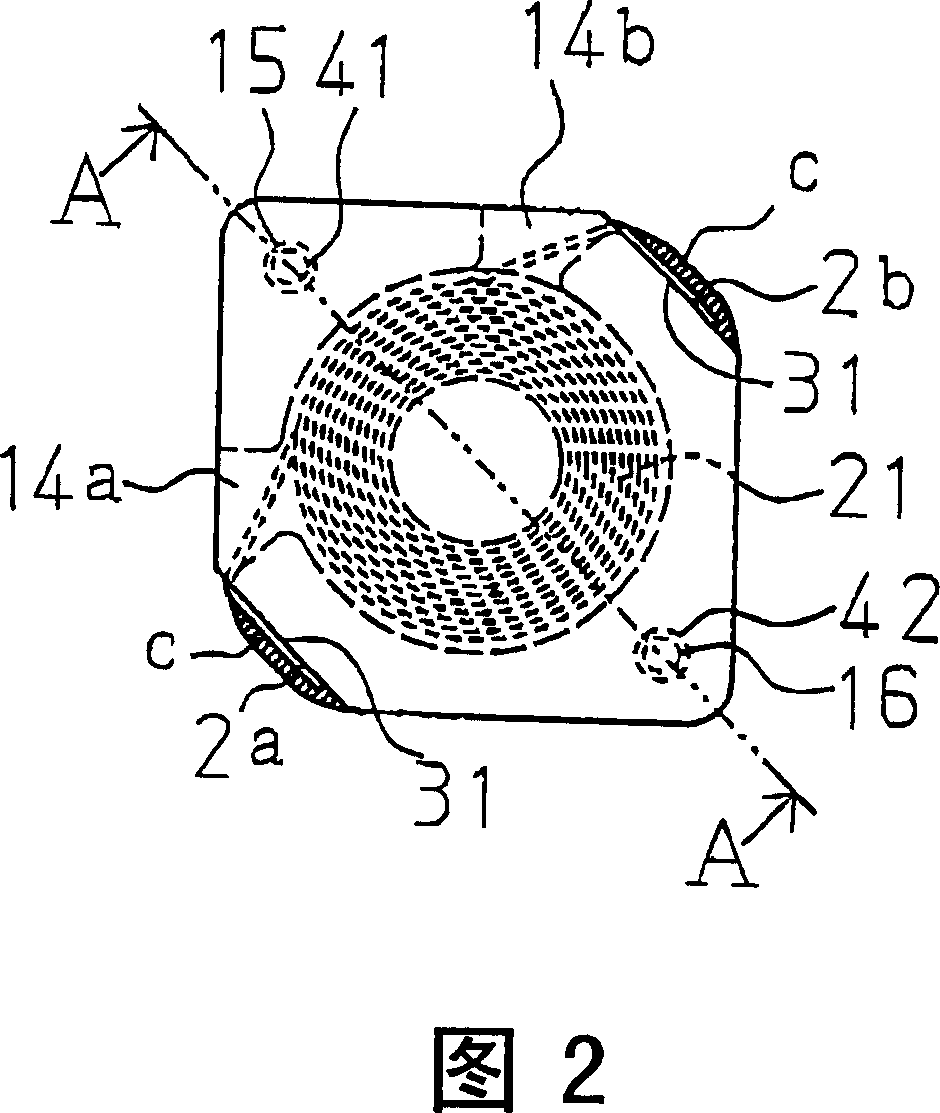

Surface installation inductor

InactiveCN1941227AHigh positioning accuracyImprove work efficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire widthSurface mounting

The present invention provides a surface-mounting inductor resolving the requirement for downsizing and a low profile having good assembling workability, an improved electrical characteristic, and no leakage magnetic flux. The surface-mounting inductor comprises a pot-type core having an external wall, a rectangular coil fixed to the pot-type core, a pair of electrodes provided on an outer periphery surface of the pot-type core, and a cover core for closing an opening end of the pot-type core. The pot-type core comprises a positioning mechanism for positioning with the cover core at the opening end, and two U shape windows having an open space adjacently over the electrode. The height of the bottom face of one U shape window is higher than that of the other U shape window by the width of a rectangular wire, and a protruding portion (43) having a height corresponding to the wire width of the rectangular coil is provided to the part of the cover core (4) corresponding to the other window (14a).

Owner:TOKYO PARTS IND CO LTD

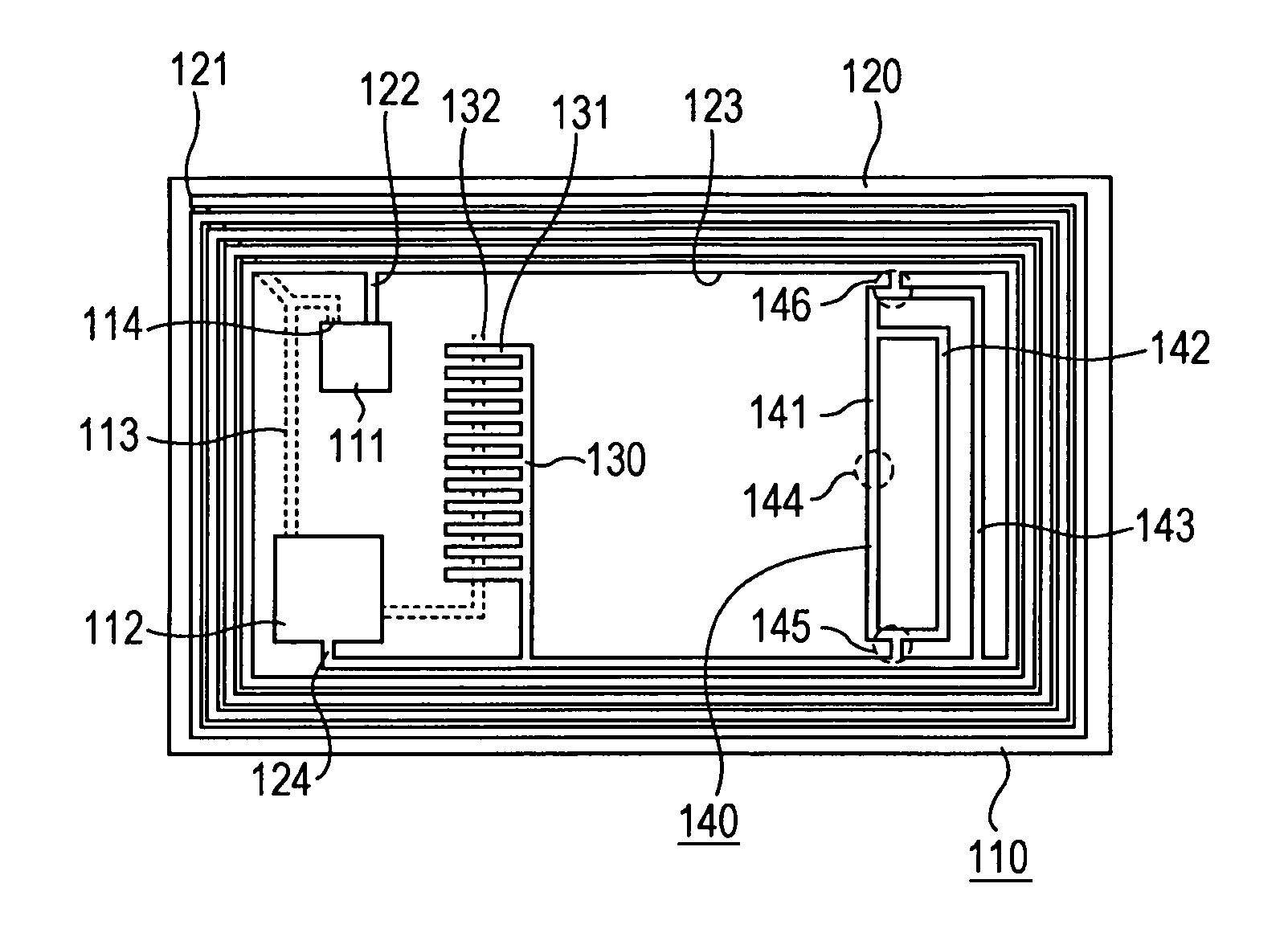

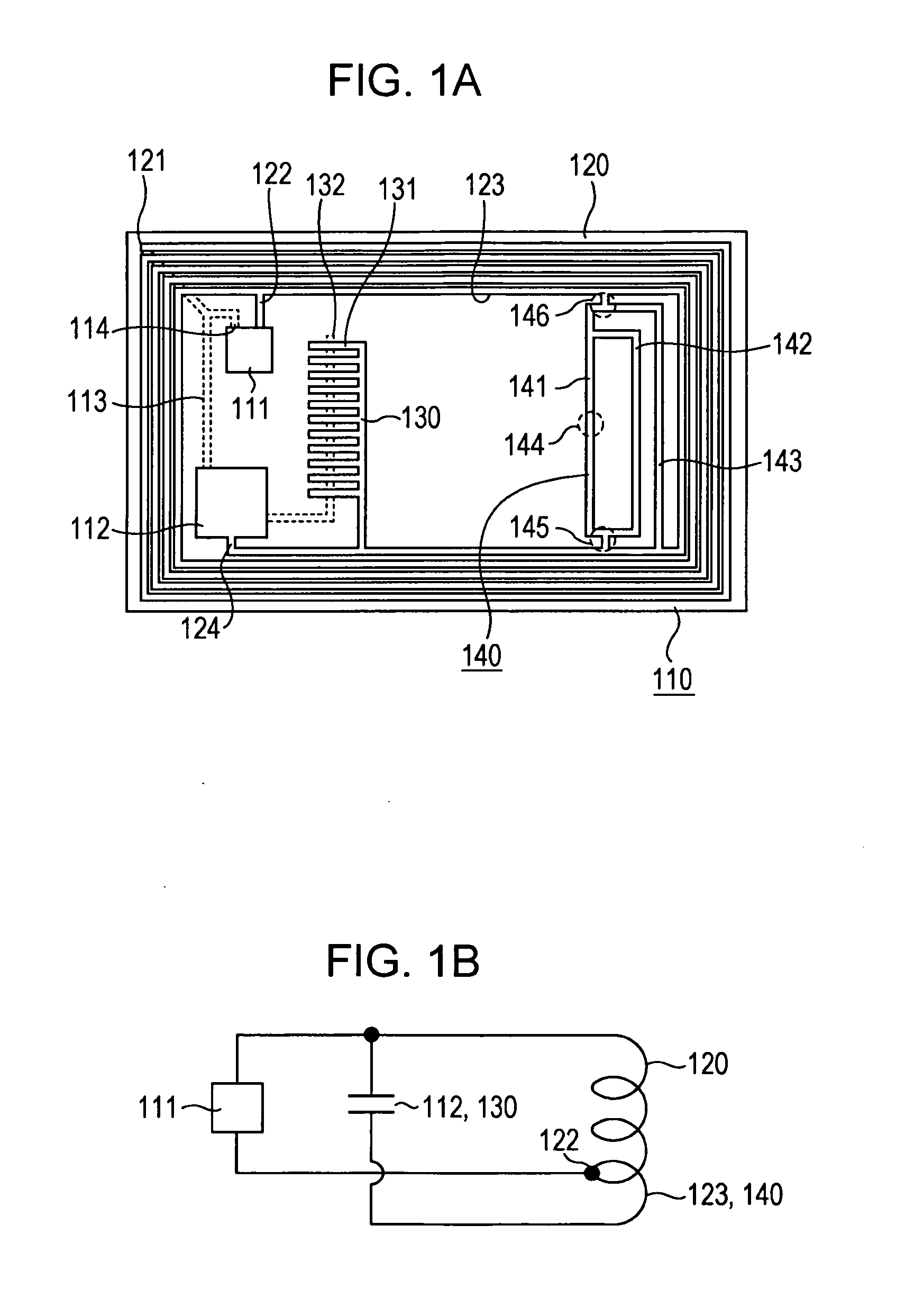

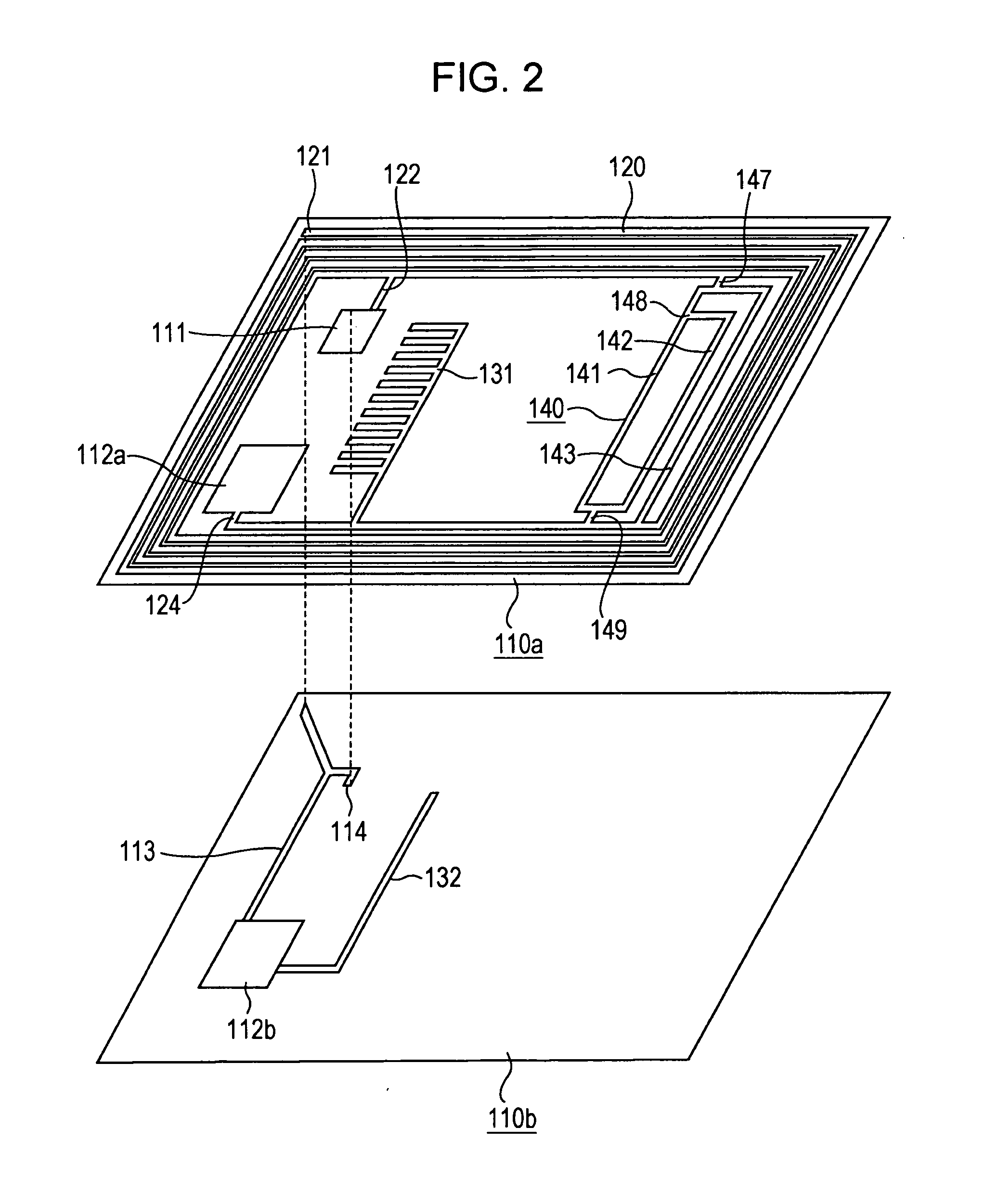

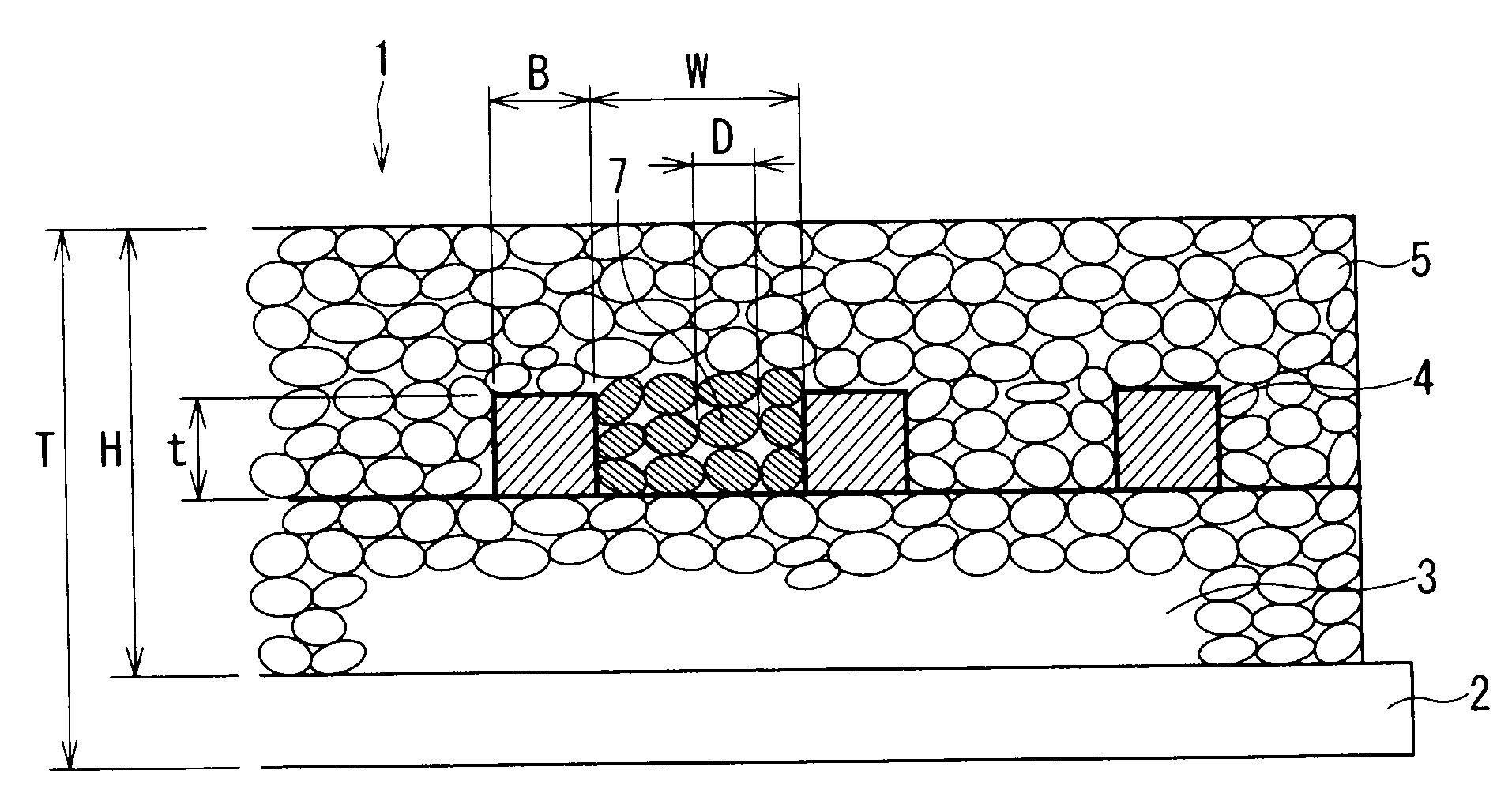

Contactless communication medium, antenna pattern-placed medium, communication apparatus, and antenna adjusting method

InactiveUS20110275318A1Increase the inductance valueLower resonance frequencyNear-field transmissionLoop antennasEngineeringElectrical conductor

A contactless communication medium includes a base made of an insulating material, an antenna coil section including a conductor wound in a planar shape on the base, an inductance adjusting conductor pattern that is connected in parallel to a part of the conductor in the antenna coil section, and is placed on the base, a capacitor connected to the antenna coil section, and a communication processing section that is connected to the antenna coil section and the capacitor to perform contactless communication processing.

Owner:SONY CORP

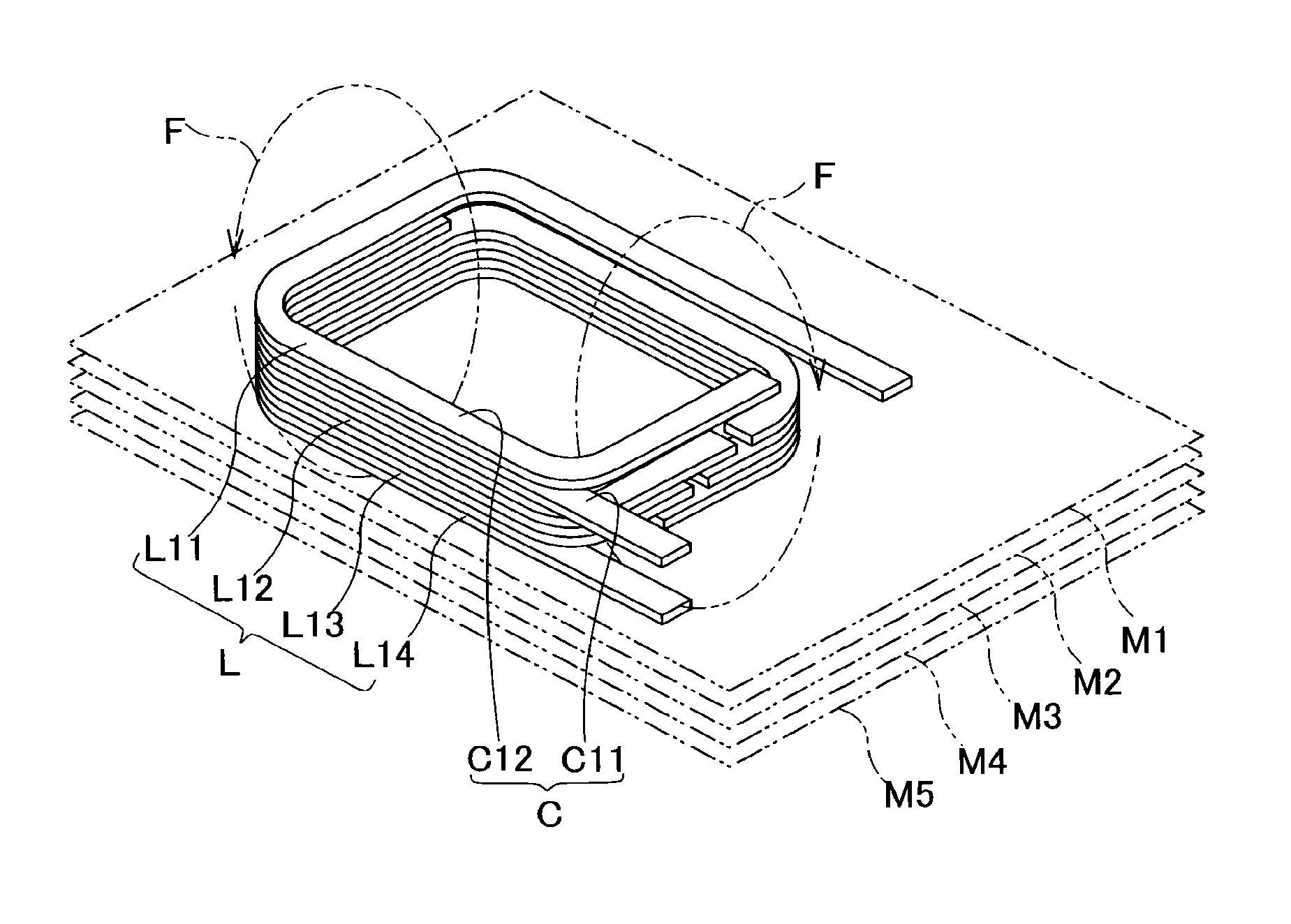

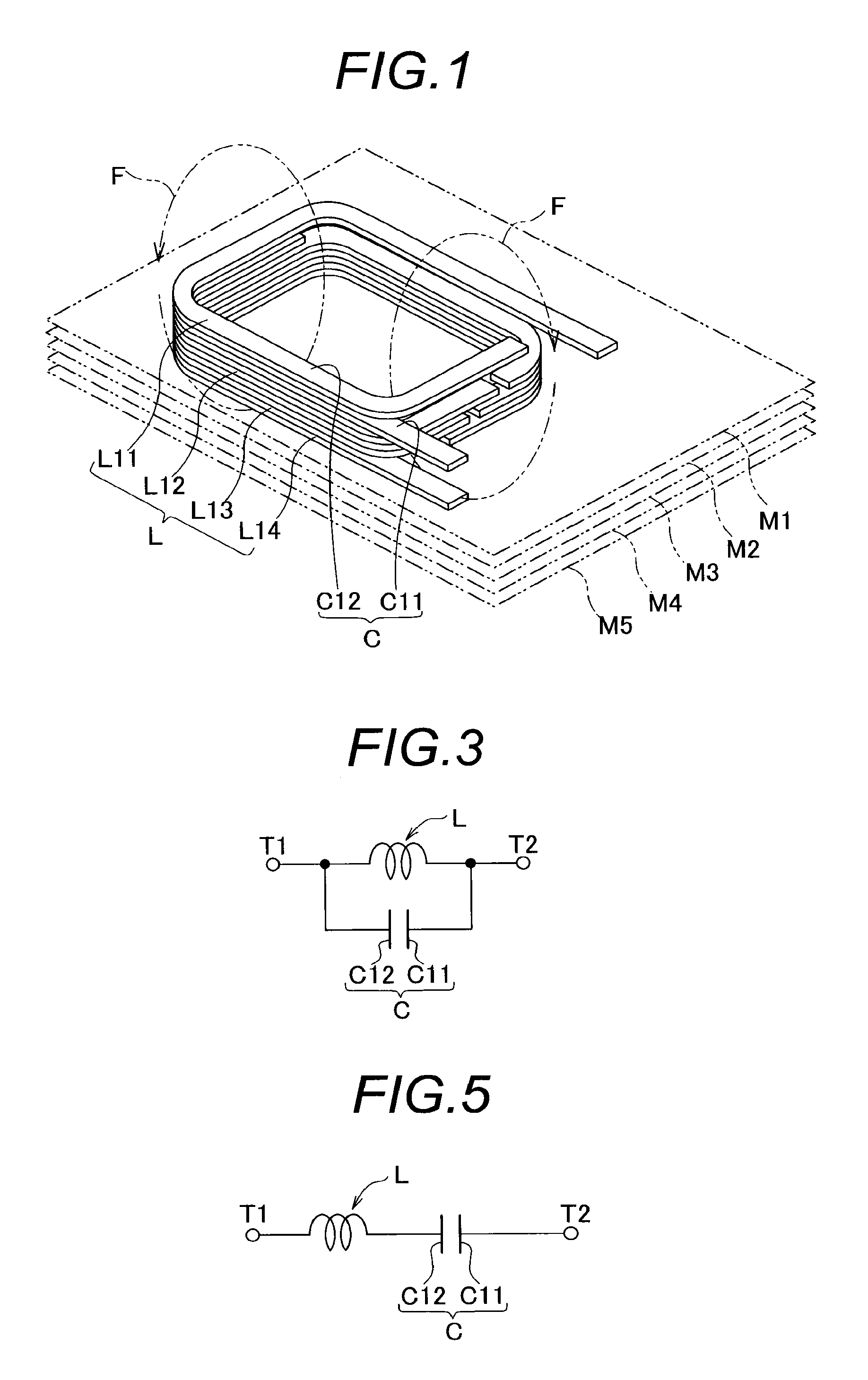

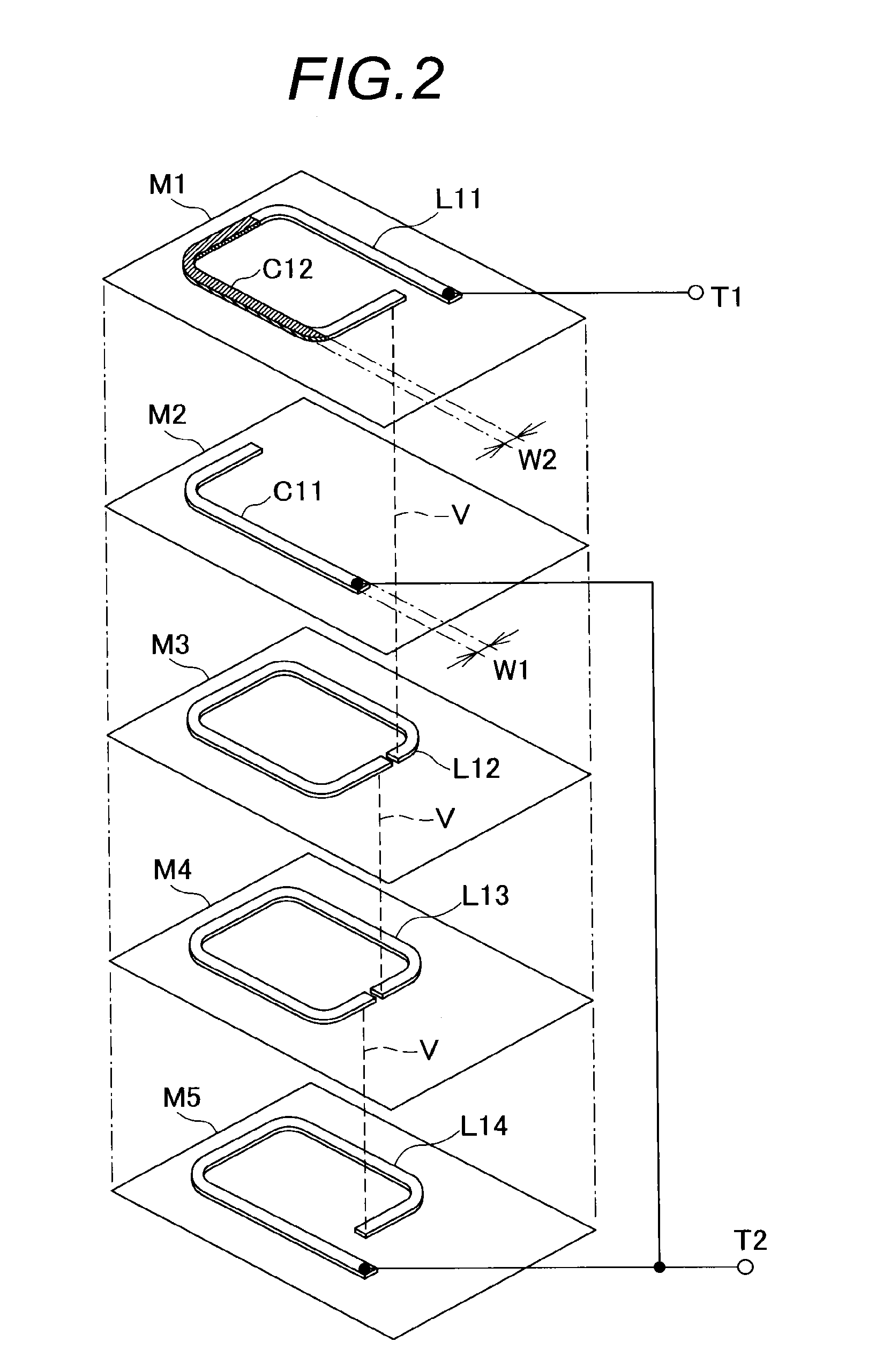

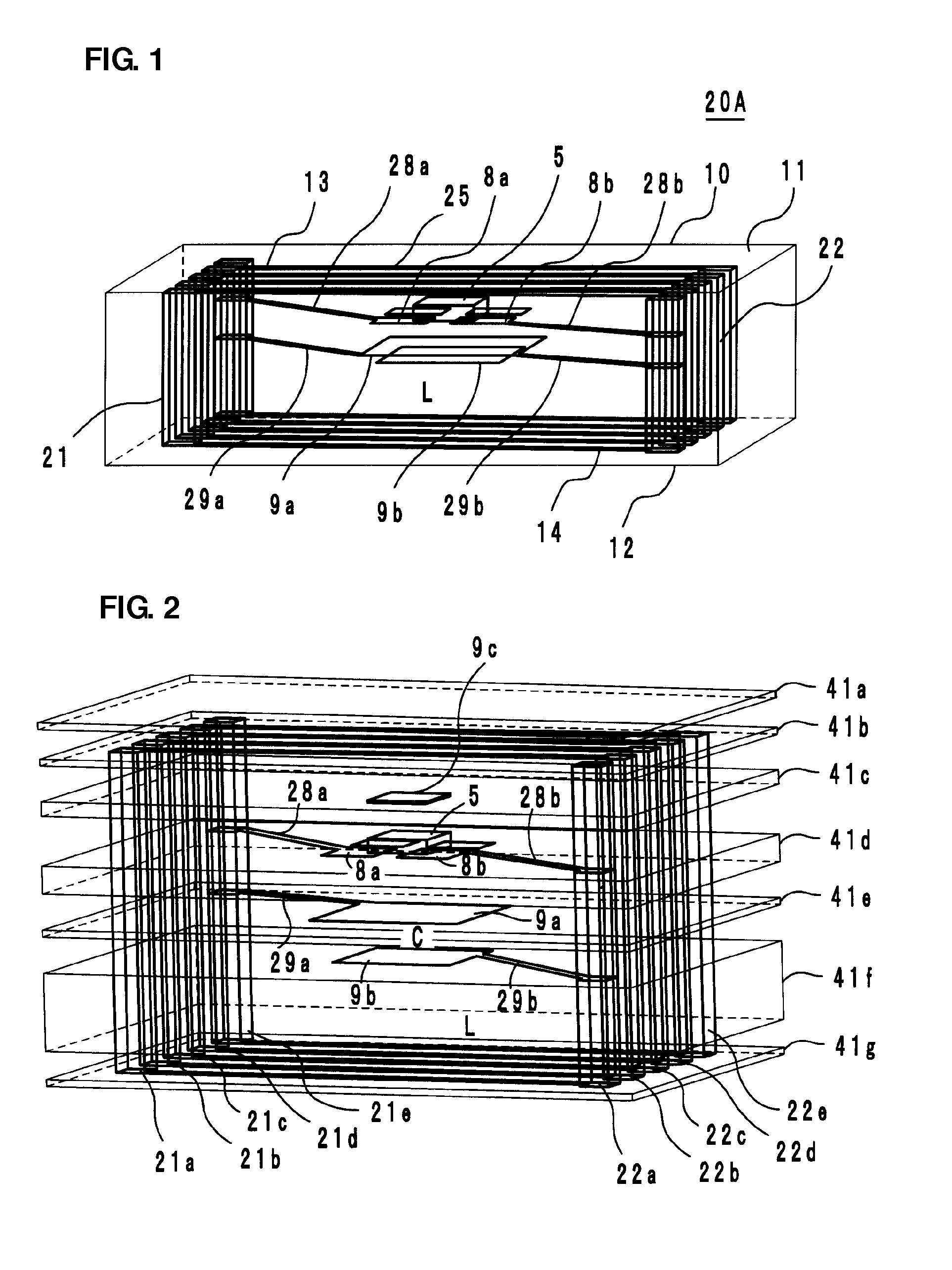

Laminated composite electronic device including coil and capacitor

ActiveUS20160307702A1Reduce the overall heightSmall sizeMultiple-port networksStructural fixed capacitor combinationsElectrical conductorEngineering

A laminated composite electronic device has a circuit including a coil and a capacitor within a laminate having a plurality of conductor layers laminated with an insulating layer interposed between the respective ones of the conductor layers. The device includes a coil conductor arranged on a first conductor layer and forming part of the coil, and a pair of capacitor electrodes for forming the capacitor, one of which is arranged on a second conductor layer such that the one capacitor electrode laps over the coil conductor when viewed from a laminating direction of the laminate, wherein the coil conductor forms part of the coil, and simultaneously serves as the other of the pair of capacitor electrode for forming part of the capacitor.

Owner:TDK CORPARATION

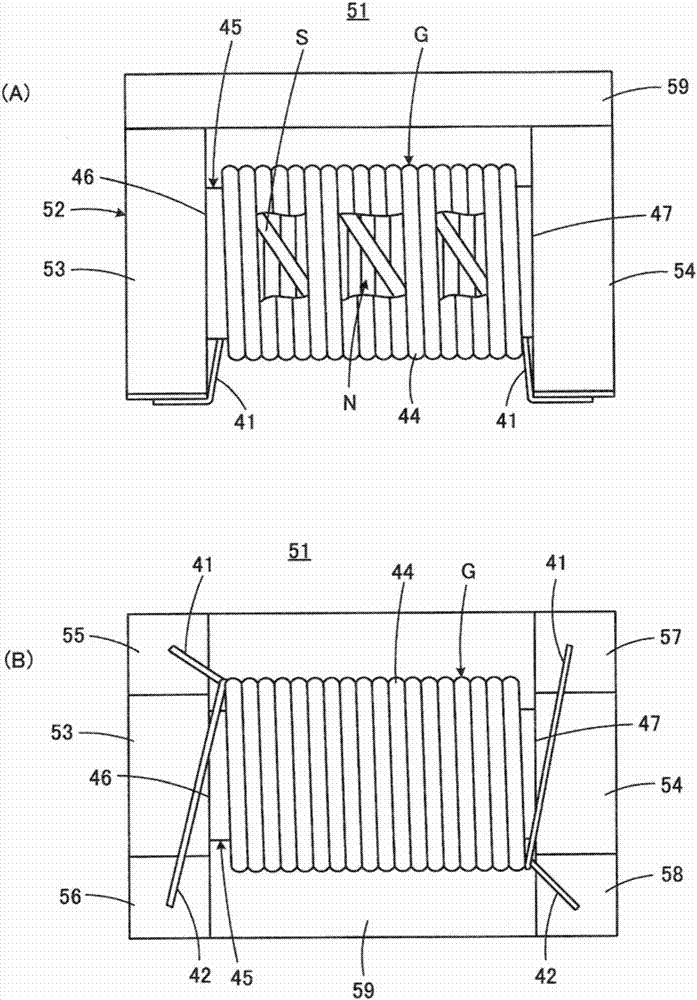

Coil component

InactiveCN107275041AIncrease the inductance valueGood Mode Conversion CharacteristicsTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresWire rodInductance

The invention provides a coil component. In a common mode choking coil as an example of the coil component, excellent model conversion characteristics can be guaranteed even the number of turns of wires is increased for obtaining high inductance. A wire assembly portion (44) formed by twisting two wires is wrapped around a winding core portion (45). The wire assembly portion (44) comprises an inner layer portion (N) that is in contact with and wound around the circumferential surface of the winding core portion with a first end portion (46) as the initial end, an outer layer portion (G) wound around the outer circumference of the inner layer portion, outward transition portions each extending from the inner layer portion to the outer layer portion, and an inward transition portion extending from the outer layer portion to the inner layer portion. The wire assembly portion is lead out from the middle position in the winding center axis direction of the inner layer portion by means of the outward transition portions to form the outer layer portion and returns to the middle position of the inner layer portion by means of the inward transition portion.

Owner:MURATA MFG CO LTD

High-magnetoconductivity soft magnetic alloy powder, inductance piece and preparation methods thereof

ActiveCN106205934AReduce power lossSolve the problem of low magnetic permeability and large power lossTransformers/inductances detailsMagnetic materialsApparent densityInductor

The invention discloses high-magnetoconductivity soft magnetic alloy powder. The alloy consists is prepared from the following components in parts by mass: 25.0 to 80.0 parts of Fe, 3.0 to 8.0 parts of Si, 15 to 55 parts of Ni, 1.0 to 7.0 parts of B and 1.0 to 5.0 parts of P. The invention further discloses an inductance piece prepared from the high-magnetoconductivity soft magnetic alloy powder, a preparation method of the high-magnetoconductivity soft magnetic alloy powder and a preparation method of the inductance piece. By the adoption of the preparation method disclosed by the invention, the soft magnetic alloy powder with various particle sizes can be prepared, and the soft magnetic alloy powder is high in magnetoconductivity, lower in power loss, higher in apparent density, high in tap density, lower in oxygen content, high in product pressing performance and high in magnetic ring density. Due to small oxygen content, few impurities, small carbon content, uniform alloy components and high sphericity degree, the high-magnetoconductivity soft magnetic alloy powder can be widely used as a raw material of a novel sintered inductor.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

Component of wireless IC device and wireless IC device

ActiveUS20110062244A1Stable characteristicsIncrease the inductance valueSemiconductor/solid-state device detailsSolid-state devicesEngineeringIc devices

A component of a wireless IC device includes a wireless IC chip and a feeding circuit substrate including a plurality of laminated resin layers. The wireless IC chip is included inside the feeding circuit substrate, and an annular electrode is arranged inside the feeding circuit substrate. The component of a wireless IC device and the radiation plate define the wireless IC device.

Owner:MURATA MFG CO LTD

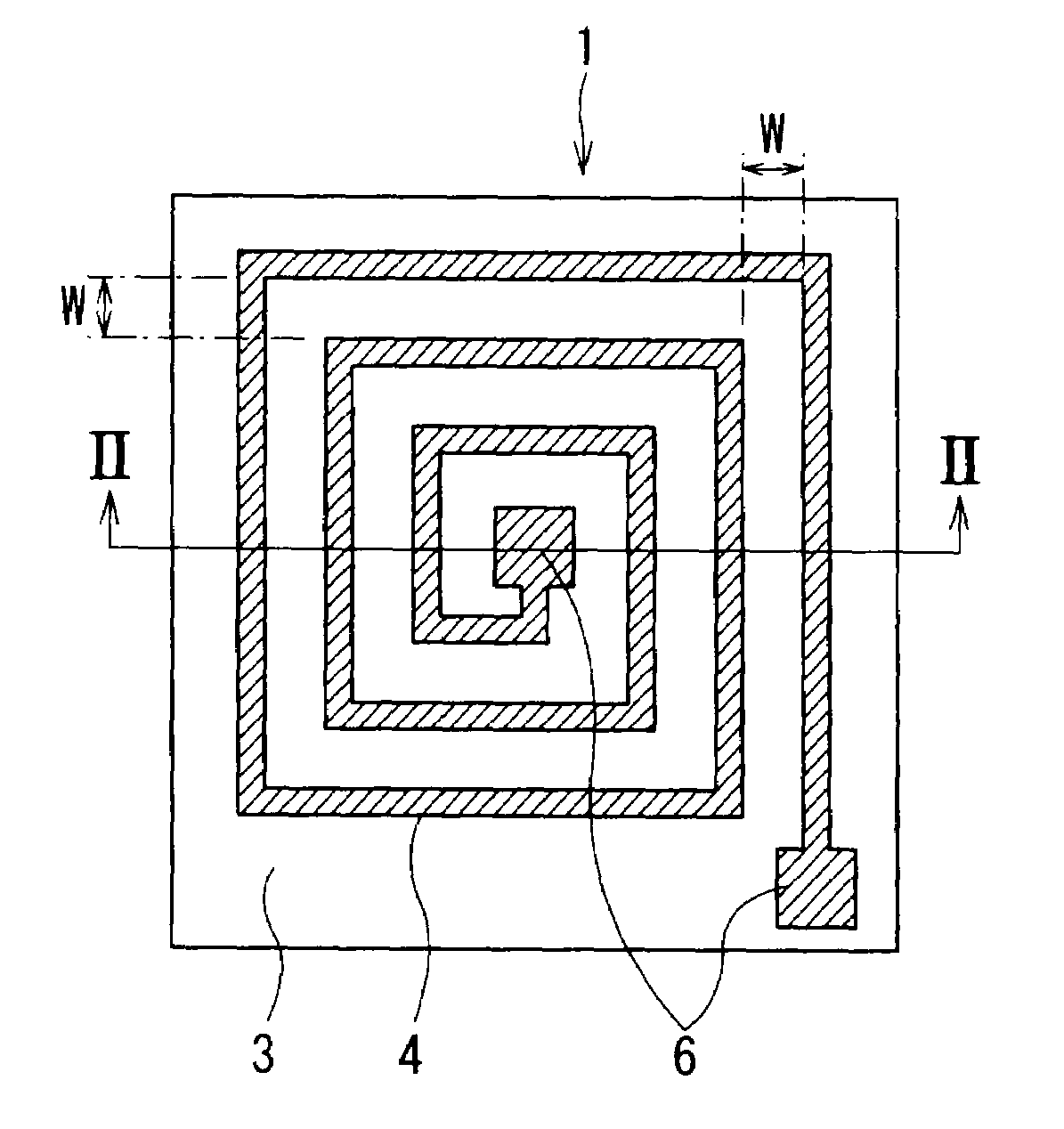

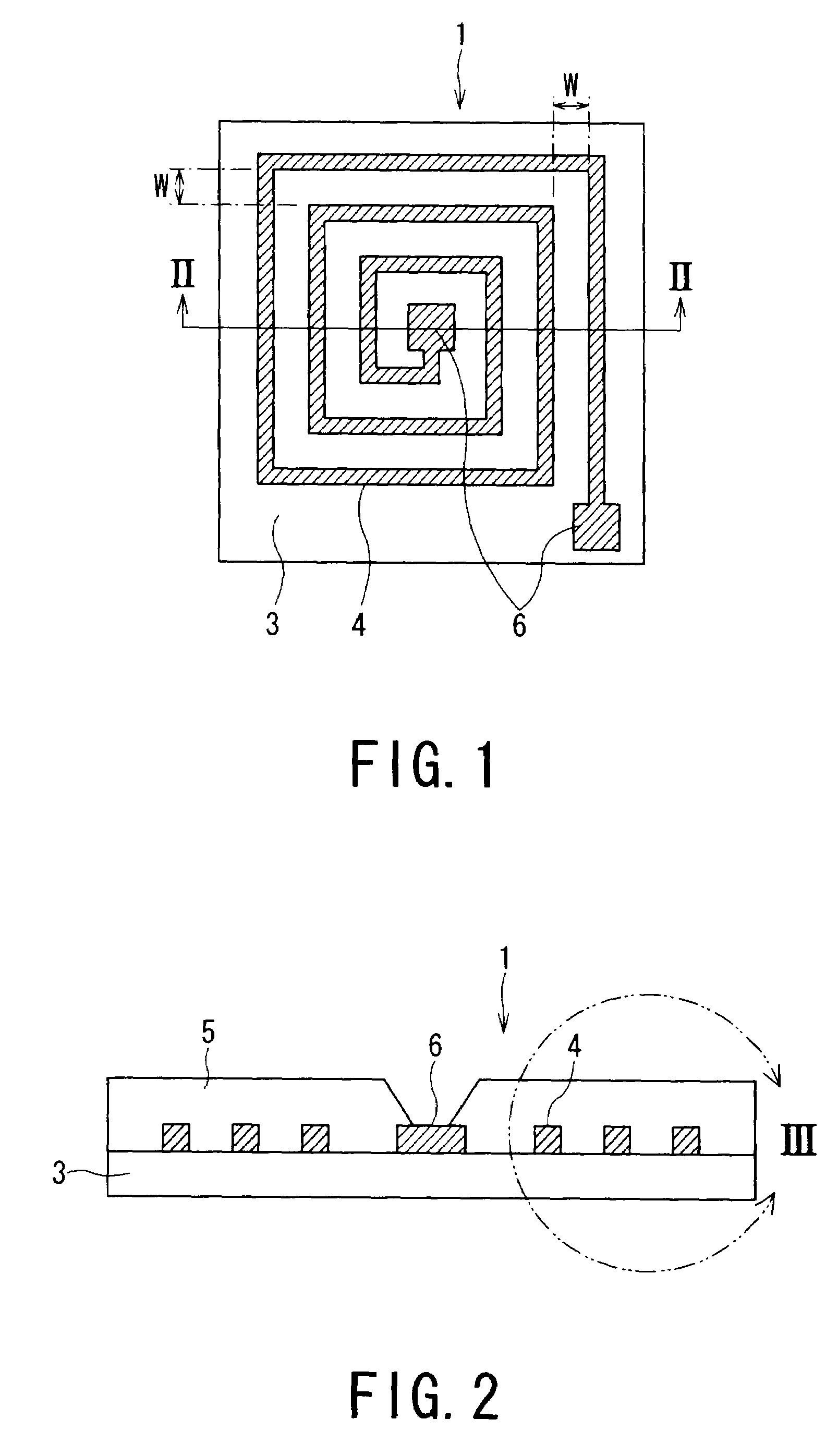

Flat magnetic element and power IC package using the same

ActiveUS7821371B2Large inductance valueReduce the overall heightTransformers/inductances casingsSemiconductor/solid-state device detailsLong axisInductor

A planar magnetic device 1 including a first magnetic layer 3, a second magnetic layer 5, and a planar coil 4 disposed between the first magnetic layer 3 and the second magnetic layer 5, wherein magnetic particles 7 having a shape ratio S / L of 0.7 to 1 when a length of a long axis is L and a length of a short axis orthogonal to the long axis is L are filled in a gap W between coil wirings of the planar coil 4. According to the planar magnetic device 1, it is possible to realize a planar magnetic device such as an inductor reduced in height by using fine particles that enable to effectively obtain a large inductance value.

Owner:KK TOSHIBA +1

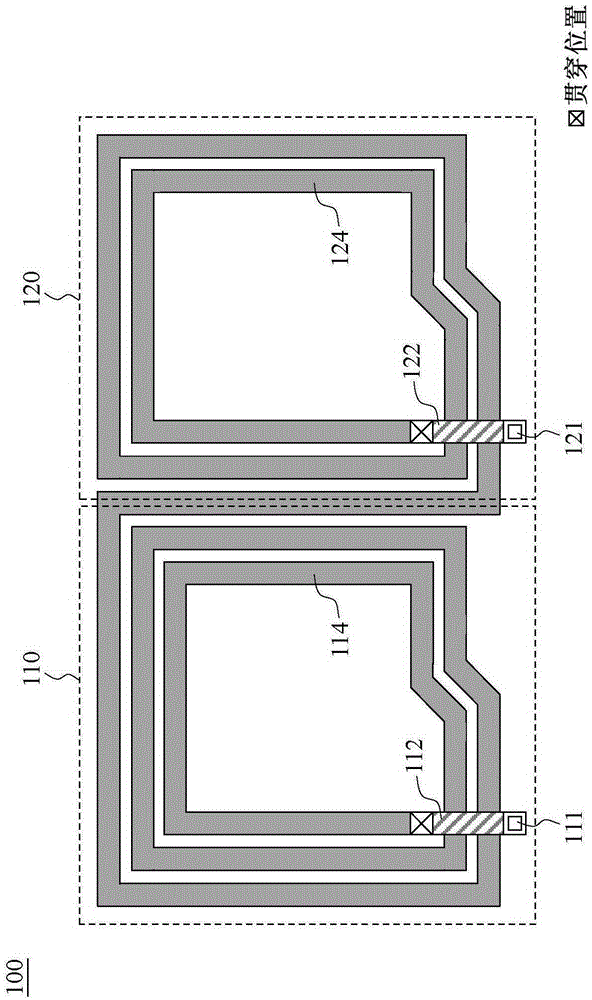

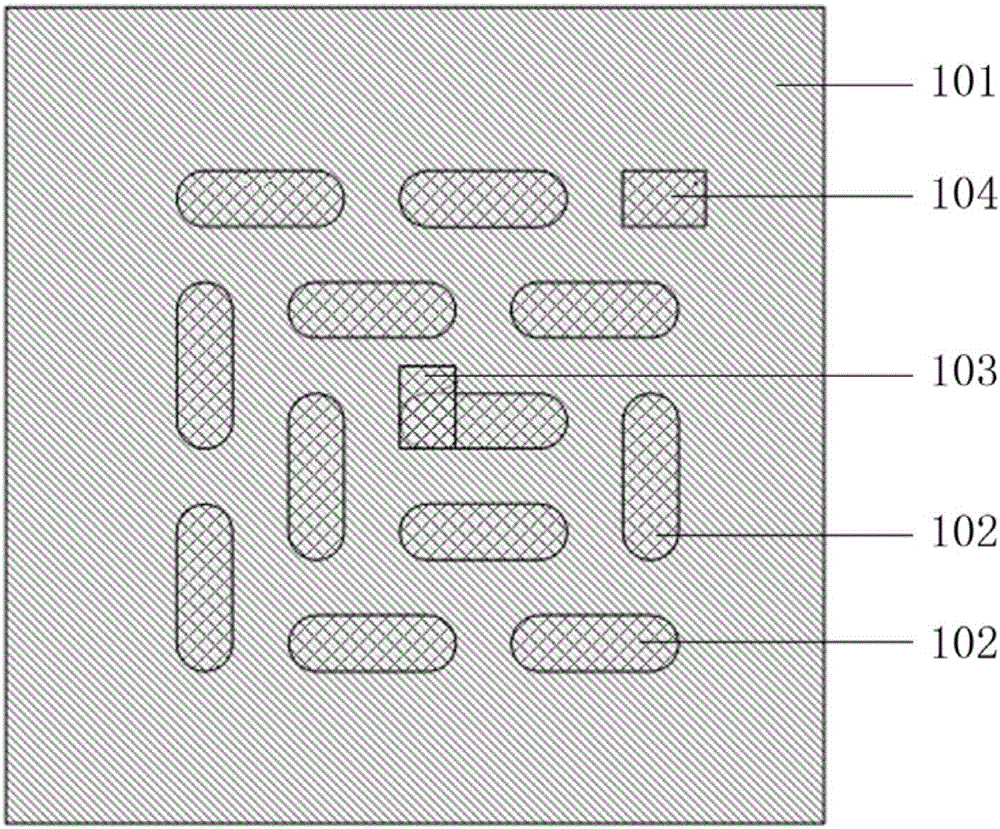

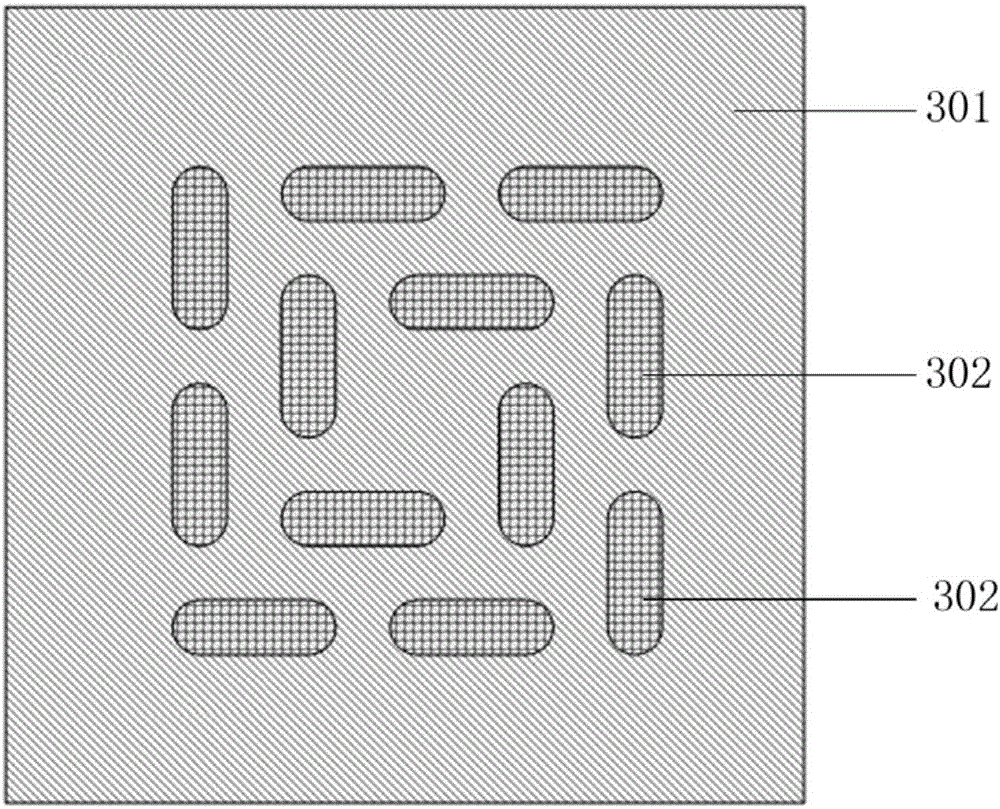

Multi-path laminated inductor with inner path and outer path current compensation function

InactiveCN102087909AReduce skin effectIncrease the inductance valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCross connectionPower flow

The invention discloses a multi-path laminated inductor with an inner path and outer path current compensation function. The multi-path laminated inductor has a multilayer structure and comprises an upper layer metal coil and a lower layer metal coil, wherein slotted parts of patterns of the upper layer metal coil and the lower layer metal coil are coincident with each other; each metal coil consists of a plurality of paths of metal wires; the path of metal wire inside the first layer of metal coil is wound to the other layer of metal coil, and is turned and connected to form an outer path of metal wire; the path of metal wire inside the other layer of metal coil is wound to the first layer of metal coil, and is turned and connected to form an outer path of metal wire; and the upper layer metal coil is interconnected with the lower layer metal coil. The invention provides a multi-coil laminated inductor with a new structure; and the influence of skin effect and proximity effect is reduced by dividing the plurality of paths and cross-connecting the upper layer metal and the lower layer metal. In the inductor, the inductance under the same area condition is improved to the great extent, and a higher inductance quality factor is effectively kept.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

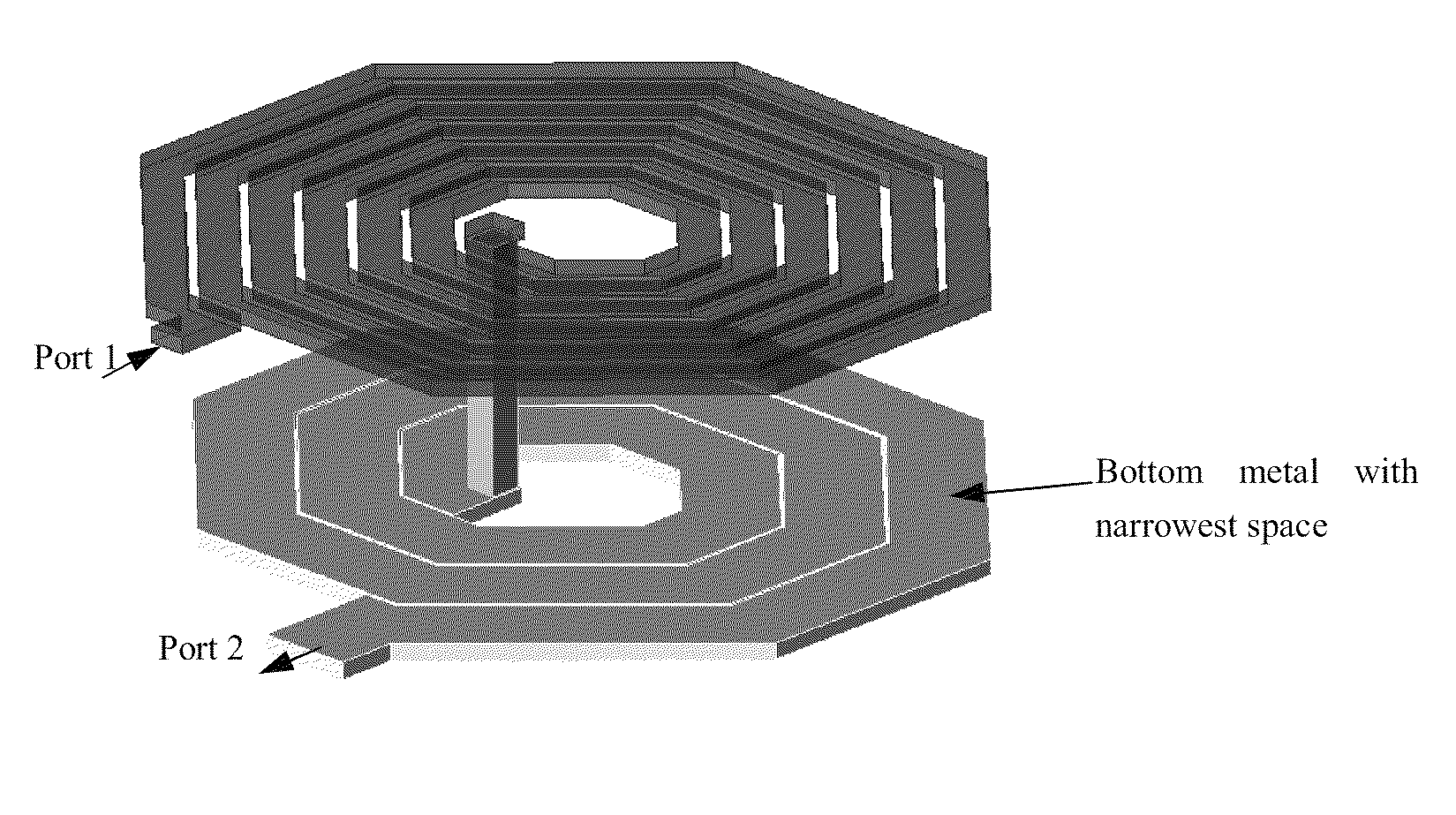

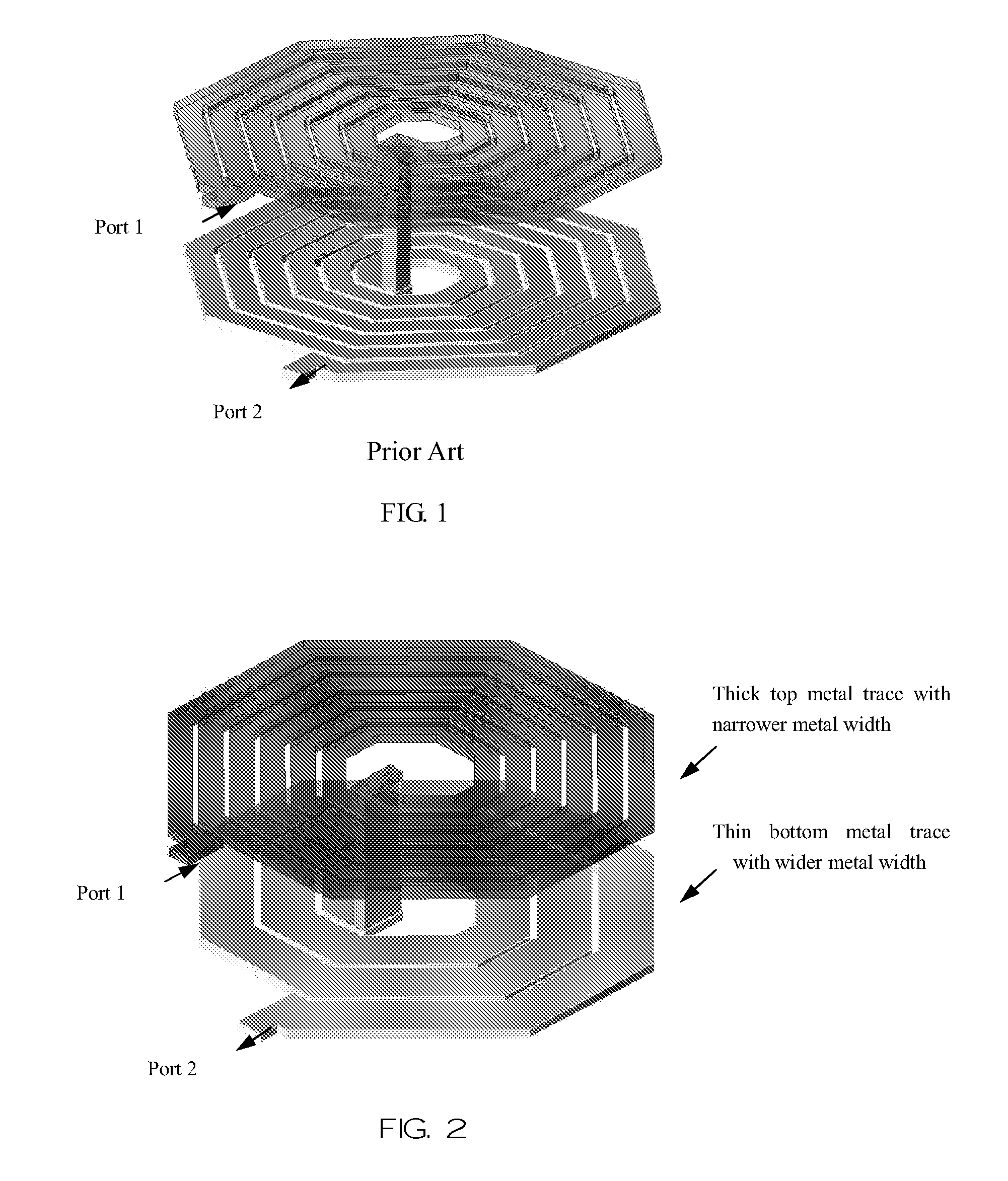

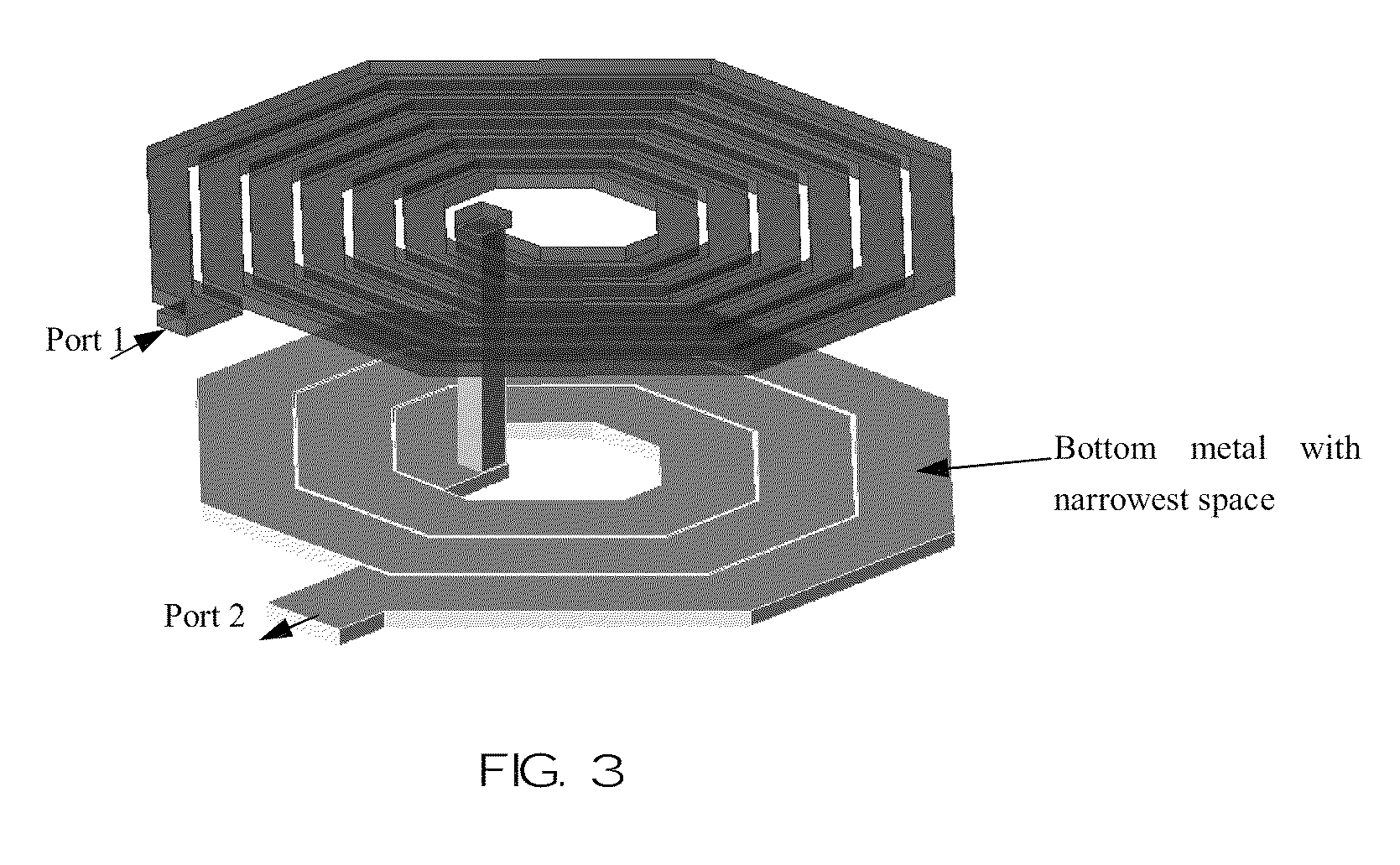

Stack inductor with different metal thickness and metal width

ActiveUS8441333B2Reduce resistanceIncrease the inductance valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsInductorInductance

A stacked inductor with different metal thickness and metal width. The stacked inductor comprises top and bottom metal traces which are aligned with each other. The thickness and width of the top and bottom metal traces are different. The top and bottom metal traces are connected at the end of metal trace with via holes. The inductance is increased with the use of the mutual inductance between top and bottom metal layers The parasitic resistor is reduced due to the difference of the top and bottom metal widths.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

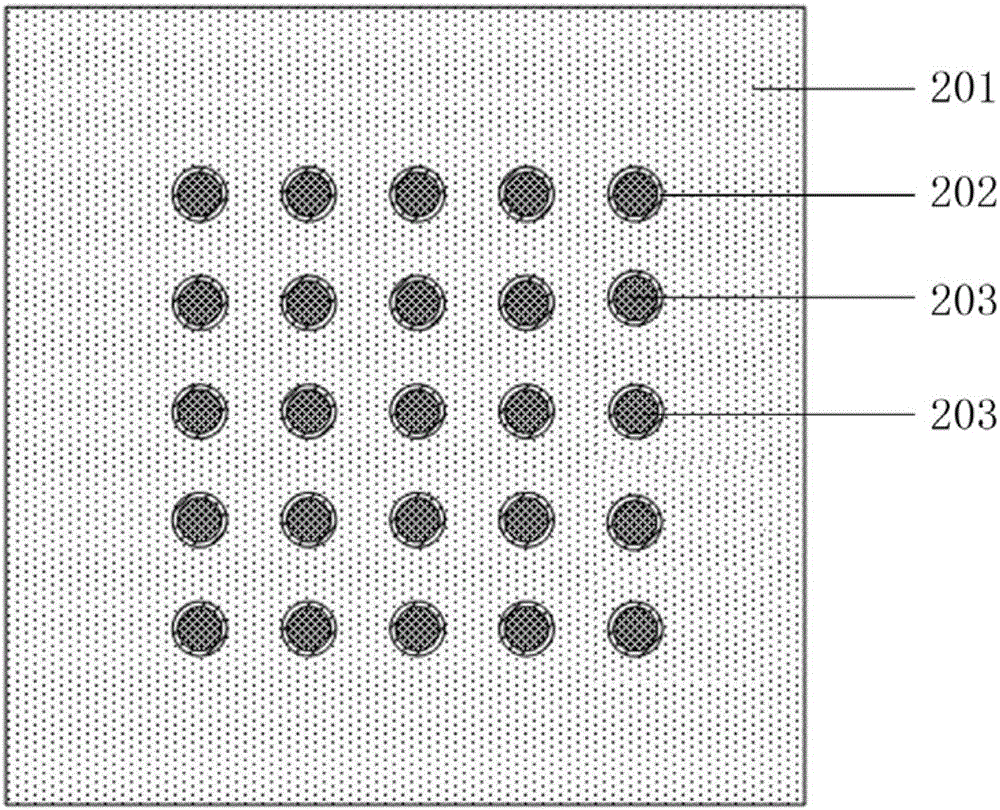

Through silicon via array-based three-dimensional spiral inductor

InactiveCN106206553AFulfil requirementsQuality improvementSemiconductor/solid-state device detailsSolid-state devicesVertical planeSpiral inductor

The invention discloses a through silicon via array-based three-dimensional spiral inductor, which comprises a top layer, an intermediate layer and a bottom layer, wherein through silicon vias in the intermediate layer are arranged into an N*N square matrix (N is greater than or equal to 5); metal posts in the through silicon vias are connected with top-layer metal interconnection lines on the top layer and bottom-layer metal interconnection lines on the bottom layer to form a series path; the series path is of a three-dimensional spiral structure (namely the three-dimensional spiral inductor) in a vertical plane; current flows to another polar plate from one polar plate of the three-dimensional spiral inductor when the series path is used; and the current sequentially passes through each metal post except for the metal post at the center. An inductance value of each through silicon via is equal to the sum of self-inductance itself and mutual inductance of adjacent through silicon via; and the total inductance value of the three-dimensional spiral inductor is equal to superposition of self-inductance values and mutual inductance values of all through silicon vias in the array, so that the quality and the inductance value of the integrated inductor can be greatly improved by the three-dimensional spiral inductor disclosed by the invention.

Owner:XIDIAN UNIV

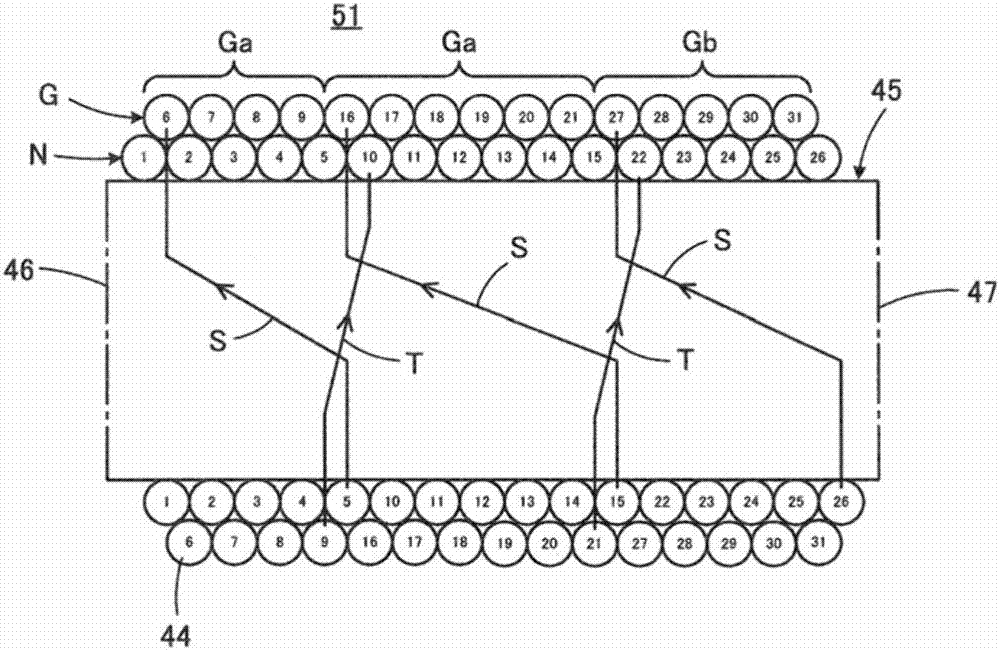

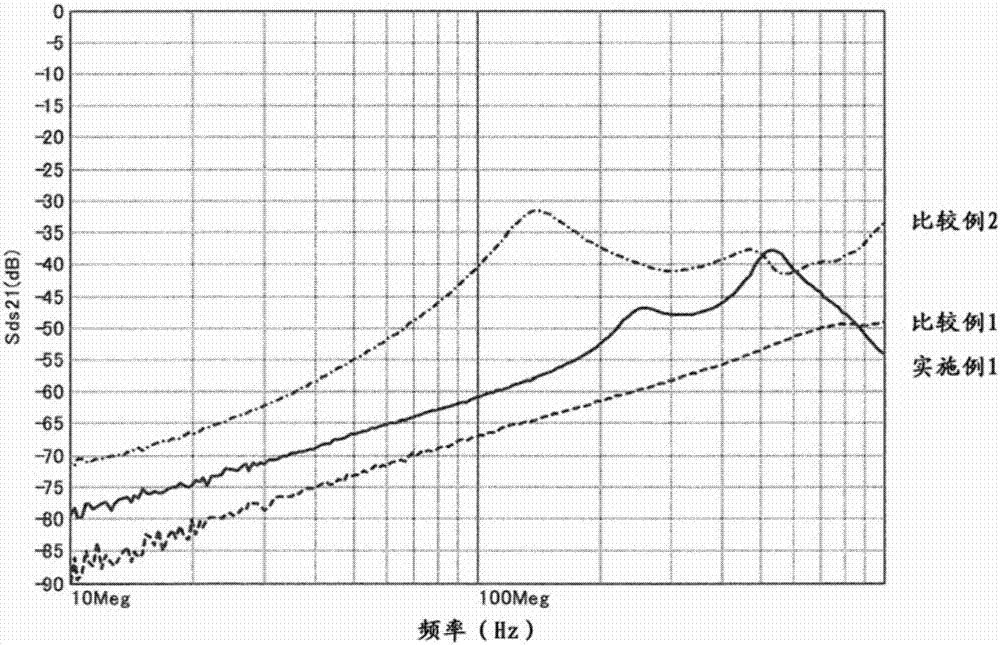

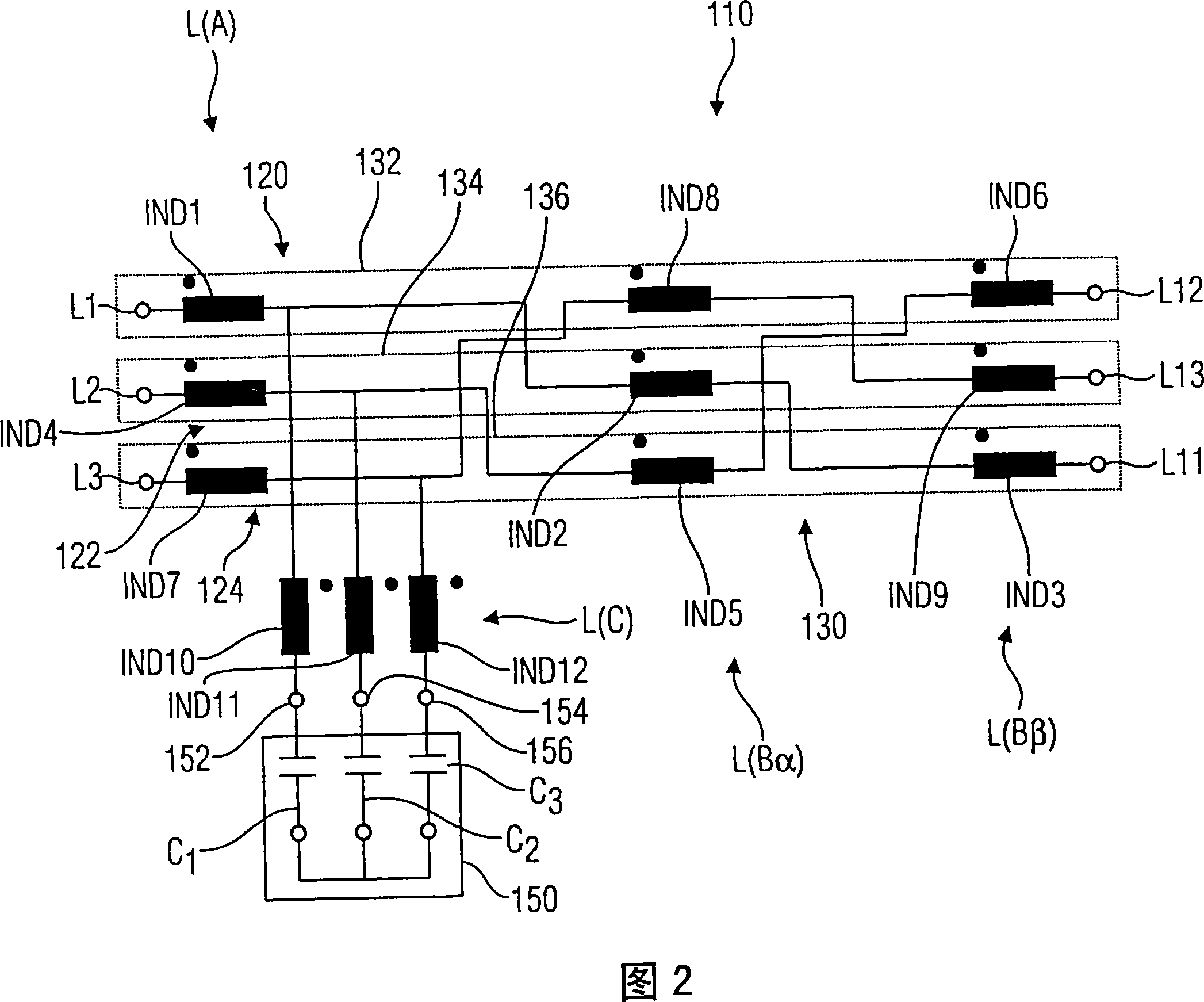

Polyphase line filter

ActiveCN101069338AReduced flow componentDecreased or even absent flow componentsMultiple-port networksTransformers/inductances coils/windings/connectionsCapacitanceInductance

A method of executing a bag of tasks application in a cluster over a distributed computing system, the cluster having a cluster resource manager. The method includes requesting that the cluster resource manager authorize access by a remote user of the distributed computing system to any idle nodes of the cluster, submitting a bag of tasks slave process to the cluster resource manager, loading the bag of tasks slave process in one of the idle nodes without an allocation operation, sequentially scheduling tasks from the bag of tasks to the bag of tasks slave process, and executing the bag of tasks slave process either until finished or until the node in which the bag of tasks slave process is loaded is required owing to a local allocation request.

Owner:科比传动技术(上海)有限公司

Magnetic epoxy resin powder solvent and method for packaging inductor by utilization of same

ActiveCN103325515AShielding Flux LeakageIncrease the inductance valueOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufactureEpoxyOrganic solvent

The invention relates to a magnetic epoxy resin powder solvent and a method for packaging an inductor by the utilization of the magnetic epoxy resin powder solvent. The magnetic epoxy resin powder solvent is characterized by comprising the following substances: 25-50% of epoxy resin powder coating material, 5-25% of curing agent, 20-50% of soft magnetic ferrite core ground powder particles and 20-50% of organic solvent. The method for packaging the inductor by the utilization of the magnetic epoxy resin powder solvent includes the following steps: performing full diluting with the organic solvent, enabling an inductance coil to face down, immersing the inductance coil into the magnetic epoxy resin powder solvent, then pacing the inductance coil on a baking rack to bake the inductance coil for 5-30min, sending the inductance coil into an oven, setting the temperature at 80-120DEG C, and baking the inductance coil for 1-3 hours. The magnetic epoxy resin powder solvent has the advantages of being capable of promoting the inductance of the inductor and saturation resistance of a current, low in consistence, good in mobility, easy to use for coating, free of sticking, and capable of promoting production efficiency; when heated, the magnetic epoxy resin powder solvent is directly solidified and will not flow, and thus uniformity of a coating can be kept; the inductance value is made to be stable, the change of error is small, quality is more reliable, and the magnetic epoxy resin powder solvent is mainly applicable to packaging of a direct-insertion inductor.

Owner:深圳市同利科斯电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com