Through silicon via array-based three-dimensional spiral inductor

A spiral inductor and through-silicon via technology, applied in inductors, electrical solid devices, circuits, etc., can solve the problems of limiting the use of inductors, large discrete inductors, and small inductor inductance values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0028] 1. The structure of three-dimensional spiral inductor

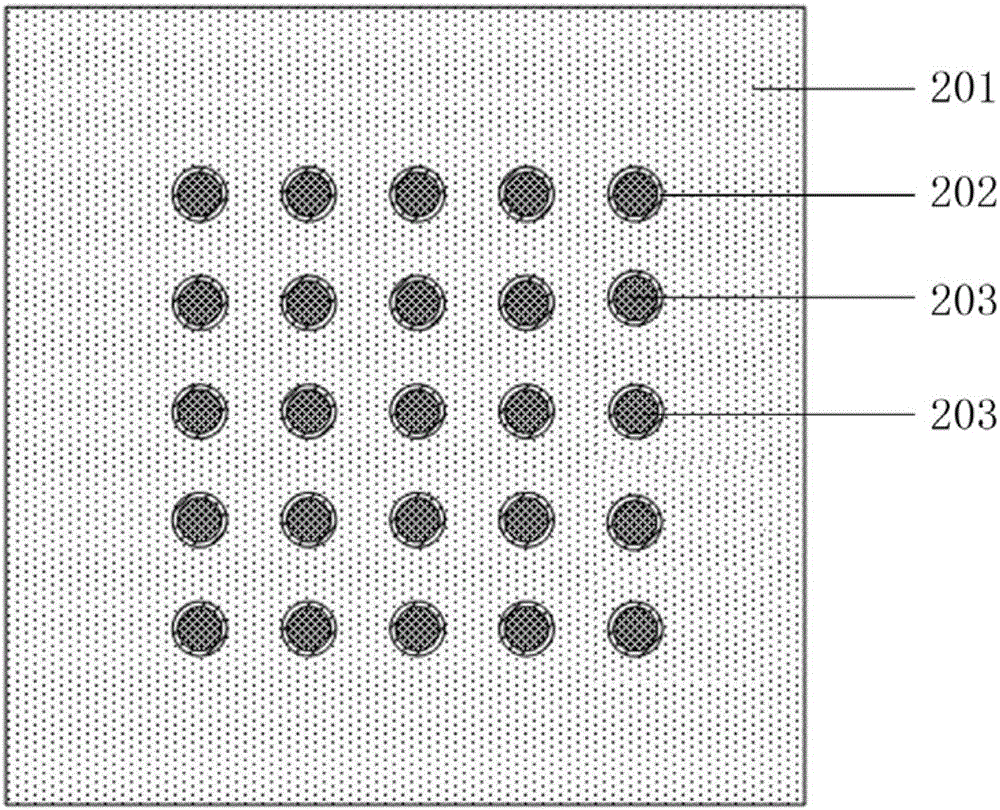

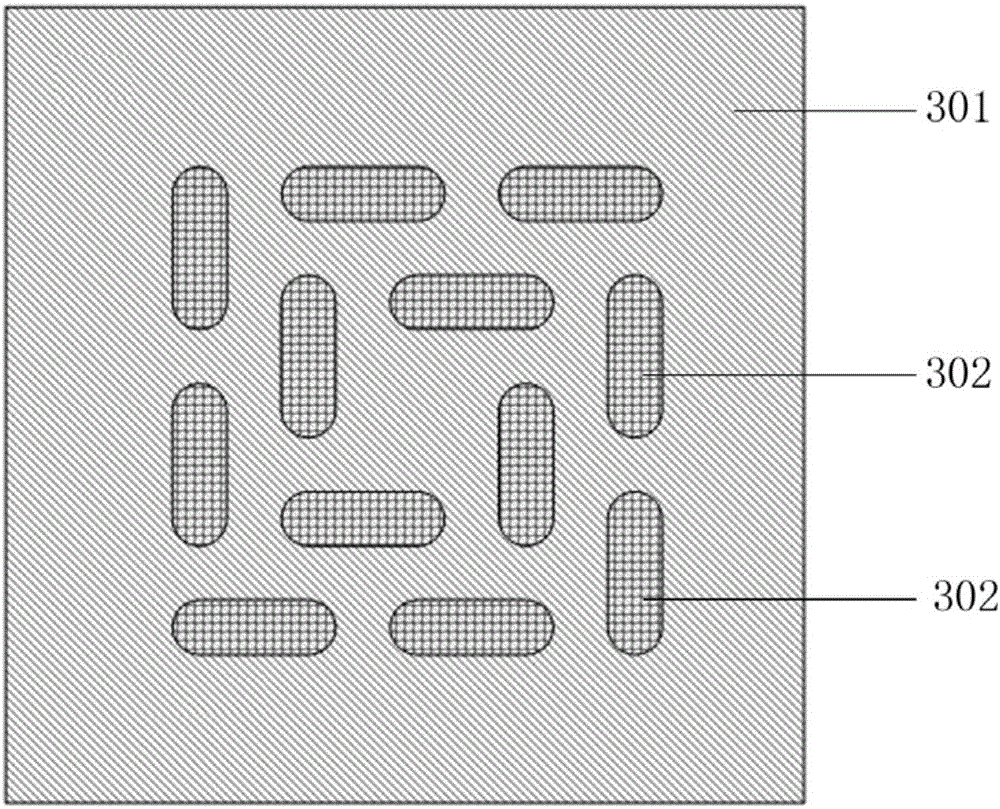

[0029] The structure of the three-dimensional spiral inductor based on the through-silicon hole array of the present invention includes: a top layer, a middle layer and a bottom layer.

[0030] 1. Top floor

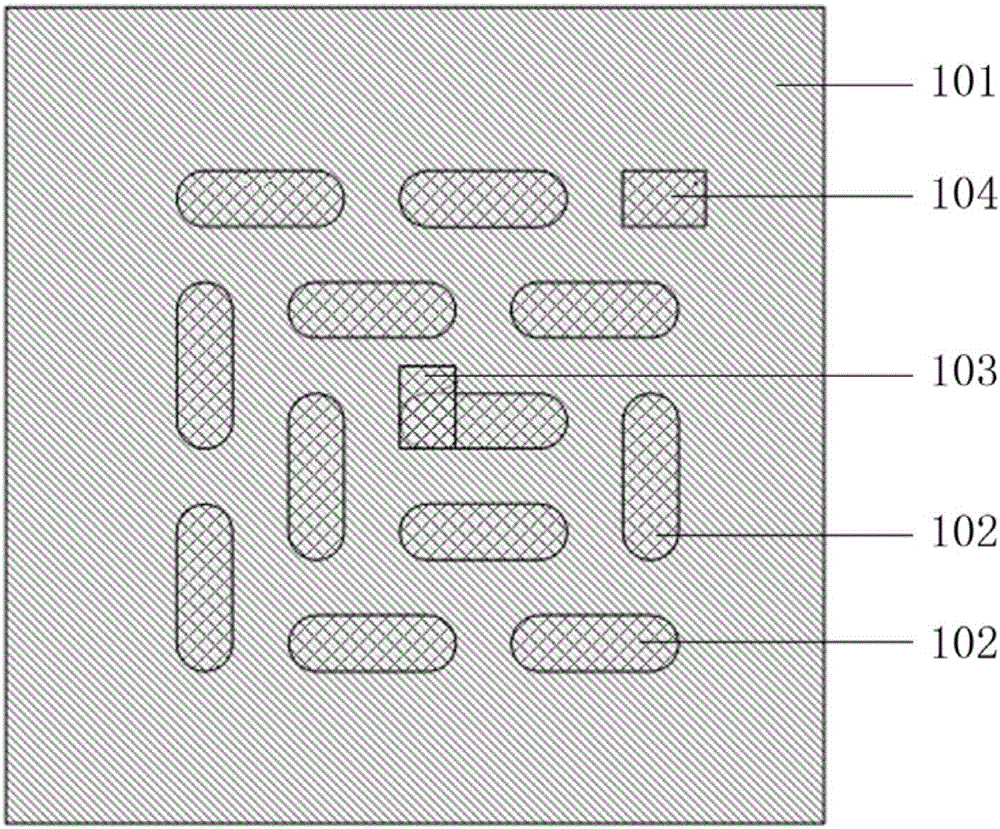

[0031] refer to figure 1 , the top layer is the top dielectric layer 101, which is made of insulating material, and the top metal interconnection 102, the top first plate metal interconnection 103 and the top second plate metal interconnection 104 are made therein.

[0032] The insulating material used for making the top dielectric layer 101 is silicon dioxide, silicon nitride or silicon oxynitride.

[0033] The material used to make the top metal interconnection 102 , the top first plate metal interconnection 103 and the top second plate metal interconnection 104 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com